Page 1

SERVICE MANUAL

DOCUMENT CREATED IN JAPAN, Jul., 2005

DIGITAL VIDEO

DVD VIDEO RECORDER

FILE NO. 810-200531

D-R4SU

D-R4SC

D-KR4SU

Mar., 2005

S

Page 2

LASER BEAM CAUTION LABEL

When the power supply is being turned on, you may not remove this laser cautions label. If it removes, radiation of a laser

may be received.

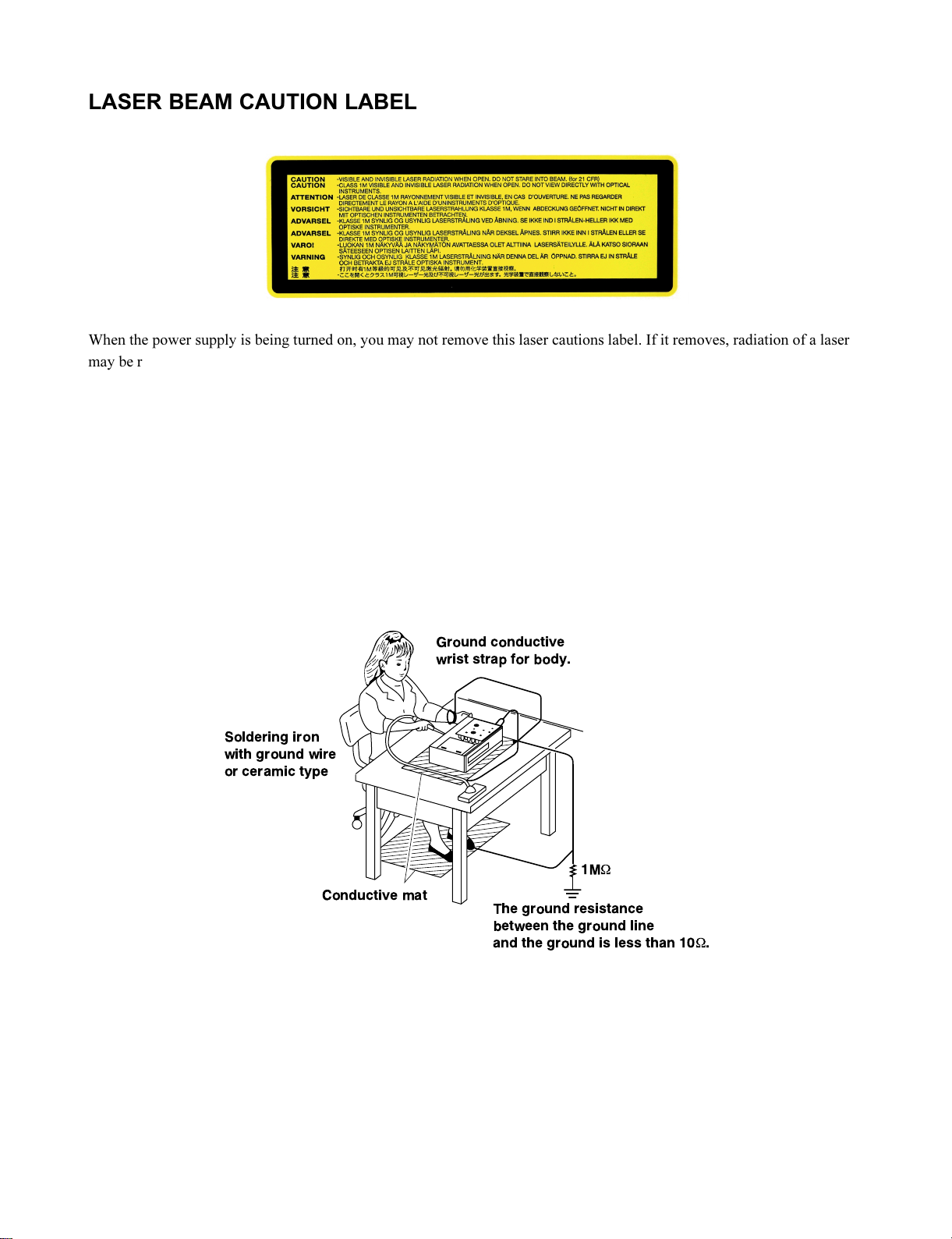

PREPARATION OF SERVICING

Pickup Head consists of a laser diode that is very susceptible to external static electricity.

Although it operates properly after replacement, if it was subject to electrostatic discharge during replacement,

its life might be shortened. When replacing, use a conductive mat, soldering iron with ground wire, etc. to

protect the laser diode from damage by static electricity.

And also, the LSI and IC are same as above.

Ground conductive

wrist strap for body.

Soldering iron

with ground wire

or ceramic type

1M

W

Conductive mat

Manufactured under license from Dolby Laboratories. “Dolby” and the double-D symbol are trademarks of Dolby Laboratories.

