Page 1

Application Guide

M-2299 Adapter Panel

Page 2

Adapter Panel

M-2299

Adapts M-2001 Series Digital Tapchanger Control

to Replace Toshiba TB-R800 Regulators

CONTROLS

• Connects easily to the M-2001 Series Digital Tapchanger Control using

mounting screws and 24-pin connector

• Provides direct mechanical replacement of the existing regulator control

• Provides built-in CT shorting protection when the M-2001 Series Digital

Tapchanger Control is removed

Page 3

The M-2299 is an adapter panel which, when combined with the M-2001 Series Digital Tapchanger

Control, provides convenient direct replacement of Toshiba TB-R800 regulators. The M-2299 mounts into

the control cabinet using the same two hinge pins which

must be saved

from the original regulator.

Interface

External connections are made via a wiring harness that connects from a fifteen-position terminal block to

the ”BT” terminal block on the existing control cabinet. An additional terminal block provides access to

auxiliary functions, including self-test alarm, user-programmable alarm, auto disable and manual raise/

lower.

Features

Separate fuses for test terminal, voltage sensing and motor power are on the front panel. Spare fuses for

each are in the fuse holder.

Binding posts on the front panel allow easy connections for test procedures.

RAISE/OFF/LOWER, AUTO/OFF/MANUAL, and VOLTAGE SOURCE switches and NEUTRAL LIGHT

are standard.

NEUTRAL LIGHT will light to indicate that the regulator is in the neutral position, for those regulators

equipped with a circuit for this purpose.

Testing Specifications

High Voltage: All input and output terminals will withstand 1500 V ac rms to chassis or instrument ground

for one minute with a leakage current not to exceed 25 mA, for all terminals to ground. Input and output

circuits are electrically isolated from each other, from other circuits and from ground.

Surge Withstand Capability: All input and output circuits are protected against system transients. Units

pass all requirements of ANSI/IEEE C.37.90.1-1989 defining surge withstand capability.

Radiated Electromagnetic Withstand Capability: All units are protected against electromagnetic radiated interference from portable communications transceivers.

Environmental

Temperature Range: Functionality is maintained from –40° to +85° C.

Humidity: Functionality is maintained under 95% relative humidity (non-condensing).

Fungus Resistance: A conformal printed circuit board coating inhibits fungus growth.

Physical

Size with M-2001 Series Digital Tapchanger Control: 12" high x 9-1/4" wide x 4-1/8" deep

(30.48 cm x 23.5 cm x 10.48 cm)

Approximate Weight: 2 lbs (0.9 kg)

Approximate Shipping Weight: 5 lbs, 7 oz (2.47 kg)

Approximate Weight with M-2001 Series Digital Tapchanger Control: 6 lbs, 2 oz (3.23 kg)

Approximate Shipping Weight with M-2001 Series Digital Tapchanger Control: 11 lbs, 2 oz (5.1 kg)

Warranty

The M-2299 Adapter Panel is covered by a five year warranty from date of shipment.

Specification subject to change without notice.

0

0

0

2

:

d

1

e

r

0

e

0

t

s

9

i

g

e

O

R

S

I

6190 - 118th Avenue North • Largo, Florida 33773-3724 U.S.A.

Printed in U.S.A. (10.24.02)

BECKWITH ELECTRIC CO., INC.

PHONE (727) 544-2326 • FAX (727) 546-0121

E-MAIL marketing@beckwithelectric.com

WEB PAGE www.beckwithelectric.com

800-2299-SP-00MC4 01/07© 2000 Beckwith Electric

Page 4

WARNING

DANGEROUS VOLTAGES, capable of causing death or serious

injury, are present on the external terminals and inside the equipment. Use extreme caution and follow all safety rules when handling, testing or adjusting the equipment. However, these internal

voltage levels are no greater than the voltages applied to the external terminals.

DANGER! HIGH VOLTAGE

– This sign warns that the area is connected to a dangerous high voltage, and you

must never touch it.

PERSONNEL SAFETY PRECAUTIONS

The following general rules and other specific warnings throughout the manual must be followed during application,

test or repair of this equipment. Failure to do so will violate standards for safety in the design, manufacture, and intended

use of the product. Qualified personnel should be the only ones who operate and maintain this equipment. Beckwith

Electric Co., Inc. assumes no liability for the customer’s failure to comply with these requirements.

– This sign means that you should refer to the corresponding section of the operation

manual for important information before proceeding.

Always Ground the Equipment

To avoid possible shock hazard, the chassis must be connected to an electrical ground. When servicing

equipment in a test area, the Protective Earth Terminal must be attached to a separate ground securely

by use of a tool, since it is not grounded by external connectors.

Do NOT operate in an explosive environment

Do not operate this equipment in the presence of flammable or explosive gases or fumes. To do so would

risk a possible fire or explosion.

Keep away from live circuits

Operating personnel must not remove the cover or expose the printed circuit board while power is applied. In no case may components be replaced with power applied. In some instances, dangerous voltages may exist even when power is disconnected. To avoid electrical shock, always disconnect power and

discharge circuits before working on the unit.

Exercise care during installation, operation, & maintenance procedures

The equipment described in this manual contains voltages high enough to cause serious injury or death.

Only qualified personnel should install, operate, test, and maintain this equipment. Be sure that all personnel safety procedures are carefully followed. Exercise due care when operating or servicing alone.

Do not modify equipment

Do not perform any unauthorized modifications on this instrument. Return of the unit to a Beckwith

Electric repair facility is preferred. If authorized modifications are to be attempted, be sure to follow

replacement procedures carefully to assure that safety features are maintained.

Page 5

PRODUCT CAUTIONS

Before attempting any test, calibration, or maintenance procedure, personnel must be completely familiar

with the particular circuitry of this unit, and have an adequate understanding of field effect devices. If a

component is found to be defective, always follow replacement procedures carefully to that assure safety

features are maintained. Always replace components with those of equal or better quality as shown in the

Parts List of the Instruction Book.

