Page 1

SERVICE HANDBOOK

DIGITAL PLAIN PAPER COPIER

e-STUDIO550/650/810

(DP-5510/6510/8110)

File No.31110201

2002-06

Page 2

Copyright 2002

TOSHIBA TEC CORPORATION

Page 3

GENERAL PRECAUTIONS REGARDING THE INSTALLATION AND SERVICE FOR THE COPIER e-STUDIO550/650/810

The installation and service should be done by a qualified service technician.

1. Transportation/Installation

• When transporting/installing the copier, move it by the casters while lifting the stoppers.

The copier is quite heavy and weighs appro ximately 200 kg (441 lb), therefore pay full attention

when handling it.

• Be sure to use a dedicated outlet with AC 115V or 120V/20A (220V, 230V, 240V/10A) or more

for its power source.

• The copier must be grounded for safety.

Never ground it to a gas pipe or a water pipe.

• Select a suitable place for installation.

Avoid excessive heat, high humidity, dust, vibration and direct sunlight.

• Also provide proper ventilation as the copier emits a slight amount of ozone.

• To insure adequate working space for the copying operation, keep a minimum clearance of

80 cm (32”) on the left, 80 cm (32”) on the right and 10 cm (4”) in the rear.

• The socket-outlet shall be installed near the copier and shall be easily accessible.

2. Service of Machines

• Basically, be sure to tur n the main switch off and unplug the power cord during service.

• Be sure not to touch high-temperature sections such as the exposure lamp, the fuser unit, the

damp heater and their periphery.

• Be sure not to touch high-voltage sections such as the chargers, high-voltage transformer,

exposure lamp control inverter, inverter for the LCD bac klight and pow er supply unit. Especially,

the board of these components should not be touched since the electirc charge may remain in

the condensers, etc. on them even after the power is turned OFF.

• Be sure not to touch rotating/operating sections such as gears, belts, pulleys, fan, etc.

• Be careful when removing the covers since there might be the parts with very sharp edges

underneath.

• When servicing the machines with the main switch turned on, be sure not to touch live sections

and rotating/operating sections. Avoid exposure to laser radiation.

• Use suitable measuring instruments and tools.

• Avoid exposure to laser radiation during servicing.

- Avoid direct exposure to the beam.

- Do not insert tools, par ts, etc. that are reflective into the path of the laser beam.

- Remove all watches, rings, bracelets, etc. that are reflective.

Page 4

3. Main Service Parts for Safety

• The breaker , door switch, fuse, thermostat, thermofuse, thermistor, etc. are particularly important

for safety. Be sure to handle/install them properly. If these parts are shorted circuit and/or

made their functions out, they may burn down, for instance, and may result in fatal accidents.

Do not allow a short circuit to occur. Do not use the parts not recommended by Toshiba TEC

Corporation.

4. Cautionary Labels

• During servicing, be sure to check the rating plate and the cautionary labels such as “Unplug

the power cord during service”, “Hot area”, “Laser warning label” etc. to see if there is any dir t

on their surface and whether they are properly stuck to the copier.

5. Disposition of Consumable Parts, Packing Materials, Used batteries and RAM-ICs

• Regarding the recovery and disposal of the copier, supplies , consumable parts, packing materials,

used batteries and RAM-ICs including litium batteries, it is recommended to follow the relevant

local regulations or rules.

6. When parts are disassembled, reassembly is basically the reverse of disassembly unless

otherwise noted in this manual or other related documents. Be careful not to reassemble

small parts such as screws, washers, pins, E-rings, star washers in the wrong places.

7. Basically, the machine should not be operated with any parts removed or disassembled.

8. Precautions Against Static Electricity

• The PC board must be stored in an anti-electrostatic bag and handled carefully using a wrist-

band, because the ICs on it may become damaged due to static electricity.

Caution: Before using the wristband, pull out the power cord plug of the copier and

make sure that there are no uninsulated charged objects in the vicinity.

Caution : Dispose of used batteries and RAM-ICs including lithium batter-

ies according to this manual.

Attention : Se débarrasser de batteries et RAM-ICs usés y compris les batteries

en lithium selon ce manuel.

Vorsicht : Entsorgung des gebrauchten Batterien und R A M -ICs (inklusive

der Lithium-Batterie) nach diesem Handbuch.

Page 5

1. SPECIFICATIONS /

ACCESSORIES / OPTIONS /

SUPPLIES

2. ERROR CODE AND SELFDIAGNOSIS

3. ADJUSTMENT

4. PREVENTIVE MAINTENANCE

(PM)

5. TROUBLESHOOTING

6. UPDATING THE FIRMWARE

7. POWER SUPPLY UNIT

8. WIRE HARNESS CONNECTION

DIAGRAMS

Page 6

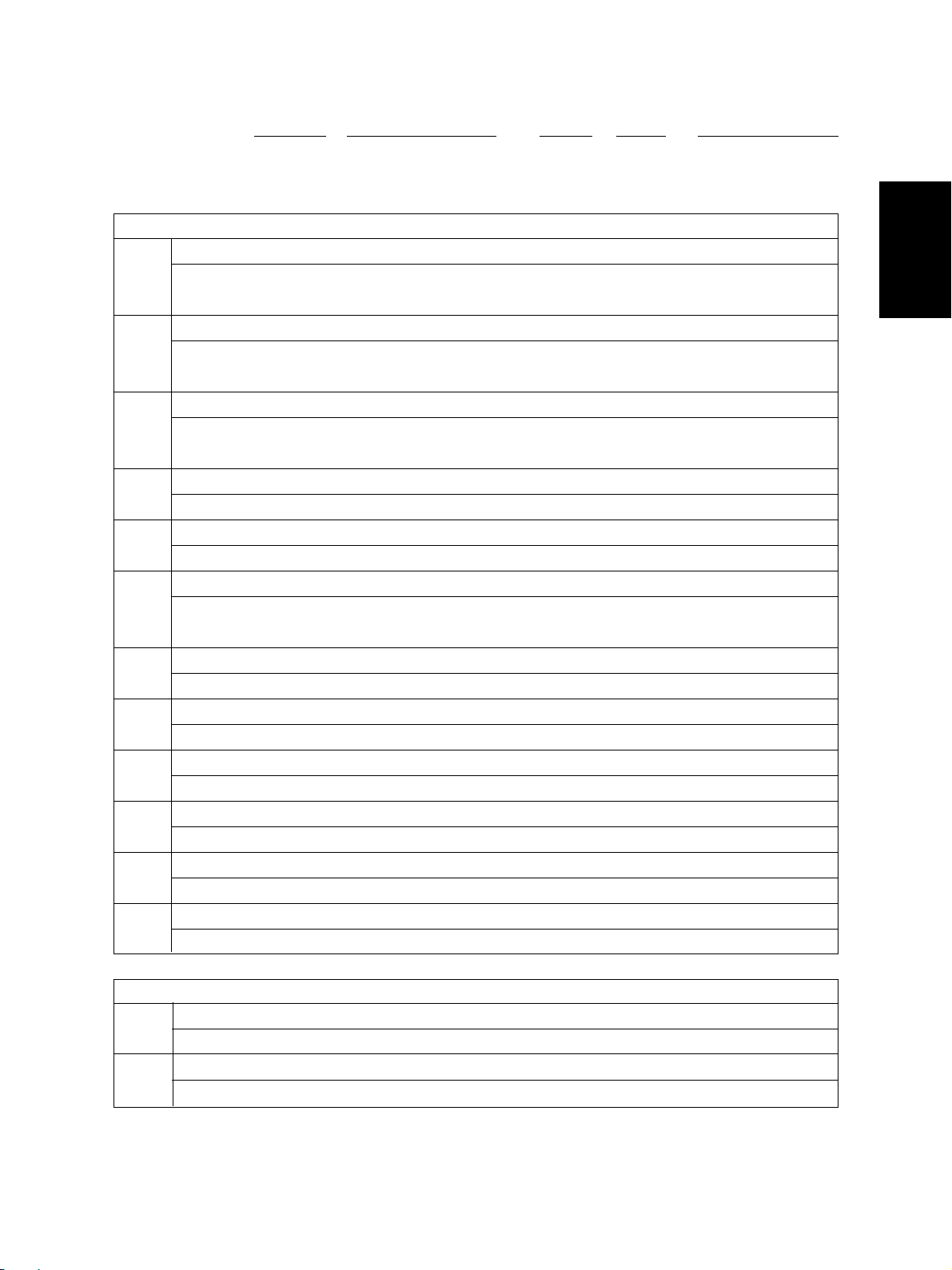

CONTENTS

1. SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES.................................................. 1-1

1. 1. Specifications ........................................................................................................................ 1-1

1. 2. Accessories........................................................................................................................... 1-5

1. 3. Options .................................................................................................................................. 1-6

1. 4. Supplies................................................................................................................................. 1-6

1. 5. System List ........................................................................................................................... 1-7

2. ERROR CODES AND SELF-DIA GNOSIS................................................................................... 2-1

2. 1. Error Codes............................................................................................................................ 2-1

2. 2. Self-diagnosis Modes............................................................................................................. 2-8

2. 2. 1. Input check (test mode 03) ....................................................................................... 2-10

2. 2. 2. Output check (test mode 03) .................................................................................... 2-16

2. 2. 3. T est print mode (04) .................................................................................................. 2-19

2. 2. 4. Adjustment mode (05)............................................................................................... 2-20

2. 2. 5. Setting mode (08) ..................................................................................................... 2-31

3. ADJUSTMENT............................................................................................................................ 3-1

3. 1. Hard Disk Formatting ............................................................................................................ 3-1

3. 2. Adjustment of Auto-toner Sensor ........................................................................................... 3-2

3. 3. Dimensional Adjustment of Copied Image.............................................................................. 3-4

3. 3. 1. Overview .................................................................................................................. 3-4

3. 3. 2. Paper alignment........................................................................................................ 3-6

3. 3. 3. Paper related adjustment .......................................................................................... 3- 7

3. 3. 4. Scanner related adjustment ..................................................................................... 3-12

3. 4. Image Quality Adjustment..................................................................................................... 3-19

3. 4. 1. Image density for copier .......................................................................................... 3-19

3. 4. 2. Sharpness adjustment for copier ............................................................................. 3-20

3. 4. 3. Gamma slope adjustment for copier ........................................................................ 3-20

3. 4. 4. Setting for range correction for copier ..................................................................... 3-21

3. 4. 5. Adjustment of background peak for range correction for copier .............................. 3-21

3. 4. 6. Adjustment of blurred/thin spotted text .................................................................... 3-22

3. 4. 7. Adjustment of image density for printer ................................................................... 3-22

3. 5. High-voltage Adjustment ....................................................................................................... 3-23

3. 6. Adjustment of Scanning Section ........................................................................................... 3-25

3. 6. 1. Carriages ................................................................................................................. 3-25

3. 6. 2. Lens unit .................................................................................................................. 3-29

3. 7. Adjustment of Paper Feeding System ................................................................................... 3-32

3. 7. 1. Sheet sidewa ys deviation caused by paper feeding ................................................ 3-32

3. 8. Adjustment of Developer Unit ............................................................................................... 3-34

3. 9. Adjustment of Fuser Unit ...................................................................................................... 3-35

3. 9. 1. Adjustment of fuser roller pressure ......................................................................... 3-35

I

JUNE 2002 © TOSHIBA TECe-STUDIO550/650/810 CONTENTS

Page 7

3. 9. 2. Setting of fuser roller temperature........................................................................... 3-36

3. 9. 3. Adjustment of fuser inlet guide ................................................................................ 3-36

3. 9. 4. High-fusing mode ..................................................................................................... 3-37

3. 10 Adjustment of Exit/Reversal Unit .......................................................................................... 3-38

3. 10. 1.Adjustment of sideways deviation at reverse discharging ....................................... 3-38

3. 11. Adjustmet of Reversing Automatic Document Feeder .......................................................... 3-39

3. 11. 1. Installing of the RADF unit ....................................................................................... 3-39

3. 11. 2.Skew adjustment ..................................................................................................... 3-40

3. 11. 3.Adjustment of solenoid ............................................................................................ 3-41

3. 11. 4.Adjustment of RADF open/close switch .................................................................. 3-42

3. 11. 5.Adjustment of RADF height ..................................................................................... 3-42

3. 12. Key Copy Counter (MU-8, MU-10)........................................................................................ 3-43

4. PREVENTIVE MAINTENANCE (PM) ......................................................................................... 4-1

4. 1. PM Support Mode ................................................................................................................. 4-1

4. 1. 1. General description ................................................................................................... 4-1

4. 1. 2. Operational flow and operational screen.................................................................... 4- 1

4. 2. General Descriptions for PM procedure.................................................................................. 4- 5

4. 3. Operational Items in Overhauling ........................................................................................... 4-5

4. 4. Preventive Maintenance Checklist ......................................................................................... 4-5

4. 5. PM Kit ................................................................................................................................... 4-19

4. 6. Jig List ................................................................................................................................... 4-20

4. 7. Precautions for Storing and Handling Supplies....................................................................... 4-21

4. 7. 1. Precautions for storing TOSHIBA supplies................................................................ 4-21

4. 7. 2. Checking and cleaning of OPC drum ........................................................................ 4-21

4. 7. 3. Checking and cleaning of drum cleaning blade and transfer belt cleaning blade ............. 4-22

4. 7. 4. Handling of drum cleaning brush and transfer belt cleaning brush ............................. 4-23

4. 7. 5. Handling of transfer belt ............................................................................................ 4-23

4. 7. 6. Checking and cleaning of fuser roller and pressure roller........................................... 4-23

4. 7. 7. Checking and replacing of cleaning web and cleaning rollers (felt, metal) .................. 4-24

5. TROUBLESHOOTING ............................................................................................................... 5-1

5.1 Diagnosis and Prescription for Each Error Code and Phenomenum .................................... 5-1

5.1.1 Paper transport jam ................................................................................................. 5-1

5.1.2 Paper misfeeding ..................................................................................................... 5-14

5.1.3 Cover open jam........................................................................................................ 5-21

5.1.4 Jams at eit/reverse section and other transport jams ............................................. 5-24

5.1.5 Original jam in RADF ............................................................................................... 5-33

5.1.6 Paper jam in finisher ................................................................................................ 5-37

5.1.7 Drive system related service call............................................................................ 5-48

5.1.8 Process system related service call ....................................................................... 5-58

5.1.9 Scanning system related ser vice call ..................................................................... 5-60

5.1.10 Fuser unit related ser vice call ................................................................................. 5-62

IIJUNE 2002 © TOSHIBA TEC e-STUDIO550/650/810 CONTENTS

Page 8

5.1.11 Communication related service call ........................................................................ 5-68

5.1.12 ADF related ser vice call .......................................................................................... 5-71

5.1.13 Laser optical unit related service call...................................................................... 5-76

5.1.14 Finisher related ser vice call .................................................................................... 5-79

5.1.15 Ser vice call for others ........................................................................................... 5-101

5.1.16 Troubleshooting for image quality control .............................................................. 5-102

5.1.17 Troubleshooting for surface potential control ......................................................... 5-105

5.2 Troubleshooting for the Image............................................................................................. 5-107

6. FIRMWARE UPDATING............................................................................................................ . 6-1

6. 1. Software Installing for Firmware Updating............................................................................ 6-2

6. 1. 1. Outline ..................................................................................................................... 6-2

6. 1. 2. Requirements........................................................................................................... 6-2

6. 1. 3. Dial-up network function .......................................................................................... 6-4

6. 1. 4. Installing of dial-up network ..................................................................................... 6-8

6. 1. 5. Setting of dial-up network ........................................................................................ 6-10

6. 1. 6. Software installing for FTP server ........................................................................... 6-14

6. 2. Operation Procedure in [3][9] Mode...................................................................................... 6-18

6. 2. 1. Outline ..................................................................................................................... 6-18

6. 2. 2. Preparation .............................................................................................................. 6-18

6. 2. 3. Updating procedure.................................................................................................. 6-20

6. 2. 4. Display ..................................................................................................................... 6-28

6. 3. Firmware Updating with Download Jig.................................................................................. 6-32

6. 3. 1. System firmware...................................................................................................... 6-33

6. 3. 2. Engine firmware ....................................................................................................... 6-39

7. POWER SUPPLY UNIT ........................................................................................................7-1

7. 1. Output Channel ..................................................................................................................... 7-1

7. 2. Fuse ...................................................................................................................................... 7-5

8. WIRE HARNESS CONNECTION DIAGRAMS ........................................................................8-1

8. 1. AC Wire Harness .................................................................................................................. 8-2

8. 2. DC Wire Harness ................................................................................................. 8-4, Appendix

IIIe-STUDIO550/650/810 CONTENTS

JUNE 2002 © TOSHIBA TEC

Page 9

1. SPECIFICATIONS / A CCESSORIES / OPTIONS / SUPPLIES

1. 1. Specifications

When the specification is different among e-STUDIO550, 650 and 810, the value for e-STUDIO650 is

shown by [ ] and the value for e-STUDIO810 is shown by { }.

• Copy process ...............Indirect electrophotographic process (dry system)

• Type ..............................Console type

• Original table ................Fixed type (left rear corner used as a guide to place originals)

• Acceptable originals .....Sheets, books and 3-dimensional objects

The automatic document feeder only accepts paper (single-sided originals:

50~127g/m2/13~34Ib.Bond, double-sided originals: 50~104g/m2/13~28Ib.Bond)

excluding carbon paper , pasted sheet and stapled sheet.

