DIGITAL MULTI FUNCTION

e-STUDIO160/200/250

File No. SHE02000200

R02092123800-TTEC

© 2002 TOSHIBA TEC CORPORATION

All rights reserved

GENERAL PRECAUTIONS REGARDING THE INSTALLATION AND SERVICE FOR e-STUDIO160/200/250 SERIES

The installation and service should be done by a qualified service technician.

1. Transportation

• When transporting/installing the copier, employ two persons and be sure to use the positions as

indicated below.

The copier is fairly heavy and weighs approximately 50 kg (110 lb), therefore pay full attention

when handling it.

4 portions

2. Installation

• Be sure to use a dedicated outlet with AC 115 or 120V/15A (220V, 230V, 240V/10A) or more for its

power source.

• The copier must be grounded for safety.

Never ground it to a gas pipe or a water pipe.

• Select a suitable place for installation.

Avoid excessive heat, high humidity, dust, vibration and direct sunlight.

• Also provide proper ventilation as the copier emits a slight amount of ozone.

• To insure adequate working space for the copying operation, keep a minimum clearance of 80

cm (32") on the left, 80 cm (32") on the right and 10 cm (4") in the rear.

• After having installed the copier, be sure to push the carrying handles into the copier.

3. Service of Machines

• Basically, be sure to turn the main switch off and unplug the power cord during service.

• Be sure not to touch high-temperature sections such as the exposure lamp, the fuser unit, the

damp heater and their periphery.

• Be sure not to touch high-voltage sections such as the chargers and the high-voltage transformer.

• Be sure not to touch rotating/operating sections such as gears, belts, pulleys, fans, etc.

• When servicing the machines with the main switch turned on, be sure not to touch live sections

and rotating/operating sections. Avoid exposure to laser radiation.

• Use suitable measuring instruments and tools.

December 2002 TOSHIBA TEC e-STUDIO160/200/250 GENERAL PRECAUTIONS

• Avoid exposure to laser radiation during servicing.

– Avoid direct exposure to beam.

– Do not insert tools, parts, etc. that are reflective into the path of the laser beam.

– Remove all watches, rings, bracelets, etc. that are reflective.

4. Main Service Parts for Safety

• The breaker, door switch, fuse, thermostat, thermofuse, thermistor, etc. are particularly important

for safety. Be sure to handle/install them properly.

5. Cautionary Labels

• During servicing, be sure to check the rating plate and the cautionary labels such as “Unplug the

power cord during service”, “Hot area”, “Laser warning label” etc. to see if there is any dirt on their

surface and whether they are properly stuck to the copier.

6. Disposition of Consumable Parts/Packing Materials

• Regarding the recovery and disposal of the copier, supplies, consumable parts and packingm a -

terials, it is recommended to follow the relevant local regulations or rules.

7. When parts are disassembled, reassembly is basically the reverse of disassembly unless otherwise noted in this manual or other related documents. Be

careful not to reassemble small parts such as screws, washers, pins, E-rings,

toothed washers in the wrong places.

8. Basically, the machine should not be operated with any parts removed or disassembled.

9. Precautions Against Static Electricity

• The PC board must be stored in an anti-electrostatic bag and handled carefully using a wristband,

because the ICs on it may become damaged due to static electricity.

Caution: Before using the wrist band, pull out the power cord plug of the copier and make

sure that there is no uninsulated charged objects in the vicinity.

Caution: Dispose of used batteries and RAM-ICs including lithium batteries according to the

manufacturer's instructions.

Attention: Se débarrasser de batteries et RAM-ICs usés y compris les batteries en lithium

selon les instructions du fabricant.

Vorsicht: Entsorgung des gebrauchten Batterien und RAM-ICs (inklusive der Lithium-Batterie)

nach Angaben des Herstellers.

e-STUDIO160/200/250 GENERAL PRECAUTIONS December 2002 TOSHIBA TEC

CONTENTS

1. ADJUSTMENT ITEMS .................................................................................................. 1-1

1.1 Error Code List ................................................................................................................... 1-1

1.2 Self-Diagnosis Modes ........................................................................................................ 1-6

1.2.1 Adjust mode (05) ..................................................................................................... 1-8

1.2.2 System mode ........................................................................................................ 1-13

1.2.3 User test mode...................................................................................................... 1-18

1.2.4 Function test ......................................................................................................... 1-21

1.2.5 MAINTENANCE .................................................................................................... 1-38

1.2.6 SERVICE LIST ...................................................................................................... 1-43

1.2.7 Country/Region code ............................................................................................ 1-49

1.2.8 Scanner parking mode .......................................................................................... 1-50

1.2.9 Speaker volume .................................................................................................... 1-51

1.2.10 Adjustment of document width sensor .................................................................. 1-52

1.3 Image Quality Control ...................................................................................................... 1-53

1.4 Copy Image Dimension Adjustment ................................................................................. 1-54

1.4.1 Adjustment of paper aligning value ....................................................................... 1-55

1.4.2 Printer unit adjustment .......................................................................................... 1-56

1.4.3 Scanner unit adjustment ....................................................................................... 1-61

1.5 Sharpness (HPF) Adjustment .......................................................................................... 1-66

1.6 Gamma Slope Correction................................................................................................. 1-67

1.7 High-Voltage Adjustment .................................................................................................. 1-68

1.7.1 Adjustment ............................................................................................................ 1-68

1.7.2 Precautions ........................................................................................................... 1-71

1.8 Adjusting the Scanner Section ......................................................................................... 1-74

1.8.1 Installing glass ...................................................................................................... 1-74

1.8.2 Installing scanner motor ........................................................................................ 1-76

1.8.3 Adjusting the carriage 1 ........................................................................................ 1-77

1.8.4 Installing carriage 2 ............................................................................................... 1-79

1.8.5 CCD unit ............................................................................................................... 1-82

1.9 Adjusting the main drive gear assembly........................................................................... 1-86

1.10 MAIN PWA replacement procedure ................................................................................. 1-90

1.11 Measurement of Transfer Guide Bias ............................................................................... 1-92

1.12 Adjustment of the doctor-sleeve gap ................................................................................ 1-94

December 2002 TOSHIBA TEC 1 e-STUDIO160/200/250 CONTENTS

2. PREVENTIVE MAINTENANCE (PM) ............................................................................ 2-1

2.1 Maintenance Performed Every 81,000 (e-STUDIO160/200 Series) and

99,000 Copies (e-STUDIO250 Series) ............................................................................... 2-1

2.2 Preventive Maintenance Check List .................................................................................... 2-1

2.3 PM Kit ................................................................................................................................ 2-14

2.4 List of Adjustment Tools .................................................................................................... 2-15

2.5 List of Grease .................................................................................................................... 2-15

3. PRECAUTIONS FOR STORING & HANDLING SUPPLIES ......................................... 3-1

3.1 Precautions for Storing TOSHIBA Supplies ........................................................................ 3-1

3.2 Checking and Cleaning of the Pressure Roller .................................................................. 3-2

3.3 Checking and Cleaning of the Cleaning Roller ................................................................... 3-2

3.4 Checking and Cleaning of the Heat Roller ......................................................................... 3-3

3.5 Checking and Replacing of the Transfer Guide Roller ........................................................ 3-3

3.6 Checking and Cleaning of Photoconductive Drum ............................................................. 3-4

3.7 Checking and Cleaning of Drum Cleaning Blade ............................................................... 3-5

4. TROUBLESHOOTING .................................................................................................. 4-1

4.1 Troubleshooting Based on Error Code ............................................................................... 4-2

4.1.1 Transporting jam in the main body .......................................................................... 4-2

4.1.2 Paper feeding jam ................................................................................................... 4-7

4.1.3 Transporting jam for the optional trays .................................................................. 4-13

4.1.4 Paper jam if some cover is opened ....................................................................... 4-18

4.1.5 Paper transporting jam at the ADF ........................................................................ 4-22

4.1.6 Paper transporting jam at the RADF ..................................................................... 4-24

4.1.7 Paper jam in finisher ............................................................................................. 4-26

4.1.8 Drive system service call ...................................................................................... 4-30

4.1.9 Temporary paper supply mechanism service call ................................................. 4-33

4.1.10 Optical system service call ................................................................................... 4-39

4.1.11 Process system service call .................................................................................. 4-41

4.1.12 Fuser system service call ..................................................................................... 4-41

4.1.13 Communications system service call .................................................................... 4-42

4.1.14 ADF or RADF system service call ......................................................................... 4-44

4.1.15 Other abnormal service call .................................................................................. 4-48

4.1.16 Laser optical system service call .......................................................................... 4-49

4.1.17 Finisher related service call .................................................................................. 4-50

4.1.18 Scanner related service call .................................................................................. 4-55

4.1.19 Printer related service call .................................................................................... 4-56

4.1.20 Fax related service call ......................................................................................... 4-56

4.1.21 OCT system service call ....................................................................................... 4-57

4.1.22 Other service call .................................................................................................. 4-57

4.2 Troubleshooting of Image ................................................................................................. 4-58

e-STUDIO160/200/250 CONTENTS 2 December 2002 TOSHIBA TEC

5. UPDATING THE FIRMWARE ........................................................................................ 5-1

5.1 Outline ................................................................................................................................ 5-1

5.2 Using the Recovery PWA ................................................................................................... 5-2

5.2.1 Using main recovery PWA ...................................................................................... 5-2

5.2.2 Using the scanner recovery PWA ........................................................................... 5-5

5.3 Using the Batch File ........................................................................................................... 5-8

5.3.1 Creating Download Disks ........................................................................................ 5-8

5.3.2 Downloading ......................................................................................................... 5-13

5.4 Using the TOSHIBA Viewer .............................................................................................. 5-20

6. WIRE HARNESS CONNECTION DIAGRAMS ............................................................. 6-1

6.1 AC Wire Harness ............................................................................................................... 6-1

APPENDIX .......................................................................................................................... A-1

Appendix A. Specifications ......................................................................................................... A-1

Appendix B. Accessories ...........................................................................................................A-5

Appendix C. Options .................................................................................................................. A-6

Appendix D. Replacement Units/Supplies .................................................................................. A-6

Appendix E. System List ............................................................................................................ A-7

Appendix F. Power Supply Unit .................................................................................................. A-8

December 2002 TOSHIBA TEC 3 e-STUDIO160/200/250 CONTENTS

1. ADJUSTMENT ITEMS

2. PREVENTIVE MAINTENANCE

(PM)

