Toshiba e-Studio250, e-Studio160, e-Studio200 User Manual

DIGITAL MULTI FUNCTION

e-STUDIO160/200/250

File No. SHE02000200

R02092123800-TTEC

© 2002 TOSHIBA TEC CORPORATION

All rights reserved

GENERAL PRECAUTIONS REGARDING THE INSTALLATION AND SERVICE FOR e-STUDIO160/200/250 SERIES

The installation and service should be done by a qualified service technician.

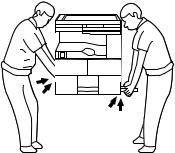

1.Transportation

•When transporting/installing the copier, employ two persons and be sure to use the positions as indicated below.

The copier is fairly heavy and weighs approximately 50 kg (110 lb), therefore pay full attention when handling it.

4 portions

2.Installation

•Be sure to use a dedicated outlet with AC 115 or 120V/15A (220V, 230V, 240V/10A) or more for its power source.

•The copier must be grounded for safety. Never ground it to a gas pipe or a water pipe.

•Select a suitable place for installation.

Avoid excessive heat, high humidity, dust, vibration and direct sunlight.

•Also provide proper ventilation as the copier emits a slight amount of ozone.

•To insure adequate working space for the copying operation, keep a minimum clearance of 80 cm (32") on the left, 80 cm (32") on the right and 10 cm (4") in the rear.

•After having installed the copier, be sure to push the carrying handles into the copier.

3.Service of Machines

•Basically, be sure to turn the main switch off and unplug the power cord during service.

•Be sure not to touch high-temperature sections such as the exposure lamp, the fuser unit, the damp heater and their periphery.

•Be sure not to touch high-voltage sections such as the chargers and the high-voltage transformer.

•Be sure not to touch rotating/operating sections such as gears, belts, pulleys, fans, etc.

•When servicing the machines with the main switch turned on, be sure not to touch live sections and rotating/operating sections. Avoid exposure to laser radiation.

•Use suitable measuring instruments and tools.

December 2002 TOSHIBA TEC |

e-STUDIO160/200/250 GENERAL PRECAUTIONS |

•Avoid exposure to laser radiation during servicing.

–Avoid direct exposure to beam.

–Do not insert tools, parts, etc. that are reflective into the path of the laser beam.

–Remove all watches, rings, bracelets, etc. that are reflective.

4.Main Service Parts for Safety

•The breaker, door switch, fuse, thermostat, thermofuse, thermistor, etc. are particularly important for safety. Be sure to handle/install them properly.

5.Cautionary Labels

•During servicing, be sure to check the rating plate and the cautionary labels such as “Unplug the power cord during service”, “Hot area”, “Laser warning label” etc. to see if there is any dirt on their surface and whether they are properly stuck to the copier.

6.Disposition of Consumable Parts/Packing Materials

•Regarding the recovery and disposal of the copier, supplies, consumable parts and packingm a - terials, it is recommended to follow the relevant local regulations or rules.

7.When parts are disassembled, reassembly is basically the reverse of disassembly unless otherwise noted in this manual or other related documents. Be careful not to reassemble small parts such as screws, washers, pins, E-rings, toothed washers in the wrong places.

8.Basically, the machine should not be operated with any parts removed or disassembled.

9.Precautions Against Static Electricity

•The PC board must be stored in an anti-electrostatic bag and handled carefully using a wristband, because the ICs on it may become damaged due to static electricity.

Caution: Before using the wrist band, pull out the power cord plug of the copier and make sure that there is no uninsulated charged objects in the vicinity.

Caution: Dispose of used batteries and RAM-ICs including lithium batteries according to the manufacturer's instructions.

Attention: Se débarrasser de batteries et RAM-ICs usés y compris les batteries en lithium selon les instructions du fabricant.

Vorsicht: Entsorgung des gebrauchten Batterien und RAM-ICs (inklusive der Lithium-Batterie) nach Angaben des Herstellers.

e-STUDIO160/200/250 GENERAL PRECAUTIONS |

December 2002 TOSHIBA TEC |

|

|

CONTENTS |

|

1. ADJUSTMENT ITEMS .................................................................................................. |

1-1 |

||

1.1 |

Error Code List ................................................................................................................... |

1-1 |

|

1.2 |

Self-Diagnosis Modes ........................................................................................................ |

1-6 |

|

|

1.2.1 |

Adjust mode (05)..................................................................................................... |

1-8 |

|

1.2.2 |

System mode ........................................................................................................ |

1-13 |

|

1.2.3 |

User test mode...................................................................................................... |

1-18 |

|

1.2.4 |

Function test ......................................................................................................... |

1-21 |

|

1.2.5 |

MAINTENANCE .................................................................................................... |

1-38 |

|

1.2.6 |

SERVICE LIST ...................................................................................................... |

1-43 |

|

1.2.7 |

Country/Region code ............................................................................................ |

1-49 |

|

1.2.8 |

Scanner parking mode .......................................................................................... |

1-50 |

|

1.2.9 |

Speaker volume .................................................................................................... |

1-51 |

|

1.2.10 Adjustment of document width sensor .................................................................. |

1-52 |

|

1.3 |

Image Quality Control ...................................................................................................... |

1-53 |

|

1.4 |

Copy Image Dimension Adjustment ................................................................................. |

1-54 |

|

|

1.4.1 Adjustment of paper aligning value ....................................................................... |

1-55 |

|

|

1.4.2 |

Printer unit adjustment .......................................................................................... |

1-56 |

|

1.4.3 |

Scanner unit adjustment ....................................................................................... |

1-61 |

1.5 |

Sharpness (HPF) Adjustment .......................................................................................... |

1-66 |

|

1.6 |

Gamma Slope Correction................................................................................................. |

1-67 |

|

1.7 |

High-Voltage Adjustment .................................................................................................. |

1-68 |

|

|

1.7.1 |

Adjustment ............................................................................................................ |

1-68 |

|

1.7.2 |

Precautions ........................................................................................................... |

1-71 |

1.8 |

Adjusting the Scanner Section ......................................................................................... |

1-74 |

|

|

1.8.1 |

Installing glass ...................................................................................................... |

1-74 |

|

1.8.2 |

Installing scanner motor ........................................................................................ |

1-76 |

|

1.8.3 Adjusting the carriage 1 ........................................................................................ |

1-77 |

|

|

1.8.4 |

Installing carriage 2 ............................................................................................... |

1-79 |

|

1.8.5 |

CCD unit ............................................................................................................... |

1-82 |

1.9 |

Adjusting the main drive gear assembly........................................................................... |