Avoid static charge

This unit contains MOS circuitry, which can be damaged by improper test or rework procedures. Care

should be taken to avoid static charge on work surfaces and service personnel.

Use caution when measuring resistances

Any attempt to measure resistances between points on the printed circuit board, unless otherwise noted

in the Instruction Book, is likely to cause damage to the unit.

Page 6

TABLE OF CONTENTS

M-2299 Adapter Panel

Application Guide

1.0 Description ................................................................................................................... 1

Standard Features ....................................................................................................... 1

2.0 Installation .................................................................................................................... 2

2.1 Removal of the Toshiba Regulator ............................................................................. 2

Figure 1 Toshiba Regulator in Cabinet .....................................................................

2.2 Installation of the M-2001 Series Digital Tapchanger Control ................................... 3

2.3 Installation of the M-2299 ........................................................................................... 3

Figure 2 M-2299 Adapter Panel and M-2001 Tapchanger Control in Cabinet ........

Figure 3 Mounting Dimensions .................................................................................

Figure 4 Wiring Harness and External Connections ................................................

2.4 Lightning Protection ..................................................................................................... 6

2

3

4

5

3.0 External Connections ................................................................................................... 6

Figure 5 M-2001 and M-2299 Typical Connections .................................................

3.1 Features ....................................................................................................................... 8

Neutral Light Circuit ..................................................................................................... 8

Auto Disable Input ....................................................................................................... 8

Local/Remote Input...................................................................................................... 8

Multi-Step Voltage Reduction ...................................................................................... 8

Operations Counter Input ............................................................................................ 8

Table 1 Multi-step Voltage Reduction External Connections ..................................

3.2 Typical Connections for Toshiba Regulators.............................................................. 9

Figure 6 Tapchanger Control and LTC Backup Control Interconnections ...............

3.3 Use of the M-0329 LTC Backup Control with the Tapchanger Control..................... 9

4.0 M-2001 Tapchanger Control Software Settings ........................................................ 10

4.1 M-0329 LTC Backup Control Settings ...................................................................... 10

7

8

9

Page 7

5.0 Test Procedures ........................................................................................................ 10

Equipment Required .................................................................................................. 10

Setup Procedure ........................................................................................................ 10

Table 2 Initial Settings ............................................................................................

10

5.1 Bench Test................................................................................................................. 11

Resistance ................................................................................................................. 11

Voltage Source Switch .............................................................................................. 11

Counter/Neutral Light/Tap Position ........................................................................... 11

Block Raise/Block Lower/Dead Band ....................................................................... 11

Figure 7 M-2299 Test Procedure External Connection..........................................

12

5.2 M-2001 Checkout Procedure ..................................................................................... 13

Basic Operational Test .............................................................................................. 13

5.3 In-Service Test .......................................................................................................... 13

6.0 Checkout Procedure .................................................................................................. 13

6.1 Power .......................................................................................................................... 13

Figure 8 Setup for Current Checkout Procedure....................................................

14

6.2 Voltage Source Switch .............................................................................................. 15

7.0 Maintenance ............................................................................................................... 15

Printed in U.S.A. (

800-2299-AG-00MC4 01/07© 2000 Beckwith Electric Co.

(#02-88)(12.18.00)

Page 8

M-2299 Application Guide

The Beckwith Electric M-2299 Adapter Panel, used

in conjunction with the M-2001 Series Digital

Tapchanger Control, uses modern electronic digital

design and digital processing circuitry to achieve

an overall stability and resolution unattainable with

electromechanical and analog design tapchanger

controls. CMOS semiconductors are used throughout

the design.

NOTE: The hinge pins

must be saved

from the

original control. The BT terminal blocks remain in

the control cabinet.

1.0 Description

Standard Features

The M-2299 Adapter Panel, with the M-2001 Series

Digital Tapchanger Control, provides a solid-state

voltage control relay designed to directly replace

the Toshiba TB-R800 control. The combination of

the Tapchanger Control and Adapter Panel includes

the following features:

1. Voltage waveform sampling and digital

processing circuitry ensure accurate rms

voltage sensing in the presence of

distortion on the input voltage and

current.

2. Accuracy exceeds the ANSI/IEEE

C57.15-1986 Class 1 specification over

the temperature range of –40° C to

+70° C.

4. Separate motor power, test terminal and

voltage sensing fuses are easily

changed from the front panel and spare

fuses are provided in their respective

fuseholders.

5. Easily tested by use of the following:

a. VOLTAGE SOURCE switch

disconnects the voltage transformer

input and connects the VOLTAGE

IN binding posts to the voltage input

and motor circuit.

b. VOLTAGE IN binding posts on the

front panel allow application of a

120 V rms nominal voltage to the

unit for test procedures.

c. METER OUT binding posts on the

front panel allow reading of the input

voltage when used in conjunction

with the BIAS TEST VOLTAGE

screen of the M-2001 Series Digital

Tapchanger Control.

d. RAISE and LOWER band edge LEDs

on the M-2001 Tapchanger Control

indicate when the input voltage is

outside the voltage band.

6. NEUTRAL light illuminates when the

regulator is in the neutral tap position.

7. AUTO/OFF/MANUAL switch allows

manual operation of the control.

3. Input and output circuits are protected

against system transients. Units pass

all requirements of ANSI/IEEE C37.90.11989, which defines surge withstand

capability. All input and output terminals

will withstand 1500 V ac rms to chassis

or instrument ground for one minute with

a leakage current not to exceed 25 mA,

from all terminals to ground. Input and

output circuits are electrically isolated

from each other, from other circuits and

from ground.

–1–

Page 9

M-2299 Application Guide

2.0 Installation

The M-2299 has hinges on the right side that allow

easy mounting into the existing Toshiba regulator

cabinet. Refer to Figure 1, below.

2.1 Removal of the Toshiba

Regulator

Refer to Figure 1, and Figure 3, Outline Dimensions.

1. Open the cabinet door of the Toshiba

regulator.

