Page 1

INSTALLATION MANUAL

TOUCH SCREEN CONTROLLER

for Air Conditioning Control System

Model: BMS-TP0641ACE

BMS-TP0641PWE

BMS-TP5121ACE

BMS-TP5121PWE

• Thank you very much for purchasing the TOSHIBA Touch Screen Controller.

• Please read this manual carefully beforehand for proper installation of the controller.

CONTENTS

Precautions for Safety.................................................................................................................... 1

Introduction ..................................................................................................................................... 2

Before Installation .......................................................................................................................... 3

1 Installation .................................................................................................................................... 3

2 Connection of Power cables/Earth wires/Signal wires ........................................................... 5

3 Trial Operation ............................................................................................................................. 8

Page 2

Precautions for Safety

• Read these "Precautions for Safety" carefully before installation.

• The precautions described below include important items regarding safety. Observe them without fail.

• After the installation work, perform a trial operation to check for any problem. Follow the Owner's

Manual to explain how to use and maintain the unit to the customer. Ask the customer to keep this

Installation Manual together with the Owner's Manual.

WARNING

• Ask an authorized dealer or qualified installation professional to install or reinstall the Touch

Screen Controller.

Improper installation may result in electric shock or fire.

• Turn off the main power supply switch or breaker before attempting any electrical work.

Make sure all power switches are off. Failure to do so may cause electric shock.

• Perform installation work properly according to this Installation Manual.

Improper installation may result in electric shock or fire.

• Do not modify the unit.

Any modification may cause a malfunction, resulting in overheating or fire.

CAUTION

Upon customer’s approval, install the Touch Screen Controller at a place which satisfies the

following conditions.

• Place where the Touch Screen Controller can be installed securely.

• Place which can reserve a sufficient service space for safe maintenance or check.

• Place where CF (Compact Flash) card can be removed easily.

• Place which provides sufficient space for connecting/checking the terminals of interface, Input-

Output ports, etc.

Avoid the following places.

• Places where a device generating high frequency (inverter, non-utility generator, medical apparatus,

or communication equipment) is installed. (A bad influence may generated by malfunction of the

controller, control error, or noise may affect such equipment.)

• Perform wiring correctly in accordance with specified the current capacity.

Failure to do so may result in short-circuiting, overheating, or fire.

• Connect the specified cables for the terminals securely to prevent external forces from

affecting them.

Failure to do so may result in disconnection, overheating, or fire.

