Toshiba GRL100-501B, GRL100-101B, GRL100-311B, GRL100-411B, GRL100-511B Instruction Manual

...

6 F 2 S 0 8 3 5

INSTRUCTION MANUAL

LINE DIFFERENTIAL RELAY

GRL100 - ∗∗∗B

© TOSHIBA Corporation 2005

All Rights Reserved.

( Ver. 2.4 )

R

Safety Precautions

Before using this product, please read this chapter carefully.

This chapter describes the safety precautions recommended when using the GRL100. Before

installing and using the equipment, this chapter must be thoroughly read and understood.

Explanation of symbols used

Signal words such as DANGER, WARNING, and two kinds of CAUTION, will be followed by

important safety information that must be carefully reviewed.

Indicates an imminently hazardous situation which will result in death or

DANGE

Indicates a potentially hazardous situation which could result in death or

WARNING

CAUTION Indicates a potentially hazardous situation which if not avoided, may result

serious injury if you do not follow the instructions.

serious injury if you do not follow the instructions.

in minor injury or moderate injury.

6 F 2 S 0 8 3 5

CAUTION Indicates a potentially hazardous situation which if not avoided, may result

in property damage.

⎯ 1 ⎯

R

DANGE

• Current transformer circuit

Never allow the current transformer (CT) secondary circuit connected to this equipment to be

opened while the primary system is live. Opening the CT circuit will produce a dangerously high

voltage.

WARNING

• Exposed terminals

Do not touch the terminals of this equipment while the power is on, as the high voltage generated

is dangerous.

• Residual voltage

Hazardous voltage can be present in the DC circuit just after switching off the DC power supply.

It takes approximately 30 seconds for the voltage to discharge.

• Fiber optic

6 F 2 S 0 8 3 5

Invisible laser radiation

Do not view directly with optical instruments.

Class 1M laser product (Transmission distance: 30km class)

- the maximum output of laser radiation: 0.2 mW

- the pulse duration: 79.2 ns

- the emitted wavelength(s): 1310 nm

CAUTION

• Earth

The earthing terminal of the equipment must be securely earthed.

CAUTION

• Operating environment

The equipment must only used within the range of ambient temperature, humidity and dust

detailed in the specification and in an environment free of abnormal vibration.

• Ratings

Before applying AC voltage and current or the DC power supply to the equipment, check that

they conform to the equipment ratings.

• Printed circuit board

Do not attach and remove printed circuit boards when the DC power to the equipment is on, as

this may cause the equipment to malfunction.

• External circuit

When connecting the output contacts of the equipment to an external circuit, carefully check the

supply voltage used in order to prevent the connected circuit from overheating.

• Connection cable

Carefully handle the connection cable without applying excessive force.

⎯ 2 ⎯

6 F 2 S 0 8 3 5

• Modification

Do not modify this equipment, as this may cause the equipment to malfunction.

• Short-bar

Do not remove a short-bar which is mounted at the terminal block on the rear of the relay before

shipment, as this may cause the performance of this equipment such as withstand voltage, etc., to

reduce.

• Tripping circuit connections

Must connect the FD (Fault Detector) output contact with A- to C-phase tripping output contacts

in series in case of the model 400 and 500 series.

• Disposal

When disposing of this equipment, do so in a safe manner according to local regulations.

This product contains a battery, which should be removed at the end-of-life of the product. The

battery must be recycled or disposed of in accordance with local regulations. The battery can be

removed by withdrawing the Signal Processing module (SPM) from the relay case, and cutting

the connecting leads and plastic strap which hold the battery.

⎯ 3 ⎯

Contents

Safety Precautions 1

1. Introduction 9

2. Application Notes 12

2.1 Protection Schemes 13

2.2 Current Differential Protection 14

2.3 Overcurrent Backup Protection 41

2.4 Transfer Trip Function 45

2.5 Out-of-step Protection 47

2.6 Thermal Overload Protection 49

2.7 Breaker Failure Protection 52

2.8 Tripping Output 55

2.9 Fault Detector 58

2.10 Autoreclose 61

2.11 Characteristics of Measuring Elements 81

6 F 2 S 0 8 3 5

2.2.1 Operation of Current Differential Protection 14

2.2.2 Segregated-phase Current Differential Protection 14

2.2.3 Zero-phase Current Differential Protection 15

2.2.4 Fail-safe Function 16

2.2.5 Remote Differential Trip 17

2.2.6 Transmission Data 19

2.2.7 Synchronized Sampling 19

2.2.8 Charging Current Compensation 25

2.2.9 Blind Zone Protection 27

2.2.10 Application to Three-terminal Lines 28

2.2.11 Dual Communication Mode 30

2.2.12 Application to One-and-a-half Breaker Busbar System 30

2.2.13 Setting 32

2.10.1 Application 61

2.10.2 Scheme Logic 63

2.10.3 Autoreclose Output Signals 80

2.11.1 Segregated-phase Current Differential Element DIF and DIFSV 81

2.11.2 Zero-phase Current Differential Element DIFG 82

2.11.3 Inverse Definite Minimum Time (IDMT) Overcurrent Element OCI and

EFI 83

2.11.4 Thermal Overload Element 84

2.11.5 Out-of-Step Element OST 84

2.11.6 Voltage and Synchronism Check Elements OVL, UVL, OVB, UVB and

SYN 85

2.11.7 Current change detection element OCD 86

2.11.8 Level Detectors 86

2.11.9 Fault Detector Elements 86

⎯ 4 ⎯

6 F 2 S 0 8 3 5

2.12 Communication System 89

2.12.1 Signaling Channel 89

2.12.2 Linking to Communication Circuit 90

2.12.3 Setup of Communication Circuit 91

2.12.4 Telecommunication Channel Monitoring 94

2.13 Fault Locator 95

2.13.1 Application 95

2.13.2 Calculation of Distance to Fault 96

2.13.3 Starting Calculation 98

2.13.4 Fault Location Display 98

2.13.5 Setting 98

3. Technical Description 102

3.1 Hardware Description 102

3.1.1 Outline of Hardware Modules 102

3.1.2 Transformer Module 109

3.1.3 Signal Processing and Communication Module 110

3.1.4 Binary Input and Output Module 111

3.1.5 Human Machine Interface (HMI) Module 116

3.1.6 Fault Detector Module 118

3.2 Input and Output Signals 119

3.2.1 Input Signals 119

3.2.2 Binary Output Signals 122

3.2.3 PLC (Programmable Logic Controller) Function 122

3.3 Automatic Supervision 123

3.3.1 Basic Concept of Supervision 123

3.3.2 Relay Monitoring 123

3.3.3 CT Circuit Current Monitoring 124

3.3.4 CT Circuit Failure Detection 125

3.3.5 Differential Current (Id) Monitoring 126

3.3.6 Telecommunication Channel Monitoring 126

3.3.7 GPS Signal Reception Monitoring (For GPS-mode only) 126

3.3.8 Relay Address Monitoring 126

3.3.9 Disconnector Monitoring 126

3.3.10 Failure Alarms 127

3.3.11 Trip Blocking 128

3.3.12 Setting 128

3.4 Recording Function 129

3.4.1 Fault Recording 129

3.4.2 Event Recording 130

3.4.3 Disturbance Recording 131

3.5 Metering Function 133

4. User Interface 134

4.1 Outline of User Interface 134

4.1.1 Front Panel 134

⎯ 5 ⎯

6 F 2 S 0 8 3 5

4.1.2 Communication Ports 136

4.2 Operation of the User Interface 138

4.2.1 LCD and LED Displays 138

4.2.2 Relay Menu 141

4.2.3 Displaying Records 143

4.2.4 Displaying the Status 147

4.2.5 Viewing the Settings 151

4.2.6 Changing the Settings 152

4.2.7 Testing 174

4.3 Personal Computer Interface 180

4.4 Relay Setting and Monitoring System 180

4.5 IEC 60870-5-103 Interface 181

4.6 Clock Function 181

5. Installation 182

5.1 Receipt of Relays 182

5.2 Relay Mounting 182

5.3 Electrostatic Discharge 182

5.4 Handling Precautions 182

5.5 External Connections 183

6. Commissioning and Maintenance 185

6.1 Outline of Commissioning Tests 185

6.2 Cautions 186

6.2.1 Safety Precautions 186

6.2.2 Cautions on Tests 186

6.3 Preparations 187

6.4 Hardware Tests 188

6.4.1 User Interfaces 188

6.4.2 Binary Input Circuit 189

6.4.3 Binary Output Circuit 190

6.4.4 AC Input Circuits 191

6.5 Function Test 192

6.5.1 Measuring Element 192

6.5.2 Timer 209

6.5.3 Protection Scheme 211

6.5.4 Metering and Recording 212

6.5.5 Fault Locator 212

6.6 Conjunctive Tests 213

6.6.1 On Load Test 213

6.6.2 Signaling Circuit Test 213

6.6.3 Tripping and Reclosing Circuit Test 213

6.7 Maintenance 216

6.7.1 Regular Testing 216

6.7.2 Failure Tracing and Repair 216

6.7.3 Replacing Failed Modules 218

⎯ 6 ⎯

6 F 2 S 0 8 3 5

6.7.4 Resumption of Service 220

6.7.5 Storage 220

7. Putting Relay into Service 221

⎯ 7 ⎯

6 F 2 S 0 8 3 5

Appendix A Block Diagram 223

Appendix B Signal List 227

Appendix C Variable Timer List 255

Appendix D Binary Output Default Setting List 257

Appendix E Details of Relay Menu 269

Appendix F Case Outline 279

Appendix G Typical External Connection 287

Appendix H Relay Setting Sheet 299

Appendix I Commissioning Test Sheet (sample) 321

Appendix J Return Repair Form 325

Appendix K Technical Data 331

Appendix L Symbols Used in Scheme Logic 343

Appendix M Multi-phase Autoreclose 347

Appendix N Data Transmission Format 351

Appendix O Example of DIF and DIFG Setting 357

Appendix P Programmable Reset Characteristics and Implementation of Thermal

Model to IEC60255-8 359

Appendix Q IEC60870-5-103: interoperability 363

Appendix R Failed Module Tracing and Replacement 377

Appendix S PLC Setting Sample 383

Appendix T Ordering 385

The data given in this manual are subject to change without notice. (Ver.2.4)

⎯ 8 ⎯

1. Introduction

The GRL100 provides high-speed phase-segregated current differential protection for use with

telecommunication systems, and ensures high reliability and security for diverse faults including

single-phase and multi-phase faults and double-faults on double-circuit lines, evolving faults

and high-impedance earth faults.

The GRL100 is used as a main protection for the following two- or three-terminal lines in EHV

or HV networks:

• Overhead lines or underground cables

Lines with weak infeed or non-infeed terminals

•

• Single or parallel lines

• Lines with heavy load current

• Short- or long-distance lines

The GRL100 can be used for lines associated with one-and-a-half busbar arrangement as well as

single or double busbar arrangement.

6 F 2 S 0 8 3 5

Furthermore, in addition to current differential protection, the GRL100 provides overcurrent backup,

thermal overload, out-of-step and breaker failure protection.

The GRL100 actuates high-speed single-shot autoreclose or multi-shot autoreclose.

For telecommunications, dedicated optical fibres or 64 kbits/s multiplexed comm unication links can

be employed.

The GRL100 is a member of the G-series family of numerical relays which utilise common

hardware modules with the common features:

The GRL100 provides the following metering and recording functions.

- Metering

- Fault record

- Event record

- Fault location

- Disturbance record

The GRL100 provides the following menu-driven human interfaces for relay setting or viewing

of stored data.

- Relay front panel; 4 × 40 character LCD, LED display and operation keys

- Local PC

- Remote PC

Password protection is provided to change settings. Eight active setting groups are provided.

This allows the user to set one group for normal operating conditions while other groups may be

set to cover alternative operating conditions.

GRL100 provides either two or three serial ports, and an IRIG-B port for an external clock

connection. A local PC can be connected via the RS232C port on the front panel of the relay.

Either one or two rear ports (RS485 or fibre optic) are provided for connection to a remote PC

and for IEC60870-5-103 communication with a substation control and automation system.

Further, Ethernet LAN port (TCP/IP protocol) can be provided as option.

Further, the GRL100 provides the following functions.

- Configurable binary inputs and outputs

⎯ 9 ⎯

6 F 2 S 0 8 3 5

- Programmable logic for I/O configuration, alarms, indications, recording, etc.

