Toshiba GD 1080, GD 1090 Service Handbook

SERVICE HANDBOOK

FACSIMILE (FOR DP4500/3500)

GD1080/1090

Click the Navigation Pane button to open the overview area and

display bookmarks and thumbnails palettes.

Click the Bookmarks to open the Contents and display Bookmarks

created for the document. Click a bookmark's name to go to the

Page marked by that bookmark.

Click the Thumbnails to open the overview area and display

thumbnail images of each document page. Click a thumbnail to go

to the Page marked by that thumbnail.

Copyright TOSHIBA TEC CORPORATION 2001

ALL RIGHTS RESERVED

GENERAL PRECAUTIONS REGARDING THE INSTALLATION

AND SER VICE FOR DP4500/3500 AND GD1080/1090

The installation and service should be done by a qualified service technician.

1. T ransportation/Installation

• When transporting/installing the copier, employ two persons and be sure to use the positions as

indicated below .

The copier is quite heavy and weighs approximately 73kg (161lb), therefore pay full attention when

handling it.

• Be sure to use a dedicated outlet with AC 115V or 120V/15A (220V, 230V , 240V/10A) or more f or

its power source.

• The copier must be grounded for saf ety.

Never g round it to a gas pipe or a water pipe.

• Select a suitable place for installation.

Av oid excessive heat, high humidity, dust, vibration and direct sunlight.

• Also provide proper ventilation as the copier emits a slight amount of ozone .

• To insure adequate working space for the copying operation, keep a minimum clearance of

80 cm (32”) on the left, 80 cm (32”) on the right and 10 cm (4”) in the rear.

2. Service of Machines

• Basically, be sure to turn the main switch off and unplug the power cord during service.

• Be sure not to touch high-temperature sections such as the exposure lamp, the fuser unit, the

damp heater and their periphery.

• Be sure not to touch high-voltage sections such as the chargers, high-voltage transformer, IH

control circuit, exposure lamp control inverter, inverter for the LCD backlight and power supply

unit. Especially, the board of these components should not be touched since the electirc charge

may remain in the condensers, etc. on them even after the power is turned OFF.

• Be sure not to touch rotating/operating sections such as gears, belts, pulleys, fan, etc.

• Be careful when removing the covers since there might be the parts with very sharp edges underneath.

• When servicing the machines with the main switch turned on, be sure not to touch live sections

and rotating/operating sections. Av oid exposure to laser radiation.

• Use suitable measuring instruments and tools.

• Av oid exposure to laser radiation during servicing.

− Av oid direct exposure to the beam.

− Do not insert tools, parts, etc. that are reflective into the path of the laser beam.

− Remove all watches, rings, bracelets , etc. that are reflective.

3. Main Service Parts for Safety

• The breaker , door switch, fuse, thermostat, thermofuse, thermistor, etc. are particularly important

for safety. Be sure to handle/install them properly.

4. Cautionary Labels

• During servicing, be sure to check the rating plate and the cautionary labels such as “Unplug the

power cord during service”, “Hot area”, “Laser w arning label” etc. to see if there is any dirt on their

surface and whether they are properly stuck to the copier.

5. Disposition of Consumable Parts/Packing Materials

• Regarding the recovery and disposal of the copier, supplies , consumable parts and packing materials, it is recommended to follow the relevant local regulations or rules.

6. When parts are disassembled, reassembly is basically the reverse of disassembly unless

otherwise noted in this manual or other related documents. Be careful not to reassemble

small parts such as screws, washer s, pins, E-rings, star washers in the wr ong places.

7. Basically , the machine should not be operated with an y parts removed or disassembled.

8. Precautions Against Static Electricity

• The PC board must be stored in an anti-electrostatic bag and handled carefully using a wristband,

because the ICs on it may become damaged due to static electricity.

Caution: Before using the wristband, pull out the power cor d plug of the copier and make

sure that there are no uninsulated charged objects in the vicinity .

Caution : Dispose of used batteries and RAM-ICs including lithium batteri es

according to the manufacturer’s instructions.

Attention : Se débarrasser de batteries et RAM-ICs usés y compris les batteries en

lithium selon les instructions du fabricant.

V orsic ht : Entsorgung des gebrauchten Batterien und RAM-ICs (inklusive

der Lithium-Batterie) nach Angaben des Herstellers.

1. ERROR CODES

2. SELF-DIAGNOSIS MODE

3. TROUBLESHOOTING

4. PRECAUTIONS FOR

INSTALLATION OF FAX UNIT

5. UPDATING THE FIRMWARE

I October 2000 © T OSHIBA TECGD1080/1090 CONTENTS

CONTENTS

1. ERROR CODES ......................................................................................................................... 1- 1

1.1 Transmission/Reception Journal and Error Code List.............................................................. 1- 1

1.2 Error Messages ..................................................................................................................... 1- 4

2. SELF-DIA GNOSIS MODE .......................................................................................................... 2-1

2.1 Test Mode (03) ....................................................................................................................... 2- 2

2.2 Adjustment Mode (05)............................................................................................................ 2- 4

2.3 Setting Mode (08) .................................................................................................................. 2- 6

2.4 Function Mode (13) ................................................................................................................ 2-7

2.5 Fax Clearing Mode (1*)........................................................................................................... 2-30

2.6 Setting the RDC Pass word..................................................................................................... 2-33

2.7 Automatic Order for Supplies ................................................................................................. 2-34

3. TROUBLESHOO TING ................................................................................................................ 3- 1

3.1 Flow Chart for Recommended Telephone Screening............................................................... 3- 2

3.2 Error Analysis Flow................................................................................................................3-5

3.3 Lists Required When Problem Has Occurred in the Field .......................................................3- 6

3.4 Other Information Required for Error Analysis ........................................................................ 3-11

4. PRECA UTIONS FOR INST ALLA TION OF FAX UNIT .................................................................4- 1

4.1 Installation of Fax Unit ........................................................................................................... 4- 1

4.2 Country/Region Code ............................................................................................................. 4- 2

5. UPDATING THE FIRMWARE ...................................................................................................... 5-1

