SERVICE MANUAL

DIGITAL PLAIN PAPER COPIER

e-STUDIO550/650/810

(DP-5510/6510/8110)

File No.31100202

2002-06

Copyright 2002

TOSHIBA TEC CORPORATION

GENERAL PRECAUTIONS REGARDING THE INSTALLATION AND SERVICE FOR THE COPIER e-STUDIO550/650/810

The installation and service should be done by a qualified service technician.

1. Transportation/Installation

• When transporting/installing the copier, move it by the casters while lifting the stoppers.

The copier is quite heavy and weighs approximately 200 kg (441 lb), therefore pay full attention

when handling it.

• Be sure to use a dedicated outlet with AC 115V or 120V/20A (220V, 230V, 240V/10A) or more

for its power source.

• The copier must be grounded for safety.

Never ground it to a gas pipe or a water pipe.

• Select a suitable place for installation.

Avoid excessive heat, high humidity, dust, vibration and direct sunlight.

• Also provide proper ventilation as the copier emits a slight amount of ozone.

• To insure adequate working space for the copying operation, keep a minimum clearance of

80 cm (32”) on the left, 80 cm (32”) on the right and 10 cm (4”) in the rear.

• The socket-outlet shall be installed near the copier and shall be easily accessible.

2. Service of Machines

• Basically, be sure to tur n the main switch off and unplug the power cord during service.

• Be sure not to touch high-temperature sections such as the exposure lamp, the fuser unit, the

damp heater and their periphery.

• Be sure not to touch high-voltage sections such as the chargers, high-voltage transformer,

exposure lamp control inverter, inverter for the LCD bac klight and pow er supply unit. Especially,

the board of these components should not be touched since the electirc charge may remain in

the condensers, etc. on them even after the power is turned OFF.

• Be sure not to touch rotating/operating sections such as gears, belts, pulleys, fan, etc.

• Be careful when removing the covers since there might be the parts with very sharp edges

underneath.

• When servicing the machines with the main switch turned on, be sure not to touch live sections

and rotating/operating sections. Avoid exposure to laser radiation.

• Use suitable measuring instruments and tools.

• Avoid exposure to laser radiation during servicing.

- Avoid direct exposure to the beam.

- Do not insert tools, par ts, etc. that are reflective into the path of the laser beam.

- Remove all watches, rings, bracelets, etc. that are reflective.

3. Main Service Parts for Safety

• The breaker , door switch, fuse, thermostat, thermofuse, thermistor, etc. are particularly important

for safety. Be sure to handle/install them properly. If these parts are shorted circuit and/or

made their functions out, they may burn down, for instance, and may result in fatal accidents.

Do not allow a short circuit to occur. Do not use the parts not recommended by Toshiba TEC

Corporation.

4. Cautionary Labels

• During servicing, be sure to check the rating plate and the cautionary labels such as “Unplug

the power cord during service”, “Hot area”, “Laser warning label” etc. to see if there is any dir t

on their surface and whether they are properly stuck to the copier.

5. Disposition of Consumable Parts, Packing Materials, Used batteries and RAM-ICs

• Regarding the recovery and disposal of the copier, supplies , consumable parts, packing materials,

used batteries and RAM-ICs including litium batteries, it is recommended to follow the relevant

local regulations or rules.

6. When parts are disassembled, reassembly is basically the reverse of disassembly unless

otherwise noted in this manual or other related documents. Be careful not to reassemble

small parts such as screws, washers, pins, E-rings, star washers in the wrong places.

7. Basically, the machine should not be operated with any parts removed or disassembled.

8. Precautions Against Static Electricity

• The PC board must be stored in an anti-electrostatic bag and handled carefully using a wrist-

band, because the ICs on it may become damaged due to static electricity.

Caution: Before using the wristband, pull out the power cord plug of the copier and

make sure that there are no uninsulated charged objects in the vicinity.

Caution : Dispose of used batteries and RAM-ICs including lithium batter-

ies according to this manual.

Attention : Se débarrasser de batteries et RAM-ICs usés y compris les batteries

en lithium selon ce manuel.

Vorsicht : Entsorgung des gebrauchten Batterien und R A M -ICs (inklusive

der Lithium-Batterie) nach diesem Handbuch.

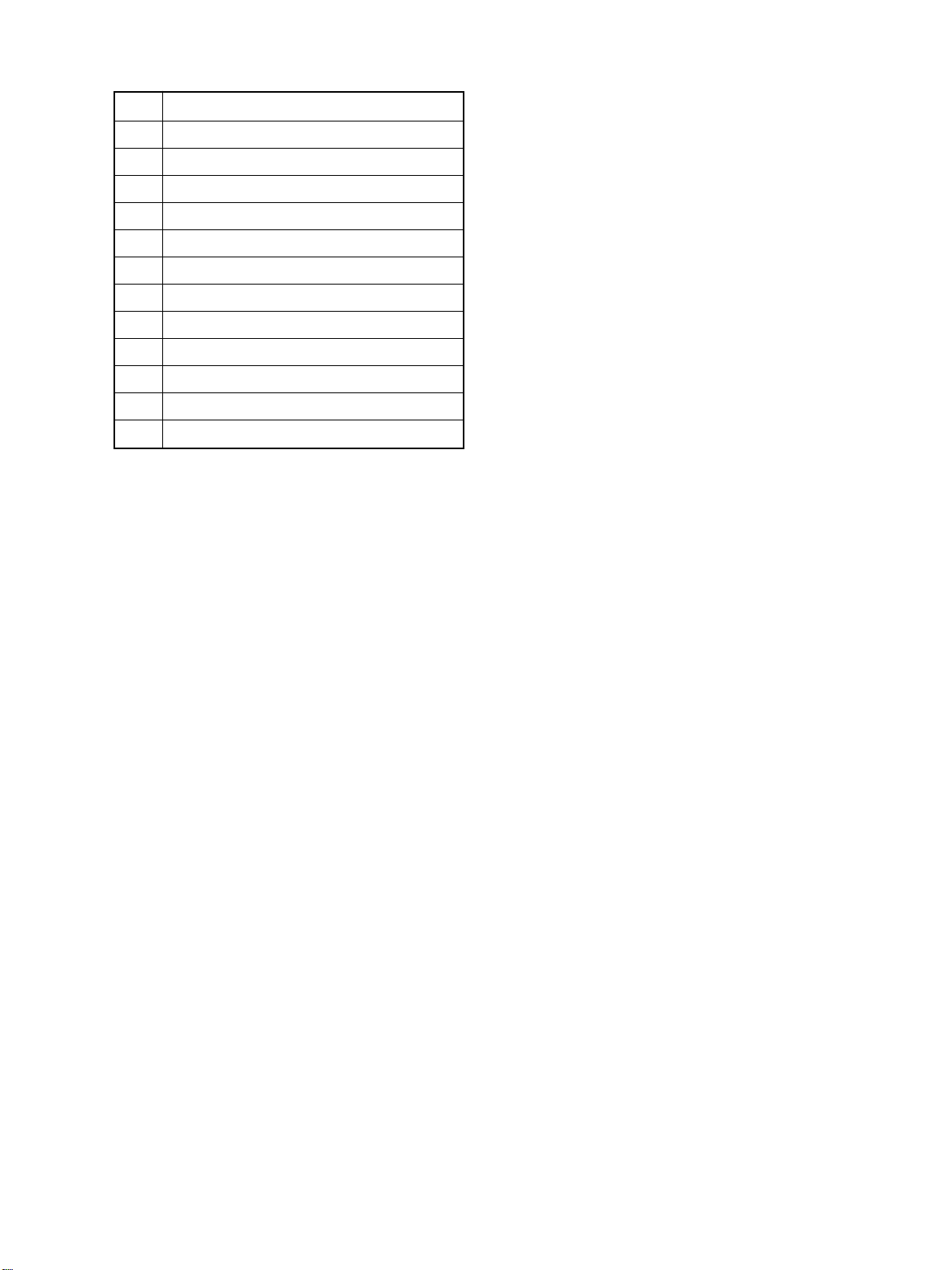

1. SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1. 1 . Specifications

1. 2 . Accessories

1. 3. Options

1. 4. Supplies

1. 5. System List

1. SPECIFICATIONS / A CCESSORIES / OPTIONS / SUPPLIES

1. 1. Specifications

When the specification is different among e-STUDIO550, 650 and 810, the value for e-STUDIO650 is

shown by [ ] and the value for e-STUDIO810 is shown by { }.

• Copy process ...............Indirect electrophotographic process (dry system)

• Type ..............................Console type

• Original table ................Fixed type (left rear corner used as a guide to place originals)

• Acceptable originals .....Sheets, books and 3-dimensional objects

The automatic document feeder only accepts paper (single-sided originals:

50~127g/m2/13~34Ib.Bond, double-sided originals: 50~104g/m2/13~28Ib.Bond)

excluding carbon paper , pasted sheet and stapled sheet.

Maximum size : A3/LD

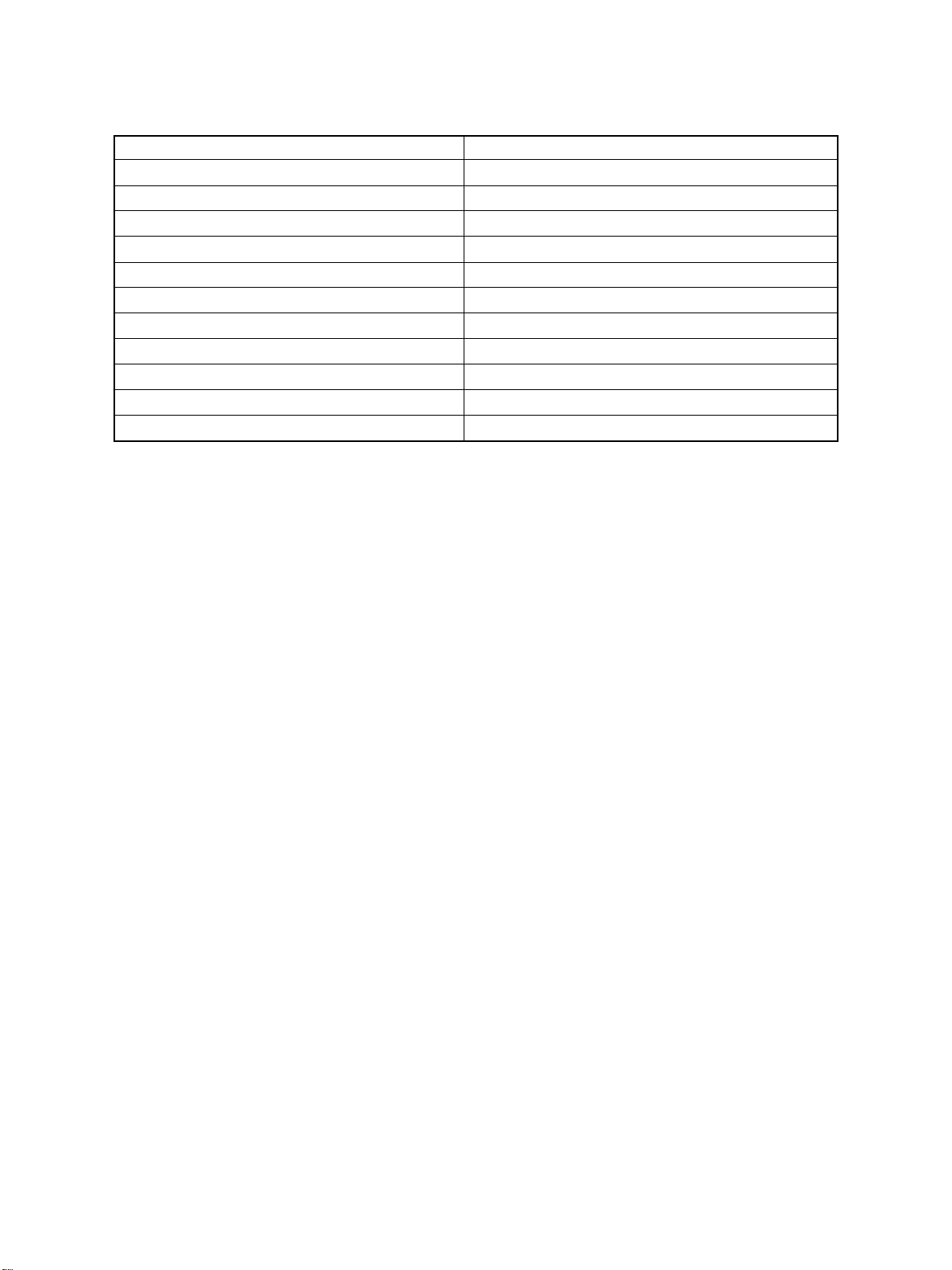

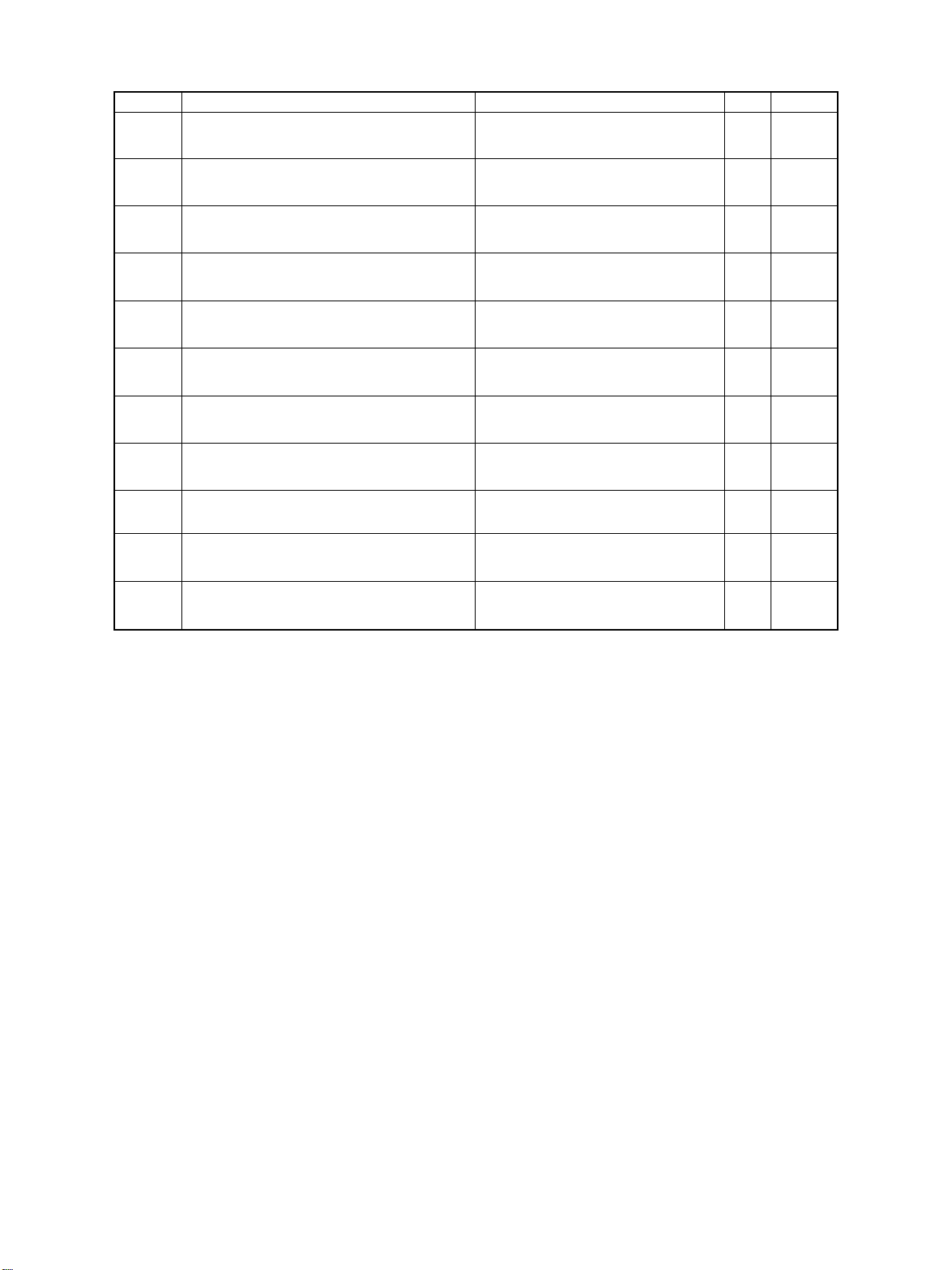

• Copy speed

e-STUDIO550 (Copies/min.)

