Toshiba G3, GA932, NV Series Instruction Manual

6F8C1590

Unified Controller

nv Series

G3 I/O Adapter Module GA932

Instruction Manual

Notes

(1) The technical information provided herein describes typical operations and applications of the product and does not

guarantee the intellectual property rights or other rights of Toshiba or third parties nor allows license of its use.

(2) No part or the whole of this document may be reproduced without prior consent.

(3) The information herein may be changed in the future without notice.

(4) All possible measures have been taken to prepare the information herein. If you have any question, comment, or find

any error, please contact us.

PROSEC, TOSLINE, TC-net are trademarks or registered trademarks of Toshiba Corporation.

Ethernet is trademarks or registered trademarks of Fuji Xerox Corporation.

Device Net is registered trademarks or registered trademarks of ODVA (Open Device Net Vender Association Inc.)

PROFIBUS is registered trademarks or registered trademarks of PROFIBUS User Organization.

MODBUS is registered trademarks or registered trademarks of Schneider automation Inc.

MELSECNET is registered trademarks or registered trademarks of Mitsubishi Electric Corporation.

UNI-WIRE is registered trademarks or registered trademarks of KURODA Pneumatics Industries Ltd.

Temposonics is registered trademarks or registered trademarks of US company MTS Systems Corporation.

Absocoder is registered trademarks or registered trademarks of SG Corporation.

Unified Controller nv series G3 I/O Adapter GA932 Module Instruction Manual

i

Safety Precautions

On the product and this instruction manual, important information for safe and correct use to

prevent danger to the user and other people as well as property damage is described.

Understand the following information (signs and symbols) before reading the text, and follow

the described items.

Description of signs

Sign Description

DANGER

Indicates that failure to avoid it will result in an immediate risk of

death or serious injury

(*1)

.

WARNING

Indicates that failure to avoid it will result in a risk of death or serious

injury

(*1)

.

CAUTION

Indicates that failure to avoid it will result in a risk of light or medium

injury

(*2)

or only property damage

(*3)

.

*1: A serious injury indicates loss of sight, injury, burns (high/low temperature), electric shock,

broken bones, or intoxication that will have aftereffects and require hospitalization or long-term

hospital visits for healing.

*2: An injury indicates an injury, burn, or electric shock that does not need hospitalization or

long-term hospital visits for healing.

*3: Property damage indicates consequential damage in terms of breakage of properties or materials.

Description of symbols

Symbol Meaning

Prohibited

Indicates “Prohibition” or “You must not do”.

Specific details are indicated near the symbol with pictures and text.

Mandatory

Indicates “Mandatory Action” or “Do as indicated”.

Specific details are indicated near the symbol with pictures and text.

Warning

Indicates Warning.

Specific details are indicated near the symbol with pictures and text.

(Note) Descriptions of Prohibition, Mandatory Action, and Warning vary depending on the display on

the main unit.

6F8C1590

ii

1. Safety Precautions on Installation

WARNING

Ground

Ground the device.

Otherwise, it may cause an electric shock

or fire.

Mandatory

Configure the emergency stop

circuit and the interlock circuit

outside the controller.

Otherwise, this may cause human injury

or machine damage if the nv series has

a failure or malfunction.

CAUTION

Prohibited

Do not install, store, or use it

in the following environments.

・ A place with a lot of dust

・ A place with corrosive gases (SO2,

H2S) ore flammable gases

・ A place with vibrations and shocks

exceeding the allowed values

・ A place with condensations due to

rapid temperature changes

・ A place with low or high temperature

outside of the installation condition

・ A place with high humidity outside of

the installation condition

・ A place with direct sunlight

・ A place near equipment generating

strong radio waves or magnetic fields

It may cause accidents.

Mandatory

Install the device in a place where

maintenance and inspection can be

done easily.

Otherwise, it may cause accidents.

Prohibited

Do not block the ventilation

hole or air inlet/outlet.

It may cause fire or failure due to

overheat.

Mandatory

For installation and wiring of

the system, observe the

installation conditions and

methods described in this

document.

Otherwise, it may cause a fall, fire,

failure, or malfunction.

Unified Controller nv series G3 I/O Adapter (GA932) Module Instruction Manual

iii

2. Safety Precautions on Maintenance and Inspection

WARNING

Mandatory

When installing or removing

the module after wiring, turn

off the external power.

Otherwise, causing an electric shock

by touching conductive part.

CAUTION

Prohibited

Do not drop, crush, or apply

strong shocks to the device or

board.

It may cause failure.

Mandatory

Before touching the device or

board, touch a grounded

metal to discharge the static

electricity of your body.

Otherwise, it may cause malfunction or

failure due to static electricity.

Mandatory

Wipe off stain on the device,

module, or board with a soft

cloth.

For severe stain, use a wet cloth wrung

tightly.

Leaving them stained may cause wrong

decision or malfunction.

Mandatory

Place a board or module

removed from the unit or base

unit on a conductive mat or

conductive bag (used for a

backup board, etc.) on a

grounded table.

Otherwise, parts may be damaged due

to static electricity.

Prohibited

Do not use benzene or thinner

to remove stain on device,

module, or board.

It may cause deformation or

discoloration of the device panel,

module, or board.

6F8C1516

iv

3. Safety Precautions on Replacement of Life Limited Parts

WARNING

Mandatory

When replacing fuses, turn off

the switch of the device.

Otherwise, it may cause an electric

shock or fire.

4. Safety Precautions on Daily Use

WARNING

No touch

Do not touch the terminals of

the module and unit during

energization.

It may cause an electric shock.

Prohibited

Do not modify, repair,

disassemble, or adjust the

device, module, or board.

It may cause an electric shock, fire,

injury, or failure.

Upon faulty operation or failure, contact

Toshiba's branch office or service

offices.

Mandatory

For capacity, frequency,

voltage, and regulation,

please use a power supply

conforming to the

specification.

If not, it may cause damage of the

device, or fire due to overheat, as well

as not obtaining the original

performance of the device.

Mandatory

When the device temperature

rises abnormally or failure

occurs in the device, stop

using and turn off the power,

then contact to one of

Toshiba's service

representatives.

Using it as it is may cause fire due to

overheat.

Unified Controller nv series G3 I/O Adapter (GA932) Module Instruction Manual

v

CAUTION

Prohibited

Do not touch anything other

than the operation part

(setting switches inside the

module), such as the IC parts

and terminals, connectors,

and soldered surfaces inside

the module.

Doing so may result in electrostatic

breakdown of the ICs and LSIs, causing

failure. Also, an injury may occur due

to the ends of the part lead wires, or

burns may occur due to hot parts.

Prohibited

Do not disassemble or modify

the device or module.

It may cause malfunction or failure as

well as loss of safety of the device.

Prohibited

Do not forcefully bend, pull, or

twist the power cord and

cables.

It may cause breaks or heating.

Prohibited

Do not insert any metal inside

the module.

It may cause fire.

Mandatory

Use wireless communication

equipments as mobile phone,

smart phone and transceiver

at least 30cm away from the

module, transmission cables

and I/O cable.

It may cause malfunctions.

5.

