Page 1

TOSHIBA

6F8A0,8,02

ELECTROMAGNETIC FLOWMETER DETECTOR

MODEL LF470

INSTRUCTION MANUAL

TOSHIBA CORPORATION

Page 2

TOSHIBA

NOTICE

This Manual is designed to assist in installing, operating, and maintaining the LF470

separate type electromagnetic flowmeter. For safety reasons, and to obtain the optimum

performance from the flowmeter, read this Manual thoroughly before working with the

product. Keep the Manual within easy reach for reference whenever needed.

The flowmeter to which this Manual refers is NOT designed for applications in which

the functioning of this product is critical to human safety, such as:

• Main control systems of nuclear power plants; safety systems in nuclear facilities

• Control systems of medical equipment, including life support machines.

,6,F,8A0.a02.

or other critical control lines directly affecting human safety.

NOTES

1. The reproduction of the contents of this Manual in any form, whether wholly or in part, is

not permitted without explicit prior consent and approval.

2. The information contained in this Manual is subject to change or review without prior

notice.

3. Be sure to follow all safety, operating and handling precautions described in this Manual

and the regulations in force in the country in which this product is to be used.

Fifth Edition

January. 2001

Copyright 2001 by Toshiba Corporation. All rights reserved.

1 -

Page 3

TOSHIBA

SAFETY PRECAUTIONS

Safety signs and labels affixed to the product and/or described in this manual give important

information for using the product safely. They help prevent damage to property and obviate

hazards for persons using the product.

Make yourself familiar with signal words and symbols used for safety signs and labels. Then

read the safety precautions that follow to prevent an accident involving personal injury,

death or damage to property.

Explanation of signal words

The signal word or words are used to designate a degree or level of hazard seriousness.

The signal words used for the product described in this manual are WARNING and

CAUTION.

A WARNING

6,F8A08^02,

Indicates a potentially hazardous situation

which, if not avoided, could result in death or

serious injury.

Safety symbols

Indicates a potentially hazardous situation

A CAUTION

The following symbols are used in safety signs and labels affixed to a product and/or in the

manual for giving safety instructions.

Indicates an action that is prohibited. Simply DON’T do this action.

The prohibited action is indicated by a picture or text inside or next to

0

•

the circle

Indicates an action that is mandatory. DO this action.

The mandatory action is indicated by a picture or text inside or next to

the circle.

Indicates a potential hazard. The potentially hazardous situation is

indicated by a picture or text inside or next to the triangle.

which, if not avoided, may result in minor to

moderate injuries or in property damage.

A

- 2

Page 4

TOSHIBA

SAFETY PRECAUTIONS (continued)

Safety Precautions for Installation and Wiring

A WARNING

I

Do not use the LF470 in an explosive atmosphere.

Using this product in an explosive atmosphere

can cause explosion.

0

DON’T

A CAUTION

.6,F8A080:2^

■ Turn off mains power before

working on pipes.

Working on pipes while

power is applied can

DO

■ Install a switch and fuse to isolate

the LF470 from mains power.

^ A power can cause electric

QO break-down.

■ Turn off mains power before

conducting wiring work.

DO

■ Do not conduct wiring work with bare

hands.

A charge even if power is

V

turned off can still cause

DON’T electric shock.

cause electric shock.

Power supply from mains

shock or circuit

Wiring while power is

applied can cause

electric shock.

Remaining electric

■ Use an appropriate device to carry and

install the LF470.

If this product falls to the

^K^P ground, injury, or

malfunction of or damage to

DO the product, can be caused.

■ Do not modify or disassemble the

LF470 unnecessarily.

— Modifying or disassembling

this product can cause

vjS/ electric shock,

DON’T malfunction of or damage

to this product.

■ Ground the LF470 independently

from power equipment.

Operating this product

without grounding can cause

electric shock or

malfunction.

■ Use crimped terminal lugs for the

terminal board and GND terminal.

Loose connections can

^ A cause electric shock. Are

from excessive current or

DO system malfunction.

■ Do not work on piping and wiring

with wet hands.

Wet hands may result in

f electric shock.

DON’T

The label shown left is

placed near the terminal

board for power input.

/ 1 \ (A black border and symbol

on yellow triangle)

Be alert to electric shock.

-

3

-

Page 5

TOSHIBA

SAFETY PRECAUTIONS (continued)

Safety Precautions for Maintenance and Inspection

A CAUTION

6,F,8A0^80^2,

■ Do not touch the LF470 main body

when high temperature fluid is be

ing measured.

The fluid raises the main

1 body temperature and can

DON’T , , ,

■ Do not conduct wiring work with wet

hands.

cause burns when

touched.

1 Wet hands may result in

DON’T

■ Do not use a fuse other than the one

specifled.

electric shock.

Using a fuse other than the

one specified can cause

( system failure, damage

or malfunction.

DON’T

■ Do not conduct wiring work when

power is applied.

Wiring while power is

1 applied can cause

electric shock.

DON’T

The label shown left is

placed near the

terminal board for

A power input.

/ (A black border and

^^ symbol on yellow

triangle)

Be alert to electric

shock.

