Page 1

SERVICE HANDBOOK

MULTIFUNCTIONAL DIGITAL SYSTEMS

e-STUDIO163/203

File No. SHE050005E0

R05092196300-TTEC

Ver05_2006-11

Page 2

Trademarks

• The official name of Windows 95 is Microsoft Windows 95 Operating System.

• The official name of Windows 98 is Microsoft Windows 98 Operating System.

• The official name of Windows Me is Microsoft Windows Millennium Edition Operating System.

• The official name of Windows 2000 is Microsoft Windows 2000 Operating System.

• The official name of Windows XP is Microsoft Windows XP Operating System.

• Microsoft, Windows, Windows NT and the brand names and product names of other Microsoft products are trademarks or registered trademarks of Microsoft Corporation in the U.S. and/or other countries.

• Molykote is a registered trademark of Dow Corning Corporation.

• Other company names and product names in this manual are the trademarks of their respective

companies.

© 2005 TOSHIBA TEC CORPORATION All rights reserved

Under the copyright laws, this manual cannot be reproduced in any form without prior written permission

of TOSHIBA TEC CORPORATION. No patent liability is assumed, however, with respect to the use of the

information contained herein.

Page 3

GENERAL PRECAUTIONS REGARDING THE SERVICE FOR e-STUDIO163/203

The installation and service should be done by a qualified service

technician.

1) Transportation/Installation

- When transporting/installing the equipment, remove the drawer, employ two persons and be sure

to hold the positions as shown in the figure.

The equipment is quite heavy and weighs approximately 32 kg (70.55 lb), therefore pay full attention when handling it.

- Be sure not to hold the movable parts or units when transporting the equipment.

- Be sure to use a dedicated outlet with AC 110 V / 13.2 A, 115 V or 127 V / 12 A, 220-240 V or 240

V / 8 A for its power source.

- The equipment must be grounded for safety.

- Select a suitable place for installation. Avoid excessive heat, high humidity, dust, vibration and

direct sunlight.

- Provide proper ventilation since the equipment emits a slight amount of ozone.

- To insure adequate working space for the copying operation, keep a minimum clearance of 80

cm (32”) on the left, 80 cm (32”) on the right and 10 cm (4”) on the rear.

- The equipment shall be installed near the socket outlet and shall be easily accessible.

- Be sure to fix and plug in the power cable securely after the installation so that no one trips over

it.

06/02

Page 4

2) General Precautions at Service

- Be sure to turn the power OFF and unplug the power cable during service (except for the service

should be done with the power turned ON).

- Unplug the power cable and clean the area around the prongs of the plug and socket outlet once

a year or more. A fire may occur when dust lies on this area.

- When the parts are disassembled, reassembly is the reverse of disassembly unless otherwise

noted in this manual or other related documents. Be careful not to install small parts such as

screws, washers, pins, E-rings, star washers in the wrong places.

- Basically, the equipment should not be operated with any parts removed or disassembled.

- The PC board must be stored in an anti-electrostatic bag and handled carefully using a wristband

since the ICs on it may be damaged due to static electricity.

Caution: Before using the wristband, unplug the power cable of the equipment and

make sure that there are no charged objects which are not insulated in the

vicinity.

- Avoid expose to laser beam during service. This equipment uses a laser diode. Be sure not to

expose your eyes to the laser beam. Do not insert reflecting parts or tools such as a screwdriver

on the laser beam path. Remove all reflecting metals such as watches, rings, etc. before starting

service.

- Be sure not to touch high-temperature sections such as the exposure lamp, fuser unit, damp

heater and areas around them.

- Be sure not to touch high-voltage sections such as the chargers, developer, high-voltage trans-

former and power supply unit. Especially, the board of these components should not be touched

since the electric charge may remain in the capacitors, etc. on them even after the power is

turned OFF.

- Make sure that the equipment will not operate before touching potentially dangerous places (e.g.

rotating/operating sections such as gears, belts pulleys, fans and laser beam exit of the laser

optical unit).

- Be careful when removing the covers since there might be the parts with very sharp edges

underneath.

- When servicing the equipment with the power turned ON, be sure not to touch live sections and

rotating/operating sections. Avoid exposing your eyes to laser beam.

- Use designated jigs and tools.

- Use recommended measuring instruments or equivalents.

- Return the equipment to the original state and check the operation when the service is finished.

3) Important Service Parts for Safety

- The breaker, door switch, fuse, thermostat, thermofuse, thermistor, IC-RAMs including lithium

batteries, etc. are particularly important for safety. Be sure to handle/install them properly. If

these parts are short-circuited and their functions become ineffective, they may result in fatal

accidents such as burnout. Do not allow a short-circuit or do not use the parts not recommended

by Toshiba TEC Corporation.

4) Cautionary Labels

- During servicing, be sure to check the rating plate and cautionary labels such as “Unplug the

power cable during service”, “CAUTION. HOT”, “CAUTION. HIGH VOLTAGE”, “CAUTION.

LASER BEAM”, etc. to see if there is any dirt on their surface and if they are properly stuck to the

equipment.

Page 5

5) Disposal of the Equipment, Supplies, Packing Materials, Used Batteries and IC-RAMs

- Regarding the recovery and disposal of the equipment, supplies, packing materials, used batter-

ies and IC-RAMs including lithium batteries, follow the relevant local regulations or rules.

Caution:

Dispose of used batteries and IC-RAMs including lithium batteries according to this manual.

Attention:

Se débarrasser de batteries et IC-RAMs usés y compris les batteries en lithium selon ce manuel.

Vorsicht:

Entsorgung der gebrauchten Batterien und IC-RAMs (inclusive der Lithium-Batterie) nach diesem Handbuch.

Page 6

Page 7

CONTENTS

e-STUDIO163/203

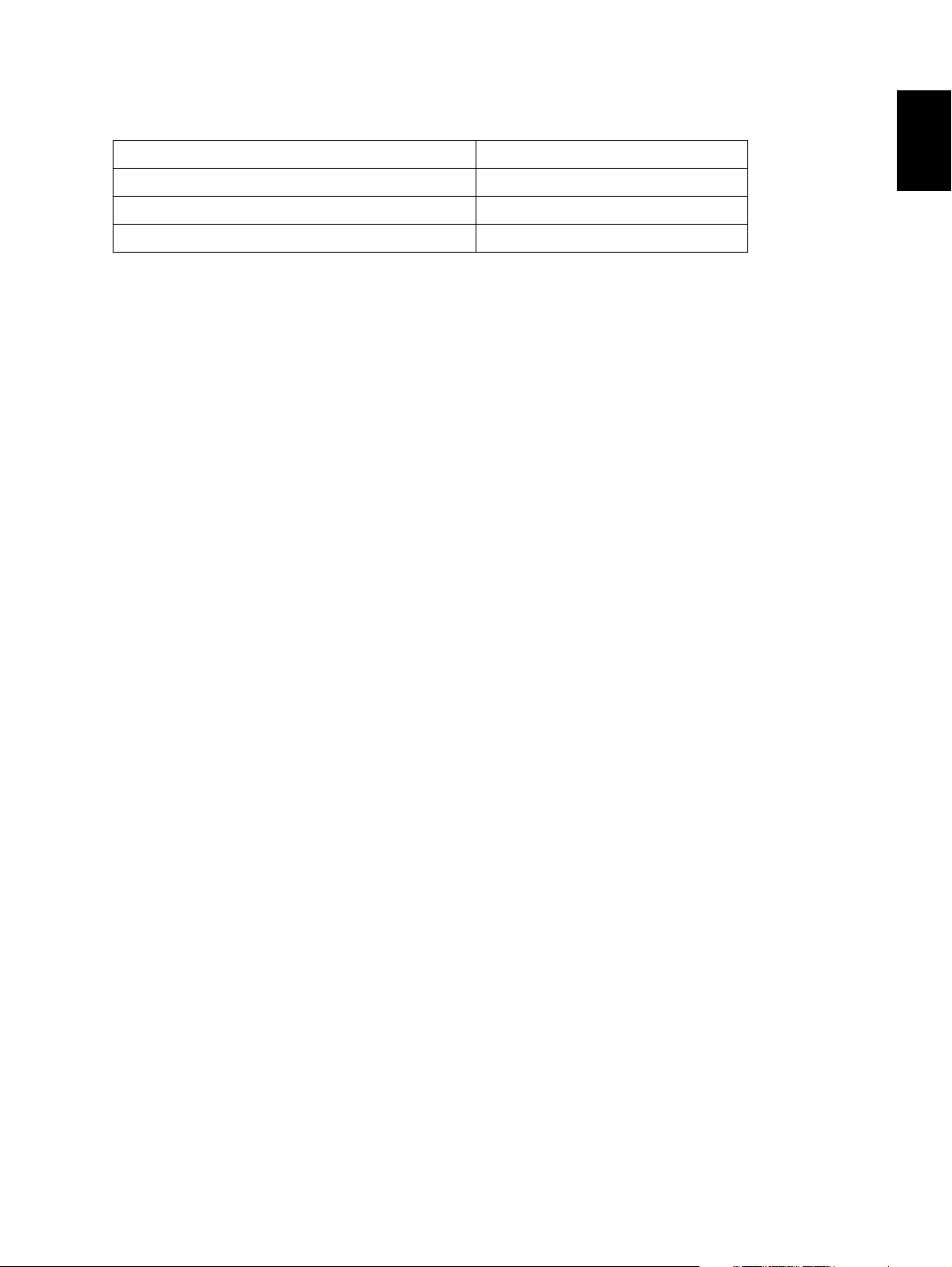

1. SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES ................................... 1-1

1.1 Specifications....................................................................................................................... 1-1

1.2 Accessories ......................................................................................................................... 1-4

1.3 Options ................................................................................................................................ 1-5

1.4 Supplies............................................................................................................................... 1-6

1.5 System List .......................................................................................................................... 1-7

2. ERROR CODE AND SELF-DIAGNOSTIC MODE........................................................ 2-1

2.1 Error Code List..................................................................................................................... 2-1

2.1.1 Jam........................................................................................................................... 2-1

2.1.2 Service call ...............................................................................................................2-2

2.2 Self-diagnosis Modes .......................................................................................................... 2-3

2.2.1 Input check (Test mode 03)...................................................................................... 2-5

2.2.2 Output check (Test mode 04) ................................................................................... 2-8

2.2.3 Test print mode (Test mode 07) ............................................................................. 2-10

2.2.4 List Print Mode (9S)................................................................................................ 2-11

2.2.5 Access code mode (8S) ......................................................................................... 2-13

2.2.6 Function Setting Mode (1*)..................................................................................... 2-15

2.2.7 Adjustment mode (05) ............................................................................................ 2-16

2.2.8 Setting mode (08) ................................................................................................... 2-32

3. ADJUSTMENT .............................................................................................................. 3-1

3.1 Adjustment of Auto-Toner Sensor ....................................................................................... 3-1

3.2 Image Dimensional Adjustment........................................................................................... 3-3

3.2.1 General description .................................................................................................. 3-3

3.2.2 Paper alignment at the registration roller ................................................................. 3-5

3.2.3 Printer related adjustment ........................................................................................ 3-7

3.2.4 Scanner related adjustment ................................................................................... 3-11

3.3 Image Quality Adjustment (Copying Function) .................................................................. 3-19

3.3.1 Density adjustment ................................................................................................. 3-19

3.3.2 Gamma slope adjustment ...................................................................................... 3-20

3.3.3 Sharpness adjustment............................................................................................ 3-21

3.3.4 Setting range correction ......................................................................................... 3-22

3.3.5 Setting range correction (Adjustment of background peak) ................................... 3-22

3.3.6 Setting range correction (Adjustment of text peak) ................................................ 3-23

3.3.7 Adjustment of smudged/faint text ........................................................................... 3-23

3.3.8 Adjustment of image density .................................................................................. 3-24

3.4 Image Quality Adjustment (Printing Function) ................................................................... 3-25

3.4.1 Adjustment of smudged/faint text ........................................................................... 3-25

3.4.2 Adjustment of image density .................................................................................. 3-26

3.5 Image Quality Adjustment (Scanning Function) ................................................................ 3-27

3.5.1 Density adjustment ................................................................................................. 3-27

3.5.2 Sharpness adjustment............................................................................................ 3-28

3.5.3 Setting range correction ......................................................................................... 3-29

3.5.4 Setting range correction (Adjustment of background peak) ................................... 3-29

3.5.5 Setting range correction (Adjustment of text peak) ................................................ 3-30

3.6 Adjustment of High-Voltage Transformer .......................................................................... 3-31

3.6.1 Adjustment ............................................................................................................. 3-31

3.6.2 Precautions ............................................................................................................ 3-37

3.7 Adjustment of the Scanner Section ................................................................................... 3-39

3.7.1 CIS unit...................................................................................................................3-39

3.7.2 CIS unit drive belt-1 ................................................................................................ 3-39

3.7.3 Scan motor (CIS unit drive belt-2) .......................................................................... 3-40

© July 2006 TOSHIBA TEC e-STUDIO163/203 CONTENTS

1

Page 8

3.8 Adjustment of the Paper Feeding System ......................................................................... 3-41

3.8.1 Sheet sideways deviation caused by paper feeding .............................................. 3-41

3.9 Adjustment of Developer Unit ............................................................................................ 3-42

3.9.1 Doctor-to-sleeve gap .............................................................................................. 3-42

3.10 Adjustment of the ADF (MR-2017) .................................................................................... 3-45

3.10.1 Adjustment of ADF Position ................................................................................... 3-45

3.10.2 Adjustment of ADF Height...................................................................................... 3-50

3.10.3 Adjustment of Skew................................................................................................ 3-52

3.10.4 Adjustment of the Leading Edge Position .............................................................. 3-54

3.10.5 Adjustment of Horizontal Position .......................................................................... 3-55

3.10.6 Adjustment of Copy Ratio....................................................................................... 3-56

3.10.7 Adjustment of ADF Opening/Closing Sensor ......................................................... 3-57

4. PREVENTIVE MAINTENANCE (PM)............................................................................ 4-1

4.1 General Descriptions for PM Procedure .............................................................................. 4-1

4.2 Operational Items in Overhauling ........................................................................................ 4-2

4.3 Preventive Maintenance Checklist....................................................................................... 4-3

4.4 PM KIT............................................................................................................................... 4-12

4.5 Jig List ............................................................................................................................... 4-13

4.6 Grease List ........................................................................................................................ 4-14

4.7 Precautions for Storing and Handling Supplies ................................................................. 4-15

4.7.1 Precautions for storing TOSHIBA supplies ............................................................ 4-15

4.7.2 Checking and cleaning of photoconductive drum................................................... 4-16

4.7.3 Checking and cleaning of drum cleaning blade...................................................... 4-17

4.7.4 Checking and cleaning of fuser roller and pressure roller ...................................... 4-17

5. TROUBLESHOOTING .................................................................................................. 5-1

5.1 Diagnosis and Prescription for Each Error Code ................................................................. 5-1

5.1.1 Paper transport jam .................................................................................................. 5-1

5.1.2 Paper misfeeding ..................................................................................................... 5-4

5.1.3 Cover open jam ........................................................................................................ 5-7

5.1.4 Transport jam (ADF)............................................................................................... 5-10

5.1.5 Drive system related service call ............................................................................ 5-13

5.1.6 Scanning system related service call ..................................................................... 5-14

5.1.7 Fuser unit related service call................................................................................. 5-15

5.1.8 ADF related service call ......................................................................................... 5-17

5.1.9 Laser optical unit related service call ..................................................................... 5-17

5.1.10 Service call for others............................................................................................. 5-18

5.2 Troubleshooting for the Image........................................................................................... 5-19

5.3 Replacement of PC Boards ............................................................................................... 5-41

5.3.1 Replacing MAIN board ........................................................................................... 5-41

5.3.2 Replacing SRAM board .......................................................................................... 5-41

6. FIRMWARE UPDATING ............................................................................................... 6-1

6.1 Firmware Updating with Download Jig ................................................................................ 6-1

6.1.1 PWA-DWNLD-350-JIG ............................................................................................. 6-3

6.1.2 Writing the data to the download jig (PWA-DWNLD-350-JIG) ................................. 6-6

6.1.3 K-PWA-DLM-320...................................................................................................... 6-7

6.2 Firmware Updating with TOSHIBA Viewer .......................................................................... 6-8

7. POWER SUPPLY UNIT ................................................................................................ 7-1

7.1 Output Channel ................................................................................................................... 7-1

7.2 Fuse..................................................................................................................................... 7-2

7.3 Configuration of Power Supply Unit..................................................................................... 7-3

e-STUDIO163/203 CONTENTS © July 2006 TOSHIBA TEC

2

Page 9

8. WIRE HARNESS CONNECTION.................................................................................. 8-1

8.1 AC Wire Harness ................................................................................................................. 8-1

8.2 DC Wire Harness....................................................................................................... Appendix

8.3 Electric Parts Layout.................................................................................................. Appendix

© July 2006 TOSHIBA TEC e-STUDIO163/203 CONTENTS

3

Page 10

e-STUDIO163/203 CONTENTS © July 2006 TOSHIBA TEC

4

Page 11

1. SPECIFICATIONS / ACCESSORIES /

OPTIONS / SUPPLIES

2. ERROR CODE AND SELF-DIAGNOSTIC

MODE

3. ADJUSTMENT

4. PREVENTIVE MAINTENANCE (PM)

5. TROUBLESHOOTING

1

2

3

4

5

6. FIRMWARE UPDATING

7. POWER SUPPLY UNIT

8. WIRE HARNESS CONNECTION

6

7

8

Page 12

Page 13

1. SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1.1 Specifications

Values in [ ] are for e- STUDIO203 in case that the specification is different among e-STUDIO163

and e-STUDIO203.