Safety Precautions on Transportation, Storage, and Disposal

CAUTION

Mandatory

Observe ordinances and

rules.

When discarding the product, observe

the ordinances and rules of the local

government.

Prohibited

For transportation and storage

of the product, use a

conductive bag and packaging

box.

Otherwise it will cause failure.

6F8C1516

vi

Restrictions on Application

This product is not developed/manufactured for use in systems involving devices that

directly affect human life (Note 1). Do not use them for such applications.

To use this product for systems that involve devices that significantly affect human safety

or maintenance of public functions (Note 2), special considerations (Note 3) are required

in system operation, maintenance, and management. In this case, contact one of

Toshiba's sales representatives.

(Note 1) Devices that directly affect human life include the following.

• Medical devices such as life supporting devices and devices for surgical units

(Note 2) Systems that involve devices that significantly affect human safety or

maintenance of public functions include the following.

• Main unit control systems of nuclear power plants, safety protection systems of

nuclear facilities, and other systems that are critical for safety

• Operation control systems of mass transportation systems and air traffic control

systems

(Note 3) Special considerations indicate sufficient discussions with Toshiba's engineers to

construct a safe system (e.g. employing fool-proof design, fail-safe design, or

redundant design).

Important matter

Unified Controller nv series is intended for persons with general knowledge of control

equipment regarding its installation, wiring, use and maintenance. Erroneous use can

result in electrical shock, fire or malfunction. Therefore if you do not have sufficient

control equipment and electric knowledge avoid performing installation, wiring, use or

maintenance by yourself and ask a person with specialized knowledge to do the work.

This manual and the separate related materials are intended for persons with general

knowledge of control equipment. Contact us for any questions about the contents.

Disclaimer

Toshiba shall not be responsible for any damage caused by an earthquake, thunderstorm,

and flood damage, fire for which Toshiba is not responsible for, acts of a third party, other

accidents, the user's willful acts or negligence, misuse, or use in abnormal conditions.

Toshiba shall not be responsible for any incidental damage (loss of business profits,

interruption of business, change or loss of stored memory) caused by use of or being

unable to use this product.

Toshiba shall not be responsible for any damage caused by failure to observe the

information described in the operation manual.

Toshiba shall not be responsible for any damage caused by malfunctions due to

combination with any connected device.

Toshiba shall not be responsible for any damage caused by malfunctions due to

combination with any application program created by the customer.

Unified Controller nv series G3 I/O Adapter (GA932) Module Instruction Manual

vii

This manual describes the overview, installation, operation and maintenance/inspection of

G3 I/O adapter module (hereafter called "GA932 module" or simply called "GA932). This

module connects I/O (G3 I/O) of PROSEC T series T3/T3H into Unified Controller nv series

type 1 light (PUM12). To use this device correctly, read "Safety precautions" first. For this

product, the repair and replacement due to wear or abrasion will be charged even during the

warranty period.

The manuals for GA932 module are as follows.

• Unified Controller nv series type 1 light Users manual – Basic hardware- (6F8C1497)

describes the main unit hardware of nv series type 1 light controller.

• Unified Controller nv series type 1 light Function Manual (6F8C1498)

Describes the functions and basic use of nv series type 1 light.

• Unified Controller nv series type 1 light T series Migration Hardware Manual

(6F8C1619)

Describes how to migrate from T series to nv series type 1 light.

• Unified Controller nv series type 1 light T series Migration Guide (6F8C1587)

Describes how to convert the system data from T series to nv series type 1 light.

• Unified Controller nv series/Integrated Controller V series

Programming Instructions (6F8C1226)

Describes the detailed specifications of the instruction words of the program languages

(LD, FBD, SFC, ST) supported by the nv series and Integrated Controller V series.

• Unified Controller nv series/Integrated Controller V series Engineering Tool 4 -Basic-

(6F8C1290)

Describes how to create, debug, print, and save programs using nV-Tool.

• Unified Controller nv series/Integrated Controller V series Engineering Tool 4 -Setup-

(6F8C1291)

Describes the method to set up nV-Tool.

• Unified Controller nv series High-speed Serial I/O System

TC-net I/O Instruction Manual (6F8C1240)

Describes TC-net I/O system, which is nv series high-speed serial I/O system.

• PROGRAMMABLE CONTROLLER PROSEC T3H USER’S MANUAL (UM-TS03***-E032)

Describes T3/T3H main unit system. Also describes General purpose digital I/O,

Analog I/O , and G3 I/O except Special I/O.

Note

Please refer to the instruction manual of each module about special

G3 I/O (Transmission module)

The figure used in the explanation is inserted to make it easier to understand of the

reader, and it is not necessarily the same as the actual product. Please understand we

may carry out improvement without particular notice in order to improve performance

and function.

Introduction

6F8C1516

viii

●

Notational conventions

The following are the notational conventions for better understanding of this document.

Important:

Describes what the user should be particularly aware of to handle the product correctly.

Note:

Describes what the user should observe to handle the product correctly.

Remark:

Describes a remark.

●

Reading this document

This document consists of the following chapters.

• Chapter 1 Introducing GA932 Module

Describes the functions, characteristics, and names and functions of the

parts of the module.

• Chapter 2 Installation and Wiring

Describes how to install it to the basic unit and how to connect cables.

• Chapter 3 Setting

Describes how to set the switches for using the module correctly.

• Chapter 4 Startup and Shutdown

Describes how to do a check before operation and how to start up and shut

down the module.

• Chapter 5 Troubleshooting

Describes troubleshooting such as what to do when failure occurs.

• Chapter 6 Maintenance and Inspection

Describes troubleshooting regarding daily inspection and periodical

inspection and how to perform inspections.

