Page 1

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Document: VF010H07A

INSTRUCTION MANUAL

INSTALLATION - OPERATION - MAINTENANCE

HCV-1JBU Vacuum Contactor, 1.5kV - 600A

HCV-1KAU Vacuum Contactor, 1.5kV - 720A

Issued: 12/05

Manufactured in the USA

Page 2

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Page 3

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

TOSHIBA

INSTRUCTION MANUAL

For the Installation, Operation and Maintenance of

HCV-1JBU Vacuum Contactor, 1.5kV – 600A

HCV-1KAU Vacuum Contactor, 1.5kV – 720A

WARNING

To contact Toshiba, address all correspondence to:

Field Service Department

Toshiba International Corporation

13131 West Little York Road

Houston, Texas 77041 USA

or call:

(713) 466-0277

(800) 231-1412

(800) 527-1204 (Canada)

Fax:(713) 466-8773

Please complete the following information for your records and retain with this manual:

Model: ___________________________________

Serial Number: _____________________________

Date of Installation: _________________________

Inspected by: ______________________________

Reference Number: _________________________

© TOSHIBA INTERNATIONAL CORPORATION, 2004

Never attempt to install, operate, maintain or dispose of this equipment until

you have first read and understood all of the relevant product warnings and

user directions that are contained in this Instruction Manual.

Page 4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Page 5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

SAFETY Page 1

IMPORTANT MESSAGES

Read this manual and follow its instructions. Signal words such as

DANGER, WARNING and CAUTION will be followed by important safety

information that must be carefully reviewed.

DANGER

WARNING

CAUTION

NOTE Gives you helpful information

Note: The contents of this manual will not become apart of or modify the warranty policy. The

terms of which are set forth at the end of this manual.

READ SAFETY SIGNS

To avoid injury, you must read and follow all safety signs.

Keep the safety signs visible and in good shape. Never remove or cover any safety

signs.

Indicates a situation that will result in death, serious injury, and severe

property damage if you do not follow instructions.

Means that you might be seriously injured or killed if you do not follow

instructions. Severe property damage might also occur.

Means that you might be injured if you do not follow instructions. Equipment

damage might also occur.

Page 6

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Page 2 SAFETY

QUALIFIED OPERATORS ONLY

Only qualified persons are to install, operate, or service this equipment according to all

applicable codes and established safety practices.

A qualified person must:

1) Carefully read the entire instruction manual.

2) Be skilled in the installation, construction or operation of the equipment and

aware of the hazards involved.

3) Be trained and authorized to safely energize, deenergize, clear, ground,

lockout and tag circuits in accordance with established safety practices.

4) Be trained and authorized to perform the service, maintenance or repair of

this equipment.

5) Be trained in the proper care and use of protective equipment such as rubber

gloves, hard hat, safety glasses, face shield, flash clothing, etc. in

accordance with established practices.

6) Be trained in rendering first aid.

SAFETY CODES

Toshiba HCV-1JBU and HCV-1KAU vacuum contactors are designed and built in

accordance with NEMA ICS 3-2, UL 508, CSA 22.2-14 and IEC 60470. Installations

must comply with all applicable state and local codes, adhere to all applicable National

Electric Code (NFPA 70) standards and instructions provided in this manual.

Page 7

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

SAFETY Page 3

HAZARDOUS VOLTAGE will cause severe injury, death, fire, explosion, and

DANGER

property damage.

• Turn off and lock out Primary and Control Circuit Power before servicing.

• Keep all panels and covers securely in place.

• Never Defeat, Modify, or Bypass any Safety Interlocks

• Qualified Operators only

Page 8

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Page 4 TABLE OF CONTENTS

SAFETY...................................................................................................................................................... 1

INTRODUCTION ........................................................................................................................................6

GENERAL DESCRIPTION.........................................................................................................................7

Components....................................................................................................................................7

- Contactor Components.................................................................................................................7

Indicators and Controls ...................................................................................................................8

- ON/OFF Indicator..........................................................................................................................8

RECEIVING, INSPECTION AND HANDLING ...........................................................................................9

Receiving and Unpacking ...............................................................................................................9

Acceptance Inspection .................................................................................................................... 9

Handling and Moving ......................................................................................................................9

- Location of Wear Gauge...............................................................................................................9

INSTALLATION..........................................................................................................................................10

Ambient Conditions ......................................................................................................................... 10

Rating Verification ........................................................................................................................... 10

Mounting the Contactor................................................................................................................... 10

Main Circuit Cable Connections...................................................................................................... 10

Ground Connections ....................................................................................................................... 11

- Ground Connection Location ........................................................................................................11

Control Circuit Connections ............................................................................................................11

- Drive Unit Location........................................................................................................................11

PRE-ENERGIZATION CHECK ..................................................................................................................12

General ...........................................................................................................................................12

Electrical Checks.............................................................................................................................12

OPERATION...............................................................................................................................................13

Moving Contactor from Disconnected to Connected Position.........................................................13

Moving Contactor from Connected to Disconnected Position.........................................................13

- Internal Connection of the Normally Energized Type ...................................................................14

- Configuration of the Drive Unit...................................................................................................... 14

- Standard Operation Circuit of the Normally Energized Type ........................................................ 15

MAINTENANCE .........................................................................................................................................16

Maintenance Program.....................................................................................................................16

Maintenance Record ....................................................................................................................... 16

Servicing Equipment ....................................................................................................................... 16

Inspection and Maintenance Types ................................................................................................17

Table 1 – Tightening Torque...........................................................................................................17

Table 2 – Check Points for Periodic Inspection .............................................................................. 18

Page 9

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

TABLE OF CONTENTS Page 5

Table 3 – Gap/Wipe Standard Values (contactor in new condition)................................................20

Vacuum Check................................................................................................................................21

- Toshiba Portable Vacuum Checker ..............................................................................................21

- Application of Test Voltage for Vacuum Check.............................................................................22

Electrical Service Life...................................................................................................................... 23

Mechanical Service Life ..................................................................................................................23

- Wipe Measurement....................................................................................................................... 23

Service Life of Capacitor.................................................................................................................23

Table 4 – Recommended Part Replacement Intervals ...................................................................23

- Capacitor Switching Life ...............................................................................................................23

STORAGE AND DISPOSAL ...................................................................................................................... 24

Storage............................................................................................................................................24

Inspection during Storage ...............................................................................................................24

Disposal

SPECIFICATIONS...................................................................................................................................... 25

Table 5 – Ratings............................................................................................................................25

WARRANTY AND LIMITATION OF LIABILITY ........................................................................................26

Page 10

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Page 6 INTRODUCTION

It is the intent of this manual to provide a guide for safely installing, operating and maintaining Toshiba

vacuum contactors. This manual consists of a section of general safety instructions and is marked

throughout with warning symbols. Read this manual thoroughly before installation, operation and

maintenance of this equipment.

