Toshiba E-studio 230, E-studio 280 Service manual

SERVICE HANDBOOK

MULTIFUNCTIONAL DIGITAL SYSTEMS

e-STUDIO200L/230/280

File No. SHE040003E0

R04022143000-TTEC

Ver05_2005-07

© 2004 TOSHIBA TEC CORPORATION

All rights reserved

GENERAL PRECAUTIONS REGARDING THE SERVICE FOR

e-STUDIO200L/230/280 SERIES

The installation and service should be done by a qualified service

technician.

1) Transportation/Installation

- When transporting/installing the equipment, employ two persons and be sure to hold the positions as shown in the figure.

The equipment is quite heavy and weighs approximately 75 kg (165.34 lb.) therefore pay full

attention when handling it.

- Be sure not to hold the movable parts or units (e.g. the control panel, ADU or RADF) when transporting the equipment.

- Be sure to use a dedicated outlet with AC 110 V / 13.2 A, 115 V or 127 V / 12 A, 220-240 V or 240

V / 8 A for its power source.

- The equipment must be grounded for safety.

- Select a suitable place for installation. Avoid excessive heat, high humidity, dust, vibration and

direct sunlight.

- Provide proper ventilation since the equipment emits a slight amount of ozone.

- To insure adequate working space for the copying operation, keep a minimum clearance of 80

cm (32”) on the left, 80 cm (32”) on the right and 10 cm (4”) on the rear.

- The equipment shall be installed near the socket outlet and shall be accessible.

04/09

2) General Precautions at Service

- Be sure to turn the power OFF and unplug the power cable during service (except for the service

should be done with the power turned ON).

- Unplug the power cable and clean the area around the prongs of the plug and socket outlet once

a year or more. A fire may occur when dust lies on this area.

- When the parts are disassembled, reassembly is the reverse of disassembly unless otherwise

noted in this manual or other related documents. Be careful not to install small parts such as

screws, washers, pins, E-rings, star washers in the wrong places.

- Basically, the equipment should not be operated with any parts removed or disassembled.

- The PC board must be stored in an anti-electrostatic bag and handled carefully using a wristband

since the ICs on it may be damaged due to static electricity.

Caution: Before using the wristband, unplug the power cable of the equipment and

make sure that there are no charged objects which are not insulated in the

vicinity.

- Avoid expose to laser beam during service. This equipment uses a laser diode. Be sure not to

expose your eyes to the laser beam. Do not insert reflecting parts or tools such as a screwdriver

on the laser beam path. Remove all reflecting metals such as watches, rings, etc. before starting

service.

- Be sure not to touch high-temperature sections such as the exposure lamp, fuser unit, damp

heater and areas around them.

- Be sure not to touch high-voltage sections such as the chargers, developer, high-voltage transformer, exposure lamp control inverter, inverter for the LCD backlight and power supply unit.

Especially, the board of these components should not be touched since the electric charge may

remain in the capacitors, etc. on them even after the power is turned OFF.

- Make sure that the equipment will not operate before touching potentially dangerous places (e.g.

rotating/operating sections such as gears, belts pulleys, fans and laser beam exit of the laser

optical unit).

- Be careful when removing the covers since there might be the parts with very sharp edges

underneath.

- When servicing the equipment with the power turned ON, be sure not to touch live sections and

rotating/operating sections. Avoid exposing your eyes to laser beam.

- Use designated jigs and tools.

- Use recommended measuring instruments or equivalents.

- Return the equipment to the original state and check the operation when the service is finished.

3) Important Service Parts for Safety

- The breaker, door switch, fuse, thermostat, thermofuse, thermistor, IC-RAMs including lithium

batteries, etc. are particularly important for safety. Be sure to handle/install them properly. If

these parts are short-circuited and their functions become ineffective, they may result in fatal

accidents such as burnout. Do not allow a short-circuit or do not use the parts not recommended

by Toshiba TEC Corporation.

4) Cautionary Labels

- During servicing, be sure to check the rating plate and cautionary labels such as “Unplug the

power cable during service”, “CAUTION. HOT”, “CAUTION. HIGH VOLTAGE”, “CAUTION.

LASER BEAM”, etc. to see if there is any dirt on their surface and if they are properly stuck to the

equipment.

5) Disposal of the Equipment, Supplies, Packing Materials, Used Batteries and IC-RAMs

- Regarding the recovery and disposal of the equipment, supplies, packing materials, used batteries and IC-RAMs including lithium batteries, follow the relevant local regulations or rules.

Caution:

Dispose of used batteries and IC-RAMs including lithium batteries according to this manual.

Attention:

Se débarrasser de batteries et IC-RAMs usés y compris les batteries en lithium selon ce manuel.

Vorsicht:

Entsorgung des gebrauchten Batterien und IC-RAMs (inclusive der Lithium-Batterie) nach diesem Handbuch.

CONTENTS

e-STUDIO200L/230/280

1. SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES ................................... 1-1

1.1 Specifications....................................................................................................................... 1-1

1.2 Accessories ......................................................................................................................... 1-6

1.3 Options ................................................................................................................................ 1-7

1.4 Supplies............................................................................................................................... 1-8

1.5 System List .......................................................................................................................... 1-9

2. ERROR CODE AND SELF-DIAGNOSTIC MODE........................................................ 2-1

2.1 Error Code List..................................................................................................................... 2-1

2.1.1 Jam........................................................................................................................... 2-1

2.1.2 Service call ...............................................................................................................2-7

2.1.3 Error in Internet FAX / Scanning Function.............................................................. 2-10

2.1.4 Printer function error............................................................................................... 2-20

2.2 Self-diagnosis Modes ........................................................................................................ 2-22

2.2.1 Input check (Test mode 03).................................................................................... 2-24

2.2.2 Output check (test mode 03) .................................................................................. 2-30

2.2.3 Test print mode (test mode 04) .............................................................................. 2-33

2.2.4 Adjustment mode (05) ............................................................................................ 2-34

2.2.5 Setting mode (08) ................................................................................................... 2-54

2.2.6 Pixel counter......................................................................................................... 2-123

2.2.7 Classification List of Adjustment Mode (05) / Setting Mode (08).......................... 2-133

3. ADJUSTMENT .............................................................................................................. 3-1

3.1 Adjustment of Auto-Toner Sensor ....................................................................................... 3-1

3.2 Image Dimensional Adjustment........................................................................................... 3-3

3.2.1 General description .................................................................................................. 3-3

3.2.2 Paper alignment at the registration roller ................................................................. 3-5

3.2.3 Printer related adjustment ........................................................................................ 3-7

3.2.4 Scanner related adjustment ................................................................................... 3-12

3.3 Image Quality Adjustment (Copying Function) .................................................................. 3-21

3.3.1 Density adjustment ................................................................................................. 3-21

3.3.2 Gamma slope adjustment ...................................................................................... 3-22

3.3.3 Sharpness adjustment............................................................................................ 3-23

3.3.4 Setting range correction ......................................................................................... 3-24

3.3.5 Setting range correction (Adjustment of background peak) ................................... 3-24

3.3.6 Adjustment of smudged/faint text ........................................................................... 3-25

3.3.7 Adjustment of image density .................................................................................. 3-26

3.4 Image Quality Adjustment (Printing Function) ................................................................... 3-27

3.4.1 Adjustment of smudged/faint text ........................................................................... 3-27

3.4.2 Adjustment of image density .................................................................................. 3-28

3.5 Image Quality Adjustment (Scanning Function) ................................................................ 3-29

3.5.1 Density adjustment ................................................................................................. 3-29

3.5.2 Sharpness adjustment............................................................................................ 3-30

3.5.3 Setting range correction ......................................................................................... 3-31

3.5.4 Setting range correction (Adjustment of background peak) ................................... 3-32

3.5.5 Setting range correction (Adjustment of text peak) ................................................ 3-32

3.6 Adjustment of High-Voltage Transformer .......................................................................... 3-33

3.6.1 Adjustment ............................................................................................................. 3-33

3.6.2 Precautions ............................................................................................................ 3-39

3.7 Adjustment of the Scanner Section ................................................................................... 3-41

3.7.1 Carriages ................................................................................................................ 3-41

3.7.2 Lens unit................................................................................................................. 3-46

3.8 Adjustment of the Paper Feeding System ......................................................................... 3-49

June 2004 © TOSHIBA TEC e-STUDIO200L/230/280 CONTENTS

1

05/05

3.8.1 Sheet sideways deviation caused by paper feeding .............................................. 3-49

3.9 Adjustment of Developer Unit ............................................................................................ 3-50

3.9.1 Doctor-to-sleeve gap .............................................................................................. 3-50

3.10 Adjustment of the RADF (MR-3016).................................................................................. 3-53

3.10.1 Adjustment of RADF position ................................................................................. 3-53

3.10.2 Adjustment of RADF height .................................................................................... 3-57

3.10.3 Adjustment of skew ................................................................................................ 3-59

3.10.4 Automatic adjustment of sensors and initialization of EEPROM ............................ 3-61

3.10.5 Adjustment of aligning ............................................................................................ 3-62

3.10.6 Adjustment of aligning at reversing ........................................................................ 3-63

3.10.7 Adjustment of reverse solenoid .............................................................................. 3-64

3.10.8 Adjustment of RADF opening/closing switch.......................................................... 3-66

3.10.9 Adjustment of RADF opening/closing sensor ......................................................... 3-67

3.10.10Adjustment of tray volume ..................................................................................... 3-68

3.11 Adjustment of the Finisher (MJ-1022)................................................................................ 3-69

3.11.1 Adjusting the jogging plate width ............................................................................ 3-69

3.11.2 Adjusting the angle of the jogging plate ................................................................. 3-71

3.11.3 Adjusting the overlap of the sensor flag ................................................................. 3-72

3.11.4 Adjusting the tension of the stack processing motor belt ....................................... 3-73

3.11.5 Releasing the stack tray guide lever fixing plate .................................................... 3-75

3.11.6 Adjustment of the upper tray angle ........................................................................ 3-76

3.11.7 DIP switch functions ............................................................................................... 3-78

3.12 Adjustment of the Finisher (MJ-1025)................................................................................ 3-80

3.12.1 Adjusting the folding position (Electrical system (Finisher/Saddle unit)) ................3-80

3.12.2 Adjusting the sensor output (Electrical system (Puncher unit; option)) .................. 3-81

3.12.3 Registering the number of punch hole (Electrical system (Puncher unit; option)).. 3-82

3.12.4 After replacing the EEP-ROM (IC1002) (Electrical system (Puncher unit; option)) 3-83

3.13 Key Copy Counter (MU-8, MU-10) .................................................................................... 3-84

4. PREVENTIVE MAINTENANCE (PM)............................................................................ 4-1

4.1 PM Support Mode................................................................................................................ 4-1

4.1.1 General description .................................................................................................. 4-1

4.1.2 Operational flow and operational screen .................................................................. 4-1

4.1.3 Work flow of parts replacement ................................................................................ 4-6

4.2 General Descriptions for PM Procedure.............................................................................. 4-7

4.3 Operational Items in Overhauling ........................................................................................ 4-8

4.4 Preventive Maintenance Checklist....................................................................................... 4-9

4.5 PM KIT............................................................................................................................... 4-24

4.6 Jig List ............................................................................................................................... 4-25

4.7 Grease List ........................................................................................................................ 4-26

4.8 Precautions for Storing and Handling Supplies ................................................................. 4-27

4.8.1 Precautions for storing TOSHIBA supplies ............................................................ 4-27

4.8.2 Checking and cleaning of photoconductive drum................................................... 4-28

4.8.3 Checking and cleaning of drum cleaning blade...................................................... 4-29

4.8.4 Checking and cleaning of fuser roller and pressure roller ...................................... 4-29

4.8.5 Checking and replacing the cleaning roller ............................................................ 4-29

5. TROUBLESHOOTING .................................................................................................. 5-1

5.1 Diagnosis and Prescription for Each Error Code ................................................................. 5-1

5.1.1 Paper transport jam .................................................................................................. 5-1

5.1.2 Paper misfeeding ................................................................................................... 5-15

5.1.3 Cover open jam ...................................................................................................... 5-22

5.1.4 Transport jam (RADF) ............................................................................................ 5-28

5.1.5 Finisher jam ............................................................................................................ 5-35

5.1.6 Drive system related service call ............................................................................ 5-47

5.1.7 Paper feeding system related service call .............................................................. 5-48

e-STUDIO200L/230/280 CONTENTS June 2004 © TOSHIBA TEC

2

5.1.8 Scanning system related service call ..................................................................... 5-54

5.1.9 Fuser unit related service call................................................................................. 5-56

5.1.10 Communication related service call........................................................................ 5-58

5.1.11 RADF related service call ....................................................................................... 5-59

5.1.12 Laser optical unit related service call ..................................................................... 5-60

5.1.13 Finisher related service call .................................................................................... 5-61

5.1.14 Service call for others............................................................................................. 5-76

5.1.15 Error in Internet FAX / Scanning Function.............................................................. 5-79

5.2 Troubleshooting for the Image........................................................................................... 5-93

5.3 Replacement of PC Boards and HDD ............................................................................. 5-115

5.3.1 Replacing HDD..................................................................................................... 5-115

5.3.2 Replacing SYS board ........................................................................................... 5-117

5.3.3 Caution when Data overwrite kit (GP-1050) is installed ...................................... 5-119

6. FIRMWARE UPDATING ............................................................................................... 6-1

6.1 Firmware Updating with Download Jig ................................................................................ 6-2

6.1.1 PWA-DWNLD-350-JIG2 (48 MB) ............................................................................. 6-4

6.1.2 PWA-DWNLD-350-JIG1 (16 MB) ........................................................................... 6-11

6.1.3 Writing the data to the download jig (PWA-DWNLD-350-JIG) ............................... 6-20

6.1.4 K-PWA-DLM-320.................................................................................................... 6-21

6.2 Firmware Updating with FSMS (Field Service Manager)................................................... 6-31

6.3 Firmware Updating with USB Storage Device................................................................... 6-43

7. POWER SUPPLY UNIT ................................................................................................ 7-1

7.1 Output Channel ................................................................................................................... 7-1

7.2 Fuse..................................................................................................................................... 7-3

7.3 Configuration of Power Supply Unit..................................................................................... 7-4

8. REMOTE SERVICE....................................................................................................... 8-1

8.1 Auto Supply Order ............................................................................................................... 8-1

8.1.1 Outline ...................................................................................................................... 8-1

8.1.2 Setting Item .............................................................................................................. 8-2

8.1.3 Setting procedure ..................................................................................................... 8-5

8.1.4 Order Sheet Format ............................................................................................... 8-12

8.2 Service Notification ............................................................................................................ 8-14

8.2.1 Outline ....................................................................................................................8-14

8.2.2 Setting ....................................................................................................................8-14

8.2.3 Items to be notified ................................................................................................. 8-19

9. WIRE HARNESS CONNECTION DIAGRAMS ............................................................. 9-1

9.1 AC Wire Harness ................................................................................................................. 9-1

9.2 DC Wire Harness....................................................................................................... Appendix

9.3 Connector Table ........................................................................................................ Appendix

