Page 1

FILE NO. A04-016

TCS-NET AIR CONDITIONING

CONTROL SYSTEM

(TOUCH SCREEN CONTROLLER)

Page 2

CONTENTS

1 OUTLINE

1-1 TCS-Net Air conditioning control system outline ............................................................................................... 4

1-2 Component .......................................................................................................................................................5

1-2-1 TCS-Net Control system component ......................................................................................................5

1-2-2 Application control component ...............................................................................................................6

1-3 Basic system component ................................................................................................................................. 7

1-3-1 Apparatus component ............................................................................................................................7

1-3-2 The control system devices ................................................................................................................... 8

1-3-3 The control system devices (Procured on site).......................................................................................9

1-3-4 Software .................................................................................................................................................9

1-4 Touch screen controller function...................................................................................................................... 10

1-5 Energy monitoring and billing function ............................................................................................................. 13

1-6 Input/Output.................................................................................................................................................... 15

2 SYSTEM CONFIGURATION

2-1 Touch screen controller system configuration .................................................................................................... 18

3 INSTALLATION

3-1 Installation work flow....................................................................................................................................... 24

3-2 Setup file data preparation .............................................................................................................................. 25

3-2-1 Control wiring diagram (Connection example) ....................................................................................... 25

3-2-2 Power meter wiring diagram (Connection example) ............................................................................... 26

3-2-3 Air conditioner address table ................................................................................................................ 27

3-2-4 Schedule table ..................................................................................................................................... 29

3-3 Setup file creation ........................................................................................................................................... 30

3-3-1 Setup file creation software (Excel macro) ........................................................................................... 30

3-3-2 Setup file contents ............................................................................................................................... 31

3-4 Control system installation ..............................................................................................................................31

3-4-1 External view ....................................................................................................................................... 34

3-4-2 Installation method ............................................................................................................................... 38

3-4-3 Device specifications ........................................................................................................................... 41

3-5 Wiring ............................................................................................................................................................. 42

3-5-1 Wiring specifications ............................................................................................................................ 42

3-5-2 Wiring diagram ..................................................................................................................................... 43

3-6 Network connection ........................................................................................................................................ 52

3-7 Control system configuration........................................................................................................................... 53

4 ADDRESS SETTING

4-1 Address setting flow .......................................................................................................................................56

4-2 Definition of address ....................................................................................................................................... 57

4-3 Address setting for air conditioner ...................................................................................................................62

4-3-1 Setting for VRF system ........................................................................................................................ 62

(1) Check at main Power-ON .............................................................................................................. 63

(2) Manual setting from wired remote controller .................................................................................. 64

(3) Line (system) address setting .......................................................................................................66

(4) Power reset ...................................................................................................................................66

(5) Indoor unit address check .............................................................................................................67

(6) Trial operation ................................................................................................................................ 67

(7) Setup of relay connector and terminator ........................................................................................ 68

(8) Central control address setting ...................................................................................................... 71

(9) Trial operation for central controller (TCB-SC642TLE2) .................................................................. 73

(10) Automatic address setting (for reference) .................................................................................... 74

(11) Clearance of address .................................................................................................................. 77

(12) Confirmation of indoor unit address and position by using the remote controller .......................... 78

(13) Address change from remote controller .......................................................................................79

(14) In case of increase the address-undefined indoor units (Extension, etc.) .................................... 81

(15) Address setup example (VRF system) ........................................................................................ 82

4-3-2 Setting for 1 to 1 system ...................................................................................................................... 85

(1) Address re-setup ........................................................................................................................... 85

(2) Indoor address change example.................................................................................................... 89

4-4 Address setting for Control System devices ................................................................................................... 91

4-4-1 Address setting flow .............................................................................................................................91

4-4-2 Setting for Intelligent server ................................................................................................................. 92

4-4-3 Setting for TCS-Net relay interface .......................................................................................................93

4-4-4 Setting for Energy monitoring relay interface ........................................................................................ 94

4-4-5 Setting for Digital I/O relay interface..................................................................................................... 95

5 TRIAL OPERATION

5-1 Trial operation..................................................................................................................................................98

5-2 Air conditioning control system troubleshooting ............................................................................................ 101

5-2-1 Faults on the air conditioner ............................................................................................................... 101

5-5-2 Faults on the air conditioning control system ...................................................................................... 101

2

Page 3

1

OUTLINE

1-1 TCS-Net Air conditioning control system outline

1-2 Component

1-2-1 TCS-Net control system component

1-2-2 Application control component

1-3 Basic system component

1-3-1 Apparatus component

1-3-2 The control system devices

1-3-3 The control system devices (Procured on site)

1-3-4 Software

1-4 Touch screen controller function

1-5 Energy monitoring and billing function

1-6 Input/Output

3

Page 4

1-1 TCS-Net Air conditioning control system outline

The TCS-Net Air conditioning control system achieves an easy-to-operate central air conditioning control

with the LCD Touch Screen Controller integrating advanced functions. The system allows operation status

monitoring, operation control, scheduled operation and error code display of up to 512 indoor units with

one controller. It is also equipped with functions for energy monitoring and billing (Individual indoor units)

and for operation control using external input/output signals.

Operation status monitoring

Monitors operation status of all air conditioners collectively.

Operation control

Controls operation of devices with the LCD touch panel. Allows detailed operation settings, such as

collective operation of an entire building or each block/tenant/area, as well as individual operation of each

indoor unit.

Operation schedule

Allows detailed operation schedule settings for each area.

Error code display

Displays failure information, location, time when the failure occurs and displays fault log information.

Energy monitoring and billing

Determines power usage for each indoor unit and outputs the calculation results as daily/monthly reports.

I/O function

Provides operation control using external input signals and outputs emergency signals to external

devices.