1-86 |

|

1.10 |

MAIN PWA replacement procedure ................................................................................. |

1-90 |

|

1.11 |

Measurement of Transfer Guide Bias ............................................................................... |

1-92 |

|

1.12 |

Adjustment of the doctor-sleeve gap................................................................................ |

1-94 |

|

December 2002 TOSHIBA TEC |

1 |

e-STUDIO160/200/250 CONTENTS |

2. PREVENTIVE MAINTENANCE (PM)............................................................................ |

2-1 |

|

2.1 |

Maintenance Performed Every 81,000 (e-STUDIO160/200 Series) and |

|

|

99,000 Copies (e-STUDIO250 Series)............................................................................... |

2-1 |

2.2 |

Preventive Maintenance Check List .................................................................................... |

2-1 |

2.3 |

PM Kit................................................................................................................................ |

2-14 |

2.4 |

List of Adjustment Tools .................................................................................................... |

2-15 |

2.5 |

List of Grease .................................................................................................................... |

2-15 |

3. PRECAUTIONS FOR STORING & HANDLING SUPPLIES ......................................... |

3-1 |

|

3.1 |

Precautions for Storing TOSHIBA Supplies........................................................................ |

3-1 |

3.2 |

Checking and Cleaning of the Pressure Roller .................................................................. |

3-2 |

3.3 |

Checking and Cleaning of the Cleaning Roller................................................................... |

3-2 |

3.4 |

Checking and Cleaning of the Heat Roller ......................................................................... |

3-3 |

3.5 |

Checking and Replacing of the Transfer Guide Roller ........................................................ |

3-3 |

3.6 |

Checking and Cleaning of Photoconductive Drum............................................................. |

3-4 |

3.7 |

Checking and Cleaning of Drum Cleaning Blade ............................................................... |

3-5 |

4. TROUBLESHOOTING .................................................................................................. |

4-1 |

|

4.1 Troubleshooting Based on Error Code ............................................................................... |

4-2 |

|

4.1.1 |

Transporting jam in the main body .......................................................................... |

4-2 |

4.1.2 |

Paper feeding jam ................................................................................................... |

4-7 |

4.1.3 |

Transporting jam for the optional trays .................................................................. |

4-13 |

4.1.4 |

Paper jam if some cover is opened ....................................................................... |

4-18 |

4.1.5 |

Paper transporting jam at the ADF........................................................................ |

4-22 |

4.1.6 |

Paper transporting jam at the RADF ..................................................................... |

4-24 |

4.1.7 |

Paper jam in finisher ............................................................................................. |

4-26 |

4.1.8 |

Drive system service call ...................................................................................... |

4-30 |

4.1.9 |

Temporary paper supply mechanism service call ................................................. |

4-33 |

4.1.10 |

Optical system service call ................................................................................... |

4-39 |

4.1.11 |

Process system service call.................................................................................. |

4-41 |

4.1.12 |

Fuser system service call ..................................................................................... |

4-41 |

4.1.13 |

Communications system service call .................................................................... |

4-42 |

4.1.14 |

ADF or RADF system service call......................................................................... |

4-44 |

4.1.15 |

Other abnormal service call .................................................................................. |

4-48 |

4.1.16 |

Laser optical system service call .......................................................................... |

4-49 |

4.1.17 |

Finisher related service call .................................................................................. |

4-50 |

4.1.18 |

Scanner related service call.................................................................................. |

4-55 |

4.1.19 |

Printer related service call .................................................................................... |

4-56 |

4.1.20 |

Fax related service call ......................................................................................... |

4-56 |

4.1.21 |

OCT system service call ....................................................................................... |

4-57 |

4.1.22 Other service call .................................................................................................. |

4-57 |

|

4.2 Troubleshooting of Image ................................................................................................. |

4-58 |

|

e-STUDIO160/200/250 CONTENTS |

2 |

December 2002 TOSHIBA TEC |

5. UPDATING THE FIRMWARE ........................................................................................ |

5-1 |

||

5.1 |

Outline................................................................................................................................ |

5-1 |

|

5.2 |

Using the Recovery PWA ................................................................................................... |

5-2 |

|

|

5.2.1 Using main recovery PWA ...................................................................................... |

5-2 |

|

|

5.2.2 Using the scanner recovery PWA ........................................................................... |

5-5 |

|

5.3 |

Using the Batch File ........................................................................................................... |

5-8 |

|

|

5.3.1 |

Creating Download Disks........................................................................................ |

5-8 |

|

5.3.2 |

Downloading ......................................................................................................... |

5-13 |

5.4 |

Using the TOSHIBA Viewer .............................................................................................. |

5-20 |

|

6. WIRE HARNESS CONNECTION DIAGRAMS ............................................................. |

6-1 |

6.1 AC Wire Harness ............................................................................................................... |

6-1 |

APPENDIX .......................................................................................................................... |

A-1 |

Appendix A. Specifications ......................................................................................................... |

A-1 |

Appendix B. Accessories ........................................................................................................... |

A-5 |

Appendix C. Options .................................................................................................................. |

A-6 |

Appendix D. Replacement Units/Supplies .................................................................................. |

A-6 |

Appendix E. System List ............................................................................................................ |

A-7 |

Appendix F. Power Supply Unit.................................................................................................. |

A-8 |

December 2002 TOSHIBA TEC |

3 |

e-STUDIO160/200/250 CONTENTS |

1.ADJUSTMENT ITEMS

2.PREVENTIVE MAINTENANCE (PM)

3.PRECAUTIONS FOR STORING & HANDLING SUPPLIES

4.TROUBLESHOOTING

5.UPDATING THE FIRMWARE

6.WIRE HARNESS CONNECTION DIAGRAMS

1. ADJUSTMENT ITEMS

1.1 Error Code List

While the error message or “Call for service” symbol is flashing, pressing the [CLEAR/STOP] key and the [8] key on the digital keys at the same time shows one of the following error codes on the copyquantity indicator as long as those keys are pressed.

