Page 1

TOSHIBA

6F8A0774

ELECTROMAGNETIC FLOWMETER

MODEL LF494 / LF404

INSTRUCTION MANUAL

TOSHIBA CORPORATION

Page 2

TOSHIBA

NOTICK

This Manual is designed to assist in installing, operating, and maintaining the

LF494/LIH04 electromagnetic: flowmeter, i’or safely reasons, and to obtain the opti

mum performance from the flowmeter, read this Manual thoroughly before working

with the product. Keep the Manual within easy reach fcjr reference whenever needed.

The flowmeter to which this Manual refers is NOT designed for applications m which

the functioning of this product is critical to human safety, such as:

♦ Main cejntro! syaicms of nuclear power plants; safely systems in nuclear facilities

• Control systems of medical equipment, including life support machines.

6F8A0774

or other ciilical control lines directly affecting human safety.

NOTES

L The reproduction of the contents of this Manual in any form, whether wholly or in part, is

not permitted without explicit prior consent and approval.

2. 1’hc information contained in this Manual is subject to change or review without prior

notice.

3. Be .sure to follow all safety, operating and handling precautions described in this Manual

and ihe regulations in force in the country in which this product is to be used.

HART is a registered trademark of ihe HART Ccrnmunication Foundation,

Teflon is a rcgislcrcd trademark of the DuPont Company.

Forth F.dition

October. 2000

€> Copyright 1999, 2000 hy To.shiha Corporation. All rights reserved.

- 1 -

Page 3

TOSHIBA

SAFETY PRECAUTIONS

Safety signs and labels affixed to the product and/or described in this manual give important

information for using the product safely. They help prevent datnagu lo property and obviate

hazards for persons using the product,

Make yourself familiar with signal words and symbols used for safely signs and labcJs, Then

read the safety precautions that follow to prevent an accident involving personal injury,

death or damage to property.

Explanation of signal words

The signal word or words arc used to designate a degree or level of hazard seriousness.

The ssignal words used for the product described in this manual arc WARNING and

CAUTION.

A WARNING

6F8A0774

Indicates a potentially hazardous situation

which, if not avoided, could result in death or

i^erious injury.

Safety .symbols

Indicates a potentially hazardous situation

A CAUTION

rhe following symbols are used in safety signs and labels affixed to a product and/or in the

manual for giving safety instructions.

Indicates an action that is prohibited. Simply DON'T do this action.

The prohibited action is indicated by a picture or text inside or next to

0

•

Л

the circle

Indicates an action that is mandatory, DO this action,

1 he mandatory action is indicated by a picture or text inside or next to

the circle.

Indicates a potential hazard. The potentially hazardous situation is

indicated by a picture or text inside or next to the triangle.

w hich, if not avoided, may result in minor lo

moderate injuries or in property damage.

- г -

Page 4

TOSHIBA

SAFETY PRECAUTIONS

Safety Precautions for Installation and Wiring

A WARNING

Do not diNCOTinecl while circuit h live unless k>cntion is known lo be nonhuzardous.

6,F8A0 7 7 4.

0

DONT

I Oo not modify or disassemble the enclosure,

xdiy Strength dcgtadsition and defects of enclosure can cause explosion.

DONT

Do not use parts of other products.

0

DONT

Do not live circuits While assembly of all components is not over.

0

DONT

Install per the National Electrlciil Code for the LS (NEC, ANSI/NFPA 70)

and the Canadian Electrical code for Canada (CEC, CAN/CSA>C22J).

О

DO

Live pari of electric circuit ora high temperature department can cause

explosion.

Protective performance degradation for hazardous location can cause

explosion.

Protective performance degradation for hazardous location can cause

explosion.

Unsuitable conduit connections for hazardous location can cause ex

plosion.

A CAUTION

■ Turn off mains power before working

on pipes.

Working on pipes while

power is applied can cause

QQ electric shock.

■ Install a switch and fuse to isolate the

LF494/LF404 from mains power.

Power supply from mains

power can cause electric

□ 0 shock or circuit breakdown.

■ Use an appnipriate device to carry

and install the LF494/LF4Q4.

If this product falls to the

ground, injury, or malfunction

of or damage to the product,

can be caused.

■ Du not modify or disassemble the

LF494/LF404 unnecessarily,

Modifyingordisasscinhling

( this product cart cause electric

shuck, malfunction uf or

DON T damage to this product.

- 3 -

Page 5

TOSHIBA

SAFETY PRECAUTIONS (continued)

Safety Precautions for Maintenance and Inspection

CAUTION

■ Turn off mains power before

conducting wiring work.

Wiring while power is applied can cause electric shock,

DO

■ Do not condnet wiring work with bare

hands.

Remaining electric charge

■ Ground the LF494/LF404 indepen

dently from power equipment,

^^9 grounding can cause electric

■ Use compression terminal lugs with

insulation sleeve for the termmul

block and GND terminal.

I even if power is turned off

DON’T

■ Do not work on piping and wiring w ith

wet hands.

f J electric shock.

DON’T

can still cause electric shock.

Wet hands may result in

^|\ pow'cr input.

/ J \ (A black border and symbol on

6F,8A0 774

Operating this product without

shock or mal fu net ion.

Loose connections can cause

electric shock, fire from

excessive current or system

malfunction.

The label shown left is placed

near the terminal board for

yellow triangle)

Be alert to electric shock.

■ Do not touch the flowmeter main

body when high temperature fluid is

being measured.

The fluid raises the main y^“V Wiring while power is applied

i body temperature and can

cause burns when toucheil.

DON’T

■ Do not conduct wiring work with wet

hands. yy neaj ihe icrininal board for

1 Wet hands may result in

electric shock.

DON’T

■ Do not use a fuse other than the one Use a rated fu.se as follow^]

¡»pvcifled.

Using a fuse other than the

\ one specified can cause

V, ;V system failure, damage or

mal ft! action.

DON’T

■ Do not conduct wiring work when

power is applied.

i can cause electric shock.

DON’T

The label shown left is placed

/w\^ power input.

/ (A black border and symbol on

yellow triangle)

Be alert to eleciric shock.

Fuse rating:

* 1 A;250V for 100 to 24t)Vacor llOVdc

• 2A^250V for 24 V dc

Dimensions:

Diameter 5.2 inm x 20 mm

Melting time characteristic:

Normal blow |

Disclaimer

Toshiba does noi 9ccep[ liitbility for any dsimagc or loss, msuerial or personal, caused its a

direct or indirect result of the operation of this product in connection with, or due to, the

occurrence of any event of force majeurc (including fire or earthquake) or the misuse of

this product, whether iutcntiounl or aeddentaJ.

- 4 -

Page 6

TOSHIBA

Handling Precautions

■ To obiairi the opiimutn pcrforiimnce from the LJ"494/LF4C4 flowmeter for yeiirs of

coHtinuou!» operation, observe Ihc following preciiutions.

(1) Do not store or instiiJl the flowmeter in:

(2) Exccjlc wiring securely and correctly,

6F8A0774

• places where there is direct sunlight. If this is unavoidable, use an appropriate

sSunshade,

• places where excessive vibration or mechanical shock occurs,

• places where high i строга lure or high humidity conditions obtain,

■ places where corrosive atmospheres obtain,

• places submerged under water,

To put the flowmeter temporarily on the floor, place ¡t carefully with something to

support it so that the tlowmcicr will not topple over,

Ground the flowmeter whth 1Ш ohm or less ground resistance* * Avoid a common

ground used with other equipment where earth current may flow. Ал independent

ground is preferable

(3) Seal the cable thoroughly at ths cable gland so that the cable is kept airtight. The

apparatus should not be provided with the cable gland. Please prepare yourself lor

the cable glands which could he used in Division 2 hazardous locations.

(4) Make sure the fluid to be measured will not freeze in the detector pipe. This can

cause damage to the detector pipe.

{5) Select appropriate wetted materials suited for the process fluid to be measured.

Otherwise, fluid leakage due to corrosion can be caused,

(6) The converter housing covers ¿re lightened securely at the time of shipment. Do

not remove these covers or glands unless it is necessary to wire new cables or re

place old ones. Otherwise, gradual deterioration of circuit isolation or damage !o

this product can be caused. Tighten the covers securely again if they have hcca re

moved.

- 5 -

Page 7

TOSHIBA

Handling Precautions (continued)

(7) Observe the lollowing precautions when you open the converter housing cover:

• Do not open the cover in the open air unprotected ugainsi rain or wind, I'his

can cause eieciiic shock cr cause damage to the flowmeter electronics,

* Do not open the cover under high ambient teraperaitire or high humidity

conditions or in corrosive atmospheres. This can cause deterioration of

system accuracy or cause damage to the flowmeter electronics,

(8) ThisS product may cause interference to radio and television sets if they are

used near the installation site. Use meta! conduits etc, for cables to prevent

this interference.

(9) Radio transmitters such as transceivers or cellular phones may cause interference

to the flowmeter if they are used near the installation site . Observe the following

precautions when using them;

• Do not use a radio transmitter while the cover of flowmeter converter is open.

» Do not use a transceiver whose output power is more than 5 W.

• Move the antenna of a radio transmitter at least 50 cm away from the ilowtneter

and signal cables when using it,

• Do not use a radio transmitter near the flowmeter while it is operating online.

The transmitter’s output impulse noise may interfere with the flowinder.

• Do not install a radio transmitter antenna near the flowmeter converter and

signal cables,

6F8A0774

(10) For reasons of flowmeter failure, inappropriate parameters, unsuitable cable con

nections or poor jnstallaiion conditions, the flowmeter may not operate properly.

To prevent any of these problems causing a system failure, it is recommended that

you have preventive measures designed and installed on the flowmeter sigttal re*

ceiving side.

- 6 -

Page 8

TOSHIBA

TabJe of Contents

6F8A0774

SAFETY PRECAUTIONS

Hiliidling Precautions .....................................

1, Product Inspection and Storage ''

1.1 Product Inspection

L2 Storage

...............................................

...........................

2* Overview .....................................................

3- Names of Parts

4, Installation

4.1 Location

..............................................

...................................

...........................................

4.2 Mounting Procedure..........................

4.3 Piping Connections

5h Wiring

...........................................

..........................

5.1 Cables ...............................................

5.2 External Device Connections and Grounding

5.3 Digital I/O Connections

5.4 Wiring Procedure

6. Operation ■ •

........

........................................

...................

.............................

6.1 Preparatory Check ............................

G.2 Zero Adjustment

7* LCD Display and Controls

...............................

.....................

7.1 Outline ..............................................

7.2 Display Formal .................................

7.3 Basic Operations

..............................

7.4 Configuration Items Scleclion Tabic

7.5 Password Input

8. Configuration Parameter Setting

.................................

8.1 Configuration items .........................................

8.2 Checking or Changing Parameters

9* Calibration ..................................................

..................

