Page 1

SERVICE HANDBOOK

FACSIMILE

GD-1210/1250/1270/1160/1260

File No. SHE060003G0

R060121A4600-TTEC

Ver07_2011-12

Page 2

Trademarks

• The official name of Windows XP is Microsoft Windows XP Operating System.

• The official name of Windows 7 is Microsoft Windows 7 Operating System.

• Microsoft, Windows, Windows NT, Windows Vista and the brand names and product names of other

Microsoft products are trademarks or registered trademarks of Microsoft Corporation in the U.S.

and/or other countries.

• Apple, AppleTalk, Macintosh, and Mac are trademarks of Apple Computer, Inc. in the U.S. and other

countries.

• PostScript is a trademark of Adobe Systems Incorporated.

• NOVELL, NetWare, and NDS are trademarks or registered trademarks of Novell, Inc.

• Molykote is a registered trademark of Dow Corning Corporation.

• Other company names and product names in this manual are the trademarks of their respective

companies.

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

Under the copyright laws, this manual cannot be reproduced in any form without prior written permission

of TOSHIBA TEC CORPORATION.

11/10

Page 3

GENERAL PRECAUTIONS REGARDING THE SERVICE FOR

GD-1210/1250/1270/1160/1260

The installation and service shall be done by a qualified service

technician.

1) Transportation/Installation

- When transporting/installing the equipment, employ four persons and be sure to hold the posi-

tions as shown in the figure.

The equipment is quite heavy and weighs approximately 120 kg (264.55 lb.), therefore pay full

attention when handling it. (e-STUDIO2500c/3500c/3510c, e-STUDIO2330C/2820C/2830C/

3520C/3530C/4520C, e-STUDIO2040C/2540C/3040C/3540C/4540C)

- When transporting/installing the equipment, employ two persons and be sure to hold the posi-

tions as shown in the figure. The equipment is quite heavy, and e-STUDIO205L/255/305 weighs

approximately 57 kg (125.66lb.), and e-STUDIO355/455 weighs approximately 60 kg (132.28

lb.), therefore pay full attention when handling it. The equipment is quite heavy, and eSTUDIO206L/256/306 weighs approximately 58 kg (127.87 lb.), and e-STUDIO356/456 weighs

approximately 61 kg (134.48 lb.), therefore pay full attention when handling it.

- When transporting/installing the equipment, employ four persons and be sure to move it by the

casters while lifting the stoppers. The equipment is quite heavy and weighs approximately 245 kg

(540.12 lb), therefore pay full attention when handling it. (e-STUDIO5520C/6520C/6530C, eSTUDIO5540C/6540C/6550C)

- When transporting/installing the equipment, employ four persons and be sure to move it by the

casters while lifting the stoppers. The equipment is quite heavy and weighs approximately 202 kg

(445.33 lb), therefore pay full attention when handling it. (e-STUDIO555/655/755/855,eSTUDIO556/656/756/856 )

- Be sure not to hold the movable parts or units (e.g. the control panel, ADU or RADF) when trans-

porting the equipment.

- Be sure to use a dedicated outlet with AC 110 V / 13.2 A, 115 V or 127 V / 12 A, 220-240 V / 8 A

for its power source.

- The equipment must be grounded for safety.

11/12

Page 4

- Select a suitable place for installation. Avoid excessive heat, high humidity, dust, vibration and

direct sunlight.

- Provide proper ventilation since the equipment emits a slight amount of ozone.

- To insure adequate working space for the copying operation, keep a minimum clearance of 80

cm (32”) on the left, 80 cm (32”) on the right and 10 cm (4”) on the rear.

- The equipment shall be installed near the socket outlet and shall be accessible.

- Be sure to fix and plug in the power cable securely after the installation so that no one trips over

it.

2) General Precautions at Service

- Be sure to turn the power OFF and unplug the power cable during service (except for the service

should be done with the power turned ON).

- Unplug the power cable and clean the area around the prongs of the plug and socket outlet once

a year or more. A fire may occur when dust lies on this area.

- When the parts are disassembled, reassembly is the reverse of disassembly unless otherwise

noted in this manual or other related documents. Be careful not to install small parts such as

screws, washers, pins, E-rings, star washers, harnesses in the wrong places.

- Basically, the equipment should not be operated with any parts removed or disassembled.

- The PC board must be stored in an anti-electrostatic bag and handled carefully using a wristband

since the ICs on it may be damaged due to static electricity.

Caution: Before using the wristband, unplug the power cable of the equipment and

make sure that there are no charged objects which are not insulated in the

vicinity.

- Avoid expose to laser beam during service. This equipment uses a laser diode. Be sure not to

expose your eyes to the laser beam. Do not insert reflecting parts or tools such as a screwdriver

on the laser beam path. Remove all reflecting metals such as watches, rings, etc. before starting

service.

- Be sure not to touch high-temperature sections such as the exposure lamp, fuser unit, damp

heater and areas around them.

- Be sure not to touch high-voltage sections such as the chargers, transfer belt, 2nd transfer roller,

developer, high-voltage transformer, exposure lamp control inverter, inverter for the LCD backlight and power supply unit. Especially, the board of these components should not be touched

since the electric charge may remain in the capacitors, etc. on them even after the power is

turned OFF.

- Make sure that the equipment will not operate before touching potentially dangerous places (e.g.

rotating/operating sections such as gears, belts pulleys, fans and laser beam exit of the laser

optical unit).

- Be careful when removing the covers since there might be the parts with very sharp edges

underneath.

- When servicing the equipment with the power turned ON, be sure not to touch live sections and

rotating/operating sections. Avoid exposing your eyes to laser beam.

- Use designated jigs and tools.

- Use recommended measuring instruments or equivalents.

- Return the equipment to the original state and check the operation when the service is finished.

- Be very careful to treat the touch panel gently and never hit it. Breaking the surface could cause

malfunctions.

3) Important Service Parts for Safety

- The breaker, door switch, fuse, thermostat, thermofuse, thermistor, batteries, IC-RAMs including

lithium batteries, etc. are particularly important for safety. Be sure to handle/install them properly.

If these parts are short-circuited and their functions become ineffective, they may result in fatal

accidents such as burnout. Do not allow a short-circuit and do not use the parts not recommended by Toshiba TEC Corporation.

4) Cautionary Labels

Page 5

- During servicing, be sure to check the rating plate and cautionary labels such as “Unplug the

power cable during service”, “CAUTION. HOT”, “CAUTION. HIGH VOLTAGE”, “CAUTION.

LASER BEAM”, etc. to see if there is any dirt on their surface and if they are properly stuck to the

equipment.

5) Disposal of the Equipment, Supplies, Packing Materials, Used Batteries and IC-RAMs

- Regarding the recovery and disposal of the equipment, supplies, packing materials, used batter-

ies and IC-RAMs including lithium batteries, follow the relevant local regulations or rules.

6) When the option has been installed:

When the EFI printer board has been installed, be sure to unplug the power cable before performing

maintenance and inspection, otherwise troubles such as a communication error may occur.

Caution:

Dispose of used batteries and IC-RAMs including lithium batteries according to this manual.

Attention:

Se débarrasser de batteries et IC-RAMs usés y compris les batteries en lithium selon ce manuel.

Vorsicht:

Entsorgung der gebrauchten Batterien und IC-RAMs (inclusive der Lithium-Batterie) nach diesem Handbuch.

Page 6

Page 7

CONTENTS

GD-1210/1250/1270/116 0/1260

1. ERROR CODES ............................................................................................................1-1

1.1 Transmission/Reception Journal and Error Code List ......................................................... 1-1

1.2 Error Messages ................................................................................................................... 1-4

2. SELF-DIAGNOSIS MODE ............................................................................................ 2-1

2.1 Test Mode (03) .................................................................................................................... 2-2

2.2 Adjustment Mode (05) .........................................................................................................2-4

2.3 Setting Mode (08) ................................................................................................................ 2-6

2.4 Function Mode (13).............................................................................................................. 2-7

2.5 FAX Clearing Mode (1*)..................................................................................................... 2-61

3. TROUBLESHOOTING .................................................................................................. 3-1

3.1 Diagnosis Over Telephone .................................................................................................. 3-1

3.2 Recommend Flow Chart for Field Service ........................................................................... 3-2

3.3 Flow Chart for Recommended Telephone Screening.......................................................... 3-3

3.4 Error Analysis Flow.............................................................................................................. 3-6

3.4.1 Self-Diagnosis function............................................................................................. 3-6

3.4.2 Precautions for diagnosis ......................................................................................... 3-6

3.5 Fault Analysis ...................................................................................................................... 3-7

3.5.1 Power-ON is not possible ......................................................................................... 3-7

3.5.2 Original transport error for RADF ............................................................................. 3-7

3.5.3 Recording paper transport error ............................................................................... 3-7

3.5.4 Image trouble ........................................................................................................... 3-7

3.5.5 Communication error ................................................................................................ 3-8

3.6 Lists Required at Problem in the Field................................................................................. 3-9

3.6.1 List printing procedure .............................................................................................. 3-9

3.6.2 List printing procedure in the equipment with service UI ........................................ 3-15

3.7 Other Information Required for Error Analysis................................................................... 3-17

4. PRECAUTIONS FOR INSTALLATION OF FAX UNIT ................................................. 4-1

4.1 Installation of FAX Unit ........................................................................................................ 4-1

4.2 Country/Region Code ..........................................................................................................4-2

5. FIRMWARE UPDATING ............................................................................................... 5-1

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

1

CONTENTS

Page 8

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

CONTENTS

2

Page 9

1. ERROR CODES

2. SELF-DIAGNOSIS MODE

3. TROUBLESHOOTING

4. PRECAUTIONS FOR INSTALLATION OF FAX

UNIT

5. FIRMWARE UPDATING

1

2

3

4

5

Page 10

Page 11

1. ERROR CODES

1.1 Transmission/Reception Journal and Error Code List

The transmission journal is shown below. The error code list and status code list are available in the following pages. The reception journal is output in the same form.

TRANSMISSION JOURNAL TIME :MM-DD-YY TIME

TEL NO.1 : XXXXXXXXX

TEL NO.2 : XXXXXXXXX

NAME : X X X X X X X

NO. FILE NO. DATE TIMED DURATION PGS TO DEPT MODE STATUS

001 001 12.01 09:00 00:55 2 ABCDG 3 xxx OK xxxx

Status code

Error code

1

Fig. 1-1

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

1 - 1

ERROR CODES

Page 12

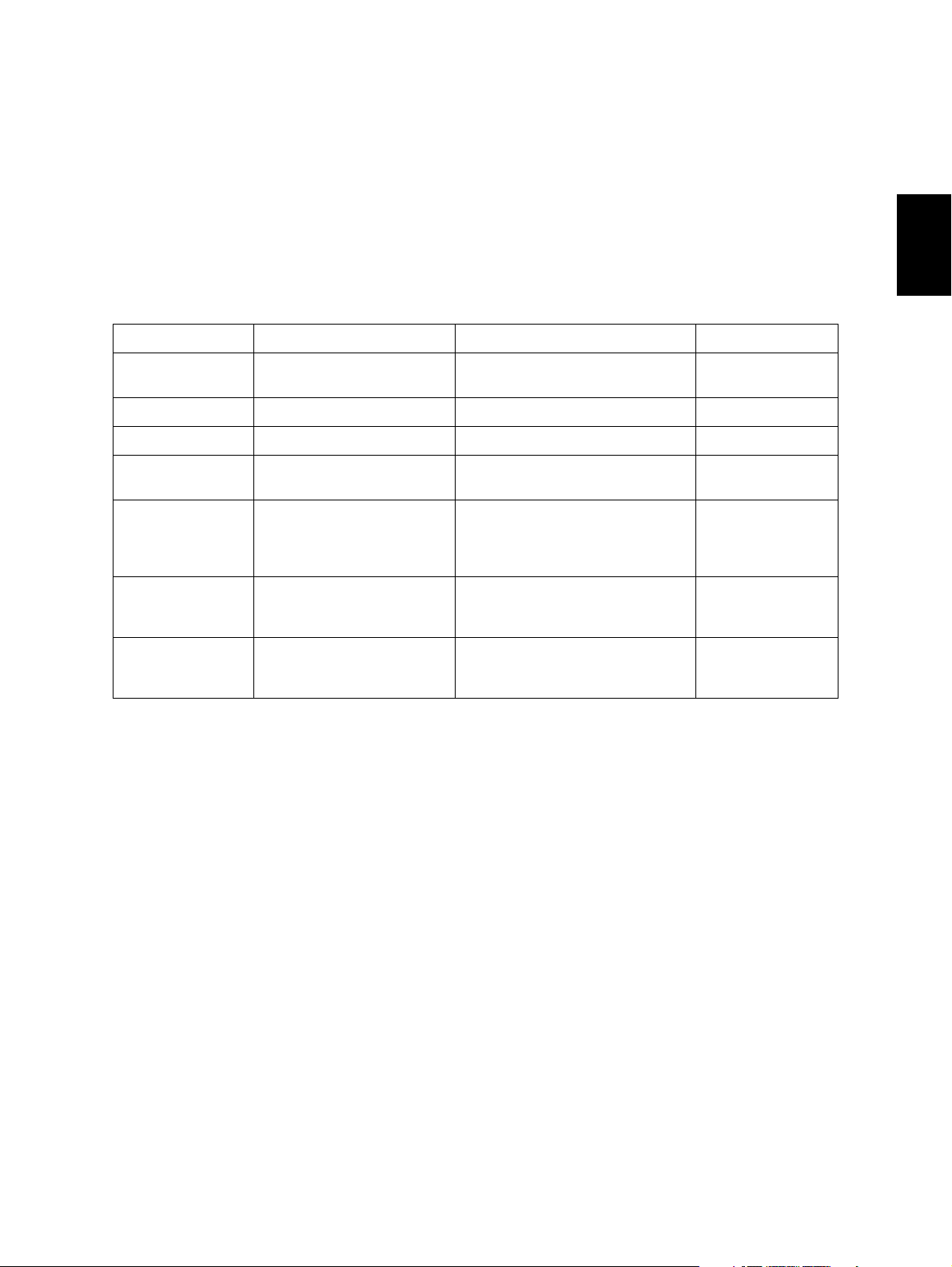

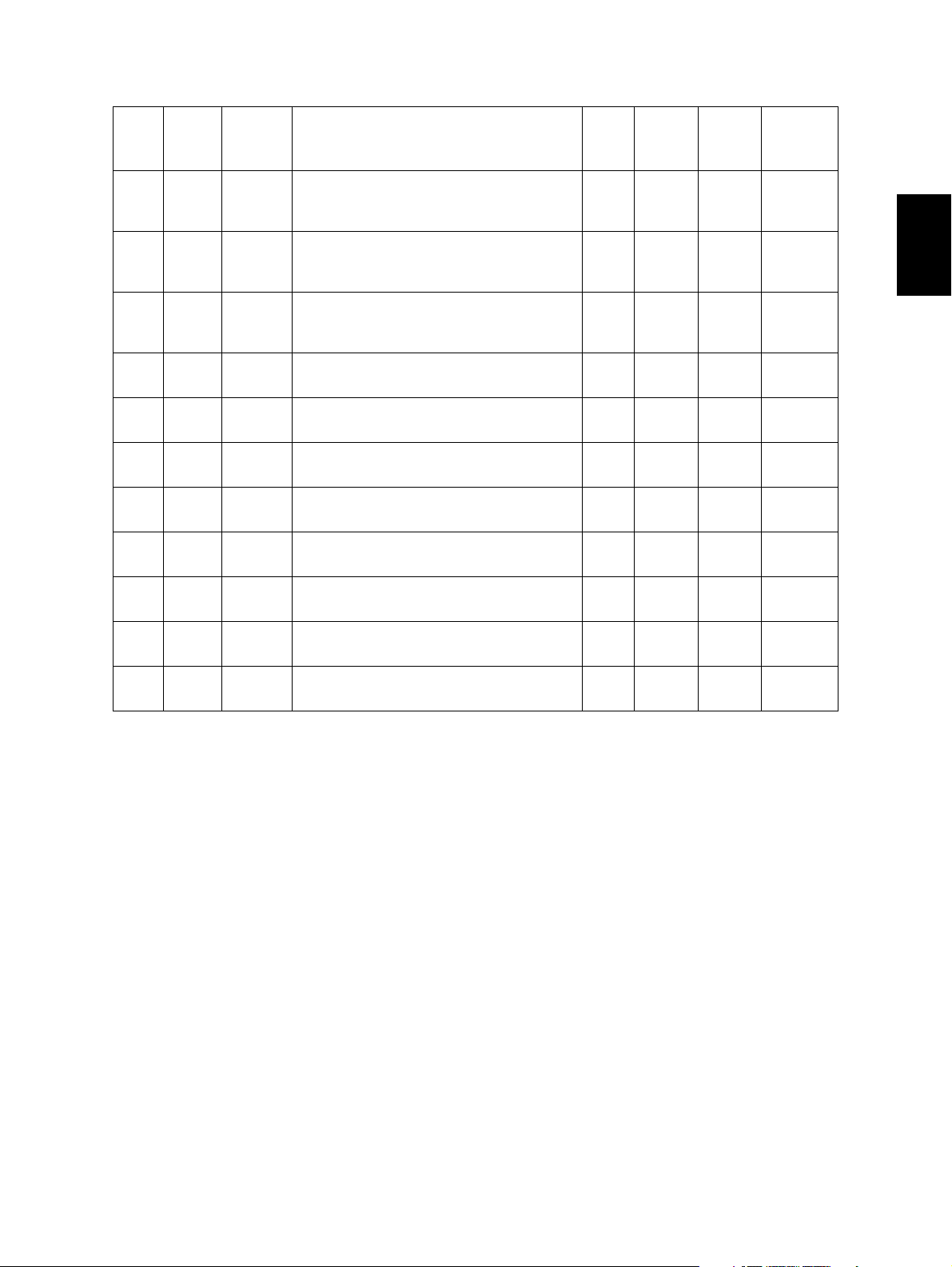

1) Error code list

If an error has occurred during communication, an error code is indicated below “STATUS” on the

transmission/reception journal.