1

Page 3

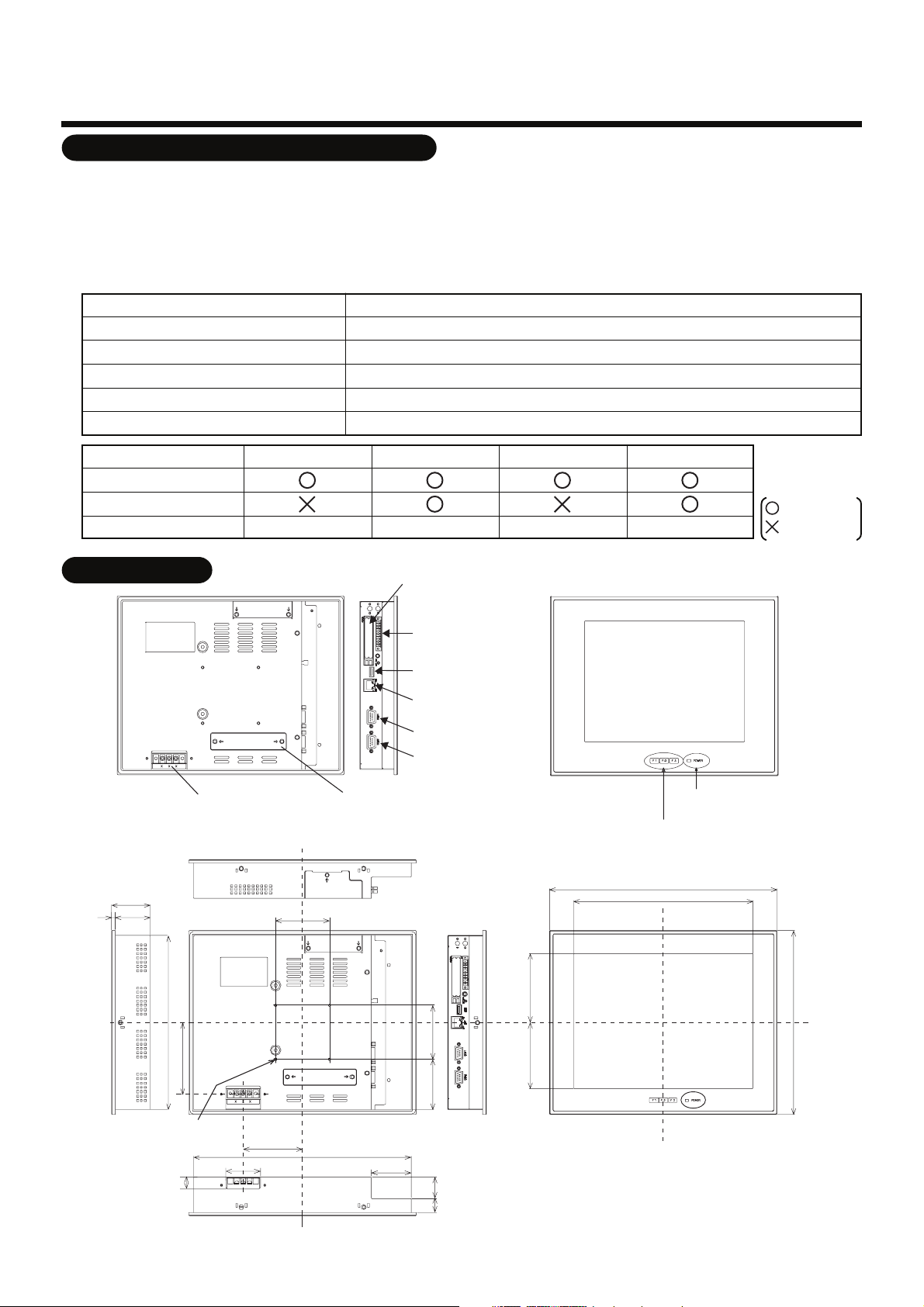

Introduction

Applications/Functions/Specifications

Applications/Functions

•

The Touch Screen Controller is equipped with the LCD display and the touch panel and has various

functions such as operation control, operation status monitoring, scheduled operation, and error code

display of up to 64 or 512 indoor units.

Specifications

•

Power supply

Power consumption

Operating temperature/humidity

Storage temperature

Dimensions

Mass

BMS-TP0641ACE BMS-TP0641PWE BMS-TP5121ACE BMS-TP5121PWE

Air conditioning control

Power distribution

Indoor units connected

Max. 64 units Max. 64 units Max. 512 units Max. 512 units

100 - 240 VAC, 50/60Hz

50VA

0°C to 50°C, 20% to 85% RH (no condensation)

-10°C to +60°C

256 (H) × 316 (W) × 54 (D) mm

3.5kg

: available

: Not available

External View

54

549

242

Power input

terminal block

75

CF (Compact Flash)

card slot (CF card for

data files)

Input/Output port

USB

Ethernet

COM1(RS-232C)

COM2(RS-485)

PCI expansion unit

connector cover

POWER LED

Function switch (F1, F2, F3)

316

249

95.7591.75

256

99.3

M4 Tap (×4 pcs.)

(depth: 10 mm max.)

16

48

82.5

302

55.5

70 75

19 30

unit: mm

2

Page 4

Before Installation

Check the following package contents.

No.

1

Touch Screen Controller

2

Fixture

3

CF(compact flash) for data file

4

CF adapter

5

Simple stand

6

Triangle thread screw (M4 × 8, Ni)

7

Card cover

8

Triangle thread screw (M3 × 6, Ni)

9

RS-485 cable

10

Installation Manual

Use the following materials to connect the signal lines and power lines. (procured on site)

No.

For RS-485

1

For digital Input/Output connection

2

For Power

3

Item

Line

Quantity

1

6

1

1

1

1

1

1

1

1

Type

Wire size

Length

Type

Wire size

Length

Type

Wire size

Remarks

For fixing the unit at pannel mount

It is inserted in the CF card slot of controller at shipment.

(For data file)

It is inserted in the CF card slot of controller at shipment.

For simple stand

For preventing CF(compact flash) from coming out

For card cover

For connecting controller and TCS-NET Relay Interface

This manual

Description

2-core shield wire

1.25mm2, 500m max. (total length)

2-core wire, 0.3mm2, 100m max

H07 RN-F or 245IEC66

0.75mm2, 50 m max.

