Page 1

TEC Ink Jet Printer

Table of Contents

BRST-10 SERIES

Owner’s Manual

Page 2

DECLARATION OF CONFORMITY (for EU only)

Manufacturer : TOSHIBA TEC CORPORATION

Address : 570 Ohito, Ohito-cho, Tagata-gun, Shizuoka-ken, Japan

declares, it sole responsibility, that the product

Product Name : Remote Printer

Model Number : BRST-10

conforms to the following standards under EMC Directive (89/336/EEC, 93/68/EEC) and

Low Voltage Directive (73/23/EEC, 93/68/EEC) :

EMC : EN55024 Information technology equipment - Immunity characteristics -

Limits and method of measurement

: EN55022 Limits and methods of measurement of radio disturbance

characteristics of information technology equipment

LVD : EN60950 Safety of imformation technology equipment, including

electrical business equipment

WARNING

This is a Class A product. In a domestic environment this product may cause radio interference in which

case the user may be required to take adequate measures.

ATTENTION

Ce produit est de classe A. Dans un environnement domestique, il peut causer des interférences radio.

Auquel cas, I’utilisateur sera amené à prendre les mesures adéquates.

Warnung

Dies ist ein Klasse A Produkt. In einer örtlichen Umgebung kann dieses Gerät Funkstörungen verursachen.

Atención

Este es un producto de la clase A. En ambientes domésticos éste producto puede causar radio

interferencias en cuyo caso el usuario deberá tomar las medldas oportunas.

VERWITTIGING

Dit is een klasse A produkt. Het gebruik hiervan kan radio interferenties veroorzaken die de gebruiker

ertoe kunnen dwingen sommige maatregelen te moeten treffen.

Schallemission : unter 70dB(A) nach DIN 45635 (ISO7779)

FCC Notice

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the user will be required to

correct the interference at this own expense.

Changes or modifications not expressly approved by the manufacturer for compliance could void the

user’s authority to operate the equipment.

Copyright © 2000

by TOSHIBA TEC CORPORATION

All Rights Reserved

570 Ohito, Ohito-cho, Tagata-gun, Shizuoka-ken, JAPAN

Page 3

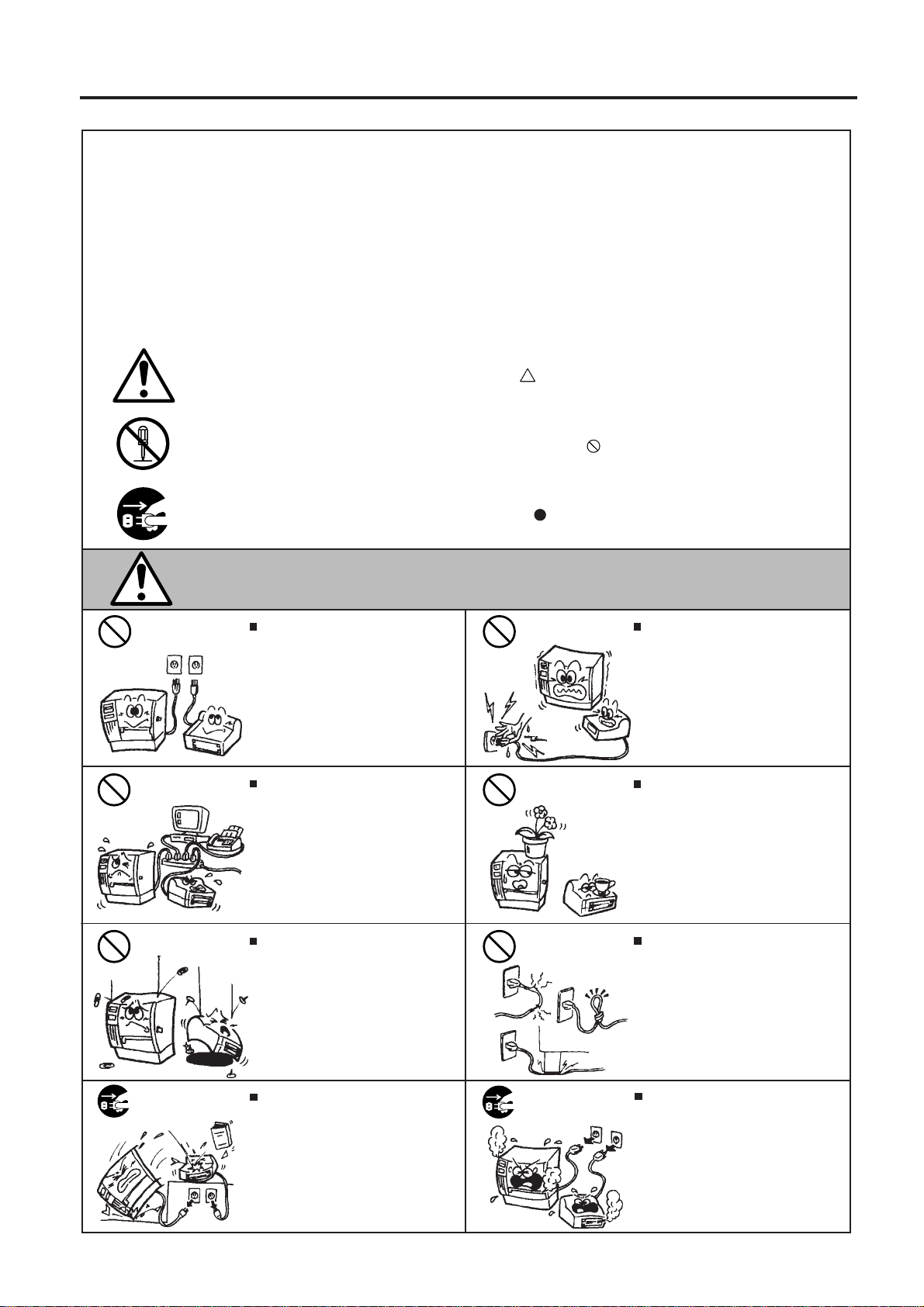

Safety Summary

Safety Summary

Personal safety in handling or maintaining the equipment is extremely important. Warnings and Cautions

necessary for safe handling are included in this manual. All warnings and cautions contained in this

manual should be read and understood before handling or maintaining the equipment.

Do not attempt to effect repairs or modifications to this equipment. If a fault occurs that cannot be rectified

using the procedures described in this manual, turn off the power, unplug the machine, then contact your

authorized TOSHIBA TEC representative for assistance.

Meaning of Each Symbol

This symbol indicates warning items (including cautions).

Specific warning contents are drawn inside the symbol.

(The symbol on the left indicates a general caution.)

This symbol indicates prohibited actions (prohibited items).

Specific prohibited contents are drawn inside or near the symbol.

(The symbol on the left indicates “no disassembling”.)

This symbol indicates actions which must be performed.

Specific instructions are drawn inside or near the symbol.

(The symbol on the left indicates “disconnect the power cord plug from the outlet”.)

EO1-13013

WARNING

Any other than the

specified AC voltage

is prohibited.

Prohibited

Prohibited

Do not use voltages other than the

voltage (AC) specified on the rating

plate, as this may cause fire or

electric shock.

If the machines share the same

outlet with any other electrical

appliances which consume large

amounts of power, the voltage will

fluctuate widely each time these

appliances operate each time these

appliances operate, and this may

cuase the machines to malfuncion. Be

sure to provide au exclusive outlet for

the machines.

Do not insert or drop metal,

flammable or other foreign objects into

the machines through the ventilation

slits, as this may cause fire or electric

shock.

This indicates that there is the risk of death or serious injury if the

machines are improperly handled contrary to this indication.

Prohibited

Prohibited

Prohibited

Do not plug in or unplug the power

cord plug with wet hands as this may

cause electric shock.

