Page 1

SERVICE MANUAL

MULTIFUNCTIONAL DIGITAL SYSTEMS

e-STUDIO182/212/242

Model: DP1830/DP2120/DP2420

Publish Date: December 2009

File No. SME09001500

R091021I2800-TTEC

Ver00_2009-12

Page 2

Trademarks

• The official name of Windows 95 is Microsoft Windows 95 Operating System.

• The official name of Windows 98 is Microsoft Windows 98 Operating System.

• The official name of Windows Me is Microsoft Windows Millennium Edition Operating System.

• The official name of Windows 2000 is Microsoft Windows 2000 Operating System.

• The official name of Windows XP is Microsoft Windows XP Operating System.

• Microsoft, Windows, Windows NT, Windows Vista and the brand names and product names of other

Microsoft products are trademarks or registered trademarks of Microsoft Corporation in the U.S.

and/or other countries.

• Apple, AppleTalk, Macintosh, and Mac are trademarks of Apple Computer, Inc. in the U.S. and other

countries.

• PostScript is a trademark of Adobe Systems Incorporated.

• NOVELL, NetWare, and NDS are trademarks or registered trademarks of Novell, Inc.

• Mylar is a registered trademark of DuPont Teijin Films U.S. Limited Partnership.

• Molykote is a registered trademark of Dow Corning Corporation.

• FLOIL is a registrated treadmark of Kanto Kasei Ltd. CORPORATION.

• TopAccess is a trademark of Toshiba Tec Corporation.

• iCLASS is a trademark of HID Corporation.

• MIFARE is a trademark of Royal Philips Electronics.

• Other company names and product names in this manual are the trademarks of their respective

companies.

© 2009 TOSHIBA TEC CORPORATION All rights reserved

Under the copyright laws, this manual cannot be reproduced in any form without prior written permission

of TOSHIBA TEC CORPORATION. No patent liability is assumed, however, with respect to the use of the

information contained herein.

Page 3

GENERAL PRECAUTIONS REGARDING THE SERVICE FOR

e-STUDIO182/212/242

The installation and service should be done by a qualified service

technician.

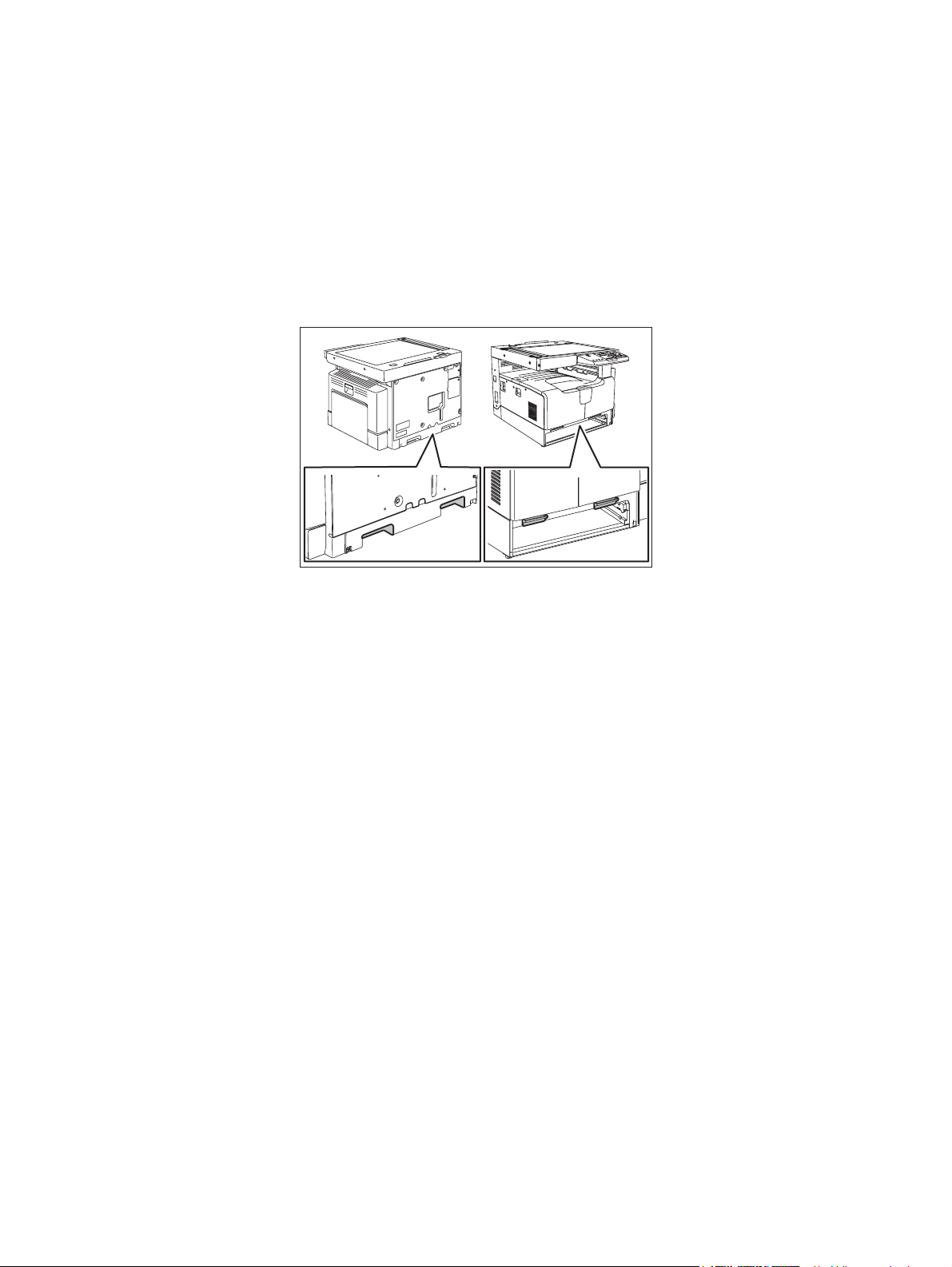

1) Transportation/Installation

- When transporting/installing the equipment, remove the drawer, employ two persons and be sure

to hold the positions as shown in the figure.

The equipment is quite heavy and weighs approximately 33 kg (72.75 lb), therefore pay full attention when handling it.

- Be sure not to hold the movable parts or units (e.g. the control panel, ADU or RADF) when trans-

porting the equipment.

- Be sure to use a dedicated outlet with AC 110 V / 13.2 A, 115 V or 127 V / 12 A, 220-240 V or 240

V / 8 A for its power source.

- The equipment must be grounded for safety.

- Select a suitable place for installation. Avoid excessive heat, high humidity, dust, vibration and

direct sunlight.

- Provide proper ventilation since the equipment emits a slight amount of ozone.

- To insure adequate working space for the copying operation, keep a minimum clearance of 80

cm (32”) on the left, 80 cm (32”) on the right and 10 cm (4”) on the rear.

- The equipment shall be installed near the socket outlet and shall be easily accessible.

- Be sure to fix and plug in the power cable securely after the installation so that no one trips over

it.

- When the equipment is used after the option is removed, be sure to install the parts or the covers

which have been taken off so that the inside of the equipment is not exposed.

2) General Precautions at Service

- Be sure to turn the power OFF and unplug the power cable during service (except for the service

should be done with the power turned ON).

- Unplug the power cable and clean the area around the prongs of the plug and socket outlet once

a year or more. A fire may occur when dust lies on this area.

- When the parts are disassembled, reassembly is the reverse of disassembly unless otherwise

noted in this manual or other related documents. Be careful not to install small parts such as

screws, washers, pins, E-rings, star washers in the wrong places.

- Basically, the equipment should not be operated with any parts removed or disassembled.

Page 4

- The PC board must be stored in an anti-electrostatic bag and handled carefully using a wristband

since the ICs on it may be damaged due to static electricity.

Caution: Before using the wristband, unplug the power cable of the equipment and

make sure that there are no charged objects which are not insulated in the

vicinity.

- Avoid expose to laser beam during service. This equipment uses a laser diode. Be sure not to

expose your eyes to the laser beam. Do not insert reflecting parts or tools such as a screwdriver

on the laser beam path. Remove all reflecting metals such as watches, rings, etc. before starting

service.

- Be sure not to touch high-temperature sections such as the exposure lamp, fuser unit, damp

heater and areas around them.

- Be sure not to touch high-voltage sections such as the chargers, developer, high-voltage trans-

former and power supply unit. Especially, the board of these components should not be touched

since the electric charge may remain in the capacitors, etc. on them even after the power is

turned OFF.

- Make sure that the equipment will not operate before touching potentially dangerous places (e.g.

rotating/operating sections such as gears, belts pulleys, fans and laser beam exit of the laser

optical unit).

- Be careful when removing the covers since there might be the parts with very sharp edges

underneath.

- When servicing the equipment with the power turned ON, be sure not to touch live sections and

rotating/operating sections. Avoid exposing your eyes to laser beam.

- Use designated jigs and tools.

- Use recommended measuring instruments or equivalents.

- Return the equipment to the original state and check the operation when the service is finished.

3) Important Service Parts for Safety

- The breaker, door switch, fuse, thermostat, thermofuse, thermistor, batteries, IC-RAMs including

lithium batteries, etc. are particularly important for safety. Be sure to handle/install them properly.

If these parts are short-circuited and their functions become ineffective, they may result in fatal

accidents such as burnout. Do not allow a short-circuit and/or do not use the parts not recommended by Toshiba TEC Corporation.

Page 5

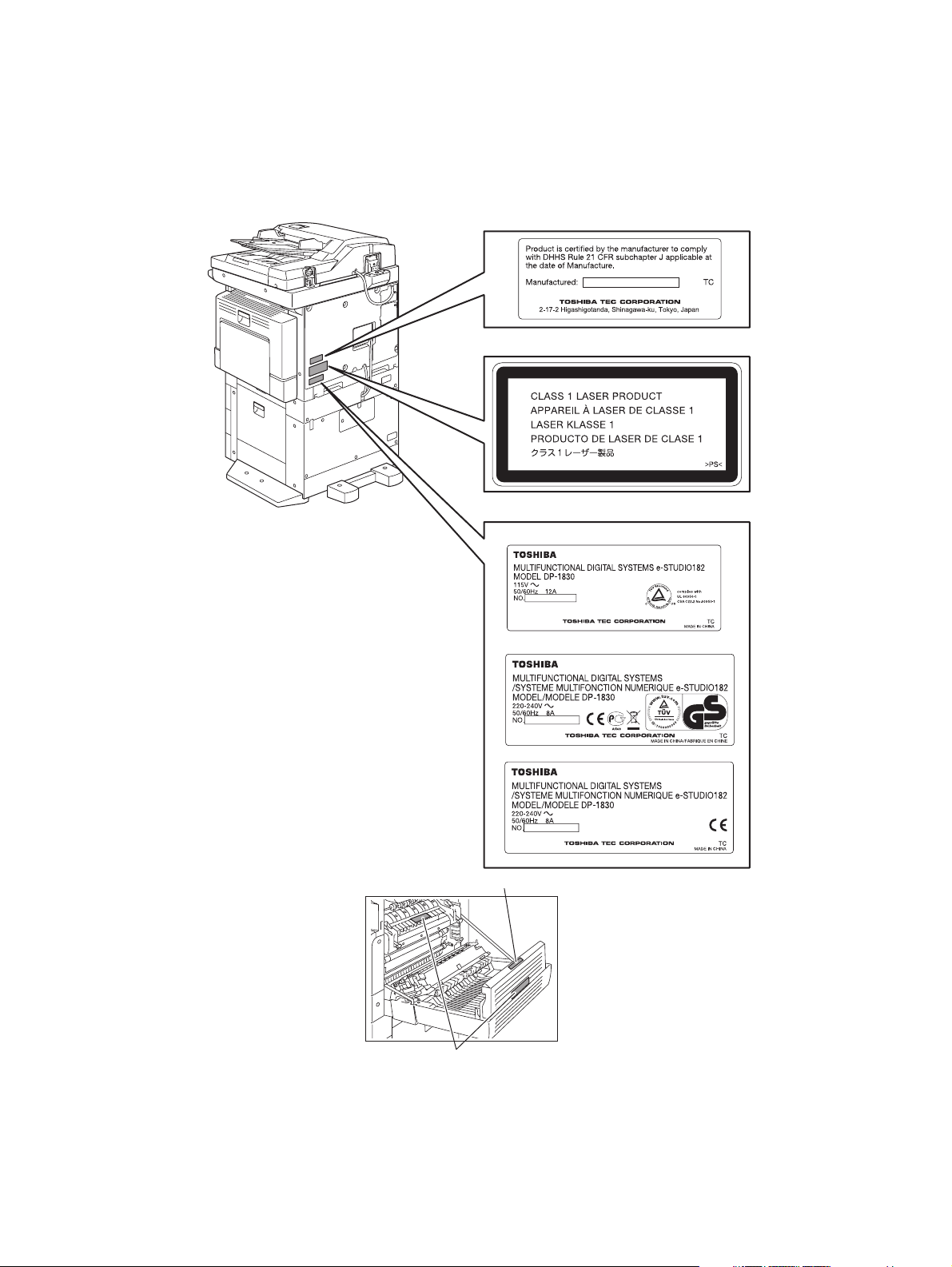

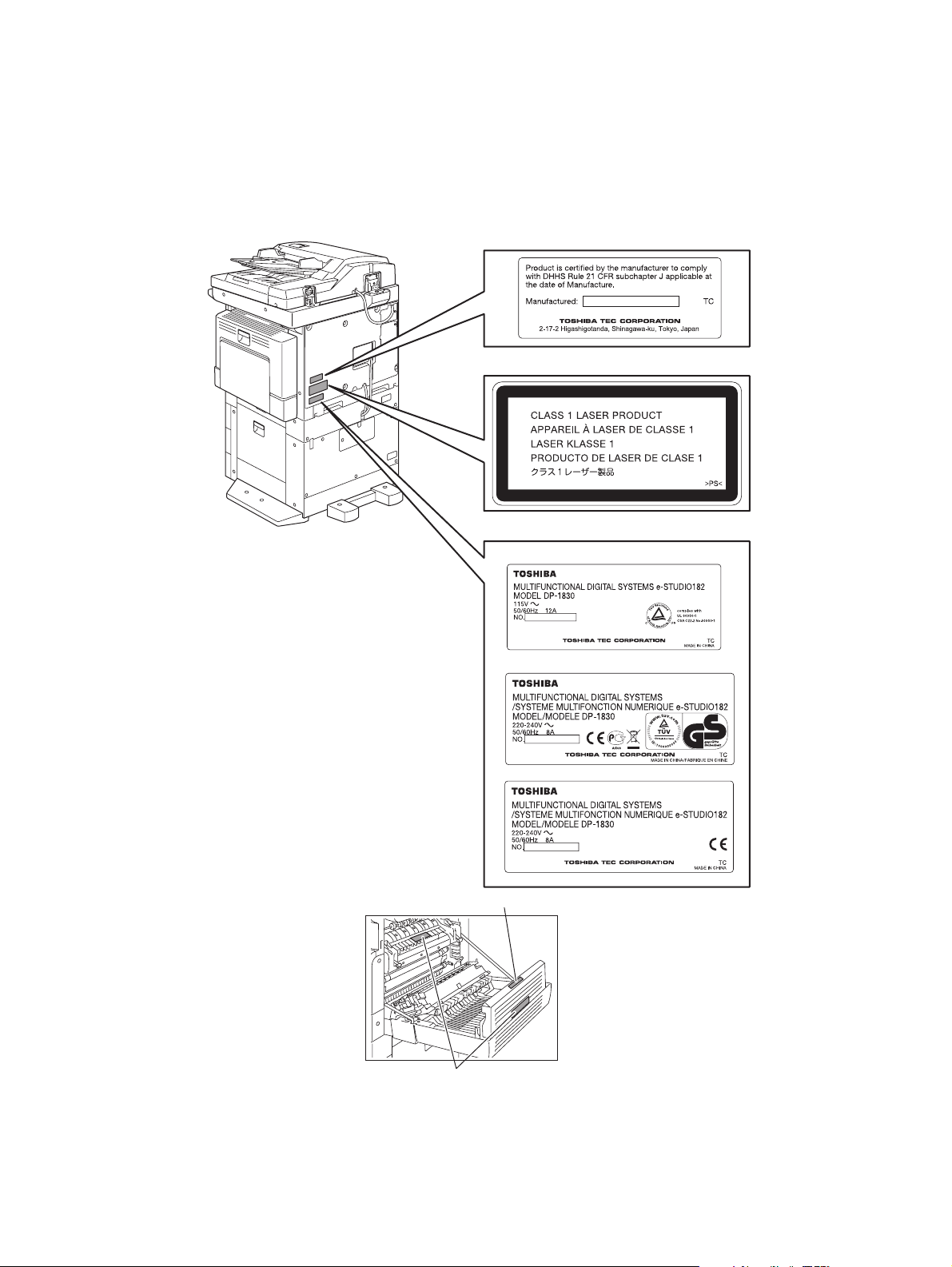

4) Cautionary Labels

- During servicing, be sure to check the rating plate and cautionary labels such as “Unplug the

