Toshiba BMS-WB01GTE SERVICE MANUAL

FILE NO. A09-006

Revised Oct.2009(1)

SERVICE MANUAL

WEB BASED CONTROLLER

Model name:

BMS-WB2561PWE (Web Server/Gateway)

BMS-WB01GTE

(Master Server)

PRINTED IN JAPAN, Jun.,2009

Web Based Controller

Service Manual

Contents

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1 PRODUCT OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 SYSTEM CONFIGURATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 LIST OF FUNCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 PRODUCT SPECIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6 SYSTEM CONNECTION DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7 PRODUCT CONNECTION DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8 SETTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9 TRIAL OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

10 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

11 APPENDIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2

Web Based Controller

SAFETY PRECAUTIONS

Important safety-related information is described on the product and in this Service Guide.

Read the following description on labels and symbols carefully and follow their directions.

[Explanation of labels]

Label Explanation

Service Manual

DANGER

WARNING

CAUTION

Indicates that the repair engineer and other third-party individuals in the vicinity may be

exposed to immediate risk of death or serious injury if operation is not performed correctly.

Indicates that the repair engineer and other third-party individuals in the vicinity may be

exposed to a risk of death or serious injury if operation is not performed correctly.

Indicates that the repair engineer and other third-party individuals in the vicinity may be

exposed to a risk of injury or that property damage (*) may result if operation is not performed

correctly or from failure of product after operation.

(*): Property damage means expanded damages to assets, furniture, livestock and/or pets.

[Explanation of symbols]

Symbol Explanation

Indicates prohibited activity

Specific prohibited actions are described in statements near the symbol.

Indicates enforced action

Specific enforced actions are described in statements near the symbol.

Indicates caution (includes danger alert and warning)

Specific content of caution is indicated in a picture or statement near the symbol.

DANGER

Turn off breaker

Prohibition

Check for ground wire

No alteration

Use designated parts

Turn off breaker before performing work.

Otherwise, one may receive electric shock from the high-voltage electricity, resulting in death or

injury.

Do not turn on the breaker when the cover of the unit is removed.

Otherwise, one may receive electric shock from the high-voltage electricity, resulting in death or

injury.

WARNING

Before fault diagnosis or beginning repair work, make sure that the ground wire is

connected to the ground terminal of the unit.

If not, ground leakage may result in electric shock hazard.

Do not alter the product.

Components of the unit should also not be taken apart or altered.

Otherwise, it may result in fire, electric shock or injury.

Use designated parts for replacement.

Using parts other than those designated may cause fire or electric shock.

3

Web Based Controller

Restricted area

Insulation

Assembly wiring caution

Insulation check

Electric shock caution

Service Manual

WARNING

Do not allow unauthorized personnel other than repair engineers to enter areas where fault

diagnosis and repair work is conducted.

Unauthorized persons may suffer injury from tools and disassembled parts.

Connect lead wires with crimping terminals and turn the closed end upwards to avoid

exposure to water.

Failure to perform this post-connection treatment may cause disasters, such as electricity leakage

and fire, on the client’s premises.

After repair, ensure that the assembly of disassembled parts and the connection and wiring

of removed wires are completed so as to restore them to their former state. Be careful not

to have the internal wires caught in the cover or other closures.

A defect in assembly or wire connection may cause disasters in the client premise, such as

electricity leakage and fire.

After repair, check for insulation between the charged part and non-charged metal part

(ground terminal) using an insulation resistance tester (500V) and ensure at least 2MΩ

resistance.

If the insulation resistance value is low, it indicates the risk of disasters, such as electricity leakage

and electric shock, on the client’s premises.

In case of performing circuit inspection while the circuit is connected to a power source (if

such condition is necessary), use rubber gloves and other measures to prevent contact

with the charged part.

Otherwise, one will risk electric shock from contacting the charged part.

Check after repair

Repair and Reinstall

Upon completion of repair, ensure that there are no abnormalities.

Risks of fire, electric shock or injury may be prevented by inspection.

Turn off the breaker before performing inspection.

Test run the system after repair and make sure that there are no abnormalities including

smoke.

Risks of fire and electric shock may be prevented by inspection.

Repair and reinstallation must be performed by qualified professional.

4

Web Based Controller

Service Manual

1 PRODUCT OVERVIEW

This product controls the air conditioning equipment in the building centrally from the browser of a client PC

connected to the network, to which the Master Server or Web Server is connected.

Up to 2048 indoor units can be connected.

Two systems are available: Master Server System and Web Server System.

The number of connected air conditioning products determines which system is to be used.

Master Server System :A Gateway is needed if there are 257 or more indoor units.

The air conditioners are controlled by one Master Server and a maximum of eight

Gateways.

Web Server System :One Web Server controls the air conditioners if the number of indoor units is less than

257.

NOTE

The Web Server and Gateway are the same product (BMS-WB2561PWE). In this document, when BMSWB2561PWE is used with the Master Server System, it is referred to as “Gateway” and when it is used in a

Web Server System, it is called “Web Server.” What BMS-WB2561PWE is called depends on the function of

the product in each system.

1-1. Main Functions

Monitoring/Controlling Air Conditioners

Enables users to monitor the operating status, setup status and error status of all their air conditioners, to start and

stop all theirs air conditioners, and change the setup details of all their air conditioners.

The air conditioners are named and categorized in a hierarchy by each floor, tenant, area, and air conditioning

system. When controlling the air conditioners, they can be set in batch by each floor, tenant or area, or they can

be set individually for each air conditioning system.The air conditioners can be controlled by linking to the locking

signals and the fire alarm signals.

