Page 1

)

A

p

Density (Consistency) Meter LQ500

Introduction

The LQ500 density (consistency) meter uses

microwave phase shift technology to determine

concentrations of solids in the material to be measured

flowing through pipes. It can perform a stable and

realtime density (consistency) measurement because

this technology is not affected by flow velocity along

with fluid color, and also is not easily affected by

contaminants and low process pressure rate. As the

LQ500 has no moving parts, it is reliable and virtually

maintenance free.

Since the output of the LQ500 is theoretically linear, it

can be applied to a wide range of density (consistency)

measurement.

<Notice>

The LQ500 requires a full pipe to measure the

density (consistency). Contact Toshiba before

installation in the following cases:

<Possibility of unfilled condition>

(a) When it is installed at the discharge of a pump.

(b) When installation is horizontal, and unfilled

condition occurs inside the pipe.

(c) A process where the pipe becomes unfilled

when the operation is stopped.

Cable for power supply

(Detector/converter)

Figure

■

Standard Configuration

• Density (Consistency) Meter: 1 set

(Detector and converter separate mounted)

• Accessories: 1 set (see Table 1 below)

Communication

Note 1: Need to prepare a power supply cable for the

External Sync control

contact in

DI / DO

Density (consistency

measurement output 4-20mA

C power supply

Ground resistance

100 ohm or less

Cable for communication

(Detector/converter)

