Toshiba BMS-TP0640ACE, BMS-TP0640PWE, BMS-TP5120PWE INSTALLATION MANUAL

INSTALLATION MANUAL

TOUCH SCREEN CONTROLLER

for Air Conditioning Control System

BMS-TP0640ACE

BMS-TP5120ACE

• Thank you very much for purchasing the TOSHIBA Touch Screen Controller.

• Please read this manual carefully beforehand for proper installation of the controller.

BMS-TP0640PWE

BMS-TP5120PWE

CONTENTS

1 Precautions for Safety .............................................................................................................. 1

2 Outline of Control System........................................................................................................ 2

3 Accessory parts ........................................................................................................................ 2

4 Selection of Installation place .................................................................................................. 3

5 Points for Installation Work ...................................................................................................... 4

6 Connecting the Network wires ................................................................................................ 6

7 Connecting the Power cable .................................................................................................... 7

8 Control Wiring Diagram (Connection example) .................................................................. 9

9 Air conditioner Address Table and Before-Trial Operation Check list .................................. 10

10 Schedule Table for Each R.C. group/indoor Name ............................................................ 12

11 Installation ................................................................................................................................ 13

12 Trial Operation ......................................................................................................................... 14

13 Trouble shooting ..................................................................................................................... 17

14 Control Specifications ............................................................................................................ 19

APPENDIX

1

• Ensure that all Local, National and International regulations are satisfied.

• Read these “Precautions for Safety” carefully before installation.

• The precautions described below include important items regarding safety. Observe them without fail.

• After the installation work, perform a trial operation to check for any problem. Follow the Owner’s Manual

• Turn off the main power supply switch (or breaker) before the controller maintenance.

• Ask the customer to keep the Installation Manual together with the Owner’s Manual.

Precautions for Safety

to explain how to use and maintain the controller to the customer.

WARNING

• Ask an authorized dealer or qualified installation professional to install/maintain the

conditioner.

• Turn off the main power supply switch or breaker before starting electrical work.

Make sure all power switches are off. Failure to do so may cause electric shock.

• Connect the connecting wire correctly.

If the connecting wire is connected in a wrong way, electric parts may be damaged.

• Do not modify the controller by removing any of the safety guards or by-bypassing any of

the safety interlock switches.

• Exposure of the controller to water or moisture before installation may cause a short-circuit

of electrical parts.

Do not store it in a wet basement or expose to rain or water.

• After unpacking the controller, examine it carefully if there is possible damage.

• Perform installation work properly according to the Installation Manual.

Inappropriate installation may result in water leakage, electric shock or fire.

• Electrical work must be performed by a qualified electrician in accordance with the

Installation Manual. Make sure the conditioner uses an exclusive power supply.

An insufficient power supply capacity or improper installation may cause fire.

• Use the specified wires for connecting the terminals securely fix. To prevent external forces

applied to the terminals from affecting the terminals.

• Conform to the regulations of the local electric company when connecting the power supply.

Inappropriate grounding may cause electric shock.

• Do not install the air conditioner in a location subject to a risk of exposure to a combustible

gas.

If a combustible gas leaks, and stays around the controller, a fire may occur.

CAUTION

Upon customer’s approval, install the Touch Screen Controller at a place which satisfies the

following conditions.

• Place where the Touch Screen Controller can be installed securely.

• Place which can reserve a sufficient service space for safe maintenance or check.

• Place where CF (Compact Flash) card can be removed easily.

• Place which provides sufficient space for connecting/checking the terminals of interface, InputOutput ports, etc.

Avoid the following places.

• Places where a device generating high frequency (inverter, non-utility generator, medical apparatus,

or communication equipment) is installed. (A bad influence may generated by malfunction of the

controller, control error, or noise may affect such equipment.)

1

2

When installed this Air Conditioning Control System in a Toshiba air conditioner, enables easy central

control of up to 64 (for BMS-TP0640ACE, BMS-TP0640PWE) or up to 512 (for BMS-TP5120ACE, BMSTP5120PWE) indoor units with multi-functions integrated into the controller. This system allows advanced,

operation control, and power-saving operation for medium to large buildings.

This system also provides elaborate, advanced functions such as operation status monitoring, control,

and scheduled operation of all air conditioners for each block, tenant or area.

Thus efficient control of air conditioners is readily with easy operation.

With an easy-to-see color LCD touch panel, this system allows you to quickly reference various settings

or detailed information and execute them by only touching the LCD panel.

Outline of Control System

3

Accessory parts

Accessory parts

Part name

Touch Screen Controller

Touch Screen Controller fixture

Guard cover

Simple stand

Terminal connector

Jumper pin

Triangle thread screw (M3 x 6)

Triangle thread screw (M4 x 8)

CF (Compact Flash) card for data files

CF (Compact Flash) card adapter

Installation Manual

(Note) Power cable is not supplied for the Touch Screen Controller. Prepare a 3-pin power cable conforming to applicable

safety standards. Be sure to connect the earth line each of the power cable securely.

Q'ty

1

6

1

1

1

2

1

1

1

1

1

Remarks

Touch panel computer

For in-wall installation

For preventing CF (Compact Flash) card from coming out

For contact input/output (connected already)

For RS-485 settings (set already)

