Page 1

INSTALLATION MANUAL

TOUCH SCREEN CONTROLLER

for Air Conditioning Control System

BMS-TP0640ACE

BMS-TP5120ACE

• Thank you very much for purchasing the TOSHIBA Touch Screen Controller.

• Please read this manual carefully beforehand for proper installation of the controller.

BMS-TP0640PWE

BMS-TP5120PWE

CONTENTS

1 Precautions for Safety .............................................................................................................. 1

2 Outline of Control System........................................................................................................ 2

3 Accessory parts ........................................................................................................................ 2

4 Selection of Installation place .................................................................................................. 3

5 Points for Installation Work ...................................................................................................... 4

6 Connecting the Network wires ................................................................................................ 6

7 Connecting the Power cable .................................................................................................... 7

8 Control Wiring Diagram (Connection example) .................................................................. 9

9 Air conditioner Address Table and Before-Trial Operation Check list .................................. 10

10 Schedule Table for Each R.C. group/indoor Name ............................................................ 12

11 Installation ................................................................................................................................ 13

12 Trial Operation ......................................................................................................................... 14

13 Trouble shooting ..................................................................................................................... 17

14 Control Specifications ............................................................................................................ 19

APPENDIX

Page 2

1

• Ensure that all Local, National and International regulations are satisfied.

• Read these “Precautions for Safety” carefully before installation.

• The precautions described below include important items regarding safety. Observe them without fail.

• After the installation work, perform a trial operation to check for any problem. Follow the Owner’s Manual

• Turn off the main power supply switch (or breaker) before the controller maintenance.

• Ask the customer to keep the Installation Manual together with the Owner’s Manual.

Precautions for Safety

to explain how to use and maintain the controller to the customer.

WARNING

• Ask an authorized dealer or qualified installation professional to install/maintain the

conditioner.

• Turn off the main power supply switch or breaker before starting electrical work.

Make sure all power switches are off. Failure to do so may cause electric shock.

• Connect the connecting wire correctly.

If the connecting wire is connected in a wrong way, electric parts may be damaged.

• Do not modify the controller by removing any of the safety guards or by-bypassing any of

the safety interlock switches.

• Exposure of the controller to water or moisture before installation may cause a short-circuit

of electrical parts.

Do not store it in a wet basement or expose to rain or water.

• After unpacking the controller, examine it carefully if there is possible damage.

• Perform installation work properly according to the Installation Manual.

Inappropriate installation may result in water leakage, electric shock or fire.

• Electrical work must be performed by a qualified electrician in accordance with the

Installation Manual. Make sure the conditioner uses an exclusive power supply.

An insufficient power supply capacity or improper installation may cause fire.

• Use the specified wires for connecting the terminals securely fix. To prevent external forces

applied to the terminals from affecting the terminals.

• Conform to the regulations of the local electric company when connecting the power supply.

Inappropriate grounding may cause electric shock.

• Do not install the air conditioner in a location subject to a risk of exposure to a combustible

gas.

If a combustible gas leaks, and stays around the controller, a fire may occur.

CAUTION

Upon customer’s approval, install the Touch Screen Controller at a place which satisfies the

following conditions.

• Place where the Touch Screen Controller can be installed securely.

• Place which can reserve a sufficient service space for safe maintenance or check.

• Place where CF (Compact Flash) card can be removed easily.

• Place which provides sufficient space for connecting/checking the terminals of interface, InputOutput ports, etc.

Avoid the following places.

• Places where a device generating high frequency (inverter, non-utility generator, medical apparatus,

or communication equipment) is installed. (A bad influence may generated by malfunction of the

controller, control error, or noise may affect such equipment.)

1

Page 3

2

When installed this Air Conditioning Control System in a Toshiba air conditioner, enables easy central

control of up to 64 (for BMS-TP0640ACE, BMS-TP0640PWE) or up to 512 (for BMS-TP5120ACE, BMSTP5120PWE) indoor units with multi-functions integrated into the controller. This system allows advanced,

operation control, and power-saving operation for medium to large buildings.

This system also provides elaborate, advanced functions such as operation status monitoring, control,

and scheduled operation of all air conditioners for each block, tenant or area.

Thus efficient control of air conditioners is readily with easy operation.

With an easy-to-see color LCD touch panel, this system allows you to quickly reference various settings

or detailed information and execute them by only touching the LCD panel.

Outline of Control System

3

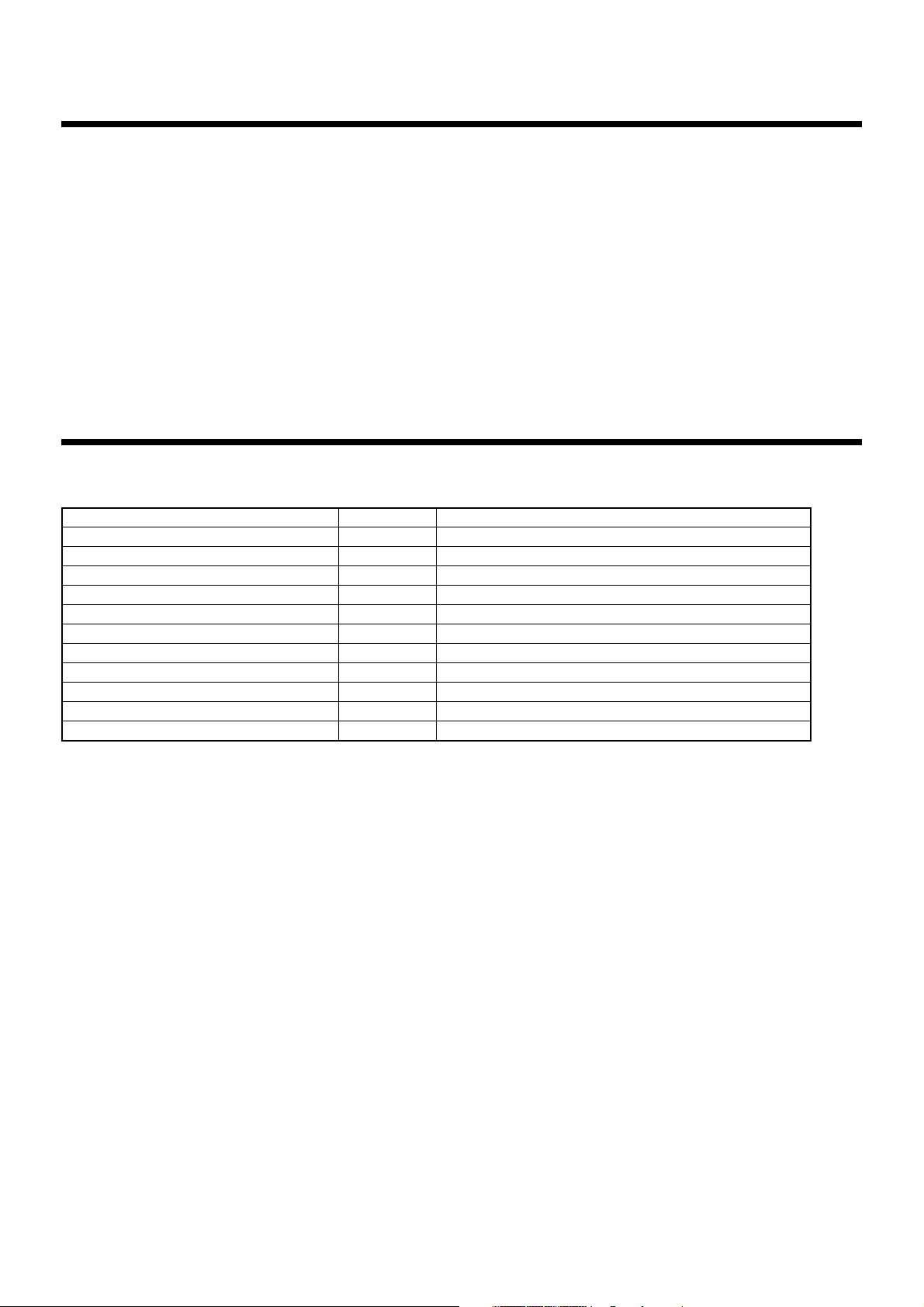

Accessory parts

Accessory parts

Part name

Touch Screen Controller

Touch Screen Controller fixture

Guard cover

Simple stand

Terminal connector

Jumper pin

Triangle thread screw (M3 x 6)

Triangle thread screw (M4 x 8)

CF (Compact Flash) card for data files

CF (Compact Flash) card adapter

Installation Manual

(Note) Power cable is not supplied for the Touch Screen Controller. Prepare a 3-pin power cable conforming to applicable

safety standards. Be sure to connect the earth line each of the power cable securely.

Q'ty

1

6

1

1

1

2

1

1

1

1

1

Remarks

Touch panel computer

For in-wall installation

For preventing CF (Compact Flash) card from coming out

For contact input/output (connected already)

For RS-485 settings (set already)

For guard cover

For simple stand

Inserted in the card slot

Inserted in the card slot

This manual

2

Page 4

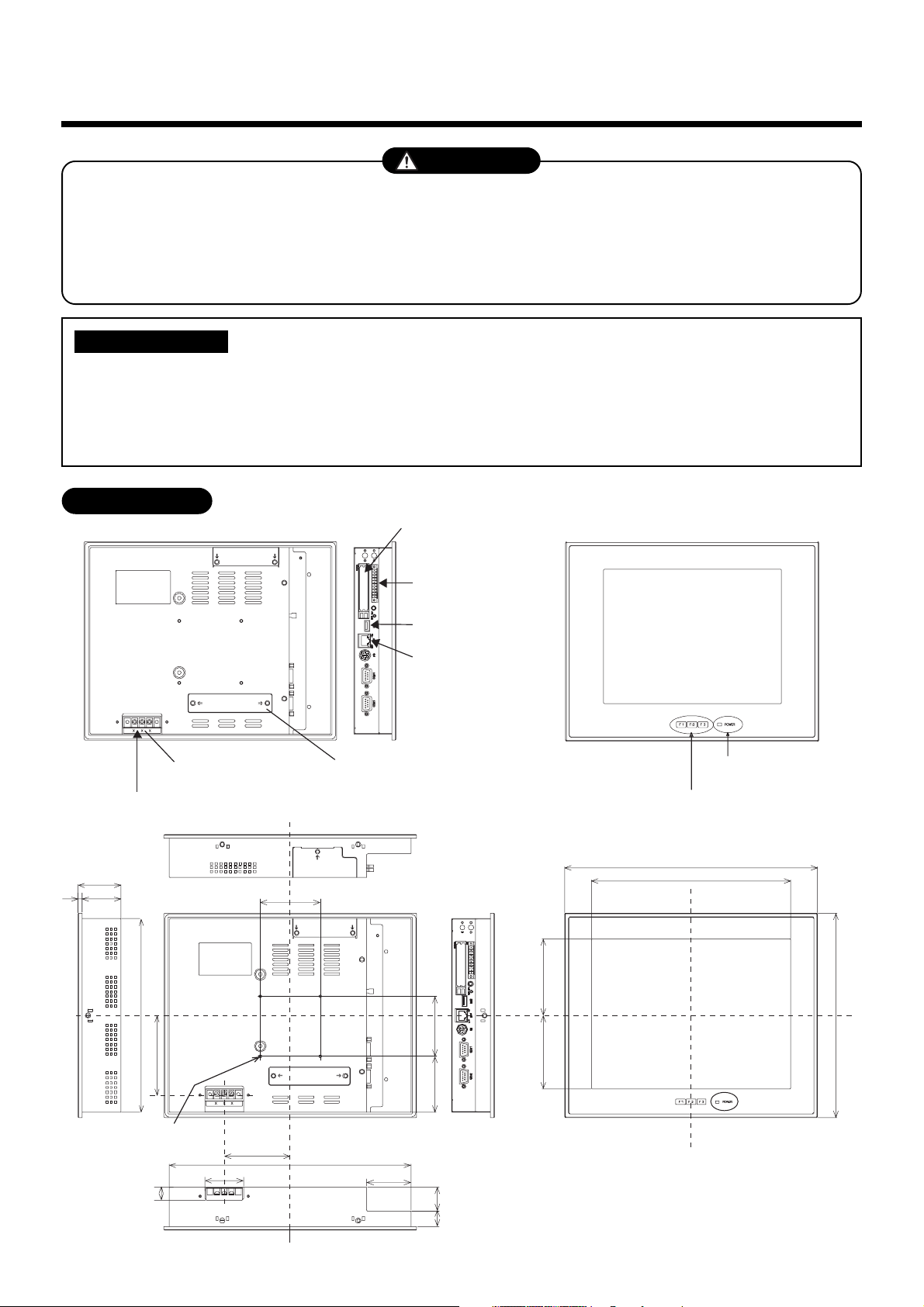

4

Selection of Installation place

WARNING

Install the Touch Screen Controller securely in a place that can sufficiently withstand the

weight of the controller.

