TOSHIBA LTM12C505N Specification

Global LCD Panel Exchange Center

To: Wistron Corporation

This specification is only used for discussing the included items.

You haven’t to approve this specification.

When we shall agree the specification, we will issue the formal one.

SPECIFICATION(TENTATIVE)

www.panelook.com

FOR

TOSHIBA TFT-LCD MODULE

LTM12C505N

NR-LTM12C505N-01

DATE OF ISSUE: 2001-10-26

Liquid Crystal Display Device Marketing & Engineering Dept.

Liquid Crystal Display Div.

TOSHIBA Corporation, Display Devices & Components Company

8, Shinsugita-cho, Isogo-ku, Yokohama, 235-8522, JAPAN

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Global LCD Panel Exchange Center

Specification No.

Revision History

www.panelook.com

Sheet 1

Date

(Rev No.)

Sheet

(New)

Item Old New Reason

LIQUID CRYSTAL DISPLAY DIVISION

Date:2001-10-26 New No.NR-LTM12C505N-01

Date: - - Old No.

←

# Special ←& Addition ← Change

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Global LCD Panel Exchange Center

Specification No.

Caution and Handling Precaution

For your end user's safety, it is strongly advised that the items with"✳"should be included in the instruction manual of the

system which may be issued by your organization.

For Safety

www.panelook.com

Sheet 2

(1) Toshiba's Standard LCD modules have not been customized for operation in extreme environments or for use in

(2) DISCONNECT POWER SUPPLY before handling LCD module.

(3) Make sure to insert the module FL connector to the inverter connector in correct position.

Warning

applications where performance failures could be life-threatening or otherwise catastrophic.

Since they must never be installed in aircraft navigation control systems (such as, but not limited to Traffic Collision

System and Air traffic Indicator), in military defense or weapons systems, in critical industrial process-control systems

(e.g., those involved in the production of nuclear energy), or in critical medical device or patient life-support systems.

DO NOT TOUCH the parts inside LCD module and the fluorescent lamp's (hereinafter called "FL") connector or cable in

order to prevent electric shock, because high voltage is supplied to these parts from the inverter unit while power supply is

turned on.

Do not insert in irregular position.

If incorrect, this may cause smoke or burn of electrical parts by high voltage of FL circuit.

If there is a possibility that the connector has been inserted incorrectly, please re-insert the connector only after you

confirm the module and FL power is completely off.

DO NOT USE the mating FL connector which Toshiba does not specify.

Otherwise, Toshiba shall not be liable for any damages caused by the connector.

Caution

(1) DO NOT DISASSEMBLE OR MODIFY the module.

Sensitive parts inside LCD module may be damaged, and dusts or scratches may mar the displays.

Toshiba does not warrant the modules, if customer disassembled or modified them.

✳

(2) DO NOT INGEST liquid crystal material, DO NOT INHALE this material, and DO NOT PERMIT this material to contact the

skin, if LCD panel is broken and liquid crystal material spills out.

In the event of inadvertent contact, immediately rinse the mouth or eyes with adequate water. If this material should

inadvertently contact the skin or clothing, wash immediately with alcohol and then rinse thoroughly with water.

✳

(3) BE CAREFUL WITH CHIPS OF GLASS that may cause injuring fingers or skin, when the glass is broken.

(4) DO NOT EXCEED the absolute maximum rating values under the worst probable conditions caused by the supply voltage

variation, input voltage variation, variation in parts' constants, ambient temperature, etc., otherwise LCD module may be

damaged.

(5) Suitable protection circuit should be applied for each system design.

DO NOT MODIFY the fuse used in the module. It may cause overheat and/or burning if dusts or metal particles are on the

PCBs in the LCD module.

LIQUID CRYSTAL DISPLAY DIVISION

Date:2001-10-26 New No.NR-LTM12C505N-01

Date: - - Old No.

←

# Special ←& Addition ← Change

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Global LCD Panel Exchange Center

Specification No.