2. Loosen the two thumbscrews on the

control panel and swing the panel

outward.

3. Disconnect the three plugs that connect

the wiring harness to the rear of the

Toshiba control panel.

4. Remove and save the two hinge pins

and lift the Toshiba control panel off of

the hinges.

NOTE: The two hinge pins

must be saved

the original control.

5. Remove all control side wiring harness

connections from the BT1 terminal block.

6. Remove all wiring connections from the

capacitor.

7. Remove the “AUTO/MANUAL, RAISE/

LOWER switch” bracket from the cabinet

by removing the two screws (save

screws).

8. Remove the panel for the “Operations

Counter, Fuse Holder and Test Jack

Fixture” (save screws).

from

b

TOSHIBA

TB-R800

478593

Figure 1 Toshiba Regulator in Cabinet

d

g

–2–

Page 10

M-2299 Application Guide

2.2 Installation of the M-2001

Series Digital Tapchanger

Control

Mount the M-2001 Tapchanger Control to the back

of the M-2299 Adapter Panel and secure with the

four screws provided. The four screws are shipped

in a drawstring bag which is attached to the adapter

panel.

2.3 Installation of the M-2299

Refer to Figure 2, below.

1. Mount the supplied printed circuit board

against the rear of the cabinet in the

screw holes from the "AUTO/MANUAL,

RAISE/LOWER switch" bracket, utilizing

saved screws. See Figure 4, Wiring

Harness and External Connections.

2. Connect the supplied printed circuit board

TB1 wiring harness to the BT1 terminal

block and capacitor. Refer to Figure 4

for wiring connections.

3. Mount the M-2299 Adapter Panel (with

the M-2001) onto the hinges in the control

cabinet and install the two hinge pins

saved from the original regulator. Leave

the panel swung outward so that the

back of the panel is accessible.

4. Connect the M-2299 and M-2001B wiring

connectors to the supplied circuit board

and Neutral Light. Refer to Figure 4 for

wiring connections.

5. Swing the adapter panel closed and turn

knob to latch securely.

NEUTRAL

LIGHT

INT

VOLTAGE

SOURCE

EXT

RAISE

LOWER

AUTO

MANUAL

VOLTAGE IN

METER OUT

TEST TERMINAL

3 AMP

VOLTAGE

.25 AMP

MOTOR POWER

6 AMP

OFF

OFF

OFF

U

UP

E

ENTER

D

DOWN

-M

0120

M-2299

TAPCHANGER CONTROL

BECKWITH

ELECTRIC

CO. INC

A

REIS

L

EWR

ROE

R

VPW

OK

COM 2

B

.

Figure 2 M-2299 Adapter Panel and M-2001 Tapchanger Control in Cabinet

–3–

Page 11

M-2299 Application Guide

VOLTAGE

SOURCE

NEUTRAL

LIGHT

INT

EXT

RAISE

9.17

[23.29]

OFF

12.00

[30.48]

LOWER

AUTO

MANUAL

VOLTAGE IN

METER OUT

FUSE

TEST TERMINAL

3 AMP

FUSE

VOLTAGE

.25 AMP

FUSE

MOTOR POWER

6 AMP

OFF

U

OFF

UP

D

DOWN

E

ENTER

-M

0120

M-2299

TAPCHANGER CONTROL

BECKWITH

ELECTRIC

CO. INC

B

A

REIS

O

L

EWR

R

E

R

VPW

OK

COM 2

.

NOTE: Values in brackets are in centimeters.

Figure 3 Mounting Dimensions

–4–

Page 12

BT1

TB1-8

C1-2

TB1-15

C1-1

TB1-13

M-2299 Application Guide

REV. A

ELECTRIC

CO. INC.

BE# 450-00200

BECKWITH

P-1778

J7

16 21

22 27

TB2

1

J5 J4

C1

+

R3

R1

1516

2324

14

13 12 11 10 9

171819202122

C7 C8

U2

C6

TB1-8

TB1-3

TB1-4

TB1-1

TB1-11

TB1-9

TB1-10

TB1-14

+

R2

RV5

78

RV1

R4

R5

+

RV4

P1

C4

F1

JP1

23456

C3

C12

1

C11

R15

R12

RV6

R11

R14

R13

R6

U3

R9

R10

R7

J1

R8

TB1

J6

1

1

BT1-6

BT1-8

BT1-7

C1-2

RV2

RV3

C2

U1

D1

D2

D3

C5

C9

15

C10

C1-1

BT1-9

BT1-1

BT1-11

BT1-10

BT1-5

BT1-4

BT1-12

BT1-1

C1-2

C1-1

J7

J6

J5

J4

Terminal Block

Connections

TB-1

Circuit Board

Capacitor

BT1

M-2001

C1-2

C1-1

To Tapchanger

REV. A

CO. INC.

BE# 450-00200

P-1778

16 21

22 27

TB2

1

J5 J4

C1

+

R3

RV5

R1

1516

2324

78

14

RV1

13 12 11 10 9

RV4

P1

JP1

23456

C3

171819202122

1

C11

RV6

C7 C8

R14

U2

U3

C6

+

R7

J1

R8

ELECTRIC

BECKWITH

J7

R2

R4

R5

+

C4

F1

C12

R15

R12

R11

R13

R6

R9

R10

Customer

Terminal Block

TB1

J6

1

1

RV2

RV3

C2

U1

D1

D2

D3

C5

C9

15

C10

1

2

6

5

4

6

5

4

6

5

4

R

R

1

1 2

1

D1

1

2

3

S4

1

2

3

S2

1

2

3

S3

BP1

B

B

BP2

2

F2

F3

2

F4

Figure 4 M-2299 Wiring Harness and External Connections

–5–

Page 13

M-2299 Application Guide

2.4 Lightning Protection

It has been determined that transient voltages in

excess of 1500 V ac rms can exist on the “ground”

lead normally tied to TB1-8 on the printed circuit

board. In the Tapchanger Controls, these voltages

are suppressed by varistors which still permit the

unit to pass a 1500 V ac Hi Pot test for one minute

with a leakage current of approximately 15 mA, all

terminals to ground.

