Page 1

Page 2

2. DISASSEMBLY & REASSEMBLY

2-1. INSTRUMENT DISASSEMBLY

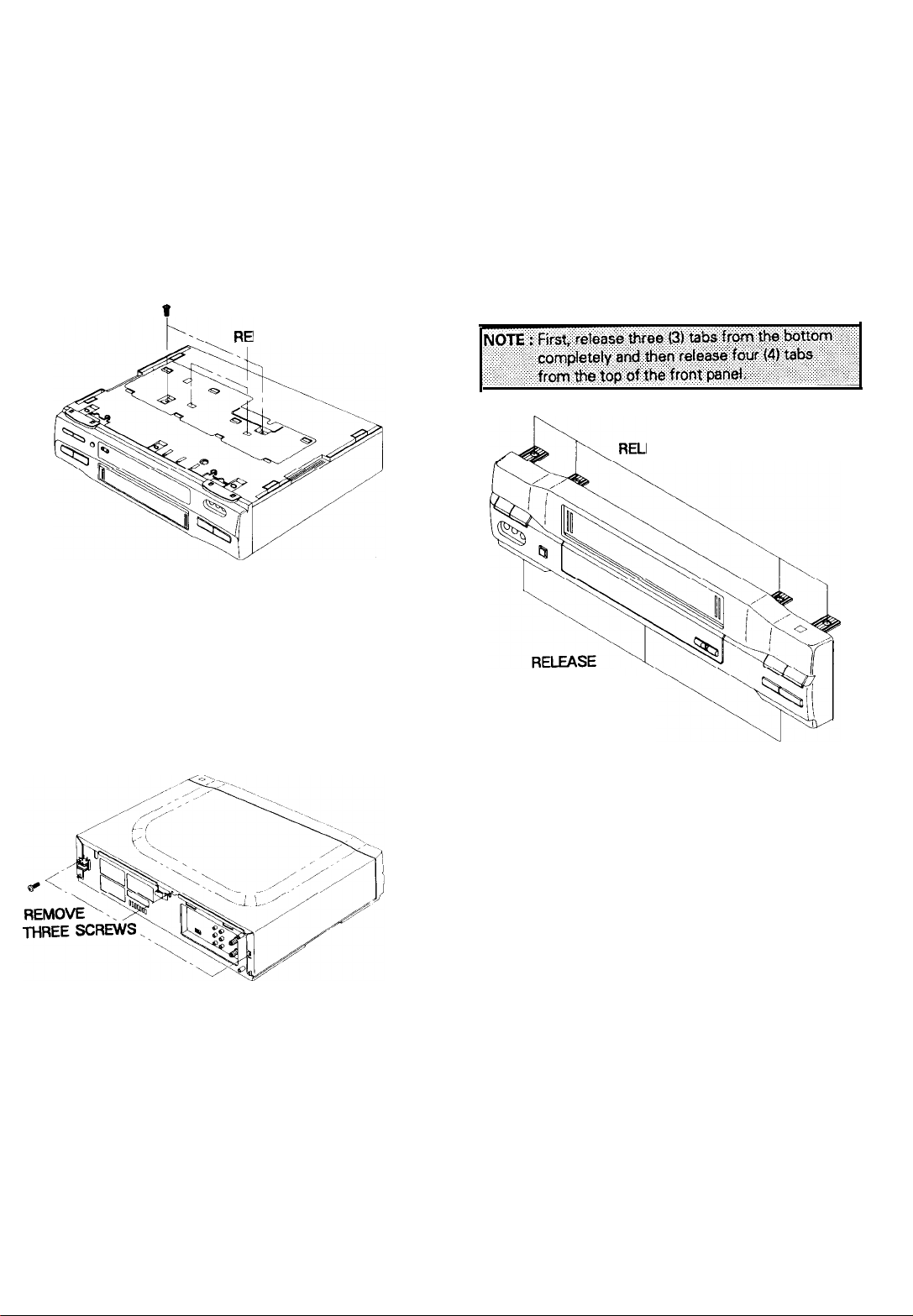

2-l-l. Bottom Cover Removal

1. Remove two

2. Release two

Fig. 1 Bottom Cover Removal

(2)

screws holding the bottom cover.

(2)

tabs from the bottom cover.

0

REMOVE TWO SCREWS

LEASE TWO TABS

2-l-2.Top Cabinet Removal

1. Remove three(3)screws located at the rear of the top

cabinet.

2. Carefully lift the back of the top cabinet and slide it to

the rear to remove.

2-l-3. Front Panel Removal

1. Remove bottom cover and top cabinet (See Fig. 1 to

2. Release three

panel.

3. Release four (4) tabs from the top of the front panel.

4. Tilt the front panel forward to remove.

THREE TABS

(3)

tabs from the bottom of the front

EASE FOUR TABS

2).

Fig. 2 Top Cover Removal

Fig. 3 Front Panel Removal

2-1

Page 3

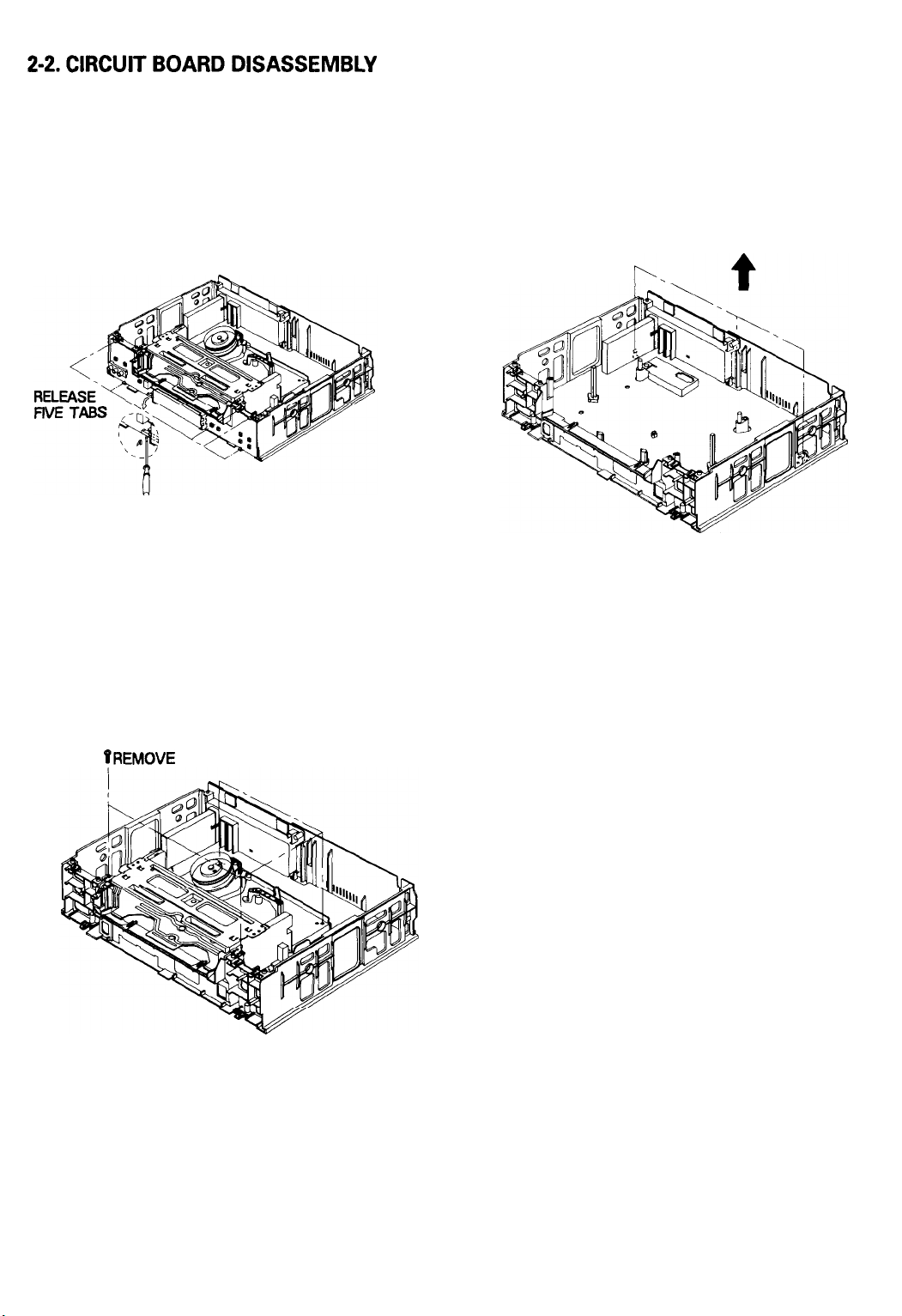

2-2-l. Function PCB Removal

1.

Follow the procedures for removing the bottom cover,

the top cabinet and the panel front. (See Fig.1 to

2. Release five

3. Release

as shown Fig. 4

(5)

tabs on the function board.

connector(CN701)

gently with using the Driver

2-2-3. Main circuit board Removal

1 .Follow the procedures for removing Fig. 1 to 6

3)

2.Release

3.Pull

arrow.

three

(3)

tabs from the frame.

out the main circuit board in the direction of the

Fig. 4 Function PCB Removal

2-2-2. Deck Ass’y Removal

1.

Follow the procedures for removing the bottom cover,

top cabinet and the front panel

2. Remove four

deck ass’y.

3. Remove two

4. Lift the deck ass’y upward to remove.

(4)

screws from the bottom and top of the

(2)

screws from the bottom of the frame.

OREMOVE

FOUR SCREWS

ass'y

(See Fig.1 to

RELEASE THREE

Fig. 6 Main Circuit Board Removal

3)

TABS

Fig. 5 Deck ass’y Removal

2-2

Page 4

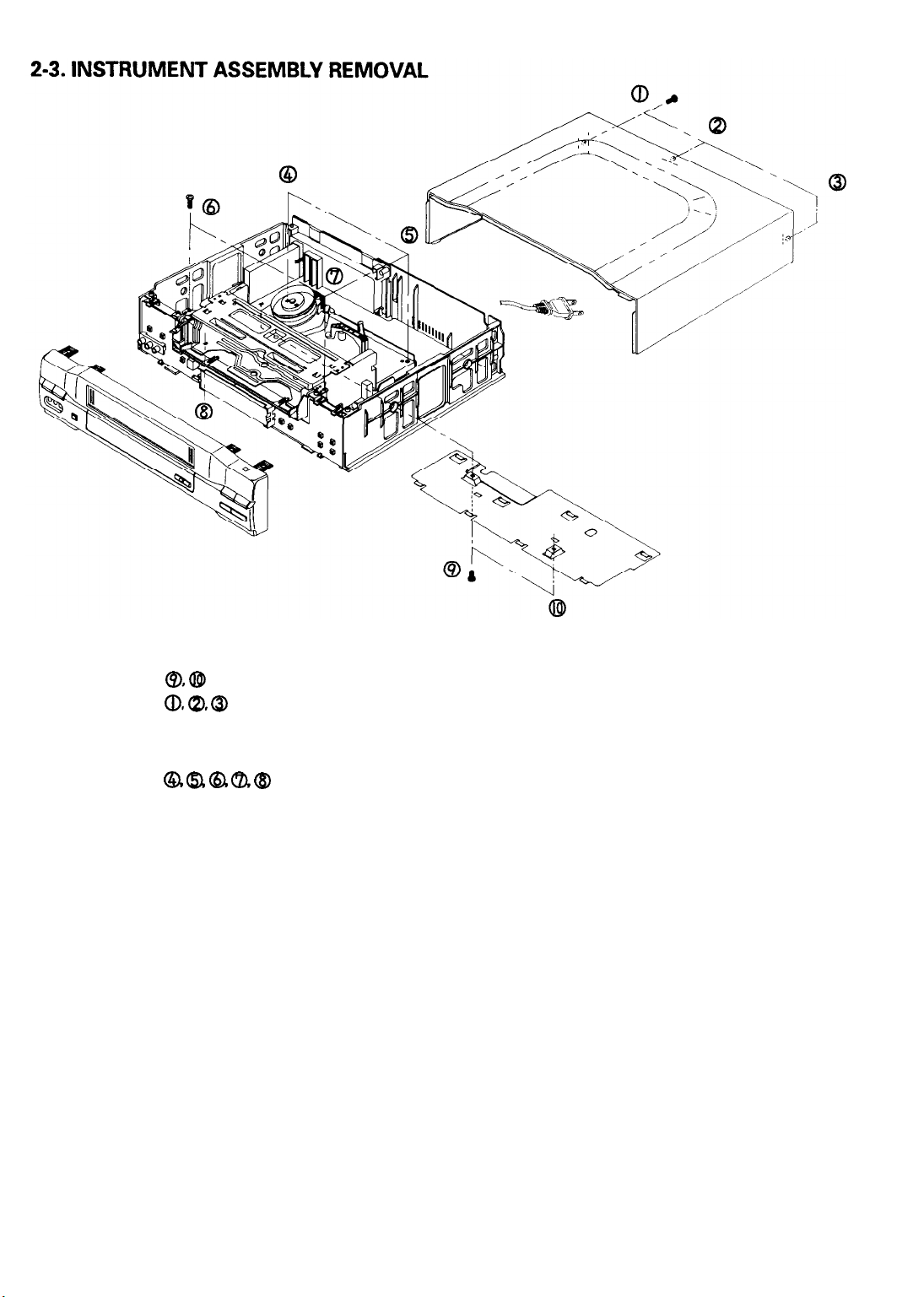

Fig. 7 Instrument Assembly Removal

1. Remove screws

2. Remove screws

3. Release the front panel as shown in Fig. 3

4. Release connector

as shown Fig. 4

5. Remove screws

follow the procedures on next page.

( @, @I 1

( (D, @, @I 1

and release the bottom cover.

and release the top cover.

(CN701)

gently with using the Driver

( @, Q (8 Q), @ )

holding the deck and

2-3

Page 5

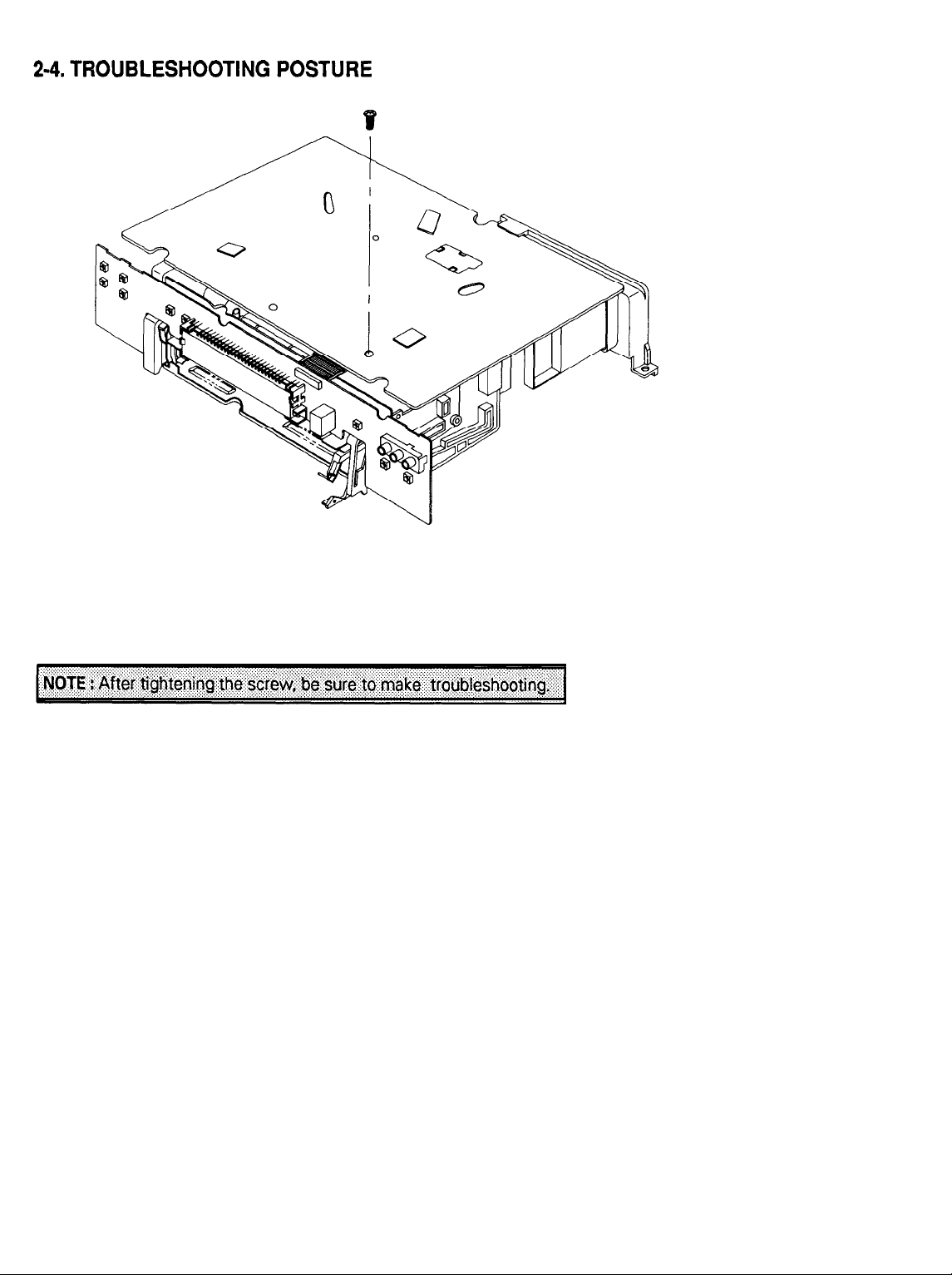

Fig. 8 Trouble Shooting Posture

&

1. Set the main PCB

2. Tighten the screw.

3. Install the Function PCB to Main PCB

DECK ass’y as shown in Fig. 8.

t

TIGHTEN THE SCREW

2-4

Page 6

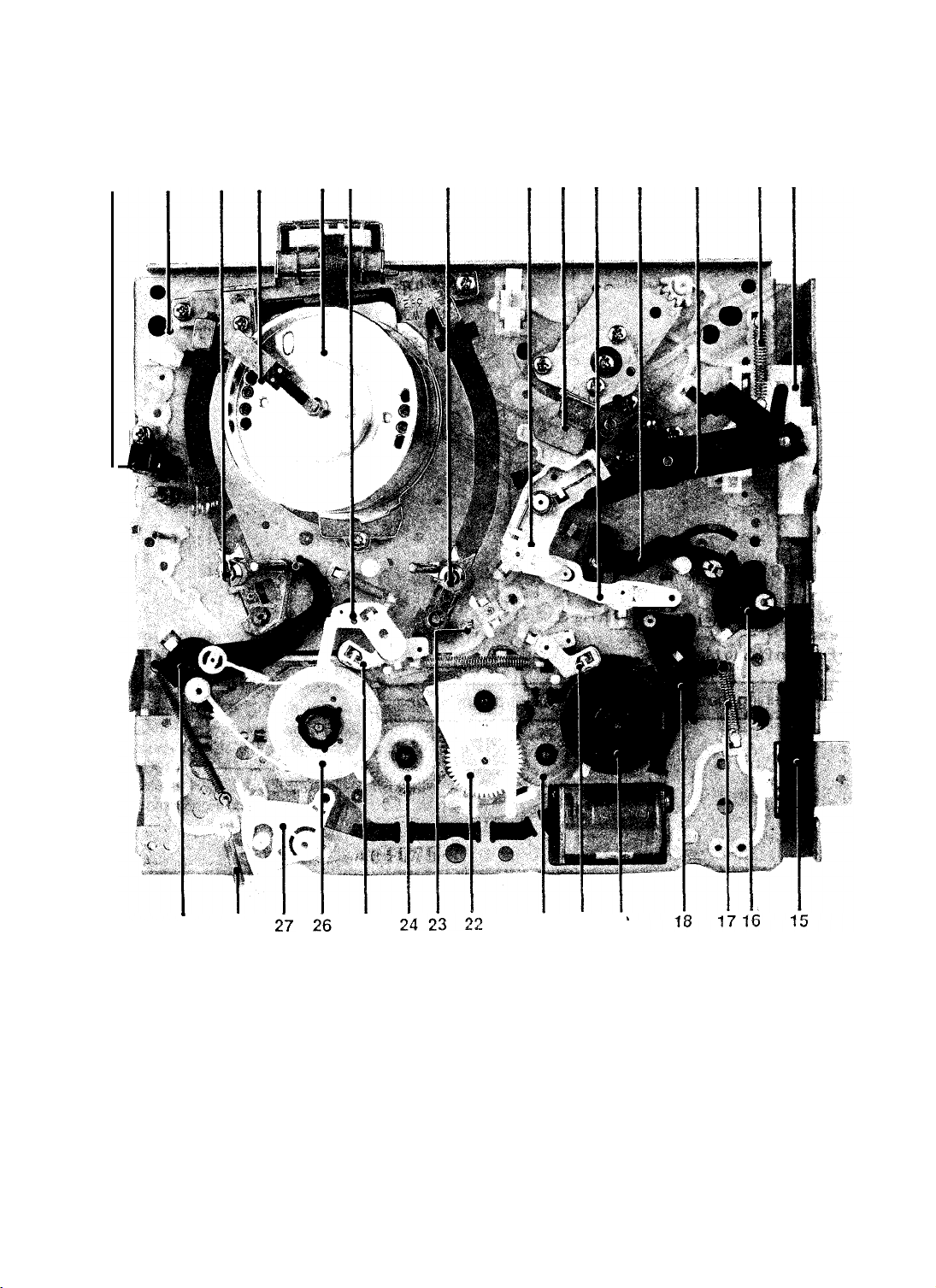

2-5. TAPE TRANSPORT MECHANISM IDENTIFICATION

2-5-l. Deck (lop

1

2 3

View)

5

4

6

7

8 9

10

11

12

13 14

.

