Page 1

SERVICE MANUAL

FACSIMILE

GD-1210/1250/1270/1160/1260

File No. SME060009D0

R060121A4400-TTEC

Ver04_2011-12

Page 2

Trademarks

• The official name of Windows XP is Microsoft Windows XP Operating System.

• The official name of Windows 7 is Microsoft Windows 7 Operating System.

• Microsoft, Windows, Windows NT, Windows Vista and the brand names and product names of other

Microsoft products are trademarks or registered trademarks of Microsoft Corporation in the U.S.

and/or other countries.

• Apple, AppleTalk, Macintosh, and Mac are trademarks of Apple Computer, Inc. in the U.S. and other

countries.

• PostScript is a trademark of Adobe Systems Incorporated.

• NOVELL, NetWare, and NDS are trademarks or registered trademarks of Novell, Inc.

• Molykote is a registered trademark of Dow Corning Corporation.

• Other company names and product names in this manual are the trademarks of their respective

companies.

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

Under the copyright laws, this manual cannot be reproduced in any form without prior written permission

of TOSHIBA TEC CORPORATION.

11/04

Page 3

GENERAL PRECAUTIONS REGARDING THE SERVICE FOR

GD-1210/1250/1270/1160/1260

The installation and service shall be done by a qualified service

technician.

1) Transportation/Installation

- When transporting/installing the equipment, employ four persons and be sure to hold the posi-

tions as shown in the figure.

The equipment is quite heavy and weighs approximately 120 kg (264.55 lb.), therefore pay full

attention when handling it. (e-STUDIO2500c/3500c/3510c, e-STUDIO2330C/2820C/2830C/

3520C/3530C/4520C, e-STUDIO2040C/2540C/3040C/3540C/4540C)

- When transporting/installing the equipment, employ two persons and be sure to hold the posi-

tions as shown in the figure. The equipment is quite heavy, and e-STUDIO205L/255/305 weighs

approximately 57 kg (125.66lb.), and e-STUDIO355/455 weighs approximately 60 kg (132.28

lb.), therefore pay full attention when handling it. The equipment is quite heavy, and eSTUDIO206L/256/306 weighs approximately 58 kg (127.87 lb.), and e-STUDIO356/456 weighs

approximately 61 kg (134.48 lb.), therefore pay full attention when handling it.

- When transporting/installing the equipment, employ four persons and be sure to move it by the

casters while lifting the stoppers. The equipment is quite heavy and weighs approximately 245 kg

(540.12 lb), therefore pay full attention when handling it. (e-STUDIO5520C/6520C/6530C, eSTUDIO5540C/6540C/6550C)

- When transporting/installing the equipment, employ four persons and be sure to move it by the

casters while lifting the stoppers. The equipment is quite heavy and weighs approximately 202 kg

(445.33 lb), therefore pay full attention when handling it. (e-STUDIO555/655/755/855, eSTUDIO556/656/756/856)

- Be sure not to hold the movable parts or units (e.g. the control panel, ADU or RADF) when trans-

porting the equipment.

- Be sure to use a dedicated outlet with AC 110 V / 13.2 A, 115 V or 127 V / 12 A, 220-240 V / 8 A

for its power source.

- The equipment must be grounded for safety.

11/12

Page 4

- Select a suitable place for installation. Avoid excessive heat, high humidity, dust, vibration and

direct sunlight.

- Provide proper ventilation since the equipment emits a slight amount of ozone.

- To insure adequate working space for the copying operation, keep a minimum clearance of 80

cm (32”) on the left, 80 cm (32”) on the right and 10 cm (4”) on the rear.

- The equipment shall be installed near the socket outlet and shall be accessible.

- Be sure to fix and plug in the power cable securely after the installation so that no one trips over

it.

2) General Precautions at Service

- Be sure to turn the power OFF and unplug the power cable during service (except for the service

should be done with the power turned ON).

- Unplug the power cable and clean the area around the prongs of the plug and socket outlet once

a year or more. A fire may occur when dust lies on this area.

- When the parts are disassembled, reassembly is the reverse of disassembly unless otherwise

noted in this manual or other related documents. Be careful not to install small parts such as

screws, washers, pins, E-rings, star washers in the wrong places.

- Basically, the equipment should not be operated with any parts removed or disassembled.

- The PC board must be stored in an anti-electrostatic bag and handled carefully using a wristband

since the ICs on it may be damaged due to static electricity.

Caution: Before using the wristband, unplug the power cable of the equipment and

make sure that there are no charged objects which are not insulated in the

vicinity.

- Avoid expose to laser beam during service. This equipment uses a laser diode. Be sure not to

expose your eyes to the laser beam. Do not insert reflecting parts or tools such as a screwdriver

on the laser beam path. Remove all reflecting metals such as watches, rings, etc. before starting

service.

- Be sure not to touch high-temperature sections such as the exposure lamp, fuser unit, damp

heater and areas around them.

- Be sure not to touch high-voltage sections such as the chargers, transfer belt, 2nd transfer roller,

developer, high-voltage transformer, exposure lamp control inverter, inverter for the LCD backlight and power supply unit. Especially, the board of these components should not be touched

since the electric charge may remain in the capacitors, etc. on them even after the power is

turned OFF.

- Make sure that the equipment will not operate before touching potentially dangerous places (e.g.

rotating/operating sections such as gears, belts pulleys, fans and laser beam exit of the laser

optical unit).

- Be careful when removing the covers since there might be the parts with very sharp edges

underneath.

- When servicing the equipment with the power turned ON, be sure not to touch live sections and

rotating/operating sections. Avoid exposing your eyes to laser beam.

- Use designated jigs and tools.

- Use recommended measuring instruments or equivalents.

- Return the equipment to the original state and check the operation when the service is finished.

- Be very careful to treat the touch panel gently and never hit it. Breaking the surface could cause

malfunctions.

3) Important Service Parts for Safety

- The breaker, door switch, fuse, thermostat, thermofuse, thermistor, IC-RAMs including lithium

batteries, etc. are particularly important for safety. Be sure to handle/install them properly. If

these parts are short-circuited and their functions become ineffective, they may result in fatal

accidents such as burnout. Do not allow a short-circuit or do not use the parts not recommended

by Toshiba TEC Corporation.

4) Cautionary Labels

Page 5

- During servicing, be sure to check the rating plate and cautionary labels such as “Unplug the

power cable during service”, “CAUTION. HOT”, “CAUTION. HIGH VOLTAGE”, “CAUTION.

LASER BEAM”, etc. to see if there is any dirt on their surface and if they are properly stuck to the

equipment.

5) Disposal of the Equipment, Supplies, Packing Materials, Used Batteries and IC-RAMs

- Regarding the recovery and disposal of the equipment, supplies, packing materials, used batter-

ies and IC-RAMs including lithium batteries, follow the relevant local regulations or rules.

6) When the option has been installed:

When the EFI printer board has been installed, be sure to unplug the power cable before performing

maintenance and inspection, otherwise troubles such as a communication error may occur.

Caution:

Dispose of used batteries and IC-RAMs including lithium batteries according to this manual.

Attention:

Se débarrasser de batteries et IC-RAMs usés y compris les batteries en lithium selon ce manuel.

Vorsicht:

Entsorgung der gebrauchten Batterien und IC-RAMs (inclusive der Lithium-Batterie) nach diesem Handbuch.

Page 6

Page 7

CONTENTS

GD-1210/1250/1270/116 0/1260

1. SPECIFICATIONS AND OUTLINE OF SYSTEM ......................................................... 1-1

1.1 FAX Options ........................................................................................................................ 1-1

1.2 Specifications....................................................................................................................... 1-2

1.3 Features .............................................................................................................................. 1-5

1.4 Accessories and Parts......................................................................................................... 1-7

1.5 Options ................................................................................................................................ 1-8

1.6 System List ........................................................................................................................ 1-10

1.6.1 e-STUDIO2500c/3500c/3510c ............................................................................... 1-10

1.6.2 e-STUDIO2330C/2820C/2830C/3520C/3530C/4520C .......................................... 1-11

1.6.3 e-STUDIO5520C/6520C/6530C ............................................................................. 1-12

1.6.4 e-STUDIO205L/255/305/355/455........................................................................... 1-13

1.6.5 e-STUDIO555/655/755/855.................................................................................... 1-14

1.6.6 e-STUDIO2040C/2540C/3040C/3540C/4540C...................................................... 1-15

1.6.7 e-STUDIO5540C/6540C/6550C ............................................................................. 1-16

1.6.8 e-STUDIO556/656/756/856.................................................................................... 1-17

1.6.9 e-STUDIO206L/256/306/356/456........................................................................... 1-18

1.7 Overview............................................................................................................................ 1-19

1.7.1 e-STUDIO2500c/3500c/3510c ............................................................................... 1-19

1.7.2 e-STUDIO2330C/2820C/2830C/3520C/3530C/4520C,

e-STUDIO2040C/2540C/3040C/3540C/4540C...................................................... 1-20

1.7.3 e-STUDIO5520C/6520C/6530C, e-STUDIO5540C/6540C/6550C ........................ 1-21

1.7.4 e-STUDIO205L/255/305/355/455, e-STUDIO206L/256/306/356/456 .................... 1-22

1.7.5 e-STUDIO555/655/755/855, e-STUDIO556/656/756/856 ...................................... 1-23

1.8 Layout of PC Boards..........................................................................................................1-24

2. LSU-RELATED FUNCTIONS .......................................................................................2-1

2.1 Recording Mode .................................................................................................................. 2-1

2.2 Recording Paper Selection Algorithm and Printing Algorithm ............................................. 2-2

2.2.1 Recording paper selection algorithm ........................................................................ 2-2

2.2.2 Printing algorithm ..................................................................................................... 2-2

2.2.3 Setting for the split recording.................................................................................... 2-6

2.3 Recording Paper and Function ............................................................................................ 2-7

2.3.1 Table of the recording paper selection modes ......................................................... 2-8

2.3.2 Others....................................................................................................................... 2-8

2.4 Energy Saver Mode............................................................................................................. 2-9

2.5 Memory Reception.............................................................................................................2-10

3. DIALING/COMMUNICATION CONTROL..................................................................... 3-1

3.1 Circuit Connection and Procedure to Change Mode ........................................................... 3-1

3.1.1 Dial call-up transmission to a telephone circuit ........................................................ 3-1

3.1.2 Selection of the communication mode ..................................................................... 3-2

3.1.3 Procedure to select the transmission mode ............................................................. 3-2

3.2 Signaling System Diagram and Signal Forms ..................................................................... 3-3

3.2.1 Circuit control signals ............................................................................................... 3-3

3.2.2 Communication with the binary signals .................................................................... 3-4

3.2.3 V.8/V.34 communication sequence ........................................................................ 3-13

3.3 FAX Automatic Switching .................................................................................................. 3-26

3.3.1 General functions ................................................................................................... 3-26

3.3.2 TEL mode ............................................................................................................... 3-26

3.3.3 FAX mode .............................................................................................................. 3-26

4. ELECTRICAL CIRCUITS ..............................................................................................4-1

4.1 Configuration ....................................................................................................................... 4-1

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

1

11/12

CONTENTS

Page 8

4.2 Description of Circuits.......................................................................................................... 4-3

4.2.1 Configuration ............................................................................................................ 4-3

4.2.2 Line path switching control circuit............................................................................. 4-5

4.2.3 Dial pulse generation circuit ..................................................................................... 4-7

4.2.4 Line current detection circuit .................................................................................... 4-9

4.2.5 CI detection circuit .................................................................................................. 4-11

4.2.6 Line monitor circuit ................................................................................................. 4-13

4.3 PC Boards ......................................................................................................................... 4-16

5. INSTALLATION ............................................................................................................ 5-1

5.1 Explanation to the Users...................................................................................................... 5-1

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

CONTENTS

2

Page 9

1. SPECIFICATIONS AND OUTLINE OF SYSTEM

1.1 FAX Options

Equipments can be used as a FAX by installing the FAX unit.

Some options can be added when the FAX unit is installed or to extend the FAX functions ( P. 1-8

"1.5 Options").

Be sure to use the FAX unit and the 2nd line for the FAX unit only in the following combinations.