·

“DTS” and “DTS Digital Out” are trademarks of Digital Theater Systems, Inc.

·

Manufactured under license from QSound Labs, Inc. U.S. patent Nos. 5,105,462, 5,208,860 and 5,440,638 and various foreign counterpart. Copyright

·

QSound Labs, Inc. 1998-2002. QXpanderTM is a trademark of QSound Labs, Inc. All rights reserved.

The ground resistance

between the ground line

and the ground is less than 10W.

Page 3

SAFETY NOTICE

SAFETY PRECAUTIONS

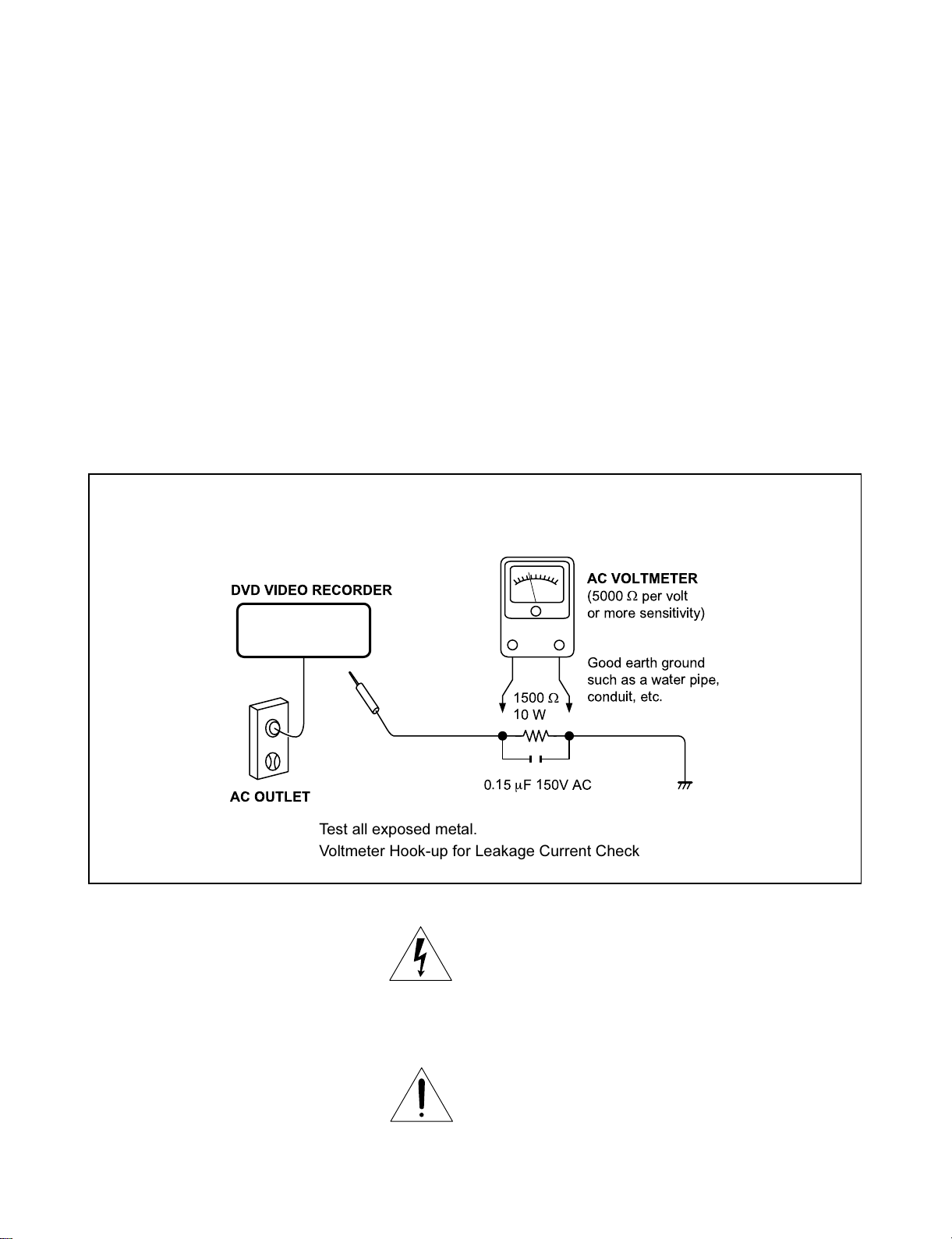

LEAKAGE CURRENT CHECK

Plug the AC line cord directly into a 120V AC outlet (do

not use an isolation transformer for this check). Use an

AC voltmeter, having 5000 W per volt or more sensitivity.

Connect a 1500 W 10 W resistor, paralleled by a 0.15 mF

150V AC capacitor between a known good earth ground

(water pipe, conduit, etc.) and all exposed metal parts of

cabinet (antennas, handle bracket, metal cabinet

screwheads, metal overlays, control shafts, etc.).

READING SHOULD NOT EXCEED 0.3V

Measure the AC voltage across the 1500 W resistor.

