Page 1

To :

This specification is only used for discussing the included items.

You haven’t to approve this specification.

When we shall agree the specification, we will issue the formal one.

SPECIFICATION(TENTATIVE)

FOR

Toshiba Matsushita Display Technology TFT-LCD MODULE

LTA170C07RF

LTA170C07RF-01

DATE OF ISSUE : 2003-06-18

TV/PC/Monitor-Use Marketing & Engineering Group2

TV/PC/Monitor-Use Marketing & Engineering Dept.

AVC-Use LCD Division

Toshiba Matsushita Display Technology Co.,Ltd.

1-9-2, Hatara-cho, Fukaya-shi, Saitama, 366-0032, JAPAN (Toshiba Fukaya Operations)

Page 2

18

Revision History

Date Sheet

’03-6-

(New)

NEW

Specification No. TENTATIVE

Item Old New Reason

TENTATIVE

SPECIFICATIONS

-

-

Sheet 1

-

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 3

Specification No. TENTATIVE

Sheet 2

Caution and Handling Precaution

For your end users' safety, it is strongly advised that the items with "Ú" should be included in the instruction

manual of the system which may be issued by your organization.

For Safety

Warning

1) SPECIAL PURPOSES

a) Toshiba Matsushita Display Technology’s Standard LCD modules have not been customized for operation

in extreme environments or for use in applications where performance failures could be life-threatening or

otherwise catastrophic.

b) Since they have not been designed for operation in extreme environments, they must never be used in

devices that will be exposed to temperatures above 50 degrees Celsius or below 0 degrees Celsius, to

X-ray or Gamma-ray radiation, or to abnormally high levels of vibration or shock which exceed Toshiba

Matsushita Display Technology’s specification limits.

c) In addition, since Toshiba Matsushita Display Technology’s Standard LCD modules have not been

designed for use in applications where performance failures could be life-threatening of catastrophic, they

must never be installed in aircraft navigation control systems (such as, but not limited to Traffic Collision

Avoidance System and Air Traffic Indicator), in military defense or weapons systems, in critical industrial

process-control systems (e.g., those involved in the production of nuclear energy), or in critical medical

device or patient life-support systems.

2) ELECTRIC SHOCK

DISCONNECT POWER SUPPLY before handling LCD modules. In order to prevent electric shock, DO NOT

TOUCH the electrode part, cables, connectors, and the fluorescent lamp’s (hereinafter called “FL”) circuit part

of a module in which FL tubes are built in as a light source of a backlight or a front light. High voltage is

supplied to these parts while power supply is turned on.

3) FL CABLE CONNECTION

Make sure to insert the module FL connector to the inverter connector in correct position and correct

polarity. If incorrect, this may cause smoke or burn of electrical parts by high voltage of FL circuit. If there is

a possibility that the connector has been inserted incorrectly, re-insert the connector only after you confirm

the module and FL power is completely off. When disconnecting the connector, do not pull on the cable.

DO NOT USE the mating FL connector which Toshiba Matsushita Display Technology does not

specify. Otherwise, Toshiba Matsushita Display Technology shall not be liable for any damages

caused by the connector.

Caution

1) Ú DISASSEMBLING OR MODIFICATION

DO NOT DISASSEMBLE OR MODIFY the modules.

Sensitive parts inside LCD module may be damaged, and dusts or scratches may mar the displays.

Toshiba Matsushita Display Technology does not warrant the modules, if customer disassembled or

modified them.

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 4

Specification No. TENTATIVE

Sheet 3

2) Ú BREAKAGE OF LCD PANEL

DO NOT INGEST liquid crystal material, DO NOT INHALE this material, and DO NOT PERMIT this material

to contact the skin, if glass of LCD panel is broken.

If liquid crystal material contacts the skin, mouth or clothing, take the following actions immediately.

In case contact to the eye or mouth, rinse with large amount of running water for more than 15 minutes. In

case contact to the skin or clothing, wipe it off immediately and wash with soap and large amount of running

water for more than 15 minutes. The skin or closing may be damaged if liquid crystal material is left adhered.

In case ingestion, rinse out the mouth well with water. After spewing up by drinking large amount of water, get

medical treatment.

3) Ú GLASS OF LCD PANEL

BE CAREFUL WITH CHIPS OF GRASS that may cause injuring fingers or skin, when the glass is broken.

Since FL is also made of glass, when FL is built in, handle it with due caution as well.

4) ABSOLUTE MAXIMUM RATINGS

DO NOT EXCEED the absolute maximum rating values under the worst probable conditions caused by the

supply voltage variation, input voltage variation, variation in parts' constants, environmental temperature,

etc., otherwise LCD module may be damaged.

5) POWER PROTECTION CIRCUIT

Employ protection circuit for power supply, whenever the specification specifies it.

A suitable protection circuit should be applied, based on each system design.

6) DISPOSAL

Always comply all applicable environmental regulations, when disposing of LCD module.

7) EDGES OF PARTS

Be careful with handling the metal flame (bezel) of a module. Even though burr disposal treatment is performed, it may cause

injuring. Be careful with edges of glass parts and touch panel identically. For designing the system, give special consideration

that the wiring and parts do not touch those edges.

8) Ú LUMINANCE DECREASE OF FL

When FL becomes extremely dark and its color changes from white to pink, stop the use of the module

immediately. FL, at the end of its life with its discharge color turns into pink as the characteristics of FL, may

adversely affect the module at the end part of FL due to temperature raising caused by depletion of the

mercury which is contained in FL tube, or may have a possibility of breakage.

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 5

Specification No. TENTATIVE

Sheet 4

For Designing the System

2-1 DESIGNING ENCLOSURE

1) MECHANICAL DIMENSIONS

Refer to the individual specification for LCD module's mechanical dimensions.

2) MOUNTING HOLES

LCD module should be assembled to the system by using all mounting holes specified in the individual

specification with the specified screws.

In addition, some modules may not be necessary to use all the mounting holes. Make comprehensive

judgments on the entire system.

3) Ú BENDING / TWISTING

Make sure to design the enclosure that bending/twisting forces are not applied to LCD module during and

after the installation into the system.

4) GASES FROM SETTING MATERIAL

Some plastic materials and shock absorbing materials (rubber) used in the system may generate gases that

may cause the deterioration of the polarizer laminated on LCD’s panel or internal parts of the module. Prior

confirmation is required.

5) GASES FROM PACKAGING MATERIAL

Some materials used for packaging (for which sulfuric acid is used in the recycling process) generate gases

that may cause the deterioration of the polarizer laminated on LCD’s panel or internal parts of the module.

Prior confirmation is required.

2-2 DESIGNING POWER SUPPLIES AND INPUT SIGNALS TO LCD MODULE

1) CAPACITY OF POWER SUPPLY

Refer to individual specification for details for capacity of power supply, and apply some protection circuit

including fuses for power supply lines.

2) SEQUENCE OF POWER SUPPLIES AND INPUT SIGNALS

Power supply lines should be designed as follows.

Power supplies should always be turned on before the input signals are applied to LCD module, and the

input signals should be disconnected before power supplies are turned off.

The detailed sequence of power supplies and signals are described in the individual specification.