Unified Controller nv series G3 I/O Adapter (GA932) Module Instruction Manual

ix

Chapter 1

Introducing

GA932 Module

...1

1.1 Functions and Characteristics of GA932 Module

········· 2

1.1.1 System configuration ············································· 4

1.1.2 Data input/output with G3 I/O module ························ 6

1.1.3 Online map/Online status for G3 I/O module ··············· 7

1.2 Names and Functions of the Parts

······························· 8

1.2.1 Names of the parts ··············································· 8

1.2.2 Functions of the parts ············································ 9

Chapter 2

Installation and

Wiring

...11

2.1 Types of I/O Base Units

············································· 13

2.2 Installing / Removing the Module

······························· 14

2.3 TC-net I/O Loop Wiring

·············································· 17

2.4 Replacing the Module

················································ 19

2.5 Handling the RUN Signal (RUN contact) of G3 I/O

······ 20

Chapter

3

Setting

...21

3.1 Switch Setting

··························································· 22

3.1.1 Operation mode setting switch (MODE) ··················· 22

3.1.2 Maintenance switch (MAINT) ································ 23

3.1.3 Node No. setting switches ···································· 23

3.2 Setting with the Engineering Tool

······························ 24

3.2.1 I/O Node registration ··········································· 25

3.2.2 Association G3 I/O adapter and I/O Node Number

and setting I/O loop scan speed ····························· 27

3.2.3 G3 I/O and I/O module registration ························· 30

3.2.4 I/O variables registration ······································ 33

Chapter

4

Startup and

Shutdown

...35

4.1 Checking the Switch before Startup

·························· 36

4.2 Startup

······································································ 36

4.3 Shutdown

·································································· 37

Chapter 5

Troubleshooting

...39

CONTENTS

6F8C1516

x

Chapter 6

Maintenance and

Inspection

...47

6.1 Inspection

································································· 49

6.1.1 Daily inspection ·················································· 49

6.1.2 Periodical inspection ··········································· 50

6.2 Maintenance Parts

····················································· 51

6.3 Life Limited Parts

······················································ 51

Appendix A

Specifications

...53

A.1 General Specifications

·············································· 54

A.2 Function Specifications

············································· 55

A.3 G3 I/O Module Support List

······································· 56

A.4 TC-net I/O Loop Transmission Specifications

············ 60

A.5 Operating Instruction for Specific Modules

··············· 61

Appendix B

Outside

Dimensions

...63

Appendix C

Related Products

...65

1

Chapter 1

Introducing GA932

Module

This chapter describes the functions, characteristics, and names and

functions of the parts of GA932 module.

1.1 Functions and Characteristics of GA932 Module

··········· 2

1.1.1 System configuration ··············································· 4

1.1.2 Data input/output with G3 I/O module ·························· 6

1.1.3 Online map/Online status for G3 I/O module ················· 7

1.2 Names and Functions of the Parts

································· 8

1.2.1 Names of the parts ·················································· 8

1.2.2 Functions of the parts ·············································· 9

Chapter 1 Introducing GA932 Module

6F8C1590

2

1.1 Functions and Characteristics of GA932 Module

G3 I/O adapter module GA932 is a module to connect PROSEC T series T3/T3H

I/O module (G3 I/O) to the Unified Controller nv series type 1 light controller.

GA932 module allows you to replace the existing PROSEC T series T3/T3H I/O

module (G3 I/O) to Unified Controller nv series type 1 light controller. One

GA932 module can be used per PUM12 and up to 76 modules (10 slots of basic

unit plus 11 slots x 6 units of expansion unit) can register 4864 points G3 I/O

(when 64 points DI/DO module is used).(However, a mixed configuration of

GA932 and SA912+SA931 can not be used, and only one can be used for

either.)

The I/O variables of G3 I/O module and the network variables can be

registered 2Kw for input and 1Kw for output per GA932 module. These Input

and output data can be assigned to the high-/medium-speed blocks

(selectable) of TC-net I/O loop scan for each GA932, the data can be input

and output between PUM12 and G3 I/O module.

■ Characteristics of GA932 module

High-speed transmission

The I/O data transmission between GA932 module and PUM12 realizes to

speed up at transmission gate array.

High reliability

The I/O data between GA932 module and PUM12 is transmitted cyclically, a

temporally error correction is performed automatically.

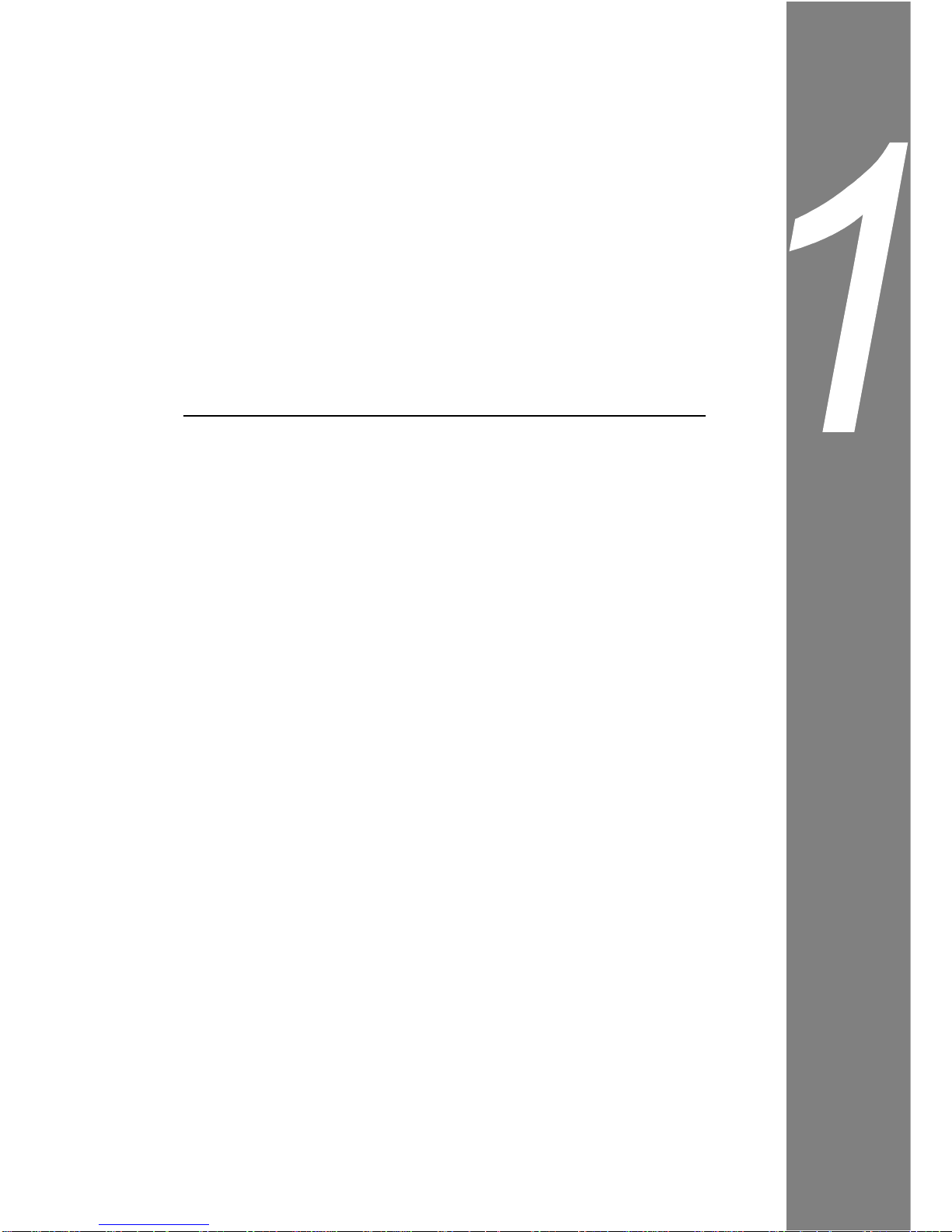

Figure 1-1 Example of using GA932

GA932

GA922-1,GA922-2 : G2 I/O adapter

SA912-1,SA912-2 : TC-net I/O adapter

GA932 : G3 I/O adapter

PUM12

Controller

High speed serial TC

-

net I/O Loop

G2 I/O

adapter

LP1

Node 14

Node: 3

Node 7

Node 8

Node 4

SA912-1

TC-net I/O

Module

G3 I/O

Module

GA922-2

GA922-1

G2-I/O

Module

LP2

G2-I/O

Module

TC-net

I/O adapter

LP2

SA912-2

TC-net I/O

Module

LP2

LP2

LP1

LP1

LP1

LP1

LP2

・When there are up to 16 I / O modules under GA 922,

GA 922 uses the node number for one module.