The test must be conducted with the AC switch on and

then repeated with the AC switch off. The AC voltage

indicated by the meter may not exceed 0.3 V. A reading

exceeding 0.3 V indicates that a dangerous potential

exists, the fault must be located and corrected.

Repeat the above test with the DVD VIDEO RECORDER

power plug reversed.

NEVER RETURN A DVD VIDEO RECORDER TO

THE CUSTOMER WITHOUT TAKING NECESSARY

CORRECTIVE ACTION.

DVD VIDEO RECORDER

AC OUTLET

Test all exposed metal.

Voltmeter Hook-up for Leakage Current Check

AC VOLTMETER

(5000Wper volt

or more sensitivity)

Good earth ground

such as a water pipe,

W

conduit, etc.

1500

10 W

0.15mF 150V AC

The lightning flash with arrowhead symbol, within an

equilateral triangle, is intended to alert the user to the

presence of uninsulated “dangerous voltage” within the

product’s enclosure that may be of sufficient magnitude to

constitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle is

intended to alert the user to the presence of important

operating and maintenance (servicing) instructions in the

literature accompanying the appliance.

Page 4

1. OPERATING INSTRUCTIONS

CONTENTS

SECTION 1

GENERAL DESCRIPTIONS

2. LOCATION OF MAIN PARTS

2-1. Location of Main Parts

2-2. Location of PC Boards

PART REPLACEMENT AND ADJUSTMENT PROCEDURES

1. REPLACEMENT OF MECHANICAL PARTS

1-1. Cabinet Replacement

1-1-1. Top Cover

1-1-2. Front Panel

1-1-3. RAM Diver

1-1-4. Rear Panel

1-1-5. Fan

1. CIRCUIT SYMBOLS AND

SUPPLEMENTARY EXPLANATION

1-1. Precautions for Part Replacement

1-2. Solid Resistor Indication

1-3. Capacitance Indication

1-4. Inductor Indication

1-5. Waveform and Voltage Measurement

1-6. Others

2. PRINTED WIRING BOARD AND

SCHEMATIC DIAGRAM

3. BLOCK DIAGRAMS

3-1. Overall Block Diagram

4. CIRCUIT DIAGRAMS

4-1. Power Supply Circuit Diagram

4-2. Front Circuit Diagram

4-2-1. Front Jack Circuit Diagram

4-2-2. Front (LED) Circuit Diagram

4-2-2. Front (L) Circuit Diagram

4-2-3. Front (R) Circuit Diagram

SECTION 2

1-2. PC Board Replacement

1-2-1. Tuner Unit PC Board

1-2-2. Digital PC Board

1-2-3. Mother PC Board

1-2-4. Power PC Board

1-2-5. Front (R), Front (L), Front (LED), and

Front Jack PC Board

2. WIRING CONNECTION DIAGRAM

SECTION 3

SERVICING DIAGRAMS

4-3. Digital Circuit Diagram

4-3-1. Digital 1 Circuit Diagram

4-4. Mother Circuit Diagram

4-4-1. Tuner Circuit Diagram

4-4-2. Timer Circuit Diagram

4-4-3. Audio Circuit Diagram

4-4-4. Video Circuit Diagram

4-3. Tuner Unit Circuit Diagram

5. PC BOARDS

5-1. Front Jack PC Board

5-2. Front (LED) PC Board

5-3. Front (L) PC Board

5-4. Front (R) PC Board

5-5. Tuner Unit PC Board

5-6. Digital PC Board

5-7. Mother PC Board

SAFETY PRECAUTION

NOTICE

ABBREVIATIONS

SECTION 4

PARTS LIST

1. EXPLODED VIEWS

1-1. Packing Assembly

1-2. Chassis Assembly

2. PARTS LIST

Page 5

GENERAL DESCRIPTIONS

SECTION 1

GENERAL DESCRIPTIONS

1. OPERATING INSTRUCTIONS

Please refer to the owner's manual about the contents.