power cable during service”, “CAUTION. HOT”, “CAUTION. HIGH VOLTAGE”, “CAUTION.

LASER BEAM”, etc. to see if there is any dirt on their surface and if they are properly stuck to the

equipment.

Certification label (For UC)

Explanatory label

Identification label

For UC

For EU

For others

Warning for high-temperature areas (ventilation holes

Warning for high-temperature areas (fuser unit

)

)

Page 6

5) Disposal of the Equipment, Supplies, Packing Materials, Used Batteries and IC-RAMs

- Regarding the recovery and disposal of the equipment, supplies, packing materials, used batter-

ies and IC-RAMs including lithium batteries, follow the relevant local regulations or rules.

Caution:

Dispose of used batteries and IC-RAMs including lithium batteries according to this manual.

Attention:

Se débarrasser de batteries et IC-RAMs usés y compris les batteries en lithium selon ce manuel.

Vorsicht:

Entsorgung der gebrauchten Batterien und IC-RAMs (inclusive der Lithium-Batterie) nach diesem Handbuch.

Page 7

ALLEGEMEINE SICHERHEITSMASSNAHMEN IN BEZUG

AUF DIE WARTUNG FÜR e-STUDIO182/212/242

Die Installation und die Wartung sind von einem qualifizierten ServiceTechniker durchzuführen.

1) Transport/Installation

- Zum Transportieren/Installieren des Gerätes werden 2 Personen benötigt. Die Kassette zuerst

herausnehmen und nur an den in der Abbildung gezeigten Stellen tragen.

Das Gerät ist sehr schwer und wiegt etwa 33 kg; deshalb muss bei der Handhabung des Geräts

besonders aufgepasst werden.

- Beim Transportieren des Geräts nicht an den beweglichen Teilen oder Einheiten halten.

- Eine spezielle Steckdose mit Stromversorgung von AC 110 V / 13.2 A, 115 V oder 127 V / 12 A,

220-240 V / 8 A als Stromquelle verwenden.

- Das Gerät ist aus Sicherheitsgründen zu erden.

- Einen geeigneten Standort für die Installation wählen. Standorte mit zuviel Hitze, hoher Luft-

feuchtigkeit, Staub, Vibrieren und direkter Sonneneinstrahlung sind zu vermeiden.

- Für ausreichende Belüftung sorgen, da das Gerät etwas Ozon abgibt.

- Um einen optimalen Kopierbetrieb zu gewährleisten, muss ein Abstand von mindestens 80 cm

links, 80 cm rechts und 10 cm dahinter eingehalten werden.

- Das Gerät ist in der Nähe der Steckdose zu installieren; diese muss leicht zu erreichen sein.

- Nach der Installation muss das Netzkabel richtig hineingesteckt und befestigt werden, damit nie-

mand darüber stolpern kann.

2) Allgemeine Sicherheitsmassnahmen in bezug auf die Wartung

- Während der Wartung das Gerät ausschalten und das Netzkabel herausziehen (ausser Wartung,

die bei einem eingeschalteten Gerät, durchgeführt werden muss).

- Das Netzkabel herausziehen und den Bereich um die Steckerpole und die Steckdose die Umge-

bung in der Nähe von den Steckerzacken und der Steckdose wenigstens einmal im Jahr reinigen. Wenn Staub sich in dieser Gegend ansammelt, kann dies ein Feuer verursachen.

- Wenn die Teile auseinandergenommen werden, wenn nicht anders in diesem Handbuch usw

erklärt, ist das Zusammenbauen in umgekehrter Reihenfolge durchzuführen. Aufpassen, dass

kleine Teile wie Schrauben, Dichtungsringe, Bolzen, E-Ringe, Stern-Dichtungsringe, Kabelbäume nicht an den verkehrten Stellen eingebaut werden.

- Grundsätzlich darf das Gerät mit enfernten oder auseinandergenommenen Teilen nicht in

Betrieb genommen werden.

Page 8

- Das PC-Board muss in einer Anti-elektrostatischen Hülle gelagert werden. Nur Mit einer Man-

schette bei Betätigung eines Armbandes anfassen, sonst könnte es sein, dass die integrierten

Schaltkreise durch statische Elektrizität beschädigt werden.

Vorsicht: Vor Benutzung der Manschette der Betätigung des Armbandes, das Netzkabel

des Gerätes herausziehen und prüfen, dass es in der Nähe keine geladenen

Gegenstände, die nicht isoliert sind, gibt.

- Setzen Sie sich während der Wartungsarbeiten nicht dem Laserstrahl aus. Dieses Gerät ist mit

einer Laserdiode ausgestattet. Es ist unbedingt zu vermeiden, direkt in den Laserstrahl zu

blicken. Keine reflektierenden Teile oder Werkzeuge, wie z. B. Schraubendreher, in den Pfad des

Laserstrahls halten. Vor den Wartungsarbeiten sämtliche reflektierenden Metallgegenstände, wie

Uhren, Ringe usw., entfernen.

- Auf keinen Fall Hochtemperaturbereiche, wie die Belichtungslampe, die Fixiereinheit, die

Heizquelle und die umliegenden Bereiche, berühren.

- Auf keinen Fall Hochspannungsbereiche, wie die Ladeeinheiten, die Entwicklereinheit, den

Hochspannungstransformator, und das Netzgerät, berühren. Insbesondere sollten die Platinen

dieser Komponenten nicht berührt werden, da die Kondensatoren usw. auch nach dem Ausschalten des Geräts noch elektrisch geladen sein können.

- Vor dem Berühren potenziell gefährlicher Bereiche (z. B. drehbare oder betriebsrelevante Bere-

iche, wie Zahnräder, Riemen, Riemenscheiben, Lüfter und die Laseraustrittsöffnung der optischen Lasereinheit) sicherstellen, dass das Gerät sich nicht bedienen lässt.

- Beim Entfernen von Abdeckungen vorsichtig vorgehen, da sich darunter scharfkantige Kompo-

nenten befinden können.

- Bei Wartungsarbeiten am eingeschalteten Gerät dürfen keine unter Strom stehenden, drehbaren

oder betriebsrelevanten Bereiche berührt werden. Nicht direkt in den Laserstrahl blicken.

- Ausschließlich vorgesehene Werkzeuge und Hilfsmittel verwenden.

- Empfohlene oder gleichwertige Messgeräte verwenden.

- Nach Abschluss der Wartungsarbeiten das Gerät in den ursprünglichen Zustand zurück

versetzen und den einwandfreien Betrieb überprüfen.

3) Sicherheitsrelevante Wartungsteile

- Der Leistungsschutzschalter, der Türschalter, die Sicherung, der Thermostat, die Ther-

mosicherung, der Thermistor, die IC-RAMs einschließlich der Lithiumakkus usw. sind besonders

sicherheitsrelevant. Sie müssen unbedingt korrekt gehandhabt und installiert werden. Wenn

diese Teile kurzgeschlossen und funktionsunfähig werden, kann dies zu schwerwiegenden

Schäden, wie einem Abbrand, führen. Kurzschlüsse sind zu vermeiden, und es sind ausschließlich Teile zu verwenden, die von der Toshiba TEC Corporation empfohlen sind.

Page 9

4) Warnetiketten

- Im Rahmen der Wartung unbedingt das Leistungsschild und die Etiketten mit Warnhinweisen

überprüfen [z. B. „Unplug the power cable during service“ („Netzkabel vor Beginn der Wartungsarbeiten abziehen“), „CAUTION. HOT“ („VORSICHT, HEISS“), „CAUTION. HIGH VOLTAGE“

(„VORSICHT, HOCHSPANNUNG“), „CAUTION. LASER BEAM“ („VORSICHT, LASER“) usw.],

um sicherzustellen, dass sie nicht verschmutzt sind und korrekt am Gerät angebracht sind.

Certification label (For UC)

Explanatory label

Identification label

For UC

For EU

For others

Warning for high-temperature areas (ventilation holes

Warning for high-temperature areas (fuser unit

)

)

Page 10

5) Entsorgung des Geräts, der Verbrauchs- und Verpackungsmaterialien, alter Akkus und IC-RAMs

- In Bezug auf die Entsorgung und Wiederverwertung des Geräts, der Verbrauchs- und Verpack-

ungsmaterialien, alter Akkus und IC-RAMs, einschließlich Lithiumakkus, sind die einschlägigen

nationalen oder regionalen Vorschriften zu befolgen.

Caution:

Dispose of used batteries and IC-RAMs including lithium batteries according to this manual.

Attention:

Se débarrasser de batteries et IC-RAMs usés y compris les batteries en lithium selon ce manuel.

Vorsicht:

Entsorgung der gebrauchten Batterien und IC-RAMs (inclusive der Lithium-Batterie) nach diesem Handbuch.

Page 11

• Laseremissionseinheit

Diese Einheit besteht aus der Laserdiode, dem Fokussierungsobjektiv, der Blende und dem Zylinderobjektiv.

- Laserdiode

Diese Laserdiode zeichnet sich durch eine geringe Regeldifferenz, eine kleine Laservariation und

einen niedrigen Schwellenstrom aus.

Die Blende der Laseremissionseinheit ist unter dem Fokussierobjektiv angeordnet, um die Form der

Laserstrahlen in der primären und sekundären Scanrichtung festzulegen.

Die Laserdiode gibt Laserstrahlen als Reaktion auf die Signale der Laseremissionssteuerung (ein/

aus) von der Lasertreiber-PC-Platine (LDR) aus. Die durch das Fokussierobjektiv geführten Laserstrahlen werden auf die Trommeloberfläche fokussiert.

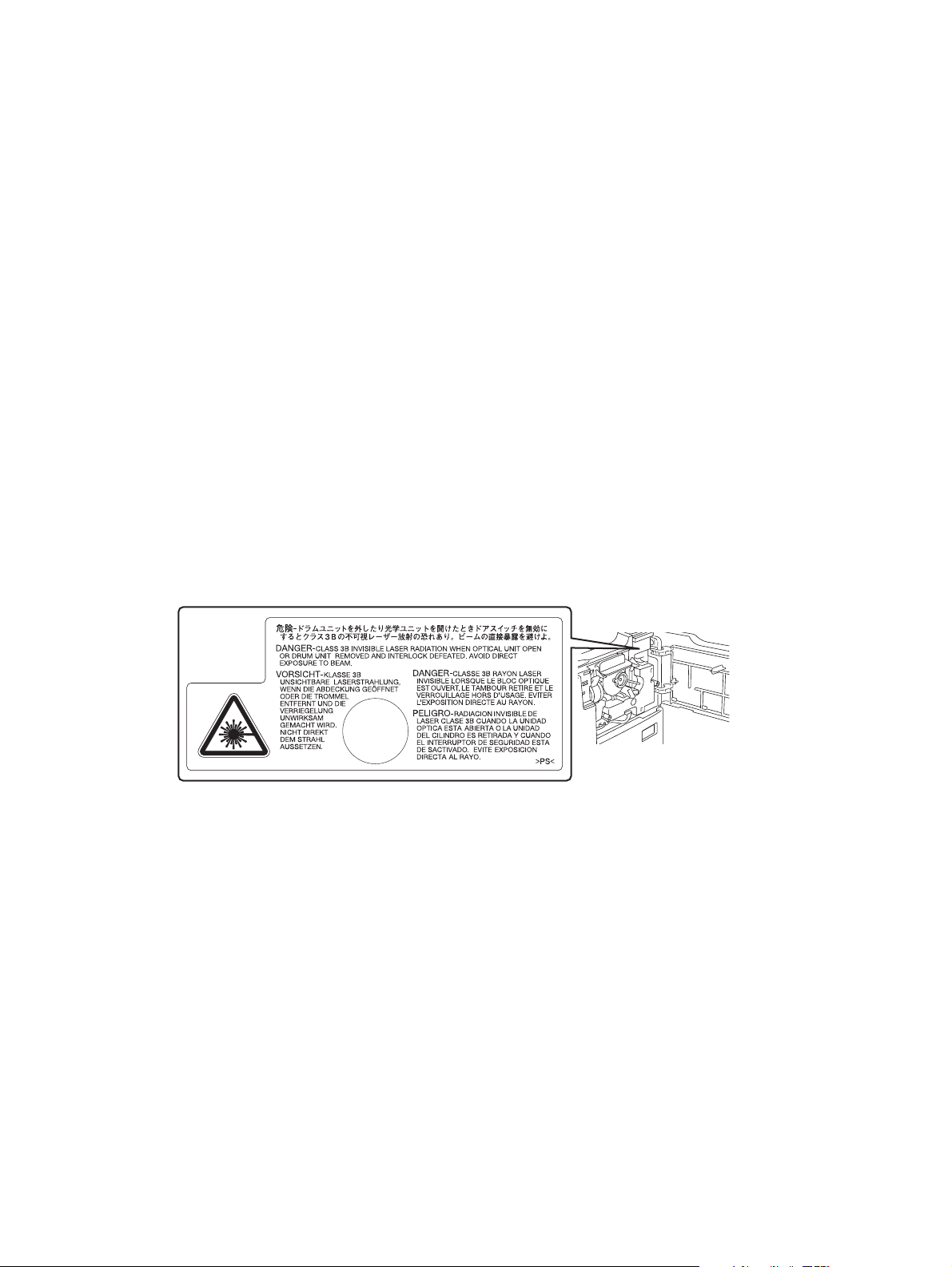

- Vorsichtsmaßnahmen im Zusammenhang mit Lasern

Dieses Gerät enthält eine Laserdiode, die einen unsichtbaren Laserstrahl emittiert.