October 2000 © TOSHIBA TEC 1 - 1 GD1080/1090 ERROR CODES

1. ERROR CODES

1.1 Transmission/Reception Journal and Error Code List

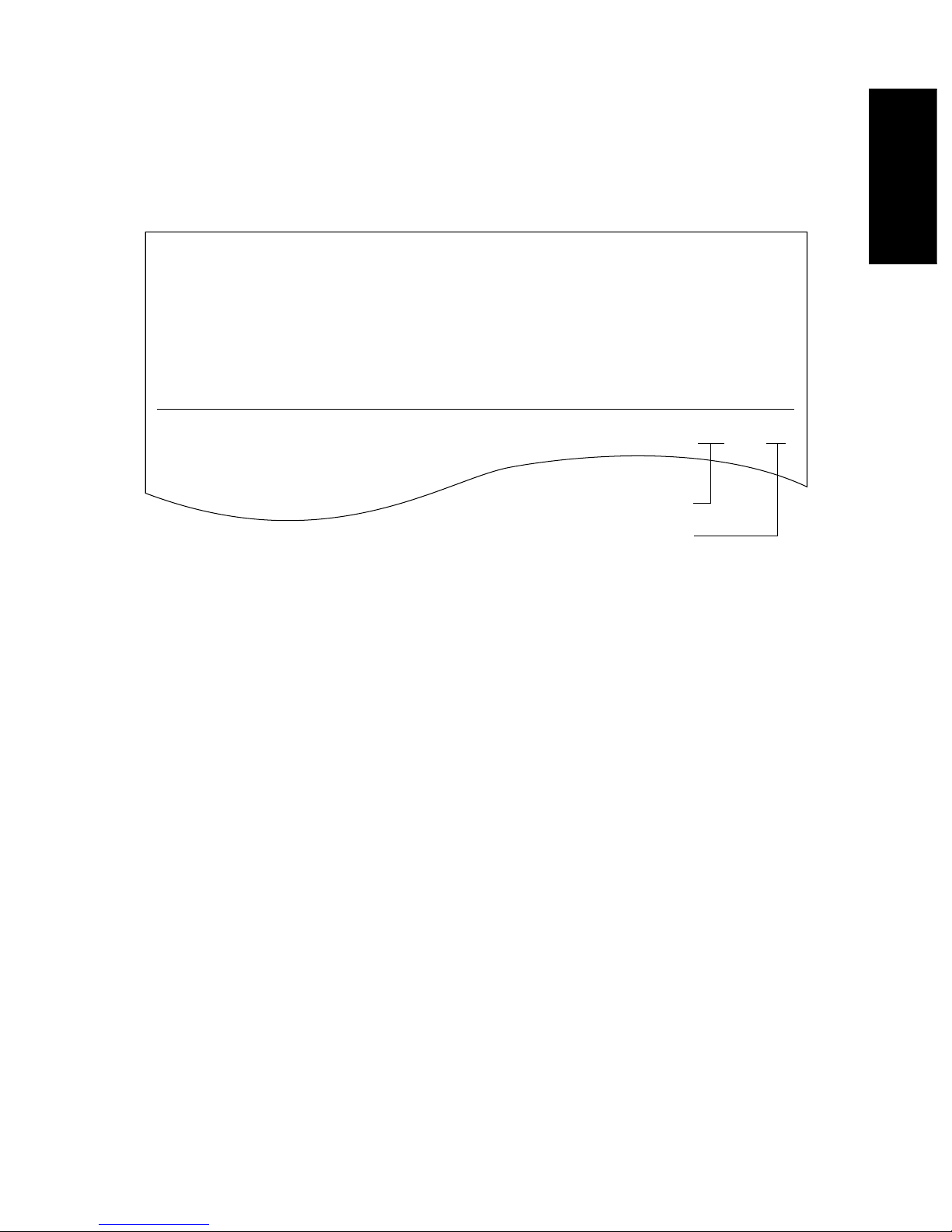

The transmission journal is shown below. The error code list and status code list are available in the

following pages. The reception journal is output in the same form.

TRANSMISSION JOURNAL TIME : MM-DD-YY TIME

TEL NO.1 : XXXXXXXXX

TEL NO.2 : XXXXXXXXX

NAME : X X X X X X X

NO. FILE NO. DATE TIME DURATION PGS TO DEPT MODE STATUS

001 001 12.01 09:00 00:55 2 ABCD G3 xxx OK xx

Status code

Error code

GD1080/1090 ERROR CODES 1 - 2 October 2000 © TOSHIBA TEC

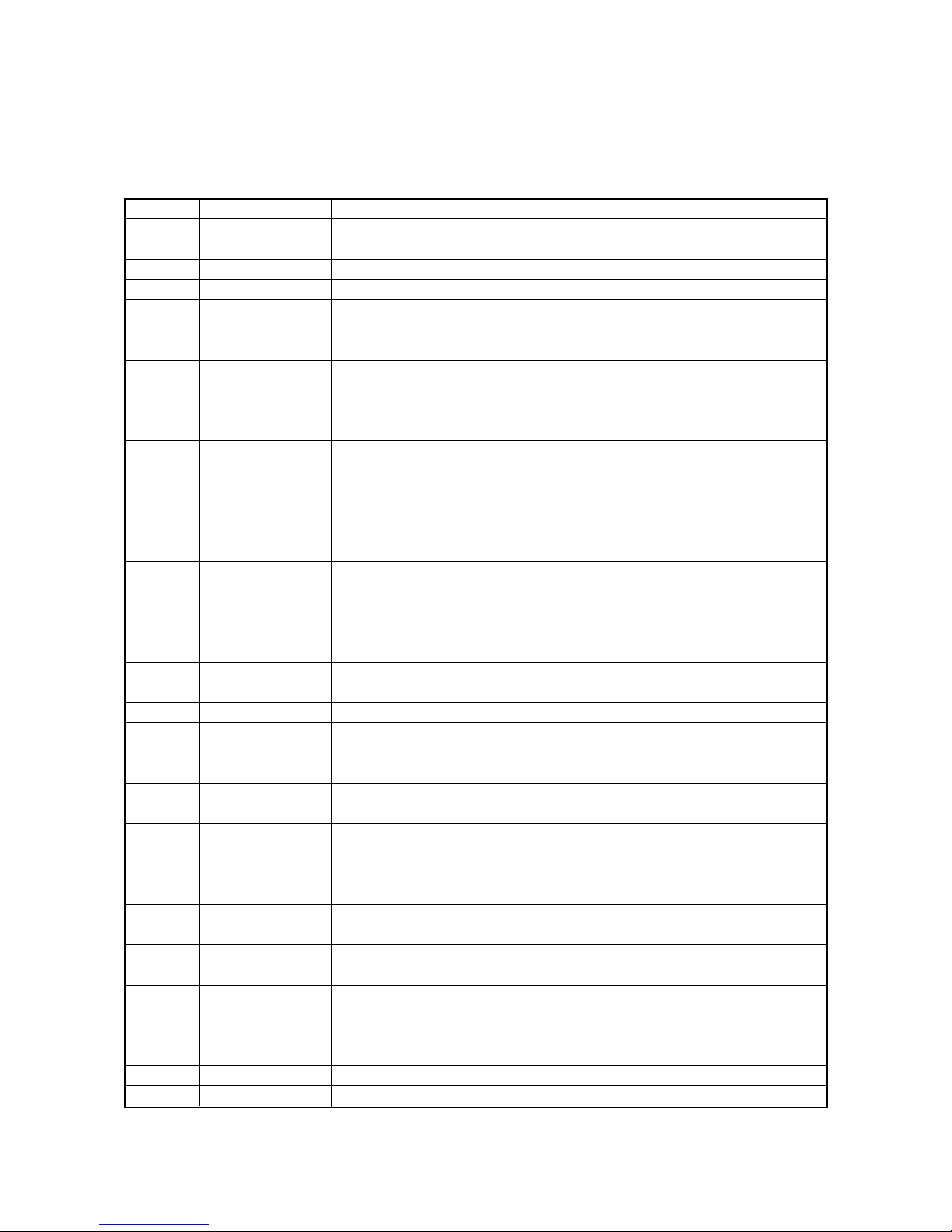

Normal

Paper jam

Original jam

Door is open

Power failure

(Reset)

Polling error

Memory full

Line is busy

Security mismatch

in relay or mail box

transmission

Initial signal not

detected

Terminal constants

not compatible

Reception of DCN

(Phase B)

DCS/DTC not detected

Training error

CFR not detected

Image signal

carrier not detected

High speed signal

not detected

Image signal carrier

disconnected

1st EOL not detected

EOL not detected

Post message not

detected

Reception of DCN

Poor image quality

Image memory error

00

11

12

13

20

30

33

42

50

53

B0

B1

B2

B3

B4

B5

C0

C1

C2

C3

C4

D0

D1

D2

E0

Remove the jamming paper.

Remove the jamming document and retransmit it.

Close the doors securely and retransmit the document.

A power failure occurred during transmission or reception, and the transmission/reception data were lost. Attempt the transmission/reception again.

Communication was stopped by the FC key.

Polling was not performed because the polling document was not found. Check

the polling document on the other side and attempt the polling again.

