Page 1

SERVICE MANUAL

Paper Feed Pedestal

KD-1025

Model: KD-1025

Publish Date: April 2009

File No. SME090003B0

R090121H2600-TTEC

Ver02_2011-12

Page 2

Trademarks

• FLOIL is a registrated trademark of Kanto Kasei Ltd. CORPORATION

• Mylar is a registered trademark of DuPont Teijin Films U.S. Limited Partnership.

• Molykote is a registered trademark of Dow Corning Corporation.

• Other company names and product names in this manual are the trademarks of their respective

companies.

© 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved

Under the copyright laws, this manual cannot be reproduced in any form without prior written permission

of TOSHIBA TEC CORPORATION.

Page 3

GENERAL PRECAUTIONS FOR INSTALLATION/SERVICING/

MAINTENANCE

The installation and service shall be done by a qualified service technician.

1. When installing the Paper Feed Pedestal KD-1025 to the equipment, be sure to follow the

instructions described in the "Unpacking/Set-Up Procedure for the KD-1025" booklet which comes

with each unit of the KD-1025.

2. The KD-1025 should be installed by an authorized/qualified person.

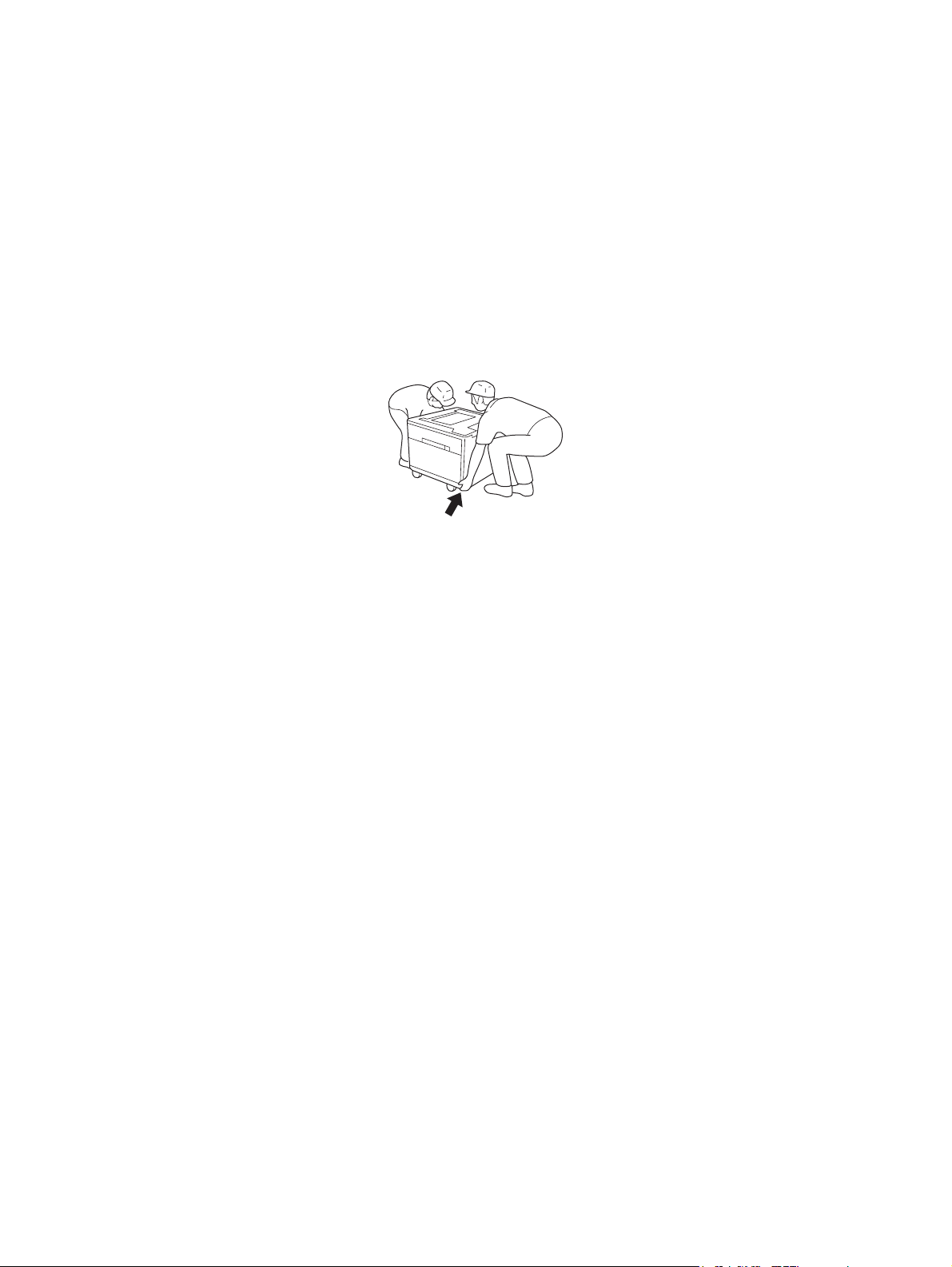

3. When transporting/installing KD-1025, employ two persons and be sure to use the positions as

indicated below.

KD-1025 is fairly heavy and weights approximately 21 kg (46.3 lb.), therefore pay full attention when

handling it.

4. Before starting installation, servicing or maintenance work, be sure to turn OFF and unplug the

equipment first.

5. Be sure to fix and plug in the power cable securely after the installation so that no one trips over it.

6. The equipment shall be installed near the socket outlet and shall be accessible.

7. Unplug the power cable and clean the area around the prongs of the plug and socket outlet once a

year or more. A fire may occur when dust lies on this area.

8. The KD-1025 is supplied with power from the equipment, requiring no additional power source.

9. The KD-1025 should be grounded to the specified positions on the machine frame.

10.When servicing or maintaining the KD-1025, be careful about the rotating or operating sections such

as gears, pulleys, sprockets, cams, belts, etc.

11.When servicing the machines with the power turned ON, be sure not to touch live sections and

rotating/operating sections.

12.When parts are disassembled, reassembly is basically the reverse of disassembly unless otherwise

noted in this manual or other related materials. Be careful not to reassemble small parts such as

screws, washers, pins, E-rings, toothed washers to the wrong places.

13.Basically, the machine should not be operated with any parts removed or disassembled.

14.Delicate parts for preventing safety hazard problems (such as thermofuses, door switches sensors,

etc. if any) should be handled/installed/adjusted correctly.

15.Use suitable measuring instruments and tools.

Page 4

16.During servicing or maintenance work, be sure to check the nameplate and other cautionary labels

(if any) to see if they are clean and firmly stuck. If not, take appropriate actions.

17.The PC board must be stored in an anti-electrostatic bag and handled carefully using a wristband,

because the ICs on it may be damaged due to static electricity.

Caution: Before using the wrist band, pull out the power cord plug of the equipment and

make sure that there is no uninsulated objects in the vicinity.

18.For the recovery and disposal of used the Paper Feed Pedestal, consumable parts, packing

materials, follow the relevant local regulations/rules.

19.Return the equipment to the original state and check the operation when the service is finished.

