Page 1

SERVICE HANDBOOK

DIGITAL PLAIN PAPER COPIER

Click the Navigation Pane button to open the overview area and

display bookmarks and thumbnails palettes.

Click the Bookmarks to open the Contents and display Bookmarks

created for the document. Click a bookmark's name to go to the

Page marked by that bookmark.

DP4500/3500

Click the Thumbnails to open the overview area and display

thumbnail images of each document page. Click a thumbnail to go

to the Page marked by that thumbnail.

Copyright TOSHIBA CORPORATION 2001

ALL RIGHTS RESERVED

Page 2

GENERAL PRECAUTIONS REGARDING THE INSTALLATION

AND SER VICE FOR THE COPIER DP4500/3500

The installation and service should be done by a qualified service technician.

1. T ransportation/Installation

• When transporting/installing the copier, employ two persons and be sure to use the positions as

indicated below .

The copier is quite heavy and weighs approximately 73kg (161lb), therefore pay full attention when

handling it.

• Be sure to use a dedicated outlet with AC 115V or 120V/15A (220V, 230V , 240V/10A) or more f or

its power source.

• The copier must be grounded for saf ety.

Never g round it to a gas pipe or a water pipe.

• Select a suitable place for installation.

Av oid excessive heat, high humidity, dust, vibration and direct sunlight.

• Also provide proper ventilation as the copier emits a slight amount of ozone .

• To insure adequate working space for the copying operation, keep a minimum clearance of

80 cm (32”) on the left, 80 cm (32”) on the right and 10 cm (4”) in the rear.

• The socket-outlet shall be installed near the copier and shall be easily accessible.

2. Service of Machines

• Basically, be sure to turn the main switch off and unplug the power cord during service.

• Be sure not to touch high-temperature sections such as the exposure lamp, the fuser unit, the

damp heater and their periphery.

• Be sure not to touch high-voltage sections such as the chargers, high-voltage transformer, IH

control circuit, exposure lamp control inverter, inverter for the LCD backlight and power supply

unit. Especially, the board of these components should not be touched since the electirc charge

may remain in the condensers, etc. on them even after the power is turned OFF.

• Be sure not to touch rotating/operating sections such as gears, belts, pulleys, fan, etc.

• Be careful when removing the covers since there might be the parts with very sharp edges underneath.

• When servicing the machines with the main switch turned on, be sure not to touch live sections

and rotating/operating sections. Av oid exposure to laser radiation.

• Use suitable measuring instruments and tools.

• Av oid exposure to laser radiation during servicing.

− Av oid direct exposure to the beam.

− Do not insert tools, parts, etc. that are reflective into the path of the laser beam.

− Remove all watches, rings, bracelets , etc. that are reflective.

Page 3

3. Main Service Parts for Safety

• The breaker , door switch, fuse, thermostat, thermofuse, thermistor, etc. are particularly important

for safety. Be sure to handle/install them properly.

4. Cautionary Labels

• During servicing, be sure to check the rating plate and the cautionary labels such as “Unplug the

power cord during service”, “Hot area”, “Laser w arning label” etc. to see if there is any dirt on their

surface and whether they are properly stuck to the copier.

5. Disposition of Consumable Parts/Packing Materials

• Regarding the recovery and disposal of the copier, supplies , consumable parts and packing materials, it is recommended to follow the relevant local regulations or rules.

6. When parts are disassembled, reassembly is basically the reverse of disassembly unless

otherwise noted in this manual or other related documents. Be careful not to reassemble

small parts such as screws, washers, pins, E-rings, star washers in the wrong places.

7. Basically , the machine should not be operated with an y parts removed or disassembled.

8. Precautions Against Static Electricity

• The PC board must be stored in an anti-electrostatic bag and handled carefully using a wristband,

because the ICs on it may become damaged due to static electricity.

Caution: Before using the wristband, pull out the power cord plug of the copier and make

sure that there are no uninsulated charged objects in the vicinity .

Caution : Dispose of used batteries and RAM-ICs including lithium batteri es

according to the manufacturer’s instructions.

Attention : Se débarrasser de batteries et RAM-ICs usés y compris les batteries en

lithium selon les instructions du fabricant.

V orsic ht : Entsorgung des gebrauchten Batterien und RAM-ICs (inklusive

der Lithium-Batterie) nach Angaben des Herstellers.

Page 4

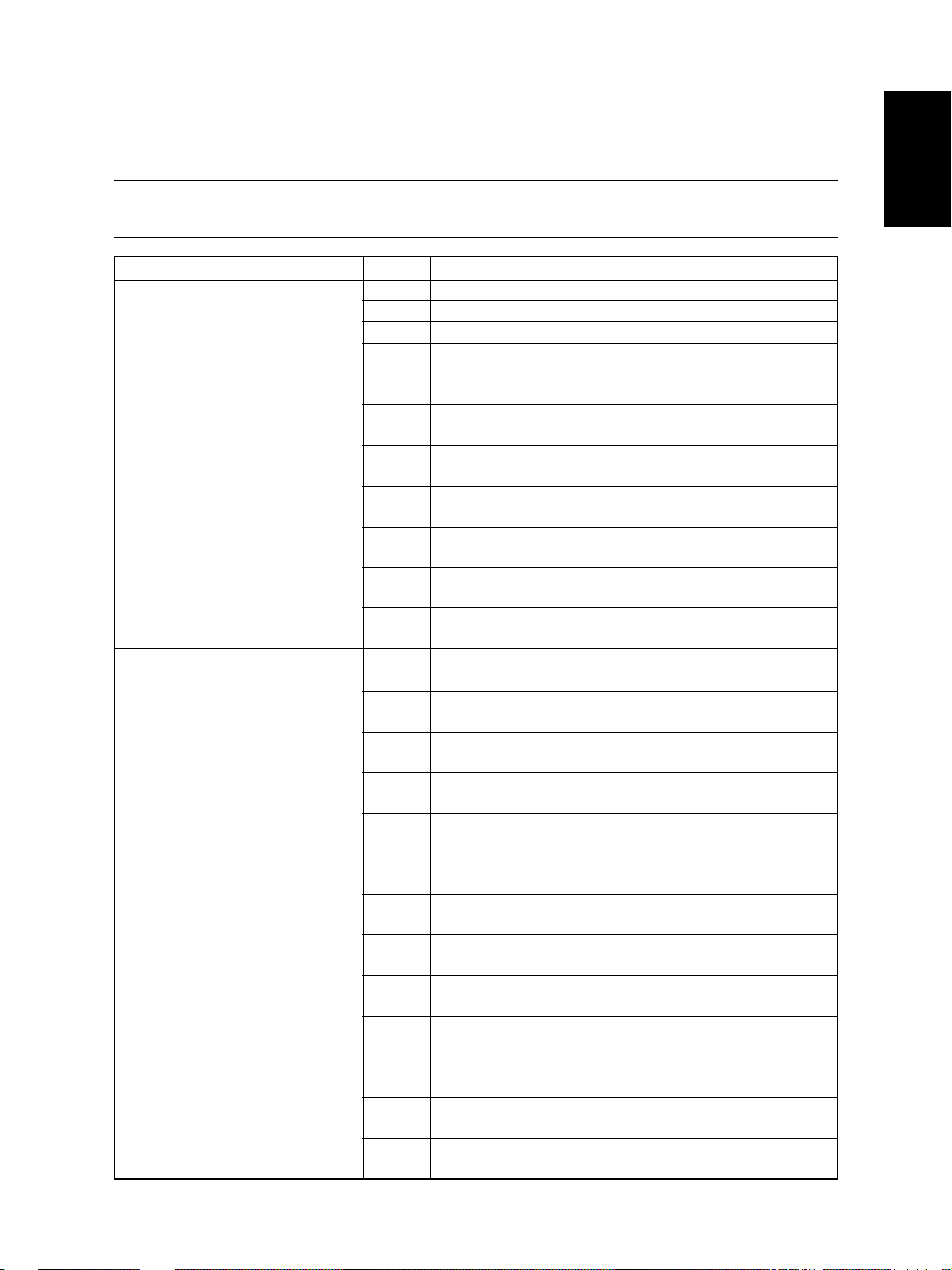

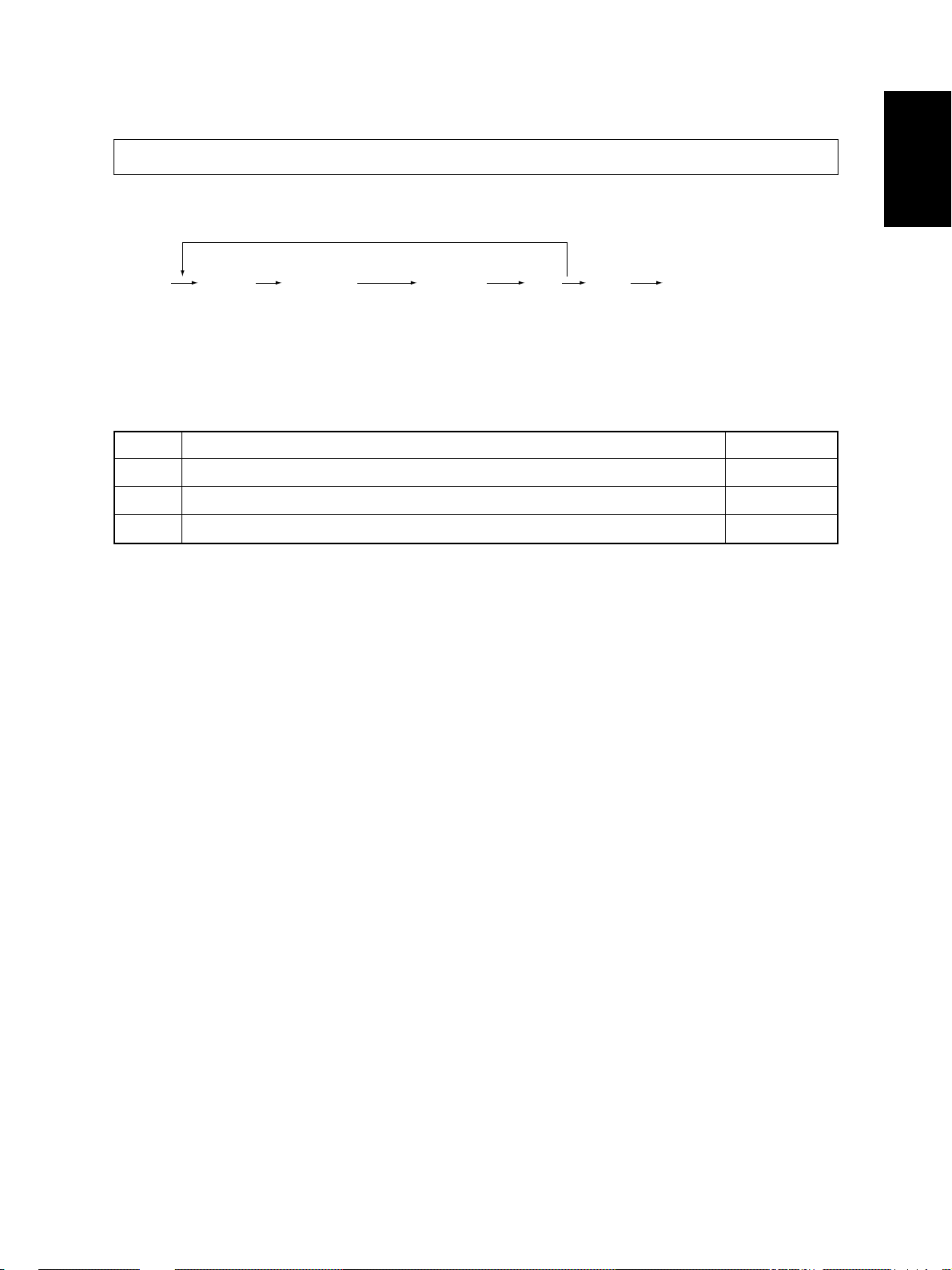

1. ERROR CODE AND SELFDIAGNOSIS

2. ADJUSTMENT

3. PREVENTIVE MAINTENANCE

(PM)

4. PRECAUTIONS FOR STORING

/ HANDLING SUPPLIES AND

PARTS

5. TROUBLESHOOTING

6. UPDATING THE FIRMWARE

7. WIRE HARNESS

CONNECTION DIAGRAMS

Page 5

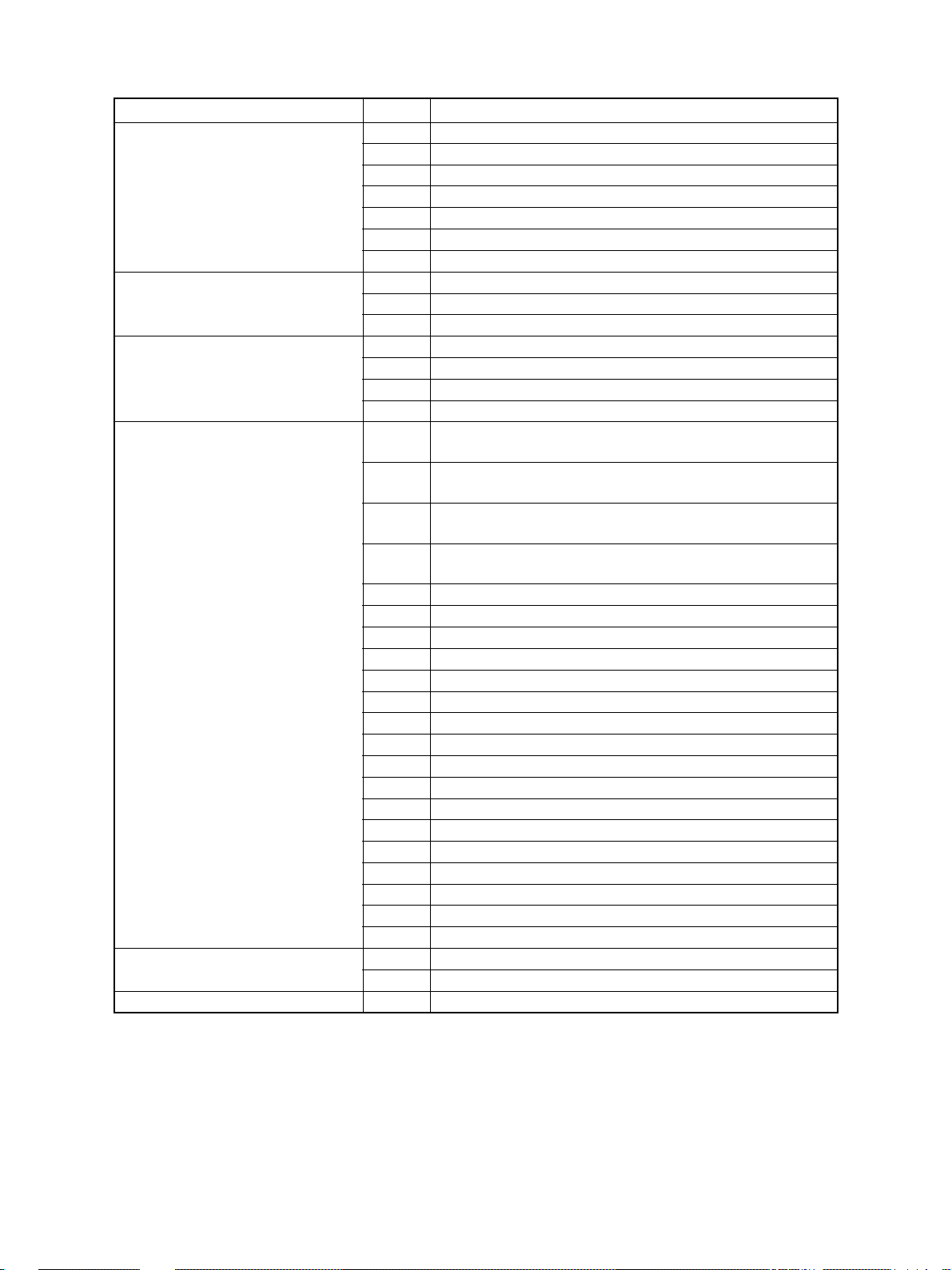

CONTENTS

1. ERROR CODE AND SELF-DIA GNOSIS ..................................................................................... 1- 1

1.1 Error Code ............................................................................................................................. 1-1

1.2 Self-Diagnosis Modes ............................................................................................................ 1-6

1.2.1 Input check (test mode 03) ....................................................................................... 1-8

1.2.2 Output check (test mode 03) ....................................................................................1-13

1.2.3 T est print mode (test mode 04) ................................................................................. 1-15

1.2.4 Adjustment mode (05)............................................................................................... 1-16

1.2.5 Setting mode (08) .....................................................................................................1-22

2. ADJUSTMENT............................................................................................................................ 2- 1

2.1 Formatting the Hard Disk ....................................................................................................... 2-1

2.2 Adjustment of Auto-Toner Sensor........................................................................................... 2-2

2.3 Dimensional Adjustment of Copied Image.............................................................................. 2- 4

2.3.1 Overview .................................................................................................................. 2-4

2.3.2 Paper alignment........................................................................................................ 2-6

2.3.3 Printer related adjustment ......................................................................................... 2- 7

2.3.4 Scanner related adjustment ...................................................................................... 2-11

2.4 Image Quality Adjustment...................................................................................................... 2-18

2.4.1 Image density ........................................................................................................... 2-18

2.4.2 Sharpness(HPF) adjustment ..................................................................................... 2-19

2.4.3 Gamma slope adjustment ......................................................................................... 2-19

