Page 1

General Precautions for Installation/Servicing/Maintenance for the KK-1600

The installation and service should be done by a qualified service technician.

1. When installing the KK-1600 to the Plain Paper Copier , be sure to follo w the instructions described in

the “Unpacking/Set-Up Procedure for the KK-1600” booklet which comes with each unit of the

KK-1600.

2. The KK-1600 should be installed by an authorized/qualified person.

3. Before starting installation, servicing or maintenance work, be sure to turn off and unplug the copier

first.

4. When servcing or maintaining the KK-1600, be careful about the rotating or operation sections such

as gear, pulleys, sprockets, cams, belts , etc.

5. When parts are disassembled, reassembly is basically the rev erse of disassembly unless otherwise

noted in this manual or other related materials. Be careful not to reassemble small parts such as

screws, washers, pins , E-rings, toothed washers to the wrong places .

6. Basically, the machine should not be operated with any parts removed or disassembled.

7. Delicate parts for preventing safety hazard problems (such as breakers, thermofuses, fuses, door

switches, sensors, etc. if any) should be handled/installed/adjusted correctly.

8. Use suitable measuring instruments and tools.

9. During servicing or maintenance wor k, be sure to check the serial No. plate and other cautionary

labels (if any) to see if they are clean and firmly fixed. If not, take appropriate actions.

10. The PC board must be stored in an anti-electrostatic bag and handled carefully using a wristband,

because the ICs on it may be damaged due to static electricity. Before using the wrist band, pull out

the power cord plug of the copier and make sure that there is no uninsulated charged objects in the

vicinity.

11. For the recov ery and disposal of used KK-1600, consumable parts and packing materials, it is recommended that the relev ant local regulations/rules should be follo wed.

12. After completing installation, servicing and maintenance of the KK-1600, return the KK-1600 to its

original state, and check operation.

Copyright 2000

TOSHIB A TEC CORPORATION

Page 2

CONTENTS

1. SPECIFICATIONS....................................................................................................... 1-1

2. OUTLINE..................................................................................................................... 2-1

2.1 Names of Various Components........................................................................................ 2-1

2.2 Layout of Electrical Parts ................................................................................................. 2-2

2.3 Harness Connection Diagram .......................................................................................... 2-4

2.4 Board Assembly ............................................................................................................... 2-5

3. OPERATIONAL DESCRIPTION ................................................................................. 3-1

3.1 General Description ......................................................................................................... 3-1

3.2 Block Diagram.................................................................................................................. 3-1

3.3 Detection of Abnormal Status ..........................................................................................3-2

3.4 Flow Chart........................................................................................................................ 3-3

4. MECHANICAL DESCRIPTION................................................................................... 4 - 1

4.1 Mechanism Drawing......................................................................................................... 4-1

4.2 Staple Operation .............................................................................................................. 4-1

5. CIRCUIT DESCRIPTION ............................................................................................ 5-1

5.1 PWA Block Diagram......................................................................................................... 5-1

5.2 Functional Description...................................................................................................... 5-1

5.3 Signal Description ............................................................................................................ 5-2

5.4 Timing Charts............................................................................................................... .... 5-3

6. DISASSEMBLY AND REPLACEMENT...................................................................... 6- 1

October 2000 © T OSHIBA TEC 1 KK-1600 CONTENTS

Page 3

1. SPECIFICATIONS

Type of stapling : Flat clinch method

2

No. of sheets stapled : 52g/m

52g/m

Paper thickness : Max. 5.5 mm

Staple capacity : 5000 staples

Dimensions : 257 (W) x 423 (D) x 173 (H) mm

Weight : Approx. 3.4 kg

Power supply : 100V - 240V (Supplied from copier)

paper, 2 sheets to 80g/m2 paper, 50 sheets

2

paper, 2 sheets to 80g/m2 paper, 48 sheets + 200g/m2, 2 sheets

October 2000 © T OSHIBA TEC 1 - 1 KK-1600 SPECIFICATIONS

Page 4

2. OUTLINE

2.1 Names of Various Components

STP power lamp

STP power code

STP base

STP staple cartridge

STP staple unit

STP 02-01-01

STP 02-01-02

October 2000 © T OSHIBA TEC 2 - 1 KK-1600 OUTLINE

Page 5

2.2 Layout of Electrical Parts

STP AC adapter

STP LED PWA

STP1

STP 02-02-01

STP2

M1 SW2

SW1

SEN2

SEN1

STP 02-02-02

KK-1600 OUTLINE 2 - 2 October 2000 © T OSHIBA TEC

Page 6

Symbols and functions of various devices

Symbol

SW1

SW2

SEN1

SEN2

M1

STP1

STP2

LED

Name

STPCOV-SW

STP cover open switch

EMPTY-SW

STP staple empty switch

PSET-SEN

STP paper set sensor

HP-SEN

STP home position sensor

STP motor

STP CONT PWA

STP sensor PWA

STP LED PWA

Function

Detects the open/close state of the cover during staple replacement, etc.

Detects the presence or absence of staples.

Detects the loading of the paper to be stapled.