’ 2

■ ■ 5

. . . 9

9

. 9

- 10

■ ■ II

■ 14

15

' 16

■ ■ 18

■ ‘ 23

■ ■ 25

25

■ ■ 27

■ ‘ 28

30

- 30

■ 31

■ ‘ 32

■ ■ 32

34

36

■ ' 42

43

' 44

- 44

‘ 44

101

9.1 Calibration Items .............................................

9.2 Calibration Using Converter Signal Source

- 7

101

102

Page 9

TOSHIBA

6F8A0774

10. Digital I/O Functions

10.1 Digital I/O SpecificaiiOQS

.........................................

...................................

10.2 Totalizer and Pulse Output ....................................

10.3 Multi-range Functions ...........................................

1G.4 High and Low Limit Alarms

10.5 Empty Pipe Alarm

10k6 Preset Point Output

..............................................

..............................................

10 J Remote Zero Adjustment

................................

......................................

10.8 Remote Selection of FiTfccl Value Output

10.9 Converter Failure Alarms

IL Communkatinns Function

.....................................

.....................................

11.1 Communications with llic AFIOO Terminal

11.2 Communications Procedure

1L3 Cautionary Notes on Communications ..................

12, Self-Diagnostics and Alarms .................................

12.1 Self-Diagnostics ....................................... ............

12.2 Output Status for Errors and Alarms

13, Maintenance and Troubleshooting

13H Maintenance

13.2 Troubleshooting

14, Principle of Operation ......................................

.......................

....................................................

......................

...................................

....................

-

.

15, Specifications ..................................................................

15.1 Flowmeter Specifications ■ ■ —

..........................

15.2 Type Specification Code .......................................

16, Outline Dimensions .

Appendix 1 . Electromagnetic Compatibility and Low Voltage

Electromagnetic Compatibility

......................................................

................................................

Low Voltage Safety.......................................................* - . . -

Safety

106

107

108

113

118

120

121

125

126

127

128

J28

129

130

131

131

134

135

136

139

142

143

143

148

151

152

152

153

- 8 -

Page 10

TOSHIBA

Ь Product Inspection and Storage

upon iirrival of the produt;i packiigc» open Ihc package and check the items contained inside.

If you do not intend ю install the product soon after opening the package, store Ihc product

and other related items in a place such as described in 1,2 below,

LI Product Inspection

The LF494/LF404 electromagnetic flowmeter is shipped in a cardboard container filled with

shock-absorbing materials. Open the package carefully and check as follows:

■ Make sure the following items arc included in the package.

(1) Model LF494/LK404 Electromagnetic Flowmeter*...,* i

(2) Instruction Manual

■ Inspect the flowmeter for indications of damage that may have occurred during shipment.

■ Make sure the type and specifications of the flowmeter are in accordance with (he

ordered spccillcations.

If you cannot find the items listed above or any problem exists, contact your nearest

Toshiba representative.

6F8A0774

..................................................... |

1.2 Storage

To store the I.r494/LF404 flowmeter after opening the package, select a

storing place as follows and keep it under the conditions described below:

(1) Avoid places where there is direct sunlight, rain or wind.

(2) Store the product in a weli-vemilaicd place. Avoid places of extremely high

humidity or extremely higher low temperature. The following environment is

recommended:

* Humidity range: 10 to 90% RH (no condensation)

• LStoruge temperature: -15 to +65* C

(3) Avoid places where vibratioiis or mechanical shock occur.

(4) Uo not leave the converter housing cover open . Open the cover only w'hen

you actually start wiring cables. I.eaving the cover open can cause gradual

deterioration of circuit isolation.

(i) To put the flowmieter temporarily on the floor, place it carefully wi\U something

to support ii so that the flowmeter will not topple over

- 9 -

Page 11

TOSHIBA

2, Overview

6F8A0774

The LP494/LF404 ciectromagiiclic flowmeter can be use in the following hai;ardous (clas

sified) locations,

(1) FM Approval

Class I , Division 2» Groups B, C and D,

Class n , Division 2, Groups K and G

Class IIE

(2) CSA Certification

Gass I , Division 2, Groups B, C and D,

Class U, Division 2, Groups E, F and G

Class in

The device measures the volumetric flow rates of electrically conductive materiaU on

the basis of Faraday's J.aw of electromagnetic induction.

The device consists of two unit.s; the detector» through which the fluid to be measured

flows, and the converter, which receives the electromorive force signals from the

delector, then converts the signals into the 4—20 mA dc signal.

Model LF494/LF404 is a sanitary elcctromagneiic flowmeter designed for applications

handling food and beverages. Sani'.ary flowmeters must be sinictured in such a way dial

operation and handling is simple, easy and thorough for the purpose of sanitary control

such as cleaning, sterilizing and drying, llic flow-meter has no obstacles in the flow

stream and it is designed to provide indispensable conditions for sanitary control and is

fit for flowrate measurcjncnt for food and beverages.

Features

Model LF494/LF404 sanitary flowmeter has Ihe following features:

(J) Fluid flow is not obstructed and pressure loss is negligible.

Toshiba's original noisc-suppression circuit with signal processing capabilities ensures

(2)

a stable oulpul.

Has no moving parts and flow indication is quick with high accuracy even under low'

(3)

flowrate measurement conditions.

Equipped with a ferrule, compatible with ISO clamp connection, at both ends of the

(4)

detector. They can be mounted or dismounted easily and securely.

No obstacles in the flow stream and nowhere remains the fluid along the detector pipe.

(5)

Thus deterioration or corrosion of fluid does not <xxmr.

High accuracy, ±0,5% of rale is possible for 0.3-10 m's velocity range.

(fi)

0,1 lo 0.3 m^s range is available oplionaljy.

The flowmeter has various flow measurement output and control functions as standard

(7)

specifications and the optional LCD display for convenient parameter settings.

• 'I’hcse functions can be selected with control keys on the panel.

Intelligent functions

(S)

* The widely used HART protocol comm uri real ions system is used as a standard

feature, HART (Highw'ay Addressable Remote Transducer) is a communications

protocol for industrial sensors recommended by HCF (HART Communication

Foundaiion).

.An easy-io-rcad LCD display (2-line x 16-character display) (optional)

(У)

• The backlit LCD display can be read even under poor lighting conditions.

- 10

Page 12

TOSHIBA

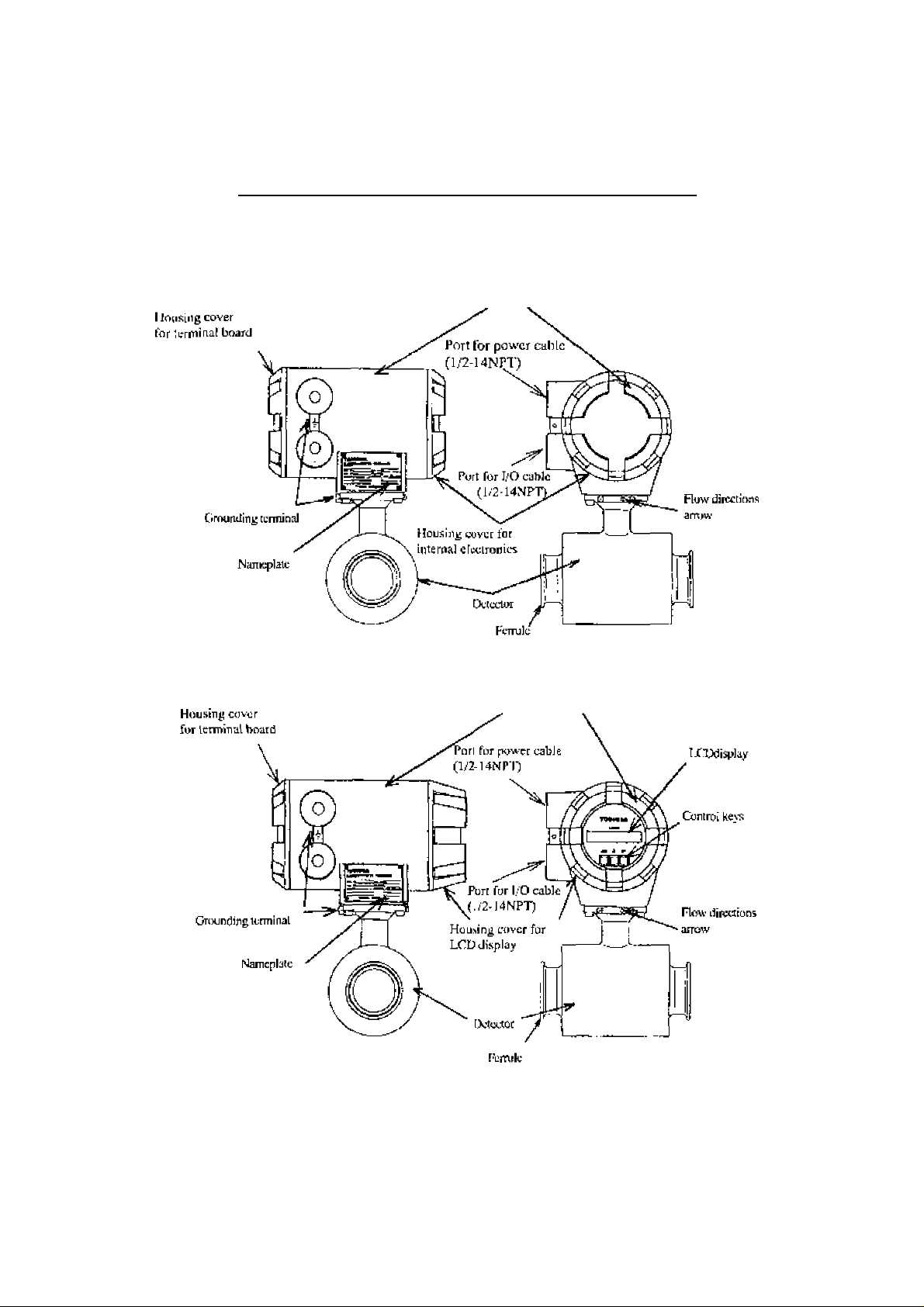

3. Names of Parts

The oulline drawing of the LF4y4/LF404 flowmeter is shown in Figure 3.1 and (lie in*

_____________

IMPORTANT

The apparatus should not be provided with the cable glands^

Please prepare yourself for the cable glands which could be used in Division2 hazardous locations.

icrnal views of tJie I.F404 converter arc shown in Fifinres 3.2 and 3,3,

____________

6F8A0774

Outline ]>ra>i^ing

Converter

LF494/LF404 withaiit LCDdispliiy(standarcl)

Convcrlcr

LF494/I J*'404with IXD display (optiimal)

Figure 3,1 OutliDe drawing of LF494/LF404 Flowmeter

- II -

Page 13

TOSHIBA

Tennina] Board of O^'404 Converter

6F8A07.74

Power supply LcrmijjLils

Digital output (DOl) D02)

tcrminalu

Internal grounding terminal

External groondini*

^ terminal

Digital input (Ur) terminal

Common for Dl, DOl and 1X)2

Figure 3*2 Teminnl Bt>ard of LF404 Converter

Current output terminal

- »2 -

Page 14

TOSHIBA

Contrri switch or kej's of LF404 Converter

6F8A0774

LF404 without LCD Dtsplay

Figure 3J Control switch or keys of LF404 Converter

-

13

-

Page 15

TOSHIBA

4. Installntion

Safety Precautions For Installation

I

Do not live ciremts under envTonmcni of explosive atmospheres.

