Page 1

D4253386A

BU Series

Thank you for purchasing our product.

Before using this CMOS camera, please read through this instruction manual

carefully in order to use this product correctly and safely.

After reading, keep this instruction manual handy so that you can refer to,

whenever you need it.

CMOS Camera

Instruction Manual

Model

B/W Camera : BU302MG / BU505MG

Information contained in this document is subject to change without prior notice.

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

Page 2

D4253386A

Contents

Contents .......................................................................................................................... 1

Safety Precautions ........................................................................................................... 2

General Handing .......................................................................................................................... 3

CASES FOR INDEMNITY (LIMITED WARRANTY) .................................................................... 5

RESTRICTION FOR USE ............................................................................................................ 6

Notes on using this product .......................................................................................................... 7

Installation ....................................................................................................................... 11

Specifications ................................................................................................................... 12

Overview ....................................................................................................................................... 12

Features ........................................................................................................................................ 12

Configuration ................................................................................................................................ 14

Connection .................................................................................................................................... 15

Connector Pin Assignment ........................................................................................................... 16

Outline Drawing ............................................................................................................................ 17

General Specifications .................................................................................................................. 18

LED status .................................................................................................................................... 20

I/O Specification ............................................................................................................................ 21

Timing Specification ...................................................................................................................... 25

Typical Spectral Response ........................................................................................................... 27

Operating Ambient Conditions ...................................................................................................... 28

Functions ................................ ................................ ................................ ......................... 30

Bootstrap Registers ...................................................................................................................... 32

DeviceControl ............................................................................................................................... 33

ImageFormatControl ..................................................................................................................... 34

Scalable ........................................................................................................................................ 35

Binning .......................................................................................................................................... 37

Decimation .................................................................................................................................... 39

Reverse ........................................................................................................................................ 41

PixelFormat ................................................................................................................................... 42

TestPattern .................................................................................................................................... 43

AcquisitionControl ......................................................................................................................... 45

ImageBuffer .................................................................................................................................. 47

TriggerControl ............................................................................................................................... 49

ExposureTime ............................................................................................................................... 53

DigitalIOControl ............................................................................................................................ 54

TimerControl ................................................................................................................................. 57

Gain .............................................................................................................................................. 59

BlackLevel .................................................................................................................................... 60

Gamma ......................................................................................................................................... 61

LUTControl ................................................................................................................................... 62

UserSetControl ............................................................................................................................. 63

EventControl ................................................................................................................................. 65

FrameSynchronization .................................................................................................................. 68

LEDIndicatorLuminance ............................................................................................................... 69

AntiGlitch / AntiChattering............................................................................................................. 70

DPCControl ................................................................................................................................... 72

SequentialShutterControl ............................................................................................................. 74

Appendix .......................................................................................................................... 77

MultiFrame and Bulk function difference ...................................................................................... 77

Warranty rules ................................................................................................................. 80

Repair .............................................................................................................................. 81

1 / 81

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

Page 3

D4253386A

Safety Signs

Description

WARNING

Indicates a potentially hazardous situation that may result in death or serious

injury (*1) in the event of improper handling.

CAUTION

Indicates a potentially hazardous situation that may result in light to moderate

injuries (*2) or only in property damage (*3)in the event of improper handling.

Safety Symbols

Description

PROHIBITED

This sign indicates PROHIBITION (Do not).

The content of prohibition is shown by a picture or words beside the symbol.

MANDATORY

This sign indicates MANDATORY ACTION (You are required to do).

The content of action is shown by a picture or words beside the symbol.

Safety Precautions

Before using this product, read these safety precautions carefully. Important information is shown in this

Instruction Manual to protect users from bodily injuries and property damages, and to enable them to use the

product safely and correctly.

Please be sure to thoroughly understand the meanings of the following signs and symbols before reading

the main text that follow, and observe the instructions given herein.

[Definition of Safety Signs]

Notes *1:“Serious injury” refers to cases of loss of eyesight, wounds, burns (high or low temperature),

electric shock, broken bones, poisoning, etc., which leave after-effects or which require

hospitalization or a long period of outpatient treatment of cure.

*2: "Light to moderate injuries" refers to injuries, burns, electric shock etc. that do not require

hospitalization or long-term treatment.

*3: "Property damage" refers to cases of extensive damage involving damage to buildings,

equipment, farm animals, pet animals and other belongings.

[Explanation of Safety Symbols]

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

2 / 81

Page 4

D4253386A

WARNING

Stop operation immediately when any abnormality or defect occurs.

If abnormal conditions are present, such as smoke, a burning smell, ingress of water or

foreign matter, or if the equipment is dropped or malfunctions, fire or electric shock may

result.

Be always sure to disconnect the power cable from the wall socket at once and contact

your dealer.

Unplug

Do not use the equipment in locations subject to water splashes.

Otherwise, fire or electric shock may result.

Do not get wet

Do not disassemble, repair, or modify the equipment.

Otherwise, fire or electric shock may result.

For internal repair, inspection, or cleaning, contact your sales representative.

Never pull apart

Do not place anything on the equipment.

If metallic objects, liquid, or other foreign matter enters the equipment, fire or electric

shock may result.

Avoid

Do not install the equipment in an unstable or inclined location or locations

subject to vibration or impact.

Otherwise, the equipment may topple over and cause personal injury.

Avoid

During an electrical storm, do not touch the power cable and the connection

cable.

Otherwise, an electric shock may result.

Do not touch

Instruction

Use the specified voltage.

Use of an unspecified voltage may result in fire or electric shock.

Do not be handled roughly, damaged, fabricated, bent forcefully, pulled, twisted,

bundled, placed under heavy objects or heated the power cable and the

connection cable.

Otherwise, fire or electric shock may result.

Avoid

General Handing

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

3 / 81

Page 5

D4253386A

CAUTION

Observe the following when installing the equipment:

·Do not cover the equipment with a cloth, etc.

·Do not place the equipment in a narrow location where heat is likely to accumulate.

Otherwise, heat will accumulate inside the equipment, possibly resulting in a fire.

Instruction

Do not place the equipment in locations subject to high moisture, oil fumes,

steam, or dust.

Otherwise, fire or electric shock may result.

Avoid

Do not install the equipment in locations exposed to direct sunlight or humidity.

Otherwise, the internal temperature of the equipment will rise, which may cause a fire.

Avoid

Use only specified the power cable and the connection cables.

Otherwise, fire or electric shock may result.

Instruction

Do not give strong impact against the equipment.

It may cause the trouble.

Avoid

When performing connection, turn off power.

When connecting the power cable and the connection cable, turn off the equipment

power.

Otherwise, fire or electric shock may result.

Instruction

Do not expose its camera head to any intensive light (such as direct sunlight).

Otherwise, its inner image pickup device might get damaged.

Avoid

Avoid short-circuiting signal output.

Otherwise, a malfunction may occur.

Avoid

Avoid giving a strong shock against the camera body.

It might cause a breakdown or damage. If your camera is used in a system where its

camera connector is subjected to strong repetitive shocks, its camera connector is

possible to break down. If you intend to use your camera in such a situation, if possible,

bundle and fix a camera cable in the place near the camera, and do not transmit a

shock to the camera connector.

Avoid

Contact your sales representative to request periodic inspection and cleaning

(every approx five years).

Accumulation of dust inside the equipment may result in fire or electric shock.

For inspection and cleaning costs, contact your sales representative.

Instruction

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

4 / 81

Page 6

D4253386A

CASES FOR INDEMNITY (LIMITED WARRANTY)

We shall be exempted from taking responsibility and held harmless for damage or losses incurred by the

user in the following cases.

● In the case damage or losses are caused by natural disasters, such as an earthquake and thunder, fire, or

other acts of God, acts by a third party, deliberate or accidental misuse by the user, or use under extreme

operating conditions.

● In the case of indirect, additional, consequential damages (loss of business interests, suspension of

business activities) are incurred as result of malfunction or non-function of the equipment, we shall be

exempted from responsibility for such damages.

● In the case damage or losses are caused by failure to observe the information contained in the

instructions in this instruction manual and specifications.

● In the case damage or losses are caused by use contrary to the instructions in this instruction manual and

specifications.

● In the case damage or losses are caused by malfunction or other problems resulting from unintended use

of equipment or software etc. that are not specified.

● In the case damage or losses are caused by repair or modification conducted by the customer or any

unauthorized third party (such as an unauthorized service representative).

● Expenses we bear on this product shall be limited to the individual price of the product.

● The item that is not described in specifications of this product is out of the guarantee.

● The case of damages or losses which are caused by incorrect connection of the cable is out of the

guarantee.

5 / 81

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

Page 7

D4253386A

RESTRICTION FOR USE

● Should the equipment be used in the following conditions or environments, give consideration to safety

measures and inform us of such usage:

1. Use of the equipment in the conditions or environment contrary to those specified, or use outdoors.

2. Use of the equipment in applications expected to cause potential hazard to people or property, which

require special safety measures to be adopted.

● This product can be used under diverse operating conditions. Determination of applicability of equipment or

devices concerned shall be determined after analysis or testing as necessary by the designer of such

equipment or devices, or personnel related to the specifications. Such designer or personnel shall assure

the performance and safety of the equipment or devices.

● This product is not designed or manufactured to be used for control of equipment directly concerned with

human life (*1) or equipment relating to maintenance of public services/functions involving factors of safety

(*2). Therefore, the product shall not be used for such applications.

(*1): Equipment directly concerned with human life refers to.

- Medical equipment such as life-support systems, equipment for operating theaters.

- Exhaust control equipment for exhaust gases such as toxic fumes or smoke.

- Equipment mandatory to be installed by various laws and regulations such as the Fire Act or Building

Standard Law

- Equipment related to the above

(*2): Equipment relating to maintenance of public services/functions involving factors of safety refers to.

- Traffic control systems for air transportation, railways, roads, or marine transportation