29

Fig.9 Deck Parts Locations

FULL ERASE HEAD

1.

STOPPER TAPE

2.

SLIDE GEAR LOADING ASS’Y

3.

HEAD BRUSH ASS’Y 14. SLIDE PINCH

4.

CYLINDER ASS’Y

5.

BRAKE SUB “L” 16. LEVER REVIEW

6.

SLIDE GEAR LOADING ASS’Y “S”

7.

LEVER PINCH COMP 18. BRAKE SUB “R” ASS’Y

8.

FULL ACE HEAD ASS’Y

9.

28

(Top View))

10. LEVER PINCH CAM

25

“T”

11. ARM REVIEW ASS’Y

12. UNIT PINCH ROLLER ASS’Y

13. SPRING SLIDE PUSH

15. SLIDE RACK HOUSING

17. SPRING BRAKE SUB “R”

19. REEL DISK “R” ASS’Y

20. BRAKE MAIN

21 20 19

“R”

2-5

ASS’Y

21. GEAR RELAY

“T”

ASS’Y

22. IDLER ASS’Y

23. PRISM LED

24. GEAR RELAY “S” ASS’Y

25. BRAKE MAIN

26. REEL DISK “L”

“L”

ASS'Y

ASSY

27. LEVER REC SWITCH

28. SPRING REC SWITCH

29. ARM TENSION FULL ASSY

Page 7

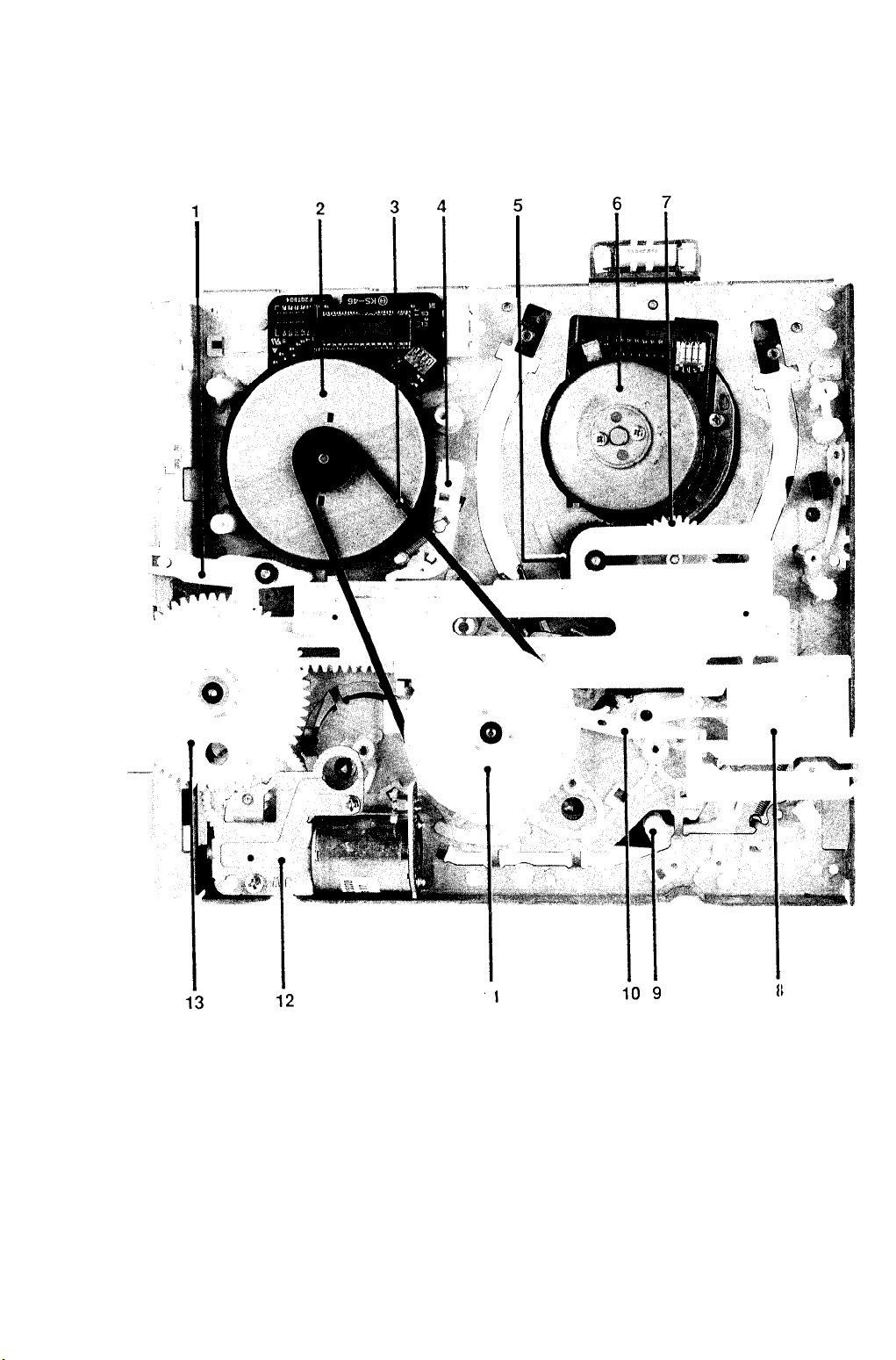

2-5-2. Deck (Bottom View)

Fig. 10 Deck Parts

1. LEVER

2. MOTOR

3. BELT CAPSTAN

4. BRAKE CAPSTAN ASS’Y

5. GEAR

6. MOTOR

7. GEAR

SLIDE PINCH

D.D CAPSTAN

LOADING

CYLINDER

LOADING

Locations

I

“R”

"L”

ASS’Y

ASS’Y

(Bottom View)

ii

8.

SLIDE MAIN

9. LEVER REC SWITCH

10. LEVER IDLER CHANGE

11. CLUTCH

12. UNIT LOADING

13. GEAR MASTER

2-B

ASS'Y

a

Page 8

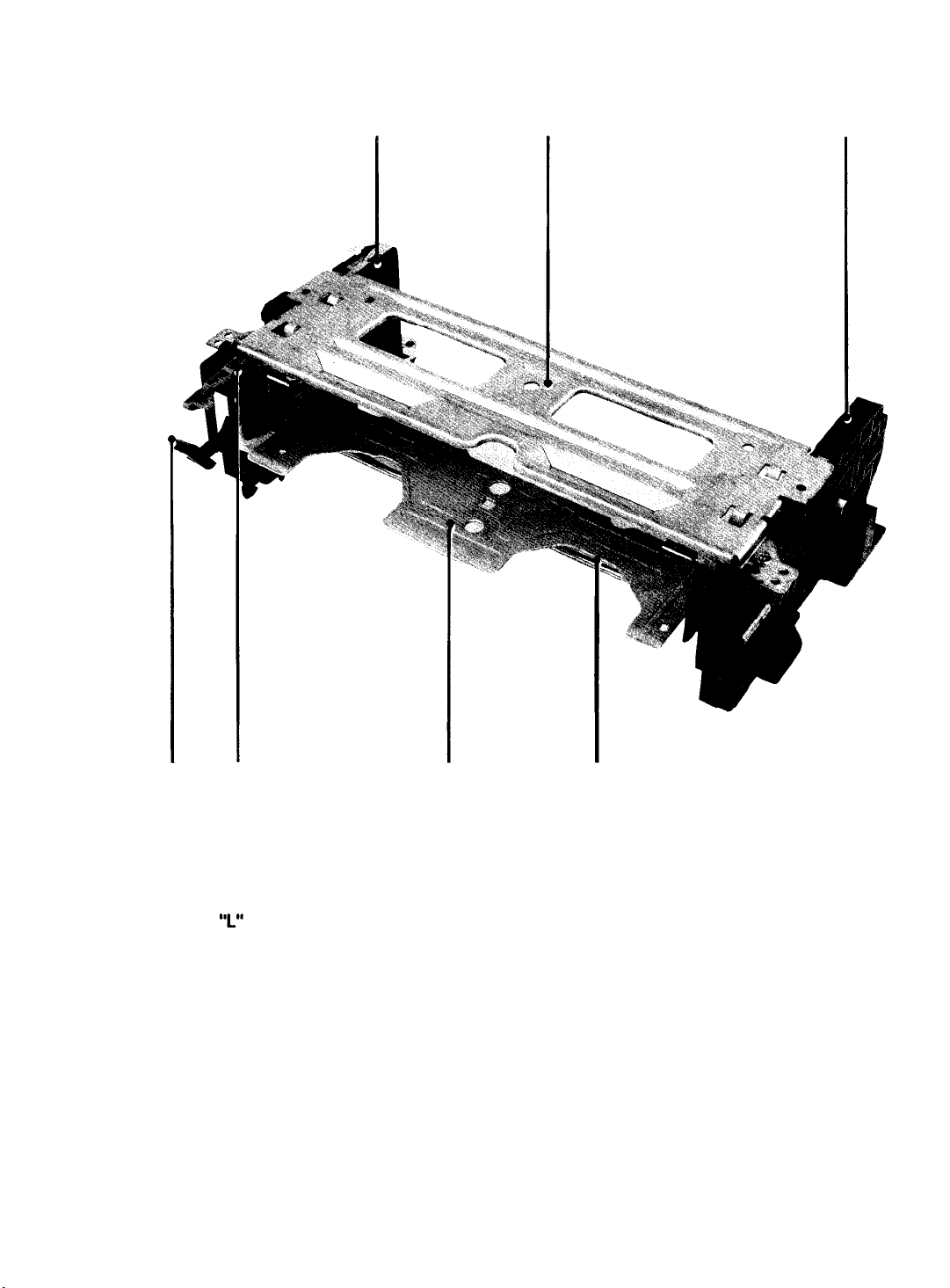

2-6. Housing Assembly

1

2

3

6

Fig. 11 Housing Parts Locations

1. CHASSIS SIDE

7

‘I”

ASS’Y

2. UPPER CHASSIS

3. CHASSIS SIDE

“R”

ASS’Y

4. SHAFT ARM ASS’Y

5. HOLDER CASSETTE ASS’Y

6. LEVER DOOR ASS’Y

7. DOOR

LOCK

5

2-7

4

Page 9

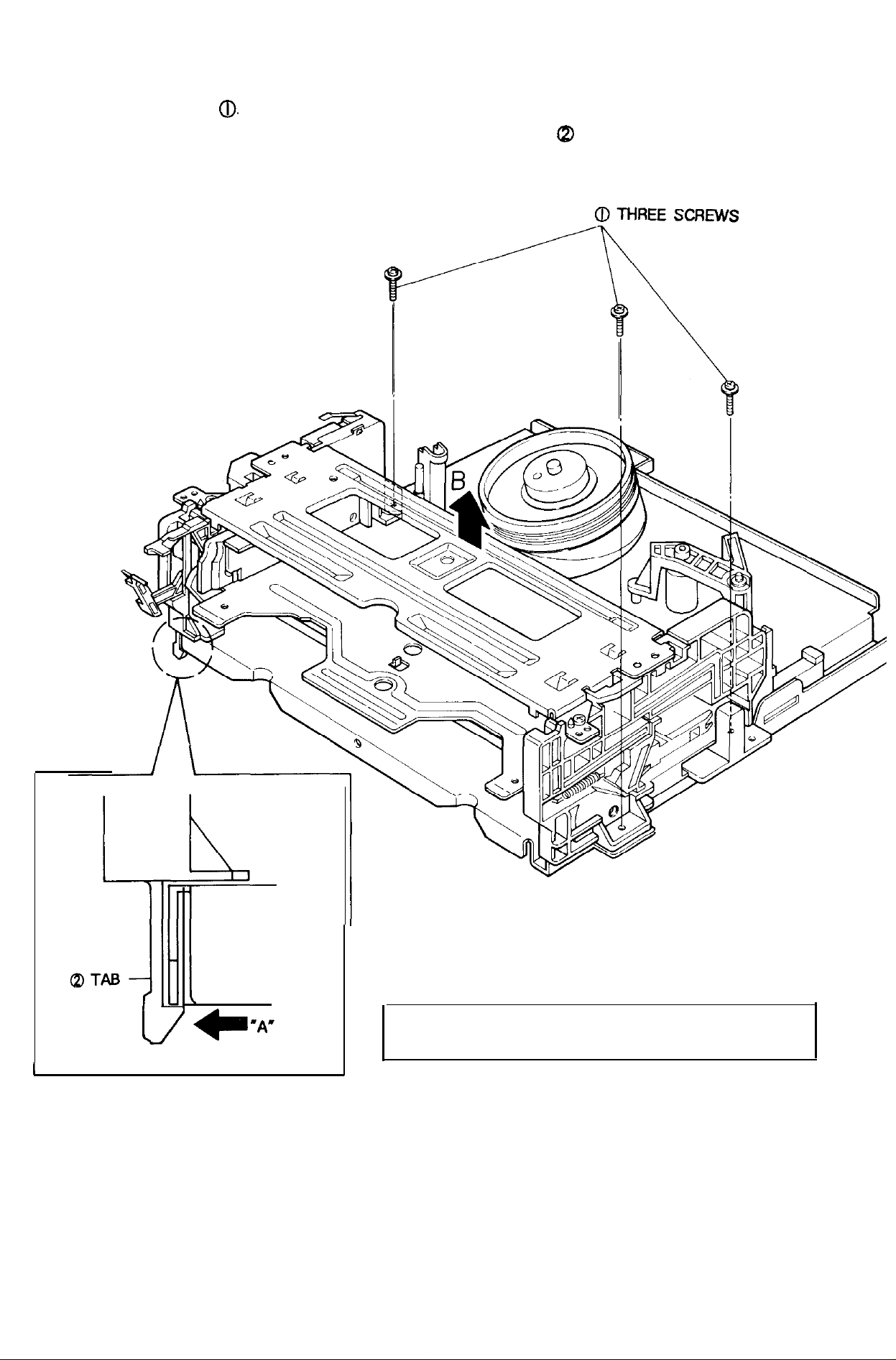

2-6-l. Removal from Main Base

1) Remove three(3) screws

2) Lift the housing ass’y in the direction of arrow ‘B’ while pushing the tab a in the direction of arrow ‘A’.

(Refer to detail drawing)

0.

MAIN BASE

I

<DETAIL>

Fig. 12 Housing Ass’y Removal from Main Base

NOTE : When p ushing the

arrow “A”, take extreme care not to damage

2-8

tab(2)

in the direction of

Page 10

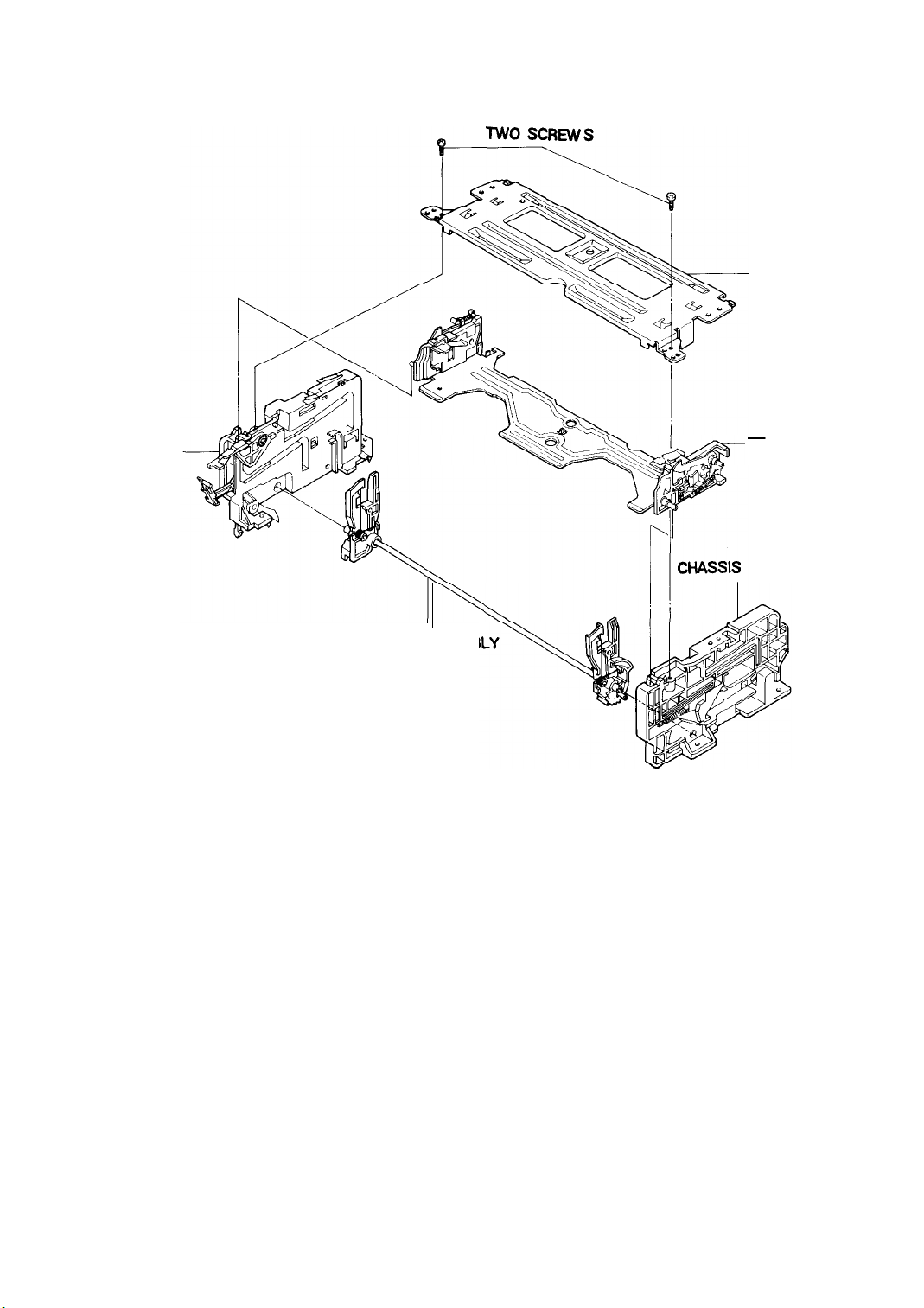

2-6-2. Disassembly

CHASSIS SIDE

‘L’

-

CHASSIS UPPER

-

HOLDER CASSTE

ASSEMBLY

Fig. 13 Housing Ass’y Removal

SHAFT

ARM

ASSEMB

SIDE” R

"

2-9

Page 11

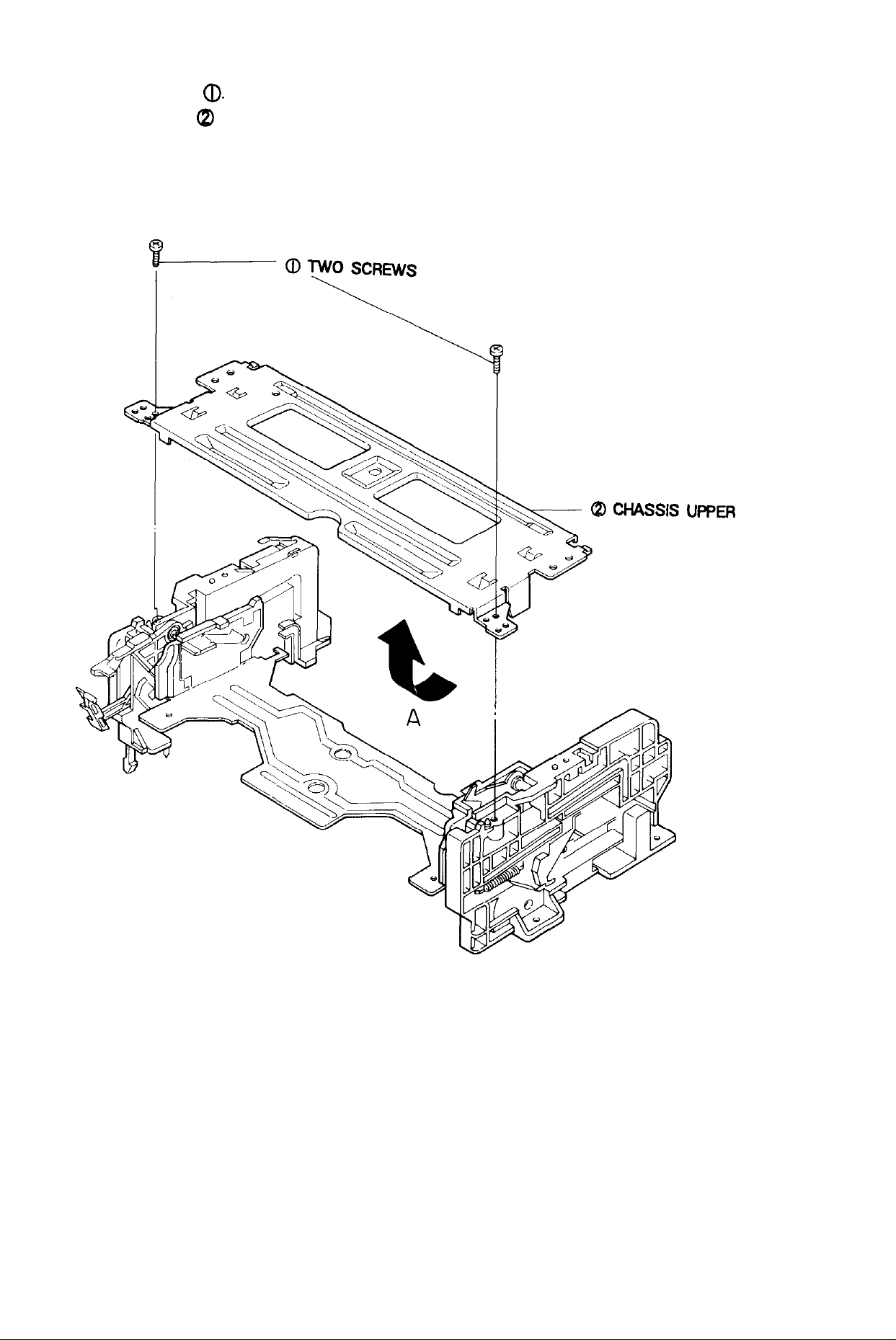

2-6-3. Upper Chassis Removal

1)

Remove

21 Lift the upper chassis QI in the direction of arrow ‘A’

two(2)

screws

a.