6F8A0 7 7.4

A WARNING

(S)

DONT

M Do not use parts of other products.

O

DOMT

f Do not live circuits While assembly of all components is not over.

0

DONT

I Install per the National Electrical Code for the US (NEC, ANSI/NFPA 70)

and the Canadian Electrical code for Canada (CEC, CAN/CSA-C22J)«

O

DO

Live part of electric circuit or a high temperature department can

cause explosion.

Protective performance degradation for hazardous location can

cause explosion.

Protective performance degradation for hazardous location can

cause explosion.

Unsuitable conduit connections for hazardous iocation can cause

explosion.

A CAUTION

■ install a switch and fuse to isolate

the LF494/L.F404 from main power.

Power supply from main

power can cause electric

shuck or circuit

QQ breakdown.

■ Use an appropriate device to carry and

install the LF494/LF404.

If his product falls to the

grou nd, i nj u ry, or

malfiincrioji of or damage (o

[jQ the product, can he caused.

■ Do m>t modify or disassemble the

LF494/LF404 unnecessarily,

Modifying or

disassembling this product

vHy cause electric shock

m a If un ction or d am age to

DON’T product

■ Do not work on piping and wiring

with wet hands.

Wet hands may result in

electric shock

DONT

-

14

■ Ground the LF494/LF4(M

Independently from power equipment.

Operating this product without

grounding can cause electric

Q0 shock or malfunction.

The label shown left is placed

near the terminal hoard for

power input,

/ J \ (A black border and symbol on

yellow triangle)

Re alcri to electric shock.

-

Page 16

TOSHIBA

4A Location

6F8A0774

To Kcicct the inslaUatioii site, follow the prccaations described below:

■ Avoid places where fluid runs in a pulsating torm,

■ Avoid plaees wiihjji the immediate proximiiy of equipment producing electrical

interference (such as motors, transformers, radio transmitters, electrolytic cells, or

oiher equipment causing electromagnetic or electrostatic interference),

■ Avoid places where excessive pipe vibration occurs,

■ Avoid places where there is direct sunlight. If this is unavoidable, use an appropriate

shade

■ Avoid places w'here corrosive atmospheres or Jiigh humidity conditions obtain,

■ Avoid places of loo great an elevation or constricted areas where clearance

for installation or maintenance work is not provided,

■ Design piping so that the detector pipe is always filled with fluid, whether the fluid is

flowing or not,

■ The LF494 detector has no adjustable piping mechanism, Insiall an adjustable short

pipe where needed.

■ Chemical injections should be conducted on the dow-nstream side of the flowmeter

15

-

Page 17

TOSHIBA

4.2 Mounting Procedure

6F8A0774

A CAUTION

■ Use an appropriate device to eatry

and inistall the LF494/LF404. working on pipes.

If his product falls lo the

A B ground, injury, of power is applied can

malfunciioit of or damage

DO to the product, can be

caused.

4.2.1 Pipe checks

Before insiaJling pipes, check for iiny leaning ns illustrated in Figure 4.1. An attempt to

unreasonably connecting pipes that arc inclined may lead to a detector breakdown or

tlnid leakage. Connecting pipes in an eccentric state may also cause local wears and leans

of linings, as well as measurement errors.

Before installing pipes, make sure lo flash the iiiierior of the pipes to remove deposited

matters.

■ Turnoff mains power before

Working on pipes while

V_y cause electric shock.

DON’T

- 16 -

Page 18

TOSHIBA

4,2,2 Installation Procedure

6F8A0774

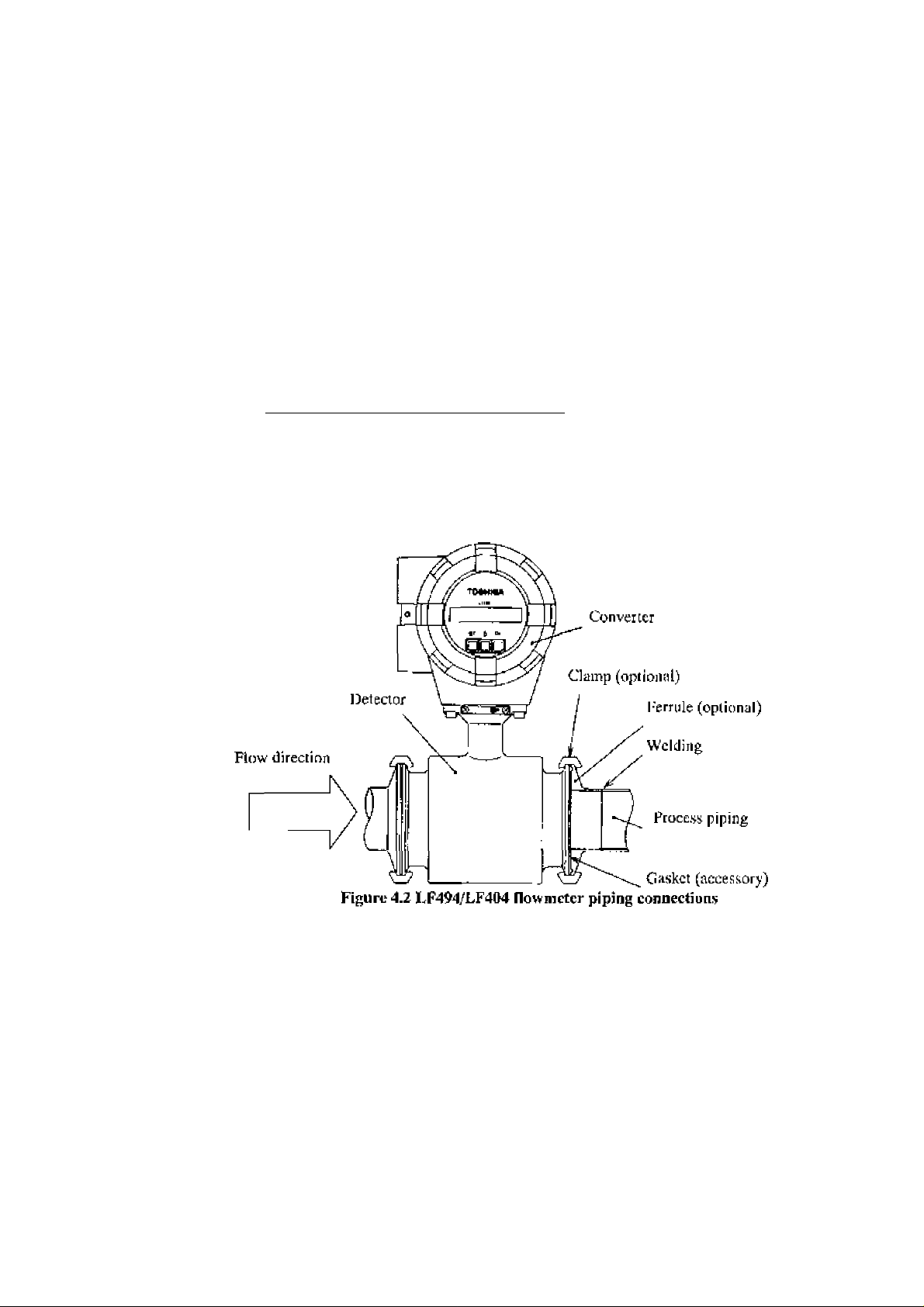

The LF4y4/LF404 adopis the ISO ^^^52 ditmp connection mcihcnJTo mount the 1.F494/LF404, see Figure 4.2 and follow the procedure below;

1. Weld a ferrule of the detector to the proces.s pipe on both upstream and downstream

sides.

2. Install the LJ’494/LI-404 between the two tcrrulcs w'hicli were welded to the pnjcess

pipes above.

3. InstaU a gasket betw^een ;he grooves of theferruJeon the detector side and lhal of the

ferrule on the process pipe for both upstream and dow^nslream sides, 1 iicn place a

clamp over the joined ferrules as shown in I’igure 4,2 and tigliien with the screw' for

both upstream and downstream process pipes.

IMPORTANT

When high-temperature fluid is being nieasuredj radiant heal from ihe detector pipe surface and

adjoining pipes may cause the ambient temperature of the converter to go above 60 °C. If the

ambient tempera lure goes above 60^ C, (ry to lower the temperature by measures such as wrap

ping hcal-insulating materials over the detector pipe and adjoining pipes.

