6F8C1127

TOSHIBA Industrial Network Computer

(ULCS2)

Hardware Instruction Manual

February 2005

©TOSHIBA Corporation 2004 - 2005.

All Rights Reserved.

…………………………………………………………………………………………………

1. No part of this manual may be reproduced in any form without permission.

. The material in this manual may be revised without notice.

. Although it has taken all possible measures about the contents of this book,

please give notice, if there are contents which should be hard to understand,

and mistaken contents.

. Please understand that our company does not assume responsibility about the

influence of the result employed irrespective of the 3rd clause.

…………………………………………………………………………………………………

i

ii

g

r

r

Safety Precautions

This instruction manual and the labels affixed to the products or equipment give important

information for using products safety. It helps prevent damages to properties and hazard to

people who use them or work with them.

Make yourself familiar with the signal words and signs in the page, then read the safety

precautions that follow and always follow the instructions to avoid hazards.

■Explanation of signal words

Signal Words Meaning of Signal Words

WARNING

Indicates a potentially hazardous situation which could result in death o

serious injury, if you do not follow the instructions.

CAUTION

*1 :”Minor or moderate injury” means an injury and a burn with unnecessary hospitalization

and long-term going to hospital regularly for medical treatment.

*2 : “Property damage” means the expansion damage in connection with a house,

household effects, and livestock and a pet.

■Hazard alert shapes and symbols

Shapes & Symbols

Indicates a potentially hazardous situation which may result in minor o

moderate injury and/or property damage, if you do not follow the instructions.

Circle band with a diagonal slash means “Prohibition” or “You must not do.”

Prohibited action is shown in the circle or described near the circle.

Filled circle means “Mandatory Action” or “Do as indicated.”

Required action is shown in the circle or described near the circle.

Triangle means “Hazard Alerting” or “Be alert against hazard.”

The kind of hazard is shown in the trian

Meaning of Shapes and Symbols

le or described near the triangle.

iii

f

● Shut off a power supply immediately and pull

out a power supply plug from a wall socket,

when there is an unusual smell from

equipment or equipment overheated and

fumes.

• If it uses then, it will become the cause of a fire

and failure. Please request check to a service

station.

Pull out a power supply plug.

● Do not carry out repair of equipment,

reconstruction, and decomposition for the

customer itself.

• It may cause a fire, an electric shock, and a

burn of the equipment.

Decompose

About Equipment Itsel

WARNING

● Do not use equipment in a place which rain,

fog, etc. enter directly inside equipment.

• Rain and fog may adhere to equipment and it

may become the cause of a fire and an electric

shock.

Prohibition

● Shut off a power supply immediately and pull

out a power supply plug from a wall socket,

when you drop equipment or you give a shock

strong against equipment.

• If it uses then, it will become the cause of a fire

and emitting smoke. Please request check to a

service station.

Pull out a power supply plug.

iv

f

● Do not put equipment on unstable places,

such as a shaky stand top and a leaning place.

• Equipment drops on the floor or falls down and

causes your injury.

Prohibition

● Use a suitable power cord.

•

If the power cord which does not suit input

power supply conditions is used, it becomes

the cause of a fire and emitting smoke.

•

If it connects with the wall socket which does

not suit input power supply conditions, it

becomes the cause of a fire and emitting

smoke.

Mandatory Action

CONFIRM

About Equipment Itsel

WARNING

● Do not put metals such as a clip, and liquids

such as coffee, into the inside of equipment.

• It causes a fire and a smoke depended short.

• When they go into equipment, shut off a power

supply, pull out a power supply plug from a

wall socket, and request check from a service

station.

Prohibition

● Do not use the power cord or power supply

plug which is broken, damaged, and

processed.

• It becomes the cause of a fire, an electric

shock, and a burn.

• Exchange the damaged power cord for a new

one.

Prohibition

v

f

● Do not shut off a power supply or do not

perform attachment and detachment of

CompactFlash, and operation of the ejector,

during operation of a system.

• It causes that the data in processing is

destroyed or disappears.

●

•

Prohibition

Consult with your service station, when you

transfer equipment. Moreover, use the packing

box of exclusive use at the time of

transportation and conveyance of equipment.

You may be injured or equipment may break, if

you move the euipment by yourself.

Mandatory Action

SYSTEM

UNDER

OPERATI

CAUTION

About Equipment Itsel

● Do not use equipment in a dusty place.

• It will become the cause of the fire and the

smoke depended short circuitry, if the inside of

equipment is covered with dust.

Prohibition

● Do not use equipment in the place upon which

the open air containing corrosive gas or salt

trespasses directly.

• It becomes the cause of emitting smoke and

failure.

Prohibition

vi

f

● Set the equipment on an airy place.

• If the fresh air inlet of equipment is plugged up

or equipment is put on the place where it tends

to be filled with heat, the temperature inside

equipment will go up and it will become the

cause of a fire and failure.

Mandatory Action

● Do not put equipment on the place where the

temperature near the place and heating

instrument upon which direct rays shine etc. is

high.

• The temperature inside equipment goes up

and it becomes the cause of a fire.

Prohibition

CAUTION

About Equipment Itsel

● Do not use a cellular phone from the

equipment in a less than 3m place.

• It becomes the cause of the abnormalities of a

system, and data disappearance.

Prohibition

● Do not put on a place with much vibration.

• Equipment moves or falls and causes an

injury.

Prohibition

vii

f

● The lithium battery is used for this equipment.

• If you put a battery into fire, or handle it wrong,

the battery will heat and it will become the

cause of exploding and igniting.

• Dispose of a used battery according to the

regulation system which the area defines.

Mandatory Action

CAUTION

About Equipment Itsel

●

Install a circuit breaker etc. in the primary input

side of equipment.

●

By separating the power supply system of this

equipment with a circuit breaker, the other

apparatus can be prevented from the

malfunction of equipment.

Mandatory Action

viii

● Do not bend a power cord by force, do not pull,

do not twist, and do not put a heavy thing on a

code.

• It becomes the cause of the fire by short

circuitry and disconnection, and an electric

shock.

Prohibition

●

Be sure to extract with a power supply plug,

without pulling a power cord, when you pull out

a power supply plug from a wall socket.

●

If a power cord is pulled, a code will get

damaged and it will become the cause of a fire

and an electric shock.

Handling the Power Cord

CAUTION

● Please do not take out and insert a power

supply plug by the wet hand.

• It becomes the cause of an electric shock.

Prohibition

Mandatory Action

ix

A

CAUTION

Protection of programs or data

■ Make the backup of important contents periodically in consideration of destruction and

the loss of programs and data.

■ Make sure the following items during saving data.

• Do not turn off power while the system is working.

• Do not take out CompactFlash in power supply ON.

• The life of the CompactFlash is about 300,000 times of writing.

It is not possible to use the CompactFlash for the usage to save data periodically by

the application program (history and trend, etc.).

■ The files in CompactFlash may be broken when GIGABINE stops without passing a

normal shutdown sequence.

Moreover, the partition may be broken, and all files in the partition may become

inaccessible, too.

Consideration by the system of the installation of UPS etc. is recommended when

thought about a sudden power failure.

bout high availability of the system

The function to try reactivating in case of its breakdown attaches to this product, and it

reactivates automatically for temporary failure.

Build up the mechanism of the operation continuance by the alternative in the system to

which the interruption of the function is not permitted in consideration of the operation stop

of this product temporary a permanent breakdown in this product and the

above-mentioned.

It takes the start time that the start time of OS (about one minute) is necessary, and

depends on the application program in addition until this device starts. It returns to normal

operation after the above-mentioned time passes when downing by any chance and

reactivating.

