Page 1

File No. 31100204

R02032112400-TTEC

Ver01 2002-09

Page 2

General Precautions for Installation/Servicing/Maintenance for the Finisher MJ-1017/1018,

Hole punch unit MJ-6003, Inserter MJ-7001

The installation and service should be done by a qualified service technician.

1. When installing the Finisher MJ-1017/1018, Hole punch unit MJ-6003, Inserter MJ7001 to the Plain Paper Copier, be sure to follow the instructions described in the

“Unpacking/Set-Up Procedure for the MJ-1017/1018/MJ-6003/MJ-7001” booklet which

comes with each unit of the MJ-1017/1018/MJ-6003/MJ-7001.

2. The MJ-1017/1018, MJ-6003, MJ-7001 should be installed by an authorized/qualified

person.

3. Before starting installation, servicing or maintenance work, be sure to turn off and

unplug the copier first.

4. When selecting the installation site, avoid placing the MJ-1017/1018/MJ-7001 and

copier on different levels or inclined floors.

5. When servicing or maintaining the MJ-1017/1018/MJ-6003/MJ-7001, be careful about

the rotating or operation sections such as gears, pulleys, sprockets, cams, belts, etc.

6. When parts are disassembled, reassembly is basically the reverse of disassembly

unless otherwise noted in this manual or other related materials. Be careful not to

reassemble small parts such as screws, washers, pins, E-rings, toothed washers to

the wrong places.

7. Basically, the machine should not be operated with any parts removed or disassembled.

8. Delicate parts for preventing safety hazard problems (such as breakers, thermofuses,

fuses, door switches, sensors, etc. if any) should be handled/installed/adjusted correctly.

9. Use suitable measuring instruments and tools.

10. During servicing or maintenance work, be sure to check the serial No. plate and other

cautionary labels (if any) to see if they are clean and firmly fixed. If not, take appropriate actions.

11. The PC board must be stored in an anti-electrostatic bag and handled carefully using

a wristband, because the ICs on it may be damaged due to static electricity. Before

using the wrist band, pull out the power cord plug of the copier and make sure that

there is no uninsulated charged objects in the vicinity.

12. For the recovery and disposal of used MJ-1017/1018/MJ-6003/MJ-7001s, consumable parts, packing materials, used batteries, and RAM-ICs including litium batteries,

it is recommended that the relevant local regulations/rules.

13. After completing installation, servicing and maintenance of the MJ-1017/1018/MJ-6003/

MJ-7001, return the MJ-1017/1018/MJ-6003/MJ-7001 to its original state, and check

operation.

Page 3

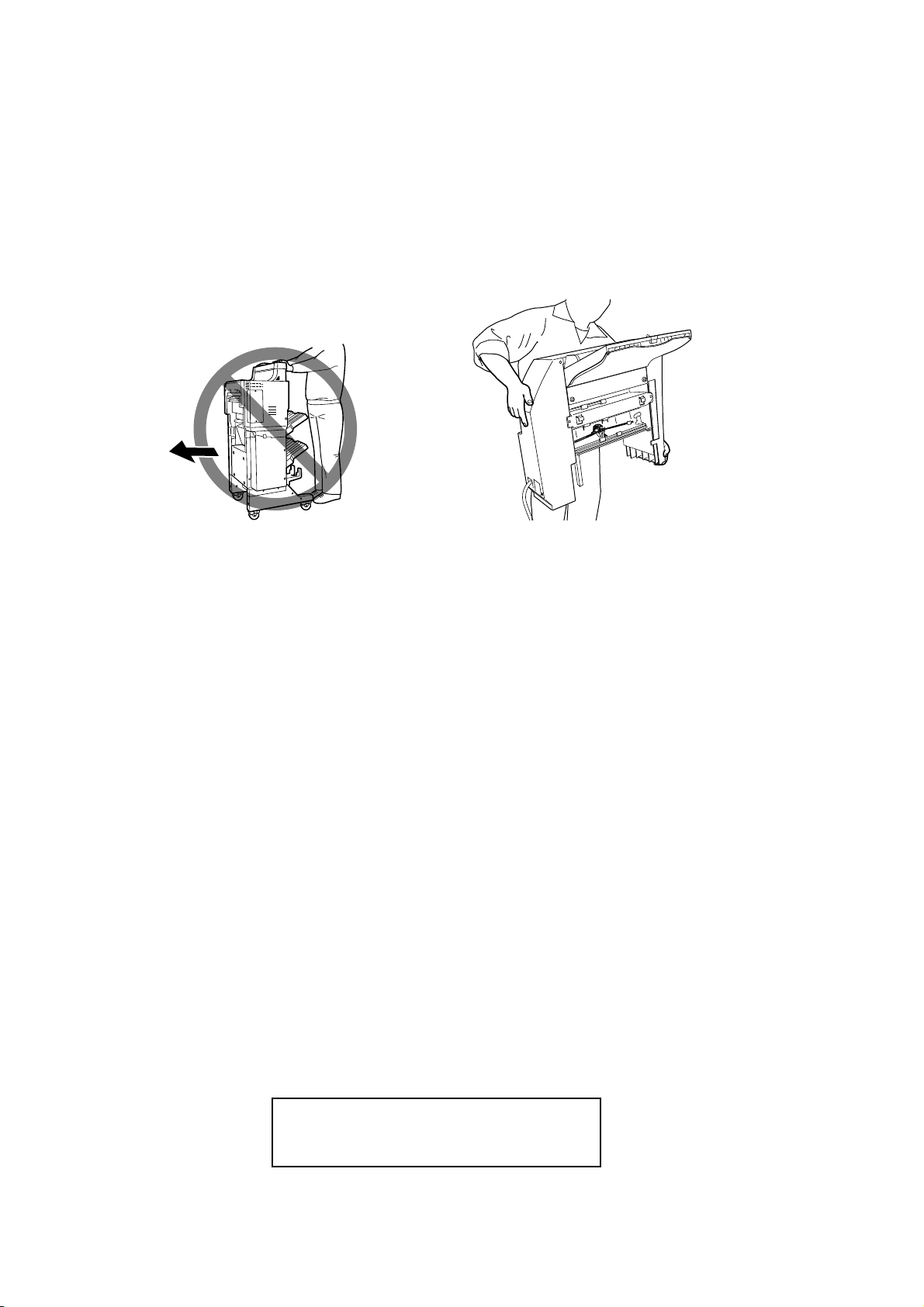

14. When you move the finisher, do not move it in the direction of the arrow as shown in

the figure [A] below otherwise it might fall down. Also, when installing the inserter MJ7001, hold it as the figure [B] below shows in order for your hands not to be caught.

[A] [B]

Copyright © 2002

TOSHIBA TEC Corporation

Page 4

INTRODUCTION

This Service Manual contains basic data and figures for the Finisher (MJ-1017)/Saddle

Finisher (MJ-1018) needed to service the machine in the field.

This manual comprises the following chapters:

Chapter 1 “General Description” introduces the finisher’s features, specifications, and

names of parts, and shows how to operate the finisher.

Chapter 2 “Finisher Unit Basic Operation” discusses the principles of operation used for

the finisher mechanical and electrical systems. It also explains the timing at

which these systems are operated.

Chapter 3 “Saddle Finisher Unit Basic Operation” discusses the principles of operation

used for the saddle stitcher unit’s mechanical and electrical systems. It also

explains the timing at which these systems are operated.

Chapter 4 “Puncher (option) Unit Basic Operation” discusses the principles of operation

used for the puncher unit’s mechanical and electrical systems. It also explains

the timing at which these systems are operated.

Chapter 5 “Inserter (option) Unit Basic Operation” discusses the principles of operation

used for the inserter units mechanical and electrical systems. It also explains

the timing at which these systems are operated.

Chapter 6 “Mechanical System” discusses how the finisher is constructed mechanically,

and shows how it may be disassembled/assembled and adjusted.

Chapter 7 “Maintenance and Inspection” provides tables of periodically replaced parts

and consumables and durables, together with a scheduled servicing chart.

Chapter 8 “Troubleshooting” shows how to troubleshoot possible faults and gives electri-

cal parts arrangement diagrams, LED/check pin diagrams by PCB, and self

diagnosis tables.

“Appendix” contains diagrams showing tables of signals, overall circuit diagrams and tables of solvents/oils.

Descriptions regarding installation are not mentioned in this Service Manual as the

Finisher (MJ-1017)/Saddle Finisher (MJ-1018)’s packing boxes contain Installation Procedures.

The descriptions in this Service Manual are subject to change without notice for product improvement or other purposes, and major changes will be communicated in the form

of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this

Service Manual and all relevant Service Information bulletins, and be able to identify and

isolate faults in the machine.

i

Page 5

ii

Page 6

CONTENTS

CHAPTER 1 GENERAL DESCRIPTION

I. FEATURES ..................................1-1

II. SPECIFICATIONS .......................1-2

A. Specifications ........................... 1-2

B. Cross Section .........................1-10

III. Using the Machine .....................1-14

A. Removing Paper Jams from the

Finisher Unit ........................... 1-14

B. Supplying the Finisher Unit with

Staples ...................................1-15

C. Removing Staple Jams from the

Finisher Unit ........................... 1-17

D. Removing Paper Jams from the

Saddle Stitcher Unit

(Saddle Finisher) ....................1-18

E. Supplying the Saddle Stitcher

Unit with Staples

(Saddle Finisher) ....................1-20

F. Removing Staple Jams from the

Saddle Stitcher Unit

(Saddle Finisher) ....................1-21

G. Removing Paper Jams from the

Puncher Unit (option) .............1-23

H. Removing Punched Scrap from

the Puncher Unit (option) .......1-25

IV. MAINTENANCE BY THE

USER ........................................1-26

A. Maintenance by the User .......1-26

CHAPTER 2 FINISHER UNIT BASIC OPERATION

I. BASIC OPERATION ....................2-1

A. Outline ......................................2-1

B. Outline of Electrical Circuitry .... 2-2

C. Inputs to and Outputs from the

Finisher Controller PCB ........... 2-4

II. FEED/DRIVE SYSTEM .............2-10

A. Outline ....................................2-10

B. Type of Delivery Paths............ 2-15

C. Feeding and Delivering .......... 2-18

D. Job Offset............................... 2-21

E. Staple Operation ....................2-24

F. Stapler Unit ............................2-32

G. Tray Operation ........................ 2-38

H. Detecting the Height of

Stack on the Tray .................... 2-40

I. Shutter Operation ................... 2-42

J. Buffer Path Operation............. 2-46

K. Detecting Jams ...................... 2-51

III. POWER SUPPLY SYSTEM .......2-56

iii

Page 7

CHAPTER 3 SADDLE STITCHER UNIT

BASIC OPERATION

I. BASIC OPERATION ....................3-1

A. Outline ......................................3-1

B. Electrical Circuitry .................... 3-2

C. Inputs to and Outputs from the

Saddle Stitcher Controller

PCB ..........................................3-3

II. FEEDING/DRIVE SYSTEM ......... 3-8

A. Outline ......................................3-8

III. PAPER OUTPUT

MECHANISM............................. 3-14

A. Outline ....................................3-14

B. Controlling the Inlet

Flappers .................................3-17

CHAPTER 4 PUNCHER UNIT (OPTION)

BASIC OPERATION

I. BASIC OPERATION ....................4-1

A. Outline...................................... 4-1

B. Inputs to and Outputs from

Punch Driver PCB .................... 4-2

II. PUNCH OPERATION ..................4-5

C. Controlling the Movement of

Sheets .................................... 3-21

D. Aligning the Sheets ................ 3-23

E. Controlling the Phase of the

Crescent Roller ...................... 3-26

IV. STITCHING SYSTEM ............... 3-28

V. FOLDING/DELIVERY

SYSTEM ....................................3-31

VI. CHECKING FOR A JAM ........... 3-38

VII. POWER SUPPLY ...................... 3-43

A. Outline ......................................4-5

B. PUNCH OPERATION ...............4-7

C. Horizontal Registration

Operation ............................... 4-11

III. POWER SUPPLY SYSTEM .......4-14

CHAPTER 5 INSERTER UNIT (OPTION)

BASIC OPERATION

I. BASIC OPERATION ....................5-1

A. Outline ......................................5-1

B. Symbols and Layout of

Electric Parts/Diagram of

Signal Blocks............................ 5-2

iv

C. Drive System ............................ 5-6

D. Operation .................................5-8

E. JAM/ERROR DETECTION AND

LED DISPLAY ........................ 5-32

F. CIRCUIT................................. 5-36

Page 8

CHAPTER 6 MECHANICAL CONSTRUCTION

I. FINISHER UNIT .......................... 6-1

A. Externals and Controls .............6-1

B. FEEDING SYSTEM ................. 6-9

C. PCBs ......................................6-13

II. SADDLE STITCHER UNIT ........6-14

A. Externals and Controls ...........6-14

B. SADDLE UNIT ....................... 6-17

C. PCBs ......................................6-27

D. Accessory .............................. 6-28

III. PUNCHER UNIT (OPTION) ...... 6-29

CHAPTER 7 MAINTENANCE AND INSPECTION

I. PERIODICALLY REPLACED

PARTS ......................................... 7-1

A. Finisher Unit ............................. 7-1

B. Saddle Stitcher Unit ................. 7-1

C. Puncher Unit (option) ............... 7-1

D. Inserter (option)........................ 7-1

II. CONSUMABLES AND

DURABLES .................................7-2

A. Externals and Controls ........... 6-29

B. Puncher Driver System .......... 6-30

C. PCBs ......................................6-41

IV. INSERTER UNIT (OPTION) ...... 6-43

A. Exterior Parts ......................... 6-43

B. Feeding Section .....................6-44

C. Drive Section .......................... 6-46

D. Upper Inserter Unit .................6-49

E. Tray Unit .................................6-50

F. Notes for Installing ................. 6-52

A. Finisher Unit ............................. 7-2

B. Saddle Stitcher Unit ................. 7-2

C. Puncher Unit (option) ............... 7-2

D. Inserter (option)........................ 7-2

III. PERIODICAL SERVICING .......... 7-2

IV. FIRMWARE UPDATING

(only for inserter section) .............7-3

CHAPTER 8 TROUBLESHOOTING

I. ADJUSTMENTS .......................... 8-1

A. Electrical System

(finisher unit) ............................ 8-1

B. Electrical System

(saddle stitcher unit) .................8-5

C. Electrical System

(puncher unit (option)) ..............8-7

D. Electric Unit/(Inserter Section

(Optional)) ................................8-9

E. Inserter Section ...................... 8-10

II. ARRANGEMENT OF

ELECTRICAL PARTS ................8-12

A. Finisher Unit ...........................8-12

B. Saddle Stitcher Unit ............... 8-19

C. Puncher Unit (option) .............8-25

D. Light-Emitting Diodes (LED)

and Check Pins by PCB .........8-29

III. TROUBLESHOOTING ............... 8-31

A. Finisher Unit ...........................8-31

B. Saddle Stitcher Unit ............... 8-41

C. Puncher Unit (option) .............8-48

D. Inserter Section (Option) ........ 8-49

v

Page 9

APPENDIX

A. FINISHER UNIT GENERAL

TIMING CHART.......................... A-1

B. SADDLE STITCHER UNIT

GENERAL TIMING CHART........ A-2

C. PUNCHER UNIT (option)

GENERAL TIMING CHART........ A-3

D. INSERTER UNIT (option)

GENERAL TIMING CHART........ A-4

E. SIGNAL AND

ABBREVIATIONS ..................... A-14

F. FINISHER UNIT CIRCUIT

DIAGRAM ................................. A-15

G. SADDLE STITCHER UNIT

CIRCUIT DIAGRAM ................. A-26

H. PUNCHER UNIT (option)

CIRCUIT DIAGRAM ................. A-34

I. INSERTER UNIT (option)

CIRCUIT DIAGRAM ................. A-41

J. SOLVENTS AND OILS ............. A-45

vi

Page 10

CHAPTER 1

GENERAL DESCRIPTION

I. FEATURES ..................................1-1

II. SPECIFICATIONS .......................1-2

A. Specifications............................. 1-2

B. Cross Section .......................... 1-10

III. Using the Machine .....................1-14

A. Removing Paper Jams from the

Finisher Unit............................. 1-14

B. Supplying the Finisher Unit with

Staples .....................................1-15

C. Removing Staple Jams from the

Finisher Unit............................. 1-17

D. Removing Paper Jams from the

Saddle Stitcher Unit

(Saddle Finisher) .....................1-18

E. Supplying the Saddle Stitcher

Unit with Staples

(Saddle Finisher) ..................... 1-20

F. Removing Staple Jams from the

Saddle Stitcher Unit

(Saddle Finisher) ..................... 1-21

G. Removing Paper Jams from the

Puncher Unit (option) ............... 1-23

H. Removing Punched Scrap from

the Puncher Unit (option) ......... 1-25

IV. MAINTENANCE BY THE

USER ........................................1-26

A. Maintenance by the User ......... 1-26

Page 11

CHAPTER 1 GENERAL DESCRIPTION

I. FEATURES

1. Accommodates large quantities of sheets

●

Normally, the finisher holds a stack of sheets 250 mm in height in its two bins (small-size

paper: equivalent to 2000 sheets)/140 mm in height (large-size paper: equivalent to 1000

sheets)

2. Has high paper transportation performance

●

The finisher is capable of handling papers between 60 and 256 gm/m2.

3. Offers a job offset function

●

The finisher has a job offset function for sorting non-stapled stacks of copies.

4. Offers four types of auto stapling

●

The finisher offers a choice of four stapling modes (1-point stapling at rear, diagonal stapling at front, diagonal stapling at rear, 2-point stapling).

5. Uses a buffer roller

●

The use of a buffer roller enables the f inisher to accept copies without interruption from the

host machine even during stapling or offset operation.

6. Has a saddle stitch function (Saddle Finisher MJ-1018)

●

The finisher can staple along the center of paper and fold it in two (up to 15 sheets).

7. Offers a punch function (option)

●

The use of the puncher unit enables the finisher to punch sheets for binders before they are

output. (The puncher unit is capable of handling papers between 60 and 256 gm/m2. It cannot handle special paper, postcards and transparencies.)

8. Insert function (option)

●

Enable the use of special type of paper and printed paper in addition to the staple sorting or

the hole punching mode (Available when the optional staple sorting and the hole punching

mode units are installed.) This paper is not run through fuser (heat).

