Page 1

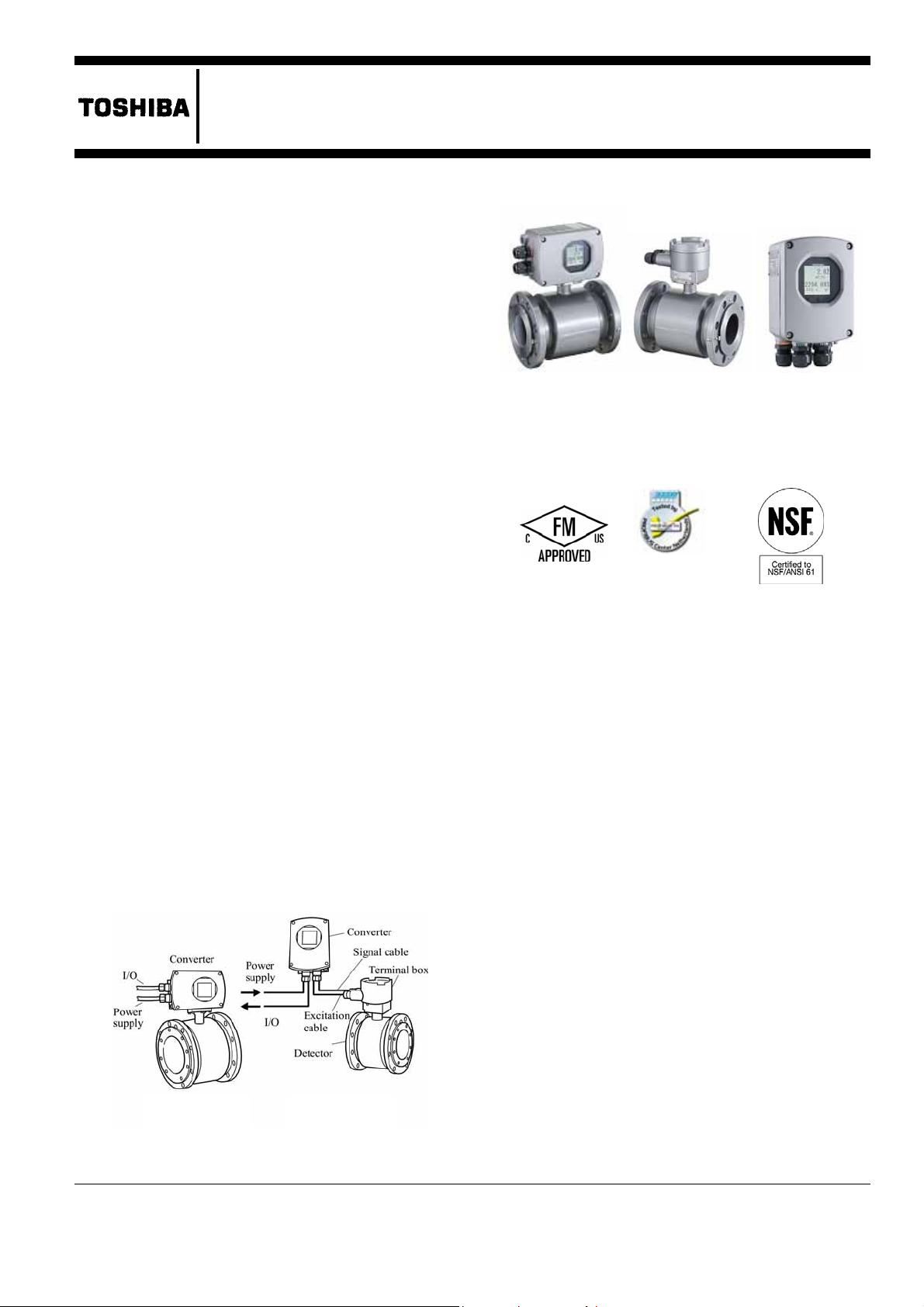

Field Intelligent Device – Mount Anywhere Series - Flanged

Electromagnetic Flowmeter

Introduction

The electromagnetic flowmeter uses Faraday’s Law of

electromagnetic induction to measure the process flow.

The device consists of two units: a detector, through

which the fluid to be measured flows and in which

low-level signals proportional to flow rates are

obtained; and a converter, which supplies excitation

current to the detector, and amplifies the signals from

the detector and then processes and converts the signals

into the 4–20 mAdc current signal or communication

signal. The meter features a Mount-Anywhere

magnetic field distribution technology, the meter is

highly immune to upstream flow disturbances.

Combined with a multi-functional converter LF620

(combined type) or LF622 (separate type) equipped

with its patented Noise-Sentry original noisesuppression circuit and advanced algorithms. The

LF654 has a very high tolerance to noise, giving the unit

a very stable output even for slurry fluid measurement.

IR (Infrared) switches enable parameter setting of the

converter without removing the cover. Flow direction

can be set in either way, and its unique 128 x 128 dot

matrix LCD display allows the LCD to be rotated

electronically to 90, 180 and 270 degrees without

opening the cover.

* HART protocol (Highway Addressable Remote Transducer) is

a communication protocol for industrial sensors recommended

by the HCF (HART Communication Foundation).

** DevComm2000 Smart Device Communicator available

through TIC for performing HART device configurations on

PC or laptop .

* PROFIBUS is the communications protocol for factory and

process automation that the PROFIBUS Organization

recommends. Instead of analog control with a conventional

analog signal (4-20 mA), it is fieldbus which digitizes all

signals. Flowmeters support PROFIBUS-PA.

* Modbus is the communication protocol that Modicon Inc.

developed. Physical layer is RS485.

LF654 /LF620

LF654 /LF622

1/2" to 18" (15 to 450 mm)

LF654/LF620F LF654 LF622F

Figure2. LF654 Mount-Anywhere Series

Flowmeters

Certification

No. Z01207

For PU and

HR lined flowmeter

Specifications

Overall Specifications

Measurement range in terms of flow velocity:

0 –1.0 ft/s to 0 – 39.4ft/s (0 – 0.3 m/s to 0 –12 m/s).

0 – 0.3 ft/s to 0 – 1.0 ft/s (0 – 0.1 m/s to 0 – 0.3 m/s)

range is available optionally.

Accuracy:

< 1/2" to 18" ( 15mm to 450mm) >

±0.2 % of Rate*

* This pulse output error result is established under standard

operating conditions at Toshiba admitted flow calibration

facility. (NIST Traceable)

* Individual meter measurement error may vary up to ±0.5% of

Rate at 1.64 ft/s (0.5m/s) or more and ±0.3% of rate ±0.039

inch/s (1mm/s) at 1.64 ft/s or less.

* Current output: plus ± 8µA (0.05% of span.)