In addition, refer to individual specifications for unused terminals.

3) FL CABLE CONNECTION

Make sure to connect correctly high-voltage wire and low-voltage wire between FL tube and inverter unit.

If high-voltage wire and low-voltage wire are connected incorrectly, it may cause insufficient brightness or

unstable operation of FL, and smoke or burn of the parts.

4) PREVENTION OF IMAGE STICKING

Design the system not to display same pattern for a long time in order to prevent image sticking on the

panel. Note that incorrect sequence of power supplies and input signals may cause the sticking on the

panel, too.

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 6

Specification No. TENTATIVE

5) GROUNDING OF METAL FRAME

Grounding of metal frame of LCD module is generally effective to prevent radiation interference from the

system design.

However, the necessity of grounding, or effective grounding method should be dependent on each system

design.

2-3 DESIGNING FOR BETTER VISIBILITY

1) PANEL ANGLE

Visibility of LCD module deeply depends on the viewing directions. The position and the angle of LCD

module in the system should be designed so that the best visibility can be obtained at the actual usage.

2) WINDOW OPENING

Dimensions of window opening of the system's enclosure should be designed as smaller than "Viewing

Area" and larger than "Active Area" specified in individual specification in order to obtain better

appearance.

3) PROTECTIVE COVER

In case of severe environmental condition like outdoor usage, a proper transparent protective cover(lens)

over LCD module is recommended to apply in order to prevent scratches, and invasion of dust, water, etc.,

from the system's window onto LCD module.

Ultra-violet ray cut filter is recommended to apply onto LCD module for outdoor operation. Strong

ultra-violet ray may cause damage the panel. However, in that case, transmittance-luminance will decrease.

Careful selection of material is required.

2-4 DESIGNING FL POWER SUPPLY CIRCUIT

Input FL starting voltage(VSFL) should be longer than two seconds. If it were not, it may cause unstable

operation of FL.

Inverter should be design to stop output when the inverter is no-load to FL tubes (due to breakage of FL, etc.)

to prevent high-voltage generation.

When high voltage is applied to FL continuously without normal operation of FL (due to output leakage within

FL wiring circuit, etc.) it may cause smoke or burn. To prevent excess current, design the inverter with a

protection circuit such as a current limiter (excess current detection) to stop inverter output.

Sheet 5

For Installation in Assembly

3-1 ESD (ELECTRO-STATIC DISCHARGE) PREVENTION

The C-MOS LSIs used in LCD module is very sensitive to ESD. The following caution should be taken

when installing LCD module to an enclosure of the system in order to prevent damage of C-MOS LSIs

used in LCD module.

1) HUMIDITY

Ambient humidity of working area is recommended to be higher than 50%RH in order to avoid ESD.

2) GROUNDING

2-1) Grounded electro-conductive mats are recommended to be covered on the floor of working area and

surface of working benches.

2-2) The grounding should be done through a resister of 0.5-1M ohms in order to prevent spark of ESD.

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 7

Specification No. TENTATIVE

Sheet 6

2-3) Person handling LCD modules should be grounded with wrist band.

2-4) Tools like soldering iron and screw drivers and working benches should be grounded.

3) IONIZER

Using ionizer (an antistatic blower) is recommended at working area in order to reduce electro-static

voltage.

4) REMOVING PROTECTION FILM

When removing protection film from LCD panel, peel off the film slowly (more than three seconds) from the

edge of the panel with round-ended tweezers or adhesive tape while blowing with ionizer toward the peeling

face to minimize ESD which may damage electrical circuit.

5) Be careful with touching metal portion of testing instruments in order to prevent unnecessary ESD.

6) Do not touch the electrode area of PCB and electrical parts like LSI, capacitor, connector pin, etc.

3-2 DUST AND STAIN PREVENTION

1) WORKING AREA

Reduce dust level in working area. Especially the level of metal particle should be decreased, otherwise

electrical circuit in LCD module may be damaged due to short circuit by metal particles.

2) PROTECTION FILM

LCD module may be shipped with "protection film" on LCD panel in order to prevent from scratches and

dust.

It is recommended to remove the film at later process of assembling.

3) FINGER PRINT

Use finger stalls or soft and dust-free gloves in order to keep clean appearance of LCD module when

handled for incoming inspection and assembly.

4) Ú WIPING OFF DUST ON THE PANEL

When LCD panel becomes dirty, wipe the panel surface off softly with absorbent cotton or another soft

cloth.

If necessary, breathe upon the panel surface and then wipe off immediately and softly again.

If the dirt can not be wiped off, follow the instructions described in individual specification.

Be careful not to spill organic solvents into the inside of LCD module. The solvents may damage driver IC

and PCB area used inside module.

The polarizer laminated to LCD panel and adhesives may be damaged by the solvents, so do not use any

organic solvents for wiping off LCD panel.

5) ADHESIVE ON LCD PANEL

Be careful not to attach adhesive, grease, etc., on LCD panel, because it is difficult to remove them without

any damages on LCD panel.

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 8

Specification No. TENTATIVE

Sheet 7

6) Ú WATER SPOTS ON THE PANEL

Avoid the dewing or water condensation.

Wipe off a spot or spots of water or mist on LCD panel softly with absorbent cotton or another cloth as soon

as possible if happened, otherwise discoloration or stain may be caused.

3-3 BENDING / TWISTING OF LCD MODULE DURING ASSEMBLY

1) INSTALLING LCD MODULE TO THE ENCLOSURE

Do not bend or twist LCD module even momentary when LCD module is installed into an enclosure of the

system.

2) FASTENING SCREWS

Fasten screws for mounting holes uniformly, otherwise bending / twisting force may be applied to LCD

module.

3) INTERFACE / FL CABLES

Do not fasten screws, with catching interface cables or FL cables between LCD module and the enclosure.

This may cause bending of LCD module, or become the cause of a failure by damaging cables.

3-4 MECHANICAL FORCES

1) Ú STRONG MECHANICAL SHOCK

Refrain from strong mechanical shock like dropping from the working bench or knocking against hard

object.

These may cause panel crack, damage of FL or other mis-operation.

2) Ú EXCESSIVE FORCE

Refrain from excessive force like pushing the surface of LCD panel. This may cause scratches or breakage

of the panel, or a failure of the module.

3) Ú SCRATCHES ON THE PANEL

Do not put heavy object such as tools, books, etc., and do not pile up LCD modules.

Be careful not to touch surface of the polarizer laminated to the panel with any hard and sharp object. The

polarizer is so soft that it can be easily scratched, even the protect film covers it.

4) CONNECTORS

When inserting or disconnecting the connectors to LCD module, be sure not to apply force against PCB nor

connecting cables, otherwise internal connection of PCB and TAB drivers may be damaged.

5) FL CABLES

Be careful not to pull the FL cables in order to avoid mechanical damage in FL lamp and soldering area.

While mounting, do not bind or twist the FL cables, or the Lamp current may not be applied as designed.

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 9

Specification No. TENTATIVE

3-5 OPERATION

Be sure that the following caution should be taken under assembly and inspection of the system.

1) POWER SUPPLY

Power supplies should always be turned off in connecting process.