Maximum size : A3/LD

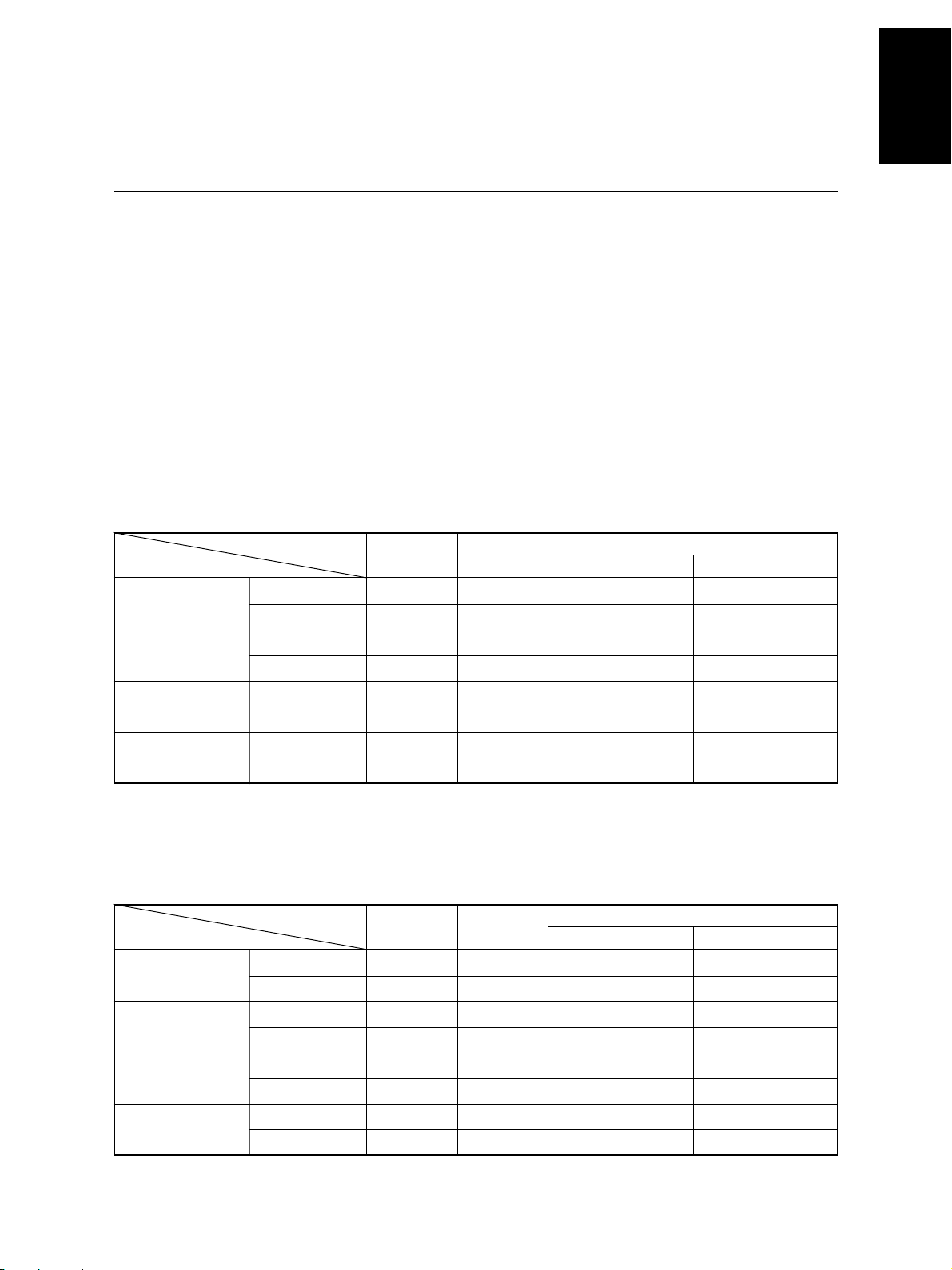

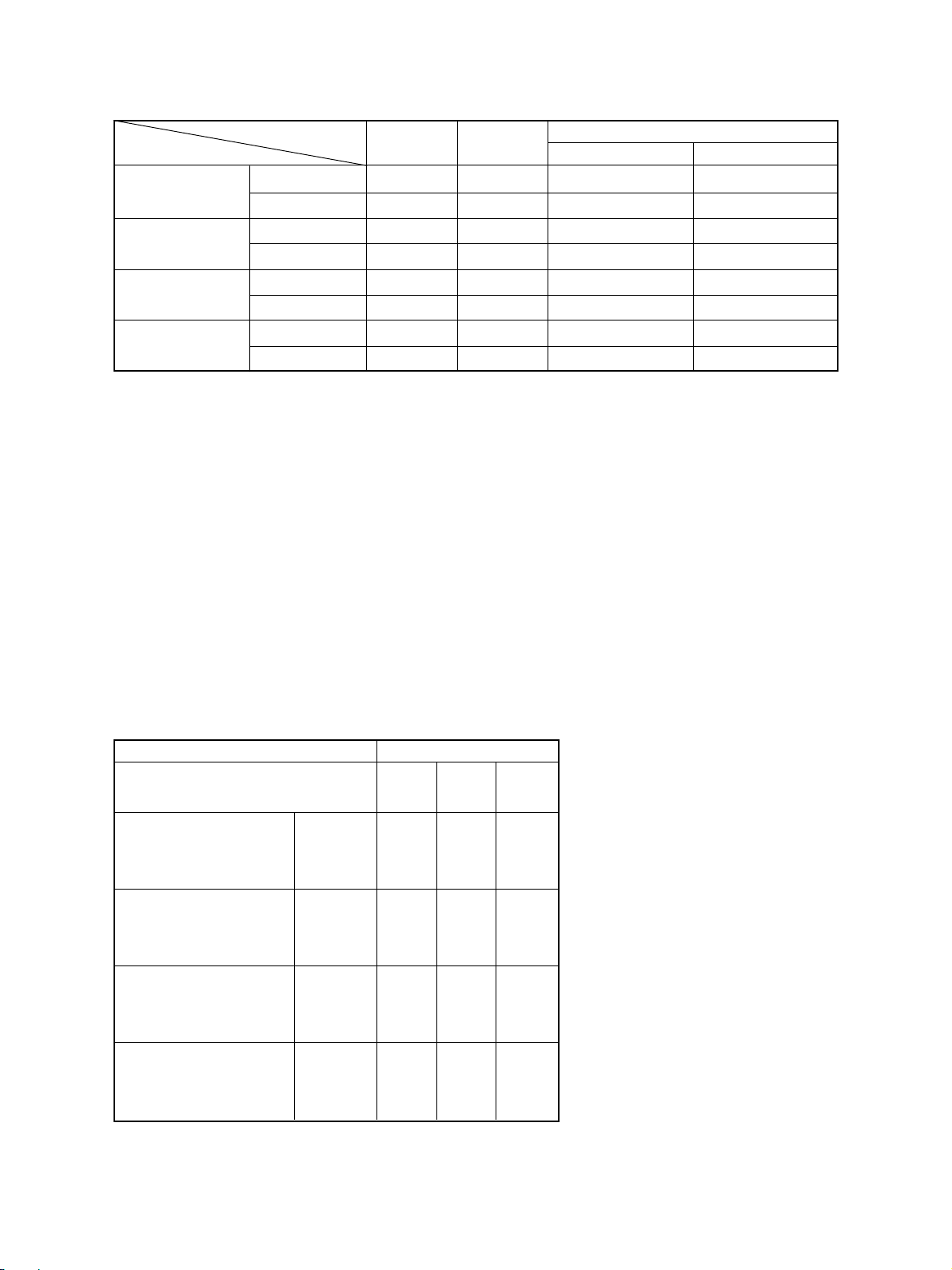

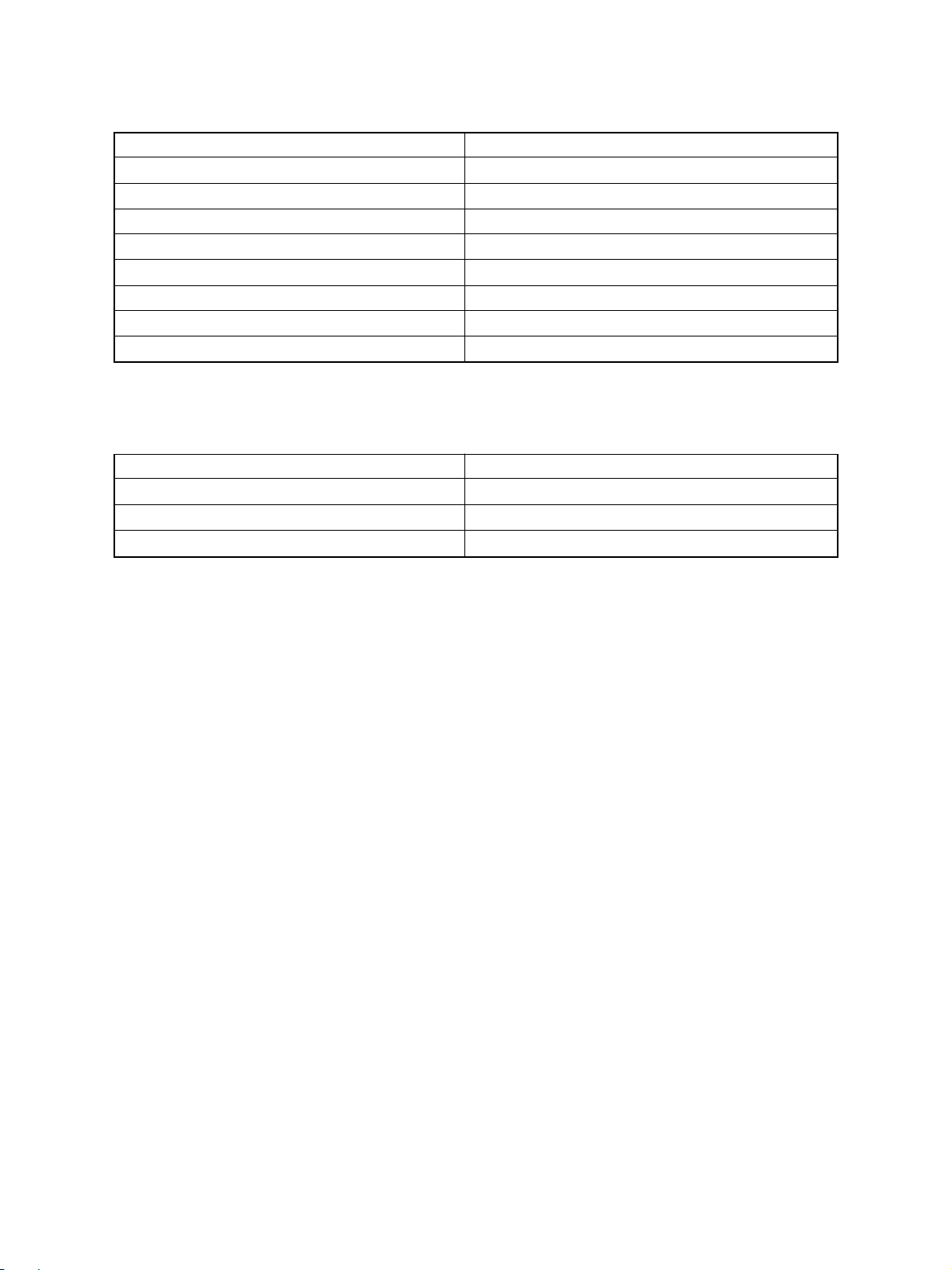

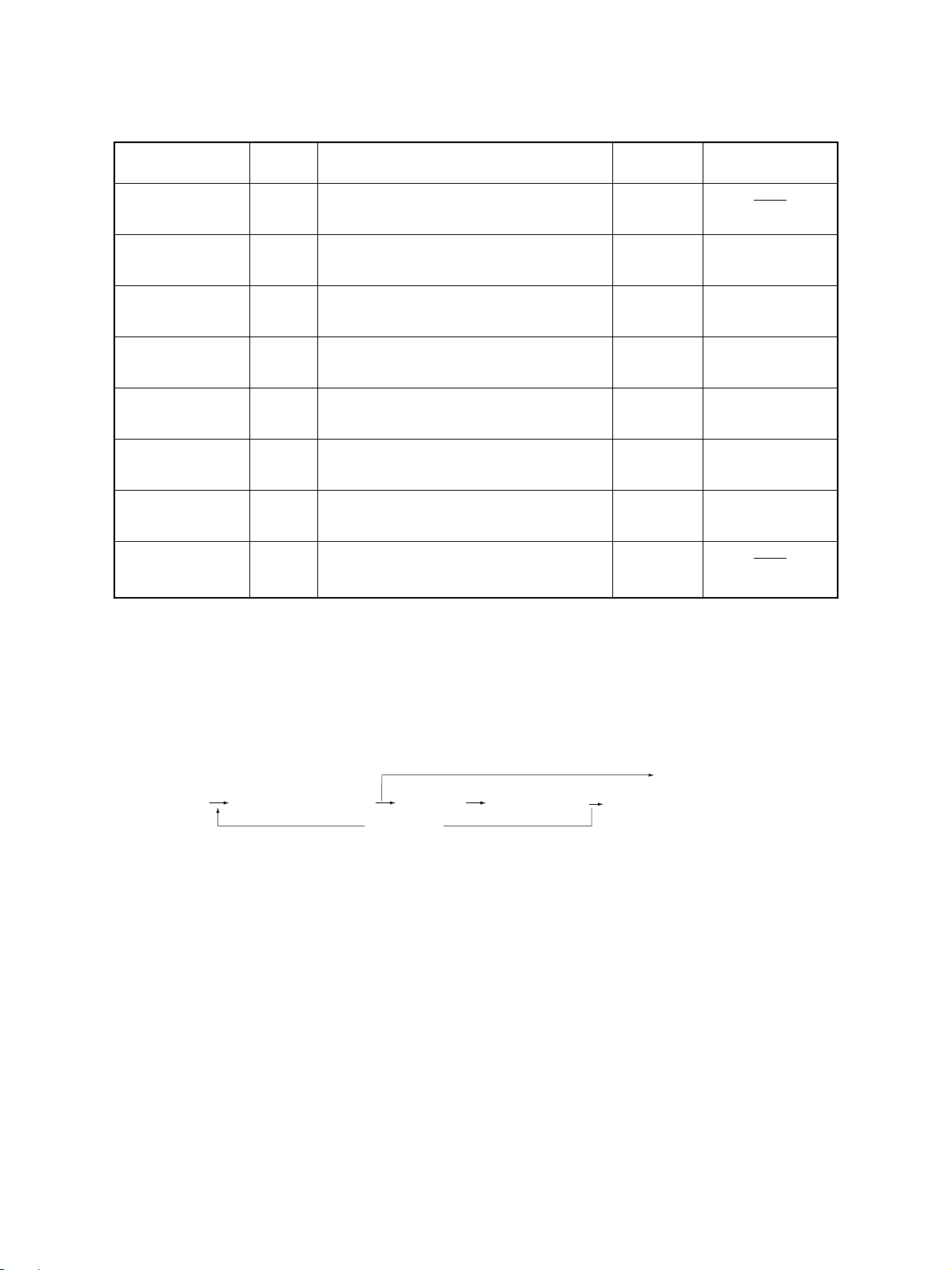

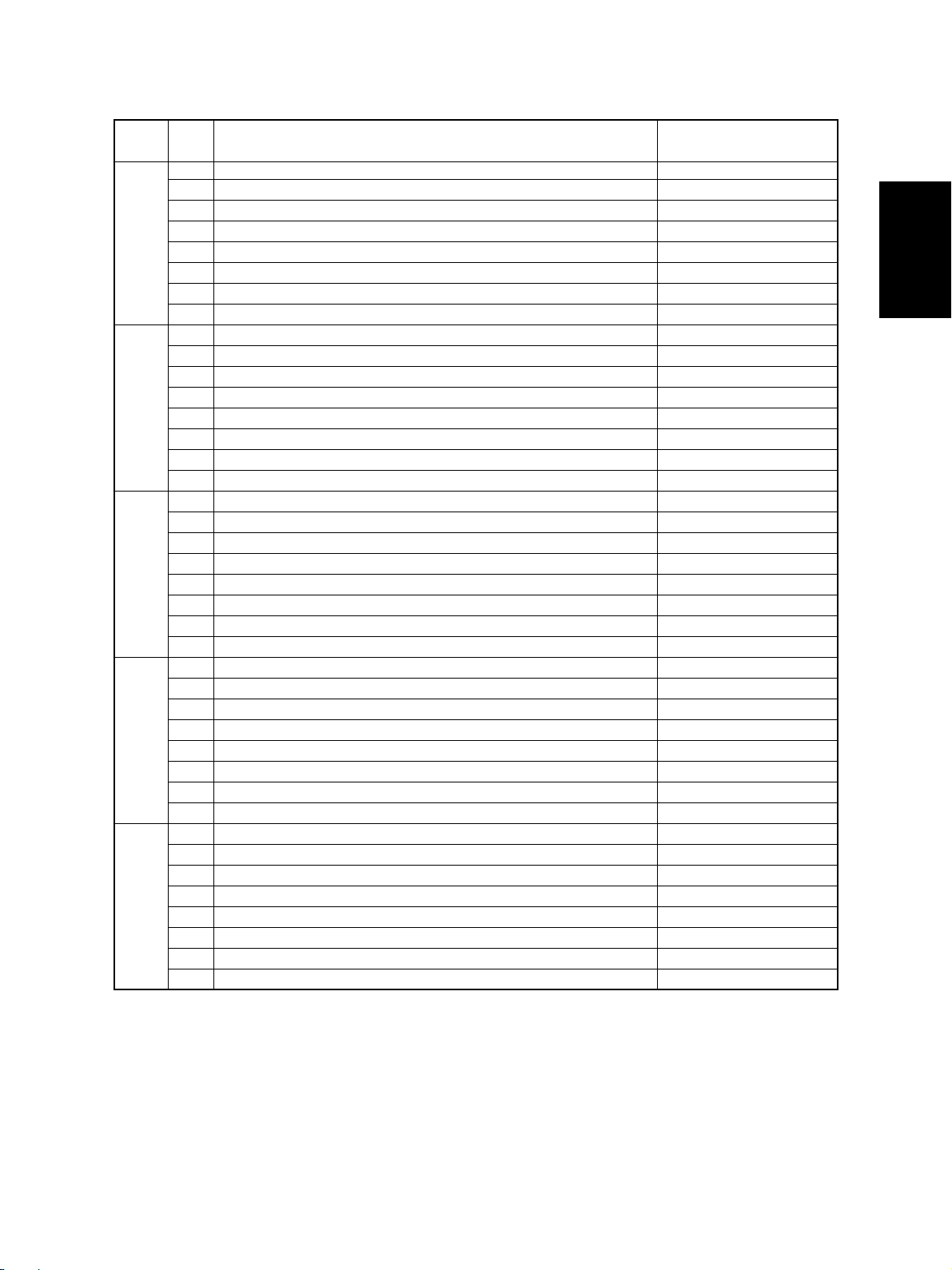

• Copy speed

e-STUDIO550 (Copies/min.)

Paper supply Tandem

Paper size Size specified Size not specified

A4, LT, B5

A4-R, B5-R,

A5-R, L T-R, ST-R

B4, LG

A3, LD

T op side discharging

Back side discharging

T op side discharging

Back side discharging

T op side discharging

Back side discharging

T op side discharging

Back side discharging

Cassette

55 55 48 33

55 55 48 30

44 — 42 33

42 — 42 30

39 — 37 33

35 — 35 30

34 — 33 33

30 — 30 30

LCF

Bypass feeding

e-STUDIO650

Paper supply Tandem

Paper size Size specified Size not specified

A4, LT, B5

A4-R, B5-R,

A5-R, L T-R, ST-R

B4, LG

A3, LD

JUNE 2002 © T OSHIBA TEC 1 - 1 e-STUDIO550/650/810 SPECIFICATIONS

T op side discharging

Back side discharging

T op side discharging

Back side discharging

T op side discharging

Back side discharging

T op side discharging

Back side discharging

Cassette

65 65 48 33

65 65 48 33

50 — 42 33

48 — 42 33

43 — 37 33

40 — 37 33

37 — 33 33

34 — 33 33

LCF

Bypass feeding

(Copies/min.)