3. PRECAUTIONS FOR

STORING & HANDLING

SUPPLIES

4. TROUBLESHOOTING

5. UPDATING THE FIRMWARE

6. WIRE HARNESS

CONNECTION DIAGRAMS

1. ADJUSTMENT ITEMS

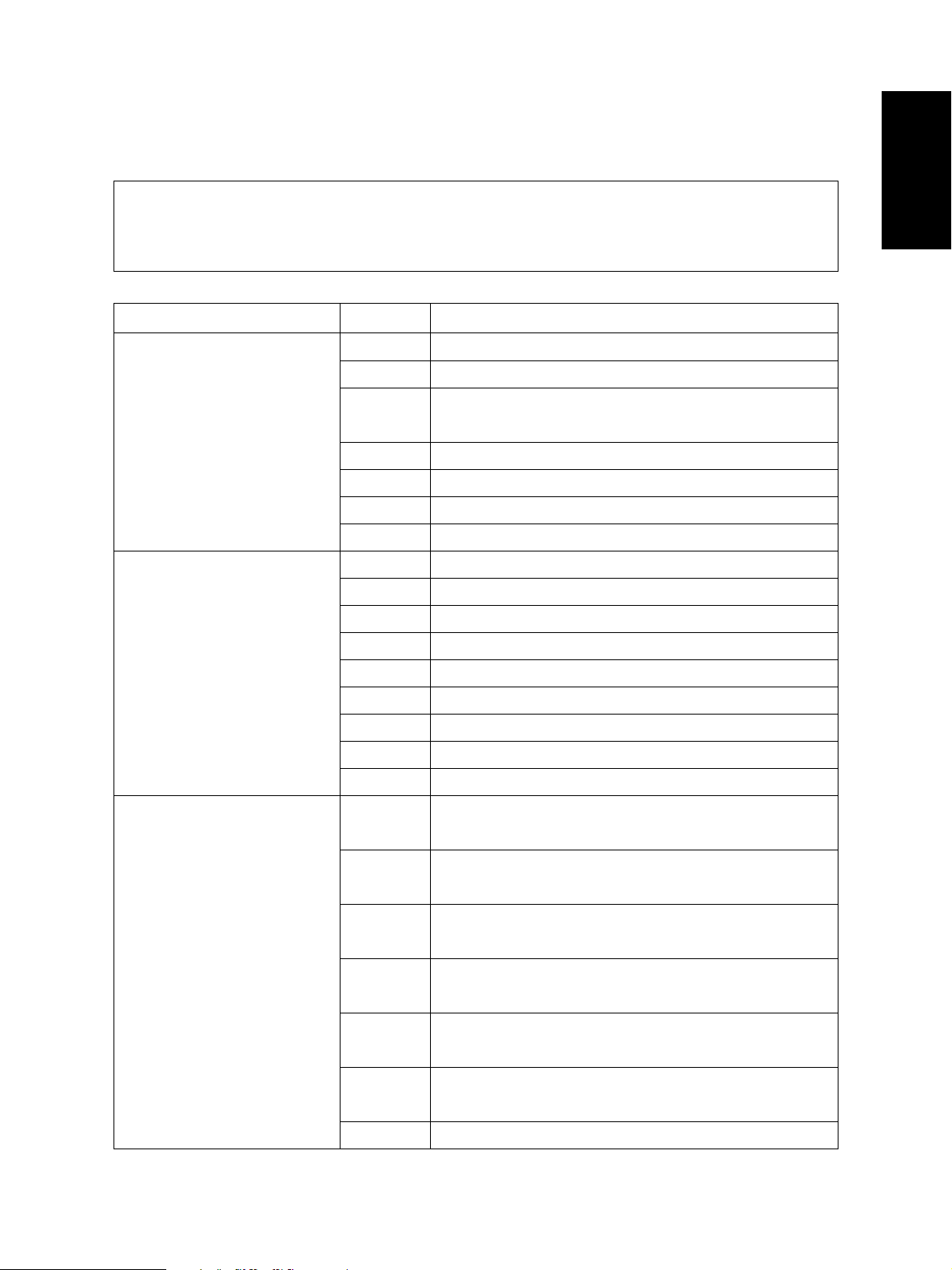

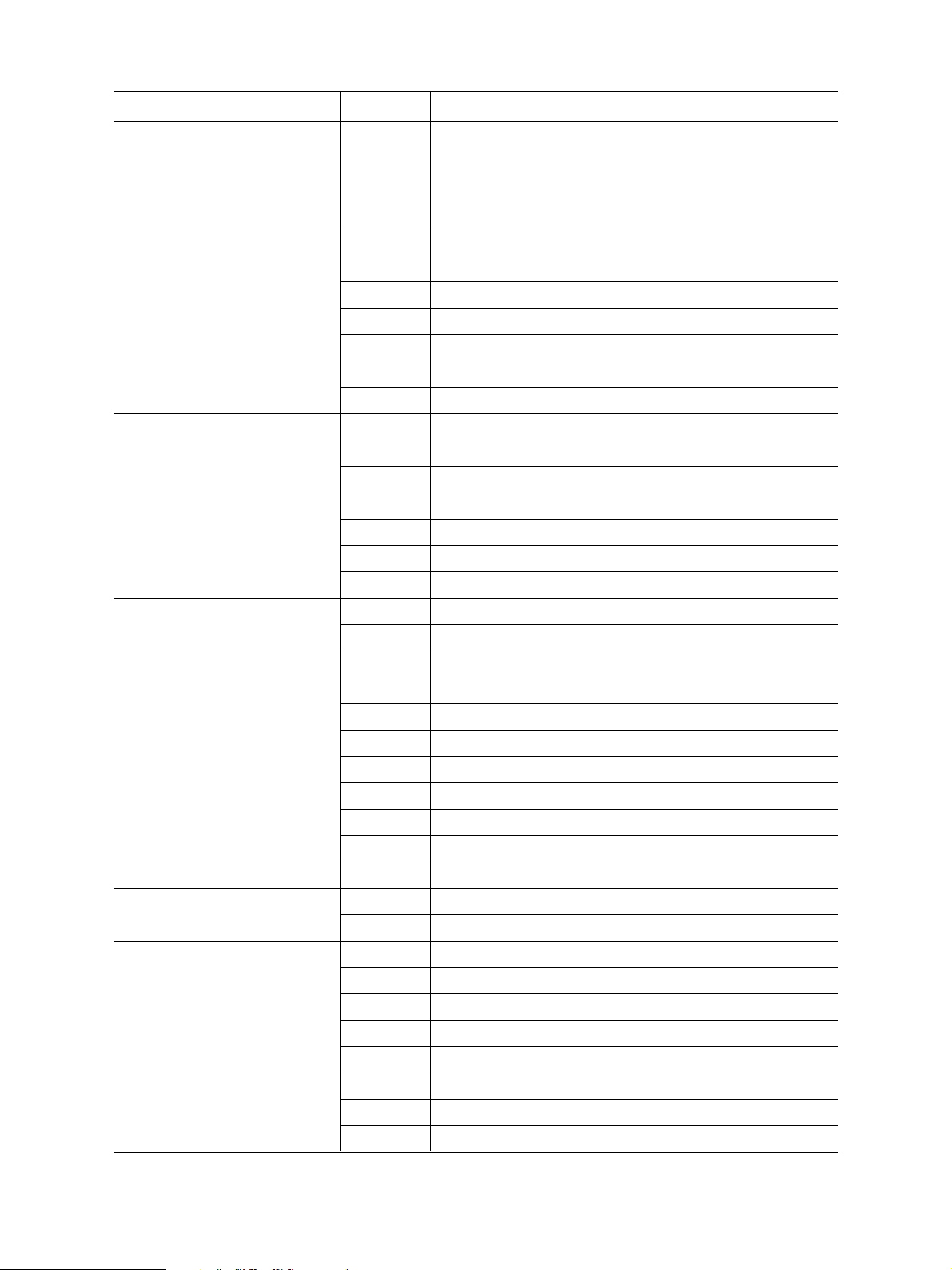

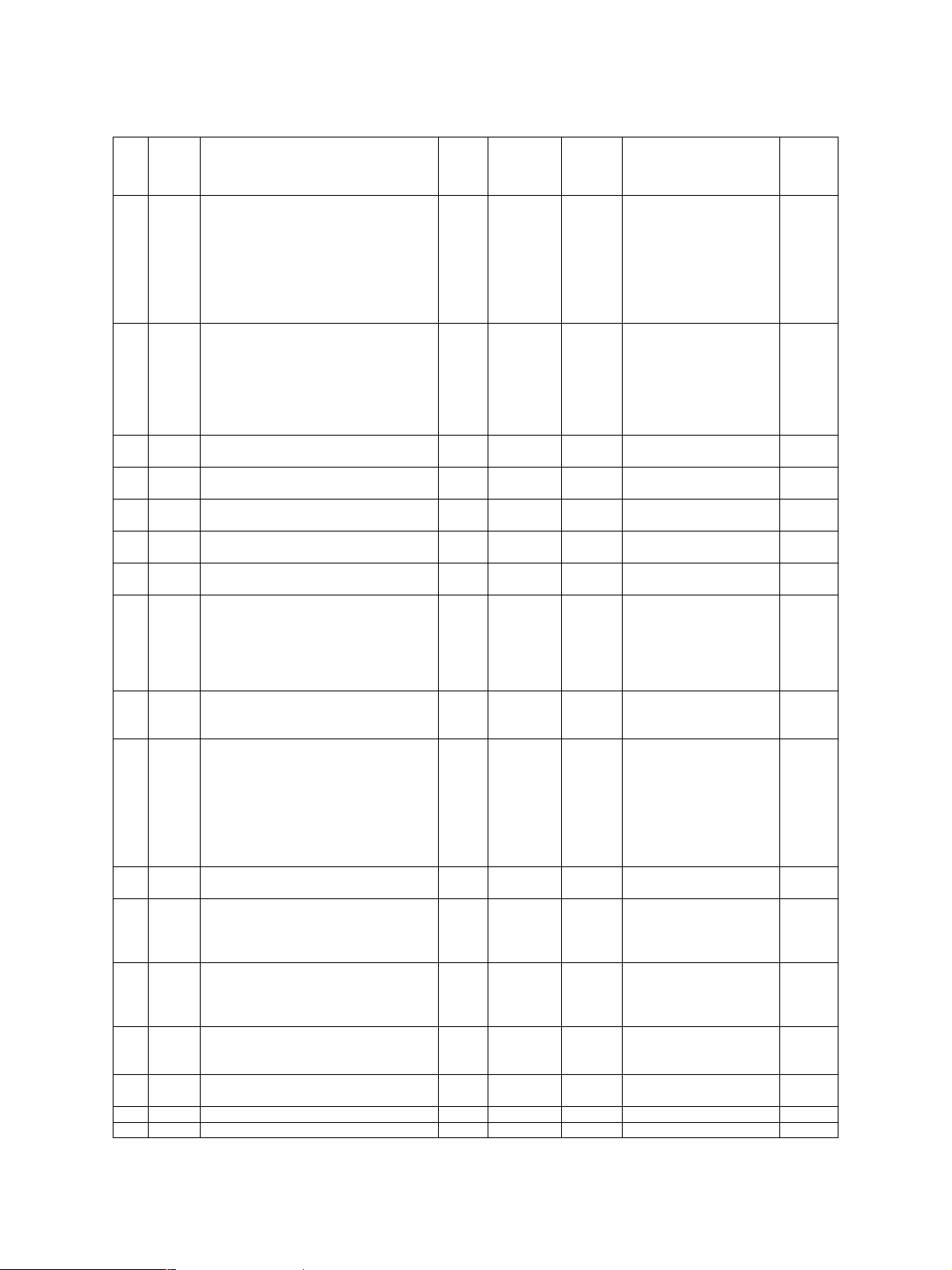

1.1 Error Code List

While the error message or “Call for service” symbol is flashing, pressing the [CLEAR/STOP] key and

the [8] key on the digital keys at the same time shows one of the following error codes on the copy-

quantity indicator as long as those keys are pressed.

Classification Error code Machine status

Transporting jam in the main

body

Paper feeding jam

Transporting jam for the

optional trays

E01 Paper jam inside the machine

E02 Paper jam near the fuser unit

E03 Paper remaining inside the machine at power on (Except

for ADF/RADF)

E04 to E07 Reserved

E08 Transporting jam inside the ADU

E09 Time out error that occurs at the paper feeding sensor

E10 Reserved

E11 Paper feeding jam at the ADU

E12 Paper feeding jam at the SFB

E13 Cassette 1 feeding jam

E14 Cassette 2 feeding jam (PFU)

E15 Cassette 3 feeding jam (PFP)

E16 Cassette 4 (CM) feeding jam (e-STUDIO200/250 series)

E17 to E18 Reserved

E19 LCF feeding jam (e-STUDIO200/250 series)

E20 to E30 Reserved

E31 Paper not reach to feed sensor from cassette 2, so paper

jam inside the main unit during cassette 2 feed

E32 Paper not reach to feed sensor from cassette 3 or 4, so

paper jam inside the main unit during the feed

E33 Paper not reach to feed sensor from LCF cassette.

(e-STUDIO200/250 series)

E34 Paper not reach to 2nd cassette feed sensor from cas-

sette 3 or 4. (Cassette 4 is e-STUDIO200/250 series)

E35 Paper jam in cassette 4 transport path

(e-STUDIO200/250 series)

E36 Paper jam in LCF transport path

(e-STUDIO200/250 series)

E37 to E40 Reserved

December 2002 TOSHIBA TEC 1 - 1 e-STUDIO160/200/250 ADJUSTMENT ITEMS

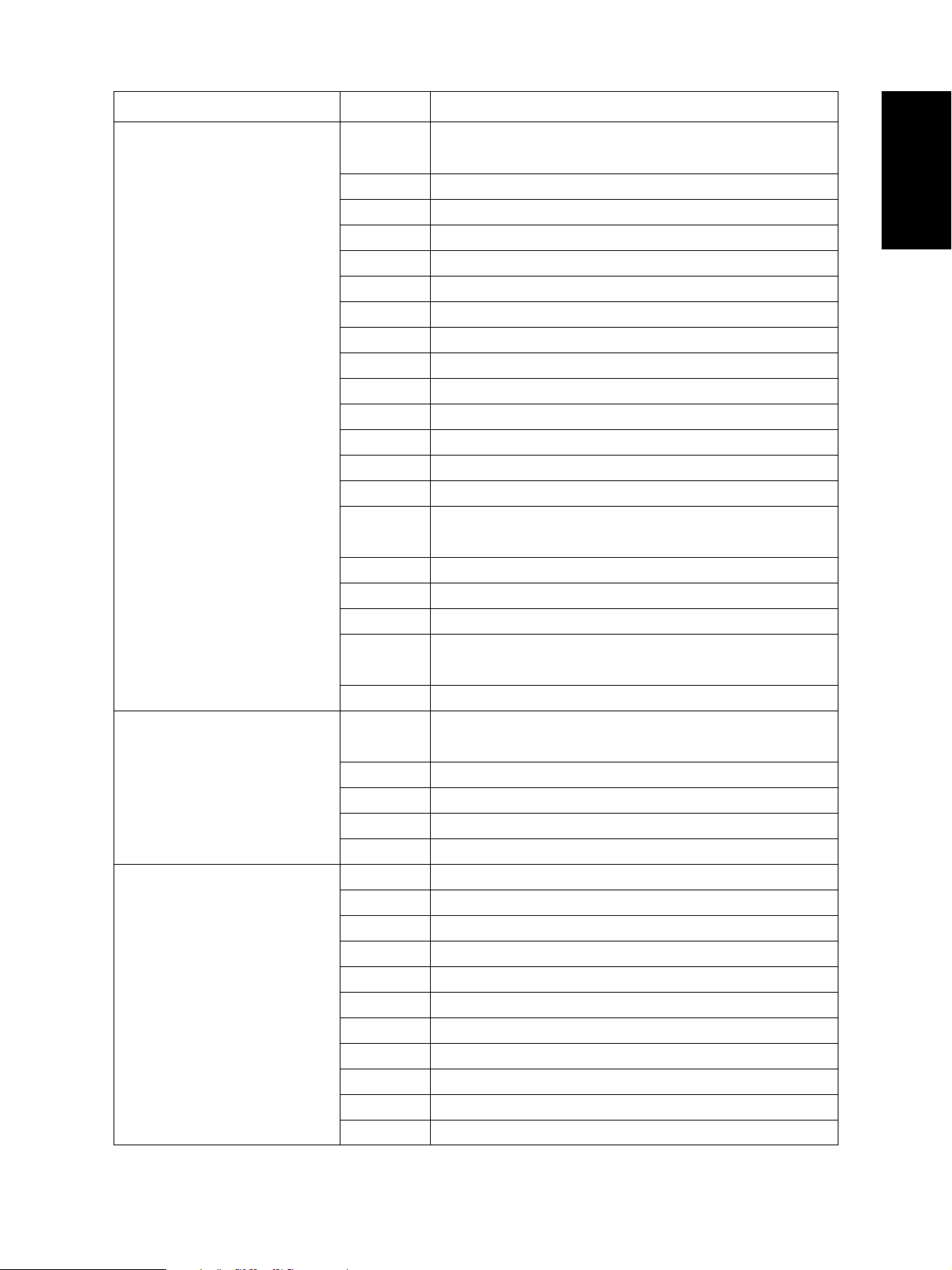

Classification Error code Machine status

Paper jam if some cover is

opened

Paper transporting jam at the

ADF or RADF

Paper jam in the finisher

(e-STUDIO200/250 series)

Life end

Other operator calls

E41 Copier front cover or side cover is opened during copying

(Copier front cover, side cover, or transport cover of job

separator/offset tray/bridge cover is opened during

copying)

E42 Side cover of cassette 2 or cassette 3 is opened during

copying

E43 ADU is opened during copying

E44 Reserved

E45 Side cover of LCF is opened during copying

(e-STUDIO200/250 series)

E46 to E70 Reserved

E71 Original feeding jam at the feeding area of the ADF or

RADF

E72 Original transporting jam at the transporting area of the

ADF or RADF

E73 Original exiting jam at the exiting area of the ADF or RADF

E74 Original reversing jam at the reversing area of the RADF

E75 to EA0 Reserved

EA1 Paper transport delay jam

EA2 Paper transport stop jam

EA3 Paper remaining on the finisher transport path at power

ON

EA4 Finisher is opened during copying

EA5 Finisher staple jam

EA6 Finisher early arrival jam

EA7 Set transport jam before stapling

EA8 to EAE Reserved

EAF Stapled set transport jam

EB1 to EZ9 Reserved

- Process unit life nearly end

- Toner is nearly empty

- No toner cartridge

- Toner empty

- No process unit

- Process unit life end

- Upper tray of the job separator is full

- Lower tray of the job separator is full

- Offset tray is full

- Finisher tray is full (e-STUDIO200/250 series)

e-STUDIO160/200/250 ADJUSTMENT ITEMS 1 - 2 December 2002 TOSHIBA TEC

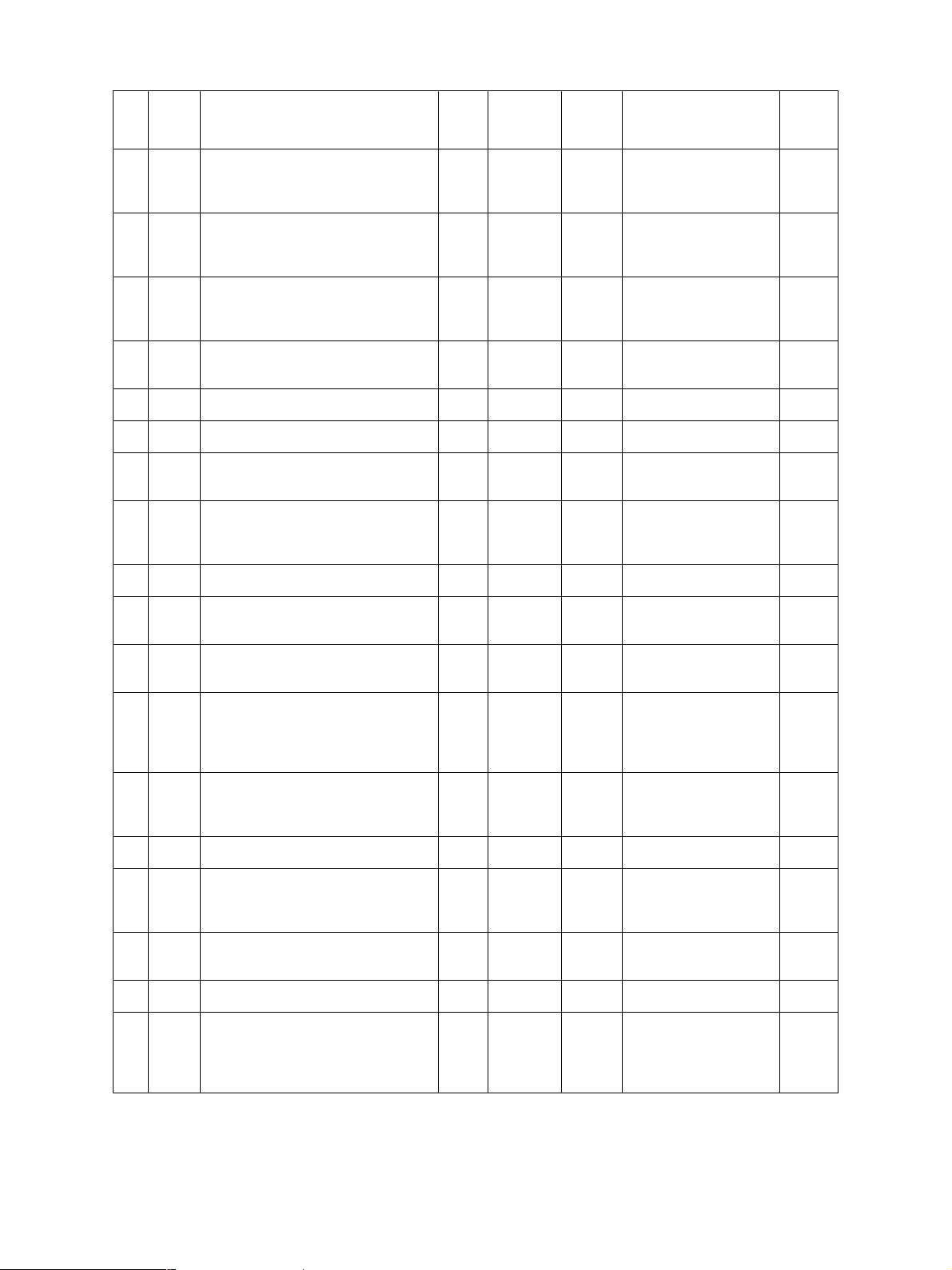

Classification Error code Machine status

Other operator calls

CALL SERVICE from drive

system

Temporary paper supply

mechanism error

- Internal tray full (when finisher bridge installed)

(e-STUDIO200/250 series)

- No paper in the cassette 1

- No paper in the cassette 2

- No paper in the cassette 3

- No paper in the cassette 4 (e-STUDIO200/250 series)

- No paper in the LCF (e-STUDIO200/250 series)

- Cassette 1 is not ready

- Cassette 2 is not ready

- Cassette 3 is not ready

- Cassette 4 is not ready (e-STUDIO200/250 series)

- LCF is not installed (e-STUDIO200/250 series)

Front cover or side cover of the copier is open

Cover of the job separator is open

Cover of the off set catch tray is open

Cover of the bridge cover is open

(e-STUDIO200/250 series)

Cover of the ADU is open

Side cover of the cassette 2 is open

Side cover of the cassette 3 is open

Side cover of the LCF is open

(e-STUDIO200/250 series)

Finisher joint is open (e-STUDIO200/250 series)

No staples (displayed only when stapling is designated)

(e-STUDIO200/250 series)

C01 Main motor drive error

C02 to C03 Reserved

C04 PFP main motor drive error

C05 Reserved

C06 LCF feed motor error (e-STUDIO200/250 series)

C07 to C10 Reserved

C11 to C12 Reserved

C13 Cassette 1 error

C14 Cassette 2 error

C15 Cassette 3 error

C16 Cassette 4 error (e-STUDIO200/250 series)

C17 Reserved

C18 LCF tray error (e-STUDIO200/250 series)

C19 LCF feed motor abnormal (e-STUDIO200/250 series)