Use a rated fuse as follows:

Fuse rating:

• 1A/250V for 100 to 240Vac or

llOVdc

• 2A/250V for 24 V dc

Dimensions:

Diameter 5.2 mm x 20 mm

Melting time characteristic:

Normal blow

Disclaimer

Toshiba does not accept liability for any damage or loss, material or personal, caused as a

direct or indirect result of the operation of this product in connection with, or due to, the

occurrence of any event of force majeure (including fire or earthquake) or the misuse of this

product, whether intentional or accidental.

-

4

-

Page 6

TOSHIBA

Handling Precautions

■ To obtain the optimum performance from the LF470 flowmeter for years of continuous

operation, observe the following precautions.

(1) Do not store or install the flowmeter in:

To put the flowmeter temporarily on the floor, place it carefully with something to

support it so that the flowmeter will not topple over.

,6,F,8A0,8:0,2.

• places where there is direct sunlight. If this is unavoidable, use an appropriate

sunshade.

• places where excessive vibration or mechanical shock occurs.

• places where high temperature or high humidity conditions obtain.

• places where corrosive atmospheres obtain.

• places submerged under water.

(2) Execute wiring securely and correctly.

Ground the flowmeter with 100 ohm or less ground resistance. Avoid a common

ground used with other equipment where earth current may flow. An independent

ground is preferable

(3) Seal the cable thoroughly at the cable gland of the converter so that the cable is

kept airtight.

(4) The converter housing covers and the cable glands are tightened securely at the

time of shipment. Do not remove these covers or glands. Otherwise, gradual dete

rioration of circuit isolation or damage to this product can be caused. Tighten the

covers or cable glands securely again if they have been removed.

(5) Make sure the fluid to be measured will not freeze in the detector pipe. This can

cause damage to the detector pipe.

(6) Select appropriate wetted materials suited for the process fluid to be measured.

Otherwise, fluid leakage due to corrosion can be caused.

-

5

-

Page 7

TOSHIBA

Handling Precautions (continued)

(7) Observe the following precautions when you open the converter housing cover:

• Do not open the cover in the open air unprotected against rain or wind. This

can cause electric shock or cause damage to the flowmeter electronics.

• Do not open the cover under high ambient temperature or high humidity

conditions or in corrosive atmospheres. This can cause deterioration of

system accuracy or cause damage to the flowmeter electronics.

(8) This product may cause interference to radio and television sets if they are

used near the installation site. Use metal conduits etc. for cables to prevent

this interference.

(9) Radio transmitters such as transceivers or cellular phones may cause interference

to the flowmeter if they are used near the installation site. Observe the following

precautions when using them:

8A0^8^0^2

• Do not use a transceiver whose output power is more than 5 W.

• Move the anteima of a transceiver or a cellular phone at least 50 cm away from

the flowmeter and signal cables when using it. Do not use a radio transmitter

or a cellular phone near the flowmeter while it is operating online. The

transmitter or cellular phone’s output impulse noise may interfere with the

flowmeter.

• Do not install a radio transmitter antenna near the flowmeter and signal cables.

(10) For reasons of flowmeter failure, inappropriate parameters, unsuitable cable

connections or poor installation conditions, the flowmeter may not operate

properly. To prevent any of these problems causing a system failure, it is

recommended that you have preventive measures designed and installed on

the flowmeter signal receiving side.

- 6

Page 8

TOSHIBA

Table of Contents

:6,F,8A0,8,0,2,

SAFETY PRECAUTIONS

Handling Precautions

............................

1. Product Inspection and Storage •

1.1 Product Inspection ...........................*

1.2 Storage

................................................

2. Overview .........................

3. Names of Parts

4. Installation

4.1 Location

4.2 Mounting Procedure

4.3 Piping Connections

5. Wiring ‘

........

5.1 Cables

..............................

.............. *............. • *

.....................................................................

....................

.........

................................... • • ■

..........

..

.............................................

.........................................................................

5.2 External Device Connections and Grounding

5.3 Wiring Procedure

6. Operation • •

6.1 Preparatory Check •

.......

.......

.......................................... • ■

................

.......

...........................................

• ............

■ 2

• 5

• 8

• 8

■ 8

• 9

10

.

11

12

13

14

18

19

20

22

.

25

25

7. Maintenance and Troubleshooting ••••••

7.1 Maintenance

7.2 Troubleshooting

8. Principle of Operation

9. Specifications

9.1 Flowmeter Specifications

9.2 Type Specification Code

10. Outline Dimensions

......................... *

......

..........................

........................*................

.............*------

.........

...........................................

............... * * *..........

..

■

............................

..........

.................................

.............................. * •

26

26

28

31

32

32

34

35

-

7

Page 9

TOSHIBA

1. Product Inspection and Storage

Upon arrival of the product package, open the package and check the items contained inside.

If you do not intend to install the product soon after opening the package, store the product

and other related items in a place such as described in 1.2 below.

1.1 Product Inspection

The LF470 electromagnetic flowmeter is shipped in a cardboard container filled with

shock-absorbing materials. Open the package carefuUy and check as follows:

■ Make sure the following items are included in the package.