June 2004 © TOSHIBA TEC e-STUDIO200L/230/280 CONTENTS

3

05/05

e-STUDIO200L/230/280 CONTENTS June 2004 © TOSHIBA TEC

4

1. SPECIFICATIONS / ACCESSORIES /

OPTIONS / SUPPLIES

2. ERROR CODE AND SELF-DIAGNOSTIC

MODE

3. ADJUSTMENT

4. PREVENTIVE MAINTENANCE (PM)

5. TROUBLESHOOTING

1

2

3

4

5

6. FIRMWARE UPDATING

7. POWER SUPPLY UNIT

8. REMOTE SERVICE

9. WIRE HARNESS CONNECTION DIAGRAMS

6

7

8

9

1. SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1.1 Specifications

Values in { } are for e-STUDIO200L and values in [ ] are for e- STUDIO280/280S in case that the

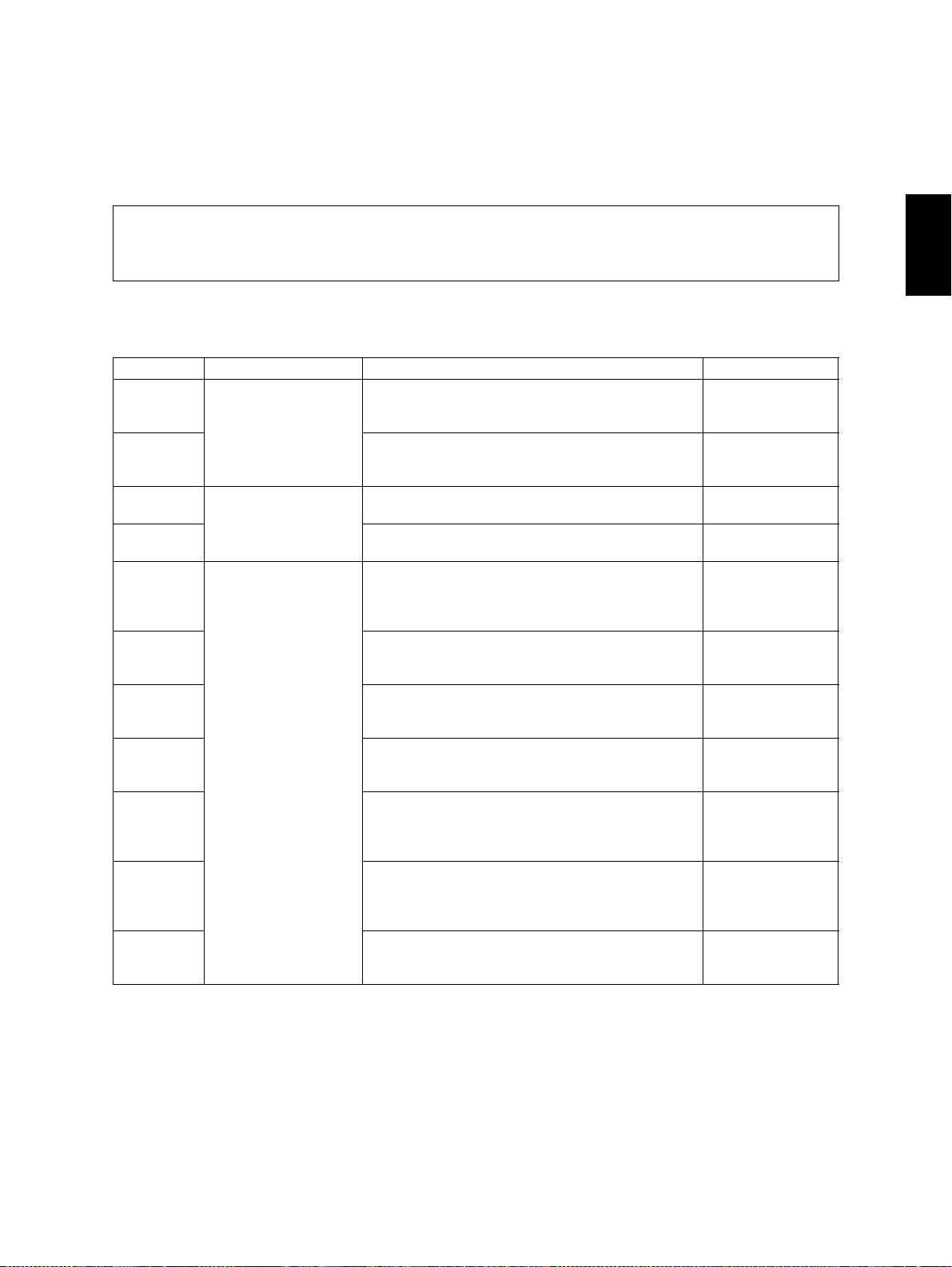

specification is different among e-STUDIO200L, e-STUDIO230/230L and e-STUDIO280/280S.

Copy process Indirect electrophotographic process (dry)

Type Desktop type (console type: when paper feed pedestal (PFP) and large

capacity feeder (LCF) are installed)

Original table Fixed type (the left rear corner used as guide to place originals)

Accepted originals Sheet, book and 3-dimensional object. The reversing automatic document

feeder (RADF) only accepts paper which are not pasted or stapled. (Singlesided originals: 50 to 127 g/m

2

to 105 g/m

/13 to 28 lb. Bond) Carbon paper are not acceptable either.

Maximum size: A3/LD

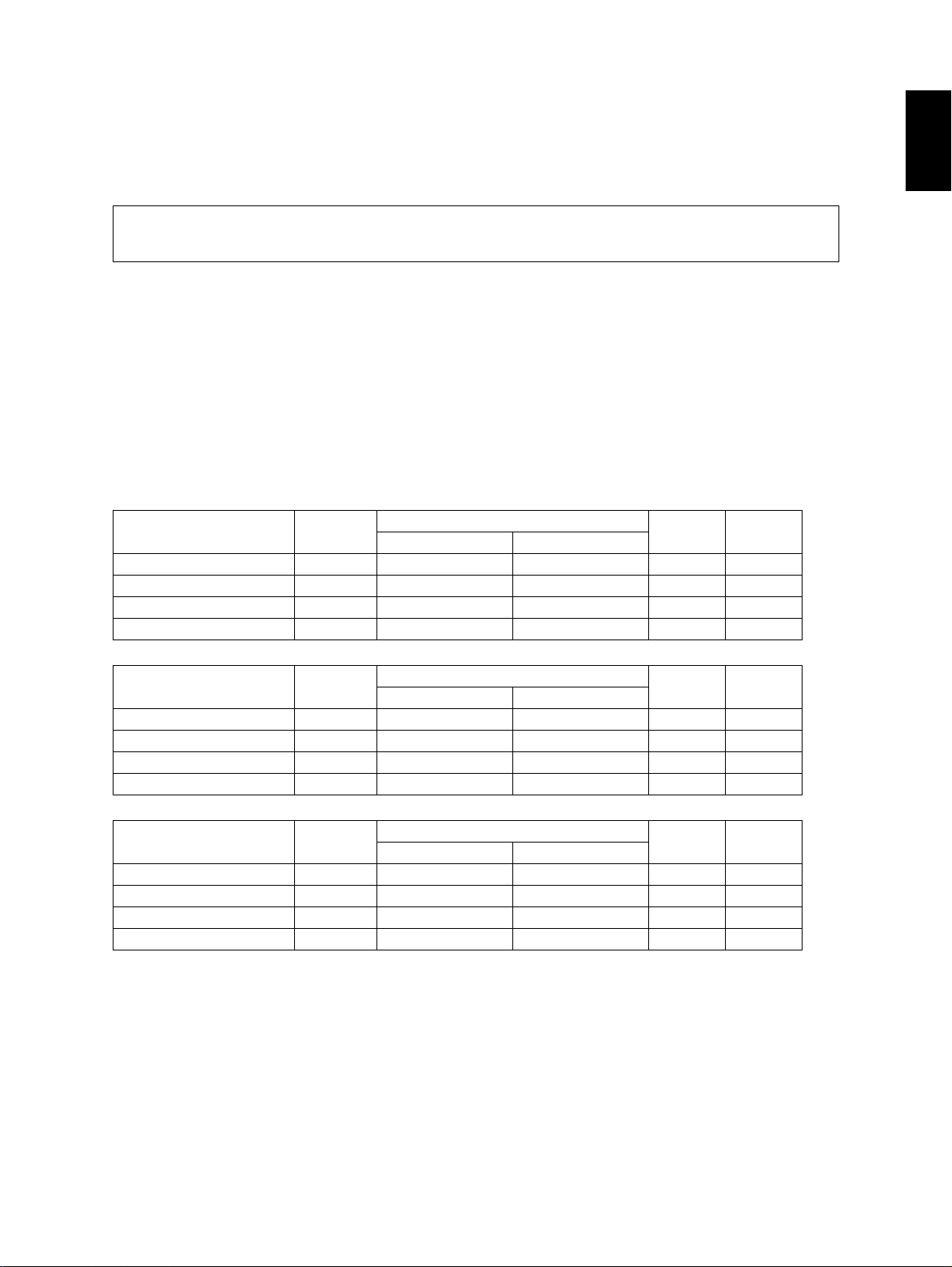

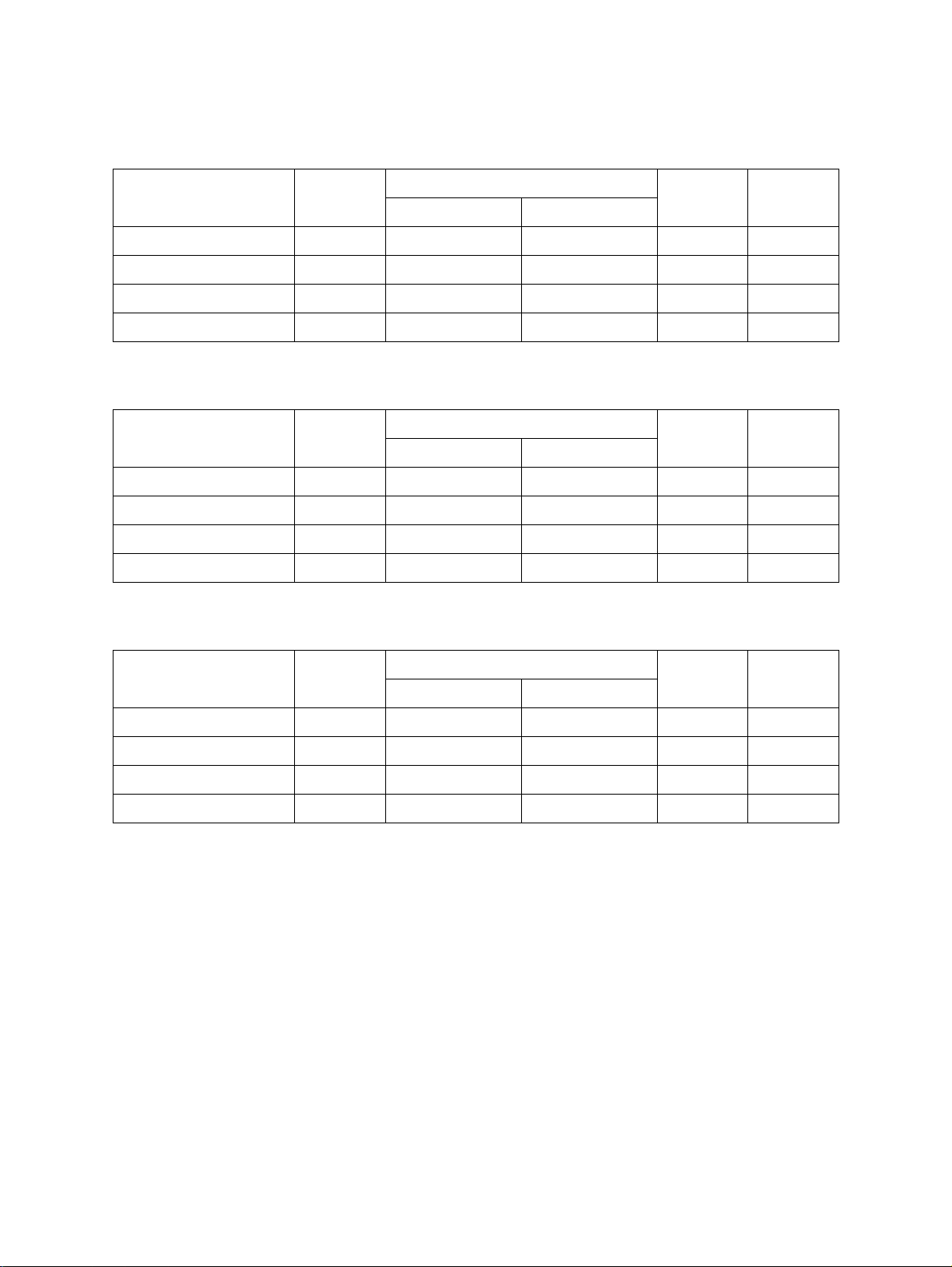

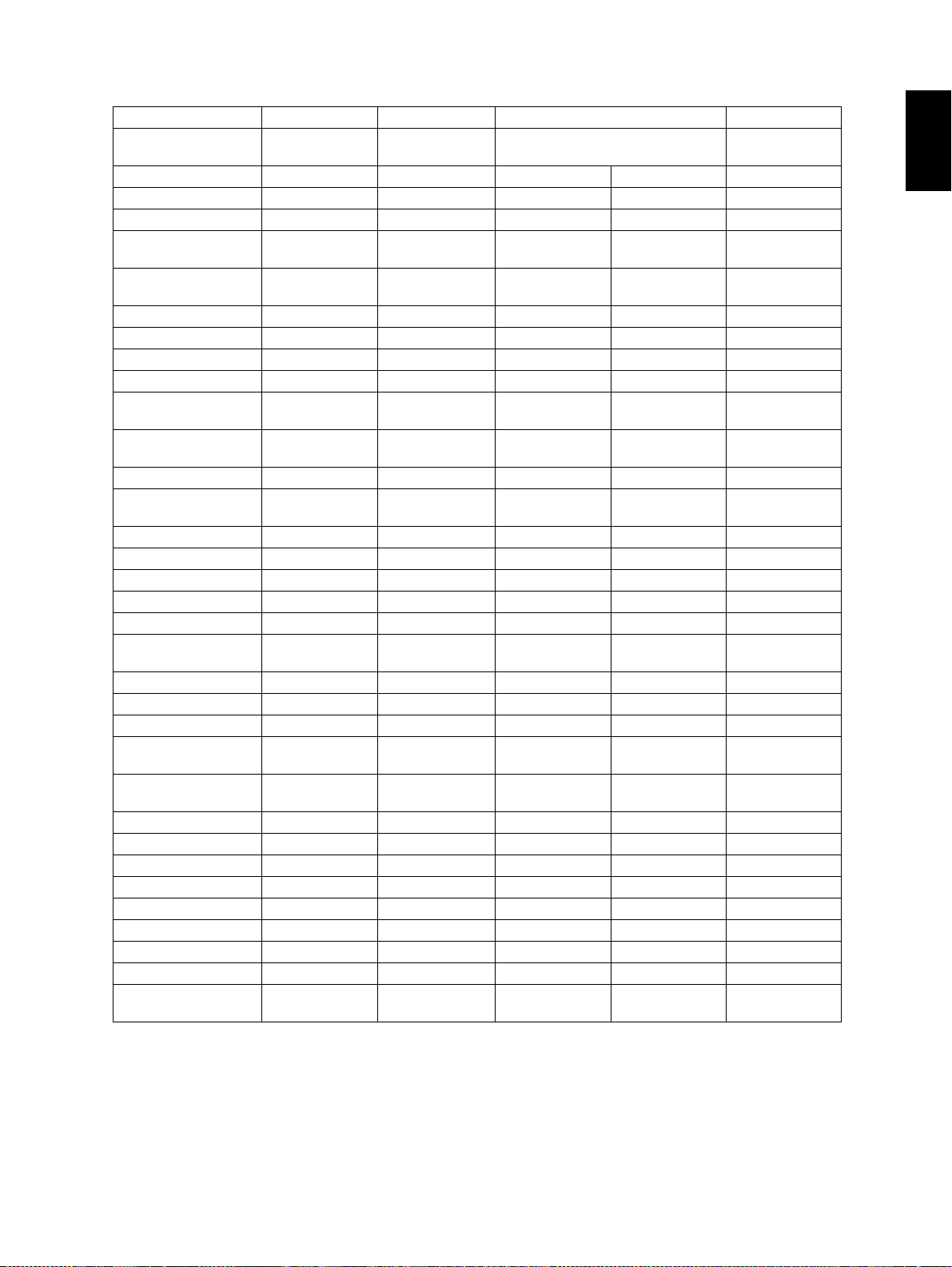

Copy speed (Copies/min.)