Fig. 14 Upper Chassis Removal

2-10

Page 12

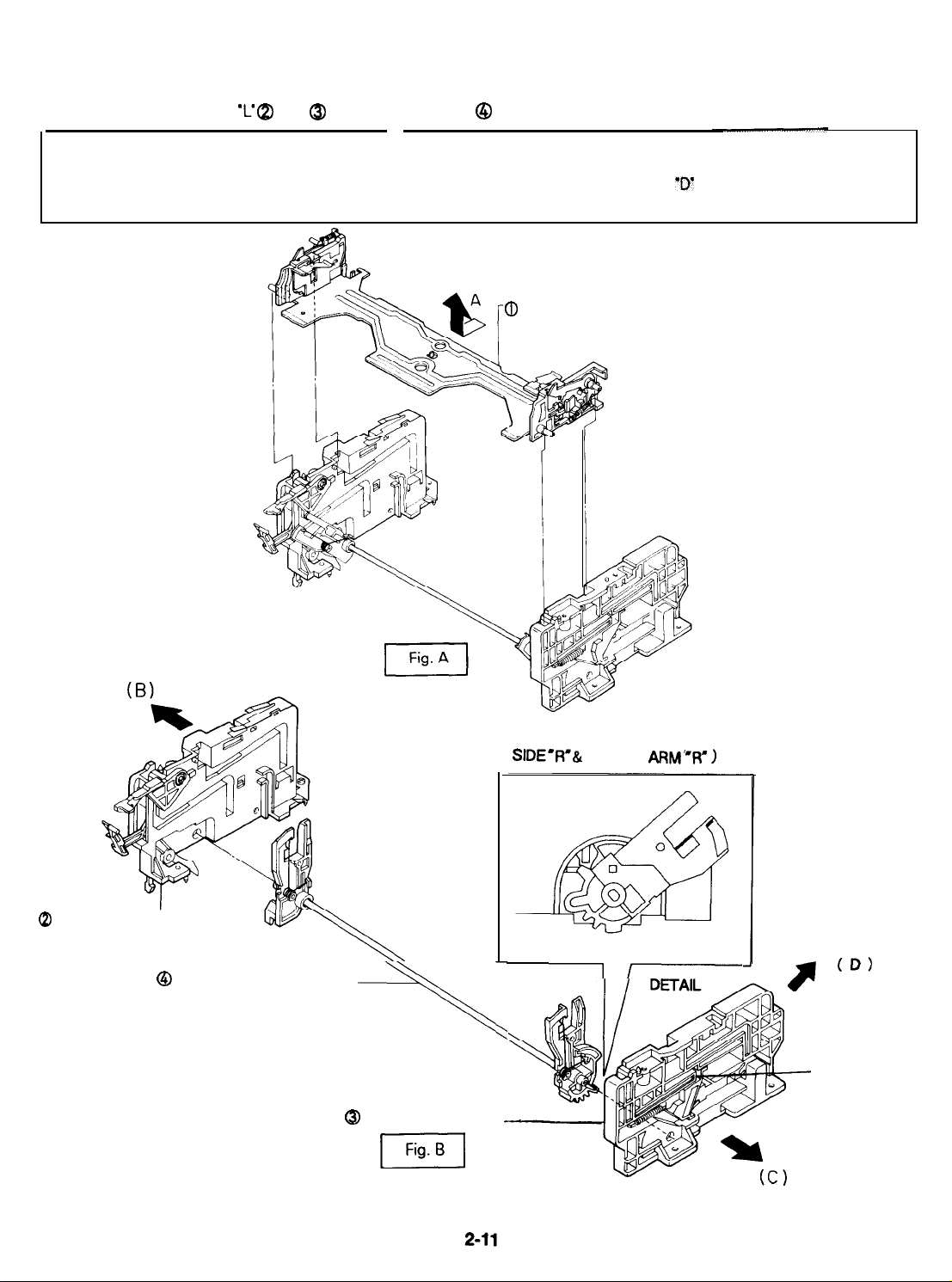

2-6-4. Holder Cassette Ass’y & Chassis Side L/R Removal

1)

Lift the holder cassette (D in the direction of arrow ‘A’ (Refer to Fig. A).

2) Remove the chassis side ‘C @ &

‘R’ @

from shaft arm ass’y @ in the direction of arrows ‘B’, ‘C’ (Refer to Fig. B).

NOTE : If you operate the deck when the

returned to their original position. If this happens by accident, push the slide damper of chassis side ‘R’ in the

direction of arrow

eject mode.

"D",

and return the slide damper in the reverse direction of arrow

holder

cassette

ass’y

is removed, the shaft

a

HOLDER

arm “R’

and the

"D"

CASSETTE ASSEMBLY

slide

when the shaft arm ass’y is in

damper are not

@ CHASSIS

Fig. 15 Holder Cassette Ass’y & Chassis Side

SlDE

l

0 SHAFT

L-

ARM

ASSEMBLY

-+N

a

CHASSIS SIDE "R"

[Fig.1

L/R

Removal

(

REASSEMBLY OF CHASSIS

SIDE-R’& SHAFT

SIDE VIEW

II

ARM’W” 1

(D)

SLIDE DAMPER

Page 13

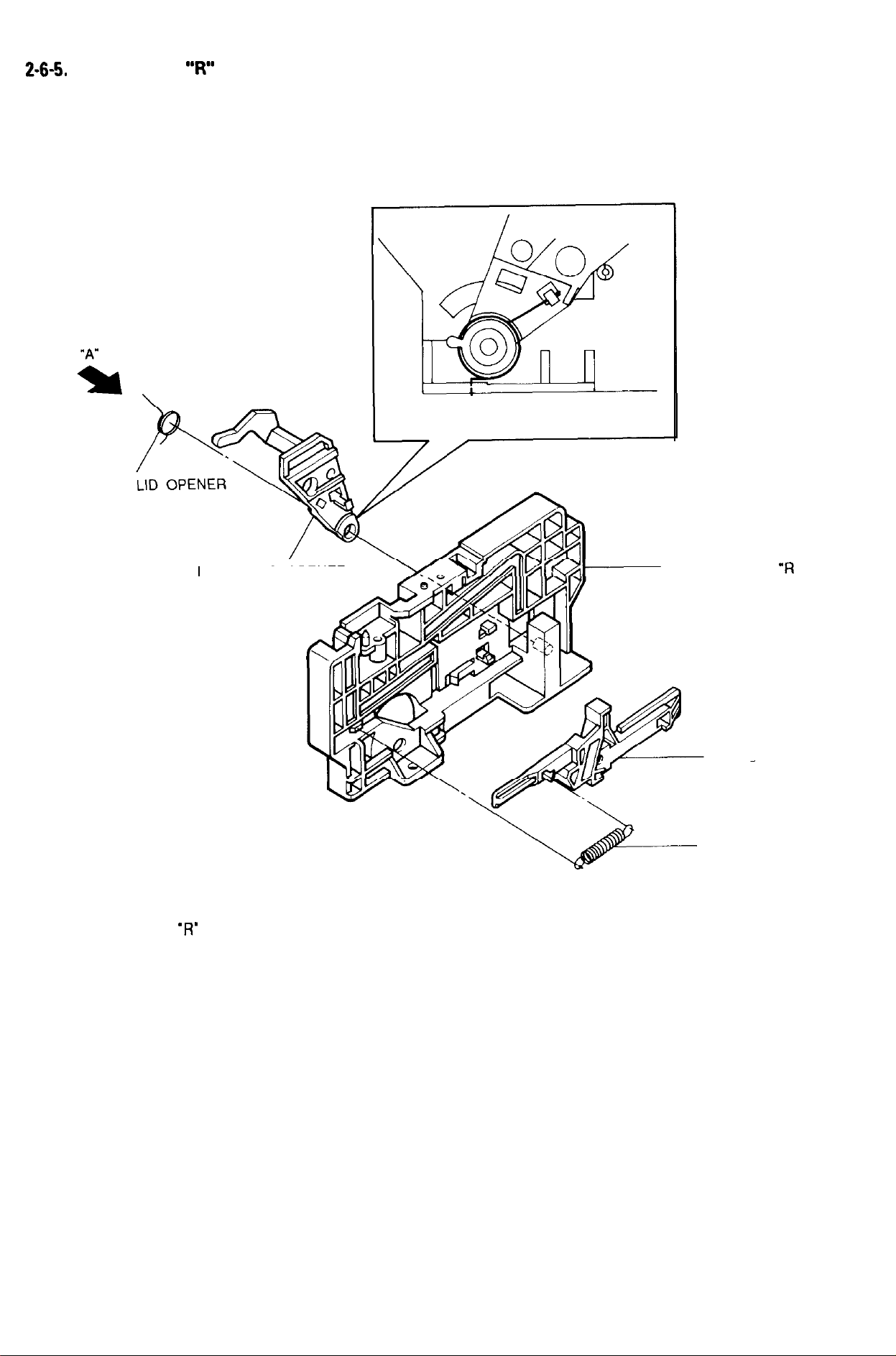

2-6-5.

Chassis Side

SPRING

“R”

Parts Locations

(SIDE VIEW “A”)

Fig. 16 Chassis Side

LEVER-LID OPENER

‘R’

Parts Locations

CHASSIS SIDE

SLIDE - DAMPER

SPRING-SLIDE DAMPER

“R

2-12

Page 14

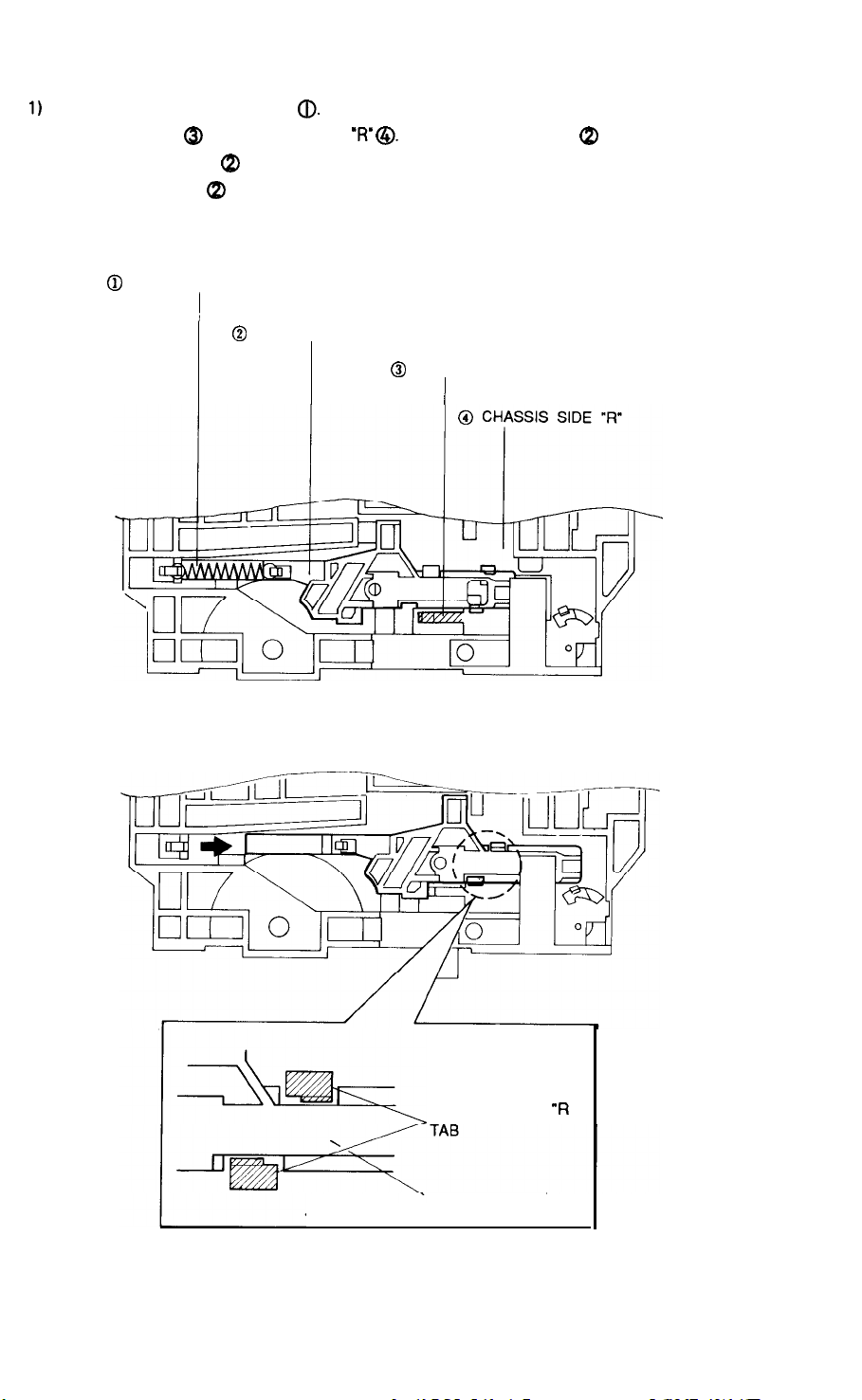

2-6-6. Slide Damper Removal

1)

Remove the spring slide damper

2) Push the stopper @ of the chassis side ‘R’ @. Move the slide damper @ in the direction of arrow.

3) Align the slide damper QI with the chassis side tab (as shown detail drawing).

4) Lift the slide damper @ to remove.

@

SPRING SLIDE DAMPER

@.

)

@

SLIDE DAMPER

@

STOPPER

I

Fig. 17 Slide Damper Removal

<DETAIL>

CHASSIS SIDE

SLIDE DAMPER

2-13

“R

Page 15

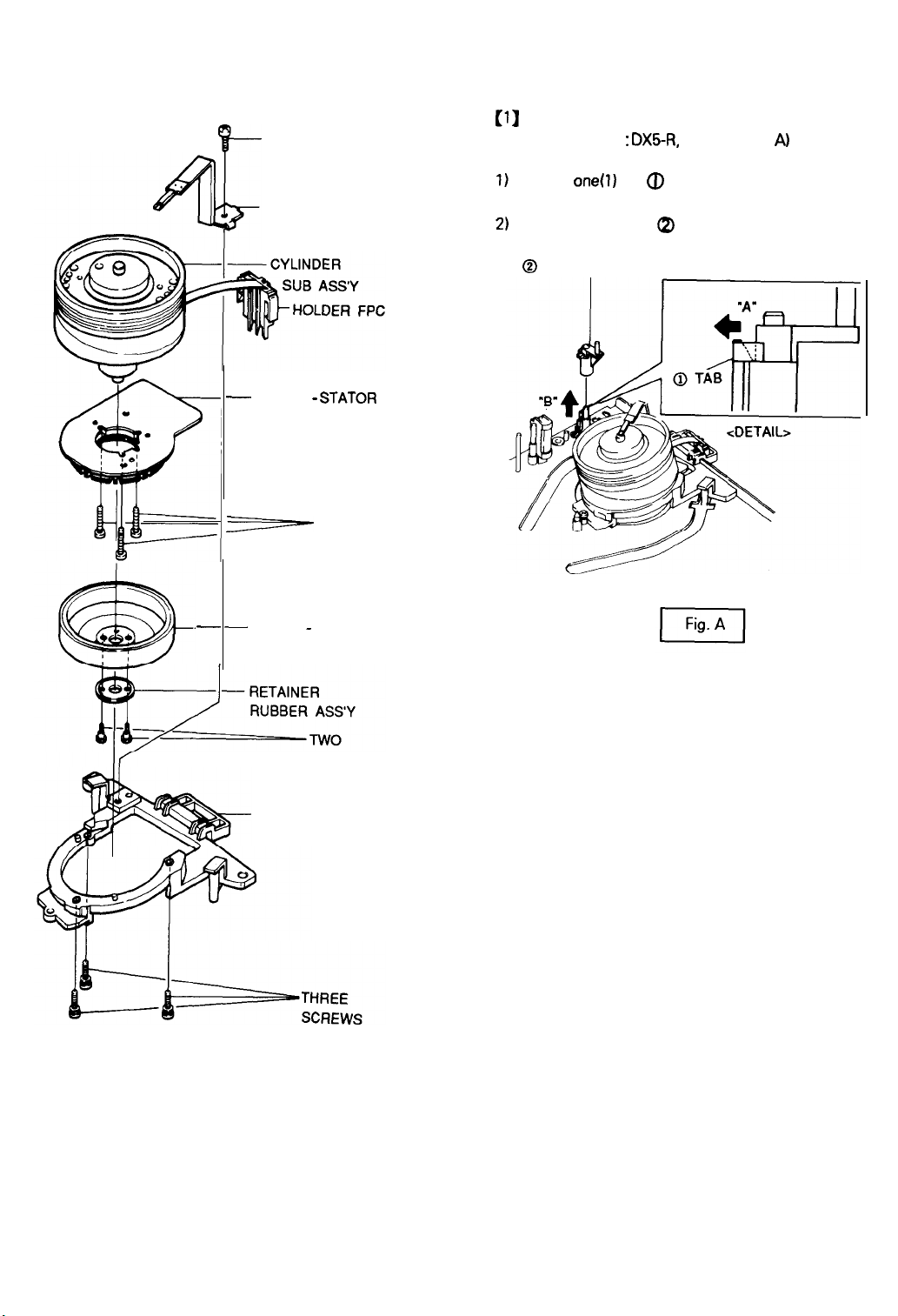

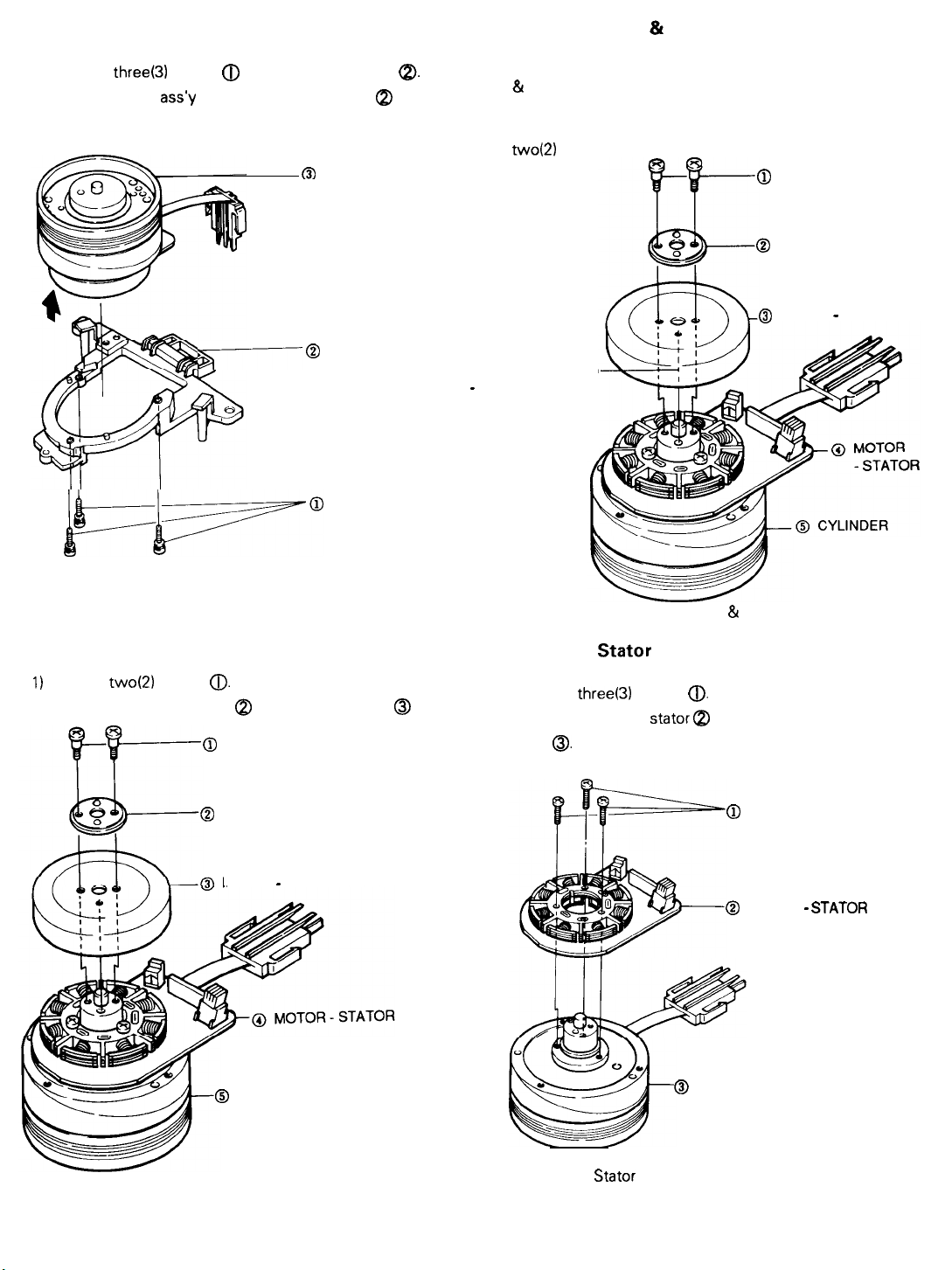

2-7. Cylinder Ass’y

2-7-l. Exploded View of Cylinder Ass’y

ONE SCREW

F-

HEAD BRUSH

-

MOTOR -

STATOR

2-7-2. Stopper Tape

(1)

Stopper Tape Removal

(Only for deck :

1)

Release

one(l)

(Refer to detail drawing)

2)

Lift the stopper tape 0, in the direction of arrow ‘B’.