Copy process Indirect electrophotographic process (dry)

Type Desktop type

Original table Fixed type (the left rear corner used as guide to place originals)

Accepted originals Sheet, book and 3-dimensional object. The automatic document feeder

(ADF) only accepts paper which are not pasted or stapled. (Single-sided orig-

inals: 50 to 127 g/m

either.

Maximum size: A3/LD

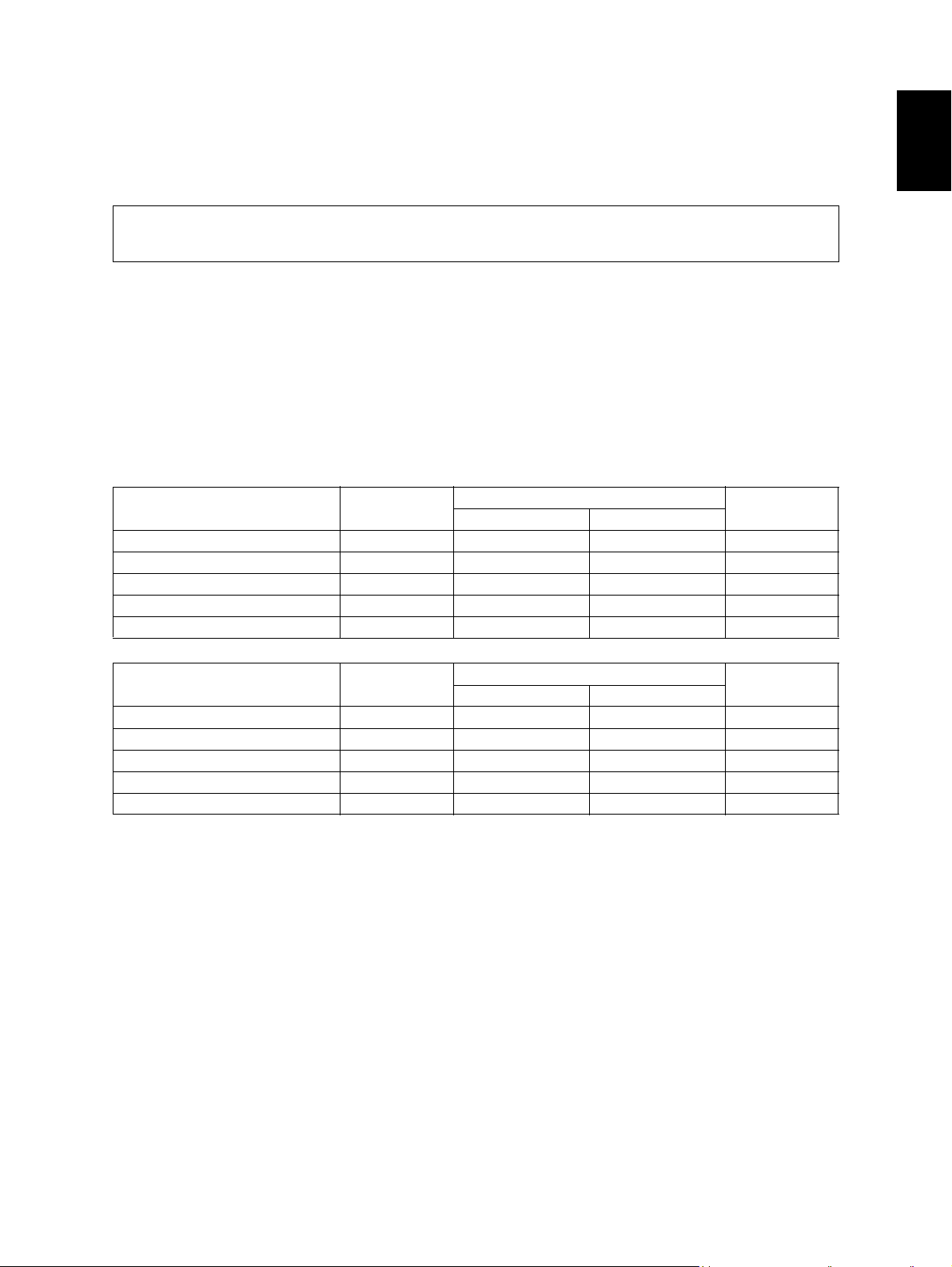

Copy speed (Copies/min.)

e-STUDIO163

Paper size Drawer

A4, B5, LT 16 16 11 16

A5-R, ST-R - 16 11 -

A4-R, B5-R, LT-R 15.5 15.5 11 15.5

B4, LG, FOLIO, COMPUTER 13 13 11 13

A3 , L D 11 11 11 11

2

/13 to 34 lb. Bond) Carbon paper are not acceptable

Bypass feed

Size specified Size not specified

PFU

1

e-STUDIO203

Paper size Drawer

A4, B5, LT 20 20 11 20

A5-R, ST-R - 20 11 -

A4-R, B5-R, LT-R 15.5 15.5 11 15.5

B4, LG, FOLIO, COMPUTER 13 13 11 13

A3 , L D 11 11 11 11

Size specified Size not specified

Bypass feed

PFU

* “–” means “Not acceptable”.

* The copy speed in the above table are available when originals are manually placed for single side,

multiple copying.

* When the ADF is used, the copy speed of 16[20] sheets per minute is only available under the fol-

lowing conditions:

• Original/Mode: Single side original/A4/LT size. APS/automatic density are not selected.

• Number of sheets: 16[20] or more.

• Reproduction ratio: 100%

© December 2005 TOSHIBA TEC e-STUDIO163/203 SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1 - 1

Page 14

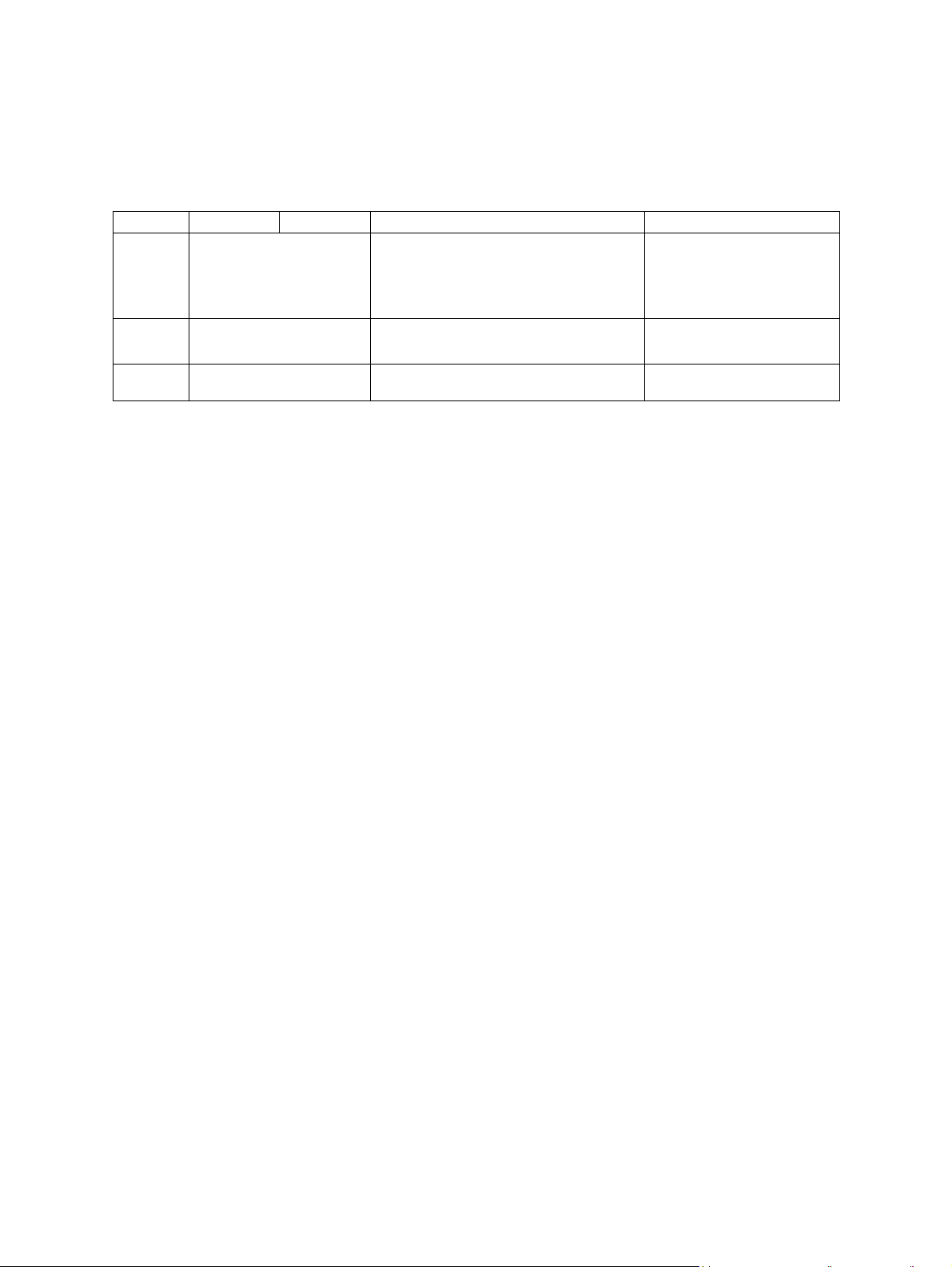

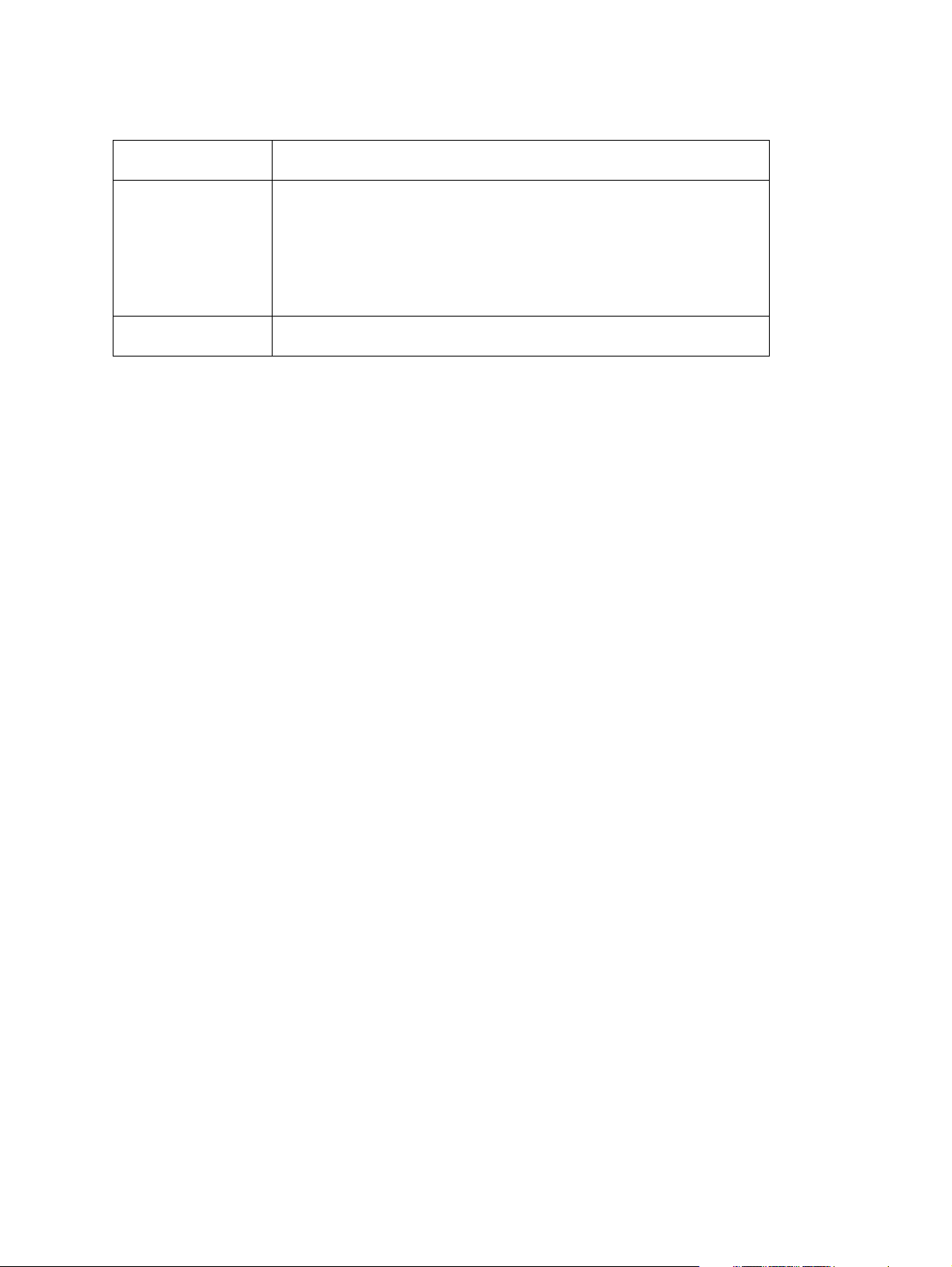

Copy speed for thick paper (Copies/min.)

e-STUDIO163/203

2

Thick 1 (81 g/m

Thick 2 (106 g/m

to 105 g/m2, 21.3 lb. Bond to 28 lb. Bond): Bypass feed on a sheet by sheet basis only

2

to 163 g/m2, 28 lb. Bond to 90 lb. Index): Bypass feed on a sheet by sheet basis only

Copy paper

Drawer PFU Bypass copy Remarks

Size A3, A4, A4-R, B4, B5,

B5-R, LD, LG, LT, LT-R,

FOLIO, COMPUTER,

13"LG, 8.5" x 8.5", 8K,

16K, 16K-R

Weight

Special

paper

64 to 80 g/m

– Tracing paper, labels, OHP film

2

A3 to A5-R, LD to ST-R, FOLIO, COMPUTER, 13"LG, 8.5" x 8.5", 8K, 16K,

16K-R

(Non-standard or user-specified sizes

can be set.)

50 to 163 g/m2(Single paper feeding)

64 to 80 g/m2(Continuous feeding)

(thickness: 80 µm or thicker),

These special papers recommended by Toshiba Tec

First copy time ..................... Approx. 7.6 sec. (A4, 100%, original placed manually)

Approx. 7.7 sec. (LT, 100%, original placed manually)

Warming-up time.................. Approx. 25 sec. (temperature: 20°C)

Multiple copying ................... Up to 999 copies; Key in set numbers

Reproduction ratio ............... Actual ratio: 100±0.5%

Zooming: 25 to 200% in increments of 1%

Resolution/Gradation ........... Scanning: 600 dpi x 600 dpi

Printing: Equivalent to 2400 dpi x 600 dpi

Gradation: 256 steps

Eliminated portion ................ Leading edges: 3.0±2.0 mm, Side/trailing edges: 2.0±2.0 mm (copy)

Leading / trailing edges: 5.0±2.0 mm, Side edges: 5.0±2.0 mm (print)

Paper feeding ......................... Standard drawer:

1 drawer (stack height 28 mm, equivalent to 250 sheets; 64 to

80 g/m

2

(17 to 22 lb. Bond))

Bypass feeding:

Stack height 11.8 mm: equivalent to 100 sheets; 64 to 80 g/m

(17 to 22 lb. Bond)

Paper Feed Unit (PFU):

Option (One drawer: stack height 28 mm, equivalent to 250

sheets; 64 to 80 g/m

2

(17 to 22 lb. Bond))

Capacity of originals in the automatic document feeder (Option)

.................................................. A3 to A5-R, LD to ST-R:

100 sheets / 80 g/m

2

(Stack height 16 mm or less)

Toner supply........................... Automatic toner density detection/supply

Toner cartridge replacing method (There is a recovered toner supply

mechanism.)