Paper supply Tandem

Paper size Size specified Size not specified

A4, LT, B5

A4-R, B5-R,

A5-R, L T-R, ST-R

B4, LG

A3, LD

T op side discharging

Back side discharging

T op side discharging

Back side discharging

T op side discharging

Back side discharging

T op side discharging

Back side discharging

Cassette

55 55 48 33

55 55 48 30

44 — 42 33

42 — 42 30

39 — 37 33

35 — 35 30

34 — 33 33

30 — 30 30

LCF

Bypass feeding

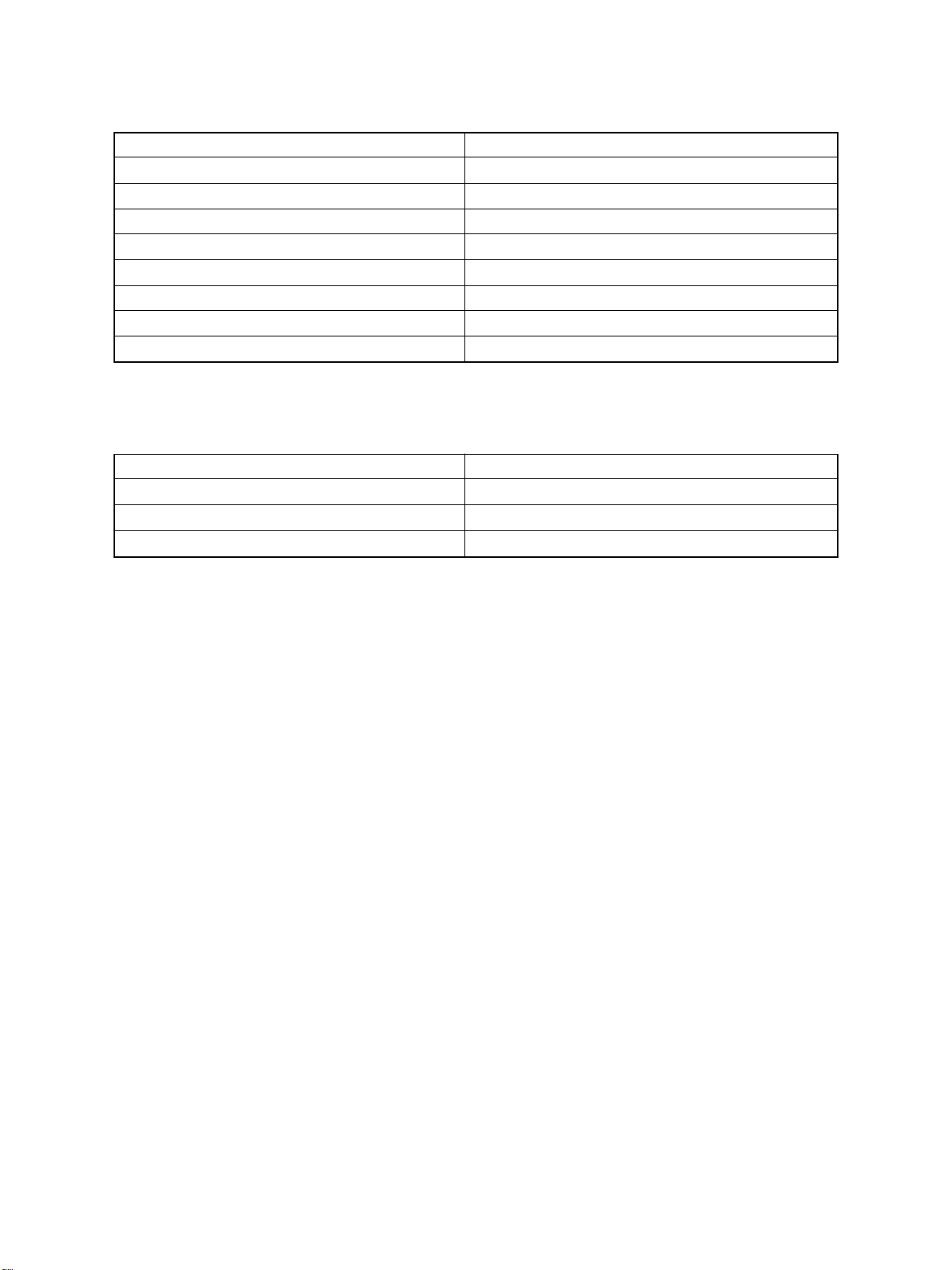

e-STUDIO650

Paper supply Tandem

Paper size Size specified Size not specified

A4, LT, B5

A4-R, B5-R,

A5-R, L T-R, ST-R

B4, LG

A3, LD

JUNE 2002 © TOSHIBA TEC 1 - 1 e-STUDIO550/650/810 SPECIFICATIONS

T op side discharging

Back side discharging

T op side discharging

Back side discharging

T op side discharging

Back side discharging

T op side discharging

Back side discharging

Cassette

65 65 48 33

65 65 48 33

50 — 42 33

48 — 42 33

43 — 37 33

40 — 37 33

37 — 33 33

34 — 33 33

LCF

Bypass feeding

(Copies/min.)

e-STUDIO810

(Copies/min.)

Paper supply

Paper size Size specified Size not specified

A4, LT, B5

A4-R, B5-R,

A5-R, L T-R, ST-R

B4, LG

A3, LD

“–” means “Not acceptable”.

*

Each copy speed described in the table of the previous page is available when doing a multiple copying

*

of the manually placed single-sided originals, and in this mode, only the top side discharging is carried

out.

When using the automatic document f eeder, each copy speed of 55 [65] {81} copies/min. is a vailable

*

only when the following conditions are met:

• Original/Mode : Single-sided original, A4/LT size, 1 sheet/APS and automatic

• Preset number of sheets: 55 [65] {81} or more.

• Reproduction ratio : 100%

T op side discharging

Back side discharging

T op side discharging

Back side discharging

T op side discharging

Back side discharging

T op side discharging

Back side discharging

Cassette

81 81 50 34

81 81 50 34

61 — 44 34

56 — 44 34

52 — 39 34

45 — 39 34

43 — 34 34

37 — 34 34

density are not selected.

Tandem

LCF

Bypass feeding

System copy speed

*

Copy mode

e-STUDIO e-STUDIO e-STUDIO

550 650 810

Single-sided originals 1 set 18"86 16"81 15"96

훹 3 sets 40"17 35"99 30"52

Single-sided copies 5 sets 61"92 53"56 45"19

Single-sided originals 1 set 21"28 20"70 20"46

훹 3 sets 42"91 39"47 36"37

Double-sided copies 5 sets 64"89 57"70 49"48

Double-sided originals 1 set 35"32 35"21 34"36

훹 3 sets 78"61 71"70 63"89

Double-sided copies 5 sets 121"96 108"01 95"06

Double-sided originals 1 set 31"77 31"49 30"88

훹 3 sets 74"75 67"97 60"58

Single-sided copies 5 sets 117"88 104"64 90"02

e-STUDIO550/650/810 SPECIFICATIONS 1 - 2 JUNE 2002 © TOSHIBA TEC

sec.

System copy speed, including

*

scanning time, is available when 10

sheets of A4-sized original are set

on RADF and one of the copy modes

in the left table is selected.

1st cassette is selected and copying

*

is at the sort mode.

Finisher, hole-punch unit and inserter

*

are installed.

Measurement deviation is included

*

since the system copy speed was

measured by actual measurement.

• Copy paper

Cassette Duplex copy LCF Bypass copy Remarks

Size A3~A5R, A4, LT A3~A5-R, LD~ST-R, No guarantee for 8K,

LD~ST-R, 13"LG, 8.5"x8.5", 8.5"x8.5", 8K, 16K, 16K-R 16K, 16K-R at duplex

8K, 16K, 16K-R

(Non-standard or user-

copy

specified sizes can be set.)

Weight 64~209g/m2, 17~110lb. -inde x 64~209g/m

2

17Ib~110Ib -index

Special Tab paper _

paper

(2nd casette only) OHP film (thickness: should be recommanded

T racing paper , labels, Special types of paper

80µm or thicker), tab paper by T oshiba.

• First copy time ..................3.3 seconds or less (A4/LT , LCF, 100%, original placed manually)

• Warming-up time ................Approx.160 seconds (e-STUDIO550/650/810, Temperature: 20°C)

Notes: 1. This is at the condition not entering the toner supply operation.

2. The auto job start is not operated.

• Multiple copying.................Up to 9999 copies; set number entered with digital keys

• Reproduction ratio..............Actual ratio: 100±0.5%

Zooming: 25~400% in increments of 1%

(25~200% when using the RADF)

• Resolution/Gradation ......... Read: 600 dpi

.........Write: Equivalent to 2400 dpi x 600 dpi

(primary scanning only : 4 division smoothing)

• Eliminated image width......Leading edge: 3.0±1.0 mm, Trailig edge: 2.0±1.0 mm, Side edges: 2.0±2.0 mm

• P aper f eeding.....................Automatic feeding: Copier cassettes–2 cassettes (Paper stac k height

55 mm, equivalent to 550 sheets; 64 to 80 g/m2 (17

to 22 lb.Bond))

LCF (Paper stac k height 137 mm: equiv alent to 2500

sheets; 64 to 80 g/m2, 17 to 22 lb.Bond)

Bypass feeding: (Paper stac k height 11 mm : equivalent to 100 sheets;

64 to 80 g/m2, 17 to 22 lb.Bond)

• Capacity of originals in the automatic document feeder

.................A3~A5-R, LD~ST-R

: 100 sheets

• Automatic duplexer............Stackless, Switchback type

• Toner supplying..................Automatic toner density detection/supply

T oner cartridge replacing method

(There is a recycle toner supplying system.)

JUNE 2002 © TOSHIBA TEC 1 - 3 e-STUDIO550/650/810 SPECIFICATIONS

• Density control ..................Automatic density mode and manual density mode selectable in 11 steps

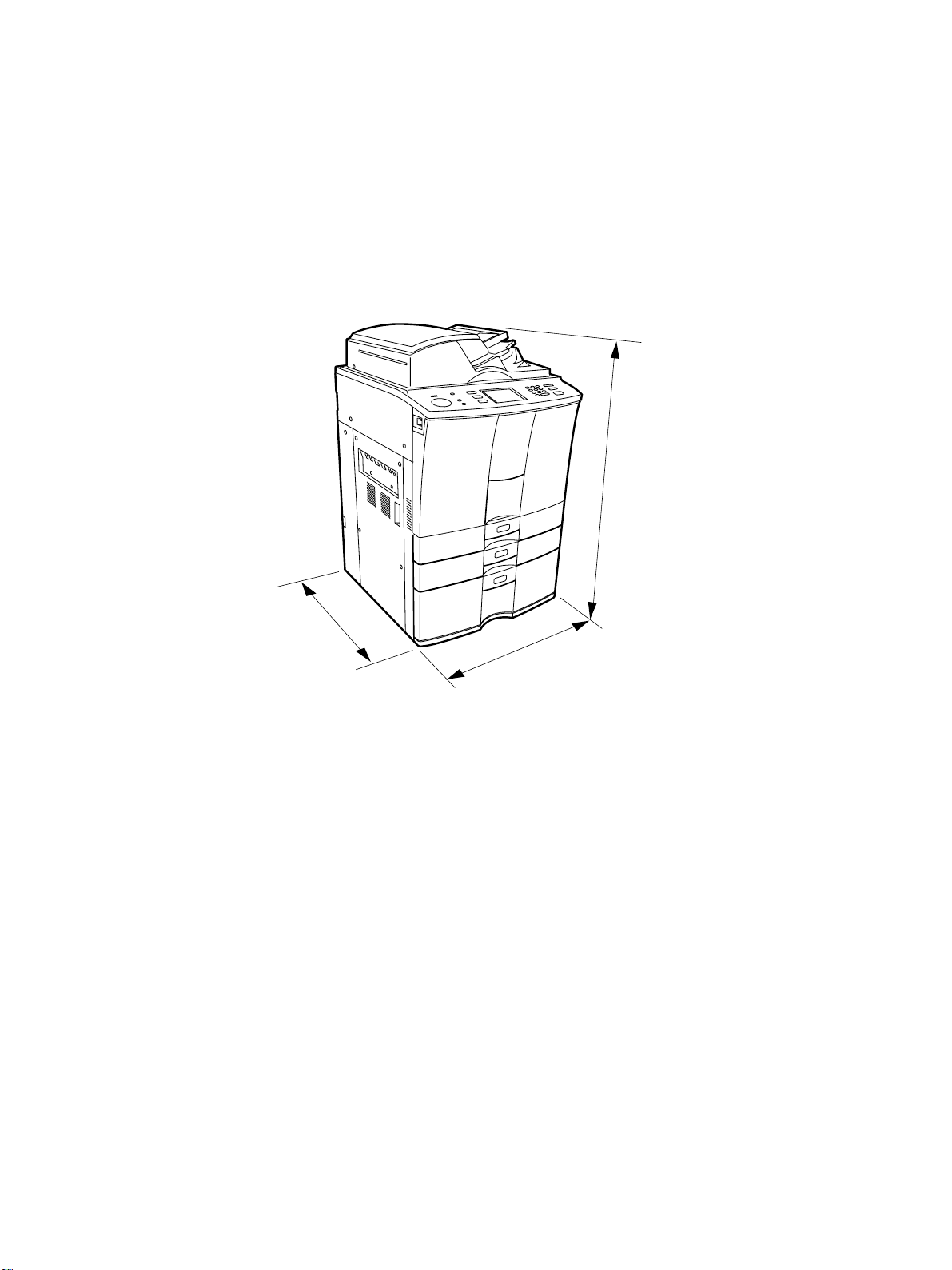

• Weight ............................... Approx. 200kg, 441lb

• P ow er requirements ........... AC 115V/15A, AC 220 – 240V/10A

• Power consumption ...........2.0 kW or less (115V series, 200V series)

The electric power is supplied to the finisher and external LCF (optional) through the copier .

*

• T otal counter ......................Electronic counter

• Dimensions of the copier ... See the figure below . (W698x D778 x H1207 mm)

1207 mm

778 mm

698 mm

e-STUDIO550/650/810 SPECIFICATIONS 1 - 4 JUNE 2002 © TOSHIBA TEC

1. 2. Accessories

Unpacking/setup instruction 1 pc.

Operator’s Manu al 1 pc. (not available for MJD)

PM sticker 1 pc. (for MJD)

Setup report 1 set. (for NAD and MJD)

Customer satisfaction card 1 pc. (for MJD)

Operator’s Manual pocket 1 pc.

P ow er cable 1 pc. (for ASD, AUD and MJD)

Warr anty sheet 1 pc. (for NAD)

Drum 1 pc.

Drum cover 1 pc.

Original feeding tray 1 pc.

Tab paper end guide 1 pc.

* Machine version

NAD: North America

MJD: Europe

AUD: Australia

ASD: Asia

JUNE 2002 © TOSHIBA TEC 1 - 5 e-STUDIO550/650/810 SPECIFICATIONS

1. 3. Options

Finisher MJ-1017, MJ-1018

Hole punch unit MJ-6003N/E/F/S

Inserter MJ-7001

Staple cartridge STAPLE-600/STAPLE-700 (for saddle stitcher)