SECTION 1

Page 6

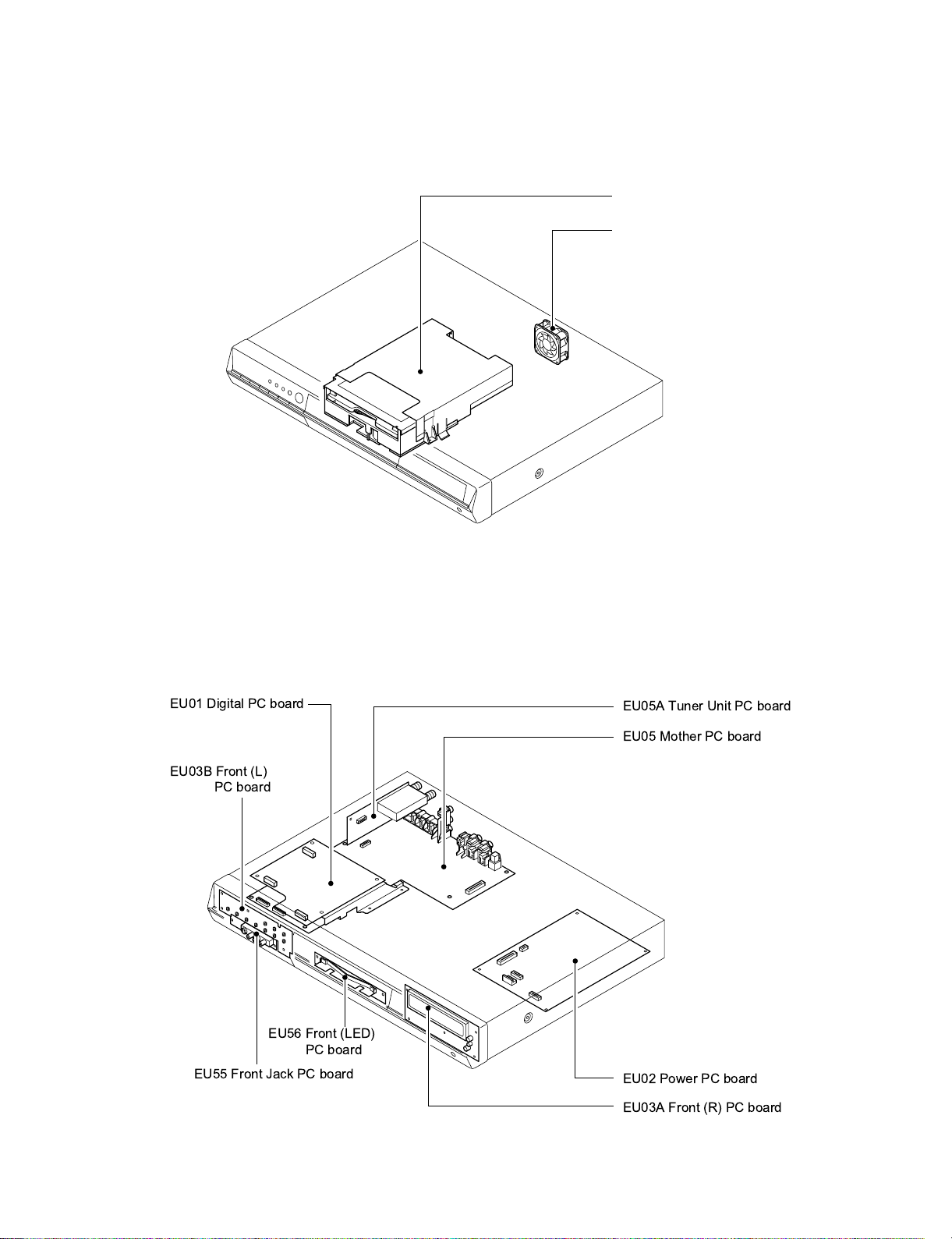

2. LOCATION OF MAIN PARTS

2-1. Location of Main Parts

RAM1 RAM DRIVE

ZG45 FAN

2-2. Location of PC Boards

EU01 Digital PC board

EU03B Front (L)

PC board

Fig. 1-2-1

EU05A Tuner Unit PC board

EU05 Mother PC board

EU56 Front (LED)

PC board

EU55 Front Jack PC board

EU02 Power PC board

EU03A Front (R) PC board

Fig. 1-2-2

Page 7

SECTION 2

PART REPLACEMENT AND

ADJUSTMENT PROCEDURES

CAUTIONS BEFORE STARTING PART REPLACEMENT

Electronic parts are susceptible to static electricity and may easily damaged, so do not forget to ground as required.

Many screws are used inside the unit. To prevent the screws from missing or dropping, etc. always use a magnetized

screwdriver in servicing. Several kinds of screws are used and some of them need special cautions. That is, take care of

the tapping screws securing molded parts and fine pitch screws used to secure metal parts. If they are used improperly,

the screw holes will be easily damaged and the parts can not be fixed.

