Page 1

BSINo. G00J132 Page 1

BSI No.: G00J132

Publish

2000/10/31

Date:

Subject: New Finisher/MJ-1014 (Service Manual)

Model: MJ1014

Category Field Application UNIT

New Model Description Others Documents

FactoryApplication: -

CONTENT

We are pleased to announce the availability of our newest finisher, the MJ-1014. The MJ-1014 is very

similar to the MJ-1006, expect for minor changes. No Service Manual has been specially prepared for

the new finisher/MJ1014 and this BSI, in which the differences from the MJ1006 are shown, is to serve

as a substitute. We explain the summary of the functions as follows. Refer to the attaching file for the

details.

Page 2

BSINo. G00J132 Page 2

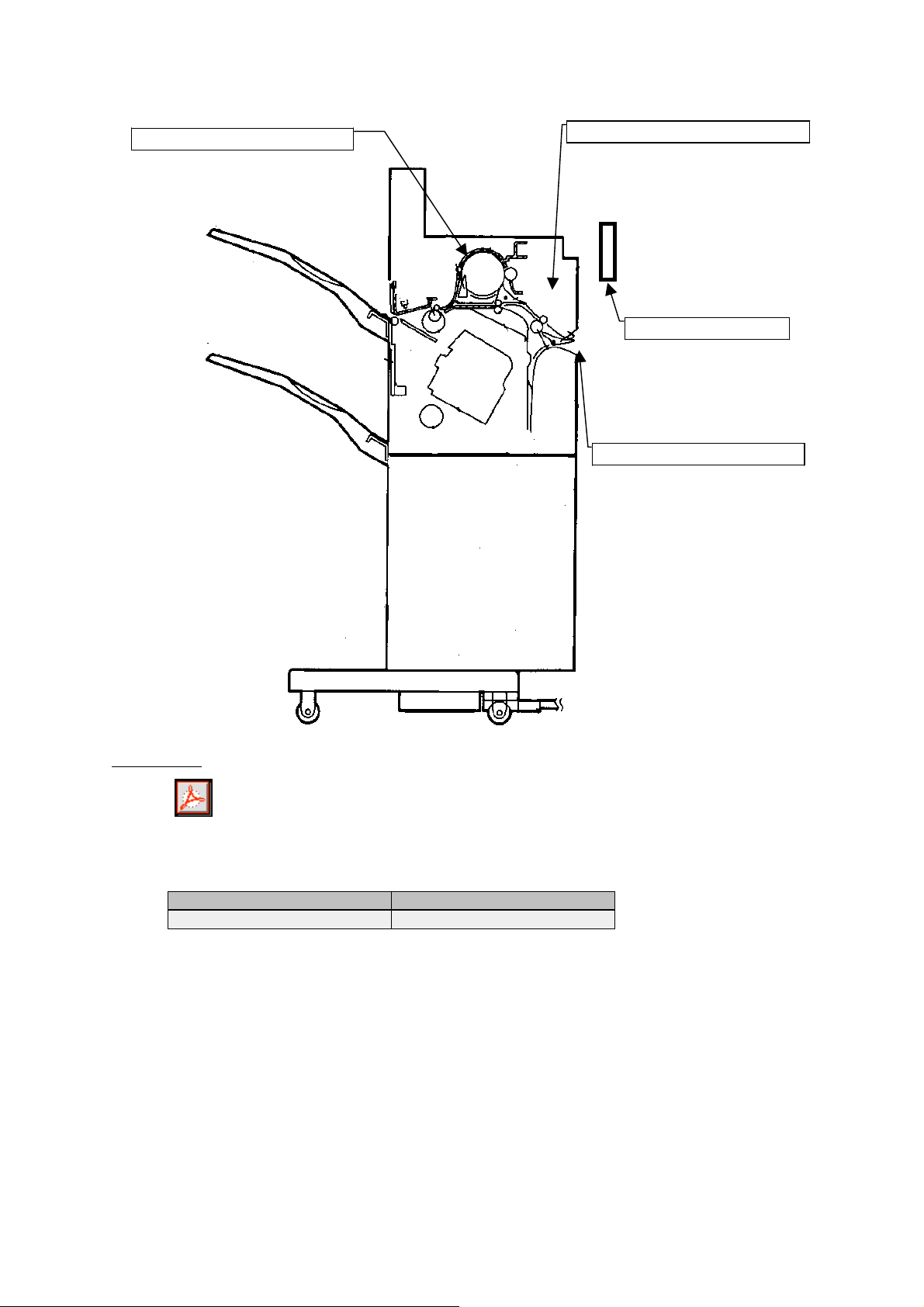

Transport drive unit

To rotate at a low, the unit of

the MJ-1005 is used.

Mid-pass drive unit

To rotate at a low,

* Gear train (arrange) change

* New motor use

Latch (accessory)

New

Entrance transport area

* To align the height of the

entrance in FC25P, the

entrance guide has been

changed.

* In order to improve the

transport function in relation

to short size paper, the

upper/lower roller width has

been expanded.