Classification |

Error code |

Machine status |

|

|

|

Transporting jam in the main |

E01 |

Paper jam inside the machine |

|

|

|

body |

E02 |

Paper jam near the fuser unit |

|

|

|

|

E03 |

Paper remaining inside the machine at power on (Except |

|

|

for ADF/RADF) |

|

|

|

|

E04 to E07 |

Reserved |

|

|

|

|

E08 |

Transporting jam inside the ADU |

|

|

|

|

E09 |

Time out error that occurs at the paper feeding sensor |

|

|

|

|

E10 |

Reserved |

|

|

|

Paper feeding jam |

E11 |

Paper feeding jam at the ADU |

|

|

|

|

E12 |

Paper feeding jam at the SFB |

|

|

|

|

E13 |

Cassette 1 feeding jam |

|

|

|

|

E14 |

Cassette 2 feeding jam (PFU) |

|

|

|

|

E15 |

Cassette 3 feeding jam (PFP) |

|

|

|

|

E16 |

Cassette 4 (CM) feeding jam (e-STUDIO200/250 series) |

|

|

|

|

E17 to E18 |

Reserved |

|

|

|

|

E19 |

LCF feeding jam (e-STUDIO200/250 series) |

|

|

|

|

E20 to E30 |

Reserved |

|

|

|

Transporting jam for the |

E31 |

Paper not reach to feed sensor from cassette 2, so paper |

optional trays |

|

jam inside the main unit during cassette 2 feed |

|

|

|

|

E32 |

Paper not reach to feed sensor from cassette 3 or 4, so |

|

|

paper jam inside the main unit during the feed |

|

|

|

|

E33 |

Paper not reach to feed sensor from LCF cassette. |

|

|

(e-STUDIO200/250 series) |

|

|

|

|

E34 |

Paper not reach to 2nd cassette feed sensor from cas- |

|

|

sette 3 or 4. (Cassette 4 is e-STUDIO200/250 series) |

|

|

|

|

E35 |

Paper jam in cassette 4 transport path |

|

|

(e-STUDIO200/250 series) |

|

|

|

|

E36 |

Paper jam in LCF transport path |

|

|

(e-STUDIO200/250 series) |

|

|

|

|

E37 to E40 |

Reserved |

|

|

|

December 2002 TOSHIBA TEC |

1 - 1 |

e-STUDIO160/200/250 ADJUSTMENT ITEMS |

Classification |

Error code |

Machine status |

|

|

|

Paper jam if some cover is |

E41 |

Copier front cover or side cover is opened during copying |

opened |

|

(Copier front cover, side cover, or transport cover of job |

|

|

separator/offset tray/bridge cover is opened during |

|

|

copying) |

|

|

|

|

E42 |

Side cover of cassette 2 or cassette 3 is opened during |

|

|

copying |

|

|

|

|

E43 |

ADU is opened during copying |

|

|

|

|

E44 |

Reserved |

|

|

|

|

E45 |

Side cover of LCF is opened during copying |

|

|

(e-STUDIO200/250 series) |

|

|

|

|

E46 to E70 |

Reserved |

|

|

|

Paper transporting jam at the |

E71 |

Original feeding jam at the feeding area of the ADF or |

ADF or RADF |

|

RADF |

|

|

|

|

E72 |

Original transporting jam at the transporting area of the |

|

|

ADF or RADF |

|

|

|

|

E73 |

Original exiting jam at the exiting area of the ADF or RADF |

|

|

|

|

E74 |

Original reversing jam at the reversing area of the RADF |

|

|

|

|

E75 to EA0 |

Reserved |

|

|

|

Paper jam in the finisher |

EA1 |

Paper transport delay jam |

|

|

|

(e-STUDIO200/250 series) |

EA2 |

Paper transport stop jam |

|

|

|

|

EA3 |

Paper remaining on the finisher transport path at power |

|

|

ON |

|

|

|

|

EA4 |

Finisher is opened during copying |

|

|

|

|

EA5 |

Finisher staple jam |

|

|

|

|

EA6 |

Finisher early arrival jam |

|

|

|

|

EA7 |

Set transport jam before stapling |

|

|

|

|

EA8 to EAE |

Reserved |

|

|

|

|

EAF |

Stapled set transport jam |

|

|

|

|

EB1 to EZ9 |

Reserved |

|

|

|

Life end |

- |

Process unit life nearly end |

|

|

|

|

- |

Toner is nearly empty |

|

|

|

Other operator calls |

- |

No toner cartridge |

|

|

|

|

- |

Toner empty |

|

|

|

|

- |

No process unit |

|

|

|

|

- |

Process unit life end |

|

|

|

|

- |

Upper tray of the job separator is full |

|

|

|

|

- |

Lower tray of the job separator is full |

|

|

|

|

- |

Offset tray is full |

|

|

|

|

- |

Finisher tray is full (e-STUDIO200/250 series) |

|

|

|

e-STUDIO160/200/250 ADJUSTMENT ITEMS |

1 - 2 |

December 2002 TOSHIBA TEC |

Classification |

Error code |

Machine status |

|

|

|

|

|

|

|

Other operator calls |

- |

Internal tray full (when finisher bridge installed) |

|

|

|

|

(e-STUDIO200/250 series) |

|

|

|

|

|

|

|

|

- |

No paper in the cassette 1 |

|

|

|

|

|

|

|

|

- |

No paper in the cassette 2 |

|

|

|

|

|

|

|

|

- |

No paper in the cassette 3 |

|

|

|

- |

No paper in the cassette 4 (e-STUDIO200/250 series) |

|

|

|

|

|

|

|

|

- |

No paper in the LCF (e-STUDIO200/250 series) |

|

|

|

|

|

|

|

|

- |

Cassette 1 is not ready |

|

|

|

|

|

|

|

|

- |

Cassette 2 is not ready |

|

|

|

|

|

|

|

|

- |

Cassette 3 is not ready |

|

|

|

|

|

|

|

|

- |

Cassette 4 is not ready (e-STUDIO200/250 series) |

|

|

|

|

|

|

|

|

- |

LCF is not installed (e-STUDIO200/250 series) |

|

|

|

|

|

|

|

|

|

Front cover or side cover of the copier is open |

|

|

|

|

|

|

|

|

|

Cover of the job separator is open |