* Refer to individual calibration data for each individual meter's

measurement error.

Combined type Se par a te t yp e

Figure1. Configuration

TIC-LF654L

Page 2

TIC-LF654L

Fluid conductivity:

3µS/cm minimum

Fluid temperature:

(-

-4 to 248 °F

20 to +120 °C):

PFA lined flowmeter

-4 to 140 °F

(-

20 to +60 °C):

Polyurethane lined flowmeter

(-

23 to 176 °F

5to +80 °C):

Hard Rubber lined flowmeter

Ambient temperature:

(-

-40 to 140 °F

40 to +60 °C):

PFA lined flowmeter

-4 to 140 °F (-20 to +60 °C):

PU lined and HR lined flowmeters

Structure:

Standard — IP 67 and NEMA 4X Watertight

Option — IP68 and NEMA 6P Submersible type

allows for accidental submergence up to 15m for

48 hours. This option is only available when PU

or HR liners are selected.

Power consumption:

Standard:10W(14VA)

at AC100V and Excitation current:0.2A

MAX:15W (22VA)

MAX:17W(24VA) with PROFIBUS

Approved hazardous location certifications:

Model: LF654/LF620F and LF654/LF622F

cFMus Nonincendive for use in

hazardous (classified) locations:

Class I, II, III, Division 2, Groups A-G

Detector and converter combination:

LF650/LF620: Combined type for standard

specification.

LF650/LF622: Separate type for standard

specification.

LF654/LF620F: Combined type with Ex approval of

Class I, II, III, Division 2 (cFMus).

LF654/LF622F: Separate type with Ex approval of

Class I, II, III, Division 2 (cFMus).

Mount-Anywhere Technology:

With TOSHIBA’s unique magnetic field

distribution technology the meter is highly immune

to upstream flow disturbances.

A minimum of 1D (one diameter) length of

upstream straight pipe from the flange is required to

maintain the specification performance.

Note: The test results were obtained and demonstrated at

TOSHIBA's flow calibration facility, Fuchu Japan.

Drinking water approvals:

PU and HR liner: NSF certified

Model LF654 Detector

Mounting style: Flange connection type

Fluid pressure:

-

15 psi or -1.0 bar (-0.1 MPa) to the nominal

pressure of the connection flange.

Note: Before shipping from the manufacturer, each detector

unit is tested by the following test condition.

Pressure… twice of the pressure index number

(ex. 300 psi in case of ASME B 16.5 class 150 flange)

Time… 15 minutes

Connection flange standards:

ASME B16.5 class 150, ASME B16.5 class 300

EN1092-1 PN10, EN1092-1 PN16

JIS B 2220 10K, JIS B 2220 20K

Principal materials:

Case — carbon steel

Flange material — carbon steel

Linings —

1/2” to 18” (15 to 450mm): PFA

1/2” to 18” (15 to 450mm): PU

4” to 18” (100 to 450mm): HR

Note: PFA liners are mechanically retained for full vacuum

service (65 to 450 mm).

Electrodes —

Type-Super smooth, polished with self cleaning

finish, and non stick shape

316L stainless steel (std.) in case of PU and HR

lining

Hastelloy C equivalent (std.)

… in case of PFA lining

Note: Electrodes are mechanically buffed and

electro-chemically polished.

Grounding rings — 316 stainless steel (std.)

Note: See Table 4 for optional materials and other

related information.

Measuring tube material — 304 stainless steel

Terminal box material — ADC12(Aluminum

alloy die casting)

Coating: Polyurethane resin coating (std.) gray colored

Dimensions and weights: See Figure 3, 4, 5 and 6.

Cable connection port: for separate type detectors.

Cable gland —

LF650: Provided as standard, G 1/2 male screws.

LF654(with cFMus):Not provided, 3/4–14NPT

male screws are required.

Applicable diameter —

0.433 to 0.512 inch (11 to 13mm)

2

Page 3

TIC-LF654L

Model LF620 and LF622 converters

Input signals

Analog signal — the voltage signal from detector,

proportional to process flow rate (for LF622

separate type converter).

Digital input DI

Signal type: 20 to 30Vdc voltage signal

Input resistance: 2.7k

Number of inputs: one point

Note: DI cannot be used with the Modbus communication.

DI function — One of the following functions can

be assigned to the DI signal.

Range switching — Selects either the higher or

lower range in the unidirectional or bidirectional

2-range setting.

Totalizer control — ‘Starts and stops’ or ‘Rest and

start’ the built-in totalizer.

Fixed-value outputs —Outputs fixed-values for

current and pulse outputs for loop check.

Zero adjustment — Executes zero adjustment

(on-stream at zero flow rate).

Output signals

Current output:

4–20mAdc (load resistance 0 to 750)

Note: The current output cannot be used with the

PROFIBUS-PA communication.

(Refer table 6 for details)

Digital outputs — Two points are available as

follows.

Digital output DO1:

Output type: Transistor open collector

Number of outputs: One point

Output capacity: 30Vdc, 200mA maximum

Note: DO1 cannot be used if Modbus

communication connection is 3 lines.

(Refer table 6 for details)

Digital output DO2 :

Output type:

Solid-state relay output (non polarity)

Number of outputs: One point

Output capacity: 150Vdc, 150mA maximum or

150Vac (peak to peak), 100mA maximum

Note: DO2 cannot be used with the Modbus

communication. (Refer table 6 for details)

DO1 and DO2 functions — One of the following

functions can be assigned to DO1 and/or DO2 .

• Pulse output (available only for DO1, DO2)

Pulse rate: MAX 10kHz (10000pps)(DO1)

MAX 100Hz (100pps)(DO2)

(Over 1kpps, auto-setting)

Pulse width: 0.5 to 500ms (but less than half of

the period for 100% flow rate)

Note: The same and simultaneous pulse is not available

between DO1 and DO2.)

• Multi-range selection outputs (Note 1)

• High, High high, Low, and/or Low low alarm

outputs (Note 2)

• Empty pipe alarm output (Note 2)

• Preset count output

• Converter failure alarm output

Note 1: Two outputs (DO1 and DO2) are needed for 4-range

switching and forward/reverse 2-range switching.

Note 2: Normal Open (default set) or Normal Close is selected

for alarm outputs when programming.

When power failure occurs, unit will be fault to Normal

Open.

Communications output:

• HART (std.) — Digital signal is superimposed on

4–20mAdc current signal as follows:

Conforms to HART protocol

Load resistance: 240 to 750

Load capacitance: 0.25µF maximum

Load inductance: 4mH maximum

• PROFIBUS (opt.)