Do not place metal objects or

water-filled containers such as flower

vases, flower pots or mugs, etc. on

top of the machines. If metal objects

or spilled liquid enter the machines,

this may cause fire or electric

shock.

Do not scratch, damage or modify

the power cords. Also, do not place

heavy objects on, pull on, or excessively bend the cords, as this may

cause fire or electric shock.

Disconnect

the plug.

If the machines are dropped or their

cabinets damaged, first turn off the

power switches and disconnect the

power cord plugs from the outlet, and

then contact your authorized

TOSHIBA TEC representative for

assistance. Continued use of the

machine in that condition may cause

fire or electric shock.

(i)

Disconnect

the plug.

Continued use of the machines in an

abnormal condition such as when the

machines are producing smoke or

strange smells may cause fire or elec-

tric shock. In these cases, immediately turn off the power switches and

disconnect the power cord plugs from

the outlet. Then, contact your authorized TOSHIBA TEC representative for

assistance.

Page 4

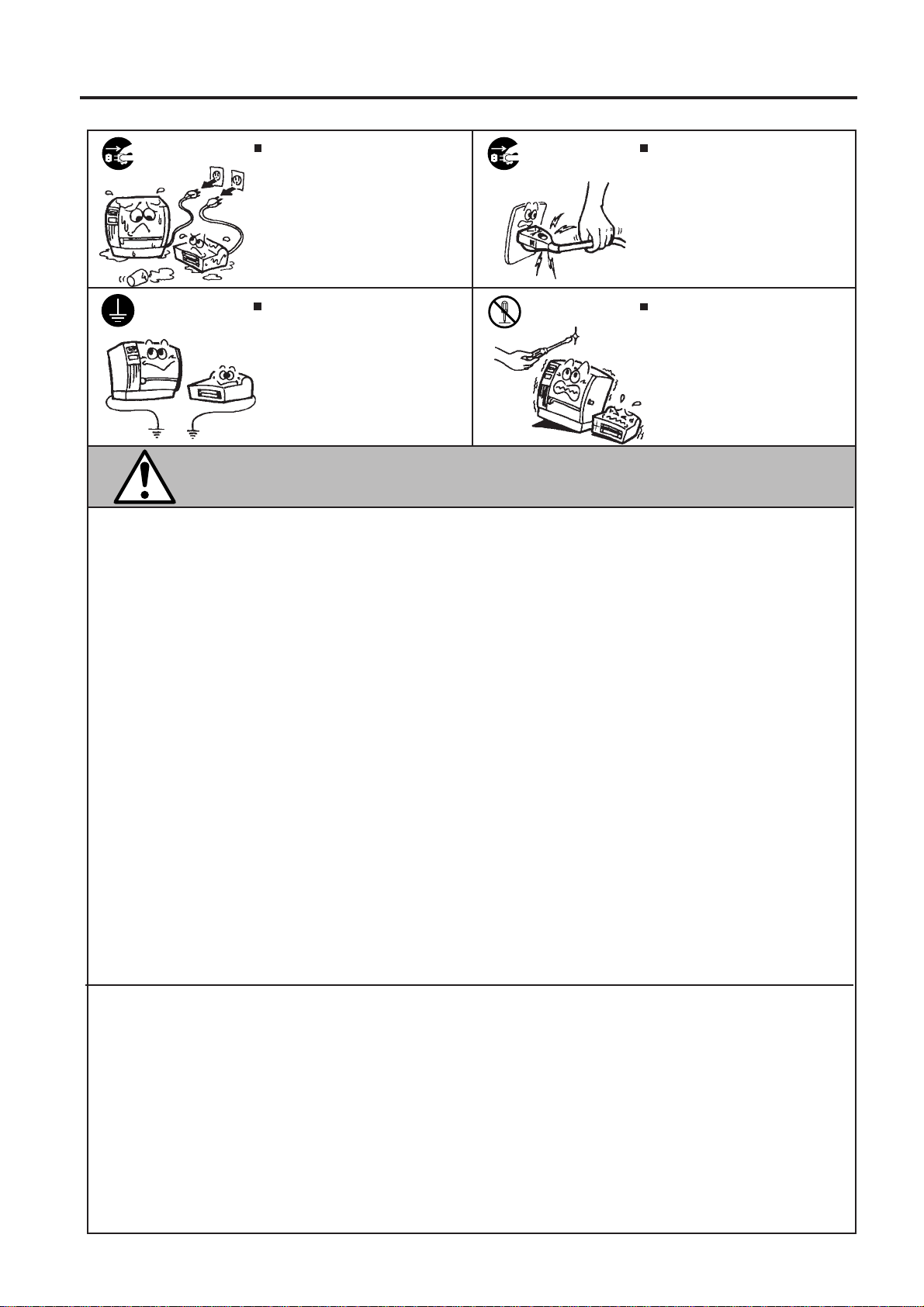

Safety Summary

EO1-13013

Disconnect

the plug.

Connect a

grounding

wire.

If foreign objects (metal fragments,

water, liquids) enter the machines,

first turn off the power switches and

disconnect the power cord plugs from

the outlet, and then contact your

authorized TOSHIBA TEC representative for assistance. Continued

use of the machine in that condition

may cause fire or electric shock.

Ensure that the equipment is

properly grounded. Extension cables

should also be grounded. Fire or

electric shock could occur on

improperly grounded equipment.

Disconnect

the plug.

No disassembling.

When unplugging the power cords,

be sure to hold and pull on the plug

portion. Pulling on the cord portion

may cut or expose the internal wires

and cause fire or electric shock.

Do not remove covers, repair or

modify the machine by yourself. You

may be injured by high voltage, very

hot parts or sharp edges inside the

machine.

This indicates that there is the risk of personal Injury or damage to

CAUTION

objects if the machines are improperly handled contrary to this indication.

Precautions

The following precautions will help to ensure that this machine will continue to function correctly.

• Try to avoid locations that have the following adverse conditions:

* Temperatures out of the specification * Direct sunlight * High humidity

* Shared power source * Excessive vibration * Dust/Gas

• The cover should be cleaned by wiping with a dry cloth or a cloth slightly dampened with a mild

detergent solution. NEVER USE THINNER OR ANY OTHER VOLATILE SOLVENT on the plastic

covers.

• USE ONLY TOSHIBA TEC SPECIFIED paper and ink.

• DO NOT STORE the paper or ink where they might be exposed to direct sunlight, high temperatures, high humidity, dust, or gas.

• Ensure that the printer is operated on a level surface.

• Any data stored in the memory of the printer could be lost during a printer fault.

• Try to avoid using this equipment on the same power supply as high voltage equipment or equipment likely to cause mains interference.

• Unplug the machine whenever you are working inside it or cleaning it.

• Keep your work environment static free.

• Do not place heavy objects on top of the machines, as these items may become unbalanced and fall

causing injury.

• Do not block the ventilation slits of the machines, as this will cause heat to build up inside the

machines and may cause fire.

• Do not lean against the machine. It may fall on you and could cause injury.

• Do not turn the machine upside down.

• Care must be taken not to injure yourself with the printer paper cutter.

• Unplug the machine when it is not used for a long period of time.

Request Regarding Maintenance

• Utilize our maintenance services.

After purchasing the machine, contact your authorized TOSHIBA TEC representative for assistance

once a year to have the inside of the machine cleaned. Otherwise, dust will build up inside the

machines and may cause a fire or a malfunction. Cleaning is particularly effective before humid

rainy seasons.

• Our preventive maintenance service performs the periodic checks and other work required to

maintain the quality and performance of the machines, preventing accidents beforehand.

For details, please consult your authorized TOSHIBA TEC representative for assistance.

• Using insecticides and other chemicals

Do not expose the machines to insecticides or other volatile solvents. This will cause the cabinet or

other parts to deteriorate or cause the paint to peel.