|

|

|

|

|

|

|

|

|

Cover of the off set catch tray is open |

|

|

|

|

|

|

|

|

|

Cover of the bridge cover is open |

|

|

|

|

(e-STUDIO200/250 series) |

|

|

|

|

|

|

|

|

|

Cover of the ADU is open |

|

|

|

|

|

|

|

|

|

Side cover of the cassette 2 is open |

|

|

|

|

|

|

|

|

|

Side cover of the cassette 3 is open |

|

|

|

|

|

|

|

|

|

Side cover of the LCF is open |

|

|

|

|

(e-STUDIO200/250 series) |

|

|

|

|

|

|

|

|

|

Finisher joint is open (e-STUDIO200/250 series) |

|

|

|

|

|

|

|

CALL SERVICE from drive |

|

No staples (displayed only when stapling is designated) |

|

|

system |

|

(e-STUDIO200/250 series) |

|

|

|

|

|

|

|

|

C01 |

Main motor drive error |

|

|

|

|

|

|

|

|

C02 to C03 |

Reserved |

|

|

|

|

|

|

|

|

C04 |

PFP main motor drive error |

|

|

|

|

|

|

|

|

C05 |

Reserved |

|

|

|

|

|

|

|

Temporary paper supply |

C06 |

LCF feed motor error (e-STUDIO200/250 series) |

|

|

|

|

|

|

|

mechanism error |

C07 to C10 |

Reserved |

|

|

|

|

|

|

|

|

C11 to C12 |

Reserved |

|

|

|

|

|

|

|

|

C13 |

Cassette 1 error |

|

|

|

|

|

|

|

|

C14 |

Cassette 2 error |

|

|

|

|

|

|

|

|

C15 |

Cassette 3 error |

|

|

|

|

|

|

|

|

C16 |

Cassette 4 error (e-STUDIO200/250 series) |

|

|

|

|

|

|

|

|

C17 |

Reserved |

|

|

|

|

|

|

|

|

C18 |

LCF tray error (e-STUDIO200/250 series) |

|

|

|

|

|

|

|

|

C19 |

LCF feed motor abnormal (e-STUDIO200/250 series) |

|

|

|

|

|

|

|

|

C20 |

Reserved |

|

|

|

|

|

|

|

December 2002 TOSHIBA TEC |

1 - 3 |

e-STUDIO160/200/250 ADJUSTMENT ITEMS |

Classification |

Error code |

Machine status |

|

|

|

CALL SERVICE from the |

C21 |

Carriage initialization error |

|

|

|

optical system |

C22 to C24 |

Reserved |

|

|

|

|

C25 |

Scanner unit watch dog error |

|

|

|

|

C26 |

Exposure lamp disconnection or peak detection error |

|

|

|

|

C27 to C30 |

Reserved |

|

|

|

CALL SERVICE from the |

C31 to C37 |

Reserved |

|

|

|

process system |

C38 |

Replaced process unit error |

|

|

|

|

C39 to C40 |

Reserved |

|

|

|

CALL SERVICE from fuser |

C41 |

Abnormal thermistor or heater disconnection at power ON |

|

|

|

area |

C42 |

Reserved |

|

|

|

|

C43 |

Warming up mode after disconnection judgment, or ab- |

|

|

normal thermistor after ready |

|

|

|

|

C44 |

Warming up mode after disconnection judgment, or heater |

|

|

abnormal after ready |

|

|

|

|

C45 |

Thermistor disconnection at the end part of heater |

|

|

|

|

C46 to C50 |

Reserved |

|

|

|

CALL SERVICE from commu- |

C51 to C55 |

Reserved |

|

|

|

nication |

C56 |

Communication error between PFC and main unit |

|

|

|

|

C57 |

Communication error between main unit and IPC |

|

|

(e-STUDIO200/250 series) |

|

|

|

|

C58 |

Communication error between IPC and finisher |

|

|

(e-STUDIO200/250 series) |

|

|

|

|

C59 to C70 |

Reserved |

|

|

|

CALL SERVICE from ADF or |

C71 |

Paper supply motor lock error |

|

|

|

RADF |

C72 |

Reserved |

|

|

|

|

C73 |

EE-PROM initialization error |

|

|

|

|

C74 |

Defective adjustment by the exit/reversal sensor detected |

|

|

|

|

C75 to C80 |

Reserved |

|

|

|

|

C81 |

Fan motor lock error |

|

|

|

|

C82 |

Document aligning lower sensor (RADF)/Aligning sensor |

|

|

(ADF) adjustment error |

|

|

|

|

C83 |

Size length adjustment error |

|

|

|

|

C84 to C89 |

Reserved |

|

|

|

e-STUDIO160/200/250 ADJUSTMENT ITEMS |

1 - 4 |

December 2002 TOSHIBA TEC |

Classification |

Error code |

Machine status |

|

|

|

|

|

|

|

CALL SERVICE from others |

C90 |

Reserved |

|

|

|

|

|

|

|

|

C91 |

SRAM abnormality (Lithium battery or SRAM chip are |

|

|

|

|

abnormal.) |

|

|

|

|

|

|

|

|

C92 to C94 |

Reserved |

|

|

|

|

|

|

|

|

C95 |

Power supply unit fan motor abnormality |

|

|

|

|

|

|

|

|

C96 |

Process unit fan motor abnormality |

|

|

|

|

|

|

|

CALL SERVICE from laser |

C97 |

Vacuum fan motor abnormality |

|

|

|

|

|

|

|

optical system |

C98 |

Clock IC abnormality |

|

|

|

|

|

|

|

|

C99 |

PFC microcomputer abnormal |

|

|

|

|

|

|

|

CALL SERVICE from finisher |

CA1 |

Polygon motor abnormal |

|

|

|

|

|

|

|

(e-STUDIO200/250 series) |

CA2 |

HSYNC abnormal |

|

|

|

|

|

|

|

|

CA3 to CB0 |

Reserved |

|

|

|

|

|

|

|

|

CB1 |

Reserved |

|

|

|

|

|

|

|

|

CB2 |

Exit motor abnormal |

|

|

|

|

|

|

|

|

CB3 |

Reserved |

|

|

|

|

|

|

|

|

CB4 |

Reserved |

|

|

|

|

|

|

|

|

CB5 |

Staple motor abnormal |

|

|

|

|

|

|

|

|

CB6 to CC2 |

Reserved |

|

|

|

|

|

|

|

|

CC3 |

Set processing motor abnormal |

|

|

|

|

|

|

|

|

CC4 to CC7 |

Reserved |

|

|

|

|

|

|

|

|

CC8 |

Front aligning motor abnormal |

|

|

|

|

|

|

|

|

CC9 |