4

Page 5

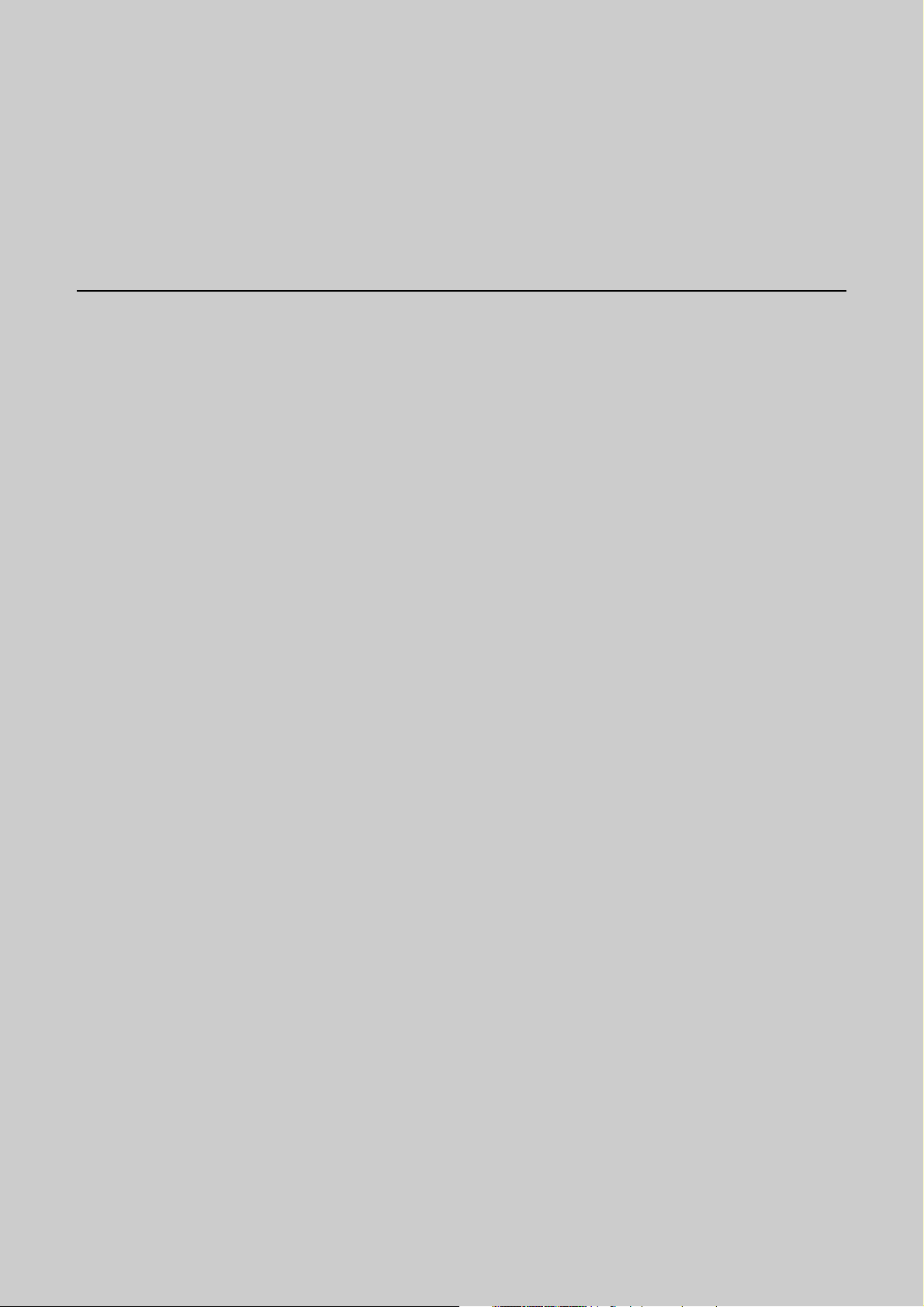

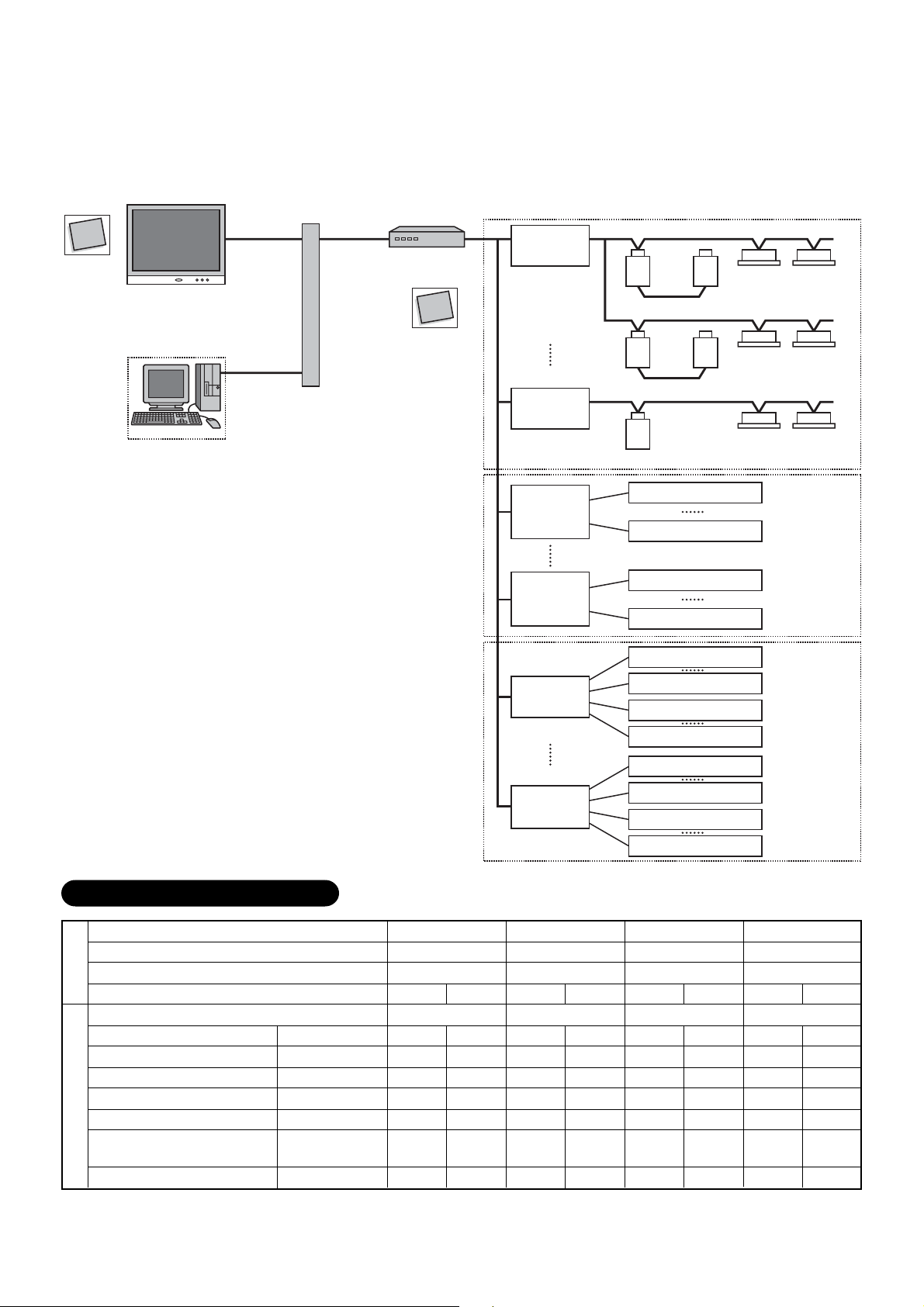

SMMS

SHRM

Master remote controller

Super Digital Inverter

Digital Inverter

TCS-Net Interface

BMS-IFLSV1E

BMS-LSV2E

Intelligent server

HUB

Power meter

I/F

BMS-IFWH3E

Energy meter

relay interface

PC

I/F

Digita l/O Relay

Interface

BMS-IFDD01E

Side remote controller

"1:1 model"