(ii)

Page 5

TABLE OF CONTENTS

Page

1. INTRODUCTION ................................................................................................ 1- 1

1.1 APPLICABLE MODEL ................................................................................ 1- 1

1.2 ACCESSORIES .......................................................................................... 1- 1

2. SPECIFICATIONS.............................................................................................. 2- 1

2.1 PRINTER .................................................................................................... 2- 1

2.2 RECEIPT PAPER ....................................................................................... 2- 2

2.3 SLIP ............................................................................................................ 2- 2

3. OVERVIEW ........................................................................................................ 3- 1

3.1 FRONT/REAR VIEW................................................................................... 3- 1

3.2 OPERATION PANEL .................................................................................. 3- 2

4. SET UP PROCEDURE....................................................................................... 4- 1

4.1 REQUIREMENTS FOR OPERATION ........................................................ 4- 1

4.2 SETTING UP THE PRINTER...................................................................... 4- 1

5. INSTALLATION PROCEDURE .......................................................................... 5- 1

5.1 CONNECTING THE POWER CORD AND CABLES .................................. 5- 1

5.2 LOADING THE HEAD UNIT/ INK CARTRIDGE ......................................... 5- 2

5.3 LOADING THE RECEIPT ROLL ................................................................. 5- 4

5.4 INSERTING THE SLIP................................................................................ 5- 6

6. REPLACING THE RECEIPT ROLL.................................................................... 6- 1

7. REPLACING THE INK CARTRIDGE.................................................................. 7- 1

8. REPLACING THE HEAD UNIT/ INK CARTRIDGE ............................................ 8- 1

9. GENERAL MAINTENANCE ............................................................................... 9- 1

9.1 CLEANING ................................................................................................. 9- 1

9.2 REMOVING JAMMED PAPER................................................................... 9- 1

10. TROUBLESHOOTING...................................................................................... 10- 1

11. ERROR MESSAGE.......................................................................................... 11- 1

EO1-13013

CAUTION:

1. This manual may not be copied in whole or in part without prior written permission of

TOSHIBA TEC.

2. The contents of this manual may be changed without notification.

3. Please refer to your local Authorized Service representative with regard to any queries

you may have in this manual.

Page 6

1. INTRODUCTION

1.1 APPLICABLE MODEL

EO1-13013

1. INTRODUCTION

Thank you for purchasing the TEC BRST-10 Series 1.5 Station bubble jet Printer. This printer is a highspeed and high-quality bubble jet printer. The interface complies with the Serial interface (conforming to

RS-232C).

This printer contains 1.5 stations; receipt and slip. Up to 42 digits can be printed on the receipt and up to

58 digits on the slip.

This manual contains general set-up and maintenance information and should be read carefully to help

gain maximum performance and life from your printer. For most queries please refer to this manual and

keep it safe for future reference.

1.1 APPLICABLE MODEL

• BRST-10-1SF-QM

Model name description

B R S T - 1 0 - 1 S F - Q M

Destination Code

QM: Standard

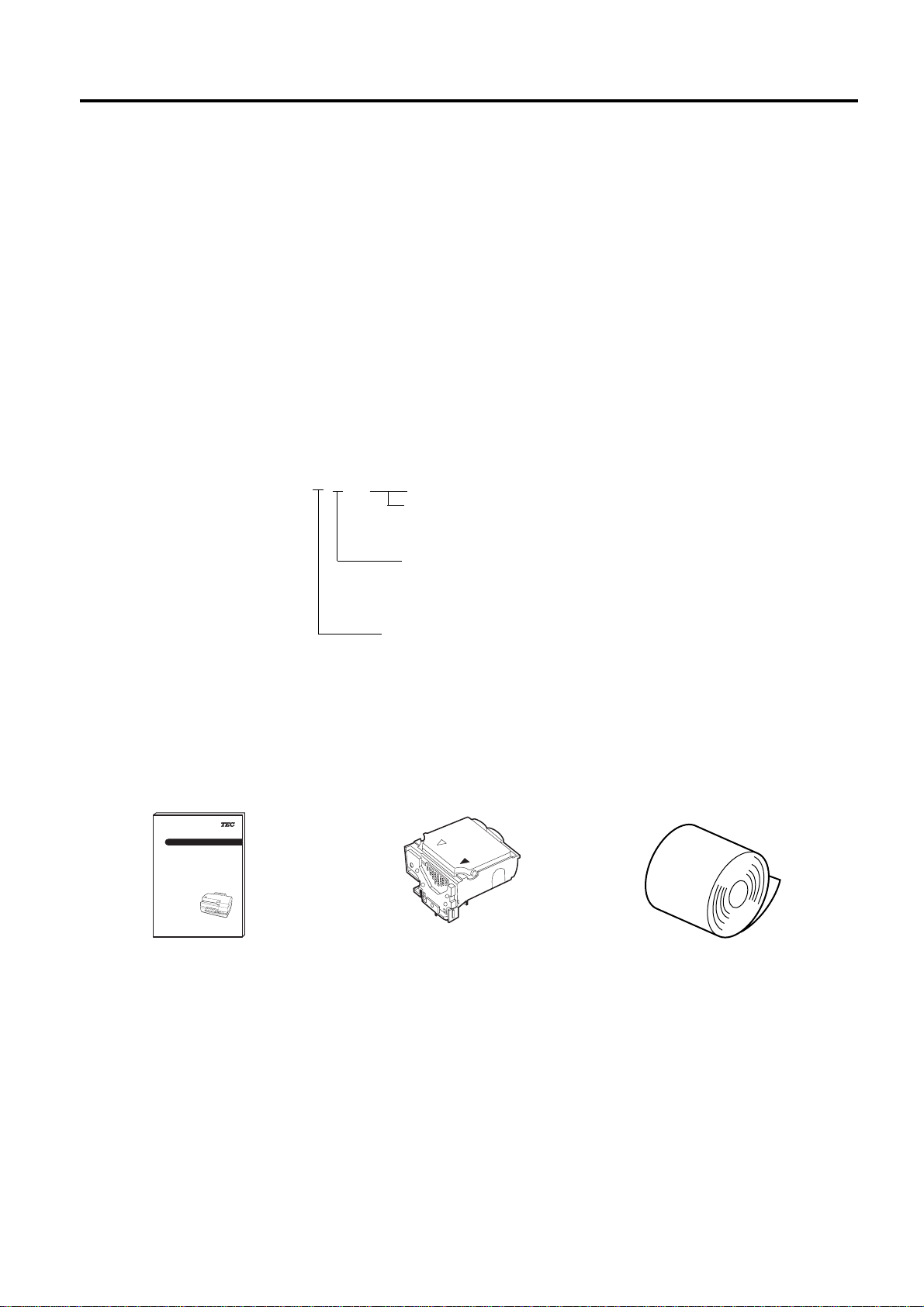

1.2 ACCESSORIES

Owner's Manual

(EO1-13013)

TEC Ink Jet Printer

BRST-10 SERIES

Owner's Manual

TOSHIBA TEC CORPORATION

Cutter Type

F: Full Cut

S: Full & Stub Cut

Interface Type

S: Serial Interface

P: Parallel Interface

Head Unit/ Ink Cartridge

Receipt Roll

1-1

Page 7

2. SPECIFICATIONS

2. SPECIFICATIONS

2.1 PRINTER

EO1-13013

2.1 PRINTER

Model

Item

Supply voltage

Current consumption

Operating temperature

Relative humidity

Printing methods

Nozzle array

Print density

Direction of print

Print speed

Paper feed speed

Maximum print width

BRST-10-1SF-QM

+24 V DC – 5 % (Recommended Power Adapter : PS-10-QM)

1.5 A maximum

5 C to 35 C

10 % to 85 % RH (no condensation applies to the printer, not the paper)

Serial bubble jet

One row in length 128 nozzle

180 x 180 dots per inch

Bi-directional (The logic seek is possible.)