Upper tray elevator motor abnormal |

|

|

|

|

|

|

|

|

CCA |

Lower tray elevator motor abnormal |

|

|

|

|

|

|

|

|

CCB |

Rear aligning motor abnormal |

|

|

|

|

|

|

|

|

CCC to CD0 |

Reserved |

|

|

|

|

|

|

|

Reserved |

F01 to F10 |

Reserved |

|

|

|

|

|

|

|

Scanner I/F |

F11 |

Scanner I/F error |

|

|

|

|

|

|

|

|

F12 |

Write error at downloading the scanner unit program |

|

|

|

|

|

|

|

|

F13 |

Download sector error of the scanner unit program |

|

|

|

|

|

|

|

|

F14 |

Scanner unit F-ROM error |

|

|

|

|

|

|

|

|

F15 to F20 |

Reserved |

|

|

|

|

|

|

|

FAX unit |

F31 |

Modem IC does not work normal |

|

|

|

|

|

|

|

|

F32 to F40 |

Reserved |

|

|

|

|

|

|

|

Offset catch tray |

F41 |

Initial detection error of the offset catch tray |

|

|

|

|

|

|

|

Reserved |

F42 to F99 |

Reserved |

|

|

|

|

|

|

|

December 2002 TOSHIBA TEC |

1 - 5 |

e-STUDIO160/200/250 ADJUSTMENT ITEMS |

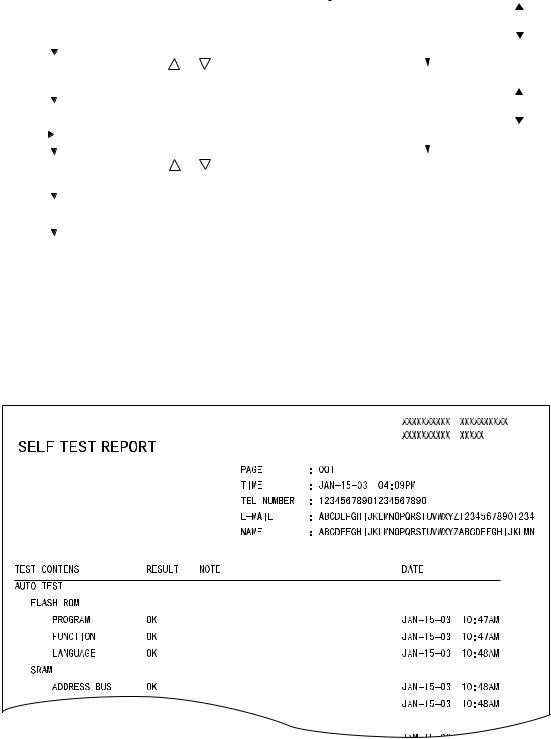

1.2 Self-Diagnosis Modes

The self-diagnosis functions are used to make the settings for the various PPC functions. This document describes the self-diagnosis functions.

For the FAX functions, refer to the SERVICE HANDBOOK (GD-1061).

For the method to enter each mode of the self-diagnosis functions, refer to the following chart.

|

Mode |

How to enter |

Definition |

How to clear |

|

|

|

|

|

|

|

Country/Region |

Turn the power on while |

Selects the country/region code. |

*1 |

|

|

code |

pressing the 0 and 2 keys. |

|

|

|

|

|

|

|

|

|

|

Adjust mode |

Turn the power on while |

Finely adjusts copy image quality. |

Turn the power off. |

||

|

|

pressing the 0 and 5 keys. |

Confirmation printing enabled by |

|

|

|

|

|

pressing the INTERRUPT key. |

|

|

|

|

|

|

|

|

System mode |

Turn the power on while |

Performs setups for the system, |

Turn the power off. |

||

|

|

pressing the 0 and 8 keys. |

maintenance, operations, printer, |

|

|

|

|

|

scanner, etc. |

|

|

|

|

|

|

|

|

Scanner parking |

Turn the power on while |

Fixes the scanner carriage in place |

Turn the power off. |

||

mode |

pressing the 0 and 9 keys. |

when transporting the copier. |

|

|

|

|

|

|

|

|

|

RAM clear |

Turn the power on while |

Clears values excluding the ones |

*2 |

|

|

|

|

pressing the 1, 3, and * keys. |

set in 08-446/447 and in the Ad- |

|

|

|

|

|

just mode (05). |

|

|

|

|

|

|

|

|

Service mode |

Press the PROGRAM key |

Performs setups for FUNCTION |

Press the |

|

|

*3 |

while REDAY is indicated, |

TEST and MAINTENANCE, and |

PROGRAM key, |

|

|

|

|

and then press the *, #, *, |

prints the Service List. |

and then press the |

|

|

|

then * keys. |

|

*, #, *, then * keys. |

|

|

|

|

|

|

|

|

FUNCTION |

After entering the service |

Conducts OPE. PANEL TEST, |

Or turn the power |

|

|

TEST |

mode, select it on the screen. |

PRINT TEST, MODEM TEST, etc. |

off. |

|

|

|

This mode is selected by |

|

Or press the |

|

|

|

turning the power on while |

|

COPY key, or |

|

|

|

pressing the 1 and 3 keys. |

|

press the MAIN |

|

|

|

|

|

|

|

|

MAINTENANCE |

After entering Service Mode, |

Performs setups for Memory Clear, |

MENU key. |

*4 |

|

|

select it on the screen. |

facsimile function, etc. |

|

|

|

|

|

|

|

|

|

Service list |

After entering Service Mode, |

Prints PROTOCOL TRACE, Total |

|

|

|

|

select it on the screen. |

Error, FUNCTION LIST, etc. |

|

|

|

|

|

|

|

|

*1: After inputting the country/region code, the copier automatically enters the warm up mode.

*2: After the RAM clear, the machine automatically enters the warm up mode.

*3: In the SERVICE MODE, each function of the FUNCTION TEST, MAINTENANCE, or SERVICE LIST in each test item of the TEST MODE (displayed by pressing the PROGRAM key), are added. When the copier enters this mode, these functions are available.

*4 The copier enters into the service mode by pressing 1 and 3 keys while turning the power on. To exit from the service mode, turn the power off.

e-STUDIO160/200/250 ADJUSTMENT ITEMS |

1 - 6 |

December 2002 TOSHIBA TEC |

|

|

Power ON |

|

|

|

"02" |

"13*" |

"05" |

"08" |

"13" |

"09" |

Country/Region |

RAM clear |

Adjust mode |

System mode |

Function test |

Scanner parking mode |

code |

|

|

|

|

|

|

|

"INT" "INT" |

|

|

|

Warming up |

Test print |

Power OFF |

|

||

"INT" : INTERRUPT key on.

Standby

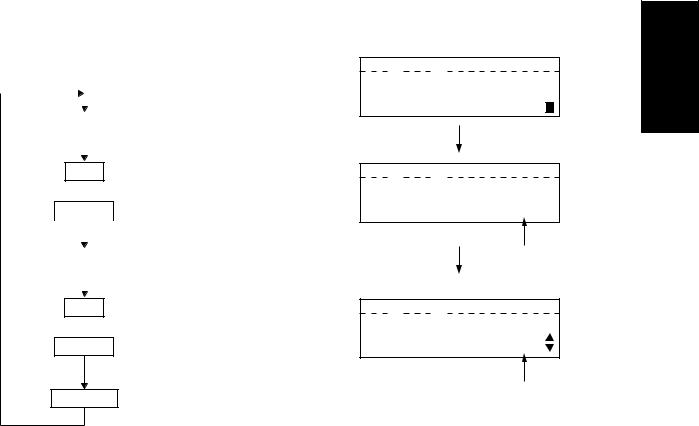

Quick reference chart for self-diagnostic mode

01-02-01

Note: Power ON |

Turn on the power switch. |

Power OFF |

Turn on the power switch. |

INT |

Press the INTERRUPT key. |

C/S |

Press the CLEAR/STOP key. |

Menu map

The menu below can be selected by pressing the program key. (However, the menu in the broken-dotted box are displayed only when the copier enters the SERVICE MODE.)