TCB-PCNT30TLE

connection interface

BMS-TP0640ACE

BMS-TP0640PWE

BMS-TP5120ACE

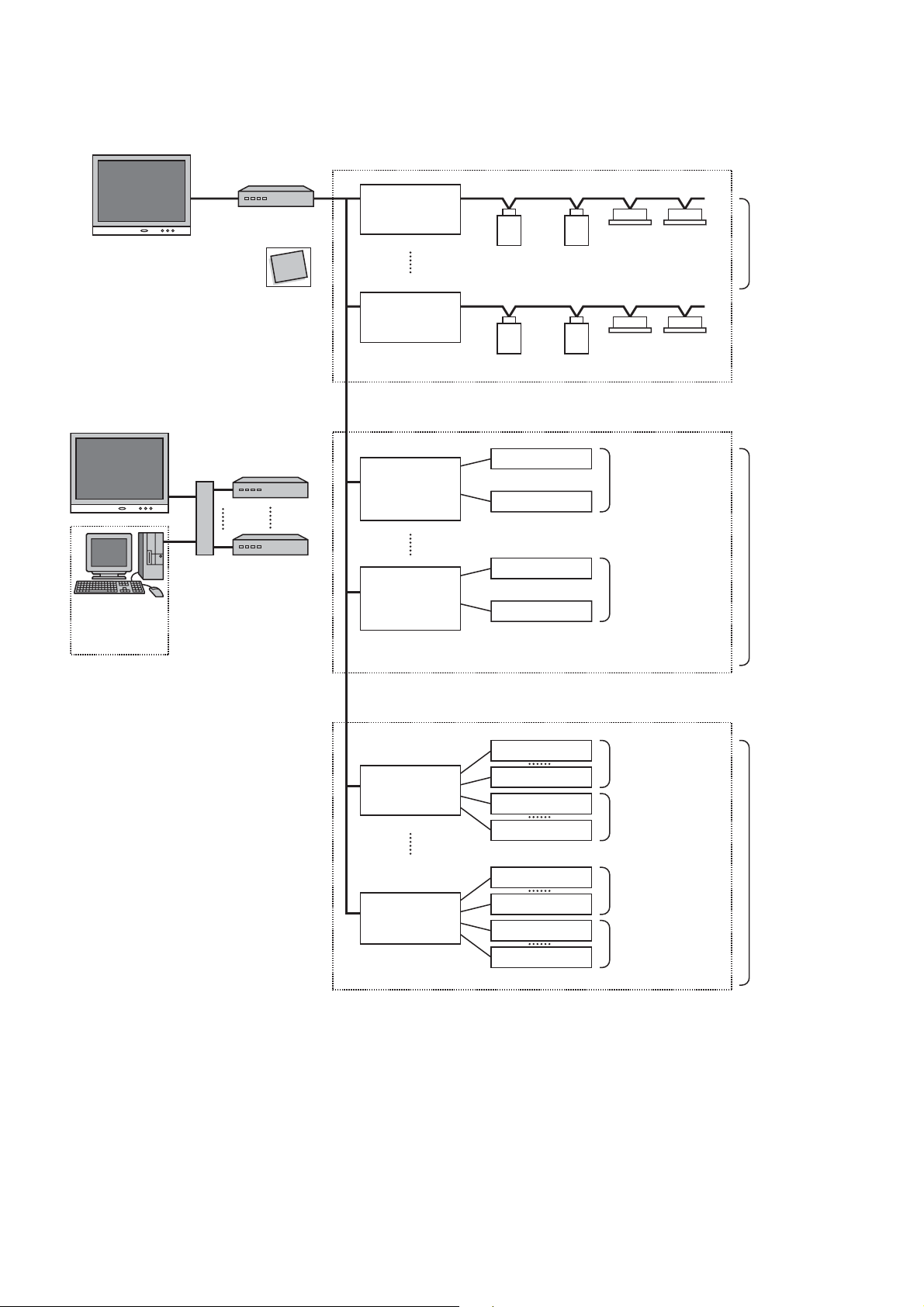

1-2 Component

1-2-1 TCS-Net control system component

BMS-TP5120PWE

PC for Energy monitoring and billing

Touch screen controller

5

Page 6

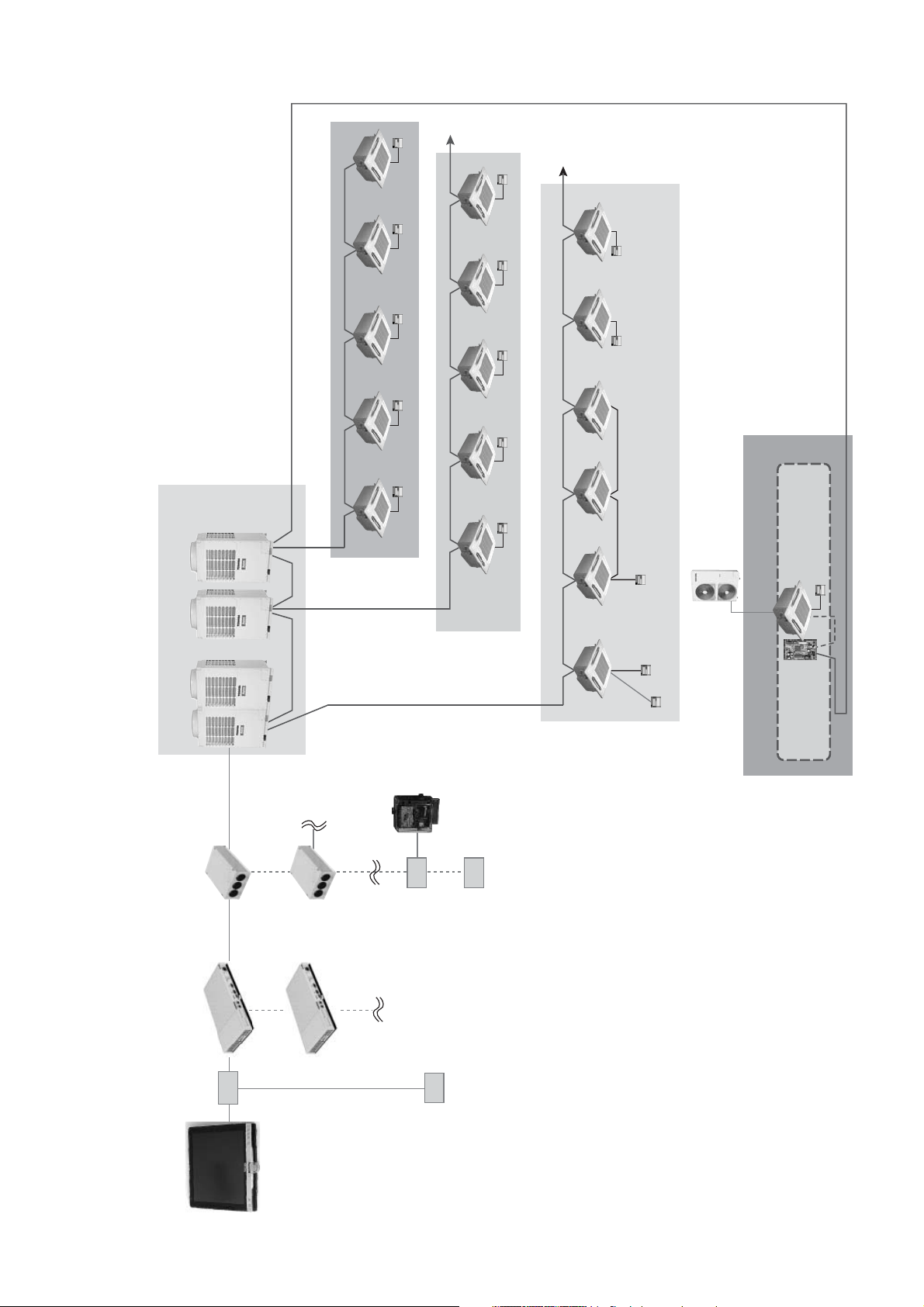

SMMS

SHRM

Super Digital Inverter

Digital Inverter

"1:1 model"

TCB-PCNT30TLE2

connection interface

TCB-IFCB-4E2

Remote location

ON/OFF control box

Network adapter

TCB-PCNT20E

AI-NETWORK

AI-NET central

control devices

Wireless

remote

controller

Sub-remote

controller

RBC-AS21E2

Wired remote controller

RBC-AMT31E

Weekly timer

RBC-EXW21E2

TCS-Net Interface

BMS-IFLSV1E

BMS-LSV2E

Intelligent

server

HUB

4-4ø hole

5

PJ17

8

ICI

5

MS10MS

TCB-PCOM1

TCB-PCOM1E

NCC-1212

41

OFFON

TOSHIBA

71

61

K100

COM COMON

OFF

T82

T81

OFF

ON

OPERATION/

75

85

Terminal

Terminal

Screw M3 6

Screw M4 8

Power peak-cut

control board

TCB-PCDM2E

4-4ø hole

41

PJ17

ICI

5

8

10

41

TCB-PCMO1

TCB-PCMO1E

55.5

45.5

D2

COM

TOSHIBA

NCC-1214

TB1

HEAT

COM COOL

50

60

Screw M3 6

Terminal

External master

ON/OFF board

TCB-PCMO2E

I/F

BMS-IFWH3E

Power

meter

I/F

Energy meter

relay interface

Digita l/O Relay Interface

BMS-IFDD01E

ON/OFF command

Alarm status output

Central remote

controller

Master ON/OFF signal

Batch drive, error output

Master ON/OFF signal

Power peak-cut control signal

Operation control command

Operation status output

Master remote controller

Side remote controller

TCB-SC642TLE2

Air-conditioning

Weekly timer

RBC-EXW21E2

Management on site

PC

PC for Energy

monitoring and

billing

1-2-2 Application control component

BMS-TP0640ACE

BMS-TP0640PWE

BMS-TP5120ACE

BMS-TP5120PWE

Touch screen

controller

6

Page 7

1-3 Basic system component

1-3-1 Apparatus component

Compact

Flash

Set up files

Touch Screen Controller

(BMS-TP0640 / 5120)

PC for Energy Monitoring

and billimg

(Procured on site)

Ethernet

Switching HUB

(Procured on site)

InteIligent Server

(BMS-LSV2E)

Compact

Flash

Intelligent server

Software

(BMS-STCC01E)

RS- 485

TCS- NET

Relay I /F

(BMS-IFLSV1E)

TCS- NET

Relay I /F

(BMS-IFLSV1E)

Energy

Monitoring

Relay I /F

(BMS-IFWH3E)

Energy

Monitoring

Relay I /F

(BMS-IFWH3E)

Main BUS

Main BUS

Main BUS

Power meter 1

Power meter 8

Power meter 1

Power meter 8

Input 1

(Procured on site)

(Procured on site)

(Procured on site)

(Procured on site)