@ STOPPER TAPE

DXS-R,

Refer to Fig.

A)

tab @ in the direction of arrow ‘A’.

p

- -

MOTOR - ROTOR

THREE

SCREWS

Fig. 19 Stopper Tape Removal

SCREWS

CYLINDER BASE

Fig. 18 Exploded View of Cylinder Ass’y

2-14

Page 16

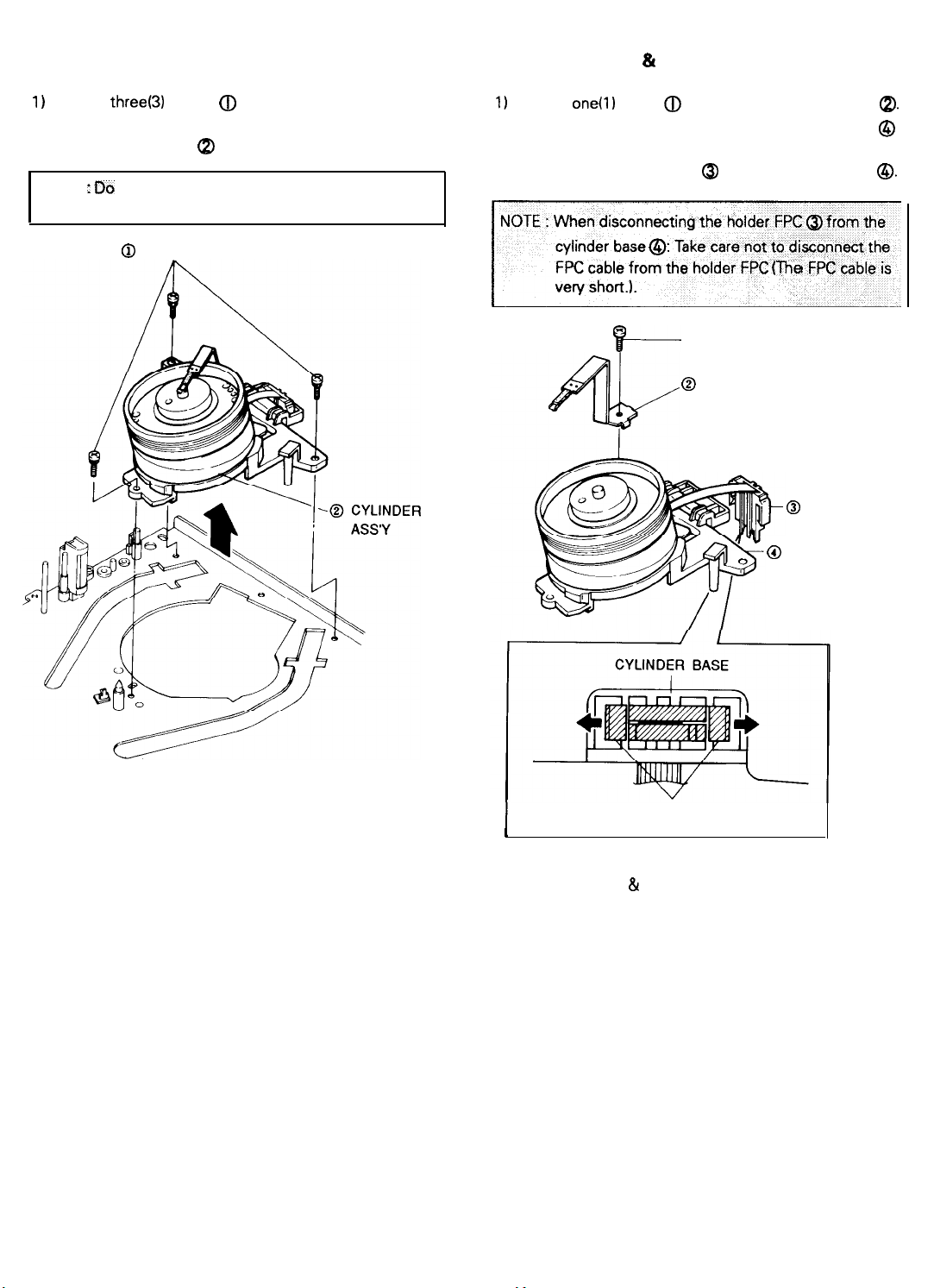

2-7-3. Cylinder Ass’y Removal from Main Base

1)

Remove threef3) screws @ holding the main base and

the cylinder ass’y.

2) Lift the cylinder ass’y Q in the direction of arrow.

NOTE

: Do

not touch the video heads during removal or.

installation.

@

THREE

SCREWS

2-7-4. Head Brush & Holder FPC Removal

1)

Remove

one(l)

screw @ and then lift the head brush

2) Release the holder FPC tab holding the cylinder base @

in the direction of arrow. (Refer to detail drawing)

3) Disconnect the holder FPC @ from the cylinder base

NOTE : When disconnecting the holder FPC @from the

cylinder base 0: Take care not to disconnect the

FPC cable from the holder FPC

(The

FPC cable is

j

a.

0.

Fig. 20 Cylinder Ass’y Removal from Main Base

IF---

HOLDER FPC TAB

I

<DETAIL : BOTTOM VIEW>

@ ONE SCREW

0

HEAD BRUSH

@

@

HOLDER FPC

CYLINDER BASE

J

Fig. 21 Head Brush & Holder FPC Removal

2-15

Page 17

2-7-5. Cylinder Ass’y Removal from Cylinder Base

2-7-7. Motor Rotor & Cylinder Sub Ass’y

1) Remove

2) Lift the cylinder

direction of arrow.

three(3)

ppa

screws 0 from the cylinder base

ass)

@from the cylinder base (p in the

m

CYLINDER ASS’Y

@

CYLINDER BASE

7

THREE SCREWS

@.

1) Make sure that phase matching holes of the motor rotor

81

the cylinder sub ass’y are aligned correctly as shown in

Fig. 16 (Refer to phase matching hole)

2) Reinstall the retainer lever ass’y @and secure with

two(2) screws.

@

TWO SCREWS

@

RETAINER

RUBBER ASS’Y

@

MOTOR - ROTOR

PHASE MATCHING

-

HOLE

SUB ASS’Y

Fig. 22 Cylinder Ass’y Removal from Cylinder Base

2-7-6. Motor Rotor Removal

1)

Remove two(2) screws

2) Lift the retainer lever ass’y @ and the motor rotor @

0.

@

TWO SCREWS

@

RETAINER

RUBBER ASS’Y

MOTOR - ROTOR

@

CYLINDER SUB ASS’Y

Fig. 24 Assembly of Motor Rotor & Cylinder Sub Ass’y

2-7-8. Motor Stator Removal

1) Remove

2) Remove the motor stator a from the cylinder sub

ass’y

Q.

three(3)

screws

@

@).

@

THREE SCREWS

@

MOTOR -

CYLINDER SUB ASSY

STATOR

Fig. 23 Motor Rotor Removal

2-l 6

Fig. 25 Motor

Stator

Removal

Page 18

2-7-9. Motor

Stator

& Cylinder Sub Ass’y

2-8. Main Deck Removal & Reassembly

1)

Reinstall the motor stator (D toward the FPC cable of

cylinder sub ass’y

2)

Secure with three(3) screws. (Refer to Fig.

Fig. 26 Assembly of Motor Stator & Cylinder Sub Ass’y

Q.

. @ MOTOR - STA

- @

CYLINDER

SUB

ASS’Y

17)

,TOR

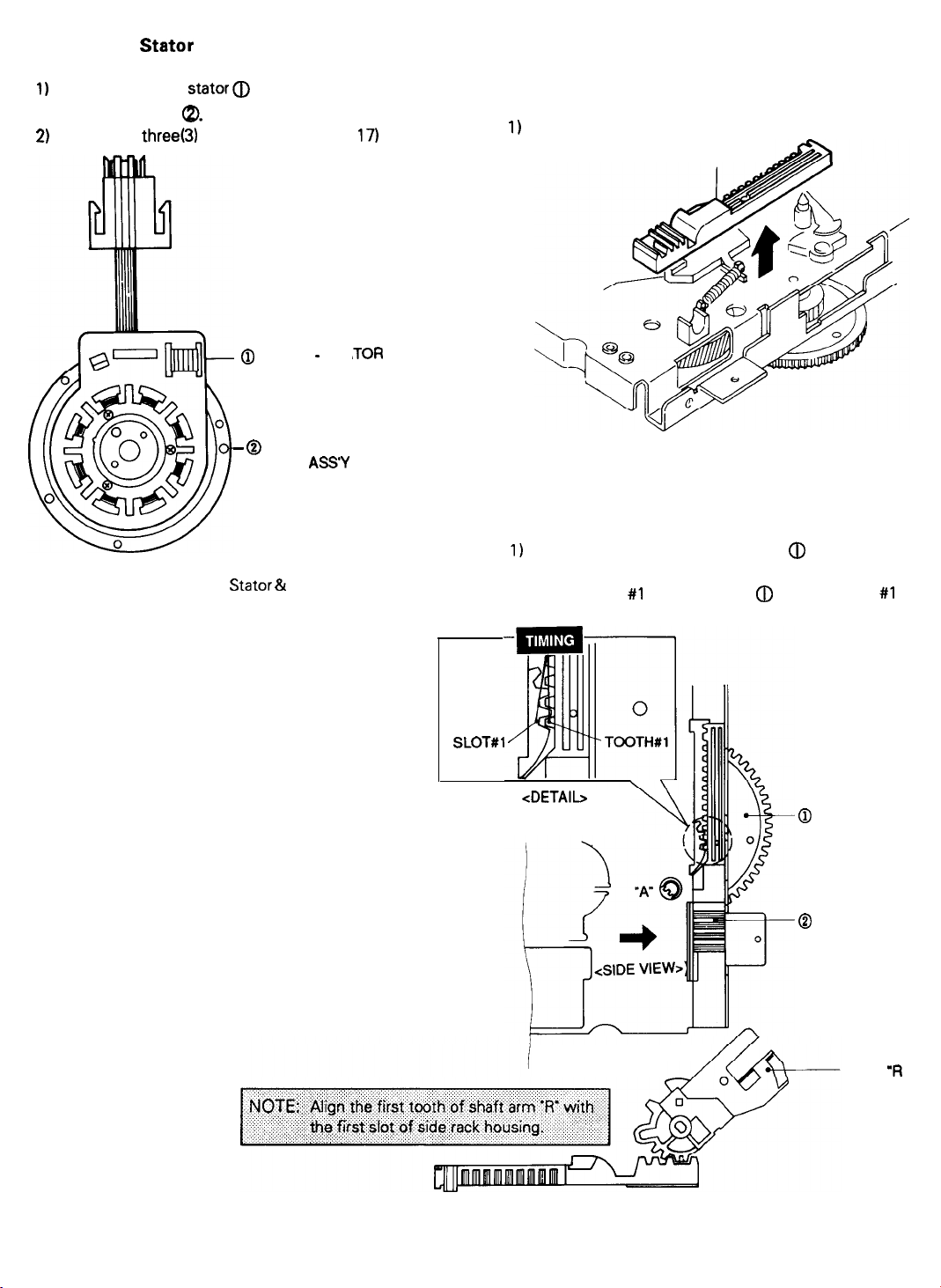

2-8-l. Slide Rack Housing Removal

1)

Lift the slide rack housing in the direction of arrow.

SLIDE RACK HOUSING

Fig. 27 Slide Rack Housing Removal

2-8-2. Assembly of Slide Rack Housing & Gear

Master

1)

Confirm that the hole of gear master @ and the hole ‘A

of main base are aligned correctly. (Eject mode)

2) Align the slot #l of gear master a with the tooth #l of

slide rack housing. (Refer to timing point)

SLOTS1

<DETAIL>

<TOP VIEW>

<SIDE VIEW>

Fig. 28 Assembly of Slide Rack Housing & Gear Master

@

GEAR MASTER

@

SLIDER RACK

HOUSING

ARM

‘R

2-17

Page 19

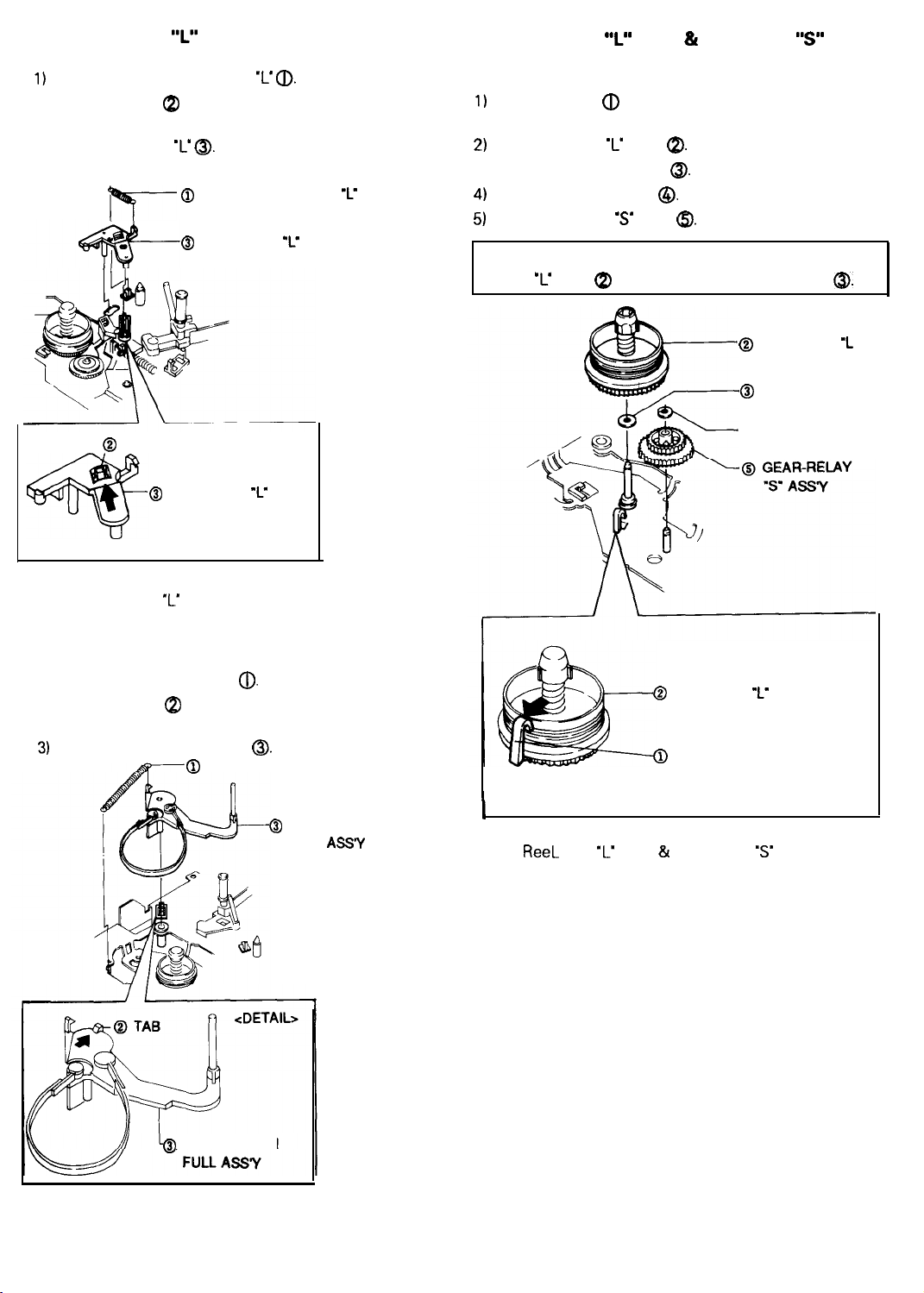

2-8-3. Brake Sub

1)

Remove the spring brake sub ‘L’

2) Release the tab Q) in the direction of arrow.

(Refer to detail drawing)

3) Lift the brake sub ‘L

“L”

Removal

a.

0.

@

SPRING-BRAKE SUB ‘L.

r7-

@

BRAKE-SUB ‘L”

2-8-5. Reel Disk

‘I”

Ass’y & Gear Relay

“s”

Ass’y Removal

1)

Release the tab

(Refer to detail drawing)

2)

Lift the reel disk ‘L ass’y

3) Remove the washer plain

4)

Remove the washer slit

5)

Lift the gear relay ‘S’ ass’y

NOTE : When reinstalling, be sure to install the reel disk

‘L’ ass’y QI after installing the washer plain

(J)

in the direction of arrow.

a.

a.

@.

a.

@

@I

REEL-DISK

ASSY

WASHER-PLAIN

@.

‘L

@

TAB

@

<DETAIL>

Fig. 29 Brake Sub

BRAKE-SUB

‘L’

Removal

“L”

2-8-4. Arm Tension Full Ass’y Removal

1) Remove the spring tension

2) Release the tab Q in the direction of arrow.

(Refer to detail drawing)

3)

Lift the arm tension full ass’y

0.

@

0.

SPRING-TENSION

@

ARM-TENSION

FULL

ASS’Y

I

Fig. 31

@

REEL-DISK

Q)

TAB

<DETAIL>

ReeL

Disk ‘L’ Ass’y & Gear Relay

Removal

@WASHER-SLIT

“L’

ASSY

‘S’

Ass’y

@

ARM-TENSION

Fig. 30 Arm Tension Full Ass’y Removal

2-18

Page 20

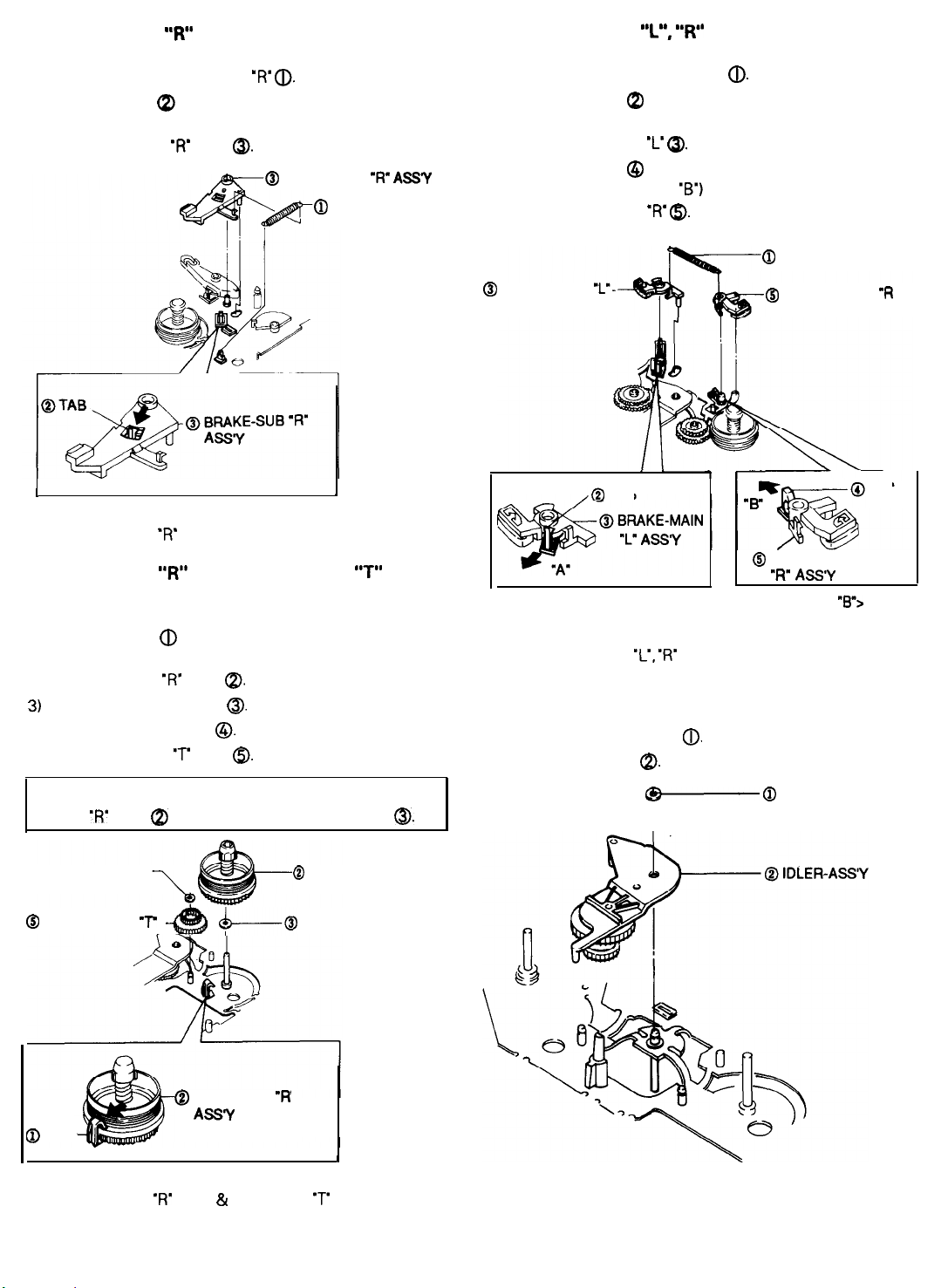

2-8-6. Brake Sub

“R”

Ass’y Removal

2-8-8. Brake Main

“L”, “R”

Ass’y Removal

1) Remove the spring brake sub ‘R’

2) Release the tab Cp in the direction of arrow.