For guard cover

For simple stand

Inserted in the card slot

Inserted in the card slot

This manual

2

4

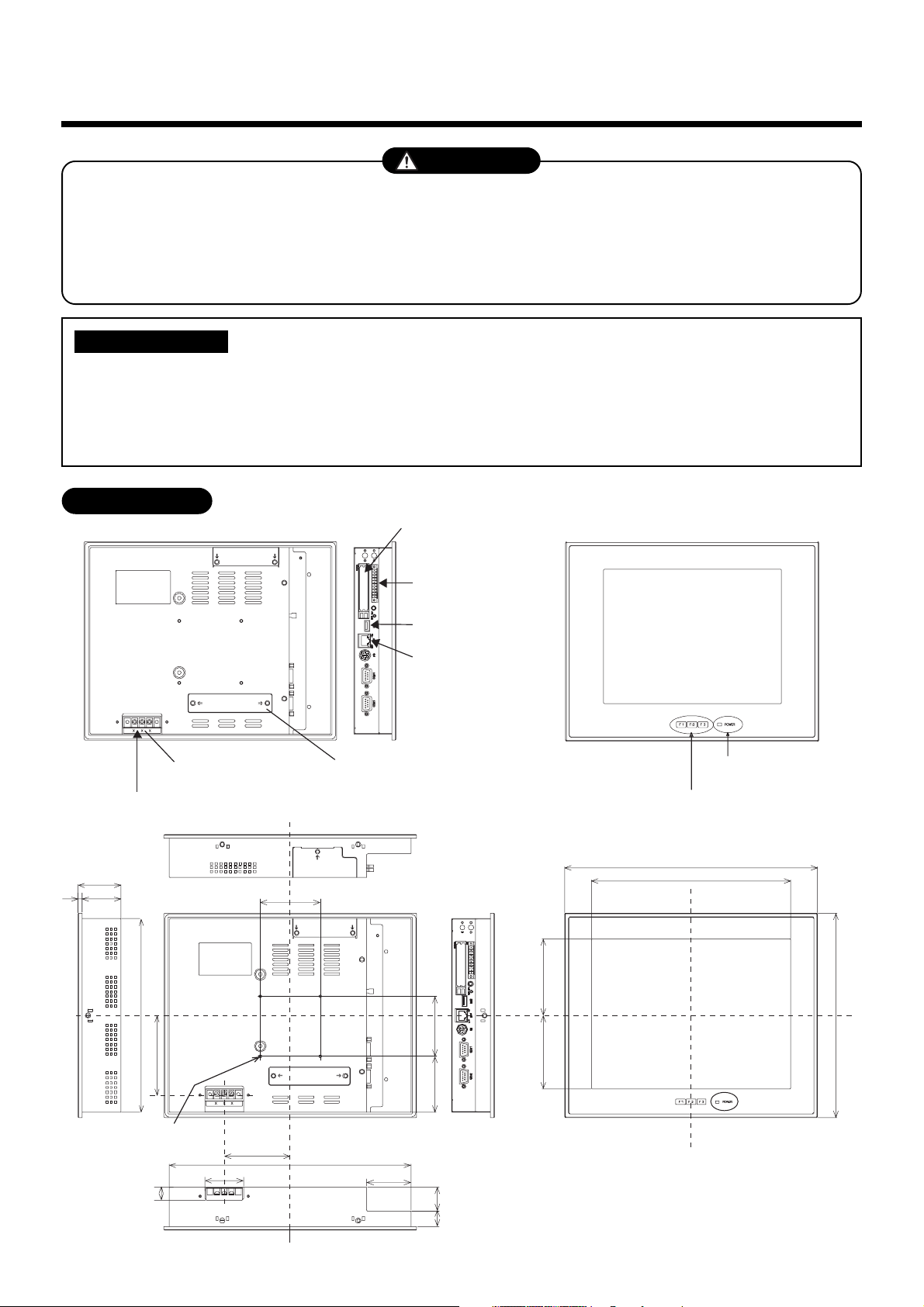

Selection of Installation place

WARNING

Install the Touch Screen Controller securely in a place that can sufficiently withstand the

weight of the controller.

If the foundation is not sturdy enough, the controller may fall and cause injury.

Perform specified installation work to guard the controller against earthquakes.

Improper installation may cause the controller to fall.

REQUIREMENT

To prevent damage on the Touch Screen Controller or personal injury, follow the instructions

below.

• Do not step, or put any heavy object on the packed controller.

• When carrying the controller, hold it paying attention not to apply excessive force.

• Do not block any of the air vents of the Touch Screen Controller.

External View

CF (Compact Flash)

card slot (CF card for

data files)

Universal Input/

Output port

Power cable

54

549

242

99.3

Power input

terminal block

75

USB mouse

Ethernet port

Intelligent

Server

PCI expansion unit

connector cover

70 75

POWER LED

Function switch (F1, F2, F3)

316

249

95.7591.75

256

M4 Tap (×4 pcs.)

(depth: 10 mm max.)