▲ CAUTION: For proper protection against system

surges, chassis ground must be connected to earth

ground.

Multiple VT grounds far apart must be avoided

since a varying difference in ground voltage could

add or subtract from the effective voltage and

cause variation in the Tapchanger Control’s

bandcenter voltage setpoint.

3.0 External Connections

Power and voltage sensing are obtained either from

a common source or from independent sources

having a nominal 120 V ac output. Normally, this is

line-to-neutral voltage, although line-to-line voltage

can also be used if recognition is made of any

phase shift between the voltage and current signals

when using line drop compensation.

Load current must be reduced by an appropriate

auxiliary current transformer to 0.2 A “full scale”

before connecting to the M-2299 current inputs.

The Beckwith Electric M-0121 (5.0 A to 0.2 A) or

M-0169 (5.0 A or 8.66 A to 0.2 A) Auxiliary Current

Transformer can be used for this purpose. The

M-0121 can be used with Beckwith Electric

Tapchanger Controls when the only burden present

is the Line Drop Compensator circuit of the voltage

regulating relay. The M-0169 is used in high burden

circuits, such as are found in paralleling schemes.

Outputs of the auxiliary CTs are protected against

overvoltage. For further information, obtain Beckwith

Electric Application Note #17, “Basic Considerations

for the Application of LTC Transformers and

Associated Controls.”

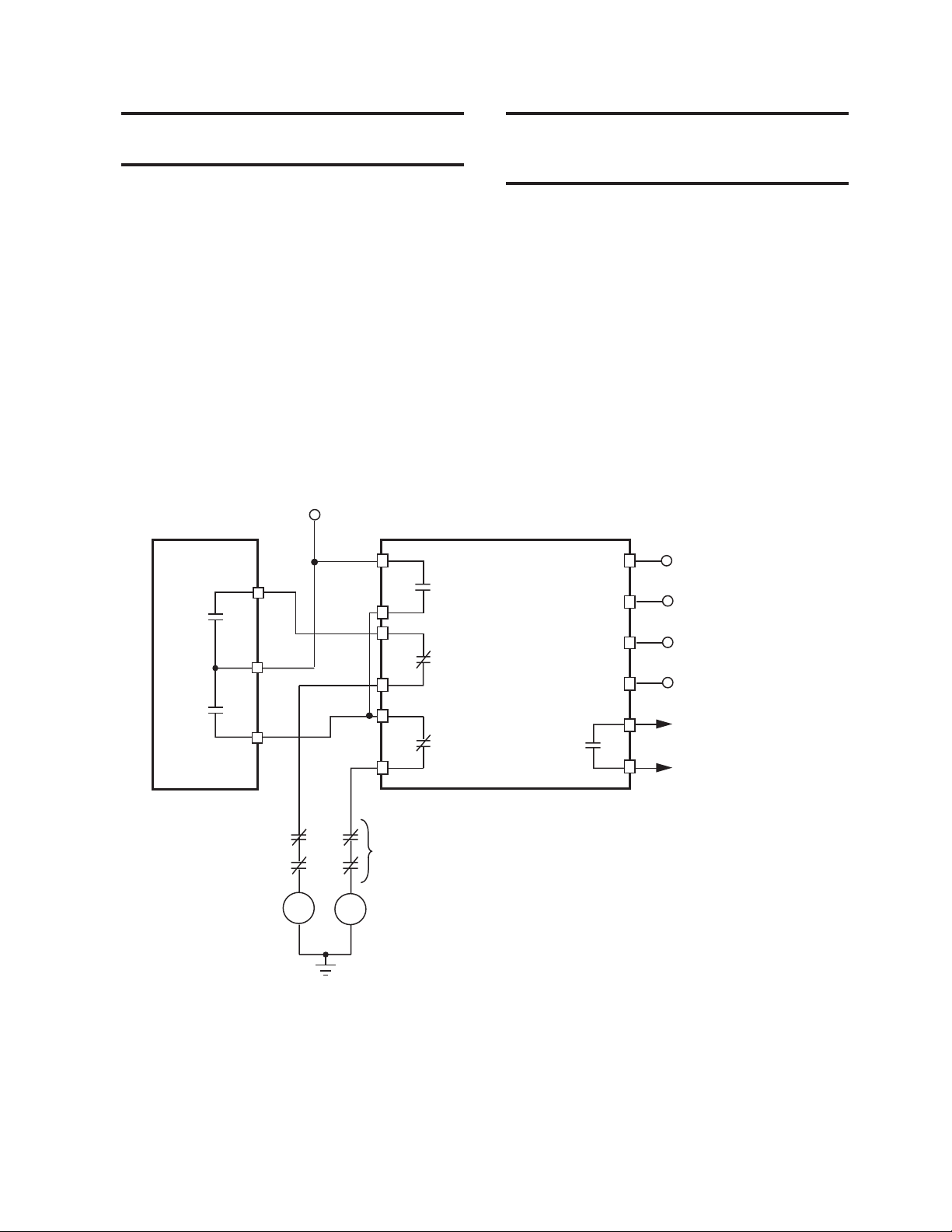

The external connections for the M-2299 are made

to terminal blocks TB1 and TB2 on the printed

circuit board. The wiring harness and external

connections for the M-2299 are shown in Figure 4,

Wiring Harness and External Connections, and

Figure 5, M-2001 and M-2299 Typical Connections.

