Page 1

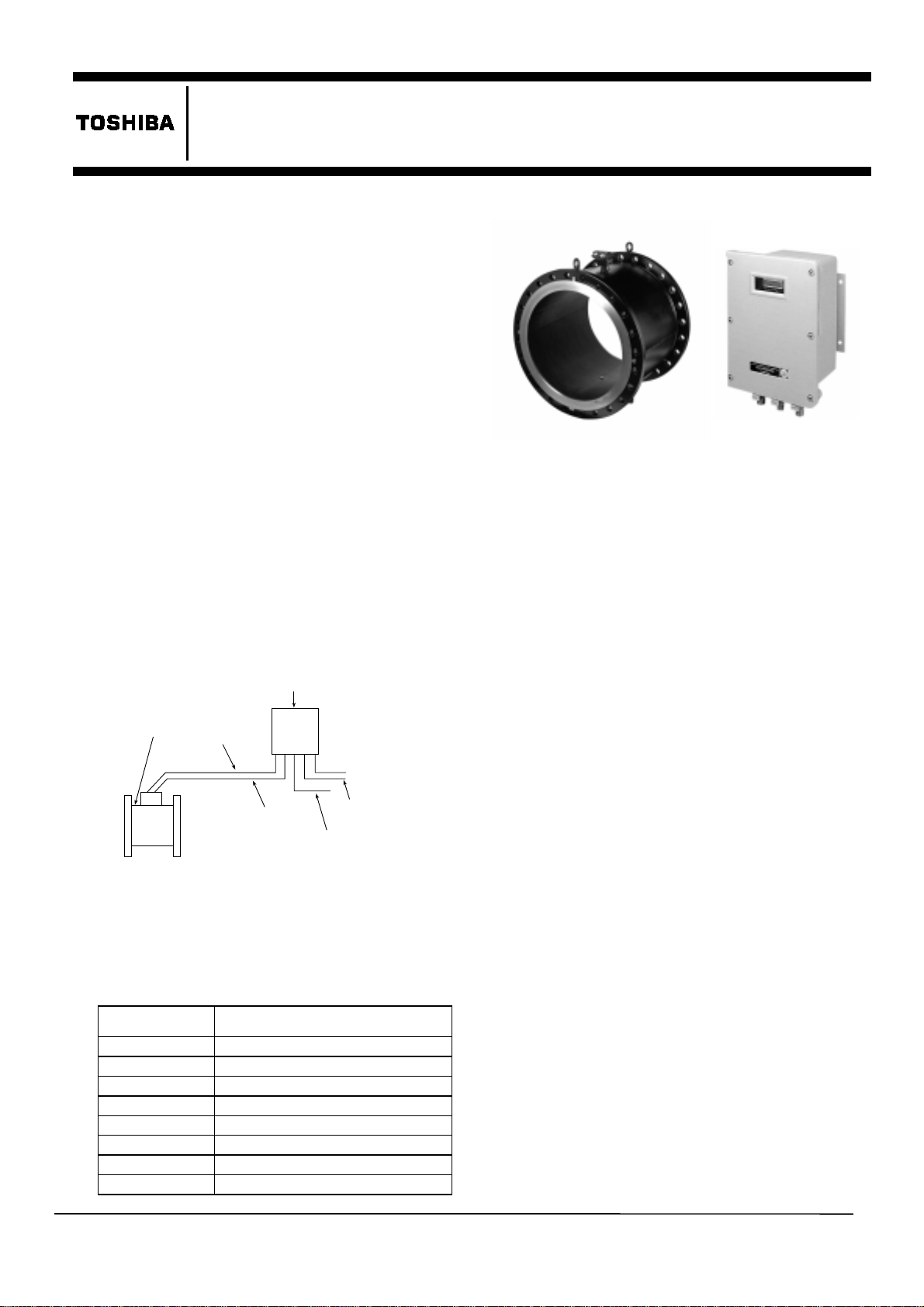

F-IN -D Series

Electromagnetic Flowmeter for

Partially-filled Pipes

Introduction

The LF502 electr oma gnetic flowmeter uses Faraday’s

Law of electromagnetic induction in the same way as

conventional electromagnetic flowmeters to measure

the flow rate. Position of electrodes in the LF502 is so

designed that it can be used even in a partially-filled

pipe to measure the flow rate.