Receipt : 8.0 lines per second

Slip : 6.4 lines per second

20 lines per second

Receipt : 71.1 mm

Slip : 98.2 mm

Dimension

Weight

Standard interface

250 mm (width) x 307 mm (depth) x 148 mm (height)

4.0 kg

Serial interface (RS-232-C)

Drawer interface

2-1

Page 8

2. SPECIFICATIONS

5

5

5

5

5

123456789

1

9

1

9

1

9

123456789

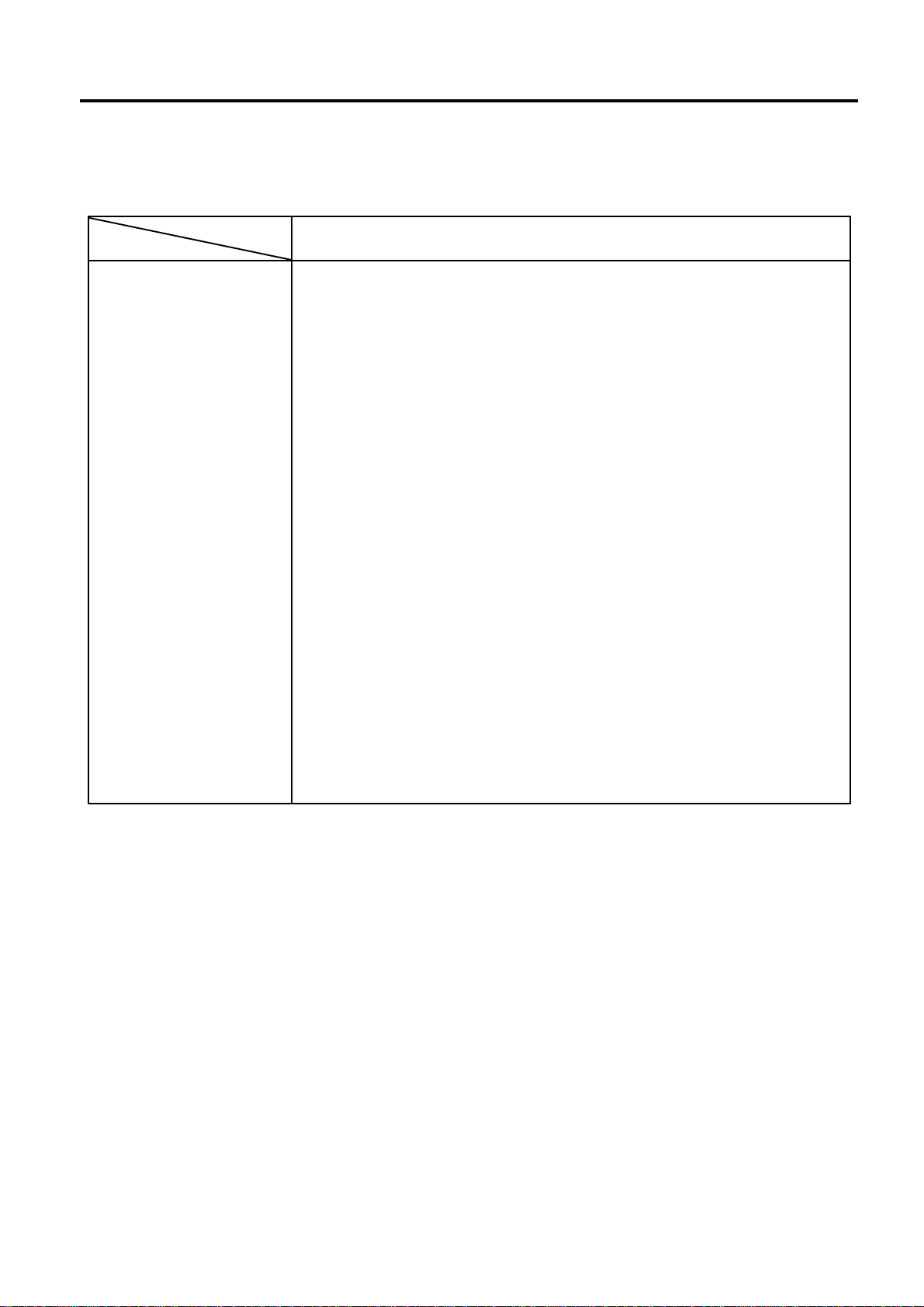

2.2 RECEIPT PAPER

EO1-13013

2.2 RECEIPT PAPER

76

71.1

9

36.1

Maximum Logo Print Area

NOTE: All dimensions are shown in

56.6

millimeters.

4.23

2.45

71.1 (42 digits)

2.45

Type White slick paper

Weight 54.3 –2 g/m

2

Thickness 0.083 – 0.005 mm

Size 76+0/-1 (W) x ø80 mm

Paper core diameter ø25 mm (Outer diameter), ø18+0/-0.5 mm (Inner diameter)

Paper end Paper end should be stuck on the paper core. Also, 1 to 1.5m

red mark should be marked on the paper within 2m from the

paper core.

Fig. 2-1

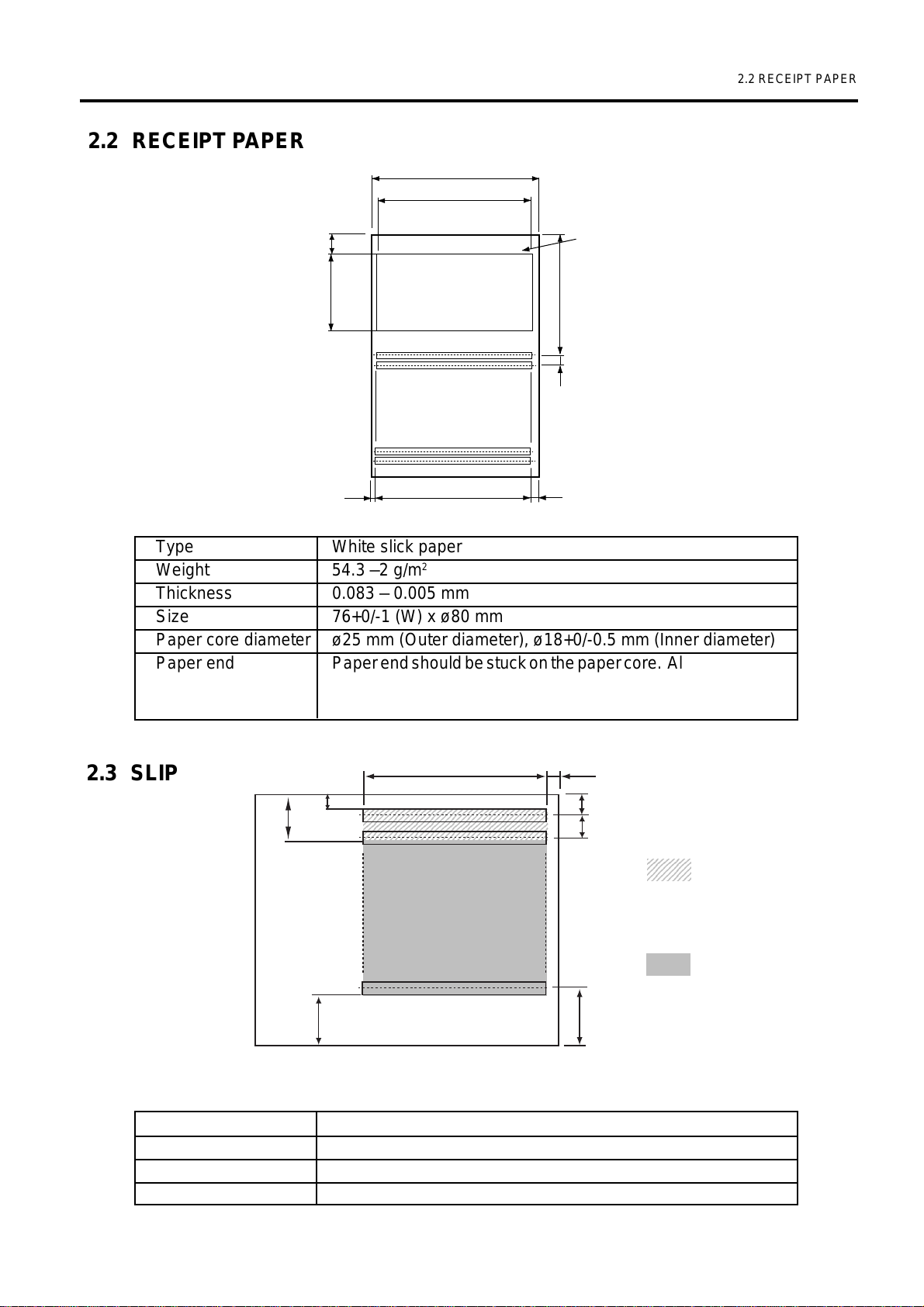

2.3 SLIP

10

3.4

98.2 (58 digits max)