2

e-STUDIO163/203 SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES © December 2005 TOSHIBA TEC

1 - 2

06/04

Page 15

Density control ..................... Automatic density mode and manual density mode selectable in 7

steps

Weight.................................. Approximately 32 kg (70.55 lb.) (excluding the developer material and

toner)

Power requirements............. AC 110 V / 13.2 A, 115 V or 127 V / 12 A

220-240 V or 240 V / 8 A (50/60 Hz)

* The acceptable value of each voltage is ±10%.

Power consumption ............. 1.5 kW or less (100 V series)

1.6 kW or less (200 V series)

* The electric power is supplied to the ADF and PFU through the equipment.

Total counter ........................ Electronical counter

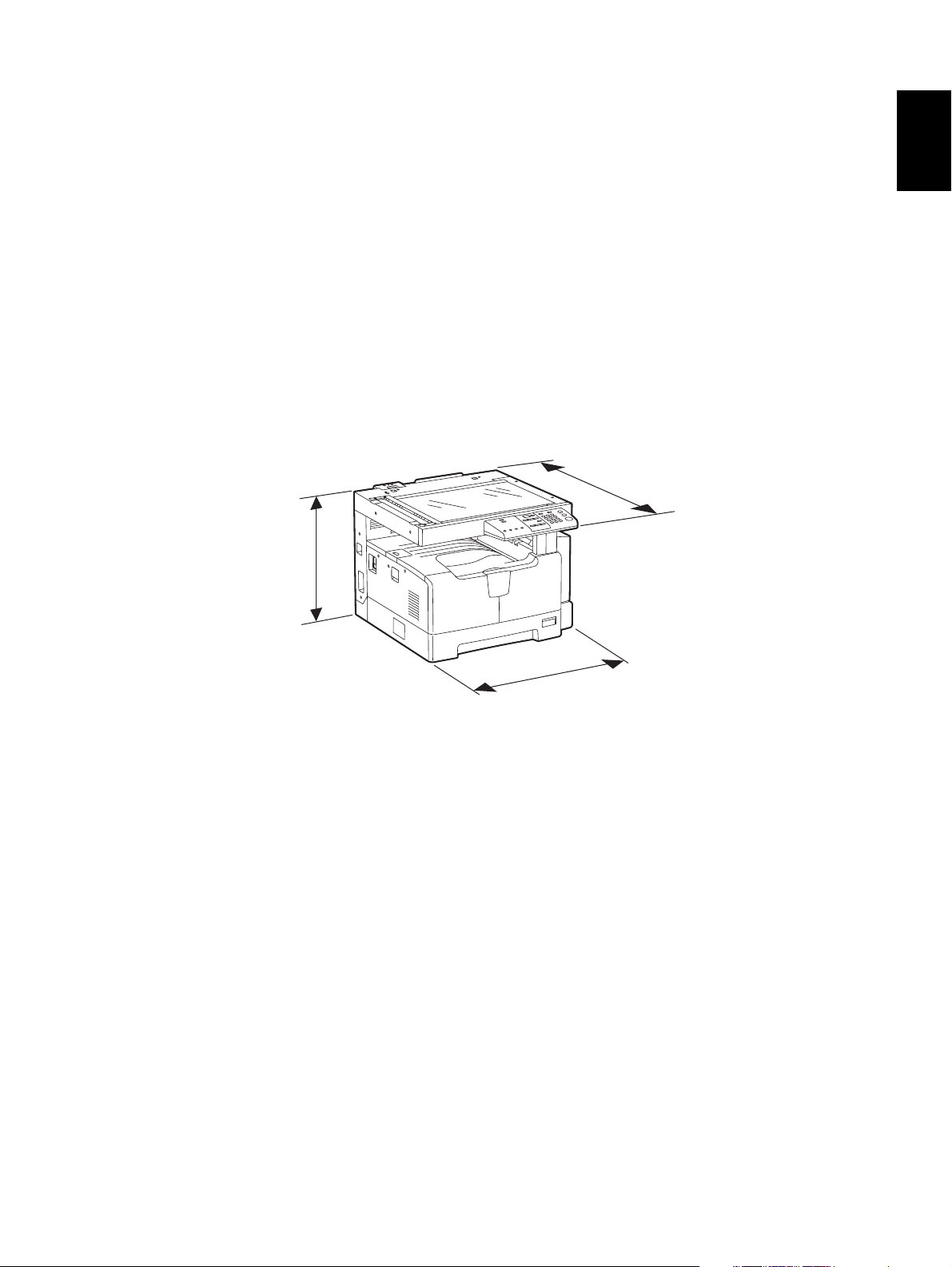

Dimensions of the equipment

.................................................. W 600 x D 643 x H 462.5 (mm): See the figure below

D

1

H

W

Fig. 1-1

© December 2005 TOSHIBA TEC e-STUDIO163/203 SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1 - 3

06/04

Page 16

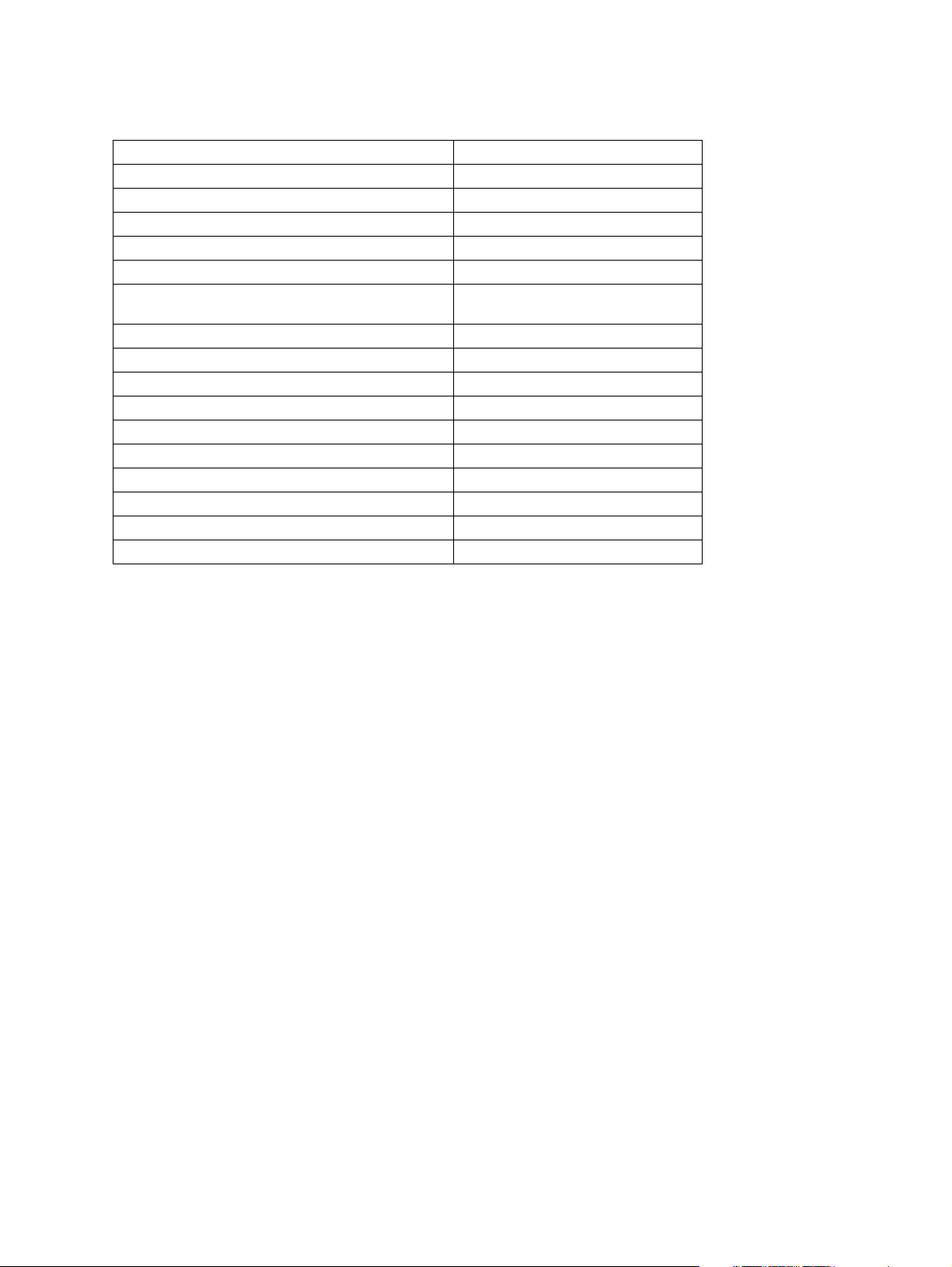

1.2 Accessories

Unpacking/setup instruction 1 set

Operator’s manual 1 pc.

Operator's manual pocket 1 pc.

Power cable 1 pc.

CD-ROM 2 pcs.

Rubber plug 6 pcs.

Transfer charger wire cleaner

(installed inside of the transfer cover)

Drum (installed inside of the equipment) 1 pc.

Developer material 1 pc.

Nozzle 1 pc.

Toner cartridge 1 pc.

Warranty sheet 1 pc. (for NAD and CND)

Setup report 1 set (for NAD, MJD and CND)

Customer satisfaction card 1 pc. (for MJD)

Packing list 1 pc. (for CND)

Customer survey sheet 1 pc. (for CND)

Certificate of conformance 1 pc. (for CND)

1 pc.

* Machine version

NAD: North America

ASD: Hong Kong / Latin America

AUD: Australia

MJD: Europe

ASU: Asia / Saudi Arabia

SAD: Saudi Arabia

ARD: Latin America

CND: China

TWD: Taiwan

KRD: Korea

JPD: Japan

e-STUDIO163/203 SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES © December 2005 TOSHIBA TEC

1 - 4

06/04

Page 17

1.3 Options

Platen Cover KA-1640 PC

Automatic Document Feeder (ADF) MR-2017

Paper Feed Unit (PFU) MY-1027 / C

Expansion Memory GC-1240

1

© December 2005 TOSHIBA TEC e-STUDIO163/203 SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1 - 5

Page 18

1.4 Supplies

Drum OD-1600 (except for China)

OD-2320 (for China)

Toner cartridge PS-ZT1640 (4) (for North America)

Developer material D-2320 (except for China)

PS-ZT1640D (4) (for Asia, Central and South America)

PS-ZT1640D5K (4) (for Asia, Central and South America)

PS-ZT1640C (4) (for China)

PS-ZT1640C5K (4) (for China)

PS-ZT1640T (4) (for Taiwan)

PS-ZT1640E (1) (for Europe)

PS-ZT1640E5K (1) (for Europe)

D-2320C (for China)

e-STUDIO163/203 SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES © December 2005 TOSHIBA TEC

1 - 6

Page 19

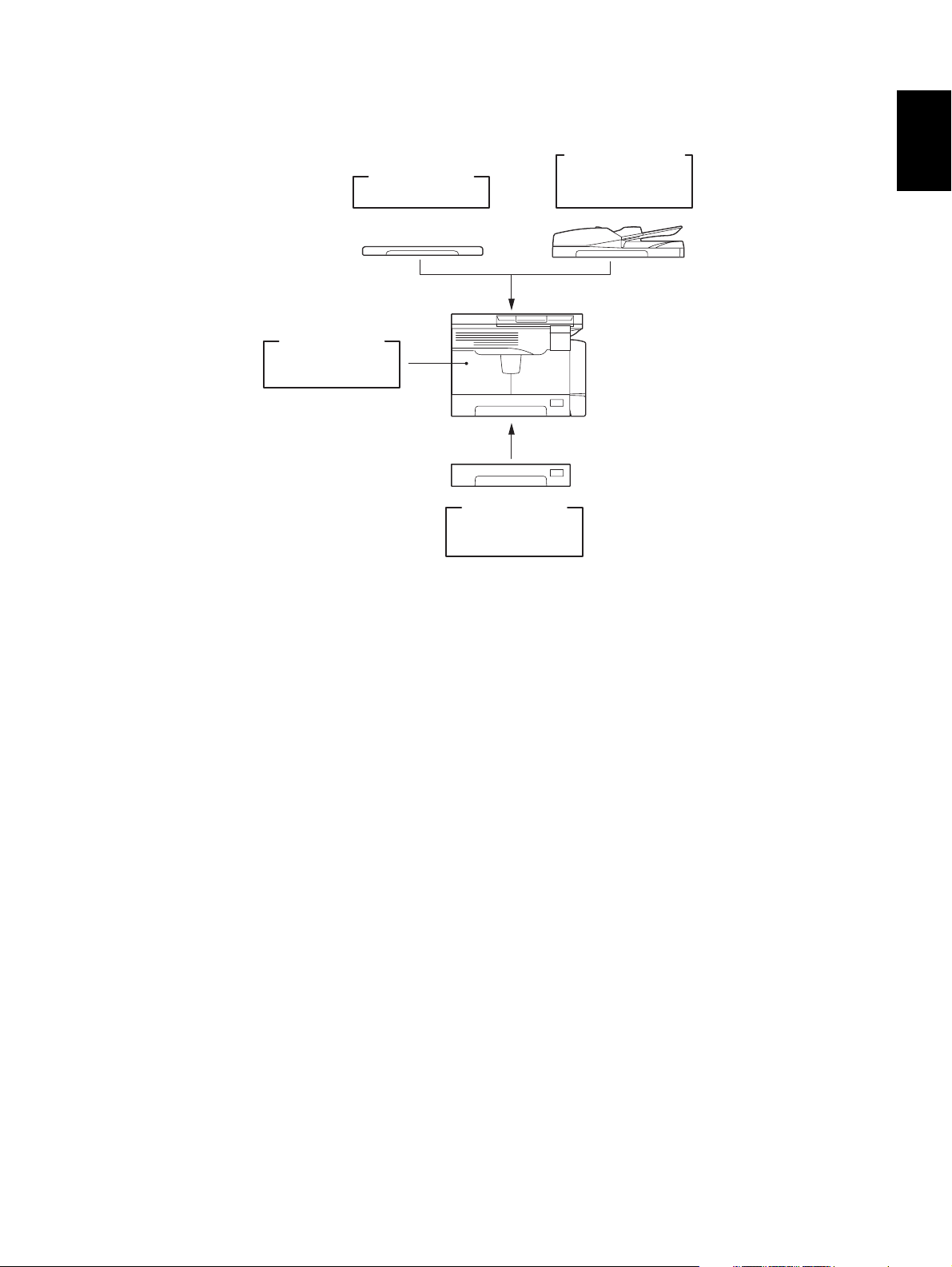

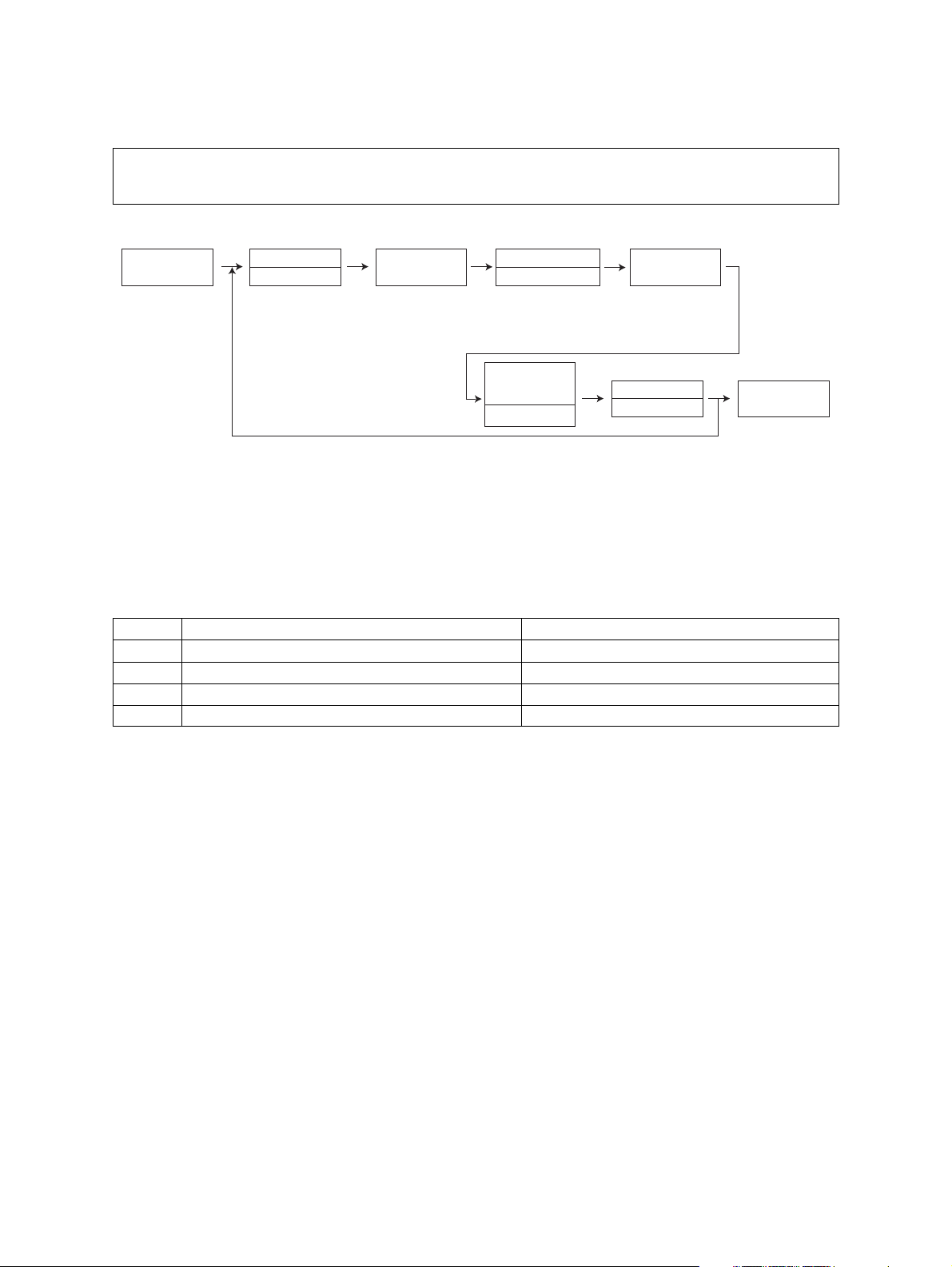

1.5 System List

Expansion

Memory

GC-1240

Platen Cover

KA-1640PC

Paper Feed

Unit (PFU

MY-1027

Fig. 1-2

Automatic

Document Feeder

(

ADF

MR-2017

)