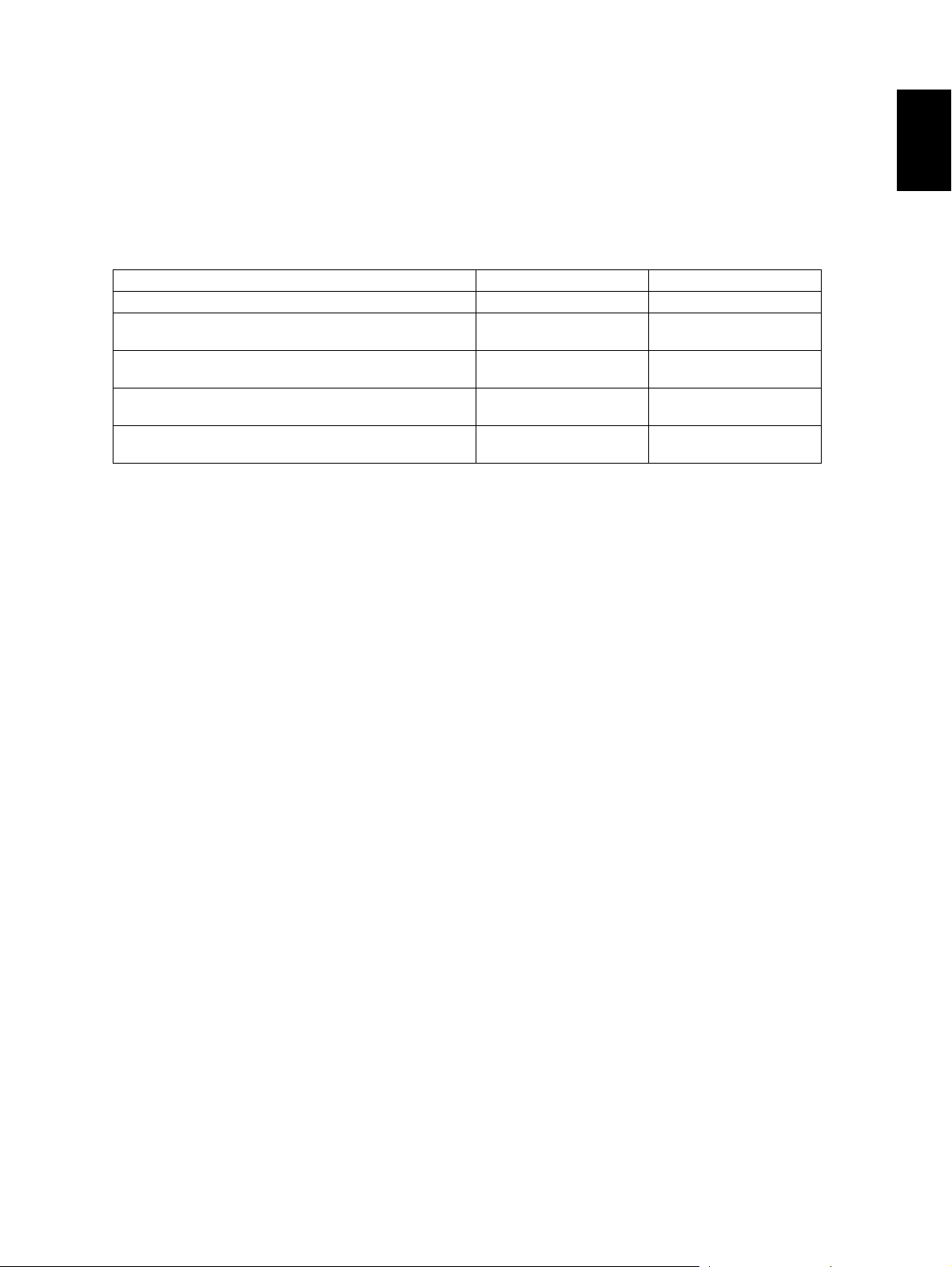

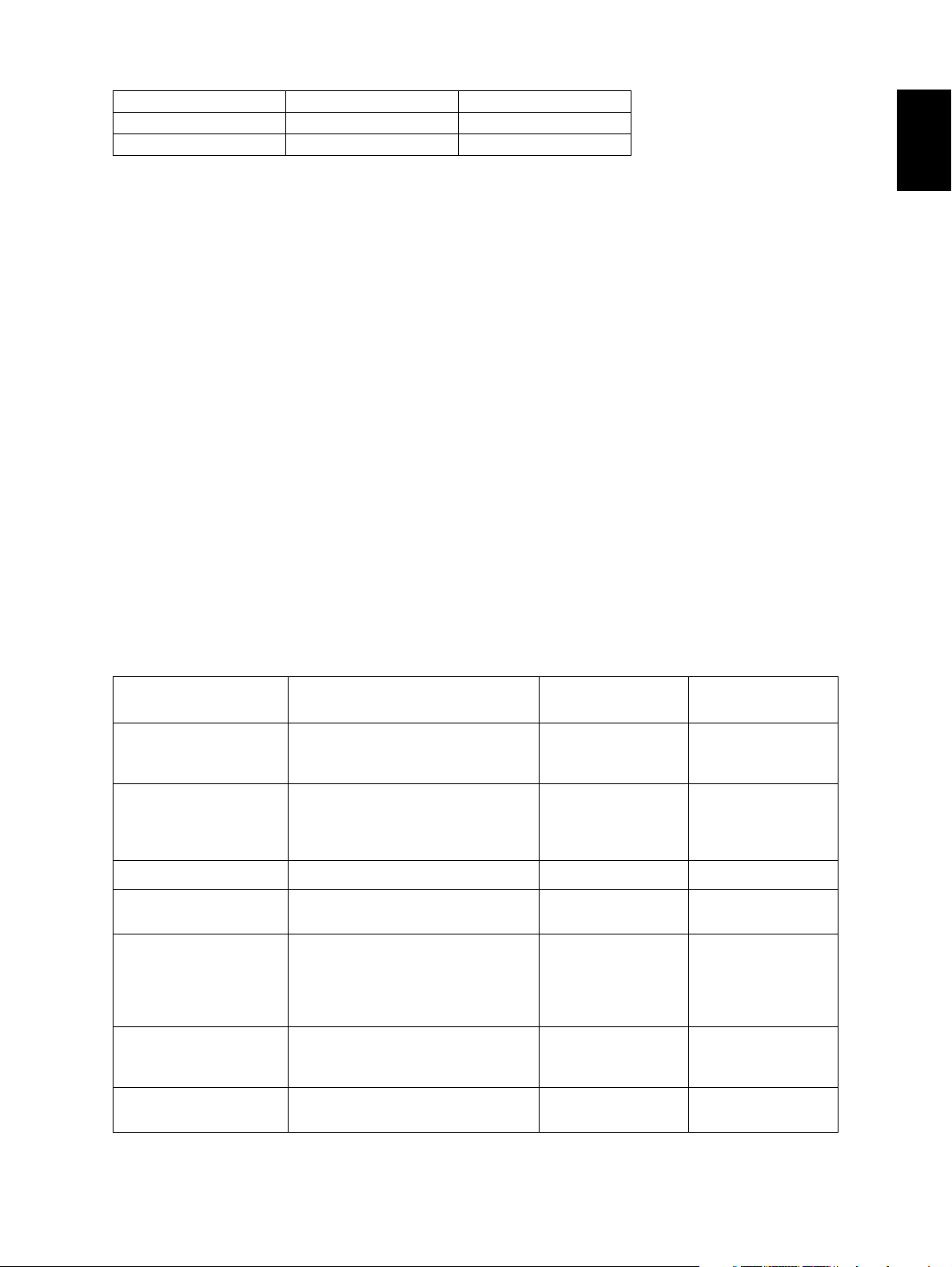

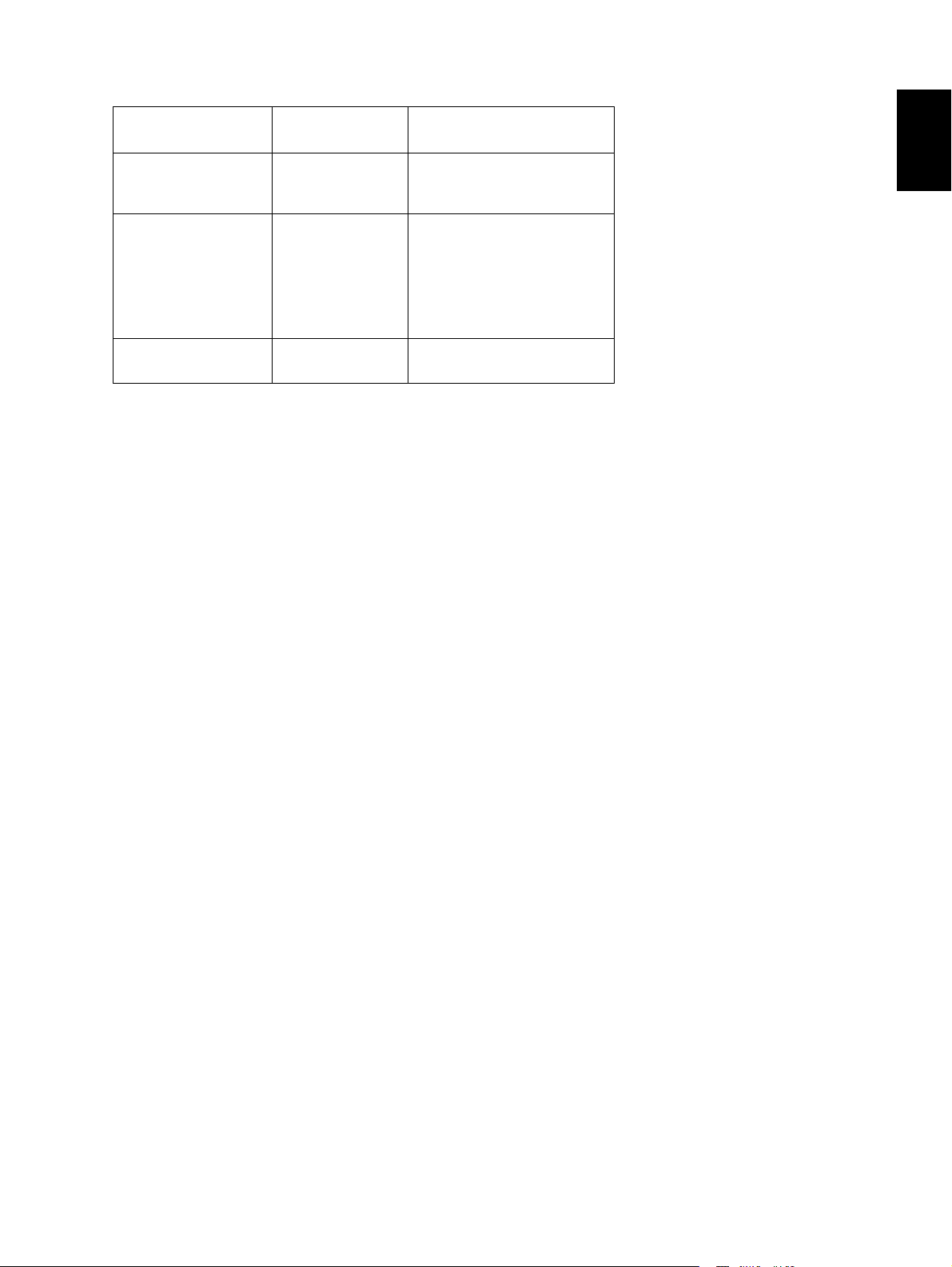

Models FAX unit 2nd line for FAX unit

e-STUDIO2500c/3500c/3510c GD-1210 GD-1160

e-STUDIO2330C/2820C/2830C/3520C/3530C/4520C,

e-STUDIO2040C/2540C/3040C/3540C/4540C

e-STUDIO5520C/6520C/6530C,

e-STUDIO5540C/6540C/6550C

e-STUDIO205L/255/305/355/455

e-STUDIO206L/256/306/356/456

e-STUDIO555/655/755/855

e-STUDIO556/656/756/856

GD-1250 GD-1260

GD-1270 GD-1260

GD-1250 GD-1260

GD-1250 GD-1260

1

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

1 - 1

11/12

SPECIFICATIONS AND OUTLINE OF SYSTEM

Page 10

1.2 Specifications

1) Main system

- Type

Desktop type transceiver

-Operation

Transmission Manual/Automatic

Reception Manual/Automatic

2) Scanner

<Scanning density> [ ]: at rotation transmission

- Horizontal direction

16 lines/mm, 8 lines/mm

[15.4 lines/mm, 7.7 lines/mm, 3.85 lines/mm]

- Vertical direction

15.4 lines/mm, 7.7 lines/mm, 3.85 lines/mm

[16 lines/mm, 8 lines/mm]

- Combination

U-Fine: 16 x 15.4 lines/mm [15.4 x 16 lines/mm]

Semi-U-Fine:8 x 15.4 lines/mm [15.4 x 8 lines/mm]

Note: Note:

Operation from the panel is automatically converted at the receiving capability of “U-Fine” combination.

Fine: 8 x 7.7 lines/mm [7.7 x 8 lines/mm]

Normal: 8 x 3.85 lines/mm [3.85 x 8 lines/mm]

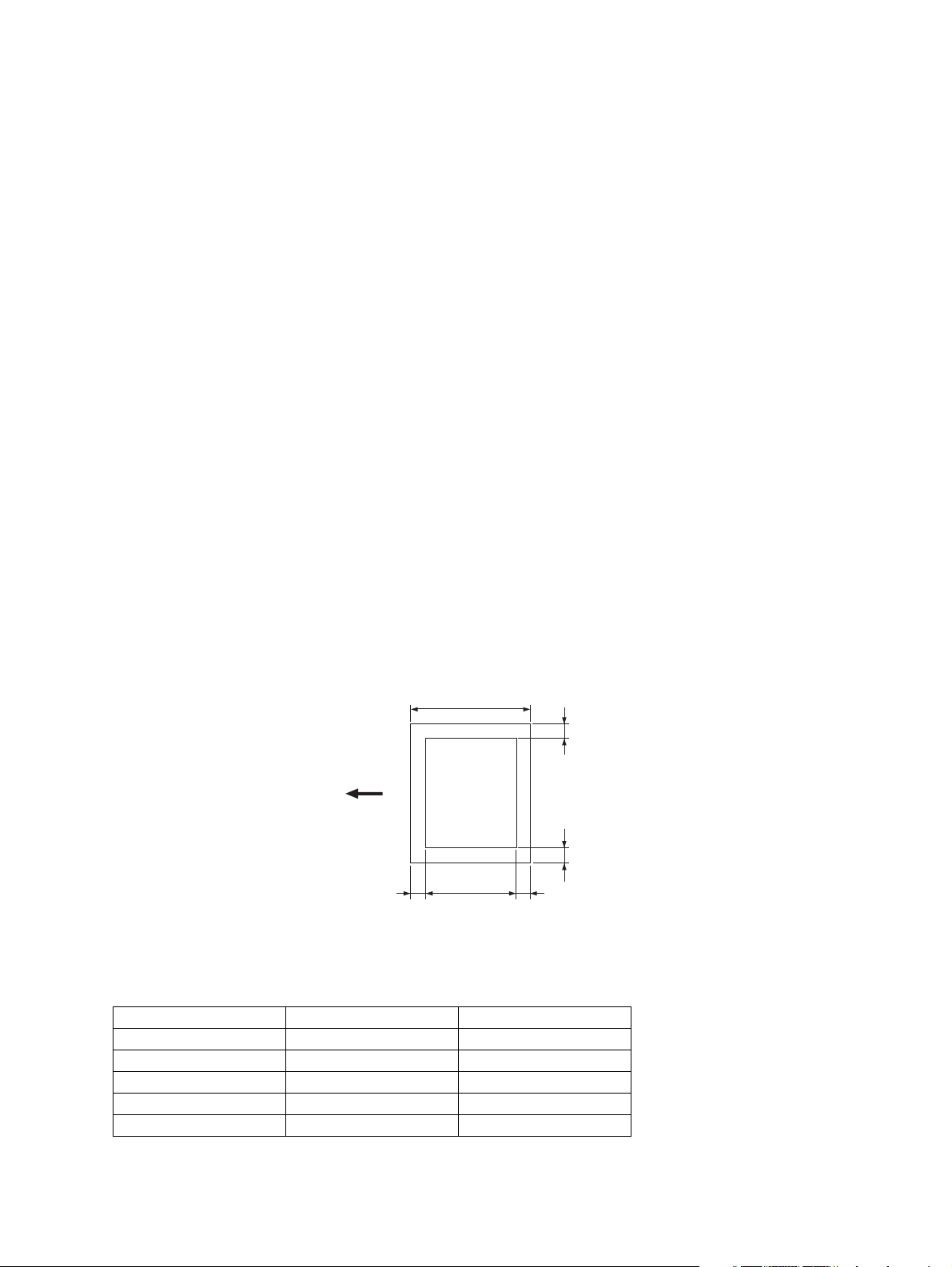

- Effective scanning area

A

Scanning

direction

B

(

Mechanical system error ±2 mm included

Fig. 1-1

Original size A B

A4 210 204.5

B4 364 358.5

A3 420 414.5

FOLIO 330 324.5

LT 216 210.5

2

3

2.53

)

(mm)

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS AND OUTLINE OF SYSTEM

1 - 2

Page 11

Original size A B

LG 355.6 350.1

LD 431.8 426.3

3) Transmission system

Circuits to be used: Subscriber line/FAX communication network (G3)

- Calling automatic transmission (including the sequential multi-address transmission)

- Calling automatic reception (polling reception)

- Called automatic transmission (polling transmission)

- Called automatic reception

- Calling manual transmission

- Calling manual reception

- Called manual transmission

- Called manual reception

Communication mode

High-speed mode (Toshiba original procedure mode)

G3 mode

ECM (Error Correction Mode)

Circuit carrier link equalization function

Embedded

Output level

–16 dBm to –8 dBm (The setting can be changed by “1 dB”.)