1

Installation

Installation Space and Maintenance Space

Space 30mm or more in between the controller and surrounding objects.

Make space for service.

Panel

30 mm or more (top)

30 mm or more (side)

Bottom view

30 mm or more (bottom)

30 mm or more (rear)

Side view

Interface side

Panel

3

Page 5

Installation Method

Two installation methods are provided. One is the panel mount with the fixture. The other is the desk top

installation using the CONTEC stand (procured on site).

(1) Panel Mount

How to install the fixture

1. Insert the controller from outside of the panel.

Panel cut size

+1

303

-0

R1 or less

+1

-0

243

Panel thickness: 1.6 - 7 mm

2. Insert the fixtures from inside of the panel.

Touch Screen

Controller

Panel

Fixture

Tightening screws excessively

may cause the screws to break.

Optimum tightening torque for

good waterproofing effect is

0.6N/m.

REQUIREMENT

Use a panel

(procured on site) of

thickness 1.6-7 mm.

(2) Desk Top Installation using the CONTEC stand (procured on site)

75 mm

75 mm

The angle adjustment lock screw.

(Loosen the screw and adjust angle.)

For reference

Display stand (not supplied with the controller)

Use the CONTEC stand (model: IPC-SND-03).

For details of the stand, visit the CONTEC web site.

Europe: http://www.contec-europe.com/

China: http://www.contec.sh.cn/

[mm]

REQUIREMENT

Do not install the unit in any of the following places.

• Humid or wet place

• Dusty place

• Place exposed to direct sunlight

• Place where there is a TV set or radio within one meter

• Place exposed to rain (outdoors, under eaves, etc.)

4

Page 6

Connection of Power cables/Earth wires/

2

Signal wires

Connect cables to the connectors and terminals specified.

REQUIREMENT

Power cable is not supplied for the Touch Screen Controller. Prepare a 3-pin power cable conforming

to applicable safety standards. Be sure to connect the earth line earth of the power cable securely.

Digital Input

Digital Output

For details of the connection,

refer to I/O port connection

on next page.

Ethernet

(To customer's PC)

Power input terminal

L

N

Power supply

Length of stripped

power cable

Connect firmly the power

cable to the power input

terminal.

35 10

45 10

COM2 Ethernet I/O port

Connect the attached

RS-485 cable to COM2.

COM2 (RS-485)

(TCS-NET relay interface)

Length of stripped digital

Input/Output connector wire

35 10

CAUTION

• Ensure to connect the breaker to the primary side of power.

5

Page 7

Connection of Power cables/Earth wires/

2

Signal wires

(continued)

I/O Port Connection

The I/O Port is used to control air conditioners by interlocking them with electric lock signals and fire alarm

signals, and to transmit air conditioner failures to other devices.

I/O Port

10 1

↓ Front (LCD side)

Pin No. Signal name

1

2

3

4

5

6

7

8

9

10

PI_PCOM

PI(0)

PI(1)

PI(2)

P_PO(0)

N_PO(0)

P_PO(1)

N_PO(1)

P_PO(2)

N_PO(2)

Input plus common

Input 0

Input 1

Input 2

Output 0+

Output 0-

Output 1+

Output 1-

Output 2+

Output 2-

Remarks

Input/Output specifications

Input

Output

Input type

Number of input

Input resistance

Output type

Number of output

Output current

Output voltage

Photo-coupler insulation

3

3k ohm

Open collector

3

Max. 100mA (per 1 output)

Less than 30V DC

(1) The example of input circuit is shown below.

It is electrically insulated by the photo-coupler.

PI_PCOM

10 k ohm

3 k ohm

1/2 W

PI(0) - PI(2)

Input/Output

connector

Input c

ontact

External power supply

(12 V - 24 V DC)

(2) The example of output circuit is shown below.

It is electrically insulated by the photo-coupler.

(External circuit)

330 ohm

PC357

P_PO(0) - P_PO(2)

2SD780A

4.7 k ohm

N_PO(0) - N_PO(2)

Input/Output

connector

load

External power

supply

(Max. 30 V DC)

6

Page 8

Connection of Power cables/Earth wires/

2

Signal wires

(continued)

The example of the system wiring connection is shown below.

Terminator Resistor Setting

RS-485 terminator resistor

•

The terminator resistors of RS-485 are set at both ends of communication cable. The RS-485

terminator resistor (at one end) of the Touch Screen Controller is set at shipment. No setting is needed.

