Page 1

1

LEVEL ONE

BASIC MULTI-FUNCTION PRODUCT TECHNOLOGY

July 26, 2022

Toshiba America Business Solutions, Inc.

25530 Commercentre Drive

Lake Forest, CA 92630

Page 2

2

Page 3

3

TABLE OF CONTENTS

INTRODUCTION ............................................................................................................................................................. 5

Minimum Technician Requirements .............................................................................................................................. 5

Baseline Exam ................................................................ ................................................................ ............................. 5

GOALS ........................................................................................................................................................................ 6

Copy Process ............................................................................................................................................................... 6

Mechanical ................................................................................................................................................................... 6

Use of Digital Multimeter (DMM) ................................................................................................................................... 6

Electronics ................................................................................................................................................................... 6

Terminology ................................................................................................................................................................. 6

COPIER TECHNOLOGY: AS OLD AS HISTORY ......................................................................................................... 7

SECTION ONE ................................................................................................................................................................ 9

The Copy Process ........................................................................................................................................................ 9

Introduction .................................................................................................................................................................. 9

Goals ........................................................................................................................................................................... 9

Example ......................................................................................................................................................................10

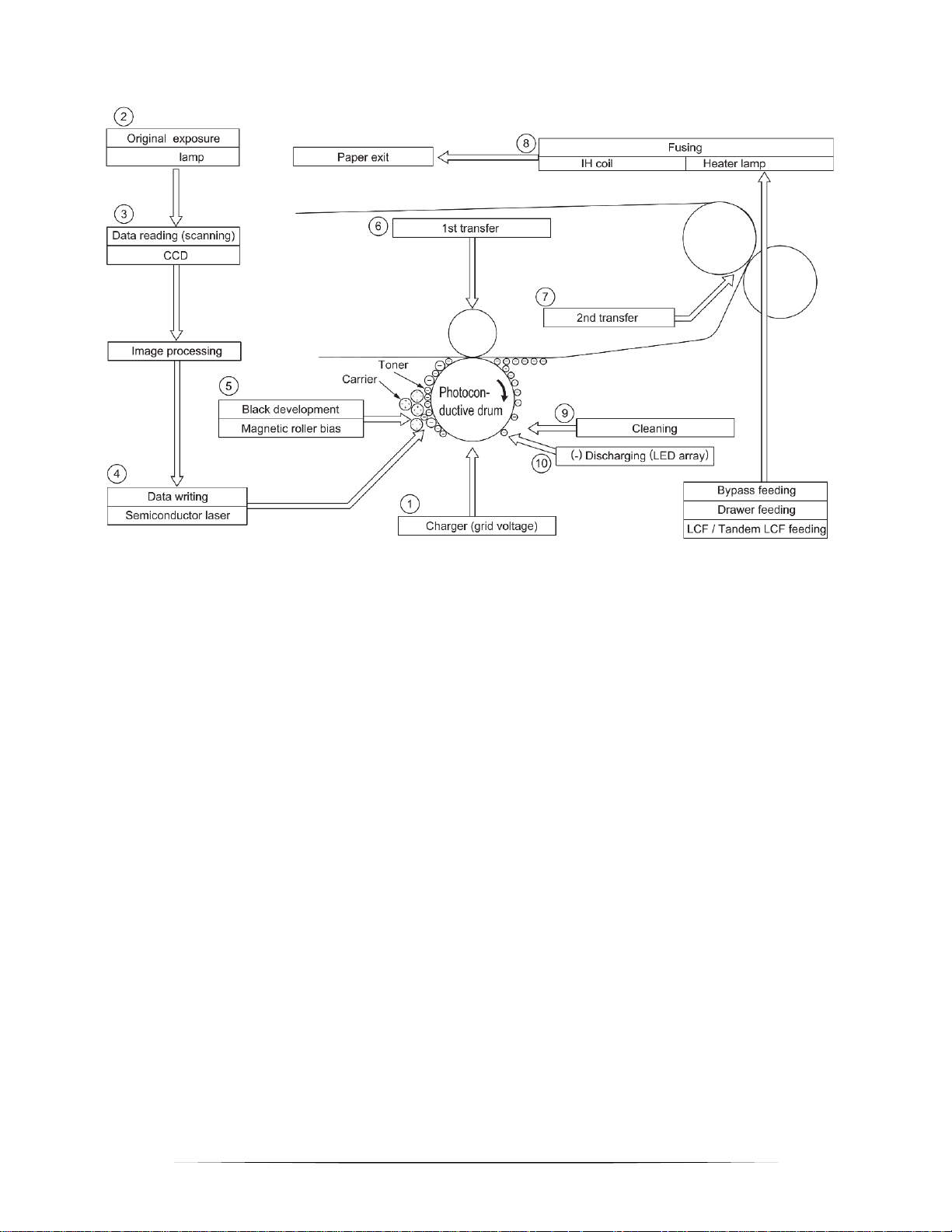

THE TEN PHASES OF THE COPY PROCESS ................................................................................................ ...........11

1. Main Charge ........................................................................................................................................................11

2. Exposing ................................................................................................................................ .............................11

3. Data Reading ................................................................................................................................ ......................11

4. Data Writing ........................................................................................................................................................11

5. Development .......................................................................................................................................................11

6. First Transfer .......................................................................................................................................................12

7. Second Transfer ..................................................................................................................................................12

8. Fusing .................................................................................................................................................................12

9. Cleaning ..............................................................................................................................................................12

10. Discharge Process ..............................................................................................................................................12

Copy Process ..............................................................................................................................................................13

SECTION TWO...............................................................................................................................................................17

The Copy Process .......................................................................................................................................................17

Goals ..........................................................................................................................................................................17

Main Charge ................................................................ ................................................................ ...............................23

Exposure.....................................................................................................................................................................27

Data Reading ..............................................................................................................................................................29

Data Writing ................................................................................................................................................................33

Development ...............................................................................................................................................................39

Transfer ................................................................ ................................................................ ......................................43

Fuser Unit ...................................................................................................................................................................49

Page 4

4

Cleaning......................................................................................................................................................................53

Discharge....................................................................................................................................................................55

SECTION THREE ...........................................................................................................................................................59

Mechanical Components .............................................................................................................................................59

Goals ..........................................................................................................................................................................59

Clutch Mechanisms .....................................................................................................................................................59

Electromagnetic Clutch................................................................................................................................................60

Spring Clutch ..............................................................................................................................................................61

Spring Clutch as a Torque Limiter ...............................................................................................................................62

One Way Clutch (Needle Bearings) ............................................................................................................................. 64

Solonoid ......................................................................................................................................................................67

Bushings .....................................................................................................................................................................68

Bearings......................................................................................................................................................................69

Gears ..........................................................................................................................................................................70

Worm Gears................................................................................................................................................................70

Pulley and Toothed Belt (Timing Belt) ..........................................................................................................................71

SECTION FOUR .............................................................................................................................................................73

Electricity and the use of a Multimeter ......................................................................................................................... 73

Introduction .................................................................................................................................................................73

Principles of Electricity ................................................................................................................................................74

Voltage and Current ................................................................ ................................................................ ....................75

Resistance ..................................................................................................................................................................75

Ohm’s Law ..................................................................................................................................................................76

TYPES OF CIRCUITS.....................................................................................................................................................77

Direct Current (DC) and Alternating Current (AC) ........................................................................................................77

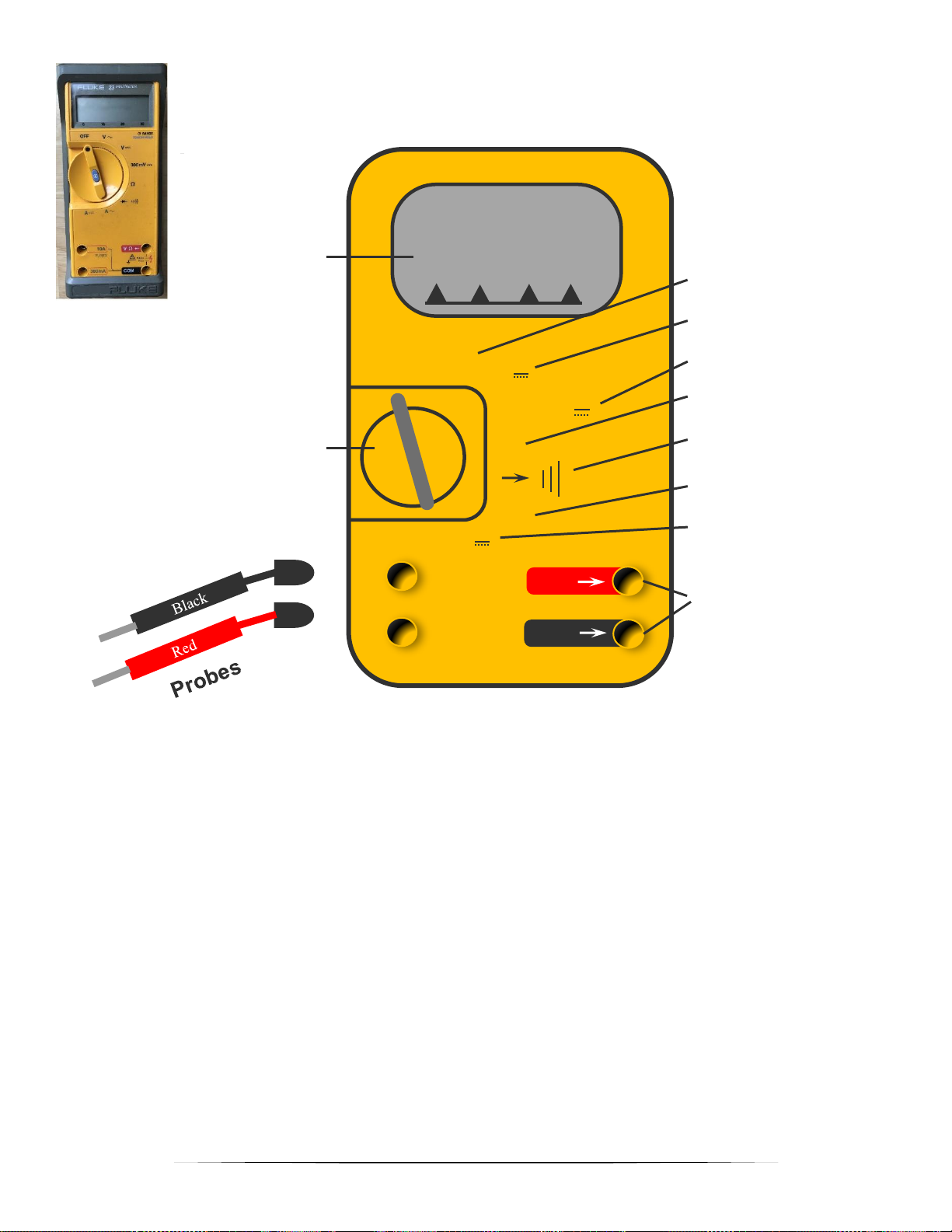

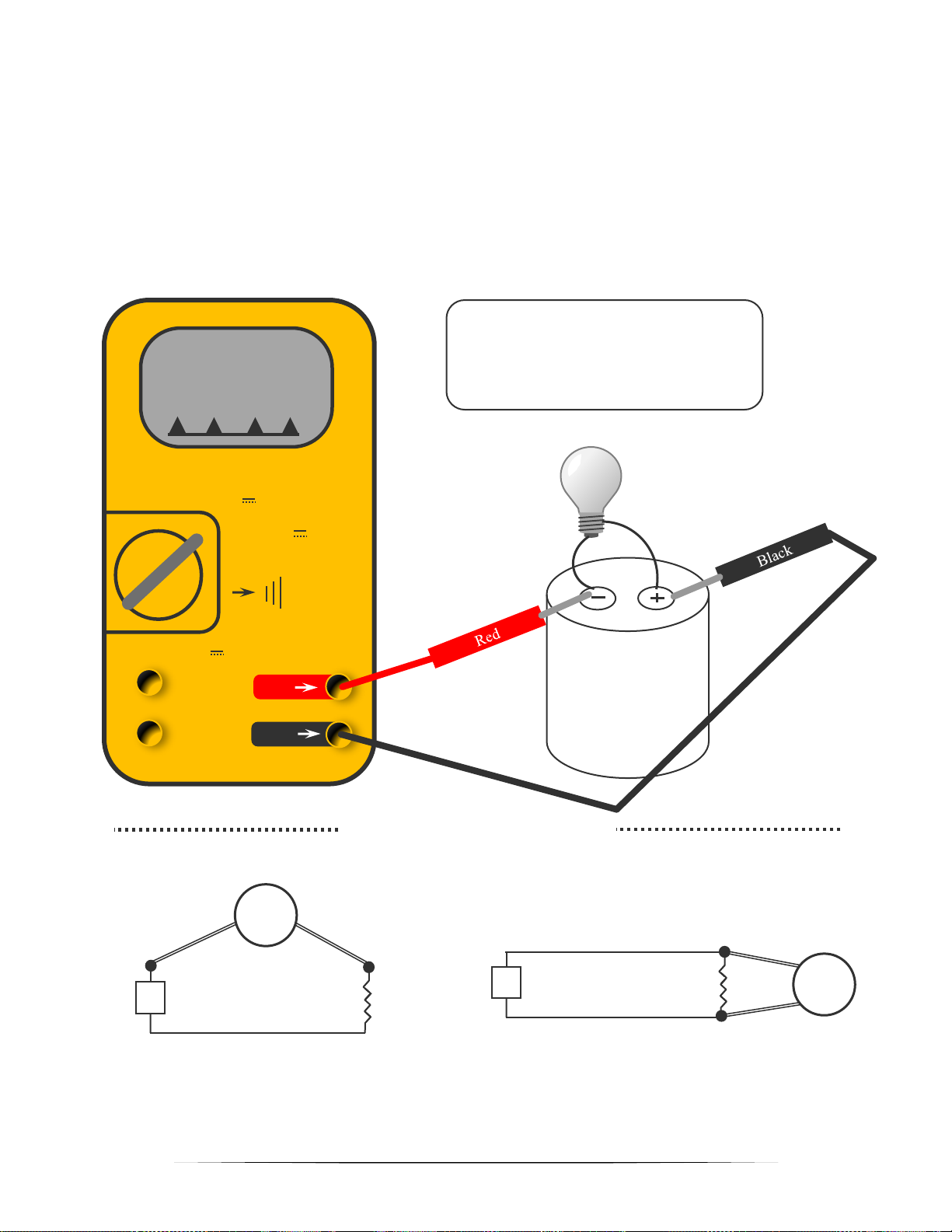

Digital Multimeters (DMM) ...........................................................................................................................................81

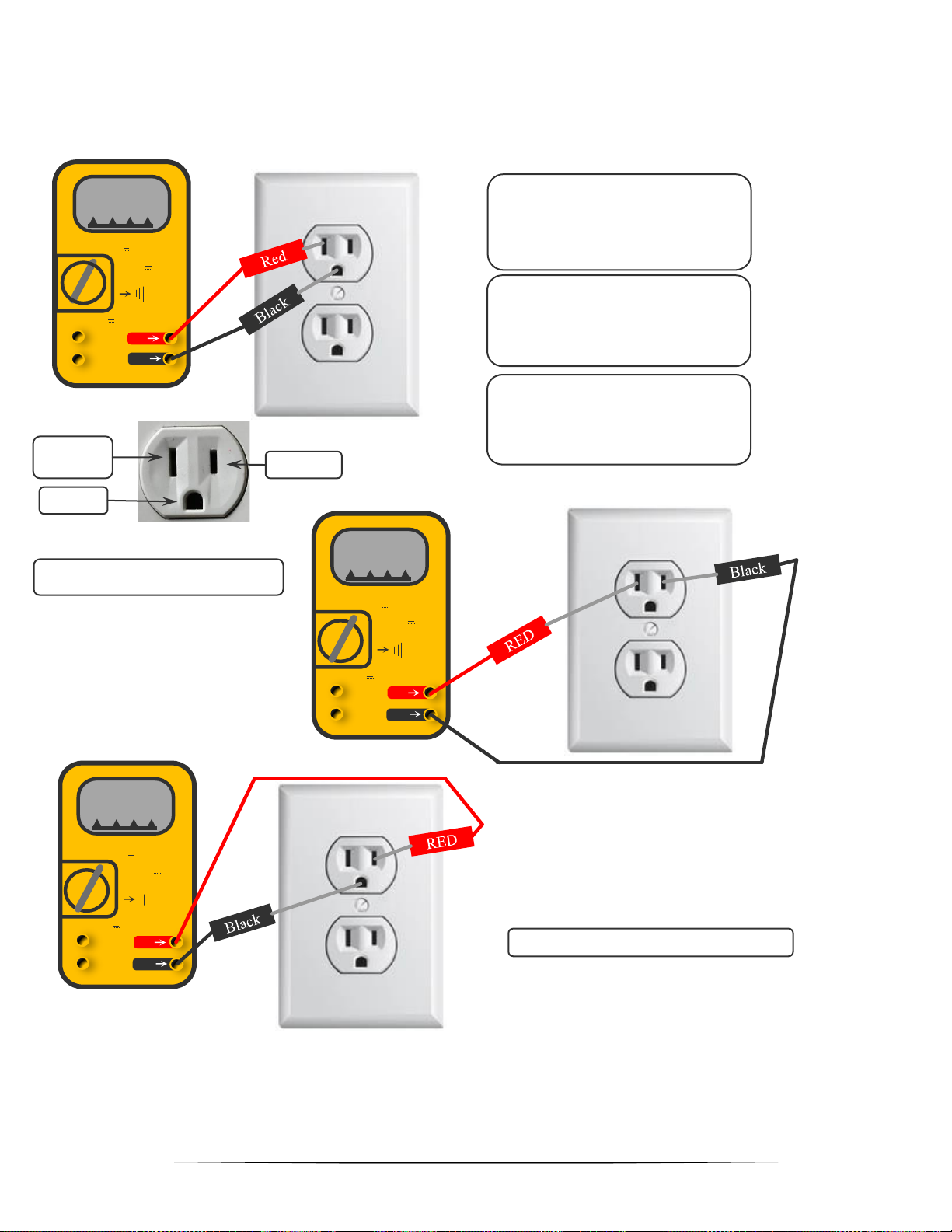

Measuring Voltage (Volts) ...........................................................................................................................................87