Attached File

MJ1014ServiceManual.pdf

Related Documents:

LinkTo: Link From:

Page 3

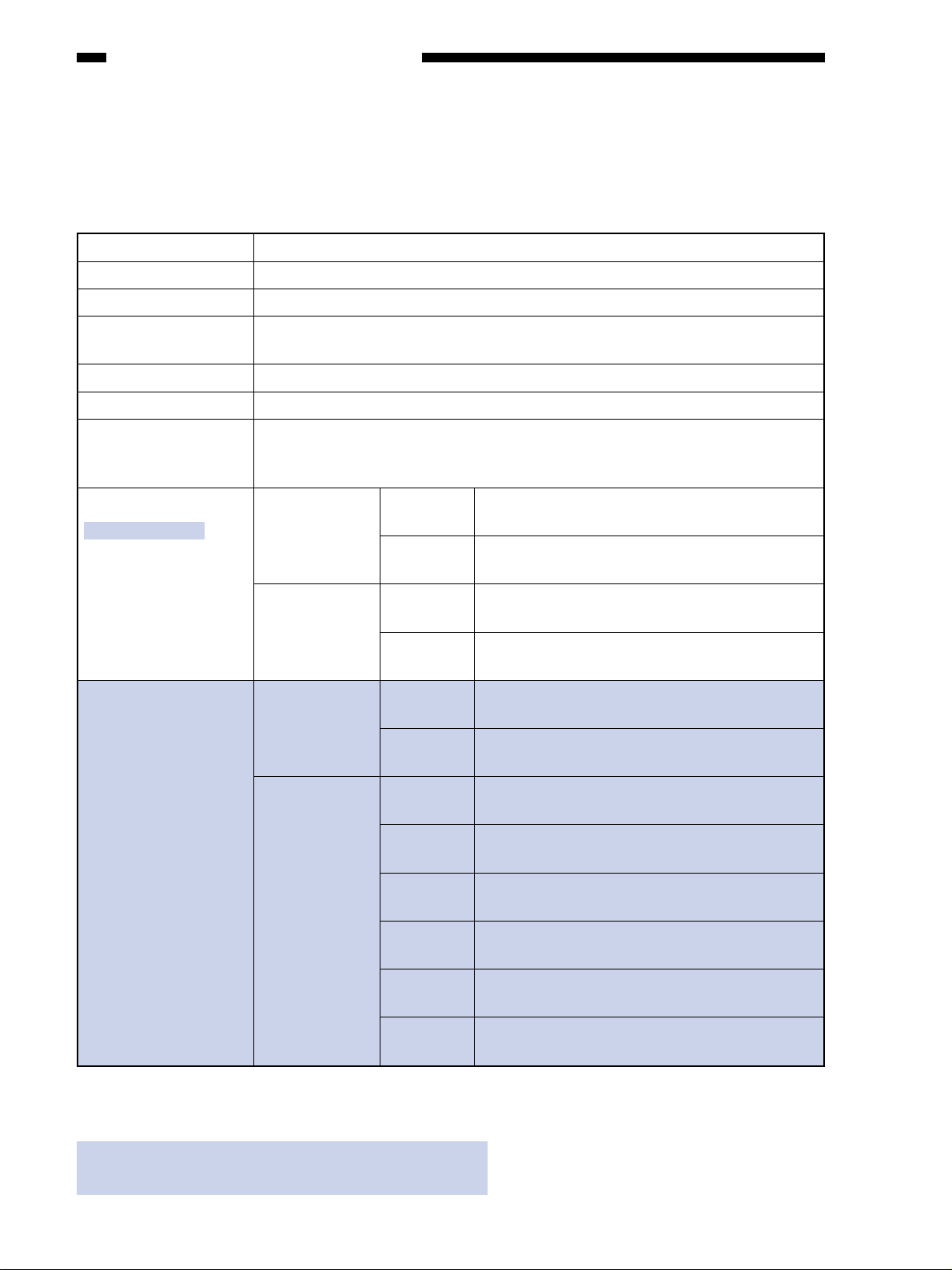

CHAPTER 1 GENERAL DESCRIPTION

II. SPECIFICATIONS

A. Specifications

1. Finisher Unit

Item

Description

Stacking method

Stacking orientation

Stacking size

Paper weight

Bins

Modes

Stacking capacity

(MJ-1006/1007)

Stacking capacity

(MJ-1014)

Trays 1 through 2: by lifting tray

Face-up

AB: A3, A4, A4-R, A5-R, B4, B5, B5-R

Inch: LD, LG, LT, LT-R, ST-R

60 to 128 g/m

2

Trays 1 through 2

Non-sort: tray 1, 2

Sort: tray 1, 2

Staple: tray 1, 2

Non staple sort Small-size Tray 1: 147 mm high (1000 sheets)

(Note 1)

Tray 2: 147 mm high (1000 sheets)

(Note 2)

Large-size Tray 1: 74 mm high (500 sheets)

(Note 1)

Tray 2: 74 mm high (500 sheets)

Staple sort Small-size Tray 1: 110 mm high/30 sets (750 sheets)

(Note 1)

Tray 2: 110 mm high/30 sets (750 sheets)

Large-size Tray 1: 74 mm high/30 sets (500 sheets)

(Note 1)

Tray 2: 74 mm high/30 sets (500 sheets)

Non staple sort Small-size Tray 1: 147 mm high (850 sheets)

(Note 5)

Tray 2: 147 mm high (850 sheets)

Large-size Tray 1: 74 mm high (400 sheets)

(Note 5)

Tray 2: 74 mm high (400 sheets)

Staple sort Small-size Tray 1: 110 mm high/30 sets (750 sheets)

(Note 4)

Tray 2: 110 mm high/30 sets (750 sheets)

Large-size Tray 1: 74 mm high/30 sets (500 sheets)

(Note 4)

Tray 2: 74 mm high/30 sets (500 sheets)

Small-size Tray 1: 110 mm high/30 sets (600 sheets)

(Note 5)

Tray 2: 110 mm high/30 sets (600 sheets)

Large-size Tray 1: 74 mm high/30 sets (400 sheets)

(Note 5)

Tray 2: 74 mm high/30 sets (400 sheets)

Small-size Tray 1: 110 mm high/30 sets (550 sheets)

(Note 6)

Tray 2: 110 mm high/30 sets (550 sheets)

Large-size Tray 1: 74 mm high/30 sets (350 sheets)

(Note 6)

Notes:

1. Approximate when computed with reference to 80 g/m

2. Alignment may not be correct if 750 or more small-size sheets are stacked on tray 2.

3. The accuracy of the stack height is ±7 mm.

4. Approximate when computed with reference to 64~80 g/m

5. Approximate when computed with reference to 81~90 g/m

6. Approximate when computed with reference to 91~105 g/m

2

paper.