・When there are 16 or more I / O modules under GA 922,

GA 922 uses the node number for two modules.

1.1 Functions and Characteristics of GA932 Module

Unified Controller nv series G3 I/O Adapter GA932 Module Instruction Manual

3

Note

•

For the supported G3 I/O modules, refer to "Appendix A.3 G3 I/O Module Support List."

CAUTION

When using G3 I/O module, a combination of

the versions

as follows is required for PUM12 and nV-Tool.

Controller type Controller

modules

nV-

Tool

PUM12 V01.70

or later

V4.13.1

or later

Before using GA932, check the versions of PUM12 and

nV-Tool. For information on how to check the versions,

refer to "Engineering Tool 4 Operation Manual–Basic(6F8C1290)."

Mandatory

Chapter 1 Introducing GA932 Module

6F8C1590

4

1.1.1 System Configuration

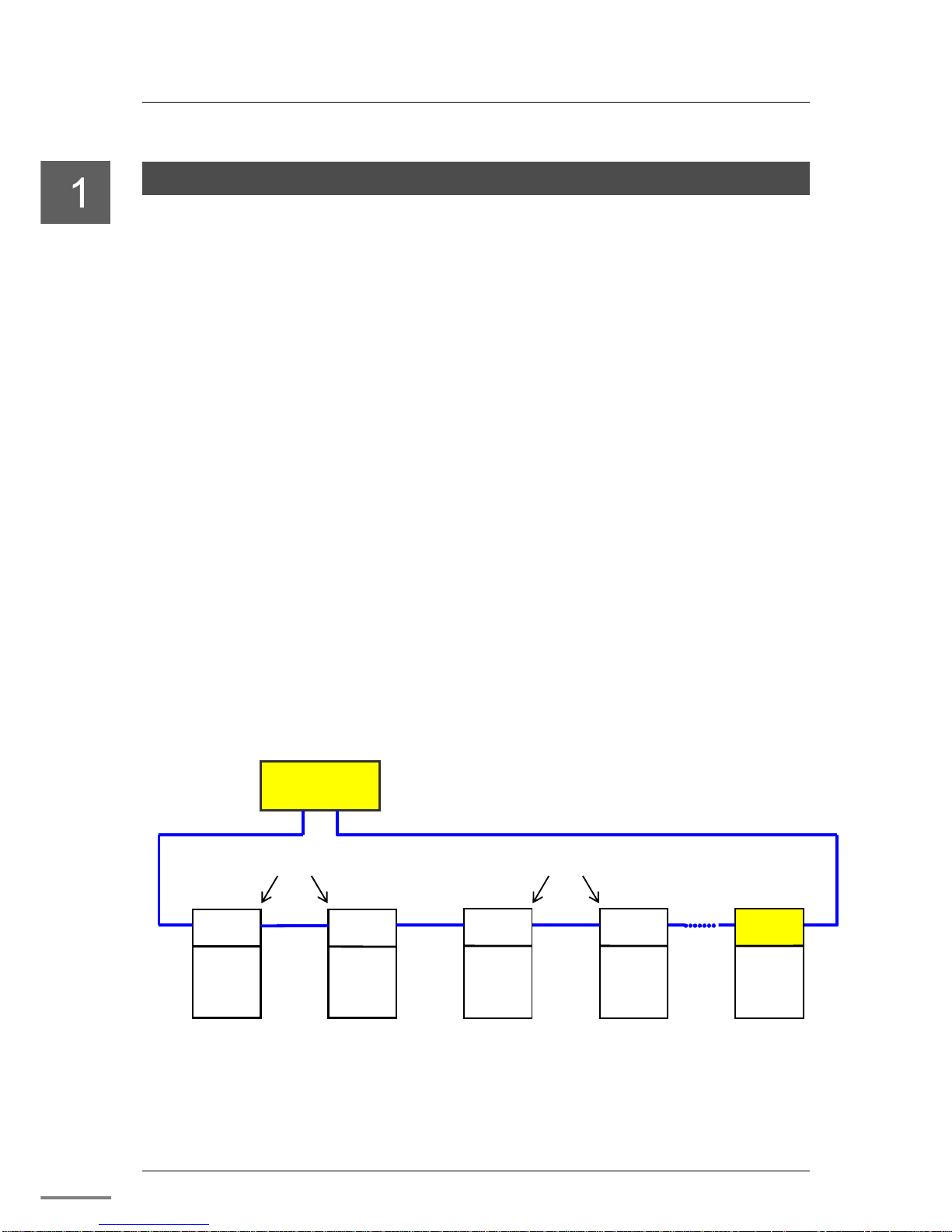

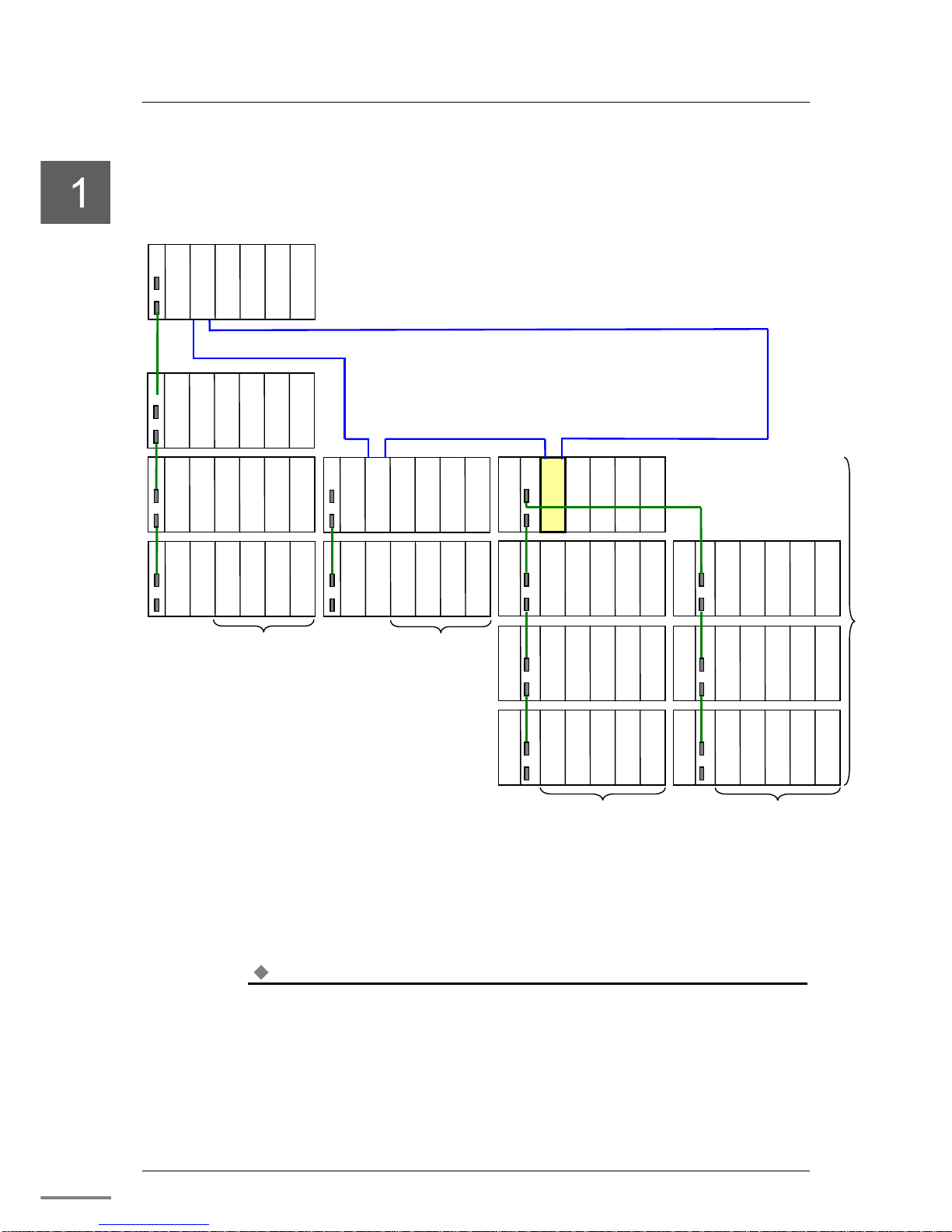

■ Example configuration of PUM12 system applying GA932

Figure 1-2 Example configuration of PUM12 system applying GA932

Note

•

GA932 or GA922 module can’t be duplicated.

IF

PS

G3 I/O

G3 I/O

G3 I/O

・・

GA932

GA932

Up to 8 modules

Up to 11 modules

(Up to 10 basic modules)

