Page 1

File No. 3110009

Page 2

General Precautions for Installation/Servicing/Maintenance

The installation and service should be done by a qualified service technician.

1. When installing the Finisher MJ-1011 to the Plain Paper Copier, be sure to follow the

instructions described in the “Unpacking/Set-Up Procedure for the MJ-1011” booklet

which comes with each unit of the MJ-1011.

2. The MJ-1011 should be installed by an authorized/qualified person.

3. Before starting installation, servicing or maintenance work, be sure to unplug the copier

first.

4. When servicing or maintaining the MJ-1011, be careful about the rotating or operating

sections such as gears, pulleys, sprockets, cams, belts, etc.

5. When parts are disassembled, reassembly is basically the reverse of disassembly

unless otherwise noted in this manual or other related materials. Be careful not to

assemble small parts such as screws, washers, pins, E-rings, toothed washers to the

wrong places.

6. Basically, the machine should not be operated with any parts removed or disassembled.

7. Delicate parts for preventing safety hazard problems (such as breakers, thermofuses,

fuses, door switches, sensors, etc. if any) should be handled/installed/adjusted correctly.

8. Use suitable measuring instruments and tools.

9. During servicing or maintenance work, be sure to check the serial No. plate and other

cautionary labels (if any) to see if they are clean and firmly fixed. If not, take appropriate actions.

10. The PC board must be stored in an anti-electrostatic bag and handled carefully using

a wristband, because the ICs on it may be damaged due to static electricity. Before

using the wrist band, pull out the power cord plug of the copier and make sure that

there is no uninsulated charged objects in the vicinity.

11. For the recovery and disposal of used MJ-1011s, consumable parts and packing materials, it is recommended that the relevant local regulations/rules should be followed.

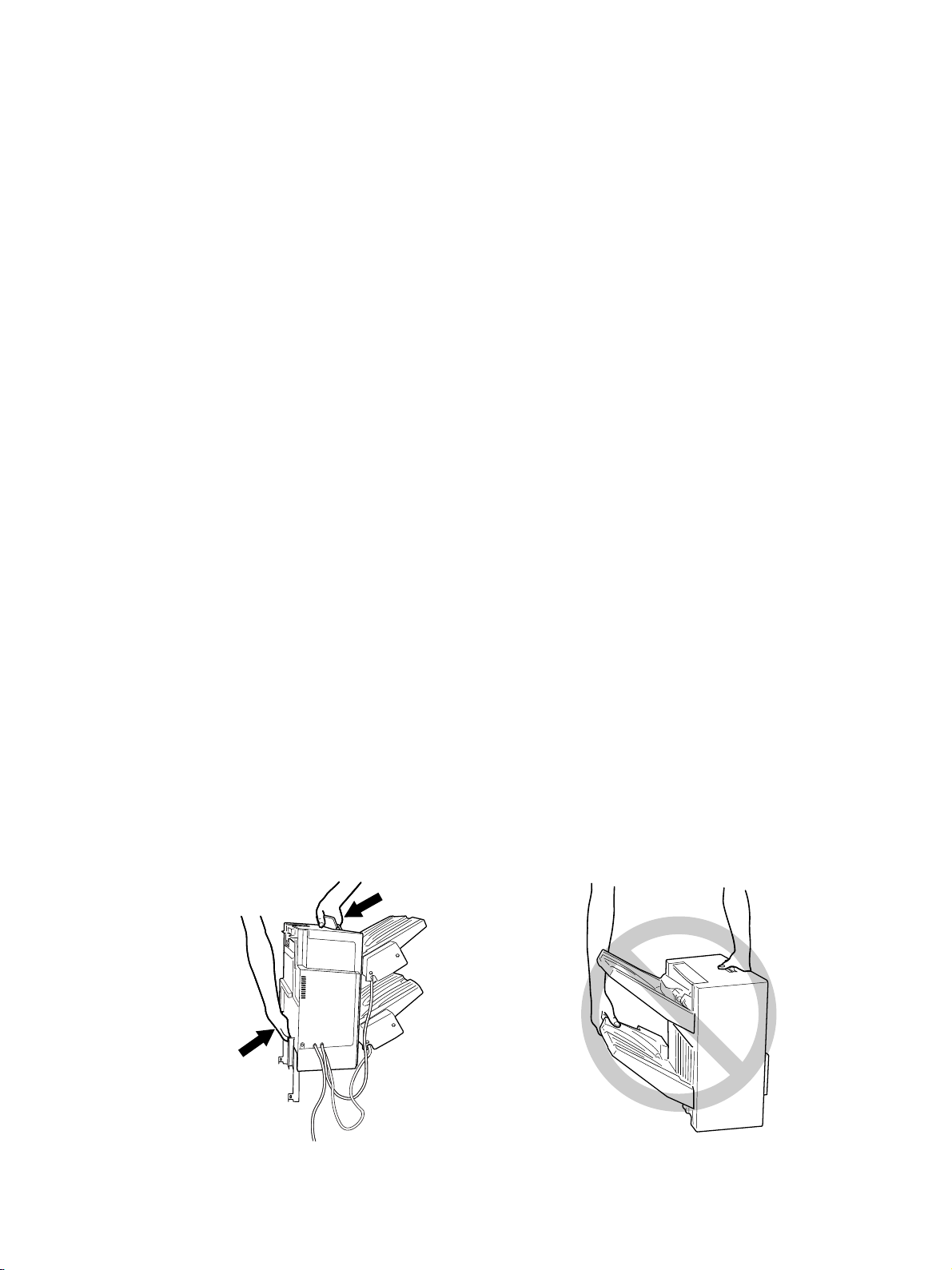

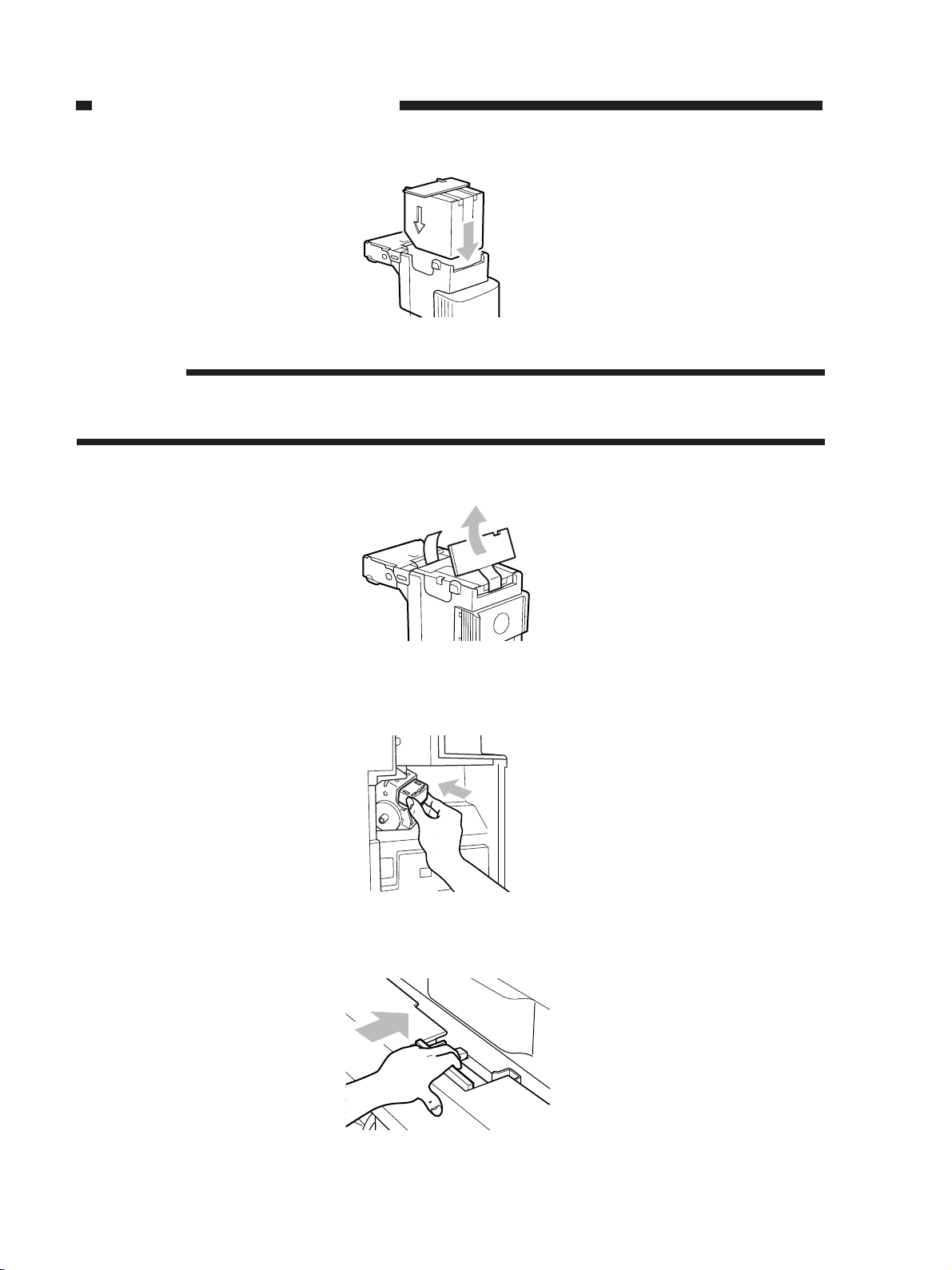

12. When the Finisher is to be carried, be sure to hold the locations shown in the figures.

Page 3

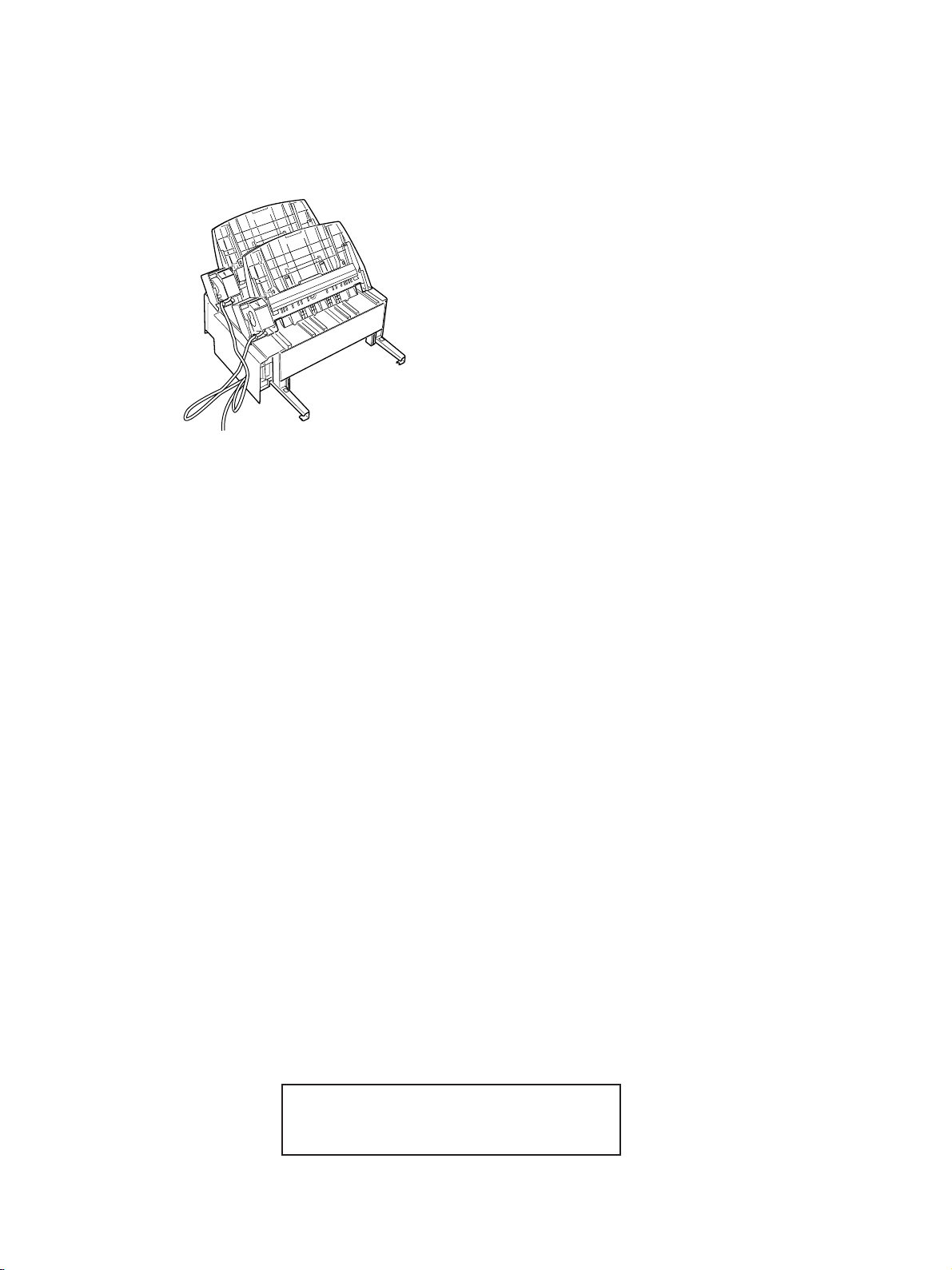

13. Place the finisher as shown in the figure below making sure that the cord is not nipped.

Copyright © 2000

TOSHIBA TEC Corporation

Page 4

INTRODUCTION

This Service Manual contains basic data and figures for the Finisher MJ-1011 needed

to service the machine in the field.

Chapter 1 General Description introduces the finisher's features, specifications, and

names of parts, and shows how to operate the finisher.

Chapter 2 Basic Operation discusses the principles of operation used for the finisher's

mechanical and electrical systems. It also explains the timing at which these

systems are operated.

Chapter 3 Mechanical System discusses how the finisher is constructed mechanically,

and shows how it may be disassembled/assembled and adjusted.

Chapter 4 Maintenance and Inspection provides tables of periodically replaced parts and

consumables and durables, together with a scheduled servicing chart.

Chapter 5 Troubleshooting provides adjustments, problem identification and electrical

parts arrangement.

Appendix containts general timing chart, tables of signals, circuit diagram and

solvent/oils.

For installation, see the Installation Procedure that comes with the finisher.

The descriptions in this Service Manual are subject to change without notice for

product improvement or other purposes, and major changes will be communicated in the

form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this

Service Manual and all relevant Service Information bulletins and be able to identify and

isolate faults in the machine.

i

Page 5

CONTENTS

CHAPTER 1 GENERAL DESCRIPTION

I. FEATURES ..................................1-1

II. SPECIFICATIONS .......................1-2

III. OPERATING THE MACHINE ...... 1-6

CHAPTER 2 BASIC OPERATION

I. BASIC CONSTRUCTION ............2-1

II. BASIC OPERATIONS..................2-8

III. FEEDING DRIVE SYSTEM .......2-11

IV. INTERMEDIARY PROCESSING

TRAY ASSEMBLY......................2-13

CHAPTER 3 MECHANICAL SYSTEM

IV. MAINTENANCE BY THE

USER ........................................1-11

V. STAPLING ................................. 2-44

VI. OPERATIONS OF THE STACK

TRAY .........................................2-47

VII. DETECTING JAMS ...................2-56

VIII.POWER SUPPLY ...................... 2-61

I. EXTERNALS AND

CONTROLS.................................3-1

II. FEEDING SYSTEM .....................3-6

III. PROCESSING TRAY ...................3-7

IV. RETURNING ROLLER .............. 3-15

V. STACK TRAY .............................3-22

VI. STACK TRAY LIFTER

UNIT ..........................................3-23

VII. STAPLER...................................3-31

VIII.PCBs ......................................... 3-32

iii

Page 6

CHAPTER 4 MAINTENANCE AND INSPECTION

I. PERIODICALLY REPLACED

PARTS.........................................4-1

II. CONSUMABLES AND

DURABLES .................................4-1

CHAPTER 5 TROUBLESHOOTING

I. ADJUSTMENTS ..........................5-1

II. TROUBLESHOOTING ...............5-12

APPENDIX

III. SCHEDULED MAINTENANCE ...4-1

III. ARRANGEMENT OF ELECTRICAL

PARTS .......................................5-17

A. GENERAL TIMING CHART........ A-1

B. SIGNALS AND

ABBREVIATIONS ....................... A-3

C. GENERAL CIRCUIT

DIAGRAM ................................... A-7

iv

D. FINISHER CONTROLLER

CIRCUIT DIAGRAM ................... A-8

E. SOLVENTS AND OILS ............. A-18

Page 7

CHAPTER 1

GENERAL DESCRIPTION

I. FEATURES ..................................1-1

II. SPECIFICATIONS .......................1-2

III. OPERATING THE MACHINE ...... 1-6

IV. MAINTENANCE BY THE

USER ........................................1-11

Page 8

CHAPTER 1 GENERAL DESCRIPTION

I. FEATURES

1. Small in Size, Light in Weight

• The finisher is designed as a small, light delivery device.

2. Mono-Frame

• The finisher is cased in a mono-frame, which has enabled reduction of the number of covers.

3. Sorting and Stapling by Stack Offset

• The finisher puts together stacks of sheets on its intermediary processing tray for offset

sorting and stapling.

4. Stack Tray

• The finisher’s stack tray is capable of holding as many as 900 sheets (BIN-1: 200 sheets,

BIN-2: 700 sheets) of small-size paper or 450 sheets (BIN-1: 100 sheets, BIN-2: 350 sheets)

of large-size paper.

Further, it can hold as many as 80 sets (BIN-1: 30 sets, BIN-2: 50 sets) of stapled stacks (each

consisting of up to 30 sheets).