16

48

82.5

302

55.5

19 30

unit: mm

3

5

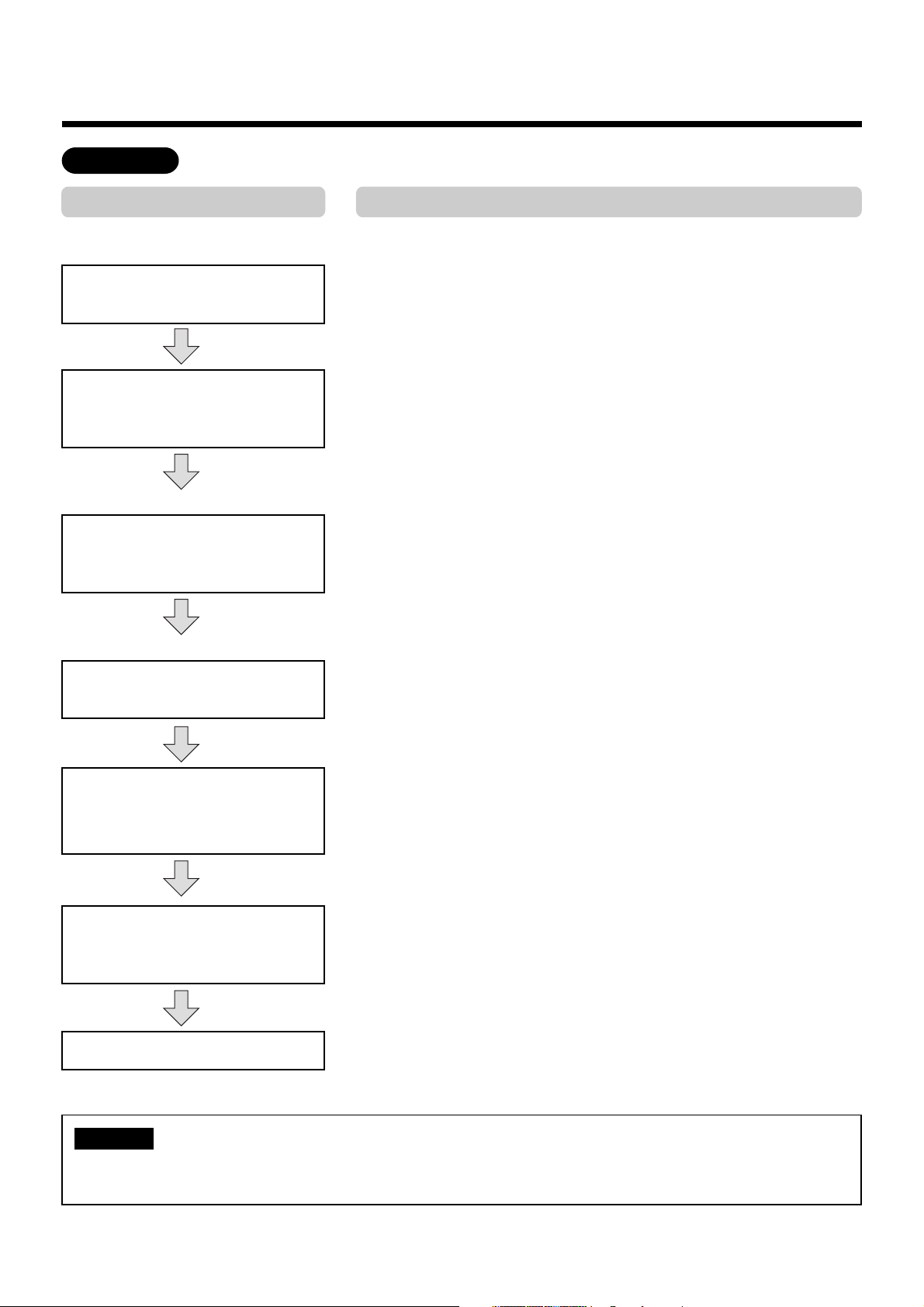

Points for Installation Work

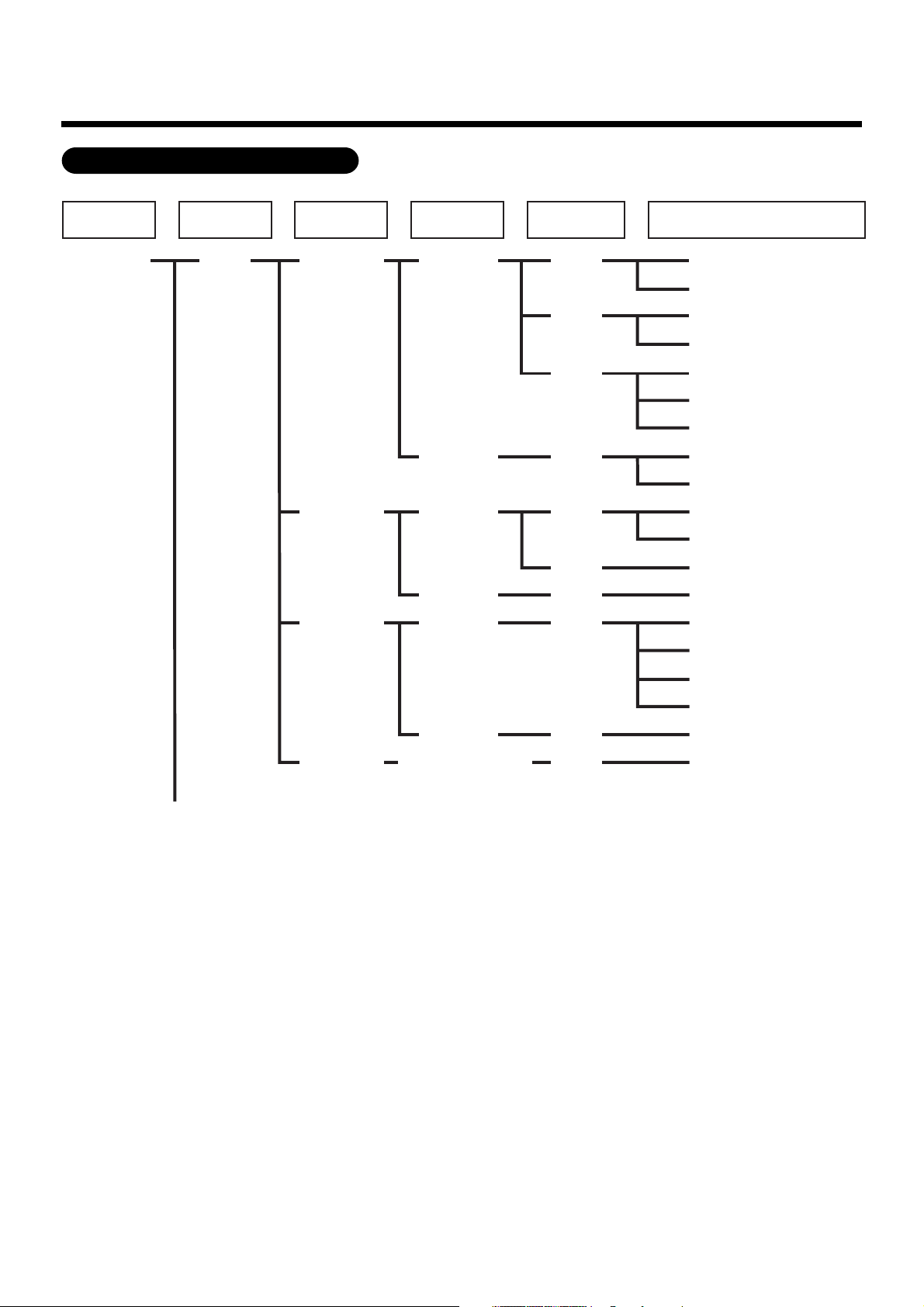

Work flow

Process

(Before work)

Determination of installation

condition

Document creation

(Data input before work)

Enter block/tenant/area names.

Enter schedules for each

R.C. group/indoor name.

(Before installation)

Electrical work

(power/control lines)

Point

• Clarify work categories.

• Determine items of detail control.

• Determine the installation position of the Touch Screen Controller.

• Create a control wiring diagram (see page 9).

• Create an address table for each block, tenant, and area (see

page 10, 11).

• Create a schedule table for each R.C. group/indoor name (see

page 12).

• Enter block/tenant/area names in each address table (see

page 11).

• Enter schedules in each schedule table (see page 12).

• Make connections according to the control wiring diagram (see

page 9).

• Intelligent Server (see APPENDIX page 6)

• TCS-NET Relay Interface (see APPENDIX page 7)

Operation mode/address settings

Trial operation and adjustments

Owner’s manual, delivery

NOTE

For installation, wiring or adjustment of the accessible components for the Touch Screen Controller,

refer to the manual “A04-016”.

• Indoor unit (see APPENDIX page 8-15)

• Checking according to the Before-Trial Operation Check list

(page 10) using the control wiring diagram.

• Operate the indoor unit for each system according to the control

wiring diagram.

Check that there is no incorrect wiring or piping, and then create

a trial operation check list (page 16).

• Give operational explanation in an easy-to-understand manner.