_______________________________

- 17 -

Page 19

TOSHIBA

4J Piping Connections

(1) Required Pipe Length

6F8A0774

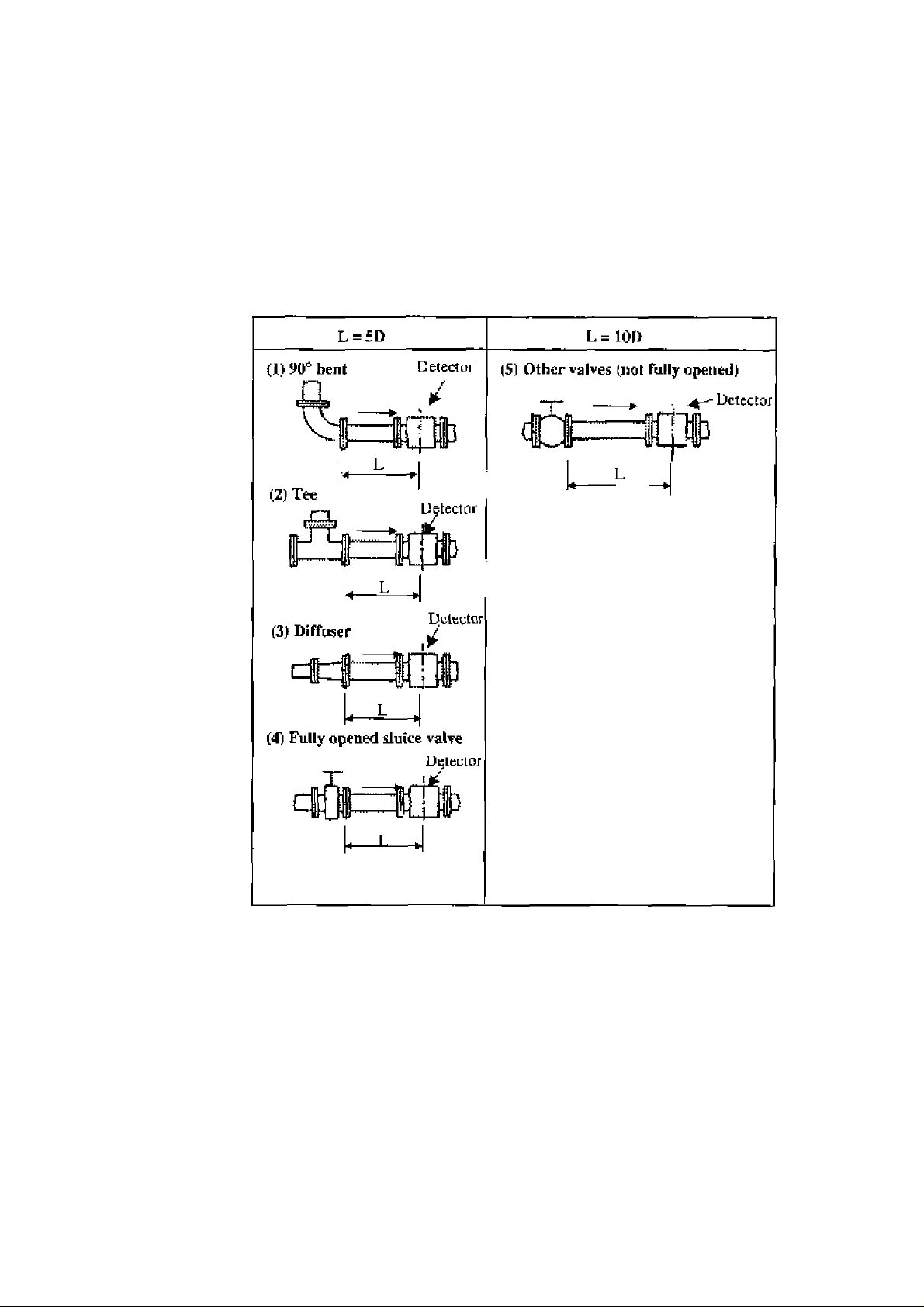

If various jaintsS ¡irc used upiitream of the cleiector oullot, the straight pipe length us

shown in Table 4J is required.

Table 4.1 Required straight pipe length on the upstream side

L: Required straight pipe ietiglh—straight pipe length plus half length of the detector.

D: Nominal bore size (diameter)

NOTES

1. The length of a reducer* if connected, can be counted as a part of the straight pipe

length.

2. No straight pipe letiglh is needed on the downstream side, if a butterfly valve is

installed downstream of the detector, do not let the valve plate protrude into the

pipe of the detector

- U -

Page 20

TOSHtBA

6F8A0774

C2) PipÊ Orientation

The detector may be installed in horizontal, vertical or sloping pipe runs as shown in

Figure 4,3, However, cxccpl for horizontal installation, llmd should flow from lower to

upper directions. See Figure 4.3.

r~

Fldw direction

I

I^Cb)

(a) Horizontal pipe instailation

(h) Vertical pipe installation

(c) Sloping pipe insialiation

Ground sgriace

Figure 43 Detector Piping Orientation

The electrodes should be positioned horizontally against the ground surface in any piping

installation. See Figure 4.4.

(Jmss-scdiiin A - A

Figure 4.4 Installation position of the detector

-

19

-

Ground surface

Page 21

TOSHIBA

6F8A0774

(3) Flow Direction

Install the delector in accordance with the flow direction arrow on the detector. See I’ignre 4,5.

If the actual flow runs opposite to the specified flow direction, the following display and

output appears.. (For bidirectional multi-range measurement, sec 103^ “Mulli-rangc

Functions/’).

* LCD display (optional)« Instantaneous How rate—indicates negative values»

Totalized flow—no a>unts added,

* Output:Current output—4.0 mA output; Pulse output—No pulses

For bidirectional range measuremenu the flow in opposite direction results in a positive

output value. See 10.3» “Multi-range Functions/’

(4) Preventing sin Empty Pipe Condition

Design an upright pipe run (Figure 4.6) or sufficicjit head pressure (Fig, 4.7) at the

downstream detector oullet if there is a possibility of the detector pipe becoming emptied.

Upright pipe run

Figure 4«6 Detector with 3n upright pipe run at dow'ustream outlet

Detector

Z

Figure 4.7 Detector with sufficient head pressure at downstream outlet

- 20 -

Page 22

TOSHIBA

6.F8A0774

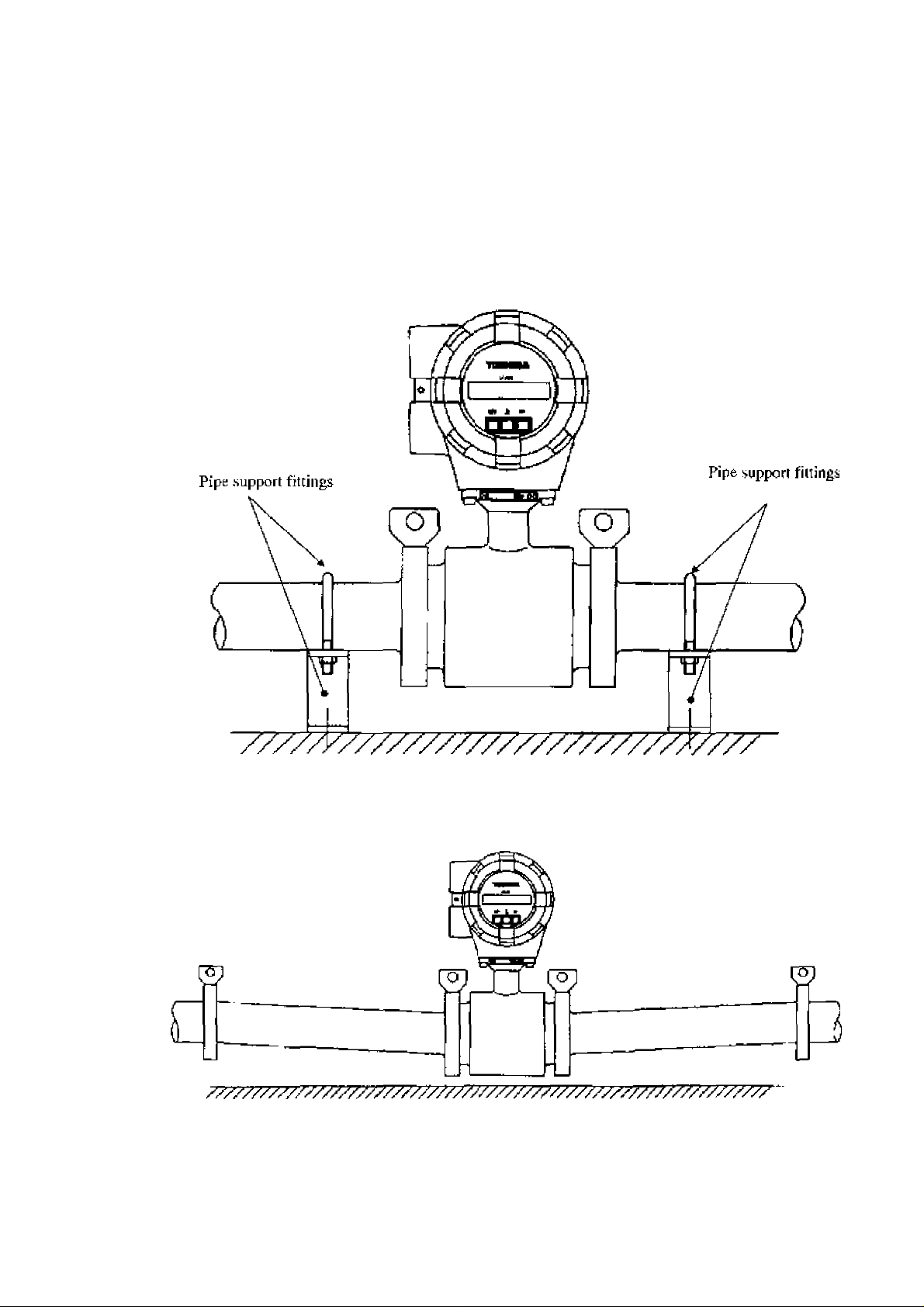

(5) Supporting Pipe

Fix Ihc relevant pipes installed on both sides of the detector by attach fittings, etc. to support

the pipe. Y iy supporting the pipes, not only the pipe vibration is reduced but also the damage

to the pipes by the electromagnetic flowmeter's weight and the fluid mass. And it protect

from fluid leakage at flange face (see Figures 4.^ and 4.9).

Figure 4,8 Example of Pipe Fixing Procedure

Figure 4,9 Model Diagram of L'nsupported Pipes

- 21 -

Page 23

TOSHIBA

6F8A07.74

(6)Groiindirif<

The grounding terminal of the LF494/LK404 Qo’ameter should be grounded with lOUohm

or less ground resistance. Use a heavy copper braid or wire (cross-sectional area 5,5 nun"

minimum) to ground the lerminal and make it as short as possible. The terminal is M4 siiic

and an M4-siiie crimped ring fug should be used to connect the wire to the terminal. Avoid a

common ground where earth currcni may fliw. An independent ground is preferable, See

Figure 4.1(1.

To prevent a iwo-poini grounding, ground the shielded cable on the receiving instrument

side,

Figure 4.10 Grounding Procedure

- 22 -

Page 24

TOSHIBA

5, Wiring

6F8A0774

Ж WARNING

DO NOT DISCONNECT WHILE CIRCLIT LS LIVE UNLESS

LOCATION IS KNOWN TO BE NONHAZARDOUS*

(S)

DON’T

Do not live circuits While assembly of all components is not over.

0

DON’T

I Install p«r the National Electrical Code for the US (NEC, ANSl/NFPA 70)

and the Canadian Electrical code for Canada (CEC, CAN/CSA-C22J)*

О

DO

Live part of electric circuit or ^ high temperature department cun

cause explosion.

Protective performance degradation for ha2ardou,s location can

cause explosion.

Unsuitable conduit connections for hazardous location ctm cause

explosion.

Ж CAUTION

■ Do not work on piping and wiring

with wet hands.

Wei hands can cause system

failure,

DON’T

■ Do nut modify or disassemble the

LF494/LF404 unnecessarily.

Modifying or disassembling

1 jj^ this product can cause elcc-

trie shock, malfunction of or

DON’T damage to this produci.

■ Use the proper cables for wiring of

power and I/O .

Using a cable other :han the

уЛ one specified may c^usc sys-

/ J \ tern failure or damage and

may break watcrproul.

Ш Ground the IvF494/LF404 properly*

Operating this product without

a grounding can cau^e system

malfunction.

DO

■ Prepare yourself for the cable glands

which could be used in Division 2

hazardous Incation.s*

The apparatus should not be

provided with the cable glands.

DO

* The label shown left is placed

Л\ near the terminal board for

/ power input.

" * Be alert to electric shock.

- 23 -

Page 25

TOSHIBA

6F8A0774

I'lowmeter acuumcy may be affccieJ by the way wiring is executed. Proceed with wiring

taking ihc foJIowiJig prccauiions:

(1) Select the cable runs away from electrical equipment (motors, transformers, or

nidio transmitters) which causes electromagnetic or electrostatic interference.