1

Input level

–43 dBm to 0 dBm

(Level –55 dBm or lower cannot be detected)

Specifications of the communication mode

High-speed mode

(Toshiba original procedure mode)

Horizontal scanning density

Vertical scanning density 3.85 lines/mm

Encoding system MH/MR/MMR/JBIG MH/MR MH/MR/MMR/JBIG

Minimum transmission

time for 1 line

Transmission speed

(image signal) and modulation method

Control signal 300 bps

Conformance to V.17/V.29/V.27 ter

8 dots/mm

300 dpi (Reception only)

16 dots/mm

7.7 lines/mm

300 dpi (Reception only)

15.4 lines/mm

2.5 ms Same as on the left Same as on the left

14.4 k/12 k/9600

7200/4800/2400 bps

V.21

G3 mode ECM

Same as on the left Same as on the left

Same as on the left Same as on the left

Same as on the left 33.6 k/31.2 k/28.8 k/

26.4 k/24 k/21.6 k/

19.2 k/16.8 k/14.4 k/

12 k/9600/7200/

4800/2400 bps

Same as on the left 2400/1200/600/

300 bps

V.34/V.8/V.21

Procedure to control the

transmission

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

Toshiba original procedure T.30 conformance Same as on the left

SPECIFICATIONS AND OUTLINE OF SYSTEM

1 - 3

Page 12

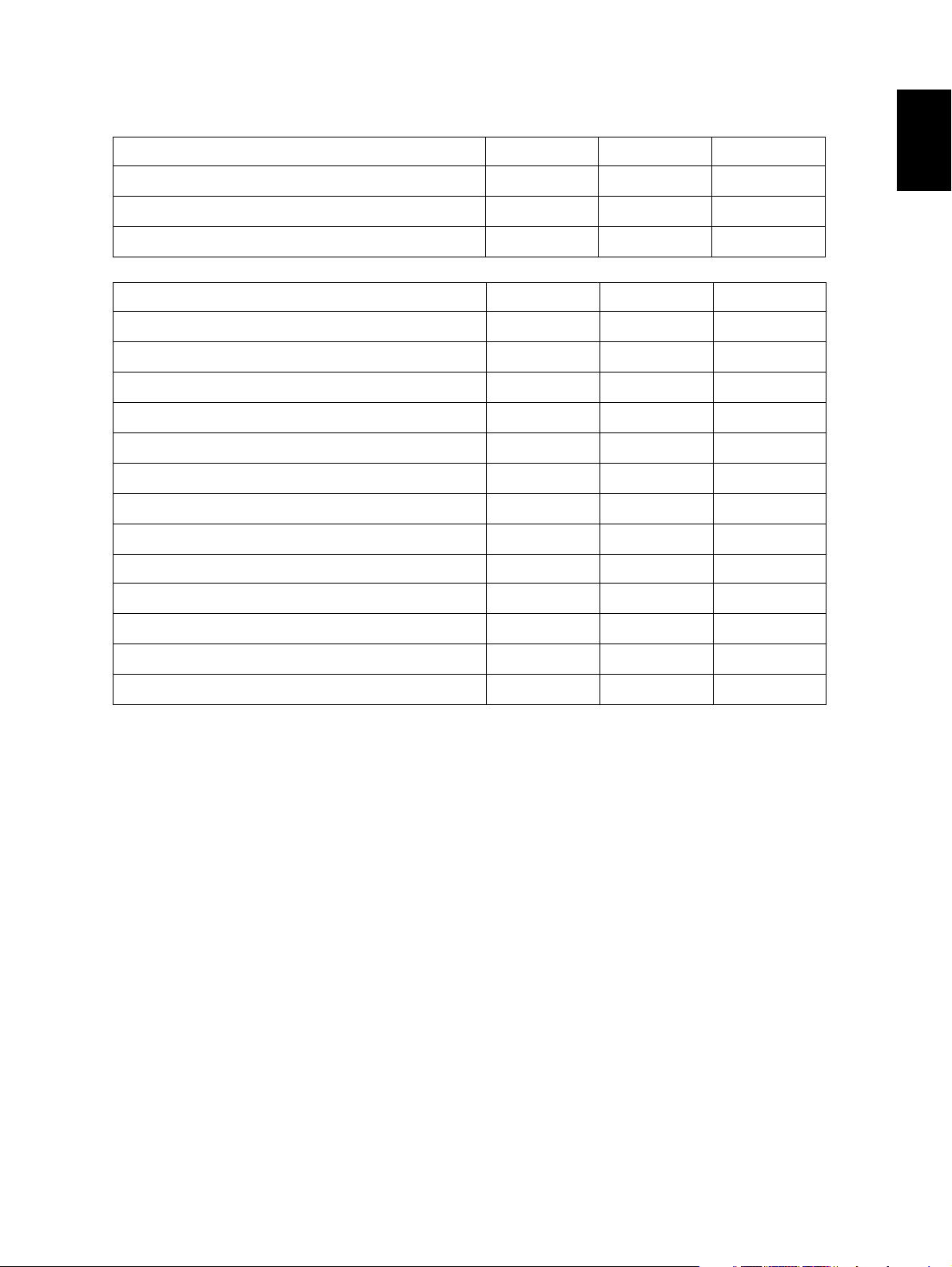

4) Recording paper

- Recording method

Electrophotographic recording method by LSU (Laser Scanning Unit)

- Horizontal printing density

24 lines/mm (96 lines/mm with the smoothing processing)

[23.1 lines/mm (92.4 lines/mm with the smoothing processing)]

- Vertical printing density

23.1 lines/mm (24 lines/mm with the smoothing processing)

- Recording paper size and the effective printing area

Unit: mm (inch)

Paper size Dimension (width x length) Printing area

A5-R 148 x 210 143 x 204.5

B5-R 182 x 257 177 x 251.5

B5 257 x 182 252 x 176.5

A4-R 210 x 297 205 x 291.5

A4 297 x 210 292 x 204.5

B4 257 x 364 252 x 358.5

A3 297 x 420 292 x 414.5

FOLIO 210 x 330 205 x 324.5

ST-R 139.7 x 216 (5.5 x 8.5) 134.7 x 210.5

LT-R 216 x 279.4 (8.5 x 11) 211 x 273.9

LT 279.4 x 216 (11 x 8.5) 274.4 x 210.5

LG 216 x 355.6 (8.5 x 14) 211 x 350.1

LD 279.4 x 431.8 (11 x 17) 274.4 x 426.3

COMP 257 x 356 (10.125 x 14) 252 x 350.5

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS AND OUTLINE OF SYSTEM

1 - 4

Page 13

1.3 Features

• A3/LD scanning

Scans data across A3/LD width and transmits in A3/LD actual size.

• High-speed scanning

Inputs an A4/LT-size transmitted document in about 0.7 seconds (A4/LT document transmitted

widthwise).

• High-speed transmission

33.6 Kbps high speed modem

Toshiba original high-speed communication modes EX and HS

JBIG encoding system

• Dual Access

- FAX transmission

There are two types of FAX transmission: Page-by-page direct transmission and memory transmission that all pages are stored in the memory before being transmitted.

- FAX reception

Basically, all pages are input in the memory before being output. This reduces the time that the

FAX communication occupies the machine, making Dual Access between the copying/faxing and

printing operation possible.

Namely, the followings are possible:

- Memory input during the memory transmission

- Memory input during the memory reception

- Copying during the memory transmission

- Reception during the copying

- Reception during the memory output

- Reception during the list output

1

• Laser printing on plain paper

Printing is made on the standard size paper (A3/LD, B4/COMP, A4/LT/LG, A4-R/LT-R, B5, B5-R,

FOLIO, and A5-R/ST-R) with the laser system.

•Gradation

256 tones, error diffusion method

• Memory communication function

Image data can be stored in the HDD. In the delayed transmission, image data read from an original

are stored in the memory, then sent when the specified time comes.

Other memory functions: multi transmission, memory reception, ECM communication, etc.

• Smoothing

The smoothing process is applied to the received images so that they are changed from 8 × 3.85,

8 × 7.7, 8 × 15.4 or 16 × 15.4 to 24 × 92.4 (equivalent to 600 × 2400dpi), then printed out.

• Editing function

Duplex transmission and duplex printing are possible.

• FAX data file storage capacity

1 GB (for transmission and reception)

Note: Note:

For hard drivers, GB means 1 billion bytes.

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

1 - 5

11/04

SPECIFICATIONS AND OUTLINE OF SYSTEM

Page 14

• Phone Book (3,000 addresses)

Up to 3,000 addresses can be registered in the Phone Book using the large LCD control panel.

• Multi-address transmission function

Data are sent to multiple addresses (400 destinations) in sequence in a single operation.

There are three ways to choose/enter the address

- Choose from the Phone Book (up to 400 destinations)

- Direct dialing (up to 400 destinations)

- Mix operation (Phone Book, Direct dialing, Group destinations: up to 400 destinations)

• Memory reception function

When the recording paper has run out or a paper jam has occurred, the memory receives and stores

the data.

• Auto-dialing function

- Delayed dialing

Documents are transmitted automatically to the preset number at the preset time.

- Redialing

When the receiving side is busy during the automatic dialing, the machine keeps dialing at a

fixed interval for a specified number of times.

• Receiving tone/completion tone

Sound notifies that the reception of a FAX document or printing of a received document has been

completed.

• List output

The following data stored in the RAM can be printed out

- Phone book information

- Function list

- Transmission journal

- Reception journal

- Memory transmission report

- Power failure list etc.

• Power saver mode

During hours in which the reception amount is small, the weekly timer works to shut off the main

power and the heater power to save power consumption.

• Drawer selection

It is possible to choose a drawer on to whose paper the received images are to be printed.

[Options]

• 2nd line

One extra line can be added by installing the 2nd line unit (option).

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS AND OUTLINE OF SYSTEM

1 - 6

11/04

Page 15

1.4 Accessories and Parts

The following accessories and parts come with the FAX unit:

Accessory GD-1210 GD-1250 GD-1270

1

Operator’s manual (for facsimile function) 1 pc.

Modular cord (2 m) 1 pc.

Unpacking instruction 1 set

Parts GD-1210 GD-1250 GD-1270

Fax unit 1 pc.

SG3 label 1 pc.

FCC Part 68 label (U.S.A.) / IC label (Canada): NA only 1 pc.

DTS label (EU): EU only 1 pc.

Teleprompt label (New Zealand): AU only 1 pc.

Notice to users label (New Zealand): AU only

Screw 5 pc.

Ground plate 1 pc.

Gasket 1 pc. 1 pc. -

Ferrite core

Bracket -

1 pc. 1 pc. 1 pc.

-1 pc.-

1 pc. 1 pc.

1 pc. 1 pc.

1 set 1 set

1 pc. 1 pc.

1 pc. 1 pc.

1 pc. 1 pc.

1 pc. 1 pc.

1 pc. 1 pc.

5 pc.

1 pc. -

-2 pc.

4 pc.

Harness clamp

Cover

- - 1 pc.

- - 3 pc.

* Apply the each label to the specified positions following the Unpacking/Setup Instruction.

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

1 - 7

09/05

SPECIFICATIONS AND OUTLINE OF SYSTEM

Page 16

1.5 Options

Extends the FAX functions when the FAX unit is installed.

Option Function

e-STUDIO2500c/

3500c/3510c

e-STUDIO2330C/

2820C/2830C/

3520C/3530C/

4520C

e-STUDIO5520C/

6520C/6530C

Reversing Automatic

Feeds originals MR-3018 MR-3018 Document Feeder

(RADF)

Finisher Sorts out docu-

ments to be output

for the FAX/copy-

ing operation

2nd line for FAX unit Adds one extra

communication line

Option Function

Reversing Automatic

Feeds originals MR-3021/3022 Document Feeder

(RADF)

Finisher Sorts out docu-

ments to be output

for the FAX/copy-

ing operation

2nd line for FAX unit Adds one extra

communication line

MJ-1101

MJ-1030

MJ-1101

MJ-1030

MJ-1031

GD-1160 GD-1260 GD-1260

e-STUDIO205L/255/305/355/

455

MJ-1101

MJ-1031

MJ-1024

e-STUDIO555/655/755/855

MJ-1027

MJ-1028

MJ-1029

MJ-1025

MJ-5004

MJ-5005

MJ-5006

GD-1260 GD-1260

MJ-1103

MJ-1104

Option Function

Reversing Automatic

Document Feeder

e-STUDIO2040C/

2540C/3040C/

3540C/4540C

Feeds originals MR-3021

MR-3022

e-STUDIO5540C/

6540C/6550C

-

e-STUDIO556/656/

756/856

-

(RADF)

Finisher Sorts out docu-

ments to be output

for the FAX/copy-

MJ-1101

MJ-1031

MJ-1106

MJ-1103

MJ-1104

MJ-1027

MJ-1028

MJ-1029

ing operation

2nd line for FAX unit Adds one extra

GD-1260 GD-1260

GD-1260

communication line

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS AND OUTLINE OF SYSTEM

1 - 8

11/12

Page 17

Option Function

e-STUDIO206L/256/306/356/

456

1

Reversing Automatic

Feeds originals MR-3021/3022

Document Feeder

(RADF)

