Copyright-2008 Toshiba America Business Solutions, Inc. (TABS). This publication contains proprietary and confidential

information retained for reference purpose by authorized TABS dealers. Unauthorized use of this information is prohibited.

TABS makes no express or implied warranty, including implied warranties of merchantability for a particular purpose, with regard

to this technical publication and disclaims any claim arising by reason of the possession or use thereof.

MJ-1027/1028

Service Manual Addendum

Supplement to the Troubleshooting

Section

Overview

This is a collection of troubleshooting hints that TABS has received during our dealer visits,

communication that we have had from technicians, and information from TABS Technical

Specialists. This list is not exhaustive and as usual the Service Manual should always be used

as a reference.

Contents

Contents ........................................................................................................................................................ 2

1. EA20 Paper Transport Stop Jam ............................................................................................................ 3

2. CB30 Tray Lift Abnormality ................................................................................................................... 3

3. CBEO Paper Folding Motor Abnormality .............................................................................................. 4

4. CB90 Paper Pushing Plate Motor Abnormality ..................................................................................... 5

5. Limitless Copies ..................................................................................................................................... 6

6. CB80 without hole punch installed (Backup RAM Data Abnormality) .................................................. 6

7. CB80 with hole punch installed (Backup RAM Data Abnormality) ....................................................... 6

8. Abnormal Noise when exit tray lowers ................................................................................................. 8

9. CB10 Feed Motor Abnormality ............................................................................................................. 8

10. Intermittent Stapling ......................................................................................................................... 8

11. Mis-Stapling ...................................................................................................................................... 8

12. Adjustments that must be done when boards are replaced ............................................................ 8

2

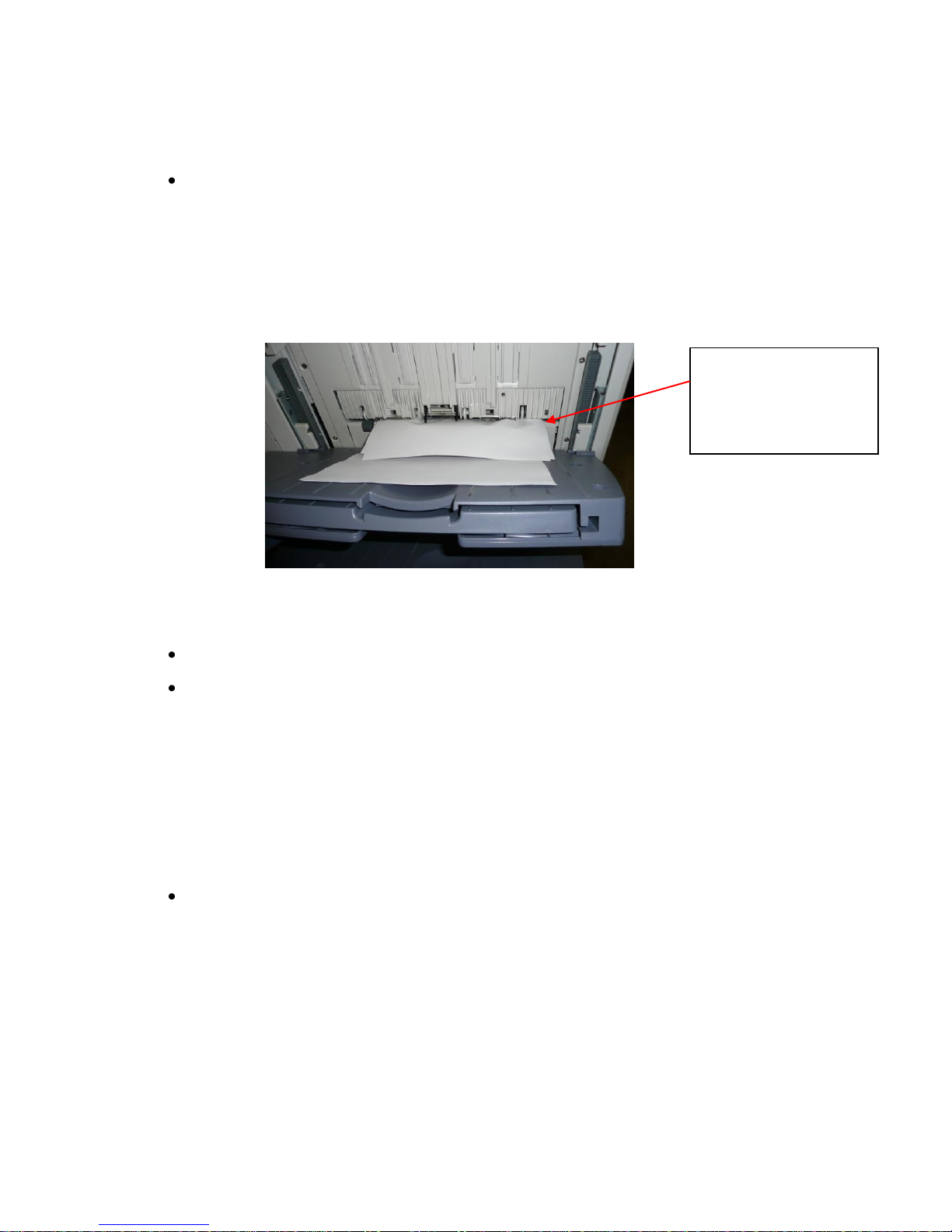

1. EA20 Paper Transport Stop Jam

Paper buckled due to

guide plate not being

lowered by escape

solenoid

There are a couple of areas that should be looked at when EA20 jamming is occurring.

Check for proper operation of Escape Solenoid (SL6) (part number 4402962760

SOLENOID).