4

5

Points for Installation Work (continued)

Management zone categories

All Block Tenant Area

Building A 1-1 (header unit)

1F

Tenant A

Tenant B

Tenant C

Shop A

Office A

Shop B

Office B

Shop C

RC

Group/Unit

101

102

103

104

105

106

107

108

(line address + indoor unit address)

Indoor Unit

1-2 (follower unit)

1-3 (header unit)

1-4 (follower unit)

1-5 (header unit)

1-6 (follower unit)

1-7 (follower unit)

1-8 (header unit)

1-9 (follower unit)

2-1 (header unit)

2-2 (follower unit)

2-3 (header unit)

2-4 (header unit)

2-5 (header unit)

2-6 (follower unit)

Shared

space

Office C

1F outdoor

air conditioner

109

110

2-7 (follower unit)

2-8 (follower unit)

2-9 (follower unit)

3-1 (header unit)

5

6

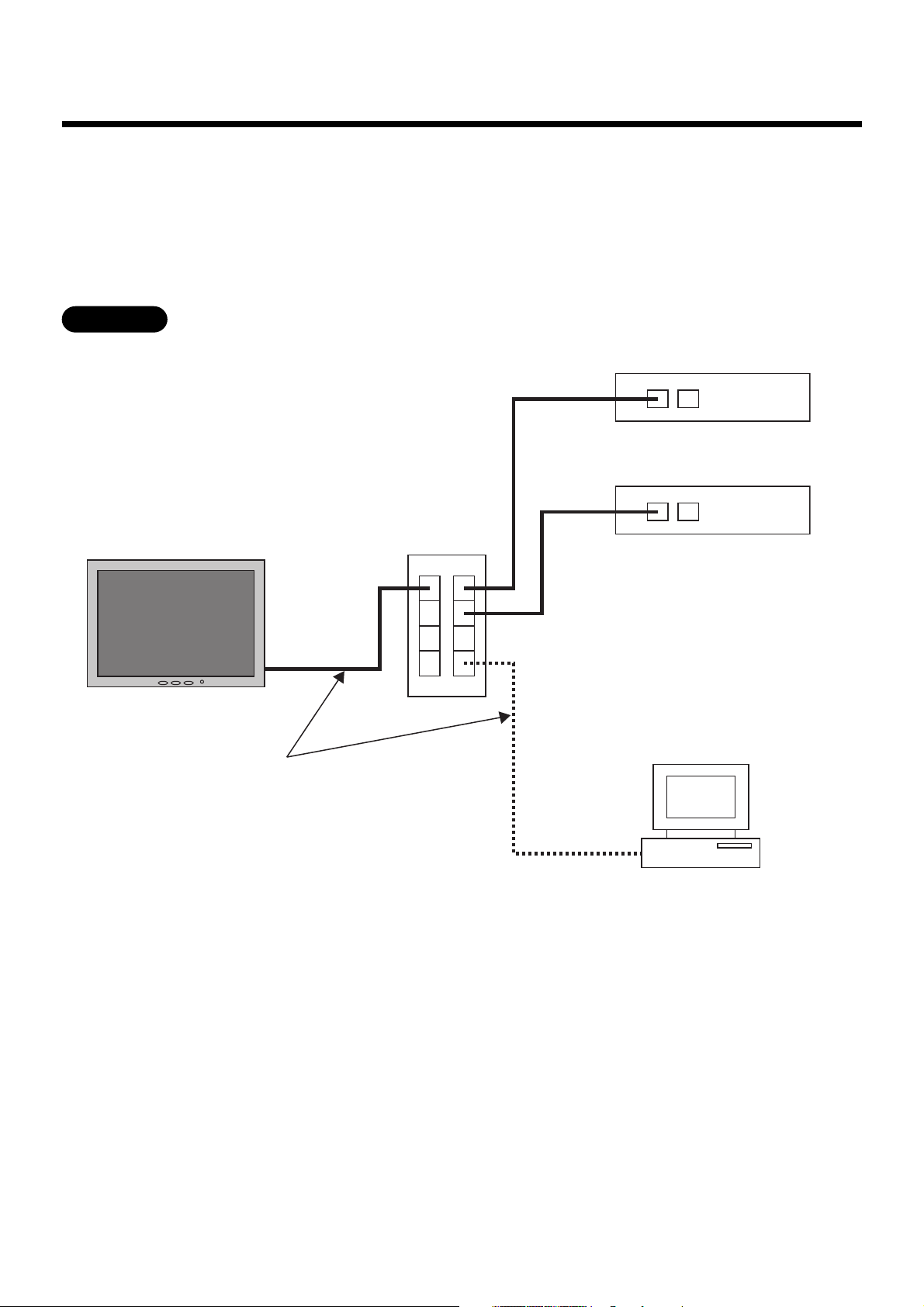

Connect the Touch Screen Controller to Intelligent Servers and to an optional PC for creating monthly

reports using network wires (category 5UTP straight wire), via a Switching HUB (procured on site).

• Connect the Ethernet port of the controller to a port of the HUB with a network wire.

• Connect the Ethernet port 1 of the Intelligent Server to a port of the HUB with a network wire.

• Connect the PC’s Ethernet port to a port of the HUB with a network wire. (Not required if there is not

Connecting the Network wires

need to create reports.)

Ethernet

Touch Screen Controller

Network wires

(category 5UTP straight wire)