If the foundation is not sturdy enough, the controller may fall and cause injury.

Perform specified installation work to guard the controller against earthquakes.

Improper installation may cause the controller to fall.

REQUIREMENT

To prevent damage on the Touch Screen Controller or personal injury, follow the instructions

below.

• Do not step, or put any heavy object on the packed controller.

• When carrying the controller, hold it paying attention not to apply excessive force.

• Do not block any of the air vents of the Touch Screen Controller.

External View

CF (Compact Flash)

card slot (CF card for

data files)

Universal Input/

Output port

Power cable

54

549

242

99.3

Power input

terminal block

75

USB mouse

Ethernet port

Intelligent

Server

PCI expansion unit

connector cover

70 75

POWER LED

Function switch (F1, F2, F3)

316

249

95.7591.75

256

M4 Tap (×4 pcs.)

(depth: 10 mm max.)

16

48

82.5

302

55.5

19 30

unit: mm

3

Page 5

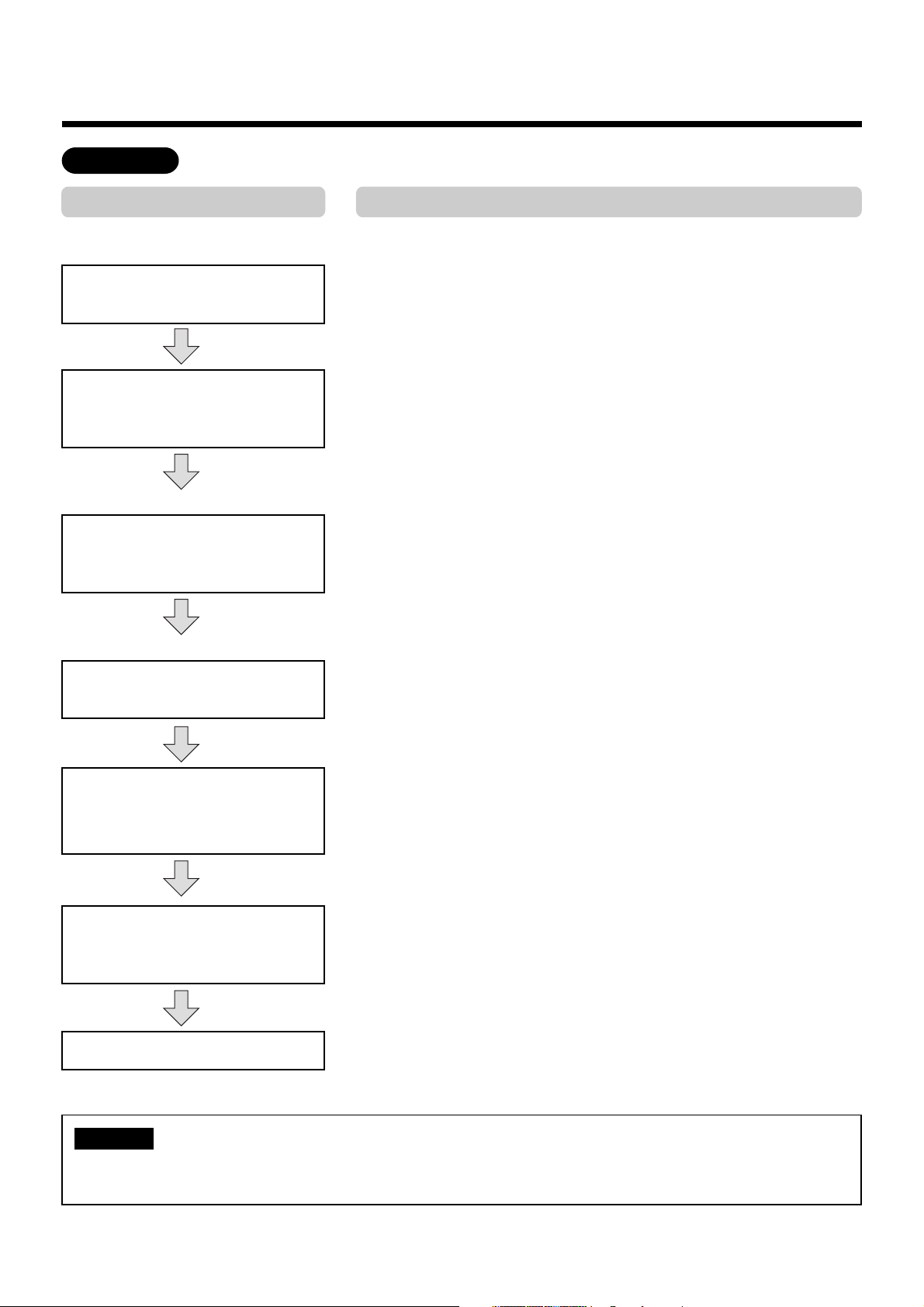

5

Points for Installation Work

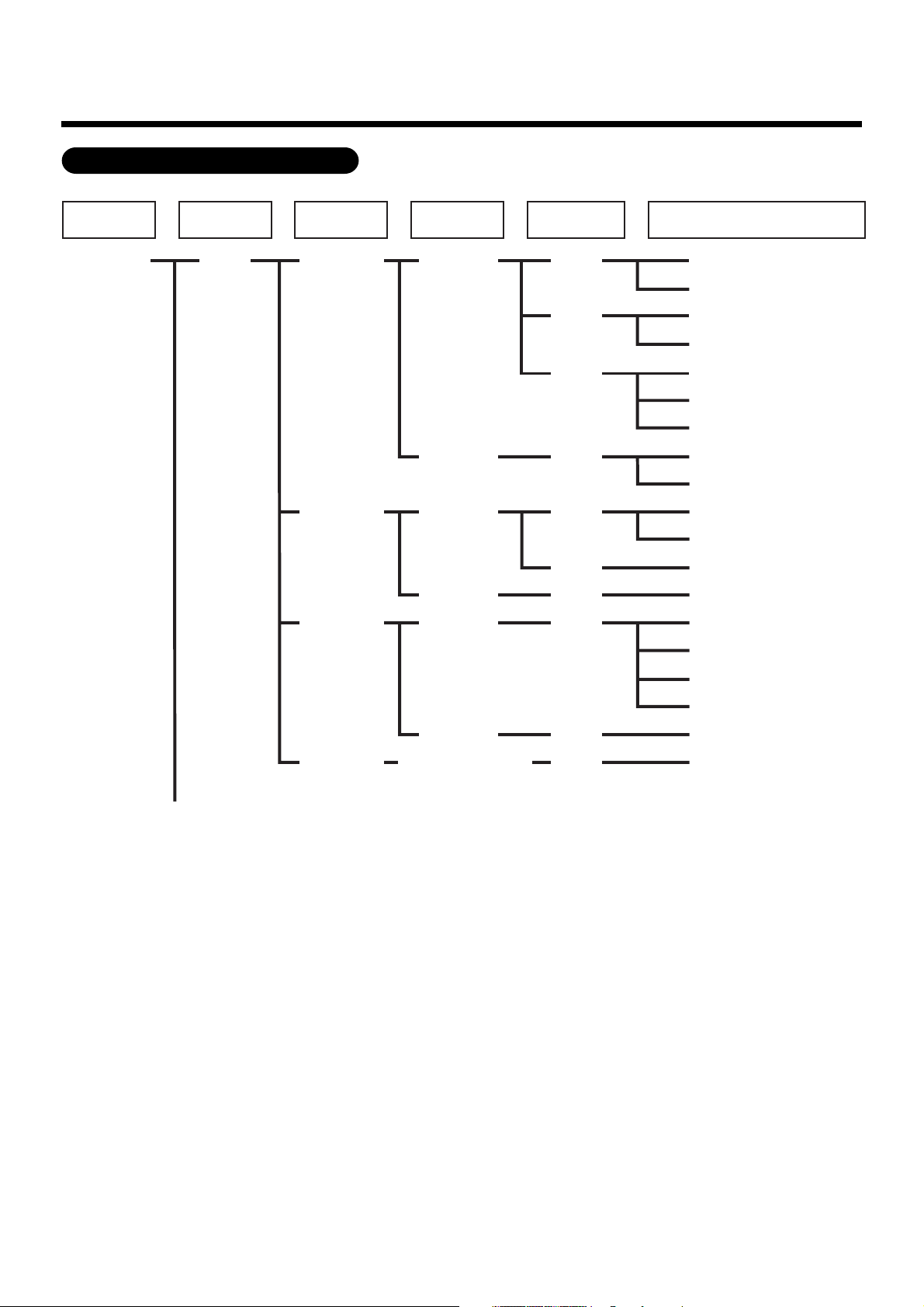

Work flow

Process

(Before work)

Determination of installation

condition

Document creation

(Data input before work)

Enter block/tenant/area names.

Enter schedules for each

R.C. group/indoor name.

(Before installation)

Electrical work

(power/control lines)

Point

• Clarify work categories.

• Determine items of detail control.

• Determine the installation position of the Touch Screen Controller.

• Create a control wiring diagram (see page 9).

• Create an address table for each block, tenant, and area (see

page 10, 11).

• Create a schedule table for each R.C. group/indoor name (see

page 12).

• Enter block/tenant/area names in each address table (see

page 11).

• Enter schedules in each schedule table (see page 12).

• Make connections according to the control wiring diagram (see

page 9).

• Intelligent Server (see APPENDIX page 6)

• TCS-NET Relay Interface (see APPENDIX page 7)

Operation mode/address settings

Trial operation and adjustments

Owner’s manual, delivery

NOTE

For installation, wiring or adjustment of the accessible components for the Touch Screen Controller,

refer to the manual “A04-016”.

• Indoor unit (see APPENDIX page 8-15)

• Checking according to the Before-Trial Operation Check list

(page 10) using the control wiring diagram.

• Operate the indoor unit for each system according to the control

wiring diagram.

Check that there is no incorrect wiring or piping, and then create

a trial operation check list (page 16).

• Give operational explanation in an easy-to-understand manner.