Do not connect or disconnect the power cables and connectors with power applied to LCD module.

2) INPUT SIGNAL

The signal should be applied after power supplies are turned on.

The signal should be removed before power supplies are turned off.

The detailed sequence of power supplies and signals are described in individual specifications.

Sheet 8

For Transportation and Storage

1) TEMPERATURE

Do not store LCD modules in high temperature, especially in high humidity for a long time (approximately

more than one month).

It is strongly recommended to store LCD modules where the temperature is in the range of 0 to 35 degrees

Celsius and the humidity is lower than 70%.

2) LOW TEMPERATURE

Liquid crystal material may be coagulated and LCD panel may be damaged at the lower temperature than

storage temperature range described in individual specification.

3) ULTRA VIOLET RAY

Store LCD module without exposure to direct sunlight or fluorescent lamps in order to prevent the module

from strong ultra violet ray.

4) CLEANLINESS

Keep the module in clean place, because any dust, hard particle may damage the polarizer, or dust

invades the inside of the module.

5) Ú CONDENSATION OF WATER

Avoid condensation of water on LCD module, otherwise it may cause mis-operation or defects. Keep away

LCD module from such ambient.

6) PACKAGING

In case of transportation or storage after opening the original packaging, LCD modules are recommended

to be repacked into the original packaging with the same method, especially with same kind of desiccant.

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 10

Specification No. TENTATIVE

- CONTENTS -

Revision History Sheet 1

Caution and Handling Precaution 2

1. Scope 10

2. Product Specifications 10

2.1 General Specifications

2.2 Absolute Maximum Ratings 11

2.3 Mechanical Specifications

2.3.1 Weight

2.3.2 Dimensional Outline 12-13

2.4 Electrical Specifications 14

2.4.1 Circuit Diagram

2.4.2 Sequence of Power Supplies and Signals

2.4.3 Timing Chart 15

2.4.4 Timing Specifications 16

2.4.5 Interface Connector 17

2.4.6 Register map 19-20

2.4.7 Colors Combination Table 21

3. Recommended Operating Conditions 22

4. Electrical Characteristics 23

4.1 Test Conditions

4.2 Specifications

5. Optical Characteristics 24

5.1 Test Conditions

5.2 Optical Specifications

6. Quality 24

6.1 Inspection AQL

6.2 Test Conditions

6.3 Dimensional Outline

6.4 Appearance Test 26

6.4.1 Test Conditions

6.4.2 Specifications

6.5 Display Quality 27

6.5.1 Test Conditions

6.5.2 Specifications

6.6 Reliability Test 28

6.6.1 Test Conditions

6.6.2 Specifications

6.7 Labels 29

7. Lifetime 30

7.1 Module

7.2 Test Conditions

8. Packaging 31

8.1 Carton

9. Warranty 32

10. Measuring Method 32

10.1 Measuring Systems

10.2 Measuring Methods 33

Sheet 9

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 11

1 2

(Dots)

G B

Specification No. TENTATIVE

1. Scope

This specification is applicable to Toshiba Matsushita Display Technology's 43 cm diagonal size TFT-LCD module

"LTA170C07RF" designed for TV.

2. Product Specifications

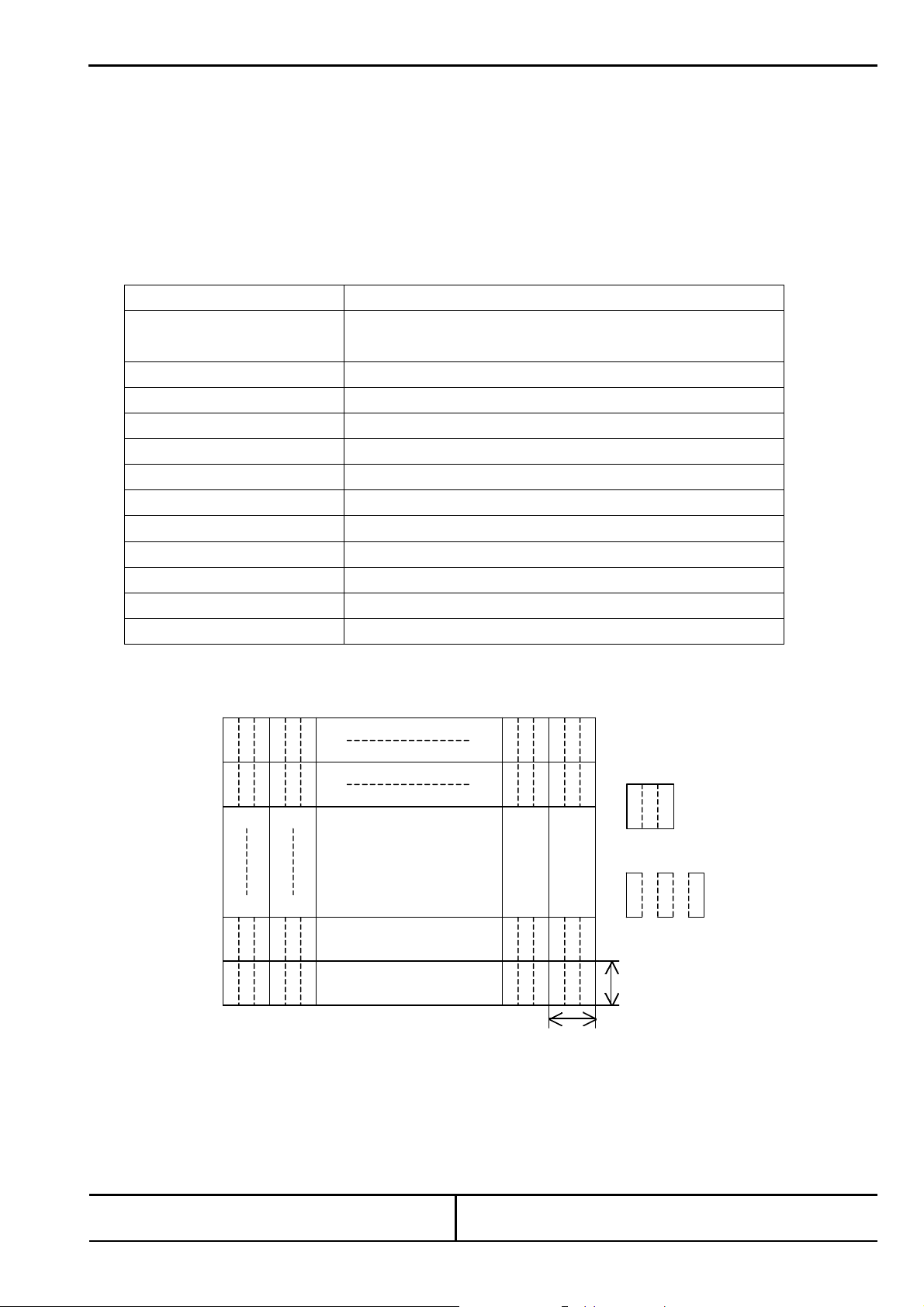

2.1 General Specifications

Item Specifications

Display Mode TN color (253 gray scales, 16,194,277 colors)

Transmissive type, Normally white

Viewing Direction 6 o'clock (in direction of maximum contrast)

Driving Method TFT active matrix

Input Signals

Dimensional Outline

Active Area

Viewing Area

Number of Pixels

Pixel Pitch

Pixel Arrangement RGB vertical stripes 1)

Surface Treatment Low Reflection & Anti-glare hard coat on LCD surface

Backlight 4 cold-cathode fluorescent lamps (L-Type)

Note 1) Display area address is as follows.