- Automatic supervision

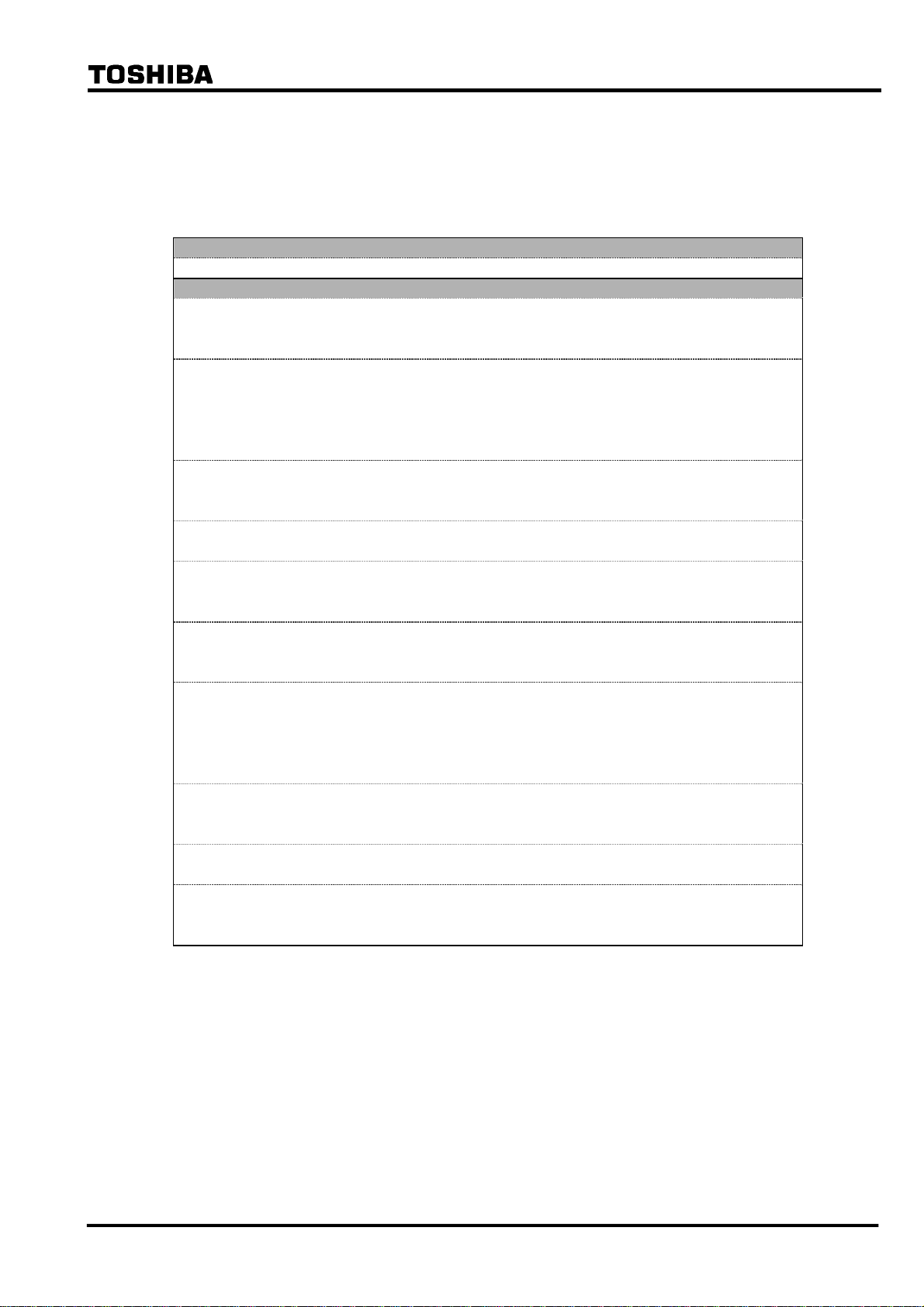

The GRL100 has the following models:

Relay Type and Model

Relay Type:

- Type GRL100; Numerical current differential relay

Relay Model:

- For two terminal line, With No autoreclose

• Model 101; 18 binary inputs, 13 binary outputs, 6 binary outputs for tripping

• Model 102; 18 binary inputs, 23 binary outputs, 6 binary outputs for tripping

- For two terminal line, With autoreclose for single breaker scheme

• Model 201; 25 binary inputs, 19 binary outputs, 6 binary outputs for tripping

• Model 202; 28 binary inputs, 37 binary outputs, 6 binary outputs for tripping

• Model 204; 22 binary inputs (12-independent), 19 binary outputs, 3 binary outputs for tripping

• Model 206; 25 binary inputs (12-independent), 37 binary outputs, 3 binary outputs for tripping

- For two terminal line, With autoreclose for one-and-a-half breaker scheme

• Model 301; 25 binary inputs, 19 binary outputs, 6 binary outputs for tripping

• Model 302; 28 binary inputs, 37 binary outputs, 6 binary outputs for tripping

- For two terminal line, With autoreclose for single breaker scheme / With fault detector

• Model 401; 28 binary inputs, 31 binary outputs, 6 binary outputs for tripping

- For two terminal line, With autoreclose for one-and-a-half breaker scheme / With fault detector

• Model 501; 28 binary inputs, 31 binary outputs, 6 binary outputs for tripping

• Model 503; 28 binary inputs, 31 binary outputs, 6 binary outputs for tripping, TFC function

- For three terminal line, With No autoreclose

• Model 111; 18 binary inputs, 13 binary outputs, 6 binary outputs for tripping

• Model 112; 18 binary inputs, 23 binary outputs, 6 binary outputs for tripping

- For three terminal line, With autoreclose for single breaker scheme

• Model 211; 25 binary inputs, 19 binary outputs, 6 binary outputs for tripping

• Model 212; 28 binary inputs, 37 binary outputs, 6 binary outputs for tripping

• Model 214; 22 binary inputs (12-independent), 19 binary outputs, 3 binary outputs for tripping

• Model 216; 25 binary inputs (12-independent), 37 binary outputs, 3 binary outputs for tripping

- For three terminal line, With autoreclose for one-and-a-half breaker scheme

• Model 311; 25 binary inputs, 19 binary outputs, 6 binary outputs for tripping

• Model 312; 28 binary inputs, 37 binary outputs, 6 binary outputs for tripping

- For three terminal line, With autoreclose for single breaker scheme / With fault detector

• Model 411; 28 binary inputs, 31 binary outputs, 6 binary outputs for tripping

- For three terminal line, With autoreclose for one-and-a-half breaker scheme / With fault detector

• Model 511; 28 binary inputs, 31 binary outputs, 6 binary outputs for tripping

• Model 513; 28 binary inputs, 31 binary outputs, 6 binary outputs for tripping, TFC function

Model 100 has the minimum configuration, having only the segregated phase current differential

protection, overcurrent backup protection scheme and thermal overload protection.

Models 200 through 500 have a full protection scheme including additional high-sensitivity differential

protection for high-impedance earth faults, breaker failure protection, out-of-step protection,

fault locator and autoreclose function. Models 200 and 400 have a single- and multi-shot

autoreclose function and are used for single breaker autoreclose schemes. Models 300 and 500

have only a single-shot autoreclose function and are used for one-and-a-half breaker

(two-breaker) autoreclose schemes. Models 400 and 500 have an independent fault detector in

the form of a check relay, and provide the highest security. Models 503 and 513 have a CT

saturation countermeasure against the external through fault current in one-and-a-half breaker

schemes.

⎯ 10 ⎯

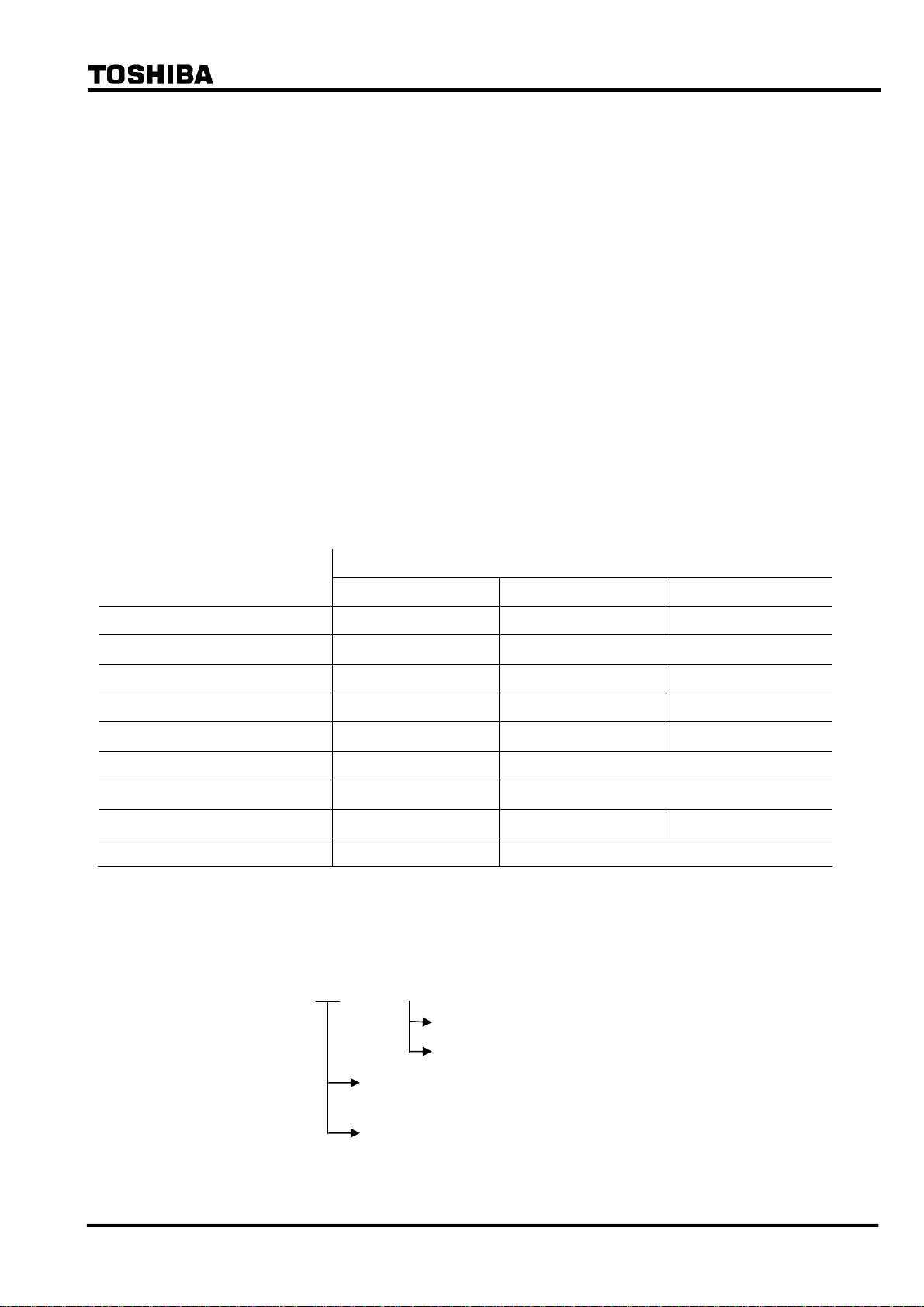

Table 1.1 GRL100 Models

6 F 2 S 0 8 3 5

(a) Two-terminal line application

Model 101B 102B 201B, 204B 202B, 206B 301B 302B 401B 501B 503B

DIF x x x x x x x x x

BU x x x x x x x x x

THM x x x x x x

ARC 1CB 1CB 2CB 2CB 1CB 2CB 2CB

FD x x x

TFC x

DIFG x x x x x x x

CCC x x x x x x x

BF x x x x x x x

OST x x x x x x x

FL x x x x x x x

(b) Three-terminal line application / Dual communication for two-terminal line application

Model 111B 112B 211B, 214B 212B, 216B 311B 312B 411B 511B 513B

DIF x x x x x x x x x

BU x x x x x x x x x

THM x x x x x x

ARC 1CB 1CB 2CB 2CB 1CB 2CB 2CB

FD x x x

TFC x

DIFG x x x x x x x

CCC x x x x x x x

BF x x x x x x x

OST x x x x x x x

FL x x x x x x x

Legend DIF: Segregated-phase current differential protection

BU: Overcurrent backup protection

THM: Thermal overload protection

ARC: Autoreclose

FD: Fault detector

TFC: Through fault current countermeasure

DIFG: Zero-phase current differential protection

CCC: Charging current compensation

BF: Breaker failure protection

OST: Out-of-step protection

FL: Fault locator

⎯ 11 ⎯

2. Application Notes

GRL100 is applicable to telecommunication system s which employ dedicated optical fibre, 64 kbit/s

multiplexed communication channels or microwave links

communication mode settings:

• A-MODE: applied when the remote terminal relay(s) is an old version of GRL100,

namely the following models.

GRL100-101A/102A/201A/202A/301A/302A/ 401A/501A/503A

GRL100-111A/112A/211A/212A/311A/312A/411A/511A/513A

GRL100-201N

• B-MODE: standard operating model which provides relay address monitoring function

and customisation of transmission data. (default)

• GPS-MODE: performs synchronised sampling using GPS. (This mode is suited to

applications where the differential relays communicate over modern switched

telecommunication networks such as Synchronous Digital Hierarchy (SDH), etc.)