Take the appropriate action referring to the following list.

Error code Content Situation and corrective action

0000 Normal

0012 Original jam Remove the jamming document and retransmit it.

0013 Door is open Close the doors securely and retransmit the document.

0020 Power failure A power failure occurred during transmission or reception, and

the transmission/reception data were lost. Attempt the transmission/reception again.

0030 Stop by paper jam during the

direct transmission

0033 Polling error Polling was not performed because the polling document was

0042 Memory full The memory became full a memory abnormality occurred dur-

0050 Line is busy Transmission is not made because the line is busy. Attempt

0053 Security mismatch in relay or mail

box transmission

00B0 Initial signal not detected NSF/DIS cannot be detected. Check the receiver and attempt

00B1 Terminal constants not compati-

ble

00B2 Reception of DCN (Phase B) DCN was received in the phase B.

00B3 DCS/DTC not detected DCS/DTC cannot be detected.

00B4 Training error The sender performed fall-back but the transmission was not

00B5 CFR not detected A training signal was sent out but CFR cannot be detected.

00C0 Image signal carrier not detected A carrier was not detected on the receiving side. Adjust the

00C1 High speed signal not detected A high-speed signal was not detected on the receiving side.

00C2 Image signal carrier disconnected Carrier disconnection was detected after the image signal was

00C3 1st EOL not detected 1st EOL was not detected after the high-speed signal was

00C4 EOL not detected EOL cannot be detected on the receiving side. Or decoding is

Remove the jamming paper and transmit it.

not found or the security codes were mismatched. Check the

polling document or security code on the other side and

attempt the polling again.

ing reception. (The pages normally received are printed out.)

Check the remaining memory space or memory status, and

attempt the reception again.

the transmission again. As the number of the redialings is

increased, the possibility for successful transmission is

increased.

Check your security code and system password of the other

side as well as your own.

the transmission again.

DIS/NSF that cannot be handled by the sender was received.

The receiver received NSS/DCS other than those declared by

DIS/NSF. Check the transmission/reception functions, and

attempt the communication again.

made. After the reception of FTT, the receiver received a timeout or DCN. Adjust the transmitter attenuator, link equalizer,

etc. and retry the communication.

Adjust the transmitter attenuator, link equalizer, etc. and retry

the transmission.

transmitter attenuator, link equalizer, etc. and retry the transmission.

Adjust the transmitter attenuator, link equalizer, etc. and retry

the transmission.

detected.

detected.

not possible with MMR.

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

ERROR CODES

1 - 2

Page 13

Error code Content Situation and corrective action

00D0 Post message not detected A post message cannot be detected. Retry the communica-

tion. MCF, RTP, RTN, PIN and PIP cannot be detected on the

sending side. MPS, EOM and EOP cannot be detected on the

receiving side.

00D1 Reception of DCN DCN was received.

00D2 Poor image quality Quality of the received image is poor. Retry the transmission.

00E8 HDD error Hardware is defective.

00F0 Software trouble Software is defective.

00F1 Hardware noise Hardware is defective.

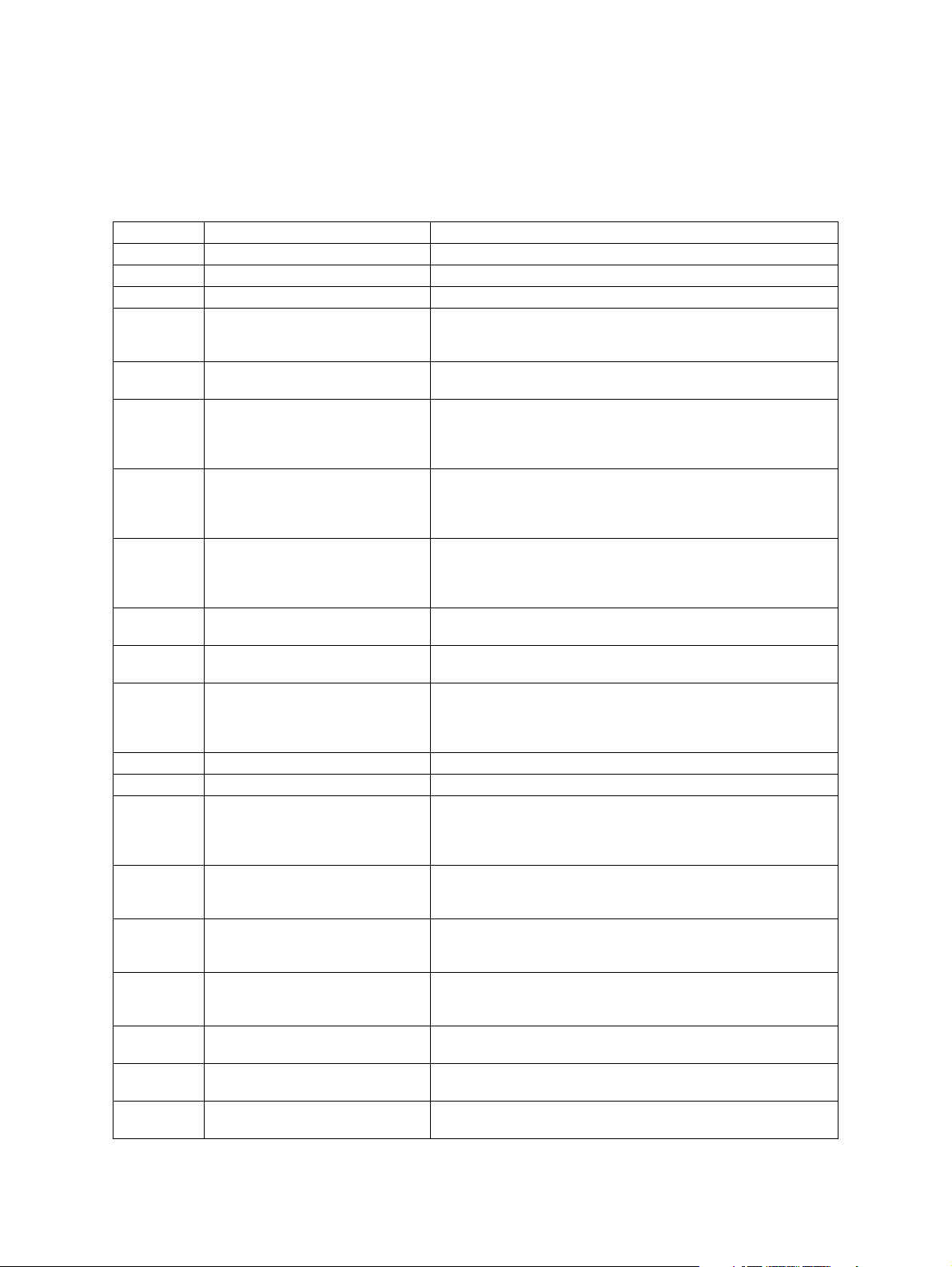

2) Status code list

Mode Transmission speed Resolution Encoding system

0 2400 8 x 3.85 MH

1 4800 8 x 7.7 MR

2 7200 8 x 15.4 MMR

3 9600 JBIG

4 12000 16 x 15.4

5 14400

6V.34

7

8 300 x 300

9

A

B

C

D

E

F

1

[Example of the indication of a status code]

522

MMR (encoding system

8 x 15.4 (resolution

14400 (transmission speed

)

)

)

For the combination of 14400 bps, 8x15.4 and MMR, as shown above, a status of “522” is indicate.

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

1 - 3

ERROR CODES

Page 14

1.2 Error Messages

Error messages are not displayed for the background jobs (memory transmission and memory reception). See the reception/transmission report for the details of the errors.

If an original jam during the direct transmission or recording paper jam during printing occurred, error

messages are displayed like when original jam occurred in the equipment.

Error messages and corrective actions

Error Symptom Message Remarks

Memory full Communication was interrupted

Line is busy Redialing was attempted for the

Initial signal not

detected

Terminal constants

not compatible

Training error Fall-back is not made success-

CFR not detected CFR (FTT) is not detected. Communication

Image signal carrier not detected

Image signal not

detected

because the memory became full.

specified number of times but the

line is still busy.

DIS is not detected. Communication

Received DIS unable to be handled.

Received DCS which is beyond

the capability of the receiver.

fully.

Became time-out after FTT was

sent out.

Image signal carrier cannot be

detected.

High-speed signal cannot be

received by the receiver.

Memory

overflow

error

Communication

error

error

Message displayed only during

the memory input.

It is not displayed during the

memory reception.

Job information is stored in the

memory when the final retry is

finished.

EOL time-out EOL timer exceeded by 13 sec-

Post message not

detected

Poor image quality TX: Received RTN/PIN/ERR

Software overdrive WDT communication terminated

Hardware noise Communication terminated due to

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

ERROR CODES

onds

Post message is not detected. Communication

error

Communication

RX: Transmitted RTN/PIN/ERR

due to software overdrive

software overdrive caused by

hardware noise

error

Communication

error

Communication

error

1 - 4

Page 15

2. SELF-DIAGNOSIS MODE

There are two types of the self-diagnosis mode for the FAX operation.

• Test mode (03), adjustment mode (05) and setting mode (08): Some items are added to the test

mode (03), adjustment mode (05) and setting mode (08) of the self-diagnosis function when the

optional FAX unit is installed.

• FAX function mode (13) and FAX clearing mode (1*): These two modes are newly added to the

machine when the FAX unit is installed. Started up by turning ON the power while pressing the specified keys are being pressed.

The followings are the modes which are added to (or extend) the PPC self-diagnosis function.

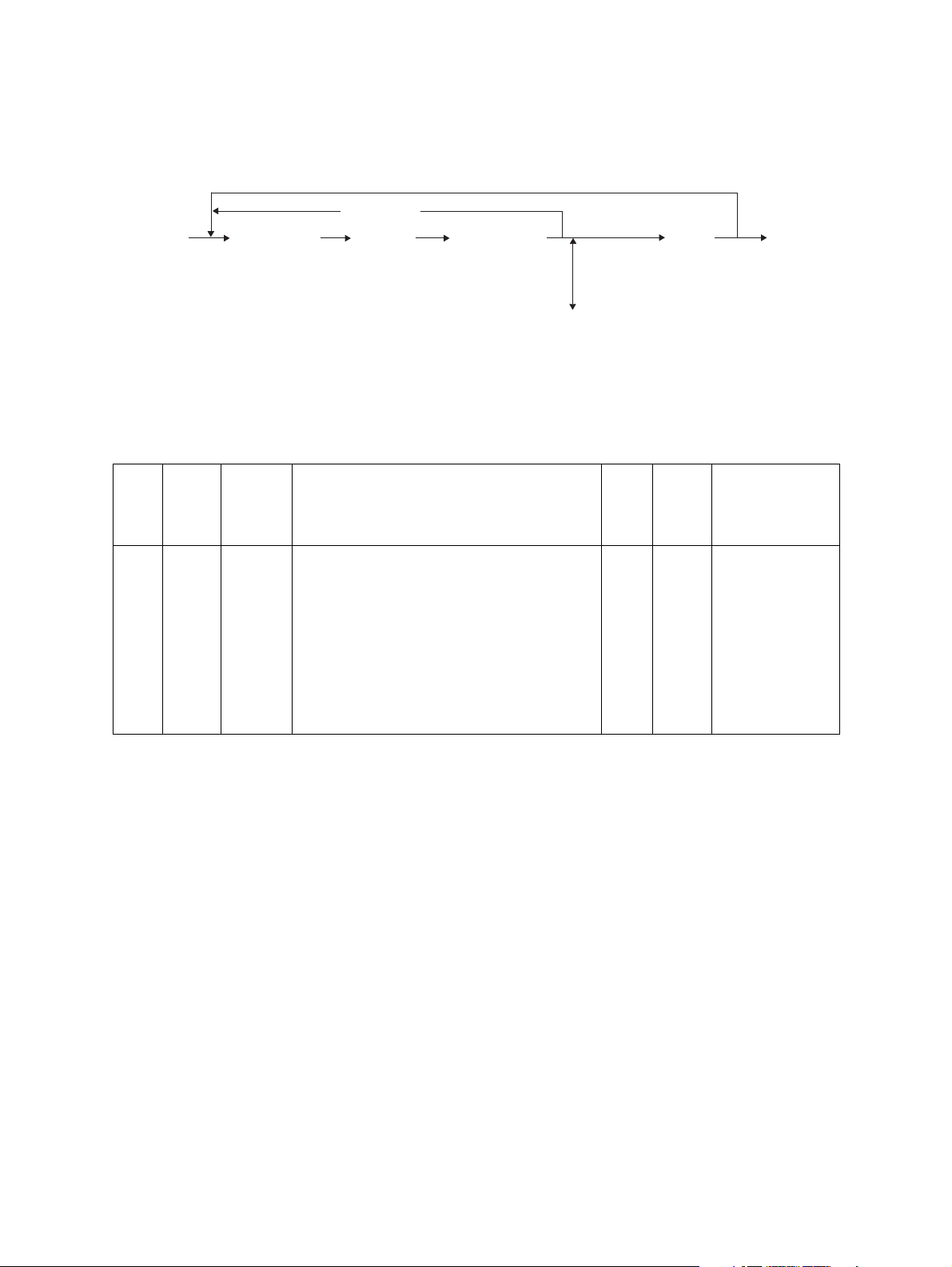

Mode For start Function Display

Test Mode [0]+[3]+[POWER] Output check (modem test, dialing

Adjustment Mode [0]+[5]+[POWER] Adjustment of the various items 100% A Test Mode

Setting Mode [0]+[8]+[POWER] Setting the destination 100% D Test Mode

FAX Function Mode [1]+[3]+[POWER] Setting functions of the various

FAX Clearing Mode [1]+[*]+[POWER] Initialization of the various memory

Trace List Output

Mode

Trace List Output

Mode

Digital keys on the list output

screen (without entering the

self-diagnostic mode)

Operating from the screen for

Service UI (without entering

the self-diagnostic mode)

test, CML test)

items

areas

(user registration area, system setting area, image data area)

Outputs the protocol trace list,

dump list and function setting list

Outputs the protocol trace list,

dump list and function setting list

100% C Test Mode

100% F Test Mode

100% CL Test Mode

USER FUNCTIONS

-

2

To enter the desired mode, turn the power ON while pressing two digital keys designated to each mode

(e.g. [0] and [5]) simultaneously.

Notes:

• To finish the self-diagnosis mode, make sure to turn the power OFF and then back ON.

When the equipment is started in one of the self-diagnosis modes, the equipment is occupied

by the mode until the power is turned OFF. In this case, the recovery processing for the FAX

operation is not performed.

• Faxes received automatically during the self-diagnosis mode may not be printed out. Be sure

to disconnect the modular code from the line connectors (LINE1, LINE2) of the equipment

before starting the self-diagnosis mode. Also, be sure to finish the self-diagnosis mode by

turning the power OFF and back ON before connecting the modular code.