Finisher Sorts out docu-

ments to be output

for the FAX/copy-

ing operation

2nd line for FAX unit Adds one extra

communication line

MJ-1101

MJ-1106

MJ-1032

MJ-1033

MJ-5004

MJ-5005

MJ-5006

GD-1260

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

1 - 9

11/12

SPECIFICATIONS AND OUTLINE OF SYSTEM

Page 18

1.6 System List

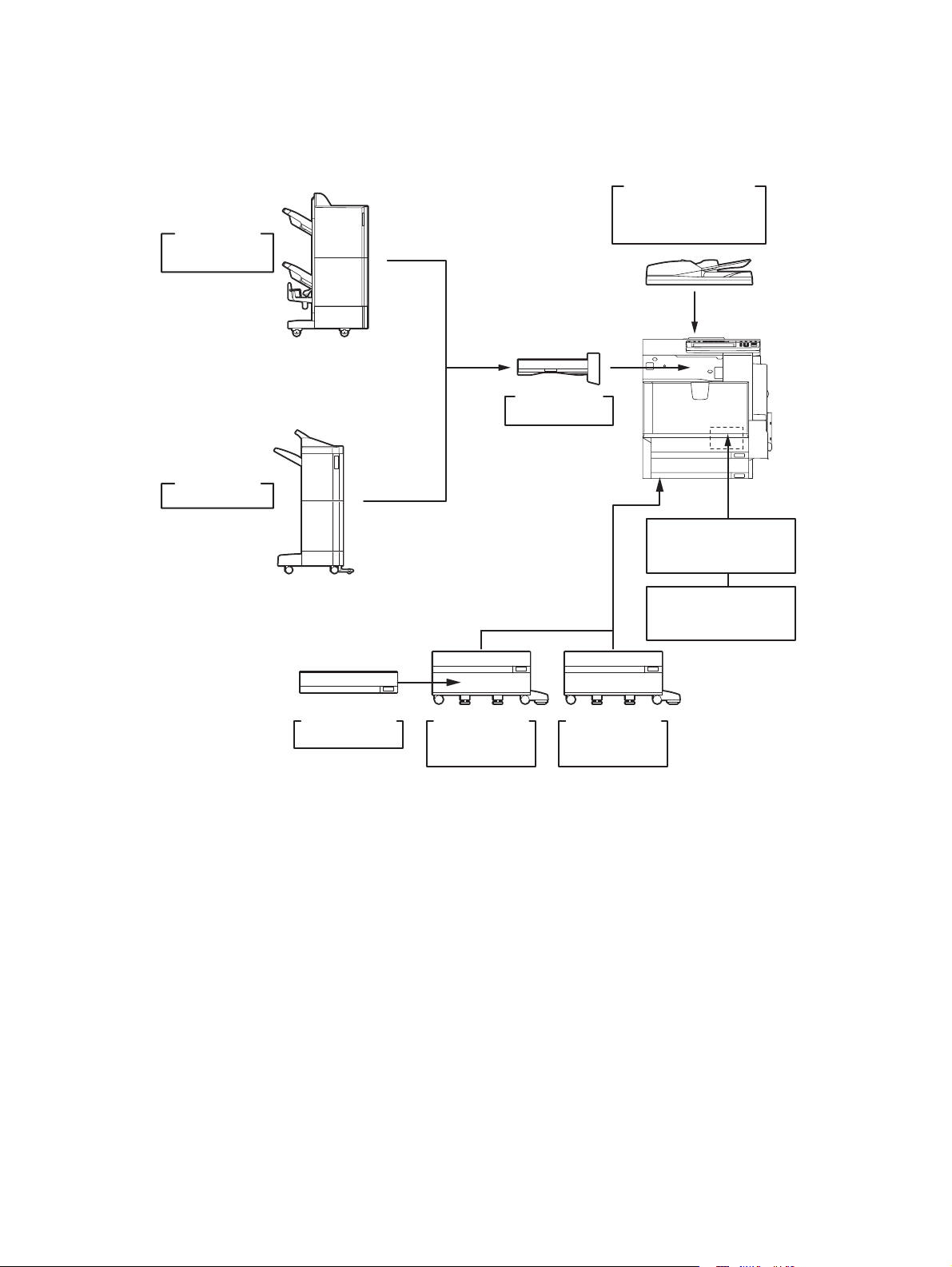

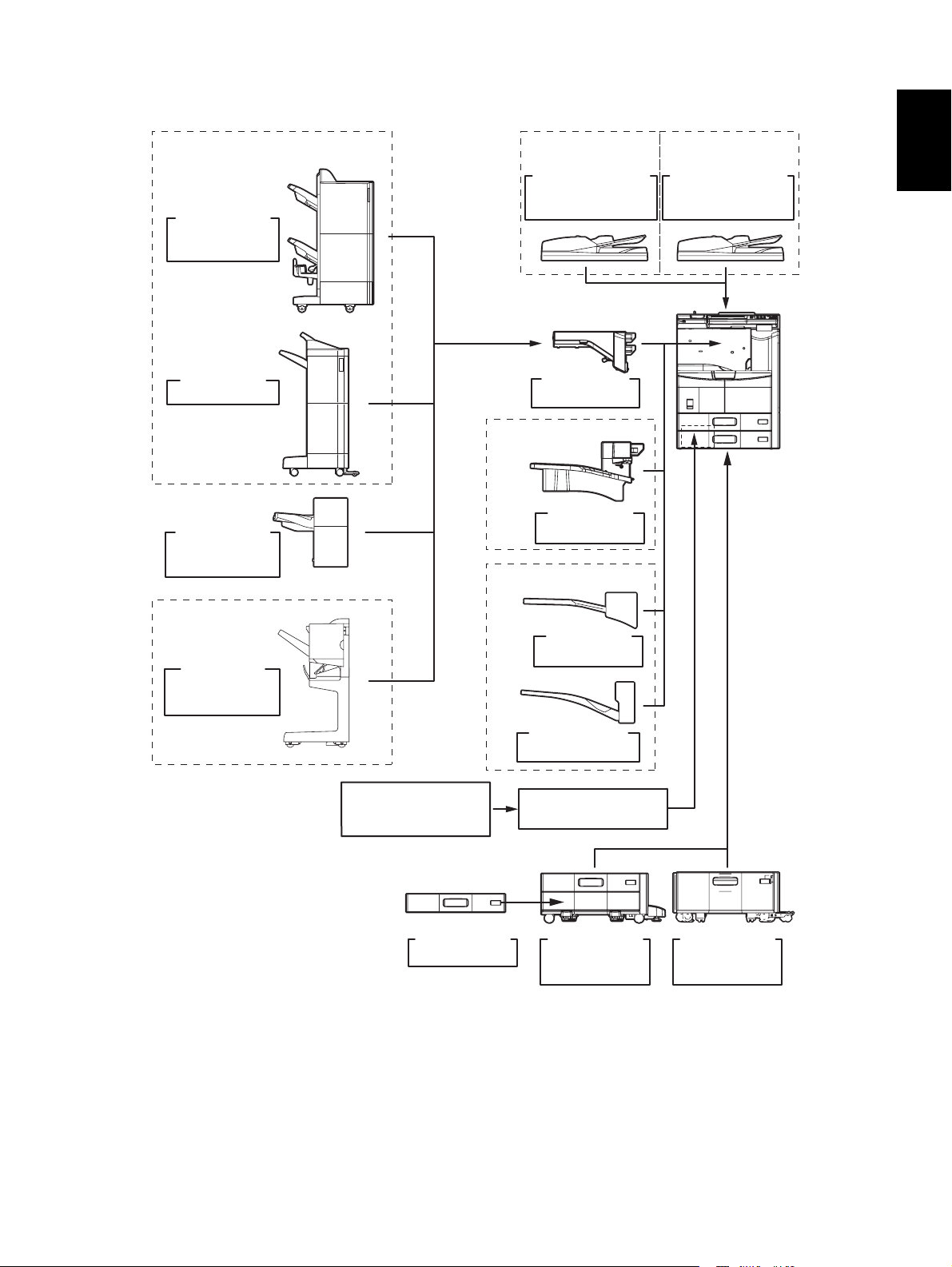

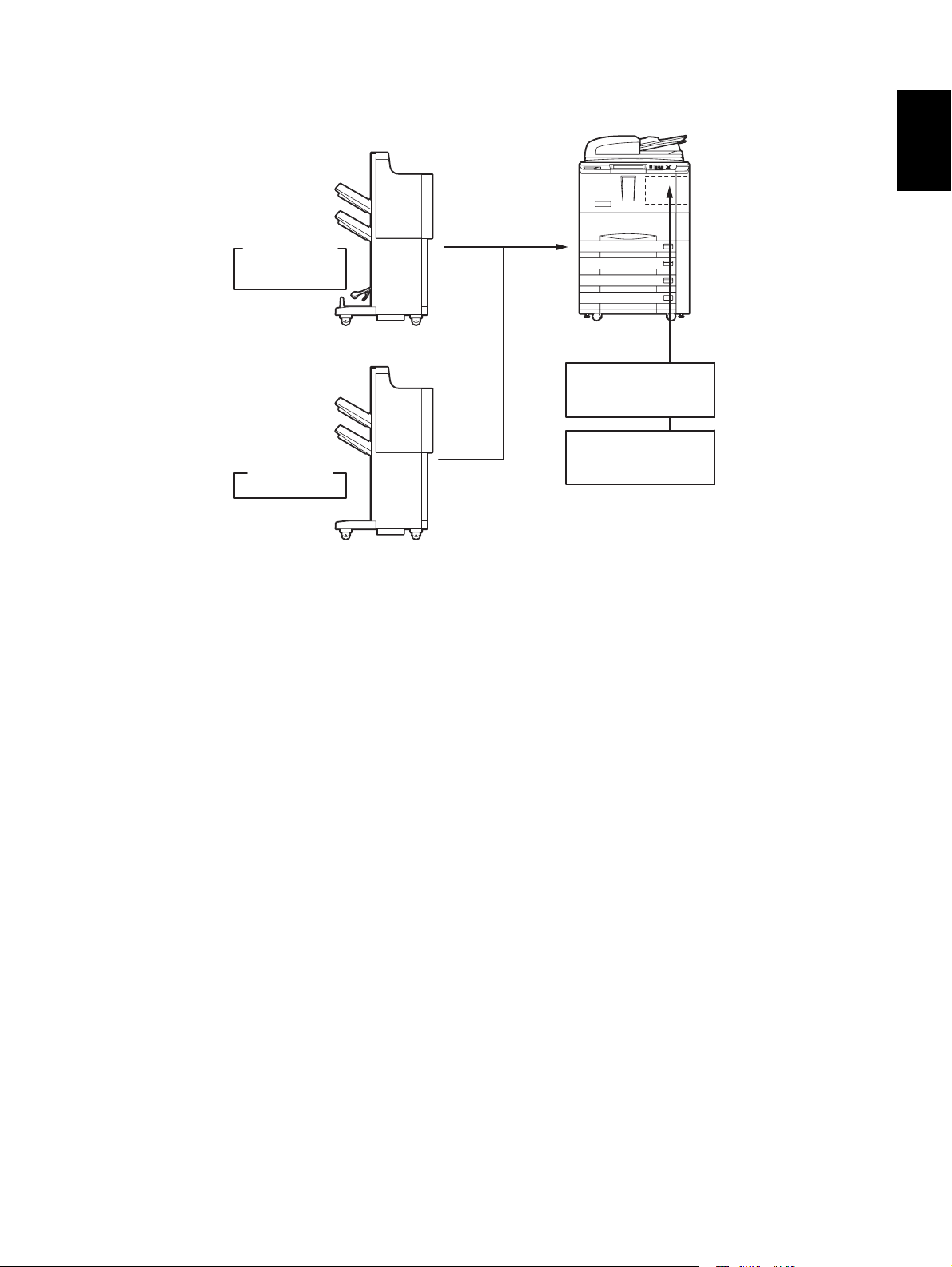

1.6.1 e-STUDIO2500c/3500c/3510c

Saddle stitch

finisher

MJ-1030

Finisher

MJ-1101

Bridge Kit

KN-3500

Reversing Automatic

Document Feeder

(

)

RADF

MR-3018

FAX

GD-1210NA/AU/AS/

unit

EU/C/TW/KR

Drawer Module

MY-1031/C

Paper Feed

Pedestal (PFP

KD-1018/C

Fig. 1-2

)

KD-1019 A4/LT/C

Large Capacity

Feeder (LCF

2nd Line for FAX

GD-1160

NA/EU-N/C/TW

)

unit

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS AND OUTLINE OF SYSTEM

1 - 10

08/04

Page 19

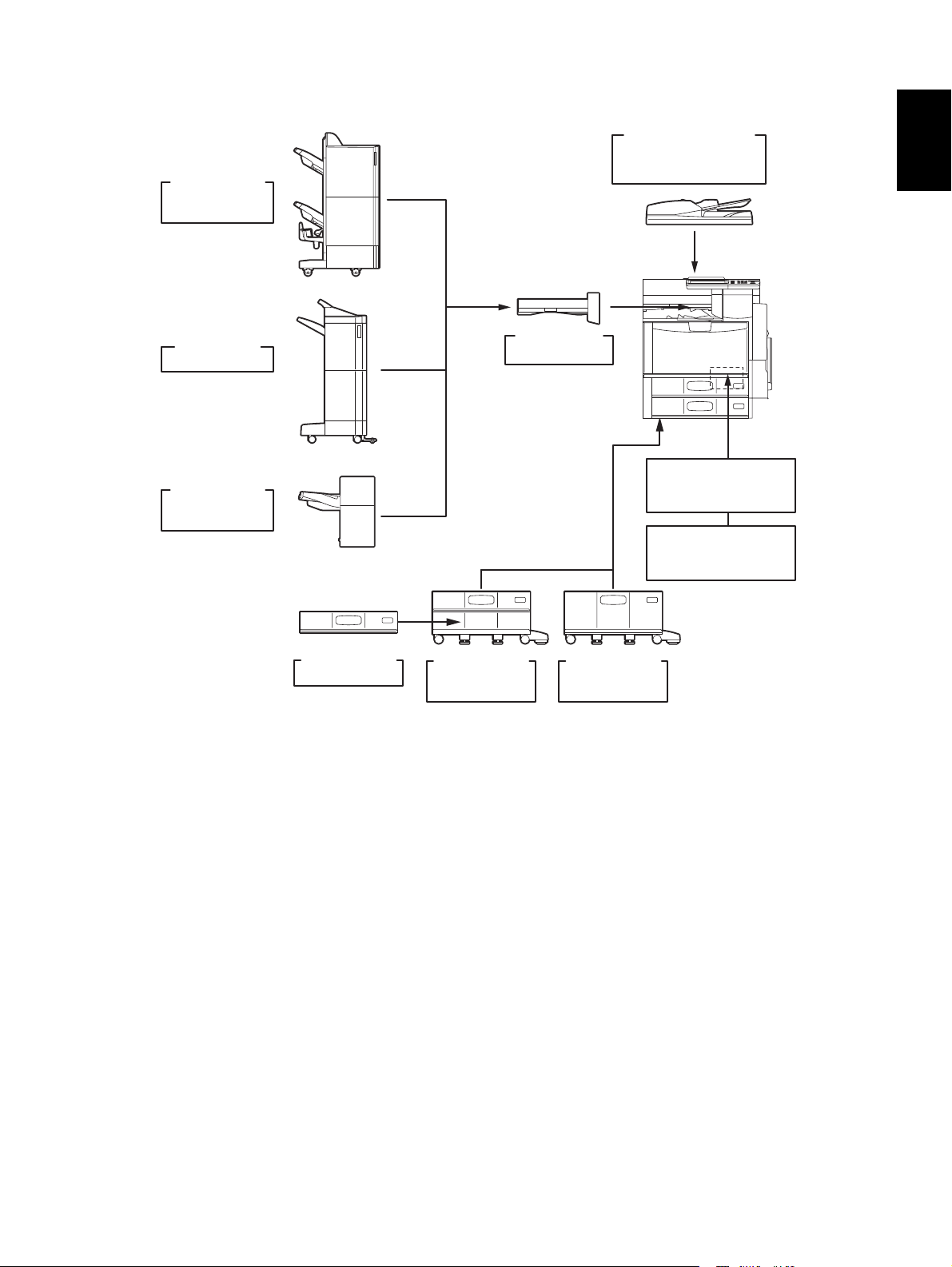

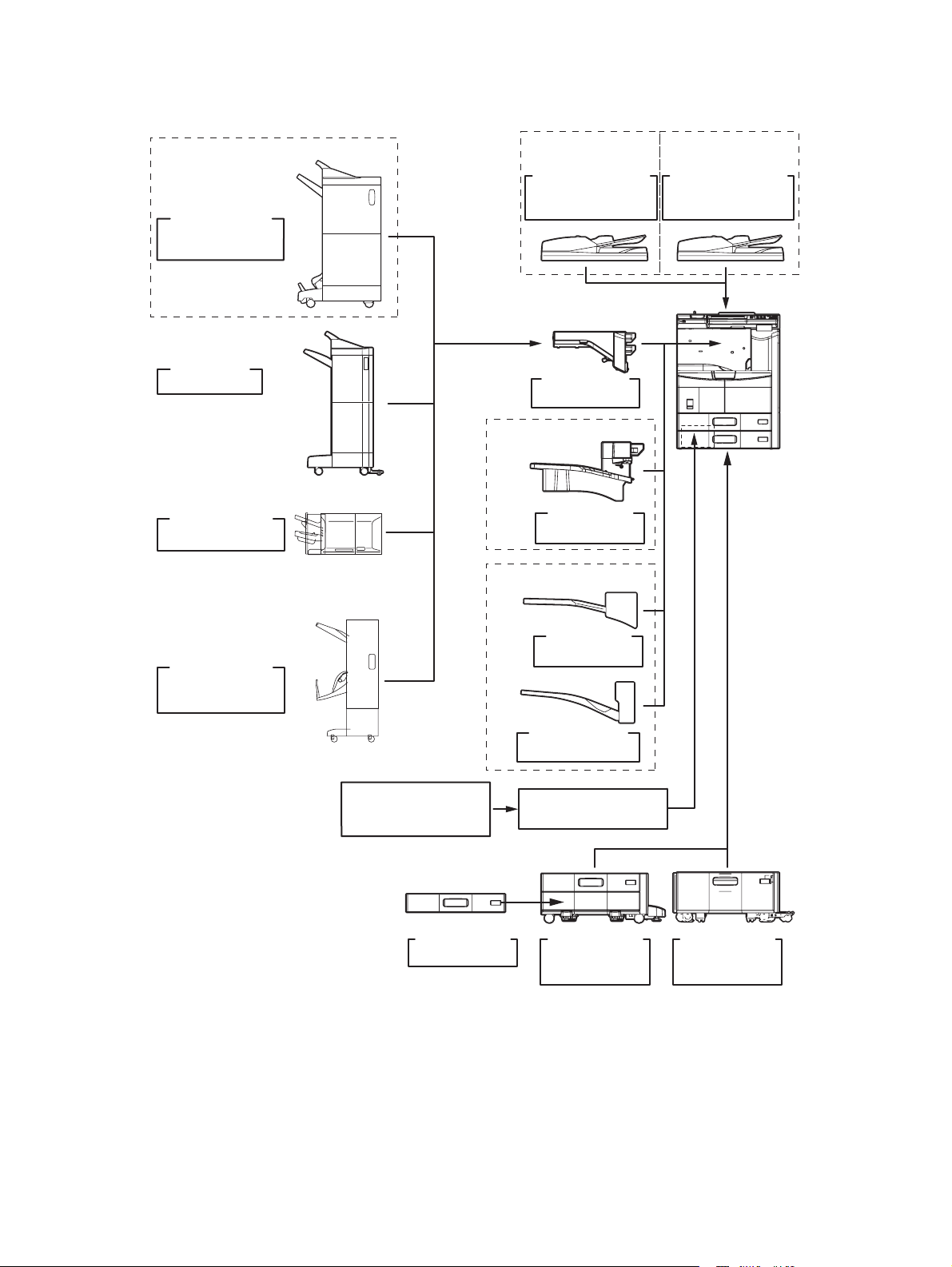

1.6.2 e-STUDIO2330C/2820C/2830C/3520C/3530C/4520C

Saddle stitch

finisher

MJ-1030

Finisher

MJ-1101

Hanging

finisher

MJ-1031

Bridge Kit

KN-4520

Reversing Automatic

Document Feeder

(

)

RADF

MR-3018

FAX

GD-1250NA/AU/AS/

2nd Line for FAX

NA/AU/EU/C/TW

unit

EU/C/TW

GD-1260

1

unit

Drawer Module

MY-1032/C

Paper Feed

Pedestal (PFP

KD-1023/C

Fig. 1-3

)

KD-1024 A4/LT/C

Large Capacity

Feeder (LCF

)