1. LQ500 Configuration Diagram

ut

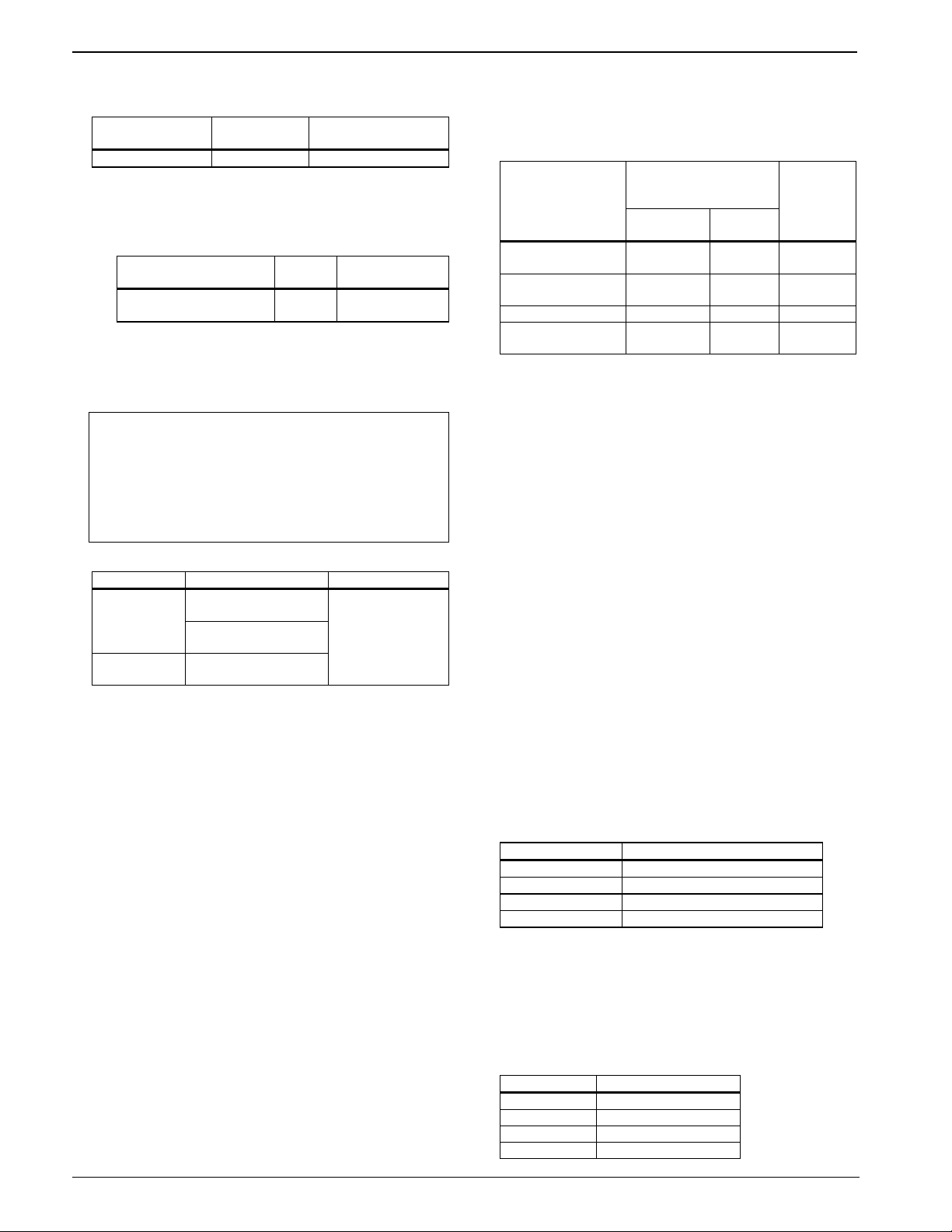

Table 1. Standard Accessories

Items Specifications Quantity

Power supply

cable

cable

Fuse

Document Instruction manual 1

LQ500.

Refer to the section of cable specifications at the

overall specifications in detail.

Between detector and

converter (*1)

Between detector and

converter (*1)

2A(T), 250 V

(glass tube, 5.2 dia. x 20 mm)

10 m

(32.8 ft)

10 m

(32.8 ft)

2

Figure 2. LQ500 Density (consistency) Meter

Specifications

■

Overall Specifications

Measurement method:

Microwave

Measurement

Meter size 50 mm (2”)

Span (*2) 2 to 50 %TS (*1) 1 to 50%TS (*1)

Lower limit setting

range (4 mA)

Upper limit setting

range (20 mA)

Setting increments 0.1%TS

Repeatability:

Meter size 50 mm (2”)

Repeatability ±0.02%TS ±0.01%TS

Note 1 : Above values are the results of commuting ability

Note 2 : Density (consistency) determination

Density

(consistency)

determination

repeatability

*The characteristics of sample reagent has errors due

to sample tests such as uneven density (consistency)

distribution.

*Full scale is the maximum value in the measurement

phase difference method

range:

0 to 48%TS 0 to 49%TS

2 to 50%TS 1 to 50%TS

*1 TS: Total Solids

*2 Span = Upper range – Lower range

*3 The material to be measured must be fluid

and be filled evenly with no voids.

80 to 300 mm

in the phase measurements of the converter.

repeatability for sample reagent;

Meter size

For the full

scale value of

2%TS or

greater

For the full

scale value of

less than 2%TS

50 mm

(2”)

±2%FS ±2%FS

±4%FS

80 to 300 mm

(3” to 12”)

(3” to 12”)

80 to 300 mm

(3” to 12”)

No. EJL- 106A

Page 2

LQ500

range, which is the upper limit setting range.

Resolution:

(2”)

80 mm (3”)to

300 mm (12”)

80 mm (3”)to

300 mm (12”)

Meter size 50 mm (2”)

Resolution 0.002%TS 0.001%TS

Note 1: Above values are the results of commuting

ability in the phase measurements of the

converter.

Note 2: Density (consistency) determination

resolution for sample reagent;

Meter size

Density(consistency)

determination repeatability

50 mm

0.1%TS 0.05%TS

* The density (consistency) determination resolution

stated above is defined due to manufacturing

limitation to make reagents with stable distribution

and a minimum difference of fluid density

(consistency).

<Notice>

1. Install a sample tap near the LQ500 as close

as possible to get an accurate density

(consistency) measurement using the LQ500.

2. Take several samples in rapid sequence for

more accurate density (consistency)

measurement with less human error factors.

Environmental conditions:

Items Temperature range Humidity range

Standard: 0 to 50 deg.C

Detector

Converter

(32 to 122 deg.F)

Option: -20 to 50 deg.C

(4 to 122 deg.F) (*1)

0 to 50 deg.C

( 32 to 122 deg.F)

5 to 85%RH

(no condensation)

*1 A rubber heater is installed at the RF part of the

detector.