1-1

Page 9

CHAPTER 1 GENERAL DESCRIPTION

II. SPECIFICATIONS

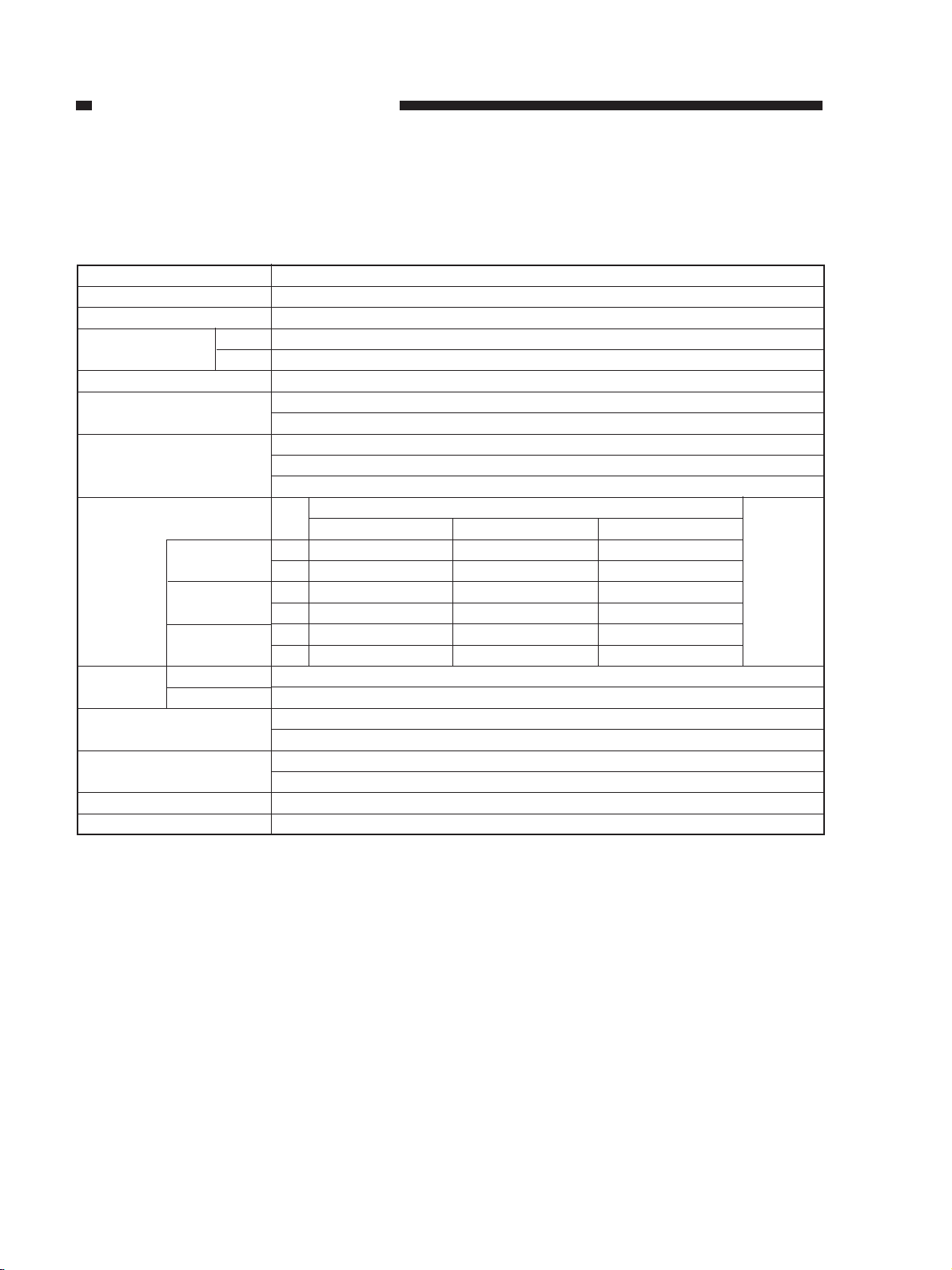

A. Specifications

Item

Stacking

Stacking mode

Stack paper size

Paper weight

Bins

Modes

Stack tray capacity

[height (sheets)]

Simple

stacking

Job offset

Staple

stacking

Stacking

width*4

Stacking size

Stapling size

Stack offset width*6

Offset width*5

Not stapled

Stapled

A/B

Inch

Description

Stack tray (tray lift mechanisms, with intermediary tray fixed in position)

Face-down stacking

A3, A4, A4-R, A5-R, B4, B5, B5-R

LD, LG, LT, LT-R, ST-R, FOLIO, COMPUTER

50 to 200 g/m2 (Plain paper), 64 to 80 g/m2 (Recycled paper)

Stack tray 2

Intermediary processing tray 1

Staple stacking

Non-staple stacking

Non-staple offset stacking

Bin

1 30mm (200 sheets) 20mm (140 sheets) 15mm (100 sheets)

2 99mm (700 sheets) 70mm (490 sheets) 49mm (350 sheets)

1 30mm (200 sheets) 20mm (140 sheets) 15mm (100 sheets)

2 99mm (700 sheets) 70mm (490 sheets) 49mm (350 sheets)

1 30 sets (170 sheets) 30 sets (110 sheets) 30 sets (80 sheets)

2 50 sets (600 sheets) 50 sets (400 sheets) 50 sets (300 sheets)

139.7 to 297 mm

210 to 297 mm

A3, A4, A4-R, B4, B5

LD, LG, LT, LT-R, ST-R, FOLIO, COMPUTER

A3, A4, A4-R, B4, B5

LD, LG, LT, LT-R, FOLIO, COMPUTER

210 to 297 mm

20 mm

Small-size*1 Middle-size*2 Large-size*3

Plain Paper/Recycled Paper

Equivalent

of

80 g/m

paper

2

1-2

Page 10

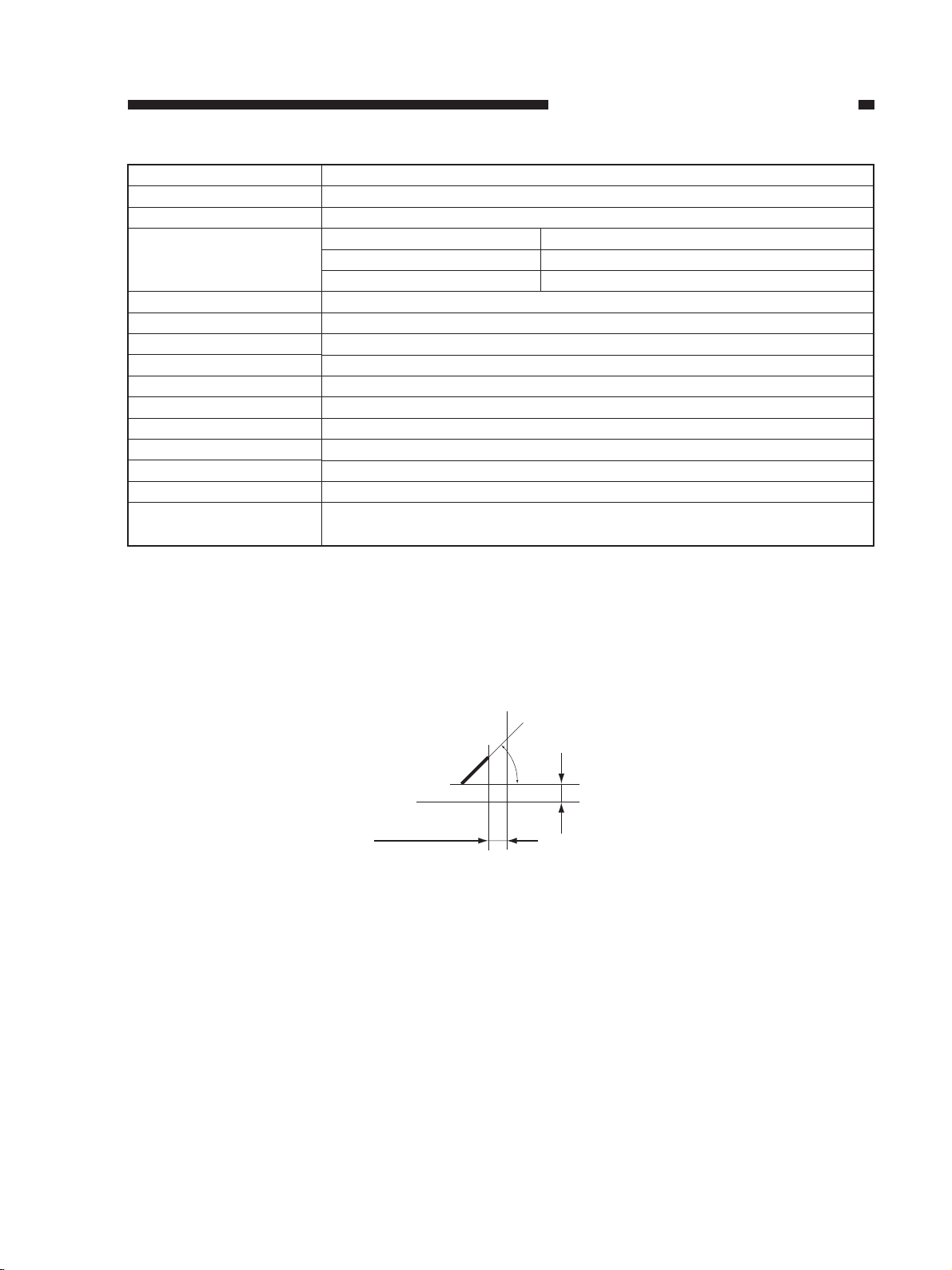

CHAPTER 1 GENERAL DESCRIPTION

Item

Stapling method

Stapling position

Stack thickness

Staple source

Staple

Staple detection

Manual stapling

Paper detection

Control panel

Display

Dimensions (W×D×H)

Weight

Power supply

Maximum power

consumption

Punching by rotating cam

1-point rear, slant (Figure 1-201)

Small-size 30 sheets max.

Medium-size 20 sheets max.

Large-size 15 sheets max.

Special cartridge (3,000 staples)

Special staple (STAPLE-1600)

Yes

No

Yes

No (operated from copier)

None (display on copier)

431 × 541 × 413 mm

17 kg

24V, 5V (from copier)

40W or less

Description

*1 Small-size, i.e., A4, A4-R, A5-R, B5, B5-R, postcard, LT, LT-R and ST-R.

*2 Medium-size, i.e., B4 and LG.

*3 Large-size, i.e., A3, FOLIO, COMPUTER and LD.

*4 The width of paper that may be put into order in the front/rear direction.

*5 The distance a stack is displaced during sorting.

*6 The width of paper that may be put into order during sorting.

45˚

5±4mm

5±4mm

Figure 1-201 Stapling Positions

1-3

Page 11

CHAPTER 1 GENERAL DESCRIPTION

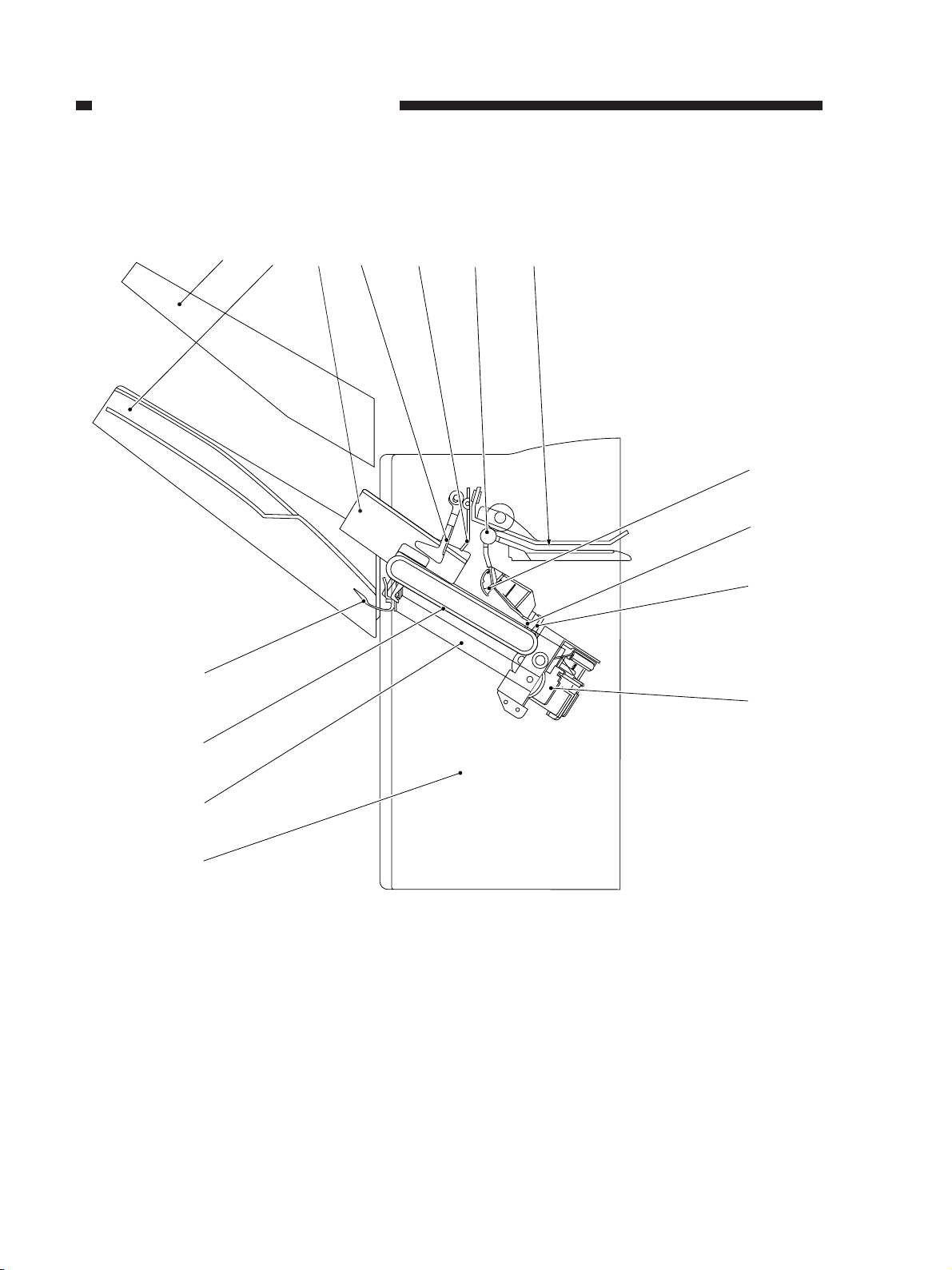

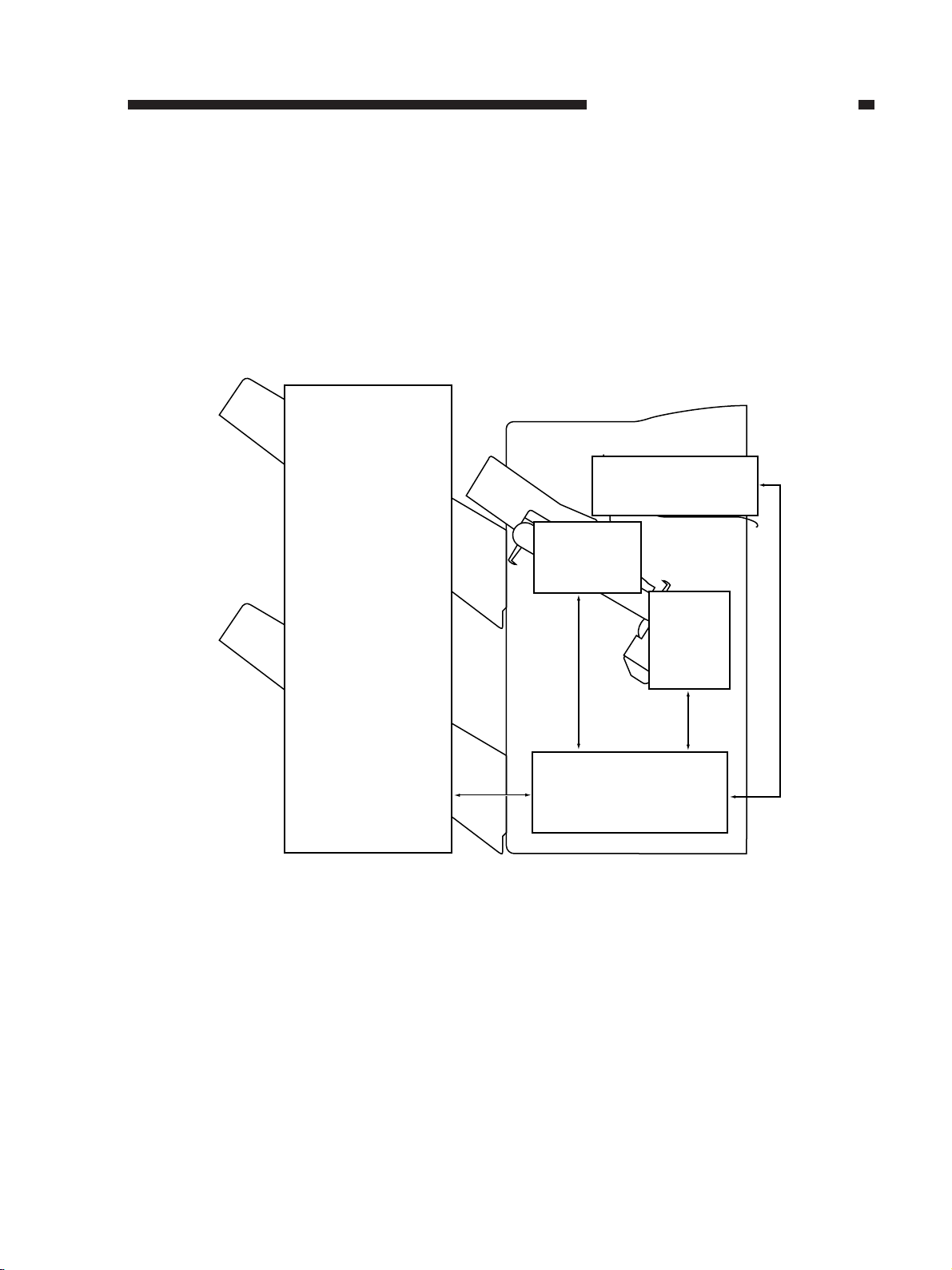

■ Cross Section

[10]

[14]

[1] [2] [3] [4] [5] [6]

[7]

[8]

[11A]

[9]

1-4

[11]

[12]

[13]

[1] Lower stack tray

[2] Jogging plate (front, rear)

[3] Paper feeding guide A

[4] Paper feeding guide B

[5] Delivery roller

[6] Paper path

[7] Returning roller

[8] Stopper plate

[9] Stapler unit

[10] Paper holding lever

[11] Stack delivery belt

[11A] Stack delivery lever

[12] Intermediary processing tray

[13] Frame

[14] Upper stack tray

Figure 1-202

Page 12

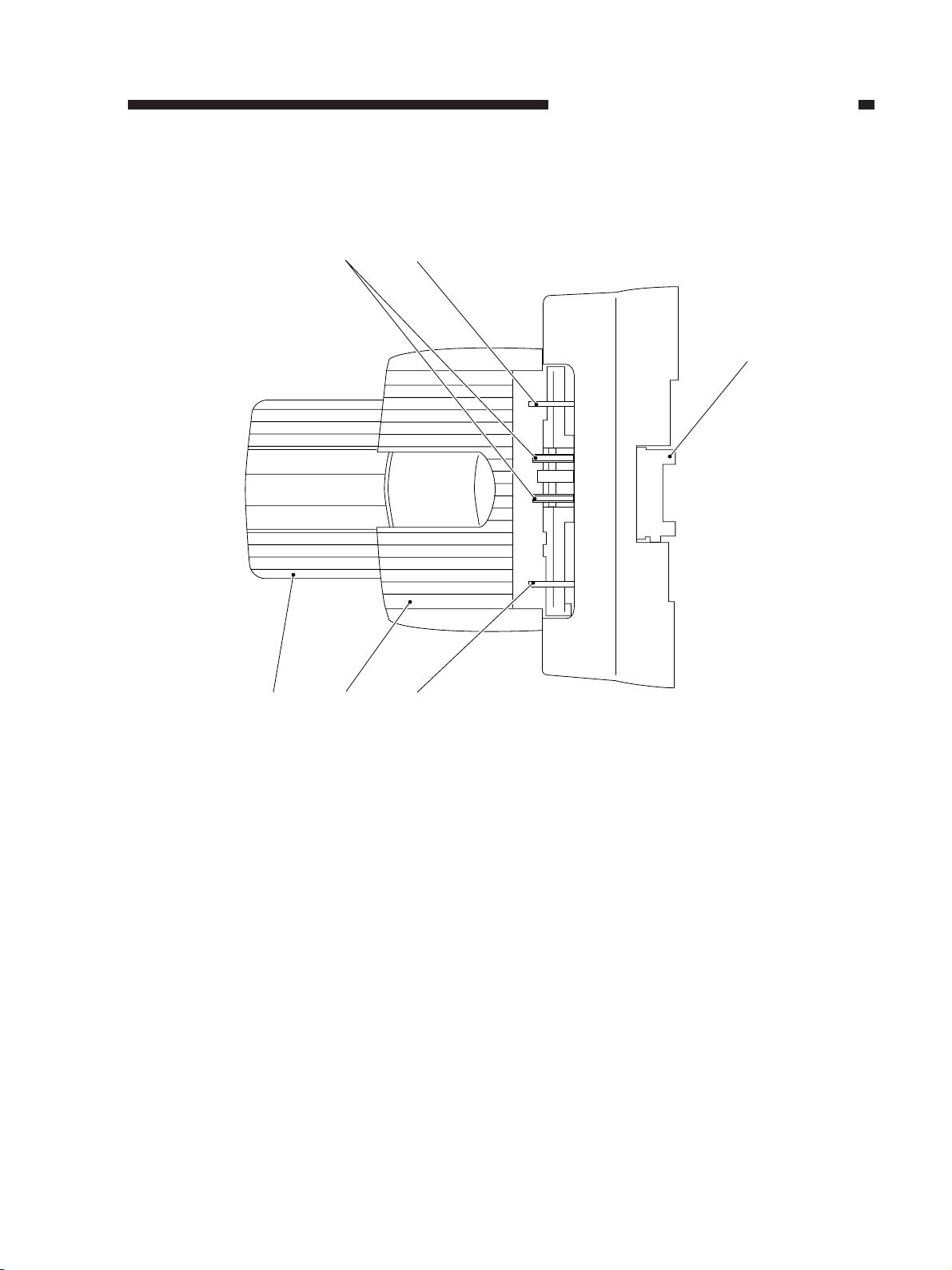

■ Top View

CHAPTER 1 GENERAL DESCRIPTION

[1] [2]