- Equipment for nuclear power generation

- Equipment related to the above

6 / 81

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

Page 8

D4253386A

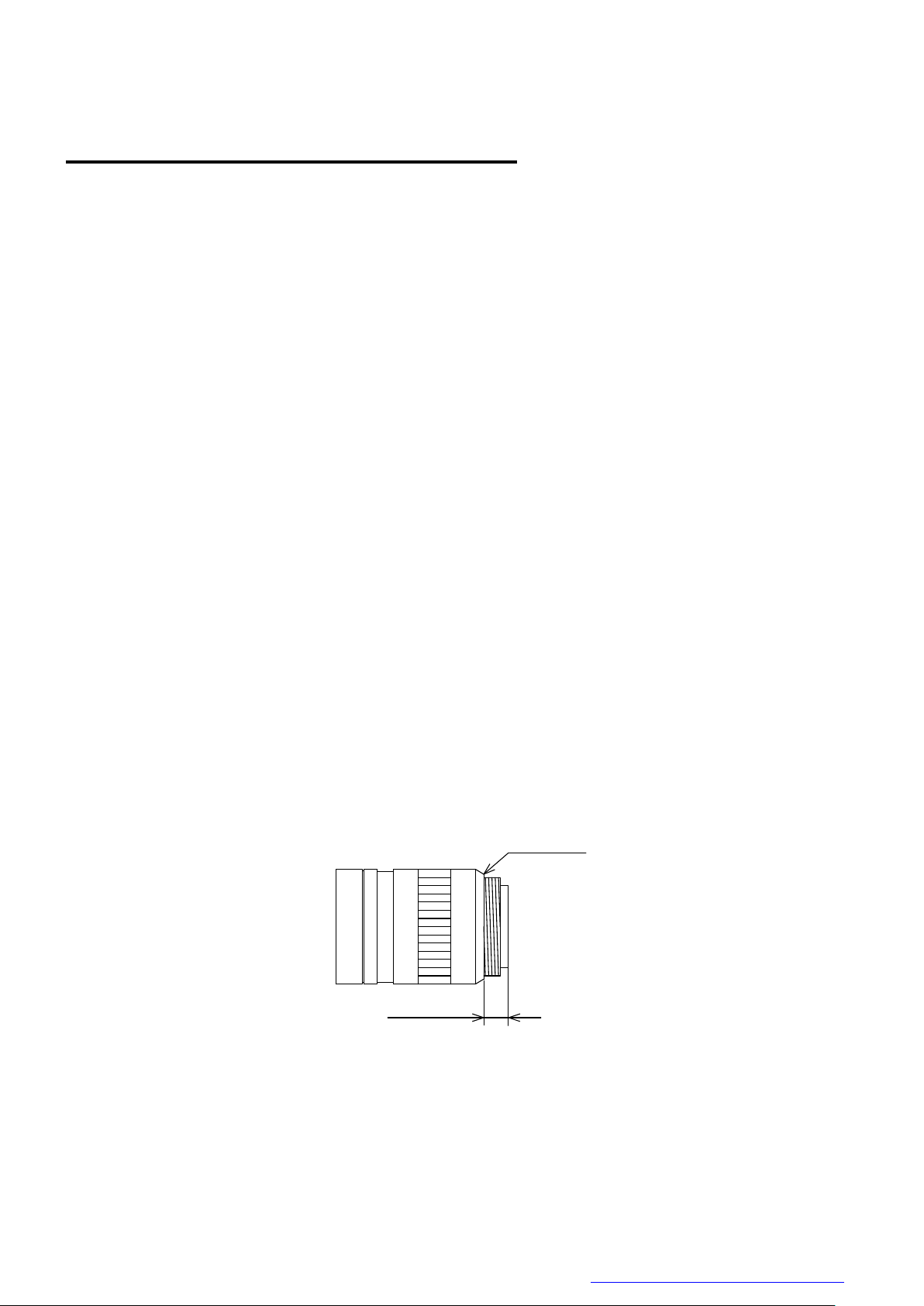

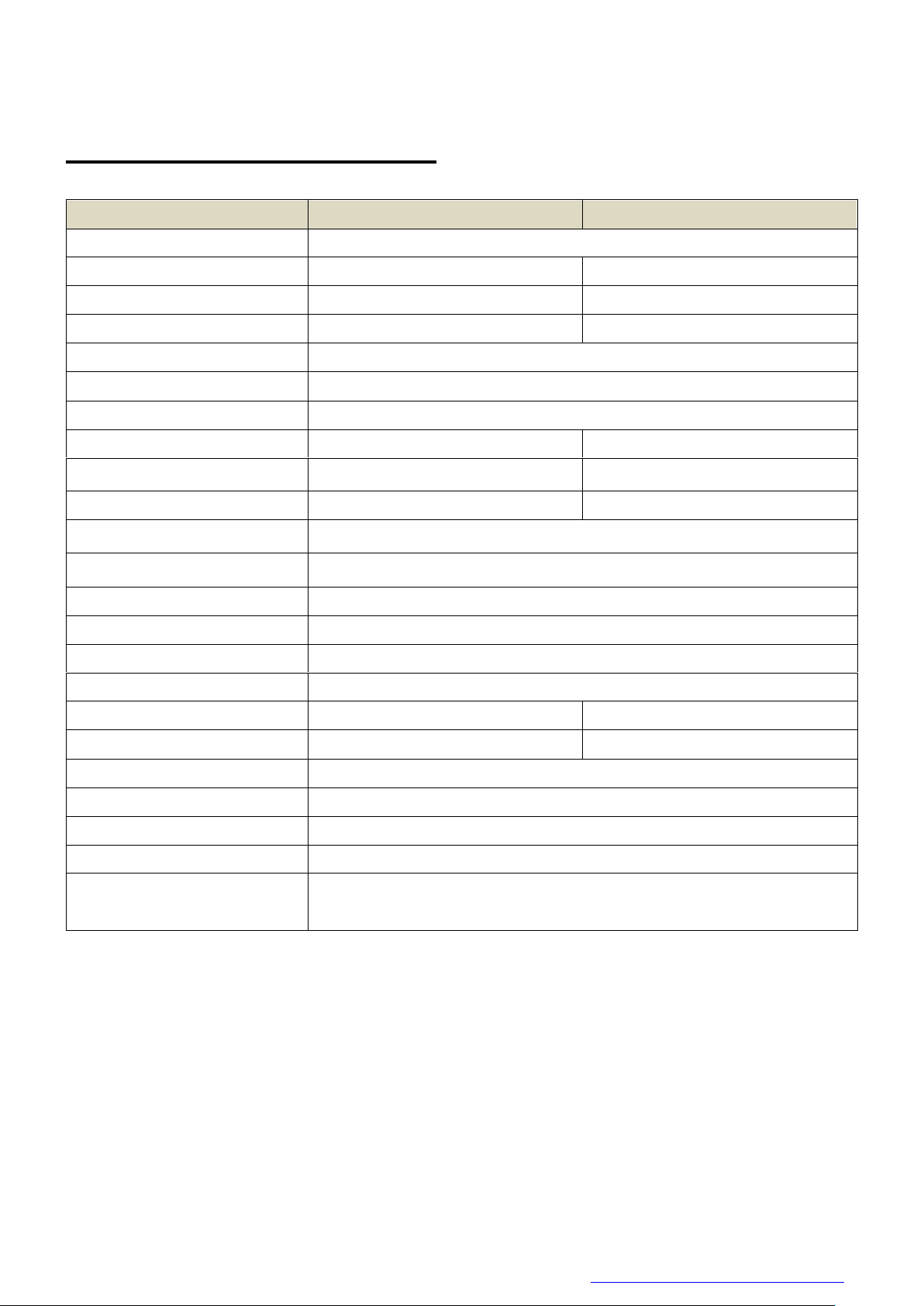

10mm or less

C-mount lens

Bottom of

the screw

Notes on using this product

● Handle carefully

Do not drop the equipment or allow it to be subject to strong impact or vibration, as such action may cause

malfunctions. Further, do not damage the connection cable, since this may cause wire breakage.

● Environmental operating conditions

Do not use the product in locations where the ambient temperature or humidity exceeds the specifications.

Otherwise, image quality may be degraded or internal components may be adversely affected. In particular,

do not use the product in areas exposed to direct sunlight. Moreover, during shooting under high

temperatures, vertical stripes or white spots (noise) may be produced, depending on the subject or camera

conditions (such as increased gain). However, such phenomena are not malfunctions.

● Check a combination with the lens

Depending on the lens and lighting you use, an image is reflected as a ghost in the imaging area. However,

this is not because of a fault of the camera.

In addition, depending on the lens you use, the performance of the camera may not be brought out fully due

to deterioration in resolution and brightness in the peripheral area, aberration and others.

Be sure to check a combination with the camera by using the lens and lightning you actually use.

When installing a lens in the camera, make sure carefully that it is not tilted.

In addition, use a mounting screw free from defects and dirt. Otherwise, the camera may be unable to be

removed.

Install a next lens; its dimension of protrusion from bottom of the screw is equal to or less than 10 mm. If a

lens does not stand to this condition, it might not be installed to this camera.

● Mounting to pedestal

When mounting this product to a pedestal, make sure carefully that lens doesn’t touch with the pedestal.

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

7 / 81

Page 9

D4253386A

● Do not expose the camera's image-pickup-plane to sunlight or other intense light directly

Its inner CMOS sensor might be damaged.

● Occurrence of moiré

If you shoot thin stripe patterns, moiré patterns (interference fringes) may appear. This is not a malfunction.

● Occurrence of noise on the screen

If an intense magnetic or electromagnetic field is generated near the camera or connection cable, noise may

be generated on the screen. If this occurs, move the camera or the cable.

● Handling of the protective cap

If the camera is not in use, attach the lens cap to the camera to protect the image pickup surface.

● If the equipment is not to be used for a long duration

Turn off power to the camera for safety.

● Maintenance

Turn off power to the equipment and wipe it with a dry cloth.

If it becomes severely contaminated, gently wipe the affected areas with a soft cloth dampened with diluted

neutral detergent. Never use alcohol, benzene, thinner, or other chemicals because such chemicals may

damage or discolor the paint and indications.

If the image pickup surface becomes dusty, contaminated, or scratched, consult your sales representative.

8 / 81

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

Page 10

D4253386A

Following information is only for EU-member states:

The use of the symbol indicates that this product may not be treated as household

waste. By ensuring this product is disposed of correctly, you will help prevent

potential negative consequences for the environment and human health, which could

otherwise be caused by inappropriate waste handling of this product. For more

detailed information about the take-back and recycling of this product, please contact

your supplier where you purchased the product.

“This symbol is applicable for EU member states only”

This equipment has been tested and found to comply with the limits for a class A digital device,

pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful interference to radio

communication.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

Defective pixels

A CMOS image sensor is composed of photo sensor pixels in a square grid array. Due to

the characteristics of CMOS image sensors, over- or under-driving of the pixels results in

temporary white or black areas (as if these are noises) appearing on the screen. This

phenomenon, which is not a defect is exacerbated under higher temperatures and long

exposure time.

Image shading

The brightness of the upper part of the screen may be different from that of the lower part. Note

that this is a characteristic of a CMOS image sensor and is not a fault.

● Disposal

When disposing of the camera, it may be necessary to disassemble it into separate parts, in accordance with

the laws and regulations of your country and/or municipality concerning environmental contamination.

[Phenomena specific to CMOS sensor]

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

9 / 81

Page 11

D4253386A

环保使用期限标识,是根据电子信息产品污染控制管理办法以及,电子

信息产品污染控制标识要求(SJ/T11364-2006)、电子信息产品环保使用

期限通则,制定的适用于中国境内销售的电子信息产品的标识。

电子信息产品只要按照安全及使用说明内容,正常使用情况下,从生产

月期算起,在此期限内,产品中含有的有毒有害物质不致发生外泄或突

变,不致对环境造成严重污染或对其人身、财产造成严重损害。

产品正常使用后,要废弃在环保使用年限内或者刚到年限的产品时,请

根据国家标准采取适当的方法进行处置。

另外,此期限不同于质量/功能的保证期限。

The Mark and Information are applicable for People's Republic of

China only.

部件名称

有毒有害物质或元素

铅(Pb)

汞(Hg)

镉(Cd)

六价铬

(Cr(VI))

多溴联苯

(PBB)

多溴二苯醚

(PBDE)

相机本体

× ○ ○ ○ ○

○

○:表示该有毒有害物质在该部件所有均质材料中的含量均在电子信息产品中有毒有害物质的

限量要求标准规定的限量要求(SJ/T11363-2006)以下

×:表示该有毒有害物质至少在该部件的某一均质材料中的含量超出电子信息产品中有毒有害

物质的限量要求标准规定的限量要求(SJ/T11363-2006)

This information is applicable for People's Republic of China only.

中华人民共和国

环保使用期限

10

ペーパーボード

纸板

Paper board

箱/箱子/Box

内部緩衝材料・袋

内部缓冲材料·袋

Internal buffer materials・Bag

<产品中有毒有害物质或元素的名称及含量>

リサイクルに関する情報(包装物)

有关再利用的信息(包装物)

Information on recycling of wrapping composition

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

10 / 81

Page 12

D4253386A

Installation

Before using this product, you shall install application software to display image and control registers of

camera, and IP configuration tool for network setting.

You can download the SDK for our USB camera products (TeliCamSDK) from the Service & Support section

of our website.

User registration is necessary to use downloading service. Please make a user registration, or contact your

sales representative.

● TOSHIBA TELI CORPORATION Top Page

http://www.toshiba-teli.co.jp/index.htm

● Service & Support

https://www.toshiba-teli.co.jp/cgi/ss/en/service.cgi

Please refer to the TeliCamSDK startup guide, about Operation environment, Installation, and Setup.