1-1

Page 12

CHAPTER 1 GENERAL DESCRIPTION

II. SPECIFICATIONS

A. Specifications

1. Finisher Unit

Item

Stacking method

Stacking orientation

Stacking size

Paper weight

Bins

Modes

Stacking capacity

Size mixing

Description

Trays 1 and 2: by lifting tray

Face-down

AB: A3, A4, A4-R, A5-R, B4, B5, B5-R, FOLIO

Inch: LD, LG, LT, LT-R, ST-R, COMPUTER

60 to 256 g/m

2

Trays 1 and 2

Non-sort: trays 1 and 2

Sort: trays 1 and 2

Staple sort: trays 1 and 2

Non sort Small-size

Non staple sort

(Note 1)

Large-size

(Note 1)

Staple sort Small-size

(Note 1)

Large-size

(Note 1)

Size mixing: 74 mm or less (500 sheets)

Staple mixing: 74 mm or less (500 sheets)

250 mm (2000 sheets)

140 mm (1000 sheets)

110 mm/50 sets (750 sheets)

74 mm/50 sets (500 sheets)

(Note 1)

(Note 1)

(Note 2)

(Note 2)

Stacking mixing

Notes:

1. Approximate when computed with reference to 80 g/m

2. Alignment may not be correct if 750 or more small-size sheets are stacked.

3. The accuracy of the stack height is ± 7 mm/0.28 in.

Face-down

2

paper.

Table 1-201

1-2

Page 13

CHAPTER 1 GENERAL DESCRIPTION

Item

Stapling

Stapling position

Stapling capacity

(Note1)

Staple supply

Staples

Staple detection

Manual stapling

Stapling size

Paper detection

Control panel

Display

Description

By rotating cam

See Figure 1-201.

Small-size

Large-size

Special staple cartridge (5000 staples)

Special (STAPLE-700: 3 cartridges of 5000 staples in a package)

Provided

Not provided

1-point diagonal Front A3, B4, A4, A4-R, B5, LD, LG, LT, LT-R,

stapling (diagonal) FOLIO, COMPUTER

1-point Rear A4-R, LT-R, LG, FOLIO

2-point A3, B4, A4, B5, A4-R, LD, LG, LT-R, FOLIO,

Provided

Not provided

Not provided

50 sheets (60 ~ 80 g/m2)

30 sheets (60 ~ 80 g/m2)

Rear A3, B4, A4, B5, LD, LT

COMPUTER

30 sheets (90 g/m2)

15 sheets (90 g/m2)

30 sheets (105 g/m2)

15 sheets (105 g/m2)

Dimensions

(W × D × H)

Weight

Power supply

Maximum power

consumption

740 × 630 × 1023 mm/29.25 × 24.88 × 40.38 in

813 × 630 × 1023 mm/32.13 × 24.88 × 40.38 in

922 × 630 × 1023 mm/36.38 × 24.88 × 40.38 in

995 × 630 × 1023 mm/39.25 × 24.88 × 41.38 in (with Puncher Unit and

Inserter Unit attached)

Finisher (MJ-1017): 42 kg/92.59 lb

Saddle finisher (MJ-1018): 62 kg/136.68 lb

Puncher unit (option): 5.4 kg/11.68 lb

Inserter unit (option): 20 kg/44.09 lb

From host machine (24 VDC, 5 VDC)

170 W or less

(with Puncher Unit attached)

(with Inserter Unit attached)

Note1: Equiv alent of 80 g/m2 paper . Including two sheets of thick stock or cov er (200 ~ 256 g/m2)

Table 1-202

Reference:

The term “small-size” stands for A4, A5-R, B5, LT, ST-R, while the term “large-size” stands for

A3, B4, A4-R, B5-R, LT-R, LD, LG, FOLIO, COMPUTER.

1-3

Page 14

CHAPTER 1 GENERAL DESCRIPTION

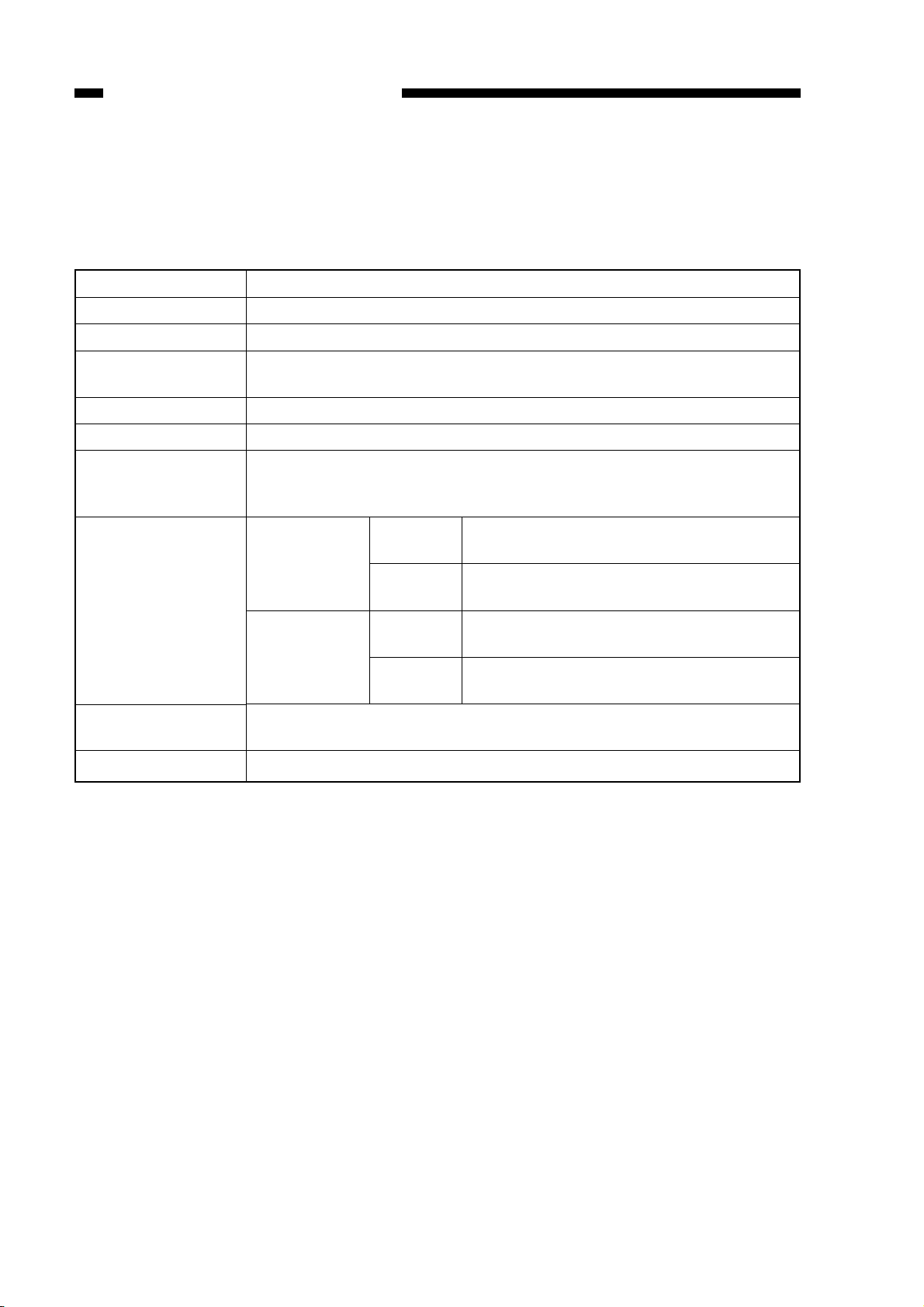

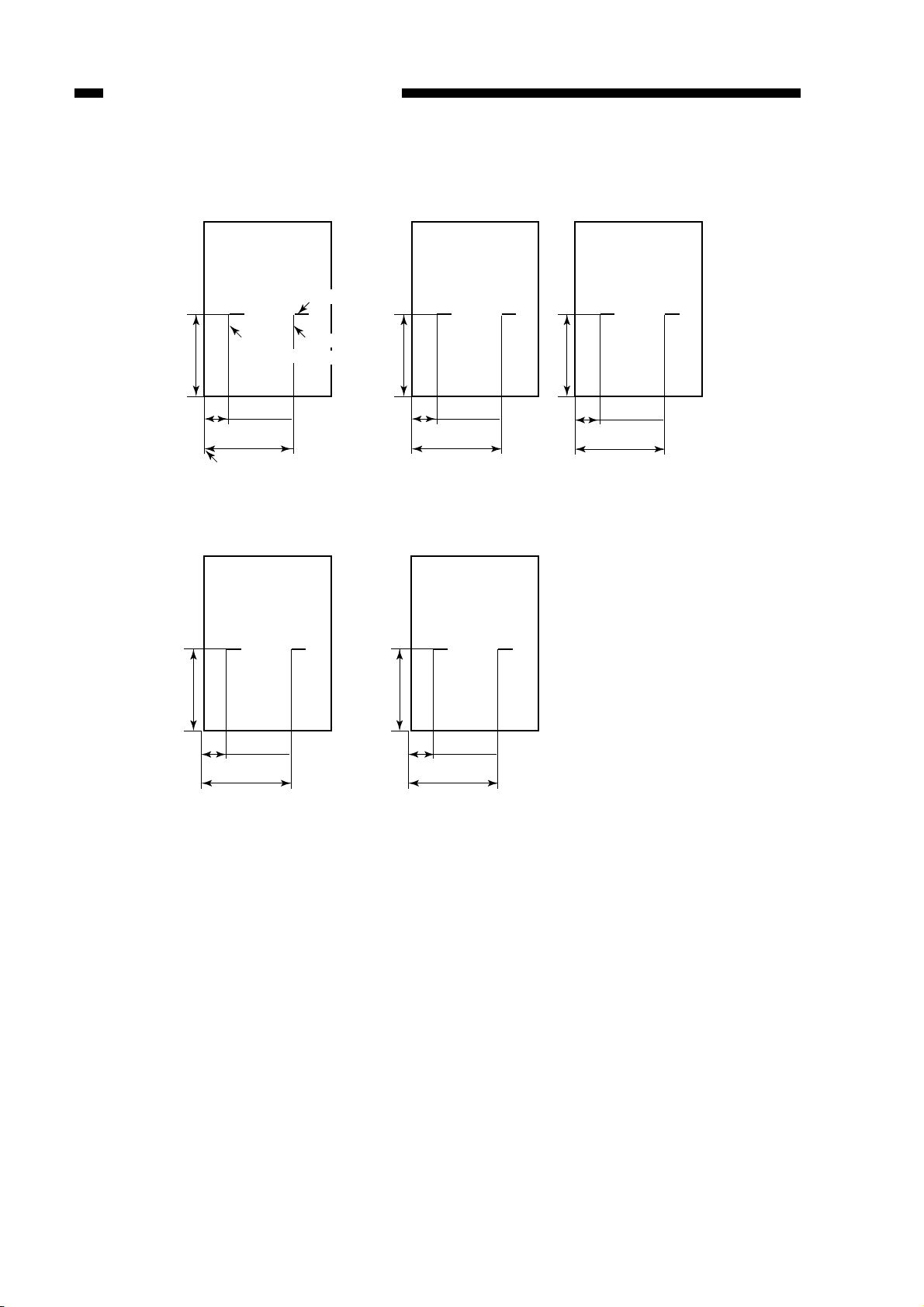

Stapling Positions (finisher unit)

1-point stapling (rear)

Specified paper width

-0.24±0.16in

2-point stapling

A3 and A4

83±4mm/

3.26±0.16in

203±4mm/

5±4mm/

7.98±0.16in

0.2±0.16in

-6±4mm/

5±4mm/

0.2±0.16in

1-point stapling

(diagonal; front)

30˚

4.4±4mm/

-0.17±0.16in

4.4±4mm/

0.17±0.16in

B4 and B5

63±4mm/

2.47±0.16in

183±4mm/

5±4mm/

7.19±0.16in

0.2±0.16in

Specified paper width

-0.24±0.16in

5±4mm/

1-point stapling

(diagonal; rear)

-6±4mm/

LD and LT

74±4mm/

2.9±0.16in

194±4mm/

7.63±0.16in

0.2±0.16in

30˚

4±4mm/

0.16±0.16in

A4-R and FOLIO LT-R and LG

62.5±4mm/

2.46±0.16in

5±4mm/

0.2±0.16in

138.5±4mm/

5.45±0.16in

5±4mm/

0.2±0.16in

62.5±4mm/

2.46±0.16in

144.5±4mm/

5.69±0.16in

Figure 1-201

1-4

Page 15

2. Saddle Stitcher Unit

CHAPTER 1 GENERAL DESCRIPTION

Item

Stapling method

Folding position

Paper size

Capacity

Paper weight

Stacking capacity

Stapling

Folding

Description

Center binding (double folding)

See Figure 1-202.

A3, B4, A4-R, LD, LT-R

W/binding: 1 sheet

W/out binding: 2 to 15 sheets

60 to 105 g/m2 (cover page up to 256 g/m2)

(including single cover page)

(Note 1)

10 sets (stack of 11 to 15 sheets), 20 sets (stack of 6 to 10 sheets),

25 sets (stack of 5 sheets or less)

Stapling position 2 points (center distribution; fixed interval)

Staple accommodation 2000 staples

Staple supply Special cartridge

Staples Special staples (STAPLE-600: 3 cartridges

of 2000 staples in a package)

Staple detection Provided

Manual stapling Not provided

Folding method Roller contact

Folding mode Double folding

Folding position Paper center

Position adjustment Provided

Power supply

From finisher unit

DC24V, DC5V

Power consumption

160 W or less

Note1: Special paper, postcards, transparencies, reproducibles, label paper and hole-punched paper

cannot be handled.

Table 1-203

1-5

Page 16

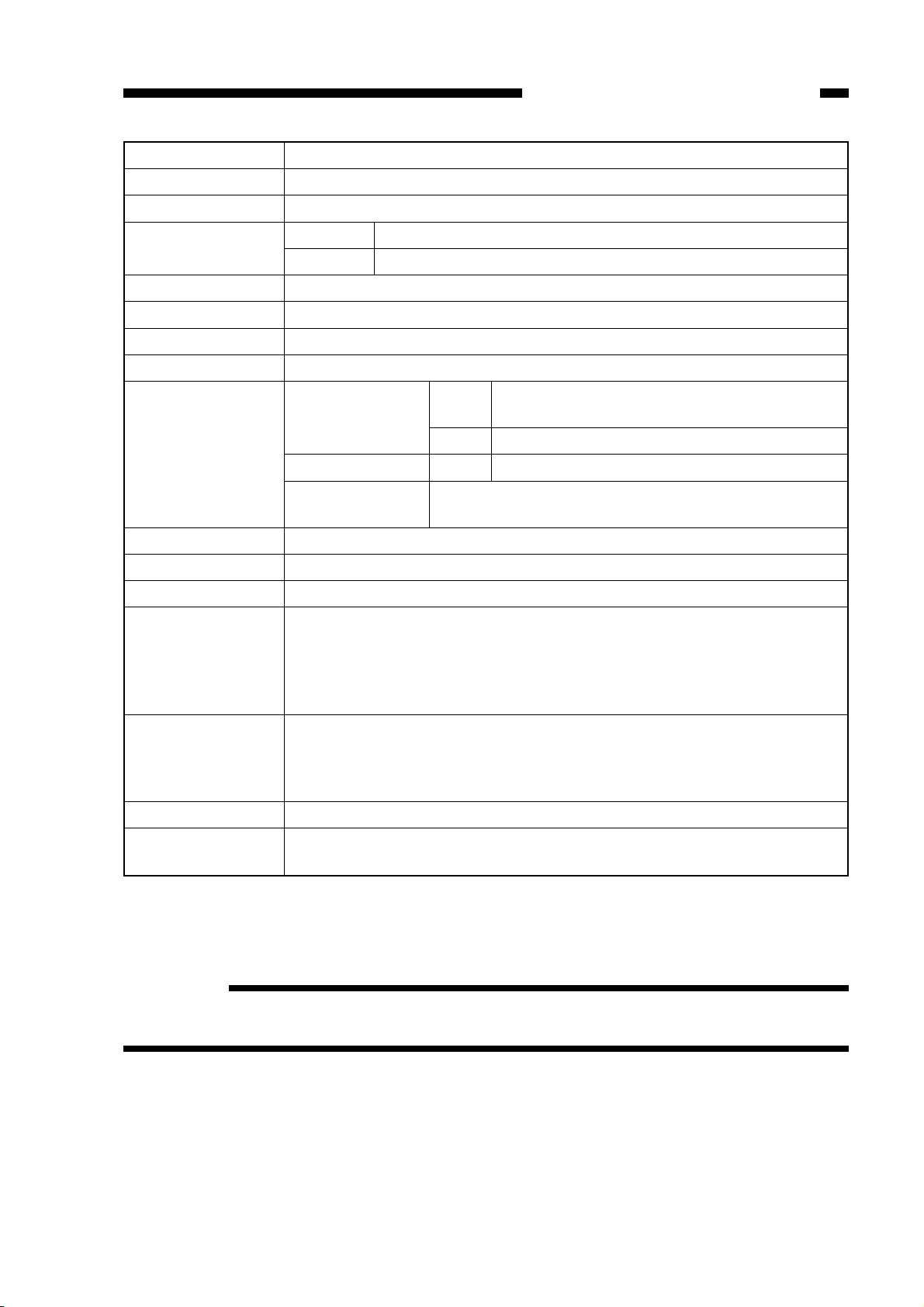

CHAPTER 1 GENERAL DESCRIPTION

Staple and Folding Position (saddle stitcher unit)