1

)

© December 2005 TOSHIBA TEC e-STUDIO163/203 SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1 - 7

Page 20

e-STUDIO163/203 SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES © December 2005 TOSHIBA TEC

1 - 8

Page 21

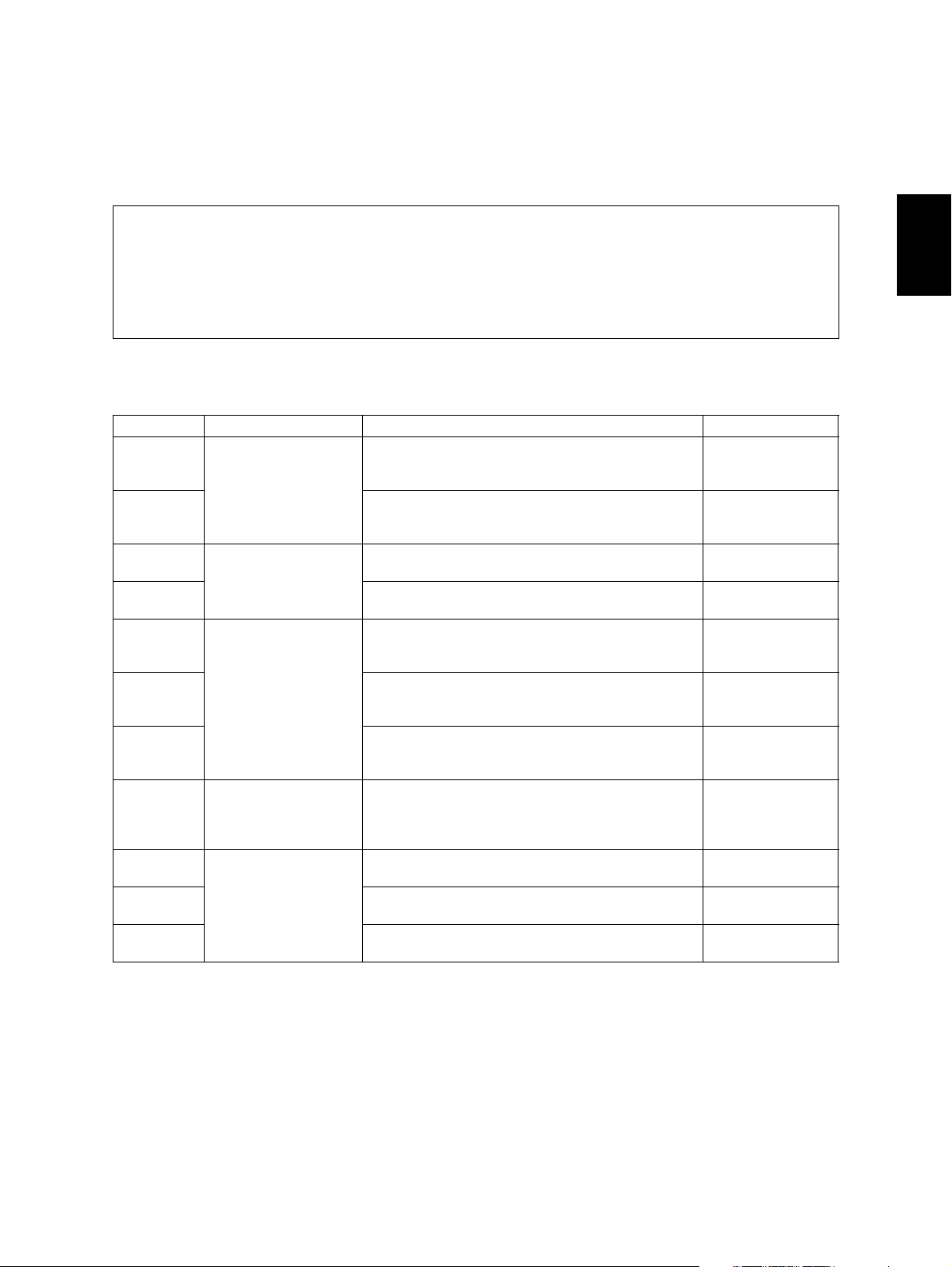

2. ERROR CODE AND SELF-DIAGNOSTIC MODE

2.1 Error Code List

• One of the following error codes is displayed with “7-segment LED” while pressing the [CLEAR/

STOP] button and the digital key [8] simultaneously when the “CLEAR PAPER” or “CALL

SERVICE” symbol is blinking.

• "CALL SERVICE" symbol blinks: A service call occurs.

• "CALL SERVICE" symbol lights: PM cycle (This symbol lights at the time of preventive maintenance. Copying can be performed.)

2.1.1 Jam

Error code Classification Contents Troubleshooting

E01 Paper exit jam Jam not reaching the exit sensor: The paper which

has passed through the fuser unit does not reach

the exit sensor.

E02 Stop jam at the exit sensor: The trailing edge of the

paper does not pass the exit sensor after its leading

edge has reached this sensor.

E03 Other paper jam Power-ON jam: The paper is remaining on the

paper transport path when power is turned ON.

E09 Jam at the registration area due to registration time-

out error

E12 Paper misfeeding Bypass misfeeding (Paper not reaching the regis-

tration sensor): The paper fed from the bypass tray

does not reach the registration sensor.

E13 Drawer misfeeding (Paper not reaching the regis-

tration sensor): The paper fed from the drawer does

not reach the registration sensor.

E14 PFU drawer misfeeding (Paper not reaching the

PFU feed sensor): The paper fed from the PFU

drawer does not reach the PFU feed sensor.

E21 Paper transport jam PFU drawer transport jam (Paper not reaching the

registration sensor): The paper does not reach the

registration sensor after it has passed the PFU feed

sensor.

E40 Cover open jam Transfer cover open jam: The transfer cover has

opened during printing.

E41 Front cover open jam: The front cover has opened

during printing.

E44 PFU cover open jam: The PFU cover has opened

during printing.

P. 5 - 1

P. 5 - 1

P. 5 - 2

-

P. 5 - 4

P. 5 - 5

P. 5 - 6

P. 5 - 3

P. 5 - 7

P. 5 - 8

P. 5 - 9

2

© December 2005 TOSHIBA TEC e-STUDIO163/203 ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 1

06/11

Page 22

Error code Classification Contents Troubleshooting

E71 ADF jam Jam not reaching the original registration sensor:

P. 5 - 10

The original fed from the original feeding tray does

not reach the original registration sensor.

E72 Jam not reaching the read sensor: The original

P. 5 - 10

does not reach the read sensor after it has passed

the registration sensor.

E73 Stop jam at the exit sensor: The trailing edge of the

P. 5 - 11

original does not pass the exit sensor after its leading edge has reached this sensor.

E86 ADF jam access cover open: The ADF jam access

P. 5 - 11

cover has opened during ADF operation.

E87 ADF open jam: ADF has opened during ADF opera-

P. 5 - 12

tion.

2.1.2 Service call

Error code Classification Contents Troubleshooting

C01 Drive system

related service call

C21 Scanning system

C26 Peak detection error: Lighting of the exposure lamp

related service call

C41 Fuser unit related

service call

C43 Thermistor abnormality during warming up or in ready

C44 Heater abnormality after abnormality judgment: The tem-

C45 Thermistor abnormality during printing: Abnormality of the

C55 Optional communi-

cation related ser-

vice call

C97 Process related

service call

CA1 Laser optical unit

related service call

CA2 H-Sync detection error: H-Sync detection PC board can-

F14 Other service call Invalid backup counter: The value of the total counter is

Main motor abnormality: The main motor is not rotating

P. 5-13

normally.

CIS unit initialization error -

P. 5-14

(white reference) is not detected when power is turned

ON.

Thermistor or heater abnormality at power-ON: Abnor-

P. 5-15

mality of service call the thermistor is detected when

power is turned ON or the temperature of the fuser roller

does not rise in a specified period of time after power is

turned ON.

status after abnormality judgment

P. 5-16

perature of the fuser roller has exceeded the range of

control (in this case, the main switch turns OFF automatically) or does not even reach the range.

P. 5-16

thermistor is detected during printing.

ADF I/F error: Communication error has occurred

between the ADF and the scanner

High-voltage transformer abnormality: Leakage of the

P. 5-18

main charger is detected.

Polygonal motor abnormality: The polygonal motor is not

P. 5-17

rotating normally.

P. 5-17

not detect laser beams.

P. 5-18

inconsistent with that of the backup counter.