Page 10

e-STUDIO810

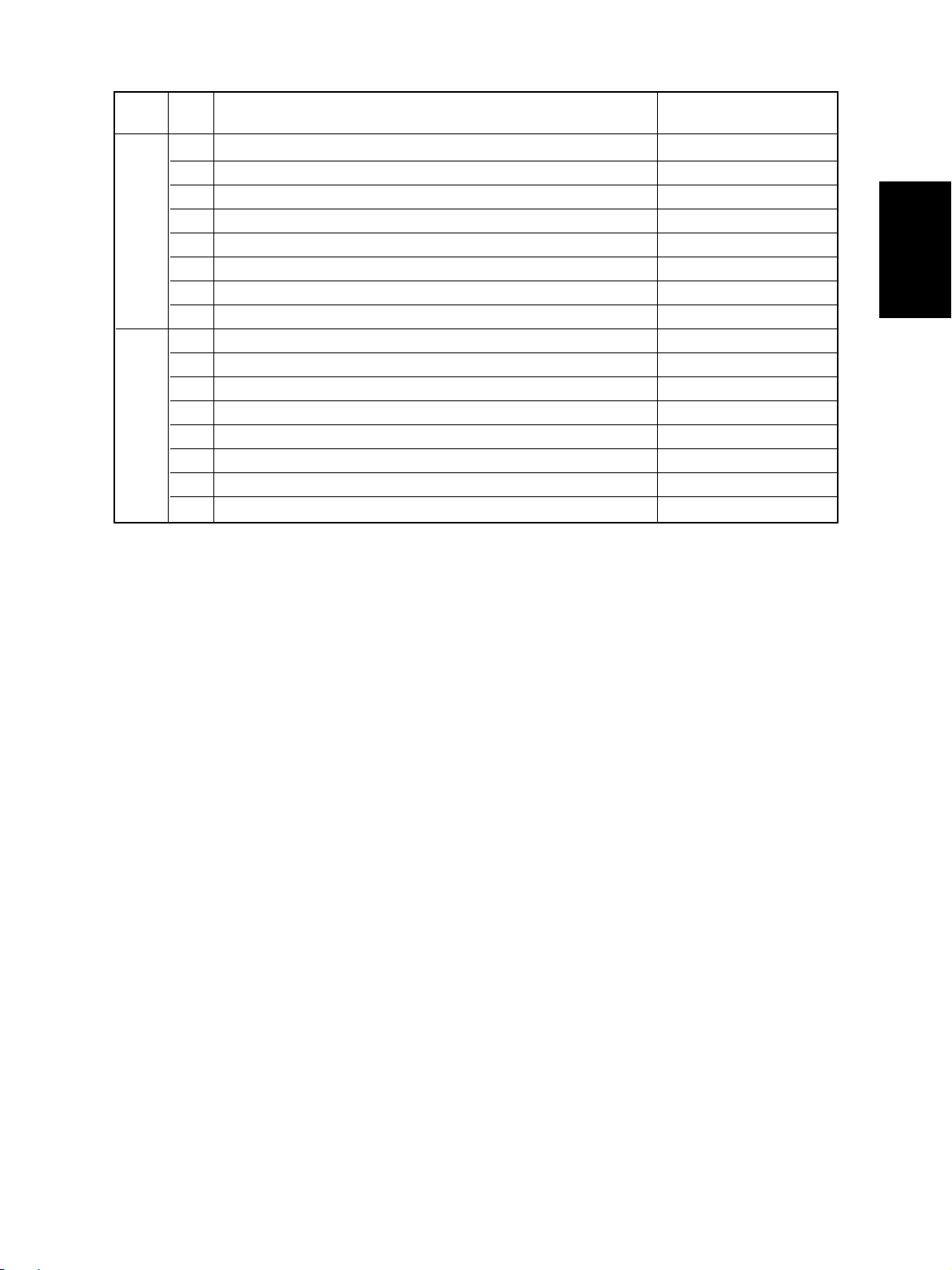

(Copies/min.)

Paper supply

Paper size Size specified Size not specified

A4, LT, B5

A4-R, B5-R,

A5-R, L T-R, ST-R

B4, LG

A3, LD

“–” means “Not acceptable”.

*

Each copy speed described in the table of the previous page is available when doing a multiple copying

*

of the manually placed single-sided originals, and in this mode, only the top side discharging is carried

out.

When using the automatic document f eeder, each copy speed of 55 [65] {81} copies/min. is a vailable

*

only when the following conditions are met:

• Original/Mode : Single-sided original, A4/LT size, 1 sheet/APS and automatic

• Preset number of sheets: 55 [65] {81} or more.

• Reproduction ratio : 100%

T op side discharging

Back side discharging

T op side discharging

Back side discharging

T op side discharging

Back side discharging

T op side discharging

Back side discharging

Cassette

81 81 50 34

81 81 50 34

61 — 44 34

56 — 44 34

52 — 39 34

45 — 39 34

43 — 34 34

37 — 34 34

density are not selected.

Tandem

LCF

Bypass feeding

System copy speed

*

Copy mode

e-STUDIO e-STUDIO e-STUDIO

550 650 810

Single-sided originals 1 set 18"86 16"81 15"96

훹 3 sets 40"17 35"99 30"52

Single-sided copies 5 sets 61"92 53"56 45"19

Single-sided originals 1 set 21"28 20"70 20"46

훹 3 sets 42"91 39"47 36"37

Double-sided copies 5 sets 64"89 57"70 49"48

Double-sided originals 1 set 35"32 35"21 34"36

훹 3 sets 78"61 71"70 63"89

Double-sided copies 5 sets 121"96 108"01 95"06

Double-sided originals 1 set 31"77 31"49 30"88

훹 3 sets 74"75 67"97 60"58

Single-sided copies 5 sets 117"88 104"64 90"02

e-STUDIO550/650/810 SPECIFICA TIONS 1 - 2 JUNE 2002 © TOSHIBA TEC

sec.

System copy speed, including

*

scanning time, is available when 10

sheets of A4-sized original are set

on RADF and one of the copy modes

in the left table is selected.

1st cassette is selected and copying

*

is at the sort mode.

Finisher, hole-punch unit and inserter

*

are installed.

Measurement deviation is included

*

since the system copy speed was

measured by actual measurement.

Page 11

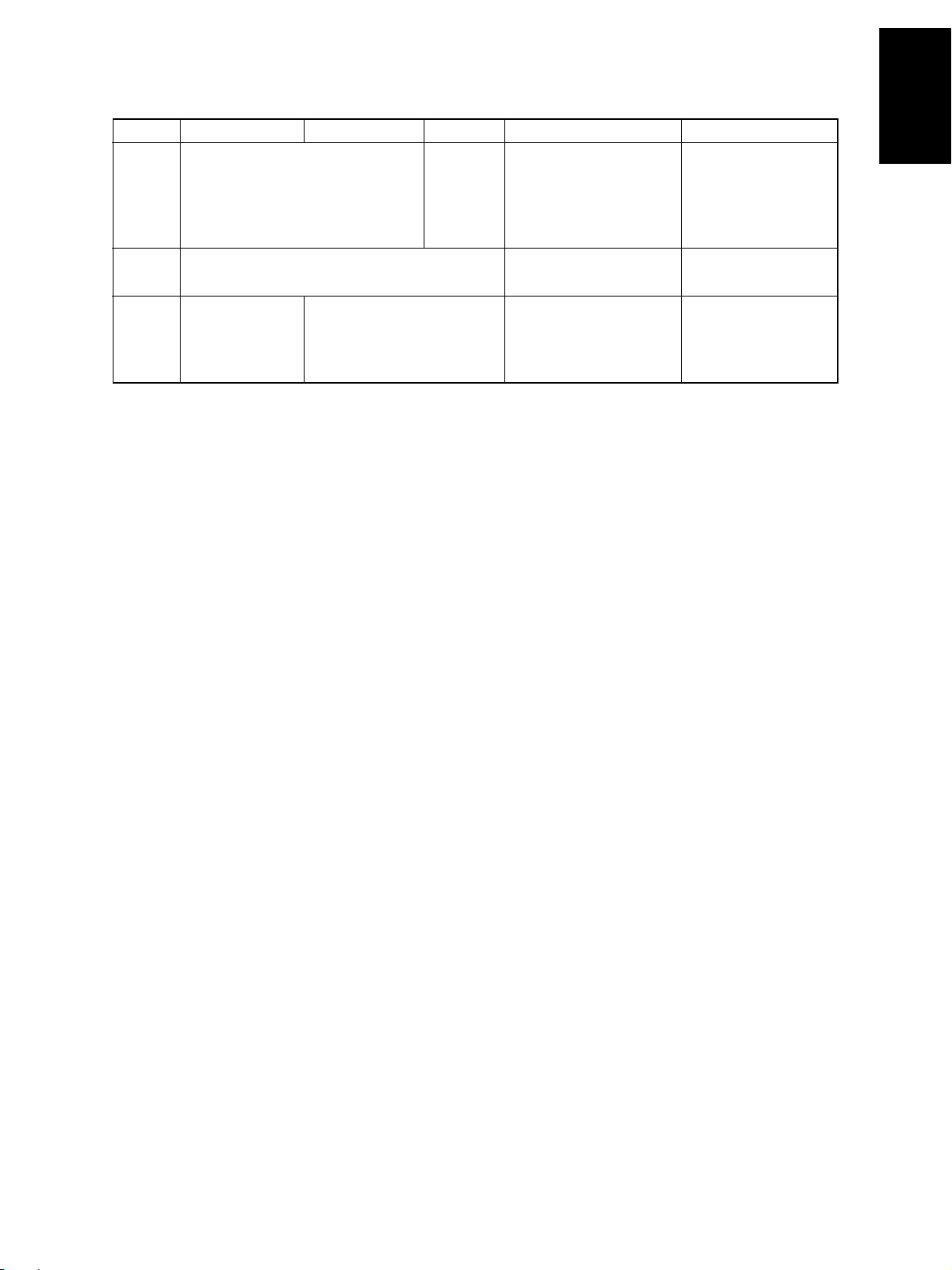

• Copy paper

Cassette Duplex copy LCF Bypass copy Remarks

Size A3~A5R, A4, LT A3~A5-R, LD~ST -R, No guarantee for 8K,

LD~ST-R, 13"LG, 8.5"x8.5", 8.5"x8.5", 8K, 16K, 16K-R 16K, 16K-R at duplex

8K, 16K, 16K-R

(Non-standard or user-

copy

specified sizes can be set.)

Weight 64~209g/m2, 17~110lb. -inde x 64~209g/m

2

17Ib~110Ib -index

Special Tab paper _

paper

(2nd casette only) OHP film (thickness: should be recommanded

T racing paper , labels, Special types of paper

80µm or thicker), tab paper by T oshiba.

• First copy time ..................3.3 seconds or less (A4/L T, LCF, 100%, original placed manually)

• Warming-up time ................ Approx.160 seconds (e-STUDIO550/650/810, T emper ature: 20°C)

Notes: 1. This is at the condition not entering the toner supply operation.

2. The auto job start is not operated.

• Multiple copying.................Up to 9999 copies; set number entered with digital keys

• Reproduction ratio..............Actual ratio: 100±0.5%

Zooming: 25~400% in increments of 1%

(25~200% when using the RADF)

• Resolution/Gradation ......... Read: 600 dpi

.........Write: Equivalent to 2400 dpi x 600 dpi

(primary scanning only : 4 division smoothing)

• Eliminated image width......Leading edge: 3.0±1.0 mm, Trailig edge: 2.0±1.0 mm, Side edges: 2.0±2.0 mm

• P aper f eeding.....................Automatic feeding: Copier cassettes–2 cassettes (Paper stac k height

55 mm, equivalent to 550 sheets; 64 to 80 g/m2 (17

to 22 lb.Bond))

LCF (Paper stac k height 137 mm: equiv alent to 2500

sheets; 64 to 80 g/m2, 17 to 22 lb.Bond)

Bypass feeding: (Paper stac k height 11 mm : equivalent to 100 sheets;

64 to 80 g/m2, 17 to 22 lb.Bond)

• Capacity of originals in the automatic document feeder

.................A3~A5-R, LD~ST-R

: 100 sheets

• Automatic duplexer............Stackless, Switchback type

• Toner supplying..................Automatic toner density detection/supply

T oner cartridge replacing method

(There is a recycle toner supplying system.)

JUNE 2002 © T OSHIBA TEC 1 - 3 e-STUDIO550/650/810 SPECIFICATIONS

Page 12

• Density control ..................Automatic density mode and manual density mode selectable in 11 steps

• Weight ............................... Approx. 200kg, 441lb

• P ow er requirements ...........AC 115V/15A, AC 220 – 240V/10A

• Power consumption ...........2.0 kW or less (115V series, 200V series)

The electric power is supplied to the finisher and external LCF (optional) through the copier .

*

• T otal counter ......................Electronic counter

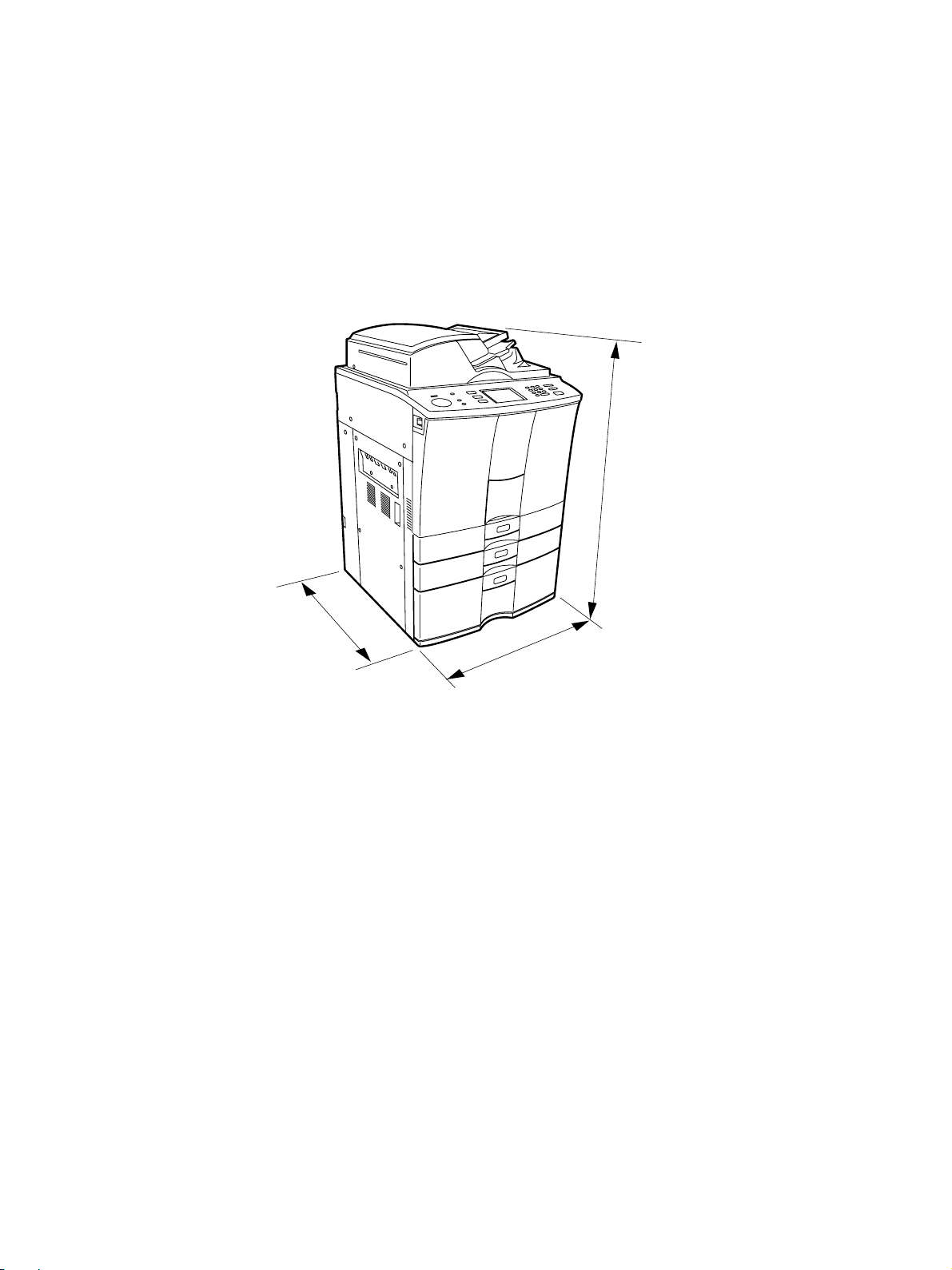

• Dimensions of the copier ... See the figure below . (W698x D778 x H1207 mm)

1207 mm

778 mm

698 mm

e-STUDIO550/650/810 SPECIFICA TIONS 1 - 4 JUNE 2002 © TOSHIBA TEC

Page 13

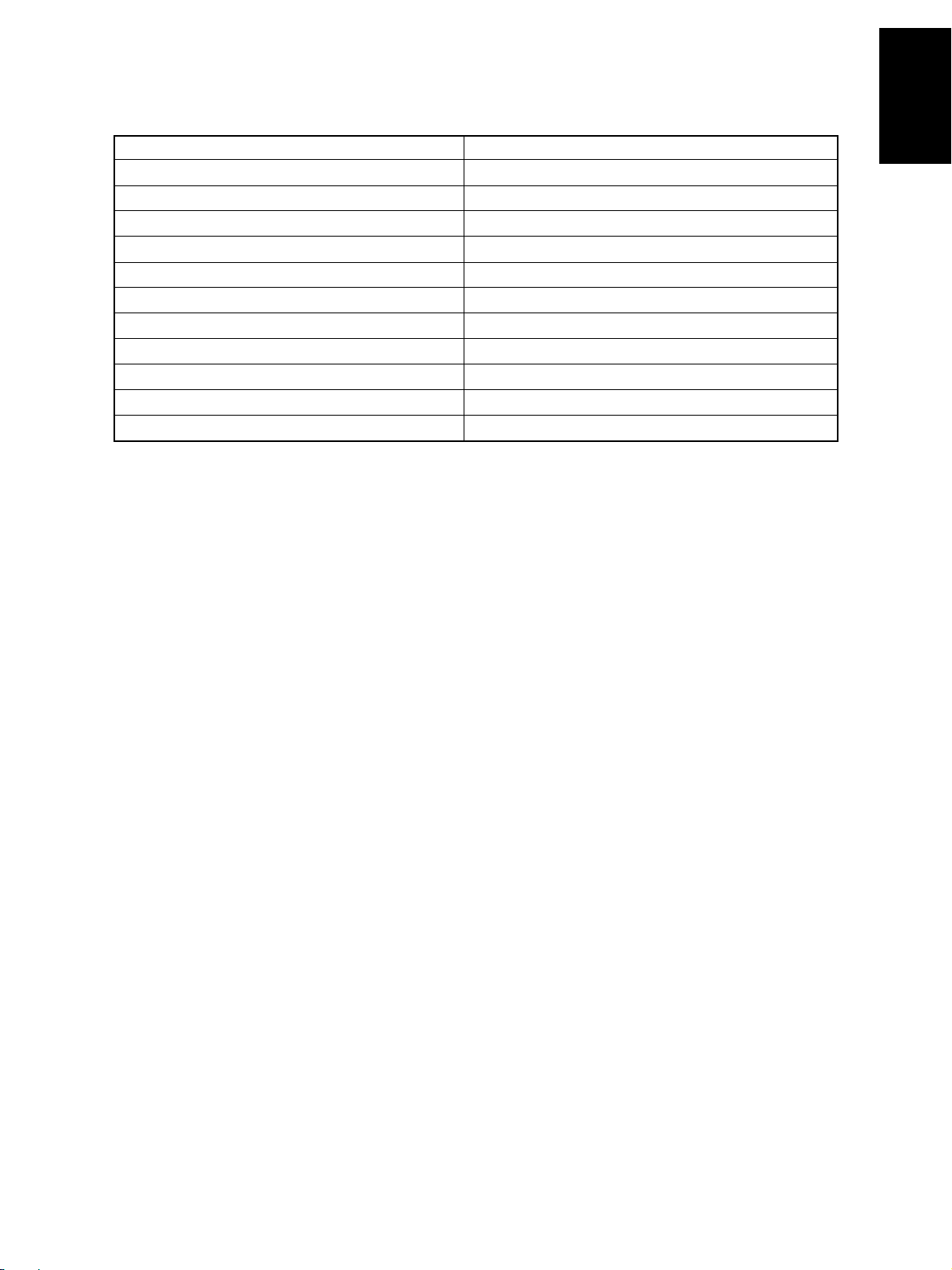

1. 2. Accessories

Unpacking/setup instruction 1 pc.