External large capacity feeder MP-4003A/L

Key copy counter/Key copy counter socket MU-8/MU-10

Damp heater kit MF-6510U/E

Printer controller GL-1020

Printer board GA-1140

1. 4. Supplies

Drum OD- 6510

Developer material D-6510

T oner PS-ZT6510/PS-ZT6510/PS-ZT -6510D

T oner bag PS-TB6510/PS-TB6510E

e-STUDIO550/650/810 SPECIFICATIONS 1 - 6 JUNE 2002 © TOSHIBA TEC

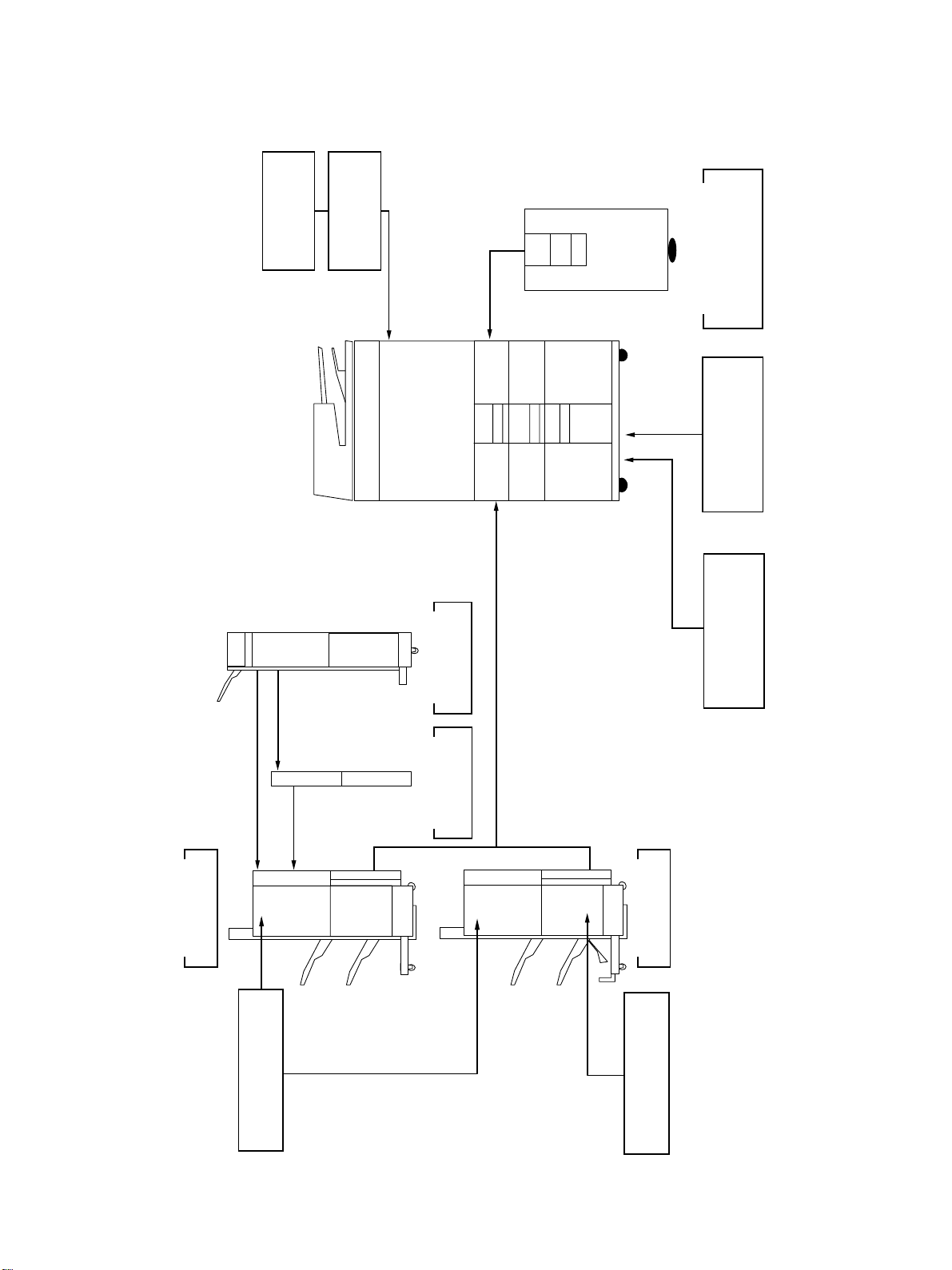

1. 5. System List

Ke y counter

Key counter socke t

MU-10

MU-8

LCF

MP-4003

Printer board

GA-1140

Finisher

MJ-1017

Staple cartridge

STAPLE-600

Inserter

MJ-7001

Hole punch unit

MJ-6003

Finisher

MJ-1018

Staple cartridge

STAPLE-700

Printer controller

GL-1020

JUNE 2002 © TOSHIBA TEC 1 - 7 e-STUDIO550/650/810 SPECIFICATIONS

2. OUTLINE OF THE MACHINE

2. 1. Sectional View

2. 2. Electric Parts Layout

2. 3. Symbols and Functions of Various Components

2. 4. Symbols and Functions of RADF Various Components

2. 5. System Block Layout

2. 6. Disassembly and Replacement of Covers and PC Boards

2. 6 . 1. Covers

2. 6. 2. PC boards

2. OUTLINE OF THE MACHINE

2. 1. Sectional View

[A] Front side vie w

32

33

34

35

36

43

44

37

38

39

45

46

5 6

4

21

3

47 48 49 50

40 41

42

19

17

18

16

30

31

1213

1415

7

10 11

89

20 21

26

272829

51

60

23

22

24

25

52

54

55

53

56

57

58

59

61

62

63

64

69

70

71

JUNE 2002 © TOSHIBA TEC 2 - 1 e-STUDIO550/650/810 OUTLINE OF THE MACHINE

68

65

66

67

1 Exposure lamp

41 Thermostat

2 Reflector

3 Mirror 1

4 Mirror 2

5 Mirror 3

6 Original glass

7 Lens

8 CCD driving PC board

9 Scanner control PC board

10 Drum

11 Drum thermistor

12 Charger wire cleaner

13 Main charger

14 Discharge LED

15 Drum cleaning b lade

16 Drum cleaning brush

17 Drum recov erly blade

18 Image quality sensor

19 Drum separation finger

42 Pressure roller thermistor

43 Exit roller

44 R e verse/e xit s witching gate

45 R e verse path roller 1

46 R e verse path roller 2

47 Transfer roller 1

48 Transfer roller 2

49 Transfer roller 3

50 Transfer roller 4

51 Registr ation roller

52 Bypass tr ansf er roller

53 Bypass separ ation roller

54 Bypass feed roller

55 Bypass pic kup roller

56 Intermiditate transf er roller

57 1st cassette tr ansf er roller

58 1st cassette feed roller

59 1st cassette separ ation roller

21 Upper de v eloper sleev e

22 L ower de v eloper sleev e

(Magnetic roller)

(Magnetic roller

23 Doctor b lade

24 Scattered toner reco v ery roller

25 A uto-toner sensor

26 Transfer belt driv en roller

27 Transfer belt po wer supply roller

28 Transfer belt

29 Transfer belt driv e roller

30 Transfer belt cleaning b lade

31 Transfer belt cleaning brush

32 Cleaning w eb

33 Cleaning w eb pushing roller

34 Fuser roller

35 Separ ation finger

36 Fuser exit roller

37 Pressure roller

38 Cleaning roller (metal)

60 1st cassette pic kup roller

)

61 2nd cassette transfer roller

62 2nd cassette feed roller

63 2nd cassette separ ation roller

64 2nd cassette pic kup roller

65 Tandem LCF transfer roller

66 Tandem LCF feed roller

67 Tandem LCF separation roller

68 Tandem LCF cassette pickup roller

69 1st cassette

70 2nd cassette

71 Tandem LCF tra y

39 Cleaning roller (f elt)

40 Fuser roller thermistor

e-STUDIO550/650/810 OUTLINE OF THE MACHINE 2 - 2 JUNE 2002 © TOSHIBA TEC

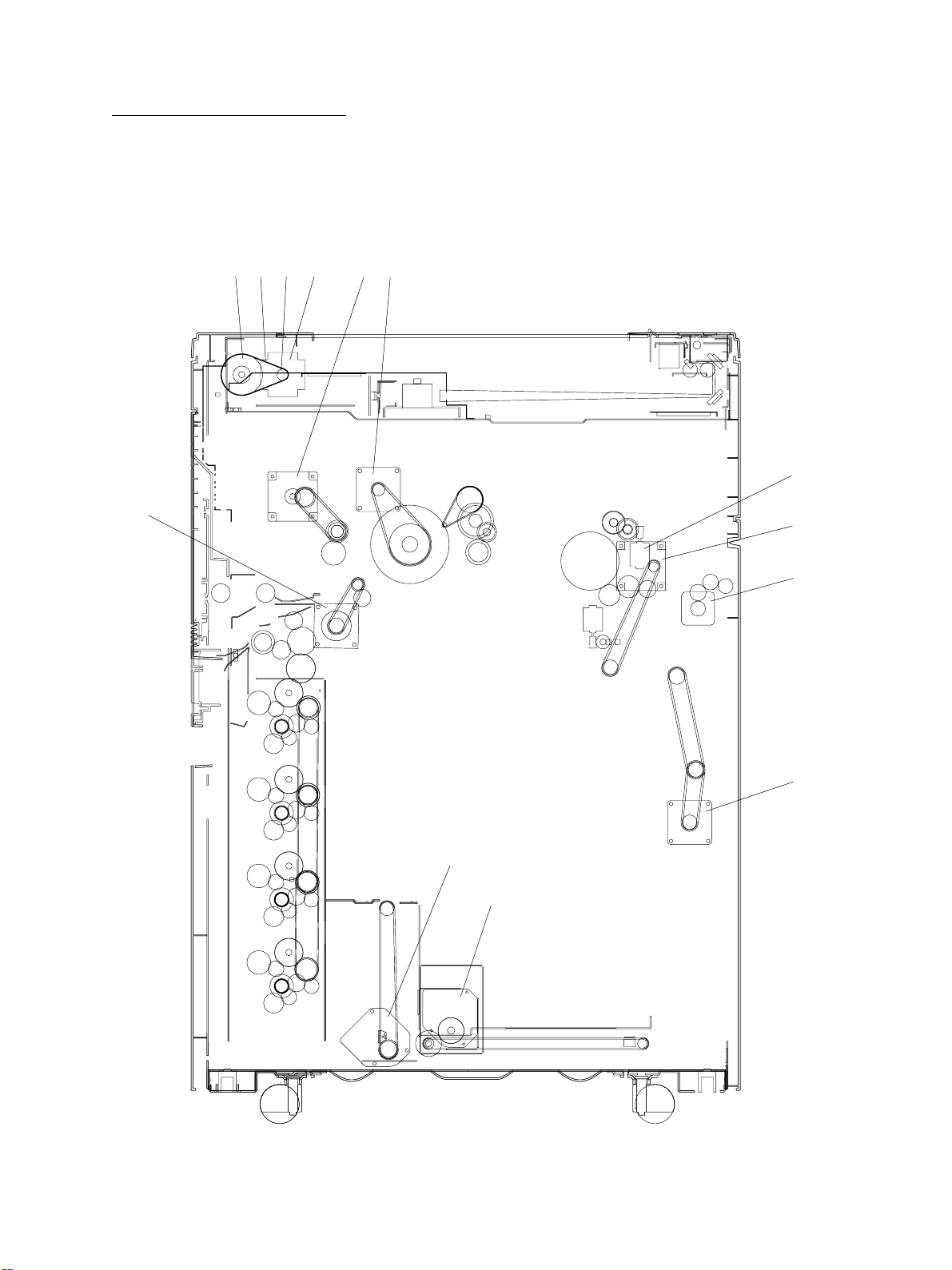

[B] Rear side view (Drive system)