Need to prepare an additional power supply either

100Vac type or 200Vac type for it by yourself.

Determine one of them at the specification code.

This option is available for detector only.

Structure: Converter;IP65,

Detector:IP67, Watertight

Note: Outdoor installation is possible. However,

provide a sunshade for the converter section if

direct sunlight is unavoidable.

Microwave power: 10 mW

Vibration resistance:

No resonance to the following levels of

vibration:

(1) No failure for 5 to 150 Hz with the following

acceleration in each device for 30 minutes in

each axis of X, Y, and Z (90 minutes);

Converter: 4.9 m/s

2

, Detector: 25m/s2

(2) No failure for 5 to 150Hz with the following

acceleration in each device for 3 minutes in

each axis of X, Y, and Z, 10 times (90

minutes as total);

Converter: 4.9 m/s

2

, Detector: 25m/s2

Note: Avoid using the LQ500 in an environment with

constant vibration.

Cables: See the Table 2

Table 2. Cable specifications

Cables Between detector

(RF part)and converter

Specifications

Power supply

Cable type

Cross-sectional

area (*3)

Number of cores 2 5 3

Cable diameter (*4)

CVVS-2C-2S

(*1)

Communi-

(24Vdc)

2 mm

11 to 13

2

mm

cation

CVVS-5C-

1.25S

2

1.25 mm2 2 mm2

11 to 13

mm2

*1 10m (32.8 ft) length is packed as standard.

*2 Need to prepare this cable by the customer.

*3 Need to use a sheathed cable.

*4 If the diameter of the cable is smaller than the inside

diameter of the packing, enlarge the cable diameter to

the same size as the packing by wrapping around the

cable.

This dimension is coming from a diameter of the

cable gland of the LQ500.

Power

supply

cable of

LQ500 (*2)

CVV-3C-2S

11 to 13

mm2

Conformance to European Community Directives:

• EMC directive 89/336/EEC

• The low voltage 93/68/EEC

• PED 97/23/EC (Note l)

Note: See table 6 in detail.

Approved hazardous locations certification:

UL/CUL Class I, Division 2, Groups A, B, C and

D (UL/CULonly for explosion proof)

Weight: Refer to Outline Dimensions (Table 3).

Part 15 of the FCC rules: Certified.

■

Detector Specifications

Meter size: 50mm (2”), 80mm (3”), 100mm (4”),

150mm (6”), 200mm (8”), 250mm

(10”), and 300mm (12”)

Flange standard and maximum working pressure:

Flange standard Maximum working pressure

ANSI Class 150 1 MPa (150 psi)

DIN10 and BS10 1 MPa (10 bar)

DIN 16 1.6 MPa (16 bar)

JIS 10K 1 MPa (10 kgf/cm2)

Note: Each product was passed a hydraulic test under

twice pressure rate for 15 minutes toward the

specification.

Fluid temperature:

0 to 100 deg.C (32 to 212 deg.F) without freezing

and bubbles conditions

Allowable fluid conductivity:

Meter size Fluid conductivity

50 mm (2”) 20 mS/cm maximum

80 mm (3”) 16 mS/cm maximum

100 mm (4”) 15 mS/cm maximum

150 mm (6”) 10 mS/cm maximum

2

Page 3

LQ500

200 mm (8”) 8 mS/cm maximum

250 mm (10”) 8 mS/cm maximum

300 mm (12”) 6 mS/cm maximum

Note 1: The LQ500 can not have an accurate density

(consistency) measurement when it is over the

specification according to reduce the microwave signal.

Note 2: The LQ500 density (consistency) measurement

for application where liquids containing highly

conductive particles such as active carbon and

metal particles may be affected. Consult

Toshiba for detail when the measuring liquid

contains such particles.

Wetting materials:

Name Materials (*1)

Main pipe

Temperature detector sheath 316 stainless steel (*4)

Applicator window Polysulfone (*4)

Applicator window sealant Fluoric rubber

*1 Avoid using the LQ500 for applications where

harmful liquids that cause corrosion, deterioration, or

changes in quantity for the wetting materials are used.