The memory became full during reception. (The pages normally received are

printed out.) Check the remaining memory space and attempt the reception again.

Transmission is not made because the line is busy. Attempt the transmission

again. As the number of the redialings are increased, the possibility for successful transmission is increased.

Check your security code and system password of the other side as well as y our

own.

NSF/DIS cannot be detected. Check the receiver and attempt the transmission

again.

DIS/NSF that cannot be handled by the sender was received. The receiver received NSS/DCS other than those declared by DIS/NSF. Check the transmission/reception functions, and attempt the communication again.

DCN was received in the phase B.

DCS/DTC cannot be detected.

The sender performed fall-back but the transmission was not made. After the

reception of FTT, the receiver received a time-out or DCN. Adjust the transmitter

attenuator, link equalizer, etc. and retry the communication.

A training signal was sent out but CFR cannot be detected. Adjust the transmitter

attenuator, link equalizer, etc. and retry the transmission.

A carrier was not detected on the receiving side. Adjust the transmitter attenuator ,

link equalizer, etc. and retry the transmission.

High-speed signals were not detected on the receiving side. Adjust the tr ansmitter attenuator, link equalizer, etc. and retry the transmission.

Carrier disconnection was detected after the image signal was detected.

1st EOL was not detected after the high-speed signal was detected.

EOL cannot be detected on the receiving side. Or decoding is not possib le with MMR.

A post message cannot be detected. Retry the communication. MCF, RTP, RTN,

PIN and PIP cannot be detected on the sending side. MPS , EOM and EOP cannot be detected on the receiving side.

DCN was received.

Quality of the received image is poor. Retry the transmission.

Hardware is defective.

[A] Error code list

If an error has occurred during communication, an error code is indicated below “STATUS” on the

transmission/reception journal.

Take the appropriate action referring to the following list.

Error code Content Situation and corrective action

October 2000 © TOSHIBA TEC 1 - 3 GD1080/1090 ERROR CODES

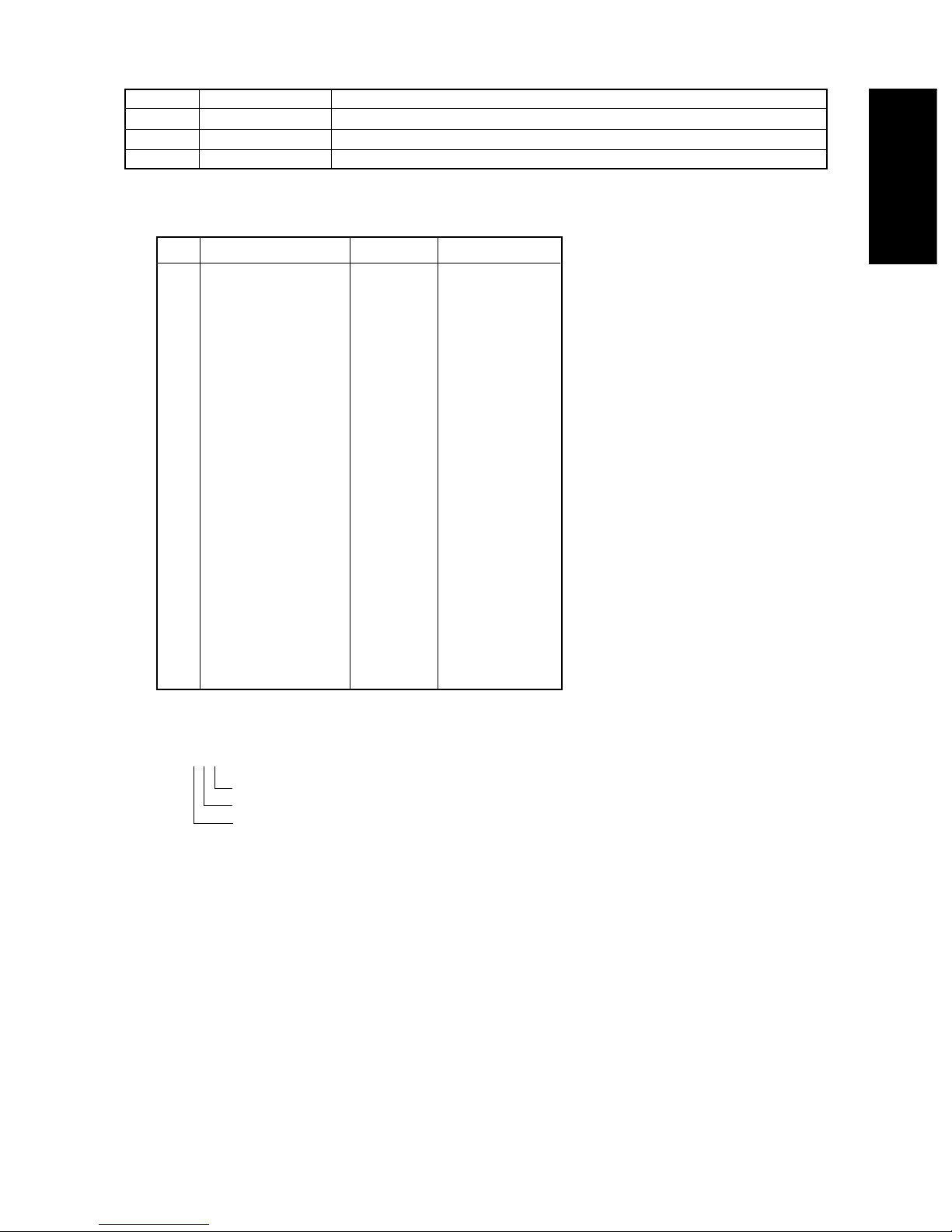

[B] Status code list

[Example of the indication of a status code]

522

MMR (encoding system)

8 x 15.4 (resolution)

14400 (transmission speed)

Mode Transmission speed Resolution Encoding system

0 2400 8 x 3.85 MH

1 4800 8 x 7.7 MR

2 7200 8 x 15.4 MMR

3 9600 JBIG

4 12000 16 x 15.4

5 14400

6 16800

7 19200

8 21600 300 x 300

9 24000

A 26400

B 28800

C 31200

D 33600

E

F

Error code Content Situation and corrective action

E8

F0

F1

HDD error

Software trouble

Hardware noise

Hardware is defective.

Software is defective.

Hardware is defective.