-

-

e-STUDIO163/203 ERROR CODE AND SELF-DIAGNOSTIC MODE © December 2005 TOSHIBA TEC

2 - 2

06/04

Page 23

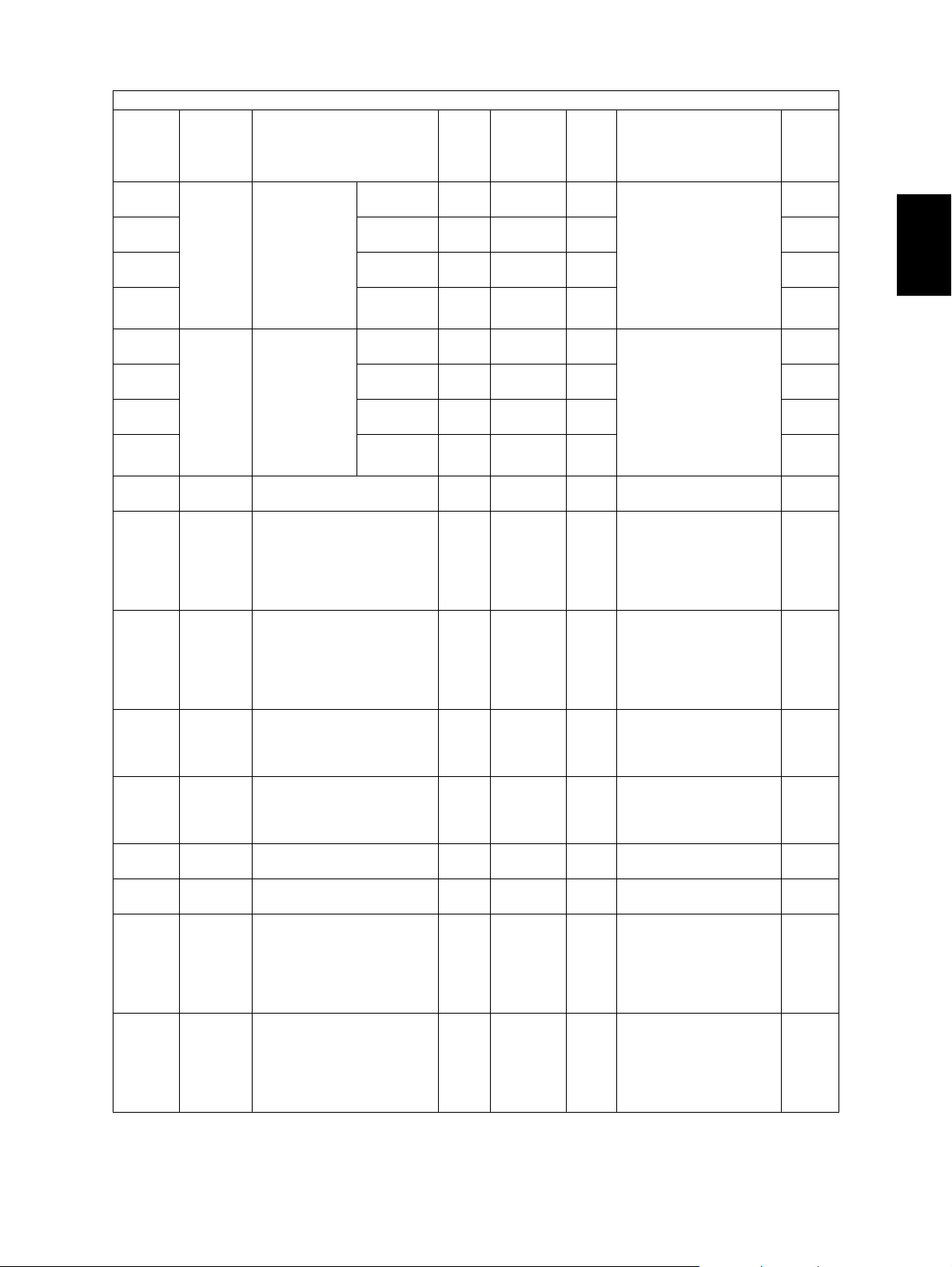

2.2 Self-diagnosis Modes

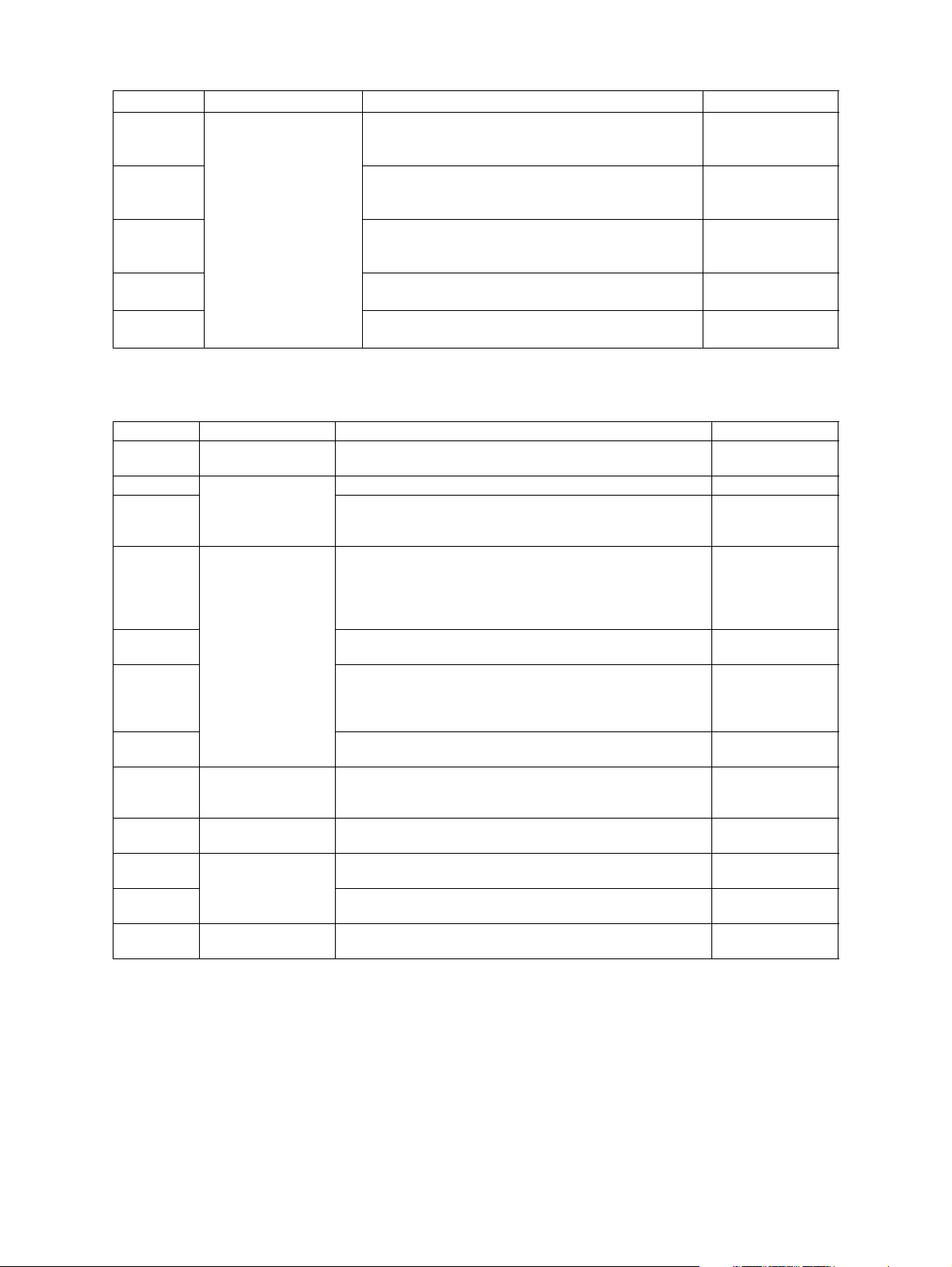

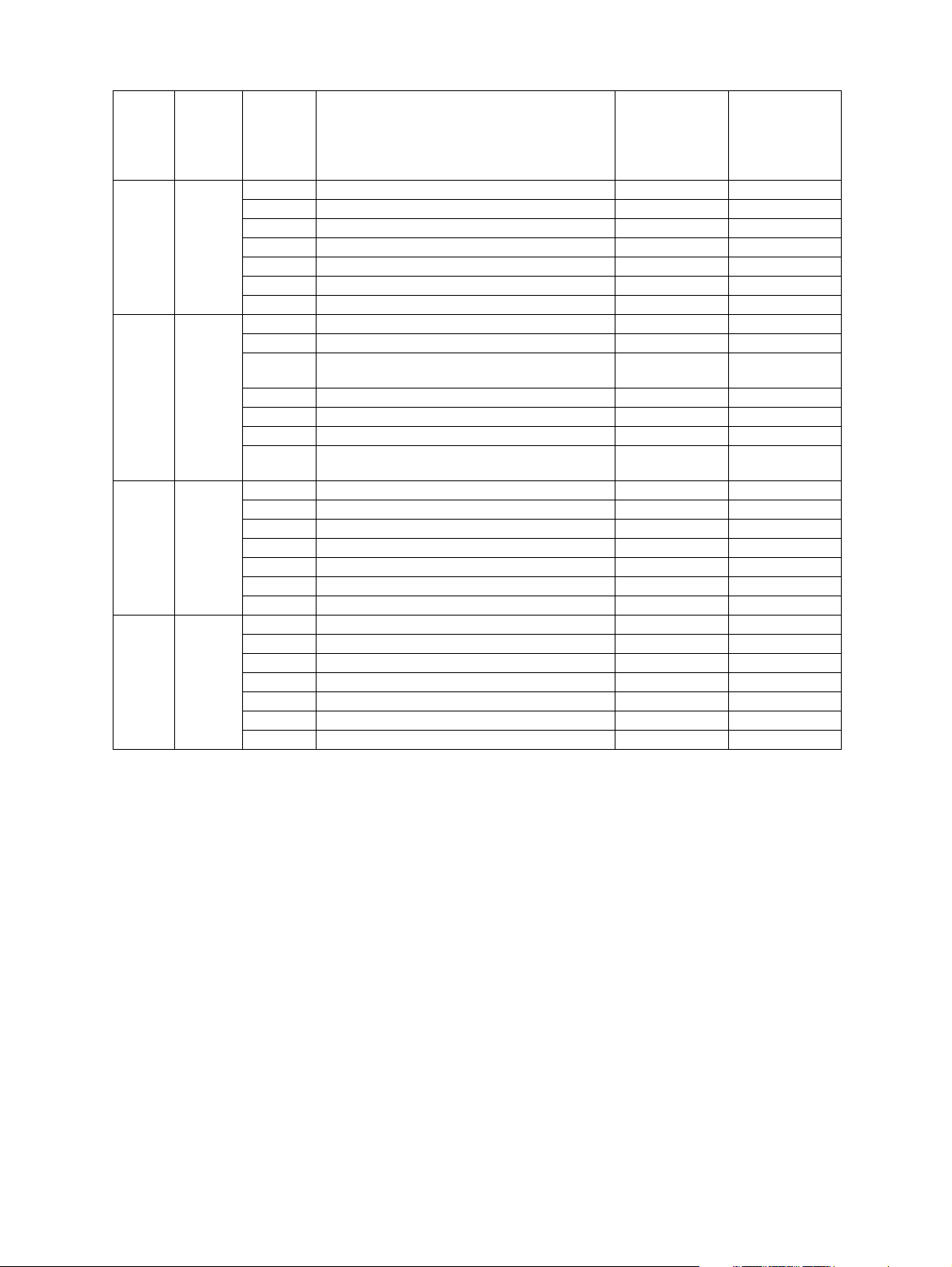

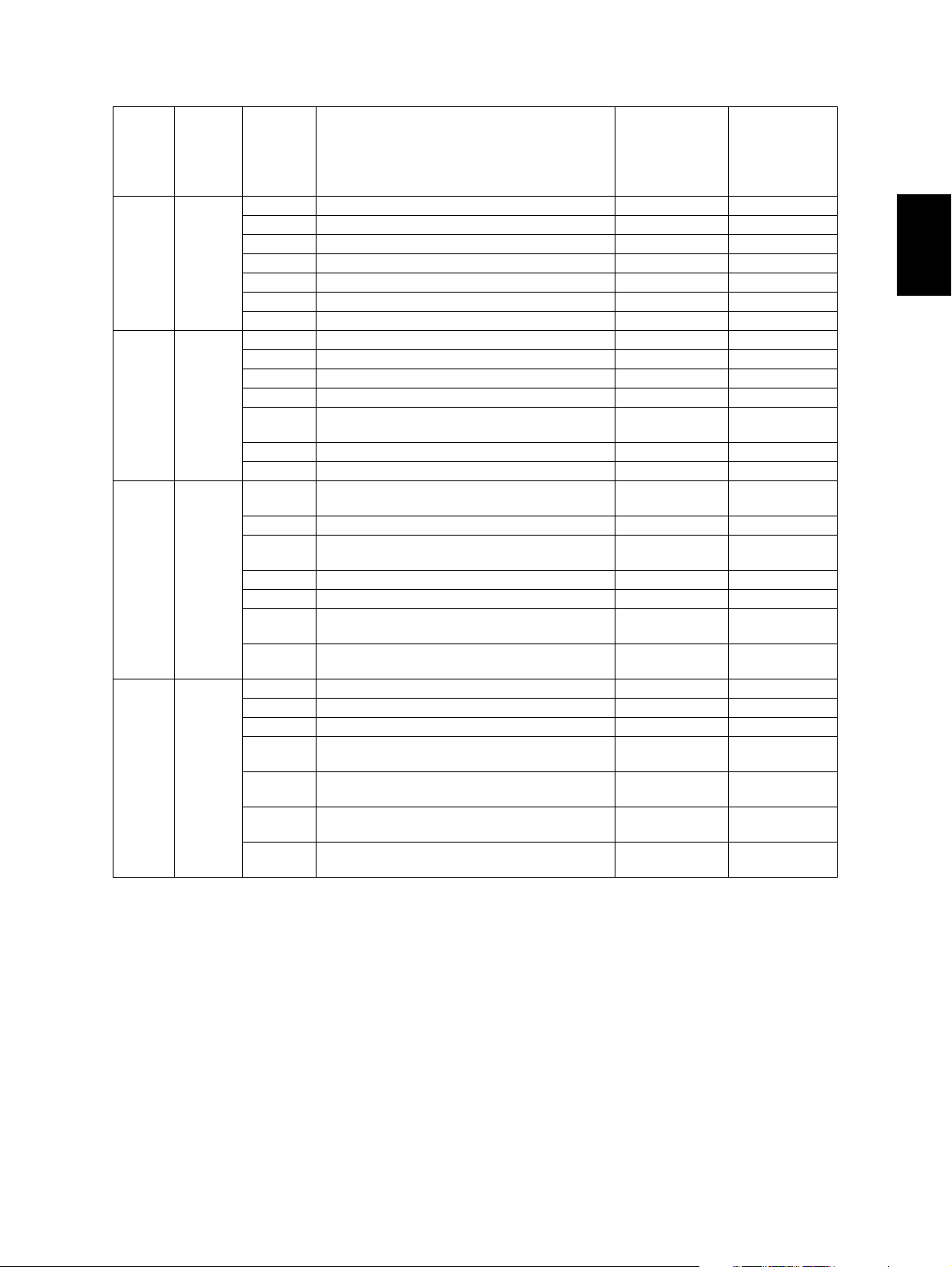

Mode For start Contents For exit Display

Input check

mode

[0]+[3]+

[POWER]

Checks the status of input signals. [POWER]

OFF/ON

Output check

mode

Te s t p r in t

mode

Adjustment

mode

Setting mode [0]+[8]+

List print mode [9]+[START]

Access code

mode

Function setting mode

[0]+[4]+

[POWER]

[0]+[7]+

[POWER]

[0]+[5]+

[POWER]

[POWER]

+[POWER]

[8]+[START]

+[POWER]

[1]+[*]+

[POWER]

Checks the status of output signals. [POWER]

OFF/ON

Outputs the test patterns. [POWER]

OFF/ON

Adjusts various items. [POWER]

OFF/ON

Sets various items. [POWER]

OFF/ON

Prints out the data lists of the codes 05/08 and

pixel counter.

[POWER]

OFF/ON

Registers / deletes the access code. [POWER]

OFF/ON

Sets the function table. [POWER]

OFF/ON

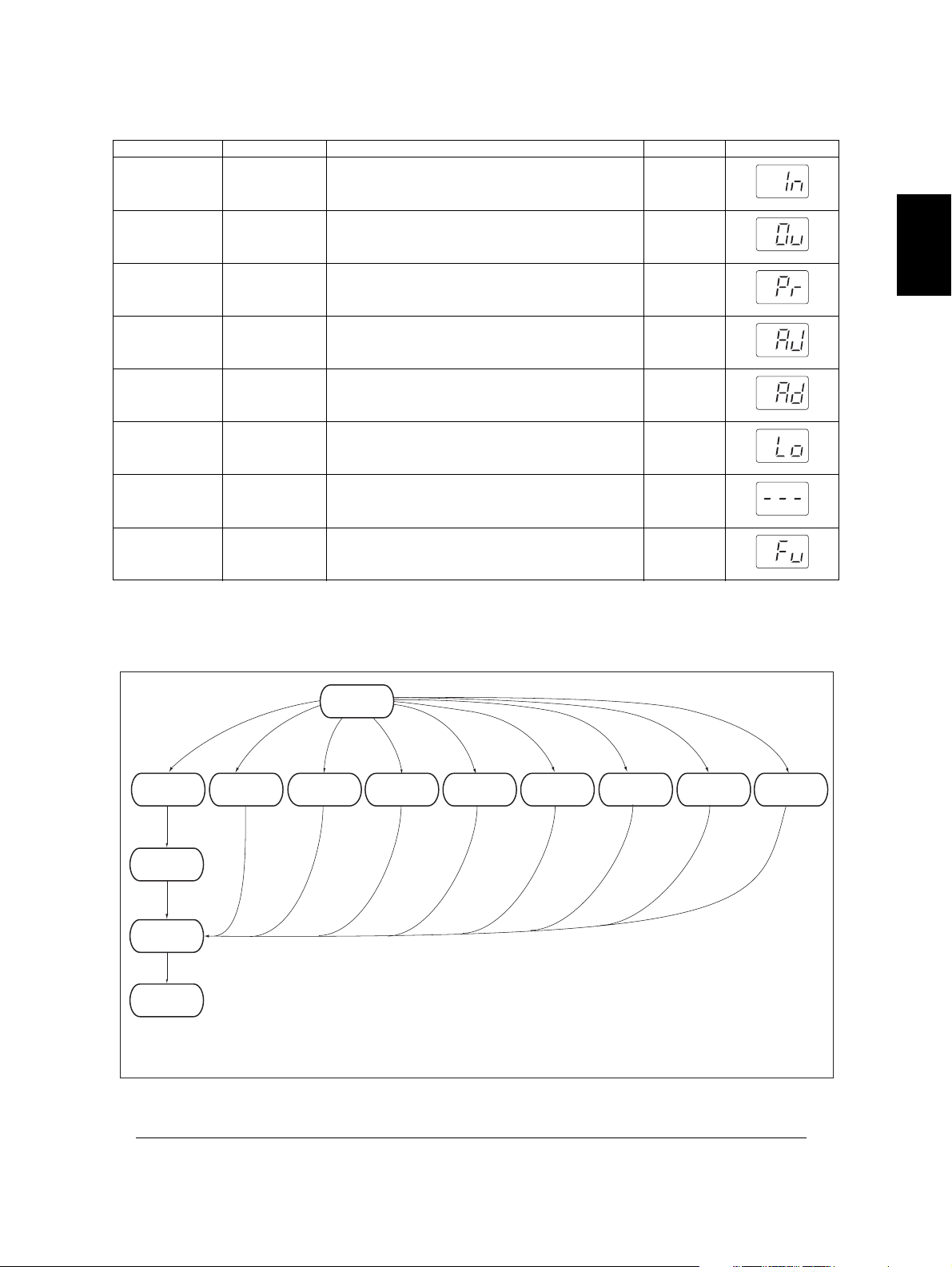

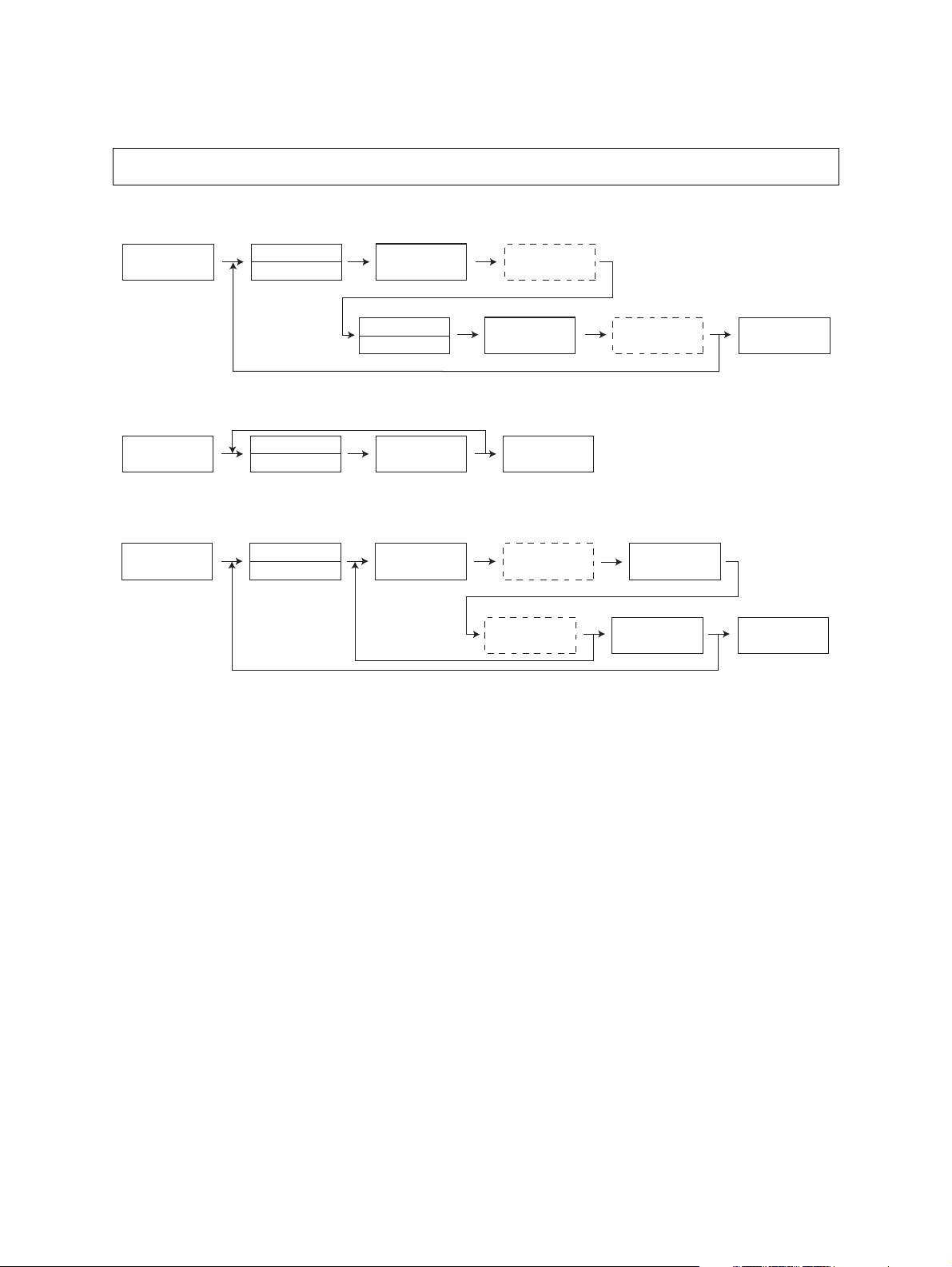

Note: Note:

To enter the desired mode, turn ON the power while two digital keys designated to each mode

(e.g. [0] and [5]) are pressed simultaneously.