Detects the home position of the drive section.

Drive the stapler.

PWA which controls the stapler.

PWA which relays the sensor signals and motor drive signals.

PWA on which the power lamp (LED) is installed.

October 2000 © T OSHIBA TEC 2 - 3 KK-1600 OUTLINE

Page 7

2.3 Harness Connection Diagram

AC

adapter

AC IN

24V

GND

J2

J1

1

2

J3

STP

CONT

PWA

1

2

1

2

3

4

5

6

7

24V

COVER

GND

H.P

5V

GND

Empty

CW

CCW

STP cover open switch

Staple unit

CN1

CN2

CN3

1

2

1

2

1

2

3

4

5

6

STP

sensor

PWA

7

M

STP motor

STP staple

empty switch

STP home

position sensor

J4

5V

1

GND

2

Set

3

STP paper set sensor

J5

GND

1

LED

2

STP LED PWA

STP 02-03-01

KK-1600 OUTLINE 2 - 4 October 2000 © T OSHIBA TEC

Page 8

2.4 Board Assembly

2J2

C16

JP2

JP1

J1

2

3

1

FU1

Q7

S

DG

Q5

S

Q6

S

DG

Q4

DSG

STPL CONTROLLER

C11

JP15

1

R16R14

G

Q3

G

D6

1

IO

2

C9

C19

JP5

JP4

JP3

1

0

D8

D5

D7

D4

C6

JP7

MADE IN JAPAN

JP6

J3

JP16

D9

Q2

1

JP13

JP9

JP8

C1

W

C5

JP17

JP11 JP12

1

Q1

D1

2

C4

1

J5

C3

D2

D3

9

D10

4G1–1231

C8

JP14

8

02

JP10

J4

4H10109

3117

STP 02-04-01

October 2000 © T OSHIBA TEC 2 - 5 KK-1600 OUTLINE

Page 9

3. OPERATIONAL DESCRIPTION

3.1 General Description

Upon detecting the loading of paper, the STP operates the motor for staple operation. The AC input

supplied from the copier is converted to a DC voltage (24V) through the AC adapter in the STP and used

as a power supply for the STP.