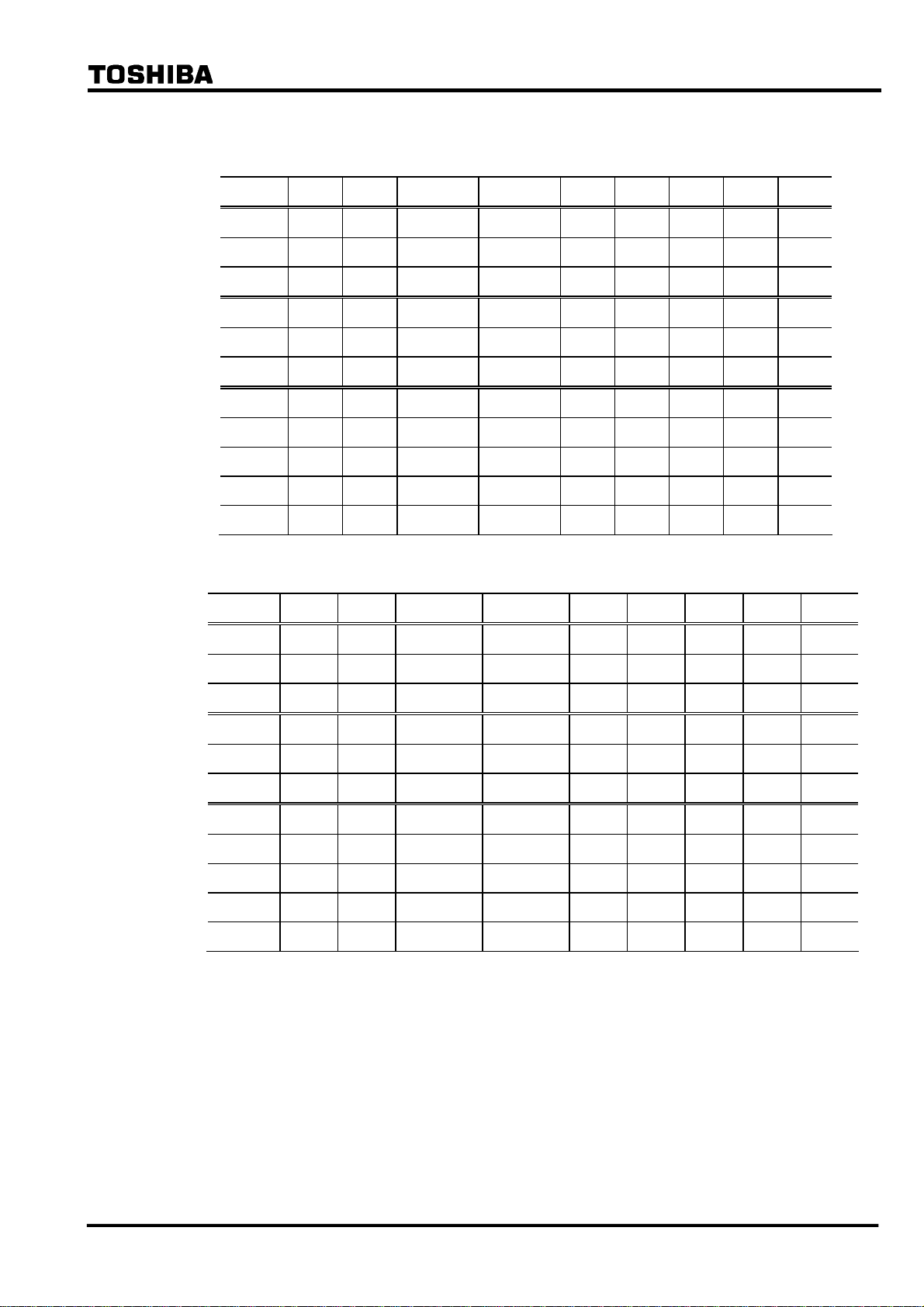

Table 2.1 shows available functions of each mode. The details of functions are described later.

6 F 2 S 0 8 3 5

and provided with the following three

Table 2.1 Communication Mode and Available Function

Function

GPS-based synchronisation

Relay address monitoring (RYIDSV)

Dual communication

Remote differential trip (RDIF)

Through fault current measure (TFC)

Open terminal detection (OTD)

Multi-phase autoreclosing (MPAR)

Simultaneous fault signal (FG)

Transfer signal 2 bit (set by PLC function) 2 bit (set by PLC function.)

× ×

× (for model 503B, 513B)

× × (set RYIDSV to Off if applied.)

× × (The alternative of RYIDSV or MPAR)

× × ×

A-MODE B-MODE GPS-MODE

Communication Mode [COMMODE]

× (The alternative of RYIDSV or MPAR)

× ×

GPS-MODE can be applied if the relay is provided with a GPS interface.

One of these modes can be selected by the scheme switch [COMMODE]. The default setting is

“B-MODE”.

(Relay Type and Model)

×

(eg.) GRL100 - ∗∗∗B - 13 - 1∗

0: without GPS I/F

1: with GPS I/F (Model 503/513 are not available)

503/513: with through fault current measure

(available for A-MODE only)

others: without through fault current measure

For details of relay models and their functions, see Table 1.1 and Appendix S.

⎯ 12 ⎯

2.1 Protection Schemes

The GRL100 provides the following protection schemes (Appendix A shows block diagrams of the

GRL100 series):

• Segregated-phase current differential protection

• Zero-phase current differential protection

• Remote differential trip function

• Stub protection

• Overcurrent backup protection

• Thermal overload protection

• Out-of-step protection

• Breaker failure protection

• Transfer trip protection

Zero-phase current differential protection enables sensitive protection for high-impedance earth

faults.

6 F 2 S 0 8 3 5

Overcurrent backup protection provides both inverse time overcurrent and definite time overcurrent

protection for phase faults and earth faults.

Out-of-step protection performs phase comparison of the local and remote voltages and operates

only when the out-of-step loci cross the protected line.

Furthermore, the GRL100 incorporates autoreclose functions for one or two breaker systems,

through-current fault countermeasures for two breaker systems, charging current compensation for

cable or long-distance lines and fault location. The autoreclose mode can be selected from

single-phase, three-phase, single- and three-phase and multi-phase modes.

The GRL100 can enhance security by attaching fault detectors such as check relays with circuits that

are independent from other circuits.

The GRL100 utilises with the microwave or fibre optic digital telecommunication systems to

transmit instantaneous current values sampled synchronously at each terminal.

⎯ 13 ⎯

(

2.2 Current Differential Protection

2.2.1 Operation of Current Differential Protection

Current differential protection compares the currents flowing into and out of the protected line.

The difference of the currents, that is, the differential current, is almost zero when a fault is

external or there is no fault, and is equal to the fault current when the fault is internal. The

differential protection operates when the difference of the currents exceeds a set value.

The GRL100 relay installed at each line terminal samples the local currents every 7.5 electrical

degrees and transmits the current data to other terminals every four samples via the

telecommunication system. The GRL100 performs master/master type current differential

protection using the current data from all terminals.

As synchronized sampling of all terminals is performed in the GRL100, the current data are the

instantaneous values sampled simultaneously at each terminal. Therefore, the differential current

can be easily calculated by summing the local and remote current data with the identical

sampling address. Thus, compensation of transmission delay time is not required.

The GRL100 utilises the individual three phase currents and residual current to perform

segregated-phase and zero-phase current differential protection.

6 F 2 S 0 8 3 5

2.2.2 Segregated-phase Current Differential Protection

The segregated-phase differential protection transmits the three phase currents to the remote

terminal, calculates the individual differential currents and detects both phase-to-phase and

phase-to-earth faults on a per phase basis.

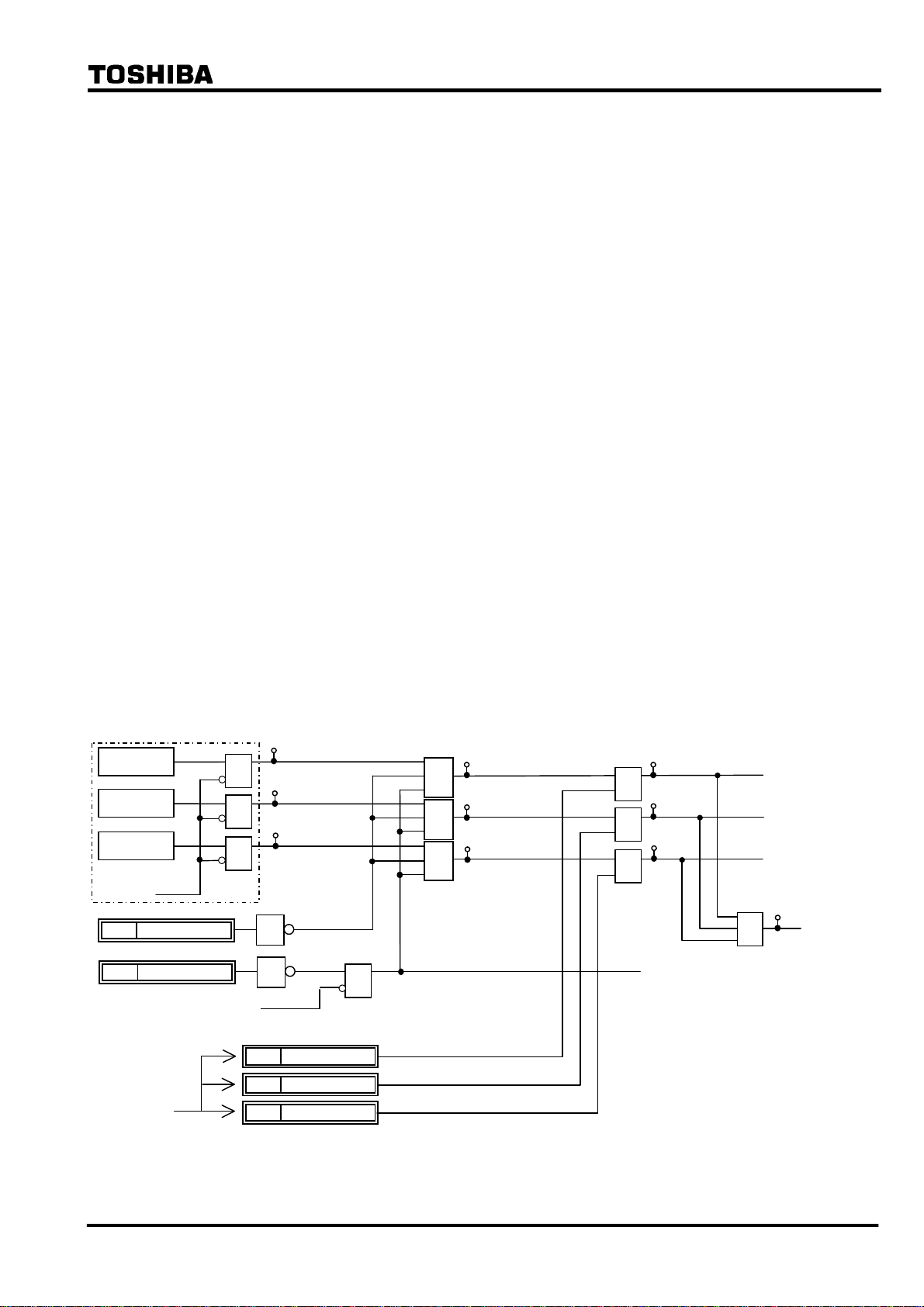

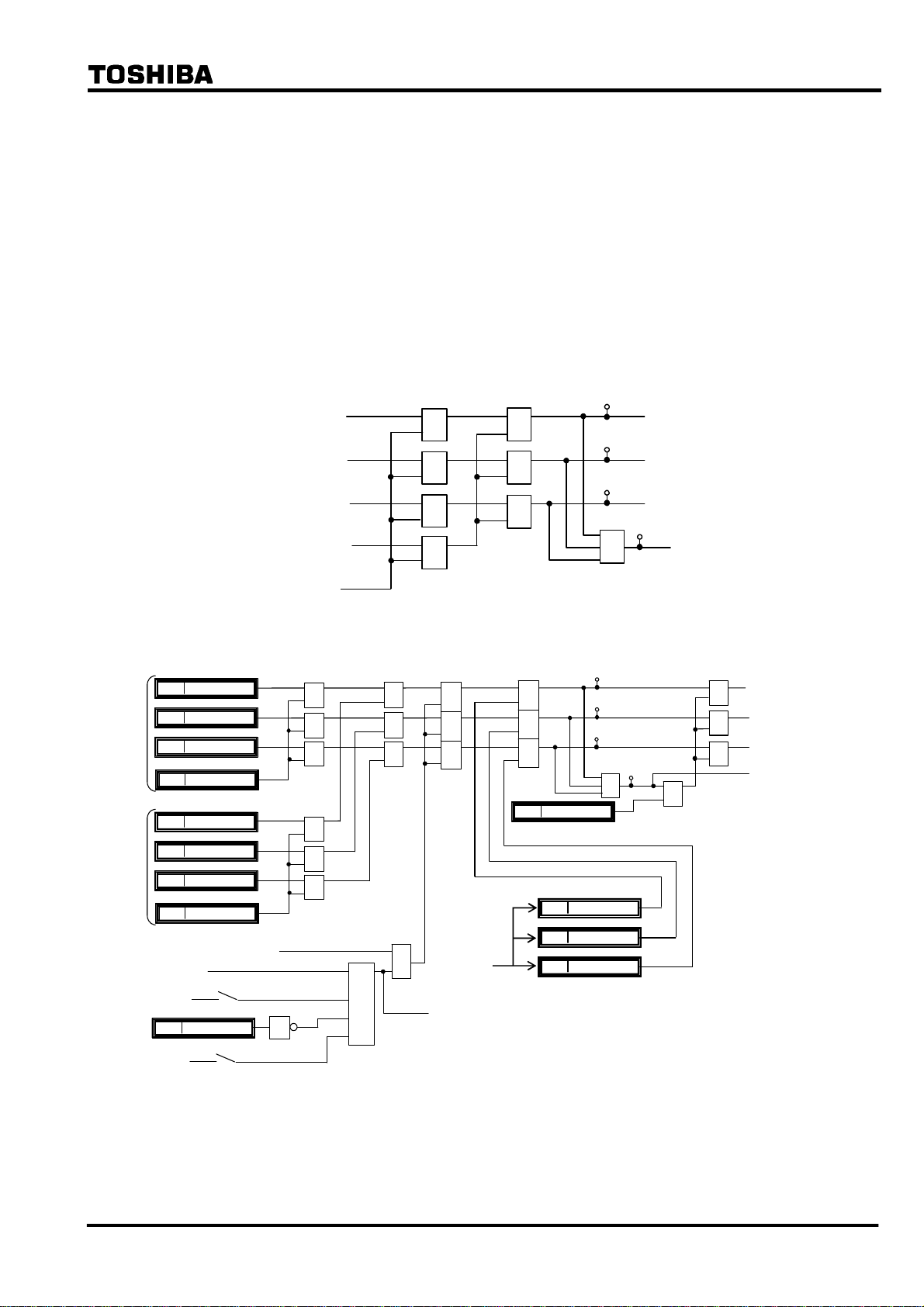

Figure 2.2.2.1 shows the scheme logic of the segregated-phase current differential protection.