A3

210±1mm/

8.27±0.04in

203±2mm/

8.21±0.08in

Stack front edge

LD

Edge

of staple

83±2mm/

3.48

±0.08in

Staple position

Edge of

staple

B4

182±1mm/

7.17±0.04in

LT-R

63±2mm/

2.7

±0.08in

183±2mm/

7.42±0.08in

A4-R

5.85±0.04in

148.5±1mm/

159.5±2mm/

39.5±2mm/

1.77±0.08in

6.5±0.08in

8.5±0.04in

216±1mm/

74±2mm/

3.14

±0.08in

194±2mm/

7.86±0.08in

5.5±0.04in

139.7±1mm/

42mm/

1.89±0.08in

162±2mm/

6.61±0.08in

Figure 1-202

1-6

Page 17

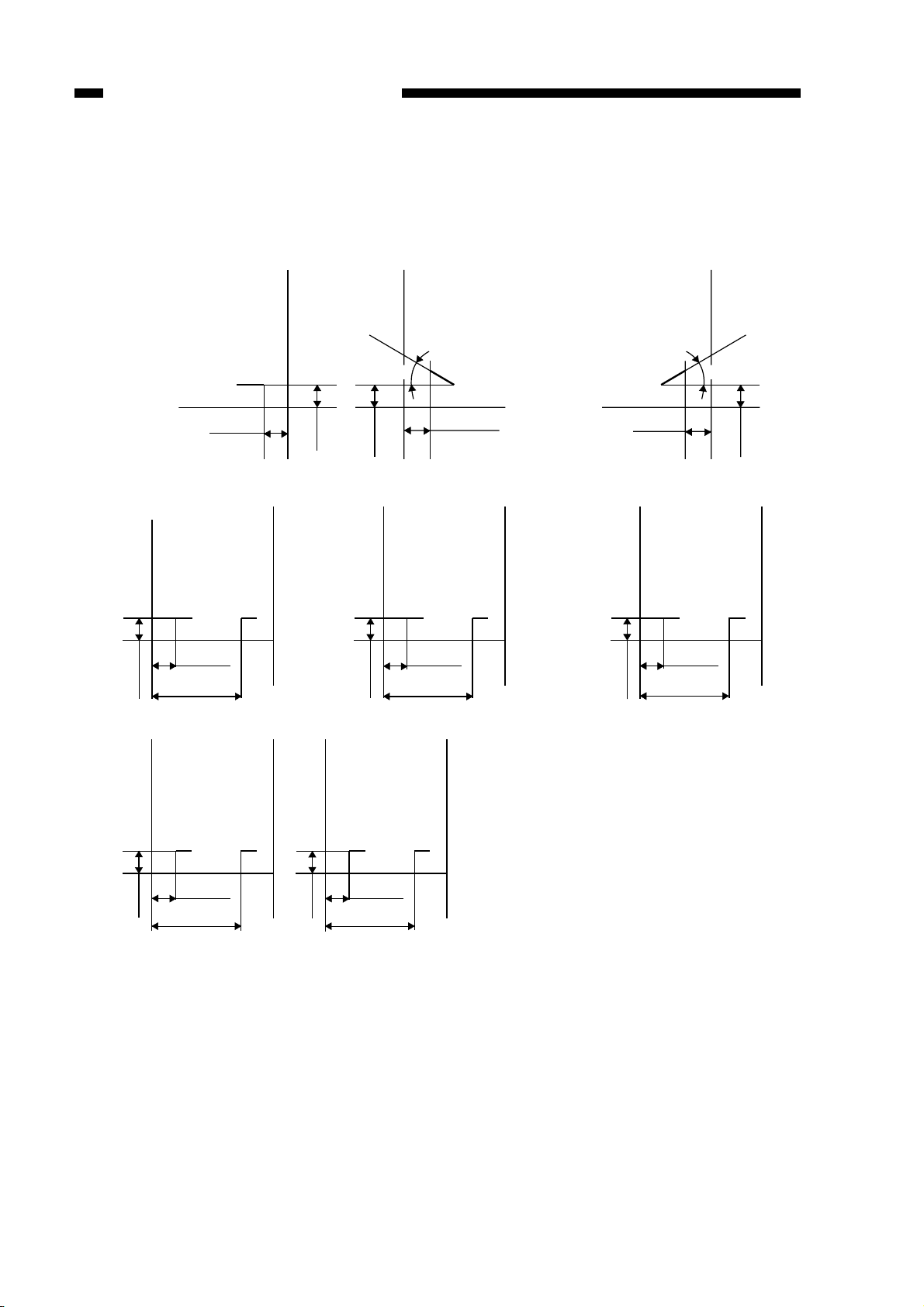

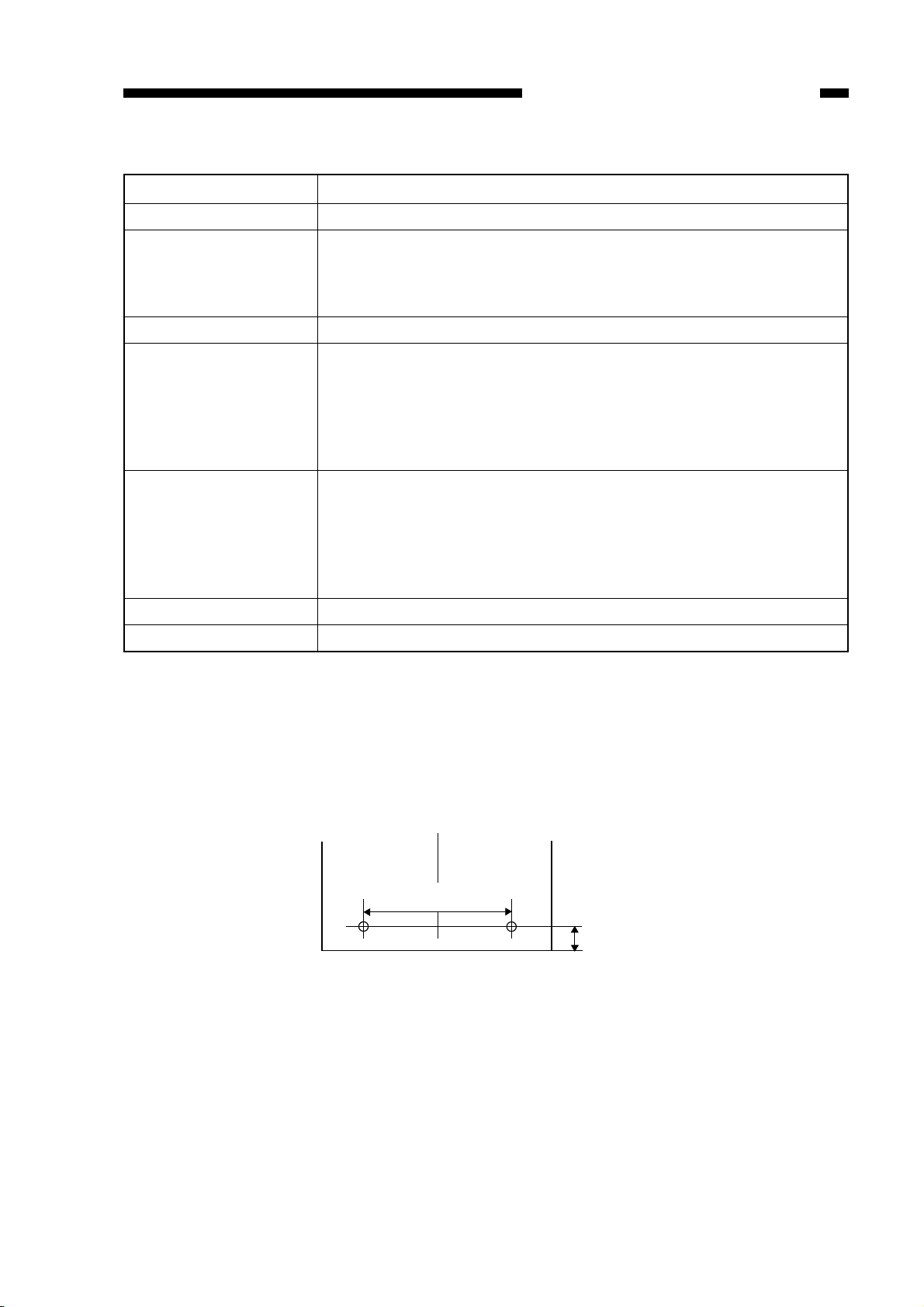

3. Puncher Unit (Option)

12±3 mm/

0.47±0.12 in

80±1 mm/

3.15±0.04 in

[1] 2 holes (Puncher Unit MJ-6003E)

CHAPTER 1 GENERAL DESCRIPTION

Item

Punching method

Paper size

Paper weight

Punched hole diameter

Punched scrap capacity

Power supply

Power consumption

Description

Sequential punching

2 holes (puncher unit MJ-6003E): A3, A4, A4-R, B4, B5, B5-R

2 or 3 holes (puncher unit MJ-6003N): 2 holes/LG, LT-R

3 holes/LD, LT

4 holes (puncher unit MJ-6003F/ 6003S): A3, A4, A4-R (MJ-6003S)

60 to 256 g/m2

(Note 1)

2 holes (puncher unit MJ-6003E): 6.5mm

2 or 3 holes (puncher unit MJ-6003N): 2 holes/8.0mm

2 holes/0.31in

3 holes/8.0mm

3 holes/0.31in

4 holes (puncher unit MJ-6003F/ 6003S): 6.5mm

2 holes (puncher unit MJ-6003E): 5,000 sheets or more (64g/m

equivalent)

2 or 3 holes (puncher unit MJ-6003N): 3,000 sheets or more (75 g/m

equivalent)

4 holes (puncher unit MJ-6003F/6003S): 5,000 sheets or more (80 g/m

equivalent)

From finisher unit (24 VDC, 5 VDC)

120 W or less

2

2

2

Note1: Transparencies, reproducibles, label paper, postcards and hole-punched paper cannot be handled.

Hole position (Puncher Unit)

Figure 1-203-1

1-7

Page 18

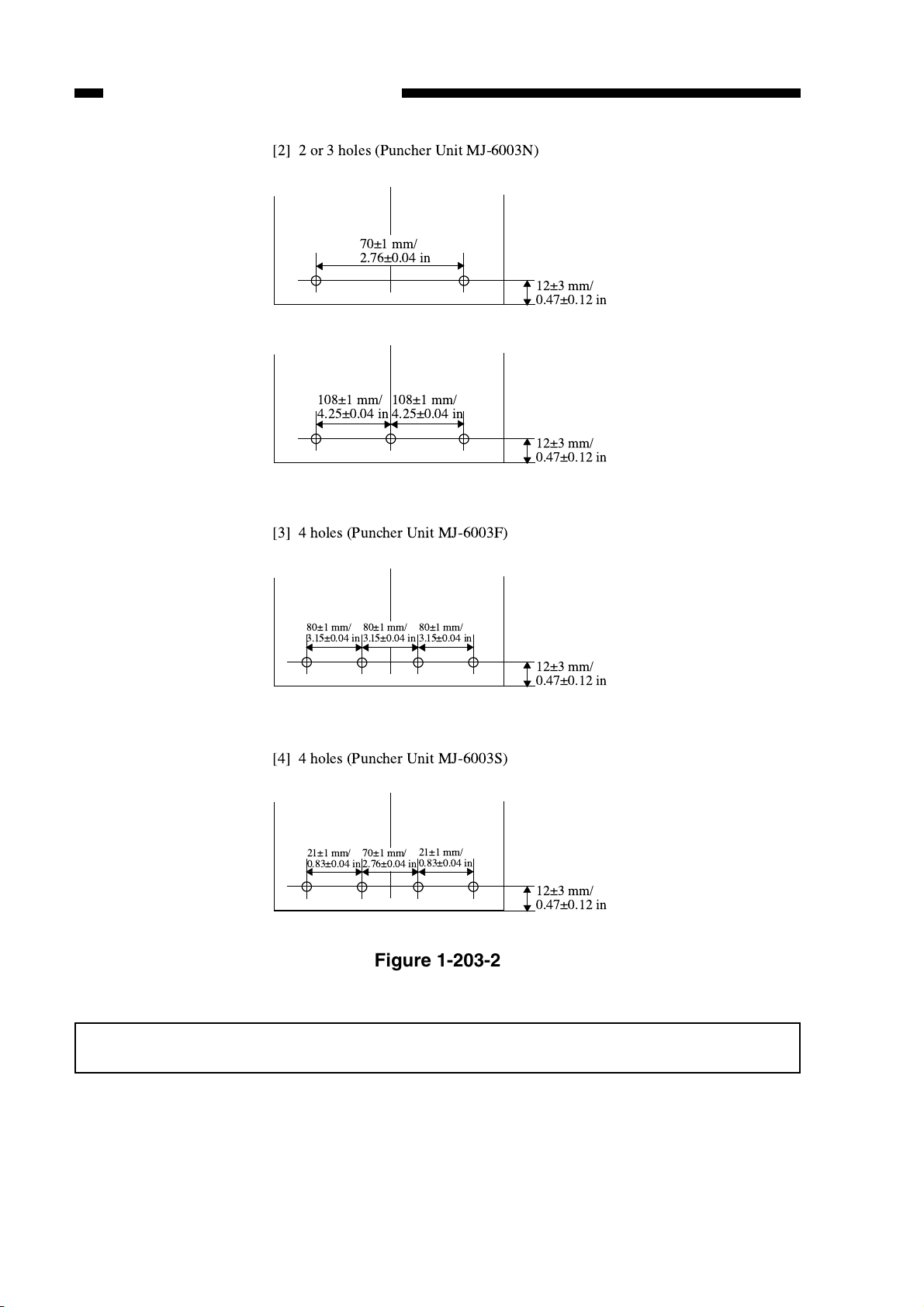

CHAPTER 1 GENERAL DESCRIPTION

[2] 2 or 3 holes (Puncher Unit MJ-6003N)

70±1 mm/

2.76±0.04 in

12±3 mm/

0.47±0.12 in

108±1 mm/

4.25±0.04 in

108±1 mm/

4.25±0.04 in

[3] 4 holes (Puncher Unit MJ-6003F)

80±1 mm/

3.1 5±0.04in

80±1 mm/

3.1 5±0.04in

80±1 mm/

3.1 5±0.04in

[4] 4 holes (Puncher Unit MJ-6003S)

12±3 mm/

0.47±0.12 in

12±3 mm/

0.47±0.12 in

1-8

21±1 mm/

0.83±0.04 in

70±1 mm/

2.76±0.04 in

21±1 mm/

0.83±0.04 in

12±3 mm/

0.47±0.12 in

Figure 1-203-2

Specifications are subject to change without notice.

Page 19

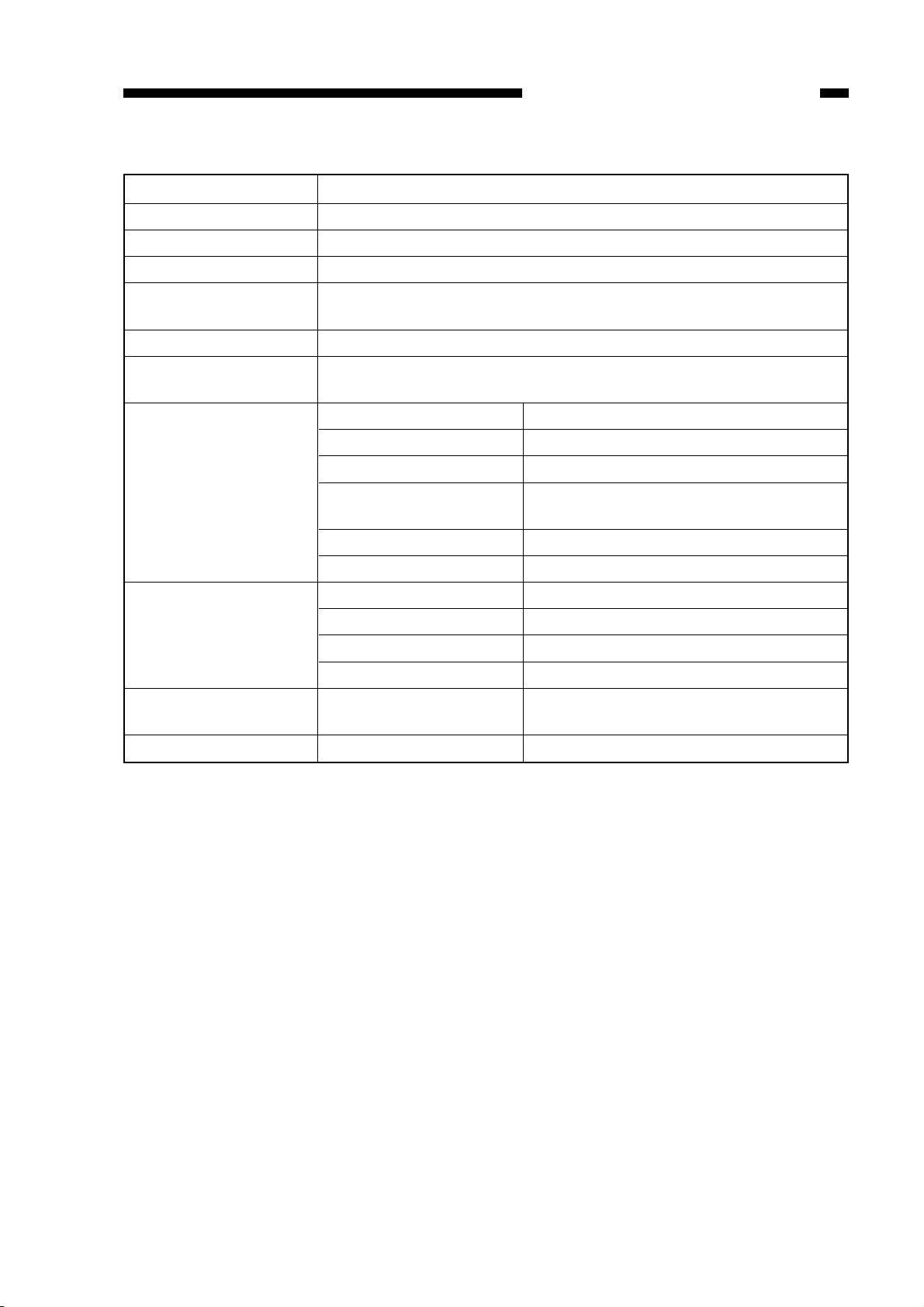

4. Inserter section

CHAPTER 1 GENERAL DESCRIPTION

Item

Paper size

Paper weight

Special papers

Laded number of

papers

A3, A4, A4-R, B4, B5, FOLIO, LD, LG, L T, LT -R

60g/m2 ~ 256g/m2 (16 lb. ~ 140 lb. Index)

OHP film, color paper (coated paper), hole-punched paper

100 at maximum for papers less than 80g/m2, number of papers up to 12mm

of laden height for papers more than 80g/m

* less than 60% of the above quantities for special papers

Inserter size

Inserter weight

533 × 612 × 1072mm (21 × 24.13 × 42.38 in) (W × D × H)

Approx. 20kg

* NOTE: Refer to 1-7, 8 for the hole position

Details

(*NOTE)

