Page 1

MULTIFUNCTIONAL DIGITAL COLOUR SYSTEMS

Operator's Manual

for Basic Functions

Page 2

EPA ENERGY STAR ® (MFD)

The United States Environmental Protection Agency (EPA) has introduced a voluntary programme, the ENERGY

STAR programme, to encourage the widespread and voluntary use of energy-efficient technologies that enhance

the workplace, improve product performance and prevent pollution. As an

TEC CORPORATION has determined that this copier model meets the

efficiency.

ENERGY STAR guidelines for this class of copier require ENERGY STAR copiers to have a ‘Sleep Mode’

feature that automatically makes the copier enter the sleep mode after a period of inactivity. The copier must also

automatically change to a ‘Low Power Mode’ (Automatic Energy Save) after a period of time since the last usage.

Specifically, this copier complies with the following requirements.

e-STUDIO2500c/3500c/3510c

‘Automatic Energy Save’-

The copier consumes less than 184 W (e-STUDIO2500c/3500c)/223 W (e-STUDIO3510c) during Energy

Save.

‘Automatic Energy Save’ Default Time-

The default time for the ‘Automatic Energy Save’ is 15 minutes.

‘Sleep Mode’

The copier consumes less than 80 W (e-STUDIO2500c/3500c)/95 W (e-STUDIO3510c) in the ‘Sleep

Mode’.

‘Sleep Mode’ Default Time-

The default time for the ‘Sleep Mode’ is 60 minutes (e-STUDIO2500c/3500c)/90 minutes

(e-STUDIO3510c).

Note1- The default setting for the ‘Sleep Mode’ and ‘Automatic Energy Save’ can be changed. Contact your

service representative to change the default settings noted above.

Note2- If the Fax or printer data is received in the sleep mode, the copier starts warming itself up and prints out

the data when it becomes ready. Also, when the start button or the energy saver button on the control

panel is pressed, the copier starts warming itself up.

ENERGY STAR Partner, the TOSHIBA

ENERGY STAR guidelines for energy

In accordance with EPA

paper.

Great White MultiUse 20 paper

If you have any questions regarding the use of recycled paper or some recommended types of recycled paper,

please contact your authorized Toshiba dealer.

ENERGY STAR programme guidelines, Toshiba recommends the following recycled

ENERGY STAR is a U.S. registered mark.

Page 3

Notice to Users

After a suitable place has been selected for the installation of the e-STUDIO2500c/3500c/3510c, please

do not change it. Avoid excessive heat, dust, vibration and direct sunlight. Also, provide proper ventilation as the copier emits a small amount of ozone.

The unit is classified as Class 1 Laser Product according to IEC 60825-1:1993/EN 60825-1.1994

including amendments.

The unit uses laser diode of output 25 mW, wave length 790 nm, continuous pulse.

For EU only

Warning:

This is a Class A product. In a domestic environment this product may cause radio interference in which

case the user may be required to take adequate measures.

Working environment

From EMC (Electromagnetic Compatibility) point of view, the operation of this product is being restricted

in following environments:

y Medical Environments: This product is not certified as a medical product according to the Medical

Product Directive 93/42/EEC.

y Domestic environments (e.g. a private living room with TV / Radio sets in the nearby surrounding

area) because this is a so called EMC class A product. In a domestic environment this product may

cause radio interference in which case the user may be required to take adequate measures!

Any consequences resulting from the use of this product in restricted working environments are not the

responsibility of TOSHIBA TEC.

The consequences of the use of this product in restricted working environments may be an electromagnetic interference with other devices or machines in the nearby surrounding area. This can result into

malfunction including data loss / data error pertaining to this product or the other devices / machines

involved in the electromagnetic interference.

Furthermore, for general safety reasons, the use of this product in environments with explosive atmospheres is not permitted.

CE compliance

This product is labelled with the CE mark in accordance with the provisions of the applicable European

Directives, notably the Low Voltage Directive 73/23/EEC and the Electromagnetic Compatibility Directive 2004/108/EEC for this product and the electric accessories, the Radio Equipment and Telecommunications Terminal Equipment Directive 99/5/EEC for the telecommunication accessories.

CE marking is the responsibility of TOSHIBA TEC GERMANY IMAGING SYSTEMS GmbH, CarlSchurz-Str. 7, 41460 Neuss, Germany, phone +49-(0)-2131-1245-0.

For a copy of the related CE Declaration of Conformity please contact your dealer or TOSHIBA TEC.

For Germany only

Machine Noise Information

Ordinance 3. GPSGV: The maximum sound pressure level is equal or less than 70 dB(A) according to

EN ISO 7779

Notice to Users 1

Page 4

Following information is for EU-member states only:

This product is marked according to the requirement in EU-Directive 2002/96/EC.

(Directive on Waste electrical and electronic equipment - WEEE)

The use of the symbol indicates that this product may not be disposed as unsorted municipal waste and

has to be collected separately. By ensuring this product is disposed of correctly, you will help prevent

potential negative consequences for the environment and human health, which could otherwise be

caused by inappropriate waste handling of this product.

For more detailed information about the take-back and recycling of this product please contact your supplier where you purchased the product.

2 Notice to Users

Page 5

Lineup of Our Manuals

Thank you for purchasing the TOSHIBA multifunctional digital colour systems e-STUDIO2500c/

3500c/3510c.

We have provided you with these manuals for the operation of this equipment. Select and read

the manual best suited to your needs.

Quick Start Guide

This Quick Start Guide describes the initial setup method of this equipment and accessories of this product such as operator’s manuals and

CD-ROMs.

Operator’s Manual for Basic Functions

This Operator’s Manual Basic Functions describes how to use the basic

functions of this equipment mainly focusing on the copying function.

Also this manual contains safety precautions for users to be observed.

Be sure to read it first carefully.

User Functions Guide

This User Functions Guide describes the functions and settings under

the [USER FUNCTIONS] button on the control panel of this equipment.

Colour Guide

This colour Guide simply explains the functions such as “copy density

adjustment”, “colour adjustment”, “copy editing”, "image editing” and

“image processing” in colour. This guide also includes the basic knowledge of colour.

Other guides are provided by the User Documentation CD-ROM in PDF files:

TopAccess Guide

This TopAccess Guide explains how to operate and set up the network

functions such as the network scanning function and job management,

using the TopAccess (Web-based utility) from client computers.

Lineup of Our Manuals 3

Page 6

Network Administration Guide

This Network Administration Guide explains the guidelines for setting up

network servers to provide various network services, and troubleshooting for network administrators.

Printing Guide

This Printing Guide explains how to install the client software for printing

from Microsoft Windows, Apple Mac OS, and UNIX computers, and print

to the equipment.

Scanning Guide

This Scanning Guide explains how to operate the scanning function of

this equipment.

e-Filing Guide

This e-Filing Guide explains how to operate the e-Filing function using

the TWAIN driver, File Downloader and e-Filing web utility.

Network Fax Guide

This Network Fax Guide explains how to use the network fax function

that enable users to operate fax and internet fax sending from a client

computer via network.

4 Lineup of Our Manuals

Page 7

User Management Guide

This User Management Guide describes how to manage this equipment

using the functions of “Department Management”, “User Management

Setting” and “User Authentication for Scan to E-mail”.

To read manuals in PDF (Portable Document Format) files

Viewing and printing this operator’s manual in PDF files require that you install Adobe Reader or

Adobe Acrobat Reader on your PC. If Adobe Reader or Adobe Acrobat Reader is not installed

on your PC, download and install it from the website of Adobe Systems Incorporated.

Lineup of Our Manuals 5

Page 8

Before Reading This Manual

This operator’s manual describes the following:

y How to use this equipment

y How to inspect and carry out maintenance on this equipment

y How to remedy mechanical and copying problems

Precautions in this manual

To ensure correct and safe use of this equipment, this operator’s manual describes safety precautions according to the three levels shown below.

You should fully understand the meaning and importance of these items before reading this

manual.

Indicates a potentially hazardous situation which, if not avoided, could result

in death, serious injury, or serious damage, or fire in the equipment or surrounding assets.

Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury, partial damage of the equipment or surrounding

assets, or loss of data.

Indicates a procedure you should follow to ensure the optimal performance of

the equipment and problem-free copying.

Other than the above, this manual also describes information that may be useful for the operation of this equipment with the following signage:

Describes handy information that is useful to know when operating the equipment.

Pages describing items related to what you are currently doing. See these

pages as required.