TC-net I/O Optical loop

Maximum 12 Node per PUM12 controller

IF

PS

G2 I/O

G2 I/O

G2 I/O

・・

GA922

IF

PS

G2 I/O

G2 I/O

G2 I/O

・・

IF

PS

G2 I/O

G2 I/O

G2 I/O

・・

IF

PS

G2 I/O

G2 I/O

G2 I/O

・・

IF

PS

G2 I/O

G2 I/O

G2 I/O

・・

IF

PS

G2 I/O

G2 I/O

G2 I/O

・・

PUM12

Number of Node of GA932 : 1 Node

Number of Node of GA922 :1 Node (When 1 or 2 units exist)

2 Node (When 3 or 4 units exist)

Up to 8 modules

IF

PS

G3 I/O

G3 I/O

G3 I/O

・・

G3 I/O

IF

PS

G3 I/O

G3 I/O

G3 I/O

・・

G3 I/O

IF

PS

G3 I/O

G3 I/O

G3 I/O

・・

G3 I/O

IF

PS

G3 I/O

G3 I/O

G3 I/O

・・

G3 I/O

IF

PS

G3 I/O

G3 I/O

G3 I/O

・・

G3 I/O

IF

PS

G3 I/O

G3 I/O

G3 I/O

・・

G3 I/O

Up to 11 modules

Up to 7 units

Vacant

Vacant

Vacant

Vacant

1.1 Functions and Characteristics of GA932 Module

Unified Controller nv series G3 I/O Adapter GA932 Module Instruction Manual

5

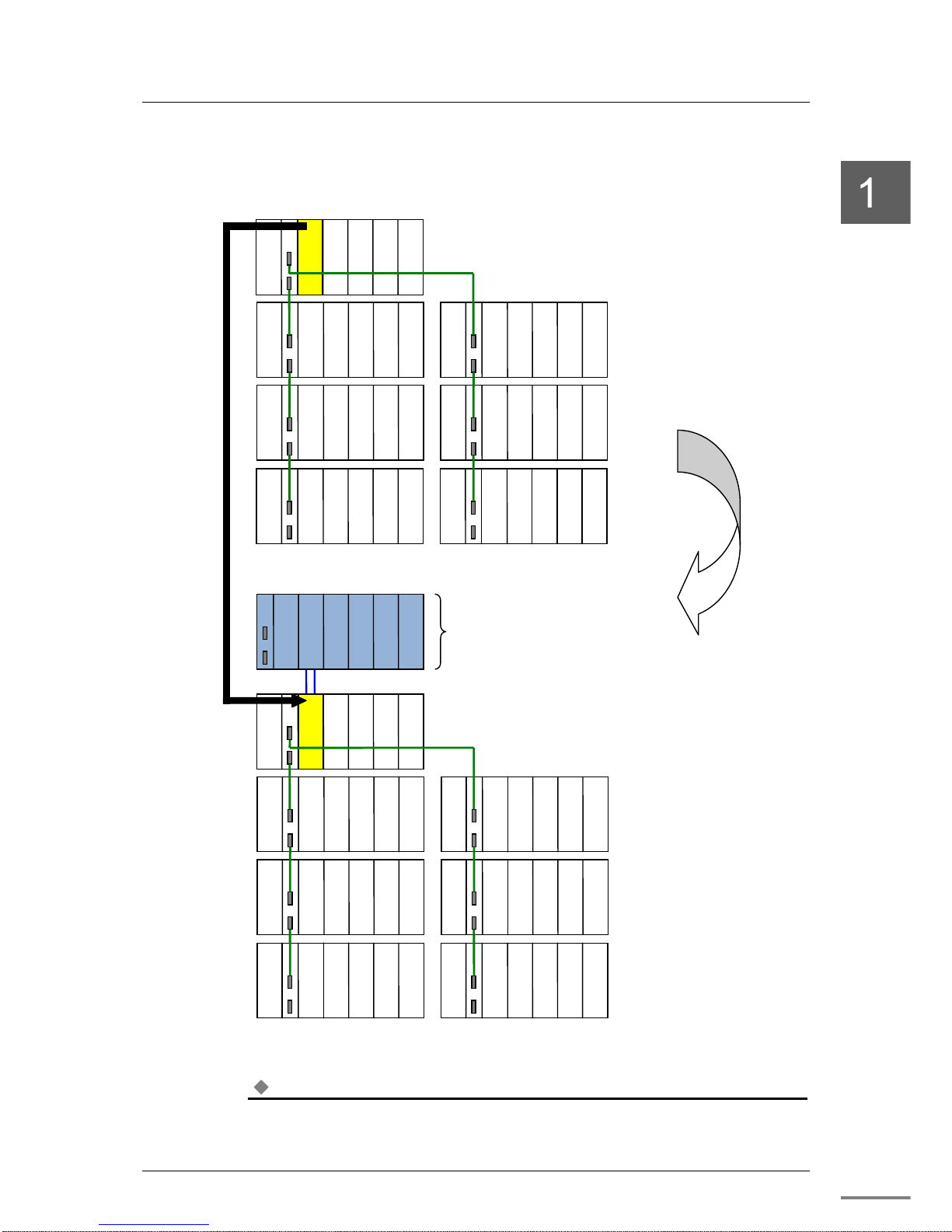

■ Example of updating from T3/T3H system to type 1 light system

Figure 1-3 Example of updating from T3/T3H system to type 1 light system

Note

•

There are restrictions when migrating from T3/T3H. For details, refer to "T series Migration