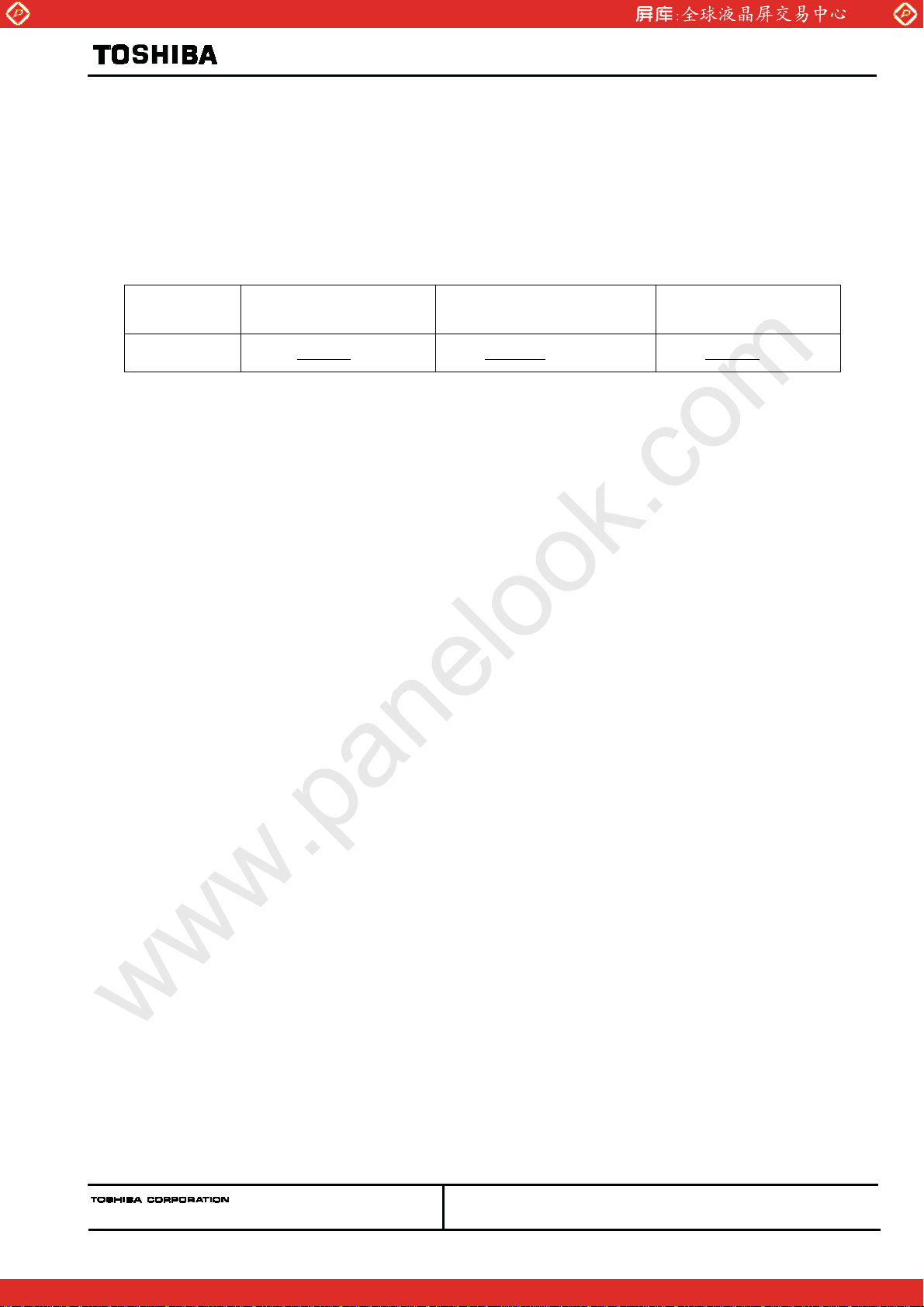

(6) Be sure that power supply output from the system should be limited to smaller values than listed shown below. (For

example Quick Arcing Fuse with listed ratings can be used.)

It is because this LCD module explained in this specification has a current limiter, with such function at power input line(s).

But it may be some possibility of overheat and/or burning of LCD module and its peripheral devices before current limiter

of the module when open-short test of the module is performed by using power supply higher than following

recommended value.

www.panelook.com

Sheet 3

Power

supply

V

DD

(7) Always comply with all applicable environmental regulations, when disposing of LCD.