1234

7

65

9

8

10

11

12

13

JUNE 2002 © TOSHIBA TEC 2 - 3 e-STUDIO550/650/810 OUTLINE OF THE MACHINE

1 Scanner motor

2 Drive pulley

3 Drive belt

4 Driven pulley

5 Drum motor

6 Dev eloper unit motor

7 Registration motor

8 Fuser motor

9 Web motor

10 Exit motor

11 R e v erse motor

12 LCF tr ay-up motor

13 LCF end fence motor

e-STUDIO550/650/810 OUTLINE OF THE MACHINE 2 - 4 JUNE 2002 © TOSHIBA TEC

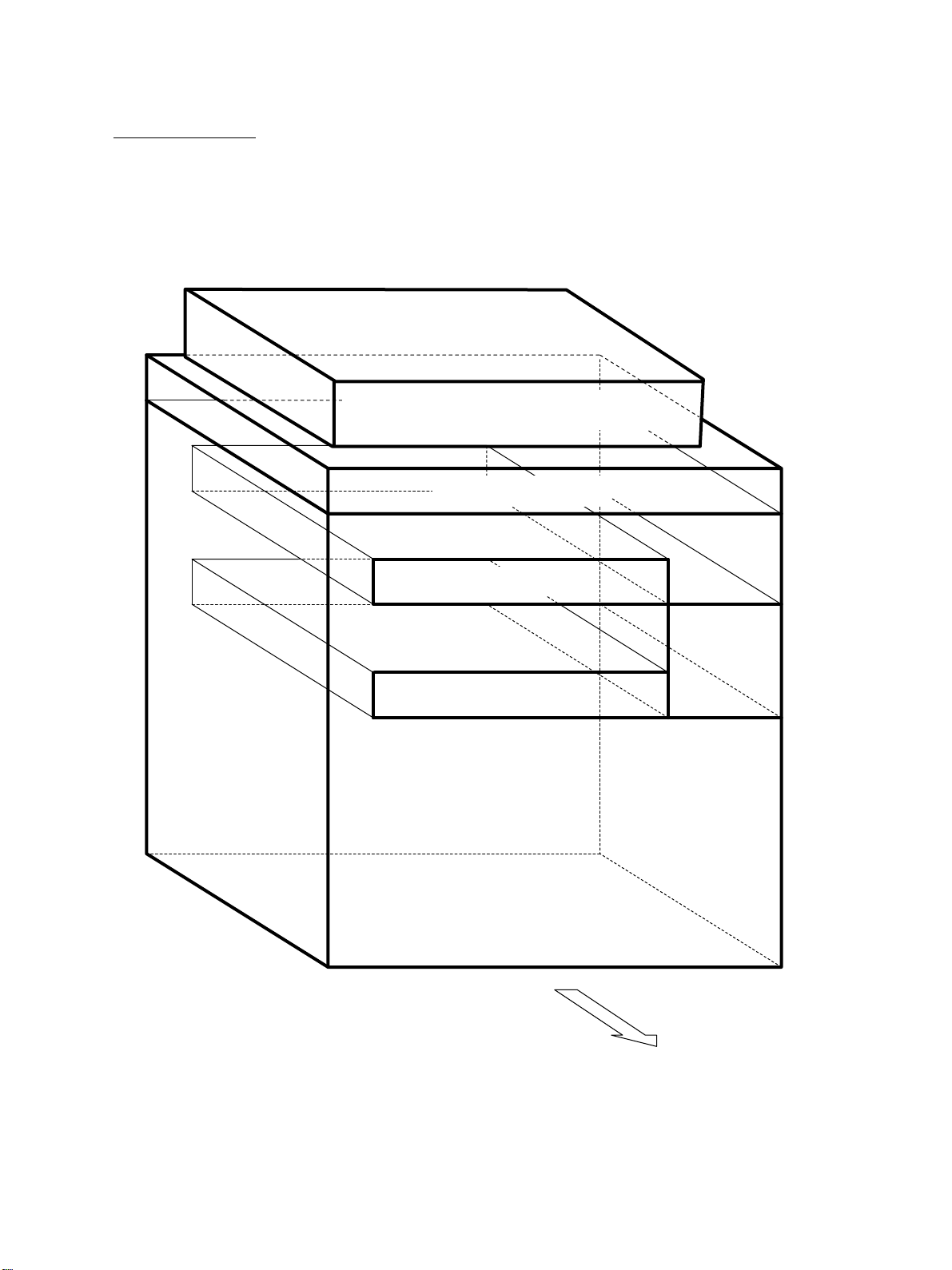

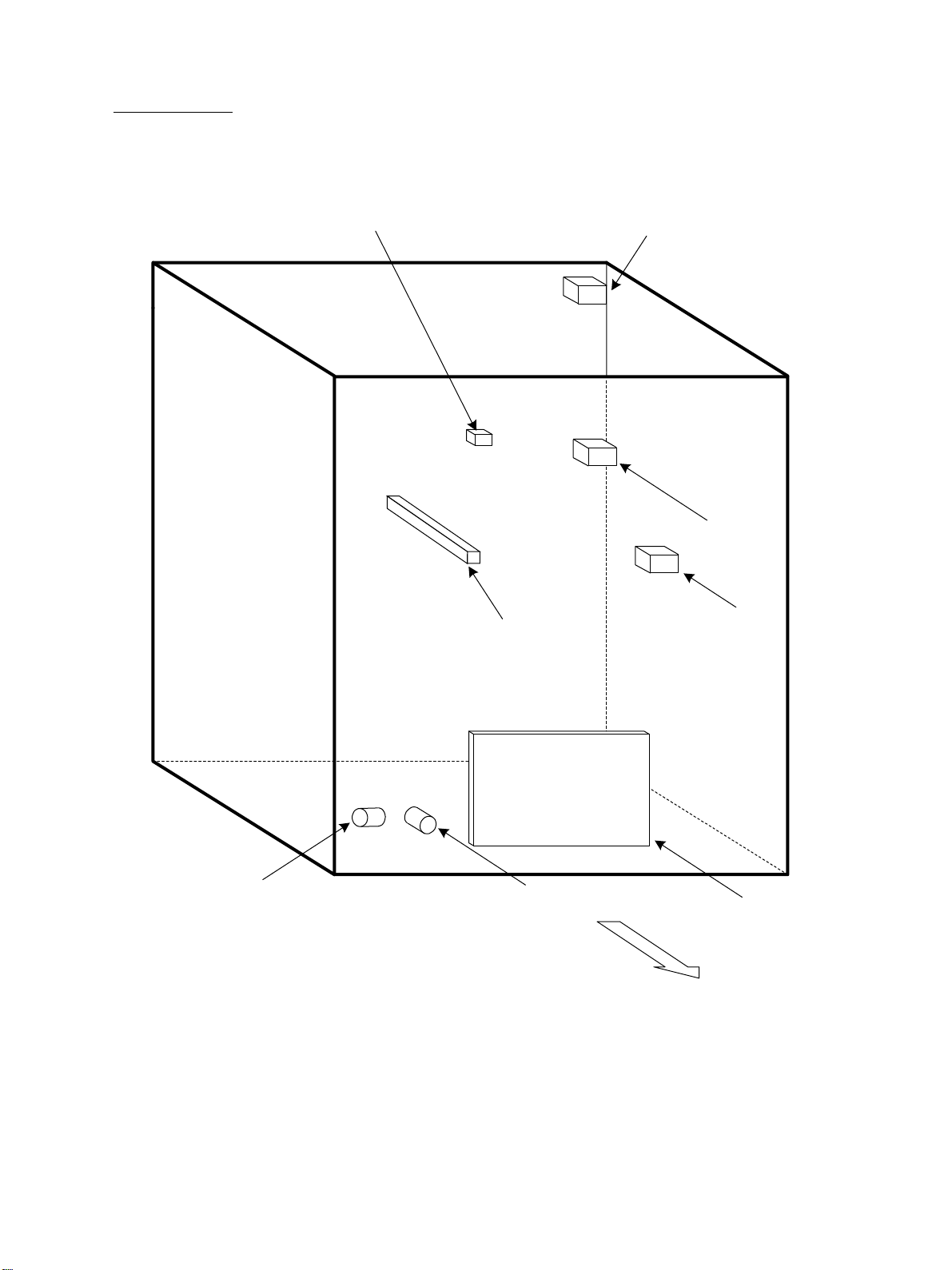

2. 2. Electric Parts Layout

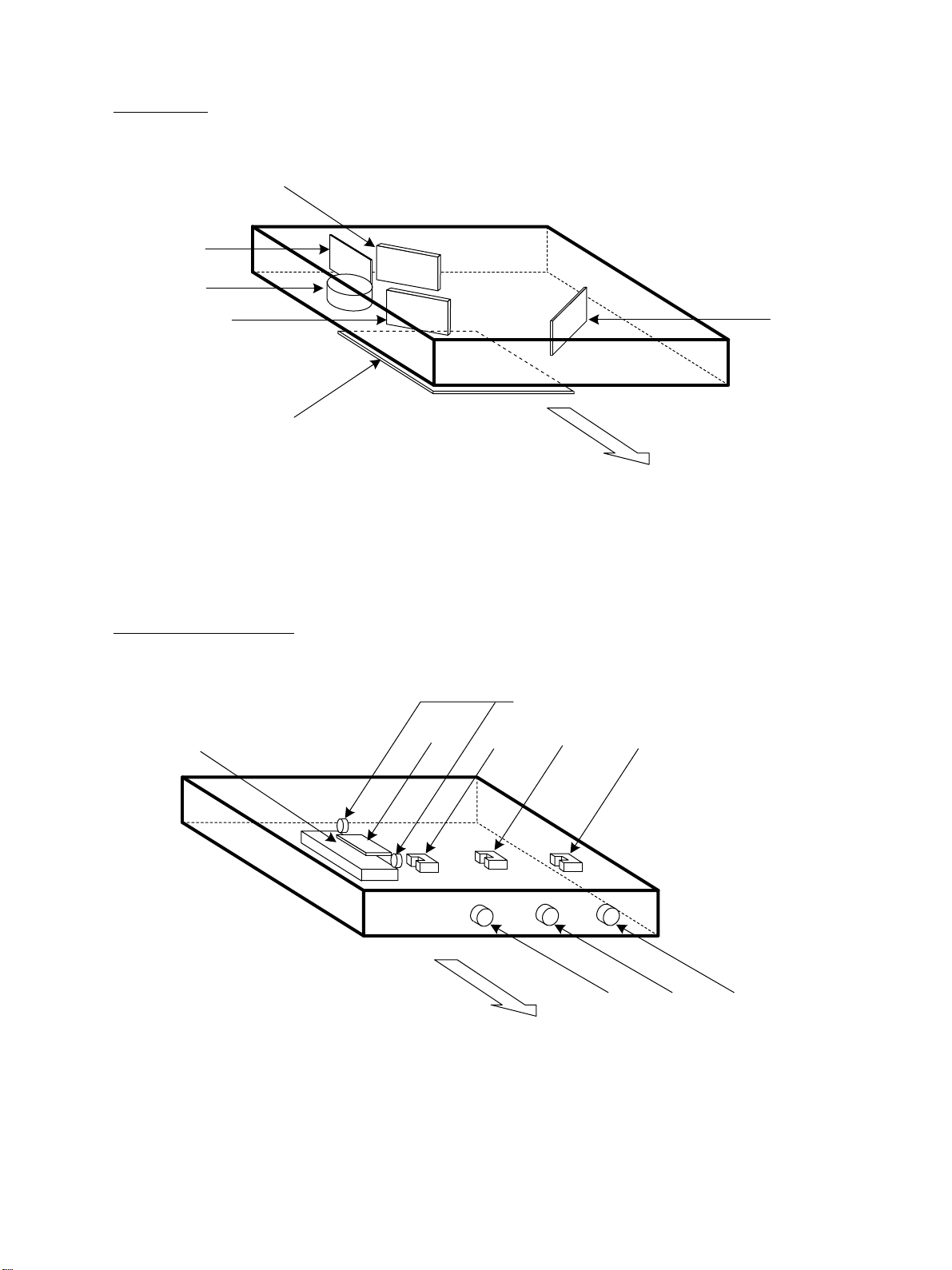

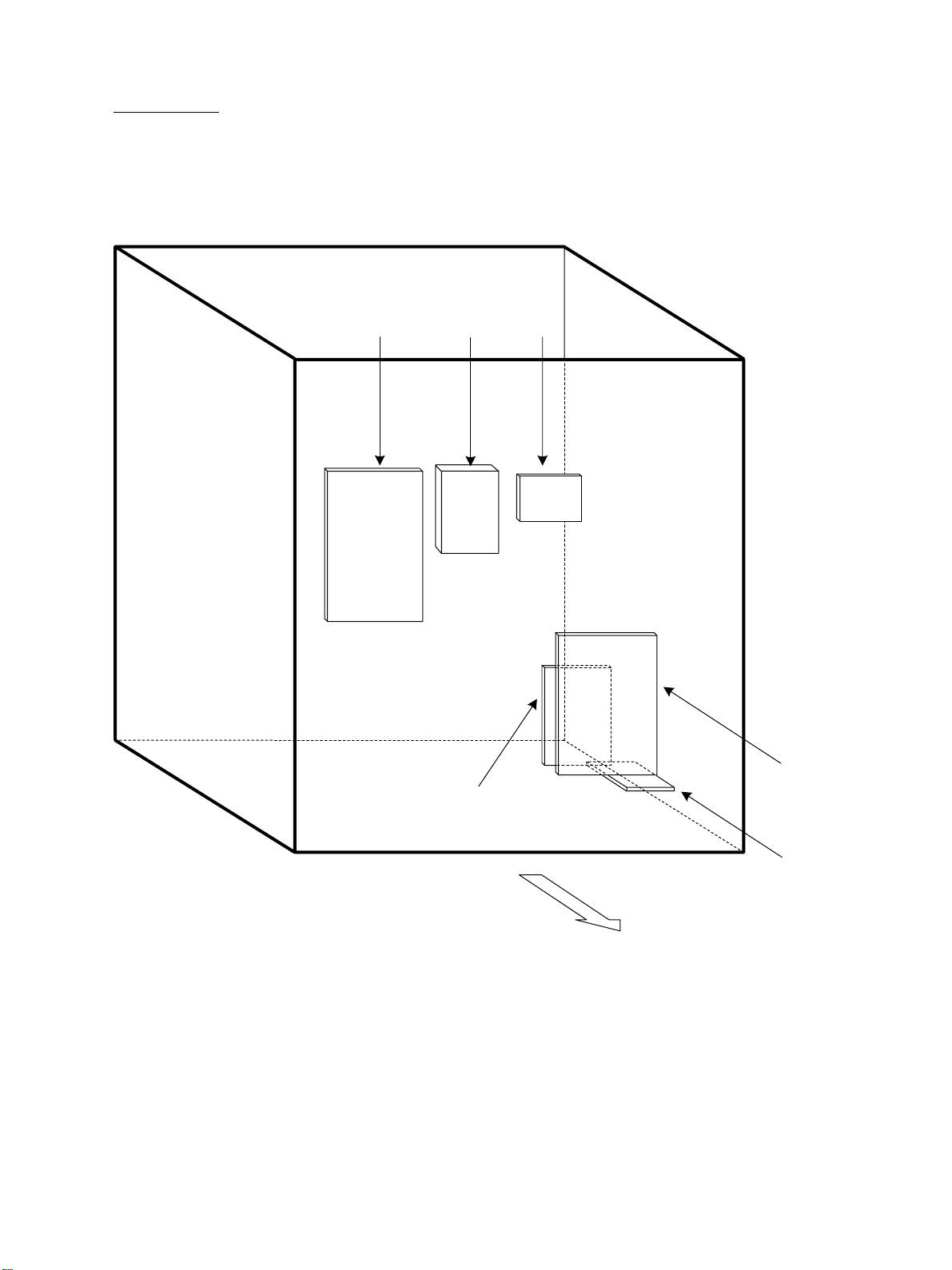

[A] Unit construction

Reversing automatic document f eeder unit

Scanner unit

Laser unit

T r ansfer/Transport unit

Copier unit

Fuser unit

Rear side

JUNE 2002 © TOSHIBA TEC 2 - 5 e-STUDIO550/650/810 OUTLINE OF THE MACHINE

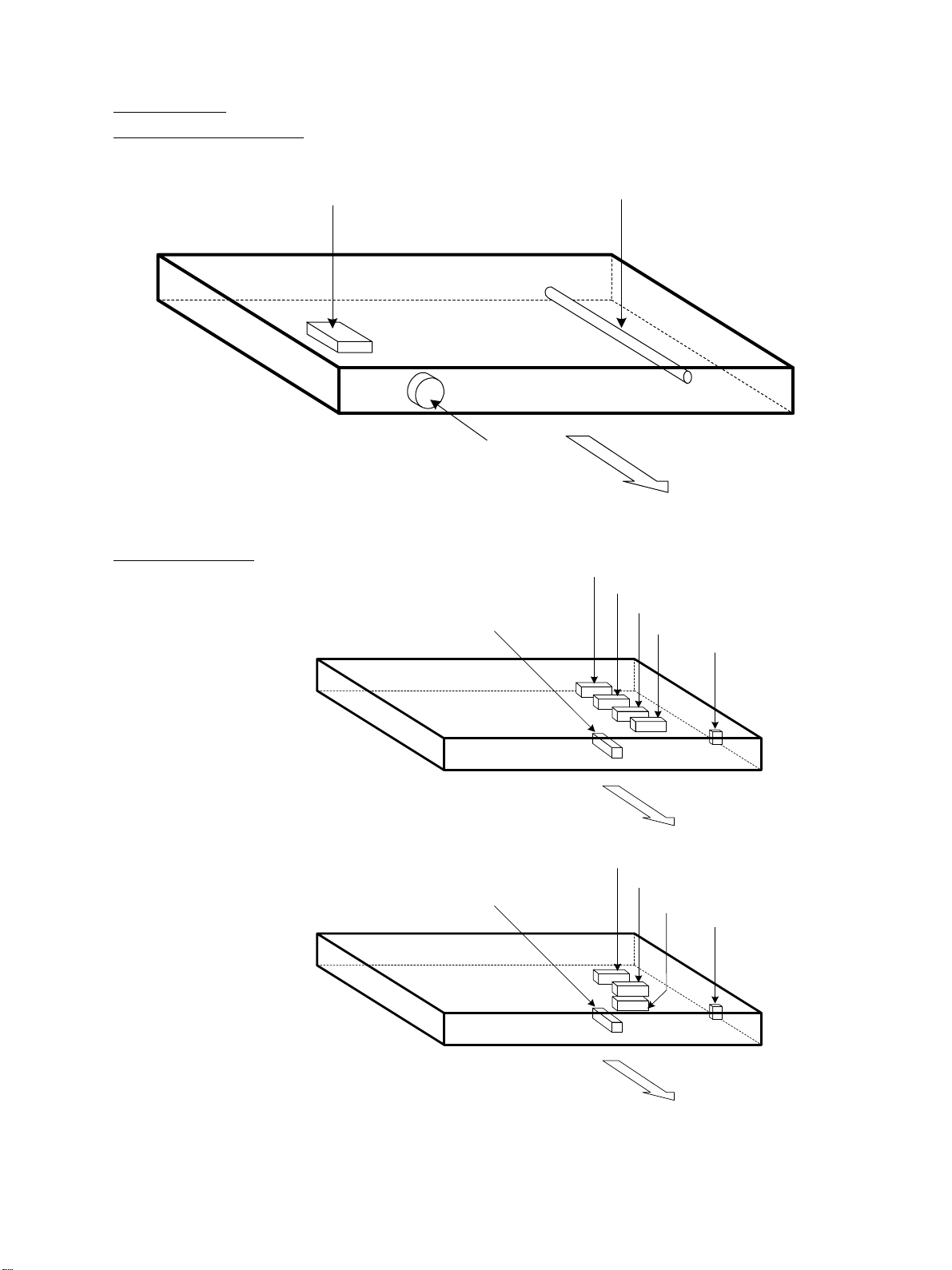

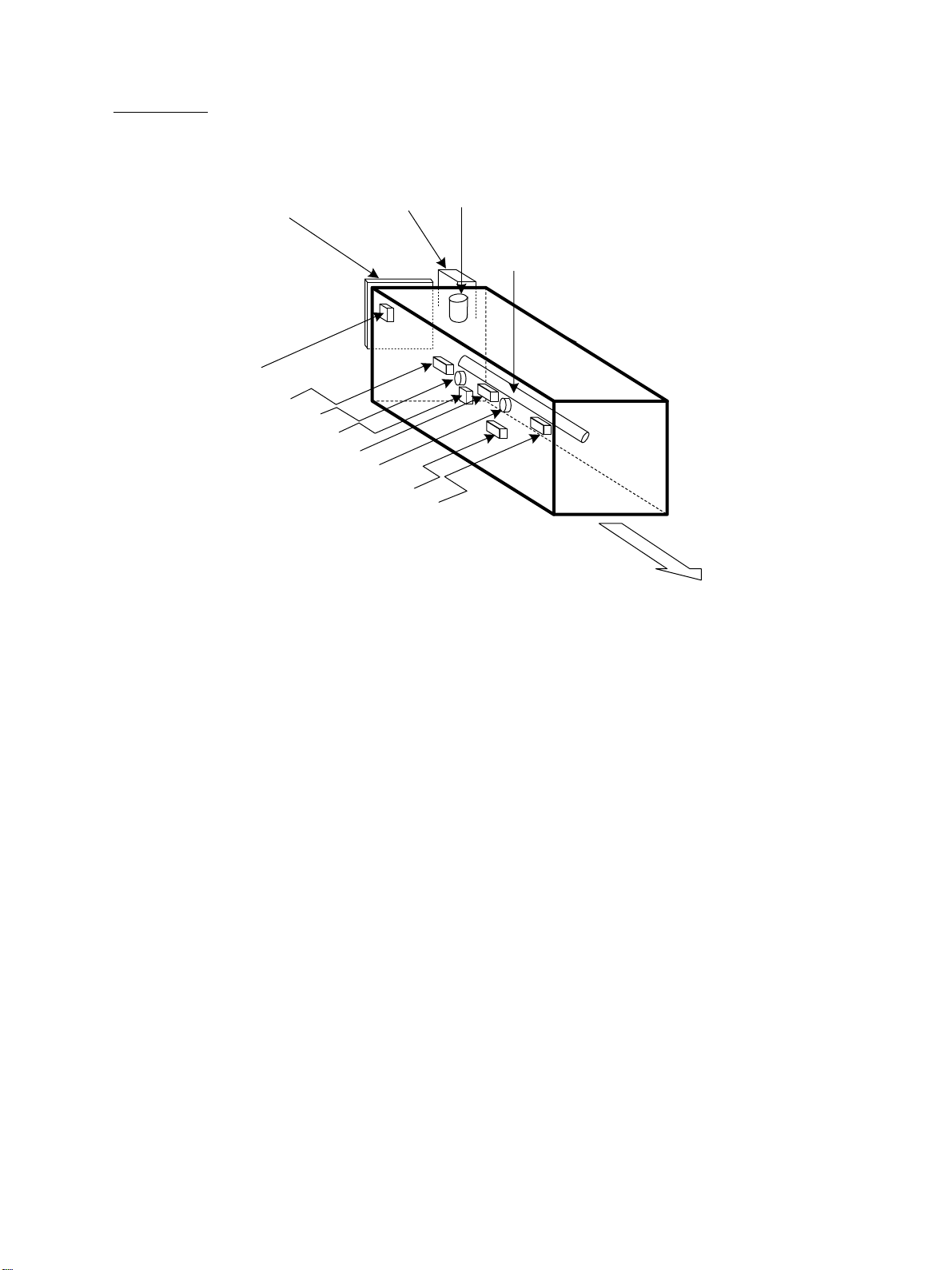

[B] Scanner unit

(B-1) Motor/Exposure lamp

(B-2) Sensor/Switch

A4 series

M31

M1

S1-5

EXP

Rear side

S1-5

S1-5

S1-5

S1-5

S2

Rear side

S1-4

S1-4

LT series

S1-4

S1-4

S2

Rear side

e-STUDIO550/650/810 OUTLINE OF THE MACHINE 2 - 6 JUNE 2002 © TOSHIBA TEC

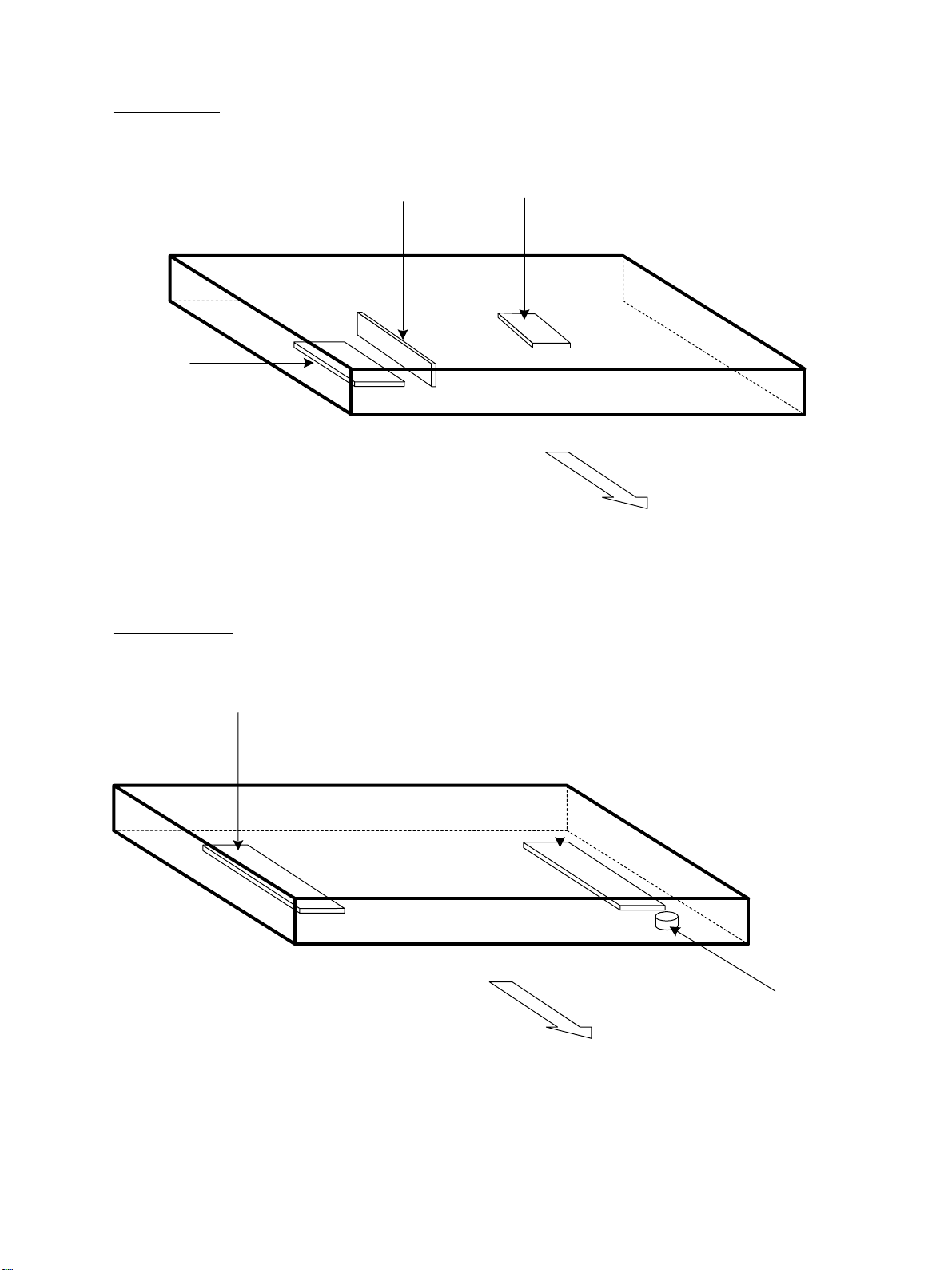

(B-3) PC board

SLG

(B-4) Other parts

CCD

INV

Rear side

DHR

DHL

THMO4

Rear side

JUNE 2002 © TOSHIBA TEC 2 - 7 e-STUDIO550/650/810 OUTLINE OF THE MACHINE

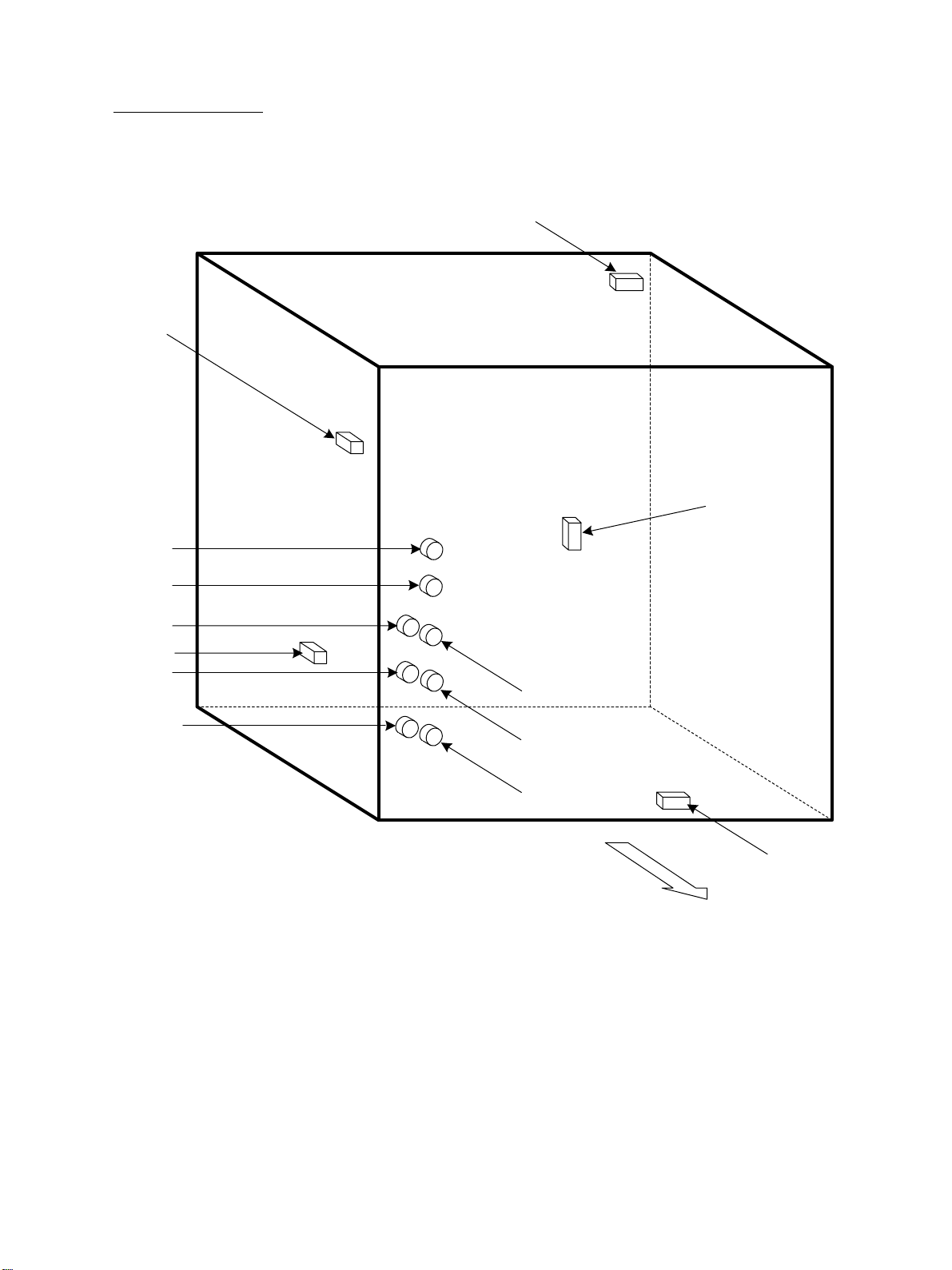

[C] Laser unit

LDR1

M2

GLV

LDR2

PLG

[D] T ransfer/Transport unit

DHT

FUSE

S5

THMO3

S4

SNS

Rear side

S3

CLT3

CLT1CLT2

Rear side

e-STUDIO550/650/810 OUTLINE OF THE MACHINE 2 - 8 JUNE 2002 © TOSHIBA TEC

[E] Fuser unit

S6