Make sure all materials at these wetting parts that are

suitable for your CIP or not before cleaning.

*2 The smoothness inside the pipe on this material is;

Type Meter size Smoothness

Standard type

Option type

*3 State the wetted materials when you choose these

options.

*4 The materials of them are changed for abrasive

applications.

Need to choose the specification code for this

application.

SCS14A cast (equivalent to

316 SS) (standard) (*2, *3)

50 to 200 mm

(1/2” to 8”)

250 & 300 mm

(10” & 12”)

50 to 300 mm

(1/2” to 12”)

No buffing

Buffing # 150

Buffing # 150

Applicator:

Serves as an antenna to send

and receive

microwave signals, one set provided.

Temperature detector: RTD (Pt100)

Fitting:

Direct fitting to vertical or horizontal

piping. (Refer to the section of Piping

Precautions.)

■

Converter Specifications

Output signals

• Density (consistency) measurement output:

4-20mAdc (load resistance 750 ohm maximum,

isolated output.)

• Density (consistency) fault or Maintenance

signal: 125Vac, 0.1A (resistive load) solid

state contact; opens when an error occurs in the

converter or when the LQ500 is in the setting

change mode, otherwise the contact remains

closed.

Communication signal:

Digital signal is superimposed on 4-20mAdc

current signal (conforming to HART protocol(*1)).

Load resistance:240 to 750 ohm

Load capacity:0.25μF maximum

*1 HART (Highway Addressable Remote

Transducer) protocol is a communications

protocol for industrial sensors recommended

by HCF (HART Communication Foundation).

Note: The optional AF900 hand-held terminal can be

used to operate the LQ500 from remote places

by connecting the AF900’s probe lead between

the LQ500’s 4-20 mA dc output signal lines.

Input signals

• External synchronized input signal:

In order to avoid problems of density

(consistency) measurement such as

inhomogeneous condition caused by

discontinuous process operation and empty pipe

condition caused by stopping process operation.

<Specification>

One dry “make” contact;

Contact capacity of 24Vdc with 0.1 to 2.0A is

required.

This contact signal can be used to start or stop

density (consistency) measurement in

synchronization with an external contact, such

as the contacts on a pump.

The measurement starts or stops as follows:

Contact closed: Starts density (consistency)

measurement.

Contact open: Stops density (consistency)

measurement.

• Density multiplier switching signal:

In order to achieve selecting up to 4 kinds of

liquid concentration measurement independently

as maximum.

<Specification>

Two voltage signals described below are required:

Input voltage: H level: 20 to 30 Vdc

L level: 2 Vdc or less

Input resistance: Approx. 3k ohm

• Conductivity correction signal:

Need to prepare an additional conductivity meter

when using this function. Install in where is able

to have a stable and accurate measurement.

<Specification>

Input signal: 4 to 20mAdc

Conductivity range: 0 to 10mS/cm

Update period for density (consistency)

measurement output and display:

Approx. 1 second

Functions by software as standard:

• Data saving function:

In order to save measurement data into the

memory of converter temporary.

The oldest data is overwritten.

<Specification>

Data storage points: 256 points maximum.

Period: 1 to 1,800 minutes (1 minute each).

ex 1: The data is saved for approx. latest 4.26

hours when programming every minute.

ex 2: The data is saved for approx. latest 21.3

3

Page 4

LQ500

hours when programming every 5

minutes.

• Moving average function:

In order to keep the average density (consistency)

output, or in order to suppress the deflection

width of the output. It helps for density

(consistency) control.

<Specification>

Enable to determine a number from 1 to 99.

• Change-rate limit function:

In order to reject the transient density

(consistency) output as noises, or a sudden

variation in the output according to intrusion by

bubbles, etc....

<Specification>

Allowable rate of change limit: 0.00 to 9.99%TS

Enable to determine a number from 0 to 99.

• Additive correction function:

Available for up to 10 kinds of mixed / blended

liquids. Sensitivity compensation can be set using

registered parameters depending on the type and

the mixing rate of liquids.

• Password function:

This function is used to limit access to changing

parameters that affect measured data by means of

a password.