• The trace list output mode can be used by operating from the Service UI screen for models in

which Service UI is embedded. For details of Service UI, refer to the Service Manual of the

MFP.

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

2 - 1

11/10

SELF-DIAGNOSIS MODE

Page 16

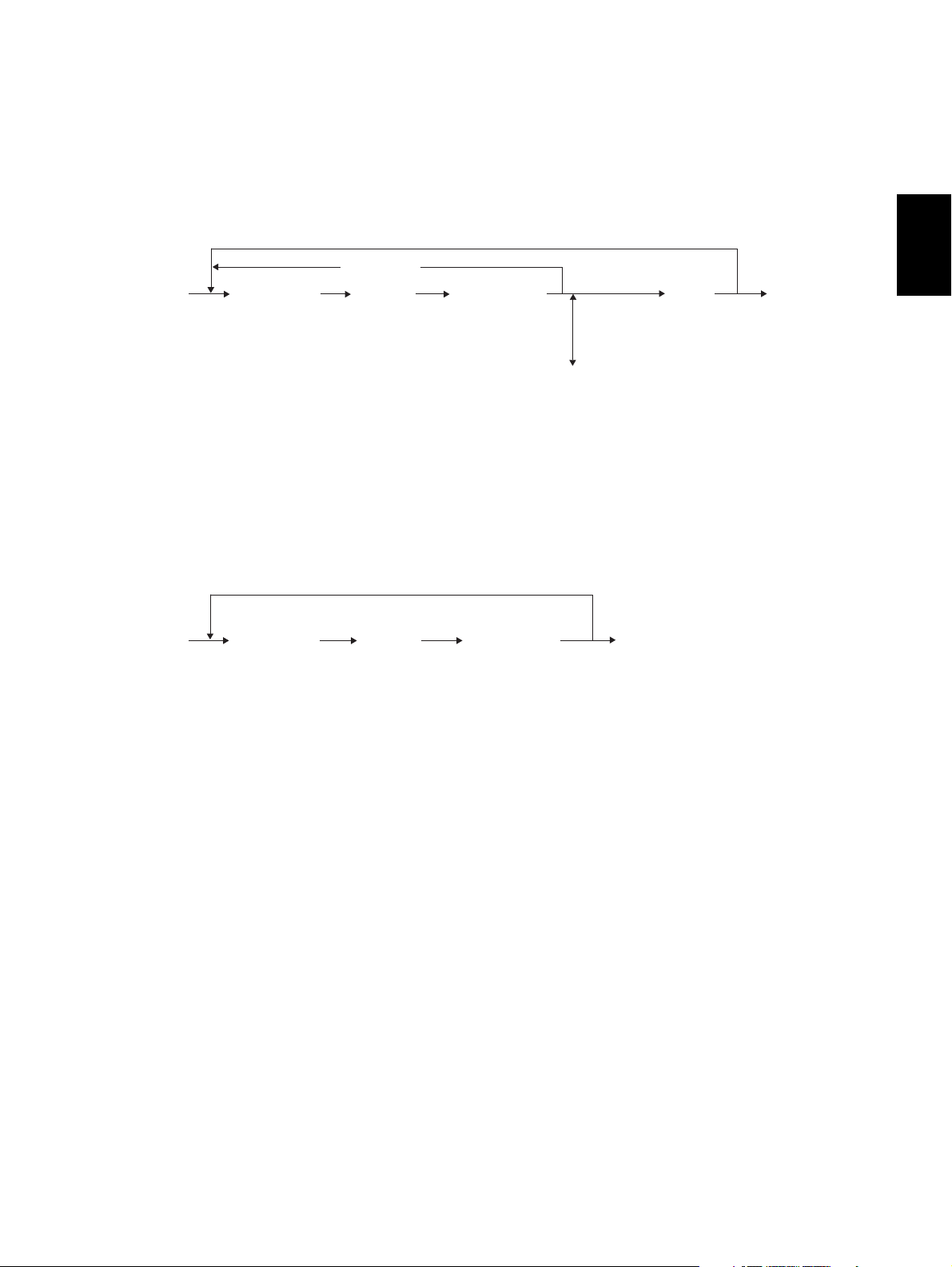

2.1 Test Mode (03)

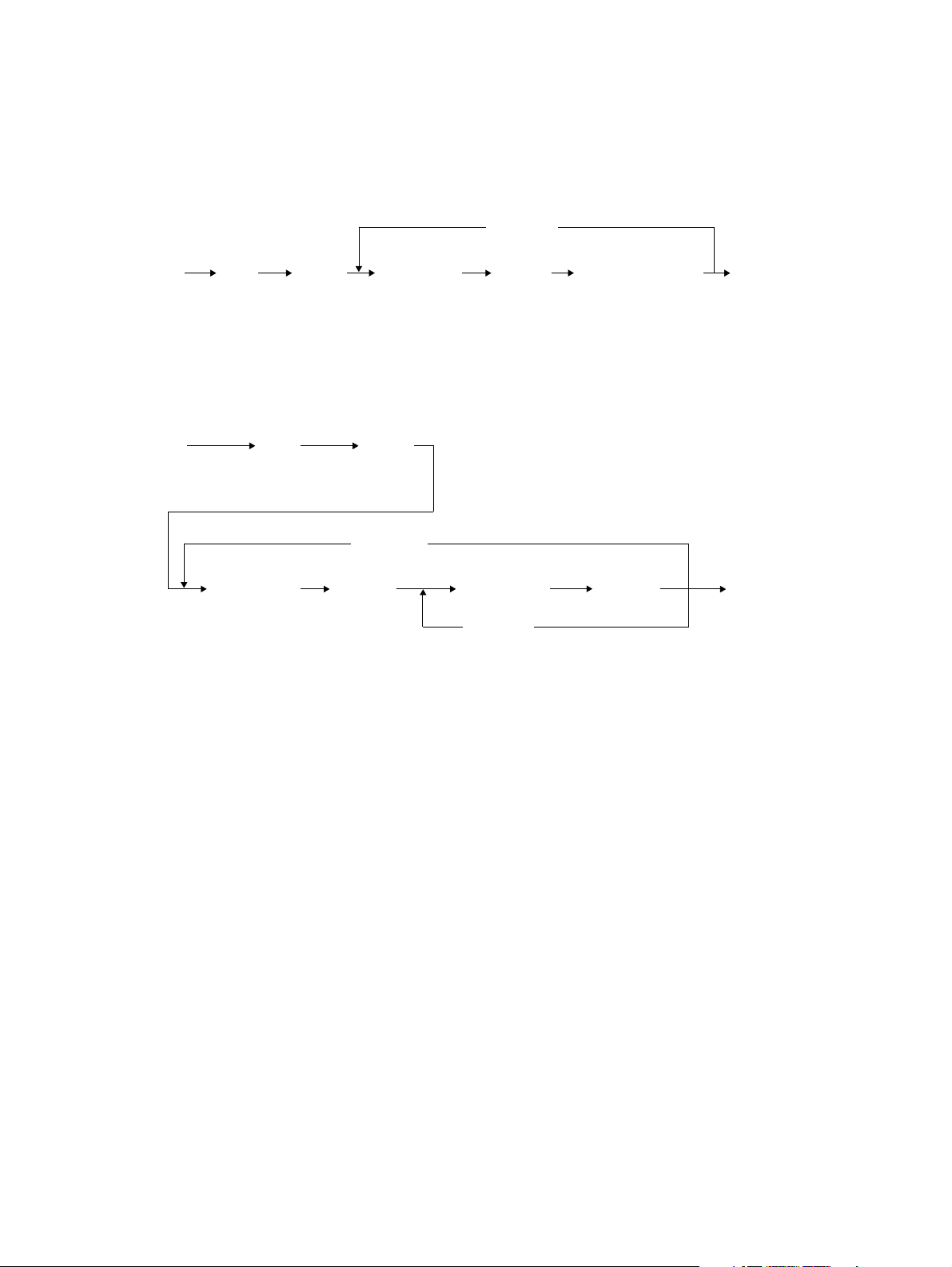

The modem test output, dialing test output and CML test output are performed in the Test Mode (03).

1) Modem test / CML test

[Operation procedure]

[0] [3][

[

POWER

FAX

](

Switch line 1 and 2

2) Dialing test

[Operation procedure]

[0] [3]

[

POWER

]

[

Digital key

(

]([

FAX

[

]

FAX

(

Switch line 1 and 2

]

)

Code

[

CLEAR

]) [

Digital key

][

START]Operation started

)(

Fig. 2-1

([

])

FAX

]

)(

Code

)

[

CLEAR

[

START

]

]

[

Digital key

[

START

Fig. 2-2

][

]

START

[

POWER] OFF

End

][

POWER] OFF

(

End

)

)

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SELF-DIAGNOSIS MODE

2 - 2

Page 17

Test code list

Code Element Test

03-301 FAX Modem test 2100 Hz

03-302 FAX Modem test 14.4 kbps (V.17)

03-303 FAX Modem test 9.6 kbps (V.29)

03-304 FAX Modem test 4.8 kbps (V.27)

03-305 FAX Modem test 300 BPS

03-306 FAX Modem test 1850 Hz

03-307 FAX Modem test 1650 Hz

03-308 FAX Modem test 1100 Hz

03-309 FAX Modem test 462 Hz

03-310 FAX Modem test 1300 Hz

03-311 FAX Modem test 33.6 kbps (V.34)

03-312 FAX Modem test 28.8 kbps (V.34)

03-313 FAX Modem test 24.0 kbps (V.34)

03-314 FAX Modem test 16.8 kbps (V.34)

03-315 FAX Dialing test 10 PPS (Tested with the digital keys)

(The dial number corresponding to the key which was pressed is kept outputting on the

circuit. The pressed key is displayed on the control panel.)

03-317 FAX Dialing test PB (Tested with the digital keys)

(The dial number corresponding to the key which was pressed is kept outputting on the

circuit. The pressed key is displayed on the control panel.)

03-318 FAX Modem test 12.0 kbps (V.17)

2

03-319 FAX Modem test 7.2 kbps (V.29)

03-320 FAX Modem test 2.4 kbps (V.27ter)

03-321 FAX Performs Read/Write test to all the image memories mounted on the FAX board and

displays the test result (status) on the control panel. Also, detects automatically whether

the extended memory is mounted or not.

03-322 FAX CML test: Turning ON the CML relay

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

2 - 3

11/10

SELF-DIAGNOSIS MODE

Page 18

2.2 Adjustment Mode (05)

Parameter setting for the FAX image processing is performed in the Adjustment Mode (05).

1) Setting parameters for the FAX image processing

[Operation procedure]

[0] [5][

[POWER]

Digital key

(

)

Code

][

START

][

Digital key

*[FC

(

Key in the adjustment value

[

CANCEL

][

]

[

]

)

CLEAR

(

In case the value is corrected

Fig. 2-3

INTERRUPT

(

Save the value in the RAM

]

[

ENTER

[OK] *1

or

]

[

POWER] OFF

]

)

* “-” can be entered with the [FC] button.

*1: For e-STUDIO2040C/2540C/3040C/3540C/4540C, e-STUDIO5540C/6540C/6550C, eSTUDIO206L/256/306/356/456 and e-STUDIO556/656/756/856.

)