e-STUDIO200L

Paper size Drawer

A4, LT, B5, A5-R, ST-R 20 20 16 20 20

A4-R, B5-R, LT-R 19 19 16 19 –

B4, LG 18 18 16 18 –

A3, LD 16 16 16 16 –

Size specified Size not specified

2

/13 to 34 lb. Bond, Double-sided originals: 50

Bypass feed

PFP LCF

1

e-STUDIO230/230L

Paper size Drawer

A4, LT, B5, A5-R, ST-R 23 23 16 23 23

A4-R, B5-R, LT-R 21.5 21.5 16 21.5 –

B4, LG 18 18 16 18 –

A3, LD 16 16 16 16 –

Size specified Size not specified

Bypass feed

PFP LCF

e-STUDIO280/280S

Paper size Drawer

A4, LT, B5, A5-R, ST-R 28 28 16 28 28

A4-R, B5-R, LT-R 21.5 21.5 16 21.5 –

B4, LG 18 18 16 18 –

A3, LD 16 16 16 16 –

Size specified Size not specified

Bypass feed

PFP LCF

* “–” means “Not acceptable”.

* The copy speed in the above table are available when originals are manually placed for single side,

multiple copying.

* When the RADF is used, the copy speed of {20}23[28] sheets per minute is only available under the

following conditions:

• Original/Mode: Single side original/A4/LT size. APS/automatic density are not selected.

• Number of sheets: {20}23[28] or more.

• Reproduction ratio: 100%

June 2004 © TOSHIBA TEC e-STUDIO200L/230/280 SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1 - 1

04/09

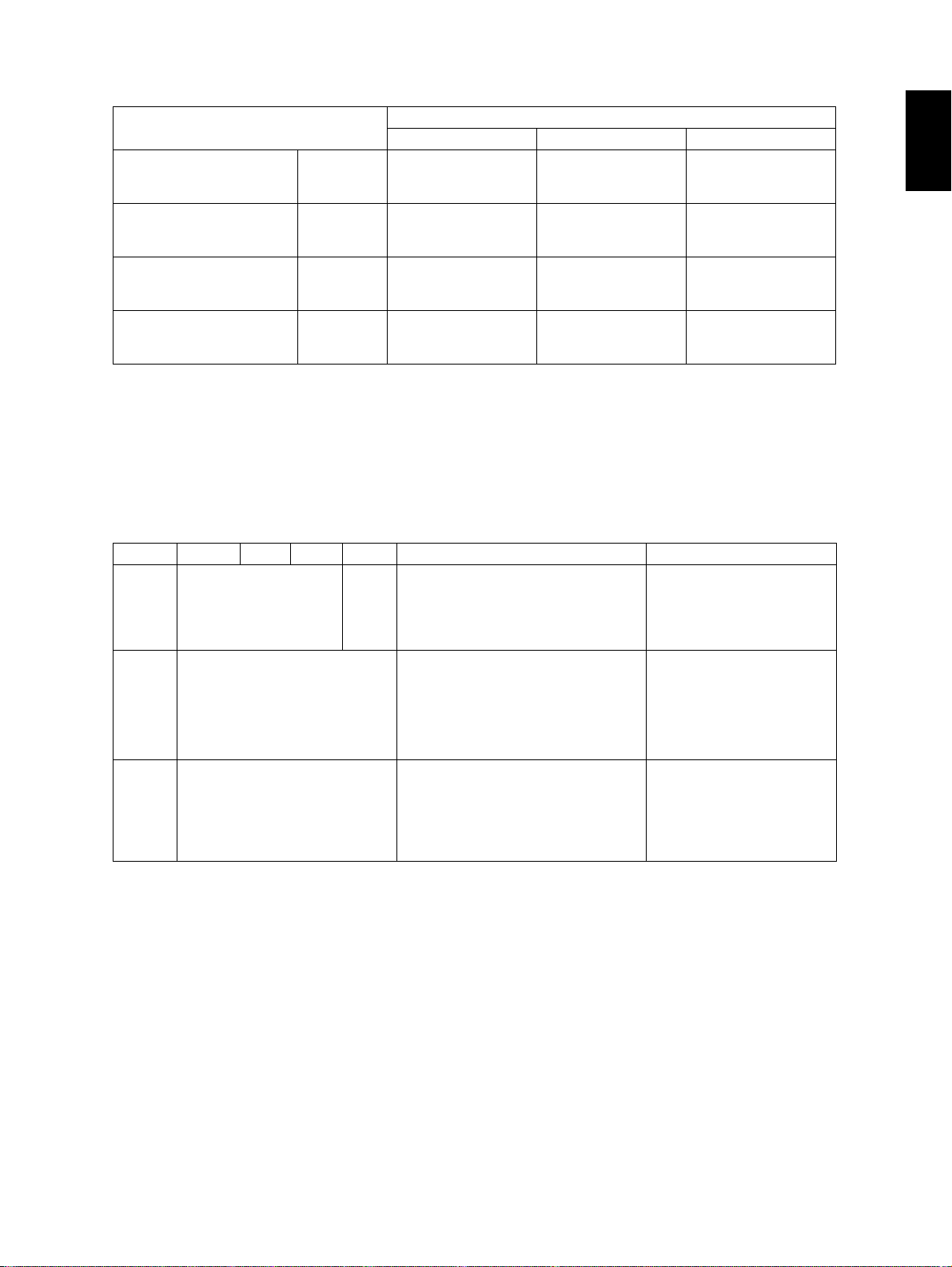

Copy speed for thick paper (Copies/min.)

e-STUDIO200L/230/280 series

Thick 1 (81 g/m

Paper size Drawer

A4, LT, B5, A5-R, ST-R {20} 23 [27] {20} 23 [27] {15} 16 [16] {20} 23 [27] {20} 23 [27]

A4-R, B5-R, LT-R {19} 21 [21] {19} 21 [21] {15} 16 [16] {19} 21 [21] {-} - [-]

B4, LG {18} 18 [18] {18} 18 [18] {15} 16 [16] {18} 18 [18] {-} - [-]

A3, LD {15} 16 [16] {15} 16 [16] {15} 16 [16] {15} 16 [16] {-} - [-]

Thick 2 (106 g/m

Paper size Drawer

A4, LT, B5, A5-R, ST-R {-} - [-] {20} 23 [27] {15} 16 [16] {-} - [-] {-} - [-]

A4-R, B5-R, LT-R {-} - [-] {19} 21 [21] {15} 16 [16] {-} - [-] {-} - [-]

B4, LG {-} - [-] {18} 18 [18] {15} 16 [16] {-} - [-] {-} - [-]

A3, LD {-} - [-] {15} 16 [16] {15} 16 [16] {-} - [-] {-} - [-]

2

to 105 g/m2, 21.3 lb. Bond to 28 lb. Bond)

Bypass feed

Size specified Size not specified

2

to 163 g/m2, 28 lb. Bond to 90 lb. Index)

Bypass feed

Size specified Size not specified

PFP LCF

PFP LCF

Thick 3 (164 g/m

Paper size Drawer

A4, LT, B5, A5-R, ST-R {-} - [-] {20} 23 [27] {15} 16 [16] {-} - [-] {-} - [-]

A4-R, B5-R, LT-R {-} - [-] {19} 21 [21] {15} 16 [16] {-} - [-] {-} - [-]

B4, LG {-} - [-] {18} 18 [18] {15} 16 [16] {-} - [-] {-} - [-]

A3, LD {-} - [-] {15} 16 [16] {15} 16 [16] {-} - [-] {-} - [-]

2

to 209 g/m2, 90 lb. Index to 115.7 lb. Index)

Bypass feed

Size specified Size not specified

PFP LCF

* Only A4/LT size is available for the LCF.

* The tolerance is within ±2.

e-STUDIO200L/230/280 SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES June 2004 © TOSHIBA TEC

1 - 2

04/09

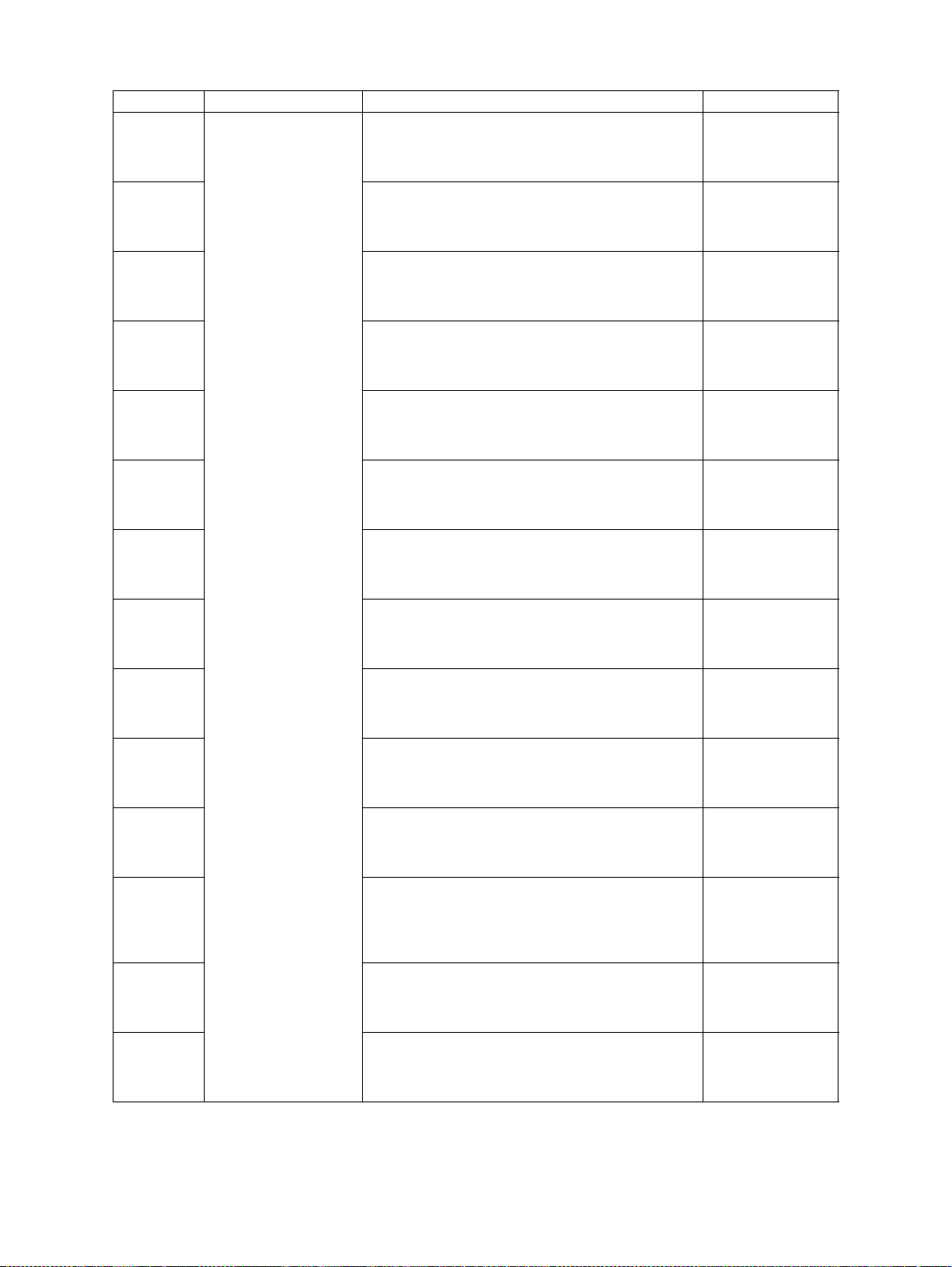

* System copy speed

Copy mode

Single-sided originals

↓

Single-sided copies

Single-sided originals

↓

Double-sided copies

Double-sided originals

↓

Double-sided copies

Double-sided originals

↓

Single-sided copies

1 set

3 sets

5 sets

1 set

3 sets

5 sets

1 set

3 sets

5 sets

1 set

3 sets

5 sets

e-STUDIO200L e-STUDIO230/230L e-STUDIO280/280S

34.18

95.53

154.28

37.44

96.81

155.54

70.26

188.48

306.64

64.65

184.73

302.58

Sec.

31.5

84.8

136.2

34.5

85.9

137.4

64.8

167.7

270.6

57.8

163.1

266.1

27.6

72.2

114.0

31.6

73.4

116.4

58.9

143.8

228.5

50.5

137.3

222.1

* The system copy speed, including scanning time, is available when 10 sheets of A4/LT size original

are set on RADF and one of the copy modes in the above table is selected. The period of time from

pressing [START] to the paper exit completely out of the equipment based on the actually measured

value.

* Upper drawer is selected and copying is at the non-sort mode.

* Automatic copy density, APS/AMS are turned off.

* Finisher is not installed.

Copy paper

Drawer ADU PFP LCF Bypass copy Remarks

Size A3 to A5-R, LD to ST-R,

Weight

Special

paper

FOLIO, COMPUTER,

13"LG, 8.5" x 8.5", 8K,

16K, 16K-R

64 to 105 g/m

17 to 28 lb. Bond

– Tracing paper, labels,

A4, LT A3 to A5-R, LD to ST-R, FOLIO,

2

COMPUTER, 13"LG, 8.5" x 8.5", 8K,

16K, 16K-R

(Non-standard or user-specified

sizes can be set.)