11 / 81

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

Page 13

D4253386A

Specifications

Overview

This BU CMOS series is an integrated-(one-body)-type camera that adopts a global shutter CMOS sensor.

These are BU302MG (3M type1/1.8) BU505MG (5M type2/3). For video output and camera control, the USB

3.0 interface standard is adopted for high transfer rate, and it is easy to integrate into industrial equipment.

Features

● High frame rate

Supporting high frame rate, BU302MG 120fps, BU505MG 75fps.

● Global shutter

As it employs a global electronic shutter similar to a CCD image sensor, clear images of even fast-moving

object are obtainable with less blur.

● USB*3.0 interface

Video output and camera control are performed via the USB 3.0 standard interface. Data transfer is up to

5Gbps (Maximum) that enables to output uncompressed video data at high frame rate.

● USB3 Vision*

This product is based on USB3 Vision Ver.1.0.

● GenICam* Ver 2.3

This product is based on GenICam Generic Interface for Cameras Ver 2.3.

● IIDC2* Digital Camera Control Specification Ver.1.0.0

This product is based on IIDC2 Digital Camera Control Specification Ver.1.0.0.

12 / 81

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

Page 14

D4253386A

● e-CON* Connector adoption

The e-CON connector adoption enables to assemble the cable easily without using special tools.

● Random Trigger Shutter

The Random Trigger Shutter function provides images in any timing by input of an external trigger signal.

Trigger control from PC is available as well.

● Scalable

Selectable video output area. This mode achieves higher frame rate by reducing vertical output area. And

reduces occupied data rate of USB bus by reducing horizontal output area.

● Binning

B/W models hove binning. In this mode, pixel data is combined by vertical and horizontal. Vertical binning

achieves high frame rate.

● Decimation

Camera reads all effective areas at high speed by skipping lines.

● Compact and lightweight

This camera is compact and lightweight; it is easy to integrate into industrial equipment.

● EU RoHS & Chinese ROHS

* USB is a unified standard established by USB-IF(USB Implementers Forum).

* USB3 Vision is a unified standard established by AIA (Automated Imaging Association).

* GeniCam is a registered trademark of EMVA (European Machine Vision Association).

* IIDC2 is a unified standard established by JIIA (Japan Industrial Association).

* e-CON (Easy & Economy connector) is a sensor connector that is normalized by the manufacturer of the

sensor, FA equipment and connector.

13 / 81

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

Page 15

D4253386A

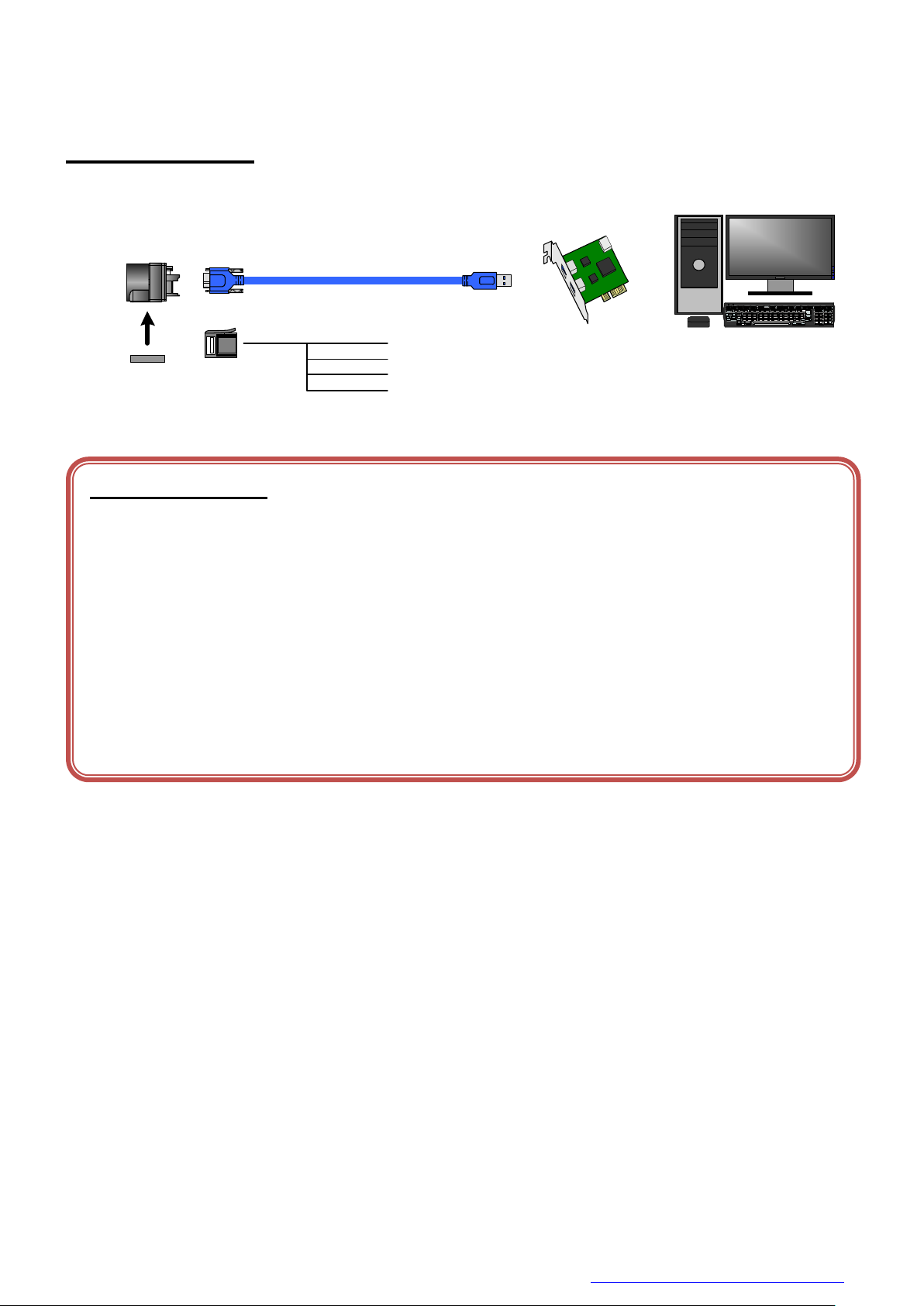

Configuration

The system configuration of this camera series is as follows;

This camera has no accessories, please prepare other equipments separately.

● Camera: This product. (BU)

● Camera mounting kit CPTBU (*1): To fix a camera to a tripod; attach this to the bottom of the camera.

● USB3.0 Cable (*2): This cable is used to connect the camera to host PC. Please use

a USB3.0 cable of Standard A - Micro B. This product is able to

connect a USB cable equipped with screw lock mechanism.

Please use it as needed.

● USB3.0 Interface Card (*2): This is the interface card to connect to the camera. Usually this

card is installed to expansion slot of PC etc.

● e-CON Cable. (*2): This cable is used to input external trigger signal and output GPIO

signal.

We recommend using shielded cable, because there is likely to be

affected by the noise depending on the operating environment of

the camera.

*1: Optional part. Contact your sales representative for details of option units.

*2: Commercial items.

14 / 81

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

Page 16

D4253386A

Camera

Host(PC etc.)

Camera mounting unit

CPTBU

Interface Card

Stream Packet →← Control Packet

USB3.0 Cable

(Mirco B) (Standard A)

1. Line2

2. Line1

3. GND

4. Line0

(e-CON)

e-CON Cable

Notes on Connection:

- Please confirm the power supply of the camera off when plugging in or pulling out the I/O Connector. It causes the

breakdown.

- If your camera is used in a system where its connectors are subjected to strong repetitive shocks, its connectors are

possible to break down. If you use your camera in such a situation, use an USB3.0 cable with a lock screw, and secure

the camera cable as close as possible to the camera body for avoid physical shock to the camera connector.

- About e-CON cable: In the case that electric-wire is long or thin, input and output voltage may not satisfy specifications

of the camera or your system by voltage drop. Please confirm wires’ specifications before use them.

- Los t packets may occur by an electrical characteristic of the transmission line of USB3.0. (USB3.0 Interface Card,

USB3.0 Cable, and USB3.0 HUB).

Connection

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

15 / 81

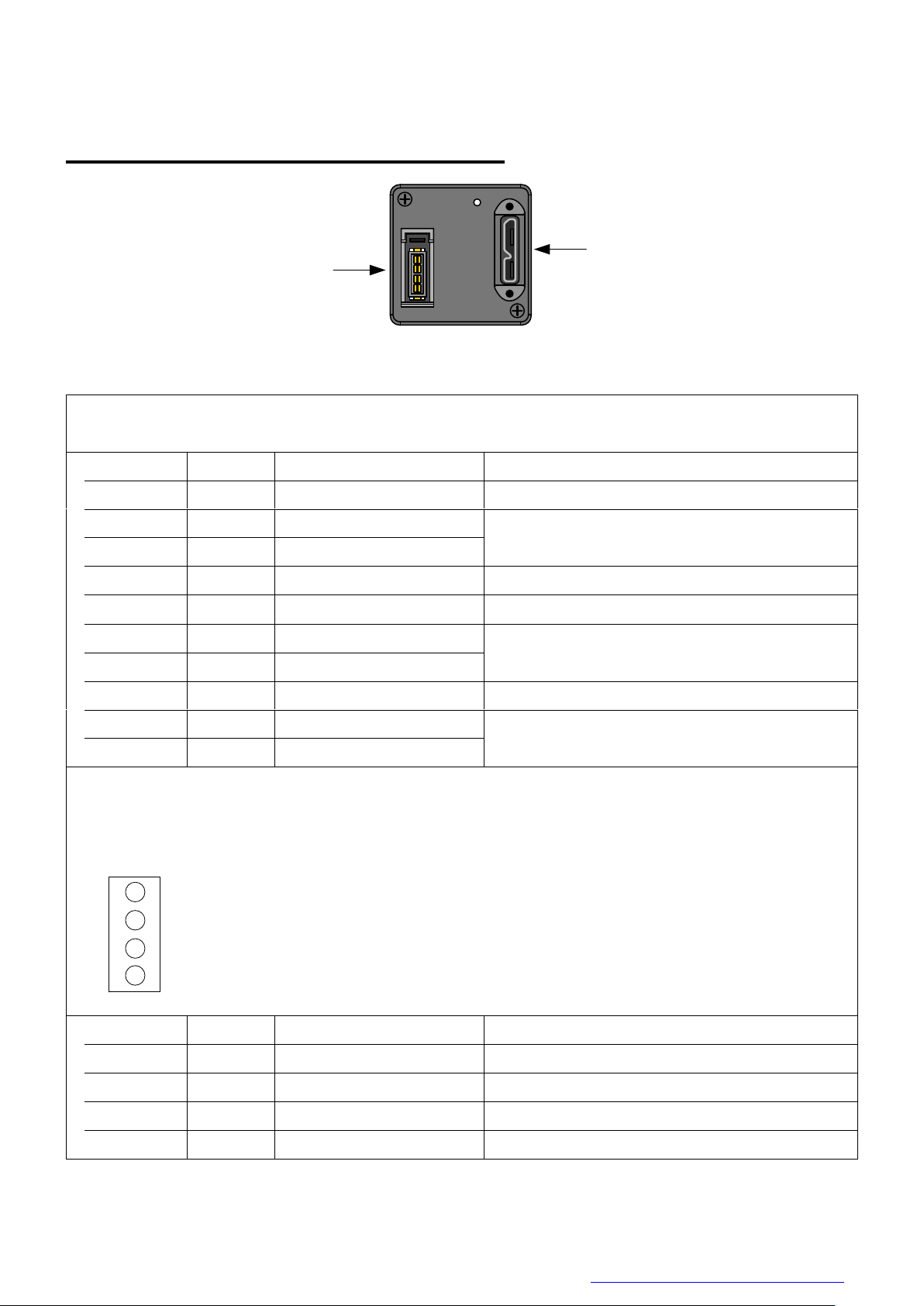

Page 17

D4253386A

①

②

1. USB3.0 Interface Connector

Connector model: WMUR-10F6L1PH5N (WIN WIN PRECISION INDUSTRIAL)

Pin No.