Recommended maximum

output current of

power supply

4.0 A 2.0 A 1.25 A

Recommended Fuse Rating

(in case of using fuse

for current limiter)

Built-in Fuse Rating

(for reference)

For Designing the System

(1) LCD module should be assembled to the system by using all mounting holes specified in this specification and with the

specified screws.

(2) Power supply lines should be designed as follows.

Power supplies should always be turned on before the input signals are supplied to LCD module, and the input signals

should be disconnected before power supplies are turned off.

If the sequence does not satisfy specified conditions, it may cause miss-operation of the panel.

Refer to "2.4.2 Sequence of Power Supplies and Signals" for the detailed specification.

(3) DO NOT GIVE high voltage to "Low Voltage" side of the FL.

For example, DO NOT USE a floating inverter which gives high voltage to "Low Voltage" side. That's because it has a

possibility to burn or smoke around the FL.

(4) Make sure to connect correctly high-voltage wire and low-voltage wire between FL tube and inverter unit.

V

(5) Input FL starting voltage(

If it were less than one second, it may cause unstable operation of FL.

Please adjust inverter circuit parameters, such as capacitor, resistor, to assure the display quality is maintained.

There is a possibility that flicker is observed by the interference of LCD operating signal timing and FL driving condition

(especially driving frequency).

(6) In case of severe environmental condition like outdoor usage, a proper transparent protective cover(lens) over LCD

module is recommended to apply in order to prevent scratches, and invasion of dust, water, etc., from the system's

window onto LCD module.

Ultra-violet ray cut filter is recommended to apply onto LCD module for outdoor operation. Strong ultra-violet ray may

cause damage the panel.

(7) Design the system not to display same pattern for a long time in order to prevent image sticking on the panel. Note that

incorrect sequence of power supplies and input signals may cause the sticking on the panel, too.

) should not be less than one second.

SFL

LIQUID CRYSTAL DISPLAY DIVISION

Date:2001-10-26 New No.NR-LTM12C505N-01

Date: - - Old No.

←

# Special ←& Addition ← Change

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Global LCD Panel Exchange Center

Specification No.

For Installation in Assembly

(1) The C-MOS LSIs used in LCD module are very sensitive to ESD (Electro-static Discharge).

Ambient humidity of working area is recommended to be higher than 50%(RH).

Person handling LCD modules should be grounded with wrist band. Tools like soldering iron and screw driver, and

working benches should be grounded.

The grounding should be done through a resistor of 0.5-1MΩ in order to prevent spark of ESD.

(2) When remove protection film from LCD panel, peer off the film slowly (more than three seconds) from the edge of the

panel, using a soft-pointed tweezers covered by Teflon or adherent tape.

(3) Reduce dust level in working area. Especially the level of metal particle should be decreased.

Use finger stalls or soft and dust-free gloves in order to keep clean appearance of LCD module when handled for

incoming inspection and assembly.

✳

(4) When LCD panel becomes dirty, wipe off the panel surface softly with absorbent cotton or another soft cloth.

If necessary, breathe upon the panel surface and then wipe off immediately and softly again.

If the dirt can not be wiped off, absorbent cotton wetted a little with normal-hexane or petroleum benzine can be used for

wiping the panel.

Be careful not to spill this solvent into the inside of LCD module. Driver ICs and PCB area used inside LCD module may

be damaged by the solvent.

✳

(5) AVOID THE CONDENSATION OF WATER

Wipe off a spot or spots of water of mist and chemicals of mist on LCD panel softly with absorbent cotton or another cloth

as soon as possible if happened, otherwise discoloration or stain may be caused. If water invade into LCD module, it may

cause LCD module damages.

✳

(6) Do not expose LCD module to the gas (which is not normally contained in the atmosphere), it may cause mis-operation or

defects.

✳

(7) DO NOT APPLY MECHANICAL FORCES.

Do not bend or twist LCD module even momentary when LCD module is installed an enclosure of the system. Bending or

twisting LCD module may cause its damages.

Make sure to design the enclosure that bending/twisting forces are not applied to LCD module when it is installed in the

system.

Refrain from strong mechanical shock like dropping from the working bench or knocking against hard object.

These may cause glass of the panel crack, damage of FL or other mis-operation.

✳

(8) Refrain from excessive force like pushing the surface of LCD panel. This may cause damage of the panel or electrical

parts on PCB.