2

2

Tray 2: 74 mm high/30 sets (350 sheets)

paper.

paper.

2

paper.

Table 1-201

1-2

Page 4

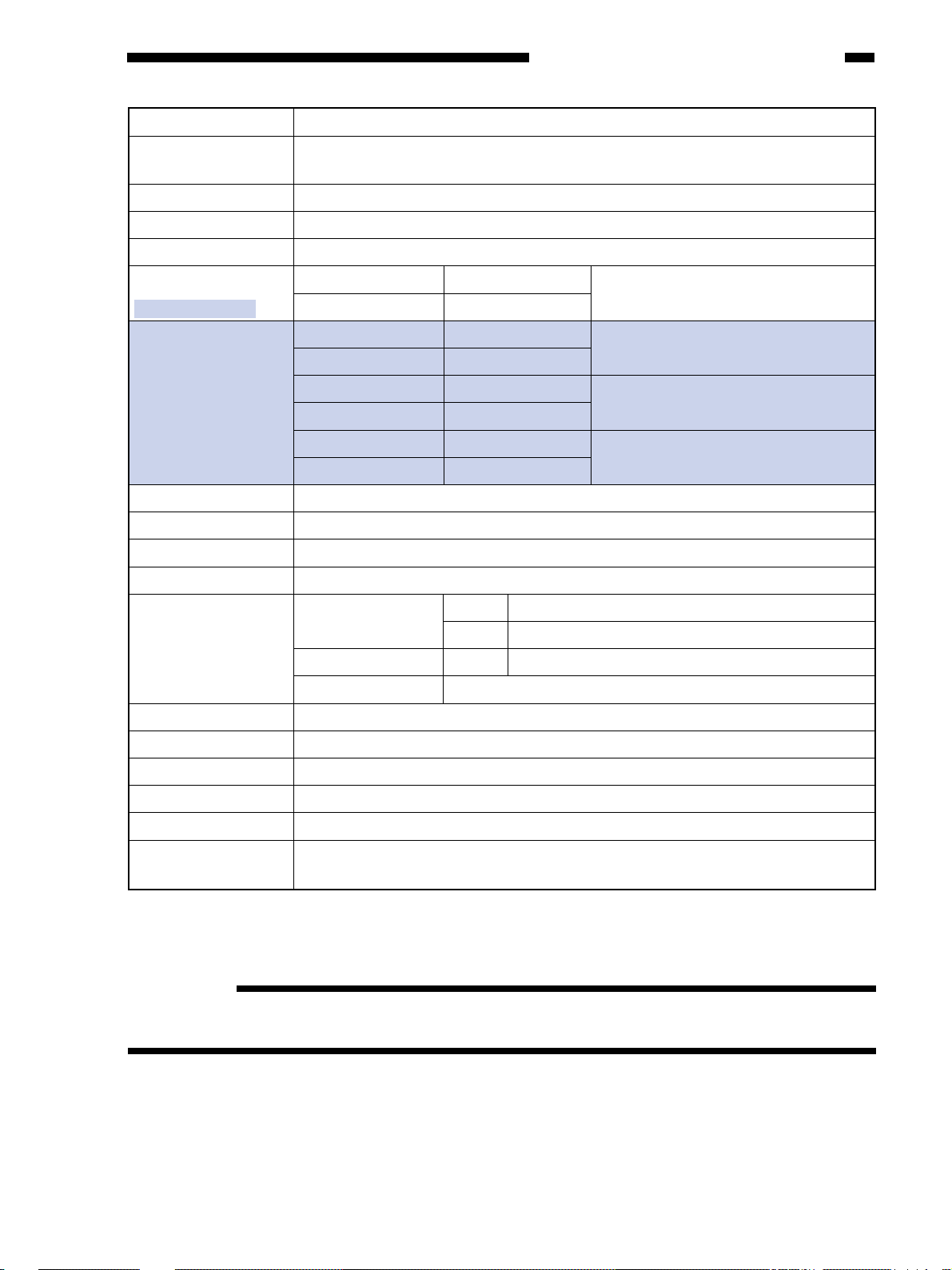

CHAPTER 1 GENERAL DESCRIPTION

Item

Size mixing

Stacking mixing

Stapling

Stapling position

Stapling capacity

(MJ-1006/1007)

Stapling capacity

(MJ-1014)

Staple supply

Staples

Staple detection

Manual stapling

Description

Size mixing: 74 mm or less

Stapling: 74 mm or less

Face-up

By rotating cam

See Figure 1-201.

Small-size 50 sheets

Large-size 30 sheets

Small-size 50 sheets

Large-size 30 sheets

Small-size 30 sheets

Large-size 15 sheets

Small-size 20 sheets

Large-size 10 sheets

Special staple cartridge (5000 staples)

Special

Provided

Not provided

Equivalent of 80 g/m2 paper

Equivalent of 64~80 g/m2 paper

Equivalent of 81~90 g/m2 paper

Equivalent of 91~105 g/m2 paper

Stapling size

Paper detection

Control panel

Dimensions

Weight

Power supply

Maximum power

consumption

1-point (diagonal) Front A3, B4, A4, A4-R, B5, LD, LG, LT, LT-R

Rear A3, B4, A4, B5, LD, LT

1-point Rear A4-R, LT-R, LG

2-point A3, B4, A4, B5, LD, LT

Tray 1, 2: provided

Not provided

716 × 603 × 1013mm (W × D × H)

MJ-1006: About 36kg, MJ-1007: About 56kg

From copier (24 VDC)

About 170 W (Average of the ordinary operation)

Table 1-202

Reference:

Small-size represents A4, B5, LT, while large-size represents A3, B4, A4-R, B5-R, LT-R, LD,

LG.

