Page 1

TOSHIBA

6F8A07.70

ELECTROMAGNETIC FLOWMETER

MODEL LF434/LF404

INSTRUCTION MANUAL

-TOSHIBA COHRORATION

Page 2

TOSHIBA

NOTICE

Tills M^iuiol is desigiisci to assist in installing, operating, and inainLaining the

LF434/lT4()4dt:clromagneric flowmeter- For safety reasons, and to obtain the opti

mum pcrtormancc from Ihe flowmeter, read this Manual thoroughly before w'orking

with the product. Keep the Manual within easy reach for reference whenever needed.

The flowmeter to which this Manual refers is NOT designed for applications in which

the functioning of this product is critical to human safety, such as:

♦ Main control systems of nuclear power plants; safety systems in nuclear facilities

• Control systems of medical equipment, including life support machines.

6F8.A077 0

or other critical control lines directly affecting human safely.

NOTES

1. The reproduction of Ihe contents of this Manual in any form» w'hether wholly or in part» is

not permitted without explicit prior consent and approval,

2. The information contained in this Manual is subject to change or review' without prior

notice.

3. Re sure to follow all ,safeiy, operating and handling precautions described in this Manual

and the regulations in force in the country in which this product is to be used,

HART is a registered trademark of the llAR'l’ C’omniumcatioii Foundation.

Teflon is a registered trademark of the DuPont Company.

I’hird Edition

October.

© Copyright 1999» 2000 by Toshiba Corporation, All rights rc,scrved.

2im

Page 3

TOSHIBA

SAFETY PRECAUTIONS

Siifeiy signs and InhcJs affixed to Ihc product iUid/ur dcscribetl in Ihis manual give imporLaiU

inibrmation for using the produci saldy. I’hcy help prevent damage lo property and obviate

hazards for persons using the product.

Make yourself familiar with signal words and symbols used for safety signs and lab els/Then

read the safely precautions that follow to prevent an accident involving personal injuiy>

death or damage to [>ropcrty,

IvxplaDation of signal words

'flic signal word or words are used to designate a degree or level of hazard seriousness,

I’he sigrial words used for the product described in this manual arc WARNING and

CAUTION,

A WARNING

6F8A0770

Indicates a potentially ha/ardous situation

which, if not avoided, could result in death or

‘icrious injury,

Safety symbols

Indicates n potentially iiazardous silualion

A CAUTION

The following symbols arc used in safely signs and labels affixed to a product and/or in the

manual for giving safely inslniciioiiM.

Indicates an action that is prohibilud. Simply [DON’T do this action,

The prohibited action is indicated by a picture or text inside or next to

0

•

A

the circk

Indicates an action that is mandatory, DO this action.

The mandatory action is indicated by a picture or text inside or next lo

the circle.

Indicarcs a poieniial hazard, The potentially hazardous situation is

indicated by a picture or text inside or next to (he triangle.

which, if not avoided, may result in minor to

moderate injuries or in properly damage.

- 2 -

Page 4

TOSHIBA

SAFETY PRECAUTIONS

Safety Precautions for Installation and Wiring

Zh WARNING

Do not disconnect while circuit \s iive onlcss locution is known to be nonhazardous.

6F8A0770,

0

DONT

I Do not modify or disassemble the enclosure.

DONT

Do not use parts of other products.

0

DONT

Do not live circuits While assembly of all components is not over.

0

DONT

Install per the National Electrical Code for the UгS (NEC, ANSI/NFPA 70)

and the Canadian Electrical code for Canada (CEC, CAN/C5A-C22.1).

O

DO

Live part of electric circuit ot a high temperature department can cause

explosion.

Strength degradEilion and defects of enclosure can cause explosion,

Protective pcrformiincc degradation for hazardous location can cause

explosion.

Protective performance degradation for hazardous location can cause

explosion.

Unsuitable conduit connections for hazardous location can cause ex

plosion.

A CAUTION

■ Turn off maius power before working

on pipes«

A Working on pipes vvhiJc

power is applied can cause

QQ electric shock.

■ Install a switch and fuse to isolate the

LF434/LF404 from mains power.

A A Power supply from mains

power can cause electric

DO t>reakdow n.

■ Use an appropriate device to carry

and install the LF434/LF404.

If this product falls to the

ground^ injury, or malfunction

of or damage to the product,

can be caused.

■ Do not modify or disassemble the

LF434/LF404 unnecessarily.

Modifying or disassembling

( jy [his product can cause electric

nOisf’T

- 3 “

shock, malfunction of or

’ damage to this product. |

Page 5

TOSHIBA

SAFETY PRECAUTIONS (contiaued)

Safety Precautions for Maintenance and Inspection

âs CAUTION

■ Turn off mains power before

conducting wiring work.

Wiring while power is applied can cause electric shock,

DO

■ Do not conduct wiring work with bare

hands.

Rcma i n i n g cJ cetr ic charge

( even if pov-'cr is turned off

^ can still cause electric shock.

DONT

■ Do not work on piping and wiring with

wet hands.

Wet hands may result in

f electric shock,

DON'T

■ Do not touch the flowmeter main

body when high temperature fluid is

being measured.

The fluid raises the main

i body temperature and can

^ cause bums when touched.

DON’T

■ Do not conduct wiring work with wet

hands.

1^0 Wet hands may result in

elccrric shock.

DONT

■ Do not use a fuse other than the one

specified.

Using a fuse other than the

j one specified can cause

j/ system failure, damage or

malfunction,

DONT

■ Ground (he LF434/LF404 indepen

dently from power equipment.

PQ shock or malfunction.

■ Use compression terminal lugs with

insulation sleeve for the terminal

block and GND terminal.

/ i \ (A black border and symbol on

■ Do not conduct wiring work when

power is applied.

I can cause electric shock,

DONT

* near the terminal board for

Use a rated fuse as follows:

Fuse rating:

^ lA/^.'inV for lilt) to 240Vac or 1 liiVdc

* 2A/2.^0V for 24 Vdc

Dimensions:

Diameter

Melting time characteristic:

6F8A07 7 0:

Operating this product without

grounding can cause electric

1.0QSC connections can cause

electric shock, fire from

excessive current or system

malfunction.

The label shown left is placed

near the terminal board for

power input.

yellow triangle)

Be alert to electric shock.

Wiring while power is applied

1 be label shown left is placed

power inp ut.

\ (A black border and symbol on

yellow triangle)

Be alert to electric shock.

5.2

mm x 20 mm

Normal blow j

Disclaimer

Toshiba does not accept liability for jny damage or loss, material or personal, caused as a

direct or indirect result of the operation of this product jii connection with, or duo to, llie

occurrence of any event of force majenre (including fire or earthquake) or the misuse of

this product, whether inicnclonal or accidentaL

- 4 -

Page 6

TOSHIBA

Handling Precautions

■ Jo obtain the oplimum performance from the LF434/LF404 flowmeter for years of

coniinLous operation, observe the following precautions.

(1) Do not store or instafi the flowmeter in:

(2) Execute wiring securely and correctly.

.6.F8A0 770

• places w here there is direct sunlight. If this is unavoidable, use ait appropriate

sunshade.

• places where excessive vibration or mechanical shock occurs,

• places where high temperature or high humidity conditions obtain.

• places where corrosive atmospheres obtain.

• places submerged under water,

To put the flowmeter temporarily on the floor, place it carefully wnth something to

support it so that the flowmeter will not topple over.

Ground the flowmeter with 100 ohm or less ground resistance. Avoid a common

ground used with other equipment where earth current may How. An independent

ground is preferable

(3) Seal the cable thoroughly at the cable gland so that the cable is kept airtiglit. 1 he

apparatus should not be provided with the cable gland. Please prepare yourself for

the cable glands w'hicb could be used in Division 2 hazardous locations.

(4) Make sure the fluid to be measured will not freeze in the detector pipe. This can

cause damage to the detector pipe.

(5) Select apprupriate welted materials suited for the process fluid to he measured.

Otherwise, fluid leakage due to corrosion can be caused.

(6) The converter housing covers are tightened securely at the time of shipment. Do

not remove these awers or glands unless it is necessary to wire new cables or re

place old ones. Otherwise, gradual deterioration of circuit isolation or damage to

this product can be caused. Tighten the covers securely again if they have been re[iioved.

L

“

5

-

Page 7

TOSHIBA

Handling Precautions (continued)

j (7) Observe the following preenulions when you open the converter housing cover:

• Do not open the cover in .he open air unprotected ngninst rain or wind, J his

cun cause electric shock or cause damage to the ilowmetcr elccironics.

* Do not open the cover under high ambient temperature or high humidity

conditions or in corrosive atmospheres^ This can cause deterioration of

system accuracy or cause damage to the flowmeter dec ironies,

(B) This product may cause interference to radio and television sets If they are

used near the installation site. Use metal conduits etc, for cables to prevent

thi.s interference.

(9) Radio Iransmiilers such as tran.sceivers or cellular phones may cause interference

to the ñowmcter if they are used near the installation site. Observe the following

precautions when using them:

• Do not use a radio transmitter while the cover of flowmeter converter is open.

• Do not use a tran.scciver whose output power is more than 5 W.

• Move the antenna of a ratio transmitter at least 50 cm away from the flowmeter

and signal cables when using it.

• Do not use a radio traiismitler near the ñowmeler while it is operating online.

The transmitter's output impulse noise may interfere with the flowmeter.

• Do not install a radio transmitter antenna near the flow'meier converter and

signal cables.

,6F8A0770

(10) For reasons of flowmeter failure, inappropriate parameters, unsuitable cable con

nections or pCHjr installation conditions, the flowmeter may not operate properly.

To prevent any of these problems causing a system failure, it is recommended that

you have preventive measures designed and iitstallcd on the flowmeter signal re

ceiving side.

- 6 “

Page 8

TOSHIBA

Table of Contents

678A0770

SAFETY PRECAETfONS

Handimg Precautions ........................................................

1, Product Inspection and Storage ...............................

1.1 Product Inspection ...................................................

1.2 Storage .....................................................................

2, Overvie>v ....................................................................

3, Names of Parts

...........................................................

4, Installation ..................................................................

4.1 Location ...................................................................

4.2 Mounting Procedure.................................................

4.3 Piping Connections

.................................................

5, Wiring .........................................................................

5A

Cables

5.2 External Device Conncc.ions and Grounding

5.3 Digital I/O Connections

5.4 Wiring Procedure ......................... ‘ '

.....................................................................

......................

6, Operation ................................................

6.1 Preparatory Check

6.2 Zero Adjustment

7, LCD Display and Controls

7.1 Outline

7.2 Display Formal

7.3 Basic Operations .................................................

7.4 Configuralion Items Selection Table ' ■

7.5 Password Input

................................................

8» Configuration Parameter Setting

8.1 Configuration Items ............................................

8.2 Checking or Changing Parameters

..............................

.................................

...................

...................................................

...................................................

..........................

.....................

9. Calibration .............................................................

9.1 Calibration Items

9.2 Calibration Using Converter Signal Source

................................................

■ 2

-■5

■

9

10

11

14

15

' 16

' 20

‘ 25

■ 27

■ 27

29

’ 30

■ 32

' 32

33

‘ 34

34

■ 36

■ 38

‘ 44

■ 45

^ 46

■ 46

■ 46

103

103

104

9

g

-

7

-

Page 9

TOSHIBA

6F8A0 7 7 0.

10, Digital I/O Functions

10.1 Digilai I'O Spccjficaiians '

L0,2 Totalizer and Pulse Output

10.3 Multi-range Functions ■ ■ ’

10.4 High and Lou Limit Alarms

10.5 Empty Pipe Alarm

10.6 Preset Point Output

10.7 Remote Zero Adjustment

10.8 Remote Selection of Fixed Value Output

10.9 Converter Failure Alarms ................................

tl. Communications Function

11.1 Communications with the AFIOO Terminal

11.2 Communications Procedure

1 L3 Cautionary Notes on Communications ‘ '

12, Self-Diagnostics and Alarms

12J Self-Diagnostics

12.2 Output Status for Errors and Alarms

13, Maintenance and Troubleshooting

13.1 Maintenance

...................

.....................

.................................

...................................

..............

........................................................

.........................

................................

...........

.............

...................

13.2 Troubleshooting

14, Principle of Operation

...................

....................

15, Specifications ..............................

15.1 Flowmeter Specifications

15.2 Type Specification Code

16, Outline Dimensions .

.................

Appendi\ 1. Electromagnetic Compatibility and Low Voltage Safety ’

Electromagnetic Compatibility

Low Voltage Safety ^ ^ ■ ■ ■ ■ ►

- 8 -

Page 10

TOSHIBA

1, Product Inspection and Storage

i;pon arrival of The product piickfige» open [lie package and check the items contained inside,

If you do not intend to install the product soon after opening llie package, store the product

and other related items in a place such as described in 1.2 below,

IJ Product Inspection

The LE^34/LF404 electromagnetic flowmeter is shipped in a cardboard cnniaincr filled with

shock-ahsorbing materials. Open the package carefully and check as follows:

■ Make sure the following items are included in the package.

(1) Model LF434/LF404 Electromagnetic Flowmeter,.,.,, i

(2) Instruction Miitiual ..............................................................

■ Inspect the flowmeter for indications of damage that may have occurred during shipment.

■ Make sure the type and spedficalions of the flowiiieter arc in accordance with the

ordered specifications,

If you cannot find the items listed above or any problem e?(ists, contact your nearest

I’oshiba representative,

6F8A0770

j

1,2 Storage

To store the LF434/LF404 flowmeter after opening the package, select a

storing place as follows and keep it under the conditions described below;

(1) Avoid places where there is direct sunlight, rain or wind.

(2) Store the product in a wcll-veniilated place. Avoid places of extremely high

humidity or extremely high or low temperature. The following cnvlroiitucnt is

recommended;

« Humidity range: 10 to 9i)% RH [no candensation)

• Storage temperature: -15 to +65* C

(2) Avoid places where vihralions or mechanical shock occur.

(4) Do not leave the converter housing cover open . Open the cover only w-hen

you actually start wiring cables. Leaving the cover open catt cause gradual

dctcrioraiion of circuit isolation,

(3) To pm the flowmeter temporarily on the floor, place it carefully with something

to support it so that the flowmeter will not topple over

- 9 -

Page 11

TOSHIBA

2. Overview

6F8A0770

The LF434/1P4U4 elecLromagnetic flowmeter can be use in the following hai:afdoLis (clas

sified) loc;iLions.

(1) FM Approval

Gass I j Division 2, Groups A, C, C and D,

Class II, Division 2, Groups P and G

Class in

(2) eSA Ccrtifieation

Class I , Division 2, Groups A. B, C and D,

Class n , Division 2, Groups R, i- and G

GassU

rhe device measures the volumetric flow rates of electrically conductive materials on

the basis of Faraday's Law of electromagnetic induction.

The device consists of two units: Ue detector, through which the fluid to be measured

flows, and Ihe converter, which receives the elcciromotivc force signals from tiie

detector, then converts the signals into the 4—20 mAdc signal.

Features

Model 1F434/LF404 flowmeter has the following features:

(1) Fluid flow is not obstructed and pressure loss is negligible.

(2) Toshiba’s original noise-suppression circuit with signal processing

Ccipcibililics ensures a stable outpul.