6,F8A0,8,0,2

1 i I i I

■ Inspect the flowmeter for indications of damage that may have occurred during shipment.

■ Make sure the type and specifications of the flowmeter are in accordance with the

If you cannot find the items listed above or any problem exists, contact your nearest

Toshiba representative.

1.2 Storage

To store the LF470 flowmeter after opening the package, select a storing

place as follows and keep it under the conditions described below:

(1) Model LF470 Electromagnetic Flowmeter

.............

j

(2) Instruction Manual............................................... 1

ordered specifications.

(1) Avoid places where there is direct sunlight, rain or wind.

(2) Store the product in a well-ventilated place. Avoid places of extremely high

humidity or extremely high or low temperature. The following environment is

recommended:

• Humidity range: 10 to 90% RH (no condensation)

• Storage temperature: -15 to +65° C

(3) Avoid places where vibrations or mechanical shock occur.

(4) Do not leave the converter housing cover open . Open the cover only when

you actually start wiring cables. Leaving the cover open can cause gradual

deterioration of circuit isolation.

(5) To put the flowmeter temporarily on the floor, place it carefully with something

to support it so that the flowmeter will not topple over

- 8

Page 10

TOSHIBA

2. Overview

Features

6f,8,AO,8^0,2,

The LF470 electromagnetic flowmeter measures the volumetric flow rates of electrically

conductive materials on the basis of Faraday's Law of electromagnetic induction.

The device consists of two units: the LF470 detector, through which the fluid to be measured

flows, and the converter, which receives the electromotive force signals from the detector,

then converts the signals into the 4—20 mA dc signal.

Every type of electromagnetic flowmeter has the following features:

■ Fluid flow is not obstructed and pressure loss is negligible.

■ The process fluid's temperature, pressure, density or flow conditions has no effect on the

accuracy of the flowmeter.

■ The flowmeter output is directly proportional to the process flow rate, thus it is easy to

read its output.

The LF470 electromagnetic flowmeter detector has the following additional features:

(1) High accuracy, ±0.8% of rate is possible for 1.0-10 m/s velocity range.

±0.8% FS is possible for 0.3-1.0 m/s velocity range.

(2) The flowmeter can be used to measure any fluids included acid and alkaline fluids,

for the reasons stated below:

• Ceramic is used for the detector pipe.

• Platinum is used for the electrode.

(3) The flowmeter is very small and light. Because of it, the flowmeter can be mount

ed on panel.

(4) It is possible to coimect to various pipes or tubes by using joints available in the

market.