R G B

R G B

R G B

R G B

R G B

R G B

R G B

R G B

1

2

479

480

C-MOS 8Bit × RGB

385 (W) × 303 (H) × 17.5 (D) (mm)

343.68 (W) × 261.60 (H) (mm)

349 (W) × 267 (H) (mm)

640 (W) × 480 (H) 1)

0.545 (W) × 0.537 (H) (mm) 1)

R G B

R G B

R G B

R G B

R G B

R G B

R G B

R G B

R G B

R

0.446mm

0.446mm

: pixel

: Sub-pixel

Sheet 10

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

New No. LTA170C07RF-01

Old

←# Special ←& Addition ← Change

No.

Page 12

Specification No. TENTATIVE

Sheet 11

2.2 Absolute Maximum Ratings 1)

Item Symbol Min. Max. Unit Checked Terminal 4)

Supply Voltage VDD -0.3 +6.0 V VDD - GND

Input Voltage of Signals VIN -0.3 VDD+0.3 V

FL Driving Voltage VFL 0 2.0 kV(rms)

FL Driving Frequency fFL 0 100 kHz

Operating Ambient Temperature 2) TOP 0 +50

Operating Ambient Humidity 2) HOP 10 90 %(RH)

Storage Temperature 2) T

Storage Humidity 2) H

Operating Temperature for Panel 3) - 0 +60

Note 1) Do not exceed the maximum rating values under the worst probable conditions taking into account the supply voltage

variation, input voltage variation, variation in part constants, and ambient temperature and so on. Otherwise the module

may be damaged.

2) Wet bulb temperature should be 39°C (Max), and no condensation of water. See figure below.

3) The surface temperature caused by self heat radiation of cell itself is specified on this item.

4) Refer to 2.4.5

-20 +60

STG

10 90 %(RH)

STG

°C

°C

°C

80%90%

60%

40%

Wet Bulb

Temperature [ C]

-20

10

0

0

10 20 30 40 50 60 70 80

Dry Bulb Temperature [ C]

30

20

40

50

20%

10%

]

)

H

R

(

%

[

y

t

i

d

i

m

u

H

Storage

Operation

2.3 Mechanical Specifications

2.3.1 Weight

2000 ± 100g

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 13

Specification No. TENTATIVE

Sheet 12

2.3.2 Dimensional Outline Unit: mm

(Front figure) Standard Tolerance: 0.5

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 14

Specification No. TENTATIVE

Sheet 13

(Back figure) Unit: mm

Standard Tolerance: 0.5

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 15

nce of Power Supplies and Signals

Unit

CN5

I/F Connector

Panel

Driver

Driver

CN3

CN2

CN4

CCFL

Input signal

Specification No. TENTATIVE

2.4 Electrical Specifications

2.4.1 Circuit Diagram

CN1

DC/DC

Converter

Controller

Liquid Crystal Panel

640 x 480 pixels

Y-

2.4.2 Seque

Note (1): OFF time (<=0.5V) should be maintained more than 150ms.

300 ms (Min)

50 ms (Max)

VDD

V

DD

0 ms (Min)

30 ms (Max)

0.5V

16 ms (Min)

4.5V

TON=460 us

X-Diver

Backlight

0 ms (Min)

Y-

300 ms (Min)

Note (1)

0 ms (Min)

30 ms (Max)

Sheet 14

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 16

Hs

2.4.3 Timing Chart

Specification No. TENTATIVE

TV

Sheet 15

Vs

Vs

Hs

Vs

Tvp

Thp

Tvb

Thb

TH

Tvd

Thd

VIH

VIL

Tvf

Thf

Hs

RGB-Data

Clk

Tvpd

Tds

Ths

Tdh

Thh

VIH

VIL

Tch

VIH

VIL

VIH

VIL

Tcl

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 17

Specification No. TENTATIVE

Sheet 16

2.4.4 Timing Specifications

1) 2) 3) 4)

Item Symbol Min. Typ. Max. Unit Remarks

Clock

(Clk)

Horizontal

(Hs)

Vertical

(Vs)

Frequency Fck 17 28.6 31.5 MHz

High time Tch 10 - - nsec

Low time Tcl 10 - - nsec

Setup time Tds 6 - - nsec DATA

Hold time Tdh 7 - - nsec

Polarity - Negative -

Setup time Ths 6 - - nsec

Hold time Thh 7 - - nsec

TH

including Blanking

Pulse width Thp 1 69 Note 1 Fck

Back porch Thb 12 104 Note 1 Fck

Display term Thd 640 Fck

Front porch Thf 1 46 - Fck

Polarity - Negative -

Phase shift Tvpd -1 0 1 Fck

TV

including Blanking

Pulse width Tvp 1 6 Note 1 TH

Back porch Tvb 2 46 Note 1 TH

Front porch Tvf 1 29 - TH

Display term Tvd 480 TH

720 910 1620 Fck Total Period

28.8 31.8 -

485 525 720 TH Frame Period

- 16.7 20.0 msec

µsec

Note 1) Thp + Thb<254, Tvp + Tvb<254

Note 2) If Hs and Vs signal is fixed to "H" or "L" level for certain period while Clock is supplied, the panel displays black with some

flicker.

Note 3) If Clock is fixed to "H" or "L" level for certain period while Hs and Vs is supplied, the panel may be damaged.

Note 4) Please adjust LCD operating signal timing and FL driving frequency, to optimize the display quality.

There is a possibility that flicker is observed by the interference of LCD operating signal timing and FL driving condition

(especially driving frequency), even if the condition satisfies above timing specifications and recommended operating

conditions shown in 3.

Note5) Do not make TH and TV fluctuate.

If TH and TV are fluctuate, the panel displays error.

Note6) In case of using the long frame period, the deterioration of display quality, noise etc. may be occurred.

Note7) Clock count of each Horizontal Scanning Time should be always the same.

V-Blanking period should be “n” X “Horizontal Scanning Time”. (n: integer)

Frame period should be always the same.