1-3

Page 5

CHAPTER 2 FINISHER UNIT BASIC OPERATION

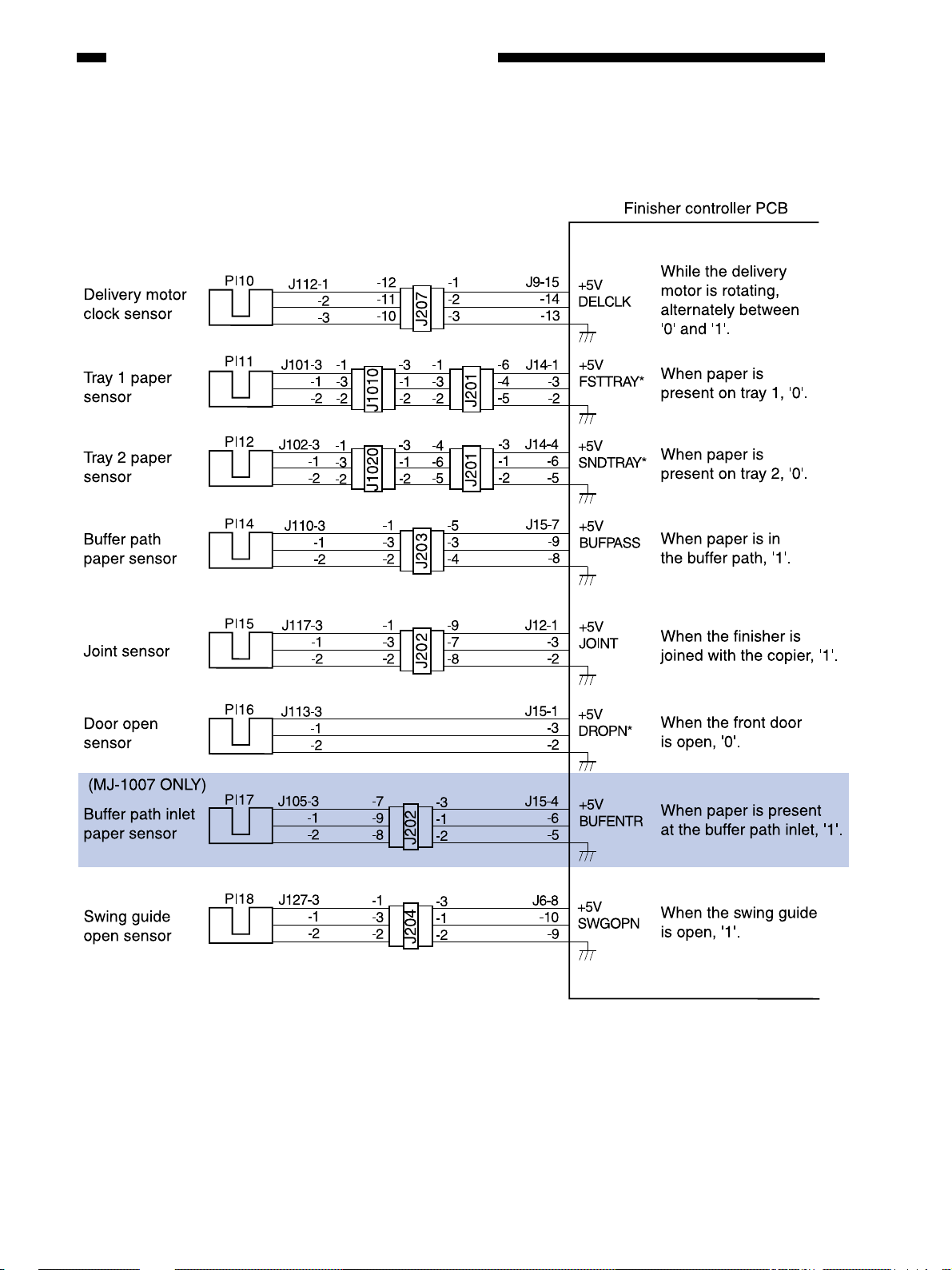

2. Inputs to the Finisher Controller PCB

2-4

Figure 2-104

Page 6

CHAPTER 2 FINISHER UNIT BASIC OPERATION

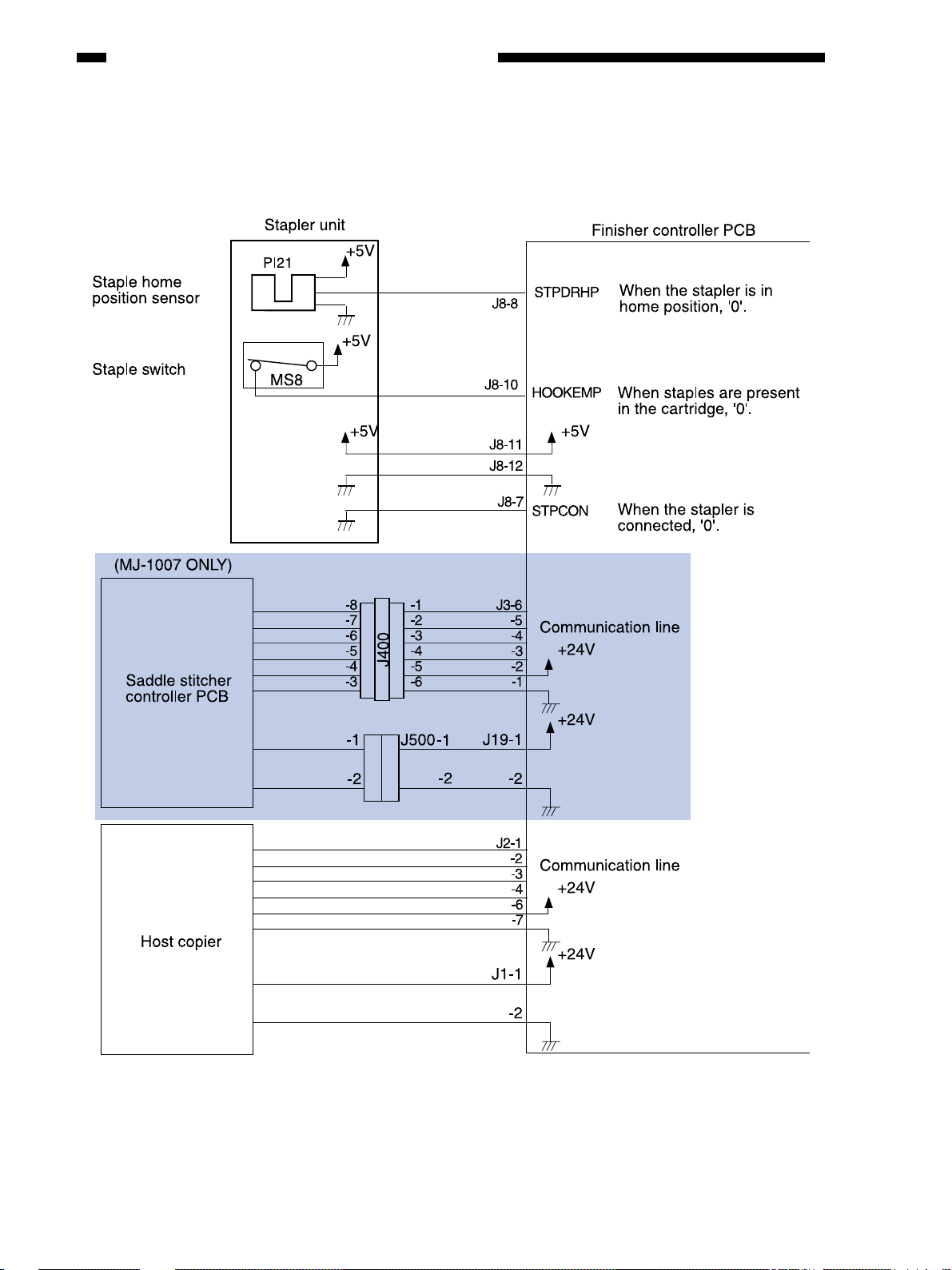

4. Inputs to and Outputs from the Finisher Controller PCB

2-6

Figure 2-106

Page 7