–6–

Page 14

M-2001

TAPCHANGER

CONTROL

FUNCTIONS

OP

COUNTER

NEUTRAL

NC

See Note

NO

+12 V dc

MANUAL RAISE

MANUAL LOWER

MANUAL

OFF

AUTO

TO

CONTROL

METER OUT

M-2299

ADAPTER PANEL

FUNCTIONS

OFF (MOM)

INT

OFF

EXT

INT

OFF

EXT

VOLTAGE IN

TEST

TERMINAL

FUSE 3A

FRONT PANEL INPUTS

MOTOR POWER

FUSE (6 A)

VOLTAGE IN

FUSE (1/4 A)

NEUTRAL

LIGHT

TB1

TB1

10

11

12

13

14

15

TB2

16

17

18

19

20

21

22

23

24

25

26

27

M-2299 Application Guide

6

1

2

3

4

5

6

7

8

9

VOLTAGE REDUCTION STEP #2 CONTACT

8

7

2

3

VOLTAGE REDUCTION

STEP #1 CONTACT

1

11

MOTOR POWER

10

NEUTRAL LIGHT SWITCH

5

N/U

4

12

LINE

CURRENT

1

SHORTING SWITCH

LOCAL/REMOTE

AUTO DISABLE

MANUAL RAISE

MANUAL LOWER

N/U

SELF-TEST ALARM (RETURN)

SELF-TEST ALARM (POLARITY)

USER-PROGRAMMABLE ALARM (RETURN)

USER-PROGRAMMABLE ALARM (POLARITY)

+12 V dc WETTING SUPPLY

POLARITY CONTACT

RESISTOR NETWORK WIPER

POSITION RESISTOR

9

20, 21 or 22

on T.C.

OPERATIONS COUNTER

SWITCH

CT

MOTOR

LR

NEUTRAL

VOLTAGE IN

(REGULATED

120 V)

CT

Toshiba Terminals

M-2299 Terminals

NOTE: The self-test alarm and user-programmable alarm contacts are shown in the de-energized state (no

voltage applied). The self-test alarm contacts open after the M-2001 passes the self-test; the user-programmable alarm contacts close when an alarm is recognized.

8 WARNING: In no case should the line current circuit be interrupted with the regulator or transformer

energized.

Do not remove auxiliary current transformers without shorting the current inputs. Death or severe

electrical shock can occur.

Figure 5 M-2001 and M-2299 Typical Connections

–7–

Page 15

M-2299 Application Guide

3.1 Features

Neutral Light Circuit

The M-2299 is prepared for use with regulators

which use a neutral light. Toshiba products require

that the Neutral Light terminal TB1-11 (BT-5) be

grounded when the light is to be illuminated.

Auto Disable Input

To disable automatic operation of the M-2299,

remove the jumper between TB2-18 and TB2-19 on

the printed circuit board. If SCADA is used to

enable and disable this function, a contact rated at

6 A minimum can be connected between the

terminals.

Local/Remote Input

Removing the jumper between TB2-16 and TB2-17

prohibits operation by disabling the M-2001

Tapchanger Control’s automatic raise and lower

outputs and also by disabling the M-2299 Adapter

Panel’s manual RAISE/OFF/LOWER toggle switch.

Removing this jumper does

supplied motor voltage input to the manual raise/

manual lower contacts on the adapter panel.

not

disable the SCADA-

Multi-Step Voltage Reduction

On the M-2299, TB1-2 and TB1-7 on the printed

circuit board are used together to provide up to

three levels of voltage reduction. The external

connections to achieve these steps are shown in

Table 1, below, and Figure 5, M-2001 and M-2299

Typical Connections. (Voltage reduction amounts

are set within the M-2001 Tapchanger Control

software.)

▲ CAUTION: Voltage applied through dry contacts

to actuate Voltage Reduction Steps 1, 2, and 3

must

be +12 V dc obtained from pin TB2-27 of the M-2299

adapter panel.

Operations Counter Input

An operations count is registered by momentarily

grounding TB1-13 through an external dry contact

from the load tapchanger. The input is level-sensitive.

Make sure that any “wetting” voltages are removed

from the counter contacts before installing the

M-2299 Adapter Panel/M-2001 Tapchanger Control.

▲ CAUTION: Do not apply either +12 V dc or 120 V

ac to this terminal.

:tniopteSnoitcudeRegatloV

egnaRreilpitluM

:1#tniopteSnoitcudeRegatloV

1ot0

tloV

1ot0

1ot0

:2#tniopteSnoitcudeRega

:3#tniopteSnoitcudeRegatloV

7-1BT

2-1BT

morf"egatloVgnitteW"ylppA

#lanimreTot72-2BT

2-1BTdna7-1BT

Table 1 Multi-Step Voltage Reduction External Connections

–8–

Page 16

M-2299 Application Guide

3.2 Typical Connections for

Toshiba Regulators

In general, the tapchanger motor must be operated

from a different transformer than the VT used to

measure regulated voltage. If this is not done,

hunting at the upper band edge may result. As soon

as the motor starts and before it is sealed in, the

motor current can drop the voltage within the band

and reset the control. Some motor seal-in schemes

are fast enough to prevent this, but others are not.

A typical connection for an M-2299 is shown in

Figure 5, M-2001 and M-2299 Typical Connections.

Connections are simplified and may not show all

functions required in a typical load tapchanging

transformer control scheme; for example, seal-in

contacts, limit switches, etc.

MOTOR

TAPCHANGER

CONTROL

R

SUPPLY

TB1-7

TB1-8

TB1-11

*

TB1-12

*

TB1-6

TB1-7

LOWER

BLK

RAISE

3.3 Use of the M-0329 LTC

Backup Control with the

Tapchanger Control

The M-0329 is a single-phase, solid-state backup

control that prevents a defective tapchanger control

from running the voltage outside the upper and

lower voltage limits. The Block Raise and Block

Lower voltage levels are set by accurately calibrated

dials.

The M-0329 LTC Backup Control is connected as a

two terminal device to the voltage transformer.

Figure 6, below, shows the typical interconnection

of the two devices with motor auxiliary relays.

The M-0329 Instruction Book is available on request

and gives added details. Please refer to the M-0329

Instruction Book for complete ordering information.