Page 5

CONTENTS

KD-1025

1. SPECIFICATIONS......................................................................................................... 1-1

2. OVERVIEW ................................................................................................................... 2-1

2.1 Front Sectional View............................................................................................................ 2-1

2.2 Layout of Electrical Parts ..................................................................................................... 2-2

2.3 Electrical Parts..................................................................................................................... 2-3

3. GENERAL OPERATION............................................................................................... 3-1

3.1 Driving System and Feeding Operation............................................................................... 3-1

3.2 Description of Operations ....................................................................................................3-2

3.3 Error Detection..................................................................................................................... 3-3

3.4 Flow Chart ........................................................................................................................... 3-4

4. DISASSEMBLY AND REPLACEMENT........................................................................ 4-1

4.1 Installation and Removal of Drawers and Covers................................................................ 4-1

4.2 PFP board (PWB) ................................................................................................................ 4-5

4.3 Upper/Lower Transport Rollers............................................................................................ 4-6

4.4 Motor ................................................................................................................................. 4-10

4.5 Feed/Separation/Pickup Roller .......................................................................................... 4-15

4.6 Switches and Sensors ....................................................................................................... 4-18

5. ELECTRIC CIRCUIT .....................................................................................................5-1

5.1 Harness Diagram................................................................................................................. 5-1

5.2 Circuit Diagram .................................................................................................................... 5-2

5.3 PC Board ............................................................................................................................. 5-5

6. PERIODIC MAINTENANCE.......................................................................................... 6-1

© 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved KD-1025

1

CONTENTS

Page 6

KD-1025 © 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved

CONTENTS

2

Page 7

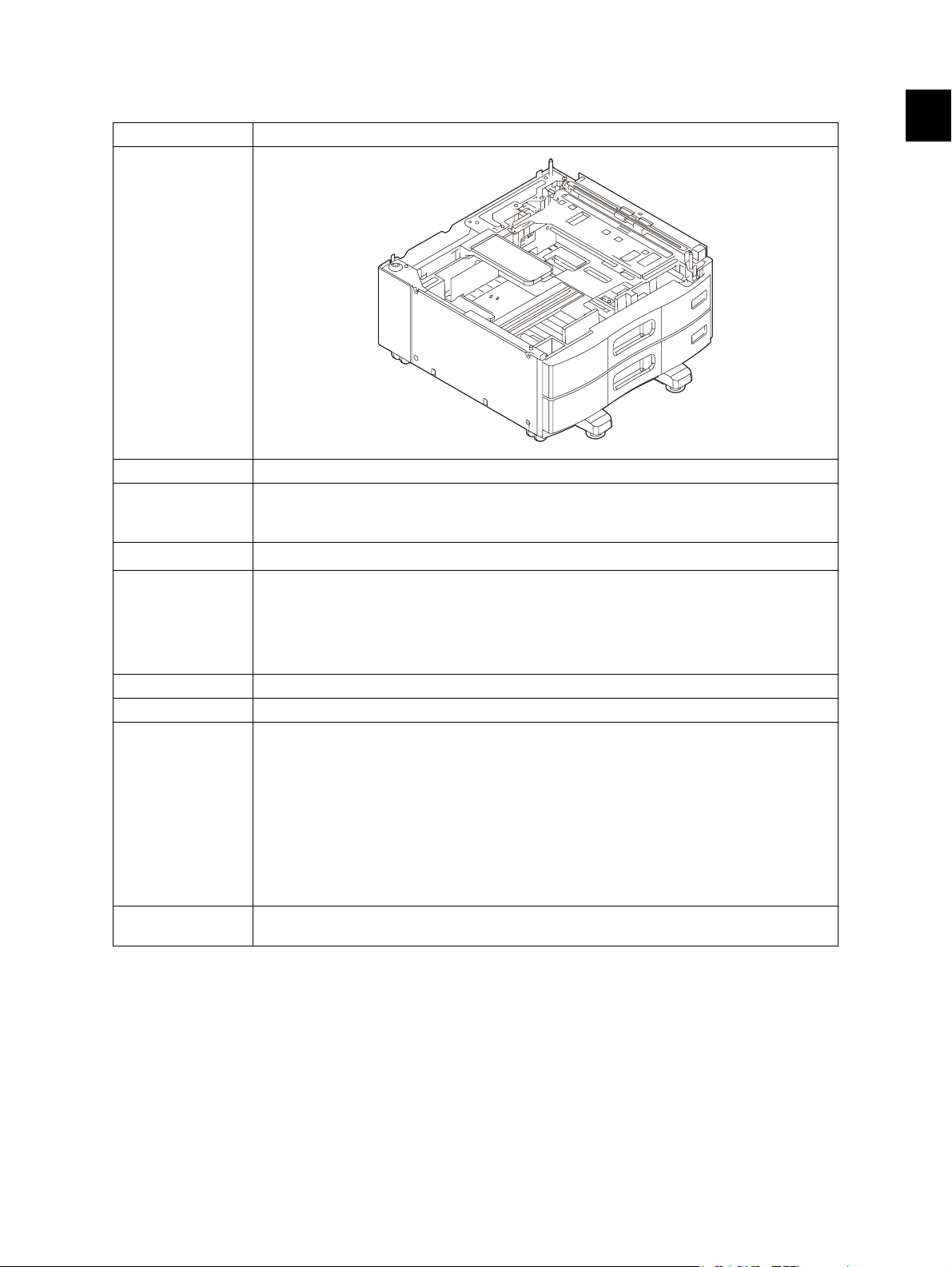

1. SPECIFICATIONS

Item KD-1025

Appearance

Feeding method Automatic feeding: 1 drawer installed from the front

Paper Size: A3, B4, A4, A4-R, B5, B5-R, A5-R, LD, LG, LT, LT-R, 8K, 16K, 16K-R, FOLIO,

Capacity of drawer

Dimensions 575 (W) × 583 (D) × 292 (H) mm

Weight Approx. 21 kg (46.3 lb.)

Power supply 5 V, 24 V (supplied from the equipment)

Accessory Unpacking Instructions (1)

Option Drawer module: MY-1033

COMPUTER, 13"LG, 8.5"x8.5"

Thickness: 64 g/m

Stack height: 60.5 mm (Approx. 550 sheets: 80 g/m

22.64 (W) × 22.95 (D) × 11.50 (H) inch

(Height - Floor to top of the front cover)

660 (W) × 701 (D) × 292 (H) mm

25.98 (W) × 27.60 (D) × 11.50 (H) inch

(Including the stabilizer cover)

Connecting plates (4)

Screws for connecting plates (6)

Fixing screw for ground wire (1)

Paper size indicator sheets (2)

Stabilizer brackets (4)

Feeding side stabilizer foot (1)

Screw for feeding side stabilizer foot (1)

Rear side stabilizer covers (2)

Front side stabilizer cover (1)

Screws for stabilizer (4)

(With this option, 2 drawers become available for feeding).

2

to 105 g/m2 (17 lb. Bond to 94.5 lb. Cover)

2

(22 lb. Bond))

1

Note:

This manual explains on the premise that 2 drawers are available (that is, the optional drawer

module is installed).