23456789012345678901234567890121234

23456789012345678901234567890121234

23456789012345678901234567890121234

23456789012345678901234567890121234

23456789012345678901234567890121234

5.35

5.12

4.23

2345678

2345678

: indicates effective

2345678

print area, however,

smudges may occur

on the paper end.

: indicates

recommended

printing area.

21.7

23.4

Fig. 2-2

NOTE: Do not use folded paper or wrinkled paper. They may cause a paper jam or reduce print quality.

Type Ordinary paper (Only single paper is available.)

Thickness 0.07 to 0.14 mm

Weight 54.3 to 105 g/m

2

Size 68 to 215.9 mm (W) x 68 to 297 mm (L)

2-2

Page 9

3. OVERVIEW

3. OVERVIEW

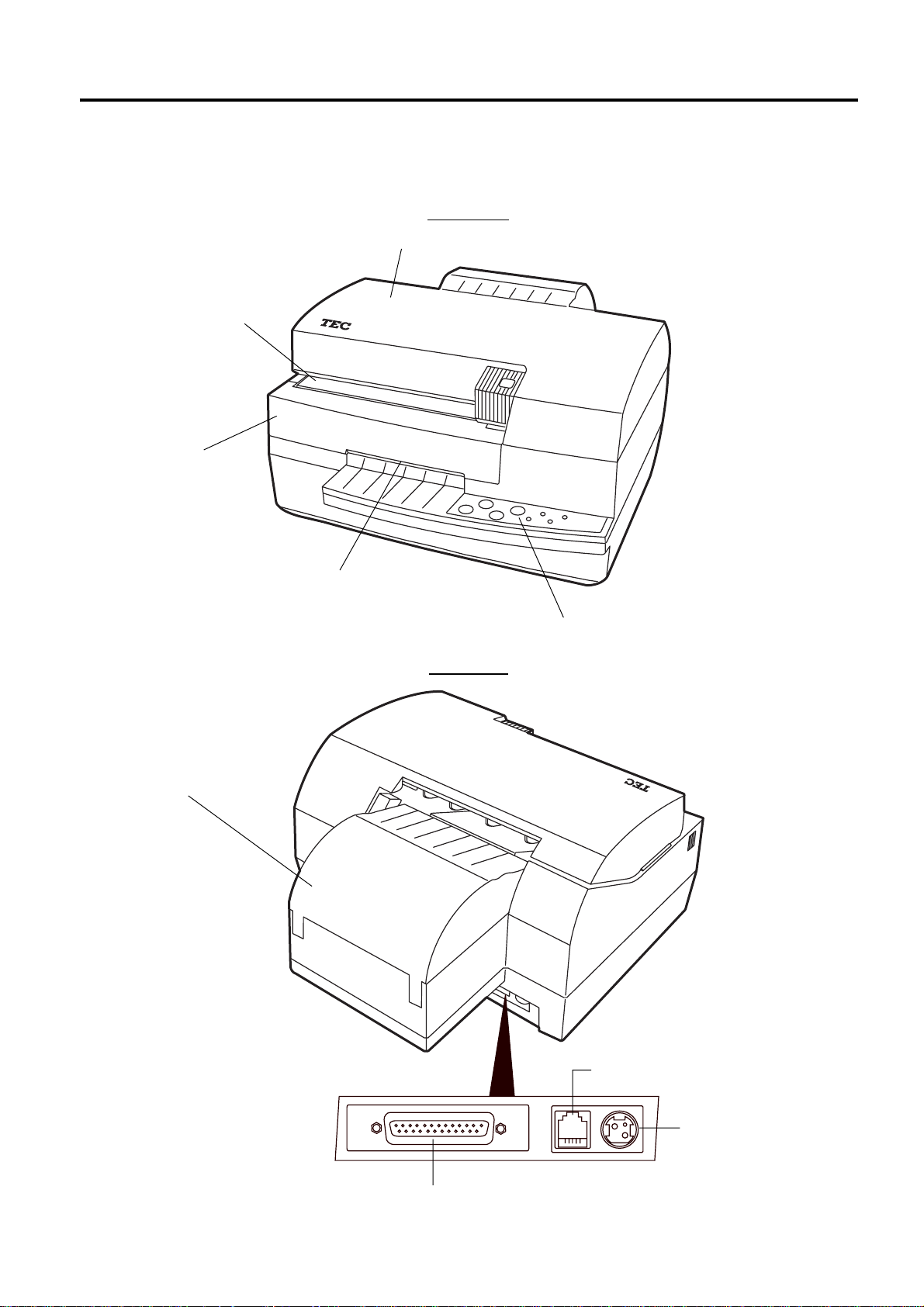

3.1 FRONT/REAR VIEW

Slip Inlet

Front Cover

EO1-13013

3.1 FRONT/REAR VIEW

Front View

Printer Cover

Paper Cover

Receipt Outlet

RESET

CART-

RIDGE

FEED

Rear View

POWER

POWER

ERROR

SLIP

INKOUT

Operation Panel

Fig. 3-1

Serial Interface Connector (RS-232C)

3-1

Drawer Interface

Connector

DC Power Inlet

Fig. 3-2

Page 10

3. OVERVIEW

3.2 OPERATION PANEL

56

CART-

RIDGE

RESET

FEED

78

POWER

2

1

SLIP

POWER

3

4

INKOUT

Fig. 3-3

ERROR

EO1-13013

3.2 OPERATION PANEL

11

1 POWER LED (Green)

11

On: Power is supplied.

Off: Power is not supplied.

Blinking: Ink is being initial operation when

the power turns ON.

22

2 SLIP LED (Green)

22

On: Slip mode

Off: Receipt mode

Blinking: Slip insertion wait state

33

3 INKOUT LED (Orange)

33

On: Ink-end detected

Off: Ink-end not detected (normal

status)

Blinking: Ink-near-end detected

44

4 ERROR LED (Red)

44

On: Paper jam error detected or

Cover open error detected or

Cutter error detected.

Off: Error not detected (normal status)

Blinking: Receipt paper end detected

55

5 POWER Switch

55

When turned on, the Power LED goes on and the printer is ready to print.

When turned off, the head unit/ ink cartridge is moved to the cleaning position and is capped. The

POWER LED is turned off.

If turned off during printing, the print data is lost.

At the moment the power is supplied from the external power supply unit, the printer is in the condition

of Power off (LED not lit) until the power switch is pressed.

When the first time the power is turned on with the external power supply unit, the initial operation is

performed.

66

6 RESET Switch

66

If you press and hold this switch for a few seconds, the initial operation is performed.

NOTE: Clean the head unit only when it becomes dirty or a dot missing occurs. Unnecessary

cleaning will waste ink.

77

7 FEED Switch

77

Used for feeding the receipt and the slip.

If there is a slip, the slip is fed.

If not, the receipt paper is fed.

88

8 CARTRIDGE Switch

88

Used for changing the ink cartridge or the head unit/ ink cartridge.