GD1080/1090 ERROR CODES 1 - 4 October 2000 © TOSHIBA TEC

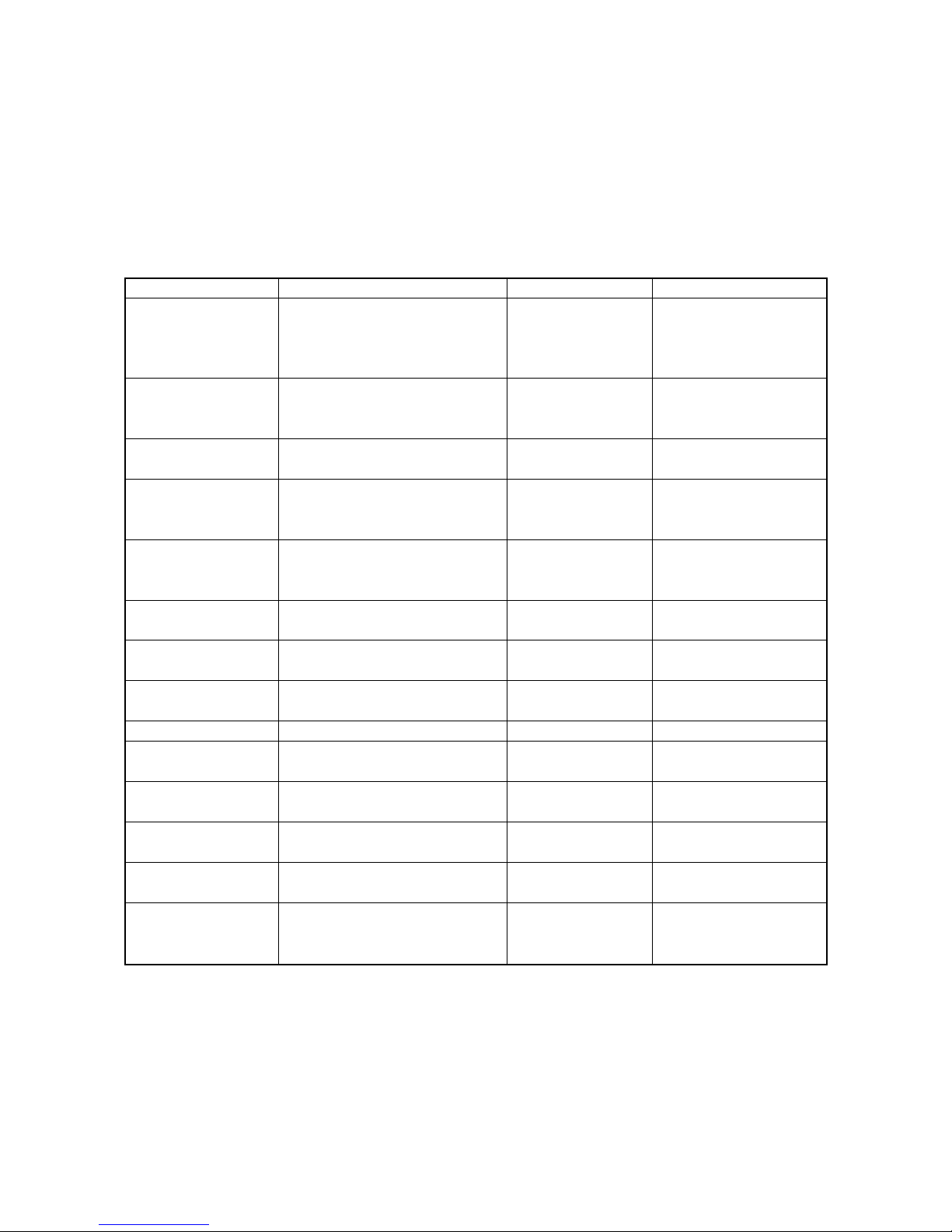

Remarks

Message displayed only

during the memory input.

It is not displayed during

the memory reception

Job information is stored

in the memory when the

final retry is finished.

1.2 Error Messages

Error messages are not displayed for the background jobs (memory transmission and memory reception). See the reception/transmission report for the details of the errors.

If an original jam during the direct transmission or recording paper jam during printing occurred, error

messages are displayed like when original jam occurred in the copier.

Error messages and corrective actions

Error

Memory full

Line is busy

Initial signal not

detected

Ter minal constants not

compatible

Training error

CFR not detected

Image signal carrier

not detected

Image signal not

detected

EOL time-out

Post message not

detected

Poor image quality

Image memory error

Software overdrive

Hardware noise

Symptom

Communication was interrupted because the memory became full.

Redialing was attempted for the

specified number of times but the line

is still busy.

DIS is not detected

Received DIS unable to be handled

Received DCS which is beyond the

capability of the receiver

Fall-back is not made successfully.

Became time-out after FTT was

sent out

CFR (FTT) is not detected

Image signal carrier cannot be detected

High-speed signal cannot be received by the receiver

EOL timer exceeded by 13 seconds

Post message is not detected

TX: Received RTN/PIN/ERR

RX: Transmitted RTN/PIN/ERR

Memory is abnormal during the

memory communication

WDT communication terminated due

to software overdrive

Communication terminated due to

software overdrive caused by hardware noise

Message

MEMORY

OVERFLOW

COMMUNICATION

ERROR

COMMUNICATION

ERROR

COMMUNICATION

ERROR

COMMUNICATION

ERROR

COMMUNICATION

ERROR

COMMUNICATION

ERROR

COMMUNICATION

ERROR

October 2000 © TOSHIBA TEC 2 - 1 GD1080/1090 SELF-DIAGNOSIS MODE

2. SELF-DIAGNOSIS MODE

There are two types of the self-diagnosis mode for the fax operation.

• Mode 03, 05 and 08: Some items are added to the modes 03, 05 and 08 of the PPC self-diagnosis

function when the optional fax unit is installed.

• Mode 13 and 1*: These two modes are ne wly added to the machine when the fax unit is installed. Started

up by turning ON the power while pressing the specified keys are being pressed.

The followings are the modes which are added to (or extend) the PPC self-diagnosis function.

Turn ON the main switch (pow er) while pressing two digital keys (ex: “0” and “5”) simultaneously to enter

each mode.

Note : To finish the self-dia gnosis mode, turn the po wer OFF and then bac k ON.

Do not cancel the mode using the keys “0” and “9”.

(A malfunction may be caused because the start-up process is not performed properly.)

Keys to be pressed

to enter each mode

[0]+[3]+[POWER]

[0]+[5]+[POWER]

[0]+[8]+[POWER]

[1]+[3]+[POWER]

[1]+[✱]+[POWER]

Digital keys on the list output

screen (Do not enter the selfdiagnostic mode)

Function

Output check (modem test, dialing test, CML

test)

Adjustment of the various items

Setting the destination

Setting functions of the various items

Initialization of the various memory areas (user

registration area, system setting area, image

data area)

Outputs the protocol trace list, dump list and

function setting list

Mode

Test mode

Adjustment mode

Setting mode

Fax function mode

Fax clearing mode

Trace list output

mode

Display

100% C

test mode

100% A

test mode

100% D

test mode

100% F

test mode

100% CL

test mode

Fax screen

GD1080/1090 SELF-DIAGNOSIS MODE 2 - 2 October 2000 © TOSHIBA TEC

2.1 Test Mode (03)

The modem test output, dialing test output and CML test output are performed in the test mode (03).