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SELF-DIAGNOSIS MODE

2 - 4

11/12

Page 19

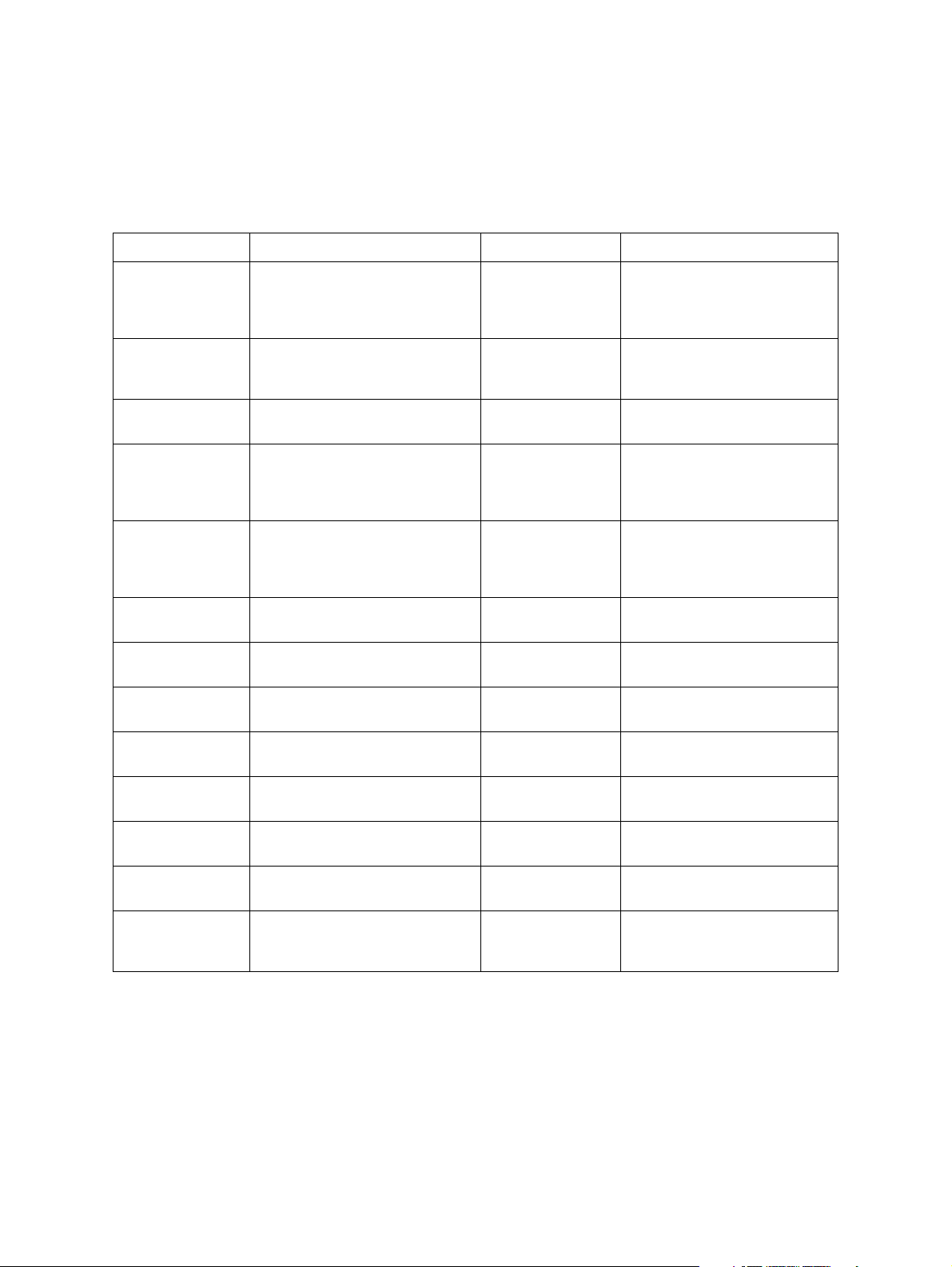

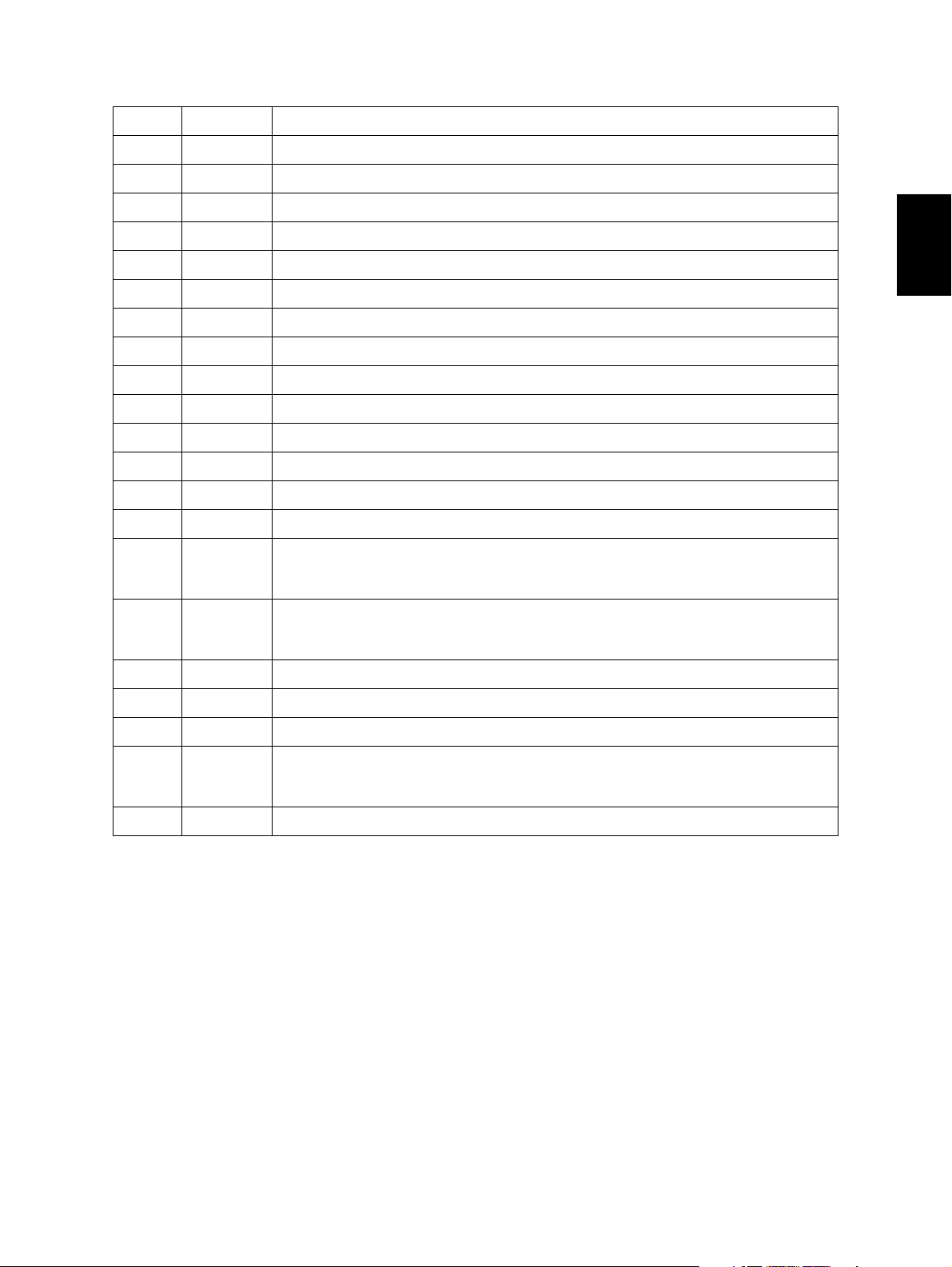

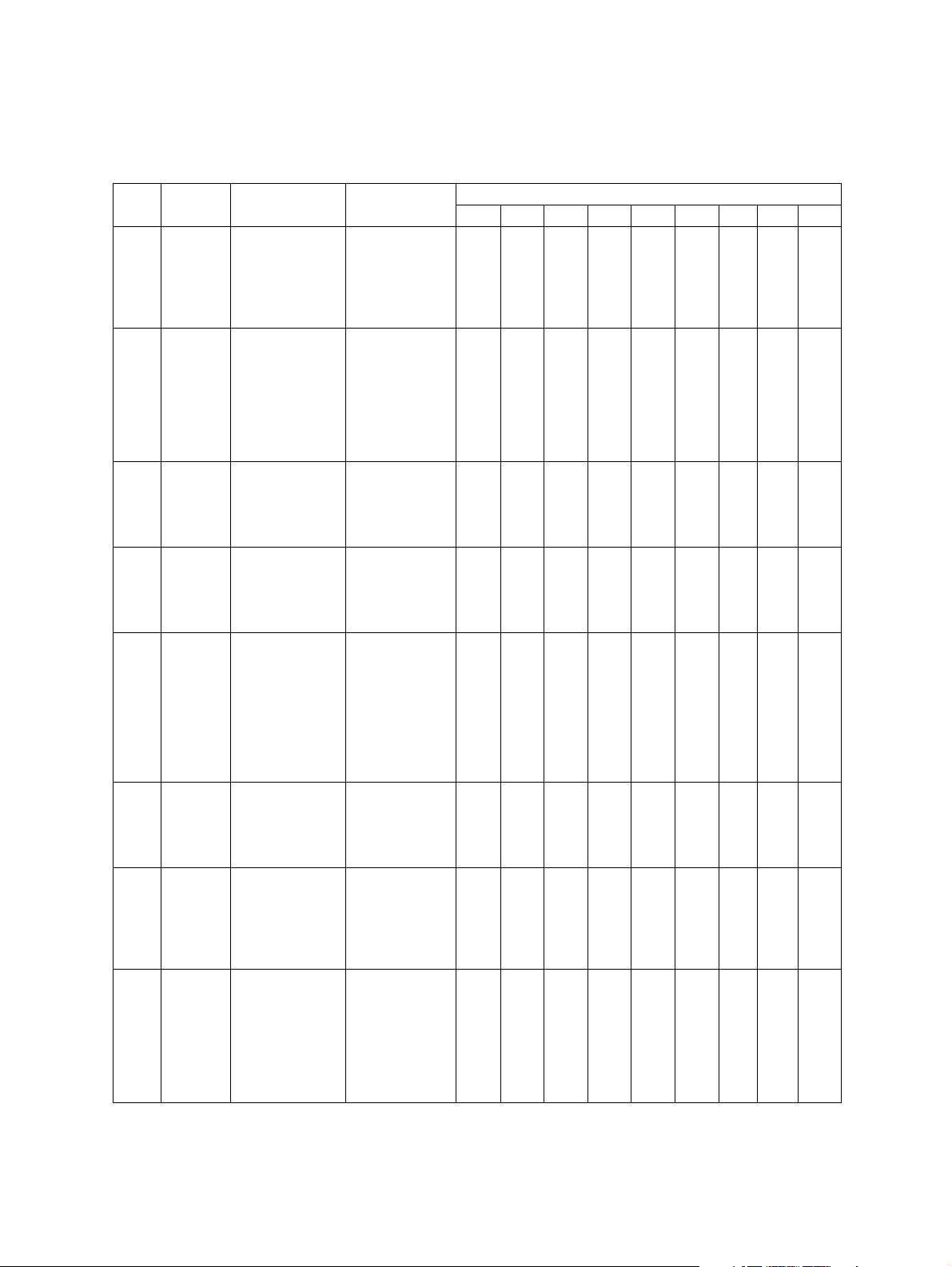

Adjustment codes for the image processing parameters

05-

05-

Code

*1

057534

Element Adjustment item Mode

Density Adjustment of the threshold value for the

binarization

Center value

Density Adjustment of the threshold value for the

binarization

Lighter step value

Code

700

701

Image

quality

mode

Default

Accept-

able

value

FAX Text 125 0 to 255

FAX Text 20 0 to 255

2

05-

702

Density Adjustment of the threshold value for the

binarization

FAX Text 20 0 to 255

Darker step value

05-

710

05-

714

05-

715

05-

719

05-

720

05-

724

05-

725

05-

729

057535

057533

057543

057542

Density Manual-density fine adjustment

Error diffusion, Center value

Density Manual-density fine adjustment

Error diffusion, Center value

Density Manual-density fine adjustment

Error diffusion, Lighter step value

Density Manual-density fine adjustment

Error diffusion, Lighter step value

Density Manual-density fine adjustment

Error diffusion, Darker step value

Density Manual-density fine adjustment

Error diffusion, Darker step value

Density Auto-density fine adjustment

Error diffusion

Density Auto-density fine adjustment

Error diffusion

FAX Photo 128 0 to 255

FAX Text /

128 0 to 255

Photo

FAX Photo 20 0 to 255

FAX Text /

20 0 to 255

Photo

FAX Photo 20 0 to 255

FAX Text /

20 0 to 255

Photo

FAX Photo 128 0 to 255

FAX Text /

128 0 to 255

Photo

*1: For e-STUDIO2040C/2540C/3040C/3540C/4540C, e-STUDIO5540C/6540C/6550C, eSTUDIO206L/256/306/356/456 and e-STUDIO556/656/756/856.

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

2 - 5

11/12

SELF-DIAGNOSIS MODE

Page 20

2.3 Setting Mode (08)

The destination is set in the Setting Mode (08).

[Operation procedure]

[0] [8]

[

POWER

]

Digital key

(

)

Code

[

CANCEL

][

START

]

][

Digital key

(

Key in a value

(

In case the value is corrected

Fig. 2-4

]

)

[

CLEAR

[

ENTER

]

or

[

INTERRUPT

]

[OK] *1

(

Save the value in the RAM

]

)

*1: For e-STUDIO2040C/2540C/3040C/3540C/4540C, e-STUDIO5540C/6540C/6550C, eSTUDIO206L/256/306/356/456 and e-STUDIO556/656/756/856.

Default value at

Code

08-

701

Code

*1

08-

9001

Element Adjustment item Mode

Destination

1: Asia 2: Australia 3: Hong Kong

4: U.S.A/Canada 5: Germany

6: Great Britain 7: Italy 8: Belgium

9: Holland 10: Finland 11: Spain

FAX

12: Austria 13: Switzerland

14: Sweden 15: Denmark

16: Norway 17: Portugal 18: France

19: Greece 20: Poland 21: Hungary

22: Czech Rep. 23: Turkey

24: South Africa 25: Taiwan

Image

mode

FAX -

product ship-

NA: 4

TW: 25

EU: 5

AU: 2

AS: 1

C: 1

[

POWER

OFF

)

the

ment

][

*1: For e-STUDIO2040C/2540C/3040C/3540C/4540C, e-STUDIO5540C/6540C/6550C, eSTUDIO206L/256/306/356/456 and e-STUDIO556/656/756/856.

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SELF-DIAGNOSIS MODE

2 - 6

11/12

Page 21

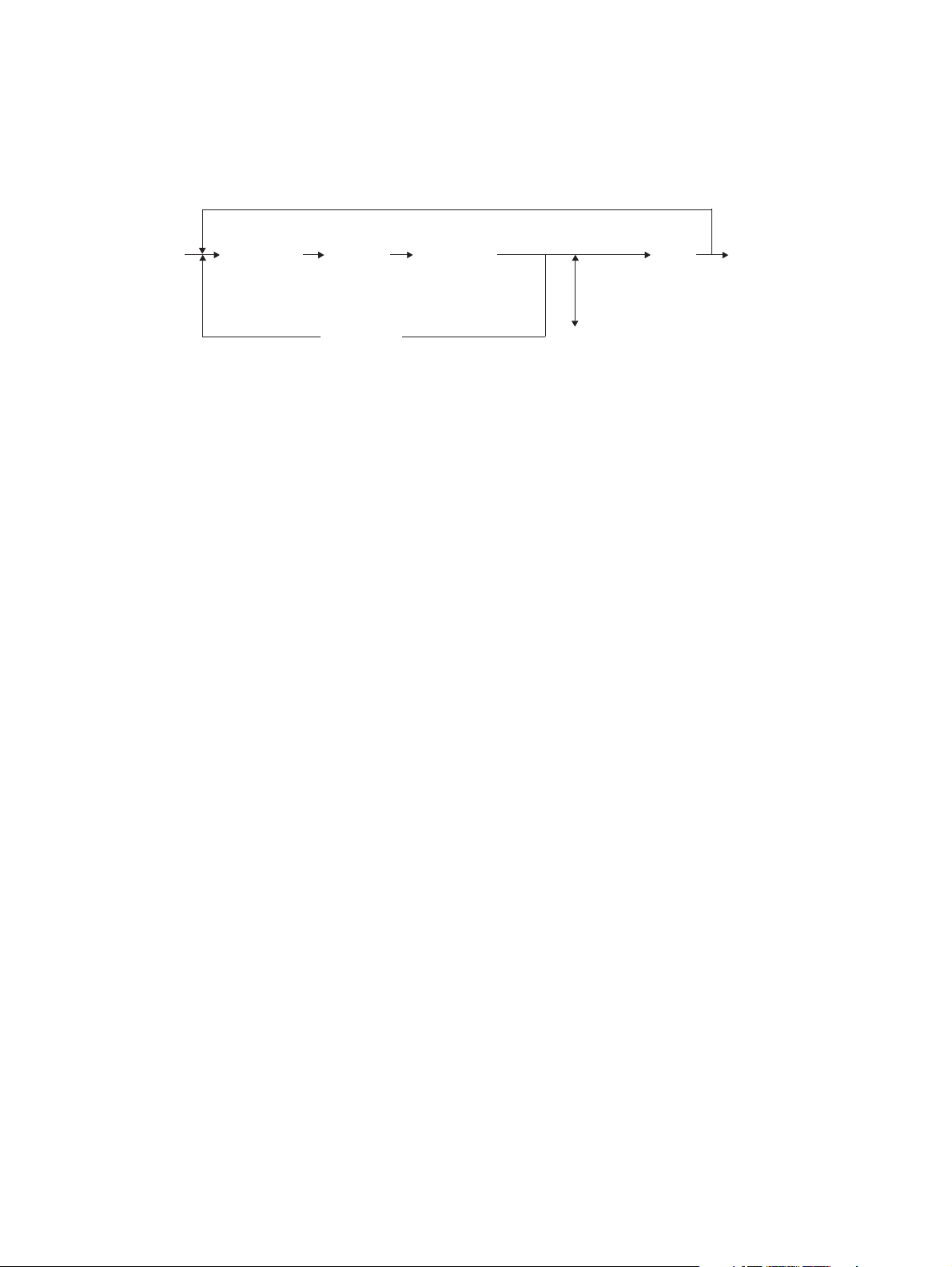

2.4 Function Mode (13)

Various functions are set in the Function Mode (13).

1) Procedure to set the functions

Key in a code and change the set value.

[Operation procedure]

[

CANCEL

[1] [3]

[

POWER

]

[

Digital key

(

Code

][

)

START

*1: For e-STUDIO2040C/2540C/3040C/3540C/4540C, e-STUDIO5540C/6540C/6550C, eSTUDIO206L/256/306/356/456 and e-STUDIO556/656/756/856.

2) Procedure to confirm the set value

]

][

Digital key

(

Key in a value

(

In case the value is corrected

Fig. 2-5

]

)

[

CLEAR

[

ENTER

or

[

INTERRUPT

[OK] *1

(

Save the value in the RAM

]

)

2

]

]

[

POWER

)

]

OFF

[Operation procedure]

[1] [3]

[

POWER

]

[

Digital key

(

Code

][

)

[

ENTER

[

INTERRUPT

START

]

[OK] *1

(

Set value cannot be changed

Fig. 2-6

]

[

POWER] OFFor

]

)

*1: For e-STUDIO2040C/2540C/3040C/3540C/4540C, e-STUDIO5540C/6540C/6550C, eSTUDIO206L/256/306/356/456 and e-STUDIO556/656/756/856.