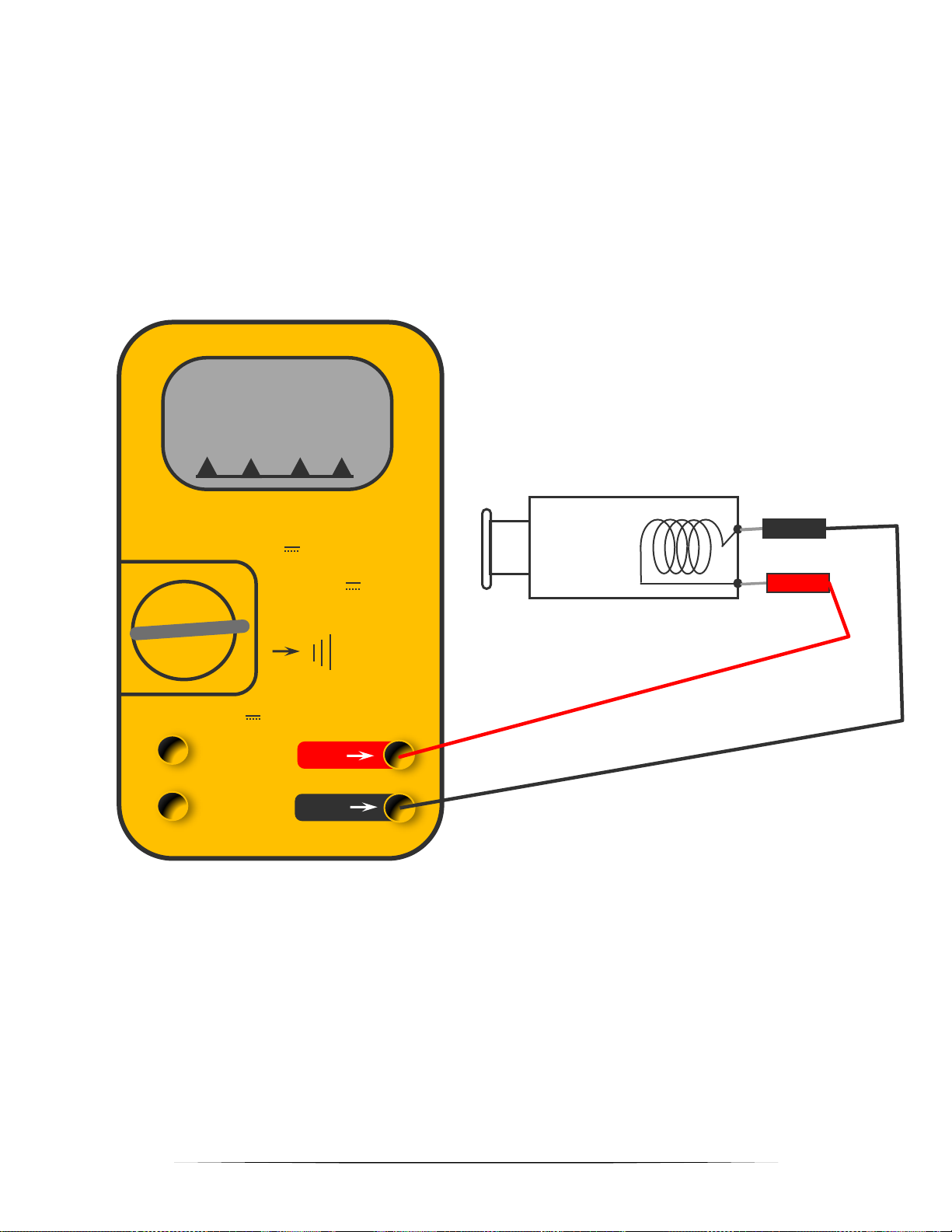

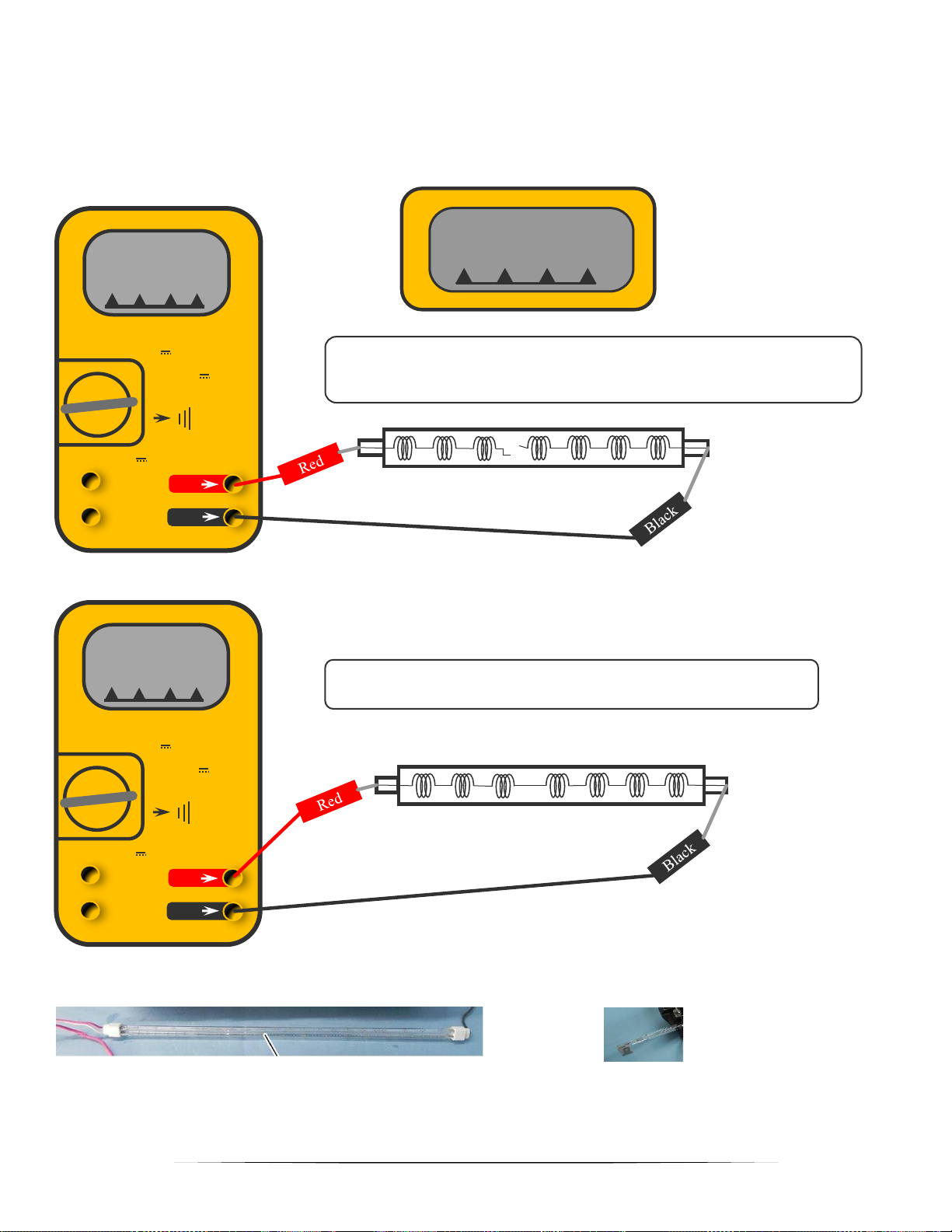

Measuring Resistance ................................................................ ................................................................ .................91

SECTION FIVE ...............................................................................................................................................................99

MFP Electronics ..........................................................................................................................................................99

The Driver Circuit ......................................................................................................................................................100

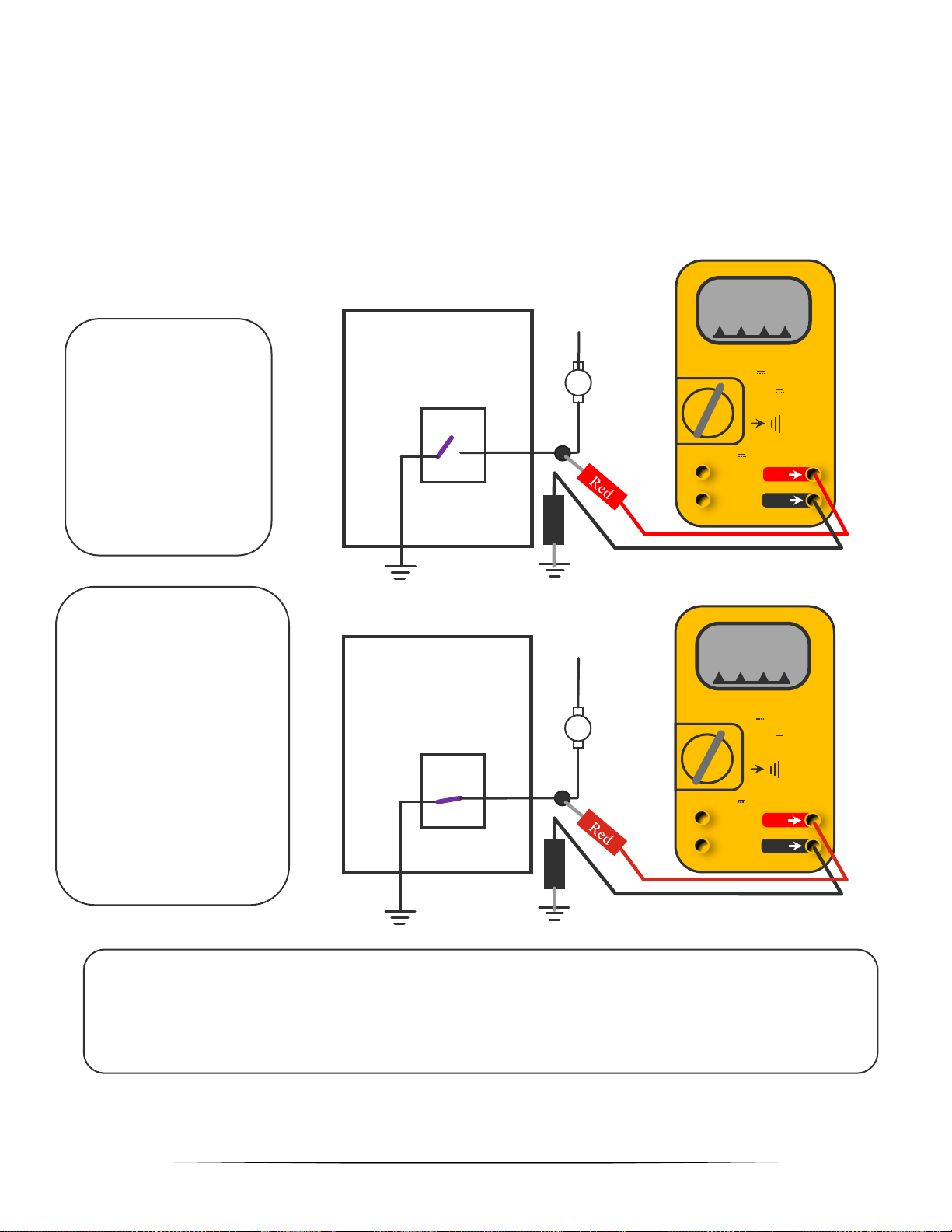

Solid State Relays (SSR) ..........................................................................................................................................101

Thermistors and Thermostats ....................................................................................................................................105

Photo Interrupters and Photo Reflectors ....................................................................................................................107

Main Switch and Power Supply .................................................................................................................................109

GLOSSERY ..................................................................................................................................................................115

Page 5

5

INTRODUCTION

Expert service is essential to the success of your company and ours. To help

us achieve the goal of expert service, Toshiba America Business Solutions

offers a wide range of general and product specific training programs (Toshiba

Technical Training Schools). To succeed in product specific classroom or

computer-based training programs, a minimal knowledge of basic copier

technology and electronics is required. And that’s the purpose of this course:

to make sure every candidate that enters a Toshiba Technical Training School

possesses the minimum prerequisites necessary to succeed.

Different technicians possess different levels of knowledge and training. Some are thoroughly informed and

have lots of experience. Others are still acquiring basic skills. Since time in the classroom is limited, the more

time we spend on basic technical skills, the less time we can devote to important product specific issues. It is

important, therefore, that each technician possess the minimum prerequisites listed below BEFORE beginning

this course:

Minimum Technician Requirements

• One-year high school or college electronics

• Six months experience in a field which requires use of hand tools and mechanical aptitude.

• 60 days’ work experience in the dealer’s shop or in the field.

This preparation course will prove to be an invaluable aid in preparing technicians for Toshiba schools, but we

want to emphasize it is not intended as a substitute for instruction gained through formal education or training.

Baseline Exam

A closed book baseline exam will be administered upon arrival at the Toshiba Digital University. This exam is

derived from the prerequisite WebStep CBT for which the technician completed prior to attending class.

Page 6

6

GOALS

Copy Process

• Understand the copy process used in most Toshiba MFP devices.

• Understand PM issues and common troubleshooting techniques associated with each

phase of the copy process.

Mechanical

• Understand the theory of operation of different standard mechanical components

used in Toshiba MFD devices.

• Understand PM issues and troubleshooting techniques associated with pertinent

mechanical components.

• Know how to repair and maintain basic mechanical components.

Use of Digital Multimeter (DMM)

• Use a DMM to make simple voltage, resistance and current measurements which are

commonly associated with the maintenance of MFP systems.

• Check continuity in components, wire harnesses, and switches.

Electronics

• Understand the theory of copier electronics and know how to check the following

devices: Circuit Boards (Inputs and outputs), Power Supply, Switches, and Sensors.

Terminology

• Understand the specialized terms used in service manuals for Toshiba Multi-

Functional Products.

Page 7

7

COPIER TECHNOLOGY: AS OLD AS HISTORY

Think about it. People have been making copies since the beginning of recorded history. In fact, the advent of

primitive copier technologies was the beginning of recorded history. Early societies engraved symbols on clay

tablets. It was slow and costly. Then came the stylus, papyrus and different types of dyes

which were used in a very labor-intensive way to create scrolls. Scribes spent their entire

lives hand-copying scrolls for kings, dukes, and other department heads. This was way

before “White-Out” when a mistake could cost a good scribe a couple of years to correct. In

the fifteenth century, the idea of moveable type put Gutenberg’s Printing Press into the

history books and a lot of those scribes were out of work. That one technological

advancement cut copy time from a few years for a standard Bible to a couple of months.

And after that, it was only another five hundred more years before mimeograph machines

began appearing in public schools across the U.S. To this day, retired classroom

teachers still haven’t gotten that blue ink residue off their hands. But it was a lot better

than scrolls.

The pace picked up rather quickly after that. In 1954 Eastman Kodak™ introduced

Verifax™ which was a dye transfer process that combined photography and printing to duplicate an original

document. Thermography was introduced by 3M™ in 1956. By skipping the need for a master negative, this

heat transfer process streamlined the copying process. A copy could be made within four to six seconds, and

copies were less expensive. But it still required special paper and there were other limitations. In 1960, the

world of copier technology took a giant step with the introduction of the indirect electrostatic copier process.

The process was owned by Xerox™ and earned itself the name “Xerography” which is Greek for “dry writing”.