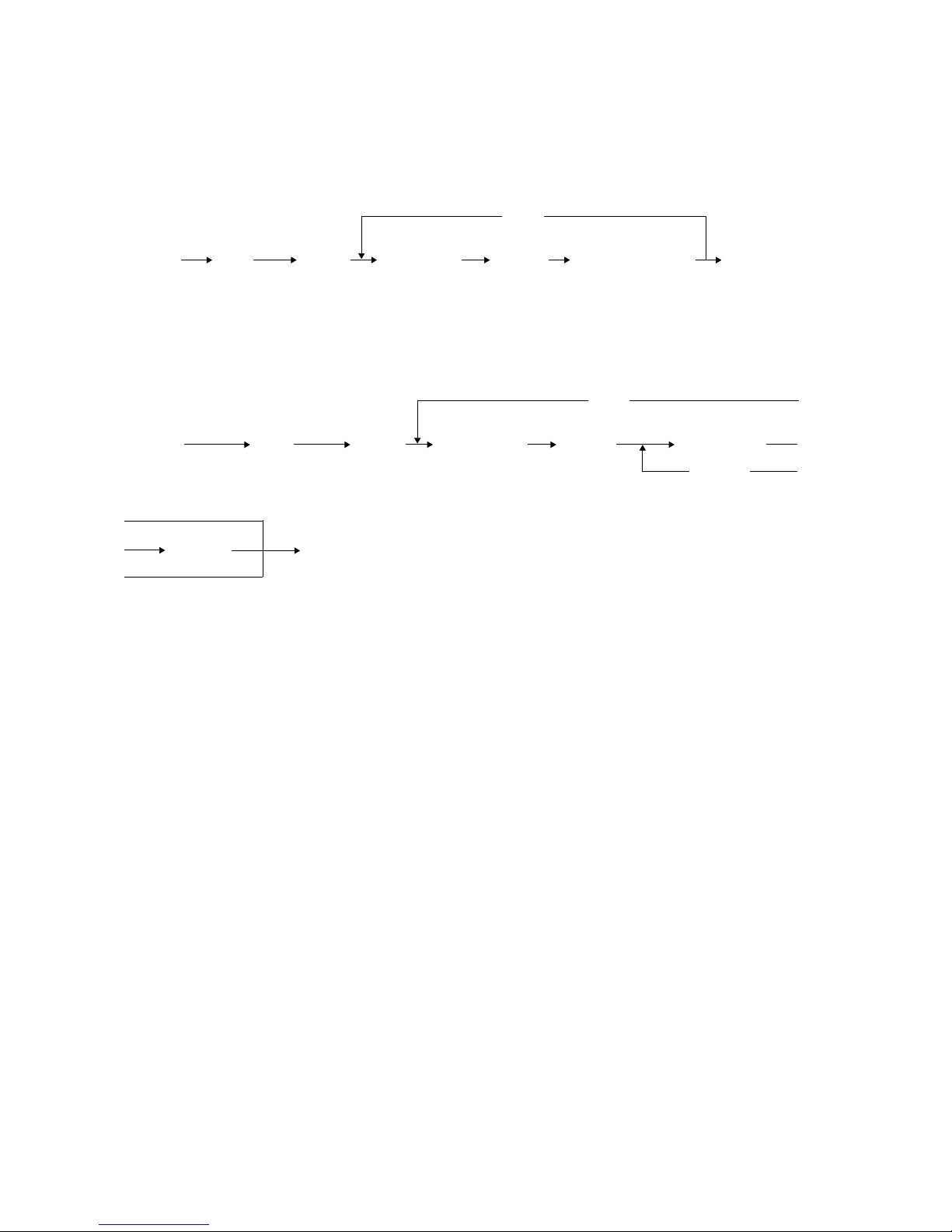

(1) Modem test/CML test

[Operation procedure]

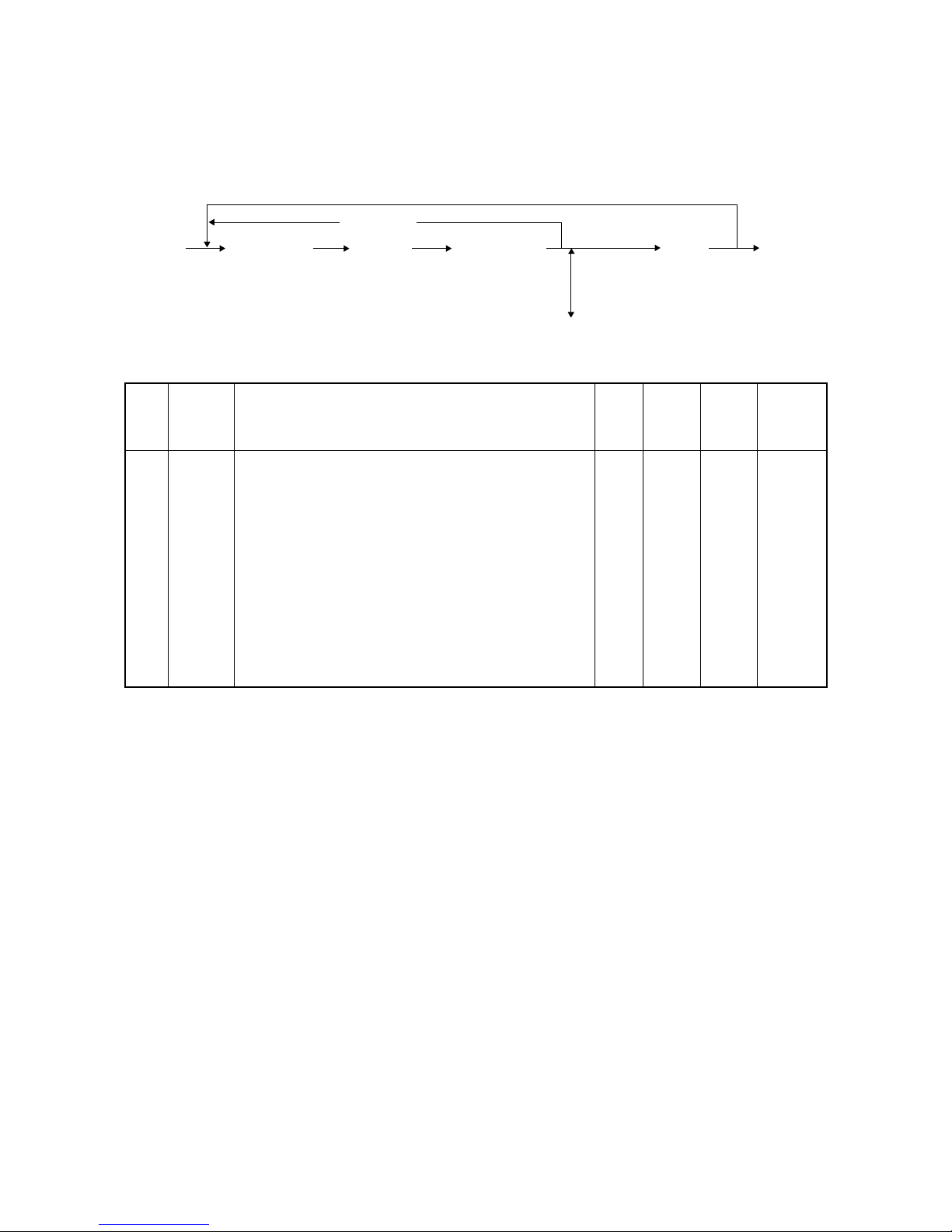

[0] [3] [FAX] ([FAX]) [Digital key] [START] Operation started [POWER] OFF

[POWER] (Switch line 1 and 2) (Code) (End)

(2) Dialing test

[Operation procedure]

[0] [3] [FAX] ([FAX]) [Digital key] [START] [Digital key]

[POWER] (Switch line 1 and 2) (Code) [START]

[START] [POWER] OFF

(End)

[C/S]

[C/S]