2

64 to 209 g/m

Index

(Continuous feeding)

50 to 209 g/m

Index

(Single paper feeding)

OHP film

(thickness: 80 µm or thicker),

tab paper, envelope

(COM10, Monarch, DL, CHO-3,

YOU-4)

, 17 lb. Bond to 110 lb.

2

, 13 lb. Bond to 110 lb.

These special papers recommended by Toshiba Tec

CHO-3: 92 mm x 235 mm

YOU-4: 105 mm x 235 mm

1

First copy time ......................... Approx. 5.4 sec. or less

(A4/LT, upper drawer, 100%, original placed manually)

Warming-up time ..................... Approx. 25 sec. (temperature: 20°C)

Multiple copying....................... Up to 999 copies; Key in set numbers

Reproduction ratio ................... Actual ratio: 100±0.5%

Zooming: 25 to 400% in increments of 1%

(25 to 200% when using RADF)

Resolution/Gradation............... Scanning: 600 dpi x 600 dpi

Printing: Equivalent to 2400 dpi x 600 dpi

Gradation: 256 steps

June 2004 © TOSHIBA TEC e-STUDIO200L/230/280 SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1 - 3

04/09

Eliminated portion.................... Leading edges: 3.0±2.0 mm, Side/trailing edges: 2.0±2.0 mm (copy)

Leading / trailing edges: 5.0±2.0 mm, Side edges: 5.0±2.0 mm (print)

Paper feeding .......................... Standard drawers:

1 or 2 drawers (stack height 60.5 mm, equivalent to 550 sheets;

64 to 80 g/m

2

(17 to 22 lb. Bond)): Depends on destinations or

versions.

PFP:

Option (One drawer or two: stack height 60.5 mm, equivalent to

550 sheets; 64 to 80 g/m

2

(17 to 22 lb. Bond))

LCF:

Option (Stack height 137.5 mm x 2: equivalent to 2500 sheets;

64 to 80 g/m

2

(17 to 22 lb. Bond))

Bypass feeding:

Stack height 11 mm: equivalent to 100 sheets; 64 to 80 g/m

2

(17

to 22 lb. Bond)

Capacity of originals in the reversing automatic document feeder (Option)

.................................................. A3 to A5-R, LD to ST-R:

100 sheets / 80 g/m

2

(Stack height 16 mm or less)

Automatic duplexing unit (ADU is available as standard equipment for some destinations or versions.)

.................................................. Stackless, Switchback type

Toner supply............................ Automatic toner density detection/supply

Toner cartridge replacing method (There is a recovered toner supply

mechanism.)

Density control......................... Automatic density mode and manual density mode selectable in 11

steps

Weight ..................................... Approximately 75 kg (165.34 lb.) (include the developer material and

drum) (The ADU and Drawer module are installed.)

Power requirements ................ AC 110 V / 13.2 A, 115 V or 127 V / 12 A

220-240 V or 240 V / 8 A (50/60 Hz)

* The acceptable value of each voltage is ±10%.

Power consumption................. 1.5 kW or less (115 V series, 200 V series)

* The electric power is supplied to the RADF, (ADU), Finisher, Job Separator, Offset Tray, PFP and

LCF through the equipment.

Total counter............................ Electronical counter

e-STUDIO200L/230/280 SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES June 2004 © TOSHIBA TEC

1 - 4

04/09

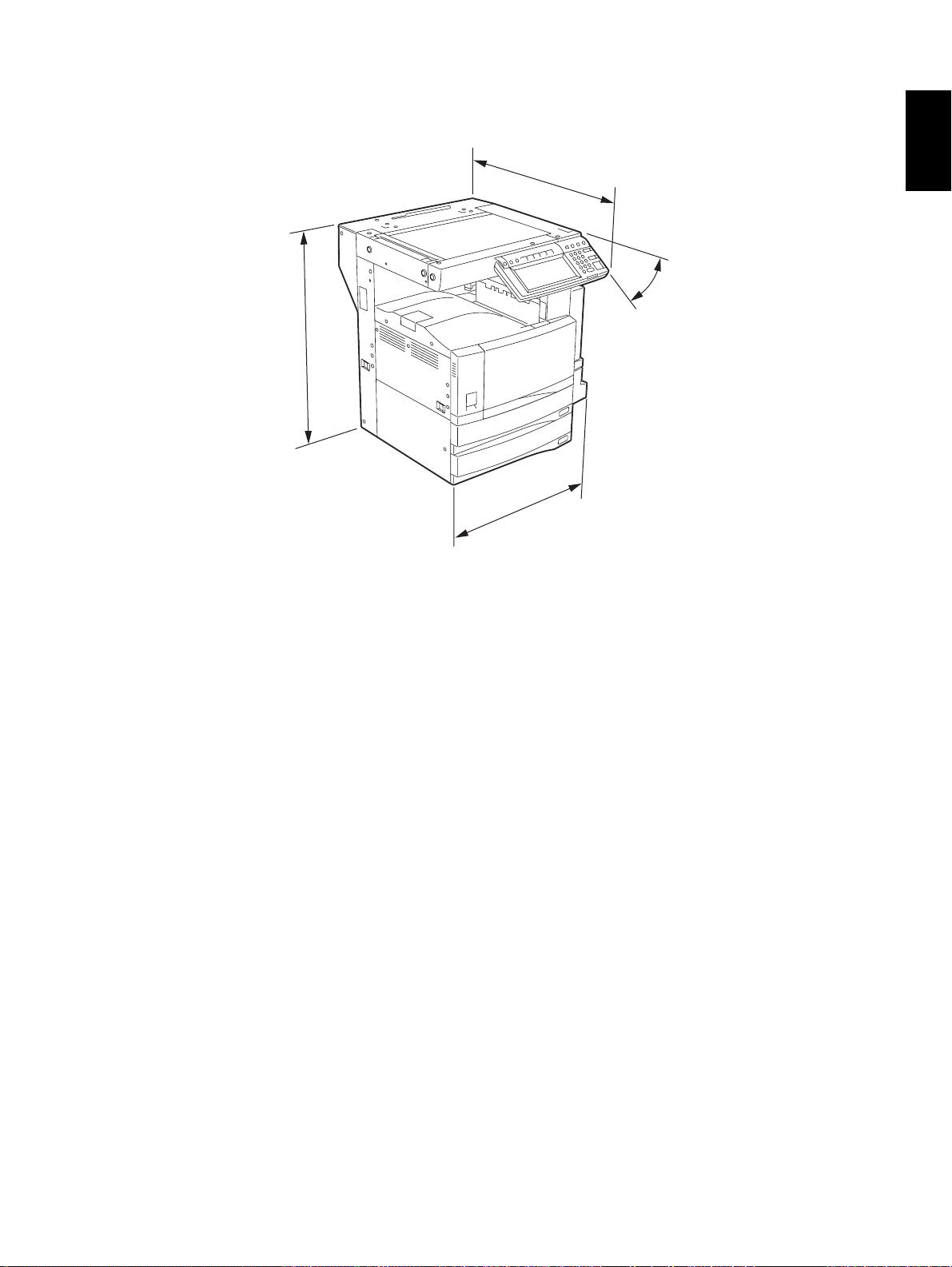

Dimensions of the equipment...................... See the figure below (W 637 x D 719 x H 739 (mm))

* When the tilt angle of the control panel is 45 degrees.

719

45°

739

637

1

Fig.1-1

June 2004 © TOSHIBA TEC e-STUDIO200L/230/280 SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1 - 5

04/09

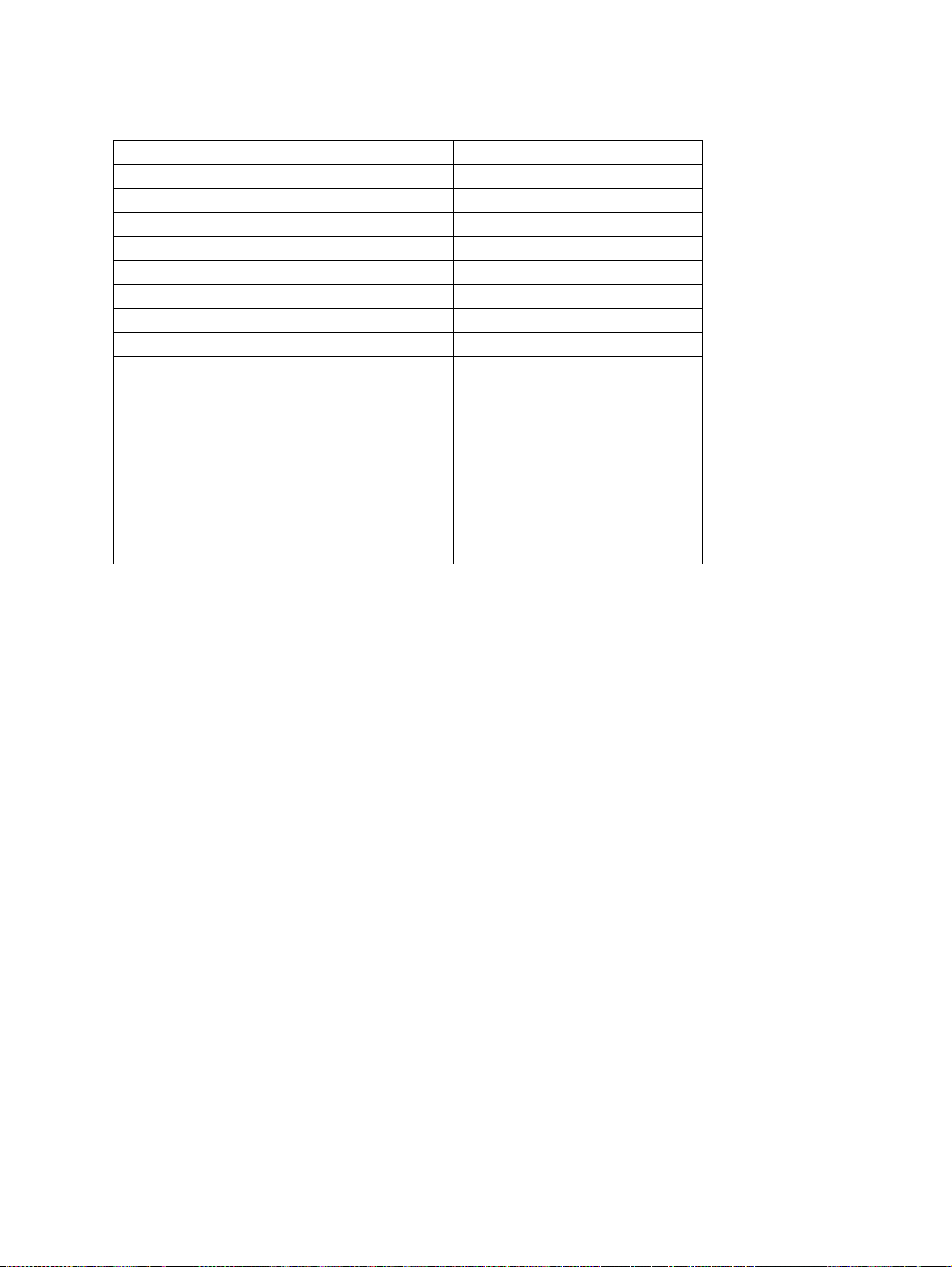

1.2 Accessories

Unpacking/setup instruction 1 set

Operator’s manual 3 pcs. (except for MJD)

Operator's manual pocket 1 pc.

Power cable 1 pc.

Warranty sheet 1 pc. (for NAD)

Setup report 1 set (for NAD and MJD)

Customer satisfaction card 1 pc. (for MJD)

Drum (installed inside of the equipment) 1 pc.

Toner cartridge 1 pc. (except for NAD, MJD)

Developer material 1 pc. (except for NAD, MJD)

Control panel stopper 1 pc.

Blind seal 1 pc.

Rubber plug 5 pcs.

CD-ROM 4 pcs.

Transfer charger wire cleaner

(installed inside of the transfer cover)

Paper stopper 1 pc.

Stopper bracket 1 pc.

1 pc.

* Machine version

NAD: North America

ASD: Central and South America / Hong Kong

AUD: Australia

MJD: Europe

ASU: Asia

SAD: Saudi Arabia

IRD: Iran

CND: China

TWD: Taiwan

JPD: Japan

e-STUDIO200L/230/280 SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES June 2004 © TOSHIBA TEC

1 - 6

04/09

1.3 Options

Platen Cover KA-3511 PC/PC-C

Reversing Automatic Document Feeder (RADF) MR-3016

Drawer Module MY-1021/-C

Paper Feed Pedestal (PFP) KD-1011/-C

Large Capacity Feeder (LCF) KD-1012 A4/LT/A4-C

Finisher (Hanging type) MJ-1022/-C

Saddle stitch Finisher MJ-1025/-C

Hole Punch Unit

MJ-6005 N/E/F/S

*1

Staple Cartridge STAPLE-1600 (for MJ-1022)

STAPLE-2000 (for MJ-1025)

Bridge Kit KN-3520/-C

Job Separator MJ-5004/-C

Offset Tray MJ-5005/-C

Key copy Counter, Key copy counter socket MU-8, MU-10

Work Tray KK-3511

Damp Heater MF-2320 U/E

Fax Board GD-1150 NA/AU/EU/TW/C/AS

2nd Line for Fax Board GD-1160 NA/EU/TW/C

Wireless LAN Adapter GN-1010

PCI Slot GO-1040/C

Scrambler Board GP-1030

Printer Kit GM-1020/GM-1030

Printer/Scanner Kit GM-2020/GM-2030

Scanner upgrade Kit GM-3020/GM-3030

Parallel interface kit GF-1140

Desk MH-1700

Harness kit for coin controller GQ-1020

Automatic Duplexing Unit (ADU) MD-0102

Slot cover KE-2330

NIC board GF-1150

Data overwrite kit GP-1050

1

* 1) N: North America E: Europe F: France S: Sweden

Notes:

• The bridge unit (KN-3520) is necessary for installation of the finisher (MJ-1022, MJ-1025).

• The finisher (MJ-1025) is necessary for installation of the hole punch unit (MJ-6005N/E/F/S).

• The PCI slot (GO-1040) is necessary for installation of the scrambler board (GP-1030) and

parallel interface kit (GF-1140).

• GM-1030/GM-2030/GM-3030 are exclusive for e-STUDIO200L.

They do not operate with e-STUDIO230/230L/280/280S.