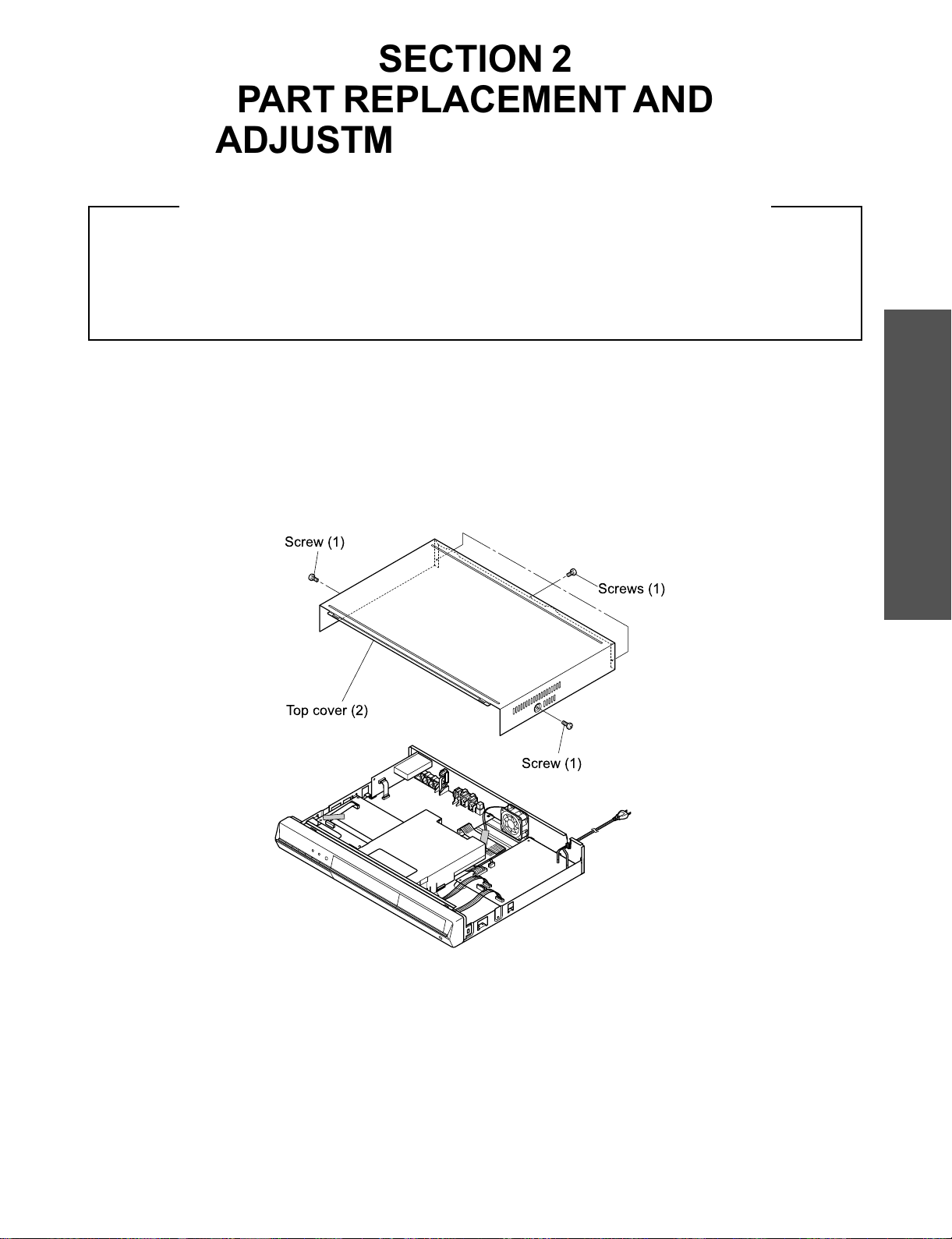

1. REPLACEMENT OF MECHANICAL PARTS

ADJUSTMENT PROCEDURES

PART REPLACEMENT AND

1-1. Cabinet Replacement

1-1-1. Top Cover

1. Remove five screws (1), then remove the top cover (2).

Screw (1)

Top cover (2)

SECTION 2

Screws (1)

Screw (1)

Fig. 2-1-1

Page 8

1-1-2. Front Panel

1. Remove the top cover. (Refer to item 1-1-1.)

2. Disconnect three connectors (1).

3. Remove one screw (2) and the earth lead.

4. Remove two screws (3) and four claws, then remove the front panel (4).

Connector (1)

Claw

Claws

Connector (1)

Screws (2)

Earth

Claw

Front panel (4)

Screws (3)

Fig. 2-1-2

1-1-3. RAM Drive

1. Remove the front panel. (Refer to item 1-1-2.)

2. Disconnect the flexible cable (1) and connector (2).

3. Remove three screws (3) and the screw (4), then remove the RAM drive (5).

4. Remove the shield cover (6).

Note:

• After replacing, attach the tape (1) to its original position.

Connector (1)

Screws (3)

Flexible

cable (1)

Screw (4)

Shield cover (6)

RAM drive (5)

Connector (2)

Fig. 2-1-3

Page 9

1-1-4. Rear Panel

1. Remove the top cover. (Refer to item 1-1-1.)

2. Remove the screw (1) and seven screws (2).

3. Remove the bush from the rear panel (3).

4. Remove two claws, then remove the rear panel (3).

5. Remove two screws (4), then remove the fan (5).

Rear panel (3)

Claw

Screw (1)

Screws (2)

Screws (4)

Bush

1-1-5. Fan

1. Remove the top cover. (Refer to item 1-1-1.)

2. Peel off the tape (1).

3. Disconnnect two connectors (2).

4. Remove two screws (3), then remove the fan (4).

Hexagonal

nuts

Tape (1)

Fig. 2-1-4

Fan (4)

Fan (5)

Screws (3)

Claw

Fig. 2-1-5

Connectors (2)