2

Table 1-204

1-9

Page 20

CHAPTER 1 GENERAL DESCRIPTION

B. Cross Section

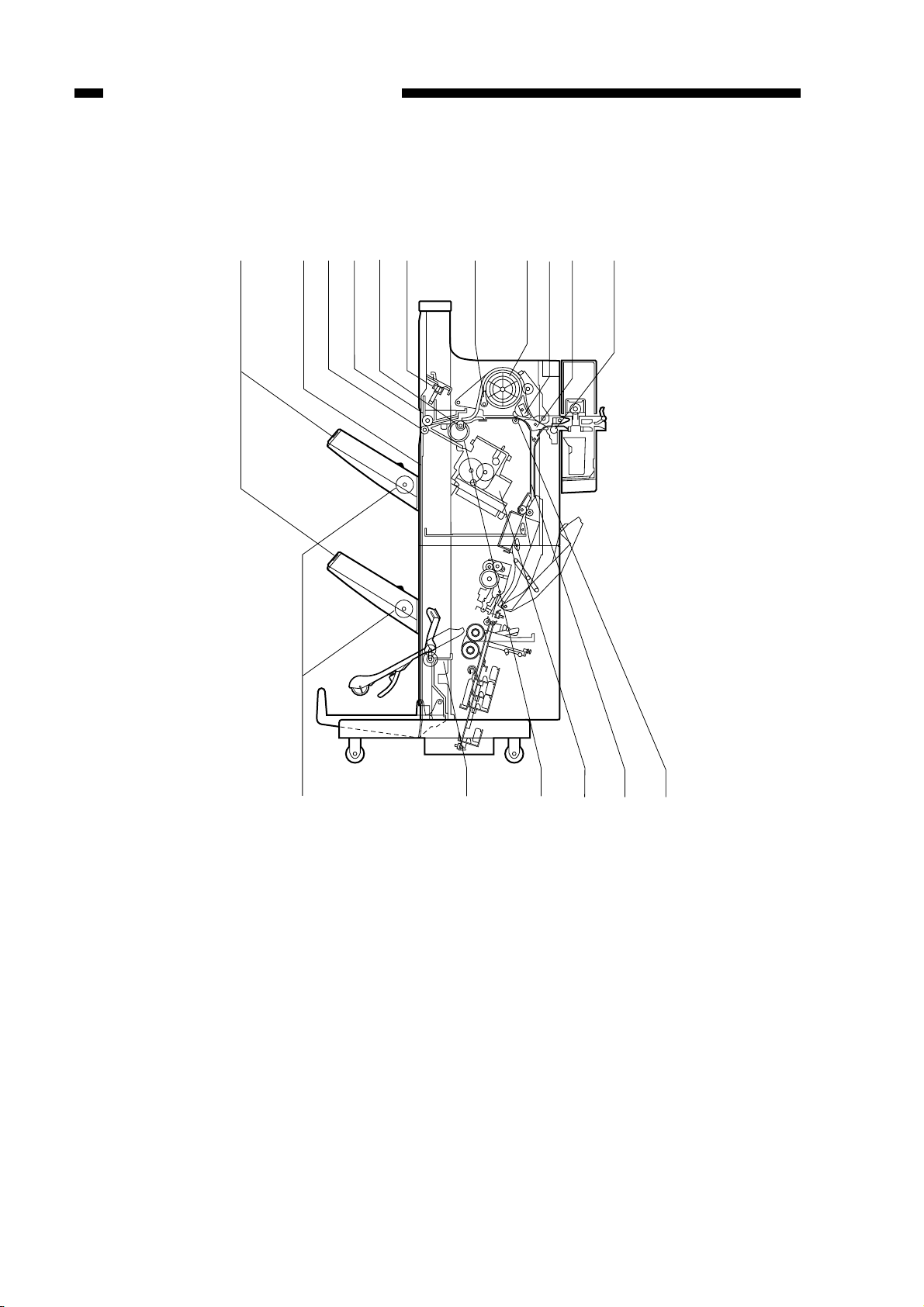

1. Finisher Unit

[1] [2] [3] [4] [5] [6] [8]

[7] [10] [11][9]

1-10

[1] Tray 1/2

[2] Shutter

[3] Deli v ery roller

[4] Swing guide

[5] Feed roller 2

[6] Height sensor

[7] Wrap flapper

[8] Buffer roller

[9] Buffer inlet flapper

[15][17][16] [14] [13] [12]

[10] Saddle stitcher flapper

[11] Inlet feed roller

[12] Feed roller 1

[13] Vertical path

[14] Stapler

[15] Feed belt

[16] Tray lift motor

[17] Saddle stitcher unit

(saddle finisher MJ-1018)

Figure 1-204

Page 21

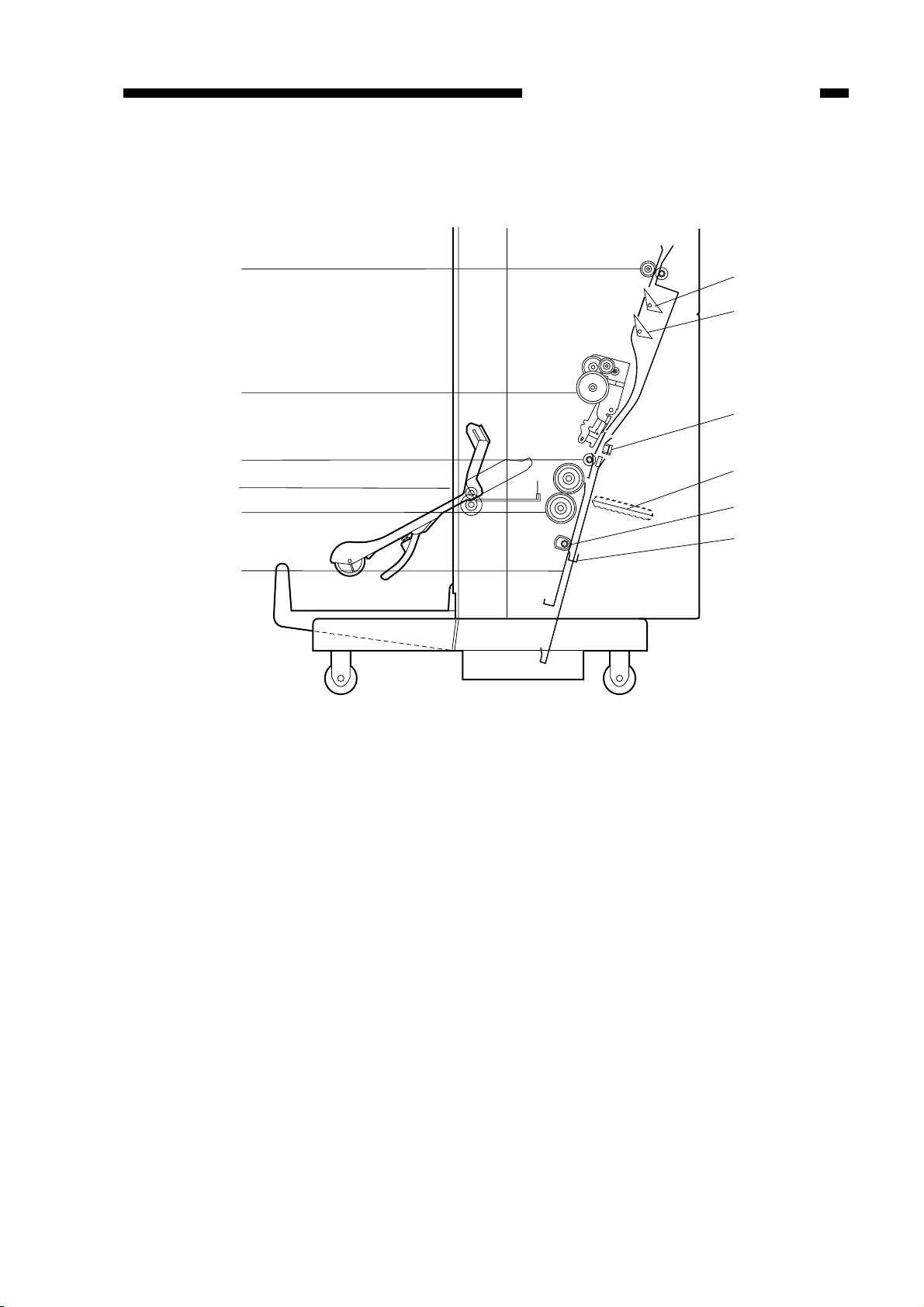

2. Saddle Stitcher Unit

CHAPTER 1 GENERAL DESCRIPTION

[6]

[5]

[4]

[3]

[2]

[1]

[7]

[8]

[9]

[10]

[11]

[12]

[1] Guide plate

[2] Pa per folding roller

[3] Deli v ery guide plate

[4] Holding roller

[5] Stitcher (front, rear)

[6] Inlet roller

[7] No.1 flapper

[8] No. 2 flapper

[9] Stitcher mount

[10] Paper pushing plate

[11] Crescent roller

[12] Paper positioning plate

Figure 1-205

1-11

Page 22

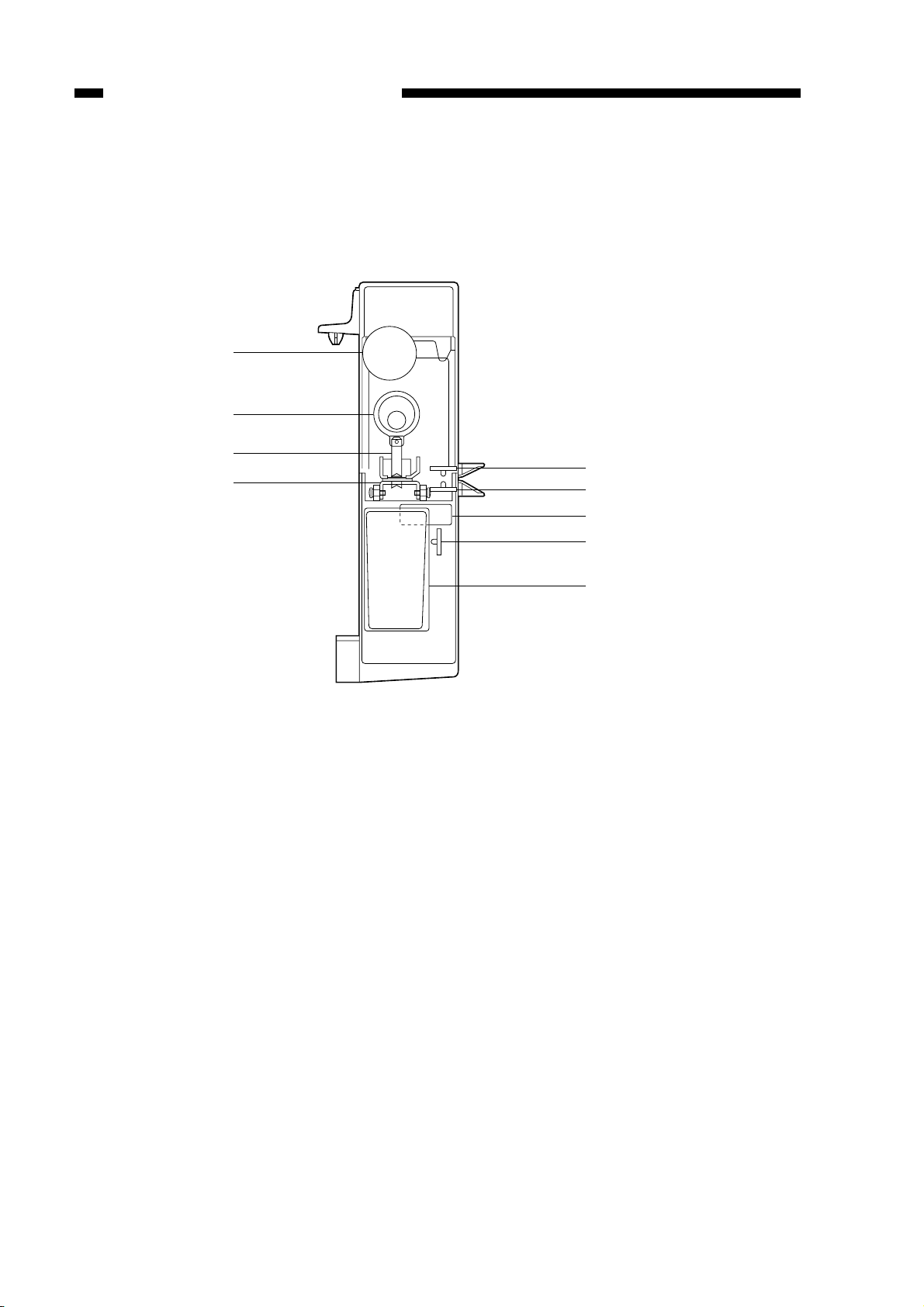

CHAPTER 1 GENERAL DESCRIPTION

3. Puncher Unit (option)

[1]

[2]

[3]

[4]

[1] Punch motor

[2] Cam

[3] Hole puncher (Punch blade)

[4] Die

[5] Photosensor PCB

[5]

[6]

[7]

[8]

[9]

[6] LED PCB

[7] Horizontal registration motor

[8] Scrap full detector PCB unit

[9] Punched scrap container

1-12

Figure 1-206

Page 23

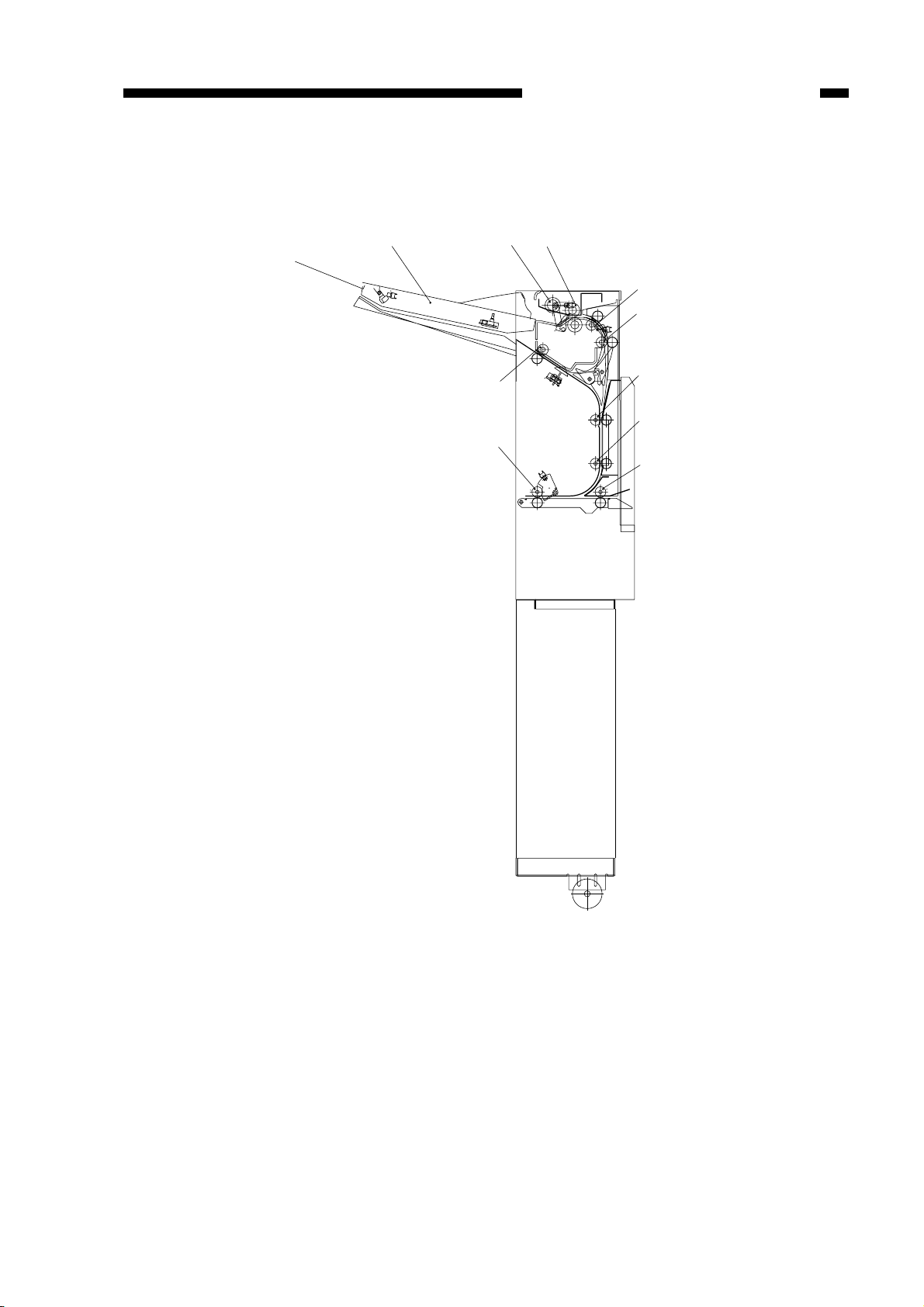

4. Inserter section (optional)

[1]

[10]

[9]

CHAPTER 1 GENERAL DESCRIPTION

[3]

[2]

[4]

[5]

[6]

[7]

[8]

[1] Tray

[2] Pickup roller

[3] Feed roller

[4] Transport roller 1

[5] Transport roller 2

[6] Transport roller 3

[7] Transport roller 4

[8] Transport roller 5

[9] Transport roller 6

[10] Reverse roller

Figure 1-207

1-13

Page 24

CHAPTER 1 GENERAL DESCRIPTION

III. Using the Machine

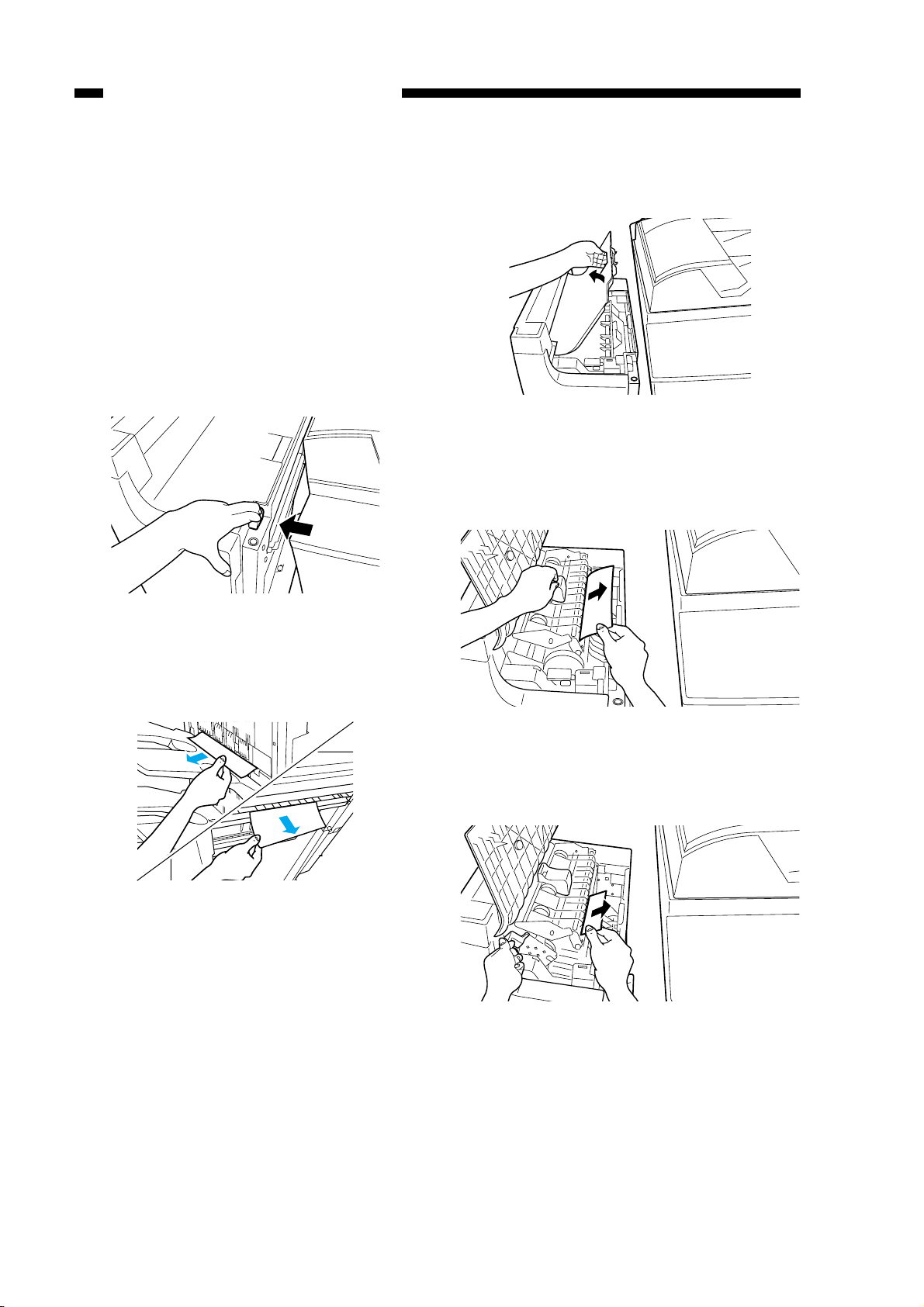

A. Removing Paper Jams

from the Finisher Unit

If the host machine indicates the finisher

paper jam message, perform the following to

remove the jam.