Da man diesen Laserstrahl nicht sehen kann, ist bei der Handhabung der Komponenten der optischen Lasereinheit, bei der Durchführung von Arbeiten und bei der Justierung des Laserstrahls

äußerste Vorsicht geboten. Arbeiten dürfen niemals anhand anderer als den vorgeschriebenen

Anleitungen durchgeführt werden; andernfalls kann es zu einer Schädigung Exposition durch Laserstrahlung kommen.

Die Lasereinheit ist vollständig mit einer Schutzabdeckung versiegelt. Solange ausschließlich die

Arbeitsschritte der vorgeschriebenen Anleitungen durchgeführt werden, tritt der Laserstrahl nicht

aus, und es besteht keine Gefahr, der Laserstrahlung ausgesetzt zu werden.

Das folgende Laser-Warnetikett ist an der Abdeckung vorne rechts angebracht.

• Warnhinweise:

- Setzen Sie sich während der Wartungsarbeiten nicht dem Laserstrahl aus.

Dieses Gerät ist mit einer Laserdiode ausgestattet. Es ist unbedingt zu vermeiden, direkt in den

Laserstrahl zu blicken. Keine reflektierenden Teile oder Werkzeuge, wie z. B. Schraubendreher,

in den Pfad des Laserstrahls halten. Vor den Wartungsarbeiten sämtliche reflektierenden Metallgegenstände, wie Uhren, Ringe usw., entfernen.

- Bei Wartungsarbeiten am eingeschalteten Gerät dürfen keine unter Strom stehenden, drehbaren

oder betriebsrelevanten Bereiche berührt werden. Nicht direkt in den Laserstrahl blicken.

- Im Rahmen der Wartung unbedingt das Leistungsschild und die Etiketten mit Warnhinweisen

überprüfen [z. B. „Unplug the power cable during service“ („Netzkabel vor Beginn der Wartungsarbeiten abziehen“), „CAUTION. HOT“ („VORSICHT, HEISS“), „CAUTION. HIGH VOLTAGE“

(„VORSICHT, HOCHSPANNUNG“), „CAUTION. LASER BEAM“ („VORSICHT, LASER“) usw.],

um sicherzustellen, dass sie nicht verschmutzt sind und korrekt am Gerät angebracht sind.

Page 12

Page 13

CONTENTS

1. SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES ................................... 1-1

1.1 Specifications .................................................................................................................... 1-1

1.2 Accessories....................................................................................................................... 1-5

1.3 Options.............................................................................................................................. 1-6

1.4 Supplies ............................................................................................................................ 1-7

1.5 System List........................................................................................................................ 1-8

2. OUTLINE OF THE MACHINE ....................................................................................... 2-1

2.1 Sectional View................................................................................................................... 2-1

2.2 Electric Parts Layout ......................................................................................................... 2-4

2.3 Symbols and Functions of Various Components ............................................................ 2-11

2.4 General Description ........................................................................................................ 2-15

2.4.1 System block diagram ..................................................................................... 2-15

2.4.2 Construction of boards..................................................................................... 2-16

2.5 Disassembly and Replacement of Covers ...................................................................... 2-18

2.5.1 Front cover....................................................................................................... 2-18

2.5.2 Inner tray.......................................................................................................... 2-18

2.5.3 Left cover ......................................................................................................... 2-18

2.5.4 Tray rear cover ................................................................................................ 2-19

2.5.5 Front right cover............................................................................................... 2-19

2.5.6 Front upper cover ............................................................................................ 2-19

2.5.7 ADU cover ....................................................................................................... 2-20

2.5.8 Right front cover .............................................................................................. 2-20

2.5.9 Right rear cover ............................................................................................... 2-21

2.5.10 Rear cover ....................................................................................................... 2-21

2.6 Disassembly and Replacement of PC boards................................................................. 2-22

2.6.1 MAIN board (MAIN) ......................................................................................... 2-22

2.6.2 SRAM board (SRAM) ...................................................................................... 2-23

2.6.3 Fuse PC board (FUS) ...................................................................................... 2-23

2.6.4 Paper feed controller PC board (PFC)............................................................. 2-24

2.6.5 Switching regulator unit (PS) ........................................................................... 2-25

2.6.6 Switching regulator cooling fan (M6) ............................................................... 2-27

2.7 Removal and Installation of Options ............................................................................... 2-28

2.7.1 MR-2020 (Automatic Document Feeder (ADF))/

MR-3023 (Reversing Automatic Document Feeder (RADF)) .......................... 2-28

2.7.2 MY-1027 (Paper Feed Unit (PFU)) .................................................................. 2-30

2.7.3 KD-1022 (Paper Feed Pedestal (PFP)) ........................................................... 2-35

3. COPY PROCESS ..........................................................................................................3-1

3.1 General Description of Copying Process .......................................................................... 3-1

3.2 Details of Copying Process ............................................................................................... 3-2

3.3 Comparison with e-STUDIO230/280............................................................................... 3-13

4. GENERAL OPERATION............................................................................................... 4-1

4.1 Overview of Operation ...................................................................................................... 4-1

4.2 Description of Operation ................................................................................................... 4-2

4.2.1 Warming-up ....................................................................................................... 4-2

4.2.2 Ready state (ready for copying)......................................................................... 4-2

4.2.3 Drawer feed copying .......................................................................................... 4-3

4.2.4 Bypass feed copying.......................................................................................... 4-4

4.2.5 Interruption copying ........................................................................................... 4-4

4.3 Detection of Abnormality ................................................................................................... 4-5

4.3.1 Types of abnormality ......................................................................................... 4-5

4.3.2 Description of abnormality ................................................................................. 4-6

5. CONTROL PANEL........................................................................................................ 5-1

5.1 General Description .........................................................................................................5-1

© 2009 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO182/212/242

1

CONTENTS

Page 14

5.2 Items Shown on the Display Panel ................................................................................... 5-2

5.2.1 Display ............................................................................................................... 5-2

5.2.2 Message ............................................................................................................ 5-3

5.3 Relation between Equipment State and Operation ........................................................... 5-4

5.4 Operation .......................................................................................................................... 5-5

5.4.1 Block diagram .................................................................................................... 5-5

5.4.2 LED display circuit ............................................................................................. 5-6

5.5 Disassembly and Replacement......................................................................................... 5-7

5.5.1 Control panel unit............................................................................................... 5-7

5.5.2 Control panel PC board (HPNL) ........................................................................ 5-7

5.5.3 LCD PC board (LCD) ......................................................................................... 5-8

6. SCANNER ..................................................................................................................... 6-1

6.1 General Description ..........................................................................................................6-1

6.2 Construction ...................................................................................................................... 6-2

6.3 Functions........................................................................................................................... 6-3

6.4 Description of Operation ................................................................................................... 6-5

6.4.1 Scanning operation............................................................................................ 6-5

6.4.2 Scan motor drive circuit ..................................................................................... 6-6

6.5 Contact Image Sensor Unit Control Circuit ....................................................................... 6-8

6.5.1 Exposure LED control circuit ............................................................................. 6-8

6.5.2 CCD control circuit............................................................................................. 6-9

6.6 Automatic Original Size Detection Circuit ....................................................................... 6-11

6.6.1 Principle of original size detection ................................................................... 6-11

6.6.2 Process of detection of original size ................................................................ 6-12

6.7 Disassembly and Replacement....................................................................................... 6-16

6.7.1 Original glass ................................................................................................... 6-16

6.7.2 Scanner top cover............................................................................................ 6-17

6.7.3 Automatic original detection sensor (APS sensor) .......................................... 6-18

6.7.4 Scan motor (M1) .............................................................................................. 6-18

6.7.5 CIS home position sensor (S1)........................................................................ 6-20

6.7.6 Platen sensor (S2) ........................................................................................... 6-20

6.7.7 CIS unit (CIS)................................................................................................... 6-21

6.7.8 CIS case .......................................................................................................... 6-23

6.7.9 CIS unit drive belt-1 ........................................................................................ 6-24

6.7.10 CIS unit drive belt-2 ......................................................................................... 6-25

7. LASER OPTICAL UNIT ................................................................................................ 7-1

7.1 General Description ..........................................................................................................7-1

7.2 Structure............................................................................................................................ 7-2

7.3 Laser Diode Control Circuit ............................................................................................... 7-5

7.4 Polygonal Motor Control Circuit ........................................................................................ 7-6

7.5 Disassembly and Replacement......................................................................................... 7-7

7.5.1 Laser optical unit................................................................................................ 7-7

8. DRIVE UNIT .................................................................................................................. 8-1

8.1 General Description ..........................................................................................................8-1

8.2 Configuration..................................................................................................................... 8-2

8.3 Functions .......................................................................................................................... 8-3

8.4 Main Motor Control Circuit ................................................................................................ 8-4

8.5 Disassembly and Replacement......................................................................................... 8-6

8.5.1 Main motor (M3) ................................................................................................ 8-6

8.5.2 Toner motor (M2)............................................................................................... 8-6

8.5.3 Main motor drive unit ......................................................................................... 8-7

9. PAPER FEEDING SYSTEM.......................................................................................... 9-1

9.1 General Description ..........................................................................................................9-1

9.2 Configuration..................................................................................................................... 9-2

9.3 Functions........................................................................................................................... 9-3

9.4 Operation .......................................................................................................................... 9-5

e-STUDIO182/212/242 © 2009 TOSHIBA TEC CORPORATION All rights reserved

CONTENTS

2

Page 15

9.4.1 Drawer ............................................................................................................... 9-5

9.4.2 Bypass tray ........................................................................................................ 9-7

9.4.3 General operation .............................................................................................. 9-9

9.5 Disassembly and Replacement....................................................................................... 9-10

9.5.1 Bypass unit ...................................................................................................... 9-10

9.5.2 Bypass tray ...................................................................................................... 9-11

9.5.3 Bypass separation pad ................................................................................... 9-11

9.5.4 Bypass roller unit ............................................................................................. 9-12

9.5.5 Bypass pickup roller ........................................................................................ 9-14

9.5.6 Bypass feed roller ........................................................................................... 9-14

9.5.7 Bypass paper sensor (S8) ............................................................................... 9-14

9.5.8 Bypass pickup solenoid (SOL2)....................................................................... 9-15

9.5.9 Bypass pickup clutch / Bypass feed clutch ...................................................... 9-16

9.5.10 Damp heater unit (DH3) / Dummy plate .......................................................... 9-18

9.5.11 Paper empty sensor (S7)................................................................................. 9-18

9.5.12 Pickup roller .................................................................................................... 9-19

9.5.13 Registration clutch (CLT1) ............................................................................... 9-20

9.5.14 Pickup solenoid (SOL1) ................................................................................... 9-20

9.5.15 Drawer pickup clutch ....................................................................................... 9-21

9.5.16 Registration roller (rubber)............................................................................... 9-22

9.5.17 Registration roller (metal) ................................................................................ 9-23

9.5.18 Feed gear unit.................................................................................................. 9-24

9.5.19 Drawer detection switch (SW5) ....................................................................... 9-24

9.5.20 Registration sensor (S4) .................................................................................. 9-25

10. DRUM RELATED SECTION....................................................................................... 10-1

10.1 General Description ........................................................................................................ 10-1

10.2 Configuration................................................................................................................... 10-2

10.3 Functions......................................................................................................................... 10-3

10.4 High-Voltage Output Control Circuit................................................................................ 10-5

10.4.1 General description.......................................................................................... 10-5

10.4.2 Description of Operation .................................................................................. 10-6

10.5 Drum Temperature Detection Circuit .............................................................................. 10-7

10.5.1 General description.......................................................................................... 10-7

10.5.2 Circuit configuration ......................................................................................... 10-7

10.6 Temperature/Humidity Detection Circuit ......................................................................... 10-8

10.6.1 General Description ......................................................................................... 10-8

10.6.2 Circuit configuration ......................................................................................... 10-8

10.7 Disassembly and Replacement....................................................................................... 10-9

10.7.1 Process unit ..................................................................................................... 10-9

10.7.2 Drum cleaner unit .......................................................................................... 10-11

10.7.3 Discharge LED (ERS).................................................................................... 10-12

10.7.4 Main charger.................................................................................................. 10-13

10.7.5 Main charger grid .......................................................................................... 10-13

10.7.6 Main charger cleaner ..................................................................................... 10-14

10.7.7 Needle electrode ........................................................................................... 10-14

10.7.8 Drum ............................................................................................................. 10-15

10.7.9 Drum cleaning blade ..................................................................................... 10-15

10.7.10 Drum separation finger ................................................................................. 10-15

10.7.11 Recovery blade ............................................................................................. 10-16

10.7.12 Transfer/Separation charger .......................................................................... 10-16

10.7.13 Charger wire ................................................................................................. 10-17

10.7.14 Transfer unit................................................................................................... 10-18

10.7.15 Ozone filter ................................................................................................... 10-19

10.7.16 Exhaust fan (M5) ........................................................................................... 10-20

10.7.17 Temperature/humidity sensor (S3) ................................................................ 10-21

10.7.18 Toner cartridge interface PC board (CTIF) .................................................... 10-22

© 2009 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO182/212/242

3

CONTENTS

Page 16

11. DEVELOPMENT SYSTEM..........................................................................................11-1

11.1 General Description ........................................................................................................ 11-1

11.2 Construction.................................................................................................................... 11-2

11.3 Functions......................................................................................................................... 11-3

11.3.1 Function of each unit ....................................................................................... 11-3

11.3.2 Functions of the toner cartridge PC board (CTRG) ......................................... 11-4

11.3.3 Recovered toner supply mechanism ............................................................... 11-6

11.4 Toner Motor Control Circuit............................................................................................. 11-7

11.5 Auto-Toner Circuit........................................................................................................... 11-8

11.5.1 General description.......................................................................................... 11-8

11.5.2 Function of auto-toner sensor.......................................................................... 11-9

11.6 Disassembly and Replacement..................................................................................... 11-11

11.6.1 Developer unit................................................................................................ 11-11

11.6.2 Developer material ........................................................................................ 11-12

11.6.3 Filling developer unit with developer material................................................ 11-13

11.6.4 Auto-toner sensor (S6) .................................................................................. 11-14

11.6.5 Drum thermistor (THMS4) ............................................................................. 11-14

11.6.6 Guide roller / Developer sleeve ..................................................................... 11-14

11.6.7 Mixer .............................................................................................................. 11-18