If the Escape Solenoid does not operate properly then an EA20 jam could occur (see

Figure 1). The items to check for include:

o Binding of linkage

o Sticking of plunger

o Defective solenoid

Figure 1

Check the proper return operation of the buffer sensor (PI14).

We have had reports that either the first (M1) or second (M8) feed motors (part

number 6LE67833000 MOTR.S-FEED) could fail. The reports from the field are that

both motors need to be replaced at the same time. The reports state that replacing

one motor does not solve the problem and that both need to be replaced at the same

time.

2. CB30 Tray Lift Abnormality

There are a couple of causes of CB30, one is intermittent and the other is constant.

Intermittent

It has been noted in the field that an intermittent CB30 bin lift motor error may occur;

it usually occurs when the lower bin is driving. The cause is linked to the tie wraps on

the harness being too tight (see Figure 2). Over time, with the bins moving up and

down, damage occurs to the harness resulting in this error. As deemed necessary,

remove the cable ties. However, if the wires have already been damaged you may

need to replace the harness. (upper part number: 4G30851000; lower part number:

4G30852000 CABLE-TRAY)

3

Figure 2

Constant

o Check the tray lift motor(s) (M5, M10) (part number 4K11102000 MOTOR-

DC).

o Check the torque limiter (see item 8 Abnormal Noise when exit tray lowers)

3. CBEO Paper Folding Motor Abnormality

CBE0 relates to a folding motor abnormality. It has been determined that the folding motor

itself can be at fault. If replacing the folding motor (part number 6LE67820000 MOTOR)

does not resolve the problem, the faulty motor could have damaged the saddle stitch control

board (part number 4G30849000 SADDLE-CONT-PCB-ASY); in this instance the board

must also be replaced.

****CAUTION – NEVER REPLACE THE BOARD BEFORE CHANGING THE MOTOR****

4

4. CB90 Paper Pushing Plate Motor Abnormality

CB90 refers to the pusher plate (part number: 4402353400 PLATE) on the saddle stitch and

there can be various causes.

Check the condition of the pusher plate (see Figure 3); it should be completely flat

with no kinks or bends in the lead edge ‘castle’ areas.

Figure 3

Clean and check the pusher plate home sensor (PI15S) – do not exchange sensors

in these finishers as they are not the same (see Figure 4). If you suspect the sensor

is at fault, order and fit the correct sensor.

PI15S Cam Assembly and Spring Bushings (Front)

Figure 4

Check the condition of the cam assembly and that the spring is still attached (see

Figure 4). Also ensure that the bushings on both sides of the pusher plate assembly

are in good condition and not elongated (see Figure 4).

5

5. Limitless Copies

Limitless means the finisher recognizes the height of the stack rather than the number of

sets). To make this modification, set dip switch 5 to the ON position. If you make this

modification, advise the end-user of two things:

1. If many sheets are stacked, it is possible that the stacks may fall from the exit tray.

2. The paper may not stack properly in the finisher tray.

6. CB80 without hole punch installed (Backup RAM Data Abnormality)

If the machine is exhibiting CB80 without a hole punch installed perform the following

adjustments

Tray Height Adjustment (MJ1027/28 Service Manual page 6-1)

Alignment Position (MJ1027/28 Service Manual page 6-1)

When replacing the finisher logic board, there are adjustments that must be performed

otherwise a CB80 error may occur, see item 13 for a list.

7. CB80 with hole punch installed (Backup RAM Data Abnormality)

In addition to the items listed in 6 above, perform Sensor Output Adjustment and Registering

the Number of Holes Adjustment. The MJ1027/28/29 Service Manual does not list these

adjustments; the adjustments are listed in the MJ1017/18 Service Manual page 8-7 (see

Figure 5).

The following adjustments should be run when changing the hole punch board or replacing

any of the sensors in the hole punch unit.

6

Figure 5 – MJ1017/18 Service Manual, Page 8-7

7

8. Abnormal Noise when exit tray lowers

Before Change

After Change

NTN

077

17A

NTN

077

17a

MODEL

P-I

Before Change

After Change

MJ-1027

MJ-1028

7-13

8-13

FC56862000

LIMITER- TORQUE

4A30736000

LIMITER-TORQUE

Sometimes when the paper exit tray lowers an abnormal noise can occur. To prevent the

noise, the grease in the torque limiter has been changed. See the diagram below to

distinguish the new torque limiter from the old one.

9. CB10 Feed Motor Abnormality

When this error occurs check the following items:

One-way bearing located inside the cam shutter (part number 4402350530 CAM-

SHUTTER). This may slip causing the error code. Clean/replace as needed.

Safety Switch (MS3) – The spring may not push hard enough on the actuator; reform

the switch arm to make good contact.

10. Intermittent Stapling

Perform Alignment Position adjustment (MJ1027/28 SM page 6-1). If the alignment is too

tight this may produce a buckle lifting the center of the paper off the stapling tray sensor

(PI4).

11. Mis-Stapling

Check the paddles and make sure they are not worn.

Check that the Paddle Solenoid (SL5) is working and that the paddles rotate during

every copy.

12. Adjustments that must be done when boards are replaced

When replacing boards and some sensors there are certain adjustments that must be done.

The adjustments can be found in Chapter 6 of the SM.

Finisher Controller PCB

8

Height Sensor Adjustment

Alignment Position

Staple Position

Buffer Roller Winding Amount

Height Sensor (PS1)

Height Sensor Adjustment

EEPROM (Q2)

Buffer Roller Winding Amount

Saddle Stitch Controller PCB

Set the new DIPSW1 so that the settings will be the same as those on the old

DIPSW1.

Hole Punch Board

Refer to item 7.

END

9

Loading...

Loading...