The electrostatic process enabled businesses to copy on plain bond paper instead of chemically treated paper.

It was fast and automatic. It copied large originals up to nine inches by fourteen inches. Clearly, the modern

age of copier technology had begun. Toshiba copiers still use a version of the

electrostatic copy process in its Multi-Functional Products.

Page 8

8

Page 9

9

SECTION ONE

The Copy Process

(An Overview)

Introduction

In section one and two, we examine the ten phases of the electrostatic copy process. First, we will look at an

overview of the entire process and then study each phase in detail. At the end of the detailed study of each

phase we will identify Print Quality and other troubleshooting issues that are frequently associated with that

phase. The more a technician knows about each phase of the process, of course, the easier it will be to track

down and diagnose problems in the field.

Goals

Upon completion of this section, you will:

• Understand the ten major phases of the electrostatic copy process.

• Know the basic construction of the photosensitive drum and how it reacts to light.

Page 10

10

TEN PHASES OF THE ELECTROSTATIC COPY PROCESS

1. Main Charge

2. Exposure

3. Data Reading

4. Data Writing

5. Development

6. First Transfer

7. Second Transfer (If used)

8. Fusing

9. Cleaning

10. Discharging

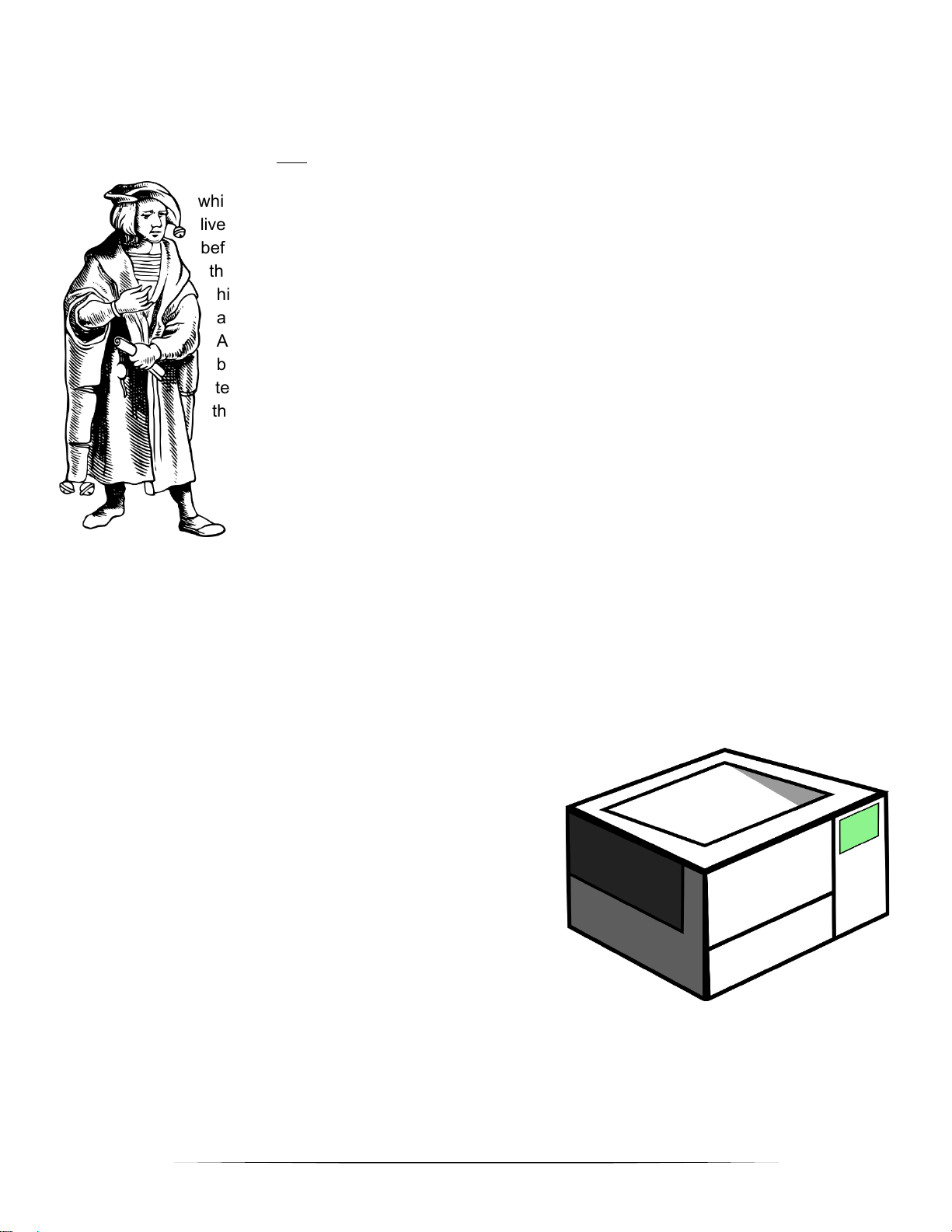

The Drum

All phases of the copy process, except Exposure, Data Reading, Second Transfer, and Fusing, act upon the

Photoconductive Drum. It receives the image to its light sensitive surface and then transfers the image from the

surface to either the paper or a transfer belt.

Various materials are used to make different types of drums. Organic Photoconductors (OPC) are the type of

drums used in Toshiba MFPs.

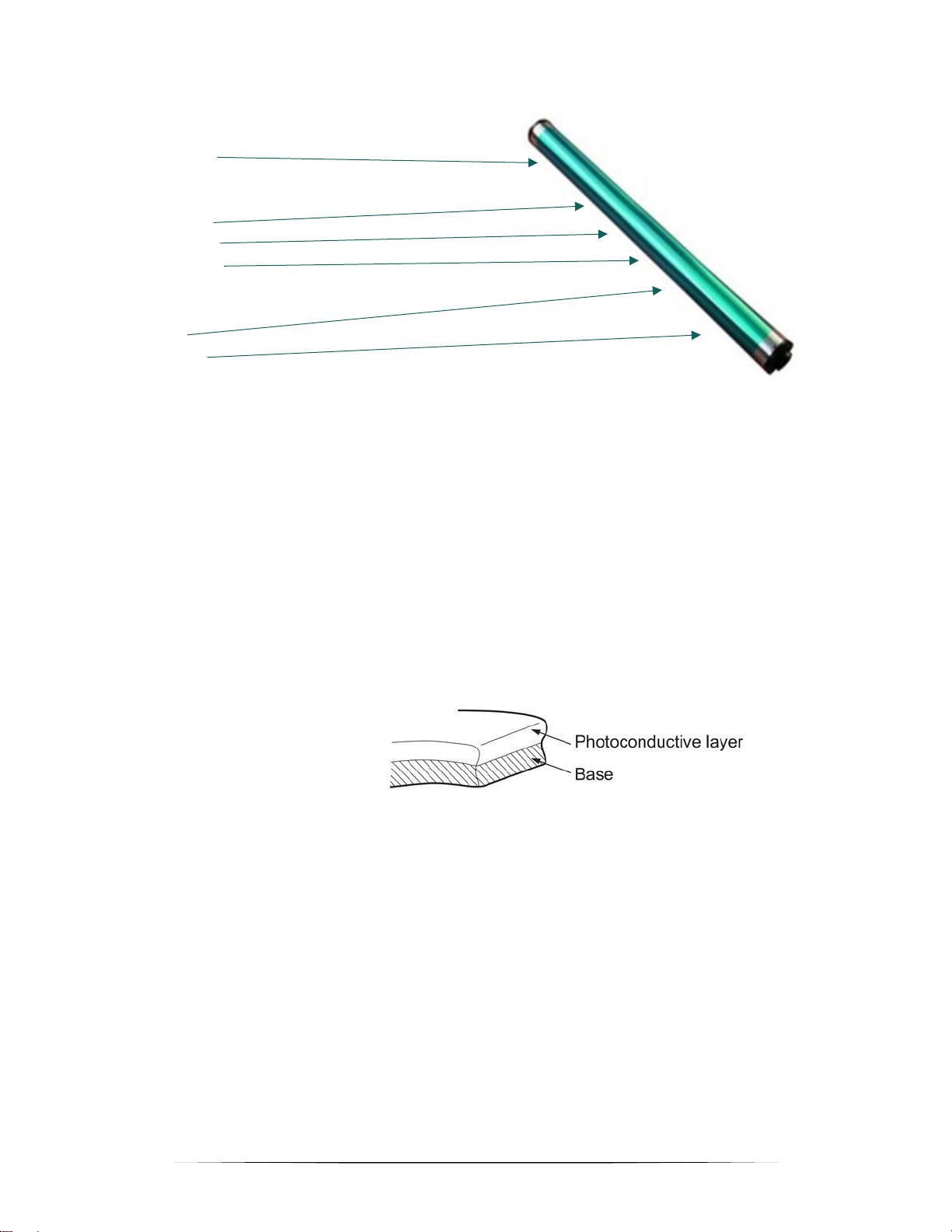

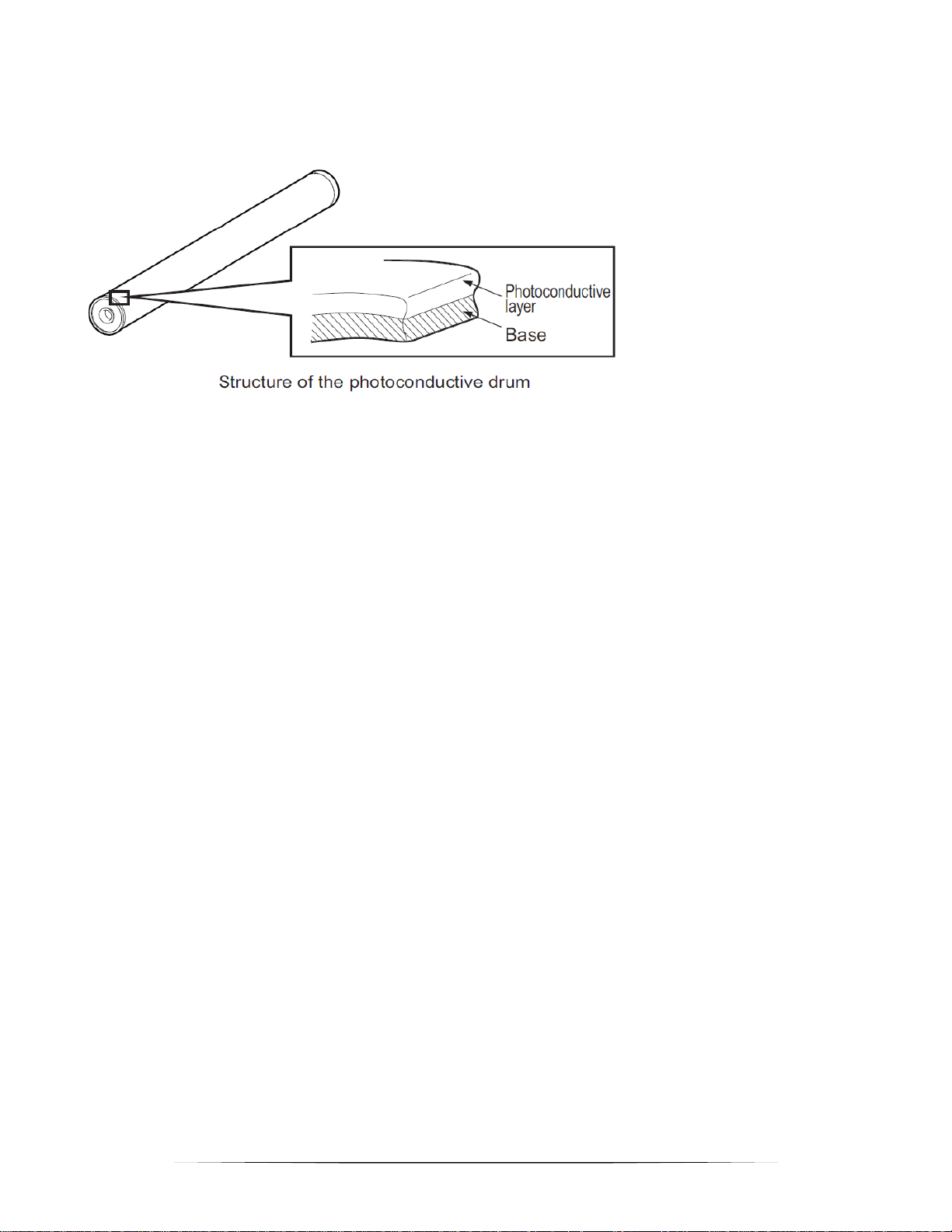

Structure of the OPC Drum

The photoconductive drum consists of two layers. The outer layer is a photoconductive layer made of an

organic photoconductive carrier (OPC), and the inner layer is an aluminum conductive base in a cylindrical

form.

The photoconductor carrier has a special property: when it is exposed to light, the electrical resistance it

possesses increases or decreases with the strength of the light. These two properties are crucial to the

execution of the copy process.

Example

Strong incident light - Decreases resistance (works as a conductor.)

Weak incident light – Increases resistance (works as an insulator.)

Page 11

11

THE TEN PHASES OF THE COPY PROCESS

1. Main Charge

To prepare for the latent image, the main charger generates a high negative voltage which places a

uniform negative charge across the surface of the Drum. The charge remains on the drum because the

surface has a high electrical resistance in the dark.

2. Exposing

Exposure is a process of illuminating the original with light and reflecting the light through a series of

mirrors and a lens unit onto a Charged Couple Device

3. Data Reading

The light reflected from the original is directed to the Charge Coupled Device (CCD) and this optical

image information is converted to electrical signals (image signals), which are then transmitted to the

image processing section. The CCD for color processing has RGB filters provided over its surface,

which allow the CCD to read the light amount in the respective ranges of wavelength. The image data

corresponding to the respective RGB colors is then transmitted to the image processing section.

4. Data Writing

Data writing is the process of converting the image signals transmitted from the image processing

section into light signals and exposing the drum surface with the light signal.

5. Development

Development is a process of making the electrostatic latent (invisible image) images visible to the eye

(visible image). Developer material is supplied to the photoconductive drum surface by means of a

magnetic roller, allowing the toner in the developer material to adhere to the areas on the drum surface

where the potential is lower than the developer bias which is applied to the magnetic roller.

Page 12

12

THE TEN PHASES OF THE COPY PROCESS continued…

6. First Transfer

First transfer is a process of transcribing the toner image (visible form) formed on the photoconductive

drum to a transfer belt. A positive bias is applied to the 1st transfer roller, causing the transfer belt to be

positively charged. This in turn helps to form an electric field between the transfer belt (positive) and the

photoconductive layer of the photoconductive drum (grounded), this making the toner image transferred

to the transfer belt.

7. Second Transfer

An electric field is formed between the 2nd transfer roller and the 2nd transfer facing roller, which

generates a paper polarization and thus the toner is transferred from the belt to the paper. When the

negative bias is applied to the 2nd transfer facing roller, the 2nd transfer roller is charged (positive), and

thus the toner is transferred from the belt to the paper.

8. Fusing

Fusing is a process of melting the toner on the paper and fixing it firmly onto the paper.

9. Cleaning

When toner is transferred from the transfer belt (or the OPC) to paper, a small amount remains on the

transfer belt (or the OPC). As remaining toner lowers the image quality, it must be scraped off. The

edge of the cleaning blade is pressed against the photoconductive drum surface to scrape off the

residual toner.

10. Discharge Process

Discharging is the process of eliminating the (-) charge remaining on the photoconductive drum before

the next charging process.

Page 13

13

Copy Process

1 Charging: Places a negative charge on the surface of the photoconductive drum.

2 Exposure: Converts images on the original into optical signals.

3 Data Reading: The optical image signals are read into the CCD and converted into electrical signals.

4 Data Writing: The electrical image signals are changed to light signals (by laser emission) which

exposes the surface of the photoconductive drum.

5 Development: Negatively charged toner is made to adhere to the photoconductive drum, producing a

visual image.

6 1st Transfer: Transfers the visible image (toner) on the photoconductive drum to the transfer belt.

7 2nd Transfer: Transfers the visible image (toner) on the transfer belt to paper.

8 Fusing: Fuses the toner image to the paper by applying heat and pressure.

9 Cleaning: Scrapes off the residual toner from the drum by the blade.

10 Discharging: Eliminates the residual charge from the surface of the photoconductive drum.

Page 14

14

Review

The following questions will help you review the material you’ve just studied and enable you to assess your

own understanding of the program.

1. Which part of the drum is most sensitive to light?

A. Upper Layer

B. Lower Layer

2. According to the passage in the workbook, in what year did the process known as “Xerography”

appear?