Hardware Manual “ (6F8C1587)

【

T3/T3H system

】

(3) Connect by TC-net I/O optical loop

IF

PS

G2 I/O

G2 I/O

G2 I/O

・・

PUM12

IF

PS

G3 I/O

G3 I/O

G3 I/O

・・

T3/T3H

IF

PS

G3 I/O

G3 I/O

G3 I/O

・・

G3 I/O

IF

PS

G3 I/O

G3 I/O

G3 I/O

・・

G3 I/O

IF

PS

G3 I/O

G3 I/O

G3 I/O

・・

G3 I/O

IF

PS

G3 I/O

G3 I/O

G3 I/O

・・

G3 I/O

IF

PS

G3 I/O

G3 I/O

G3 I/O

・・

G3 I/O

IF

PS

G3 I/O

G3 I/O

G3 I/O

・・

G3 I/O

IF

PS

G3 I/O

G3 I/O

G3 I/O

・・

GA932

IF

PS

G3 I/O

G3 I/O

G3 I/O

・・

G3 I/O

IF

PS

G3 I/O

G3 I/O

G3 I/O

・・

G3 I/O

IF

PS

G3 I/O

G3 I/O

G3 I/O

・・

G3 I/O

IF

PS

G3 I/O

G3 I/O

G3 I/O

・・

G3 I/O

IF

PS

G3 I/O

G3 I/O

G3 I/O

・・

G3 I/O

IF

PS

G3 I/O

G3 I/O

G3 I/O

・・

G3 I/O

T3/T3H

【

type1 light system

】

(2) Add type1 light controller(PUM12)

(1)

Replace T3/T3H with GA932.

(2)

Add type1 light controller(PUM12)

(Add G2 I/O if necessary)

(3)

Connect

PUM12 and GA932

by TC-net I/O optical loop.

(1) Replace

T3/T3H with

GA932

Chapter 1 Introducing GA932 Module

6F8C1590

6

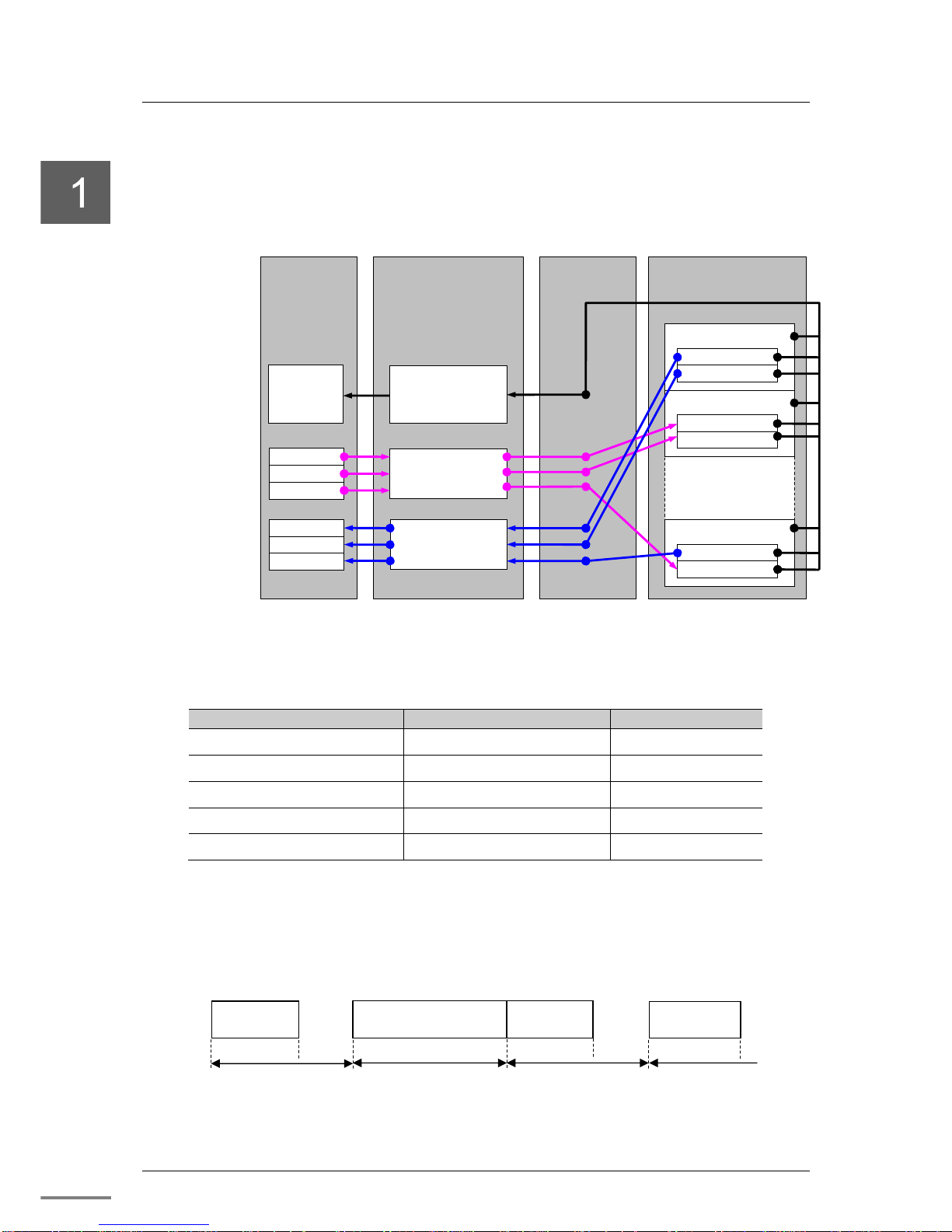

1.1.2 Data input/output with G3 I/O module

By referring the download information by the nv-Tool, GA932 module

transfers G3 I/O input data and G3 I/O output data to TC-net I/O loop scan

memory.

Figure 1-4 G3 I/O data I/O overview

Table 1-1 TC-net I/O loop scan assignment memory map

Use

TC-net I/O loop scan block No

. Number of used blocks

G3 I/O management information (Node No.-3) 1

G3 I/O control information (Node No.-3)×16+96 1

G3 I/O output data (Node No.-3)×16+640 Maximum 16

G3 I/O input data

1152

Maximum 32

Online map (Node No.-3)×16+96+8 2

In addition, G3 I/O input/output operation cycle in GA932 module starts

next I/O after 10ms form the beginning of one input/output.

When the input/output time exceeds 10ms, the next input/output is started

immediately after completion of the input/output.

*1: For input/output time, refer to "Appendix A.2 GA932 Specifications."