Improved functional magnetic field distribution technique enables a high-precision flow measurement continually from low-level to fully-filled flow conditions.

This

eliminates unnecessary piping work such as lifting

the downstream pipe section to fill the detector pipe.

Compared with flowmeters measuring the flow rate by

means of flow level, the obstructionless LF502 flowmeter does not usually allow mud, sands and other

solid sediment stay at the bottom of the detector pipe

is

and

unaffected by wave or floating solids on the fluid

surface.

The

AF100 hand-held terminal or the Model 275 HART

communicator can be used to communicate with the

flowmeter

munications protocol. See the communications output

specifications for details about the HART protocol.

from remote places using the HART com-

Converter

Detector

Signal cable

Excitation

cable

Power supply

4-20 mA dc

Digital I/O

LF502

150

to

(

”

to

6

Fi gu r e 2. LF502 El ec t r o m ag n et i c F l owme t e r

for Partially-filled Pip es

Fluid-level range:

x

30 mm (1 1/4”) to fully-filled condition for Meter

sizes 150 mm (6”) to 300 mm (12”)

of

x

10%

inside tube diameter to fully-filled condition

for Meter sizes 350 mm (14”) to 600 mm(24”)

Accuracy:

±2 % FS (when measurement range is

standard)

The accuracy is measured under standard

Note:

operating

conditions at Toshiba's calibration facility.

Required straight pipe length:

minimum on upstream side and

10D

5D minimum on downstream side

D is a nominal meter size.

Note:

Fluid conductivity:

Fluid temperature:

Ambient temperature:

100µS/cm minimum

0 to 55 °C (32 to 131 °F)

–10 to 50 °C (14 to 122 °F)

600

24

mm

)

”

Figure 1. LF502 Configuration

Specifications

„

Overall Specifications

Measurement range:

Meter size

in mm (inch)

150 mm (6”)

200 mm (8”)

250 mm (10”)

300 mm (12”)

350 mm (14”)

400 mm (16”)

500 mm (20”)

600 mm (24”)

Measurement range

0 –

60 m3/h (std) to 0 – 300m3/h

0 – 110 m

0 – 175 m

0 – 250 m

0 – 350 m

0 – 450 m

0 – 710 m

0 –1000 m

3

3

3

3

3

3

/h (std) to 0 – 550m3/h

/h (std) to 0 – 875m3/h

/h (std) to 0 –1250m3/h

/h (std) to 0 –1750m3/h

/h (std) to 0 –2250m3/h

/h (std) to 0 –3550m3/h

3

/h (std) to 0 –5000m3/h

„

Detector Specifications

Meter sizes:

150 mm (6”), 200 mm (8”), 250 mm

(10”), 300 mm (12”), 350 mm (14”), 400 mm

(16”), 500 mm (20”), and 600 mm (24”)

0

Fluid pressure:

to 2.0 MPa under fully-filled fluid

condition for flange-connected flowmeters

Connection flange standards:

ANSI 150, BS 16,

DIN PN16 and others.

Structure:

NEMA 4 (IP 67) Watertight (standard),

NEMA 6 (IP 68) Submersible (option)

Coating:

Phthalic acid resin coating, pearl-gray colored

(standard for watertight type) or black tar epoxy

(option for watertight type and specified

exclusively for submersible type)

EJL- 064A

Page 2

LF502

2

Principal materials:

— carbon steel

Case

Linings

— The following are the standards:

Teflon PFA for Meter sizes 150 mm (6”) to 400

mm (16”), chloroprene rubber for Meter sizes

500 mm (20”) and 600 mm(24”)

Electrodes

Grounding rings

See Table 1 for optional materials and other

— 316L stainless steel (standard)

— 316 stainless steel (standard)

related information.