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

2 - 7

11/12

SELF-DIAGNOSIS MODE

Page 22

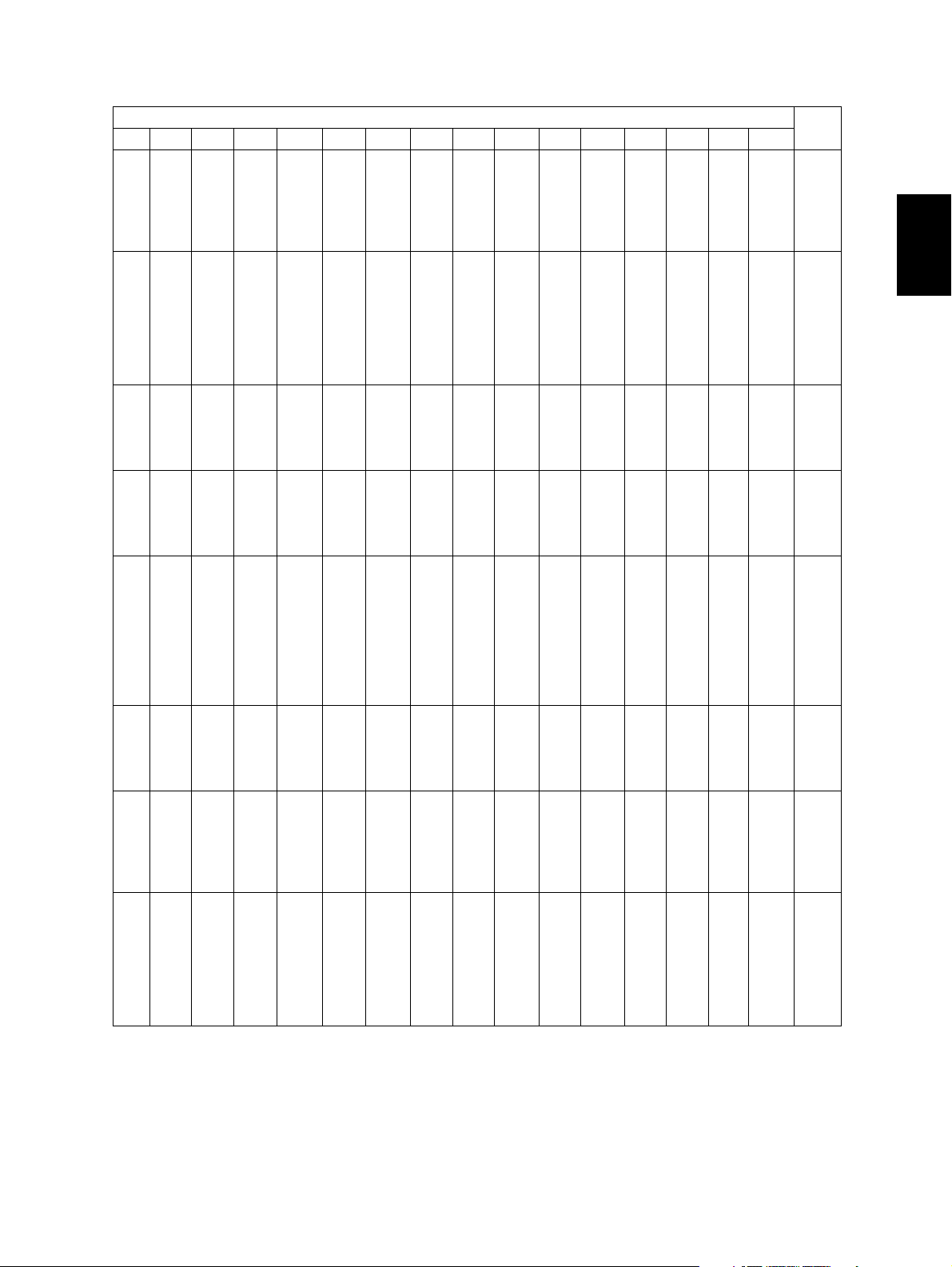

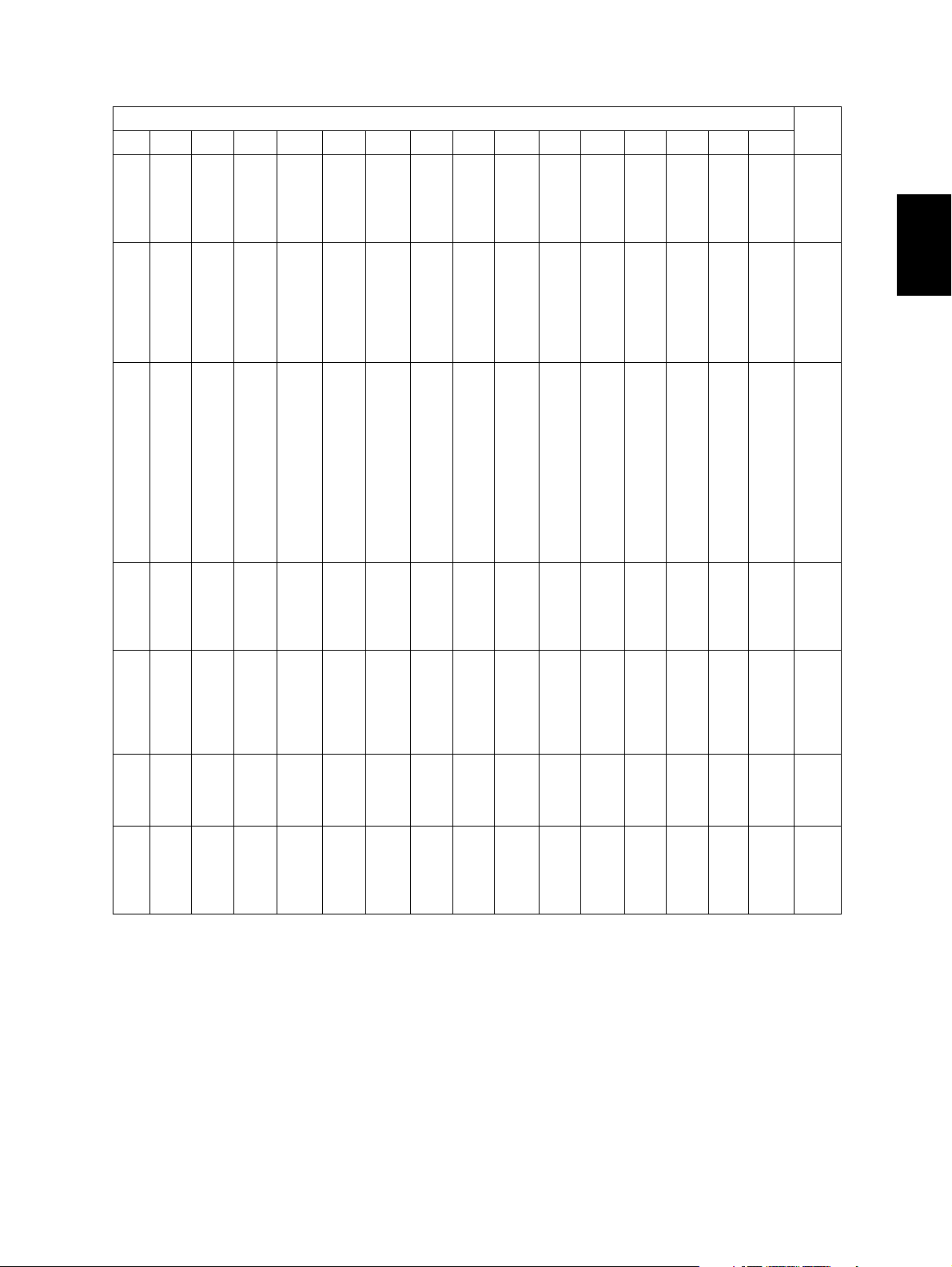

Function code list (100-999)

100-299 Adjustment within the dialing standards

13-

13-

13-

13-

13-

13-

13-

13-

Adjust-

ment

DTC frequency

(PSTN)

(Line 1)

DTC

time

(PSTN)

(Line 1)

LCC

allowed

gaps

(PSTN)

(Line 1)

DTC

allowed

gaps

(PSTN)

(Line 1)

DTC/

LCC for

PSTN

(Line 1)

DTC

time out

(PSTN)

(Line 1)

DTC frequency

(PABX)

(Line 1)

DTC

time

(PABX)

(Line 1)

Function Setting

Sets the dial

tone frequency

to be detected

for the PSTN.

0: 300-600 Hz

1: 300-650 Hz

2: 390-550 Hz

3: 400-450 Hz

4: 350-480 Hz

5: 300-500 Hz

Sets the time

for a tone

sounds to be

determined as

dial tone for the

PSTN.

0: 2 sec

1: 800 ms

2: 400 ms

3: 1 sec

4: 1.3 sec

5: 1.8 sec

6: 2.5 sec

7: 500 ms

Sets the interruption time for

the PSTN to be

ignored during

0: OFF

1: 50 ms

2: 100 ms

3: 200 ms

LCC.

Sets the interruption time for

PSTN to be

ignored during

0: OFF

1: 320 ms

2: 160 ms

3: 240 ms

DTC.

Selects which is

0: BZT

to be used for

the PSTN, DTC

or LCC.

1: LCC 5 sec

2: DTC only

3: FRN

4: DTC (JPN)

5: NO

Sets how long

the dial tone

detection is performed.

0: 20 sec

1: 10 sec

2: 8 sec

3: 15 sec

4: 3.3 sec

Sets the dial

tone frequency

to be detected

for PABX.

0: 300-600 Hz

1: 300-650 Hz

2: 390-550 Hz

3: 400-450 Hz

4: 350-480 Hz

5: 300-500 Hz

Sets the time

for a tone

sounds to be

determined as

dial tone for the

PAB X.

0: 2 sec

1: 800 ms

2: 400 ms

3: 1 sec

4: 1.3 sec

5: 1.8 sec

6: 2.5 sec

7: 150 ms

(DTC/LCC)

(DTC/LCC)