Arrestor:

Arrestors are installed in the LQ500 current

output (4-20mAdc) and AC power lines.

Operation panel and Display:

Used to check data or change various settings.

Operation switches: 5 switches.

Display: 4-line, 20-character LCD (dot-matrix)

with backlight.

Power supply:

100 to 240Vac 50/60Hz (Allowable voltage: 85 to

264Vac)

Note: An additional power supply is required when

choosing an optional environmental

temperature specification type (-20 to 50 deg.C).

Refer to the section of Environmental

conditions in detail.

Note2: UL/CUL Hazardous locations type does not

have a power switch. Please prepare a power

switch outside. (Rated 250V AC,10A above,

DPST: Double-Pole/Single-Throw)

Use the power switch for Hazardous

locations in Hazardous locations area.

Power consumption: Approx. 25VA (100Vac),

Approx. 35VA (240Vac)

Housing material: Steel plate

Coating: Polyurethane

MTBF: 135.8 months under 25 deg. C (77 deg. F)

based on MLL-HDBK-217F

Installation

■

Outline Dimensions

100 (3.9”)

(H)

(X) (L)

Figure 3. LQ500 detector outline dimensions

Table 3. LQ500 detector outline dimensions

Size (mm) X (mm) H (mm) L (mm)

50 (2”) 170 (6.7”) 225 (8.9”) 300 (11.8”) Approx.22 Approx.21 (46 lb) Approx. 21

80 (3”) 200 (7.9”) 225 (8.9”) 300 (11.8”) Approx.30 Approx31 (68 lb) Approx. 26

100 (4”) 220 (8.7”) 240 (9.4”) 300 (11.8”) Approx.31 Approx.34 (75 lb) Approx. 29

150 (6”) 270 (10.6”) 260 (10.2”) 300 (11.8”) Approx.43 Approx.44 (97 lb) Approx. 42

200 (8”) 320 (12.6”) 290 (11.4”) 300 (11.8”) Approx.52 Approx.54 (119 lb) Approx. 48

250 (10”) 300 (11.8”) 315 (12.4”) 350 (13.8”) Approx.68 Approx.68 (150 lb) Approx. 64

300 (12”) 360 (14.2”) 340 (13.4”) 350 (13.8”) Approx.85 Approx.99 (218 lb) Approx. 76

DIN 16 ANSI 150 JIS 10K

190 (7.5”)250 (9.8”)

Weight (kg)

Unit: mm

4

Page 5

LQ500

p

A

p

Contact signal I/O port (2)

74 (2.9”)

234 (9.2”)

communication port

Converter power

supply cable port

Reserved

(25)

(1.0”)

(15)

320 (12.6”)

45

15

(1.8”)

Converter

(0.6”)

360 (14.2”)

(0.6”)

390 (15.4”)

Contact signal I/O port (1)

Figure 4. LQ500 Converter outline dimensions

■

Installation Precautions

(1) Install the LQ500 in an environment free from

vibration and corrosive gases and in a place

which allows easy on-site maintenance.

(2) Provide a clearance space both detector and

converter to the front, rear, and above the unit.

See Figure 5.

(3) Provide a sunshade for the detector and

converter if direct sunlight is unavoidable

when installing outdoors.

(4) The LQ500 cannot be installed in an

environment where there is a possibility that

flammable or explosive gases may leak.

(5) The LQ500 should avoid the following

environmental installations:

• Places where condensation accumulates due

to sudden temperature changes.

• Places of low or high temperature that is out

of the specification.

• Places near equipment that produces strong

electric waves or electrolytes.

• Places where flammable or explosive gas

may be generated.

Unit: mm

Converter

Maintenance

ace

s

RF part

Maintenance

s

ace

500 (19.7”)

Back

Front

500 (19.7”)

600 (23.6”)

Detector

500 (19.7”)

600 (23.6”)

500 mm (19.7”) maintenance

space is also needed above unit.

Figure 5. Clearance space

Unit: mm

Weight: 7kg(15 lb)

110

(4.3”)

(119)

(4.7”)

Density signal output port

Grounding terminal

■

Piping Precautions

(1) A vertical installation of the LQ500 is

recommended.