This manual and all accompanying drawings should be considered a permanent part of the equipment.

They should be readily available for review and reference at all times. This manual is not intended to

cover all details, combinations, or variations of the equipment. Always refer to drawings accompanying

the equipment for additional details.

All safety warnings must be followed to ensure personal safety. General safety instructions are

found on pages 1 through 3. Read and save these instructions for future reference.

Follow all precautions to attain proper equipment performance and longevity.

Dimensions shown in the manual are in metric and/or their English equivalent.

This manual is divided into major sections of interest, as follows:

GENERAL DESCRIPTION – Provides a description of the equipment, information on major

components and how they function, plus rating information.

RECEIVING, INSPECTION AND HANDLING – Describes procedures for receiving, unpacking,

inspecting, handling, lifting and moving the contactors.

INSTALLATION – Provides information on installing the contactor.

PRE-ENERGIZATION CHECK – Provides a checklist for preparing the equipment for energization.

OPERATION – Provides information on operation of the contactor, circuit diagrams, operating

sequence description.

MAINTENANCE – Lists the basic maintenance procedures for this equipment necessary for safe and

reliable operation.

DISPOSAL – Lists procedures for the safe disposal of the equipment when the service life has expired.

STORAGE – Provides guidelines for storing new equipment for an extended period of time.

SPECIFICATIONS – Covers ratings and other specifications of the contactor.

WARRANTY AND LIMITATION OF LIABILITY – Details Toshiba International Corporation’s standard

warranty terms.

Page 11

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

GENERAL DESCRIPTION Page 7

COMPONENTS

The Toshiba HCV-1JB and HCV-1KA vacuum

contactors described in this manual are suitable

for use on systems of 1.5kV, 600A and 1.5kV,

720A respectively.

Arc interruption is accomplished inside sealed

vacuum interrupters mounted on track-resistant

insulators. Vacuum interrupters use low-surge

contact materials, which exhibit low current

chopping levels reducing switching overvoltage.

Front view (Figure 1):

1. Insulation frame

2. Vacuum Interrupter

3. Primary terminal

4. Flexible conductor

Side view (Figure 2):

1. Drive unit

2. Auxiliary switch

3. Shaft

Rear view (Figure 3):

1. Closing coil

2. Opening spring

3. Terminal block

1

Figure 1 - Front of Contactor

3

2

4

2

Figure 2 - Right Side of Contactor

Figure 3 - Rear of Contactor

1

3

2

3

1

Page 12

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Page 8 GENERAL DESCRIPTION

INDICATORS AND CONTROLS

The following indicator is provided:

On-Off Indicator - Indicates if the contactor is

OFF (Green) or ON (Red). When the indicator

reads OFF, the main contacts of the contactor

are open. When the indication is ON, the main

contacts are closed. See Figure 4.

Figure 4 - ON/OFF Indicator

Page 13

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

RECEIVING, INSPECTION AND HANDLING Page 9

RECEIVING AND UNPACKING

The contactor units are subjected to factory

production testing prior to being packed and

shipped.

ACCEPTANCE INSPECTION

Confirm that the contactor is complete, correct

as specified and undamaged from shipment and

handling.

Upon receipt of the equipment, do the following:

1. Make an immediate inspection for damage

that might have occurred during shipment. If

damage is discovered, it should be noted

with the carrier prior to accepting the

shipment, if possible.

2. Carefully unpack the equipment sufficiently

to check for missing parts or concealed

damage.

3. Check for the presence of accessories that

are shipped with the contactor:

- Contactor wear gauge (Figure 5).

4. Keep the contactor upright.

CAUTION

File a claim with the carrier for any damaged or

missing items and immediately notify the nearest

Toshiba representative.

WARNING

Never lay the contactor on

its side or upside down.

This may cause damage.

Do not install or energize

equipment that has been

damaged. Damaged

equipment can fail during

operation, resulting in fire

and explosion.

HANDLING AND MOVING

Care and caution should be used when handling

the contactor to avoid damage to the equipment

and personal injury. Always keep the equipment

in a generally upright position.

Figure 5 - Location of Wear Gauge

Page 14

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Page 10 INSTALLATION

AMBIENT CONDITIONS

WARNING

Toshiba HCV-1JBU and HCV-1KAU contactors

are intended for use in usual service conditions

as defined in NEMA ICS 1. The temperature of

the cooling air (ambient air temperature)

surrounding the contactor should be between the

limits of -5°C (23°F) and +40°C (104°F). The

altitude of the equipment installation should not

exceed 3300-ft (1000 m).

In particular, avoid the following installation

conditions:

- Excessive dust

- Corrosive gases

- Extreme variations in temperature

- Very high or low humidity

- Vibrations

- Inclined locations

If there is a chance that condensation can occur

at the installation location, a space heater should

be installed inside the contactor enclosure.

NOTE: Temperature, altitude or other

conditions outside of the usual limits

may require derating or other special

equipment. Contact your nearest

Toshiba representative for additional

information.

Do not install this

equipment in areas where

unusual service conditions

exist. Using this equipment

in other than usual service

conditions can result in

equipment failure.

MOUNTING THE CONTACTOR

The contactor is designed to mount to a flat,

vertical surface. If there are any noticeable gaps

between the contactor and the mounting surface,

fill them in using flat washers as spacers.

Fasten the contactor using four (4) M8 hex

head bolts. The tightening torque should be

120-150 kgf-cm (9-11 ft-lb). See Table 1 for

tightening torque specifications.