[3]

[4] [5] [6]

[1] Stack delivery belt

[2] Rear jogging plate

[3] Grip

[4] Stack extension tray

[5] Stack tray

[6] Front jogging plate

Figure 1-203

1-5

Page 13

CHAPTER 1 GENERAL DESCRIPTION

III. OPERATING THE MACHINE

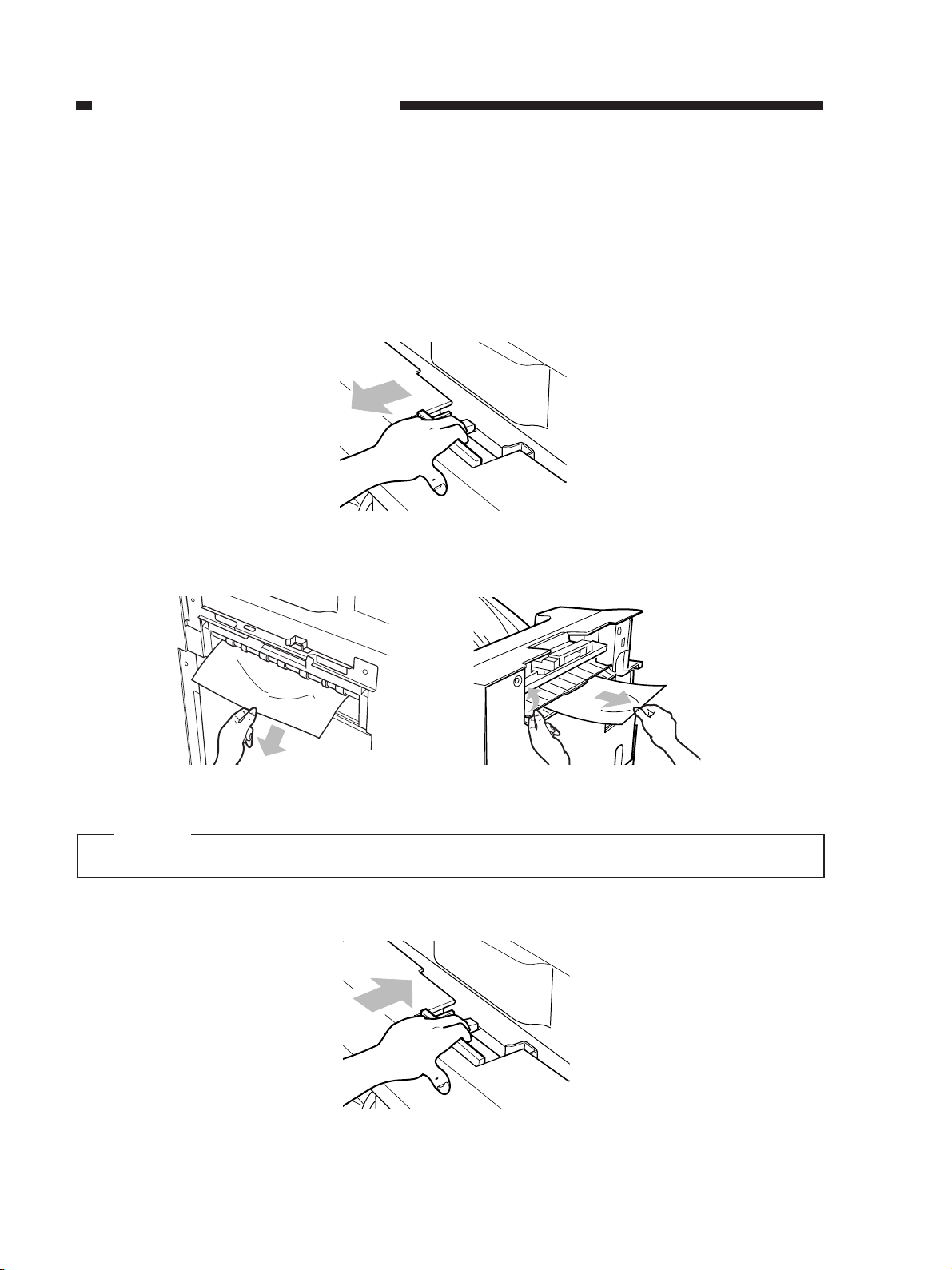

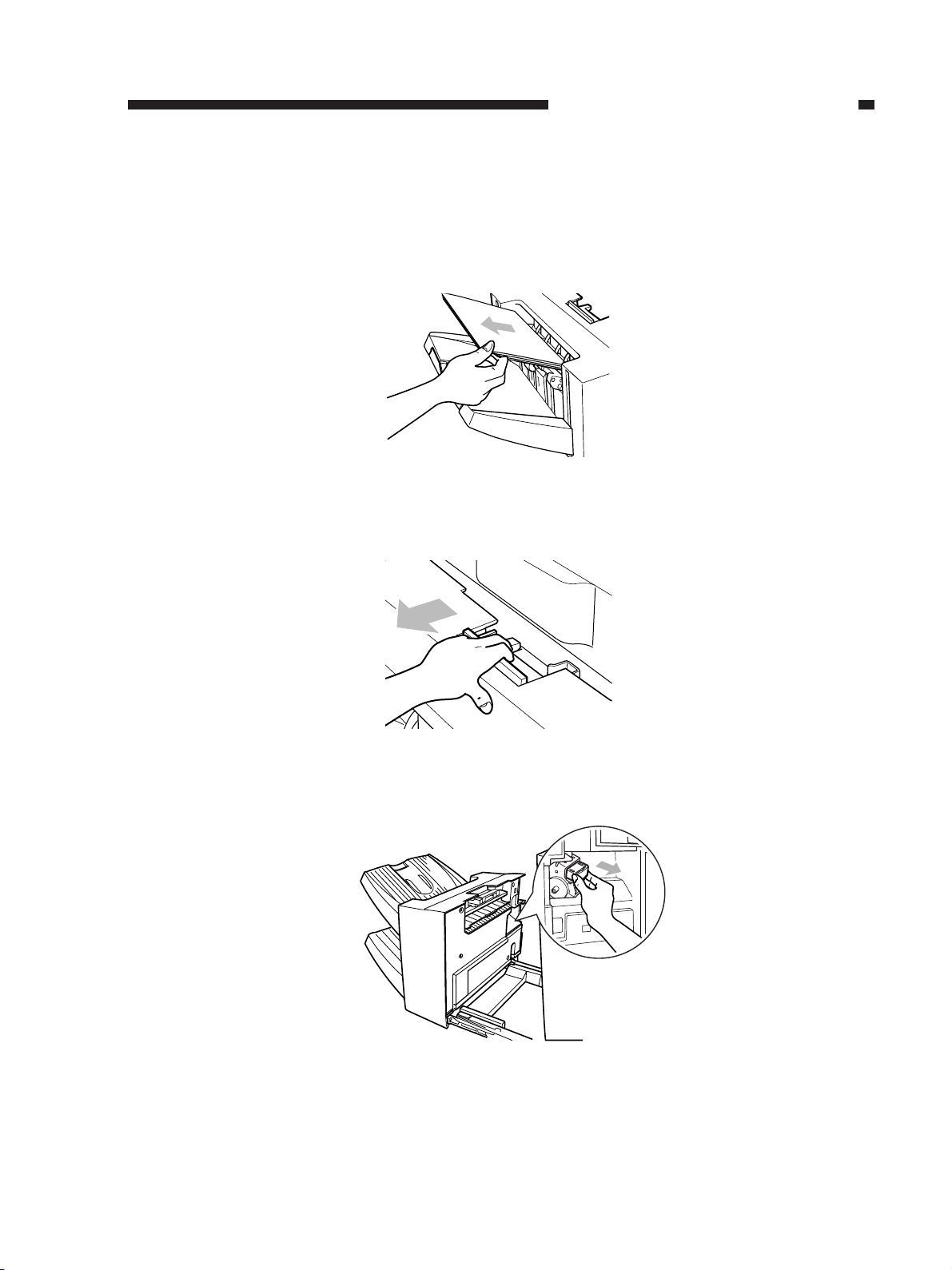

A. Removing Paper Jams

If the Jam indicator is turned on to indicate the presence of a jam in the finisher, perform the

following:

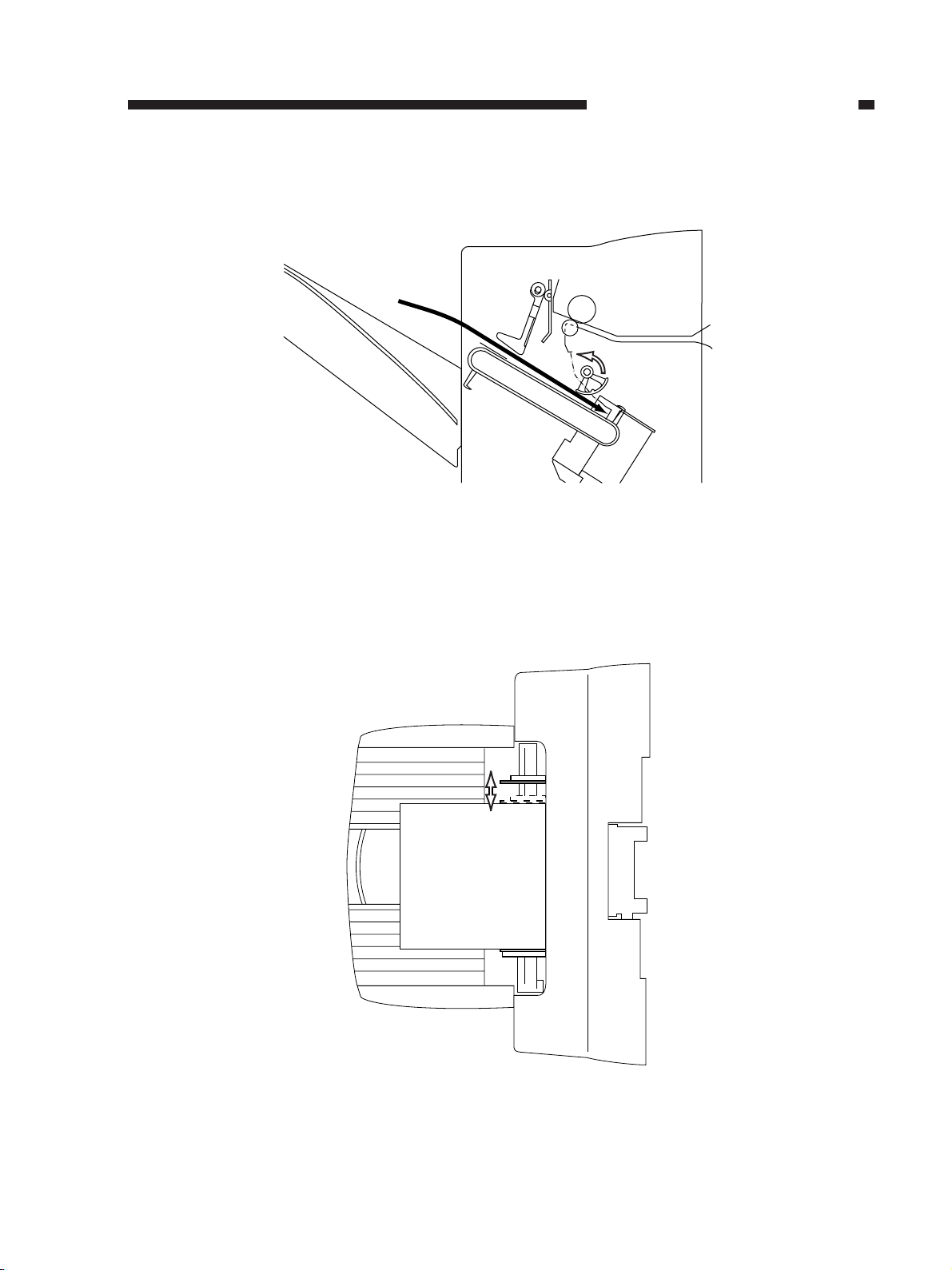

1) Grasping the grip, disconnect the finisher from the copier.

Figure 1-301

2) Remove the paper visible from the outside.

Figure 1-302

Caution:

Do not remove the paper from the intermediary processing tray before removing the jam.

3) Connect the finisher to the copier.