Output signals of differential elements DIF-A, -B and -C can perform instantaneous tripping of

the breaker on a per phase basis and start the incorporated autoreclose function.

Note: For the symbols used in the scheme logic, see Appendix L.

DIF-A

DIF-B

DIF-C

Communication

failure

DIF_BLOCK

1585

CRT_BLOCK

1544

TELEPROTEC TION OFF

from IEC103 command)

&

&

&

1

1

41

42

43

&

82: DIF-A_TRIP

&

83: DIF-B_TRIP

&

84: DIF-C_TRIP

&

401

&

402

&

403

&

43C ON

DIF.FS-A_TP

DIF.FS-B_TP

DIF.FS-C_TP

400

≥1

DIF.FS_TRIP

DIF-A_FS

1616

DIF-B_FS

1617

DIF.FS_OP

1618

DIF-C_FS

Figure 2.2.2.1 Scheme Logic of Segregated-phase Current Differential Protection

⎯ 14 ⎯

6 F 2 S 0 8 3 5

Tripping output signals can be blocked by the PLC command DIF_BLOCK and CRT_BLOCK.

The output signals of DIF-A, DIF-B and DIF-C are also blocked when a communication circuit

failure is detected by the data error check, sampling synchronism check or interruption of the

receive signals. For DIF-A_FS, DIF-B_FS and DIF-C_FS signals, see Section 2.2.4.

The differential elements DIF have a percentage restraining characteristic with weak restraint in

the small current region and strong restraint in the large current region, to cope with CT

saturation. (For details of the characteristic, see Section 2.11.)

Erroneous current data may be transmitted from the remote terminal when the remote relay is

out-of-service for testing or other purposes. To prevent false operation in this case, the relay sets

the receiving current data to zero in the differential current calculation upon detecting that the

remote terminal is out-of-service.

If the relay is applied to a three-terminal line, the zero setting is performed only for the current

data received from an out-of-service terminal.

Figure 2.2.2.2 shows the remote terminal out-of-service detection logic. The local terminal

detects that the remote terminal is out-of-service by receiving a signal LOCAL TEST which is

transmitted when the scheme switch [L. TEST] is set to "ON" at the terminal under test. As an

alternative means, the local terminal can detect it by using the circuit breaker and disconnector

status signal CBDS-A, B and C transmitted from the remote out-of-service terminal. The signal

CBDS-A is "1" when both the circuit breaker and disconnector are closed. Thus, out-of-service

is detected when either the circuit breaker or disconnector is open in all three phases.

Zero setting of the receive current data is also performed at the terminal under test. If the scheme

switch [L. TEST] is set to "ON" or the signal R.DATA_ZERO is input by PLC, all the receive

current data transmitted from the in-service terminal is set to zero and this facilitates the local

testing. The zero setting of the receive current data is not performed by the alternative way as

mentioned above.

The out-of-service detection logic can be blocked by the scheme switch [OTD].

Receiving

signal from

Remote

Terminal 1

(∗) Out-of-service detection logic for the remote 2 is same as above.

R.DATA_ZERO

1623

LOCAL_TEST1

CBDS-A

CBDS-B

CBDS-C

[OTD]

(+)

"ON"

≥1

≥1

1

1

(+)

&

[Open1]

"ON"

≥1

≥1

REM1_IN_SRV: Remote 1 i n-servic e

REM1_OFF_SRV: Remote 1 out-of-service

REM1_NON_USE: Rem ote 1 not used

Figure 2.2.2.2 Out-of-Service Detection Logic

Note: When a communication circuit is disconnected or communication circuit failure occurs, do

not close the circuit breaker. When closing it, make sure that the DIF element is blocked.

(Otherwise, it may cause malfunction.)

207

REM1_IN_SRV

208

REM1_OFF_SRV

209

1

REM1_NON_USE

2.2.3 Zero-phase Current Differential Protection

The GRL100 provides sensitive protection for high-impedance earth faults by employing

zero-phase current differential protection. For more sensitive protection, residual current is

introduced through an auxiliary CT in the residual circuit instead of deriving the zero-phase

current from the three phase currents.

⎯ 15 ⎯

6 F 2 S 0 8 3 5

The zero-phase current differential element has a percentage restraining characteristic with weak

restraint. For details of the characteristic, see Section 2.11.

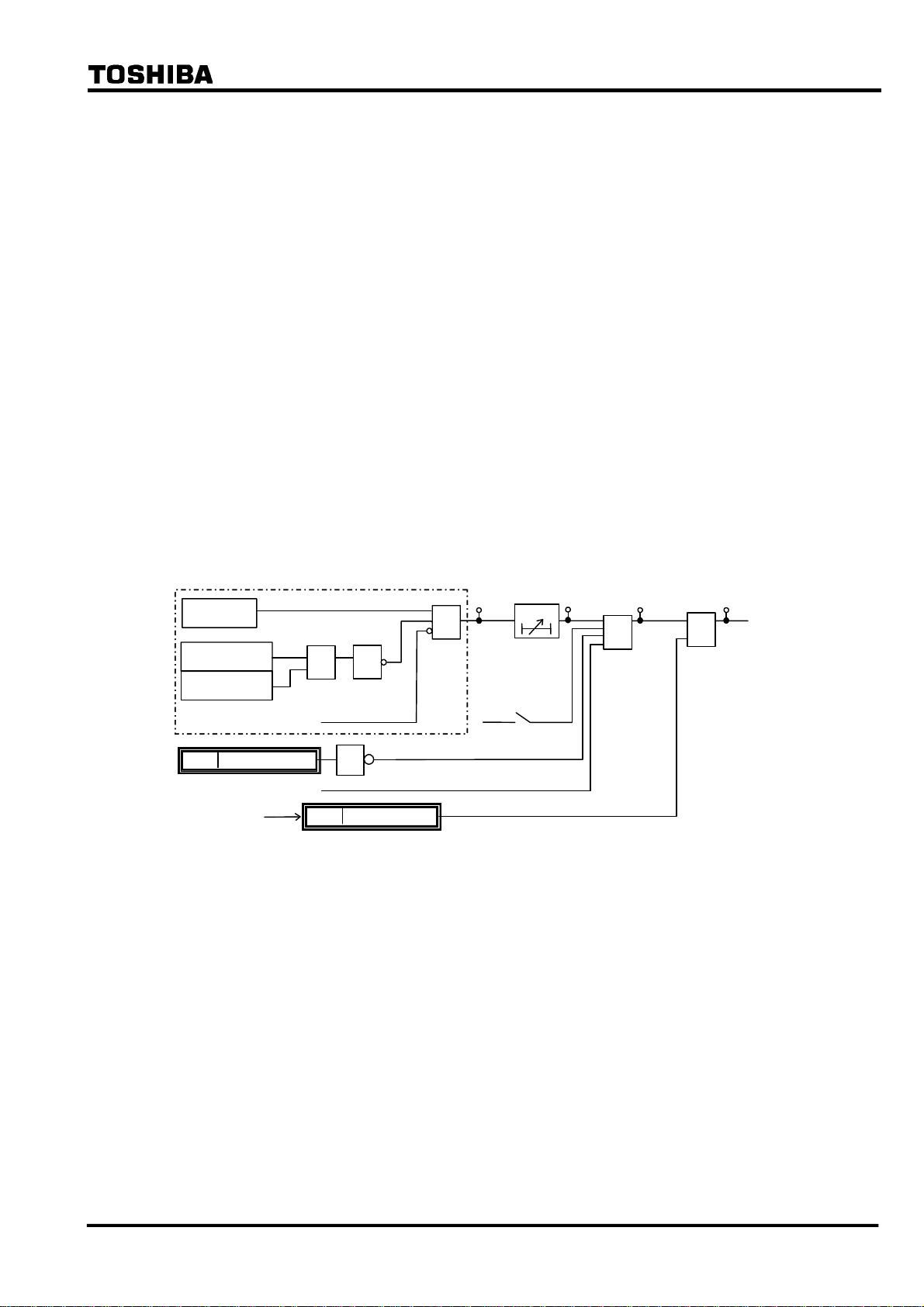

The scheme logic is shown in Figure 2.2.3.1. The output signal of the differential element DIFG

performs time-delayed three-phase tripping of the circuit breaker with the tripping output signal

DIFG.FS_TRIP. DIFG.FS_TRIP can start the incorporated autoreclose function when the

scheme switch [ARC-DIFG] is set to "ON".

Tripping output signal can be blocked by the PLC command DIFG_BLOCK and CRT_BLOCK.

The output signal is also blocked when a communication circuit failure is detected by data error

check, sampling synchronism check or interruption of the receive signals. For DIFG_FS signal,

see Section 2.2.4.

Since the DIFG is used for high-impedance earth fault protection, the DIFG output signal is

blocked when zero-phase current is large as shown in the following equation:

Σ ⎜I

01⎜ ≥ 2 pu or Σ ⎜I02⎜ ≥ 2 pu

where,

Σ ⎜I

Σ ⎜I

01⎜: Scalar summation of zero-phase current at local terminal relay

02⎜: Scalar summation of zero-phase current at remote terminal relay

pu: per unit value

In GPS-mode setting and backup mode (refer to 2.2.7.2), DIFG is blocked.

DIFG

Σ⏐I01⏐≥2PU

Σ⏐I02⏐≥2PU

Communication failure

DIFG_BLOCK

1586

43C ON

DIFG.FS_OP

Figure 2.2.3.1 Scheme Logic of Zero-phase Current Differential Protection

≥1

1619

1

1

DIFG_FS

TDIFG

44

+

t 0

0.00-10.00s

[DIFG]

"ON"

&

85

DIFG_TRIP

86

&

404

&

DIFG.FS_TRIP

2.2.4 Fail-safe Function

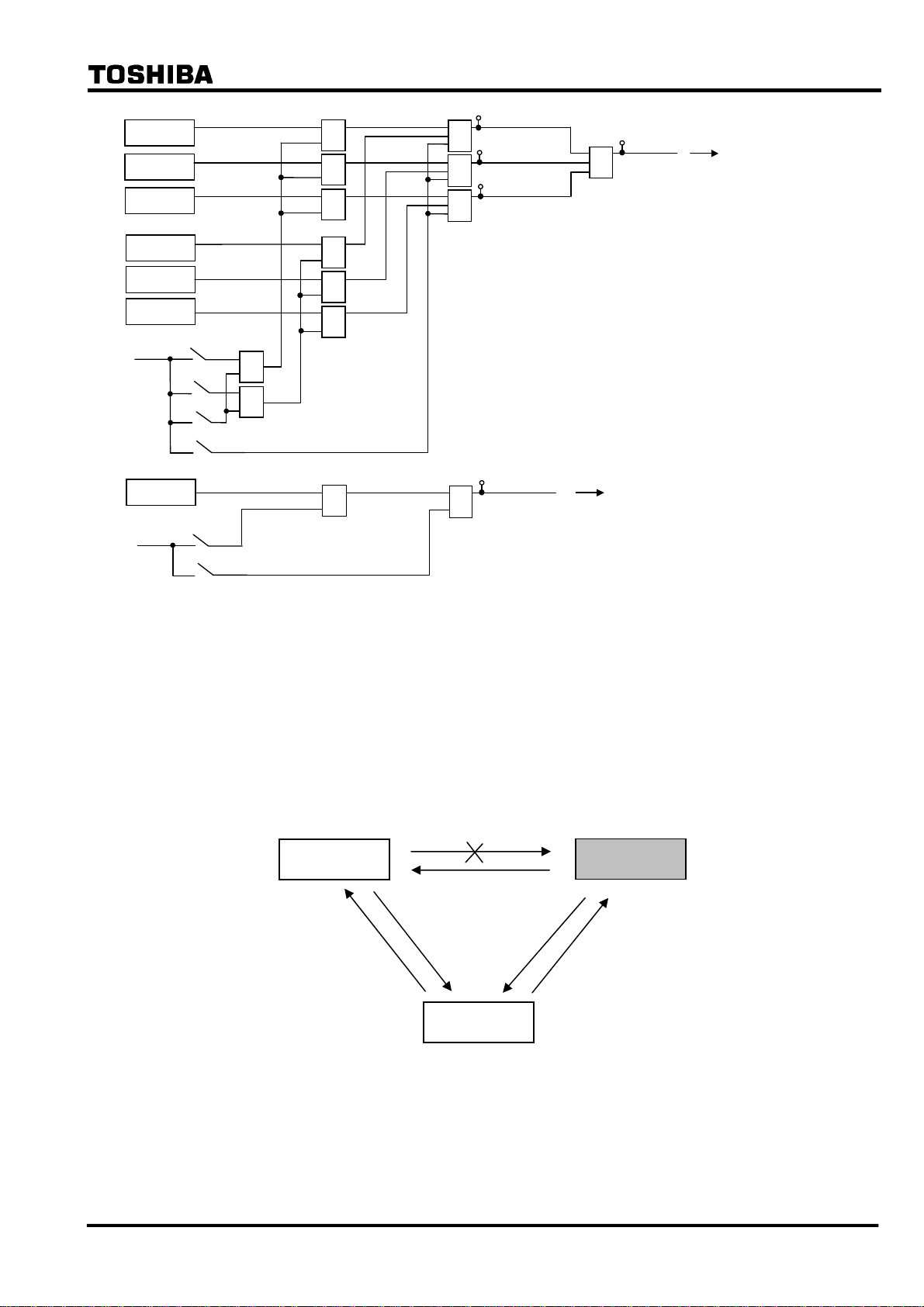

GRL100 provides OC1, OCD and EFD elements. These are used for fail-safe to prevent

unnecessary operation caused by error data in communication failure. OC1 is phase overcurrent

element and its sensitivity can be set. OCD is phase current change detection element, and EFD

is zero-sequence current change detection element. Both of the OCD and EFD sensitivities are

fixed. The scheme logic is shown in Figure 2.2.4.1.