C20 Reserved

December 2002 TOSHIBA TEC 1 - 3 e-STUDIO160/200/250 ADJUSTMENT ITEMS

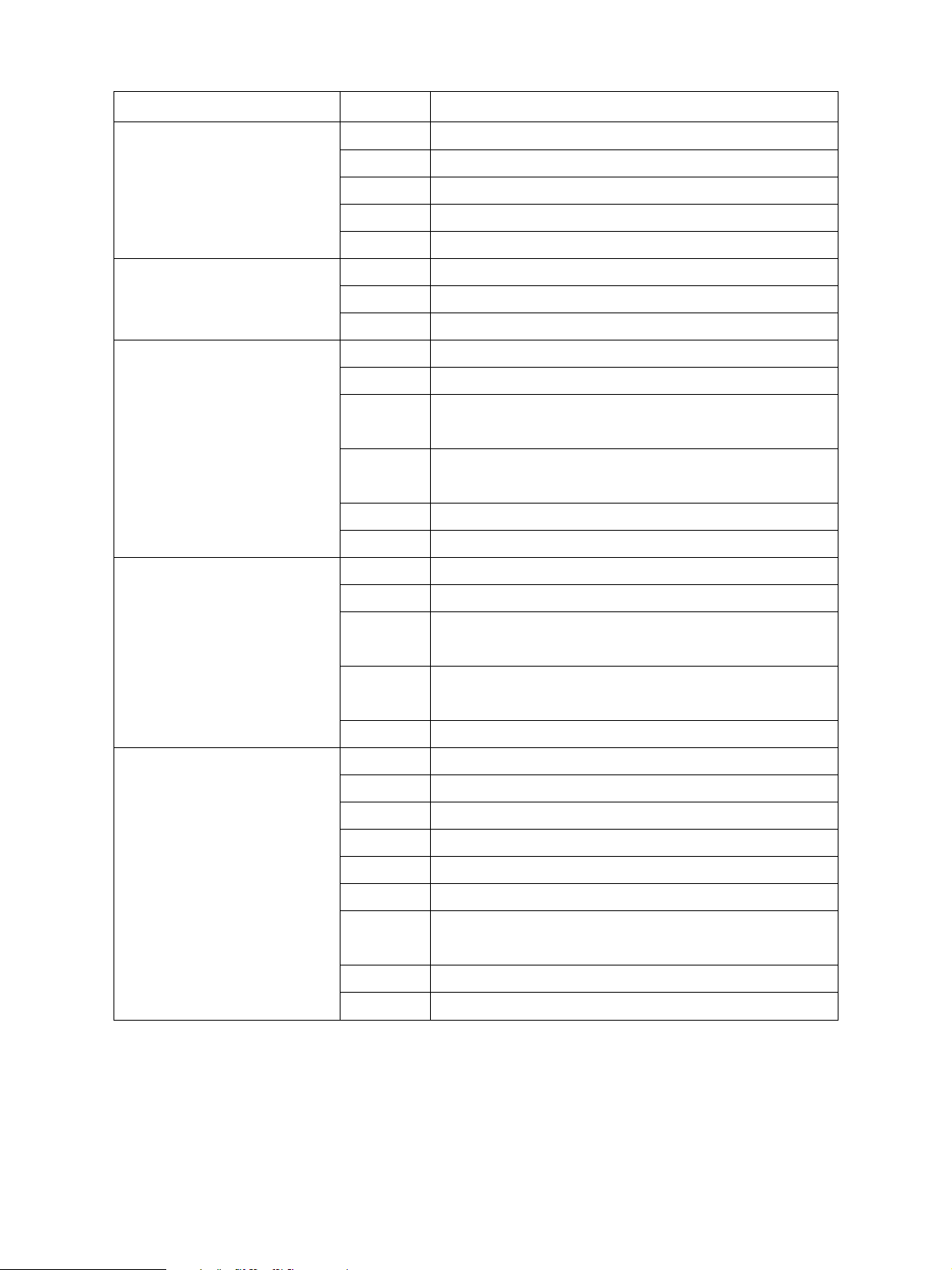

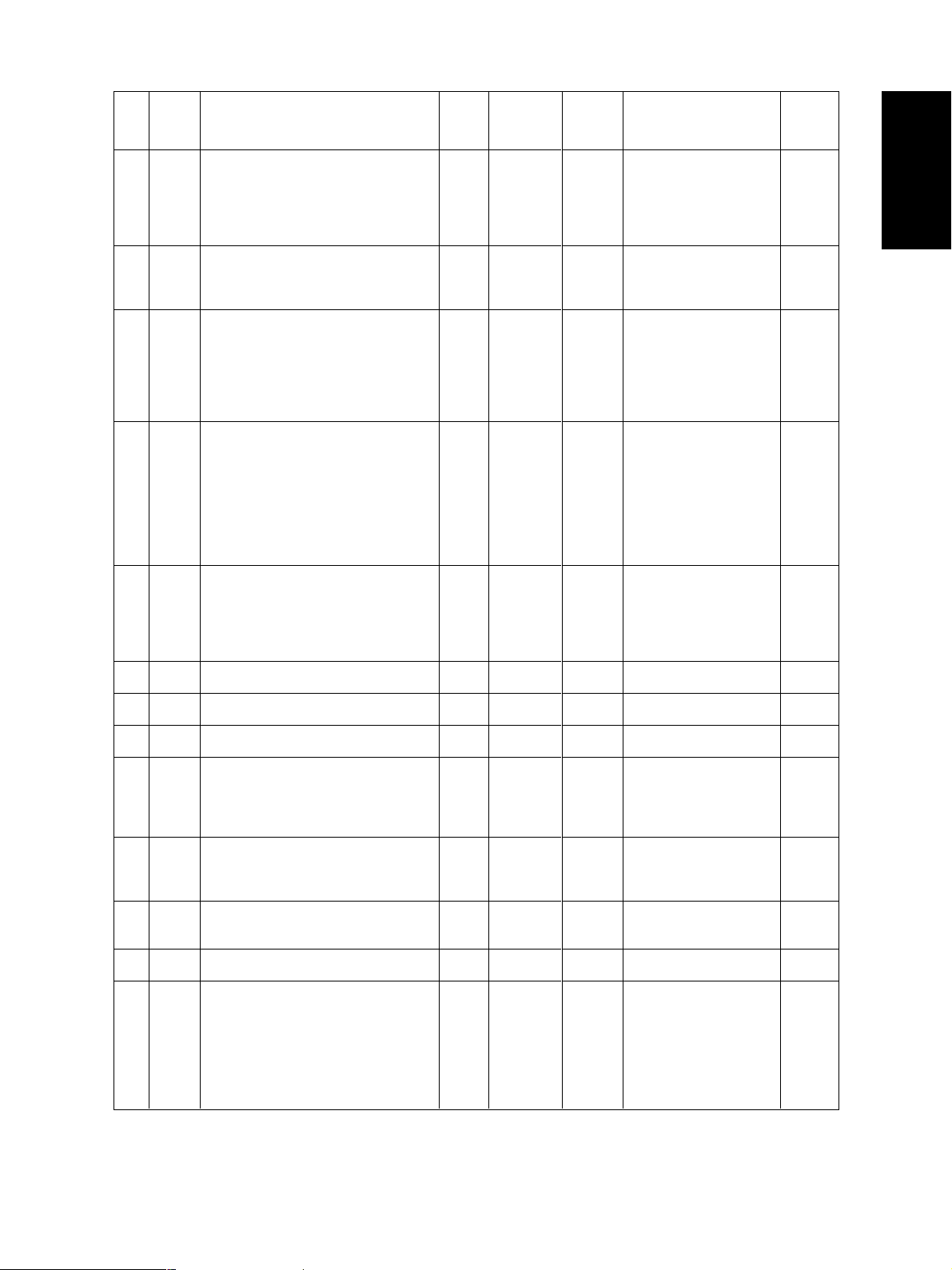

Classification Error code Machine status

CALL SERVICE from the

optical system

CALL SERVICE from the

process system

CALL SERVICE from fuser

area

CALL SERVICE from commu-

nication

C21 Carriage initialization error

C22 to C24 Reserved

C25 Scanner unit watch dog error

C26 Exposure lamp disconnection or peak detection error

C27 to C30 Reserved

C31 to C37 Reserved

C38 Replaced process unit error

C39 to C40 Reserved

C41 Abnormal thermistor or heater disconnection at power ON

C42 Reserved

C43 Warming up mode after disconnection judgment, or ab-

normal thermistor after ready

C44 Warming up mode after disconnection judgment, or heater

abnormal after ready

C45 Thermistor disconnection at the end part of heater

C46 to C50 Reserved

C51 to C55 Reserved

C56 Communication error between PFC and main unit

CALL SERVICE from ADF or

RADF

C57 Communication error between main unit and IPC

(e-STUDIO200/250 series)

C58 Communication error between IPC and finisher

(e-STUDIO200/250 series)

C59 to C70 Reserved

C71 Paper supply motor lock error

C72 Reserved

C73 EE-PROM initialization error

C74 Defective adjustment by the exit/reversal sensor detected

C75 to C80 Reserved

C81 Fan motor lock error

C82 Document aligning lower sensor (RADF)/Aligning sensor

(ADF) adjustment error

C83 Size length adjustment error

C84 to C89 Reserved

e-STUDIO160/200/250 ADJUSTMENT ITEMS 1 - 4 December 2002 TOSHIBA TEC

Classification Error code Machine status

CALL SERVICE from others

CALL SERVICE from laser

optical system

CALL SERVICE from finisher

(e-STUDIO200/250 series)

C90 Reserved

C91 SRAM abnormality (Lithium battery or SRAM chip are

abnormal.)