6 Before Reading This Manual

Page 9

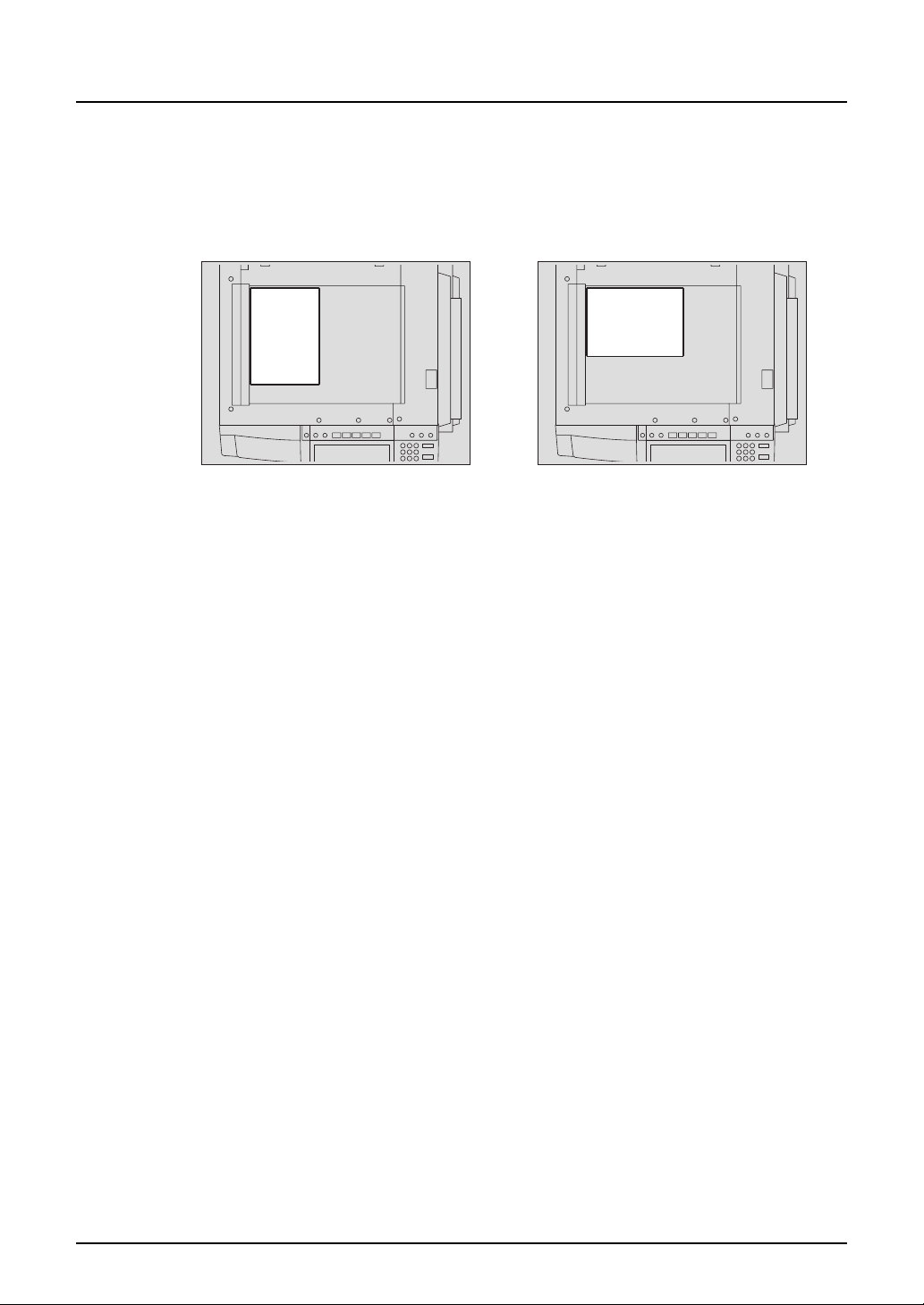

Description of original/paper direction

Paper or originals of A4 and B5 size can be placed either in a portrait direction or in a landscape

direction. In this manual, “-R” is added to this paper size when this size of paper or original is

placed in a landscape direction.

e.g.) A4 size original on the original glass

Placed in a portrait direction: A4 Placed in a landscape direction: A4-R

Paper or originals of A3 or B4 size can only be placed in a landscape direction, therefore “-R” is

not added to these sizes.

Trademarks

y Microsoft and Windows are the trademarks of Microsoft Corporation in the US and other

countries.

y Adobe, Adobe Acrobat, Adobe Reader and Adobe Acrobat Reader are the trademarks of

Adobe Systems Incorporated.

y Other company or product names shown in this manual may be a brand name or a trade-

mark of each company.

©2006 TOSHIBA TEC CORPORATION All rights reserved

Under the copyright laws, this manual cannot be reproduced in any form without prior written

permission of TOSHIBA TEC CORPORATION. No patent liability is assumed, however, with

respect to the use of the information contained herein.

Before Reading This Manual 7

Page 10

8 Before Reading This Manual

Page 11

CONTENTS

Notice to Users .............................................................................................1

Lineup of Our Manuals.................................................................................3

Before Reading This Manual ....................................................................... 6

TOSHIBA Quality is Second to None........................................................17

Features of the e-STUDIO2500c/3500c/3510c ..........................................19

General Precautions...................................................................................21

Disclaimer Notice ....................................................................................... 27

Forgery Prevention Function/Storage of Colour Copies ........................28

Chapter 1 BEFORE USING EQUIPMENT

Description of Each Component............................................................... 30

Main components .................................................................................... 30

Configuration of options........................................................................... 34

Control panel ........................................................................................... 37

Adjustment of the angle of the control panel ........................................... 39

Touch panel............................................................................................. 41

Preparation 1- Turning Power On/Off ......................................................45

Turning power on..................................................................................... 45

When department or user management is used .....................................46

Preparation 2- Turning power off (Shutdown) ........................................ 50

Turning power off (Shutdown) .................................................................50

Preparation 3- Setting Copy Paper ..........................................................54

Acceptable copy paper ............................................................................54

Setting copy paper (size change) ............................................................ 56

Changing the setting of paper size .......................................................... 61

Drawer for special uses ...........................................................................62

Placing paper in the Large Capacity Feeder (optional) ...........................65

Chapter 2 HOW TO MAKE COPIES

Setting Originals.........................................................................................68

Acceptable originals ................................................................................68

Placing originals on the glass.................................................................. 70

Using the Reversing Automatic Document Feeder (optional) .................72

Making Copies ............................................................................................ 76

Initial (Default) settings ............................................................................76

Copying procedure ..................................................................................77

Scanning the next originals during copying (Auto job start) ....................82

Interrupt copying in progress and make other copies

(Interrupt copying) ...................................................................................84

CONTENTS 9

Page 12

Bypass Copying ......................................................................................... 85

Bypass copying .......................................................................................85

Bypass copying on standard size paper.................................................. 86

Bypass copying on non-standard size paper...........................................91

Proof Copy ..................................................................................................95

Chapter 3 SETTING OF BASIC COPY MODES

Paper Selection........................................................................................... 98

Automatic Paper Selection (APS)............................................................98

Manual paper selection ......................................................................... 100

Copying mixed-sized originals in one operation (mixed original size) .. 101

Switching Colour Mode............................................................................103

Enlargement and Reduction Copying ....................................................104

Automatic Magnification Selection (AMS) ............................................. 104

Specifying both original size and copy size separately .........................106

Using the zoom buttons or the one-touch zoom buttons .......................108

Selecting Finishing Modes ...................................................................... 110

Type of finishing mode ..........................................................................110

Name of each part in the Finisher (optional) ......................................... 111

Sort/Group copying................................................................................ 112

Rotate sort mode ...................................................................................114

Staple sort mode ...................................................................................116

Magazine sort & saddle stitch mode (booklet mode).............................118

Hole punch mode (optional) .................................................................. 121

Manual stapling (MJ-1101 only) ............................................................ 123

Duplex Copying ........................................................................................ 125

1-sided original -> 1-sided copy (default setting at installation).............126

1-sided original -> 2-sided copy ............................................................127

2-sided original -> 2-sided copy ............................................................128

2-sided original -> 1-sided copy ............................................................129

Book-type original -> 2-sided copy ........................................................ 130

Original Mode............................................................................................ 134

Copy Density Adjustment........................................................................ 136

Automatic copy density mode................................................................ 136

Manual copy density mode....................................................................137

Chapter 4 IMAGE ADJUSTMENT

Colour Balance (YMCK Adjustment) ......................................................140

RGB Adjustment.......................................................................................142

One-Touch Adjustment............................................................................143

10 CONTENTS

Page 13

Background Adjustment..........................................................................144

Sharpness .................................................................................................145

Twin Colour (2-Colour) Copy...................................................................146

TWIN COLOUR SELECTABLE.............................................................146

RED & BLACK....................................................................................... 149

Monocolour copying ................................................................................ 152

Hue ............................................................................................................ 153

Saturation ................................................................................................154

Chapter 5 USING THE EDITING FUNCTIONS

IMAGE SHIFT ............................................................................................ 157

Creating a right or left margin ................................................................157

Creating a top or bottom margin............................................................159

Creating a bookbinding margin.............................................................. 161

EDGE ERASE ............................................................................................ 163

BOOK CENTRE ERASE............................................................................ 164

DUAL PAGE ..............................................................................................166

2IN1 / 4IN1 .................................................................................................168

MAGAZINE SORT ..................................................................................... 171

EDITING ..................................................................................................... 173

Trimming / Masking ...............................................................................173

Mirror image ..........................................................................................176

Negative/Positive reversal .....................................................................177

XY ZOOM ...................................................................................................178

COVER SHEET..........................................................................................180

SHEET INSERTION ...................................................................................183

TIME STAMP ............................................................................................. 186

PAGE NUMBER......................................................................................... 187

JOB BUILD ................................................................................................189

IMAGE DIRECTION ...................................................................................193

BOOK - TABLET .......................................................................................195

ADF / SADF ...............................................................................................196

Continuous feed mode ..........................................................................196

Single feed mode .................................................................................. 197

FULL IMAGE ............................................................................................. 199

CONTENTS 11

Page 14

Chapter 6 e-FILING

e-Filing....................................................................................................... 202

Creating User Boxes ................................................................................ 204

Changing Data of User Boxes ................................................................. 206

Deleting User Boxes.................................................................................209

Storing Documents in e-Filing ................................................................ 211

Printing Stored Documents .....................................................................216

Printing the whole document ................................................................. 216

Test printing........................................................................................... 218

Printing the stored document after changing the settings .....................219

Deleting Folders or Documents ..............................................................221

Appendix ...................................................................................................223

Storing documents in the shared folder................................................. 223

Chapter 7 TEMPLATE

Template....................................................................................................228

Template in “Useful Template” ..............................................................228

Registering User Groups and Templates...............................................230

Registering a template in the public template group .............................230

Registering the new user group.............................................................235

Registering a template in the user group...............................................238

Changing Data of User Groups and Templates.....................................243

Changing the data of a user group ........................................................ 243

Changing the data of a template ........................................................... 246