M-0329

90 BACKUP

1

120 VAC POWER

2

3

REGULATED VOLTAGE

4

84R

TB1-9

TB1-10

84L

14

BLK

LOWER

LIMIT SWITCHER, AUXILIARY CONTACTS AS

REQUIRED IN MOTOR CONTROL CIRCUITS

84R - RAISE MOTOR AUXILIARY RELAY

84L - LOWER MOTOR AUXILIARY RELAY

15

L

TB1-9

*

NOTE: If first customer protection is not required, delete these connections.

Figure 6 Tapchanger Control and LTC Backup Control Interconnections

ALARM

–9–

Page 17

M-2299 Application Guide

4.0 M-2001 Tapchanger Control

Software Settings

Adjust the BANDCENTER setting to the nominal

voltage desired. Adjust the BANDWIDTH setting to

the desired voltage band, centered on the

Bandcenter setpoint, that the voltage must exceed

before timer and subsequent tapchanger operation

occurs. Adjust the TIME DELAY setpoint to a

sufficient amount to eliminate excessive tapchanger

operations. The LINE DROP COMPENSATOR

should be set for the line impedance from the

transformer to the load center. For further information,

obtain Beckwith Electric Application Note #17,

“

Basic Considerations for the Application of LTC

Transformers and Associated Controls

.”

4.1 M-0329 LTC Backup Control

Settings

The BANDCENTER and BANDWIDTH dials on the

M-0329 LTC Backup Control should be set so that

the Block Lower limit is a small amount

(approximately 2 V) below the lower band limit of

the Tapchanger Control, and the Block Raise limit

is a similar amount above the upper limit if line drop

compensation is not used.

If line drop compensation is used, the M-0329

Block Raise limit should be set at the maximum

voltage desired at the transformer secondary under

full load.

The M-0329 LTC Backup Control also includes a

deadband or runback function that regulates the

maximum voltage from the transformer. This “Lower”

function operates slightly above the Block Raise

limit and is connected to force the tapchanger to

lower the voltage if the upper limit is exceeded.

5.0 Test Procedures

Equipment Required

• 0–200 mA current supply with phase angle

settings of 0° to +90°

• 90–145 V ac voltage source at 60 Hz

• High impedance true RMS voltmeter with

accuracy on ac of at least ±0.2% of

reading

• Accurate Stop watch

Set-up Procedure

1. Make electrical connections as shown

in Figure 7, Test Procedure External

Connection.

NOTE: There is a one second delay between

out-of-band condition and panel LED indication.

2. Initial settings

sgnitteSlaitinI

retnecdnaBV0.021

htdiwdnaBV0.2

ecnatsiseRCDLV0.0

ecnatcaeRCDLV0.0

gnilellaraPdohteMtnerruCgnitalucriC

BV0.531

esiaRkcol

rewoLkcolBV0.501

dnabdaeDV0.2

remiTsdnoces0.5

–10–

Table 2 Initial Settings

Page 18

M-2299 Application Guide

5.1 Bench Test

NOTE: This test assumes that the M-2001

Tapchanger Control is connected to the M-2299

Adapter Panel.

1. Apply 120.0 V ac from power source.

2. The display of the M-2001 will

automatically advance to Local Voltage

screen.

3. Increase voltage to 121.2; LOWER LED

should light.

4. Decrease voltage to 118.8; RAISE LED

should light.

5. Set input voltage to 120.0 V ac. Wait

for RAISE and LOWER LEDs to

extinguish.

6. Increase voltage to 122.0 V ac.

7. Start timing when voltage passes

121.0 V.

8. Stop timing when lamp connected to

LOWER output lights (should be 5

seconds).

Resistance

1. Apply 100.0 mA in-phase current to

TB1-14 (load current-polarity) and

TB1-15 (load current-return) of the

adapter panel. (Set S

IR.)

2. Set LDC Resistance to 24.0 V; RAISE

LED should light.

3. Increase input voltage to 132.0 V ac;

RAISE and LOWER LEDs should be

extinguished.

4. Set LDC Resistance to –24.0 V; LOWER

LED should light.

5. Decrease input voltage to 108.0 V ac;

both RAISE and LOWER LEDs should

extinguish.

6. Set LDC Resistance to 0.0 V.

to LDC and S2 to

1

Voltage Source Switch

1. Set AUTO/OFF/MANUAL switch to OFF.

2. Set VOLTAGE SOURCE switch to EXT.

3. Verify no manual Raise or Lower output.

4. Attach voltmeter to Meter Out terminals.

5. Verify no voltage is present.

6. Apply 120 V ac to the Voltage In jack

(Black-Neutral, Red-Hot).

7. Set AUTO/OFF/MANUAL switch to

AUTO.

8. Verify normal raise and lower operation.

9. Return the VOLTAGE SOURCE switch

to INT.

Counter/Neutral Light

1. Set the M-2001 Tapchanger Control to

display the Operations Count screen.

2. Verify counter operation by connecting

a switch between TB1-13 (operations

counter input) and TB1-8 (neutral) of the

adapter panel.

3. Jumper TB1-11 (neutral light) to TB1-8

(neutral).

4. The neutral light on the adapter panel

should light.

5. Remove the jumper.

Block Raise/Block Lower/Dead Band

1. Set Block Raise to 126.0 V.

2. Set Block Lower to 114.0 V.

3. Set the M-2001 Tapchanger Control to

display the Bias Voltage screen.

4. Press ENTER.

5. Increase voltage to 126.5 V; BR should

appear on the screen.

6. Increase voltage to 128.5 V; BR goes

off and FL appears on the screen.

7. Decrease voltage to 113.5 V; BL appears

on the screen.