C92 to C94 Reserved

C95 Power supply unit fan motor abnormality

C96 Process unit fan motor abnormality

C97 Vacuum fan motor abnormality

C98 Clock IC abnormality

C99 PFC microcomputer abnormal

CA1 Polygon motor abnormal

CA2 HSYNC abnormal

CA3 to CB0 Reserved

CB1 Reserved

CB2 Exit motor abnormal

CB3 Reserved

CB4 Reserved

CB5 Staple motor abnormal

CB6 to CC2 Reserved

CC3 Set processing motor abnormal

Reserved

Scanner I/F

FAX unit

Offset catch tray

Reserved

CC4 to CC7 Reserved

CC8 Front aligning motor abnormal

CC9 Upper tray elevator motor abnormal

CCA Lower tray elevator motor abnormal

CCB Rear aligning motor abnormal

CCC to CD0 Reserved

F01 to F10 Reserved

F11 Scanner I/F error

F12 Write error at downloading the scanner unit program

F13 Download sector error of the scanner unit program

F14 Scanner unit F-ROM error

F15 to F20 Reserved

F31 Modem IC does not work normal

F32 to F40 Reserved

F41 Initial detection error of the offset catch tray

F42 to F99 Reserved

December 2002 TOSHIBA TEC 1 - 5 e-STUDIO160/200/250 ADJUSTMENT ITEMS

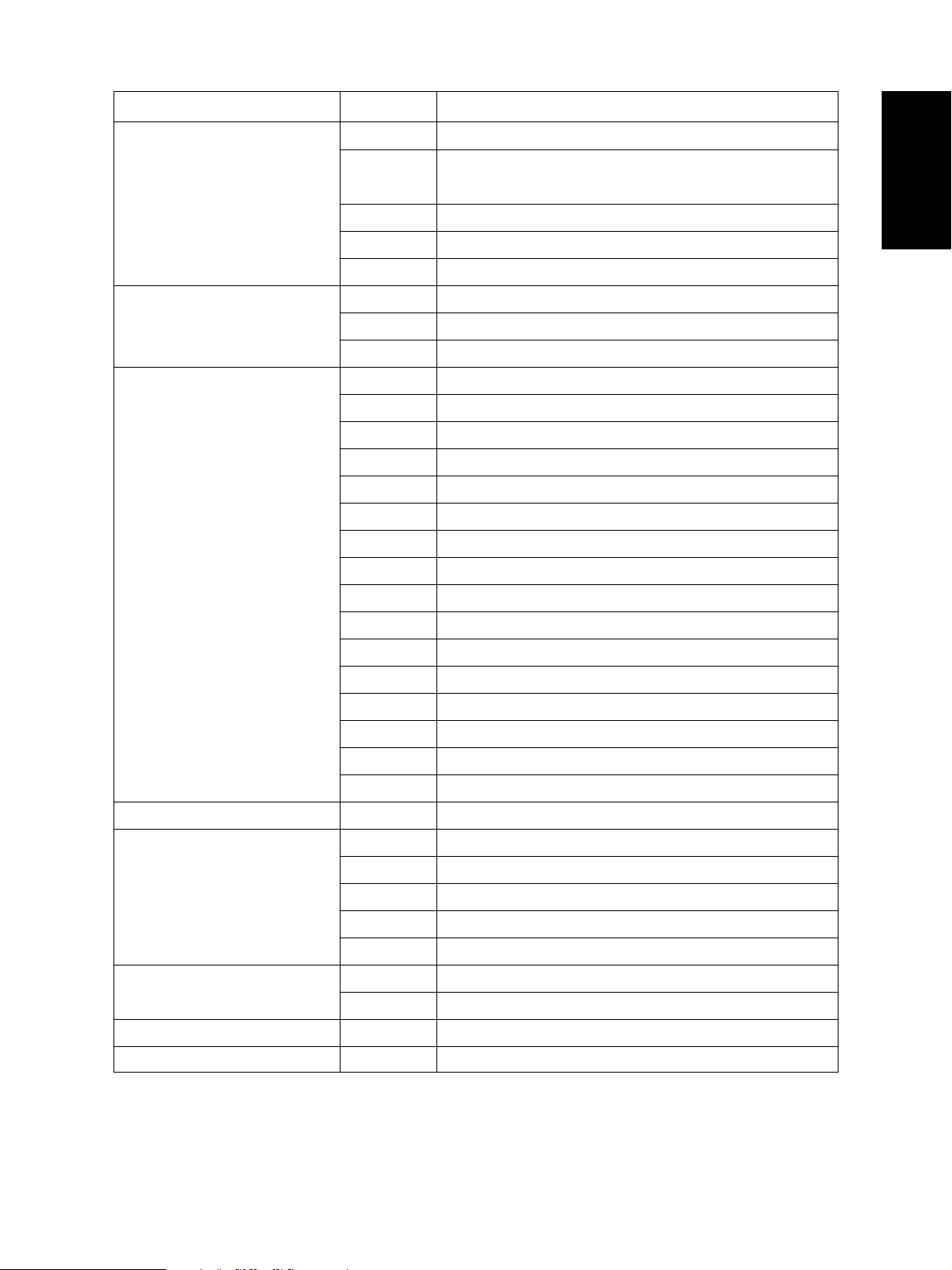

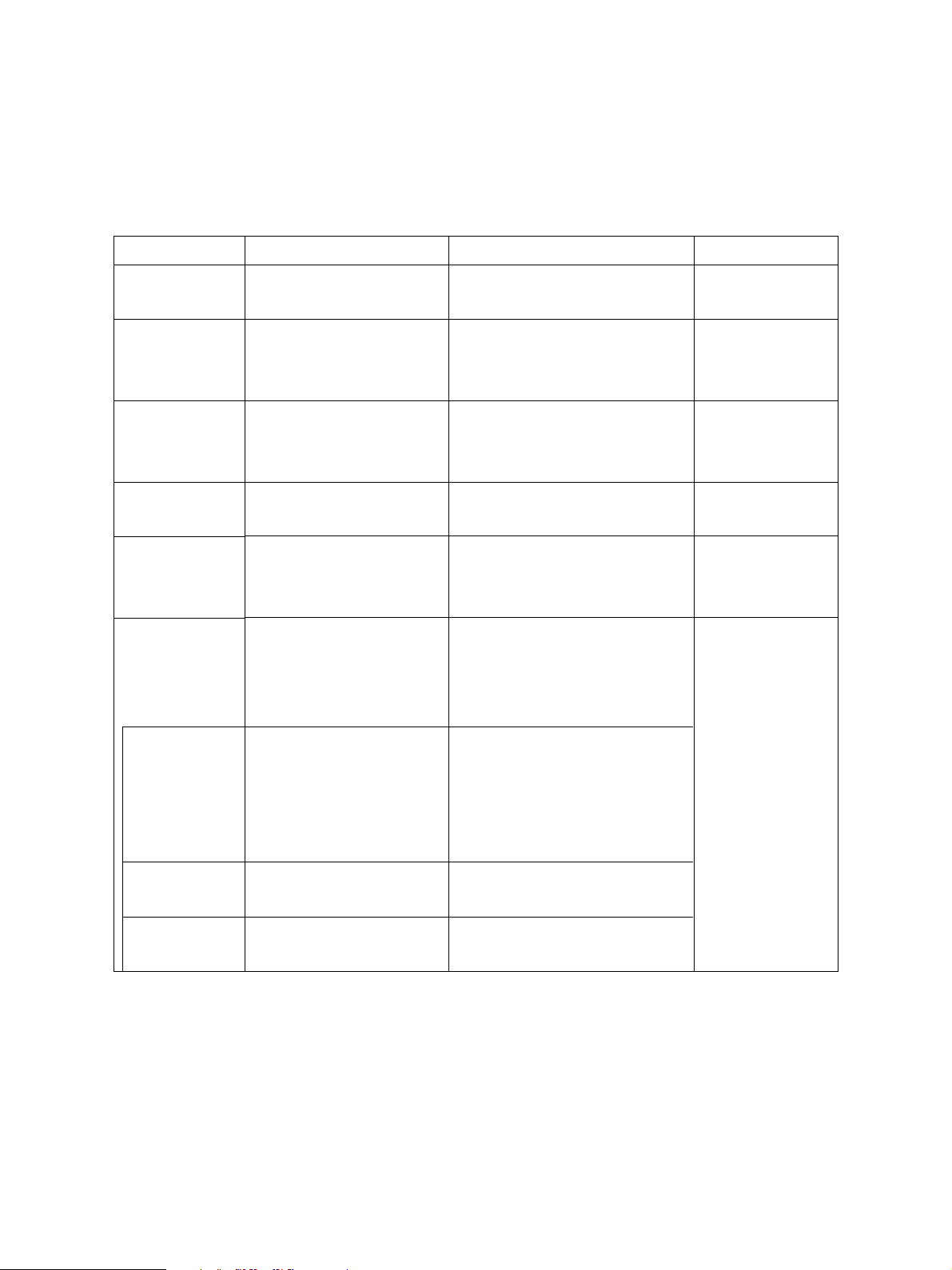

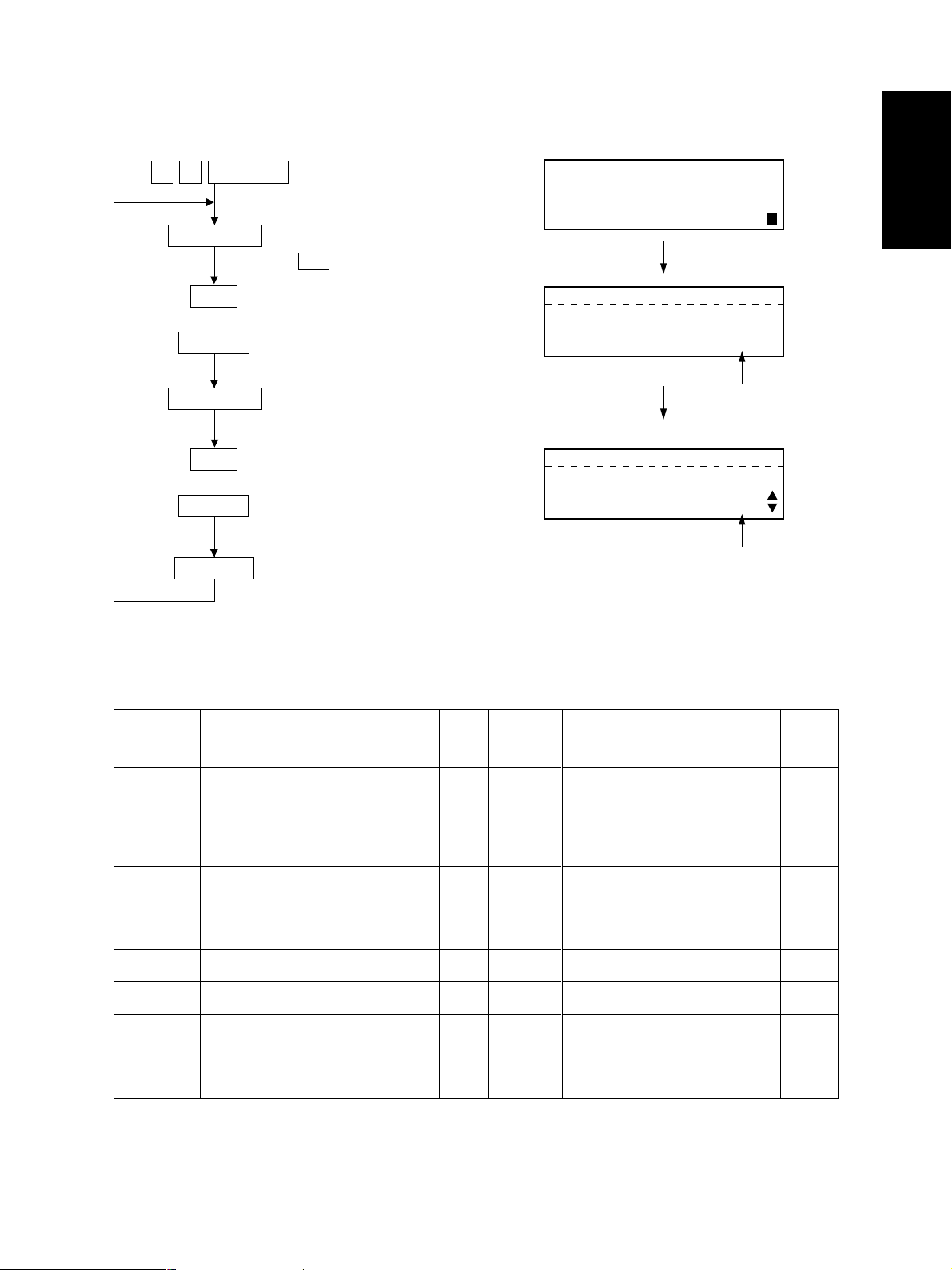

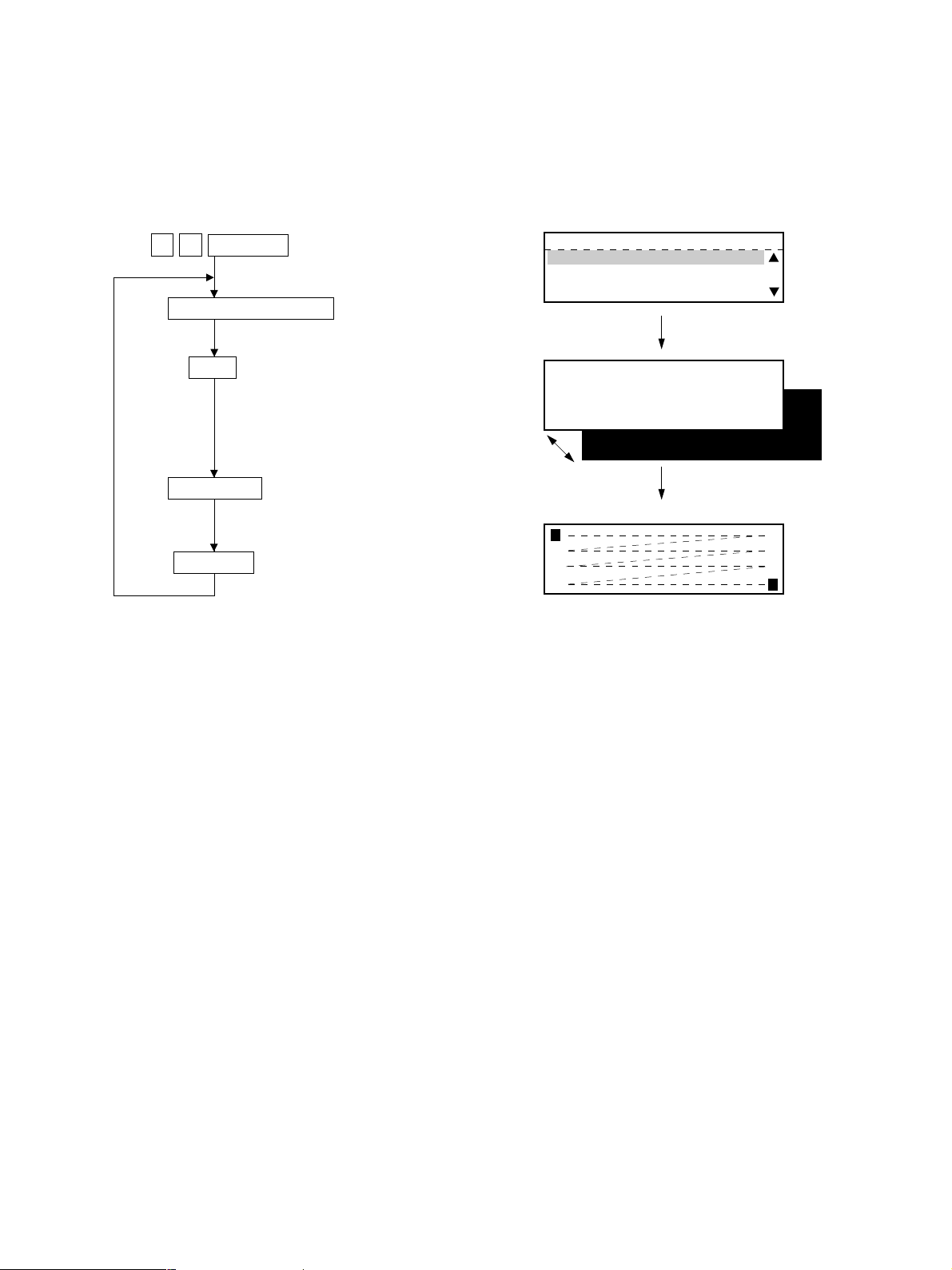

1.2 Self-Diagnosis Modes

The self-diagnosis functions are used to make the settings for the various PPC functions. This document

describes the self-diagnosis functions.

For the FAX functions, refer to the SERVICE HANDBOOK (GD-1061).

For the method to enter each mode of the self-diagnosis functions, refer to the following chart.

Mode

Country/Region

code

Adjust mode

System mode

Scanner parking

mode

RAM clear

Service mode

How to enter

Turn the power on while

pressing the 0 and 2 keys.

Turn the power on while

pressing the 0 and 5 keys.

Turn the power on while

pressing the 0 and 8 keys.

Turn the power on while

pressing the 0 and 9 keys.

Turn the power on while

pressing the 1, 3, and * keys.

Press the PROGRAM key

*3

while REDAY is indicated,

and then press the *, #, *,

then * keys.

Definition

Selects the country/region code.

Finely adjusts copy image quality.

Confirmation printing enabled by

pressing the INTERRUPT key.

Performs setups for the system,

maintenance, operations, printer,

scanner, etc.

Fixes the scanner carriage in place

when transporting the copier.

Clears values excluding the ones

set in 08-446/447 and in the Ad-

just mode (05).

Performs setups for FUNCTION

TEST and MAINTENANCE, and

prints the Service List.

How to clear

*1

Turn the power off.

Turn the power off.

Turn the power off.

*2

Press the

PROGRAM key,

and then press the

*, #, *, then * keys.

FUNCTION

TEST

MAINTENANCE

Service list

*1: After inputting the country/region code, the copier automatically enters the warm up mode.

*2: After the RAM clear, the machine automatically enters the warm up mode.

*3: In the SERVICE MODE, each function of the FUNCTION TEST, MAINTENANCE, or SERVICE LIST

in each test item of the TEST MODE (displayed by pressing the PROGRAM key), are added. When

the copier enters this mode, these functions are available.

*4 The copier enters into the service mode by pressing 1 and 3 keys while turning the power on. To exit

from the service mode, turn the power off.

After entering the service

mode, select it on the screen.

This mode is selected by

turning the power on while

pressing the 1 and 3 keys.

After entering Service Mode,

select it on the screen.

After entering Service Mode,

select it on the screen.

Conducts OPE. PANEL TEST,

PRINT TEST, MODEM TEST, etc.

Performs setups for Memory Clear,

facsimile function, etc.

Prints PROTOCOL TRACE, Total

Error, FUNCTION LIST, etc.

Or turn the power

off.

Or press the

COPY key, or

press the MAIN

MENU key. *4

e-STUDIO160/200/250 ADJUSTMENT ITEMS 1 - 6 December 2002 TOSHIBA TEC

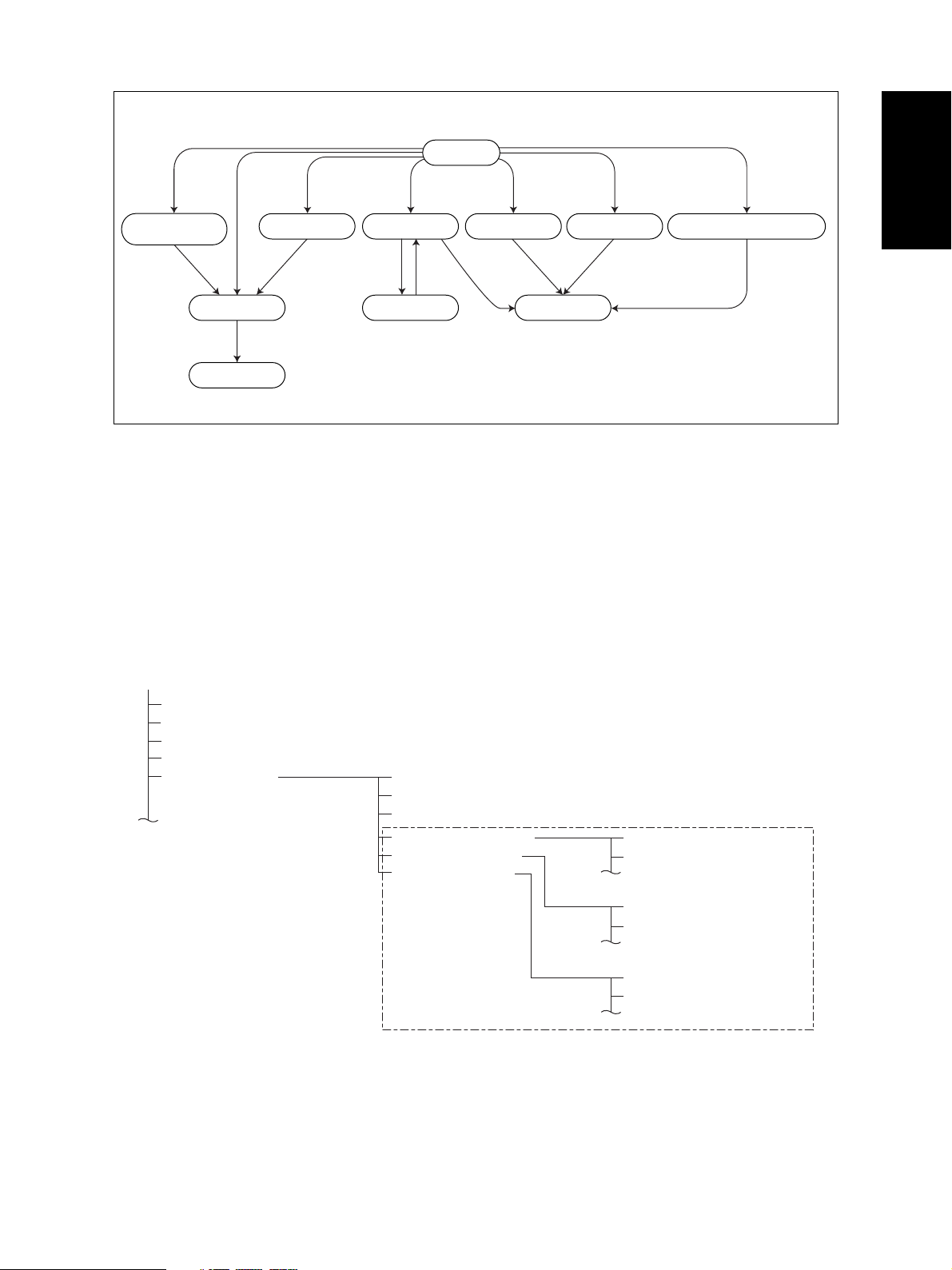

Power ON

"02"

Country/Region

code

Standby

"13*" "05"

RAM clear

"INT""INT"

Test printWarming up

"INT" : INTERRUPT key on.

Quick reference chart for self-diagnostic mode

"08" "13" "09"

System modeAdjust mode

Function test

Power OFF

Scanner parking mode

01-02-01

Note: Power ON Turn on the power switch.

Power OFF Turn on the power switch.

INT Press the INTERRUPT key.

C/S Press the CLEAR/STOP key.

Menu map

The menu below can be selected by pressing the program key. (However, the menu in the broken-dotted

box are displayed only when the copier enters the SERVICE MODE.)