Protocol: PROFIBUS-PA

Baud rate: 31.25kbps

Bus voltage: 9-30VDC

Consumption electric current of bus: less than 16mA

Manufacture Ident-No.: 093B

Standard Ident-No.: 9740

HEX

HEX

Slave address: 0-126 (Default address is 126)

Profile: Profile Ver.3.01 for Process Control

Devices

Function blocks: AI(Flow)×1 , Totalizer×1

• MODBUS (opt.)

Physical layer : RS485

Protocol : Modbus

Mode : RTU

Baudrate : 4800, 9600, 19200bps

Data length : 8bit

Parity bit : None, Odd, Even

Stop bit : 1bit, 2bit

Error check : CRC-16

Max. station number : 32(with Master device)

Max. cable length : 1.2km (Note)

Note: This length is specification of 3 line

connection.

3

Page 4

TIC-LF654L

LCD display:

Full dot-matrix 128×128 dot LCD display

(back–light provided)

A parameter change will rotate the display.

Parameter settings — Parameters can be set as

follows:

• IR Switches: Three key switches are provided

to set configuration parameters.

• Digital communication: HART, PROFIBUS

or Modbus is needed to set parameters.

• Zero adjustment: Zero point adjustment can

be started by pressing the switch in the

converter.

• Damping: 0.1 to 60 seconds (selectable in one

second increments)

“Field re-verification”

Mag-Prover– Toshiba’s

Zero span calibration tool allows unit to be

re-calibrated and verified using an internal software

program (For more information contact Toshiba

International Corp.)

Conditions when power fails:

Parameter setting values are stored in non–volatile

memory and the values will be restored when the

power returns to normal condition.The outputs and

display will remain as follows when power fails.

• Current output: 0mAdc

• Digital output: OFF

• LCD display: No display

• HART: No communication

• PROFIBUS: No communication

• Modbus: No communication

Power supply:

One of the following can be selected:

• 100 to 240Vac, 50/60Hz

(allowable voltage 80 to 264Vac)

110Vdc

(allowable voltage 90 to 130Vdc)

• 24Vdc (allowable voltage 18 to 36Vdc)

Surge protection:

Arresters are installed in the power supply and a

current signal output circuit to help protect the meter

from lightning and improve personnel safety.

Case: Aluminum alloy (equal to IP 67)

Coating:

Acrylic resin-baked coating, pearl–gray colored

Cable connection port:

Cable glands —

LF620 and LF622 without cFMus Approval:

Provided as standard, outer diameter of cableφ

11~13mm

Material Nylon 66

G (PF) 1/2 male threads.

LF620F and LF622F with cFMus Approval:

Not provided, 1/2–14NPT male threads are

required.

Applicable diameter —

0.433 to 0.512 inch (11 to 13mm)

Note: When PROFIBUS option is specified, cable gland size is

φ6〜8mm for signal cable, φ11〜13mm for power

cable

Vibration resistance:

No resonance to the following levels of vibration:

2

• 10 to 150Hz with acceleration of 9.8m/s

• Vibration of 30Hz with 29.4 m/s

2

in 4h in each

direction will not cause any defect to unit.

Note: Avoid using the flowmeter in an environment with

constant vibration.

Dimensions and Weights:

See Figure 7 (for Separate type)

MTBF:

Converter: 220,000 hours (25 years) at 77 °F (25 °C)

based on strict military specification

MIL-HDBK-217F

Detector: 350,000 hours (40 years) at 77 °F (25 °C)

based on strict military specification

MIL-HDBK-217F

4

Page 5

Installation

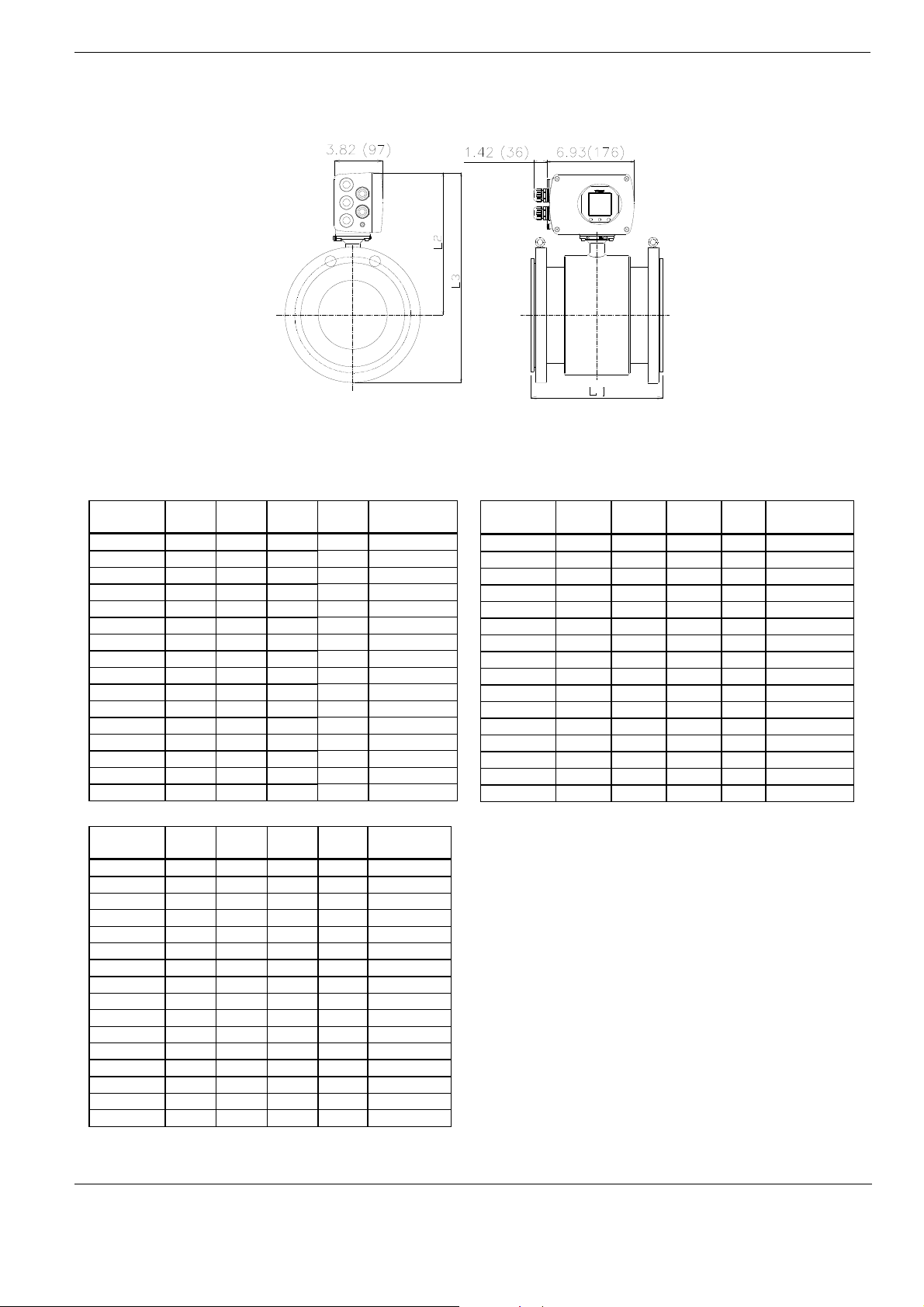

Dimensions

TIC-LF654L

Unit: inch (mm)

Note1: Eye bolts are provided at the top for flowmeters sized 8" (200mm) or above, and further, a roll-prevention base is provided for

flowmeters sized 10" (250mm) or larger.

