Toshiba H9 Series Sales Brochure

ADJUSTABLE SPEED DRIVES

H9 Series

Innovative Technology

The H9 adjustable speed drive is the most advanced heavy

duty drive ever offered by Toshiba. It is a blend of a robust

power platform and a state-of-the-art control scheme.

With its dual 32-bit processor controls, the H9 provides

the ability to operate the toughest of applications while

still maintaining a high level of control.

Powerful Solution

The H9 is rated at 120% of its full load amps for up to 60 seconds. The motor-flux braking

technology allows the H9 to provide as much as 25% of its rated power for use in stopping a

high inertia load without the use of a dynamic braking resistor. For applications requiring heavier

breaking capabilities, most frame sizes include a dynamic breaking transistor as standard.

Advanced Control

The H9 can operate using open or closed-loop controls. Toshiba’s advanced vector-control

algorithm offers speed regulation of 0.1% sensorless and 0.01% with motor feedback. The

H9 has the ability to switch on-the-fly between speed and torque modes. While operating in

the feedback vector-control mode, the H9 can generate a zero-speed torque to hold the shaft

stationary while the motor is stopped.

CHECK OUT OUR

Special Features

Free Downloadable Programming Software•

NEMA 1•

DC Link Reactors on Most HP Ratings•

UL and cUL Listed•

NEC 2005 Motor Overload Retention (No External Motor Overloads Required)•

G9 ASD SERIES FOR

SEvERE DUTy AnD

ExTREmE COnDITIOn

APPLICATIOnS

Isolated Input

The H9 is setting a new industry standard by providing an optically isolated current (0 to 20 mA)

or voltage inputs (0 to 10 VDC).

Advanced Functionality

Q

80%

>

10s

On Delay

Out 1

If motor torque is greater than

80% for over 10 seconds, close

the Out 1 contact.

(Simplied programming example)

New Interface

The H9’s removable LED/LCD display allows the user to transfer parameter settings from one drive

to another. The startup wizard and built-in rotary encoder allow for intuitive programming and quick

access to parameters and monitoring information. Easy access to the drive’s monitoring information

makes troubleshooting and application startup a snap. With a built-in real-time clock and faultrecording ability, the user can access monitoring data as well as up to 20 previous time-stamped

fault codes.

Programmable I/O

Toshiba's H9 provides users with the most flexible and adaptable interface in the industry. Eight

configurable discrete inputs and three configurable dry-contact outputs can be set for normallyopen or normally-closed operation, and can be programmed to a number of user-defined functions.

The H9 also includes an isolated programmable voltage or current input as well as two other analog

programmable and adjustable inputs. Two programmable analog outputs complete the package to

allow for the highest level of process customization.

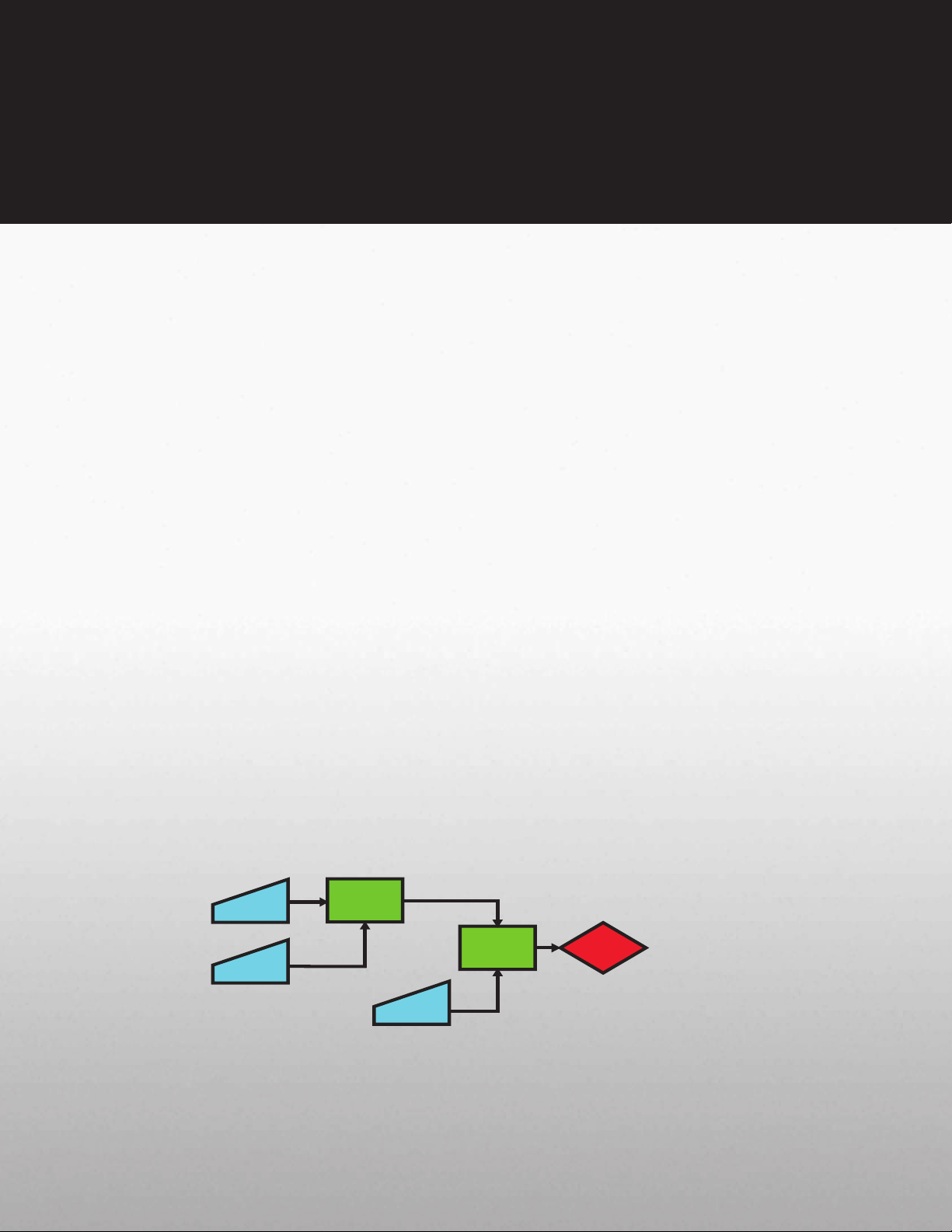

My Function

Toshiba's My Function allows the user to utilize logic-type programming without the expense of a

micro PLC. The user is given access to read all analog and discrete I/O, as well as the ability to

monitor and perform data comparisons. When programmed in a user-defined logic sequence, the

use of this data will allow a higher level of process control not normally seen in an adjustable speed

drive. These functions, along with timers, counters, and comparators, allow the H9 to perform tasks

above and beyond simply running a motor.

Process Control

The built-in proportional/integral/derivative (PID) control loop provides regulation of processes

without the need for external devices. Deviation limits, online switching, and delay-filtering functions

are included in the drive to enhance the flexibility and the reliability of the PID process control. The

H9 also provides torque control and drooping-control functions to allow precise matching of motor

torque for load-sharing applications.

Loading...

Loading...