Consider the backup device etc. for the system by which this interruption time becomes a

problem.

x

A

A

y

Although the safety measures to this equipment are fully performed, if equipment should

hang up, please turn off AC switch, or pull out AC power supply plug from a wall socket,

and turn off a power supply.

However, to the program in this case, or failure and loss of data, our company does not

take any responsibility.

The cautions display label is attached on the left side of equipment as shown in the

following figure, in order to prevent unprepared operation of ejector of the CompactFlash

under operation.

bout an emergenc

bout a cautions display label

xi

A

WARNING

bout a warning display label

The warning display label is attached on the appointed place of this equipment.

Inform a service station, when the label is lost, the sentence on the label is hard to see by

dirt.

xii

■Since this product was not developed and manufactured so that the equipment to affect

people's life etc. could be directly used for the system included (Note 1), do not use it for

those uses.

■Since special consideration (Note 3) is needed about employment, maintenance, and

management of a system when using it for the system (Note 2) containing the

equipment which is related to people’s safety, and does the serious influence for public

functional maintenance, consult with our or our company.

・ Note 1 The equipments to affect people's life etc. directly are as follows;

- Apparatus for medical treatments, such as a life support system and

apparatus for operating rooms

・ Note 2 The system containing the equipment which is related to the people’s safety

and does the serious influence for public functional maintenance means the

following.

- They are the operation control system of an important system, and a

system and a group transportation system, and an air-traffic control

system on the main opportunity control system of a nuclear power plant,

the safe protection system of a nuclear institution, and other safety.

Usagerestrictions

・ Note 3 The special deliberation means that you make the sufficient consideration

with the engineer of our company, and build a safe system (a foolproof

design, a fail-safe design, a redundant design being carried out).

・TOSHIBA does not take any responsibility about the damage produced by use under

conditions incongruent (a fire, an earthquake, the action by the third person, other

accidents, and misuse by customer, and an application program), in addition unusual.

・TOSHIBA does not take any responsibility about the subordinate damage (loss of

enterprise profits, enterprise discontinuation, change or disappearance of the contents

of memory, etc.) to be produced by using or being impossible to use this product.

・TOSHIBA does not take any responsibility about the damage produced without keeping

the contents indicated by the instruction manual.

・TOSHIBA does not take any responsibility about the damage produced from incorrect

operation by combination with the apparatus connected etc.

・Be sure to perform a scheduled inspection. TOSHIBA does not take any responsibility

about the damage produced by having neglected the scheduled inspection.

Qualification

xiii

xiv

INTRODUCTION

This manual aims at understanding the outline of equipment to people which have the TOSHIBA

Industrial Network Computer GIGABINE type II used, and letting you understand about the

various operation methods required for employment, and the correspondence at the time of obstacle

generating.

Please use correctly for often surely reading this manual, before use of this equipment.

This manual contains the following chapters.

Chapter 1: The Outline of GIGABINE

Chapter 2: The Composition of GIGABINE

Chapter 3: The Specification of GIGABINE

Chapter 4: Description of Operations

Chapter 5: Installation

Chapter 6: Preservation (Maintenance)

Please fully utilize this manual and profit by GIGABINE type II effectively.

Moreover, please also read collectively the description offered from a system integrator.

xv

……………………………………………………………………………………………………

Trademark

・GIGABINE is the registered trademark of TOSHIBA CORPORATION.

・CompactFlash and CF are the trademarks of SanDisk.

・Microsoft and Windows are the registered trademarks of U.S. Microsoft Corporation, in the

U.S. and other countries.

・UNIX is a registered trademark of Open Group, in the U.S. and other countries.

xvi

Each company may be using the name of goods as a trademark found in this book, respectively.

……………………………………………………………………………………………………

CONTENTS

Safety Precautions

Introduction

The Notation Method of This Manual

Explanation of a Term

The notice about embedded software

Chapter 1 The Outline of GIGABINE.......................................................1

1.1 The Purpose and the Use................................................................................................................................. 3

1.2 Feature ............................................................................................................................................................. 4

Chapter 2 The Composition of GIGABINE...........................................5

2.1 Appearance and Composition ......................................................................................................................... 6

2.2 Product Repertory ........................................................................................................................................... 7

Chapter 3 The Specification of GIGABINE...........................................9

3.1 Hardware Specification.................................................................................................................................10

3.2 Specification of Installation Environment..................................................................................................... 12

Chapter 4 Description of Operations....................................................13

4.1 Name and Function of Each Part................................................................................................................... 14

4.2 Operation (ON and OFF of Power Switch)................................................................................................... 22

Chapter 5 Installation ...........................................................................23

5.1 The Installation Direction and Its Method ................................................................................................... 24

5.2 Installation and Maintenance Space.............................................................................................................. 26

5.3 Cable Connection..........................................................................................................................................31

5.4 Power Supply Wiring....................................................................................................................................36

5.5 Grounding of System .................................................................................................................................... 37

Chapter 6 Preservation (Maintenance).................................................39

6.1 Inspection......................................................................................................................................................40

6.2 Failure Diagnosis .......................................................................................................................................... 41

6.3 Repair and Exchange..................................................................................................................................... 42

Appendix.................................................................................................43

Appendix1 Appearance and Size.....................................................................................................................44

Appendix 2 Screw Hole Pitch of the Bottom Side........................................................................................... 45

Appendix 3 Connector Pin Map......................................................................................................................... 46

xvii

The Notation Method of This Manual

This manual uses the following notation methods.

Marks

・ CAUTION : Be sure to read. If the mistaken handling or operation is carried out, a

phenomenon that people may get injured, or the material damage may be

generated is shown.

◆Requirement◆ : It is shown that you should protect in order not to cause disappearance of

data, failure of the equipment, and a performance fall, and that you should

know about specification or a function.

メモ

Memo

Example) : Concrete examples are shown.

※ : Another operation which can do the same thing is shown.

)

)

: Convenient knowledge and additional knowledge are shown.

『 』 : Other reference manuals are shown.

「 」 : The reference place in this manual is shown.

xviii

Explanation of a Term

The following terms may be used in this manual.

CompactFlash

The standard of the small memory card which U.S. SanDisk advocated and was developed

originally. A flash memory chip and a controller chip are mounted in the inside of a card, and it

can be recognized as a storage device of ATA conformity from PC etc. by processing with this

controller chip.

GIGABINE

Connection equipment between RS485 which is a control system network, and Ethernet which is

an information system network. Data exchange of both sides is performed by this equipment.

JHEXAS

Option software of GIGABINE. The software component group for building the supervisory

control system by Java.

Linux

OS compatible with UNIX developed for PC. Although only a kernel is meant in a narrow

definition, the package summarized including peripheral software is meant in many cases. It is

distributed according to GPL (Ge neral Public License).

xix

The Notice about Embedded Software

The software shown below is included in the TOSHIBA Industrial Network Computer GIGABINE.

The notice based on the contract of IBM Corporation

CONTAINS

IBM Developer Kit for Linux

Runtime Modules

(c) Copyright IBM Corporation 1997-2000

All Rights Reserved

(TM)

The notice based on the contract of Apache Software Foundation

This product includes software developed by the Apache Software Foundation (http://www.apache.org/).

, Java

(TM)

2 Technology Edition, Version 1.3.0

xx

Chapter 1 The Outline of GIGABINE

Chapter

1

The Outline of

GIGABINE

1

Chapter 1 The Outline of GIGABINE

The TOSHIBA Industrial Network Computer GIGABINE type II is the equipment which equips the

interface of the control system network which performs RS485 communication, and the information

system network which performs Ethernet communication, and performs the routing function between the

both.

With the various flexible functions of HEXABINE built in, the performance was raised by leaps and

bounds and the scope of this equipment was expanded widely.