Note2: Cable glands are not provided for LF654 of cFMus approved type. Refer to the cable connection port at converter.

ASME B 16.5 class 150 dimensions:

Meter size

(inch)

1/2 5.51 8.07 9.84 4 approx. 11.0

1 6.30 8.31 10.43 4 approx. 16..0

1-1/4 7.87 8.62 10.94 4 approx. 20.0

1-1/2 6.69 8.66 11.18 4 approx. 20.0

2 7.09 9.09 12.09 4 approx. 29.0

2-1/2 7.87 9.29 12.80 4 approx. 38.0

3 9.06 9.69 13.43 4 approx. 45..0

4 9.45 10.28 14.80 8 approx. 64.0

5 9.84 10.71 15.71 8 approx. 73.0

6 10.24 11.34 16.85 8 approx. 93.0

8 11.81 12.24 19.02 8 approx. 139.0.

10 13.78 13.15 21.14 12 approx. 207.0

12 15.75 14.65 24.13 12 approx. 315.0

14 17.72 14.88 25.39 12 approx. 403.0

16 19.69 15.79 27.20 16 approx. 509.0

18 21.65 16.69 29.21 16 approx. 617.0

L1

(inch)

L2

(inch)

L3

(inch)

No. of

bolts

Weight

(lbs)

EN 1092-1 PN 16 dimensions:

Meter size

(mm)

15 140 203 251 4 approx. 6.0

25 160 209 272 4 approx. 7.5

32 200 217 285 4 approx. 10.0

40 170 218 288 4 approx. 10.5

50 180 232 310 4 approx. 14.5

65 200 237 325 4 approx. 16.5

80 230 255 347 8 approx. 21.5

100 240 262 367 8 approx. 26.5

125 250 273 399 8 approx. 31.0

150 260 285 425 8 approx. 37.5

200 300 310 475 12 approx. 54.0

250 350 335 535 12 approx. 78.0

300 400 3 65 588 12 approx. 117.0

350 450 3 74 619 16 approx. 156.5

400 500 3 97 677 16 approx. 202.5

450 550 4 20 730 20 approx. 249.5

L1

(mm)

L2

(mm)

L3

(mm)

No. of

bolts

Weight

(kg)

JIS B 2220 10K dimensions:

Meter size

(mm)

15 140 203 251 4 approx. 6.0

25 160 209 272 4 approx. 8.5

32 200 217 285 4 approx. 10.5

40 170 218 288 4 approx. 10.0

50 180 232 310 4 approx. 13.5

65 200 237 325 4 approx. 16.5

80 230 255 347 8 approx. 18.0

100 240 262 367 8 approx. 23.5

125 250 273 399 8 approx. 30.0

150 260 285 425 8 approx. 37.0

200 300 310 475 12 approx. 48.5

250 350 335 535 12 approx. 74.0

300 400 365 588 16 approx. 102.0

350 450 374 619 16 approx. 127.0

400 500 397 677 16 approx. 175.0

450 550 420 730 20 approx. 217.0

Note 3 : 1 inch = 25.4 mm

L1

(mm)

L2

(mm)

L3

(mm)

No. of

bolts

Weight

(kg)

Figure 3. LF650/LF620 and LF654/LF620F

combined type flowmeters

Meter Sizes 1/2" (15) to 18"

(450mm) for Toshiba lay length

5

Page 6

TIC-LF654L

Note1: Eye bolts are provided at the top for flowmeters sized 8" (200mm) or above, and further, a roll-prevention base is

Note2: Cable glands are not provided for LF654 of cFMus approved type. Refer to the cable connection port at converter.

provided for flowmeters sized 10" (250mm) or larger.

ASME B 16.5 class 150 dimensions:

Meter size

(inch)

1/2 7.90 8.07 9.84 4 approx. 11.0

1 7.90 8.31 10.43 4 approx. 16..0

1-1/4 7.90 8.62 10.94 4 approx. 20.0

1-1/2 7.90 8.66 11.18 4 approx. 20.0

2 7.90 9.09 12.09 4 approx. 29.0

2-1/2 7.90 9.29 12.80 4 approx. 38.0

3 7.90 9.69 13.43 4 approx. 45..0

4 9.80 10.28 14.80 8 approx. 64.0

5 9.80 10.71 15.71 8 approx. 73.0

6 11.80 11.34 16.85 8 approx. 93.0

8 13.80 12.24 19.02 8 approx. 139.0.

10 17.70 13.15 21.14 12 approx. 207.0

12 19.70 14.65 24.13 12 approx. 315.0

14 21.70 14.88 25.39 12 approx. 403.0

16 23.60 15.79 27.20 16 approx. 509.0

18 23.60 16.69 29.21 16 approx. 617.0

L1

(inch)

L2

(inch)

L3

(inch)

Unit: inch (mm)

No. of

bolts

Weight

EN 1092-1 PN16 dimensions:

Meter size

(mm)

15 200 203 251 4 approx. 6.0

25 200 209 272 4 approx. 7.5

32 200 217 285 4 approx. 10.0

40 200 218 288 4 approx. 10.5

50 200 232 310 4 approx. 15.0

65 200 237 325 4 approx. 17.0

80 200 255 347 8 approx. 21.5

100 250 262 367 8 approx. 26.5

125 250 273 399 8 approx. 31.0

150 300 285 425 8 approx. 38.0

200 350 310 475 12 approx. 55.5

250 450 335 535 12 approx. 83.5

300 500 3 65 588 12 approx. 125.5

350 550 3 74 619 16 approx. 166.0

400 600 3 97 677 16 approx. 215.0

450 600 4 20 730 20 approx. 257.0

L1

(mm)

L2

(mm)

L3

(mm)

No. of

bolts

Weight

(kg)

(lbs)

JIS B 2220 10K dimensions:

Meter size

(mm)

15 200 203 251 4 approx. 6.5

25 200 209 272 4 approx. 8.5

32 200 217 285 4 approx. 10.5

40 200 218 288 4 approx. 10.5

50 200 232 310 4 approx. 13.5

65 200 237 325 4 approx. 16.5

80 200 255 347 8 approx. 18.0

100 250 262 367 8 approx. 23.5

125 250 273 399 8 approx. 30.0

150 300 285 425 8 approx. 38.0

200 350 310 475 12 approx. 50.0

250 450 335 535 12 approx. 80.0

300 500 365 588 16 approx. 110.5

350 550 374 619 16 approx. 136.0

400 600 397 677 16 approx. 187.5

450 600 420 730 20 approx. 224.5

Note 3 : 1 inch = 25.4 mm

L1

(mm)

L2

(mm)

L3

(mm)

No. of

bolts

Weight

(kg)

Figure 4. LF650/LF620 and LF654/LF620F

combined type flowmeters

Meter Sizes 1/2" (15) to 18"

(450mm) for ISO lay length

6

Page 7

TIC-LF654L

Note1: Eye bolts are provided at the top for flowmeters sized 8”(200mm) or above, and further, a

roll-prevention base is provided for flowmeters 10”(250mm) or larger.