Page 10

1-2. PC Board Replacement

Screw (2)

Tuner Unit

PC board (4)

Screw (3)

Claw

Flexible

cable (1)

1-2-1. Tuner Unit PC Board

1. Remove the top cover. (Refer to item 1-1-1.)

2. Disconnect the flexible cable (1).

3. Remove the screw (2) and the screw (3).

4. Remove the claw, then remove the Tuner Unit PC board (4).

1-2-2. Digital PC Board

1. Remove the top cover. (Refer to item 1-1-1.)

2. Peel off the tape (1).

2. Disconnect the flexible cable (2).

3. Remove four screws (3), then remove the Digital PC board (4).

Fig. 2-1-6

Note:

• The Digital PC board (4) is connected to the Mother PC board (5) by three connectors (6). Take notice when removing.

Flexible

cable (2)

Connector

Tape (1)

Flexible

cable (2)

Screws (3)

Connector (6)

Digital PC

board (4)

Claw

Remove the connector claw

in the direction indicated

by the arrows to release the

flexible cable.

Connectors (6)

Mother PC board (5)

Fig. 2-1-7

Page 11

1-2-3. Mother PC Board

1. Remove the rear panel. (Refer to item 1-1-4.)

2. Remove the Tuner Unit PC board. (Refer to item 1-2-1.)

3. Remove the Digital PC board. (Refer to item 1-2-2.)

4. Disconnect three connectors (1).

5. Remove five screws (2) and the screw (3).

6. Pull out the Mother PC board (4) toward the rear side (indicated by the arrow).

Connectors (1)

Screws (2)

Fig. 2-1-8

Screw (3)

Connector (1)

Mother PC

board (4)

Page 12

1-2-4. Power PC Board

1. Remove the top cover. (Refer to item 1-1-1.)

2. Peel off the tape (1).

3. Disconnect four connectors (2).

4. Remove four screws (3), then remove the Power PC board (4).

Tape (1)

Connectors (2)

Connectors (2)

Power

PC board (4)

Connectors (2)

Screws (3)

Fig. 2-1-9

Page 13

1-2-5. Front (R), Front (L), Front (LED) and Front Jack PC Boards

1. Remove the front panel. (Refer to item 1-1-2.)

2. Peel off two tapes (1).

3. Remove four screws (2), then remove the stay (3).

4. Remove four screws (4) and two screws (5), then remove the Front (R) PC board (6) and Front (LED) PC board (7).

5. Remove two screws (8), then remove the Front Jack PC board (9).

6. Remove four screws (10), then remove the Front (L) PC board (11).

Note:

• After replacing, attach the tape (1) to its original position.

Front (L) PC board (11)

Front panel

Front Jack

PC board (9)

Tapes (1)

Screws (10)

Screws (5)

Front (LED)

PC Board (7)

Fig. 2-1-10

Screws (2)

Screws (8)

Stay (3)

Screws (4)

Front (R) PC board (6)

Note:

• Fasten with the tape, taking care so that the wire does not hang over the tray door.

Stay

Front (R) PC board

Front (LED)

PC board

Fasten with the tape.

Front (L) PC boardTray doorWire

Fig. 2-1-11

Front Jack

PC board

Page 14

2. WIRING CONNECTION DIAGRAM

After the servicing is complete, return the wiring to its original state by using the diagram below as a reference.

Tuner Unit

PC board

WB01

W051

W101

W104

Mother PC board

Digital PC board

RAM Drive

Fan

W801

Power PC board

W701

W102

Front panel

: Tape

: Flexible cable

Fig. 2-2-1

Page 15

SECTION 4

PARTS LIST

SAFETY PRECAUTION

The parts identified by ! ( ) mark are critical for safety. Replace only with part number specified.

The mounting position of replacement is to be identical with originals.

The substitute replacement parts which do not have the same safety characteristics as specified in the parts list may create

shock, fire or other hazards.

NOTICE

The part number must be used when ordering parts in order to assist in processing, be sure to include the model number

and description.

ABBREVIATIONS

Integrated Circuit (IC)

•

Capacitor (Cap)

•

• Capacitance Tolerance (for Nominal Capacitance more than 10pF)

Table 4-2-1

Symbol

Tolerance %B± 0.1C± 0.25D± 0.5

Symbol

Tolerance %

• Capa citan ce Tolerance (for Nominal Capacitance 10pF or less)

Symbol

Tolerance pFB± 0.1C± 0.25D± 0.5

Resistor (Res)

•

• Resistance tolerance

Symbol

Tolerance %B± 0.1C± 0.25D± 0.5

P

+ 100

0

Q

+ 30

– 10

T

+ 50

– 10

Ex. 10pF G = 10pF ± 2pF

F

± 1

U

+ 75

– 10

Table 4-2-2

F

± 1

Table 4-3-1

F

± 1

G

± 2

V

+ 20

– 10

G

± 2

G

± 2

J

± 5

W

+ 100

– 10

J

± 5

K

± 10

X

+ 40

– 20

Ex. 10µF J = 10µF ± 5%

K

± 10

M

± 20

Y

+ 150

– 10

M

± 20

N

± 30

Z

+ 80

– 20

PARTS LIST

SECTION 4

Ex. 470WJ = 470W± 5%

Page 16

1. EXPLODED VIEWS

1-1. Packing Assembly

ZF10

ZF11

ZF12

(D-R4SU/KR4SU)

ZF13

ZF01

ZF35

Fig. 4-4-1

Note: The shape of the packing

material is sometimes different.