(Refer to detail drawing)

3) Lift the brake sub ‘R’ ass’y

I

<DETAIL>

Fig. 32 Brake Sub ‘R’ Ass’y Removal

2-8-7. Reel Disk

“R”

Ass’y & Gear Relay

@.

@

a.

BRAKE-SUB

@

SPRING-BRAKE

Removal

‘R” ASSY

SUB l R

I

“T”

1) Remove the spring brake main

2) Release the tab a in the direction of arrow ‘A’.

(Refer to detail drawing ‘A’)

3) Lift the brake main ‘L’

4) Release the tab @ in the direction of arrow ‘B’.

(Refer to detail drawing ‘B’)

5) Lift the brake main ‘R’

@

BRAKE-MAIN

ASSY

<DETAIL “A”>

,O

I’-

TAB

a.

a.

@.

0

SPRING-BRAKE MAIN

@

BRAKE-MAIN

ASSY

“B

@

BRAKE-MAIN

“R” ASSY

<DETAIL

“R

TAB

“B”>

1) Release the tab a in the direction of arrow.

(Refer to detail drawing)

2) Lift the reel disk ‘R’ ass’y

3)

Remove the washer plain

4) Remove the washer slit

5) Lift the gear relay

NOTE : When reinstalling, be sure to install the reel disk

‘R’

ass’y 8) after installing the washer plain

@WASHER-SLIT

@

GEAR-RELAY

@

TAB

Fig. 33 Reel Disk ‘R’ Ass’y & Gear Relay ‘T’ Removal

7”

<DETAIL>

a.

0.

0.

‘T’

ass’y

@I.

&-----@

@

REEL-DISK

ASSY

@

REEL-DISK l R

ASSY

WASHER-PLAIN

“R

1

0.

Fig. 34 Brake Main ‘L’,

‘R’

Ass’y Removal

2-8-9. Idler Ass’y Removal

1) Remove the washer slit

2) Lift the idler ass’y

Fig. 35 Idler Ass’y Removal

0.

a.

@-

@ WASHER-SLIT

2-19

Page 21

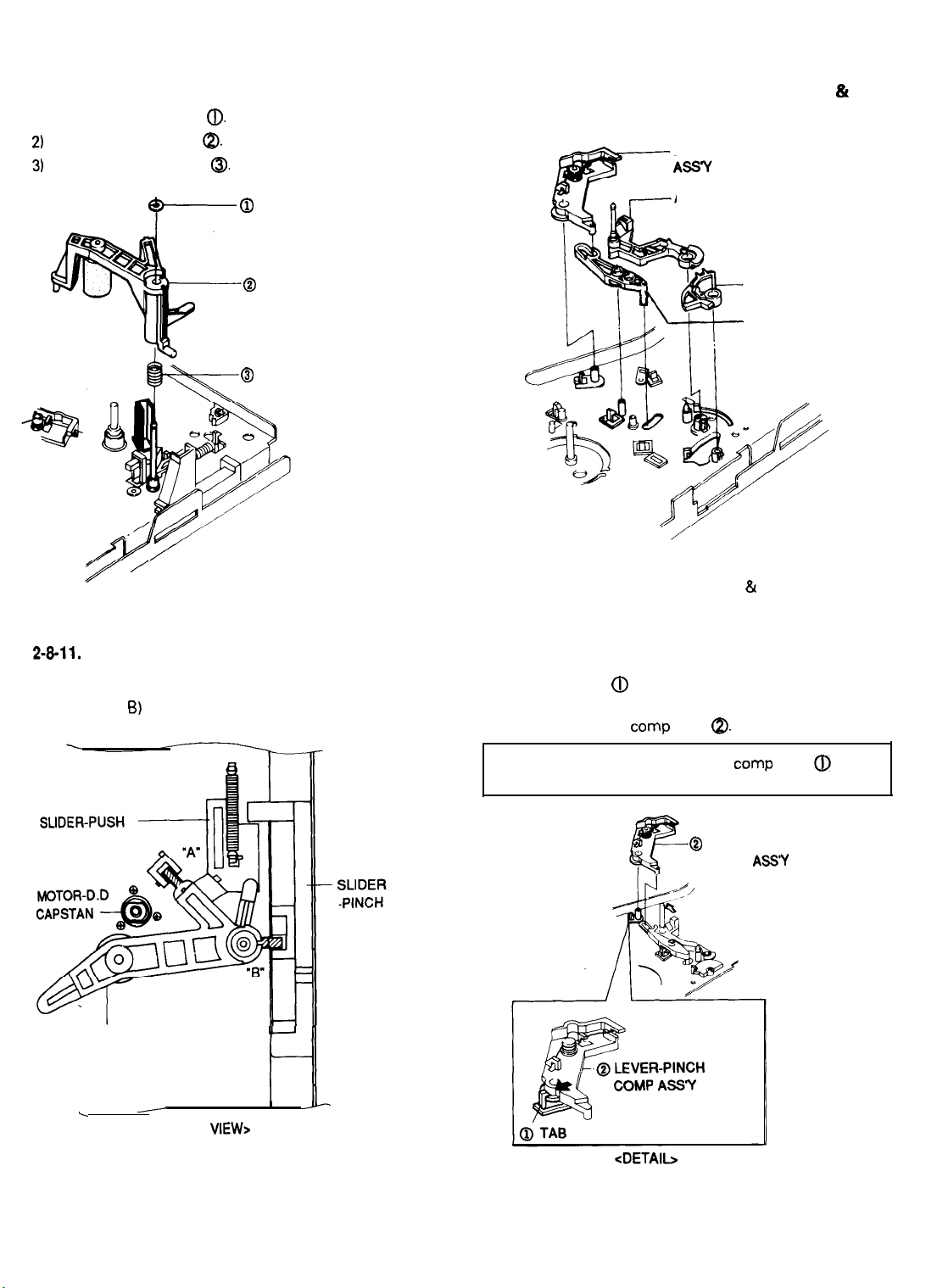

2-8-10. Unit Pinch Roller Ass’y Removal

1) Remove the washer slit

2)

Lift the unit pinch roller

3)

Lift the spring arm pinch

(D.

@.

a.

2-8-12. Exploded View of Lever Pinch Comp Ass’y,

Lever Pinch Cam, Arm Review Ass’y &

Lever Review Ass’y

LEVER-PINCH COMP

&p

Fig. 36 Unit Pinch Roller Ass’y Removal

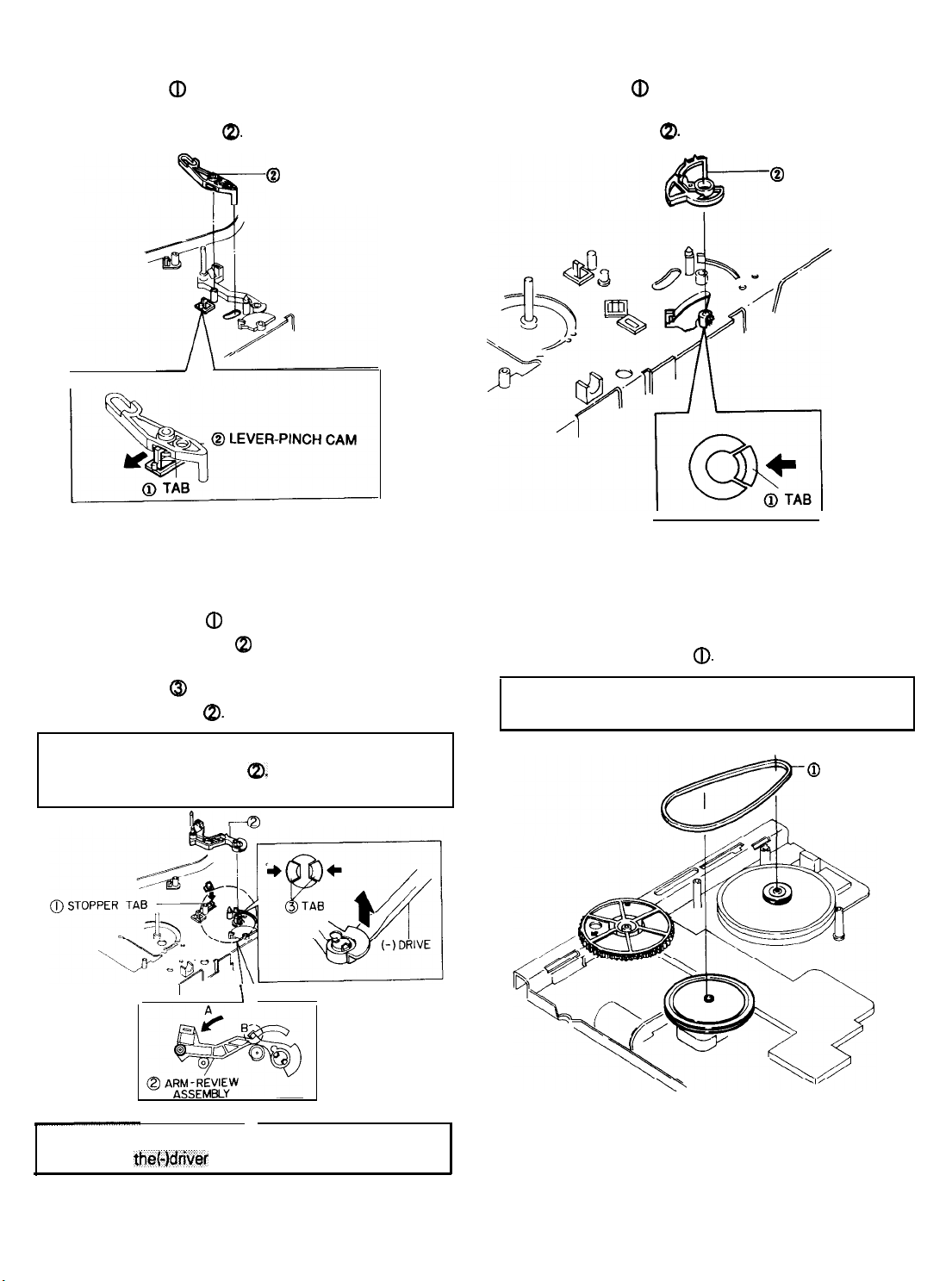

2-8-11.

Assembly of Unit Pinch Roller

1) Install the unit pinch roller as shown in Fig. 29.

(Refer to A,

6)

Q WASHER-SLIT

@

UNIT-PINCH ROLLER

@

SPRING-ARM PINCH

ARM-REVIEW ASSY

LEVER-REVIEW

LEVER-PINCH CAM

Fig. 38 Exploded View of Lever Pinch Comp Ass’y, Lever

Pinch Cam, Arm Review Ass’y 81 Lever Review

Ass’y

2-8-13. Lever Pinch Comp Ass’y Removal

1) Release the tab @ in the direction of arrow.

(Refer to detail drawing)

2) Lift the lever pinch camp ass’y

@.

UNIT-PINCH ROLLER

.

Fig. 37 Assembly of Unit Pinch Roller

-

<TOP

VIEW>

!-II

t-l

I y

NOTE : Don’t touch the lever pinch camp ass’y @ to

audio head base during removal.

@

LEVER-PINCH

COMP

<DETAIL>

Fig. 39 Lever Pinch Comp Ass’y Removal

2-20

ASS’Y

Page 22

2-8-14.

Lever Pinch Cam Removal

1) Release the tab a in the direction of arrow.

(Refer to detail drawing)

2)

Lift the lever pinch cam

a.

2-8-18. Lever Review Removal

(j)

1) Release the tab

(Refer to detail drawing)

2) Lift the lever review

in the direction of arrow.

a.

@

LEVER-PINCH CAM

r

<DETAIL>

Fig. 40 Lever Pinch Cam Removal

2-8-l 5. Arm

1) Push the stopper tab (D in the direction of arrow.

2) Pull the arm review ass’y Q in the direction of arrow ‘A’

and then confirm ‘B’. (Refer to detail drawing ‘A’)

3) Release the tab

the arm review ass’y

Review Ass’y Removal

@ in the direction of arrow and then lift

a.

@ LEVER REVIEW

<DETAIL>

Fig. 42 Lever Review Removal

2-8-17.

1) Remove the belt capstan

Belt Capstan Removal

a.

NOTE : Take extreme care not to touch the grease when

removing or reinstalling.

NOTE : Take extreme care not to damage when removing

the arm review ass’y

(B

part of detail drawing

I

NOTE:

Fig. 41 Arm Review Ass’y Removal

Be sure to remove the arm review assy with

using

the(-)dri

Cp.

A)

ARM REVIEW ASSEMBLY

\ \,

DETAIL “A”

DETAIL "B”

Fig. 43 Belt Capstan Removal

2-21

@

BELT-CAPSTAN

Page 23

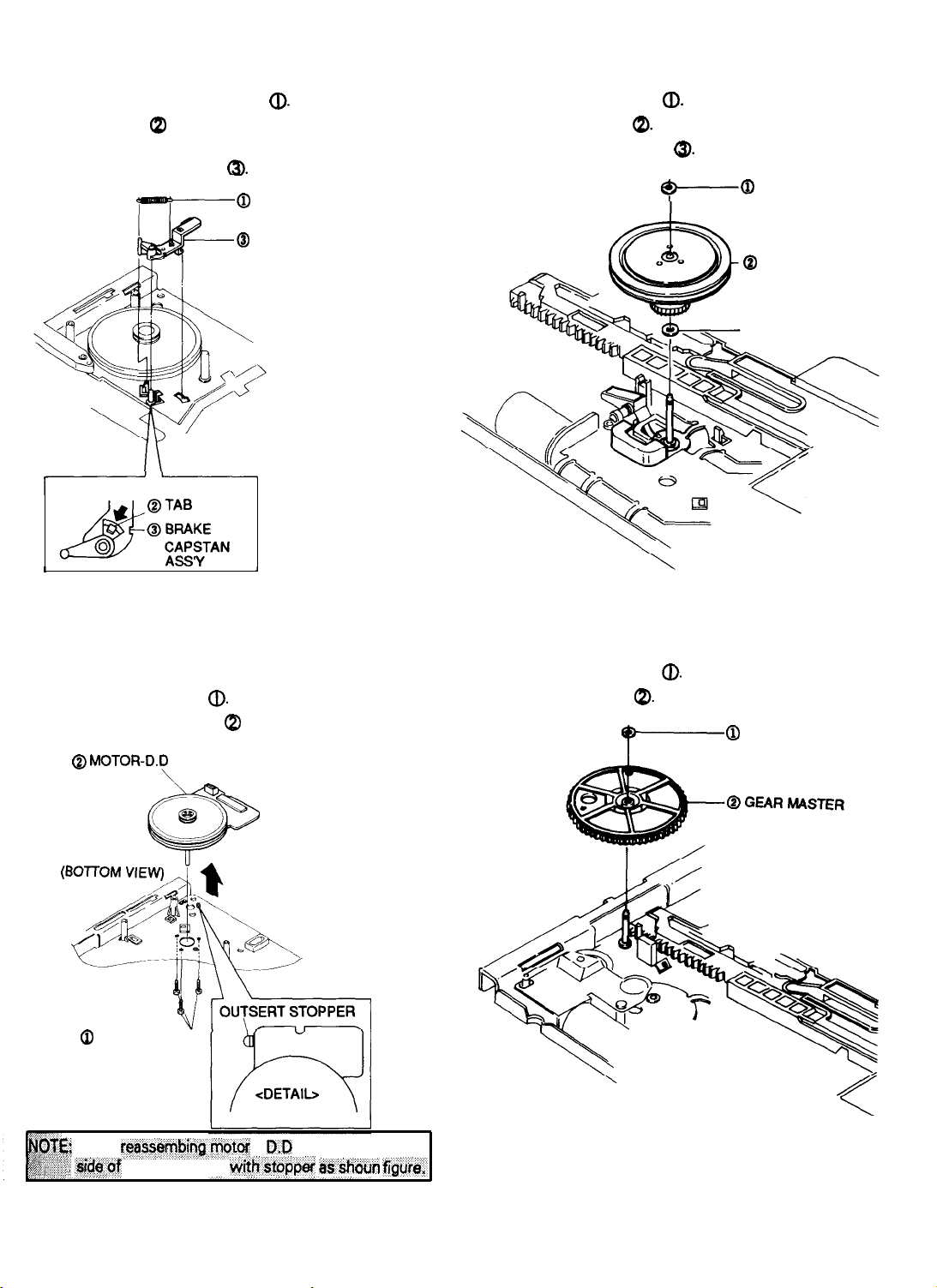

2-8-18.

1)

2)

3)

Brake Capstan Ass’y Removal

Remove the spring brake capstan

Release the tab Q in the direction of arrow.

(Refer to detail drawing)

Lift the brake capstan ass’y

(J).

a.

@

SPRING-BRAKE

CAPSTAN

@

BRAKE CAPSTAN

ASSY

l--------l

2-8-20.

Clutch Ass’y Removal

1)

Remove the washer slit

2)

Lift the clutch

3) Remove the washer plain

ass’y

QI.

a>.

9-0

@.

WASHER-SLIT

Q

CLUTCH-ASSY

@WASHER-PLAIN

1

<DETAIL>

Fig. 44 Brake Capstan Ass’y Removal

2-8-19.

Motor D.D

1)

Remove

2)

Lift the motor D.D capstan (p in the direction of arrow.

(Bottom view)

three(3)

Q MOTOR-D.P

(TOP VIEW)

0

THREE SCREWS

Capstan

screws @. (Top view)

CAPSTAN

1

Removal

Fig.46 Clutch Ass’y Removal

2-8-21. Gear Master Removal

1)

Remove the washer slit

2)

Lift the gear master

Q).

@

0

WASHER-SLIT

C When

Fig. 45 Motor D.D Capstan Removal

reyemf$qkytor -

.sid$.of

capstan wafer

R-R

&th-doppef

capstan@,. align

trs’doun

fi&ia,.