The outputs of DIF.FS_OP and DIFG.FS_OP signals are connected to DIF-A_FS, DIF-B_FS,

DIF-C_FS and DIFG_FS respectively by PLC function. These are connected at the default

setting.

The fail-safe functions are disabled by [DIF-FS] and [DIFG-FS] switches. In the [DIF-FS], OC1

or OCD or both elements can be selected. If these switches are set to “OFF”, the signals of

DIF.FS_OP and DIFG.FS_OP are “1” and the fail-safe is disabled.

⎯ 16 ⎯

6 F 2 S 0 8 3 5

+

+

OC1-A

OC1-B

OC1-C

OCD-A

OCD-B

OCD-C

[DIF-FS]

EFD

[DIFG-FS]

"OC"

OCD"

"

BOTH"

"

OFF"

"

"ON"

409

≥

1

&

&

&

&

&

&

≥1

≥

1

&

DIF.FS-A_OP

410

≥

1

DIF.FS-B_OP

411

≥

1

DIF.FS-C_OP

≥

1

DIFG.FS_OP

412

408

≥

1

DIF.FS_OP

DIFG_FS

(see Fig. 2.2.3.1.)

DIF-A_FS

DIF-B_FS

DIF-C_FS

(see Fig. 2.2.2.1.)

OFF"

"

Figure 2.2.4.1 Fail-safe Logic

2.2.5 Remote Differential Trip

Note: This function is available only when the three-terminal protection is applied by

setting the scheme switch [TERM] to “3-TERM”. In the case of A-MODE setting,

this function is not available.

When one of the telecommunication channels fails, the terminal using the failed channel is

disabled from performing current differential protection, as a result of the failure being detected

through by the telecommunication channel monitoring.

GRL100

GRL100

GRL100

Figure 2.2.5.1 Protection Disabled Terminal with Channel Failure

The remote differential trip (RDIF) function enables the disabled terminal to trip by receiving a

trip command from the sound terminal, which continues to perform current differential

protection.

⎯ 17 ⎯

6 F 2 S 0 8 3 5

Figure 2.2.5.2(a) and (b) show the RDIF scheme logic at RDIF command sending terminal (=

sound terminal) and command receiving terminal (= disabled terminal). The sound terminal

sends the command when the tripping signals RDIF-A-S, RDIF-B-S, RDIF-C-S or RDIF-S are

output locally and the scheme switches [RDIF] and [TERM] are set to “ON” and “3-TERM”

respectively. The RDIF command is sent to the remote terminal via the 64kb/s digital link

together with other data and signals.

The receiving terminal outputs a local three-phase trip signal RDIF-TRIP under the conditions

that when the command RDIF1 or RDIF2 is received from either of the remote terminals, local

differential protection does not operate, the scheme switches [RDIF] and [TERM] are set to

“ON” and “3-TERM” respectively and no communication channel failure exists in the channel

which received the RDIF command.

When the RDIF function is applied, the command sending signals and receiving signals must be

assigned by PLC function.

DIF-A_TRIP

DIF-B_TRIP

DIF-C_TRIP

DIF-G_TRIP

&

&

&

≥1

≥1

≥1

&

451

452

453

≥1

RDIF-A-S

RDIF-B-S

RDIF-C-S

454

RDIF-S

Receiving

signal from

Remote

Terminal 1

Receiving

signal from

Remote

Terminal 2

RDIF-A-R1

1684

RDIF-B-R1

1685

RDIF-C-R1

1686

RDIF-R1

1687

RDIF-A-R2

1716

RDIF-B-R2

1717

RDIF-C-R2

1718

RDIF-R2

1719

DIF elements not operated

43C ON

1598

[TERM]

+

“3-TERM” &

RDIF_BLOCK

[RDIF]

+

“ON”

RDIF_ON

≥1

≥1

≥1

≥1

≥1

≥1

1

(a) Sending terminal

≥1

≥1

≥1

&

&

&

&

1649

DIF.FS_OP

RDIF_ON

(b) Receiving Terminal

&

&

&

RDIF_3PTP

1624

1625

1626

456

457

458

≥1

RDIF-A_FS

RDIF-B_FS

RDIF-C_FS

RD.FS-A_ TRIP

RD.FS-B_ TRIP

RD.FS-C_ TRIP

455

&

≥1

≥1

≥1

RD.FS-A TP

RD.FS-B TP

RD.FS-C TP

RD.FS_TRIP

Figure 2.2.5.2 Remote Differential Trip

⎯ 18 ⎯

6 F 2 S 0 8 3 5

2.2.6 Transmission Data

The following data are transmitted to the remote terminal via the 64kb/s digital link. The data

depends on the communication mode and whether a function is used or not. The details are

shown in Appendix N.

A-phase current

B-phase current

C-phase current

Residual current

Positive sequence voltage

A-phase differential element output signal

B-phase differential element output signal

C-phase differential element output signal

A-phase breaker and disconnector status

B-phase breaker and disconnector status

C-phase breaker and disconnector status

Scheme switch [LOCAL TEST] status

Scheme switch [TFC] status

Reclose block command

Sampling synchronization control signal

Synchronized test trigger signal

User configurable data

Current and voltage data are instantaneous values which are sampled every 30 electrical degrees

(12 times per cycle) and consist of eleven data bits and one sign bit. This data is transmitted

every sample to the remote terminal.

Three differential element outputs and the transfer trip command are related to remote terminal

tripping and are transmitted every sampling interval.

Other data is transmitted once every power cycle.

The data transmission format and user configurable data are also shown in Appendix N.

A synchronized test trigger signal is used to test the differential protection simultaneously at all

terminals. For details, see Section 6.5.3.

In addition to the above data, cyclic redundancy check bits and fixed check bits are transmitted to

monitor the communication channel. If a channel failure is detected at the local terminal, all the

local and remote current and voltage data at that instant are set to zero and outputs of the

differential protection and out-of-step protection are blocked, and these protections of remote

terminal are also blocked because the channel failure is also detected at the remote terminal.

2.2.7 Synchronized Sampling

The GRL100 performs synchronized simultaneous sampling at all terminals of the protected

line. Two methods are applied for the sampling synchronization; intra-system synchronization

and GPS-based synchronization. The former is applied to communication modes A-MODE and

⎯ 19 ⎯

6 F 2 S 0 8 3 5

B-MODE, and the latter is applied to GPS-MODE.

The intra-system synchronization keeps the sampling timing error between the terminals within

±10μs or ±20μs and the GPS-based system keeps it within ±5μs or ±10μs for two- or

three-terminal applications.

In both methods, the sampling synchronization is realized through timing synchronization

control and sampling address synchronization control. These controls are performed once every

two power cycles.

2.2.7.1 Intra-system Synchronized Sampling for A-MODE and B-MODE

The synchronized sampling is realized using sampling synchronization control signals

transmitted to other terminals together with the power system data. This synchronized sampling

requires neither an external reference clock nor synchronization of the internal clocks of the

relays at different terminals. The transmission delay of the channel is corrected automatically.

Timing synchronization

One of the terminals is selected as the time reference terminal and set as the master terminal. The

other terminal is set as the slave terminal. The scheme switch [SP.SYN] is used for the settings.

Note: The master and slave terminals are set only for the convenience of the sampling timing

synchronization. The GRL100s at all terminals perform identical protection functions and

operate simultaneously.

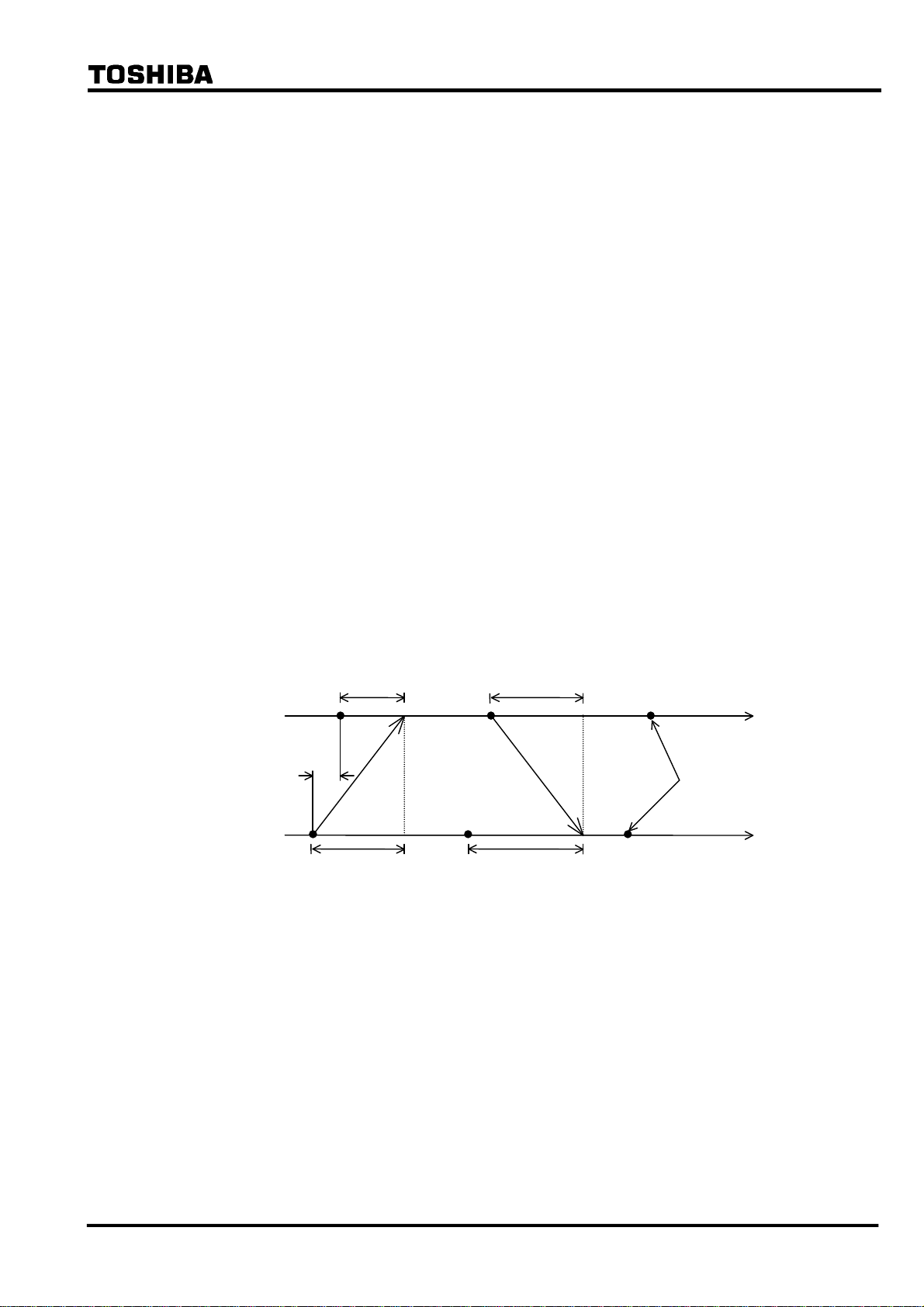

To perform timing synchronization for the slave terminal, the sampling time difference between