11.6.8 Replacement of Oil Seal ................................................................................ 11-20

12. FUSER / EXIT UNIT ....................................................................................................12-1

12.1 General Description ........................................................................................................ 12-1

12.2 Configurations................................................................................................................. 12-2

12.3 Functions......................................................................................................................... 12-3

12.4 Operation ........................................................................................................................ 12-5

12.5 Fuser Unit Control Circuit................................................................................................ 12-6

12.5.1 Configuration ................................................................................................... 12-6

12.5.2 Temperature detection section ........................................................................ 12-7

12.6 Disassembly and Replacement..................................................................................... 12-12

12.6.1 Fuser / Exit unit.............................................................................................. 12-14

12.6.2 Pressure roller unit / Fuser roller unit............................................................. 12-14

12.6.3 Exit roller........................................................................................................ 12-15

12.6.4 Exit sensor (S5) ............................................................................................ 12-16

12.6.5 Separation finger ......................................................................................... 12-18

12.6.6 Center heater lamp / Side heater lamp (LAMP1/LAMP2) .............................. 12-19

12.6.7 Fuser roller .................................................................................................... 12-20

12.6.8 Pressure roller .............................................................................................. 12-20

12.6.9 Center thermistor / Side thermistor / Edge thermistor

(THMS1/THMS2/THMS3)............................................................................. 12-22

12.6.10 Fuser thermostat (THMO1)............................................................................ 12-22

12.6.11 Exit motor (M7): Option.................................................................................. 12-23

13. AUTOMATIC DUPLEXING UNIT (ADU) (OPTION: MD-0103) .................................. 13-1

13.1 General Description ........................................................................................................ 13-1

13.1.1 Specifications of MD-0103............................................................................... 13-2

13.2 Construction.................................................................................................................... 13-3

13.3 Functions......................................................................................................................... 13-4

13.4 Drive of ADU ................................................................................................................... 13-5

13.5 Description of Operation ................................................................................................ 13-6

13.6 Disassembly and Replacement..................................................................................... 13-11

13.6.1 Automatic Duplexing Unit (ADU) ................................................................... 13-11

13.6.2 ADU driving PC board (ADU) ........................................................................ 13-12

13.6.3 ADU motor (M8)............................................................................................. 13-12

13.6.4 Upper transport roller..................................................................................... 13-13

13.6.5 Lower transport roller..................................................................................... 13-13

13.6.6 Paper guide ................................................................................................... 13-14

e-STUDIO182/212/242 © 2009 TOSHIBA TEC CORPORATION All rights reserved

CONTENTS

4

Page 17

14. POWER SUPPLY UNIT .............................................................................................. 14-1

14.1 Construction.................................................................................................................... 14-1

14.2 Operation of DC Output Circuit ....................................................................................... 14-2

14.3 Output Channel............................................................................................................... 14-3

14.4 Fuse ................................................................................................................................ 14-4

14.5 Configuration of Power Supply Unit ................................................................................ 14-5

14.6 AC Wire Harness ............................................................................................................ 14-6

15. EXTERNAL COUNTERS ............................................................................................15-1

15.1 Outline............................................................................................................................. 15-1

15.2 Signal .............................................................................................................................. 15-1

15.2.1 Pin Layout........................................................................................................ 15-1

15.2.2 Details of the signals........................................................................................ 15-2

15.3 Notices ............................................................................................................................ 15-3

15.3.1 Setting code..................................................................................................... 15-3

15.3.2 Setting value change and restrictions when using the totalizer

(DocuLyzerNW) .............................................................................................. 15-3

15.3.3 Setting value change and restrictions when using the coin controller ............. 15-3

15.3.4 Simultaneous Installation of External Counters ............................................... 15-3

16. PC BOARDS ............................................................................................................... 16-1

© 2009 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO182/212/242

5

CONTENTS

Page 18

e-STUDIO182/212/242 © 2009 TOSHIBA TEC CORPORATION All rights reserved

CONTENTS

6

Page 19

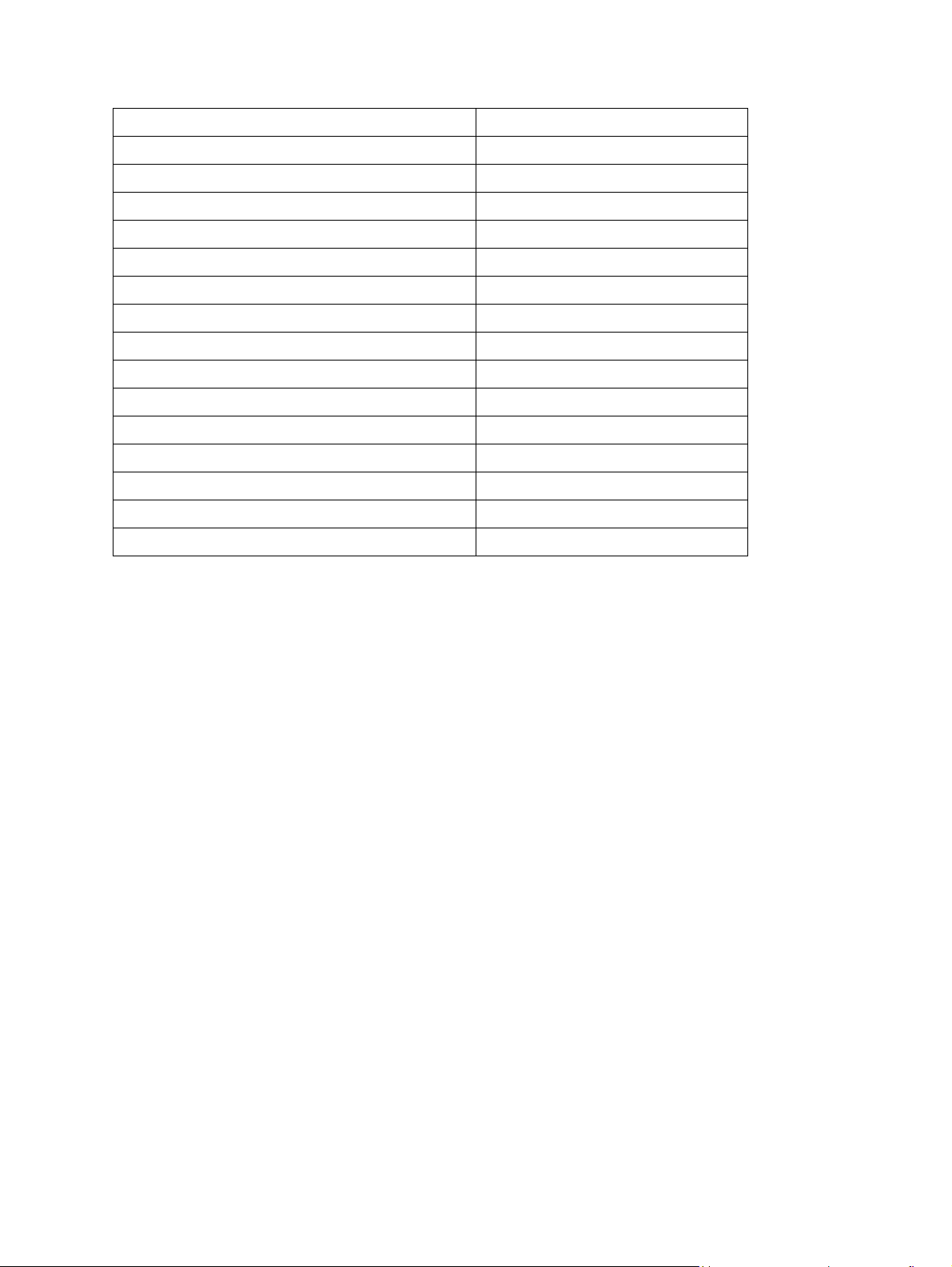

1. SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1.1 Specifications

When the value is different among e-STUDIO182, 212 and 242, the value for

e-STUDIO212 is shown by [ ] and the value for e-STUDIO242 is shown by { }.

Copy process Indirect electrophotographic process (dry)

Type Desktop type

Original table Fixed type (the left rear corner used as guide to place originals)

Accepted originals Sheet, book and 3-dimensional object. The automatic document feeder

(ADF) and reversing automatic document feeder (RADF), only accepts paper

which are not pasted or stapled. (Single-sided originals: 50 to 127 g/m

34 lb. Bond) Carbon paper are not acceptable either.

Maximum size: A3/LD

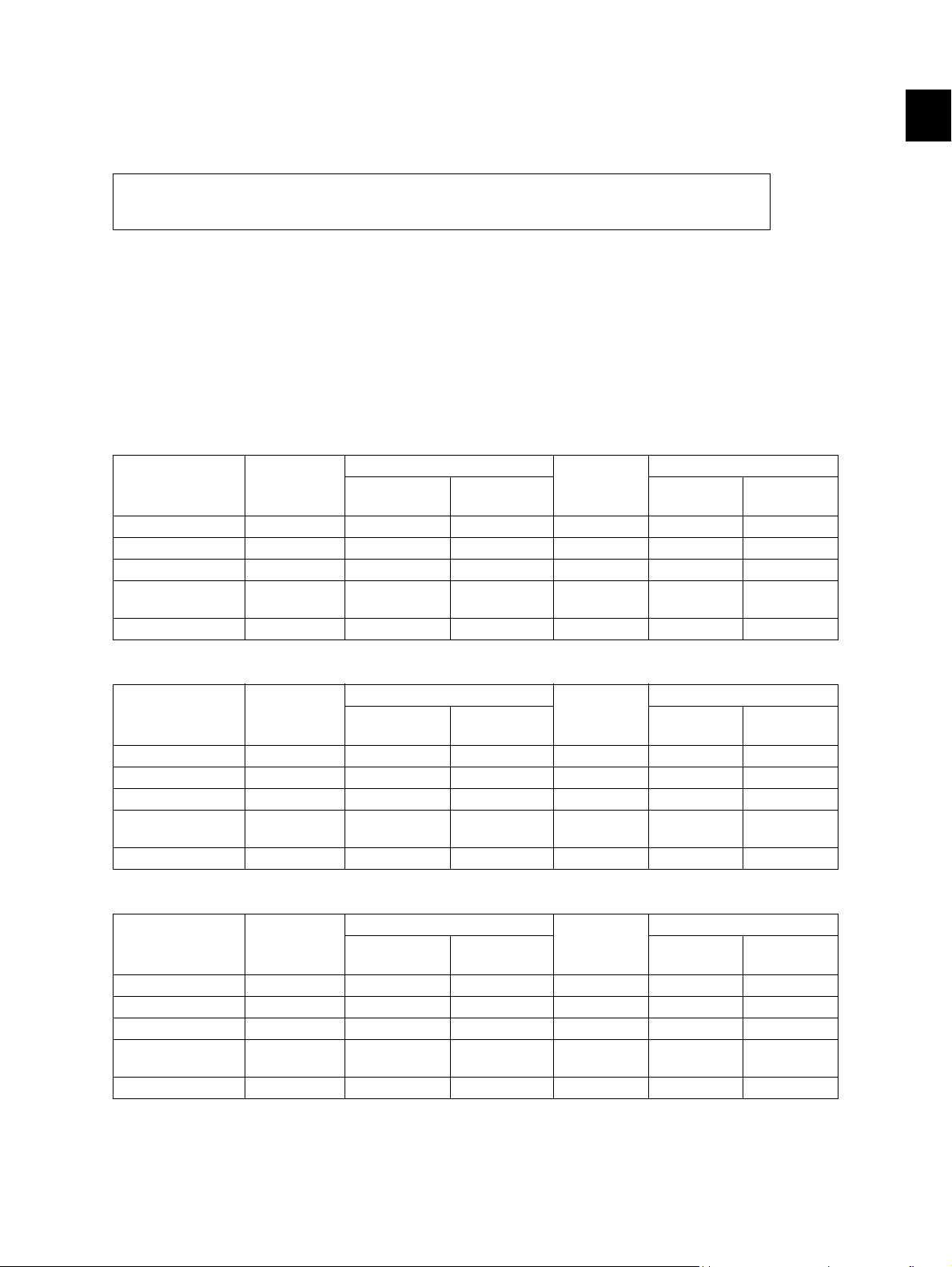

Copy speed (Copies/min.)

e-STUDIO182

Bypass feed

Paper size Drawer

A4, B5, LT 18 16 11 16 16 16

A5-R, ST-R - 16 11 - 16 16

A4-R, B5-R, LT-R 15.5 15.5 11 15.5 15.5 15.5

B4, LG, FOLIO,

COMPUTER

A3 , L D 11 11 11 11 11 11

13 13 11 13 13 13

Size

specified

Size not

specified

PFU

Upper

drawer

PFP

2

Lower

drawer

1

/13 to

e-STUDIO212

Bypass feed

Paper size Drawer

A4, B5, LT 21 20 20 20 20 20

A5-R, ST-R - - 20 - 20 20

A4-R, B5-R, LT-R 15.5 15.5 15.5 15.5 15.5 15.5

B4, LG, FOLIO,

COMPUTER

A3 , L D 11 11 11 11 11 11

13 13 13 13 13 13

Size

specified

Size not

specified

PFU

Upper

drawer

PFP

Lower

drawer

e-STUDIO242

Bypass feed

Paper size Drawer

A4, B5, LT 24 23 23 23 23 23

A5-R, ST-R - - 23 - 23 23

A4-R, B5-R, LT-R 17.5 17.5 17.5 17.5 17.5 17.5

B4, LG, FOLIO,

COMPUTER

A3, LD 12.5 12.5 12.5 12.5 12.5 12.5

15 15 15 15 15 15

Size

specified

Size not

specified

PFU

Upper

drawer

PFP

Lower

drawer

* “–” means “Not acceptable”.

* The copy speed in the above table are available when originals are manually placed for single side,

multiple copying.

© 2009 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO182/212/242

1 - 1

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

Page 20

* When the ADF and RADF are used, the copy speed of 16[20] {23} sheets per minute is only

available under the following conditions:

• Original/Mode: Single side original/A4/LT size. APS/automatic density are not selected.