I/O

Signal

Function

1 -

VBUS

Power

2 I/O

D-

USB2.0 differential pair

3 I/O

D+

4 -

NC

Not connected

5 -

GND

Ground for power return

6 O

SSTX-

SuperSpeed transmitter differential pair

7 O

SSTX+

8 -

GND_DRAIN

Ground for SuperSpeed signal return

9 I

SSRX-

SuperSpeed receiver differential pair

10 I SSRX+

2. I/O Connector

Connector (Camera side) 37204-62B3-004PL (Sumitomo 3M) or equivalent

Matching connector (Cable side) Connectors which conformed to e-CON

e.g. 37104 series (Sumitomo 3M), RITS 4P series (Tyco)

* Matching connector is not an accessory of this product.

Pin assignment

↑TOP

*Above figure is connector view from insert side.

Pin No.

I/O

Signal

Function

1 I/O

Line2

GPIO Input / Output

2 O

Line1

GPIO Output

3 -

GND

Ground

6 I

Line0

GPIO Input

1

2

3

4

Connector Pin Assignment

Rear View

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

16 / 81

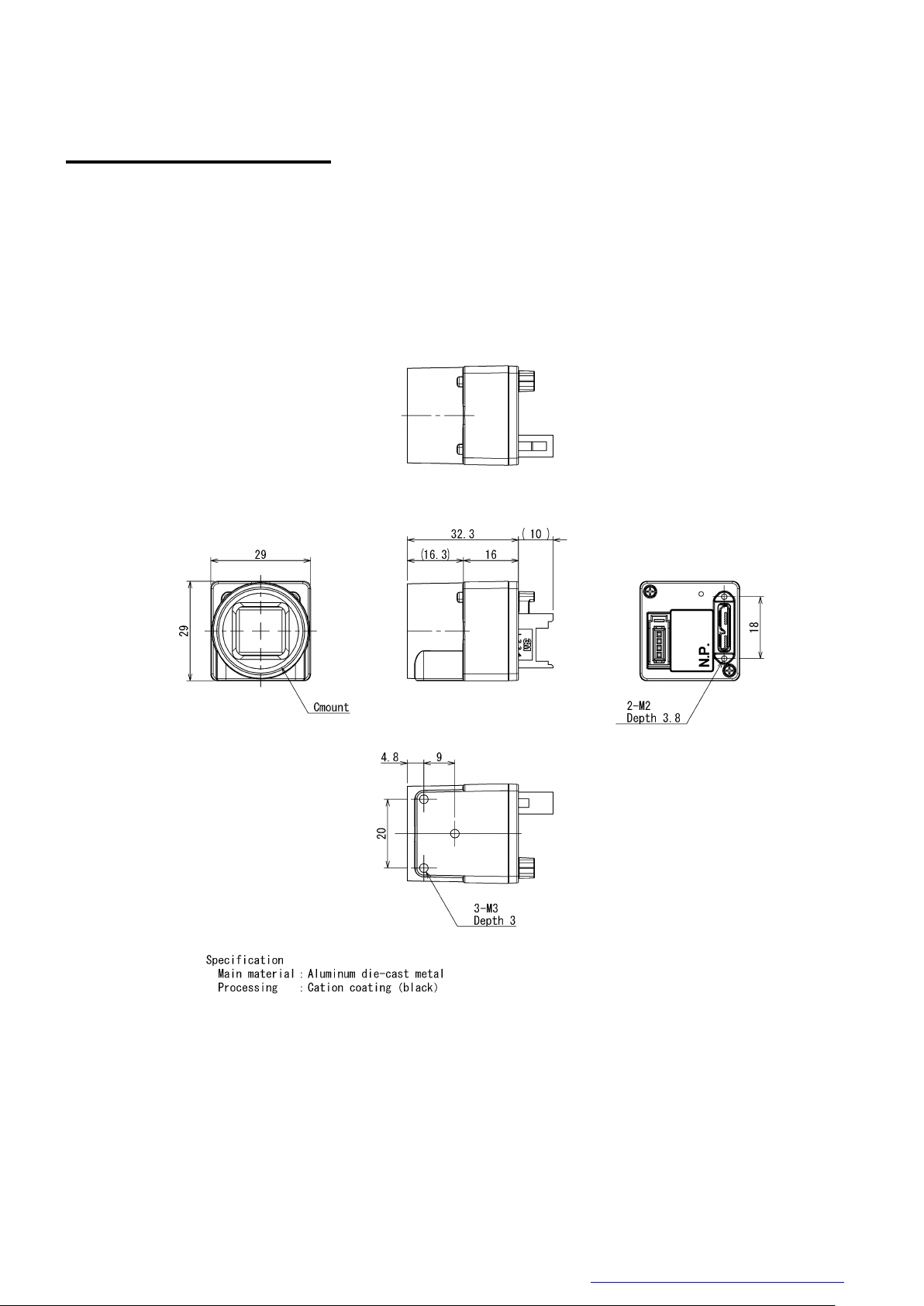

Page 18

D4253386A

Outline Drawing

17 / 81

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

Page 19

D4253386A

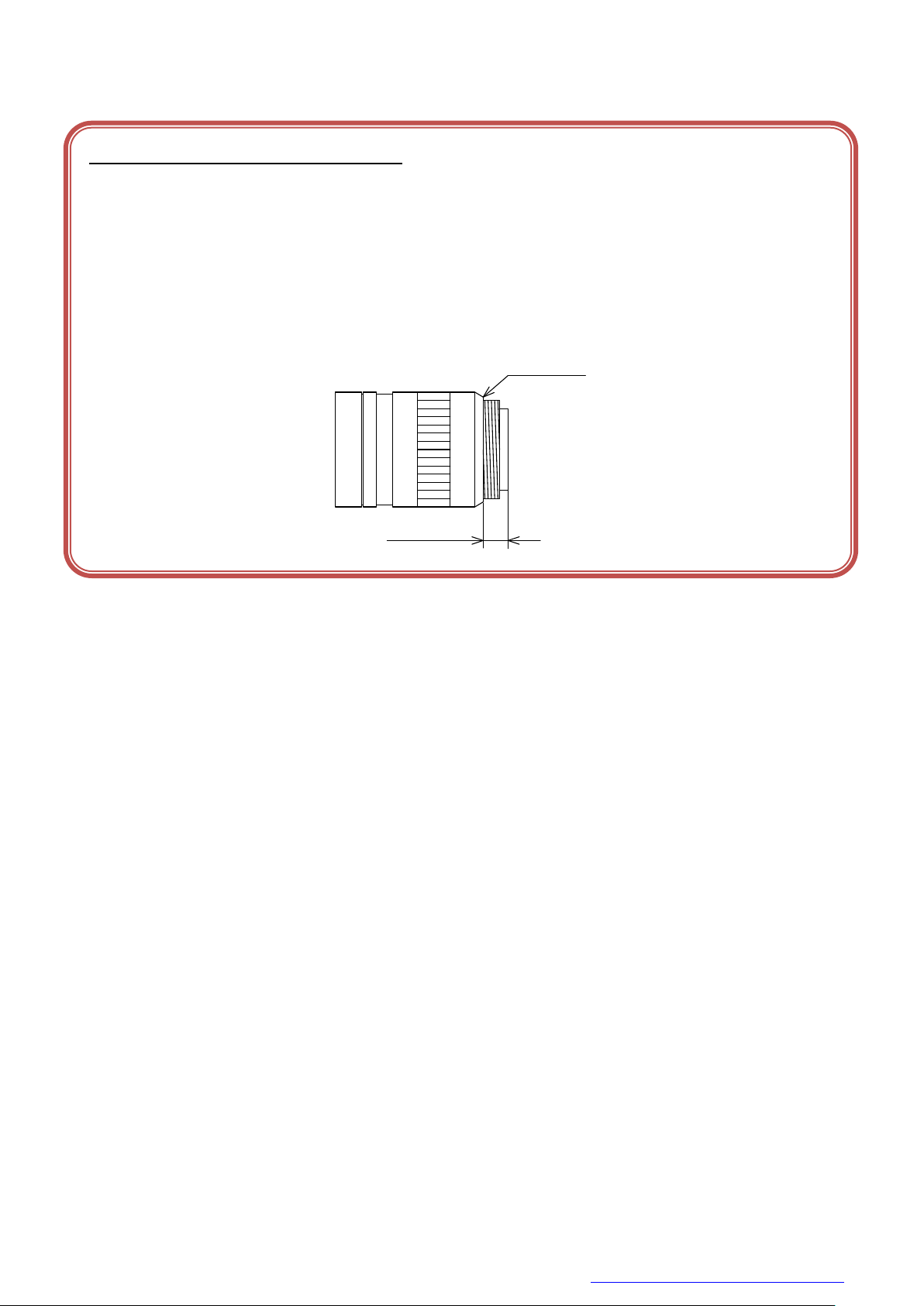

Model Name

BU302MG

BU505MG

Imager

CMOS image sensor

Number of effective pixels (H) × (V)

2064 x 1544

2464 x 2056

Optical Size

type1/1.8

type2/3

Scanning area (H) × (V)[mm]

7.12 × 5.33

8.50 × 7.09

Pixel size (H) × (V)[μm]

3.45 ×3.45

Scan method

Progressive

Electronic shutter method

Global shutter

Aspect ratio

4 : 3

6 : 5

Sensitivity

3250lx, F5.6, 1/120s

2100lx, F5.6, 1/75s

Minimum illuminance (*1)

7lx

5lx

Power supply

DC +5V5% (from USB connector)

Power consumption (*2)

3.2W (maximum)

Interface

USB 3.0 (Only SuperSpeed is supported)

Transmission speed

5Gbps (maximum)

Protocol

USB3 Vision

Image format

Mono8, Mono10, Mono12

Number of Video out pixels (H) × (V)

2048 × 1536

2448 × 2048

Maximum Frame rate (*2)

120fps

75fps

Dimensions

29 mm(W) x 29 mm (H) x 16 mm (D) (Not including protrusion)

Mass

Approximately 33g

Lens mount

C-mount

Flange back

17.526mm

Camera body grounding:

insulation status

Non-Conductive between circuit GND and camera body

General Specifications

B/W model

*1 F1.4, Gain: Maximum (+24dB), video level: 50%

*2 at the all pixel readout

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

18 / 81

Page 20

D4253386A

Notes on combination of C-mount lens:

- Depending on the lens you use, the performance of the camera may not be brought out fully due to the deterioration in

resolution and brightness in the peripheral area, occurrence of a ghost, aberration and others. When you check the

combination between the lens and camera, be sure to use the lens you actually use.

- In addition, use a mounting screw free from defects and dirt. Otherwise, the camera may be unable to be removed.

- As for the C-mount lens used combining this camera, the projection distance from bottom of the screw should use

10mm or less.