A. 1940

B. 1960

C. 1980

D. 1990

3. What is the charge of the latent image?

A. Positive

B. Negative

C. Neutral

D. AC

Memory

Put the following important items into “memory”

• During the electrostatic copy process, light reflected off the original image is directed to a

Charge Coupled Device (CCD). The CCD converts the reflected light into electrical signals.

These signals are then sent to the Data Writing section where the signals are turned back

into light (using either an LED array or a LASER). This light strikes the drum surface which

eliminates or reduces the charge. The eliminated or reduced charge causes toner to be

attracted to the drum surface. The toner is then transferred to a belt and then to paper or

directly to paper and fused to form an identical copy.

• The important characteristic of photoconductors is their ability to change resistance in

proportion to the intensity of light.

• In the dark, the photosensitive layer of the drum has a high resistance (insulator).

• When exposed to light, the resistance is reduced, and the drum surface becomes a

conductor.

• The more a technician knows about each phase of the copy process, the better she or he

will be able to identify the source of Print Quality problems.

Page 15

15

4. What is the charge of the toner particles that are attracted to the latent image?

A. Positive

B. Negative

C. Neutral

D. AC

5. Which of the following accurately states the order of the nine phases of the copy process?

A. Main Charge

Data Reading

Data Writing

Development

First Transfer

Second Transfer (If color device)

Fusing

Cleaning

Discharging

B. Main Charge

Data Reading

Development

Data Writing

First Transfer

Second Transfer (If color device)

Fusing

Cleaning

Discharging

Page 16

16

Page 17

17

SECTION TWO

The Copy Process

(A Closer Look)

Goals

Upon completion of this section, you will:

• Have a detailed understanding of each phase of the copy process.

• Know the major components associated with each phase of the copy process.

• Know the basic preventive maintenance principles associated with each phase of the copy process

Page 18

18

Toshiba’s Organic Photoconductor (OPC)

A photoconductor is defined as a light sensitive material which acts as a conductor when exposed to light and

an insulator in the dark. Toshiba’s Organic Photoconductor meets that definition.

The drum consists of a photoconductive layer on the outside and an aluminum base material on the inside.

Changes in the intensity of light falling on the drum create changes in the electrical resistance of the drum

surface. When exposed to light, the electrical resistance is reduced, and the drum becomes a conductor. The

greater the intensity of light, the less the resistance and the better conductor the surface becomes. In the dark,

conductivity does not change. As light changes the conductive and insular characteristics of the drum,

electrons can move more freely or less freely between the photosensitive material on the surface and the

aluminum base material, thus changing the charge potential on the surface.

By first applying a uniform negative charge to the surface of the drum, and then exposing the drum to light from

the LASER or LED assembly, a change in the surface charge takes place which corresponds to the details of

the original document or print job. The high intensity of the light (which represents the image) causes the drum

surface to become more conductive in those areas and the negative charge dissipates. Essentially the LASER

or LED assembly is “Writing” an invisible image on the surface of the drum. The amount of charges that is

dissipated on the drum surface is directly proportional to the intensity of the light. The higher the intensity, more

charge is dissipated. The lower the intensity, less charge is dissipated from the drum. In this way, many

different levels of density can be reproduced.

This invisible image is called the “Latent Image”. When toner particles with a negative charge are attracted to

the “more positive” areas of the drum surface (this is the area of the drum which was exposed to an intensity of

light), it becomes a visible image that can be transferred either to a transfer belt or directly to paper.

Page 19

19

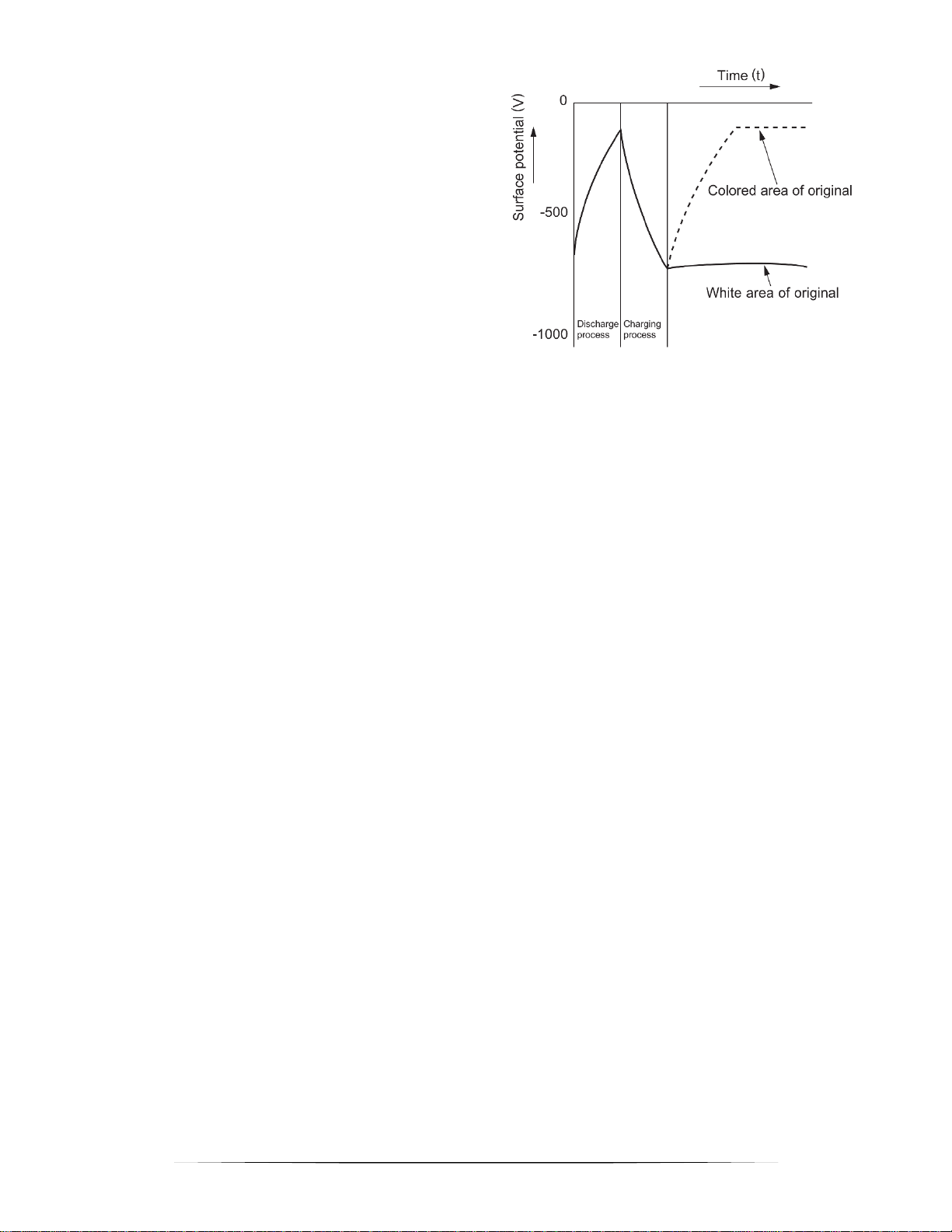

The diagram shows the changes in electrical charge on

the drums surface in relation to the light from the

LASER or LED assembly. As you can see, the areas on

the drum corresponding to colored areas on the original

are deprived of negative charge, while the areas on the

drum corresponding to white areas retain the negative

charge. Thus, it forms a negative charge image on the

drum surface. This negative charge image is called an

“electrostatic latent image.”

Service Tips (for the drum)

• If the condition of the drum surface deteriorates, print quality will of course be negatively affected.

• The drum is temperature as well as light sensitive.

• Store the drum in a cool dry place.

• Exposure to light for an extended period may cause light shock, which could cause permeant damage

to the drum. The drum may recover if placed in the dark.

The following are also potential causes of damage to the drum, and thus, to the quality of the drum.

Fatigue Occurs over time with wear. The drum’s ability to accept a charge potential

decreases.

Physical Damage Scratching or touching the surface will cause imperfections on the copy or print.

Surface Contamination If the equipment is not properly cleaned and maintained, contaminants can coat

the drum causing print quality problems.

Page 20

20

Review: OPC Drum

1. True or False: The photoconductor most frequently used in Toshiba’s products – OPC – consists of a

photoconductive material and an aluminum base.

A. True

B. False

2. True or False: When exposed to light the electrical resistance of the drum surface is increased.

A. True

B. False

3. True or False: The greater the intensity of the light to which the drum is exposed, the less the

resistance and the better conductor the surface becomes.

A. True

B. False

4. True or False: In the dark, the resistance of the drum remains unchanged.

A. True

B. False

Memory

Put the following important items into “memory”

• Electrical resistance of the drum surface decreases in direct proportion to the intensity of

light to which it is exposed.

• The drum insulates in the dark and conducts in the light.

• The shift in charge potential over the surface of the drum is what enables the system to

create a latent image.

• If the condition of the drum surface deteriorates, print quality will be negatively affected.

Page 21

21

5. If the OPC is exposed to ambient light for a long period of time, what is the best action to take to restore

the drum?

A. Put the drum in a dark place and let it recover.

B. Turn the machine OFF and back ON.

C. Wipe it off.

D. Open the windows.

6. Wear on the drum over time can cause ________________ condition which can decrease the ability of

the OPC to accept charge.

A. Filming

B. Oxidation

C. Radioactive

D. Fatigue

7. Why is it a good idea for a technician to know as much as possible about the construction and

dynamics of the OPC?

A. Because of the raise you will get.

B. It makes you a better person.

C. It will better enable you to diagnose and correct print quality problems.

D. So, you can march to the beat of a different drummer.

Page 22

22

Page 23

23

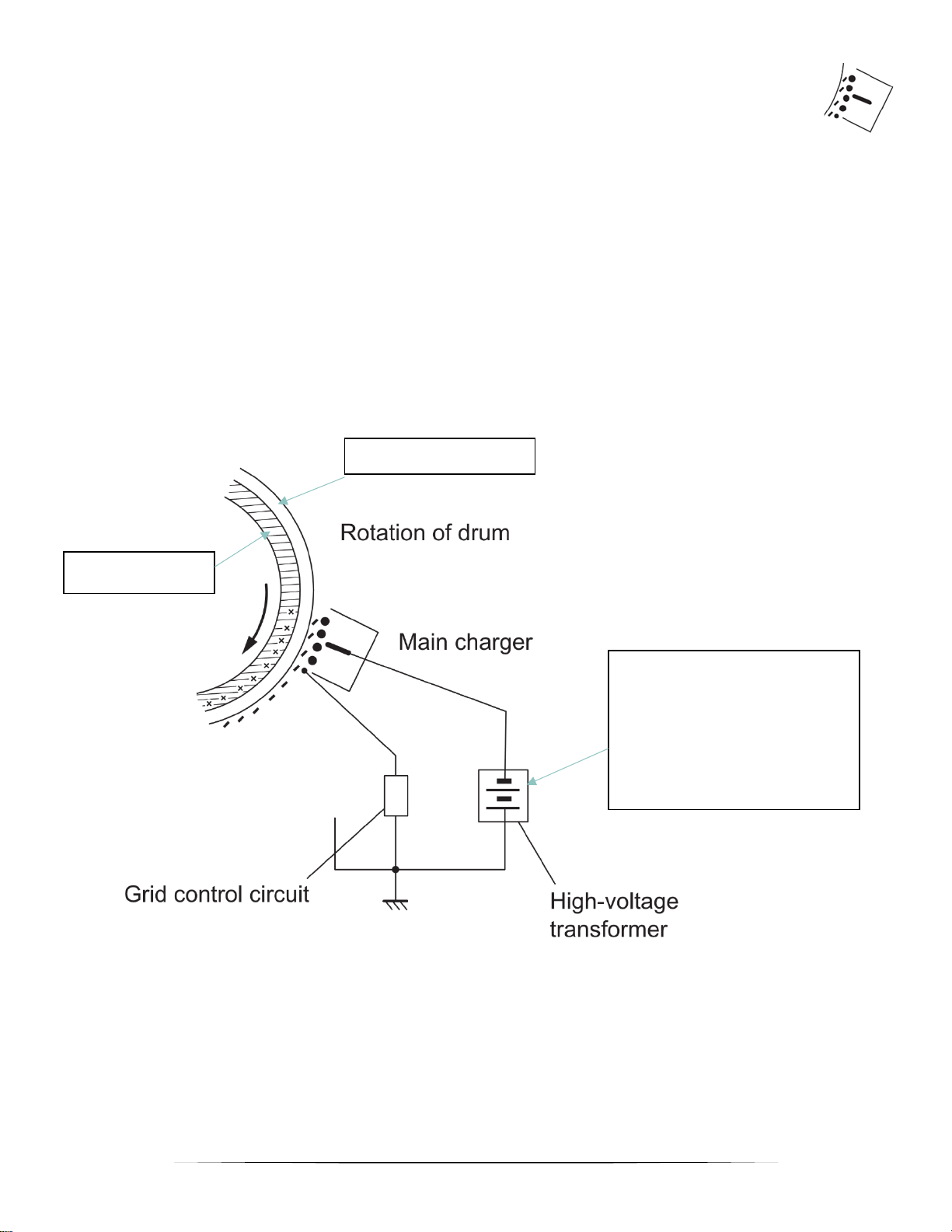

Main Charge

The copy process begins when the main charger creates a negative charge on the drum surface.

The high voltage transformer generates a high negative voltage to the needle electrode. A strong negative

charge inside the housing of the main charger is created. The grid has two functions: first, it regulates how

much negative charge is allowed to the drum. Secondly, it ensures a uniform charge across the surface of the

drum.

The strong negative charge on the drum surface is balanced by the positive charges that are formed in the

aluminum core beneath the photosensitive layer. Since the main charge takes place in the dark, the drum

maintains a high resistance which prevents any kind of conductivity from neutralizing the ions. As a result, a

uniform negative charge is established and maintained across the entire surface of the OPC drum.

The ultimate purpose of the Main Charge is to prepare the photoconductive layer for the LASER exposure

which will follow.

Photosensitive Layer

The HVT generates a negative

voltage to charge the needle

electrode and the grid. The

charge is dissipated through

the grid to the drum surface.

Aluminum Base

Page 24

24

Service Tips for Charging System

Any contamination (dirt, toner, oxidation, etc.) or deformation (bending or breaking) of the needle

electrode or grid will result in degrading print quality. The following are print quality problems that are

sometimes associated with a Main Charger that has not been maintained properly.

Malfunction

Effect on System

Effect on Copies

Broken Needle

Electrode

No Main Charge

Solid copies

Worn or dirty Needle

Electrode or Grid

Uneven Charge

Uneven Image Density

Charge potential higher

than factory spec.

Excessive charge on drum

Charge potential lower

than factory spec.

Insufficient charge on drum

Proper Maintenance

Replace needle electrode and grid at specified PM intervals and clean the housing on schedule.

Memory

Put the following important items into “memory”

• The copy process begins when the Main Charger places a uniform negative charge over

the photosensitive layer of the OPC.

• The components used to create the Main Charge are the HVT, Needle Electrode, Grid and

the OPC.

• The Main Charge is executed in total darkness which preserves the insular character of the

OPC and thus “holds” the charge.

• The Main Charge prepares the drum surface to receive the light produced from the LASER

or LED assembly.

• If the condition of the Main Charger is not well maintained, print quality will be negatively

affected. The Charger should always be cleaned or changed according to the PM

schedule.

Page 25

25

Review: Main Charge

1. The potential of the OPC after the Main Charge is executed is:

A. Positive

B. Negative

2. List the primary components used to execute Main Charge.

__________________________________________________________________________________

__________________________________________________________________________________

3. True or False: Since the Main Charge is executed in the dark, the electrical resistance at the

surface of the OPC is decreased and a positive charge is created.