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 18

Specification No. TENTATIVE

2.4.5 Interface Connector

CN1 INPUT SIGNAL

Connector : IL-FHR-BF50S-HF / JAE

Mating Connector : TBD / JAE

Terminal No. Symbol Function

1 GND

2 Clk Clock

3 GND

4 Vs Vertical Sync.

5 Hs Horizontal Sync.

6 1) NC

7 GND

8 R0 Red Display Data 0 (LSB)

9 R1 Red Display Data 1

10 R2 Red Display Data 2

11 R3 Red Display Data 3

12 GND

13 R4 Red Display Data 4

14 R5 Red Display Data 5

15 R6 Red Display Data 6

16 R7 Red Display Data 7 (MSB)

17 GND

18 G0 Green Display Data 0 (LSB)

19 G1 Green Display Data 1

20 G2 Green Display Data 2

21 G3 Green Display Data 3

22 GND

23 G4 Green Display Data 4

24 G5 Green Display Data 5

25 G6 Green Display Data 6

26 G7 Green Display Data 7 (MSB)

27 GND

28 B0 Blue Display Data 0 (LSB)

29 B1 Blue Display Data 1

30 B2 Blue Display Data 2

31 B3 Blue Display Data 3

32 GND

33 B4 Blue Display Data 4

34 B5 Blue Display Data 5

35 B6 Blue Display Data 6

36 B7 Blue Display Data 7 (MSB)

37 GND

38 GND

39 REGEN After I2C data input, it is supplied to 2nd register at internal V-latch signal

by “H”-level of this pin input during 1Vs period.

40 2) INV Input Data Inversion Control: GND: normal, VDD: Data Inversion

41 2) GND

42 2) SCL I2C Clock

43 2) SDA I2C Data

44 VDD Power Supply : +5.0V

45 VDD Power Supply : +5.0V

46 VDD Power Supply : +5.0V

47 VDD Power Supply : +5.0V

48 1) NC

49 1) NC

50 GND

Note 1) NC terminal should be open.

Note 2) In case of using 6bit input data, please use higher 6bit (bit7-bit2).

In this case, it is recommended to fix bit0 and bit1 on GND.

Sheet 17

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 19

Specification No. TENTATIVE

CN2, 3, 4, 5 CCFL POWER SOURCE

Connector: BHSR-02VS-1 / JAPAN SOLDERLESS TERMINAL MFG CO., LTD.

Mating Connector: SM02B-BHSS-1 / JAPAN SOLDERLESS TERMINAL MFG CO., LTD.

Terminal No. Symbol Function

1 V

2 V

CCFL Power Supply (high voltage)

FLH

CCFL Power Supply (low voltage)

FLL

Sheet 18

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 20

1

STV ADDRESS (7:0)

Black Line FRC Level: Black line level control by

t Position adjustment

for internal patter (setup X 64)

internal patter (setup X 64)

nal pattern, and

2.4.6 I2C Register Map

Address

0 00 STH ADDRESS (7:0) Horizontal start position spec. (CLK) 10110101 10111100

2 02

3 03 CTL Width (7:0)

4 04

5 05 R INTEND (7:0)

6 06

7 07 For Black Belt CTL Width (7:0)

8 08 STOP Signal Control (7:0)

9 09

12 0C

13 0D

14 0E

15 0F SIG LEVEL

16 10 DIN 0p (7:0)

17 11 DIN 32p (7:0)

18 12 DIN 64p (7:0)

19 13 DIN 96p (7:0)

20 14 DIN 128p (7:0)

21 15 DIN 160p (7:0)

22 16 DIN 192p (7:0)

23 17 DIN 224p (7:0)

24 18 DIN 256p (7:0)

25 19

26 1A DIN 0p (7:0)

27 1B DIN 32p (7:0)

28 1C DIN 64p (7:0)

29 1D DIN 96p (7:0)

30 1E DIN 128p (7:0)

31 1F DIN 160p (7:0) Gamma GEF setup (160, G) 10110110

32 20 DIN 192p (7:0) Gamma GEF setup (192, G) 11000111

33 21 DIN 224p (7:0) Gamma GEF setup (224, G) 11011000

34 22 DIN 256p (7:0) Gamma GEF setup (256, G) (LSB7Bit:validity) 01110011

35 23 G_Gm_th: G_Gamma Through 0: Through, 1:ON

36 24

b7 b6 b5 b4 b3 b2 b1 b0

01

CTL Setup all (7:4) OEV Hold (3:0)

OEV Setup (7:4) CKV Setup (3:0)

H Start Position H: End Position

V: Start Position V: End Position

R ON G ON B ON

R_Gm

th

G_Gm

th

TVD

SEL

Black Line

FRC Level

Data Initial Value Sub

CENT

DIN 0p (7:0)

Inite

State

ON

OFF

Black Line Level

Win

ON

R_Gm Offset (6:0)

G_Gm Offset (6:0)

SIG SEL (3:0)

Specification No. TENTATIVE

Vertical start position spec. (Hs) 00110010 00101000

CTL Setup all: CTL ON Phase setup

OEV Hold: Gate ON Width setup

CTL Width: CTL ON Width setup 00110101 00110010

OEV Setup: Gate ON Phase setup

CKV Setup: Gate ON Clock Phase setup

R INTEND: Souce scan Interval setup 00010111 00110011

DI OFF: DI stop 0: DI=ON, 1: DI=OFF

DI

OFF

UD LR

UD: Up/Down Reversal 0:Up, 1: Reversal

LR: Right/Left Reversal 0:Right, 1: Reversal

Inite State OFF: 0:normal, 1: Inite State OFF

Sausce signal output time in centering mode 00110101

Timing control for V Blancking’s gate voltage 11010110

1/256 Gray scale setp

Black Line Level: control of center Gray Scale

H Start Position: Horizontal star

for internal patter (setup X 64)

H end Position: Horizontal end Position adjustment

for internal patter (setup X 64)

V Start Position: Vertical start Position adjustment

V end Position: Vertical end Position adjustment for

R_ON: R signal control 0:R=L, 1: R=input value

G_ON: G signal control 0:G=L, 1: G=input value

B_ON: B signal control 0:B=L, 1: B=input value

Win_ON: Display window control for internal pattern

0: No-window, 1: Window

SIG_SEL: Internal patten select

Gray scale level control for inter

Black level contorol

Gamma REF setup (0, R) 00000000

Gamma REF setup (32, R) 00110011

Gamma REF setup (64, R) 01100000

Gamma REF setup (96, R) 10000100

Gamma REF setup (128, R) 10100000

Gamma REF setup (160, R) 10110110

Gamma REF setup (192, R) 11000111

Gamma REF setup (224, R) 11011000

Gamma REF setup (256, R) (LSB7Bit:validity) 01110011

R_Gm_th: R_Gamma Through 0: Through, 1:ON

R_Gm_Offset: R_Gamma offset setup

Gamma GEF setup (0, G) 00000000

Gamma GEF setup (32, G) 00110011

Gamma GEF setup (64, G) 01100000

Gamma GEF setup (96, G) 10000100

Gamma GEF setup (128, G) 10100000

G_Gm_Offset: G_Gamma offset setup

Gamma BEF setup (0, B) 00000000

Sheet 19

Contents

normal wide

00101100 00101001

01100110

00000000

00000000

00100100

00100100

11100000

10000000

10000000

10000000

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 21

Specification No. TENTATIVE

37 25

38 26

39 27

40 28

41 29 DIN 160p (7:0) Gamma BEF setup (160, B) 10110110

42 2A DIN 192p (7:0) Gamma BEF setup (192, B) 11000111

43 2B DIN 224p (7:0) Gamma BEF setup (224, B) 11011000

44 2C DIN 256p (7:0) Gamma BEF setup (256, B) (LSB7Bit:validity) 01110011

45 2D B_Gm_th: B_Gamma Through 0: Through, 1:ON

46 2E Rdc: EMI Function On/Off (Reduce) 0: OFF, 1: ON

8Bit/6Bit: FRC Function On/Off 0: OFF, 1: ON

Rdm: Noise shape random setup 0: Random, 1: Fix

NS_DZ: FRC Mode setup 0: NS, 1:4Frame dither

47 2F

B_Gm

th

Rdc 8Bit

6Bit

DIN 32p (7:0)