(2) Deteriorarion of fJowmetcr circuit insulation occurs if the converter interior or

cable ends gel w^et or humidified. 'I’his in turn causes malfunction of flowmeter

or noise problems, Avoid a rainy day if the flowmeter is to be installed outdoors,

l-ven indoors, prevent w^ater from splashing over the flowmeter. Try to finish the

W'iring as quickly as possibJe

(3) The converter has a surge-ai>sorbing barrier installed inside. Therefore, do not

conduct a wdthsiand voltage test for Ihe converter. To check ihe insulation of the

converter, use a voltage of 250 V dc or le.ss.

-

24

-

Page 26

TOSHIBA

5.1 Cables

Use the kind of cables shown in Table 5.1 to vsdre the converter.

Nnme

Power cable

I/O cable The number of wires for the output cable depends on the

Notei Use a four-wire cable if the arresters are to be used. See Figure 5.1 below.

5*2 EtKlernal Device Connections and Grounding

The terminal board comieciion;s of ihe 1T494/LF404 flowmeter are shown in Figure 5.1.

Proceed with wiring as described in Section 5.4, “Wiring Procedure."’

Cable type

Three-wire sheathed

cable (Note)

system specifications. Use a shielded cable with nominaJ

cross-sectional area of 1.25 mm^ and overall diameter of

11 to 15 mm.

Table 5*1 Cables

Nominal

cross-sectional

area

2 mm^

6F8A0774

Overall diameter

11 to 15 mm

If power supply is specified as DC, use LI ds positive (+) and L2 as negative (-) terminals.

Instrument Panel:

ordered separately

Currentoulput (4-20mAde)

Flowmeter

(■*■) Hs)

I LI I l^|FGt|l3tc|[cq*4 rn|noa|DQl| " f ^ I

T

______

^

..................

_____________________

I - ground resistant’^

! ***^ Grounded with 1 OOtior less

. V L>jgita] Output 1

: > ragiu^ O^rtput 2

‘ > Digital Input (20 lo 30 V dc)

1 -

IV wire

5,5mnr

or more

I/O cable

■7:^

W >wcr cable

^ '

' \

Power Switch

*1 To use the arresters, ground the GNI) terminal using the wire shown in broken line.

*2 Locale an cxiernal double-pole power switch on the powder line near the flow'meicr and within easy

operation. Mark one the switch as the disconnecting device for the flowmeter,

Use an appropriate swiicli of the rating shown below:

Recommended sw'ilch rating; Rating 250 V ac, fiA or more

Inrush current 15 A or more

— > pQWCï Supply

Figure 5*1 Terminal Block Connections

-

25

-

Page 27

TOSHIBA

6F8A07 74

IMPORTANT

(1) The grounding terminal of the LF494/UH04 flo^mEtcr should be grounded with

100 ohm or less ground resiiilance. Use a heavy copper braid or wire

(cross-seciioniil area 5 .5 mn:" minimum) to ground the terminal and make it as

short as possible. The icnninal is M4 size and an M4-sizc crimped ring lug should

be used lo connect the wire to the tenninaU Avoid a common ground where earth

current may flow . An independent ground is preferable^ See Figure

conductive pipeline grounding and noii-conducrive pipeline grounding procedures.

(2) To prevent a wo-poinl grounding, ground the shielded cable on the receiving

inshiimenl side.

5.2 . for a

I If connection pipe is conductive:

Connect between the grounding terminal

and both ends of the mating flanges with

a heavy copper braid or wire

(cross-section 5.5 min‘ minimum).

If connection pipe is non-conductive:

Use a heavy copper braid or wire

(cross-scciiiin 5.5 mm^ minimum) to

ground he terminal with UK) ohm or

less ground resistance*

Figure 5.2 Grounding Procedure

- 26 -

Page 28

TOSHIBA

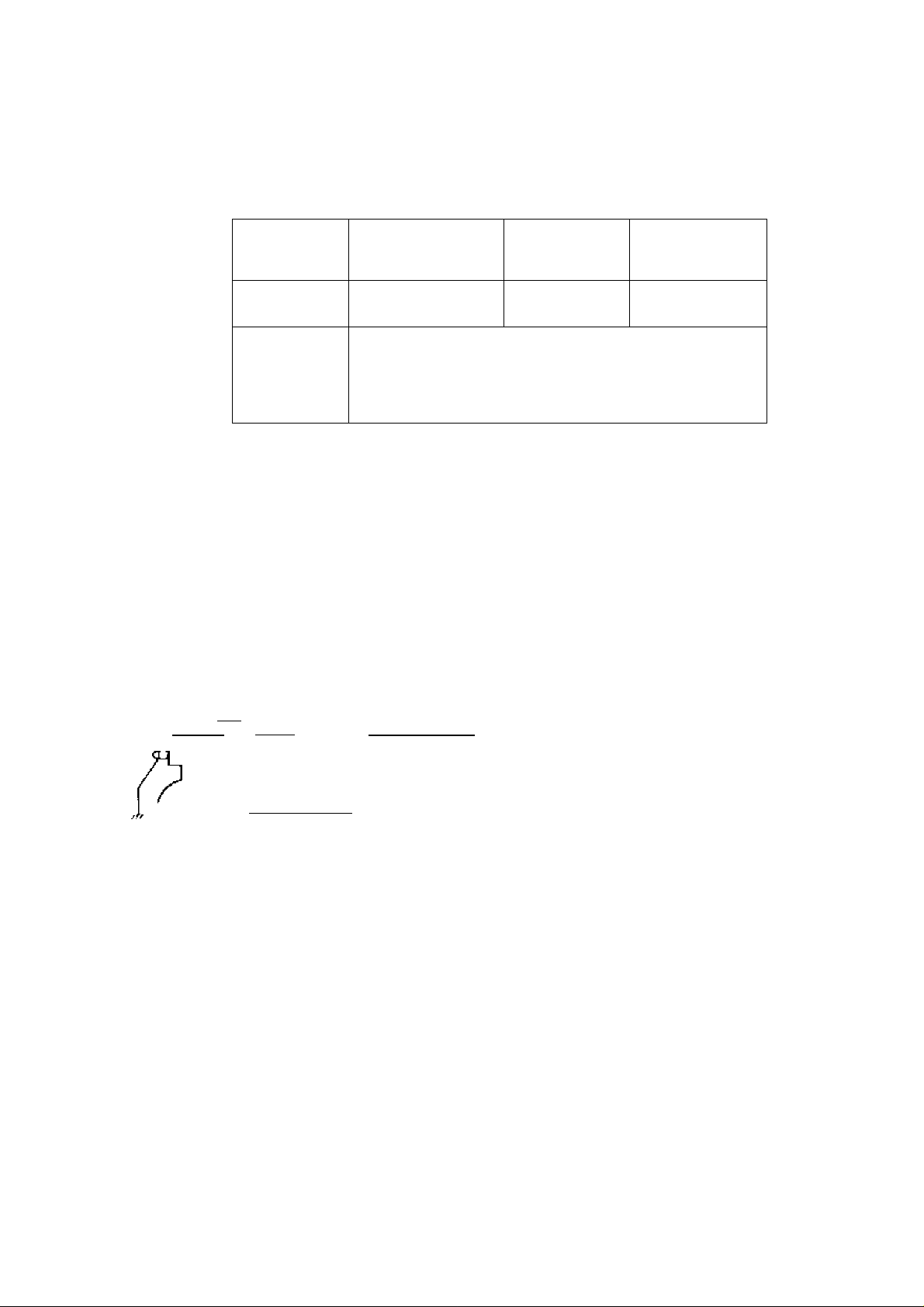

53 Digital I/O Connections

Digital I/O icrmmEils cottsiM ol conlact oulpul lerniiiials (jilatidard DOl Eind optional

D02), voJlage signal input terminal (Dl, opcioiial), and signal common terminal {COM).

Hach terminal (DOl, D02 and DI) is isolated from internal circuits. Terminal (COM) is

the signal common for the other three terminals {DOl, DOl and DI).

Functions can be assigned for each xnninal with Ihe LCD control keys (option). See

Chapter 10, ‘‘Digital I/O Functions/

To connect an electromagnetic relay ot counter lo the contact output tcrrtiinal (DOl or 1>02)^

put a surge-absorbing diode into the input circuil of the relay or counter. See Figure 5.3 for

an example of electromagnetic counter connection,

6F8A0774

Note I: Use a surge-absorbing diode of the rating: current rating lAand voltage rating

200 V minimum.

Note 2: The Solidstaie relay, photo-coupler and resistor are not provided for the standard

model (the one whth no digital I/O specifications). l.eavc the terminals for D02 and

Dl open.

Figure 5.3 Electromagnetic Counter Connection Exntnple

- 27 -

Page 29

TOSHIBA

S.4 Wiring Procedure

5A1 Cable Terminationi

6F8A0774

Cable termination and cable connections are described below.

A CAUTION

■ Ho not con d net w i ri n g work wt e n ■ Eto not w'ork on piping and wiring

power is applied.

Wiring while power is ap-

1 plied can cause clccinc 1 electric shock.

shock.

DONT DONT

IMPORTANT

Ttic apparatus should not be provided with the cable glands.

Please prepare yourself for the cable glands which could be used in Division2 hazardous

locations.

with wet hands.

Wet hands may result in

Use cables as specified in Table 5.1 ^ First, Remove the cable sheath about 70 mm from the

end to expose the coated wires and then strip the wires about 10 [nm. Then attach an

M4-sis:e compression terminal lug to the end of each wire using a compression tool. The

compression terminal should be of Ihe kind with insulated sleeve to prevent shorts between

adjacent terminals. The overall length oi thc wire with the terminal attached should be about

6(.) nmi. Sec Figure .‘5,4 below,

M4-sizc compression terminal lug

- 28 -

Page 30

TOSHIBA

5A2 Cable Connections

6F8A0774

Connect the term incited cable wires to the terminal board as described below.

IMPORTANT

Connect the wires securely to :hc terminal board. A loose connection may result in

unsaiisfacLory flowmeter performance. Make sure the wires arc securely connected.

(J) Remove the housing cover for the terminal board shown in Figure 3.1. The terminal board

is located inside the converter as shown in Figure 3,2. Connect the crimped terminal of

each wire to the specified pin of the terminal board . See Figure 5.1 for the terminal board

configuration, Tighten each crimped terminal to the terminal board wiih a screw using a

l*hil!ips screwdriver as shown in Figure 5.6. Loose connection may result in unsatisfactory

flowmeter performance. Make sure the wire is securely connected.

NOTE

ITic appropriate torque for tightening the terminal board screws is J .2 Ntn (12 kgf- cm).

(2) After the terminal block connecriorij pull the cable a little so that the cable runs straight

from (he terminal block without unnecessary winding.