Scheduled Operation for Air Conditioners

Operation of all air conditioners can be scheduled. Up to 10 setups can be programmed for each day, and it is

possible to prevent users from forgetting to switch off by setting a stop schedule. During scheduled operation, users

can set the Power status (On/Off), Operation mode, Temperature setup, Remote control operation restricted/

allowed and Return back. In the master schedule, users can set weekly schedules and five types of special day

schedules, as well as monthly schedules for 12 months.

Distributing Power used by Air Conditioners

It is possible to distribute the power to be used for each air conditioner. In the billing schedule setup, it is possible

to monitor the operation time period and power distribution during both working hours and non-working hours

separately. Note that power distribution requires the Energy Monitoring Relay Interface (sold separately).

Warning List

Displays all current warnings in a list. Warning history is also displayed in a list.

Occurrence of an alarm is notified by E-mail.

Summer Time

Summer time can be set.

5

Web Based Controller

Service Manual

2 SYSTEM CONFIGURATION

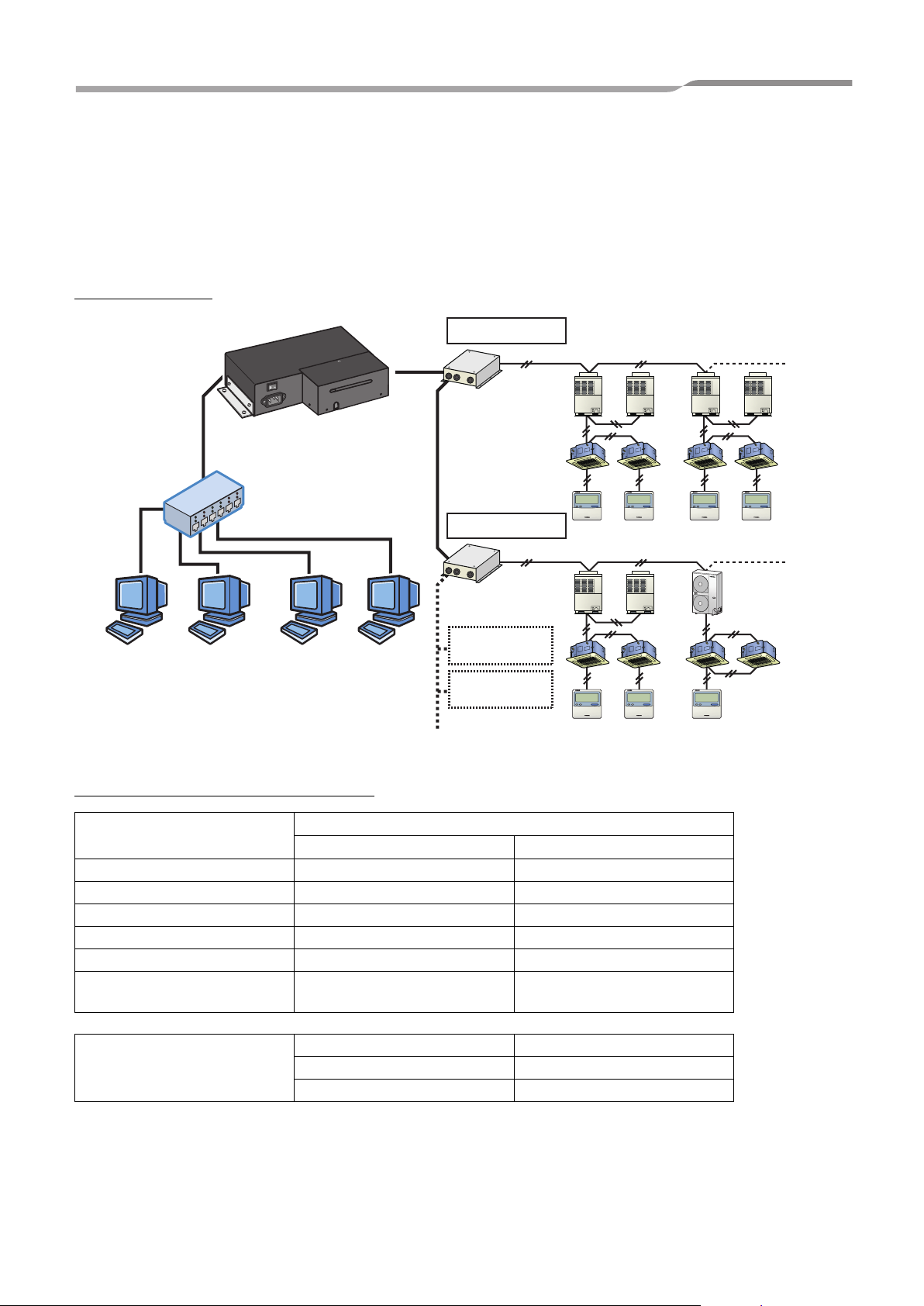

2-1. Web Server System (In case of connecting 256 FCUs

or less)

System diagram

BMS-WB2561PWE

(Web Server)

Ethernet

PC (WINDOWS) *Local supply

RS-485

HUB

Network, Intranet, connection

through LAN port

TCS-Net Relay I/F

BMS-IFLSV3E

TCS-Net Relay I/F

BMS-IFLSV3E

I/F for Power Meter

(BMS-IFWH4E2)

I/F for I/O signal

(BMS-IFDD02E2)