(3) lias no moving parts and How indication is quick with high accuracy even under low

flowrate measurement conditions,

(4) No obstacles in the flow stream ami nowhere remains the fluid along the detector

pipe. Thus deterioration or corrosion of fluid does not occur,

(5) High accuracy, ±0.5% of rale is possible for 0,3-10 rrv’s velocity range. (). I to 0.3

m/s range is available optionally.

(6) 'I'he flowmeter has various How measurement outpul and control functions as

standard specifications and the optional IXD display for convenient parameter

settings.

' These funciions can he selected with control keys on the panel.

(8) Intelligent functions

* The widely used HART [protocol communications system is used as a standard

feature. HART (Highway Addressable Remote Transducer) is a commtmications

protocol for industrial sensors recommended bvHCF (HART Communication

Foundalion).

(9) An casy-to-rcad LCD display (2-iine x 16-character display) (optional)

* The backlit LCD display can be read even under poor lighting conditions.

- 1 0 -

Page 12

TOSHIBA

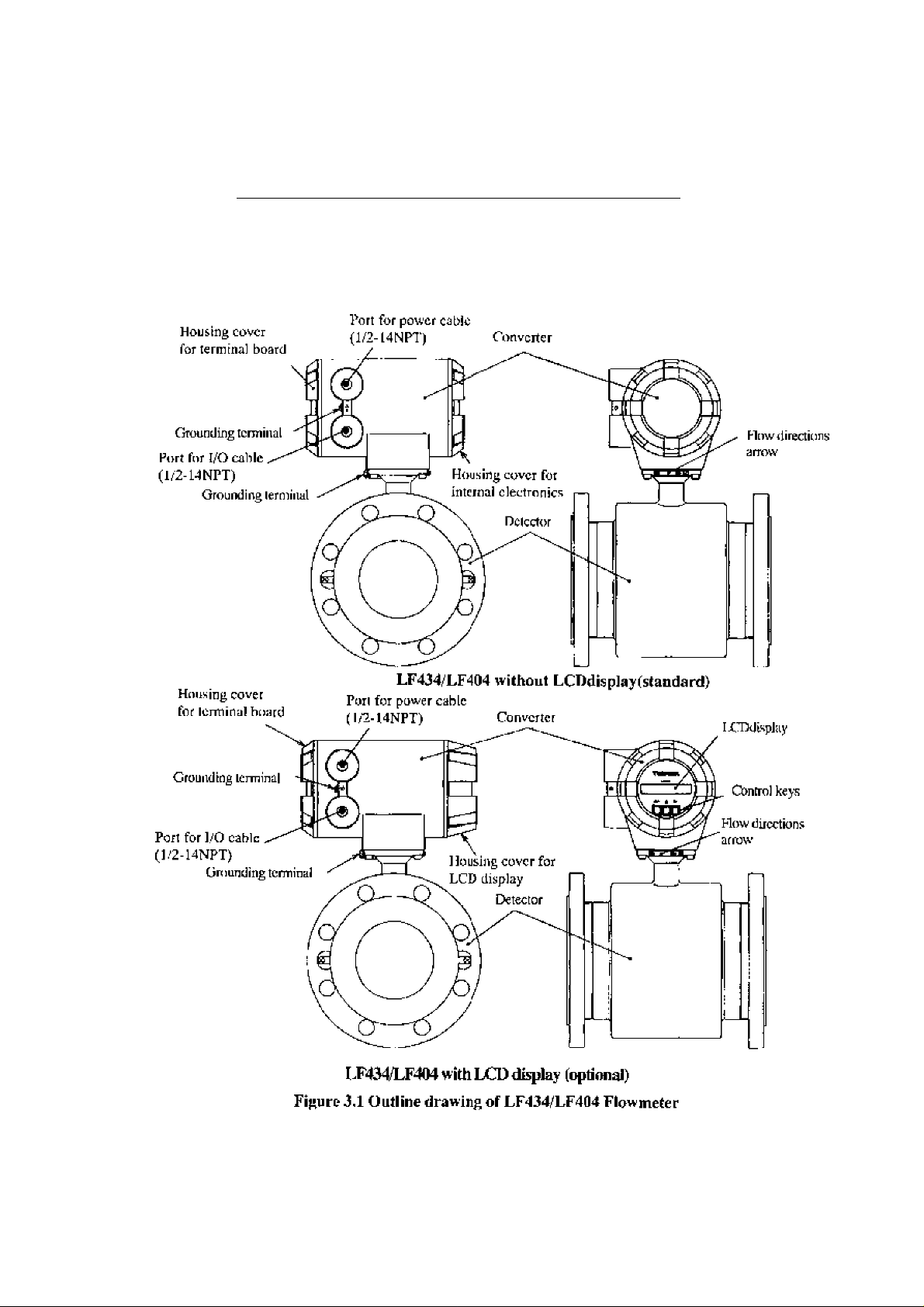

3. Names of Parts

Tht: oulliEie drawing of ihe LF434/LF404 ilowm&ter is shown in Figure 3,1 and the in-

______________

IMPORTANT

The apparatus should not be provided with the cab'c glands.

Please prepare yourself for the cable glands which could be used in Division2 hazardous locations.

tcrnal views of the LF4[14 converter are shown in 1 ifiiires 3,2 and 3.3,

Outline Drawing

_______________

6F8A0770

- M -

Page 13

TOSHIBA

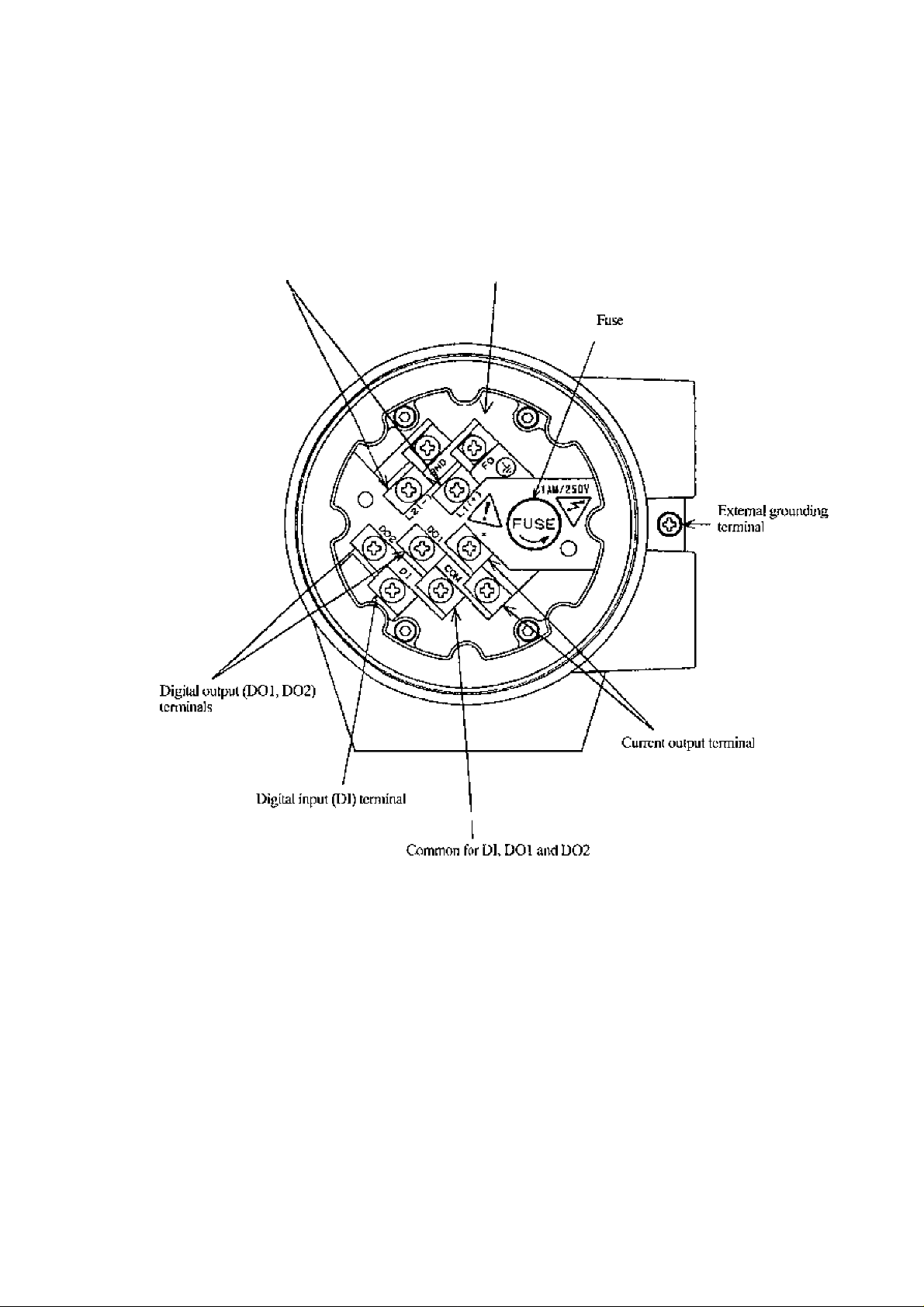

Terminal Board ol'LF404 Converter

.6F8A07 7 0

Power supply lerminal:^

interna] gi\>uniJing terminal

Figure 3.2 Terminal Board of LF404 Converter

- 1 2 -

Page 14

TOSHIBA

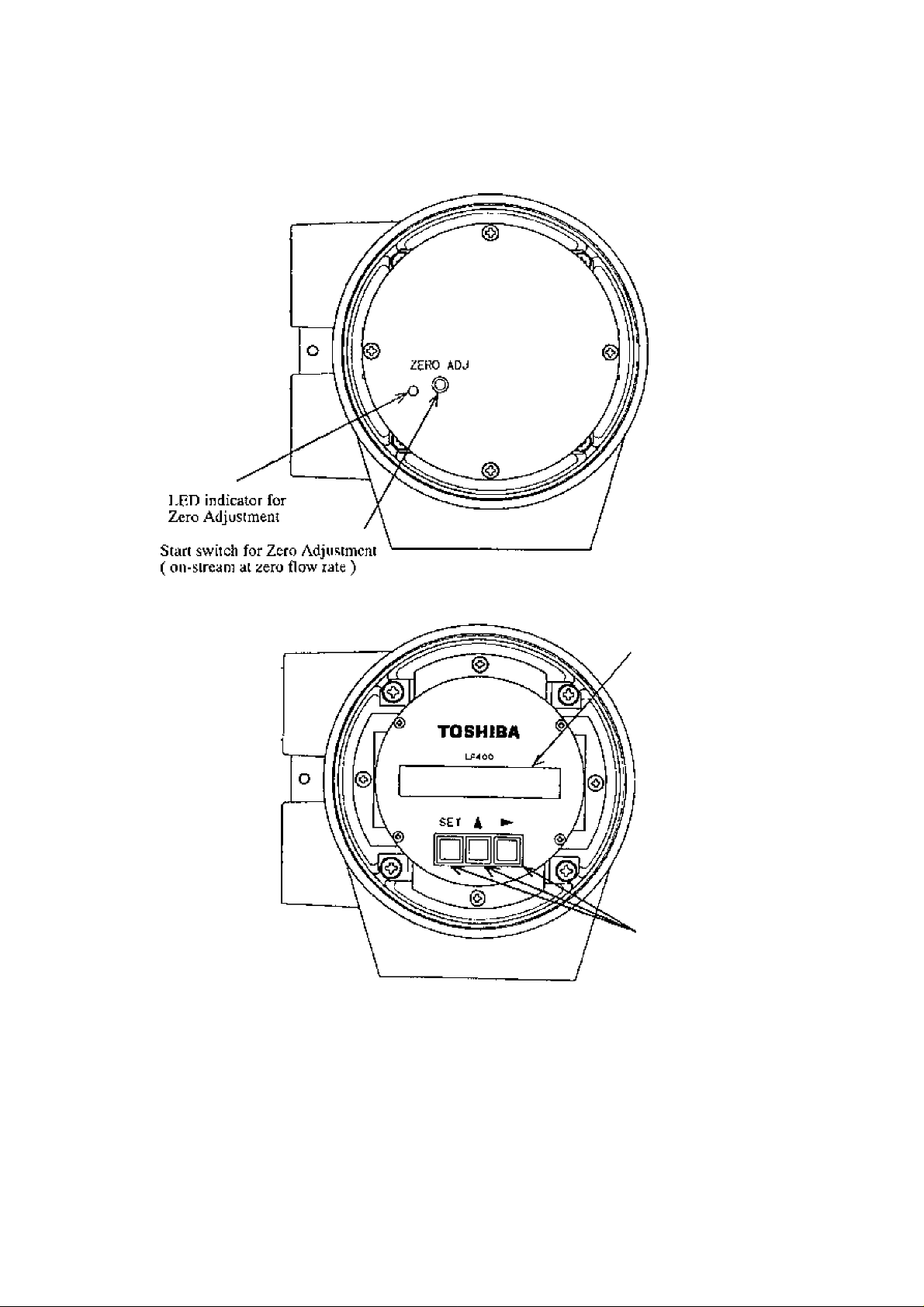

Control switch or keys of LF404 Converter

6F8A0770

LF4M v^ithout LCD Display

LF4(W wilh TXD Display

LCD display

Control keys

Figure 33 Control switch or keys of LF404 Converter

-

13

-

Page 15

TOSHIBA

4. Installation

Safety Precautions for Installation

Do not live circuits under environmeiu of explosive aimosphcrcs.

6F8A0770

A WARNING

0

DON’T

Do not use parts of other products.

0

DON’T

l>o not Jive circuits While assembly of all components is not over.

0

DON’T

Install per the National r.lectricnl Code for the US (NEC, AN\SJ/NFPA 70)

and the Canadian Electrical code for Canada (CEC» CAN/CSA-C22»!).

O

DO

Live part of electric circuit or a high tompcralure department can

cause explosion.

Protective performance degradation for hazardous locatinn can

cause explosion.

Protective performAnce degradation for haijardous location can

cause explosion.

Unsuitable conduit connections for hazardous location can cause

explosion.

A CAUTION

■ Install a switch and fuse to isolate

the LF434/LF404 from main power.

Power supply from main

power can cause electric

shock or ci rcu It

DO breakdown.

■ Use an appropriate device to carry and

install the LF434/LF404.

If his product falls to the

ground, injury, or

malfunction of or damage to

PQ the product, can he caused.

■ Do not modify or disassemble the

LF434/LF404 unnecessarily.

Modifying or

disassembling this product

1 jjw can cause electric shock,

malfunction or damage to

DON’T this product.

■ Do not work on piping and wiring

with wet hands.

Wet hands may result in

V Jy electric shock

DON’T

- 14 -

■ Ground the LF434/LF4M

independently from power equipment.

Operaliiig this product without

grounding can cause electric

0 Q sh ock or m a Ifu notion.

1 he label shown left is placed

near tile terminal board for

power input.

/ J \ (A black border and .symbol on

yellow triangle)

be alert to dcctric shock.

Page 16

TOSHIBA

4.1 Location

6F8A077.0

['ey

fielect the inslallatioi] site, follow the precautions described below:

■ Avoid places where fluid runs in a pulsating form.

■ Avoid places within the immediaic proximity of equipment producing declricul

inleгf^^rencc (such as motors, transformers, radio irunsmittcrs, electrolytic ceils, or

other equipment causing electromagitclic or electrostatic interference),

■ Avoid places where excessive pipe vibration occurs.