1-6

Figure 1-303

Page 14

CHAPTER 1 GENERAL DESCRIPTION

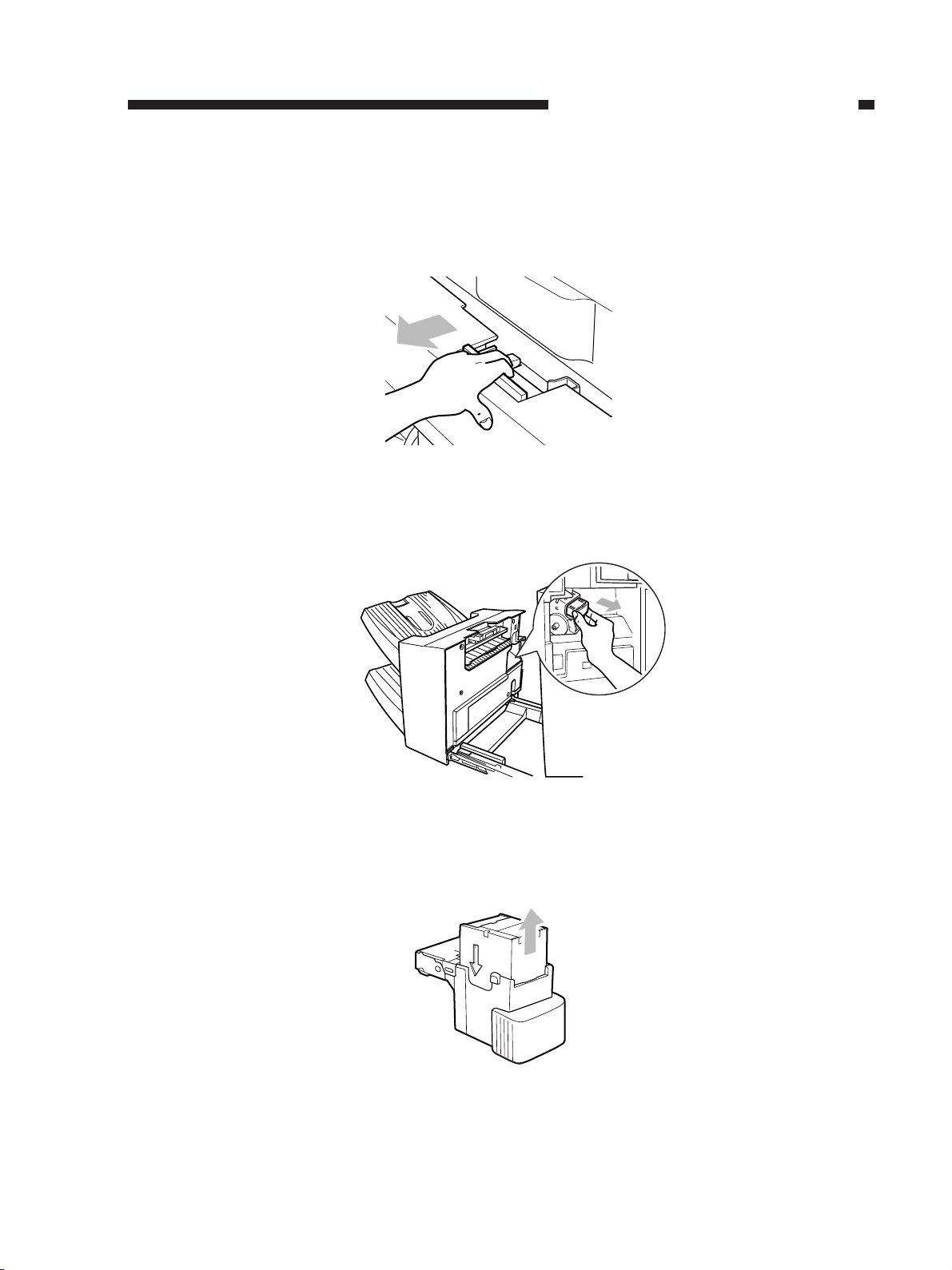

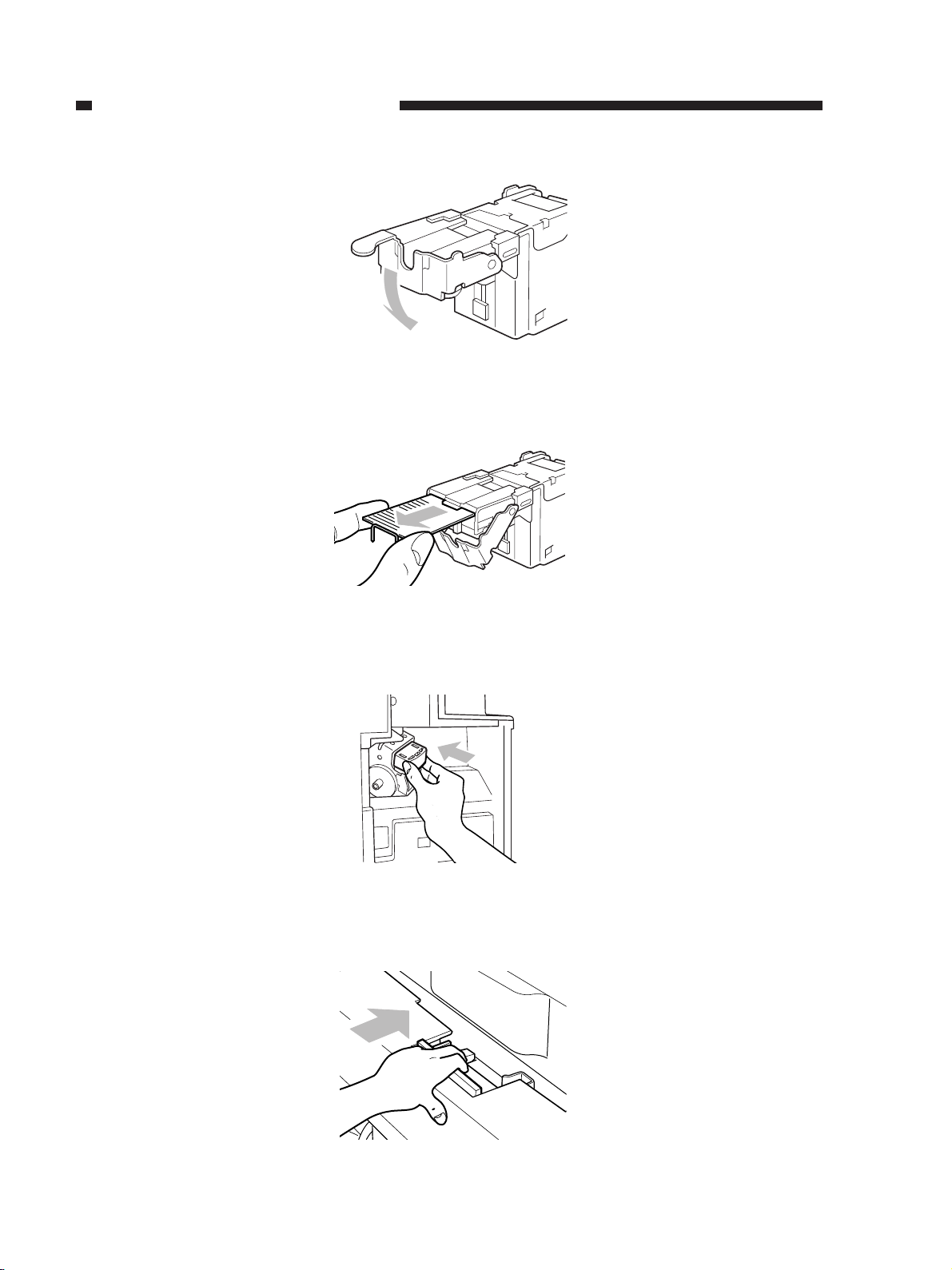

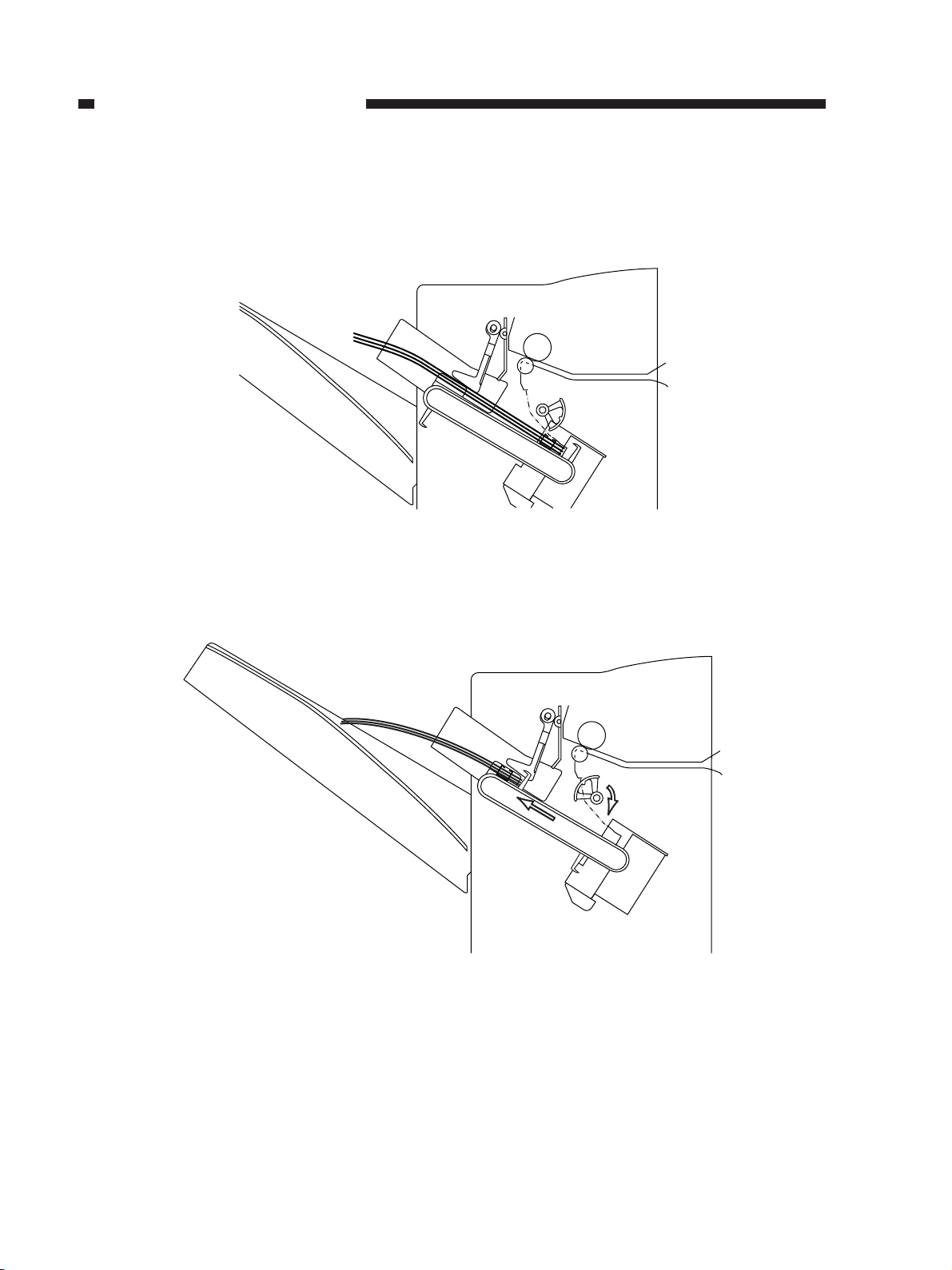

B. Supplying the Stapler Unit with Staples

If the Add Staples indicator turns on, perform the following:

1) Grasping the grip, disconnect the finisher from the copier.

Figure 1-304

2) Pick up the staple cartridge by its left and right side (light blue) and pull it off.

Figure 1-305

3) Pick up the empty staple case by its left and right side and pull it off.

Figure 1-306

1-7

Page 15

CHAPTER 1 GENERAL DESCRIPTION

4) Set the new staple case.

Figure 1-307

Reference:

No more than one staple case may be set. Be sure to use a staple cartridge specially designed for

the machine.

5) Remove the seal used to hold the staples together by pulling it straight up.

Figure 1-308

6) Fit the staple cartridge into the stapler unit.

Figure 1-309

7) Connect the finisher to the copier.

1-8

Figure 1-310

Page 16

CHAPTER 1 GENERAL DESCRIPTION

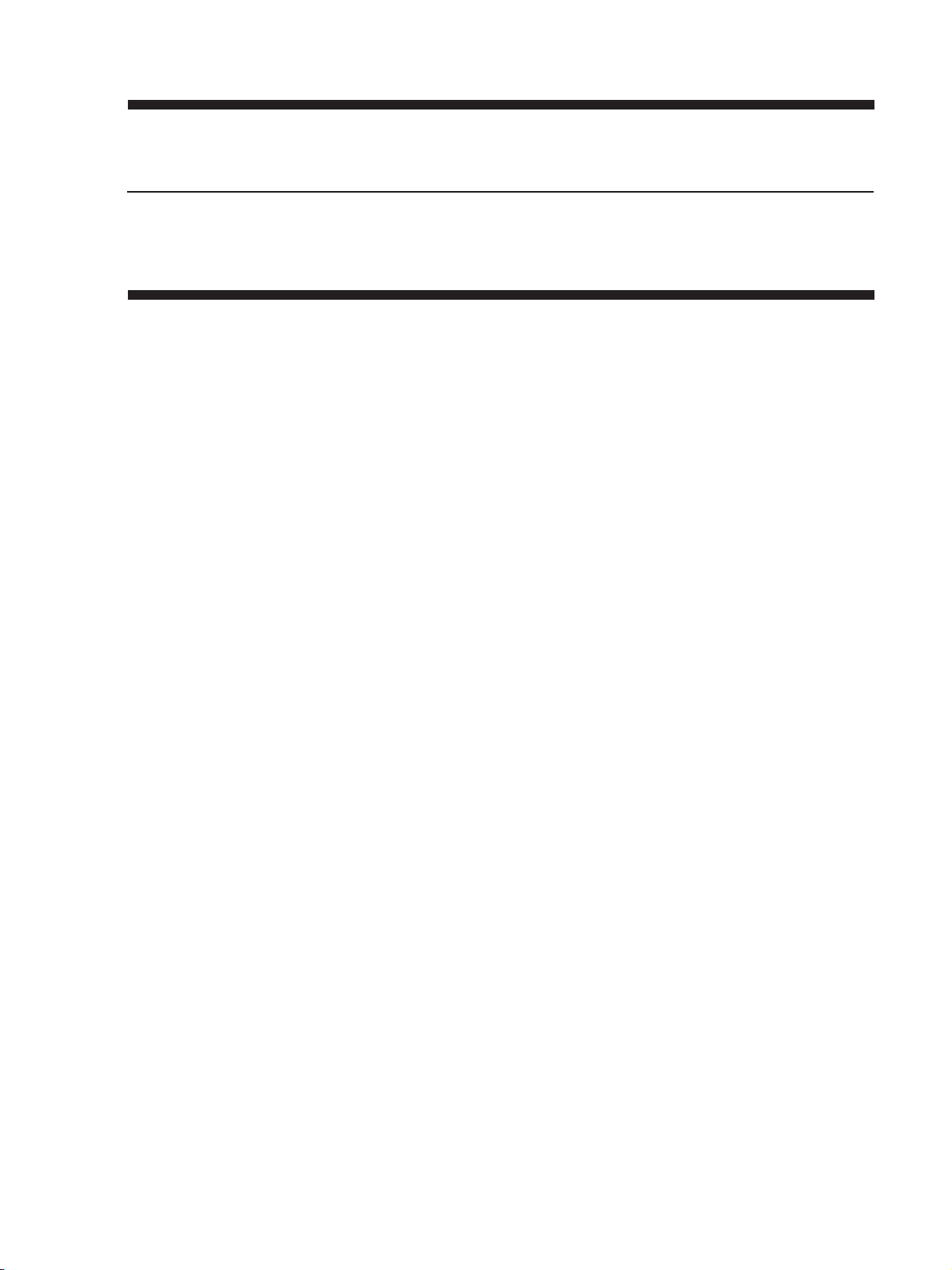

C. Removing a Staple Jam from the Stapler Unit

If the Staple Jam indicator turns on to indicate a staple jam in the stapler unit, perform the

following:

1) Remove the paper waiting to be stapled from the processing tray.

Figure 1-311

2) Grasping the grip, disconnect the finisher from the copier.

Figure 1-312

3) Pick up the staple cartridge by its left and right side (light blue) and pull it off.

Figure 1-313

1-9

Page 17

CHAPTER 1 GENERAL DESCRIPTION

4) Shift down the staple cartridge.

Figure 1-314

5) Remove all staples that slid out of the staple case.

Figure 1-315

6) Shift the tab of the staple cartridge back to its initial position, and fit the staple cartridge into the

stapler unit.

Figure 1-316

7) Connect the finisher to the copier.

1-10

Figure 1-317

Page 18

CHAPTER 1 GENERAL DESCRIPTION

IV. MAINTENANCE BY THE USER

A. Maintenance by the User

No.

Replacement of the staple cartridge

1

Item

Timing

When prompted on the copier’s display

Table 1-401

1-11

Page 19

CHAPTER 2

BASIC OPERATION

I. BASIC CONSTRUCTION ............2-1

II. BASIC OPERATIONS ..................2-8

III. FEEDING DRIVE SYSTEM .......2-11

IV. INTERMEDIARY PROCESSING

TRAY ASSEMBLY......................2-13

V. STAPLING ................................. 2-44

VI. OPERATIONS OF THE STACK

TRAY .........................................2-47

VII. DETECTING JAMS ...................2-56

VIII.POWER SUPPLY ...................... 2-61

Page 20

CHAPTER 2 BASIC OPERATION

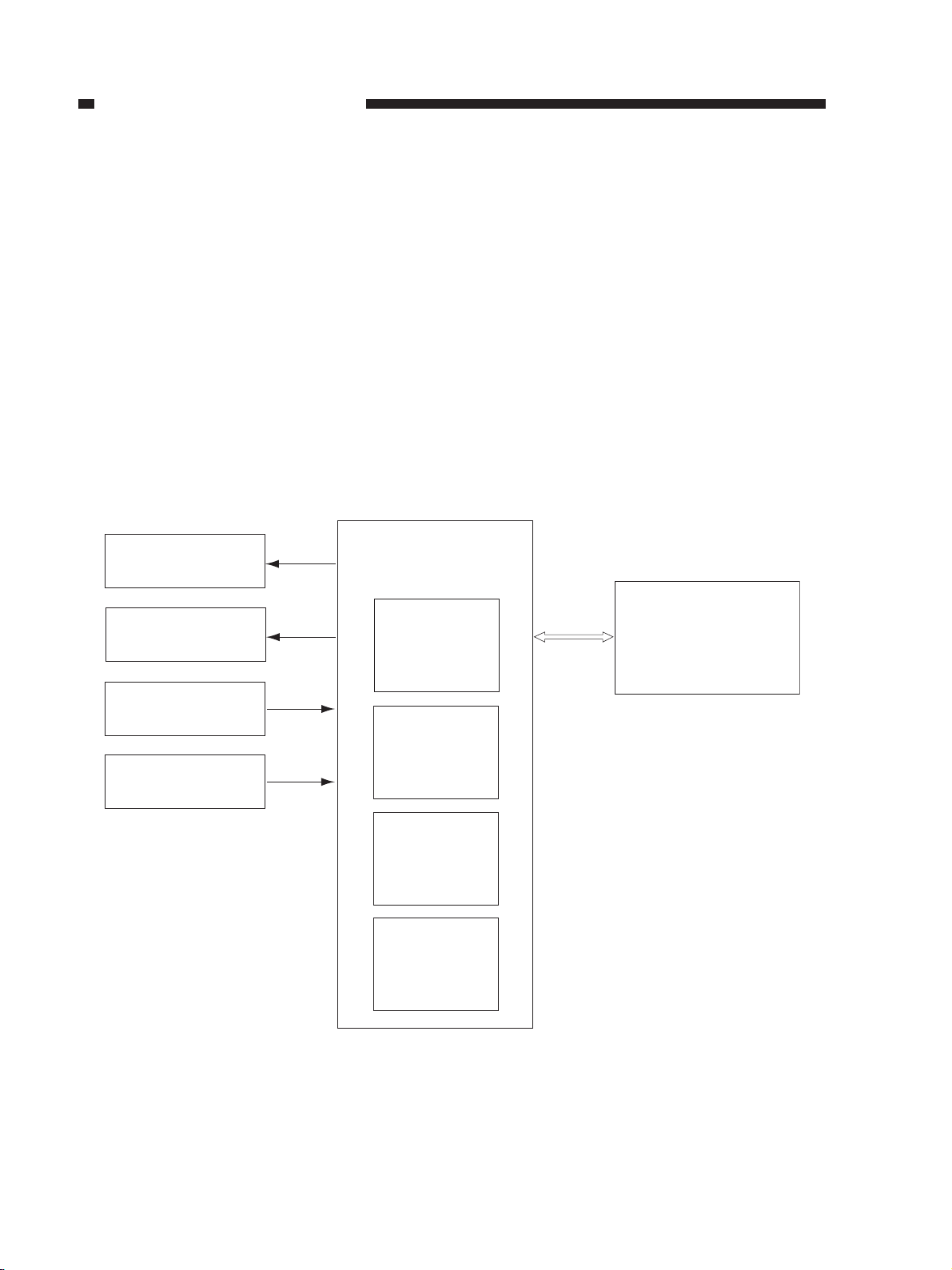

I. BASIC CONSTRUCTION

A. Outline

The finisher consists of four blocks: intermediary processing tray assembly, stapler assembly,

and stack tray assembly. Figure 2-101 is a functional diagram of the finisher.

Delivery assembly

Intermediary

processing

tray assembly

Stack tray

assembly

Stapler

assembly

Figure 2-101

Finisher controller

PCB

2-1

Page 21

CHAPTER 2 BASIC OPERATION

B. Outline of Electrical Circuitry

The finisher’s operation sequences are controlled by the finisher controller PCB, which is a 32-

bit CPU. The finisher controller PCB is also used to control communication (serial) with the copier.

The CPU on the finisher controller PCB is equipped with a built-in ROM used to store

operation sequence programs.

The finisher controller PCB drives solenoids, motors etc., in response to various commands

coming from the copier through serial communication lines. On the other hand, it communicates

the state of each sensor and switch to the copier in the serial mode of communication.