TCC-LINK

SMMS

TCC-LINK

SMMS

SMMS

MiNi-SMMS

System product configuration table

Product name

Web Server BMS-WB2561PWE 1

Indoor Unit (TCC-LINK integrated model) Max. 256

TCS-NET Relay Interface BMS-IFLSV3E Max. 8

Energy Monitoring Relay Interface BMS-IFWH4E2 Max. 4

Digital Input/Output Relay Interface BMS-IFDD02E2 Max. 4

Central Remote Controller TCB-SC642TLE

BMS-CM1280TLE

OS Windows XP,Vista

Client PC specification

Browser Internet Explorer 6.0 or 7.0

Display 1,024 X 768 more

Model name Max. connectable units

Web Server System

Max. 10

6

Web Based Controller

Service Manual

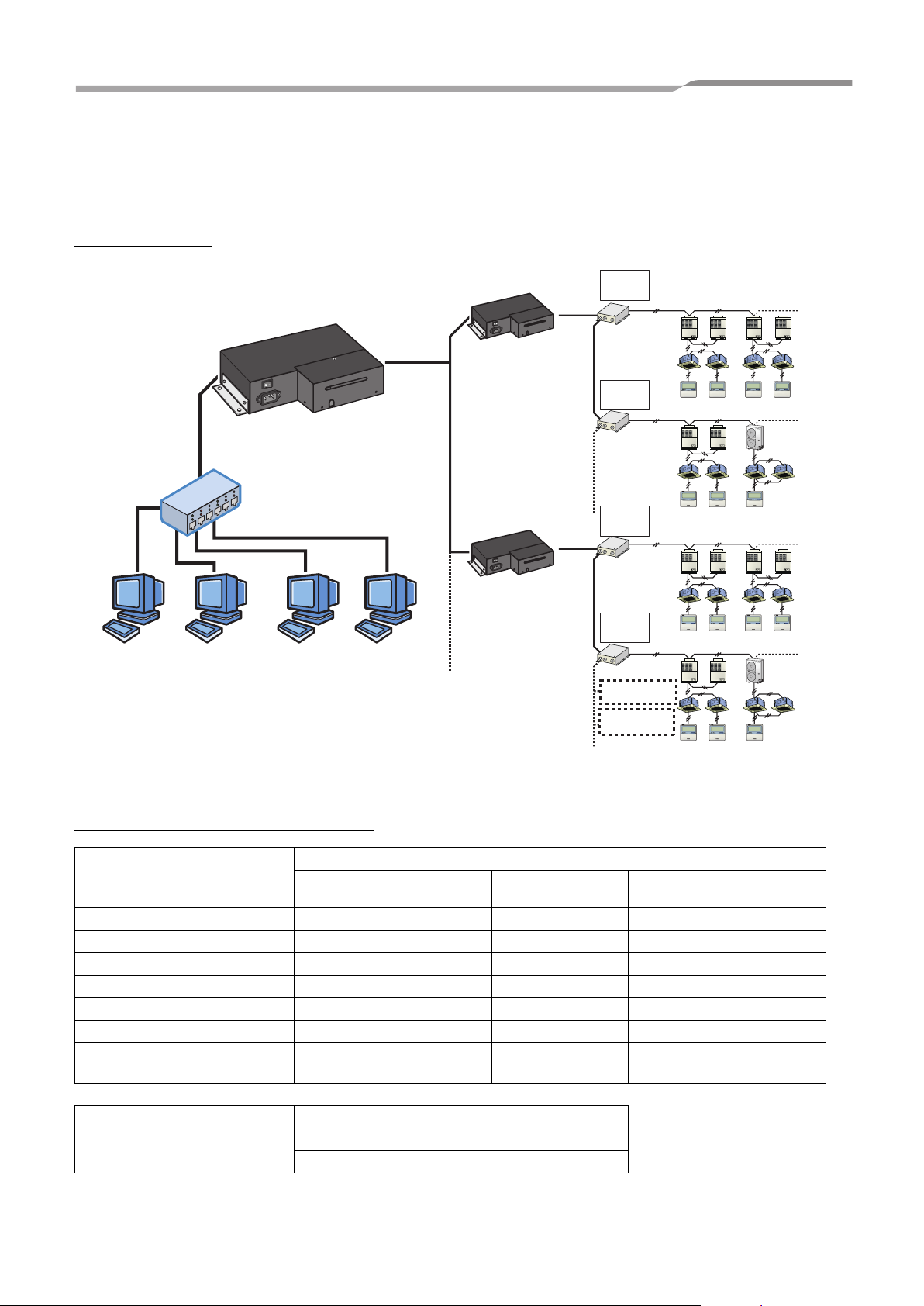

2-2. Master Server System (In case of connecting 257

FCUs or more)

System diagram

TCS-Net

BMS-WB01GTE

(Master Server)

Ethernet

BMS-WB2561PWE

(Gateway)

Relay I/F

TCC-LINK

SMMS

SMMS

HUB

PC (WINDOWS) *Local supply

Network, Intranet, connection through LAN port

Enable to connector up to 2,048 FCUs

System product configuration table

RS-485

BMS-WB2561PWE

(Gateway)

RS-485

TCS-Net

Relay I/F

TCS-Net

Relay I/F

TCS-Net

Relay I/F

I/F for Power Meter

(BMS-IFWH4E2)

I/F for I/O signal

(BMS-IFDD02E2)

TCC-LINK

MiNi-SMMS

SMMS

TCC-LINK

SMMS

SMMS

TCC-LINK

MiNi-SMMS

SMMS

Master Server System

Product name

Model name

Max.