DTC&LCC

Code

100

101

102

103

104

105

106

107

Default

ASM AUS HKG USA DEU GBR ITA BEL NDL

000011111

000322222

000322222

111111111

222222222

000111111

000011111

000622222

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SELF-DIAGNOSIS MODE

2 - 8

11/10

Page 23

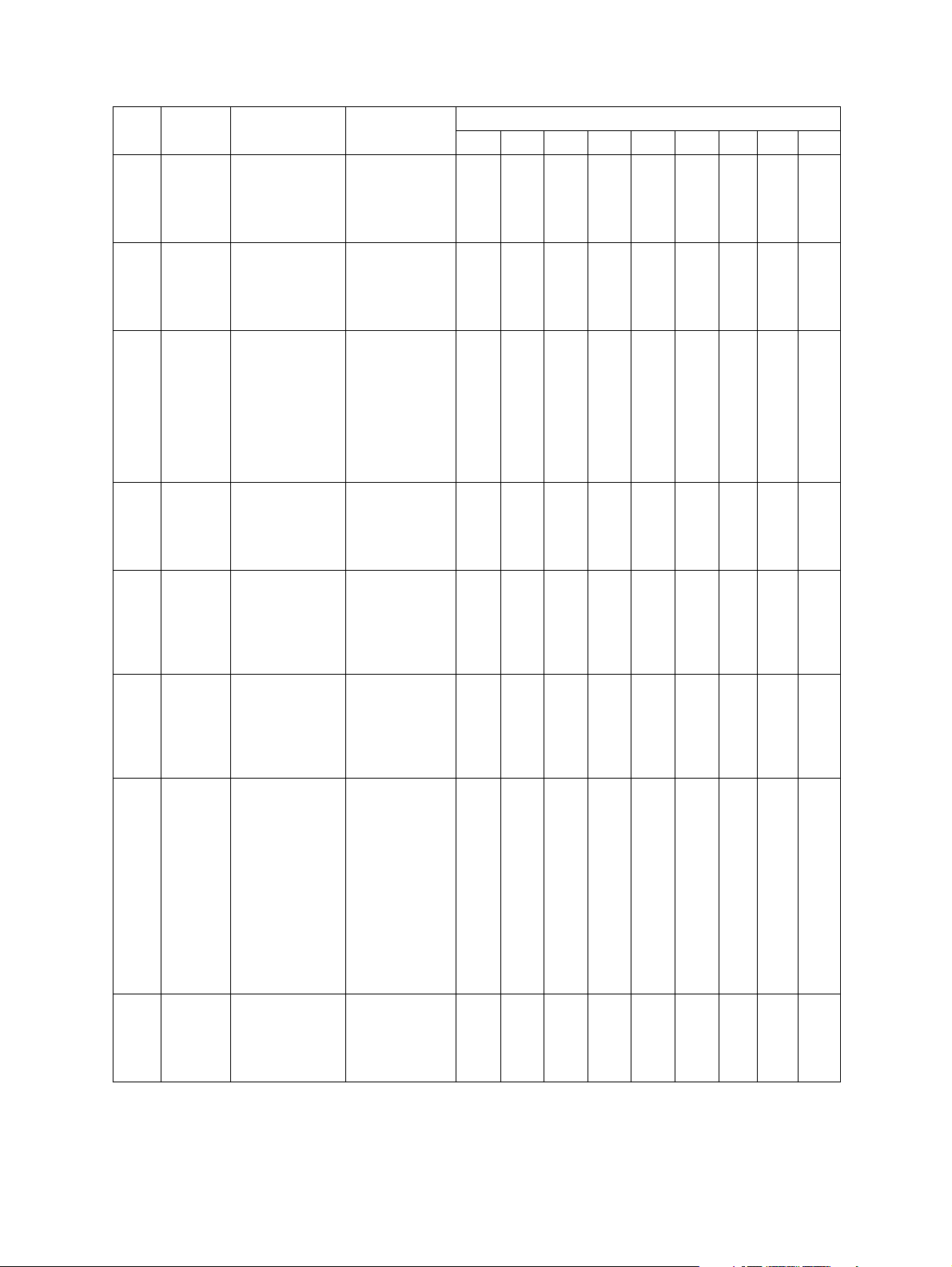

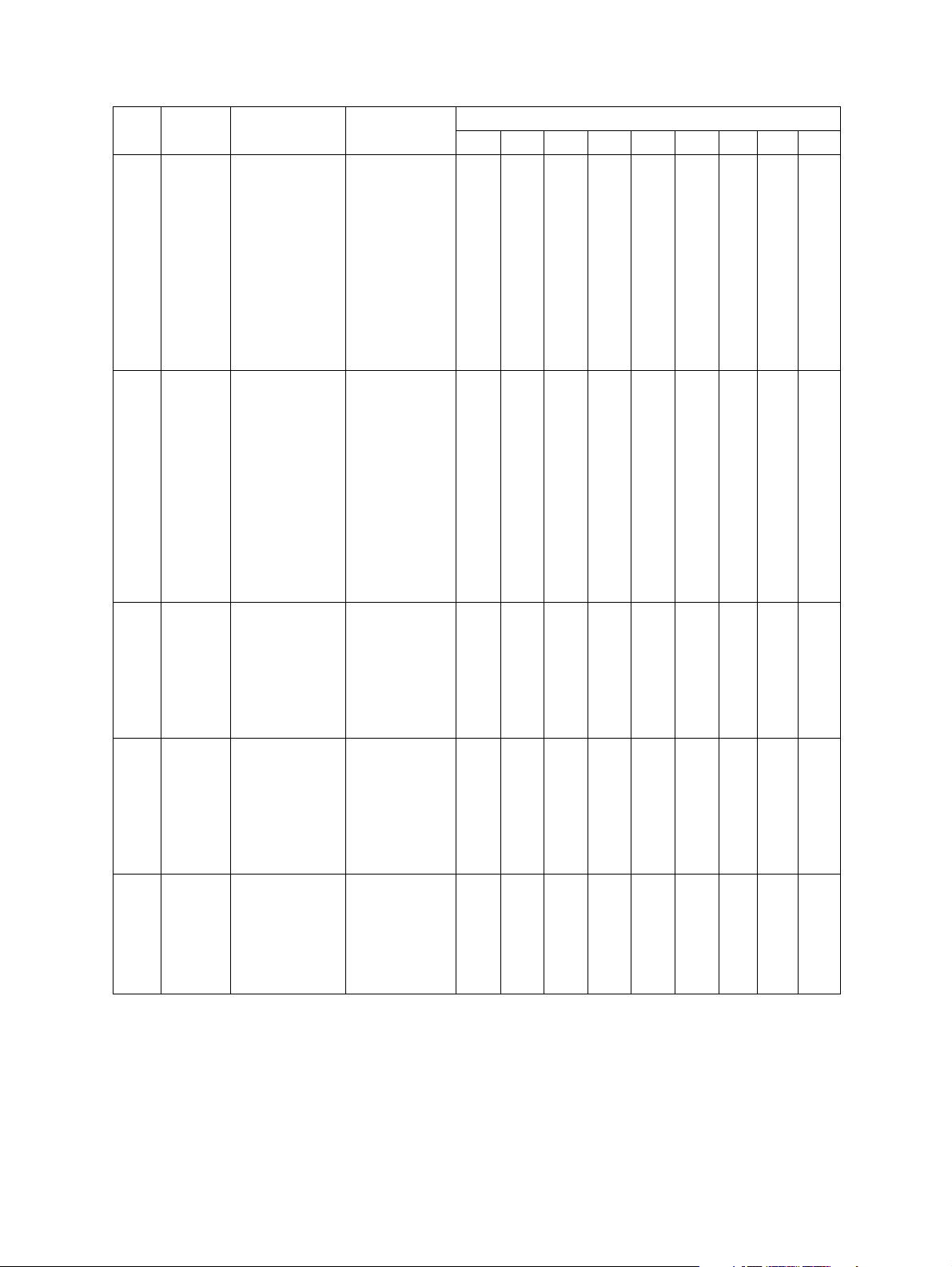

Default

FIN ESP AUT CHE SWE DNK NOR PRT FRA GRC POL HUN CZE TUR ZAF TWN

Code

11111 1111111100113-

100

22222 2222222200213-

101

22222 2222222200213-

102

2

11111 1111111111113-

103

22222 2222222222213-

104

11111 1111111100113-

105

11111 1111111100113-

106

22222 2222222200213-

107

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

2 - 9

11/10

SELF-DIAGNOSIS MODE

Page 24

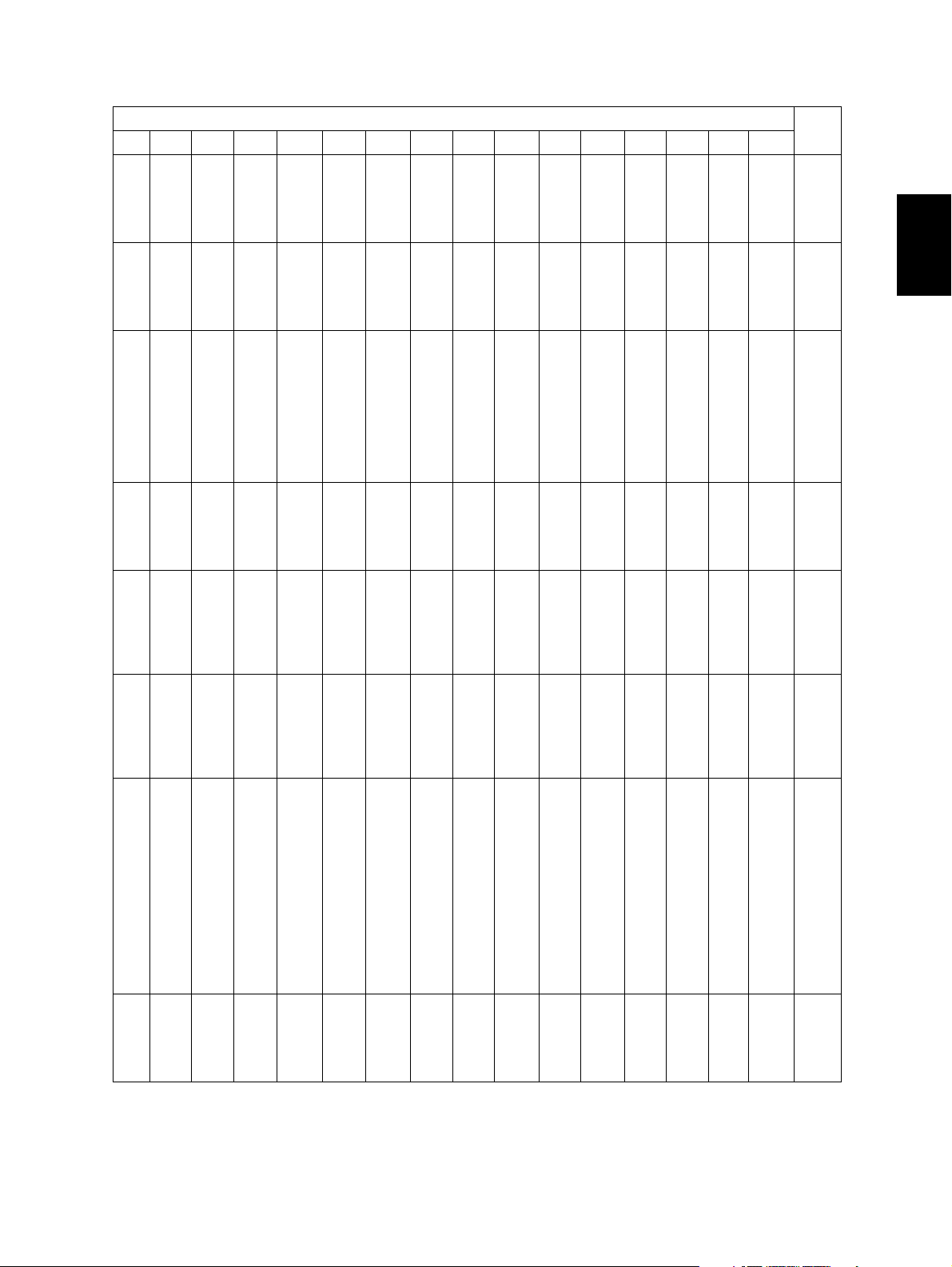

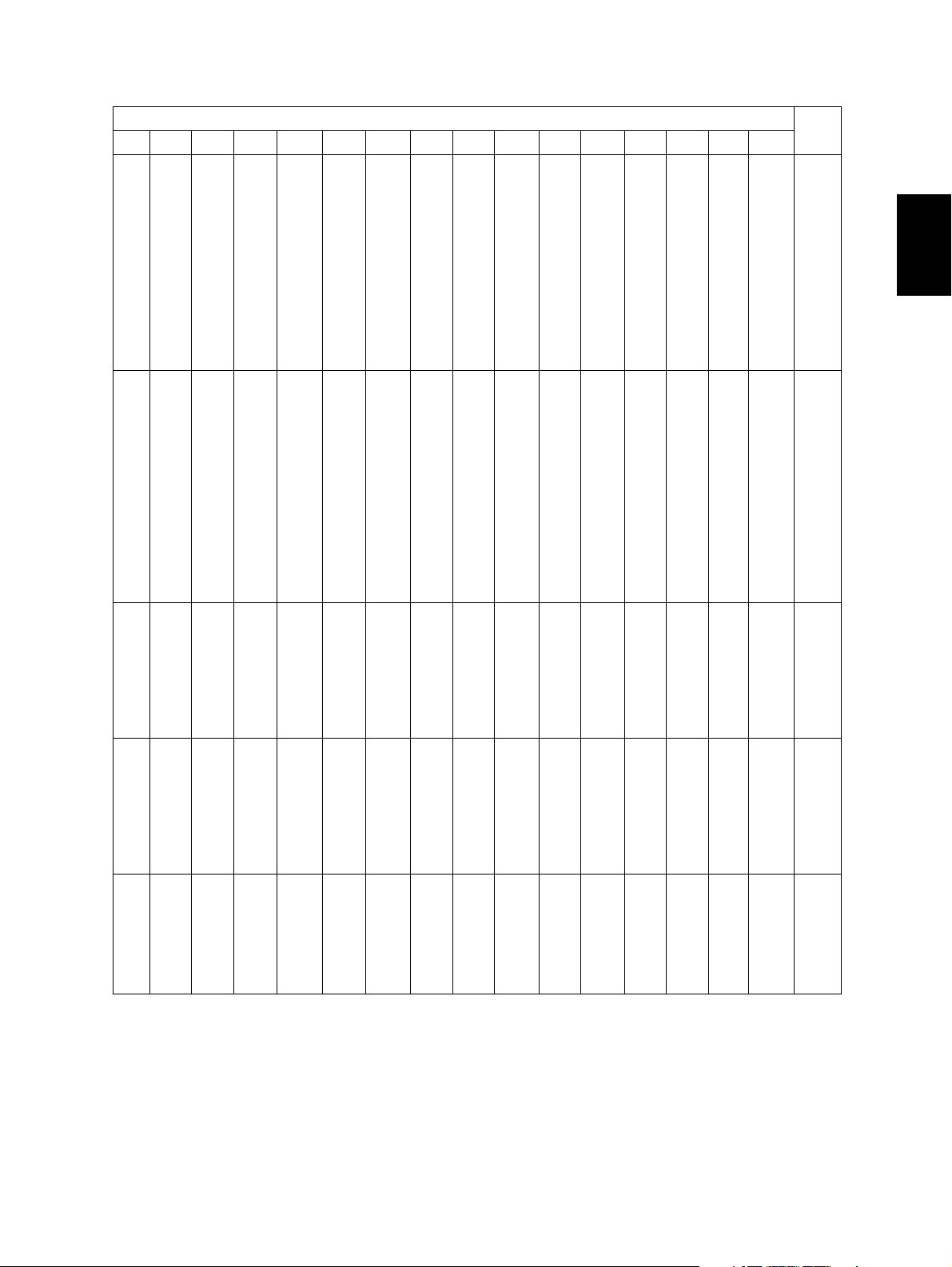

Code

13-

108

13-

109

13-

110

13-

111

13-

112

13-

116

13-

117

13-

122

Adjust-

ment

LCC

allowed

gaps

(PABX)

(Line 1)

DTC

allowed

gaps

(PABX)

(Line 1)

DTC/

LCC for

PABX

(Line 1)

DTC

time out

(PABX)

(Line 1)

BTC frequency

(Line 1)

Dial T1

timer

(Line 1)

Dial stop

after T1

CML

make

time

before

dialing

Function Setting

Sets the interruption time for

the PABX to be

ignored during

0: OFF

1: 50 ms

2: 100 ms

3: 200 ms

LCC.

Sets the interruption time for

the PABX to be

ignored during

0: OFF

1: 320 ms

2: 160 ms

3: 240 ms

DTC.

Selects which is

0: BZT

to be used for

the PABX, DTC

or LCC.

1: LCC 5 sec

2: DTC only

3: FRN

4: DTC (JPN)

5: NO

Sets how long

the dial tone

detection is performed.

0: 20 sec

1: 10 sec

2: 8 sec

3: 15 sec

4: 3.3 sec

Sets the busy

0: Not

tone frequency

to be detected

for the PSTN

and PABX.

1: 300-600 Hz

2: 350-550 Hz

3: 300-500 Hz

4: 300-700 Hz

Sets the time to

wait for a

response from

the receiver

after dialing is

0: 60 sec

1: 35 sec

2: 90 sec

3: 55 sec

4: 115 sec

completed.

In case of T1

time-out (no

0: OFF

1: ON

response from

the receiver)

during the automatic dialing,

redialing is not

performed and

it is determined

that the transmission is terminated due to

error.

Pause before

dialing

0: 0 ms

1: 10 ms

¦

255:2550 ms

Default

ASM AUS HKG USA DEU GBR ITA BEL NDL

000033333

111111111

555555555

(DTC/LCC)

(DTC/LCC)

DTC&LCC

000111111

000111111

detected

030322222

000100000

222222222

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SELF-DIAGNOSIS MODE

2 - 10

11/10

Page 25

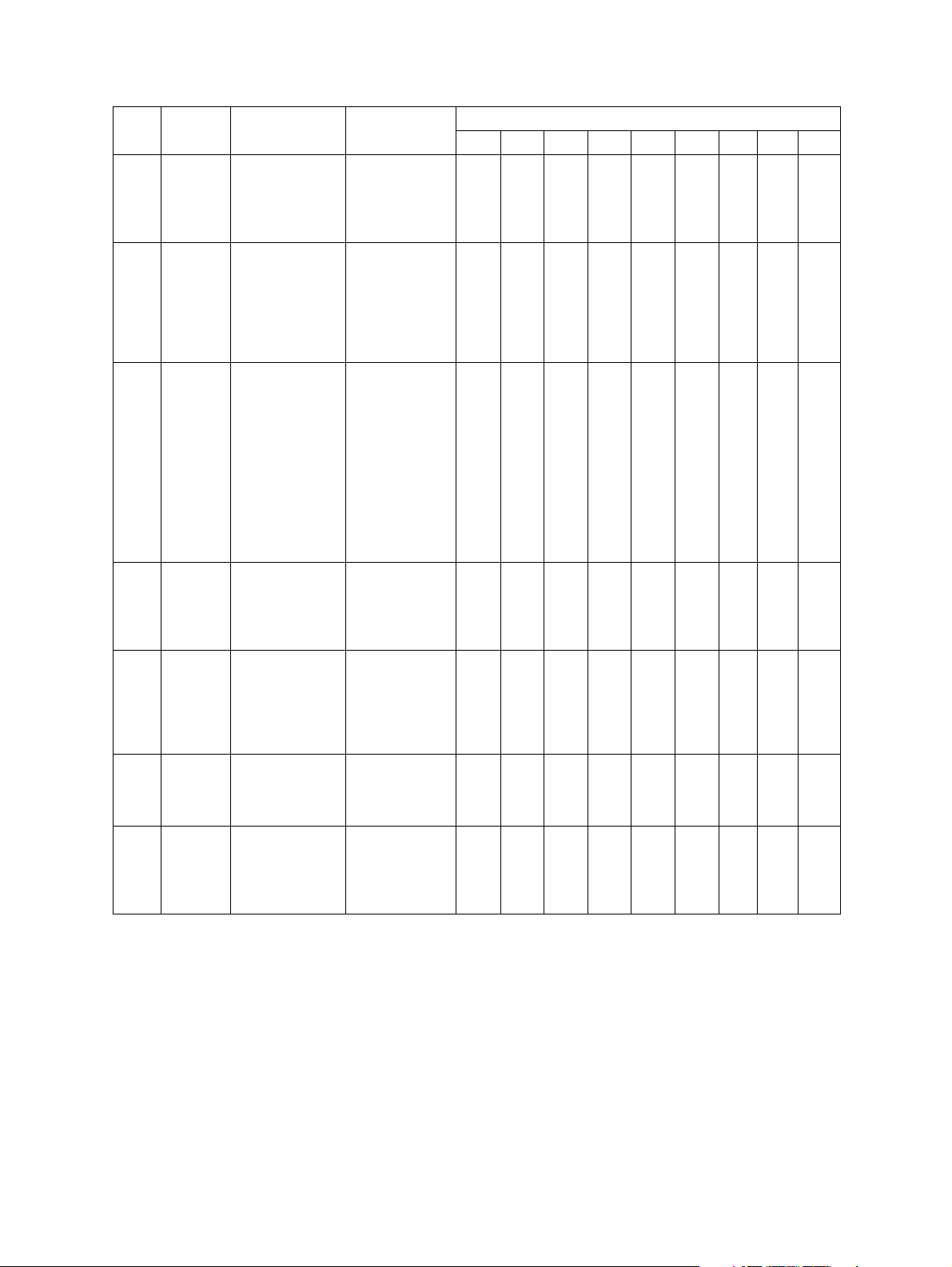

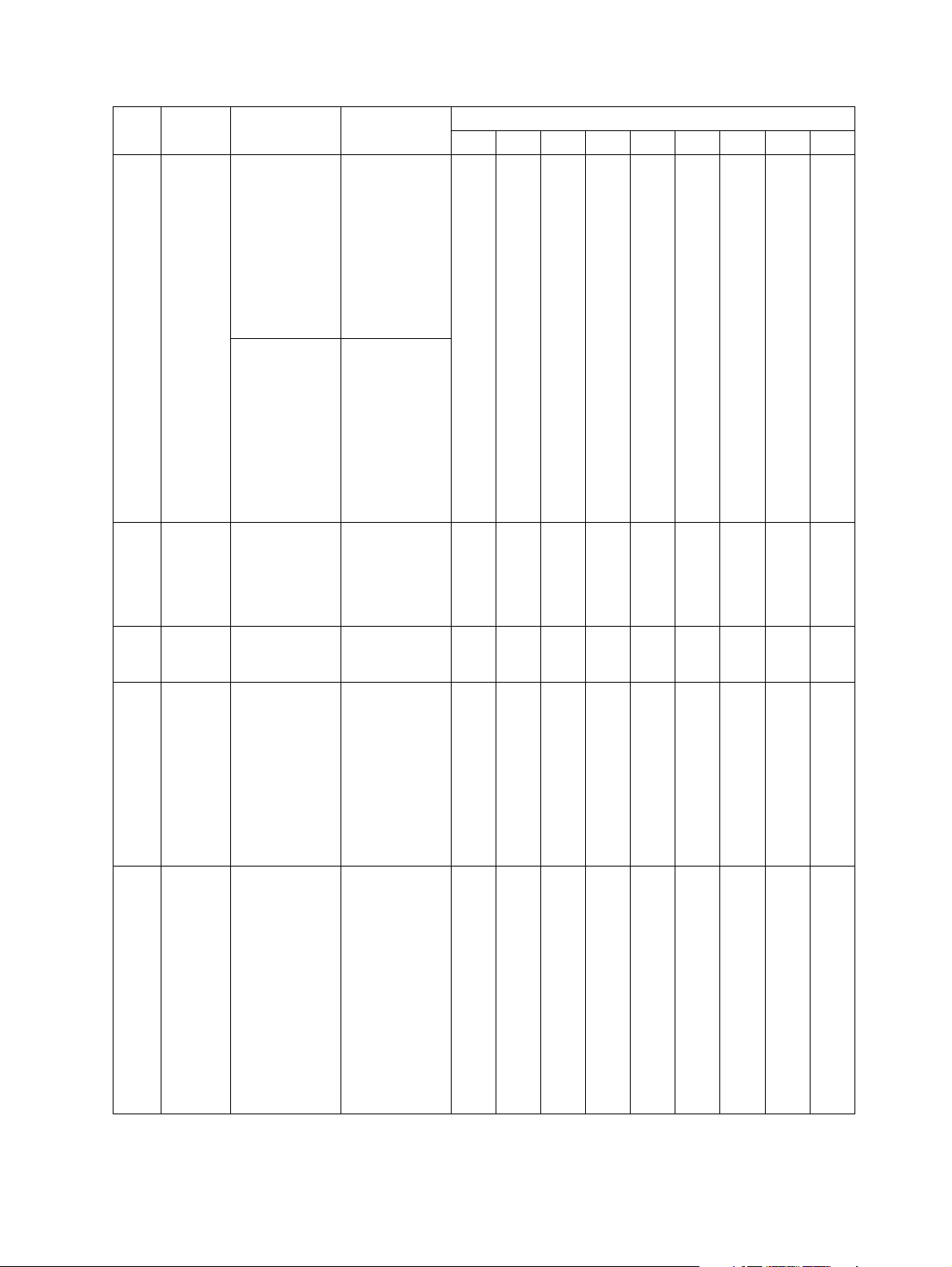

Default

FIN ESP AUT CHE SWE DNK NOR PRT FRA GRC POL HUN CZE TUR ZAF TWN

Code

33333 3333333300213-

108

11111 1111111111113-

109

55555 5555555555513-

110

11111 1111111100113-

111

11111 1111111100113-

112

22222 2222222200313-

116

2

00000 0000000000013-

117

22222 2222222222213-

122

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

2 - 11

11/10

SELF-DIAGNOSIS MODE

Page 26

Code

13-

123

13-

125

13-

127

13-

128

13-

129

13-

132

13-

135

Adjust-

ment

CML

hold

time

after

dialing

Dial

information

(Line 1)

Internal

retry

Redialing

counter

Time for

a pause

(Line 1)

Interdigit

pause

(Line 1)

Redialing interval

(Line 1)

Function Setting

Pause after

dialing

0: 0 ms

1: 10 ms

¦

255:2550 ms

Sets the definition of the DP

dial.