„

Converter Specifications

Input signals

Analog input:

voltage signal from detector and is

proportional to process flow rate

Digital input (DI)

Voltage signal: High level 20 to 30 V

Low level 2 V

Input resistance: 2.7 k:

Number of inputs: one point

DI function

— One of the following functions can

be assigned to DI signal:

• Unidirectional 2-range switching signal

(lower range with high DI voltage level)

• Bidirectional 2-range switching signal

(lower range with high DI voltage level)

• Totalizer start/stop

— Starts and stops the

built-in totalizer. (Totalizer starts with high DI

voltage level and stops with low DI voltage

level.)

• Zero adjustment

— Starts zero adjustment (on-

stream at zero flow rate) when DI voltage level

low after remaining high for 10 to 20 seconds.

goes

• Fixed-value outputs

— Outputs fixed values

for current output (and pulse output if used).

Outputs fixed values when DI voltage is high.

Output signals

Analog output:

4–20 mA

dc;

Load resistance 0 to 1 k:

Digital outputs:

— 2 points (D1 and D2)

Output type: Solidstate relay contact outputs

(non polarity)

Capacity: 150 V

150 V

dc, 150 mA maximum or

ac, 100 mA maximum (peak)

Number of outputs: Two points

D1 and D2 functions

— Two of the following

functions can be assigned to D1 and D2.

•

Pulse output (available only for D1)

Pulse rate: 3.6 to 360000 pulses/hour

Pulse width: 5 to 100 ms (but less than half of

the period for 100 % flow rate)

• Multi-range selection outputs

(1) One point (D1 or D2) output

Unidirectional 2-range automatic selection

signal or bidirectional 2-range automatic

selection signal

dc or less

dc

(2) Two point (D1 and D2) outputs

Unidirectional 4-range automatic selection

signal or bidirectional 4-range automatic

selection signal

•

High and/or low limit alarm outputs

Outputs an alarm signal if the flow rate output

goes above high limit value or below low limit

value

Setting range: –10 to 110 % of range

Output

•

Empty pipe alarm output

status: Contact ON when alarm occurs.

Outputs an alarm signal if the detector pipe is

emptied.

Output

•

Preset point output

status: Contact ON when alarm occurs

Outputs a signal when the built-in totalizer

count reaches the preset point.

Setting range: 1 to 999999 counts

Output

•

Converter failure alarm output

status: Contact ON when alarm occurs

Outputs an alarm signal if the converter detects

an erroneous condition other than high/low

limit or empty pipe alarm conditions.

Communications output

superimposed on 4–20 mA

— A digital signal is

dc current signal

(conforms to the HART protocol).

1

Load resistance: 240 : to

k:

Load capacitance: 0.22 µF maximum

HART (Highway Addressable Remote

Note:

Transducer) protocol is a communications

protocol for industrial sensors recommended by

HCF (HART Communication Foundation).

Output display:

2-line,16-character LCD display

(backlit) shows flow rate and total flow in various

engineering units. Up to two set of data can be

displayed.

Damping:

Parameter settings:

5 to 600 s

Configuration parameters can

be set using the control keys on the LCD display.

Zero and span calibration:

Built-in calibration signal source allows converter

unit check.

Zero adjustment:

Zero point adjustment can be

started by pressing a combination of control keys

on the LCD display.

Conditions when power fails:

The output and display will remain as follows

when power fails. Parameter setting values are

stored in non-volatile memory and the values will

be re-stored

when the power returns to normal

condition.

• Current output: 0 mA

dc

• LCD display: No display

Digital output: OFF

•

Page 3

LF502

Power supply:

One of the following power supply

specifications can be selected:

• 100 to 120 V

ac (90 to 132 V ac), 50/60 Hz

• 200 to 240 V ac (180 to 264 V ac), 50/60 Hz

(option)

• 24 V dc (22 to 27 V

Power consumption:

Surge protection:

the

power supply and current signal output circuit.