-

9

-

Page 11

TOSHIBA

3. Names of Parts

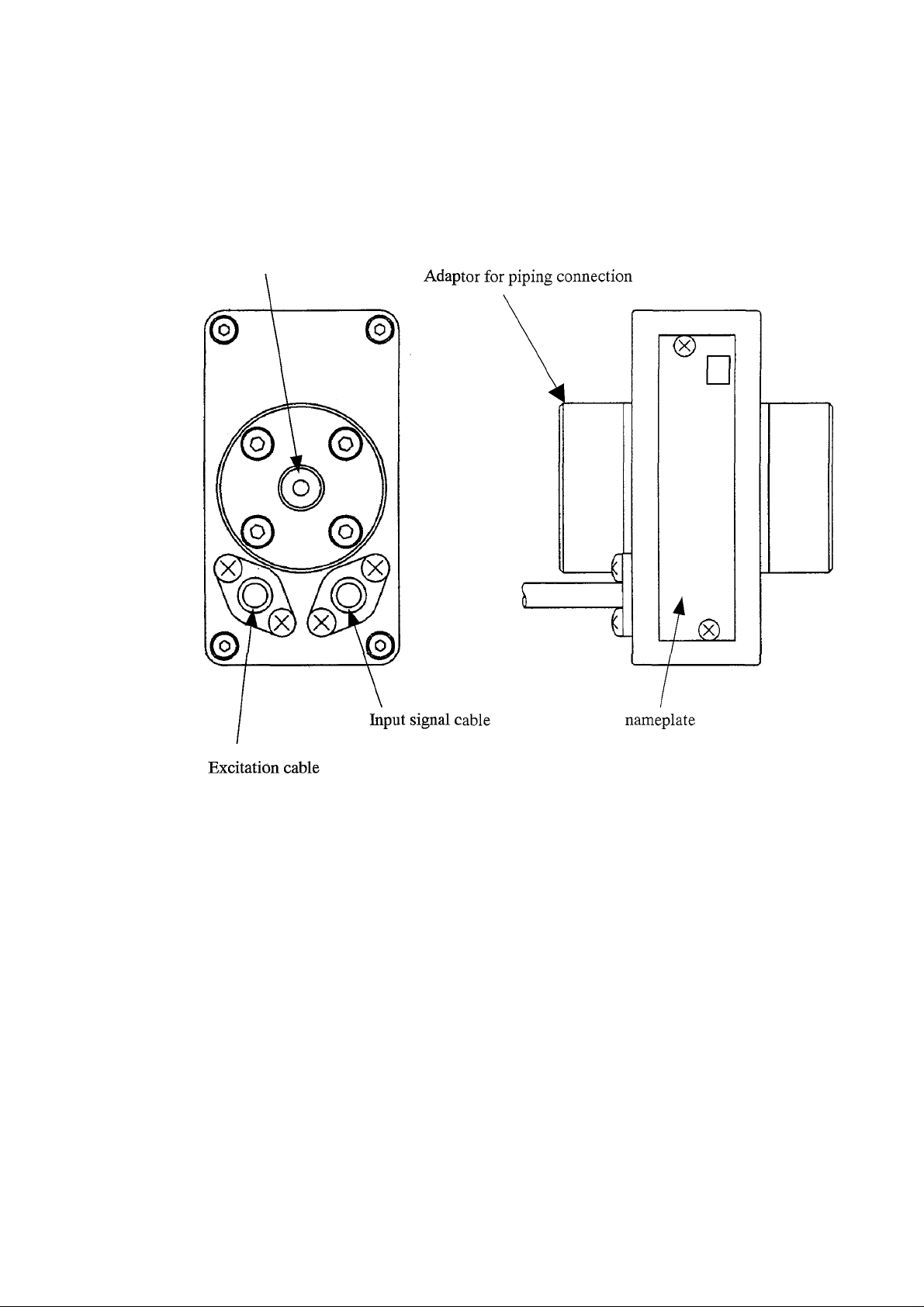

The outline drawing of the LF470 flowmeter is shown in Figure 3.1.

■ Oufline Drawing

Taper pipe thread

(R female screw)

6f,8M8V2

Figure 3.1 Outline drawing of LF470 Flowmeter Detector

10 -

Page 12

TOSHIBA

4. Installation

Safety Precautions for Installation

I

Do not use the LF470 in an explosive atmosphere.

Using this product in an explosive atmosphere

can cause explosion.

®

DON’T

8A0,80,2

A WARNING

A CAUTION

■ Install a svritch and fuse to isolate

the LF470 from main power.

Power supply from main

power can cause electric

shock or circuit

0Q breakdown.

■ Do not modify or disassemble the

LF470 unnecessarily.

Modifying or

disassembling this product

1 can cause electric shock,

malfunction or damage to

DON’T this product.

■ Do not work on piping and wiring

with wet hands.

'N Wet hands may result in

V electric shock

DON’T

■ Use an appropriate device to carry and

install the LF470.

If his product falls to the

ground, injury, or

malfunction of or damage to

PQ the product, can be caused.

■ Ground the LF470 independently

from power equipment.

Operating this product without

grounding can cause electric

PQ shock or malfunction.

The label shown left is placed

near the terminal board for

power input.

/ J

\ (A black border and symbol on

yellow triangle)

Be alert to electric shock.

-11 -

Page 13

TOSHIBA

4.1 Location

6f,8A0,802,

To select the installation site, follow the precautions described below:

■ Avoid places where fluid runs in a pulsating form.

■ Avoid places within the immediate proximity of equipment producing electrical

interference (such as motors, transformers, radio transmitters, electrolytic cells, or

other equipment causing electromagnetic or electrostatic interference).

■ Avoid places where excessive pipe vibration occurs.

■ Avoid places where there is direct sunlight. If this is unavoidable, use an appropriate

shade

■ Avoid places where corrosive atmospheres or high humidity conditions obtain.

■ Avoid places of too great an elevation or constricted areas where clearance

for installation or maintenance work is not provided.

■ Design piping so that the detector pipe is always filled with fluid, whether the fluid is

flowing or not.

■ The LF470 detector has no adjustable piping mechanism. Install an adjustable short

pipe where needed.

I I I I i I I I

■ Chemical injections should be conducted on the downstream side of the flowmeter.

- 12 -

Page 14

TOSHIBA

4.2 Mounting Procedure

A CAUTION

■ Use an appropriate device to carry

and install the LF470.

_ If his product falls to the

^ ^ ground, injury, of

malfunction of or damage V y cause electric shock.

DO to the product, can be

caused.

■ Turn off mains power before

working on pipes.

DON’T

4.2.1 Installation Procedure

To mount the LF470, see Figure 4.1 and follow the procedures below.

(1) In case of method of piping by nipple and union

(1-1) Connect the R female screw of the LF470 with the nipple.

(1-2) Coimect the nipple with the pipe by the union.

(2) In case of method of piping by jont

(2-1) Connect the R female screw of the LF470 with the joint.

(2-2) Connect the Joint with the pipe

Working on pipes while

power is applied can

Flow direction

-------------

NOTES:

(1) Preventing from leaking, seal up R male screw with sealant which is appropriate material to

the process fluid to be measured.

(2) Keep that the inner diameters of the nipple, the joint and pipe on the sides of the detector larger

than that of LF470. If not, the air bubbles will stagnate in the measuring pipe and they may dis

turb the normal measurement of flow rate.

►

Figure 4.1 LF470 flowmeter piping connections

13

-

Page 15

TOSHIBA

4.3 Piping Connections

(1) Required Pipe Length

If various joints are used upstream of the detector outlet, the straight pipe length as

shown in Table 4.2 is required.