© 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved KD-1025

1 - 1

SPECIFICATIONS

Page 8

KD-1025 © 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS

1 - 2

Page 9

2. OVERVIEW

2.1 Front Sectional View

16 17

8

9

24

28

Fig. 2-1

12

27

26

15

19

12

6

2523

Symbol Name Symbol Name

1 Upper drawer tray-up sensor (S4) 15 Upper drawer pickup roller

2 Upper drawer empty sensor (S6) 16 Upper drawer tray

10

13

14

11

20

21

22

18

4

5

3

7

2

3 Upper drawer feed sensor (S2) 17 Upper drawer elevator

4 Upper transport roller 18 Lower drawer tray-up sensor (S5)

5 Upper drawer feed clutch (CLT2) 19 Lower drawer empty sensor (S7)

6 Upper drawer feed roller 20 Lower drawer feed clutch (CLT3)

7 Upper drawer separation roller 21 Lower drawer feed roller

8 Upper drawer 22 Lower drawer separation roller

9 Lower drawer 23 Lower drawer pickup roller

10 Upper drawer tray-up motor (M2) 24 Lower drawer tray

11 Lower drawer feed sensor (S3) 25 Lower drawer tray-up motor (M3)

12 Upper drawer elevator coupling 26 Lower drawer elevator

13 Lower transport roller 27 Lower drawer elevator coupling

14 Transport clutch (CLT1) 28 Adjuster

© 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved KD-1025

2 - 1

OVERVIEW

Page 10

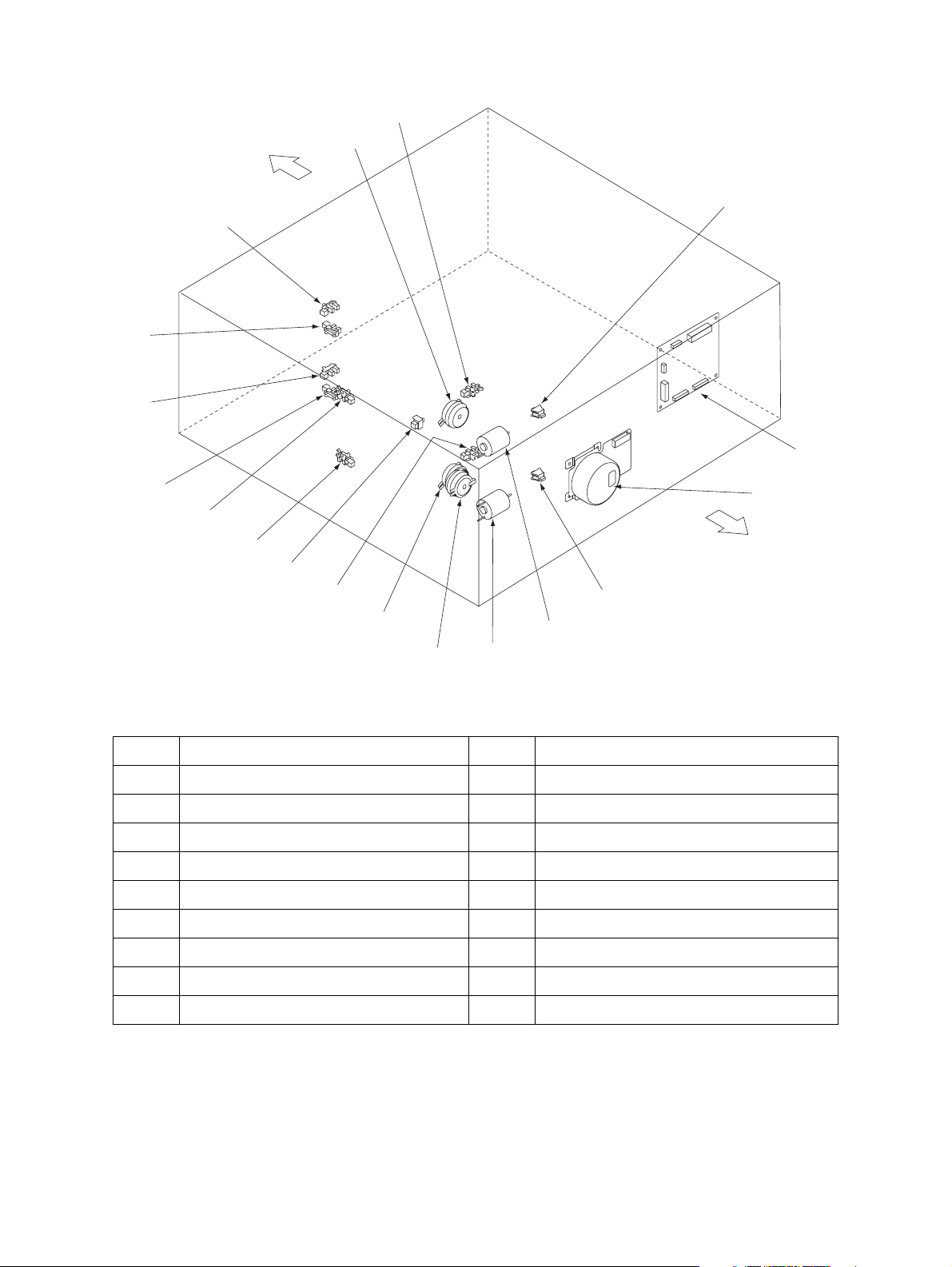

2.2 Layout of Electrical Parts

S10

Front side

CLT2

S4

S7

S5

S2

S6

S3

S1

S11

CLT3

CLT1

S8

PWB

M1

Rear side

S9

M2

M3

Fig. 2-2

Symbol Name Symbol Name

M1 PFP motor S4 Upper drawer tray-up sensor

M2 Upper drawer tray-up motor S5 Lower drawer tray-up sensor

M3 Lower drawer tray-up motor S6 Upper drawer empty sensor

CLT1 Transport clutch S7 Lower drawer empty sensor

CLT2 Upper drawer feed clutch S8 Upper drawer detection switch

CLT3 Lower drawer feed clutch S9 Lower drawer detection switch

S1 Side cover open/close switch S10 Upper drawer paper stock sensor

S2 Upper drawer feed sensor S11 Lower drawer paper stock sensor

S3 Lower drawer feed sensor PWB PFP board

KD-1025 © 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved

OVERVIEW

2 - 2

Page 11

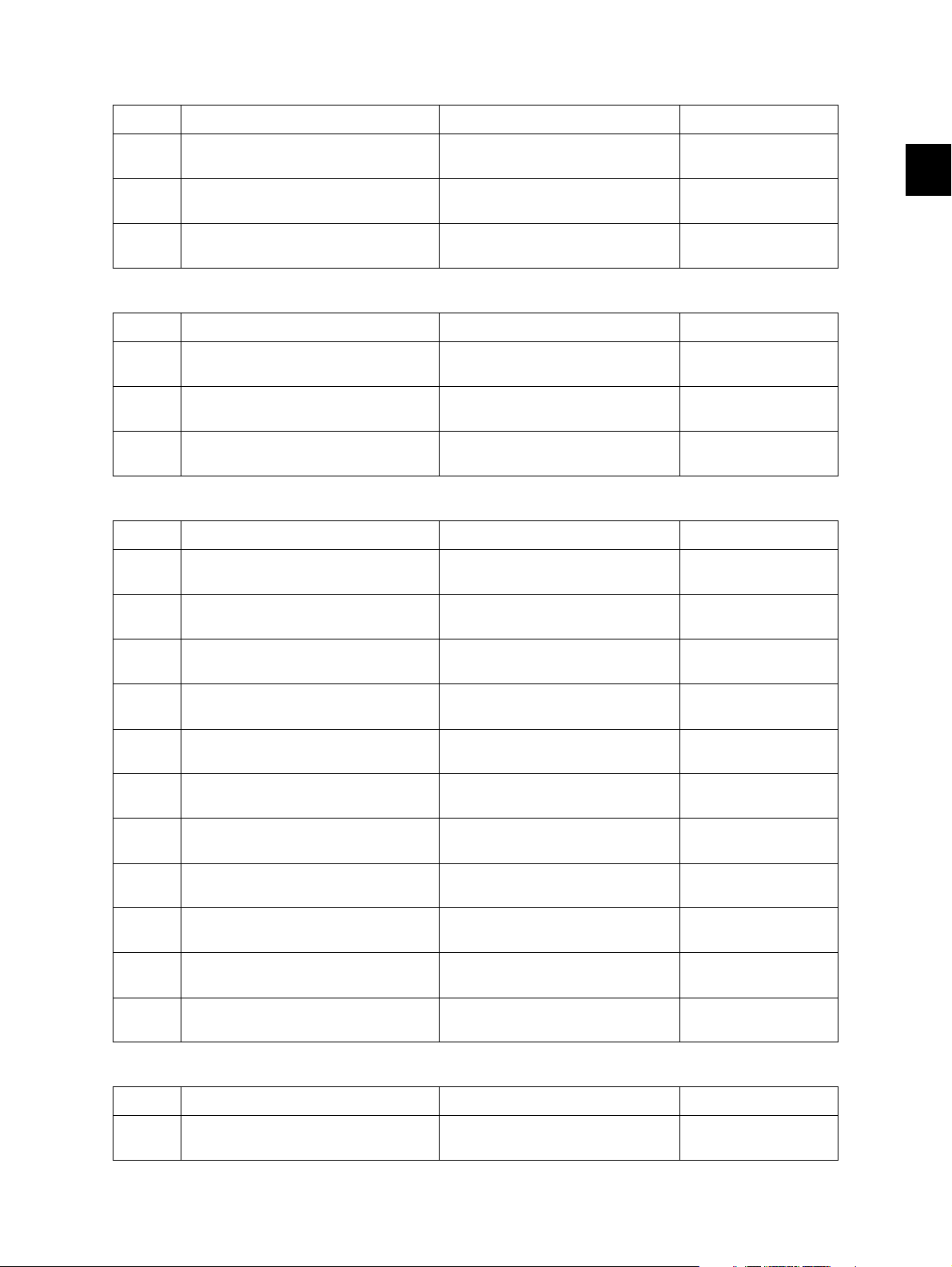

2.3 Electrical Parts

1. Motor

Symbol Name Function Remarks

M1 PFP-MTR

PFP motor

M2 T-UP-U-MTR

Upper drawer tray-up motor

M3 T-UP-L-MTR

Lower drawer tray-up motor

Drives feeding and transport Brushless motor

Lifts up the upper drawer tray Brush motor

Lifts up the lower drawer tray Brush motor

2. Electromagnetic clutch

Symbol Name Function Remarks

CLT1 TR-CLT

Transport clutch

CLT2 FED-U-CLT

Upper drawer feed clutch

CLT3 FED-L-CLT

Lower drawer feed clutch

Drives transport

Drives roller to pick up paper from

the upper drawer

Drives roller to pick up paper from

the lower drawer

3. Switches and Sensors

Symbol Name Function Remarks

S1 SIDE-COV-SW

Side cover open/close switch

S2 FED-U-SNR

Upper drawer feed sensor

Side cover open/close detection Push switch

Detects timing to feed paper/

misfeeding

Photo interrupter

2

S3 FED-L-SNR

Lower drawer feed sensor

S4 TOP-U-SNR

Upper drawer tray-up sensor

S5 TOP-L-SNR

Lower drawer tray-up sensor

S6 EMP-U-SNR

Upper drawer empty sensor

S7 EMP-L-SNR

Lower drawer empty sensor

S8 CST-U-SW

Upper drawer detection switch

S9 CST-L-CST

Lower drawer detection switch

S10 PST-U-SNR

Upper drawer paper stock sensor

S11 PST-L-SNR

Lower drawer paper stock sensor