Cast aluminum

Case:

Coating:

Painting color:

Structure:

Melamine resin

Light gray (munsell N7)

NEMA 4 (IP 67) Watertight

Cable connection port:

dc) (option)

approximately 24 VA

Surge protectors are installed in

Rc(PT) 3/4 male screw

Vibration resistance:

No resonance to the following levels of vibration:

• 5 to 33 Hz with acceleration of 9.8 m/s

Avoid

Note:

using the flowmeter in an environment

with constant vibration.

Installation

„

Dimensions

2

Unit: mm

JIS 10K flange dimensions:

Meter

size (mm)L1(mm)L2(mm)L3(mm)

150

200

„

Dimensions

266 245 385 8 approx. 35

300 271 436 8 approx. 80

Roll-prevention base

No. of

bolts

Mass

(kg)

Unit: mm

Figure 4. Detector Dimensions for Meter Sizes

250 mm (10”) to 600 mm (24”)

See the following tables for dimensions of L1, L2 and

L3 in Figure 4 above, and the number of bolts required

for each flange.

Figure 3. Detector Dimensions for Meter Sizes

150 mm (6”) and 200 mm (8”)

See the following tables for dimensions of L1, L2 and

L3 in Figure 3 above, and the number of bolts required

for each flange.

BS16 and DIN PN16 flange dimensions:

Meter

size (mm)L1(mm)L2(mm)L3(mm)

150

200

266 245 388 8 approx. 35

300 271 441 12 approx. 80

No. of

bolts

Mass

(kg)

ANSI class 150 flange dimensions:

Meter

size (inch)L1(inch)L2(inch)L3(inch

6

10 1/2 9 5/8 15 1/8 8 approx. 78

8

11 3/4 10 5/8 17 1/2 8 approx. 178

No. of

bolts

Mass

(lb)

BS16 and DIN PN16 flange dimensions:

Meter

size (mm)L1(mm)

250

300

350

400

500

600

350 306 509 12 approx. 110

400 329 559 12 approx. 120

450 351 611 16 approx. 130

500 386 676 16 approx. 180

600 401 758 20 approx. 190

600 452 872 20 approx. 250

L2

(mm)L3(mm)

No. of

bolts

ANSI class 150 flange dimensions:

Meter

size (i nch)L1(inch)L2(inch)L3(inch)

10

13 3/4 12 20 1/8 12 approx. 244

12

15 3/4 13 22 3/4 12 approx. 267

14

17 3/4 13 7/8 24 7/8 12 approx. 289

16

19 5/8 15 1/4 27 3/8 16 approx. 400

20

23 5/8 15 3/4 30 3/8 20 approx. 422

24

23 5/8 17 3/4 34 5/8 20 approx. 556

No. of

bolts

JIS 10K flange dimensions:

Meter

size (mm)L1(mm)

250

300

350

400

500

600

350 306 506 12 approx. 110

400 329 551 12 approx. 120

450 351 596 16 approx. 130

500 386 666 16 approx. 180

600 401 738 16 approx. 190

600 452 849 24 approx. 250

L2

(mm)L3(mm)

No. of

bolts

Mass

(kg)

Mass

(lb)

Mass

(kg)

3

Page 4

LF502

4

„

Dimensions (Converter)

Flow regulation

valve etc1

Observation window

Detector

Unit: mm

Mass: approx. 18 kg

(including mounting bracket)

Four-Dia. 12 holes

Figure 5. Converter Dimensions

Piping Precautions

„

(1) Flange connection

The flowmeter has upstream and downstream

flanges on the ends of detector pipe. Connect

these flanges with the flanges on both sides of

pipeline bore using connection bolts after

inserting a packing between them. See Figure 6.

Tighten the bolts in even increments diagonally

across.

Observation

window

Upstream

flange

Downstream flange

Observation window

10D minimum

The length of reducers, if used, can be

Note:

5D minimum

counted as a part of straight pipe length.