Note2: Cable glands are not provided for LF654 of cFMus approved type. Refer to the cable connection

ASME B 16.5 class 150 dimensions:

Meter size

(inch)

1/2 5.51 6.77 8.54

1 6.30 7.01 9.13

1-1/4 7.87 7.32 9.65

1-1/2 6.69 7.36 9.88

2 7.09 7.80 10.79

2-1/2 7.87 7.99 11.50

3 9.06 8.39 12.13

4 9.45 8.98 13.50

5 9.84 9.41 14.41

6 10.24 10.04 15.55

8 11.81 10.94 17.72

10 13.78 11.85 19.84

12 15.75 13.35 22.83

14 17.72 13.58 24.09

16 19.69 14.49 25.91

18 21.65 15.39 27.91

L1

(inch)

L2

(inch)

L3

(inch)

No. of

bolts

4 approx. 9.0

4 approx. 14.0

4 approx. 18.0

4 approx. 18.0

4 approx. 27.0

4 approx. 36.0

4 approx. 42.0

8 approx. 62.0

8 approx. 71.0

8 approx. 91.0

8 approx. 137.0

12 approx. 205.0

12 approx. 313.0

12 approx. 401.0

16 approx. 507.0

16 approx. 614.0

Weight

(lbs)

EN1092-1 PN 16 dimensions:

Meter size

(mm)

15 140 170 218 4 approx. 4.0

25 160 176 239 4 approx. 5.5

32 200 184 252 4 approx. 8.0

40 170 185 255 4 approx. 8.5

50 180 199 277 4 approx. 12.5

65 200 204 292 4 approx. 14.5

80 230 222 314 8 approx. 19.5

100 240 229 334 8 approx. 24.5

125 250 240 366 8 approx. 29.0

150 260 252 392 8 approx. 35.5

200 300 277 442 12 approx. 52.0

250 350 302 502 12 approx. 76.0

300 400 332 555 12 approx. 115.0

350 450 341 586 16 approx. 154.5

400 500 364 644 16 approx. 200.5

450 550 387 697 20 approx. 247.5

L1

(mm)

(L2)

(mm)

L3

(mm)

No. of

bolts

Weight

(kg)

JIS B 2220 10K dimensions:

Meter size

(mm)

15 140 170 218 4 approx. 4.0

25 160 176 239 4 approx. 6.5

32 200 184 252 4 approx. 8.5

40 170 185 255 4 approx. 8.0

50 180 199 277 4 approx. 11.5

65 200 204 292 4 approx. 14.5

80 230 222 314 8 approx. 16.0

100 240 229 334 8 approx. 21.5

125 250 240 366 8 approx. 28.0

150 260 252 392 8 approx. 35.0

200 300 277 442 12 approx. 46.5

250 350 302 502 12 approx. 72.0

300 400 332 555 16 approx. 100.0

350 450 341 586 16 approx. 125.0

400 500 364 644 16 approx. 173.0

450 550 387 697 20 approx. 215.0

L1

(mm)

(L2)

(mm)

L3

(mm)

Figure 5. Separate type detectors LF654

Meter sizes 1/2" (15) to 18"

(450mm) for Toshiba lay length

No. of

bolts

Weight

(kg)

7

Page 8

TIC-LF654L

p

Note1: Eye bolts are provided at the top for flowmeters sized 8" (200mm) or

above, and further, a roll-

ASME B 16.5 class 150 dimensions:

Meter size

(inch)

1/2

1

1-1/4

1-1/2

2

2-1/2

3

4

5

6

8

10

12

14

16

18

L1

(inch)

7.90

7.90

7.90

7.90

7.90

7.90

7.90

9.80

9.80

11.80

13.80

17.70

19.70

21.70

23.60

23.60

L2

(inch)

6.77 8.54

7.01 9.13

7.32 9.65

7.36 9.88

7.80 10.79

7.99 11.50

8.39 12.13

8.98 13.50

9.41 14.41

10.04 15.55

10.94 17.72

11.85 19.84

13.35 22.83

13.58 24.09

14.49 25.91

15.39 27.91

L3

(inch)

No. of

bolts

4 approx. 9.0

4 approx. 14.0

4 approx. 18.0

4 approx. 18.0

4 approx. 27.0

4 approx. 36.0

4 approx. 42.0

8 approx. 62.0

8 approx. 71.0

8 approx. 91.0

8 approx. 137.0

12 approx. 205.0

12 approx. 313.0

12 approx. 401.0

16 approx. 507.0

16 approx. 614.0

Weight

(lbs)

EN 1092-1 PN16 dimensions:

Meter size

(mm)

15 200 170 218 4 approx. 4.0

25 200 176 239 4 approx. 5.5

32 200 184 252 4 approx. 8.0

40 200 185 255 4 approx. 8.5

50 200 199 277 4 approx. 13.0

65 200 204 292 4 approx. 15.0

80 200 222 314 8 approx. 19.5

100 250 229 334 8 approx. 24.5

125 250 240 366 8 approx. 29.0

150 300 252 392 8 approx. 36.0

200 350 277 442 12 approx. 53.5

250 450 302 502 12 approx. 81.5

300 500 332 555 12 approx. 123.5

350 550 341 586 16 approx. 164.0

400 600 364 644 16 approx. 213.0

450 600 387 697 20 approx. 255.0

L1

(mm)

(L2)

(mm)

L3

(mm)

No. of

bolts

Weight

(kg)

revention base is provided for flowmeters sized

JIS B 2220 10K dimensions:

Meter size

(mm)

15 200 170 218 4 approx. 4.5

25 200 176 239 4 approx. 6.5

32 200 184 252 4 approx. 8.5

40 200 185 255 4 approx. 8.5

50 200 199 277 4 approx. 11.5

65 200 204 292 4 approx. 14.5

80 200 222 314 8 approx. 16.0

100 250 229 334 8 approx. 21.5

125 250 240 366 8 approx. 28.0

150 300 252 392 8 approx. 36.0

200 350 277 442 12 approx. 48.0

250 450 302 502 12 approx. 78.0

300 500 332 555 16 approx. 108.5

350 550 341 586 16 approx. 134.0

400 600 364 644 16 approx. 185.5

450 600 387 697 20 approx. 222.5

Note 3 : 1 inch = 25.4 mm

L1

(mm)

(L2)

(mm)

L3

(mm)

No. of

bolts

Figure 6. Separate type detectors LF654

Meter sizes 1/2" (15) to 18"

(450mm) for ISO lay length

Weight

(kg)

8

Page 9

0.59(15

y

Digital i

TIC-LF654L

5.35(136)

)

3.82(97

)

4.84(123)

2.91(74

)

)

)

8

0

1

1

1

2

(

(

0

7

4

2

.