Ethernet port

Switching HUB

Ethernet port 1

Ethernet port 2

PC for creating monthly reports

Intelligent Server No.1

Intelligent Server No.2

6

7

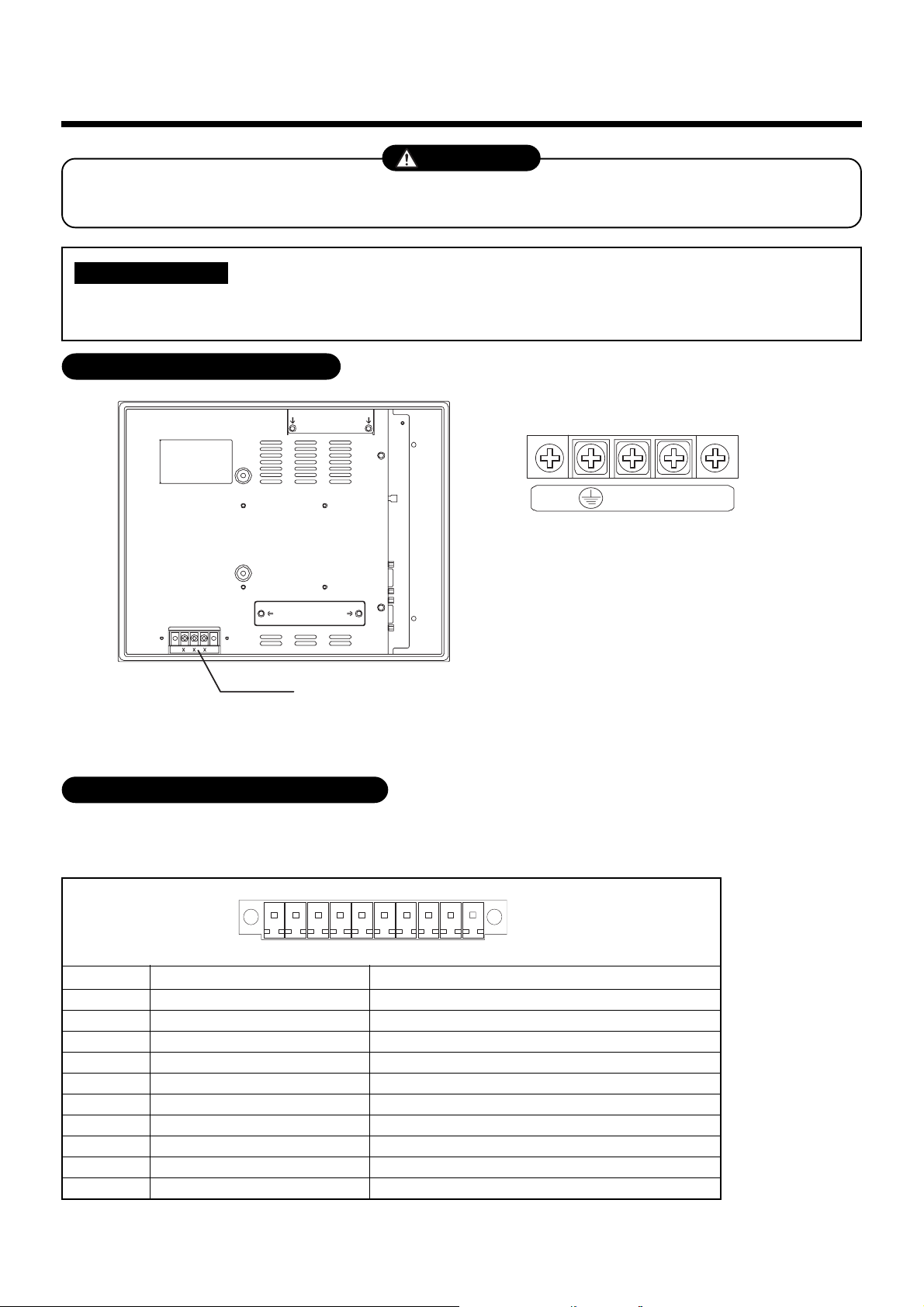

Connecting the Power cable

CAUTION

Connect a proper input AC voltage to the power input terminal block. Failure to do so may cause a

failure.

REQUIREMENT

Power cable is not supplied for the Touch Screen Controller. Prepare a 3-pin power cable conforming

to applicable safety standards. Be sure to connect the earth line each of the power cable securely.

Power Input Terminal Block

■■

■ Power Input Terminal Block

■■

L

N

Rated input voltage: 100 to 240 VAC

Power input terminal block

For M3.5 screws

Terminal pitch: 8.9 mm

Universal Input/Output Port (I/O)

This port is provided with electrically-insulated 3 inputs and 3 outputs for universal use.

■ ■

■ Universal Input/Output port connector

■ ■

10 1

↓ Front (LCD side)

Pin No. Signal name

1

2

3

4

5

6

7

8

9

10

Connector: MC1,5/10-GF-3,5(PHOENIX CONTACT)

Cable connector: MC1,5/10-STF-3,5(PHOENIX CONTACT)

PI_PCOM

PI(0)

PI(1)

PI(2)

P_PO(0)

N_PO(0)

P_PO(1)

N_PO(1)

P_PO(2)

N_PO(2)