01. DEFAULT SETTINGS

02. LISTS

03. INITIAL SETUP

04. MENU LIST

05. TEST MODE

01. AUTO TEST

02. INDIVIDUAL TEST

03. TEST RESULT LIST

04. FUNCTION TEST

05. MAINTENANCE

06. SERVICE LIST

Service mode

01. OPE PANEL TEST

02. PRINT TEST

01. MEMORY CLEAR

02. SET FUNCTION

01. PROTOCOL TRACE

02. TOTAL ERRORS

01-02-02

December 2002 TOSHIBA TEC 1 - 7 e-STUDIO160/200/250 ADJUSTMENT ITEMS

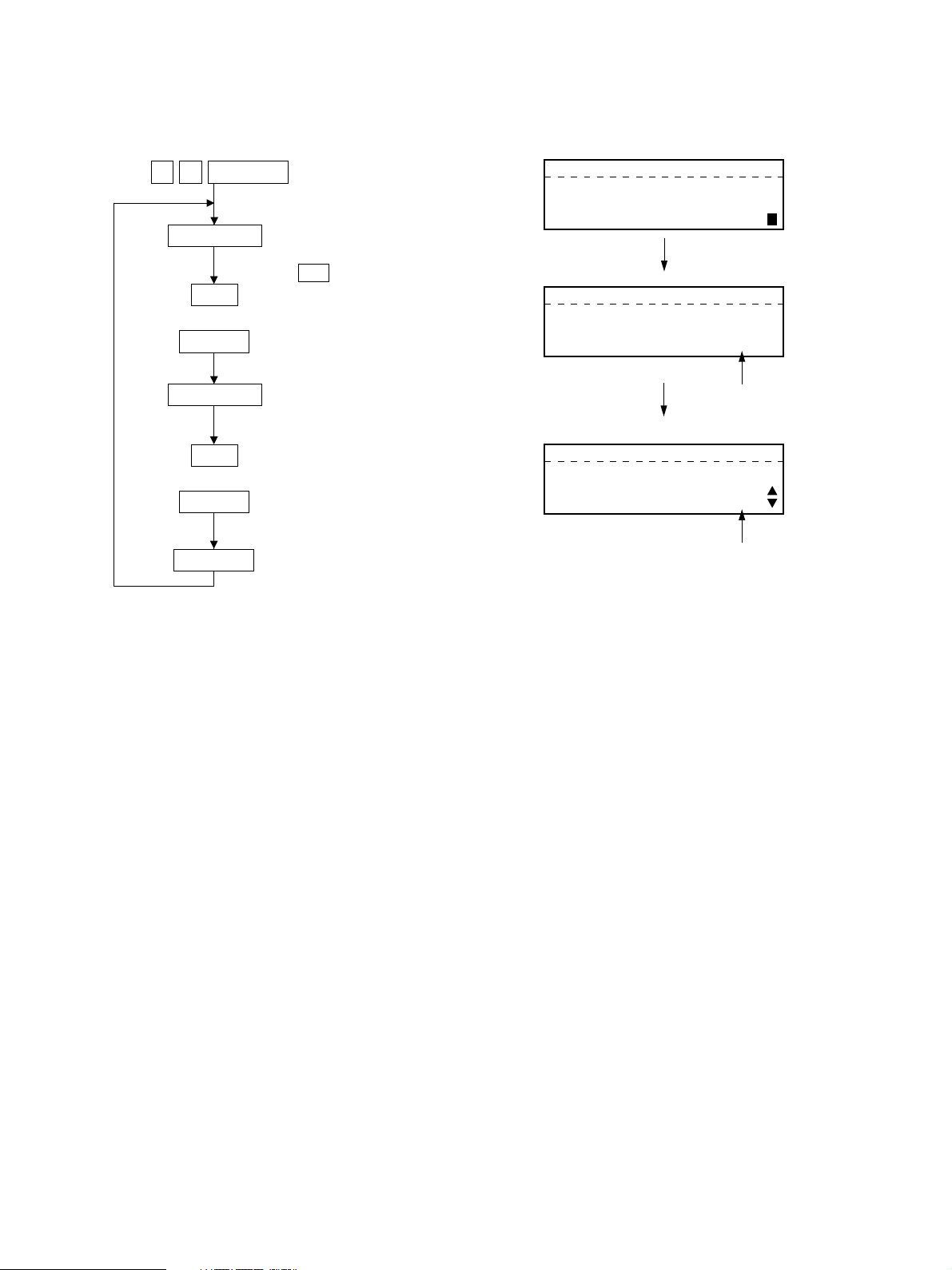

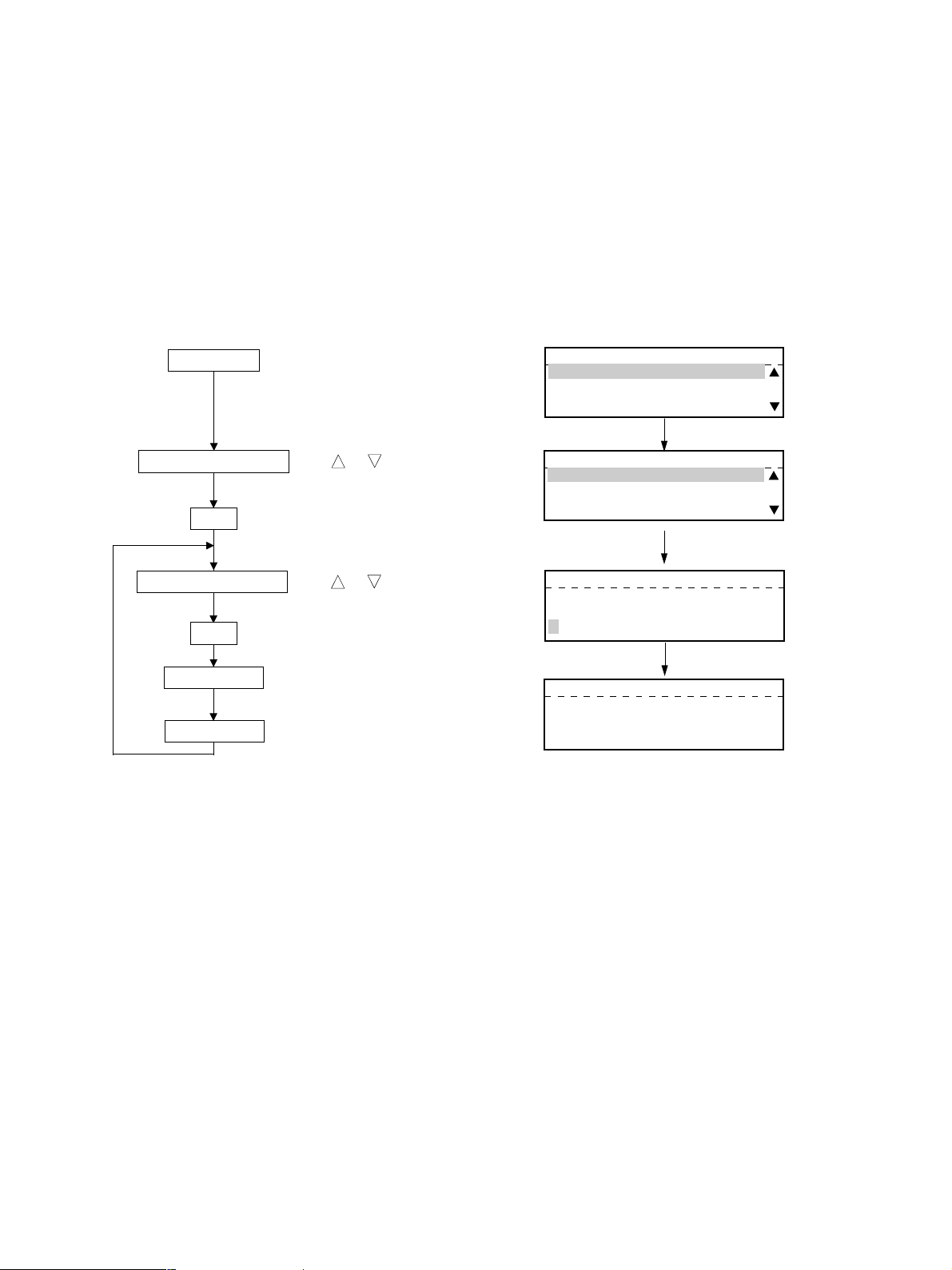

1.2.1 Adjust mode (05)

<Key used in operation> <Display messages>

0 5

Digital Keys

SET

or

START

Digital Keys

SET

or

START

Cancel

Power ON

Enter code

( C/S used to correct value)

Adjustment value

TEST MODE A

MC=

TEST MODE A

MC=

205

Enter code

TEST MODE A

MC=205

DT= 156

Adjustment value

e-STUDIO160/200/250 ADJUSTMENT ITEMS 1 - 8 December 2002 TOSHIBA TEC

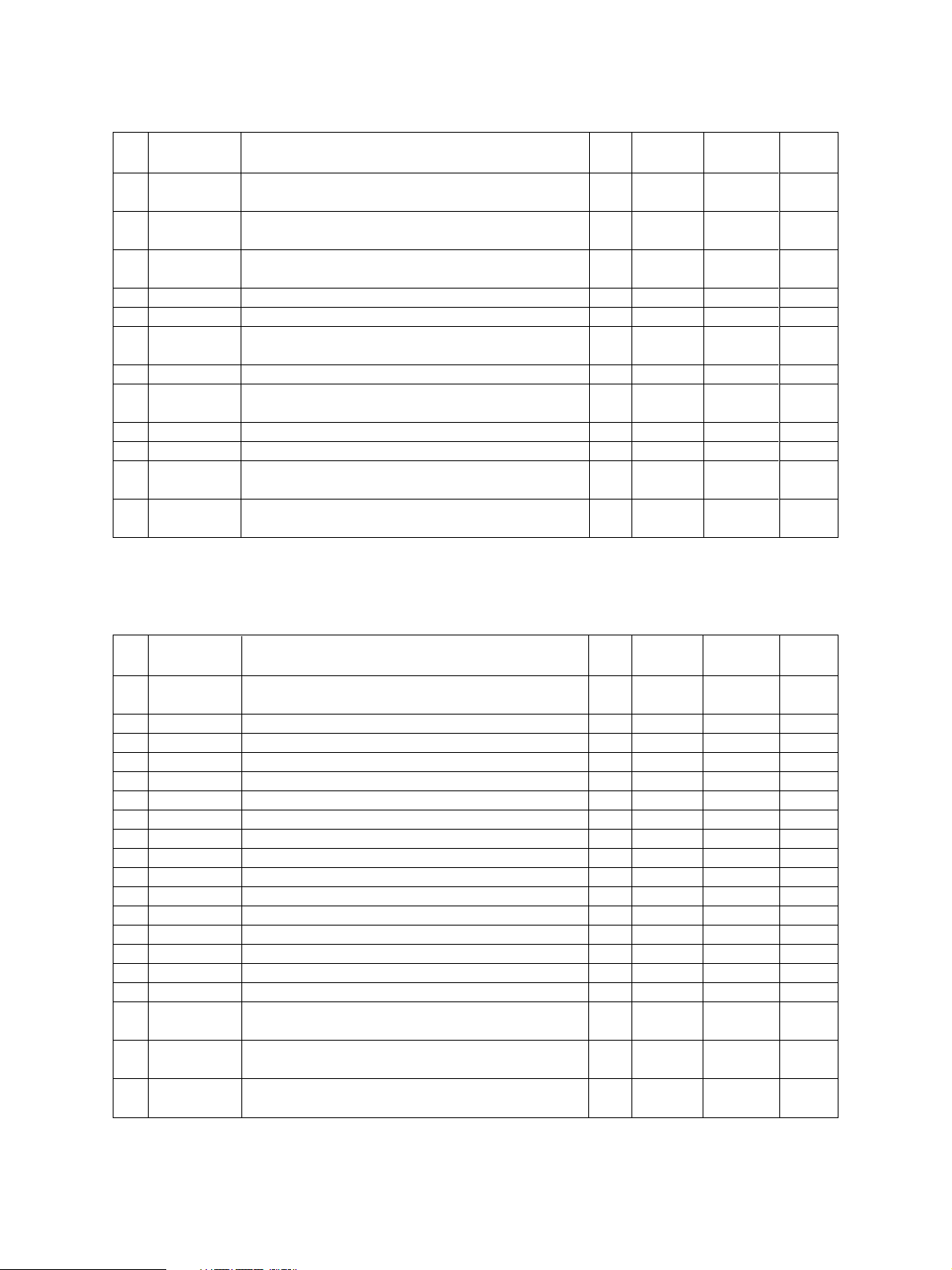

ADJUST MODE (05) ITEMS

Process unit adjustment

Code

205

210

220

221

233

234

235

261

Factor

Development

Charging

Transfer

Transfer

Separation

Separation

Separation

Laser

Adjustment item (05)

Developer bias DC adjustment

• Increment/decrement by U/D (Up/Down) key

• Real-time high voltage output

• Developer bias DC ON

Grid voltage initial value adjustment

• Increment/decrement by U/D key

• Real-time high voltage output (Charge ON)

Transfer transformer DC output High adjustment

• Increment/decrement by U/D key

• Real-time high voltage output (Transfer High ON)

Transfer transformer DC output Center adjustment

• Increment/decrement by U/D key

• Real-time high voltage output (Transfer Center ON)

Separation output High adjustment

• Increment/decrement by U/D key

• Real-time high voltage output (Separation-High ON)

Separation output Center adjustment

• Increment/decrement by U/D key

• Real-time high voltage output (Separation-Center ON)

Separation output Low adjustment

• Increment/decrement by U/D key

• Real-time high voltage output (Separation-Low ON)

Laser power 600 DPI Initial value adjustment

• Increment/decrement by U/D key

• No polygon rotation

• Real-time laser output

(Results of automatic laser adjustment)

(Laser ON)

Mode

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

Default

156

(166)

104

(118)

180

142

(155)

67

49

35

39

(53)

Acceptable

Guaranteed

*1

*1

*1

value

0-255

0-255

value

0-223

0-255

0-255

0-255

0-255

0-255

0-255

Refer to

page

1-70

1-70

1-70

1-70

1-70

1-70

1-70

*1 : The value in parentheses is for the model e-STUDIO200/250 series.

December 2002 TOSHIBA TEC 1 - 9 e-STUDIO160/200/250 ADJUSTMENT ITEMS

Scanning adjustment

Code

304

305

306

354

355

356

357

358

365

366

380

381

Factor

Scanner

mechanism

Scanner

mechanism

Scanner

mechanism

R/ADF

RADF

R/ADF

R/ADF

R/ADF

R/ADF

RADF

ADF

ADF

Adjustment item (05)

Scanner feed magnification 0.1 %/step

Scanner feed misalignment 0.126 mm/step

(600 DPI)

CCD scanning misalignment 0.04233 mm/step

R/ADF aligning amount (surface) 0.5 mm/step

RADF aligning amount (back) 0.5 mm/step

ADF position sensor adjustment or RADF sensor automatic

adjustment

R/ADF transport speed fine adjustment 0.1 %/step

R/ADF horizontal misalignment adjustment

0.04233 mm/step

RADF top position adjustment (surface) 0.1 mm/step

RADF top position adjustment (back) 0.1 mm/step

ADF document width sensor adjustment, narrowest document

guide width

ADF document width sensor adjustment, widest document

guide width

*1 : The entry of code enables automatic adjustment.

Mode

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

Default

128

128

128

10

10

-

50

128

50

50

-

-

Acceptable

value

0-255

85-171

5-251

0-20

0-20

0-100

0-255

0-100

0-100

*1

*1

*1

Refer to

page

1-62

1-63

1-61

1-52

1-52

Printer adjustment

Code

400

410

417

418

419

421

430

431

432

433

440

441

442

443

444

445

450

451

452

Factor

Printer system

Printer system

Printer system

Printer system

Printer system

Printer system

Printer system

Printer system

Printer system

Printer system

Printer system

Printer system

Printer system

Printer system

Printer system

Printer system

Printer system

Printer system

Printer system

Adjustment item

Polygon motor speed fine adjustment 600 DPI

0.2%/step

Laser start position 600 DPI Cassette 1

Laser start position 600 DPI Cassette 2

Laser start position 600 DPI Cassette 3/LCF

Laser start position 600 DPI Cassette 4

Main motor speed fine adjustment Approx. 0.1%/step

Top margin 0.7 mm/step

Left margin 0.1 mm/step

Right margin 0.1 mm/step

Bottom margin 0.1 mm/step

Top position Cassette 1 0.4 mm/step

Top position Cassette 2 0.4 mm/step

Top position Bypass (SFB) 0.4 mm/step

Top position LCF 0.4 mm/step

Top position PFP 0.4 mm/step

Top position ADU 0.4 mm/step

Aligning amount Copier cassette (Cassette 1)

Long size (0.52 mm/step) Paper length of min. 259 mm

Aligning amount Copier cassette (Cassette 1)

Short size (0.52 mm/step) Paper length of max. 258 mm

Aligning amount Cassette 2 (PFU)

Long size (0.52 mm/step) Paper length of min. 322 mm

Mode

PPC

PPC

PPC

PPC

PPC

PPC

PPC

PPC

PPC

PPC

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

Default

128

108

106

119

128

124 (130)

0

0

0

0

23

7

8

8

7

8

14

14

22

Acceptable

Value

108-148

0-255

0-255

0-255

0-255

78-178

0-30

0-255

0-255

0-255

0-40

0-15

0-15

0-15

0-15

0-15

0-31

0-31

0-31

Refer to

page

1-56

1-57

1-57

1-57

1-57

1-58

1-64

1-64

1-65

1-65

1-59

1-59

1-59

1-59

1-59

1-59

1-55

1-55

1-55

*1 : The value in parentheses is for the model e-STUDIO200/250 series.

e-STUDIO160/200/250 ADJUSTMENT ITEMS 1 - 10 December 2002 TOSHIBA TEC

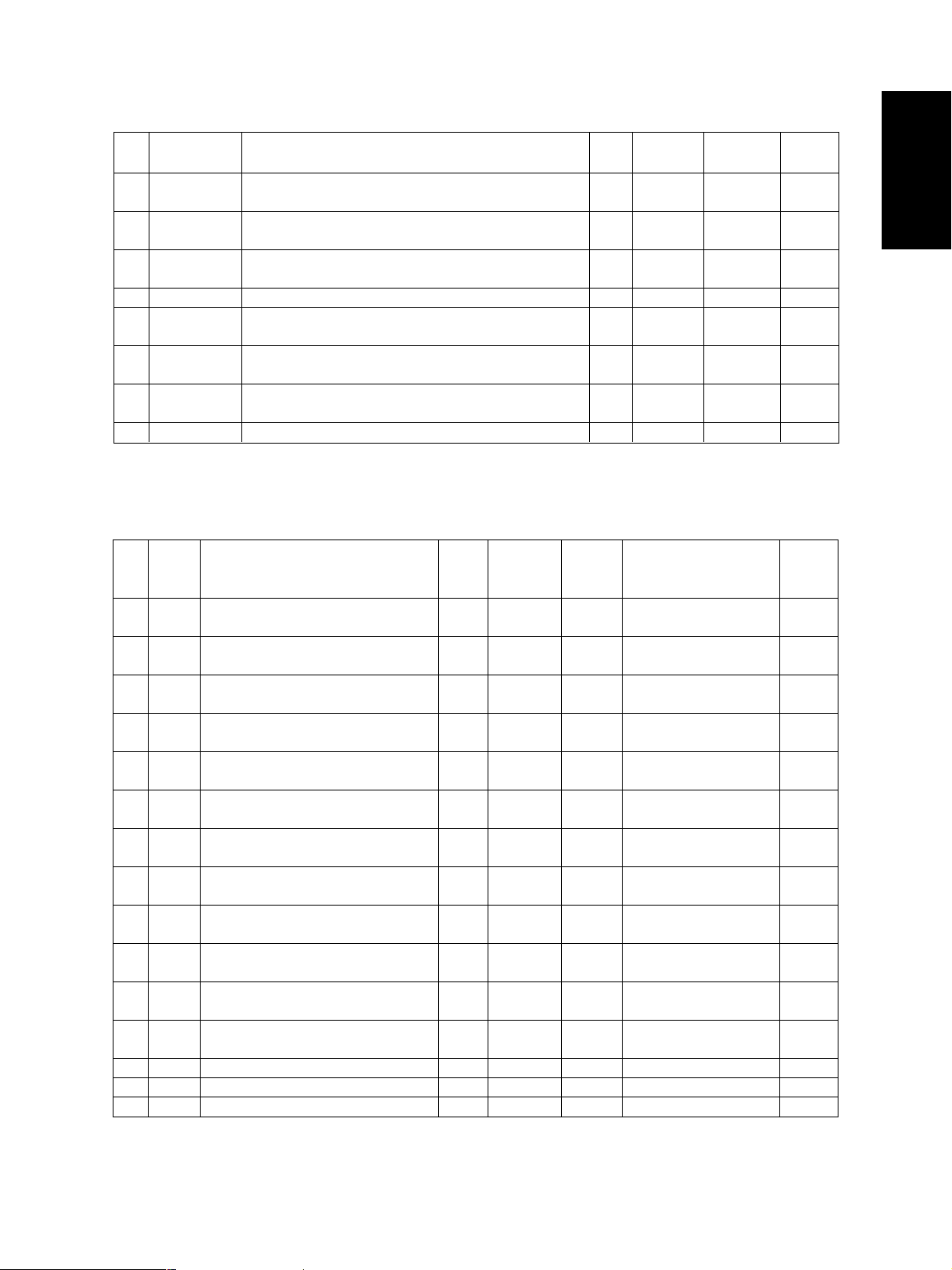

Printer adjustment

Code

453

455

456

457

458

463

465

497

Factor

Printer system

Printer system

Printer system

Printer system

Printer system

Printer system

Printer system

Printer system

Adjustment item

Aligning amount Cassette 2 (PFU)

Short size (0.52 mm/step) Paper length of max. 321 mm

Aligning amount ADU

(e-STUDIO160: 0.7 mm/step, e-STUDIO200/250: 0.47 mm/step)

Aligning amount PFP Short size (0.52 mm/step)

Paper length of max. 321 mm

Aligning amount LCF 0.52 mm/step

Aligning amount Bypass (SFB) Short size (0.52 mm/step )

Paper length of max. 258 mm

Aligning amount PFP Long size (0.52 mm/step)

Paper length of min. 322 mm

Aligning amount Bypass Long size (0.52 m/step)

Paper length of min. 259 mm

Laser start position 600 DPI Bypass

Scan image processing parameter 600 DPI

Code

501

503

504

505

506

507

508

509

510

512

514

515

593

594

595

Factor

Density

Density

Density

Density

Density

Density

Density

Density

Density

Density

Density

Density

Density

Density

Density

Manual density fine adjustment Center

value

Ditto

Ditto

Manual density fine adjustment Light step

value

Ditto

Ditto

Manual density fine adjustment Dark step

value

Ditto

Ditto

Auto density fine adjustment

Ditto

Ditto

ϒ data inclination correction

ϒ data inclination correction

ϒ data inclination correction

Adjustment item

Mode

ALL

ALL

ALL

ALL

ALL

ALL

ALL

PPC

*1 : The value in parentheses is for the model e-STUDIO200/250 series.