✳

(9) Do not put heavy object such as tools, books, etc., and do not pile up LCD modules.

Be careful not to touch surface of the polarizer laminated to the panel with any hard and sharp object. The polarizer is so

soft that it can easily scratched, even the protect film covers it.

(10) When inserting or disconnecting the connectors to LCD module, be sure not to apply force against PCB, nor connecting

cables, otherwise internal connection of PCB and TAB drivers may be damaged.

Do not fasten screws while putting cables like those for interface or FL between LCD module and the enclosure.

Make sure to insert the module FL connector to the inverter connector in correct position.

If incorrect, this may cause smoke or burn of electrical parts by high voltage of FL circuit.

www.panelook.com

Sheet 4

LIQUID CRYSTAL DISPLAY DIVISION

Date:2001-10-26 New No.NR-LTM12C505N-01

Date: - - Old No.

←

# Special ←& Addition ← Change

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Global LCD Panel Exchange Center

Specification No.

(11) Be careful not to pull the FL cables of the backlight in order to avoid mechanical damage in FL lamp and soldering area.

Be careful not to pull or not to hurt the FPC (Flexible Printed Circuit) cables.

(12) Power supplies should always be turned off in assembling process.

Do not connect or disconnect the power cables and connectors with power applied to LCD module. This may cause

damage of module circuit.

The signal should be applied after power are turned on. And the signal should be removed before power supplies are

turned off. (Refer to "For Designing The System"(2).)

(13) In case of LCD long period operation, discoloration of light guide or optical sheet will be happened due to ultra violet

and heat from CCFL. As the result, there is possibility to have out of specification for the optical characteristic as “5.2”.

But this is not irregular phenomena. Moreover, CCFL also has the characteristic of color shift by long period operation.

For Transportation and Storage

(1) Do not store LCD module in high temperature, especially in high humidity for a long time (approximately more than one

month).

It is recommended to store LCD module where the temperature is in the range of 0 to 35 °C and the relative humidity is

lower than 70%.

(2) Store LCD module without exposure to direct sunlight or fluorescent lamps in order to prevent the module from strong

ultra violet ray.

✳

(3) Avoid condensation of water on LCD module, otherwise it may cause mis-operation or defects. Keep away LCD module

from such ambient.

(4) In case of transportation of storage after opening the original packing. LCD module are recommended to be repacked into

the original packaging with the same method, especially with same kind of desiccant.

www.panelook.com

Sheet 5

LIQUID CRYSTAL DISPLAY DIVISION

Date:2001-10-26 New No.NR-LTM12C505N-01

Date: - - Old No.

←

# Special ←& Addition ← Change

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Global LCD Panel Exchange Center

Specification No.

www.panelook.com

- CONTENTS -

Sheet 6

Revision History

Caution and Handling Precaution

1. Scope

2. Product Specifications

2.1 General Specifications

2.2 Absolute Maximum Ratings

2.3 Mechanical Specifications

2.3.1 Weight

2.3.2 Dimensional Outline

2.4 Electrical Specifications

2.4.1 Circuit Diagram

2.4.2 Sequence of Power Supplies and Signals

2.4.3 Timing Chart

2.4.4 Timing Specifications

2.4.5 Interface Connector

2.4.6 Colors Combination Table

3. Recommended Operating Conditions

4. Electrical Characteristics

4.1 Test Conditions

4.2 Specifications

5. Optical Characteristics

5.1 Test Conditions

5.2 Optical Specifications

6. Quality

6.1 Inspection AQL

6.2 Test Conditions

6.3 Dimensional Outline

6.4 Appearance Test

6.4.1 Test Conditions

6.4.2 Specifications

6.5 Display Quality

6.5.1 Test Conditions

6.5.2 Specifications

6.6 Reliability Test

6.6.1 Test Conditions

6.6.2 Specifications

6.7 Labels

7. Lifetime

7.1 Module

7.2 Lamp

7.2.1 Test Conditions

7.2.2 Specifications

8. Packaging

8.1 Carton

9. Warranty

10. Regulation

11. Measuring Method

11.1 Measuring Systems

11.2 Measuring Methods

Sheet 1

2

7

7

18

19

20

21

28

29

30

30

30

LIQUID CRYSTAL DISPLAY DIVISION

Date:2001-10-26 New No.NR-LTM12C505N-01

Date: - - Old No.