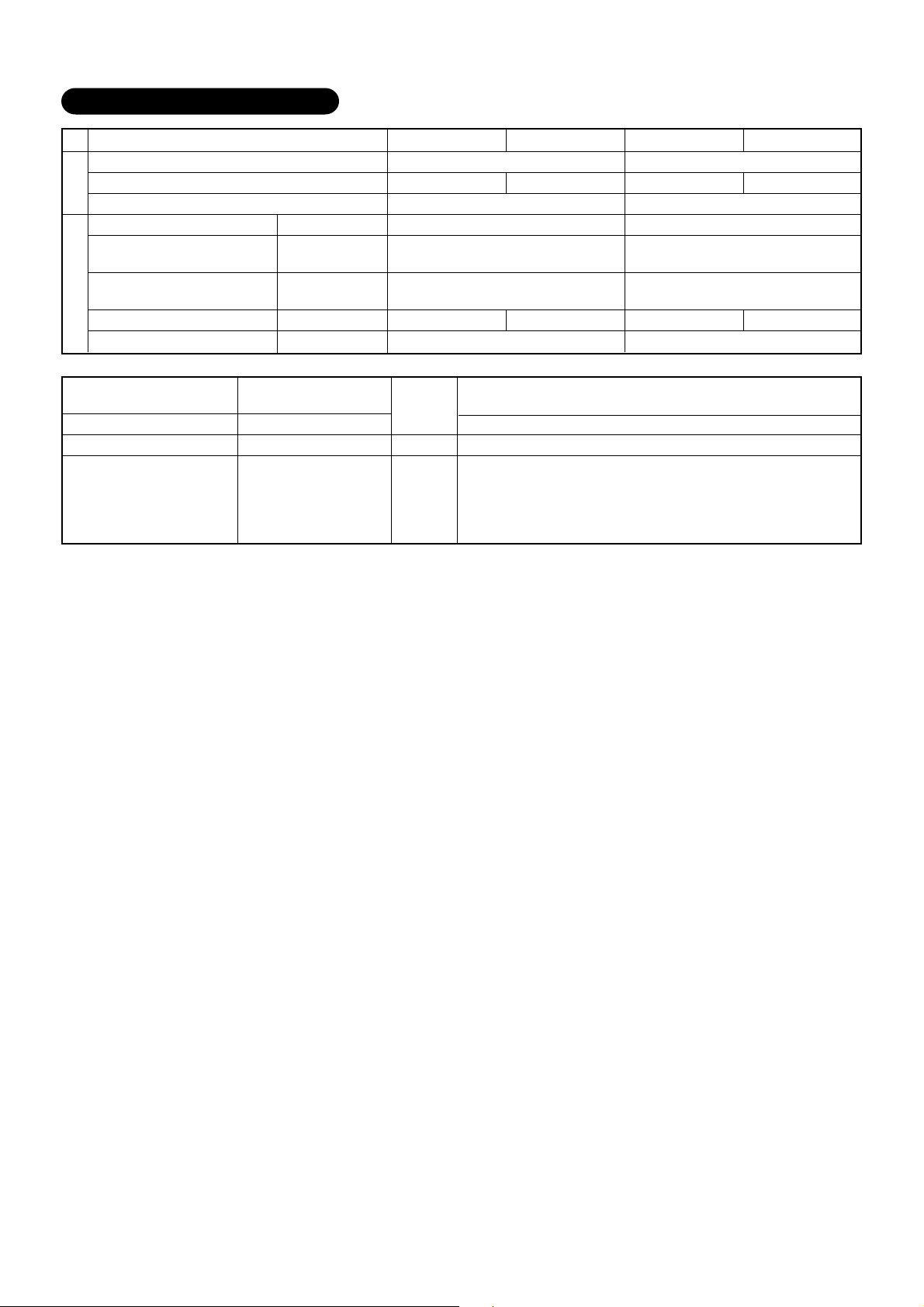

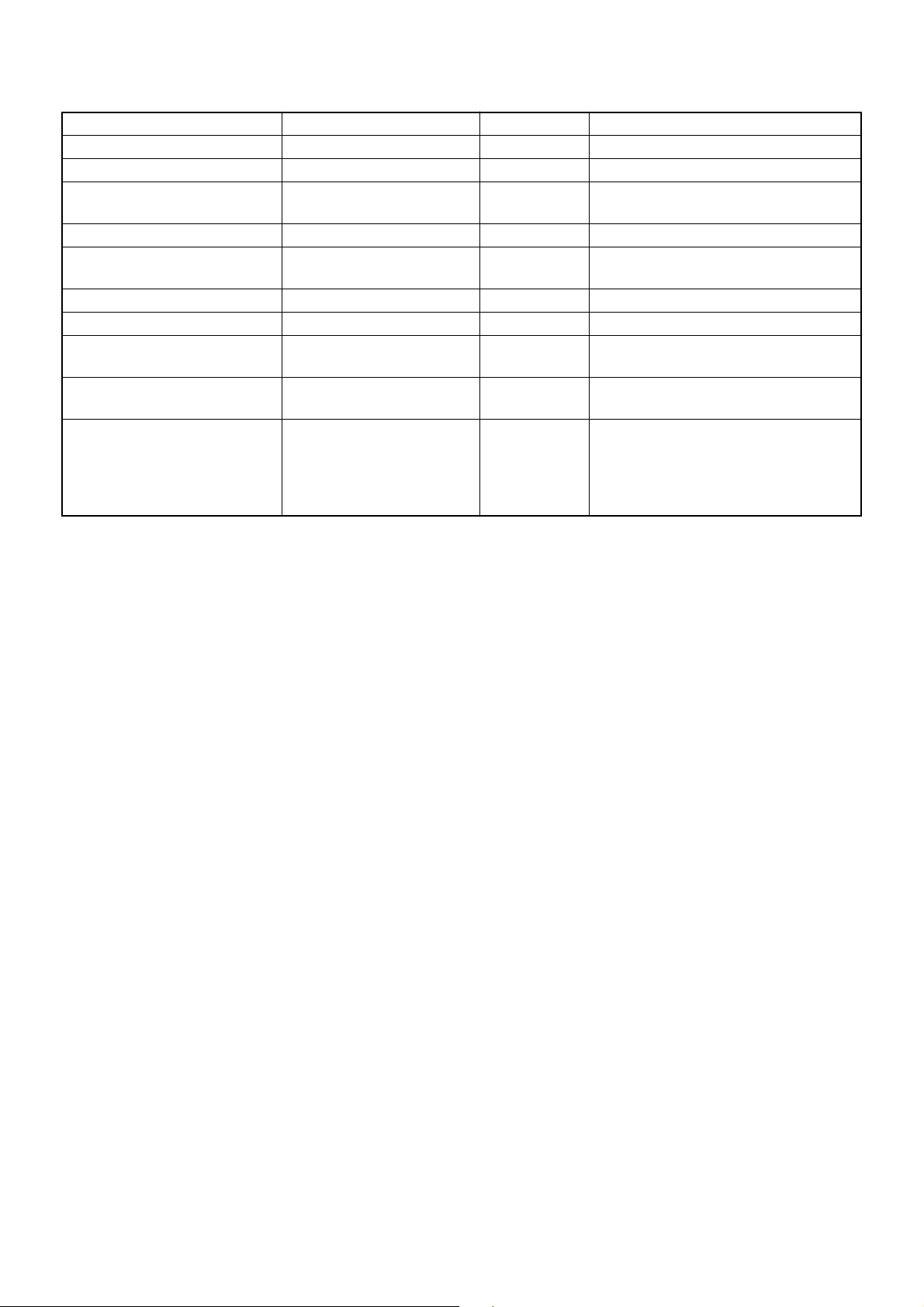

System Configuration Table

Monitoring/Control/Scheduling/Fault code display

Energy monitoring and billing

Indoor units connected

Function

Digital I/O

Touch Screen Controller

Intelligent Server

Intelligent Server Software

TCS-NET Relay I/F

Energy Monitoring Relay I/F

Devices

Digital I/O Relay I/F

PC (for Energy monitoring

and billing)

Switching HUB

BMS-LSV2E

BMS-STCC01E

BMS-IFLSV1E

BMS-IFWH3E

BMS-IFDD01E

Procured on site

Procured on site

Digital I/O

Relay I /F

(BMS-IFDD01E)

Digital I/O

Relay I /F

(BMS-IFDD01E)

Input 8

Output 1

Output 4

Input 1

Input 8

Output 1

Output 4

××××

××

Max. 64 units Max. 64 units Max. 512 units Max. 512 units

×× × ×

BMS-TP0640ACE BMS-TP0640PWE BMS-TP5120ACE BMS-TP5120PWE

Ч ЧЧЧЧЧЧЧ

Ч ЧЧЧЧЧЧЧ

Ч ЧЧЧЧЧЧЧ

×× × ×

×× × ×

×× × ×

×(*

)

×(*

)

×(*

)

×(*

)

×(*

)

×(*

)

×(*

)

×(*

)

(*) A Switching HUB is required when using two or more Intelligent servers or when connecting to a PC for Energy Monitoring

and billing.