Recalling Templates.................................................................................251

When recalling a template in a public group..........................................251

When recalling a template in a user group............................................253

Deleting User Groups or Templates .......................................................256

Deleting a user group ............................................................................256

Deleting a template................................................................................ 258

Chapter 8 JOB STATUS

Job Status .................................................................................................262

Confirming Print Job Status.................................................................... 263

Print jobs ...............................................................................................263

Proof print jobs ......................................................................................267

Private print jobs.................................................................................... 270

12 CONTENTS

Page 15

When using department codes..............................................................275

Confirming Scan Job Status ...................................................................278

Log List...................................................................................................... 279

Confirming job history in log list.............................................................280

Registering into address book from log lists..........................................284

Printing journals (send/receive log list)..................................................286

Print Status Display..................................................................................287

Releasing print job errors ......................................................................287

Error Code.................................................................................................290

Chapter 9 BLINKING GRAPHIC SYMBOLS

Blinking Graphic Symbols....................................................................... 300

Drawer Display on the Touch Panel ....................................................... 301

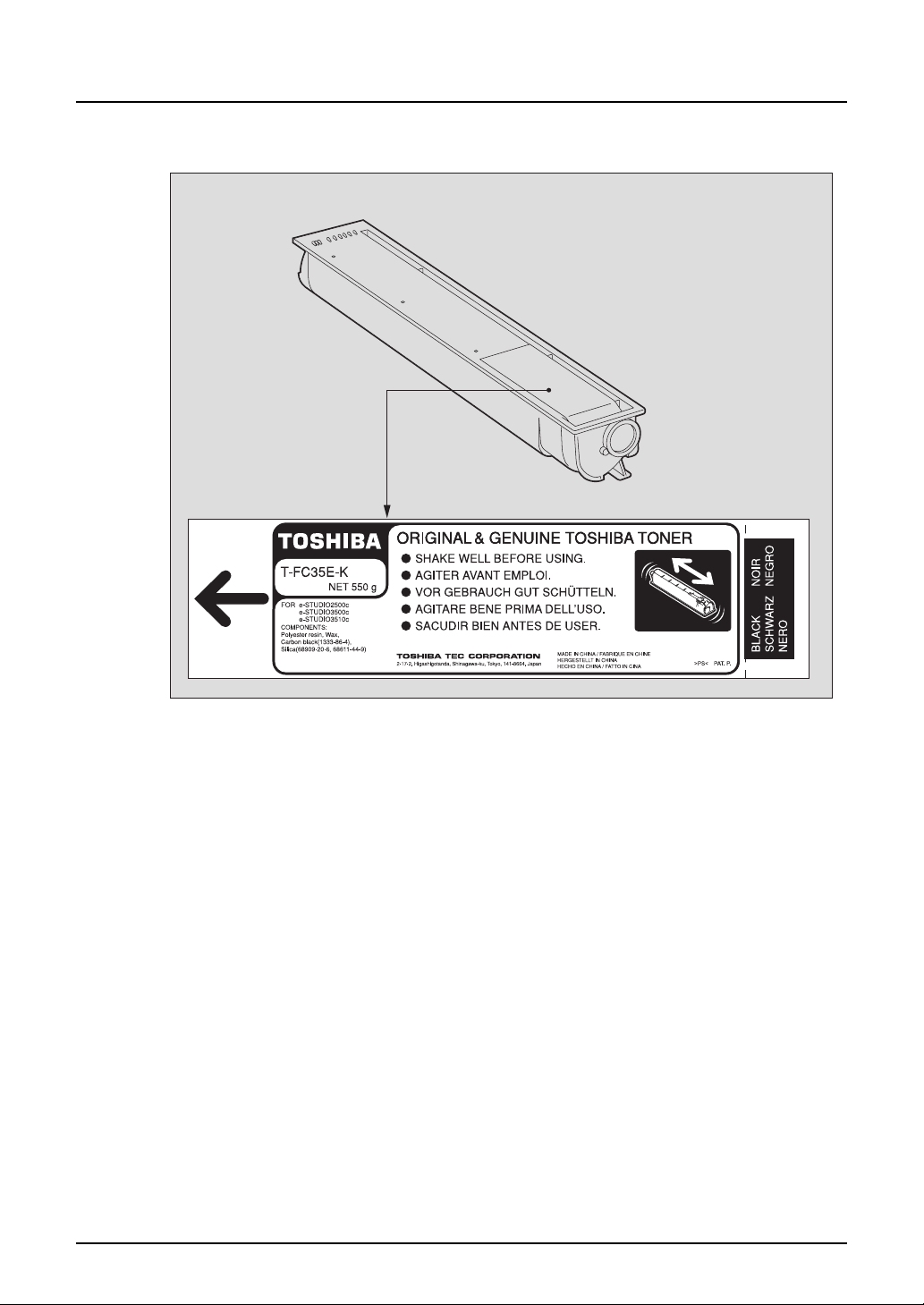

Replace Toner Cartridge Symbol............................................................ 302

Recommendation for original toner ....................................................... 303

Replacing the toner cartridge ................................................................ 304

Cleaning the slit glasses........................................................................305

Cleaning the chargers ...........................................................................308

Replace Toner Bag Symbol ..................................................................... 309

Jam Symbols ............................................................................................ 311

Misfeed in the Reversing Automatic Document Feeder (optional) ........311

Misfeed in drawer feeding area .............................................................314

Misfeed in the Large Capacity Feeder (optional)...................................315

Misfeed in the Paper Feed Pedestal (optional) ..................................... 316

Misfeed on the bypass tray.................................................................... 316

Misfeed in the automatic duplexing unit ................................................ 317

Misfeed in the jam releasing cover ........................................................ 318

Misfeed in the fuser unit ........................................................................319

Misfeed in the Bridge Unit (optional) ..................................................... 322

Misfeed in the Finisher and the Hole Punch Unit

(optional: MJ-1101, MJ-6101)................................................................323

Misfeed in the Saddle Stitch Finisher and the Hole Punch Unit

(optional: MJ-1030, MJ-6004)................................................................328

Misfeed in the Saddle Stitch Unit (optional)...........................................330

Call Service Symbol ................................................................................. 333

Chapter 10 WHEN THIS MESSAGE APPEARS

“Toner near Empty” ............................................................................... 337

“Time for Slit glass and Main charger cleaning”...................................340

CONTENTS 13

Page 16

Cleaning the slit glass............................................................................ 340

Cleaning the chargers ...........................................................................343

“Check staple cartridge” ......................................................................... 344

Finisher (optional: MJ-1101)..................................................................344

Finisher (optional: MJ-1030)..................................................................346

“Check staple cartridge in the Saddle Stitch Unit” ...............................348

“Examine stapler” .................................................................................... 350

Finisher (optional: MJ-1101)..................................................................350

Finisher (optional: MJ-1030)..................................................................352

“READY (CHECK STAPLER)” ................................................................. 354

“Examine stapler in the Saddle Stitch Unit” .........................................355

“READY (CHECK SADDLE STITCH STAPLER)”....................................358

“READY (HOLE PUNCH DUST BIN IS FULL)”........................................ 359

Hole Punch Unit (optional: MJ-6101, MJ-6004).....................................359

“POWER FAILURE”..................................................................................360

“Time for periodic maintenance”............................................................ 361

“Check paper size setting on control panel for drawer N”...................362

During copying (using a drawer)............................................................362

During copying (using the bypass tray) ................................................. 365

During printing from the FAX or Printer (using a drawer) ......................366

During printing from the Printer (using the bypass tray) ........................368

“Cannot print this paper size Select the other drawer”....................... 370

“Cannot print this paper type Set the other paper type”..................... 371

“Reboot the machine”..............................................................................372

Chapter 11 MAINTENANCE

Daily Inspection ........................................................................................374

Simple Troubleshooting ..........................................................................375

Equipment does not start.......................................................................375

Paper jamming occurs frequently .......................................................... 375

Display does not change when buttons or icons are pressed ...............375

Functions cannot be set ........................................................................376

Image density is too low ........................................................................376

Image density is too high....................................................................... 376

Image trouble ........................................................................................376

Chapter 12 SPECIFICATIONS & OPTIONS

e-STUDIO2500c/3500c/3510c Specifications .........................................380

14 CONTENTS

Page 17

Specifications of Options ........................................................................ 384

Packing List .............................................................................................. 388

Copying Function Combination Matrix ..................................................389

Combination Matrix 1/2.......................................................................... 389

Combination Matrix 2/2.......................................................................... 390

Image Quality Adjustment Combination Matrix..................................... 391

Combination Matrix 1/2.......................................................................... 391

Combination Matrix 2/2.......................................................................... 392

INDEX ....................................................................................................................................... 393

CONTENTS 15

Page 18

16 CONTENTS

Page 19

TOSHIBA Quality is Second to None

e-STUDIO2500c/3500c/3510c Toner Cartridges.

It is recommended that genuine TOSHIBA supplies and parts be used to obtain optimum results.

TOSHIBA Quality is Second to None 17

Page 20

Supplies / Parts

y Dependability

Genuine Toshiba supplies are subjected to the strictest of inspections so that every supply

you receive will perform at optimal levels.

y High Productivity

Genuine Toshiba supplies are created to meet the demands of our competitive world and

provide highspeed reliable copies when you need them.

y Stable Image Quality

Genuine Toshiba supplies are designed to provide consistently stable image output.

y Copier Kind

Genuine Toshiba supplies are designed to keep the copier and all its parts in trouble-free

working order.

Reduction of machine wear is due to Toshiba’s intimate knowledge of the copier’s characteristics ensuring the highest standard of care.

y Machine Balance

From the beginning Toshiba supplies and machines were made for each other. Whenever

Toshiba designs a new machine, it also designs a new toner that is made just for that

machine. By using Genuine Toshiba supplies with Toshiba copiers, you are guaranteed optimum performance.