Figure 1-5 G3 I/O data input/output operation cycle

G2I/O

:

G2I/O

adapter

GA932

TC-net I/O loop scan

memory

G3 I/O

management

information

G3 I/O output data

G3 I/O input data

U

nit #0

Expansion unit #

1

Expansion unit #

6

Input module

Input

module

Output module

Output module

Input module

Output module

nv -controller

I/O variable 1

I/O variable 2

I/O variable 3

I/O variable 4

I/O variable 5

I/O variable 6

G3 I/O

Diagnosis

processing

*1

10ms

*1

10ms

*1

10ms

*1

G3 I/O

Input /Output

G3 I/O

Input /Output

G3 I/O

Input /Output

G3 I/O

Input /Output

1.1. Functions and Characteristics of GA932 Module

Unified Controller nv series G3 I/O Adapter GA932 Module Instruction Manual

7

Note

•

GA932 imports input data of G3I/O, but does not perform output processing for G3 I/O, while

PUM12 is “HALT”. Therefore, even when PUM12 is “HALT”, the communication module of G3

I/O (Ex. TOSLINE-F10 (MS311)) imports input data captured as G3 I/O, the LED indicating the

reception status may blink.

The reason why G3 I/O transmission module, such as TOSLINE-F10 (MS311), flicks the LED

which indicates the data receiving though the nv controller is halted is described above.

1.1.3 Online map/Online status for G3 I/O module

When G3 I/O transmission module is used, the online map and online status of

the transmission module is entered into the resister of the nv-controller. For the

register configuration, refer to the function manual of each controller.

Table 1-2 Online map/Online status for the transmission module

Controller type

Register type

type1 light Special register (SW register)

Refer to "Appendix A.3 G3 I/O Module Support List" about transmission

module to enter online map and online status.

Chapter 1 Introducing GA932 Module

6F8C1590

8

1.2 Names and Functions of the Parts

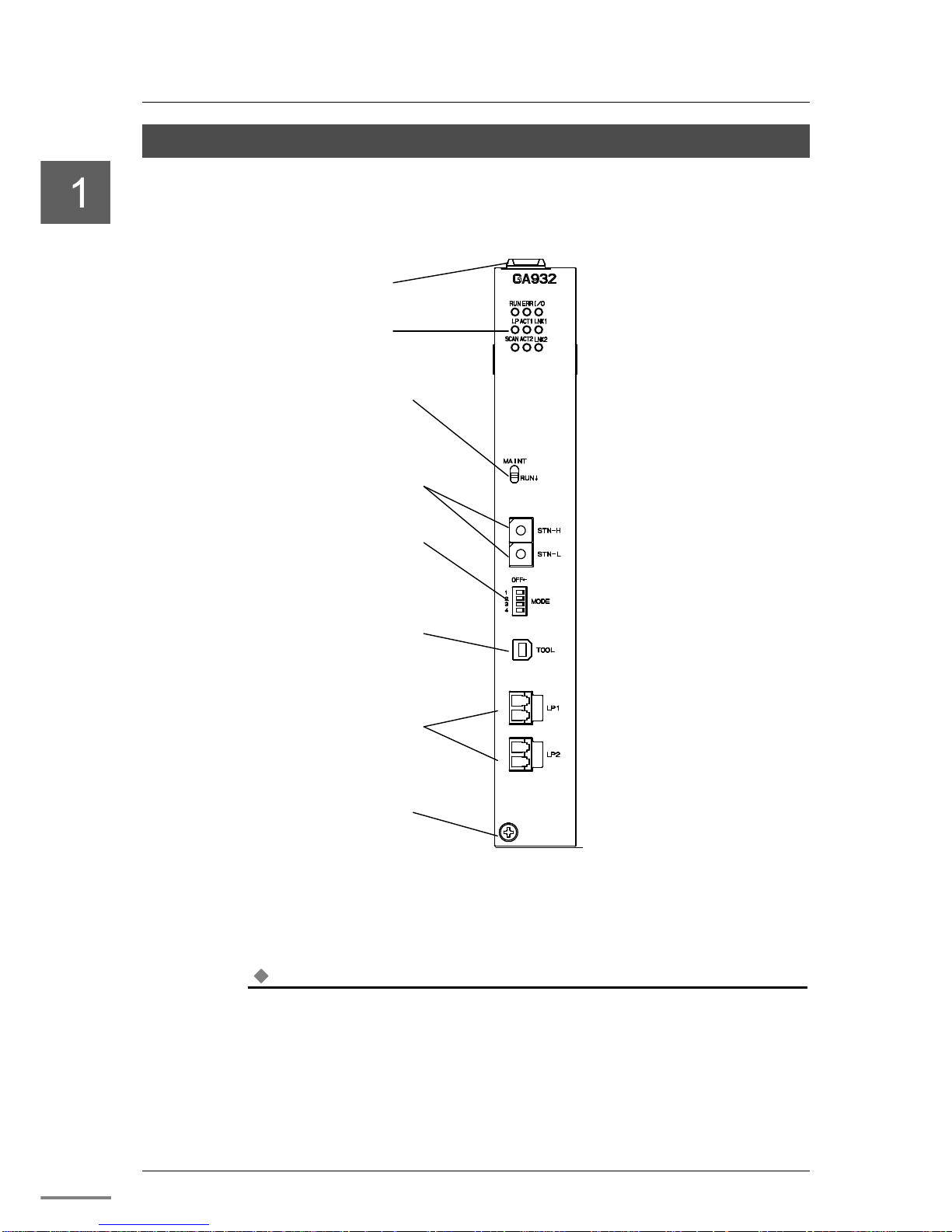

1.2.1 Names of the parts

Figure 1-6 shows the names of the parts of GA932 module.

Figure 1-6 Names of the parts of GA932

Note

•

Tool connector “TOOL” is a connector dedicated to maintenance of our company, so please do

not use it. GA932 may stop working.

•

Do not remove the tool connector cap.

State display

LED

Operation mode setting

switch

Maintenance switch

Node No

. setting switch

S

lide lever

Tool connector

(

For maintenance of our

company

)