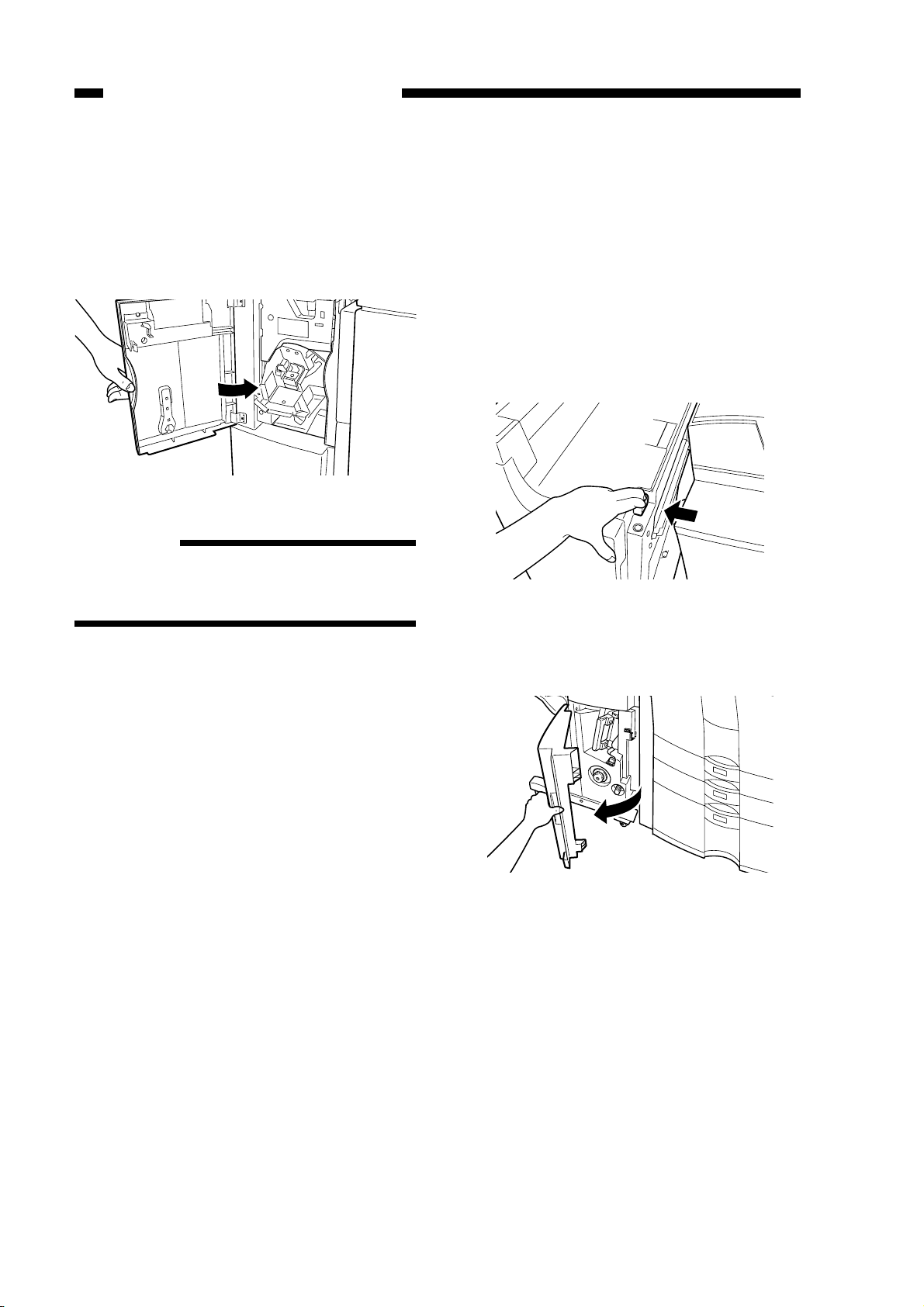

1) Holding the finisher unit as shown, move

it to detach it from the host machine.

3) Open the upper cover, and check the inside of the finisher.

Figure 1-303

4) Lift the buffer roller co ver , and remove the

jam.

Figure 1-301

2) Remove any jam visible from the outside.

Figure 1-302

Figure 1-304

5) Lift the buffer roller, and remove the jam.

Figure 1-305

1-14

Page 25

CHAPTER 1 GENERAL DESCRIPTION

6) Return the buffer roller and the b uffer roller

cover to their original positions, and close

the upper cover.

Figure 1-306

7) Connect the finisher to the host machine.

B. Supplying the Finisher

Unit with Staples

If the host machine indicates the finisher

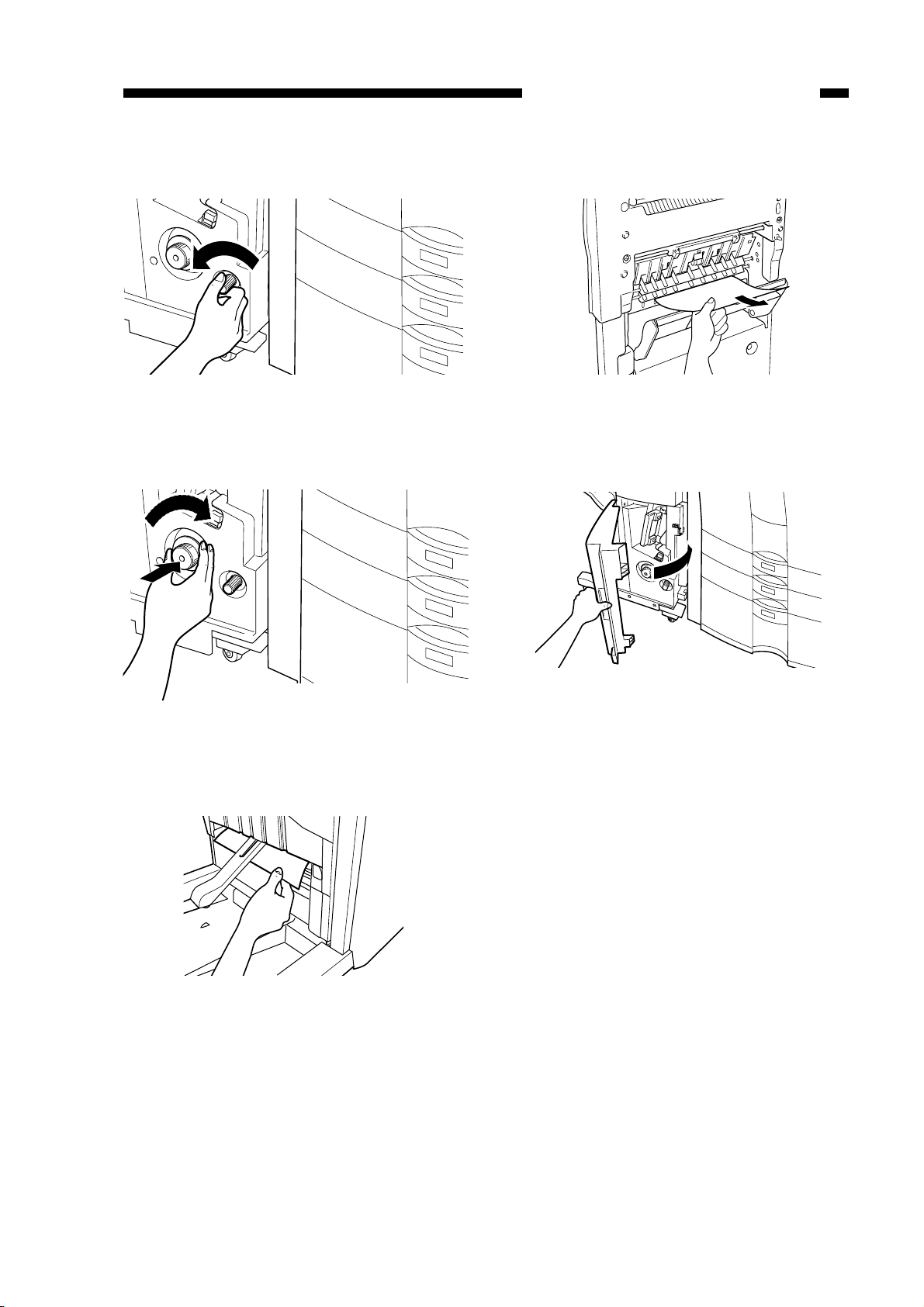

unit staple supply message, perform the following to supply it with staples.

1) Open the front cover.

Figure 1-308

2) Shift down the blue lever.

Figure 1-307

8) Operate as instructed on the display.

Figure 1-309

3) When the staple cartridge has slightly slid

out, hold and pull it out.

Figure 1-310

1-15

Page 26

CHAPTER 1 GENERAL DESCRIPTION

4) Hold the empty staple case on its sides, and

slide it out.

Figure 1-311

5) Set a new staple case.

6) Pull the length of tape (used to hold the

staples in place) straight out.

Figure 1-313

7) Push in the stapler unit until the blue lever

returns to its original position.

Figure 1-312

Reference:

You may set no more than one staple

cartridge at a time.

Make sure that the new cartridge is one

specifically designed for the finisher unit.

Figure 1-314

8) Check to make sure that the stapler has

been locked in place, and close the front

cover.

Figure 1-315

1-16

Page 27

CHAPTER 1 GENERAL DESCRIPTION

C. Removing Staple Jams

from the Finisher Unit

If the host machine indicates the finisher

unit staple jam message, perform the following to remove the jam.

1) Remove the stack waiting to be stapled

from the delivery tray.

Figure 1-316

4) When the staple cartridge has slightly slid

out, hold and pull it out.

Figure 1-319

5) Shift down the tab on the staple cartridge.

2) Open the front cover.

Figure 1-317

3) Shift down the blue lever.

Figure 1-320

6) Remove all staples that have slid out of the

staple case.

Figure 1-321

Figure 1-318

1-17

Page 28

CHAPTER 1 GENERAL DESCRIPTION

7) Return the tab on the staple cartridge to its

original position.

8) Return the staple cartridge to its original

position, and close the front cover.

Figure 1-322

Reference

When the cover has been closed, the stapler

unit will automatically execute idle punching

several times to advance the staples.

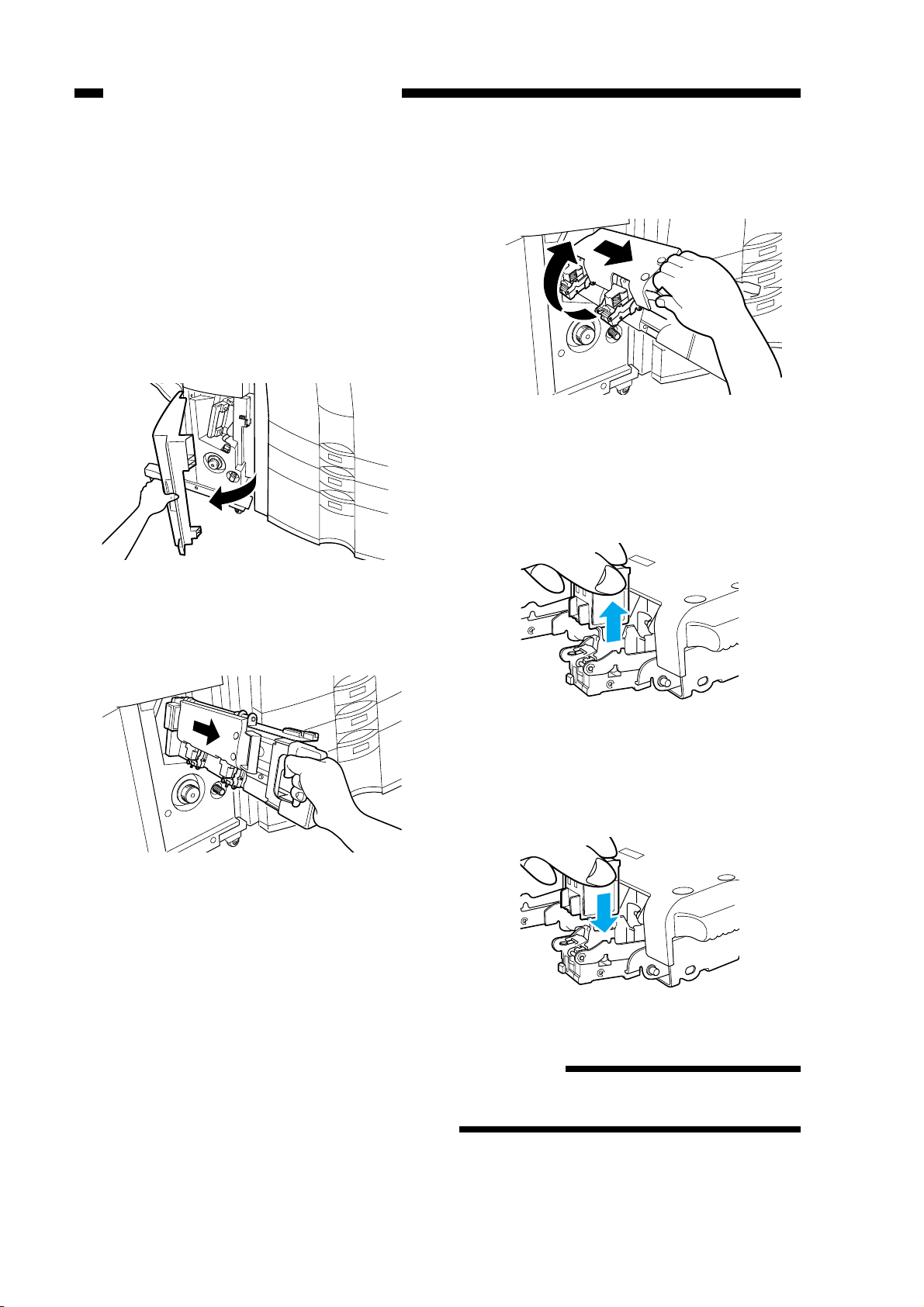

D. Removing Paper Jams

from the Saddle Stitcher

Unit (Saddle Finisher)

If the host machine indicates the saddle

stitcher unit paper jam message, perform the

following to remove the jam.

1) Holding the saddle stitcher unit as shown,

move it to detach it from the host machine.

Figure 1-323

2) Open the front lower cover.

Figure 1-324

1-18

Page 29

CHAPTER 1 GENERAL DESCRIPTION

3) Turn the knob on the left side.

Figure 1-325

4) Turn the knob on the right side while pushing it in.

6) Open the inlet cover, and remov e the jam.

Figure 1-328

7) Close the front lower cover .

Figure 1-326

5) Remove the jam.

Figure 1-327

Figure 1-329

8) Connect the finisher unit.

9) Operate as instructed on the display.