Toner

y Optimum Image Quality

Toshiba toner is manufactured using ultra-fine quality materials under precisely controlled

conditions to ensure that your Toshiba copiers will continually generate sharp high-quality

images.

y Cost Advantage

Genuine Toshiba toner provides value. Only the proper amount of toner is used during the

reproduction process thereby enabling the machine to continue to operate until all the toner

has been used. In this way you get the full value from each cartridge used.

y Environmental Harmony

Genuine Toshiba toner is manufactured with the environment in mind. To care for Mother

Earth, we use embossed or plastic labels making our toner cartridge fully recyclable. In addition, dust and ozone levels have been reduced to improve the working environment.

y User Friendly

Before approving our toners for sale, we test them to be sure that they pass the strictest of

health standards. This takes the worry out of handling the toner.

General

y Service and Support Benefits

Toshiba’s Service technicians are certified to keep your copier performing at optimum levels.To ensure continuous image quality, utilize an authorized Toshiba Service provider to

care for and perform periodical maintenance on your copier.

18 TOSHIBA Quality is Second to None

Page 21

Features of the e-STUDIO2500c/3500c/3510c

The e-STUDIO2500c/3500c/3510c is a Multifunctional Digital Colour System with high speed

and high image quality. The e-STUDIO2500c/3500c/3510c is equipped with the network function

such as the printing and scanning one for comprehensive use to meet the needs of your office.

The e-STUDIO2500c/3500c/3510c also provides superior cost performance for black-and-white

copying and high colour reproduction and fine colour adjustment for colour copying so that you

can make copies as expected.

The e-STUDIO2500c/3500c/3510c offers the following convenient features, functions and

options.

y The copying speed is as follows.

- e-STUDIO2500c

- e-STUDIO3500c

- e-STUDIO3510c

y Warm-up time has been drastically shortened to approximately 99 seconds

y An all-in-one controller, as standard equipment, is installed to perform the effective network

functions.

y A 1/2 VGA wide panel improves operability and efficiency, and makes the viewing easier.

y A universal design is adopted for the control panel whose angle can be changed.

y Frequently used document styles can be stored in e-Filing in this equipment. You can easily

print the file in a specified style by recalling the saved style using the touch panel, or reorder

pages in the file as desired using TopAccess. Namely, one file saved in the e-Filing can be

repeatedly utilized and thus your workload is reduced.

y Received Fax documents can be stored in e-Filing without printing them.

y Scanned originals can be sent via Fax (optional) and E-mail simultaneously.

y Electronic sorting improves both colour and black-and-white copying productivity.

y Comes with rich editing functions such as trimming, masking and mirror.

y Supporting High-compression PDF makes data handling smoother.

y Loading the page memory and hard disc as standard equipment enables 2in1 / 4in1, Elec-

tronic sorting and magazine sorting, etc.

y A fixing system that uses less oil reduces the amount adhering to the paper.

y By simply replacing the cartridge, you can add toner without dirtying your hands.

y A wide variety of media from thick paper (up to 256 g/m

encies, waterproof paper, etc. is acceptable.

y The image quality technology offers successive stable copy images.

y Installing an optional finisher offers quick automatic sorting, stapling and hole punching

(optional) of copies.

y Installing a finisher with an optional saddle stitching function attached allows you to select

the saddle stitching mode which will automatically staple the centre of the documents just

like a book.

y Two energy-saving features are available: 1. ENERGY SAVER MODE: Unnecessary elec-

tricity at READY status is cut off, 2. SLEEP MODE: The minimum power consumption is kept

if the equipment is not used for a specified period.

y Improved security-related features

ment.

y The built-in wireless LAN unit and Bluetooth-compliant options are introduced to respond to

users’ wide-ranging needs.

*1

colour

colour

colour

: 25 copies per minute, Black-and-white: 35 copies per minute

*1

: 35 copies per minute, Black-and-white: 35 copies per minute

*1

: 35 copies per minute, Black-and-white: 45 copies per minute

(when 1-sided LT landscape continuous copying is performed in the non-sort mode without the Reversing Automatic Document Feeder being used)

2

*3

ensure users of a safe and pleasant working environ-

*2

.

), sticker labels, overhead transpar-

*1 Copying speed of "Full colour”, “Auto colour”, “Twin colour” and “Mono colour”

*2 Options not installed

Features of the e-STUDIO2500c/3500c/3510c 19

Page 22

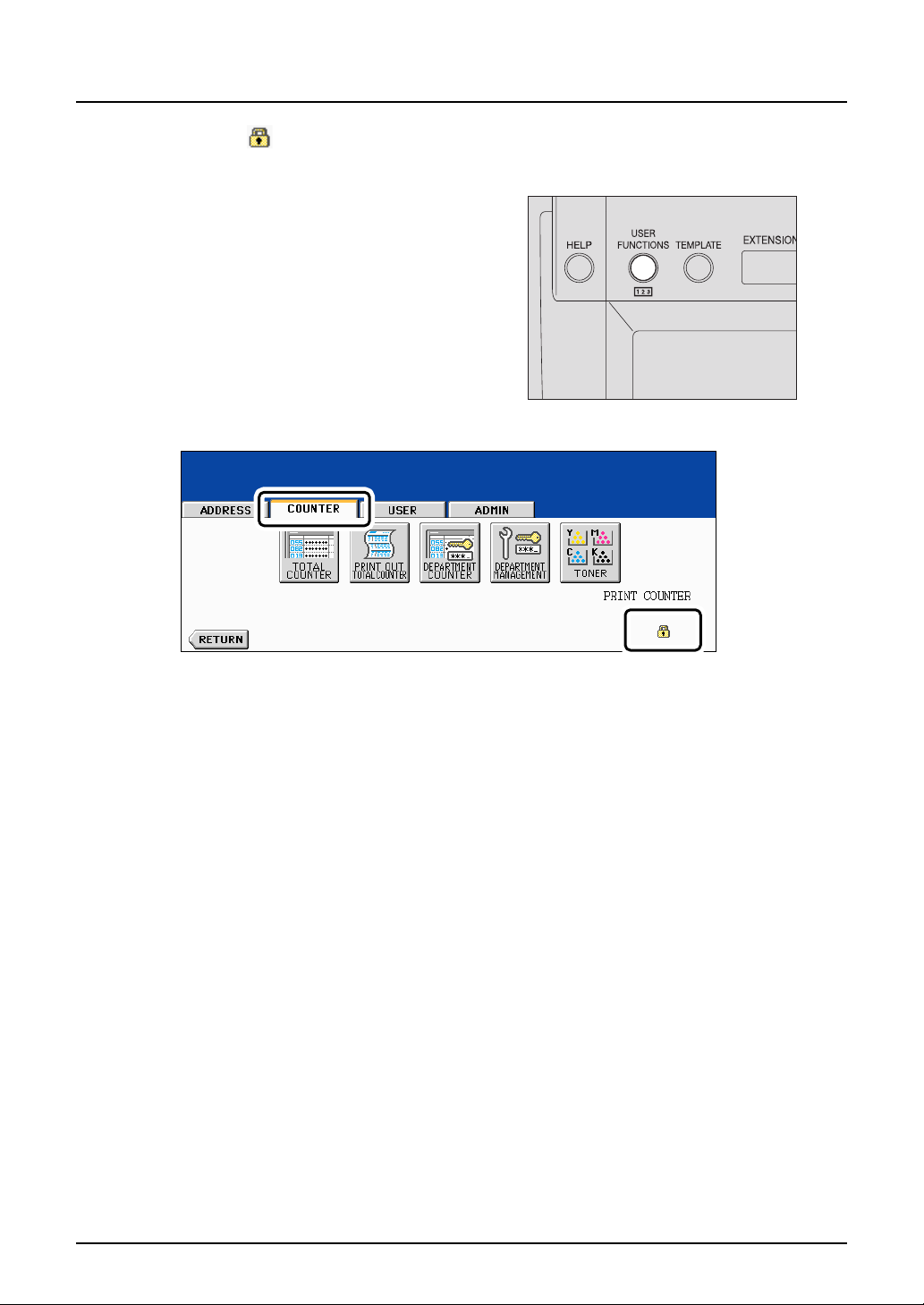

*3 An icon appears on the touch panel when the encryption function is enabled on this equipment.

< How to check active status of encryption function >

Press the [USER FUNCTIONS] button on the

control panel, and then click the [COUNTER]

tab on the touch panel. This icon appears at

the right bottom of the touch panel if the

encryption function is enabled.

Contact your service technician for the use of

the encryption function.

20 Features of the e-STUDIO2500c/3500c/3510c

Page 23

General Precautions

When installing or moving

Warning

y This Multifunctional Digital Colour Systems requires 220 to 240 V AC, 8 A 50/60 Hz electric

power.

Do not use a power supply with a voltage other than that specified.

Avoid multiple connections in the same outlet. This could cause a fire or give you an electric

shock. If you are considering increasing the number of outlets, contact an electrician.

y Always connect this Multifunctional Digital Colour Systems to an outlet with an earth connec-

tion to avoid the danger of fire or electric shock in case of short-circuiting. Contact your service representative for the details. Be sure to use a 3-conductor, grounded wall outlet.

In areas, except U.S. and Canada, where a 2-pin plug is used, the Multifunctional Digital

Colour Systems must be grounded for safety. Never ground it to a gas pipe, a water pipe, or

any other object not suitable for grounding.

y Plug the power cord securely into the outlet. If it is not plugged in properly, it could heat up

and cause a fire or give you an electric shock.

y Do not damage, break or attempt to repair the power cord.

The following things should not be done to the power cord.