(3) Attach the terminal cover and screw the housing cover for the terminal block. To keep the

housing seal, lighten securely the cover using a tool fitting with the groove on the cover

- 2& -

Page 31

TOSHIBA

6. Operation

6F8A0774

A CAUTION

Do not touch the LF494/LF404 main body when

high temperature fluid i.s beii^ measured.

Thc fluid raises the main

Q

DONT

6*1 Preparatory cheek

Follow the procedure described below to prepare before starting the (low tneasurerrienl.

System Check

Check the wiring between the converter and related instruments.

Make sure all Ihc bolts of connection flanges on which the flowmeter is mounted

securdy tightened.

body tempera lure and can

cause burns when touched.

Make sure the direction of flow arrow is in accordance with actual flow.

Make sure the flowmeter is grounded with IDO ohm or less ground resistance.

Make sure the converter housing covers are securely tightened.

Placing System On-Stream

l.ct the fluid go through the delector pipe. When the detector is filled with the

fluid, stop the fluid and keep it still in Ihc detector pipe.

Supplying Electric Power

Make sure the powder supply is as specified.

Checking Converter Parameters

Check the configuration parameter settings, Refer to Chapter 7, "LCD Display

and Controls,” Chapter 8, “Configuration Parameter Selling/’ and Chapter 11,

“Communications Function/'

Zero Adjustment

Wail for 30 minutes to warm up the flowmeter, 1 hen making sure the fluid holds

still in the detector pipe, starts the zero adjustment.

Refer to 6,2, “Zero Adjustment.’"

On line measurement

After checking the items and conducting the ze ro adjustment as listed above, let the fluid go

through the detector pipe. Output (4-20 mA dc) directly proportional to the flow rale can be

obtained.

30 -

Page 32

TOSHIBA

6F8A0774.

62 Zero Adjustment

To conduct zero adjustment of the flowmeter, the fluid in ihc detector pipe must be held stilL

There are three different ways to start the ^ero adjusimeni:

(1) I^essingthe zero adjustment switch for the model without IX^D display

(2) Pressing a combination of control keys for the model with LCD display

(sec 8.2.8, ‘Zero Adjustment ’)

(2) Sending a command signal from a HAR'l’ communications device

(such as the AFIOO hand-held terminal).

The follow'ing is the procedure for starting the zero adjustment for the model without LCD

display.

■ J’ress the zero adjustment switch for more than 3 seconds.

(Note [hat once the zero adjustment is started, there is no way to caitceJ the zero

adjuslmem sequence.)

Then the LHD indicator lights and [he zero adjustment sequence will start. 1 he zero

adjustment sequence lasts about 3 to 6 seconds. (Zero adjusimcrit duration depends on

the excitation current frequency. Jl lakes about 3 seconds for 24 Hz setting and about 6

seconds for 12 Hz and 6 Hz settings.)

When the zero adjustment sequence ends, the LliD indicator goes off.

To conduct the zero adjustment, it is necessary to open the converter housing cover for

inicmaJ electronics and press the switch. Observe the following precautions when you

open the hou.sittg cover:

(1) Do not open the cover in the open air unprotected against rain or wind.

It you adjvist the ilowiucier in the rain, this can cau^e electric shock or damage to the

flowmeicr electronics. If wind blows against the internal circuitry of the converter, output

may fluctuate and fail to indicate correct measuring values.

(2) l>o not conduct the zero adjustment when the amhieni humidity is high, By opening the

cover in high humidity conditions, the measuring accuracy may he reduced or damage

caused to the flowmeter electronics.

- 31

Page 33

TOSHIBA

1, LCD Display and Controls (option)

You can select the operation modCj change the configuration pariinictcrs or cxeculc

operation-specific functions using the control keys on the panel. How to operate these

keys is described in this chapter.

7.1 Outline

The LF404 Converter has an optional LCD display. The LCD display can be used to set and

indicate various configuration parameters, Figure 7.1 shows the front view of LCD display.

(1) Do not open the housing cover for LCD display in the open air unprotected against rain or

wind. If you open the housing cover for LCD display in the rain, ii can cause electric

shock or damage to the flowmeter electronics. If wind blows against ihc internal circuitry

of the converter, the output may fluctuate and fails to indicate correct measuring values.

(2) Du not open the housing cover for LCD display w'hen the ambient humidity is higli.

I3y opening The cover in high huraidity conditions, the measuring accuracy may be re

duced or damage caused to the flewmeiei electronics,

6F8A0774

Housing cover for

'^LCD display

Figure 7.1 LF404 Converter with LCD display

LCD display

A 2-linc X 16-character liquid crystal display. 1 he backlit display enables an easy-to-read

indication even under poor lighting conditions. Instantaneous flow rates or totalized How in

the measurement mode, or configuration parameters in the setling mode can be displayed.

- 32 -

Page 34

TOSHIBA

6F8A0774

■ Control Keys

Changing the operation mode, checking or changing parameters can be done with these keys.

To operate these keys, you have to open the converter housing cover. Observe the following

precautions when you open the housing cover:

rnnetions of each control key when pressed are shown in the table l>clow.

Control keys

SET

□

Basic functions of control keys

Oocs into the iteins sdeetion aeijucTice.

K, 00 n/s

lit). 0 Ï

Ones into the dct^Mcel-ltcni specifying sequence for each selcctetl iicin in

measarement, setting or calihralion modes.

Al :£i, CJRR.

1—\

'

-------

Al'.EX. CUftR

/

.selection sequence

A1:EX. CURB,

0

selection sequence

Stores the sclcct2:<j Juta in the setting mode.

Bl:UfllT 1

%

status of chairging the data

Changes itenrs (alphabet letter and number) in the items selection sequence,

and changes parameters (numbers andi'or units) in the detailed-item specifying

sequence in measurcnient« selling nr calibration nnodes.

C2:RA^G£ 1

02. 000 in/s

r—N

date;[J,2UUOm/s

Starts and stops the totali/er in the incasurement mode.

F lOCO

100.0 %

step the totali/cr

Changes digits (alphabet letter and number) in the items selection sequence,

and starts the detailed-item specifying sequence by indicating the left-most

digit with the cursor

D1: DAMPING

_______

,

-----

w

\

00 s s

setting mode siaitjs of finish changing

Moves the cursor frocn Ictl Iti right (from the right end reverts to the left end) in

measurement mode

B1 :UNIT 1

%

Status of finish changing

C?:RANGE 1

03. OOO ñ/%

darctoOOOm/s

(Note)

F

tool ID' C

1ÛR. 0 %

start the totalizer

D1 : DAHPINO

00. 5 S

►

□

Resets the iotaligcr in the measurenient cnodc. (Nutgl

Note: To operate the totalizer, it is preterabk U> set the indicating unit (UNIT I and/or UNIT 2)

to one of the units appropriate for totalization just to make sure it is operating eorreclly.

See 10.2, "Totalizer and Pulse Output/'

Gl : COUNT RATE

1. 23£-4

Indicate cursor un^er ‘ I ’

F '000 C

00. 0 1£

start the tiitaiizer

- 33 -

1—A

*

—/

1

----

1—/

Cl: COUNT SATE

[. 23E-4 m’

Indicate cursor under

0 m*

F

\

TOO 0 X

reset the totalizer

c

Page 35

TOSHIBA

7.2 Display Format

6 F8 AO 7 7.4

In ihe me-isurcment mode» measured data are displayed in UNIT 1 (primary indioaling unit)

and UNIT 2 (secondary indicating unit). As to indicating units, see 8.2,4, ‘"Indicating Unit '’

Display Format

DisSplayed in UNIT 1 indicating unit.

I— *‘C ' indicated when lotfd tlow is cc>unted.

IF 10 0 0 0 0

10 0.0 %

____________-¿L.

M Measured Value Display Format

(1) Flow rate

_

___

Upper 4 digits maximum arc cTfcctive (for the selected span).

r

")

“ C ’’ is indicated when

communication is in progress.

I b t

I C

L _ - .

Displayed in UNIT 2 indicating unit.

'The unit of time

-The unit of flow

‘7 digits (9999999) maximum including decimal

point

'Flow direction: Forward “ (blank space);

Reverse “

-

34

-

Page 36

TOSHIBA

(2) Totiìlizer

F 9 9 9 9 9 9 9 S C

I I I I- ..............................................................

(3) Volumetric flow

F 9 9 9 . 9 9 ml

I J I.......................................

.....

I

LJ

6F8A0774

L- “C” is indtcaietj when (oial tlow in counted

Increments per cnunling rale, Refer (o

8.2.10, '"Counting Rate/’

Wrapfi iirounci after 99yy9y99.

“F’ for forward and “R" for reverac direction ilow

will be displayed

Displays down [o the smallest digit of counting rale.

J_

^ "'C” is indicated when volumetric flow is counted.

— The unit of flow

N) % display

-10 0.0 %

..................................................

.....

1 1 J

-

--------

8 digits (999^9^99) maximum including decimal

point

If (he flow count exceeds 999 99 9 99 , wraps around.

"F" for forward and “R” for reverse direciion

flow will displayed.

Displayed dowm to i).l %.

Displays up to 125.0 %.

— Plow direction: Fomard " “ (blank space);

Reverse

- 3i

Page 37

TOSHIBA

6F8A0774

13 Itasic operations

How measurement in the mcasuicinent mode, checking or changing configuration

parameters in the setting mode and a converter unit check in the calibration mode arc

the basic operations of the LF404 converter

7J,1 Mode Change

The Lr404 converter has three operation modes: measurement, setting and calibration.

The system stays in the measurement mode after the power is turned on. To change the

mode to the selling or calibration mode, press [SET] and select the desired item using

( ► ] and [ A. ] keys. To return to the measurement mode, scJect “tP (MliASURH

MODE) for the number column of configuration items (such as AO or BO), Sec 7.4,

“Configuration Items Selection Table.”

■ Measurement mode

: measures the process flow and displays and outputs the measured process values, The

flowmeter can measure the flow velocity, flow rates, or totalised How, The flowmeter

first goes into this mode when power is turned on.

Setting mode

r used Lo check or change various configuration parameters used in the measurement

mode. These parameter values are displayed while checking or changing these values

hut the flowmeter outputs the measured process values as in the measurement mode.

See 7.4, "Configuration items Selection Table” and S.2, “Checking or Changing

Parameters” for details. Configuration items are from A1, A2, A3 to Ml.

Cnlibration mode

: used to check the converter internal circuits. The intemally generated simulation signal

is used to check the measurin| span and excitation current value. The current output of

the flowmeter changes in accordance with the simulation signal. The status of each

digital output is held to the value just before the .system moved into the calibration

mode. See 7,4, ^'Configuration Items Selection Table” and Chapter 9, “Calibration” for

details. Configuration items are from M lo N4,

-

36

-

Page 38

TOSHIBA

Change mode flow

SET A ^

□ □□ arc sJiown tQ control keys, anti LF404 display is changed lo

6F8A0774

------------

Measurement mode

^ indicaied.