2

1.1 The Purpose and the Use

As shown in a figure, GIGABINE type II is located between an information system Network layer and

a control system Network layer, and performs the protocol conversion between an information system

network and a control system network.

Seamless access between the information system network which based Ethernet, and the control system

network which performs RS485 communication is realized.

Information

Network

Ethernet

Chapter 1 The Outline of GIGABINE

GIGABINE

Control Network RS485

Control Node

・・・・

… …

↑Sensor / Actuator ↑Sensor / Actuator

Control Node

Example of the System Configuration

Control Node

… …

GIGABINE

Control Network RS485

Control Node

・・・・

3

Chapter 1 The Outline of GIGABINE

1.2 Feature

GIGABINE type II is the equipment with the feature shown below.

・It is the higher rank model which raised the performance of HEXABINE by leaps and bounds.

・The whole equipment is manufactured compact in order to make an installation space small.

・It has the environment-proof nature suitable for factory automation use, and the continuation

operation for 24 hours is possible.

・The design without the life parts, such as a cooling fan brought us “maintenance-free.”

4

Chapter 2 The Composition of GIGABINE

Chapter

2

The Composition of

GIGABINE

5

Chapter 2 The Composition of GIGABINE

2.1 Appearance and Composition

The appearance of GIGABINE type II and a composition article (accessories) list are shown below.

Composition article (accessories) list

Instruction manual (this manual) : 1

Rack-mount kit (option) : 1

6

2.2 Product Repertory

The product repertory of GIGABINE type II has case specification, memory capacity, and the kind

following by the difference in an interface.

In case you place an order, please specify in product code shown below.

Product Repertory

Product code of GIGABINE

1 2 3 4 5 6 7 8 9 10 11 12 13 14

U L C S 2 * * * * *****

Chapter 2 The Composition of GIGABINE

Details「3.1 Hardware specification」

)

An underline spec. means a standard type and a

hatched item means a user selectable.

Cabinet Specification

B: Metal case

Capacity of CompactFlash

0: None

Capacity of the Main Memory (SDRAM)

1: 128MB

L

ONWORKS

0: None

Number of Ethernet Channels

1: 1ch, 2: 2ch

Rack-mount Kit

0: None

Power Cord Cramp

0: None

Serial Port 1 Specification

2: RS-232C, 4: RS-485

, 1: 128MB, 2: 256MB, 5: 512MB

, 2: 256MB

Specification

, F: TP/FT-10(FTT-10A), 1: TP/XF-1250

, 1: With Kit

,1: With Cord Cramp

7

Chapter 2 The Composition of GIGABINE

8

Chapter 3 The Specification of GIGABINE

Chapter

3

The Specification of

GIGABINE

9

Chapter 3 The Specification of GIGABINE

3.1 Hardware Specification

The hardware specification of GIGABINE type II is shown below.

■Hardware Specification

Item Specification

CPU 32-bit CPU + Neuron Chip

Main Memory 128MB/256MB/512MB Memory

Capacity

Interface

Power Supply

Environmental

Conditions

Outside Size

Compact Flash 128MB/256MB

10BASE-T/100BASE-Tx

Ethernet

Serial Interface

RS-485, RS-232C

Digital

Input/Output

Rated Voltage 100/240Vac

Tolerance Range 85~132Vac/180~264Vac

Rated Frequency 50/60Hz

Power Consumption

Temperature

Humidity

Weight 2.5kg

Two port are provided for the standard type

Maximum cable length: 100m

Maximum transmission rate: 115,200bps, respectively.

Serial Port-1: For general-purpose communication, RS-485 and

RS-232C selection

Serial Port-2: For maintenance console, RS-232C

Insulation: Serial Port-1: insulated against the internal circuit

Serial Port-2: un-insulated against the internal circuit

Maximum cable length: RS-232C 15m,RS-485 500m

Digital Input: 4-point

Digital Output: 4-point

30VA

Operation: 0~50℃

Storage: -20~60℃

Operation: 10~90%RH (Without C on de nsat i o n)

Storage: 10~90%RH (Without Conde nsati o n)

370(W)×39(H)×198(D)

Unit in mm (A projection thing is not included.)

10

Chapter 3 The Specification of GIGABINE

■Digital Input/Output Specification

Item Specification

Power Supply Voltage 24V~5V±5%

Insulating Block

Connector of GIGAGBINE Side FUJITSU: FCN-365P024-AU

Recommended Cable OMRON: XW2Z-□□□A

Recommended Terminal Block OMRON: XW2D-20G6

Number of Input Points 4-point

Input Signal Dry contact point

Input

Output

Input Filter Approx. 5ms

Input Current MAX approx. 10mA/point

Over-Current Protection Constant current diode mounted for each point

Number of Output Points 4-point

Output Signal Dry contact point

Output Current MAX approx. 50mA/point

Digital Input/Output

Eight-point packed insulation with signal common

11

Chapter 3 The Specification of GIGABINE

3.2 Specification of Installation Environment

(1) Ambient Conditions

The specification of ambient conditions is shown below.

■Ambient Specification

Item Operation Storage

Temperature 0~50℃ -20~60℃

Temperature

Change

Humidity

(without condensation)

Vibration 2.45m/s2 or the less 4.91m/s2 or the less

Shock 24.5m/s2 or the less 49.0m/s2 or the less

(2) Power Supply Conditions

The specification of power supply conditions is shown below.

15℃/H 15℃/H

10~90%RH

10~90%RH

(without condensation)

■Power Supply Specification

Item Specification

Rated Voltage

Power Supply

Grounding

Tolerable Range 85~132Vac/180~264Vac

Frequency 50/60Hz±3Hz, or the less

Tolerable Power

Interruption

100/240Vac

Single phase with grounding

20ms, or the less

Exclusive grounding

(Grounding resistance: 100ohms, or the less)