THM1

THMO2

IH

S7

THM2

THMO1

M30

THM5

THM3

M3

IHCOIL

Rear side

JUNE 2002 © TOSHIBA TEC 2 - 9 e-STUDIO550/650/810 OUTLINE OF THE MACHINE

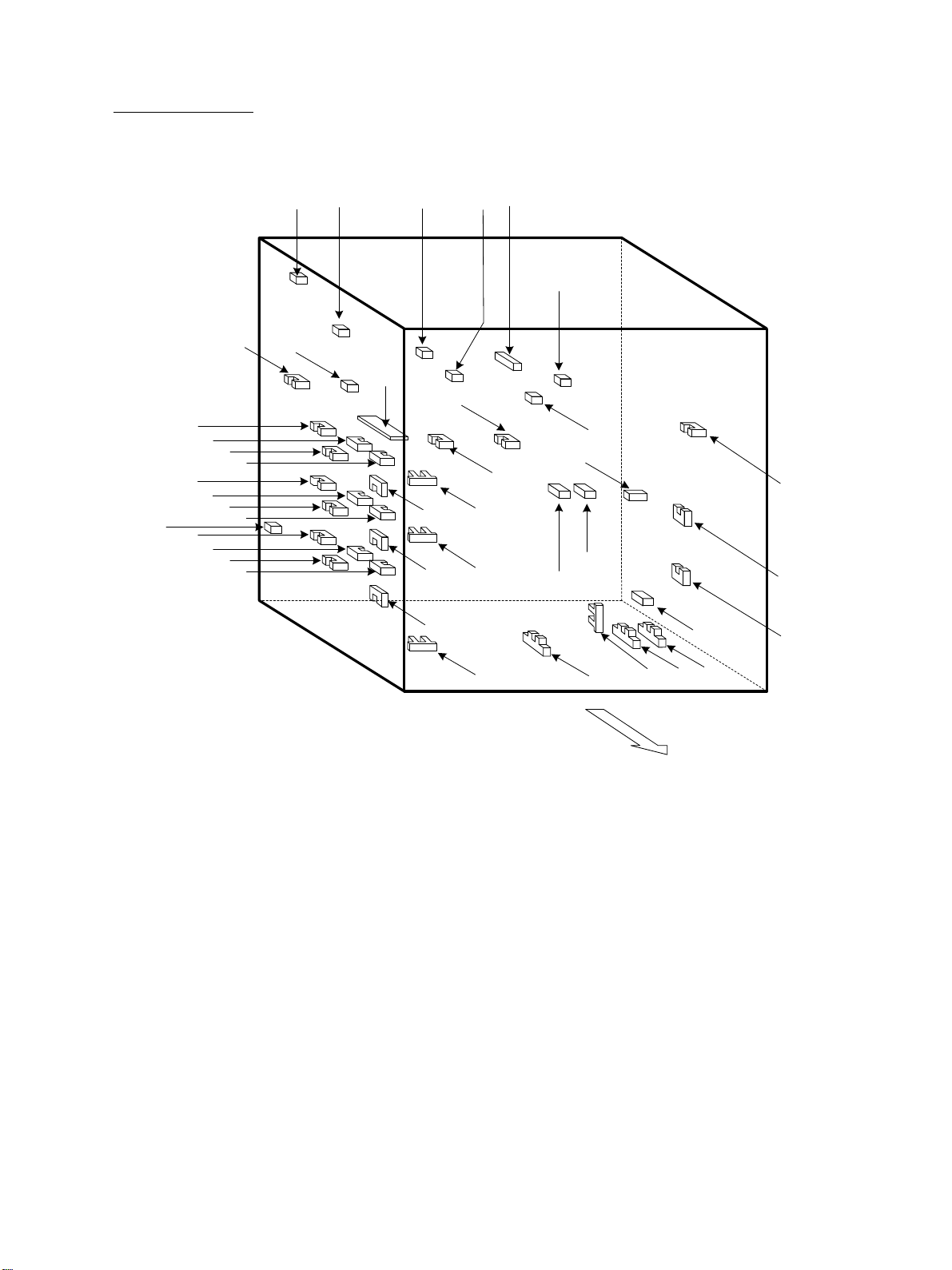

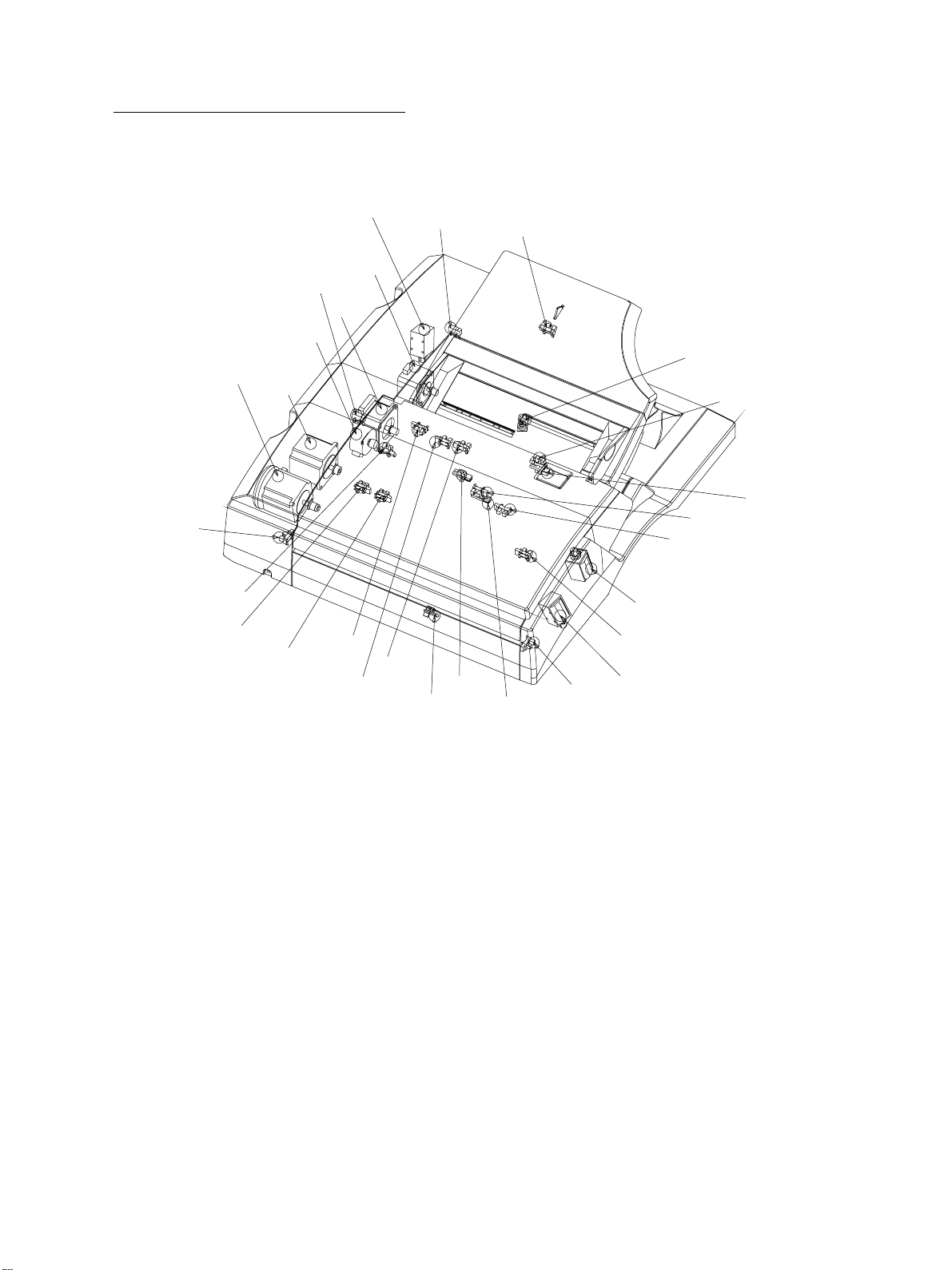

[F] Copier unit

(F-1) Motor/Fa n

M19

M20

M26

M27

M28

M29

M18

M17

M25

M24

M16

M15

M21

M22

M14

M13

M23

M12

M11

M10

M9

M8

M7

M6

M4

M5

M32

Rear side

e-STUDIO550/650/810 OUTLINE OF THE MACHINE 2 - 10 JUNE 2002 © TOSHIBA TEC

(F-2) Clutch/Solenoid

SOL1

CLT4

SOL2

SOL3

CLT5

CLT6

SOL5

CLT8

CLT10

CLT7

CLT9

CLT11

SOL4

Rear side

JUNE 2002 © TOSHIBA TEC 2 - 11 e-STUDIO550/650/810 OUTLINE OF THE MACHINE

(F-3) Sensor/Switch

S25

S26

S32

S38

S27

S33

S39

S28

S34

S40

S49

S29

S35

S41

S52

S50

S14

S51

S15

S31

S37

S42

S21

S30

S36

S16S17

S20

S19

S22

S24

S23

S18

S13

S10

S11

S12

S43

S44

S47

Rear side

S46S45

e-STUDIO550/650/810 OUTLINE OF THE MACHINE 2 - 12 JUNE 2002 © TOSHIBA TEC

(F-4) PC board

SYS

HDD

MOT

LGC

HVT

MOT2

Rear side

JUNE 2002 © TOSHIBA TEC 2 - 13 e-STUDIO550/650/810 OUTLINE OF THE MACHINE

(F-5) Other parts

THM4

S8

S9

S48

ERS

NF1

BRK1

PS

Rear side

e-STUDIO550/650/810 OUTLINE OF THE MACHINE 2 - 14 JUNE 2002 © TOSHIBA TEC

[G] Reversing automatic document f eeder

APS

RMOT

DLMTS

SIZE2

TLMOT

FMOT

SIZE1

COPSW

LMOT

SSOL

SMOT

COPS

EMPS

a

b

LLMTS

DFOPSW

READS

LNGS

TRYS

LOES

c

DFOPEN

TRVR

SOES

SSBS

REGS

ITFS

RSOL

SIZE3

LSOL

JUNE 2002 © TOSHIBA TEC 2 - 15 e-STUDIO550/650/810 OUTLINE OF THE MACHINE

2. 3. Symbols and Functions of Various Components

The column <P-I> shows the page and item number in the parts list.