Page 17

1-2. Chassis Assembly

EU01

EU05A

WB01

EU05

W051

ZG20

RAM1

ZG45

P801

EU02

EU03B

EU55

EU56

EU03A

ZG01

Fig. 4-4-2

Page 18

2. PARTS LIST

Location

No.

P801 P000416780 Cord,Power UL

!

RAM1 P000438600 DVD-RAM DAV-WR412(RAM-R650)

!

W051 P000433820 Cable,Flexible FFC,40P,L280

WB01 P000439330 Cable,Flexible FFC,11P,L90

ZF01 P000438630 Remote Control Unit SE-R0176

ZF10 P000416410 Owners Manual,OP English,D-R4SU/SC/KR4SU

!

ZF11 P000416400 Owners Manual,ST English,D-R4SU/SC/KR4SU

!

ZF12 P000416430 Owners Manual,Quick Spanish,D-R4SU/KR4SU

!

ZF13 P000416420 Owners Manual,Quick English,D-R4SU/SC/KR4SU

!

ZF10 P000416450 Owners Manual,OP French,D-R4SC

!

ZF11 P000416440 Owners Manual,ST French,D-R4SC

!

ZF35 P000416800 IR Blaster RWS1000-0062E

ZG01 P000438710 Panel Assy,Front D-R4SU/R4SC

ZG01 P000440030 Panel Assy,Front D-KR4SU

ZG20 P000438610 Cover,Top

ZG45 P000401260 Fan,DC 5025LL12SND2

Part No. Description

- MECHANICAL PARTS -

Page 19

Location

No.

EU01 P000439050 PC Board Assy Digital,D-R4SU/KR4SU

EU01 P000439340 PC Board Assy Digital,D-R4SC

IC202 P000378050 IC SN74AHC1G04HDCKR

IC203 P000378050 IC SN74AHC1G04HDCKR

IC302 P000416750 IC BA25BC0FP

IC303 P000440410 IC MM1573DNRE

IC304 P000391240 IC NJM2125F

IC306 P000378040 IC SN74AHC1G08HDCKR

IC307 79040306 IC PST594JMT

IC315 P000377920 IC SN74LV244APWR

Q301 79050018 Transistor,Chip 2SA1162-Y

Q302 79050018 Transistor,Chip 2SA1162-Y

Q303 79050018 Transistor,Chip 2SA1162-Y

Q304 79050018 Transistor,Chip 2SA1162-Y

Q305 79050018 Transistor,Chip 2SA1162-Y

Q306 79050016 Transistor,Chip 2SC2712-Y

Q307 79050016 Transistor,Chip 2SC2712-Y

Q308 79050018 Transistor,Chip 2SA1162-Y

Q309 79050018 Transistor,Chip 2SA1162-Y

X201 P000440380 Oscillator,Crystal

X302 79089168 Oscillator,Crystal

X303 P000377990 Oscillator,Crystal 27.0M

Part No. Description

- ELECTRICAL PARTS -

- INTEGRATED CIRCUITS -

- TRANSISTORS -

- MISCELLANEOUS -

EU02 P000438620 PC Board Assy Power

!

EU03A P000438660 PC Board Assy Front(R)

- INTEGRATED CIRCUITS -

IC101 P000416700 IC PT6315

- DIODES -

D101 79060019 Diode,Chip 1SS355

- MISCELLANEOUS DS101 P000440490 Display,FL VFD20-0812FN

MT101 P000440420 Module,IR GP1UM261XK0F

S107 P000377940 Switch,Push-Lever

EU03B P000438670 PC Board Assy Front(L)

- MISCELLANEOUS S101 P000391050 Switch,Tact

S102 P000391050 Switch,Tact

S103 P000391050 Switch,Tact

S104 P000391050 Switch,Tact

S105 P000391050 Switch,Tact

S106 P000391050 Switch,Tact

S108 P000391050 Switch,Tact

S109 P000391050 Switch,Tact

S110 P000391050 Switch,Tact

S112 P000391050 Switch,Tact

EU05 P000438650 PC Board Assy Mother

- INTEGRATED CIRCUITS IC701 P000391180 IC PST3222NR

IC702 P000391150 IC DC74HCT125M

IC901 P000440480 IC PCM1755DBQR

IC902 P000440510 IC RC4580IDR

IC903 P000416650 IC,Terminal,OPT LAF1001-0301F

IC906 79040397 IC MM1575ANRE

Page 20

Location

No.