TC-net I/O loop

Optical connector

Fixing screw

1.2. Names and Functions of the Parts

Unified Controller nv series G3 I/O Adapter GA932 Module Instruction Manual

9

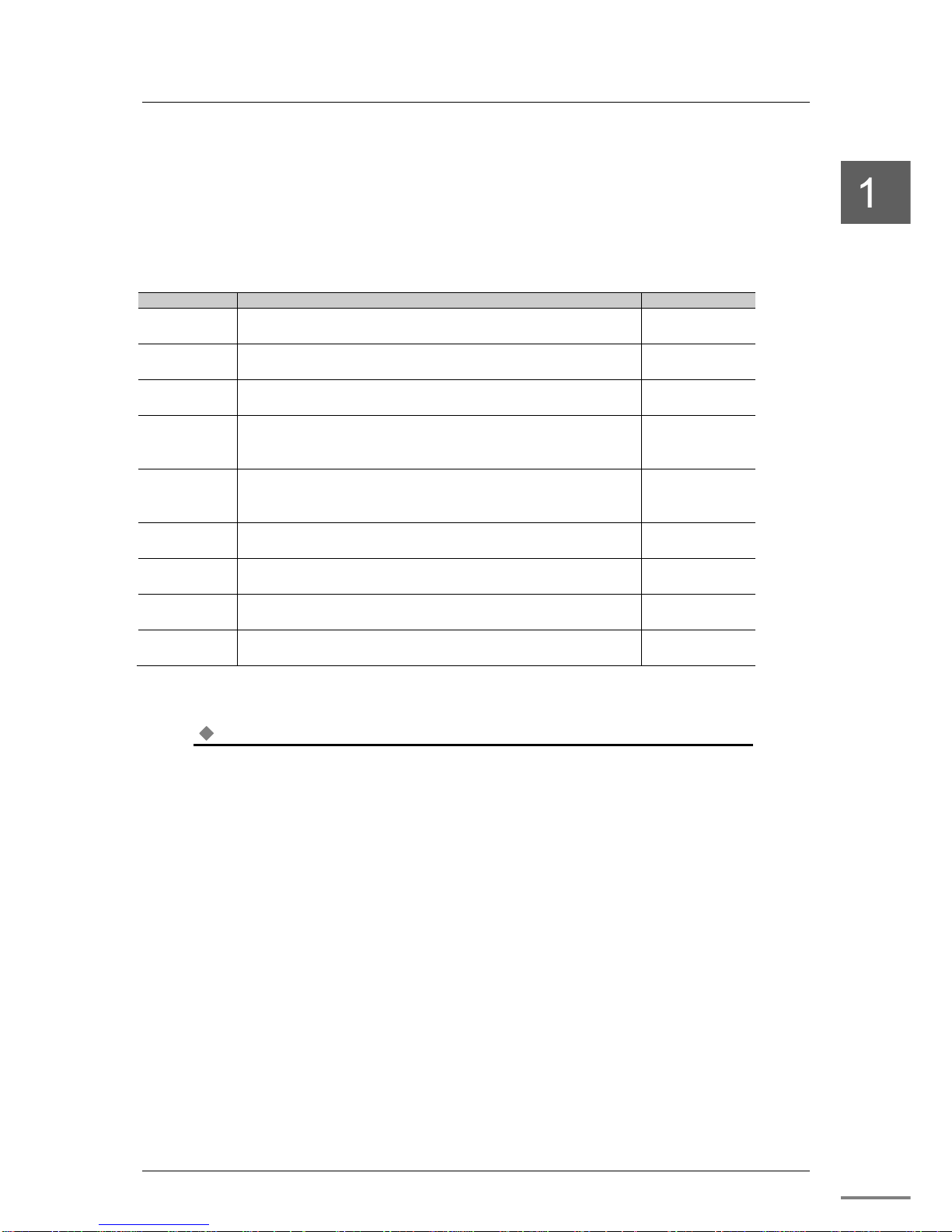

1.2.2 Functions of the parts

The major functions of the parts are as shown below.

■ State display LED

Table 1-3 Details on the state display LED

LED name

Display

Normal display

RUN (green) ON: Module is normal

OFF: Module is abnormal

ON

ERR (red) ON: Module is abnormal

OFF: Module is normal

OFF

I/O(green)

ON: Accessing I/O

OFF: Stop accessing I/O

ON

LP (green) ON: TC-net I/O Loops establishment

OFF: TC-net I/O Loops have loop cutting point

Blinking: Node number duplication

ON

SCAN(green) ON: TC-net I/O Loop scan data transmission is in execution

OFF: TC-net I/O Loop scan data transmission is under suspension

Blinking: Duplication detection of scan talker block

ON

ACT1(green) Blinking: LP1 transmission is performed successfully

Other: Transmission is not performed

Blinking

LINK1(green) ON: LP1 link has been established normally

OFF: No link has been established

ON

ACT2(green) Blinking: LP2 transmission is performed successfully

Other : Transmission is not performed

Blinking

LINK2(green) ON: LP2 link has been established normally

OFF: No link has been established

ON

Note

•

Check the LED state from the front.

•

When the maintenance switch is set to the maintenance state (MAINT), only ERR LED goes on.

Chapter 1 Introducing GA932 Module

6F8C1590

10

■ Operation mode setting switch (MODE)

MODE is the switch for setting the operation mode. Please use this switch all

OFF. For details, refer to "Chapter 3 Setting."

■ Maintenance switch (MAINT)

MAINT is used to restart GA932 module.

For details, refer to "Chapter 3 Setting."

■ Node number setting switch

Node number setting switch is a rotary switch for setting the Node number of

the unit on which GA932 module is installed.

For details, refer to "Chapter 3 Setting."

■ TC-net I/O loop optical connector

This connector is used to connect TC-net I/O optical cable.

Refer to "Appendix A.4 TC-net I/O loop transmission specification" for

applicable optical cable, "Chapter 2 Installation and Wiring” for wiring optical

cables.

■ Tool Connector

This tool connector is for maintenance of our company. Please use with

attached tool connector cap attached.

■ Slide lever

Operate when removing GA932 module from the base unit.

For details, refer to "Chapter 2 Installation and Wiring”

■ Fixing screw

This screw is to fix GA932 module to the base unit.

For details, refer to "Chapter 2 Installation and Wiring”

CAUTION

GA932 is not removable when online. Do not insert or

remove GA932 module while the power is ON. Also,

Please do not connect or disconnect other modules and

cables while the power is ON.

Mandatory

CAUTION

G3 I/O does not do degeneracy recovery. G3 I/O is not

removable when online, GA932 does not perform access

check after disconnectiong abnormal G3 I/O.Turn off the

power of the basic unit and the expansion unit ,and then

restart it after replacing G3 I/O.

Mandatory

11

Chapter 2

Installation and Wiring

This chapter describes how to install and wire GA932 module.

Before installation and wiring, read this operation manual thoroughly.

2.1 Types of I/O Base Units

················································ 13

2.2 Installing / Removing the Module

································· 14

2.3 TC-net I/O Loop Wiring

················································ 17

2.4 Replacing the Module

·················································· 19

2.5 Handling the RUN Signal (RUN contact) of G3 I/O

········ 20

Chapter 2 Installation and Wiring

6F8C1590

12

WARNING

Before installing or removing the module,

make sure that the power of the I/O base

unit to which GA932 module is installed is

turned off.

Otherwise, it may cause an electric shock.

Mandatory

WARNING

Do not touch the interior of the product

except the switches.

It may cause an electric shock.

Prohibited

CAUTION

Install it under an environment that

satisfies the product specifications.

When installing it under an environment that does not

satisfy the product operating temperature range, apply

forced cooling with cooling equipment.

Operating temperature range: 0 to 55°C

Prohibited

CAUTION

Before installation or wiring, remove the

static electricity from your body.

The static electricity accumulated in the human body may

cause failure of the product.

Prohibited

CAUTION

Do not touch the cables carelessly.

Applying stress to the cables may cause malfunction or

accidents.

Prohibited

CAUTION

Do not perform wiring, insertion or

installation of the module, removal or

replacement of the base unit while the

power is on.

It may cause an electric shock.

Prohibited

CAUTION

When installing the product to the I/O base

unit, do not to break or bend the pins of G3

I/O bus connector.

Prohibited

CAUTION

When it is hard to insert the module to the

I/O base unit, remove it and then try to

install it again rather than trying to install it

forcefully.

Prohibited

CAUTION

Use a screwdriver.

To prevent damage to the screws, use a screwdriver that

is suitable for the screws.

Prohibited

Loading...

Loading...