0: Normal

1: Shift

2: Reverse

Normal: n

Shift: n+1

Reverse: 10-n

n=Dial No.

When dialing is

interrupted

0: OFF

1: ON

because any of

the settings for

DTC/LCC is not

satisfied during

redialing, that

redialing is

ignored since it

is considered

as an internal

retry.

Sets the number of redialings.

0: No retry

1: 1 redialing

¦

14: 14 redial-

Sets the time

for a pause

when it is

inserted

between the

dial numbers.

Sets the interval

between digits

for DP dialing.

0: 0 sec

1: 1 sec

2: 2 sec

3: 4 sec

4: 3.3 sec

5: 10 sec

0: 900 ms

1: 550 ms

2: 700 ms

3: 800 ms

Sets the interval

0: Default

between redialings.

1: 1 min

¦

15: 15 min

Default

ASM AUS HKG USA DEU GBR ITA BEL NDL

100 100 100 100 100 100 100 100 100

000000000

000011000

524534335

ings

422422320

002303322

313100322

(3 min)

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SELF-DIAGNOSIS MODE

2 - 12

11/10

Page 27

Default

FIN ESP AUT CHE SWE DNK NOR PRT FRA GRC POL HUN CZE TUR ZAF TWN

Code

100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 13-

123

00001 0200000000013-

125

00100 1100000000013-

127

33145 4935433355213-

128

22202 2212444444413-

129

2

01332 2220330000013-

132

02221 0013333333213-

135

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

2 - 13

11/10

SELF-DIAGNOSIS MODE

Page 28

Code

13-

137

13-

138

13-

139

13-

140

13-

141

Adjust-

ment

DP

make/

break

ratio

(Line 1)

MF timing

(Line 1)

DTC RX

ATT

(PSTN)

(Line 1)

DTC RX

ATT

(PABX)

(Line 1)

MF TXATT

(Line 1)

Function Setting

Sets the make/

0: 60/40

break ratio for

DP dialing.

1: 67/33

2: 63/37

3: 50/50

4: 67/33

5: 70/30

(20 PPS, TWN

only)

Sets the ON/

OFF timing of

MF signals. Do

not set the

value “4” for the

function code

138 and 268 to

0: 80/80 ms

1: 70/70 ms

2: 70/150 ms

3: 60/60 ms

4: 80/100 ms

5: 150/50 ms

6: 150/240 ms

ensure minimum time of the

MF signal duration ruled in

TBR21

(Requirement

4.8.2.4, 4.8.2.5)

Sets the reception level when

the dial tone is

detected for the

PSTN.

0: -24 dBm

1: -27 dBm

2: -30 dBm

3: -33 dBm

4: -36 dBm

5: -39 dBm

6: -42 dBm

7: -45 dBm

Sets the reception level when

the dial tone is

detected for the

PABX.

0: -24 dBm

1: -27 dBm

2: -30 dBm

3: -33 dBm

4: -36 dBm

5: -39 dBm

6: -42 dBm

7: -45 dBm

Sets the attenuator value for

the MF signal.

0: 0 dB

1: -1 dB

¦

15: -15 dB

(Value

decreased one

by one)

Default

ASM AUS HKG USA DEU GBR ITA BEL NDL

111001010

(10 PPS)

(10 PPS)

(10 PPS)

(10 PPS)

(20 PPS)

202440011

666666666

666666666

385355555

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SELF-DIAGNOSIS MODE

2 - 14

11/10

Page 29

Default

FIN ESP AUT CHE SWE DNK NOR PRT FRA GRC POL HUN CZE TUR ZAF TWN

Code

01000 1011010011513-

137

2

02001 2000403122413-

138

66666 6666666666613-

139

66666 6666666666613-

140

55555 5555555533313-

141

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

2 - 15

11/10

SELF-DIAGNOSIS MODE

Page 30

Code

13-

142

13-

143

13-

149

13-

150

13-

151

Adjust-

ment

International

DTC frequency

International

dial

access

code

(Line 1)

ATT

control

(Line 1)

BTC ON

time

(Line 1)

BTC

OFF

time

(Line 1)

Function Setting

Selects the fre-

00: No detecquency range

for the dial

tone of the first

pause to be

detected.

01: 300-600 Hz

02: 300-650 Hz

03: 390-550 Hz

04: 400-450 Hz

05: 350-480 Hz

06: 300-500 Hz

07: France

Selects the fre-

10: No detecquency range

for the dial

tone to be

detected after

dialing the second international dial

access code.

Sets the international

access code.

11: 300-600 Hz

12: 30-650 Hz

13: 390-550 Hz

14: 400-450 Hz

15: 350-480 Hz

16: 300-500 Hz

17: France

Numeric value

of 3 digits

(Default set-

ting: 4 digits)

Sets the

receiver atten-

0: OFF

1: -3 dB

uator.

Sets time that

a busy-tone

0: 80-650 ms

1: 450-550

signal is output to be deter-

2: 200-650

mined it is ON.

3: 400-600

4: 120-550

5: 420-610

Sets time that

a busy-tone

0: 80-650 ms

1: 450-550

signal is not

output to be

2: 200-650

determined it is

OFF.

3: 400-600

4: 160-600

5: 170-700

6: 380-630

7: 150-470

Default

ASM AUS HKG USA DEU GBR ITA BEL NDL

000000000

tion

Dual Tone

(not used)

tion

Dual Tone

(not used)

1000 1000 1000 1000 1000 1000 1000 1000 1000

000000000

222222222

ms

ms

ms

ms

ms

222222222

ms

ms

ms

ms

ms

ms

ms

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SELF-DIAGNOSIS MODE

2 - 16

11/10

Page 31

Default

FIN ESP AUT CHE SWE DNK NOR PRT FRA GRC POL HUN CZE TUR ZAF TWN

Code

000000000000000213-

142

1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 13-

143

2

000000000000000013-

149

222222222222222213-

150

222222222222222213-

151

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

2 - 17

11/10

SELF-DIAGNOSIS MODE

Page 32

Code

13-

152

13-

153

13-

200

13-

201

13-

203

13-

206

13-

210

13-

211

13-

213

Adjust-

ment

MF dial

level

balance

(Line 1)

Italian

Intermittent

DTC

function

(Line 1)

Exchang

e type

(Line 1)

Dial

selection

(Line 1)

Dialer

type

(Line 1)

Local/

distant

dial

(Line 1)

Exchang

e type

(Line 2)

Dial

selection

(Line 2)

Dialer

type

(Line 2)

Function Setting

Sets the difference between

the high output

and low output

of the MF signal.

0: 0 dB

1: -1 dB

¦

4: -4 dB

(Value

decreased

one by one)

Sets Italian

intermittent

0: OFF

1: ON

DTC function.

Selects the

exchange type.

Selects the

0: PSTN

1: PABX

0: Not

access type for

the PABX.

1: Local/Dis-

2: Access

Selects the dial

type.

Key in an

access code

designated for

the access type

0: DP

1: MF

Numeric value

of 3 digits (4

digits for the

default setting)

selected for the

function code

201.

Local: 2 digits

Distant: 2 digits

Access Digit: 3

digits

Selects the

exchange type.

Selects the

0: PSTN

1: PABX

0: Not

access type for

the PABX.

1: Local/Dis-

2: Access

Selects the dial

type.

0: DP

1: MF

Default

ASM AUS HKG USA DEU GBR ITA BEL NDL

222222222

000000100

000000000

111111111

defined

tant

Digit

111111111

1000 1000 1000 1000 1000 1000 1000 100 1000

000000000

111111111

defined

tant

Digit

111111111

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SELF-DIAGNOSIS MODE

2 - 18

11/10

Page 33

Default

FIN ESP AUT CHE SWE DNK NOR PRT FRA GRC POL HUN CZE TUR ZAF TWN

Cod

e

222222222222222213-

152

2

000000000000000013-

153

000000000000000013-

200

111111111111111113-

201

111111111111111113-

203

1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 13-

206

000000000000000013-

210

111111111111111113-

211

111111111111111113-

213

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

2 - 19

11/10

SELF-DIAGNOSIS MODE

Page 34

Code

13-

216

13-

220

13-

221

13-

222

13-

223

13-

224

13-

225

Adjust-

ment

Local/

distant

dial

(Line 2)

DTC frequency

(PSTN)

(Line 2)

DTC

time

(PSTN)

(Line 2)

LCC

allowed

gaps

(PSTN)

(Line 2)

DTC

allowed

gaps

(PSTN)

(Line 2)

DTC/

LCC for

PSTN

(Line 2)

DTC

time out

(PSTN)

(Line 2)

Function Setting

Key in an

access code

designated for

the access type

Numeric value

of 3 digits (4

digits for the

default setting)

selected for the

function code

211.

Local: 2 digits

Distant: 2 digits

Access Digit: 3

digits

Sets the dial

tone frequency

to be detected

for the PSTN.

0: 300-600 Hz

1: 300-650 Hz

2: 390-550 Hz

3: 400-450 Hz

4: 350-480 Hz

5: 300-500 Hz

Sets the time

for a tone

sounds to be

determined as

dial tone for the

PSTN.

0: 2 sec

1: 800 ms

2: 400 ms

3: 1 sec

4: 1.3 sec

5: 1.8 sec

6: 2.5 sec

7: 500 ms

Sets the interruption time for

the PSTN to be

ignored during

0: OFF

1: 50 ms

2: 100 ms

3: 200 ms

LCC.

Sets the interruption time for

the PSTN to be

ignored during

0: OFF

1: 320 ms

2: 160 ms

3: 240 ms

DTC.

Selects which is

0: BZT (DTC/

to be used for

the PSTN, DTC

or LCC.

1: LCC 5 sec

2: DTC only

3: FRN (LCC/

4: DTC (JPN&

5: NO

Sets how long

the dial tone

detection is performed.

0: 20 sec

1: 10 sec

2: 8 sec

3: 15 sec

4: 3.3 sec

Default

ASM AUS HKG USA DEU GBR ITA BEL NDL

1000 1000 1000 1000 1000 1000 1000 1000 1000

000011111

000322222

000322222

111111111

222222222

LCC)

DTC)

USA)

DTC&LCC

000111111

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SELF-DIAGNOSIS MODE

2 - 20

11/10

Page 35

Default

FIN ESP AUT CHE SWE DNK NOR PRT FRA GRC POL HUN CZE TUR ZAF TWN

Code

1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 13-

216

111111111111100113-

220

2

222222222222200213-

221

222222222222200213-

222

111111111111111113-

223

222222222222222213-

224

111111111111100113-

225

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

2 - 21

11/10

SELF-DIAGNOSIS MODE

Page 36

Code

13-

226

13-

227

13-

228

13-

229

13-

230

13-

231

13-

232

13-

236

Adjust-

ment

DTC frequency

(PABX)

(Line 2)

DTC

time

(PABX)

(Line 2)

LCC

allowed

gaps

(PABX)

(Line 2)

DTC

allowed

gaps

(PABX)

(Line 2)

DTC/

LCC for

PABX

(Line 2)

DTC

time out

(PABX)

(Line 2)

BTC frequency

(Line 2)

Dial T1

timer

(Line 2)

Function Setting

Sets the dial

tone frequency

to be detected

for the PABX.

0: 300-600 Hz

1: 300-650 Hz

2: 390-550 Hz

3: 400-450 Hz

4: 350-480 Hz

5: 300-500 Hz

Sets the time

for a tone

sounds to be

determined as

dial tone for the

PABX.

0: 2 sec

1: 800 ms

2: 400 ms

3: 1 sec

4: 1.3 sec

5: 1.8 sec

6: 2.5 sec

7: 150 ms

Sets the interruption time for

the PABX to be

ignored during

0: OFF

1: 50 ms

2: 100 ms

3: 200 ms

LCC.

Sets the interruption time for

the PABX to be

ignored during

0: OFF

1: 320 ms

2: 160 ms

3: 240 ms

DTC.

Selects which is

0: BZT (DTC/

to be used for

the PABX, DTC

or LCC.

1: LCC 5 sec

2: DTC only

3: FRN (LCC/

4: DTC (JPN&

5: NO

Sets how long

the dial tone

detection is performed.

0: 20 sec

1: 10 sec

2: 8 sec

3: 15 sec

4: 3.3 sec

Sets the busy

0: Not

tone frequency

to be detected

for the PSTN

and PABX.

1: 300-600 Hz

2: 350-550 Hz

3: 300-500 Hz

4: 300-700 Hz

Sets the time to

wait for a

response from

the receiver

after dialing is

0: 60 sec

1: 35 sec

2: 90 sec

3: 55 sec

4: 115 sec

completed.

Default

ASM AUS HKG USA DEU GBR ITA BEL NDL

000011111

000622222

000033333

111111111

555555555

LCC)

DTC)

USA)

DTC&LCC

000111111

000111111

detected

030322222

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SELF-DIAGNOSIS MODE

2 - 22

11/10

Page 37

Default

FIN ESP AUT CHE SWE DNK NOR PRT FRA GRC POL HUN CZE TUR ZAF TWN

Cod

e

11111 1111111100113-

226

22222 2222222200213-

227

2

33333 3333333300213-

228

11111 1111111111113-

229

55555 5555555555513-

230

11111 1111111100113-

231

11111 1111111100113-

232

22222 2222222200313-

236

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

2 - 23

11/10

SELF-DIAGNOSIS MODE

Page 38

Code

13-

245

13-

247

13-

249

13-

262

13-

267

13-

268

Adjust-

ment

Dial

information

(Line 2)

Internal

retry

(Line 2)

Time for

a pause

(Line 2)

Interdigit

pause

(Line 2)

DP

make/

break

ratio

(Line 2)

MF timing

(Line 2)

Function Setting

Sets the definition of the DP

dial.

0: Normal

1: Shift

2: Reverse

Normal: n

Shift: n+1

Reverse: 10-n

n=Dial No.

When dialing is

interrupted

0: OFF

1: ON

because any of

the settings for

DTC/LCC is not

satisfied during

redialing, that

redialing is

ignored since it

is considered

as an internal

retry.

Sets the time

for a pause

when it is

inserted

between the

dial numbers.

Sets the interval

between digits

for DP dialing.

0: 0 sec

1: 1 sec

2: 2 sec

3: 4 sec

4: 3.3 sec

5: 10 sec

0: 900 ms

1: 550 ms

2: 700 ms

3: 800 ms

Sets the make/

0: 60/40(10

break ratio for

DP dialing.