October 2000 © TOSHIBA TEC 2 - 3 GD1080/1090 SELF-DIAGNOSIS MODE

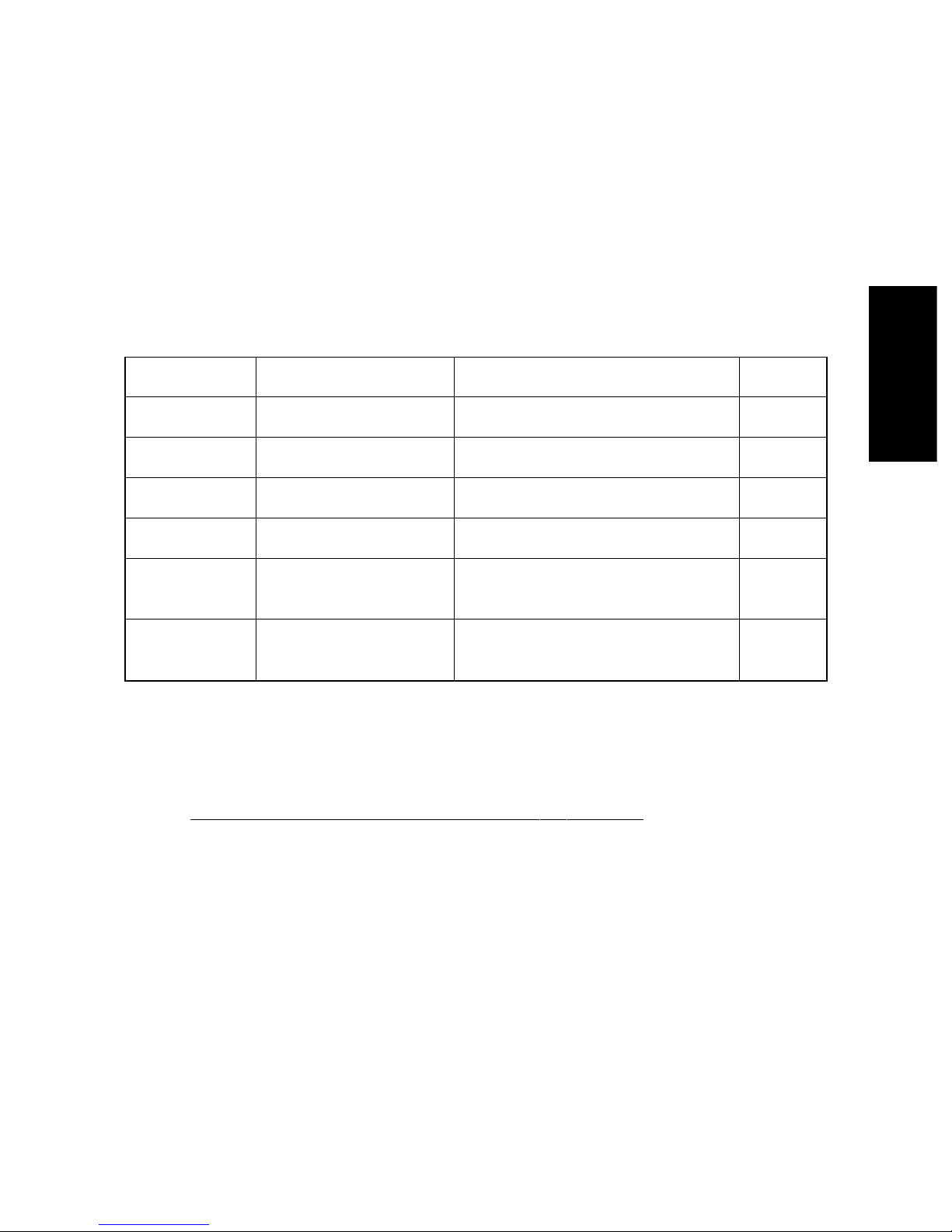

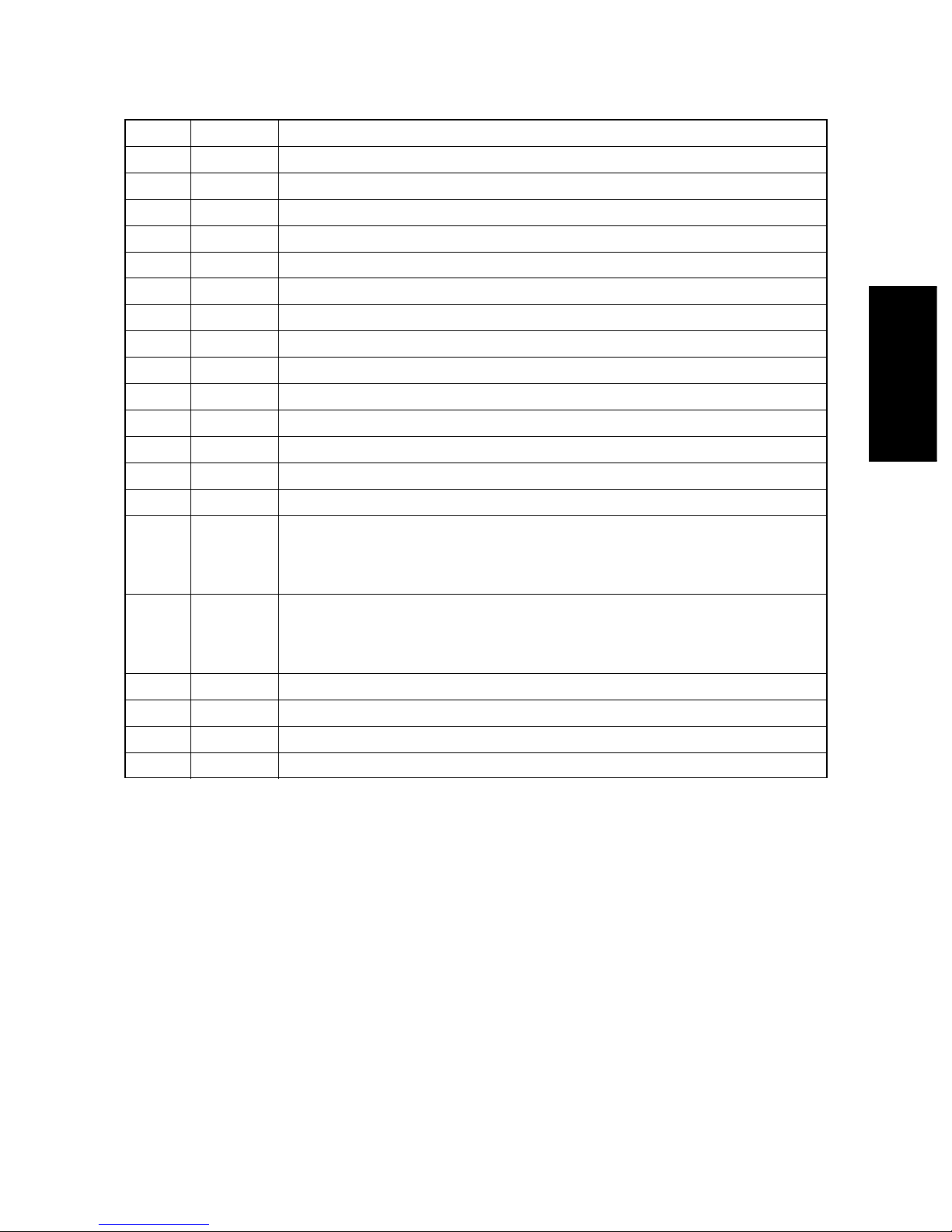

Test code list

Code

301

302

303

304

305

306

307

308

309

310

311

312

313

314

315

317

318

319

320

322

Element

Fax

Fax

Fax

Fax

Fax

Fax

Fax

Fax

Fax

Fax

Fax

Fax

Fax

Fax

Fax

Fax

Fax

Fax

Fax

Fax

Test

Modem test 2100 Hz

Modem test 14.4 kbps (V.17)

Modem test 9.6 kbps (V.29)

Modem test 4.8 kbps (V.27)

Modem test 300 BPS

Modem test 1850 Hz

Modem test 1650 Hz

Modem test 1100 Hz

Modem test 462 Hz

Modem test 1300 Hz

Modem test 33.6 kbps (V.34)

Modem test 28.8 kbps (V.34)

Modem test 24.0 kbps (V.34)

Modem test 16.8 kbps (V.34)

Dialing test 10PPS (Tested with the digital keys)

(The dial number corresponding to the key which w as pressed is k ept outputting

on the circuit. The pressed key is displayed on the control panel.)

Dialing test PB (Tested with the digital keys)

(The dial number corresponding to the key which w as pressed is k ept outputting

on the circuit. The pressed key is displayed on the control panel.)