Operator’s Manu al 1 pc. (not available for MJD)

PM sticker 1 pc. (for MJD)

Setup report 1 set. (for NAD and MJD)

Customer satisfaction card 1 pc. (for MJD)

Operator’s Manual pocket 1 pc.

P ow er cable 1 pc. (for ASD, AUD and MJD)

Warr anty sheet 1 pc. (for NAD)

Drum 1 pc.

Drum cover 1 pc.

Original feeding tray 1 pc.

Tab paper end guide 1 pc.

* Machine version

NAD: North America

MJD: Europe

AUD: Australia

ASD: Asia

JUNE 2002 © T OSHIBA TEC 1 - 5 e-STUDIO550/650/810 SPECIFICATIONS

Page 14

1. 3. Options

Finisher MJ-1017, MJ-1018

Hole punch unit MJ-6003N/E/F/S

Inserter MJ-7001

Staple cartridge STAPLE-600/STAPLE-700 (for saddle stitcher)

External large capacity feeder MP-4003A/L

Key copy counter/Key copy counter socket MU-8/MU-10

Damp heater kit MF-6510U/E

Printer controller GL-1020

Printer board GA-1140

1. 4. Supplies

Drum OD- 6510

Developer material D-6510

T oner PS-ZT6510/PS-ZT6510/PS-ZT -6510D

T oner bag PS-TB6510/PS-TB6510E

e-STUDIO550/650/810 SPECIFICA TIONS 1 - 6 JUNE 2002 © TOSHIBA TEC

Page 15

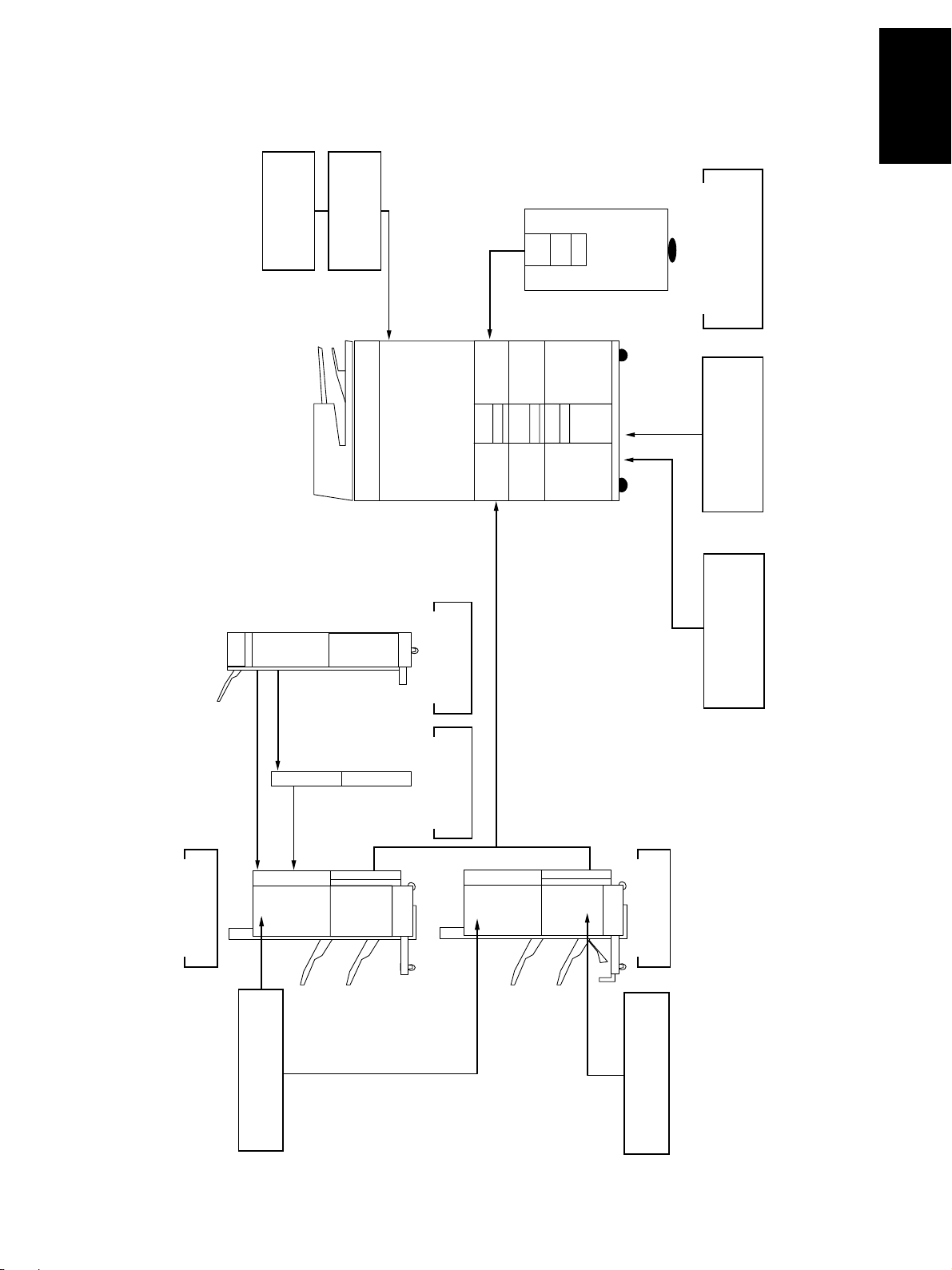

1. 5. System List

Ke y counter

Key counter socke t

MU-10

MU-8

LCF

MP-4003

Printer board

GA-1140

Finisher

MJ-1017

Staple cartridge

STAPLE-600

Inserter

MJ-7001

Hole punch unit

MJ-6003

Finisher

MJ-1018

Staple cartridge

STAPLE-700

Printer controller

GL-1020

JUNE 2002 © T OSHIBA TEC 1 - 7 e-STUDIO550/650/810 SPECIFICATIONS

Page 16

2. ERR OR CODES AND SELF-DIAGNOSIS

2. 1. Error Codes

Instead of the set number, one of the following error codes is displayed with pressing the [CLEAR] key and

the digital key “8” simultaneously when the “CLEAR PAPER” or “CALL SERVICE” symbol is flashing.

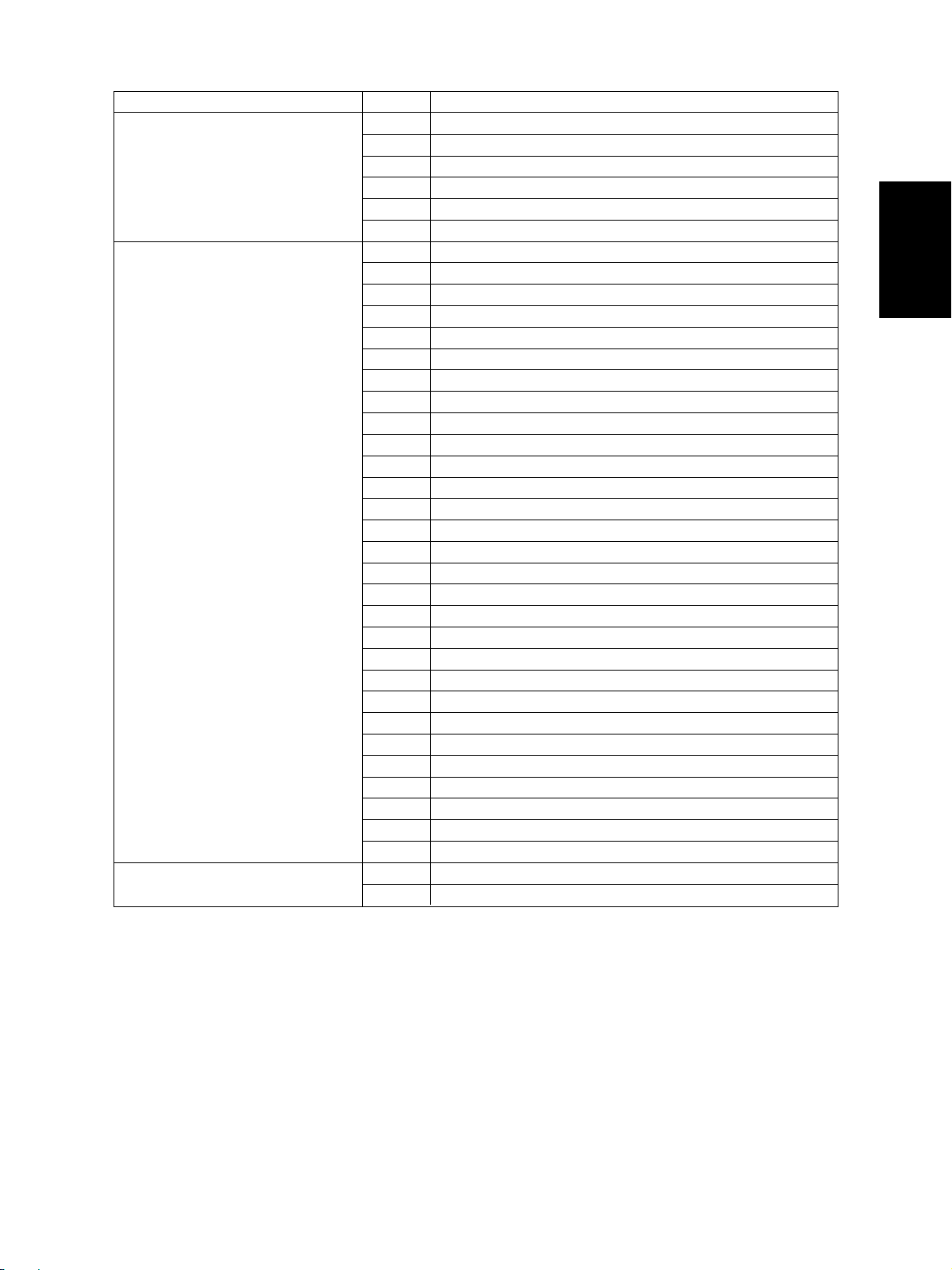

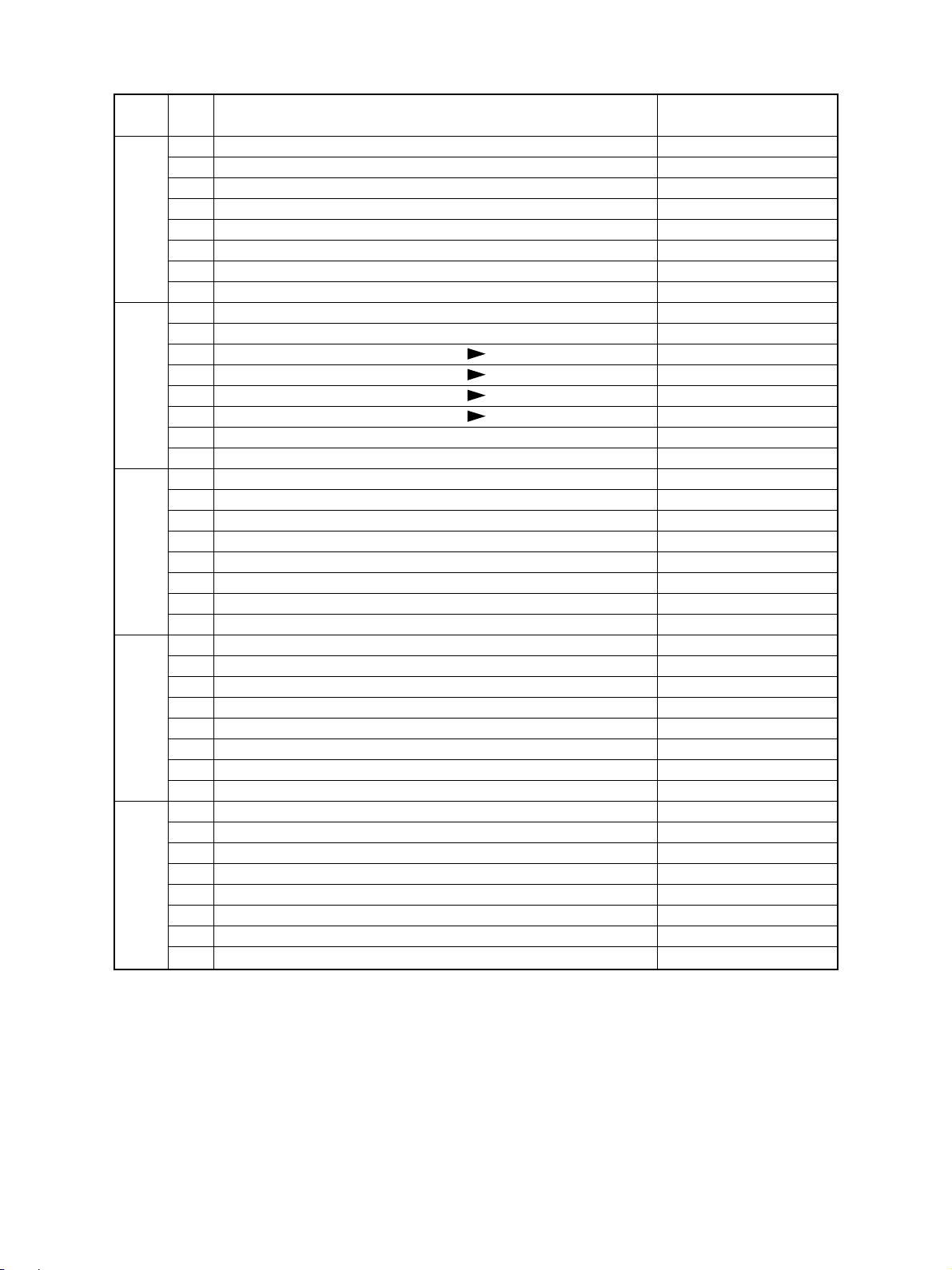

Group

Paper transport jam inside the E01 Leading edge of paper not reaching the fuser exit sensor

copier (1) E02 T railing edge of paper not passing the fuser e xit sensor

Paper misfeeding E11 Misfeeding during duplex printing

Paper transport jam inside the copier (2) E20 Paper fed from the 1st cassette

Error Code

E03 Paper remaining inside the copier at power ON

E09 Jam caused by an abnormal HDD

(paper not reaching the registration sensor)

E12 Bypass misfeeding

(paper not reaching the registration sensor)

E13 1st cassette misfeeding

(paper not reaching the 1st cassette feed sensor)

E14 2nd cassette misfeeding

(paper not reaching the 2nd cassette feed sensor)

E15 3rd cassette misfeeding

(paper not reaching the 3rd cassette feed sensor)

E16 4th cassette misfeeding

(paper not reaching the 4th cassette feed sensor)

E18 Tandem LCF misfeeding

(paper not reaching the tandem LCF feed sensor)

E19 External LCF misfeeding

(paper not reaching the external LCF feed sensor)

(not reaching the registration sensor)

E21 Paper fed from the 1st cassette

(not reaching the 1st cassette transport sensor)

E22 Paper fed from the 2nd cassette

(not reaching the registration sensor)

E23 Paper fed from the 2nd cassette

(not reaching the 1st cassette transport sensor)

E24 Paper fed from the 2nd cassette

(not reaching the 2nd cassette transport sensor)

E25 Paper fed from the e xternal LCF

(not reaching the registration sensor)

E30 Paper fed from the 3rd cassette

(not reaching the registration sensor)

E31 Paper fed from the 3rd cassette

(not reaching the 1st cassette transport sensor)

E32 Paper fed from the 3rd cassette

(not reaching the 2nd cassette transport sensor)

Machine Status

JUNE 2002 © T OSHIBA TEC 2 - 1 e-STUDIO550/650/810

ERROR CODES AND SELF-DIAGNOSIS

Page 17

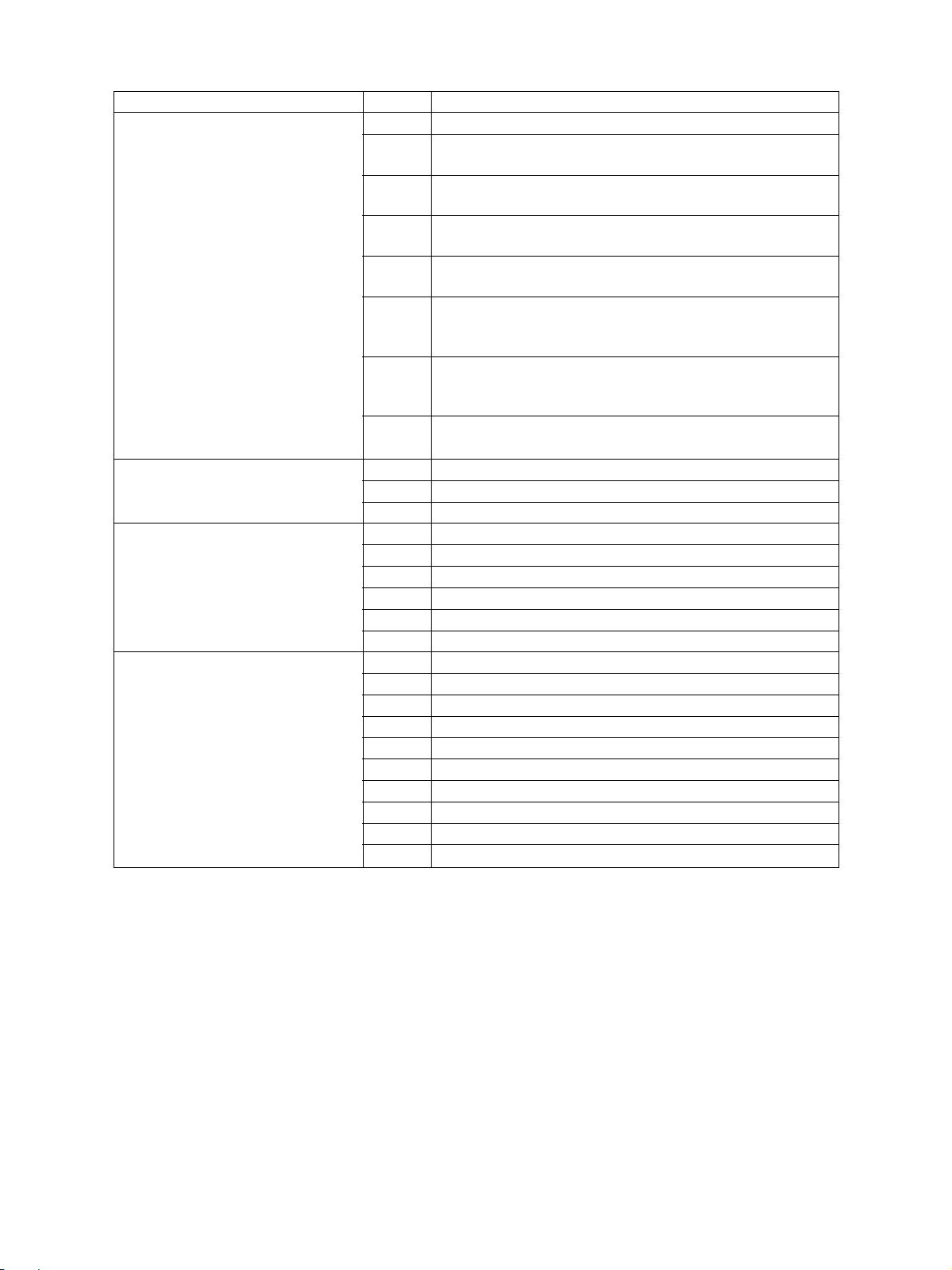

Group

Paper transport jam inside the copier (2) E33 Paper fed from the 3rd cassette

Cover open jam E41 Front cover opened during printing

Transpor t jam (exit/reversing section E5 0 Leading edge of paper not reaching the reverse sensor 2

and others) E51 Leading edge of paper not reaching the transport sensor 1

T r ansport jam (RADF) E71 Original feeding jam

Error Code

(not reaching the 3rd cassette transport sensor)