connectable units

Notes

Master Server BMS- WB01GTE 1

Gateway BMS- WB2561PWE Max. 8

Indoor Unit (TCC-LINK integrated model) Max. 2048 Max. 256 units per Gateway

TCS-NET Relay Interface BMS-IFLSV3E Max. 64 Max. 8 units per Gateway

Energy Monitoring Relay Interface BMS-IFWH4E2 Max. 32 Max. 4 units per Gateway

Digital Input/Output Relay Interface BMS-IFDD02E2 Max. 32 Max. 4 units per Gateway

Central Remote Controller TCB-SC642TLE

BMS-CM1280TLE

Max. 80 Max. 10 units per Gateway

OS Windows XP,Vista

Client PC specification

Browser Internet Explorer 6.0 or 7.0

Display 1,024 X 768 more

7

Web Based Controller

2-3. Communication Specification

TCC-LINK Topology Bus

Signal wire type 2-core shield wire

Wire size, length In case of 1.25mm

In case of 2.00mm

Number of nodes Max. 100

(Sum of indoor units, outdoor units, central remote controllers, and interfaces)

Transmission rate 9.6kbps

Polarity No

RS-485 Topology Bus

Signal wire type 2-core shield wire

Length Max. 500m (Total length)

Number of nodes Max. 32

Transmission rate 115.2kbps

Polarity Yes

2

(AWG16): Max. 1,000m (Total length)

2

(AWG14): Max. 2,000m

Service Manual

Ethernet Network interface 10BASE-T/100BASE-TX (Auto-sensing)

Transmission rate 10M bps (10BASE-T)

100M bps (100BASE-TX)

Transmission media In case of 10BASE-T: Category 3 or Category 5

In case of 100BASE-TX: Category 5 (*)

Straight/Crossover Use a straight cable or crossover cable depending on use.

Length Max. segment length: 100m

Connection RJ-45 connector

(*) LAN cable: Unshielded twisted pair (UTP)