MAIN CIRCUIT CABLE CONNECTIONS

Route cables that connect to the contactor to

avoid interference with sharp edges and moving

parts. Observe minimum bending radius for the

type of cable used.

Power cables should be braced and/or laced to

withstand short-circuit forces wherever such

cables are unsupported. Power cables should

be adequately sized to carry the maximum

continuous current in accordance with NEC

requirements and should have an adequate

voltage rating. Cables should be dressed and

terminated as appropriate to the voltage class

and cable manufacturer’s recommendations.

Fasten the cables to the main circuit terminals.

Use 35 mm Class 8.8 M10 or M12 hex head

bolts, 2 flat washers, a lock washer and a nut.

While securely preventing the nut from rotating

with a wrench, torque the bolt to 250-315 kgfcm (18-23 ft-lb) for M10 bolts or 450-565 kgf-cm

(32-41 ft-lb) for M12 bolts.

Page 15

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

INSTALLATION Page 11

CAUTION

GROUND CONNECTIONS

The contactor must be grounded in accordance

with the requirements of the National Electrical

Code, Article 250 or applicable local standards.

WARNING

It is very important that the contactor be

adequately grounded to protect the operator

from injury in the event of short circuits or other

abnormal occurrences and to ensure that the

metal parts of the equipment, other than live

parts, remain at ground potential.

The ground terminal is located on the left side

of the contactor as shown in Figure 6. To make

the ground connection, first remove the

fastening M8 hex head bolt and crimp-on

terminal (provided with the contactor) and crimp

the terminal to the end of the ground wire.

Use two wrenches to

torque the connection to

prevent applying excessive

force to the terminal, which

can damage the frame.

Proper grounding

connections must be made

to the contactor before

incoming power is applied.

The ground wire should be 8 AWG or larger.

Then reattach the terminal using the same bolt

previously removed and torque to 9-11 ft-lb

(120-150 kgf-cm).

CONTROL CIRCUIT CONNECTIONS

WARNING

Control circuit wiring is connected to the

contactor by means of a drive unit (black plastic

box) located on the right side frame (Figure 7).

Either AC or DC supply voltage may be

connected to the drive unit.

The standard operating voltage for the control

circuit is 100-240V AC/DC. Figure 8 in the

OPERATION section of this manual show the

internal connections of the drive unit, closing

coils, and auxiliary switch.

Hazardous Voltage. Turn off

and lock out all primary and

control circuit power

sources prior to performing

this pre-energization check.

Applying the specified

power to the drive unit will

immediately activate the

coils and close the

contactor.

Figure 6 - Ground Connection Location

Figure 7 - Drive Unit

Page 16

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Page 12 PRE-ENERGIZATION CHECK

GENERAL

BEFORE ENERGIZING THE CONTACTOR for

the first time, follow the procedure below to verify

that the equipment is properly installed and

functional.

DANGER

WARNING

WARNING

WARNING

WARNING

• All blocks or other temporary braces used for

shipment must be removed.

• Install all panels, guards, and covers if

removed.

• Check for any loose connections and confirm

that all wiring is correct per wiring diagrams.

• A supply of spare parts should be

established.

• Instruction manuals and diagrams should be

collected and filed.

Hazardous Voltage. Turn off

and lock out all primary and

control circuit power

sources prior to performing

this pre-energization check.

Do not operate this

equipment until a complete

safety inspection has been

made.

Do not energize damaged

equipment that has not

been repaired or verified.

Do not remove, cover or

destroy any safety signs.

Do not operate this

equipment if any panels or

covers have been removed.

ELECTRICAL CHECKS

WARNING

An electrical insulation resistance test should be

performed to verify that the contactor and

associated field wiring are free from short circuits

and grounds. Refer to the MAINTENANCE

Section of this manual for additional information.

WARNING

Electrical shock hazard.

Do not touch energized

components during a test

using auxiliary power.

Hazardous voltages are

present during dielectric

testing which can result in

serious injury or death.

High potential tests should

be performed only by

qualified personnel.

Page 17

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

OPERATION Page 13

MOVING THE CONTACTOR FROM THE OFF

TO THE ON POSITION

TO MOVE THE CONTACTOR TO THE ON

POSITION:

1. Turn ON circuit control power to move the

contactor to the ON position

2. Verify that the position indicator reads ON

(Red).

MOVING THE CONTACTOR FROM THE ON

TO THE OFF POSITION

TO MOVE THE CONTACTOR TO THE OFF

POSITION:

1. Turn OFF circuit control power to move the

contactor to the OFF position

2. Verify that the position indicator reads OFF

(Green).