The ICs on the finisher controller PCB have the following functions:

■ IC1 (CPU): Controls sequence

■ IC2 (RAM): Stores various kinds of data temporarily

■ IC3 (ROM): Stores sequence program

■ IC4 (Communication IC): Communicates with the copier

Finisher controller

Solenoid

PCB

Motor

Sensor

Switch

IC1

CPU

IC2

RAM

IC3

ROM

IC4

Communication

IC

Copier

(CPU on DC

controller PCB)

2-2

Figure 2-102

Page 22

CHAPTER 2 BASIC OPERATION

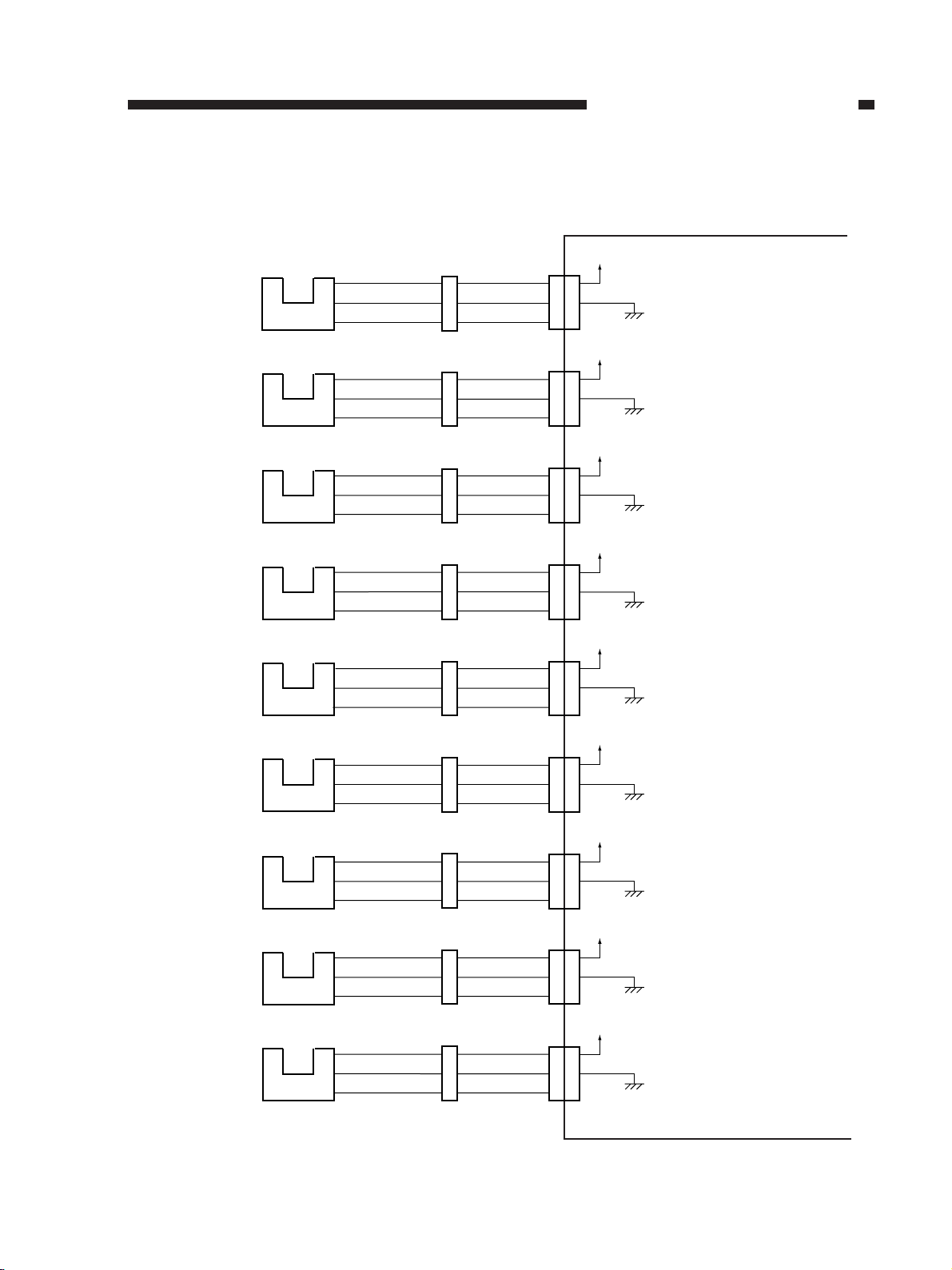

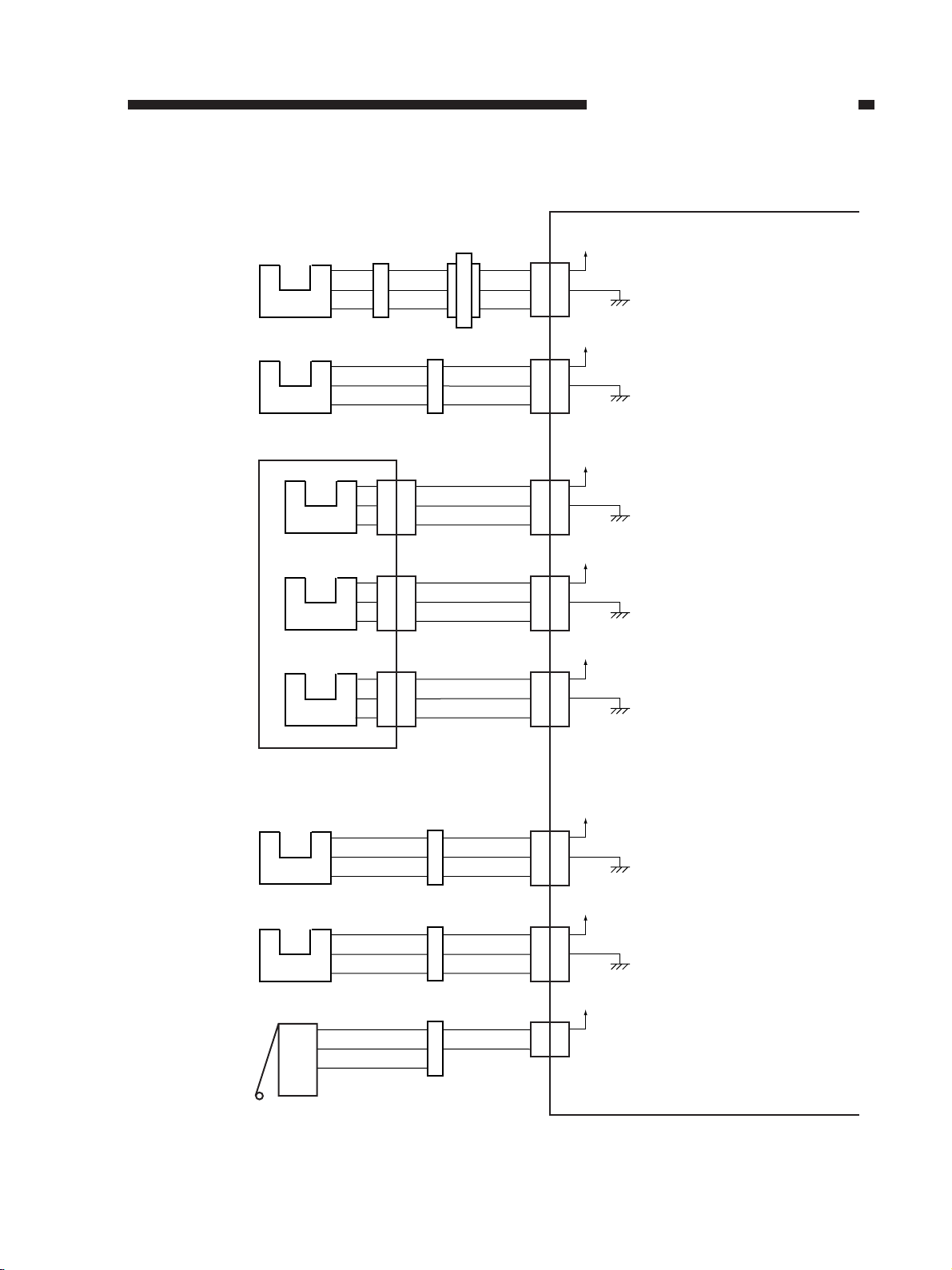

C. Inputs to and Outputs from the Finisher Controller PCB

• Inputs to the Finisher Controller PCB (1/3)

Delivery motor

clock sensor

Inlet paper sensor

Returning roller

home position sensor

Finisher joint sensor

Intermediary

processing tray

paper sensor

S1

S2

S3

S4

S5

J602

J605

J606

J609

J504

J601

J601

J601

J608

J501

Finisher controller PCB

J10

A1

A2

A3

B1

B2

B3

B4

B5

B6

A1

A2

A3

7

8

9

J10

J10

J11

J9

S1D

S2D

S3D

S4D

S5D

+5V

Pulses according to the rotation

speed of the delivery motor.

+5V

When paper is moving over

the sensor, '1'.

(The light-detecting plate is at S2.)

+5V

When the returning roller is

at the home position, '1'.

(The light-blocking plate is at S3.)

+5V

When the finisher is connected

to the copier, '0'.

(The light-blocking plate is not at S4.)

+5V

When paper is over the sensor, '1'.

(The light-blocking plate is at S5.)

A1

A2

A3

B1

B2

B3

B4

B5

B6

A1

A2

A3

7

8

9

Front jogging plate

home position sensor

Rear jogging plate

home position sensor

Stack delivery lever

home position sensor

Lower stack tray lift

motor clock sensor

S6

S7

S8

S9

J502

J503

J505

J603

Figure 2-103

J501

J501

J501

J601

10

11

12

A4

A5

A6

J9

1

2

3

4

5

6

10

11

12

A4

A5

A6

J9

J9

J10

S6D

S7D

S8D

S9D

+5V

When the front jogging plate is

at the home position, '1'.

(The light-blocking plate is at S6.)

+5V

When the rear jogging plate is

at the home position, '1'.

(The light-blocking plate is at S7.)

+5V

The stack delivery plate is

at the home position, '0'.

(The light-blocking plate is not at S8.)

+5V

Pulses according to the rotation speed

of the lower stack tray lift motor.

1

2

3

4

5

6

2-3

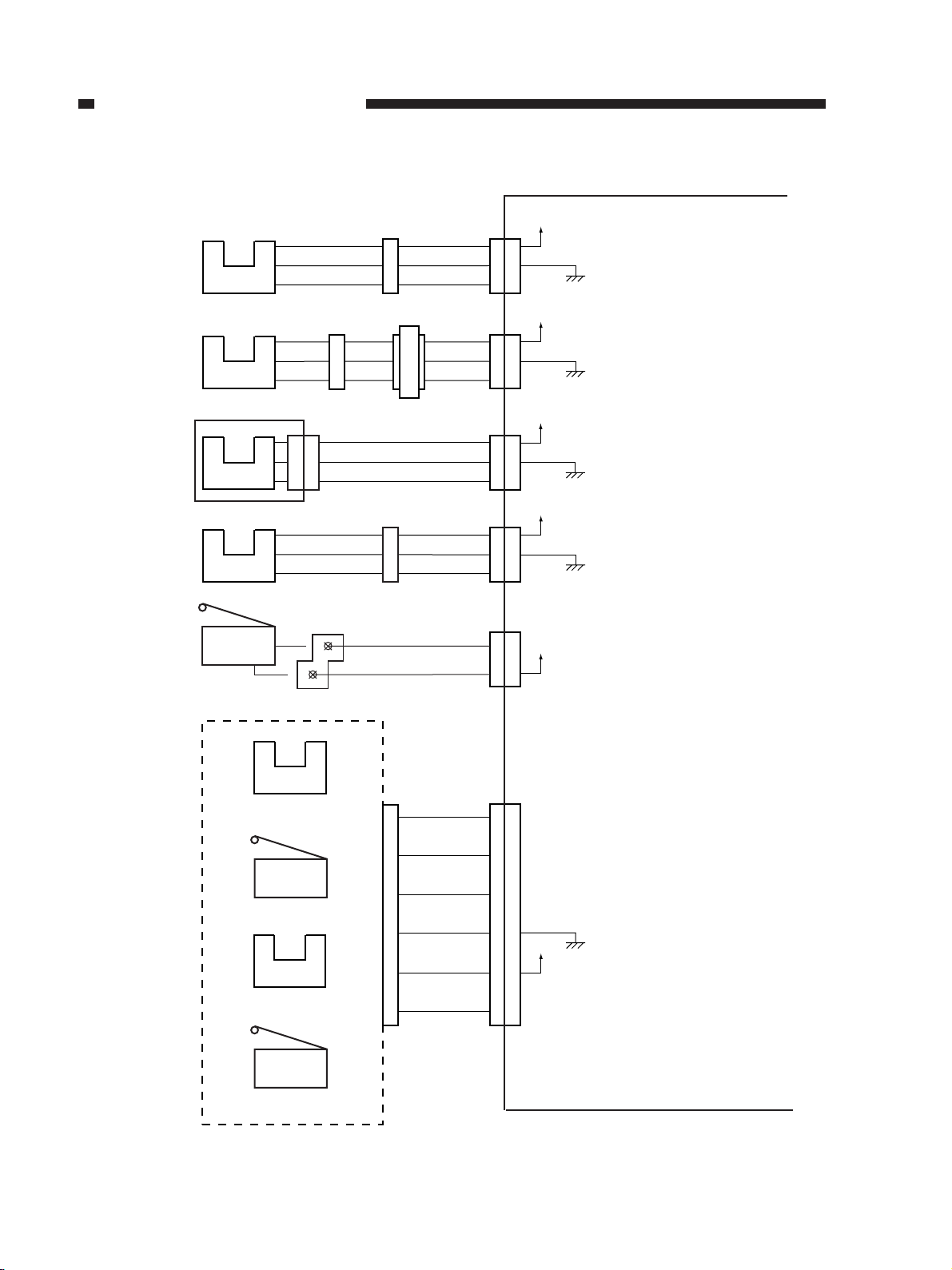

Page 23

CHAPTER 2 BASIC OPERATION

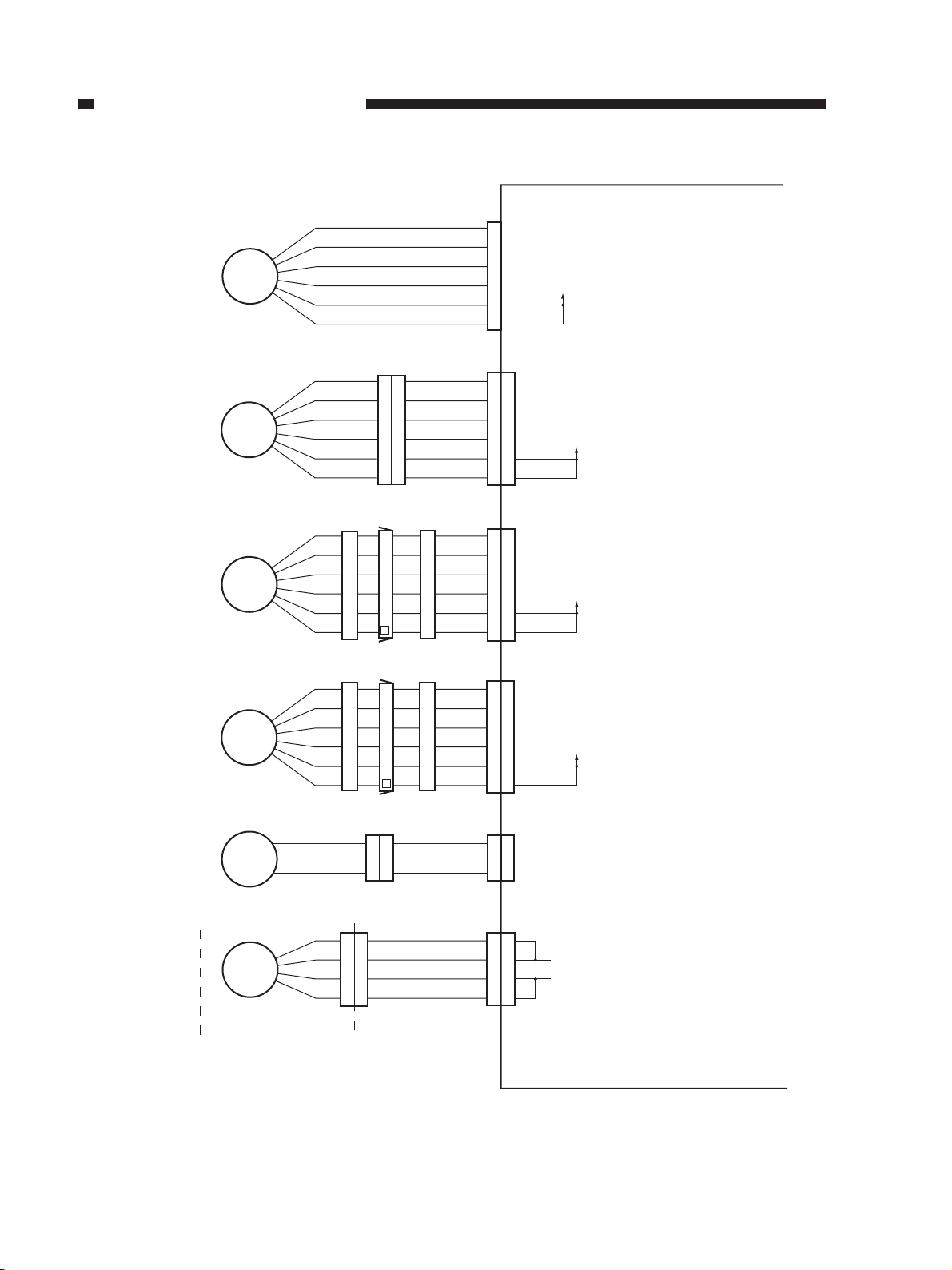

• Inputs to the Finisher Controller PCB (2/3)

Stack tray paper

height sensor

Lower stack tray

paper sensor

Lower stack tray

lower limit sensor

Lower stack tray

upper limit sensor

Stapler safety

switch

S10

S11

S12

Sonser PCB

S13

S14

J1102 J1101 J902

J612

J612

11

11

12

12

13

13

N.O.

COM

J607

J611

Finisher controller PCB

J601

J10

+5V

B7

B7

B8

B8

S10D

B9

B9

J901

J15

1

2

3

J11

B3

B2

B1

J11

A7

A8

A9

J7

1

+5V

S10D

+5V

S12D

+5V

S13D

S14D

+24V

1

2

3

J608

B3

B2

B1

J608

A7

A8

A9

J801

212

When the top of paper is

detected,

'1'.

(The light-blocking is at S10.)

When paper is over the lower stack

tray paper sensor,

'1'.

(The light-blocking plate is at S11.)

When the lower stack tray is

at the lower limit,

'1'.

(The light-blocking plate is at S12.)

When the upper stack tray is

at the upper limit,

'1'.

(The light-blocking plate is not at

S13.)

When the switch is open,

'1'.

Staple edging

sensor

No-staple

detecting switch

Stapling home

position sensor

Stapler cartridge

detector switch

2-4

S15

S16

S17

S18

Stapler unit

J402

13

8

9

11

12

7

Figure 2-104

J401

13

13

8

9

11 11

12 12

7

8

9

7

J8

S15D

S16D

S17D

+5V

S18D

The tip of the staple is not at the

stapling position,

(The light-blocking plate is not at S15.)

When the stapler has no staples, '1

When the stapler is at the stapling

home position,

(The light-blocking plate is at S17.)

When the stapler cartridge is not set,

'1'.

'.

'0'.

'1'.