When the switch is pressed with the printer cover removed, the carriage is moved to the head unit/ ink

cartridge replacement position.

Press this switch again after changing the ink cartridge or the head unit/ ink cartridge, and the carriage

is moved to home position and the initial operation is performed.

3-2

Page 11

4. SET UP PROCEDURE

4.1 REQUIREMENTS FOR OPERATION

EO1-13013

4. SET UP PROCEDURE

4.1 REQUIREMENTS FOR OPERATION

This printer has the following requirements:

• The ECR or POS terminal must have a serial port.

• To communicate with the ECR or POS terminal, an RS-232C cable is required.

RS-232C cable ................25 pins

■ Interface Cables

Use the serial printer cable CBLST-50-2-QM supplied by TOSHIBA TEC or its equivalent.

To prevent radiation and reception of electrical noise, the interface cables must meet the following

requirements:

• Fully shielded and fitted with metal or metalised connector housings.

• Kept as short as possible.

• Should not be bundled tightly with power cords.

• Should not be tied to power line conduits.

NOTE: Use the RS-232C cable which connector securing screws are inch type.

Controller side

D-SUB 9-pin female

PIN-No

Case

2

3

8

4

5

6

Signal

FG

RXD

TXD

CTS

DTR

GND

DSR

Printer side

D-SUB 25-pin male

PIN-No

1

2

3

4

6

7

20

Signal

FG

TXD

RXD

RTS

DSR

SG

DTR

4.2 SETTING UP THE PRINTER

• Place the printer on a flat, stable surface.

• Use a grounded electrical outlet. Do not use an adapter plug.

• Be sure there is adequate room around the printer for easy operation and maintenance.

• Keep your work environment static free.

4-1

Page 12

5. INSTALLATION PROCEDURE

5.1 CONNECTING THE POWER CORD AND CABLES

5. INSTALLATION PROCEDURE

WARNING!

1. Before connecting the power cord and cables to the printer, turn the power of the ECR or POS

terminal OFF.

2. To avoid injury and printer damage, be careful not to catch your fingers or any objects while the

carriage moves right and left in the initial performance.

3. Please be careful when handling ink cartridges, not to get ink on your hands or in your eyes.

If you accidently get ink on your hands wash them with soap and water. If any ink should get

into your eyes immediately flush them out with clear water.

4. Never touch the metal portion of the head unit/ ink cartridge. Doing so will injure your fingers.

CAUTION:

1. Do not put anything on the printer cover and never press on it.

2. Use only TOSHIBA TEC specified paper. Use of non-specified paper may lower the print

quality or shorten the cutter life.

3. Set the receipt roll in the correct direction. Failure to do this may cause a paper jam error.

4. Do not drop or shake the head unit/ ink cartridge. Doing so may cause ink to spill over. Once

ink gets on your clothes, it cannot be removed.

EO1-13013

Operation panel

indication:

SWITCH

POWER

LED

: LED off

: Not depressed.

: LED on

POWER

: Depressed.

: LED blinking

5.1 CONNECTING THE POWER CORD AND CABLES

NOTE: Please use the TEC PS-10-QM AC adapter. To purchase it, please contact your nearest

TOSHIBA TEC service representative.

1. Connect the serial interface cable (corresponding to inch screws) to the printer.

2. If the EPSON* drawer is connected, connect the drawer interface cable.

3. Connect the power cord so that the D cut section faces up.

4. Plug in the AC adapter. The printer performs initial operation.

Serial Interface Cable

(RS-232C)

to Host

to EPSON Drawer

to AC Adapter

Drawer interface Cable

DC Power Cable

* EPSON is a trademark of SEIKO EPSON CORPORATION.

5-1

Fig. 5-1

Page 13

5. INSTALLATION PROCEDURE

5.2 LOADING THE HEAD UNIT/ INK CARTRIDGE

1. Open the printer cover while holding the handle, and remove it.

Printer Cover

CAUTION

Do not put anything

on the cover and

never press it.

* The above sticker is attached

to the printer cover.

Pressing the cover may

reduce print quality.

EO1-13013

5.2 LOADING THE HEAD UNIT/ INK CARTRIDGE

2. Turn the power ON by pressing and holding the

[POWER] switch. The carriage automatically moves

to the head unit/ ink cartridge replacement position.

Carriage

CART-

RIDGE

RESET

FEED

POWER

SLIP

POWER

Fig. 5-2

ERROR

INKOUT

Fig. 5-3

5-2

Page 14

5. INSTALLATION PROCEDURE

5.2 LOADING THE HEAD UNIT/ INK CARTRIDGE

EO1-13013

3. Unpack a head unit/ ink cartridge. Remove the protection pad from the head unit/ ink cartridge. 1

4. Remove the protection sheet from the head unit/ ink cartridge. 2

NOTES: 1. Do not touch the area that had been under the protection sheet with your fingers or with any

object.

2.To avoid the head unit/ ink cartridge from which the protection sheet has been removed from

getting dry, install it into the printer as soon as possible after removing the protection sheet.

3.Do not install the head unit/ ink cartridge with the protection pad and the protection sheet

attached. Doing so will damage the printer.

4.Do not remove the protection sheet while the head unit/ ink cartridge faces down. Also do

not drop or shake the head unit/ ink cartridge. Doing so may cause ink to spill over. Once

ink gets on your clothes, it cannot be removed.

Protection pad

1

2

Protection Sheet

Fig. 5-4

5. Load the head unit/ ink cartridge onto the carriage, and then fully push it in the arrow-indicated

direction until the hook secures the cartridge.

Head Unit/ Ink Cartridge

Hook

Carriage

5-3

Fig. 5-5

Page 15

5. INSTALLATION PROCEDURE

EO1-13013

5.3 LOADING THE RECEIPT ROLL

6. Depress the [CARTRIDGE] switch.

The printer performs the initial operation. After the initial

operation is finished, the carriage returns to the home

position (right end).

CART-

RIDGE

RESET

FEED

POWER

SLIP

POWER

ERROR

INKOUT

7. Insert the two hooks into the holes on the top cover, and then close the printer cover slowly.

Printer Cover

Hooks

Top Cover

Fig. 5-6

5.3 LOADING THE RECEIPT ROLL

1. Open the paper cover toward the rear 1.

2. Cut off both adhesive areas of a new receipt roll.

NOTE: Do not insert the receipt paper with adhesive portions into the printer. If so, adhesive will

attach to the feed roller. This may cause a slant print or a paper jam.

Adhesive

Adhesive

Fig. 5-7

5-4

Page 16

5. INSTALLATION PROCEDURE

3. Load the receipt roll into the paper holder as the figure shows. 2

Receipt Roll

Paper Cover

EO1-13013

5.3 LOADING THE RECEIPT ROLL

NOTE:

Set the receipt roll in correct

direction.

Cut the paper end to make it

sharp.

4. Insert the receipt straight into the receipt inlet. 3

The auto loading mechanism feeds and cuts the receipt automatically.

NOTE: If the rear paper release lever is not pushed down, the

auto loading mechanism does not perform.

The ERROR LED turns off, and the printer becomes ready to

print.

Receipt Inlet

3

Rear Paper Release

Lever (blue)

CART-

RIDGE

RESET

FEED

POWER

SLIP

POWER

Fig. 5-8

ERROR

INKOUT

Fig. 5-9

5. Close the paper cover slowly.

5-5

Page 17

5. INSTALLATION PROCEDURE

5.4 INSERTING THE SLIP

EO1-13013

5.4 INSERTING THE SLIP

1. When the host sends the slip print command to the printer,

the SLIP LED blinks.

2. Insert the slip straight into the slip inlet while aligning the

right side of the slip with the slip inlet.

Slip Inlet

Slip

CART-

RIDGE

CARTRIDGE

RESET

RESET

FEED

FEED

POWER

POWER

POWER

SLIP

POWER

SLIP

ERROR

INKOUT

ERROR

INKOUT

Fig. 5-10

NOTES: 1.