Page 18

T

A

A

A

y

A

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

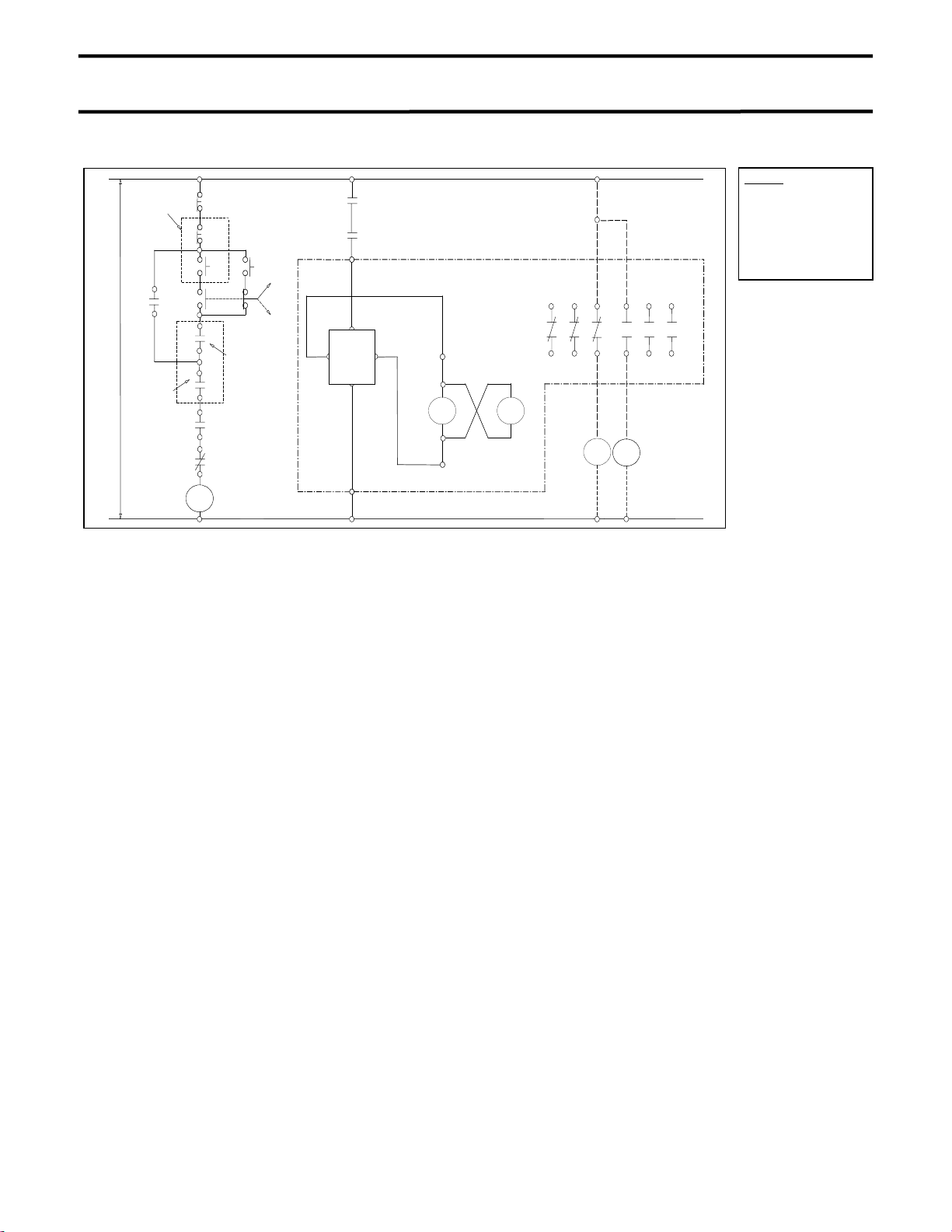

Page 14 OPERATION

LEGEND

52 CC …. Closing Coil

T1-T4 ….. Terminal Block

R S T

Vacuum Bottles

U V W

A1-A2…... Closing Supply

AC/DC

T4

T3

T2

T1

52

CC

52

CC

16 15 14 13 12 11

26 25 24 23 22 21

uxiliar

Switch

56

Drive Unit

12

1 A2

Closing Supply

AC/DC

Figure 8 – Internal Connection of the Normally Energized Type

T1

1

2

52

CC

TIMER

T2

LEGEND

52 CC …. Closing Coil

T1-T2 ….. Terminal Block

A1-A2…... Closing Supply

AC/DC

VOLTAGE

DETEC

SWITCHING

OSCILLATION

POWER

Figure 9 – Configuration of the Drive Unit

Page 19

A

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

OPERATION Page 15

LEGEND

Remote

Opera ti on

Swit ch

100/110V

200/220V

Stop

C/DC

Interlock

CR

OFF

OFF

ON

Star t

Interlock

DrS

(Door Switch)

2E (Overl oad)

CR

ON

Local

Remote

A1

Dri ve

Unit

A2

CR

CR

52

CC

T1

T2

Auxil iary

Switch

52

CC

16 15 14 13 12 11

26 25 24 23 22 21

GL

RL

VCTT

52 CC …. Closing Coil

T1-T2 ….. Terminal Block

GL ……… Green Light

RL ……… Red Light

CR……… Control Relay

A1-A2…... Closing Supply

AC/DC

Figure 10 - Standard Operation Circuit of the Normally Energized Type.

Page 20

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Page 16 MAINTENANCE

MAINTENANCE PROGRAM

In order to ensure continued reliable and safe

operation of the equipment, a program of

periodic maintenance must be established.

Operating and environmental conditions will

usually dictate the frequency of inspection

required. NFPA Publication 70B "Electrical

Equipment Maintenance" may be used as a

guide for setting up the maintenance program.

DANGER

WARNING

WARNING

NOTE: Refer to the SAFETY section of this

manual for important information.

Contact with energized

components can cause

severe injury, death and

property damage. Turn off

and lock out primary and

control circuit power before

servicing.

Improper maintenance can

cause severe injury, death

and property damage. Only

qualified and authorized

persons are to install,

operate or service this

equipment.

Grease is conductive. Do

not allow grease or any

other substances to

contaminate insulating

materials. Contaminated

insulators can allow a

short-circuit or ground

fault to occur.

MAINTENANCE RECORD

Keep a permanent record of all maintenance

work. At a minimum, this record should include

information on:

1. Items inspected

2. Reports of any testing

3. Equipment condition

4. Corrective actions or adjustments

5. Date of work

6. Comments

The degree of detail of the record will depend

somewhat on the operating conditions.

SERVICING EQUIPMENT

For your safety, turn off and lock out main and

control circuit power before servicing the

contactor. Certain minimum safety procedures

must be followed:

1. Only qualified personnel should attempt

this service.

2. Never perform service on or next to

exposed components energized with line

voltage.

WARNING

Failure to adhere to these

safety procedures can

result in severe injury,

death and property

damage.

Page 21

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

MAINTENANCE Page 17

RECOMMENDED INSPECTION AND

MAINTENANCE TYPES

NOTE: Refer to the SAFETY section of this

manual for important information.

1. Acceptance Inspection

This inspection confirms that the contactor is

complete, correct as specified and

undamaged from shipment. The procedure

for this inspection is outlined in the

RECEIVING, INSPECTION AND

HANDLING section of this manual.

2. Patrol Inspection

Inspection is made of the condition of the

contactor while it is energized. Check that

no unusual sounds or smells exist externally.

Check for any abnormal discoloration due to

overheating. Inspect for signs of damage to

the insulation frame, OPEN/CLOSE indicator

and other components.

Inspection Frequency:

3. Periodic Inspection

Inspection is performed with the contactor

de-energized. The lubrication of sliding and

rotating parts is checked and the mechanism

is lubricated if needed.

Inspection Frequency:

or every 20,000 operations (normal).