,6,F8A0,8,02,

Table 4.2 Required straight pipe length on the upstream side

L: Required straight pipe length—straight pipe length plus half length of the detector.

D: Nominal bore size (diameter)

NOTES

1. The length of a reducer, if cormected, can be counted as a part of the straight pipe

length.

2. No straight pipe length is needed on the downstream side. If a butterfly valve is

installed downstream of the detector, do not let the valve plate protrude into the

pipe of the detector

-

14

-

Page 16

TOSHIBA

(2) Pipe Orientation

¿FMO.8^0^2

The detector may be installed in horizontal, vertical or sloping pipe runs as shown in

Figure 4.2. However, except for horizontal installation, fluid should flow from lower to

upper directions. See Figure 4.3.

Figure 4.2 Detector Piping Orientation

The electrodes should be positioned horizontally against the ground surface in any piping

installation. See Figure 4.3.

Cross-section A - A

Ground surface

Figure 4.3 Installation position of the detector

-

15

-

Page 17

TOSHIBA

(3) Flow Direction

,6,F8A0,8,02

.j

... .... .i.. ..

_j,^.

Install the detector in accordance with the flow direction arrow on the detector. See Figure 4.4.

over

side

Figure 4.4 Flow direction arrow on the detector

(4) Preventing an Empty Pipe Condition

Design an upright pipe run (Figure 4.5) or sufficient head pressure (Fig. 4.6) at the

downstream detector outlet if there is a possibility of the detector pipe becoming emptied.

Upright pipe run

Figure 4.5 Detector with an upright pipe run at downstream outlet

Detector

/

Figure 4.6 Detector with sufficient head pressure at downstream outlet

16

-

Page 18

TOSHIBA

(5) Supporting Pipe

6,F8A0^8,0^2

Fix the relevant pipes installed on both sides of the detector by attach fittings, etc. to support

the pipe. By supporting the pipes, not only the pipe vibration is reduced but also the damage

to the pipes by the electromagnetic flowmeter's weight and the fluid mass. And it protect

from fluid leakage at flange face (see Figures 4.7 and 4.8).

Figure 4.7 Example of Pipe Fixing Procedure

-

17

-

Page 19

TOSHIBA

5. Wiring

,6,F,8A0 8,0 2,

A CAUTION

■ Do not work on piping and wiring

with wet hands.

Wet hands can cause

system failure.

DON’T

■ Do not modify or disassemble the

LF470 unnecessarily.

Modifying or

disassembling this product

1 can cause electric shock,

DON’T , ,

Flowmeter accuracy may be affected by the way wiring is executed. Proceed

with wiring taking the following precautions:

malfunction of or damage to this product.

■ Ground the LF470 properly.

Operating this product

without a grounding can

O

DO

cause system

malfunction.

The label shown left is

placed near the terminal

/board for power input.

— Be alert to electric

shock.

(1) Select the cable runs away from electrical equipment (motors, transformers, or

radio transmitters) which causes electromagnetic or electrostatic interference.

(2) Deterioration of flowmeter circuit insulation occurs if the converter interior or

cable ends get wet or humidified. This in turn causes malfunction of flowmeter

or noise problems. Avoid a rainy day if the flowmeter is to be installed outdoors.

Even indoors, prevent water from splashing over the flowmeter. Try to finish the

wiring as quickly as possible

(3) The excitation and input signal cables transmit extremely minute signals. Pass each

of them alone and independently through a thick walled steel conduit, and loacate

it at as much a distance as possible from other great-current cabling, nor in parallel

with such cabling.

(4) The converter has a surge-absorbing barrier installed inside. Therefore, do not

conduct a withstand voltage test for the converter. To check the insulation of the

converter, use a voltage of 250 V dc or less.

(5) After wiring, attach the terminal cover of the converter.

- 18 -

Page 20

TOSHIBA

5.1 Cables

(1) Standard cable

Name

The standard cable shown in Figure 5.1 is connected when shipped.

The cable length can be ordered (option).

Table 5.1 Cables

Cable type

Length

Nominal

cross-sectional area

6F8A08,0,2

i

.......i.......i.......j.......

1....._j

.......i.......

Overall

diameter

Excitation

cable

Input signal

cable

(2) Elongate cable longer than 5m

By using scotch cast, the cable shown in Figure 5.2 can be connected with standard cable

(5m).

Three-core chloroprene

cabtyre cable

Two-core sheathed

chloroprene cabtyre cable

5m 0.5 mm^

5m

0.3 mm2

Table 5.2 Cables

Name

Cable type

Nominal

Overall diameter

cross-sectional area

Excitation

cable

Input signal

cable

Three-core chloroprene cabtyre

cable

Two-core sheathed chloroprene

cabtyre cable

2 mm2

0.75 mm2 11 to 13 mm

11 to 13 mm

6 to 8 mm

6 to 8 mm

-

19

-

Page 21

TOSHIBA

5.2 External Device Connections and Grounding

The connections for the LF470 detector are shown in Figure 5.1 and 5.2.

Proceed with wiring as described in Section 5.3, “Wiring Procedure.”