June 2004 © TOSHIBA TEC e-STUDIO200L/230/280 SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1 - 7

05/05

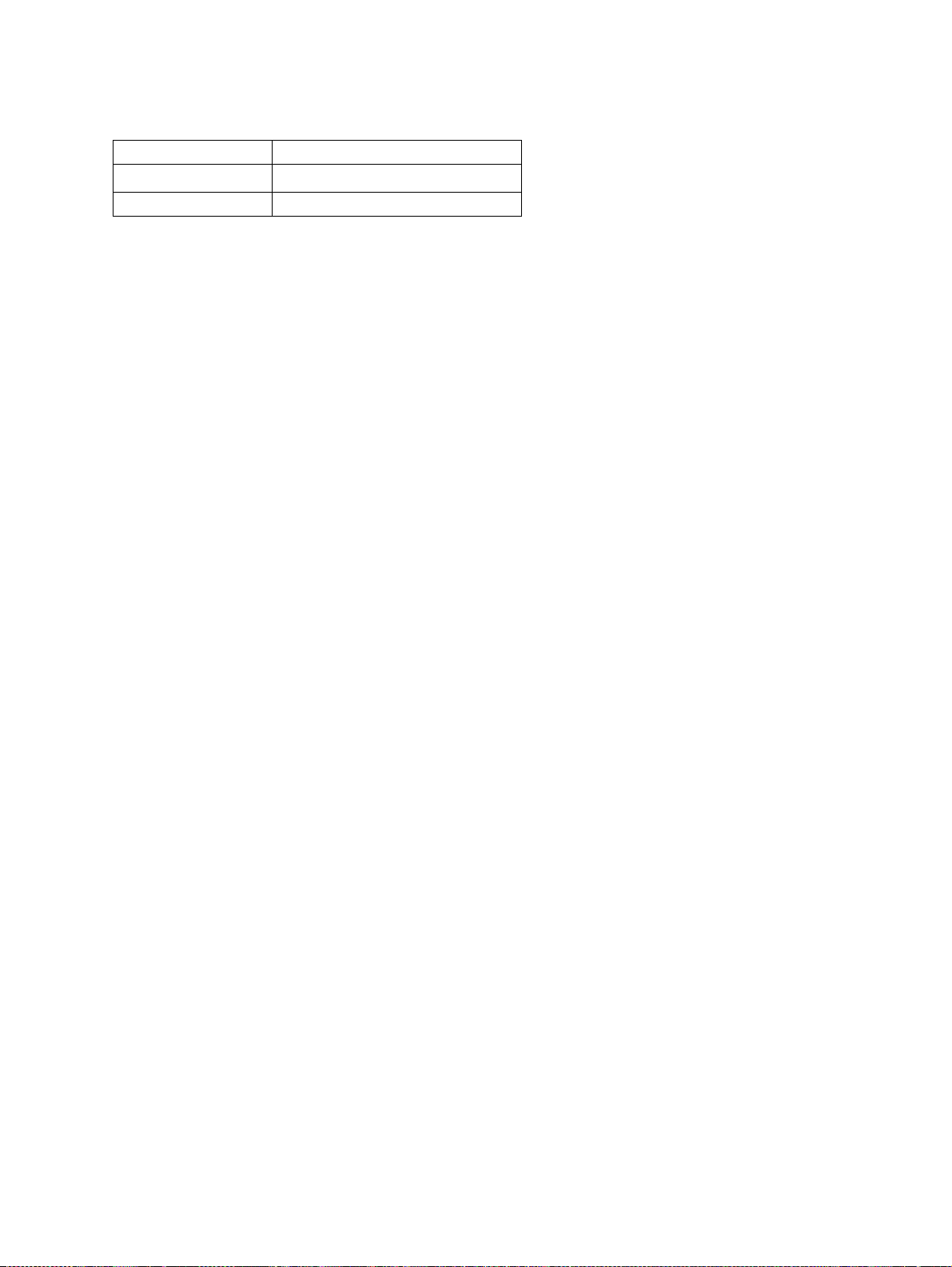

1.4 Supplies

Drum OD-1600

Toner cartridge

Developer D-2320 /C

PS-ZT2320 /T/D/C/E

* 1) T: Taiwan D: Asia C: China E: Europe NONE: North America

*1

e-STUDIO200L/230/280 SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES June 2004 © TOSHIBA TEC

1 - 8

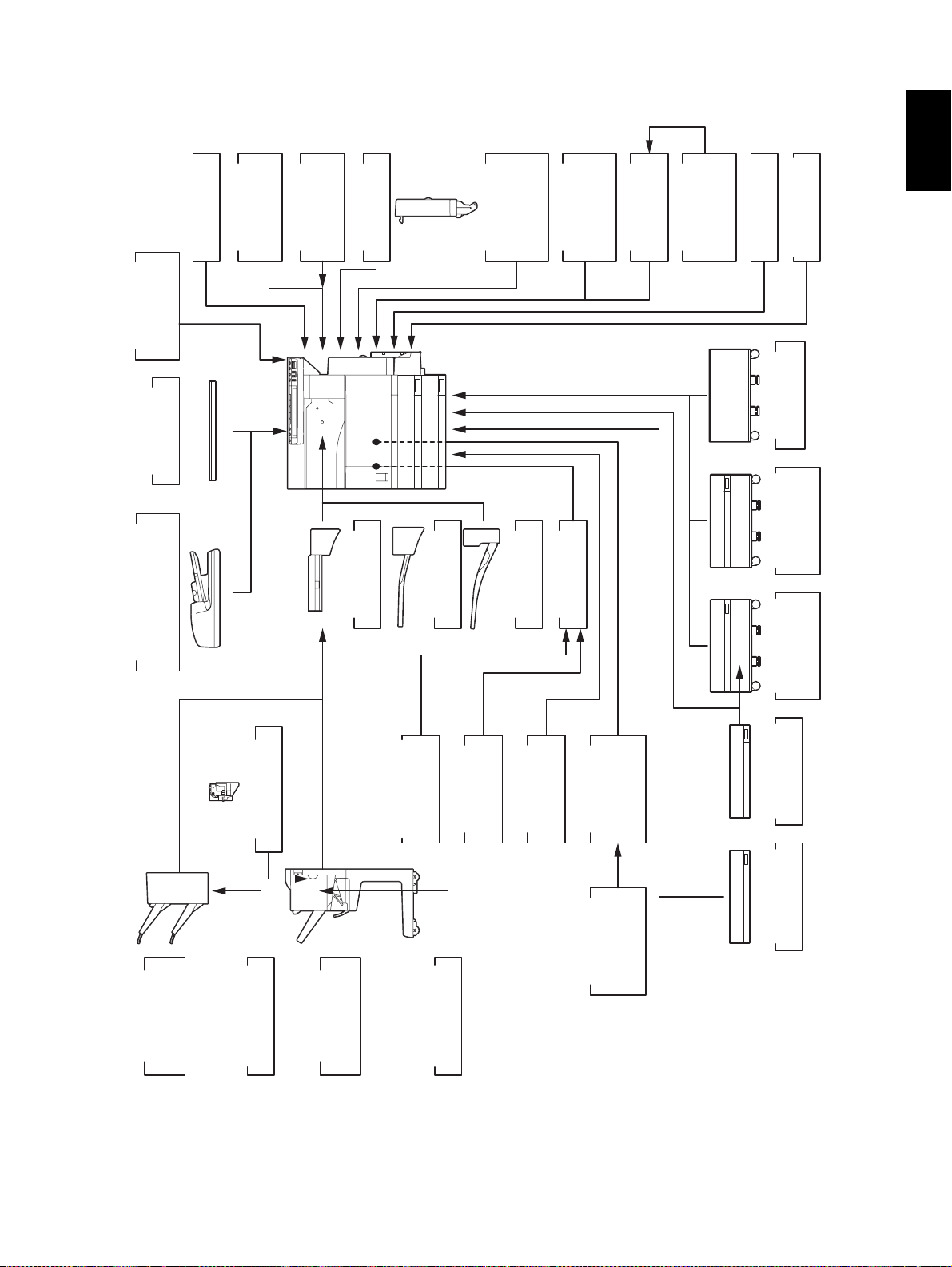

1.5 System List

MU-8

Counter

KK-3511

Key Copy

Work Tray

GQ-1020

coin controller

Harness kit for

KA-3511

Platen Cover

)

MU-10

Key Copy

Counter Socket

MF-2320 U/E

Damp Heater

)

ADU

(

MD-0102

Automatic

Duplexing Unit

Printer/

GM-2020/

Scanner Kit

GM-2030

Printer Kit

GM-1020/

Scanner

GM-1030

Upgrade Kit

GM-3030

GM-3020/

NIC board

GF-1150

GP-1050

Data overwrite kit

Desk

MH-1700

1

RADF

(

MR-3016

Reversing Automatic

Document Feeder

)

Hole Punch Unit

MJ-6005 N/E/F/S

KN-3520

Bridge Kit

MJ-5004

Job Separator

kit

Parallel interface

GF-1140

Scrambler

Board

MJ-5005

Offset Tray

GP-1030

Wireless LAN

PCI Slot

Adapter

GN-1010

GO-1040

GD-1150

FAX Board

FAX Board

2nd Line for

TW/C/AS

NA/AU/EU/

GD-1160

NA/EU/TW/C

Feeder (LCF)

Large Capacity

KD-1012 A4/LT

KD-1011

Paper Feed

Pedestal (PFP)

MY-1021

Drawer Module

KE-2330

Slot cover

Finisher

MJ-1022

Hanging type

(

June 2004 © TOSHIBA TEC e-STUDIO200L/230/280 SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