(1) Motors

Symbol Name Function P-I Remarks

M1 SCAN-MOT Driving of the carriages 33-6 (B-1)

Scanner motor

M2 M/DC-POL Driving of the polygonal mirror 31-10 [C]

Polygonal motor

M3 WEB-MOT Cleaning web take-up 25-29 [E]

Web motor

M4 FEED-MOT Driving of the feeding section 6-2 (F-1)

Feed motor

M5 CST-TRY-MOT1 Driving ups of the 1st and 6-20 (F-1)

Cassette tray-up motor 2nd cassettes

M6 CST -TRY-MOT2 Driving ups of the tandem LCF tray 6-20 (F-1)

Casette tray-up motor 2

M7 RGST-MOT Driving of the registration roller 6-26 (F-1)

Registration motor

M8 DEV-MOT Driving of the developer unit 40-22 (F-1)

Developer unit motor

M9 DRUM-MOT Driving of the drum 39-18 (F-1)

Drum motor

M10 TRB-CAM-MOT Contact/Release of the transfer belt 18-7 (F-1)

Transfer belt cam motor

M11 REV-MOT Dr iving of the reverse section 13-5 (F-1)

Reverse motor

M12 USTNR-AUG-MOT Recovery of the toner scraped with 45-2 (F-1)

Used toner transport motor the transfer belt cleaning blade

M13 EXIT-MOT Driving of the exit roller 13-25 (F-1)

Exit motor

M14 FUSER-MOT Driving of the fuser unit 24-5 (F-1)

Fuser motor

M15 TRB-MOT Driving of the transfer belt 18-26 (F-1)

Transfer belt motor

M16 FUR-MOT Dr iving of the transfer belt cleaning 30-12 (F-1)

Cleaning brush drive motor brush

M17 CH-CLN-MOT Driving of the charger wire cleaner 37-8 (F-1)

Charger wire cleaner drive motor

M18 TNR-MOT Toner supply 44-27 (F-1)

New toner supply motor

M19 TNR-RCY-HOP-MOT Driving of the recycle toner hopper 46-15 (F-1)

Toner recycle hopper motor

M20 RCY-TNR-MOT Transpor ting of the recycle toner 46-19 (F-1)

Recycle toner transport motor

M21 HTR-FAN-MOT Cooling down of the copier inside 31-7 (F-1)

Heater fan motor

e-STUDIO550/650/810 OUTLINE OF THE MACHINE 2 - 16 JUNE 2002 © TOSHIBA TEC

Symbol Name Function P-I Remarks

M22 ADU-FAN-MOT1 Cooling down the reverse section 15-12 (F-1)

Reverse section fan motor 1

M23 ADU-FAN-MOT2 Cooling down the reverse section 15-12 (F-1)

Reverse section fan motor 2

M24 EXIT-FAN-MOT Cooling down of the exit section 31-7 (F-1)

Exit fan motor

M25 DUCT-OUT-FAN-MOT Sucking of ozone 31-7 (F-1)

Duct out fan motor

M26 LSU-FAN-MOT Cooling down of the laser unit 31-7 (F-1)

Laser unit fan motor

M27 DUCT-IN-FAN-MOT Cooling down of the copier inside 40-25 (F-1)

Duct in fan motor

M28 SYS-FAN-MOT Cooling down of the copier inside 52-24 (F-1)

System fan motor

M29 DEV-FAN-MOT Sucking of the toner in the developer 40-13 (F-1)

Developer unit fan motor unit

M30 IH-FAN-MOT Cooling down of the IH board 24-17 [E]

IH fan motor

M31 SLG-FAN-MOT Cooling down of the SLG board 32-10 (B-1)

SLG fan motor

M32 END-F-MOT Moving of the end fence 9-22 (F-1)

End fence motor

JUNE 2002 © TOSHIBA TEC 2 - 17 e-STUDIO550/650/810 OUTLINE OF THE MACHINE

(2) Sensos and switches

Symbol Name Function P-I Remarks

S1-5 APS 1-5 Original size detection 36-6 (B-2)

Automatic original detection sensor

S2 HOME-SNR Carriage home position detection 36-12 (B-2)

Carriage home position sensor

S3 TR-SNR 1 Paper detection at the reversed 20-23 [D]

Transpor t sensor 1 paper transport path

S4 TR-SNR 2 Paper detection at the reversed 20-23 [D]

Transpor t sensor 2 paper transport path

S5 TR-SNR 3 Paper detection at the reversed 20-23 [D]

Transpor t sensor 3 paper transport path

S6 WEB-SNR Cleaning web take-up amount 25-8 [E]

Web detection sensor detection

S7 FUS-EXIT-SNR Paper detection at the fuser unit 25-8 [E]

Fuser unit exit sensor

S8 MAIN-SW ON/OFF of the copier AC power 28-11 (F-5)

Main switch supply

S9 DOOR-SW Turning OFF of the AC power supply 28-24 (F-5)

Front door switch when opening the front cover

Interlock switch

S10 EXIT-SNR Paper detection at the exit section 15-25 (F-3)

Exit sensor

S11 RVS-SNR Paper detection at the reverse section 15-14 (F-3)

Reverse sensor 1

S12 RVS-SNR Paper detection at the reverse section 15-14 (F-3)

Reverse sensor 2

S13 EXIT-COV-SW Cover open/close detection at the 15-11 (F-3)

Exit cover switch exit cover

S14 DEV-SW Detection of the developer unit 5-16 (F-3)

Developer unit switch presence or absence

S15 TNR-SW Toner car tridge detection 44-18 (F-3)

Toner cartridge switch

S16 DRUM-SUF-SNR Detection of the drum surface 5-13 (F-3)

Drum surface potential sensor potential

S17 ATTNR-SNR Toner density detection 42-26 (F-3)

Auto-toner sensor

S18 TNLVL-SNR Toner adhesion amount detection 49-16 (F-3)

Image quality sensor

S19 CH-HOME-SW Detection of the wire cleaner home 37-13 (F-3)

Wire cleaner home position switch position

S20 MID-TR-SNR Paper detection at the feeding section 17-6 (F-3)

Intermediate transport sensor

S21 RGST-SNR Paper detection at the registration 16-6 (F-3)

Registration sensor section

S22 TR-BELT-SW 1 Transfer belt release position 18-3 (F-3)

Transfer belt release switch detection

e-STUDIO550/650/810 OUTLINE OF THE MACHINE 2 - 18 JUNE 2002 © TOSHIBA TEC

Symbol Name Function P-I Remarks

S23 TR-BELT-SW 2 Transfer belt contact position 18-2 (F-3)

Transfer belt contact switch detection

S24 TNR-FULL-SNR Used toner full detection 45-17 (F-3)

Toner bag full detection sensor

S25 COV-R-SNR Feed cover open/close detection 28-7 (F-3)

Feed cover sensor

S26 CST1-TR-SNR 1st cassette paper detection 7-18 (F-3)

1st cassette transport sensor

S27 CST1-TRY-SNR 1st cassette tray position detection 7-18 (F-3)

1st cassette tray-up sensor

S28 CST1-FED-SNR 1st cassette paper detection 7-18 (F-3)

1st cassette feed sensor

S29 CST1-EMP-SNR Detection of 1st cassette paper 7-18 (F-3)

1st cassette empty sensor presence or absence

S30 CST1-BTM-SNR 1st cassette position lower limit 7-18 (F-3)

1st cassette bottom sensor detection

S31 CST1-SNR Detection of 1st cassette presence or 7-18 (F-3)

1st cassette detection sensor absence

S32 CST2-TR-SNR 2nd cassette paper detection 7-18 (F-3)

2nd cassette transport sensor

S33 CST2-TRY-SNR 2nd cassette tray position detection 7-18 (F-3)

2nd cassette tray-up sensor

S34 CST2-FED-SNR 2nd cassette paper detection 7-18 (F-3)

2nd cassette feed sensor

S35 CST2-EMP-SNR Detection of 2nd cassette paper 7-18 (F-3)

2nd cassette empty sensor presence or absence

S36 CST2-BTM-SNR 2nd cassette position lower limit 7-18 (F-3)

2nd cassette bottom sensor detection

S37 CST2-SNR Detection of 2nd cassette presence 7-18 (F-3)

2nd cassette detection sensor or absence

S38 LCF-TR-SNR Paper detection at the tandem LCF 7-18 (F-3)

Tandem LCF transpor t sensor feeder section

S39 LCF-TRY-SNR Tandem LCF tray position detection 7-18 (F-3)

Tandem LCF tray-up sensor

S40 LCF-FED-SNR Paper detection at the tandem LCF 7-18 (F-3)

Tandem LCF feed sensor feeder section

S41 LCF-EMP-SNR Detection of paper presence or 7-18 (F-3)

Tandem LCF empty sensor absence at tandem LCF

S42 LCF-SNR Detection of the tandem LCF tray 7-18 (F-3)

Tandem LCF detection sensor presence or absence

S43 LCF-BTM-SNR Tray home position detection 8-14 (F-3)

Tandem LCF bottom sensor

S44 END-F-STP-SNR End fence stop position detection 8-14 (F-3)

End fence stop position sensor

JUNE 2002 © TOSHIBA TEC 2 - 19 e-STUDIO550/650/810 OUTLINE OF THE MACHINE

Symbol Name Function P-I Remarks

S45 EMP-SNR-SS Paper position detection at the 18-14 (F-3)

Standby side empty sensor standby side

S46 END-F-HP-SNR End fence home position detection 18-14 (F-3)

End fence home position sensor

S47 PR-MST-SS Detection of the paper mis-stacking 18-16 (F-3)

Standby side paper mis-stacking sensor at the standby side

S48 HTR-SW Detection of the fuser unit presence 24-7 (F-5)

Fuser unit switch or absence

S49 SFB-COV-SNR Open/close detection of the bypass 28-7 (F-3)

Bypass feed unit cover sensor feed unit cover

S50 SFB-FED-SNR Paper detection at the bypass feeding 10-23 (F-3)

Bypass sensor

S51 SFB-SIZE-SNR Paper size detection at the bypass 12-9 (F-3)

Bypass paper size detection sensor feed width detection

S52 TEMP/HUMI-SNR Detection of the temperature and 3-103 (F-3)

Temperature/humidity sensor humidity of the copier inside

e-STUDIO550/650/810 OUTLINE OF THE MACHINE 2 - 20 JUNE 2002 © TOSHIBA TEC

(3) Electromagnetic spring clutches

Symbol Name Function P-I Remarks

CLT1 TR-DRV-CLT Dr iving of the reversed paper 19-21 [D]

Reversed paper transport driving clutch transpor t section

CLT2 REV-TR1-CLT Reversed paper transporting 20-21 [D]

Reversed paper transport clutch 1

CLT3 REV-TR2-CLT Reversed paper transporting 20-21 [D]

Reversed paper transport clutch 2

CLT4 MDL-TR-CLT Paper transporting 17-23 (F-2)

Intermediate transport clutch

CLT5 SFB-FEED-CLT Driving of the bypass pickup roller 11-13 (F-2)

Bypass feed clutch

CLT6 CST1-TR-CLT 1st cassette paper transporting 7-26 (F-2)

1st cassette transport clutch

CLT7 CST1-FED-CLT Driving of 1st cassette pickup roller 7-26 (F-2)

1st cassette feed clutch

CLT8 CST2-TR-CLT 2nd cassette paper transporting 7-26 (F-2)

2nd cassette transport clutch

CLT9 CST2-FED-CLT Driving of 2nd cassette pickup roller 7-26 (F-2)

2nd cassette feed clutch

CLT10 LCF-TR-CLT Tandem LCF paper transpor ting 7-26 (F-2)

Tandem LCF transpor t clutch

CLT11 LCF-FED-CLT Driving of the tandem LCF pickup 7-26 (F-2)

Tandem LCF feed clutch roller

(4) PC boards

Symbol Name Function P-I Remarks

SLG PWA-F-SLG Control of the scanning section and 36-1 (B-3)

Scanning section control PC board (SLG board) image processing

CCD PWA-F-CCD Preprocessing control of the CCD 32-17 (B-3)

CCD driving PC board (CCD board) image data

SYS PWA-F-SYS Control of the whole copier 52-10 (F-4)

System PC board (SYS board) Data processing

LGC PWA-F-LGC Control of the whole copier 52-14 (F-4)

Logic PC board (LGC board)

LDR1 PWA-F-LDR1 Driving of the laser diode 31-10 [C]

Laser driving PC board 1 (LDR board 1)

LDR2 PWA-F-LDR2 Driving of the laser diode 31-10 [C]

Laser driving PC board 2 (LDR board 2)

SNS PWA-F-SNS Detection of the laser beam position 31-10 [C]

H-Sync detection PC board

IH PS-IH Control of the fuser unit IH coil 24-16 [E]

IH control board

FUSE PWA-F-FUS Cutting of the electric current to the 21-30 [D]

Fuse PC board damp heater

JUNE 2002 © TOSHIBA TEC 2 - 21 e-STUDIO550/650/810 OUTLINE OF THE MACHINE

Symbol Name Function P-I Remarks

MOT PWA-F-MOT Driving of the drum motor and 24-21 (F-4)

Motor driving PC board transfer belt motor

MOT2 PWA-F-MOT2 Driving of the reverse motor 13-19 (F-4)

Motor driving PC board 2

PLG PWA-F-PLG Control of the printing section and 31-16 [C]

Laser control PC board (PLG board) image processing

(5) Heaters and lamps

Symbol Name Function P-I Remarks

EXP LP-EXPO Exposing of original to the light 34-3 (B-1)

Exposure lamp

DHR DNP- HTR-R Preventing of the condensation in the 36-11 (B-4)

Scanner damp heater (R) scanning section (for mirrors)

DHL DNP-HTR-L Preventing of the condensation in the 36-9 (B-4)

Scanner damp heater (L) scanning section (for lens)

DHD D-HTR Keeping of the drum warm 21-28 [D]

Drum damp heater

IHCOIL IH-COIL Heating up of the fuser roller 25-36 [E]

IH coil

(6) Solenoid

Symbol Name Function P-I Remarks

SOL1 SFB-SOL Driving of the bypass pickup roller 10-8 (F-2)

Bypass pickup solenoid

SOL2 GATE-SOL Switching of the gate at the reverse 15-2 (F-2)

Gate solenoid section

SOL3 SEP-FING-SOL Driving of the dr um separation finger 30-17 (F-2)

Drum separation finger solenoid

SOL4 END-F-SOL Moving of the lever to detect the 8-9 (F-2)

End fence solenoid paper mis-stacking at the standby

side tray

SOL5 LCF-PICK-SOL Driving of the Tandem LCF pickup 7-36 (F-2)

Tandem LCF pickup solenoid roller

(7) Transformer

Symbol Name Function P-I Remarks

HVT PS-HVT Generating of the voltages for the 51-19 (F-4)

High-voltage transformer followings:

• main charger wire

• main charger grid

• developer bias

• drum cleaning brush

e-STUDIO550/650/810 OUTLINE OF THE MACHINE 2 - 22 JUNE 2002 © TOSHIBA TEC

(8) Others

Symbol Name Function P-I Remarks

INV INV-EXP Control of the exposure lamp 34-4 (B-3)

Lamp inverter

HDD HDD Storing of the image data 52-16 (F-4)

Hard disk

GLV MIR-GLV Control of the laser 31-10 [C]

Galvanometer mirror

PS PS-ACC Power supplying 51-18 (F-5)

Switching power supply

THMO1 THERMO-HTR Preventing of the fuser unit 26-4 [E]

Center thermostat over-heating

THMO2 THERMO-S-HTR Preventing of the fuser unit 26-4 [E]

Side thermostat over-heating

THMO3 DAMP-HTR Preventing of the dump heater 21-31 [D]

Dump heater thermostat over-heating

THMO4 THERMO-EXP Preventing of the dump heater 36-9 (B-4)

Expousre lamp thermostat over-heating in scanner section

THM1 THMS-S-HTR Detection of the surface temperature 26-6 [E]

Fuser roller side thermistor (front) at the drum edges/Abnormal detection

THM2 THMS-HTR Detection of the surface temperature 26-6 [E]

Fuser roller center thermistor at the drum center

THM3 THMS-S-HTR Detection of the surface temperature 26-6 [E]

Fuser roller side thermistor (rear) at the drum edges

THM4 THMS-DRM Detection of the drum surface 49-12 (F-5)

Drum thermistor

THM5 THMS-L-HTR Detection of the surface temperature 26-28 [E]

Pressure roller thermistor of the pressure roller

NF1 NOIZ-FILTER1 Noize cut 51-7 (F-5)

Noize filter 1

BRK1 BREAKER1 Safety switch 51-6 (F-5)

Breaker 1

BRK2 BREAKER2 Safety switch 51-6 (F-5)

Breaker 2

ERS CD-ERS Removing of the residual charge from 37-11 (F-5)

Discharge lamp the drum surface

JUNE 2002 © TOSHIBA TEC 2 - 23 e-STUDIO550/650/810 OUTLINE OF THE MACHINE

2. 4. Symbols and Functions of RADF Various Components

(1) Motors

Symbol Name Function Remarks

RMOT RMOT ·Driving of the transport roller Stepping motor

Read motor (P83-I27)

SMOT SMOT ·Driving of the small original exit roller Stepping motor

Small original exit motor and small original reverse roller (P87-I14)

TLMOT UDMOT ·Driving of the tray lift motor Stepping motor

Tray lift motor (P86-I20)

FMOT FMOT ·Driving of the f eed roller , pic kup roller Stepping motor

Feed motor and registration roller (P86-I19)

LMOT LMOT ·Driving of the large original e xit roller Stepping motor

Large original exit motor and large original reverse roller (P87-I13)

(2) Solenoids

Symbol Name Function Remarks

ESSOL ESSOL ·Disengagement of the large original DC solenoid

Disengagement solenoid exit roller (P89-I4)

LSOL LSOL ·Switching of the large original exit DC solenoid

Large original exit solenoid

SSOL SSOL ·Switching of the small original exit DC solenoid

Small original exit solenoid

flapper (P89-I3)

flapper and reverse flapper (P87-I1)

(3) PC boards

Symbol Name Function Remarks

DFLG PW A-F-ADF ·Control of the ADF (P88-I13)

ADF PC control board

(ADF board)

e-STUDIO550/650/810 OUTLINE OF THE MACHINE 2 - 24 JUNE 2002 © TOSHIBA TEC

(4) Switches and sensors

Symbol Name Function Remarks

COPSW COV-OPN-SW Detecting if the jam access cover is Mi cro switch

Cover open/close s witch opened/closed (Interlock switch) (P86-I13)

DFOPSW DF-OPN-SW Detecting if RADF is opened/closed Micro switch

RADF open/close switch (Interlock switch) (P88-I101)

DFOPNS DF-OPN-SNS Detecting if RADF is opened/closed Semiconductive

RADF open/close sensor photosensor (P89-101)

APS AUTO-PS-SNS Detecting the angle opened and Semiconductive

APS operation sensor switching ON/OFF of the APS sensor photosensor (P86-I105)

