Page 1

BSINo. G00I099 Page 1

BSI No.: G00I099

Publish

2000/09/19

Date:

Subject: Countermeasure Method when Toner Scattering in the Market

(Temporary Method)

Model: DP4580, DP5570, DP6570, DP8070

Category Field Application UNIT

Request from the field To be applied when necessary Cleaner, Developer

FactoryApplication: -

CONTENT

When toner scattering/image soiling in the market occurs, be sure to carry out the following

procedure.

[Cause and Countermeasure]

In intermittent copying of a small number of sheets, there is a tendency for the toner density to

change highly and toner scattering /image soiling may be caused.

When toner scattering/image soiling happened, the following actions are required.

Course of Action Item

A Suppress a rise in toner concentration. ATC control

ATC: Auto-toner circuit)

B By creating a toner reservoir, even if toner scattering is

carried out, image soiling should not happen.

C The developer is in a degraded state at this time, and

the scattered toner has been deposited in the toner

filter, and the duct suction capability is reduced.

Note

Item C recommends that this be performed as part of a scheduled inspection (PM).

[Temporary countermeasure procedure]

1. Exchange of developer duct cover

Exchange of developer duct

cover

Exchange of cleaner stay

Exchange of developer material

Exchange of toner filter

Page 2

(1) Developer material should be removed

from the developer unit

(2) Turn over the developer unit.

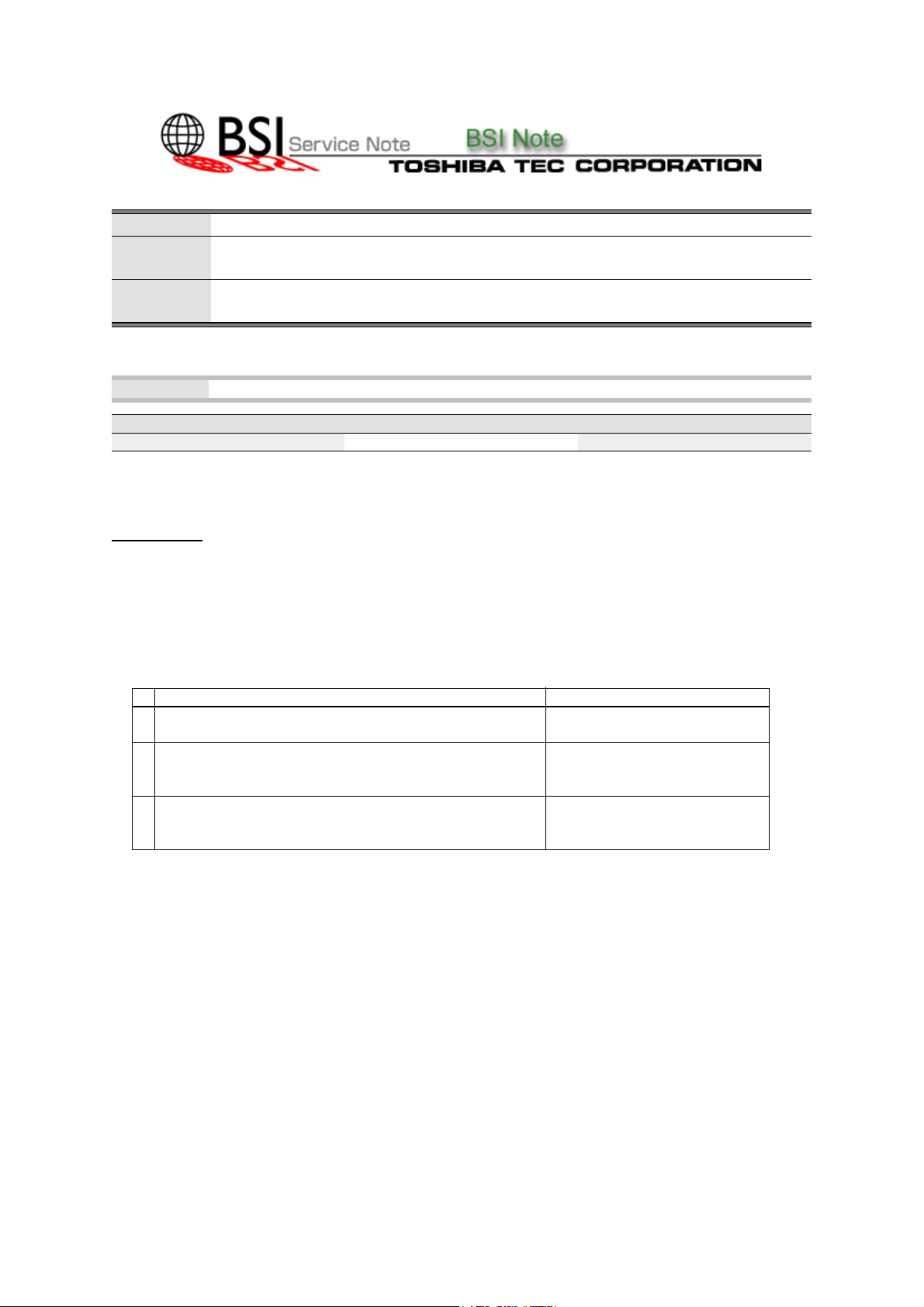

(3) The claws on the right and left shown in

figure A on the right are removed from the

developer unit. (see arrow

withdrawn towards the front (see arrow

(4) The new duct cover is attached using the

procedure opposite to that in (3). At this time,

be careful to how you turn the harness of

The projecting area of the duct should be slid

into the developer unit groove (arrow

), and the duct is

1

2

).