A. True

B. False

4. What will happen to copy quality if the Needle Electrode is not installed?

__________________________________________________________________________________

5. What will happen to the copy quality if the Main Charge is less than what the factory specifies?

__________________________________________________________________________________

Page 26

26

Page 27

27

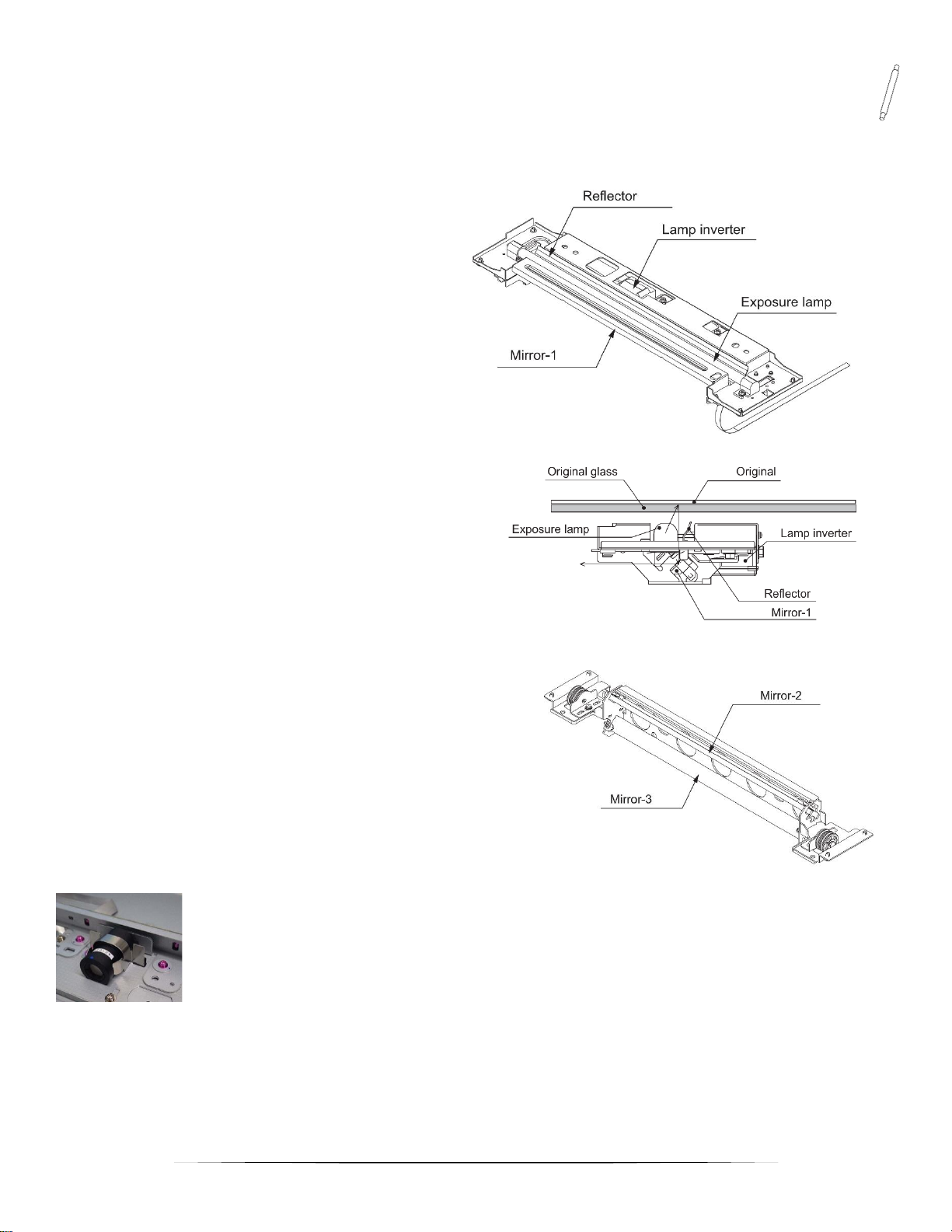

Exposure

The exposure process enables the machine to illuminate the original document and transport the reflected light

to the Charged Couple Device (CCD).

Carriage 1 shown here consists of the Exposure

lamp, Lamp inverter, Reflector, and Mirror 1. On

newer systems, the Exposure Lamp has been

changed from a Xenon lamp to an LED lamp.

When the LED lamp was introduced, this

eliminated the need for the Lamp inverter. So,

on most newer systems you will not see a Lamp

inverter.

Mirror 1 directs the light reflected from the original to the

carriage 2 described below.

Carriage 2 consists of mirror 2 and mirror 3 and directs the

reflected light from mirror 1 through the mirrors 2 and 3 to

the lens.

This carriage is driven by the same scan motor as that for

the carriage 1 at half the scanning speed of the carriage 1

(The scanning distance is also half that of the carriage 1).

The light reflected from the mirror 3 described above is led to the CCD placed at the focal

point of the lens which is in a fixed position.

Page 28

28

Service Tips for Exposure

Any contamination (dirt, moisture, film etc.) or deformation (cracks) of the optical system will of course

obstruct the reflected light and degrade quality of the scan. The following are copy quality problems that are

sometimes associated with Optics and Exposure problems.

Malfunction

Effect on System

Effect on Copies

Broken Exposure Lamp

No light, the CCD does not

receive any light therefore

there is no image data.

Solid copies

Dirt, dust, etc.

Reduced light causes the

CCD to interpret the image

incorrectly

Uneven Image Density or

backgrounding

Obstruction in optical

path

Light will not be reflected

properly

Line or background band

Mirror out of position

Light will not be reflected

properly

Skewed image

Proper Maintenance

Clean reflecting surfaces, lens and original glass at specified PM intervals.

Memory

Put the following important items into “memory”

• In the scanning section, the surface of the original is irradiated with a direct light and the

reflected light is led through mirrors, a lens and a slit to CCD.

• A lens and a slit to CCD is where optical–to–electrical conversion is performed, converting

the optical image data into an electrical (analog) signal.

• The analog signal is changed to a digital signal, which then undertakes various corrective

processes necessary for image formation.

Page 29

29

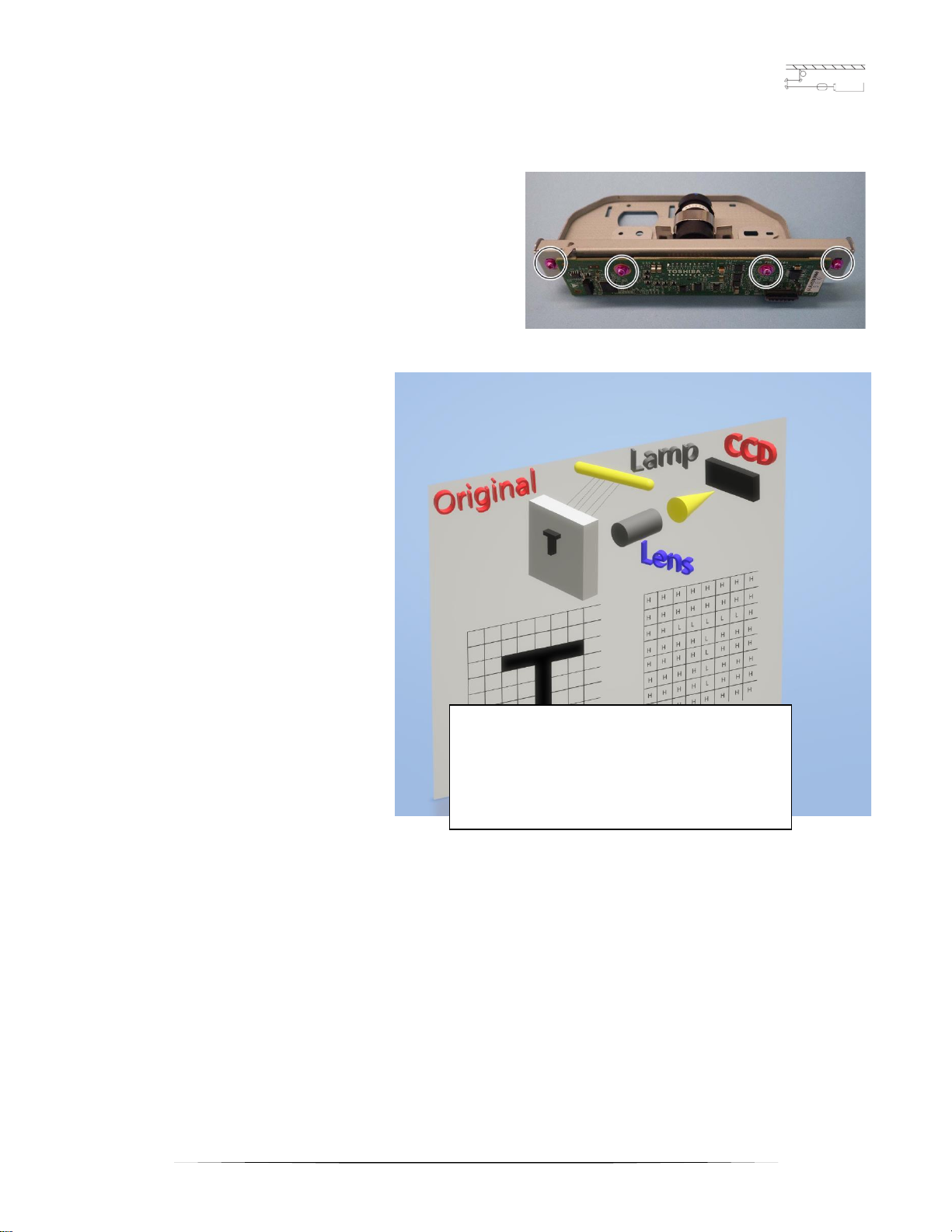

Data Reading

This device is a digital camera. Although a little different than the one you have on your smart phone. Rather

than having a square sensor, it utilizes an inline sensor. The

inline sensor is taking pictures line by line as the scanner

moves underneath the original.

Just like a digital camera, the CCD driving PC board

processes signal amplification, signal integration and

Analog to Digital conversion.

Reflected Light to Electrical Signal

During the scanning process, the reflected

light from the original document is

transmitted – one line at a time – to a

Charged Coupled Device (CCD).

The CCD consist of an array of light

sensitive elements which can sense the

incoming light and convert it to an analog

voltage. Each output of each picture

element on the CCD is an analog voltage

with a value that corresponds to the

density of the scanned original image at a

point on the line.

The denser the image (dark space), the less intense the reflected light, and the lower the output signal from the

CCD. The less dense the image (white space), the more intense the reflected light, and the greater the output

value of the signal.

H=High voltage analog output of CCD

(non-image)

L=Low voltage analog output of CCD

(image)

Page 30

30

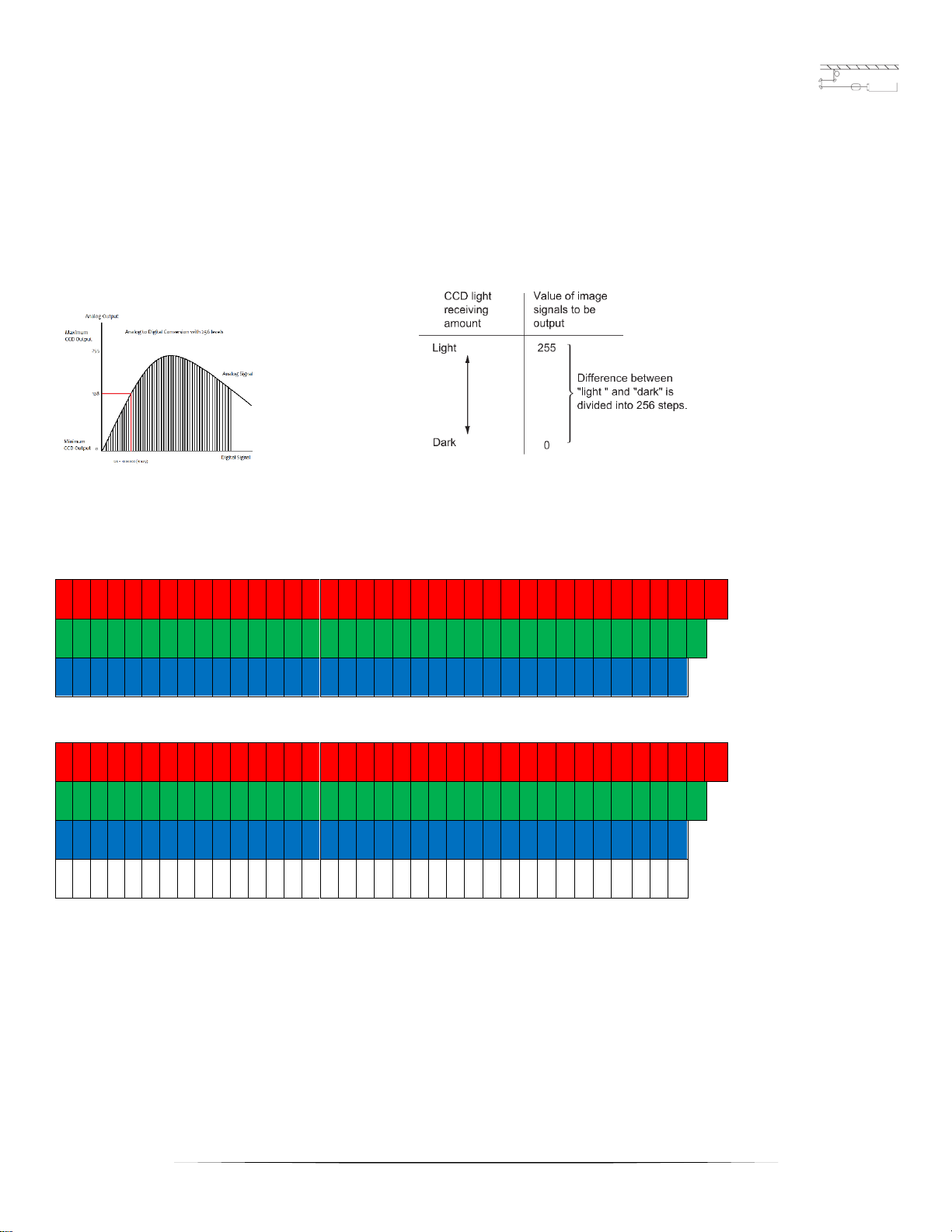

Data Reading continued…

Conversion from Analog to Digital Signal

Before being stored in RAM, the analog signal from each element of the CCD must be converted to a binary

number (digital signal). An Analog to Digital (A/D) converter on the controller board converts the analog voltage

output from each picture element of the CCD to a binary number. The number (digital data) also corresponds

to the density of the original document at a particular point on the line. The digital information is then stored in

memory (RAM).

Models with a color scanner use either a 3-line CCD consisting of 3 color devices (red, green and blue) or a 4line CCD consisting of 3 color devices (red, green and blue) plus 1 black device.

3 Line CCD example”

4 Line CCD example:

The RGB filters are used to separate the light reflected from the original into the primary colors which are then

read by the CCD sensor as data of the amount of light

Page 31

31

Data Reading continued…

In the following example, for easy understanding, the original is rendered in red only, and the scanning of the

original is done in an order of Red – Green – Blue.

In the first scanning, the red filter inside the CCD is used to

extract only red light. Since the red original only reflects red light,

there occurs no contrast between the letter part and the

background of the original causing the received light level

(voltage) of the CCD sensor to increase overall. This data does

not allow the letter part of the original to be illuminated with the

laser, therefore, no cyan image is transferred to the drum.

In the second scanning, the green filter inside the CCD is used to

extract only green light. Since the red original does not reflect

green light, the letter part of the original becomes a shadow,

causing the received light level (voltage) of the CCD sensor to

decrease. Based on this data, the letter part of the original is

illuminated with laser, and the development process follows. The

magenta image is developed and transferred from the drum to

the transfer belt.

In the third scanning, the blue filter of the RGB filter inside the

CCD is used to extract only blue light. Since the red original does

not reflect blue light, the letter part of the original becomes a

shadow, causing the received light level (voltage) of the CCD

sensor to decrease. Based on this data, the letter part of the

original is illuminated with laser and the development process

follows. The yellow image is transferred from the drum to the

transfer belt.

Therefore, yellow and magenta toners adhere overlaid on the transfer belt to produce the color red. The red image is then

transferred to the paper.

Page 32

32

Review: Data Reading

1. During the data reading process, the reflected light from the original document is collected by the

________________.

a. Lens

b. Drum

c. Charged Couple Device

d. Mirror 3

2. True or False: A CCD converts the reflected light from the original document into a digital signal.

a. True

b. False

3. True or False: During the data reading process, analog signals are converted into digital binary data and

stored in RAM.

a. True

b. False

4. In the example given in the text, the dark area of the original document would produce a

________________ output signal from the CCD than the light areas.

a. Lower

b. Higher

5. True or False: Before the data is stored in RAM, the analog signal from each element of the CCD must be

converted into a binary number.

a. True

b. False

Page 33

33

Data Writing

Data writing is a process of converting the image signals transmitted from the image processing section into light signals

and exposing the drum surface with the light signal.

Namely, the image signals transmitted from the image processing section are converted into optical signals (laser

emission) by the semiconductor laser element, which are then used to expose the drum surface, thus forming an

electrostatic latent image there.

The laser optical unit radiates the laser beam onto the photoconductive drum responding to the digital image signals

transmitted from the scanner, USB, network, etc. to create the latent image. Image signal is converted into the light

emission signal of the laser diode on the laser driving PC board (LDR), then radiated on the drum through the optical

elements such as cylinder lenses, polygonal mirror and fΘ lens. The unit must not be disassembled in the field as they are

very sensitive to dust and finely adjusted at the factory.

Page 34

34

Data Writing continued…

1. Laser Emission Unit

This unit consists of the laser diode, finite focus lens, aperture, and cylinder lens.