01. DEFAULT SETTINGS |

|

|

|

|

|

|

|

|

|

|

|

|

|

02. LISTS |

|

|

|

|

|

|

|

|

|

|

|

|

|

03. INITIAL SETUP |

|

|

|

|

|

|

|

|

|

|

|

|

|

04. MENU LIST |

|

|

|

|

|

|

|

|

|

|

|

|

|

05. TEST MODE |

|

|

|

01. AUTO TEST |

|

|

|||||||

|

|

|

|

|

|||||||||

|

|

|

|

02. INDIVIDUAL TEST |

|

|

|||||||

|

|

|

|

|

|||||||||

|

|

|

|

03. TEST RESULT LIST |

|

|

|||||||

|

|

|

|

|

|||||||||

|

|

|

|

04. FUNCTION TEST |

|

|

|

|

|

01. OPE PANEL TEST |

|||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

05. MAINTENANCE |

|

|

|

|

|

02. PRINT TEST |

|||

|

|

|

|

06. SERVICE LIST |

|

|

|

|

|

01. MEMORY CLEAR |

|||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

02. SET FUNCTION |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

01. PROTOCOL TRACE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Service mode |

|

|

|

02. TOTAL ERRORS |

|||||

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|||||||

01-02-02

December 2002 TOSHIBA TEC |

1 - 7 |

e-STUDIO160/200/250 ADJUSTMENT ITEMS |

1.2.1 Adjust mode (05) |

|

<Key used in operation> |

<Display messages> |

|

0 |

|

|

5 |

|

Power ON |

|

|

|

TEST MODE A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

Enter code |

MC= |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

Digital Keys |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

( |

C/S |

used to correct value) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

SET |

|

|

|

|

|

|

TEST MODE A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MC= |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

or |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

205 |

|

|

|

|

|

||||||||||||||||||

|

|

|

|

START |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Digital Keys |

|

Adjustment value |

|

|

|

|

|

Enter code |

||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

SET |

|

|

|

|

|

|

TEST MODE A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MC=205 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

or |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

DT= |

156 |

|

|

|

|

|

||||||||||||||||||||||||||||||||

|

|

|

|

START |

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Adjustment value |

||||||||||||

|

|

|

|

Cancel |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

e-STUDIO160/200/250 ADJUSTMENT ITEMS |

1 - 8 |

December 2002 TOSHIBA TEC |

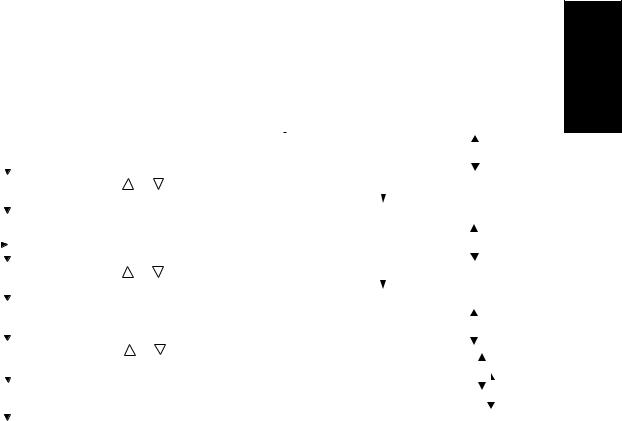

ADJUST MODE (05) ITEMS

Process unit adjustment

Code |

Factor |

Adjustment item (05) |

Mode |

Default |

Acceptable |

Refer to |

|

|

|

|

|

value |

page |

|

|

|

|

|

|

|

205 |

Development |

Developer bias DC adjustment |

ALL |

156 |

0-255 |

1-70 |

|

|

• Increment/decrement by U/D (Up/Down) key |

|

(166) |

|

|

|

|

• Real-time high voltage output |

|

|

|

|

|

|

• Developer bias DC ON |

|

|

|

|

|

|

|

|

|

|

|

210 |

Charging |

Grid voltage initial value adjustment |

ALL |

104 |

0-255 |

1-70 |

|

|

• Increment/decrement by U/D key |

|

(118) |

Guaranteed |

|

|

|

• Real-time high voltage output (Charge ON) |

|

|

value |

|

|

|

|

|

*1 |

0-223 |

|

|

|

|

|

|

|

|

220 |

Transfer |

Transfer transformer DC output High adjustment |

ALL |

180 |

0-255 |

1-70 |

|

|

• Increment/decrement by U/D key |

|

|

|

|

|

|

• Real-time high voltage output (Transfer High ON) |

|

|

|

|

|

|

|

|

|

|

|

221 |

Transfer |

Transfer transformer DC output Center adjustment |

ALL |

142 |

0-255 |

1-70 |

|

|

• Increment/decrement by U/D key |

|

(155) |

|

|

|

|

• Real-time high voltage output (Transfer Center ON) |

|

*1 |

|

|

|

|

|

|

|

|

|

233 |

Separation |

Separation output High adjustment |

ALL |

67 |

0-255 |

1-70 |

|

|

• Increment/decrement by U/D key |

|

|

|

|

|

|

• Real-time high voltage output (Separation-High ON) |

|

|

|

|

|

|

|

|

|

|

|

234 |

Separation |

Separation output Center adjustment |

ALL |

49 |

0-255 |

1-70 |

|

|

• Increment/decrement by U/D key |

|

|

|

|

|

|

• Real-time high voltage output (Separation-Center ON) |

|

|

|

|

|

|

|

|

|

|

|

235 |

Separation |

Separation output Low adjustment |

ALL |

35 |

0-255 |

1-70 |

|

|

• Increment/decrement by U/D key |

|

|

|

|

|

|

• Real-time high voltage output (Separation-Low ON) |

|

|

|

|

|

|

|

|

|

|

|

261 |

Laser |

Laser power 600 DPI Initial value adjustment |

ALL |

39 |

0-255 |

|

|

|

• Increment/decrement by U/D key |

|

(53) |

|

|

|

|

• No polygon rotation |

|

*1 |

|

|

|

|

• Real-time laser output |

|

|

|

|

|

|

(Results of automatic laser adjustment) |

|

|

|

|

|

|

(Laser ON) |

|

|

|

|

|

|

|

|

|

|

|

*1 : The value in parentheses is for the model e-STUDIO200/250 series.