IMPORTANT

(1) The input signal cable and excitation cable are attached to the detector. Be sure to use the at

tached cable, check the specification of the detector.

(2) The converter side ends of the attached cables are covered with caps to prevent exposure to

humidity. Do not remove the caps from the cable until directly before wiring to the converter.

(3) Be sure to use thick walled steel conduit (22mm) for each the signal cable and the excitation

cable between the detector and the converter, and locate it as far as possible from other great

current cabling and it is not parallel with such cabling. Use flexible conduits at the cable outlets

of the detector.

(4) The FG terminal of the converter should be grounded with 100 ohm or less ground resistance.

Use a heavy copper braid or wire (cross-sectional area 5.5 mm^ minimum) to ground the termi

nal and make it as short as possible.

6,F^8A0,8,0,2

for Converter

/■—^\ r-S

Excitation cable

(Three-core chloroprene cabtyre cable)

- 20 -

Page 22

TOSHIBA

• Grounding:

Ground the FG terminal (or the external grounding terminal) of the converter securely with 100

ohm or less ground resistance as shown in Figure 5.2. (The E terminal of the converter is

connected internally to the FG terminal and the converter case.)

Furthermore, if the pipeline is not of conductive material, grounding rings are needed for the

detector to stabilize fluid potential as the fluid potential is unstable and may cause incorrect

measurement.

,6P,8A0 8,0,2

j ! ! I I ! i

Figure 5.2 Wiring between the detector and the converter

- 21 -

Page 23

TOSHIBA

5.3 Wiring Procedure

Use cables as specified in Table 5.1 and Table 5.2.

5.3.1 Cable Termination

Cable termination and cable coimections are described below.

A CAUTION

6F8A0802

....

i„.

...J...

...I

.....J.....1....

i.............

■ Do not conduct wiring work when

power is applied.

Wiring while power is ap-

1 plied can cause electric

■ Do not work on piping and wiring

with wet hands.

Wet hands may result in

1 electric shock.

shock.

DON’T

I

Input signal Cable

Remove each core coating for cable as shown in Figure 5.3. Next, attach the insulating sleeve

crimp-style terminals (Note). Then, connect to the converter’s terminal block A and B and

twist the shields together. Cover with the terminal contraction tubes before attaching the

crimp-style terminal and connecting to the converter’s terminal block G .

DON’T

Note: Set the size of insulating sleeve crimp-style terminal as below.

Converter type size of insulating sleeve crimp-style terminal

LF420

LF230

M3.5

M4

Insulating sleeve crimp-style terminals

Figure 5.3 Input signal cable end processing

terminal contraction tubes

- 22 -

Page 24

TOSHIBA

Notes:

shield

6F8A0,8,0,2

I I i ! { i I I

Removing core coating for cable, be careful not to scratch and not to cut off cable and

shield.

Untying shields from cables as shown in Figure 5.4.

a .Open shield by tools like tweezers.

b .Pull the cable from shield.

cable

c .Stretch out shield.

Figure 5.4 Untying shields from cables

-

23

-

Page 25

TOSHIBA

I

Excitation Cable

6f,8A0,a0^2

Remove each core coating for cable as shown in Figure 5.5. Next, attach the insulating

sleeve crimp-style terminals (Note). Then, connect to the converter’s terminal block X and Y.

Also, connect the red cable core to converter’s terminal block E.

Note: Set the size of insulating sleeve crimp-style terminal as below.

Converter type size of insulating sleeve crimp-style terminal

LF420

LF230

Insulating sleeve crimp-style terminals

(Note)

Figure 5.5 Excitation cable end processing

M3.5

M4

5.3.2 Cable Connections

Refer to the converter instruction manual, to connect the terminated cable wires to the

converter’s terminal board.

IMPORTANT

Connect the wires securely to the terminal board. A loose connection may result in

unsatisfactory flowmeter performance. Make sure the wires are securely connected.

-

24

-

Page 26

TOSHIBA

6. Operation

6.1 Preparatory check

,6F,8A0,8,0,2,

A CAUTION

Do not touch the LF470 main body when high

temperature fluid is being measured.

The fluid raises the main

body temperature and can

cause burns when touched.

DON’T

Follow the procedure described below to prepare before starting the flow measurement.

System Check

Check the wiring between the converter and related instruments.

Check the wiring between the converter and the detector.

Make sure all the bolts of connection flanges on which the flowmeter is mounted

securely tightened.

Make sure the direction of flow arrow is in accordance with actual flow.

Make sure the flowmeter is grounded with 100 ohm or less ground resistance.

Make sure the converter housing covers are securely tightened.

Placing System On-Stream

Let the fluid go through the detector pipe. When the detector is filled with the

fluid, stop the fluid and keep it still in the detector pipe.

Supplying Electric Power

Make sure the power supply is as specified.

Checking Converter Parameters

Check the configuration parameter settings. Refer to Chapter 7, “LCD Display

and Controls,” Chapter 8, “Configuration Parameter Setting,” and Chapter 11,

“Communications Function.”