Detects timing to feed paper/

misfeeding

Detects if the upper drawer has

lifted up

Detects if the lower drawer has

lifted up

Detects presence/absence of paper

in the upper drawer

Detects presence/absence of paper

in the lower drawer

Detects the presence/absence of

the lower drawer

Detects the presence/absence of

the lower drawer

Detects that the paper stock is

insufficient in the upper drawer

Detects that the paper stock is

insufficient in the lower drawer

Photo interrupter

Photo interrupter

Photo interrupter

Photo interrupter

Photo interrupter

Push switch

Push switch

Photo interrupter

Photo interrupter

4. PC board

Symbol Name Function Remarks

PWB PWB-F-503S

PFP board

© 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved KD-1025

Control of PFP devices

OVERVIEW

2 - 3

Page 12

KD-1025 © 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved

OVERVIEW

2 - 4

Page 13

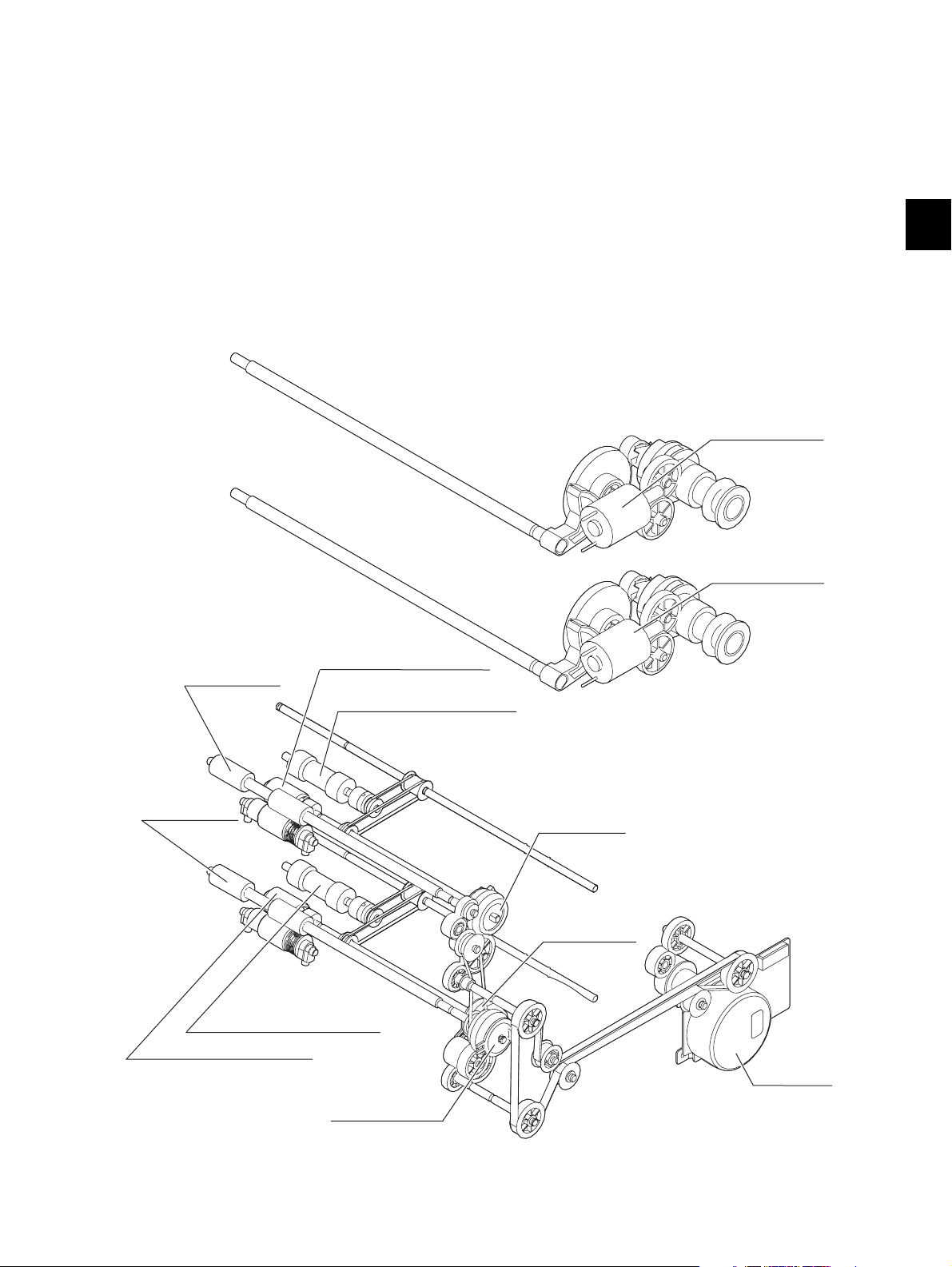

3. GENERAL OPERATION

3.1 Driving System and Feeding Operation

The Paper Feed Pedestal (PFP) mainly consists of the drawer, pickup roller, feed roller, separation

roller, transport roller, and drive systems for these components.

• Feeding/Transport system

The PFP motor drives the pickup roller, feed roller, and transport roller which are located in the

feeding area.

• Drawer tray system

This system raises and lowers the tray.

Upper drawer

tray-up motor

3

Upper

transport roller

Lower

transport roller

Lower drawer

tray-up motor

Upper drawer feed roller

Upper drawer pickup roller

Upper drawer

feed clutch

Lower drawer

feed clutch

Lower drawer pickup roller

Lower drawer feed roller

PFP motor

Transport clutch

Fig. 3-1

© 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved KD-1025

3 - 1

GENERAL OPERATION

Page 14

3.2 Description of Operations

[A] From power ON to ready

(1) When the equipment is turned ON, the power is also supplied to the feeder unit. And when the

power is supplied, the feeder unit detects and judges the clock frequency output from the LGC

board on the equipment to control transport speed of the unit.

(2) After that, the tray-up motor (M2)/(M3) is turned ON to raise the corresponding tray. When the

tray-up sensor (S4)/(S5) is turned ON correspondingly, the tray-up motor (M2)/(M3) is turned

OFF to stop the tray. If the empty sensor (S6)/(S7) is OFF (H) at this time, it is judged that there

is no paper in the drawer. If the empty sensor is ON (L), it is assumed that there is paper in the

drawer, and the tray stays in the raised position until the drawer is pulled out.

(3) If the power is turned ON when the drawer has been pulled out, the tray-up motor for that drawer

is not turned ON. The tray is raised as soon as the drawer is installed, and it detects if there is

paper in the drawer.

(4) If either of the drawer feed sensors (S2), (S3) is ON (there is paper in the transport path) when

the power is turned ON, that means paper jam has occurred and operation is disabled until the

paper is removed.

[B] Ready status

(1) Trays detect the paper as described above, and the equipment goes into ready status.

(2) The tray goes down automatically when the drawer is removed and it is raised as soon as the

drawer is installed again and checks if there is paper in the drawer.

[C] From the start to the end of copying