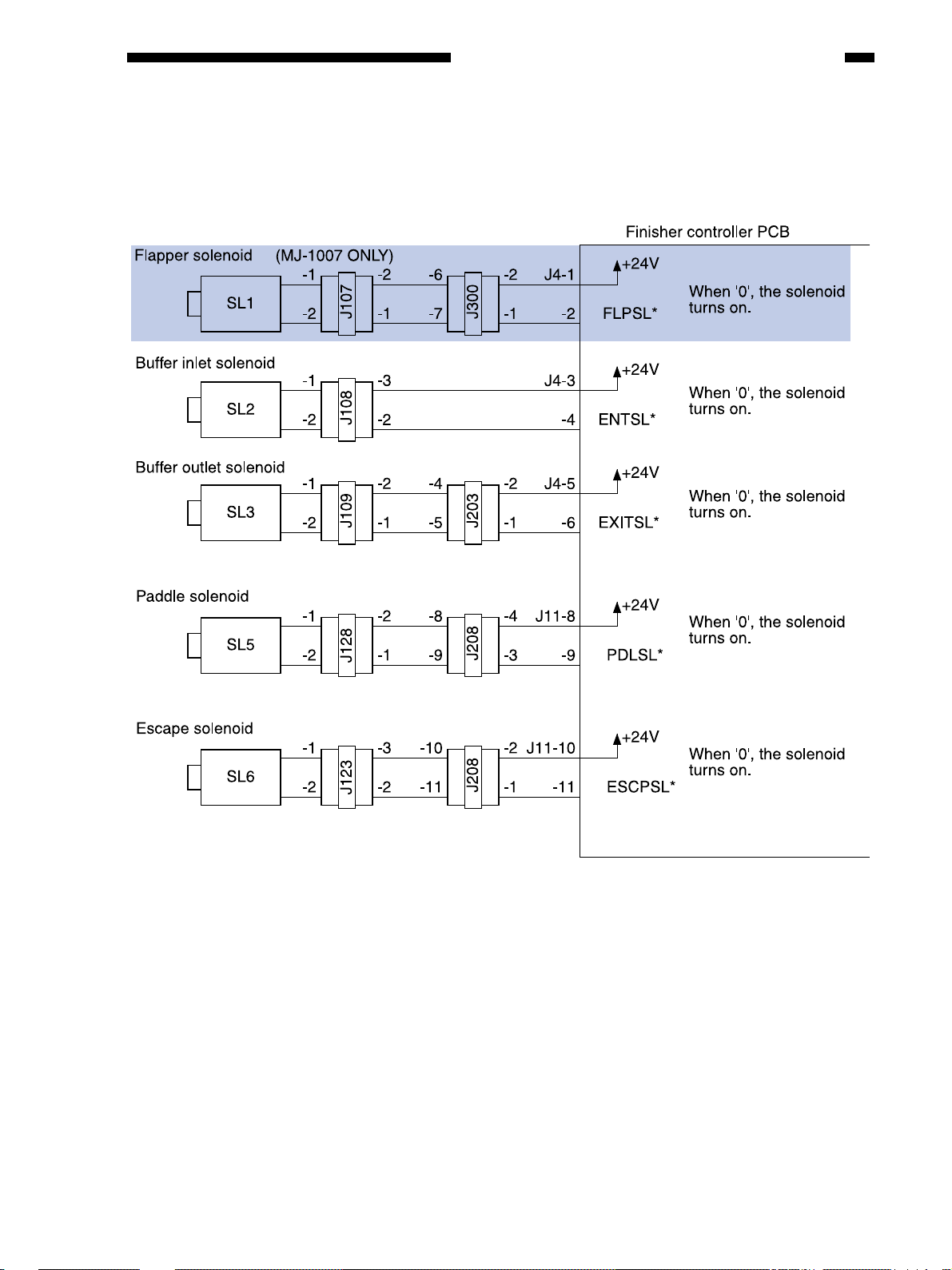

CHAPTER 2 FINISHER UNIT BASIC OPERATION

5. Outputs from the Finisher Controller PCB

Figure 2-107

2-7

Page 8

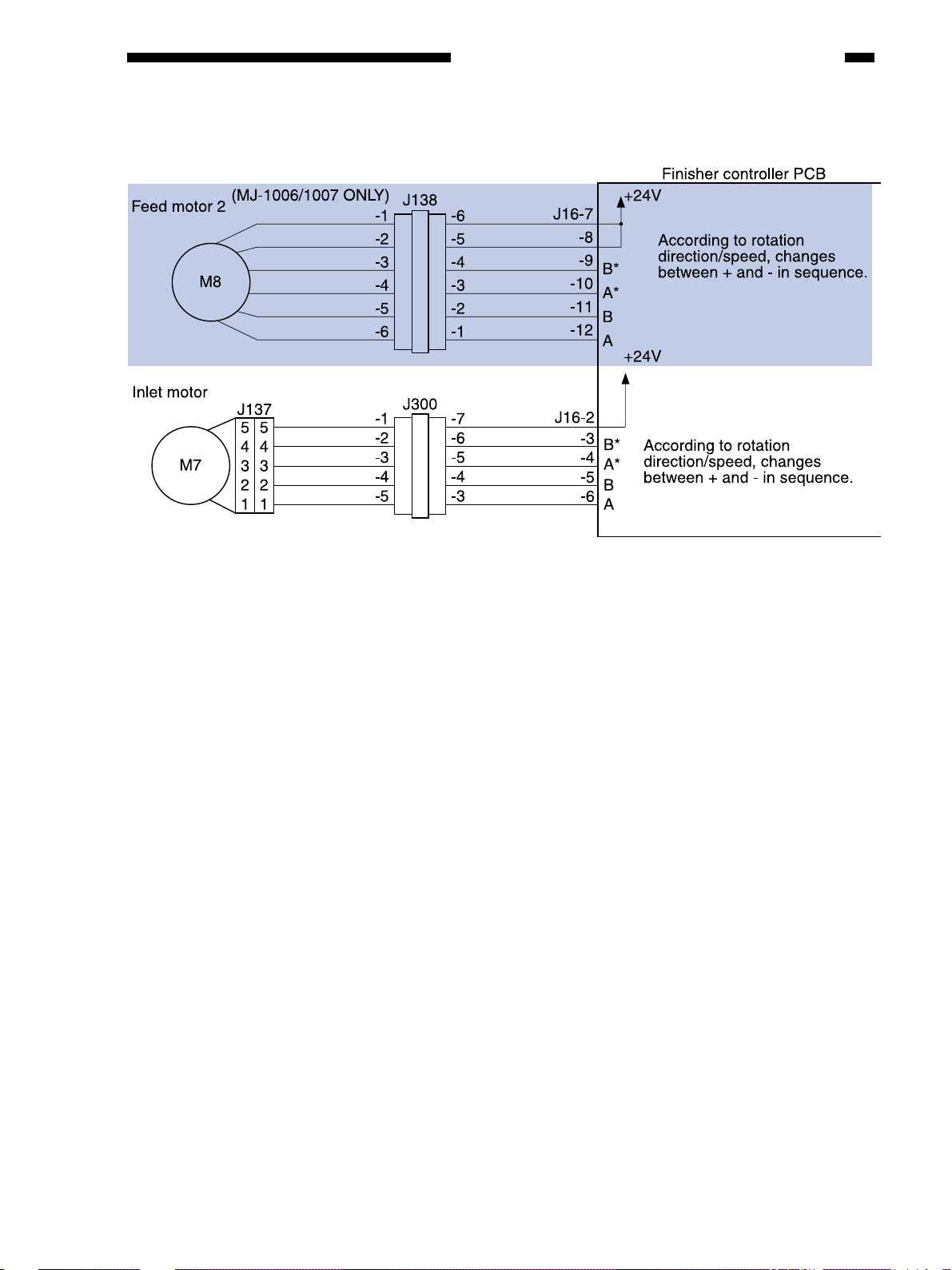

CHAPTER 2 FINISHER UNIT BASIC OPERATION

7. Outputs from the Finisher Controller PCB

Figure 2-109

2-9

Page 9

C. Feeding and Delivering

CHAPTER 2 FINISHER UNIT BASIC OPERATION

1. Outline

: MJ-1006/1007 ONLY

The finisher mov es copies arriving from the copier to the normal tray , or the saddle stitcher unit

(Saddle Finisher MJ-1007) according to the mode of delivery. On the trays, the copies are subjected

to job offset or stapling as instructed by the copier.