7

Page 8

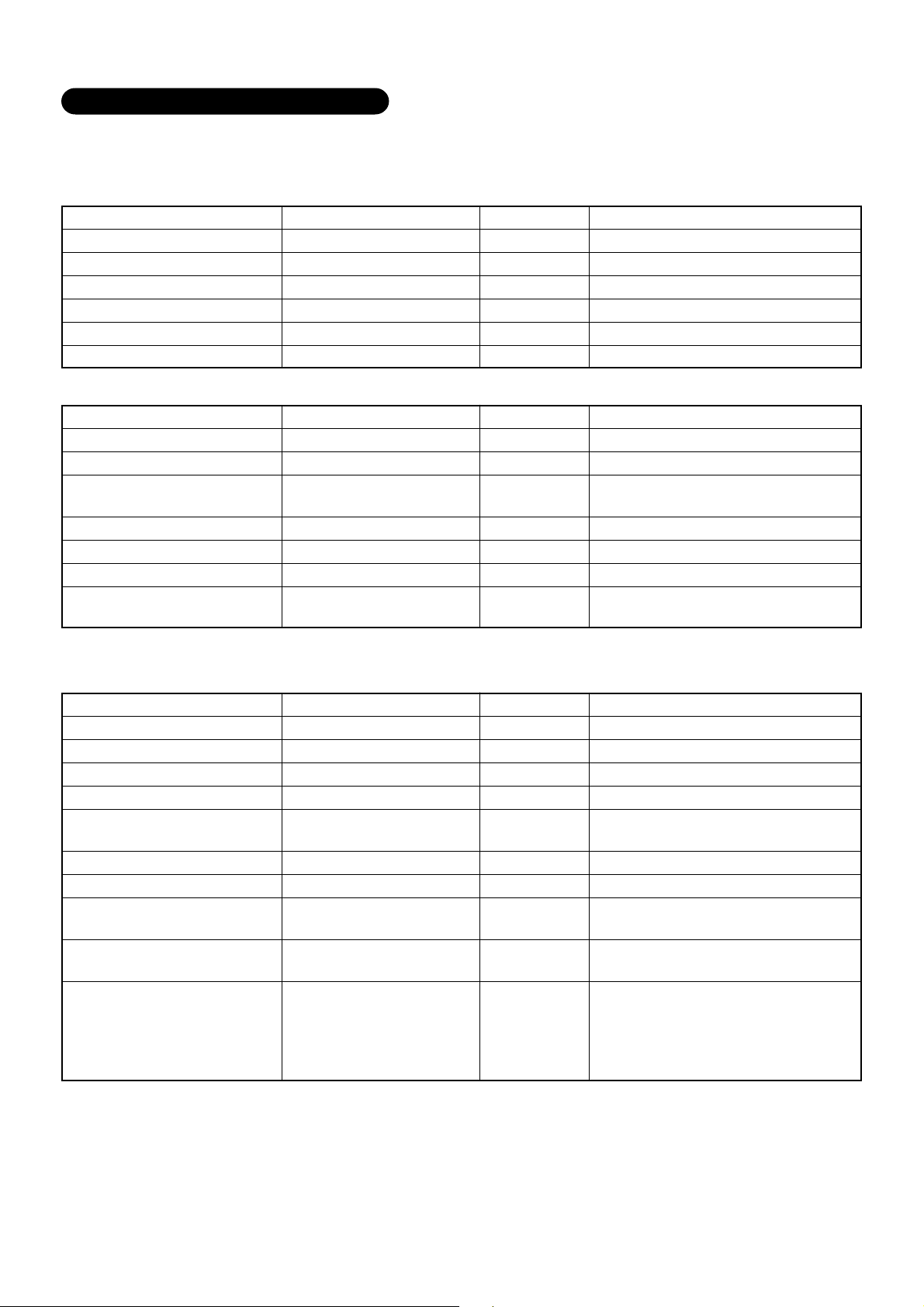

1-3-2 The control system devices

Name

Touch Screen Controller

Intelligent Server

Intelligent Server

Model

name

BMS-TP0640ACE

BMS-TP5120ACE

Software

BMS-TP0640PWE

BMS-LSV2E

BMS-STCC01E

BMS-TP5120PWE

Appearance Performance

Operation monitoring

Operation control

Operation schedule

Error code display

Fire alarm input

Energy monitoring data saving to CF card

Data collection

Data collection software

(This software is used for the Intelligent server)

Interface

TCS-Net Relay

Relay Interface

Energy Monitoring

Interface

Digital I/O Relay

BMS-IFLSV1E

BMS-IFWH3E

BMS-IFDD01E

Protocol transformation

Main BUS to RS-485

Power meter interface

Input and output interface

Fire alarm input

Key input

Error output

8

Page 9

1-3-3 The control system devices (Procured on site)

Name

Mesurement of power consumption.

Output data by pulse signal

Power meter

Network with

Touch screen controller

Intelligent server

Energy monitoring PC

Ethernet wire

Switching HUB and

Energy monitoring calculation

Electricity billing calculation

Monthly report creation

and billing

Performance Specification

Pulse output type

Pulse generator constants: 1kWh/pulse or 10kWh/pulse

Pulse duration: 50 - 1000 ms

Output terminal: ON/OFF contactor

HUB:

10BASE-T compliant (*)

Number of ports: as required

Ethernet wire: Category5 UTP straight cable (with HUB)

Category5 UTP cross cable (without HUB)

Microsoft Excel is required for the energy monitoring and

billing function

OS: Windows 2000 or newer

Excel: Excel 2000 or newer

PC for energy monitoring

* 100BASE-T compliant HUB is required when using 5 or more servers, or 2 or more controllers.

1-3-4 Software

Name

Monthly report

creation software

Monthly report creation

Power distribution calculation

Billing calculation

Daily sum report creation

Performance Note

This software is provided on CD-ROM

9

Page 10

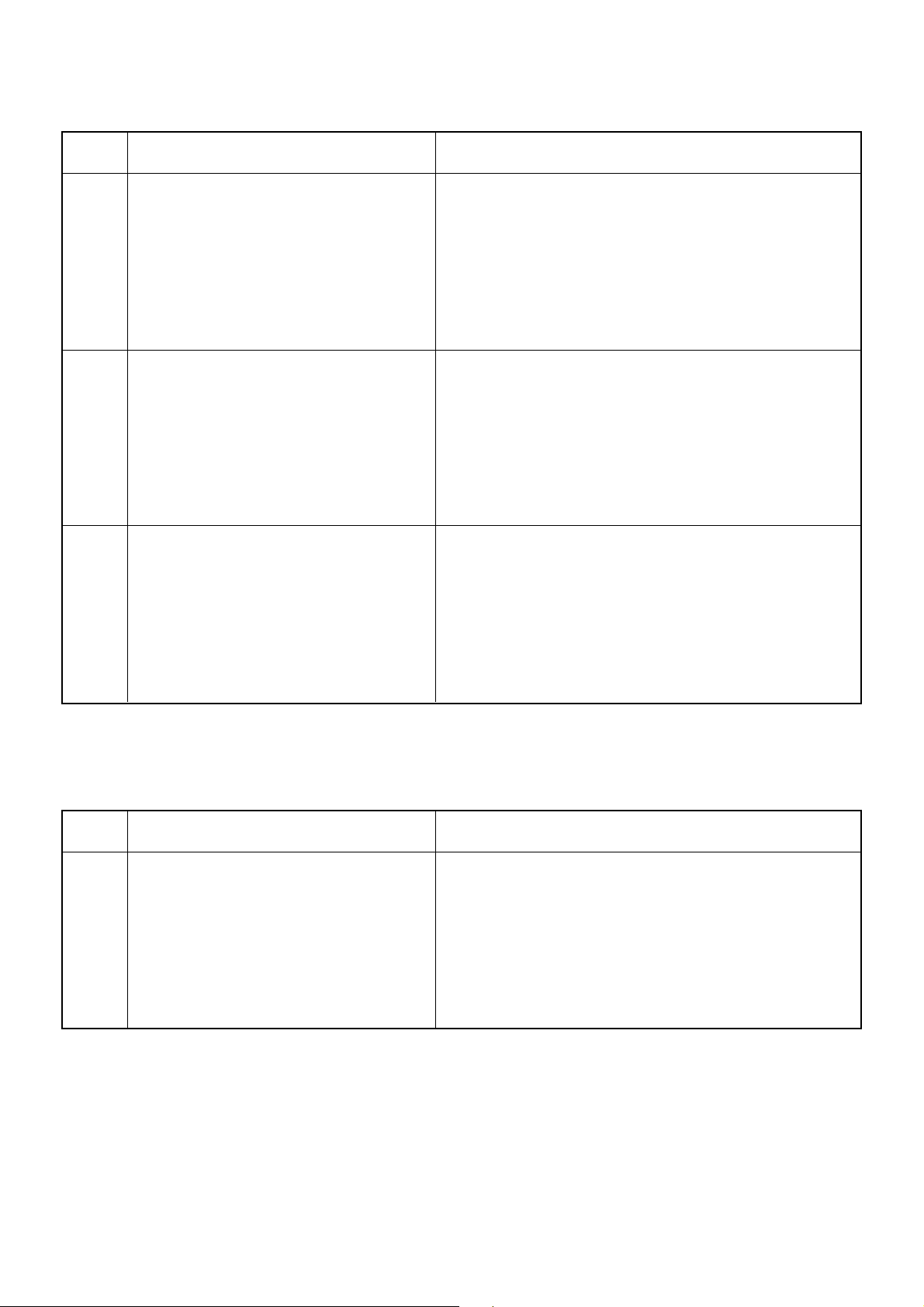

1-4 Touch screen controller function

Monitoring

All Indoor unit conditions can be monitored by the controller.

Monitoring Items

Mode

FAN mode

Louver setting

Set Temperature

Inlet air temperature

R/C control prohibition

Control

All Indoor unit operations can be controled within the user's selected division.