NOTE: Refer to Table 2 for the schedule of

Periodic Inspections.

4. Unscheduled Inspection

Inspections are implemented as required.

Inspection Frequency:

NOTE: The inspection frequency and points

to be inspected may vary from the

above recommendations depending

on the status of use, frequency of

switching and other factors.

Once every 6 months

Once every 1-2 years

As needed

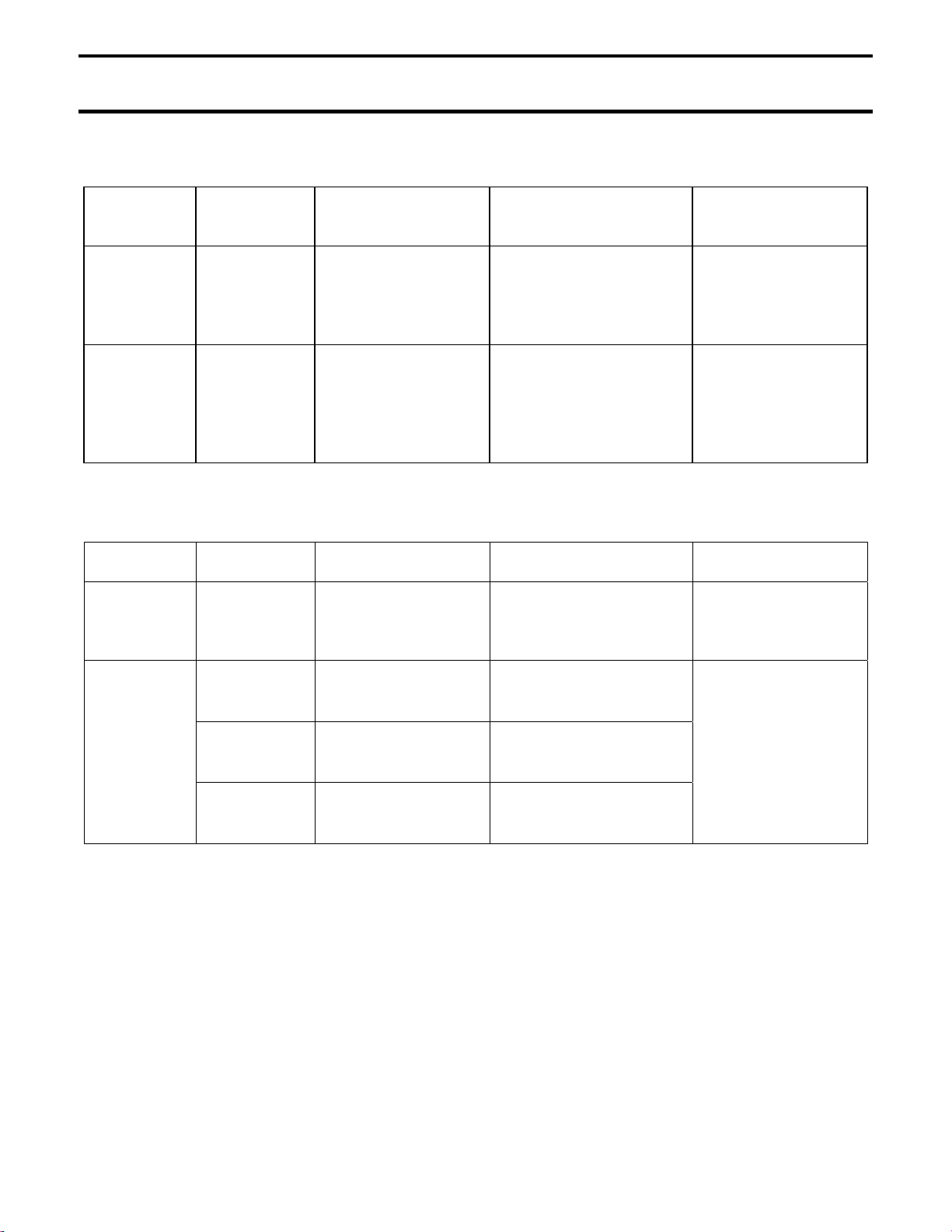

Table 1 - Tightening Torque

Screw Nominal

Diameter

M4 15-20 kgf-cm (13-17 in-lb)

M5 30-40 kgf-cm (26-34 in-lb)

M6 50-65 kgf-cm (43-56 in-lb)

M8 120-150 kgf-cm (9-11 ft-lb)

M10 250-315 kgf-cm (18-23 ft-lb)

M12 450-565 kgf-cm (32-41 ft-lb)