12

4

Chapter 4 Description of Operations

Chapter

Description of

Operations

13

Chapter 4: Description of Operations

4.1 Name and Function of Each Part

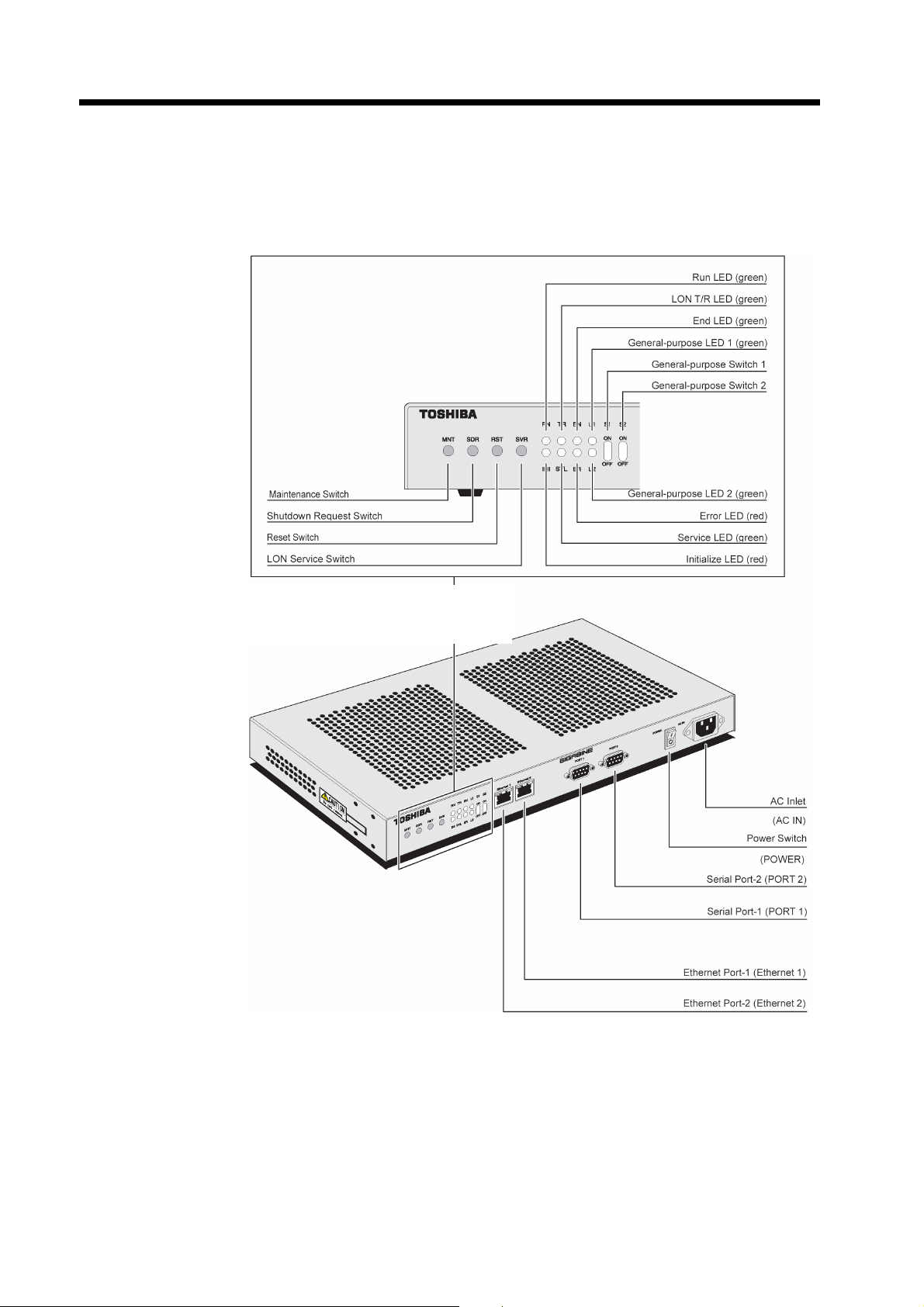

The name and function of each part are shown below.

Metal Case Type:

■GIGABINE type II seen from the front

■GIGABINE type II seen from the forward left side

14

Chapter 4: Description of Operations

(1) LED Display

There are eight kinds of the following LED in the front panel of GIGABINE type II.

・ Run LED(green/RN)

・ Initialize LED(red/INI)

・ LON T/R LED(green/TR)

・ Service LED(green/SVL)

・ End LED(green/EN)

・ Error LED(red/ER)

・ General-purpose LED(green/L1, L2)

■Run/Initialize/End/Error LED (RN/INI/EN/ER)

These LEDs are turned on according to the internal state of GIGABINE type II.

LED Status

RN It illuminates green when the equipment is under operation.

INI

EN It illuminates green when the shutdown of the equipment is completed.

ER

It illuminates red when the equipment is under initialization, writing to

CompactFlash, and maintenance mode.

It illuminates red when the user program under initialization, and at the time of

stop.

It blinks by user program setting.

■General-purpose LED(L1/L2)

These LEDs can be set up a display state by the user program.

LED Status

It illuminates green the main unit is under normal operation.

L1

L2

When its operation is set by the user program, it follows the setting of the user

program.

It illuminates green when the CompactFlash starts, and it blinks when the

equipment is under normal operation.

When its operation is set by the user program, it follows the setting of the user

program.

15

Chapter 4: Description of Operations

By investigating the length of the blink interval of ER LED, the cause of unusual operation of

equipment is analyzable.

Red-Short→ Green-Long→Red-Short

①

→Green-Long→……

Red-Short→Green-Short→ Red-Short

②

→Green-Short→……

Red-Long→Red-Short→Green-Short

③

→……

The combination pattern of the state of ① to ③ is shown in the following table. The following blink

is repeated, in the cycles of about 5 seconds.

① ●○○○●○○○ Illu minates red twice in one cycle.

② ○●○●○●○● Green illuminates up at equal intervals with red.

③ ●●●○○○●○ Lon g interval blink, short interval blink

①+② ●●○●●●○● Illuminates green twice in one cycle.

①+③ ●●●○●○●○ Illuminates green three times in one cycle.

②+③ ●●●●○●●● Illuminates green once in one cycle.

①+②+③ ●●●●●●●● Illuminates red

Status LED Display Cause of Error

Java VM stops, STAT_ERR1 is set by the program.

STAT_ERR2 is set by the program.

STAT_ERR3 is set by the program.

●: illuminates red ○: illuminates green

■LON T/R LED(green/TR)

This LED illuminates green while the LON interface of GIGABINE type II performs data transmission.

(It is not used with this product)

■End LED(green/EN)

This LED illuminates green when GIGABINE type II completes shutdown operation.

■Service LED(green/SVL)

This LED expresses the service state of a neuron chip. (It is not used with this product)

Moreover, yellow and green LED are embedded at each modular connector of the Ethernet port, and

each LED expresses the following states, respectively.

■TRX LED(yellow)

While equipment is performing transmission operation via the corresponding Ethernet port, this LED

illuminates or blinks.

16

Chapter 4: Description of Operations

■LINK LED(green)

When the corresponding Ethernet port is connected normally, this LED illuminates or blinks.

TRX LED

LINK LED

(2) Push Button Switch

There are four kinds of following switches on the front panel of GIGABINE type II.

■Reset Switch (RST): for maintenance

A push on a reset switch reboots the equipment.

Carry out reset operation, after shutdown of the equipment.

■Maintenance Switch (MNT): for maintenance

Do not usually touch this switch, since it is prepared for maintenance.

■LON Service Switch (SVR)

It is not used with this product.

■Shutdown Request Switch (SDR) : for maintenance

It is the switch which makes GIGABINE type II shutdown. If this switch is pushed, GIGABINE type II

will go into shutdown operation.

Completion of shutdown operation of GIGABINE type II illuminates EN LED.

◆

Requirement

Turn off the power supply switch or press the reset switch after the shutdown completion.

If the power switch of the equipment is turned off or the equipment is reset before the completion of a

shutdown, the write-in data to CompactFlash may be lost.

◆

(3) Snap Switch

■Snap Switch (S1, S2): for general purpose

The ON/OFF state of these switches can be read by the user program.

Be sure the following items.

・ Do not touch on the switch for maintenance (Reset Switch, Maintenance Switch,

and Shutdown Request Switch).

the possibility of the data disappearance by data destruction of a memory.

・ Do not operate a switch by the wet hand.

CAUTION

If it touches during equipment operation, there is

17

Chapter 4: Description of Operations

r

(4) Communication Port

・Ethernet Port-1

This port is used as 10BASE-T/100BASE-Tx interface. The eight pin modular plug of the

twisted-pair cable is connected.

・Ethernet Port-2

This port is used as 10BASE-T/100BASE-Tx interface. The eight pin modular plug of the

twisted-pair cable is connected.

This port does not exist in an one Ethernet channel model.

・Serial Port-1

It is a serial port for high-speed communication. It has the control signal required in order to support

modem connection. It can be selected from RS-485 or RS-232C according to a use. D-Sub9 pin male

connector is mounted for this port.

・Serial Port-2: for maintenance

It is the serial port of the RS-232C interface for maintenance consoles. D-Sub9 pin male connector is

mounted for this port.

Serial Port-2 cannot be used for data communications, since it is mounted fo

maintenance consoles.

CAUTION

18

Chapter 4: Description of Operations

r

r

(5) Power Switch

It is the switch which performs ON/OFF of AC power supply of equipment.