Setting the slip

Paper feed roller

Slip side guide

Slip

Fig. 5-11

• Insert the slip until it fits against the paper feed roller and the slip side guide.

• Setting the slip after the SLIP LED blinks is recommended.

2. Slip paper

• Use the flat paper which is not curled, folded, warped, or wrinkled. Failure to do

this may cause ink smudge resulting from contact with the ink cartridge or a paper

feed error after printing. If the paper end is much curled or folded, the slip paper

may not be set. (In this case, the printer feeds the paper.)

3. Removing the jammed slip

• Check the SLIP LED blinks, and then remove the jammed paper with the [FEED]

switch.

• If the paper cannot be removed with the [FEED] switch, open the printer cover and

pull out the jammed paper manually.

5-6

Page 18

6. REPLACING THE RECEIPT ROLL

6. REPLACING THE RECEIPT ROLL

EO1-13013

6. REPLACING THE RECEIPT ROLL

To replace the receipt roll and to release a paper jam, the following steps should be followed.

WARNING!

To avoid injury and printer damage, be careful not to catch your fingers or any objects while the

carriage moves right and left in the initial performance.

CAUTION:

1. Use only TOSHIBA TEC specified paper. Use of non-specified paper may lower the print

quality or shorten the cutter life.

2. Set the receipt roll in the correct direction. Failure to do this may cause a paper jam error.

1. Turn the power OFF by pressing and holding the [POWER] switch.

2. Open the printer cover while holding the handle, and remove it. (Refer to Section 5.2 LOADING THE

HEAD UNIT/ INK CARTRIDGE)

3. While pushing the front cover in direction 1, remove it in direction 2.

4. Open the paper cover backward. 3

Paper Cover

3

Front Cover

1

2

Fig. 6-1

6-1

Page 19

6. REPLACING THE RECEIPT ROLL

EO1-13013

6. REPLACING THE RECEIPT ROLL

5. Pull up the rear paper release lever (blue). 4

6. Push down the front paper release lever in direction 5, and then remove the receipt roll in direction 6.

Rear Paper Release Lever (blue)

4

6

5

Front Paper Release Lever

Fig. 6-2

7. Return the front cover.

8. Pull down the rear paper release lever (blue).

9. Insert the two hooks into the holes on the top cover, and then close the printer cover slowly.

10.Turn the power ON by pressing and holding the [POWER]

switch.

The POWER LED and ERROR LED turn on.

CARTRIDGE

RESET

FEED

POWER

SLIP

POWER

ERROR

INKOUT

11.Put the new receipt roll into the paper holder. (Refer to Section 5.3 LOADING THE RECEIPT ROLL)

12.Insert the receipt straight into the receipt inlet.

The auto loading mechanism feeds and cuts the receipt automatically.

The ERROR LED turns off, and the printer becomes

ready to print.

13.Close the paper cover slowly.

CART RIDGE

RESET

FEED

POWER

SLIP

POWER

ERROR

INKOUT

6-2

Page 20

7. REPLACING THE INK CARTRIDGE

7. REPLACING THE INK CARTRIDGE

7. REPLACING THE INK CARTRIDGE

The INKOUT LED on or blinking shows that ink is getting

low. The printer can print until ink is fully finished, however,

please replace the ink cartridge with a new one earlier.

CART-

RIDGE

RESET

POWER

FEED

WARNING!

1. To avoid injury and printer damage, be careful not to catch your fingers or any objects while

the carriage moves right and left in the initial performance.

2. Please be careful when handling ink cartridges, not to get ink on your hands or in your eyes.

If you accidently get ink on your hands wash them with soap and water. If any ink should get

into your eyes immediately flush them out with clear water.

CAUTION:

1. Do not put anything on the printer cover and never press on it.

2. Do not drop or shake the head unit/ ink cartridge. Doing so may cause ink to spill over. Once

ink gets on your clothes, it cannot be removed.

POWER

SLIP

or

EO1-13013

ERROR

INKOUT

1. Remove the printer cover. (Refer to 5.2 LOADING THE HEAD UNIT/ INK CARTRIDGE.)

2. Depress the [CARTRIDGE] switch for 3 seconds.

By this operation, the carriage moves to the head unit/ ink

cartridge replacement position.

NOTES: 1. If the printer cover is closed, the carriage will

CART-

RIDGE

RESET

FEED

POWER

SLIP

POWER

ERROR

INKOUT

not move to this position by this operation.

2. Never perform this operation except for the

or

ink cartridge replacement.

Carriadge

Fig. 7-1

3. While pushing the hook in direction 1, remove the ink cartridge from the head unit in diretion 2.

Ink Cartridge

2

Hook

1

7-1

Fig. 7-2

Page 21

7. REPLACING THE INK CARTRIDGE

7. REPLACING THE INK CARTRIDGE

EO1-13013

4. Unpack a new ink cartridge. Pull down both arrow sections remove the protection pad from the

cartridge.

NOTES: 1. Do not touch the ink outlet on the bottom of the ink cartridge with your fingers or any

objects.

2.To avoid the ink cartridge from which the protection pad has been removed from getting

dry, install it into the head unit as soon as possible after removing the protection pad.

3.Do not drop or shake the head unit/ ink cartridge. Doing so may cause ink to spill over.

Once ink gets on your clothes, it cannot be removed.

Protection Pad

Ink Cartridge

Fig. 7-3

5. Insert the ink cartridge into the head unit so that the black and yellow arrows on the ink cartridge line

up with the black and yellow arrows on the carriage.

NOTE: When installing the ink cartridge into the head unit, fully push the ink cartridge until the hook

secures the cartridge.

Head Unit

Carriage

Black arrow

Yellow arrow

Fig. 7-4

Hook

6. Depress the [CARTRIDGE] switch.

The printer performs the initial operation. After the initial

operation is finished, the carriage returns to the home position

(right end), and the power LED stops blinking and remains

on.

7. Insert the two hooks into the holes on the top cover, and then

close the printer cover slowly. The ERROR LED turns off,

and the printer becomes ready to print.

NOTE: Failure to close the printer cover fully may cause an

error condition.

7-2

CART-

RIDGE

CART-

RIDGE

RESET

RESET

FEED

FEED

POWER

POWER

SLIP

SLIP

POWER

POWER

ERROR

INKOUT

ERROR

INKOUT

Page 22

8. REPLACING THE HEAD UNIT/ INK CARTRIDGE

8. REPLACING THE HEAD UNIT/ INK CARTRIDGE

EO1-13013

8. REPLACING THE HEAD UNIT/ INK CARTRIDGE

If the head unit gets dirty or a dot missing occurs, clean the head unit. (Refer to 9.1 CLEANING)

If these phenomena still remain, replace the head unit/ ink cartridge with a new one by the following

procedure.

WARNING!

1. To avoid injury and printer damage, be careful not to catch your fingers or any objects while the

carriage moves right and left in the initial performance.

2. Please be careful when handling ink cartridges, not to get ink on your hands or in your eyes. If

you accidently get ink on your hands wash them with soap and water. If any ink should get into

your eyes immediately flush them out with clear water.

3. Never touch the metal portion of the head unit/ ink cartridge. Doing so will injure your fingers.

CAUTION:

1. Do not put anything on the printer cover and never press on it.

2. Do not drop or shake the head unit/ ink cartridge. Doing so may cause ink to spill over. Once

ink gets on your clothes, it cannot be removed.

1. Turn the power ON by pressing and holding the [POWER]

switch.

CART-

RIDGE

RESET

FEED

POWER

SLIP

POWER

ERROR

INKOUT

2. Remove the printer cover. (Refer to 5.2 LOADING THE HEAD UNIT/ INK CARTRIDGE.)

3. Depress the [CARTRIDGE] switch for 3 seconds. By this operation, the carriage moves to the head

unit/ ink cartridge replacement position. (Refer to 7. REPLACING THE INK CARTRIDGE)

NOTES: 1. If the printer cover is closed, the carriage will not move to this position by this operation.