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

1 - 11

08/04

SPECIFICATIONS AND OUTLINE OF SYSTEM

Page 20

1.6.3 e-STUDIO5520C/6520C/6530C

Saddle stitch

finisher

MJ-1104

Finisher

MJ-1103

Fig. 1-4

FAX

GD-1270NA/AU/AS/

2nd Line for FAX

NA/AU/EU/C/TW

unit

EU/C/TW

GD-1260

unit

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS AND OUTLINE OF SYSTEM

1 - 12

09/05

Page 21

1.6.4 e-STUDIO205L/255/305/355/455

e-STUDIO355/455

Saddle stitch

Finisher

MJ-1024

Finisher

MJ-1101

Finisher

(

Hanging type

MJ-1031

e-STUDIO355/455

Reversing Automatic

Document Feeder (RADF

MR-3022

Bridge Kit

KN-2520

e-STUDIO355/455

Job Separator

)

e-STUDIO205L/255/355

MJ-5006

e-STUDIO205L/255/355

Reversing Automatic

)

Document Feeder (RADF

MR-3021

)

1

e-STUDIO205L/255/305

Saddle stitch

Finisher

MJ-1025

2nd Line for

FAX Unit

GD-1260

Drawer Module

MY-1033

Fig. 1-5

Job Separator

MJ-5004

Offset Tray

MJ-5005

FAX Unit

GD-1250

Paper Feed

Pedestal (PFP)

KD-1025

Large Capacity

Feeder (LCF)

KD-1026

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

1 - 13

11/12

SPECIFICATIONS AND OUTLINE OF SYSTEM

Page 22

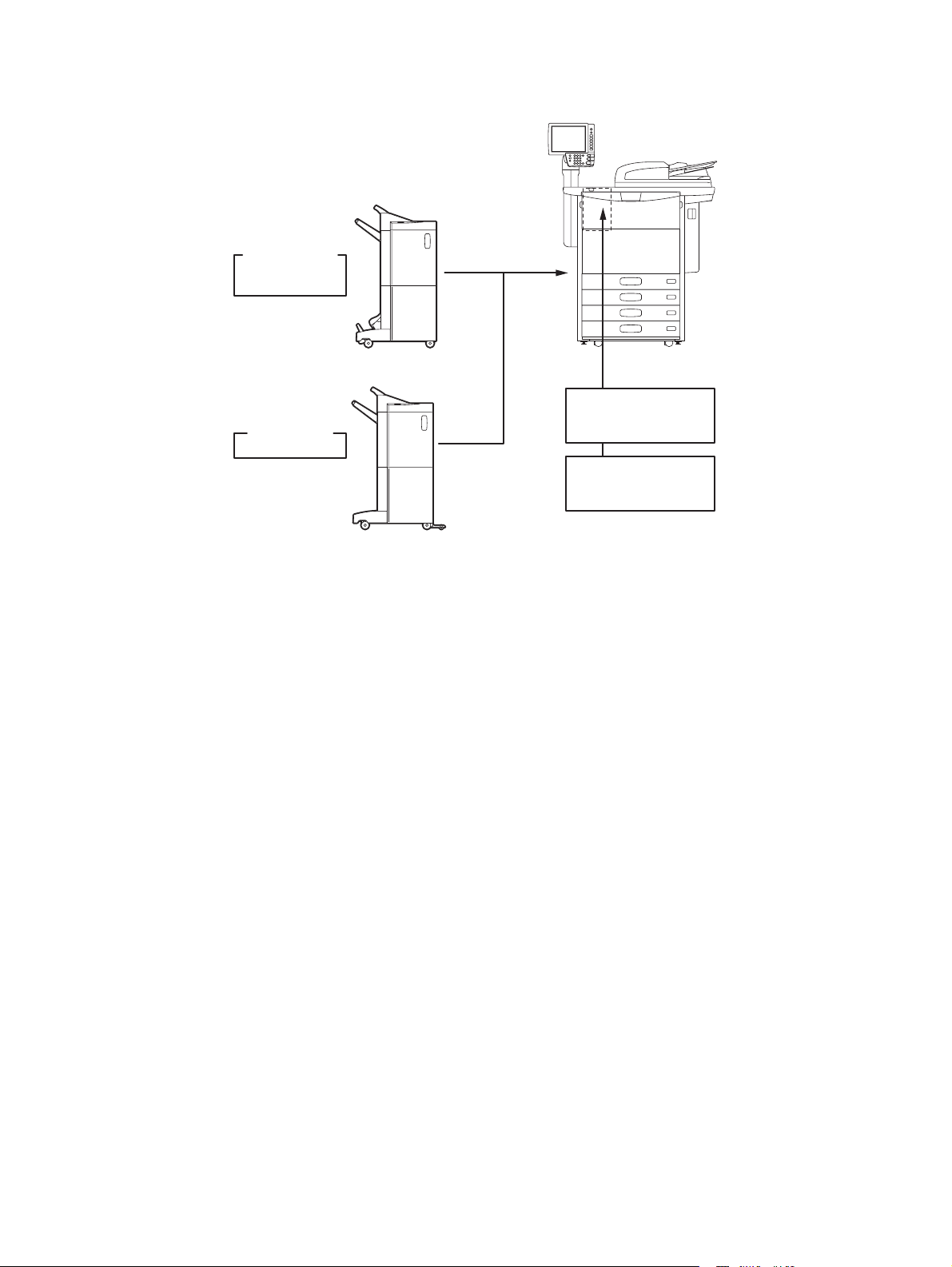

1.6.5 e-STUDIO555/655/755/855

Saddle stitch

finisher

MJ-1028/1029

FAX

GD-1250NA/EU/AU/AS/C

unit

Finisher

MJ-1027

Fig. 1-6

2nd Line for FAX

GD-1260

NA/EU-N/AU/C

unit

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS AND OUTLINE OF SYSTEM

1 - 14

09/05

Page 23

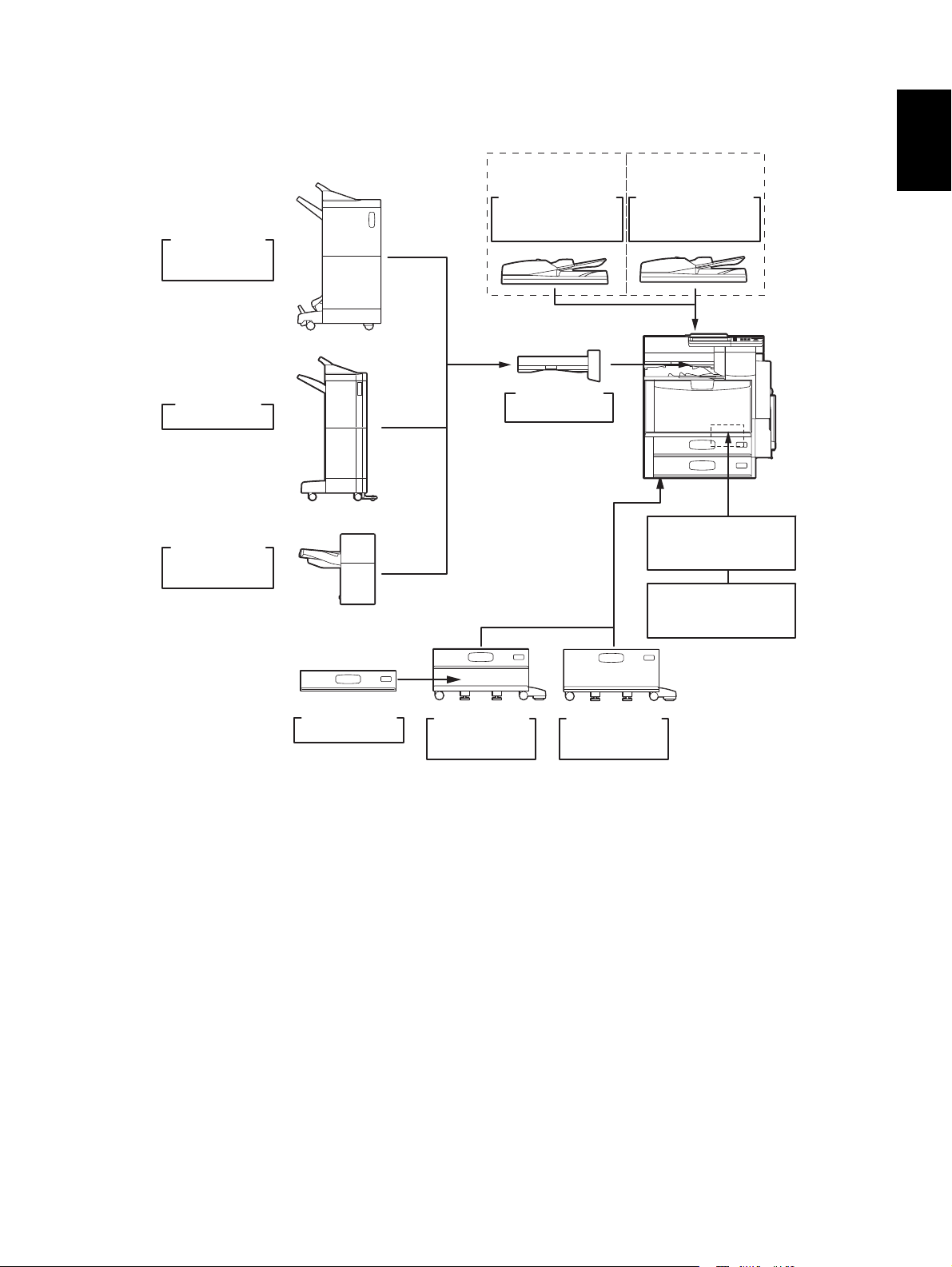

1.6.6 e-STUDIO2040C/2540C/3040C/3540C/4540C

e-STUDIO3540C/4540C

Reversing Automatic

Document Feeder (RADF

Saddle stitch

finisher

MJ-1106

MR-3022

e-STUDIO2040C/2540C

/3040C

Reversing Automatic

)

Document Feeder (RADF

MR-3021

1

)

Finisher

MJ-1101

Hanging

finisher

MJ-1031

Drawer Module

MY-1035/C

Paper Feed

Pedestal (PFP

KD-1027/C

Fig. 1-7

Bridge Kit

KN-4530

)

KD-1028 A4/LT/C

Large Capacity

Feeder (LCF

FAX

GD-1250NA/AU/AS/

2nd Line for FAX

NA/AU/EU/C/TW

)

unit

EU/C/TW

GD-1260

unit

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

1 - 15

11/04

SPECIFICATIONS AND OUTLINE OF SYSTEM

Page 24

1.6.7 e-STUDIO5540C/6540C/6550C

Saddle stitch

finisher

MJ-1104

Finisher

MJ-1103

Fig. 1-8

FAX

GD-1270NA/AU/AS/

2nd Line for FAX

NA/AU/EU/C/TW

unit

EU/C/TW

unit

GD-1260

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS AND OUTLINE OF SYSTEM

1 - 16

11/04

Page 25

1.6.8 e-STUDIO556/656/756/856

Saddle stitch

finisher

MJ-1028/1029

FAX

GD-1250NA/EU/AU/AS/C

unit

1

Finisher

MJ-1027

Fig. 1-9

2nd Line for FAX

GD-1260

NA/EU-N/AU/C

unit

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

1 - 17

11/12

SPECIFICATIONS AND OUTLINE OF SYSTEM

Page 26

1.6.9 e-STUDIO206L/256/306/356/456

e-STUDIO356/456

Saddle stitch

Finisher

MJ-1106/C

Finisher

MJ-1101

Inner Finisher

MJ-1032

e-STUDIO356/456

Reversing Automatic

Document Feeder (RADF

MR-3022

Bridge Kit

KN-2520

e-STUDIO356/456

Job Separator

MJ-5006

e-STUDIO206L/256/356

e-STUDIO206L/256/356

Reversing Automatic

)

Document Feeder (RADF

MR-3021

)

Saddle stitch

Finisher

MJ-1033

2nd Line for

FAX Unit

GD-1260

Drawer Module

MY-1033

Fig. 1-10

Job Separator

MJ-5004

Offset Tray

MJ-5005

FAX Unit

GD-1250

Paper Feed

Pedestal (PFP)

KD-1025

Large Capacity

Feeder (LCF)