Figure 7. Required Straight Pipe Length on

Upstream and Downstream Sides

External Connections

„

Signal cable

(2-wire shielded

sheathed cable)

Excitation cable

(3-wire sheathed cable)

Digital I/O cable

(multi-wire

shielded cable)

Current output cable

(2-wire shielded cable)

Power cable

(2-wire cable)

Figure 8. Converter Terminal Connections

Signal cable (2-wire shielded s heathed cable)

Thick walled steel conduits

Excitation cable (3-wire sheath ed cable)

Grounding

terminal

(M6 screw)

Intermediate

voltage (IV)

wire, 5.5 mm

minimum

100 • or less

ground resistance

2

Packing

Flow direction

Figure 9. Detector Terminal Connections

Detector

Figure 6. Flange Connection

„

(2) Required straight pipe length

The straight pipe length is required to prevent

uneven flow velocity and a disturbance on the

fluid surface in the detector pipe. The required

straight pipe length should be as follows:

• Downstream side: L = 5D minimum

• Upstream side: L = 10D minimum

where,

L = straight pipe length (straight pipeline length

+ half length of detector pipe length)

Wiring Precautions

(1) Be sure to use thick walled steel conduit (22

mm) for signal and excitation cable wiring

between the detector and converter. The

conduit screw is R(PT)1/2. Use flexible

conduits at the cable outlets of the detector as

needed.

(2) Make the grounding wire as short as possible.

Do not use a common ground shared with other

equipment where earth current may flow.

independent

earth ground is recommended.

An

Page 5

LF502

)

)

)

)

)

Q

)

)

)

(

)

(

(

)

p

(

)

)

)

p

)

p

)

p

g

poxy

poxy

poxy

)

Ordering Information

1. When ordering the LF502 flowmeter, refer to

Table 1 and 2 (Type Specification Codes). An

entry must be made for each of the columns in

each of these tables.

2. Fluid characteristics:

(1) Type of fluid to be measured and its

characteristics

(2) Fluid temperature

(3) Fluid pressure

(4) Electrical conductivity of the fluid

3. Measuring range

4. Digital I/O specifications

5. Ordering scope:

(1) Actual flow calibration data:

6. Other items

Specifications other than standard items

(required or not)

Table 1. Type Specification Code

( Model LF502 Flowmeter)

Model Specification Code

K 150 mm (6"

L 200 mm (8"

M 250 mm (10"

N 300 mm (12"

P 350 mm (14"

R 500 mm (20"

S 600 mm (24"

C ANSI 150

F BS16

H DIN PN16

J JIS 10K

Z other

B SUS316L+SUS316

C SUS316L+SUS316L

D Ti

E Hastelloy C+Hastelloy C

F SUS316L+SUS304

Z other

T Teflon PFA

C Chloro

Z other

A 100 to 120 V ac, 50/60 Hz

B 24 V dc

C 200 to 240 V ac, 50/60 Hz

Z other

A Panel, wall mount (carbon steel SS400

B Panel, wall mount (304 stainless steel

C Pi

D Pi

Z other

A not provided

Z other

B 30 m

C other len

B Phthalic acid resin

C Black tar e

D Black tar e

E Black tar e

Z other

Description

LF502 Electromagnetic Flowmeter

Meter size

400 mm (16"

Connection flange standard

Electrode and Grounding Ring Material

titanium)+Ti

Lining Material

rene rubber

Power Supply

Converter Mounting Bolts and Nuts

e mount (carbon steel SS400

e mount (304 stainless steel

Detector Connection Bolts, Nuts and

Packings

Dedicated Preformed Cable

rovided

ths, provided

Coating of detector

(for submersible type

standard.

titanium

standard

resin 0.3 mm

resin 0.5 mm

resin 0.5 mm

Size

AB

Size groups.

A: 150 mm (6”) to 400 mm (16”)

B: 500 mm (20”) and 600 mm (24”)

Size code explanati on:

Standard

Option

Not available

–

5

Page 6

Year 2000 Com plianc e:

„

This equipment does not have any clock in itself. Thus, there is no problem in the

year 2000 com pliance .

Misuse of this product can result in damage to property or human injury.

Read related manuals carefully before using this product.

Specifications are subject to change without notice

Printed in Japan 11/98 (TDOC)

© TOSHIBA Corporation 1998

All Rights Reserved.

EJL- 064A

Loading...

Loading...