E34 Paper fed from the 4th cassette

(not reaching the registration sensor)

E35 Paper fed from the 4th cassette

(not reaching the 1st cassette transport sensor)

E36 Paper fed from the 4th cassette

(not reaching the 2nd cassette transport sensor)

E37 Paper fed from the 4th cassette

(not reaching the 3rd cassette transport sensor)

E38 Paper fed from the 4th cassette

(not reaching the 4th cassette transport sensor)

E3C Paper fed from the tandem LCF

(not reaching the registration sensor)

E3D Paper fed from the tandem LCF

(not reaching the 1st cassette feed sensor)

E3E Paper fed from the tandem LCF

(not reaching the 2nd cassette feed sensor)

E3F Paper fed from the tandem LCF

(not reaching the tandem LCF transport sensor)

E44 Feed cover opened during printing

E45 LCF side cover opened during printing

E46 Bypass feed unit cover opened during printing

E47 Exit cover opened during printing

E52 Leading edge of paper not reaching the transport sensor 2

E54 Leading edge of paper not reaching the transport sensor 3

E55 Paper remaining on the transport path when CRUN is OFF

E57 Leading edge of paper not reaching the reverse sensor 1

E58 Trailing edge of paper not passing the reverse sensor 1 or

reverse sensor 2

E59 T railing edge of paper not passing the e xit sensor

E5A Leading edge of paper not reaching the exit sensor

E72 Original transport jam

E73 Original discharging jam

E74 Original reversing jam

E76 Small original discharging jam

E77 Scanning section transport jam

E7B RADF opened at the original transporting

E7C RADF opened at the large original discharging

E7D RADF opened at the small original reversing

E7E RADF opened at the small original discharging

E7F RADF opened at the original scanning section

Machine Status

e-STUDIO550/650/810

ERROR CODES AND SELF-DIAGNOSIS

2 - 2 JUNE 2002 © T OSHIBA TEC

Page 18

Group

T ransport jam (RADF) E8 0 Jam access cover opened at the original feeding

Paper jam in finisher E9F Punching jam

Paper transport jam inside the EB5 Paper left on the transport path

copier (3) EB6 Paper left on the transport path

Error Code

E81 Jam access cover opened at the original transporting

E82 Jam access cover opened at the large original dischaging

E83 Jam access cover opened at the small original reversing

E84 Jam access cover opened at the small original discharging

E85 Jam access cover opened at the original scanning section

EA1 Finisher paper transport delay jam

EA2 Finisher paper transport stop jam

EA3 Paper remaining inside the finisher at power ON

EA4 Finisher front door opened during printing

EA5 Finisher stapling jam

EA6 Finisher early arrival jam

EA7 Stack transport jam before stapling

EA8 Saddle stitcher stapling jam

EA9 Saddle stitcher door opened during printing

EAA Paper remaining at the saddle stitcher at power ON

EAB Saddle stitcher paper transport stop jam

EAC Saddle stitcher paper transport delay jam

EAD Print end command time-out jam

EAE Receiving time time-out jam

EB3 Ready time time-out jam

EC0 Inserter feeding delay jam

EC1 Inserter feeding stop jam

EC2 Inserter reverse path delay jam 1

EC3 Inserter reverse path stop jam 1

EC4 Inserter reverse path delay jam 2

EC5 Inserter reverse path stop jam 2

EC6 Inserter transport delay jam 1

EC7 Inserter transport stop jam 1

EC8 Inserter transport delay jam 2

EC9 Inserter transport stop jam 2

ECA Paper remaining in the inserter when power is ON

ECB Wrong size of inserter

ECC Inserter feeding Jam

Machine Status

JUNE 2002 © T OSHIBA TEC 2 - 3 e-STUDIO550/650/810

ERROR CODES AND SELF-DIAGNOSIS

Page 19

Group

Paper feeding system related service call

Scanning system related service call C26 Peak detection error

Processing system related service call C36 Abnormal main charger wire cleaner drive motor

Fuser unit related service call C41 Abnormal thermistor or heater at the power ON

Error Code

C04 Abnormal feed motor

C1 3 Abnormal 1st cassette tray (Paper can be fed from cassettes

other than the 1st cassette.)

C14 Abnormal 2nd cassette tray (Paper can be fed from cassettes

other than the 2nd cassette.)

C15 Abnormal 3rd cassette tray (Paper can be fed from cassettes

other than the 3rd cassette.)

C16 Abnormal 4th cassette tray (Paper can be fed from cassettes

other than the 4th cassette.)

C1 8 Abnormal tandem LCF tray-up motor

(Paper can be fed from cassettes other than the tandem LCF

cassette.)

C1A Abnormal tandem LCF end fence motor

(Paper can be fed from cassettes other than the tandem LCF

cassette.)

C1C Abnormal external LCF tray-up motor

(Paper can be f ed from cassettes other than the external LCF)

C27 Carriage home position sensor not going OFF within a fixed time

C28 Carriage home position sensor not going ON within a fixed time

C37 Abnormal transfer belt cam motor

CD1 Abnormal drum cleaning brush motor

CD2 Abnormal used toner transport motor

CD3 Abnormal recycle toner transport motor

CD4 Full toner bag

C43 Abnormal thermistor after abnormality judgment

C44 Abnormal fuser after abnormality judgment

C45 Abnormal side thermistor after the copier has become ready

C46 Abnormal pressure roller thermistor during a ready state

C47 Abnormal IH power voltage / IH initialization error

C48 IGBT high temperature

C49 Abnormal IH circuit or coil

C4A Cleaning web finished

CD5 Web motor signal path error

Machine Status

e-STUDIO550/650/810

ERROR CODES AND SELF-DIAGNOSIS

2 - 4 JUNE 2002 © T OSHIBA TEC

Page 20

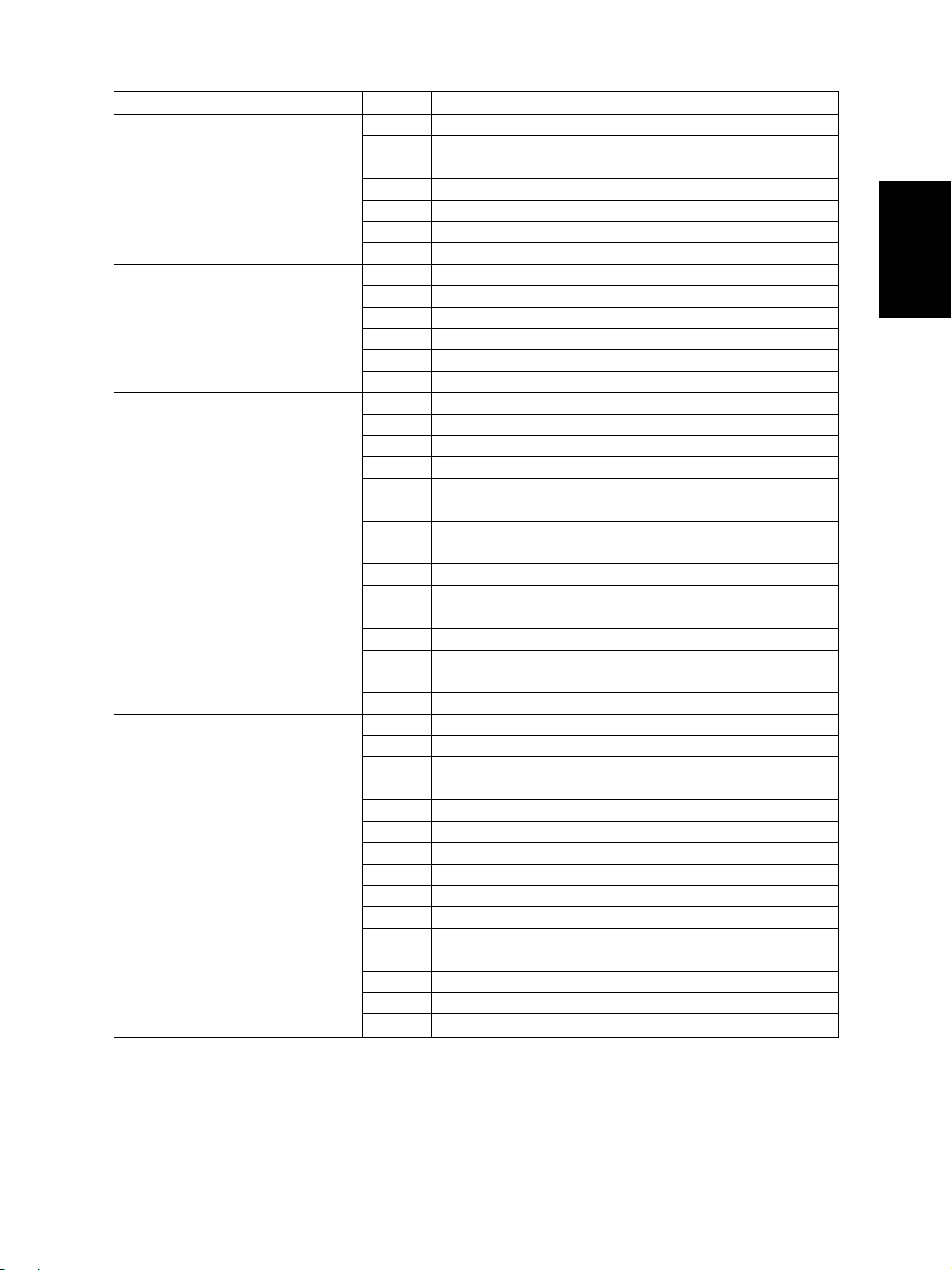

Group

Communication related service call C55 RADF I/F error

RADF related service call C73 EEPROM initialization error

Laser optical unit related service call CA1 Abnormal polygonal motor

Finisher related service call CB1 Abnormal feed motor

Error Code

C56 Communication error between main CPU and PFC

C57 Communication error between main CPU and IPC board

C58 Communication error between IPC board and finisher

C59 Communication error between main CPU and laser CPU

F07 Communication error between SYS board and LGC board

F11 Communication error between SYS board and SLG board

C82 Read sensor adjustment error

C83 Original length sensor adjustment error

C84 Small original reverse sensor adjustment error

C85 Abnormal tray lift motor

C86 Large original exit sensor adjustment error

CA2 H-Sync detection error

CA3 Secondary scanning coarse adjustment error

CA5 Laser power adjustment error

CA6 Laser calibration error

CA9 Image data transmission error from SYS board

CAA Secondary scanning fine adjustment error

CAB Secondary scanning inter-page compensation error

CAC Primary scanning dot adjustment error

CD 0 Laser initializing time out

CE0 Abnormal comparator

CE1 Beam sensor detection error

CE2 Sensor busy error

CE3 Primary scanning adjustment error

CE4 Abnormal window comparator

CB2 Abnormal delivery motor

CB3 Abnormal tray lift motor

CB4 Abnormal alignment motor

CB5 Abnormal staple motor

CB6 Abnormal stapler shift motor

CB7 Abnormal height sensor

CB8 Abnormal backup RAM data

CB9 Abnormal saddle stitcher paper pushing plate motor

CBA Abnormal saddle stitcher stitch motor (front)

CBB Abnormal saddle stitcher stitch motor (rear)

CBC Abnormal saddle stitcher alignment motor

CBD Abnormal saddle stitcher guide motor

CBE Abnormal saddle stitcher paper folding motor

CBF Abnormal saddle stitcher paper positioning plate motor

Machine Status

JUNE 2002 © T OSHIBA TEC 2 - 5 e-STUDIO550/650/810

ERROR CODES AND SELF-DIAGNOSIS

Page 21

Group

Finisher related service call CC0 Abnormal saddle stitcher sensor connector connection

Service call for others C94 Abnormal main CPU

Error Code

CC1 Abnormal saddle stitcher microswitch

CC2 Abnormal communication between finisher and saddle stitcher

CC4 Abnormal swing motor

CC5 Abnormal horizontal registration motor

CC6 Abnormal punch motor

CC7 Abnormal punch unit backup RAM data

CCC Communication error between inserter and finisher

CCD Abnormal inserter EEPROM

CCE Abnormal inserter fan

F10 HDD formatting error

Machine Status

e-STUDIO550/650/810

ERROR CODES AND SELF-DIAGNOSIS

2 - 6 JUNE 2002 © T OSHIBA TEC

Page 22

<<Error history (08-253)>>

(Example of display)

Copy mode

A Paper source

0: Not selected 1: Bypass feeding 2:Tandem LCF 3: 1st cassette 4: 2nd cassette 5: 3rd cassette

6: 4th cassette 7: Duplex printing 8: External LCF 9: Inserter

B Paper size code

0: Not selected 1: A5-R 2: ST-R 3: LT 4: A4 5: B5-R 6: LT-R 7: A4-R 8: OTHER/UNIV 9: B5

A: FOL/COM B: LG C: B4 D: LD E: A3 F: 13'LG G: 8.5*8.5 H: 8K I:16K J:16K-R

C Sort mode/Staple mode

0: Non-sort/Non-staple 1: Group 2: Sort 7: Staple sort (standard) 8: Staple sort (2 places)

9: Staple sort (rear side) A: Saddle stitch

D ADF mode

0: Not used 1: AUTO FEED (SADF) 2: STACK FEED

E APS/AMS mode

0: Not selected 1: APS 2: AMS

F Duplex mode

0: Not selected 1: Book 2: Two-sided/Single-sided 4: T wo-sided/Duple xed

8: Single-sided/Duplexed

G Not used

0: Not used

H Image shift

0: Not used 1: Book 2: Left 3: Right

I Editing

0: Not used 1: Masking 2: Trimming 3: Mirror image 4: Negative/Positive

J Edge erasing/Dual-page

0: Not used 1: Edge erase 2: Dual-page 3: Edge erase & Dual-page

K Not used

0: Not used

L Function

0: Not used 1: Copying 2: Not used 3: Not used 4: LAN printer 5: DSS

EA1

Error code

3 digits

0 2 0 6 2 6 1 7 5 7 3 2

YYMMDDHHMMSS

with its last 2 digits)

6 4

MMM

3 digits

3 digits12 digits (Year indicated

6 4

NNN

2 3 6 2 1 0 0 0 0 0 0 0

ABCDEFGHIJKL

12 digits

Reproduction ratio

MMM Primary scanning reproduction ratio

Shown in hexadecimal

NN N Secondary scanning reproduction ratio

Shown in hexadecimal

The latest 20 errors data can be displayed in the setting mode (08-253).