Laser diode

The laser diode features low drop,

small laser variation and low

threshold current. The aperture

limits the primary and secondary

scanning laser beam shapes at

the laser irradiation position.

The laser diode radiates the laser

beam responding to the laser

emission control (ON/OFF)

signals from the laser driving PC

board (LDR). Laser beams which

passed through the finite focus

lens are focused on the drum

surface.

The following figure shows the laser beam being emitted from the apertures

of the laser diode. A single beam array laser diode is mainly used for the

laser emission unit; however, some models adopt a four-beam array type

laser diode (four laser beams are emitted from one color laser diode) for faster radiation.

[1] Laser diode (1-beam)

[2] Laser diode (4-beam)

[3] Polygonal motor

[4] Drum

Page 35

35

Data Writing continued…

2. Polygonal Motor Unit

This unit consists of the polygonal motor, polygonal mirror and polygonal mirror cover.

Polygonal motor

This motor rotates the polygonal mirror in high speed. The DC motor controls the rotation speed of the mirror motor

Polygonal mirror

This mirror reflects the

emitted laser beams (four

beams per color).

As the polygonal mirror is

rotated by the polygonal

motor, the reflected laser

lights moves in sync with

the rotation. The direction

of the movement is the

primary scanning

direction. One scan is

performed on one plane of the polygonal mirror. As the polygonal mirror

has eight planes, eight scans are performed in one rotation.

Polygonal mirror cover / base

Polygonal mirror cover reduces the windage loss and noise, prevents

adhesion of foreign matters onto the mirror surface and releases heat

The images to the right show the laser beams reflecting off the

polygonal mirrors.

One scan is completed by one completion of steps (A) to (C).

One scan is performed on one plane of the polygonal mirror.

Eight scans can be performed in one rotation.

Page 36

36

Data Writing continued…

3. fθ Lenses 1 and 2

These two lenses perform the following adjustment on the laser beams reflected by the polygonal mirror.

Uniform-velocity scanning

Since the polygonal mirror is rotating at a uniform velocity,

the laser beam reflected from the mirror scans over the drum

surface at a uniform angular velocity; namely, the pitch

between the dots on the drum is wider at both ends than at

the center of the scanning range.

The fθ lenses help to correct this difference, making all the

dot-to-dot pitches equal on the drum surface.

Face tilt correction

The reflected face of the polygonal mirror is tilted slightly to

one side against the perfect vertical. Horizontal deviation of

the laser light which is caused by the tilt is corrected.

Sectional shape of the laser beam

The shape of the laser beam spotted on the drum is

adjusted.

Page 37

37

Data Writing continued…

H-Sync detection PC board

The laser liight which is started to be scanned from one of the reflected

planes on the polygonal mirror is reflected by the H-Sync detection mirror

and enters the PIN diode on the H-Sync signal detection PC board. The

primary scanning synchronizing signal is generated based on this

reflection.

Slit glass

The slit glass is located where the laser beams are output from

the laser optical unit, and it protects the unit from dust.

Alos, a shutter is attached to the upper side of the slit glass in

order to prevent toner or dust from adhering to the slit glass,

and it is normally closed. It is closed/opened by the shutter

motor. It is opened just before the laser beams are emmitted

and it closes just after the emission is finished. If toner or dust

adheres to the slit glass, images are affected. The slit glass is

cleaned with a brush attached to the shutter.

Reflecting mirrors

These reflecting mirrors reflect and lead the laser beams scanned by the polygonal mirror and corrected by the fθ lenses

to the drum. The laser beams of Y, M, C, and K colors are directed to the drum by respectively different routes using one

mirror for Y color beam and three each for M, C, and K color beams.

Mirror motor

At each of the third reflecting mirrors for M, C, and K color laser beams, a mirror motor is installed to make tilt adjustment

for the mirror. The parallel correction for the four scanning lines is performed by adjusting the tilt of mirrors in the following

manner:

(A) A test pattern is written on the transfer belt. This is read by the image position aligning sensors to

recoginize the error in scanning lines.

(B) With the Y color scanning line as the standard, a mirror motor installed at each of the M, C, and K color

beam mirrors is driven to adjust the degree of laser beam parallelization by inclining the motor.

Page 38

38

Data Writing continued…

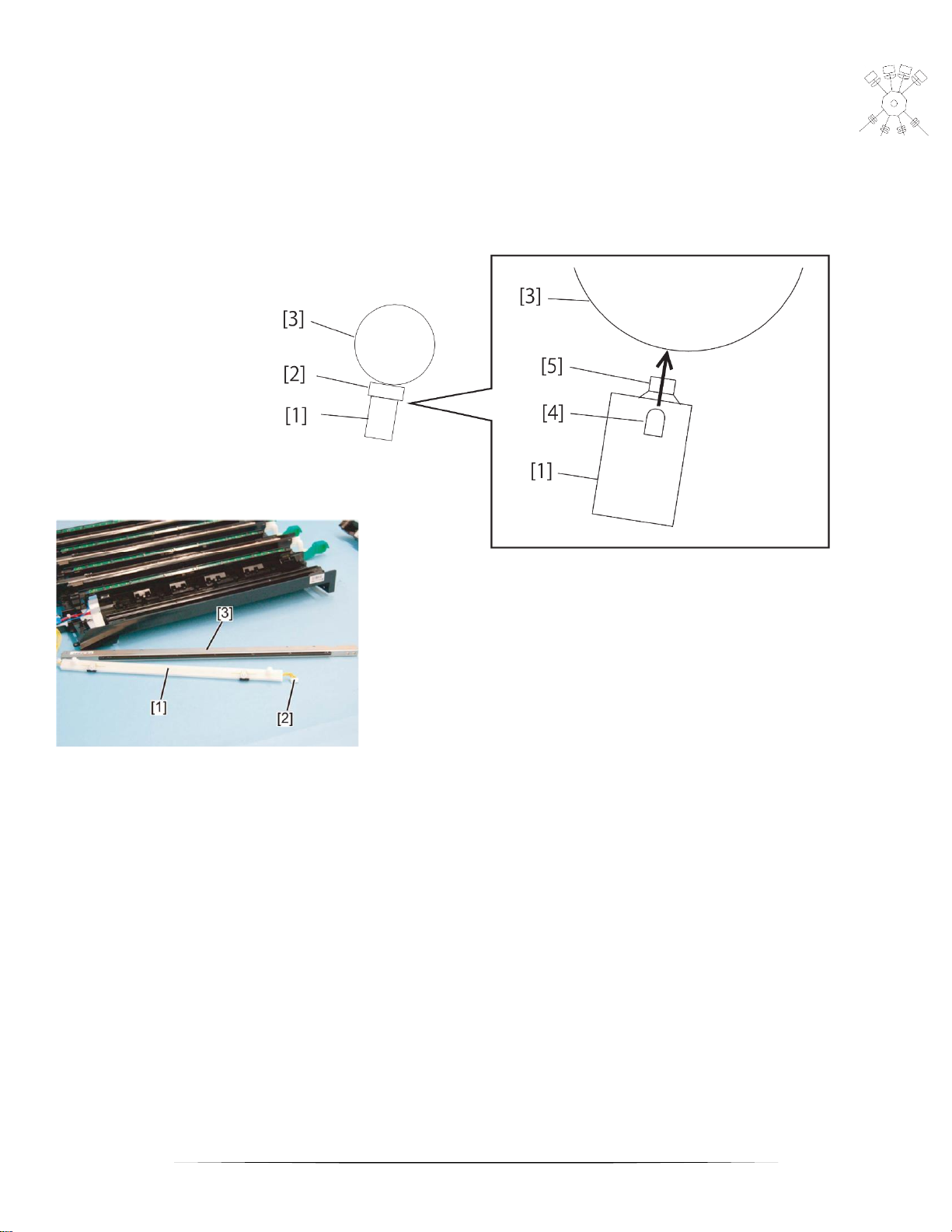

LED Print Head

Another method for writing the image is the use of an LED print head rather than a laser assembly. This method uses an

LED as its light source for radiating direct light onto the photoconductive drum.

[1] LED print head

[2] LED gap spacer

(front/rear)

[3] Drum

[4] LED

[5] Lens

1. Harness Holder

2. Connector

3. LED Print Head

Difference between the laser unit andd the LED head

To form images, the laser unit diffuses light from its light source using lenses, reflects the light onto the reflecting mirrors

and exposes the photoconductive drum to the reflected light. On the other hand, the LED print head emits light from its

LEDs arranged in a line directly onto the photoconductive drum.

Therefore the LED print head has advantages such as more space saving, requiring fewer parts, easier adjustment,

longer life, less noise and shorter light path, compared with the laser unit. However, the LED print head has some points

for which special care must be taken in image processing, such as uneven light output or the necessity of strict control of

the distance between the LED print head and the photoconductive drum.

Page 39

39

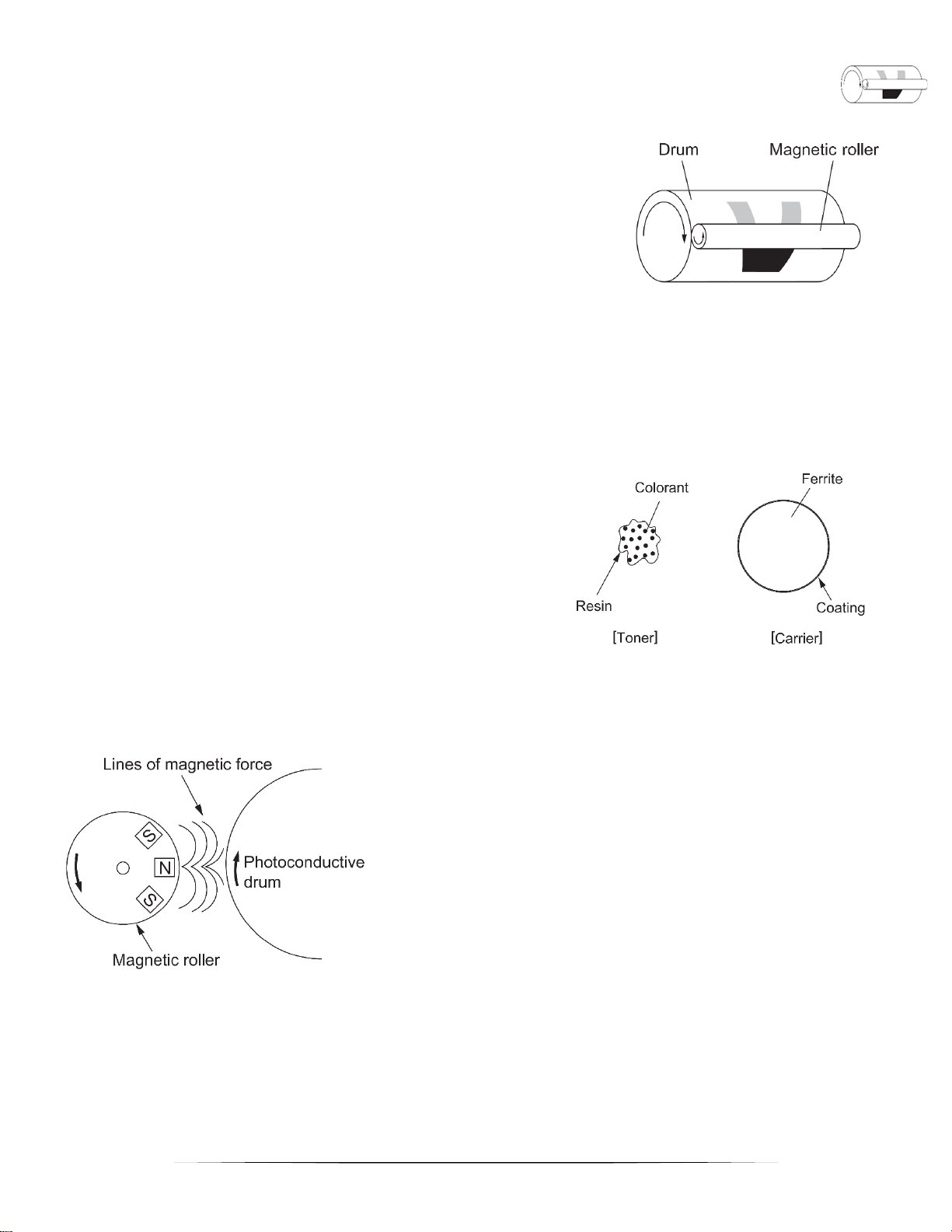

Development

Development is a process of making the electrostatic latent images visible to the

eye (visible image). Developer material is supplied to the photoconductive drum

surface by means of a magnetic roller, allowing the toner in the developer

material to adhere to the areas on the drum surface where the potential is lower

than the developer bias which is applied to the magnetic roller (reverse

development)

Developer Material

The developer material is comprised of a mixture of toner and carrier. The toner is charged to a negative polarity and the

carrier to a positive polarity, due to friction with each other caused by mixing.

Carrier is 5 to 10 times as large as toner.

Toner: Mainly consists of resin and coloring.

Carrier: Consists of ferrite, and over its surface resin coating to

provide consistent frictional electrification.

Toner + Carrier = Developer

Magnetic Roller “Getting the toner to the drum”

Magnetic brush development technique

Inside magnetic rollers, the south and north poles are arranged as shown

in the figure to the left. The developer material forms a brush-like fluff

which contacts the photoconductive drum surface. The magnetic roller

rotates in the opposite direction of the OPC drum, but at their contact

point, the surfaces move in the same direction.

Several magnets are contained inside the magnetic roller sleeve. The

sleeve rotates around the magnets. Lines of magnetic force are created.

Page 40

40

Development Continued…

The ferrite carrier beads (with toner attached) are attracted to the

opposite poles within the roller. As the sleeve continues to rotate, the

developer moves along the adjacent magnets. This causes a fresh

supply of developer at the contact point between the roller and the

drum.

As the drum turns, negatively charged toner is

attracted to the areas of the photosensitive drum

which have a potential lower than the developer

bias.

These, of course, are the areas that have been

discharged by the Laser. If the charge potential on

the drum (from the main charger) is -500V, for

example, and the bias voltage of the developer is 400V, only those dots on the drum that have been

discharged (by the Laser) will attract toner and

create a visible image.

It may seem contradictory for a negative charge to be attracted to another negative charge but remember

that voltage is a relative measure from one point to another. If the toner has a charge of -425VDC and the

drum has a charge of -300VDC, then the toner will be attracted to the drum as if it had a positive charge

potential. The discharged area of the drum at -300VDC is relatively positive from the point of view of the

toner particle at -425VDC.

Page 41

41

Service Tips for Development

Proper PM is especially important to perform on the Developer Unit because the consequences of

not doing so can be severe. It is extremely difficult to clean up a machine after a bad developer spill. These

often require shop work and are generally caused by poor maintenance.

Malfunction

Effect on System

Effect on Copies

Over used carrier

Carrier efficiency

deteriorates

Low image density, Toner

scattering, Fogging

High toner to carrier

ratio

Too much toner

Backgrounding, Excessive

toner in the machine

Low toner to carrier ratio

Not enough toner

Low image density,

Decreased life of developer,

Possible damage to OPC

PM is very important. Replace developer material and other parts at recommended intervals. When you replace

the developer, check for wear to bushings, gears, and mylars and replace if worn. Vacuum developer material

from the interior, particularly around the gears where it causes extreme wear. Take care not to vacuum around

the toner sensor, which can be damaged by static.

Page 42

42

Page 43

43

Transfer

Transfer is a process of dealing a toner image from the photoconductive drum onto paper. A toner image formed on the

photoconductive drum is temporarily transferred onto the transfer belt, and the toner image is then transferred from the

transfer belt onto paper.

The first transfer from the drum to the transfer belt is called the 1st transfer, and the second transfer from the transfer belt

to paper is called 2nd transfer.

To form a color image, the images of yellow (Y), magenta (M), cyan © and black (K) are transferred and overlaid on the

transfer belt in order, and then the overlaid images are transferred onto paper.

After the completion of the 2nd transfer, the residual toner on the transfer belt is scraped off by the transfer belt cleaning

blade and then transported to the waste toner box.

The figure below is an example for the configuration of the transfer unit. Parts or mechanisms shown below may not be

installed in some models.

Belt Clinging

Roller Before

2nd Transfer

Waste Toner

Auger

Transfer Belt

Cleaner Unit

Facing Roller

TBU Drive Roller

Lift Roller

Transfer Belt

Cleaning Blade

1st Transfer

Roller (Y)

1st Transfer

Roller (M)

1st Transfer

Roller (C)

Winding

Roller

1st Transfer

Roller (K)

2nd Transfer

Roller

Registration

Sensor

Image Quality

Sensor

Paper Clinging

Detection

Sensor

Page 44

44

Transfer Continued…

Functions

Transfer Belt

This belt, made of electrical resistance resin, is formed in a highly-precise technique.