COPS COV-OPN-SNS Detecting if the jam access cover is Semiconductiv e

Cover open/close sensor opened/closed photosensor (P81-I29)

EMPS EMP-SNS Detecting the presence or absence of Semiconductive

Empty sensor original during feeding photosensor (P81-I29)

ULMTS UP-LMT-SNS Detecting the upper limit of the lifting tra y Semiconductive

Upper limit sensor photosensor (P81-I29)

SIZES1 SIZE-SNS1 Detecting the original width Semiconductiv e

Original width sensor 1 photosensor (P91-I103)

SIZES2 SIZE-SNS2 Detecting the original width Semiconductiv e

Original width sensor 2 photosensor (P91-I103)

SIZES3 SIZE-SNS3 Detecting the original width Semiconductiv e

Original width sensor 3 photosensor (P91-I103)

REGS REG-SNS Detecting original at the registering Semiconductive

Registration sensor section photosensor (P91-I103)

TRYS TRY-SNS Detecting the original length on the tray Semiconductive

Tray sensor photosensor (P93-I102)

LLMTS LO-LMT-SNS Detecting the lower limit of the lifting tray Semiconductive

Lower limit sensor photosensor (P82-I36)

ITFS INT-F-SNS Detecting original on the small original Semiconductive

Intermediate transpor t sensor

transport path photosensor (P90-I103)

SOES SO-EX-SNS Detecting original at the small original Semiconductiv e

Small original exit sensor e xit photosensor (P84-I105)

READS READ-SNS Detecting original at the scanning Semiconductive

Read sensor section photosensor (P83_I36)

LNGS LENG-SNS Detecting the original length Semiconductive

Original length sensor photosensor (P82-I31)

SSBS SO-SB-SNS Detecting original at the small original Semiconductive

Small original reverse sensor

reverse section photosensor (P84-I31)

TRV R TRY-VR Detecting the original width on the trayRotary volume

Tray width sensor (P93-I6)

LOES LO-EX-SNS Detecting original at the large original Semiconductive

Large original exit sensor exit photosensor (P85-I15)

JUNE 2002 © TOSHIBA TEC 2 - 25 e-STUDIO550/650/810 OUTLINE OF THE MACHINE

2. 5. System Block Layout

ADF

CCD

Serial-I/F

PWA-F-SLG-340

Flash

ROM

AmpAmp

CPU

32

or

ASIC

S-CPU

SRAM

Serial-I/F

32

Controller

Printer

A/DA/D

32

SDRAM

Image Data

ASIC

ADR/DAT-Bus

Image Data

32

16

SRAM

PCI-Bus

32

ASIC

16

IDE-I/F

Laser Unit

PWA-F-CCD2-340

PWA-F-PLG-340

JIG

Download

16

32

ROM

Flash

32

Local-

Bus

4

RTC

D/A

ROM

Flash

NVRAM

32

32

ASIC

8

LD

PWA-F-LDR-340

ASIC

Image Data

ASIC

32

SDRAM

PWA-F-LDR-340

32

LD

ASIC

PWA-F-SCN-340

8

8 8

PWA-F-SYS-340

SRAM

8

Laser

ROM

Flash

Image Data

Image Data

Beam

ASIC

D/A

ADR/DAT-Bus

Serial-I/F

Sensor

PWA-F-SNS-340

PWA-F-LGC-340

L-CPU

SRAM

SRAM

Gate

Mirror

Galvanic

DRV

Galvano

D/A

ROM

Flash

NVRAM

Serial-I/F

ADR/DAT-Bus

Array

ROM

Flash

M-CPU

Serial-I/F

ADR/DAT-Bus

PFC

IPC

LCF

Printer Board

HDD

123

456

LCD

789

C

O

P

Y

C

L

R

A

S

Y

-C

O

0

M

P

A

N

E

TANDEM LCF

Finisher

e-STUDIO550/650/810 OUTLINE OF THE MACHINE 2 - 26 JUNE 2002 © TOSHIBA TEC

2. 6. Disassembly and Replacement of Covers and PC boards

2. 6. 1. Covers

[A] Front co v er/Front side right inner cover

(1) Open the front cov er.

(2) Pull out 2 L-shaped pins and take off the front

cover.

L-shaped

pin

Front cover

(3) Remove 2 screws and take off the front side

right inner cover .

[B] Feed side rear cov er/Feed side top cover/

Feed side center cov er

(1) Remov e 1 scre w and take off the feed side

rear cover.

(2) Remove 2 screws and take off the feed side

top cover.

(3) Open the bypass unit tr a y and remo ve 2

screws. Then remo ve 6 screws and take off

the feed side center cov er.

Front side right inner cover

Feed side

top cover

Feed side

center cover

Feed side

rear cover

[C] Exit side top cover/Exit side rear cover/

Exit side bottom cover

(1) Remove 2 screws and take off the exit side

Exit side

rear cover

Exit side

top cover

top cover.

(2) Remove 1 screw and take off the exit side

rear cover.

(3) Remove 6 screws and take off the exit side

bottom cover.

Exit side

bottom cover

JUNE 2002 © TOSHIBA TEC 2 - 27 e-STUDIO550/650/810 OUTLINE OF THE MACHINE

[D] Rear cover

(1) Loosen 1 screw (sho wn by a white arrow),

remove 6 scre ws, release 2 hooks and take

off the rear cover.

Hook

[E] Right top cover

(1) Remov e 1 screw and take off the right top

cover.

[F] Left top cover

(1) Remov e 1 screw and take off the left top

cover.

Right top cover

Left top cover

e-STUDIO550/650/810 OUTLINE OF THE MACHINE 2 - 28 JUNE 2002 © TOSHIBA TEC

2. 6. 2. PC boards

[A] System control board (SYS board)/Hard disk/

Logic board (LGC board)

(1) Remove the rear co ver.

(2) Disconnect 1 connector .

(3) Remov e 2 scre ws (shown by 2 white arrows),

loosen 14 screws and take off the rear feed

side inner cover (plate co v er).

(4) Remove 1 screw (shown by a white arrow),

loosen 8 screws and take off the rear e xit

side inner cover (plate co v er).

(5) Disconnect 7 connectors, remov e 6 screws

and take off the SYS board.

(6) Disconnect 2 connectors, remov e 4 screws

and take off the hard disk with the brac k et.

(7) Remove 4 screws and release the hard disk

from the bracket.

Rear feed side

inner cover

SYS board Hard disk bracket

Rear exit side

inner cover

(8) Disconnect 19 connectors, remove 6 screws

and take off the LGC board.

[B] High-voltage transformer

(1) Disconnect 7 connectors to the SYS board

and hard disk.

(2) Remove 9 screws and take off the brack et

with the LGC board and hard disk.

LGC board

SYS board

Hard disk

JUNE 2002 © TOSHIBA TEC 2 - 29 e-STUDIO550/650/810 OUTLINE OF THE MACHINE

(3) Disconnect 19 connectors to the LGC board.

(4) Remov e 6 screws and take off the bracket

with the LGC board.

LGC board

(5) Disconnect 6 connectors, remov e 1 screw ,

release 3 lock supports and take off the highvoltage transf ormer.

[C] Po wer supply unit

(1) Remov e the SYS board, hard disk and LGC

board with the bracket.

(2) Remov e 4 screws and take off the bracket of

the power supply unit.

High-voltage transformer

Lock support

(3) Disconnect 1 link connector .

(4) Remov e 9 connectors and pull out the po wer

supply unit.

Note: Be careful not for the power supply unit to be

caught by harnesses.

Link connector (3)

e-STUDIO550/650/810 OUTLINE OF THE MACHINE 2 - 30 JUNE 2002 © TOSHIBA TEC

3. COPY PROCESS

3. 1. General Description

3. 2. Details of Copy Process

3. 3. Comparison of Copy Process to 6570/5570

3. COPY PROCESS

3. 1. General Description

Image processing

10

9

8

Discharging

Original exposure

2 3

Xenon lamp

29W

1

-733V (grid voltage)

Discharging

LED array (wavelength 660nm x 16)

Blade cleaning

Fur brush cleaning

7

Fusing

Fuser roller

700~1450W

Charging

–

–

–

–

Scanning

CCD

600dpi, 7500pixel

–

–

–

–

– –

++++

–

–

–

–

Transfer/Separation

80µA

4

Writing

Semiconductor laser

Pw=3.8nJ/mm

2

Toner

Carrier

–

–

+

–

++

+

–

+

–

++

+

–

–

–

Bias -500VDC+AC

5

Development

Magnetic roller

Bypass feeding

6

Cassette feeding

(1) Charging: Negatively charges the surface of the

photoconductive drum.

훹

(2 ) Original exposure: Converts images into optical

signals.

훹

(3) Scanning: Converts image optical signals into

electrical signals.

훹

(4 ) Writing: Conv erts image electrical signals into

optical signals (laser emission) and exposes

them to the surface of the photoconductive drum.

훹

(5) Development: Makes the negatively-charged

toner adhere to the photoconductive drum and

forms a visible image.

훹

Cleaning brush + Blade

LCF feeding

5µA

(6) Transfer: Transfers the visible image on the

photoconductive drum onto a paper .

Separation: Separates the paper from the drum

together with the toner.

훹

(7) Fusing: Fuses the toner on the paper by applying

heat and pressure.

훹

(8 ) Fur brush cleaning: Cleans dirt and paper dust

on the drum.

훹

(9 ) Blade cleaning: Forcibly removes the residual

toner on the drum.

훹

(10) Discharging: Discharges any remaining

negative charge on the drum.

JUNE 2002 © TOSHIBA TEC 3 - 1 e-STUDIO550/650/810 COPY PROCESS

3. 2. Details of Copy Process

(1) Photoconductive drum

The photoconductive drum has two layers, an outer

and an inner lay er. The outer la yer is a photoconductive

layer made of an organic photoconductive carrier

(OPC). The inner layer is an aluminum conductive

base in a cylindrical form.

The photoconductive carrier has the characteristic

that its electrical resistance changes depending on

the strength of the light exposed.

Example:

· Strong light촞

Resistance is decreased (works as a conductor.)

· Weak light촞

Resistance is increased (works as an insulator.)

[Formation of electrostatic latent image]

In the processes of charging, scanning, printing and

discharging described below , negative potential on

the areas of the drum corresponding to black areas

of the original is eliminated, while the areas of the

drum corresponding to white areas remains the

negative charge.

As this image on the drum formed by the negative

potential is invisible, it is called an “electrostatic latent image.”

Photoconductive layer

Aluminum conductive base

Structure of the photoconductive drum (OPC)

Time (t)

0

– 500

Black area of original

Surface potential (V)

Discharging

process

– 1000

Charging

process

White area of original

Electric potential on the photoconductive drum

Main charger

(2) Charging

Charging is a process of uniformly applying a charge

uniformly to the photoconductive drum surface.

The charger wire produces a negative corona dis-

Rotation of drum

charge, which is controlled by the grid so that the

drum surface is uniformly charged with negative potential.

The surface potential on the drum is determined by

the grid potential and controlled to a certain value

by the grid control circuit.

e-STUDIO550/650/810 COPY PROCESS 3 - 2 JUNE 2002 © TOSHIBA TEC

Discharge

transformer

Grid control circuit

(3) Scanning

Scanning is a process of exposing the original to

the light and converting the reflection into electrical

signals.

The light reflected from the original is impor ted to

the charge coupled device (CCD) and this optical

image information is converted into electrical signals (image signals), which are then sent to the

image processing section.

CCD

Image processing

section

(Example)

(4) Writing

Writing is a process of converting the image signals

sent from the image processing section into optical

signals and exposing the drum surface to the light.

Semiconductor laser element converts image signals sent from the image processing section into

optical signals (laser emission) and exposes the

drum surface to the light to form an electrostatic

latent image on it.

CCD light

receiving

amount

Light

쩪

쩪

Dark 0

Image

processing

section

Polygonal mirror

Photo-

conductive

drum

V alue of

image signals

to be output

255

Difference between

"light " and "dark" is

divided into 256

steps.

Laser Drive

board

Semiconductor

laser element

JUNE 2002 © TOSHIBA TEC 3 - 3 e-STUDIO550/650/810 COPY PROCESS

(5) Development

Development is a process of making the electrostatic latent images visible to the eye (visible images).

Developer material is supplied to the photoconductive drum surface by magnetic roller. The toner in

the developer material adheres to the areas on the

drum surface where the potential is lower than the

developer bias which is applied to the magnetic roller

(reverse development method).

Magnet

Magnetic roller

Bias voltage

–500 VDC

Photoconductive

drum

Toner

Carrier (always attracted

onto the magnet)

Toner

The (–) potential

of the drum being

higher than the

developer bias

The (–) potential

Toner

of the drum being

lower than the

developer bias

Photoconductive layer

Aluminum conductive

base

Dru m Magnetic roller

White background Half tone Solid

– 700V

– 600V

– 500V

– 400V

– 300V

– 200V

– 100V

White background

0

Image not developed

Image is developed by

toner

Bias

potential

e-STUDIO550/650/810 COPY PROCESS 3 - 4 JUNE 2002 © TOSHIBA TEC

• Developer material

The developer material is a mixture of toner and

carrier. The toner is charged to negative polarity and

the carrier to positive polarity , due to the friction with

each other caused by mixing.

Toner :Mainly consists of resin and carbon.

Carrier : Consists of ferrite and resin coating on its

surface to provide consistent frictional electrification.

Resin (90~95%)

[Toner]

Carbon

(5~10%)

5~20µm

Ferrite

30~100µm

[Carrier]

Note:

If the developer material is used for a long time (beyond its normal life span),

the toner is caked onto the carrier.

훹

The carrier’s (charging) performance is lowered.

Symptom: 1. Image density is decreased.

2. Toner scattering occurs.

3. Background fogging occurs.

Solution: Replace new developer material.

• Magnetic roller

- Magnetic brush development The south and north poles are arranged inside the

magnetic rollers, as shown in the right figure. The

developer material forms a brush-like fluff which contacts the photoconductive drum surface.

훹

This is caused by the lines of magnetic force between the south and north poles.

No frictional electrification

on the area where the toner

is caked on

Photoconductive

drum

Toner

Lines of

magnetic force

Carrier

S

N

S

Magnetic roller

JUNE 2002 © TOSHIBA TEC 3 - 5 e-STUDIO550/650/810 COPY PROCESS

Additional Explanation

The life of the toner cartridge (number of copies) varies depending on the following conditions.

1. Coverage of originals (printing image ratio of the original size) and density of original background

2. Size and density of originals

3. The existence of solid black when making copies (when a book is copied and the original cover is

partially open)

4. Temperature and humidity in the room when making copies

5. Copy density and image quality mode

As indicated in the figure below , the life of the toner cartridge varies depending on the copy mode and

coverage of originals

74,000

70,000

60,000

50,000

40,000

30,000

20,000

A

46,000

40,000

30,000

20,000

A

27,000

20,000

B

15,000

C

38,000

30,000

20,000

A

Type of originals

A.

B.

C.

e-STUDIO550/650/810 COPY PROCESS 3 - 6 JUNE 2002 © TOSHIBA TEC

(6) T ransfer/Separation

Transfer:

Transfer is a process of transfering the toner image

(visible image) formed on the drum surface onto the

paper.

An electric charge applied by the high voltage power

supply flows to the transfer belt from the power

supply roller. Then it flows to the paper and photo

conductor. The toner, which has been developed

on the photo conductor, is transfered to this paper

with an electric charge.

Separation:

The paper is absorbed to the belt and separated

from the drum by the electrostatic attraction acting

between the belt (plus charge) and the polarization

charge (minus charge) on the bottom surface of the

paper.

Toner

Drum

Transfer

belt

Paper

Drum

Aluminum conductive base

Photoconductive layer

E

Paper

Transfer belt

Reference

Combined use of transfer belt and

•

separation finger

To prevent the copy paper from failing to

be separated during the operation, due to

incomplete transfer belt charging or

absorption of moisture, and thus jamming

up the cleaner, a separation finger

mechanically separates any copy paper

which fails to be separated.

Power supply roller

Separation finger

Rotation of drum

Paper movement

Transfer belt

JUNE 2002 © TOSHIBA TEC 3 - 7 e-STUDIO550/650/810 COPY PROCESS

(7) Fusing

Fusing is a process of melting and fixing the toner

on the paper.

Method : The melting point of the toner (main

ingredient: resin) is 100~110°C.

훹

(Heat) The toner is melted by the heat of the

surface of the fuser roller .

+

(Pressure) The pressure roller is pressed against

the fuser roller by the springs to increase

adherence of the melted toner to the

paper.

훹

Heat and pressure are applied to the

paper when it passes between the fuser

roller and pressure roller.

||

(Fusing) The toner is fixed on the paper.

Fuser roller

Paper

Pressure

IH coil Fuser roller

Separation finger

Paper mov ement

Pressure

(8) Cleaning

Cleaning is a process of recovering the residual toner

on the photoconductive drum.

1. The cleaning brush scrapes off the excessive

toner and paper wastes. The flicker scrapes off

the toner on the brush.

Also, too pervent the cleaning b lade from

scratching the surface of the drum to make a

circumferential streak, the varistor is attached

between the brush and earth.

2. Cleaning blade scrapes off the residual toner on

the drum.

3. The reco very blade pic ks up the scraped toner .

Pressure roller

Cleaning blade

Drum rotation

Cleaning brush

Flicker

Recovery blade

e-STUDIO550/650/810 COPY PROCESS 3 - 8 JUNE 2002 © TOSHIBA TEC

(9) Discharging

Discharging is a process of eliminating the (–) charge

remaining on the photoconductive drum before the

next charging process begins.