Page 24

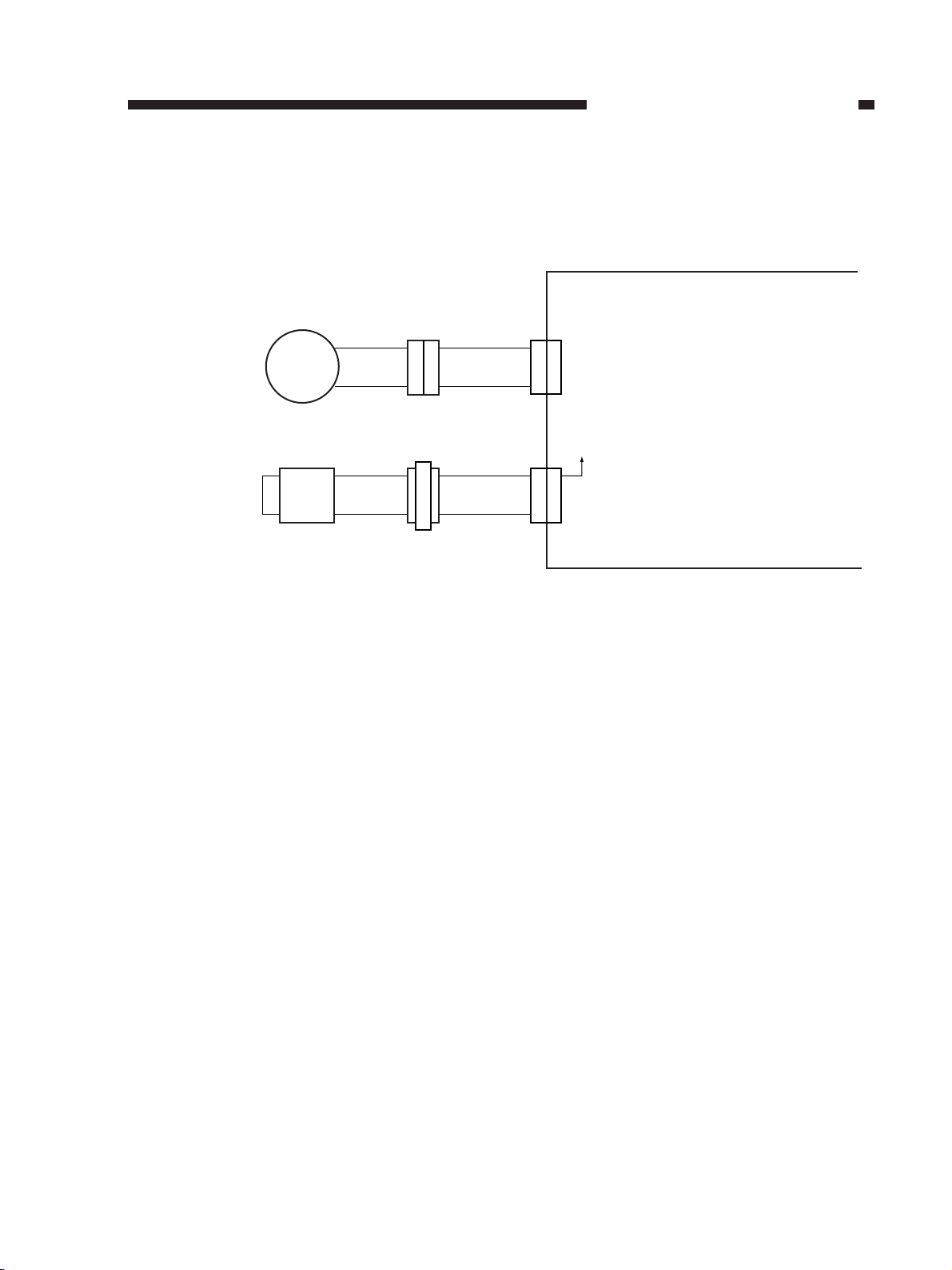

• Inputs to the Finisher Controller PCB (3/3)

10

J612

2

2

3

3

4

4

J612

5

5

6

6

7

7

J612

8

8

9

9

10

J704 J604

J702

Upper stack tray

lift motor

clock sensor

Upper stack tray

paper sensor

Stack tray

nearly full sensor

Upper stack tray

full sensor

Lower stack tray

full sensor

J705

S19

S20

J612

S21

J612

S22

J612

S23

Sensor PCB

J601

J701

J608

J608

J608

CHAPTER 2 BASIC OPERATION

Finisher controller PCB

J10

A7

A8

A9

J12

1

2

3

J11

B12

B11

B10

J11

B9

B8

B7

J11

B6

B5

B4

+5V

S19D

+5V

S20D

+5V

S21D

+5V

S22D

+5V

S23D

Pulses according to the rotation

speed of the upper stack tray

lift motor

When the paper is over the upper

stack tray paper sensor, '1'

(The light-blocking plate is at S20.)

When the upper/lower stack tray is

at the nearly full position, '1'

(The light-blocking plate is at S21.)

When the upper stack tray is

at the full position, '1'

(The light-blocking plate is at S22.)

When the lower stack tray is

at the full position, '1'

(The light-blocking plate is at S23.)

A7

A8

A9

1

2

3

B12

B11

B10

B9

B8

B7

B6

B5

B4

Stack tray collision

prevention sensor

Upper stack tray

upper limit sensor

Stack processing

safety switch

S24

S25

S26

COM

N.O.

J703

J610

J1202

Figure 2-105

J701

J608

A4

A5

A6

J1201

J12

4

5

6

A4

A5

A6

1

22

J11

J16

+5V

S24D

+5V

S25D

+24V

S26D

When the upper stack tray collides

with paper stacked on the lower

stack tray, '1'

(The light-blocking plate is at S24.)

When the upper stack tray is

at the upper limit, '1'

(The light-blocking plate is at S25.)

When the switch is open, '1'.

4

5

6

1

2-5

Page 25

CHAPTER 2 BASIC OPERATION

• Outputs of the Finisher Controller PCB (1/2)

Delivery motor

Stack processing

motor

M1

J202J203

M2

Finisher controller PCB

J4

1

M1DA

2

M1DB

3

M1DA*

4

M1DB*

5

24V

6

J5

J201

1

1

M2DA

2

2

M2DB

3

3

M2DA*

4

4

M2DB*

5

5

6

6

By changing the sequence of drive

pulses (A, A*, B, B*) and the

frequency, the timing of the rotation

is controlled.

By changing the sequence of drive

pulses (A, A*, B, B*) and the

frequency, the timing of the rotation

is controlled.

(See p. 2-14)

24V

Front jogging motor

Rear jogging motor

Upper stack tray lift

motor

Stapler motor

M3

M4

M5

M6

Stapler unit

J306

J708

J402

J304

J305J307

J707

J302

J303

J301

J301

J401

10

11

12

J6

1

1

M3DA

2

2

M3DB

3

3

M3DA*

4

4

M3DB*

5

5

6

6

By changing the sequence of drive

pulses (A, A*, B, B*) and the

frequency, the timing of the rotation

is controlled.

24V

(See p.2-30.)

J6

7

7

M4DA

8

8

M4DB

9

9

M4DA*

10

M4DB*

11

12

J14J706

M5D1

121

2

M5D2

By changing the sequence of drive

pulses (A, A*, B, B*) and the

frequency, the timing of the rotation

is controlled.

(See p. 2-30)

24V

CW rotation at M5D1

CCW rotation at M5D1 '1', M5D2 '0

Stop at M5D1 '0', M5D2 '0

'0',

M5D2 '1

'.

'.

'.

J8

1

1

2

2

4

4

5

5

M6D1

M6D2

CW rotation at M6D1

CCW rotation at M6D1 '1', M6D2 '0

Stop at M6D1 '0', M6D2 '0

'0',

M6D2 '1

'.

'.

'.

2-6

Figure 2-106

Page 26

• Outputs of the Finisher Controller PCB (2/2)

Lower stack tray

lifter motor

Paper holding lever

drive solenoid

M7

J1006 J1005

SL1

J1001J1003 J1002

J1004

CHAPTER 2 BASIC OPERATION

Finisher controller PCB

121

121

J3

2

J13

2

M7D1

M7D2

24V

SL1D

CW rotation at M7D1"0", M7D2"1"

CCW rotation at M7D1"1", M7D2"0"

Stop at M7D1"0", M7D2"0"

Solenoid ON at SL1D"0"

Figure 2-107

2-7

Page 27

CHAPTER 2 BASIC OPERATION

II. BASIC OPERATIONS

The finisher is designed to operate as follows:

1. Paper arrives from the copier.

Figure 2-201

2. Paper reaches the intermediary processing tray.

Figure 2-202

2-8

Page 28

CHAPTER 2 BASIC OPERATION

3. Paper is moved until it butts against the stopper plate by the work of the returning roller.

Figure 2-203

4. The paper is put into order by the work of the front/rear jogging plate.

Figure 2-204

2-9

Page 29

CHAPTER 2 BASIC OPERATION

5. Operations 1 through 4 are repeated until a specific number of sheets have been stacked on the

intermediary processing tray.

6. The sheets are stapled (if stapling is selected).

Figure 2-205

7. The stack on the intermediary processing tray is moved to the stack tray.

Figure 2-206

2-10

Page 30

CHAPTER 2 BASIC OPERATION

III. FEEDING DRIVE SYSTEM

A. Outline

Paper coming from the copier is sent to the intermediary processing tray, on which it is

arranged and offset/stapled for delivery to the stack tray.

The machine detects jams using the inlet sensor (S2).

Figure 2-301 shows the construction of the feeding drive system.

Notation

M1

M2

Feeding guide A

Returning roller

Delivery motor

Stack processing motor

S1

S2

S5

Delivery motor clock sensor

Inlet sensor

Intermediary processing tray paper sensor

Feeding guide B

Name

Table 2-301

S1

M1

S2

J10A-3

S1D

J4

Delivery roller

J10B-3

S2D

M2

Finisher controller PCB

J5

Stack delivery lever

S5

One-way clutch

J9-9

S5D

Figure 2-301

2-11

Page 31

CHAPTER 2 BASIC OPERATION

B. Delivery

Paper coming from the copier is sent to the intermediary processing tray by the work of the

delivery motor (M1), and the movement of paper is monitored by the inlet sensor (S2).

The delivery slot of the machine is equipped with a feeding guide (A/B). The feeding guide A/

B holds down the trailing edge of paper using its own weight so as to help move paper as far as the

returning roller.

Feeding guide A

Feeding guide B

Delivery roller

S2

Figure 2-302

2-12

Page 32

CHAPTER 2 BASIC OPERATION

IV. INTERMEDIARY PROCESSING TRAY ASSEMBLY

A. Intermediary Processing Tray Operation

1. Outline

The intermediary processing tray is designed to organize sheets coming from the copier into a

stack for offset and stapling operations.

The intermediary processing tray assembly consists of a returning roller and stack delivery

belts, the latter of which are equipped with stack delivery levers and operate as a pair.

When paper reaches the intermediary processing tray, the intermediary processing tray paper

sensor (S5) is turned on.

When the copier is turned on, the stack processing motor (M2) is driven so as to move the

returning roller and the stack processing belt to the home position.

Returning roller home position sensor (S3)

Stack processing

motor

M2

Motor direction

Clockwise

Counterclockwise

One-way clutch

Stack delivery belt

Figure 2-401

Drive

Stack delivery belt

Returning roller

Returning roller

Returning roller

Arrow in Figure 2-401

Stack tray side

Drive torque

Strong

Weak

Table 2-401

2-13

Page 33

CHAPTER 2 BASIC OPERATION

2. Controlling the Stack Processing Motor (M2)

The stack processing motor (M2) is a 4-phase stepping motor.

The direction of the rotation (clockwise/counterclockwise) and the speed of the motor are

controlled by the phase of the pulse signals BUNDPINA and BUNDPINB from the CPU to IC10,

which generates pulse signals A, A*, B, B* in response for control.

The motor torque is controlled based on combinations of current control signals BUNDCUR1

and BUNDCUR2 from the CPU to IC10.

The machine drives the motor using a high torque when rotating it clockwise (to drive the stack

delivery belt); on the other hand, it drives the motor at a low torque when rotating it

counterclockwise (to drive the returning roller).

IC1

CPU

BUNDPINA

BUNDPINB

BUNDCUR1

BUNDCUR2

IC10

Motor

driver

Figure 2-402

A

A*

B

B*

24V

J5-1

-5

-3

-2

-6

-4

Stack processing

motor

M2

2-14

Page 34

CHAPTER 2 BASIC OPERATION

3. Stacking Limit on the Intermediary Processing Tray

The intermediary processing tray is capable of holding as many sheets of paper as are indicated

in Table 2-402.

When a specific count is exceeded (copies or originals), as many sheets as indicated are put

into order and offset on the intermediary processing tray; then, the stack is delivered to the stack

tray to deal with the remaining number of sheets.

For offset, all sheets of the same stack are moved in the same direction.

Large-size

15

Cassette

Paper deck

Small-size30Medium-size

20

Small-size: A4, A4-R, A5-R, B5, B5-R, postcard, LT, LT-R,

ST-R

Medium-size: B4, LG

Large-size: A3, FOLIO, COMP, LD

Table 2-402

2-15

Page 35

CHAPTER 2 BASIC OPERATION

B. Returning Roller

1. Outline

The returning roller serves to butt paper from the copier against the stopper plate to correct its

placement in the feeding direction.

The returning roller is driven in a clockwise direction when the stack processing motor rotates

counterclockwise.

Returning roller

Stopper plate

Figure 2-403

2-16

Page 36

CHAPTER 2 BASIC OPERATION

2. Outline of Operations

The returning roller operates as follows:

1. Paper arrives from the copier.

Figure 2-404a

2. The returning roller rotates clockwise to butt the paper reaching the intermediary processing

tray against the stopper plate.

Stopper plate

Figure 2-404b

3. The returning roller makes a single rotation and waits in its home position. In the case of

large-/medium-size paper, it waits where it will hold down the paper in position.

Figure 2-404c

2-17

Page 37

CHAPTER 2 BASIC OPERATION

4. When the next sheet of paper arrives from the copier, operations 1 and 2 are repeated to

organize a stack.

When the last sheet of each stack has been butted against the stopper plate, the returning roller

moves past its home position and stops after making a 1/8 rotation.

Figure 2-404d

5. When a single set has been arranged, the stack is delivered by the work of the stack delivery

lever. At the same time, the returning roller rotates in the opposite direction.

Since the returning roller has not been at the home position, no interference with the stack

occurs. (See II.B. “Outline of Operations.”)

Figure 2-404e

2-18

Page 38

CHAPTER 2 BASIC OPERATION

6. The stack processing belt reaches its home position to end the delivery operation. At the same

time, the returning roller stops at the home position.

Home position

Figure 2-404f

7. Thereafter, operations 1 through 6 are repeated when the next sheet arrives for the next stack.

■ Holding Down Paper (manual feed, large-/medium-size paper)

In the case of manual pickup, the intermediary processing tray holds as many as two sheets.

When large-size paper is fed manually, it tends to buckle, requiring the returning roller to hold it

down until the next sheet arrives.

Returning roller

Holds down the paper

after it its butted against

the stopper plate.

Figure 2-405

2-19

Page 39

CHAPTER 2 BASIC OPERATION

3. Sequence of Operations

(1) Normal

1st sheet delivery signal 2nd sheet delivery signal

Inlet sensor (S2)

Delivery motor (M1)

Stack processing

motor (M2)

Returning roller

home position sensor (S3)

Stack delivery lever

home position sensor (S8)

Intermediary processing

tray paper sensor (S5)

: CW rotation (stack delivery operation)

*1: Varies depending on the length of paper.

*2: 0.2 sec.

*3: 0.3 sec.

*4: To prevent interference with the stack during delivery, the returning roller is given a 1/8 turn

after it has reached its home position.

*1 *1

*2 *2

*3 *4

Figure 2-406

: CCW (returning operation)

2-20

Page 40

(2) Holding Down Paper

CHAPTER 2 BASIC OPERATION

1-1 Delivery

signal*1

Inlet sensor (S2)

Delivery motor (M1)

Stack processing

motor (M2)

Returning roller home

position sensor (S3)

Stack delivery lever home

position sensor (S8)

Intermediary processing

tray paper sensor (S5)

*1: A-B delivery (n number of stack, nth sheet)

*2: Varies depending on the length of paper.

*3: 0.2 sec.

*4: 0.3 sec; after the returning operation, the returning roller is driven continuously and stopped where its

end can hold down the paper.

*5: Holds down the paper.

*6: To prevent interference with the stack during delivery, the returning roller is given a 1/8 turn

after it has reached its home position.

*2

*3 *3 *3 *4*4

1-2 Delivery

signal*1

2-1 Delivery

signal*1

*6

2-2 Delivery

signal*1

*3

*5*5

: CCW rotation (returing operation): CW rotation (stack delivery operation)

*6

Figure 2-407

2-21

Page 41

CHAPTER 2 BASIC OPERATION

C. Driving the Stack Delivery Belt

1. Outline of Operations

The stack delivery belts are driven when the stack processing motor (M2) rotate clockwise, and

two belts are designed to move in sync.

Each stack delivery belt is equipped with two stack delivery levers on opposite sides. A single

stack is delivered for each half cycle of the belt movement.

When the copier is turned on, the stack processing motor (M2) is driven to set the stack

delivery lever to its home position.

Stack

Stack delivery belt

Stack delivery lever

Figure 2-408

M2

One-way clutch

2-22

Page 42

CHAPTER 2 BASIC OPERATION

2. Outline of Operations

The stack delivery belt operates as follows:

1. When the copier’s Start key is pressed and a copy is delivered to the intermediary processing

tray, the paper is butted against the stopper plate so that it is arranged. As many sheets as

specified are stacked on the intermediary processing tray.

Figure 2-409a

2. The stack delivery belt is driven to move the stack in the direction of the stack tray with the

help of the stack delivery lever.

Figure 2-409b

2-23

Page 43

CHAPTER 2 BASIC OPERATION

3. The stack delivery belt is decelerated immediately before the stack is delivered to the stack

tray, thereby avoiding disruption of the stack by impact.

Figure 2-409c

4. The stack is delivered to the stack tray and the lever stops in front of its home position.

2-24

Figure 2-409d

Page 44

CHAPTER 2 BASIC OPERATION

5. When the stack tray has moved down, both stack delivery belt and returning roller move to the

home position to wait for the next sheet.

Figure 2-409e

2-25

Page 45

CHAPTER 2 BASIC OPERATION

3. Sequence of Operations

1st sheet delivery signal 2nd sheet delivery signal

Inlet sensor (S2)

Delivery motor (M1)

Stack processing

motor (M2)

Returning roller home

position sensor (S3)

Stack delivery lever home

position sensor (S8)

Intermediary processing

tray paper sensor (S5)

Front jogging plate

motor (M3)

Front jogging plate home

position sensor (S6)

Rear jogging plate

motor (M4)

Rear jogging plate home

position sensor (S7)

Stack tray lifter

motor (M5), (M7)

*1 *1

*2

*3

*2

*3

*9

*4

*5

*6 *8

*7

Stack tray paper

height sensor (S10)

Stack tray paper

sensor (S11), (S20)

Paper holder drive

solenoid (SL1)

: CW rotation : CCW rotation

→

Stack processing motor: CW

Front jogging plate motor: CW

Rear jogging plate motor: CW

Stack tray lifter motor: CW

stack delivery/CCW → returning operation

→

move to front/CW → move to rear

→

move to rear/CCW → move to front

→

up/CCW - down

*1: Varies depending on the length of paper.

*2: 0.2 sec.

*3: 0.3 sec.

*4: Varies depending on the length of paper.

*5: 0.5 sec.

*6: Stops temporarily.

*7: Drives until the stack tray paper height sensor is turned OFF.

*8: After the stack tray has moved up and stopped, driven until the stack delivery lever reaches its

home position.

*9: Comes ON 0.2 sec. after the stack processing motor turns ON.

Figure 2-410a

2-26

Page 46

CHAPTER 2 BASIC OPERATION

1st sheet delivery signal

Inlet sensor (S2)

Delivery motor (M1)

Stack processing

motor (M2)

Returning roller home

position sensor (S3)

Stack delivery lever home

position sensor (S8)

Intermediary processing

tray paper sensor (S5)

Front jogging

plate motor (M3)

Front jogging plate home

position sensor (S6)

Rear jogging

plate motor (M4)

2nd sheet delivery signal

*1 *1

*2

*3

*2

*3

*5

*6 *8

Rear jogging plate home

position sensor (S7)

Stapling ON signal

Stack tary lifter

motor (M5), (M7)

Stack tray paper

height sensor (S10)

Stack tray paper

sensor (S11), (S20)

: CW rotation : CCW rotation

Stack processing motor: CW → stack delivery/CCW → returning

Front jogging plate motor: CW → move to front/CCW → move to rear

Rear jogging motor: CW → move to front/CCW → move to front

Stack tray lifter motor: CW → move up/CCW → move down

*1: Varies depending on the length of paper.

*2: 0.2 sec.

*3: 0.3 sec.

*4: ON at 0.1 sec after the returning roller is turned off

*5: 0.5 sec.

*6: Stops temporarily.

*7: Driven until the stack tray paper height sensor is turned off.

*8: When the stack tray has moved up and stopped, driven until the stack delivery lever reaches its

home position.