Avoid installing horizontally (install LQ500

vertically) in case of follow ing e nvir onmen ts.

(2) Install the LQ500 in a pipeline where the

pipe is always filled with fluid and without

bubbles or entrapped air. If these conditions

are not satisfied, the measured value varies

or may give an inaccurate reading. It is

recommended that the LQ500 is installed at

the outlet instead of the suction side.

(3) Avoid places where sediment collects at the

bottom of the pipe.

(4) Avoid places where air gets into the fluid. To

avoid this problem, install the LQ500 to the

outlet of a pump, not to the suction side.

(5) When installing the detector horizontally,

install it so that the RF-part of it is oriented up

(that is, a pair of applicators stay horizontally)

600 (23.6”)

to make it easier for maintenance work and to

obtain its specified performance.

(6) The LQ500 can be installed in either direction

(upstream or downstream) and without

requiring a straight pipe section. Install it in a

place allowing easy on-site maintenance.

In the case of Wall mounting

360 (14.2”)

74 (2.9”)

In the case of 50A (2”) mounting

Steel pipe U bolt

(M10)

360 (14.2”)

Steel pipe

(50A) (2”)

a) Places where bubbles or environments

air remain in the pipe.

b) Places where solids concentration in

the fluid is not even because solids in

the fluid stay either at the bottom or

top of the pipe due to slow fluid

velocity or other reason.

c) Pipe size is enlarged to install a larger

meter sized LQ500.

5

Page 6

LQ500

V

(7) Install an adjustable piping mechanism if there

is a possibility that the detector pipe may not fit

between mating flanges.

(8) Install the LQ500 in a place where enough

water pressure is applied. Therefore, it is

recommended that the LQ500 be installed as

far away as possible from the pipe outlet

opened to atmosphere. This is to prevent the

effects of air being trapped in the liquid.

(9) If there is a possibility of no liquid flow or

uneven liquid distribution occurring when a

pump is off, use an external synch control

signal to operate the LQ500 only when the

pump is working.

(10) Provide a stop valve at upstream and

downstream of the detector, and between stop

valves and the LQ500 provide the four valves

described below with a stop valve attached to

each: 1) sampling outlet valve; 2) zero point

water inlet valve; 3) vent valve; and 4) drain

valve. If it is not possible to stop the fluid at the

point where the LQ500 is installed, provide a

bypass pipe with a stop valve provided in the

middle. These valves are needed to drain the

fluid from the detector

pipe and fill it with

drinking water (density or consistency 0%) to

adjust the zero point. See Figures 6 and 7.

(11) Use gaskets for piping of the size conformed to

flange rating and of the material appropriate

for the liquid to be measured.

Install this valve to the side of the pipe in the

case of horizontal installation. It is

recommended that a 1-inch ball valve be

installed to the side of the pipe.

Stop

valve

Bypass

pipe

Stop valve

ent valve

Zero point water pipe

LQ500

Stop valve

Flow direction

(from down to up directions)

Zero point water valve

Drain valve

Drain pipe

Figure 6. Recommended Installation

(vertical installation)

Stop valve

Vent v a lve

LQ500

Sampling

valve

Zero point

water valve

Stop valve

Drain

valve

NOTE:

• Zero point water valve:

Used to supply drinking water (density or

consistency 0%) to the detector pipe for zero

point adjustment. Install this valve at the top of

the pipe in the case of horizontal installation. It

is recommended that a 1-inch ball valve be

installed on the top of the pipe and zero point

water supplied through this inlet using a vinyl

hose etc.

Note: If valve water pipe is connected to this

valve, air cannot be extracted. Therefore,

another valve (vent valve) is needed to

extract air.

• Vent valve:

Used to vent process fluids to open air when

performing zero adjustment. This helps the

drinking water (density or consistency 0%)

enter the detector pipe easily. Install this valve

on the top of the pipe in the case of horizontal

installation.

• Drain valve:

Used to drain the fluids before supplying

drinking water (density or consistency 0%) to

the detector pipe for zero adjustment. Install

this valve at the lowest point of the pipe. It is

recommended that a 1-inch ball valve be

installed at the lowest point of the pipe.