Zero Adjustment

Wait for 30 minutes to warm up the flowmeter. Then making sure the fluid holds

still in the detector pipe, starts the zero adjustment.

Refer to 6.2, “Zero Adjustment.”

On-line measurement

After checking the items and conducting the zero adjustment as listed above, let the fluid go

through the detector pipe. Output (4-20 mA dc) directly proportional to the flow rate can be

obtained.

25

-

Page 27

TOSHIBA

7. Maintenance and Troubleshooting

A CAUTION

6P,8A0,8,0,2

i I i I

■ Do not conduct wiring work when

power is applied.

Wiring while power is

\^Z applied can cause electric

DON’T

7.1 Maintenance IMPORTANT

It is recommended that the detector pipe be cleaned once a year.

■ Cleaning the pipe wall inside of detector

If the fluid to be measured contains slurry; a high concentration of electrically conductive

solids, the slurry may accumulate as sticking on the pipe wall inside of detector.

The sticking causes a reduction of flow measuring outputs when it is not cleaned inside pipe

of detector for a long time.

The flowmeter needs to make sure it remains around the wall inside pipe or not when the

following condition had happened.

■ Do not touch the LF470 main body

when high temperature fluid is be-

ing measured.

The fluid raises the main

V^/ body temperature and can

DON’T cause burns.

(1) The flowmeter becomes a reduction of its output.

(2) The flowmeter caimot improve its output in spite of being calibrated.

The flowmeter is required to remove along with clean it using a soft brush. It will be come

back the usual and stable flow measurement after cleaning.

The pipe wall is never scratched when cleaning.

*Toshiba recommends to clean inside pipe periodically when this condition will be

come easily.

*It is better to choose the suitable diameter which becomes more than 3 m/s as its

flow velocity to avoid this condition generally.

Notes: Before uninstalling the flowmeter(detector) from the pipe, necessarily confirm the

fluid of temperature and chemical property, and empty the fluid from detector. Pre

pare the way to protect operator and system from bad influence; high temperature

fluid and chemical property

- 26 -

Page 28

TOSHIBA

6F8A0802

Operative life

The operative life of this flowmeter is 10 years from the date of shipment. The life of the

flowmeter differs depending on the environmental conditions and the way it was used. To

extend the life of the flowmeter, inspect the flowmeter periodically and clean or replace

components if necessary.

27

-

Page 29

TOSHIBA

7.2 Troubleshooting

(1) Flow rate is not indicated.

6,F8A0,8^0,2

E a problem occurs while using the LF470, foUow the flowcharts described below.

You may find a way to solve the problem. The flowcharts are based on three symp

toms (1) to (3). K you cannot solve the problem, contact your nearest Toshiba repre

sentative.

- 28 -

Page 30

TOSHIBA

(2) Flow rate indication is not correct.

.6.F,8A0802^

-

29

-

Page 31

TOSHIBA

(3) Flow rate indication is not stable.

,6.F8A080,2

i ! I i i i i i

-

30

-

Page 32

TOSHIBA

8. Principle of Operation

The operating principle of the electromagnetic flowmeter is based on Faraday's Law of

electromagnetic induction and it is designed to measure the volumetric flow rate of fluid. An

insulated pipe of diameter D is placed vertically to the direction of a magnetic field with

flux density B (see Figure 8.1). When an electrically conductive fluid flows in the pipe, an

electrode voltage E is induced between a pair of electrodes placed at right angles to the

direction of magnetic field. The electrode voltage E is directly proportional to the average

fluid velocity V.

The following expression is applicable to the voltage.

,6F,8A0,80,2

i........ .... .

j,.

.....

....

...... .....

.. ... ... ... ... .1.... ..

E = KxBxDxV[V]

Volumetric flow rate Q [m^/s] is;

7T X

Q =

Using the Equation 8.1 and 8.2

E=KxBxDx

E=

Therefore, volumetric flow rate is directly proportional to the induced voltage.

7T XD

X V

...........

...................

4

TT X

............

(Eq. 8.1)

(Eq. 8.2)

xQ

(Eq.8.3)

E = induced electrode voltage [V]

K = constant

B = magnetic flux density [T]

D = meter pipe diameter [m]

V = fluid velocity [m/s]

ri

U LZr

Square-Wave Excitation

Figure 8.1 Principle of Operation

The LF470 electromagnetic flowmeter uses the square-wave excitation method, which pro

vides long-term stable operation. With square-wave excitation, the LF470 offers reliable

measurement without being affected by electrostatic or electromagnetic

interference, or electrochemical polarization between the electrodes and the fluid to be

measured.

-

31

Page 33

TOSHIBA

9. Specifications

The flowmeter specifications and the type specification code used when ordering the flowmeter

are described in this chapter.

9.1 Flowmeter Specifications

■ Overall Specifications

6^R8A0a0,2

Meter size: 2.5mm(0.1”), 4mm(0.16”), 6mm(0.25”)

Measurement range in terms of flow velocity:

0-0.3 m/s to 0-10 m/s

System accuracy: See the following table.