- Twisting it

- Bending it

- Pulling it

- Placing anything on it

- Making it hot

- Situating it near radiators or other heat sources

This could cause a fire or give you an electric shock. If the power cord is damaged, contact

your service representative.

y When removing the plug from the outlet, do not pull the power cord. Always hold the plug

when removing it from the outlet. If the power cord is pulled, the wires may become broken

and this could cause a fire or give you an electric shock.

y Make sure that the ventilation holes are not blocked up.

If the temperature within the Multifunctional Digital Colour Systems becomes too high, a fire

could result.

y Do not move the Multifunctional Digital Colour Systems to another building, up and down the

stairs or for any great distance.

This could cause an injury or give you and electric shock. When lifting or moving the Multifunctional Digital Colour Systems, contact your service representative.

y Do not move the Multifunctional Digital Colour Systems with optional equipment, such as the

finisher, attached.

This could cause a fire or give you an electric shock. When lifting or moving the Multifunctional Digital Colour Systems, contact your service representative.

y When moving the Multifunctional Digital Colour Systems, be sure to shut down the power

prior to pulling out the plug from the outlet. If the power cord is damaged, this could cause a

fire or give you an electric shock.

y The socket outlet shall be near the equipment and be easily accessible.

y Pull out the plug from the outlet more than once a year to clean around the prongs. Accumu-

lating dust and dirt could cause a fire due to the heat released by electric leakage.

General Precautions 21

Page 24

Caution

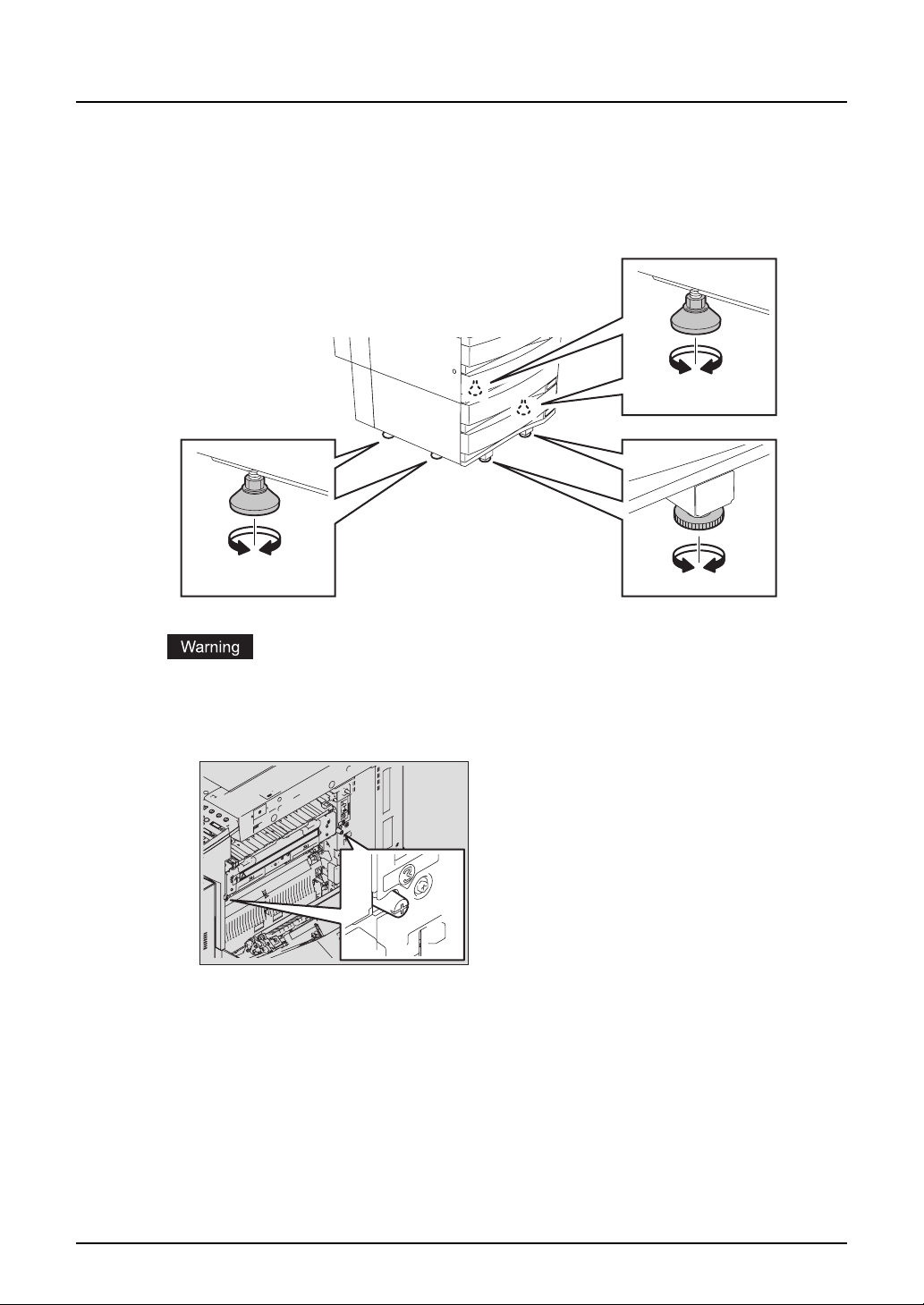

The Paper Feed Pedestal (optional) has 4 antiskid devices and 2 fall-preventing stoppers under

its bottom. When moving this equipment, turn them in the direction of arrows (see figures below)

and raise them to unfix the equipment. After it has been moved, be sure to turn them in the

opposite direction and lower them to fix it.

y Do not install the equipment by yourself or try to move it once it has been installed. This

could result in an injury or damage to the device. Contact your service representative if the

equipment needs to be installed or moved.

y Do not remove these screws. The fuser unit could fall over and injure someone.

22 General Precautions

Page 25

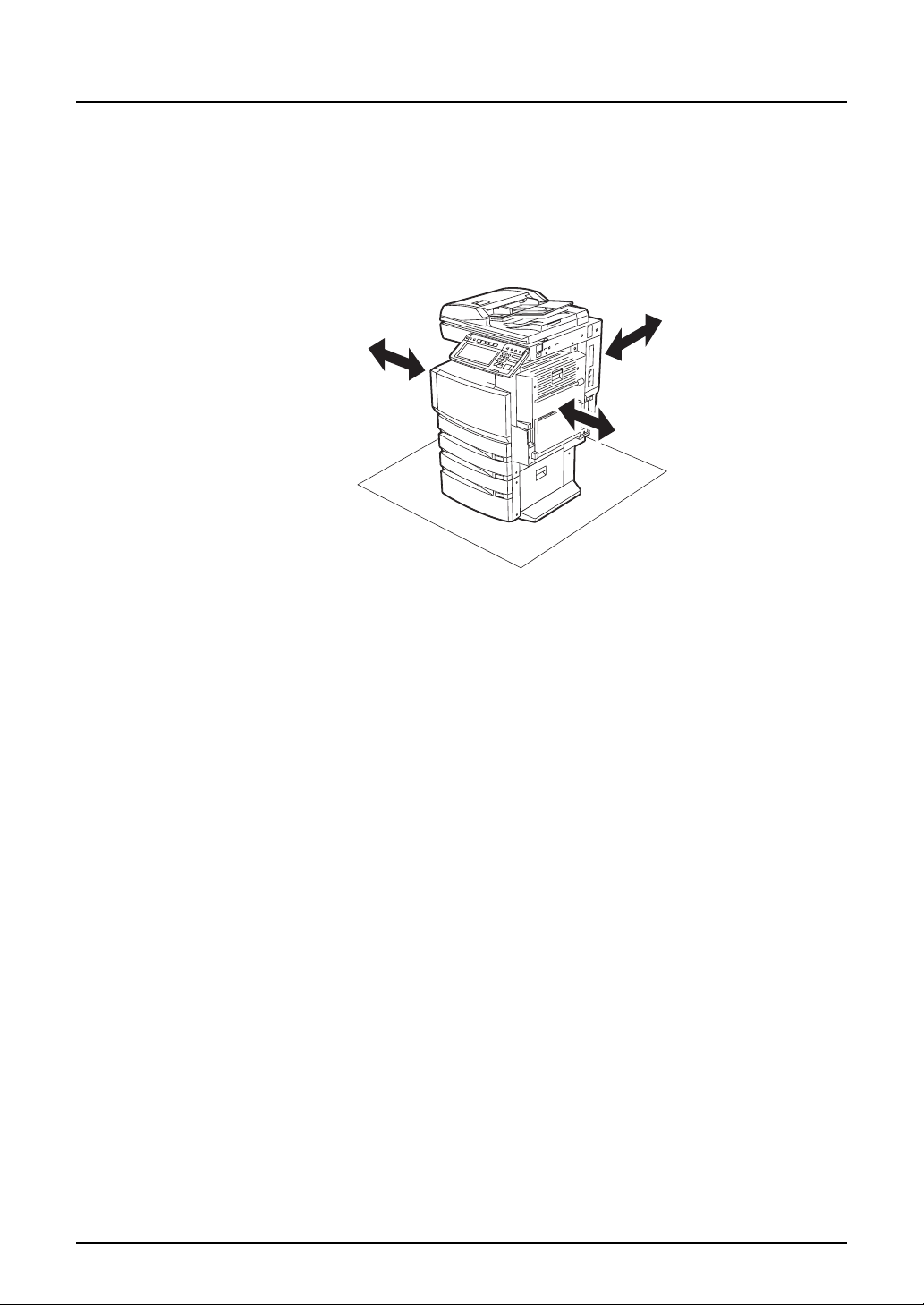

Other points

y Make sure that there is enough space around the system to facilitate changing of parts,

maintenance and clearing paper jam.

If there is insufficient space, some operations, such as bypass feeding, will become difficult

and the Multifunctional Digital Colour Systems could even break down.