10mm or less

C-mount lens

Bottom of

the screw

19 / 81

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

Page 21

D4253386A

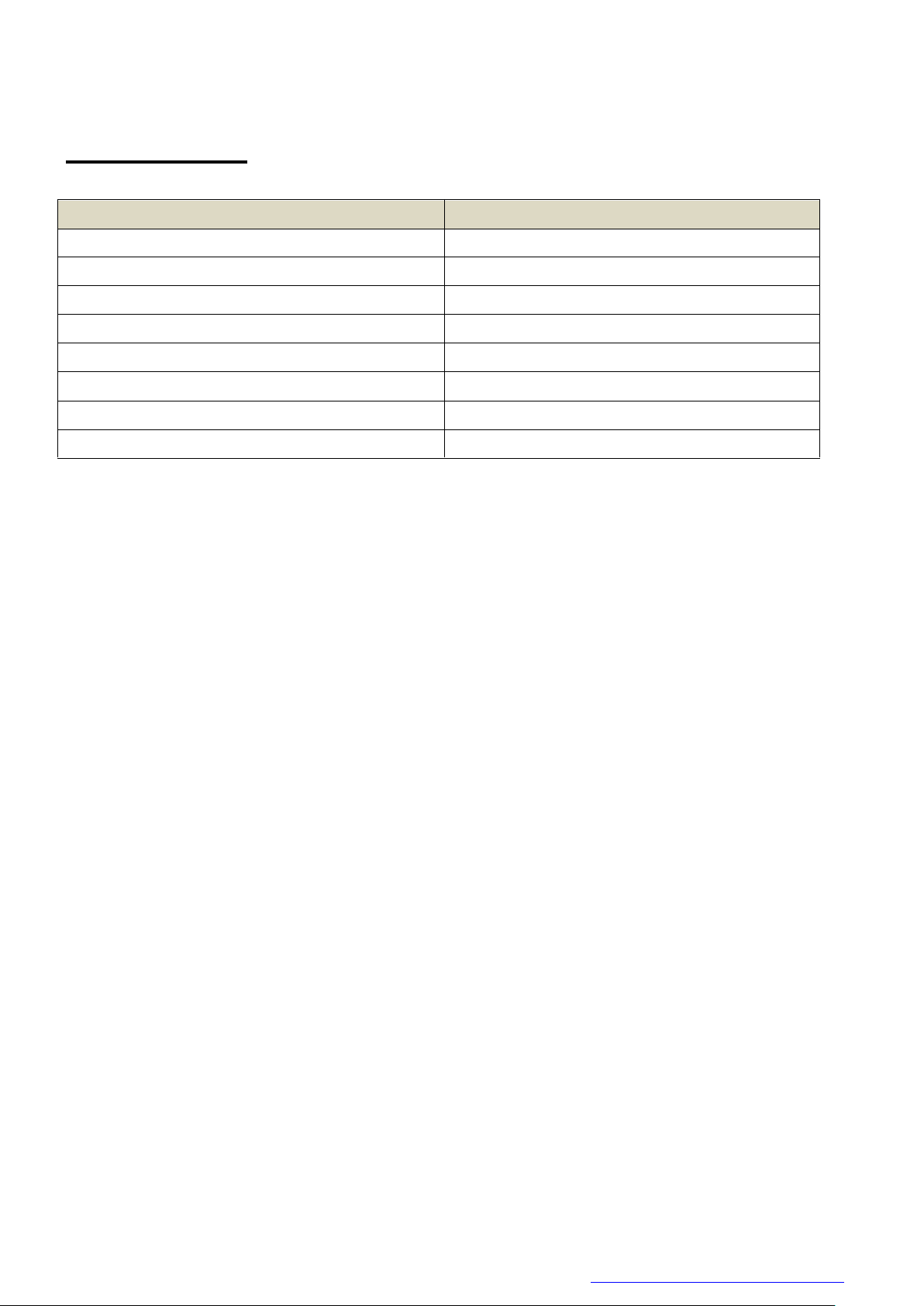

Camera state

Lamp indication

No power

Off

Link detection in progress

Fast flash green (ON:20ms, OFF:60ms)

Connection Error

Flash alternate red / green

SuperSpeed connected, but no data being transferred

Flash green (ON: 200ms, OFF: 800ms)

SuperSpeed connected, waiting for trigger

Flash orange (ON: 200ms, OFF: 800ms)

Data being transferred

Fast flash green (ON:60ms, OFF:20ms)

Error during data transfer

Solid Red (Time period: 500ms)

Stand-by

Super slow flash orange (ON:200ms, OFF: 2800ms)

LED status

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

20 / 81

Page 22

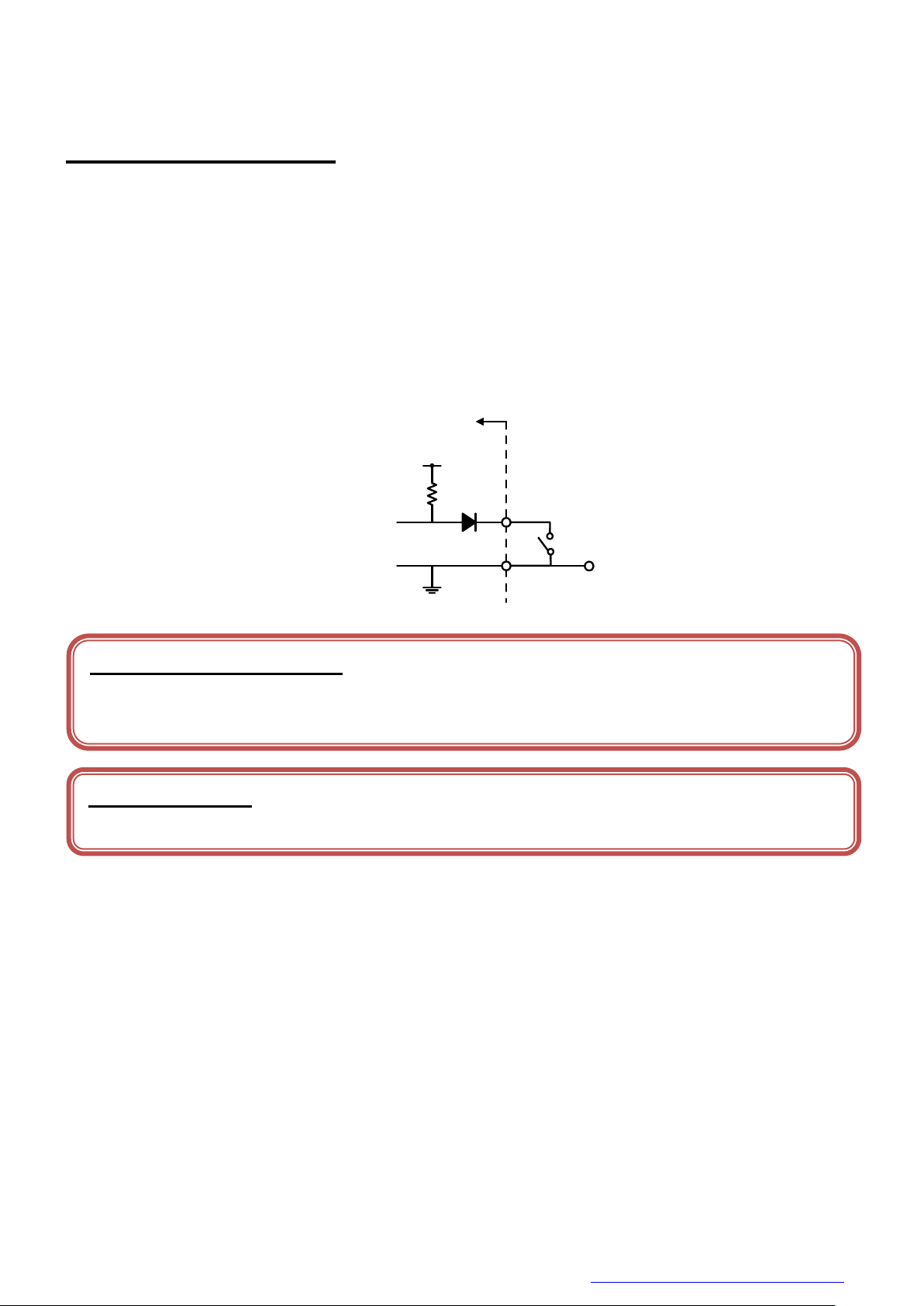

D4253386A

Inside

DC3.3V

0V

10kΩ

Notes of external trigger signal:

Depending on cable length, cable kinds and input current of trigger input line, Random Trigger Shutter operation may not

satisfy timing specification or camera may not receive EXT_TRIG signal. Please confirm it before use.

Notes of input level:

Line0 and Line2 have different input level. Please use input level within the voltage described in this specification.

I/O Specification

● Signal Specification

- Line0 (GPIO Input, I/O connector : 4 pin)

Input Circuit : LVTTL

Level : Low 0 ~ 0.5V, High 2.0 ~ 24.0V

Polarity : High active / Low active (initial factory setting: Low active)

Pulse Width : Minimum 50μs

Input circuit diagram

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

21 / 81

Page 23

D4253386A

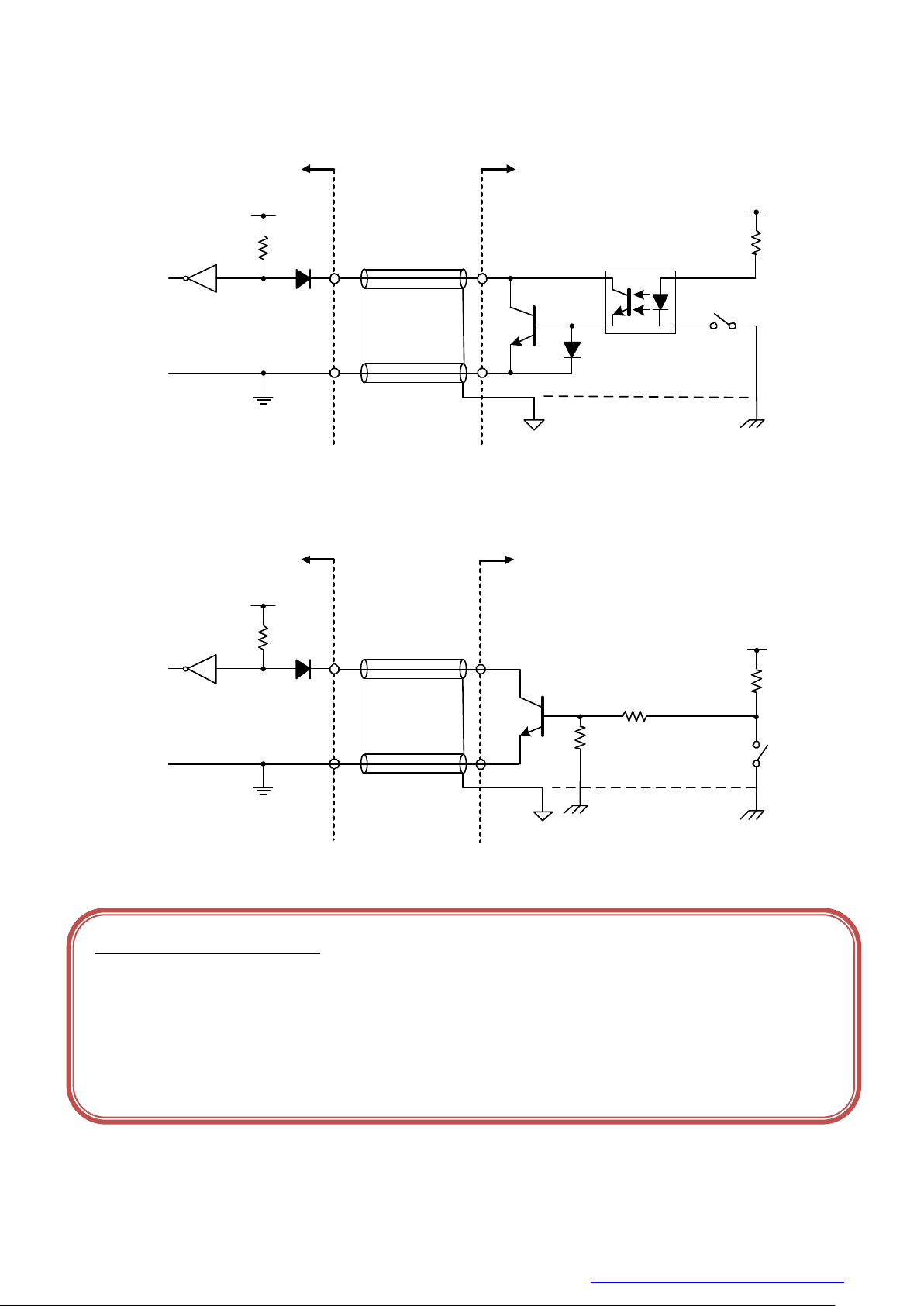

● External trigger input recommended circuit

CAMERA Inside

DC3.3V

10kΩ

4

3

Photocoupler

Camera

GND

Your

GND

Your system

Your

Secondary GND

Your

GND

Your system

Your

FRAME GND

DC3.3V

10kΩ

4

3

Camera

GND

CAMERA Inside

Notes of trigger input cable:

- The recognition of the trigger signal depends on the length, characteristic or driving current of the cable. Therefore

please confirm your system about those conditions.