■ Avoid places where there is direct sunlight. !f this is unavoidable, use an appropriate

shade

■ Avoid places where corrosive atmospheres or high humidity conditions obtain,

■ Avoid places of too great an elevation or constricted areas where clearance

for installation or maintenance work is not provided,

■ Design piping so that the dcicetor pipe is always filled with fluid, whether the Quid is

flowing or not,

■ The LF434 detector has no adjustable piping mechanism. Install an adjustable short

pipe w'here needed.

■ Chemical injections should be conducted on the downstream side of the flowmeter.

- 15 -

Page 17

TOSHIBA

4*2 Mounting Procedure

6F8A0770

A CAUTION

■ Use ati approprìate devìce lo carry

and instali thè LF434/LP404*

_ If his product fallii to thè

A & g round, i nj u ry, of

malfuiiction of or damage

DO lo thè produci, can be

caused.

4*2,t Pipe checks

Before installing pipes, cheek for iuiy leanitig or misplacement (or eccentricity) as

iJlusitratcd in Figure 4.1. An attempt to unreasonably connecting pipes that are inclined

may lead to a detector breakdown or fluid leakage. Connecting pipes in an eccentric state

may also cause local wears and tears of linings and grounding rings, as well as

measurement errors.

Before installing pipes* make sure to flash the interior of the pipes to remove deposited

matters.

■ Tum off mains power before

working on pipes.

Working on pipes while

power is applied can

cause

electric shock*

DONT

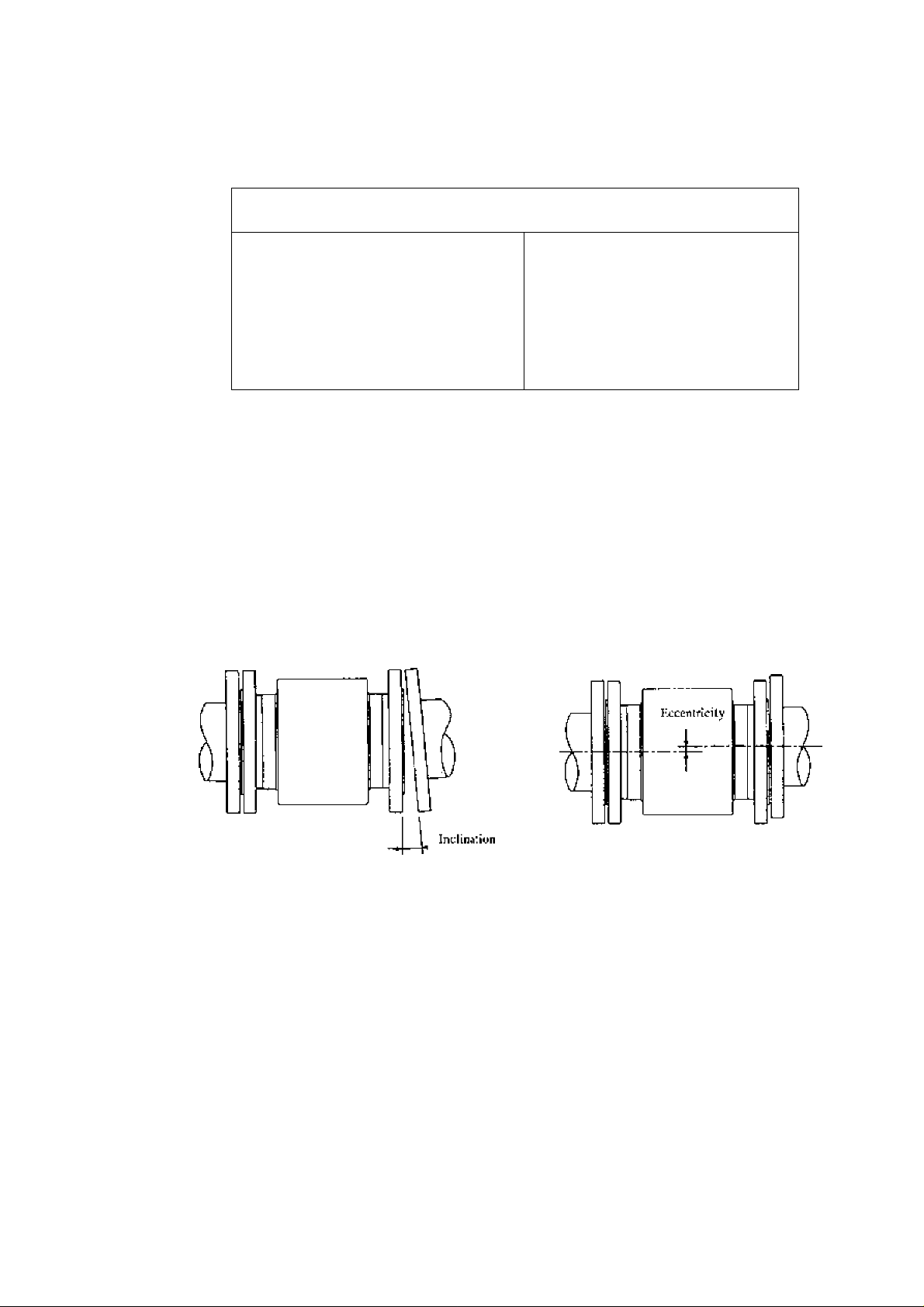

(a) Pipe leaning (b) Pipe axis misplacement (or eccentricity)

Figure 4.1 Pipe leaning and axis misplacement

- 1 6 -

Page 18

TOSHIBA

4.2.2 Installation Procedure

IMPORTANr

When high-temperuiure fluid is being measured, radiant heal from the detector pipe surface

and adjoining pipes may cause the ambient temperature of the converter to go above 6t)

If the ambient lemperature goes above 60° C, try to lower the temperature by measures such

as wrapping heat-insulating materials over the detector pipe and adjoining pipes.

6F8A0770

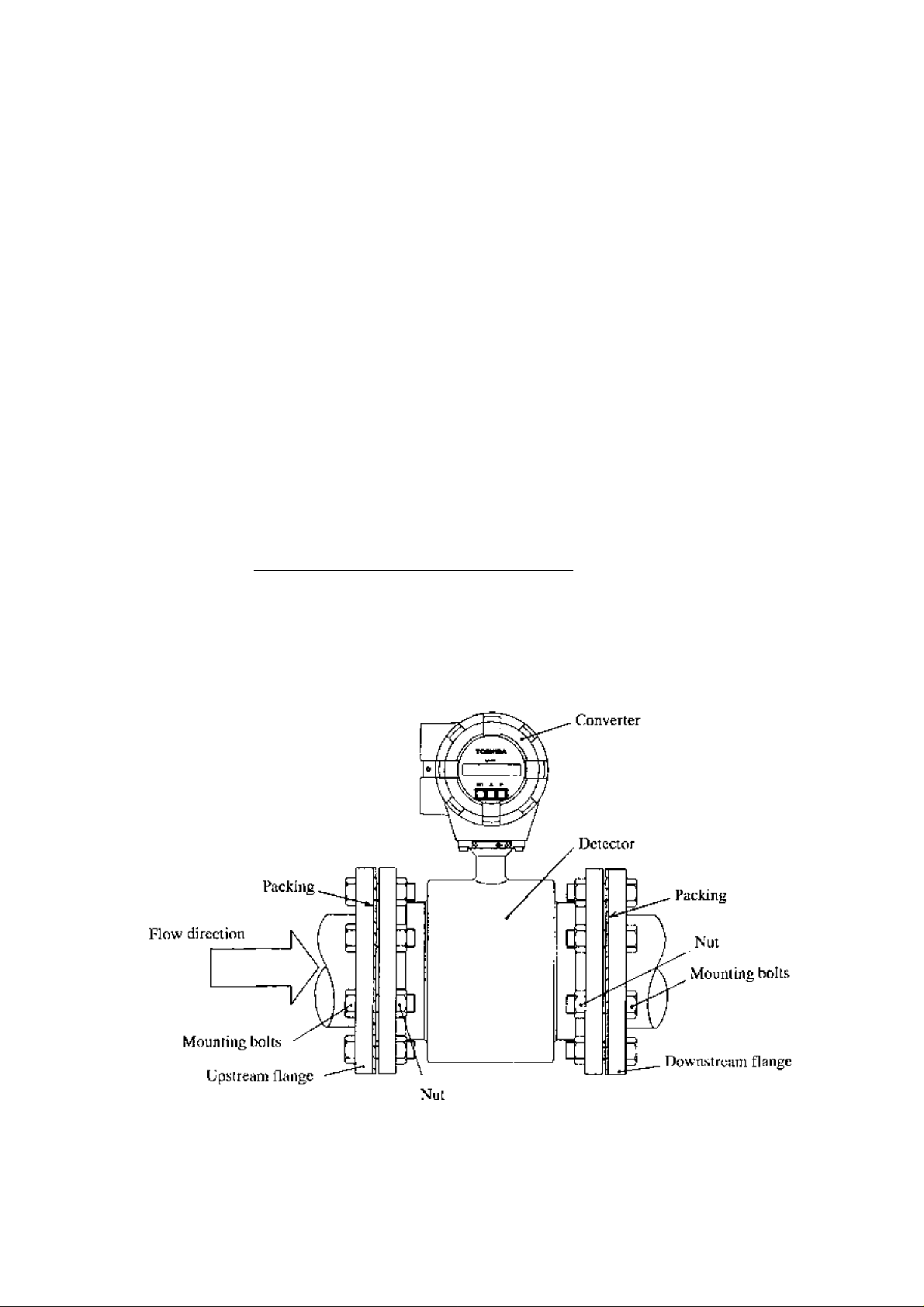

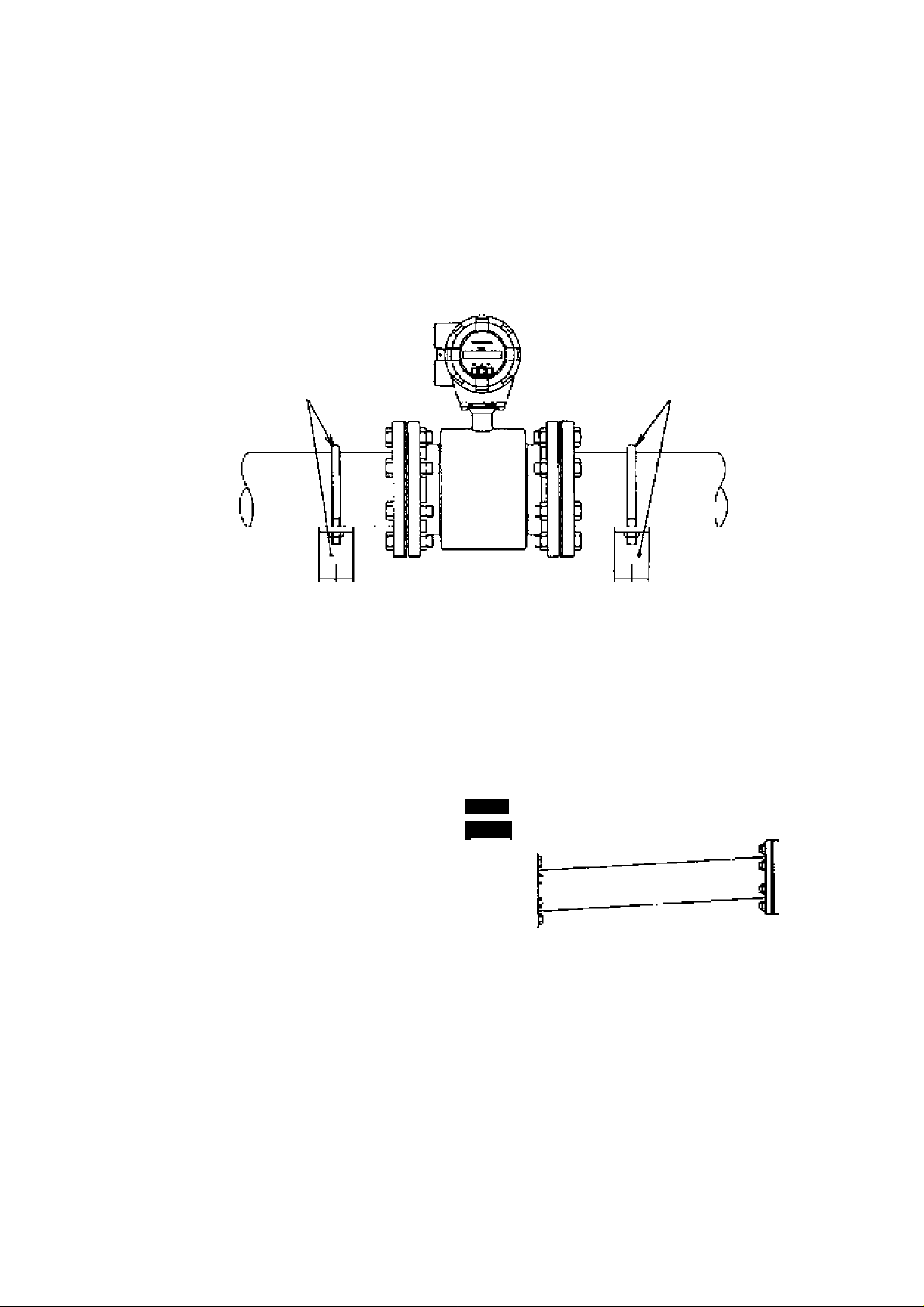

To mouiu thu LF434/J.F404, plai:c il between Itic upstream and downstream pipe flanges

and tighten it with flange holts and nuts. See f igure 4,2 t Tablc4,1 and follow ihe

procedure below:

1. Place one of the flange packing next to the upstream (or downstream) pipe llattge. Altgi^

the holes of the packing with those of the flange so that the holes arc not obstructed.

2, Insert the Lh’434 detector in pipeline in accordance with the flow direction arrow on the

detector.

3, Insert the bolts, one at a time, through the hole in the upstream (or downstream) pipe

flange and packing, and then through the hole of the detector flange. Then thread nuts,

one at a time, on each end of the bolts, finger-tighten. This will help support the detector

on one side.

4, Insert the downstream (or upstream) packing between the detector flange and the down

stream (or upstream) pipe flange. Align the holes of the packing with those of tlie flanges

so that the holes are not obstructed.

5. Inert the bolts, one at a time, through the hole in the downstream (or upstream) pipe

flange and packing, and tJien through the hole of the detector flange. Then thread nuts,

one at a time, on each end of the holts, finger-tighten. This will help support the detector.