Modem test 12.0 kbps (V.17)

Modem test 7.2 kbps (V.29)

Modem test 2.4 kbps (V.27ter)

CML test: Turning ON the CML relay

GD1080/1090 SELF-DIAGNOSIS MODE 2 - 4 October 2000 © TOSHIBA TEC

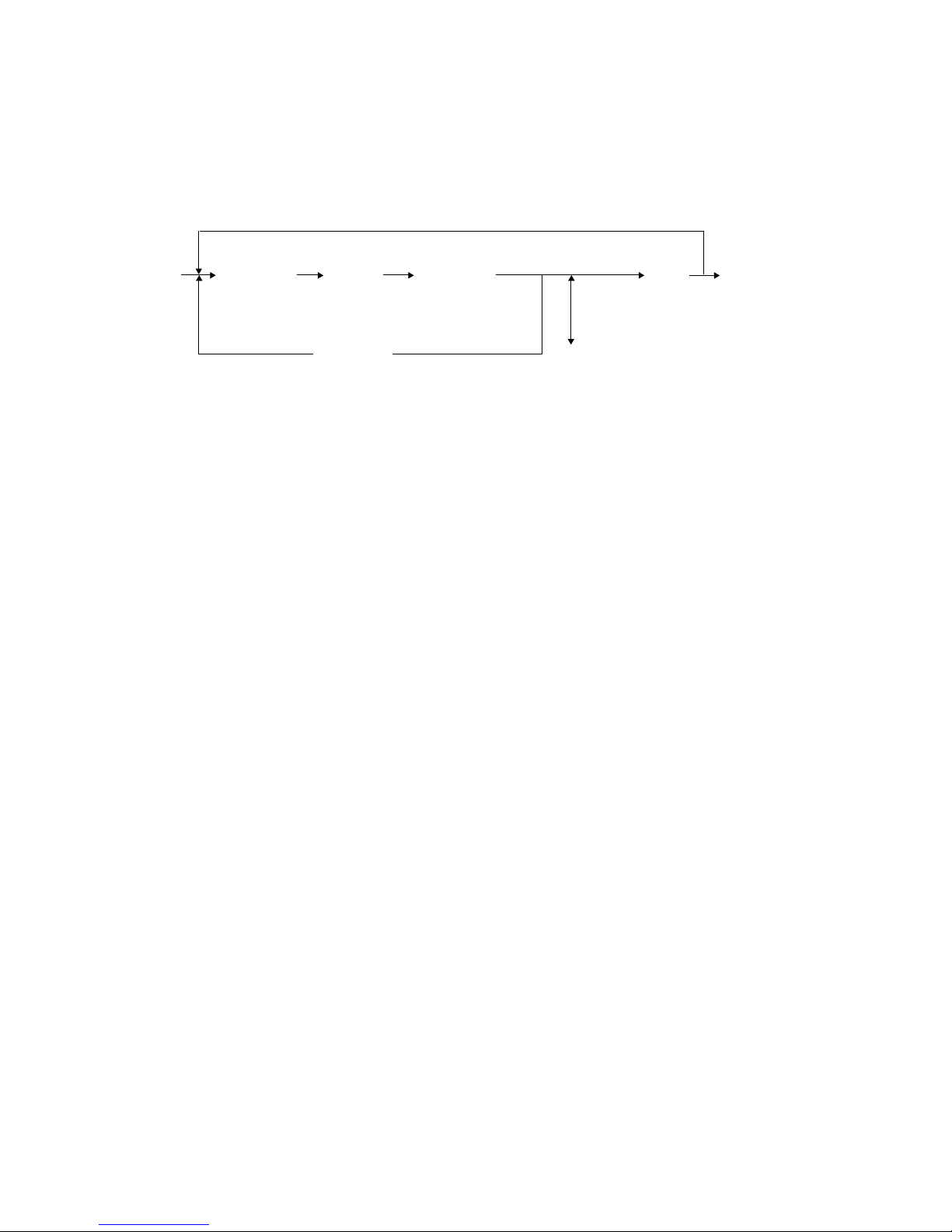

2.2 Adjustment Mode (05)

Parameter setting for the fax image processing is performed in the adjustment mode ‘05’.

(1) Setting parameters for the fax image processing

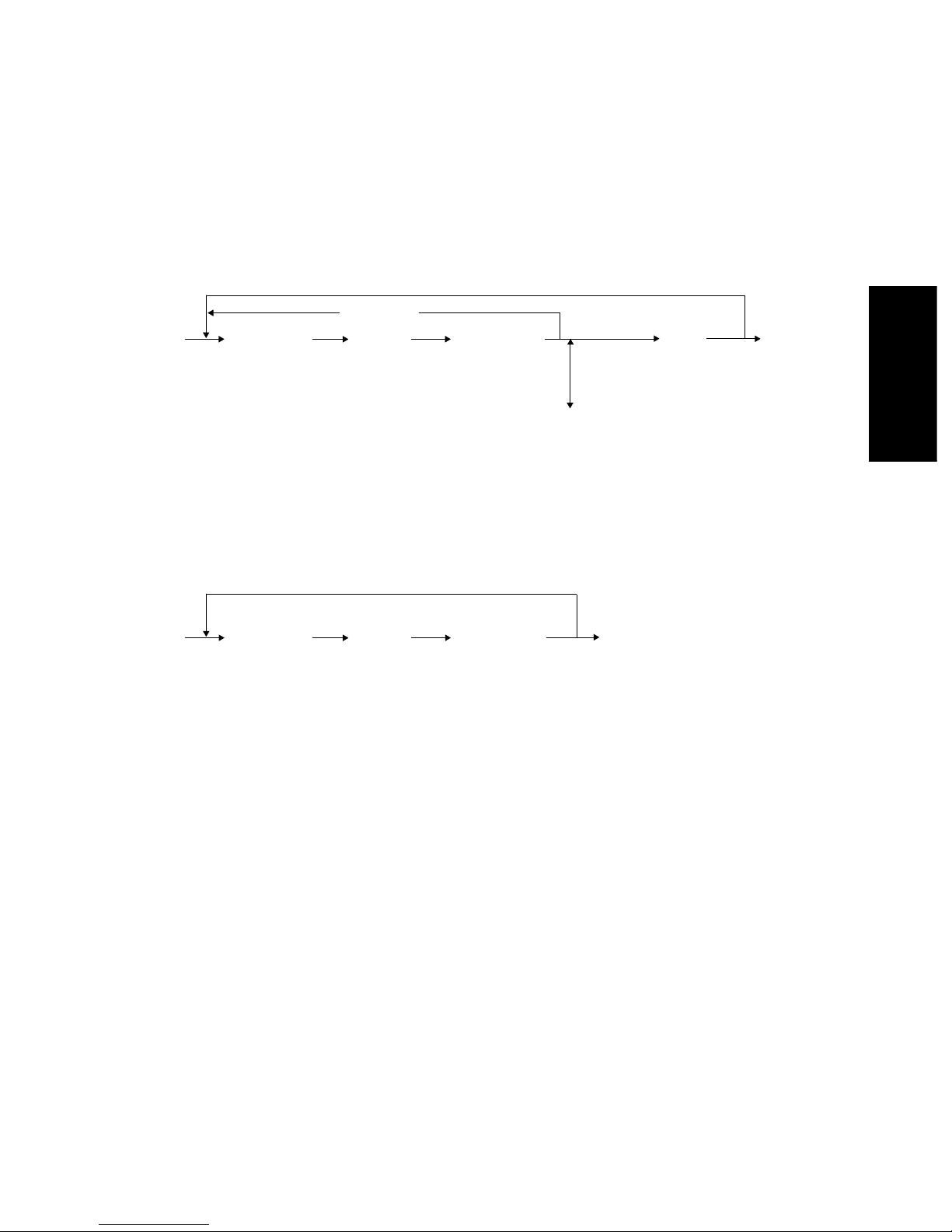

[Operation procedure]

[SET]

[0] [5] [Digital key] [START] [Digital key] or [POWER] OFF

[POWER] (Code) *[FC] key [INTERRUPT]

(Input adjustment value) (Save the value in the RAM)

[CANCEL] [C/S]

(In case the value is corrected)

* “–” can be entered with the [FC] key.