(1) When the [START] button is pressed, the feed/transport and exit motors of the equipment and

the PFP motor (M1) are turned ON at the same time.

(2) When the equipment judges that PFP is ready for feeding paper, it turns ON the feed clutch

(CLT2)/(CLT3) of the selected drawer. This clutches drive the pickup roller and feed roller to feed

paper from the tray.

(3) When the drawer feed sensor (S2)/(S3) comes ON, the transport clutch (CLT1) is turned ON to

drive the PFP transport roller.

(4) A fixed time after the drawer feed sensor (S2)/(S3) comes ON, the feed clutch (CLT2)/(CLT3) is

turned OFF and feeding from the drawer is completed.

(5) The paper is transported to the equipment by the PFP transport roller. A fixed time after the

leading edge of the paper reaches the drawer feed sensor (S2), if the trailing edge of the

previously sent sheet still remains at the copier feed sensor, the transport clutch (CLT1) is turned

OFF to stop the transport of the paper.

(6) A fixed time after the paper turns the resist clutch ON, PFP becomes ready for feeding the next

sheet of paper, and the procedures (1) to (5) are repeated.

(7) When the copying operation is completed, the feed/transport motor, exit motor, PFP motor (M1),

and transport clutch(CLT1) are turned OFF and the transport roller is stopped.

KD-1025 © 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved

GENERAL OPERATION

3 - 2

Page 15

3.3 Error Detection

[A] Jam detection

(1) Paper jams (E150), (E160) and (E300 to E360) occur in the following cases.

• Feed sensor (S2)/(S3) is not turned ON within a specified period of time after the feeding is

started.

• The leading edge of the paper does not pass the feed sensor (S2)/(S3) in the transport path

within a specified period of time.

(2) Open the side cover of the PFP and remove all the paper remaining on the transport path and

close the side cover to clear the paper jam. If either of the drawer feed sensors (S2)/(S3) is still

ON when the side cover is closed, it is determined that there is still paper on the transport path

and the paper jam status is not cleared.

(3) When a paper jam occurs in the PFP during continuous copying, the paper that was fed before

the jam is copied normally.

[B] Call for Service

(1) The tray is raised when the power is turned ON or the drawer is inserted or pulled out. If the tray-

up sensor (S4)/(S5) is not turned ON within a specified period of time after the tray has started to

raise, a message that the selected drawer cannot be used is displayed on the control panel.

3

(2) The state (1) is cleared by opening the drawer and solving the problems.

© 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved KD-1025

3 - 3

GENERAL OPERATION

Page 16

3.4 Flow Chart

(Upper drawer feeding)

Press [START

Transport system control

Feed/transport motor ON

Exit motor ON

PFP motor ON

PFP motor

rotating normally?

Upper drawer feed clutch ON

PFP

Upper drawer feed

sensor ON?

PFP transport clutch ON

]

YES

YES

NO

Call for Service

"C040"

NO

Paper jam

"E150"

Upper drawer feed clutch OFF

2nd drawer feed sensor

Copier’s transport clutch ON

B

KD-1025 © 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved

GENERAL OPERATION

Copier’s

ON?

YES

A

Fig. 3-2

3 - 4

NO

Paper jam

"E320"

Page 17

AB

Copier’s

1st drawer feed sensor

ON?

YES

Copier’s registration

sensor ON?