JUNE 2002 © T OSHIBA TEC 2 - 7 e-STUDIO550/650/810

ERROR CODES AND SELF-DIAGNOSIS

Page 23

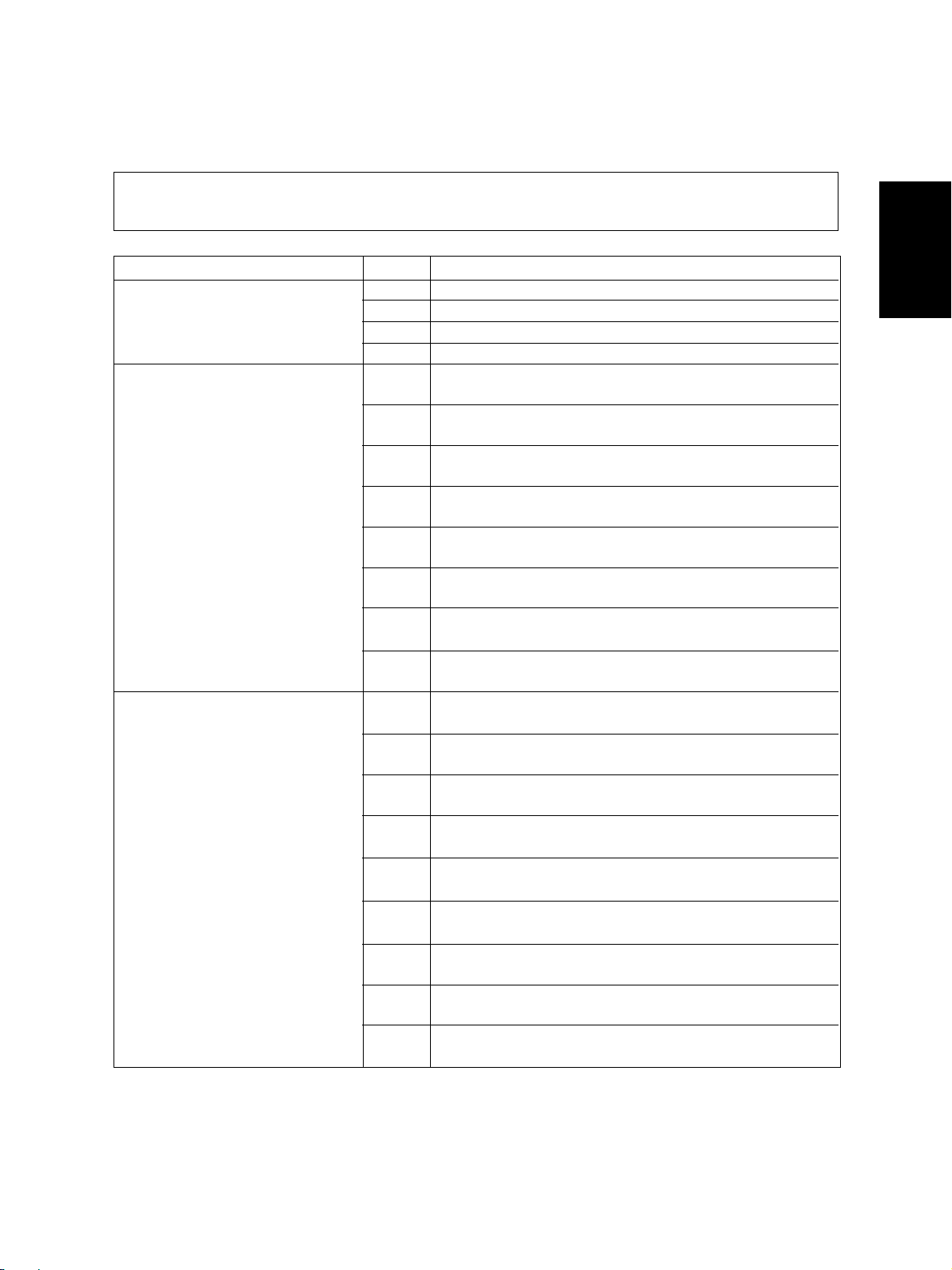

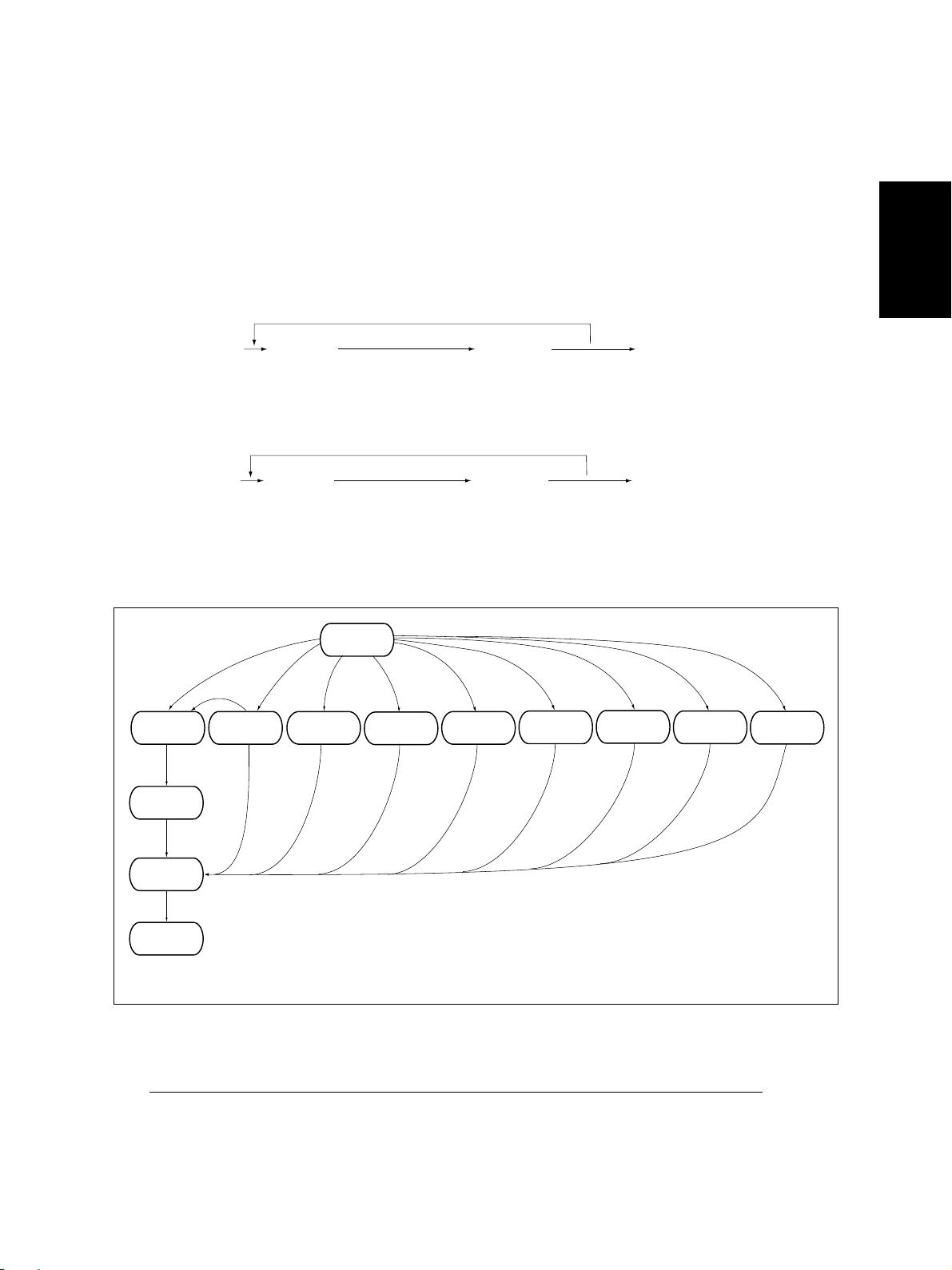

2. 2. Self-diagnosis Modes

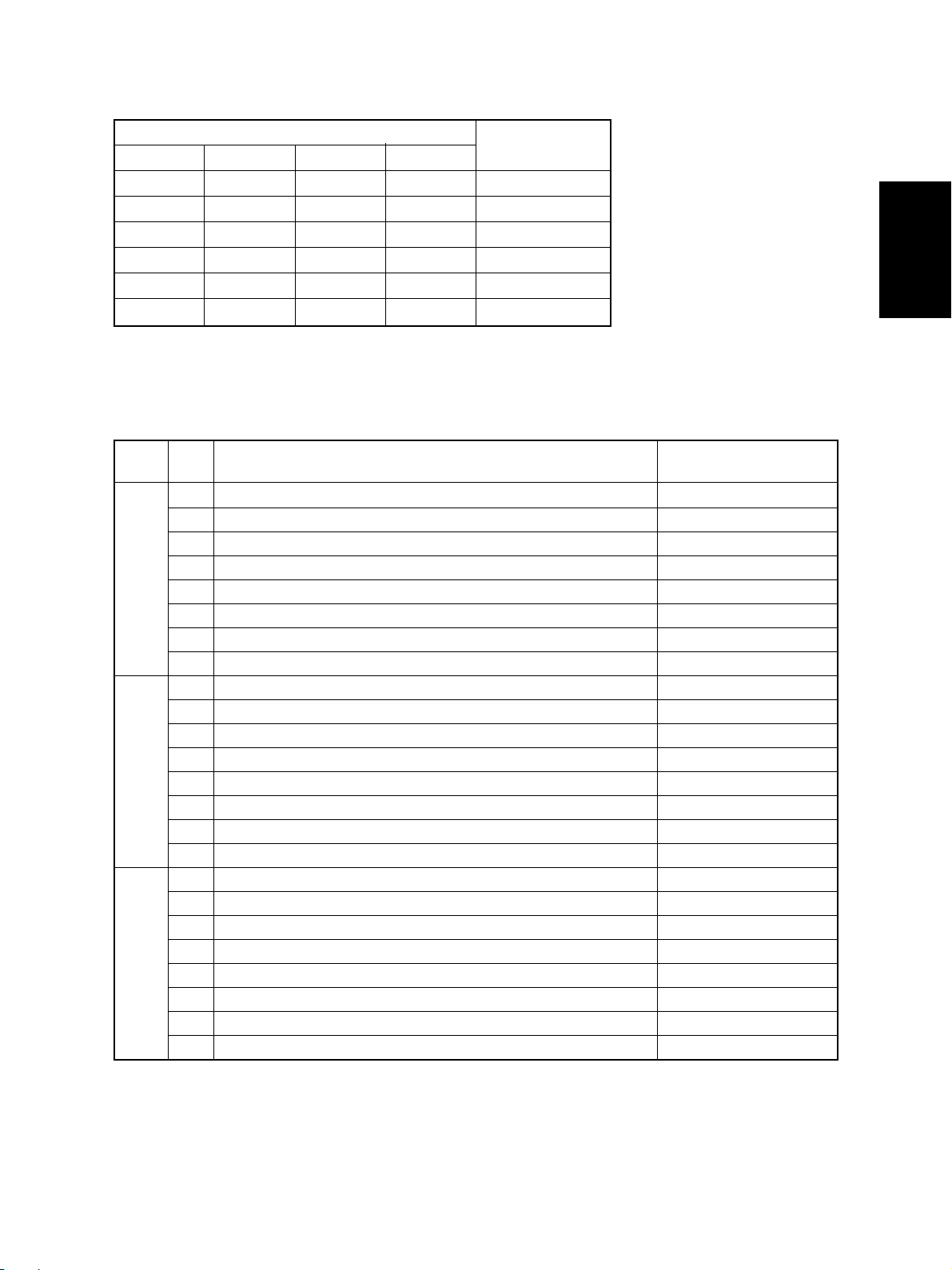

Mode

Control panel [0]+[1]+ All LEDs on the control panel are lit, and all [CLEAR] or

check mode [POWER] the LCD pixels flash.

T est mode [0]+[3]+ Checks the status of input/output signals. [POWER] 100% C

Test print mode [0]+[4]+ Outputs the test patterns. [POWER] 100% P A4

Adjustment mode [0]+[5]+ Adjusts various items. [POWER] 100% A A4

Setting mode [0]+[8]+ Sets various items. [POWER] 100% D

List printing mode

PM support mode

Firmware [3]+[9]+ Performs updating of the firmware. [POWER]

update mode [POWER] OFF/ON

Keys to

press exit

[POWER] OFF/ON TEST MODE

[POWER] OFF/ON TEST PRINT

[POWER] OFF/ON TEST MODE

[POWER] OFF/ON TEST MODE

[9]+[START]

+[POWER]

[6]+[START]

+[ POWER ]

Prints out the data lists of the codes 05 and [POWER] 100% L A4

08 and PM support mode. OFF/ON LIST PRINT

Perf orms auto-toner adjustment and clears [POWER] 100% K

each counter. OFF/ON TEST MODE

Contents

Keys to

[POWER] OFF/ON

Display

Note: To enter the desired mode, turn ON the power while two digital keys designated to each mode (e.g. [0] and

[5]) are pressed simultaneously.

<Operation procedure>

• Control panel check mode (01):

[CLEAR] or [POWER]OFF/ON

(Exit)

[0] [1]

[POWER]

Notes: 1. A mode can be canceled only by pressing the [CLEAR] key during the key check and by the [CLEAR]

key or [POWER] OFF/ON during the LED and LCD are lit.

2. Key Check Keys with LED (Press to turn OFF the LED.)

(LED/LCD lit)

Keys without LED (Press to display the message on the control panel.)

[START]

[START]

(Key check) [CLEAR] (Exit)

e-STUDIO550/650/810

ERROR CODES AND SELF-DIAGNOSIS

2 - 8 JUNE 2002 © T OSHIBA TEC

Page 24

• Test mode (03): Refer to “2.2.1. Input check (test mode 03)” and “2.2.2. Outpout check (test mode 03)”.

• Test print mode (04): Refer to “2.2.3. Test print mode (04)”.

• Adjustment mode (05): Refer to “2.2.4. Adjustment mode (05)”.

• Setting mode (08): Refer to “2.2.5. Setting mode (08)”.

• List printing mode (9S):

[9] [START]

[POWER]

(code)

101:Adjustment mode(05)

(List starts to be printed)

[START]

102:Setting mode(08)

103: PM support mode

• PM support mode (6S):

[6] [START]

[POWER]

(code) [POWER] OFF/ON

1: Auto-toner adjustment

2: PM management screen

[START]

(Operation started)

• Firmware update mode (39): Refer to “6. FIRMWARE UPDATING”.

[POWER]

ON

T est print

mode

Adjustment

mode

[0][8][0][4]

Setting

mode

Warming up

Standby

Normal

[CLEAR]

Control panel

check mode

*1

[0][1] [0][3] [0][5]

Test mode

[POWER] OFF/ON

(Exit)

(Exit)

[9][START]

List print

mode

PM support

[6][START]

mode

[3][9]

Firmware

update mode

[POWER]

OFF

*2

To user

State transition diagram of self-diagnosis modes

*1 In the “Control panel check mode”, copying is disabled. Enter the standby state by pressing the

[CLEAR] key to start copying.

*2 Turn OFF the power after using the self-diagnosis mode, and leave the copier to the user.

JUNE 2002 © T OSHIBA TEC 2 - 9 e-STUDIO550/650/810

ERROR CODES AND SELF-DIAGNOSIS

Page 25

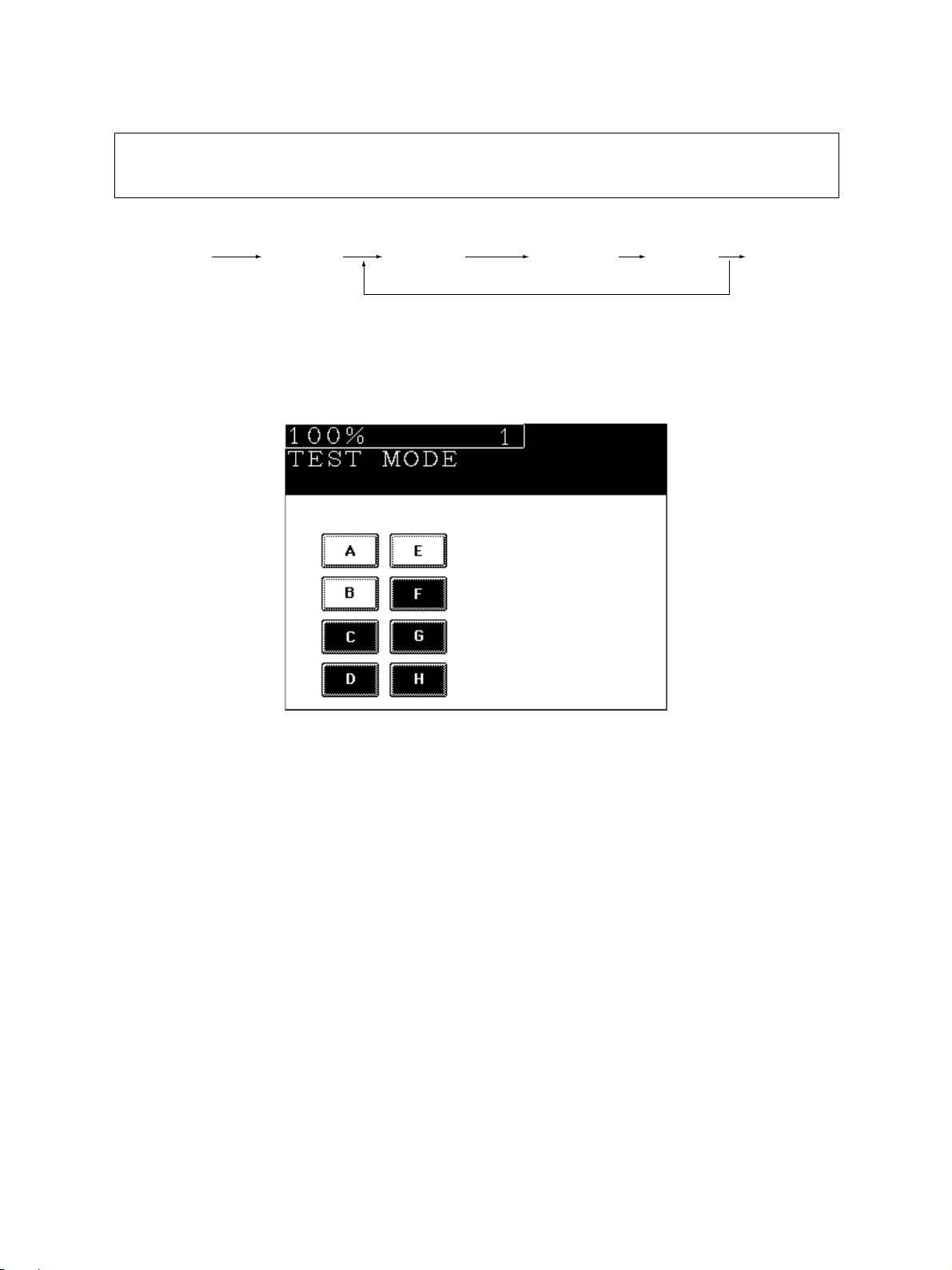

2. 2. 1. Input check (test mode 03)

The state of each input signal can be checked by pressing the [ENERGY SAVER] key and the

digital keys in the test mode (03).

<Operation procedure>

[0] [3]

[POWER]

Note: Initialization is performed before the copier enters the test mode.