6. While centering Ihe detector with ihe longitudinal axis of the pipeline, tighten the bolts

with a wrench diagonally across in even increrr^nis

______________________________

Figure 4,2 LF434/LF4Ü4 flowmeter piping connectinns

- 17 -

Page 19

TOSHIBA

6F8A07 7.0

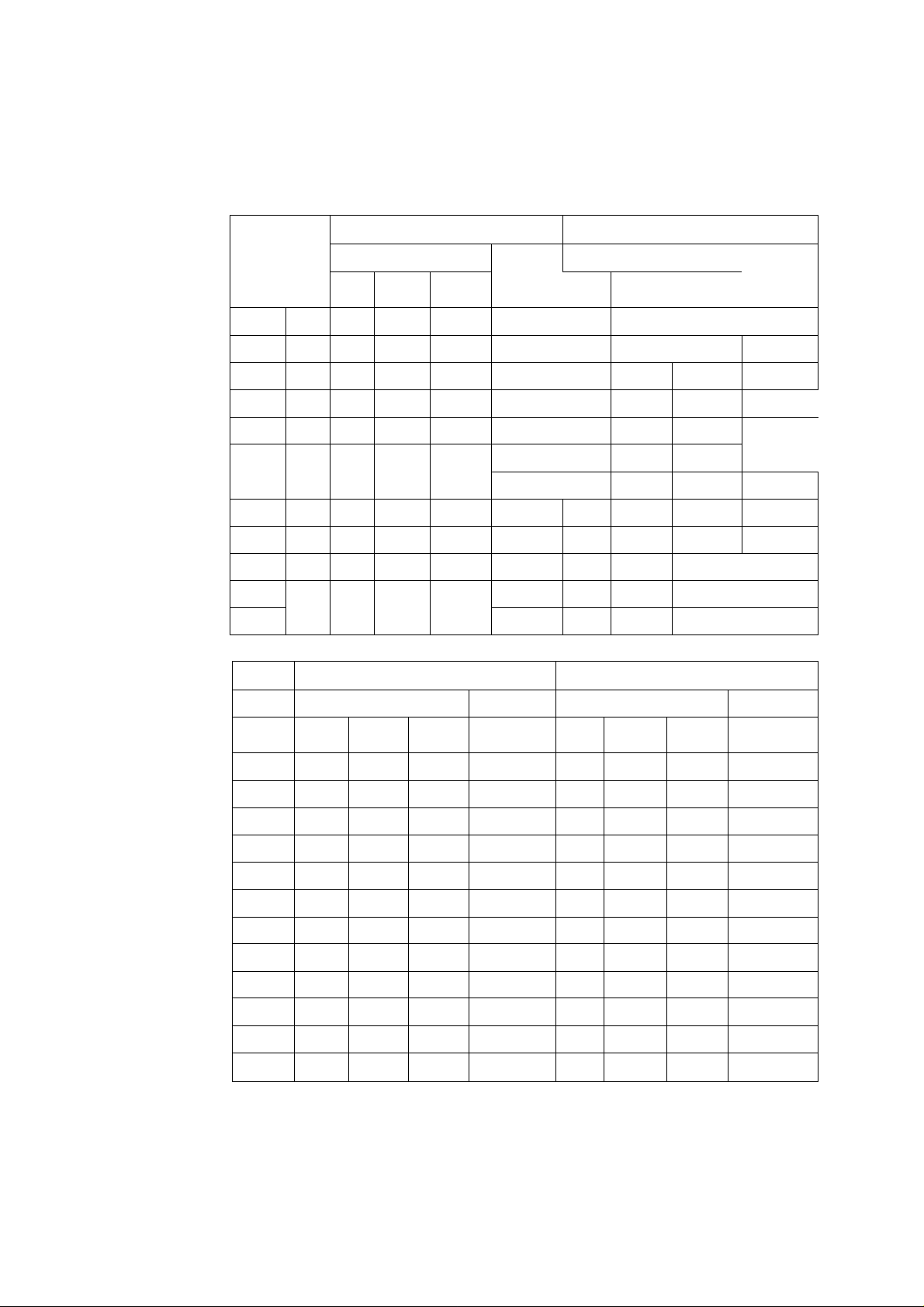

Table 4.1 Bolt length and Nut tightening torque

ANSI class 150

3”

4”

Clamping

lorque

[N-m]

10 to 13

33 to 41

20 O’o 25

67 10 S3

73(0 91 16 1 i.^S" 5.7” 70 to 88

Clamping

lorque

[NmJ

P.C.S

4

4 3/4”

8

S

16

Jiexagon head boll.s

P.C.S

Mc(cr size

15mm 1;2”

25irim 1" 4 1/2” 2.25”

40mm 1 L'2"

50mm r 4 5/K” 2.75” 26 to 32 8 5/8“ 2.8” 13 to 16

80mm T 4

lOOmm 4"

15Cmm 6" S 3/4” 3.25” 46 to 57 12 3/4“ 4.1“ 30 to 38

20f)mm 8" 8 3/4” 3.5" 6010 75 12 4.7“

25Umm 10’' 12 7/S” 3.^"

500mm 12” 12 7/8”

350mm 14” 12 1” 4.5' 105(0 131 20 1 1.'8“ 5.9” 71 to 89

400mm Ifi” 16 1” 4.5" 98 10 123 20 1 i/4”

Meier

size

P.C.S

Machine Bolts

Diame

P.CS

4

4

8

Hotagon head bolts

ter

1/2” 2” 5 to 7 4 1/2“ 2” 5 hi 7

1/2” 2.5’ 15 to 18

5/8”

5/8” .3”

DIN.'BS 1(1

Diurne-

ler

I,cngih

finml

Length

linch]

ANSI class 300

Machine Bolts

Diame

ter

5.''8” 2.5’' 13 lo 16

3/4“ 3.4”

3/4” 3.7” 24 to 30

1”

Diame

ter

Length

finchl

2,8" 22 to 28

5.4” 57 to 71

6 3”

I31N/BS 16

Lengih

Imml

c:iamping

20tn25

47 to

9810 123

Clamping

torque

[NmJ

ttjrquc

f^‘m|

15mm 4 M12 55 5 to 7 4 M12 .55 5 10 7

25mm 4 M12 60 12 to J8 4 M12

40mm

SOmrri 4 M16 65 26 to 33 4 M16

80mm 8 M16 70 17 to 21 8 M16

100mm 8 M16 75 20 lo25 8 M16 7.5 20 to 25

150mm 8 M20 80 48 to 60 8 M20

200mm 8 M20 85

250mm 12 M20 90 60 to 75 12 M24

300mm 12 M20

35 Omm 16

4{)0inm 16 M24 105 93 to 116 16 M27 115

4 M16

M20

65

95 62 to 78

19 to 23

63 to 79 12 M20 90 42 to 53

65 to 82

4

M16 65 19 to 23

12

16 M24

M24

60 12 to 18

65

70 17 to 21

80 48 to 60

95 72 to 90

lOO 78 to 98

lit) 74 to 93

26 to 33

105 to !31

- 1 8 -

Page 20

TOSHIBA

6F8A0770

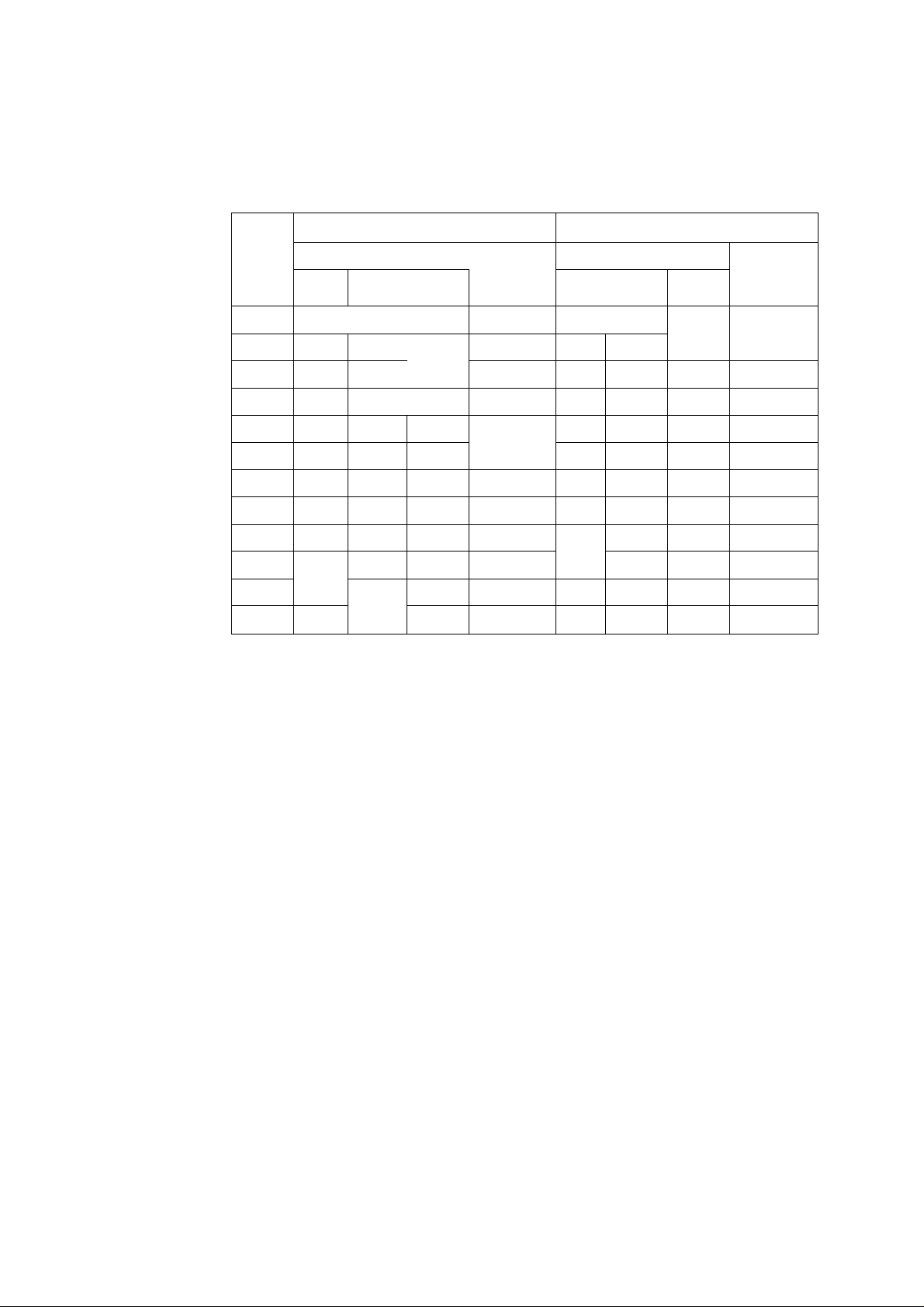

Table 4«1 Bolt length and Nut tightening torque(contjnued)

JIS lOK

M«ler

iSmtn 4 M12 50

Zinmi 4 M16 55 13 to 16

40mm

50mm

K{)inm K M16 65 17 to 21 8

lOOmm S M16 70 20 to 25 8 M20 SO 25 to 32

150mm K M20

2№mm 12 M20 SO

250mm 12 M22 S5

300mm 16

350mm 16

4(J0mm 16 M24 95

[Icxaeon head ht>Us

P.C.S

Diamc-

icr

A

4 M)6 60 26 to 33 8 VI !6 65 13 to 16

M16

M22 85 54 to 67 16

M22 68 to 85 16 M30 125 93 to 116

length

fmml

60 19 to 23

SO 4S to 60 12 M22 9i) 35 to 44

Clamping

torque

[N^m]

5 to 7

42 to 53

66 to H2

93 to ] 16

Hcxagoit head bolts

Djantc-

P.C.S

4

4 M16 60 13 to 16

4

12 M22 95 46 to 58

12

16 M30 140 116 to 145

JiS 20K

Clamping

Length

tcr

M12 55 5 to 7

M16 65

M2U 75 21 to 26

M24 110 72 lo<X)

M24

[mini

110

torque

[NiuJ

] 9 to 23

59 to 74

-

19

-

Page 21

TOSHIBA

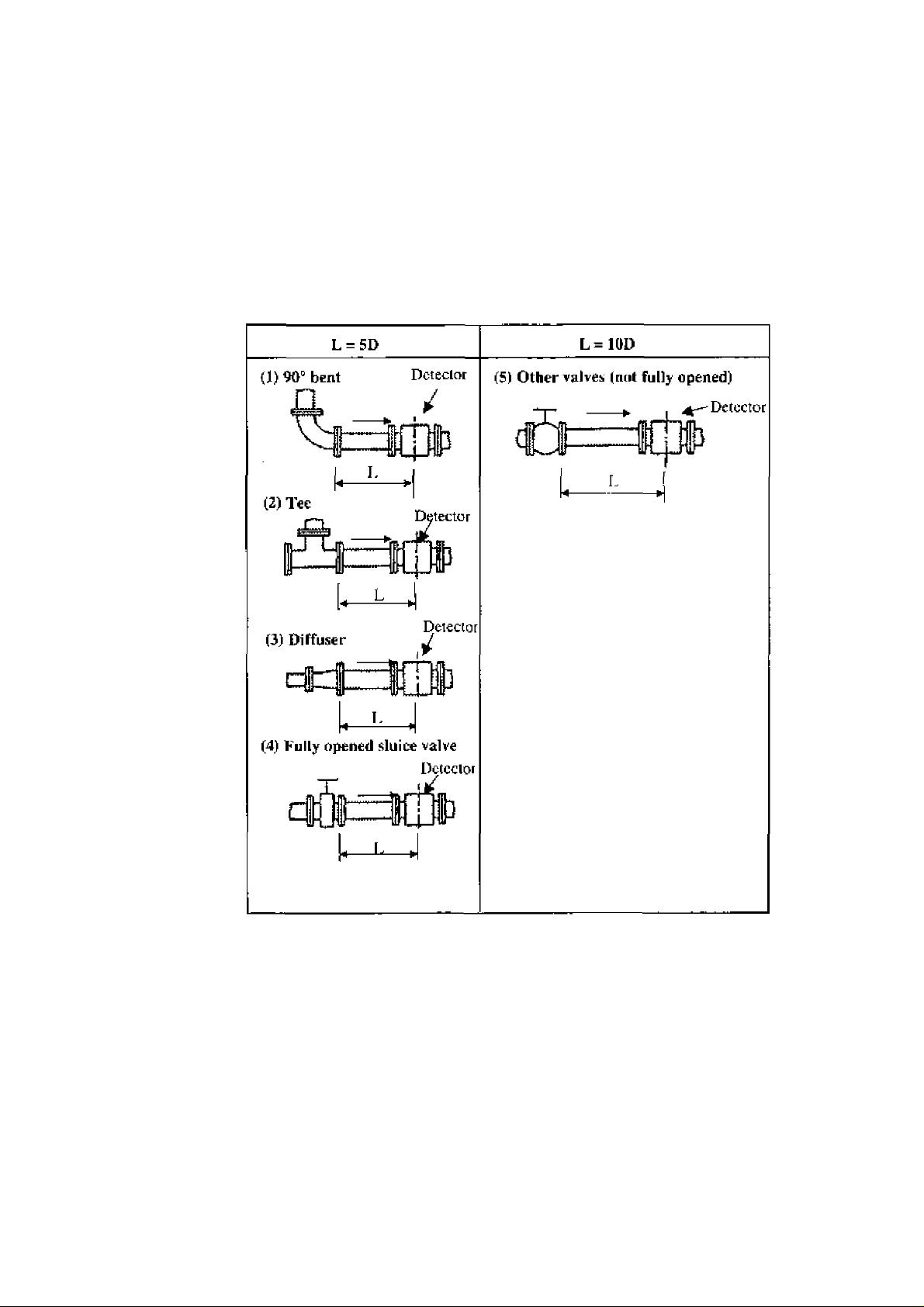

4.3 Piping Connections (t) Required Pipe Length

6F8A0770

[f various; joints are used upstream of Itie deiecior outlet^ llie straight pipe length

shown in TiibJe 4,2 is required.