Table 9.1 System accuracy

Flow rate as a

percentage of

range

50 to 100%

0 to 50%

0.3 -1.0 m/s

±0.8%ofFS

Accuracy

1.0-10 m/s

±0.8% of rate

±0.4%ofFS

Note: The accuracy above is measured under standard operating conditions at

Toshiba's calibration facility.

Fluid conductivity:

Adaptor Material

Stainless steel and other

metal

Polyvinyl chloride

(shock-resistant)

50 fxS/cm minimum

Fluid temperature

-10 to +120 °C

(Standard)

-10 to +60 °C

(Option)

Ambient temperature:

Structure:

Power consumption:

Converter type

Fluid pressure:

Pipe joints:

-10 to +60 °C

IP67(NEMA4) Watertight

LF420

LF230

-O.lMPa to IMPa

Rc(PT)l/4 female screw

Rc(PT)l/8 female screw

Rc(PT)3/8 female screw

Rc(PT)l/2 female screw

NPT 1/4 female screw

-

32

-

Power supply

Approx. 10W(17VA)

Approx.l4W(25VA)

(Standard)

(Option)

(Option)

(Option)

(Option)

Page 34

TOSHIBA

Table 9.2 Relation between liquid velocity and flow rate at each meter size

6^R8A0,8^0^2

Principal materials

Case— Cast Aluminum

Lining— Ceramic

Electrodes—^Pt-Ir

See Table 9.3 Type Specification Code for optional materials and other related

information.

Coating: Phthalic acid resin coating pearl-gray colored

Mass: Approx. 1.0kg (for each size excluding cables)

Meter size

mm Inch 0.3 m/s 1 m/s

2.5 0.1

4

6

0.16

0.25

0.005301 m^/h

0.08835 l/min

0.013570 m^/h

0.2262 l/min 0.7540 l/min

0.030540 m^/h 0.10180 m%

0.5089 l/min

Flow velocity

0.01767 m%

0.2945 l/min 2.945 l/min

0.04524 m>

1.6965 l/min

10 m/s

0.1767

0.4524 m^/h

7.540 l/min

1.0180 mVh

16.965 l/min

-

33

-

Page 35

TOSHIBA

9.2 Type Specification Code

Table 9.3 Type Specification Code (Model LF470 Detector)

8A0^8^0^2

Model

1 2 3 4 5 6

L F 4 7 0

Specification Code

7

9 10 11

8

2

4

6

D

E

A

B

C

D

E

Z

A

D

E

F

Z

c

D

Z

12 13 14

A

B

A

B

Z

Description

LF470 Detector

Meter size

2.5mm (1/10”)

4mm (1/6”)

6mm (1/4”)

Assembled converter

LF420

LF230

Pipe connection port (adapter)

Rc(PT)l/4 female screw (standard)

Rc(PT)l/8 female screw

Rc(PT)3/8 female screw

Rc(PT)l/2 female screw

NPTl/4 female screw

other

Pipe connection material

316 stainless steel (standard)

Ti (titanium)

Polyvinyl chloride(shock-resistant) + Ta (tantalum for) grounding ring plate

Polyvinyl chloride + Pt-Ir grounding ring plate

Other

Gasket material

Fluoric rubber for acid-resistant (Standard) (Notel)

Fluoric rubber for alkali-resistant (Notel)

other

Mounting board

Not provided (standard)

Provided (SUS304)

Flow and calibration velocity range

0.3 to 10 m/s (Standard range calibration)

0.3 to 10 m/s (Specified range calibration)

other

Dedicate Preformed Cable length

A

B

C

D

5m (standard) (Note2)

5m or more (extension cable dia. 12mm, + Scotch cast connection)

5m or more (extension cable dia. 7mm, + Scotch cast connection) (Note2)

5m or more (extension cable dia. 7mm, with no connector termination) (Note2)

Coating

phthalic acid resin coating, pearl-gray colored (standard)

A

other

Z

Notel: Consult Toshiba before ordering when choose materials at the wetting parts.

Note2: A set of cable ground sized 7mm diameter for converter is packed when the code “A”, “C” or “D” are chosen.

-

34

-

Page 36

TOSHIBA

10. Outline Dimensions

6f^8,A0^0i2

Weight: approv. 1.0kg

Figure 10.1 LF470 Outline Dimension

-

35

-

Page 37

TOSHIBA

,6,F8A0,8,0,2^

Figure 10.2 Mounting plate (option)

-

36

-

unit: mm

Page 38

TOSHIBA

USER'S FORM

NOTES

6F,8A0^8a2^

Unit purchased from

Name

Title

Company

Address

City/State or Province

Country

Tel

Fax

Model/Specification Code LF470

Serial No.

Industrial Equipment Department

l-l,Shibaura 1-chome, Minato-ku, Tokyo, 105, Japan

Tel.: (03)3457-4900 Fax.: (03)5444-9268

37

Page 39

TOSHIBA

6^R8,A0^8^0^2

DISTRIBUTION

m

COPY

ISSUED

DEVEROPMENT &

DESGING

GROUP 5

APPROVED BY

QECKED BY ,/2.,'o\

Ifh. Fl4^

PBEPmOBY

ffi'f REGISTERED

-

38

-

Loading...

Loading...