1: 67/33(10

2: 63/37(10

3: 50/50(10

4: 67/33(20

5: 70/30

(10 PPS, TWN

only)

Sets the ON/

OFF timing of

MF signals. Do

not set the

value “4” for the

function code

138 and 268 to

0: 80/80 ms

1: 70/70 ms

2: 70/150 ms

3: 60/60 ms

4: 80/100 ms

5: 150/50 ms

6: 150/240 ms

ensure minimum time of the

MF signal duration ruled in

TBR21.

(Requirement

4.8.2.4, 4.8.2.5)

Default

ASM AUS HKG USA DEU GBR ITA BEL NDL

000000000

000011000

422422320

002303322

111001010

PPS)

PPS)

PPS)

PPS)

PPS)

202440011

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SELF-DIAGNOSIS MODE

2 - 24

11/10

Page 39

Default

FIN ESP AUT CHE SWE DNK NOR PRT FRA GRC POL HUN CZE TUR ZAF TWN

Code

00001 0200000000013-

245

2

00100 1100000000013-

247

22202 2212444444413-

249

01332 2220330000013-

262

01000 1011010011513-

267

02001 2000403122413-

268

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

2 - 25

11/10

SELF-DIAGNOSIS MODE

Page 40

Code

13-

269

13-

270

13-

271

13-

272

13-

273

13-

279

Adjust-

ment

DTC RX

ATT

(PSTN)

(Line 2)

DTC RX

ATT

(PABX)

(Line 2)

MF TXATT

(Line 2)

International

DTC frequency

(Line 2)

International

dial

access

code

(Line 2)

ATT

control

(Line 2)

Function Setting

Sets the

reception

level when

the dial tone

is detected

for the

PSTN.

0: -24 dB

1: -27 dB

2: -30 dB

3: -33 dB

4: -36 dB

5: -39 dB

6: -42 dB

7: -45 dB

Sets the

reception

level when

the dial tone

is detected

for the

PABX.

0: -24 dB

1: -27 dB

2: -30 dB

3: -33 dB

4: -36 dB

5: -39 dB

6: -42 dB

7: -45 dB

Sets the

attenuator

value for the

MF signal.

0: 0 dB

1: -1 dB

¦

15: -15 dB

(Value

decreased one

by one)

Selects the

frequency

range for

the dial tone

of the first

pause to be

detected.

00: No detec-

tion

01: 300-600 Hz

02: 300-650 Hz

03: 390-550 Hz

04: 400-450 Hz

05: 350-480 Hz

06: 300-500 Hz

07: France

Dual Tone

(not used)

Selects the

frequency

range for

the dial tone

to be

detected

after dialing

the second

international dial

access

10: No detec-

tion

11: 300-600 Hz

12: 300-650 Hz

13: 390-550 Hz

14: 400-450 Hz

15: 350-480 Hz

16: 300-500 Hz

17: France

Dual Tone

(not used)

code.

Sets the

international

access

Numeric value

of 3 digits

(Default setting: 4 digits)

code.

Sets for the

receiver

0: OFF

1: -3 dB

attenuator.

Default

ASM AUS HKG USA DEU GBR ITA BEL NDL

666666666

666666666

385355555

000000000

1000 1000 1000 1000 1000 1000 1000 1000 1000

000000000

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SELF-DIAGNOSIS MODE

2 - 26

11/10

Page 41

Default

FIN ESP AUT CHE SWE DNK NOR PRT FRA GRC POL HUN CZE TUR ZAF TWN

Co

de

666 666666666666613-

269

666 666666666666613-

270

555 555555555533313-

271

000 000000000000213-

272

2

1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 13-

273

000 000000000000013-

279

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

2 - 27

11/10

SELF-DIAGNOSIS MODE

Page 42

Code

13-

280

13-

281

13-

282

13-

283

Adjust-

ment

BTC ON

time

(Line 2)

BTC

OFF

time

(Line 2)

MF dial

level

balance

(Line 2)

Italian

intermittent

DTC

function

(Line 2)

Function Setting

Sets the time

range for the

0: 80-650 ms

1: 450-550

busy tone ontime.

2: 200-650

3: 400-600

4: 120-550

5: 420-610

Sets the time

range for the

0: 80-650 ms

1: 450-550

busy tone offtime.

2: 200-650

3: 400-600

4: 160-600

5: 170-700

6: 380-630

7: 150-470

Sets the difference between

the high output

and low output

of the MF signal.

0: 0 dB

1: -1 dB

¦

4: -4 dB

(Value

decreased one

by one)

Sets Italian

intermittent

0: OFF

1: ON

DTC function.

Default

ASM AUS HKG USA DEU GBR ITA BEL NDL

222222222

ms

ms

ms

ms

ms

222222222

ms

ms

ms

ms

ms

ms

ms

222222222

000000100

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SELF-DIAGNOSIS MODE

2 - 28

11/10

Page 43

Default

FIN ESP AUT CHE SWE DNK NOR PRT FRA GRC POL HUN CZE TUR ZAF TWN

Code

22222 2222222222213-

280

22222 2222222222213-

281

2

22222 2222222222213-

282

00000 0000000000013-

283

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

2 - 29

11/10

SELF-DIAGNOSIS MODE

Page 44

300-699 Adjustments for switching function specifications

13-

13-

13-

13-

13-

Adjust-

ment

CI history hold

time

(Line 1)

CI

detection frequency

range

(Line 1)

Handling of

negative

answer

TX

attenuation

value

(V.17)

(Line 1)

Cable

equalizer

(V.17)

(Line 1)

Function Setting

Sets the time

for the CI history to remain.

Sets the frequency range

for CI detection.

0: 5 sec

1: 8 sec

2: 14 sec

0: 12-80 Hz

1: 16-55 Hz

2: 20-55 Hz

3: 22-55 Hz

4: 5-200 Hz

Sets whether

the RTN

0: Abnormal

1: Normal

received is handled as abnormal (NG) or

normal when

the data are

slightly abnormal.

Abnormal: DCN

is transmitted to

stop the communication.

Normal:

Next page is

transmitted normally.

Sets the

modem transmission level for

communication

other than V.34.

0: 0 dB

1: -1 dB

¦

15: -15 dB

(Value

The smaller the

value is, the

higher the

transmission

level becomes.

If errors occur

frequently or

training is not

sent, the transmission level

should be

changed.

Sets the equalizer value which

has frequency

characteristics.

0: 0 dB

1: -4 dB

2: -8 dB

3: -12 dB

For the longdistance communication, it is

recommended

to set a large

value.

ASM AUS HKG USA DEU GBR ITA BEL NDL

111222222

000011111

111000000

10 10 10 10 12 12 12 12 12

decreased

one by

one)

000000000

Code

312

313

317

325

328

Default

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SELF-DIAGNOSIS MODE

2 - 30

11/10

Page 45

Default

FIN ESP AUT CHE SWE DNK NOR PRT FRA GRC POL HUN CZE TUR ZAF TWN

Code

22222 2 222222211213-

312

11111 1 111111100013-

313

00000 0 000000011013-

317

12 12 12 12 12 12 12 12 12 12 12 12 12 10 10 13 13-

325

2

00000 0 000000000013-

328

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

2 - 31

11/10

SELF-DIAGNOSIS MODE

Page 46

Code

13-

331

13-

335

13-

338

13-

339

13-

340

13-

346

13-

350

Adjust-

ment

Echo

protection

delay

(high

speed)

(V.21)

Modem

speed

initial

value

Forcible

line

monitoring

CI-ON

determine

time

(Line 1)

CI-OFF

determine

time

(Line 1)

Recording width

capacity

declaration

High

speed

carrierOFF

detection

timer

Function Setting

Sets if a delay

(500 ms) is

0: OFF

1: ON (500

inserted before

sending the

V.21 signal and

timing is shifted

to avoid the line

echo.

Sets the initial

modem speed

0: 2,400 bps

1: 14.4 kbps

to be declared

by DIS/DCS.

4: 4,800 bps

5: 12 kbps

8: 9,600 bps

9: 9,600 bps

12: 7,200 bps

13: 7,200 bps

Selects the line

to monitor.

0: OFF

1: Line 1

2: Line 2

CI ON-satiable

time.

0: 175 ms

1: 125 ms

2: 800 ms

3: 145 ms

CI OFF-satiable time.

0: 650 ms

1: 350 ms

2: 175 ms

3: 90 ms

Selects either

one of the fol-

0: Paper

1: Drawer

lowings to

declare the

maximum

recording width

to the other

party when the

specified paper

size is not available; the largest

paper in the

other drawer or

the drawer for

the largest

paper.

Sets the time to

determine the

0: 1.5 sec

1: 6 sec (FTZ)

carrier signal is

stopped completely.

Default

ASM AUS HKG USA DEU GBR ITA BEL NDL

101111111

ms)

111111111

(V.17)

(V.17)

(V.17)

(V.17)

000000000

000000000

222222222

000000000

111111111

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SELF-DIAGNOSIS MODE

2 - 32

11/10

Page 47

Default

FIN ESP AUT CHE SWE DNK NOR PRT FRA GRC POL HUN CZE TUR ZAF TWN

Code

11111 1111111111113-

331

11111 1111111111113-

335

2

00000 0000000000013-

338

00000 0000000000013-

339

22222 2222222222213-

340

00000 0000000000013-

346

11111 1111111111113-

350

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

2 - 33

11/10

SELF-DIAGNOSIS MODE

Page 48

Code

13-

351

13-

355

13-

356

13-

357

13-

359

13-

361

Adjust-

ment

Off-hook

alarm

Memory

transmission

report

Multi

address

transmission

report

Direct

document

transmission

report

Multi

polling

report

ITU-T

Relay

transmission

(originator)

report

Function Setting

Sets the volume

of the alarm

0: No alarm

1: Level 1

sounded when

the handset has

been left off the

¦

7: Level 7

cradle even

though the

communication

is finished.

Sets whether

the memory

0: OFF

1: On Error

transmission

report is output

or not. Also,

selects the out-

2: ALWAYS

3: On Error

5: On Error

put conditions.

6: Always (W)

7: On Error

Sets whether

the multiaddress transmission report

is printed or not.

0: OFF

1: Always

2: On error

3: Always (W)

4: On error

Also, selects

the output condition.

Sets whether

the direct transmission report

0: OFF

1: Always

2: On error

is printed or not.

Also, selects

the output condition.

Sets whether

the multi-polling transmis-

0: OFF

1: Always

2: On error

sion report is

printed or not.

Also, selects

the output condition.

Sets whether

the report is

printed or not.

Also, selects

the output con-

0: OFF

1: Always

2: On error

3: Always (W)

4 On error

dition.

Default

ASM AUS HKG USA DEU GBR ITA BEL NDL

000033333

(Min.)

(Max.)

777766666

(BZT)

(BZT/W)

(W)

444433333

(W)

111111111

222211111

333333333

(W)

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SELF-DIAGNOSIS MODE

2 - 34

11/10

Page 49

Default

FIN ESP AUT CHE SWE DNK NOR PRT FRA GRC POL HUN CZE TUR ZAF TWN

Code

33333 3333333300013-

351

66666 6666666677713-

355

33333 3333333344413-

356

2

11111 1111111111113-

357

11111 1111111122213-

359

33333 3333333333313-

361

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

2 - 35

11/10

SELF-DIAGNOSIS MODE

Page 50

Code

13-

362

13-

363

13-

365

13-

367

13-

368

13-

370

Adjust-

ment

Result

report

printout

for relay

hub station

ITU-T

Relay

transmission

(end station)

report

Printing

function

for relay

station

(reception

report)

F-code

acceptance list

Journal

autooutput

Communication

result on

journal

(OK/NG)

Function Setting

Sets whether

the relay multiaddress transmission report

is printed or not.

0: OFF

1: Always

2: On error

3: Always (W)

4: On error

Also, selects

the output condition.

Sets whether

the report is

transported or

not. Also,

selects the

0: OFF

1: Always

2: On error

3: Always (W)

4: On error

transport condition.

Sets whether

the relay multi-

0: OFF

1: ON

address reception report is

printed or not.

Sets whether

the acceptance

0: OFF

1: Remote

list is printed

when the data

are sent into the

2: Remote

confidential box

or bulletin board

or not. Also,

3: ON

selects the output condition.

Sets whether

the journal is

0: OFF

1: ON

output automatically or not.

Selects whether

0: Not

the communication result (OK/

1: Reported

NG) is reported

on the journal or

not.

Default

ASM AUS HKG USA DEU GBR ITA BEL NDL

444433333

(W)

222222222

(W)

000011111

000011111

ON, local

OFF

OFF, local

ON

111111111

111111111

reported

13-

371

13-

372

Communication

result on

journal

(error

code)

CI

detection

counter

setting

for autoRX

Selects whether

the communication error code

is reported on

the journal or

not.

Sets the CI

counter value

for the machine

to enter the

automatic

reception mode.

0: Not

reported

1: Reported

0: Once

1: Once

¦

15: 15 times

(Value

increased one

by one)

111111111

141222222

(Line 1)

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SELF-DIAGNOSIS MODE

2 - 36

11/10

Page 51

Default

FIN ESP AUT CHE SWE DNK NOR PRT FRA GRC POL HUN CZE TUR ZAF TWN

Code

33333 3333333344413-

362

22222 2222222222213-

363

11111 1111111100013-

365

11111 1111111100013-

367

2

11111 1111111111113-

368

11111 1111111111113-

370

11111 1111111111113-

371

22222 2222222211213-

372

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

2 - 37

11/10

SELF-DIAGNOSIS MODE

Page 52

Code

13-

373

13-

375

13-

377

13-

378

13-

379

13-

382

13-

389

13-

391

13-

394

13-

398

Adjust-

ment

Speaker

volume

(monitor

tone)

Discard

parameter on

printing

Printing

mode

(Reduction in

vertical

direction)

Discard

printing

Maximum

reduction rate

in vertical

direction

Reception

information on

received

document

RX

mode

(PSTN)

ECM

function

Recovery

transmission

retaining time

Line

default

Function Setting

Sets the

0: Level 0

speaker volume for onhook status or

¦

7: Level 7

protocol monitor.

Sets the data

0: 0 mm (No

length to be discarded when

the received

data exceed the

effective record-

1: 10 mm

2: 18 mm

3: 22 mm

4: 34 mm

ing length.

Sets if the

0: Autoreceived document is reduced

1: No reducautomatically in

the vertical

direction to

appropriate

recording size.

Selects if the

discard printing

0: OFF

1: ON

is performed.

Sets the maximum reduction

0: 90%

1: 75%

rate in the vertical direction.

Sets if the

receiver infor-

0: OFF

1: ON

mation is

printed on

received document.

Selects the

receiving mode.

0: TEL

1: FAX

2: TEL/FAX

Sets if the ECM

communication

0: OFF

1: ON

is performed.

Sets the time

for the HDD to

retain data

1: 1 hour

¦

24: 24 hours

when the transmission was

terminated due

to an error.

Sets the line

default Line 1 or

0: Line 1

1: Line 2

Line 2

Default

ASM AUS HKG USA DEU GBR ITA BEL NDL

444333333

(Min.)

(Max.)

111111111

elimination)

000000000

reduction

tion

111111111

010111111

000000000

111111111

111111111

666666666

000000000

GD-1210/1250/1270/1160/1260 © 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved

SELF-DIAGNOSIS MODE

2 - 38

11/10

Page 53

Default

FIN ESP AUT CHE SWE DNK NOR PRT FRA GRC POL HUN CZE TUR ZAF TWN

Code

33333 3333333344313-

373

11111 1111111111113-

375

00000 0000000000013-

377

2

11111 1111111111113-

378

11111 1111111100113-

379

00000 0000000000013-

382

11111 1111111111113-

389

11111 1111111111113-

391

66666 6666666666613-

394

00000 0000000000013-

398

© 2006 - 2011 TOSHIBA TEC CORPORATION All rights reserved GD-1210/1250/1270/1160/1260

2 - 39

11/10

SELF-DIAGNOSIS MODE

Page 54

Code

13-

430

13-

433

13-

501

13-

509

13-

510

Adjust-

ment

TX

attenuation

value

(V.17)

(Line 2)

Cable

equalizer

(V.17)

(Line 2)

Communication

control

in case

PPR is

received

four

times

Modem

speed

for overseas

communication

(except

V.34)

Position

of

header

for

transmission

information

Function Setting

This value is to

set the modem

transmission

level for communication

other than V.34.

The smaller the

0: 0 dB

1: -1 dB

¦

15: -15 dB

(Value

decreased one

by one)

value is, the

higher the

transmission

level becomes.