Fig. 47 Gear Master Removal

2-22

Page 24

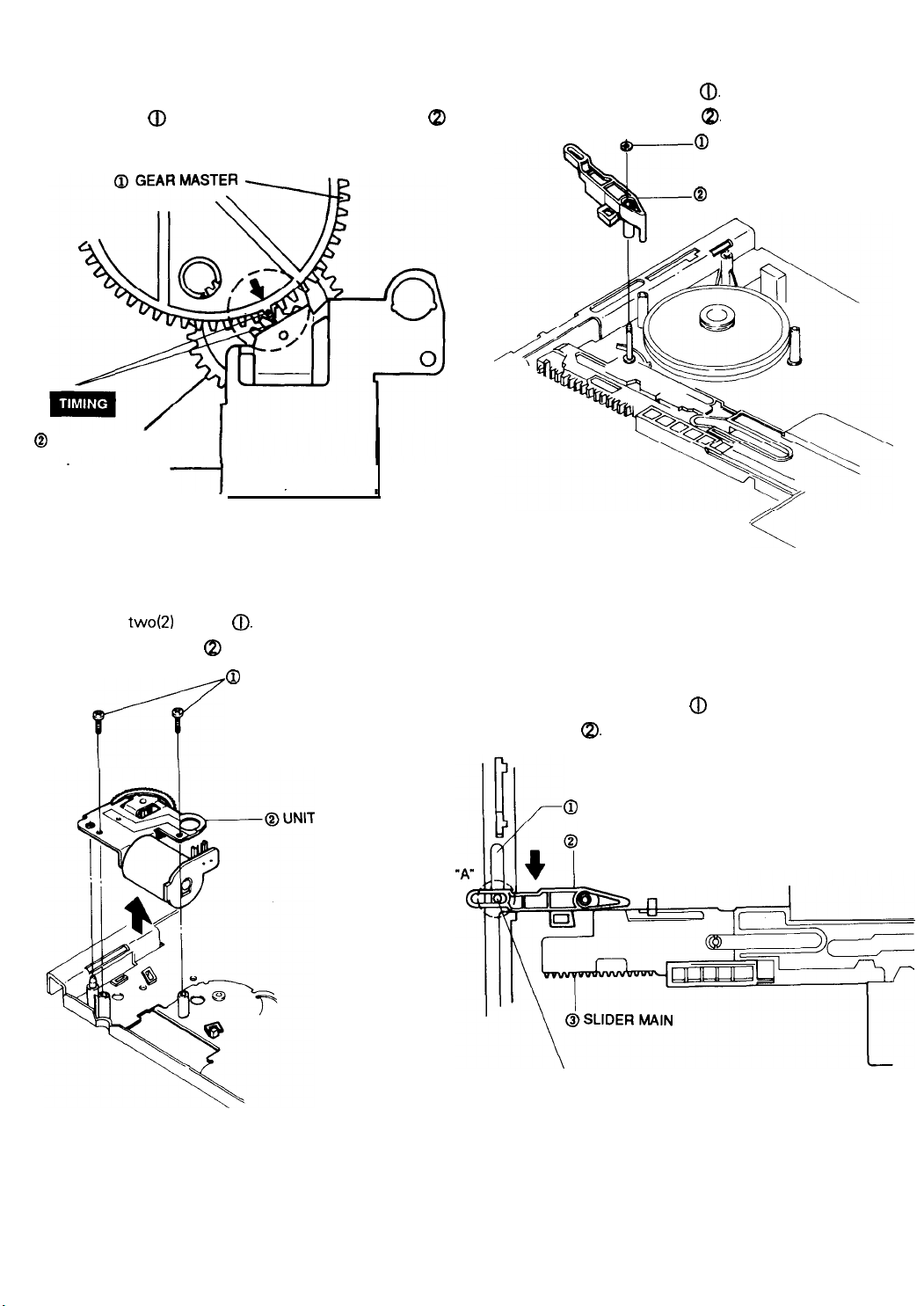

2-8-22.

Assembly of Gear Master

2-8-24.

Lever Slide Pinch Removal

1)

When reinstalling, be sure to align the arrow mark of

gear master

(Refer to timing point)

@

GEAR WORM WHEEL

UNIT LOADING

a

with gear home of gear worm wheel

00

Fig. 48 Assembly of Gear Master

2-8-23.

Unit Loading Removal

1) Remove the washer slit

a

2) Lift the lever slide pinch

a.

a,

@

WASHER-SLIT

@I

LEVER SLIDER PINCH

/

<-,

Fig. 50 Lever Slide Pinch Removal

1)

Remove twoQ) screws

2) Lift the unit loading @ in the direction of arrow.

0.

Q

TWO SCREWS

p--?

LOADING

Fig. 49 Unit Loading Removal

2-8-25.

SLIDER PINCH BOSS

Assembly of Lever Slide Pinch

1)

Pull the slide pinch @to the end in the direction

of arrow.

2) Insert the slide pinch

pinch (p. (Refer to ‘A’ part)

@

SLIDER-PINCH

LEVER SLIDER PINCH

Fig. 51 Assembly of Lever Slide Pinch

(j)

into the hole of lever slide

2-23

Page 25

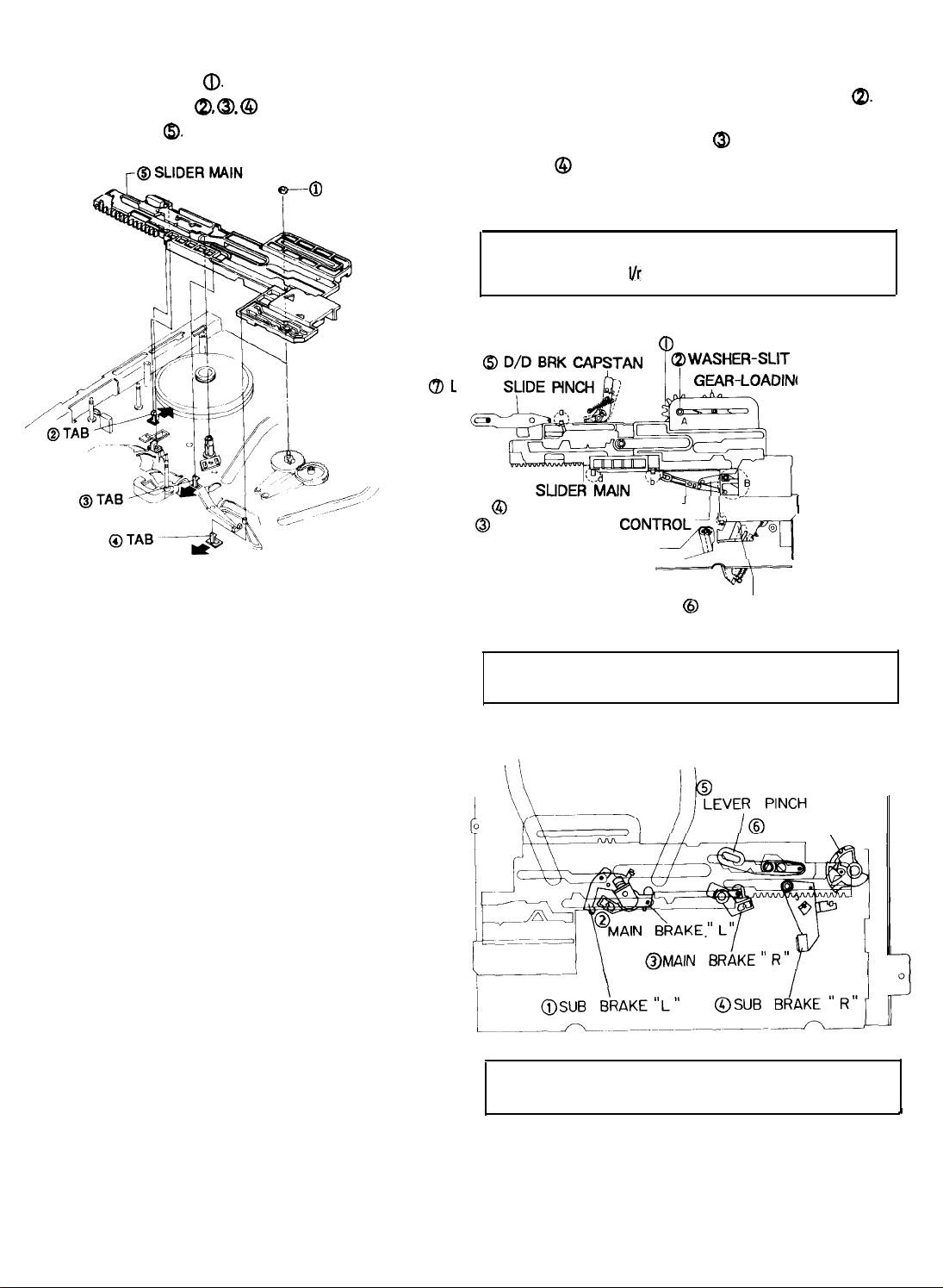

2-8-28. Slide Main Removal

2-8-27. Assembly of Slide Main

1) Remove the washer slit

2) Release

3) Lift the slide main

three(3)

tabs

6).

a.

QI, @,

@ in the direction of arrow.

@

WASHER SLIT

CBL

1) Install the shaft of gear loading ‘R’ ass’y into the left of

the main slide hole and secure with the washer slit

(Refer to ‘A’)

2) Insert the lever tension control

change @ into the slide main hole. (Refer to

3) After confirming the above items

main and secure with tabs

NOTE:

Be sure to assemble the side main when the

gear loading

i/r

assy is inunloading posision.

@

Q)

and the lever idler

1), 2)

install the slide

(a,

b,

c).

GEAR-LOADING’R’ASSEMBLY

a

EVER

0

LEVER-IDLER CHANGE

0

LEVER-TENSION

’

CONTB~~

G "L" ASSEMBLY

I

a.

‘B’)

Fig. 52 Slide Main Removal

7

@

LEVER-REC

NOTE :

Fig. 53 Assembly of Slide Main (Bottom view)

‘r-------’

NOTE: Six parts should be installed into the side

Seven parts should be installed into the

side main hole.

LEVER REVIEW

\

main hold.

S/W

I

CAM

I

A

Fig. 54 Assembly of side

2-24

Main(Top

view)

Page 26

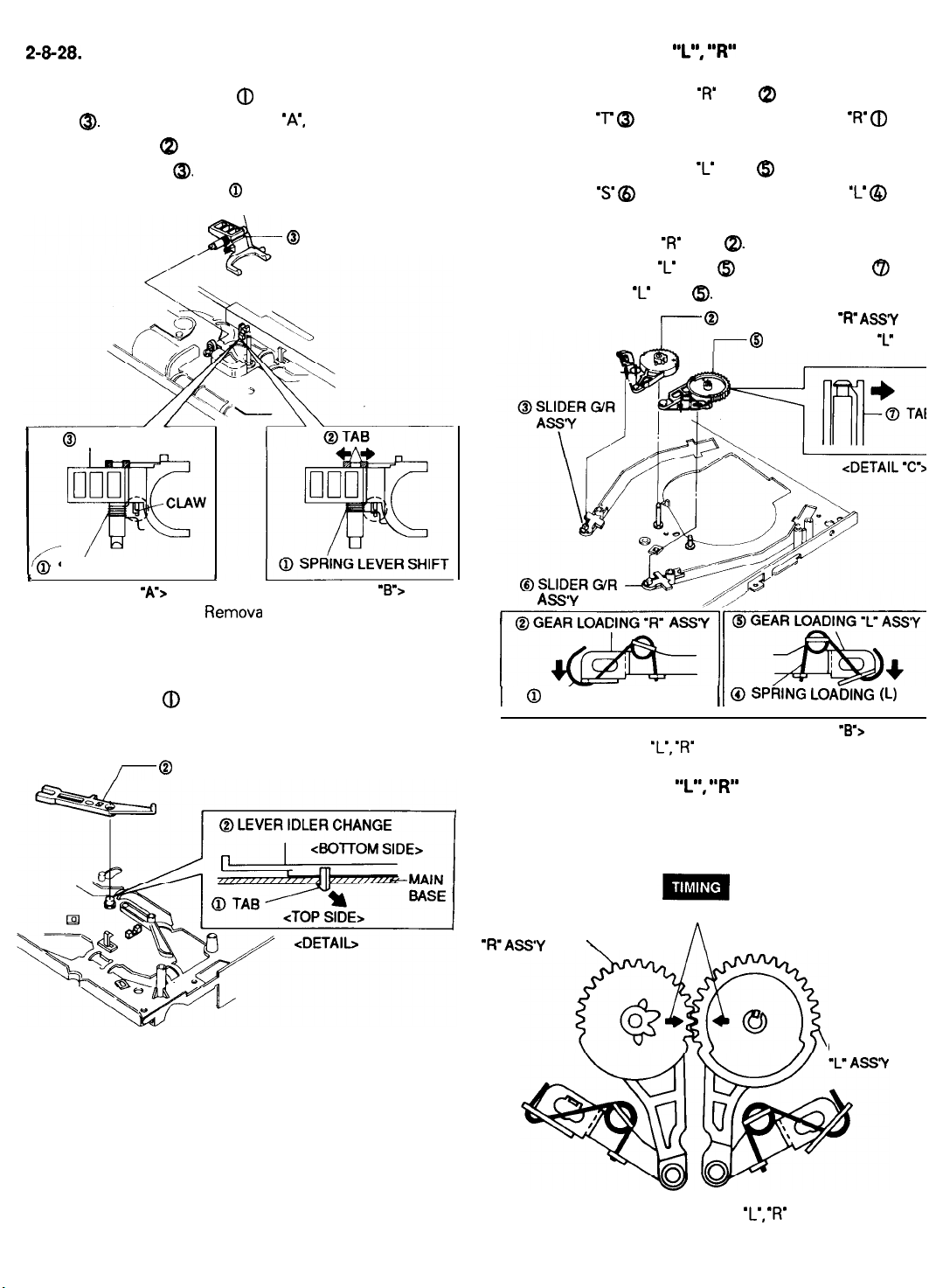

2-8-28.

Lever Shift Ass’y Removal

2-8-30. Gear Loading

‘I”, “R”

Ass’y Removal

1) Hang the spring lever shift (D to the claw of the lever

shift @. (Refer to detail drawings ‘A’, ‘B’)

2) Release the tab @ in the direction of arrow.

3) Lift the lever shift

@I

LEVER SHIFT

I

F

*

Fig. 55 Lever Shift Ass’y

,

@

SPRING LEVER SHIFT

<DETAIL

“A”>

@.

@

SPRING LEVER SHIFT

\

@

LEVER SHIFT

<DETAIL ‘B’>

Remova

1) Remove the gear loading ‘R’ ass’y @ from the slide

guide roller ‘T

in the direction of arrow. (Refer to detail drawing ‘A’)

2) Remove the gear loading ‘L’ ass’y Q from the slide

guide roller

in the direction of arrow. (Refer to detail drawing ‘B’)

3) Lift the gear loading ‘R’ ass’y

4) Lift the gear loading ‘L’ ass’y @ by pushing the tab Q of

the gear loading ‘L’ ass’y a. (Refer to detail drawing ‘C’)

ASS’Y

(3,

by pushing the spring loading ‘R’

‘s’

@ by pushing the spring loading ‘L’ @

a.

f---- @

GEAR LOADING

@

GEAR LOADING

44’

a

‘R’ AS’Y

‘L’

ASS

2-8-29. Lever Idler Change Removal

1) Release the tab @ in the direction of arrow.

(Refer to detail drawing)

2) Lift the lever idler change

7

@ LEVER IDLER CHANGE

Fig. 56 Lever Idler Change Remo

@

SPRING LOADING (R)

<DETAIL “A”>

Fig. 57 Gear Loading ‘L’,

2-8-31. Gear Loading

1) When reinstalling, be sure to align two arrows as shown

in Fig. 58. (Refer to timing point)

GEAR LOADING

“R’ASS’Y

ALIGN TWO ARROWS

\

11 @ SPRlNG LoADlNG (L)

‘R’

Ass’y Removal

‘I”, “R”

<DETAIL

Ass’y

9%

GEAR LOADING

Fig. 58 Assembly of Gear Loading ‘L’, ‘R’ Ass’y

2-25

Page 27

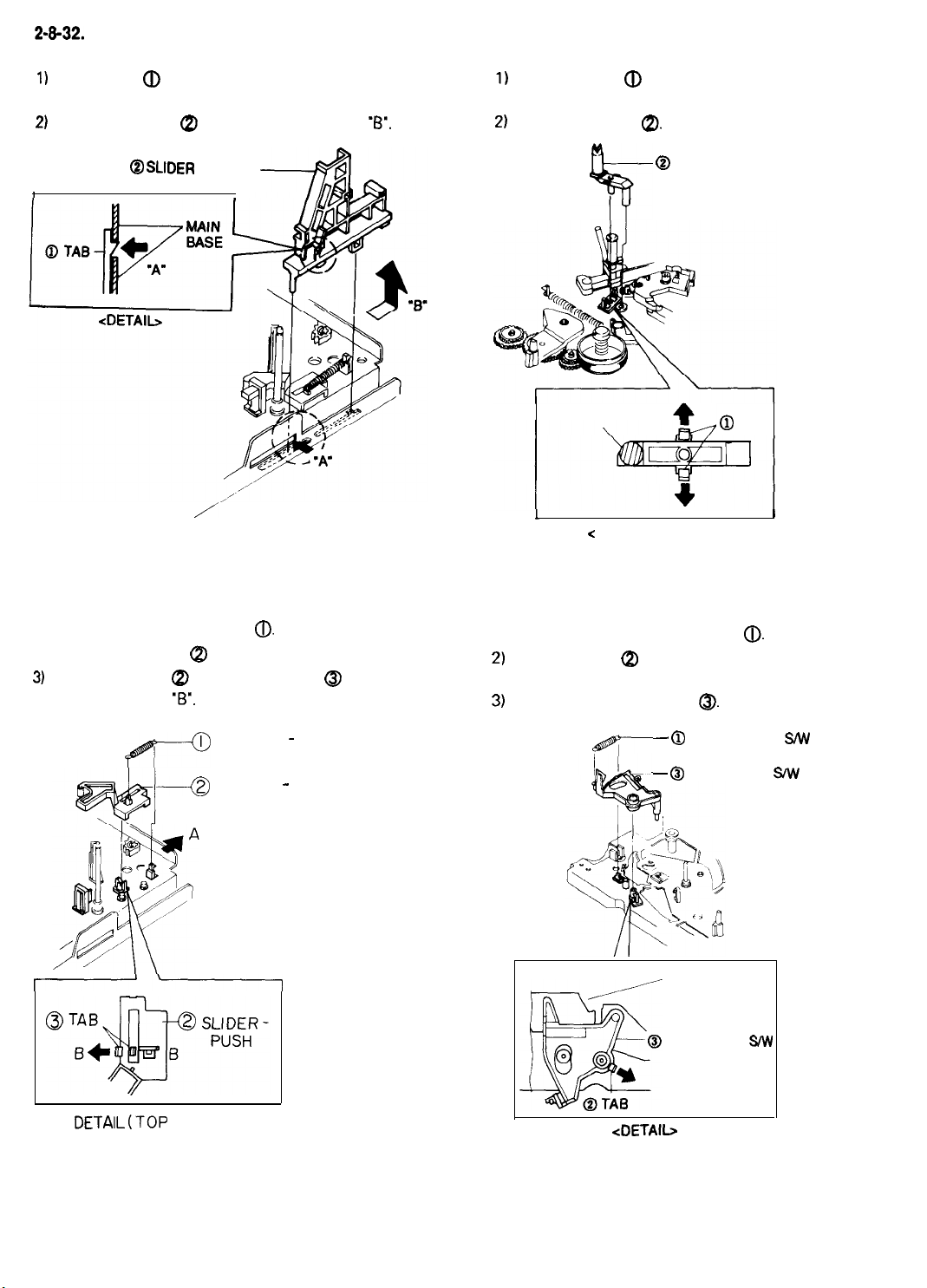

2-8-32.

Slide Pinch Removal

1)

Push the tab @ in the direction of arrow ‘A’.

(Refer to detail drawing)

2)

Lift the slide pinch @ in the direction of arrow

@ SLIDER

I

PINCH

‘6’.

2-8-34. Prism LED Removal

1)

Release the tab @ in the direction of arrow.

(Refer to detail drawing)

2)

Lift the prism LED

Q).

0

PRISM-

LED

VT

PRISM

LED

@

TAB

/

Fig. 59 Slide Pinch Removal

2-8-33. Slide Push Removal

1) Remove the spring slide push

2) Push the slide push Q in the direction of arrow ‘A’.

3)

Lift the slide push Q) by pushing the tab Q in the

direction of arrow ‘B’. (Refer to detail drawing)

fl

4

0.

SPRING - SLIDE PUSH

SLIDER - PUSH

l------I

1

<

DETAIL

Fig. 61 Prism LED Removal

+

-TOP VIEW>

I

2-8-35. Lever Record Switch Removal

1) Remove the spring record switch

2)

Release the tab QI in the direction of arrow.

(Refer to detail drawing)

3)

Lift the lever record switch

__ @

6

SPRING REC

- @

LEVER REC

MAIN BASE

0.

0.

S/W

C/W

DETAIL(TOP VIEW)

Fig. 60 Slide Push Removal

<DETAIL

Fig. 62 Lever Record Switch Removal

2-26

LEVER REC

SIW

Page 28

2-8-36. Full Erase Head Removal

1)

Remove one0 ) screw

2)

Lift the magnet WE head 8).