2

[POWER]

Warming up

Ready

[POWER]

OFF

To user

*1

Normal

Input check

[0][3] [0][4]

mode

Output check

mode

ON

[0][7] [0][5] [0][8] [1][*][9][START] [8][START]

Test print

mode

Adjustment

mode

Setting

mode

List print

mode

Access code

mode

Function

setting mode

State transition diagram of self-diagnosis modes

Fig. 2-1

*1 Turn OFF the power after using the self-diagnosis modes, and leave the equipment to the user.

© December 2005 TOSHIBA TEC e-STUDIO163/203 ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 3

Page 24

<Operation procedure>

• Input check mode (03): Refer to P. 2-5 "2.2.1 Input check (Test mode 03)".

• Output check mode (04): Refer to P. 2-8 "2.2.2 Output check (Test mode 04)".

• Test print mode (07): Refer to P. 2-10 "2.2.3 Test print mode (Test mode 07)".

• Adjustment mode (05): Refer to P. 2-16 "2.2.7 Adjustment mode (05)".

• Setting mode (08): Refer to P. 2-32 "2.2.8 Setting mode (08)".

• List print mode (9S):Refer to P. 2-11 "2.2.4 List Print Mode (9S)"

• Access code mode (8S): P. 2-13 "2.2.5 Access code mode (8S)"

• Function setting mode (1*): P. 2-15 "2.2.6 Function Setting Mode (1*)"

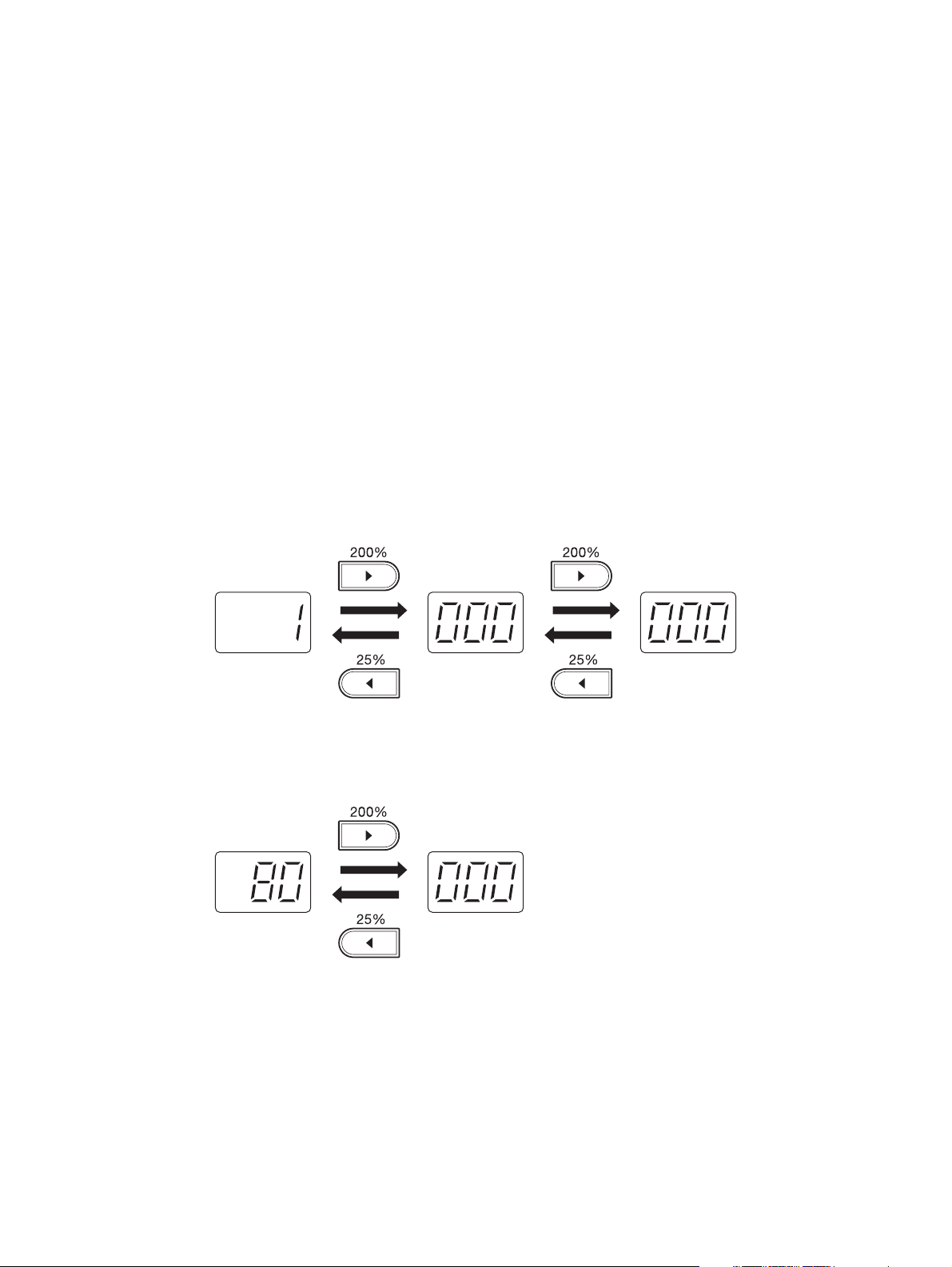

<Number display>

The numbers are displayed on a 7-segment LED.

A number of more than 3 digits long is separated as follows, and is displayed from the high-order position. Press the reproduction ratio button ([200%] or [25%]) to shift the display to the 3 digits of the next

lower/higher order.

E.g.1) Displaying 1,000,000

Fig. 2-2

E.g. 2) Displaying 80,000

Fig. 2-3

e-STUDIO163/203 ERROR CODE AND SELF-DIAGNOSTIC MODE © December 2005 TOSHIBA TEC

2 - 4

Page 25

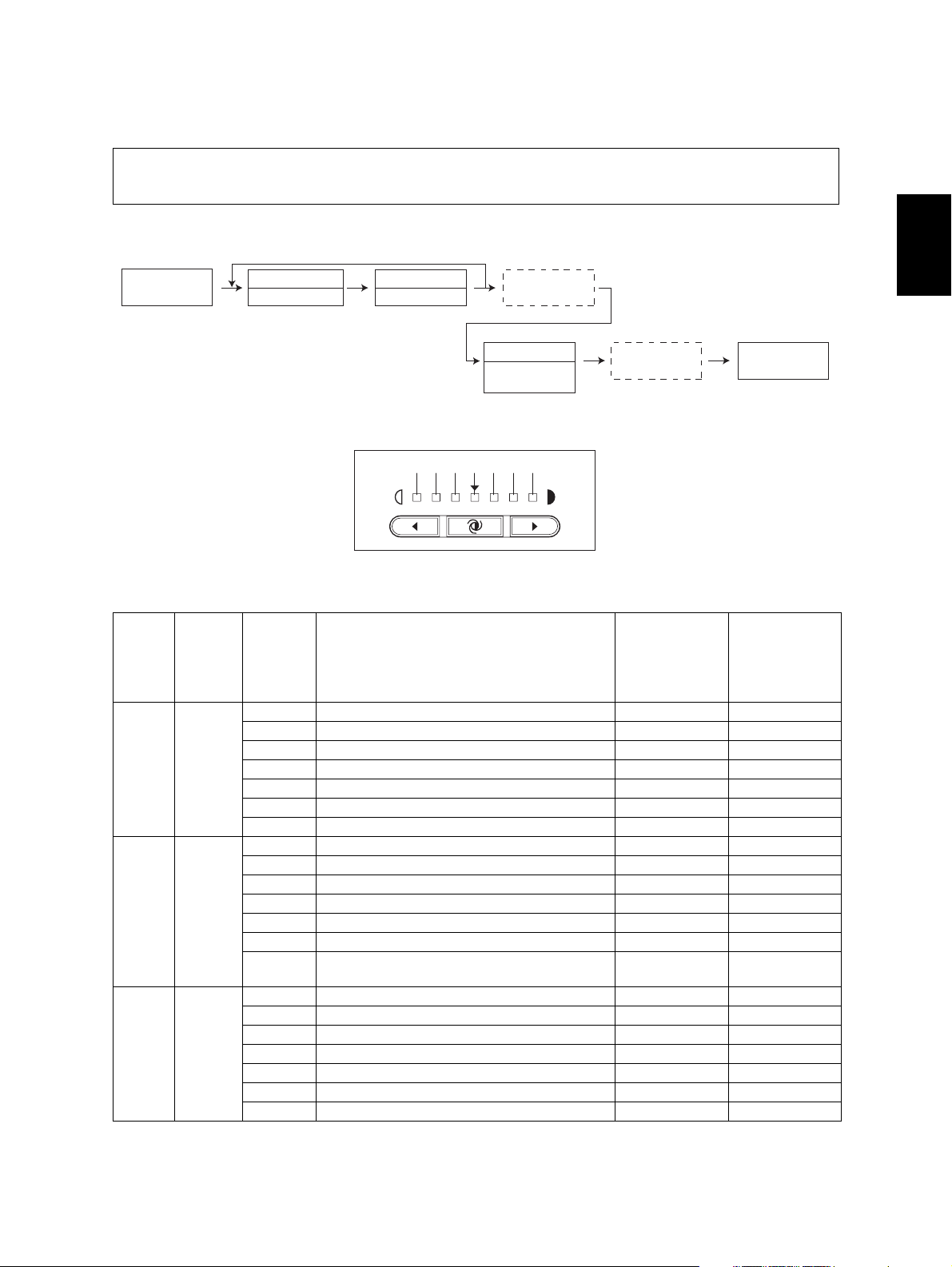

2.2.1 Input check (Test mode 03)

The status of each input signal can be checked by pressing the [INTERRUPT] button, and the digital keys in the test mode (03).

<Operation procedure>

[0][3]

[POWER]

Group

[INTERRUPT]

Number

[Digital keys]

LED ON

END

[FUNCTION

CLEAR]

LED OFF

[POWER]

OFF/ON

Group is displayed by ON/OFF of the [INTERRUPT] LED, and the number keyed in is displayed with

the 7-segment LED. Each status is indicated by ON/OFF of the 7 [DENSITY LED] s.

6543210

Fig. 2-4 Display position of the density LED

Display

[INTER

RUPT]

LED

OFF [1]

OFF [4]

OFF [6]

Number

[Digital

keys]

position

of the

density

LED

0- -1- -2- -3- -4 Bypass paper sensor No paper Paper present

5 Bypass unit connection Not connected Connected

6- -0- -1- -2- -3- -4- -5 Paper empty sensor No paper Paper present

6 Drawer detection switch Drawer not

0- -1- -2- -3- -4- -5 PFU paper empty sensor No paper Paper present

6- --

Items to check ON OFF

Drawer

installed

installed

2

© December 2005 TOSHIBA TEC e-STUDIO163/203 ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 5

Page 26

[INTER

RUPT]

Number

[Digital

LED

OFF [7]

OFF [8]

OFF [9]

OFF [0]

keys]

Display

position

of the

Items to check ON OFF

density

LED

0- -1- -2- -3- -4- -5 PFU feed sensor Paper present No paper

6 PFU drawer detection switch No drawer Drawer present

0- -1- -2 Polygonal motor rotation status (Open the

platen cover)

Abnormal rotation

Normal rotation

3- -4 PFU board connection Not connected Connected

5- -6 24 V power supply

24 V OFF 24 V ON

(Front cover opening/closing)

0- -1- -2 PFU cover opening/closing switch Cover opened Cover closed

3 Front cover opening/closing switch Cover opened Cover closed

4- -5 Exit sensor Paper present No paper

6 Registration sensor Paper present No paper

0- -1- -2- -3 Developer unit switch Not connected Connected

4 Fuser unit switch Connected Not connected

5- -6 Externally counter connection Not connected Connected

e-STUDIO163/203 ERROR CODE AND SELF-DIAGNOSTIC MODE © December 2005 TOSHIBA TEC

2 - 6

06/11

Page 27

[INTER

RUPT]

LED

ON [1]

ON [2]

ON [4]

ON [5]

Number

[Digital

keys]

Display

position

of the

Items to check ON/Blinking OFF

density

LED

0- -1- -2- -3- -4- -5 High-voltage transformer error Normal Error

6- -0- -1- -2- -3- -4 CIS home position sensor Home position Other than

home position

5 Platen sensor Cover opened Cover closed

6 ADF connection Connected Not connected

0 ADF read sensor Original

No original

present

1- -2 ADF exit sensor Original

No original

present

3 ADF opening/closing sensor ADF opened ADF closed

4 ADF cover opening/closing sensor Cover opened Cover closed

5 ADF empty sensor Original

No original

present

6 ADF tray sensor Original

No original

present

0- -1- -2- -3 ADF original width sensor-2 Original

No original

present

4 ADF original width sensor-1 Original

No original

present

5 ADF original length sensor Original

No original

present

6 ADF registration sensor Original

No original

present

2

© December 2005 TOSHIBA TEC e-STUDIO163/203 ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 7

06/11

Page 28

2.2.2 Output check (Test mode 04)

Status of the output signals can be checked by keying in the following codes in the test mode 04.

<Operation procedure>

Procedure 1

[0][4]

[POWER]

Procedure 2

[0][4]

[POWER]

Procedure 3

[0][4]

[POWER]

Code

[Digital keys]

Code

[Digital keys]

Code

[Digital keys]

[START]

Stop code

[Digital keys]

[START]

[START] [CLEAR]

Operation

ON

[START]

[POWER]

OFF/ON

Operation

ON

Operation

OFF

Operation

[FUNCTION

CLEAR]

OFF

[POWER]

OFF/ON

[POWER]

OFF/ON

e-STUDIO163/203 ERROR CODE AND SELF-DIAGNOSTIC MODE © December 2005 TOSHIBA TEC

2 - 8

Page 29

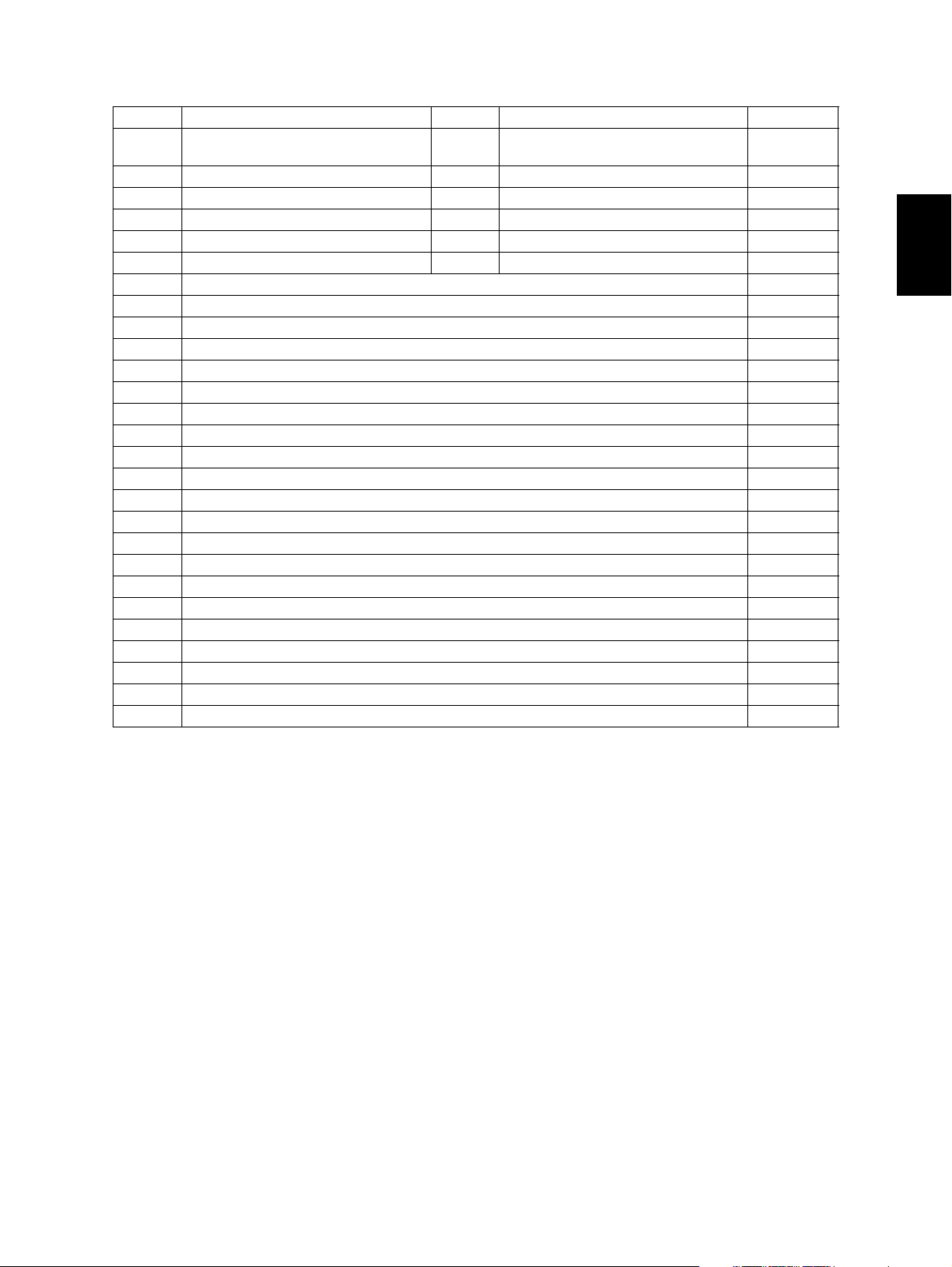

Code Function Code Function Procedure

101 Main motor ON (operational without

151 Code No. 101 function OFF 1

developer unit)