4

Page 6

5

Points for Installation Work (continued)

Management zone categories

All Block Tenant Area

Building A 1-1 (header unit)

1F

Tenant A

Tenant B

Tenant C

Shop A

Office A

Shop B

Office B

Shop C

RC

Group/Unit

101

102

103

104

105

106

107

108

(line address + indoor unit address)

Indoor Unit

1-2 (follower unit)

1-3 (header unit)

1-4 (follower unit)

1-5 (header unit)

1-6 (follower unit)

1-7 (follower unit)

1-8 (header unit)

1-9 (follower unit)

2-1 (header unit)

2-2 (follower unit)

2-3 (header unit)

2-4 (header unit)

2-5 (header unit)

2-6 (follower unit)

Shared

space

Office C

1F outdoor

air conditioner

109

110

2-7 (follower unit)

2-8 (follower unit)

2-9 (follower unit)

3-1 (header unit)

5

Page 7

6

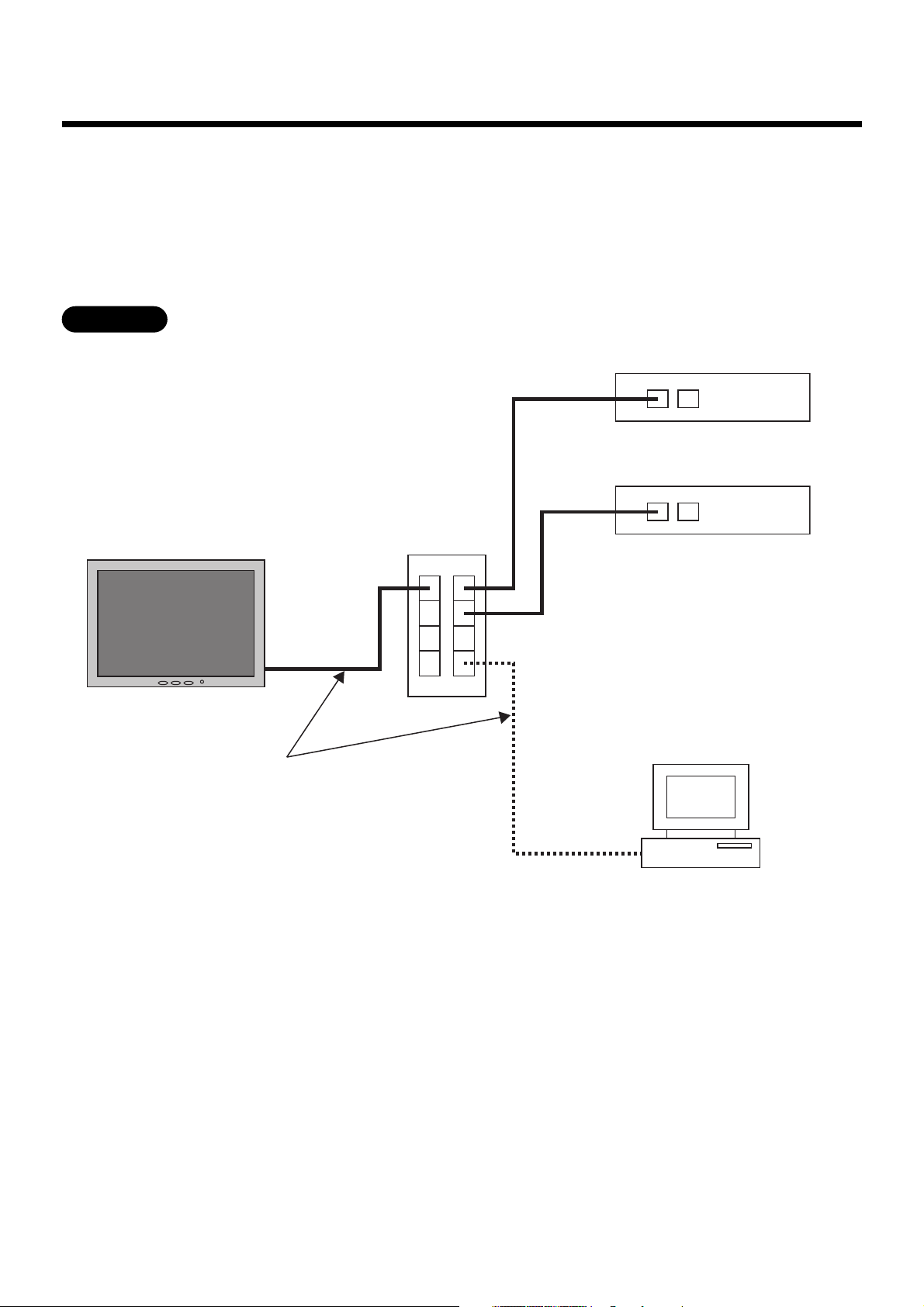

Connect the Touch Screen Controller to Intelligent Servers and to an optional PC for creating monthly

reports using network wires (category 5UTP straight wire), via a Switching HUB (procured on site).

• Connect the Ethernet port of the controller to a port of the HUB with a network wire.

• Connect the Ethernet port 1 of the Intelligent Server to a port of the HUB with a network wire.

• Connect the PC’s Ethernet port to a port of the HUB with a network wire. (Not required if there is not

Connecting the Network wires

need to create reports.)

Ethernet

Touch Screen Controller

Network wires

(category 5UTP straight wire)

Ethernet port

Switching HUB

Ethernet port 1

Ethernet port 2

PC for creating monthly reports

Intelligent Server No.1

Intelligent Server No.2

6

Page 8

7

Connecting the Power cable

CAUTION

Connect a proper input AC voltage to the power input terminal block. Failure to do so may cause a

failure.

REQUIREMENT

Power cable is not supplied for the Touch Screen Controller. Prepare a 3-pin power cable conforming

to applicable safety standards. Be sure to connect the earth line each of the power cable securely.

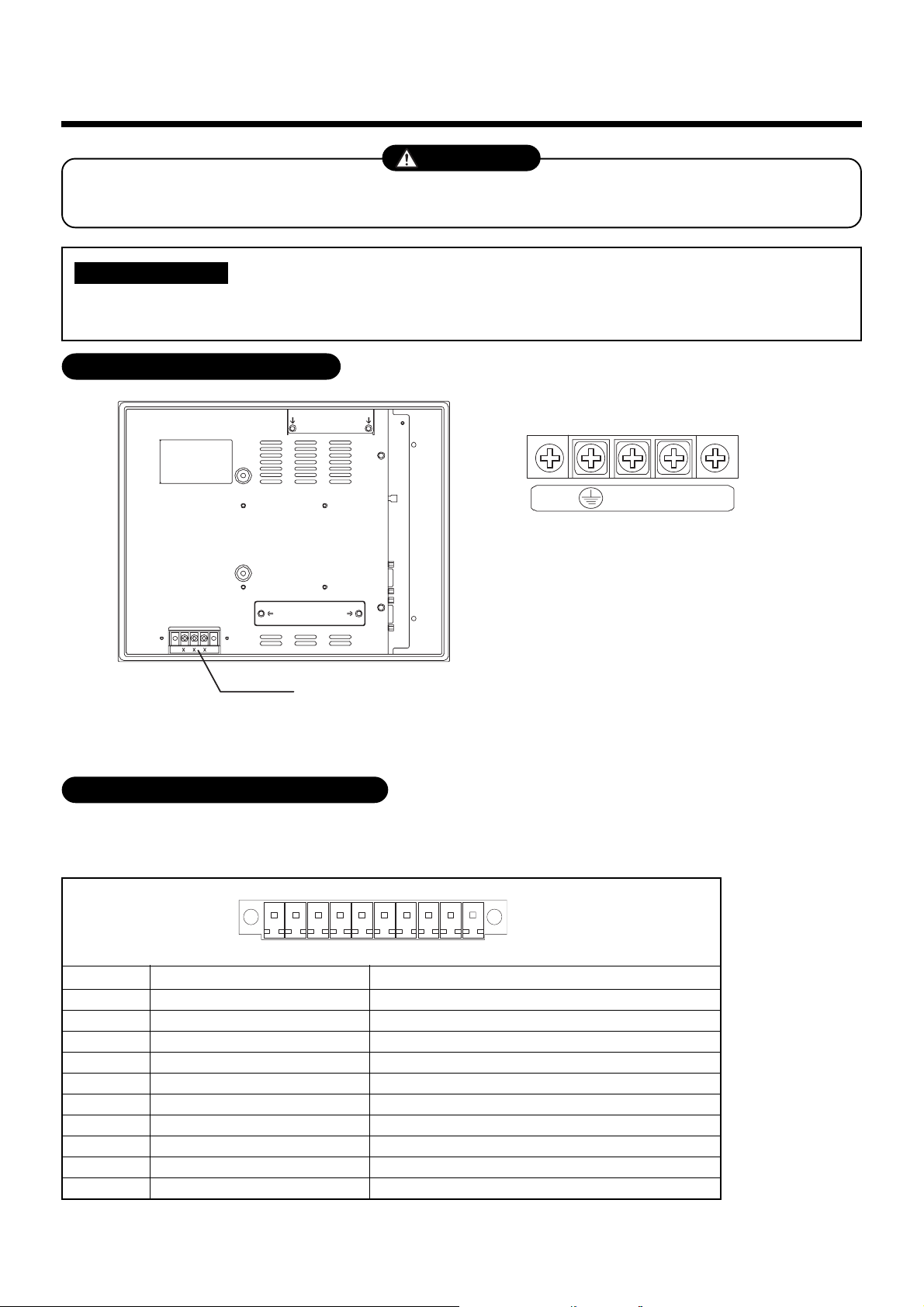

Power Input Terminal Block

■■

■ Power Input Terminal Block

■■

L

N

Rated input voltage: 100 to 240 VAC

Power input terminal block

For M3.5 screws

Terminal pitch: 8.9 mm

Universal Input/Output Port (I/O)

This port is provided with electrically-insulated 3 inputs and 3 outputs for universal use.

■ ■

■ Universal Input/Output port connector

■ ■

10 1

↓ Front (LCD side)

Pin No. Signal name

1

2

3

4

5

6

7

8

9

10

Connector: MC1,5/10-GF-3,5(PHOENIX CONTACT)

Cable connector: MC1,5/10-STF-3,5(PHOENIX CONTACT)

PI_PCOM

PI(0)

PI(1)

PI(2)

P_PO(0)

N_PO(0)

P_PO(1)

N_PO(1)

P_PO(2)

N_PO(2)

Universal input plus common

Universal input 0

Universal input 1

Universal input 2

Universal output 0+

Universal output 0-

Universal output 1+

Universal output 1-

Universal output 2+

Universal output 2-

Remarks

7

Page 9

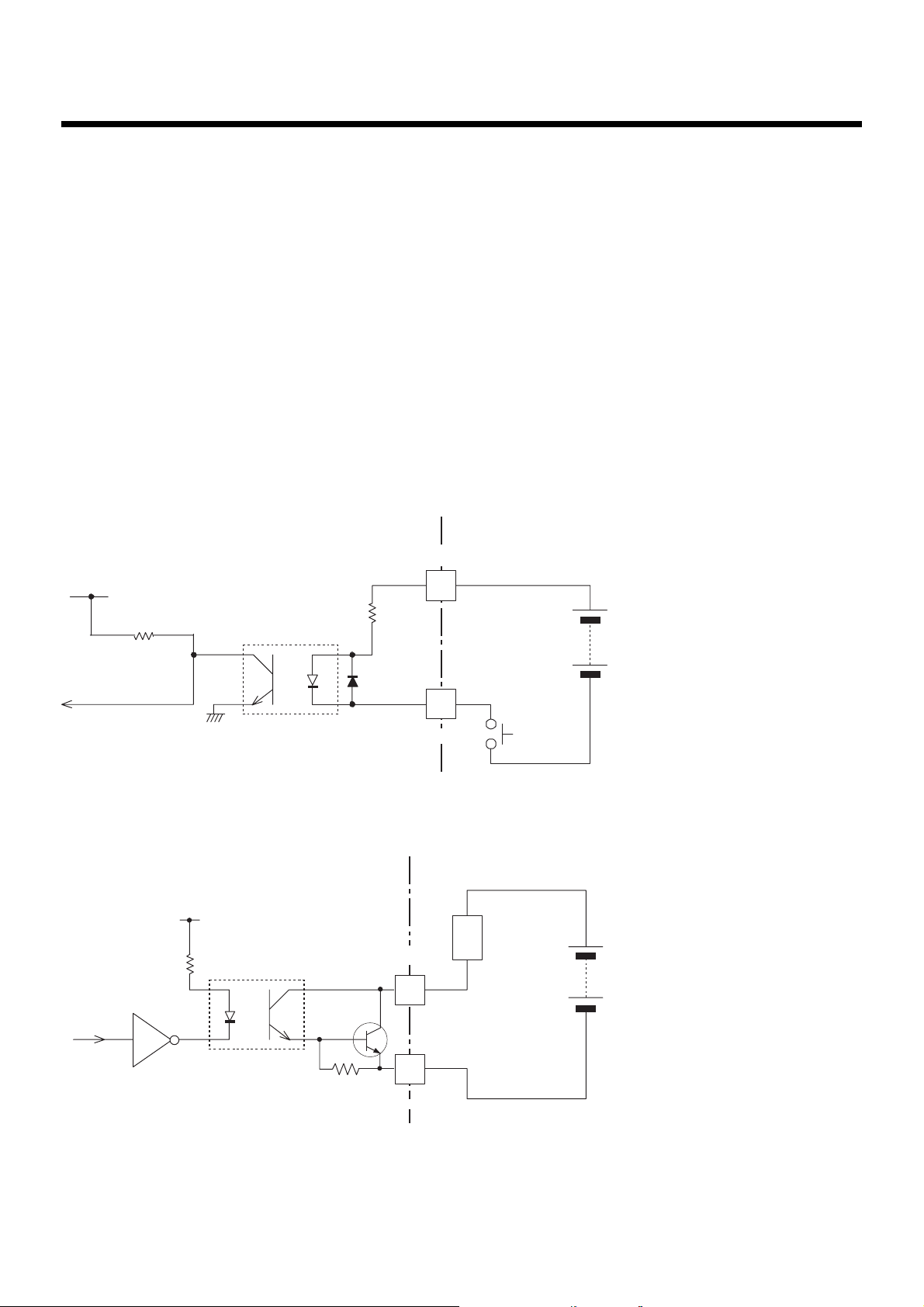

■■

■ Specifications

■■

[Input]