December 2002 TOSHIBA TEC |

1 - 9 |

e-STUDIO160/200/250 ADJUSTMENT ITEMS |

Scanning adjustment

Code |

Factor |

Adjustment item (05) |

|

Mode |

Default |

Acceptable |

Refer to |

|

|

|

|

|

|

value |

page |

|

|

|

|

|

|

|

|

304 |

Scanner |

Scanner feed magnification |

0.1 %/step |

ALL |

128 |

0-255 |

1-62 |

|

mechanism |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

305 |

Scanner |

Scanner feed misalignment |

0.126 mm/step |

ALL |

128 |

85-171 |

1-63 |

|

mechanism |

|

(600 DPI) |

|

|

|

|

|

|

|

|

|

|

|

|

306 |

Scanner |

CCD scanning misalignment |

0.04233 mm/step |

ALL |

128 |

5-251 |

1-61 |

|

mechanism |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

354 |

R/ADF |

R/ADF aligning amount (surface) |

0.5 mm/step |

ALL |

10 |

0-20 |

|

|

|

|

|

|

|

|

|

355 |

RADF |

RADF aligning amount (back) |

0.5 mm/step |

ALL |

10 |

0-20 |

|

|

|

|

|

|

|

|

|

356 |

R/ADF |

ADF position sensor adjustment or RADF sensor automatic |

ALL |

- |

*1 |

|

|

|

|

adjustment |

|

|

|

|

|

|

|

|

|

|

|

|

|

357 |

R/ADF |

R/ADF transport speed fine adjustment |

0.1 %/step |

ALL |

50 |

0-100 |

|

|

|

|

|

|

|

|

|

358 |

R/ADF |

R/ADF horizontal misalignment adjustment |

ALL |

128 |

0-255 |

|

|

|

|

|

0.04233 mm/step |

|

|

|

|

|

|

|

|

|

|

|

|

365 |

R/ADF |

RADF top position adjustment (surface) |

0.1 mm/step |

ALL |

50 |

0-100 |

|

|

|

|

|

|

|

|

|

366 |

RADF |

RADF top position adjustment (back) |

0.1 mm/step |

ALL |

50 |

0-100 |

|

|

|

|

|

|

|

|

|

380 |

ADF |

ADF document width sensor adjustment, narrowest document |

ALL |

- |

*1 |

1-52 |

|

|

|

guide width |

|

|

|

|

|

|

|

|

|

|

|

|

|

381 |

ADF |

ADF document width sensor adjustment, widest document |

ALL |

- |

*1 |

1-52 |

|

|

|

guide width |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*1 : The entry of code enables automatic adjustment. |

||||

Printer adjustment

Code |

Factor |

|

Adjustment item |

|

Mode |

Default |

Acceptable |

Refer to |

|

|

|

|

|

|

|

|

|

Value |

page |

|

|

|

|

|

|

|

|

||

400 |

Printer system |

Polygon motor speed fine adjustment |

600 DPI |

PPC |

128 |

108-148 |

1-56 |

||

|

|

|

|

|

0.2%/step |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

410 |

Printer system |

Laser start position 600 DPI |

|

Cassette 1 |

PPC |

108 |

0-255 |

1-57 |

|

|

|

|

|

|

|

|

|

|

|

417 |

Printer system |

Laser start position 600 DPI |

|

Cassette 2 |

PPC |

106 |

0-255 |

1-57 |

|

|

|

|

|

|

|

|

|

|

|

418 |

Printer system |

Laser start position 600 DPI |

|

Cassette 3/LCF |

PPC |

119 |

0-255 |

1-57 |

|

|

|

|

|

|

|

|

|

|

|

419 |

Printer system |

Laser start position 600 DPI |

|

Cassette 4 |

PPC |

128 |

0-255 |

1-57 |

|

|

|

|

|

|

|

|

|

||

421 |

Printer system |

Main motor speed fine adjustment |

Approx. 0.1%/step |

PPC |

124 (130) |

78-178 |

1-58 |

||

|

|

|

|

|

|

|

|

|

|

430 |

Printer system |

Top margin |

0.7 mm/step |

|

PPC |

0 |

0-30 |

1-64 |

|

|

|

|

|

|

|

|

|

|

|

431 |

Printer system |

Left margin |

0.1 mm/step |

|

PPC |

0 |

0-255 |

1-64 |

|

|

|

|

|

|

|

|

|

|

|

432 |

Printer system |

Right margin |

0.1 mm/step |

|

PPC |

0 |

0-255 |

1-65 |

|

|

|

|

|

|

|

|

|

|

|

433 |

Printer system |

Bottom margin |

0.1 mm/step |

|

PPC |

0 |

0-255 |

1-65 |

|

|

|

|

|

|

|

|

|

||

440 |

Printer system |

Top position Cassette 1 |

0.4 mm/step |

ALL |

23 |

0-40 |

1-59 |

||

|

|

|

|

|

|

|

|

||

441 |

Printer system |

Top position Cassette 2 |

0.4 mm/step |

ALL |

7 |

0-15 |

1-59 |

||

|

|

|

|

|

|

|

|

||

442 |

Printer system |

Top position Bypass (SFB) |

0.4 mm/step |

ALL |

8 |

0-15 |

1-59 |

||

|

|

|

|

|

|

|

|

|

|

443 |

Printer system |

Top position LCF |

|

0.4 mm/step |

ALL |

8 |

0-15 |

1-59 |

|

|

|

|

|

|

|

|

|

|

|

444 |

Printer system |

Top position PFP |

|

0.4 mm/step |

ALL |

7 |

0-15 |

1-59 |

|

|

|

|

|

|

|

|

|

|

|

445 |

Printer system |

Top position ADU |

|

0.4 mm/step |

ALL |

8 |

0-15 |

1-59 |

|

|

|

|

|

|

|

|

|||

450 |

Printer system |

Aligning amount Copier cassette (Cassette 1) |

ALL |

14 |

0-31 |

1-55 |

|||

|

|

Long size (0.52 mm/step) Paper length of min. 259 mm |

|

|

|

|

|||

|

|

|

|

|

|

|

|||

451 |

Printer system |

Aligning amount Copier cassette (Cassette 1) |

ALL |

14 |

0-31 |

1-55 |

|||

|

|

Short size (0.52 mm/step) Paper length of max. 258 mm |

|

|

|

|

|||

|

|

|

|

|

|

|

|

||

452 |

Printer system |

Aligning amount Cassette 2 (PFU) |

|

ALL |

22 |

0-31 |

1-55 |

||

|

|

Long size (0.52 mm/step) Paper length of min. 322 mm |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*1 : The value in parentheses is for the model e-STUDIO200/250 series. |