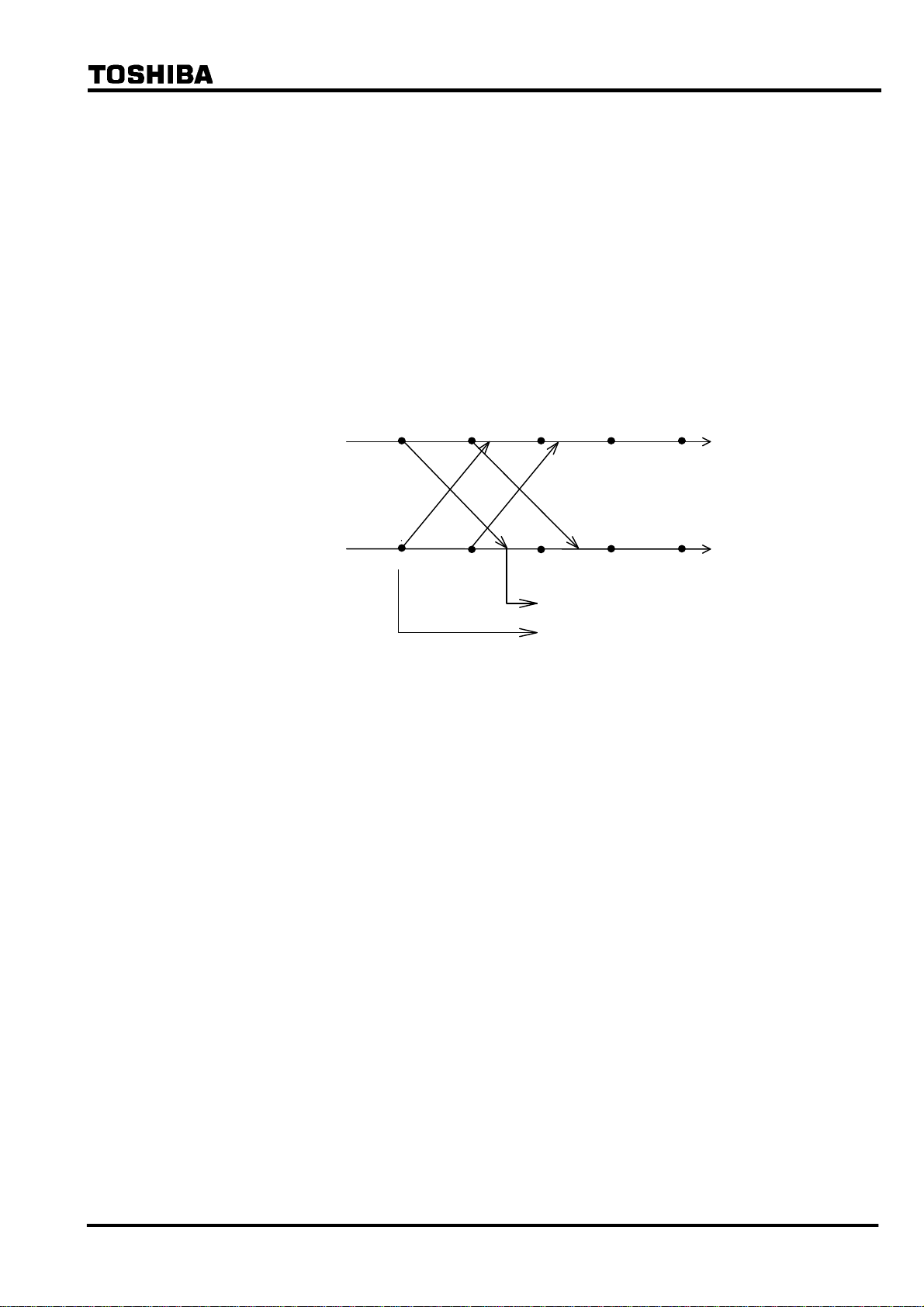

master and slave terminals is measured. The measurement principle of the sampling time

difference ΔT is indicated in Figure 2.2.7.1. The master terminal and slave terminal perform

their own sampling and send a signal that becomes the timing reference for the other terminal.

Master

terminal

Slave

terminal

TM

ΔT

Td1

Figure 2.2.7.1 Timing Synchronization

T

d2

t

Sampling

timing

t

T

F

Each terminal measures the time TM and TF from its own sampling instant to the arrival of the

signal from the other terminal. As is evident from the figure, the times TM and TF can be

obtained by equation (1) and (2) where Td1 and Td2 are the transmission delay of the channel in

each direction. The sampling time difference ΔT can be obtained from the resulting equation (3).

TM = Td1 − ΔT (1)

TF = Td2 + ΔT (2)

ΔT = {(TF − TM) + (Td1 − Td2)}/2 (3)

The slave terminal advances or retards its sampling timing based on the time ΔT calculated from

equation (3), thereby reducing the sampling time difference with the master terminal to zero.

This adjustment is performed by varying the interval of the sampling pulse generated by an

⎯ 20 ⎯

6 F 2 S 0 8 3 5

oscillator in the slave terminal.

The difference of the transmission delay time Tdd (= Td1 − Td2) is set to zero when sending and

receiving take the same route and exhibit equal delays. When the route is separate and the

sending and receiving delays are different, Tdd must be set at each terminal to be equal to the

sending delay time minus the receiving delay time. The maximum Tdd that can be set is 10ms.

(For setting, see Section 4.2.6.7. The setting elements of transmission delay time difference are

TCDT1 and TCDT2.)

The time TM measured at the master terminal is sent to the slave terminal together with the

current data and is used to calculate the ΔT.

The permissible maximum transmission delay time of the channel is 10ms.

In case of the three-terminal line application, the communication ports of the GRL100 are

interlinked with each other as shown in Figure 2.2.7.2, that is, port CH1 of one terminal and port

CH2 of the other terminal are interlinked. For the setup of the communication system, see

Section 2.12.3.

When terminal A is set as the master terminal by the scheme switch [SP.SYN], the

synchronization control is performed between terminals A and B, and terminals B and C. The

terminal B follows the terminal A and the terminal C follows the terminal B. The slave terminals

perform the follow-up control at their communication port CH2.

When the master terminal is out-of-service in A-MODE, the slave terminal that is interlinked

with port 1 of the master terminal takes the master terminal function. In the case shown in Figure

2.2.7.2, terminal B takes the master terminal function when the master terminal A is

out-of-service. In B-MODE and GPS-MODE, even if the master terminal is out-of-service, the

master terminal is not changed. If DC power supply of the out-of-service terminal is “OFF”,

differential elements at all terminals are blocked. Therefore, the [TERM] setting change from

“3TERM” to “2TERM” is required.

Terminal A

GRL100

CH1

CH2

Master

CH1 CH2

GRL100

Terminal C

Slave

Terminal B

CH2

GRL100

CH1

Slave

Communication

port

Figure 2.2.7.2 Communication Link in Three-terminal Line

Sampling address synchronization

The principle of sampling address synchronization control is indicated in Figure 2.2.7.3. After

time synchronization has been established, the slave terminal measures the time from sending its

own timing reference signal until it returns from the master terminal. The transmission delay

time Td1 from slave to master terminal can be calculated from equation (4).

⎯ 21 ⎯

6 F 2 S 0 8 3 5

Td = ({To − (T − TM)}/2 + Tdd)/2 (4)

The calculated transmission delay time Td1 is divided by the sampling interval T. The mantissa

is truncated and the quotient is expressed as an integer. If the integer is set to P, the reception at

the slave terminal of the signal sent from the master terminal occurs at P sampling intervals from

the transmission. Accordingly, by performing control so that the sampling address of the slave

terminal equals integer P when the sampling address = 0 signal is received from the master

terminal, the sampling address of the slave terminal can be made the same as the master term inal.

T

t

Master

terminal

T

M

Slave

terminal

T

F

T

d1

T

O

T

d2

t

Figure 2.2.7.3 Sampling Address Synchronization

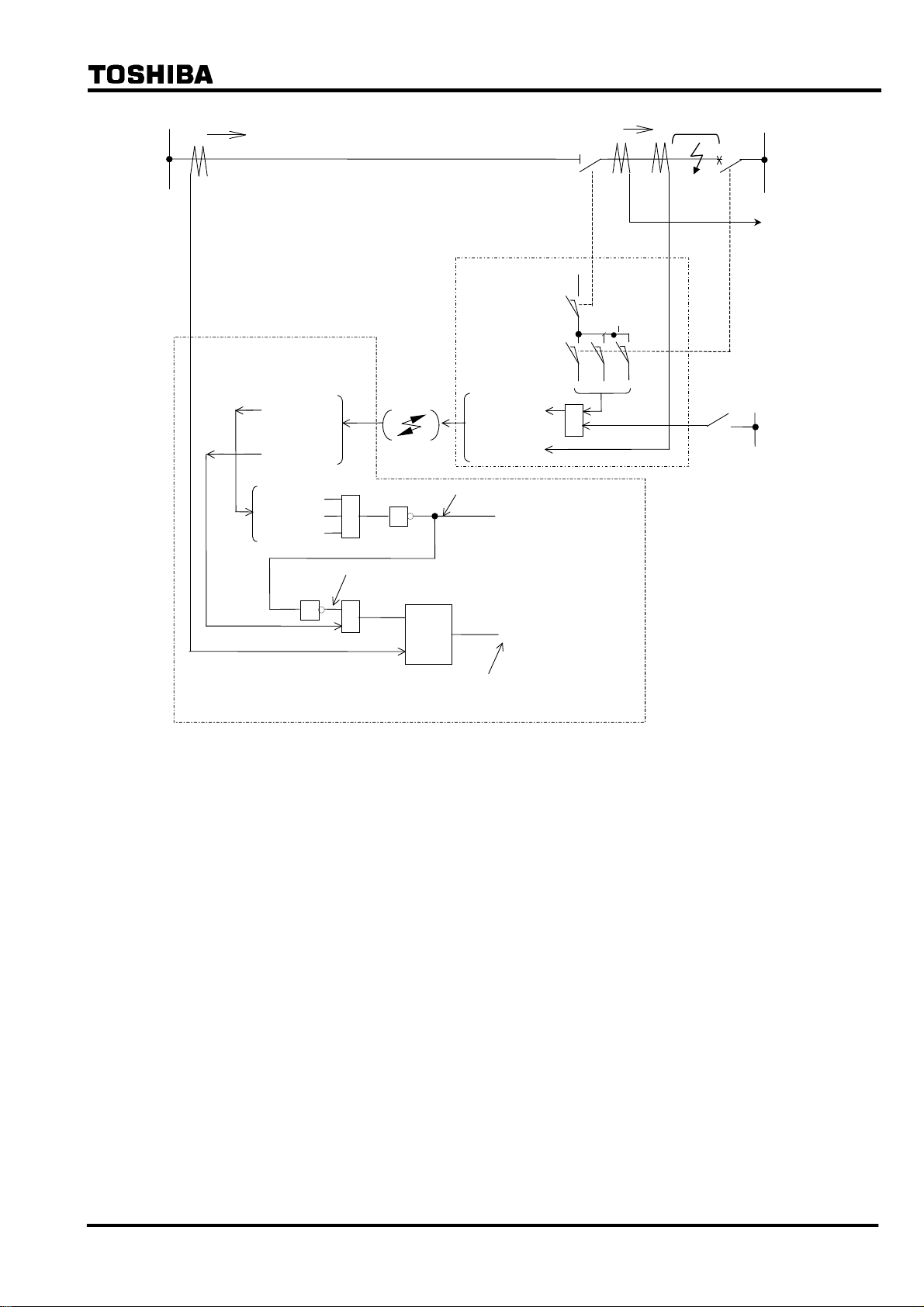

2.2.7.2 GPS-based Synchronized Sampling for GPS-MODE

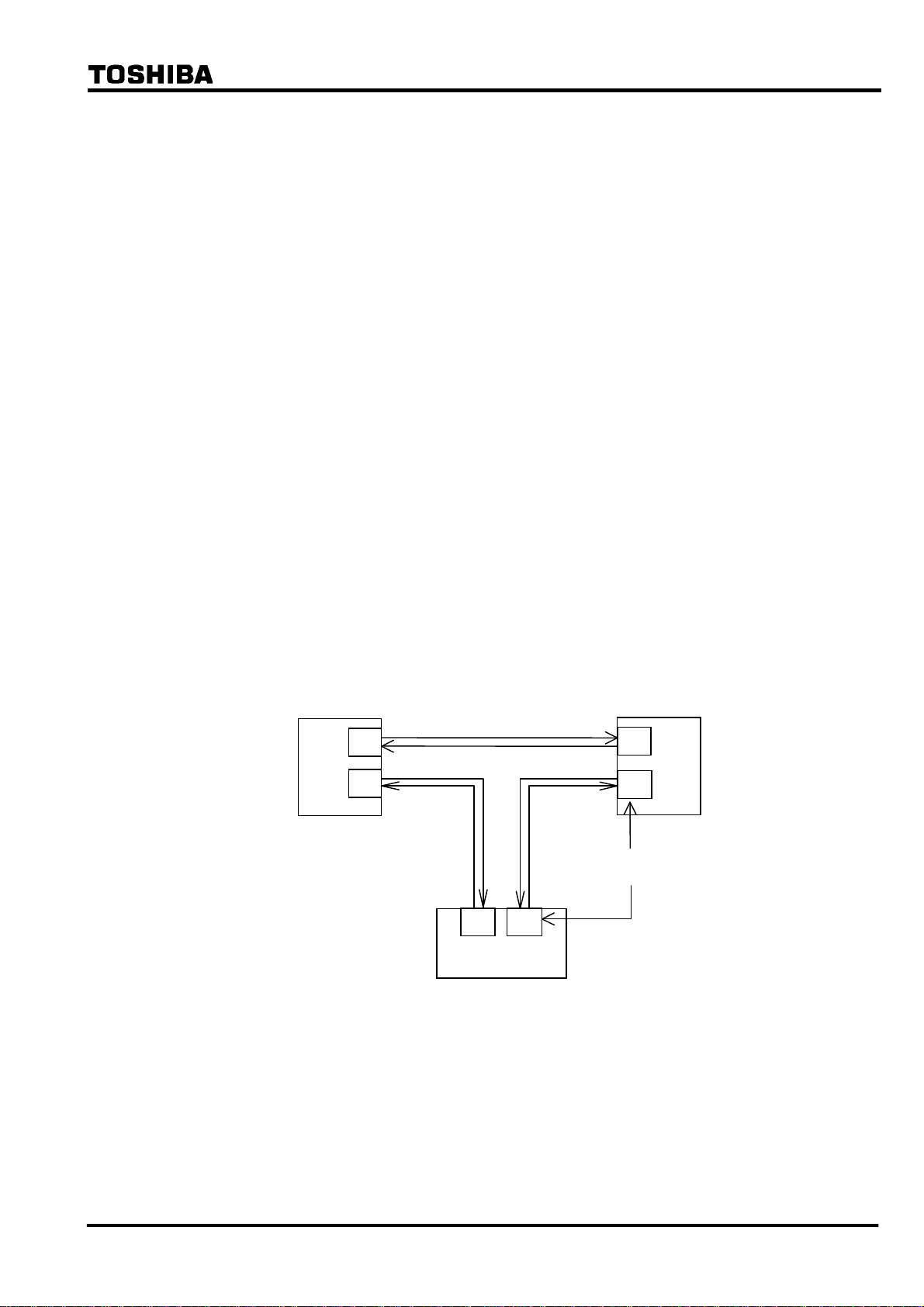

The relays at all terminals simultaneously receive the GPS clock signal once every second.