Tightening Torque

Page 22

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

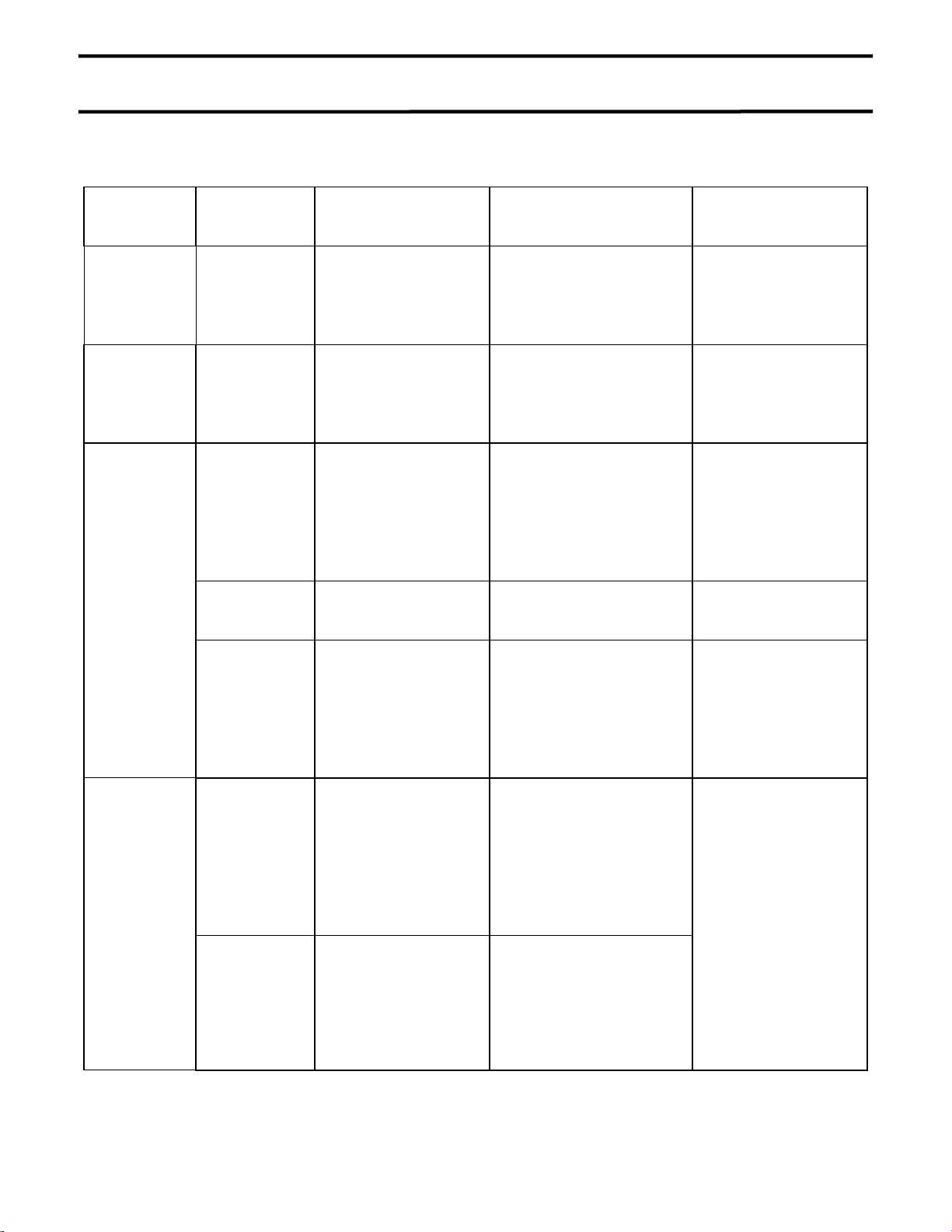

Page 18 MAINTENANCE

Table 2 - Check Points for Periodic Inspection

Check

Point

Operating

Mechanism

Dust or

Electro-

Closing coil Visual inspection. Check for discoloration,

Spring Visual inspection. Check for rust,

Check Item Check Method Criteria Disposition

Loose bolts,

nuts or

screws

foreign

matter inside

magnets

Tighten using

screwdriver or

wrench.

Visual inspection. The contactor should be

Visual inspection. Check for rust,

Make sure all bolts,

nuts and screws are

tight.

clean and contain no

foreign matter.

discoloration, wear, or

loose mountings.

and burned parts.

deformation,

discoloration, or

damage.

Tighten if loose.

See Table 1 for

tightening torque

specifications.

Wipe with a clean

dry cloth.

Wipe with a clean

dry cloth.

Wipe with a clean

dry cloth.

Wipe with clean dry

cloth. Lubricate if

necessary.

Smooth

operation

Main Circuit Terminals

and movable

conductors.

Loose bolts,

nuts or

screws

Vacuum

contact wear.

Vacuum

level.

Visual inspection or

touch. Check

lubrication.

Visual inspection.

Tighten using

screwdriver or

wrench.

Tighten using a

wrench.

See Electrical

Service Life (Page

23).

Apply 10kV AC for 1

minute.

Make sure moving parts

operate smoothly.

Make sure there is no

discoloration or loose

fasteners.

Make sure all bolts,

nuts and screws are

tight.

Check contact wear and

wipe.

Check vacuum level by

withstand voltage test.

Apply a small

amount of

lubrication.

Check the cause

and repair. Tighten

connections to

contactor. See

(Table 1) for

tightening torque

specifications.

See Table 1 for

tightening torque

specifications.

Replace vacuum

interrupter.

If breakdown occurs,

contact Toshiba.

Page 23

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

MAINTENANCE Page 19

Table 2 – Check Points for Periodic Inspection (cont.)

Check

Point

Main Circuit Dust on

Insulation

Frame and

Flanges

Control

Circuits

Drive unit Visual inspection. Check for overheating

Check Item Check Method Criteria What to do

Visual inspection. Make sure there is no

surface of

vacuum

interrupter

Dust, foreign

matter or

damage

Auxiliary

Switch

Visual inspection. Make sure there is no

See Table 3. Contact wear and wipe.

dust on the surface.

dust, foreign matter or

breakage.

Make sure there is no

dust.

and discoloration.

Wipe with a clean,

dry cloth.

Wipe with a clean,

dry cloth. If

damaged, contact

Toshiba.

Replace if wear or

damage is

excessive. See

Table 1 for

tightening torque

specifications

Replace if damaged.

Wiring Visual inspection.

Tighten using a

screwdriver.

Insulation

Resistance

Measurement

Resistance

Resistance

from main

circuit to

ground

from control

circuits to

ground

Measure insulation

resistance between

phases, between

electrodes, and

between circuits and

ground. Megger test

at 1000V.

Measure insulation

resistance between

circuits and ground.

Megger test at

500V.

Check for discoloration

and tightness.

Resistance should be

50MΩ or greater.

Resistance should be

1MΩ or greater.

Repair if

disconnected.

Tighten if loose.

See Table 1 for

tightening torque

specifications.

If the insulation

resistance is low,

wipe off the vacuum

interrupter and other

insulation surfaces

with a clean dry

cloth and then

repeat the test. If

necessary, replace

faulty parts.

Page 24

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Page 20 MAINTENANCE

Table 2 – Check Points for Periodic Inspection (cont.)

Check

Point

Dielectric

Strength

Open/Close

Operation

Table 3 - Gap/Wipe Standard Values (contactor in new condition).

Parts

Vacuum

Interrupter

Check Item Check Method Criteria What to do

Measure

main circuit

--- Perform open/close

Normally

energized

type

Measure dielectric

strength between

phases and between

circuits and ground.

operation by electric

operation test to

confirm the correct

operation.

Gap Wipe Allowable Wear

0.091-0.098 in.

(2.3-2.5 mm)

10kV AC or 14kV DC for

1 minute.