2. Never perform this operation except for the head unit/ ink cartridge replacement.

4. Remove the head unit/ ink cartridge from the carriage while pulling up the hook in the arrow-indicated

direction.

Head Unit/ Ink Cartridge

Carriage

8-1

Hook

Fig. 8-1

Page 23

8. REPLACING THE HEAD UNIT/ INK CARTRIDGE

8. REPLACING THE HEAD UNIT/ INK CARTRIDGE

EO1-13013

5. Unpack a new head unit/ ink cartridge. Remove the protection pad from the head unit/ ink cartridge. 1

6. Remove the protection sheet from the head unit/ ink cartridge. 2

NOTES: 1. Do not touch the area that had been under the protection sheet with your fingers or with any

object.

2.To avoid the head unit/ ink cartridge from which the protection sheet has been removed from

getting dry, install it into the printer as soon as possible after removing the protection sheet.

3.Do not install the head unit/ ink cartridge with the protection pad and the protection sheet

attached. Doing so will damage the printer.

4.Do not remove the protection sheet while the head unit/ ink cartridge faces down. Also do

not drop or shake the head unit/ ink cartridge. Doing so may cause ink to spill over. Once

ink gets on your clothes, it cannot be removed.

Protection pad

1

2

Protection Sheet

Fig. 8-2

7. Load the head unit/ ink cartridge onto the carriage, and then fully push it until the hook secures the

cartridge. (Refer to 5.2 LOADING THE HEAD UNIT/ INK CARTRIDGE)

8. Depress the [CARTRIDGE] switch.

The printer performs the initial operation. After the initial

operation is finished, the carriage returns to the home

CART-

RIDGE

RESET

FEED

POWER

SLIP

POWER

ERROR

INKOUT

position (right end), and the power LED stops blinking and

remains on.

9. Insert the two hooks into the holes on the top cover, and then

close the printer cover slowly. The ERROR LED turns off,

and the printer becomes ready to print.

CART-

RIDGE

RESET

FEED

POWER

SLIP

POWER

ERROR

INKOUT

NOTE: Failure to close the printer cover fully may cause an

error condition.

8-2

Page 24

9. GENERAL MAINTENANCE

9.1 CLEANING

9. GENERAL MAINTENANCE

WARNING!

1. Be sure to disconnect the power cord prior to performing any maintenance.

2. Do not use any tool that may damage the head unit.

3. DO NOT POUR WATER directly onto the printer.

CAUTION:

1. Do not use a sharp object to clean the head unit. Doing so may damage the head unit, causing

poor print quality or missing dots.

2. Never use an organic solvent like thinner or benzine for cleaning. Using such solvents may

discolor the covers, cause poor print quality, or printer failure.

3. Do not touch the head unit nozzle, as the head unit may fail due to static electricity.

EO1-13013

9.1 CLEANING

9.1.1 Cover and Paper Path

To help retain the high quality and performance of your printer it should be cleaned regularly . The

greater the usage on the printer, the more frequent the cleaning.

1. Turn the power off.

2. Wipe the covers with a dry soft cloth. Clean stains on the covers with a soft cloth slightly

moistened with a mild detergent solution. After that, wipe the covers with a soft moist cloth.

3. Remove dust or paper particles with a slightly moistened soft cloth or air brush.

9.1.2 Head Unit

If the head unit becomes dirty or a dot missing occurs, clean the head unit in the following

procedure.

NOTE: Clean the head unit only when it becomes dirty or a dot missing occurs. Unnecessary

cleaning will waste ink.

1. Turn the power on.

2. Depress and hold the [RESET] switch. Then, the printer performs the head cleaning process

automatically.

9.2 REMOVING JAMMED PAPER

1. Turn the power off.

2. Remove the printer cover. (Refer to 5.2 LOADING THE HEAD UNIT/ INK CARTRIDGE)

3. Remove the front cover. (Refer to 6. REPLACING THE RECEIPT ROLL)

4. Open the paper cover foward the rear.

5. Pull up the rear paper release lever (blue).

6. Remove the jammed paper while pushing down the front paper release lever.

9-1

Page 25

10. TROUBLESHOOTING

10. TROUBLESHOOTING

10.TROUBLESHOOTING

WARNING!

If you cannot solve a problem with the following solutions, do not attempt to repair it yourself. Turn

the power off, unplug the printer, then contact your TOSHIBA TEC representative for assistance.

EO1-13013

Symptom

The power does not turn

on.

Receipt paper or Slip is not

issued.

No print however the

POWER LED lights.

Check Point

• Is the power cord plugged in

correctly?

• Is the power supplied to the AC

outlet?

• Has the fuse or circuit breaker

blown?

• Is the receipt roll loaded

properly?

• Is the printer jammed with the

receipt?

• Is the interface cable connected

correctly?

• Does the specifications of the

interface cable meet that of the

host or the printer?

Solution

• Plug in correctly.

• If it is not a power failure, check

for the power supply to the AC

outlet with another electric

appliance. When the power is

not supplied, contact your

nearest power company.

• Check the fuse or circuit

breaker.

• Refer to page 6-1 and load the

receipt roll properly.

• Refer to page 9-1 and remove

the jammed receipt, and reload

the receipt roll.

• Connect the interface cable

correctly.

• Use a TOSHIBA TEC original

interface cable.

Dim print

• Is ink getting low?

• Refer to page 9-1 and clean the

head unit. If this problem still

occurs, replace the ink cartridge

with a new one.

One print line missing

• Is the head unit dirty?

Is ink getting low?

• Refer to page 9-1 and clean the

head unit. If this problem still

occurs, replace the ink cartridge

or head unit/ ink cartridge with a

new one.

Irregular print/ blurred print

• Is proper paper used?

• Refer to page 2-2 and use the

TOSHIBA TEC specified paper.

Paper feed slantwise

• Is the paper damp?

• Is the paper folded or wrinkled?

• Do not use damp paper.

• Do not use old paper or folded

paper. Use a new one.

• Is the paper damp?

• Do not use damp paper.

If any problem occurs excepting the above, please contact your nearest TOSHIBA TEC representative.

10-1

Page 26

11. ERROR MESSAGE

11. ERROR MESSAGE

Error Item

Ink end

Ink near end

No head

Head temperature

No receipt paper (Receipt paper ended.)

11. ERROR MESSAGE

PANEL-LED Display

ERROR

POWER

INKOUT

SLIP

ERROR

POWER

INKOUT

SLIP

ERROR

POWER

INKOUT

SLIP

ERROR

POWER

INKOUT

SLIP

ERROR

POWER

INKOUT

SLIP

EO1-13013

The receipt paper exists but is not loaded automatically.

Slip jam (issue)

Printer cover open or Front cover open

Cutter position

Head position

Temperature

Receipt jam (at the auto loading)

ERROR

POWER

INKOUT

SLIP

ERROR

POWER

INKOUT

SLIP

ERROR

POWER

INKOUT

SLIP

ERROR

POWER

INKOUT

SLIP

ERROR

POWER

INKOUT

SLIP

ERROR

POWER

INKOUT

SLIP

ERROR

POWER

INKOUT

SLIP

ERROR

While returning at the printer power ON

Slip is required.

Head Unit / Ink Cartridge replacement has not been

finished yet.

POWER

INKOUT

SLIP

ERROR

POWER

INKOUT

SLIP

ERROR

POWER

INKOUT

SLIP

NOTE: In case other combination of LEDs except for the above light or blink, turn the power off,

and then turn the power on. If this does not restore the LEDs, contact your nearest

TOSHIBA TEC representative for assistance.

11-1

Page 27

Page 28

TEC

Loading...

Loading...