102 Toner motor ON (normal rotation) 152 Code No. 102 function OFF 1

103 Polygonal motor ON (600 dpi) 153 Code No. 103 function OFF 1

108 Registration clutch ON 158 Code No. 108 function OFF 1

110 ADU motor ON (low speed) 160 Code No. 110 function OFF 1

118 Laser ON 168 Code No. 118 function OFF 1

201 Pickup solenoid ON/OFF 3

202 PFU pickup solenoid ON/OFF 3

203 PFU transport clutch (high speed) ON/OFF 3

204 Bypass pickup solenoid ON/OFF 3

205 PFU transport clutch (low speed) ON/OFF 3

218 Key copy counter count up 2

235 Discharge LED ON/OFF 3

236 Exhaust fan ON/OFF (low speed) 3

237 Exhaust fan ON/OFF (high speed) 3

249 Developer bias [-DC] ON/OFF 3

252 Main charger ON/OFF 3

253 Separation bias ON/OFF 3

255 Transfer guide bias ON/OFF 3

256 Transfer transformer ON/OFF 3

261 Scan motor ON (Automatically stops at limit position) 2

267 Contact image sensor (CIS) Unit ON/OFF 3

281 ADF feed motor ON/OFF (normal rotation) 3

282 ADF feed motor ON/OFF (reverse rotation) 3

283 ADF read motor ON/OFF (normal rotation) 3

410 Switching regulator cooling fun ON/OFF (low speed) 3

411 Switching regulator cooling fun ON/OFF (high speed) 3

2

© December 2005 TOSHIBA TEC e-STUDIO163/203 ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 9

06/11

Page 30

2.2.3 Test print mode (Test mode 07)

The embedded test pattern can be printed out by keying in the following codes in the test print mode

(07).

<Operation procedure>

[0][7]

[POWER]

Code

[Digital keys] [Digital keys]

[START] [START]

Drawer number

0: Bypass

1: Drawer

2: PFU

Operation

Continuous

Test Printing

[START]

Stop

[CLEAR]

[POWER]

OFF/ON

Notes:

1. Test printing is set by default to continue until the [CLEAR] button is pressed, or an error

occurs. Note that printing may therefore continue until the paper set in the specified drawer

completely runs out.

2. When an error occurs, it is indicated on the panel, but the recovery operation is not performed. Turn OFF the power and then back ON to clear the error.

3. During test printing, all button operations are disabled when the Message lamps on the control panel light.

Code Types of test pattern Remarks

111 Primary scanning direction 33 gradation steps Error diffusion

113 Secondary scanning direction 33 gradation steps Error diffusion

142 Grid pattern Pattern width: 2 dots, Pitch: 10 mm

149 Solid black pattern (Whole area) A3/LD

e-STUDIO163/203 ERROR CODE AND SELF-DIAGNOSTIC MODE © December 2005 TOSHIBA TEC

2 - 10

06/04

Page 31

2.2.4 List Print Mode (9S)

Lists of the function setting, adjustment mode (05), setting mode (08), system setting, memory

dump, etc. can be output in this mode.

ROM versions of the System firmware and scanner (ADF) are printed on the top right of each list.

• T280SY0Wxxx: System firmware ROM version

• Vxxxx: Scanner ROM version (ADF ROM version)

<Setting procedure>

101: FUNC (FUNC, 05/08) data list

102: System setting list

2

[9][START]

[POWER]

List code

[Digital keys]

101:FUNC (FUNC,05/08) Data list

102:FUNCTION list

List starts

to be printed

[START]

[POWER]

OFF/ON

103: Memory dump list

Address

[9][START]

[POWER]

List code

[Digital keys] [Digital keys]

103:Memory dump list

[START]

specification

(6 digits)

Size

specification

[Digital keys]

(4 digits)

[START]

Outputs a memory dump list of a specified size from a specified address.

Notes:

• Key in 6 digits for the address specification and 4 digits for the size specification.

• Key in using the digital keys as in the table below to enter the letters A to F.

Letter of alphabet A B C D E F

Digital keys [*] [0] [*] [1] [*] [2] [*] [3] [*] [4] [*] [5]

[START]

[POWER]

OFF/ON

E.g.)When outputting an 80 size dump list from the address 0x0000A0

Display Key-in order

Address specification (6 digits) 0000A0 [0] -> [0] -> [0] -> [0] -> [*] -> [0] -> [0]

Size specification (4digits) 0080 [0] -> [0] -> [8] -> [0]

© December 2005 TOSHIBA TEC e-STUDIO163/203 ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 11

06/04

Page 32

Output sample (103: Memory dump list)

Fig. 2-5

e-STUDIO163/203 ERROR CODE AND SELF-DIAGNOSTIC MODE © December 2005 TOSHIBA TEC

2 - 12

06/04

Page 33

2.2.5 Access code mode (8S)

Storing/deleting of the access code, and confirming and changing of the counter value can be done

in the access code mode (8S).

Note: Note:

Department management must be enabled in FUNC-18 (bit-2) before you can use a registered

access code.

<Setting procedure>

Registering the access code

Stores

value in RAM

[START]

[8][START]

[POWER]

Access code

[Digital keys]

(3 digits)

Notes:

• Register up to 99 access codes in 3-digit numbers from 001 to 999.

• If the [START] button is pressed with an access code which has been already registered, a

beep sounds and the display returns to the initial screen.

Confirm

[START]

Access code

(blinks)

Does not store

value in RAM

[CLEAR]

[POWER]

OFF/ON

2

Deleting the access code

Auto search

[INTERRUPT]

[8][START]

[POWER]

Access code

[Digital keys]

Access code

Confirm

[FUNCTION

CLEAR]

"---"

(blinks)

Deleting

[FUNCTION

CLEAR]

Cancel

[CLEAR]

Notes:

• Auto search for the access code: Every time the [INTERRUPT] button is pressed, registered

access codes are displayed in order.

• If the [START] button is pressed with an access code which has not been registered previously, the display returns to the initial screen.

[POWER]

OFF/ON

© December 2005 TOSHIBA TEC e-STUDIO163/203 ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 13

Page 34

Confirming and changing of the access code counter value

Auto search

[INTERRUPT]

[8][START]

[POWER]

Access code

[Digital keys]

Displaying

3 digits

Correct

[Digital keys]

Access code

Displays

higher digits

[200%]

Displays

lower digits

[25%]

Confirm

[200%]

Displaying

3 digits

Correct

[Digital keys]

Confirm

[25%]

Displays

higher digits

[200%]

Displays

lower digits

[25%]

Stores

value in RAM

[START]

Displaying

3 digits

Correct

[Digital keys]

[POWER]

OFF/ON

Notes:

• A counter value is separated as follows: 1 000 280 070, and is displayed from the high-order

position. Press the reproduction ratio button ([200%] or [25%]) to shift the counter value display to the 3 digits of the next lower/higher order.

• Change of the counter value can be registered only after the [START] button is pressed. If the

[CLEAR] button is pressed before the registration is completed, the changed value is also

canceled.

• Only the total counter value for each access code can be confirmed.

<Operation procedure>

Follow the procedure bellow to key in an access code when the access code mode is set.

When an access code

"Displays the access

code mode"

[POWER]

*: Apply the same procedure when the equipment enters the interruption mode.

Key in access code

[Digital keys]

Cancel

[CLEAR]

[START]

When an access code

registered previously

which has already been

registered is entered

"Displays number of copies"

which has not been

is entered

Normal

operation

e-STUDIO163/203 ERROR CODE AND SELF-DIAGNOSTIC MODE © December 2005 TOSHIBA TEC

2 - 14

06/04

Page 35

2.2.6 Function Setting Mode (1*)

The function tables can be set in the function setting mode (1*).

Each function table consists of 8 bits, and each bit is assigned to one function. To set a function,

place a 0 or 1 in the bit which enables the function you want to set.

<Operation procedure>

2

[1][*]

[POWER]

FUNC type

[Digital keys] [Digital keys]

Displaying

bit-7, -6

Correct

[0] or [1]

[START] [START]

[200%]

Code

Displaying

bit-5, -4, -3

Correct

[0] or [1]

[200%]

Stores

value in RAM

[INTERRUPT]

Notes:

• Place a 0 or 1 in the bit you want to set in the function table.

• Press the [CLEAR] button in the middle of the setting to return to the initial screen.

FUNC Type

100 FUNC

101 PCFUNC

102 HOME

[FUNCTION

CLEAR]

Displaying

bit-2, -1, -0

Correct

[0] or [1]

[POWER]

OFF/ON

FUNC (100)

Code Bit Default Items Contents

7 0 Undefined - -

6 1 Undefined - -

5 0 Undefined - -

4 0 Undefined - -

18

© December 2005 TOSHIBA TEC e-STUDIO163/203 ERROR CODE AND SELF-DIAGNOSTIC MODE

3 1 Undefined - -

2 0 Department Code

setting

1 0 Undefined - -

0 0 Undefined - -

0: No

1: Yes

2 - 15

This bit setting determines whether or not the

department control function is available.

Page 36

2.2.7 Adjustment mode (05)

Items in the adjustment mode list in the following pages can be corrected or changed in the adjustment mode (05). Turn ON the power with pressing the digital keys [0] and [5] simultaneously in

order to enter this mode.

Classification List of Adjustment Mode (05)

Classification Adjustment Mode (05)

ADF

Image

Paper feeding

Drive

Development

Scanner

Charger [Main charger bias] 210

Transfer [Transfer bias] 220,221,222

Separation [Separation bias] 233,234,235

Process [Toner recycle] 280

Laser

[Aligning amount] 354

[Transporting] 357,358,365

[Printer density] 667-0 to 4,672-0 to 4

[Image density] 501,503,504,505,506,507,508,509,510,512,514,515,532,533,534,845,

846,847,850,851,852,855,856,857,860,861,862

[Gamma table] 609

[Gamma slope] 593,594,595

[Background adjustment]

[Sharpness] 620,621,622,623,865-0 to 2,866-0 to 2,867-0 to 2

[Smudged/Faint text] 648,654,655,664,665

[Margin] 430,431,432,433,435,436,437,438

[Range correction] 535,536,537,570,571,572,693,694,695,820,821,822,825,826,827,830,

[Paper pushing

amount]

[Aligning amount] 450-0 to 2,451-0 to 2,458-0 to 2,460-0 to 2,461-0 to 2,462-0 to 3,

[Exit motor] 424

[Main motor] 421

[Auto-toner] 200,201

[Developer bias] 205

[Temperature] 270

[Relative humidity] 247

[Drum temperature] 248

[LED] 311,312,313

[Position] 305,306

[Carriage position] 359

[Shading position] 350,351

[Reproduction ratio] 340

[Peak] 310

[Write starting] 410,411,440,441,442

[Polygonal motor] 401,405

[Laser power] 286

[Sideways deviation] 497-0 to 5

600,601,602,869,870,871

831,832,835,836,837

466-0 to 7

463-0 to 2,464-0 to 2

e-STUDIO163/203 ERROR CODE AND SELF-DIAGNOSTIC MODE © December 2005 TOSHIBA TEC

2 - 16

06/07

Page 37

Note: Note:

The density LED blinks while performing adjustment for the items which take time.

Be sure not to turn the power OFF nor perform any other operations while the density LED is

blinking.

Procedure 1

Stores

value in RAM

[0][5]

[POWER]

* Press [#] to enter minus (-).

Code

[Digital keys]

[START]

Adjust a value

[Digital keys] *

[INTERRUPT]

Does not store

value in RAM

[FUNCTION

CLEAR]

Procedure 2

2

[POWER]

OFF/ON

[0][5]

[POWER]

Procedure 3

[0][5]

[POWER]

* Press [#] to enter minus (-).

Procedure 4

[0][5]

[POWER]

[Digital keys]

Code

[Digital keys]

Code

[Digital keys]

Code

[START]

[START]

[START]

Value

displayed

Adjust a value

[Digital keys] *

Set manually

%

] / [200%]

[25

Sub code

[Digital keys]

[FUNCTION

CLEAR]

[START]

Start

[START]

Stores

value in RAM

[INTERRUPT]

Does not store

value in RAM

[FUNCTION

CLEAR]

[START]

[POWER]

OFF/ON

[POWER]

OFF/ON

Adjust a value

[Digital keys] *

* Press [#] to enter minus (-).

© December 2005 TOSHIBA TEC e-STUDIO163/203 ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 17

06/04

Stores

value in RAM

[INTERRUPT]

Does not store

value in RAM

[FUNCTION

CLEAR]

[POWER]

OFF/ON

Page 38

Procedure 6

[0][5]

[POWER]

Procedure 7

[0][5]

[POWER]

Code

[Digital keys]

Code

[Digital keys]

[START]

[START]

Automatic

adjustment

Automatic

adjustment

Error

[FUNCTION

CLEAR]

Does not store

value in RAM

[FUNCTION

CLEAR]

Error

[CLEAR]

Stores

value in RAM

[INTERRUPT]

Does not store

value in RAM

[FUNCTION

CLEAR]

Start

[START]

[POWER]

OFF/ON

[POWER]

OFF/ON

Procedure 17

Stores

value in RAM

[0][5]

[POWER]

Code

[Digital keys]

[START]

Automatic

adjustment

[INTERRUPT]

Does not store

value in RAM

[FUNCTION

CLEAR]

Adjustment

%

] / [200%]

[25

Set manually

Note: Note:

The fuser roller temperature control at the adjustment mode is different from that at the normal

state.

Therefore, the problem of fusing efficiency may be occurred in the test copy at the adjustment

mode. In that case, turn ON the power normally, leave the equipment for approx. 3 minutes after

it has become ready state and then start up the adjustment mode again.

[POWER]

OFF/ON

e-STUDIO163/203 ERROR CODE AND SELF-DIAGNOSTIC MODE © December 2005 TOSHIBA TEC

2 - 18

Page 39

Test print pattern in Adjustment Mode (05)

Procedure

[0][5]

[POWER]

Test code Types of test pattern Remarks

1 Grid pattern Pattern width: 2 dots,

4 Solid black pattern (whole area) A3/LD

Test Code

[Digital keys]

[INTERRUPT]

Drawer number

[Digital keys]

0: Bypass

1: Drawer

2: PFU

[START]

Pitch: 10mm

[POWER]

OFF/ON

2

© December 2005 TOSHIBA TEC e-STUDIO163/203 ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 19

06/04

Page 40

Notes:

• The digit after the hyphen in “Code” of the following table is a sub code.

• In “RAM”, the SRAM of the board in which the data of each code is stored is indicated. “M”

and “SYS” stands for the MAIN board.