October 2000 © TOSHIBA TEC 2 - 5 GD1080/1090 SELF-DIAGNOSIS MODE

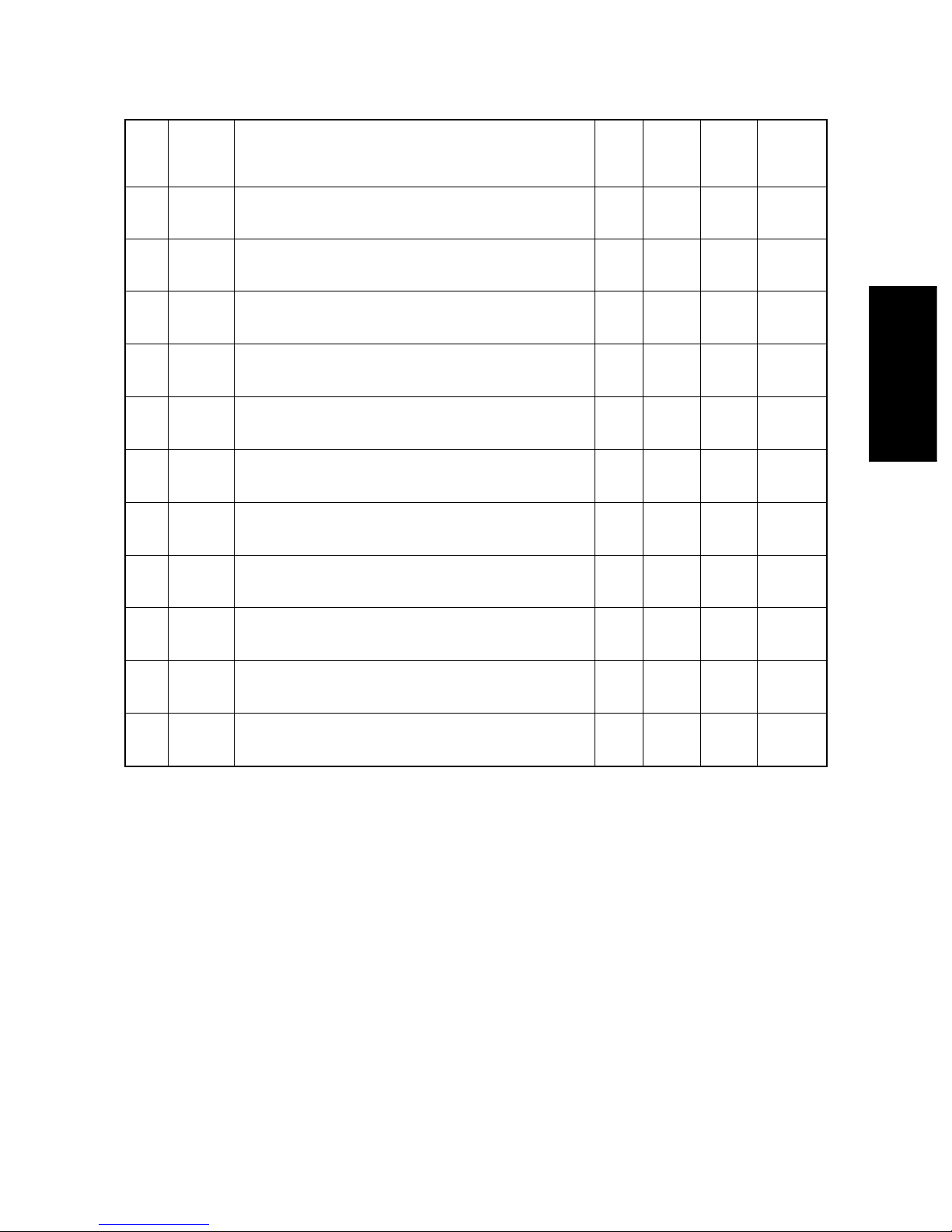

Code

700

701

702

710

714

715

719

720

724

725

729

Element

Density

Density

Density

Density

Density

Density

Density

Density

Density

Density

Density

Adjustment item

Adjustment of the threshold value for the digitization

Center value

Adjustment of the threshold value for the digitization

Lighter step value

Adjustment of the threshold value for the digitization

Darker step value

Manual-density fine adjustment

Error diffusion, Center value

Manual-density fine adjustment

Error diffusion, Center value

Manual-density fine adjustment

Error diffusion, Lighter step value

Manual-density fine adjustment

Error diffusion, Lighter step value

Manual-density fine adjustment

Error diffusion, Darker step value

Manual-density fine adjustment

Error diffusion, Darker step value

Auto-density fine adjustment

Error diffusion

Auto-density fine adjustment

Error diffusion

Mode

Fax

Fax

Fax

Fax

Fax

Fax

Fax

Fax

Fax

Fax

Fax

Image

quality

mode

Text

Text

Text

Photo

Text/

photo

Photo

Text/

photo

Photo

Text/

photo

Photo

Text/

photo

Default

120

20

20

128

128

12

20

25

20

128

128

Accept-

able

value

0~255

0~255

0~255

0~255

0~255

0~255

0~255

0~255

0~255

0~255

0~255

Adjustment codes for the image processing parameters

GD1080/1090 SELF-DIAGNOSIS MODE 2 - 6 October 2000 © TOSHIBA TEC

2.3 Setting Mode (08)

The destination is set in the setting mode (08).

[Operation procedure]

[CANCEL] [SET]

[0] [8] [Digital key] [ START] [Digital key] or [POWER]

[POWER] (Code) (Enter a value) [INTERRUPT] OFF

(Save the value in the RAM)

[C/S]

(In case the value is corrected)

Code

701

Element

Fax

Adjustment item

Destination

1: Asia 2: Australia 3: Hong Kong

4: U.S.A 5: Ger many 6: Great Britain

7: Italy 8: Belgium 9: Holland

10: Finland 11: Spain 12: Austria

13: Switzerland 14: Sweden 15: Denmark

16: Norway 17: Portugal 18: France

19: Greece 20: Poland 21: Hungary

22: Czech Rep. 23: Turkey 24:South Afr ica

Mode

Fax

Image

mode

ALL

Default

AU: 2

UC: 4

EUR: 5

Accept-

able

value

October 2000 © TOSHIBA TEC 2 - 7 GD1080/1090 SELF-DIAGNOSIS MODE

(2) Procedure to confirm the set value

[Operation procedure]

[SET]

[1] [3] [Digital key] [START] or [POWER] OFF

[POWER] (Code) [INTERRUPT]

(Set value cannot be changed)

2.4 Function Mode (13)

Various functions are set in the function mode (13).

(1) Procedure to set the functions

Enter a code using the digital keys and change the set value.

[Operation procedure]

[CANCEL] [SET]

[1] [3] [Digital key] [START] [Digital key] or [ POWER]

[POWER] (Code) (Enter a value) [INTERRUPT] OFF

(Save the value in the RAM)

[C/S]

(In case the value is corrected)

Loading...

Loading...