I'able 4.2 Required straight pipe length on the upslreinn side

L: Required straight pipe length—straight pipe leiiglh pius half length of the detector.

D: Nominal hore size (diameter)

NOTES

1. The length of a reducer, if connected, can he counted as a part of the straight pipe

length.

2.

No straight pipe length is needed on the downstream side, If a butterfly valve is

installed dowiLStream of the detector, do not let the valve plate protrude into the

pipe of the detector

- 20 -

Page 22

TOSHIBA

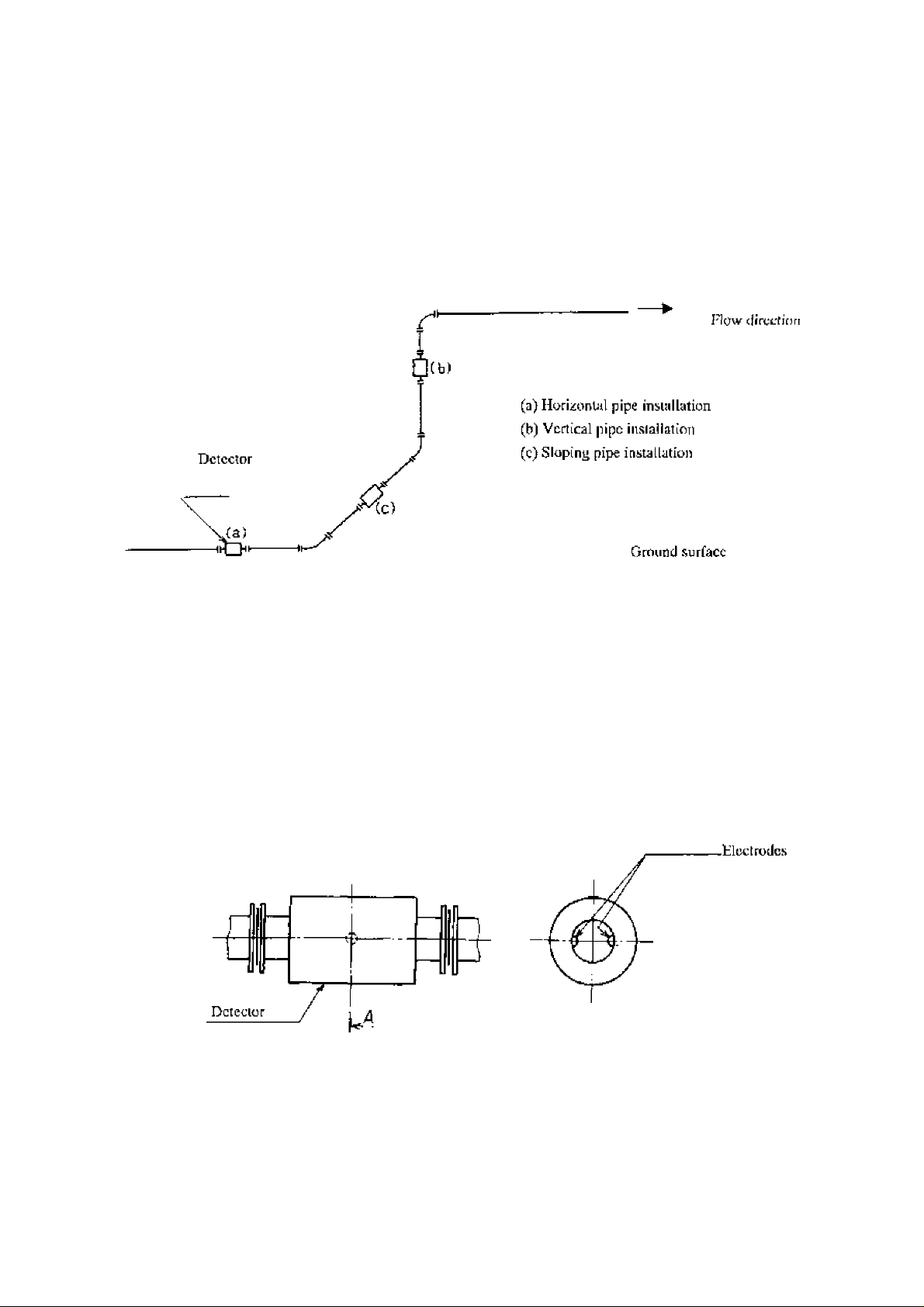

(2) Pipe Orientatir>n

6F8A0770

The delector may

Figure However, except forhorizonlal iiislallatiuii, Quid should flow from lower lo

upper directions- See Figure 4.3.

be

installed in hori/ontal, vertical or sloping pipe runs as shown in

Figure 4.3 Detector Piping Orientation

I hc cJccirodcs should be posilioned horizonlaJly against the ground surface in any piping

installation. See Figure 4.4.

Cmss-scction A - A

Ground surface

Figure 4.4 [nstallatioti position of the detector

- 21 -

Page 23

TOSHIBA

(3) Flow Direction

6F8A0770

Inculi the detector in accord<i!tcowilli (he flow directi on arre won the detector. See Figure 4.ò.

] 11 he act u iit l fi ow mn s opposi te to t h e specif i eci flow d i ree lio it, t ho follo win g d ì spi ay i\lìd

output appears., (For bidirectional multhrange moasurorrient, see 10,3/‘Mulii-rarige

Functions,’*).

' LCD display (optional)i Instantaneous flow rate—indicates negativo values,

Totalized flow—no counts added.

■ Output:Current output— 4.0 mA output; Pulse output^—^No pulses

I'or bidirectional range measurement, the flow in opposite direction results in a positive

output value. Sec 10.3, ‘"Multi-range Functions.*’

Flow direction arrow

Figure 45 Flow direction arrow on the detector

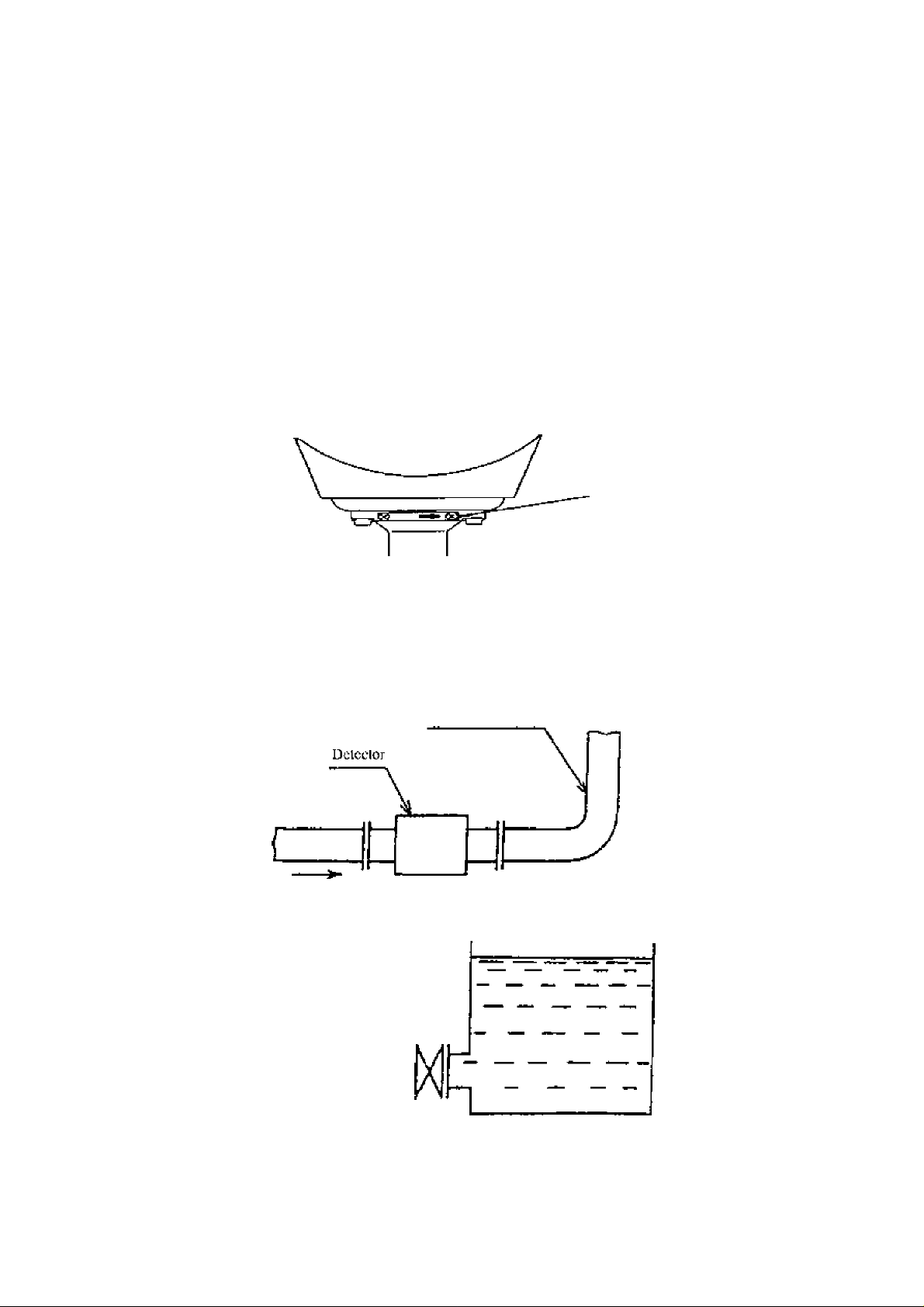

(4) Preventing an Empty Pipe Condition

Design an upright pipe run (Figure 4.6) or sufficicni head pressure (Fig. 4,7) at the

downstream detector outlet if there is a possibiiity of the detector pipe becoming emptied*

Upright pipe run

Figure 4.6 Detector with an upright pipe run at downstream outlet

Detector

CH

Figure 4.7 Detector with suftldecit head pressure at downstream outlet

~ 22 -

Page 24

TOSHIBA

(5) Supporting Pipe

6.F8A0.770

Fix the relevant pipes Installed on both sides; of the detector by attach fittings, etc. to support

the pipe,

to the pipes by the dectmmagnctic flow'metcr’s weight and the fluid ma5;s. And it protect

from fluid leakage at flange face (sec Figures 4.8 and 4.9),

By

supporting the pipes, not only the pipe vibration is reduced but also the damage

Pipe support fittings

/////^//////////////////////////

Pipe support fittings

Figure Example of Hpe Fixing Procedure

K'5-5!

t

-flii

7777////7/777777777777777777777777777777777777777777777777777777~

Figure 4,9 Moclel Diagram of Unsuppuried Pipes

- 23 -

Page 25

TOSHIBA

6F8A.07 7 0

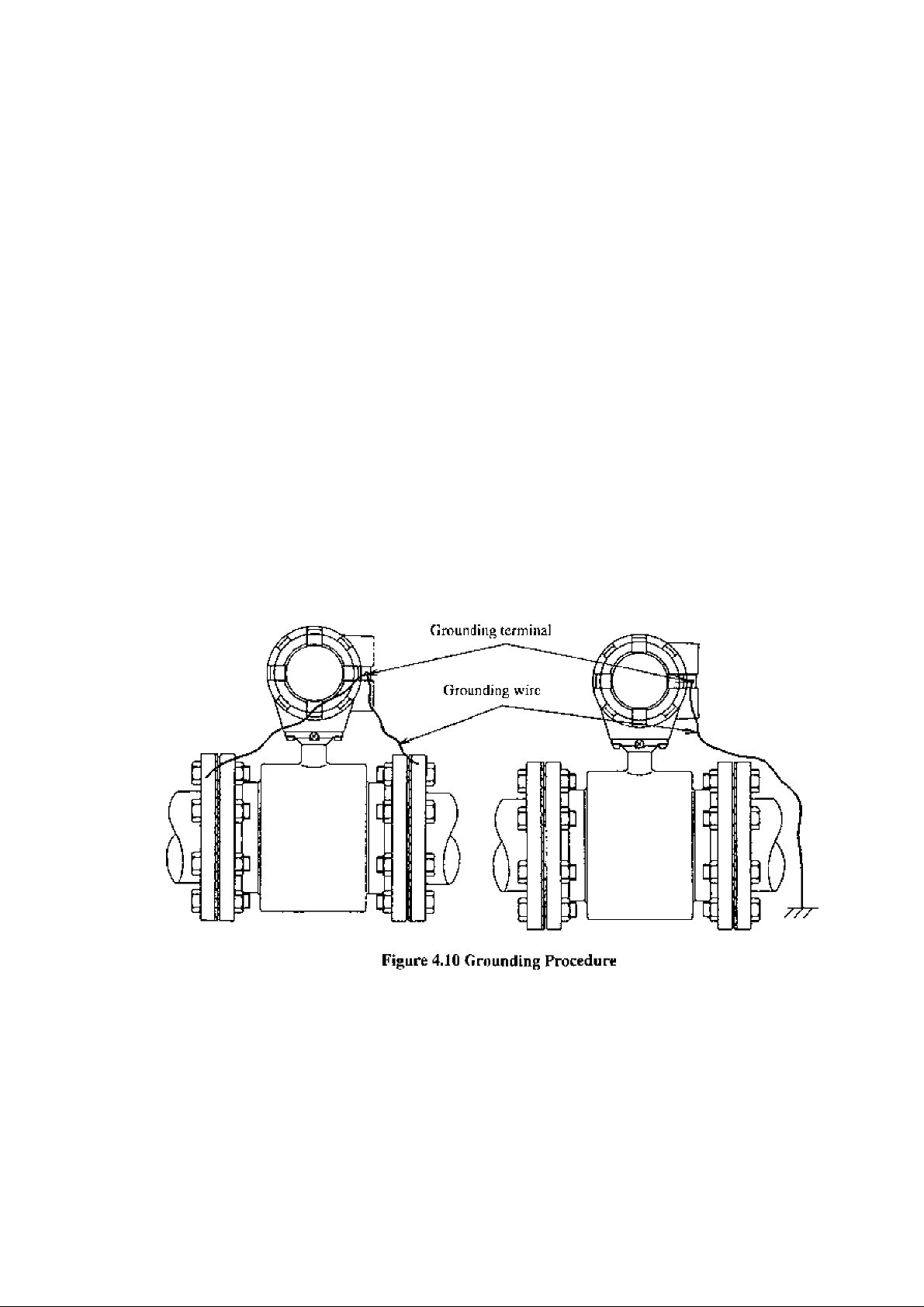

(6)Gruunding

The grounding [ermin^l of ihc Ll'434/Lh4t)4 flowmeter ithould be grounded with 100 ohm

or less ground resistance. Use a heavy copper braid or wire (cross-sectional area mm"

minimum) to ground the terminal anJ make it as shon as possible. The terminal is M4 size

and an M4‘sizc crimped ring lug should be used to connect the wire to the terminal. Avoid a

common ground where earth current may flow, An independent ground is preferable. Sec

Figure 4,li), for a conductive pipeline grounding and non-cjondactive pipeline grounding

procedures.

To prevent a two-poinl grounding, ground the shielded cable on the receiving instrument

side.

I If connection pipe is conductive:

Connect between the grounding terminal

and both ends of the mating flanges with

a heavy copper braid or wire

(cross-section 5,5 mm" minimum).