-

37

-

Page 39

TOSHIBA

6F8A0.7.7 4

7.3.2 ConflguriitioTi Parameter Selecticin in Setting and Calibration Modes

Process as follows lo select the desired items, to chock or change the item setting value,

■ To selticts the desired item :

Key operation

SET

□

▲

□

►

□

□□

Display example Description

10. 00 rci/s

Measure value displays.(Mcasurcmcnto mode)

100. 0 %

Al: EX. CURR,

Bl; UNIT!

Bl; UNIT!

C2; RANGE 1

Pressing [SILT], the system changes to the items

selection sequence. (Note)

And the cursor appears under alphabet (A),

Change the alphabet to ''E” by pressing [ ^ ].

* If cursor is tile number, the number is increased

by pressing [a ].

Then move the cursor (o the number by pressing

[ ► ]

* If cursor is the number, the cursor is

changed to the alphabet by pressing f ► ],

Selects the desired item (indicated by an

alphabet letter and a number) first by selecting

llie digit (alphabet or number) with [ ► ] and

then changing the value with ( a ].

The example shows “C2: RANGE V’

Note: In case of that the convrtcr is type for special specifications and seitcd password^

changing measurement mode to items selection sequence, password-input mode appears.

See 7,5"Password Ltput ‘for details about Password-input mode

Sec 7,3.3 ’’Converter for Special spccifications”for to differentiate the converter for

special specifications and normal.

- 33 -

Page 40

TOSHIBA

6F8A0774

To change the setting value:

Key operation

^ ►

□ □

SKY

□

□

: □

►

□

Display example Description

Items selection sequence displays.

C?: RAWGE 1

Selects the desired item (indicated by an

alphabet letter and a number) first by selecting the

digit (alphabet or number) with [ ► ] and then

changing the value w'ith [▲ j.The example shows

“C2:RANGE 1 '

Press [SET] to vSelect the desired item setting

C2; RANGE 1

02. 000 n/s

value. And the cursor disappears and the item

setting value displays.

You can check it.

C2: RANGE 1

02. 000 m/s

C2; RANGE 1

¡2. 000 m/s

C2: RANGE 1

12. 000 m/s

Pressing [ ► ), the cursor appears.

Parameter changing sequence

Change the value by pressing ].

Then move the cursor to another digit by pressing

[ ► 1-

Change the value by pressing Then move

□ □

▲ ►

C2: RANGE 1

05. 000 m/s

the CLirsor to another digit by pressing [ ► j and

change the value.

In This example repeal (his prercess tmiil the

display shows "'05. ODOm/s

5ET

C2: RANGE 1

05. 000 m/s

▲

C2: RANGE 1

02. OOO m/s

i

S\:y

C2: RANGE 1

05. 000 m/s

□

Бу pressig [SET], flickers the selected value to

confirm changes made for the selected item.

By pressing [-^1» to return to the parameter

changing sequence.

By pressing [SE'l 1, stores the indicated value and

Slop flickering of data.

-

39

-

Page 41

TOSHIBA

6F8A0774

To return the measurement value:

Key operation Display exampJe Description

SET

□

i

►

□

▲

□

□ □

C2: RANGE 1

0. 5000 m/s

C2: RANGE 1

C2; RANGE 1

C3: RANGE 1

CO . MEAS. MODE

Checking the setting value or after setted the

value.

By pressing [Sii.T], return to the items selection

sequence.

Items selection sequence displays.

Then move Ihe cursor to the number bv pressing

[ ► ]

* If cursor is the number, the number is changed

to the alphabet by pressing [ ► ].

Change the alphabet to ‘‘B” by pressing [ a ].

** If cursor is the number, the number is

increased by pressing [ ^ ].

By pressing [ ► ] and [ A ], select

-0:MEAS, MODE"

Ttie example shows “CO: HEAS MODE'’

SET

□

10. 00 m/s

TOO. 0 %

- 40 -

Pressing [SE'r], returns to measurement mode.

Page 42

TOSHIBA

6F8A0774

7<3<3 Converter for Speciii) pacifications

The converter for special specifications is added some setting parameters. To

differentiate the converter for special specifications and normal, remove housing

cover for the tcrminii] txiard shown in Figure7.2. The converter marked as shown

in Figure 7.2 is for special specificationsj and non^marked is normal.

The added setting parameters are following items.

(1) Password input/scuing

(2) 4-20mA alarm out setting

(3) DI detective level setting

(4) Preset function

See 8.2, “Checking or Changing Parameters’' for details.

Hxample; F400 0113

Figure 7.2 LF404 Cotiveiter for special specifications

- 41 -

Page 43

TOSHIBA

7.4 Configuration Items (Selection Table

6F8A0774

In the setting and calibration modess configuration items can be selected as shown beJow. For

exampie, the excitation current can be selected by the item AJ, To change the parameters for

the selected items, see the following chapters. To return to the measurement mode, select "‘0”

for the number (such as AÜ).

Setting mode items (Al, A2, A3 to Ml): See Chapter 8, “Configuration Parameter Set ling. ’

Calibration mode item (N1 to N4): See Chapter 9, ^'Calibration.”

A n

B *1

c n

D M

E *1

F n

G

If

1

0

1

Kxeitatiun Cur*

rent *2

Indicating

Unit 1

Range T ype

*2

Damping

Constant

Zem

Adjust me 111

DOl Function

*2

Couniing Rale

*1

*2

PfCSCl Count

*2

High Alarm Set *2High Alarm

2

Meter Size

Indicating

Unit 2

Range ]

Low Cutoff

D02 Function

Pulse Widlh

Preset Punct

Value *2

*■2

3 4

Excitatioc Fre

quency *2

Range 2

"2

4-20 mA Aim.

Output '‘2

D[ Funciien

*2

•2

Low' A lam Set “2Low Alarm

"2

Password

Range 3

DOl Alarm

Active Set *2

Value *2

*2

5

Range 4

D02 Alarm

Active Set *2

*2

6

Range

Hysteresis *2

DI Det. Level

^2

J

K

L n

M n

N *1

Empty Pipe

*1

Alarm

*l

Rtite-ofehangc Limit

Fixed‘Value

Output *2

Zero Offset

Adjustment

Flow Rate

Cal *1

Control

Limit I’ime

Fixcd-currcnl

Output *2

Flow Rate

S\g5i)% "2

Fixed-pulse

Output *^2

Flow Rate

Cal H)n% ^2

Exciting

Current Check

*1: Returns to Ihe measurement mode.

"*2:Password-pro(ecied parameter

Note: “A4:Password”, ”n3:4-20Alm.Ou(\ "1’6:D[ Dcl,[x;vel \ and "H2:Freset Fund” are added

parameters in the converter for special specifications.

-

42

-

Page 44

TOSHfBA

7.5 Password Input

6F8A0774

Password input is ^ddcd parameters in the cenverier for special specifications {refer to

733 “Converter for Special specifieauons”). Only in case of the converter for special

specifications, read thisS section.

The converter for special specifications have the password ,That protects from calibrating and

changing part of parameter that influences mea.surement,.

Sec 7.4 ’Configuration Items Sclecticn Table’" for details of password-protected parameter.

See W.2,17 "'Password” for password selling.

^Setting 4IU0’ to [he password or Ihe normal ainverter (see 7.3.3 "Converter for Special

specifications"), password input mode does not appear and all configuration parameter

and calibrate can be changed,

■ To input password:

The following example shows how to input password ,123.

Key operatiort

Displsiy example

De$(cription

SET

□

▲

□

□ □

SET

SET

□

lO. 00 jn/s

IDO. 0 %

PASSWORD INPUT

DOO

PASSWORD INPUT

100

PASSWORD INPUT

m

120

123

PASSWORD INPUT

123

A1: EJ{. CURR.

Measure value displays.(Measuremento mode)

Pres^iing [SET], password input mode and the

cursor Eippears,

Change the value by pressing [ a. ],

Move the cursor to another digit by prc.ssing

f ► ] and change the value by premising [ a j.

In this example repeat this process until the dis

play shows "T23h"

Pressing [SET], the cursor disappears and the

changed display flickers. Press [SET] again to

input the value.

Whether input password agrees or dose not agree ,

the items selection sequence, "AT :EX. CURR” ap

pears.

Eui if input password docs not agree, you can not

change setting parameter and calibrate.

See 7.4 ’’Configuration Hems Selection Table” for

details.

- 43 -

Page 45

TOSHIBA

8. Configuratiim Parameter Setting

8»1 Configuration Items

To check or change parameters, first sdcci the desired configuration item as described in

7,3,2. The configuration items are Jisted below, Sec each section for detailed procedure.

6F8A0774

Section Configuration item

8.2.1

S.2 .2 Meter Size

8.2.3

8,2.4

8.2.5

8.2.6

8.2.7 Low Cutoff

8.2,8

8,2,9 Digital I/O

Excitation Current

Excitation Frequency

Indicating unit

Range Type

Span (range)

Hysteresis

Damping Constant

Zero Adiustment

8.2.tt> Couniing Rate

Pulse Width

8,2.11 Preset Count

8,2,12

8.2,13

8.2,14

8.2.15

8.2.16

8.2.17

8.2.18

8.2.19

8,2,20

High/Low Alarm

Alarm Limit Value

Empty Pipe Alarm

Ratc-of ehange Limit

Control Limit Time

Fixed‘Value OiKpul

Zero Offset Adjustment

Password *

4-20inA Alarm Output '*

DT detective Level

Preset Function *

Display example

Al: EX. CURR.

A2: meter SIZE

A3: EX. FREQ.

Bl: UNIT 1

Cl: RANGE TYPE

C2: RANGE 1

C

6; RANGE HYST

D1: DAMPING 05.0 s

D2: LOW CUT

El; ZERO ADJUST. 0. 1 %

FI; DOl FUNCT, 1: H ALM

Gl; COUNT RATE

G2: PLS. INIDTH

HI; PRESET COUNT

11: H. ALARM SET

12: H. ALARM VAL

Jl; EMPTY ALM

K1; LIMIT RATE

KZ: LIMIT TIME

Li: FIXED OUT

Ml: MANUAL ZERO -000 1 %

A4: PASSWORD 123

D3; 4-20 ALM. OUT 1 ;4. 0mA

F6; Dl DET LEVEL

H2: PRESET FUMCT

0. 2100 A

LSINGLE

01, 000 m/s

05. 0 %

05. 0 %

G. OOE-U

020 ms

00009000

flOO. Q %

0;OFF

05. 5 %

1 : H LEVEL

0:H0LD

50 m

24 Hz

ON

01 s

OFF

m/s

Page

45

47

49

51

55

63

65

67

68

71

74

76

79

82

85

89

91

95

97

99

"A4:Password^ ”D3:4-30ALM.OL T6;DI DP'rLEVHL", and ■H2:PRtiSHT

FUNCT'' arc added parameters in the converter for special specifications (refer to

7,3.3 ‘"Converter for Special specifications’'). The normal converter does not have

these selling parameters.