If discharging does not occur, the following

phenomenon will occur:

The (–) charge remains on the photoconductive

drum.

훹

Uneven charge is applied to the drum during the

next copy.

훹

The next copy has a double image. (Preceding image

appears.)

Solution :

Expose the entire surface of the photoconductive

drum to the light by the discharge LED array.

훹

The photoconductive drum becomes electrically

conductive.

훹

All the (–) charges remaining on the photoconductive

drum are conducted to the ground.

훹

The preparation for the next copy is completed.

Dischage LED array

Drum

JUNE 2002 © TOSHIBA TEC 3 - 9 e-STUDIO550/650/810 COPY PROCESS

3. 3. Comparison of Copy Process to 6570/5570

Process

1. Photoconductive drum

(1) Sensitivity

(2) Surface potential

2. Charging

OD-6570 (OPC drum) OD-6510 (OPC drum)

Highly sensitized drum Same as 6570/5570

–650 V (grid voltage –720V) –700 V (grid voltage –733V)

Scolotron method (constant current) Same as 6570/5570

6570/5570 e-STUDIO550/650/810

Grid output variable Same as 6570/5570

3. Surface potential controlling

Non e Surface potential sensor

4. Writing

(1) Light source Semiconductor laser (adjustment Same as 6570/5570

not required)

(2) Light amount 4.0 nJ/mm

2

3.8nJ/mm

2

5. Image density control Image quality sensor Same as 6570/5570

6. Development

(1) Magnetic roller Two magnetic rollers Same as 6570/5570

(2) Auto-toner Magnetic bridge-circuit method Same as 6570/5570

(3) Toner supply Toner hopper system Toner cartridge system

(There is a toner recycle system.)

(4) Toner-empty detection Density detection method/lever joint Density detection system

use

(5) Toner T-6570/6570E T-6510/6510E/6510D

(6) Developer material D-6570J D-6510

(7) Developer bias DC-400V + AC DC-500V + AC

7. Transfer

(1) Transfer Transfer belt Transfer belt

(Electrical resistance is lower than

6570/5570.)

(2) Power supply roller Power supply roller Power supply roller

Separation auxiliary roller Separation auxiliary roller

8. Separation Transfer belt charging Same as 6570/5570

Separation finger applied Same as 6570/5570

9. Discharging

(1) Discharging position Discharge by exposure after cleaning Same as 6570/5570

(2) Discharge lamp Discharge by red LED Same as 6570/5570

(3) Pre-cleaning discharge N one Same as 6570/5570

10. Cleaning

(1) System Blade + Brush Same as 6570/5570

(2) Recovered toner Not acceptable Reuse (by the toner recycle system)

11. Cleaning brush bias Earth Varistor 430V

e-STUDIO550/650/810 COPY PROCESS 3 - 10 JUNE 2002 © TOSHIBA TEC

Process 6570/5570 e-STUDIO550/650/810

12. Fusing

(1) System Long-life heat roller system Same as 6570/5570

· Fuser roller: · Fuser roller:

Fluoroplastic-coated roller (ø60) Fluoroplastic-coated roller (ø60)

· Pressure roller: · Pressure roller:

PFA tube roller (ø60) PFA tube roller (ø60)

(2) Cleaning · Fuser roller cleaning roller (ø33) · Cleaning web (for fuser roller cleaning)

· Cleaning felt roller (ø27)

· Pressure roller cleaning felt roller (ø28) · Pressure roller cleaning felt roller

· Cleaning metal roller · Pressure roller cleaning metal roller

(3) Heater Halogen lamp (Lamp system) IH coil (Induction heating system)

(Lamp rating: 800W + 300W)

ON/OFF control by thermistor Same as 6570/5570

JUNE 2002 © TOSHIBA TEC 3 - 11 e-STUDIO550/650/810 COPY PROCESS

4. GENERAL OPERATION

4. 1 . Overview of Operation

4. 2. Operation

4. 2. 1. Warming-up

4. 2. 2. Standby state (ready for copying)

4. 2. 3. Cassette feed copying with [ST ART] key ON

4. 2. 4. Bypass copying

4. 2. 5. Interrupt copying

4. 3. Abnormality Detection

4. 3. 1. Abnormality classification

4. 3. 2. Abnormality description

4. 4. Flow Chart

4. 4. 1 . Power ON to ready

4. 4. 2. Automatic feed copying

4. GENERAL OPERATION

4. 1. Overview of Operation

Copier operation Operation during warming-up, pre-running and standby

Automatic f eed copying by pressing [ST AR T] key

Copying operation Bypass copying

Interrupt copying

4. 2. Operation

4. 2. 1. Warming-up

(1) Initialization

• Power turned ON

• IH coil turned ON

• Set number “1” and “WAIT W ARMING UP” displayed

• Fan motors turned ON

• Scanning section initialization

~Carriage moving to home position and stopping there

~Carriage moving to peak detection position

~Exposure lamp turned ON ~ P eak detection (White color is detected b y the shading correction plate.)

~ Exposure lamp turned OFF

~Carriage moving to home position

• Feed unit initialization

~Each cassette tray going up

• Writng section initialization

~Polygonal motor rotating

~Beam position controlled

• Other

~Main charger cleaner operating

(2) Pre-running operation

Pre-running operation is started when the temperature of the fuser roller reaches a certain temperature.

(Pre-running is not carried out when the fuser roller has been already hot enough.)

• Fuser roller rotating

• Drum rotating

~Drum motor, used toner transport motor turned ON

• Image quality control

~Patch formed on drum and its reflective ratio read out to set an optimal condition.

(3 ) When fuser roller temperature becomes sufficient for fusing:

• IH coil turned OFF

• Set number “1” and “READ Y” displayed

JUNE 2002 © TOSHIBA TEC 4 - 1 e-STUDIO550/650/810 GENERAL OPERATION

4. 2. 2. Standby state (ready for copying)

• Keys on control panel enab led

• When no key is pressed f or a certain period of time:

~ Set number “1” and reproduction ratio “100%” displayed and copier returning to normal standby

state

4. 2. 3. Cassette feed copying with [START] key ON

(1) [START] key ON

• “READ Y” displa y changed to “COPYING”

• Main charger, de veloper bias and discharge lamp turned ON/Each fan rotating at a high speed

• Drum, transfer belt, fuser unit and developer unit rotating

(2 ) Cassette paper feeding

• Feed motor and feed clutch turned ON

~ Pickup roller, feed roller and tr ansport roller rotating

• Paper reaching transport roller

~Cassette transport sensor turned ON

• Feed clutch turned OFF after a certain period of time

• Paper reaching registration roller

~Registration sensor turned ON and aligning performed

• Feed motor stopping after a certain period of time

(3) Carriage operation

• Exposure lamp turned ON → White shading compensation is carried out.

• Scanning motor turned ON → Carriages 1 and 2 start to advance.

• Copier entering toner supply operation with developer material toner density being lower than pre-set

value

(4 ) In a certain time after carriage operation:

• Registration motor turned ON → Paper is sent to the transfer section.

• Copies counted

(5 ) In a certain time after registration motor is turned ON:

• T ransf er charger ON

(6 ) Carriage scanning termination

• Scanning motor turned OFF

• Exposure lamp turned OFF

• Registration motor turned OFF (after paper trailing edge has passed registration sensor)

e-STUDIO550/650/810 GENERAL OPERATION 4 - 2 JUNE 2002 © TOSHIBA TEC

(7) Paper discharging

• Exit sensor detecting passing of paper trailing edge

• Main charger, dev eloper bias and discharge lamp turned OFF

• Each operation of drum, transfer belt, fuser unit and developer unit stopping and each fan returning

to standby mode rotation

• “READY” displa yed and copier entering standby mode

JUNE 2002 © TOSHIBA TEC 4 - 3 e-STUDIO550/650/810 GENERAL OPERATION

0

22

536

1365

1423

1906

236

1365

250

3680

220

830

260 830

890

1790

1280

1830

1270

1780

260

3240

3330

430

260 4040

2980

2470

Timing chart for copying one A4 sized sheet fed from the 1st cassette

(ms)

Forward rotation

Reverse rotation

Scanner motor

Exposure lamp

Drum motor

1st cassette feed clutch

1st cassette feed sensor

Registration sensor

Registration motor

MVDEN signal

Main charger

Developer bias

Discharge lamp

Exit sensor

e-STUDIO550/650/810 GENERAL OPERATION 4 - 4 JUNE 2002 © TOSHIBA TEC

4. 2. 4. Bypass copying

(1) Paper inserted into bypass feed tra y.

• SFB feed sensor turned ON

~ “READY FOR BYPASS FEEDING” displa y ed

(2) [START] key pressed

• “READY FOR BYPASS FEEDING” displa y changed to “COPYING”

• Main charger, de veloper bias and discharge lamp turned ON/Each fan rotating at a high speed

• Drum, developer unit, transfer belt, and fuser roller rotating

(3 ) Sheet-bypass feeding

• Bypass pickup solenoid turned ON and feed motor rotating in reverse

~ Bypass pickup roller lowered

• Bypass feed clutch turned ON

~ Bypass feed roller, paper f eed roller , and separation roller rotating

• Aligning operation

• Paper reaching registration roller

• Bypass pickup solenoid, feed motor and bypass feed clutch turned OFF in a certain period of

time later

(4 ) Same operations as (3) through (6) of cassette feed cop ying with [START] k ey ON carried out

4. 2. 5. Interrupt copying

(1 ) [INTERRUPT] key pressed

• Interruption lamp turned ON

• Copying operation temporarily halted and carriages-1 and -2 returning to their home position

• “JOB INTERRUPTED JOB 1 SA VED” displa y ed

• Copying mode set to automatic density and 1-to-1 reproduction ratio and copy quantity indicator

unchanged

(2 ) Preferred copying modes specified

(3 ) After an interrupt copying is terminated:

• “PRESS INTERRUPT T O RESUME JOB 1” displayed

• Interruption lamp turned OFF/Copier returning to conditions before interruption when [INTERRUPT]

key is pressed again

• “READY TO RESUME JOB 1” displa yed

(4) [START] key pressed

• Back to copying operation before interruption

JUNE 2002 © TOSHIBA TEC 4 - 5 e-STUDIO550/650/810 GENERAL OPERATION

4. 3. Abnormality Detection

When an abnormality occurs in the copier, a symbol corresponding to the type of the abnormality is

displayed to dr aw the operater’s attention.

4. 3. 1. Abnormality classification

A) Abnormalities which can be cleared without resetting the door switch

(1) Add paper

(2 ) Paper misf eed in bypass

(3) Set key copy counter

B) Abnormalities which cannot be cleared without resetting the door switch.

(1 ) Misfeed in copier

(2 ) Developer unit not installed properly

(3 ) Add toner

C ) Abnormalities which cannot be cleared without turning OFF the main switch

(1 ) Call for service

4. 3. 2. Abnormality description

A-1) Add paper

Empty sensor detects the presence or absence of paper.

[When cassette is not installed]

No Cassette detected

훹

Tray not going up (empty sensor OFF)

훹

“Add paper” displayed

훹

[START] key disabled

[When cassette is installed]

Cassette detected

훹

Tray going up (empty sensor OFF)

훹

“Add paper” displayed

훹

[START] key disabled

e-STUDIO550/650/810 GENERAL OPERATION 4 - 6 JUNE 2002 © TOSHIBA TEC

• When power is turned ON or feed unit initializing is operated:

↓

Presence or absence of paper detected

Tray motor ON ~ Tray going up

When tray-up sensor is not turned ON within a certain period of time:

T ra y being abnormal “Add paper” displayed regardless of paper being present

↓

or not

↔

Turn ON and OFF the power to clear this condition.

When tray-up sensor is turned ON within a certain period of time:

~ Tray motor stopping

At this time, if empty sensor is ON ~ Determined there is a paper

if empty sensor is OFF ~ Determined there is no paper

↓

“Add paper” display blinked

• When the remaining sheets of paper are getting short during copying:

→Tray-up sensor turned OFF → Tray-up motor turned ON ~ Tray going up

→Tray-up sensor turned ON → Tray motor stopping

• When empty sensor is turned OFF despite tray-up sensor being ON during copying:

↓

Determined there is no paper

↓

“Add paper” display blinked

↓

Copying stopped

JUNE 2002 © TOSHIBA TEC 4 - 7 e-STUDIO550/650/810 GENERAL OPERATION

A-2) Bypass misfeed ( )

• When doing a bypass feeding:

Bypass feed pickup solenoid turned ON

↓

Registration sensor turned ON

* When the registration sensor is not turned ON after a certain period of time (E12):

↓

Bypass misfeeding

↓

“Clear paper” symbol ( ) displayed

↓

Copying operation disabled

Solution: Remove paper from the bypass tray, and the bypass sensor will be turned OFF.

A-3) Set key copy counter

• When the key copy counter (optional) is pulled out from the copier which installs it:

“Set key copy counter” displayed

↓

Copying operation disabled

• When the counter is pulled out during copying:

Copying is stopped when the key copy counter is pulled out.

e-STUDIO550/650/810 GENERAL OPERATION 4 - 8 JUNE 2002 © TOSHIBA TEC

B-1) Misfeed in copier ( )

• Paper leading edge jam detected by e xit sensor

Registration motor turned ON

↓

Exit sensor not turned ON within 0.975 sec.

↓

“Clear paper” symbol ( ) displayed (E01)

↓

Copying stopped

Registration

motor

Exit sensor

Timer

ON

ON

0

0.975sec.

• Paper trailing edge jam deteced by exit sensor

Registration motor OFF

↓

Exit sensor not turned OFF within 0.952 sec.

↓

“Clear paper” symbol ( ) displayed (E02)

↓

Copying stopped

• Immediately after power is turned ON:

↓

Any of all sensors at transport path detecting paper (ON)

↓

“Clear paper” symbol ( ) displayed (E03)

• Front cover opened during copying

↓

“Clear paper” symbol ( ) displayed (E41)

Registration

motor

Exit sensor

Timer

Misfeed in copier (E01)

OFF

ON

0

Misfeed in copier (E02)

0.952sec.

• Paper leading edge jam detected by registration sensor

Registration sensor not turned ON within a certain period of time after paper leading edge has

passed transport roller

↓

“Clear paper” symbol ( ) displayed (E20, 22, 25, 30, 34, 3C)

• When a sheet of paper is fed at reverse section:

Registration sensor not turned ON within a certain period of time after reverse motor has been

turned ON

↓

“Clear paper” symbol ( ) displayed (E11)

JUNE 2002 © TOSHIBA TEC 4 - 9 e-STUDIO550/650/810 GENERAL OPERATION

• When a sheet of reversed paper is transported:

Transport sensor 1 not detecting paper in a certain timing

↓

“Clear paper” symbol ( ) displayed (E51, 52, 53, 54)

• When a sheet of paper is fed:

Feed sensor not turned ON after feed clutch has been turned ON

↓

“Clear paper” ( ) symbol display ed (E13, 14, 15, 16, 18, 19: Error codes change depending

on the cassette used.)

B-2 ) Add toner ( )

Toner density lowered

↓

Toner empty detected: Auto toner sensor

↓

Control circuit “Replace toner cartridge” symbol ( ) displayed: Cop ying cannot be started.

↓

Solution: Open the front cover and replace the toner cartridge.

Toner supply operation: copying can be started.

B-3) Replace toner bag ( )

Toner bag becoming full with used toner

↓

Used toner transport auger moving to feed side: Toner bag full detection sensor ON

↓

“Replace toner bag” symbol ( ) displayed

• T oner bag full detection sensor turned ON during copying

↓

Copying stopped after the last sheet copied has been discharged

Solution: Replace to a new toner bag by a service technician.

B-4 ) Developer unit not installed properly

Developer unit desconnected

↓

“Developer unit not installed properly” displayed

Solution: Connect the de v eloper unit connector and close the front cov er .

C-1) Call for service

When the [CLEAR] and “8” keys are pressed simultaneously when the “Call for service” symbol is

blinking, an error code appears on the message display.

For the contents of the error codes, ref er to the “SER VICE HANDBOOK”.

e-STUDIO550/650/810 GENERAL OPERATION 4 - 10 JUNE 2002 © TOSHIBA TEC

4. 4. Flowchart

4. 4. 1. Power ON to ready

Restart

Main SW ON

DC power supply ON

YES

Is cover opened?

NO

IH coil ON

· Scanner motor ON

· Cassette tray-up

motor ON

Is registration

sensor ON?

NO

Is exit sensor ON?

NO

(Start initializing)

YES

YES

Is transport

YES

sensor 1 ON?

NO

A

JUNE 2002 © TOSHIBA TEC 4 - 11 e-STUDIO550/650/810 GENERAL OPERATION

Jam

"E03"

A

Polygonal motor rotating

Scanning section initialization

NO

Is

toner full detection

sensor ON?

NO

Is toner empty?

YES

Toner supply

Is initialization

finished?

YES

YES

NO

NO

Drum motor ON

for 6 sec.

Is

toner full detection

sensor ON?

Have

20sec. passed after

initialization started?

YES

Call for service

(used toner full clear operation)

YES

T oner bag replacement

NO

Is

fuser roller temperature

high enough to start

pre-running?

YES

Pre-running started

Is

fuser roller temperature

high enough to

be ready?

YES

Pre-running finished

Ready

"C26"

NO

Is thermistor

cut down?

YES

NO NO NO

Is heater

cut down?

YES

Is

polygonal motor

NG?

YES

Call for service Call for service Call for service

"C41" "C44" "CA1"

e-STUDIO550/650/810 GENERAL OPERATION 4 - 12 JUNE 2002 © TOSHIBA TEC

4. 4. 2. Automatic feed copying