@

f---

@

Fig. 63 Full Erase Head Removal

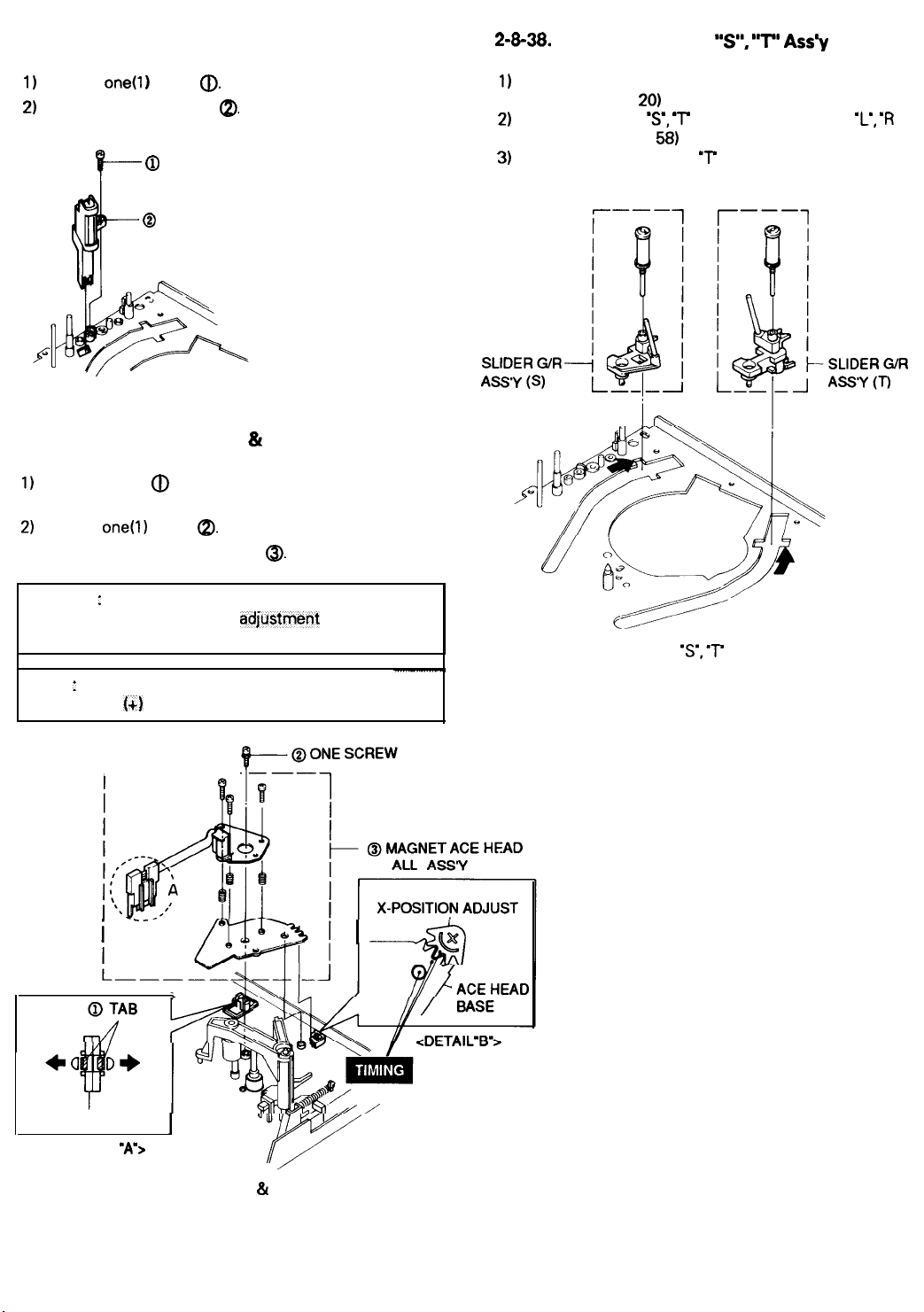

2-8-37. ACE Head Removal & Reassembly

1)

Release the tab @ holding holder ACE toward arrows.

(Refer to detail drawing ‘A’)

2)

Remove

3) Lift the magnet ACE head ass’y

one(l)

screw

Q).

ONE SCREW

MAGNET F/E HEAD

QI.

@.

2-8-38.

Slide Guide Roller “s”,

1)

Remove the cylinder ass’y from the main base.

(Refer to Fig. 19,

2)

Remove the slide

ass’y. (Refer to Fig.

3)

Move the guide roller ‘S’, ‘T ass’y to slot and then lift it

to remove. (Refer to arrow)

20)

‘s’, T

from the gear loading ‘L’,

58)

“T” Ass’y

Removal

‘R

Assembly : When reinstalling, be sure to align the three

teeth of X-Position adju$tment gear with the

two slot of ACE head base.

NOTE : When adjusting the X-position adjustment gear

using

1~)

driver, do not adjust by force.

r-------

i --

I

---%J

r-n/

-r-z

,#

Fig. 65 Slide Guide Roller

‘s’, ‘T

Ass’y Removal

HOLDER ACE

<DETAIL

Fig. 64 ACE Head Ass’y Removal & Reassembly

I

‘A=>

“ul

1

7

2-27

Page 29

2-8-39. Slide Guide Roller “S”,

“T”

Ass’y

(When all parts except the cylinder

assembly are removed.)

1) Push four(4) Lever Locks a of the housing ass’y

Simultaneously. (Refer to Fig. 66)

2) Push the holder cassette

turning the gear master Q toward arrow ‘A’.

(Refer to Fig.

3) Load the gear loading L, R ass’y @. a to the middle

position of guide rail by turning the gear master

toward arrow ‘A’. (Refer to Fig. 66, 67)

4)

Install the slide guide roller S, T @, QJ into rail slot and

then move it to the position of gear loading L, R ass’y

0, a.

5)

Turn the gear master @ toward arrow ‘A’. (Eject mode)

66)

(Refer to Fig.

67)

ass)

@toward arrow ‘B’ while

Q

k2_0

Fig. 66 How to operate the Housing Ass’y

HOMIER CASSETTE

ASSEMBLY

@

SLIDER

ASSY (T)

G/R

Fig. 67 Assembly of Slide Guide Roller

‘s’, ‘r

Ass’y

2-28

Page 30

3-2. TAPE TRANSPORT SYSTEM

3-2-l. Location of Tape Transport Adjustment (Adjustment Reference)

The lower flange height of the tape guide is used as the basic reference point for transport adjustments.

To keep the height of the tape guide, do not apply excessive force onto the main base to prevent damage.

FULL ERASE

TENSION POLE

#l

GUIDE POLE

SUPPLY

Fig. 1 Location of Tape Transport Adjustment

F/E

HEAD

KEEL DISK

#3

GUIDE SHAFT

TAKE UP REEL DISK

CYLINDER ASS’Y

GUIDE ROLLER

PINCH ROLLER

PINCH ROLLER

‘r

CAPSTAN SHAFT

ADJUSTING :

CHECKING :

REVIEW POLE

I-]

Fig. 2 Tape Travel Diagram

3-3

Page 31

3-2-2. Tape Transport System Adjustment

1) Pm-adjustment

When parts are replaced, perform the required adjustments

by referring to the procedures for the tape transport

system. When parts are replaced, the tape path may be

changed.

First run a T-l 60 tape and be sure excessive tape wrinkle

does not occur at any tape guide.

1. If tape wrinkles at the S. T-guide rollers, turn

the S,T-guide rollers until the wrinkle

2. If tape still wrinkles at the tape

do the tilt adjustment of the A/C head.

drsappears.

gurde,

2) Adjustment procedures

1. A/C head assembly adjustment

Test

Point

:

TP302 (Envelope)

TP804

TP202

TP201 (Control Pulse)

Test Tape :

L

(Audio

Out)

(H’D

SW Pulse

ST-N1

(Blank Tape (T-160)

-Trigger)

CCREW (6)

ITU An.11 IST

ADJUST GEAR(E).

\

SCREW(D)

X - POSITION LOCKING

SCREW (A)

HEIGHT ADJUST

Fig.

4 Locatron of A/C Head Adjustment Screw

AUDIO HEAD

VIDEO TAPE

I

CONTROL HEAD

SCREW(C)

TILT

ADJUST

X - POSITION

HOLE (F)

0 -

0.25mm

0

Fig. 3 Location of Test Point (Main

a. A/C head height adjustment

1. Run the alignment tape (ST-Nl) In the playback

mode.

2. Observe the surface of the audio head using a

dental mirror.

3. Turn screws(A), (B), (C) clockwise or

counterclockwise until the gap of the lower tape

edge and the lower edge of the control head is

about 0.25 mm. (Refer to

Fig.

PCB)

4. and 5.)

I----

Fig.

5 A/C Head

Height

Adjustment

b. A/C head tilt adjustment

1. Playback a T-160 tape and observe the

the tape at the lower flange of the tape

2. Confirm that there IS no curl or wnnkle at the lower

flange of the tape guide, as shown In Fig. 6

3. If a curls or wrinkle of the tape has

the screw (C) tilt adjust on the

until It disappears, as shown in

4. Reconfirm the A/C head height.

A/C

posItron

of

guide.

(B).

occured, slrghtlyturn

head ass’y clockwise

Fig.

6

(B)

(BAD)

Fig. 6 Tape Guide Check

3-4

Page 32

c. Audio azimuth adjustment

I,

Playback the alignment tape

2.

Connect the channel-l scope probe to TP804.

3. Adjust screw

level. (See Fig.

(B)

vertically to

4)

(ST-N1

achieve

1

maxrmum

audro

d. A/C head position (X-Point) adjustment

2. Linearity adjustment

(S,%guide

adjustment)

Test

Pornt

:

TP302

(Envelope)

TP202

(H’D

SW Pulse

Test Taoe : (Mono

Scooe

;

7KHz)

rollers

-Trigger)

Playback the alignment tape (

1.

Connect the

2.

Connect the CH-2 scope probe to

3.

trigger head switchrng pulse.

Set the tracking preset to “6 5 ms”

4.

button

Connect the CH-1 scope probe to TP302 and the CH-2

5.

scope probe to

Turn the screw

6

Insert the adjusting driver

7

gear Adjust the driver in

envelope waveform.

NOTE : Since the adjusting gear unit may be damaged,

do not adjust by force when adjusting the X-point using

adjusting driver (+). After turn the X-point adjusting

screw(D) counterclockwise a little, preform the adjustment

After adiustiment is completed, tighten the screw.

CH2

PROBE

H’D

SIW

PULSE

TP202

CHI PROBE

CTL PULSE

TPZOI

CH-1

scope probe to

A/V

of remote control. (Refer to

TP202

trrgger on CH-1.

(E)

counterclockwrse (See

ST-Nl).

TP202.

TP201

using

(+) Into

X-positron

erther drrectron

and

the tracking

Fig.

7 and

8)

Frg. 4).

adjustrng

for maxrmum

the

Fig.

9 Location of Test Point

1 Playback the alignment tape (Mono

2. Observe the video envelope signal on an oscilloscope

triggered by the head

3. Make sure the

mum or maxrmum output) meets the

shown In

NOTE

:

a=Maximum output of the video RF envelope.

b=Minimum output of the video RF envelope at the

entrance side.

c=Minimum output of the video RF envelope at the

center point.

d=Minimum output of the video RF envelope at the exit

side.

video

Frg.

10. If It does not, adjust as follows

(Main

PCB)

Sccope

swrtchrng

envelope waveform

pulse.

specrfrcatron

;

SP)

(In Its mrnl-

;

Frg.

7 Tracking Preset Adjustment

REMOTE

BUTTONS

I

CONTROL PULSE MOVEMENT

I

A

Tracklng

.d

PUSH

Fig. 8 Control Pulse Adjustment

I

b,dla 2

0.70

c/a 2

0.85

Fig.

10 Envelope Waveform Adjustment

3-5

Page 33

4. If the section A in Fig. 11 does not meet the

specification, adjust the S-guide roller up or down

5.

If the section B in Fig. 11 does not meet the

specification, adjust T-guide roller up or down.

Slightly loosen the set screw at the lower part of the

6

S, T-guide rollers with a (Hex Wrench the guide roller can be adjusted with reasonable

tightness. (Refer to Fig. 12)

0.9mm)

so that

Frg.

11 Adjustment Points

SET SCREW

Frg.

12

7. Playback the alignment tape (Mono Scope ;

8. Connect an oscrlloscope CH-1 to TP302 and CH-2 to

TP202

ENVELOPE

--H----

L

IDEAL ENVELOPE

9. Turn the

10. After the adjustment IS completed, tighten the set

on the same PCB for

driver to

Frg.

1

obtain

13.

screws

-GUIDE

l==I

tnggerrng.

gurde

roller heads with a flat head

flat video RF envelope as shown

ROLLER

SP).

(a)

screw

In

“s”

HEIGHT

TOO HIGH

GUIDE ROLLER

Fig. 13 S, T-Guide Roller Height Adjustments

IS)

HE3

“S”

HEIGHT

TOO LOW

3-6

TOO HIGH

“T”

HEIGHT

TOO LOW

GUIDE ROLLER

(T)

Page 34

3. Check for transitional operation from

R.P.S

play

Check transition from

a prerecorded SP tape, make sure the entrance side of

envelope comes to an appropriate steady state within 3

seconds as shown in Fig. 14.

R.P.S

mode to play mode, using

to

5 Tape wrinkle check

1. Run T-l 60 tape in playback, FPS, RPS and

the pause mode and observe tape wrinkle at each

guide.

2. If excessive tape wrinkle i‘s observed in the mode shown

below, perform the associated adjustment shown below.

If the envelope wavdorm does not reach

specified

peak-to-peak amplitude within 3 seconds, adjust

as follows

1.

Make sure there is no gap between the supply roller

lower flange and the

supply guide roller again.

2. Change operation mode from the

mode again and make sure entrance side of envelope

rises within 3 seconds.

Fig. 14

:

tape.lf

there is a gap, adjust the

R.P.S

to the play

Video envelope rising when operation mode

is switched from

RPS

to play mode.

a. Playback mode

-Tape wrinkle at the S,T-guide roller section : Linearity

adjustment.

-

Tape wrinkle at tape guide flange : A/C head assembly

coarse adjustment.

4. Envelope check

1.

Make recordings on T-l 20 and T-l 60 tapes, and make

sure the playback output envelope meets the

specification as shown in Fig. 15.

2. Playback a self recorded tape (recording made on this

unit), (with a T-l

specification as shown in Fig. 15. In SLP mode,

should be same as

the upper cylinder should be checked.

Fig. 15 Envelope Output and-output Level Difference

20)

the video envelope should meet the

(B).

If the head gap is wide,

B/A2

0.55

Bl g 150mV

(A)

3-7

Page 35

3-3. REEL TORQUE

3-3-l. Reel Torque

1. The rotation of the capstan motor operates the

clutch ass’y through the capstan motor belt.

2. Brake operation and shift operation in

are done by a slide lever.

3. Transmission of accurate driving force is done by

gears. (clutch ass’y)

MODE TORQUE g/cm GAUGE

PBIREC

RPS

1 OOf30

170f30

Cassette Torquemeter

Cassette Torquemeter

FFIREW Min 300g/cm

FWREW

Torque Gauge

F/E

HEAD-

3 f

OSmm

ARM - TENSION

FULL

ASSY

CAM TENSION

ADJUST

SPRING

TENSION

__

J

0

on

I

-

_

.‘~~~E..‘If.the.si>kd’is.~ut

:::::: “...’ :,,.:. ::.

‘,‘,.Y

,,

-I.,

clutch

,:::::,,.::..::. : 5:.

. .:.

3-3-2.

Location of Tension Pole and Back Tension

of above chart, replace the

as+

an~,tticx”recheck.

: -.

Adjustment

1.

Remove the housing ass’y and set the deck to play

mode.

2. Adjust the tension cam to

center of the supply roller.

3. The back tension meter should be used for

checking the back tension.

Back tension, should be 41 - 51 g.cm.

If it is not, adjust the tension cam.

Counterclockwise : Torque UP

Clockwise

2.5-3.5mm

:

Torque DOWN

from the

:..+..

,:t’

-_I

Fig. 16 Tension Pole and Back Tension Adjustment

Fig. 17 Back Tension Tape Torque Cassette

TENSION BAND

3-B

Page 36

4-2. SERVO/VIDEO SECTION ADJUSTMENT

I. Head Switching Point

I) “PB”, Alignment tape color bars.

?)

TP202 (H’D S/W),

3) *

Connect an oscilloscope’s CH-1 to TP202 fo

triggering and CH-2 to TP802.

*

Adjust VR201 so that the head switching pc

is positioned 6.5 +

edge as shown.

sw3oHz

TP802Wideo

0.5H

from the V-SYNC

SWITCHING POINT

out) & VR201.

Ii

nt

?ft

Ic

!. CCD COMB

1

“E-E”(Stop Mode),

(V.

IN jack on the rear panel)

!I

D308 & VR301.

!) *

Push the “LINE IN” button on the remote

2Vp-p

color bar signal.

control to receive LINE signal

*

Connect an oscilloscope’s CH-1 to D308 and

the VCR to REC mode.

*

Adjust VR301 to make minimum color portion

on the color bar signal.

color

/

I

7-i-,

19

se1

noise

-6.5l-l f 0.5H-

<

Before Adjust

>

<

After Adjust

>

(Main PCB-Top Side)

4-3

Page 37

7-1. PACKING ASSEMBLY

7-2

Page 38

Page 39

Page 40

Page 41

7-5.

HOUSING ASSEMBLY

H532 ’

H531--

\

\

\

-___-___--_________A

I

7-6

Page 42

7-6.

AT0 I

REMOTE CONTROL ASSEMBLY

AT06

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Page 49

Page 50

Page 51

Page 52

Page 53

Page 54

Page 55

Page 56

Page 57

Page 58

Page 59

Page 60

Page 61

Page 62

Page 63

Page 64

Page 65

Page 66

Page 67

Page 68

Page 69

Page 70

Page 71

Page 72

Page 73

Page 74

Page 75

Page 76

Page 77

Page 78

Page 79

Page 80

Page 81

Page 82

Page 83

Page 84

Page 85

Page 86

Page 87

Page 88

6. REPLACEMENT PARTS LIST

6-1. REPLACEMENT PARTS LIST FOR

NOTE :

0

The PC board assembly with

0

This parts listed on the base model M-472. For

*

mark is no longer available after the end of the production.

M-472,M-462,M-45

on the difference list.

IL /C

NO

;

922

951

952

956

958

Al01

AlOlC

Al 02A

.:j: PARTS NO.

70790704

70790086

70790085

70790154

70790154

70790852

70790601 62724-0090-00

70790848 64042-0222-05

t.. REPLACEMENT

-

MECHANICAL PARTS

’ NO,

67008-130-l 71

67334-600-310

67304-l 03-410

67334-601-830

67334-601-830

69000-501-317

DESCRIPTION;SPECIFlCATION-

-

SCREW PH;

WASHER

WASHER-PLAIN;3.2X6X0.5

SLIT

SLIT WASHER:~.~X~X~.~(RED)

ASSY PANEL FRONT;M-472

MASK

DOOR-CASSETTE;ABS94HB

M-462,M-45

+M3X3

FE FZY

SLIT;Pl2.5XPl5XT0.5

WASHER;2.5X9XO.5(RED)

SPRING;SUS 304(GE/RCA)

different parts only are I

POLYSLIDER

BLK M472

isted

I

Al 04A 70790795 62002-0037-01

Al 04C

70790082

67158-240-l 63

Al20 70790635 63312-0163-00

Al20A

70790081 67158-230-120

A701 70790851 65003-0044-42

A702 70790682 65231-0133-00

A704

8210

8251

8252

70790169

70790218 67158-240-121

70790560 61641-0023-00

70790517

8253 70790515

8254 70790609 62724-021

68654-604-720

61473-0107-00

61473-0105-00

l-00

8255 70790735 61472-0104-01

8256

70790691 66823-0059-00

8257 70790524 61494-0009-00

8258 70790510

8259 70790534

61453-0003-00

61533-0095-00

CABINET-TCP;TEXTURE

SCREW-TAP

COVER-BOTTCM;SECC

SCREW-TAP

PACKING CASE;M-472 SW3 A YEL

CUSHION-F/B;EPS#58

NITRCN BAG-SET;570X550X0,5T

SCREW-TAP

SLIDER-MAlN;FQvf

GEAR-LOADING L ASSY;X-5

GEAR-LOADING R ASSY;X-5

SPRING-BRAKE

GEAR-MASTER;PQvl(MSO-44)

MJTOR-D.D CAPSTAN;F2QTB04

BELT-CAPSTAN;CY-65 FR W2 T2 L88.6

CLUTCH-ASSY;

LEVER-SLIDER

BH;2-4X16

TITE BH;3XlO

TITE;BH +TB

TO.625 M-462

FE FZB

TO.5

M-461

T12.4 NAT

CAF'STAN;ES

PINCH;PBT

W-IT

SV-50

FE FZY

T15

3 L12

SUS304WPB

Z60

T4 NAT

W442

PAL

SWRCHl8A ZPC3

P10.4

SP NAT

L390

8260

8261

8262

70790514 61473-0102-00

70790531 61533-0090-00

70790532

8263 70790607

8264 70790713

8265

8266

70790692 66823-0060-00

70790523

8267 70790649

8268 70790597

CB81A

DTOIA

H500

70790078

70790755

70790797

61533-0091-00

62724-0207-00

67172-0173-00

61474-0103-00

63324-0299-00

62614-0014-00

67098-I 30-065

63323-0427-00

62052-0014-01

GEAR-W#Rf#liEEL;PCM

LEVER-SH I FT;PBT T2.5

LEVER-IDLER

SPRING-LEVER

UNIT-LOADING(ASSY);X-5

fv0TCR-LOADING

GEAR-WORM

HOLDER-SHAFT;PCM

BRAKE-CAPSTAN

SCREW TAP

HOLDER-TIMER;ABS 94HB BLK M-456

HOUSING-ASSY;X5FL263OB(TSB)

61

LOADING;PBT

TITE BH;3XlO

MO.55

CHANGE;PBT

SHIFT;TS SUS304WPB

ASSY;fQM+RF370C

NAT

ASSY;FQJ

257

SP NAT

T3.3

X-5

MO.55 Wo NAT

X-5

FE FZB

P10.7 ID

Page 89

NUTE :

0

The PC board assembly with* mark is no longer available after the end of the production.

0

This parts listed on the base model M-472. For

on the difference list.

M-462,M-45

different parts only are listed

mu.