YES

Copier’s registration

clutch

Counter ON/OFF

Copier’s transport clutch OFF

PFP transport clutch OFF

Copier’s registration

clutch

Copier’s

exit sensor

ON?

ON

OFF

NO

NO

NO

3

Paper jam

"E310"

Paper jam

"E300"

Paper jam

"E010"

Copier’s

exit sensor

OFF?

NO

Remaining number of

copies = 0?

Feed/transport motor OFF

Exit motor OFF

PFP motor OFF

Ready

Fig. 3-3

YES

YES

YES

NO

Paper jam

"E020"

© 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved KD-1025

3 - 5

GENERAL OPERATION

Page 18

KD-1025 © 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved

GENERAL OPERATION

3 - 6

Page 19

4. DISASSEMBLY AND REPLACEMENT

4.1 Installation and Removal of Drawers and Covers

[A] Drawers

(1) Pull out the drawer fully and remove 1 screw

at the back right to remove the stopper.

(2) Pull out the drawer further and take it out.

Fig. 4-1

[B] Drawer cover

4

Stopper

(1) Take out the drawer.

P.4-1 "[A] Drawers"

(2) Remove 4 screws and take off the drawer

cover.

Fig. 4-2

© 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved KD-1025

4 - 1

DISASSEMBLY AND REPLACEMENT

Page 20

[C] Stabilizer cover

(1) Take out the drawer.

P.4-1 "[A] Drawers"

Note:

The drawer must be taken out only when

taking off the front side stabilizer cover.

(2) Remove 2 screws and take off the front side

stabilizer cover.

(3) Remove 1 screw and take off the feeding

side stabilizer foot.

(4) Remove 2 screws and take off the rear side

stabilizer cover.

Feeding side

stabilizer foot

Front side

stabilizer cover

Fig. 4-3

[D] Rear cover

(1) Take off the rear side stabilizer cover.

P.4-2 "[C] Stabilizer cover"

(2) Remove 2 screws on the rear cover.

(3) Take off the rear cover.

Rear side stabilizer cover

Fig. 4-4

Fig. 4-5

KD-1025 © 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved

DISASSEMBLY AND REPLACEMENT

4 - 2

Page 21

[E] Feeding side front cover

(1) Take out the drawer.

P.4-1 "[A] Drawers"

(2) Remove 2 screws and take off the feeding

side front cover.

[F] Feeding side rear cover

(1) Open the side cover.

(2) Remove 2 screws, and take off the feeding

side stabilizer foot and the feeding side rear

cover.

4

Fig. 4-6

[G] Side cover

(1) Open the side cover and remove 1 screw on

the belt.

Feeding side rear cover

Feeding side stabilizer foot

Fig. 4-7

Belt

Fig. 4-8

© 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved KD-1025

4 - 3

DISASSEMBLY AND REPLACEMENT

Page 22

(2) Take off the block from the side cover.

(3) Take off the side cover while pushing the

front side of the side cover inward.

(4) Disconnect 1 connector.

Block

Fig. 4-9

Connector

Fig. 4-10

KD-1025 © 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved

DISASSEMBLY AND REPLACEMENT

4 - 4

Page 23

4.2 PFP board (PWB)

(1) Take off the rear cover.

P.4-2 "[D] Rear cover"

(2) Disconnect 6 connectors, remove 2 screws,

and release 2 locking supports to take off the

PFP board.

Locking

supports

Fig. 4-11

Screws

4

PFP board

© 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved KD-1025

4 - 5

DISASSEMBLY AND REPLACEMENT

Page 24

4.3 Upper/Lower Transport Rollers

[A] Upper transport roller

(1) Open the side cover and remove 1 screw on

the belt.

P.4-3 "[G] Side cover"

(2) Remove 3 screws and take off the transport

roller along with the bracket.

(3) Remove 1 clip, and take off the gear and the

collar.

Bracket

Fig. 4-12

Collar

(4) Remove 1 clip and slide the bushing to take

off the transport roller.

Gear

Clip

Bushing

Clip

Fig. 4-13

Transport rollers

Fig. 4-14

Bushing

KD-1025 © 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved

DISASSEMBLY AND REPLACEMENT

4 - 6

Page 25

[B] Lower transport roller

(1) Take off the rear cover.

P.4-2 "[D] Rear cover"

(2) Loosen 1 screw fixing the tensioner bracket.

(3) Remove the belt.

4

Fig. 4-15

Note:

When installing the belt, be sure to confirm

the gap between the belts with the following

procedure.

1. Install the belt in KD-1025.

2. Tighten 1 fixing screw of the tensioner

bracket.

3. Confirm that the gap between the belts is

approx. 3 mm.

Fig. 4-16

Approx.3mm

Fixing screw

Fig. 4-17

© 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved KD-1025

4 - 7

DISASSEMBLY AND REPLACEMENT

Page 26

(4) Remove 2 screws and take off the bracket of

the feeding gear.

(5) Remove 1 connector and take off the

transport clutch.

Fig. 4-18

Transport clutch

(6) Remove the coupling, pin, and clip.

Connector

Fig. 4-19

Coupling

Pin

Clip

Fig. 4-20

KD-1025 © 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved

DISASSEMBLY AND REPLACEMENT

4 - 8

Page 27

(7) Take off the side cover and the feeding side

front cover.

P.4-3 "[G] Side cover"

P.4-3 "[E] Feeding side front cover"

(8) Remove 3 screws and take off the transport

roller along with the bracket.

(9) Remove 1 clip, and take off the gear and the

collar.

Bracket

4

Fig. 4-21

Collar

Gear

(10) Remove 1 clip and slide the bushing to take

off the transport roller.

Clip

Bushing

Clip

Fig. 4-22

Transport rollers

Fig. 4-23

Bushing

© 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved KD-1025

4 - 9

DISASSEMBLY AND REPLACEMENT

Page 28

4.4 Motor

[A] Upper drawer tray-up motor

(1) Take off the rear cover.

P.4-2 "[D] Rear cover"

(2) Disconnect 1 connector and take off the

harness clamp from the bracket.

(3) Remove 2 screws and take off the tray-up

motor along with the bracket.

Fig. 4-24

(4) Remove 2 screws and take off the tray-up

motor from the bracket.

Bracket

Fig. 4-25

Tray-up motor

Fig. 4-26

KD-1025 © 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved

DISASSEMBLY AND REPLACEMENT

4 - 10

Page 29

[B] Lower drawer tray-up motor

(1) Take off the rear cover.

P.4-2 "[D] Rear cover"

(2) Loosen 1 screw fixing the tensioner bracket.

(3) Remove the belt.

4

Fig. 4-27

Note:

When installing the belt, be sure to confirm

the gap between the belts with the following

procedure.

1. Install the belt in KD-1025.

2. Tighten 1 fixing screw of the tensioner

bracket.

3. Confirm that the gap between the belts is

approx. 3 mm.

Fig. 4-28

Approx.3mm

Fixing screw

Fig. 4-29

© 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved KD-1025

4 - 11

DISASSEMBLY AND REPLACEMENT

Page 30

(4) Remove 2 screws and take off the bracket of

the feeding gear.

Note:

Match the protruding portion of the clutch

with the position shown in the figure for

assembling.

(5) Disconnect the connector of the lower

drawer tray-up motor and remove 2 harness

clamps from the bracket.