To insure optimal operation, allow clearances of at least 80 cm on the right, and 10 cm on the

left and behind.

10cm

10cm

80cm

y Be sure to fix the power cable securely so that no one trips over it.

y Adverse environmental conditions may affect the safe operation and performance of the Mul-

tifunctional Digital Colour Systems, and the Multifunctional Digital Colour Systems could

break down.

- Avoid locations near windows or with exposure to direct sunlight.

- Avoid locations with drastic temperature fluctuations.

- Avoid too much dust.

- Avoid location that suffer from vibration.

y Allow the air to flow freely and make sure there is a ventilator.

With inadequate ventilation, the unpleasant odor released by ozone will begin to dominate

the atmosphere.

When using the Multifunctional Digital Colour Systems

Warning

y Do not place metallic objects or containers with water (flower vases, coffee cups, etc.) on or

near the Multifunctional Digital Colour Systems. And keep paper clips and staples away from

the air vent. This could cause a fire or give you an electric shock.

y If the Multifunctional Digital Colour Systems becomes excessively hot, smoke comes out of it

or there is an odd smell or noise, proceed as follows.

Turn the main switch OFF and remove the plug from the outlet, then contact your service

representative.

y If the Multifunctional Digital Colour Systems will not be used for more than one month,

remove the plug from the outlet for safety purposes during that time.

This could cause a fire or give you an electric shock if an insulation failure occurs.

General Precautions 23

Page 26

Caution

y Do not place heavy objects (4 kg or more) on the original glass and do not press on it with

force.

Breaking the glass could cause personal injury.

y Do not place heavy objects (4 kg or more) on the Multifunctional Digital Colour Systems. If

the objects fall off, this could cause injury.

y Do not remove or connect the plug with wet hands, as this could give you an electric shock.

y Do not touch the fuser unit or the metal area around it. Since they are very hot, you could be

burned or the shock could cause you to get your hand injured in the machine.

y When changing the angle of the control panel, be careful not to catch your hands in the gap

between the equipment and the control panel. This could cause personal injury.

y Be careful not to let your fingers be caught when closing the drawer. This could injure you.

y Be careful not to let your fingers be caught between the equipment and the automatic

duplexing unit. This could injure you.

y Do not place 3.3 kg or more of objects on an optional work table. Breaking the work table

could cause personal injury.

y Do not touch the metal portion of the guide plate in the automatic duplexing unit as it could

burn you.

24 General Precautions

Page 27

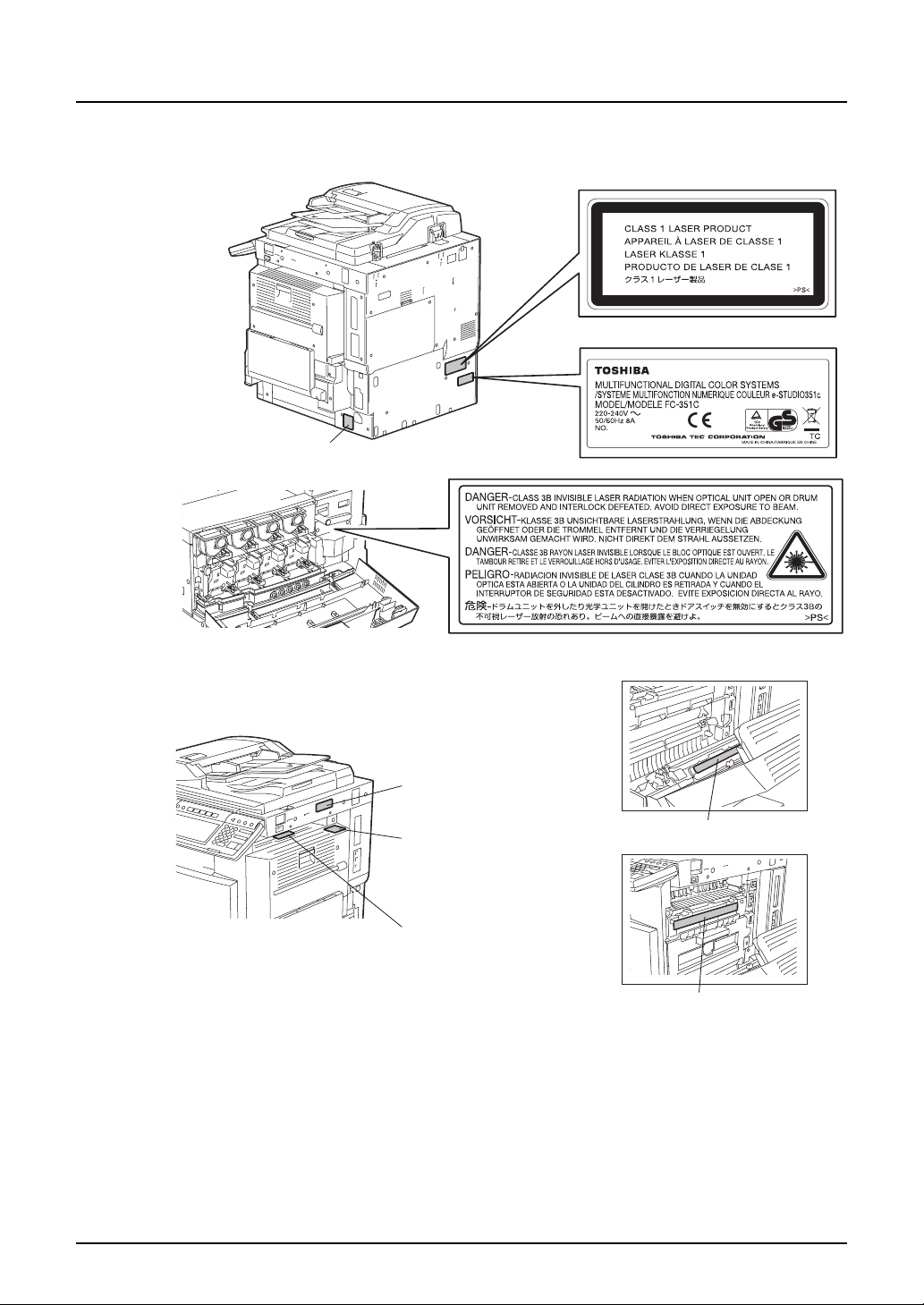

Position of Certification label, etc.

Explanatory label

Identification label

Warning for grounding wire

Warning label

Warning for

high temperature area

(

fuser unit

Warning for

high temperature area

(

ventilation holes

Warning for

high temperature area

(

fuser unit

)

)

)

Warning for handling transfer belt

Warning for high temperature area

General Precautions 25

Page 28

Other points

y Be very careful to treat the touch panel gently and never hit it. Breaking the surface could

cause malfunctions.

y Do not turn the power OFF with jammed paper left inside the Multifunctional Digital Colour

Systems.

This could cause malfunctions when the main switch is turned ON next time.

To turn the power OFF, see P.50 “Turning power off (Shutdown)”.

y Be sure to turn the power OFF when leaving the office or if there is a power outage. How-

ever, Do not turn the power OFF if the weekly timer is in use.

To turn the power OFF, see P.50 “Turning power off (Shutdown)”.

y Be careful because the paper exit area and paper just after exiting are hot.

During maintenance or inspection

Warning

y Never attempt to repair, disassemble or modify the Multifunctional Digital Colour Systems by

yourself. You could cause a fire or get an electric shock.

Always contact your Service representative for maintenance or repair of the internal parts of

the Multifunctional Digital Colour Systems.

y Always keep the plug and outlet clean. Prevent them from accumulating dust and dirt. This

could cause a fire and give you an electric shock due to the heat released by electric leakage.

y Do not let liquids such as water and oil get into the system when cleaning the floor. This

could cause a fire and give you an electric shock.

Caution

y Do not touch the stapling area. The actual needle point could cause you personal injury.

Saddle Stitch Finisher (optional) P.355

Finisher (optional) P.350

Other points

y Do not use such solvents as thinner or alcohol when cleaning the surface of the Multifunc-

tional Digital Colour Systems.

- This could warp the shape of the surface or leave it discoloured.

- When using a chemical cleaning pad to clean it, pay attention to any cautionary points.

When handling supplies

Caution

y Never attempt to incinerate toner cartridges and toner bags. Dispose of used toner car-

tridges and toner bags in accordance with local regulations. ( P.302 “Replace Toner Cartridge Symbol”, P.309 “Replace Toner Bag Symbol”)

26 General Precautions

Page 29

Disclaimer Notice

The following notice sets out the exclusions and limitations of liability of TOSHIBA TEC CORPORATION (including its employees, agents and sub-contractors) to any purchaser or user (‘User’)

of the e-STUDIO2500c/3500c/3510c, including its accessories, options and bundled software

(‘Product’).

1. The exclusion and limitations of liability referred to in this notice shall be effective to the fullest extent permissible at law. For the avoidance of doubt, nothing in this notice shall be taken

to exclude or limit TOSHIBA TEC CORPORATION’s liability for death or personal injury

caused by TOSHIBA TEC CORPORATION’s negligence or TOSHIBA TEC CORPORATION’s fraudulent misrepresentation.

2. All warranties, conditions and other terms implied by law are, to the fullest extent permitted

by law, excluded and no such implied warranties are given or apply in relation to the Products.

3. TOSHIBA TEC CORPORATION shall not be liable for any loss, cost, expense, claim or damage whatsoever caused by any of the following:

(a) use or handling of the Product otherwise than in accordance with the manuals, including

but not limited to Operator’s Manual, User’s Guide, and/or incorrect or careless handling or

use of the Product;

(b) any cause which prevents the Product from operating or functioning correctly which

arises from or is attributable to either acts, omissions, events or accidents beyond the reasonable control of TOSHIBA TEC CORPORATION including without limitation acts of God,

war, riot, civil commotion, malicious or deliberate damage, fire, flood, or storm, natural

calamity, earthquakes, abnormal voltage or other disasters;

(c) additions, modifications, disassembly, transportation, or repairs by any person other

than service technicians authorized by TOSHIBA TEC CORPORATION; or

(d) use of paper, supplies or parts other than those recommended by TOSHIBA TEC CORPORATION.