.

7

8

)

)

0

6

7

7

1

1

(

(

9

3

6

9

.

.

6

6

)

6

3

(

2

4

.

1

Note: Cable glands are not provided for LF622F cFMus approved type.

Refer to the part Cable connection port at detector.

Note: 1 inch = 25.4 mm

Figure 7. Separate type converter LF622 and LF622F

External Connections

● Combined type LF650/LF620 flowmeter and LF654/LF620F flowmeters

Unit: inch (mm)

Weight: Approx. 7 lb (3.5 kg)

Instrument panel : Ordered separatel

Grounding with 100Ω or less

Power switch

(External double-pole pow er switch)

Power supply

Current output ( 4〜20mAdc)

or PROFIBUS

ground resistance

or Modbus

(20〜30Vdc)

Digital output 2

np ut

NOTE:

In th e case of th e int egral ty pe, the signal line

( A, B, G ) and th e excitat ion lin e ( E, X, Y ) are

the connector joints.

Ⅳ wire 5.5mm2 or more

Grounding with 100Ω or less

ground resistance

Signal common for DI and DO

Digital output 1

Grounding with 100Ω or less

ground resistance

I/O cable

Power cable

*1 Locate an external double-pole power switch on the power line near the flowmeter within easy reach of operation.

Use the appropriate switch rating as shown below:

Switch rating: 250Vac, 6A or more

In rush current: 15A or more

Figure 8. Combined type LF650/LF620 and LF654/LF620F flowmeters Wiring Diagram

9

Page 10

G

ith 100

Ω

Inst

o

P

Digital i

Si

DO

Digital

2

d

● Separate type LF650/LF622 flowmeter and LF654/LF622F flowmeter

rument panel : Ordered separately

rounding w

Power switch

(Ext ernal double-pole power switch)

or Modbus

ground resistance

Current output (4 〜20mAdc)

r PROFIBUS

gnal common for DI and

G rounding w it h 100Ωor le s s

ground resistan ce

Digital output 1

ower supply

(20〜30Vdc)

nput

output

or less

I/O cable

Power cable

Connected detector

TIC-LF654L

Ⅳ wire 5.5mm2 or more

G rounding with 100Ω or less

ground resistance

Thick walled steel conduit

Signal cable

(2 -w ire sh ielded hard-rubber sh eat hed cabl e)

Exci ta ti o n ca b l e

(3 -w ire sh ielded hard-rubber c ab le)

Figure 9. Separate type LF650/LF622 and LF654/LF622F flowmeters wiring Diagram

Table 1. LF620, LF620F, LF622 and LF622F Converters Signal Table

Symbol Description Cable

L1 (+)

L2 (−)

GND Ground (for arrester)

FG Frame groun

DI Digital Input (20〜30Vdc)

DO1 Digital Output 1

DO2 Digital Output 2

COM Signal Common for DI, DO1, DO2

+

−

X

Y Excitation Output

E

A

B Signal Input

G

T+ Modbus(+)

T- Modbus(-)

TG Modbus(GND)

Note: Symbol of the terminal is changed as follows for Modbus.

DO2 → T+, DI → T-, COM → TG

Power supply Power cable (CVV)

I/O cable (CVV-S)

Current Output (4〜20mAdc)

or PROFIBUS

Shielded cable for

Excitation cable

(for LF622,LF622F only)

(for LF622,LF622F only)

Twisted-pair polyethylene

insulated vinyl sheath cable

(JKEV,AWG24(0.2mm

PROFIBUS-PA

Signal cable

2

))

10

Page 11

Wiring Precautions

(1) Explosion proof type flowmeters are not provided

with cable glands.

Refer to the part Cable connection port at detector

and converter.

(2) Connect the grounding wire (IV wire 5.5mm² or

more) to a good earth ground (100 or less ground

resistance). Make the wire as short as possible. Do

not use a common ground shared with other

equipment where earth current may flow. An

independent earth ground is recommended.

(3) The allowable cable lengths between the detector

and converter for the separate type flowmeter

depend on the electrical conductivity of the object

fluid. See Figure 10.

TIC-LF654L

(6) The electromagnetic flowmeter is not equipped with

terminating resistors. Use the terminating resistor

unit for PROFIBUS-PA or junction box, if

necessary.

(7) Only one PROFIBUS-PA cable goes through a

cable gland of the Electromagnetic Flowmeter.

Please use the junction box at system configuration

(8) Install a terminator to flowmeter that connected to

end of Modbus network.

300

200

100

50

30

20

10

.

(4) DO1, DO2 and DI use the same common terminal

(COM). This COM can not be connected to other

equipment which have their own ground terminal.

(Power supply for connecting to DI or DO, etc…)

Need to wire separately.

Wiring Precautions (PROFIBUS or

Modbus)

(1) For wiring path, avoid places near electrical

equipment that may cause electromagnetic induction

or electrostatic induction interference (such as a

motor, transformer and wireless transmitter).

(2) Use a PROFIBUS-PA cable or a RS485 twisted-pair

cable for signal cable.

In addition, make sure to use a shielded cable to

improve noise resistance. Installation of signal cable

in metal conduit is recommended.

(3) General cables are designed for indoor use where

cables are not exposed to humidity, rain, etc. When

you install cables, make sure to check the operating

conditions such as the operating temperature range

of the cable by contacting its manufacturer.

(4) When you carry out cable end treatment, use a

dedicated cable stripper to avoid the core wire of the

cable being nicked or damaged. In addition, for

cables, be careful of allowable maximum bend

diameter. (Do not allow excessive twisting or

bending of cables).

(5) Consider installing a PROFIBUS-PA arrester in the

communication path of PROFBUS-PA so that the

electromagnetic flowmeter will not be affected by

lightning, etc.