Universal input plus common

Universal input 0

Universal input 1

Universal input 2

Universal output 0+

Universal output 0-

Universal output 1+

Universal output 1-

Universal output 2+

Universal output 2-

Remarks

7

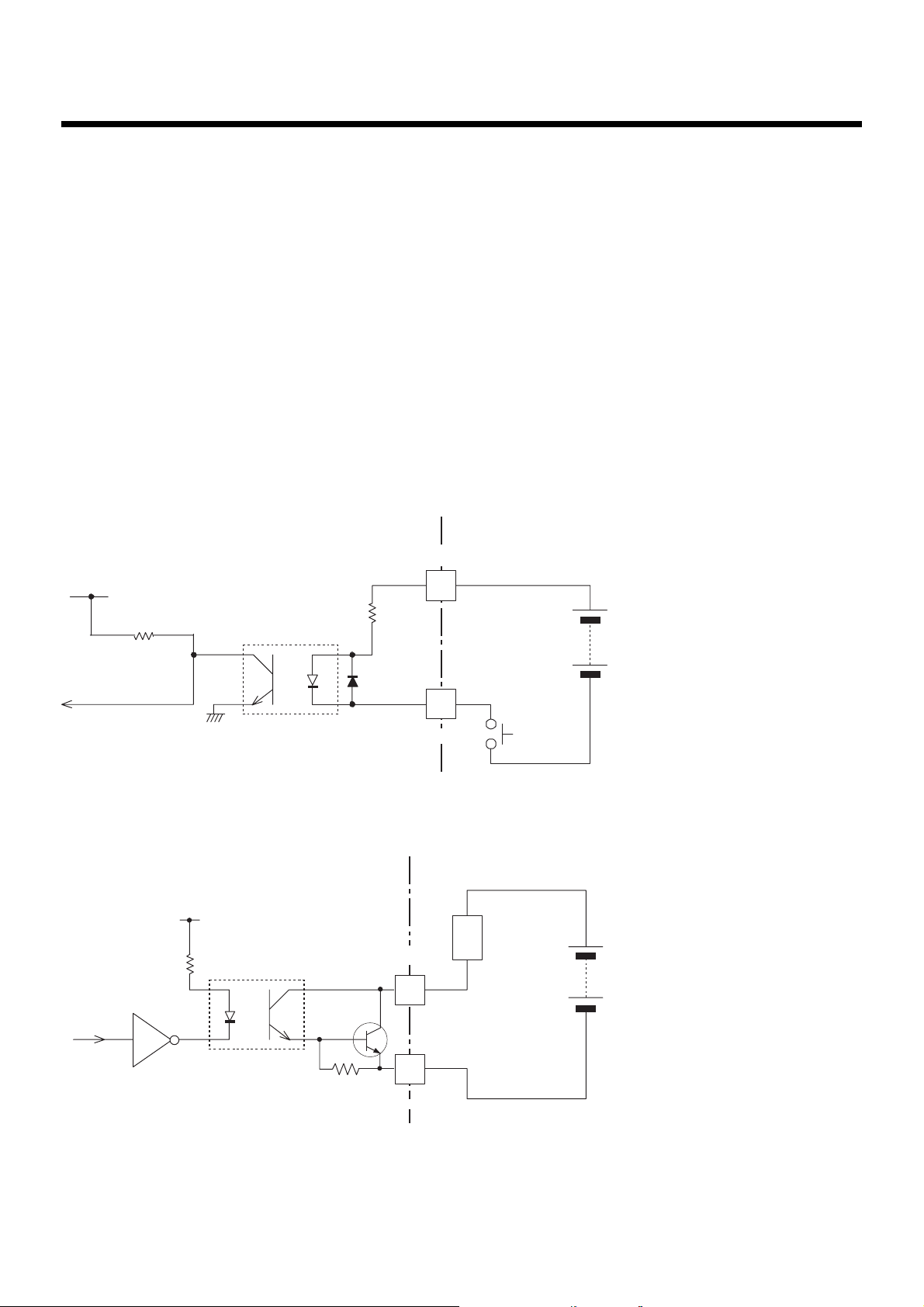

■■

■ Specifications

■■

[Input]

Input system : Current-driven input insulated by photo-coupler

Input resistance : 3 k ohms

Number of input signals : 3

External circuit power voltage : 12 to 24 V DC (±10%)

[Output]

Output system : Open-collector output insulated by photo-coupler

Output rating : 30 V DC, 100 mA maximum

Number of output signals : 3

■■

■ External Input/Output circuit

■■

(1) Input circuit

PI_PCOM

10 k ohm

(2) Output circuit

330 ohm

PC357

3 k ohm

1/2 W

P_PO(0) - P_PO(2)

2SD780A

PI(0) - PI(2)

Input/Output

connector

(External circuit)

load

External power supply

(12 V - 24 V DC)

Input

contact

External power supply

(Max. 30 V DC)

4.7 k ohm

N_PO(0) - N_PO(2)

Input/Output

connector

8

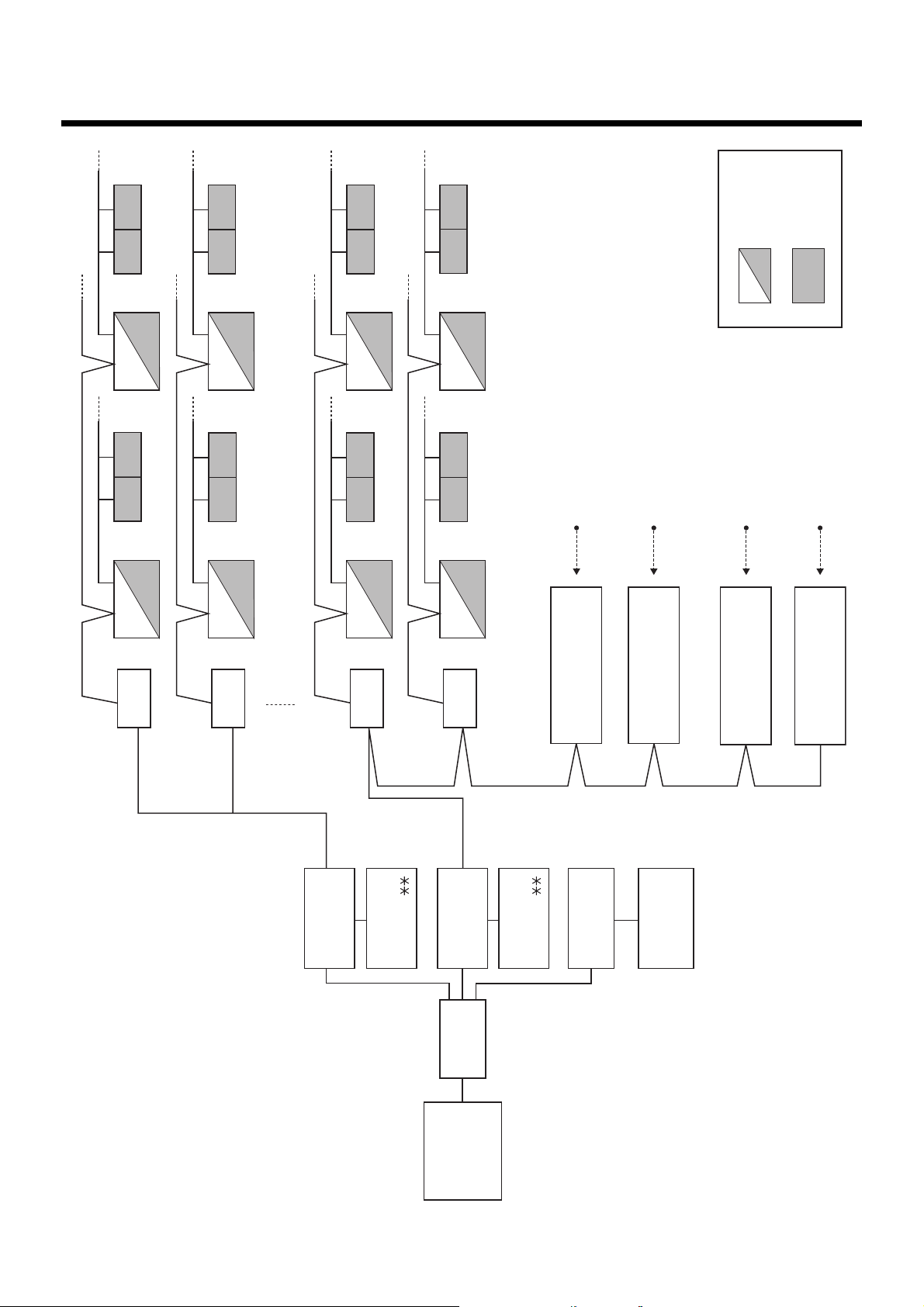

Control Wiring Diagram

8

(Connection example)