Image

mode

PPC

PPC

PPC

PPC

PPC

PPC

PPC

PPC

PPC

PPC

PPC

PPC

PPC

PPC

PPC

Image

quality

mode

Photo

Text/Photo

Text

Text/Photo

Photo

Text

Text/Photo

Photo

Text

Photo

Text/Photo

Text

Text/Photo

Photo

Text

Default

139

133

130

28

18

20

13

20

18

140

133

130

0

0

0

Default

16

26

(23) *1

16

16

21

18

28

101

Acceptable

L ← V → D

L ← V → D

L ← V → D

L ← V → D

L ← V → D

L ← V → D

Acceptable

value *1

0-255

0-255

0-255

0-255

V → L

0-255

V → L

0-255

V → L

0-255

V → D

0-255

V → D

0-255

V → D

0-255

0-255

0-255

0-9

0-9

0-9

Value

0-31

0-31

0-31

0-31

0-31

0-31

0-31

0-255

Refer to

page

1-55

1-55

1-55

1-55

1-55

1-55

1-55

1-57

Refer to

page

1-53

1-53

1-53

1-53

1-53

1-53

1-53

1-53

1-53

1-53

1-53

1-53

1-67

1-67

1-67

*1 L: Light, V: Value, D: Dark

December 2002 TOSHIBA TEC 1 - 11 e-STUDIO160/200/250 ADJUSTMENT ITEMS

Scan image processing parameter 600 DPI

Code

620

621

622

693

694

695

Factor

Image

quality

Image

quality

Image

quality

Density

Adjustment item

No. of units: HPF table number

0: Use of default value

1: Text/Photo mode

2: Photo mode

3: For Text mode

4 - 9: Unused

No. of tens: Filter combination intensity

0: Use of default value

1 - 9: Filter combination intensity

Ditto

Ditto

Range correction on original set on the

ADF or RADF.

Set whether the value of the background

peak and text peak are fixed or not.

If they are fixed, the range correction is

performed with standard values.

The values of the background peak and

text peak affect the reproduction of the

background density and text density re-

spectively.

The number of units: Data while automatic

density is selected.

The number of tens: Data while manual

density is selected.

Background peak Text peak

1: fixed fixed

2: varied fixed

3: fixed varied

4: varied varied

Image

mode

PPC

PPC

PPC

PPC

Image

quality

mode

Text/Photo

Photo

Text

Text/Photo

Photo

Text

Default

1

2

3

12

12

44

Acceptable

value *1

0-99

The larger the intensity

coefficient the stronger the

intensity.

0-99

0-99

11-14

21-24

31-34

41-44

Refer to

page

1-66

1-66

1-66

e-STUDIO160/200/250 ADJUSTMENT ITEMS 1 - 12 December 2002 TOSHIBA TEC

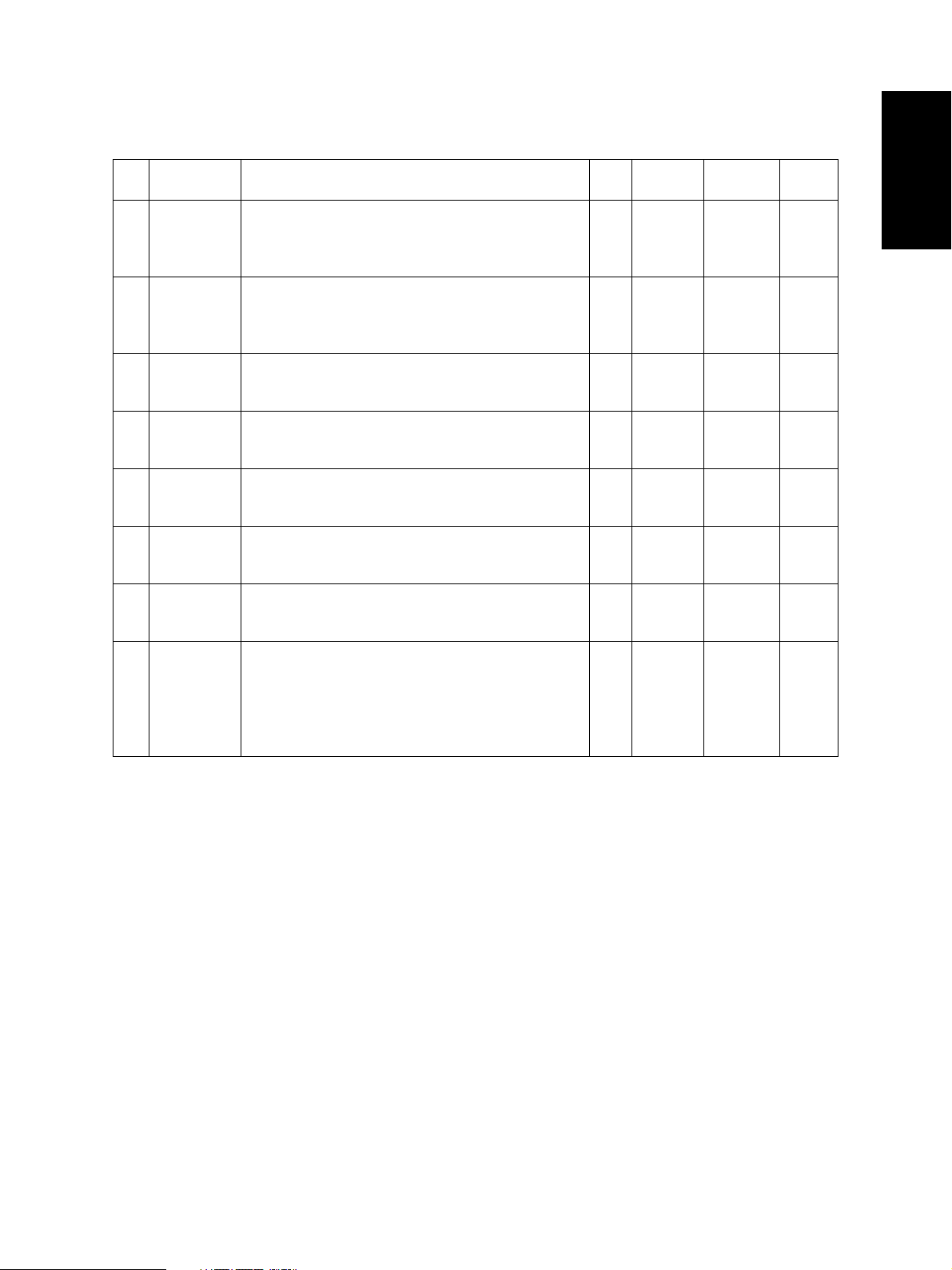

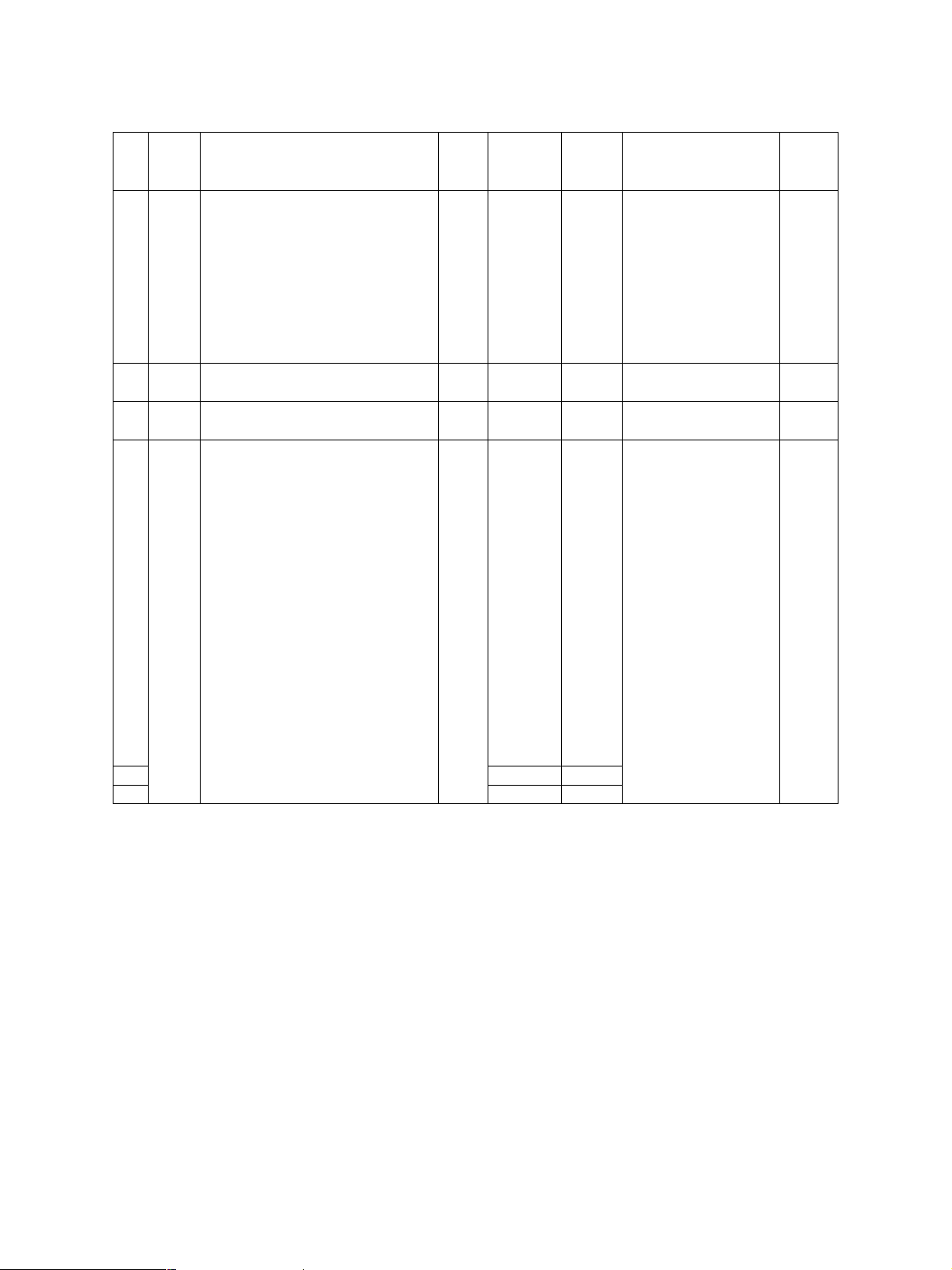

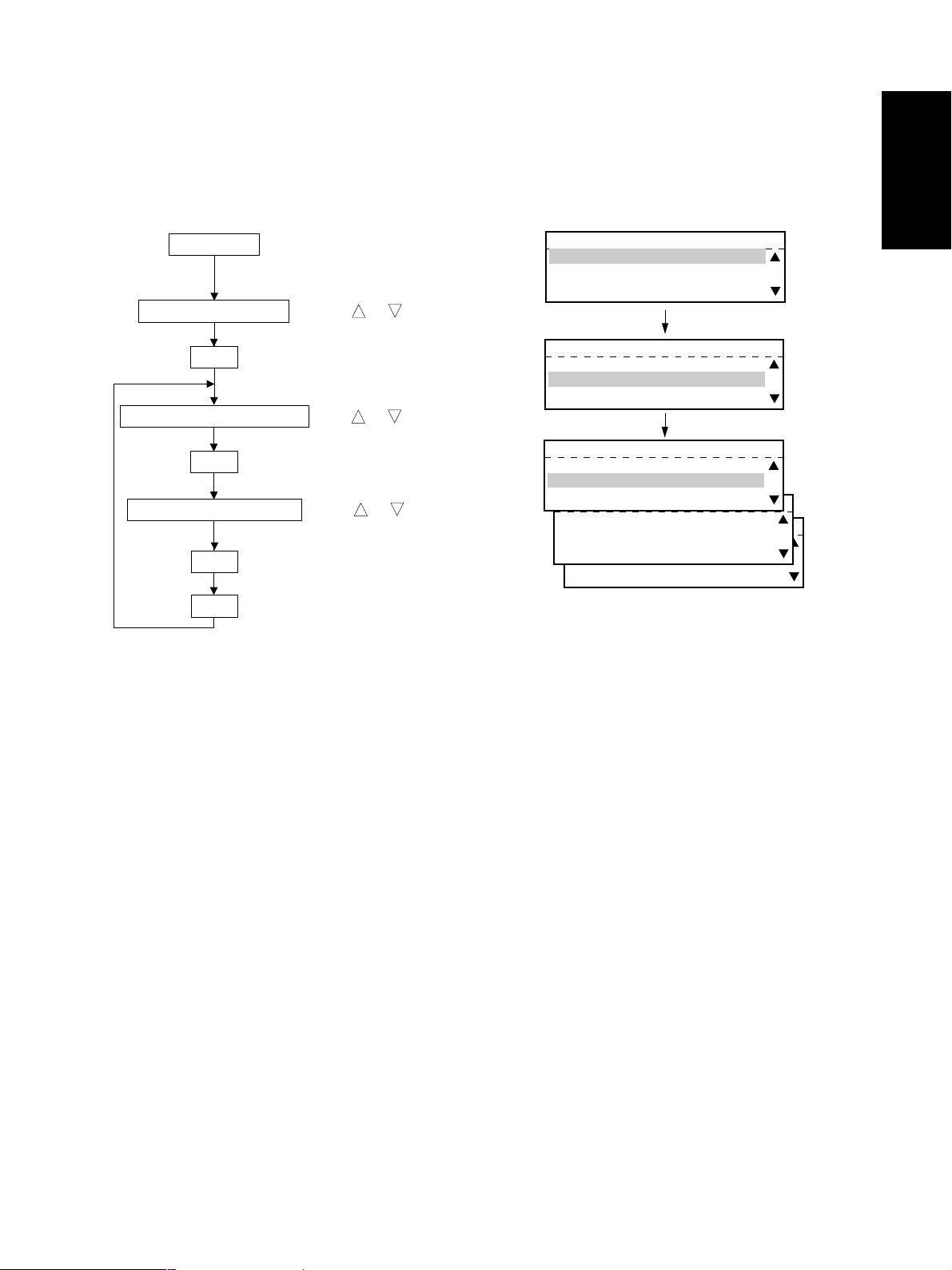

1.2.2 System mode

<Key used in operation> <Display messages>

0 8

Digital Keys

SET

or

START

Digital Keys

SET

or

START

Cancel

Power ON

Enter code

( C/S used to correct value)

Setting value

TEST MODE D

MC=

TEST MODE D

MC=

204

Enter code

TEST MODE D

MC=204

DT= 1

Setting value

SYSTEM MODE (08) ITEMS

Code

202

204

205

206

207

Factor

SYS

SYS

SYS

SYS

SYS

Selection of external counter

0: No external counter

1: With coil controller

2: Non-standard: With copylizer/key

3: With key counter

Auto clear [sec]

0: Invalid 1: 15s 2: 30s 3: 45s 4: 60s

5: 75s 6: 90s 7: 105s 8: 120s

9: 135s 10: 150s 11: 180s 12: 210s

13: 240s 14: 270s 15: 300s

Auto low power 0: Invalid 1: Valid

(Time is set on panel.)

Auto sleep 0: Invalid 1: Valid

(Time is set on panel.)

Display for key counter setting

0: Set key copy counter

1: ASK CASHIER TO SWITCH ON

* Valid when 08-202 is set to 3 (With key

counter).

Setting item

card

Mode

ALL

ALL

ALL

ALL

ALL

Image

quality

mode

Default

0

3

1

1

0

*1 : The entry of code enables automatic execution.

Acceptable

value *1

0-3

0-15

0-1

0-1

0-1

Refer to

page

December 2002 TOSHIBA TEC 1 - 13 e-STUDIO160/200/250 ADJUSTMENT ITEMS

SYSTEM MODE (08) ITEMS

Code

224

225

226

227

228

246

250

251

252

255

256

300

340

351

352

355

374

Factor

SYS

SYS

SYS

SYS

SYS

SYS

MAINT

MAINT

MAINT

MAINT

MAINT

OPE.

MAINT

COUNT

COUNT

COUNT

COUNT

Setting item

SFB paper size

0: A3 (8K) 1: A4 (16K) 2: A4R (16KR)

3: A5R 4: B4 5: B5 6: B5R

7: LETTER 8: LETTER-R

9: LEDGER 10: LEGAL

11: STATEMENT-R 12: COMPUTER

13: FOLIO 14: Undefined

15-17: Reserved

Copier cassette paper size

0: A3 (8K) 1: A4 (16K) 2: A4R (16KR)

3: A5R 4: B4 5: B5 6: B5R

7: LETTER 8: LETTER-R 9: LEDGER

10: LEGAL 11: STATEMENT-R

12: COMPUTER 13: FOLIO

14: Reserved 15: Reserved

Cassette 2 paper size (Same as 08-225)

Cassette 3 paper size (Same as 08-225)

(e-STUDIO200/250 series)

Cassette 4 paper size (Same as 08-225)

(e-STUDIO200/250 series)

Clearing copy jobs at auto clear

0: No clearing 1: Clearing

Service personnel telephone number

PM counter setting value

PM counter present value

08-251: Operates when other than 0

Object of 08-352

PFP installation status

0: Auto (Automatically changed to 1

or 2 by observing the PFC cassette

installation status.)

1: PFP (Cassette 3)

2: PFP (Cassette 3,4)

(e-STUDIO200/250 series)

3: Reserved 4: None

LCF paper size

0: A4 1: LT 2: Reserved

MAX . 9

0: 999

1: 99

2: 9

Drum end counter setting value.

Display of total counter data

(Confirmed by listing and changed by

memory writing)

A3/LD double count

0: Single count 1: Double count

Display of drum lite counter

ADF/RADF scan counter

Mode

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

Image

quality

mode

Default

14

NAD: 7

Acceptable

value *1

0-14

0-13

Other: 1

NAD: 7

0-13

Other: 1

NAD: 7

0-13

Other: 1

NAD: 7

0-13

Other: 1

0

0-1

20 digits

Own M/C registration area

NAD:

e-STUDIO160/

200: 81000

e-STUDIO250:

99000

Othre: 0

0

0

NAD: 1

0-999999

0-999999

0-4

0-2

Other: 0

0

e-STUDIO160/

200: 27000

e-STUDIO250:

33000

0-2

0-99999

(0: Not displayed)

Display only

1

0

0-1

Display only

0-999999

*1 : The entry of code enables automatic execution.