Protrusion

Fig. 4-30

(6) Remove 2 screws and take off the tray-up

motor along with the bracket.

Fig. 4-31

Bracket

Fig. 4-32

KD-1025 © 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved

DISASSEMBLY AND REPLACEMENT

4 - 12

Page 31

(7) Remove 2 screws and take off the tray-up

motor from the bracket.

[C] PFP motor

(1) Take off the rear cover.

P.4-2 "[D] Rear cover"

(2) Disconnect 1 connector.

(3) Remove 4 screws and take off the PFP

motor.

Tray-up motor

4

Fig. 4-33

[D] PFP motor assembly

(1) Take off the rear cover.

P.4-2 "[D] Rear cover"

(2) Loosen 1 screw fixing the tensioner bracket.

Connector

PFP motor

Fig. 4-34

Fig. 4-35

© 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved KD-1025

4 - 13

DISASSEMBLY AND REPLACEMENT

Page 32

(3) Remove the belt.

Note:

When installing the belt, be sure to confirm

the gap between the belts with the following

procedure.

1. Install the belt in KD-1025.

2. Tighten 1 fixing screw of the tensioner

bracket.

3. Confirm that the gap between the belts is

approx. 3 mm.

Fig. 4-36

Approx.3mm

(4) Remove 1 connector and take off the PFP

motor assembly.

Fixing screw

Fig. 4-37

Connector

PFP motor assembly

Fig. 4-38

KD-1025 © 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved

DISASSEMBLY AND REPLACEMENT

4 - 14

Page 33

4.5 Feed/Separation/Pickup Roller

[A] Drawer feeding unit

(1) Pull out the drawer for which the drawer

feeding unit will be taken off and the drawer

immediately above.

P.4-1 "[A] Drawers"

(2) Remove 1 screw and pull the drawer feeding

unit toward the inside of the copier.

[B] Separation roller

(1) Take off the drawer feeding unit.

P.4-15 "[A] Drawer feeding unit"

(2) Remove 1 screw and take off the separation

roller holder.

Upper drawer feeding unit

4

Lower drawer feeding unit

Fig. 4-39

Fig. 4-40

(3) Remove the lever from the holder and take

off the separation roller with the shaft.

Lever

Separation roller

Fig. 4-41

© 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved KD-1025

4 - 15

DISASSEMBLY AND REPLACEMENT

Holder

Page 34

(4) Remove the cover, the arbor, and the clutch

spring from the shaft, and then take off the

separation roller.

[C] Feed roller

(1) Take off the drawer feeding unit.

P.4-15 "[A] Drawer feeding unit"

(2) Take off the separation roller holder.

P.4-15 "[B] Separation roller"

(3) Remove the clip and take off the feed roller.

Arbor

Separation roller

Clutch spring

Shaft

Cover

Arbor

Fig. 4-42

Feed roller

Clip

[D] Pickup roller

(1) Take off the drawer feeding unit.

P.4-15 "[A] Drawer feeding unit"

(2) Raise the pickup arm and release the pickup

roller assembly.

(3) Remove the belt and take off the pickup

roller assembly.

Fig. 4-43

Pickup roller

assembly

Belt

Fig. 4-44

KD-1025 © 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved

DISASSEMBLY AND REPLACEMENT

4 - 16

Page 35

(4) Remove pulley, one-way clutch, and 3 E-

rings to take off the pickup roller.

[E] Drawer feed clutch (CLT2/CLT3)

(1) Take off the drawer feeding unit.

P.4-15 "[A] Drawer feeding unit"

(2) Remove 2 screws, and take off the clutch

bracket and the bushing.

Pulley

One-way clutch

Pickup roller

E-rings

4

Fig. 4-45

Bushing

(3) Remove 1 connector and take off the clutch.

Note:

Match the protruding portion of the clutch

with the position shown in the figure for

assembling.

Clutch bracket

Fig. 4-46

Protrusion

Clutch

Connector

Fig. 4-47

© 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved KD-1025

4 - 17

DISASSEMBLY AND REPLACEMENT

Page 36

4.6 Switches and Sensors

[A] Tray-up sensor (S4/S5)/paper empty sensor (S6/S7)

(1) Take off the drawer feeding unit.

P.4-15 "[A] Drawer feeding unit"

(2) Remove 1 screw and take off the front side

cover.

Front side cover

Fig. 4-48

(3) Disconnect the connector and release the

latch to take off the tray-up sensor.

(4) Disconnect the connector and release the

latch to take off the empty sensor.

[B] Paper stock sensor (S10/S11)

(1) Take off the drawer feeding unit.

P.4-15 "[A] Drawer feeding unit"

(2) Pull up the paper stock sensor lever.

(3) Disconnect the connector and release the

latch to take off the paper stock sensor.

Tray-up sensorEmpty sensor

Fig. 4-49

Paper stock sensor

Paper stock

sensor lever

Fig. 4-50

KD-1025 © 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved

DISASSEMBLY AND REPLACEMENT

4 - 18

Page 37

[C] Upper/lower drawer feed sensor (S2/S3)

(1) Take off the side cover.

P.4-3 "[G] Side cover"

(2) Remove 6 screws and take off the guide.

(3) Disconnect 1 connector.

(4) Release the latches and take off the sensor.

4

Guide

Fig. 4-51

Upper drawer feed sensor

Latches

[D] Side cover open/close switch (S1)

(1) Take off the side cover.

P.4-3 "[G] Side cover"

(2) Remove 6 screws and take off the guide.

Lower drawer feed sensor

Fig. 4-52

Guide

Fig. 4-53

© 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved KD-1025

4 - 19

DISASSEMBLY AND REPLACEMENT

Page 38

(3) Release the latches and take off the switch.

(4) Disconnect the connector.

[E] Upper/lower drawer detection switches (S8/S9)

(1) Take out the drawer.

P.4-1 "[A] Drawers"

(2) Take off the rear cover.

P.4-2 "[D] Rear cover"

(3) Take off the PFP motor assembly.

P.4-13 "[D] PFP motor assembly"

(4) Disconnect the connectors connected to the

drawer detection switch.

(5) Release the latches and remove the switch

from the front side.