1-19

Page 30

CHAPTER 1 GENERAL DESCRIPTION

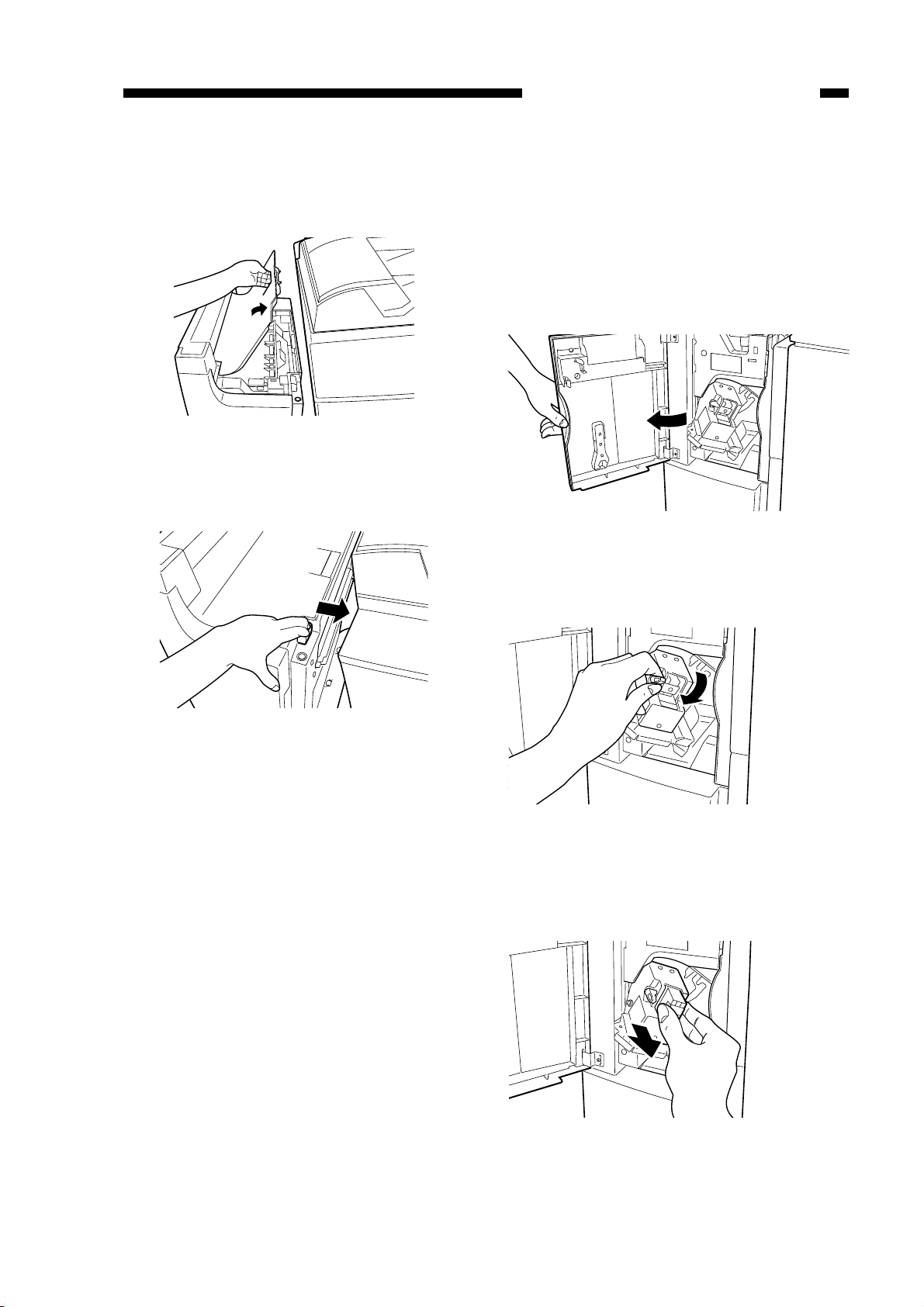

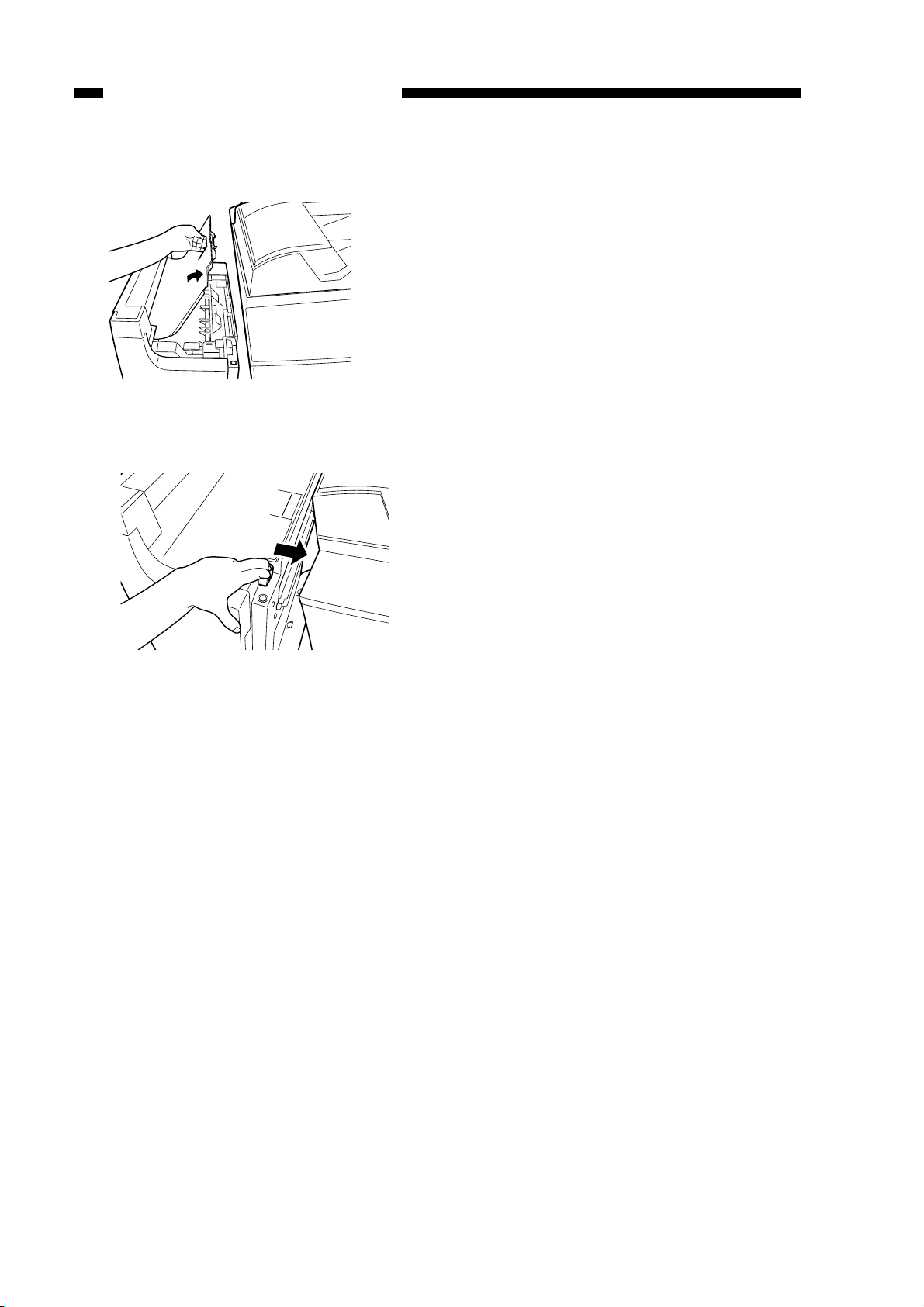

E. Supplying the Saddle

Stitcher Unit with Staples

(Saddle Finisher)

If the host machine indicates the saddle

stitcher unit staple supply message, perform the

following to supply it with staples.

1) Open the front lower cover.

Figure 1-330

3) Pull the stitcher unit to the front once, and

then shift it up.

Figure 1-332

4) Hold the empty cartridge on its sides, and

remove it.

2) Slide out the stitcher unit.

Figure 1-331

Figure 1-333

5) Set a new cartridge.

Figure 1-334

Reference

You must always replace both cartridges at

the same time.

1-20

Page 31

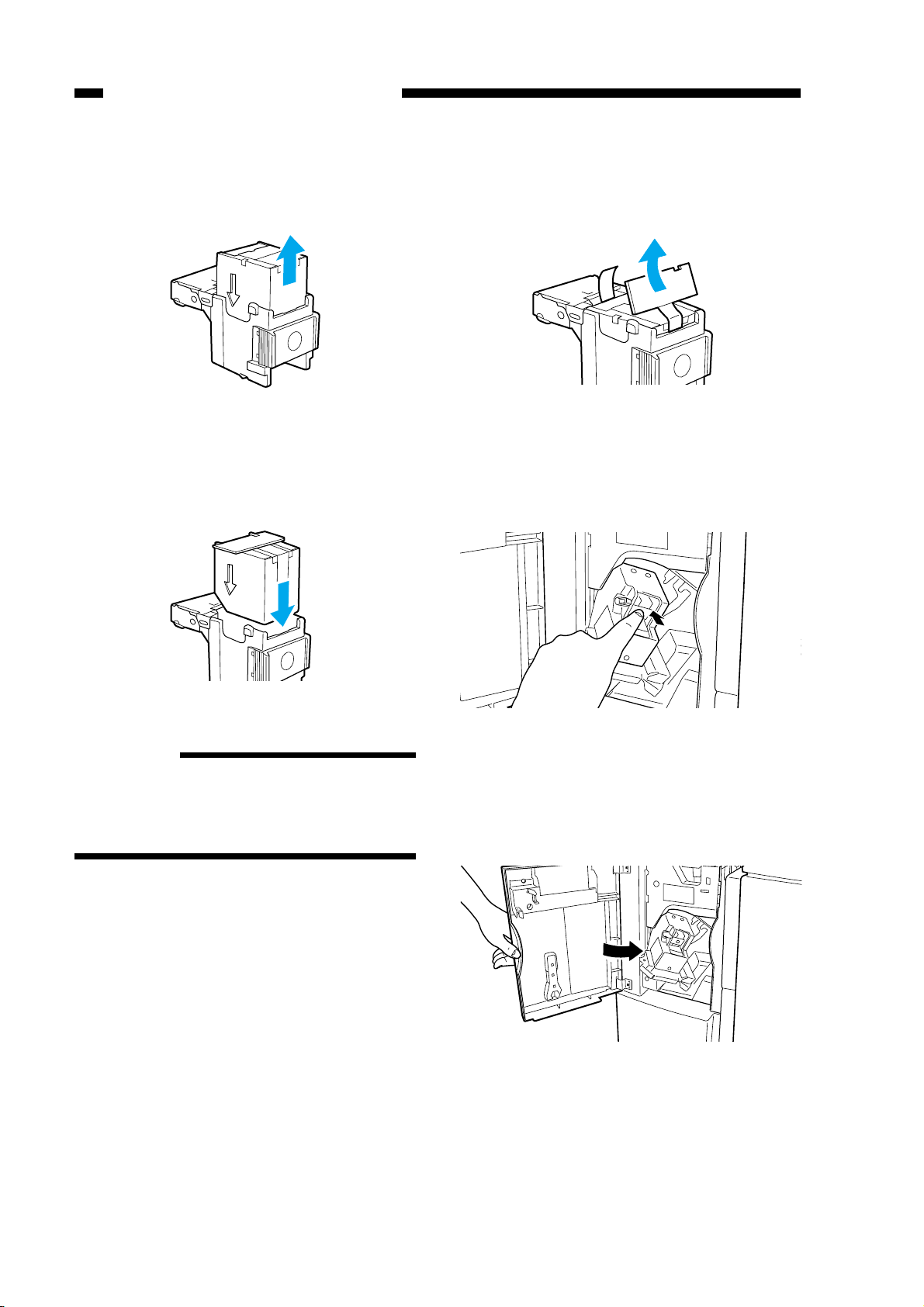

CHAPTER 1 GENERAL DESCRIPTION

6) Pull the stitcher to the front once, and then

return it to its original position.

Figure 1-335

7) Push in the stitcher unit, and close the front

cover.

F. Removing Staple Jams

from the Saddle Stitcher

Unit (Saddle Finisher)

If the host machine indicates the saddle

stitcher unit staple jam message, perform the

following to remov e the jam.

1) Open the front lower cover.

Figure 1-337

Figure 1-336

2) Slide out the stitcher unit.

Figure 1-338

3) Pull the stapler of the stitcher unit to the

front once, and then shift it up.

Figure 1-339

1-21

Page 32

CHAPTER 1 GENERAL DESCRIPTION

4) Hold the cartridge on its sides, and remove

it.

Figure 1-340

5) Push down on the area identified as A, and

pull up the tab identified as B.

7) Return the cartridge to its original position.

Figure 1-343

8) Pull the stitcher of the stitcher unit to the

front once, and then return it to its original

position.

Figure 1-341

6) Remove the staple jam, and return the tab

B to its original position.

Figure 1-342

Figure 1-344

9) Push the stitcher unit back to its original

position, and close the front lower cov er.

Figure 1-345

Reference

Whenever you have removed a staple jam, be

sure to execute staple edging.

1-22

Page 33

CHAPTER 1 GENERAL DESCRIPTION

G. Removing Paper Jams

from the Puncher Unit

(option)

If the display indicates a paper jam on the

puncher unit, perform the following to remov e

the jam:

1) Open the front cover of the puncher unit.

4) Holding the finisher unit as shown, move

it to detach it from the most machine.

Figure 1-349

5) Remove any jam visible from the outside.

Figure 1-346

2) Align the triangle mark on the knob within

the range marked by .

Figure 1-347

3) Close the front cover of the puncher unit.

Figure 1-350

6) Open the upper cover, and check the inside of the finisher.

Figure 1-351

7) Lift the buffer roller cover , and remove the

jam.

Figure 1-348

Figure 1-352

1-23

Page 34

CHAPTER 1 GENERAL DESCRIPTION

8) Return the buffer roller and the b uffer roller

cover to their original position, and close

the upper cover.

Figure 1-353

9) Connect the finisher to the host machine.

Figure 1-354

10) Operate as instructed on the display.

1-24

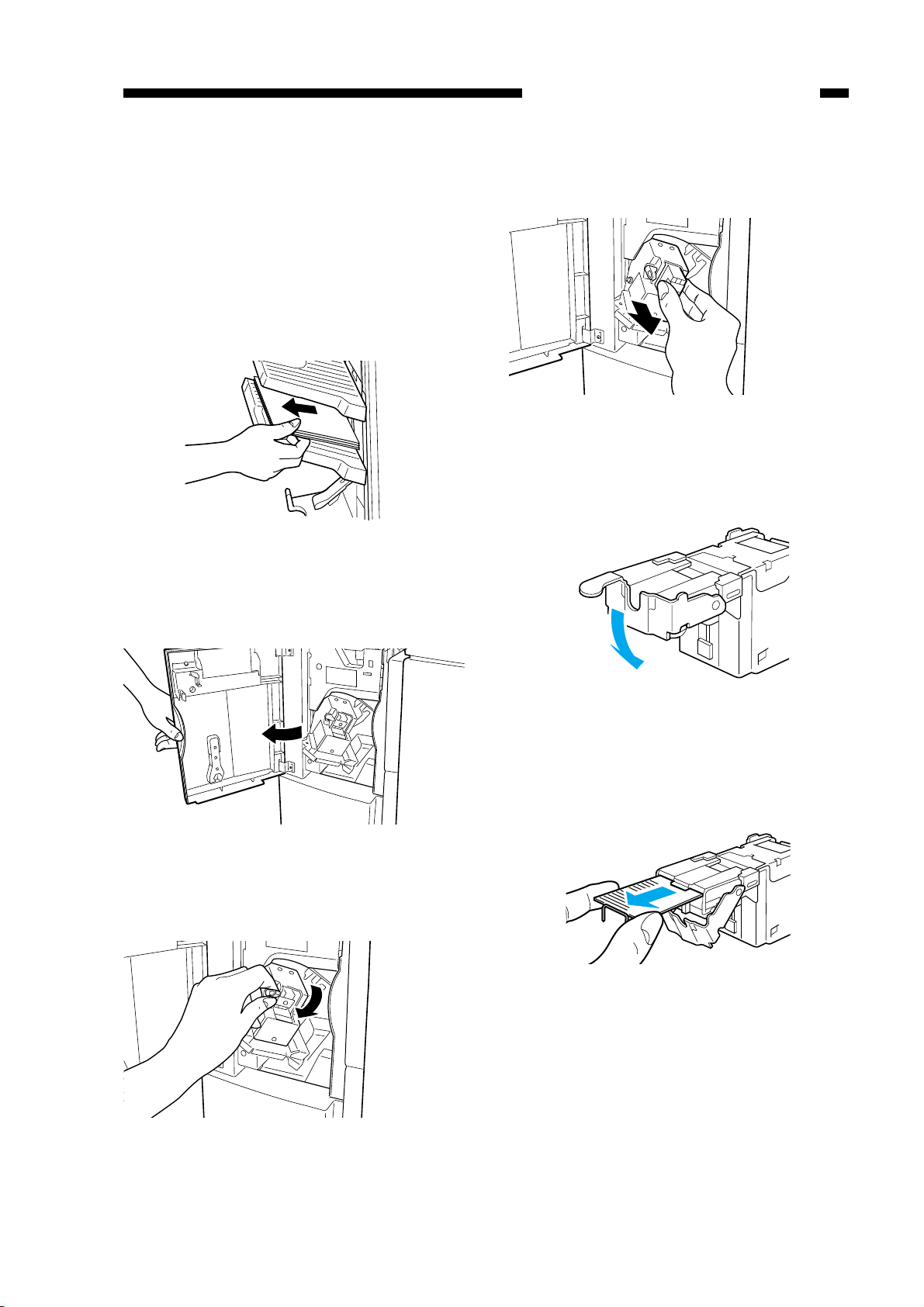

Page 35

CHAPTER 1 GENERAL DESCRIPTION

H. Removing Punched Scrap

from the Puncher Unit

(option)

If the display indicates a punched scrap full

state on the puncher unit, perform the following to remove the punched scrap:

1) Open the front cover of the puncher unit.

Figure 1-355

2) Slide out the punched scrap container.

4) Return the punched scrap container to its

original position.

Figure 1-358

Figure 1-356

3) Discard the punched scrap.

Figure 1-357

1-25

Page 36

CHAPTER 1 GENERAL DESCRIPTION

IV. MAINTENANCE BY THE USER

A. Maintenance by the User

No.

1

2

Item

Replacing the staple cartridge (finisher unit)

Replacing the staple cartridge (saddle stitcher

unit)

When the appropriate indication is made on

the host machine’s display.

Timing

Caution:

The finisher unit and the saddle stitcher unit use different cartridge types. Be sure that the

appropriate type is used for each.

Table 1-401

1-26

Page 37

CHAPTER 2

FINISHER UNIT BASIC OPERATION

1. This chapter discusses the purpose and role of each of the finisher’s functions, and the principles of operation used for the finisher mechanical and electrical systems. It also explains the

timing at which these systems are operated.The symbol in drawings indicates transmission

of mechanical drive, and signals marked by together with the signal name indicates the

flow of electrical signals.

2. In descriptions of digital circuits on the finisher, “1” indicates a high signal voltage level, while

“0” indicates a low signal voltage level. Voltage values differ according to circuit.

A microprocessor is used on the finisher. A description of microprocessor operation is omitted

in this chapter as it is practically impossible to check internal operation of the microprocessor.

Descriptions in this chapter also assume that PCBs will not be repaired at user sites. For this

reason, descriptions of circuits on PCBs is limited to block diagrams. Two types of block diagrams are provided for separate functions: diagrams indicating details from sensors up to input

sections of major PCBs, and diagrams indicating details from the output sections of major

PCBs up the loads.

I. BASIC OPERATION ....................2-1

A. Outline .......................................2-1

B. Outline of Electrical Circuitry...... 2-2

C. Inputs to and Outputs from the

Finisher Controller PCB .............2-4

II. FEED/DRIVE SYSTEM ............. 2-10

A. Outline .....................................2-10

B. Type of Delivery Paths .............2-15

C. Feeding and Delivering ............2-18

D. Job Offset ................................ 2-21

E. Staple Operation ...................... 2-24

F. Stapler Unit .............................. 2-32

G. Tray Operation.......................... 2-38

H. Detecting the Height of

Stack on the Tray...................... 2-40

I. Shutter Operation .................... 2-42

J. Buffer Path Operation ..............2-46

K. Detecting Jams ........................2-51

III. POWER SUPPLY SYSTEM .......2-56

Page 38

I. BASIC OPERATION

A. Outline

CHAPTER 2 FINISHER UNIT BASIC OPERATION

The finisher is designed to deliver copies arriving from its host machine, and its modes of

delivery include simple stacking, job offset

(Note)

, and staple.