STAPLE-1600

Staple Cartridge

Finisher

MJ-1025

Saddle stitch

STAPLE-2000

Staple Cartridge

Fig.1-2

1 - 9

05/05

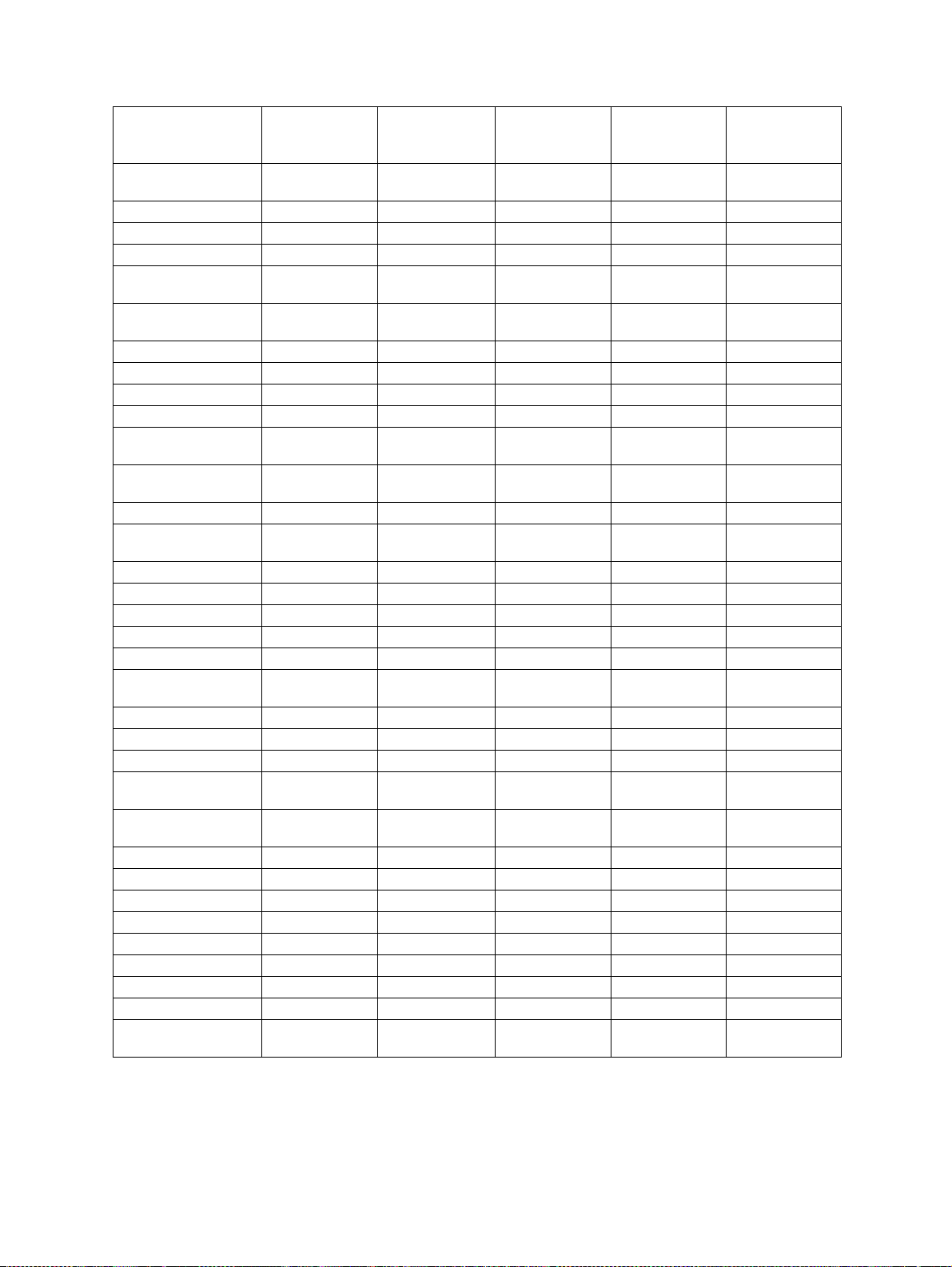

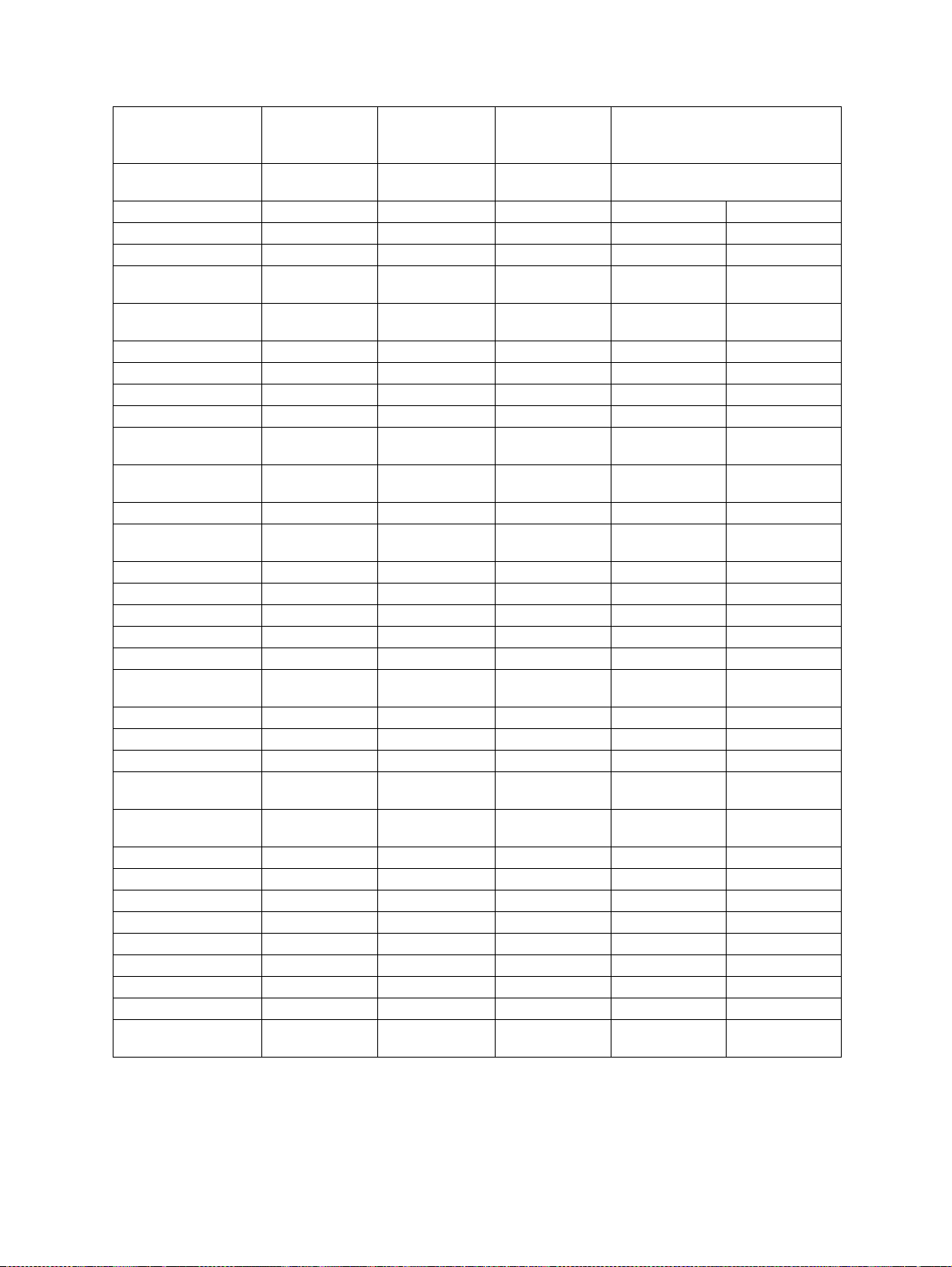

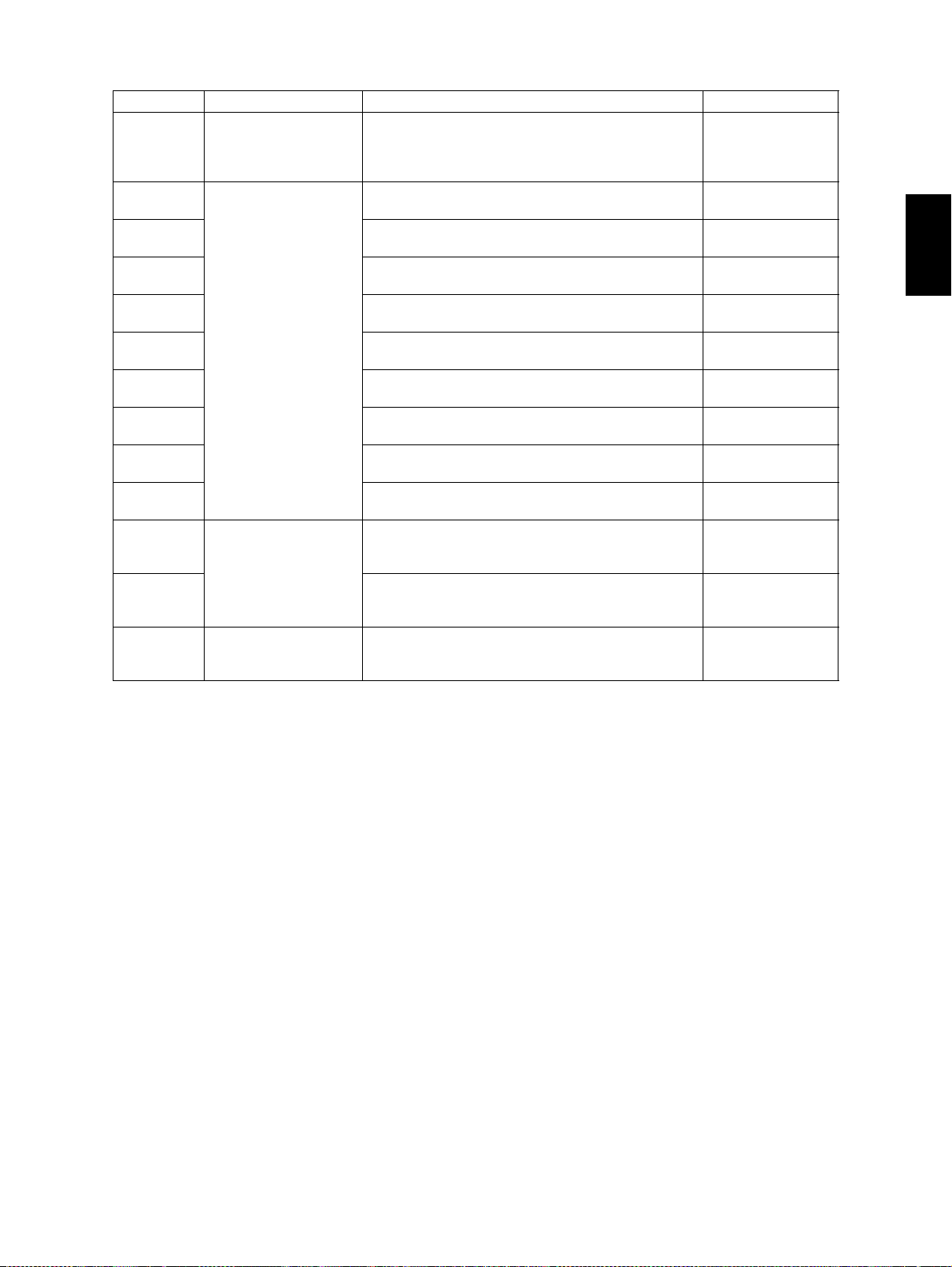

e-STUDIO280/280S

Central and

Area North America

Machine version

(destination)

NAD

(115V)

Model name e-STUDIO280 e-STUDIO280 e-STUDIO280 e-STUDIO280 e-STUDIO280

Platen cover KA-3511PC KA-3511PC KA-3511PC KA-3511PC KA-3511PC

RADF MR-3016 MR-3016 MR-3016 MR-3016 MR-3016

Drawer module

(for Equipment)

Drawer module

(for PFP)

Standard MY-1021 Standard Standard MY-1021

MY-1021 MY-1021 MY-1021 MY-1021 MY-1021

Slot cover - Standard - - KE-2330

ADU Standard MD-0102 Standard Standard MD-0102

PFP KD-1011 KD-1011 KD-1011 KD-1011 KD-1011

LCF KD-1012LT KD-1012A4 KD-1012A4 KD-1012A4 KD-1012A4

Finisher

(Hanging type)

Staple cartridge

(for MJ-1022)

MJ-1022 MJ-1022 MJ-1022 MJ-1022 MJ-1022

STAPLE-1600 STAPLE-1600 STAPLE-1600 STAPLE-1600 STAPLE-1600

Saddle stitch finisher MJ-1025 MJ-1025 MJ-1025 MJ-1025 MJ-1025

Staple cartridge

(for MJ-1025)

STAPLE-2000 STAPLE-2000 STAPLE-2000 STAPLE-2000 STAPLE-2000

Hole punch unit MJ-6005N MJ-6005E MJ-6005E MJ-6005E/F/S MJ-6005E

Bridge kit KN-3520 KN-3520 KN-3520 KN-3520 KN-3520

Job separator MJ-5004 MJ-5004 MJ-5004 MJ-5004 MJ-5004

Offset tray MJ-5005 MJ-5005 MJ-5005 MJ-5005 MJ-5005

Key copy counter MU-8 MU-8 MU-8 MU-8 MU-8

Key copy counter

socket

MU-10 MU-10 MU-10 MU-10 MU-10

Work tray KK-3511 KK-3511 KK-3511 KK-3511 KK-3511

Damp heater MF-2320U Standard Standard MF-2320E Standard

Fax board GD-1150NA GD-1150AS GD-1150AU GD-1150EU GD-1150AS

2nd line for Fax

board

Wireless LAN

adapter

GD-1160NA GD-1160EU GD-1160EU GD-1160EU GD-1160EU

GN-1010 GN-1010 GN-1010 GN-1010 GN-1010

PCI slot GO-1040 GO-1040 GO-1040 GO-1040 GO-1040

Scrambler board GP-1030 GP-1030 GP-1030 GP-1030 GP-1030

Parallel interface kit GF-1140 GF-1140 GF-1140 GF-1140 GF-1140

NIC board Standard GF-1150 Standard Standard GF-1150

Printer/Scanner kit GM-2020 GM-2020 GM-2020 GM-2020 GM-2020

Printer kit GM-1020 GM-1020 GM-1020 GM-1020 GM-1020

Scanner upgrade kit GM-3020 GM-3020 GM-3020 GM-3020 GM-3020

Desk MH-1700 MH-1700 MH-1700 MH-1700 MH-1700

Harness kit for coin

controller

GQ-1020 GQ-1020 GQ-1020 GQ-1020 GQ-1020

South America/

Hong Kong

ASD

(220-240V)

Australia Europe Asia

AUD

(220-240V)

MJD

(220-240V)

ASU

(220-240V)

e-STUDIO200L/230/280 SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES June 2004 © TOSHIBA TEC

1 - 10

04/09

Area Saudi Arabia Iran China Taiwan

Machine version

(destination)

SAD

(127V)

IRD

(220-240V)

CND

(220-240V)

TWD

(110V)

Model name e-STUDIO280 e-STUDIO280 e-STUDIO280S e-STUDIO280 e-STUDIO280

Platen cover KA-3511PC KA-3511PC Standard Standard KA-3511PC

RADF MR-3016 MR-3016 MR-3016 MR-3016 MR-3016

Drawer module

(for Equipment)

Drawer module

(for PFP)

MY-1021 Standard Standard Standard Standard

MY-1021 MY-1021 MY-1021 MY-1021 MY-1021

Slot cover KE-2330 - - - -

ADU MD-0102 Standard MD-0102 Standard MD-0102

PFP KD-1011 KD-1011 KD-1011 KD-1011 KD-1011

LCF KD-1012A4 KD-1012A4 KD-1012-C KD-1012-C KD-1012A4

Finisher

(Hanging type)

Staple cartridge

(for MJ-1022)

MJ-1022 MJ-1022 MJ-1022-C MJ-1022-C MJ-1022

STAPLE-1600 STAPLE-1600 STAPLE-1600 STAPLE-1600 STAPLE-1600

Saddle stitch finisher MJ-1025 MJ-1025 MJ-1025 MJ-1025 MJ-1025

Staple cartridge

(for MJ-1025)

STAPLE-2000 STAPLE-2000 STAPLE-2000 STAPLE-2000 STAPLE-2000

Hole punch unit MJ-6005E MJ-6005E MJ-6005E MJ-6005E MJ-6005E

Bridge kit KN-3520 KN-3520 KN-3520-C KN-3520-C KN-3520

Job separator MJ-5004 MJ-5004 MJ-5004-C MJ-5004-C MJ-5004

Offset tray MJ-5005 MJ-5005 MJ-5005-C MJ-5005-C MJ-5005

Key copy counter MU-8 MU-8 MU-8 MU-8 MU-8

Key copy counter

socket

MU-10 MU-10 MU-10 MU-10 MU-10

Work tray KK-3511 KK-3511 KK-3511 KK-3511 KK-3511

Damp heater Standard Standard Standard Standard Standard

Fax board GD-1150NA N/A GD-1150C GD-1150C GD-1150TW

2nd line for Fax

board

Wireless LAN

adapter

GD-1160NA N/A GD-1160C GD-1160C GD-1160TW

GN-1010 GN-1010 GN-1010 GN-1010 GN-1010

PCI slot GO-1040 GO-1040 GO-1040C GO-1040C GO-1040

Scrambler board GP-1030 GP-1030 GP-1030 GP-1030 GP-1030

Parallel interface kit GF-1140 GF-1140 GF-1140 GF-1140 GF-1140

NIC board GF-1150 Standard GF-1150 Standard Standard

Printer/Scanner kit GM-2020 Standard GM-2020 Standard GM-2020

Printer kit GM-1020 GM-1020 GM-1020 GM-1020 GM-1020

Scanner upgrade kit GM-3020 GM-3020 GM-3020 GM-3020 GM-3020

Desk MH-1700 MH-1700 MH-1700 MH-1700 MH-1700

Harness kit for coin

controller

GQ-1020 GQ-1020 GQ-1020 GQ-1020 GQ-1020

1

June 2004 © TOSHIBA TEC e-STUDIO200L/230/280 SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1 - 11