Side cover open/close switch

Latches

Fig. 4-54

Drawer detection switch

Fig. 4-55

KD-1025 © 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved

DISASSEMBLY AND REPLACEMENT

4 - 20

Page 39

5. ELECTRIC CIRCUIT

5.1 Harness Diagram

side cover open/close switch

transport clutch

lower drawer tray-up motor

upper drawer feed sensor

J508

2

6

6

PFPFEDCLT

1

J505

2

CN244

CN244

PFPTRML-A

+24V

upper drawer tray-up motor

J509

1

1

J507

1

2

8

1

12345

8

12345

8

PFPTRMU-B

PFPTRMU-A

PFPTRML-B

PFPSIDECOV

2

SG

J511

J520

J520

CN243

CN243

PFPFED2

5VFUSE

321

SG

lower drawer feed sensor

J510

321

B20

1234567

8765432

B20

1234567

B20

1234567

SG

PFPFED1

5VFUSE

NC

PFPCSTSWL

SG

13

13

B17

B18

B19

B2A1B1

B17

B18

B19

B17

B18

B19

PFPMPLL

+24V

+24V

PFPCSTNEMPL

5VFUSE

SG

101112

101112

B12

B13

B14

B15

B16

B9B8B7B6B5B4B3

B12

B13

B14

B15

B16

B12

B13

B14

B15

B16

SIZE1

SIZE2

SIZE3

SCSWC

SCSWB

PFP PC Board

PFPCSTUPL

PFPRGCLTL

5VFUSE

5VFUSE

+24V

SG

CN248

CN248

B11

B10

B9B8B7B6B5B4B3B2B1

B10

B11

B11

B12

B10

B10

B11

B10

B11

PFPFED1

PFPSIDECOV

SIZE0

PFPCSTEMPL

SG

123456789

123456789

B13

B12

B14

B13

SG

PFPFED2

NC

Equipment

B16

B15

B14

B15

B16

B17

B18

RETS6

RETS7

NC

PFPRST

PFPCSTNEMPU

PFPCSTSWU

5VFUSE

SG

1011121314

1011121314

CN318

CN318

J525

J525

B19

CN241

CN241

CN241

RETS5

SG

CN247

CN247

B1B2B3B4B5B6B7B8B9

A20

B20

B1B2B3B4B5B6B7B8B9

A20A20

B1B2B3B4B5B6B7B8B9

RETS3

RETS4

PFPRGCLTU

+24V

A18

A19

A2

A18

A19

A18

A19

RETS1

RETS2

PFPCSTUPU

5VFUSE

A16

A17

A16

A17

A16

A17

PIFCKB

RETS0

SG

5VFUSE

A12

A13

A14

A15

A9A8A7A6A5A4A3

A12

A13

A14

A15

A12

A13

A14

A15

DRV2

DRV1

DRV0

PIFCKC

PFPCSTEMPU

SG

123456789

123456789

A16

A15

A14

A13

A12

A11

A10

A9A8A7A6A5A4A3A2A1

A16

A17

A18

A5A6A7A8A9

SG

PFPMGAIN

PG

PG

A19

PGPGPFPCLK

+24V

A2A3A4

A1A2A3A4A5A6A7A8A9

A20

A1A2A3A4A5A6A7A8A9

A1

PG

+24V

PFPMBK

123456789

123456789

A10

A11

A11

A10

A13

A14

A12

A15

A10

A11

A10

A11

+5V

DRV7

DRV6

DRV5

DRV4

DRV3

PFPMCLK

PFPMPLL

PFPMCW

PFPMON

+5V

SG

101112

CN246

CN246

101112

5

2

1

J336

lower drawer

detection switch

4

4

113

2

101112

13

14

J632

lower drawer paper stock sensor

Drawer module

98765

J517

J630

9

321

321

J634

lower drawer tray-up sensor

3

1

J631

lower drawer feed clutch

2

2 345678

J633

lower drawer empty sensor

1413121110

1

321

2

1

J355

upper drawer

detection switch

3

2

4

J516

J630

10

121314

11

9

321

J632

upper drawer paper stock sensor

3

1

J631

upper drawer feed clutch

98765

1413121110

2

1

2 345678

321

J633

upper drawer empty sensor

321

J634

upper drawer tray-up sensor

J506

PFP motor

11

10

12

987654321

Fig. 5-1

© 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved KD-1025

ELECTRIC CIRCUIT

5 - 1

Page 40

5.2 Circuit Diagram

Fig. 5-2

KD-1025 © 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved

ELECTRIC CIRCUIT

5 - 2

Page 41

5

Fig. 5-3

© 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved KD-1025

5 - 3

ELECTRIC CIRCUIT

Page 42

side cover opening/closing switch

upper drawerfeed sensor

lower drawerfeed sensor

Equipment

PFP motor

tray-up motor unit

lower drawer

tray-up motor unit

transport clutch

upper drawer

lower drawerpaper stock sensor

lower drawerdetection switch

lower drawertray-up sensor

lower drawerfeed clutch

lower drawerempty sensor

upper drawer paper stock sensor

upper drawer detection switch

upper drawer tray-up sensor

upper drawer feed clutch

upper drawer empty sensor

Fig. 5-4

KD-1025 © 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved

ELECTRIC CIRCUIT

5 - 4

Page 43

5.3 PC Board

5

Fig. 5-5

© 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved KD-1025

5 - 5

ELECTRIC CIRCUIT

Page 44

KD-1025 © 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved

ELECTRIC CIRCUIT

5 - 6

Page 45

6. PERIODIC MAINTENANCE

1

1

Fig. 6-1

Symbols used in the checklist

Cleaning Lubrication/Coating Replacement Operation check

2

3

2

3

6

A: Clean with

alcohol

O: Clean with soft

pad, cloth or

vacuum

cleaner

W1: White grease

(Molykote EM-30L)

W2: White grease

(Molykote HP-300)

AV: Alvania No.2

L: Launa 40

Value: Replacement cycle

R: Replace if deformed or

Preventive Maintenance Checklist

Note:

Page-Item (P-I) is described in the column of the Parts list.

Items to check Cleaning

1 Pickup roller

(upper/lower)

2 Feed roller

(upper/lower)

3 Separation roller

(upper/lower)

4 Drive gear

(tooth face/shaft)

5 Transport roller

(upper/lower)

A80

A80

AAV, W2 80 *c1

AR

Lubrication/

Coating

W1 *c2

damaged

Replacement

(x 1,000 sheets)

O: After cleaning or

Operation

check

replacement, confirm

there is no problem.

Parts list

<P-I>

Remarks

6 Paper guide O

7 GCB bushing

bearing

8 One side of the

plastic bushing

© 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved KD-1025

L

W1

PERIODIC MAINTENANCE

6 - 1

Page 46

* c1. Separation roller

Apply an even coat of grease (Alvania No.2) to all round the inside of the spring. When replacing the

separation roller, apply adequate amount of white grease (Molykote HP-300) on the places of the

holder shown in the figure (4 places).

Separation roller

Apply grease

on the inside entirely

Lever

Separation roller

Fig. 6-2

Fig. 6-3

Note:

Make sure that the grease does not adhere to the roller surface. Wipe it off with alcohol if

adhered.

* c2. Drive gears in the paper feeding section (teeth of gears and shafts)

Apply some white grease (Molykote EM-30L) to the teeth of gears and shafts of the drive gears.

Note:

Make sure that oil is not running over or scattered around as the gear is rotated coming into the

clutch after applying Molykote to the gear which is located near the clutch. The quantity of

Molykote should be smaller than that to be applied to the other parts.

Holder

KD-1025 © 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved

PERIODIC MAINTENANCE

6 - 2

Page 47

REVISION RECORD

Ver.02

Page Contents

- The TOSHIBA logo on the cover page has been changed.

- The copyright description on the back side of the cover page has been changed.

5-1 The model name in "5.1 Harness Diagram" has been changed.

Ver.01

Page Contents

4-7 “Note” and an illustration for installing the belt have been added.

4-11 “Note” and an illustration for installing the belt have been added.

4-14 “Note” and an illustration for installing the belt have been added.

5-1 “5.1 Harness Diagram” has been corrected.

Ver.02 <2011.12.15>

Ver.01 <2010.02.05>

© 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved KD-1025

1

REVISION RECORD

Page 48

KD-1025 © 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved

REVISION RECORD

2

Page 49

Page 50

Loading...

Loading...