--- If not normal, check

0.091-0.102 in.

(2.3-2.6 mm)

If breakdown occurs,

contact Toshiba.

and repair. If

necessary, replace

faulty parts.

0.051 in. (1.3 mm)

Auxiliary

Switch

a-contact

b-contact

Delayed

b-contact

0.157±0.016 in.

(4±0.4 mm)

0.157±0.016 in.

(4±0.4 mm)

0.098±0.012 in.

(2.5±0.3 mm)

0.118±0.012 in.

(3±0.3 mm)

0.118±0.012 in.

(3±0.3 mm)

0.177±0.020 in.

(4.5±0.5 mm)

---

Page 25

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

MAINTENANCE Page 21

VACUUM CHECK

A sufficient level of vacuum is necessary for

proper performance of the vacuum interrupters.

Although vacuum leaks are rare, the vacuum

integrity should be checked periodically. The

relationship between dielectric breakdown

voltage of the contact gap and internal vacuum

interrupter pressure has been found to be

generally predictable. Therefore, vacuum

interrupter integrity is checked by performing a

high potential test across the open gap of the

interrupter.

TEST EQUIPMENT:

Toshiba offers a compact vacuum checker (Type

CI35-1D, Figure 11) which enables a quick and

easy check on vacuum interrupter internal

pressure. Alternatively, any commercially

available AC high potential tester may be used

which is capable of delivering at least 25 milliamperes at 10 kV for a period of one minute.

PRECAUTIONS:

Applying abnormally high voltage across a pair

of contacts in vacuum may produce X-rays. The

radiation may increase with the increase in

voltage and/or decrease in contact spacing. Xradiation produced during this test with

recommended voltage and normal contact

spacing is extremely low and well below the

maximum permitted by standards. As an

additional safety measure, however, it is

recommended that all personnel keep at least 1

meter (3.3 ft) away from the vacuum circuit

breaker while this test is performed.

WARNING

Radiation exposure hazard.

X-rays may cause illness or

injury. Stay at least 1 meter

(3.3 ft) away from the circuit

breaker during the vacuum

check test.

WARNING

TEST PROCEDURE:

1. The contactor should be disconnected from

the main circuit and be in the OFF position.

2. Connect all the line side primary terminals

together and to the output of the vacuum

checker or AC hi-pot machine. Connect all

the load side primary terminals together and

to the ground terminal of the vacuum

checker or AC hi-pot machine.

3. Increase the voltage from zero to 10kV AC at

a rate of approximately 1kV per second.

Hold the voltage at this value for 1 minute

and observe the current drawn by the

interrupter. See Figure 12.

4. Decrease the voltage back to zero.

Figure 11 - Toshiba Portable Vacuum

Checker

Hazardous voltages are

present during dielectric

testing which can result in

severe injury or death.

Only qualified personnel

should conduct this testing.

Page 26

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Page 22 MAINTENANCE

CRITERIA:

1. If a current flow above 5 milli-amperes is

observed or if breakdown occurs, one or

more of the interrupters has insufficient

vacuum and must be replaced.

Exception: If the current exceeds 5 milli-

amperes the first time the voltage is brought

up, reduce the voltage to zero and increase it

again. It may be necessary to repeat this

procedure a few times.

2. If the contactor fails to meet criteria 1, then

repeat the test on each pole separately to

identify the damaged interrupter or

interrupters.

3. If the voltage can be held for 1 minute and

the current flow does not exceed 5 milliamperes, the interrupter has a sufficient

vacuum level.

After the test is complete, discharge any residual

static charge from the primary terminals of the

circuit breaker.

If a vacuum checker or AC hi-pot tester is not

available, a DC hi potential test may be

conducted. If a DC test is conducted, the test

voltage must be increased to 14kV DC. The test

duration for DC tests and the criteria for

acceptance remain the same as for AC tests.

WARNING

Do not use DC hi-pot

testers which employ

unfiltered half-wave

rectifiers. The peak

voltages produced by these

testers may exceed the

recommended value of

14kV. This can result in the

production of harmful Xrays and may invalidate the

test results.

1 minute

10kV AC

(14kV DC)

Voltage

Zero

10 sec 10 sec

Time

Figure 12 - Application of Test Voltage for

Vacuum Check

Page 27

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

MAINTENANCE Page 23

ELECTRICAL SERVICE LIFE

The electrical service life of the vacuum

interrupter is defined by the electrode wear and

the number of open/close operations

(mechanical life).

To determine electrode wear, measure the

distance between the lever and washer in the

closed (ON) state, as shown in Figure 13. This

dimension is called the “wipe”. If the 1.0mm

contact wear gauge cannot be inserted, then

the end of the service life has been reached.

The maximum number of open/close operations

is 500,000 regardless of the magnitudes of the

currents interrupted. Contact Toshiba for

information regarding replacement of the

vacuum interrupters.

The drive unit and the closing coils also have

an electrical service life of 500,000 operations.

As a result, these parts should be replaced

around 500,000 operations.

MECHANICAL SERVICE LIFE

The normally energized type has a mechanical

service life of 2.5 million operations. The

mechanical service life of the vacuum

interrupters is 500,000 operations.

For the components listed in Table 4,

replacement or detailed inspection and cleaning

are recommended after the indicated number of

operations.

Isolation

Flange

A

Figure 13 - Wipe Measurement

Table 4 - Recommended Part Replacement

Intervals

Part Name Number of Operations

for Replacement

Vacuum Interrupter 500,000

Auxiliary Switch 200,000

Moveable Core Detailed inspection and

cleaning every 500,000

operations.

Stationary Core Detailed inspection and

cleaning every 500,000

operations.

Closing Coil 500,000

Flexible Conductor 500,000

SERVICE LIFE – CAPACITOR SWITCHING

Switching of the capacitor loads produces

severe conditions for contactors, such as high

frequency inrush current and phase-to-phase

recovery voltage more than twice the normal

voltage.

The criterion for the maximum number of the

capacitor current switching operations is shown

in Figure 14. The vacuum interrupter should be

replaced when the number of switching

operations in the graph is reached.