All operations inv olved in these modes are controlled by the finisher controller PCB, according

to the appropriate commands from the host machine.

In the case of the Saddle Finisher, copies from the host machine may be routed to the saddle

stitcher unit.

Swing guide drive system

Alignment drive system

Stapler drive system

Delivery drive system

Feeder drive system

Tray drive system

Control system

Shutter drive system

Saddle stitcher unit control system

(Saddle Finisher)

Tray drive system

Figure 2-101

Note:

The term job offset refers to shifting each sorting job, separating a single

stack into several stacks.

2-1

Page 39

CHAPTER 2 FINISHER UNIT BASIC OPERATION

B. Outline of Electrical Circuitry

The finisher’s sequence of operation is controlled by the finisher controller PCB. The finisher

controller PCB is a 16-bit microprocessor (CPU), and is used for communication with the host

machine (serial) in addition to controlling the finisher’s sequence of operations.

The finisher controller PCB responds to the various commands coming from the host machine

through a serial communications line to drive solenoids, motors, and other loads. In addition, it

communicates the finisher’s various states (information on sensors and switches) to the host machine through a serial communications circuit.

In the case of the Saddle Finisher, the f inisher controller PCB not only communicates with the

saddle stitcher controller PCB but also communicates the saddle stitcher unit’s various states (information on sensors and switches) to the host machine.

The ICs used on the finisher controller PCB are designed for the following:

●

IC1 (CPU)

Controls sequence of operations.

●

IC2 (EP-ROM)

Backs up adjustment values.

●

IC3

Contains sequence programs.

●

IC6/IC7 (RAM)

Backs up initial setting data.

●

IC4 (communications IC)

Communicates with the host machine and the saddle stitcher unit.

●

IC9 (regulator IC)

Generates PWM.

Figure 2-102 shows the flow of signals between the finisher and the options controller.

2-2

Page 40

CHAPTER 2 FINISHER UNIT BASIC OPERATION

Saddle stitcher

controller PCB

(Saddle Finisher)

Punch driver PCB

(Puncher unit (option))

Host machine

(DC controller PCB CPU)

Connecting with inserter

Saddle stitcher

controller PCB

(Saddle Finisher)

Finisher controller

PCB communication

IC1

CPU

IC2

EEP-ROM

IC4

IC

IC3

EP-ROM

IC6/IC7

RAM

IC9

Regulator IC

Finisher controller

PCB communication

IC1

CPU

Motor

Solenoid

Switch

Sensor

Motor

Solenoid

Host machine

(DC controller PCB CPU)

Punch driver PCB

(Puncher unit (option))

Inserter

driver PCB

(Inserter unit

(option)

)

Figure 2-102

IC2

EEP-ROM

IC4

IC

IC3

EP-ROM

IC6/IC7

RAM

IC9

Regulator IC

Switch

Sensor

2-3

Page 41

CHAPTER 2 FINISHER UNIT BASIC OPERATION

C. Inputs to and Outputs from the Finisher Controller PCB

1. Inputs to the Finisher Controller PCB

Finisher controller PCB

Inlet sensor

Delivery sensor

Stapling tray

sensor

Shutter open

sensor

Alignment plate

home position

sensor

Stapler shift home

position sensor

PI1

PI3

PI4

PI5

PI6

PI7

J106-3

J134-1

J122-3

J118-3

J121-3

J129-3

-7

-1

-2

-2

-3

-1

-2

-1

-2

-1

-2

-1

-2

-9

-8

-3

-2

-1

-1

-3

-2

-1

-3

-2

-4

-6

-5

-1

-3

-2

J202

J208

J207A

J205

J207A

J210

-3

-1

-2

-5

-6

-7

-11

-9

-10

-3

-1

-2

-8

-6

-7

-3

-1

-2

J17-7

J11-3

J9A-1

J12B-4

J9A-4

J12A-4

-9

-8

-2

-1

-3

-2

-6

-5

-6

-5

-6

-5

+5V

PENT

+5V

PDEL

+5V

STPTY

+5V

STOPN

+5V

JOGHP

+5V

STPHP

When the sensor detects

paper, “1”.

When the sensor detects

paper, “1”.

When the sensor detects

paper, “1”.

When the shutter opens, “1”.

When the alignment plate

is at the home position, “1”.

When the stapler is at the

home position, “1”.

Tray 1 home

position sensor

2-4

PI8

J130-3

J14A-1

-1

-2

-3

-2

+5V

TRYHP 1

When the tray 1 is at the

home position, “1”.

Figure 2-103

Page 42

CHAPTER 2 FINISHER UNIT BASIC OPERATION

2. Inputs to the Finisher Controller PCB

Finisher controller PCB

Delivery motor

clock sensor

Tray 1 paper

sensor

Tray 2 paper

sensor

Buffer path paper

sensor

Joint sensor

Door open

sensor

PI10

PI11

PI12

PI14

PI15

PI16

J120-1

J2011-3

J8011-3

J110-3

J117-3

J1130-3

-9

-2

-3

-1

-1

-3

-2

-2

-1

-1

-3

-2

-2

-1

-2

-1

-2

-1

-2

-8

-7

J2010

J8010

-1

-3

-2

-3

-1

-2

-3

-1

-2

-3

-4

-5

J207A

-1

-3

-2

-7

-9

-8

J113

J9A-9

+5V

-8

DELCLK

-7

-3

J14A-4

-1

-2

J201

J14B-7

-3

-1

-2

J801

J12A-1

-3

-1

-2

J12B-1

J24-4

+5V

-6

FSTTRAY*

-5

+5V

-9

SNDTRAY*

-8

+5V

-6

BUFPASS

-5

+5V

-3

JOINT

-2

+5V

-3

DROPN

-2

While the delivery motor

is rotating, alternately

between “0” and “1”.

When paper is present on

tray 1, “0”.

When paper is present on

tray 2, “0”.

When paper is in the

buffer path, “1”.

When the finisher is joined

with the host machine, “1”.

When the front door is

open, “0”.

Buffer path inlet

paper sensor

Swing guide

open sensor

Tray 1 lift

motor clock

sensor 1

Tray 1 lift

motor clock

sensor 2

Tray 2 lift

motor clock

sensor 1

Tray 2 lift

motor clock

sensor 2

PI17

PI18

PI9

PI19

PI23

PI24

J105-3

J127-3

J6011-3

J6011-6

J8021-3

J24-1

J11-8

-10

-12

-11

+5V

-3

BUFENTR

-2

+5V

SWGOPN

-9

+5V

SFTCLK11

+5V

-9

SFTCLK12

-8

+5V

-6

SFTCLK21

-5

+5V

-3

SFTCLK22

-2

-1

-2

-1

-1

-2

-1

-2

-4

-5

-3

-2

-4

-6

-5

J6010

-1

-3

-2

-4

-6

-1

-5

-2

J8020

-1

-6

-3

-4

-2

-5

-3

-1

-2

-6

-4

-5

-3

-1

-2

-6

-4

-5

J204

-3

-1

-2

J601

J801

J14A-10

-3

-1

-2

-6

-4

-5

-6

-4

-5

-9

-7

-8

J14A-7

J14B-4

J14B-1

-4

-6

-5

-1

-3

-2

-4

-6

-5

-1

-3

-2

When paper is present at

the buffer path inlet, “1”.

When the swing guide is

open, “1”.

When the tray 1 lift motor

is rotating, alternately

between “1” and “0”.

When the tray 1 lift motor

is rotating, alternately

between “1” and “0”.

When the tray 2 lift motor

is rotating, alternately

between “1” and “0”.

When the tray 2 lift motor

is rotating, alternately

between “1” and “0”.

Figure 2-104

2-5

Page 43

CHAPTER 2 FINISHER UNIT BASIC OPERATION

3. Inputs to the Finisher Controller PCB

PI20

Swing motor

clock sensor

PI25

Tray 2 home

position sensor

Height sensor

Door switch

N. O.

MS1

C.

J112-1

Swing guide closed detecting switch 1

N. O.

C.

MS2

PS1

J125-1

-2

-3

J135-3

-1

-2

J114-3

-2

-2

-4

-1

-2

-3

-4

J112-1

-2

-5

-4

-3

J212

-1

-2

-1

-2

J207B

-3

-2

-4

-1

-2

-3

-1

-4

J112

J209

-7

-8

-9

-1

-2

-1

-2

J14B-10

J213

J9B-5

J6-2

-3

-4

-2

-1

J5-1

J5-6

-4

-3

-12

-11

-1

-3

-4-1

-2

-7

Finisher controller PCB

+5V

SWGCLK

When the swing motor is

rotating, alternately between

“0” and “1”.

+5V

TRYHP2

+5V

Height

PWR

When the tray 2 is home

position, “1”.

Measures the distance between

the sensor and the top of the

stack on the tray.

+24V

+24VMOVE

DRSW

+24V SHIFT

When the front door

and the upper cover

are closed, “1”.

Swing guide closed detecting switch 2

N. O.

C.

MS6

Safety zone switch

J131-1

MS3

C.

N. C.

N. O.

-3

-2

Shutter closed detecting switch

MS4

N. C.

N. O.

C.

J140-3

-2

-1

J206-1

Tray coming close detection switch

J138

MS9

N. C.

N. O.

C.

-3

-1

J1151

-3

-2

-1

J1151

-4

-3

J5-8

-9

J5-3

-5

-4

J7-7

-6

-5

J5-11

-10

+24VSTPL

+24VSHIFT

TRAYSAF

SHUTCLD

TRYLMT

+24VSHIFT

SWGGCLD

When the swing

guide is closed, “1”.

When the tray is at

the delivery slot, “1”.

When the shutter is

closed, “1”.

When the tray 1 gets

close to the tray 2: "0"

J209

J206-1

-4

-3

-3

-4

-2

-3

J115

-3

-4

-2

-3

-3

J115

-2

-1

2-6

Figure 2-105

Page 44

CHAPTER 2 FINISHER UNIT BASIC OPERATION

4. Inputs to and Outputs from the Finisher Controller PCB

Staple edging

sensor

Staple home

position sensor

Cartridge switch

Staple switch

Stapler unit

Finisher controller PCB

When a staple is at the edge of

*

the stapler, “0”.

When the stapler is at the home

*

position, “0”.

*

When a cartridge is present, “0”.

When staples are present in the

*

cartridge, “0”.

*

When the stapler is connected,

“0”.

Saddle stitcher

controller PCB

Host machine

J400-9 J400-1

-8

-7

-6

-5

-4

J51-3

-4

-1

-2

-8

-9

-11

-12

-6

-7

-5

CONNECT

-2

-3

-4

-5

-6

Communication line

J2-1

Communication line

JS1

Figure 2-106

2-7

Page 45

CHAPTER 2 FINISHER UNIT BASIC OPERATION

5. Outputs from the Finisher Controller PCB

Finisher controller PCB

Flapper solenoid

SL1

Buffer inlet solenoid

SL2

Buffer outlet solenoid

SL3

Paddle solenoid

SL5

Escape solenoid

SL6

-1 -2

J107

-2

-1 -3

J108

-2

-1 -2

J109

-2

-1 -2

J128

-2

-1 -3

J123

-2

-1 -2

J701

-2 -1

-1 -11

-2 -10

J207B

-10 -2

-11 -1

J207A

J12A-7

J12B-9

-10-2

J24-7

J9B-1

J9A-10

-11-2

-8-1

-8-1

-2-1

+24V

When "0", the solenoid turns on.

FLPSL*

+24V

When "0", the solenoid turns on.

ENTSL*

+24V

When "0", the solenoid turns on.

EXITSL*

+24V

When "0", the solenoid turns on.

PDLSL*

+24V

When "0", the solenoid turns on.

ESCPSL*

Belt escape solenoid

SL7

First feed motor

M1

Delivery motor

Alignment motor

-1 -2

-2

J10-6

-1

-2

-4

-3

-5

J501

J10-6

-1

-1

-2

-4

-3

-5

-1 -2

J500

-2 -1

J12B-7

J10-1

-8

BESCPSL*

-2

-3

B*

-4

A*

-5

B

-6

A

+24V

When "0", the solenoid turns on.

+24V

According to rotation direction/speed,

changes between + and - in sequence.

According to rotation

direction/speed, changes

between + and -.

According to rotation

direction/speed, changes

between + and - in sequence.

2-8

Figure 2-107

Page 46

CHAPTER 2 FINISHER UNIT BASIC OPERATION

6. Outputs from the Finisher Controller PCB

Stapler shift motor

Staple motor

Tray 1 lift motor

J115-1

-2

-1

-2

Finisher controller PCB

According to rotation

direction/speed, changes

between + and - in sequence.

According to rotation

direction/speed, changes

between + and -.

According to rotation

direction/speed, changes

between + and -.

Tray 2 lift motor

Swing motor

Second feed motor

Inlet feed motor

According to rotation

direction/speed, changes

between + and -.

According to rotation

direction/speed, changes

between + and -.

According to rotation

direction/speed, changes

between + and -.

Figure 2-108

According to rotation

direction/speed, changes

between + and - in sequence.

2-9

Page 47

CHAPTER 2 FINISHER UNIT BASIC OPERATION

II. FEED/DRIVE SYSTEM

A. Outline

The finisher is designed to operate according to the commands from its host machine to deli ver

arriving copies to trays in the appropriate mode: simple stacking, job offset, stapling.

See Figure 2-201 for a diagram of the three modes of delivery (four for the Saddle Finisher).

Method of delivery

Normal

delivery

Saddle stitch delivery (Saddle Finisher only)

Simple stacking

Job offset

Staple

Figure 2-201

Front diagonal

Rear 1-point

Rear diagonal

2-point

Normal delivery tray

Normal delivery tray

To saddle stitcher unit

(Saddle Finisher)

Figure 2-202

2-10

Page 48

1. Normal Delivery

a. Simple Stacking

The finisher delivers copies directly to the tray.

Tray Tray

CHAPTER 2 FINISHER UNIT BASIC OPERATION

CopiesCopies

Delivery roller

Figure 2-203

Feed roller 1

Feed roller 2

2-11

Page 49

CHAPTER 2 FINISHER UNIT BASIC OPERATION

b. Job Offset

The finisher forwards all copies of each sort job to the stapling tray. The first sort job on the

stapling tray is delivered with a shift to the front of about 30 mm, and the second sort job is deli vered without being shifted. Whether the fi rst copy or the last cop y of a sort job should be shifted is

determined by the host machine.

Tray

Each sort job is stacked

alternately.

Figure 2-204

Swing guide

Stapling tray

Results of Delivering 4 Sets

Direction of delivery

Delivery roller

Figure 2-205

Figure 2-206

Stopper

Feed roller 1

Copies handled

by job offset

2-12

Page 50

CHAPTER 2 FINISHER UNIT BASIC OPERATION

c. Stapling

The finisher stacks copies arriving from its host machine on the stapling tray. Then, it staples

and delivers the copies to the appropriate tray.

Tray

Copies

Staple

Swing guide

Delivery roller

Front diagonal stapling

Rear diagonal stapling

Stapling

tray

Stopper

Figure 2-207

Rear 1-point stapling

Feed roller 1

Paper width/2

2-point stapling

Figure 2-208

2-13

Page 51

CHAPTER 2 FINISHER UNIT BASIC OPERATION

2. Saddle Stitch Delivery (Saddle Finisher)

A copy arriving in the finisher from the host machine is routed to the saddle stitcher by the

paper deflecting plate. The saddle stitcher executes stitching and saddling operations on the copy

and then delivers it to the saddle stitcher tray.

For discussions of stacks in the saddle stitcher, see Chapter 3.

To saddle stitcher

Figure 2-209

2-14

Page 52

CHAPTER 2 FINISHER UNIT BASIC OPERATION

B. Type of Delivery Paths

The finisher has three different paper paths for delivery, each selected to suit paper size and

delivery mode.

1. Straight Path

When stacking copies shown in Table 2-201, the copies pass under the buffer roller.

Copy size Length or width 182 mm or less

Typical copy examples A5-R, ST-R, thick paper

Table 2-201

Delivery roller

Buffer roller

Figure 2-210

2. Buffer Paper Path 1

When stacking copies shown in Table 2-202, the copies pass over the buffer roller, increasing

the distance between copies.

Copy size Length and width 182 mm or more

Typical copy examples A3, B4, A4, A4-R, B5, B5-R, LD, LG, LT, LT-R, (excluding

transparencies and thick stock)

Table 2-202

Buffer roller

Delivery roller

Figure 2-211

Feed roller 2

2-15

Page 53

CHAPTER 2 FINISHER UNIT BASIC OPERATION

3. Buffer Paper Path 2

This is the paper path when copy sizes shown in Table 2-203 are stacked. A maximum of three

copies (three originals or more in the staple mode) are wrapped round the buffer roller, during

which job offset and stapling are performed on the stapling tray.

Copy size Length 182 to 232mm, and width 182 to 297mm

Typical copy examples A4, B5, LT, (excluding transparencies and thick stock)

Table 2-203

The following sho ws paper deli very operation in the case of three originals in the staple mode.

1) The first copy is mov ed in the direction of the buffer roller.

Buffer roller

First copy

Figure 2-212

2) The first copy wraps around the buffer roller and, at the same time, the second copy arrives

from the host machine.

First copy

Second copy

Figure 2-213

2-16

Page 54

CHAPTER 2 FINISHER UNIT BASIC OPERATION

3) The second copy is laid ov er the first copy and, at the same time, the third copy arri ves from the

host machine.

First copy

Second copy

Third copy

Figure 2-214

4) The first, second and third copies are simultaneously pulled into the stapling tray.

Second copy

Third copy

First copy

Figure 2-215

Cauiton:

The third copy as explained here is moved through buffer paper path 1. This fact is omitted from the

discussion to avoid interrupting the sequence of operations.

2-17

Page 55

CHAPTER 2 FINISHER UNIT BASIC OPERATION

C. Feeding and Delivering

1. Outline

The finisher moves copies ar ri ving from the host mac hine to the deli very tray, stapling tray, or

the saddle stitcher unit (Saddle Finisher) according to the mode of delivery. On the stapling tray, the

copies are subjected to job offset or stapling as instructed by the host machine.

The first feed motor (M1), second feed motor (M8) and inlet feed motor (M9) are stepping

motors, and delivery motor (M2) is a DC motor . These motors are controlled by the microprocessor

(CPU) on the finisher controller PCB, and rotate either clockwise or counterclockwise.