Input system : Current-driven input insulated by photo-coupler

Input resistance : 3 k ohms

Number of input signals : 3

External circuit power voltage : 12 to 24 V DC (±10%)

[Output]

Output system : Open-collector output insulated by photo-coupler

Output rating : 30 V DC, 100 mA maximum

Number of output signals : 3

■■

■ External Input/Output circuit

■■

(1) Input circuit

PI_PCOM

10 k ohm

(2) Output circuit

330 ohm

PC357

3 k ohm

1/2 W

P_PO(0) - P_PO(2)

2SD780A

PI(0) - PI(2)

Input/Output

connector

(External circuit)

load

External power supply

(12 V - 24 V DC)

Input

contact

External power supply

(Max. 30 V DC)

4.7 k ohm

N_PO(0) - N_PO(2)

Input/Output

connector

8

Page 10

Control Wiring Diagram

8

(Connection example)

U1,U2

U1,U2

U3,U4

U1,U2

U1,U2

U3,U4

U1,U2 U1,U2 U1,U2 U1,U2

U1,U2 U1,U2

U3,U4

U1,U2 U1,U2

U1,U2 U1,U2

U3,U4

U1,U2

U1,U2

8 door-lock control signal inputs

8 fire alarm inputs

Outdoor unit

8 power meter inputs

Indoor unit

8 power meter inputs

Main Bus

16th floor

U3,U4

BMS-

IFLSV1E

15th floor

TCS-NET Relay Interface

U3,U4

BMS-

IFLSV1E

TCS-NET Relay Interface

2nd floor

9th-16th

floor

Server

Intelligent

BMS-LSV2E

U3,U4

BMS-

IFLSV1E

1st floor

TCS-NET Relay Interface

software

Intelligent server

Intelligent

BMS-STCC

U3,U4

BMS-

IFLSV1E

TCS-NET Relay Interface

1st-8th

floor

Server

BMS-LSV2E

HUB

Switching

software

BMS-STCC

Intelligent server

BMS-IFDD01E

Relay Interface

Digital Input/Output

PC for creating

monthly reports

Relay Interface

Digital Input/Output

BMS-IFDD01E

Printer

Energy Monitoring

BMS-IFWH3E

Relay Interface

Relay Interface

Energy Monitoring

BMS-IFWH3E

Touch Screen

Controller

9

Page 11

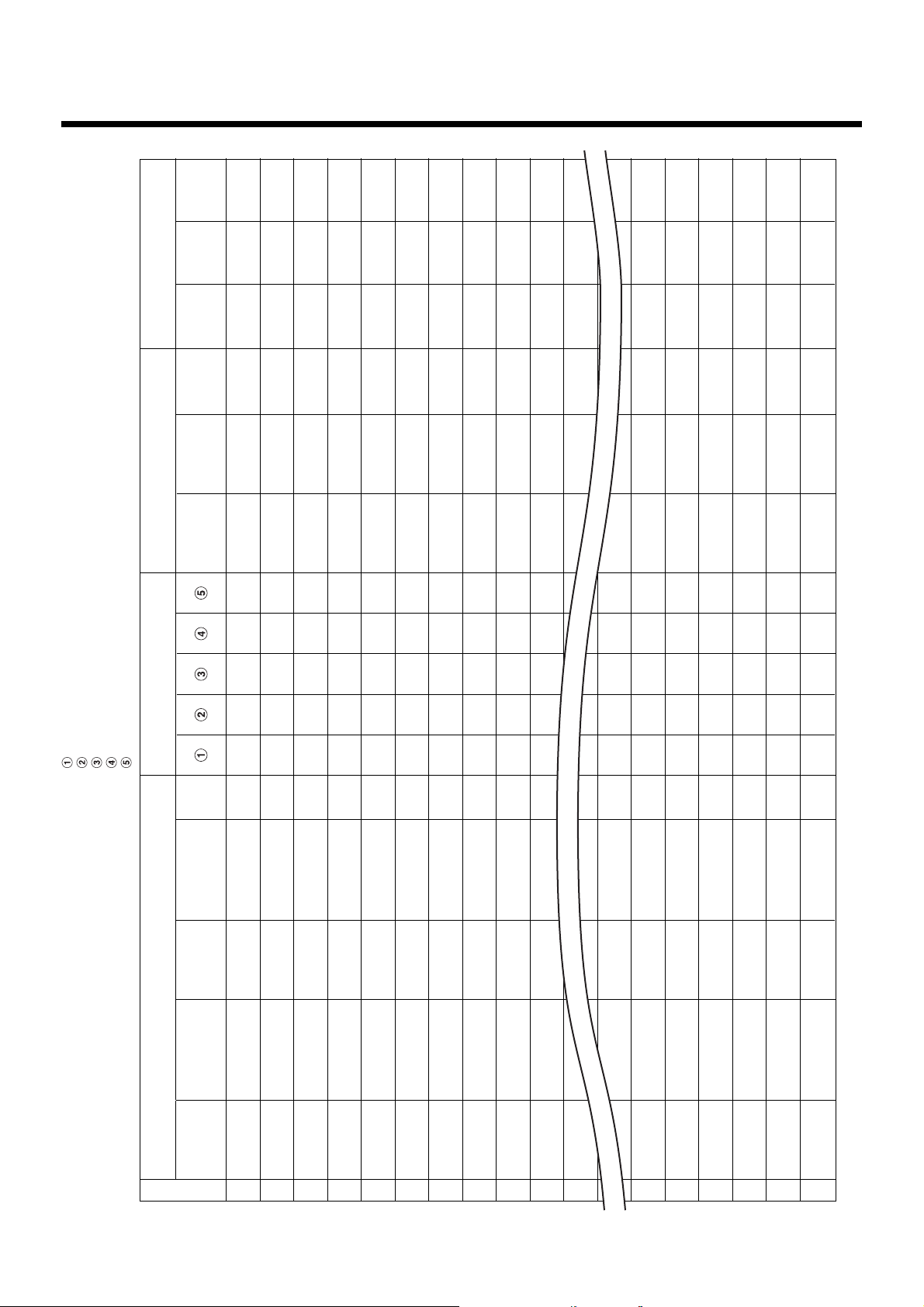

Air conditioner Address Table

9

and Before-Trial Operation Check list: ( )

No.

Fire alarm

No.

Key input

and Input/Output data

Power

Device Energy Monitoring

Display name

meter No.

Area

name

name

Tenant

Block

name

Address Information

Refrigerant line address

Indoor unit address

Group address

Intelligent Server address

TCS-NET relay I/F address

Header

Indoor unit

R.C. group/

Air Conditioner List

Outdoor unit

Outdoor

• Building name:

unit

model name

unit

name

model name

refrigerant

1

2

3

4

5

6

7

8

9

10

11

12

15

16

17

18

19

20

10

Page 12

Air conditioner Address Table and Before-Trial

Operation Check list (Example)

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

No.

Fire alarm

1

No.

Key input

and Input/Output data

Power

Device Energy Monitoring

Display name

meter No.

Area

name

name

Tenant

1

1

1

Shop A

Shop A

Tenant A

Tenant A

1

1

1

1

Shop A

Shop A

Tenant A

Tenant A

1

1

1

1

Shop A

Shop B

Tenant A

Tenant B

1

1

1

1

Shop C

Shop D

Tenant B

Tenant B

1

1

1

2

Shop E

Shop F

Tenant B

Tenant C

1

1

2

2

Shop F

Shop G

Tenant C

Tenant C

1

1

2

2

Office

Office A

Tenant C

1

2

Office

Office A

1

1

1

2

2

Meeting room

Meeting room

Office A

Office A

2

2

2

2

3

3

A

B

Shared space

2

2

3

Shop H

Tenant D

Block

Address Information

Refrigerant line address

Indoor unit address

Group address

Intelligent Server address

TCS-NET relay I/F address

Header

Indoor unit

R.C. group/

1F

name

1

1

1

unit

model name

MMU-AP0091H

unit

name

PAC-B1 • IF-1

1F

1F

1F

2

2

2

2

3

4

0

0

0

MMU-AP0091H

MMU-AP0091H

MMU-AP0091H

PAC-B1 • IF-1

PAC-B1 • IF-1

PAC-B1 • IF-1

1F

1F

1F

1

1

2

0

0

5

6

7

1

0

1

1

MMK-AP0091H

MMU-AP0091H

PAC-B1 • IF-1

MMK-AP0091H

PAC-B1 • IF-2

PAC-B1 • IF-3

1F

1F

1F

0

0

0

8

9

1

1

1

1

MMK-AP0091H

MMK-AP0091H

MMK-AP0091H

PAC-B1 • IF-4

PAC-B1 • IF-5

PAC-B1 • IF-1

1F

1F

1F

1

1

0

0

0

2

3

4

2

1

1

1

MMK-AP0091H

MMK-AP0091H

MMK-AP0091H

PAC-M • IF-2

PAC-M • IF-3

PAC-M • IF-4

1F

1F

1F

0

0

0

5

6

7

1

1

1

MMK-AP0091H

MMK-AP0091H

MMK-AP0091H

PAC-M • IF-5

PAC-M • IF-6

PAC-M • IF-7

1F

2F

2F

1

1

0

1

2

8

1

2

3

1

1

0

MMK-AP0091H

MMK-AP0091H

MMK-AP0091H

PAC-M • IF-8

PAC-S • 2F-1

2F

0

3

1

MMK-AP0091H

PAC-S • 2F-2

Air Conditioner List

model name

Outdoor unit

Outdoor

refrigerant

• Building name:

1

MMY-AP1401HT8

PAC-B1

2

3

4

5

6

7

8

9

10

11

MMY-AP1401HT8

PAC-M

12

13

14

15

16

17

MMY-AP1401HT8

PAC-S

18

19

20

11

Page 13

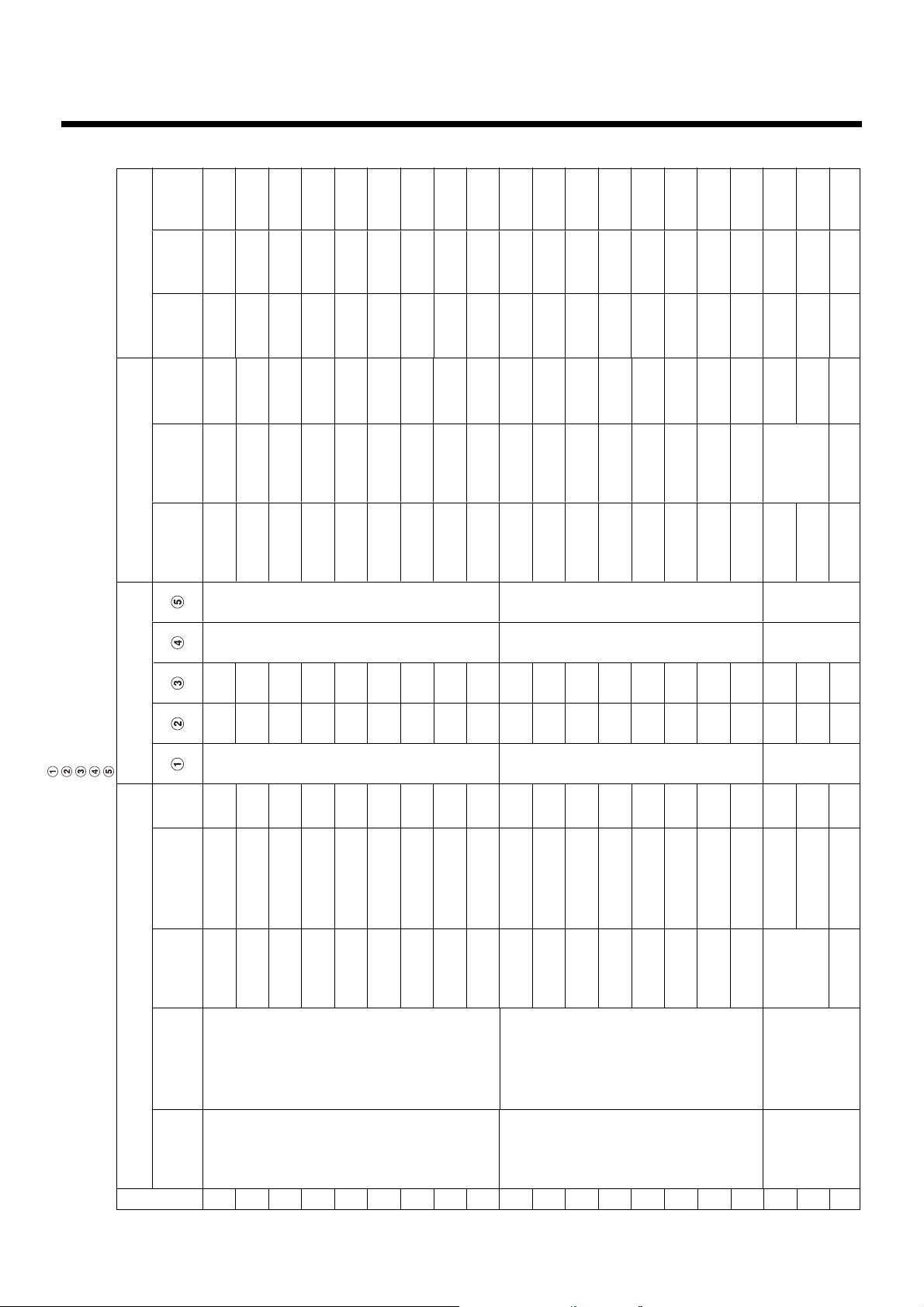

Schedule Table for

10

Each

R.C. group/indoor Name

:

:

:

:

:

:

:

:

PAC-B1, 1F-6

Night-duty room

B1

Run

Stop

8:00

9:30

Monday to Saturday

Run

Stop

Stop

10:00

Run

Run

16:30

Stop

Stop

22:00

Stop

Stop

23:58

:

:

:

:

:

:

:

:

:

:

PAC-B1, 1F-3 to 1F-5

Warehouse

XX Electric Co., Ltd.

B1

:

:

:

:

:

:

:

:

PAC-B1, 1F-1

Consultation room

XX Dental Clinic

B1

8:00

12:00

13:00

19:00

Monday to Friday

Run

Stop

Stop

8:00

19:00

Monday to Saturday

:

21:00

21:00

:

:

:

:

:

:

:

Schedule Table ( / )

R.C. group/unit name

Area

• Building name:

Tenant

1

Block

Day of the week

2

3

4

5

6

7

8

Schedule Table (Example)

R.C. group/unit name

Area

Tenant

• Building name: XXX Building

Block

1

2

3

Day of the week

4

5

6

7

8

12

Page 14

11

Installation

Touch Screen Controller

Make space for installation and service.

Install the Touch Screen Controller in a wall (standard) or on the dedicated stand (when available on site).

In-wall installation

■■

■Conditions for installation

■■

Space 30 mm or more between the controller and

surrounding objects as the ambient temperature

must satisfy the installation space requirements.

Panel

30 mm or more (top)

30 mm or more (bottom)

30 mm or more (rear)

Top view

30 mm or more (side)

Interface side

Panel

■■

■Attaching Fixture

■■

■Panel cut size

+1

303

-0

R1 or less

+1

-0

243

REQUIREMENT

Use a panel

(procured on site) of

thickness 1.6-1.7 mm.

Panel thickness: 1.6 -1.7 mm

[mm]

1. Insert the controller from outside of the panel.

2. Insert the fixtures from inside of the panel.

Touch Screen

Controller

Panel

Fixture

Bottom view

For reference

Display stand (not supplied with the controller)

Use the CONTEC stand (model: IPC-SND-03).

For details of the stand, visit the CONTEC web site.

Europe: http://www.contec-europe.com/

China: http://www.contec.sh.cn/

REQUIREMENT

• Check that the installation dimensions on the rear of the

Touch Screen Controller equal the installation

dimensions of the CONTEC stand.

• Use the screws supplied with the stand to install the

controller.

13

Tightening screws excessively

may cause the screws to break.

Optimum tightening torque for

good waterproofing effect is

0.6N/m.

75 mm

75 mm

The angle adjustment lock screw.

(Loosen the screw and adjust angle.)

Page 15

12

Trial Operation

Item Description

Preparation

Entering names

Checks before trial

operation (control

wiring)

Trial operation

startup

Preparation of necessary

documents

Entry of setting conditions

Checking installation work

Checking control wiring

using the before-trial

operation check list.

Checking block/tenant/area

names

Checking schedules

Power on

Initial screen

System initialization

Check point

● Meeting with the customer on setting information

Creation of control wiring system diagram

Creation of air conditioner address table

Creation of schedule table for each R.C. group/indoor name

● Create a setting file including setting data.

● Set the setting data in the Touch Screen Controller by

overwriting (copy) the data on its CF (Compact Flash) card.

● Power supply wiring

● Control wiring

● Grounding of units

● Check control wiring specifications and wire sizes.

● Check block/tenant/area names using the air conditioner

address table.

● Check schedules using the schedule table for each R.C.

group/indoor name.

● Turn on the Touch Screen Controller with the Intelligent

Server and the relay interface turned on.

● The controller software starts automatically, and the total

building control screen appears.

● Select “System Initialize” from the option to initialize the

system.

When “System Initialize” is selected, a message “Will you

re-cold start all intelligent server?” appears. Select “Yes”.

The setting file is transmitted from the Intelligent Server to

the relay interface.

The L1 or L2 LED of the Intelligent Server blinks during the

startup process. When the startup processing ends

successfully, the L1 and L2 LEDs turn off. If the startup

processing fails, the L1 LED lights up. Retry “System

Initialize” from the Touch Screen Controller in this case. Or

select “TPC-CON” on the hidden Windows task bar at the

bottom of the LCD screen. You can see a message on the

screen during the system reset. The “Access Start”

message appears at the end of several message lines. It

takes several minutes for system initialization.

Trial operation

Checking communication

status (referring to the

control wiring system

diagram)

Checking operation status

using the before-trial

operation check list.

● Select air conditioning screen after System Initialize to check

communication status and connection of air conditioners.

Check that there is no orange frame on the command button

of the air conditioner, which indicates a communication

error. If an orange frame is present, check power on (or off),

control line wiring, and address setting of the air conditioner.

● Check operation status for each block, tenant, area, and

R.C. group/indoor name.

- ON/OFF

- Operation mode

- Set temperatures

Check all indoor units whether controls can be changed from

the Touch Screen Controller to the R.C. group/indoor, and

whether the setting changed by the remote controller is

reflected on the Touch Screen Controller on both the Touch

Screen Controller side and the on-site remote controller side.

14

Page 16

12

Trial Operation (continued)

Trial Operation Check list

Tenant Block

Area

Set temperature

indoor

R.C. group/

E

E

Block

Tenant

Check list

Area

R.C. group/

Block

indoor

E

E

E

B

E

E

E

E

E

E

E

B

B

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

• D .............. COOL

• E ... COOL/HEAT

• F ................ HEAT

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

Tenant

ON/OFF Operation mode

Area

indoor

R.C. group/

Display name

Block name Tenant name Area name

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

• A ............. O N

• B .... ON/OFF

• C ........... OF F

No.

R.C. group/indoor

• Building name:

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

15

Page 17

Trial Operation Check list (Example)

OK

OK

OK

OK

OK

OK

OK

OK

OK

E

E

E

E

B

B

OK

OK

OK

OK

E

E

E

E

B

B

Block

Tenant

Area

R.C. group/

Block

Tenant

Check list

Area

R.C. group/

Block

Tenant

indoor

indoor

OK

OK

OK

E

E

E

E

B

B

OK

OK

OK

E

E

E

E

B

B

OK

OK

OK

E

E

E

E

B

B

OK

OK

OK

E

E

E

E

B

B

OK

OK

OK

E

E

E

E

B

B

OK

OK

OK

OK

E

E

E

E

B

B

OK

OK

OK

OK

E

E

E

E

B

B

OK

OK

OK

OK

E

E

E

E

B

B

OK

OK

OK

OK

E

E

E

E

B

B

OK

OK

OK

OK

E

E

E

E

B

B

OK

OK

OK

OK

E

E

E

E

B

B

OK

OK

OK

OK

E

E

E

E

B

B

OK

OK

OK

OK

E

E

E

E

B

B

OK

OK

OK

OK

E

E

E

E

B

B

OK

OK

OK

OK

E

E

E

E

B

B

OK

OK

OK

OK

E

E

E

E

B

B

OK

OK

OK

OK

E

E

E

E

B

B

OK

OK

OK

OK

E

E

E

E

B

B

• D .............. COOL

• E ... COOL/HEAT

• F ................ HEAT

ON/OFF Operation mode Set temperature

Display name

Block name Tenant name Area name

No.

R.C. group/indoor

• Building name:

B

Area

B

indoor

R.C. group/

PAC-B1, 1F-1

1

B

B

B

B

B

B

PAC-B1, 1F-2

PAC-B1, 1F-3

PAC-B1, 1F-4

2

3

4

B

B

B

B

B

B

PAC-B1, 1F-5

PAC-B1, 1F-6

PAC-B1, 1F-7

5

6

7

B

B

B

B

B

B

PAC-B1, 1F-8

8

PAC-M-1

PAC-B1, 1F-9

9

10

B

B

B

B

PAC-M-2

PAC-M-3

11

12

B

B

B

B

PAC-M-4

PAC-M-5

13

14

B

B

B

B

PAC-M-6

PAC-M-7

15

16

B

B

B

B

PAC-S-1

PAC-M-8

17

18

B

B

B

B

PAC-S-2

PAC-S-3

19

20

• A ............. O N

• B .... ON/OFF

• C ........... OF F

16

Page 18

13

Trouble shooting

Regarding faults that may occur after installation, trial operation, and adjustments of Air conditioning

control system and their remedies:

Faults of air conditioner

• The Touch Screen Controller displays an error code and description that are the same as those

displayed on the remote controller.

• Check the faulty air conditioner according to the check points of each error code of the air conditioner.

Faults of air conditioning control system

Faults detected by Touch Screen Controller

• Touch Screen Controller displays an error code and description. (Not displayed on the remote

controller)

• Take remedial action according to the description and possible causes of each error code in the table

below.

Error

code

S00

S01

S06

S07

Description

Intelligent server

communication

error.

Communication

error between

Indoor and BMS.

BMS-IFWH

communication

error.

BMS-IFDD

communication

error.

Possible causes

Intelligent Server is not powered on.

Switching HUB is not powered on.

Improper connection of network cable.

Malfunction of Intelligent Server.

Air conditioner is not powered on.

Improper TCC-LINK connection.

Malfunction of Intelligent Server.

Malfunction of Relay Interface.

Energy Monitoring Relay Interface is not powered

on.

Improper RS-485 cable connection.

Malfunction of Energy Monitoring Relay Interface.

Malfunction of Intelligent Server.

Digital I/O Relay Interface is not powered on.

Improper RS-485 cable connection.

Malfunction of Digital I/O Relay Interface.

Malfunction of Intelligent Server.

Remedy

Remove the cause and then

power on the Intelligent Server,

Switching HUB, and Touch

Screen Controller.

Remove the cause and then

power on the air conditioner,

Intelligent Server, and Relay

Interface.

Remove the cause and then

power on the Energy Monitoring

Relay Interface and Intelligent

Server.

Remove the cause and then

power on the Digital I/O Relay

Interface and Intelligent Server.

17

Page 19

Other faults

No.

1

2

3

4

5

6

Description

Nothing is displayed on

the Touch Screen

Controller screen.

Remote controller does

not work. (Central

control in progress)

Remote controller does

not work. (Operation

switchover control in

progress)

Scheduled operation of

air conditioners is

disabled.

Air conditioner stops

(out of control).

Power distribution

result is incorrect.

Possible causes

Touch Screen Controller is not powered on.

Backlight turns off automatically due to no

touch-screen operation for 10 minutes.

Malfunction of Touch Screen Controller.

Air Conditioning Control System

malfunctioned or stopped after local

prohibition is set by the system.

Operation mode range selection is set by

the Air Conditioning Control System.

Air Conditioning Control System is not

working.