4. Subject to paragraph 1, TOSHIBA TEC CORPORATION shall not be liable to Customer for:

(a) loss of profits; loss of sales or turnover; loss of or damage to reputation; loss of production; loss of anticipated savings; loss of goodwill or business opportunities; loss of customers; loss of, or loss of use of, any software or data; loss under or in relation to any contract;

or

(b) any special, incidental, consequential or indirect loss or damage, costs, expenses,

financial loss or claims for consequential compensation;

whatsoever and howsoever caused which arise out of or in connection with the Product or

the use or handling of the Product even if TOSHIBA TEC CORPORATION is advised of the

possibility of such damages.

TOSHIBA TEC CORPORATION shall not be liable for any loss, cost, expense, claim or damage caused by any inability to use (including, but not limited to failure, malfunction, hang-up,

virus infection or other problems) which arises from use of the Product with hardware, goods

or software which TOSHIBA TEC CORPORATION has not directly or indirectly supplied

Disclaimer Notice 27

Page 30

Forgery Prevention Function/Storage of Colour Copies

Forgery prevention function

This copier has a forgery prevention function. Please ensure that your digital full-colour copier is

not used for making copies of prohibited items.

Storage of colour copies

y The copies should be kept in a place which is not exposed to light to prevent fading when

they are stored for a long time.

y If copies are kept pressed between plastics made of chloroethylene for a long time, the toner

may melt and stick to the plastic due to high pressure and high temperature. Keep them in

polyethylene binders.

y When a colour copy is folded, the toner at the fold can become separated.

y The toner on the copies may melt if it touches solvent. If the ink on the copies has not com-

pletely dried, the toner may also melt. Keep copies away from solvent.

y When copies are kept near an extremely high temperature such as a heater, the toner may

melt. Keep them at room temperature and do not allow this to vary very much.

28 Forgery Prevention Function/Storage of Colour Copies

Page 31

1.BEFORE USING EQUIPMENT

This chapter describes what you need to know before using this equipment, such as how to turn the power

ON or how to set copy paper.

Description of Each Component ...........................................................................30

Main components..............................................................................................................................30

Configuration of options ....................................................................................................................34

Control panel.....................................................................................................................................37

Adjustment of the angle of the control panel.....................................................................................39

Touch panel.......................................................................................................................................41

Preparation 1- Turning Power On/Off....................................................................45

Turning power on ..............................................................................................................................45

When department or user management is used ...............................................................................46

Preparation 2- Turning power off (Shutdown)......................................................50

Turning power off (Shutdown) ...........................................................................................................50

Preparation 3- Setting Copy Paper........................................................................54

Acceptable copy paper......................................................................................................................54

Setting copy paper (size change)......................................................................................................56

Changing the setting of paper size....................................................................................................61

Drawer for special uses.....................................................................................................................62

Placing paper in the Large Capacity Feeder (optional) .....................................................................65

Page 32

1 BEFORE USING EQUIPMENT

Description of Each Component

Main components

1

2

10

3

9

4

8

5

13

7

6

14

1. Reversing Automatic Document Feeder (Optional, MR-3018)

A stack of originals placed on this are scanned one sheet by one. Both sides of original can

be scanned. Maximum 100 sheets (80 g/m

originals can be placed in one go.

(The maximum number of sheets may vary depending on the media type of the originals.)

P.72 “Using the Reversing Automatic Document Feeder (optional)”

P.311 “Misfeed in the Reversing Automatic Document Feeder (optional)”

2

), 80 sheets (90 g/m2) (or stack height 16 mm) of

11

12

2. Operator’s Manual pocket (Back side)

Keep the Operator’s Manual in this.

3. Automatic duplexing unit

This is a unit to make copies on both sides of paper. Open it when paper jams occur.

P.317 “Misfeed in the automatic duplexing unit”

4. Bypass tray

Use this to make copies on special media types such as overhead transparencies, waterproof paper.

P.85 “Bypass copying”

P.316 “Misfeed on the bypass tray”

5. Paper feed cover

Open this cover when releasing a paper misfeed in the drawer feeding area.

P.314 “Misfeed in drawer feeding area”

30 Description of Each Component

Page 33

6. Paper feed cover (optional)

Open this cover when releasing a paper misfeed in the Paper Feed Pedestal (optional) or

Large Capacity Feeder (optional).

P.315 “Misfeed in the Large Capacity Feeder (optional)”

P.316 “Misfeed in the Paper Feed Pedestal (optional)”

7. Paper size indicator

8. Paper Feed Pedestal (optional, KD-1018) and Additional Drawer Module (optional,

MY-1031) or Large Capacity Feeder (optional, KD-1019)

9. Drawers

2

Maximum 550 sheets (80 g/m

), 450 sheets (90 g/m2) of plain paper can be placed in one

go.

10. Front cover

Open this cover when you replace the toner cartridge and clean the charger.

P.302 “Replace Toner Cartridge Symbol”

P.309 “Replace Toner Bag Symbol”

P.340 ““Time for Slit glass and Main charger cleaning””

11. Power switch

Turn the power of the equipment ON or OFF with this.

P.45 “Turning power on”

12. Connector for USB storage device

Use this connector when retrieving scanning data to USB storage device.

See the Scan Guide for details.

13. Network interface connector

Use this connector when connecting this equipment with network.

14. USB terminal (4-pin)

With this terminal, the equipment can be connected to your PC using a commercially available USB cable.

Description of Each Component 31

Page 34

1 BEFORE USING EQUIPMENT

1

11

10

9

8

2

3

16 15 14 13

4

5

6

(12)

7

1. Platen sheet

P.374 “Daily Inspection”

2. Original glass

Use this to copy three-dimensional originals, book-type originals and special paper such as

overhead transparencies or tracing paper, as well as plain paper.

P.68 “Setting Originals”

3. Touch panel

Use this to set copying density, colour adjustment, finishing mode and various types of other

functions.

P.41 “Touch panel”

4. Control panel

Use this to make copies, enter the number of copy sets, and perform and set various types

of other functions.

P.37 “Control panel”

32 Description of Each Component

Page 35

5. Charger cleaner

P.340 ““Time for Slit glass and Main charger cleaning””

6. Toner bag

P.309 “Replace Toner Bag Symbol”

7. Slit glass cleaner

Use this if the copied or printed paper is stained.

P.340 ““Time for Slit glass and Main charger cleaning””

8. Paper exit stopper

Use this to prevent the exiting paper from falling. Open this when you make a large amount

of copies on a larger size of paper (e.g.A3, A4).

9. Receiving tray

10. Scanning area

The data of originals transported from the Reversing Automatic Document Feeder (optional,

MR-3018) are scanned here.

P.374 “Daily Inspection”

11. Original scale

Use this to check the size of an original placed on the original glass.

12. Touch panel contrast adjustment volume

Use this when it is difficult to see the display on the touch panel.

13. Black toner cartridge

14. Cyan toner cartridge

15. Magenta toner cartridge

16. Yellow toner cartridge

P.302 “Replace Toner Cartridge Symbol”

Description of Each Component 33

Page 36

1 BEFORE USING EQUIPMENT

Configuration of options

8

10 9

1 2

7

3

4 5 6

1. Original Cover (KA-3511PC)

Holds an original.

2. Reversing Automatic Document Feeder (MR-3018)

Automatically feeds a placed stack of originals one by one to have them copied.

3. Bridge Unit (KN-3500)

Acts as a relay for the finisher and this equipment.

4. Large Capacity Feeder (KD-1019)

2

This feeder enables you to feed up to 2500 sheets (80 g/m

), 2000 sheets (90 g/m2) of A4

paper.

5. Paper Feed Pedestal (KD-1018)

Adds one drawer to the equipment.

6. Additional Drawer Module (MY-1031)

Enables one drawer to be added to the Paper Feed Pedestal.

7. Finisher (MJ-1101)

This finisher enables sort/group finishing and stapling. The Hole Punch Unit (optional,

MJ-6101) can be installed to this finisher. The Bridge Unit (optional, KN-3500) is required for

the installation of this finisher.

34 Description of Each Component

Page 37

8. Saddle Stitch Finisher (MJ-1030)

This finisher enables saddle stitching, in addition to sort/group finishing and stapling. The

Hole Punch Unit (optional, MJ-6004) can be installed to this finisher. The Bridge Unit

(optional, KN-3500) is required for the installation of this finisher.

9. Hole Punch Unit (MJ-6101)

This unit enables you to punch holes on printouts. It can be used by installing it on the Finisher (MJ-1101).

10. Hole Punch Unit (MJ-6004)

This unit enables you to punch holes on printouts. It can be used by installing it on the Finisher (MJ-1030).

Other options available are as follows. Contact your service technician or Toshiba product distributors for details.

Work Table (KK-3511)

This is a small table for placing originals while the equipment is operated.

y Installed on the right-hand side of the equipment

y Cannot be installed with e-BRIDGE ID Gate at the same time

FAX Unit (GD-1210)

This is a unit for using the equipment as a Fax.

y Installed inside of the equipment

2nd Line for Fax Unit (GD-1160)

This unit enables to add a line to the Fax to make it 2nd line.

y Installed inside of the equipment

y The Fax Unit (GD-1210) is necessary.