1st Transfer Roller (Y), (M), (C), (K)

When the 1st transfer bias from the high voltage transformer is applied to this roller, a toner image is transferred from the

photoconductive drum onto the transfer belt. The roller presses the transfer belt and the photoconductive drum causing

them to contact one another.

TBU Drive Roller

This roller [1] rotates the transfer belt with the drive

transmitted from the transfer belt motor. This roller is also

known as the “2

nd

Transfer Facing Roller”. It contacts with the

2nd transfer roller, holding the transfer belt between them to

nip paper. When the 2nd transfer bias (negative polarity) is

applied from the high voltage power supply to the 2nd transfer

facing roller, a toner image is transferred onto paper.

To clean off the toner adhered on the 2nd transfer roller,

positive bias is applied on the 2nd transfer facing roller to

transport the positively charged toner on the 2nd transfer roller

to the transfer belt.

Winding Roller

This roller applies tensile force to the transfer belt.

Lift Roller

The roller retains the contacting position of the transfer belt and the photoconductive drum. When only a black (K) image

is being transferred, the transfer belt cam motor lifts up the 1st transfer rollers of yellow (Y), magenta (M) and cyan (C),

together with this roller.

Page 45

45

Transfer Continued…

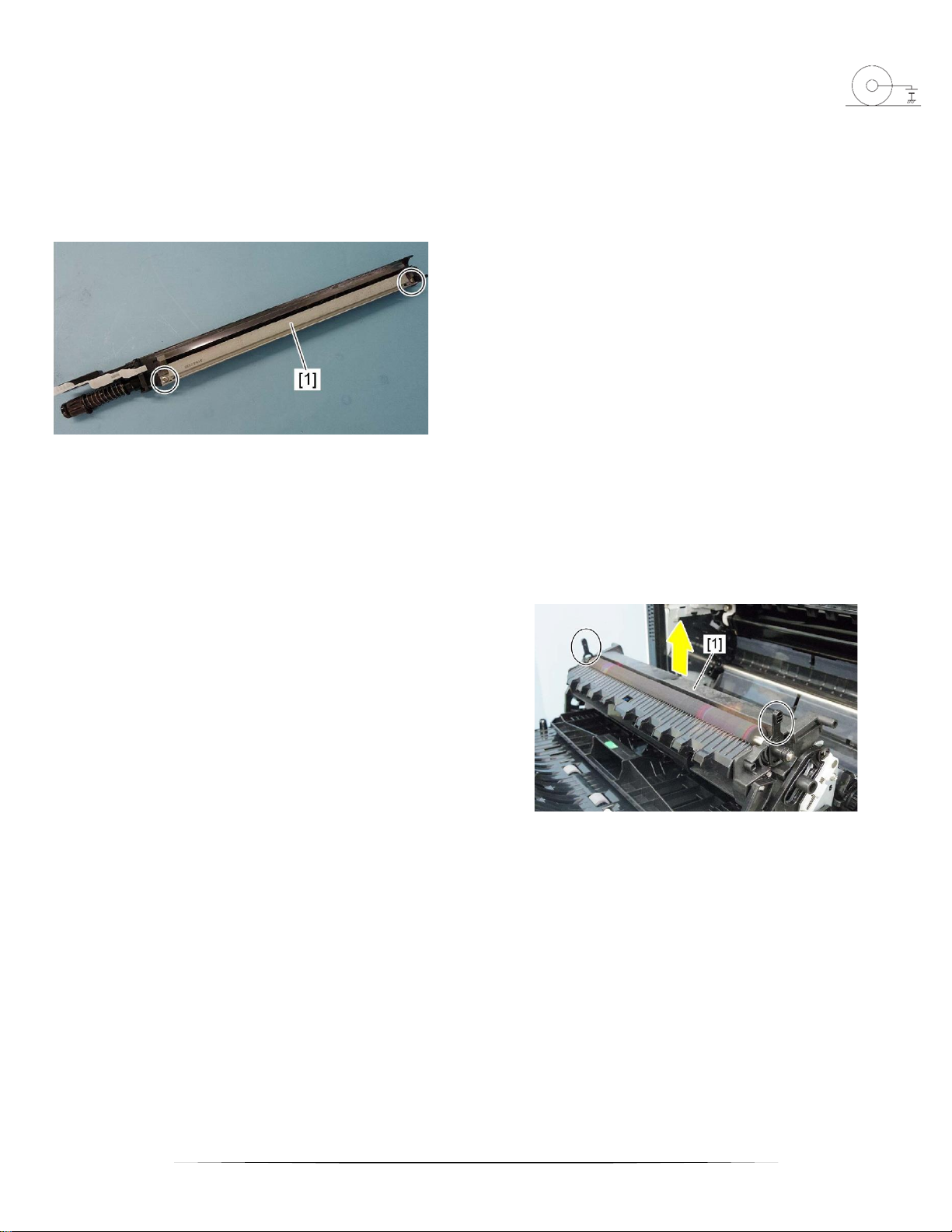

Transfer Belt Cleaning Blade

This blade [1] removes the residual toner, paper dust or foreign objects on the transfer belt surface. It is pressed onto the

transfer belt unit by its spring. The recovery blade and urethan seal prevent the removed residual toner or other objects

from leaking out of the transfer belt cleaning unit.

Waste Toner Auger

This auger transports the residual toner, paper dust or foreign objects scraped off by the transfer belt cleaning blade to the

waste toner box.

2nd Transfer Roller

This metal roller, covered with sponge [1], is located to face the 2nd

transfer facing roller through the transfer belt.

Page 46

46

Transfer Continued…

Direct transfer method

In some black/white models, a transfer roller is used instead of a

transfer belt.

Page 47

47

Transfer Continued…

Service Tips for Transfer

Proper maintenance of the transfer system

Malfunction

Effect on System

Effect on Copies

Broken Exposure Lamp

No light, the CCD does not

receive any light therefore

there is no image data.

Solid copies

Dirt, dust, etc.

Reduced light causes the

CCD to interpret the image

incorrectly

Uneven Image Density or

backgrounding

Obstruction in optical

path

Light will not be reflected

properly

Line or background band

Mirror out of position

Light will not be reflected

properly

Skewed image

Proper Maintenance

Inspect the transfer belt and replace the transfer belt cleaning blade at specified PM intervals.

Memory

Put the following important items into “memory”

• In the scanning section, the surface of the original is irradiated with a direct light and the

reflected light is led through mirrors, a lens and a slit to CCD.

• A lens and a slit to CCD is where optical–to–electrical conversion is performed, converting

the optical image data into an electrical (analog) signal.

• The analog signal is changed to a digital signal, which then undertakes various corrective

processes necessary for image formation.

Page 48

48

Page 49

49

Fuser Unit

General Description

The fuser unit fuses the toner image transferred to paper using the IH coil or heater lamp. When paper is

transported to the fuser unit, toner is fused by applying heat and pressure on the paper with the fuser roller (or

fuser belt) and the pressure roller.

The fuser unit consists of the fuser belt, fuser roller, IH coil, pressure roller, separation fingers, separation

plate, thermopiles, thermistors, thermostats, sensor etc.

The rollers in the fuser unit are driven by the fuser motor.

[1] Pressure roller

[2] Pressure roller heater lamp

[3] Entrance guide

[4] Fuser roller

[5] Fuser belt

[6] Fuser belt thermister

[7] Fuser belt thermostat

[8] Paper guide

[9] Separation plate

[10] Separation fingers

[11] Pressure roller thermostat

[12] Pressure roller thermistor

[13] IH coil

[14] Satellite roller / Heat pipe roller

[15] Heater lamp

[16] Heat roller

Page 50

50

Fuser Unit Continued

The toner is melted by the heat of the heat roller. The paper is heated and pressed while it is being

passed between the heat roller and the pressure roller and thus the toner is fused on the paper.

A lamp or IH coil is used as the heat source of the fuser unit. Then a thermistor, for detecting and controlling the

temperature of the heat roller, and a thermostat, for preventing abnormal temperature rise, are attached.

To apply heat from the heat source to the paper, the heat roller which directly heats the paper and the pressure roller

which heats the paper via the fuser belt are embedded. This mechanism varies depending on models.

Service Tips for Fuser Unit

Proper maintenance of the Fuser Unit will prevent the unit from making marks on the paper, creasing the

paper, making noise and misfeeding.

Malfunction

Effect on System

Effect on Copies

Fuser temp. too low

Heat roller doesn’t heat

enough

Toner doesn’t melt.

Toner rubs off.

Heat Roller Surface

Damage

Toner sticks to roller or belt.

Marks on the copy

PM Replace parts at appropriate PM intervals. Clean toner from paper guides. Clean and lubricate proper lubrication

points and replace worn gears.

Page 51

51

Fuser Unit Continued

Memory

Put the following important items into “memory”

• During the fuser process, heat and pressure permanently bond the toner image into the

fibers of the paper.

• The main elements of the fusing process are: Heat roller or belt, Lamp or IH Coil and

pressure roller.

• The heat melts the toner and the pressure fixes it into the fibers of the paper.

Page 52

52

Page 53

53

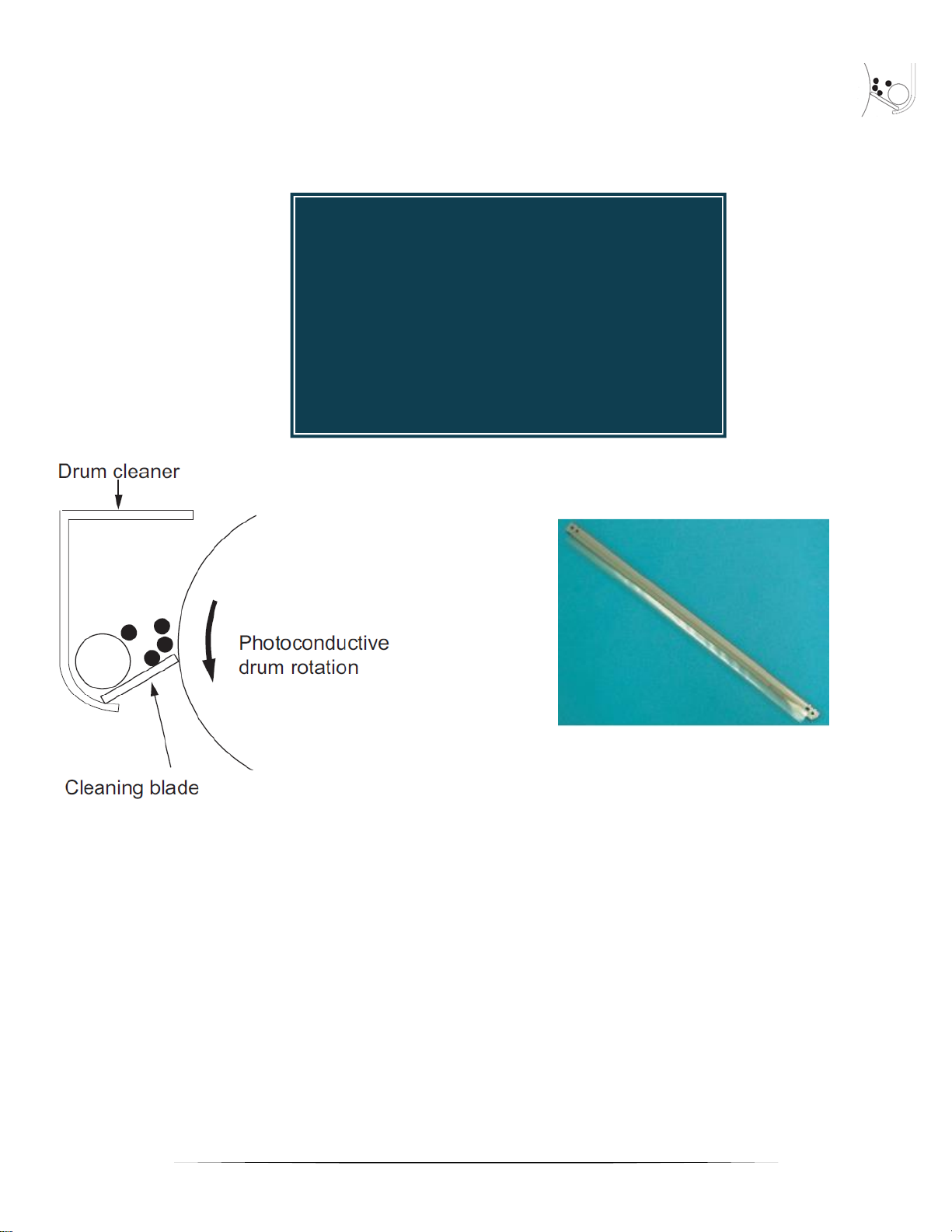

Cleaning

During the cleaning process, residual toner is removed from the drum surface in preparation for the next copy cycle.

Some of the toner that was applied to the drum during the development process remains as residue even after the image

has been transferred. That residue must be cleaned off and captured. Two blades are used to accomplish this function.

The cleaning blade touches the drum surface to scape off the toner. The toner is caught by the recovery blade and

deposited into a receptacle. A recovery auger moves the toner to a waste container where it remains until discarded. In

some models, the residual toner is moved from the recovery auger back to the developer unit. These models “recycle” the

residual toner.

PRIMARY COMPONENTS

• DRUM AND RESIDUAL TONER

• CLEANING BLADE

• RECOVERY BLADE

Page 54

54

Cleaning continued…

Service Tips for Cleaner Unit

Proper maintenance of the Fuser Unit will prevent the unit from making marks on the paper, creasing the

paper, making noise and misfeeding.

Malfunction

Effect on System

Effect on Copies

Nicks or burrs in blade

Possibly damages the drum

Streaks on copies

Paper dust or other

contaminants

Poor cleaning

Streaks on copies

Worn recovery blade

Toner gets by recovery

blade creates toner spillage

in the machine

Toner spots on copies

PM Proper maintenance includes cleaning and replacing parts at prescribed intervals. Since paper dust can cause

cleaning blade failure, cleaning of the entire machine is necessary for good blade life. Always replace the cleaning blade

when replacing the drum to make sure both components wear evenly together. Avoid touching the cleaning blade with

fingers. The oils on your hand may damage the blade or the drum surface.

Memory

Put the following important items into “memory”

• During the cleaning process the Cleaning Blade scraps the excess toner off the drum and a

Recovery Blade collects it in a receptacle.

• Toner is removed from a cleaning unit by a recovery auger and transported to a waste

toner container.

• Some models recycle the waste toner by returning it back into the developer unit.

Page 55

55

Discharge

During the discharge process, any charge from the latent image that remains on the drum is eliminated by light from an

LED array.

An LED assembly exposes the drum to light. The electrical resistance of the drum surface drops. The drum becomes

conductive. All remaing charges dissipate to ground.

The discharge process prepares the drum to receive the Main Charge which is the beginning of the next copy cycle. If the

discharge process were not executed, the residual charge would build up and the Main Charge of the next cycle would be

uneven. In that case, the previous image may be superimposed onto the image of the subsequent cycle.

The light makes the drum conductive and all

charges on the drum are dissipated to ground

in preparation for the next copy cycle.

Page 56

56

Service Tips for Discharge

Failures of the Discharge LED array can cause uneven charges on the drum surface.