Scheduled operation is not set or nonoperation date/special day setting is not

updated. (The setting must be updated

every year.)

Scheduled operation is not set correctly.

Incorrect input of door-lock signal.

Improper connection between power meter

and BMS-IFWH3E

Charging schedule is not set correctly.

Non-operation date/special day setting is

not updated. (The setting must be updated

every year.)

Remedy

Power on the Touch Screen Controller.

Touch the Touch Screen

Controller screen.

Power off and on the Touch

Screen Controller.

Power off and on the air

conditioner.

Check the operation mode range

selection setting, and correct it if

wrong.

Power on the equipment of the

system.

Perform setting for scheduled

operation.

Check the scheduled operation

setting, and correct it if wrong.

Correct the signal connection.

Correct the connection.

Check the charging schedule

setting, and correct it if wrong.

Fault judgment by Intelligent Server

No.

1

An LED other than

“RN” LED at the upper

left is lighting or

flashing after 10

minutes passed from

power on of Intelligent

Server.

Indication

No Relay Interface is powered on.

Communication with any Relay Interface

fails due to improper RS-485 connection or

disconnection of connector.

Malfunction of Intelligent Server.

Faults of Relay Interface

No.

1

2

LED2 (green) does not

light.(RS-485

communication error)

LED3 (orange) does

not light.

Indication

Intelligent Server is not powered on.

Improper RS-485 connection or

disconnection of connector.

Improper connection of TCC-LINK main bus

due to disconnection or lack of terminating

resistors, etc.

Possible causes

Possible causes

Remedy

Check whether every Relay

Interface is powered on (shown by

LED1 lighting red), and turn on

them if powered off.

Correct the connection.

Power off and on the Intelligent

Server.

Remedy

Power on the Intelligent Server.

Correct the connection.

Correct the connection.

18

Page 20

14

Control Specifications

Basic Functions

Function Item

Operation

Setting

Indication

Schedule

Fire alarm input

Recording

●ON/OFF

Operation mode (cooling/

heating/fan only)

Air flow (High/Mid/Low)

Temperature (18-29 °C)

Operation enable/disable

●ON

●OFF

●Failures/errors

●Details of failure

●Operation under master

schedule

●Operation under selective

schedule

●Leaving-ON prevention

setting

●Extra-charging schedule

setting

●Fire alarm interlocking

control

●Monthly data file output

Description

Master operation and setting of:

- Entire building

- Each block *

- Each tenant *

- Each area *

- Each R.C. group/indoor *

Displays in green on the screen for each R.C. group/indoor.

Displays in red on the screen for each R.C. group/indoor.

Displays in orange on the screen for each R.C. group/indoor.

Displays with inspection codes and characters.

●Basic-week pattern, specific-day pattern, and monthly setting of

selected R.C. group/indoor can be set. Annual schedule is fixed

upon completion of all settings, which enables auto operation.

●

Performs weekly operation/stop of selected

automatically. Selective schedule is effective only for date/time

modified temporarily.

●Schedule setting for 10 patterns/day (ON/OFF total 20 patterns/

day) is available.

●Schedule setting for specified day of the week is available for each

R.C. group/indoor.

●This setting is available for specified day of the week by using OFF

setting for each R.C. group/indoor.

●

Extra-charging time zone can be set for specified day of the week

for each

operation setting.

●Stops operation of all air conditioners at a time upon receiving a fire

alarm signal.

●Indicates an occurrence of fire.

●Outputs air conditioner operating hours and the number of ON/OFF

times to a file for each R.C. group/indoor.

●Outputs air conditioner operating hours within the extra-charging

time zone to a file for each R.C. group/indoor.

●Outputs failure information to a file for each R.C. group/indoor.

1

2

3

4

R.C. group/indoor

R.C. group/indoor

independently from the scheduled

*1 Block: One floor zone of building

*2 Tenant: Shops and shared zone

3

*

Area: Tenant shop/office zone

*4 R.C. group/indoor: Indoor unit system controlled by single remote controller (group)

Specifications

Item Description

Power supply

Power consumption

Operating condition temperature, Humidity

Dimensions

Mass

100 - 240 V, AC 50/60 Hz

50 VA

0 - 40 °C, 20 - 85%RH

316 (W) x 256 (H) x 54 ( D) mm

Approx. 3.5 kg

19

Page 21

APPENDIX

APPENDIX

Touch Screen Controller System Configuration ................................................................................ 1

Wiring Specifications ........................................................................................................................ 3

Touch Screen Controller Connection Diagram ................................................................................. 4

Address setting Flow ........................................................................................................................ 5

Address Setting for Component Device ........................................................................................... 6

Intelligent Server ...................................................................................................................... 6

TCS-NET Relay Interface address setting ............................................................................. 7

Air conditioner address setting (example) ............................................................................... 8

Address Setting for Air Conditioner .................................................................................................. 9

Setting for VRF system ........................................................................................................... 9

Manual setting from wired remote controller .......................................................................... 10

Line (system) address setting ............................................................................................... 12

Power reset ............................................................................................................................ 12

Indoor unit address check ..................................................................................................... 13

Trial operation ........................................................................................................................ 13

Setup of relay connector and terminator ............................................................................... 14

Page 22

APPENDIX

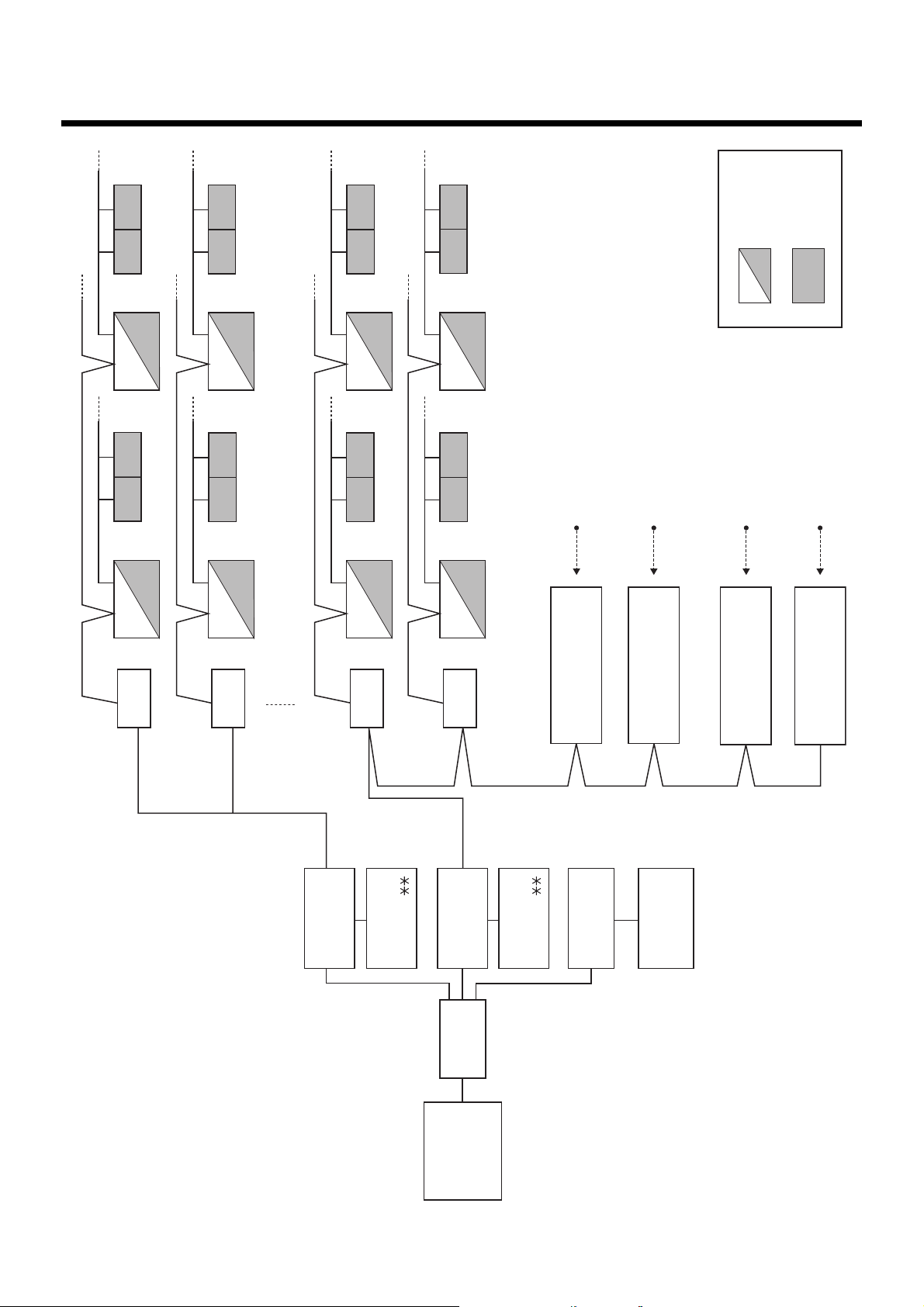

Touch Screen Controller System Configuration

Ethernet

InteIligent Server

(BMS-LSV2E)

Touch Screen Controller

(BMS-TP0640/5120)

Intelligent server Software

(BMS-STCC01E)

(*) A Switching HUB is required when using

two or more Intelligent Servers or when

connecting to a customer PC.

Switching HUB

Customer PC

Compact

Flash

RS-485

(BMS-IFDD01E)

TCS-NET

Relay I/F

(BMS-IFLSV1E)

TCS-NET

Relay I/F

(BMS-IFLSV1E)

MAX 8

Energy

Monitoring

Relay I/F

(BMS-IFWH3E)

Energy

Monitoring

Relay I/F

(BMS-IFWH3E)

MAX 4

Digital I/O

Relay I/F

(BMS-IFDD01E)

Digital I/O

Relay I/F

MAX 4

TCC-LINK Main Bus

Max. 64 air conditioners

per relay I/F

TCC-LINK Main Bus

Max. 64 air conditioners

per relay I/F

Power meter 1

(with pulse generator)

Power meter 8

(with pulse generator)

Power meter 1

(with pulse generator)

Power meter 8

(with pulse generator)

Input contact 1

Input contact 8

Load 1

Load 4

Input contact 1

Input contact 8

Load 1

Load 4

Max. 8 power

meters per relay I/F

Max. 8 power

meters per relay I/F

Max. 8 input

contacts per

relay I/F

Max. 4 loads

per relay I/F

Max. 8 input

contacts per

relay I/F

Max. 4 loads per

relay I/F

Max. 512 indoor

units (64 units x 8)

per Intelligent

Server

Max. 32 (8 x 4)

power meter

Max. 32 (8 x 4)

digital inputs

Max. 16 (4 x 4)

digital outputs

-1-

Page 23

APPENDIX

System Configuration Table

Touch Screen Controller

Air conditioning control

Power distribution

Indoor units connected

Function

Intelligent Server

Intelligent Server Software

TCS-NET Relay I/F

Component

Energy Monitoring Relay I/F

Digital I/O Relay I/F

Switching HUB

Network wire

PC

Power meter

*1:The number of network wires and the number of switching HUB port vary with the number of Intelligent Server connected.

*2:100 BASE-T compliant is required in using 5 or more server, or 2 or more controllers.

*3:The number of power meters vary with power meter specifications.

BMS-LSV2E

BMS-STCC01E

BMS-IFLSV1E

BMS-IFWH3E

BMS-IFDD01E

Procured on site

Procured on site

Procured on site

Procured on site

BMS-TP0640ACE BMS-TP0640PWE BMS-TP5120ACE BMS-TP5120PWE

– ±

Max. 64 units

Max. 8 units

– Max. 4 units

Max. 4 units

Remarks

Comply with 10BASE-T

Number of ports: As required

1

Category 5 UTP straight wire

*

OS: Windows 2000 or later, Excel 2000 or later

3

Pulse output type pulse: 1 kw-hr/pulse or 10 kw-hr/pulse

*

Pulse duration: 50 - 1000 ms

Output terminal: ON/OFF contactor

...