Controlable division

Whole building

All tenant

All area

Unit

Setting Items

Mode

Fan mode

Louver setting

Set temperature

Inlet air temperature

R/C control prohibition (7 combinations)

ON/OFF

prohibition

1

2

3

4

5

6

7

×

–

–

×

×

–

×

MODE

prohibition

–

×

–

×

–

×

×

SET TEMP

prohibition

–

–

×

–

×

×

×

10

Page 11

Management zone categories

All Block Tenant Area

Building A 1-1 (header unit)

1F

Tenant A

Shop A

RC

Group/Unit

101

(line address + indoor unit address)

Indoor Unit

1-2 (follower unit)

102

1-3 (header unit)

1-4 (follower unit)

103

1-5 (header unit)

1-6 (follower unit)

1-7 (follower unit)

Office A

104

1-8 (header unit)

1-9 (follower unit)

Tenant B

Shop B

105

2-1 (header unit)

2-2 (follower unit)

Tenant C

Office B

Shop C

106

107

108

2-3 (header unit)

2-4 (header unit)

2-5 (header unit)

2-6 (follower unit)

2-7 (follower unit)

2-8 (follower unit)

109

110

2-9 (follower unit)

3-1 (header unit)

Shared

space

Office C

1F outdoor

air conditioner

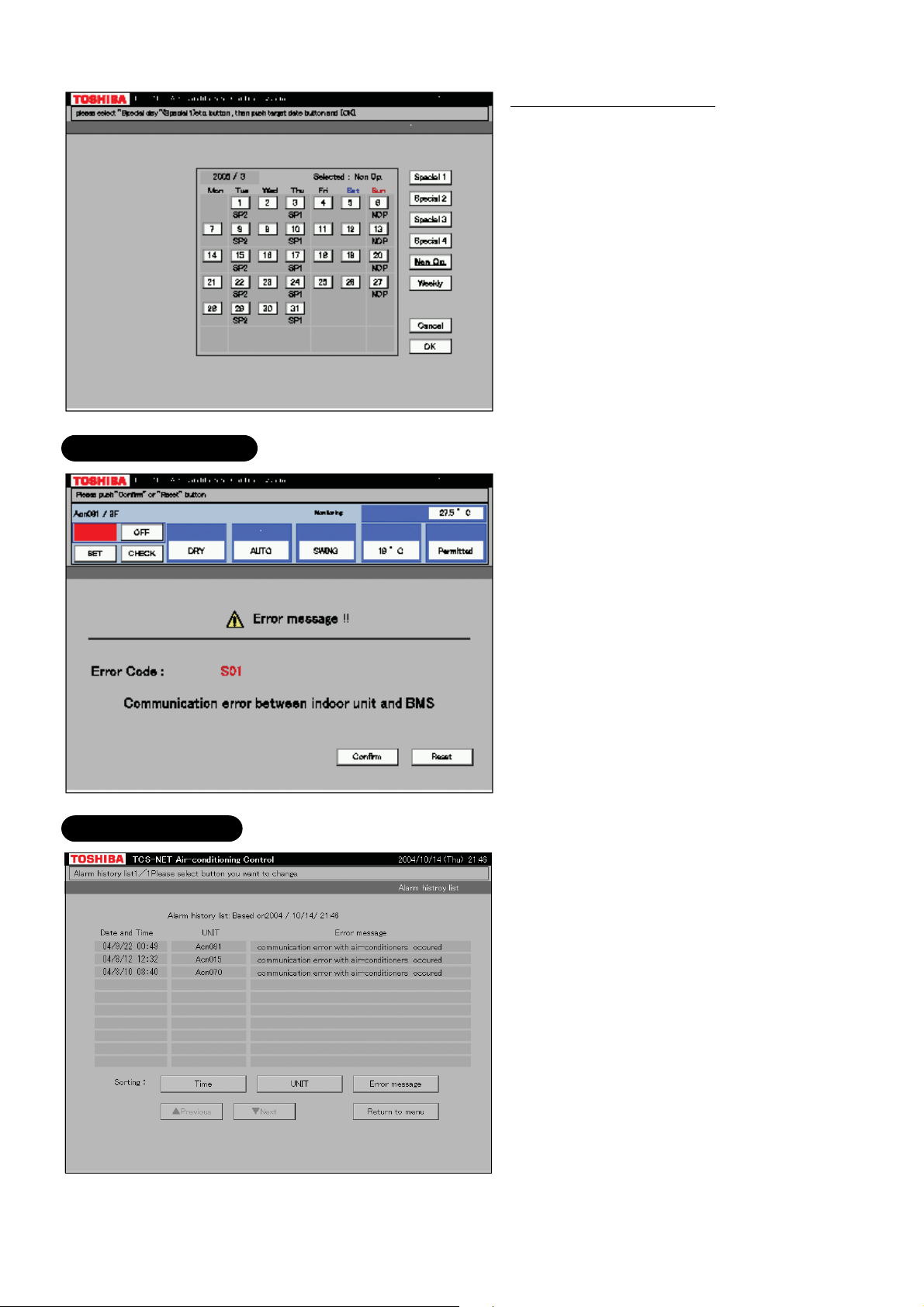

Scheduling

A basic operation schedule pattern is determined by setting the weekly and monthly operation schedules.

The schedules can be set for each area.

Weekly schedule setting

Up to 20 patterns a day (including ON and

OFF) can be set.

11

Page 12

Error code display

Monthly schedule setting

Schedule patterns except for weekly schedule

patterns can be set as special-days.

Up to four special-day patterns can be set.

Non-operation dates can also be set.

When an error occurs on a device, an error

code is displayed.