Malfunction

Effect on System

Effect on Copies

Failure of the LEDs

Residual charges are not

dissipated

Streaks on copies

Backgrounding

Developer Depletion

Toner dusting

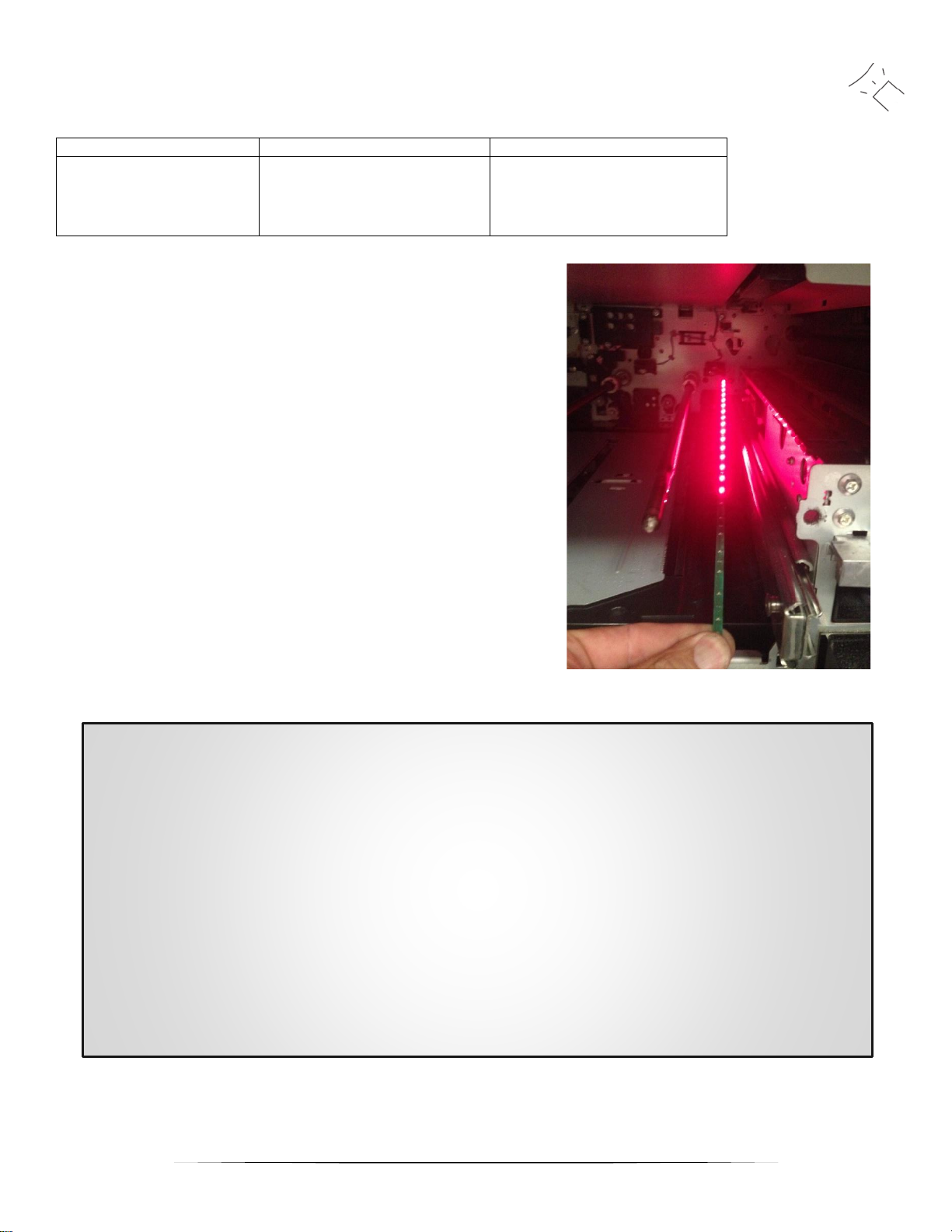

An example of testing the LED array in 03 test mode shows the front

side of the array has failed.

Memory

Put the following important items into “memory”

• During the discharge process a discharge lamp illuminates the drum surface which

reduces the electrical resistance and causes the residual charges to dissipate to ground.

• The discharge function prepares the drum to receive the main charge.

Page 57

57

Review: Discharge

1. List three effects that may occur if the discharge lamps do not illuminate.

a. _______________________________________________________

b. _______________________________________________________

c. _______________________________________________________

2. What does the discharge LED do to the drum?

a. The surface becomes more of a conductor

b. The surface becomes more of an insulator

c. The surface shifts from AC to DC

d. It turns from a dark green to a light green

3. What is the next thing that happens after the discharge LED has neutralized the residual charges on the

drum?

a. The cycle starts again with the main charge

b. The exposure sequence is initiated

c. The transfer step is initiated

d. The toner is cleaned off by the cleaning blade

Page 58

58

Page 59

59

SECTION THREE

Mechanical Components

The mechanical operation of a MFP depends on several assembly systems – Drive Assemblisies, Optical Assemblies,

Paper Feed Assemblies, Developer Assemblies, etc. – working together. Each assembly is made up of individual

components such as drive shafts, gears, bearings, bushings, solenoids, motors, sensors, pulleys and timing belts. The

best way to understand how these major assemblies are built and function is to see them in action on a machine. But

that’s hard to do in a book like this. To help prepare for the classes in which you will receive hands-on training and get a

“feel” for all the components in a MFP, we will examine some of the basic parts which the larger assemblies are made.

Goals

Upon completion of this section, you will:

• Understand the theory of operation of standard mechanical components used in Toshiba MFP’s.

• Understand how the individual components operate together within the system.

• Understand PM issues and troubleshooting techniques associated with the mechanical components.

• Know how to repair and maintain the components.

The following components will be examined in this section:

• Clutch Mechanisms

• Electro-Magnetic Clutch

• Spring Clutch

• Torque Limiter

• One-way Clutch

• Solenoid

• Bearing

• Bushing

• Gears

• Pulley

• Timing Belt

•

Clutch Mechanisms

A clutch can transmit or cease the transmission of mechanical energy from a source such as a motor, drive shaft or a gear

assembly to a drive mechanism such as a roller. Toshiba MFP’s make use of several types of clutches or clutch like

components. In this section, we will look at the electromagnetic clutch and the torque limiter, etc.

Page 60

60

Electromagnetic Clutch

The electromagnetic clutch uses a magnetic force to engage and disengage spinning plates that are usually attached to

some kind of drive shaft. When the idler plate and drive plate disengage, the drive mechanism stops. When engaged, the

drive mechanism continues.

Below is a diagram of an electromagnetic clutch. The system is designed to turn and stop the turning of the shaft it is

attached to. When current flows through the coil inside the clutch, the magnetism attracts the drive plate to the driven

plate and the high friction between the two causes the separate sections to rotate together.

Service Tips for Electromagnetic Clutch

Dirt

Generally, two things can happen to the electromagnetic clutch that may cause a failure. If the inside gets dirty or

"gummed up", then as the drive plate turns, the driven plate may get some "drive" and turn when it shouldn't. In short, the

driven part may begin to "creep".

Wear

Worn plates cause a different failure. If too worn, the plates can either slip completely in which case the system will get no

"drive" at all. Or there may be partial slippage in which case the driven part won't move properly.

Malfunction

Effect on System

Effect on Copies

Dirt or contamination causes freespinning plate to move stationary plate

when it should not.

Drive shaft moves when

it shouldn't.

Driven part creeps forward.

Worn plates

Plates slip.

Either no drive at all,

or not enough drive.

PM

Area around the drive shaft and bushings should be kept clean, and lubricated as per the Preventive

Maintenance guide. The electromagnetic clutch mechanism ls often sealed. If that's the case and there's a

failure, there's not much you can do but replace the part. Sometimes, however, you can open them up and

service the plates. Opening an electromagnetic clutch is typically done when there is a specific problem, not on

a regular basis.

Page 61

61

Spring Clutch

The function of the Spring Clutch

is basically the same as the electromagnetic

clutch. It can transmit or

disengage power from a source.

In a one-way spring clutch like the

one in the diagram, a clutch

spring is wrapped tight around a

hub. A gear or other device may

turn the hub and-when the

spring is wrapped tight-the hub

also turns the roller or other mechanism

to which it is attached. To

disengage, a stop pawl-activated

by a solenoid or other mechanical

activator-grabs the end of the

spring and stops it. The spring expands (opens up). When expanded, the hub continues to spin, but the roller is not

engaged. The rotation of the gear is thus transmitted to the roller only when the stop pawl is out of engagement.

When the spring is wrapped tight around the hub, the gear turns the hub and the hub turns the roller.

When the stop pawl grabs the end of the spring, the spring expands. When expanded, the gear still turns the

hub, but the hub does not tum the roller.

Stop Pawl

Stop Groove

Gear

Hub

Frame / Bracket

Bushing / Collar

Clutch Spring

Sleeve

Arbor

Roller

Stop Pawl Released

Gear

Hub

Clutch Spring

Arbor

Roller

Stop Pawl When Operated

Clutch Spring

Arbor

Roller

Hub

Gear

Page 62

62

Spring Clutch as a Torque Limiter

A Torque Limiter is physically like a spring clutch, but it lacks the conventional stop-pawl

mechanism that would completely disengage the drive from the source. As such, a torque

limiter serves a different purpose. It is used when a driven part must be able to “slip”. The

amount of drive (torque) is limited so the driven part can be stalled without stalling the entire

drive system.

The purpose of a torque limiter is NOT to engage and disengage mechanical rotation, but to

limit the amount of drive (torque) a roller or other component gets in the “driven” direction. It

limits the torque by adding a “slippage” factor to the process.

Torque Limiters are often used to modulate the rotation and torque of paper separation rollers.

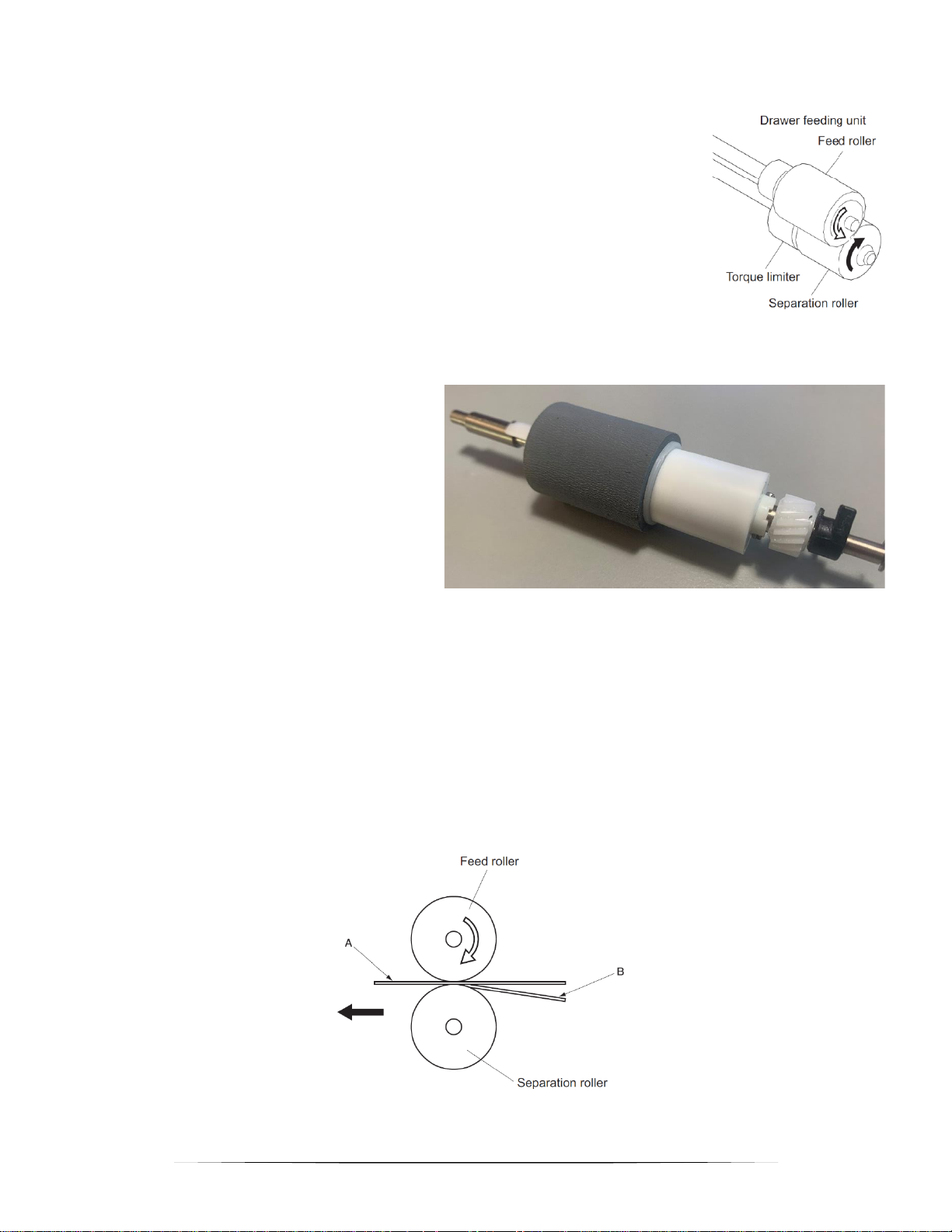

DSDF Separation Roller Assembly.

The torque limiter is held to the shaft with a pin on the

right side and connects to he separation roller with

two pawls. This allows the roller to “slip” if two sheets

of paper are feed through at the same time. The

slpippage causes the bottom sheet of the two to stop

in place allowing only one sheet to pass through. Thus

preventing multi-sheet feeding.

Example

When only one sheet enters between the rollers:

Since the transporting force of the feed roller is greater than the braking force of the separation roller, the separation roller

follows the feed roller, making the sheet go forward.

When two sheets enter between the rollers at the same time:

Since the transporting force of the feed roller and the breaking force of the separation roller are greater than the frictional

force between two sheets, the paper “A” is transported to the direction of the black arrow and the paper “B” is braked by

the separation roller and is not transported any further.

Page 63

63

Service Tips for Spring Clutch and Torque Limiter

The two primary issues related to Spring Clutch mechanisms are proper lubrication and attention to wear.

When the device is acting as a Spring Clutch and it has too much lubricant, it may slip when it should be

grabbing. If it slips, paper may not reach alignment points at the right time, or you could get a paper misfeed

problem. When the mechanism is functioning like a Torque Limiter and it has too much lubricant, torque will not

be properly modulated which results in paper feed problems.

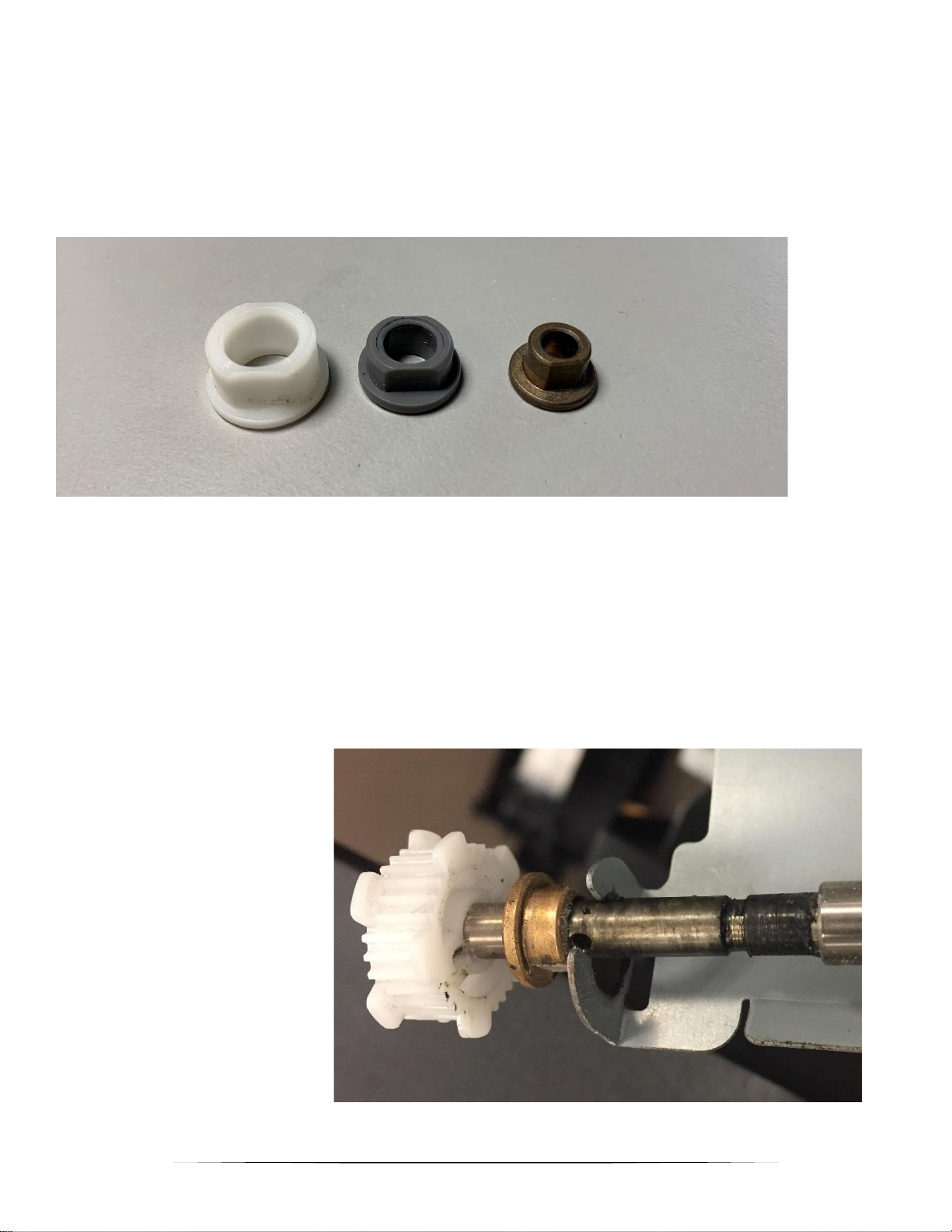

If the Spring Clutch has too little lubricant, it may grab when it shouldn’t which will cause the shaft to “creep”.