2.4.4 Setting for the range correction ................................................................................. 2-20

2.5 High-Voltage Adjustment........................................................................................................ 2-21

2.6 Adjustment of Developer Unit ................................................................................................ 2-27

2.6.1 Adjustment of the doctor-sleeve gap......................................................................... 2-27

2.6.2 Adjustment of the developer polarity position............................................................ 2-29

2.7 Adjustment of Scanning Section............................................................................................ 2-30

2.7.1 Adjustment of carriages ............................................................................................ 2-30

2.7.2 Lens unit................................................................................................................... 2-3 4

2.8 Adjustment of Angle of the Printed Image.............................................................................. 2-37

2.9 Adjustment of Sidewa ys De viation of Sheet Caused by P aper F eeding.................................. 2-38

2.10 Key Copy Counter (MU-8, MU-10) .......................................................................................... 2-39

3. PREVENTIVE MAINTENANCE (PM) ......................................................................................... 3- 1

3.1 Maintenance Performed Every 150,000(DP4500) and

116,000 Copies (DP3500) ................................................................................................... 3- 1

3.2 Maintenance Performed Every 450,000(DP4500) and

348,000 Copies (DP3500) ................................................................................................... 3- 1

3.3 Cleaning the Units Which Have Processed 75,000 Copies (DP4500)/58,000 Copies (DP3500).. 3-1

3.4 Preventive Maintenance Checklist ......................................................................................... 3- 1

I October 2000 © T OSHIBA TECDP4500/3500 CONTENTS

Page 6

3.5 PM Kit ................................................................................................................................... 3-10

3.6 Jig List...................................................................................................................................3-11

4. PRECA UTIONS FOR STORING / HANDLING SUPPLIES AND PARTS ....................................4- 1

4.1 Precautions for Storing TOSHIBA Supplies............................................................................ 4-1

4.2 Checking and Cleaning of Photoconductive Drum .................................................................. 4- 1

4.3 Checking and Cleaning of Drum Cleaning Blade..................................................................... 4-2

4.4 Checking and Replacement of Pressure Roller Cleaning Roller .............................................. 4- 3

4.5 Checking and Cleaning of Fuser Roller and Pressure Roller ................................................... 4- 3

5. TROUBLESHOOTING ................................................................................................................ 5- 1

5.1 Diagnosis and Prescription for Each Error Code..................................................................... 5-1

5.1.1 Paper transport jam ..................................................................................................5- 1

5.1.2 Paper misf eeding ...................................................................................................... 5-10

5.1.3 Cover open jam ........................................................................................................ 5-17

5.1.4 T ransport jam (ADU and other area).......................................................................... 5-23

5.1.5 T ransport jam (RADF) ............................................................................................... 5-27

5.1.6 Paper jam in finisher ................................................................................................. 5-28

5.1.7 Drive system related service call .............................................................................. 5-48

5.1.8 Paper feeding system related service call................................................................. 5-49

5.1.9 Scanning system related service call........................................................................ 5-55

5.1.10 Fuser unit related service call ................................................................................... 5-57

5.1.11 Communication related service call .......................................................................... 5-60

5.1.12 ADF related service call............................................................................................ 5-63

5.1.13 Laser optical unit related service call ........................................................................ 5-65

5.1.14 Finisher related service call ...................................................................................... 5-66

5.1.15 Service call for others............................................................................................... 5-94

5.2 Troubleshooting for the Image ................................................................................................ 5-95

5.3 Troubleshooting for the Blown Fuse........................................................................................ 5-117

6. UPDA TING THE FIRMWARE ...................................................................................................... 6-1

6.1 Installing Software for Firmware Update ................................................................................. 6- 2

6.1.1 Outline ...................................................................................................................... 6- 2

6.1.2 Requirements ........................................................................................................... 6-2

6.1.3 Dial-up networking function ....................................................................................... 6-3

6.1.4 Installing dial-up networking ...................................................................................... 6-7

6.1.5 Setting dial-up networking ......................................................................................... 6-9

6.1.6 Installing software for FTP server ............................................................................. 6-13

6.2 Operation Procedure in [3][9] Mode........................................................................................ 6- 17

6.2.1 Outline ...................................................................................................................... 6-17

6.2.2 Preparation ...............................................................................................................6-17

6.2.3 Updating firmware ..................................................................................................... 6-19

IIOctober 2000 © TOSHIBA TEC DP4500/3500 CONTENTS

Page 7

6.2.4 Display .....................................................................................................................6-25

6.3 Updating the Firmware Using the Downloading Jig ................................................................. 6-29

6.3.1 System firmware....................................................................................................... 6-30

6.3.2 Engine firmware ........................................................................................................ 6-37

7. WIRE HARNESS CONNECTION DIAGRAMS ............................................................................ 7- 1

7.1 AC Wire Harness....................................................................................................... 7-2

7.2 DC Wire Harness ............................................................................................. Appendix

III October 2000 © TOSHIBA TECDP4500/3500 CONTENTS

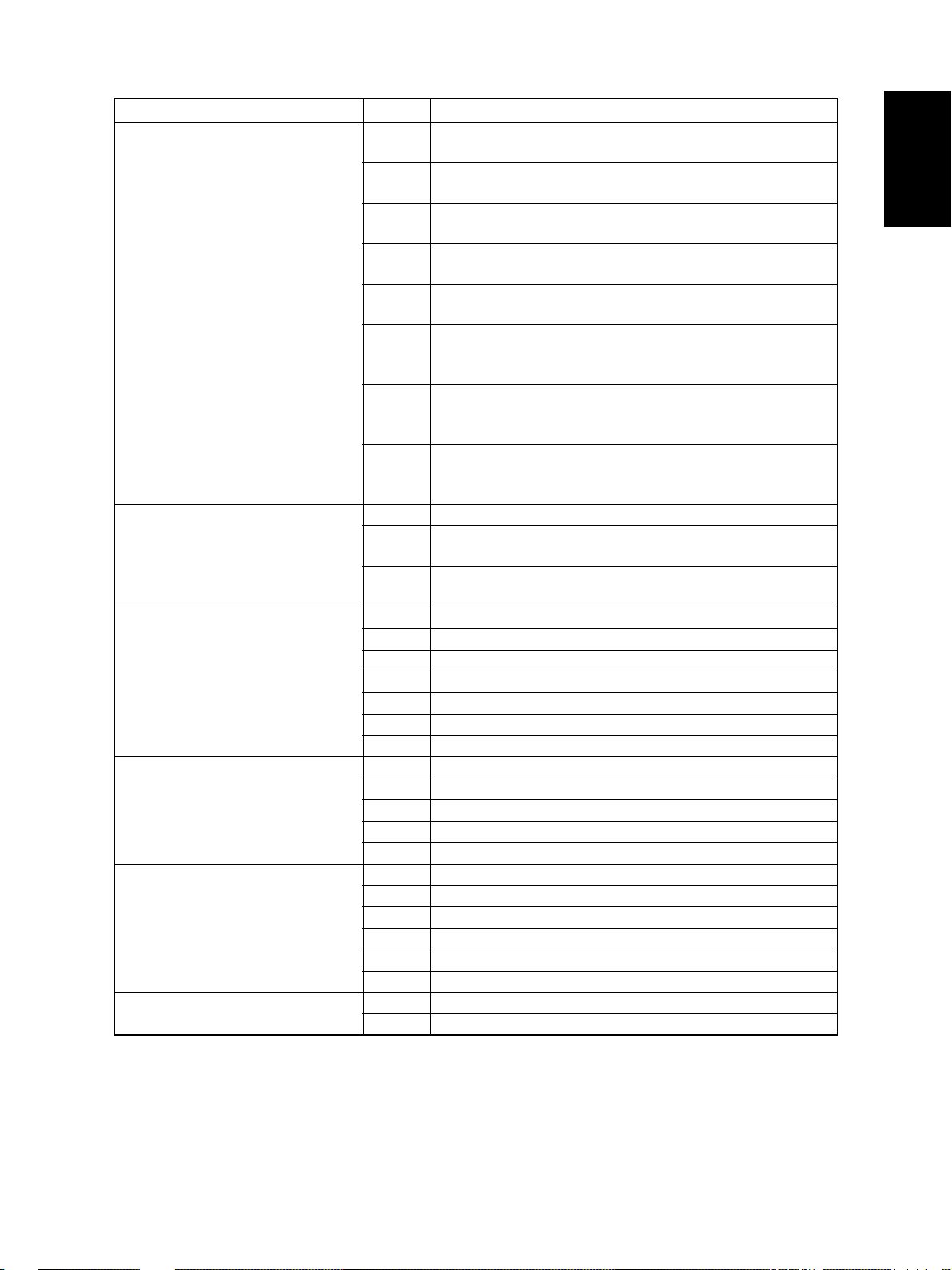

Page 8

1. ERROR CODES AND SELF-DIAGNOSIS

1.1 Error Code

One of the following error codes is displayed instead of the set number while the [CLEAR/STOP] key and the

digital key “8” are pressed simultaneously when the “CLEAR PAPER” or “CALL SERVICE” symbol is flashing.

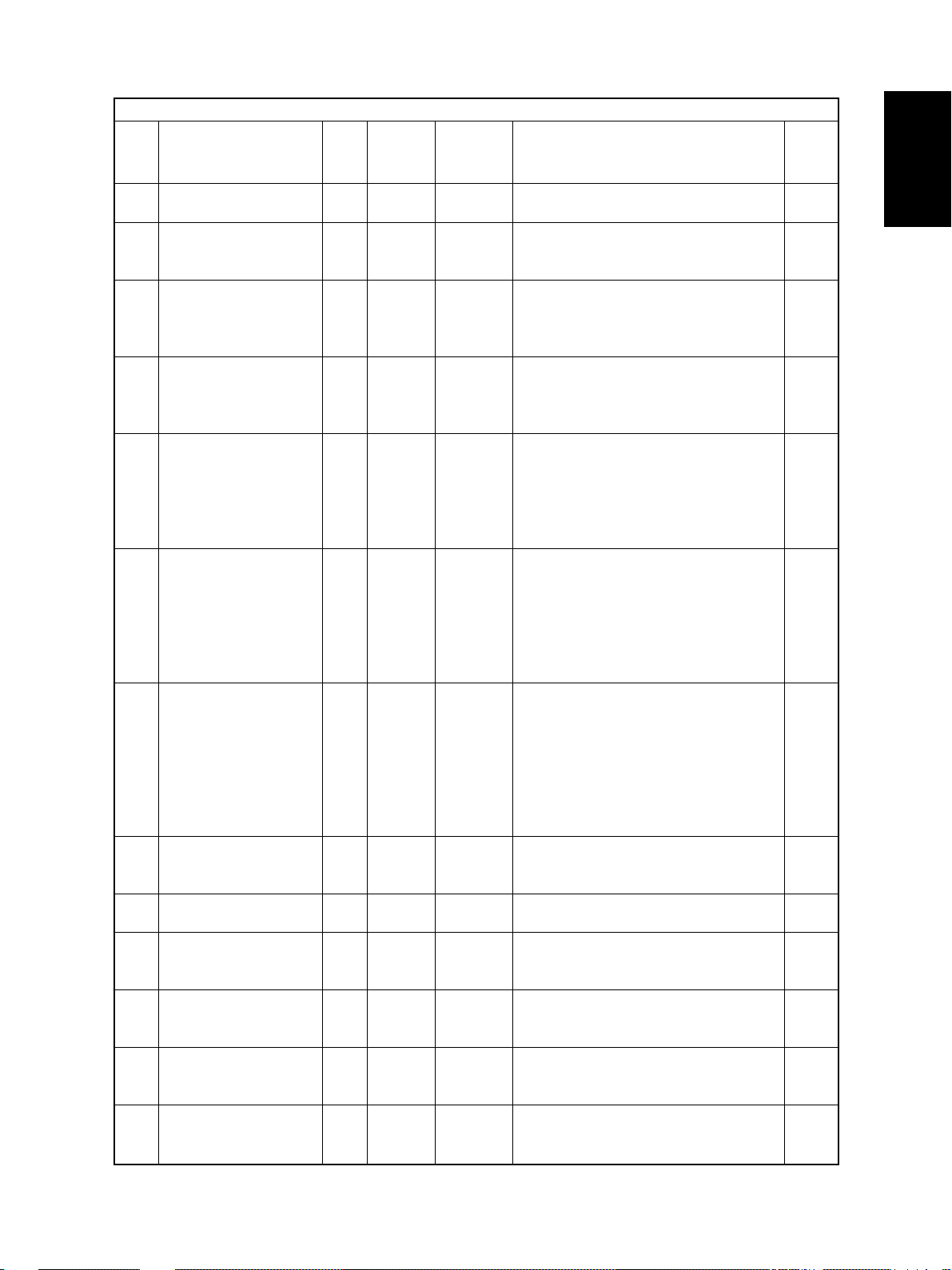

Group

Paper transport jam inside the E01 Leading edge of paper not reaching the exit sensor

copier (1) E02 Trailing edge of paper not passing the exit sensor

Paper misfeeding E11 ADU misfeeding

Paper transport jam inside the E20 Paper fed from the upper cassette

copier (2) not reaching the registration sensor

December 2000 © TOSHIBA TEC 1 - 1

Error Code

E03 Paper remaining inside the copier at power ON

E09 HDD is abnormal

(paper not reaching the registration sensor)

E12 Bypass misfeeding

(paper not reaching the registration sensor)

E13 Upper cassette misfeeding

(paper not reaching the upper feed sensor)

E14 Lower cassette misfeeding

(paper not reaching the lower feed sensor)

E15 PFP upper cassette misfeeding

(paper not reaching the PFP upper feed sensor)

E16 PFP lower cassette misfeeding

(paper not reaching the PFP lower feed sensor)

E19 LCF misfeeding

(paper not reaching the LCF feed sensor)

E21 Paper fed from the lower cassette

not reaching the registration sensor

E22 Paper fed from the lower cassette

not reaching the upper feed sensor

E30 Paper fed from the PFP upper cassette

not reaching the registration sensor

E31 Paper fed from the PFP upper cassette

not reaching the upper feed sensor

E32 Paper fed from the PFP upper cassette

not reaching the lower feed sensor

E33 Paper fed from the PFP lower cassette

not reaching the registration sensor

E34 Paper fed from the PFP lower cassette

not reaching the upper feed sensor

E35 Paper fed from the PFP lower cassette

not reaching the lower feed sensor

E36 Paper fed from the PFP lower cassette

not reaching the PFP upper feed sensor

E3C Paper fed from the LCF

not reaching the registration sensor

E3D Paper fed from the LCF

not reaching the upper feed sensor

E3E Paper fed from the LCF

not reaching the lower feed sensor

Machine Status

DP4500/3500 ERROR CODES AND SELF-DIAGNOSIS

Page 9

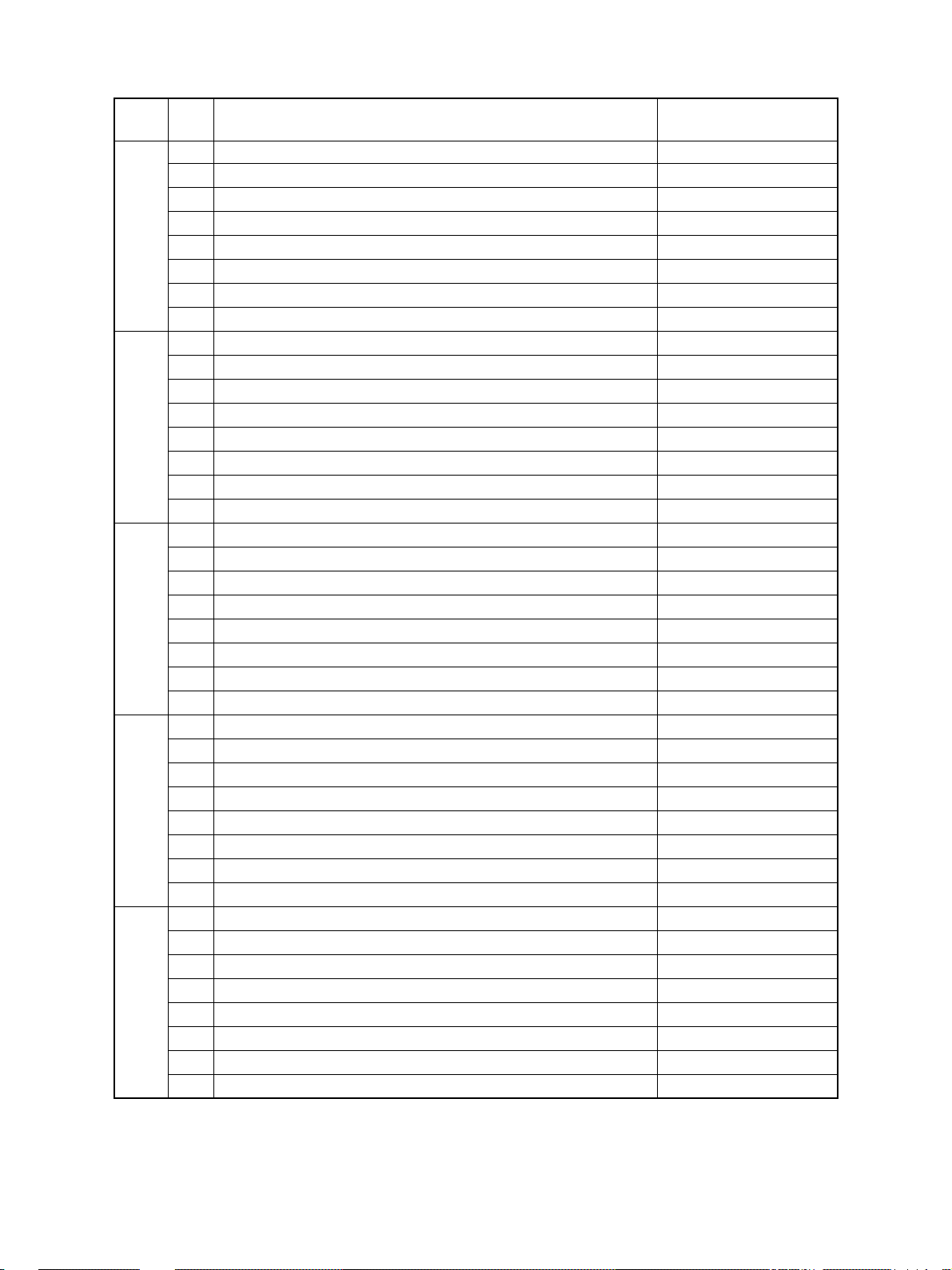

Group

Cover open jam E40 Jam access cover opened during printing

Transport jam (ADU and other area) E51 ADU stack jam (paper not reaching the ADU entrance sensor)