–11–

—Bench Test Complete—

Page 19

M-2299 Application Guide

Supply

120 V Fixed

H

I

I

R1

H

Input

Variac

Supply

Adjustable

80 to 140 V ac

N

S2

R

L

I

C1

H

N

Discrete Elements or Doble F2200

Normally open

pushbutton test switch

for Functional Indicator

120 V Lamp or Relay Coil

Polarity Contact

1

TB1

(approx. 1200 ý, 15 W or greater)

S1

LDC

OFF

Resistor Network Wiper

Voltage Reduction Step #2 Input

2

Position Resistor

3

4

Tapchanger Raise Output

Tapchanger Lower Output

Voltage Reduction Step #1 Input

5

6

7

(approx. 2.2 µF, 600 V ac Mylar Film)

Neutral

Motor Power

Regulated Voltage

8

9

Neutral Light

11

10

Operations Counter Input

Load Current (Polarity)

N/U

12

Load Current (Return)

13

14

15

Contact Wetting Supply (+12 V dc)

27

TB2

Local/Remote

16

17

Jumpers in place for motor power continuity.

Auto Disable

18

19

Load

I

Position

Tap

Figure 7 M-2299 Test Procedure External Connection

–12–

Page 20

M-2299 Application Guide

5.2 M-2001 Checkout Procedure

NOTE: This test of the M-2001 assumes that the

unit remains connected to the adapter panel.

Basic Operational Test

1. Apply 120.0 V ac to TB1-9 (motor power)

and TB1-10 regulated voltage) of adapter

panel.

2. Connect neutral to TB1-8 (neutral).

3. Verify local voltage y input voltage

±0.3 V.

4. Apply 100.0 mA in-phase current to

TB1-14 (load current-polarity) and

TB1-15 (load current-return) of the

adapter panel. Verify Control Load I y

100 mA and Power Factor y 1.0 ±0.02.

5. Verify UP, DOWN and ENTER buttons

work.

—Checkout Procedure Complete—

5.3 In-Service Test

1. Set the M-2001 Tapchanger Control to

display Bias Voltage screen.

2. Press ENTER.

3. Use UP and DOWN buttons to cause

RAISE and LOWER outputs.

—In-Service Test Complete—

6.0 Checkout Procedure

NOTE: All Beckwith Electric units are fully cali-

brated at the factory. There is no need to re-calibrate

the units before initial installation.

Set the AUTO/OFF/MANUAL switch to OFF.

Inspect the MOTOR POWER and VOLTAGE fuses

to ensure they are correctly sized and have not

blown.

6.1 Power

1. Remove any external connection

between TB1-9 and TB1-10 which are

located on the adapter panel printed

circuit board. Also remove any voltage

applied to TB1-9 externally. Using a

voltmeter, make sure that the voltage

applied to TB1-10 is nominal 120 V ac

with respect to TB1-8 (neutral). Apply

power to TB1-10 (hot) and TB1-8

(neutral).

8 WARNING: Voltage applied at the

test terminal may energize the regulator or transformer to a high voltage through the voltage

transformer.

Death or severe electrical shock can occur.

Do not connect any voltage source at the

OUT

test terminal.

2. Connect a voltmeter to the METER OUT

test terminal on the front of the adapter

panel. 120 V ac should be indicated.

METER OUT

METER

Return unit to desired settings

▲ CAUTION: Do not reverse the ground and hot

wires when connecting an external source. A 3 AG

fuse (F2) is installed to protect the relay from damage if these connections are accidentally reversed.

Spare fuses are supplied inside the fuse holders.

Units returned with only a blown fuse are not covered by warranty, and a nominal repair charge will be

made for replacement of the fuse. Please check the

fuse before returning the unit for repair, in order to

avoid unnecessary repair charges.

–13–

Page 21

M-2299 Application Guide

3. Apply motor power to TB1-9 (hot) and

TB1-8 (neutral). Set the AUTO/OFF/

MANUAL switch to MANUAL and using

the RAISE/OFF/LOWER switch, verify

that the motor runs in the proper direction

when this switch is in the RAISE and

LOWER positions.

4. Set the AUTO/OFF/MANUAL switch to

the AUTO position. Refer to the Field

Checkout Procedure as found in the

Status & Setpoint Review Guide of the

M-2001 Tapchanger Control Instruction

Book for test/operation procedures.

5. As shown in Figure 6-1, Typical External

Connections, in the M-2001B Instruction

Book, temporarily place a shorting device

across the LDC-CT secondary to short

the line drop compensator circuit, and

place another shorting device across

TB1-3 and TB1-4 to short the circulating

current paralleling input, for the load

current check. Insert an ammeter

between the polarity input and TB1-14.

Open the load current shorting device

and with a known load on the transformer

or regulator, measure the current in the

load current circuit to ensure that this

current is correct for 0.2 A full load.

6. Replace the shorting device across the

load current input and remove the

ammeter. Reconnect polarity to the unit

and remove both jumpers. The LINE

DROP COMPENSATOR will be

activated. Correct CT polarity can be

checked by simply incorporating

sufficient +R compensation. The

regulator should time out and run so as

to raise the output voltage.

8 WARNING: In no case should the load current

circuit be interrupted with the regulator or transformer energized.

Do not remove auxiliary current transformers

without shorting the current inputs.

Death or severe electrical shock can occur.

M-2299

TAPCHANGER

CONTROL

TB1 on printed circuit board

N/U

3

N/U

4

14

A

200 mA

15

LOAD CURRENT

AUX

CT

5 A

Figure 8 Setup for Current Checkout Procedure

Normally 1-CT on

X , X , X bushing

123

Shorting

device

LDC-CT

XXXX:5 A

–14–

Page 22

M-2299 Application Guide

6.2 Voltage Source Switch

The VOLTAGE SOURCE switch will disconnect all

power from the unit when in the EXT position with

no source connected to the front panel voltage and

motor power inputs.

▲ CAUTION: Do not reverse the ground and hot

wires when connecting an external source. A 3 AG

(F2) is installed to protect the relay from damage if

these connections are accidentally reversed.

With the VOLTAGE SOURCE switch in the EXT

position, the sensing and motor power circuits are

connected to the VOLTAGE IN binding post on the

front panel. The unit can be tested using an external

120 V rms source of proper polarity applied to these

terminals. Testing can be accomplished by adjusting

the amplitude of the external source.