• Sampling valve:

Used to extract fluids for manual analysis.

Stop valve

Bypass pipe

Figure 7. Recommended Installation

(horizontal installation)

■

Wiring Precautions

(1) Provide a switch and a fuse to isolate the unit

from the mains power for ease of maintenance.

(2) Ground the LQ500 with 100 ohm or less

ground resistance. Do not use a common

ground shared by other power equipment.

(3) Use the accessorious cables for communication

and power supply between detector and

converter. Connect cables to the terminals that

match the marking on the cables.

(4) Use a sheathed cable with 2mm

2

cross-sectional area for AC power cable.

(5) The cables should be free from vibration and

should have no slack in the cables.

(6) Wire the LQ500 output in conduit separated

from those of AC power cable, control signals,

alarm signal or other cables which could

become the source of noise.

(7) Use a 2-wire shielded sheathed cable to wire

the LQ500 output (4-20mAdc) and

conductivity signal. Ground the shielded cable

on the receiving instrument side for both cable.

6

Page 7

LQ500

pply

Tx+

TX-

Rx+

Rx-

SG

FG

+24V

0V

FG

Converter

L1

L2

AO+

AO-

DI3

DI2

COM2

DO1

COM1

DI

COM

FG

CVV

CVVS

Power su

Ground terminal (PE)

(Ground resistance 100 ohm or less)

Density (consistency) measurement output

(4-20mAdc, 750 ohm max., isolated output)

Density multiplier switching voltage inputs

(H level: 20 to 30 Vdc, L level: 2 Vdc or less and Input

resistance: Approx. 3k ohm)

Density (consistency) measurement output

(4-20mAdc, 750 ohm max., isolated output)

External synch. Control contact signal input

(Contact capacity: 24Vdc, 0.1 to 1A)

CVV

Chassis ground terminal

(Ground resistance 100 ohm or less)

100 to 240 Vac, 50/60Hz

Ground terminal

(Ground resistance 100 ohm or less)

RF part

Notice 1: Do not connect to the “FG” terminals neither communication cable nor power supply cable in the detector side.

Notice 2: Either “PE” terminal on the terminal block in the converter on the chassis ground terminal of the unit should be grounded with 100

Notice 3: Ground the shielded cable on the receiving instrument side.

Notice4: UL/CUL Hazardous locations type does not have a power switch. Please prepare a power switch outside. (Rated 250V AC,10A above,

Ec+

Ec-

FG

Tx+

Tx-

Rx+

Rx-

SG

FG

+24V

0V

FG

ohm or less ground.

DPST: Double-Pole/Single-Throw)

Use the power switch for Hazardous locations in Hazardous locations area.

CVVS

Conductivity

signal input

(4-20mAdc)

CVVS

Communication cable

CVVS

Power supply cable

Figure 8. External connections

(8) As the cable port is made air-tight using a

packing, tighten the cable gland securely when

all the wiring is completed. If the diameter of

the cable is smaller than the inside diameter of

the packing, enlarge the cable diameter to the

same size as the packing by wrapping valves

around the cable Its suitable diameter is 11mm.

Tighten the terminal screws securely. Its

suitable torque is 1.0 to 1.7 N⋅m.

(9) Screws at the terminals are needed to tighten

with 1.2 N·m torque (1.4 N·m is maximum).

(10) Do not turn on the power supply under the

uninstalled condition.

(11) Each cable in the communication cable and

power supply cable between detector and

converter has a banded marks for each

terminals. Connect them correctly without any

mismatches.

•Wiring when communications function is used

By connecting the cable lead of the optional

AF900 hand-held terminal to the density

(consistency) measurement output, you can

operate the LQ500 from remote places.

1) Make sure the load resistance of 4-20mAdc

line of output is between 240 and 750 ohm,

and the load capacitance is 0.25µF maximum.

2) The AF900’s cable lead can be connected to

the LQ500 anywhere along the current output

line. For example, the cable lead may be

connected to the signal terminals on the

receiving side in the control room. See Figure

9.