Adjustment mode (05)

Default

Code

200 Devel-

Classi-

fication

oper

Items

Automatic adjustment of

auto-toner sensor

(Fuser heater ON)

201 Devel-

oper

Correction of auto-toner

sensor

(Fuser heater ON)

205 Devel-

oper

Developer bias DC output

adjustment

210 Charger Main charger grid bias out-

put adjustment

220 Transfer Transfer transformer DC

output adjustment (H)

221 Transfer Transfer transformer DC

output adjustment (C)

222 Transfer Transfer transformer DC

output adjustment (L)

233 Separa-

tion

234 Separa-

tion

235 Separa-

tion

247 Devel-

oper

248 Devel-

oper

270 Devel-

Separation transformer DC

output adjustment (H)

Separation transformer DC

output adjustment (C)

Separation transformer DC

output adjustment (L)

Relative humidity latest

value

Drum temperature latest

value

Temperature latest value ALL 25

oper

280 Process Forced performing of idling

for toner recycle

286 Laser Laser power adjustment ALL 60

Func-

tion

<Accept-

able

RAM Contents

value>

ALL - - As the value increases,

the sensor output

increases correspondingly.

The value starts changing approx. 2 minutes

after this adjustment was

started and is automatically set in the range of

2.35 to 2.45 V.

* Selection is disable

when developer unit

is not installed.

(Chap. 3.1)

ALL 141

<0-255>

M Corrects the control

value of the auto-toner

sensor setup in 05-200.

* Selection is disable

when developer unit

is not installed.

ALL 135

<0-255>

ALL 78

<0-255>

ALL 128

<0-255>

ALL 141

<0-255>

ALL 108

M As the value increases,

the transformer output

increases correspond-

M3

ingly. Remove the developer unit and install the

M3

adjustment jig to make

adjustment.

M3

(Chap. 3.6)

M3

<0-255>

ALL 55

M3

<0-255>

ALL 55

M3

<0-255>

ALL 36

M3

<0-255>

ALL 50

<0-100>

ALL 25

<0-100>

M Displaying of the relative

humidity latest value.

M Displaying of the drum

temperature latest value.

M Displaying of the temper-

<0-50>

ature latest value.

ALL - M Perfom this adjustment

before the replacement

of the developer material.(The toner is forcibly

removed from the

cleaner.)

M When the value

<0-255>

increases, the laser output increases correspondingly.

Proce-

dure

17

3

3

2

2

2

6

3

e-STUDIO163/203 ERROR CODE AND SELF-DIAGNOSTIC MODE © December 2005 TOSHIBA TEC

2 - 20

06/07

Page 41

Adjustment mode (05)

Default

Code

Classi-

fication

Items

Func-

tion

<Accept-

able

value>

305 Scanner Image location adjustment

of secondary scanning

ALL 105

<51-206>

direction

(scanner section)

306 Scanner Image location adjustment

of primary scanning direction

ALL 127

<121-

136>

(scanner section)

310 Scanner Forced performing of peak

ALL - - Activates the light inten-

detection

311 Scanner LED (R) current effective

value setting

312 Scanner LED (B) current effective

value setting

313 Scanner LED (YG) current effective

value setting

340 Scanner Reproduction ratio adjust-

ment of secondary scan-

ALL 76

<0-255>

ALL 62

<0-255>

ALL 160

<0-255>

ALL 134

<76-181>

ning direction

(scanner section)

350 Scanner Shading posi-

tion adjustment

Original

glass

ALL 128

<118-

138>

351 ADF ALL 128

<118-

138>

354 ADF Adjustment of ADF paper

alignment

357 ADF Fine adjustment of ADF

transport speed

ALL 10

<0-20>

ALL 50

<0-100>

RAM Contents

Proce-

dure

SYS When the value

increases by “1”, the

image shifts by approx.

0.0640 mm toward the

trailing edge of the

paper.

During this adjustment,

the density LED blinks.

SYS When the value

increases by “1”, the

image shifts by approx.

0.169 mm toward the

front side of the paper.

During this adjustment,

the density LED blinks.

sity adjustment control

During this adjustment,

the density LED blinks.

SYS Displays total of the ini-

tial value and light intensity correction value.

SYS Displays total of the ini-

tial value and light intensity correction value.

SYS Displays total of the ini-

tial value and light intensity correction value.

SYS When the value

increases by “1”, the

reproduction ratio in the

secondary scanning

direction (vertical to

paper feeding direction)

increases by approx.

0.0947%.

During this adjustment,

the density LED blinks.

SYS 0.064 mm/step

SYS 1

During this adjustment,

the density LED blinks.

SYS When the value

increases by “1”, the

aligning amount

increases by approx.

0.4 mm.

SYS When the value

increases by “1”, the

reproduction ratio of the

secondary scanning

direction when using the

ADF increases by

approx. 0.1%.

During this adjustment,

the density LED blinks.

1

2

1

7

1

1

1

1

1

1

1

© December 2005 TOSHIBA TEC e-STUDIO163/203 ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 21

06/04

Page 42

Adjustment mode (05)

Default

Code

Classi-

fication

Items

Func-

tion

<Accept-

able

value>

358 ADF ADF sideways deviation

adjustment

359 Scanner Carriage position adjust-

ment during scanning from

ALL 128

<0-255>

ALL 128

<0-255>

ADF

365 ADF ADF leading

edge position

adjustment

401 Laser Fine adjustment of polygo-

nal motor rotation speed

405 PPC 131

(adjustment of primary

scanning direction reproduction ratio)

410 Laser Adjustment of primary

scanning laser writing start

411 PRT 88

position.

for single sided original

ALL 50

<0-100>

PRT 134

<0-255>

<0-255>

PPC 88

<0-255>

<0-255>

421 Drive Adjustment of

secondary

PPC/

PRT

<0-255>

scanning

direction

reproduction

ratio

(fine adjustment of main

motor speed)

424 Drive Fine adjust-

ment of exit

PPC/

PRT

<0-255>

motor speed

128

160

RAM Contents

SYS When the value

Proce-

dure

1

increases by “1”, the

image of original fed

from the ADF shifts

toward the rear side of

paper by approx.

0.169 mm.

During this adjustment,

the density LED blinks.

SYS When the value

1

increases by “1”, the carriage position when

using the ADF shifts by

approx. 0.1 mm toward

the original feeding side.

During this adjustment,

the density LED blinks.

SYS When the value

1

increases by “1”, the

copied image of original

fed from the ADF shifts

toward the trailing edge

of paper by approx.

0.2 mm.

During this adjustment,

the density LED blinks.

M When the value

1

increases by “1”, the

reproduction ratio of pri-

M1

mary scanning direction

increases by approx.

0.07%. (approx. 0.1 mm/

step)

M When the value

1

increases by “1”, the writing start position shifts to

M1

the front side by approx.

0.0423 mm.

When “1” is set at 08203, the adjustment

value set at 05-411 will

also be reflected to 05-

410.

M When the value

1

increases by “1”, the

reproduction ratio of secondary scanning direction increases by approx.

0.04%.

M When the value

1

increases by “1”, the

rotation becomes faster

by approx. 0.05%.

e-STUDIO163/203 ERROR CODE AND SELF-DIAGNOSTIC MODE © December 2005 TOSHIBA TEC

2 - 22

06/04

Page 43

Adjustment mode (05)

Default

Code

Classi-

fication

Items

Func-

tion

<Accept-

able

value>

430 Image Top margin adjustment

(blank area at the leading

PPC 9

<0-255>

edge of the paper)

431 Image Left margin adjustment

(blank area at the left of the

PPC 0

<0-255>

paper along the paper

feeding direction)

432 Image Right margin adjustment

(blank area at the right of

PPC 110

<0-255>

the paper along the paper

feeding direction)

433 Image Bottom margin adjustment

(blank area at the trailing

PPC 153

<0-255>

edge of the paper)

435 Image Top margin adjustment

(blank area at the leading

PRT 24

<0-255>

edge of the paper)

436 Image Left margin adjustment

(blank area at the left of the

PRT 0

<0-255>

paper along the paper

feeding direction)

437 Image Right margin adjustment

(blank area at the right of

PRT 0

<0-255>

the paper along the paper

feeding direction)

438 Image Bottom margin adjustment

(blank area at the trailing

PRT 0

<0-255>

edge of the paper)

440 Laser Adjustment of

secondary

441 PFU ALL 21

scanning

laser writing

442 Bypass

450-0 Paper

feeding

450-1 Middle

start position

Paper aligning

amount

adjustment at

the registra-

450-2 Short size ALL 22

tion section

(Drawer/Plain

paper)

451-0 Paper

feeding

451-1 Middle

Paper aligning

amount

adjustment at

the registra-

451-2 Short size ALL 14

tion

section (PFU/

Plain paper)

Drawer ALL 14

<0-40>

<0-40>

ALL 8

feeding

<0-15>

Long size ALL 22

<0-63>

ALL 22

size

<0-63>

<0-63>

Long size ALL 14

<0-63>

ALL 14

size

<0-63>

<0-63>

RAM Contents

M When the value

Proce-

dure

1

increases by “1”, the

blank area becomes

wider by approx.

M1

0.0423 mm.

2

M1

M1

M1

M1

M1

M1

M When the value

1

increases by “1”, the

image shifts toward the

M1

leading edge of the

paper by approx.

M1

0.2 mm.

M When the value

4

increases by “1”, the

aligning amount

M4

increases by approx.

0.9 mm.

M4

<Paper length>

Long size:

M4

M4

M4

330 mm or longer

Middle size:

220 mm to 329 mm

Short size:

219 mm or shorter

© December 2005 TOSHIBA TEC e-STUDIO163/203 ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 23

06/02

Page 44

Adjustment mode (05)

Default

Code

Classi-

fication

Items

Func-

tion

<Accept-

able

value>

458-0 Paper

feeding

458-1 Middle

458-2 Short size ALL 10

Paper aligning

amount

adjustment at

the registration section

(Bypass feeding/Plain

Long size ALL 10

<0-63>

ALL 10

size

<0-63>

<0-63>

paper)

460-0 Paper

feeding

460-1 Middle

460-2 Short size ALL 10

Paper aligning

amount

adjustment at

the registration section

(Bypass feeding/Thick

Long size ALL 10

<0-63>

ALL 10

size

<0-63>

<0-63>

paper 1)

461-0 Paper

feeding

461-1 Middle

461-2 Short size ALL 10

Paper aligning

amount

adjustment at

the registration section

(Bypass feeding/Thick

Long size ALL 10

<0-63>

ALL 10

size

<0-63>

<0-63>

paper 2)

462-0 Paper

feeding

462-1 Middle

462-2 Short size ALL 10

462-3 Postcard ALL 10

463-0 Paper

feeding

463-1 Middle

463-2 Short size ALL 10

Paper aligning

amount

adjustment at

the registration section

(Bypass feeding/Thick

paper 3)

Paper aligning

amount

adjustment at

the registration section

(Bypass feeding/OHP film)

464-0 Paper

feeding

464-1 Middle

464-2 Short size ALL 26

Paper aligning

amount

adjustment at

the registration section

(Bypass feeding /Envelope)

Long size ALL 10

<0-63>

ALL 10

size

<0-63>

<0-63>

<0-63>

Long size ALL 10

<0-63>

ALL 10

size

<0-63>

<0-63>

Long size ALL 26

<0-63>

ALL 26

size

<0-63>

<0-63>

RAM Contents

M When the value

Proce-

dure

4

increases by “1”, the

aligning amount

M4

increases by approx.

1.4 mm.

M4

<Paper length>

Long size:

330 mm or longer

Middle size:

M4

M4

220 mm to 329 mm

Short size:

219 mm or shorter

M4

M4

M4

M4

M4

M4

M4

M4

M4

M4

M4

M4

M4

M4

e-STUDIO163/203 ERROR CODE AND SELF-DIAGNOSTIC MODE © December 2005 TOSHIBA TEC

2 - 24

Page 45

Adjustment mode (05)

Default

Code

Classi-

fication

Items

Func-

tion

<Accept-

able

value>

466-0 Paper

feeding

466-1 Postcard ALL 0

466-3 Envelope ALL 0

Adjustment of

paper pushing amount/

Bypass feeding

Plain

paper

ALL 0

<0-255>

<0-255>

<0-255>

466-4 Thick

paper 1

466-5 Thick

paper 2

466-6 Thick

paper 3

ALL 0

<0-255>

ALL 0

<0-255>

ALL 0

<0-255>

466-7 OHP film ALL 0

<0-255>

497-0 Laser Adjustment of

drawer side-

497-1 PFU ALL 128

ways deviation

497-5 Bypass

501 Image Density

adjustment

503 Text/Photo PPC 128

504 Text PPC 128

Fine adjustment of “manual density”/

Center value

505 Image Density

adjustment

506 Photo PPC 33

507 Text PPC 33

Fine adjustment of “manual density”/

Light step

value

508 Image Density

adjustment

509 Photo PPC 33

510 Text PPC 33

Fine adjustment of “manual density”/

Dark step

value

512 Image Density

adjustment

514 Text/Photo PPC 128

515 Text PPC 128

Fine adjustment of “automatic density”

Drawer ALL 128

<0-255>

<0-255>

ALL 128

feeding

<0-255>

Photo PPC 128

<0-255>

<0-255>

<0-255>

Text/Photo PPC 33

<0-255>

<0-255>

<0-255>

Text/Photo PPC 33

<0-255>

<0-255>

<0-255>

Photo PPC 128

<0-255>

<0-255>

<0-255>

532 Image Range correc-

tion/Back-

533 Photo PPC 22

ground peak

adjustment

Text/Photo PPC 32

<0-255>

<0-255>

534 Text PPC 46

<0-255>

RAM Contents

M When the value

Proce-

dure

4

increases by “1”, the

driving speed of bypass

M4

feed roller increases by

approx. 0.2 ms when the

M4

paper transport is started

from the registration sec-

M4

tion.

2

* Postcard is sup-

M4

ported only for JPN

model.

M4

M4

M When the value

4

increases by “1”, the

image shifts toward the

M4

front side by 0.0423 mm.

M4

SYS When the value

1

increases, the image at

the center step becomes

SYS 1

darker.

SYS 1

SYS When the value

1

increases, the image of

the “light” steps becomes

SYS 1

lighter.

SYS 1

SYS When the value

1

increases, the image of

the “dark” steps

SYS 1

becomes darker.

SYS 1

SYS When the value

1

increases, the image

becomes darker.

SYS 1

SYS 1

SYS When the value

1

increases, the background becomes more

SYS 1

brightened.

SYS 1

© December 2005 TOSHIBA TEC e-STUDIO163/203 ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 25

06/04

Page 46

Adjustment mode (05)

Default

Code

Classi-

fication

Items

Func-

tion

<Accept-

able

value>

535 Image Range correc-

tion/Text peak

536 Text PPC 254

adjustment

Text/Photo PPC 246

<0-255>

<0-255>

537 Photo PPC 236

<0-255>

570 Image Range correc-

tion on original manually

set on the

original glass

Text/Photo PPC EUR:12

UC:12

JPN:22

<11-14,

21-24,

31-34,

41-44>

571 Photo PPC 12

<11-14,

21-24,

31-34,

41-44>

572 Text PPC 22

<11-14,

21-24,

31-34,

41-44>

593 Image Gamma data

slope adjust-

594 Image Photo PPC 5

ment

Text/Photo PPC 5

<1-9>

<1-9>

595 Image Text PPC 5

<1-9>

600 Image Background

adjustment

Text/Photo PPC 3

<1-9>

601 Photo PPC 3

<1-9>

602 Text PPC 3

<1-9>

609 Image Switching of the scanner

Gamma correction table

ALL 0

<0-4>

when paper is fed from the

ADF

RAM Contents

Proce-

dure

SYS When the value

decreases, the text

becomes darker.

SYS 1

SYS 1

SYS Sets whether the values

of the background peak

and text peak are fixed

or not. One’s place is an

adjustment for “automatic density” and ten’s

place is for “manual density”. Once they are

SYS 1

fixed, the range correction is performed with

standard values. The

values of the background

peak and text peak affect

SYS 1

the reproduction of the

background density and

text density respectively.

1: fixed/fixed

2: varied/fixed

3: fixed/varied

4: varied/varied

* Background peak/

Text peak

SYS Select the slope of

Gamma curve (The

larger the value is, the

SYS 1

larger the slope

becomes.)

SYS 1

SYS When the value

decreases, the background becomes darker.

SYS 1

When the value

increases, the back-

SYS 1

ground becomes lighter.

SYS The larger the value is,

the lighter the density of

the highlight areas

becomes.

1

1

1

1

1

e-STUDIO163/203 ERROR CODE AND SELF-DIAGNOSTIC MODE © December 2005 TOSHIBA TEC

2 - 26

06/05

Page 47

Adjustment mode (05)

Default

Code

Classi-

fication

Items

Func-

tion

<Accept-

value>

620 Image Sharpness

Text/Photo PPC EUR: 1

adjustment

JPN: 0

<0-96>