*4

*7

Figure 2-410b

2-27

Page 47

CHAPTER 2 BASIC OPERATION

D. Arranging Sheets and Offsetting Sheets

1. Outline

Sheets are arranged in a breadthwise direction on the intermediary processing tray by the work

of the front/rear jogging plate.

The front jogging plate is driven by the front jogging plate motor (M3), while the rear jogging

plate is driven by the rear jogging plate motor (M4).

The front jogging plate home position sensor (S6) serves to find out whether the front jogging

plate is at the home position; the rear jogging plate home position sensor (S7), on the other hand,

serves to find out whether the rear jogging plate is at its home position.

Tables 2-403 and -404 show how sheets are arranged and possible sizes:

Mode

Non-sort

Staple sort

Sort

Operation

Offset (front)

Offset (rear)

Offset

Table 2-403

Possible sizes

Small-size

Medium-size

Large-size

A4, A4-R, B5

LT, LT-R, ST-R

B4

LG

A3, FOLIO, COMP

LD

Table 2-404

Reference:

The finisher is initialized at the start of the operation. At power-on, the front/rear jogging plates

move to the home position if they are not at the home position.

2-28

Page 48

Front

Front jogging plate

home position

sensor (S6)

CHAPTER 2 BASIC OPERATION

Front jogging plate

Stack tray

Rear jogging plate

Front jogging motor (M3)

Rear jogging motor (M4)

Figure 2-411

Rear

Rear jogging plate

home position sensor (S7)

2-29

Page 49

CHAPTER 2 BASIC OPERATION

2. Controlling the Jogging Motor

Figure 2-419 is a diagram of the front jogging motor (M3) and the rear jogging motor (M4).

Both motors are 4-phase stepping motors.

IC1 (CPU) generates the following signals (Table 2-405) for control of the motors.

Function

Controls direction and

speed of motor rotation

Enables motor drive

Switches drive current

Notation

JOGPINA

JOGPINB

FJOGPER

BJOGPER

FJOGCUR

BJOGCUR

Front jogging motor

Rear jogging motor

Front jogging motor

Rear jogging motor

Front jogging motor

Rear jogging motor

Motor

Table 2-405

IC1 controls the timing of JOGPINA and JOGPINB to suit the direction (clockwise/

counterclockwise) and speed of the motor.

IC1 generates either FJOGPER or BJOGPER depending on which motor to drive. When

FJOGPER is generated, IC11 sends JOGPINA and JOGPINB to IC12 (motor driver IC) in

response to FJOGPER.

IC12 generates 4-phase motor drive signals (FJOGA, FJOGB, FJOG_A, FJOB_B) in response

to JOGPINA and JOGPINB. Likewise, IC11 sends JOGPINA and JOGPINB to IC13 (motor driver

IC) in response to BJOGPER.

IC13 generates 4-phase motor drive signals (BJOGA, BJOGB, BJOG_A, BJOB_B) in

response to JOGPINA and JOGPINB.

FJOGPER and BJOGPER are motor drive enable signals and the motor in question is driven in

response.

To keep the motor at rest, IC12 and IC13 continue to generate the phase signals they sent,

thereby putting the motor on hold.

FJOGCUR, BJOGUR and JSTPOFF from IC1 are current switching signals (Table 2-406) sent

to the motors.

2-30

State

Driving the motor

Keeping the motor on hold

Keeping the motor free

Control current

High-level current (high torque)

Low-level current (low torque)

Current OFF (free)

Table 2-406

Page 50

Finisher controller PCB

CHAPTER 2 BASIC OPERATION

IC1

(CPU)

JOGPINA

JOGPINB

FJOGPER

BJOGPER

FJOGCUR

BJOGCUR

IC11

5V

JSTPOFF

IC11

5V

5V

5V

+24VP

FJOGA

FJOG_A

IC12

FJOGB

FJOG_B

+24VP

BJOGA

BJOG_A

IC13

BJOGB

BJOG_B

11

8

12

10

Front jogging

J6

plate motor

1

5

M3

3

2

6

4

Rear jogging

J6

plate motor

7

M4

9

Figure 2-412

2-31

Page 51

CHAPTER 2 BASIC OPERATION

3. Rear Jogging (staple sort)

The machine’s stapler is fixed in position at the rear so that they are arranged at the rear when

the staple mode is selected.

When the Start key has been pressed and the copier has communicated the paper size, the rear

jogging plate moves to the home position and the front jogging plate moves to a specific point* and

is kept in wait.

*Half of the width of the paper from the middle of the tray+10 mm to the front.

Paper arriving from the copier is moved to the intermediary processing tray.

When paper has been deposited on the intermediary processing tray, the returning roller butts it

against the stopper plate so that it is put into order in the feeding direction. The paper is then moved

to the stapling position, and arranged once again toward the rear by the work of the front jogging

plate.

Home position of

the rear jogging plate

Half of paper

width +10mm

Middle of the stack tray

Home position of

the front jogging plate

Figure 2-413a

Home position of the

rear jogging plate

A3,A4

A

20mm

2-32

Home position of the

front jogging plate

Figure 2-413b

Page 52

CHAPTER 2 BASIC OPERATION

4. Offset Jogging (non stapling)

a. Sort

In the sort mode, the stack of sheets on the intermediary processing tray is moved so that it is

arranged; this is called the “offset operation.”

The distance of the offset is 20 mm.

The direction of the offset (front/rear) of each set is the opposite of the direction of the offset

used for the immediately preceding job. If it was offset to the front, the present job will be offset to

the rear and vice versa.

When the paper size is communicated by the copier, the finisher controller PCB drives both the

front and the rear jogging plates at the same time, thereby moving them to a specific point; i.e. the

width of paper placed in the middle of the stack tray + 10 mm on both sides (Figure 2-414a).

Sheets are arranged by driving either the front or the rear jogging plate. When they are put into

order against the front, the rear jogging plate is moved to the edge of the stack; when sheets are put

into order against the rear, the front jogging plate is moved to the edge of the stack.

If the paper is A4 or A3, however, the home position of the front jogging plate (if jogging is

against the front) or of the rear jogging plate (if jogging is against the rear) will serve as the point of

reference for offset operation. The jogging plate used (the rear jogging plate if jogging is against

the front, or the front jogging plate if jogging is against the rear) is kept in wait at the home position.

The jogging plate is moved to the edge of the stack from its home position for the jogging

operation (Figure 2-414b).

If the number of sheets (copies or originals) is more than the maximum number of sheets the

intermediary processing tray is designed to hold, as many sheets as allowed are delivered as a stack

once; thereafter, the subsequent sheets are arranged in the same direction.

Offset distance

20mm

Rear jogging plate

home position

20mm

Front jogging plate

home position

Figure 2-414a

2-33

Page 53

CHAPTER 2 BASIC OPERATION

A3,A4

20mm

Figure 2-414b

Rear jogging plate

home position

Front jogging plate

home position

2-34

Page 54

CHAPTER 2 BASIC OPERATION

b. Non-Sort

In the non-sort mode sheets are arranged by butting against the front (offset to the front).

Rear jogging plate

home position

20mm

A3,A4

Figure 2-415a

20mm

Front jogging plate

home position

Rear jogging plate

home position

Front jogging plate

home position

Figure 2-415b

2-35

Page 55

CHAPTER 2 BASIC OPERATION

5. Outline of Operations

a. Staple Sort

The machine operates as follows in the staple sort mode:

1. The copier’s Start key is pressed.

The copier communicates data such as on staple mode selection and paper size.

2. The front jogging plate moves from the home position to a specific position*.

*Half the width of paper from the middle of the stack tray+10 mm toward the front.

Rear jogging plate

home positon

Middle of

Half the width

of paper +10mm

10mm

the stack tray

Figure 2-416a

3. The paper is deposited on the intermediary processing tray.

Front jogging plate

home position

2-36

Figure 2-416b

Page 56

CHAPTER 2 BASIC OPERATION

4. The front jogging plate is driven and arranged.

5. The front jogging plate is returned to its position in operation 2.

Figure 2-416c

6. For each delivery of paper, operations 3 through 5 are repeated.

7. When a single set has been put into order, stapling is started.

8. The stack processing belt is driven to move the stack to the stack tray.

Figure 2-416d

9. The stack tray is moved up to a specific height.

10. Thereafter, operations 3 through 8 are repeated.

2-37

Page 57

CHAPTER 2 BASIC OPERATION

Reference:

If the number of originals is higher than the maximum number of sheets allowed on the

intermediary processing tray, the stack is not stapled but is delivered to the stack tray. The

remaining sheets will be handled in the same way without stapling.

2-38

Page 58

CHAPTER 2 BASIC OPERATION

b. Offset Jogging

The machine operates as follows in offset jogging:

In the non-sort mode, sheets are offset only against the front.

1. The copier’s Start key is pressed.

The copier communicates such data such as on sort mode selection and paper size.

2. The front/rear jogging plate is moved from the home position to a specific point*.

*Width of paper placed in the middle of the stack tray+10 mm in both sides.

Rear jogging

home position

10mm

10mm

Figure 2-417a

3. The paper is deposited on the intermediary processing tray.

Front jogging

home position

Figure 2-417b

2-39

Page 59

CHAPTER 2 BASIC OPERATION

4. The rear jogging plate is driven to jog the paper if jogging is against the front: if jogging is

against the rear, the front jogging plate is driven.

5. The front or the rear plate is returned to its position in operation 2.

20mm

Figure 2-417c

6. For each delivery of paper, operations 3 through 5 are repeated.

7. The stack is delivered.

a) If the number of originals is the maximum number of sheets allowed on the intermediary

processing tray or fewer,

Each set is delivered to the stack tray.

b) If the number of originals is higher than the maximum number of sheets allowed on the

intermediary processing tray,

The stack on the intermediary processing tray is delivered to the stack tray. Thereafter, the

remaining sheets are jogged in the same offset position and delivered to the stack tray.

2-40

Figure 2-417d

Page 60

CHAPTER 2 BASIC OPERATION

8. The stack tray is moved up to a specific height.

9. Thereafter, operations 3 through 9 are repeated using alternately different jogging plates.

20mm

Figure 2-417e

2-41

Page 61

CHAPTER 2 BASIC OPERATION

5. Sequence of Operations

(1) Offset (2 originals, 2 sets)

1-1 Delivery

signal*1

Inlet sensor (S2)

Delivery motor (M1)

Stack processing

motor (M2)

Returning roller home

position sensor (S3)

Stack delivery lever home

position sensor (S8)

Intermediary processing

tray paper sensor (S5)

Front jogging

plate motor (M3)

Front jogging plate home

position sensor (S6)

Rear jogging

plate motor (M4)

Rear jogging plate home

position sensor (S7)

*1: A-B delivery signal (n number of stack, nth sheet).

*2: Varies depending on the length of the paper.

*3: 0.2 sec.

*4: 0.3 sec.

*5: Varies depending on the size of the paper.

*6: 0.5 sec.

*7: Holds down the edge of paper until stack delivery ends.

1-2 Delivery

signal*1

*2

*3

Stack processing motor: CW ® stack delivery/CCW ® returning

Front jogging plate motor: CW ® move to front/CCW ® move to rear

Rear jogging plate motor: CW ® move to rear/CCW ® move to front

Stack tray lifter motor: CW ® move up/CCW ® move down

*4

: CW rotation : CCW rotation

*2

*3

*5

*5 *5

*4

2-1 Delivery

signal*1

*2 *2

*5

*3

*7

*4 *3

2-2 Delivery

signal*1

*5

*5 *5

*4

*6

*7

2-42

Figure 2-418a

Page 62

(2) Stapling (2 originals, 2 sets)

CHAPTER 2 BASIC OPERATION

1-1 Delivery

signal*1

Inlet sensor (S2)

Delivery motor (M1)

Stack processing

motor (M2)

Returning roller home

position sensor (S3)

Stack delivery lever home

position sensor (S8)

Intermediary processing

tray paper sensor (S5)

Front jogging

plate motor (M3)

Front jogging plate home

position sensor (S6)

Rear jogging

plate motor (M4)

Rear jogging plate home

position sensor (S7)

*2

*3

1-2 Delivery

signal*1

*2

*4

*3

*5 *5 *5 *5

*4

2-1 Delivery

signal*1

*2 *2

*3

*8 *8

*4 *3

2-2 Delivery

signal*1

*5 *5

*4

*7*7

Stapling ON signal

*6 *6

: CW rotation : CCW rotation

Stack processing motor: CW ® stack delivery/CCW ® returning

Front jogging plate motor: CW ® move to front/CCW ® move to rear

Rear jogging motor: CW ® move to rear/CCW ® move to front

Stack tray lifter motor: CW ® moveup/CCW ® move down

*1: A-B delivery signal (n number of stack, nth sheet).

*2: Varies depending on the length of the paper.

*3: 0.2 sec.

*4: 0.3 sec.

*5: Varies depending on the size of the paper.

*6: Turns on 100 msec after the returning roller turns off.

*7: 0.5 sec.

*8: Holds down the edge of paper until stapling and stack delivery end.

Figure 2-418b

2-43

Page 63

CHAPTER 2 BASIC OPERATION

V. STAPLING

1. Outline

The machine’s stapler unit is fixed in position at the rear, and is not designed to shift or swing.

The stapler unit staples at a single position only, and stapling is on the front side of a stack and

from under.

The machine does not allow for manual stapling or manual insertion stapling.

The size of paper and the thickness of each stack for stapling are as follows:

Paper size

A4, A4-R, B5

LT, LT-R

B4

LG

A3, FOLIO, COMPUTER

LD

Table 2-501

Paper thickness (sheets)

30

20

15

Stapling home

position

Stapling position

Figure 2-501

Reference:

If the number of sheets (copies or originals) is higher than the number of sheets allowed for

stapling, the stack will not be stapled but will be delivered to the stack tray.

2-44

Page 64

CHAPTER 2 BASIC OPERATION

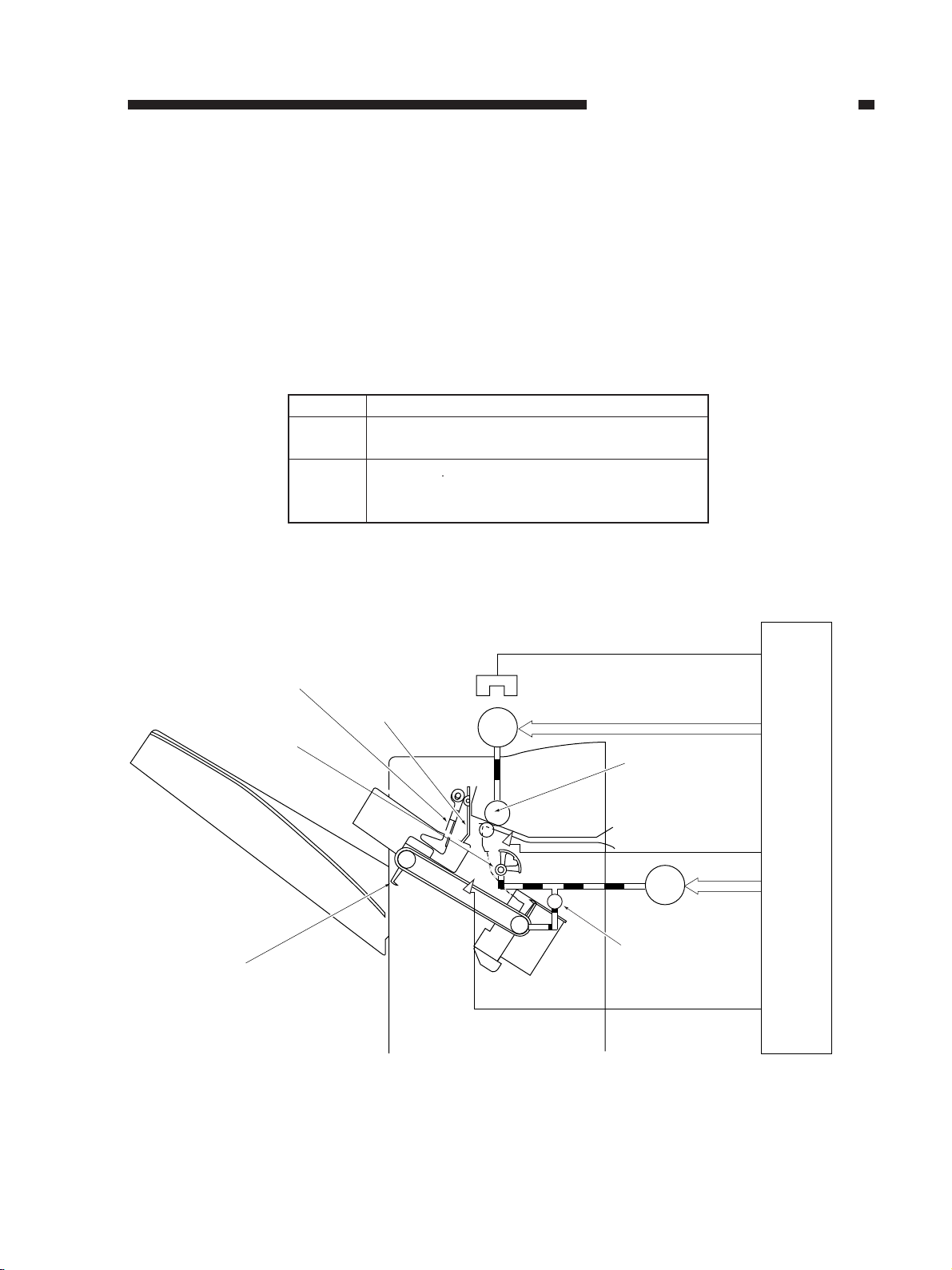

2. Stapling Unit

The motors, switches and sensors associated with the stapler are as follows:

Notation

M6

S14

S15

S16

S17

S18

Name

Stapler motor

Stapler safety switch

Staple edging detection

sensor

No-staple detection

switch

Stapling home position

sensor

Stapler cartridge

switch

SW/PI

–

SW

PI

SW

PI

SW

Description

Used to punch staples into sheets.

Used to protect the user.

Used to find out if the staple is at

a position for stapling. If not,

causes the stapler to execute idle

punching to enable stapling.

Used to detect the staples in the

cartridge.

Used to detect the home position

for stapling.

Used to find out whether a

cartridge is set inside the stapler

unit.

Inside the stapler unit

Inside the stapler unit

Inside the stapler unit

Inside the stapler unit

Inside the staple unit

Inside the stapler unit

Remarks

SW: Microswitch

PI: Photointerruptor

Table 2-502

The stapler safety switch (S14) is used to cut off power to the stapler motor in the event that a

finger gets into the stapler assembly or something similar happens.

Note:

If the Start key is pressed without removing the paper on the stack tray, the paper may not be

arranged or stapled correctly.

2-45

Page 65

CHAPTER 2 BASIC OPERATION

3. Controlling the Stapler Motor

Figure 2-502 is a diagram of the stapler motor (M6), which is a DC motor.

The direction of rotation is switched by the signals (Table 2-503) from the finisher controller

PCB IC1 (CPU) to the motor drive circuit.

The power to the stapler motor (24 VP) can be cut off by the stapler safety switch (S14).

Stapler safety

24VP

J7-1

-2

switch

N.O.