Fault log display

12

Page 13

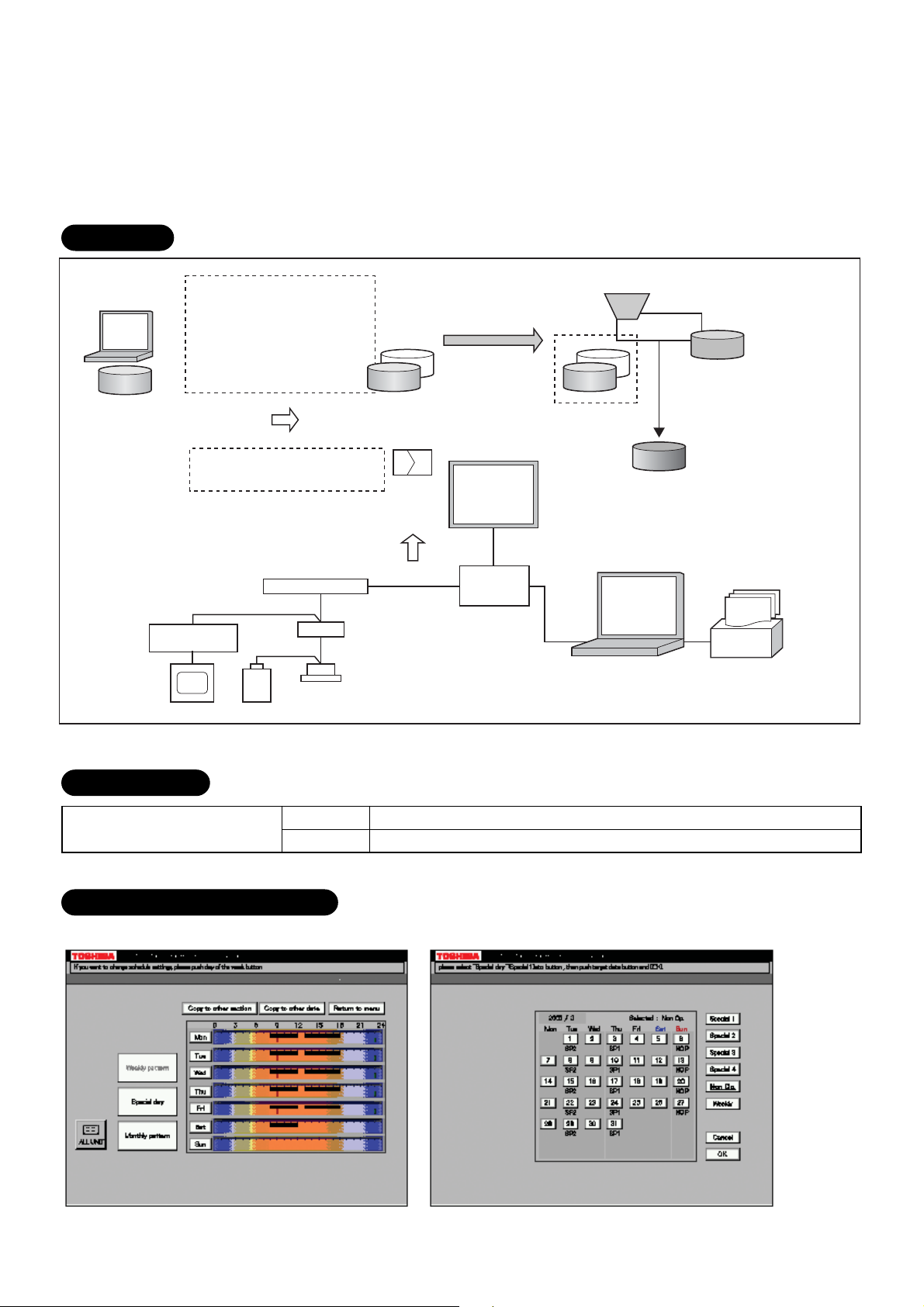

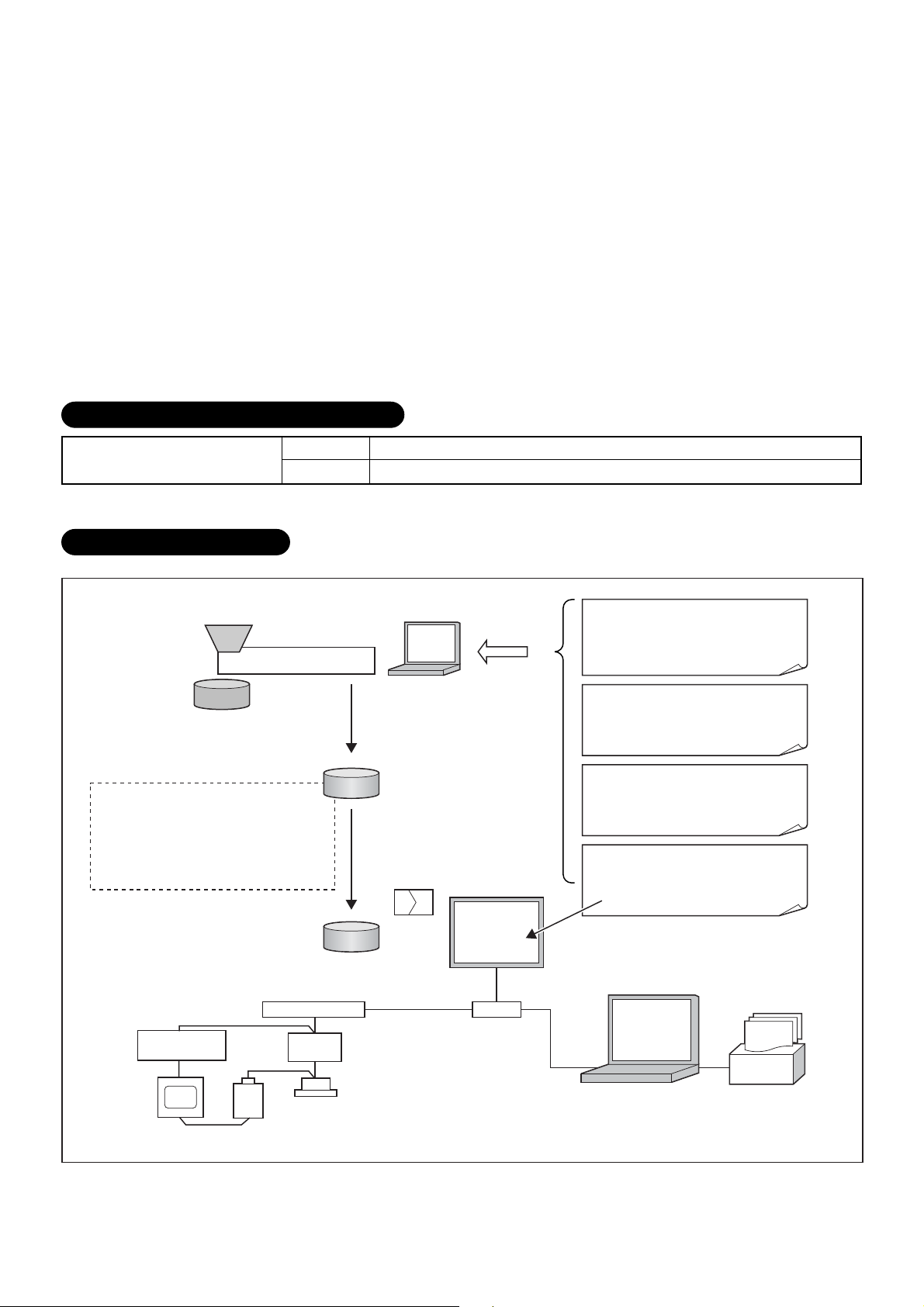

1-5 Energy monitoring and billing function

Distributes the total power consumption for each indoor unit according to the billing schedule that has been

set by the Touch Screen Controller. The system setup file and the operation result file saved on the CF card

of the Touch Screen Controller are uploaded onto the PC. The PC calculates the power distribution result

using the dedicated report creation software (Excel macro) to create spreadsheets and monthly reports.

Data flow

Setup file creation

software

Setup file

monitoring I/F

Power meter

Setup file

• Tenant name, etc.

• Air conditioner information, etc.

• Setting values for energy

monitoring and billing

Air conditioner specific

characteristic values

Tenant names for reports

Air conditioner operation result

Power meter pulse counter value

Intelligent Server

RS-485

Energy

IF

Air conditioner

Main BUS

Monthly meter-read

file Setup file

Records to

CF card

Every

15 min

Ethernet

File transfer (FTP)

Touch Screen

Controller

HUB

(procured on

locally)

Energy

Ethernet

monitoring

and billing

software

PC (procured on site)

Report creation software

(Excel macro)

Excel

Default data file

Monthly report, spreadsheet

(Excel file)

Printer

Printer for monthly reports

(procured on site)

Specification

PC operating system

OS

Excel

A PC and printer for energy monitoring and billing should be procured on site.

Windows 2000 or newer

Excel 2000 or newer is required separately.

Electricity billing schedule

Touch Screen Controller sets a billing schedule for monthly reports.

13

Page 14

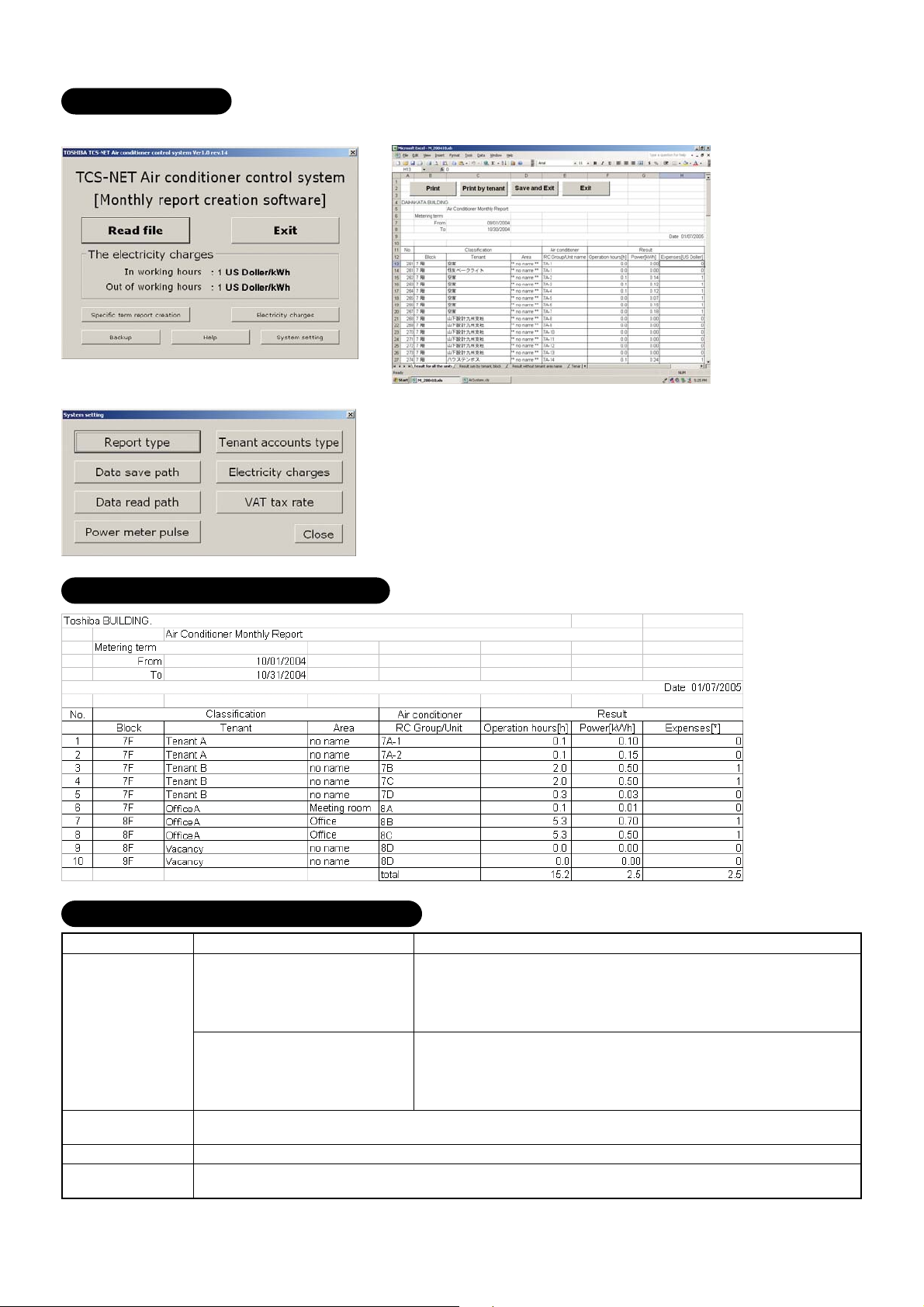

Monthly Report

The report creation software creates monthly reports in an Excel file format.

Monthly report printout example

Report creation software functions

Function

Monthly report

creation

Power distribution

calculation

Billing calculation

Daily sum report

creation

Creates operation result reports

for each indoor unit group.