The paper paths are equipped with the following four sensors for detection of paper (arrival,

passage):

●

Inlet sensor (PI1)

●

Delivery sensor (PI3)

●

Stapling tray sensor (PI4)

●

Buffer path paper sensor (PI14)

In addition, each delivery tray is equipped with a sensor designed to detect the presence/absence of paper on it.

●

No.1 tray paper sensor (PI11)

●

No.2 tray paper sensor (PI12)

If a copy fails to reach or move past each sensor within a specific period of time, the finisher

controller PCB identifies the condition as a jam, and stops the ongoing operation, and at the same

time, informs the host machine of the condition. When all doors are closed after the paper jam is

removed, the buf fer path inlet paper sensor (PI17) checks whether or not copies are being detected

in addition to the above four sensors (inlet sensor, delivery sensor, stapling tray sensor and buffer

path paper sensor). If the sensors detect a copy, the finisher unit judges that paper jams have not

completely been removed, and sends the paper jam remov al signal to the host machine again.

2-18

Page 56

CHAPTER 2 FINISHER UNIT BASIC OPERATION

Finisher controller PCB

Swing motor drive signal

Tray 2 lift motor drive signal

Escape solenoid drive signal ESCPSL

Shift motor clock signal 1 SFTCLK 21

Shift motor clock signal 2 SFTCLK 22

Delivery motor drive signal

Alignment motor drive signal

Swing motor clock signal SWGCLK

Delivery motor clock signal DELCLK

Shift motor clock detection signal 1 SFTCLK11

PI20

PI10

Tray 1 lift motor drive signal

Paddle solenoid drive signal PDLSL

PI19

Shift motor clock detection signal 2 SFTCLK12

M5

PI9

M7

M2

Second feed motor drive signal

SL5

First feed motor drive signal

M1M8 M9

Inlet feed motor drive signal

Buffer outlet solenoid drive signal EXITSL

SL3

SL2

SL1

SL7

M6

Stapler motor drive signal

Stapler shift motor drive signal

Flapper solenoid drive signal FLPSL

Buffer inlet solenoid drive signal EXTSL

Belt escape solenoid drive signal BESCPSL

M3

PI24

PI23

M

10

Figure 2-216

M4

SL6

2-19

Page 57

CHAPTER 2 FINISHER UNIT BASIC OPERATION

Finisher controller PCB

detection signal BUFPASS

Buffer path paper

detection signal BUFENTR

Delivery detection signal PDEL

Buffer path inlet paper

No. 1 tray paper detection signal FSTTRAY

No. 2 tray paper detection signal SNDTRAY

Stapling tray paper detection signal STPTY

PI3

PI14

PI11

PI4

PI12

PI17

Inlet paper detection signal PENT

PI1

2-20

Figure 2-217

Page 58

CHAPTER 2 FINISHER UNIT BASIC OPERATION

D. Job Offset

1. Outline

In the job offset mode, sort jobs and entire copy groups are shifted to the front for delivery to

the tray, and other copies are delivered to the tray without a shift.

The copies are shifted by the alignment plate. The alignment plate is checked by the alignment

plate home position sensor (PI6) to find out whether it is at the home position.

The finisher controller PCB drives the alignment motor (M3) at power-on to return the align-

ment plate to its home position.

The finisher controller PCB stops the delivery motor (M2) when the trailing edge of the copy

has moved past the feed roller 2. Then, the f inisher controller PCB rotates the deliv ery motor counterclockwise, and drives the swing motor (M7). As a result, the drive of the delivery motor is transmitted to the swing guide to move up the guide. When the swing guide open sensor (PI18) detects

the swing guide, the delivery motor stops, and the swing guide is held at the up position.

When the swing guide has moved up, the feed belts attached to the feed roller 2 mov e the copy

to the stapling tray. The presence of paper on the stapling tray is monitored by the stapling tray

sensor (PI4). (The first sheet is fed to the stapling tray while the swing guide is moving up.)

The finisher controller PCB drives the alignment motor (M3) in advance, and keeps the alignment plate in wait at a point 10 mm behind the trailing edge of a sheet. Whenever one sheet is

moved to the stapling tray, each sheet is aligned, and when the fifth or last sheet in a sort job/group

is fed to the stapling tray, the escape solenoid (SL6) moves the guide plate away and under the

stapling tray. From then on, the alignment motor shifts the sheets to the front by 30 mm.

When the copy has been shifted, the finisher controller PCB rotates the alignment motor counterclockwise to move the alignment plate to a point 10 mm behind the trailing edge of the sheet.

This alignment operation is repeated until alignment of the fifth or last sheet in a sort job is completed. At this time, the swing guide is moved down and is closed, and the delivery motor rotates

clockwise to deliver the sheet.

2-21

Page 59

CHAPTER 2 FINISHER UNIT BASIC OPERATION

Guide plate

Alignment plate

Alignment plate

home position sensor (PI6)

Escape solenoid

(SL6)

Sequence of Operation (job offset)

Inlet sensor (PI1)

Delivery sensor (PI3)

Inlet feed motor (M9)

First feed motor (M1)

Second feed motor (M8)

Delivery motor (M2)

Paper

Alignment motor (M3)

Figure 2-218

Start signal

Host machine delivery signal

2-22

Staple tray sensor (PI4)

Alignment motor (M3)

Alignment plate home

position sensor (PI6)

Swing motor (M7)

Swing guide open

sensor (PI18)

Swing guide closed

detecting switch 1 (MS2)

Escape solenoid (SL6)

: Motor CW rotation : Motor CCW rotation

Figure 2-219

Page 60

CHAPTER 2 FINISHER UNIT BASIC OPERATION

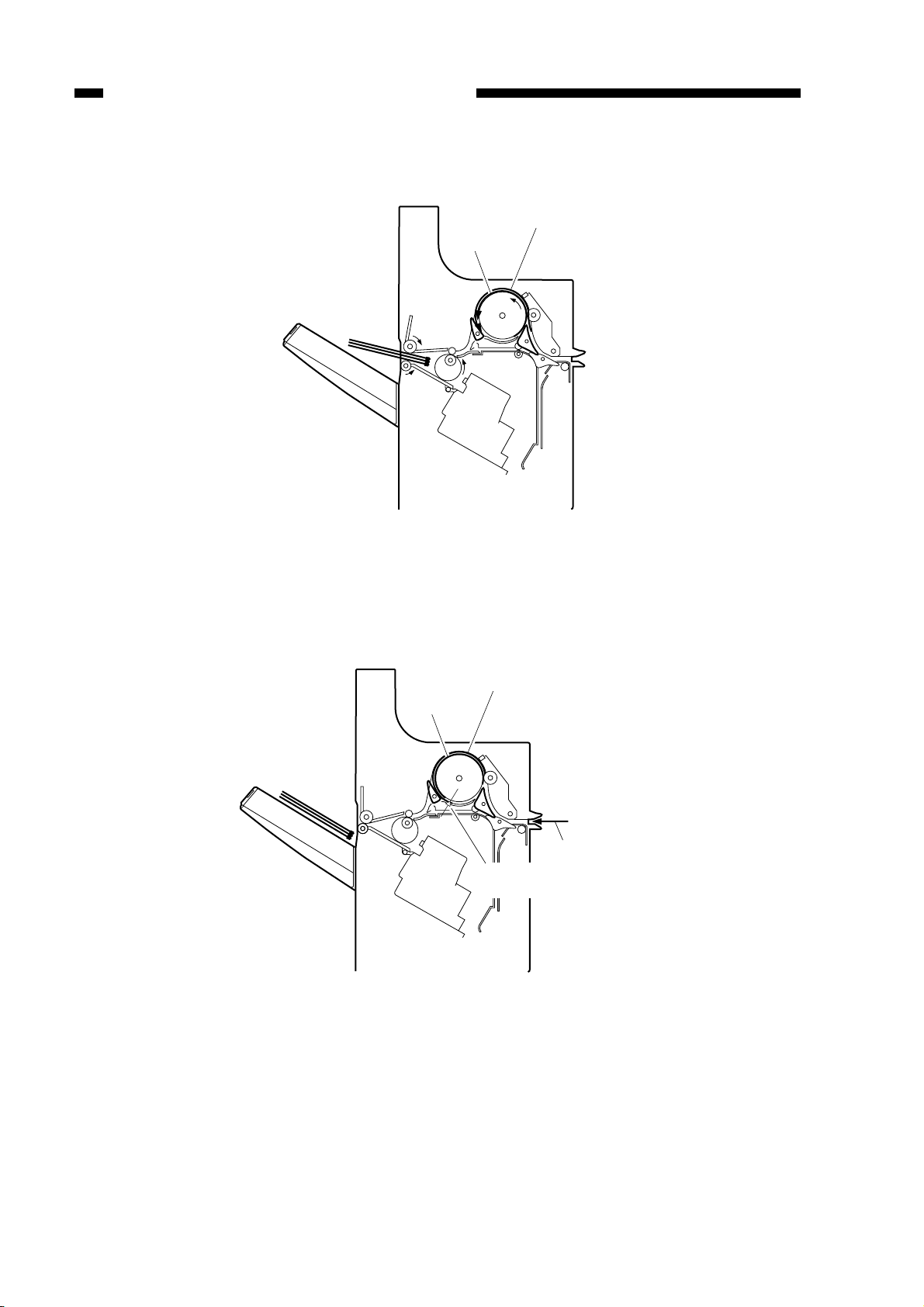

2. Flow of Job Offset Operations

1) The swing guide moves up and, at the same time, the feed belts move the sheet to the stapling

tray.

Swing guide

Offset sheet

Feed roller 2

Knurled belts

Tray 1/2

Delivery

roller

Stapling tray

Stopper

Figure 2-220

2) The alignment plate shifts the sheet to the front.

Existing stack

Alignment plate

Offset sheet

Figure 2-221

3) The swing guide moves down and, at the same time, the delivery roller delivers the sheet.

Offset sheet

Swing guide

Tray 1/2

Feed roller 2

Knurled belts

Delivery

roller

Stapling tray

Stopper

Figure 2-222

2-23

Page 61

CHAPTER 2 FINISHER UNIT BASIC OPERATION

E. Staple Operation

1. Outline

The stapler unit staples a stack of as many sheets as specified.

The stapling position differs according to the selected staple mode and paper size.

The stapler unit is checked by the stapler shift home position sensor (PI7) to find out whether it

is at the home position.

When starting operation after power-on, the finisher controller PCB drives the stapler shift

motor (M4) to return the stapler unit to the home position. If the stapler is already at the home

position, it is kept as it is in wait.

Stapler shift

motor (M4)

Sheets

Stapler shift home

position sensor (PI7)

Stapler

Figure 2-223

2-24

Page 62

CHAPTER 2 FINISHER UNIT BASIC OPERATION

Paper width/2

Front diagonal stapling

Rear diagonal stapling

2-point stapling

Rear 1-point stapling

Figure 2-224

2-25

Page 63

CHAPTER 2 FINISHER UNIT BASIC OPERATION

2. First Sheet

The finisher controller PCB stops the delivery motor (M2) as soon as the trailing edge of the

first sheet has moved past the feed roller 2. Then, it rotates the delivery motor clockwise to switch

the gear drive to the swing motor (M7), causing the swing guide to mo ve up. When the swing guide

open sensor (PI18) finds the swing guide at the up position, the swing motor stops, maintaining the

swing guide at the up position.

When the swing guide has moved up, the knurled belts of the feed roller 2 mov e the sheet to the

stapling tray. (The first sheet is fed to the stapling tray while the swing guide is moving up.) The

presence of paper on the stapling tray is detected by the stapling tray sensor (PI4).

The finisher controller PCB drives the alignment motor (M3) when the stapling tray paper

sensor has detected paper to put sheets in order . The alignment plate is k ept in w ait in adv ance at a

point 10 mm behind the trailing edge of the paper.

The swing guide is kept in wait at the up position until the last sheet is output onto the stapling

tray.

Swing guide

First sheet

Tray 1/2

Feed roller 2

Knurled belts

Delivery roller

Stapling tray

Stapler

Figure 2-225

2-26

Page 64

Swing guide

Swing guide open

sensor (PI18)

CHAPTER 2 FINISHER UNIT BASIC OPERATION

Swing guide closed

detecting switch 1,2

(MS2/MS6)

Delivery roller

Swing motor

clock sensor

(PI20)

Delivery motor

clock sensor

(PI10)

Swing motor (M7)

Delivery motor (M2)

Figure 2-226

2-27

Page 65

CHAPTER 2 FINISHER UNIT BASIC OPERATION

3. Second and Subsequent Sheets

The finisher controller PCB turns on the belt escape solenoid (SL7) before the trailing edge of

the second and subsequent sheets have mov ed past the feed roller 2 to make the knurled belt escape.

This operation is performed to reduce the time it takes for the trailing edge of the paper to fall on the

stapling tray, and to improve the product duty. The finisher controller PCB turns on the paddle

solenoid (SL5) as soon as the trailing edge of the second and subsequent sheets have mov ed past the

feed roller 2, causing the drive of the second feed motor (M8) to rotate the paddle. The sheets are

pushed by the paddle and moved to the stapling tray. Almost simultaneously with the trailing edge

of the sheet falling into the stapling tray , the belt escape solenoid turns off to return the knurled belts

that were in the escape position to its original position, and feed the sheet onto the stapling tray.

When the sheet has been output onto the stapling tray , the finisher controller PCB rotates the alignment motor (M3) to put the sheets in order.

Swing guide

Second and

subsequent

sheets

Paddles

Feed roller 2

Tray 1/2

Delivery

roller

Stapling tray

Figure 2-227

Knurled belts

SL7

Belt escape solenoid

Stapler

2-28

Page 66

Knurled belts

CHAPTER 2 FINISHER UNIT BASIC OPERATION

Escape direction

Belt escape

solenoid (SL7)

Figure 2-228

Paddles

Paddle

solenoid (SL5)

Paddles

Second and

subsequent sheets

First sheet

Stapler

M8

Second feed motor

Stopper

Figure 2-229

2-29

Page 67

CHAPTER 2 FINISHER UNIT BASIC OPERATION

4. Last Sheet

When the last sheet has been put in order, the finisher controller PCB turns on the alignment

motor (M3) to move the alignment plate to the alignment position (to butt the plate against the

stack). Then, the finisher controller PCB rotates the swing motor (M7) counterclockwise to move

down the swing guide.

The finisher controller PCB moves the stapler according to the staple mode for stapling.

From then on, it rotates the delivery motor (M2) clockwise to deliver the stack to the tray.

Swing guide

Sheets

Feed roller 2

Knurled belts

Tray 1/2

Delivery

roller

Stapling tray

Stapler

Figure 2-230

2-30

Page 68

Swing guide

CHAPTER 2 FINISHER UNIT BASIC OPERATION

Delivery roller

Swing motor (M7)

Delivery motor (M2)

Figure 2-231

2-31

Page 69

CHAPTER 2 FINISHER UNIT BASIC OPERATION

F. Stapler Unit

Stapling is executed by the staple motor (M6). A single rotation of the cam by the motor results

in one stapling operation.

The cam is checked by the staple home position sensor (PI22) to find out whether it is at the

home position.

The stapler motor is controlled by the microprocessor (IC1) on the finisher controller so that it

is rotated clockwise or counterclockwise.

When the stapling home position sensor is off, the finisher controller PCB rotates the stapler

motor clockwise until the sensor turns on so as to return the stapling cam to its initial state.

The presence/absence of the staple cartridge is detected by the staple switch (MS8). The presence/absence of staples inside the staple cartridge is detected by the staple detecting switch (MS9).

The staple edge sensor (PI21) is used to find out whether a staple has been edged out to the end of

the cartridge.

The finisher controller PCB does not driv e the staple motor (M6) unless the swing guide closed

detecting switch 2 (MS6) is on (i.e., the swing guide is closed). This is to protect against injuries

that could occur when a finger is stuck inside the stapler.

2-32

Page 70

CHAPTER 2 FINISHER UNIT BASIC OPERATION

Figure 2-232

M6

Staple motor drive

signal

Staple edge detection signal

Finisher controller PCB

Stapling home

position detection signal

Figure 2-233

Cartridge detection signal

Staple detection signal

2-33

Page 71

CHAPTER 2 FINISHER UNIT BASIC OPERATION

Start signal

Host machine delivery signal

Inlet sensor (PI1)

Delivery sensor (PI3)

Inlet feed motor (M9)

First feed motor (M1)

Second feed motor (M8)

Delivery motor (M2)

Stapling tray sensor (PI4)

Alignment motor (M3)

Alignment guide home

position sensor (PI6)

Swing guide open

sensor (PI18)

Swing guide closed

detecting switch 1 (MS2)

Paddle solenoid (SL5)

Belt escape solenoid

(SL7)

Staple motor (M6)

First sheet

Stacking

Second sheet

Stapling

Delivery

Staple home position

sensor (PI22)

Stapler shift motor (M4)

: Motor CW rotation : Motor CCW rotation

Figure 2-234

2-34

Page 72

CHAPTER 2 FINISHER UNIT BASIC OPERATION

5. Shifting the Stapler Unit

The stapler unit is moved by the stapler shift motor (M4). Its home position is detected by the

stapler shift home position sensor (PI7). When the start signal arrives from the host machine, the

stapler moves to the center of its mov ement range. This mov ement occurs regardless of the selected

mode of delivery, as no specific mode is recognized at this point in time. When the command for

stapling arrives from the host machine after the f irst sheet has reached the host machine pre-registration sensor, the stapler mo v es to the staple w ait position to suit the appropriate stapling position

and paper size.

See Figures 2-235 and later for an idea of the wait position according to the stapling mode.

a. Front Diagonal Stapling

The position is the same as the stapling position.

Stapling tray delivery

direction

Stopper

Stopper

Guide plate

Stapler

Figure 2-235

2-35

Page 73

CHAPTER 2 FINISHER UNIT BASIC OPERATION

b. Rear 1-Point Stapling

The stapler is kept in wait at the center position. The stapler is mov ed to and from the stapling

position for each stapling operation.

Stopper

Stapling position

Wait position

Stapling tray delivery

direction

Stopper

Stapler

Guide plate

Figure 2-236

c. Rear Diagonal Stapling

For A4, LT and B5 sizes, the stapler is kept in wait toward the rear away from the stapling

position. The stapler is moved to and from the stapling position for each stapling operation.

Stapler

Wait position

Stapling position

Stopper

Stapling tray delivery

direction

2-36

Stopper

Guide plate

Figure 2-237

Page 74

CHAPTER 2 FINISHER UNIT BASIC OPERATION

d. 2-Point Stapling

The stapler is kept in wait at the center of the paper. Stapling occurs at two points, first at the

rear and then at the front.

Stopper

Stapling position

Wait position

Stapler

Stapling tray delivery

direction

Stapling position

Guide plate

Figure 2-238

Stopper

2-37