- Pin 3 is signal ground. It isn’t conducted with camera frame.

Using shield cable, terminal processing of the shield is referred as above.

- Please confirm the EMC adaptability in whole of your system.

- Isolated I/F

- Non-Isolated I/F

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

22 / 81

Page 24

D4253386A

- Line2 (GPIO Input / Output, initial factory setting: Input, I/O connector : 1 pin)

Inside

DC5.0V

10kΩ

1

3

IOLineModeAll

Notes of external trigger signal:

Depending on cable length, cable kinds and input current of trigger input line, Random Trigger Shutter operation may not

satisfy timing specification or camera may not receive EXT_TRIG signal. Please confirm it before use.

Notes of input level:

Line0 and Line2 have different input level. Please use input level within the voltage described in this specification.

- Input signal specification

Level : Low 0 ~ 0.5V, High 4.0 ~ 5.0V

Polarity : High active / Low active (initial factory setting: Low active)

Pulse Width : Minimum 50μs

- Output signal specification

Output Circuit : 5V CMOS

Maximum Current : +/-32mA

Polarity : High active / Low active (initial factory setting: Low active)

Signal Source : TIMER0 ACTIVE

USER OUTPUT

EXPOSURE ACTIVE

FRAME ACTIVE

FRAME TRANSFER

FRAME TRIGGER WAIT

Input / Output circuit diagram

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

23 / 81

Page 25

D4253386A

- Line1 (GPIO Output, I/O connector : 2 pin)

Output Circuit : 5V CMOS

Maximum Current : +/-32mA

Polarity : High active / Low active (initial factory setting: Low active)

Signal Source : TIMER0 ACTIVE

USER OUTPUT

EXPOSURE ACTIVE

FRAME ACTIVE

FRAME TRANSFER

FRAME TRIGGER WAIT

24 / 81

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

Page 26

D4253386A

T2

T1

USB bus

Exposure

Image Image

Model Name

format

T1

[ms]

T2

[s]

Default Framerate

[fps]

BU302MG

Mono8

8.1

1/(Frame Rate setting)

120

Mono10, Mono12

9.6

60

BU505MG

Mono8

12.9

75

Mono10, Mono12

15.3

37

Timing Specification

Image data outputs are transferred with USB bulk transfer. Timing numerical value below is described by

absolute prerequisite that camera can use transmission band without restriction of other device. When there

is other device on the same bus, the value described below is not guaranteed.

● In normal shutter mode

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

25 / 81

Page 27

D4253386A

Image

USB bus

Exposure

TRIG_IN

T3

T1

Image

USB bus

Exposure

TRIG_IN

T3

T1

T4

Model Name

T3 [μs]

T4 [μs]

BU302MG

15.8

29.5

BU505MG

18.8

32.6

Notes of random trigger shutter mode:

- In the period when FRAME_TRIGGER_WAIT (GPIO signal) is inactive, user must not input external trigger signal to

this camera.

- When the interval of the input trigger signal is extremely short, or when the trigger signal is noisy, there is a possibility

of causing the malfunction. In this case, please input a proper trigger signal.

● In Random Trigger Shutter mode

Edge mode / Bulk mode (at all pixels readout)

Level mode (at all pixels readout)

* The value of T1 is the same as the value of normal shutter mode.

* T3 and T4 are typical value.

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

26 / 81

Page 28

D4253386A

Typical Spectral Response

* The lens characteristics and light source characteristics is not reflected in table.

● BU302MG / BU505MG

27 / 81

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

Page 29

D4253386A

Notes on Heat Radiation:

The temperature of camera housing must be kept less than 50 °C.

Please provide sufficient heat radiation depending on your installation.

Operating Ambient Conditions

● Ambient conditions

- Operating Assurance

Temperature: 0°C to +40°C, Camera housing temperature: less than 50°C

Humidity: 10% to 90% (no condensation)

- Storage Assurance

Temperature: -20°C to +60°C

Humidity: 90% or less (no condensation)

● EMC Conditions

- EMI (Electro-Magnetic Interference): EN61000-6-4

FCC Part 15 Subpart B Class A

- EMS (Electro-Magnetic Susceptibility): EN61000-6-2

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

28 / 81

Page 30

D4253386A

Notes on Conformity of the EMC:

The adaptability of the safety standard of this camera is assured in the condition of combination with the following parts:

- USB Cable USB3-KR1-A-MBS-030 (OKI Electric Cable Co., Ltd.)

- e-CON Cable 3.0m, Shield cable (Fabricated parts)

Parts:

- e-CON connector XN2A-1470 (OMRON Corporation)

- Shielded wire UL1533 (AWG28) (Hitachi cable, Ltd.)

Connection:

e-CON

1

2

3

4

BNC

GPIO(Line2)

GPIO(Line1)

GND

TRIG IN(Line0)

GPIO(Line2)

GPIO(Line1)

TRIG IN(Line0)

BNC

Please confirm the EMC adaptability when it combines with parts other than them.

29 / 81

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

Page 31

D4253386A

Category

Function

USB3 Vision

Bootstrap Registers

USB3 Vision standard registers

DeviceControl

DeviceControl

Device information

ImageFormatControl

ImageFormatSelector

Image format selection

Scalable

Scalable control

Binning

Binning control

Decimation

Decimation control

Reverse

Image flip

PixelFormat

Pixel format selection

TestPattern

Test pattern control

AcquisitionControl

AcquisitionControl

Image stream start / stop

ImageBuffer

Image buffer control

TriggerControl

Trigger control

ExposureControl

Exposure time control

DigitalIOControl

DigitalIOControl

GPIO signal control

CounterAndTimerControl

TimerControl

Timer0Active signal control

AnalogControl

Gain

Gain control

BlackLevel

Black level control

Gamma

Gamma correction

LUTControl

LUTControl

LUT control

UserSetControl

UserSetControl

Load / Save user setting

EventControl

EventControl

Event packet control

VenderUniqueControl

FrameSynchronization

Frame synchronization control

LEDIndicatorLuminance

LED luminance control

AntiGlitch

AntiGlitch control

AntiChattering

AntiChattering control

DPCControl

DPCControl

Defect pixel correction control

SequentialShutterControl

SequentialShutterControl

Sequential shutter control

Functions

This section introduces standard functions. BU CMOS series provides following functions.

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

30 / 81

Page 32

D4253386A

Function

BU302MG

BU505MG

Bootstrap Registers

○

○

DeviceControl

○

○

ImageFormatSelector

○

○

Scalable

○

○

Binning

○

○

Decimation

○

○

Reverse

○

○

PixelFormat

○

○

TestPattern

○

○

AcquisitionControl

○

○

ImageBuffer

○

○

TriggerControl

○

○

ExposureControl

○

○

DigitalIOControl

○

○

TimerControl

○

○

Gain

○

○

BlackLevel

○

○

Gamma

○

○

LUTControl

○

○

UserSetControl

○

○

EventControl

○

○

FrameSynchronization

○

○

LEDIndicatorLuminance

○

○

AntiGlitch

○

○

AntiChattering

○

○

DPCControl

○

○

SequentialShutterControl

○

○

Features supported by each model are as follows.

Details of each feature are described in following pages.

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

31 / 81

Page 33

D4253386A

USB3 Vision ABRM

Register

Visibility

Access

Description

UserDefinedName

Expert

R/W

Store user’s arbitrary string in non-volatile memory.

USB3 Vision SIRM

Register

Visibility

Access

Description

StreamEnable

-

R/W

Open and close the stream channel.

USB3 Vision EIRM

Register

Visibility

Access

Description

EventEnable

Expert

R/W

Activate event notification function.

Please refer to EventControl section as well.

TriggerEventTest

Expert

W

Issue test event packet.

Bootstrap Registers

This camera is based on USB3 Vision.

Please refer to USB3 Vision specification for details about Bootstrap Registers defined in USB3 Vision.

AIA (Automated Imaging Association) USB3 Vision Homepage.

http://www.visiononline.org/vision-standards-details.cfm?type=11

Followings are commonly used registers.

● Registers

● Note

When opening and closing the stream channel, it is required to control StreamEnable plus SDK setups on

your application. Please refer to the TeliCamSDK for details.

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

32 / 81

Page 34

D4253386A

Register

Visibility

Access

Description

DeviceReset

Expert

W

Resets the device.

DeviceVendorName

Beginner

R

Returns the vendor name.

DeviceModelName

Beginner

R

Returns the model name.

DeviceManufacturerInfo

Beginner

R

Returns the manufacturer information.

DeviceVersion

Beginner

R

Returns the device version.

DeviceID

Beginner

R

Returns the device ID (serial number).

DeviceControl

Registers of this category provide various information of the camera. And you can set the free user ID to the

camera.

● Registers

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

33 / 81

Page 35

D4253386A

Register

Visibility

Access

Description

ImageFormatSelector

Beginner

R/W

Selects an image format.

ImageFormatSelector

Function

Format0 (*)

Scalable

Format1

Binning

Format2

Decimation

ImageFormatControl

Registers of this category are related to image format control.

● Registers

● Setting

- Select an image format.

Set a following value to “ImageFormatSelector” register. Setting value is Enumeration type.

* initial factory setting

● Note

Changing “ImageFormatSelector” register value is invalid during image stream data output.

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

34 / 81

Page 36

D4253386A

⇒

( X , Y )=( 4 * i , 2 * j )

A + 4 * m

B + 2 * n

Register

Visibility

Access

Description

Width

Beginner

R/W

Sets width (in pixels) of the image data.

Height

Beginner

R/W

Sets Height (in pixels) of the image data.

OffsetX

Beginner

R/W

Sets horizontal offset (in pixels) from the origin to the region of interest.

OffsetY

Beginner

R/W

Sets vertical offset (in pixels) from the origin to the region of interest.

Scalable

BU series provides the scalable that can read out defined area of the screen.

In the scalable mode, camera reads out only necessary area at the normal speed and reads out other area

at high speed. The frame rate can be faster when the vertical height size is small. However, the frame rate

cannot be faster only when the horizontal width size is small.

Only single rectangle is selectable. Concave or convex shape is not selectable.

- Window size: {A + 4 × m (H)} × {B + 2 × n (V)}

A, B = minimum unit size

m, n = integer

The window size is equal or less than maximum image size.

- Start address: {4 x i (H)} x {2 x j (V)}

i, j = integer

The window size is equal or less than maximum image size.

● Registers

Scalable

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

35 / 81

Page 37

D4253386A

Model

BU302MG

BU505MG

Width/OffsetX unit size

4

4

Height/OffsetY unit size

2 2 Minimum unit size

64 x 64

64 x 64

Maximum unit size (*)

2048 x 1536

2448 x 2048

● Setting

- Select an image format.

Select “Fomat0” of “ImageFormatSelector” register.

- Set image size and image start position

Set the following value to “Width”, “Height”, “OffsetX”, “OffsetY” registers. Setting value is Integer type.

“Width”, “Height” registers are image size setting. “OffsetX”, “OffsetY” registers are image start position

setting.