←

# Special ←& Addition ← Change

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Global LCD Panel Exchange Center

(

)

Specification No.

1. Scope

This specification is applicable to Toshiba's 36cm diagonal size TFT-LCD module "LTM12C505N" designed for Personal

Computer.

2. Product Specifications

2.1 General Specifications

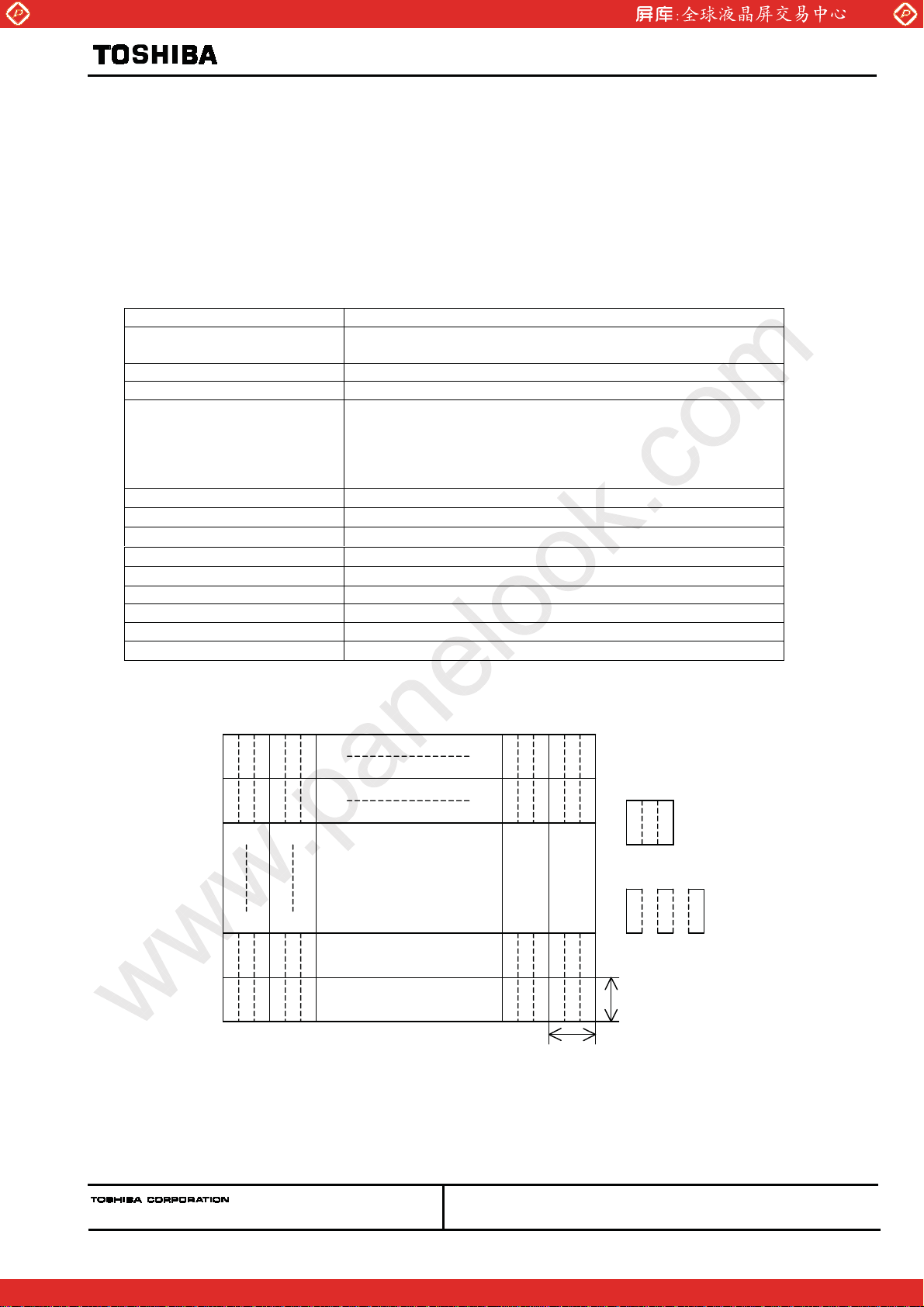

Item Specifications

Display Mode TN color(64 gray scales, 262,144 colors)