Figure 2.2.7.4 shows the GPS-based synchronized sampling circuit at one terminal. The GPS

clock signal is received by the GPS receiver HHGP1 and input to a time difference measurement

circuit in the GRL100. The circuit measures the time difference ΔT between the GPS clock and

the internal clock generated from the crystal oscillator. The oscillator is controlled to

synchronize with the GPS clock using the measured ΔT and outputs 2,400 Hz (50Hz rating)

sampling signals to the current sampling circuit (analog to digital converter).

GPS

Line

GRL100

GPS receiver

HHGP1

Time

difference

measurement

ΔT

Crystal

oscillator

Lead/lag control

Analog/digital

converter

Synchronous control

Figure 2.2.7.4 GPS Clock-based Sampling

Timing synchronization

When the GPS signal is received normally at every line terminal, the GRL100 performs

synchronized sampling based on the received clock signal. The GRL100 can provide a backup

synchronization system if the GPS signal is interrupted at one or more terminals, and perform

synchronized sampling without any external reference clock. The backup system becomes valid

by setting the scheme switch [GPSBAK] to "ON".

⎯ 22 ⎯

6 F 2 S 0 8 3 5

In the backup modes, the percentage restraint in the small current region can be increased from

the normal 16.7% ((1/6)Ir in Figure 2.9.10.1) in accordance with the PDTD setting which is the

probable transmission delay time difference between send and receive channels.

Backup modes, Mode 1, 2A and 2B are initialised when the backup system is set valid.

If the GPS signal interruption occurs when the backup is set invalid, the sampling runs based on

the local clock. When the arrival time of the remote signal measured from local sampling instant

deviates from a nominal time, the protection is blocked.

Mode 0: When the GPS signal is received normally, the sampling is performed synchronizing

with the received clock signal thus realizing synchronized sampling at all terminals. Difference

of the transmission delay time for the channel in each direction and fluctuation of the delay time

can be permitted.

The GRL100 performs the protection based on the nominal current differential characteristics.

When the GPS signal has interrupted for more than ten seconds at any of the terminals, the mode

changes to Mode 1 at all terminals.

Mode 1: The terminal which loses its GPS signal first functions as the slave terminal. If all

terminals lose their signals simultaneously, then the scheme switch [SP.SYN] setting determines

which terminal functions as the slave or master. The slave terminal adjusts the local sampling

timing to synchronize the sampling with other terminal which is receiving the GPS signal

regularly or with the master terminal.

Note: When two terminals are receiving the GPS signal regularly, the slave terminal

synchronizes with the terminal that is interlinked with port 2 of the slave terminal.

When the GPS signal has been restored, the mode shifts from Mode 1 back to Mode 0.

If, during Mode 1 operation, a failure occurs in the communication system, the sampling timing

adjustment is disabled and each terminal runs free. If the free running continues over the time

determined by the PDTD setting or the apparent phase difference exceeds the value determined

by the PDTD setting, the mode shifts from Mode 1 to Mode 2A at all terminals.

Mode 2A: In this mode, the intra-system synchronization described in 2.2.7.1 is applied

assuming that the transmission delay time for the channel in each direction is identical.

Fluctuation of the delay time can be permitted.

The current differential protection is blocked in this mode.

When the GPS signal has been restored, the mode shifts from Mode 2A to Mode 0.

If the GPS signal interruption occurs a set period following energisation of the relay power

supply or the mode returned to Mode 0 from Mode 1, 2A or 2B, then the transmission delay time

measurement will not be completed in Mode 0, and the mode changes to Mode 2A.

When the apparent current phase difference has stayed within the value determined by the PDTD

setting, the scheme switch [AUTO2B] for automatic mode change is set to "ON" and [TERM] is

set to "2TERM", the mode changes from Mode 2A to Mode 2B at both terminals.

The mode can be changed to Mode 2B manually through a binary input signal "Mode 2B

initiation" or user interface. Before this operation, it must be checked that the transmission delay

time difference between send and receive terminals is less than the PDTD setting and the SYNC

ALARM LED is off. If these conditions are not satisfied, the operation may cause a false

tripping.

Note: The mode change with the binary input signal is performed by either way:

• If the binary input contact is such as to be open when the relay is in service, set

the BI to "Inv" (inverted). The mode changes when the contact is closed more

⎯ 23 ⎯

θ

6 F 2 S 0 8 3 5

than 2 seconds and then open.

• If the binary input contact is such as to be closed when the relay is in service, set

the BI to "Norm" (normal). The mode changes when the contact is open more

than 2 seconds and then closed.

For the BISW4, see Section 3.2.1.

In the three-terminal application, the mode change to Mode 2B is available even

when one of the three communication routes is failed.

Mode 2B: The same intra-system synchronization as in Mode 2A is applied.

When the GPS signal has been restored, the mode shifts from Mode 2B to Mode 0.

If a failure occurs in the communication system, the sampling timing adjustment is disabled and

each terminal runs free.

The mode shifts from Mode 2B to Mode 2A, when the apparent load current phase difference

exceeds the value determined by the PDTD setting for pre-determined time.

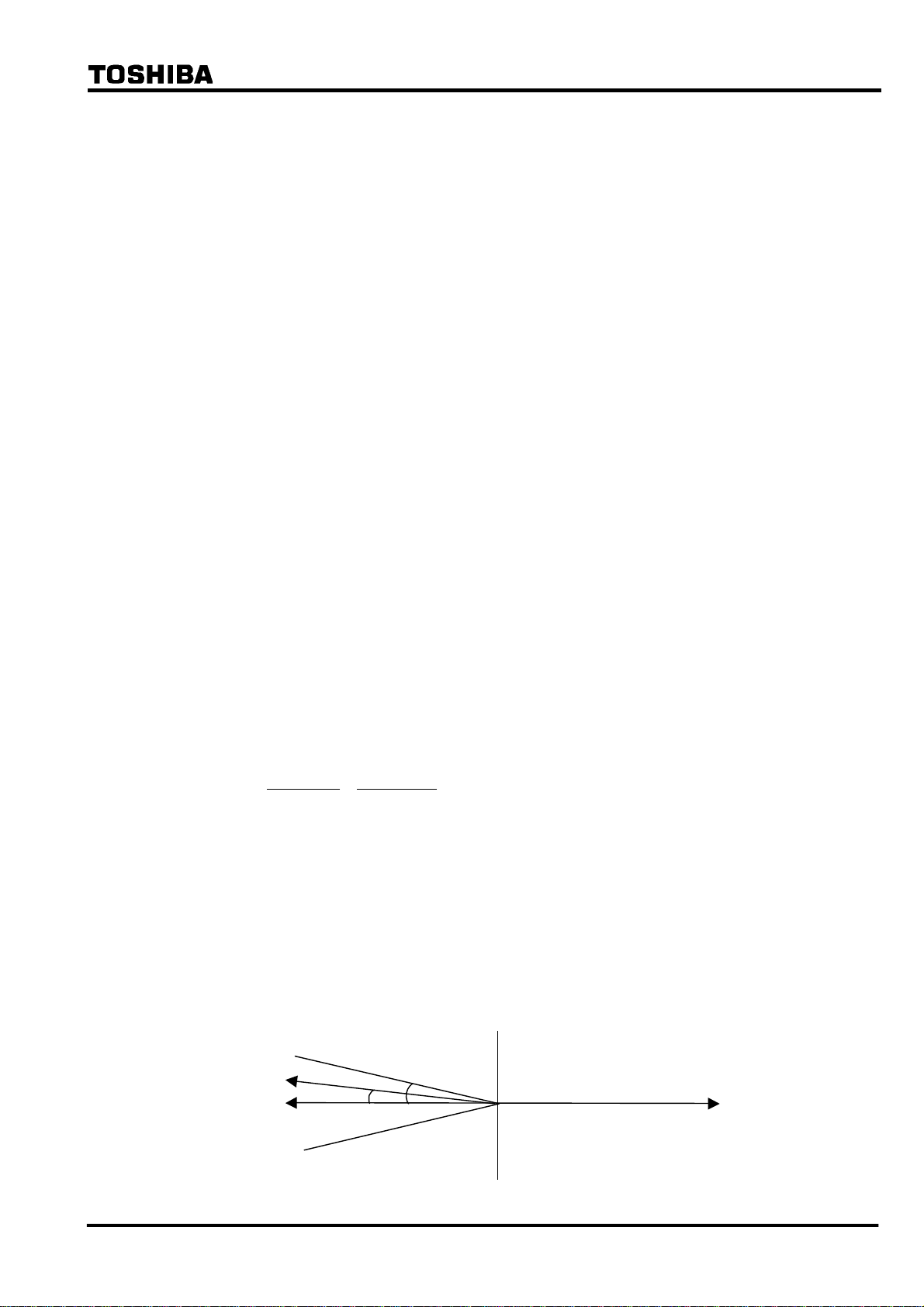

Checking the current phase difference (For two-terminal application setting only)

The current phase difference is checked using the following equations:

I

1A ⋅ cos θ < 0

1A ⋅ I1B sin θ < I1A ⋅ I1B sin θs

I

I

1A > OCCHK

I

1B > OCCHK

Where,

I

1A = Positive sequence component of load current at local terminal

1B = Positive sequence component of load current at remote terminal

I

θ = Phase difference of I

1B from - I1A

θs = Critical phase difference

= CHKθ‐HYSθ

CHKθ =

PDTD(μs)

2

360°

×

20000(μs)

+ 8.5°

HYSθ = Margin of phase difference checking

OCCHK = Minimum current for phase difference check

If the magnitude of I

1A and I1B exceed the setting and the conditions for both equations above are

established, then the sampling is regarded to be synchronized.

If the current phase difference exceeds a set value, the "SYNC ALARM" LED on the front panel

is lit.

Checking the current phase difference is enabled by setting the scheme switches [TERM] to

"2TERM" and [SRCθ] to "I".

I1B

-I1A

s

θ

I1A

Figure 2.2.7.5 Current Phase Difference Check

⎯ 24 ⎯

6 F 2 S 0 8 3 5

Sampling address synchronization

The same method as described in section 2.2.7.1 is employed in Mode 0 and Mode 2A where the

sampling synchronization must be established. It is not employed in Mode 1 and 2B because the

sampling address synchronization has already been established in the previous mode.

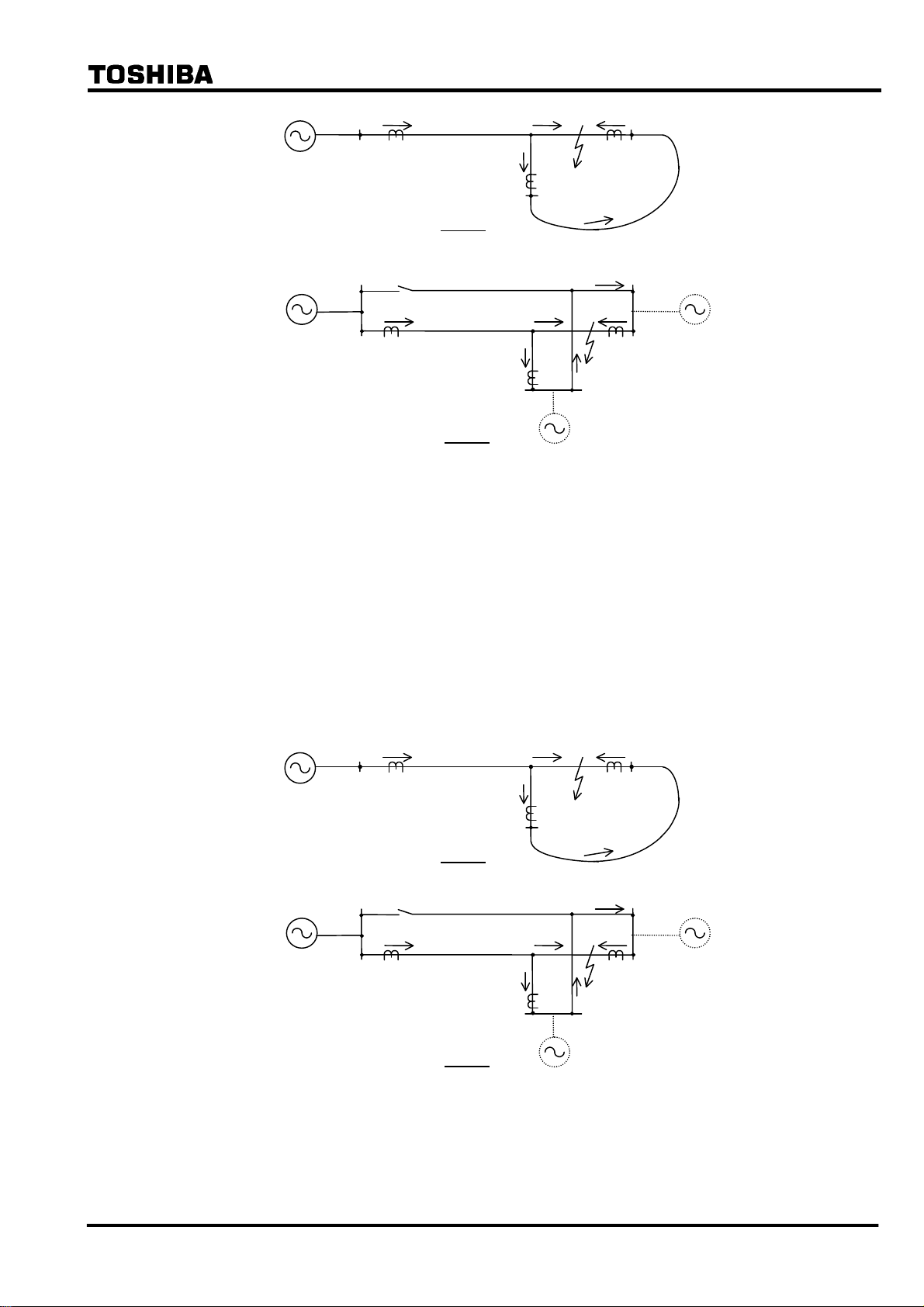

2.2.7.3 Differential Current Calculation

Synchronized sampling allows correct calculation of differential current even in the presence of

a transmission time delay. This processing is indicated in Figure 2.2.7.6. As indicated in the

figure, sampling synchronization is established between terminals A and B, and both the

sampling timing and sampling address match. The instantaneous current data and sampling

address are both sent to the other terminal. The GRL100 refers to the sampling address affixed to

the received data and uses local data with the same sampling address to calculate the differential

current. This allows both terminals to use data sampled at the same instant to perform the

differential current calculation, no matter how large the transmission time delay is.