Refer to

page

e-STUDIO160/200/250 ADJUSTMENT ITEMS 1 - 14 December 2002 TOSHIBA TEC

Code

375

376

377

385

386

388

389

400

401

402

403

404

406

407

408

Factor

COUNT

COUNT

COUNT

COUNT

COUNT

COUNT

COUNT

Process

Process

Process

Process

Process

Process

Process

Process

Setting item

COPY job (print) counter

PRINTER job (print) counter

FAX job (print) counter

Total counter in scanner unit (display)

Platen scan count

LOAD instruction for total counter when

replacing the main PWA Scanner unit →

Copier

SAVE instruction for total counter when

replacing the scanner unit Copier → Scanner unit

Thermistor heater status counter

0: No error occurrence

1: C41 1st thermistor or heater error

when starting W-UP

2: C41 2nd thermistor or heater error

when starting W-UP

3: Reserved

4: C43 Thermistor error during W-UP

5: C44 Heater error during W-UP

6: C43 Thermistor error after ready

7: C44 Heater error after ready

8: C45 Heater end thermistor error af-

ter ready (High temperature)

9: C44 High temperature heater error

10: C45 Heater end thermistor error af-

ter ready (Low temperature)

Drum life counter

Power on hours counter

(7-digit display: Hour 5-digit, minute 2digit)

Total power ON hours

Fuser counter

Always double count for A3, B4, LD, LG,

COM, A4R, LTR, and FOLIO

Developer material counter.

Always double count for A3, B4, LD, LG,

COM, A4R, LTR, and FOLIO.

Clear by installing a new PU.

Pre-run start time

0: Invalid 1: 30 sec 2: 35 sec

3: 40 sec 4: 45 sec 5: 50 sec

6: 55 sec 7: 60 sec

Pre-run operation time

0: Invalid 1: 5 sec 2: 10 sec

3: 15 sec 4: 20 sec 5: 25 sec

6: 30 sec 7: 40 sec 8: 50 sec

9: 60 sec 10: 150 sec

Pre-run operation time for thick paper

0: Invalid 1: 1 sec 2: 2 sec 3: 3 sec

4: 4 sec 5: 5 sec 6: 6 sec 7: 7 sec

8: 8 sec 9: 9 sec 10: 10 sec

11: 12 sec 12: 14 sec 13: 16 sec

14: 18 sec 15: 20 sec

Mode

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

Image

quality

mode

Default

0

0

0

0

0

0

0

(2)

*1

10

*1 : The entry of code enables automatic execution.

Acceptable

value *1

Double counted if printing

A3 or LD size paper

Double counted if printing

A3 or LD size paper

Double counted if printing

A3 or LD size paper

0-999999

0-999999

*1

*1

0-10

0-999999

0-9999959

Counter area added

0-999999

Counter area added

0-999999

Counter area added

0-7

0-10

0-15

Refer to

page

1-90

December 2002 TOSHIBA TEC 1 - 15 e-STUDIO160/200/250 ADJUSTMENT ITEMS

Code

410

411

412

413

446

*2

447

*2

462

480

481

483

486

503

504

550

603

604

611

614

Factor

Process

Process

Process

Process

Process

Process

PRINT

PRINT

PRINT

PRINT

Image

processing

F/W

Image

processing

F/W

F/W

F/W

F/W

Setting item

Fixing temperature when printing

4: 170°C 5: 175°C 6: 180°C 7: 185°C

8: 190°C 9: 195°C 10: 200°C

11: 205°C 12: 210°C 13: 215°C

Fixing temperature when ready

0: 170°C 1: 175°C 2: 180°C 3: 185°C

4: 190°C 5: 195°C 6: 200°C

7: Drop control ON

Fixing temperature in low power state

0: OFF 1: 120°C 2: 130°C 3: 140°C

4: 150°C 5: 160°C

Fixing temperature for thick paper

0: Invalid 1: 195°C 2: 200°C 3: 205°C

4: 210°C

Correction for transfer output ON timing.

(0: -110 ms -----18: +70 ms)

Correction for transfer output OFF timing.

(0: +110 ms -----18: -70 ms)

Setting for switchback operation to copy

mixed-size originals form RADF

0: Invalid 1: Valid

Cassette priority selection

0: A4/LT 1: LCF 2: Cassette 1

3: Cassette 2 4: Cassette 3

5: Cassette 4

Auto cassette change

0: None 1: Normal

Polygon motor preceding start-up setting

0: Valid (DF, platen) 1: Invalid

2: DF only

Time for suspension of the Polygonal motor pre-running

(0: 15 sec, 1: 30 sec, 2: 45 sec)

Density default in image quality mode

0: AUTO 1: Light 3 2: Light 2

3: Light 1 4: Center 5: Dark 1

6: Dark 2 7: Dark 3

Also reflected on panel.

Special paper selection

0: FOLIO/B size

1: 13" LEGAL (South America only)

2: K size (China only)

Image mode default

0: Standard 1: Photo 2: Text

Auto duplex mode (when document is

loaded into DF)

0: Invalid 1: Simplex/Duplex

2: Duplex/Duplex

APS priority selection

0: APS 1: AMS 2: None (100%)

3: Reserved

Book duplex document selection

0: Left-hand open 1: Right-hand open

The function clear LED blinks. Blinks when

the value is different from the present default value after copying (until auto clear

or all clear.)

0: Invalid (Always off) 1: Valid

*1 : The value in parentheses is for the model e-STUDIO200/250 series.

*2 : This value should be adjusted at the factory. Do not change the value in

Mode

ALL

Image

quality

mode

Default

8

Acceptable

value *1

4-13

Refer to

page

(10)

*1

ALL

ALL

7

NAD: 5

0-7

0-5

Other: 4

(NAD: 3)

(Other: 2) *1

ALL

0

0-4

(2)

*1

ALL

11

0-18

1-91

10 ms/step

ALL

ALL

ALL

ALL

ALL

PPC

PPC

PPC

PPC

PPC

PPC

PPC

ALL

ALL

1

(11) *1

0

0

1

0

0

0

0

0

0

0

0

1

0-18

10 ms/step

0-1

0-5

0-1

0-2

0-2

0-8

0-2

0-2

0-2

0-3

0-1

0-1

1-91

the field. When the main PWA is replaced, it should be entered again.

e-STUDIO160/200/250 ADJUSTMENT ITEMS 1 - 16 December 2002 TOSHIBA TEC

Code

618

620

635

641

642

648

649

650

652

665

673

685

688

Factor

F/W

F/W

F/W

F/W

F/W

F/W

F/W

F/W

F/W

Setting item

Default setting for mixed size originals

0: OFF

1: ON

* Setting 08-618 to 1 (ON) and 08-641 to

4 (alternate) simultaneously is not allowed.

APS forced start (Exclude RADF)

0: Valid (One time pressing)

1: Reserved

2: Invalid

Process for last page (one-sided original)

at duplex copying

0: One-side copy

1: Double-sided copy (blank paper is

added to as the last even numbered

page to output the copy in the same

orientation with previous pages.)

Auto sort mode (when document is loaded

into DF)

Also set on panel.

0: Invalid 1: Staple 2: Sort 3: Invalid

4: Vertical and horizon. alternate

5: Sort offset

* Setting 08-641 to 4 (alternate) and 08-

618 to 1 (ON) simultaneously is not al-

lowed.

Sorter mode priority selection (at all clear)

Also set on panel.

0: NON SORT 1: STAPLE 2: SORT

3: Reseved 4: ALTERNATION

5: SORT OFFSET

6: NON SORT OFFSET

Initialization of finisher bin at all clear

0: Valid 1: Invalid

Magazine sort setting

0: Left-hand open 1: Right-hand open

2in1/4in1 setting

0: Horizontal write 1: Vertical write

Cascade operation setting

(e-STUDIO200/250 series)

0: No cascade

1: 1 → 2 (Endless stack included)

2. Reserved

Set PPC area default.

05: Adjust area, γ adjust store area

08: Setting (PPC-FUNC) area

(Except the counter values)

Resetting drum-related counters,

08-355, 08-401.

(Valid when 08-689 is set to 1.)

Paper feeding by turns at duplex copying

0: Invalid 1: Valid

UI shortcut key

0: Invalid

1: Valid (REDUCE/ENLARGE and ZOOM

UP/DOWN only)

2: Valid (Cassette paper size setting only)

3: Valid (All, REDUCE/ENLARGE, ZOOM

UP/DOWN, and cassette paper size

setting)

Mode

PPC

Memory

PPC

PPC

PPC

PPC

ALL

Expansion

PPC

Expansion

PPC

Expansion

PPC

Self-

check

Self-

check

PPC

PPC

Image

quality

mode

Default

0

0

0

2

0

0

0

0

1

Acceptable

value *1

0-1

0-2

0-1

0-5

0-6

0, 1

0-1

0-1

0-2

*1

1

1

0-1

0-4

*1 : The entry of code enables automatic execution.

Refer to

page

1-90

December 2002 TOSHIBA TEC 1 - 17 e-STUDIO160/200/250 ADJUSTMENT ITEMS

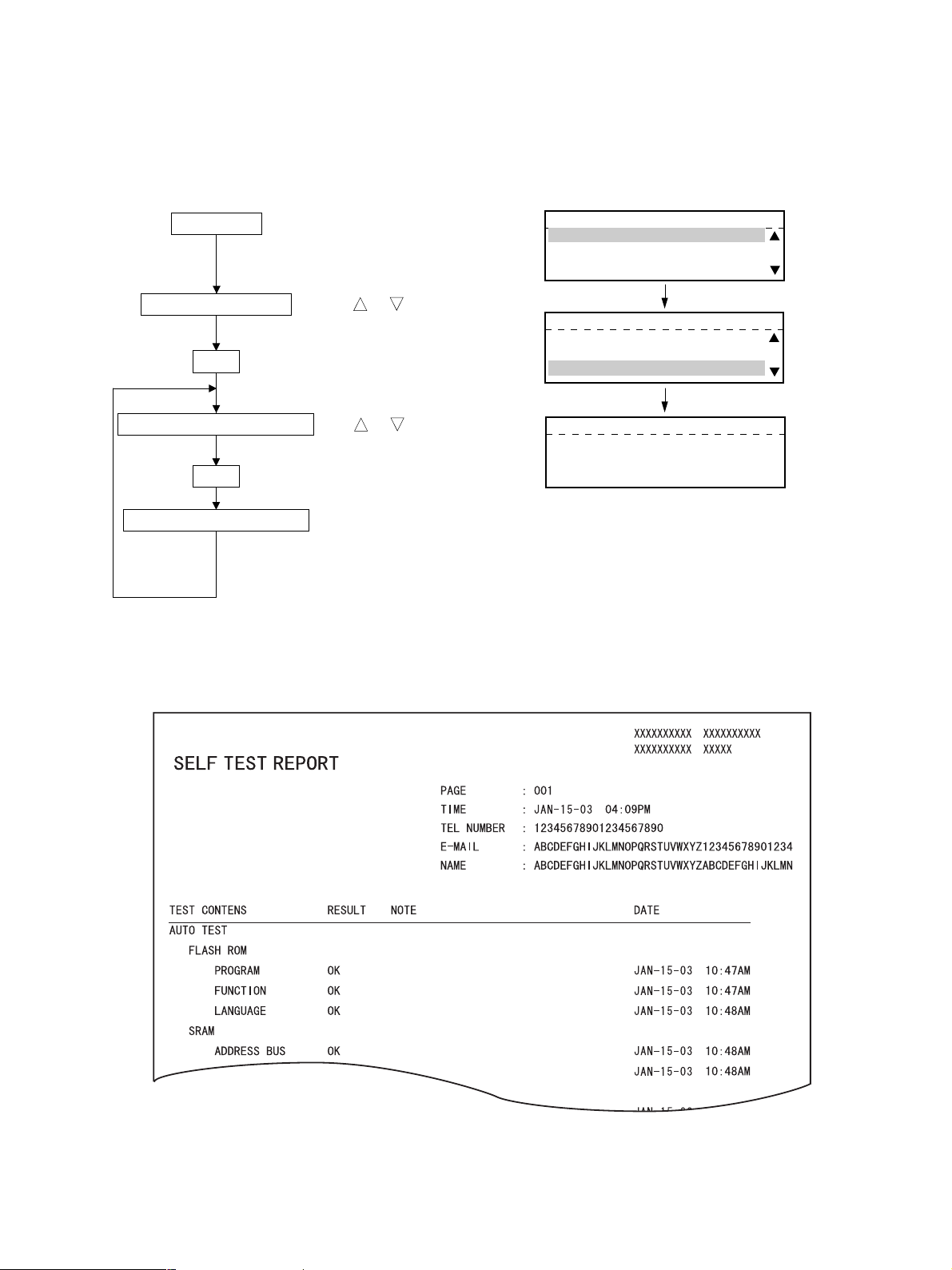

1.2.3 User test mode

When you press the PROGRAM key and enter the TEST mode from the menu, the items that can be

tested by the user are displayed.

(1) AUTO TEST

This mode allows the user to independently diagnose the machine by automatically performing a

series of tests.

<Key used in operation> <Display messages>

PROGRAM

Press the PROGRAM key

PROGRAM

01.DEFAURT SETTINGS

02.LISTS

03.INITIAL SETUP

Select TEST MODE

Use or keys

TEST MODE

01.AUTO TEST

02.INDIVIDUAL TEST

SET

Select AUTO TEST

SET

Auto test run

End of TEST

Test Items

a) Flash ROM test Calculates and compares the check sums of the firmware, function data and

Use or keys

It takes about 2 minutes to

finish TEST

03.TEST RESULT LIST

AUTO TEST

-------------------

AUTO TEST

Completed

language information with the previously stored corresponding check sum

values.

b) SRAM test Same as Function Test.

c) DRAM test Same as Function Test.

d) MODEM test Same as Function Test.

e) SCANNER test Same as Function Test.

f) CODEC test Same as Function Test.

g) Printer test Checks each part of the printer (fan, HVPS, polygon, heater, LSU) and prints

one page of test pattern (not performed when there is no paper).

h) Phonebook data test Calculates and compares the check sum of the phonebook with the previ-

ously stored check sum value.

i) Network board test (with GF-1110)

e-STUDIO160/200/250 ADJUSTMENT ITEMS 1 - 18 December 2002 TOSHIBA TEC

(2) INDIVIDUAL TEST

The user can perform a test in interactive mode and locate the faulty point from the test result. The test

result is printed in the form of a report.

<Key used in operation> <Display messages>

PROGRAM

Press the PROGRAM key

PROGRAM

01.DEFAURT SETTINGS

02.LISTS

03.INITIAL SETUP

Select TEST MODE

SET

Use or keys

TEST MODE

01.AUTO TEST

02.INDIVIDUAL TEST

03.TEST RESULT LIST

Select INDIVIDUAL TEST

Use or keys

INDIVIDUAL TEST

SET

01.ADF TEST

02.KEY TEST

03.LED LIST

Select item to be tested

SET

CIS

Test Items

a) ADF test Transports and ejects originals to check the transport system. Transports

Use or keys

Selected test is performed

TEST MODE

04.LCD TEST

TEST MODE

05.SPEAKER TEST

06.SWITCH TEST

07.TEST PRINT

and ejects a certain number of originals and displays the number of the

originals. The tester checks that this value matches the number of the origi-

nals. A transport speed can be selected with the resolution key.

b) Key test Press all the keys on the operation panel to check if they are detected nor-

mally. The key test ends when the STOP key is pressed in the end. If there is

any key which is not detected when pressed before the STOP key is pressed,

it will be judged to be an error.

c) LED test When the test is performed, all the LEDs will come on. If there is any LED

which is not lit when visually checked, it will be judged to be an error.

d) LCD test All the dots on the display go off (turn black). When the Start key is then

pressed, all the dots light (turn white). If there is any dot which does not light

or go off when visually checked, it will be judged to be an error.

e) Speaker test Check that the volume level from the speaker changes.

f) Sensor test Sensor test.

Open and close the covers by following the guidance appearing on the dis-

play.

g) Printer test Checks the printer function by printing two test patterns.

December 2002 TOSHIBA TEC 1 - 19 e-STUDIO160/200/250 ADJUSTMENT ITEMS

(3) TEST RESULT LIST

Prints the results of (1) AUTO TEST and (2) INDIVIDUAL TEST.

<Key used in operation> <Display messages>

PROGRAM

Press the PROGRAM key

PROGRAM

01.DEFAURT SETTINGS

02.LISTS

03.INITIAL SETUP

Select TEST MODE

Use or keys

TEST MODE

01.AUTO TEST

SET

Select TEST RESULT LIST

SET

Print TEST RESULT LIST

If there is any NG in the RESULT column, the corresponding test is problematic. An test with an

asterisk (*) cannot be executed unless the corresponding option is installed.