Viewing Direction 6 o'clock (in direction of maximum contrast)

Driving Method TFT active matrix

Input Signals LVDS interface

Active Area

Viewing Area

Bezel Opening

Number of Pixels

Pixel Pitch

Pixel Arrangement RGB vertical stripes

Surface Treatment Anti-glare and hard coat 3H on LCD surface

Backlight Single cold-cathode fluorescent lamp for sidelighting

Dimensional Outline

www.panelook.com

Transmissive type, Normally white

CLK+,CLKIN0+,IN0IN1+,IN1IN2+,IN2-

245.76 (W)× 184.32 (H) (mm)

247.76 (W)× 186.32 (H) (mm)

250.4 (W)× 188.9 (H) (mm)

1024 (W)× 768

0.240 (W)× 0.240 (H) (mm)

261.0 (W)× 199.0 (H)× 5.0max. (D) (mm)

(H)

1)

Sheet 7

1)

1)

Note 1)

1 2 1023 1024

R G B

1

2

R G B

R G B

R G B

R G B

R G B

R G B

R G B

R G B

767

R G B

R G B

R G B

768

R G B

R G B

R G B

R G B

0.279mm

R G B

R

G

0.279mm

: pixel

: Sub-pixel

B

Dots

LIQUID CRYSTAL DISPLAY DIVISION

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Date:2001-10-26 New No.NR-LTM12C505N-01

Date: - - Old No.

←

# Special ←& Addition ← Change

www.panelook.com

Global LCD Panel Exchange Center

Specification No.

www.panelook.com

Sheet 8

2.2 Absolute Maximum Ratings

Item Symbol Min. Max. Unit Checked Terminal

Supply Voltage

Input Voltage of Signals

FL Driving Voltage

FL Driving Frequency

Operating Ambient Temperature

Operating Ambient Humidity

Storage Temperature

Storage Humidity

Operating Temperature for Panel

1)

4)

V

DD

V

IN

V

FL

f

2)

2)

2)

2)

3)

FL

T

OP

H

OP

T

STG

H

STG

-0+60

-0.3 +4.0 V

V

-0.3

DD

+0.3

-2.0kVrms

0100kHz

0+50

10 90 %(RH)

-20 +60

10 90 %(RH)

V

- GND

DD

VLVDS interface

°

C

°

C

°

C

Note1) Do not exceed the maximum rating values under the worst probable conditions taking into account the supply voltage

variation, input voltage variation, variation in part constants, and ambient temperature and so on. Otherwise the module

may be damaged.

2) Wet bulb temperature should be 39°C Max, and no condensation of water. See figure below.

3) The surface temperature caused by self heat radiation of cell itself is specified on this item.

4) Refer to 2.4.5

Wet Bulb

Temperature [ C]

30

20

10

0

0

-20 10 20 30 40 50 60 70 80

Dry Bulb Temperature [ C]

2.3 Mechanical Specifications

2.3.1 Weight

275 ± 20 (g)

40

50

60

95%

80%

60%

40%

20%

10%

Storage

Operation

Humidity [%(RH)]

LIQUID CRYSTAL DISPLAY DIVISION

Date:2001-10-26 New No.NR-LTM12C505N-01

Date: - - Old No.

←

# Special ←& Addition ← Change

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Global LCD Panel Exchange Center

Specification No.