U1,U2

U1,U2

U3,U4

U1,U2

U1,U2

U3,U4

U1,U2 U1,U2 U1,U2 U1,U2

U1,U2 U1,U2

U3,U4

U1,U2 U1,U2

U1,U2 U1,U2

U3,U4

U1,U2

U1,U2

8 door-lock control signal inputs

8 fire alarm inputs

Outdoor unit

8 power meter inputs

Indoor unit

8 power meter inputs

Main Bus

16th floor

U3,U4

BMS-

IFLSV1E

15th floor

TCS-NET Relay Interface

U3,U4

BMS-

IFLSV1E

TCS-NET Relay Interface

2nd floor

9th-16th

floor

Server

Intelligent

BMS-LSV2E

U3,U4

BMS-

IFLSV1E

1st floor

TCS-NET Relay Interface

software

Intelligent server

Intelligent

BMS-STCC

U3,U4

BMS-

IFLSV1E

TCS-NET Relay Interface

1st-8th

floor

Server

BMS-LSV2E

HUB

Switching

software

BMS-STCC

Intelligent server

BMS-IFDD01E

Relay Interface

Digital Input/Output

PC for creating

monthly reports

Relay Interface

Digital Input/Output

BMS-IFDD01E

Printer

Energy Monitoring

BMS-IFWH3E

Relay Interface

Relay Interface

Energy Monitoring

BMS-IFWH3E

Touch Screen

Controller

9

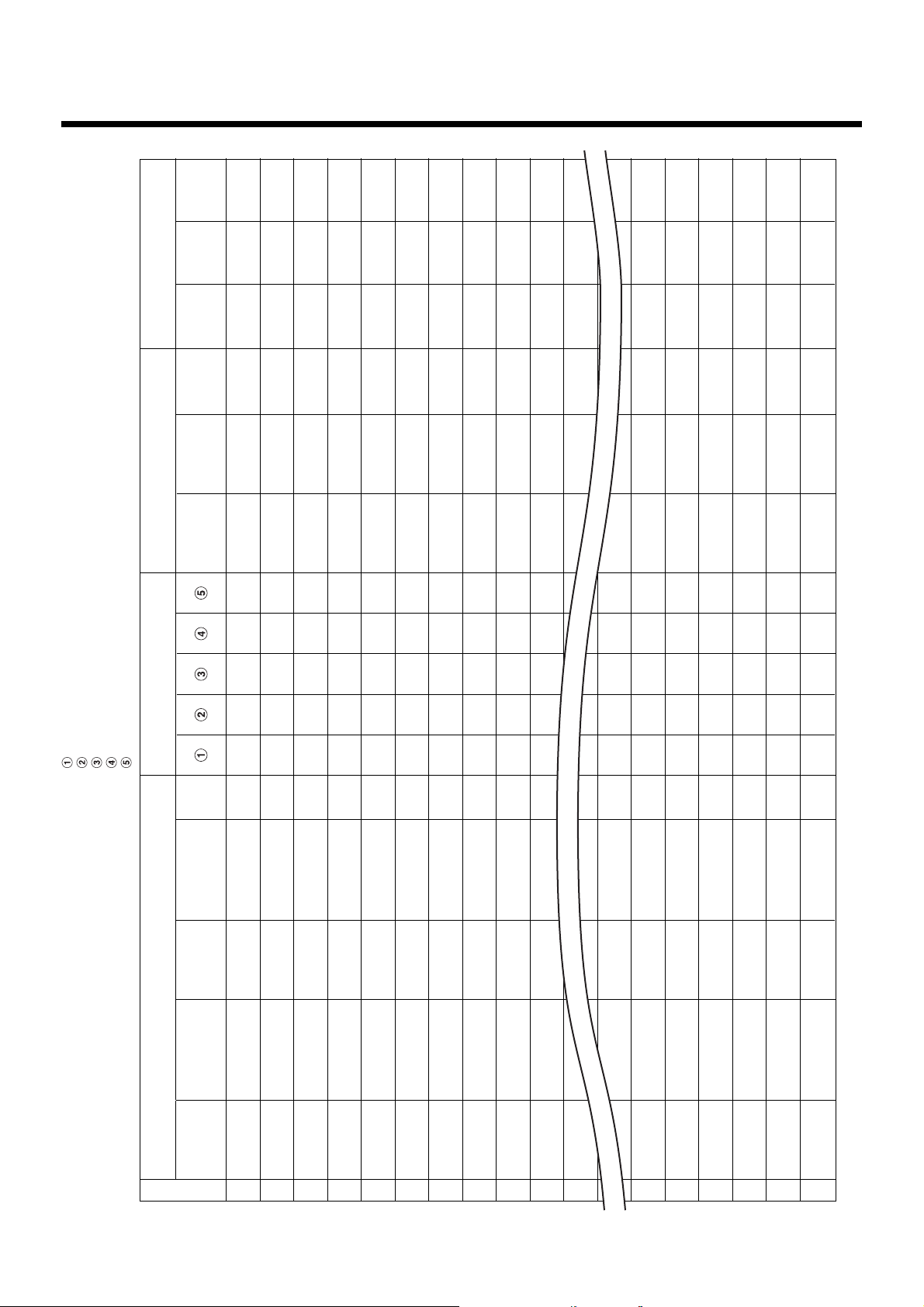

Air conditioner Address Table

9

and Before-Trial Operation Check list: ( )

No.

Fire alarm

No.

Key input

and Input/Output data

Power

Device Energy Monitoring

Display name

meter No.