If connection pipe is non-conductive;

L’se H heavy copper braid or w ire

(cross-scction 5.5 minimum) to

ground he terminal w'jth 100 ohm or

less ground resistance.

- 24 -

Page 26

TOSHIBA

5. Wiring

A WARNING

DO NOT DiSCONNfXT WHILE CIRCUIT IS LIVE UNLESS

LOCATION IS KNOWN TO BE NONHAZARDOUS*

Live pari of eleciric circuit or a high tempeniiure deparimciit can

0

DONT

Do not live circuits While assembly of all componems not over.

cause explosion.

6F8A0770

0

DON’T

I

Jnstail per the National Electrical Code for Che US (NEC, ANSI/NFPA 70)

and the Canadian Electrical code for Canada (CEC, CAN/C5A-C22,1)<

O

DO

Protective performance degradalioii fur haiiarduus lucalion can

cause explosion.

Unsuiiable conduit connections for hazardous location can cause

explosion.

A CAUTION

■ Do not work OR piping and >viring

with wet hands.

Wet hands can cause system

0

DON’T

■ Do not modify or disassemble the

LF434/LK4fl4 unnecessarily»

t this product can cause elec-

DON’T damage TO ihis product»

■ Use the proper cables for wiring of

power and I/O <

/ J \ tern failure or damage and

failure.

Modifying or disassembling

trie shock, malfunction of or

Using a cable other lhan the

one specified may cause sys-

mav break, waterproof.

■ Ground the LF434/LF404 properly.

Operating this product wilhoul

o

DO

■ Prepare yourself for the cable glands

which could l>e used in Division 2

hazardous locations»

DO

A

a grounding can cause system

malfunction.

Tite apparatus should not be

provided with the cable glands.

The label shown left is placed

near the terminal board for

power input.

Be alert to electric shock.

- 25 -

Page 27

TOSHIBA

6F8A0770

Howmeter accuracy mfiy be affected by the way wiring isS executed. Proceed witii w-iring

taking the following precautions:

(1) Select the cable runs away from electrical equipment (motors, transformers, or

radio transmitters) which causes eleciromagnciic or dcctrosiatic interference.

(2) Deterioration of llow^meter drcuil insulation occurs if the converter interior or

cable ends get wet or Ituniidilied. This in turn causes malfunction of flowmeter

or noise problems. Avoid a rainy day if the flow meter is to be installed outdoors.

Even indoors^ prevent water from splashing over ihc flowmeter. Try to finish the

wiring as quickly as possible

(3) The converter has a surge-absoit>ing barrier installed inside. Therefore, do not

conduct a withstand voltage test for the converter. J o check the insulation of the

converter, use a voltage of 250 V dc or less.

- 28 -

Page 28

TOSHIBA

5Л Cables

Use the kind of ciibles shown in Tahle lo wire the converler.

Table 5.1 Cables

Name Cable type

Power cable

1/0 cable I'he number of wires for the output cable depends on Ihc

Notei Use a four-wire cable if the arresters are to be used. See Figure 5.1 below,

5.2 External Device Connections and Grounding

The terminal board connections of the LF434/LF404 flowmeter arc shown in Figure 5.1.

Proceed with wiring as described in Section 5.4, '‘Wiring Procedure.”

Three-wire sheathed

cable (Note)

system spccificiirions. Use a shielded cable with nominal

cross-scctional area of 1.25 inrii^ and overall diameter of

n to 13 mm.

Nominal

cross-.sectional

area

2

mm^

6.F.8A07 7 0

Overall diameter

11 to 13 mm

If power supply is specified as DC, use M as positive (+) and 1.2 as negative (-) terminals.

Instrument Panel:

ordered separately

■; Cument output (4—20 mA dc)

Plown-fceler

[C1 |~1^Трс|51с|[сОы[ ni|oQ^noi| -

’ ■ \

IV wire

5.5тзп"

or more

*^1 To use the arresters, ground the ON 13 terminal using the wire shown in broken line.

*2 Locate an external double-pole power switch on the power line near the flowmeter and within easy

operation. Mark one the switch as the tlisconnecting device for the flow^meler.

Use an appropriate switch of the rating shown below:

1/0 cable

R>wer cable

Recommended sw'itch rating; Rating 25D V ac, 6A or more

Inrush current 15 Лог more

- Digital Output I

; ■; r>igilai 2

: Digjiit! Input (20 to 30 V de)

*1

Cixrourided with 1 (X)Q or less

..........

! ground resistance.

— > Power Supply

It “"2 ^

Power Switch

Figci re 5.1 Term in a t В lock Connection s

- 27 -

Page 29

TOSHIBA

6F8A0770

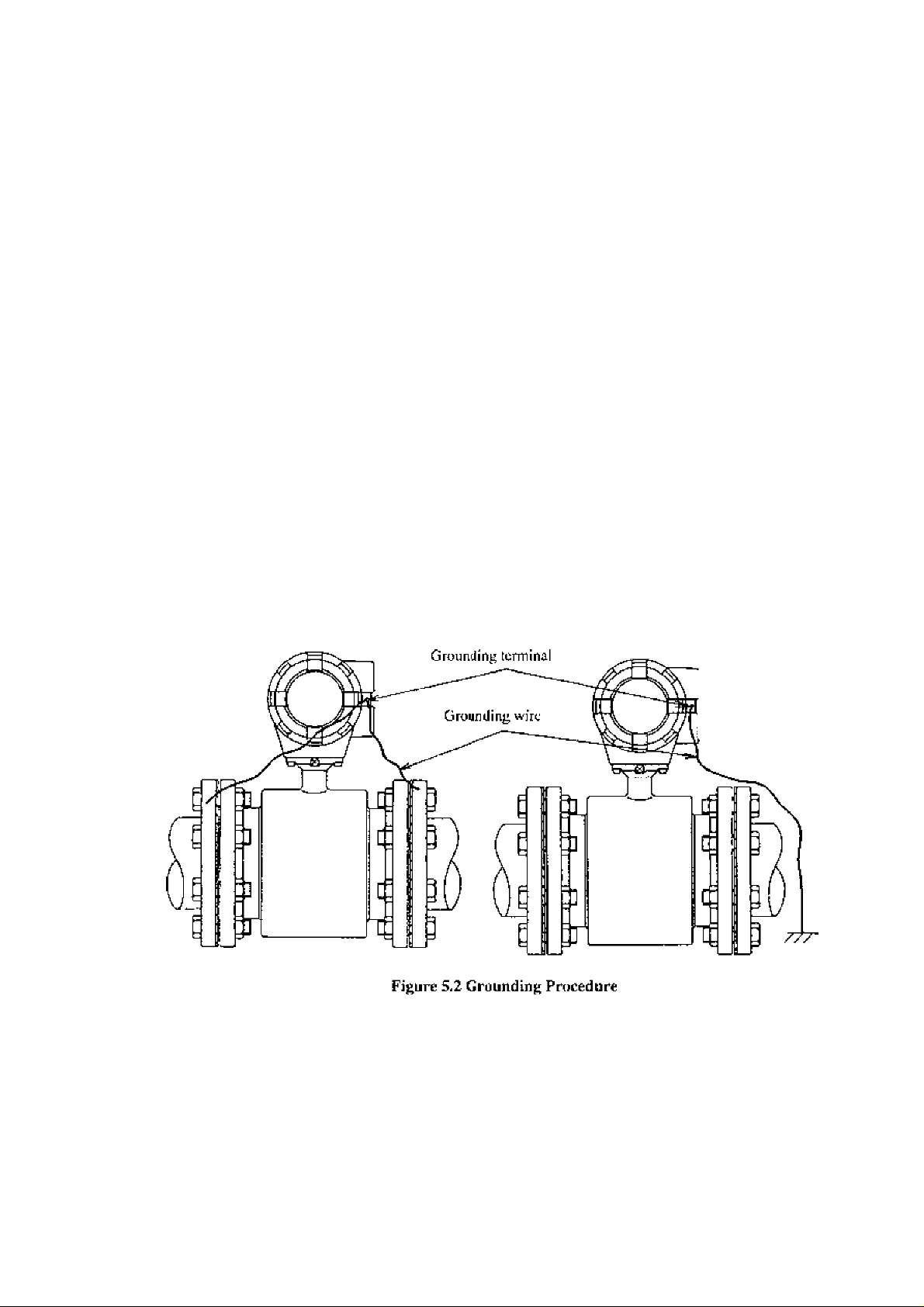

IMPORTANT

(1) The grounding terminal of the LF434/Lr404 ilowmeter should be grounded with

100 ohm or less ground resistance. Use a heavy copper braid or wire

(cross-sectional area .S..'? inm' minimLim) to ground the icrminaJ and make it as

short as possible, ITie terminal is M4 size and an M4-size crimped ring lug should

be used to connect the wire to the lermina!. Avoid a comirion ground where earth

current may flow'. An independent ground is preferable. See Figure 5,2. fora

conductive pipeline grounding and non-conductive pipeline grounding procedures.

(2) To prevent a tw'o-point grounding, ground the shielded cable on the receiving

instrument side.

I If conneetton pipe is conductive:

Conned between the grounding terminal

and both ends of the mating flanges with

a heavy copper braid or wire

{cross-section 5,5 mm" minimum).

If connection pipe is non-conductive:

Use u heavy copper braid or wdre

(cross-section 5.5 mm^ minimum) to

ground he terminal with 100 ohm or

Jess ground resistance.

- 28 -

Page 30

TOSHIBA

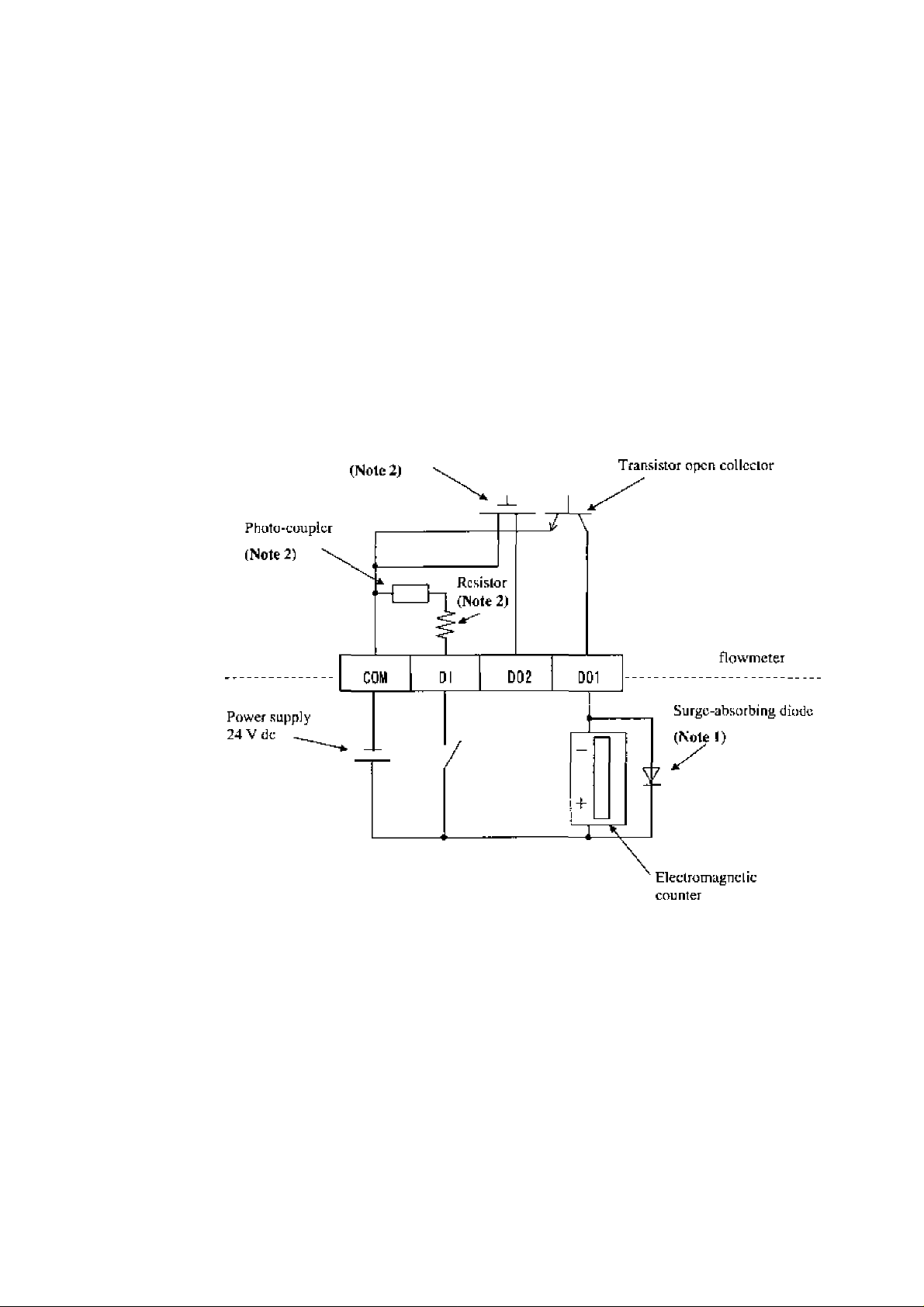

53 Digital I/O ConnecUons

Pigiial li O terminals consist of conti.ct output terminals (standard DOl and optional

D02), voltage signal input terminal (1)1, optional), and signal common terminal (COM),

Each terminal (DOl, D02 and Dl) is isolated from internal circuits, Terminal (COM) is

the signal common for the other three terminals (PC I, D02 and DI).

Functions can he assigned for each terminal with the LCD control keys (option). See

Chapter 10, “Digital t/0 Functions.’"

To ciinnect an electromagnetic relay or counter to the contact output terminal (DOl Or D02),

put a surge^absorbing diode into the input circuit of the relay or counter. See Figure 5,3 for

an example of electromagnetic counter connection.

6F8A0770

Solidbtate rchiy

Note 1; Use a surge-absorbing diode of the rating: current rating lA and voltage rating

200 V minimum.

Note 2; The Solidstaic relay, photo-coupler and resistor are not provided fiir the standard

model (the one with no digital I/O specifications), Leave the terminals for D02 and

Di open.

Figure 53 Electromagnetic Counter Connoction Example

- 2 9 -

Page 31

TOSHIBA

SA Wiring Procedure

5,4.1 Cable Termination

6F8AÛ770

Cable terminaLion Eind cabJe connections are described below.

âs CAUTION

■ Do not conduct w'iriitg work w hen

power is applied.

Wiring while power is ap-

( plied can cause eledric

shuck.

DON^T

■ Do not work on piping and w^nring

with wet hands.

Wet hands may result in

electric shock.

0

DON’T

IMPORTANT

The apparatus should not be provided wilh the cable glands,

Please prepare yourself for the cable glands which could be used in Division2 hazardous

locations.

Use cables as specified in Table 5,1. First. Remove the cable sheath about 70 mm from the

end to expose the coated wires and then strip the wires about 10 mm. Then attach an

M4’size compression terminal lug to the end of each wire using a compression looL The

compression terminal should be of Ihe kind with insulated sleeve to prevent shorts betw^een

adjacent terminals. The overall length of the wire with the terminal attached should be about

60 mm. See Figure 5.4 bdow'.