www.panelook.com

Sheet 9

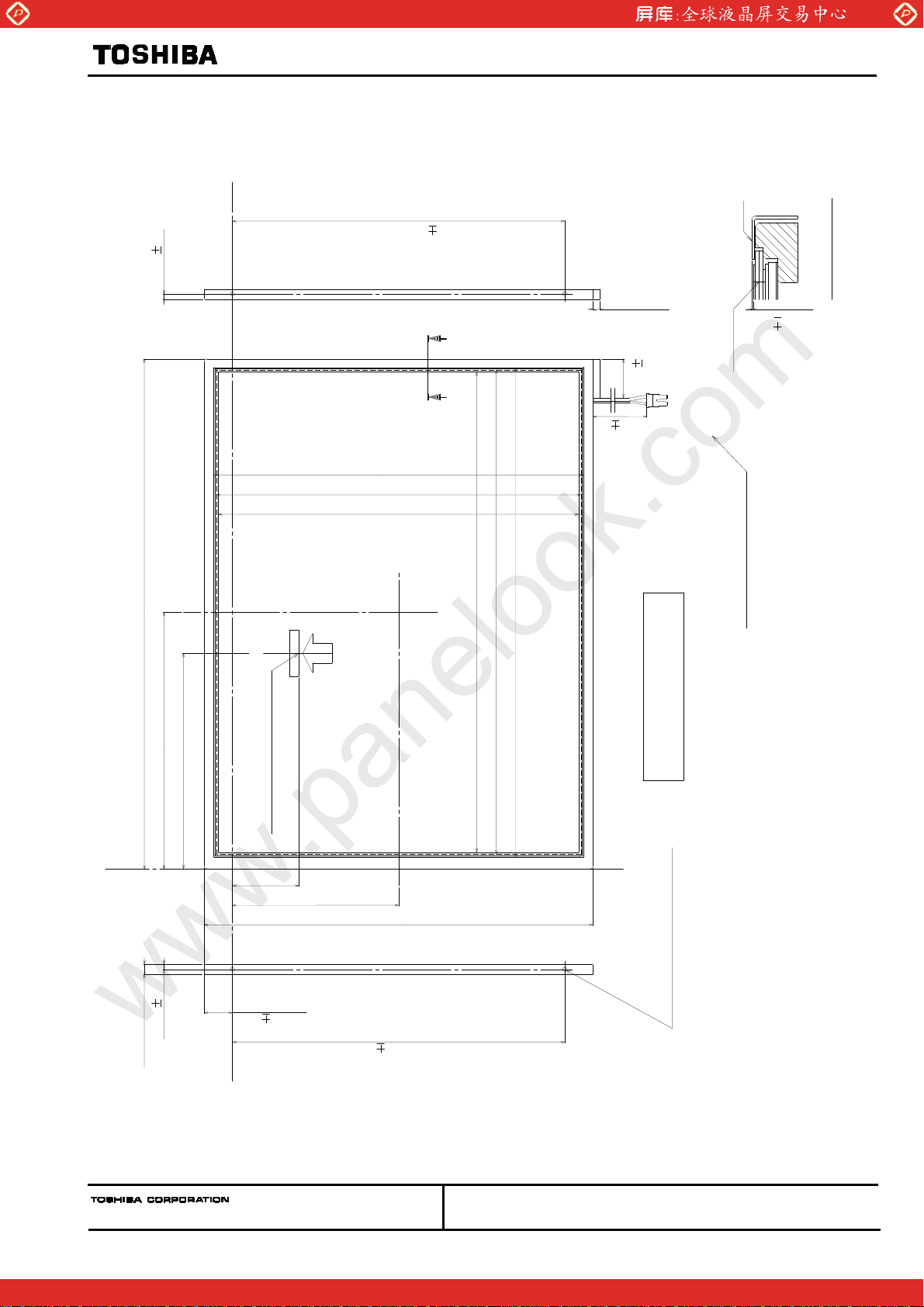

2.3.2 Dimensional Outline

(front figure)

0.3

2.8

0.3

AA

186.32 (Viewing Ar ea)

184.32 (Active Are a)

170

188.9 (Bezel Opening )

Unit : mm

Standard Tolerance: ±0.5

Bezel

A-A Cross Sectio n

3.5(MAX)

1

0.1

0.1

0.5

Active Area

20

5

15

261

5.0(Max.)

131.4

0.3

2.8

110.4

CN2:BHSR-02VS-1(JST)

245.76 (Active Area )

247.76 (Viewing Area )

250.4 (Bezel Openi ng)

TENTATIVE

CN1:DF19L-20P-1H(HIROSE)

34

85

199

0.3

14.5

0.3

170

4-M2 P0.4 (Depth 2.2MAX)

LIQUID CRYSTAL DISPLAY DIVISION

Date:2001-10-26 New No.NR-LTM12C505N-01

Date: - - Old No.

←

# Special ←& Addition ← Change

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Loading...

Loading...