• Number of sheets: 16[20] {23}

• Reproduction ratio: 100%

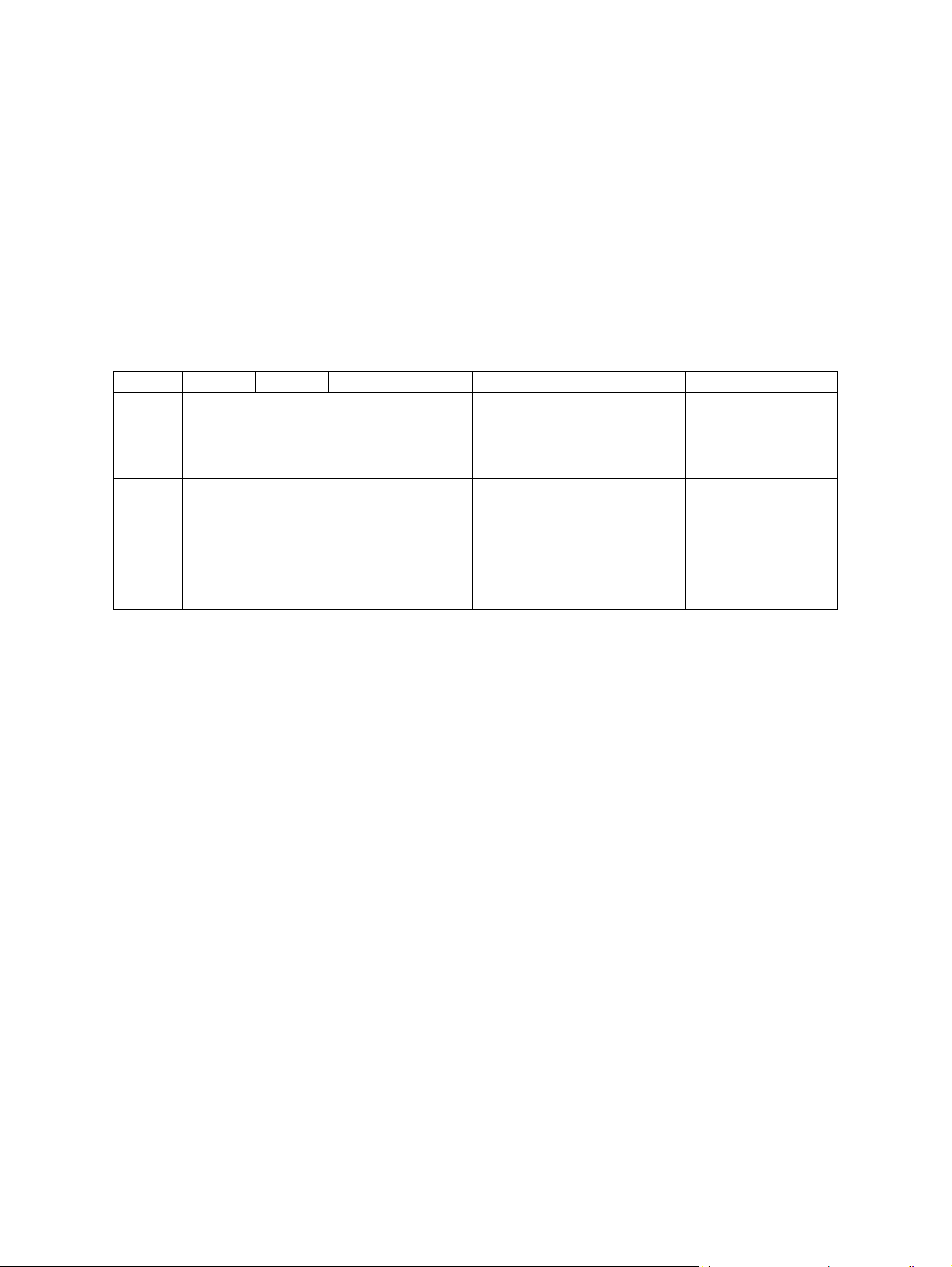

Copy speed for thick paper (Copies/min.)

e-STUDIO182/212/242

Thick 1 (81 g/m

2

to 105 g/m2, 21.3 lb. Bond to 28 lb. Bond): Bypass feed on a sheet by sheet baisis

only

Thick 2 (106 g/m

2

to 163 g/m2, 28 lb. Bond to 90 lb. Index): Bypass feed on a sheet by sheet baisis only

Copy paper

Drawer PFU PFP ADU Bypass copy Remarks

Size A3, A4, A4-R, B4, B5, B5-R,

Weight

Special

paper

A5-R(Only for PFP), LD, LG, LT, LT-R,

ST-R(Only for PFP), FOLIO, COMPUTER,

13"LG, 8K, 16K, 16K-R

2

64 to 80 g/m

– Tracing paper, labels, OHP film

, 17 lb. Bond to 21.3 lb. Bond 50 to 163 g/m

First copy time ..................... e-STUDIO182/212

Approx. 7.6 sec. (A4, 100%, original placed manually)

Approx. 7.7 sec. (LT, 100%, original placed manually)

e-STUDIO242

Approx. 7.5 sec. (A4/LT, 100%, original placed manually)

A3 to A5-R, LD to ST-R,

FOLIO, COMPUTER, 13"LG,

8.5" x 8.5", 8K, 16K, 16K-R

(Non-standard or userspecified sizes can be set.)

2

(Single paper feeding)

64 to 80 g/m

(Continuous feeding)

(thickness: 80 µm or thicker),

2

These special papers

recommended by

Tos h i b a Te c

Warming-up time.................. Approx. 25 sec. (temperature: 20°C)

Multiple copying ................... Up to 999 copies; Key in set numbers

Reproduction ratio ............... Actual ratio: 100±0.5%

Zooming: 25 to 200% in increments of 1%

Resolution/Gradation ........... Scanning: 600 dpi x 600 dpi

Printing: Equivalent to 2400 dpi x 600 dpi

Gradation: 256 steps

Eliminated portion ................ Leading edges: 3.0±2.0 mm, Side/trailing edges: 2.0±2.0 mm (copy)

Leading / trailing edges: 5.0±2.0 mm, Side edges: 5.0±2.0 mm (print)

e-STUDIO182/212/242 © 2009 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1 - 2

Page 21

Paper feeding ......................... Standard drawer:

1 drawer (stack height 28 mm, equivalent to 250 sheets; 64 to 80 g/m

(17 to 22 lb. Bond))

Bypass feeding:

Stack height 11.8 mm: equivalent to 100 sheets; 64 to 80 g/m

22 lb. Bond)

Paper Feed Unit (PFU):

Option (One drawer: stack height 28 mm, equivalent to 250 sheets; 64

to 80 g/m

2

(17 to 22 lb. Bond))

Paper Feed Pedestal (PFP):

Option (One drawer or two: stack height 60.5 mm, equivalent to 550

sheets; 64 to 80 g/m

2

(17 to 22 lb. Bond))

Capacity of originals in the ADF/RADF (Option)

.................................................. A3 to A5-R, LD to ST-R:

100 sheets / 80 g/m

2

(Stack height 16 mm or less)

Automatic duplexing unit (ADU: Option)

.................................................. Stackless, Switchback type

Toner supply ........................... Automatic toner density detection/supply

Toner cartridge replacing method (There is a recovered toner supply

mechanism.)

2

(17 to

2

1

Density control ..................... Automatic density mode and manual density mode selectable in 7

steps

Weight.................................. Approx. 32.0 kg ( 70.55 lb.) (for NAD and MJD)

Approx. 33.2 kg ( 73.19 lb.) (for CND)

Approx. 33.0 kg ( 72.75 lb.) (for others)

Power requirements...AC 110 V / 13.2 A, 115 V or 127 V / 12 A

220-240 V or 240 V / 8 A (50/60 Hz)

* The acceptable value of each voltage is ±10%.

Power consumption ... 1.5 kW or less (100 V series)

1.6 kW or less (200 V series)

* The electric power is supplied to the ADF/RADF, PFU, PFP and ADU through the equipment.

Total counter ..............Electronical counter

© 2009 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO182/212/242

1 - 3

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

Page 22

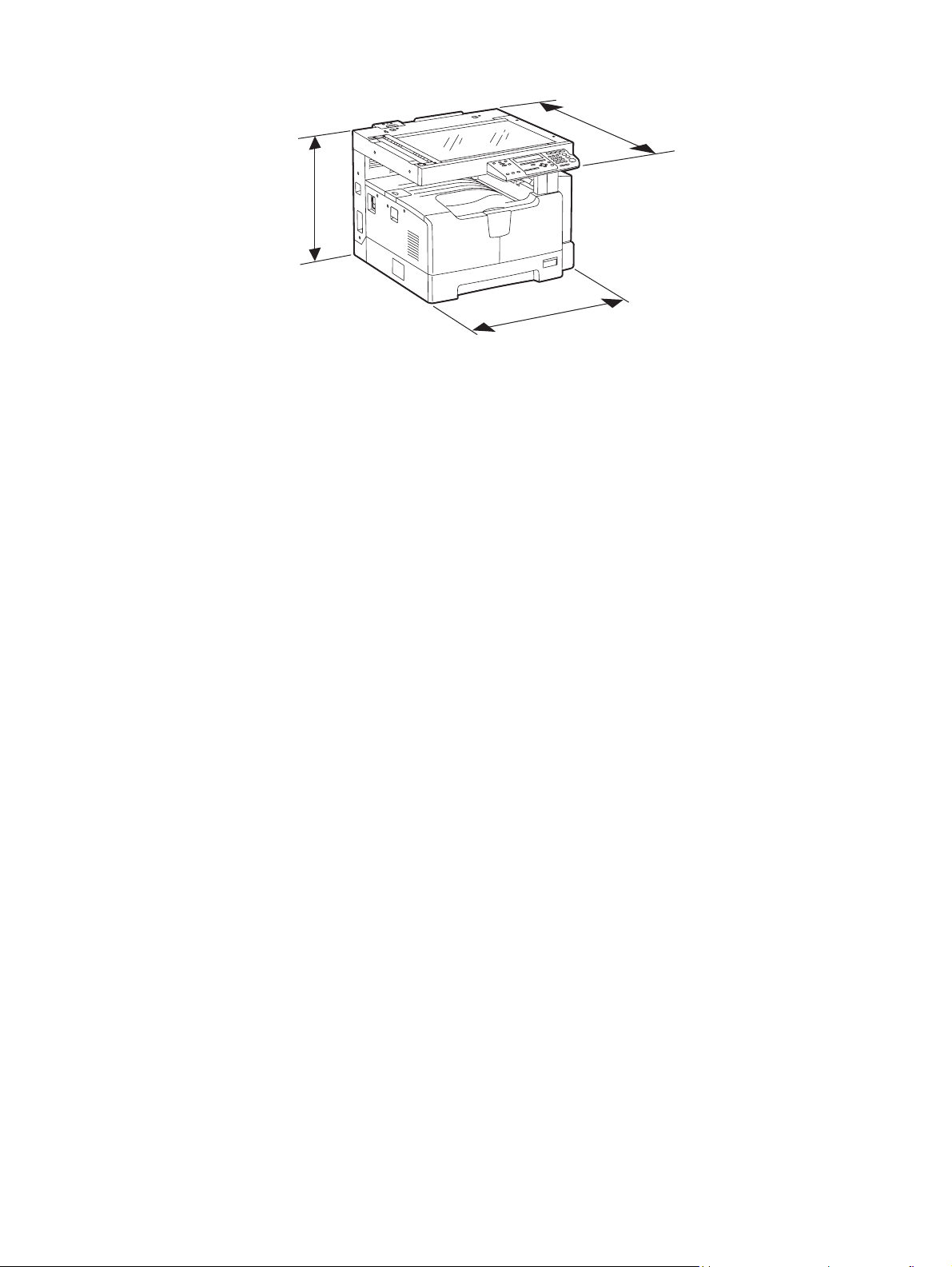

Dimensions of the equipment .................. W 600 x D 658.6 x H 462.5 (mm): See the figure below

D

H

W

Fig. 1-1

e-STUDIO182/212/242 © 2009 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1 - 4

Page 23

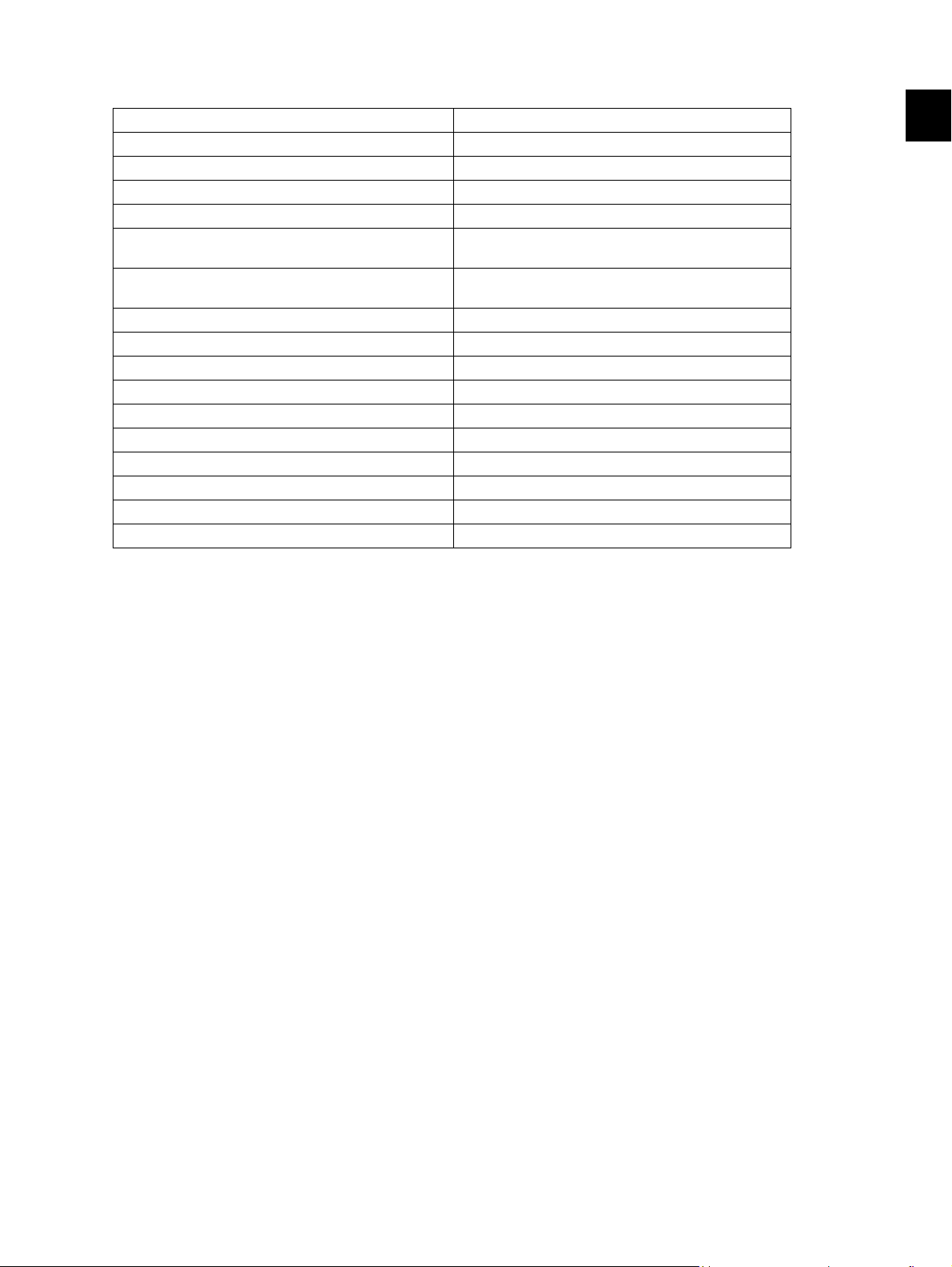

1.2 Accessories

Unpacking/setup instruction 1 set

Operator’s manual 1 pc.