DIN 64p (7:0)

DIN 96p (7:0)

DIN 128p (7:0)

B_Gm Offset (6:0)

Rdm NS DZ Sig

VREF_Offset (7:0)

Gamma BEF setup (32, B) 00110011

Gamma BEF setup (64, B) 01100000

Gamma BEF setup (96, B) 10000100

Gamma BEF setup (128, B) 10100000

B_Gm_Offset: B_Gamma offset setup

SEL

ON

Sig SEL ON: Input signal select 0: Imput, 1: Internal

Reference input for Gamma-Test 00000000

Sheet 20

10000000

11000000

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 22

2.4.7 Colors Combination Table

Display

Basic

Color

Black

Blue

Green

Light Blue

Red

Purple

Yellow

White

Gray

Scale

of Red

Black

Dark

↑

↓

Light

Red

Gray

Scale

of

Green

Black

Dark

↑

↓

Light

Green

Gray

Scale

of

Blue

Black

Dark

↑

↓

Light

Blue

Gray

Scale

of

White

&

Black

Dark

↑

↓

Light

Black

White

Note1 L: Low level voltage, H: High level voltage

R7R6R5R4R3R2R1R0 G7 G6 G5 G4 G3 G2 G1 G0

LLLLLLLL LLLLLLLL LLLLLLLL

LLLLLLLL LLLLLLLL HHHHHHHH

LLLLLLLL HHHHHHHH LLLLLLLL

LLLLLLLL HHHHHHHH HHHHHHHH

HHHHHHHH LLLLLLLL LLLLLLLL

HHHHHHHH LLLLLLLL HHHHHHHH

HHHHHHHH HHHHHHHH LLLLLLLL

HHHHHHHH HHHHHHHH HHHHHHHH

LLLLLLLL LLLLLLLL LLLLLLLL

LLLLLLLH LLLLLLLL LLLLLLLL

LLLLLLHL LLLLLLLL LLLLLLLL

LLLLLLHH LLLLLLLL LLLLLLLL

LLLLLHLL LLLLLLLL LLLLLLLL

HHHHHHLH LLLLLLLL LLLLLLLL

HHHHHHHL LLLLLLLL LLLLLLLL

HHHHHHHH LLLLLLLL LLLLLLLL

LLLLLLLL LLLLLLLL LLLLLLLL

LLLLLLLL LLLLLLLH LLLLLLLL

LLLLLLLL LLLLLLHL LLLLLLLL

LLLLLLLL LLLLLLHH LLLLLLLL

LLLLLLLL LLLLLHLL LLLLLLLL

LLLLLLLL HHHHHHLH LLLLLLLL

LLLLLLLL HHHHHHHL LLLLLLLL

LLLLLLLL HHHHHHHH LLLLLLLL

LLLLLLLL LLLLLLLL LLLLLLLL

LLLLLLLL LLLLLLLL LLLLLLLH

LLLLLLLL LLLLLLLL LLLLLLHL

LLLLLLLL LLLLLLLL LLLLLLHH

LLLLLLLL LLLLLLLL LLLLLHLL

LLLLLLLL LLLLLLLL HHHHHHLH

LLLLLLLL LLLLLLLL HHHHHHHL

LLLLLLLL LLLLLLLL HHHHHHHH

LLLLLLLL LLLLLLLL LLLLLLLL

LLLLLLLH LLLLLLLH LLLLLLLH

LLLLLLHL LLLLLLHL LLLLLLHL

LLLLLLHH LLLLLLHH LLLLLLHH

LLLLLHLL LLLLLHLL LLLLLHLL

HHHHHHLH HHHHHHLH HHHHHHLH

HHHHHHHL HHHHHHHL HHHHHHHL

HHHHHHHH HHHHHHHH HHHHHHHH

Specification No. TENTATIVE

B7 B6 B5 B4 B3 B2 B1 B0

Sheet 21

Gray Scale

Level

-

-

-

-

-

-

-

L 0

L 0

L 0

L 0

L 4

:

:

:

:

:

:

L5…

L252

L253

L254

Red L255

L 0

L 0

L 0

L 0

L 4

:

:

:

:

:

:

L5…

L252

L253

L254

Green L255

L 0

L 0

L 0

L 0

L 4

:

:

:

:

:

:

L5…

L252

L243

L254

Blue L255

L 0

L 0

L 0

L 0

L 4

:

:

:

:

:

:

L5…

L252

L253

L254

White L255

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 23

V

: Low Voltage Line

: AC Ampere Meter

FL Inverter

A

A

Specification No. TENTATIVE

Sheet 22

3. Recommended Operating Conditions

1) 5) 6)

Item Min. Typ. Max. Unit Remarks

Supply Voltage VDD 4.75 5.0 5.25 V

Current Consumption I

Inrush current I

*2

- 190 270 mA(rms)

DD

*3

- - 2100 mA(peak)

RS

Allowable Ripple Voltage VRP - - 100 mV(p-p)

FL Driving Voltage VFL 909 1010 1111 V(rms) IFL=(6.0)mA(rms)

FL Start Voltage - - 2150 V(rms)

FL Driving Frequency fFL 30 - 70 kHz

FL Input Current per Lamp IFL 5.5 6.1 8.0 mA(rms) Per a Lamp

Input Low Level VIL 0 --- 0.7 V

2)

Ta=0 °C

9)

3) 4)

7) 8) 9)12)

9)

9)11)

Input High Level VIH 2.2 VDD V

IIL -100 - IIH - - 100

µA

µA

VIL =0V Input leakage current

VIH = VDD

Note 1) The module should be always operated within these ranges. The "Typ." shows the recommendable value.

Note 2) Checked Pin Terminal: V

, GND (GND : Vss = 0V )

DD

Note 3) Checked Pin Terminal : R0-R7 and G0-G7 and B0-B7,GND (0V),

Note 7) Checked Pin Terminal: V

FLH1-VFLL1

, V

FLH2-VFLL2

, V

FLH3-VFLL3

, V

FLH4-VFLL4

Note 8) If FL input current is higher than typical value, then FL lifetime become shorter.

Note 9) Measuring Method of IFL :

This TFT-LCD module uses twin FL lamps.

So the measuring value of AC ampere meter is FL input currents of two lamps.

TFT Module

FLL

VFLH

: High Voltage Line

Note 10) Please adjust LCD operating signal timing and FL driving frequency, to optimize the display quality.

There is a possibility that flicker is observed by the interference of LCD operating signal timing and FL driving

frequency, even if the condition satisfies above recommended operating condition and timing specification shown in 2.4.4

Note 11) Input FL starting voltage (V

) should not be less than one second.

SFL

If it were less than one second, it may cause unstable operation of FL.