Data Overwrite Kit (GP-1060)

This is a kit to delete the temporarily stored data when copy, print, scan, Fax, internet Fax and

network Fax are performed.

y Installed inside of the equipment

512 MB Expansion Memory (GC-1250)

This memory enables the B4, A3 and FOLIO (LD, LG, 13" LG, COMP) size originals to be

scanned with the slim PDF format.

y Installed inside of the equipment

256 MB Expansion Memory (GC-1260)

This memory enables scanning in the full colour, auto colour and image smoothing mode with

600 dpi.

y Installed inside of the equipment

Wireless LAN Module (GN-1041)

This module enables the equipment to be used in a wireless LAN environment.

y Installed inside of the equipment

y The Antenna (GN-3010) is necessary.

y The equipment cannot be connected to the wireless and wired LAN at the same time.

Bluetooth Module (GN-2010)

This module enables the Bluetooth printing.

y Installed inside of the equipment

y The Antenna (GN-3010) is necessary.

Description of Each Component 35

Page 38

1 BEFORE USING EQUIPMENT

Antenna (GN-3010)

This is used when the Wireless LAN module and Bluetooth Module are installed.

y When the Wireless LAN module (GN-1041) is installed, it is placed on the back right side of

the equipment.

y When the Bluetooth Module (GN-2010) is installed, it is placed on the back left side of the

equipment.

36 Description of Each Component

Page 39

Control panel

Use the buttons on the control panel for various operations and settings through the equipment.

1. [HELP] button

Use this button to display a desired operation procedure.

2. [USER FUNCTIONS] button

Use this button for paper size or media type setting of drawers, and registration of the copy,

scan and FAX settings (including a default setting change.) See the User Functions Guide

for the functions enabled by this button.

3. [TEMPLATE] button

Use this button to store and recall frequently used copy, scan, and FAX settings.

4. [EXTENSION] button

Any operation with this button is invalid at present. This button is to extend functions in the

future.

5. [e-FILING] button

Use this button to access saved image data.

6. [SCAN] button

Use this button to use the scanning function.

7. [COPY] button

Use this button to use the copier function.

8. [FAX] button

Use this button to use the FAX / Internet FAX function.

9. PRINT DATA / MEMORY RX / FAX communication lamps

These lamps show the status of FAX data reception and FAX communication.

Description of Each Component 37

Page 40

1 BEFORE USING EQUIPMENT

10. [INTERRUPT] button

Use this button to interrupt the copy job in process and perform another one. The interrupted

job is resumed by your pressing this button again.

11. [JOB STATUS] button

Use this button to confirm each job status, printing status, and FAX transmission/reception

status of a print job, scan job and FAX job. ( P.262 “Job Status”)

12. [ACCESS] button

Use this button when the department code or user information has been set. If this button is

pressed after copying, the next user cannot use functions such as copying without keying in

the department code or user information. See the User Functions Guide for the department

and user management.

13. [ENERGY SAVER] button

Use this button when you want to shut down the equipment or when you want the equipment

enter into the energy saving mode. When you press this button, the menu for the energy

saving mode appears. Press the [SLEEP] button on this menu to enter into the energy saving mode and press the [SHUTDOWN] button to shut down the equipment.

14. [FUNCTION CLEAR] button

When this button is pressed, all selected functions are cleared and returned to the default

settings.

15. [STOP] button

Use this button to stop any scanning and copying operations in progress.

16. [START] button

Use this button to start copying, scanning and FAX operations.

17. [CLEAR] button

Use this button to correct numbers keyed in, such as the copy quantity.

18. ERROR lamp

This lamp lights when an error occurs and the equipment needs some actions to be taken.

19. [MONITOR/PAUSE] button

Use this button only when a FAX Unit (optional) is installed. (See the Operator’s Manual for

Facsimile Function for details.)

20. Digital keys

Use these keys to enter any numbers such as the copy quantity.

21. Touch panel

Use this panel for the various settings of each function of the copier, scanner and FAX. This

panel also indicates the status of the equipment, such as when you run out of paper or there

is a paper jam.

38 Description of Each Component

Page 41

Adjustment of the angle of the control panel

When adjusting the angle of the control panel

The angle of the control panel is adjustable at any angle between 7 and 45 degrees from the

horizontal position.

When changing the angle of the control panel, be careful not to catch your hands in the gap

between the equipment and the control panel. This could injure you.

When fixing the angle of the control panel

The angle of the control panel can be fixed by using the stopper on the backside of the control

panel (at 7 degrees from the horizontal position). The stopper is located on A when the equipment is set up. Move it from the position A to B before fixing it.

A: The position where the angle is adjustable.

B: The position where the angle is fixed.

A

B

Description of Each Component 39

Page 42

1 BEFORE USING EQUIPMENT

Slide the stopper (in the posi-

1

tion A) slightly to the right, and

then pull it out.

Fit the latches of the stopper in

2

the hole of the position B and

insert them turning the stopper itself.

Shift the stopper to the left

3

until it clicks.

The angle of the control panel is fixed at

7 degrees.

40 Description of Each Component

Page 43

Touch panel

When the power is turned on, the basic menu for the copier function appears on this touch

panel. The status of the equipment is also displayed on the touch panel with messages and illustrations.

1. Message 10. Original mode button

2. Reproduction ratio 11. [PROOF COPY] button

3. Number of copy sets 12. Density adjustment buttons

4. APS/AMS* or currently selected paper size 13. Simplex / duplex button

5. Remaining paper level 14. Colour mode button

6. Date and time 15. Paper source selection buttons

7. [SETTINGS] button 16. Equipment status indication area

8. Finisher button 17. Function setting area

9. Enlargement/Reduction ([Zoom...]) button 18. Index buttons

* APS: Automatic paper selection, AMS: Automatic magnification selection

2 3 654

YYYY.MM.DD

7

8

9

10

11

12

18

17

1

13

1416 15

Message display

The following information appears at the top of the touch panel:

Equipment status, operational instructions, cautionary messages, reproduction ratios, number of

copy sets, paper size of a selected drawer, amount of paper in a selected drawer and date and

time.

Touch-buttons

Press these buttons on the touch panel lightly to set various functions.

Index buttons

Press these buttons to switch menus. The type and number of the index buttons vary depending

on the function of the copier, scanner and e-Filing.

Function setting area

This area includes buttons for selecting and setting each function.

[SETTINGS] button

Press this button to confirm currently set functions.

Description of Each Component 41

Page 44

1 BEFORE USING EQUIPMENT

(An example is shown below.)

Buttons appearing on the various menus are as follows (some buttons may not appear on the

menu):

42 Description of Each Component

Page 45

Clearing functions selected

When you press the selected button, the function which has been selected is cleared. Or the

selected setting is cleared automatically by the automatic function clear* when the equipment

has been left inactive for a specified period of time.

* Automatic function clear:

This function works when a specified period of time has passed since the last paper exit or the

last entry of any button. This function returns all the function settings to default without the need

to press the [FUNCTION CLEAR] button. When the department or user management function is

being used, the display returns to the department code or user information input menu. When

these functions are not being used, the display returns to the basic menu of the copier function.

The period for the automatic function clear is set at 45 seconds by default at the time of installation of the equipment. See the User Functions Guide for change of this setting.

Adjusting the contrast of the touch panel

Turn this adjustment volume on the left side of the control panel to adjust the contrast of the

touch panel.

Description of Each Component 43

Page 46

1 BEFORE USING EQUIPMENT

Setting letters

The following menu appears when any letter entry is required for the operations of scanning, eFiling, template and Internet FAX.

Use the buttons on the touch panel for letter entry and use the digital keys on the control panel

for number entry.

The following buttons are used for letter entry.

[Space]: Press this to enter a space.

[CANCEL]: Press this to cancel the entry of letters.

[ENTER]: Press this to fix all entered letters.

[Back Space]: Press this to delete the letter before the cursor.

: Press them to move the cursor.

[Shift]: Press this to enter capital letters.

[Caps Lock]: Press this to switch capital letters and small letters.

[Next]: Press this to access the special keys.

44 Description of Each Component

Page 47

Preparation 1- Turning Power On/Off

Turning power on

Open the switch cover, and then turn the power switch on.

y The equipment starts warming-up. “Wait Warming Up” appears during warming-up.

y While the equipment is warming up, you can use the auto job start function.

( P.82 “Scanning the next originals during copying (Auto job start)”)

The equipment will be ready for copying after about 99 seconds and “READY” appears.

When you turn the power of the equipment OFF, do not simply turn the power switch to turn it off

but be sure to shut it down.

P.50 “Turning power off (Shutdown)”

When the use of the equipment is managed under department management or user management function, you need to enter the department code or user information before making a copy.

For details, see P.46 “When department or user management is used”.

Preparation 1- Turning Power On/Off 45

Page 48

1 BEFORE USING EQUIPMENT

When department or user management is used

When the use of the equipment is managed under department management or user management function, each user needs to enter the department code or user information.

Department management

You can restrict users or manage copy volumes made by an individual group or department in

your company using the department codes. When the copy volume is controlled under the

department code, enter the code after turning the power on. See the User Functions Guide for

setting and registration of the department codes.

When the power is turned on, the following menu appears.

This menu also appears when the [ACCESS] button is pressed or the automatic function clear

has worked.

Key in a department code (5 digits) previously registered and press the [ENTER] button. The

menu will switch and the equipment will be ready to be used.

If the department code keyed in is incorrect, the menu does not change. In this case, press the

[FUNCTION CLEAR] button and then key in the correct code.

When copying is finished

When you finish all operations, press the [ACCESS] button to prevent unauthorized use of the

equipment. The display returns to the department code input menu.

46 Preparation 1- Turning Power On/Off

Page 49

User management

Users of the equipment can be limited and the available functions and past record of each user

can be controlled by using the user management function. When the equipment is managed

under this function, turn the power of the equipment ON and enter the information required (e.g.

user name, password) to use the equipment. The menu for entering user information also