Operator’s manual pocket 1 pc. (for NAD)

Power cable 1 pc.

CD-ROM 2 pcs.

Rubber cap 6 pcs. (for MJD, ASD, ASU and SAD)

2 pcs. (for NAD, CND, AUD, TWD, KRD and ARD)

Transfer charger wire cleaner

(installed inside of the transfer cover)

Drum (installed inside of the equipment) 1 pc.

Developer material 1 pc.

Nozzle 1 pc. (for NAD)

Toner cartridge 1 pc.

Warranty sheet 1 pc. (for NAD and CND)

Setup report 1 set (for NAD, MJD and CND)

Customer satisfaction card 1 pc. (for MJD)

Packing list 1 pc. (for CND)

Customer survey sheet 1 pc. (for CND)

Certificate of conformance 1 pc. (for CND)

1 pc.

* Machine version

NAD: North America

ASD: Hong Kong / Latin America

AUD: Australia

MJD: Europe

ASU: Asia / Saudi Arabia

SAD: Saudi Arabia

ARD: Latin America

CND: China

TWD: Taiwan

KRD: Korea

JPD: Japan

1

© 2009 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO182/212/242

1 - 5

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

Page 24

1.3 Options

Platen Cover KA-1650PC/PCC

Automatic Document Feeder (ADF) MR-2020/C

Reversing Automatic Document Feeder (RADF) MR-3023/C

Paper Feed Unit (PFU) MY-1027/C

Paper Feed Pedestal (PFP) KD-1022/C

Paper Feed Controller (PFC) GH-1060/C

Drawer Module MY-1028/C

Automatic Duplexing Unit (ADU) MD-0103/C

Fax Kit GD-1221NA/EU/AU/TW/CN/KR

External Keyboard GJ-1060/C/EU/KR/TW

Network Printer Kit GA-1191/C/KR/TW

Scanner Upgrade Kit GA-1201/C/KR/TW

Operator’s manual pocket KK-1660/C

Damp Heater MF-1640U/E

Harness Kit GQ-1130

Desk MH-1640

Notes:

• When the paper feed pedestal (KD-1022) or automatic duplexing unit (MD-0103) is installed,

the paper feed controller (GH-1060) is also required to be installed.

• The external keyboard (GJ-1060) is necessary for the installation of the fax kit (GD-1221) and

the scanner upgrade kit (GA-1201).

e-STUDIO182/212/242 © 2009 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1 - 6

Page 25

1.4 Supplies

Drum OD-1600 (except for China)

OD-2320 (for China)

Toner cartridge PS-ZT1810 (1) (for North America)

PS-ZT1810A (1) (for Central and South America)

PS-ZT1810D (1) (for Asia)

PS-ZT1810D5k (1) (for Asia)

PS-ZT1810C (1) (for China)

PS-ZT1810C10k (1) (for China)

PS-ZT1810C5k (1) (for China)

PS-ZT1810T (1) (for Taiwan)

PS-ZT1810T5k (1) (for Taiwan)

PS-ZT1810E (1) (for Europe)

PS-ZT1810E5K (1) (for Europe)

Developer material D-2320 (except for China)

D-2320C (for China)

1

© 2009 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO182/212/242

1 - 7

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

Page 26

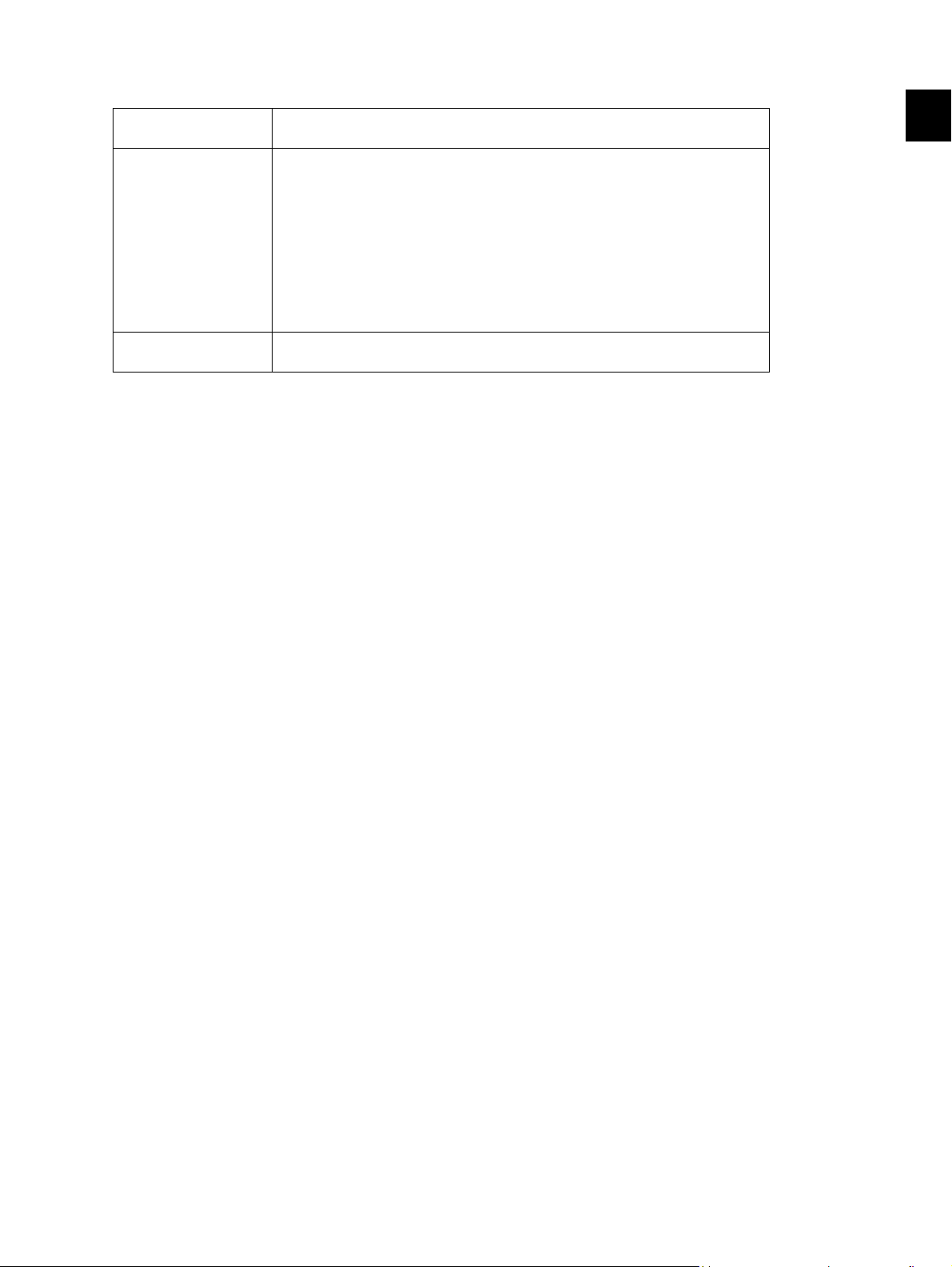

1.5 System List

)

RADF

(

MR-3023

Document Feeder

Reversing Automatic

)

ADF

(

MR-2020

Automatic

Document Feeder

KA-1650PC

Platen Cover

Automatic

Duplexing Unit

GJ-1060

MF-1640

Damp Heater

External Keyboard

)

ADU

(

MD-0103

)

PFC

(

GH-1060

Controller

Paper Feed

Network

GA-1191

Printer Kit

)

PFU

(

MY-1027

Paper Feed Unit

Scanner

GA-1201

Upgrade Kit

Desk

MH-1640

)

PFP

(

Pedestal

Paper Feed

KD-1022

MY-1028

Drawer Module

GQ-1130

Harness Kit

Fig. 1-2

Fax Kit

GD-1221

e-STUDIO182/212/242 © 2009 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1 - 8

Page 27

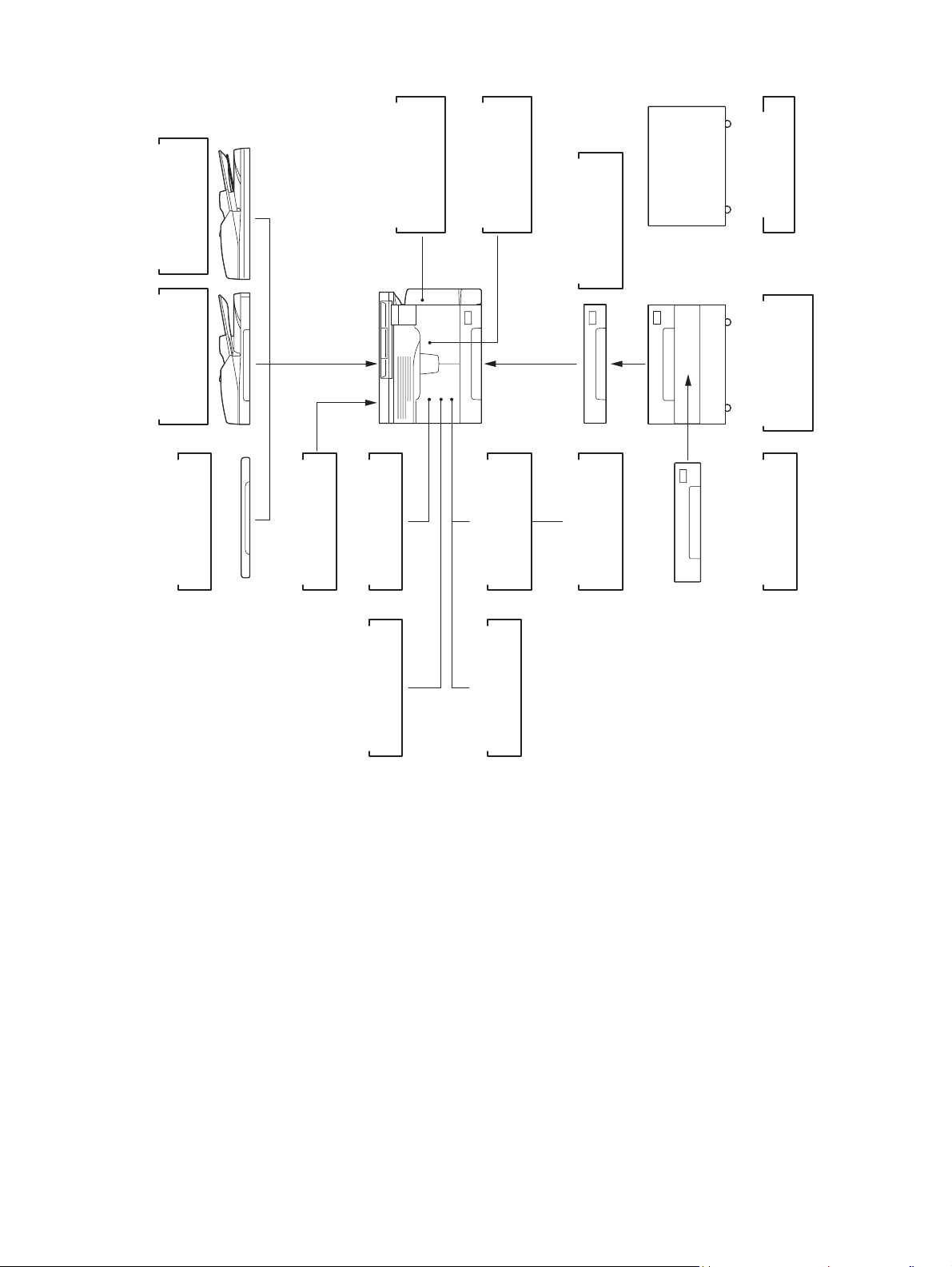

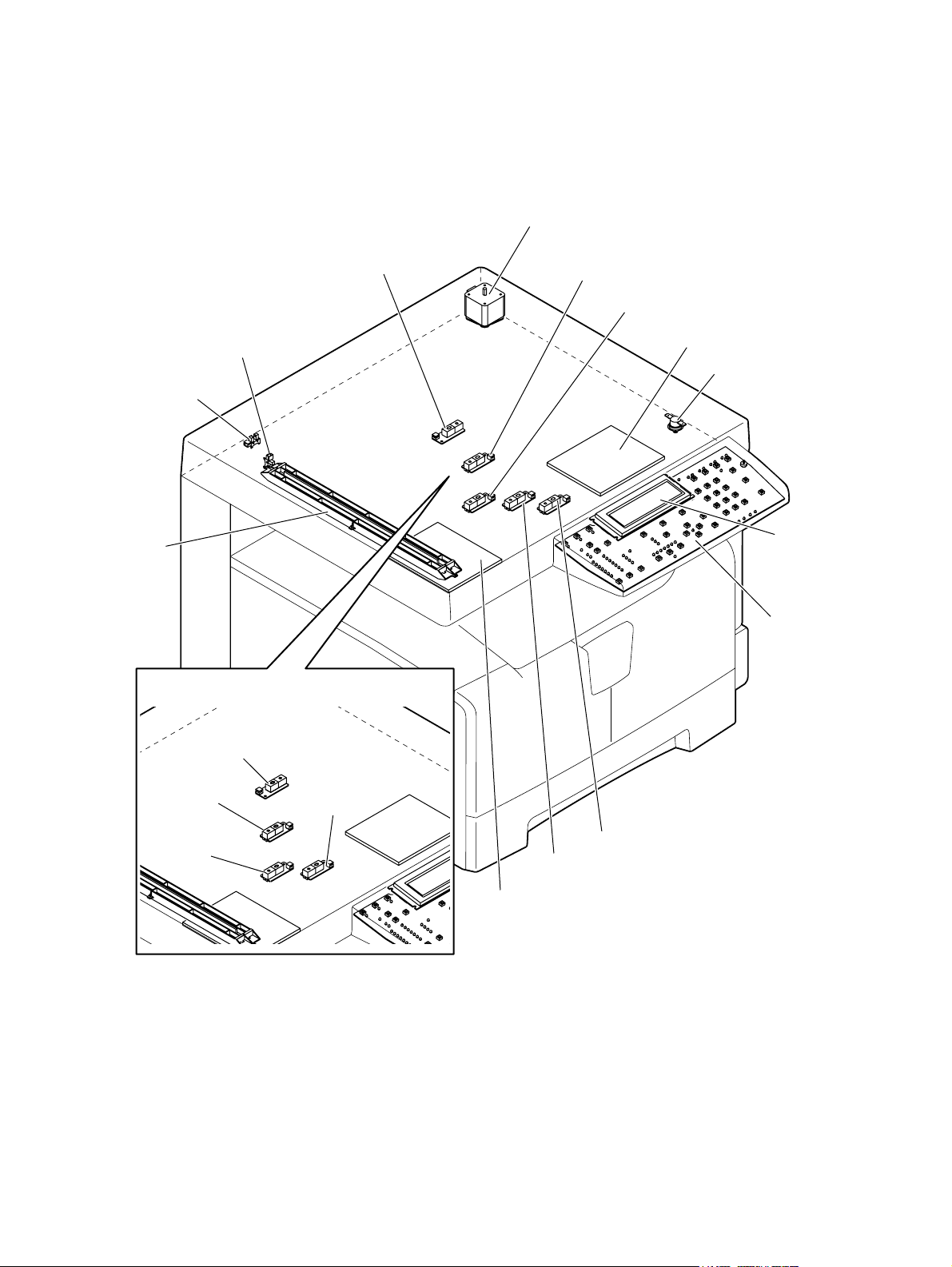

2. OUTLINE OF THE MACHINE

2.1 Sectional View

1. Front side

A2 A1A3

K4

A4

K2

A7

J7J6

I5

I9

F1F2F3

H3

H2

J4J5 J8

A5

A6

K5

J3

J9

J1

J2

L3

L1

I7

H4

H5

H1

G2

G1

G3

L3

I1

C5

L2

E2

E1

2

E5

K3

A1 Original glass

A2 ADF original glass

A3 Contact image sensor unit (CIS)