Terminal A

4 3210

t

i

A(0)

i

B(0)

Terminal B

Figure 2.2.7.6 Calculation of Differential Current with Transmission Delay Time

i

B(1)

i

A(1)

i

A(0)

Differential current calculation

i

B(0)

Sampling address number

t

4 3210

Protection in anomalous power system operation

Even when any of the terminals is out-of-service, the GRL100 in-service terminal can still

provide the differential protection using the out-of-service detection logic. For details of the

out-of-service detection logic, see Section 2.2.2.

When one terminal is out-of-service in a two-terminal line, the other terminal continues the

current differential protection using the local current irrespective of whether it is a master

terminal or a slave terminal.

When one terminal is out-of-service in a three-terminal line, synchronized sampling is

established between the remaining two terminals as follows and the differential protection is

maintained.

• If the master terminal is out-of-service, one of the slave terminals takes over the master

terminal synchronized sampling function and enables current differential protection

between the remaining terminals to be performed.

• If the slave terminal is out-of-service, the master and another slave terminal maintain the

differential protection.

When two terminals are out-of-service in a three-terminal line, the remaining terminal continues

the current differential protection using the local current irrespective of whether it is a master

terminal or a slave terminal.

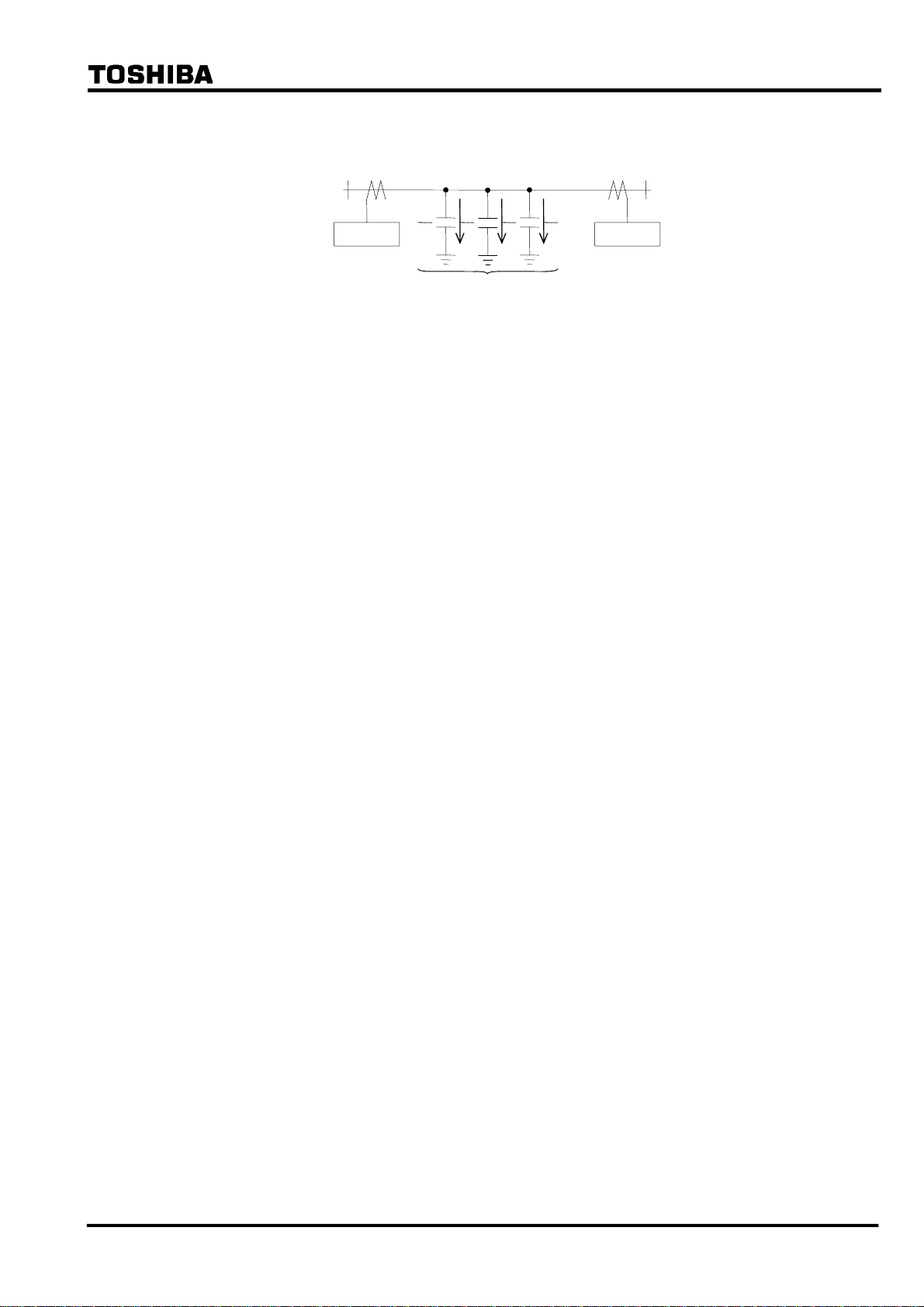

2.2.8 Charging Current Compensation

When differential protection is applied to underground cables or long overhead transmission

⎯ 25 ⎯

6 F 2 S 0 8 3 5

lines, the charging current which flows as a result of the capacitance of the line (see Figure

2.2.8.1) appears to the protection relay as an erroneous differential current.

Terminal A Terminal B

GRL100 GRL100

Ic

Figure 2.2.8.1 Charging Current

The charging current can be compensated for in the setting of the relay’s differential protection

sensitivity but only at the expense of reduced sensitivity to internal faults. In addition, the actual

charging current varies with the running voltage of the line and this must be taken into account in

the setting.

In order to suppress the effect of the charging current while maintaining the sensitivity of the

differential protection, GRL100 is equipped with a charging current compensation function,

which continuously re-calculates the charging current according to the running line voltage and

compensates for it in its differential current calculation. The running line voltage is measured by

VT inputs to GRL100.

The user enters values for line charging current and for the line voltage at which that charging

current was determined in the settings [DIFIC] and [Vn], and these values are used by the relay

to calculate the capacitance of the line. The relays at each line end share the line capacitance

between them, that is they divide by two for a two-terminal line, and by three for a three-terminal

line. In the case of a three-terminal line, if the relay at one terminal is out-of-service for testing

(see out-of-service terminal detection), the other two terminals are automatically re-configured

to divide the line capacitance by two.

Each terminal continuously calculates its share of the charging current at the running line voltage

on a sample by sample basis as follows:

Ic = C

dV

/ dt

where,

Ic = line charging current

C = line capacitance calculated from settings [DIFIC] and [Vn]

V = measured line voltage

The relay then calculates the line current compensated for the charging current on a sample by

sample basis as follows:

I = I’ - Ic

where,

I = compensated current

I’ = actual measured current

Note that since GRL100 calculates both the charging current and compensated line current on a

sample by sample basis, all necessary phase information is inherently taken into account.

⎯ 26 ⎯

6 F 2 S 0 8 3 5

2.2.9 Blind Zone Protection

The GRL100 relay has “Out-of-Service Detection Logic” as described in Section 2.2.2. This

logic functions automatically to detect the remote CB or DS (line disconnecting switch) opened

condition as shown in Figure 2.2.9.1. If the remote CB or DS is opened, the received remote

current data is set to “zero” Ampere at the local terminal, and the local relay can be operated with

only local current like a simple over current relay. Therefore, this logic function is used for blind

zone protection.

The zone between CB and CT at the remote terminal is the blind zone in Figure 2.2.9.1. If a fault

occurs within this zone, the busbar protection should operate first and trip the CB at the remote

terminal, but the fault remains and the fault current (IF) is fed continuously from the local

terminal. Since this phenomenon is an external fault for the current differential protection

scheme, the blind zone fault cannot be cleared. The fault may be cleared by remote backup

protection following a time delay, but there is a danger of damage being caused to power system

plant. Fast tripping for this type of fault is highly desirable. The Out-of-Service Detection Logic

is effective for a fault where a blind zone between CT and CB on the line exists as shown in

Figure 2.2.9.1.

If the CB and DS condition are introduced at the remote terminal as shown in Figure 2.2.9.1, the

GRL100 relay at the local terminal can operate with only local current and the fault can be

cleared, because the remote current data is automatically cancelled as explained above.

Please note the “CB Close Command” signal must be connected to the GRL100 relay to prevent

unwanted operation for a CB close operation (manual close and/or autoreclose). Unwanted

operation may be caused if the close timing of the CB auxiliary contact is delayed relative to the

CB main contact. Therefore, the CB close command signal resets forcibly the Out-of-Service

Detection Logic before the CB main contact is closed.

CB and DS status signals are input by PLC. If the out-of-service detection is not used, its logic

can be blocked by the scheme switch [OTD].

⎯ 27 ⎯

6 F 2 S 0 8 3 5

LOCAL

IL (=IF)

DIFF RELAY GRL100

(LOCAL)

CBDS-A,B,C

IR(Current)

CBDS-A

CBDS-B

CBDS-C

≧1

LINE

DIFF RELAY GRL100

(REMOTE)

52A 52C 52B

Comm. Link

1

(Cancel circuit of rem ot e t e rminal current IR)

CBDS-A,B,C

IR(Current)

(Remote terminal closed: “0” logic)

Remote terminal “OPEN”

≧

IR (=IF)

DS

89L1

1

Blind Zone

CB

FAULT

CB CLOSE COMMAND

REMOTE

BUSBAR

PROT.

1

&

IR

IL

If DS or CB signals (CBDS -A, B, C) changes to “ 0” , r emo te cu rrent d ata

(IR) is cancelled to zer o (0). Therefor e, differential curr ent (Id ) eq uals to

local current (IL).

Σ

Differential Current (Id)

Figure 2.2.9.1 Blind Zone Protection

2.2.10 Application to Three-terminal Lines

When current differential protection is applied to a three-terminal line, special attention must be

paid to the fault current flowing out of the line in the case of an internal fault and CT saturation at

the outflowing terminal in case of an external fault.

Fault current outflow in case of internal fault

In case of a two-terminal line, fault current never flows out from the terminals for an internal

fault. But in case of a three-terminal line with an outer loop circuit, a partial fault current can

flow out of one terminal and flow into another terminal depending on the fault location and

magnitude of the power source behind each terminal.

Case 1 in Figure 2.2.10.1 shows a fault current outflow in a single circuit three-terminal line with

outer loop circuit. J and F in the figure indicate the junction point and fault point. A part of the

fault current flowing in from terminal A flows out once from terminal C and flows in again from

terminal B through the outer loop.

Case 2 shows the outflow in a double-circuit three-terminal line. The outer loop is generated

when one terminal is open in the parallel line. A part of the fault current flowing in from terminal

A flows out from the fault line to the parallel line at terminal C and flows in again at terminal B

through the parallel line.

⎯ 28 ⎯

A

A

A

A

6 F 2 S 0 8 3 5

J

C

Case 1

B F

Open

Case 2

C

J

F

B

Figure 2.2.10.1 Fault Current Outflow in Internal Fault

The larger current outflows from terminal C when the fault location is closer to terminal B and

the power source behind terminal C is weaker. In case of a double-circuit three-terminal line,

50% of the fault current flowing in from terminal A can flow out from terminal C if terminal C is

very close to the junction and has no power source behind it.

These outflows must be considered when setting the differential element.

CT saturation for an external fault condition

In case of a two-terminal line, the magnitude of infeeding and outflowing currents to the external

fault is almost the same. If the CTs have the same characteristics at the two terminals, the CT

errors are offset in the differential current calculation.

B

J

C

Case 1

Open

J

C

Case 2

F

B

F

Figure 2.2.10.2 Fault Current Distribution

But in case of a three-terminal line, the magnitude of the current varies between the terminals

and the terminal closest to the external fault has the largest magnitude of outflowing fault

current. Thus, the CT errors are not offset in the differential current calculation. Thus, it is

⎯ 29 ⎯

Loading...

Loading...