(±

available –

±

1 unit

1 unit

...

not available)

±

– ±

Max. 512 units

Max. 4 units

1 unit per Intelligent Server

(max. 4 units in total)

Up to 8 units per Intelligent Server

(max. 32 units in total)

– Max. 4 units

Max. 4 units

2

*

-2-

Page 24

Wiring Specifications

Power supply specifications

APPENDIX

Device Input voltage

Touch Screen Controller

Intelligent Server

TCS-NET Relay Interface

Energy Monitoring Relay Interface

Digital I/O Relay Interface

100 - 240 V, AC 50/60 Hz

85 - 132 V, AC 50/60 Hz

180 - 264 V, AC 50/60 Hz

220 - 240 V, AC 50/60 Hz

Power

consumption

50 VA

30 VA

2.4 W

2.8 W

6.5 W

Power cable

wire size

0.75 mm

2

Remarks

Procure on site

Communication wiring specifications

Inter-device connection Control wiring

specifications

Intelligent Server ↔ TCS-NET

Relay Interface

Intelligent Server ↔ Energy

Monitoring Relay Interface

Intelligent Server ↔ Digital I/O

Relay Interface

TCS-NET Relay Interface ↔ Air

conditioner

Energy Monitoring Relay Interface

↔ Power Meter

Digital I/O Relay Interface ↔ Digital

Input/Output

*1: Use the D-sub (9 pin) wire supplied with the Intelligent Server software. If its length is short, use a shield wire.

*2: Total length per TCS-NET Relay Interface

D-sub (9-pin) wire *

(If length is short) Use a

shield wire

Shield wire

Shield wire

Shield wire

Shield wire

1

Number of

cores

4

2

2

2

2

2

2

2

Wire size

2

(mm

)

2

1.25 mm

2

1.25 mm

2

1.25 mm

2

1.25 mm

2

2.0 mm

2

0.3 mm

2

0.3 mm

Length

(m)

Max. 500

Max. 500

Max. 500

Max.1000*

Max.2000*

Max. 100

Max. 100

Polarity

With polarity

With polarity

With polarity

2

No polarity

2

No polarity

No polarity

With polarity

Remarks

Supplied with

Intelligent

Server software

Procure on site

Procure on site

Procure on site

Procure on site

Procure on site

Procure on site

Procure on site

Ethernet wire specifications

When Switching HUB is not used

Inter-device connection Control wiring

specifications

Touch Screen Controller ↔

Intelligent Server

Ethernet (cross)

Category 5 UTP cross wire

When Switching HUB is used

Inter-device connection Control wiring

specifications

Touch Screen Controller ↔

Switching HUB

Switching HUB ↔ Intelligent

Server

Ethernet (straight)

Category 5 UTP straight wire

Ethernet (straight)

Category 5 UTP straight wire

Number of

cores

8

Number of

cores

8

8

Wire size

2

(mm

)

–

Wire size

2

(mm

)

–

–

Length

(m)

Max. 100

Length

(m)

Max. 100

Max. 100

Polarity

–

Polarity

–

–

Remarks

Procure on site

Remarks

Procure on site

Procure on site

-3-

Page 25

APPENDIX

Touch Screen Controller Connection Diagram

SW6

ON

TCC-LINK

TERMINATOR

12

SW5

RS-485

ON

TERMINATOR

1

2

RS-485

TCS-NET RELAY

INTERFACE

SW6

ON

TCC-LINK

TERMINATOR

12

SW5

ON

RS-485

TERMINATOR

1

2

RS-485

TCS-NET RELAY

INTERFACE

ADDRESS

ADDRESS

U4U3

U2U1

Outdoor

unit

SW1

8

U2U1

U2U1

Indoor unit

Remote

controller

U4U3

U2U1

Outdoor

unit

SW1

1

U2U1

Remote

controller

U2U1

Indoor unit

Outdoor

unit

Indoor unit

Remote

controller

Outdoor

unit

Indoor unit

Remote

controller

U4U3

U2U1

U2U1

U4U3

U2U1

U2U1

Yellow

Brown

B

A

Red

Crimp 3 wires with

a closed end wire joint.

Orange

A

B

Red/Orange

Brown/Yellow

Power supply

Power supplyPower supplyPower supplyPower supplyPower supply

TCC-LINK

TCC-LINK

FG

U1U2

ABLNLNLNLNLN LN

FG

U1U2

AB

U4U3

Indoor unit

U4U3

Indoor unit

Central remote

controller

Central remote

controller

INTELLIGENT SERVER

(BMS-LSV2E)

TOUCH SCREEN CONTROLLER

(BMS-TP0640/5120)

SW1

4

ADDRESS

DIGITAL I/O

INTERFACE

(BMS-IFDD01E)

SW1

1

ADDRESS

DIGITAL I/O

INTERFACE

(BMS-IFDD01E)

SW1

4

ADDRESS

DI 1

DI 2

DI 3

DI 4

DI 5

DI 6

DI 7

DI 8

DI 1

DI 2

DI 3

DI 4

DI 5

DI 6

DI 7

DI 8

DI 1

DI 2

DI 3

DI 4

DI 5

DI 6

DI 7

DI 8

Input contact 1

Input contact 2

Input contact 3

Input contact 4

Input contact 5

Input contact 6

Input contact 7

Input contact 8

RS-485

DO1

DO2

DO3

DO4

GND

+12V

RS-485

DO1

DO2

DO3

DO4

GND

+12V

Load 1

Load 2

Load 3

Load 4

Input contact 1

Input contact 2

Input contact 3

Input contact 4

Input contact 5

Input contact 6

Input contact 7

Input contact 8

Load 1

Load 2

Load 3

Load 4

Power meter 1

Power meter 2

Power meter 3

Power meter 4

Power meter 5

Power meter 6

Power meter 7

Power meter 8

ENERGY

MONITORING

INTERFACE

SW1

1

ADDRESS

ENERGY

MONITORING

INTERFACE

-4-

DI 1

DI 2

DI 3

DI 4

DI 5

DI 6

DI 7

DI 8

BA BA BA

RS-485

Power meter 1

Power meter 2

Power meter 3

Power meter 4

Power meter 5

Power meter 6

Power meter 7

Power meter 8

BA

RS-485

Page 26

Address Setting Flow

APPENDIX

Setting flow

Power on

Manual address setting

Line address setting

Power reset

Indoor unit address check

Trial operation (R.C. group/indoor name)

Contents

Indoor units/Outdoor units

Setting from main wired remote controller

(Line/Group/Indoor address setting)

Dip Switch setting on outdoor interface

P.C.board

Power reset to activate line address

7 segment display on outdoor interface

P.C.board check line/indoor address on

remote controller

Test operation in each R.C. group/

indoor name one by one

Reference page.

page 10

page 12

page 12

page 13

page 13

Setup of relay connector and SW30-2

Central controller exsit ?

Central control device setting

TCS-NET control system setting

Intelligent server

TCS-NET relay I/F

Energy monitoring relay I/F

Digital I/O relay I/F

Central control wiring and terminator

setting

When central remote controller is

connected, setup the central control

address with following the installation

manual included in the central control

devices.

Switch setting

CF (Compact Flash) card mounting

page 14

Trial operation for Touch panel controller Operation from touch screen controller

-5-

Page 27

APPENDIX

Address Setting for Component Device

Intelligent Server

Installing CF (Compact Flash) card

WARNING

• Do not insert or remove the CF (Compact Flash) card during power on of the Intelligent Server.

Doing so may cause a failure.

• If the CF (Compact Flash) card is not inserted properly, the Intelligent Server does not work.

Insert the attached CF (Compact Flash) card fully into the CF (Compact Flash) card slot on the side of

the Intelligent Server.

CF (Compact Flash) card

CF (Compact Flash) card slot

RS-485 operation mode setting

CAUTION

If the RS-485 mode set switch is set incorrectly, the Intelligent Server will not work.

The RS-485 mode set switch is provided on the bottom board of the Intelligent Server.

Set the switch as follows:

1234

OFF ON ON OFF

LED indicator side

RS-485 mode set

switch

1234

1

ON

A terminator resistor is connected between TX(+) and TX(-).

OFF

No terminator resistor is connected between TX(+) and TX(-).

2

ON

A terminator resistor is connected between RX(+) and RX(-).

OFF

No terminator resistor is connected between RX(+) and RX(-).

3

ON

Half-duplex mode (Note 1)

OFF

Full-duplex mode (Note 2)

4 Not used

AC inlet side

1ON234

(Note 1) Transmit data sent from the Intelligent Server is not received by the same server during transmission.

(Note 2) Transmit data sent from the Intelligent Server is also received by the same server during transmission.

-6-

Page 28

APPENDIX

Address Setting for Component Device (continued)

TCS-NET Relay Interface address setting

The following settings are necessary to use TCS-NET Relay Interfaces.

• SW1 Relay interface address set switch

When two or more TCS-NET Relay Interfaces are used, set a different address for SW1 to avoid

address duplication. Assign addresses in an ascending order.

CAUTION

• Set relay interface addresses according to the air conditioner address table.

For the relay interface whose address SW=1, perform terminator resistor setting.

• When the SW1 setting has been changed, push reset switch SW7. The new address setting is

read.

• SW5 RS-485 terminator resistor select switch

Set “120ohm” only when the TCS-NET Relay Interface address SW1=1, and set “open” for other

relay interfaces.

• SW6 TCC-LINK Terminator resistor select switch

The TCC-LINK terminator resistor is set on the air conditioner side. Set SW6 to “open”.

• SW7 Reset switch

When performing address setting for SW1, push this reset switch after address setting to read the

set value.

FGU1U2ABLN

RS-485 TCC-LINK

SW1

SW4

1

SW6

ON

1

SW5

ON

1

2

2

SW7

LED5LED3LED1

LED4

LED2

ON

234

SW3

SW2

SW3

SW4

SW2

SW1

SW5

Relay interface address set switch

1-8

0, 9-F

Relay interface address

Not used

Test switch (0 usually)

Test switch (all OFF usually)

Test switch

RS-485 terminator resistor select switch

1ON2

1ON2

1ON2

1ON2

60 ohm 120 ohm 120 ohm Open

SW6

TCC-LINK Terminator resistor select switch

1ON2 1ON2

Note:Bit 2 is not used.

100 ohm Open

SW7

LED1

LED2

LED3

LED4

LED5

Reset switch

Power indicator

RS-485 communication status indicator

TCC-LINK Communication status indicator

TCC-LINK Communication error indicator

Test indicator

-7-

Page 29

APPENDIX

Air conditioner address setting (example)

CAUTION

To control air conditioners by the Touch Screen Controller, set the air conditioner addresses as R.C.

group/indoor for each TCS-NET Relay Interface.

U1,U2

U1,U2

U1,U2

U1,U2

Relay interface

(Custom)

"1:1 model"

connection

interface

U3,U4

Model: TCB-

PCNT30TLE

unit

Relay interface

Main bus

TCS-NET Relay Interface: Max. 8 units per Intelligent Server

Outdoor

unit

Outdoor

U5,U6

U3,U4

U1,U2

unit

Outdoor

A,B

RC

RC

A,B

RC

A,B

RC

A,B

RC

A,B

A,B

A,BA,B

RC RC

A,B

RC

A,B

RC

A,B

RC

A,B

RC

A,B

Intelligent Server

Switching HUB

An example of air conditioner address setting

Touch Screen Controller

Relay interface

U3,U4

unit

Outdoor

U1,U2 U1,U2

unit

Outdoor

U5,U6

-8-

U1,U2 U1,U2 U1,U2 U1,U2 U1,U2 U1,U2 U1,U2 U1,U2

U1,U2

Indoor

unit

A,B

A,B

A,B

A,B

RC

RC

RC

RC

"Central Remote Controller Installation Manual and Owner's Manual".

1234

11111122222333 33 4

Line address

Line address

* For the "1:1 model" connection interface and the HA control interface, refer to the

12345612345123 45 1

00000000122000 00 0

Indoor unit address

Group address

Indoor

Page 30

APPENDIX

Address Setting for Air Conditioner

Setting for VRF system

In this air conditioner, it is required to set up address to the indoor unit before starting operation. Set up

the address according to the following setup procedure.

CAUTION

1. Set up address after wiring work.

2. Be sure to turn on the power in order of indoor unit → outdoor unit. If turning on the power in the

reverse order, a check code [E19] (Error of No. of header units) is output. When a check code is

output, turn on the power again.

3. To set up an address, it is unnecessary to operate the air conditioner.

4. It requires maximum 10 minutes (Usually, approx. 5 minutes) to set up automatically an address to

1 line.