KD-1026

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS AND OUTLINE OF SYSTEM

1 - 18

11/12

Page 27

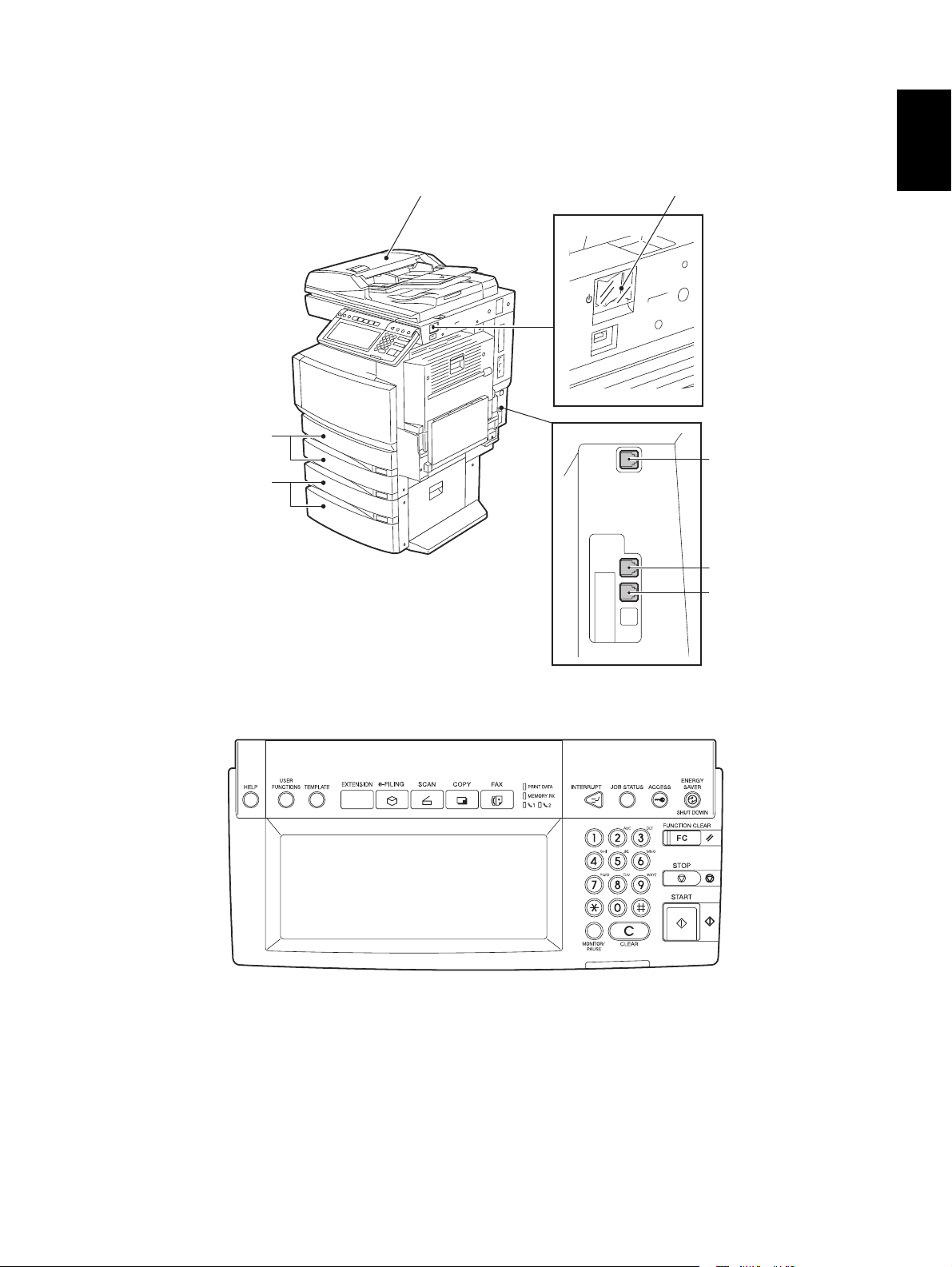

1.7 Overview

r

1.7.1 e-STUDIO2500c/3500c/3510c

Reversing automatic document feeder

Drawers

Paper feed pedestal

or

Large capacity feeder

1

Power switch

LINE2 connecto

LINE connector

TEL connector

Fig. 1-11

Fig. 1-12

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

1 - 19

09/05

SPECIFICATIONS AND OUTLINE OF SYSTEM

Page 28

1.7.2 e-STUDIO2330C/2820C/2830C/3520C/3530C/4520C, e-

r

STUDIO2040C/2540C/3040C/3540C/4540C

Drawers

Paper feed pedestal

or

Large capacity feeder

Reversing automatic document feeder

Power switch

LINE2 connecto

LINE connector

TEL connector

Fig. 1-13

Fig. 1-14

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS AND OUTLINE OF SYSTEM

1 - 20

11/04

Page 29

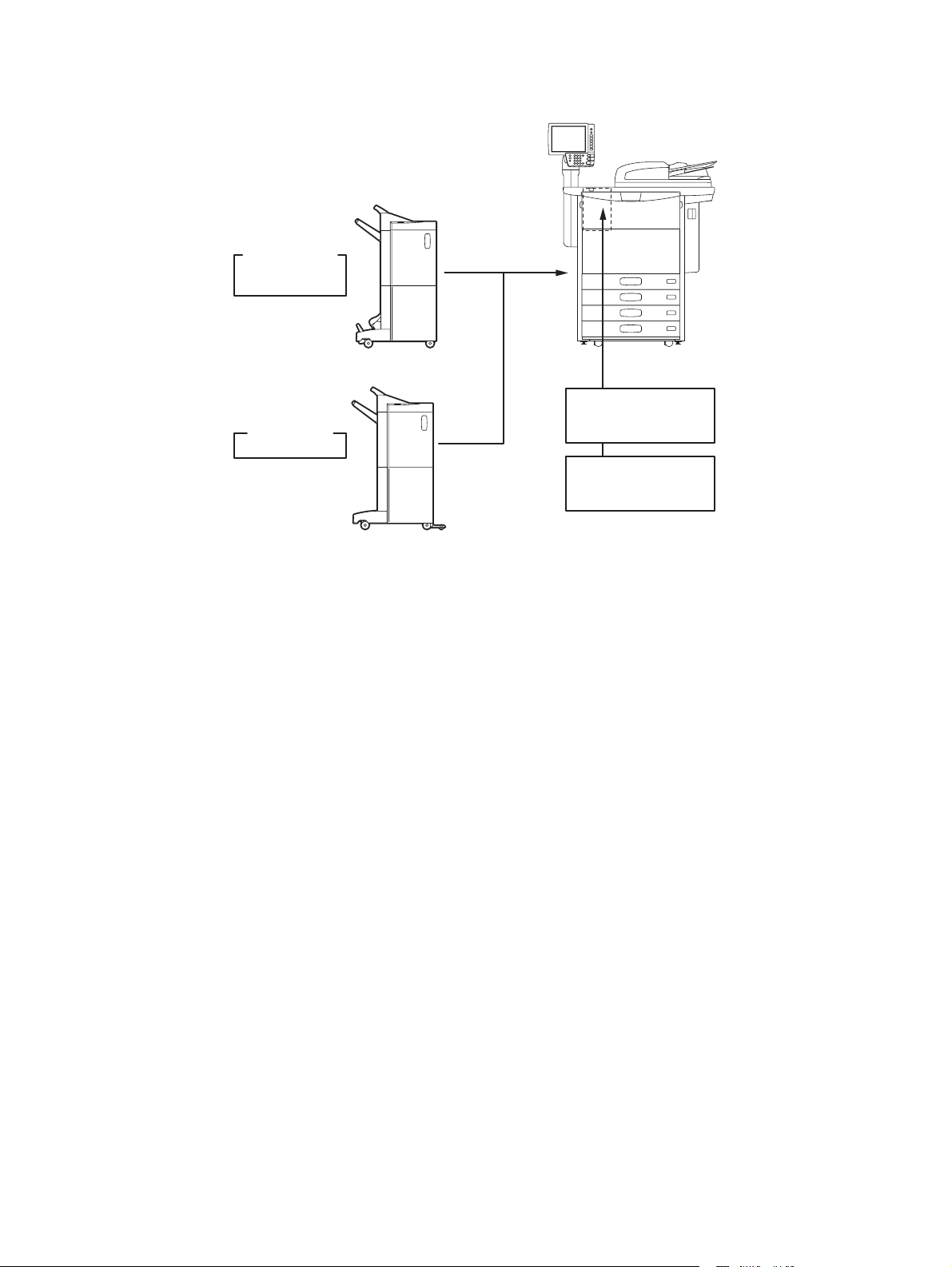

1.7.3 e-STUDIO5520C/6520C/6530C, e-STUDIO5540C/6540C/6550C

r

Drawers

Drawers

or

Large capacity feeder

LINE2 connector

LINE connector TEL connecto

Power switch

1

Fig. 1-15

Fig. 1-16

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

1 - 21

11/04

SPECIFICATIONS AND OUTLINE OF SYSTEM

Page 30

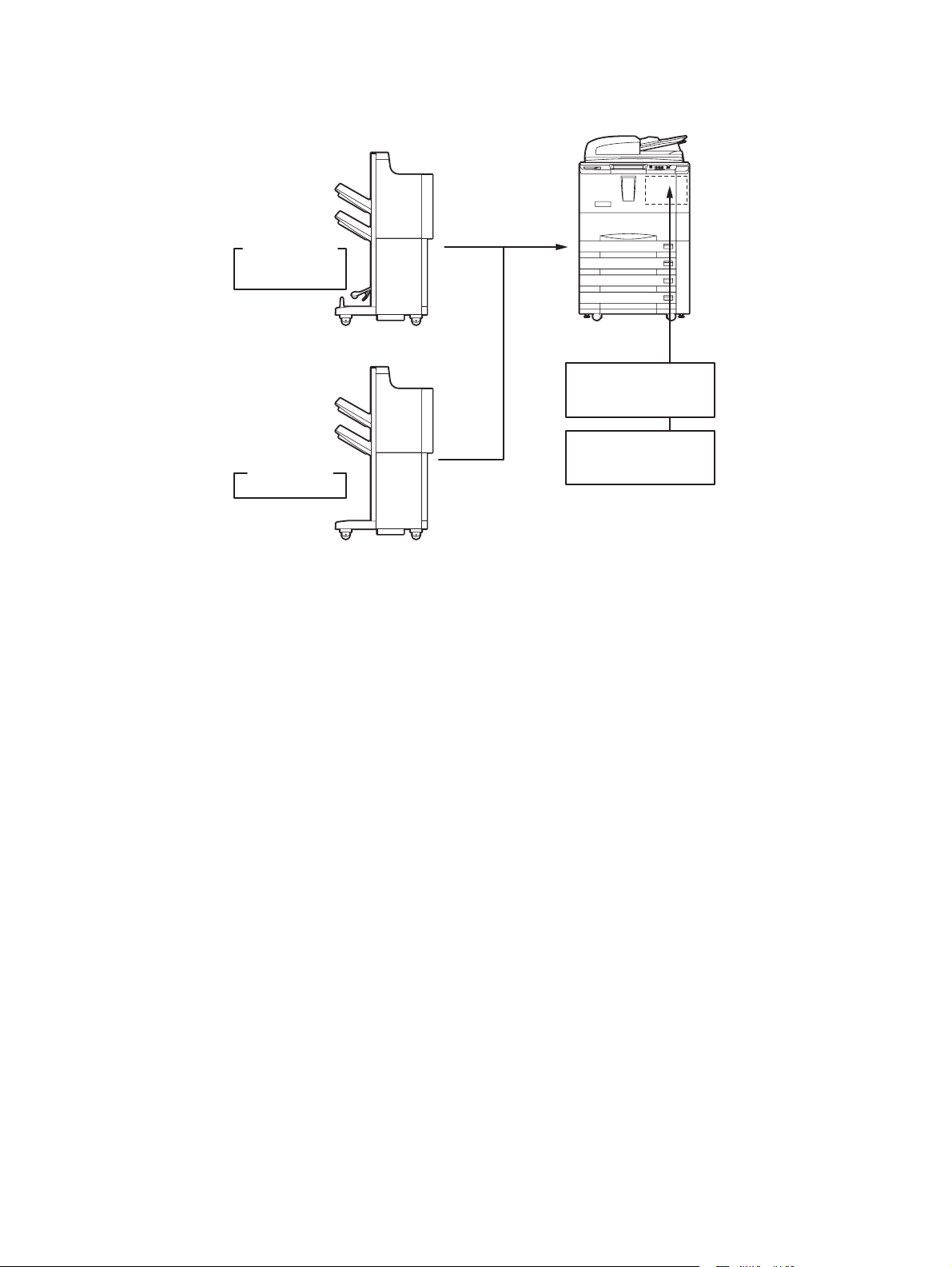

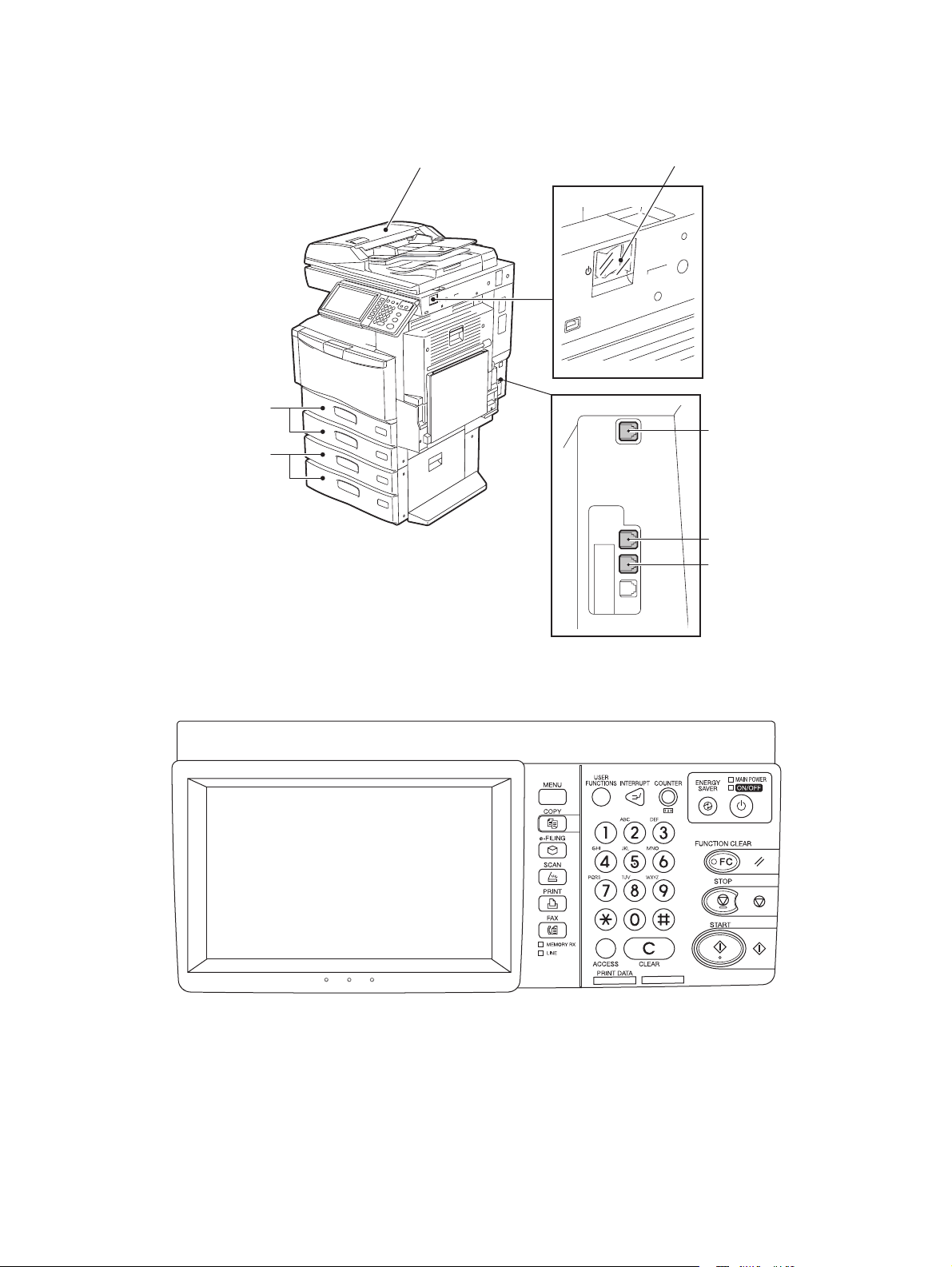

1.7.4 e-STUDIO205L/255/305/355/455, e-STUDIO206L/256/306/356/456

Power switch

TEL connector

LINE connector

LINE2 connector

Fig. 1-17

Fig. 1-18

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS AND OUTLINE OF SYSTEM

1 - 22

11/12

Page 31

1.7.5 e-STUDIO555/655/755/855, e-STUDIO556/656/756/856

Power switch

1

LINE2 connector

LINE connector

TEL connector

Fig. 1-19

Fig. 1-20

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

1 - 23

11/12

SPECIFICATIONS AND OUTLINE OF SYSTEM

Page 32

1.8 Layout of PC Boards

e-STUDIO2500c/3500c/3510c

e-STUDIO2330C/2820C/2830C/3520C/3530C/4520C

e-STUDIO2040C/2540C/3040C/3540C/4540C

FAX

NCU

FAX PWR

MDM

e-STUDIO205L/255/305/355/455

e-STUDIO206L/256/306/356/456

e-STUDIO5520C/6520C/6530C

e-STUDIO5540C/6540C/6550C

NCU

FAX

MDM

FAX PWR

e-STUDIO555/655/755/855

e-STUDIO556/656/756/856

MDM

FAX

MDM

FAX

FAX PWR

NCU

NCU

Fig. 1-21 Rear side of the equipment

Symbol Name Function

FAX FAX board Controls the FAX function

MDM MDM board Control the MODEM function (for 2nd line)

NCU1 NCU1 board Control the line of telephone (for 1st line)

NCU2 NCU2 board Control the line of telephone (for 2nd line)

FAX PWR FAX power board Supplies the power (-12V, +24V) of FAX

FAX PWR

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS AND OUTLINE OF SYSTEM

1 - 24

11/12

Page 33

2. LSU-RELATED FUNCTIONS

2.1 Recording Mode

This machine offers various printing modes such as the selection of the applicable recording paper and

the recording method, etc. to meet users’ needs. To take full advantage of these features, it is important

to understand the concepts of the recording paper selection algorithm and printing algorithm as

described in 2. 2.

2

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

2 - 1

LSU-RELATED FUNCTIONS

Page 34

2.2 Recording Paper Selection Algorithm and Printing Algorithm

Before printing the received image, the preset settings are evaluated in the order of the following 1) and

2), and the printing is performed based on the result.

1) Recording paper selection algorithm

- Basically, the received image is printed on a sheet of paper of the same size as the original.

However, if this size is not available, this algorithm determines on which size of recording paper

the output should be made. (Actual Size Mode/Free Mode)

2) Printing algorithm

- Determines how the received image is to be printed. (Discard printing/Vertical reduction printing/

Regular size reduction printing/Split printing)

2.2.1 Recording paper selection algorithm

It is possible to distinguish the size of each received image (A3(LD)/B4(LG)/A4(LT)/B5/A5). Basically,

recording paper of the same size as the original is used for printing. If recording paper of the size is not

available, this algorithm selects paper of another size according to the setting in the Setting Mode.

1) Actual Size Mode (13-517: 0)

- Printing is performed when regular size reduction is not applied to the received image. In this

mode, an A4/LT received image is printed on a B4 recording paper.

2) Free Mode (13-517: 1)

- Printing is performed on any available recording paper.

2.2.2 Printing algorithm

Recording paper has its effective printing area. Even if the size of the original paper and the recording

paper are the same, the length of the original is normally longer.

This means that the received image would be divided onto two sheets. To prevent this, the printing

algorithm works as described in the following pages.

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

LSU-RELATED FUNCTIONS

2 - 2

Page 35

Discard / Vertical reduction / Regular size reduction / Split printing flow chart

START

Recording

paper of the same

size as the original's

available?

Yes

No

1

Smaller size paper

available?