M4-sizc compression terminal lug

- 30 -

Page 32

TOSHIBA

5A2 Cable Connections

(1) Remove the housing cover for the terminal board shown in Figure 3.1. The lerminal board

6F8A0770

Connect rtie terminaled cable wires

IMPORTANT

Connect the wires securely to the lerminal board. A loose connection may result in

unsatisfactory ilowmelcr perform a nee. Make sure the wires are securely connected,

is located inside the converter as shown in Figure 3.2, Connect the crimped terminal of

each wire to the specified pin of the terminal board . Sec Figure 5,1 for the terminal board

configuration. Tighten each crimped terminal to the terminal board with a screw using a

Phillips screw-driver asshow-n in Figure Loose connection may result in unsatisfactory

flowmeter performance. Make sure the wire is securely connected.

i:y

ihe terminal board as described below.

(2) After the terminal block connection, pull the cable a little so that the cable runs .straight

from the terminal block without unnecessary w-inding.

(3) Attach the terminal cover and screw the housing cover for the terminal block. To keep Ihe

housing seal, tigliten securely Ihe cover using a tool fitting with the groove on the cover.

-

31

-

Page 33

TOSHIBA

6, Operation

6,1 Preparatory check

6F8A0770

A CAUTION

n Do not touch the LF434/LF404 maio body when

high temperature fluid h being measured«

The fluid raises the main

0

DON’T

hollow the proceclurc described bdo^v to prepare before starling the flow measuremem.

System Check

Check the wiring bciween the converter and related instruments,

Make sure all the boils of connection flanges on which the flowmeter is mounted

securely tightened.

Make sure the direction of flow arrow is in accordance with actual flow.

Make sure the flowmeter is grounded with ICO ohm or less ground resisiance.

Make sure the converter housing covers arc securely tightened.

body leinperaturc and can

cause burns when touched.

Placing System On-Stream

Let the fluid go through the detector pipe. When the detector is filled with the

fluid, stop the fluid and keep

Supplying Electric Power

Make sure the power supply is as specified.

Checking Converter Parameters

Check the configurntion paramcicr settings. Refer to Chapter 7, "‘LCD Display

and Controls,” Chapter 8, ‘"Configuration Parameter Setting,and Chapter 11,

“Commiinications Eunclioii,”

Zero Adjustment

Wail for 30 minutes to warm up the flov-mieter. Then making sure the fluid holds

still in the detector pipe, starts the zero adjustment.

Refer 10

On-line measurement

Alter checking the items and conducting the zero adjustment as listed above, let the fluid go

through the detector pipe. Output (4-20 iriA dc) directly proportional to the flow' rate can be

obtained.

62 ,

“Zero Adjustment.”

it s ti ll ¡n

the detector pipe.

- 32 -

Page 34

TOSHIBA

6,2 Zero Adjustment

6F8A0770

To conduct /oro adjustJiieitl of the flowmeter, iho fluid in the delector pipe must be held still.

There arc three different ways to slatl the zero adjustment:

(1) Pressing the zero adjustment switch for the model without LCD display

(2) Pressing a combination of control keys for the model with LCD display

(see 8,2-ii, "Zero Adjust men I'')

(3) Sending a command signal from a HART communications device

(such as the AFIOO hand-held terminal),

The following is the procedure for starting the zero adjustment for the model without LCD

display,

■ Press the zero adjustment switch for more than 3 seconds.

(Note that once the 7ero adjustment is started, there is no way to cancel the zero

adjustment sequence.)

Then the Li3D indicator lights and the zero adjustment sequence will start. The zero

adjustment sequence lasts about 3 to 6 seconds, (Zero adjustment duration depends on

the excitation current frequency. It lakes about 3 seconds for 24 Hz selling and about 6

seconds for 12 Hz and 6 Hz settings.)

When the zero adjustment sequence ends, the LED indicator goes off.

I’o conduct the zero adjustment, it is necessary to open the cojtverter housing cover for

internal electronics and press the switch. Observe the following precautions w'hcn you

open the housing cover:

(1) Do not open the cover in the open air unprotected against rain or wind.

If yon adjust the flowmeter in ihe rain, this can cause electric shock or damage to the

llow'meler electronics. If wind blow's against the internal circuitry of the converter, output

may flticttiate and fail to indicate correct measuring values.

(2) Do not conduct the zero adjustment when the ambient humidity is higli. By opening the

cover in high humidity conditions, the measuring accuracy may be reduced or damage

caused to the flowmeter electronics.

- 33 -

Page 35

TOSHIBA

7. LCD Display and Controls (option)

You can select the operation mode, change the configuration parameters or execute

operation-specific functions using the control keys on the panel. How to operate these

keys is described in this chapter.

7,1 Outline

The LF404 Converter lias an optional LCD display. The LCD display can be used to set and

jrdicare various configuration parameters. Figure 7.1 shows the front view of LCD display.

(1) Do not open the housing cover for LCD display in the open air unprotected against ruin or

wind. If you open the housing cover for LCD display in the rain, it can cause electric

shock or damage to the flowmeter electronics. If wind blow-s against the internal circuitry

of the converter, the output may fluctuate and fails to indicate correct measuring values.

(2) Do not open the housing cover for LCD display when the ambient humidity is high*

liy opening the cover in high humidity conditions, the measuring accuracy may be re

duced or damage caused to the flowmeter electronics.

6F8.A077 0

Housing cover for

^LCD display

Figure 7.1 LF404 Converter with LCD display

LCD display

A 2-linc X 1 h-characier liquid crystal display. The backlit display enables an easy4o-rcud

indication even under poor lighting conditions. Instantaneous flow rates or totalized flow in

the measurement mode, or configuration parameters in the setting mode can be displayed.

- 34 -

Page 36

TOSHIBA

■ Control Keys

Functions of each control key when pressed are shown in the table below.

6F8A0770

Changing the opefiition mode, checking or changing parameters can be done with thej^e keys,

To operate these keys, yon have to open the converter hotising cuver. Observe the following

precautions when you open the housing cover:

Control kevs

SE T

□

▲

□

Basic Functions of control keys

(jocs inii> the items selection scqucnec.

10.00 (iv/s Л1:ЕХ. CdRR

100.0 %

Goes into the detailed-item specifying sequence for each selected ¡tent in

A1:EX CURR.

bcicctioa iiequcncc

Stores ihe sclccteLl tljita in the setting mode.

B1:UNIT 1

%

status tif changing the data status of iinish changing

Changes items (alphabet letter and iminherj in the items selection sequence,

and change.«, parameters (iiuniltcrs and.^'or units) in the detailed-ilem specifying

OZiRAUGE 1

02. DOO i/s

datc:0.2f)Q0m/s

Starts and stops t:ie totalizer in the mcasufcmccit mode. (Note)

F '000 ri''

00. 0 %

stop the totalizer Stan The totalizer

Changes digits {alphabet letter iind number) in the items seleclioir .scqiience,

and slarls the detniled'itcni S[>ecifying sequence by indicating the left-most

'

------

/

’—/

,—к

1—

1

----

\

1

-----

\

1—/

sckclion scqaciicc '

A1:EX. CURR.

0. гюоА

Bl:UK!T 1

%

C2:fiANGE 1

03, 000 ffl/s

F IODI C

100. 0 \

------

/

D1: DAMPING

00. 5 S

Cl ; COUNT RATE

1. 2JE-'^ iD^

Indicate cursor under '2'

0

100. 0 %

reset the totalizer

Dl: OA^PIPIG

OQ. 5 S

setting mode status of finish changing

Moves the cursor from kf( to right (from the right end reverts to the left end) in

►

□

Note: To opcrsrtc ihe totalizer, it is prefern bJe to set the indicating unit (UNIT 1 tmd.'br UN IT 2)

to one of the units appropriate for totalization just to make sure it is operating correctly.

See 1(1.2, ‘^Totalizer and Pulse Output,”

ihc above sc<uicrux.

Gl: CCUNT RATE

1. Z2Ì-A n-

[ndicalD ourstjr umler ‘ I ’

Rescis the lotjlly.cr in Ihe measurement mode. {Note)

F lODO

-

_________

100. 0

%

sfnrt the totalizer

35

-

1—\

'

Page 37

TOSHIBA

12 Display Format

6F8A0770

In Ihc mcdAurcment mode> measured dala are displayed in UNH’ I (primary indicating uniO

and UNIT 2 (secondary indicating unit). As to indicating units, see 8,2.4, '"Indicating Unit

Display Format

Displayed in UNIT I indicating unii.

I— “C is indicated when lota) flow is counted.

i

___________________________

10 0,0

_______________

%

Measured Value Display Format

(1) Flow rate

____

Upper 4 digits ma^iimum arc effective (for the selected span).

r

yr:F 1 0 0 0 0 0

.. .. J

___

[ he unit of time

■The unit of flow

7 digits (9999999) maximum including decimal

I c

*

(

_____

..

Displayed in UNIT 2 indicating unit

C is indicated when

communication is in progress.

- 36 -

point

Flow direction: Forward “ (blank space);

Reverse

Page 38

TOSHIBA

6F8A077.0

(2) Totiìlìzer

I 1 l_L

9 9 9 9 9 9 9 9 C

........................

....

.......................

(3) Volumetric flow

F 9 9 9.9 9 n I C

.......................

....

I I , I I I I 1 I I

^ LJ

- “C’ is indi cateti wben total llow is counted.

Jnerements per counting rate. Refer to

H.2 10, “Counting Rate/"

Wraps around after 999^999?.

for forward and "R"' for reverse direction flow

will be displayed

Displays down to the smallest digit of courting rate,

•- ' C" is indicated when volumetric flow is counted.

— The unit of flow

8

digits (99999999) maxinium including decimal

point

If tjtc flow count exceeds 99999999, wraps around.

(4) % display

"10 0,0 15

.

............................

Ill

“F" forfonvard and “R'* for rcvcr.se direction

flow will displayed.

Displayed down to 0,1

Displays tip to 125,0 %.

i'low'direction: Forw'ard “ (blank space);

% .

Reverse

-

37

-

Page 39

TOSHIBA

7 J Basic operations

6F8A0770

Flow mea^surcjncni in Ihe measurement mode, checking or changing configuration

parameters in ihe setting mode and a converter unit check in the calibration mode are

the basic operations of the LF404 converter*

7*3*1 Müde Change

The 1.F4(I4 converter has three operation modes: measurement* setting and calibration.

The system slays in the measurement mode after the power is turned on* To change (he

mode to the setting or calibration mode, press [SRT] and select the desired item using

[ ► ] and [ A ] keys. To return to the measurement mode, select “0" {MEASURE

MODE) for the number column of configuration items (such as AU or B[)). See 7.4*

“Configuration Items Selection Table,"

■ Measurement mode

: measures ttic process flow and displays and outputs the measured process values. The

flowmeter can measure the flow velocity, flow rates* or totalized flow. I’he flowmeter

first goes into this mode when power is turned on.

Setting mode

: used to check or change various configuration parameters used in the measurement

mode. These parameter values are displayed while checking or changing ihe.se values

but the flowmeter outputs the Tieasured process values as in the measurement mode.

See 7,4, “Configuration Items Selection Table" and 8.2, “Checking or Changing

Parameters" for details. Configuration items are from Al, A2, A3 to Ml.

Calibrtttion mode

: used to check the converter iniernal circuits. The internally generated simulation signal

is used to check the measuring span and excitation current value. The current output of

the flowmeter changes in acoŒtlance with the simulation signal. The stains of each

digital output is held to the value just before the system moved into the calibration

mode. Sec 7.4, “Configuration Items Selection t able" and Chapter 9, “Calibration" for

details. Configuration items are from N1 to N4,

- 38 -

Page 40

TOSHIBA

Change mode flow

SHT ^ ►

□ □□ are shown lo conirol keys, and LF4f)4 display is changed to

Measureineni mode

-------------

6F8A0770

^ indicEited.

- 39 -

Page 41

TOSHIBA

Key o)>erntion Display example Description

6F8A0770

7.3.2 Configuration Parameter Selection in Setting and Calibration Modes

Process as follows to select the desired items, to check or change the item setting value.

B Tu selects the desired item ;

SFT

□

▲

□

►

□

□ □

10. 00 m/s

100.0 S¡

Al; EX. CURR.

B1: UNITl

Bl; UNITl

C2; RANGE 1

Measure value displays .(Me a suremento mode)

l*ressing [Sti'fJj the system changes to the items

selection sequence. (Note)

And the cursor appears under alphabet (A).

Change the alphabet to “B” by pre.ssing [ -^ ],

* If cursor is the number, the number is increased

by pressing [-^ ],

Then move the cursor to the number by pressing

[ ► 1

* If cursor is the number, Ihc cursor is

changed to the alphabet by pressing

Selects the desired item (indicated by an

alphabet letter and a number) first by selecting

the digit (alphabet or number) with [

then changing the value w^lth [ ^ ].

The example shows “C2: RANGE 1

\ > ] .

> ]

and

Note: In case of that the convrter is type for special specifications and serted password,

changing measurement mode lo items selection sequence, password-input mode appears.

Sec 7.5’Tassword Inpul'Tor details about Password-input mode

See 7.3.3 '^Converter for Special specifications'Tor to differentiate the converter for

special specifications and normal.

-

40

Page 42

TOSHIBA

6F8A0770

To change the setting value:

Key operation

□ □

SET

□

►

□

Ж .

i □

►

□

Dhplay example Description

items selection sequence displays.

C2: RANGE 1

C2: RANGE 1

02. 000 m/s

C2; RANGE 1

02. 000 m/s

C2: RANGE 1

n.

000 m/s

C2; RANGE 1

12. 000 m/a

Selects the desired item (indicated by an

alphabet letter and a number) first by selecting the

digit (alphabet or number) with [ ► ] and then

changing the value with [a. ].The example shows

“C2:RANGT 1’^

Press [SET] to select the desired item setting

value. And the cursor disappears and the item

setting value displays.

You can check it.

Pressing [ ► ], the cursor appears.

Parameter changing sequence

Change the value by pressing [ a ].

rhen move the cursor to another digii by pressing

i ► ]■

□ □

1 ó

▲ ►

SLT

□

SET

□

C2: RANGE 1

05. 000 m/s

C2: RANGE 1

05. 000 m/s

C2; RANGE 1

02. 000 m/s

02 :

RANGE 1

05. 000 m/s

Change the value by pressing [-^j, ITicn move

the cursor to another digit by pressing [ ► ] and

change the value.

In this example repeat this process until the

display shows “05. OOOm/s

By pressig [SET], flickers the selected value tu

confirm changes made for the selected item.

By pressing [-^j, In return to the parameter

changing sequence.

By pressing [SET], stores the indicated value and

Slop flickering of data.

-

41

-

Page 43

TOSHIBA

Key 0 pera É ion Display example Description

6.F8A0770

To ri^turn th£ meu^urement value:

1 □

□ □

SET

n

►

□

▲

A ►

C2: RANGE 1

0. SQOO m/s

C2: RANGE 1

C2: RANGE 1

C3: RANGE

CO; MEAS, MODE

2

Checking Ihe selling vuloe or after seiteci the

value.

By

pressing [SET], return to the items sdectioii

sequence.

Items selection sequence displays.

Then move the cursor to the number by pressing

[ ► ]

* [f cursor is the number, the number is changed

to the alphabet by pressing [ ► j,

Change the alphabet to *‘B'’ by pressing [ a j.