SW6

ON

TCC-LINK

TERMINATOR

12

SW5

ON

RS-485

TERMINATOR

1

2

RS-485

TCS-NET RELAY

INTERFACE

SW6

ON

TCC-LINK

TERMINATOR

12

SW5

ON

RS-485

TERMINATOR

1

2

RS-485

TCS-NET RELAY

INTERFACE

ADDRESS

ADDRESS

U4U3

SW1

8

U2U1

Outdoor

unit

U2U1

U2U1

Indoor unit

Remote

controller

U4U3

U2U1

Outdoor

SW1

1

unit

U2U1

Remote

controller

U2U1

Indoor unit

Outdoor

unit

Indoor unit

Remote

controller

Outdoor

unit

Indoor unit

Remote

controller

U4U3

U2U1

U2U1

U4U3

U2U1

U2U1

U4U3

Indoor unit

U4U3

Indoor unit

Yellow

A

Caution:

RS-485 cable has polarity.

If incorrectly connected, it

does not work.

Red

Brown

B

Crimp 3 wires with

a closed end wire joint.

Orange

A

B

Red/Orange

Brown/Yellow

Power supply

Power supplyPower supplyPower supply

TCC-LINK

TCC-LINK

FG

U1U2

ABLNLNLN LN

FG

U1U2

AB

Central remote

controller

Central remote

controller

TOUCH SCREEN

CONTROLLER

Switching HUB

Customer's PC

SW1

4

ADDRESS

DIGITAL I/O

INTERFACE

SW1

1

ADDRESS

ENERGY

MONITORING

INTERFACE

DI 1

DI 2

DI 3

DI 4

DI 5

DI 6

DI 7

DI 8

DI 1

DI 2

DI 3

DI 4

DI 5

DI 6

DI 7

DI 8

Input contact 1

Input contact 2

Input contact 3

Input contact 4

Input contact 5

Input contact 6

Input contact 7

Input contact 8

Load 1

DO1

DO2

DO3

DO4

GND

+12V

BA BA

RS-485 RS-485

Load 2

Load 3

Load 4

Power meter 1

Power meter 2

Power meter 3

Power meter 4

Power meter 5

Power meter 6

Power meter 7

Power meter 8

The setting of the Touch Screen Controller is done at shipment. No setting is required.

7

Page 9

3

•

•

•

•

Trial Operation

Before Trial operation

Setting File Creation

The setting file is necessary to use the Touch Screen Controller.

Please inquire of your local sales office about it.

The setting file will be copied to the Compact Flash card inserted in the CF slot of the Touch Screen

Controller.

Trial Operations of Air Conditioner and Each Interface

Confirm the trial operations of the air conditioner and the each interface. And turn on the power of each

device.

Trial operation

Start-up of the Touch Screen Controller

Connect the power cable, earth wire and signal wire of the Touch Screen Controller.

Insert the compact flash containing the setting file in the CF slot and turn on the power.

The initial screen appears.

Initialization

It is necessary to initialize the system to make the setting file effective.

Operational Procedure

(1) Press the [MENU] button. The menu screen appears.

(2) Press the [SYSTEM RESET] button on the menu screen.

The message to confirm the operation appears. Press [Yes] to execute.

Then, the system re-starts up.

Confirmation of Communication with Each Interface

•

When the communication with the interface listed on the setting file is disconnected, the communication

error is displayed on the Touch Screen Controller. Press the [Alarm List] button to confirm whether the

communication error occurs or not. (Communication error judging time: Approx. 15 minutes)

The suspected causes of the communication error will be as follows.

• The interface is not powered.

• The address setting of the interface is incorrect.

• The communication between the Touch Screen Controller and the interface is disconnected.

• The setting file is incorrect.

Confirmation of Communication with Air Conditioner

•

When the communication with the air conditioner is disconnected, the communication error is displayed

on the Touch Screen Controller. The frame of air conditioner button on the screen is displayed orange.

The suspected causes of the communication error will be as follows.

• The air conditioner is not powered.

• The address setting of the air conditioner is incorrect.

• The communication between the TCS-NET relay interface and the air conditioner is disconnected.

• The communication between the Touch Screen Controller and the TCS-NET relay interface is

disconnected.

• The setting file is incorrect.

8

Page 10

EH99852501

Loading...

Loading...