|||||

e-STUDIO160/200/250 ADJUSTMENT ITEMS |

1 - 10 |

December 2002 TOSHIBA TEC |

Printer adjustment

Code |

Factor |

Adjustment item |

Mode |

Default |

Acceptable |

Refer to |

|

|

|

|

|

|

|

Value |

page |

|

|

|

|

|

|

|

|

453 |

Printer system |

Aligning amount Cassette 2 (PFU) |

ALL |

16 |

0-31 |

1-55 |

|

|

|

Short size (0.52 mm/step) Paper length of max. 321 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

455 |

Printer system |

Aligning amount ADU |

|

ALL |

26 |

0-31 |

1-55 |

|

|

(e-STUDIO160:0.7mm/step, e-STUDIO200/250:0.47mm/step) |

|

(23) *1 |

|

|

|

|

|

|

|

|

|

|

|

456 |

Printer system |

Aligning amount PFP Short size (0.52 mm/step) |

ALL |

16 |

0-31 |

1-55 |

|

|

|

Paper length of max. 321 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

457 |

Printer system |

Aligning amount LCF |

0.52 mm/step |

ALL |

16 |

0-31 |

1-55 |

|

|

|

|

|

|

|

|

458 |

Printer system |

Aligning amount Bypass (SFB) Short size (0.52 mm/step ) |

ALL |

21 |

0-31 |

1-55 |

|

|

|

Paper length of max. 258 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

463 |

Printer system |

Aligning amount PFP Long size (0.52 mm/step) |

ALL |

18 |

0-31 |

1-55 |

|

|

|

Paper length of min. 322 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

465 |

Printer system |

Aligning amount Bypass Long size (0.52 m/step) |

ALL |

28 |

0-31 |

1-55 |

|

|

|

Paper length of min. 259 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

497 |

Printer system |

Laser start position 600 DPI Bypass |

PPC |

101 |

0-255 |

1-57 |

|

|

|

|

|

|

|

|

|

*1 : The value in parentheses is for the model e-STUDIO200/250 series.

Scan image processing parameter 600 DPI

|

|

|

Image |

Image |

|

Acceptable |

Refer to |

|

Code |

Factor |

Adjustment item |

quality |

Default |

||||

mode |

value *1 |

page |

||||||

|

|

|

mode |

|

||||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

501 |

Density |

Manual density fine adjustment Center |

PPC |

Photo |

139 |

0-255 |

1-53 |

|

|

|

value |

|

|

|

L ← V → D |

|

|

|

|

|

|

|

|

|

|

|

503 |

Density |

Ditto |

PPC |

Text/Photo |

133 |

0-255 |

1-53 |

|

|

|

|

|

|

|

L ← V → D |

|

|

|

|

|

|

|

|

|

|

|

504 |

Density |

Ditto |

PPC |

Text |

130 |

0-255 |

1-53 |

|

|

|

|

|

|

|

L ← V → D |

|

|

|

|

|

|

|

|

|

|

|

505 |

Density |

Manual density fine adjustment Light step |

PPC |

Text/Photo |

28 |

0-255 |

1-53 |

|

|

|

value |

|

|

|

V → L |

|

|

|

|

|

|

|

|

|

|

|

506 |

Density |

Ditto |

PPC |

Photo |

18 |

0-255 |

1-53 |

|

|

|

|

|

|

|

V → L |

|

|

|

|

|

|

|

|

|

|

|

507 |

Density |

Ditto |

PPC |

Text |

20 |

0-255 |

1-53 |

|

|

|

|

|

|

|

V → L |

|

|

|

|

|

|

|

|

|

|

|

508 |

Density |

Manual density fine adjustment Dark step |

PPC |

Text/Photo |

13 |

0-255 |

1-53 |

|

|

|

value |

|

|

|

V → D |

|

|

|

|

|

|

|

|

|

|

|

509 |

Density |

Ditto |

PPC |

Photo |

20 |

0-255 |

1-53 |

|

|

|

|

|

|

|

V → D |

|

|

|

|

|

|

|

|

|

|

|

510 |

Density |

Ditto |

PPC |

Text |

18 |

0-255 |

1-53 |

|

|

|

|

|

|

|

V → D |

|

|

|

|

|

|

|

|

|

|

|

512 |

Density |

Auto density fine adjustment |

PPC |

Photo |

140 |

0-255 |

1-53 |

|

|

|

|

|

|

|

L ← V → D |

|

|

|

|

|

|

|

|

|

|

|

514 |

Density |

Ditto |

PPC |

Text/Photo |

133 |

0-255 |

1-53 |

|

|

|

|

|

|

|

L ← V → D |

|

|

|

|

|

|

|

|

|

|

|

515 |

Density |

Ditto |

PPC |

Text |

130 |

0-255 |

1-53 |

|

|

|

|

|

|

|

L ← V → D |

|

|

|

|

|

|

|

|

|

|

|

593 |

Density |

ϒ data inclination correction |

PPC |

Text/Photo |

0 |

0-9 |

1-67 |

|

|

|

|

|

|

|

|

|

|

594 |

Density |

ϒ data inclination correction |

PPC |

Photo |

0 |

0-9 |

1-67 |

|

|

|

|

|

|

|

|

|

|

595 |

Density |

ϒ data inclination correction |

PPC |

Text |

0 |

0-9 |

1-67 |

|

|

|

|

|

|

|

|

|

*1 L: Light, V: Value, D: Dark

December 2002 TOSHIBA TEC |

1 - 11 |

e-STUDIO160/200/250 ADJUSTMENT ITEMS |

Scan image processing parameter 600 DPI

|

|

|

|

Image |

Image |

|

Acceptable |

Refer to |

|

Code |

Factor |

Adjustment item |

quality |

Default |

|||||

mode |

value *1 |

page |

|||||||

|

|

|

|

mode |

|

||||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

||

620 |

Image |

No. of units: HPF table number |

PPC |

Text/Photo |

1 |

0-99 |

1-66 |

||

|

quality |

0: Use of default value |

|

|

|

The larger the intensity |

|

||

|

|

1: Text/Photo mode |

|

|

|

|

coefficient the stronger the |

|

|

|