[START] ([ENERGY

SAVER])

[Digital key] (LCD ON)

[POWER]

OFF/ON

(Exit)

[Example of display during input check]

Items to be checked and the state of the copier with the icons [A] to [H] displayed in black are listed on the

following pages.

e-STUDIO550/650/810

ERROR CODES AND SELF-DIAGNOSIS

2 - 10 JUNE 2002 © TOSHIBA TEC

Page 26

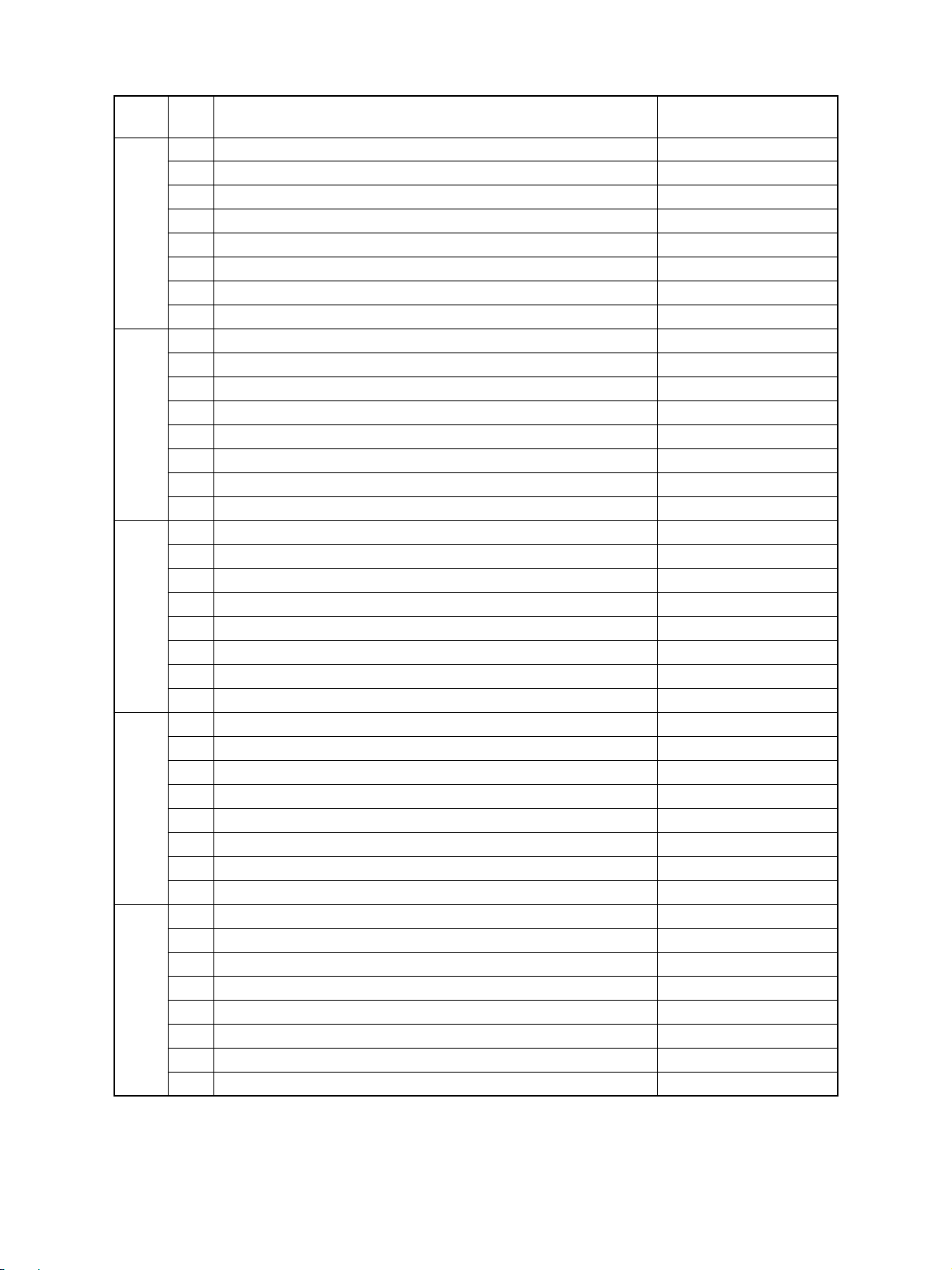

[ENERGY SAVER] key: OFF ( [ENERGY SAVER] LED: OFF)

Digital

Icon Items to check

key with black icon

A—

B External LCF feed sensor No paper —

C External LCF tray-up sensor Top position

[1]

[2]

[3]

[4]

[5]

D External LCF tray bottom sensor Bottom position

E External LCF tray sensor Stack opened

F External LCF empty sensor No paper

G External LCF set sensor Unit opened

H External LCF connection Not connected

A 1st cassette feed sensor No paper

B 1st cassette transport sensor No paper

C 1st cassette tray top sensor Top position

D 1st cassette tray bottom sensor Bottom position

E 1st cassette detection switch Cassette installed

F 1st cassette paper empty sensor No paper

G—

H—

A 2nd cassette feed sensor No paper

B 2nd cassette transport sensor No paper

C 2nd cassette tray top sensor Top position

D 2nd cassette tray bottom sensor Bottom position

E 2nd cassette detection switch Cassette installed

F 2nd cassette paper empty sensor No paper

G—

H—

A 3rd cassette feed sensor / Tandem LCF feed sensor No paper

B 3rd cassette transport sensor / Tandem LCF transport sensor No paper

C 3rd cassette tra y top sensor / Tandem LCF tray top sensor T op position

D 3rd cassette tray bottom sensor Bottom position

E 3rd cassette detection switch / Tandem LCF cassette detection switch Cassette installed

F

3rd cassette paper empty sensor/ Tandem LCF f eeding side paper empty sensor

G Feed cover open/close switch Cover opened

H—

A 4th cassette feed sensor No paper

B 4th cassette transport sensor No paper

C 4th cassette tray top sensor Top position

D 4th cassette tray bottom sensor Bottom position

E 4th cassette detection switch Cassette installed

F 4th cassette paper empty sensor No paper

G—

H—

Copier state

No paper

JUNE 2002 © T OSHIBA TEC 2 - 11 e-STUDIO550/650/810

ERROR CODES AND SELF-DIAGNOSIS

Page 27

Digital

Icon Items to check

key with black icon

A—

B Reverse sensor 2 No paper

C Reverse sensor 1 No paper

[6]

[7]

[8]

[9]

[0]

D—

E Exit/Reversing section connection Not connected

F Fuser unit exit sensor No paper

G Exit sensor Paper present

H Exit cover open/close switch Cover opened

A Tandem LCF end fence home position sensor Home postion

B Tandem LCF end fence stop position sensor Stop position

C Bypass paper size detection sensor 3 ( Table1)

D Bypass paper size detection sensor 2 (

E Bypass paper size detection sensor 1 ( Table1)

F Bypass paper size detection sensor 0 ( Table1)

G Bypass unit cover open/close switch Door closed

H Bypass sensor No paper

A Tandem LCF tray bottom sensor Bottom position

B Tandem LCF connection switch Connected

C Tandem LCF standby side mis-stacking sensor Paper loaded improperly

D—

E—

F—

G—

H Tandem LCF standby side empty sensor No paper

A Transport sensor 1 Paper present

B Transport sensor 2 Paper present

C Transport sensor 3 Paper present

D—

E—

F—

G—

H—

A—

B—

C—

D Finisher connection (IPC board connection) Not connected

E Fuser unit switch Fuser unit installed

F—

G—

H Developer unit switch Developer unit installed

Table1)

Copier state

e-STUDIO550/650/810

ERROR CODES AND SELF-DIAGNOSIS

2 - 12 JUNE 2002 © TOSHIBA TEC

Page 28

Table 1. Relation between the state of the bypass paper size detection sensor and paper size (width).

Bypass paper width sensor

3210

0 1 1 1 A3/LD

1 0 1 1 A4-R/LT-R

1 1 0 1 A5-R/ST-R

1 1 1 0 Post card

0 0 1 1 B4/LG

1001B5-R

Paper width size

[ENERGY SA VER] k e y: ON ([ENERGY SAVER] LED: ON)

Digital

Icon Items to check

key with black icon

A Front door s witch Door opened

B—

C Exit sensor Paper present

[1]

[2]

[3]

D—

E T oner full detection sensor Toner bag full

F—

G Fuser unit exit sensor No paper

H—

A—

B—

C Total counter connection Not connected

D Auto-toner sensor connection Not connected

E—

F Cleaner unit connection Not connected

G Wire cleaner stop position switch Other than stop position

H Exit jam access door open/close switch Door opened

A—

B—

C—

D—

E—

F Key cop y counter connection Not connected

G T oner cartridge switch No cartridge

H—

Copier state

JUNE 2002 © T OSHIBA TEC 2 - 13 e-STUDIO550/650/810

ERROR CODES AND SELF-DIAGNOSIS

Page 29

Digital

Icon Items to check

key with black icon

A—

B—

C—

[4]

[5]

[6]

[7]

[8]

D—

E Registration sensor Paper present

F—

G T ransfer belt release s witch Other than release position

H Transfer belt contact switch Other than contact position

A—

B—

C—

D—

E—

F RADF connection RADF connected

G RADF open/close sensor RADF opened

H Carriage home position sensor Home position

A—

B—

C—

D Automatic original detection sensor (APS-5) (for A 4 /LT s e ries) No original

E Automatic original detection sensor (APS-4) (f o r A 4 /LT s er ies) No original

F Automatic original detection sensor (APS-3) (for A 4/LT s e r ies) No original

G Automatic original detection sensor (APS-2) (f o r A 4 /LT s e r ies) No original

H Automatic original detection sensor (APS-1) (for A4 series) No original

A RADF tray sensor Original present

B RADF empty sensor Original present

C RADF jam access cover open/close switch Cover opened

D RADF open/close switch RADF opened

E RADF large original exit sensor Original present

F RADF intermediate sensor Original present

G RADF read sensor Original present

H RADF registration sensor Original present

A RADF lifting tray lower limit sensor Lower limit position

B RADF lifting tray upper limit sensor Upper limit position

C RADF small original exit sensor Original present

D RADF small original reverse sensor Original present

E RADF original length sensor Original present

F RADF original width sensor-1 Original present

G RADF original width sensor-2 Original present

H RADF original width sensor-3 Original present

Copier state

e-STUDIO550/650/810

ERROR CODES AND SELF-DIAGNOSIS

2 - 14 JUNE 2002 © TOSHIBA TEC

Page 30

Digital

Icon Items to check

key with black icon

A—

B—

C—

[9]

[0]

D—

E—

F—

G RADF APS operation sensor APS sensors operated

H RADF 24V power supply Power OFF

A—

B—

C—

D—

E—

F—

G—

H—

Copier state

JUNE 2002 © T OSHIBA TEC 2 - 15 e-STUDIO550/650/810

ERROR CODES AND SELF-DIAGNOSIS

Page 31

2. 2. 2. Output check (test mode 03)

State of the output signals can be checked by entering the codes in the following table in the test

mode 03.

Procedure 1

[0] [3]

[POWER]

Procedure 2

[0] [3]

[POWER]

Procedure 3

[0] [3]

[POWER]

Procedure 4

[0] [3]

[POWER]

(Code) [START]

(Code) [START]

(Code) [START] [START]

(Code)

[START]

Operation

started

Operation

(One direction)

Operation

started

[POWER] OFF

Code to stop

operation

[CLEAR]

Operation

stopped

[START]

Test mode

standby

Operation

stopped

[CLEAR]

[POWER]

OFF/ON

(Exit)

[POWER]

OFF/ON

(Exit)

Test mode

standby

[POWER]

OFF/ON

(Exit)

Code Function Code Function Procedure

101 Drum motor ON 151 Code 101 operation OFF 1

102 New toner supply motor ON 152 Code 102 operation OFF 1

103 Polygonal motor (600dpi) ON 153 Code 103 operation OFF 1

108 Registration motor ON 158 Code 108 operation OFF 1

110 Reversed paper transport driving clutch ON 16 0 Code 110 operation OFF 1

111 Drum separation finger solenoid ON 161 Code 111 operation OFF 1

11 2 Developer unit motor ON 16 2 Code 112 operation OFF 1

113 Fuser motor ON 163 Code 113 operation OFF 1

11 4 Transfer belt motor ON 164 Code 114 operation OFF 1

11 5 Cleaning brush drive motor ON 1 6 5 Code 115 operation OFF 1

11 6 Used toner transport motor ON 166 Code 116 operation OFF 1

11 8 Laser ON 16 8 Code 118 operation OFF 1

119 Fuser moter (low speed) ON 169 Code 119 operation OFF 1

120 Exit motor (normal) ON 170 Code 120 operation OFF 1

e-STUDIO550/650/810

ERROR CODES AND SELF-DIAGNOSIS

2 - 16 JUNE 2002 © TOSHIBA TEC

Page 32

Code Function Procedure

121 Exit motor (increased speed) ON 171 Code 121 operation OFF 1

122 External LCF feed motor ON 172 Code 122 operation OFF 1

123 Toner recycle hopper motor ON 173 Code 122 operation OFF 1

124 Web motor ON 174 Code 122 operation OFF 1

125 Feed motor ON 175 Code 122 operation OFF 1

126 Reverse motor (normal/forward rotation) ON 176 Code 122 operation OFF 1

127

Reverse motor (increased speed/forward rotation) ON

128 Reverse motor (normal/reverse rotation) ON 1 78 Code 122 operation OFF 1

129

Reverse motor (increased speed/reverse rotation) ON

131 Recycle toner transport motor ON 181 Code 122 operation OFF 1

201 1st cassette feed clutch ON/OFF 3

202 2nd cassette feed clutch ON/OFF 3

203 Intermediate transport clutch ON/OFF 3

204 Bypass feed clutch ON/OFF 3

206 Tandem LCF pickup solenoid ON/OFF 3

207 T andem LCF end f ence reciprocating movement 2

208 T andem LCF end f ence motor ON/OFF 3

209 Tandem LCF feed clutch ON/OFF 3

210 Tandem LCF transport clutch ON/OFF 3

211 RADF feed motor (forward rotation) ON/OFF 3

212 RADF feed motor (reverse rotation) ON/OFF 3

213 RADF read motor (forward rotation) ON/OFF 3

218 Key cop y counter count-up 2

219 Exit fan ON/OFF 3

220 Reversed paper transport clutch 1 ON/OFF 3

221 Reversed paper ransport clutch 2 ON/OFF 3

225 4th cassette transport clutch ON/OFF 3

226 3rd cassette feed clutch ON/OFF 3

228 4th cassette feed clutch ON/OFF 3

229 1st cassette transport clutch ON/OFF 3

230 2nd cassette transport clutch ON/OFF 3

231 3rd cassette transport clutch ON/OFF 3

234 Bypass pickup solenoid ON/OFF 3

235 Discharge lamp ON/OFF 3

238 System fan ON/OFF 3

240 Developer unit fan ON/OFF 3

24 3 Main charger wire cleaner motor ON 2

24 4 Transfer belt cam motor UP/DOWN 3

24 5 Transfer belt supply roller bias TR1 ON/OFF 3

24 6 Transfer belt supply roller bias TR2 ON/OFF 3

24 7 Transfer belt supply roller bias TR3 ON/OFF 3

177 Code 122 operation OFF 1

179 Code 122 operation OFF 1

JUNE 2002 © T OSHIBA TEC 2 - 17 e-STUDIO550/650/810

ERROR CODES AND SELF-DIAGNOSIS

Page 33

Code Function Procedure

248 Developer bias +DC ON/OFF (Operation is possible without the developer unit.) 3

249 Developer bias -DC1 ON/OFF (Operation is possible without the developer unit.) 3

250 Developer bias -DC2 ON/OFF (Operation is possible without the developer unit.) 3

251 Developer bias -DC3 ON/OFF (Operation is possible without the developer unit.) 3

252 Main charger ON/OFF (Operation is possible without the developer unit.) 3

254 Duct in fan ON/OFF 3

255 Transfer belt cleaning brush bias ON/OFF (Operation is possible without the dev eloper unit.) 3

257 Duct out fan (high speed) ON/OFF 3

258 Duct out fan (low speed) ON/OFF 3

259 Heater fan (high speed) ON/OFF 3

260 Heater fan (low speed) ON/OFF 3

261

Scanner motor ON (automatically stopping at the limit position, speed changeable by the ZOOM keys)

264 SLG fan ON/OFF 3

267 Exposure lamp ON/OFF 3

270 Tandem LCF tray motor ON (tray lifted) 2

271 External LCF tray motor ON (tray lifted) 2

272 External LCF feed clutch ON/OFF 3

273 External LCF transport clutch ON/OFF 3

274 Gate solenoid ON/OFF 3

276 Cassette tray-up motor 1 ON (1st cassette tray lifted) 2

278 Cassette tray-up motor 1 ON (2nd cassettetray lifted) 2

27 9 Cassette tray-up motor 2 ON (3rd cassettetray lifted) 2

28 0 Cassette tray-up motor 2 ON (4th cassettetray lifted) 2

28 3 RADF large original exit roller (forward rotation) ON/OFF 3

28 4 RADF large original exit roller (reverse rotation) ON/OFF 3

28 5 RADF small original exit roller (forward rotation) ON/OFF 3

28 6 RADF small original exit roller (reverse rotation) ON/OFF 3

287 RADF large original exit solenoid ON/OFF 3

288 RADF small original exit solenoid ON/OFF 3

289 RADF disengagement solenoid ON/OFF 3

290 RADF tray lift motor ON (tray lifted) 2

29 2 Laser unit fan (high speed) ON/OFF 3

293 Laser unit fan (low speed) ON/OFF 3

29 5 Power OFF mode 4

450 IH fan (high speed) ON/OFF 3

451 IH fan (low speed) ON/OFF 3

45 2 Reverse section fan 1 (high speed) ON/OFF 3

45 3 Reverse section fan 1 and 2 (low speed) ON/OFF 3

454 Reverse section fan 2 (high speed) ON/OFF 3

2

e-STUDIO550/650/810

ERROR CODES AND SELF-DIAGNOSIS

2 - 18 JUNE 2002 © TOSHIBA TEC

Page 34

2. 2. 3. Test print mode (test 04)

The built-in test pattern can be printed out by entering the following codes in the test print mode (04).

<Operation procedure>

[0] [4]

[POWER]

Notes: 1. An error code is displayed on the control panel if an error occurs in the process, but no recovery

Code Types of test pattern Remarks

11 1 Primary scanning direction, 33 gradation steps, error diffusion

11 3 Secondary scanning direction, 33 gradation steps, error diffusion

142 Grid pattern (Pattern width: 2 dots, Pitch: 10 mm)

(Code) [START]

operation is performed.

2. Turn the power OFF, and then turn it back ON to clear the error.

Operation

(Test pr int)

[CLEAR]

[POWER]

OFF/ON

(Exit)

JUNE 2002 © T OSHIBA TEC 2 - 19 e-STUDIO550/650/810

ERROR CODES AND SELF-DIAGNOSIS

Page 35

2. 2. 4. Adjustment mode (05)

Items in the adjustment mode list in the following pages can be corrected or changed in this adjustment mode (05). Turn ON the power with pressing the digital ke ys [0] and [5] simultaneously in order

to enter this mode.

Procedure 1

[0] [5]

[POWER]

Procedure 2

[0][5]

[POWER]

Procedure 3

[0] [5]

[POWER]

[Digital key]

(Code)

(Code)

[Digital key]

(Code)

[START]

[CANCEL]

[START]

[START]

[CLEAR]

or

[CANCEL]

[Digital key]

[JOB STATUS] key

*

(Enter a value)

(Corrects value)

(Value

displayed)

[UP]

or

[DOWN]

(Enter a value)

(Corrects value)

[SET]

or

[INTERRUPT]

(Stores value in RAM)

[CLEAR]

* Press [JOB STATUS] to enter “–”.

[SET]

or

[INTERRUPT]

(value unchangable)

[SET]

or

[INTERRUPT]

(Stores value in RAM)

[RESET]

[ENERGY

SAVER]

(Test copy)

([ENERGY SAVER]

(Test copy)

[POWER]

OFF/ON

(Exit)

[POWER]

OFF/ON

(Exit)

[START])

[POWER]

OFF/ON

(Exit)

Procedure 4

[0] [5]

[POWER]

e-STUDIO550/650/810

[Digital key]

(Code)

[CANCEL]

[START]

ERROR CODES AND SELF-DIAGNOSIS

[Digital key]

(Sub code)

[CLEAR]

(Corrects value)

[START]

2 - 20 JUNE 2002 © TOSHIBA TEC

[Digital key]

* [JOB STA TUS] k ey

Enter a

value

(Corrects value)

[SET]

[ENERGY

or

[INTERRUPT]

(Stores value in

RAM)

[CLEAR]

* Press [JOB STA TUS] to enter “–”.

SAVER]

Test

copy

[POWER]

OFF/ON

(Exit)

Page 36

Procedure 6

[0] [5]

[POWER]

Procedure 13

[0] [5]

[POWER]

Procedure 15

[0] [5]

[POWER]

[Digital key]

(Code)

[Digital key]

(Code)

[Digital key]

(Code)

[START]

[START]

[START]

[CLEAR]

[CANCEL]

[Digital key]

(Sub code)

(Corrects value)

Automatic

adjustment

[CLEAR]

Automatic

adjustment

[START]

[POWER]

OFF/ON

(Exit)

[Digital key]

* [JOB STA TUS] k ey

Enter a

value

(Corrects value)

[SET]

or

[INTERRUPT]

(Stores value in

RAM)

[SET]

[ENERGY

or

[INTERRUPT]

(Stores value in

RAM)

SAVER]

Test

copy

[POWER]

OFF/ON

(Exit)

[CLEAR]

* Press [JOB STA TUS] to enter “–”.