* initial factory setting

● Note

Changing “Width”, “Height”, “OffsetX”, “OffsetY” register value is invalid during image stream data output.

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

36 / 81

Page 38

D4253386A

2048

2448

1224

All pixel readout

Binning

1024

Register

Visibility

Access

Description

BinningHorizontal

Beginner

R/W

Set horizontal binning.

BinningVertical

Beginner

R/W

Set vertical binning.

Binning

B/W models have 2 x 2 binning. In the binning mode, a pixel is added with the neighboring pixel(s). This

increases the sensitivity of the image. It’s alike scalable, the frame rate can be faster and USB bandwidth

occupation decrease.

● Registers

Binning operation (e.g. BU505MG)

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

37 / 81

Page 39

D4253386A

● Setting

- Select an image format.

Select “Fomat1” of “ImageFormatSelector” register.

- Set binning operation

Set the “2” to “BinningHorizontal”, “BinningVertical” registers. When you set up a value of the one side for

horizontal or vertical binning, the other side of the value is set up automatically. Setting value is Integer

type.

● Note

Binning is disabled when the camera is running in Scalable mode or Decimation mode.

Scalable and Decimation are disabled when the camera is running in Binning mode.

Changing “BinningHorizontal”, “BinningVertical” register value is invalid during image stream data output.

38 / 81

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

Page 40

D4253386A

2048

2448

All pixel readout

Decimation

1024

1224

Register

Visibility

Access

Description

DecimationHorizontal

Biginner

R/W

Set the number of horizontal Decimation line(s).

DecimationVertical

Beginner

R/W

Set the number of vertical Decimation line(s).

Decimation

Cameras have 2 x 2 decimation, cameras read all effective areas at high speed by skipping lines.

● Registers

Decimation operation (e.g. BU505MG)

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

39 / 81

Page 41

D4253386A

● Setting

- Select an image format.

Select “Fomat2” of “ImageFormatSelector” register.

- Set Decimation lines

Set the “2” to “DecimationHorizontal”, “DecimationVertical” registers. When you set up a value of the one

side for horizontal or vertical binning, the other side of the value is set up automatically. Setting value is

Integer type.

● Note

Decimation is disabled when the camera is running in Scalable mode or Binning mode.

Scalable and Binning are disabled when the camera is running in Decimation mode.

Changing “DecimationHorizontal”, “DecimationVertical” register value is invalid during image stream data

output.

40 / 81

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

Page 42

D4253386A

ReverseX

ReverseY ReverseX+ReverseY

Register

Visibility

Access

Description

ReverseX

Expert

R/W

Flip image in horizontal direction.

ReverseY

Expert

R/W

Flip image in vertical direction.

Value

Image reverse

FALSE (*)

Non reverse

TRUE

Reverse

Reverse

Image can be flipped in horizontal and/or vertical direction.

● Registers

● Setting

- Set image reverse

Set the following value to “ReverseX”, “ReverseY” registers. Setting value is Boolean type.

* initial factory setting

● Note

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

41 / 81

Page 43

D4253386A

Register

Visibility

Access

Description

PixelCoding

Beginner

R/W

Selects a pixel coding.

PixelSize

Beginner

R/W

Selects a bit size of image pixel.

PixelEndian

Beginner

R/W

Selects a pixel endian.

PixelFormat

Beginner

R

Returns a selected pixel format.

PixelFormat is conformed to AIA Pixel Format Naming Convention.

PixelSize

PixelCoding

Bpp8

Bpp10

Bpp12

Mono

PixelFormat ID

Mono8 (*)

Mono10

Mono12

0x01080001

0x01100003

0x01100005

PixelFormat

Select a pixel format of image stream data.

● Registers

● Setting

- Set PixelFormat

PixelFormat is determined by combination of “PixelCoding” and “PixelSize” register. Select a following

combination to “PixelCoding” and “PixelSize” register. Setting values are Enumeration type.

B/W model

* initial factory setting

● Note

Changing “PixelSize” register value is invalid during image stream data output.

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

42 / 81

Page 44

D4253386A

TestPattern

BU series supports test pattern data output. Camera provides following Test patterns;

Black White

GreyA GreyB

GreyHorizontalRamp GreyVerticalRamp

GreyScale

Test pattern (e.g. BU505MG)

43 / 81

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

Page 45

D4253386A

Register

Visibility

Access

Description

TestPattern

Beginner

R/W

Selects a test pattern.

TestPattern

function

Off (*)

Test pattern disable(Normal data output)

Black

All pixel = 0 LSB

White

All pixel = 255 @Mono8

GreyA

All pixel = 170 @Mono8

GreyB

All pixel = 85 @Mono8

GreyHorizontalRamp

Horizontal Ramp

GreyVerticalRamp

Vertical Ramp

GreyScale

Grey scale

● Registers

● Setting

- Select a test pattern output

Set the following value to “TestPattern” register. Setting value is Enumeration type.

The camera generates a test pattern.

● Note

* initial factory setting

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

44 / 81

Page 46

D4253386A

Register

Visibility

Access

Description

AcquisitionMode

Beginner

R/W

Selects an acquisition mode.

AcquisitionStart

Beginner

W

Executes the image stream output start.

AcquisitionStop

Beginner

W

Executes the image stream output stop.

AcquisitionAbort

Beginner

W

Executes the image stream output abort.

AcquisitionFrameCount

Beginner

R/W

Sets the number of frames to transfer in MultiFrame mode.

AcquisitionFrameRateControl

Beginner

R/W

Activates frame rate setting.

AcquisitionFrameRate

Beginner

R/W

Sets frame rate of image stream.

AcquisitionFrameIntervalControl

Beginner

R/W

Activates frame interval setting.

AcquisitionFrameInterval

Beginner

R/W

Sets frame interval of image stream.

AcquisitionMode

Function

Continuous (*)

Continuous image transfer

MultiFrame

Multi frame image transfer

AcquisitionControl

Make a setting of image stream and control image stream output.

Camera starts image stream output by receiving AcquisitionStrat command. And there are some registers

that require camera to stop image stream output to change values.

Acquisition frame rate is variable. Maximum acquisition frame rate depends on camera operation mode

(scalable.)

● Registers

● Setting

- Select an acquisition mode

Set the following value to “AcquisitionMode” register. Setting value is Enumeration type.

* initial factory setting

- Set the number of frames to transfer (In MultiFrame mode)

Set the number of frames to transfer to “AcquisitionFrameCount”. Setting value is Integer type.

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

45 / 81

Page 47

D4253386A

AcquisitionFrameRateControl

Function

NoSpecify (*)

The frame rate is determined by giving priority to ExposureTime setting value.

Manual

The frame rate is determined by giving priority to AcquisitionFrameRate setting value.

AcquisitionFrameRate

Value

Minimum

0.5[Hz]

Maximum (*)

Depend on register setting of "Height".

Notes on Frame Drops of Image:

Depends on your PC or USB3.0 interface card configurations, images may not be captured normally (e.g. frame drops

may occur). In this case, change to frame rate setting lower.

- Open/Close stream channel (to be ready to receive stream data)

Set “1” to “StreamEnable” in Bootstrap Registers before “AcquisitionStart”.

Set “0” to “StreamEnable” in Bootstrap Registers before “AcquisitionStop” or “AcquisitionAbort”.

- Start image stream output

The camera starts image stream output by executing “AcquisitionStart” register command.

- Stop image stream output

The camera stops image stream output by executing “AcquisitionStop” register command.

The camera aborts image stream output by executing “AcquisitionAbort” register command.

- Set frame rate

Set the “AcquisitionFrameRateControl” register to “Manual”.

And set the following value to “AcquisitionFrameRate” register. Setting value is Float type.

The range of register setting depends on camera model, and camera operation mode.

“AcquisitionFrameInterval” register is a reciprocal of “AcquisitionFrameRate”.

* initial factory setting

* initial factory setting

● Note

Changing “AcquisitionFrameRateControl”, “AcquisitionFrameRate”, “AcquisitionFrameIntervalControl”,

“AcquisitionFrameInterval” register value is invalid during image stream data output.

When exposure time setting is longer than frame rate setting, camera operation gives priority to exposure

time setting.

When opening and closing the stream channel, it is required to control StreamEnable plus SDK setups on

your application. Please refer to the TeliCamSDK for details.

46 / 81

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

Page 48

D4253386A

Register

Visibility

Access

Description

ImageBufferMode

Beginner

R/W

Selects Image Buffer mode.

ImageBufferFrameCount

Beginner

R

Returns the number of frames stored in the buffer.

ImageBufferRead

Beginner

W

Executes the image buffer read.

ImageBuffer

This section describes ImageBuffer control of AcquisitionControl category.

Camera stores images temporarily in image buffer, and read them out in arbitrary timing.

This function is typically used in Random Trigger Shutter mode.

Please refer to TriggerControl section as well.

● Registers

● Setting

- Activate trigger mode

Set “On” to “TriggerMode” register, and set “TriggerSoftware” or “Line0”, “Line2” to ”TriggerSource”

register.

- Activate image buffer mode

Set “On” to “ImageBufferMode” register.

- Open/Close stream channel (to be ready to receive stream data)

Set “1” to “StreamEnable” in Bootstrap Registers before “ImageBufferRead”.

Set “0” to “StreamEnable” in Bootstrap Registers after completion of image acquisition from image buffer.

- Capture and store images

Input trigger signals to capture and store images.

“ImageBufferFrameCount” register shows the number of frames stored in the buffer.

The maximum number of frames storable depends on the image size. (maximum 64MByte.)

- Set the number of frames to transfer (In ImageBuffer mode)

Set the number of frames to transfer to “AcquisitionFrameCount”. Setting value is Integer type.

- Read images from the buffer

Read the number of AcquisitionFrameCount image(s) from the buffer by executing “ImageBufferRead”

register command (it is equivalent to write value 10 to “AcquisitionCommand” register).

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

47 / 81

Page 49

D4253386A

● Note

When opening and closing the stream channel, it is required to control StreamEnable plus SDK setups on

your application. Please refer to the TeliCamSDK for details.

[Start] button in TeliCamViewer can’t deal with “StreamEnable” register alone.

Please substitute procedure “StreamEnable” = 1 to following instructions.

- Push [Start] button on TeliCamViewer main window.

- Execute [AcquisitionStop] in XML window.

48 / 81

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

Page 50

D4253386A

Trigger Mode

Synchronization

Exposure Control

Normal Shutter mode

Free run

“ExposureTime” register control

Random Trigger Shutter mode

HardwareTrigger

-Edge mode:TriggerSequence0

-Bulk mode:TriggerSequence6

“ExposureTime” register control

-Level mode:TriggerSequence1

Trigger pulse width control

SoftwareTrigger

-Edge mode:TriggerSequence0

-Bulk mode:TriggerSequence6

“ExposureTime” register control

TriggerControl

This section describes trigger control of TriggerControl category for the BU series.

This camera series provides two kinds of exposure synchronization.

1. Normal Shutter mode : Free run operation (internal synchronization)

2. Random Trigger Shutter mode : Synchronized with external trigger input

In Random Trigger Shutter mode, two kinds of trigger input are available.

1. Trigger signal via the I/O connector (HardwareTrigger)

2. Trigger command via the USB interface (SoftwareTrigger)

The following table shows the combination of operation mode of this camera series.

Table. Operation Mode

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

* The camera operation not mentioned above is not guaranteed.

49 / 81

Page 51

D4253386A

Image

USB bus

Exposure

Trigger

ExposureTime

USB bus

Exposure

Trigger

Pulse Width

Image

Image

USB bus

Exposure

Trigger

ExposureTime

Image Image

TriggerAdditionalParameter = 3

USB bus

Exposure

Trigger signal

Image

TriggerDelay

- Edge mode (TriggerSequence0)

The exposure time is determined by Exposure Time setting.

- Level mode (TriggerSequence1)

The exposure time is determined by the pulse width of the trigger signal.