Note 12) If FL input current is higher than typical value, the deterioration of display quality may be occurred.

Note 13) Inverter should be designed to meet the follow conditions:

(1) The positive and negative waveforms of lamp current and voltage should be symmetric.

The symmetric ratio should be larger than 90%. And the waveform should be approached a sine-curve.

(2) It is recommended to using push/pull type”-inverter. Because the backlight unit of t his LCD-Panel is designed for

“push/pull type”-inverter.

(3) Please set the all input voltages (CN2, CN3, CN4, CN5) synchronization.

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 24

1. White

3 2 4 5 6 7 8

Specification No. TENTATIVE

4. Electrical Characteristics

4.1 Test Conditions

Ambient Temperature : Ta 25±3°C

Ambient Humidity : Ha 55±15%(RH)

Supply Voltage : VDD 5.0 V

Input Signal : “Typ”-value of timing specification shown in 2.4.4

FL Inverter : HIU-473 for LTA140C060F (Harison Toshiba Lighting corp. )

FL Input Current : IFL 6.0mA(rms) / Lamp

FL Driving Frequency : fFL 50kHz

4.2 Specifications

Item Symbol Min. Typ. Max. Unit Remark

Sheet 23

Current Consumption

Note 1) The value of IDD is measured in the following pattern.

IDD

- 190 270 mA

1

2. Yellow

3. Purple

4. Red

5. Light Blue

6. Green

7. Blue

8. Black

VDD Terminal Current

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 25

Specification No. TENTATIVE

Sheet 24

5. Optical Characteristics

5.1 Test Conditions

It is same as 4.1

The measuring method is shown in 11.

5.2 Optical Specifications

Specifications Item Symbol Conditions

Min. Typ Max.

Viewing Angle

Contrast Ratio CR

Luminance L

Chromaticity

White

Note 1): Refer to "11. Measuring Method".

Note 2) Photometer : BM-5A TOPCON (Aperture 2°)

Note 3): The above test limit must be applied for initial use. Characteristics will be shifted by long period operation,

but it is not irregular phenomena. Theoretically brightness characteristics will be decreased due to CCFL

degradation and color shift due to optical components change.

θ

t r - 4 10 ms Response Time

t f

xR - 0.640 - - Red

yR

xG - 0.300 - - Green

yG

xB - 0.138 - - Blue

yB

xW 0.220 0.280 0.340 -

yW

CR>=10

θ=0°, φ=0°

θ=0°, φ=0°

θ=0°, φ=0° Gray Scale

Level=L255 (White)

Gray Scale Level:L255

θ=0°, φ=0° - 0.330 - Ditto

Ditto

Ditto

φ= 180°

φ= 0°

φ= 90°

φ= -90°

50 80 - °

50 80 - °

50 80 - °

50 80 - °

300 400 - -

- 12 20 ms

350 450 - cd/m2

- 0.600 - -

- 0.060 - -

0.220 0.280 0.340 -

Unit Remark

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 26

Specification No. TENTATIVE

6.Quality

6.1 Inspection AQL

Total of Major Defects : AQL 0.65 %

Total of Minor Defects : AQL 1.5 %

Sampling Method : ANSI/ASQC Z1.4 (Level 2)

6.2 Test Conditions

1) Ambient Temperature : 25±5°C

2) Ambient Humidity : 65±20% (RH)

3) Illumination : Approximately 500 lx under the fluorescent lamp

4) Viewing Distance : Approximately 30cm by the eyes of the inspector from the module

5) Inspection Angle : θ=0°, φ=0°

6.3 Dimensional Outline

The products shall conform to the dimensions specified in 2.3.2.

Definition of Major and Minor defects are as follows.

Item Description Class

Important Dimensions Dimensional outline, Dimensional between

the mounting holes.

Others Dimensions specified in this specifications Minor

Sheet 25

Major

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 27

Specification No. TENTATIVE

6.4 Appearance Test

6.4.1 Test Conditions

1) Condition: Non-operating : PCB Appearance, Soldering, Bezel, Plastic Frame, Connectors

Same as 6.2

2) Condition: Non-operating and operating : Black and White Spots/Lines

Same as 6.2

6.4.2 Specifications

Item Description Class

Pattern peeling snapping, electrically short Major PCB Appearance

Repair portion on PCB is not covered by epoxy resign Minor

Soldering Cold solder joint, lead move when pulled Major

Bezel, Frame,

Connectors

Spots/Lines

Note 1) Inspection area should be within viewing area.

Note 2) Dusts which are bigger not less than 0.10mm (0.1 ≤ W) shall be judged by "Average Diameter".

1)2)

Average Diameter D = (a+b) /2 (mm)

Distinct stain, rust or scratch Minor

(Bright Line)

Line width (mm) Length (mm) Acceptable count

W ≤ 0.01

0.01< W ≤ 0.10 N ≤ 2

0.10< W

(Bright Spot)

Average diameter (mm) Acceptable count/side

D ≤ 0.10

0.10 < D ≤ 0.3 N ≤ 2

0.3 < D

(Non-Bright Line)

Line width (mm) Length (mm) Acceptable count

W ≤ 0.01

0.01< W ≤ 0.10 N ≤ 3

0.10< W

Non-Bright Spot

Average diameter (mm) Acceptable count/side

D ≤ 0.10

0.10 < D ≤ 0.3 N ≤ 3

0.3 < D

(Total Spots and Lines): N ≤ 5

- Neglect

0.3 ≤ L ≤ 1.0

0

- Neglect

0.3 ≤ L ≤ 1.0

0

Neglect

Neglect

2)

2)

Minor

a

b

Sheet 26

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 28

Specification No. TENTATIVE

Sheet 27

6.5 Display Quality

6.5.1 Test Conditions

1) Inspection Area : Within viewing area

2) Condition : Same as test conditions shown in 4.1 and 6.2

3) Test Pattern : White display pattern (gray scale level L255) , Black display pattern (gray scale level L0)

Red display pattern (gray scale level L255), Green display pattern (gray scale level L255)

Blue display pattern (gray scale level L255)

6.5.2 Specifications

Item Description / Specifications Class

Function No display, Malfunction Major

Display Quality

1)2)3)

Missing line Major

Missing Sub-Pixels

1) Bright defects : 5 pcs. maximum

2) Dark defects : 10 pcs maximum 2)

3) Total sub-pixel defects : 10 pcs maximum

Minor

2)3)

Various uniformity (mura) : neglect

Inconspicuous flicker, crosstalk, Newton's ring and other defects :

neglect

Black and White

Spots/line

Backlight Missing (Non-operating) Major

Note 1) Defects of both color filter and black matrix are counted as bright or dark defects.

Inspection area should be within the active area.

Note 2) Bright defect means a bright spot (sub-pixel) on the display pattern of gray scale L0.

Dark defect means a dark spot (sub-pixel) on the display pattern of gray scale L255.

Note 3) Bright spot which can not be found by using 5%ND-Filter shall not be counted as a defect.

Note 4) Test pattern : White and black 1dot-checker display pattern (gray scale level L255 and L0),

Note 5) Test Pattern : White display pattern (gray scale level L127), Black display pattern (gray scale level L0)

Same as 6.4.2 5) Minor

4)5)

-

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 29

Specification No. TENTATIVE

Sheet 28

6.6 Reliability Test

6.6.1 Test Conditions

1) The module should be driven and inspected under normal test conditions.