Yes

No

Larger size paper

available?

No

Recording

paper run out

Yes

1

2

Received image fitsin

the effective printing area of the

recording paper?

Use the short

length paper?

(

See the note below.

No

Discard

printing function

Blank

space *within the

discard parameter?

Vertical reduction

function ON?

ON?

No

No

Yes

No

Regular size

reduction function

ON?

Normal (actual size

Yes

Yes

)

Yes

No

printing

Discard printing

(

actual size

)

)

No

Image not

output

Regular

size reduction

function ON?

Yes

Regular size

reduction printing

Regular size

reduction function

ON?

Yes

No

No

Regular size

reduction printing

Image not

output

Image not

output

Yes Yes

Reduction ratio "R"

calculated from the

actual image data.

"R" within the max.

reduction ratio?

Yes

Vertical reduction

printing

No

Note: Short length paper are the recording paper of A4/B5/A5/LT/

ST against A3/B4/A4/LD/LT size originals respectively.

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

Regular size

reduction

printing

LSU-RELATED FUNCTIONS

2 - 3

Page 36

1) Discard printing

- Since the trailing edge area of the original is normally blank, this blank area is cut off to allow the

image fit in one sheet in this mode. Image reduction is not performed.

- Maximum discarding amount:

0 mm: Discard not performed

10 mm: Corresponding to the inside the TTI

18 mm: Corresponding to the outside the TTI 1

22 mm: Corresponding to the outside the TTI 2

34 mm: A4 → LT conversion

(TTI: Transmission Terminal Identifier)

When the discard function is ON (13–378:1):

Actual size recording is performed with no vertical reduction nor division. The original image is

recorded as it is. Namely, the data exceeding the effective printing area are discarded.

A

B

Area B is discarded.

A : Effective printing length

B : Recording data length outside the

effective printing area

(

A + B = Recording data length

Fig. 2-1

A

)

Discard parameter (13-375: 0 to 4)

The following parameters are available:

Discard function Length of B (Discard parameter) Set value

OFF 0 mm 0

ON 10 mm 1

18 mm 2

22 mm 3

34 mm 4

Reference: These parameters should be set by the service technician (in the FAX Function Mode).

2) Vertical reduction printing (13–377: 0)

- The recording data length is reduced so that the image fits in the recording paper.

The data can be reduced up to 90/75%, and the machine automatically selects the appropriate

ratio.

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

LSU-RELATED FUNCTIONS

2 - 4

Page 37

3) Regular size reduction printing (13–517: 1)

- When the discard and vertical reduction printing cannot be applied to the received image, and

any of the combinations A3 → B4, A3 → A4, B4 → A4, B4 → B5, B4 → A5, A4 → B5, A4 → A5,

COMP → LT, COMP → ST, LD → COMP, LD → LG/LT, LD → ST, LT → ST, FOLIO → B5, FOLIO

→ A5 is satisfied, the regular size reduction printing is performed.

In case that the recording data length is within the effective printing length A, but the recording

paper of the same size as the original’s or larger size is not available;

2

A

B

A × reduction

ratio

B × reduction

ratio

A3 B4, A3

A4

B4 A4, B4 B5, B4 A5, A4 B5,

A4 A5 , COMP

LD COMP, LD

LT ST, FOLIO

Fig. 2-2

LT, COMP ST,

LG/LT, LD

B5, FOLIO

ST,

A5

In case that the recording data length exceeds the effective printing length A, the vertical reduction printing is not applicable and larger size recording paper is not available;

(In the following example, A4/LT original was sent but the recording length exceeds A4 size and

the data do not fit in A4/LT even if the vertical reduction is performed. The reduction B4 → A4 or

A3 → A4 is applied in this case.)

A

C

B

A × reduction

ratio

C × reduction

ratio

D

B × reduction

ratio

D × reduction

ratio

Fig. 2-3

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

2 - 5

LSU-RELATED FUNCTIONS

Page 38

4) Split printing

When the recording data do not fit in a recording paper even if vertical reduction is performed for the

recording data length (the recording data length is exceeding the effective printing length of the largest recording paper in the drawer installed in the machine), the recording data are divided onto two

sheets while vertical reduction is performed.

A

B

Fig. 2-4

A× vertical reduction ratio

B × vertical reduction ratio

2.2.3 Setting for the split recording

1) Split recording onto A4/B5/A5/ST

Set as to whether split recording onto the short length paper (A4/B5/A5/ST) is to be performed or

not.

When this function is disabled, split recording for A3/B4/A4 data onto A3/B4/A4/LG/LT recording

paper is not performed.

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

LSU-RELATED FUNCTIONS

2 - 6

Page 39

2.3 Recording Paper and Function

The size of the recording paper on which the received image data are printed is determined according

to the presence/absence of the recording paper and the above-mentioned function settings. Relation

between the recording paper size and the function settings is described in this section.

2

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

2 - 7

LSU-RELATED FUNCTIONS

Page 40

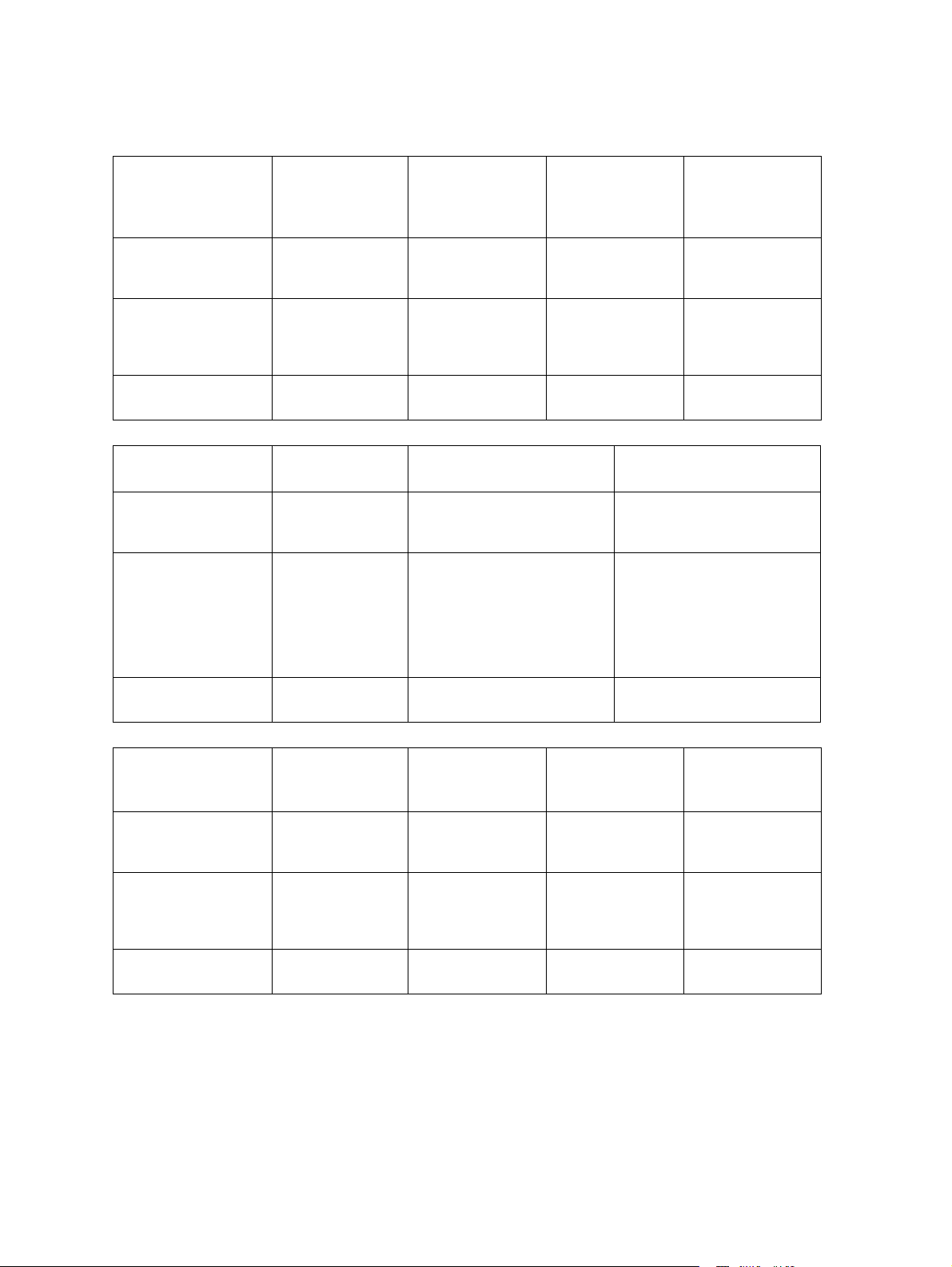

2.3.1 Table of the recording paper selection modes

<Selection of recording paper: in case the recording data length do not exceed the effective recording

length of the recording paper>

Recording data size

A4-R B4 A3 LG LD

A4-R

1

A4

2

FOLIO

3

B4

4

B4

A3

A4-R

A4 A4 A4

*2

A3

*1

A4 B5

A4

A4-R A4-RB5-R

A3

*1 *2 *1 *1

FOLIO

*1 *1 *1 *1 *1 *1 *1

B5

B4

Priority

A3

5

*2 *2

FOLIOFOLIO

*1 *1

A4-R

B4

*1 *1 *1 *1

A5 LT ST

LT-R

A5

A4

FOLIO

B5

LT-R

LT

LG

COMP

LD

LT

LT-R

LD

LG

*2*1

COMP COMP

*2

LG

LD

LT-R

LT LT

COMP

COMP

LD

LT-RA4-R

LT

LG

LD ST

COMPCOMP

*1*2 *1

LG

LT-R

*1 *1 *2

LT-R

LT

LG

FOLIO

FOLIO

B4B4

*2

A3

*2

A4-R

A4

*1

*2

B4

*2

A3

*2*1 *1 *1

ST-R ST-R

*1*1 *1

*2

B5B5 B5 B5

6

*1 *1

B5-R B5-R B5-RB5-RB5-R

7

*1 *1 *1 *1

A5-R A5-R A5-R

8

A3 LD

*2

FOLIO

*1: Can be used when the regular size reduction function is ON (when it is OFF, the data are stored

in the memory.)

*2: When the data are output in the primary scanning direction, it is printed in the center of the

recording paper.

2.3.2 Others

1) For the users with the TTI outside setting, it is recommended to set the discard parameter to 18 mm.

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

LSU-RELATED FUNCTIONS

2 - 8

*1

*1

Page 41

2.4 Energy Saver Mode

The fuser unit, main power and power supply for the control panel can be shut off during a specified

period of time such as night time that the machine is in the ready mode, using a weekly timer function of

the equipment. When a FAX is received in the Energy Saver Mode, the fuser unit, main power and

power supply for the control panel are automatically turned ON. Printing is then started when the

machine reaches the specified temperature. The Energy Saver Mode is useful for hours in which the

amount of communication is small and immediate printing is not necessary.

The setting of the Energy Saver Mode and time (start time, end time) are made on the USER FUNCTIONS screen. (Default setting is made by the weekly-timer function of the equipment.)

2

Energy Saver Mode

Auto Power

Save Mode

Sleep Mode Automatically or by

Super Sleep Mode Automatically or by

How to enter the

mode

Automatically Can be set in the

pressing the

[ENERGY SAVER]

button

pressing the [ON/OFF]

button for 2 seconds

Timer setting How to cancel the mode

Returns to the default screen by

USER FUNCTIONS

Screen.

Can be set in the

USER FUNCTIONS

Screen.

Can be set in the

USER FUNCTIONS

Screen.

receiving FAX document, or by

pressing the [START] button

Returns to the FAX screen by press-

ing the [FAX] button/

Returns to the default screen by

receiving FAX document, or by

pressing the [START] button

Returns to the FAX screen by press-

ing the [FAX] button.

Returns to the default screen by

receiving FAX document, or by

pressing the [ON/OFF] button.

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

2 - 9

11/04

LSU-RELATED FUNCTIONS

Page 42

2.5 Memory Reception

Basically, the receiving FAX data are once stored in the HDD, then the data are printed out after the

reception process is finished.

The memory reception is performed until the 1 GB HDD (for transmission and reception) becomes full.

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

LSU-RELATED FUNCTIONS

2 - 10

11/04

Page 43

3. DIALING/COMMUNICATION CONTROL

3.1 Circuit Connection and Procedure to Change Mode

3.1.1 Dial call-up transmission to a telephone circuit

START

Detecting a calling signal?

NO

Detecting an off-hook signal?

NO

DC circuit closed

After detecting the dial tone,

or 3.3 seconds elapsed

Selection signal sent out

YES

YES

3

END

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

3 - 1

Standby state

DIALING/COMMUNICATION CONTROL

Page 44

3.1.2 Selection of the communication mode

This machine has three types of communication mode. The mode to be used is determined according

to the combination of the types of the circuits and communication and available function of the other

side’s machine.

Communication mode

Toshiba original procedure ECM G3

Telephone circuit {{{

3.1.3 Procedure to select the transmission mode

START

*1

Other side machine has the

Toshiba original

procedure mode?

YES

Communication using the

Toshiba original procedure

NO

Other side machine has

ECM mode?

NO

Other side machine has G3 mode?

YES

YES

ECM communication

G3 communication

*1: This step is only checked when the other side machine has CRP2 (+ CRP1) or when the trans-

mission is started by the CRP calling. (The first transmission to the other side with CRP1 only

is performed in the ECM mode.)

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

DIALING/COMMUNICATION CONTROL

3 - 2

Page 45

3.2 Signaling System Diagram and Signal Forms

3.2.1 Circuit control signals

The following circuit control signals are used in the binary and tonal procedures.

• Circuit control signals

CED Called station identification

Indicates that the sender is a FAX machine in the automatic called

mode. (*1)

CNG Calling tone

Indicates that the sender is a FAX machine in the automatic calling

mode. (*1)

*1: This signal can be sent manually.

• Signal form

Signal name Signal form Signal form

3

CED f: 2100 ±15 Hz

CNG f: 1100 ±38 Hz

f

t

f

t

f

L

t

t: 2.6 - 4.0 sec

t: 0.5 sec ±15%

(L: 3 sec)

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

3 - 3

DIALING/COMMUNICATION CONTROL

Page 46

3.2.2 Communication with the binary signals

In the Toshiba original procedure/G3 modes, communication is performed with the binary procedure as

follows.

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

DIALING/COMMUNICATION CONTROL

3 - 4

Page 47

(1) Binary procedure

• Transmission and reception in the Toshiba original procedure/G3 modes

Transmtter Receiver

CED

NSF•CSI•DIS

NSS•TSI•DCS

Training

TCF

CFR

Image signal

3

Mode ch a n ge pos s ible*

Informing that there is

the next page

EOM

MCF

NSF•CSI•DIS

NSS•TSI•DCS

Training

TCF

CFR

Image signal

MPS

MCF

Image signal

MCF

DCN

Fig. 3-1

* Mode change is possible only for the original set manually.

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

3 - 5

DIALING/COMMUNICATION CONTROL

Page 48

• Transmission and reception in the ECM mode

ECM (Error Correction Mode) conforms to T.30.

When an error has occurred to the received image data, the receiving station informs the

sending station of the occurrence of the error, and the sending station sends the image data

again.

Transmtter Receiver

CED

NSF•CSI•DIS

NSS•TSI•DCS

Training

TCF

CFR

Only error frame retransmitted

Page 1 completed

Page 2 completed

Image s

Image s

ignal

PPS NULL

MCF

Image signal

PPS MPS

PPR

ignal retransmitted

PPS MPS

MCF

Image signal

PPS EOP

MCF

DCN

256 frames received

Error occurred

Fig. 3-2

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

DIALING/COMMUNICATION CONTROL

3 - 6

Page 49

• Cancellation during the transmission

If the [STOP] button is pressed during the direct transmission or memory input, the display to

confirm the cancellation appears. The communication is finished normally regardless of the

presence/absence of the next page or mode changes by pressing the [STOP] button.

If the [STOP] button is pressed anytime except during the transmission of the image data,

DCN is forcibly sent to terminate the communication.