8

Web Based Controller

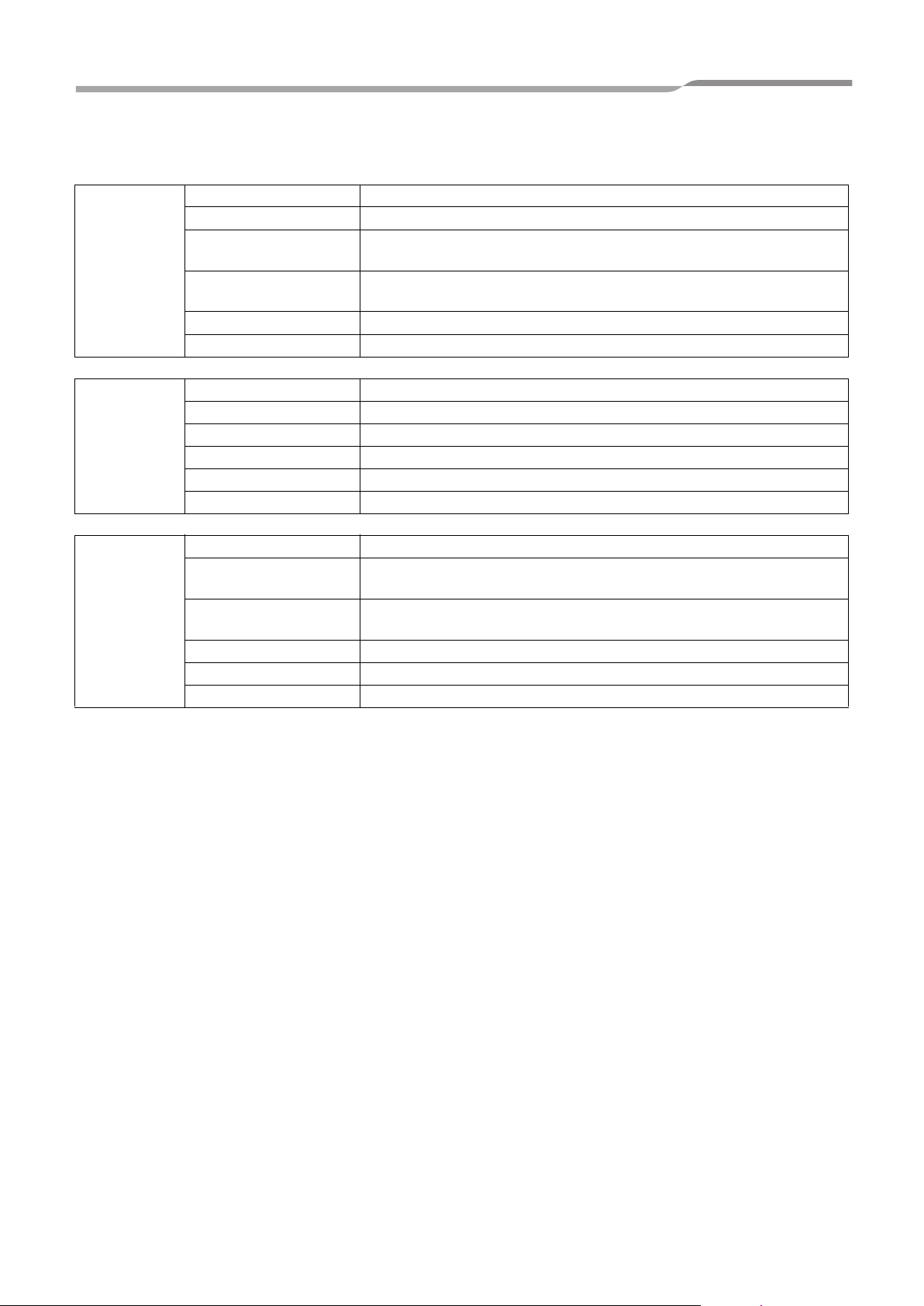

3 LIST OF FUNCTIONS

Function Details

User account Number of user registrations 256

Type of user account Administrator

Power user

Guest

Air conditioner category Category structure 3 levels

Level names (“Floor”, “Tenant”, “Area”) can be changed

Monitoring screen format Monitoring screen Icon screen; List screen

Monitoring air conditioner status Start/Stop

Operation mode

Set temperature

Fan speed

Louver

Remote control prohibition /

permission

Warning

Filter sign

Room temperature

Return back

Controlling air conditioner Start/Stop

Operation mode

Set temperature

Fan speed

Louver

Remote control prohibition /

permission

Filter sign reset

Return back

Operation schedule Number of registrations Equivalent to the number of indoor units

Settable period 7 days, Up to 1 week later including current date

Number of set points per day 10 settings

Interval of set point 1 minute

Settable parameters Start/Stop

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9 SWING /NO SWING

9

9

9

Operation mode

Set temperature

Remote control prohibition / permission

Return back

Service Manual

9

Web Based Controller

Master schedule Number of registrations 256

Settable period Up to 12 months later including current month

Number of set points per day 10 settings

Interval of set point 1 minute

Number of days assigned

special day schedule

Settable parameters Start/Stop

Weekly schedule pattern By day schedule: 7 patterns, Monday through Sunday

Special day schedule pattern By special day schedule: 5 patterns

Schedule assigning unit By indoor unit

Billing schedule Number of registrations 128

Singularity settable period Up to 12 months later including current month

Number of set points per day 10 settings

Interval of set point 1 minute

Number of days assigned

special day schedule

Settable parameters Working hours/Non-working hours

Number of schedule patterns By day schedule: 7 patterns, Monday through Sunday

Schedule assigning unit By indoor unit

Warning display Number of cases 4096

Date/Time of warning

Warning code

Warning details

Warning history display Number of cases 4096

Date/Time of warning

Date/Time of recovery

Warning code

Warning details

Air conditioner communication error display

Alarm E-mail

Number of recipient registration 8

Sending warning details Communication error (system error) and air conditioner warning