LQ500 converter

Density meter output

Hand-held terminal

AF900 (option)

Control room

Instrument (load)

Figure 9. Wiring for communication function

7

Page 8

LQ500

Ordering Information

When ordering the LQ500, refer to Table 4. Type

Specification Code. An entry must be made for each of

the columns.

The following items must also be specified:

1. Fluid characteristics:

• Type of material to be measured

• Density (consistency) (max., normal, min.)

• Temperature (max., normal, min.)

• Pressure (max., normal, min.)

• Conductivity (max., normal)

2. Measurement range

3. Tag number (specify “None” if not needed)

4. Hand-held terminal Required or not

(Refer to Table 5 below.)

5.Other specific items

No. EJL-106A

Page 9

LQ500

ead re

oduc

.

Table 4. Type Specification Code

(LQ500 Density (consistency) Meter)

TYPE CAT Code SPECIFICATION

1 2 3 4 5 6 7 8 9

L Q 5 0 0 Microwave Density (Consistency) Meter

A Standard

Meter Size

0 5 50mm (2")

0 8 80mm (3")

1 0 100mm (4")

1 5 150mm (6")

2 0 200mm (8")

2 5 250mm (10")

3 0 300mm (12")

Mounting Style

B JIS 10K flange connection

C ANSI 150 flange connection

F DIN 16 flange connection

Purpose

A Standard

B for PED (150 to 300 mm

C for UL/CUL Hazardous locations

Wetting parts

A SCS14A cast (Equivalent to 316L

B SCS14A cast (Equivalent to 316L

C SCS14A cast (Equivalent to 316L

D Hastelloy C pipe

Cable length between detector

A 10 m (32.8 ft) (standard)

B 20 m (65.6 ft)

C 30 m (98.4 ft)

D 40 m (131.2 ft)

E 50 m (164 ft)

X None (Note 3)

Optional specifications

None (standard) (blank codes are

A B Pipe buffing type

A C -20 to 50 deg.C (-4 to 122 deg.F)

A D Pipe buffing type with -20 to 50

A E -20 to 50 deg.C (-4 to 122 deg.F)

A F Pipe buffing type with -20 to

Note 1: The specification of PED (Pressure Equipment

Directive) is required from 150 to 300 mm (6" to

12") when the installation location is in the Europe.

Note 2: The differences between standard type are RTD

sensor and Applicator window.

Note 3: Toshiba recommends to using our specified cable.

ISO9001 and ISO14001 are certified.

Misuse of this product can result in damages to property or human injury.

R

10 11 12 13 14

(6" to 12") for EU) (Note 1)

type

SS) pipe (standard)

SS) pipe with teflon PFA coating for

sticky application

SS) pipe for abrasive application

(Note 2)

(RF part) & converter

required.)

environment temperature

specification, 200 to 240 Vac power

supply type of LQ500

deg.C (-4 to 122 deg.F) environment

temperature specification, 200 to 240

Vac power supply type of LQ500

environment temperature

specification, 100 to 120 Vac power

supply type of LQ500

50deg.C (-4 to 122deg.F)

environment temperature

specification, 100 to 120 Vac power

supply type of LQ500

lated manuals carefully before using this pr

t

Table 5. Type Specification Code

(AF900 Hand-held Terminal)

Model Specification Code

12345 6 7 8 9 10 11 12

AF 9 0 0 Hand-held terminal

L Q 3 For use with LQ series

A Display language English

A A 3 Standard

Description

Table 6. PED matrix

Flange

mm 50 80 100 150 200 250 300

inch 2 3 4 6 8 10 12

DIN16 SEP Certified

DIN10 SEP Certified

ANSI150 SEP Certified

SEP: Not required the PED.

Certified: The PED is certified.

Check your flange type and its meter size of the LQ500

whether it corresponds to the PED or not when its

installing location is in the Europe.

If yes, you need to choose the code “B” at the 10th

column in the specification code (Table 4)

Meter Size

Specifications are subject to change without notice.

Printed in Japan 2006-11 (TDOC)

© TOSHIBA Corporation 2003

All Rights Reserved.

9

Loading...

Loading...