Press the [JOB STATUS] button, and select the transmission job to cancel, then press the

[CANCEL] button on the LCD display to cancel the memory transmission or polling transmission.

Transmtter

[

JOB STATUS] button

[

CANCEL] button

CED

NSF•CSI•DIS

NSS•TSI•DCS

Training

TCF

CFR

Image signal

EOP

MCF

DCN

Receiver

3

Fig. 3-3

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

3 - 7

DIALING/COMMUNICATION CONTROL

Page 50

(2) Binary signals

NSF Non-Standard Facility

Informs that the receiving station (machine) has a non-standard facility.

NSC Non-Standard Facility Command

Command to transmit using the non-standard facility which is selected corresponding to

NSF (i.e., Polling etc.).

NSS Non-Standard Facility Setup

Command to transmit using the non-standard facility which is selected corresponding to

NSF or NSC.

CSI Called Subscriber Identification

Provides the telephone number of the called station. Used to check the identity of the called

station.

CIG Calling Subscriber Identification

Provides the telephone number of the calling station. Used to check the identity of the calling station (Polling, etc.).

TSI Transmitting Station Identification

Provides the telephone number of transmitting station. Used to check the identity of the

transmitting station.

DIS Digital Identification Signal

Informs that the receiving station (machine) has a standard facility (G3/G2).

DTC Digital Transmit Command

Command to transmit using the standard facility which is selected corresponding to DIS

(i.e., Polling, etc.).

DCS Digital Command Signal

Commands to transmit using the standard facility which is selected corresponding to DIS or

DTC.

SUB Sub-address

Indicates that the FIF information is a sub-address in the domain on the call-in side.

SEP Select Polling

Indicates that the FIF information is a sub-address for the polling mode.

PWD Password

Indicates that the FIF information is a password for the polling mode in a reception.

Indicates that the FIF information is a password for transmission in a transmission.

CFR Confirmation of Reception

Informs that the FAX is ready to receive data.

FTT Failure to Train

Informs that the TCF signal has not received correctly and requests the re-training.

EOM End of Message

Informs that the the 1st page has been transmitted and there is the next page; command to

return to the beginning of the phase B.

MPS Multi-page Signal

Informs that the 1st page has been transmitted and there is the next page; command to

return to the beginning of the phase C.

EOP End of Procedure

Informs that a document has been transmitted and there is no more pages.

MCF Message Confirmation

A reply to MPS, EOM or EOP; informing that image signals have been received correctly

and the FAX is ready to receive data.

RTN Retrain Negative

Informs that a document has not been received correctly; requests for the retraining or

phase synchronization to receive the next page.

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

DIALING/COMMUNICATION CONTROL

3 - 8

Page 51

PIP Procedure Interrupt Positive

Informs that the image signals have been received correctly and requests the operator’s

reply by telephone or to return to the beginning of the phase B to continue the communication (i.e., CALL Request, etc.).

PIN Procedure Interrupt Negative

Informs that the image signals have not been received correctly and requests for operator’s

reply by telephone or to return to the beginning of the phase B to continue the communication.

PRI-EOM Procedure Interrupt EOM

Command similar to EOM. Operation by operator is necessary.

PRI-MPS Procedure Interrupt MPS

Command similar to MPS. Operation by operator is necessary.

PRI-EOP Procedure Interrupt EOP

Command similar to EOP. Operation by operator is necessary.

DCN Disconnect

Command to disconnect the FAX line and to connect the telephone line. Reply from the

other side is not necessary.

RR Receive Ready

Informs that the FAX is ready to receive documents and requests for data to set the reception mode. (ECM mode)

RNR Receive Not Ready

Informs that the FAX is not in the receivable state. (ECM mode)

PPR Partial Page Request

Informs that a part of page (ECM block) has not been received correctly. The number of the

frame needs to be corrected is informed by the FIF. (EC mode)

PPS Partial Page Signal

Informs that a part of page (ECM block) or one page has been transmitted. (EC mode)

CTC Continue to Correct

Replies to the 4th PPR which requests to correct the image signal; informs that the transmitting station will continue to correct the frame data. (ECM mode)

CTR Response for Continue to Correct

Replies to CTC and informs that the receiving station has received and accepted the CTC.

(EC mode)

EOR End of Retransmission

Informs that the transmitting station has completed the correction of the error frame data

(binary signal) of the previous ECM block. (ECM mode)

3

ERR Response for End Retransmission

Replies to EOR and requests to transmit the image signal of the next ECM block. (ECM

mode)

RTP Retrain Positive

Informs that the message has been received completely and that the subsequent message

can be continued after receiving the synchronization signal and CFR signal.

CRP Command Repeat

Requests to resend all the commands including optional frames because the preceding

command has been received incorrectly.

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

3 - 9

DIALING/COMMUNICATION CONTROL

Page 52

(3) Frame structure of binary signals

Each binary signal frame is comprised of the following sequence and fields. However, some

binary signals do not have the FIF field inserted.

FFACFCFFIFFCSF

Preample

F : Flag sequence

Indicates the start or end of a frame. Also establishes the frame synchronization.

A : Address field

Informs the address.

C : Control field

Informs if this frame is the last one in this procedure.

FCF: FAX control field

Informs the type of the binary signal.

FIF: FAX information field

Informs FAX information such as the functions.

FCS: Frame check sequence

Checks if there was any error in the transmission from A to FIF.

• Format of F, A and C

Format

b

1

b

2

b

3

b

4

b

5

b

6

b

7

b

8

F 01111110

A 11111111

C 1100x000

* When this frame is the last frame, X = 1.

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

DIALING/COMMUNICATION CONTROL

3 - 10

Page 53

• FCF format of each binary signal

Binary signal

b

1

b

2

b

3

NSF 00000100

NSC 10000100

NSS x1000100

CSI 00000010

CIG 10000010

TSI x1000010

DIS 00000001

DTC 10000001

DCS x1000001

SUB x1000011

SEP 10000101

PWD(Rx)10000011

PWD(Tx)x1000101

CFR x0100001

FTT x0100010

EOM x1110001

MPS x1110010

EOP x1110100

MCF x0110001

RTN x0110010

PIP x0110101

PIN x0110100

PRI-EOMx1111001

PRI-MPSx1111010

PRI-EOPx1111100

DCN x1011111

RR x1110110

RNR x0110111

PPR x0111101

PPS x1111101

CTC x1001000

CTR x0100011

EOR x1110011

ERR x0111000

RTP x0110011

CRP x1011100

b

4

Format

b

5

b

6

b

7

b

8

3

• X = 1 for the station which received DIS.

• X = 0 for the station which received a response signal to DIS.

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

3 - 11

DIALING/COMMUNICATION CONTROL

Page 54

(4) Training

The training is performed in the binary procedure to surely transmit the image signals.

• Training signal

The training signal is transmitted following the DCS signal at the modem speed specified by

the DCS signal. Responding to this training signal, the receiving side adjusts the auto-equalizer.

• Format of the training signal

- 14.4 Kbps, 12 Kbps

Segment 1 Segment 2 Segment 3 Segment 4

Alternation

of ABAB

106 msec 1240 msec 27 msec 20 msec

Equalizer

adjustment

pattern

Chain-store

information

sequence

1393 msec

Scrambled binary data “1”

Fig. 3-4

- 9600 bps, 7200 bps

Segment 1 Segment 2 / Segment 3 Segment 4

V.29

No signal

20 msec 53 msec+160 msec 20 msec

Repeating 2-state

signal

(

Binary

253 msec

Fig. 3-5

)(

- 4800 bps, 2400 bps

Segment 1Segment 2 Segment 3 Segment 4

Continuous

180° phase

inversion

(

Binary

0° to 180°

2-phase pattern

)

V.27ter

Non-

modulated

carrier

No signal

Scrambled data “1”

Hexa or octal

Segment 5

Scrambled data “1”

(

Binary

(

)

TCF

TCF

)

TCF

Hexa or octal)

4,800 bps: 923 msec,

2,400 bps: 1158 msec

Fig. 3-6

• TCF signal

An error may occur in the image data if the training is not performed correctly. The transmitting side sends a TCF signal and checks if any error occurs in image data before the image

data communication to follow. When the receiving side detects an error in the TCF signal, it

transmits an FTT signal to the transmitting side to request the retraining. When there is no

error, the receiving side transmits a CFR signal.

The TCF signal transmits all zeros for 1.5 seconds at the same modem speed as that for the

training signal.

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

DIALING/COMMUNICATION CONTROL

3 - 12

Page 55

3.2.3 V.8/V.34 communication sequence

1) Outline

- V.8 is performed as a startup procedure to switch to V.34. V.8 can connect an existing facsimile

machine to the equipment using a data modem or other V-series modems. The V.34 modem has

a modem circuit previously recommended, allowing it to be also connected to the existing

modems while they are upper compatible.

- New technologies such as the pre-emphasis technology *1 and the probing technology *2 are

fully used. The pre-emphasis technology *1 not only speeds up the modulation, but also gains

the S/N ratio. The probing technology examines the line characteristics and optimizes the

modem for the line condition. Therefore, not only do these technologies speed up the transmission momentarily, but also the average speed of the process during the data transmission is

increased.

- For V.8 and the pre/post-FAX transmission for V.34, the procedure is speeded up by the full

duplex communication.

- Following 14 types of the image transmission speed are available: *3

33.6 kbps/31.2 kbps/28.8 kbps/26.4 kbps/24.0 kbps/21.6 kbps/19.2 kbps/16.8 kbps/14.4 kbps/

12.0 kbps/9.6 kbps/7.2 kbps/4.8 kbps/2.4 kbps

- The modulating speed (baud rate) *4 can be selected from 2,400, 3,000, 3,200 symbol/sec (mandatory), or 2,743, 2,800, 3,429 symbol/sec (option). The data rate can be set more accurately

than the conventional modem.

3

*1: A signal is sent while raising the output level in the high-frequency band in which the noise

is relatively loud.

*2: Tone signal called “Probing Tone” is sent for the receiver to examine the line characteris-

tics of the line.

*3: In the ITU-T Recommendation, it is described as “data rate”. “Image transmission speed”

is the same as “data rate”.

*4: In the ITU-T Recommendation, it is described as “symbol speed”. The “Symbol rate”,

“Modulating speed”, and “Baud rate” are the same thing. This machine cannot realize the

speed of 2,743 symbol/sec.

Notes:

1. ECM is used in the V.34 procedure. If the setting for the ECM transmission/reception of the

user data is set to “Not performed”, the V.8 procedure is not performed and the procedure is

not switched to V.34. V.17 or lower is selected in this case.

2. When the transmission/reception speed is set to 14.4 kbps or slower, the V.8 procedure is not

performed, and V.17 or lower is selected.

3. See “Late start (P3-20)” to move to the V. 8/V.34 procedure after starting with the V.21 proce-

dure.

4. After the V.34 procedure is started, the fallback for the V.34 procedure is performed.

However, the fallback for the V.17 mode or lower mode is not performed.

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

3 - 13

DIALING/COMMUNICATION CONTROL

Page 56

2) Standard procedure

Transmitter Receiver

Network interaction

(

Phase 1

)

( P3-15)

Probing/Ranging

(

Phase 2

)

( P3-16)

Equalizer/Echo

canceller training

(

Phase 3

)

( P3-17)

Final training

(

Phase 4

)

( P3-17)

Control channel

( P3-18)

Line closed

The available modulation mode is in formed.

Each declares that it has V.34 capability. The

procedure moves to V.34 in the phase 2.

After the information about the modem capability is exchanged, the receiver determines

the modulation speed based on the result of

reception of the probing signal which was sent

by the transmitter.

To determine the image transmission speed,

the transmitter sends a training signal.

The optimum image transmission speed is

determined according to the training signal

received.

The pre-FAX transmission which is the same

as that for the normal T.30 is performed at

1,200 bps.

The training signal is sent with the determined

Primary channel

parameter, then the image data are sent.

( P3-19)

Image data

( P3-19)

The post-FAX transmission which is the same

as that for the normal T.30 is performed at

Communication

1,200 bps.

end procedure

( P3-20)

Line opened

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

DIALING/COMMUNICATION CONTROL

Line opened

Fig. 3-7

3 - 14

Page 57

- Network interaction (Phase 1)

The V.8 procedure is performed as the startup procedure for the V.34 high-speed modem.

In the V.8 procedure, mainly the optimum modulation method (V series modem mode) that can

be operated between the transmitter and receiver is determined.

Transmitter

Signal name Abbreviation Function Remarks

Calling tone CNG 1100 Hz tone signal specified

by T.30 indicating the sender

is a FAX machine in the automatic calling mode.

Call Menu signal CM Mainly indicates an available

modulation method such as

V.21, V.27ter, V.29, V.17,

V.34, etc.

CM terminator CJ Indicates the detection of the

JM signal or the termination of

CM signal.

Call Indicator signal CI Indicates the general commu-

nication functions. It is sent

when the V.8 procedure is

restarted.

Modulated by V.21 (L) *1.

Transmission rate: 300 bps

Modulated by V.21 (L) *1.

Transmission rate: 300 bps

For the late start only.

(P3-20)

Modulated by V.21 (L) *1.

Transmission rate: 300 bps

Receiver

Signal name Abbreviation Function Remarks

Answer amplitude tone ANSam 2100 Hz tone signal ampli-

tude-modulated to 15 Hz.

Joint Menu signal JM Indicates the terminal type

such as a FAX machine.

Response to a CM sent from

the transmitter and informs

available modulation method.

Tone equivalent to CED of the

conventional machine.

Modulated by V.21 (H) *1.

Transmission rate: 300 bps

-

3

*1 V.21 (L) ..........Low frequency channel defined by the V.21 recommendation 1,080±100 Hz

(980 Hz: 1, 1,180 Hz: 0)

V.21 (H) ..........High frequency channel defined by the V.21 recommendation 1,750±100 Hz

(1,650 Hz: 1, 1,850 Hz: 0)

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

3 - 15

DIALING/COMMUNICATION CONTROL

Page 58

- Probing/Ranging (Phase 2)

Examines the line characteristics and sets the parameters for the modulation related items such

as the modulating speed.

Transmitter

Signal name Abbreviation Function Remarks

INFO sequence INFO0c Informs the modem capability

Transmission rate: 600 bps

such as modulating speed

and frequency transmission

capability (two frequency

bands (high and low) used to

examine the line characteristics), and requests for adjusting.

Tone B B Synchronization between the

modems by 1200 Hz tone sig-

To ne

B B

nal

Line probing signal L1 L1 Tone signal to analyze the line

characteristics by probing

Line probing signal L2 L2

is a signal that shifts the

B

phase B 180°.

Probing is to examine the line

characteristics.

Tone signal between 150

Hz and 3,750 Hz in units of

150 Hz

Receiver

Signal name Abbreviation Function Remarks

INFO sequence INFO0a Informs the modem capability

such as the modulating speed

and frequency transmission

capability.

Tone A A Synchronization between the

modems by 2,400 Hz tone

Tone

A A

signal

Transmission rate: 600 bps

is a signal that shifts the

A

phase A 180°.

INFO sequence INFO0h Based on the analysis of the

Transmission rate: 600 bps

line probing signal sent from

the transmitter, it informs the

pre-emphasis filter and modulating speed to be used for the

data transmission.

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

DIALING/COMMUNICATION CONTROL

3 - 16

Page 59

- Equalizer and echo canceller training (Phase 3)

Training (adjustment) is performed according to the parameters set in the phase 2 to optimize the

filters such as an equalizer.

Transmitter

Signal name Abbreviation Function Remarks

S signal S Short training

signal

S S

PP signal PP Used by the modem of the

receiver to train the equalizer.

TRN signal TRN Used by the receiver to deter-

mine the transmission rate.

is a signal made as the

S

result of phase transition of S.

- Final training (Phase 4)

The settings such as the maximum value for the data rate, selection of the trellis encoder, and

data rate which can be supported are made in this phase.

Transmitter/receiver

Signal name Abbreviation Function Remarks

PPh signal PPh Used by the modem of the

other side to train the equalizer.

ALT signal ALT -

Modulation parameter MPh Informs the parameters used

for the image transmission

such as maximum data signal

rate and type of the trellis coding/pre-coding.