Transport jam (RADF) E71 Original feeding jam

Paper jam in finisher E91 Leading edge of paper not reaching the relay unit transport

Paper transport jam inside the EB5 Paper left on the transport path due to multiple feeding

copier (3) EB6 Paper left on the transport path due to multiple feeding

Drive system related service call C0 1 Main motor is abnormal

Error Code

E41 Front cover opened during printing

E42 PFP side cover opened during printing

E43 ADU opened during printing

E44 Side cover opened during printing

E45 LCF side cover opened during printing

E48 Relay unit opened during printing

E52 ADU transport jam (paper not reaching the ADU exit sensor)

E55 Paper remaining on the transport path when CRUN is OFF

E72 Original transport jam

E73 Original discharging jam

E74 Original reversing jam

sensor-1

E92 Trailing edge of paper not passing the relay unit transport sen-

sor-1

E93 Leading edge of paper not reaching the relay unit transport

sensor-2

E94 Trailing edge of paper not passing the relay unit transport sen-

sor-2

E9F Punching jam

EA1 Finisher paper transport delay jam

EA2 Finisher paper transport stop jam

EA3 Paper remaining inside the finisher at power ON

EA4 Finisher front door opened during printing

EA5 Finisher stapling jam

EA6 Finisher early arrival jam

EA7 Stack transport jam before stapling

EA8 Saddle stitcher stapling jam

EA9 Saddle stitcher door opened during printing

EAA Paper remaining at the saddle stitcher at power ON

EAB Saddle stitcher paper transport stop jam

EAC Saddle stitcher paper transport delay jam

EAD Print end command time-out jam

EAE Receiving time time-out jam

EAF Stapled stack transport jam

EB3 Ready time time-out jam

Machine Status

DP4500/3500 ERROR CODES AND SELF-DIAGNOSIS

1 - 2 December 2000 © TOSHIBA TEC

Page 10

Group

Paper feeding system related service call

Scanning system related service call C2 6 Peak detection error

Fuser unit related service call C4 1 Thermistor or heater is abnormal at power ON

Communication related service call C55 ADF I/F is abnormal

RADF related service call C7 1 ADF feed motor is abnormal

Laser optical unit related service call CA 1 Polygonal motor is abnormal

Error Code

C0 4 PFP motor is abnormal

(paper can be fed from cassettes other than PFP cassette)

C1 3 Upper cassette tray is abnormal (paper can be fed from the

cassettes other than the copier cassettes)

C1 4 Lower cassette tray is abnormal (paper can be fed from the

cassettes other than the copier cassettes)

C1 5 PFP upper cassette tray is abnormal (paper can be fed from

the cassettes other than the PFP upper cassette)

C16 PFP lower cassette tray is abnormal (paper can be fed from the

cassettes other than the PFP lower cassette)

C1 8 LCF tray-up motor is abnormal

(paper can be fed from the cassettes other than the LCF

cassette)

C1A LCF end fence motor is abnormal

(paper can be fed from the cassettes other than the LCF

cassette)

C1B LCF motor is abnormal

(paper can be fed from the cassettes other than the LCF

cassette)

C2 7 Carriage home position sensor not going OFF within a fixed

time

C28 Carriage home position sensor not going ON within a fixed

time

C4 3 Thermistor is abnormal after abnormality judgment

C4 4 Fuser is abnormal after abnormality judgment

C45 Side thermistor is abnormal after the copier has become ready

C4 7 IH power voltage is abnormal/IH initialization error

C4 8 IGBT high temperature

C4 9 IH circuit or coil is abnormal

C5 7 Communication error between main CPU and IPC board

C5 8 Communication error between IPC board and finisher

F07 Communication error between SYS board and LGC board

F11 Communication error between SYS board and SLG board

C7 3 EEPROM initialization error

C7 4 Reverse sensor adjustment error

C8 1 Fan motor is abnormal

C8 2 Read sensor adjustment error

C8 3 Original length sensor adjustment error

CA2 H-Sync detection error

Machine Status

December 2000 © TOSHIBA TEC 1 - 3

DP4500/3500 ERROR CODES AND SELF-DIAGNOSIS

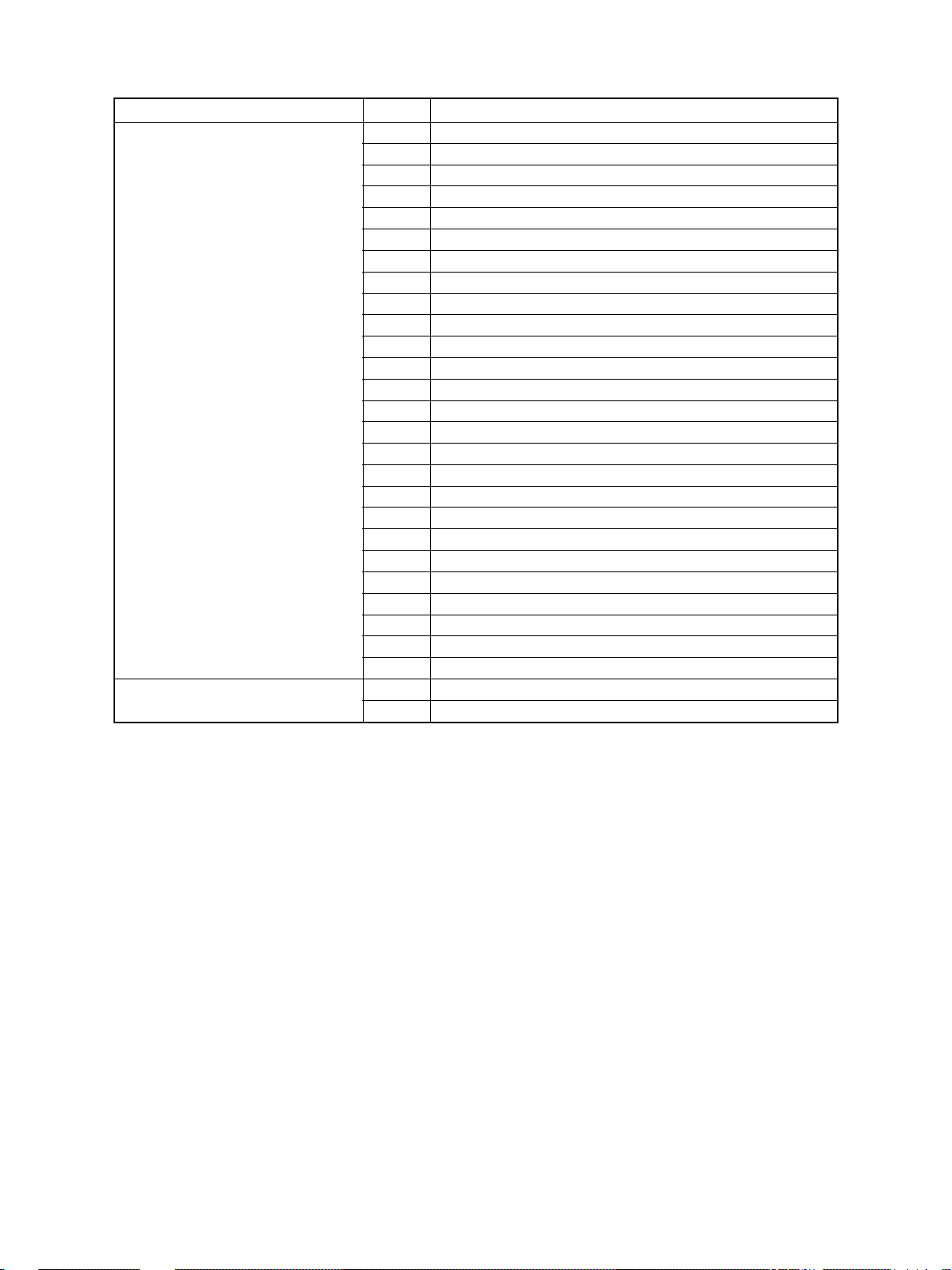

Page 11

Group

Finisher related service call CB1 Feed motor is abnormal

Service call for others C 9 4 Main CPU is abnormal

Error Code

CB2 Delivery motor is abnormal

CB3 Tray lift motor is abnormal

CB4 Alignment motor is abnormal

CB5 Staple motor is abnormal

CB6 Stapler shift motor is abnormal

CB7 Height sensor is abnormal

CB8 Backup RAM data are abnormal

CB9 Saddle stitcher paper pushing plate motor is abnormal

CBA Saddle stitcher stitch motor (front) is abnormal

CBB Saddle stitcher stitch motor (rear) is abnormal

CBC Saddle stitcher alignment motor is abnormal

CBD Saddle stitcher guide motor is abnormal

CBE Saddle stitcher paper folding motor is abnormal

CBF Saddle stitcher paper positioning plate motor is abnormal

CC 0 Saddle stitcher sensor connector connection error

CC 1 Saddle stitcher microswitch error

CC 2 Communication error between finisher and saddle stitcher

CC 3 Stack processing motor is abnormal

CC 4 Swing motor is abnormal

CC 5 Horizontal registration motor is abnormal

CC 6 Punch motor is abnormal

CC 8 Front jogging motor is abnormal

CC 9 Upper stack tray lift motor is abnormal

CCA Lower stack tray lift motor is abnormal

CCB Rear jogging motor is abnormal

F10 HDD initialization error

Machine Status

DP4500/3500 ERROR CODES AND SELF-DIAGNOSIS

1 - 4 December 2000 © TOSHIBA TEC

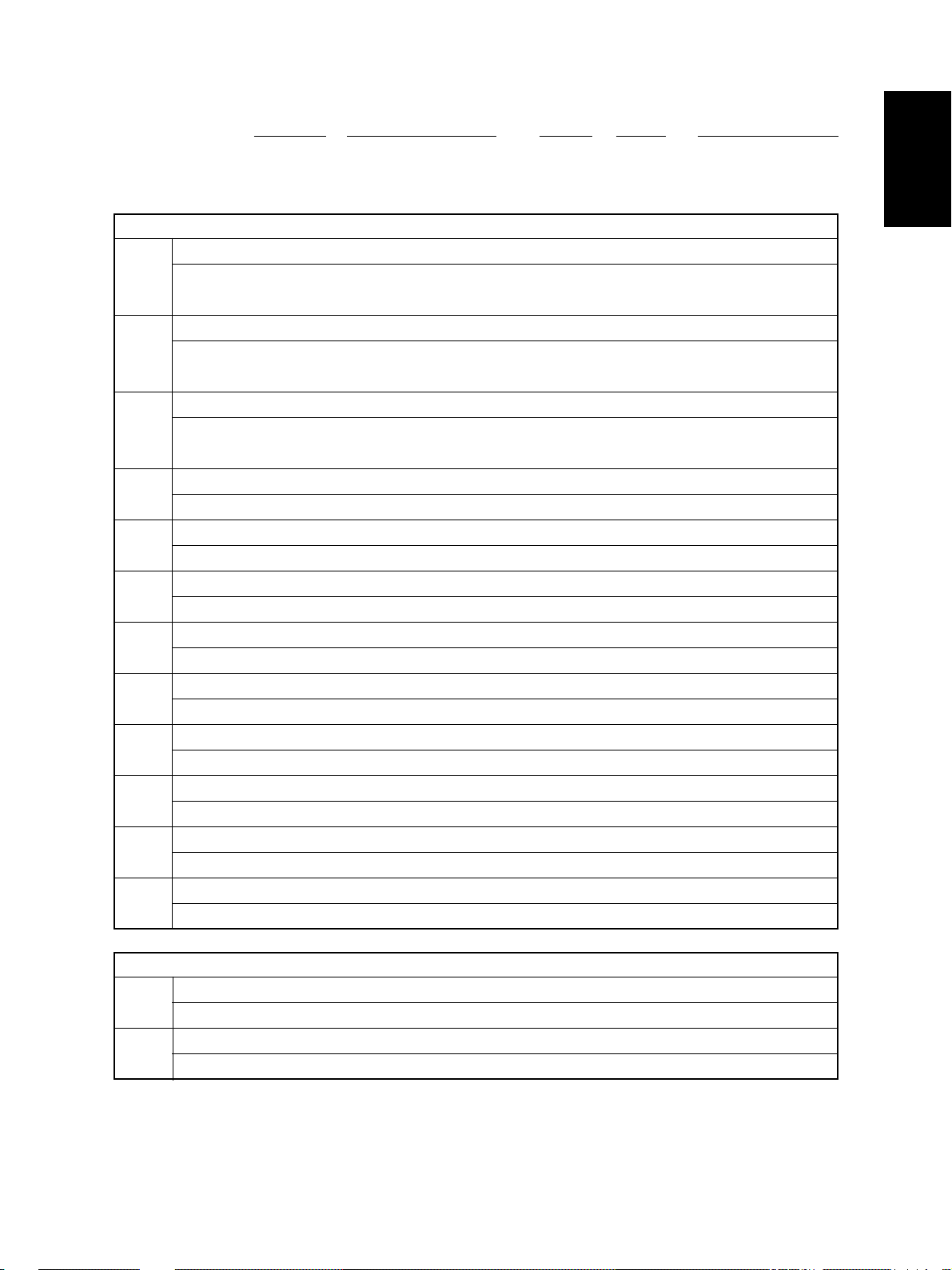

Page 12

<<Error history (08-253)>>

(Example of display)

Copy mode

A Paper source

0: Not selected 1: Bypass feeding 2: LCF 3: PFP(U) 4: Not used 5: PFP(L) 6: ADU feeding

7: Upper cassette 8: Lower cassette

B Paper size code

0: Not selected 1: A5-R 2: ST-R 3: LT 4: A4 5: B5-R 6: LT-R 7: A4-R 8: O THER/UNIV 9: B5

A: FOL/COM B: LG C: B4 D: LD E: A3 F: 13'LG G: 8.5*8.5 H: 8K I:16K J:16K-R

C Sort mode/Staple mode

0: Not selected 1: Group 2: Sort 7: Staple (stapling one corner -1) 8: Staple (stapling 2 places)

9: Staple (stapling one corner -2) A: Saddle stitch

D ADF mode

0: Not used 1: A UTO FEED (SADF) 2: STACK FEED

E APS/AMS mode

0: Not selected 1: APS 2: AMS

F Duplex mode

0: Not selected 1: BOOK 2: Two-sided/Single-sided 4: Two-sided/Duplex 8: Single-sided/Duplex

G Not used

0: Not used

H Image shift

0: Not used 1: BOOK 2: LEFT 3: RIGHT

I Editing

0: Not used 1: Masking 2: Trimming 3: Mirror image 4: Negative/Positive

J Edge erasing/Dual-page

0: Not used 1: Edge erase 2: Dual-page 3: Edge erase & Dual-page

K Not used

0: Not used

L Function

0: Not used 1: Copying 2: Fax input 3: Fax printing 4: LAN printer 5: DSS

EA1

Error code

3 digits

0 0 1 2 2 6 1 7 5 7 3 2

YYMMDDHHMMSS

with its last 2 digits)

6 4

MMM

3 digits

3 digits12 digits (Year indicated

6 4

NNN

2 3 6 2 1 0 0 0 0 0 0 0

ABCDEFGHIJKL

12 digits

Reproduction ratio

MMM Primary scanning reproduction ratio

Shown in hexadecimal

NN N Secondary scanning reproduction ratio

Shown in hexadecimal

The latest 8 error data can be displayed in the setting mode (08-253).

December 2000 © TOSHIBA TEC 1 - 5

DP4500/3500 ERROR CODES AND SELF-DIAGNOSIS

Page 13

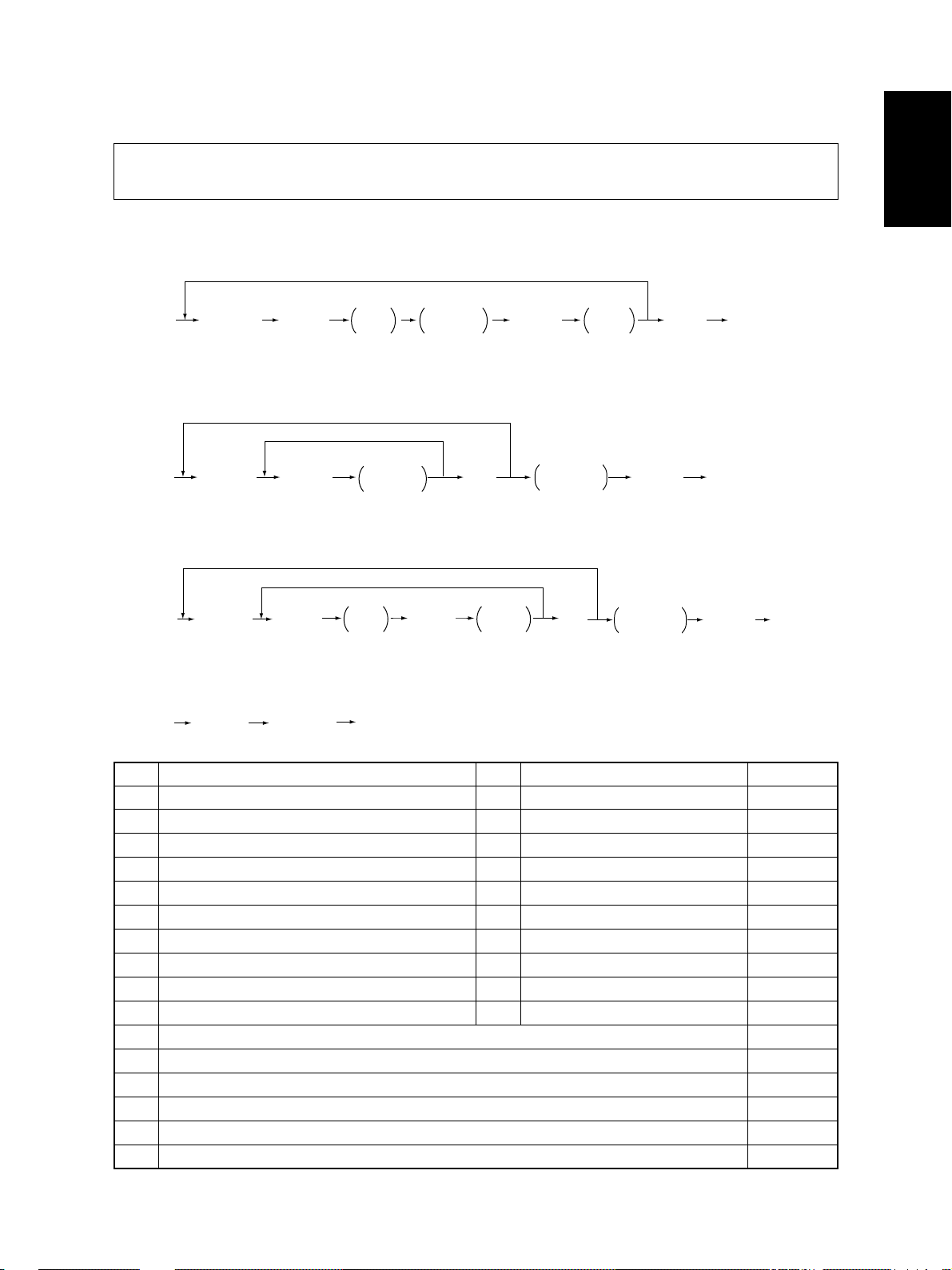

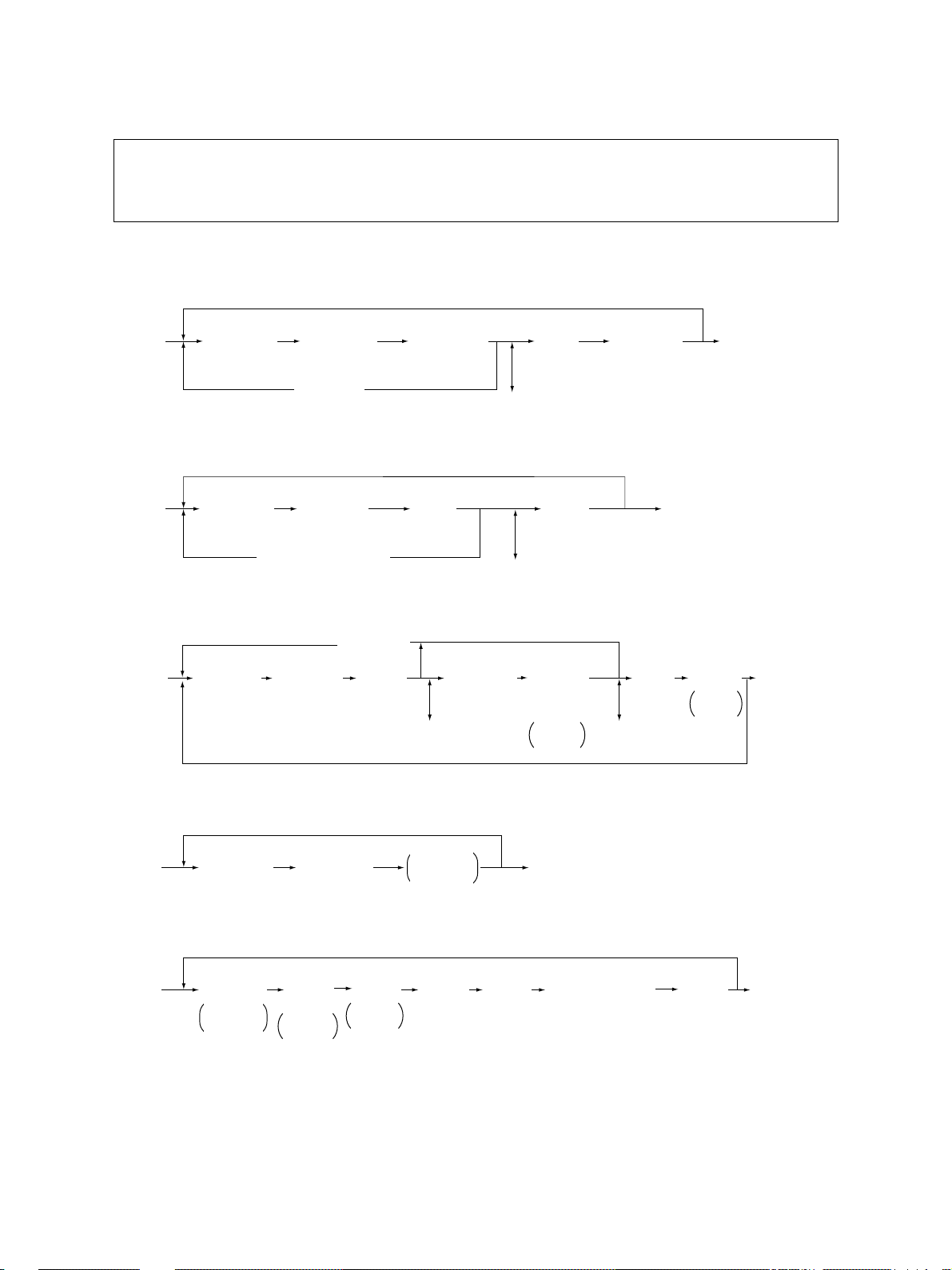

1.2 Self-Diagnosis Modes

Since this copier is designed to cope with multifunctions such as those of a network printer and DSS, there

are many setting items which are related to each other in the self-diagnosis modes.

Malfunctions such as machine locking can be caused by the internal structural problem of the program

when a normal operation is attempted by pressing [0] and [9] simultaneously or [C/S] on the control panel

subsequently to the adjustment.

Therefore, turn OFF the power after using the self-diagnosis mode for adjustment after unpacking, service

or prev entive maintenance , and then leav e the machine to the customer .

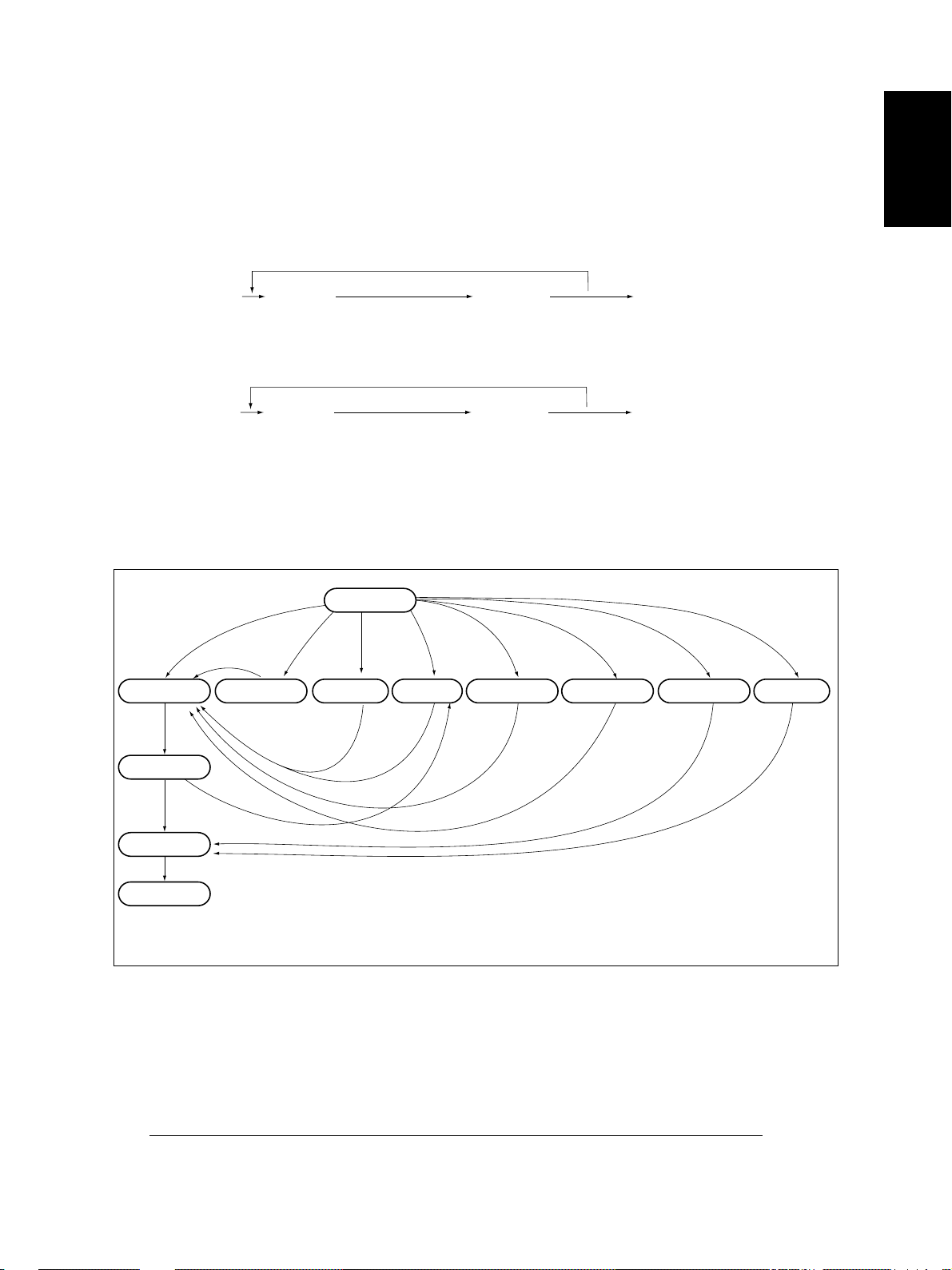

Mode

Whole control panel

items lighting mode

Test mode

Test print mode

Adjustment mode

Setting mode

List printing mode

Unit replacement

mode

Note: To enter the desired mode, turn ON the power while two digital keys designated to each mode (e.g. [0] and

[5]) are pressed simultaneously.

Keys to

press exit

[0]+[1]+

[POWER]

[0]+[3]+

[POWER]

[0]+[4]+

[POWER]

[0]+[5]+

[POWER]

[0]+[8]+

[POWER]

[9]+[ST AR T]

+[ POWER]

[6]+[ST ART]

+[ POWER]

All LEDs on the control panel are lit, and all

the LCD pixels flash.

Checks the status of input/output signals.

Outputs the test patterns.

Adjusts various items.

Sets various items.

Prints out the lists for the codes 05 and 08.

Performs auto-toner adjustment and clears

the process counters.

Function

Keys to

[C/S]or

[0]+[9]

[0]+[9]

[0]+[9]

[0]+[9]

[0]+[9]

[POWER]

OFF

[POWER]

OFF

Display

100% C

TEST MODE

100% P A4

TEST PRINT

100% A A4

TEST MODE

100% D

TEST MODE

100% L A4

LIST PRINT

100% K

TEST MODE

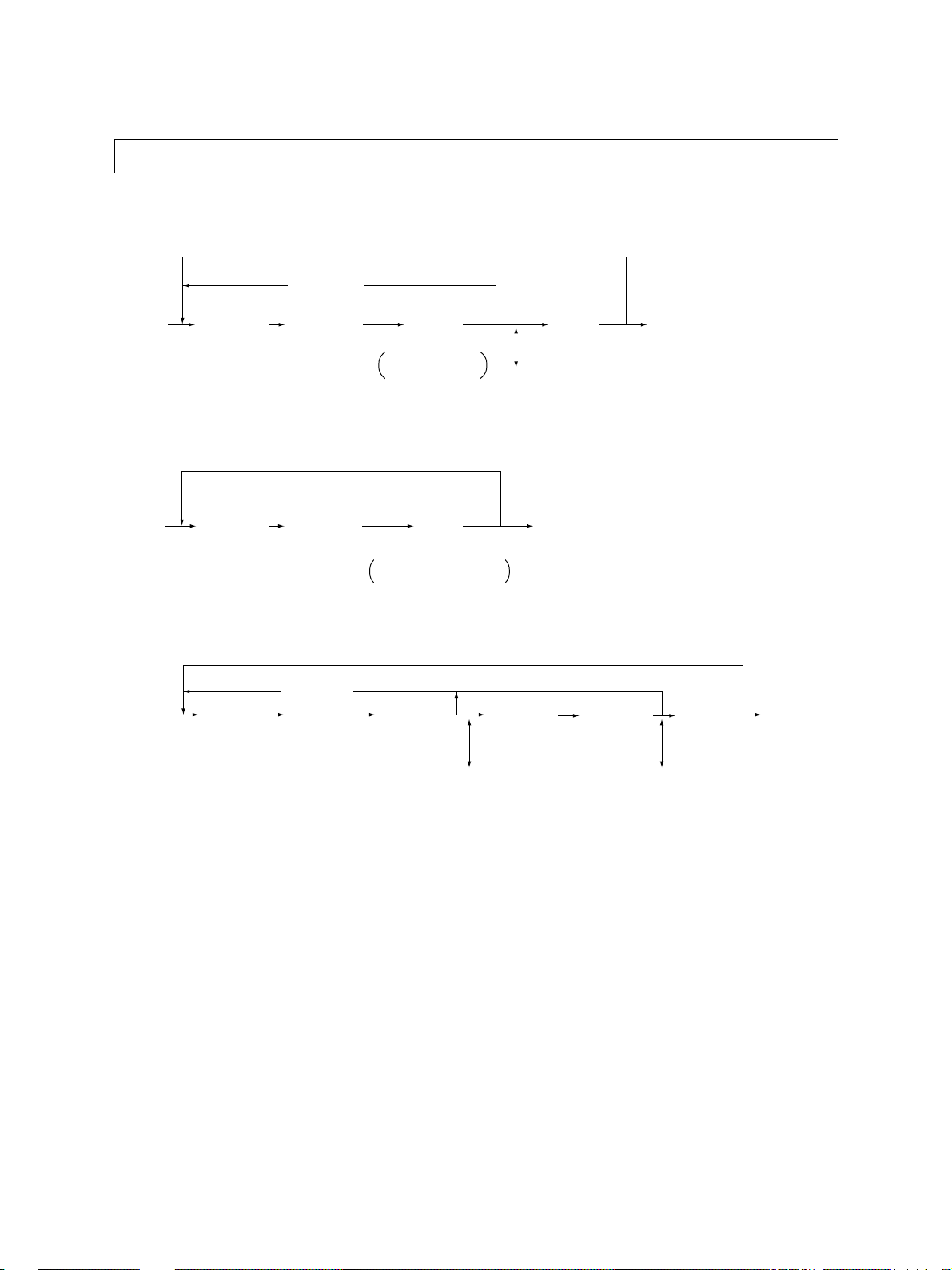

<Operation procedure>

• Whole control panel items lighting mode (01):

[0] [1]

[POWER]

Notes: 1. The mode can be canceled only by pressing the [C/S] key during the key check.

2. Key Check Keys with LED (Press to turn OFF the LED)

DP4500/3500 ERROR CODES AND SELF-DIAGNOSIS

(All control

panel LEDs lit)

Keys without LED (Press to display the message on the control panel)

[START]

[START]

(Key check) [C/S] (Exit)

1 - 6 December 2000 © TOSHIBA TEC

[C/S] or [0] [9]

(Exit)

Page 14

• Test mode (03): Refer to “1.2.1 Input check (test mode 03)” and “1.2.2 Outpout check (test mode 03)”.

• Test print mode (04): Refer to “1.2.3 Test print mode (04)”.

• Adjustment mode (05): Refer to “1.2.4 Adjustment mode (05)”.

• List print mode

[9] [START]

[POWER]

(code)

101:05 adjustment mode

(List starts to be printed)

102: 08 setting mode

• Unit replacement mode

[6] [START]

[POWER]

(code) [POWER] OFF

1: Auto-toner adjustment

2: Drum life counter resetting (08-401)

3: Resetting of the copier running time counter (08-402) and fuser unit counter (08-403)

4: Resetting of the separation charger life counter (08-497)

[STA RT]

(Operation started)

• Setting mode (08): Refer to “1.2.5 Setting mode (08)”.

[POWER] ON

Warming up

Normal

[C/S]

Whole control

panel items lit

*2

[0][1] [0][3]

Test mode

[0][5]

Adjustment mode

[0][9][0][9]

Setting mode

[0][9]

[STA RT]

[0][8] [0][4] [9][S]

T est print mode

[0][9]

[POWER] OFF

List print mode

[6][S]

Unit replacement

mode

Standby

*1

[0][5]

[POWER] OFF

*3

To user

[S]: START key

[C/S]: CLEAR/STOP key

State transition diagram of self-diagnosis mode

*1 Only when the copier is put into the adjustment mode by turning ON the power while the digital keys

[0] and [5] are pressed simultaneously and then becomes standby state by pressing [0] and [9]

simultaneously, it can go back to the adjustment mode by the pressing of [0] and [5] simultaneously.

*2 In the “whole control panel items lighting mode”, copying is disabled. Enter the standby state by

pressing [0] and [9] simultaneously or [C/S] key to perform copying.

*3 Turn OFF the power after using the self-diagnosis mode, and leave the copier to the user .

December 2000 © TOSHIBA TEC 1 - 7

DP4500/3500 ERROR CODES AND SELF-DIAGNOSIS

Page 15

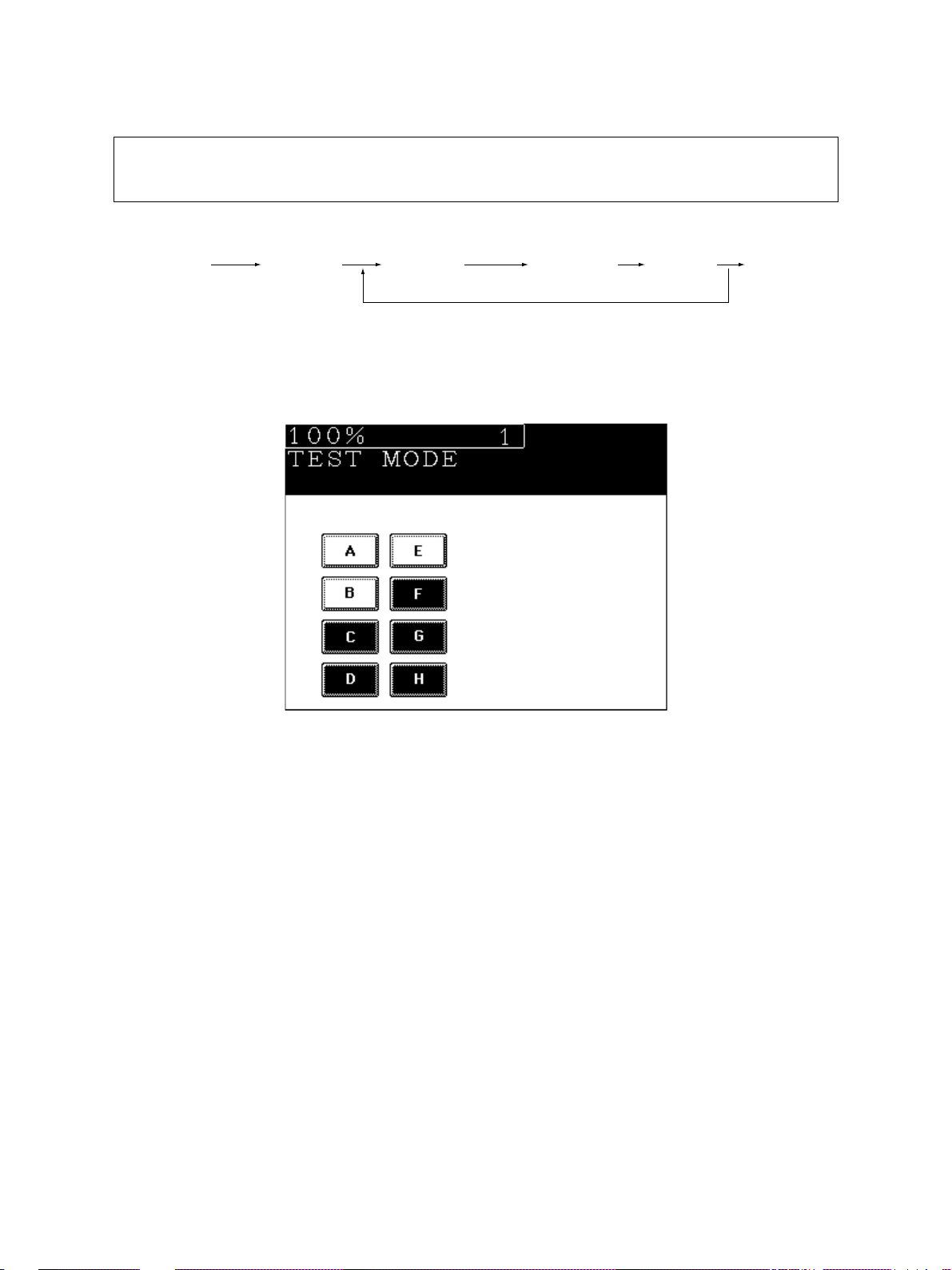

1.2.1 Input check (test mode 03)

The state of each input signal can be checked b y pressing the [FAX] key and the digital keys in the

test mode (03).

<Operation procedure>

[0] [3]

[POWER]

Note: Initialization is performed before the copier enters the test mode.

[ST ART] ([F AX]) [Digital key] (LCD ON) [0] [9]

(Exit)

[Example of display during input check]

Items to be checked and the state of the copier with the icons [A] to [H] displayed in black are listed on the

following pages.

DP4500/3500 ERROR CODES AND SELF-DIAGNOSIS

1 - 8 December 2000 © TOSHIBA TEC

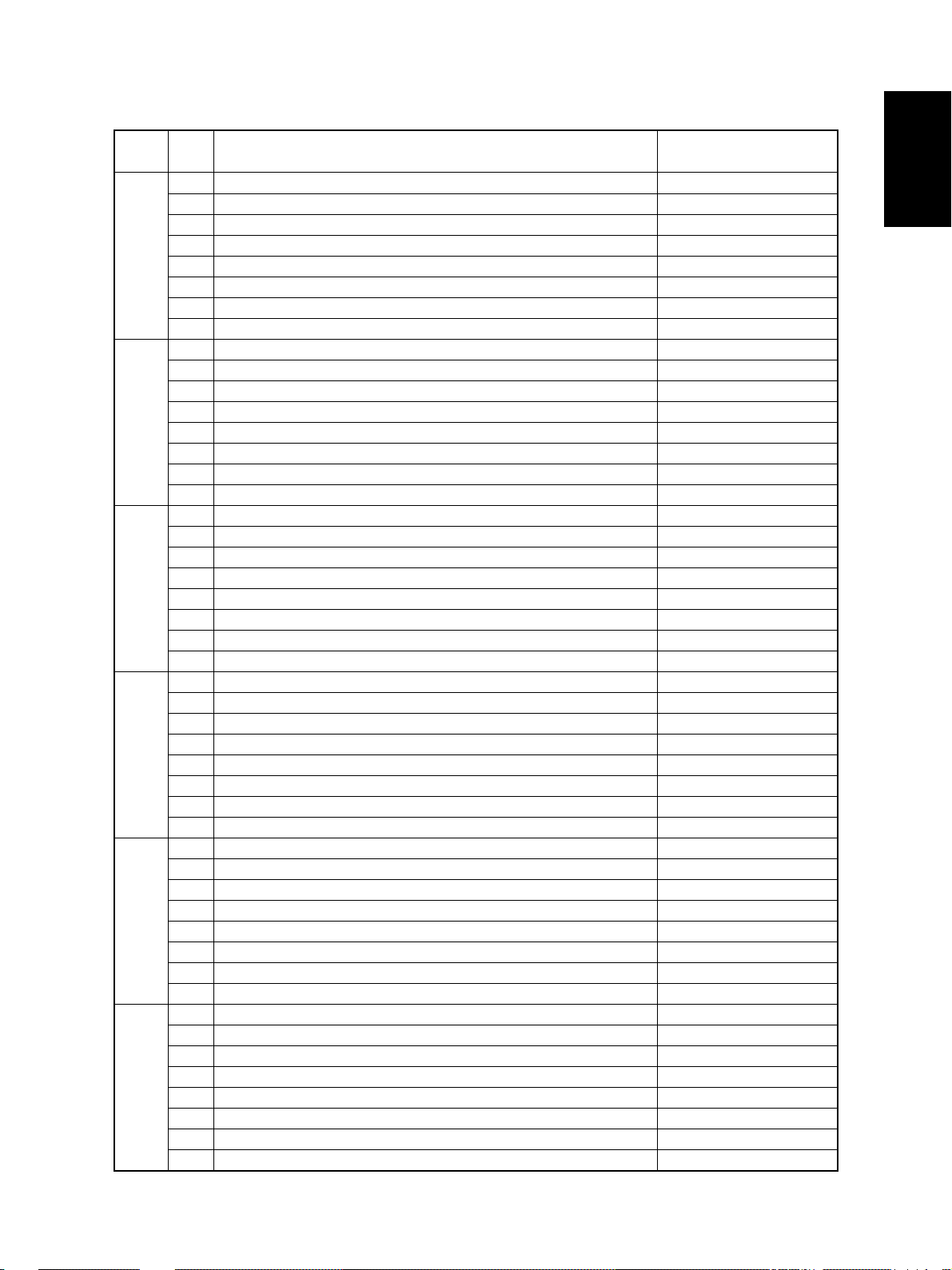

Page 16

[FAX] key: OFF ( [FAX] LED: OFF)

Digital

key with black icon

Icon Items to check

A—

B LCF connection Not connected

C—

[1]

[2]

[3]

[4]

[5]

[6]

D Bypass feed sensor Paper does not exist

E ADU connection Not connected

F ADU opening/closing switch ADU opened

G ADU exit sensor There is paper

H ADU entrance sensor There is paper

A—

B—

C PFP upper cassette paper-stock sensor Paper is almost finished

D PFP upper feed sensor There is paper

E PFP connection Not connected

F PFP side cover opening/closing switch Cover opened

G PFP upper cassette paper-empty sensor No paper

H PFP upper cassette tray-up sensor Tray at upper limit position

A LCF tray bottom sensor Tray at bottom position

B LCF paper mis-insertion detection sensor Paper not inserted properly

C—

D—

E—

F—

G—

H LCF feed side paper-stock sensor Paper is almost finished

A—

B—

C PFP lower cassette paper-stock sensor Paper is almost finished

D PFP lower feed sensor There is paper

E PFP motor rotation condition (motor is being rotated in the output check (03)) Abnormal rotation

F—

G PFP lower cassette paper-empty sensor No paper

H PFP lower cassette tray-up sensor Tray at upper limit position

A LCF end fence home position sensor Fence at home position

B LCF end fence stop position sensor Fence at stop position

C LCF standby side paper-empty sensor No paper

D LCF side cover opening/closing switch Cover closed

E LCF motor rotation condition (motor is being rotated in the output check (03)) Abnormal rotation

F LCF tray-up sensor Tray at upper limit position

G LCF feed sensor No paper

H LCF feed side paper-empty sensor No paper

A—

B—

C—

D—

E Upper feed sensor There is paper

F—

G Upper cassette paper-empty sensor No paper

H Upper cassette tray-up sensor Tray at upper limit position

Copier state

December 2000 © TOSHIBA TEC 1 - 9

DP4500/3500 ERROR CODES AND SELF-DIAGNOSIS

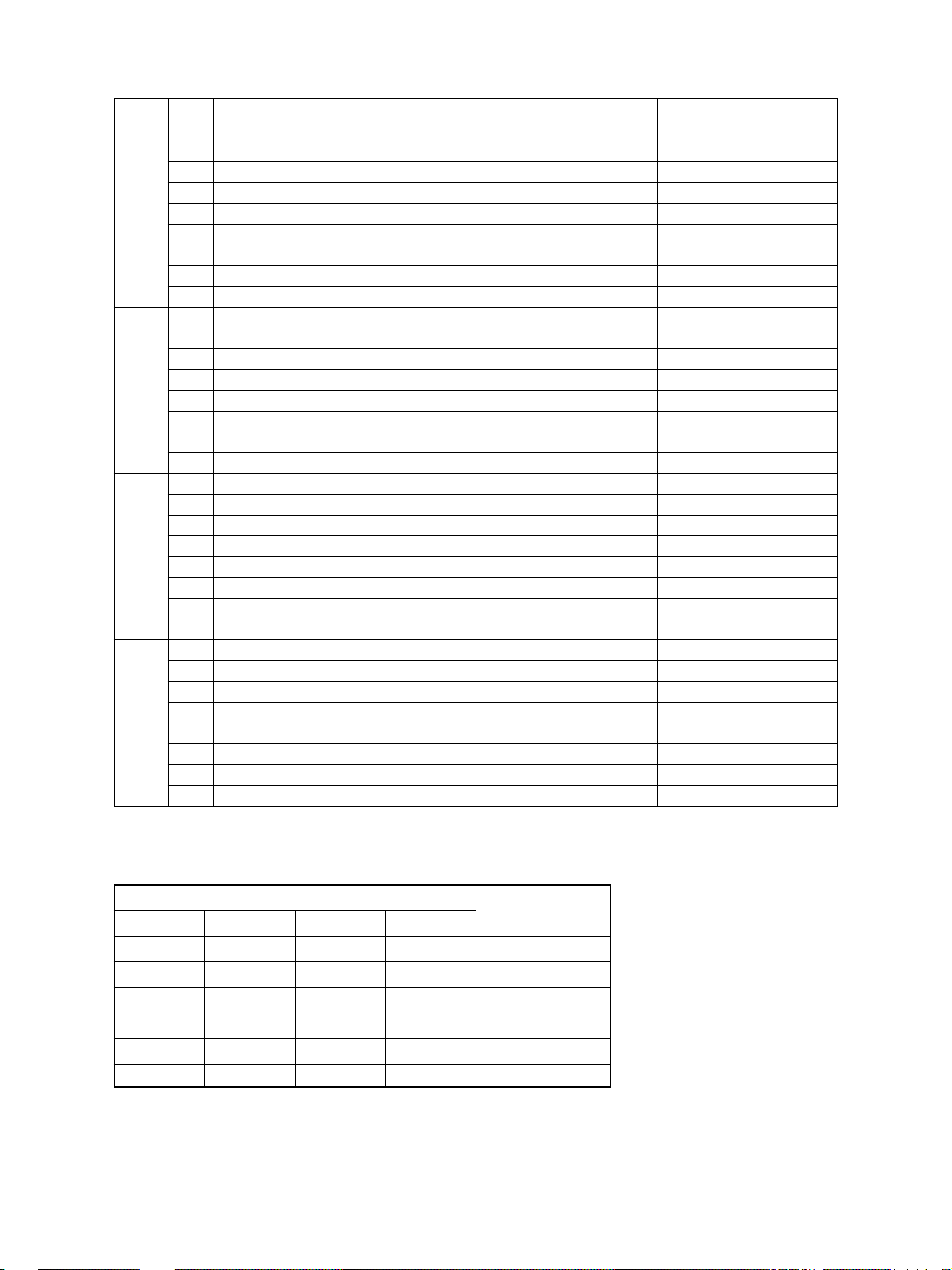

Page 17

Digital

key with black icon

Icon Items to check

A—

B—

C—

[7]

[8]

[9]

[0]

D—

E Lower feed sensor There is paper

F—

G Lower cassette paper-empty sensor No paper

H Lower cassette tray-up sensor Tray at upper limit position

A Bypass feed paper width sensor-3 See table 1.

B Bypass feed paper width sensor-2 See table 1.

C Bypass feed paper width sensor-1 See table 1.

D Bypass feed paper width sensor-0 See table 1.

E—

F—

G—

H PFP upper cassette detection sensor No cassette

A—

B—

C—

D PFP lower cassette detection sensor No cassette

E—

F—

G Upper cassette detection sensor No cassette

H Upper cassette paper-stock sensor Paper is almost finished

A—

B—

C—

D LCF cassette detection switch No cassette

E—

F—

G Lower cassette detection sensor No cassette

H Lower cassette paper-stock sensor Paper is almost finished

Copier state

Table 1. Relation between the state of the bypass feed paper width sensor and paper siz e (width).

Bypass paper width sensor

3210

0 1 1 1 A3/LD

1 0 1 1 A4-R/LT-R

1 1 0 1 A5-R/ST-R

1 1 1 0 Card size

0 0 1 1 B4-R/LG

1 0 0 1 B5-R

DP4500/3500 ERROR CODES AND SELF-DIAGNOSIS

Paper width size

1 - 10 December 2000 © TOSHIBA TEC

Page 18

[FAX] key: ON ([FAX] LED: ON)

Digital

key with black icon

Icon Items to check

A—

B—

C—

[1]

[2]

[3]

[4]

[5]

D IPC board connection Not connected

E—

F Polygonal motor rotation condition (motor is being rotated in the output check (03)) Abormal rotation

G Toner cartridge detection switch OFF

H 24V power supply OFF

A Registration sensor There is paper

B Exit sensor There is paper

C Auto-toner sensor connection Not connected

D Front cover switch Cover opened

E—

F—

G Side door switch Side cover opened

H Main motor rotation condition (motor is being rotated by in the output check (03)) Abormal rotation

A—

B Key copy counter connection Not connected

C Toner bag full detection sensor Toner is full

D Fuser unit connection Unit connected

E Relay unit transport sensor-2 No paper

F Relay unit opening/closing switch Cover opened

G—

H Relay unit paper full detection sensor Paper not full

A—

B—

C—

D—

E—

F—

G Relay unit installation Not installed

H Relay unit transport sensor-1 No paper

A—

B—

C—

D—

E—

F RADF connection RADF connected

G Platen sensor Platen cover opened

H Scanner carriage home position sensor Home position

Copier state

December 2000 © TOSHIBA TEC 1 - 11

DP4500/3500 ERROR CODES AND SELF-DIAGNOSIS

Page 19

Digital

key with black icon

Icon Items to check

A—

B—

C—

[6]

[7]

[8]

[9]

[0]

D APS sensor (APS-5/for A4 series) / (APS-6/for LT series) No original

E APS sensor (APS-4/for A4 series) No original

F APS sensor (APS-3) No original

G APS sensor (APS-2) No original

H APS sensor (APS-1) No original

A RADF tray sensor Original present

B RADF empty sensor Original present

C RADF jam access cover opening/closing switch Cover opened

D RADF opening/closing sensor RADF opened

E RADF exit sensor Original present

F RADF reverse sensor Original present

G RADF read sensor Original present

H RADF registration sensor Original present

A—

B—

C—

D—

E RADF original length sensor Original present

F RADF original width sensor-1 Original present

G RADF original width sensor-2 Original present

H RADF original width sensor-3 Original present

A—

B—

C—

D—

E—

F—

G—

H—

A—

B—

C—

D—

E—

F—

G—

H—

Copier state

DP4500/3500 ERROR CODES AND SELF-DIAGNOSIS

1 - 12 December 2000 © TOSHIBA TEC

Page 20

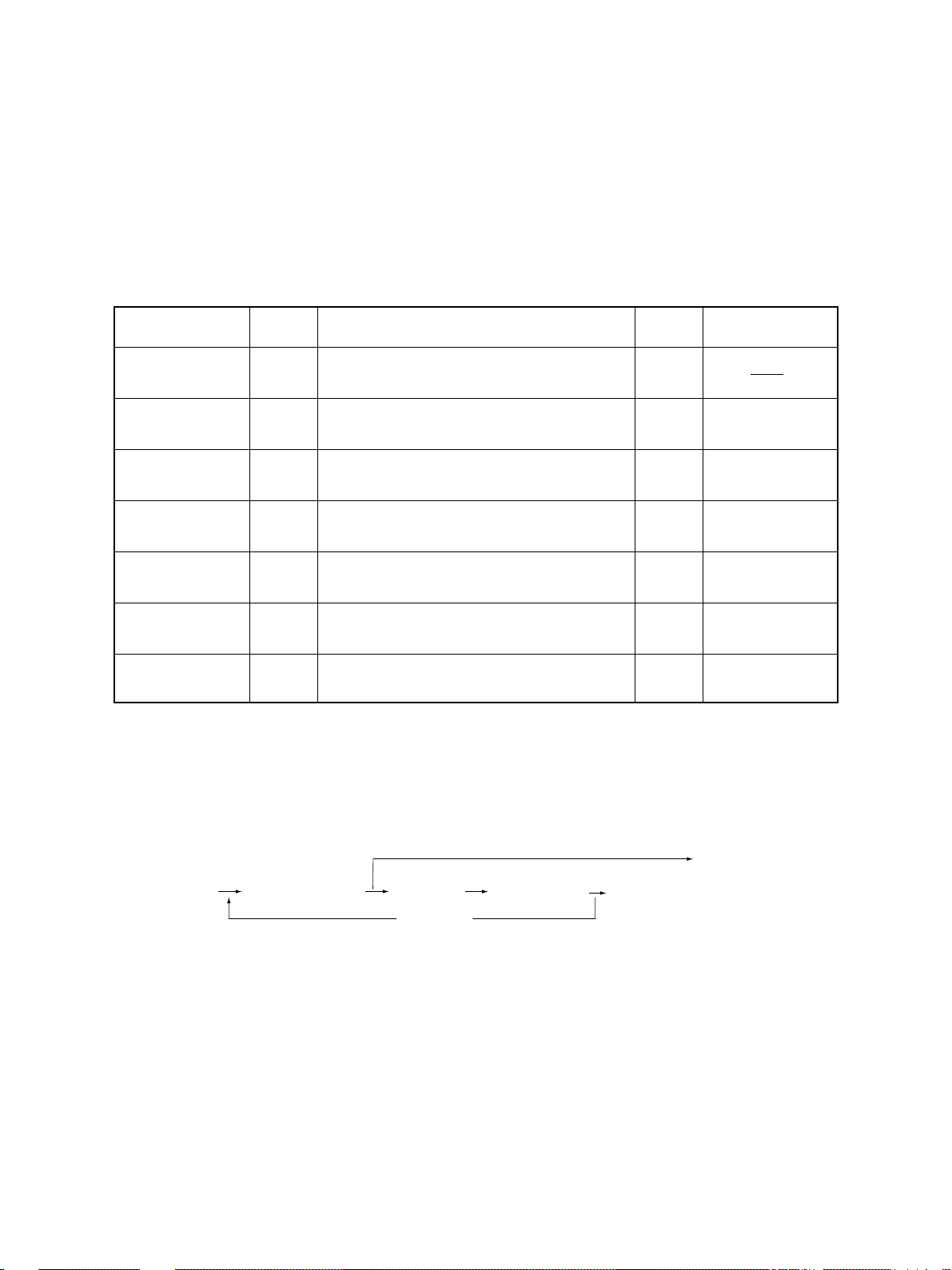

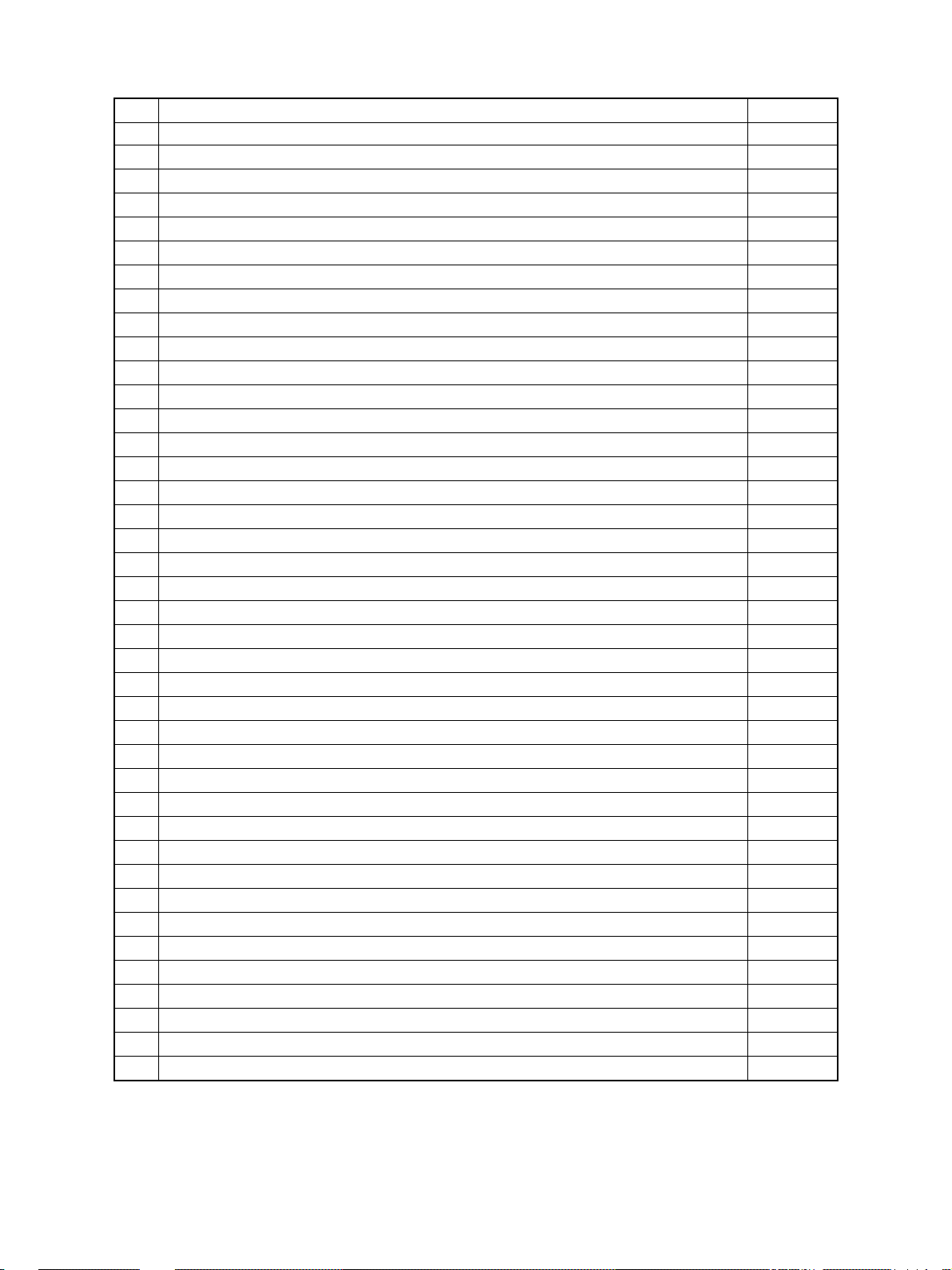

1.2.2 Output check (test mode 03)

State of the output signals can be checked by entering the codes in the following table in the test

mode 03.

<Operation procedure>

Group (1)

[0] [3]

[POWER]

(Code) [START ]

Operation

started

Code to stop

operation

[START]

Operation

stopped

[0] [9]

(Exit)

Warming up

Group (2)

[0] [3]

[POWER]

(Code)

[STAR T]

Operation

(One direction)

[C/S] [0] [9]

Test mode

standby

Warming up

(Exit)

Group (3)

[0] [3]

[POWER]

(Code) [START] [START] [C/S] [0] [9]

Operation

started

Operation

stopped

Test mode

standby

(Exit)

Warming

up

Group (4)

[0] [3]

[POWER]

Code Function Code Function Procedure

10 1 Main motor ON 15 1 Code 101 operation OFF 1

10 2 Toner motor ON 152 Code 102 operation OFF 1

10 3 Polygonal motor (600dpi) ON 1 53 Code 103 operation OFF 1

10 8 Registration clutch ON 15 8 Code 108 operation OFF 1

109 PFP motor ON 159 Code 109 operation OFF 1

11 0 ADU motor (215mm/s) ON 16 0 Code 110 operation OFF 1

11 8 Laser ON 1 68 Code 118 operation OFF 1

12 0 Exit motor ON / forward rotation 17 0 Code 120 operation OFF 1

12 1 Exit motor ON / reverse rotation 17 1 Code 121 operation OFF 1

12 2 LCF motor ON 17 2 Code 122 operation OFF 1

201 Upper cassette feed clutch ON/OFF 3

202 Lower cassette feed clutch ON/OFF 3

20 3 Transport clutch (high speed) ON/OFF 3

204 Bypass feed clutch ON/OFF 3

20 5 Transport clutch (low speed) ON/OFF 3

20 6 LCF pickup solenoid ON/OFF 3

(Code)

[START]

[POWER] OFF

December 2000 © TOSHIBA TEC 1 - 13

DP4500/3500 ERROR CODES AND SELF-DIAGNOSIS

Page 21

Code Function Procedure

20 7 LCF end fence reciprocating movement 2

208 LCF end fence motor ON/OFF 3

209 LCF feed clutch ON/OFF 3

210 LCF transport clutch ON/OFF 3

211 RADF feed motor ON/OFF / forward rotation 3

212 RADF feed motor ON/OFF / reverse rotation 3

213 RADF read motor ON/OFF / forward rotation 3

214 RADF read motor ON/OFF / reverse rotation 3

215 RADF reverse motor ON/OFF / forward rotation 3

216 RADF reverse motor ON/OFF / reverse rotation 3

21 7 Sub-separation fan ON/OFF 3

21 8 Key copy counter count-up 2

21 9 Middle cooling fan ON/OFF 3

222 ADU clutch ON/OFF 3

225 PFP transport clutch ON/OFF 3

226 PFP upper cassette feed clutch ON/OFF 3

228 PFP lower cassette feed clutch ON/OFF 3

23 2 Relay unit gate solenoid ON/OFF 3

23 5 Discharge lamp ON/OFF 3

23 6 Exhaust fan (low speed) ON/OFF 3

23 7 Exhaust fan (high speed) ON/OFF 3

23 8 IH control board cooling fan / developer unit cooling fan ON/OFF 3

24 1 Fuser unit cooling fan ON/OFF 3

24 2 Upper cassette tray-up motor ON (tray raised) 2

24 3 Lower cassette tray-up motor ON (tray raised) 2

24 8 Developer bias +DC ON/OFF 3

24 9 Developer bias -DC1 ON/OFF 3

252 Main charger ON/OFF 3

25 3 Separation charger ON/OFF 3

25 5 Transfer guide bias ON/OFF 3

25 6 Transfer charger ON/OFF 3

261 Scanner motor ON (automatically stops at the limit position, speed can be changed by the ZOOM keys) 2

26 7 Scanner exposure lamp ON/OFF 3

26 8 Laser unit fan (high speed) ON/OFF 3

271 LCF tray-up motor UP/DOWN 2

27 8 PFP upper cassette tray-up motor ON (tray raised) 2

28 0 PFP lower cassette tray-up motor ON (tray raised) 2

29 4 RADF reverse solenoid ON/OFF 3

29 5 Power OFF mode 4

297 RADF fan motor ON/OFF 3

DP4500/3500 ERROR CODES AND SELF-DIAGNOSIS

1 - 14 December 2000 © TOSHIBA TEC

Page 22

1.2.3 T est print mode (test mode 04)

The built-in test pattern can be printed out by entering the following codes in the test print mode (04).

<Operation procedure>

[0] [4]

[POWER]

Note: An error code is displayed on the control panel if an error occurs in the process, but no recovery operation

Code Types of test pattern Remarks

11 1 Primary scanning direction, 33 gradation steps, error diffusion

11 3 Secondary scanning direction, 33 gradation steps, error diffusion

142 Grid pattern (Pattern width: 2 dots, Pitch: 10 mm)

(Code) [STAR T] [0] [9]

(Test pr int)

is performed.

Turn the power OFF and then back ON to clear the error.

[C/S]

Warming upOperation

(Exit)

December 2000 © TOSHIBA TEC 1 - 15

DP4500/3500 ERROR CODES AND SELF-DIAGNOSIS

Page 23

1.2.4 Adjustment mode (05)

Items in the adjustment code list on the following pages can be corrected or changed in this adjustment mode (05). Turn ON the power while the digital keys [0] and [5] are pressed sim ultaneously to

enter this mode.

<Procedure>

Group 1

[SET]

[0] [5]

[POWER]

[Digital key]

(Code)

[ST AR T] [0] [9]

[CANCEL]

[Digital key]

*[FC] key

(Enter a value)

(Corrects value)

or

[INTERRUPT]

(Stores value in RAM)

[C/S]

(Test copy)

[FAX]

(Exit)

* Press [FC] to enter “–”.

Group 2

[0] [5]

[POWER]

Group 3

[0] [5]

[POWER]

Group 4

[0] [5]

[POWER]

Group 5

[Digital key]

(Code)

[Digital key]

(Code)

[Digital key]

(Code)

[UP]

[START]

[C/S] or [CANCEL]

[CANCEL]

[START]

[ST ART] [0] [9]

[Digital key]

(Sub code)

or

[DOWN]

(Enter a value)

(Corrects value)

[START]

[C/S]

(Corrects value)

Automatic

adjustment

[SET]

or

[INTERRUPT]

(Stores value in RAM)

[RESET]

[Digital key]

* [FC] key

Enter a

value

(Exit)

[0] [9]

(Exit)

[SET]

or

[INTERRUPT]

(Stores value in

RAM)

[C/S]

(Corrects value)

* Press [FC] to enter “–”.

[F AX]

Test

copy

[0] [9]

(Exit)

[0] [5]

[POWER]

DP4500/3500 ERROR CODES AND SELF-DIAGNOSIS

[Cassette]

Selects

cassette

[Digital key]

Selects

output

pattern

1: Code 401, 421, 440~444

2: Code 445, 498

[F AX]

T est

copy

[Digital key]

(Code)

[ST ART]

(Adjustment)

1 - 16 December 2000 © TOSHIBA TEC

[Digital key]

(Enter a value)

(Stores value in RAM)

[SET]

or

[INTERRUPT]

[0] [9]

(Exit)

Page 24

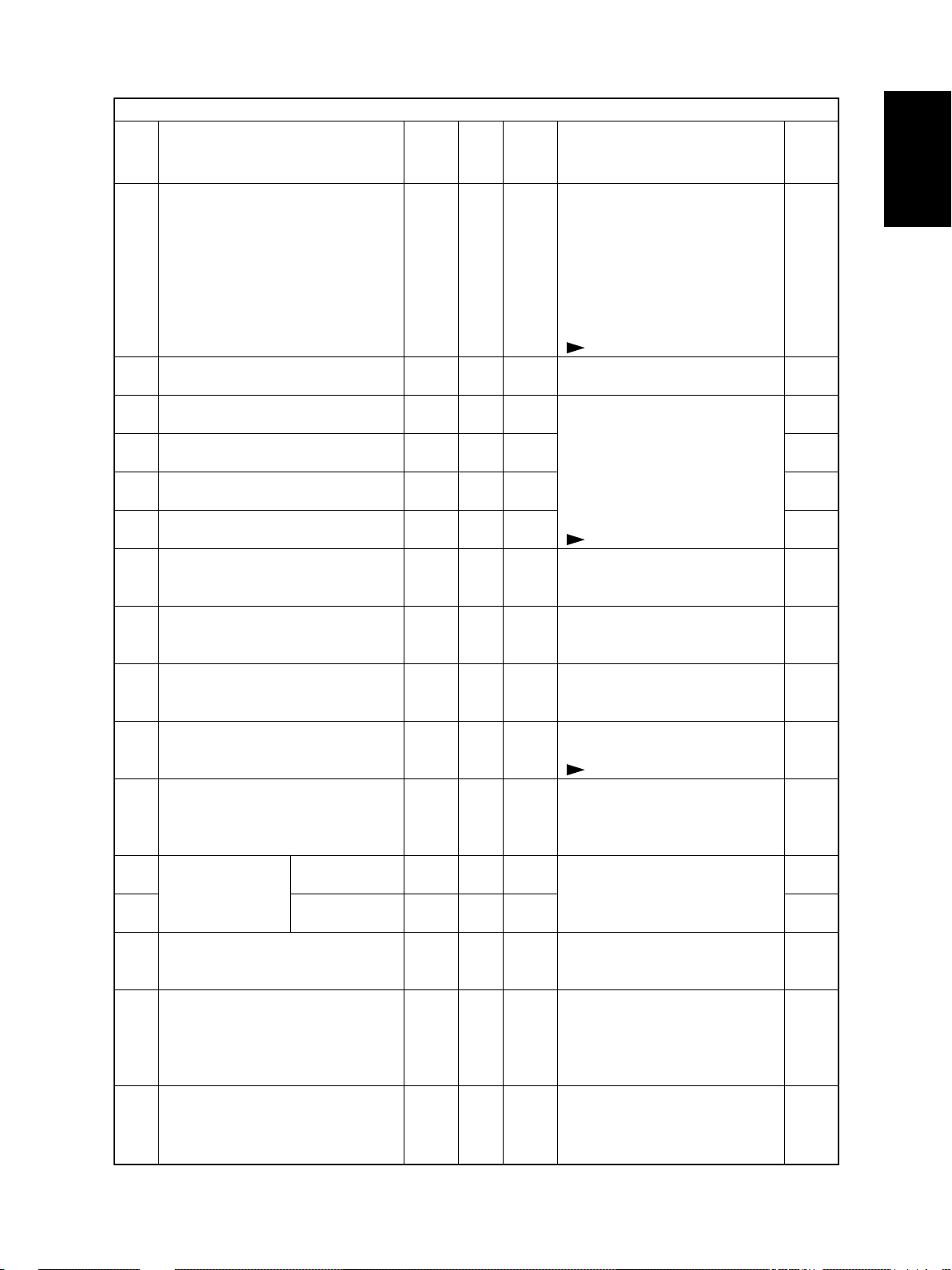

Adjustment mode (05)

Code Items to adjust Mode

Automatic adjustment of auto-toner

200

sensor (Fuser heater ON)

201

Manual adjustment of auto-toner sensor initial value(Fuser heater ON)

Developer bias DC output adjustment

205

210

Main charger grid bias output

adjustment

T ransf er transformer DC output adjust-

221

ment/center value

Separation transformer AC output

231

adjustment/center value

Laser power adjustment

286

305

Adjustment of scanner secondary

scanning start position deviation

306

Adjustment of scanner primary scanning start position deviation

308

Distortion mode

340

Adjustment of scanner secondary

scanning reproduction ratio

354

Adjustment of for single-sided

RADF paper paper

alignment for double-sided

355

paper

Automatic adjustment of RADF sen-

356

sor and EEPROM initialization

357

Fine adjustment of RADF transport

speed

358

RADF sideways deviation adjustment

ALL – –

ALL 128 0~255

ALL 193 0~255

ALL 158 0~255

ALL 117 0~255

ALL 159 0~255

ALL 117 0~255

ALL 128 0~255

ALL 128 0~255

ALL – –

ALL 128 0~255

ALL 10 0~20

ALL 10 0~20

ALL – –

ALL 50 0~100

ALL 128 0~255

Default

Accept-

able Contents

value

- As the value increases, the sensor output increases correspondingly.

- The value starts changing

approx. 2 minutes after this adjustment was started and is automatically set in the range of 2.35

to 2.45V.

( chapter 2.2)

Adjustment value of auto-toner

sensor can be displayed.

As the value increases by “1”, output from the transformer increases

correspondingly. Remove the developer unit and install the service

jig to make adjustment. However,

the service jig is not necessary to

adjust the developer bias DC.

( chapter 2.5)

When the value increases by “1”,

the laser output increases correspondingly.

When the value increases by “1”,

the image shifts toward the leading

edge of paper by approx. 0.17mm.

When the value increases by “1”,

image shifts toward the rear side

of paper by approx. 0.0423mm.

Moves the carriages to the adjustment position.

( chapter 2.3.4)

When the value increases by “1”,

the reproduction ratio of the secondary scanning direction decreases by approx. 0.025%.

When the value increases by “1”,

the aligning amount increases by

approx. 0.5mm.

Perf orm the adjustment and initialization when the PC board or sensor of the RADF is replaced.

When the value increases by “1”,

the reproduction ratio of the secondary scanning direction on original fed from the RADF increases

by approx. 0.1%.

When the value increases by “1”,

the image of original fed from the

RADF shifts toward the rear side

of paper by approx. 0.0423mm.

Operation

procedure

group

–

2

2

2

2

2

2

1

1

4

1

1

1

4

1

1

December 2000 © TOSHIBA TEC 1 - 17

DP4500/3500 ERROR CODES AND SELF-DIAGNOSIS

Page 25

Adjustment mode (05)

Code Items to adjust Mode

365

RADF leading for single-sided

edge position paper

adjustment for double-sided

366

paper

Fine adjustment of polygonal motor

401

rotation speed (Reproduction ratio

405

adjustment of primary scanning direction)

410

Adjustment of primary scanning laser

411

writing start position

421

Fine adjustment of For units other

main motor rotation than the fax

speed For the fax

422

(Reproduction ratio

adjustment of secondary scanning

direction)

Top margin adjustment (blank area

430

at the leading edge of the paper)

Left margin adjustment (blank area

431

at the left of the paper along the paper feeding direction)

Right margin adjustment (blank area

432

at the right of the paper along the paper feeding direction)

Bottom margin adjustment (blank

433

area at trailing edge of paper)

Top margin adjustment (blank area

435

at the leading edge of the paper)

Left margin adjustment (blank area

436

at the left of the paper along the paper feeding direction)

Right margin adjustment (blank area

437

at the right of the paper along the paper feeding direction)

Bottom margin adjustment (blank

438

area at the trailing edge of the paper)

440

Secondary Upper cassette

441

scanning laser Lower cassette

442

write start position Bypass feed

443

444

445

448-0

Paper aligning PFP upper cas-

amount adjustment sette/Long size

(at the copier regis- PFP upper cas-

448-1

tration section) sette/ Middle size

448-2

DP4500/3500 ERROR CODES AND SELF-DIAGNOSIS

LCF

PFP

ADU

PFP upper cassette/Short size

ALL 50 0~100

ALL 50 0~100

PRT 133 0~255

PPC 129 0~255

PPC 128 0~255

PRT 128 0~255

ALL 13 8 0~255

FAX 139 0~255

PPC 0 0~255

PPC 0 0~255

PPC 0 0~255

PPC 0 0~255

PRT 24 0~255

PRT 0 0~255

PRT 0 0~255

PRT 0 0~255

ALL 7 0~15

ALL 24 0~40

ALL 8 0~15

ALL 8 0~15

ALL 8 0~15

ALL 8 0~15

ALL 10 0~63

ALL 10 0~63

ALL 8 0~63

Accept-

Default

1 - 18 December 2000 © TOSHIBA TEC

able Contents

value

When the value increases by “1”,

the copied image of original fed from

the RADF shifts toward the trailing

edge of paper by approx. 0.1mm.

When the value increases by “1”,

the reproduction ratio of the primary scanning direction increases

by approx. 0.07%. (approx.0.5mm/

4steps)

When the value increases by “1”,

the writing start position shifts to the

front side by approx. 0.0423mm.

When the value increases by “1”,

the reproduction ratio of the secondary scanning direction increases by approx. 0.055%.

(approx. 0.5mm/4steps)

When the value increases by “1”,

the blank area becomes wider by

approx. 0.0423mm.

When the value increases by “1”,

the image shifts toward the leading edge of paper by approx.

0.4mm.

When the value increases by “1”,

the aligning amount increases by

approx. 0.8mm.

<Paper length>

Long size: 330mm or longer

Middle size: 220mm~329mm

Short size: 219mm or shorter

Operation

procedure

group

1

1

5

1

1

1

5

1

1

1

1

1

1

1

1

1

5

5

5

5

5

5

3

3

3

Page 26

Adjustment mode (05)

Code Items to adjust Mode

449-0

Paper aligning PFP lower cas-

amount adjustment sette/Long size

(at the copier regis- PFP lower cas-

449-1

tration section) sette/ Middle size

449-2

450-0

450-1

450-2

452-0

452-1

452-2

455-0

455-1

455-2

457

458-0

458-1

458-2

458-3

Fine adjustment of A4-R / LT-R

468-0

binding position / B4

468-1

folding position A3 / LD

468-2

Adjustment of LCF

497-4

sideways

deviation

Adjustment of ADU Long size

498-0

sideways Short size

498-1

deviation

Fine adjustment of Center value

501

manual density

503

504

505

506

507

PFP lower cassette/Short size

Upper cassette

/Long size

Upper cassette

/Middle size

Upper cassette

/Short size

Lower cassette

/Long size

Lower cassette

/Middle size

Lower cassette

/Short size

ADU/Long size

ADU/Middle size

ADU/Short size

LCF

Bypass feed

/Long size

Bypass feed

/Middle size

Bypass feed

/Short size

Bypass feed

/post card

(A4 / LT or smaller)

Light step value

ALL 10 0~63

ALL 10 0~63

ALL 8 0~63

ALL 20 0~63

ALL 22 0~63

ALL 19 0~63

ALL 12 0~63

ALL 10 0~63

ALL 10 0~63

ALL 38 0~63

ALL 38 0~63

ALL 38 0~63

ALL 8 0~63

ALL 28 0~63

ALL 28 0~63

ALL 21 0~63

ALL 24 0~63

ALL 0 -14~14

ALL 0 -14~14

ALL 0 -14~14

ALL 12 8 0~255

ALL 14 8 0~255

ALL 14 8 0~255

PPC 128 0~255

(Photo)

PPC 128 0~255

(Text/Photo)

PPC 128 0~255

(Text)

PPC 20 0~255

(Text/Photo)

PPC 12 0~255

(Photo)

PPC 26 0~255

(Text)

Accept-

Default

(25 for JPN)

(23 for JPN)

able Contents

value

When the value increases by “1”,

the aligning amount increases by

approx. 0.8mm.

<Paper length>

Long size: 330mm or longer

Middle size: 220mm~329mm

Short size: 219mm or shorter

When the value increases by “1”,

the aligning amount increases by

approx. 0.5mm.

When the value increases by “1”,

the aligning amount increases by

approx. 0.8mm.

When the value increases by “1”,

binding / folding position shifts toward the right page by 0.25mm.

When the value increases by “1”,

the image shifts toward the front

side by 0.0423mm.

When the value increases by “1”,

the image shifts toward the front

side by 0.0423mm.

When the value increases, the image of the center step density becomes darker.

When the value increases, the image of the “light” steps becomes

lighter.

Operation

procedure

group

3

3

3

3

3

3

3

3

3

3

3

3

1

3

3

3

3

3

3

3

3

5

5

1

1

1

1

1

1

December 2000 © TOSHIBA TEC 1 - 19

DP4500/3500 ERROR CODES AND SELF-DIAGNOSIS

Page 27

Adjustment mode (05)

Code Items to adjust Mode

508

Fine adjustment of Dark step value

manual density

509

510

512

Fine adjustment of automatic density

514

515

570

Range correction on original

manually set on the original glass

571

572

593

Gamma data slope adjustment

594

595

620

Sharpness adjustment (HPF inten-

sity)

621

622

PPC 20 0~255

(Text/Photo)

PPC 25 0~255

(Photo)

PPC 14 0~255

(Text)

PPC 128 0~255

(Photo)

PPC 128 0~255

(Text/Photo)

PPC 128 0~255

(Text)

PPC 12 11~14,

(Text/Photo)

PPC 12 31~34,

(Photo) 41~44

PPC 44

(Text)

PPC 0 0~9

(Text/Photo)

PPC 0 0~9

(Photo)

PPC 0 0~9

(Text)

PPC 1 0~99

(Text/Photo)

PPC 2 0~99

(Photo)

PPC 5 0~99

(Text)

Accept-

Default

value

(12 for JPN)

(8 for JPN)

(44 for JPN)

21~24,

able Contents

When the value increases, the image of the “dark” steps becomes

darker.

When the value increases, the image becomes darker.

Set whether the value of the

background peak and text peak are

fixed or not.

If they are fixed, the range

correction is performed with

standard values.

The values of the background peak

and text peak affect the

reproduction of the background

density and text density respectively.

Background peak Text peak

1: fixed fixed

2: varied fixed

3: fixed varied

4: varied varied

When the value increases, the image becomes darker.

The number of units: Enter one of

the following fixed values in the

copying mode.

1: Text/Photo 2: Photo 5: Text

The number of tens: intensity

0: default value

1 to 9: when the value increases,

the image becomes sharper.

• In case of Te xt/Photo mode (code

620),

2 1

Fixed value for the Text/

Photo mode

Enter a number (0 to 9)

Operation

procedure

group

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

DP4500/3500 ERROR CODES AND SELF-DIAGNOSIS

1 - 20 December 2000 © TOSHIBA TEC

Page 28

Adjustment mode (05)

Code Items to adjust Mode

693

Range correction on original set on

the RADF

694

695

PPC 12 11~14,

(Text/Photo)

PPC 12 31~34,

(Photo) 41~44

PPC 44

(Text)

Accept-

Default

(44 for JPN)

21~24,

able Contents

value

Set whether the value of the

background peak and text peak are

fixed or not.

If they are fixed, the range

correction is performed with

standard values.

The values of the background peak

and text peak affect the

reproduction of the background

density and text density respectively.

Background peak Text peak

1: fixed fixed

2: varied fixed

3: fixed varied

4: varied varied

Operation

procedure

group

1

1

1

December 2000 © TOSHIBA TEC 1 - 21

DP4500/3500 ERROR CODES AND SELF-DIAGNOSIS

Page 29

1.2.5 Setting mode (08)

The items in the setting code list can be set or changed in this setting mode (08).

<Procedure>

Group 1

[CANCEL]

[0] [8]

[POWER]

[Digital key]

(Code)

[START]

[Digital key]

or

[Select icon]

Sets or

changes value

(Corrects value)

[C/S]

[SET]

or

[INTERRUPT]

(Stores value in RAM)

Group 2

[0] [9]

(Exit)

[0] [8]

[POWER]

Group 3

[0] [8]

[POWER]

[Digital key]

(Code)

[Digital key]

(Code)

[START]

[SET]

[INTERRUPT]

Adjustment value

cannot be changed

[CANCEL]

[START] [Digital key]

(1st setting)

(Corrects value)

or

[0] [9]

(Exit)

[START] [Digital key]

[C/S]

(2nd setting)

(Corrects value)

[SET]

or

[INTERRUPT]

(Stores value in RAM)

[C/S]

[0] [9]

(Exit)

DP4500/3500 ERROR CODES AND SELF-DIAGNOSIS

1 - 22 December 2000 © TOSHIBA TEC

Page 30

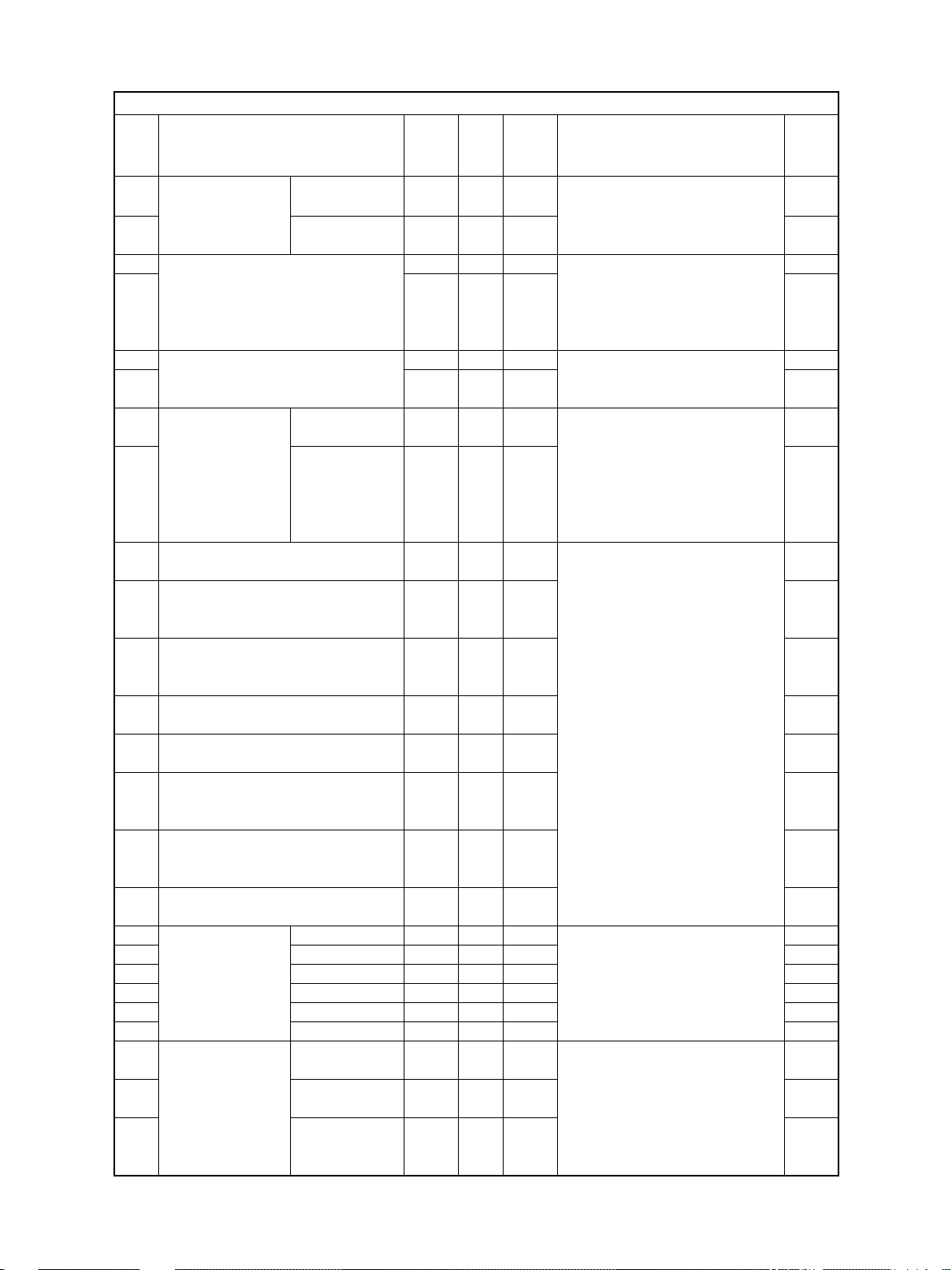

Code Name Mode Default

200

Date and time setting

201

Destination selection

202

Setting for externally installed copy counter

203

Line adjustment mode

204

Auto clear timer setting

205

Energy saver timer setting

206

Auto-power off timer

setting

220

Language displayed at

power ON

224

Paper size for bypass

feed

Paper size for upper cas-

225

sette

226

Paper size for lower cassette

227

Paper size for PFP upper cassette

228

Paper size for PFP lower

cassette

ALL – 13 digits

ALL 0:EUR 0~2

1:UC

2:JPN

ALL 0 0~3

ALL 0 0~1

ALL 3 0~10

ALL 11 0~15

ALL 9 0~20

ALL 0 0~4

ALL UNDEF 0~255

ALL JPN:A4 0~255

UC: LT

EUR:A4

ALL JPN:A3 0~255

UC: LD

EUR:A3

ALL JPN:A4-R 0~255

UC: LT-R

EUR:A4-R

ALL JPN:B4 0~255

UC: LG

EUR:A4

Setting mode (08)

Accept-

able

Value

Year / month / date / day / hour / minute / second

Example: 00 03 01 5 13 27 49

0:EUR 1:UC 2:JPN

0: External copy counter not used

1: Coin controller

2: Copy key card

3: Key copy counter

0: For factory shipment 1: For line

*Field: ‘0' must be selected

*Need to be checked when K-SRAM

was changed.

Timer to return the machine to the default

settings when the [START] key is not

pressed after the function and mode were

set.

0: Max. (150 sec.)

1 to 10: Set number X 15 sec.

Timer to automatically switch to the energy saving mode when the copier has

not been used.

0: Disabled 1: 30sec. 2: 60sec. 3: 90sec.

4: 120sec. 5: 150sec. 6: 3min. 7: 4min.

8: 5min. 9: 7min. 10: 10min. 11: 15min.

12: 20min. 13: 30min. 14: 45min. 15: 60min.

Timer to automatically turn OFF the power

when the copier has not been used.

0: 3min. 1: 5min. 2: 10min. 3: 15min.

4: 20min. 5: 25min. 6: 30min. 7. 40min

8. 50min. 9: 60min. 10: 70min. 11. 80min.

12. 90min. 13. 100min. 14. 110min.

15. 120min. 16. 150min 17. 180min.

18. 210min. 19. 240min. 20. Not used

0: Language1 1: Language2

2: Language3 3: Language4

4: Language5

Press the icon on the LCD to select the

size

Press the icon on the LCD to select the

size

Press the icon on the LCD to select the

size

Press the icon on the LCD to select the

size

Press the icon on the LCD to select the

size

Contents

Operation

procedure

group

1

1

1

1

1

1

1

1

1

1

1

1

1

December 2000 © TOSHIBA TEC 1 - 23

DP4500/3500 ERROR CODES AND SELF-DIAGNOSIS

Page 31

Code Name Mode Default

Paper size (A3)

229

feeding/widthwise direction

Paper size (A4-R)

230

feeding/widthwise direction

Paper size (A5-R)

231

feeding/widthwise direction

Paper size (B4)

232

feeding/widthwise direction

Paper size (B5-R)

233

feeding/widthwise direction

Paper size (LT-R)

234

feeding/widthwise direction

Paper size (LD)

235

feeding/widthwise direction

Paper size (LG)

236

feeding/widthwise direction

Paper size (ST-R)

237

feeding/widthwise direction

Paper size (COMPUTER)

238

feeding/widthwise direction

Paper size (FOLIO)

239

feeding/widthwise direction

Paper size (13 inch LG)

240

feeding/widthwise direction

Paper size (8.5X8.5inch)

241

feeding/widthwise direction

Paper size (Non-standard)

242

feeding/widthwise direction

Paper size (8K)

244

feeding/widthwise direction

Paper size (16K-R)

245

feeding/widthwise direction

Service call telephone

250

number

PM counter setting value

251

PM counter current value

252

Error history display

253

PFP/LCF installation

255

Paper size for LCF

256

ALL 420/297 182~432

ALL 297/210 182~432

ALL 210/148 182~432

ALL 364/257 182~432

ALL 257/182 182~432

ALL 279/216 182~432

ALL 432/279 182~432

ALL 356/216 182~432

ALL 216/140 182~432

ALL 356/257 182~432

ALL 330/210 182~432

ALL 330/216 182~432

ALL 216/216 182~432

ALL 432/279 148~432

ALL 390/270 182~432

ALL 270/195 182~432

ALL 0 14 digits

ALL

DP4500: 150000

DP3500: 116000

(0 for JPN)

ALL 0

ALL – –

ALL 0 0~4

ALL JPN:A4 0~255

UC: LT

EUR:A4

Setting mode (08)

Accept-

able

Value

/140~297

/140~297

/140~297

/140~297

/140~297

/140~297

/140~297

/140~297

/140~297

/140~297

/140~297

/140~297

/140~297

/105~297

/140~297

/140~297

Telephone numbers up to 14 digits can

be entered. Use the HELP/INFO key to enter a hyphen (-).

0~99999999

0~99999999

Displays the latest 8 error data.

0: Automatic

1: PFP single cassette type installed

2: PFP two cassette type installed

3: LCF installed

4: PFP/LCF not installed

Press the icon on the LCD to select the

size

Contents

Operation

procedure

group

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

1

1

1

2

1

1

DP4500/3500 ERROR CODES AND SELF-DIAGNOSIS

1 - 24 December 2000 © TOSHIBA TEC

Page 32

Code Name Mode Default

Copying total counter

257

value

MAX9 selection

300

Original counter display

302

Screen selection

331

A3/LD double count set-

352

ting

Upper cassette counter

356

Lower cassette counter

357

Bypass feed counter

358

LCF counter

359

PFP upper cassette

360

counter

Copy scan counter

361

Copy counter

362

Fax scan counter

363

Fax transmission coun-

364

ter

Fax reception counter

365

Fax/list counter

366

Printer counter

367

DSS scan counter

368

PFP lower cassette

370

counter

ADU counter

372

ADF counter

374

HDD error counter

390

HDD error counter

391

HDD error counter

392

ALL – 1~2

PPC 0 0~2

ALL 0 0 or 2

EUR : 2

ALL 0 0~1

ALL 1 0~1

ALL 0

ALL 0

ALL 0

ALL 0

ALL 0

ALL 0

ALL 0

ALL 0

ALL 0

ALL 0

ALL 0

ALL 0

ALL 0

ALL 0

ALL 0

ALL 0

PPC 0 0~32767

FAX 0 0~32767

LAN 0 0~32767

DSS

Setting mode (08)

Accept-

able

Value

1: > (Counter value displayed at left is

2: < (Counter value displayed at right is

0:999 1:99 2:9

0: Not displayed 2: Displayed

0: Copy 1: FAX

0: Single count 1: Double count

0~99999999

0~99999999

0~99999999

0~99999999

0~99999999

0~999999999

0~999999999

0~999999999

0~999999999

0~999999999

0~999999999

0~999999999

0~999999999

0~999999999

0~99999999

0~99999999

Counter for paper fed from the upper cassette

Counter for paper fed from the lower cassette

Counter for paper fed from the bypass tray

Counter for paper fed from LCF

Counter for paper fed from the PFP upper

cassette

Counts number of scannings in the copying mode.

Counts number of printings in the copying mode.

Counts number of scannings in the fax

transmission mode.

Counts number of documents transmitted

Counts number of polling documents received

Counts number of fax documents and lists/

reports (including group list) which are

output

Counts number of printings in the printer

mode

Counts number of scannings in the DSS

scanner mode

Counts paper fed from the PFP lower cassette

Counts number of automatic duplex copies

Counts papers fed from ADF

Reset by HDD formatting

Reset by HDD formatting

Reset by HDD formatting

Contents

overwritten on the counter value on the

right)

overwritten on the counter value on the

left)

( 1-32)

Operation

procedure

group

–

1

1

1

1

1

1

1

1

1

2

2

2

2

2

2

2

2

1

1

1

2

2

2

December 2000 © TOSHIBA TEC 1 - 25

DP4500/3500 ERROR CODES AND SELF-DIAGNOSIS

Page 33

Code Name Mode Default

Fuser roller thermistor

400

error counter

Drum life counter

401

(enter 0 to reset the counter)

Copier running time

402

counter

(enter 0 to reset the counter)

Fuser unit counter

403

(enter 0 to reset the counter)

Developer material

404

counter

(enter 0 to reset the counter)

Pre-running time before

408

1st print (thick paper)

Fuser roller temperature

410

during printing

Fuser roller temperature

411

during standby state

Fuser roller temperature

412

in energy saver mode

Fuser roller temperature

413

for thick paper

Correction of toner den-

414

sity adjustment value

Correction of toner sup-

455

ply amount

Setting for switchback

462

operation to copy mixedsized original on RADF

Speed switching of sub-

469

separation fan

ALL 0 0~19

ALL 0

ALL 0

ALL 0

ALL 0

ALL 0 0~15

ALL 12 0~14

ALL 12 0~12

ALL 0 0~1

ALL 2 0~4

ALL 0 0~8

ALL 0 0~2

ALL 0 0~1

ALL 0 0~1

Setting mode (08)

Accept-

able

Value

0: No error 1: C41 occurred once

2: C41 occurred continuously

3: Not used 4: Error C43 5: Error C44

6: Error C43 7: Error C44 8: Error C45

9: Error C44 10: Error C47 11: Error C47

12: Error C48 13: Error C49 14: Error C47

15: Error C48 16: Error C49 17: Error C47

18: Error C48 19: Error C49

0~99999999

0~99999999

0~99999999

0~99999999

Counts drum rotation time (sec.)

Counts the copier running time (min.)

Counts the fuser roller rotation time (sec.)

Counts the total consumed paper (Long

size: double count)

0: Not used 1: 1sec. 2: 2sec. 3: 3sec.

4: 4sec. 5: 5sec. 6: 6sec 7: 7 sec 8: 8sec.

9: 9sec. 10: 10sec. 11: 12 sec. 12: 14sec.

13: 16sec. 14: 18sec. 15: 20sec.

0: 140°C 1: 145°C 2: 150°C 3: 155°C

4: 160°C 5: 165°C 6: 170°C 7: 175°C

8: 180°C 9: 185°C 10: 190°C

11: 195°C 12: 200°C 13: 205°C

14: 210°C

0: 140°C 1: 145°C 2: 150°C 3: 155°C

4: 160°C 5: 165°C 6: 170°C 7: 175°C

8: 180°C 9: 185°C 10: 190°C 11: 195°C

12: 200°C

0: OFF 1: 100°C

0: Not used 1: 195°C 2: 200°C

3: 205°C 4: 210°C

Corrects the toner density adjustment

value set in 05-201.

0: 0 bit (No correction) 1: +3 bit 2: +6 bit

3: +9 bit 4: +12 bit 5: -3 bit 6: -6 bit

7: -9 bit 8: -12 bit

Corrects the rotation time of the toner motor during toner supply

0: 100% 1: 90% 2: 80%

0: Disabled 1: Enabled

0: High speed 1: Low speed

Contents

Operation

procedure

group

1

1

1

1

1

1

1

1

1

1

1

1

1

1

DP4500/3500 ERROR CODES AND SELF-DIAGNOSIS

1 - 26 December 2000 © TOSHIBA TEC

Page 34

Code Name Mode Default

Paper source priority

480

selection

Paper source automatic

481

alternation

Feeding retrying

482

Pre-running rotation of

483

polygonal motor

Auto-stop of pre-running

484

rotation of polygonal

motor

Rotation of polygonal

485

motor during the

standby state

Auto-stop timer for pre-

486

running rotation of polygonal motor

Polygonal motor rotation

489

number during the

standby state

Polygonal motor rotation

490

in the energy saver

mode

Separation charger life

497

counter (enter 0 to reset

the counter)

Density mode priority

503

selection at power on

Copy mode priority se-

550

lection

Screen setting for auto-

602

matic energy saver/automatic power off

Setting for automatic

603

duplexing mode

APS priority selection

604

ALL 0 0~5

ALL 1 0~2

ALL 0 0~1

ALL 0 0~2

ALL 0 0~1

ALL 0 0~1

ALL 0 0~2

ALL 5 0~5

ALL 0 0~1

ALL 0

PPC 0 0~1

PPC 0 0~2

ALL 1 0~1

EUR: 0

PPC 0 0~3

PPC 0 0~2

Setting mode (08)

Accept-

able

Value

0: A4/LT 1: LCF 2: Upper cassette

3: Lower cassette 4: PFP upper cassette

5: PFP lower cassette

Set if the cassette is automatically changed to the

other cassette which has the paper of the same size

when paper in the selected cassette has run out.

0: OFF

1: ON (Changed to the cassette which has the same

2: ON (Changed to the cassette which has the same

0: ON 1: OFF

0: ON (Motor starts rotating when original

1: OFF

2: ON (Motor starts rotating when original

0: Motor stops (according to the setting

1: Motor not stopped

0: Rotated (corresponding to the setting

1: Stopped

0: 15 sec. 1: 30sec. 2: 45sec.

This setting only effective when 08-484

is set to “0”

0: 38090.55[rpm] 1: 35000[rpm]

2: 30000[rpm] 3: 25000[rpm]

4: 20000[rpm] 5: 10000[rpm]

0: Stopped 1: 10000[rpm]

0~99999999

Counts the total number of consumed

paper (Long size: double count)

0: Automatic density 1: Manual density

0: Text/Photo 1: Photo 2: Text

0: Display OFF 1: Display ON

0: Disabled 1: Single-sided to duplex

2: Two-sided to duplex

3: User selection

0: APS 1: AMS 2: None

Operation

Contents

paper direction and size: ex. A4 to A4)

paper size. Paper with the different direction is acceptable as long as the size is the same: ex. A4 to

A4-R, L T-R to L T)

is placed on the RADF tray or original

glass.

is placed on the RADF tray.

vaue in 08-486)

value in 08-489)

procedure

group

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

December 2000 © TOSHIBA TEC 1 - 27

DP4500/3500 ERROR CODES AND SELF-DIAGNOSIS

Page 35

Code Name Mode Default

RADF priority mode se-

607

lection

BOOK duplex copy

611

Summer time mode

612

Paper size designation

613

for OTHER key

Original size priority

618

(same/mixed size)

Time lag before auto-

619

start of bypass feeding

Blank copying preven-

625

tion mode during RADF

jamming

Outer guide elimination

626

when paper size is not

selected for a bypass

feed printing

Rotation printing in the

627

non-sort mode for original fed from RADF

Direction priority of origi-

628

nal image

Department manage-

629

ment setting

PPC 0 0~1

PPC 0 0~1

ALL 0 0~1

PPC JPN:A5R 0~255

EUR:FOLIO

UC:COMP

PPC 0 0~1

ALL 4 0~10

PPC 0 0~1

PPC 1 0~1

PPC 0 0~1

PPC 0 0~2

PPC 7 0~7

Setting mode (08)

Accept-

able

Value

0:Continuous feed (original fed by press-

1: Single feed (original automatically fed

0: Left page to right page

2: Right page to left page

0: Not summer time 1: Summer time

Press the icon on the LCD to select the

size

0: Same sized original

1: Mixed sized original

Time to take to add paper and resume

paper feeding when paper in the bypass

tray has run out during the bypass feed

copying.

0: Paper is not dra wn in unless the START

1~10: Setting value x 0.5sec.

0: Disabled

1: Enabled (Printing is started after the

When a size is not selected for a bypass

feed printing,