S14

IC1

(CPU)

STPLON

STPLCW

STPLCCW

Finisher controller PCB

Clockwise

Counterclockwise

Direction

Q27

Q29

Figure 2-502

Output signal

STPLCW/STPLON

STPLCCW/STPLON

Table 2-503

Q26

Q28

Stapler motor

J8-1

-2

-4

-5

M6

2-46

Page 66

CHAPTER 2 BASIC OPERATION

VI. OPERATIONS OF THE STACK TRAY

1. Moving the Stack Tray Up and Down

a. Outline

The machine is equipped with two stack trays, to which stacks which have been arranged and

offset/stapled are delivered.

When paper is delivered to the upper stack tray, the upper stack tray paper sensor (S20) is

turned on. When paper is delivered to the lower stack tray, the lower stack tray paper sensor (S11)

is turned on.

The upper stack tray is moved up/down by the work of the upper stack tray lift motor (M5).

The lower stack tray is moved up/down by the work of the lower stack tray lift motor (M7).

If the stack tray is not at its home position when the copier is turned on, the stack tray lift motor

is driven to move it to its home position. (The home position of the stack tray is a point 12.5 mm

above the point where the stack tray paper height sensor has detected the top of the stack tray.)

The position of the stack tray is monitored in reference to the number of clock pulses generated

by the stack lift motor clock sensor since the stack tray paper height sensor (S10) was turned on.

The upper limit of the upper stack tray is checked by the upper stack tray upper limit sensor

(S25), while the lower limit of the lower limit is checked by the lower stack tray full sensor (S23).

The upper limit of the lower stack tray is checked by the lower stack tray upper limit sensor

(S13), while the lower limit of the lower limit is checked by the lower stack tray lower limit sensor

(S12). When the stack tray upper limit/lower limit is turned on, the stack tray lift motor can be

driven only in the opposite direction to the limit identified by the sensor in question.

The limit of the sheets on the stack tray is detected by the paper height sensor and the full load

sensor if the sheets are not stapled. If the sheets are stapled, a count of stacks is used in addition to

the height of paper detected by the paper height sensor and the lower limit sensor. When the stack

exceeds the height or the maximum number of sets, an overstacking condition will be identified

and communicated to the copier.

Not stapled

Stapled

Parameters of identifying stacking limit

Height of the stack detected

Height of the stack detected by paper height sensor

and lower limit sensor or the number of sets

Tale 2-601

2-47

Page 67

CHAPTER 2 BASIC OPERATION

Upper stack tray lift motor (M5)

Upper stack tray

Lower stack tray

Upper stack tray

upper limit sensor (S25)

Lower stack tray

upper limit sensor (S13)

Stack tray

paper height sensor flag

Stack tray

paper height sensor (S10)

Upper & Lower stack tray

nearly full sensor (S21)

Upper stack tray

full sensor (S22)

Lower stack tray

full sensor (S23)

Lower stack tray

lift motor (M7)

2-48

Lower stack tray

lower limit sensor (S12)

Figure 2-601

Page 68

CHAPTER 2 BASIC OPERATION

b. Moving the Stack Tray Up and Down

After a stack of sheets has been delivered, the stack tray moves down until the stack tray paper

height sensor (S10) is turned off and then stops; thereafter, it moves up to a point 12.5 mm after the

paper height sensor (S10) has detected the top face of the stack tray.

Moving the

stack tray down

Stack tray

Figure 2-602

Figure 2-603

Moving the

stack tray up

2-49

Page 69

CHAPTER 2 BASIC OPERATION

c. Sequence of Operations

The following figure shows the sequence of operations used to move the stack tray up/down.

1-1 Delivery

signal*1

Inlet sensor (S2)

Delivery motor (M1)

Stack processing

motor (M2)

Returning roller home

position sensor (S3)

Stack delivery lever home

position sensor (S8)

Intermediary processing

tray paper sensor (S5)

Front jogging

plate motor (M3)

Front jogging plate home

position sensor (S6)

Rear jogging

plate motor (M4)

Rear jogging plate home

position sensor (S7)

Stack tray

lifter motor (M5), (M7)

Stack tray paper

height sensor (S10)

Stack tray paper

sensor (S11), (S20)

*3

*2

*4

1-2 Delivery

signal*1

*2

*3

*4 *6

*5

2-1 Delivery

signal*1

*2 *2

*8

*3

*4 *3

*9*7 *9*7

2-2 Delivery

signal*1

*4

*6 *8

*5

2-50

: CW rotation : CCW rotation

Stack processing motor: CW ® stack delivery/CCW ® returning

Front jogging plate motor: CW ® move to front/CCW ® move to rear

Rear jogging plate motor: CW ® move to rear/CCW ® move to front

Stack tray lifter motor: CW ® move up/CCW ® move down

*1: A-B delivery signal (n number of stack, nth sheet).

*2: Varies depending on the length of paper.

*3: 0.2 sec.

*4: 0.3 sec.

*5: Varies depending on the size of paper.

*6: 0.5 sec.

*7: Moves down until the stack tray paper height sensor is turned off.

*8: Driven until the stack delivery lever reaches the home position.

*9: Moves up 12.5mm after the stack tray paper sensor is turned on.

Figure 2-604

Page 70

CHAPTER 2 BASIC OPERATION

2. Checking the Height of the Stack on the Stack Tray

In all modes, the height of the stack on the stack tray is identified in reference to the height of

the stack on the tray using the stack tray paper height sensor (S10).

After a stack has been delivered, the stack tray moves down until the stack tray paper height

sensor (S10) is turned off, and then stops; thereafter, it moves up 12.5 mm after the paper height

sensor (S10) has detected the top of the paper on the stack tray.

If the stack tray lower limit sensor detects the stack tray while the stack tray full sensor (S22,

S23) is detecting the top of the stack, the finisher controller PCB communicates an overstacking

condition to the copier; the stack tray then starts to move up when the stack has been removed from

the stack tray in preparation for the next sheet.

OFF

Stack tray paper

height sensor (S10)

Stack tray paper

height sensor flag

Figure 2-605a

The flag is pushed by

the stack of paper

Figure 2-605b

2-51

Page 71

CHAPTER 2 BASIC OPERATION

3. Counting the Sets on the Stack Tray

Table 2-602 shows the maximum number of sheets allowed on the stack tray.

In the staple mode, the number of sets on the stack tray is checked to identify the stacking limit

in addition to the result of detecting the height of the stack.

Each single stack is counted as one, and a stack tray overstacking condition is identified when

the total reaches 30, upon which a communication is sent to the copier. In response, the copier

indicates a message on its control panel prompting removal of the stacks.

If the staple sort mode is selected while there is paper on the stack tray, the copier will indicate

a message on its control panel requesting the removal of the paper. If the Start key is pressed

without removing the paper, the sheets may not always be arranged or stapled correctly.

If the Start key is pressed without removing the paper, the count will be cleared when it is

pressed and a new count will be started.

Stacking limit

Small-size

Medium-size

Large-size

30 (30 stacks max.)

30 (20 stacks max.)

30 (15 stacks max.)

Table 2-602

2-52

Page 72

CHAPTER 2 BASIC OPERATION

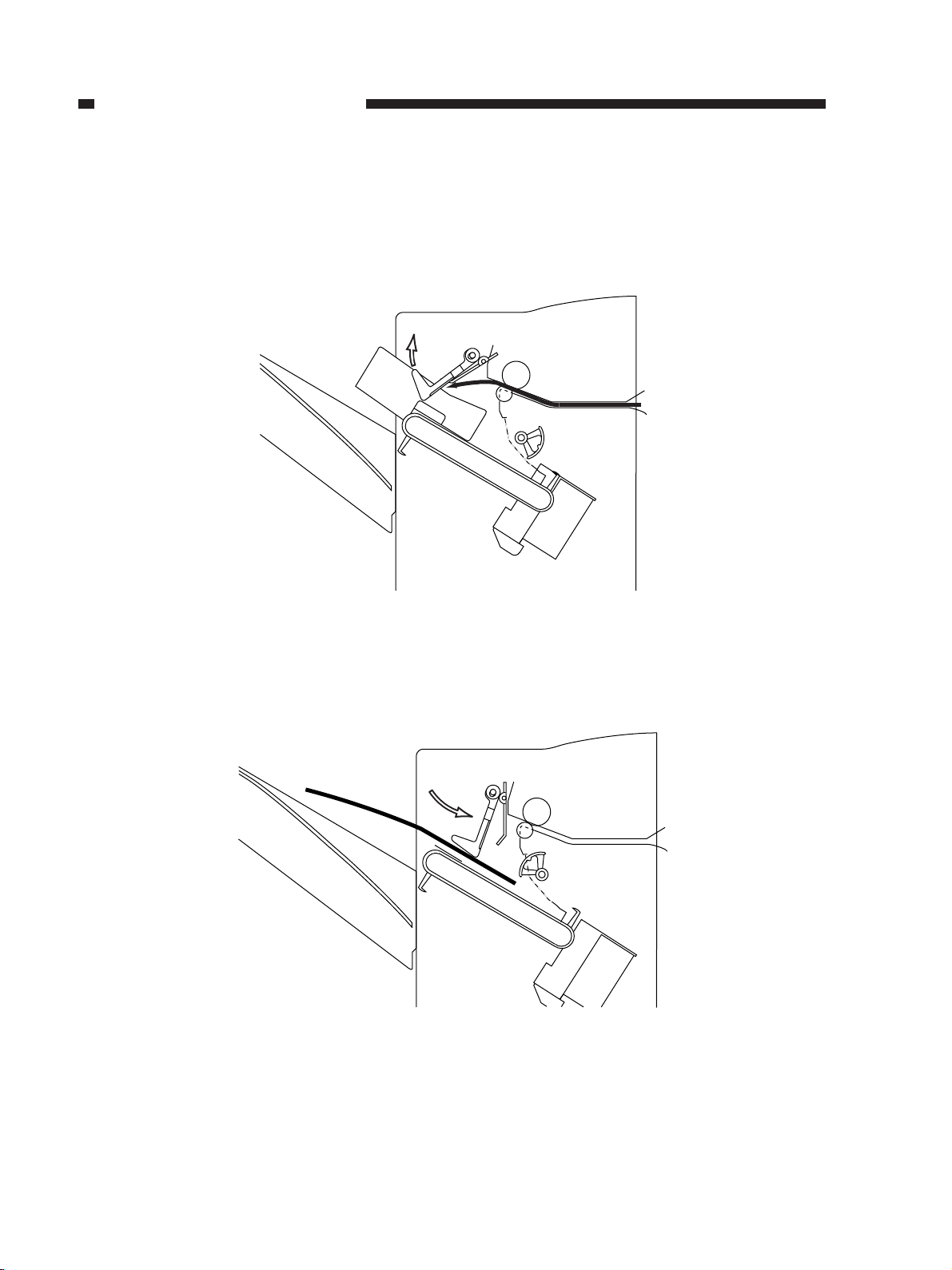

4. Operation of the Paper Holding Lever

The paper holding lever is found to the side of the stack tray paper height sensor. The paper

holding lever is designed to prevent wrong detection of the height of paper otherwise caused by

curling of paper.

The paper holding lever is driven by the paper holding lever drive solenoid (SL1) and it

operates as follows:

When a stack of sheets is delivered to the stack tray, the stack is deposited on the paper holding

lever.

When sheets have been put onto a stack, the stack tray moves down until the stack tray paper

height sensor (S10) is turned off, and then stops.

At this time, the paper holding solenoid (SL1) is turned ON, the paper holding lever moves

inside the finisher, leaving the stack of sheets.

The stack tray then moves 12.5 mm from the point at which the stack tray paper height sensor

(S10) has detected the top of the paper.

At this time, the paper holding solenoid (SL1) is turned OFF, the paper holding lever which has

been inside the finisher moves out to the top of the stack to hold down the stack against the stack

tray.

The above operations are repeated to keep the sheets in place.

Paper holding lever

Figure 2-606

Solenoid (SL1)

2-53

Page 73

CHAPTER 2 BASIC OPERATION

5. Controlling the Tray Lift Motors

a. Outline

Figure 2-607 and 2-608 are block diagrams showing the tray lift motors (M5, M7) drive

circuits.

The tray lift motors are DC motors.

The direction of motor rotation is switched by signals (Tables 2-603, 2-604) from the finisher

controller PCB IC1 (CPU) to the motor drive circuit.

When the upper stack tray reaches the upper stack tray upper limit sensor (S25) and the sensor

sends signals (S25D), Q14 will be cut off, and the motors will stop their clockwise rotation.

Likewise, when the upper stack tray reaches the lower stack tray full sensor (S23) and the

sensor sends signals (S23D), or the stack tray collision prevention sensor (S24) detects a collision

and sends signals (S24D), Q15 will be cut off, and the motors will stop their counterclockwise

rotation.

Also, when the lower stack tray reaches the lower stack tray upper limit sensor (S13) and the

sensor sends signals (S13D), or the stack tray collision prevention sensor (S24) detects a collision

and sends signals (S24D), Q20 will be cut off, and the motors will stop their clockwise rotation.

Likewise, when the lower stack tray reaches the lower stack tray lower limit sensor (S12) and

the sensor sends signals (S12D), Q21 will be cut off, and the motors will stop their

counterclockwise rotation.

Only the clockwise rotation of the drive power supply (+24V) for the upper stack tray lift

motor is interrupted by the stack processing safety switch (S26).

Finisher controller PCB

IC1

(CPU)

Lower stack tray

full sensor

Stack tray collision

prevention sensor

Upper stack tray

upper limit sensor

S23D

S24D

STKT1PWM

STKT1CW

STKT1CCW

S25D

S23

S24

S25

Direction

Clockwise

Counterclockwise

+24V

Q15

Q17

Q14

Q16

Figure 2-607

Output signal

STKT1PWM/STKT1CW

STKT1PWM/STKT1CCW

J16-1

-2

J14-1

-2

S26

Stack processing

safety switch

Upper stack tray

lift motor

M5

2-54

Table 2-603

Page 74

CHAPTER 2 BASIC OPERATION

Finisher controller PCB

IC1

(CPU)

Lower stack tray

lower limit sensor

Lower stack tray

upper limit sensor

Stack tray collision

prevention sensor

STKT2PWM

STKT2CW

STKT2CCW

S12

S13

S24

S12D

S13D

S24D

Q21

Q23

+24V

Q20

Q22

J3-1

-2

Lower

stack tray

lift motor

M7

Direction

Clockwise

Counterclockwise

Figure 2-608

Output signal

STKT2PWM/STKT2CW

STKT2PWM/STKT2CCW

Table 2-604

2-55

Page 75

CHAPTER 2 BASIC OPERATION

VII.DETECTING JAMS

A. Outline

The following sensors are used to check the presence/absence of paper as well as to find out

whether paper is being moved properly:

• Inlet sensor (S2)

• Returning roller home position sensor (S3)

• Stack delivery lever home position sensor (S8)

Further, the following sensor is used to find out whether stapling is performed correctly:

• Stapling home position sensor (S17)

A check is made for a jam at such times as programmed in the CPU on the finisher controller

PCB. When a jam is detected, the ongoing delivery operation is stopped, and a Jam message is

indicated on the control panel.

Figure 2-701

Inlet sensor (S2)

Returning roller home

position sensor (S3)

Stack delivery lever home

position sensor (S8)

2-56

Page 76

CHAPTER 2 BASIC OPERATION

1st sheet delivery signal 2nd sheet delivery signal Jam detection

*1 Error*1 Normal

*1: 1.5 sec.

Inlet sensor (S2)

Delivery motor (M1)

B. Detecting Paper Jams

A paper jam may be any of the following:

1. Inlet Sensor Delay Jam

The inlet sensor (S2) does not detect paper within 1.5 sec. after the finisher controller PCB has

detected the paper delivery signal from the copier.

Figure 2-702

2. Inlet Sensor Stationary Jam

The inlet sensor (S2) does not go off after it has been turned on and paper has supposedly been

moved until its trailing edge should have left the delivery roller (paper size + 26 mm) and then for

an additional length of 24 mm.

1st delivery signal 2nd delivery signal Jam detection

Inlet sensor (S2)

Delivery motor (M1)

*1: paper length + 50mm.

*1 Error*1 Normal

Figure 2-703

3. Power-On Jam

The inlet sensor (S2) of the finisher is on when the power is turned on or the finisher is

connected to the copier.

2-57

Page 77

CHAPTER 2 BASIC OPERATION

4. Stack Delivery Jam

The stack delivery lever does not reach the stack delivery lever home position sensor (S8) after

it has supposedly been moved over the distance. Or, it does not leave the stack delivery lever home

position sensor after it has supposedly been moved over the distance.

A check for this type of jam is made while paper is being moved. If the foregoing condition is

detected during initialization, it will be identified as an error.

1-2 Delivery

signal*1

Inlet sensor (S2)

Delivery motor (M1)

Intermediary processing

tray paper sensor (S5)

Stack processing

motor (M2)

Returning roller home

position sensor (S3)

Stack delivery lever home

position sensor (S8)

*1: A-B delivery signal (n number of stack, nth sheet).

*2: Varies depending on the length of paper.

*3: Driven until the stack delivery lever reaches the home position.

1-2 Delivery

signal*1

2-1 Delivery

signal*1

*2 *2 *3*3

: CW rotation (stack delivery) : CCW rotaion (returning operation)

0.3sec 0.3sec

Normal

2-2 Delivery

signal*1

Jam detection

Figure 2-704a (not reaching the home position)

2-1 Delivery

signal*1

2-2 Delivery

signal*1

Jam detection

Error

Inlet sensor (S2)

Delivery motor (M1)

Intermediary processing

tray paper sensor (S5)

Stack processing

motor (M2)

Returning roller home

position sensor (S3)

Stack delivery lever home

position sensor (S8)

*1: A-B delivery signal (n number of stack, nth sheet).

*2: Varies depending on the length of paper.

*3: Driven until the stack delivery lever leaves its home position.

2-58

*2 *2*30.3sec 0.3sec

Normal Error

: CW rotation (stack delivery) : CCW rotation (returning operation)

Figure 2-704b (not leaving the home position)

Page 78

CHAPTER 2 BASIC OPERATION

5. Stack Return Jam

The returning roller does not reach the returning roller home position sensor after it has

supposedly been moved over the distance by the stack processing motor (M2). Or, it does not leave

the returning roller home position sensor after it has supposedly been moved over the distance.

A check for this type of jam is made while paper is being moved. If the foregoing condition is

detected during initialization, it will be identified as an error.

1st sheet delivery signal

Inlet sensor (S2)

Delivery motor (M1)

Intermediary processing

tray paper sensor (S5)

Stack processing

motor (M2)

Returning roller home

position sensor (S3)

: CW rotation (stack delivery) : CCW rotation (returning operation)

*1: Varies depending on the length of paper.

*2: Driven until the returning roller reaches the home position sensor

*1 *2 *1 *2

2nd sheet delivery signal

Figure 2-705a (not reaching the home position)

1stsheet delivery signal

Inlet sensor (S2)

2nd sheet delivery signal

Jam detection

ErrorNormal

Jam detection

Delivery motor (M1)

Intermediary processing

tray paper sensor (S5)

Stack processing

motor (M2)

Returning roller home

position sensor (S3)

: CW rotation (stack delivery) : CCW rotation (returning operation)

Figure 2-705b (not leaving the home position sensor)

*1 *2 *1 *2

ErrorNormal

2-59

Page 79

CHAPTER 2 BASIC OPERATION

C. Stapler Jam

A staple jam is detected as follows:

1. Stapler Staple Jam

A stapler staple jam is identified as follows: stapling starts; the stapler leaves the stapling home