45 days per a special day schedule

Operation mode

Set temperature

Remote control prohibition

Return back

45 days per a special day schedule

By singularity schedule: 5 patterns

9

9

9

9

9

9

9

9

9

Service Manual

10

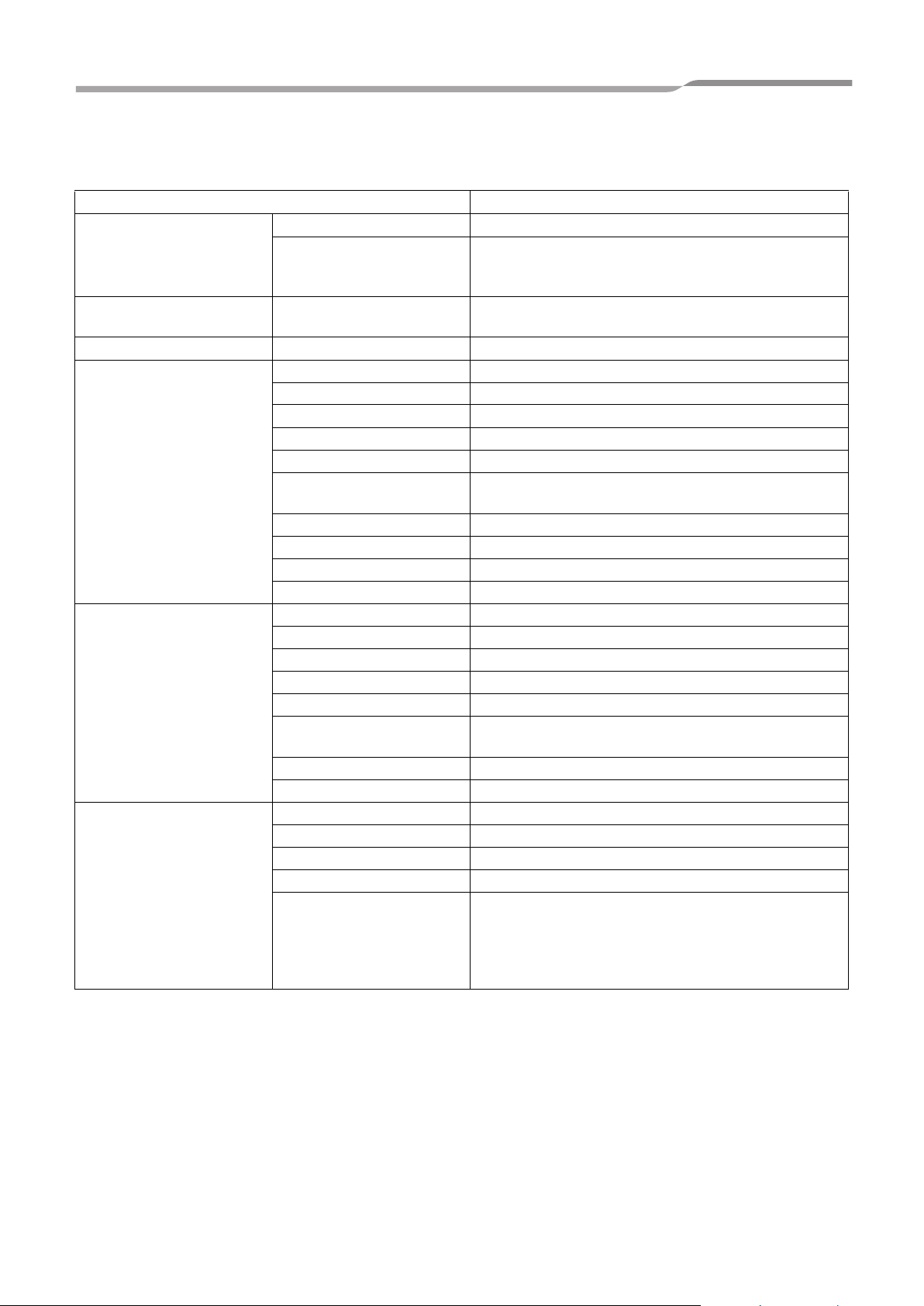

Web Based Controller

Operation history 9 (Operation from client PC is recorded)

Number of cases recordable 200

Air conditioner operation –

Schedule setting

History clear

Account setting

Alarm E-mail setting 9

Time setting

Automatic meter reading setting

Manual meter reading operation

Operation mode restriction

setting

Setting from system setting

screen

User logon/logoff

Scheduler operation –

Air conditioner status change –

Power distribution

Data keeping period Daily report file: Stored for 3 months

Automatic meter reading

Manual meter reading

Centigrade/Fahrenheit Temperature display switching

Set temperature Unit of 1°C or 0.5°C switching

Return back

Summer time

Control by linking to locking signal

Control by linking to fire alarm signal

Operation mode restriction

Time setting

9

9

9

9

9

9

9

9

9

9

Monthly report file: Stored for 3 months

Files that exceeded their keeping period are automatically

deleted.

9

9

9

9

9 (Only settable on scheduler)

9

Summer time enable/disable setting

Shift time: 1 hour fixed

Setting by month/week (Xth week + final week)/day/hour/minute

Default setting by selecting country (Region) is not supported.

9

9

9

9

Service Manual

11

Web Based Controller

4 PRODUCT SPECIFICATION

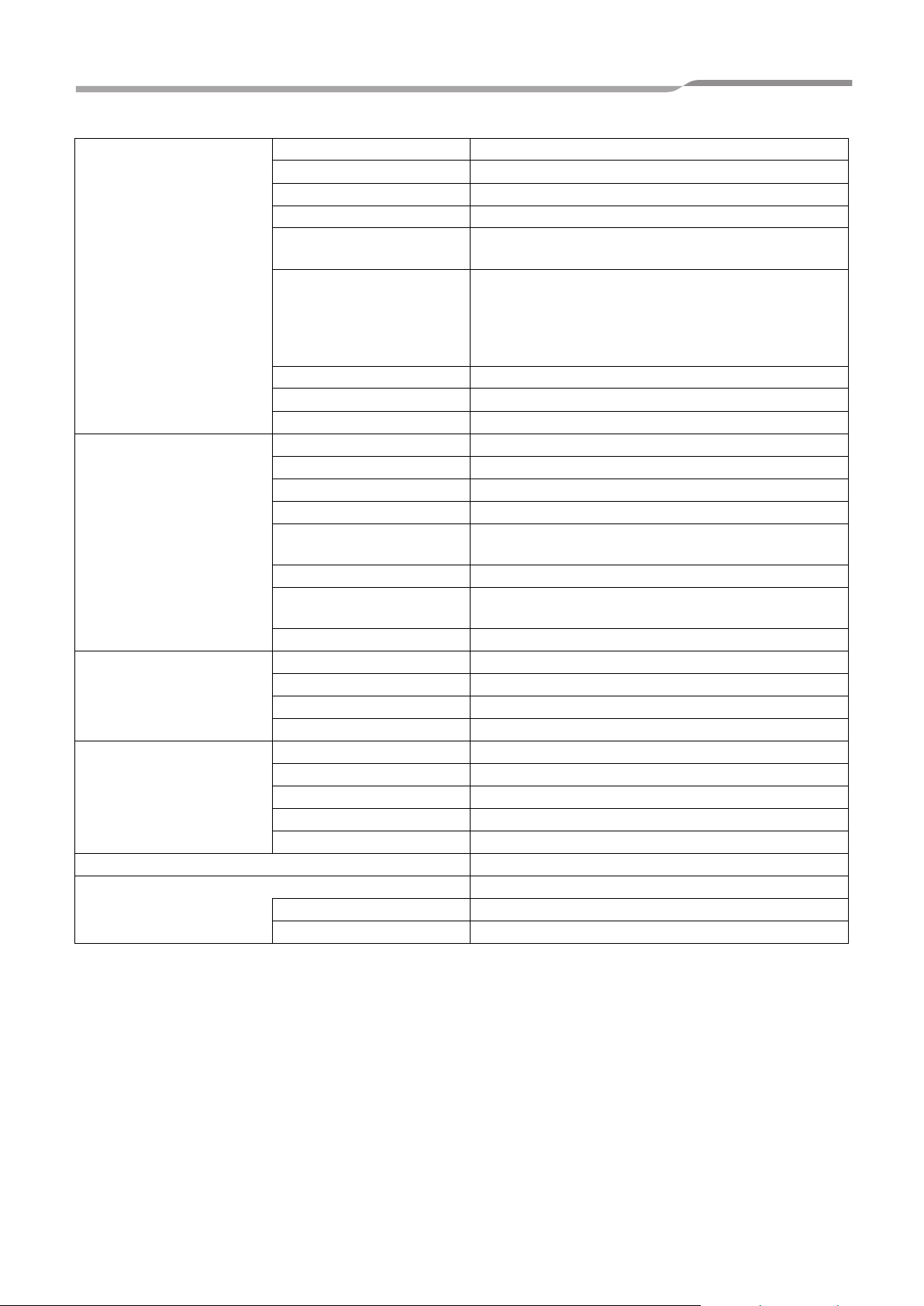

BMS-WB01GTE • BMS-WB2561PWE (Master Server, Web Server / Gateway)