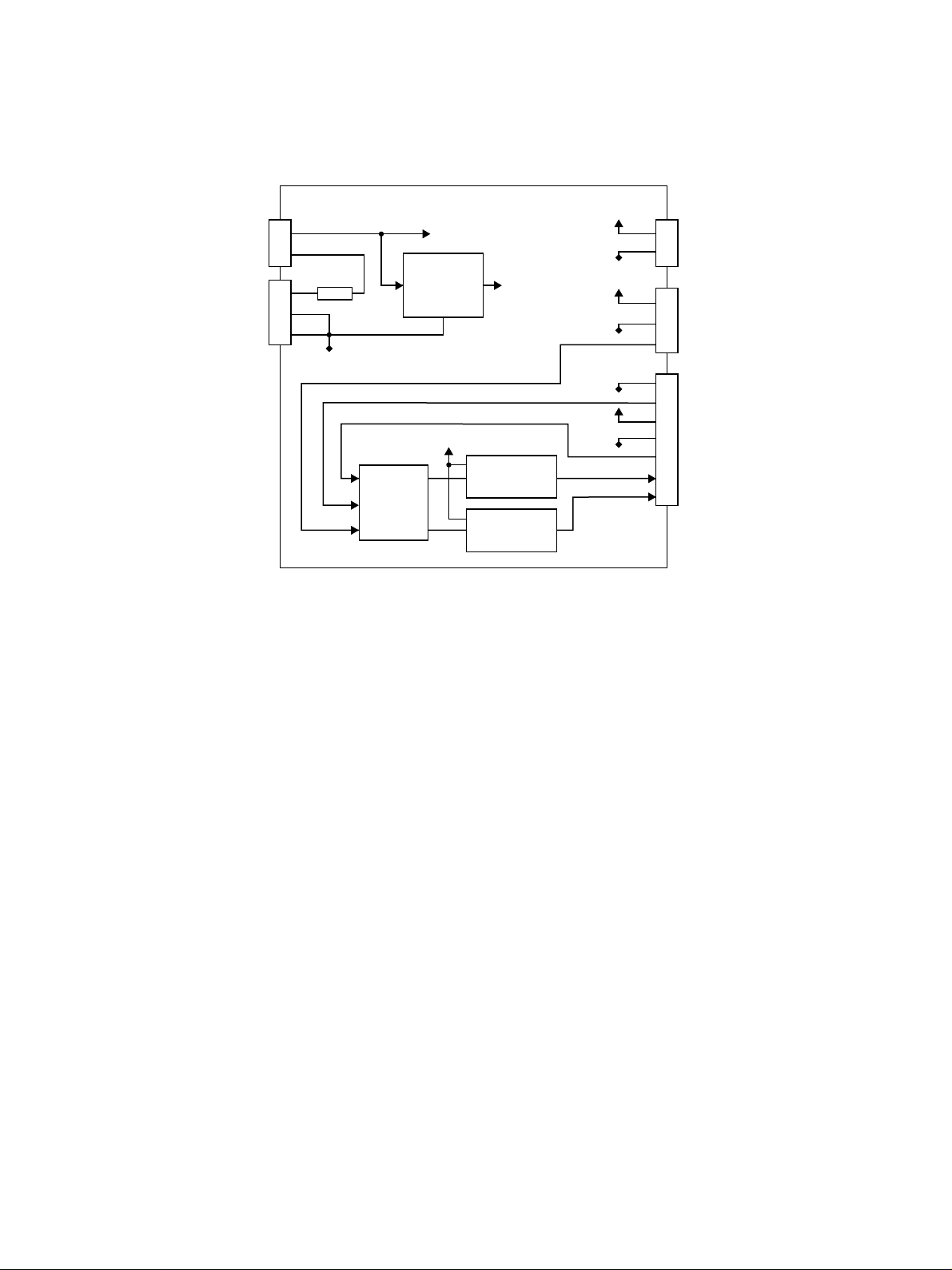

3.2 Block Diagram

STP cover open switch

STP paper set sensor

STP LED PCB

Staple unit

M STP motor

STP staple empty switch

STP home position sensor

STP 03-02-01

AC

adapter

+24V

J2

J1

J4J5J3

STP

CONT

PWA

STP

sensor

PWA

The STP consists of the AC adapter, STP CONT PWA, sensors, power indicator LED, staple unit, etc.

The staple unit consists of the STP motor, STP Sensor PWA for relaying the sensor signals, mechanical

drive section, etc.

October 2000 © T OSHIBA TEC 3 - 1 KK-1600 OPERATIONAL DESCRIPTION

Page 10

3.3 Detection of Abnormal Status

• Cover Open/Close Detection

The STP cover open s witch turns OFF when the cover is opened. Since the s witch is connected to the

power supply, the power supply to the STP is cut when the switch turns OFF. For this reason, all the

operation is disabled while the cov er is open. When the STP cov er is closed, the delivery of the power

supply is resumed to light the STP power lamp and enable stapling.

• Staple Empty Detection

Upon detecting a staple empty state, the STP staple empty switch resets the motor drive circuit so that

the motor does not operate ev en if the STP paper set sensor detects the presence of paper . This error

state is reset when staples are supplied causing the STP paper set sensor to detect the presence of

staples.

KK-1600 OPERATIONAL DESCRIPTION 3 - 2 October 2000 © TOSHIBA TEC

Page 11

3.4 Flow Chart

Copier power ON

STP cover open

switch

Close

STP power lamp ON

Load paper into STP.

(STP paper set sensor ON)

STP staple

empty switch

OK?

OK

Open

STP power lamp OFF

NG

Stampling stopped

Supply staples

STP motor operates

to start stapling.