Use or keys

02.INDIVIDUAL TEST

03.TEST RESULT LIST

TEST RESULT LIST

Printing accepted

e-STUDIO160/200/250 ADJUSTMENT ITEMS 1 - 20 December 2002 TOSHIBA TEC

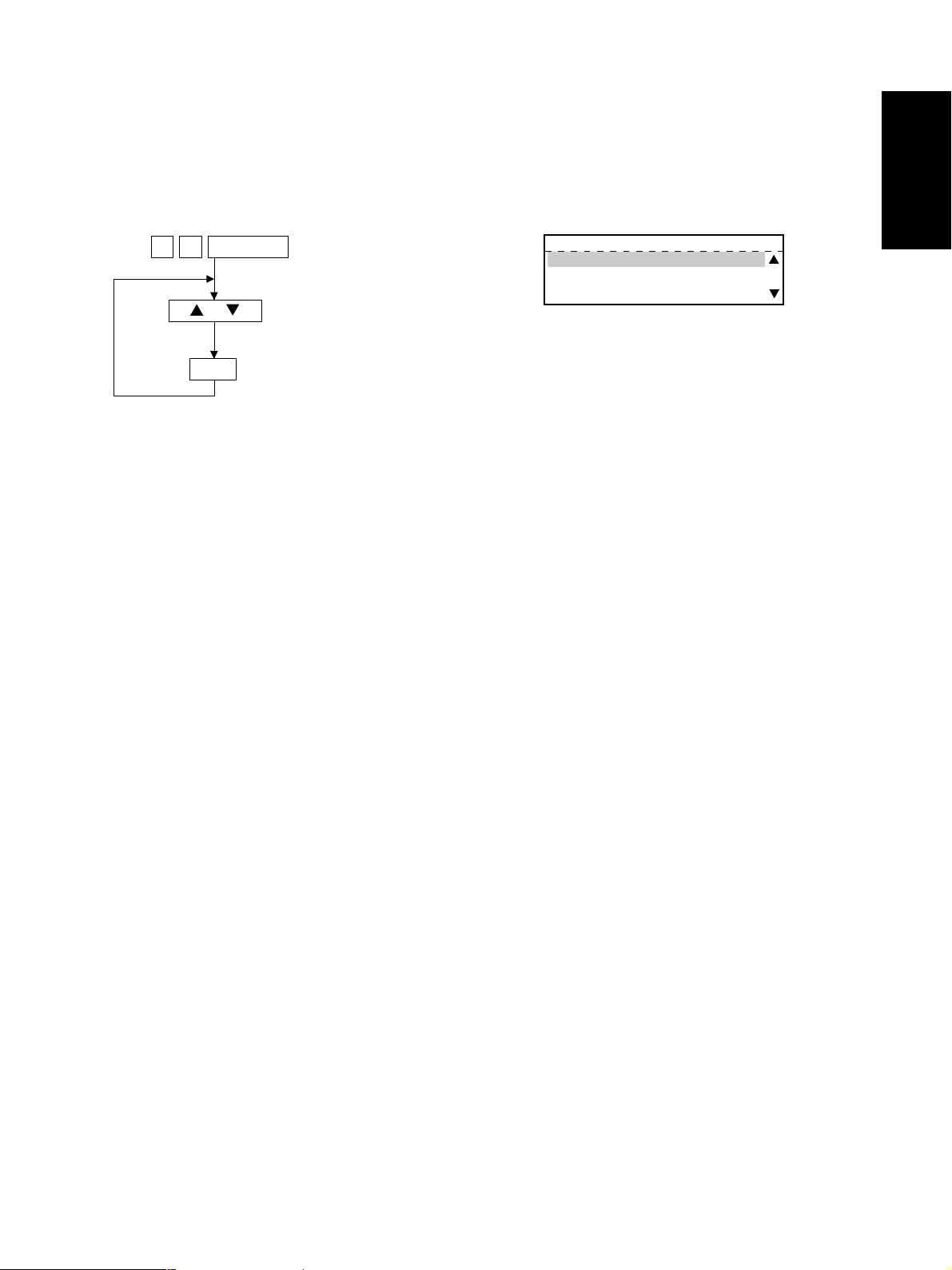

1.2.4 Function test

The function test checks each function of the copier. To enter the function test mode, follow the procedure

below, or enter the Service mode (*,#,*,*) and select the menu for the function test

<Key used in operation> <Display messages>

1 3

Power ON

FUNCTION TEST

01.OPE.PANEL TEST

02.PRINT TEST

03.MODEM TEST

or

SET

The following tests can be conducted in the Function test mode.

01. OPE. PANEL TEST

02. PRINT TEST

03. MODEM TEST *1 (Factory test)

04. SENSOR TEST

05. SRAM TEST

06. DRAM TEST

07. CLOCK IC TEST

Select test menu

08. SCANNER TEST

09. CODEC TEST

10. OUTPUT TEST

11. PRINTER BOARD TEST *2

*1: When the FAX kit (GD-1061) is not installed, the test is not present.

*2: When the PCL kit (GA-1031) is not installed, the test is not present.

December 2002 TOSHIBA TEC 1 - 21 e-STUDIO160/200/250 ADJUSTMENT ITEMS

(1) 01. OPE PANEL TEST

This test checks the control panel display. When any key other than START and CLEAR/STOP is pressed

during the display test, O and X are displayed alternately in the lower right of the display.

<Key used in operation> <Display messages>

1 3

Power ON

01.OPE. PANEL TEST

SET

START

Cancel

All display dots keep turning on

and off alternatery for one second

each. (All LEDs turn on.)

The cursor moves (from the

upper left to the lower right).

FUNCTION TEST

01.OPE.PANEL TEST

02.PRINT TEST

03.MODEM TEST

Select test menu

e-STUDIO160/200/250 ADJUSTMENT ITEMS 1 - 22 December 2002 TOSHIBA TEC

(2) 02. PRINT TEST

The test pattern is printed when a number is entered according to the displayed instructions

<Key used in operation> <Display messages>

1 3

02.PRINT TEST

Power ON

Digital Keys

SET

Digital Keys

SET

Digital Keys

SET

Digital Keys

SET

START

C/S

Select test menu

Enter print code

Select paper cassette (C)

Print setup 1 (T)

Print setup 2 (B)

*1

FUNCTION TEST

01.OPE.PANEL TEST

02.PRINT TEST

03.MODEM TEST

PRINT TEST

P=

115

Print code

115

C=1

T=128

B=100

C = Paper cassette selection

T = Print setup 1

B = Print setup 2

C

0: Stack feed bypass (SFB)

1: 1st cassette

2: 2nd cassette (PFU)

3: 3rd cassette (PFP/LCF)

4: 4th cassette

T

Character density 0 to 255 panel setting.

B

Background density 0 to 255 panel setting.

Some codes do not have T or B.

*1: Be sure to press this key after printing starts.

(If this key is not pressed, the copier keeps printing)

December 2002 TOSHIBA TEC 1 - 23 e-STUDIO160/200/250 ADJUSTMENT ITEMS

TEST PRINT (02) ITEMS

Code

109

Electrical

110

Electrical

111

Image processing

112

Electrical

113

Image processing

114

Electrical

115

Electrical

116

Electrical

121

Image processing

122

Image processing

123

Image processing

124

Image processing

135

Image processing

136

Image processing

137

Image processing

138

Image processing

141

Image processing

142

Image processing

Factor

Test pattern item

All-surface halftone (latter part) Error diffusion

Halftone density 0 to 255 panel setting

Scanning 256 levels (latter part) Error diffusion

Scanning 33 levels (latter part) Error diffusion

Scanning 17 levels (latter part) Error diffusion

Feed 33 levels (latter part) Error diffusion

Feed 17 levels (latter part) Error diffusion

Scanning 1 dot line (latter part) 2-level

Character density 0 to 255 panel setting

Background density 0 to 255 panel setting

Scanning 24 dot line (latter part) 2-level

Character density 0 to 255 panel setting

Background density 0 to 255 panel setting

All-surface halftone (foregoing part) Error diffusion

Scanning 256 levels (foregoing part) Error diffusion

Scanning 33 levels (foregoing part) Error diffusion

Scanning 16 levels (foregoing part) Error diffusion

All-surface horizontal 1 dot line, horizontal 1 dot space

All-surface vertical 1 dot line, vertical 1 dots pace

All-surface horizontal 2 dot line, horizontal 2 dot space

All-surface vertical 2 dot line, vertical 2 dot space

1 dot grid pattern (10 mm pitch)

2 dot grid pattern (10 mm pitch)

Item to be confirmed

All completely black at T=0.

All completely white at T=255.

The density should change

smoothly between black and white.

There should be 33 levels in a tran-

sition between black and white.

There should be 17 levels in a tran-

sition between black and white.

There should be 33 levels in a tran-

sition between black and white.

There should be 17 level in a transi-

tion between black and white.

Black when both T and B are 0.

White when both T and B are 255.

Black when both T and B are 0.

White when both T and B are 255.

All completely gray.

The density should change

smoothly between black and white.

There should be 33 levels in a tran-

sition between black and white.

There should be 16 levels in a tran-

sition between black and white.

Grid of 10 by 10 mm square. The

line width increases as the code increases (141→142→145→146).

Test 142 is used for 1.4 Adjustment.

145

Image processing

146

Image processing

149

Image processing

150

Image processing

151

Image processing

e-STUDIO160/200/250 ADJUSTMENT ITEMS 1 - 24 December 2002 TOSHIBA TEC

Grid pattern of 4 sets of 1 dot line, horizontal 2 dots space

(10 mm pitch)

Grid pattern of 4 sets of 2 dot line, horizontal 2 dots space

(10 mm pitch)

A3 all completely black

A3 all white

Rightward rising slant line 1 dot (5 mm pitch)

All completely black

All completely white

The line interval in the main scan-

ning direction should be 5 mm. The

line should be straight.

(3) 03. MODEM TEST (Factory test)

Refer to the Service Handbook (GD-1061).

(4) 04. SENSOR TEST

When the machine enters the SENSOR TEST Mode, the status of each sensor is indicated on the display.

The status can be checked by selecting the corresponding bit.

(For items to be checked, refer to the Sensor Test Items table.)

<Key used in operation> <Display messages>

1 3

Power ON

04.SENSOR TEST

SET

or

Cancel

<Display messages>

Select test menu

Display selection

1 (A1)

01001010 00100010 00000001

A

01001010 00100010 00000001

I

01001110 00100000 00000001

00001010 00100110

FUNCTION TEST

02.PRINT TEST

03.MODEM TEST

04.SENSOR TEST

BIT

7------0

11 (I8)

12 (S1)

01001010 00100010

S

01001110 00100000

01001110 00100000 00000001

P

00001010 00100110

20 (P5)

December 2002 TOSHIBA TEC 1 - 25 e-STUDIO160/200/250 ADJUSTMENT ITEMS

• Explanation of status display

When the sensor test is carried out, the status

of each sensor is indicated on the display with

0 or 1.

Each signal is divided into 8-bit blocks.

The character on the left edge of the display

indicates as follows:

A: Signal input to ASIC

I: Signal input to the IO port

S: Signal from the scanner or R/ADF

P: Signal from the option connected to the

PFC

The display is switched using the or key.

Example 1:

Confirm whether the front cover is open or close.

The front cover is equipped with the 24-V ON/OFF

switch (Interlock switch) and the front cover switch.

The status of both switches is 1 when the cover is

open, and 0 when it is close.

When the status of the one is 0 and that of the other

is 1 as shown in the example, there is something

wrong with either of these switches.

Status display example

A

I

A1

IO1

IO4

IO7

S

S1

S3

P

P1

P4

01001010 00100010 00000001

A

01001010 00100010 00000001

I

A2

IO2

IO5

IO8

S2

S4

P2

P5

IO3 Bit1

A3

IO3

IO6

P3

01001110 00100000 00000001

00001010 00100110

IO4 Bit2

Front cover

Open Close

IO3 bit 1 (Interlock switch) 1 0

IO4 bit 2 (Front cover switch) 1 0

e-STUDIO160/200/250 ADJUSTMENT ITEMS 1 - 26 December 2002 TOSHIBA TEC

Example 2:

Confirm whether or not the optional memory PWA

is installed, with the status of bits 6 and 7 of IO1 on

the display.

Memory expansion slot on the back of the copier

As shown in the table below, bits 6 and 7 detect the

upper slot and lower slot, respectively.

The installation of the memory PWA can be con-

firmed with these bits.

PWA Bit 7 Bit 6

Not inserted (upper and lower slots) 1 1

Inserted into the upper slot 1 0

Inserted into the lower slot 0 1

Inserted into both slots 0 0

(1: No PWA inserted / 0: PWA inserted)

The capacity of memory installed can be confirmed,

with bits 4 and 5 of IO1.

Bit 6 (MEM1)

Bit 7 (MEM2)

IO1

Bit7

A

I

IO1

Bit6

01001010 00100010 00000001

01001010 00100010 00000001

Slot (upper)

Slot (lower)

01001110 00100000 00000001

00001010 00100110

December 2002 TOSHIBA TEC 1 - 27 e-STUDIO160/200/250 ADJUSTMENT ITEMS

SENSOR TEST (04) ITEMS

Data

1 (A1)

ASIC1

A/D

CH0

2 (A2)

ASIC1

A/D

CH2

3 (A3)

ASIC1

A/D

CH3

4 (IO1)

I/O

E0100C

5 (IO2)

I/O

E01006

Bit

7

A/D CH0 b7

6

A/D CH0 b6

5

A/D CH0 b5

4

A/D CH0 b4

3

A/D CH0 b3

2

A/D CH0 b2

1

A/D CH0 b1

0

A/D CH0 b0

7

A/D CH2 b7

6

A/D CH2 b6

5

A/D CH2 b5

4

A/D CH2 b4

3

A/D CH2 b3

2

A/D CH2 b2

1

A/D CH2 b1

0

A/D CH2 b0

7

A/D CH3 b7

6

A/D CH3 b6

5

A/D CH3 b5

4

A/D CH3 b4

3

A/D CH3 b3

2

A/D CH3 b2

1

A/D CH3 b1

0

A/D CH3 b0

7

MEM2DET

6

MEM1DET

5

SDRAM2ID

4

SDRAM1ID

3

PCLSET

2

AU1SET

1

DRUM

0

FUSE

7

6

5

4

3

2

1

0

FAXDET

Input info.

-

-

-

-

-

-

-

Function

Fusing thermistor A/D value

The value for temperature data is expressed with 8 bits.

Fusing side thermistor A/D value

The value for temperature data is expressed with 8 bits.

Drum thermistor A/D value

The value for temperature data is expressed with 8 bits.

Option MEM2 connection signal

(PWA-F-MEM Optional memory PWA)

Option MEM1 connection signal

(PWA-F-MEM Optional memory PWA)

Detection signal for MEM PWA2 256 M bit SDRAM

Detection signal for MEM PWA1 256 M bit SDRAM

PCL PWA connection detection signal

I-FAX PWA connection detection signal

Presence or absence detection of process unit

Detection of new or old process unit

-

-

-

Reserved

Reserved

Reserved

Reserved

FAX PWA (GD-1061) connection signal

Value

00H-FFH

00H-FFH

00H-FFH

0: Connected

1: Not connected

0: Connected

1: Not connected

0: 256 M bit

1: 64 M bit/128 M bit

0: 256 M bit

1: 64 M bit/128 M bit

0: Connected

1: Not connected

0: Connected

1: Not connected

0: Without 1: With

0: Normal 1: New

-

-

-

-

-

-

-

0: Connected

1: Not connected

e-STUDIO160/200/250 ADJUSTMENT ITEMS 1 - 28 December 2002 TOSHIBA TEC

Data

6 (IO3)

I/O

E01008

7 (IO4)

I/O

E0100A

8 (IO5)

I/O

E02006

9 (IO6)

I/O

E02008

Bit

7

6

5

4

BUCS

3

FDS2ON

2

FDS1ON

1

24VONOFF

0

COS1ON

7

IPCDET

6

PCDET

5

4

5ROMSEL

3

PSS3

2

FCOSON

1

PESON

0

LPSON

7

6

5

4

JCONECT

3

2

FSELECT

1

0

7

TESTMON

6

PMSTS

5

JPASSW

4

JJAMSW

3

JCOSON

2

JPOSON

1

JFLS2ON

0

JFLS1ON

Input info.

-

-

-

-

-

-

-

-

-

-

Function

Reserved

Reserved

Reserved

Battery abnormal condition detection signal

EXT-SEN (Exit sensor)

FED-SEN (Feed sensor)

Cover open (Interlock SW) detection

TC-SW (Toner cartridge switch) *1

IPC PWA (Finisher) connection signal

PC-I/F PWA connection signal

-

RCVROM (MAIN recovery PWA) installation detection

CST-SW (Paper cassette switch)

FRCOV-SW (Front cover switch) *1

PE-SEN (Paper empty sensor) Cassette 1

T-UP-SEN (Tray-up sensor) Cassette 1

-

-

-

Connection of any of JSP or OCT

Reserved

Connection of BRIDGE COVER

-

Reserved

TNRE-SEN (Toner empty sensor)

Polygon motor synchronizing signal

Connection of OCT

Jam detection/jam detection/middle jam detection

*2

JSP cover open/OCT cover open/BRIDGE COVER cover

open *2

Paper in upper stacker/-/BRIDGE COVER exit jam

detection *2

Upper stacker paper full/offset initial position/-

*2

Lower stacker/paper full/paper full

*2

Value

-

-

-

0: Normal

1: Battery abnormal condition

0: No paper

1: Paper detected

0: Paper detected

1: No paper

0: Closed 1: Open

0: With 1: Without

0: Connected

1: Not connected

0: Connected

1: Not connected

-

0: RCVROM installed

1: Not installed

0: Closed 1: Open

0: Closed 1: Open

0: Paper loaded

1: Paper empty

0: Not lifted up 1: Lifted up

-

-

-

0: Connected

1: Not connected

-

0: BRIDGE COVER connected

1: JSP or OCT

-

-

0: Toner empty

1: Toner detected

0: Synchronous

1: Asynchronous

0: OCT connected

1: BRIDGE COVER or JSP

0: No paper 1: Paper present (JSP/OCT)

0: No paper

1: Paper present (BRIDGE COVER)

0: Cover closed

1: Cover open

0: No paper 1: Paper detected (JSP/OCT)

0: Paper detected

1: No paper (BRIDGE COVER)

0: Normal/non-initial

1: paper full/initial position

0: Normal 1: Paper full (JSP/OCT)

0: Paper full 1: Normal (BRIDGE COVER)

*1: The detection of the presence or absence of a toner cartridge is correctly displayed only when the front

cover is open.

*2: One of the three options is indicated (only one of them can be connect).

December 2002 TOSHIBA TEC 1 - 29 e-STUDIO160/200/250 ADJUSTMENT ITEMS

Data

10 (IO7)

I/O

E0200A

11 (IO8)

I/O

E50000

Low order

8 bits

12 (S1)

Scanner sensor

status 1

Upper 8 bits

13 (S2)

Scanner sensor

status 1

Low order

8 bits

14 (S3)

Scanner sensor

status 2

Upper order

8 bits

Bit

7

6

5

4

3

2

1

0

7

6

5

4

3

2

1

0

7

6

5

4

3

2

1

0

7

6

5

4

3

2

1

0

7

6

5

4

3

2

1

0

Input info.

-

-

-

-

16MBDET

-

MMSYNC

G/PCHK

CTR-CNT

ENABLE

MCONECT

MPSS3ON

MPSS2ON

MPSS1ON

MPSS0ON

MPESON

Function

Reserved

Reserved

Reserved