A4 Scanner damp heater (Left side) DH1

A5 Scanner damp heater (Right side) DH2

A6 Scanner damp heater thermostat THMO2

A7 Automatic original detection sensor S9-S13

B1 Laser optical unit

B2 Polygonal motor M4

C1 Pickup roller

C2 Separation claw

C3 Paper empty sensor S7

C4 Registration sensor S4

C5 Registration roller

E1 Bypass pickup roller

E2 Bypass feed roller

E3 Bypass separation pad

E4 Bypass paper sensor S8

B1B2 C1 C2C3

F4

I11

I4 I3I2I6I8

I10K1

Fig. 2-1

C4

E3

E4

© 2009 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO182/212/242

2 - 1

OUTLINE OF THE MACHINE

Page 28

E5 Bypass tray

F1 Needle electrode

F2 Main charger

F3 Main charger grid

F4 Toner cartridge

G1 Transfer charger wire

G2 Separation charger wire

G3 Transfer guide roller

H1 Drum

H2 Discharge LED

H3 Drum cleaning blade

H4 Recovery blade

H5 Drum separation finger

I1 Developer sleeve (Magnetic roller)

I2 Mixer-1

I3 Mixer-2

I4 Mixer-3

I5 Doctor blade

I6 Auto-toner sensor S6

I7 Toner recovery auger

I8 Toner recycle auger

I9 Drum thermistor THMS4

I10 Drum damp heater DH3

I11 Drum damp heater thermostat THMO3

J1 Fuser roller

J2 Pressure roller

J3 Fuser roller separation finger

J4 Center heater lamp LAMP1

J5 Side heater lamp LAMP2

J6 Center/Side/Edge thermistor THMS1/2/3

J7 Fuser thermostat THMO1

J8 Exit roller

J9 Exit sensor S5

K1 Front cover opening/closing switch SW4

K2 Front cover opening/closing interlock switch SW3

K3 Temperature/humidity sensor S3

K4 Switching regulator

K5 ADU cover opening/closing interlock switch SW2

L1 ADU upper transport roller

L2 ADU lower transport roller

L3 ADU paper guide

e-STUDIO182/212/242 © 2009 TOSHIBA TEC CORPORATION All rights reserved

OUTLINE OF THE MACHINE

2 - 2

Page 29

2. Rear side

M8

M1 M2

M5

M7

S2 S1

2

M1 Scan motor

M2 Toner motor

M3 Main motor

M5 Exhaust fan

M6 Switching regulator cooling fan

M7 Exit motor (Option)

M8 ADU motor (Option)

S1 CIS home position sensor

S2 Platen sensor

SW5 Drawer detection switch

CLT1 Registration clutch

SOL1 Pickup solenoid

SOL2 Bypass pickup solenoid

CLT1

SW5

Fig. 2-2

M3SOL1SOL2 M6

© 2009 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO182/212/242

2 - 3

OUTLINE OF THE MACHINE

Page 30

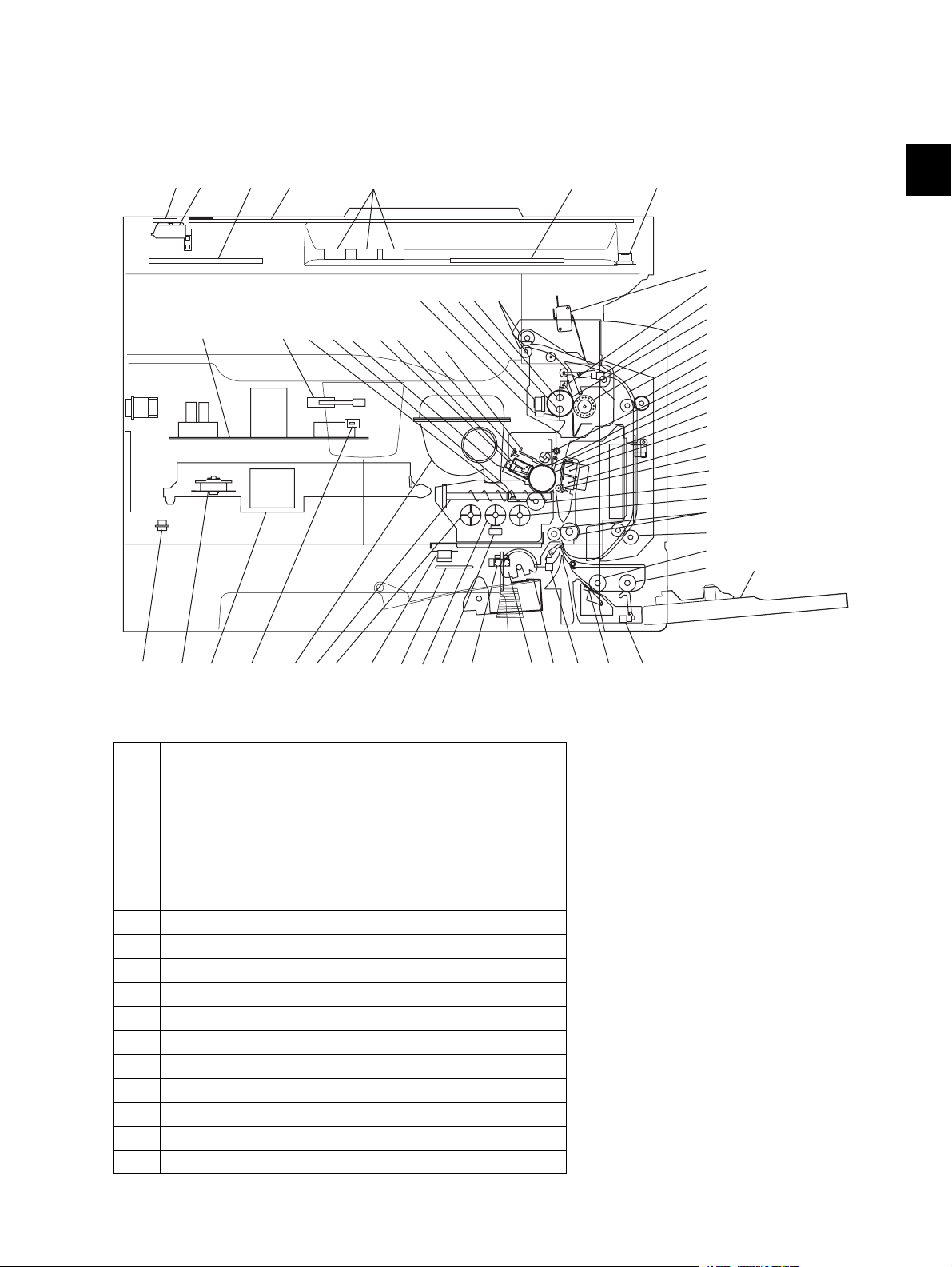

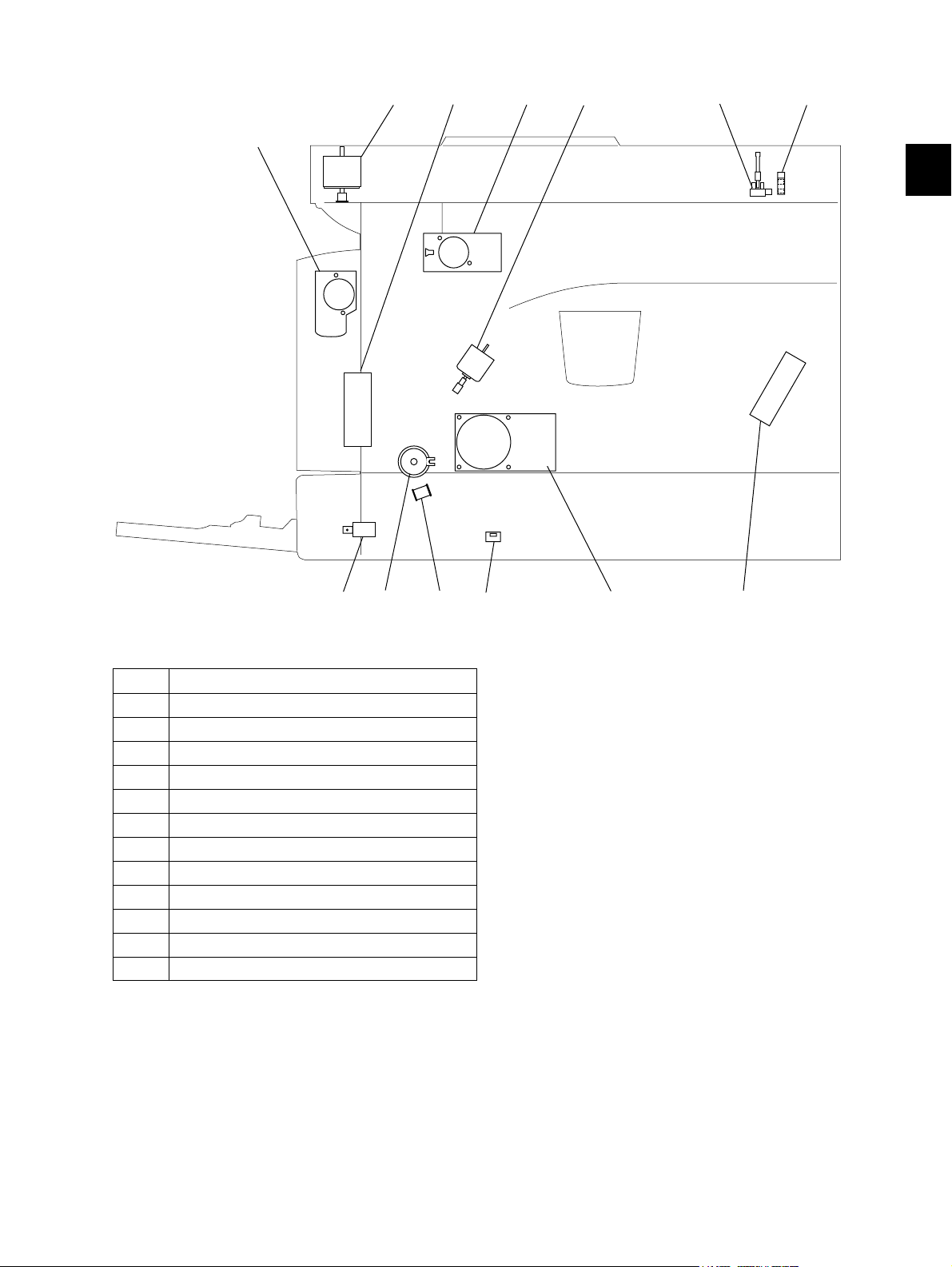

2.2 Electric Parts Layout

[A] Scanner, control panel

M1

S1

S2

CIS

LT series models

S13

S12

S11

DH2

THMO2

LCD

HPNL

S13

S12

S11

S10

S10

S9

DH1

Fig. 2-3

e-STUDIO182/212/242 © 2009 TOSHIBA TEC CORPORATION All rights reserved

OUTLINE OF THE MACHINE

2 - 4

Page 31

[B] Power supply section, switches

PS

2

SW3

SW2

SW4

SW1

S3

Fig. 2-4

© 2009 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO182/212/242

2 - 5

M6

OUTLINE OF THE MACHINE

Page 32

[C] Laser optical unit, fuser unit, toner cartridge section

CTRG

CTIF

M2

M7

S5

LAMP1

LAMP2

SNS

THMO1

THMS1

LDR

THMS2

M4

Fig. 2-5

e-STUDIO182/212/242 © 2009 TOSHIBA TEC CORPORATION All rights reserved

OUTLINE OF THE MACHINE

2 - 6

THMS3

Page 33

[D] Developer unit section

S6

2

ERS

M5

THMS4

FUS

THMO3

DH3

Fig. 2-6

© 2009 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO182/212/242

2 - 7

OUTLINE OF THE MACHINE

Page 34

[E] Driving section

SRAM

MAIN

CLT1

M3

PFC

SOL1

Fig. 2-7

e-STUDIO182/212/242 © 2009 TOSHIBA TEC CORPORATION All rights reserved

OUTLINE OF THE MACHINE

2 - 8

S4

Page 35

[F] Drawer section

2

SW5

S7

Fig. 2-8

© 2009 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO182/212/242

2 - 9

OUTLINE OF THE MACHINE

Page 36

[G] Bypass unit, automatic duplexing unit

M8

ADU

S8

SOL2

Fig. 2-9

e-STUDIO182/212/242 © 2009 TOSHIBA TEC CORPORATION All rights reserved

OUTLINE OF THE MACHINE

2 - 10

Page 37

2.3 Symbols and Functions of Various Components

The column "P-I" shows the page and item number in the parts list.