STP 03-04-01

October 2000 © T OSHIBA TEC 3 - 3 KK-1600 OPERATIONAL DESCRIPTION

Page 12

4. MECHANICAL DESCRIPTION

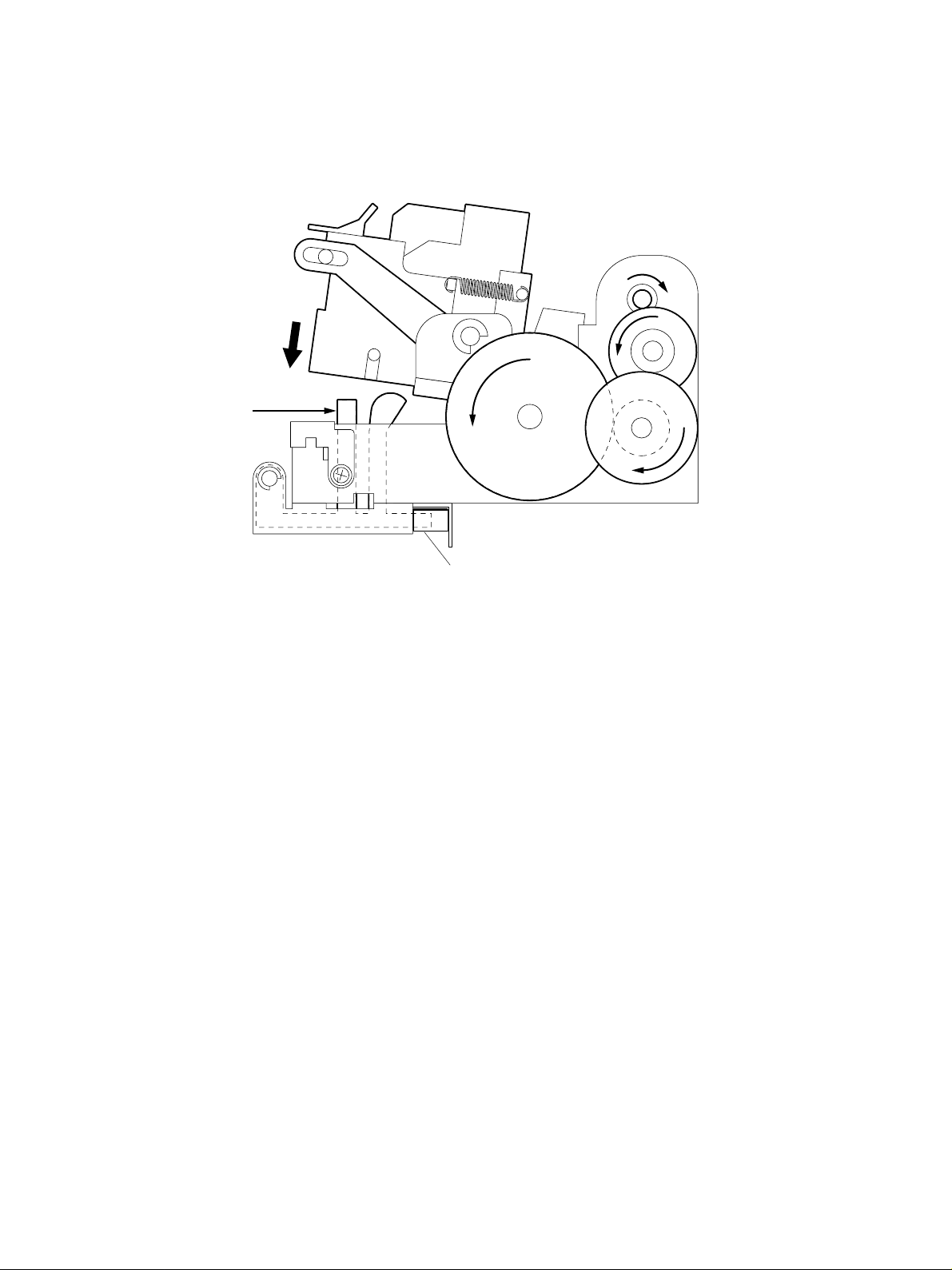

4.1 Mechanism Drawing

Paper set

STP paper set sensor

STP 04-01-01

4.2 Staple Operation

The staple operation of the STP is performed only by the rotation of the STP motor through the combination of the gears and cams.

The loading of paper is detected when the paper detection lev er is pushed. When paper is loaded into the

stapler, the paper detection lever is pushed causing the STP paper set sensor to detect the presence of

paper.

When the presence of paper is detected, if staples are availab le, the STP motor is operated to drive the

gears and cams to perform staple operation. If no staples are available, the STP does not operate until

staples are supplied. When one time of staple operation is finished, the STP returns to its original state

and stands by until the next presence of paper is detected.

Staples are loaded in the cartridge and its capacity is about 5,000 staples. When the cartridge is supplied with staples or a new cartridge is installed, perform staple operation without staples (7 to 8 times) to

feed staples to a position where stapling is possible.

October 2000 © T OSHIBA TEC 4 - 1 KK-1600 MECHANICAL DESCRIPTION

Page 13

5. CIRCUIT DESCRIPTION

5.1 PWA Block Diagram

5V

STP cover open

switch

STP AC adapter

J2

J1

1

2

1

2

3

FU1

GND

Motor

24V

Q3

switching

regulator

PAPER_SENS

STPL_H/P

HOOK_SW

24V

Motor drive

5V

circuit

GND

GND

GND

5V

GND

CW

CCW

5V

1

2

STP LED PWA

J5J4J3

1

STP paper set

2

sensor

3

1

2

3

4

5

6

7

STP sensor PWA

controll

circuit

Motor drive

circuit

STP 05-01-01

5.2 Functional Description

The STP operates the stapler through the STP controller PWA. When the power of the copier is turned

on, a power supply is also delivered to the STP to enab le stapling. When paper is loaded into the stapler ,

the STP paper set sensor detects the presence of paper (changing from “High” to “Low”), and 200 ms

later the CW signal turns ON (changing from “Low” to “High”) to operate the STP motor forward. When

the motor operates, the gears and cams of the stapler operate for stapling. When the STP home position

sensor detects the home position of the stapler (changing from “High” to “Low”) after the CW signal is

activated, the CW signal turns OFF.

If the STP home position sensor remains at “High” le vel (a f ailure to return to the home position) for some

reason even if a fixed time (approx. 900 ms) has elapsed after the CW signal turns ON, the CW signal

turns OFF and 100 ms later the CCW signal is turned ON (changing from “Lo w” to “High”) to oper ate the

STP motor rev ersely. In practice, how e ver, if the STP has locked up mechanically , an o verload occurs so

that the fuse installed on the STP CONT PWA will blow or the protective circuit of the AC adapter will

function to cut the delivery of the power supply (shutdown).

If the stapler is not at the home position when the power is turned on (“High” le vel), about 60 ms later the

CCW signal is turned ON (changing from “Low” to “High”) to operate the motor reversely allowing the

stapler to return to the home position.

October 2000 © T OSHIBA TEC 5 - 1 KK-1600 CIRCUIT DESCRIPTION

Page 14

5.3 Signal Description

Signal Name

STPCOV

STPPSET

STPHP

STPEMP

Part Name

STP cover open

switch

STP paper set

sensor

STP home

position sensor

STP staple

empty switch

Functional Description

Detects the open/close

state of the cover during

staple replacement, etc.

Detects the loading of the

paper to be stapled.

Detects the home position

of the drive section.

Detects the presence or

absence of staples.

Status

Open: Power off

Low: Paper loaded

Low: Home position

Low: No staples

Note

Microswitch

Photo sensor

Photo sensor

Microswitch

The STP cover open switch detects the open or close state of the cover. A microswitch is used for the

switch. A power supply is delivered to the stapler when the cover is closed, and cut off when open.

The STP paper set sensor detects the loading of paper. A photo sensor is used f or the s witch. The signal

goes LOW when the paper to be stapled is loaded.

The STP home position sensor detects the home position of the stapler. A photo sensor is used for the

sensor. It is mounted on the STP sensor PWA and detects the home position every stapling.

The STP staple empty switch detects the presence or absence of staples. A microswitch is used for the

sensor. When staples have run out or no cartridge is mounted, the signal is detected at “Low” level.

KK-1600 CIRCUIT DESCRIPTION 5 - 2 October 2000 © T OSHIBA TEC

Page 15

5.4 Timing Charts

• Staple operation

200ms

STP paper set sensor

STP staple empty switch

STP home position sensor

CW

CCW

H

L

H

L

H

L

H

L

H

L

• Staple operation (When staples have run out during operation)

200ms 200ms

STP paper set sensor

STP staple empty switch

H

L

H

L

No staples

858ms

STP home position sensor

CW

CCW

H

L

H

L

H

L

October 2000 © T OSHIBA TEC 5 - 3 KK-1600 CIRCUIT DESCRIPTION

Page 16

• Reverse operation (When the motor has locked up)

200ms 900ms

STP paper set sensor

H

L

STP staple empty switch

STP home position sensor

CW

CCW

H

L

H

L

H

L

H

L

100ms

• Reverse operation (When the stapler is not at the home position at power on time)

POWER ON

STP paper set sensor

STP staple empty switch

H

L

H

L

H

L

STP home position sensor

CW

CCW

H

L

H

L

H

L

60ms

KK-1600 CIRCUIT DESCRIPTION 5 - 4 October 2000 © T OSHIBA TEC

Page 17

6. DISASSEMBLY AND REPLACEMENT

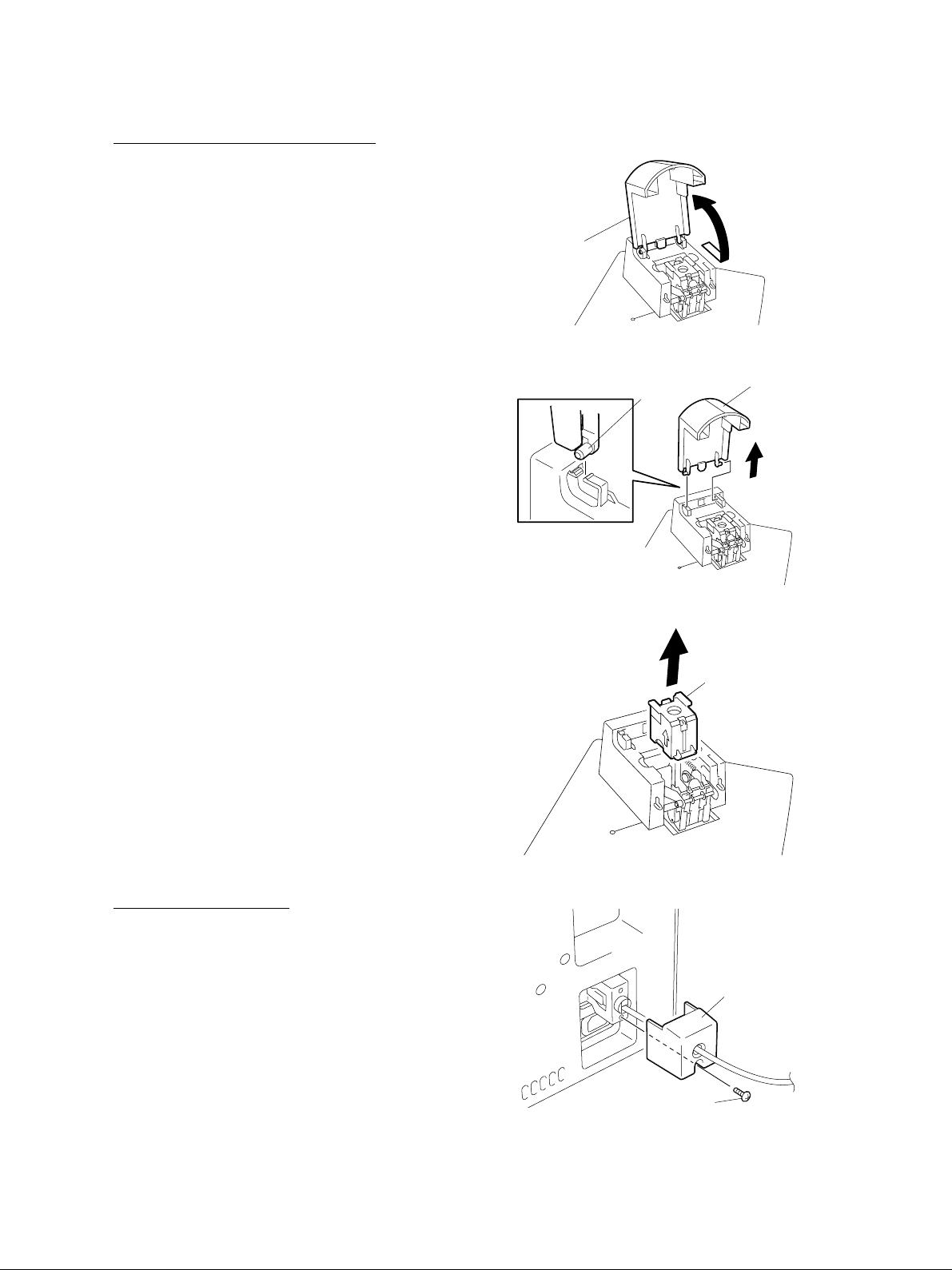

[A] STP cover/STP staple cartridge

1. Pull STP cover to release one hook and open

STP cover.

STP cover

314-1

Fig. 6-1

2. Release 2 hooks and detach STP cover.

3. Release 2 hooks and remove STP staple cartridge.

Hook

Fig. 6-2

STP cover

314-2

STP staple cartridge

321-1

Fig. 6-3

[B] STP bottom cover F

1. Remove one screw and detach connector cov er.

Connector cover

Screw

315

Fig. 6-4

October 2000 © TOSHIBA TEC 6 - 1 KK-1600 DISASSEMBLY AND REPLACEMENT

Page 18

2. Remove 2 scre ws and remove connector plate .

3. Release 2 hooks and detach connector .

Hook

4. Release the power cable from the hook of the

manual pocket.

5. Remove 2 screws , release 2 hooks, and remov e

stapler.

Connector plate

Manual pocket

Power cable

Hook

Screw

316-1

Fig. 6-5

316-2

Fig. 6-6

Stapler

317

Screw

Fig. 6-7

6. Remove one screw and detach STP bottom

cover F.

Screw

STP bottom cover F

318

Fig. 6-8

KK-1600 DISASSEMBLY AND REPLACEMENT 6 - 2 October 2000 © TOSHIBA TEC

Page 19

[C] STP bottom cover R

1. Remove stapler. (See Fig. 6-4 to 6-7)

2. Remove 4 screws and detach STP bottom cov er

R.

[D] STP staple cover

1. Detach STP cover. (See Fig. 6-1 and 6-2)

STP bottom cover R

Screw

Screw

319

Fig. 6-9

STP staple cover

2. Remove STP staple cartridge. (See Fig. 6-3)

3. Remove stapler. (See Fig. 6-4 to 6-7)

4. Detach STP bottom cover R. (See Fig. 6-9)

5. Remove one screw, release 5 hooks, and detach STP staple cover.

[E] STP cover open switch

1. Detach STP cover. (See Fig. 6-1 and 6-2)

2. Remove STP staple cartridge. (See Fig. 6-3)

3. Remove stapler. (See Fig. 6-4 to 6-7)

4. Detach STP bottom cover. (See Fig. 6-9)

5. Detach STP staple cover. (See Fig. 6-10)

6. Detach one connector from STP controller PWA

(J2) and release 3 clamps.

Hook

Clamp

Fig. 6-10

Fig. 6-11

Hook

Screw

Clamp

321-2

Connector

321-3

7. Remove one screw and remov e STP cover open

STP cover open switch

switch.

Screw

321-4

Fig. 6-12

October 2000 © TOSHIBA TEC 6 - 3 KK-1600 DISASSEMBLY AND REPLACEMENT

Page 20

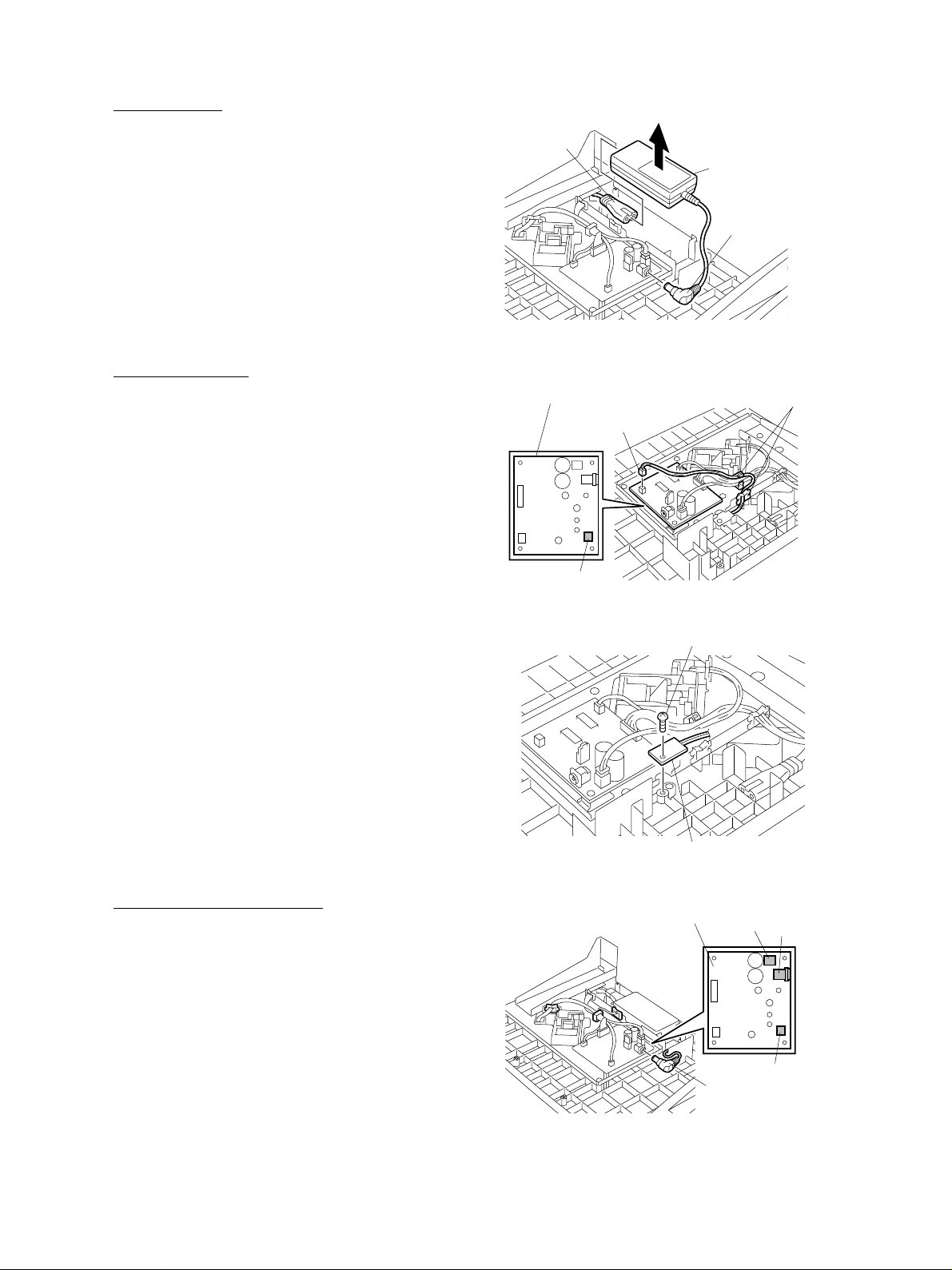

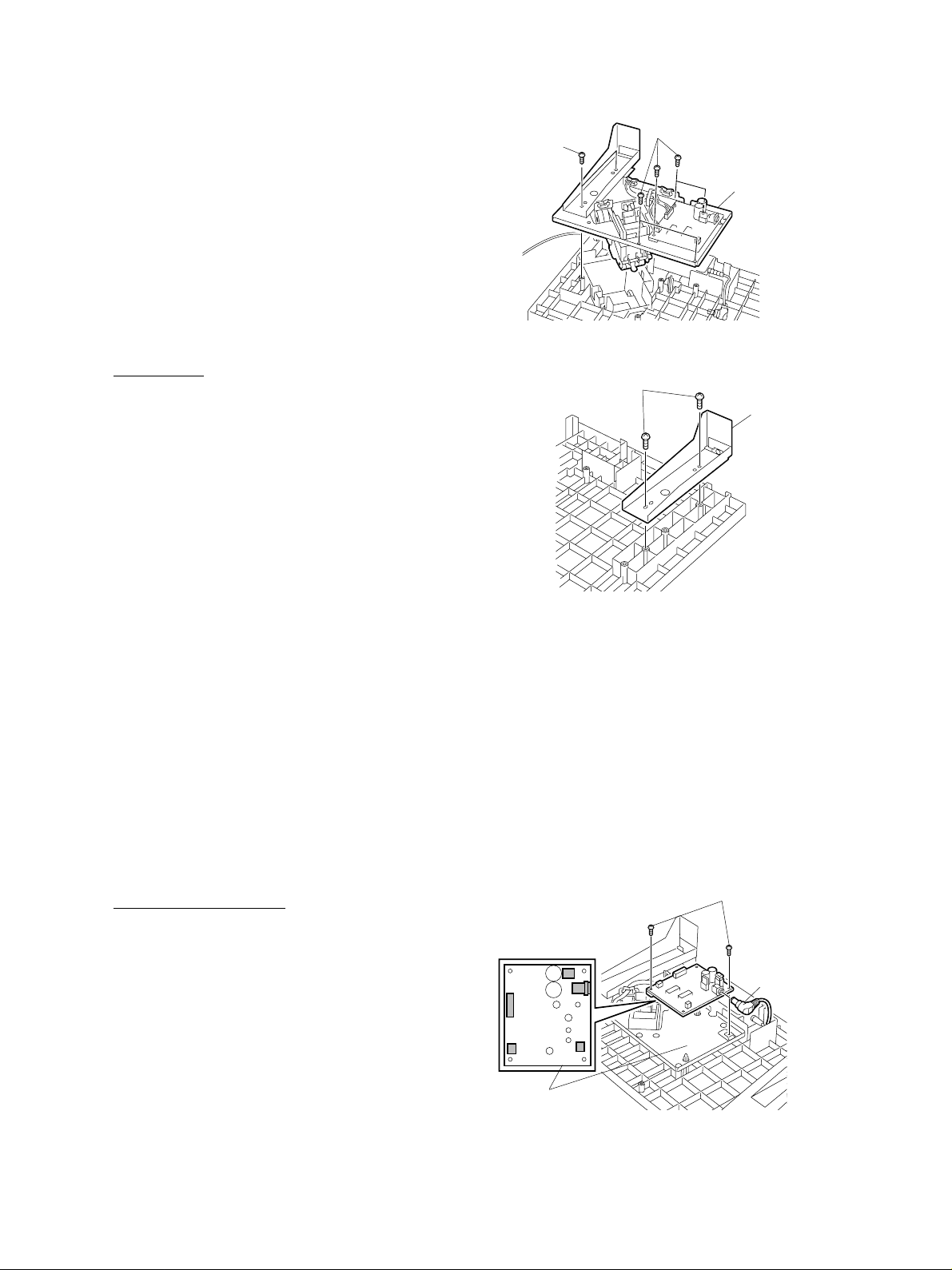

[F] AC adapter

1. Remove stapler. (See Fig. 6-4 to 6-7)

2. Detach STP bottom cover R. (See Fig. 6-9)

3. Detach AC adapter jack from STP controller

PWA (J1).

4. Detach power cord and remov e AC adapter.

[G] STP LED PW A

1. Remove stapler. (See Fig. 6-4 to 6-7)

2. Detach STP bottom cover R. (See Fig. 6-9)

3. Remove A C adapter. (See Fig. 6-13)

4. Detach one connector from STP controller PWA

(J5) and release 2 clamps.

5. Remove one screw and remo ve STP LED PW A.

Power cord

STP controller PWA

connector

J5

AC adapter

AC adapter jack

322-1

Fig. 6-13

clamp

322-2

Fig. 6-14

Screw

STP LED PWA

322-3

Fig. 6-15

[H] STP base stay assembly

1. Remove stapler. (See Fig. 6-4 to 6-7)

STP controller PWA

J2

J1

2. Detach STP bottom cover R. (See Fig. 6-9)

3. Detach AC adapter jack and the connectors

from STP controller PWA (J1/J2/J5).

4. Release 4 clamps.

J5

AC adapter jack

323

Fig. 6-16

KK-1600 DISASSEMBLY AND REPLACEMENT 6 - 4 October 2000 © TOSHIBA TEC

Page 21

5. Remove 7 screws and remove STP base stay

assembly.

[I] STP base

1. Detach STP cover. (See Fig. 6-1 and 6-2)

2. Remove STP staple cartridge. (See Fig. 6-3)

3. Remove stapler. (See Fig. 6-4 to 6-7)

4. Detach STP bottom cover F. (See Fig. 6-8)

5. Detach STP bottom cover R. (See Fig. 6-9)

6. Detach STP staple cover. (See Fig. 6-10)

7. Remove STP cov er open switch. (See Fig. 6-11

Screw

Screw

STP base

stay assembly

324

Fig. 6-17

Screw

STP stay

and 6-12)

8. Remove A C adapter. (See Fig. 6-13)

9. Remove STP LED PWA. (See Fig. 6-14 and

6-15)

8. Remove STP base sta y assemb ly. (See Fig. 616 and 6-17)

9. Remove 2 scre ws and remo ve STP stay.

[J] STP controller PWA

1. Remove stapler. (See FIG. 6-4 to 6-7)

2. Detach STP bottom cover R. (See FIG. 6-9)

3. Detach AC adapter jack and all connectors from

STP controller PWA.

4. Remove 2 screws and remove STP controller

PWA.

STP

controller PWA

325

Fig. 6-18

Screw

AC adapter

jack

326

Fig. 6-19

October 2000 © TOSHIBA TEC 6 - 5 KK-1600 DISASSEMBLY AND REPLACEMENT

Page 22

[K] STP staple unit

1. Remove stapler. (See Fig. 6-4 to 6-7)

2. Detach STP bottom cover R. (See Fig. 6-9)

3. Remove STP base sta y assembly. (See Fig. 6-

STP controller PWA

Clamp

16 and 6-17)

4. Detach the connectors from STP controller PWA

(J3/J4) and release 2 clamps.

5. Remove 2 scre ws and remove STP staple unit.

J3

J4

327

Fig. 6-20

STP staple unit

Screw

328

Fig. 6-21

KK-1600 DISASSEMBLY AND REPLACEMENT 6 - 6 October 2000 © TOSHIBA TEC

Loading...

Loading...