Manual address setting is recommended for TCS-NET control system

Manual address: Setup from the wired remote controller

* It is temporarily necessary to set the indoor unit and wired to 1 by 1.

(In group operation and in time without remote controller)

5. Automatic address setup is also available besides manual setup.

Automatic address: Setup from SW15 on the interface P.C. board of the header unit

6. To set up an address automatically, the setup at outdoor side is necessary.

(Address setup cannot be performed by power-ON only.)

-9-

Page 31

APPENDIX

Manual setting from wired remote controller

CAUTION

Be sure to allocate Line (system) /Group/Indoor address one by one to match the address setting

table and setup file that is prepared beforehand.

If wrong value is set, a problem such as error of communication with air conditioner will occur.

Header

Outdoor unit

Indoor unit

Remote

controller

Indoor address

Group address

Line address

At shipment, all address are 0099 (Address unset status)

12 34

00 12

11 11

Follower

Line address

(At shipment:1)

Dip Switch setting

on interface P.C.board

Indoor, group, line

address are set

manually for each

R.C. group/indoor

name one by one.

(Step 1)

Arrange one indoor unit and one remote controller (RBC-AMT21E) set to 1 by 1.

Note: Don’t use simple remote controller or wireless remote controller.

(Address setting is not available.)

Connect wired remote

controller individually

when manual address

setting

-10-

Page 32

APPENDIX

Address Setting for Air Conditioner (continued)

(Step 2)

Note )

When setting the line address from the remote controller, do not use address 29 and 30.

The address 29 and 30 cannot be set up in the outdoor unit. Therefore if they are incorrectly set up, a

check code [E04] (Indoor/outdoor communication circuit error) is output.

Turn on the power.

1

Item code

Line (system) address

Indoor address

Group address

12

13

14

(Wiring example in 2 systems)

System System

#1

system

Indoor Indoor Indoor

Line address → 1

Indoor address → 1

Group address → 1

In the above example, under condition of

no inter-unit wire of the remote controller,

set the address after individual connecting

of the wired remote controller.

Remote

controller

Header

indoor

unit

1

2

2

1

3

2

Follower

indoor

unit

#2

system

Indoor Indoor

2

1

2

Push simultaneously

tons for 4 seconds or more.

LCD changes to flashing.

(Line address)

2

2

2

Using the setup temp. /

buttons, set to the item code.

3

Using the timer time / buttons, set

up the line address.

(Match it with the line address on the interface P.C.

board of the header unit in the identical R.C. group/

indoor.)

4

Push

SET

button.

(OK when display goes on.)

2

(Indoor address)

5

Using the setup temp. / buttons, set

6

Using the timer time / buttons, set

to the item code.

up the indoor address.

7

Push

SET

button.

(OK when display goes on.)

SET

+

+ but-

CL

Group address

Individual : 0000

Header unit : 0001

Follower unit : 0002

In case of group control

Operation procedure

1 → 2 → 3 → 4 → 5 → 6 →

→

8 → 9 → 10 → 11

7

SET DATA

UNIT No.

R.C. No.

CODE No.

End

Data

11

UNIT

1

SET

CL

4, 7, 10

Item code

3, 6, 9

2, 5, 8

-11-

(Group address)

8

Using the setup temp. / buttons, set

9

Using the timer time / buttons, set

Individual =

unit =

10

Push

to the item code.

.

SET

button.

, Header unit = , Follower

(OK when display goes on.)

11

Push button.

Setup operation finished.

(Status returns to normal stop status.)

Page 33

Line (system) address setting

APPENDIX

1. Using SW13 and 14 on the interface P.C.

board of the header unit in each system, set

Header unit interface P.C. board

ON

1

2 3 4

up the system address for each system.

(At shipment from factory: Set to Address 1)

Note) Be careful not to duplicate with other refriger-

ant line.

SW11

1ON2 3 4

SW06

System address switch on outdoor interface P.C. board

System

address

1

2

3

4

5

6

7

8

9

10

11

12

13

14

SW13 SW14

12341234

ЧЧЧЧЧ

Ч

ЧЧ

Ч

ЧЧЧ

Ч

ЧЧ

Ч

ЧЧЧЧ

Ч

ЧЧ

Ч

ЧЧЧ

Ч

×××

{

××

{

{{

{

{{{

{

{{

{

××

{

×

{

{{

××

×

{

×

{{

×

{{

×

×

×

×

{

{

{

{

System

address

15

16

17

18

19

20

21

22

23

24

25

26

27

28

1ON2 3 4

SW12

ON ONON ON

1

2 3 4

SW07

1ON2 3 4

SW13

11 2 3 4

SW09SW08

1ON2 3 4

SW14

1 2 3 4

SW10

({: Switch ON, × : Switch OFF)

SW13 SW14

12341234

××

×

{

{{

{

{{{

{

{{

{

{{{{

{

{{

{

{{{

{{{

{{{{

××××

×××

×

{

××

××

××

×

×

{{

{

{

×

×

×

×

×××

××

×

{

{

{

×

{

×

{

: Is not used for setup of system address. (Do not change setup.)

2. Check that the relay connectors between [U1U2] and [U3U4] terminals are come out in all the header

units to which the central control is connected.

(At shipment from factory: No connection of connector)

CAUTION

Be sure to allocate different line address for each R.C. group/indoor as much as possible even if there

are two or more TCS-NET relay interfaces.

Power reset

• To activate line address on both outdoor and indoor unit side, power supply is temporarily reset.

• When power is supplied again, be sure to the power of indoor unit prior to the outdoor unit.

-12-

Page 34

SW01 SW02

Display A

Display B

D600 D601

CN30 CN31

SW06 SW07 SW09SW08

CN32 SW04

SW05 SW15

SW03

D602 D603

D604

SW01 SW02

Display A

Display B

D600D601

CN30 CN31

SW06 SW07 SW09SW08

CN32 SW04

SW05 SW15

SW03

D602 D603 D604

Address Setting for Air Conditioner (continued)

Indoor unit address check

APPENDIX

Step

1

2

3

Item

Power - on

Display check

System

information

check

(Outdoor side)

Operation and check contents

Initial communication takes a couple of minutes.

During initial communication, 7-segment display section is as follows as follows.

Display [A] --- [U1], flashing Display [B] --- [ - - 0] --> [ - - i] flashing

After initial communications, [U1] are displayed in 7-segment display section.

(If error code is displayed in display section [B], remove the cause reffering to “trouble

shooting” of installation or service manual.)

Rotary switch setup 7-segment display

SW01

System capacity

No. of connected

SW02

1

1

SW03

2

3

3

3

[No. of indoor units]

[A]

[No. of HP]

[B]

[HP]

[ ]

outdoor units

No. of connected

1

4

[No. of outdoor units]

4

[ ]

indoor units

Indoor address

6

1 to 16

1 to 3

[Indoor unit address]

[Capacity (HP)]

No. and capacity

Note) Indoor unit address No. is choosen by changing SW02 and SW03.

SW02

1 to 16

1 to 16

1 to 16

SW03

1

2

3

Indoor address

SW02 setup number

SW02 setup number +16

SW02 setup number +32

7-segment [A]

[01] to [16]

[17] to [32]

[33] to [48]

4

Address

information

check

(indoor side)

<On the header outdoor interface P.C.board>

7-segment

display A

2nd.

place

1st.

place

3rd.

place

7-segment

display B

2nd.

place

1st.

place

<Procedure> (Operation while the air

conditioner operates)

1

If it stops, push button.

2

Push

UNIT

button.

The unit NO is displayed on the LCD.

(Disappears after several seconds) The displayed unit No indicates the line address and

indoor address. (If there is other indoor unit

connected to the same remote controller

(Group control unit), other unit No is displayed

every pushing

UNIT

button.)

Interlace P.C. board

Indoor address

Line address

3

End

1

2

Operation procedure

SET DATA

SET

CODE No.

UNIT No.

R.C. No.

UNIT

CL

Trial operation

-13-

Please refre to the trial operation on the manual of air conditioner.

1 → 2 → 3

End

Page 35

APPENDIX

Setup of relay connector and terminator

• After trial operation for each R.C. group/indoor, set the relay connector and terminator resistor for all

R.C. group/indoor which are connected from one TCS-NET relay interface.

<Procedure>

1

How to set up terminator resistor (SW30)

When all the address setups have finished in the same

refrigerant system, put the terminator resistor (SW30) in the

same central control line into one.

• Remain only SW30-2 of the header outdoor unit with the

least line address number as it is ON.

(With terminal resistor)

• Set up SW30-2 of the other header outdoor units to OFF.

(Without terminal resistor)

2

Connect the relay connector between [U1U2] and

[U3U4] of the header outdoor unit for each R.C. group/

indoor.

Header outdoor unit interface P.C. board

1ON2

1

SW30

1ON2 3 4

SW11

1ON2 3 4

SW06

1ON2 3 4

SW12

ON ONON ON

1

2 3 4

SW07

1ON2 3 4

SW13

11 2 3 4

SW09SW08

1ON2 3 4

SW14

2

U1 U2

For internal

wiring between

indoor and

outdoor

U3 U4

For wiring of

central control

system

For internal

wiring between

outdoor units

SW30

1 2 3 4

SW10

U5 U6

<System diagram (example)>

Ethernet

Touch Screen Controller

(BMS-TP0640 / 5120)

Switching HUB

PC for Energy

Monitoring

Range for each

setting procedure

RS- 485

InteIligent Server

(BMS-LSV2E)

Compact

Flash

InteIligent Server

Software

(BMS-STCC01E)

TCS- NET

Relay I / F

(BMS-IFLSV1E)

No.1

TCS- NET

Relay I / F

(BMS-IFLSV1E)

No.2

TCS- NET

Relay I / F

(BMS-IFLSV1E)

No.3

Main BUS

Line address

=1

Main BUS

Line address

=2

Main BUS

Line address

=3

Main BUS

Line address

=4

Main BUS

Line address

=5

-14-

Main BUS

Line address

=6

Page 36

Address Setting for Air Conditioner (continued)

12 3

TCS-NET

relay

interface

U3 U4

Header

unit

Follower unit

U3 U4

U3 U4

Header unit

Follower unit

U3 U4

APPENDIX

Header unit

U3 U4

Before address setup

During setup of address

After address setup

Outdoor interface

P.C. board

SW13, 14

(Line address)

SW30-2

Terminal-end resistance

of indoor/outdoor communi

cation line/central control

communication line

Relay connector

U1 U2 U5 U6

U1 U2

A B

Remote

controller

U1 U2 U5 U6

U1 U2

A B

Remote

controller

Relay

connector

U1 U2 U5 U6

U1 U2

A B

Remote

controller

U1 U2 U5 U6

U1 U2

A B

U1 U2 U5 U6

U1 U2

A B

Remote

controller

Individual Group

TCS-NET

relay

interface

Relay

connector

U1 U2 U5 U6

U1 U2

U3 U4

SW30

A B

Remote

controller

Header

unit

21

ON

OFF

U1 U2

Follower unit

U3 U4

SW30

U1 U2 U5 U6

A B

Remote

controller

21

ON

OFF

Relay

connector

ON

OFF

U1 U2

Follower unit

U3 U4

21

ON

SW30 SW30

U1 U2 U5 U6

A B

OFF

Header unit Header unit

U3 U4

21

SW30

U1 U2 U5 U6

U1 U2

A B

Remote

controller

U3 U4

U1 U2 U5 U6

U1 U2

A B

Remote

controller

Individual Group

Header unit Follower unit Follower unitHeader unit Header unit

1 2

ON

Connect short

after

address setup

(Setup is

unnecessary.)

(Setup is

unnecessary.)

Open

OFF after

address setup

Connect short

after

address setup

(Setup is

unnecessary.)

(Setup is

unnecessary.)

Open Open

OFF after

address setup

Connect short

after

address setup

Relay

connector

21

ON

OFF

Relay

connector

Setup at shipment

from factory

3 1

ON

Indoor side

Line address

Indoor unit address

Group address

1

1

0

1

2

0

2

1

1

2

2

2

3

1

0

POINT

Relay connector — NOTE —

Never connect a relay connector until address setup for all the R.C. group/indoor finishes;

otherwise address cannot be correctly set up.

After this setting, if central control devices (central remote controller or ON/OFF controller), set up the

central control address.

(For the central control address setup, refer to the installation manual of the central control devices.)

-15-

Page 37

Page 38

EH99841201

Loading...

Loading...