04/09

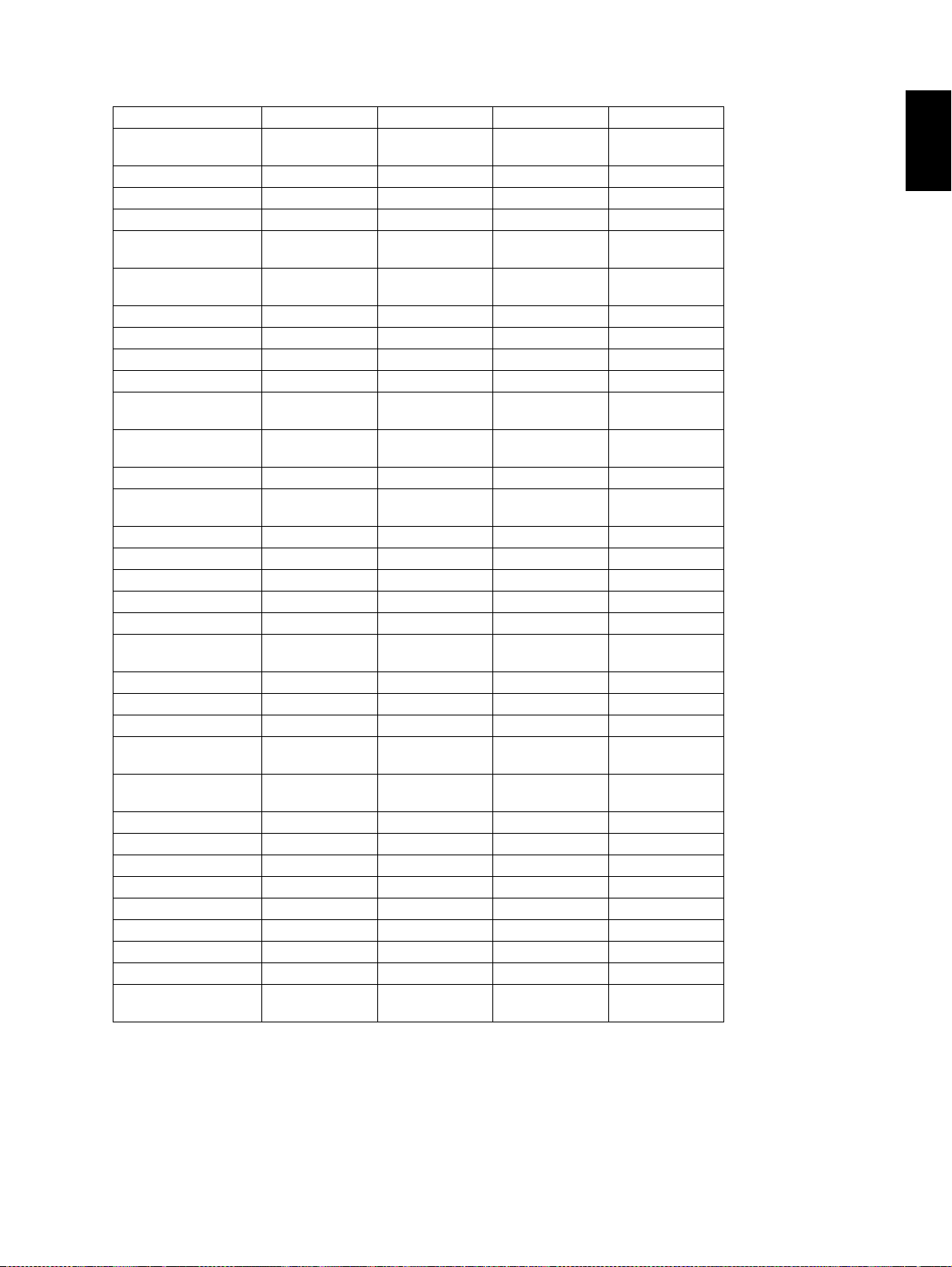

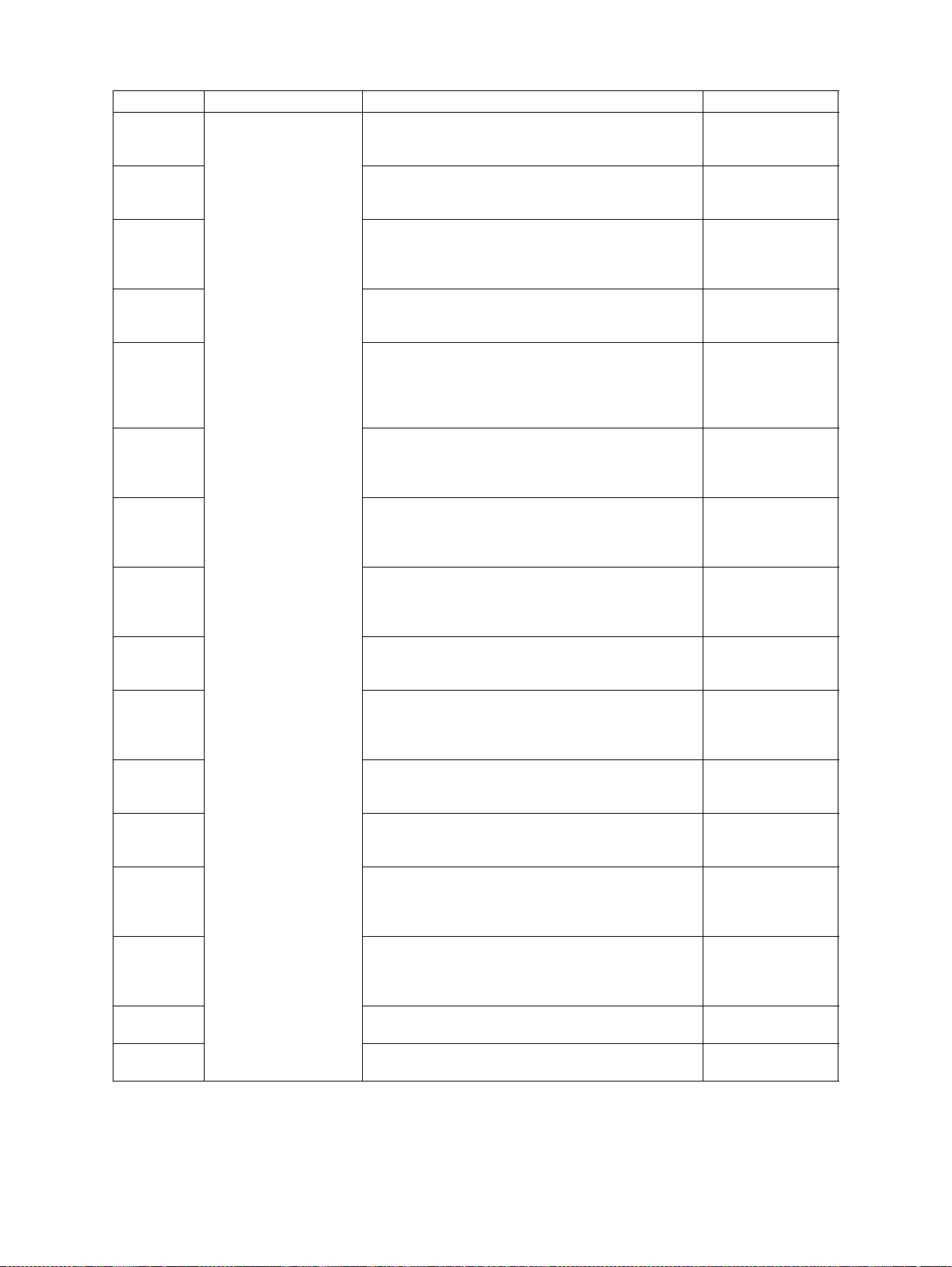

e-STUDIO230/230L

Central and

Area North America

Machine version

(destination)

NAD

(115V)

Model name e-STUDIO230 e-STUDIO230 e-STUDIO230 e-STUDIO230 e-STUDIO230L

Platen cover KA-3511PC KA-3511PC KA-3511PC KA-3511PC KA-3511PC

RADF MR-3016 MR-3016 MR-3016 MR-3016 MR-3016

Drawer module

(for Equipment)

Drawer module

(for PFP)

Standard MY-1021 Standard Standard MY-1021

MY-1021 MY-1021 MY-1021 MY-1021 MY-1021

Slot cover - Standard - - Standard

ADU Standard MD-0102 Standard Standard MD-0102

PFP KD-1011 KD-1011 KD-1011 KD-1011 KD-1011

LCF KD-1012LT KD-1012A4 KD-1012A4 KD-1012A4 KD-1012A4

Finisher

(Hanging type)

Staple cartridge

(for MJ-1022)

MJ-1022 MJ-1022 MJ-1022 MJ-1022 MJ-1022

STAPLE-1600 STAPLE-1600 STAPLE-1600 STAPLE-1600 STAPLE-1600

Saddle stitch finisher MJ-1025 MJ-1025 MJ-1025 MJ-1025 MJ-1025

Staple cartridge

(for MJ-1025)

STAPLE-2000 STAPLE-2000 STAPLE-2000 STAPLE-2000 STAPLE-2000

Hole punch unit MJ-6005N MJ-6005E MJ-6005E MJ-6005E/F/S MJ-6005E

Bridge kit KN-3520 KN-3520E KN-3520 KN-3520 KN-3520

Job separator MJ-5004 MJ-5004 MJ-5004 MJ-5004 MJ-5004

Offset tray MJ-5005 MJ-5005 MJ-5005 MJ-5005 MJ-5005

Key copy counter MU-8 MU-8 MU-8 MU-8 MU-8

Key copy counter

socket

MU-10 MU-10 MU-10 MU-10 MU-10

Work tray KK-3511 KK-3511 KK-3511 KK-3511 KK-3511

Damp heater MF-2320U Standard Standard MF-2320E MF-2320E

Fax board GD-1150NA GD-1150AS GD-1150AU GD-1150EU GD-1150EU

2nd line for Fax

board

Wireless LAN

adapter

GD-1160NA GD-1160EU GD-1160EU GD-1160EU GD-1160EU

GN-1010 GN-1010 GN-1010 GN-1010 GN-1010

PCI slot GO-1040 GO-1040 GO-1040 GO-1040 GO-1040

Scrambler board GP-1030 GP-1030 GP-1030 GP-1030 GP-1030

Parallel interface kit GF-1140 GF-1140 GF-1140 GF-1140 GF-1140

NIC board Standard GF-1150 Standard Standard GF-1150

Printer/Scanner kit GM-2020 GM-2020 GM-2020 GM-2020 GM-2020

Printer kit GM-1020 GM-1020 GM-1020 GM-1020 GM-1020

Scanner upgrade kit GM-3020 GM-3020 GM-3020 GM-3020 GM-3020

Desk MH-1700 MH-1700 MH-1700 MH-1700 MH-1700

Harness kit for coin

controller

GQ-1020 GQ-1020 GQ-1020 GQ-1020 GQ-1020

South America/

Hong Kong

ASD

(220-240V)

Australia Europe

AUD

(220-240V)

MJD

(220-240V)

e-STUDIO200L/230/280 SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES June 2004 © TOSHIBA TEC

1 - 12

04/09

Area Asia Saudi Arabia China Taiwan

Machine version

(destination)

ASU

(220-240V)

SAD

(127V)

CND

(220-240V)

TWD

(110V)

Model name e-STUDIO230 e-STUDIO230 e-STUDIO230 e-STUDIO230

Platen cover KA-3511PC KA-3511PC Standard KA-3511PC

RADF MR-3016 MR-3016 MR-3016 MR-3016

Drawer module

(for Equipment)

Drawer module

(for PFP)

MY-1021 MY-1021 Standard Standard

MY-1021 MY-1021 MY-1021 MY-1021

Slot cover KE-2330 KE-2330 - -

ADU MD-0102 MD-0102 Standard MD-0102

PFP KD-1011 KD-1011 KD-1011 KD-1011

LCF KD-1012A4 KD-1012A4 KD-1012A4 KD-1012A4

Finisher

(Hanging type)

Staple cartridge

(for MJ-1022)

MJ-1022 MJ-1022 MJ-1022-C MJ-1022

STAPLE-1600 STAPLE-1600 STAPLE-1600 STAPLE-1600

Saddle stitch finisher MJ-1025 MJ-1025 MJ-1025 MJ-1025

Staple cartridge

(for MJ-1025)

STAPLE-2000 STAPLE-2000 STAPLE-2000 STAPLE-2000

Hole punch unit MJ-6005E MJ-6005E MJ-6005E MJ-6005E

Bridge kit KN-3520 KN-3520 KN-3520-C KN-3520

Job separator MJ-5004 MJ-5004 MJ-5004-C MJ-5004

Offset tray MJ-5005 MJ-5005 MJ-5005-C MJ-5005

Key copy counter MU-8 MU-8 MU-8 MU-8

Key copy counter

socket

MU-10 MU-10 MU-10 MU-10

Work tray KK-3511 KK-3511 KK-3511 KK-3511

Damp heater Standard Standard Standard Standard

Fax board GD-1150AS GD-1150NA GD-1150C GD-1150TW

2nd line for Fax

board

Wireless LAN

adapter

GD-1160EU GD-1160NA GD-1160C GD-1160TW

GN-1010 GN-1010 GN-1010 GN-1010

PCI slot GO-1040 GO-1040 GO-1040C GO-1040

Scrambler board GP-1030 GP-1030 GP-1030 GP-1030

Parallel interface kit GF-1140 GF-1140 GF-1140 GF-1140

NIC board GF-1150 GF-1150 Standard Standard

Printer/Scanner kit GM-2020 GM-2020 Standard GM-2020

Printer kit GM-1020 GM-1020 GM-1020 GM-1020

Scanner upgrade kit GM-3020 GM-3020 GM-3020 GM-3020

Desk MH-1700 MH-1700 MH-1700 MH-1700

Harness kit for coin

controller

GQ-1020 GQ-1020 GQ-1020 GQ-1020

1

June 2004 © TOSHIBA TEC e-STUDIO200L/230/280 SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1 - 13

04/09

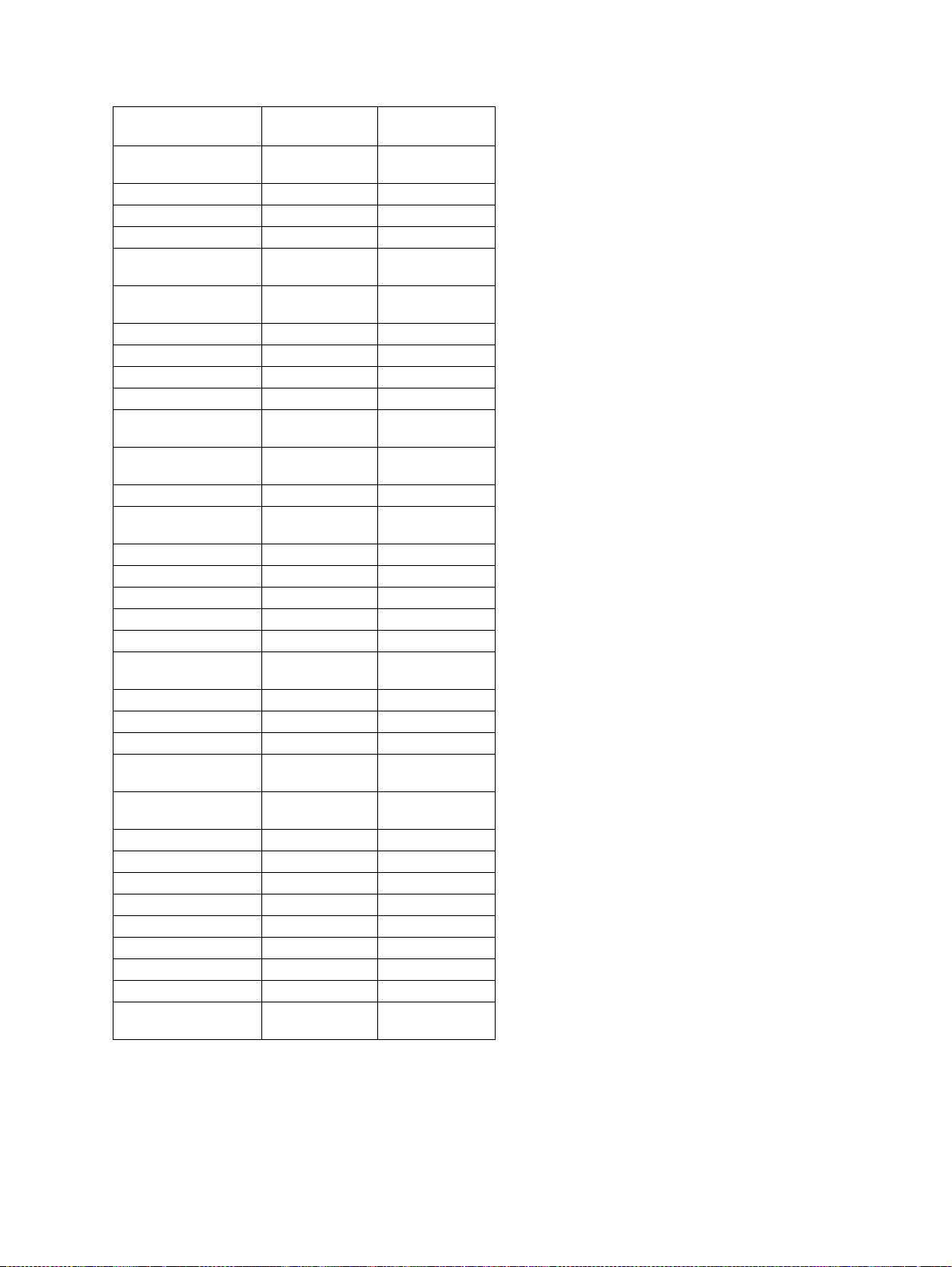

e-STUDIO200L

Area North America

Machine version

(destination)

NAD

(115V)

Model name e-STUDIO200L e-STUDIO200L

Platen cover KA-3511PC KA-3511PC

RADF MR-3016 MR-3016

Drawer module

(for Equipment)

Drawer module

(for PFP)

MY-1021 MY-1021

MY-1021 MY-1021

Slot cover Standard Standard

ADU MD-0102 MD-0102

PFP KD-1011 KD-1011

LCF KD-1012LT KD-1012A4

Finisher

(Hanging type)

Staple cartridge

(for MJ-1022)

MJ-1022 MJ-1022

STAPLE-1600 STAPLE-1600

Saddle stitch finisher MJ-1025 MJ-1025

Staple cartridge

(for MJ-1025)

STAPLE-2000 STAPLE-2000

Hole punch unit MJ-6005N MJ-6005E

Bridge kit KN-3520 KN-3520

Job separator MJ-5004 MJ-5004

Offset tray MJ-5005 MJ-5005

Key copy counter MU-8 MU-8

Key copy counter

socket

MU-10 MU-10

Work tray KK-3511 KK-3511

Damp heater MF-2320 Standard

Fax board GD-1150NA GD-1150AS

2nd line for Fax

board

Wireless LAN

adapter

GD-1160NA GD-1160EU

GN-1010 GN-1010

PCI slot GO-1040 GO-1040

Scrambler board GP-1030 GP-1030

Parallel interface kit GF-1140 GF-1140

NIC board GF-1150 GF-1150

Printer/Scanner kit GM-2030 GM-2030

Printer kit GM-1030 GM-1030

Scanner upgrade kit GM-3030 GM-3030

Desk MH-1700 MH-1700

Harness kit for coin

controller

GQ-1020 GQ-1020

Central and

South America

ASD

(220-240V)

e-STUDIO200L/230/280 SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES June 2004 © TOSHIBA TEC

1 - 14

04/09

2. ERROR CODE AND SELF-DIAGNOSTIC MODE

2.1 Error Code List

One of the following error codes is displayed at the upper right of the screen while pressing the

[CLEAR] button and the digital key [8] simultaneously when the “CLEAR PAPER” or “CALL SERVICE” symbol is blinking.