The inlet motor (M7), the feed motor (M1), and the feed motor (M8) are the stepping motors,

and the delivery motor (M2) is a DC motor. These motors are controlled by the microprocessor

(CPU) on the finisher controller PCB, and rotate either clockwise or counterclockwise.

The paper paths are equipped with the following five sensors for detection of paper (arrival,

passage):

●

Inlet sensor (PI1)

●

Delivery sensor (PI3)

●

Stapling tray sensor (PI4)

●

Buffer path paper sensor (PI14)

In addition, each delivery tray is equipped with a sensor designed to detect the presence/absence of paper on it.

●

No 1 tray paper sensor (PI11)

●

No. 2 tray paper sensor (PI12)

If a copy fails to reach or move past each sensor within a specific period of time, the finisher

controller PCB identifies the condition as a jam, and stops the ongoing operation and at the same

time informs the copier of the condition.

2-17

Page 10

CHAPTER 2 FINISHER UNIT BASIC OPERATION

2-18

Figure 2-216

Page 11

CHAPTER 2 FINISHER UNIT BASIC OPERATION

Figure 2-218

Figure 2-219

2-21

Page 12

CHAPTER 2 FINISHER UNIT BASIC OPERATION

Figure 2-233

2-31

Page 13

CHAPTER 2 FINISHER UNIT BASIC OPERATION

Figure 2-239

H. Detecting the Height of the Stack on the Tray

1. Outline

The number of sheets delivered to the tray and the number of sets (stapling or job of fset operations) are stored in memory by the finisher controller PCB. The height of the stack is check ed by the

height sensor (PS1). See Table 2-202 for the maximum loading capacity of each tray.

The finisher controller PCB stops operation when the conditions in Table 2-202 occur, informing the host copier that the tray is full.

Table 2-202

(MJ-1006/1007)

Stacking

Tray

Tray 1

Tray 2

Note: 1. The capacity for non-staple sort mode is approximate and computed based on 80 g/m2 paper.

2. Alignment for stacks consisting of 750 sheets or more is not guaranteed.

3. The accuracy of the stack height is ±7mm.

mode

Small-size

147 mm high

(1000 sheets)

147 mm high

(1000 sheets)

Non-staple sort Staple sort

Large-size

74 mm high

(500 sheets)

74 mm high

(500 sheets)

Small-size

750 sheets/30

sets, fewer of two

(or, 110 mm high)

750 sheets/30

sets, fewer of two

(or, 110 mm high)

Large-size

500 sheets/30

sets, fewer of two

(or, 110 mm high)

500 sheets/30

sets, fewer of two

(or, 110 mm high)

2-38

Page 14

(MJ-1014)

CHAPTER 2 FINISHER UNIT BASIC OPERATION

Tray

Tray 1

Tray 2

Stacking mode

Equivalent of

64~80 g/m

2

Equivalent of

~90 g/m

81

2

paper

Equivalent of

91~105 g/m

Equivalent of

64~80 g/m

2

Equivalent of

81~90 g/m

2

Equivalent of

91~105 g/m

paper

2

paper

paper

paper

2

paper

Small-size

--

147 mm high

(850 sheets)

--

--

147 mm high

(850 sheets)

--

Non-staple sort Staple sort

Large-size

--

74 mm high

(400 sheets)

--

--

74 mm high

(400 sheets)

--

Small-size

750 sheets/30 sets

(110 mm high)

600 sheets/30 sets

(110 mm high)

550 sheets/30 sets

(110 mm high)

750 sheets/30 sets

(110 mm high)

600 sheets/30 sets

(110 mm high)

550 sheets/30 sets

(110 mm high)

Note:

1. The term “small-size” stands for A4, LT, and B5.

2. The term “large-size” stands for A3, A4-R, B4, LG, LD and LT-R.

Large-size

500 sheets/30 sets

(74 mm high)

400 sheets/30 sets

(74 mm high)

350 sheets/30 sets

(74 mm high)

500 sheets/30 sets

(74 mm high)

400 sheets/30 sets

(74 mm high)

350 sheets/30 sets

(74 mm high)

Figure 2-240

2-39

Page 15

CHAPTER 2 FINISHER UNIT BASIC OPERATION

Figure 2-252

2-47

Page 16

CHAPTER 2 FINISHER UNIT BASIC OPERATION

4. Buffer Path Paper Sensor Stationary Jam

The sheet does not move past the buffer path paper sensor when an equivalent of twice the

feeding length of the sheet has been fed after the buffer pa th paper sensor turned on.

Figure 2-257

5. Delivery Sensor Delay Jam

a. Smaller than B5 or Non-standard Size Paper Path

The delivery sensor does not detect paper when an equi v alent of 260 mm has been fed after the

inlet sensor is turned on.

Figure 2-258

b. Standard Size Above B5 Paper Path and Buffer Path

The delivery sensor does not detect paper when an equi v alent of 460 mm has been fed after the

buffer path inlet pa per sensor is turned on.

Figure 2-259

: MJ-1006/1007 ONLY

2-50

Page 17

CHAPTER 2 FINISHER UNIT BASIC OPERATION

6. Delivery Sensor Stationary Jam

The sheet does not move past the delivery sensor when an equivalent of twice the feeding

length of the sheet has been fed after the delivery sensor turned on.