(6) AC Inlet

AC power cord is connected to this inlet. The power supply of equipment can be used for both a

100Vac system and a 200Vac system. Moreover, there is no adjustment of the voltage change to

operating voltage.

Dtails「3.1 Hardware Specification」

ince the AC power cord is not attached to GIGABINE type II, prepare the AC powe

ord according to the safety requirements of each country.

o not use any AC power cord other than the AC power cord with 3-pin plug

dapted to the input voltage.

o not use it with the grounding pin disconnected.

CAUTION

)

(7) CompactFlash Slot

The slot of a CompactFlash card is prepared in the left side of GIGABINE type II.

A CompactFlash card is mounted here. The software update in the field by exchanging CompactFlash

became easy. The eject button attached to the slot side is pushed, and CompactFlash is taken out from

the equipment.

Do not perform attachment and detachment of CompactFlash, and operate the

ejector during system operation.

・It becomes the cause which data in processing is destroyed or disappears.

CAUTION

CompactFlash Slot

Ejecto

19

Chapter 4: Description of Operations

r

(8) Function Switch

The function switch is prepared for the bottom of GIGABINE type II.

The setup at the time of factory shipments of a function switch is as follows.

1 2 3 4 5 6 7 8

ON OFF OFF OFF OFF OFF OFF OFF

■The Bottom View of GIGAIBNE type II

Function Switch

Four screw holes for surface-of-a-wall attachment

AC Inlet Side

RS-485 Mode Setting Switch

Do not operate this switch. This function switch at the bottom is a switch only fo

servicemen.

LED Display Side

CAUTION

4-M4 screw holes

20

Chapter 4: Description of Operations

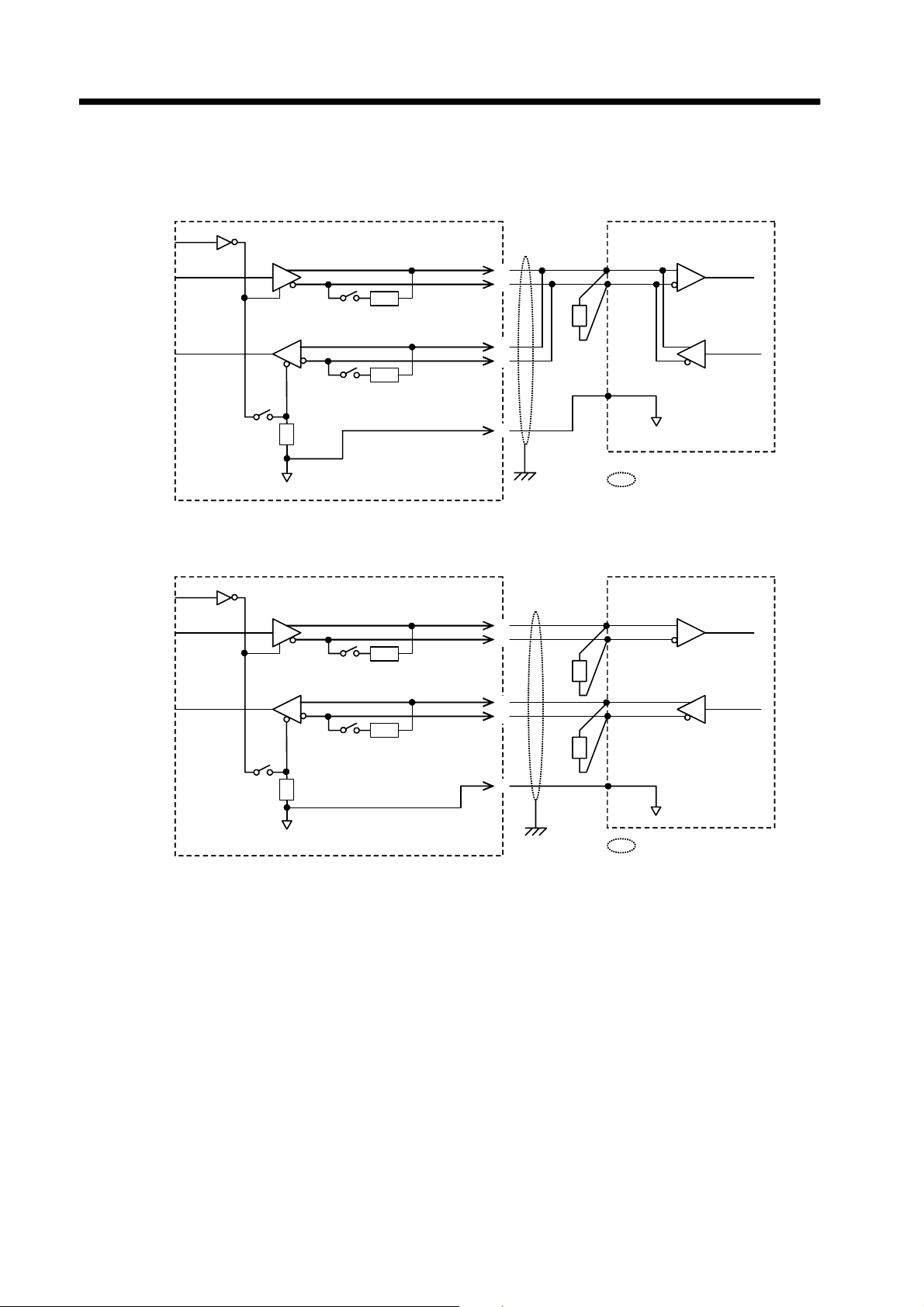

(9) Port 1 RS-485 Operation Mode Setting Switch

■The Bottom View of GIGAIBNE type II

Four screw holes for surface-of-a-wall attachment

AC Inlet Side

Internal Block Diagram

RTS

TXD

LED Display Side

RS-485 Mode Setting Switch

1 ON Termination resistor exists between TX(+)~TX(-)

OFF Termination resistor does not exist between TX(+)~TX(-)

2 ON Termination resistor exists between RX(+)~RX(-)

OFF Termination resistor does not exist between RX(+)~RX(-)

3 ON Half duplex operation (note 1)

OFF Full duplex operation (note 2)

4 Not in use

(Note 1) The transmitting data of a self-station is not received by itself

during data transmission.

(Note 2) The transmitting data of a self-station is also received by itself

during data transmission.

1

TX(+)

TX(-)

100Ω

2>

1>

4-M4 screw holes

RXD

2

100Ω

3

10kΩ

RX(+)

RX(-)

3>

4>

21

Chapter 4: Description of Operations

4.2 Operation (ON and OFF of Power Switch)

The operation method of power supply ON/OFF of the equipment is shown below.

(1) ON Operation of Power Switch

The power supply switch at the front of equipment is turned ON. (It pushes down from the "O" side to

the "|" side)

(2) OFF Operation of Power Switch

The power supply switch at the front of equipment is turned OFF. (It pushes down from the "|" side to

the "O" side)

Do not operate the equipment by the wet hand.

WARNING

22

5

Chapter 5 Installation

Chapter

Installation

23

Chapter 5: Installation

d

5.1 The Installation Direction and Its Method

The installation direction of the equipment and its method have four kinds of the rack-mounted

installation, plane installation, and surface-of-a-wall installation shown below.

In rack-mounted installation, it is attached in a 19 inch rack by using the rack-mount kit. In case of

plane installation, please install downward by making the bottom of this equipment the uneven level

place which is not. In surface-of-a-wall installation, the bottom of this equipment is opposed to the

uneven surface of a wall which is not, and it is installed. The screw hole for fixing this equipment is

prepared for the bottom (four places).

In addition, this equipment cannot be installed by any methods other than the following four kinds.

Screw hole pitch「Appendix 2 Screw Ho le Pitch of the Bottom Side」

)

(1) Rack-mounted Installation

・Support parts are required for the back and

bottom side of this equipment.