* If cursor is the number, the number is

increased by pressing [ a j,

By pressing [ ► ] and [ a j, select

‘^0;MEAS. MODE’’

The example shows "'C0;NEAS. MODE’’

SE T

□

10, DO m/s

100. 0

%

- 42 -

Pressing [SET], returns to mcasuremeiu mode.

Page 44

TOSHIBA

6F8A0770

7.3.3 Converter for Special spedtlcalions

The converter for special specifications is added some setting parameters. To

differentiate the converter for special specifications and normal, remove housing

cover for the terminal board shown in Figure?,2. The converter marked as shown

in Figure 7.2 is for special specifications, and nor-marked is normal.

The added setting parameters are following items.

{!) Password input/setting

(2) 4-20mA alarm out setting

(3) Dl detective level setting

{4) Preset function

See 8.2, “Checking or Changing Parameters'’ for details.

Example: F400 0И2

Figure 7.2 LF4D4 Converter for special specifications

- 43 -

Page 45

TOSHIBA

lA

Configuration Items Selection Table

6F8A0770

In the selling and calibrEilion modes, configuration items can be selected as shown below, For

example, the excitation current can be selected by the item AL To change ihe parameters for

ibe selected items, see the following chapters, To return to the measurement mode, select‘‘0’'

for the number (such as AO),

Setting mode items (Al, A2, A3 to Ml): Sec Chapter S, ‘‘Configuration Parameter Setting,"

Calibration mode item (N1 to N4): See Chapter 9, “Calibration.”

0 1

A

n

*1

B

C *1

D *1

"1

£

^1

F

^1

G

H *1

I *1

*1

J

*1

K

L *1

*1

M

*1

N

Escilaiioti Cur

rent *2

Indicating

Unii 1

Range I’ype Range 1

Daniping

Constant

Zero

Meter Size

Incl ¡eating

Unit 2

Ijdw Cutoff 4-20 inA Alin.

2

"2

*2

3

Excitation Fre

quency

*2

Range 2

Ouiput

*2

Adjustment

DQl Function *2D02 Fuiictio]] *2DI Function

C.^ounling Kate

Preset Count

High AloTin Set

Empty Pipe

Alarm

Rutc^tj^

change Lindt

Fixed-value

Output

*2

" 2

*2

*2

False Width

Presel Fuiict

*2

High Alarm

Value *2

Control

Limit Time

Fixed-currem

Outpu! ’2

^2

Low AJam Set *2Low Alarm

Fixed-pulse

Outpal *2

Zero Offset

Adjustment

*2

J’low Rate

Sig 50% ^2

Flow Rate

Cal 100% *2

Flow Rale

Cal [}%

Passwoni

Range 3

*2

DOI Alarm

Active Set ^2

*2

Value

Fxciling

CTurrcnt Check

4 S 5

"2

Range 4

"2

D02 Alarm

Active Set

*2

**2

*2

Range

Hysteresis *2

Dl Dct.lxivd

*2

*1: Returns lo the measurement mode.

®2:Passw'ord-protected parameter

Note: “A4:Password’, ' rB:4‘20Alm.OutT6:D1 Dot.Level ^ and ”H2;Presc( Funct” are added

parajneiers in the converter for special specifications.

- 44 -

Page 46

TOSHIBA

7*5 Password input

■ Т» input password:

Key operation

6F8A0770

l*as$word input is added parameters in the converter for special specifications (refer to

7.3.3 “Converter for Special specifications”). Only in case of the converter for special

specificationsT read this seciion,

The converter for special specifications have the password .That protects from calibrating and

changing part of parameter that influences measurement..

See 7,4 "Configuration Items Selection Table ” for details of password-protected parameter.

* See S 3.17 ‘‘Password” for password setting,

^Setting ‘000' to the password or the normal converter (sec 7.3,3 "Converter for Special

specifications"), password input mode does not appear and all configuration paraEuetcr

and calibrate can be changed.

The following example shows how \o input password ,123.

Display example

Description

SET

□

□

□ □

SET

SET

□

10. 00 m/s

100. 0

%

PASSWORD 1NPUT

000

PASSWORD INPJT

m

PASSWORD INPUT

100

120

123

PASSWORD INPUT

123

Al: EX CURR.

Measure value dispJays.fMcasureniCTUo mode)

Pressing [SHT], password input mode and the

cursor appears.

Change the value by pressing [ ^ j.

Move the cursor to another digit by pressing

[ ► ] and change the value by pressing [ a ].

in this example repeat this process until the dis

play shows “123,"

Pressing [SET], the cursor disappears and the

changed display flickers. Press [SET) again to

input the value.

Whether input password agrees or dose not agree ,

the items selection sequence, “Al :EX. CURR“ ap

pears.

But if input password does not agree, you can not

change setting parameter and calibrate.

Sec 7.4 "Configuration Items Selection Table” for

details.

- 45 -

Page 47

TOSHIBA

8, Configuration Parameter Setting

8.1 Configuration Items

To check or change parameters, first select the desired configuration item as described in

7,3,2. The configuration items arc listed bdow. See each section for detailed procedure.

6F8A0770

Section

8.2.1

8.2,2

8.2.3

8.2.4

8.2.5 Range I’ype

Configurr^Cion item

ExcUmion Current

Meter Size

li:xcitalion Freiiuency

Indicating unit

Span (range)

Hysteresis

8.2.6

8.2.7

8.2.S

8.2.9

8.2.10

Damping Constarli

Low Cutoff

Zero Adiustmenl

Digital I/O

Counting Rate

Pulse Width

8.2.11

8.2,12

Preset Count

lligh/low Alarm

Alarm Limit Value

8.2,13

8.2,14

Empty Pipe Alarm

Rate-of-change Limit

Control LiiTiil Time

8.2,15

8.2,16

; 8.2.17

8,2,18

8.2.19

8.2.20

Fixed-value Output

Zero Offset Adiustmeiit

Password *

4-2ymA Alarm Output

D1 detective Jjivel *

Preset Function *

^ A4: Password”D3'4-2(}AJ.M,OUT’Tfi'DI DETJd^VFi;\ and ’H2;PRbSb'I

Display example Page

Al; EX, CURR. 0. ZlOO A

A2: METER SIZE

A3: EX, FREQ.

Bl: UNIT 1

Cl: RANGE TYPE

C2: RANGE 1

C6: RANGE HYST

Dl: DAMPING

D2: LOW CUT 05, Û

El; ZERO ADJUST.

FI: DOl FUNCT. 1 : H ALM

GI: COUNT RATE

G2: PLS, WIDTH

HI : PRESET COUNT 00009000

11: H, ALARM SET

12 : H. ALARM VAL

Jl: EMPTY ALM

K1: LIMIT RATE

K2: LIMIT TIME

LI; FIXED OUT OFF

Ml: MANUAL ZERO

A4: PASSWORD

D3; 4-20 ALM OUT

F6: Dl OET, LEVEL

HZ: PRESET FUNCT D:H0LD

50 nun

24

H;

1 :SINGLE

01. 000 m/s

05, 0

%

05. 0 s

%

0. 1

%

6. OOE-ll

020 ms

+ 100.0

%

0;0FF

05. 5

%

01 s

-000, 1 %

123

1:4. OmA

1: H LEVEL

n/s

ON

73

76

78

81

84

87

91

93

97

99

101

47

49

51

.53

57

65

67

69

70

FUNCl" arc added parameters in the converter for special specifications (refer to

7.3.3 “Converter for Special specifications'’). The normal converter docs not have

these selling parameters.

’ 46 -

Page 48

TOSHIBA

8.2 Checking or Changing Paramctm

6F8A0770

8.2.1 Excktalion Current

Proceed iiii follows ui check or change the cxcilution curreju setting value.

■ To check the exciting current setting value;

Key operation

SET

□

SET

□

Dispiay example Description

Press ISHT] first to start the items selection sequence

A1: EX. CURR.

0. 21QDA

A1: EX. CURR.

and select Al; EX, CURR froiri arnung the

configuration items using [ ] and [ ▲ ] keys.

'[’hen press [SEP] again to dispiay the exciting

current setting value.

Pressing [SE'F), the system returns to the items

iselection sequence.

- 47 "

Page 49

TOSHIBA

IMPORTANr

The exciling current vitlue h faclory set when shipped. Do not change the value unless the value

differs from that writien on the nameplate of the fiowmeter

6F8A0770

'J\) change the excitation current setting value«

The following example shows how lo change ihc excitation current setiing value

fromC.l900AtoO,2150A,

Key operation

SET

□

►

□

^ ►

n

SET

□

SET

□

Display example Description

Press [SET] first to start the items selection

Al: EX. CURB,

0. 19D0A

Al: EX. CURB.

g. 1900A

Al: EX. CLRR.

0, Z90QA

Q. 2100A

0. 2150A

Al : EX. CURR.

0, 2150A

Al: EX. CURR.

sequence and select Al: EX, CURR from among

(he configuration items using [ ► ] and [ a ] keys.

Then press [SET] again to display the excitation

current setting value fO.1900 A in this example).

Pressing [ ► ], the cursor appears. Then press [ ► ]

as many times as necessary to move the cursor to the

digit to be changed.

Change The value by pressi ng [ a ]. TTien move the

cursor to another digit by pressing [ ► ] and change

the value. In this example repeat this process until the

display shows “0.2l.i0A.'' (Note)

Pressing [SET], the cursor disappears and the

changed display flickeri. Press [SET] again to save

the value.

Pressing [SET], the system returns to the items

jielection sequence.

Note: The valid range is from 0.0500A to 0,2300A, Tf you try to set the value above

0.2400A, the error message * H. OVEK SPEC appears. Set the value w'ithin the valid

range.

- 48 -

Page 50

TOSHIBA

8*2*2 Meter Si/e

Key operation Display example Description

6F8A0770

Proceed as iollow's to check or change the meter size of the detector.

■ To check the meter size:

SET

□

SHT

□

AZ: METER SIZE

50 min

METER SIZE

Press [SET] first [0 start the items selection sequence

and select A2: METER SIZE from among the

configuration items using [ ► j and [ ^ ] keys Then

press [SET] again to display the current meter size.

Pressing [SET], the system returns to the items

selection sequence.

- 49 -

Page 51

TOSHIBA

IMPORTANT

Meter size is factory set when shipped. Do not chfnigc the meter sii^e unless it differs

fram the specified value.

6F8A0770

To change the meter size:

The following example shows how to change the meter size from 50 mm to 100 mm.

Key operation

SET

□

►

□

□

SE T

□

SET

□

Display example DeiiCription

Press [SET] first to start the items selection

AZ: METER SIZE

SO mu

A2: METER SIZE

SO nn

AZ: METER SIZE

100 mm

A2: METER SIZE

100 itn

A2: METER SIZE

sequence and select A2: MEITUISIZE from among

(he configuration items using [ ► ] and [-a. ] keys.

Press [iiHT’J again to display the current meter size

Í50 mm in this example).

Pressing [ ► j, the cursor appears.

Select "T(X) nun” by pressing [ a ] as many times

as necessary. (Note)

Pressing [SE T], the cursor disappears and the changed

display flickers, Press [SE TJ again to save the value.

Pressing [SET], the system returns to the items

selection sequence.

Nole: The meter size is changed as shown below by pressing [ ^ ].

-► 2,5 mm 15mm-^LUi)mm 6fH)mm^0.1in 0,5 in ^4 in- ■ 24 in

If the meter si/e has been changed, other setting values (such as span and counting rale)

will be affected depending on the measuring unit used. Therefore, check those setting

values if you have changed the mctci size.

- 5D -

□

Page 52

TOSHIBA

8<2,3 Excitation Frequency

Key operation Display example Description

6F8A0770,

Proceed «s follows to check or change the excitation frequency.

■ To check the excitation frequency:

sr/r

□

SET

□

A3: EX, FREQ,

A3; EX. FREQ.

24 Hz

Press [SET] first to start the items selection,

sequence and select A3: EX. FREQ, from among

the configuration items using [ ► ] and [ a. ]

keys. Then press [SET] again to display the

current excitation frequency.

Pressing [SET], ihe system returns to the items

sdcolion sequence.

- 51 '

Page 53

TOSHIBA

6F8A0.770

To change the excitatLon frequency:

The excitalion frequency ciin be belecled from 6,12 and 24 Hz. The charaderistics of

tile flowmeier chnnge in accordance wiih the selected frequency as shown beJow', 24 Hz

is The default setting w 'he n shipped from the factory.

Excitation frequency

Zero point stability Good

Response lime

Fluid noise resistant

The following example shows how to change the excitation frequency from 24 Hz lo 12 Hz.

Key operation

SET

►

Display example

A3: EX. FREQ.

A3: EX. FREQ.

□

6 Hz 12 Hz 24 Hz

Description

Press [SET] first to start the items selection sequence

and select A3; EX. FREQ, from among the

configuration items using [ ► ] and [ a ] keys. Pre.ss

24 Hz

[SET) again to display the current excitation frequency

(24 Hz in this example).

Pressing [ ► ], the cursor appears.

24 Hz

▲

□

SET

□

SHT

A3: EX. FREEI.

12 Hz

A3: EX. FREÍ.

12 Hz

A3: EX. FREQ.

Select “12 Hz” by pressing [ * ] twice. The

excitation frequency changes as follows:

p d Hz -► 12 Hz -►24 Hz ^

Pressing fSE'I’j, the cursor disappears and the changed

display flickers. Press [SET] again to save the value.

Pressing [SET), the system returns to the items

selcdicm sequence.

- 52 -

Page 54

TOSHIBA

S.2.4 Indicating Unit

6F8A0770

You can seleci one ot Ihe 29 engineering units Jisted below as mt indicating unit.

• Now velocity: m/s, (fl/s)

• Flow rate: mVs» mVirrin, mVh, mVd

l/s, 1/min, 111, 1. d

ml/s, ml/min, ml/h, ml/d

(bbl/y), (bbl/min), (bbl/h), (bbl/d)

(gal/s), {gal/inin), (gai/h), (gat/d)

• Volumetric flow: 1, ml, (gai)

(totalized flow)

• Other units: COUNT (totalized flow without a unit), RANGE (1 to 4)

Code of volumetric

flow direction: F(fixed forward How), R(fixed reverse flow),

Bfautomatic selection bi-directional flow) )

Notes

1. Units in parentheses, such as '‘bbl”, and '■‘ft'’ arc show^n only when the meter si/c is

selected in inches. They arc not shown when the meter size is selected in mm.

2.

If COUNT or liANGE is selected, the display is shown as follows:

COUNT: displays totalized flew counts (8 digits) without a unit,

RANGE: displays the range number (1 to 4),

3. Only in case of the converter for special specifications (refer to

Special specifications”),

‘Time units /d, and flow rate units bbl/s, bbl/min, bb]/h, bbl/d, bbl can he selected,

‘Code of volumetric flow' direction F(fixcd forward flow'), R(fixcd reverse flow),

B(automaiic selection bi-directional flow) can be selected.

13 3

"‘Converter for

Two indicating units (primary unit: UNIT 1, secondary unit: UNIT 2) can be seJeaed.

Proceed as follow^s to check or change these tw'o indicating units.

- 53 -

Page 55

TOSHIBA

6F8A0.7 7 0

To check Ihe indicating unitui:

Key operation Display example

Sin'