[POWER]

OFF/ON

(Exit)

Note: The fuser roller temperature control is different from it at the normal state. Theref ore, the problem of

fusing efficiency may be occured in the test copy at the adjustment mode.

In that case, turn ON the power normally , leav e the copier for appro x. 3 minuites after it has become

ready state and then start up the adjustment mode again.

JUNE 2002 © T OSHIBA TEC 2 - 21 e-STUDIO550/650/810

ERROR CODES AND SELF-DIAGNOSIS

Page 37

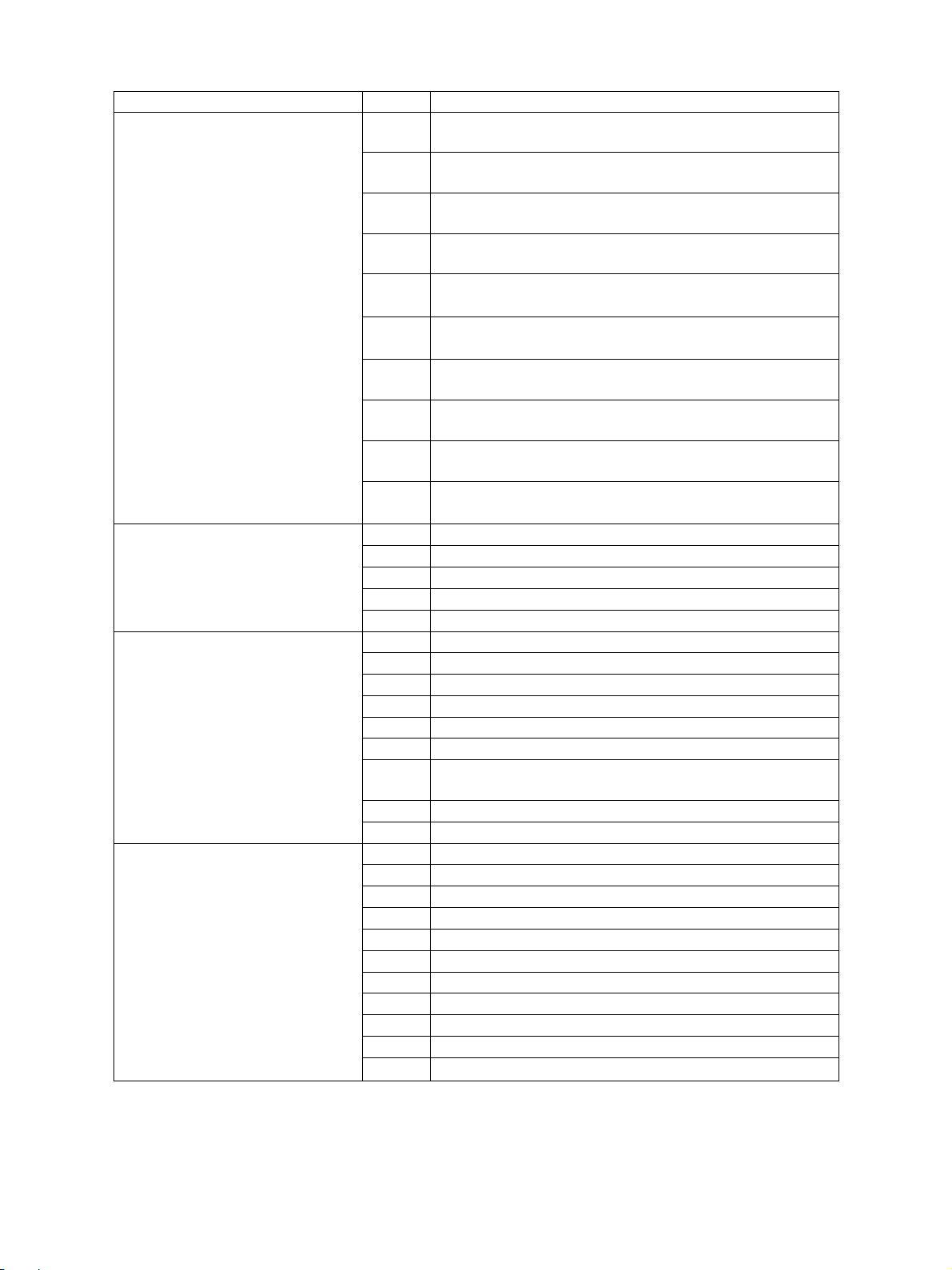

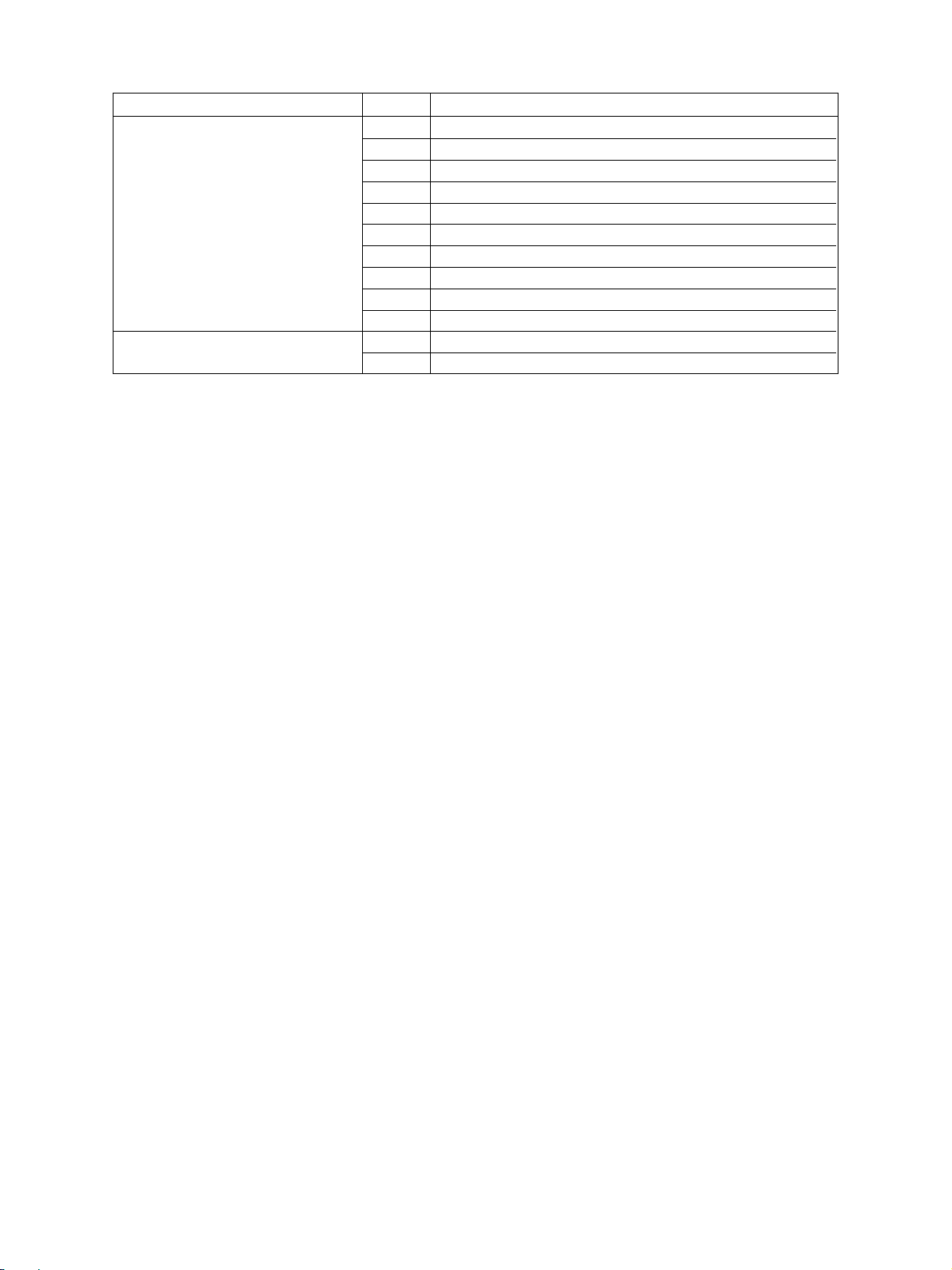

Adjustment mode (05)

Code Items to adjust Function

200

Automatic adjustment of auto-toner

sensor (Fuser heater ON)

201

Correction of auto-toner sensor

(Fuser heater ON)

Developer bias DC output adjustment

205

206

Developer bias actual value

210

Main charger grid bias output

adjustment

211

Main charger grid bias actual value

ALL – –

ALL – 0~255

ALL 141 0~255

ALL – 0~255

ALL 112 0~255

ALL – 0~255

Default

Accept-

able Contents

value

- As the value increases, the

sensor output increases

correspondingly.

- The value starts changing

approx. 2 minutes after this

adjustment was started and is

automatically set in the range of

2.45 to 2.55V.

( Chapter 3.2.)

As the value increases by “1”,

output from the transformer

increases correspondingly.

( Chapter 3.5.)

The developer bias value at the

latest printing is displayed.

As the value increases by “1”,

output from the transformer

increases correspondingly.

( Chapter 3.5.)

The main charger grid bias value

at the latest printing is displayed.

Operation

procedure

6

3

3

2

3

2

221

T r ansfer transf ormer DC output adjustment/center value

242

Control status of the drum surface

potential sensor

Image quality control

268

Display of the exposure corrected value

Image quality control

269

Display of limiter flag

Enforced performing of Image quality

290

control

Image quality control

291

Control status display

ALL 175 0~255

ALL 0 0~255

ALL 0 -255

~255

ALL 0 0~255

ALL – –

ALL 0 0~255

The voltage for the transfer belt

power supply roller can be

adjusted but cannot be

measured.

* When carrying out an adjustment,

close the front cover and be

careful not to touch the highvoltage section.

3

2

2

2

6

2

e-STUDIO550/650/810

ERROR CODES AND SELF-DIAGNOSIS

2 - 22 JUNE 2002 © TOSHIBA TEC

Page 38

Adjustment mode (05)

Code Items to adjust Function

292

Display of the output Sensor light

value of the image source OFF

quality sensor

ALL – 0~1023

Default

Accept-

able Contents

value

The output value of the image

quality sensor is displayed when

the sensor light source is OFF.

Operation

procedure

2

293

296

Display of the light amount adjustment

result of the image quality sensor

305

Adjustment of scanner secondary

scanning start position deviation

306

Adjustment of scanner primary scanning start position deviation

308

Distortion mode

340

Adjustment of scanner secondary

scanning reproduction ratio

354

Adjustment of for single-sided

RADF paper original

alignment for two -sided

355

Automatic adjustment of RADF sen-

356

sor and EEPROM initialization

357

Fine adjustment of RADF transport

speed

358

RADF sideways deviation adjustment

Drum surface

original

ALL – 0~1023

ALL – 0~255

ALL 13 7 0~255

ALL 128 0~255

ALL – –

PPC 1 28 0~255

ALL 10 0~20

ALL 10 0~20

ALL – –

ALL 50 0~100

ALL 12 8 0~255

The output value of the image

quality sensor on the drum surface

(without a test pattern) is

displayed.

LED light amount adjustment of

the sensor, which makes the light

amount reflected from the drum a

standard velue is displayed.

When the value increases by “1”,

the image shifts toward the

leading edge of paper by approx.

0.1213mm.

When the value increases by “1”,

image shifts toward the rear side

of paper by approx. 0.0423mm.

Moves the carriages to the

adjustment position.

( Chapter 2.3.4.)

When the value increases by “1”,

the reproduction ratio of the

secondary scanning direction

decreases by approx. 0.025%.

When the value increases by “1”,

the aligning amount increases by

approx. 0.5mm.

Perform the adjustment and

initialization when the ADF board

or sensor of the RADF is

replaced.

When the value increases by “1”,

the reproduction ratio of the

secondary scanning direction on

original fed from the RADF

increases by approx. 0.1%.

When the value increases by “1”,

the image of original fed from the

RADF shifts toward the rear side

of paper by approx. 0.0423mm.

2

2

1

1

6

1

1

1

6

1

1

JUNE 2002 © T OSHIBA TEC 2 - 23 e-STUDIO550/650/810

ERROR CODES AND SELF-DIAGNOSIS

Page 39

Adjustment mode (05)

Code Items to adjust Function

365

RADF leading for single-sided

edge position original

adjustment for two-sided

366

original

RADF original tray Minimum

367

width sensor Maximum

368

adjustment

Fine adjustment of polygonal motor

401

rotation speed (Reproduction ratio adjustment of primary scanning direc-

405

tion)

Adjustment of primary scanning laser

410

writing start position

411

Adjustment of the Normal speed

424-0

exit motor speed

424-1

425-0

425-1

Adjustment of the Normal speed

426-0

reverse motor speed

426-1

427-0

427-1

Top margin adjustment (blank area at

430

the leading edge of the paper)

Left margin adjustment (blank area

431

at the left of the paper along the paper feeding direction)

Right margin adjustment (blank area

432

at the right of the paper along the paper feeding direction)

Bottom margin adjustment (blank

433

area at trailing edge of paper)

Increased speed

Normal speed

Increased speed

Increased speed

Normal speed

Increased speed

ALL 50 0~100

ALL 50 0~100

ALL – –

ALL – –

PRT 1 33 0~255

PPC 129 0~255

PPC 1 28 0~255

PRT 1 28 0~255

PPC 1 28 0~255

PPC 1 28 0~255

PRT 1 28 0~255

PRT 1 28 0~255

PPC 1 28 0~255

PPC 1 28 0~255

PRT 1 28 0~255

PRT 1 28 0~255

PPC 0 0~255

PPC 0 0~255

PPC 0 0~255

PPC 0 0~255

Default

Accept-

able Contents

value

When the value increases by “1”,

the copied image of original fed from

the RADF shifts toward the trailing

edge of paper by approx. 0.1mm.

When the value increases by “1”,

the reproduction ratio of the

primary scanning direction

increases by approx. 0.07%.

(approx.0.5mm/5steps)

When the value increases by “1”,

the writing start position shifts to

the front side by approx.

0.0423mm.

When the value increases by “1”,

the rotation speed increases by

approx. 0.24%.

When the value increases by “1”,

the rotation speed increases by

approx. 0.32% (e-STUDIO550),

0.37% (e-STUDIO650) or 0.43%

(e-STUDIO810).

Same as 424-0.

Same as 424-1.

When the value increases by “1”,

the rotation speed increases by

approx. 0.195%.

When the value increases by “1”,

the rotation speed increases by

approx. 0.28% (e-STUDIO550),

0.32% (e-STUDIO650) or 0.37%

(e-STUDIO810).

Same as 426-0.

Same as 426-1.

When the value increases by “1”,

the blank area becomes wider by

approx. 0.0423mm.

Operation

procedure

1

1

6

6

1

1

1

1

13

13

13

13

13

13

13

13

1

1

1

1

e-STUDIO550/650/810

ERROR CODES AND SELF-DIAGNOSIS

2 - 24 JUNE 2002 © TOSHIBA TEC

Page 40

Adjustment mode (05)

Code Items to adjust Function

435

Top margin adjustment (blank area at

the leading edge of the paper)

Left margin adjustment (blank area

436

at the left of the paper along the paper feeding direction)

Right margin adjustment (blank area

437

at the right of the paper along the paper feeding direction)

Bottom margin adjustment (blank

438

area at the trailing edge of the paper)

439

Secondary 1st cassette

440

scanning laser 2nd cassette

441

write start position 3rd cassette or

442

443

444

445

446

Adjustment of 4th cassette

remaining paper

detect ion Tandem LCF

447

/Paper empty

Paper aligning 3rd cassette

448-0

amount adjustment /Long size

(at the copier 3rd cassette

448-1

registration section) /Middle size

448-2

448-3

449-0

449-1

449-2

449-3

450-0

450-1

450-2

450-3

tandem LCF

Bypass feeding

External LCF

4th cassette

Duplex feeding

3rd cassette

/Short size

3rd cassette

/Thick paper

4th cassette

/Long size

4th cassette

/Middle size

4th cassette

/Short size

4th cassette

/Thick paper

1st cassette

/Long size

1st cassette

/Middle size

1st cassette

/Short size

1st cassette

/Thick paper

PRT 24 0~255

PRT 0 0~255

PRT 0 0~255

PRT 0 0~255

ALL 20 0~40

ALL 8 0~15

ALL 8 0~15

ALL 8 0~15

ALL 8 0~15

ALL 8 0~15

ALL 8 0~15

ALL 10 0~31

ALL 10 0~31

ALL 9 0~31

ALL 9 0~31

ALL 8 0~31

ALL 20 0~31

ALL 9 0~31

ALL 9 0~31

ALL 8 0~31

ALL 20 0~31

ALL 11 0~31

ALL 11 0~31

ALL 15 0~31

ALL 15 0~31

Default

Accept-

able Contents

value

When the value increases by “1”,

the blank area becomes wider by

approx. 0.0423mm.

When the value increases by “1”,

the image shifts toward the

leading edge of paper by approx.

0.4mm.

When the value increases by “1”,

the aligning amount increases by

approx. 0.8mm.

<Paper length>

Long size: 330mm or longer

Middle size: 220mm~329mm

Short size: 219mm or shorter

Operation

procedure

1

1

1

1

1

1

1

1

1

1

1

1

1

13

13

13

13

13

13

13

13

13

13

13

13

JUNE 2002 © T OSHIBA TEC 2 - 25 e-STUDIO550/650/810

ERROR CODES AND SELF-DIAGNOSIS

Page 41

Adjustment mode (05)

Code Items to adjust Function

452-0

452-1

452-2

452-3

Adjustment of 4th cassette

453

remaining paper

detection

/Paper full Tandem LCF

454

Paper aligning Duplex feeding

455-0

amount adjustment /Long size

( at the copier Duplex feeding

455-1

registration section) /Middle size

455-2

455-3

456-0

456-1

457-0

457-1

458-0

458-1

458-2

458-3

458-4

2nd cassette

/Long size

2nd cassette

/Middle size

2nd cassette

/Short size

2nd cassette

/Thick paper

Duplex feeding

/Short size

Duplex feeding

Thick paper

T andem LCF

/Normal paper

Tandem LCF

/Thick paper

External LCF

/Normal paper

External LCF

/Thick paper

Bypass feeding

/Long size

Bypass feeding

/Middle size

Bypass feeding

/Short size

Bypass feeding

/Thick paper

Bypass feeding

/Post card

ALL 12 0~31

ALL 9 0~31

ALL 8 0~31

ALL 20 0~31

ALL JPN: 8 0~31

ALL JPN: 8 0~31

ALL 11 0~31

ALL 11 0~31

ALL 15 0~31

ALL 15 0~31

ALL 16 0~31

ALL 18 0~31

ALL 8 0~31

ALL 8 0~31

ALL 20 0~31