Insulate a rack and an attache

rack-mount kit with a plastic

screw, a miler sheet, etc.

(3) Surface-of-a-wall Installation-A

・The installation method to the surface of a wall

which turned the front up

(2) Plane Installation

・The standard installation method

(4) Surface-of-a-wall Installation-B

・The installation method to the surface of a wall

which turned the left side up

24

Chapter 5: Installation

r

r

・ Select from four kinds of the above figure, when the equipment is installed.

When installing by the other method, unusual operation and failure may be

brought to the equipment.

・ Be sure to fix in surface-of-a-wall installation using the screw hole at this bottom

of equipment (four places).

When equipment is fixed by methods other than specification, the equipment

may fall and the failure of the equipment may be brought.

・ It is recommended to fix in a screw hole (four places) at the bottom fo

prevention of equipment fall also in plane installation.

・ Insulate a rack and an attached rack-mount kit with a plastic screw, a mile

sheet, etc.

CAUTION

In addition, please use a plastic screw for fixation.

25

Chapter 5: Installation

5.2 Installation and Maintenance Space

When installing equipment, each space of an "installation space" and a "maintenance space" is required.

The direction of an installation space and a maintenance space changes with each installation methods.

Installation space:

It is the space which is needed at least in order to use or employ this equipment.

Maintenance space:

It is the space which is needed in case a maintenance person performs check and maintenance for this

equipment.

(1) Installation Space

The space more than the following size is required for an installation space to each field of this

equipment. Moreover, install the equipment in the place which can perform not sealing but moderate

air circulation.

26

Item

Installation

Space

Chapter 5: Installation

Unit in mm

Directi

on

Top 50 100

Bottom 50 0 0 0

Front 100 100 100 100

Rear 100

Right

Left

*1): ”Surface-of-a-wall contiguity is possible” means that the field can be close to the surface of a

Rack-mounted

Installation

Surface-of-a-wall

contiguity is possible

Surface-of-a-wall

contiguity is possible

wall, and it can be installed. It is not surely the meaning that it must be close to the surface of

a wall, and must be installed.

*1)

*1)

Plane Installation

Surface-of-a-wall

contiguity is possible

100 100 100

100 100 100

*1)

Surface-of-a-wall

Installation-A

Surface-of-a-wall

contiguity is possible

100

Surface-of-a-wall

contiguity is possible

*1)

contiguity is possible

Installation-B

Surface-of-a-wall

*1)

Surface-of-a-wall

*1)

27

Chapter 5: Installation

■Dust Conditions

GIGABINE type II should be used in the environment with a dirt concentration 0.3mg/m3, or the less.

Dirt concentration is about 0.07 mg/m

in the place of smoking permission.

GIGABINE type II should be installed in the environment whose dirt concentration 0.3 mg/m

less.

■Corrosive Gas

GIGABINE type II should be installed in the environment where the sum total of the evaluating point

of each corrosive gas factor becomes 25 or less points, with reference to the following table.

Classification

Environmental Factor

Annual Average

Temperature (℃)

Annual Average

Humidity (%)

Gas(ppm)

Corruption Degree

(Equivalent Salinity)

(mg/cm2)

The Sum Total of the Evaluating Point=A+B+C1+C2+C3+C4+C5+D

A

B

SO2 C1

NO2 C2

H2S C3

CL2 C4

NH3 C5

D

3

in the clean office of prohibition of smoking, about 0.2 mg/m3

3

, or the

1 2 3 4

Measu

red

Value

Evalua

tion

Value

Measu

red

Value

Evalua

tion

Value

Measu

red

Value

Evalua

tion

Value

Measu

red

Value

Evalu

ation

Value

≦ 20 1 ≦ 25 2 ≦ 30 4 >30 8

≦ 50 1 ≦ 60 8 ≦ 75 16 >75 24

≦.04 1 ≦.08 3 ≦ .2 6 ≦5 9

≦.02 1 ≦.05 3 ≦ .1 6 ≦5 9

≦.003 1 ≦.01 8 ≦ .1 14 ≦10 20

≦.002 1 ≦.01 10 ≦ .1 20 ≦1 30

≦.1 1 ≦ 1 2 ≦ 10 4 ≦100 8

≦.03 1 ≦.06 8 ≦.12 16 >.12 24

28

Chapter 5: Installation

t

t

t

(Calculation Example)

Environmental Conditions Evaluating Point

Annual Average Temperature : 23℃ A=2 point

Annual Average Humidity : 55% B=8 point

SO2 : 0.03ppm C1=1 point

NO2 : 0.04ppm C2=3 point

H2S : 0.002ppm C3=1 point

CL2 : 0.001ppm C4=1 point

NH3 : 0.05ppm C5=1 point

Corruption Degree : 0.5ppm D=8 point

The Sum Total of the Evaluating Point: 2+8+1+3+1+1+1+8=25 poin t

Perform the following items.

・Install the equipment in the place appropriate for the specified installation space

conditions.

・Install the equipment in the place appropriate for the specified environmental

conditions.

Be careful of the following items.

・Do not install the equipment in a place which the open air containing corrosive gas

or salt enters directly.

・Do not install the equipment in the high temperature places where direct sunligh

hits, near the heating instrument, etc.

・Install the equipment in the place with moderate air circulation instead of airtigh

space.

・Do not push the ejector of the CompactFlash of the left side of the equipmen

during installation.

WARNING

CAUTION

29

Chapter 5: Installation

(2) Maintenance Space

A maintenance space is required, in case installation or maintenance is performed. A plane view shows

a maintenance space below.

*1) : The range in which a maintenance person works is shown. In case equipment is fixed, it is

Back Side

Front Side

GIGABINE type II

1,000

*1)

1,000

*1)

Unit in mm

: Maintenance Space

: Installation Space

Plane View

necessary to prepare the space to which the equipment front (cable connection side) is turned

to the front, and a maintenance person works.

30

5.3 Cable Connection

t

k

In case of the connection of AC power cord and a signal cable, connect the cables in the following

procedure.

(1) Connection of AC Power Cord

・Confirm that the power switch of GIGABINE type II is OFF.

・The code clamp of AC inlet is raised upwards, and AC power cord is inserted in AC inlet.

・A clamp is pushed down to the front and AC power cord is fixed.

・AC power cord is inserted in a power supply wall socket.

Perform the following items.

・Check whether power supply conditions conform to specification given in this boo

before inserting a power supply plug.

・Do not use the power cord or power supply plug which is broken, damaged, and

processed.

・Do not take out and insert a power cord by the wet hand.

Perform the following thing about a power cord and a power supply plug.

・ Have the portion of a plug by hand and extract it, when you pull out a power cord

from a power supply wall socket.

・ Perform extraction and insertion of a power supply plug after checking that a

power supply switch is "OFF."

・ Do not bend a power cord by force, do not pull, do not twist, and do not put a

heavy thing on a cord. Moreover, the ground of a power supply wall socke

should check surely connecting.

・ Since the AC power cord is not attached to GIGABINE type II, prepare the AC

power cord according to the safety requirements of each country.

・ Do not use any AC power cord other than the AC power cord with 3-pin plug

adapted to the input voltage.

・ Do not use it with the grounding pin disconnected.

Chapter 5: Installation

WARNING

CAUTION

31

Chapter 5: Installation

(2) Connection of Ethernet Cable

・The modular plug of the twisted-pair cable for Ethernet signals is inserted in the modular jack of

"Ethernet port-1 / 2" of a front panel.

Push in until it sounds "click", in the case of modular plug insertion. Even if the power supply of

equipment is switched on, extraction and insertion of a cable is possible.