7.0 Maintenance

Due to the nature of the circuitry in the M-2001

Tapchanger Control, field repair is not

recommended. All units are fully calibrated at the

factory prior to shipment; there is no need to recalibrate a unit prior to initial installation. In the

event that a unit does not operate properly, it

should be established that the problem is caused

by a malfunction of the Tapchanger Control and not

caused by an external fault or wiring error. Check

for blown fuses on the Adapter Panel. If the

Tapchanger Control is still not operating properly,

set the AUTO/OFF/MANUAL switch on the Adapter

Panel to MANUAL. Once this is accomplished, the

Tapchanger Control can be disconnected and

returned to Beckwith Electric. Pack the unit carefully

(in the original carton if possible), assuring that

there is adequate packing material to protect the

contents.

NOTE: Any equipment returned for repair must be

sent with transportation charges prepaid. The equipment must remain the property of the user. The warranty is void if the value of the unit is invoiced to

Beckwith Electric at the time of return or if the unit

is returned with transportation charges collect.

If under warranty, units will be repaired rapidly and

returned at no cost and with return transportation

paid if the fault is found to be due to workmanship

or failure of material. If a unit is under warranty and

express shipment for return of the repaired unit is

requested, shipping charges will be billed at the

current rate. If the fault is due to abuse or misuse,

or if the unit is out of warranty, a modest charge will

be made. Repair can normally be expected to take

two weeks, plus shipping time. If faster service is

required, it should be requested at the time of

return.

NOTE: Adapter panels returned with only a blown

fuse are not covered by warranty and a nominal repair charge will be made for replacement of the fuse.

Please check the fuses before returning the adapter

panel for repair in order to avoid unnecessary repair

charges.

To help in analyzing the problem, a complete

description of the malfunction and conditions leading

to the failure should be included with the unit.

–15–

Page 23

M-2299 Application Guide

This Page Left Intentionally Blank

–16–

Page 24

Legal Information

Patent

The units described in this manual are covered by

U.S. Patents, with other patents pending.

Buyer shall hold harmless and indemnify the Seller,

its directors, officers, agents, and employees from

any and all costs and expense, damage or loss,

resulting from any alleged infringementof United

States Letters Patent or rights accruing thereform or

trademarks, whether federal, state, or common law,

arising from the Seller’s compliance with Buyer’s

designs, specifications, or instructions.

Warranty

Seller hereby warrants that the goods which are the

subject matter of this contract will be manufactured

in a good workmanlike manner and all materials

used herein will be new and reasonably suitable for

the equipment. Seller warrants that if, during a

period of five years from date of shipment of the

equipment, the equipment rendered shall be found

by the Buyer to be faulty or shall fail to peform in

accordance with Seller’s specifications of the

product, Seller shall at his expense correct the

same, provided, however, that Buyers shall ship the

equipment prepaid to Seller’s facility. The Seller’s

responsibility hereunder shall be limited to replacement value of the equipment furnished under this

contract.

Seller makes no warranties expressed or implied

other than those set out above. Seller specifically

excludes the implied warranties of merchantibility

and fitness for a particular purpose. There are no

warranties which extend beyond the description

contained herein. In no event shall Seller be liable for

consequential, exemplary, or punitive damages of

whatever nature.

Any equipment returned for repair must be sent

with transportation charges prepaid. The equipment

must remain the property of the Buyer. The aforementioned warranties are void if the value of the

unit is invoiced to the Seller at the time of return.

Indemnification

The Seller shall not be liable for any property

damages whatsoever or for any loss or damage

arising out of, connected with, or resulting from

this contract, or from the performance or breach

thereof, or from all services covered by or furnished

under this contract.

In no event shall the Seller be liable for special,

incidental, exemplary, or consequential damages,

including but not limited to, loss of profits or

revenue, loss of use of the equipment or any

associated equipment, cost of capital, cost of

purchased power, cost of substitute equipment,

facilities or services, downtime costs, or claims or

damages of customers or employees of the Buyer

for such damages, regardless of whether said claim

or damages is based on contract, warranty, tort

including negligence, or otherwise.

Under no circumstances shall the Seller be liable

for any personal injury whatsoever.

It is agreed that when the equipment furnished

hereunder are to be used or performed in connection with any nuclear installation, facility, or

activity, Seller shall have no liability for any

nuclear damage, personal injury, property damage,

or nuclear contamination to any property located at

or near the site of the nuclear facility. Buyer agrees

to indemnify and hold harmless the Seller against

any and all liability associated therewith whatsoever whether based on contract, tort, or otherwise.

Nuclear installation or facility means any nuclear

reactor and includes the site on which any of the

foregoing is located, all operations conducted on

such site, and all premises used for such operations.

Notice:

Any illustrations and descriptions by Beckwith

Electric Co., Inc. are for the sole purpose of

identification.

The drawings and/or specifications enclosed herein

are the proprietary property of Beckwith Electric

Co., Inc., and are issued in strict confidence;

therefore, shall not be used as a basis of reproduction of the apparatus described therein without

written permission of Beckwith Electric Co., Inc.

No illustration or description contained herein

shall be construed as an express warranty of

affirmation, promise, description, or sample, and

any and all such express warranties are specifically

excluded nor shall such illustration or description

imply a warranty that the product is merchantable

or fit for a particular purpose. There shall be no

warranties which extend beyond those contained in

the Beckwith Electric Co., Inc. terms of sale.

All rights reserved by Beckwith Electric Co., Inc. No reproduction may be made without prior written approval

of the Company.

Page 25

0

0

0

2

:

d

1

e

r

0

e

0

t

s

9

i

g

e

O

R

S

I

BECKWITH ELECTRIC CO., INC.

6190 - 118th Avenue North • Largo, Florida 33773-3724 U.S.A.

PHONE (727) 544-2326 • FAX (727) 546-0121

E-MAIL marketing@beckwithelectric.com

WEB PAGE www.beckwithelectric.com

© 2001 Beckwith Electric Co.

Printed in USA

800-2299-AG-00MC4 01/07

Loading...

Loading...