Service Manual

9

12565

11

171

250

280

292

19

105

4-Ø4.6

145

210

71.6

BMS-IFLSV3E (TCS-NET Relay Interface)

200

1

2

3

4

5

6- 5.5 mounting holes

22787822

147

66

63.6

Top side

70

156

170

Bottom side

Power Supply 220-240 VAC 50/60 Hz

Input Current 0.2 A

Operating

temperature/humidity

0 to 40 °C, 10 to 90 %RH

(no condensation)

Storage temperature -20 to 60 °C

Dimension

250 (W) × 71.6 (H) × 210 (D) mm

292 (W) including the fixing metal plate

(

Mass 2.2 kg

Power supply 220 - 240 VAC, 50/60 Hz

Power consumption 2.4 W

Operating

temperature/humidity

0 to 40 °C, 10 to 90% RH

(no condensation)

Storage temperature -20 to +60 °C

Dimensions 66 (H) x 170 (W) x 200 (D) mm

Mass 1 kg

)

22787822

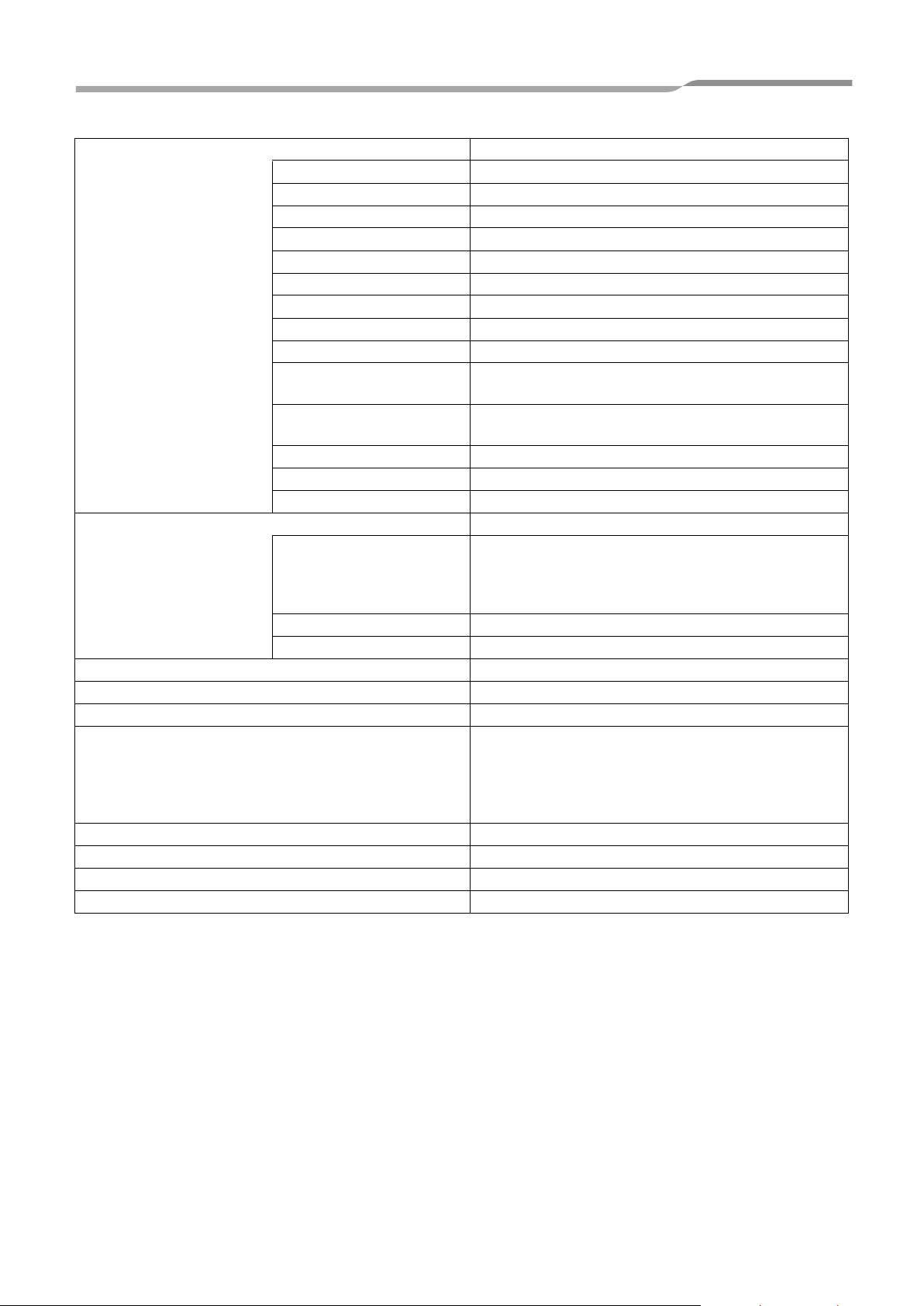

BMS-IFWH4E2 (Energy Monitoring Relay Interface)