CAUTION

Perform the following items in case of connection of the Ethernet signal cable.

・ A twisted-pair cable should be used the cable suitable for specification.

・ Use a cable with shield covering, in order to meet CE Marking regulations.

・ Have the portion of a plug by hand and extract it, when you pull out a cable from

a modular jack.

・ Do not bend a power cord by force, do not pull, do not twist, and do not put a

heavy thing on a cable.

・ Do not take out and insert a cable by the wet hand.

・ Make the right connection according to directions.

(3) Connection of Serial Port-1/2

・Confirm that the power switch of GIGABINE type II is OFF.

・The connector of a signal cable is inserted in the connector of "PORT 1 or 2" of the equipment front

panel.

・The connector is fixed to "PORT 1 or 2" on the front panel of the equipment with the fixed screw (two

right and left) of connector.

Fix a connector firmly with the screw of two right and left.

Turn off the power supply of this equipment, when you take out and insert a cable.

32

Chapter 5: Installation

Perform the following items in case of connection of the serial signal cable.

・ A serial cable should be used the cable suitable for specification.

・ Use a cable with shield covering, in order to meet CE Marking regulations.

・ Check the pin number of a connector on "Appendix 3 Connector Pin Map", when

you manufacture a cable.

・ Pin arrangement of Serial Port -1 changes with specifications.

・ Do not take out and insert a cable, when the power supply of this equipment is

switched on.

・ Have the portion of a plug by hand and extract it, when you pull out a cable from

the connector of the equipment.

・ Do not bend a power cord by force, do not pull, do not twist, and do not put a

heavy thing on a cable.

・ Do not take out and insert a cable by the wet hand.

・ Make the right connection according to directions.

CAUTION

33

Chapter 5: Installation

●RS-485 The example of 2 line system cable connection

RTS

TXD

1

OFF

GIGABINE

TX(+)

TX(-)

2>

1>

I/F of Opposite Device

TRX(+)

TRX(-)

RXD

RXD

RX(+)

RX(-)

2

ON

3

OFF

3>

4>

5>

ULCS2

LG

FG

●RS-485 The example of 4 line system cable connection

RTS

TXD

RXD

1

ON

2

ON

3

OFF

GIGABINE

TX(+)

TX(-)

RX(+)

RX(-)

2>

1>

3>

4>

5>

TXD

LG

: Shield

I/F of Opposite Device

TRX(+)

TRX(-)

RXD

TXD

34

LG

LG

FG

: Shield

Chapter 5: Installation

r

g

(4) Connection of the Cable for the Connector Terminal Block Conversion Unit

・The connector of the equipment back panel is fixed with the fixed screw (two right and left) of

connector.

Fix the screws firmly by two right and left.

Turn off the power supply of this equipment in case of extraction and insertion of a cable.

Perform the following items in case of connection of the cable for the connecto

terminal block conversion unit.

・A cable should be used the cable suitable for specification.

・Have the portion of a plug by hand and extract it, when you pull out a cable from

the connector of the equipment.

・Do not bend a power cord by force, do not pull, do not twist, and do not put a heavy

thing on a cable.

・Do not take out and insert a cable by the wet hand.

・Make the ri

ht connection according to directions.

CAUTION

35

Chapter 5: Installation

5.4 Power Supply Wiring

In accordance with the power supply specification of GIGABINE type II, a circuit breaker is installed

in the primary side of a power supply wall socket.

Grounding of GIGABINE type II is connected to an exclusive grounding line (100ohms or the less of

grounding resistance).

Perform the following items.

・ Please connect with the power supply wall socket which suited the specified

power supply conditions.

・ Be sure to install a circuit breaker in the primary side of a power supply wall

socket.

Grounding is considered as exclusive grounding for GIGABINEs 100ohms or the

less. Be sure the following items.

・Do not share a common grounding of the apparatus with a possibility of generating

electric load change or the big electric noise, such as an air-conditioner, a

refrigerator, a motor, a vending machine, and a welding machine.

WARNING

CAUTION

36

5.5 Grounding of System

The example of the system incorporating GIGABINE type II is shown in the following figures.

GIGABINE type II is grounded for the grounding terminal of exclusive use (100ohms or the less of

grounding resistance), and dissociates and grounds with the electric apparatus which may generate big

load change and the electric noise.

Moreover, to a cabinet, as shown in the following figure, GIGABINE type II is floated from a cabinet,

and it is mounted and separated with grounding for cabinets.

Chapter 5: Installation

Insulation Processing

Insulation Processing

Cabinet

Insulation Sheet

Inside Panel

Grounding is connected to the grounding line (100ohms or the less of grounding resistance) of

exclusive use.

37

Chapter 5: Installation

38

6

Chapter 6 Preservation (Maintenance)

Chapter

Preservation

(Maintenance)

39

Chapter 6: Preservation (Maintenance)

quip

6.1 Inspection

The durable life of this equipment is ten years.

However, this equipment has life parts shown in the following table. When this equipment is installed

in the temperature range which satisfies the conditions shown in the following table, it can be used as

maintenance-free for ten years.

■Life Parts List

Life Parts Durable Life Ambient Temperature of Equipment

Aluminum Electrolytic Capacitor

(Power Supply Module)

Lithium Battery 10 years 30℃

CompactFlash

*: When CompactFlash is procured by the customer, the writing time might be different.

Moreover, please carry out the following thing periodically as preventive maintenance. In addition,

please contact your service station about a request of scheduled inspection service.

)

10 years 35℃

300,000 times of

writing *

Environmental Conditions「3.2 Specification of Installation Environment」

-

(1) Dirt of Equipment

The dirt of equipment is wiped out with the cloth which attached thin neutral detergent is extracted

firmly. Furthermore, it is wiped out with dry cloth once more.

If a detergent spray is covered over equipment or it is wiped out with medicine, such

as alcohol, benzine, and thinner, the failure of the equipment may occur and the

communication data etc. may disappear.

CAUTION

(2) Inspection of the Ambient Conditions

Clean and check the surroundings of the equipment periodically.

If it continues using equipment while the fresh air inlet of equipment had been

closed, an internal temperature rises, a fire may break out, or the failure of the

equipment may occur and communication data may disappear.

Clean and check periodically the circumference of the fresh air inlet of the

e

ment.

CAUTION

40

6.2 Failure Diagnosis

Please read this chapter before judging that it is failure, if the following phenomenon occurs in the

handling of this equipment.

The contents of a check and a solution are shown below.

(1) Power Supply Is Not Turned On.

Phenomenon Check Point Solution

Is AC power cord inserted in the

A power supply is not

turned on.

RN LED (green) does

not light up.

(2) The Display of LED

Phenomenon Check Point Solution

TRX LED(green) and

LINK LED(yellow) do

not light up.

INI LED(red) and ER

LED(red) light up. ER

LED(red) repeats blink.

power supply wall socket?

Is the power supply switch turned

on?

Does the power come to the

power supply wall socket?

Is the modular jack connected to

the Ethernet port?

Is the apparatus of the opposite

side connected?

Since it is failure, please contact your service station.

Chapter 6: Preservation (Maintenance)

Once turn off the power supply switch

in this front of equipment, and insert in

a wall socket.

Turn ON a power supply switch.

Check that the circuit breaker by the

side of power supply primary turns on.

Insert a modular jack.

Connect the apparatus of the opposite

side.

(3) In Case of Abnormalities or Failure

Phenomenon Solution

An unusual smell and

unusual overheating

have been noticed.

Turn off a power supply switch and pull out AC power cord.

Since it is failure, please contact your service station.

41

Chapter 6: Preservation (Maintenance)

6.3 Repair and Exchange

When the failure occurs in this equipment, TOSHIBA will exchange the whole equipment.