5

3

Allowable cable length (m)

3 5 10 20 30 50 100 200

Conductivity (S/cm)

Figure 10. Electrical Conductivity and Cable

Meter Size

Length

To select the meter size:

See Table 2 and 3 to find meter sizes within the velocity

of 0.3 to 39.4 ft/s (0.1 to12m/s) for a specified full-scale

(measuring range high limit) flow. Select one that has

its full-scale velocity between 3.0 and 10 ft/s (1 and

3m/s).

Note: Make sure the full-scale flow rate used for the final

planning stage stays within 39.4ft/s (12m/s) in terms of

flow velocity.

Table 2. Flow Rate and Flow velocity

(English unit)

Unit: gal/min

Size

(inch)

0.328 ft/s 0.98 ft/s 3.0ft/s 10 ft/s 39.4 ft/s

1/2' 0.2801 0.8403 2.561 8.532 33.61

1 0.7781 2.334 7.115 23.72 93.37

1 ¼ 1.275 3.824 11.66 38.86 153.0

1 ½ 1.992 5.975 18.21 60.71 239.0

2 3.112 9.337 28.46 94.86 373.5

2 ½ 5.260 15.78 48.09 160.3 631.2

3 7.967 23.90 72.85 242.8 956.1

4 12.45 37.35 113.8 379.4 1,494

5 19.45 58.35 177.9 592.9 2,334

6 28.01 84.03 256.1 853.8 3,361

8 49.80 149.4 455.3 1,518 5,975

10 77.81 233.4 711.5 2,372 9,337

12 112.0 336.1 1,025 3,415 13,445

14 152.5 457.5 1,394 4,648 18,300

16 199.2 597.5 1,821 6,071 23,902

18 252.1 756.3 2,305 7,684 30,251

Flow rate

11

Page 12

TIC-LF654L

Table 3. Flow Rate and Flow velocity

(SI unit)

Unit: m3/h

Flow rate

Size

(mm)

15

25

32

40

50

65

80

100

125

150

200

250

300

350

400

450

0.1 m/s 0.3 m/s 1.0 m/s

0.06362 0.1908 0.6361 1.908 7.634

0.1767 0.5301 1.767 5.301 21.21

0.2895 0.8686 2.895 8.686 34.74

0.4523 1.357 4.523 13.57 54.29

0.7067 2.120 7.067 21.20 84.82

1.195 3.583 11.95 35.83 143.4

1.809 5.428 18.09 54.28 217.1

2.827 8.482 28.27 84.82 339.3

4.417 13.25 44.17 132.5 530.1

6.361 19.08 63.61 190.8 763.4

11.31 33.93 113.1 229.3 1,357

17.67 53.01 176.7 530.1 2,121

25.45 76.34 254.5 763.4 3,054

34.64 103.9 346.4 1,039 4,156

45.23 135.7 452.3 1,357 5,429

57.25 171.7 572.5 1,717 6,871

3.0

m/s

12

m/s

About establishment environment

Do not store or install the flowmeter:

• Where there is direct sunlight.

• Where excessive vibration or mechanical shock

occurs.

• Where high temperature or high humidity

conditions exist.

• Where corrosive atmospheres exist.

• Places that can be submerged under water.

• When placing the flowmeter temporarily on the

floor, support it, i.e., with a block so that the

flowmeter does not topple over.

In areas like the following, there may be the case that

infrared switches do not function correctly. (If these

are unavoidable, use an appropriate cover.)

(1) Where unit (operation panel) is exposed to direct

sunlight, reflection of light onto window pane

and diffused light reflection.

(2) Where smoke and steam may occur.

(3) Where exposed to direct snow, ice or mud.

Ordering Information

1. When ordering the LF654 series flowmeters, refer

to Tables 4 and 5 (Type Specification Codes).

An entry must be made for each of the columns in

each of these tables.

2. Fluid characteristics:

(1) Type of fluid to be measured and its characteristics

(2) Fluid temperature

(3) Fluid pressure

(4) Electrical conductivity of the fluid

3. Measuring range

4. I/O function setting

5. Ordering scope

Flow calibration data

6. Other items

Specifications other than standard items

Consult a Toshiba representative when choosing

materials for lining, electrodes, and grounding rings.

Toshiba International Corp. (Houston) stocks

Hazardous location certification type

flowmeters as standard inventory.