1. Motors

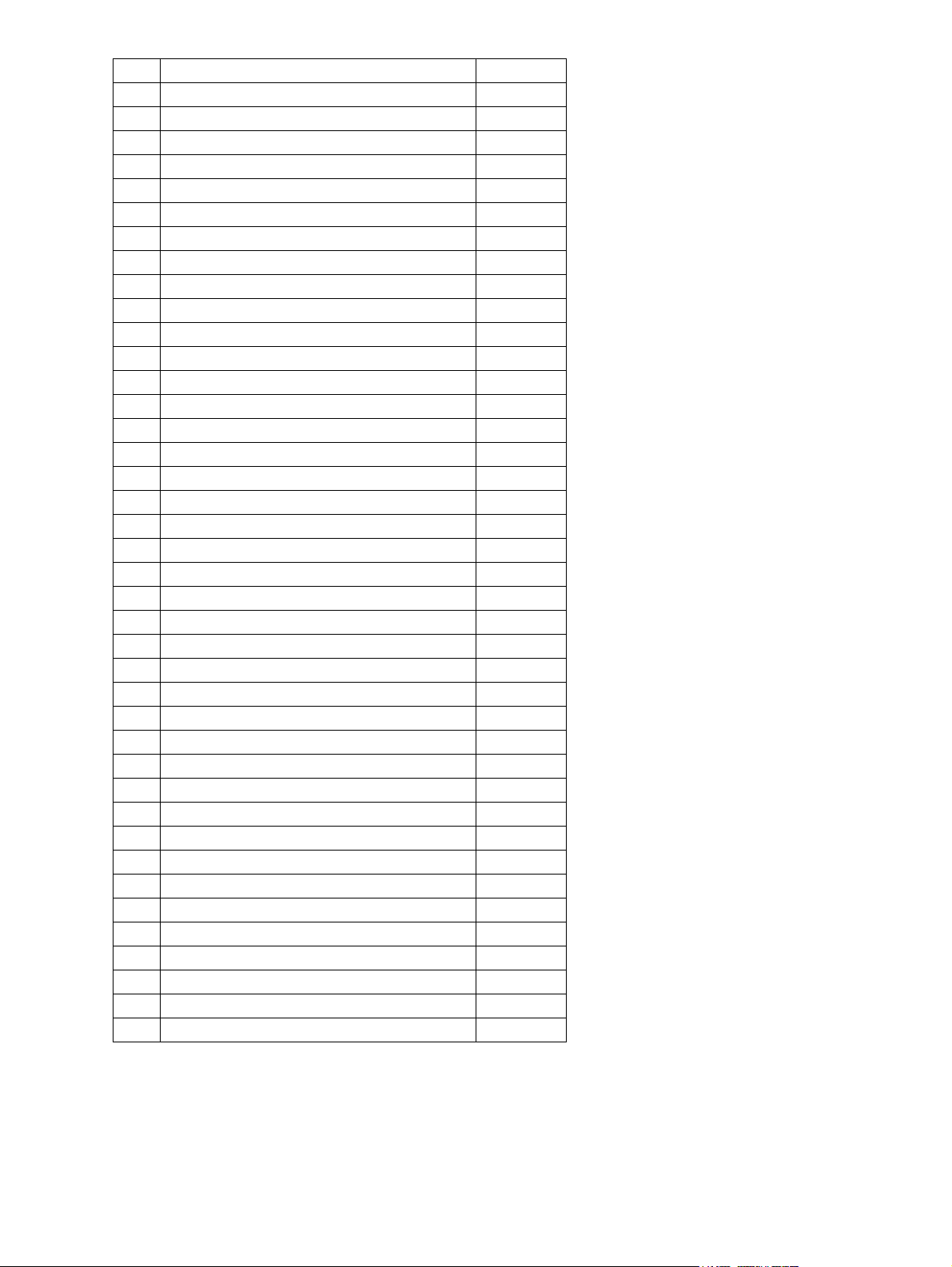

Symbol Name Function Remarks P-I

M1 SCAN-MOT

Scan motor

M2 TNR-MOT

Toner motor

M3 MAIN-MOT

Main motor

M4 M/DC-POL

Polygonal motor

M5 EXT-FAN-MOT

Exhaust fan

M6 PS-FAN-MOT

Switching regulator cooling fan

M7 EXIT-MOT

Exit motor

M8 ADU-MOT

ADU motor

Driving the CIS Fig. 2-3 10-1

Supplying the toner Fig. 2-5 12-15

Driving the drum, developer unit,

registration roller, Pickup roller, feed

roller, cleaner unit

Driving the polygonal mirror Fig. 2-5 5-13

Exhausting ozone and cooling down

the equipment inside

Cooling down the switching regulator Fig. 2-4 5-11

Driving the fuser unit and exit roller

*Option

Driving the automatic duplexing unit

*Option

Fig. 2-7 12-2

Fig. 2-6 11-23

Fig. 2-5 MD-0103

Fig. 2-9 MD-0103

2

2-2

1-23

© 2009 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO182/212/242

2 - 11

OUTLINE OF THE MACHINE

Page 38

2. Sensors and switches

Symbol Name Function Remarks P-I

S1 HOME-SNR

CIS home position sensor

S2 PLTN-SNR

Platen sensor

S3 TEMP/HUMI-SNR

Temperature/humidity sensor

S4 RGST-SNR

Registration sensor

S5 EXIT-SNR

Exit sensor

S6 ATTNR-SNR

Auto-toner sensor

S7 EMP-SNR

Paper empty sensor

S8 SFB-SNR

Bypass paper sensor

S9-13 APS 1-3, APS-C, APS-R

Automatic original detection sensor

SW1 MAIN-SW

Main switch

SW2 ADU-COV-INTLCK-SW

ADU cover opening/closing interlock

switch

Detecting CIS home position Fig. 2-3 10-106

Detecting the opening/closing of platen

Fig. 2-3 9-101

cover or RADF

Detecting the temperature and humidity

Fig. 2-4 5-16

inside the equipment

Detecting the transporting paper at the

Fig. 2-7 15-107

registration roller section

Detecting the transporting paper at the

Fig. 2-5 24-8

exit section

Detecting the density of toner in the

Fig. 2-6 21-46

developer unit

Detecting presence/absence of paper

Fig. 2-8 15-107

in the drawer

Detecting presence/absence of paper

Fig. 2-9 13-101

on the bypass tray

Detecting original size

* S9: only for A4 series models

Fig. 2-3 9-9,

9-19

Turning ON/OFF of the equipment Fig. 2-4 5-4

Controlling cutoff and supply of the 24V

Fig. 2-4 6-8

voltage by opening/closing of the ADU

cover

SW3 FRNT-COV-INTLCK-SW

Front cover opening/closing interlock

switch

SW4 FRNT-COV-SW

Front cover opening/closing switch

SW5 CST-SW

Drawer detection switch

Controlling cutoff and supply of the 24V

voltage by opening/closing of the front

cover

Detecting the opening/closing of the

front cover

Detecting presence/absence of the

drawer

Fig. 2-4 1-5

Fig. 2-4 1-101

Fig. 2-8 16-110

3. Electromagnetic clutch

Symbol Name Function Remarks P-I

CLT1 RGST-CLT

Driving the registration roller Fig. 2-7 16-21

Registration clutch

4. Solenoids

Symbol Name Function Remarks P-I

SOL1 CST-SOL

Pickup solenoid

SOL2 SFB-SOL

Bypass pickup solenoid

Controlling the power transmission of

the feed roller

Controlling the power transmission of

the bypass pickup roller

Fig. 2-7 16-9

Fig. 2-9 14-15

e-STUDIO182/212/242 © 2009 TOSHIBA TEC CORPORATION All rights reserved

OUTLINE OF THE MACHINE

2 - 12

Page 39

5. PC boards

Symbol Name Function Remarks P-I

MAIN PWA-F-MAIN

Main PC board (MAIN board)

SRAM PWA-F-SRAM

SRAM PC board (SRAM board)

LDR PWA-F-LDR

Laser driving PC board (LDR board)

SNS PWA-F-SNS

H-sync signal detection PC board

(SNS board)

HPNL PWA-F-HPNL

Control panel PC board

(HPNL board)

CTIF PWA-F-CTIF

Toner cartridge interface PC board

(CTIF board)

CTRG PWA-F-CTRG

Toner cartridge PC board

(CTRG board)

FUS PWA-F-FUS

Fuse PC board (FUS board)

PFC PWA-F-PFC

Paper feed controller PC board

(PFC board)

Controlling the whole system and

Fig. 2-7 7-1

image processing

Storing the setting information of the

Fig. 2-7 7-33

equipment

Driving the laser diode Fig. 2-5 5-13

Detecting the laser beam position Fig. 2-5 5-13

Detecting the button entry and

Fig. 2-3 4-20

controlling LED and LCD on the control

panel

Interface for detecting the toner

Fig. 2-5 7-30

cartridge

(Detecting the CTRG board)

Storing the status of the toner cartridge Fig. 2-5 103-3

Supplying power to each damp heater

Fig. 2-6 7-12

* Optional for NAD/MJD/CND model,

standard for other models

Controlling the automatic duplexing unit

Fig. 2-7 7-35

and paper feed pedestal

*Option

2

ADU PWA-F-ADU

ADU driving PC board (ADU board)

Controlling the automatic duplexing unit

*Option

Fig. 2-9 MD-0103

6. Lamps and heaters

Symbol Name Function Remarks P-I

LAMP1 CNTR-LAMP

Center heater lamp

LAMP2 SIDE-LAMP

Side heater lamp

ERS LP-ERS

Discharge LED

DH1 SCN-DH-L

Scanner damp heater (Left)

DH2 SCN-DH-R

Scanner damp heater (Right)

DH3 DRM-DH

Drum damp heater

Heating the center section of the fuser

roller

Heating the section of both sides of the

fuser roller

Removing the residual charge from the

drum surface

Preventing condensation in the

scanner unit

* Optional for NAD/MJD/CND model,

standard for other models

Preventing condensation in the

scanner unit

* Optional for NAD/MJD/CND model,

standard for other models

Preventing condensation of the drum

* Optional for NAD/MJD/CND model,

standard for other models

Fig. 2-5 23-12

Fig. 2-5 23-13

Fig. 2-6 20-13

Fig. 2-3 9-17

Fig. 2-3 9-18

Fig. 2-6 8-6

1-13

© 2009 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO182/212/242

2 - 13

OUTLINE OF THE MACHINE

Page 40

7. Thermistors and thermostats

Symbol Name Function Remarks P-I

THMS1 THMS-C-HTR

Center thermistor

Detecting the surface temperature at

the center of the fuser roller (for

Fig. 2-5 23-6

controlling the center heater lamp)

THMS2 THMS-S-HTR

Side thermistor

Detecting the surface temperature at

the rear side of the fuser roller (for

Fig. 2-5 23-6

controlling the side heater lamp)

THMS3 THMS-EDG-HTR

Edge thermistor

Detecting the surface temperature at

the edge of the rear side of the fuser

Fig. 2-5 23-6

roller (for preventing overheating)

THMS4 THMS-DRM

Drum thermistor

THMO1 THERMO-FSR

Detecting the temperature on the drum

Fig. 2-6 21-49

surface

Preventing overheating in the fuser unit Fig. 2-5 23-5

Fuser thermostat

THMO2 THERMO-SCN-DH

Scanner damp heater thermostat

Preventing overheating in the scanner

damp heater

Fig. 2-3 9-20

* Optional for NAD/MJD/CND model,

standard for other models

THMO3 THERMO-DRM-DH

Drum damp heater thermostat

Preventing overheating in the drum

damp heater

Fig. 2-6 8-7

* Optional for NAD/MJD/CND model,

standard for other models

8. Others

Symbol Name Function Remarks P-I

CIS CIS

Contact image sensor unit

PS PS-ACC

Switching regulator

LCD LCD

LCD panel

Reading originals Fig. 2-3 9-8

• Generating DC voltage and

Fig. 2-4 5-2

supplying it to each section of the

equipment

• Generating high voltage and

supplying it to the main charger,

developer, transfer and separation

units

• Supplying AC power to the heater

lamp

Displaying each information Fig. 2-3 4-19

e-STUDIO182/212/242 © 2009 TOSHIBA TEC CORPORATION All rights reserved

OUTLINE OF THE MACHINE

2 - 14

Page 41

2.4 General Description

2.4.1 System block diagram

)

device

10BASE-T/

USB connector

(

LAN connector

(

100BASE-TX)USB connector

Network printer kit

)

device

(

USB connector

)

16 bit

(

SDRAM bus

)

host

(

Scanner upgrade kit

16

SDRAM

SDRAM

16 16

SDRAM

64 MB

32 MB

16 MB

Battery

FAX board

NCU board

MODEM

8

SRAM

Battery

SRAM board

Control panel

8

128 kB

RTC

Download JIG

TELBOOK board

External keyboard

16

16

16

CPU bus (16 bit)

512 kB

Flash ROM

8

4 MB

Flash ROM

2

Clutches

Solenoids

Bypass unit

I/O

PFU

Motors

Sensors

Switches

8

)

ASIC

I/O port

(

Copy key card /

Coin controller

: Option

8

MAIN board

ADF/RADF

AFE

CIS

Driver

M

Scan motor

)

High voltage

DC

(

DC

LVPS

HVPS

Power supply unit

AC

SoC

(System controller)

D/A

converter

Laser optical unit

Fig. 2-10

ASIC

Laser diode

LDR board

Laser beam sensor

SNS board

A/D

converter

Drum thermistor

Auto-toner sensor

Developer unit

sensor

Thermistors

Temperature/humidity

Fuser unit

ADU

PFC

PFP

© 2009 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO182/212/242

OUTLINE OF THE MACHINE

2 - 15

Page 42

2.4.2 Construction of boards

[ 1 ] Construction diagram of boards

This system consists of the following including the MAIN board as a main board.

Control panel

HPNL

Toner cartridge

CTRGCTIF

Laser optical unit

LDR

SNS

Automatic duplexing unit

ADU

AC input

Scanner unit

CIS

FUS

PS-ACC

Main switch Cover opening/closing

SRAM

HVPS

LVPS

interlock switches

:

DC power supply line

:

AC power supply line

:

Signal line

MAIN

PFC

Fig. 2-11

[ 2 ] Function of each board

• MAIN board:

This is the board taking the leading part in all systems. It consists of the SoC, ASIC, memory

(SDRAM, Flash ROM), etc. In the SoC (System control), which is a core of this MAIN board, the

functions of the CPU, image processing, page memory control, CODEC, external interface (USB)

control, etc. are embedded and performed by one chip.

Based on the data input from the control panel, the SoC controls each system, such as the ASIC,

each memory, CIS unit and laser optical unit, and thus permitting the scanning of originals and the

printing of data.

• SRAM board:

This is the board on which the SRAM for storing the user's setting information and counter value and

its backup function are mounted. When the MAIN board is replaced, attaching this board to the new

MAIN board can assume the data of the previous equipment.

• HPNL board:

This is the board on which each button switch and LEDs on the control panel, and the LCD control

circuit are mounted.

• CTRG board:

This is the board on which the IC chip for storing information about the toner cartridge (number of

prints, identification data, etc.) is mounted.

• CTIF board:

This is the interface board with the CTRG board in the toner cartridge. Information written in the IC

chip on the CTRG board is read into the SoC on the MAIN board through this board.

• LDR board:

This is the board on which the laser diode and the ASIC are mounted. The laser is emitted based on

the image data signal output from the SoC on the MAIN board.

e-STUDIO182/212/242 © 2009 TOSHIBA TEC CORPORATION All rights reserved

OUTLINE OF THE MACHINE

2 - 16

Page 43

• SNS board:

This is the board on which the light sensor for detecting the radiating position of the laser is

mounted. It outputs the H-sync signal to the SoC on the MAIN board.

• PS-ACC:

This is the unit to generate each DC (high/low) voltage, which is used in the equipment, from the

external AC electric power input. This is then provided to each electric part.

• FUS board:

This is the board to provide AC electric power for driving the damp heater.

* Optional for NAD/MJD/CND model, standard for other models.

•CIS:

This is the unit witch performs optical-to-electrical conversion to convert the light reflected by the

original into the electrical signals. It consists of a light source (LEDs), optical system, CCD sensor,

etc.

• PFC board:

This is the board to control the optional Automatic Duplexing Unit (ADU) and optional Paper Feed

Pedestal (PFP).

• ADU board: