Page 1

MULTIFUNCTIONAL DIGITAL SYSTEMS

Operator's Manual

for Copying Functions

Page 2

Page 3

Preface

Thank you for purchasing the TOSHIBA multifunctional digital systems.

We have provided you with this manual for the operation of this equipment.

This operator’s manual describes the following:

y How to use this equipment

y How to inspect and carry out maintenance on this equipment

y How to remedy mechanical and copying problems

Be sure to read this manual before using this equipment. Keep this manual handy and retain it

for future reference.

Preface 1

Page 4

Notice to Users

FCC NOTICE

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own expense.

WAR NIN G

Changes or modification made to this equipment, not expressly approved by TOSHIBA TEC or parties authorized by

TOSHIBA TEC, could void the user’s authority to operate the equipment.

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

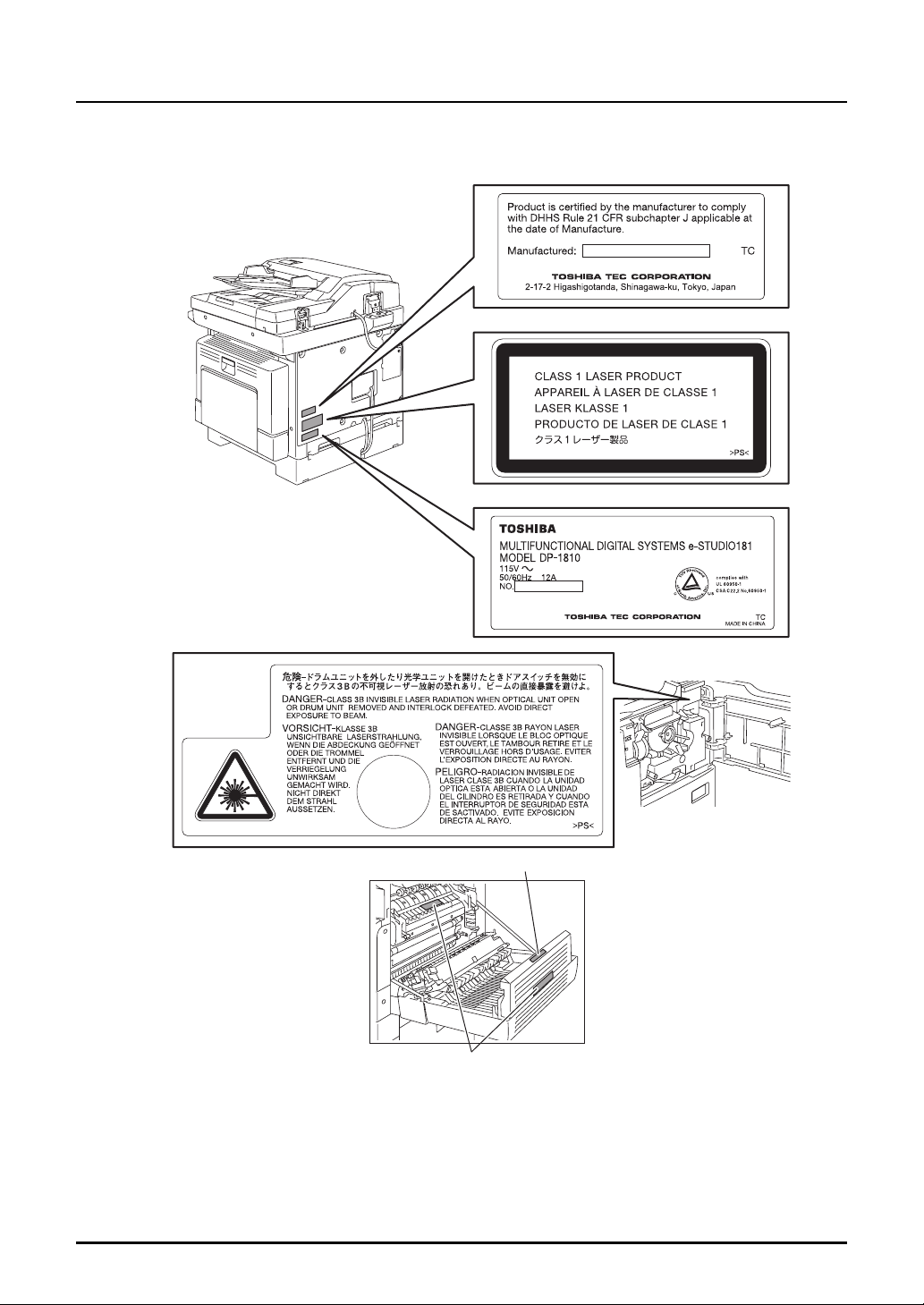

User Safety

This TOSHIBA multifunctional digital systems does not produce laser radiation hazardous to the user. It is certified as

a Class 1 laser product under the U.S Department of Health and Human Services (DHHS) Radiation Performance

Standard according to the Radiation Control Health and Safety Act of 1968 including amendments.

Protective housing and external covers completely confine the laser beam light emitted inside the multifunctional digital systems. The laser beam cannot escape from the machine during any phase of user operation.

Regulations implemented on August 2, 1976 by the Bureau of Radiological Health (BRH) of the U.S Food and Drug

Administration apply to laser products manufactured from August 1,1976. Laser products marketed in the United

States must comply with these regulations.

CAUTION

Using controls or adjustments or performing procedures, other than those specified herein may result in hazardous

radiation exposure.

The unit is classified as Class 1 Laser Product according to IEC60825-1:1993, IEC60825-1:2007 including amendments.

The unit uses laser diode of output Max. 7 mW, wave length 785 nm, continuous pulse.

Regulatory Information

TOSHIBA is dedicated to preserving the environment by sponsoring Call2Recycle, a program of the Rechargeable

Battery Recycling Corporation. For more information and for drop-off locations, visit www.rbrc.org or call 1-800-822-

8837.

Notice regarding CR coin cell batteries, applicable to California, U.S.A. only: Perchlorate Material - special handling

may apply.

See http://www.dtsc.ca.gov/hazardouswaste/perchlorate/

2 Notice to Users

Page 5

Before Reading This Manual

To read manuals in the PDF file format

This manual is stored in PDF (Portable Document Format) in the co-packed User Documentation CD-ROM. The operator’s manual in the PDF can be displayed/printed using Adobe Reader

or Adobe Acrobat Reader. If neither is installed in your computer, download one of them. This

can be done via the website of Adobe Systems Incorporated.

How to read this manual

Symbols in this manual

To ensure correct and safe use of this equipment, this operator’s manual describes safety precautions according to the three levels shown below.

You should fully understand the meaning and importance of these items before reading this

manual.

Indicates a potentially hazardous situation which, if not avoided, could result

in death, serious injury, or serious damage, or fire in the equipment or surrounding assets.

Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury, partial damage of the equipment or surrounding

assets, or loss of data.

Indicates information to which you should pay attention when operating the

equipment.

Other than the above, this manual also describes information that may be useful for the operation of this equipment with the following signage:

Describes handy information that is useful to know when operating the equipment.

Pages describing items related to what you are currently doing. See these

pages as required.

Before Reading This Manual 3

Page 6

Description of original/paper direction

Paper or originals of LT size can be placed either in a portrait direction or in a landscape direction. In this manual, “-R” is added to this paper size when this size of paper or original is placed

in a landscape direction.

e.g.) LT size original on the original glass

Placed in a portrait direction: LT Placed in a landscape direction: LT-R

Paper or originals of LD or LG size can only be placed in a landscape direction, therefore “-R” is

not added to these sizes.

Trademarks

y Microsoft, Windows, Windows NT, and the brand names and product names of other

Microsoft products are trademarks of Microsoft Corporation in the US and other countries.

y Adobe, Adobe Acrobat, Adobe Reader, Adobe Acrobat Reader, and PostScript are trade-

marks of Adobe Systems Incorporated.

y Other company or product names shown in this manual may be a brand name or a trade-

mark of each company.

©2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved

Under the copyright laws, this manual cannot be reproduced in any form without prior written

permission of TOSHIBA TEC CORPORATION. No patent liability is assumed, however, with

respect to the use of the information contained herein.

4 Before Reading This Manual

Page 7

CONTENTS

Preface........................................................................................................... 1

Notice to Users ............................................................................................. 2

Before Reading This Manual ....................................................................... 3

TOSHIBA Quality Is Second to None.......................................................... 9

General Precautions................................................................................... 11

Disclaimer Notice ....................................................................................... 17

Environmental Information........................................................................18

Chapter 1 PREPARATION

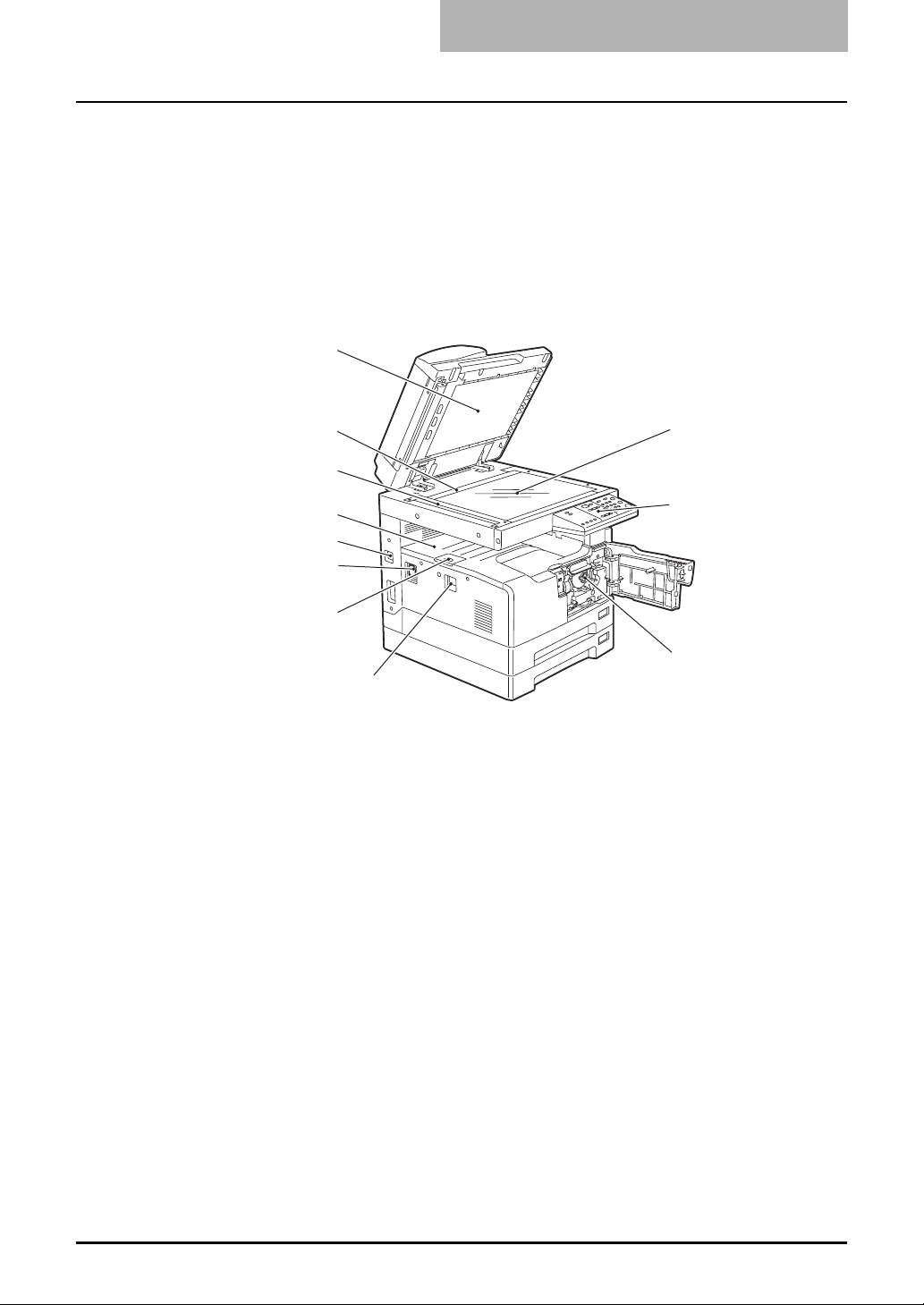

Description of Each Component...............................................................20

Front / Right side ..................................................................................... 20

Left side / Inner side ................................................................................ 21

Configuration of options........................................................................... 23

Control panel ........................................................................................... 24

Preparation 1 - Turning Power ON............................................................27

Turning power ON ................................................................................... 27

Saving energy when not in use - Energy saving mode - ......................... 28

Preparation 2 - Placing Copy Paper..........................................................30

Acceptable media types ..........................................................................30

Recommended paper.............................................................................. 31

Placing paper in drawers......................................................................... 32

Preparation 3 - Registering Size of Paper Placed ................................... 36

Registering standard size (LD, LT, LT-R, LG, ST-R)............................... 36

Registering other standard sizes .............................................................37

Chapter 2 HOW TO MAKE COPIES

Placing Originals ........................................................................................40

Acceptable originals ................................................................................ 40

Placing originals on the original glass ..................................................... 41

Placing booklet-type originals such as books or catalogs .......................42

Using Automatic Document Feeder (optional)......................................... 43

Placing originals on Automatic Document Feeder (optional)................... 44

Making Copies ............................................................................................45

Stopping/Resuming copying.................................................................... 46

Interrupting copying and making another copy - Interrupt copy - ............ 47

Using Bypass Tray .....................................................................................48

Bypass copying ....................................................................................... 49

CONTENTS 5

Page 8

Chapter 3 COPYING FUNCTIONS

Default Settings ..........................................................................................52

Paper Selection........................................................................................... 53

Automatic paper selection (APS)............................................................. 53

Manual paper selection ........................................................................... 54

Zooming In/Out Copy Image...................................................................... 56

Automatic magnification selection (AMS) ................................................56

Specifying both the sizes of the original and the copy paper ..................58

Specifying reproduction ratio manually.................................................... 59

Copying in Same Page Order as Originals - Sort Copying - ................. 61

Copying Both Sides of Card into 1 Page - ID CARD - ............................63

Selecting Image Mode................................................................................ 65

Adjusting Density Level.............................................................................66

Chapter 4 SETTINGS AND MANAGEMENT OF EQUIPMENT

Switching Operation Sound On/Off .......................................................... 68

Checking Total Number Copied ................................................................ 69

Changing of the Enabled Energy Saving Mode.......................................70

Chapter 5 TROUBLESHOOTING

When Message Lamp is Lit/Blinking ........................................................ 72

Paper Jams .................................................................................................75

Checking position of paper jams ............................................................. 75

Paper jams within Automatic Document Feeder (optional) (Lower) ........76

Paper jams within Automatic Document Feeder (optional) (Upper) ........78

Paper jams on bypass tray...................................................................... 80

Paper jam behind transfer unit ................................................................ 81

Paper jams within fuser unit .................................................................... 82

Paper jams within Paper Feed Unit (optional)......................................... 84

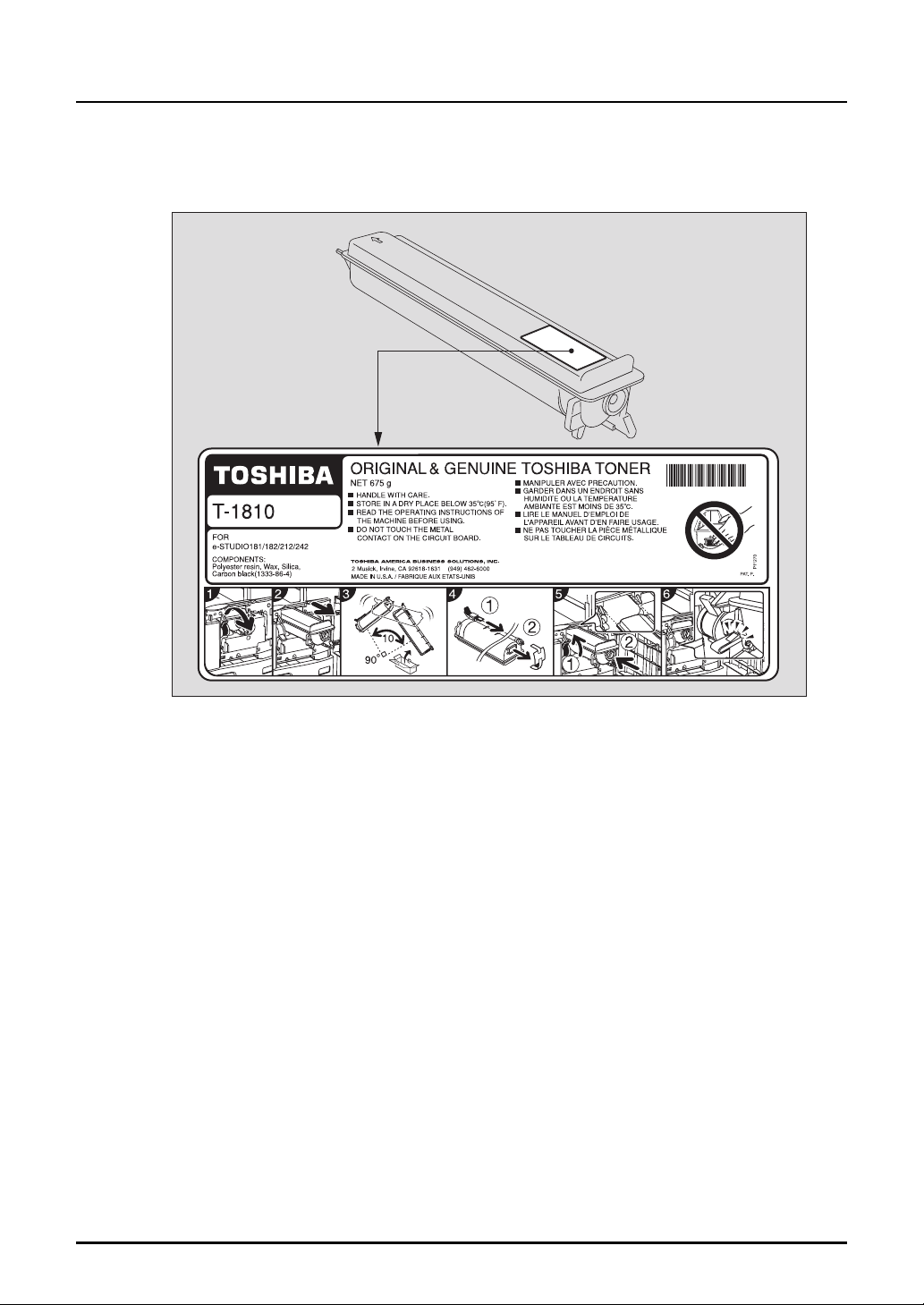

Replacing Toner Cartridge ........................................................................85

Before Calling Service Technician............................................................90

General operation.................................................................................... 90

Toner-related items ................................................................................. 91

Original/Copy paper-related items........................................................... 91

Image trouble .......................................................................................... 92

6 CONTENTS

Page 9

Chapter 6 MAINTENANCE AND INSPECTION

Daily Inspection .......................................................................................... 96

Cleaning charger ..................................................................................... 97

Cleaning transfer charger........................................................................ 98

Chapter 7 SPECIFICATIONS AND OPTIONS

e-STUDIO181 Specifications ................................................................... 102

Continuous copying speed .................................................................... 103

Packing list ............................................................................................ 103

Specifications of Options ........................................................................ 104

INDEX .......................................................................................................................................105

CONTENTS 7

Page 10

8 CONTENTS

Page 11

TOSHIBA Quality Is Second to None

Recommended toner cartridges

To assure optimal printing performance, we recommend that you use only genuine TOSHIBA

toner cartridges.

If you use a TOSHIBA-recommended toner cartridge, you can utilize the following three functions of this equipment:

Cartridge detecting function:

This function checks if the toner cartridge is correctly installed and notifies you if it is not.

Toner remaining check function:

This function notifies you when there is little toner remaining in the cartridge.

Image quality optimization function:

This function controls image quality according to the characteristics of the toner to be used and

enables you to print images of an optimal quality.

If you are using a toner cartridge other than the one we recommend, the equipment may not be

able to detect whether it is installed or not. Therefore, even if the toner cartridge is correctly

installed, the toner lamp lights or blinks and printing may not be performed. You may also not be

able to utilize the image quality optimization and the toner remaining check functions.

If you are using a toner cartridge other than the one we recommend, toner is not recognized. If

this is a problem for you, please contact your service representative. Remember you will not be

able to utilize the Toner remaining check function and Image quality optimization function as we

mentioned.

TOSHIBA Quality Is Second to None 9

Page 12

Supplies / Parts

Dependability

Genuine TOSHIBA supplies are subjected to the strictest of inspections so that every supply you

receive will perform at optimal levels.

High Productivity

Genuine TOSHIBA supplies are created to meet the demands of our competitive world and provide high-speed reliable copies when you need them.

Stable Image Quality

Genuine TOSHIBA supplies are designed to provide consistently stable image output.

Copier Friendly Supplies

Genuine TOSHIBA supplies are designed to help to keep the equipment and all its parts in trouble-free working order. Reduction of machine wear is due to TOSHIBA’s intimate knowledge of

the equipment’s characteristics ensuring the highest standard of care.

Perfectly Suited Supplies

From the beginning TOSHIBA supplies and machines were made for each other. Whenever

TOSHIBA designs a new machine, it also designs a new toner that is made just for that

machine. By using genuine TOSHIBA supplies with TOSHIBA equipment, you are guaranteed

optimum performance.

Toner

General

Optimum Image Quality

TOSHIBA toner is manufactured using ultra-fine quality materials under precisely controlled conditions to ensure that your TOSHIBA equipment will continually generate sharp high-quality

images.

Cost Advantage

Genuine TOSHIBA toner provides value. Only the proper amount of toner is used during the

reproduction process, thereby enabling the machine to continue to operate until all the toner has

been used. In this way you get the full value from each cartridge used.

Environmental Harmony

Genuine TOSHIBA toner is manufactured with the environment in mind. We use embossed or

plastic labels for our toner cartridges making them fully recyclable. In addition, dust and ozone

levels have been reduced to improve the working environment.

User Friendly

Before approving our toners for sale, we test them to be sure that they pass the strictest of

health standards. This takes all the worry out of handling the toner.

Service and Support Benefits

TOSHIBA’s Service technicians are certified to keep your equipment performing at optimum levels. To ensure continuous image quality, utilize an authorized TOSHIBA Service provider to care

for and perform periodical maintenance on your equipment.

10 TOSHIBA Quality Is Second to None

Page 13

General Precautions

When installing or moving

Warning

y This equipment requires 115 V, 12 A, 50/60 Hz electric power.

Do not use a power supply with a voltage other than that specified.

Avoid multiple connections in the same outlet. This could cause a fire or give you an electric

shock. If you are considering increasing the number of outlets, contact an electrician.

y Always connect this equipment to an outlet with a ground connection to avoid the danger of

fire or electric shock in case of short-circuiting. Contact your service representative for the

details. Be sure to use a 3-conductor, grounded wall outlet.

In areas, except the U.S. and Canada, where a 2-pin plug is used, the equipment must be

grounded for safety. Never ground it to a gas pipe, a water pipe, or any other object not suitable for grounding.

y Plug the power cable securely into the outlet. If it is not plugged in properly, it could heat up

and cause a fire or give you an electric shock.

y Do not damage, break or attempt to repair the power cable.

The following things should not be done to the power cable.

- Twisting it

- Bending it

- Pulling it

- Placing anything on it

- Making it hot

- Situating it near radiators or other heat sources

This could cause a fire or give you an electric shock. If the power cable is damaged, contact

your service representative.

y Do not install the equipment by yourself or try to move it once it has been installed. This

could result in an injury or damage to the device. Contact your service representative if the

equipment needs to be installed or moved.

y Pull the plug out from the outlet more than once a year to clean around the prongs. Accumu-

lating dust and dirt could cause a fire due to the heat released by electric leakage.

General Precautions 11

Page 14

Caution

y Avoid placing the equipment in a place unsuitable for its weight and also make sure the sur-

face is level.

Remember that if the equipment falls over, serious injuries could result.

Weight of the equipment: approx. 70.1 lb.

y When removing the plug from the outlet, do not pull the power cable. Always hold the plug

when removing it from the outlet. If the power cable is pulled, the wires may become broken

and this could cause a fire or give you an electric shock.

y Make sure that the ventilation holes are not blocked up.

If the temperature within the equipment becomes too high, a fire could result.

Other points

y The socket outlet shall be installed near the equipment and shall be easily accessible.

y Make sure that there is enough space around the system to facilitate changing of parts,

maintenance and clearing paper jams.

If there is insufficient space, some operations, such as bypass feeding, will become difficult

and the equipment could even break down.

To insure optimal operation, allow clearances of at least 31.5" on the right, and 3.9" on the

left and behind.

3.9"

3.9"

31.5"

y Be sure to fix the power cable securely so that no one trips over it.

y Adverse environmental conditions may affect the safe operation and performance of the

equipment, and the equipment could break down.

- Avoid locations near windows or with exposure to direct sunlight.

- Avoid locations with drastic temperature fluctuations.

- Avoid too much dust.

- Avoid locations that suffer from vibration.

y Make sure that the air is able to flow freely and that there is sufficient ventilation.

With inadequate ventilation, the unpleasant odor released by the ozone will begin to dominate the atmosphere.

12 General Precautions

Page 15

When using the equipment

Warning

y Do not take off the cover of the equipment; otherwise you could be injured or get an electric

shock.

y Do not remove or connect the plug with wet hands, as this could give you an electric shock.

y Do not place any container with liquid (flower vases, coffee cups, etc.) on or near the equip-

ment. This could cause a fire or give you an electric shock.

y Keep paper clips and staples away from the air vent. If not, a fire could result or you could

get an electric shock.

y If the equipment becomes excessively hot, smoke comes out of it or there is an odd smell or

noise, proceed as follows.

Turn the power OFF and remove the plug from the outlet, then contact your service representative.

y If the equipment will not be used for more than one month, remove the plug from the outlet

for safety purposes during that time.

If an insulation failure occurs, this could cause a fire or give you an electric shock.

Caution

y Do not place heavy objects (9 lb. or more) on the original glass and do not press on it with

force. Breaking the glass could cause personal injury.

y Do not place heavy objects (9 lb. or more) on the equipment. If the objects fall off, this could

cause injury.

y Be careful not to let your fingers be caught when closing the drawer. This could injure you.

y Do not touch the fuser unit or the metal area around it. Since they are very hot, you could be

burned or the shock could cause you to get your hand injured in the machine.

y Be careful not to let your fingers be caught between the equipment and the side cover. This

could injure you.

y Do not touch the hinge (= a connecting part) on the rear side of the Automatic Document

Feeder (optional). This could catch and injure your fingers when you open or close the Automatic Document Feeder (optional).

General Precautions 13

Page 16

Position of Certification label, etc.

Certification label

Explanatory label

Identification label

Warning label

14 General Precautions

Warning for high-temperature areas (ventilation holes

Warning for high-temperature areas (fuser unit

)

)

Page 17

Other points

y Do not turn the power OFF with jammed paper left inside the equipment. This could cause

malfunctions when the main switch is turned ON next time.

y Be sure to turn the power OFF when leaving the office or if there is a power failure.

y Be careful because the paper exit area and paper just after exiting are hot.

y Do not place anything other than paper on the receiving tray. This could disturb a normal

operation and cause malfunctions.

y Do not touch the photoconductive drum surface or the transfer charger. This could cause

image problems.

y Do not open/close the covers and the bypass tray, or pull out the drawers during printing.

During maintenance or inspection

Warning

y Never attempt to repair, disassemble or modify the equipment by yourself. You could cause

a fire or get an electric shock.

Always contact your service representative for maintenance or repair of the internal parts of

the equipment.

y Do not let liquids such as water and oil get into the system when cleaning the floor. This

could cause a fire and give you an electric shock.

Caution

y Always keep the plug and outlet clean. Prevent them from accumulating dust and dirt. This

could cause a fire and give you an electric shock due to the heat released by electric leakage.

Other points

y Do not use such solvents as thinner or alcohol when cleaning the surface of the equipment.

- This could warp the shape of the surface or leave it discolored.

- When using a chemical cleaning pad to clean it, pay attention to any cautionary points.

When handling supplies

Warning

y Never attempt to incinerate toner cartridges. Dispose of used toner cartridges in accordance

with local regulations.

Other points

y Read the operator’s manual carefully to replace the toner cartridge using the correct proce-

dure. An improper procedure could cause toner leakage or scattering.

y Do not open the toner cartridge forcibly. This could cause toner leakage or scattering.

y Keep the toner cartridge out of the reach of children.

y If toner is spilt on your clothes, wash it off with cold water. Your clothes will be stained with

toner and it will not come out if you use warm water.

y If toner leaks from the toner cartridge, be careful not to inhale or touch it.

General Precautions 15

Page 18

First-aid measures

If you inhale or touch toner, etc; carry out the following treatment.

y Inhalation: Remove from exposure area to fresh air immediately. Contact a physician if there is any

difficulty in breathing or other signs of distress.

y Skin Contact: Wash with soap and water. Wash clothing before reuse. If irritation occurs or is persis-

tent, seek medical attention.

y Eye Contact: Immediately flush eyes with plenty of water for at least 15 minutes. If irritation persists,

call a physician.

y Ingestion: Dilute stomach contents with several glasses of water.

16 General Precautions

Page 19

Disclaimer Notice

The following notice sets out the exclusions and limitations of liability of TOSHIBA TEC CORPORATION (including its employees, agents and sub-contractors) to any purchaser or user (‘User’)

of the e-STUDIO181, including its accessories, options and bundled software (‘Product’).

1. The exclusion and limitations of liability referred to in this notice shall be effective to the fullest extent permissible at law. For the avoidance of doubt, nothing in this notice shall be taken

to exclude or limit TOSHIBA TEC CORPORATION’s liability for death or personal injury

caused by TOSHIBA TEC CORPORATION’s negligence or TOSHIBA TEC CORPORATION’s fraudulent misrepresentation.

2. All warranties, conditions and other terms implied by law are, to the fullest extent permitted

by law, excluded and no such implied warranties are given or apply in relation to the Products.

3. TOSHIBA TEC CORPORATION shall not be liable for any loss, cost, expense, claim or damage whatsoever caused by any of the following:

(a) use or handling of the Product otherwise than in accordance with the manuals, including

but not limited to Operator’s Manual, User’s Guide, and/or incorrect or careless handling or

use of the Product;

(b) any cause which prevents the Product from operating or functioning correctly which

arises from or is attributable to either acts, omissions, events or accidents beyond the reasonable control of TOSHIBA TEC CORPORATION including without limitation acts of God,

war, riot, civil commotion, malicious or deliberate damage, fire, flood, or storm, natural

calamity, earthquakes, abnormal voltage or other disasters;

(c) additions, modifications, disassembly, transportation, or repairs by any person other than

service technicians authorized by TOSHIBA TEC CORPORATION; or

(d) use of paper, supplies or parts other than those recommended by TOSHIBA TEC CORPORATION.

4. Subject to paragraph 1, TOSHIBA TEC CORPORATION shall not be liable to Customer for:

(a) loss of profits; loss of sales or turnover; loss of or damage to reputation; loss of production; loss of anticipated savings; loss of goodwill or business opportunities; loss of customers; loss of, or loss of use of, any software or data; loss under or in relation to any contract;

or

(b) any special, incidental, consequential or indirect loss or damage, costs, expenses, financial loss or claims for consequential compensation;

whatsoever and howsoever caused which arise out of or in connection with the Product or

the use or handling of the Product even if TOSHIBA TEC CORPORATION is advised of the

possibility of such damages.

TOSHIBA TEC CORPORATION shall not be liable for any loss, cost, expense, claim or damage caused by any inability to use (including, but not limited to failure, malfunction, hang-up,

virus infection or other problems) which arises from use of the Product with hardware, goods

or software which TOSHIBA TEC CORPORATION has not directly or indirectly supplied.

Disclaimer Notice 17

Page 20

Environmental Information

ENERGY STAR® Program

Toshiba Tec Corporation, as a member of the ENERGY STAR Program, attaches the ENERGY

STAR logo to all products which meet the ENERGY STAR Program requirements.

The ENERGY STAR Program aims at the promotion of the development and wider usage of

office equipment including energy-efficient computers in order to address environmental issues

such as global warming. Manufacturers that participate in this program can attach the ENERGY

STAR logo to products after confirming that they meet the energy saving standards of this program. Also, these standards and logo are commonly used within the U.S. Environmental Protection Agency (EPA) and participating countries.

Specified products, sales countries or regions may not be included.

To distinguish whether or not the product meets the ENERGY STAR Program requirements,

check if the corresponding logo is on the product.

If you have any questions, contact your service representative.

Energy saving features

Energy saving features are provided in this product in order to reduce power consumption when

it is not being used.

Low power mode

The equipment automatically enters this mode when a specified period of time*1 has passed

since the last use. “ALP” appears on the LED display in this mode.

Sleep mode / Super sleep mode

The equipment automatically enters this mode when a specified period of time*2 has passed

since the last use.

mode, the LED display is blank.

*1 If you want to change the time until the low power mode is entered, contact your service technician.

*2 You can change the time until the sleep mode / super sleep mode is entered.

P.70 “Changing of the Enabled Energy Saving Mode”

*3 For the conditions needed to cancel the sleep mode / super sleep mode, see the following page:

P.28 “Canceling conditions for energy saving mode”

*3

In the sleep mode, “SLP” appears on the LED display. In the super sleep

18 Environmental Information

Page 21

1.PREPARATION

This chapter describes what you need to know before using this equipment, such as how to turn the power

ON or how to set copy paper.

Description of Each Component ...........................................................................20

Front / Right side...............................................................................................................................20

Left side / Inner side..........................................................................................................................21

Configuration of options ....................................................................................................................23

Control panel.....................................................................................................................................24

Preparation 1 - Turning Power ON.........................................................................27

Turning power ON.............................................................................................................................27

Saving energy when not in use - Energy saving mode -...................................................................28

Preparation 2 - Placing Copy Paper......................................................................30

Acceptable media types ....................................................................................................................30

Recommended paper........................................................................................................................31

Placing paper in drawers...................................................................................................................32

Preparation 3 - Registering Size of Paper Placed................................................36

Registering standard size (LD, LT, LT-R, LG, ST-R)..........................................................................36

Registering other standard sizes.......................................................................................................37

Page 22

1 PREPARATION

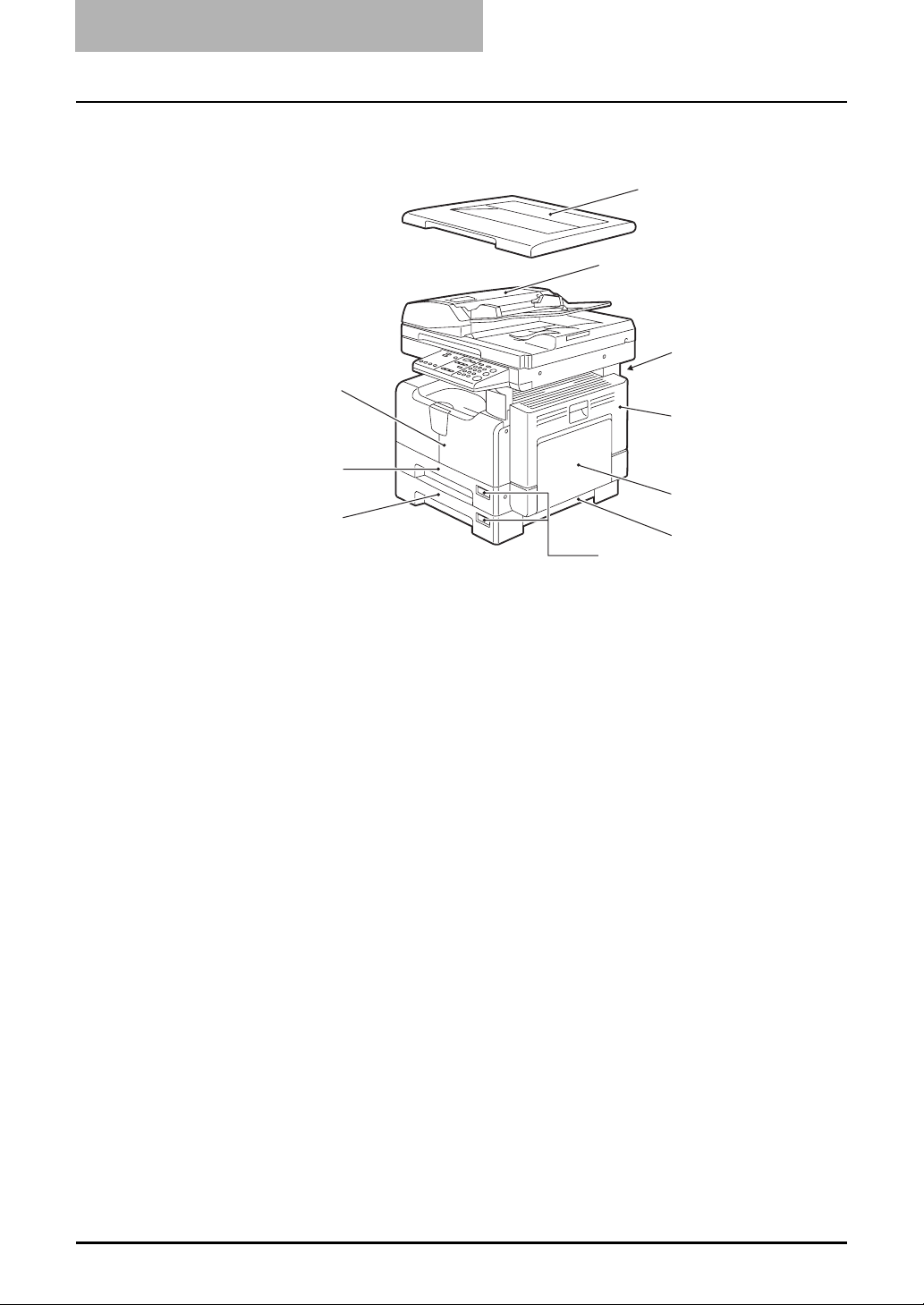

Description of Each Component

Front / Right side

10

9

8

1

2

3

4

5

6

7

1. Platen Cover (optional, KA-1650PC)

Place an original on the original glass and start copying with this cover closed.

2. Automatic Document Feeder (optional, MR-2020)

A stack of originals placed on this are scanned one sheet after another. Maximum 100

sheets (or stack height 0.62") of originals can be placed in one go.

(The maximum number of sheets can be placed may vary depending on the media type of

the originals.)

P.44 “Placing originals on Automatic Document Feeder (optional)”

P.75 “Paper Jams”

3. Operator’s Manual pocket (Back side)

Keep the Operator’s Manual in this.

4. Side cover

5. Bypass tray

Use this to make copies on special media types such as thick paper, overhead transparencies or tracing paper.

P.48 “Using Bypass Tray”

P.75 “Paper Jams”

6. Paper feed cover (of the Paper Feed Unit (optional))

7. Paper size indicator

8. Paper Feed Unit (optional, MY-1027)

Use this to add one more drawer to the equipment. A maximum of 250 sheets of plain paper

can be placed in one go.

20 Description of Each Component

Page 23

9. Drawer

Maximum 250 sheets of plain paper can be placed in one go.

10. Front cover

Open this cover when you replace the toner cartridge.

P.85 “Replacing Toner Cartridge”

Left side / Inner side

11

10

1

9

8

2

7

6

5

3

4

1. Original glass

Use this to copy three-dimensional originals, book-type originals and special paper such as

overhead transparencies or tracing paper, as well as plain paper.

P.40 “Placing Originals”

2. Control panel

Use this to perform copying, key in the copy quantity, or set other functions.

P.24 “Control panel”

3. Toner cartridge

P.9 “Recommended toner cartridges”

P.85 “Replacing Toner Cartridge”

4. Power switch

Turn the power of the equipment ON or OFF with this.

P.27 “Preparation 1 - Turning Power ON”

5. Paper exit stopper

Use this to prevent the exiting paper from falling. Open this when you make a large amount

of copies on a larger size of paper (e.g. LD, LG).

6. AC-IN terminal

Use this to connect the co-packed power cable and the equipment.

Description of Each Component 21

Page 24

1 PREPARATION

7. USB terminal (4-pin)

With this terminal, the equipment can be connected to your PC using a commercially available USB cable.

y Use a USB2.0 Hi-Speed certified cable: USB cable supporting the USB2.0 Hi-Speed

y Connect the equipment with a PC directly by the USB cable. When it is connected with a

8. Receiving tray

9. Scanning area

The data of originals transported from the Automatic Document Feeder (optional, MR-2020)

are scanned here.

P.96 “Daily Inspection”

10. Original scale

Use this to check the size of an original placed on the original glass.

11. Platen sheet

P.96 “Daily Inspection”

mode (480 Mbps of transfer speed) certified by the USB Implementers Forum.

PC via a USB hub, the equipment may not be recognized.

22 Description of Each Component

Page 25

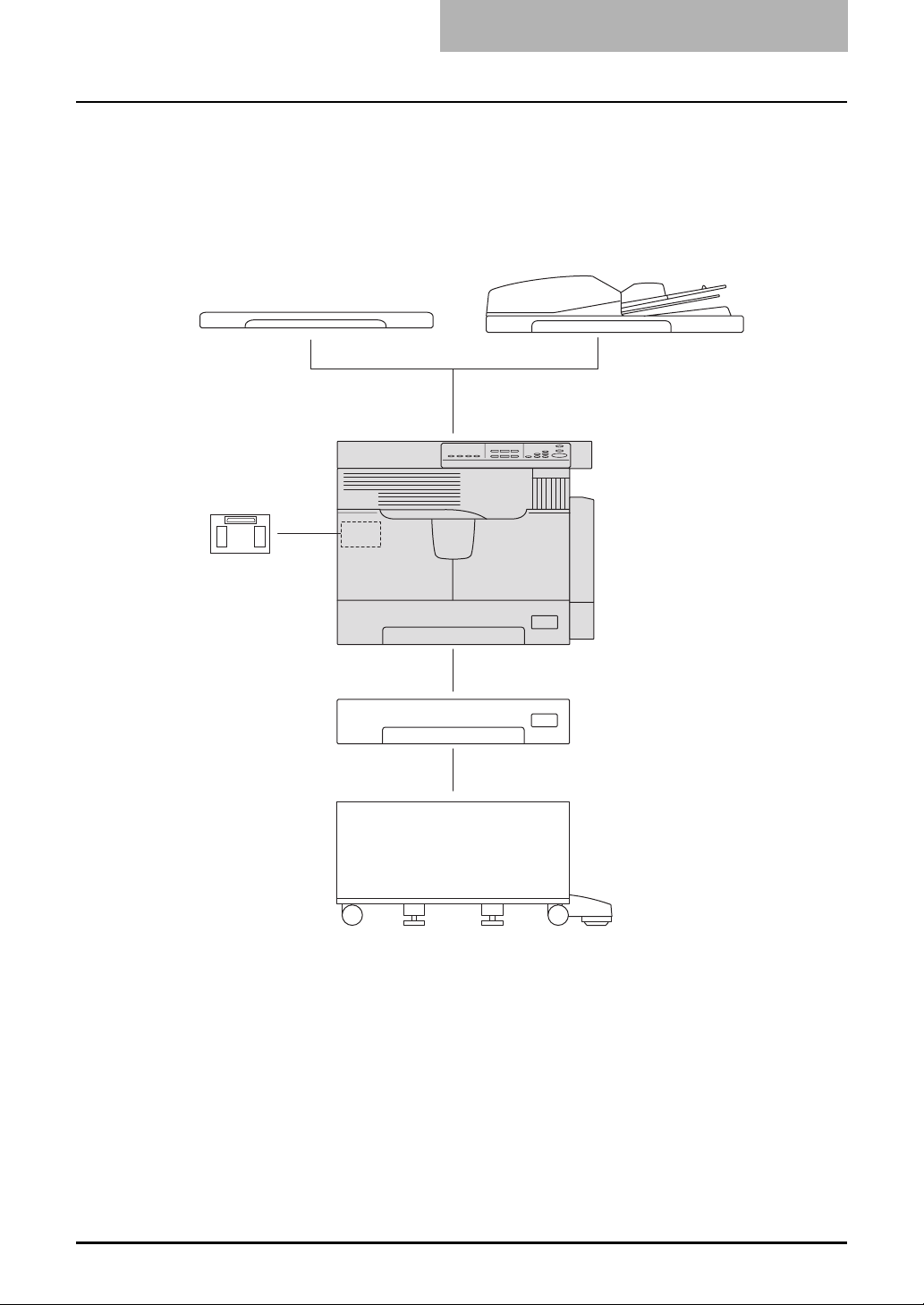

Configuration of options

The options listed below are available. Contact your service technician or service representative

for the details.

Platen Cover

(

KA-1650PC

Expansion Memory

(GC-1240

)

Automatic Document Feeder

(

MR-2020)

)

Main body

Paper Feed Unit

(

MY-1027

(

MH-1640

)

Desk

)

Description of Each Component 23

Page 26

1 PREPARATION

Control panel

12 34 8 9 10

16

1. [SORT] button/lamp

Use this to use the sorting function.

P.61 “Copying in Same Page Order as Originals - Sort Copying -”

2. Media type setting button/lamps

Use this button to switch the media type of paper placed on the bypass tray.

P.48 “Using Bypass Tray”

1165 7

121315 141718192021

3. [DATA] lamp

The lamp blinks when print data are being received from a PC connected to the equipment.

4. Message lamps

Each of five lamps shows you the current status of the equipment.

For the meaning of each lamp and countermeasure of each status, see the following page:

P.72 “When Message Lamp is Lit/Blinking”

5. Zoom buttons/lamp

Use them to set reproduction ratio. The lamp above the button is lit when the reproduction ratio is 100%.

For how to zoom in or out copy image, see the following page:

P.56 “Zooming In/Out Copy Image”

6. LED display

Use this to display the number of copies set. The reproduction ratio appears here when the

copy qty. / zoom display selecting button (7) is pressed.

7. Copy qty. / zoom display selecting button/lamp

The display of (6) is switched between copy quantity and reproduction ratio each time you

press this button. The lamp beside the “%” mark is lit when the reproduction ratio appears.

24 Description of Each Component

Page 27

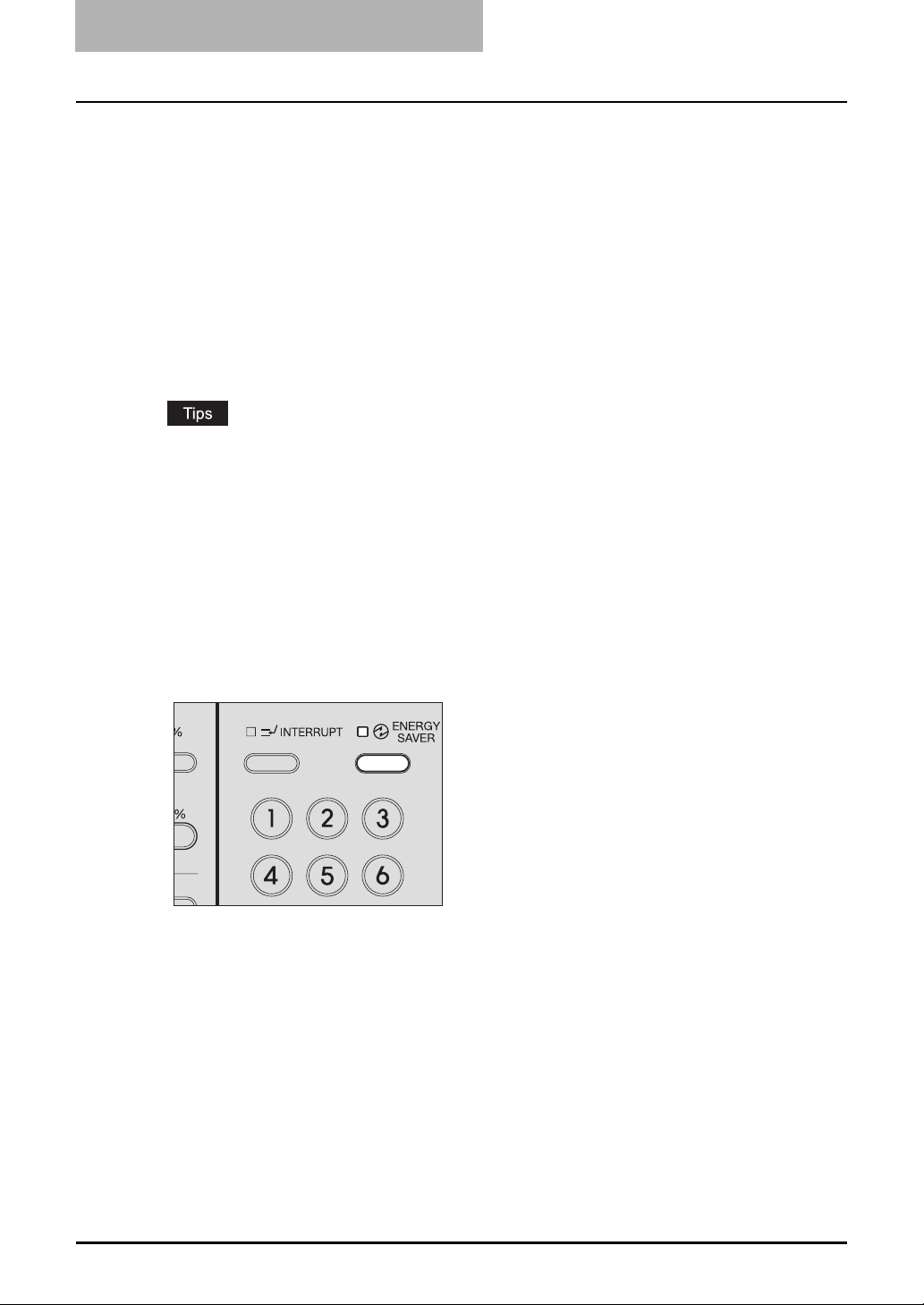

8. [INTERRUPT] button/lamp

Use this to interrupt the copy job in process and perform another one (= interrupt copying).

For the details of interrupt copying, see the following page:

P.47 “Interrupting copying and making another copy - Interrupt copy -”

9. [ENERGY SAVER] button/lamp

Use this to let the equipment enter into the energy saving mode when the equipment is not

used. The lamp is lit when the equipment is in the energy saving mode.

For the details of the energy saving mode, see the following page:

P.28 “Saving energy when not in use - Energy saving mode -”

10. [FUNCTION CLEAR] button/lamp

This lamp blinks when copying is finished. Use this button to clear the set copy functions.

11. [CLEAR/STOP] button

Use this to stop the copy job in process or return the copy quantity keyed in to “1”.

12. [START] button/lamp

Use this to start copying. Copies can be made when the lamp is lit. It blinks when the equipment is waiting for copying to be started.

For basic copy operations, see the following page:

P.45 “Making Copies”

13. Digital keys

Use them to key in any number such as copy quantity.

14. Original mode button/lamps

Use this button to set the image quality of copy according to that of an original.

For the details of image quality, see the following page:

P.65 “Selecting Image Mode”

15. Density adjustment buttons/lamps

Use this button to adjust the density of copy image. The [AUTO] lamp below the

(automatic copy density mode) button is lit when the density is being automatically adjusted.

For the details of density adjustment, see the following page:

P.66 “Adjusting Density Level”

16. Paper jam position lamps

The lamp blinks when an original or copy paper is jammed. The position where the lamp is

blinking shows where the paper jam has occurred.

P.75 “Paper Jams”

17. [DRAWER] button/lamps

Use this button to select a drawer or the bypass tray to be used as a paper source. The lamp

of the paper source currently selected is lit. The lamp blinks when the selected drawer or tray

is running out of paper.

When paper in the drawer or on the bypass tray has run out, see the following page to add

paper:

P.30 “Preparation 2 - Placing Copy Paper”

18. Original setting lamp

The lamp is lit when originals are placed on the Automatic Document Feeder (optional).

This lamp blinks in the following situations:

- When the original needs to be placed on the original glass (When the [START] button is

pressed without the original cover being opened after copies are made)

Description of Each Component 25

Page 28

1 PREPARATION

- When the originals need to be placed on the Automatic Document Feeder (optional)

- When the Automatic Document Feeder (optional) on which the originals are placed is

19. [COPY] button/lamps

Use this button to select the size of paper to be used. The lamp of the paper size currently

selected blinks when this size of paper is not placed in the drawer or on the bypass tray.

See the following page for details:

P.54 “Manual paper selection”

20. [ORIGINAL] button/lamps

Use this button to specify the size of an original.

P.58 “Specifying both the sizes of the original and the copy paper”

21. APS/AMS selecting button/lamps

Automatic paper selection (APS): The equipment detects the size of original and automatically selects the same size of copy paper.

P.53 “Paper Selection”

Automatic magnification selection (AMS): Set the size of copy paper to be used in advance.

The equipment then detects the size of original and automatically selects the most suitable

reproduction ratio to the copy paper.

P.56 “Automatic magnification selection (AMS)”

(When a paper jam in the Automatic Document Feeder is released)

raised.

APS and AMS are available only when originals are placed on the Automatic Document

Feeder (optional, MR-2020).

26 Description of Each Component

Page 29

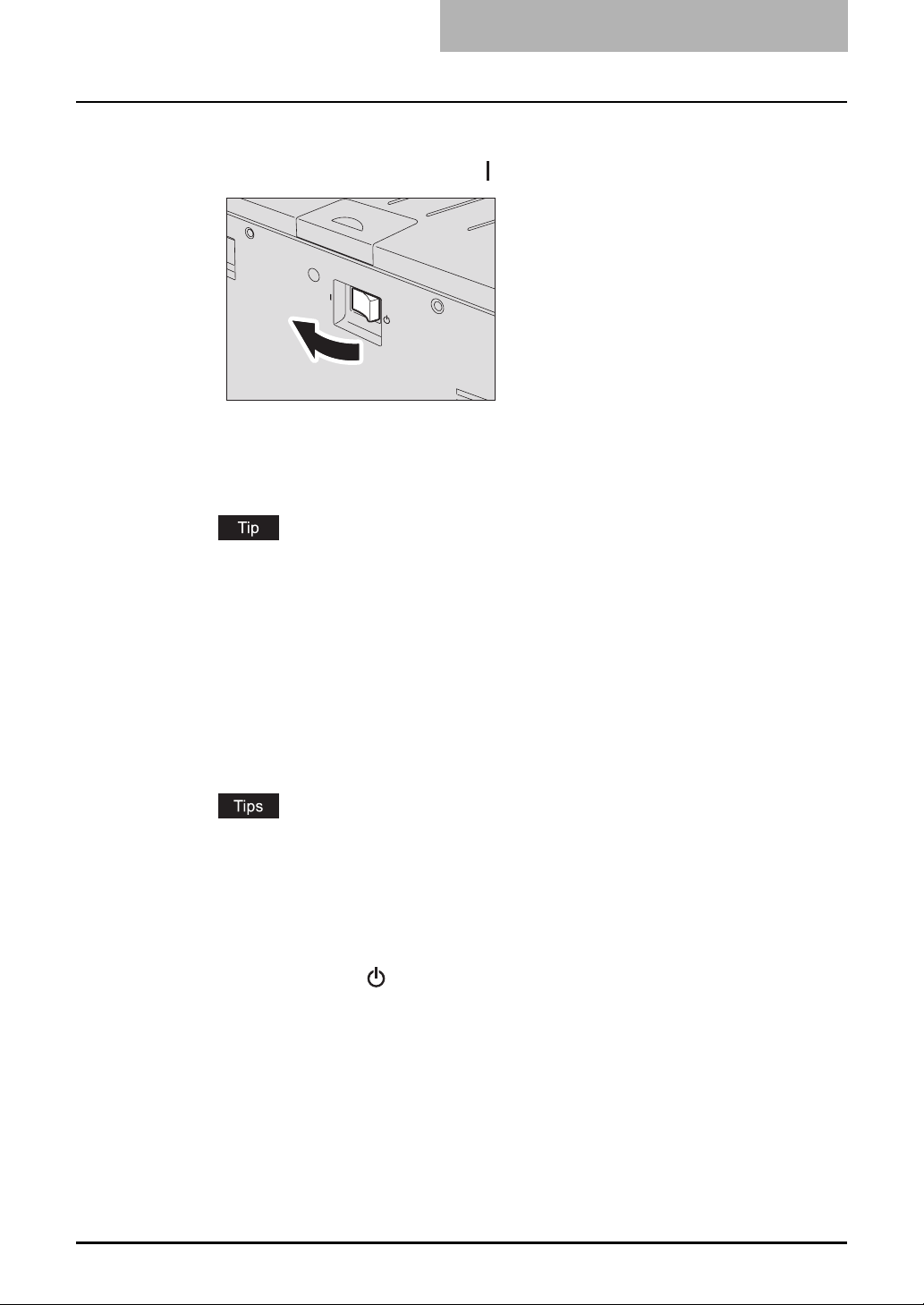

Preparation 1 - Turning Power ON

Turning power ON

Press the power switch to “ ” (ON) side.

1

The equipment starts warming itself up. The warm-up time takes approx. 25 seconds.

When the warm-up has finished, the [START] lamp is lit to show that the equipment is

ready for copying.

If you press the [START] button with an original placed while the warm-up is still continuing, copying automatically starts after it has finished. This is called auto job start. When

the job is reserved, the [START] lamp blinks to show you the current status.

However, this function cannot be accessed while “0” is blinking on the LED display

(approx. 15 seconds).

Key in the access code if the equipment is managed under the

2

access code function.

Key in the 3-digit access code, and then press the [START] button. Then the equipment

is ready for copying.

y If the access code function is enabled, press the [FUNCTION CLEAR] button after

any operation has been finished to prevent unauthorized use of the equipment.

y For the details of the access code setting, ask your service technician.

Turning power OFF

Press the power switch to “ ” (OFF) side.

Preparation 1 - Turning Power ON 27

Page 30

1 PREPARATION

Saving energy when not in use - Energy saving mode -

To reduce power consumption, the equipment automatically enters into the energy saving mode

when a specified period of time has passed since its last use. You can also turn the equipment

into this mode manually.

Types of energy saving mode

There are two types of the energy saving mode as follows.

Sleep mode: The power consumption is 18 W. “SLP” appears on the LED display, and only the

[ENERGY SAVER] lamp is lit.

Super sleep mode: The power consumption is 4 W. The LED display is blank, and only the

[ENERGY SAVER] lamp is lit.

y Either the sleep mode or the super sleep mode is enabled. The enabled mode and the time

until the mode is entered (Auto sleep time) can be changed.

P.70 “Changing of the Enabled Energy Saving Mode”

y There is another one called the low power mode. Since the time until the low power mode is

entered (Auto low power time) and the time until the energy saving mode is entered (Auto

sleep time) work simultaneously, if auto sleep time is set shorter than auto low power time,

the equipment enters into the energy saving mode, but not into the low power mode.

P.18 “Energy saving features”

To turn the equipment into the energy saving mode manually

Check that the equipment is in the ready status, and press the [ENERGY SAVER] button.

The equipment is now in the energy saving mode. The [ENERGY SAVER] lamp is lit.

Canceling conditions for energy saving mode

The energy saving mode is canceled under the following conditions. After the warm-up has been

completed, the equipment goes into the ready status.

Sleep mode

y When any of the buttons on the control panel is pressed

y When this equipment is connected to a PC with a USB cable

y When printing is performed from a PC connected with this equipment

y When the Platen Cover (optional) or the Automatic Document Feeder (optional) is raised

y When originals are placed on the Automatic Document Feeder (optional)

28 Preparation 1 - Turning Power ON

Page 31

Super sleep mode

y When the [ENERGY SAVER] button on the control panel is pressed

y When the Platen Cover (optional) or the Automatic Document Feeder (optional) is raised

If this equipment is connected to your PC with a USB cable, change the setting so that it does

not enter the super sleep mode.

P.70 “Changing of the Enabled Energy Saving Mode”

Preparation 1 - Turning Power ON 29

Page 32

1 PREPARATION

Preparation 2 - Placing Copy Paper

Place copy paper in an appropriate paper source before you start copying.

Acceptable media types

Standard size plain paper (17 to 20 lb. Bond) can be used for the drawers in the equipment and

the Paper Feed Unit (optional). See the table below for the details.

Feeder Media type Paper size

Drawers of

the equipment and

Paper Feed

Unit

(optional)

Bypass tray Plain paper

*1 “Maximum sheet capacity” refers to the maximum number of sheets when TOSHIBA-recommended

paper is used. See the following page for the TOSHIBA-recommended paper:

P.31 “Recommended paper”

*2 13 to 16 lb. Bond paper can be used if it is set on the bypass tray sheet by sheet.

*3 Be sure to use the overhead transparencies that TOSHIBA recommends. When transparencies other

than the TOSHIBA-recommended ones are used, this could cause an equipment malfunction.

Plain paper

(17 - 20 lb. Bond)

(17 - 20 lb. Bond)

THICK PAPER 1

(21 - 28 lb. Bond)

THICK PAPER 2

(29 lb. Bond - 90 lb.

Index)

Tracing paper

(20 lb.)

Sticker labels 1 sheet

Transparencies

LT f o r m at:

LD, LG, LT, LT-R, COMP, 13"LG

A/B format:

A3, A4, A4-R, B4, B5, B5-R, FOLIO

LT f o r m at:

*2

LD, LG, LT, LT-R, ST-R, COMP, 13"LG

A/B format:

A3, A4, A4-R, A5-R, B4, B5, B5-R, FOLIO

*3

LT only

Maximum sheet

capacity

250 sheets

(17 lb. Bond)

250 sheets

(20 lb. Bond)

100 sheets

(17 lb. Bond)

100 sheets

(20 lb. Bond)

1 sheet

(21 - 28 lb. Bond)

1 sheet

(29 lb. Bond - 90

lb. Index)

1 sheet

1 sheet

*1

You cannot mix various paper sizes in one drawer.

Abbreviations for LT format sizes:

LT: Letter, LD: Ledger, LG: Legal, ST: Statement, COMP: Computer

30 Preparation 2 - Placing Copy Paper

Page 33

Recommended paper

To ensure the best copy performance, TOSHIBA recommends the paper types listed below. If

you want to use paper other than that we recommend, contact your service technician.

Media type Product name

Plain paper TIDAL / Hammermill 20 lb. Bond

THICK PAPER 1 Laser / Hammermill 24 lb. Bond

THICK PAPER 2 Laser / Hammermill 32 lb. Bond

Tracing paper Tracing paper / Ostrich International 20 lb. Bond only

Sticker labels 5165 / Avery

Transparencies

*1 Be sure to use the overhead transparencies that TOSHIBA recommends. When transparencies other

than the TOSHIBA-recommended ones are used, this could cause an equipment malfunction.

*1

Paper types not acceptable

Do not use the types of paper listed below since they may cause paper jams.

y Damp paper

y Creased paper

y Wrinkled paper or paper prone to be curled

y Paper whose surface is extremely smooth or rough

Do not use the types of paper listed below since they may cause an equipment malfunction.

y Paper whose surface is specially treated

y Paper once printed with other copiers or printers

Exact Index / WAUSAU 90 lb. Index

X-10.0 / Folex

Storing paper

Observe the following cautions when storing copy paper:

y Wrap copy paper in its wrapping paper to prevent it from gathering dust.

y Do not expose copy paper to direct sunlight.

y Store copy paper in a damp-free place.

y Store copy paper on a flat surface to prevent it from being creased or bent.

Preparation 2 - Placing Copy Paper 31

Page 34

1 PREPARATION

Placing paper in drawers

Follow the procedure below to place copy paper in the drawer.

For the acceptable paper, see the following page:

P.30 “Acceptable media types”

Turn the power of the equipment ON.

1

Pull out the drawer carefully.

2

Pull out the drawer until it comes to a stop.

Press down the paper plate.

3

Press it down until you hear a click sound and it is no longer lifted up.

32 Preparation 2 - Placing Copy Paper

Page 35

Pull out the trailing guide (A), and then reinstall the guide at the

4

position of the desired paper size.

A

The paper size is indicated on the bottom inner surface of the drawer.

While pushing the green knob of the side guides fully, widen the

5

gap between them.

Widen the gap with both hands.

Preparation 2 - Placing Copy Paper 33

Page 36

1 PREPARATION

6

Place paper in the drawer.

y The maximum number of sheets that can be placed at one time is 250 (17 to 20 lb.

Bond). Be sure that the stack height of paper is not higher than the line indicated at

the inner side of the side guide and trailing guide.

P.30 “Acceptable media types”

y Fan the paper well before placing it in the drawer, otherwise multiple feeding could

occur. Be careful that the paper does not cut your fingers.

y Place the paper face up. You may tell its “face” by the note on its wrapping paper.

Adjust the side guides to the desired paper size.

7

Be sure that a gap of approx. 0.02" (less than 0.04" in total) is left between the paper and

each side guide (shown as “A” in the picture). If the gap is inappropriate, this could cause

a paper misfeed.

A

34 Preparation 2 - Placing Copy Paper

Page 37

Be sure that the stack of paper fits completely under the latches of

8

the side guides.

Change the paper size indicator to match the size of paper placed.

9

Push the drawer straight into the equipment slowly until it comes to

10

a stop.

Do not let your fingers be caught when closing the drawer.

This could cause injury.

Register the paper size into the equipment.

When you place paper, register the size of the paper into the equipment. Be sure that the

size is registered correctly, or it could cause a paper jam.

For the registration of paper size, see the following page:

P.36 “Preparation 3 - Registering Size of Paper Placed”

Be sure to register the paper size when you have changed the paper size in the drawer,

as well as when you place paper in the corresponding drawer for the first time.

Preparation 2 - Placing Copy Paper 35

Page 38

1 PREPARATION

Preparation 3 - Registering Size of Paper Placed

When you place paper in a drawer for the first time or when you place paper whose size is different from that of the paper which has been placed in the drawer, the new paper size needs to be

registered into the equipment.

Registration of standard sizes (LD, LT, LT-R, LG, ST-R) differs from that of standard sizes other

than these.

Registering standard size (LD, LT, LT-R, LG, ST-R)

In this section, LT size is registered in the drawer of the equipment as an example.

Press and hold the [COPY] and [DRAWER] buttons simultaneously

1

for more than two seconds.

“Fnc” appears on the LED display.

Press the [DRAWER] button several times until the lamp of the

2

drawer in which you placed paper is lit.

36 Preparation 3 - Registering Size of Paper Placed

Page 39

Press the [COPY] button several times until the lamp of the paper

3

size you placed in the drawer is lit.

If the [FUNCTION CLEAR] button is pressed at this step, the size is not registered and

the equipment will return to its normal status.

Press the [START] button.

4

The paper size has been registered.

Registering other standard sizes

When standard size paper other than LD, LT, LT-R, LG or ST-R is placed, register this size as

“OTHER” size. Key in the code number of the paper size to register it as “OTHER” size.

See the table below for the code number of each size.

Paper size Code No. Paper size Code No.

A3 01 B5-R 06

A4 02

A4-R 03 FOLIO 13

B4 04 COMP 14

B5 05 13"LG 16

*1 A5-R and ST-R can be placed only on the bypass tray.

In this section, A4 size is registered in the drawer of the equipment as an example.

Press and hold the [COPY] and [DRAWER] buttons simultaneously

1

for more than two seconds.

“Fnc” appears on the LED display.

A5-R

*1

07

Preparation 3 - Registering Size of Paper Placed 37

Page 40

1 PREPARATION

2

3

Press the [DRAWER] button several times until the lamp of the

drawer in which you placed paper is lit.

Press the [COPY] button several times until the [OTHER] lamp is lit.

“Fxx” appears in the LED display. (Two digits come at “xx”.)

Key in the code number of the paper placed in the drawer.

4

e.g.) Placing A4 size (= code number “02”)

If the [FUNCTION CLEAR] button is pressed at this step, the size is not registered and

the equipment will return to its normal status.

Press the [START] button.

5

The paper size has been registered as “OTHER” size.

38 Preparation 3 - Registering Size of Paper Placed

Page 41

2.HOW TO MAKE COPIES

This chapter describes basic copy operations.

Placing Originals.....................................................................................................40

Acceptable originals ..........................................................................................................................40

Placing originals on the original glass ...............................................................................................41

Placing booklet-type originals such as books or catalogs .................................................................42

Using Automatic Document Feeder (optional) ..................................................................................43

Placing originals on Automatic Document Feeder (optional) ............................................................44

Making Copies.........................................................................................................45

Stopping/Resuming copying..............................................................................................................46

Interrupting copying and making another copy - Interrupt copy - ......................................................47

Using Bypass Tray..................................................................................................48

Bypass copying.................................................................................................................................49

Page 42

2 HOW TO MAKE COPIES

Placing Originals

Acceptable originals

Booklets, three-dimensional objects and some types of special media can be placed on the original glass, as well as plain paper. When the Automatic Document Feeder (optional) is used, a

stack of plain paper originals can be automatically scanned one by one.

Setting position

Original glass Plain paper

Automatic

Document Feeder

(optional)

*1 The automatic size detection function is not enabled for A/B format.

*2 “Special media types” refers to special paper which is not acceptable for the Automatic Document

Feeder (optional), such as overhead transparencies or tracing paper.

*3 Do not place heavy objects (9 lb. or more) and do not press on it with force.

*4 Its paper weight should be between 13.3 lb. and 33.8 lb.

*5 Some media types may not be used.

*6 ST size originals must be placed in a landscape direction.

Type of origi-

nals

Special media

*2

types

Booklets

3-dimensional

objects

Plain paper LD, LG, LT, LT-R, COMP, ST-R

Maximum

size

11.69" x 17.01" Not acceptable for automatic

Acceptable sizes for auto-

matic size detection

size detection

of standard sizes

*1

Remarks

*3

*4, *5, *6

Maximum number of originals scanned in one go

Up to 250 original sheets can be scanned at one time. When the number of sheets to be

scanned exceeds 250 or the built-in memory in the equipment becomes full during the scanning

of the copy job, scanning stops, the [FUNCTION CLEAR] lamp blinks and the [START] lamp is

lit.

To copy the data scanned so far, press the [START] button. To delete them, press the [FUNCTION CLEAR] button.

When non-sort copying or sort copying for one set is performed, only the [FUNCTION CLEAR]

lamp blinks. Thus only data deletion is possible. After doing this, perform copying again with the

original divided.

40 Placing Originals

Page 43

Placing originals on the original glass

Plain paper or some special media types which are not acceptable for the Automatic Document

Feeder (optional), such as overhead transparencies or tracing paper, should be placed on the

original glass.

Do not place heavy objects (9 lb. or more) and do not press on it with force.

Breaking the glass could injure you.

Raise the Platen Cover (optional) or the Automatic Document

1

Feeder (optional).

Place the original face down on the original glass and align it

2

against the left rear corner of the glass.

When copying highly transparent originals

When copying highly transparent originals such as overhead transparencies or tracing

paper, place a blank sheet of paper (A), the same size as the original or larger, over the

original (B).

A

B

Lower the Platen Cover (optional) or the Automatic Document

3

Feeder (optional) carefully.

Placing Originals 41

Page 44

2 HOW TO MAKE COPIES

Placing booklet-type originals such as books or catalogs

Place a book-type original on the original glass.

Do not place heavy objects (9 lb. or more) and do not press on it with force.

Breaking the glass could injure you.

Raise the Platen Cover (optional) or the Automatic Document

1

Feeder (optional).

Open the desired page of the original and place it face down.

2

Align it against the left rear corner of the glass.

Lower the Platen Cover (optional) or the Automatic Document

3

Feeder (optional) carefully.

y Do not try to lower the Platen Cover (optional) or the Automatic Document Feeder

(optional) forcibly when the original is very thick. There will be no problem in copying

even if they are not fully lowered.

y Do not look fully at the original glass since intensive light may leak out during copy-

ing.

42 Placing Originals

Page 45

Using Automatic Document Feeder (optional)

When a stack of originals are placed on the Automatic Document Feeder (optional), the originals

are automatically scanned one by one. The following types of originals are available:

Media types Maximum size

Plain paper 11.69" x 17.01" 100 sheets

y Some media types may not be used.

y The maximum number of sheets acceptable varies depending on the media types of the

originals.

y ST size originals must be placed in a landscape direction.

y Sizes which the Automatic Document Feeder (optional) can detect automatically are LD, LG,

LT, LT-R, COMP and ST-R.

Maximum number of

sheets acceptable

(or stack height 0.62")

Paper weight

13.3 - 33.8 lb.

Precautions for Automatic Document Feeder (optional)

Do not use the following types of original since such types may cause a paper jam or damage to

the equipment:

y Extremely wrinkled, folded or curled ones

y Ones with carbon paper

y Taped, pasted or cut-out ones

y Clipped or stapled ones

y Ones with holes or tears

y Damp ones

y Overhead transparencies or tracing paper

y Coating paper (e.g. coated with wax)

y Ones with many holes punched (e.g. loose leaf paper)

The following types of originals are usable but need extra care:

y Ones which cannot be made to slide with the fingers or whose surface is specially treated

(they may not be able to be separated from each other at feeding)

y Folded or curled ones (should be smoothed out before being used)

When black streaks appear on the copied image

If the scanning area or the guide area is dirty, image problems such as black streaks on the copied image may occur. Weekly cleaning of these areas is recommended.

P.96 “Daily Inspection”

Placing Originals 43

Page 46

2 HOW TO MAKE COPIES

Placing originals on Automatic Document Feeder (optional)

Align all the originals.

1

Place them face up and align the side guides to the original length.

2

y The top sheet of the originals will be scanned first.

y The total sheets of originals placed must not exceed 100 (13.3 to 20 lb.) or the stack

height of the originals must not exceed 0.62" regardless of their sizes.

When placing a large amount of originals with a long width

Pull out the original stopper so that the exiting originals will not fall. When replacing this

stopper, lift it slightly and push it in.

44 Placing Originals

Page 47

Making Copies

Follow the procedure below to make copies.

The reproduction ratio or density of the copied image can be set. See the following page for the

details:

P.51 “COPYING FUNCTIONS”

Check if paper is placed in the drawer.

1

For the acceptable types and sizes of paper, see the following pages:

P.30 “Acceptable media types”

P.32 “Placing paper in drawers”

Place the original.

2

For acceptable originals or how to place originals, see the following pages:

P.40 “Acceptable originals”

P.44 “Placing originals on Automatic Document Feeder (optional)”

P.41 “Placing originals on the original glass”

P.42 “Placing booklet-type originals such as books or catalogs”

Key in the desired number of copies (= copy quantity) when you

3

copy more than one set.

e.g.) 5 sets

If you want to correct the copy quantity keyed in, press the [CLEAR/STOP] button, and

then key in the correct number.

Select the copy modes as required.

4

P.51 “COPYING FUNCTIONS”

Press the [START] button.

5

Copying starts. The paper will exit with its copied side down.

The paper exit area and exiting paper are hot immediately after the exit. Handle them

with care.

Making Copies 45

Page 48

2 HOW TO MAKE COPIES

When the number of sheets exiting has exceeded 250

To prevent exiting paper from falling off the receiving tray, the equipment causes copying to

pause when approx. 250 sheets of paper have continuously exited. At this time the [START]

lamp is lit and the [FUNCTION CLEAR] lamp blinks on the control panel. Also the paper jam

position lamp ( ) at the middle is lit.

Remove the paper from the receiving tray, and then press the [START] button. Copying

resumes.

Press the [FUNCTION CLEAR] button to end the copy job.

When the paper has run out

When the paper in the drawer has run out during copying, the copying stops and the paper

empty lamp blinks.

The [DRAWER] lamp corresponding to the one whose paper has run out blinks.

Add paper to the drawer and press the [START] button. Copying then resumes.

Stopping/Resuming copying

Press the [CLEAR/STOP] button to stop scanning or copying.

Press the [CLEAR/STOP] button during scanning or copying.

1

Scanning or copying stops. Press the [CLEAR/STOP] button again to end the copy job.

Press the [START] button to resume the copy job.

2

46 Making Copies

Page 49

Interrupting copying and making another copy - Interrupt copy -

You can interrupt copying of one job and make another copy job (= interrupt copying). The copy

quantity or functions applied to the interrupted job are stored in the memory of this equipment,

so that you will not need to set them again when the interrupted job resumes.

Interrupt copying is available only when the originals are placed on the Automatic Document

Feeder (optional) and the sort functions are used.

Press the [INTERRUPT] button.

1

The [INTERRUPT] lamp blinks, and the lamp will be fully lit after a while.

When the [INTERRUPT] button is pressed during scanning, the [INTERRUPT] lamp

blinks, and then the lamp will be fully lit after the scanning has finished.

Replace the original with a new one.

2

Select the copy modes as required, and then press the [START]

3

button.

Interrupt copying starts.

After you have finished interrupt copying, press the [INTERRUPT]

4

button.

The copying status returns to the one before the interruption.

Even if you do not press the [INTERRUPT] button, a certain time after the interrupt copying has finished, the auto clear function will work and the interrupt mode will automatically be cleared.

Press the [START] button.

5

The job interrupted will resume.

Making Copies 47

Page 50

2 HOW TO MAKE COPIES

Using Bypass Tray

Place paper on the bypass tray when you use the following media types as copy paper:

y Thick paper (21 lb. Bond to 90 lb. Index)

y Special media types such as tracing paper, sticker labels or overhead transparencies

y Standard size paper which cannot be placed in a drawer (e.g. ST-R)

Using the bypass tray is recommended also for copying on standard-size paper other than those

placed in the drawers. The following sizes are available for bypass copying:

Media type Paper size

Plain paper

(17 - 20 lb. Bond)

THICK PAPER 1

(21 - 28 lb. Bond)

THICK PAPER 2

(29 lb. Bond - 90 lb. Index)

Tracing paper

(20 lb.)

Sticker labels 1 sheet

Transparencies

*1 “Maximum sheet capacity” refers to the maximum number of sheets when TOSHIBA-recommended

paper is used. See the following page for the TOSHIBA-recommended paper:

P.31 “Recommended paper”

*2 13 to 16 lb. Bond paper can be used if it is set on the bypass tray sheet by sheet.

*3 Be sure to use the overhead transparencies that TOSHIBA recommends. When transparencies other

than the TOSHIBA-recommended ones are used, this could cause an equipment malfunction.

*2

*3

LT format:

LD, LG, LT, LT-R, ST-R, COMP, 13"LG

A/B format:

A3, A4, A4-R, A5-R, B4, B5, B5-R, FOLIO

LT only

Maximum sheet

capacity

100 sheets (17 lb. Bond)

100 sheets (20 lb. Bond)

1 sheet

(21 - 28 lb. Bond)

1 sheet

(29 lb. Bond - 90 lb. Index)

1 sheet

1 sheet

*1

When you place paper of a larger size, pull out the paper holder before you start bypass copying.

48 Using Bypass Tray

Page 51

Bypass copying

This section describes the bypass copying procedure.

Place paper straight on the bypass tray face down. Then align the

1

side guides to the paper length while holding (A).

y Be sure that the stack height of paper does not exceed the indicators of the side

y Fan the stack of paper well before placing it on the bypass tray.

y Do not push the paper forcibly into the entrance of the bypass feeder. This could

A

guides.

cause a paper misfeed.

Press the [COPY] button several times until the lamp of the paper

2

size you placed on the bypass tray is lit.

If you copy on standard size paper other than LD, LT, LT-R, LG or ST-R, select [OTHER]

and key in the code number of the paper placed on the bypass tray.

e.g.) Placing A4 size (= code number “02”)

For the paper sizes to be registered as OTHER size, see the following page:

P.37 “Registering other standard sizes”

Using Bypass Tray 49

Page 52

2 HOW TO MAKE COPIES

Press the [START] button.

3

The paper size has been registered.

Press the media type setting button until the lamp of the media type

4

placed on the bypass tray is lit.

You can select the media type from the following three:

THICK PAPER 1: Thick paper (21 to 28 lb. Bond)

THICK PAPER 2: Thick paper (29 lb. Bond to 90 lb. Index), sticker labels

TRANSPARENCY: Overhead transparencies

y You do not need to select the media type when you use plain paper (17 to 20 lb.

Bond) or tracing paper.

y If you select a different media type from the one you placed on the bypass tray, this

could cause a paper jam or the quality of the copied image could be lowered.

Place the original.

5

Select the other copy modes as required, and then press the

6

[START] button.

Copying starts.

When you make copies on overhead transparencies using the bypass tray, pick up the

transparencies which have exited onto the receiving tray one by one. If the transparencies pile up, they may become curled and not be good for projection.

y When the paper on the bypass tray has run out during copying, copying continues

with the paper of the same size in the drawer as the one on the bypass tray. (If the

size of the paper on the bypass tray has not been registered in advance, however,

copying stops. In this case, add paper to the bypass tray and press the [START] button to resume copying.)

y When bypass copying has finished, the [FUNCTION CLEAR] lamp blinks. Press the

[FUNCTION CLEAR] button so that the paper size setting for the bypass tray will be

cleared. Press the [FUNCTION CLEAR] button again so that bypass copying will be

switched to copying with drawer feeding.

50 Using Bypass Tray

Page 53

3.COPYING FUNCTIONS

This chapter describes various functions related to copy operations, such as how to make enlargement or

reduction copies, or how to adjust the quality of copy images.

Default Settings.......................................................................................................52

Paper Selection.......................................................................................................53

Automatic paper selection (APS) ......................................................................................................53

Manual paper selection.....................................................................................................................54

Zooming In/Out Copy Image..................................................................................56

Automatic magnification selection (AMS)..........................................................................................56

Specifying both the sizes of the original and the copy paper ............................................................58

Specifying reproduction ratio manually .............................................................................................59

Copying in Same Page Order as Originals - Sort Copying -...............................61

Copying Both Sides of Card into 1 Page - ID CARD -..........................................63

Selecting Image Mode ............................................................................................65

Adjusting Density Level .........................................................................................66

Page 54

3 COPYING FUNCTIONS

Default Settings

Initial settings established when the equipment is powered on before any of the user functions

are changed are called default settings. Each setting returns to its default when the power is

turned ON, when the energy saving mode is canceled, and when the [FUNCTION CLEAR] button is pressed.

Each default setting of this equipment at the time of the installation is shown below.

Item Contents Default setting at installation

Reproduction ratio 25 - 200% 100%

Copy quantity 1 - 999 1

Paper selection

Density adjustment Automatic copy density mode, Manual

Image mode TEXT/PHOTO, PHOTO, TEXT TEXT/PHOTO

Sorting Non-sort copying, sort copying Non-sort copying

*1 The automatic paper selection (APS) can be set only when the Automatic Document Feeder (optional) is

used.

If you need to change the default settings listed above, contact your service representative.

Automatic paper selection (APS)

Manual paper selection

copy density mode

*1

Automatic paper selection (APS)

,

Automatic copy density mode

52 Default Settings

Page 55

Paper Selection

You can select the size of copy paper in two ways; one is automatic paper selection in which the

equipment automatically selects copy paper of the same size as the original, and the other is

manual paper selection in which you can select the desired paper size manually.

Automatic paper selection (APS):

The equipment detects the size of the original placed and automatically selects copy paper of

the same size as the original. This function is enabled only when standard size originals (LD, LG,

LT, LT-R, COMP, ST-R) are used and also the Automatic Document Feeder (optional) is used.

Manual paper selection:

You can select the desired size of copy paper manually. This function can be used in a case the

APS cannot be used, such as when originals are non-standard sizes or overhead transparencies, or when an original is placed on the original glass.

Automatic paper selection (APS) can be used only when you place originals on the Automatic

Document Feeder (optional).

Automatic paper selection (APS)