12

Page 13

TIC-LF654L

√

√

√

√

√

√

√

√ √

√ √

√ √

√ √

√ √

√ √

√ √

√

√ √

√ √

d

d

d

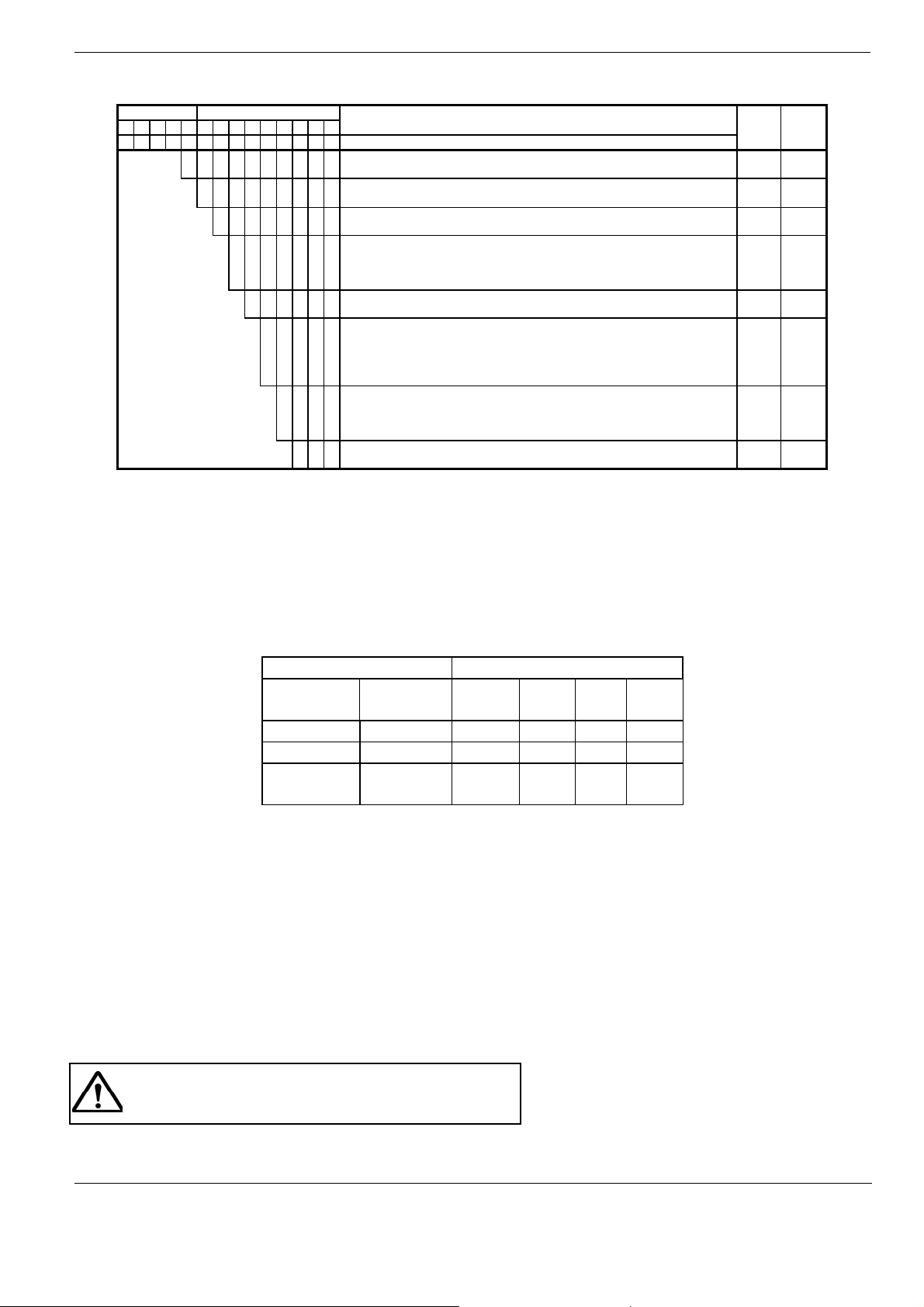

Table 4. Specification Code (Flange type detector LF654 Series)

Model Specification Code

1 2 3 4 5 6 7 8 9 10 11 12 13 14

L F 6 5 Flange type electromagnetic flowmeter detector

Meter size

D ½"(15mm)

E 1"(25mm)

S 1¼"(32mm)

F 1½"(40mm)

G 2"(50mm)

W 2½"(65mm)

H 3"(80mm)

J 4"(100mm)

U 5”(125mm)

K 6"(150mm)

L 8"(200mm)

M 10"(250mm)

N 12"(300mm)

P 14"(350mm)

Q 16"(400mm) √

R 18"(450mm)

Mounting Style(Note1)(Note6)

L Detector/Converter combined type

M Detector/Converter separate type √ √

Connection flange standard, Overall length

C ASME B 16.5 class 150, ISO length

D ASME B 16.5 class 300, ISO length

G EN 1092-1 PN 10, ISO length

H EN 1092-1 PN 16, ISO length

1 ASME B 16.5 class 150, Toshiba length

2 ASME B 16.5 class 300, Toshiba length

5 EN 1092-1 PN 10, Toshiba length

6 EN 1092-1 PN 16, Toshiba length

C Ti (titanium)

D Pt-Ir (platinum/iridium)

E Ta (tantalum)

F Hastelloy C (Equivalent) (Standard for PFA lining)

Lining Materials (Note 3)

C PFA

N PU(Polyurethane) with NSF certified

E HR(Hard Rubber) with NSF certifie

Grounding Ring Material (Note 3)(Note 4)

C 316 stainless steel

D 316L stainless steel

E Ti (titanium)

F Ta (tantalum)

G Pt-Ir (platinum/iridium)

H Hastelloy C (Equivalent)

Flow and calibration velocity range

A 1.0 to 32.8 ft/s (standard range calibration)

(Note 5)

Excitation and Signal Cables

A not provide

Coating

F PU coating pearl-gray colore

Cblack tar epoxy resin

4

Z Other(Note 2)

Electrode Material (Note 3)(Note 4)

B 316L stainless steel (Standard for PU, HR lining)

Usage

cFMus Class 1 Division 2 Hazardous Location

Description

Size code explanation: √ : Object : Standard : Option –: Not available

Note1: In case of LF654 with cFMus approval, Cable glands are not provided. Refer to the part of “Cable connection port” at detector and converter.

Note2: Connection flange standard EN 1092-1 PN10, EN 1092-1 PN 16,JIS B 2220 10K and JIS B 2220 20K are optional for both ISO length and Toshiba

length.

Note3: Consult Toshiba before ordering when choosing materials at the wetting parts.

Note4: In case of PU and HR lining with NSF approval, only 316/316L stainless steel are available, and Hastelloy C & Ti are undergoing testing.

Note5: User specified range upon request, additional charges apply.

Note6: Potting kit is available for submersible option when selecting Detector/Converter separate type with PU or HR lining. Please consult Toshiba for

details.

Detector category

Gr.-A Gr.-B

√

√

–

–

–

–

–

–

–

14

Page 14

TIC-LF654L

/

Table 5. Specification Code for converters

Model Specification Code

1 2 3 4 5 6 7 8 9 10 11 12 13 14

L F 6 2 Electromagnetic flowmeter converter

0 Combined (Integral) type

2 Separate (Remote) type

F Purpose

A Shape

2 Digital input/output

E Instruction manual

Converter mounting fitting

A

C

E

Current output and Communication function(Note1)

1

2

3

Power supply(Note2)

1

2

3

cFMus class I, Division 2 approved

Standard type with case

None

Panel, Accessory for wall mounting (BNP material: SUS304)

Accessory for pipe installation (BNP material: SUS304)

Digital output points 2 (DO1+DO2) +Digital input point 1 (DI)

Current output + HART communication

PROFIBUS communication

Current output + Modbus (RS485) communication

100Vac-240Vac 50/60Hz, 110Vdc

24Vdc

110Vdc

English

Code explanation: : Standard : Option –: Not available

Note 1: When PROFIBUS communication is provided, current output(4-20mA) and HART communication cannot be used.

When Modbus communication is provided, digital output points 1(DO1) and digital output points (DO2),

digital input point 1(DI), HART communication cannot be used.

Refer to Table 6 for more details.

Note2: Select 110Vdc for test report inspected under the condition of 110Vdc.

Table6. Communication functions and output selection table

Selection of Function Availability of outputs

Code

(10th digit)

1 HART

2 PROFIBUS X

3 Modbus

Selected

Communication

4-20mAdc DO1 DO2 DI

Code explanation: :Available X:Not Available

Note: When digital output 1 function and Modbus communication function are used at one time, TG (signal ground) of the

Modbus communication function cannot be connected (2 line connection).

Contents

(Note)

X X

LF620

type

–

–

–

LF622

type

–

ISO9001 and ISO14001 are certified.

Misuse of this product can result in damages to property or human injury.

Read related manuals carefully before using this product.

15

Specifications are subject to change without notice.

Printed in Japan 2012-7 (TDOC)

© TOSHIBA Corporation 2012

All Rights Reserved.

http://www.toshiba.com/ind

Loading...

Loading...