-

44

-

Page 46

TOSHIBA

8.2 Checking or Changing Parameters

6F8A0774

8.2.1 Excitation Current

Proceed üs follows to check or change ibe excitation current setting value.

■ To check the exciting current setting value:

Key operation

SET

□

SET

□

Display example

A1: EX. CURR.

0. ?100A

A1; EX. CURR.

Description

Press [SFT] first to start the items selection sequence

and select Air EX. CURR from among the

configuration items asing [ ► ] and [ a. ] keys.

Then press [SET] again to display the exciting

current setting value.

Pressing [SET], the system returns lo the items

selection sequence.

- 45 -

Page 47

TOSHIBA

IMPORTANT

The exciting currenl value h factory iset when shipped. Do nol change the value unless the value

dilTers from that wriiieii on tlie nameplate of the fiowmeter,

6F8A0774

■ To chitrige the excitation current iictting value:

I’he following example shows how' ro change the excitation current setting value

from 0.1900AIO 0.2150A,

Key openïlJun

SET

□

□

□□

SET

□

SET

□

Display example

A1: EX. CURH.

D. TgOOA

A1: EX. сияя.

0. 19Û0A

AT: EX. CURH,

0. 2900A

0. 2iOOA

0. 2150A

AT; £X. CURR,

0. 2T5DA

Al: EX. CURR.

Description

Press [SET] first to start the itemsS selection

sequence and select Al: EX. CDRR from among

the configuration items using [ ► ]and[A]keys.

Then press [SET] again to display the excitation

current setting value (0.1900 A in this example).

Pressing [ ► ], the cursor appears. 'I'hen press [ ► )

as many times as necessary' to move the cursor to the

digit to be changed.

Change the value by pressing [ a J, I’hcn move the

cursor to another digit by pressing [ ► ] and change

the value, In this example repeat this process until the

display shows “0.215ÜA.” (Note)

Pressing ]SET], the cursor disappears and the

changed display flickers. Press [SET] again to save

the value.

Pressing [SET], the system returns to the item.s

■¡election sequence.

Note: The valid range is from O.OfiOOA to 0.2300A. If you try to set the value altove

(].24tlOAj the error messsage * H. OVER SPhC appears. Set the value within the valid

range.

—

45

—

Page 48

TOSHIBA

6F8A0774

8.2,2 Meter Si^e

Proceed as folJows lo check or change the meter si7e of ihc cictecior.

■ To check Che meter size:

Key operation Display exjimple

SET

A2: METER SIZE

□

SET

A2: HETER SEZE

50 m

□

Description

Press [SET] first to start the items selection sequence

and select A2: METER SIZE from among the

cojifiguralitm items using [ ► ] and [ a ] keys Then

press [SET] again to display the current meter size.

Pressing [SET], the system returns to the iiems

selection sequence.

- A 7 -

Page 49

TOSHIBA

6F8A0774,

To change the meter ssize:

IMPORTANT

Meter sii^e iii 1 actory set when shipped. Do not change the meter size unless it differs

from the specified value.

The following example shows how lo change The meter size from 5f) mm to 100 mm.

Key operation

SET

□

□

▲

□

SET

□

SET

n

Display example

A2; METER SIZE

50 nur

M: METER SIZE

50 nut

AZ: METER SIZE

100 inin

KZ\ METER SIZE

100 mm

AZ: METER SIZE

Description

Press [SET| first to start the uems selection

sequence and select A2: METERSIZE from among

the configuration items using [ ► ]and[A]keys.

Press [SET] again to display the current meter size

fSO mm ill this e.xample).

Pressing [ ► ], the cursor apijcars.

Select "‘100 mm” by pressing [ a ] as many times

as necessary. (Note)

Pressing [SET], the cursor disappears and the changed

display flickers. Press [SET] again to save the value.

Pressing [SET], the system relurns to the items

selection sequence.

Note: The meter size is changed as shown below by pressing [ a ],

2.5 mm 15 mm “► 100 iiiin f^iXl mm —►0.1 in 0,5 in^4 in • 24 in

c:

Tf the meter size has been changed, other setting values (such as span and counting rate)

will be affected depending on the measuring unit u.sed. therefore, check those setting

values if you have changed the meter size,

- 43

□

Page 50

TOSHIBA

6F8A0774

8.2.3 Excitation Frequency

Proceed aii follows lo check or change the excitation frequency.

■ To check the excitation frequencyr

Key operation

SET

□

SET

n

t

___

1

Display example Description

Press [SEl’l first to start the items selection

A3: EX. FREQ.

24 Hz

A3: EX. FREQ.

sequence and select A3: EX. FREQ, from among

the coniigutation items using [ ► ] and [ ^ ]

keys. Then press [SET] again to display the

current excitation frequency.

Pressing [SET], the system returns to the items

selection sequence.

- 49 -

Page 51

TOSHIBA

6F8A0774

To change the excitation frequency:

The excitation frequency can be selected from f>, 12 and 24 Hz- T he characteristics of

the ilÜWmeter change in accordance with the seiected frequency as shown below. 24 J lx

is the défailli setting when shipped from the factory.

Kxcitation frequency

Zero point stability Good

Response time

Fluid noise resistant

i’he following example show's how to change the excitation frequency from 24 ll2 to 12 Hz,

Key operation

SHT

►

Display example Description

A3: EX. FREg.

A3: EX. FREQ.

□

24 Hz

24 Hz

12 Hz

Press [SE'J ] First to start the items selection sequence

and select A3: EX* FREQ, from among the

configuration items using [ ► ] and [ a ] keys. Press

[SET] again to display the current excitation frequency

f24 JIz in this example).

Pressing [ ► ], the cursor appears.

24 Hz

▲

n

SET

□

SET

□

A3: EX. FREQ.

12 Hz

A3: EX. FREQ.

12 Hz

A3: EX. FREQ.

Select "T2 Hz'' by pressing [a j twice. The

excitation frequency changes as follows:

6 Hz 12 Hz -►24 Hz —1

Pressing [SFTJj the cursor disappears and the changed

display flickers, Press [SET] again to save the value.

Pressing [SET], [he syslem returns to the items

selection sequence,

- 5D -

Page 52

TOSHIBA

S.2.4 Indic^tting Unit

6F8A0774

You can select one of the 29 engineering units lisled below as an indicating unil,

• Flow velocity: m/s, (ft/sj

• Flow rate: m-Vs, mVmin, mVd

l/s> 1/min, i/h, 1/d

mf/s» ml/minT ml/h, ml/d

(bbi/s), (hbJ/min), (bbl/h), (bbl/d)

(gal/s), (gal/min), (gdl/Ji), (gitl/d)

• Volumetric ilowi m^ I, ml, (gal)

(totalized flow)

• Other units: %> COL'NT (lotdlized flow wiihoul a unit), RANGE (1 to 4)

(• Code of volumetric

flow direction: F(fixcd forw ard flow)> R(fixcd reverse flow),

n(automa(ic selection bi-directional flow) )

Notes

L Units in parentheses, such as ‘W’, ‘"gal” and “ft” are shown only when the meter size is

selected in inches. They are nof sliown when the mcler size is selected in mm.

2. If COUNT or RANGE is selected, the display is shown as followii:

COUNT: displays totalized How counts (8 digits) without a unit.

RANGE: displays the range njmbcr(l to 4).

3. Only in case of the converter for special specifications (refer to 7,3,3 “Converter for

Special specifications”),

•Time units /d, and flow rate uni is bbl/s, bbl/min, bbUh. bbl/d, bb( can be ,selected*

•Code of volutuctric flow direction F(fixed forward flow)^ R(fixed reverse flow),

ll(autoinaiic selection bi-dircctional flow) can be selected,

Two indicating unils (primary unit: UNIT 1, secondary unit: UNIT 2) can l?e selected.

Proceed as follows to check or change these two indicating units.

- 51 -

Page 53

TOSHIBA

6F8A0774,

To check the indicating units:

Key operation

SEI

□

SET’

n

1__1

Primary indicating unii and secondary indJcaling unit can be sdecied by ihe following

configurailon items:

01: UNIT 1 primary indicating uni:

B2; UNIT 2 secondary indicating unit

Display example

B1: UNIT 1

%

B1: UNIT 1

Description

Press [SET] first to siarl the items selection

sequence and select Bl: UNIT 1 from among the

configuration items using [ ► ] and [a ] keys.

Then press fSHT] again to display the current

primary indicatiriii uniL

Pressing [SUT], the system returns to the items

selection sequence.

- 52 -

Page 54

TOSHIBA

6F8A0774

■ Ti) change the mdicating unit 11):

The following exiimple shows how to change the primary indicating unit from % to ml/s.

Key operation

SET

□

►

□

▲

1

---

1

U

► Bl: UNIT 1

□

▲

1—1

Display example

Bl: UNIT 1

\

ei: UNIT 1

%

Bl; UNIT 1

n( B

ml _ B

Bl: UNIT 1

nl/s

Description

Press [St'l] first to Stan the items selection sequence

to select Bl: UMT1 from among the conllguration

items using [ ► ] and [ a. ] keys Then press [SF.TJ

again to display the current primary indicatingunit {%

in this example).

Pressing [ ► j, the cursor appears,

Select ‘‘mi” as the first unit of primary indicating unit

by pressing 1 J as many limes as necessary. (Notcl)

Pressing [ ► ], the cursor moves to the second unit

(lime unit) of primary indicating unit.

Select *‘s” as the second unit (time un it) of primary

indicating unit by pressing f ^ ] as many times as

necessary. (Note 2)

SET

□

SET

n

Notes: l.The first unit (volumetric units etc.) changes us shown; below;

Bl: UNIT 1

n!/s

Bl: UNIT 1

I

------

► %

---------

I

----

‘ RANGH^^

Units in parentheses, sSuch as "bhr\ “gal’ and “ft” ate shown only when the

meter size is seiccicd in inches. They are not shown when the meter sii:c is

sciccteci in mm.

E^ressing (SET’], the cursor disappears and the changed

display flickers. Press [SET] again to save the unit.

Pressing [SET], the system returns to the item

selection sequence.

► in^

------

► i-------—► ml

----

COUNT*— (ft/s)^

---------

---------

m/s+

--------

2. rhe second unit (time unit) changes as shown below;

—► /s------► /min

-----

^/h

-----------

/d

------------- ---------------

► (bbJ)—

(gal>i-

- 53 -

Page 55

TOSHIBA

6F8A0774,

I To chiingo the mdiciitiag unit (2):

Only in case of the convcacc lor special specifications (refer to 7,33 ^‘Converter for

Special specificaiions’'), Code of vciumctric flow direction F(fi>ced forward flow),

R(fixed reverse flow'), B(auiomatic selection bi-directional flow) can be selected,

In case of normal converter* the code of volumetric flow direction does not appear.

The following example shows how to change the primary indicating unit from F to K,

Key operation

Sb'l

□

□

►

I

_ _

1

►

□

▲

□

Display example

Bl: UNIT 1

Bl: UNIT 1

m* F