2) The module should not have condensation of water (moisture) on the module.

3) The module should be inspected after two or more hours storage in normal conditions (15 - 35°C,45 - 65%(RH)).

4) A module shall be used only for one test.

6.6.2 Specifications

The module shall have no failure in the following reliability test items.

Test Item Test Conditions Result

High Temperature Operation 1) 50°C 192 h OK 3p/3p

High Temperature Storage 2) 60°C 192 h OK 3p/3p

High Temperature

High Humidity operation 1)

Low Temperature Operation 1) 0°C 192 h OK 3p/3p

Low Temperature Storage 2) -20°C 192 h OK 3p/3p

Temperature Shock 2) -20°C ⇔ 60°C

Mechanical Vibration 2) 10 - 57Hz half-sine pulse 0.075mm,

Mechanical Shock 2) 50×9.8m/s2 , 11ms,

Note 1) Operating

Note 2) Non-Operating

Definitions of failure for judgment shall be as follows:

1) Function of the module should be maintained.

2) Current consumption should be smaller than the specified value.

3) Appearance and display quality should not have distinguished degradation.

4) Luminance should be larger than 50% of the minimum value. (Refer to 5.2 Optical Specifications)

40°C 90% 192 h OK 3p/3p

OK 3p/3p

1.0h 1.0 h

5 cycles

OK 3p/3p

57-500Hz, 1.0×9.8m/s2 , 11min/cycles

once for X.Y.Z each directions, 0.5h each

OK 3p/3p

±X, ±Y, ±Z direction,

one time each directions

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 30

LTA170C07RF

( 21) 6

100

9

Specification No. TENTATIVE

Sheet 29

6.7 Labels

(1) Product Label

Serial number : 3A 0 00001

• ‚ ƒ „ …

• : Module type code

‚ : Manufacturing code

ƒ : Lot code 3 A

(1) (2)

(1):Year code-end of the A. D.

(2):Month code-alphabet

àJan. : A - Dec. : L

„ : Revision No.

… : Serial code decimal, 5 figures

Toshiba Matsushita Display Technology Co., Ltd.

MADE IN JAPAN

* ∆ ∆ G 3 A 0 0 0 0 0 1 *

(78)

unit: mm

(2) Caution Labels

Ÿ High Voltage Ÿ Disposal of CCFL

HIGH VOLTAGE

CAUTION

RISK OF ELECTRIC SHOCK. DISCONNECT

THE ELECTRIC POWER BEFORE SERVICING.

35

9

(3) Label Locations

TBD

Toshiba Matsushita Display Technology Co.,Ltd

A: Product Label

B: Caution Label (High Voltage)

C: Caution Label (Disposal of CCFL)

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 31

Specification No. TENTATIVE

7. Lifetime

7.1 Module (except lamp)

MTTF (Mean Time To Failure) : 50,000 h

(This value is not assurance time but inference value by following conditions.)

Conditions : Ambient temperature : 25±5°C (No wind)

Ambient humidity : 65%(RH)

7.2 Lamp

7.2.1 Test Conditions

Ambient temperature : 25±5°C (No wind)

Lamp current : 6.0mA(rms)/Lamp

Lighting condition : continuous lighting

Driving frequency : 50kHz

7.2.2 Specifications

MTBF : 50,000 h

Definitions of failure for judgment shall be as follows.

1) LCD luminance becomes half of the minimum value specified in 5.2.

2) Lamp doesn't light normally.

Sheet 30

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 32

8. Packaging

8.1 Carton (internal package)

(1) Packaging Form

Corrugated cardboard box

TENTATIVE

Specification No. TENTATIVE

Sheet 31

(2) Packaging Method

1) 2) :

Note 1) : Total weight : (Approx.) 12.7kg

Note 2) : Acceptable number of piling : 12sets

(3) Packaging Material :

Number Quantity Description

•

‚

ƒ

„

…

†

Toshiba Matsushita Display Technology Co.,Ltd

5

1 set

1

3

1 set

Static electricity

Protective sack

Holder (inner box)

Static electric

Protective square bag

Silicagel (100g×3)

Carton

Plastics adhesive tape

520 mm

420 mm

271 mm

Date: 2003-06-18

Date: - -

New No. LTA170C07RF-01

Old

No.

←# Special ←& Addition ← Change

Page 33

Upper Side

Left Side

( =-90 )

Lower Side

( =0 )

Y

( =0 )

( =0 )

LCD Module

Specification No. TENTATIVE

Sheet 32

9. Warranty

Finish of warranty term is until arrival at your factory. (except defect which is clearly responsible for Toshiba

Matsushita Display Technology Co., Ltd.)

10. Measuring Method

10.1 Measuring System

X-Y Stage

Photometer

Screen Center

500 mm

LCD Module Driving Circuit

Stage Controller

Light Shielded Room

(1) The measurement point is the center of the active area except the measurement of Luminance Uniformity.

(2) Photometer : BM-7/BM-5A TOPCON (Aperture 2°)

(3) Definition of and :

Measurement

Direction

( =180 )

X

Right Side

( =90 )

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

←# Special ←& Addition ← Change

New No. LTA170C07RF-01

Old

No.

Page 34

Specification No. TENTATIVE

Sheet 33

10.2 Measuring Methods

(1) Luminance:

The luminance of the center on a white raster (gray scale level L255) shall be measured.

Measurement shall be executed 30 minutes after the lamp is lit up.

(2) Contrast Ratio:

The contrast ratio can be calculated by the following expression.

Contrast Ratio (CR) = L255 / L0

L255 : Luminance on the white raster (gray scale level L255)

L 0 : Luminance on the black raster (gray scale level L0)

(3) Viewing Angle

Viewing angle is defined as the angles(θ,φ), in which specified contrast ratio can be obtained.

(Refer to 11.1(3) for the axes.)

Note) Measuring system for Viewing Angle

(a) The measurement point is the center of the active area except the measurement of Luminance Uniformity.

(b) Photometer: Ez Contrast 160R (ELDIM)

(4) Chromaticity :

The values (x,y) of chromaticity coordinates should be measured for the White, Red, Green and Blue Raster(gray scale

level L255) each with a photometer.

(5) Response Time :

The response time is measured using a photo detector (photodiode) which measures the light intensity of the pixels.

Input Signal : All High All Low All High

(White Display) (Black Display) (White Display)

(bright)

Light intensity

(dark)

t f : Fall time is the time for the light intensity of the pixels to go from 10% of its maximum to 90% of its maximum.

t r : Raise time is the time for the light intensity of the pixels to go from 90% of its maximum to 10% of its maximum.

Photodiode : S1223-01 HAMAMATSU PHOTONICS K.K.

White Display : White Raster (gray scale level L255)

Black Display : Black Raster (gray scale level L0)

t r t f

90%

10% 10%

90%

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-06-18

Date: - -

New No. LTA170C07RF-01

Old

No.

←# Special ←& Addition ← Change

Loading...

Loading...