1818 53.5 103.5

234

1818

92.5

(193)

64.5

220

63.6

246

Power supply 220 - 240 V, AC 50/60 Hz

Power consumption 2.8 W

Operating temperature/

humidity

Storage temperature -20 to +60 °C

Dimensions

Mass 1.65 kg

Power supply 220 - 240 V, AC 50/60 Hz

Power

meter

input

0 to 40 °C, 10 to 90% RH

(no condensation)

66(H) x 193(W) x 246(D) mm

Power meter input Photo-coupler insulation

Input points 8 points

Input registance 9 k ohm

Input "ON" current 1 mA

Input pulse condition 50 m - 1000 m sec

12

Web Based Controller

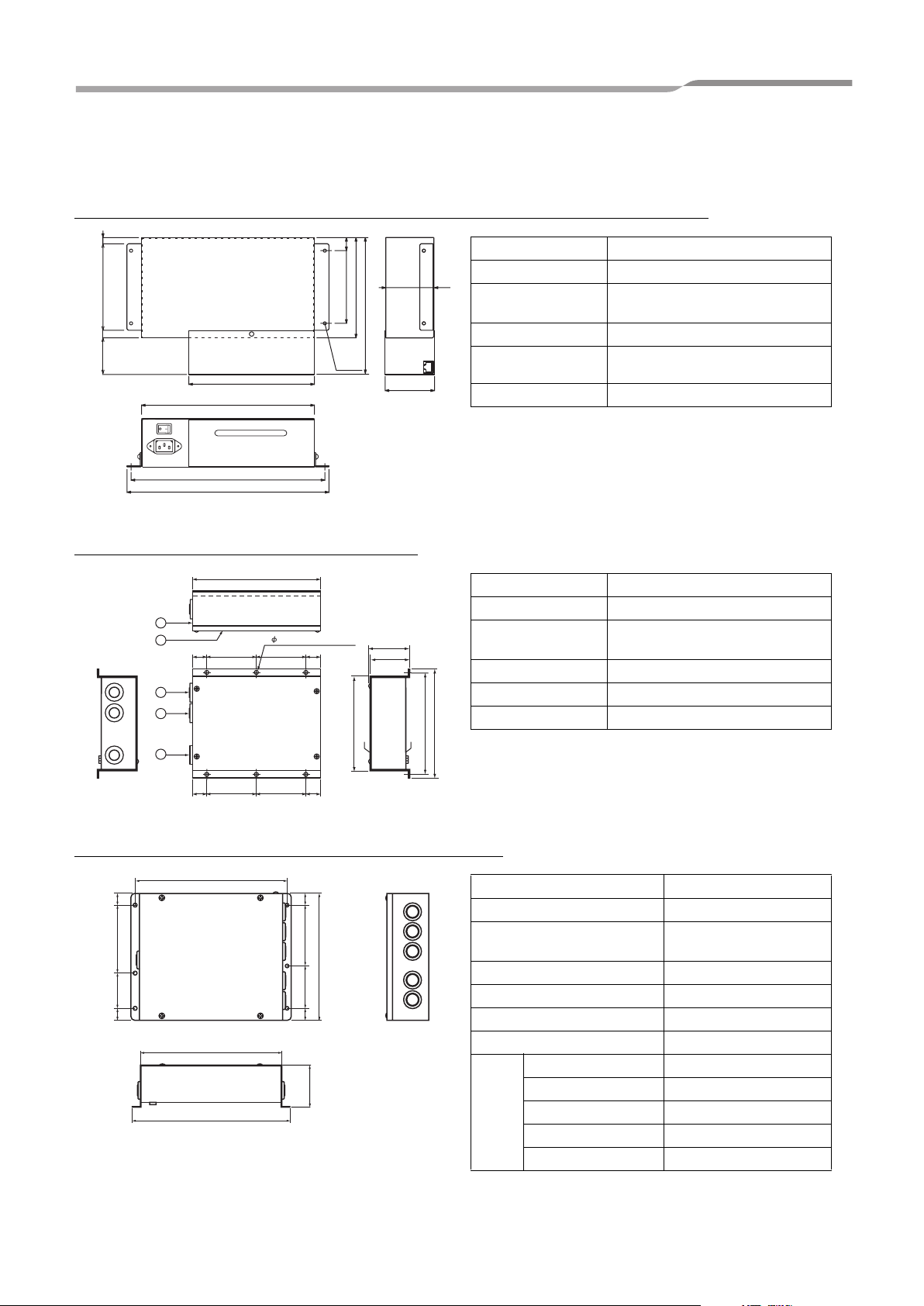

BMS-IFDD02E2 (Digital Input / Output Relay Interface)

1818 53.5 103.5

234

220

246

1818

92.5

64.5

63.6

(193)

66

Power supply 220 - 240 V, AC 50/60 Hz

Power consumption 6.5 W

Operating temperature/humidity

Storage temperature -20 to +60 °C

Dimensions

Mass 1.65 kg

Digital

input

Digital

output

External power supply for

Input/Output

Service Manual

0 to 40 °C, 10 to 90% RH

66(H) x 193(W) x 246(D) mm

Input type Photo-coupler insulation

Input points 8 points

Input registance 9 k ohm

Input "ON" current 1 mA

Output type Open collector

Output points 4 points

Output current Max. 35 mA (per point)

Output voltage Less than DC 24V

DC 12 V, 120 mA

13

Loading...

Loading...