10

8

6

4

2

Switching Life (ten thousand)

1

20 40 60 200 400 600

10 100 1000

Switching Current (A)

Figure 14 - Capacitor Switching Life

Page 28

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Page 24 DISPOSAL AND STORAGE

STORAGE

If the contactor is to be stored for any length of

time prior to installation, the following

precautions should be taken.

1. The original packing should be restored, if

possible.

2. Do not subject the equipment to moisture or

sunrays. Store in cool, clean, and dry

location.

3. Place a dust cover over the contactor

packaging to protect against dirt and

moisture.

4. Store in an upright position.

INSPECTION DURING STORAGE

Routine scheduled inspection is necessary if

storage is for an extended period. The unit

should be checked for condensation, moisture,

corrosion, and vermin.

Prior to installation, the contactor should be

carefully examined for evidence of physical

damage, corrosion, or other deterioration. Refer

to the PRE-ENERGIZATION Section of this

manual.

The MAINTENANCE section of this manual

describes various types of inspections

recommended for this contactor during the

operation period.

DISPOSAL

Contact your state environmental agency for

details on disposal of electrical components and

packaging in your particular area.

Page 29

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

SPECIFICATIONS Page 25

Table 5 - Ratings

Items HCV-1JBU HCV-1KAU

Rated Insulation Voltage kV 1.5

Rated Operation Voltage V 208-1500

Rated Operational Current A 600 720

Rated Frequency Hz 50/60

Rated Making Current kA 6.0

(close 100 times)

Rated Breaking Current kA 4.8

(close-open 25 times)

Rated Insulation Level kV AC 10 Impulse 45 AC 10 Impulse 30

Rated Short-Time Current kA 9.0 – 1 sec.

3.6 – 30 sec.

Method of Operation Non-latch

Mechanical Operation Million 2.5

Electrical Operation Million 0.5

Operational Voltage Standard 100-240V AC/DC

Auxiliary Switch 3 N.O. – 3 N.C.

Switching Frequency Times/h 1200

(close 100 times)

(close-open 25 times)

7.2

5.76

10.8 – 1 sec.

4.3 – 30 sec.

Page 30

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

WARRANTY AND LIMITATION OF LIABILITY Page 26

Toshiba International Corporation ("Company") warrants that all equipment and parts described herein will be free

from defects in materials and workmanship. THIS WARRANTY WILL EXPIRE EIGHTEEN (18) MONTHS AFTER

THE DATE ON WHICH SUCH EQUIPMENT AND PARTS (EXCLUDING REPAIRED OR REPLACEMENT

EQUIPMENT AND PARTS FURNISHED PURSUANT TO THIS WARRANTY) ARE SHIPPED BY THE COMPANY

TO THE INITIAL PURCHASER OR TWELVE (12) MONTHS AFTER SUCH EQUIPMENT AND PARTS

(EXCLUDING REPAIRED OR REPLACEMENT EQUIPMENT AND PARTS FURNISHED PURSUANT TO THIS

WARRANTY) ARE FIRST PLACED IN OPERATION, WHICHEVER PERIOD FIRST EXPIRES.

The Company will, at its option, repair or replace such equipment or part which is defective under the terms of the

foregoing warranty, free of charge; provided

defect, and (2) furnishes the Company satisfactory proof thereof, and (3) establishes that the equipment or part has

been properly installed, maintained and operated within the limits of rated capacity and normal usage and in

accordance with this manual, and (4) if requested by the Company, returns the defective equipment or part to the

Company and pays all expenses incurred in connection with such return. The repaired or replacement equipment or

part will be delivered, free of charge, to the purchaser F.O.B. the Company's warehouse or, at the Company's

option, F.O.B. a Company authorized service shop, not loaded on truck or other carrier. The purchaser will pay the

costs applicable to the equipment or part following such delivery, including, without limitation, all handling,

transportation, assembly, insurance, testing and inspection charges.

THE FOREGOING OBLIGATION TO REPAIR OR REPLACE EQUIPMENT PARTS SHALL BE THE SOLE AND

EXCLUSIVE REMEDY OF THE PURCHASER, ITS CUSTOMERS AND USERS OF THE EQUIPMENT AND

PARTS FOR BREACH OF THE FOREGOING WARRANTY. THE COMPANY WILL HAVE NO OBLIGATIONS TO

DISASSEMBLE ANY EQUIPMENT OR PART WHICH IS DEFECTIVE WITHIN THE TERMS OF THE ABOVE

WARRANTY OR TO INSTALL ANY REPAIRED OR REPLACEMENT PART OR EQUIPMENT OR TO PAY ANY

COSTS INCURRED IN CONNECTION WITH ANY SUCH DISASSEMBLY OR INSTALLATION. THE COMPANY,

TOSHIBA CORPORATION AND THEIR SUPPLIERS AND SUBCONTRACTORS HEREBY DISCLAIM ALL

OTHER EXPRESS, STATUTORY AND IMPLIED WARRANTIES, INCLUDING, WITHOUT LIMITATION, ALL

EQUIPMENT AND PARTS FURNISHED PURSUANT TO THE FOREGOING WARRANTY AND ALL IMPLIED

WARRANTIES OF MERCHANTABILITY.

The total liability of the Company, Toshiba Corporation and their suppliers and subcontractors for any

loss, damage or claim, whether in contact, tort (including negligence and liability without fault), or

otherwise, arising out of, connected with or resulting from the equipment and parts described in this

manual or the performance or breach of any contract for the sale or supply of such equipment and

parts, or from the design, manufacture, sale, delivery, resale, installation, technical direction or

supervision of installation, inspection, testing, repair, replacement, operation, maintenance or use of

any such equipment or part or any service relating thereto furnished by the Company shall not in any

event exceed the price allocable to the equipment, part or service which gives claim, loss or damage.

In no event, whether as a breach of contract or warranty, alleged negligence, liability without fault, or

otherwise, shall the Company, Toshiba Corporation or their suppliers or subcontractors be liable for

special or consequential damages, including, without limitation, loss or profits or revenue, loss of

equipment described herein or any associated equipment, cost of capital, cost of substitute equipment

or parts, facilities or services, down-time costs, labor costs or claims of customers of the purchaser for

such damages.

the purchaser (1) promptly notifies the Company in writing of such

Loading...

Loading...