: MJ-1006/1007 ONLY

Figure 2-260

7. Stapling Tray Sensor Stationary Jam

a. With Stapling

The sheet does not move past the stapling tray sensor 1.6 sec after the delivery motor (M2)

turned on.

Figure 2-261

b. Without Stapling

The sheet does not move past the stapling tray sensor 2 sec after the deli very motor (M2) turned

on.

Figure 2-262

c. Job Offset

The sheet does not move past the stapling tray sensor 1 sec after the deli very motor (M2) turned

on.

8. Stapling Tray Sensor Delay Jam

No check is made for jams using the stapling tray sensor for either staple or job offset mode.

2-51

Page 18

CHAPTER 2 FINISHER UNIT BASIC OPERATION

III. POWER SUPPLY SYSTEM

1. Outline

The finisher controller PCB is supplied with 24 VDC power when the copier is turned on.

Some of the 24 VDC po wer is used to dri v e the motors and the solenoids etc., while the rest is used

for sensors and ICs on PCBs after being turned into 5 VDC by the w ork of the regulator IC (Q14) on

the finisher controller PCB. The 24 VDC po wer is also used to feed power from the f inisher controller PCB to the saddle stitcher controller PCB.

Some of the 24 VDC po wer used to dri ve motors is cut off when the door switch (MS1) is made

open. The power to the saddle stitcher controller PCB, however, will not be cut off.

Figure 2-301 is a block diagram showing the power supply system.

Figure 2-301

2. Protection Functions

The 24 VDC power channel used to drive motors and solenoids is equipped with a circuit

breaker (CB1) for protection against overcurrent. The 24 V channel used to drive the feed motor 1

(M1), feed motor 2 (M8), inlet pass motor (M7), alignment motor (M3), and stapler shift motor

(M4) is equipped with a fuse, which is designed to melt in the presence of overcurrent.

: MJ-1006/1007 ONLY

Caution:

Replace the lithium battery only with the one listed in the Parts Catalog. Use of different battery may

present a risk of fire or explosion. The battery may cause a fire or present chemical burn hazard if

mistreated. Do not recharge, disassemble, or dispose of it by fire.

Keep the battery out of reach of children and discard any used batteries promptly.

2-52

Page 19

CHAPTER 3

SADDLE STITCHER UNIT

BASIC OPERATION (MJ-1007)

I. BASIC OPERATION.................... 3-1

A. Outline .......................................3-1

B. Electrical Circuitry ......................3-2

C. Inputs to and Outputs

from the Saddle Stitcher

Controller PCB...........................3-3

II. FEEDING/DRIVE SYSTEM.........3-8

A. Outline .......................................3-8

III. PAPER DEPOSITING

MECHANISM.............................3-14

A. Outline .....................................3-14

B. Controlling the Inlet

Flappers...................................3-17

C. Controlling the Movement

of Sheets..................................3-21

D. Aligning the Sheets..................3-22

E. Controlling the Phase of

the Crescent Roller ..................3-25

IV. STITCHING SYSTEM ...............3-27

V. FOLDING/DELIVERY

SYSTEM....................................3-30

VI. CHECKING FOR A JAM ...........3-35

VII. POWER SUPPLY ......................3-39

Page 20

CHAPTER 4

MECHANICAL CONSTRUCTION

(A) FINISHER UNIT ..........................4-1

I. EXTERNALS AND

CONTROLS...............................4-1

A. External Covers ...................4-1

II. FEEDING SYSTEM ...................4-7

III. PCBs........................................4-13

(B) SADDLE STITCHER UNIT

(MJ-1007) ..................................4-14

Page 21

CHAPTER 5

MAINTENANCE AND INSPECTION

I. PERIODICALLY REPLACED

PARTS.........................................5-1

A. Finisher Unit...............................5-1

B. Saddle Stitcher Unit

(MJ-1007) ..................................5-1

II. CONSUMABLES AND

DURABLES .................................5-1

A. Finisher Unit...............................5-1

B. Saddle Stitcher Unit

(MJ-1007) ..................................5-1

III. PERIODICAL SERVICING ..........5-1

Page 22

CHAPTER 6

TROUBLESHOOTING

I. ADJUSTMENTS ..........................6-1

A. Electrical System

(finisher unit) ..............................6-1

B. Electrical System/MJ-1007

(saddle stitcher unit) ..................6-4

C. Mechanical System....................6-8

II. ARRANGEMENT OF

ELECTRICAL PARTS..................6-9

A. Finisher Unit...............................6-9

B. Saddle Stitcher Unit .................6-15

C. Var iable Resistors (VR),

Light-Emitting Diodes (LED),

and Check Pins by PCB ...........6-21

III. TROUBLESHOOTING...............6-23

A. Finisher Unit.............................6-23

B. Saddle Stitcher Unit

(MJ-1007) ................................6-31

Page 23

CHAPTER 6 TROUBLESHOOTING

3. Motors

6-12

Figure 6-203

Table 6-203

Page 24

4. Solenoids

CHAPTER 6 TROUBLESHOOTING

Figure 6-204

Table 6-204

6-13

Page 25

APPENDIX

A. Signal and Abbreviations............ A-1

B. Finisher Unit General Circuit

Diagram...................................... A-2

C. Finisher Unit Controller Circuit

Diagram...................................... A-3

D. Saddle Stitcher Unit General

Circuit Diagram (MJ-1007)........ A-11

E. Saddle Stitcher Unit Controller

Circuit Diagram (MJ-1007)........ A-12

F. Solvents and Oils...................... A-19

Page 26

B. Finisher Unit General Circuit Diagram

(MJ-1007)

(MJ-1006/1007)

(MJ-1007)

A-2

Loading...

Loading...