H510

H520

H521

H522

H523

H524

H525

H526

H531

H532

H533

H535

H540

H541

H542

H543

H544

H545

H550

HSS

JKOIA

LDGIA

LD71A

PT6lA

PT62A

S601A

S602A

T201

T202

T203

T204

T207

T208

T209

T210

T211

T212

T216

T217

T218

T219

T220

T221

~PAR+f$4cl~

70790581

70790645

70790641

70790540

70790542

70790618

70790618

70790541

70790579

70790530

70790617

70790539

70790583

70790578

70790565

70790616

70790538

70790620

70790504

70790179

70790420

70790648

70790786

70790647

70790647

70790642

70790642

70790557

70790556

70790592

70790596

70790595

70790594

70790608

70790522

70790520

70790549

70790613

70790537

70790615

70790686

70790567

70790569

REPLAfXMENT

62202-0103-00

63322-0317-00

63321-0314-00

61533-0102-00

61533-0104-00

62724-0220-00

62724-0220-00

61533-0103-00

62201-0102-00

61532-0101-00

62724-0219-00

61533-0100-00

62203-0104-00

62201-0101-00

61642-0032-00

62724-0218-00

61533-0099-00

62724-0222-00

61403-0073-00

67158-230-081

63014-0153-00

63323-0313-00

63324-0411-00

63323-0312-00

63323-0312-00

63322-0311-00

63322-0311-00

61574-0023-00

61574-0021-00

62613-0013-00

62614-0011-00

62614-0009-00

62614-0007-00

62724-0208-00

61474-0099-00

61474-0095-00

61543-0071-00

62724-0215-00

61533-0098-00

62724-0217-00

66603-0005-00

61643-0027-00

61643-0029-00

NO.

DESf;RIPTIQN;SPECIFICATLON

CMSSIS-UPPEf?;SECC Tl.0

HOLDER-CASSETTE(ASSY);SECC

HOLDER-CASSElTE;SECC

LEVER-LOCK(f?);SECC

LEVER-LCCK(L);SECC T1.2

SPRING-LEVER

SPRING-LEVER

LEVER-KEY

CHASSIS-SIDE

LEVER-LIGHT

SPRING-LIGHT

LEVER-DOOR;PCM(LUCEL NIOSP-LD)

CHASSIS-SIDE

CHASSIS-SIDE

SLIDER-DAMPER;PCM(LUCEL NIOS-LD)

SPRING-SLIDE

LEVER-LID

SPRING-LID

SHAFT-ARIv!(ASSY);SUM24L

SCREW-TAP

BRACKET-JACK;SPTE TO.5

HOLDER-LED;M

HOLDER-C.B.C;ABS94HB

HOLDER-PHOTO;POM

HOLDER-PHOTO;PCM

HOLDER-TR;m

HOLDER-TR;PQvl

REEL-DISK L

REEL-DISK R

BRAKE-SUB

BRAKE-SUB R ASSY;PBT LUPOX EG 5000H X-5

BRAKE-MAIN L ASSY;PBT X-5

BRAKE+lAIN R

SPRING-BRAKE

GEAR-RELAY S

GEAR-RELAY(T);PEBAXY6333

ARM-TENSION FULL ASSY;X-5

SPRING-TENSION;ES

LEVER-REC

SPRING-REC

MAGNET-F/E HEAD;X-5

SLIDER-G/R

SLIDER-G/R ASSY(T);X-5

LOCK;ES SUS304WPB

LCCK;ES SUS304WPB

CASSETTE;M(LUCEL NIOS-LD)

"L";ABS(HF-380) TIO

SHUTTER;PCM(LUCEL NlOS-LD)

SHUTTER;ES SUS304WF'B

'"R""(ASSY);ABS X5FL0505A

'"R";ABS(HF-380) TlO

DMPER;ES SUS304WPB

C!fENER;PCM(LUCEL NlOS-LD)

0PENER;TS MPB

BH;2-3X8

ASSY;PCM 030

ASSY;m

L;PBT

X-5

ASSY;PBT X-5

MAlN;ES SUS304WPB

ASSY;PEBAX

S/W;PBT

S/W;ES SUS304

ASSY(S);X-5

NAT X-5

NAT

1/8H

T1.2

P10.55 108.9 0

X5FL0405A

FE FZY

BLK M-461

X-5

D X-5

MO.5

MO.5

SUS304M'B

P10.35 ID2.1

P10.23 03.5

X5FL0810A

HRB 50

P10.2 ID2

P10.2 ID2

BLK

PT0.35 ID

hM8

241

X-5

NA

BLK X-5

P10.2

T5

X-5

BLK X-5

T4 BLK

P10.4 I

NAT

X-5

SP

SP X-5

L14

B

1

62

Page 90

NOTE

:

0

The PC board assembly with

0

This parts listed on the base model M-472. For

on the difference list.

*

mark is no longer available after the end of the production.

M-462,M-45

different parts only are listed

[L/C NO.

T223 70790561

T224

T225

T226

T227 70790551

T228

T229

T230

T231

T232

T233

T234

T236

T237

T238

T300

T301

T303

TM401

U602A 70790081

YlO4

PARTS NO.

70790687

70790562

70790535

70790533

70790529

70790610

70796161

70790566

70790614

70790714

70790559

70790805

70790623

70790746

70790776

70790708

70790715

70796352

REPLACEMENT NO.

61642-0022-00

66603-0006-00 MAGNET-ACE HEAD ALL(ASSY);X-5

61642-0024-00

61533-0096-00 LEVER-REVIEW;ZYTEL T3.8 BLK

61544-0073-00 ARM-REVIEW ASSY;PPS X-5

61533-0094-00

61532-0093-00

62724-0212-00

62713-0054-00

61643-0025-00

62724-0216-00

67172-0174-00

61603-0006-00

63383-0031-00

62724-0239-00

69020-124-067

69000-400-204

67084-0076-00 HEAD-BRUSH(ASSY);SECC20/2O+CARBON

67179-0194-00

67158-230-120

AC68-10707A

DESCRIPTION;SPECIFICATlON

SLIDER-RACK

SLIDER-PINCH;PCM

LEVER-PINCH

LEVER-PINCH

SPRING-PINCH(CCMP);TS

PRISM-LED;PfvMA 05

SLIDER-PUSH;LUPOX 2150 T2 NTR

SPRING-SLIDE

UNIT-PINCH ROLLER(ASSY);X-5

IDLER-ASSY;PCIv!

STOPPER-TAPE;F'CM

SPRING-ARM

CYLINDER

CYLINDER SUB

UNIT-TM

SCREW-TAP

INSTRUCTION;(IQNER'S

HGUSING;PCM

T2 NAT

CAM;PC T5

CQ'vlP;PBT

IF-850

PUSH;ES SUS304WPB

X-5

T2 NAT X-5 DECK

PINCH;CS SUS304

ASSY;CX+D4N/TSB

ASSY;CX5-D4NITSB

BLCCK;TMVH2-A05A

TITE BH;3XlO

T10.5 BLK

X-5

T13.3 X-5

SWPB PIl.0

WPB P10.4 ID7

Vl NTSC

FE FZY

MANUAL M-472

ID6 0D8

P10.55 D3

ENG/SPA

*

U621

ICO2

ICO3

IClOl

IC201

IC301

IC302

IC303

IC5Ol

IC601

IC602

IC603

IC604

IC621

IC801

IC802

IC901

70796404

70796240

70795271

70796016

70796383

70796236

70796235

70796234

70796299

70796388

70795131

70796390

70795269

70796298

70795803

70795803

70796384

-

ELECTRICAL PARTS

69657-301-277 ASSY MAlN;M-472

-

INTEGRATED CIRCUITS

84161-0027 PHOTO-COUPLER;PC817FN

A4008-0757

A4008-0112 IC-REGULATION;KIA 7809P

A4008-1247

84012-0456

84012-0452

84012-0299

B4012-0273

ACOg-10450D

62119-401-300

84008-0264 IC-LCGIC;HEF4094BP/TC4094BP

A4008-0754

84012-0110

62119-401-310

62119-401-310

A4012-0653

-

TRANSISTORS

-

-

-

ST

lC;S43lC/LM431C

IC;KA8334B QFP

IC-LINEAR;LA7425

IC-LINEAR;LA7416

IC-LINEAR;LC7975J

IC_LINEAR;LA7286

IC-MCU;HD6433726SC65F

IC;KA8301(N.M)

IC;KA7533

IC-LINEAR;XL24C02

IC;KA8403

IC;KA8403

IC-LINEAR;KS55148-13

SIP TAPG

60PIN TRAY

DIP BULK VIDEO-PROCESS

DIP BULK

DIP CCD

DIP

M-672

DIP

DIP BULK

DIP

cM3S

24P

6-3

Page 91

NOTE

:

0

The PC board assembly with* mark is no longer available after the end of the production.

0

This parts listed on the base model M-472. For

M-462,M-45

different parts

only are listed

on the difference list.

IL/C

NO.

001

Q02

Q03

004

QlOl

0102

0103

0104

0201

Q202

0203

0307

Q309

Q310

0311

0312

Q314

0315

Q316

Q317

0318

Q501

Q502

Q503

Q504

0601

0602

Q603

0604

06101

Q6102

06103

Q6104

Q801

Q901

DO1

DO2 70796301

DO3

DO4

DO5

DO6

DO7

PARTS NO.

70795647

70795142

70795143

70795137

70795143

70795817

70795135

70795135

70795496

70795134

70795138

70795138

70795134

70795136

70795136

70795136

70795138

70796359

70795136

70795136

70795136

70795141

70795138

70795138

70795571

70795136

70795136

70795138

70795134

70795572

70795136

70795136

70795571

70795134

70795136

70796301

70796301

70796301

70795587

70795150

70795150

REPLACEMENT NO.

A4056-0027

62139-301-311

62147-401-835

62137-701-010

62147-401-835

62137-701-012

62137-302-441

62137-302-441

A4050-0001

62137-103-380

62137-701-013

62137-701-013

62137-103-380

62137-302-740

62137-302-740

62137-302-740

62137-701-013

62137-701-023

62137-302-740

62137-302-740

62137-302-740

62137-702-020

62137-701-013

62137-701-013

62137-701-020

62137-302-740

62137-302-740

62137-701-013

62137-103-380

62137-701-021

62137-302-740

62137-302-740

62137-701-020

62137-103-380

62137-302-740

-

DIODES

84104-0094

84104-0094

84104-0094

84104-0094

84102-0006

62169-406-482

62169-406-482

-

DESCRIPTION;SPECIFICATlON

TRSWITCHING;KSC5039F

TRANSISTOR;KTC 3203Y-AT(TAPG)

TRANSISTOR;KSA 928A-Y

TRANSISTOR;KSR

TRANSISTOR;KSA 928A-Y

TRANSISTOR;KSR

TRANSISTOR;KSC

TRANSISTQR;KSC

TRANSISTOR;2SD 1468SQ

TRANSISTOR;KSA

TRANSISTOR;KSR

TRANSISTOR;KSR

TRANSISTQR:KSA

TRANSISTOR;KSC

TRANSISTOR;KSC

TRANSISTOR;KSC

TRANSISTOR;KSR

TRANSISTOR

TRANSISTOR;KSC

TRANSISTOR;KSC

TRANSISTOR;KSC

TRANSISTOR;KSC

TRANSISTOR;KSR

TRANSISTOR;KSR

TRANSISTOR;KSR

TRANSISTOR;KSC

TRANSISTOR;KSC

TRANSISTOR;KSR

TRANSISTOR;KSA

TRANSISTOR;KSR

TRANSISTOR;KSC

TRANSISTOR;KSC

TRANSISTOR;KSR

TRANSISTOR:KSA

TRANSISTOR;KSC

DIODE-RECT;ERAl5-06

DIODE-RECT;ERA15-06

DIQDE-RECT;ERA15-06

DIQDE-RECT;ERA15-06

DIODE-FR;EGOlC(3,3)V 5OOMA(O,l)VS

DIQDE;lN4148 SAJvISUNG

DIODE;lN4148 SAMSUNG

1001 TAPG

1003 TAPG

2328-Y TAPG

2328-Y TAPG

733-Y TAPG

1004 TAPG

1004 TAPG

733-Y TAPG

945-Y TAPG

945-Y TAPG

945-Y TAPG

1004 TAPG

;KSR

945-Y TAPG

945-Y TAPG

945-Y TAPG

1008-Y TAPG

1004 TAPG

1004 TAPG

2001 TAPG

945-Y TAPG

945-Y TAPG

1004 TAPG

733-Y TAPG

2002 TAPG

945-Y TAPG

945-Y TAPG

2001 TAPG

733-Y TAPG

945-Y TAPG

40W

TAPG

TAPG

2004 TAPG

600V 1A T

600V 1A T

600V IA T

600V IA T

IOMHZ Sl/NPN

6-4

Page 92

NOTE

:

0

The PC board assembly with* mark is no longer available after the end of the production.

0

This parts listed on the base model M-472. For

on the difference list.

M-462,M-45

different parts only are listed

IL/C

NO.

DlOI

0102

0103

D201

0202

0203

D204

0205

030

0301

D303

0304

D305

0307

0308

D309

D31

D3ll

032

033

034

035

D36

037

0501

D601

D603

0604

0605

D606

0607

D6101

D6102

D6103

0902

D903

0904

LD601

ZDlOl

ZD102

ZD201

ZD202

ZD31

PARTS NO.

70735150

70796385

70796385 A4104-0053

70795150 62169-406-482

70795150 62169-406-482

70795150 62169-406-482

70795150 62169-406-482

70795150

70795150

70795150

70795150

70795150

70795150

70795150

70795150

70795150 62169-406-482

70795656

70795150 62169-406-482

70796300 84102-0077

70796300

70795656 84102-0047

70796385 A4104-0053

70795150 62169-406-482

70795656

70795150

70795150 62169-406-482

70795150 62169-406-482

70796385 A4104-0053

70795150 62169-406-482

70795150 62169-406-482

70795150 62169-406-482

70795150 62169-406-482

70795150 62169-406-482

70795150 62169-406-482

70795150 62169-406-482

70795150 62169-406-482

70795150 62169-406-482

70796302 84150-0286

70795147

70795272 A4106-0062

70795355

70795355 62169-423-092

70795422 A4106-0068

REPLACEMENT NO.

62169-406-482

A4104-0053

62169-406-482

62169-406-482

62169-406-482

62169-406-482

62169-406-482

62169-406-482

62169-406-482

62169-406-482

B4102-0047

84102-0077

84102-0047

62169-406-482

62169-403-821

62169-423-092

DESCRIPTION;SPECIFICATlON

DlCDE;lN4148 SAMSUNG

1A

DIODE-RECT;lN4002 IOOV

DIODE-RECT;lN4002 IOOV

DIODE;lN4148 SAMSUNG

DIODE;lN4148 SAMSUNG

DIODE;lN4148 SAMSUNG

DICDE;lN4148 SAMSUNG

DICDE;lN4148 SAMSUNG

DIODE;lN4148 SAMSUNG

DIODE;lN4148 SAMSUNG

DIODE;lN4148 SAMSUNG

DIODE;lN4148 SAMSUNG

DIODE;lN4148 SAJvlSUNG

DIODE;lN4148 SAhlSUNG

DIODE;lN4148 SAMSUNG

DIODE;lN4148 SAMSUNG

DIODE-FR;ERA18-04

DIODE;lN4148 SAMSUNG

DIODE-SW;FML-G02S 200V

DIODE-SW;FML-G02S 200V

DIODE-FR;ERAl8-04

DIODE-RECT;lN4002 IOOV

DIODE;lN4148 SAMSUNG

DIODE-FR;ERAl8-04

DIODE;lN4148 SAMSUNG

DIODE;lN4148 SAMSUNG

DIODE;lN4148 SAMSUNG

DIODE-RECT;lN4002 IOOV

DIODE;lN4148 SAMSUNG

DIODE;lN4148 SAMSUNG

DIODE;lN4148

DIODE;lN4148 SAMSUNG

DIODE;lN4148 SAMSUNG

DIODE;lN4148 SAMSUNG

DIODE;lN4148 SAMSUNG

DIODE;lN4148 SAMSUNG

DICDE;lN4148 SAMSUNG

LED_INFRARED;GL381 Jl

DIODE-ZENER;h!TZ

DIODE-ZENER;UZP33B 30/36

DIODE-ZENER;MT

DIODE-ZENER;MT

DIODE-ZENER;UZP-18B

400V

400V

400V

SWSUNG

5.18

6.8B

6.88

SI

1A SI

0.8A 0.4US

2.5A

2.5A

0.8A 0.4US

IA SI

0.8A 0.4US

IA

SI

YEL

5MA T

17119V

40NS BULK

40NS BULK

95ONM/3;5V

20MA T

I

T

T

T

65

Page 93

NUlt

:

0

The PC board assembly with* mark is no longer available after the end of the production.

l

This parts listed on the base model M-472. For

on the difference list.

M-462,M-45

different parts only are listed

IL/C

NO. PARTS NO.

ZD32

ZD601

co2

co3

co4 70795417

co5

CO6

co7

CO8 70795578

co9

Cl0

Cl01

Cl02 70795114

Cl03 70795075

Cl04 70795114

Cl05

Cl06

Cl07

Cl1

Cl2

Cl3

Cl4

Cl6

c201

c202

C204 70795072

C205

C206 70795072

C207

C208 70796209

c209 70796209

c210

c211

c212 70795247

C213 70796207

C214 70795247

C215

C217

C218

c219 70795113

c220

c221

70795438

70796360

70795404

70795239

70795252

70795417

70795404

70795580

70795088

70796389

70795627

70796149

70796207

70795430

70796231

70795586

70795759

70795404

70796288

70795075

70796211

70796205

70796381

70795072

70795621

70795075

70795621

70796211

70796381

REPLACEMENT NO.

A4106-0076

62169-403-838

-

CAPACITORS

Al100-0536

All00-0423

All00-0580

All00-0450

All00-0580

A1100-0536

All04-0379

All04-0396

61417-110-224

81102-0277

61617-408-010

61407-117-104

61617-408-010

61637-504-101

61637-504-331

AllOO-0961

61627-204-220

81102-0279

61507-121-941

61507-121-411

A1100-0536

Al100-0745

61407-117-104

61407-117-101

All04-0609

61407-117-101

Al100-0958

Al100-0970

All00-0970

All04-0611

61407-117-101

All00-0444

Al100-0961

All00-0444

61617-405-470

61407-117-104

61617-405-470

61617-406-100

All04-0609

All04-0611

-

DESCRIPTION;SPECIFICATlON

DIODE-ZENER;UZP-43B

DIODE-ZENER;MTZ27C

C-CER/&llC;CKS

C-CERAMIC;CK45B

C-CER/%lIC;CK

C-CERPMIC;CK45B

C-CERf&!lC;CK

C-CER/%llC;CKS

C-ELEC;CE04F

C-ELEC;CE04H

C-CERAMIC

C-FILM;CQ

C-ELEC;CEAP 50V 1M

C-CERAMlC.AXIAL;CAX

C-ELEC;CEAP 50V 1M

C-ELEC;CEAP

C-ELEC;CEAP

C-CERAMlC,CHIP;CK

C-ELEC;CEAP

C-FILM;CQ

C+QLYESTER;CQ92lM

C-POLYESTER;CQ921M

C-CERAMlC;CKS

C-CER&llC,CHIP;CK

C-CERAMIC.AXIAL;CAX

C-CERA/vllC.AXIAL;UP050F

C-ELEC;CE 04

C-CERAMIC.AXIAL;UP050F

C-CER!MIC,CHIP;CK

C-CERAMlC,CHIP;CK 08 Y5P

C-CERAMlC,CHIP;CK

C-ELEC;CE 04

C-CER&llC.AXIAL;UP05OF

C-CERAMIC.CHIP;UCN

C-CERAMIC,CHIP;CK

C-CERAMIC.CHIP;UCN

C-ELECTROLYTIC;CE04W

C-CERPMIC.AXIAL;CAX

C-ELECTF?QLYTIC;CE04W

C-ELEC;CEAP 35V

C-ELEC;CE 04

C-ELEC;CE 04

45 B 400V 101-K SC B 2G 101-K

400V B 1032

45 B 400V T 3300-M

400V 222M

45 B 400V T 3300-M

45 B 400V 101-K SC B 2G 101-K

200VT 820-M

200VT

HK;CK45B

922 M 50V T 103-J

16V IOOM SG(6.3Xll)

16V

16V

922 M 50V T 183-J

45 B 400V 101-K SC B 2G 101-K

-40/85

-40/85

-40185

-40/85

40/46V IOMA

4R7-M KMEISTX-25/105

TAPG 500V 220-K

RSS(4X7)

Y TAPG

RSS(4X7)

330M

73

22M

73

OB

73

SG(lOXl2.5)

Y5V

25V 104-Z

NP(6Xll)

TAPG

TAPG

OB

053 Y

053 Y 102M

Y TAPG 16V 0.01-N

10M RSS(5X7)

1OOV

Y5V

50V T 473-Z

Y TAPG

1042

35V T

1042

Y5V 16V

50V 820-K

YSP

50V 820-K

16V T 100-M SRE

1042

102M

Y5V

25V 104-Z

TAPG 25V

TAPG 25V

35V T

16V T 100-M SRE

T

16lSCE

2G 1032

SCF2G332Ml6BS

121SC

E 2G 222M

SCF2G332M16BS

STXIKME-401105

ECQBlHlOSJF3

16V

0.01-N

C2010

ECQBiH183JF3

332-J

C20

16V

0.01-N

4R7-M

SRE

4X5

103-Z

IOOOP

4R7-M

20X12

20X12

20X12

C2010

IOOOP

47M(RSS

47M(RSS

SRE

6.3X

6.3X

4X5

I

16B,

12BS

6-6

Loading...

Loading...