Area

name

name

Tenant

Block

name

Address Information

Refrigerant line address

Indoor unit address

Group address

Intelligent Server address

TCS-NET relay I/F address

Header

Indoor unit

R.C. group/

Air Conditioner List

Outdoor unit

Outdoor

• Building name:

unit

model name

unit

name

model name

refrigerant

1

2

3

4

5

6

7

8

9

10

11

12

15

16

17

18

19

20

10

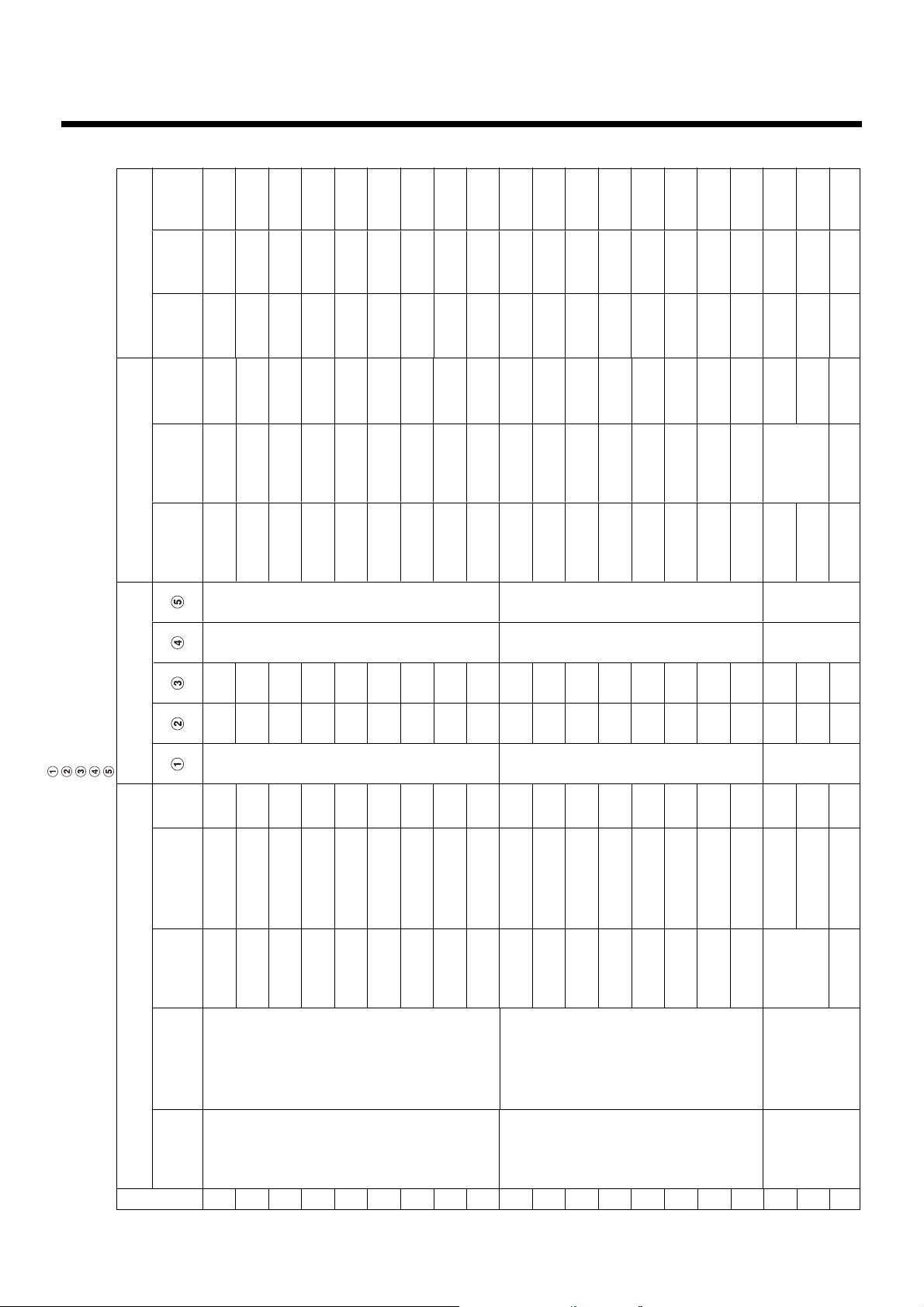

Air conditioner Address Table and Before-Trial

Operation Check list (Example)

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

No.

Fire alarm

1

No.

Key input

and Input/Output data

Power

Device Energy Monitoring

Display name

meter No.

Area

name

name

Tenant

1

1

1

Shop A

Shop A

Tenant A

Tenant A

1

1

1

1

Shop A

Shop A

Tenant A

Tenant A

1

1

1

1

Shop A

Shop B

Tenant A

Tenant B

1

1

1

1

Shop C

Shop D

Tenant B

Tenant B

1

1

1

2

Shop E

Shop F

Tenant B

Tenant C

1

1

2

2

Shop F

Shop G

Tenant C

Tenant C

1

1

2

2

Office

Office A

Tenant C

1

2

Office

Office A

1

1

1

2

2

Meeting room

Meeting room

Office A

Office A

2

2

2

2

3

3

A

B

Shared space

2

2

3

Shop H

Tenant D

Block

Address Information

Refrigerant line address

Indoor unit address

Group address

Intelligent Server address

TCS-NET relay I/F address

Header

Indoor unit

R.C. group/

1F

name

1

1

1

unit

model name

MMU-AP0091H

unit

name

PAC-B1 • IF-1

1F

1F

1F

2

2

2

2

3

4

0

0

0

MMU-AP0091H

MMU-AP0091H

MMU-AP0091H

PAC-B1 • IF-1

PAC-B1 • IF-1

PAC-B1 • IF-1

1F

1F

1F

1

1

2

0

0

5

6

7

1

0

1

1

MMK-AP0091H

MMU-AP0091H

PAC-B1 • IF-1

MMK-AP0091H

PAC-B1 • IF-2

PAC-B1 • IF-3

1F

1F

1F

0

0

0

8

9

1

1

1

1

MMK-AP0091H

MMK-AP0091H

MMK-AP0091H

PAC-B1 • IF-4

PAC-B1 • IF-5

PAC-B1 • IF-1

1F

1F

1F

1

1

0

0

0

2

3

4

2

1

1

1

MMK-AP0091H

MMK-AP0091H

MMK-AP0091H

PAC-M • IF-2

PAC-M • IF-3

PAC-M • IF-4

1F

1F

1F

0

0

0

5

6

7

1

1

1

MMK-AP0091H

MMK-AP0091H

MMK-AP0091H

PAC-M • IF-5

PAC-M • IF-6

PAC-M • IF-7

1F

2F

2F

1

1

0

1

2

8

1

2

3

1

1

0

MMK-AP0091H

MMK-AP0091H

MMK-AP0091H

PAC-M • IF-8

PAC-S • 2F-1

2F

0

3

1

MMK-AP0091H

PAC-S • 2F-2

Air Conditioner List

model name

Outdoor unit

Outdoor

refrigerant

• Building name:

1

MMY-AP1401HT8

PAC-B1

2

3

4

5

6

7

8

9

10

11

MMY-AP1401HT8

PAC-M

12

13

14

15

16

17

MMY-AP1401HT8

PAC-S

18

19

20

11

Loading...

Loading...