3

).

.

B

BSINo. G00I099 Page 2

2. Exchange of developer material

Add the new developer material to the developer unit in the predetermined method.

3. Exchange of cleaner stay

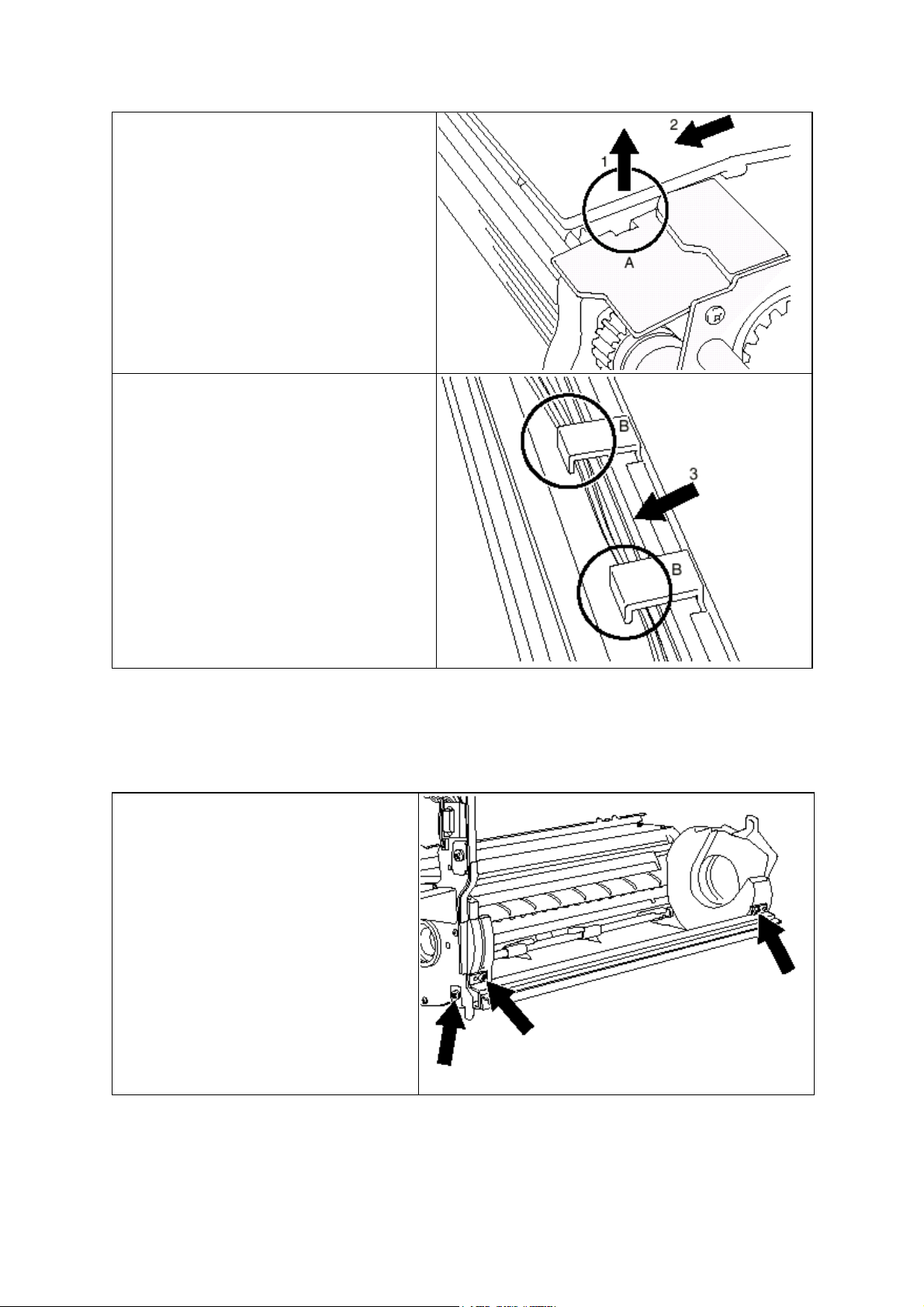

(1) Remove the drum.

Refer to the method below.

Service Handbook

Periodical Maintenance

2.

Periodic Inspection Check List

11. Drum

(2) Remove 3 screws. (See 3 arrows.)

(3) Remove the cleaner stay.

(4) Attach the new cleaner stay and fix the

3 screws.

4. Exchange of toner filter

Change the toner filter based on the following notes.

Service Handbook

Periodical Maintenance

2.

Page 3

BSINo. G00I099 Page 3

Periodic Inspection Check List

37. Toner filter

5. ATC control......10 bits lower

(1) Install the cleaner unit and the developer unit to the machine.

(2) Adjustment code 05 pre-running and ATC automatic adjustment in code 200.

Check that the control panel message changes to the adjustment mode after about 3

z

minutes.

After checking, adjust to a value 10 bits lower than the displayed value using the DOWN key

z

on the display.

After checking, push the Setting key.

z

[Countermeasure Part]

The parts for the above procedure are shown below.

Name

Developer duct cover &

Cleaner stay

Developer material

P-I

202-35

202-2

Part No. Note

4406368980KIT-REPL

Service Kit (New) Note 1

ACE-C/D

4409863570

PM part

D-6570

Toner filter 48-12

4406334900

PM part

FILTER-DEV-F300

Note 1

When this countermeasure is made, be sure to use the service kit (4406368980

KIT-REPLASE-C/D). Do not use available single parts.

Attached File

Related Documents:

LinkTo: Link From:

Loading...

Loading...