ICB10 P000440500 IC XC6209F502PR

ICW01 P000391260 IC MM1568DJBEG

ICX03 79040382 IC MM1140XFFE

ICX04 79040369 IC MM1113XFBE

ICX05 P000440500 IC XC6209F502PR

ICX31 79040371 IC BA7046F

ICX32 P000363370 IC NJM2330MV

Q901 79050014 Transistor,Chip HN1C03F

Q902 79050014 Transistor,Chip HN1C03F

Q904 79050001 Transistor,Chip RN2402

Q905 79050100 Transistor,Chip RN1402

Q906 79050001 Transistor,Chip RN2402

Q907 79050100 Transistor,Chip RN1402

Q908 79050100 Transistor,Chip RN1402

QB08 79050016 Transistor,Chip 2SC2712-Y

QW02 79050100 Transistor,Chip RN1402

QW03 79050018 Transistor,Chip 2SA1162-Y

QW04 79050018 Transistor,Chip 2SA1162-Y

QX06 79050018 Transistor,Chip 2SA1162-Y

QX09 79050018 Transistor,Chip 2SA1162-Y

QX31 79050016 Transistor,Chip 2SC2712-Y

QX32 79050100 Transistor,Chip RN1402

QX33 P000440390 Transistor,Chip RN1404

D702 79060028 Diode,Chip 1SS226

D901 79060019 Diode,Chip 1SS355

D902 79060019 Diode,Chip 1SS355

J901 P000440440 Jack,RCA MSD-244V-09

JW01 P000440450 Jack,RCA MSP-801V1-02-01-B

JW02 P000440460 Jack,RCA MSD-243V-18

JX01 P000440470 Jack,RCA MSP-830V-07

X700 P000391040 Oscillator,Crystal 12.5MHz

X701 P000363400 Oscillator,Crystal 32.768kHz

Part No. Description

- TRANSISTORS -

- DIODES -

- MISCELLANEOUS -

EU05A P000438680 PC Board Assy Tuner

- MISCELLANEOUS MB01 P000440520 Tuner 115-V-JA45AT

!

EU55 P000438690 PC Board Assy Front Jack

- MISCELLANEOUS J170 P000387300 Jack,DV

J171 P000402780 Jack,3P+1Y/C

EU56 P000438700 PC Board Assy Front(LED)

- DIODES D110 P000440400 Diode,LED SLR343BBT3F

D111 P000440400 Diode,LED SLR343BBT3F

Page 21

SPECIFICATIONS

Power requirement during operation

Power requirement at standby

Power supply

Mass

External dimension

Incoming channels

Antenna input/output terminal

Signal system

Laser

Format

Image recording system

Sound recording system

VIDEO input

VIDEO output

S-VIDEO input

S-VIDEO output

COMPONENT output(Y, PB, PR)

AUDIO input

AUDIO output

DIGITAL AUDIO OUTPUT BITSTREAM/PCM

(OPTICAL terminal)

Remote control

Operating conditions

Clock display

Clock accuracy

• The design and specifications may change without prior notice.

• The Illustrations and screens described in this manual may be exaggerated or simplified for easy recognition and may be slightly different from the actual unit.

21W

2.7W

120V AC, 60 Hz

3.5kg

Width 430 x Height 58 x Depth 304mm

TV : 2-69CH, Cable : 1-125CH

VHF/UHF : 75W, F Connector

Standard NTSC Color TV system

Semiconductor laser, Wavelength : 650nm/780nm

DVD -VR format

DVD-Video format

MPEG2

Dolby Digital M1

1.0Vp-p (75W), Sync signal negative, Pin jack x 2 systems, 1 at rear, 1 in front

1.0Vp-p (75W), Sync signal negative, Pin jack x 1 system, 1 at rear

(Y) 1.0Vp-p (75W), Sync signal negative,

(C) 0.286Vp-p (75W) 1 at rear, 1 in front

Mini DIN4 Pin x 2 systems

(Y) 1.0Vp-p (75W), Sync signal negative,

(C) 0.286Vp-p (75W) 1 at rear

Mini DIN4 Pin x 1 system

Y output (green), 1.0Vp-p (75W), Sync signal negative, Pin jack x 1 system

PB, PR output (blue, red), 0.7Vp-p (75W), Pin jack x 1 system each

2.0V (rms), 22kW or above, pin jack (L, R) x 2 systems

1 at rear, 1 in front

2.0V (rms), 2.2kW or below, pin jack (L, R) x 1 system

1 at rear

Optical connector x 1 system

Wireless remote control (SE-R0176)

Temperature: 41°F~95°F (5°C~35°C)

Position: Horizontal

12 hour digital display

Quartz (monthly deviation: approximately ±30 seconds)

Page 22

TOSHIBA CORPORATION

1-1, SHIBAURA 1-CHOME, MINATO-KU, TOKYO 105-8001, JAPAN

Loading...

Loading...