2.1.1 Jam

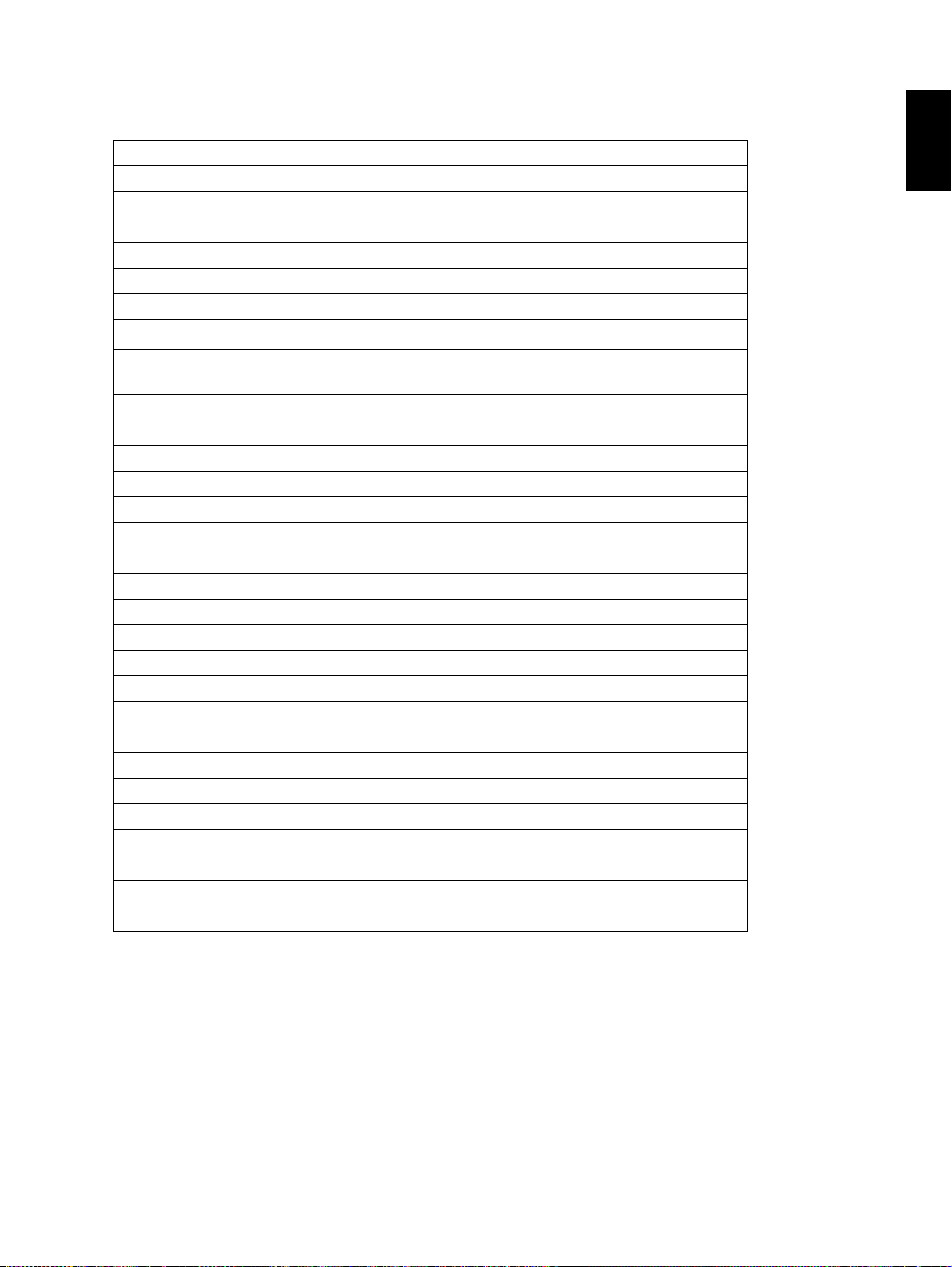

Error code Classification Contents Troubleshooting

E010 Paper exit jam Jam not reaching the exit sensor: The paper which

has passed through the fuser unit does not reach

the exit sensor.

E020 Stop jam at the exit sensor: The trailing edge of the

paper does not pass the exit sensor after its leading

edge has reached this sensor.

E030 Other paper jam Power-ON jam: The paper is remaining on the

paper transport path when power is turned ON.

E090 HDD abnormality causes jam: Image data to be

printed cannot be prepared.

E110 Paper misfeeding ADU misfeeding (Paper not reaching the 1st trans-

port sensor): The paper which has passed through

ADU does not reach the 1st transport sensor during

duplex printing.

E120 Bypass misfeeding (Paper not reaching the 1st

transport sensor): The paper fed from the bypass

tray does not reach the 1st transport sensor.

E130 Upper drawer misfeeding (Paper not reaching the

1st transport sensor): The paper fed from the upper

drawer does not reach the 1st transport sensor.

E140 Lower drawer misfeeding (Paper not reaching the

2nd transport sensor): The paper fed from the lower

drawer does not reach the 2nd transport sensor.

E150 PFP upper drawer misfeeding (Paper not reaching

the PFP upper drawer feed sensor): The paper fed

from the PFP upper drawer does not reach the PFP

upper drawer feed sensor.

E160 PFP lower drawer misfeeding (Paper not reaching

the PFP lower drawer feed sensor): The paper fed

from the PFP lower drawer does not reach the PFP

lower drawer feed sensor.

E190 LCF misfeeding (Paper not reaching the LCF feed

sensor): The paper fed from the LCF does not

reach the LCF feed sensor.

Ch.5.1.1

Ch.5.1.1

Ch.5.1.1

Ch.5.1.1

Ch.5.1.2

Ch.5.1.2

Ch.5.1.2

Ch.5.1.2

Ch.5.1.2

Ch.5.1.2

Ch.5.1.2

2

June 2004 © TOSHIBA TEC e-STUDIO200L/230/280 ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 1

Error code Classification Contents Troubleshooting

E200 Paper transport jam Upper drawer transport jam (Paper not reaching the

Ch.5.1.1

registration sensor): The paper does not reach the

registration sensor after it has passed the 1st transport sensor.

E210 Lower drawer transport jam (Paper not reaching the

Ch.5.1.1

registration sensor): The paper does not reach the

registration sensor after it has passed the 1st transport sensor.

E220 Lower drawer transport jam (Paper not reaching the

Ch.5.1.1

1st transport sensor): The paper does not reach the

1st transport sensor after it has passed the lower

drawer feed sensor.

E270 Bypass transport jam (paper not reaching the regis-

Ch.5.1.1

tration sensor): The paper does not reach the registration sensor after it has passed the 1st transport

sensor.

E280 ADU transport jam (paper not reaching the registra-

Ch.5.1.1

tion sensor): The paper which has passed through

ADU and the 1st transport sensor does not reach

the registration sensor during duplex printing.

E300 PFP upper drawer transport jam (Paper not reach-

Ch.5.1.1

ing the registration sensor): The paper does not

reach the registration sensor after it has passed the

1st transport sensor.

E310 PFP upper drawer transport jam (Paper not reach-

Ch.5.1.1

ing the 1st transport sensor): The paper does not

reach the 1st transport sensor after it has passed

the 2nd transport sensor.

E320 PFP upper drawer transport jam (Paper not reach-

Ch.5.1.1

ing the 2nd transport sensor): The paper does not

reach the 2nd transport sensor after it has passed

the PFP upper drawer feed sensor.

E330 PFP lower drawer transport jam (Paper not reach-

Ch.5.1.1

ing the registration sensor): The paper does not

reach the registration sensor after it has passed the

1st transport sensor.

E340 PFP lower drawer transport jam (Paper not reach-

Ch.5.1.1

ing the 1st transport sensor): The paper does not

reach the 1st transport sensor after it has passed

the PFP lower drawer feed sensor.

E350 PFP lower drawer transport jam (Paper not reach-

Ch.5.1.1

ing the 2nd transport sensor): The paper does not

reach the 2nd transport sensor after it has passed

the PFP upper drawer feed sensor.

E360 PFP lower drawer transport jam (Paper not reach-

Ch.5.1.1

ing the PFP upper drawer feed sensor): The paper

does not reach the PFP upper drawer feed sensor

after it has passed the PFP lower drawer feed sensor.

E3C0 LCF transport jam (Paper not reaching the registra-

Ch.5.1.1

tion sensor): The paper does not reach the registration sensor after it has passed the 1st transport

sensor.

E3D0 LCF transport jam (Paper not reaching the 1st

Ch.5.1.1

transport sensor): The paper does not reach the 1st

transport sensor after it has passed the 2nd transport sensor.

e-STUDIO200L/230/280 ERROR CODE AND SELF-DIAGNOSTIC MODE June 2004 © TOSHIBA TEC

2 - 2

Error code Classification Contents Troubleshooting

E3E0 Paper transport jam LCF transport jam (Paper not reaching the 2nd

Ch.5.1.1

transport sensor): The paper does not reach the

2nd transport sensor after it has passed the LCF

feed sensor.

E400 Cover open jam Transfer cover open jam: The transfer cover has

Ch.5.1.3

opened during printing.

E410 Front cover open jam: The front cover has opened

Ch.5.1.3

during printing.

E420 PFP side cover open jam: The PFP side cover has

Ch.5.1.3

opened during printing.

E430 ADU open jam: The ADU has opened during print-

Ch.5.1.3

ing.

E440 Side cover open jam: The side cover has opened

Ch.5.1.3

during printing.

E450 LCF side cover open jam: The LCF side cover has

Ch.5.1.3

opened during printing.

E480 Bridge unit open jam: The bridge unit has opened

Ch.5.1.3

during printing.

E490 Job separator cover open jam: The job separator

Ch.5.1.3

cover has opened during printing.

E491 Offset tray cover open jam: The offset tray cover

Ch.5.1.3

has opened during printing.

E510 Paper transport jam

(ADU section)

Stop jam in the ADU: The paper does not reach the

ADU exit sensor after it has passed the ADU

Ch.5.1.1

entrance sensor.

E520 Jam not reaching the ADU entrance sensor: The

Ch.5.1.1

paper does not reach the ADU entrance sensor

after it is switchbacked in the exit section.

E550 Other paper jam Paper remaining jam on the transport path: The

Ch.5.1.1

paper is remaining on the transport path when printing is finished (caused by a multiple paper feeding).

2

June 2004 © TOSHIBA TEC e-STUDIO200L/230/280 ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 3

Error code Classification Contents Troubleshooting

E711 RADF jam Jam not reaching the original length sensor: The

Ch.5.1.4

original fed from the original feeding tray does not

reach the original length sensor.

E712 Jam not reaching the registration sensor: The origi-

Ch.5.1.4

nal fed from the original feeding tray does not reach

the registration sensor.

E713 Stop jam at the original length sensor: The trailing

Ch.5.1.4

edge of the original does not pass the original

length sensor after its leading edge has reached

this sensor.

E714 Feed signal reception jam: The feed signal is

Ch.5.1.4

received even no original exists on the original

feeding tray.

E721 Jam not reaching the read sensor: The original

Ch.5.1.4

does not reach the read sensor after it has passed

the registration sensor (when scanning obverse

side) or the reverse sensor (when scanning reverse

side).

E722 Jam not reaching the exit sensor (during scanning):

Ch.5.1.4

The original which passed the read sensor does not

reach the exit sensor when it is transported from the

scanning section to exit section.

E723 Jam not reaching the reverse sensor (during scan-

Ch.5.1.4

ning): The original which passed the read sensor

does not reach the reverse sensor when it is transported from the scanning section to reverse section.

E724 Stop jam at the registration sensor: The trailing

Ch.5.1.4

edge of the original does not pass the registration

sensor after its leading edge has reached this sensor.

E725 Stop jam at the read sensor: The trailing edge of the

Ch.5.1.4

original does not pass the read sensor after its leading edge has reached this sensor.

E726 Transport/exit signal reception jam: RADF receives

Ch.5.1.4

the transport/exit reception signal from the equipment when no original is at the exposure waiting

position.

E731 Stop jam at the exit sensor: The trailing edge of the

Ch.5.1.4

original does not pass the exit sensor after its leading edge has reached this sensor.

E741 Stop jam at the reverse sensor: The trailing edge of

Ch.5.1.4

the original does not pass the reversal sensor after

its leading edge has reached this sensor.

E742 Jam not reaching the reverse sensor (during

Ch.5.1.4

reverse feeding): The leading edge of the original

does not reach the reverse sensor when original is

fed from the reverse section.

E743 Jam not reaching the exit sensor (during reverse

Ch.5.1.4

feeding): The original does not reach the exit sensor after it has passed the reverse sensor when the

original is exited from the reverse section.

E860 RADF jam access cover open: The RADF jam

Ch.5.1.4

access cover has opened during RADF operation.

E870 RADF open jam: RADF has opened during RADF

Ch.5.1.4

operation.

e-STUDIO200L/230/280 ERROR CODE AND SELF-DIAGNOSTIC MODE June 2004 © TOSHIBA TEC

2 - 4

Loading...

Loading...