- Bulk mode (TriggerSequence6)

Camera exposes and transfers multiple frames by a single trigger.

Trigger sequence

Operation point of HardwareTrigger is at the edge of trigger signal, and active edge polarity is able to change

by register setting. And you can add delay time from trigger edge to exposure start by register setting.

Details of Random Trigger Shutter operation, refer to "Timing" of "Specification".

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

Trigger Delay

50 / 81

Page 52

D4253386A

Register

Visibility

Access

Description

TriggerMode

Beginner

R/W

Selects Random Trigger Shutter mode.

TriggerSequence

Beginner

R/W

Selects trigger sequence.

TriggerSource

Beginner

R/W

Selects trigger source of Random Trigger Shutter.

TriggerAdditionalParameter

Expert

R/W

Sers the number of frames to exposure in Bulk mode.

TriggerDelay

Beginner

R/W

Sets trigger delay.

TriggerSoftware

Beginner

W

Executes software trigger.

TriggerMode

Function

Off (*)

Normal Shutter Mode

On

Random Trigger Shutter mode

TriggerSequence

Function

TriggerSequence0 (*)

Edge mode

TriggerSequence1

Level mode

TriggerSequence6

Bulk mode

TriggerSource

Function

Line0 (*)

Hardware trigger (I/O connector : 4 pin)

Line2

Hardware trigger (I/O connector : 1 pin)

TriggerSoftware

Software trigger

● Registers

● Setting

- Select trigger mode

Set the following value to “TriggerMode” register. Setting value is Enumeration type.

* initial factory setting

- Select trigger sequence

Set the following value to “TriggerSequence” register. Setting value is Enumeration type.

* initial factory setting

In Normal Shutter mode, the exposure time is determined by “ExposureTime” register value regardless of

“TriggerSequence” register setting.

- Select trigger source

Set the following value to “TriggerSource” register. Setting value is Enumeration type.

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

* initial factory setting

51 / 81

Page 53

D4253386A

TriggerAdditionalParameter

Value

Minimum (*)

0 [frame]

Maximum

255 [frames]

TriggerDelay

Value

Minimum (*)

0.00[μs]

Maximum

2000000.00[μs]

- Set the number of frames to exposure (In Bulk mode)

Set the number of frames to exposure to “TriggerAddtionalParameter”. Setting value is Integer type.

* initial factory setting

- Set trigger delay (HardwareTrigger operation only)

Set the following value to “TriggerDelay” register. Setting value is Float type.

Adds delay time from trigger edge to exposure start.

* initial factory setting

- Grabs image stream by software trigger

When executes “TriggerSoftware” register command, software trigger command is generated. Camera

starts exposure by receiving software trigger command.

● Note

In SoftwareTrigger operation, the delay time from “TriggerSoftware” to exposure is not guaranteed.

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

52 / 81

Page 54

D4253386A

Register

Visibility

Access

Description

ExposureTimeControl

Beginner

R/W

Selects exposure time control mode.

ExposureTime

Beginner

R/W

Sets absolute exposure time.

AcquisitionFrameRateControl

Function

NoSpecify

The frame rate is determined by giving priority to AcquisitionFrameRate setting value.

Manual (*)

The frame rate is determined by giving priority to ExposureTime setting value.

Model

BU302MG

BU505MG

ExposureTime (*)

8000 [μs]

13000 [μs]

ExposureTimeMin

30 [μs]

30 [μs]

ExposureTimeMax

16000000 [μs]

16000000 [μs]

ExposureTime

BU series is able to adjust exposure time by using electric shutter control.

BU USB series provides two kinds of exposure time control mode.

- Manual : The exposure time is determined by “ExposureTime” register setting value.

- NoSpecify : The exposure time is determined by “AcquisitionFrameRate” register setting value

● Registers

● Setting

- Select exposure time control mode

Set the “ExposureTimeControl” register to “Manual”.

Set the following value to “ExposureTime” register. Setting value is Float type.

* initial factory setting

● Note

* initial factory setting

53 / 81

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

Page 55

D4253386A

EXT_TRIG

Exposure

VD

CMOS Transfer

USB Bus

TIMER0 ACTIVE

EXPOSURE

ACTIVE

FRAME ACTIVE

FRAME

TRANSFER

FRAME TRIGGER

WAIT

Delay Duration

* ActiveLow

Register

Visibility

Access

Description

LineModeAll

Beginner

R/W

Selects the Input / Output of each Line.

LineInverterAll

Beginner

R/W

Selects the polarity of each Line signal.

LineStatusAll

Beginner

R

Returns the status of each Line signal.

UserOutputValueAll

Beginner

R/W

Sets the user output value.

LineSelector

Beginner

R/W

Selects the Line of I/O connector.

LineSource

Beginner

R/W

Selects the source of the output signal.

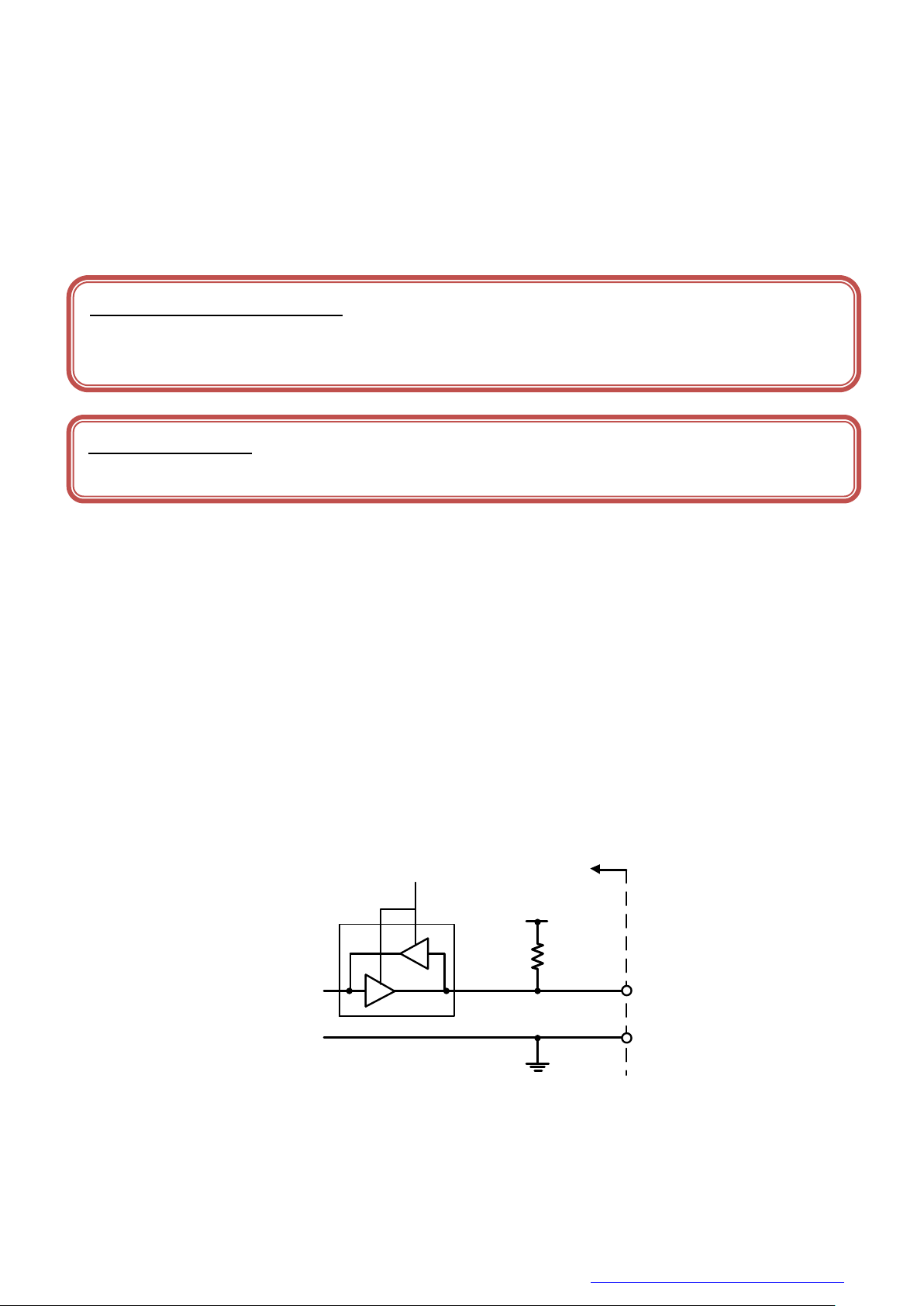

DigitalIOControl

This section describes DigitalIOControl category for the BU series.

This camera provides GPIO output selected by the register setting. And the polarity of the signal is able to

switch by the register setting. The following chart shows the specifications of the selectable signals.

● Registers

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

Selectable signals

54 / 81

Page 56

D4253386A

LineModeAll

I/O connector pin assignment

0 (*)

Input

1

Output

LineSelector

I/O connector pin assignment

Line1 (*)

2 pin: GPIO Output

Line2

1 pin: GPIO Input / Output

LineSource

Signal description

Off (*)

No output.

FrameTriggerWait

Indicating waiting a Random Trigger Shutter.

An External trigger is input during this period, exposure starts immediately.

FrameActive

Period from exposure start to CMOS transfer completion.

FrameTransfer

Period of transferring image data on USB bus.

ExposureActive

Period from exposure start to exposure end.

UserOutput

Outputs the value set in “UserOutputValueAll”.

Timer0Active

This signal can be used as strobe control signal.

The delay time and pulse width of this signal are configurable.

● Setting

- Select the Input / Output

Set the following value to “LineModeAll” register. Setting value is Integer type.

Each bit corresponds to each Line (bit0=Line0, bit1=Line1).

Line2 is available. Line0 is dedicated input. Line1 is dedicated output.

* initial factory setting

- Select the Line of the I/O connector

Set the following value to “LineSelector” register. Select the line to output “LineSource” signal.

Setting value is Enumeration type.

* initial factory setting

- Select the source of GPIO output signal

Set the following value to “LineSource” register to change GPIO output signal selected by “LineSelector”.

Setting value is Enumeration type.

- Set the UserOutput signal

Set the following value to “UserOutputValueAll” register. Setting value is Integer type.

Each bit corresponds to each Line (bit0=Line0, bit1=Line1).

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

55 / 81

* initial factory setting

Page 57

D4253386A

Line1 and Line2 are available. Line0 is dedicated input.

UserOutputValueAll

Function

0 (*)

Low level output

1

High level output

LineInverterAll

Function

0 (*)

non inverted

1

inverted

Timer0Active

UserOutput

ExposureActive

FrameTransfer

FrameActive

FrameTriggerWait

Internal Trigger

TimerControl

UserOutputValueAll[2]

Line0

UserOutput

LineSourceLineInverterAll

UserOutputValueAll[1]

LineModeAll

Internal Trigger

(GPIO_Input)

Line2

(GPIO_Input/Output)

Line1

(GPIO_Output)

TriggerSource

* initial factory setting

- Select the polarity of each signal

Set the following value to “LineInverterAll” register. The setting value is Integer type.

Each bit corresponds to each Line. All Lines are settable.Inverter is also inserted to UserOutputValue.

* initial factory setting

● Note

About the details of Timer0Active signal, refer to “TimerControl” of "Functions".

Copyright © 2016 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/index.htm

GPIO internal circuit diagram

56 / 81

Page 58

D4253386A

TRIG_IN

(Line0)

Exposure

TIMER0 ACTIVE

Delay Duration

※ ActiveLow

EXPOSURE ACTIVE

Trigger

(Frame Start Trigger)

TriggerDelay

TimerTriggerSource = Line0Active

TimerTriggerSource = ExposureStart

TimerTriggerSource = FrameTrigger

Register

Visibility

Access