Please contact your service station.

42

Appendix

Appendix

43

Appendix

Appendix 1 Appearance and Size

44

Appendix 2 Screw Hole Pitch of the Bottom Side

A total of four screw holes for this equipment fixation for surface-of-a-wall attachment (M4 size) is in

the equipment bottom.

Please attach screw hole size and the depth within 6-8mm in M4 size.

Please refer to the bottom side layout shown below and a screw hole sectional view about a detailed

size.

Metal case type:

Screw Hole × 4

Appendix

AC inlet side

Bottom Side View

LED display side

Unit in mm

45

Appendix

Appendix 3 Connector Pin Map

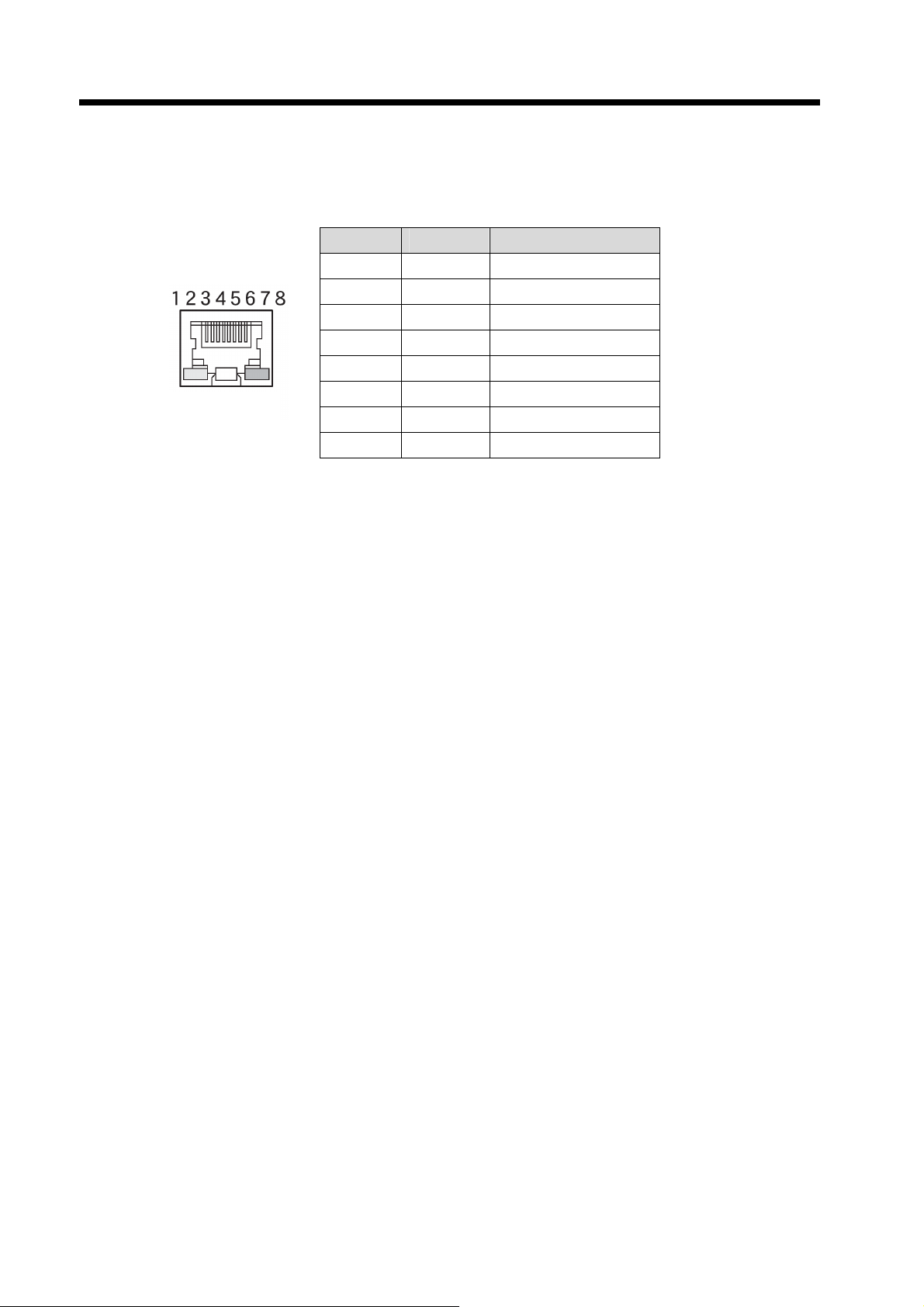

(1) Ethernet Interface : Ethernet port-1/2

Connector: 8pin modular plug

Pin No. Signal Meaning

1 TD+ Data Output+

2 TD- Data Output-

3 RD+ Data Input+

4 N.C. No Connection

5 N.C. No Connection

Pin layout

6 RD- Data Input-

7 N.C. No Connection

8 N.C. No Connection

46

Appendix

(2) RS-232C Interface : Serial port - 1/2

Connector: D-Sub 9 pin plug connector (fixed screw : 4-40 UNC)

Pin No. Signal Meaning Signal Meaning

1 N.C. No Connection N.C. No Connection

2 RD Receive Data RD Receive Data

3 SD Send Data SD Send Data

4 ER

5 GND Signal Ground GND Signal Ground

6 N.C. No Connection N.C. No Connection

7 RS Request to Send RS

8 CS Clear to Send CS

9 N.C. No Connection N.C. No Connection

Port 1

Data Terminal Ready

N.C. No Connection

Port 2

Turn back connection

(3) RS-485 Interface : Serial port - 1

Connector: D-Sub 9 pin plug connector (fixed screw : 4-40 UNC)

Pin No. Signal Meaning

1 Tx(-) Send Data (-)

2 Tx(+) Send Data (+)

3 Rx(+) Receive Data (+)

4 Rx(-) Receive Data (-)

5 GND Signal Ground

6 N.C. No Connection

7 N.C. No Connection

8 N.C. No Connection

9 N.C. No Connection

47

Appendix

(4) Digital Input/Output Connector

Pin

No.

A10 N.C. No Connection B10 N.C. No Connection

A11 N.C. No Connection B11 N.C. No Connection

A12 N.C. No Connection B12 N.C. No Connection

Signal Meaning

A1 P.S(+) Power Pin (+) B1 P.S(-) Power Pin (-)

A2 DI1(+)

A3 DI2(+)

A4 DI3(+)

A5 DI4(+)

A6 DO1(+)

A7 DO2(+)

A8 DO3(+)

A9 DO4(+)

Digital Input 1 (+)

Digital Input 2 (+)

Digital Input 3 (+)

Digital Input 4 (+)

Digital Output 1 (+)

Digital Output 2 (+)

Digital Output 3 (+)

Digital Output 4 (+)

Pin

No.

Signal Meaning

B2 DI1(-)

B3 DI2(-)

B4 DI3(-)

B5 DI4(-)

B6 DO1(-)

B7 DO2(-)

B8 DO3(-)

B9 DO4(-)

Digital Input 1 (-)

Digital Input 2 (-)

Digital Input 3 (-)

Digital Input 4 (-)

Digital Output 1 (-)

Digital Output 2 (-)

Digital Output 3 (-)

Digital Output 4 (-)

48

TOSHIBA Distributed Control Network Computer GIGABINE

ULCS2 Hardware Instruction Manual

2nd Edition February 28, 2005

Issued by

Industrial and Power Systems & Services Company

1-1, Shibaura 1-chome, Minato-ku, TOKYO, 105-8001, JAPAN

The material in this manual may be revised without notice.

©TOSHIBA Corporation 2004-2005. All Rights Reserved.

No part of this manual may be reproduced in any form without permission.

Loading...

Loading...