These can be totalled by the

touch screen controller based

upon the setup files.

Creates 4 types of spreadsheets

for monthly reporting.

Calculates power distribution for each indoor unit group

Calculates expenses for each indoor unit group

Totals daily reports in specified range to create a monthly report.

Description

Remarks

Operation result report type:

• Display operation hours

• Display operation hours, display by In/Out working hours

• Display operation hours/consumption/billing

•

Display operation hours/consumption/billing, display by In/Out working hours

Spreadsheet type:

• Operation result for all the units

• Operation result without tenant, Area name

• Operation result sum by tenant, block

• Accounts sum by tenant

14

Page 15

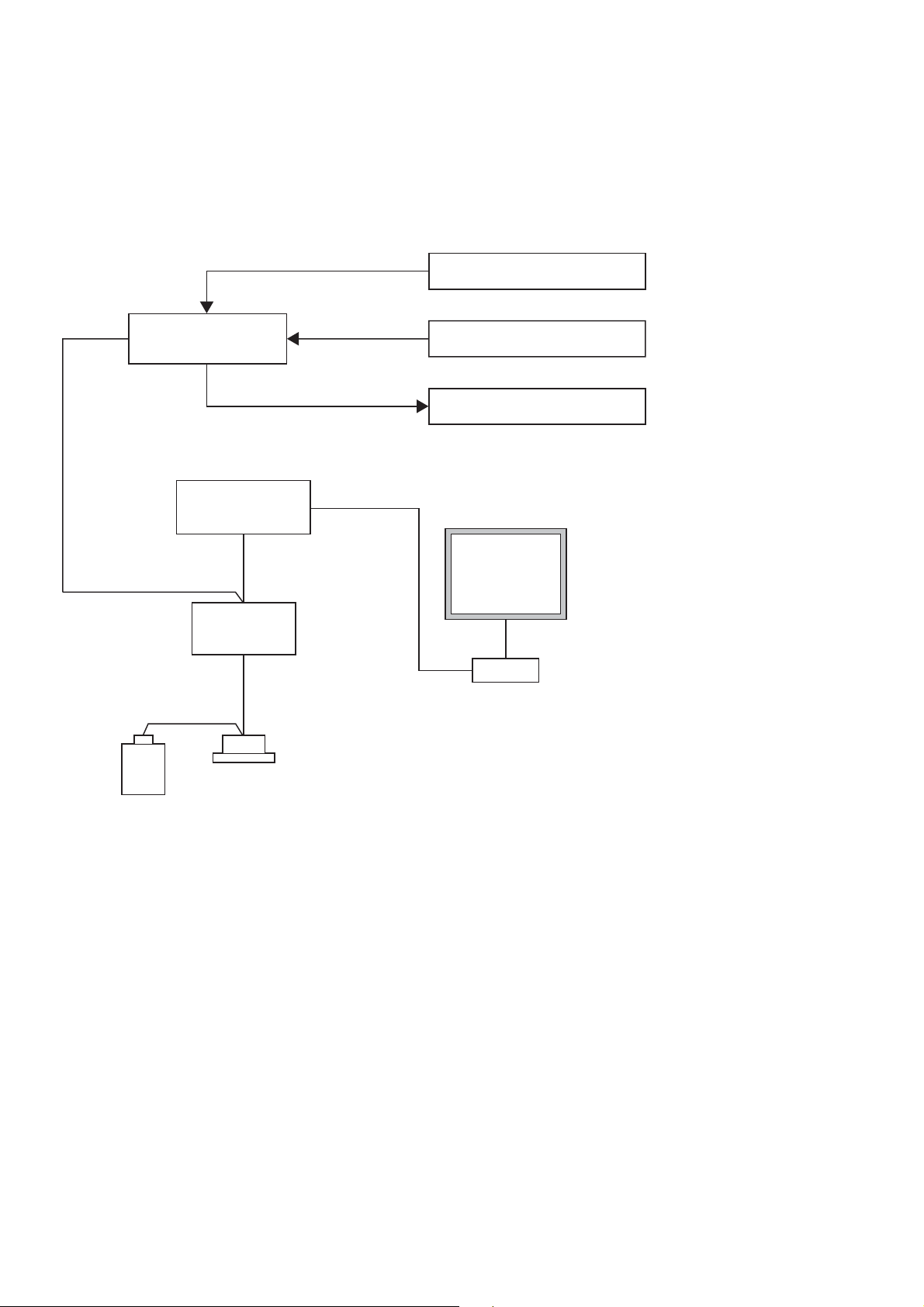

1-6 Input/Output

This system controls the air conditioners by interlocking them with electric lock signals and fire alarm

signals and can transmit air conditioner emergency signals to other devices.

Fire alarm input

RS- 485

Digital I/O

Relay I/F

Intelligent

Server

TCS-Net

Relay I/F

Air conditioner

Main BUS

Ethernet

Door-lock input

Error output

Touch Screen

Controller

HUB

Ethernet

• Controls Air conditioners by

interlocking with input signals.

• Outputs Air conditioner error

to external devices.

15

Page 16

16

Page 17

2

SYSTEM CONFIGURATION

2-1 Touch screen controller system configuration

17

Page 18

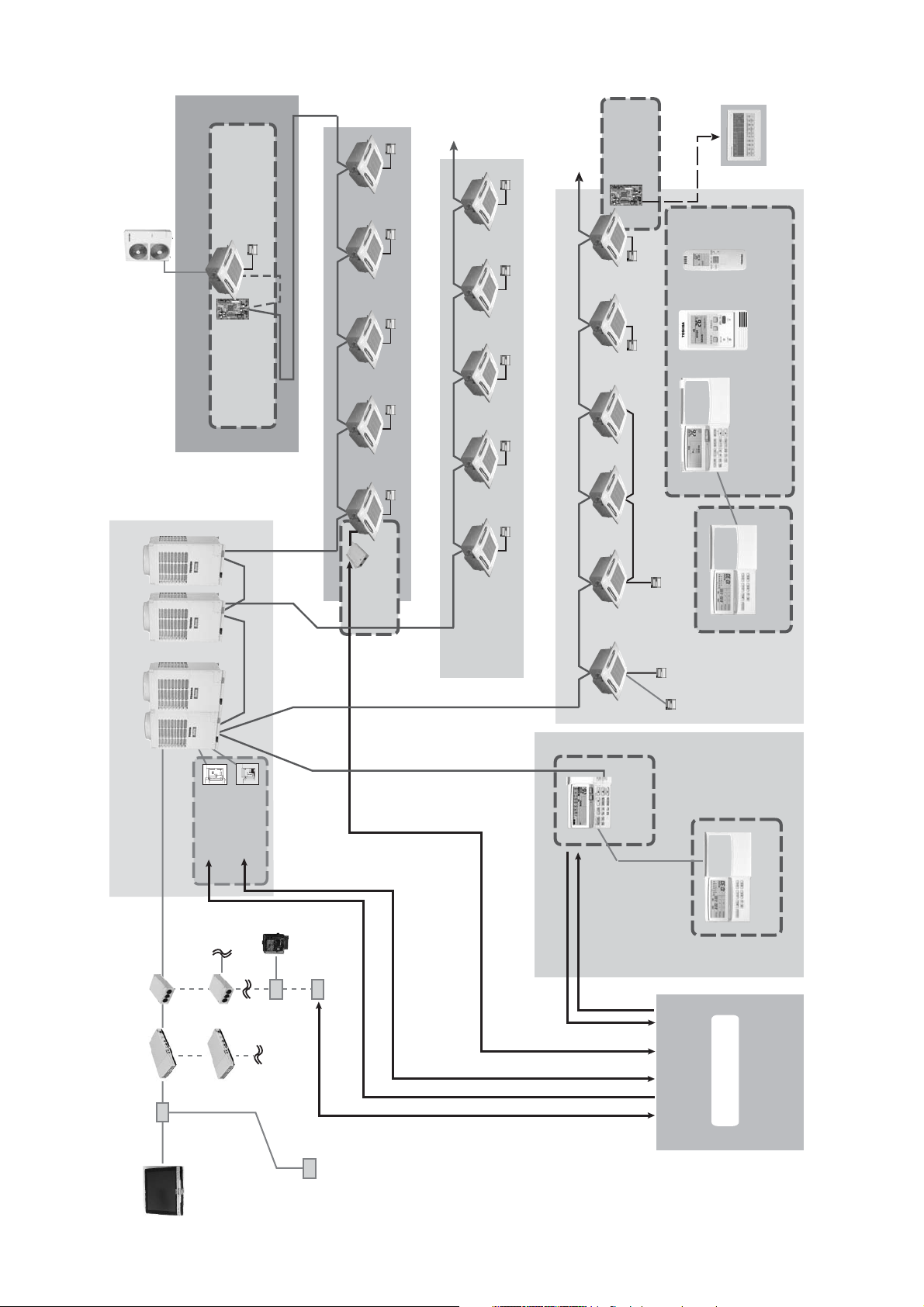

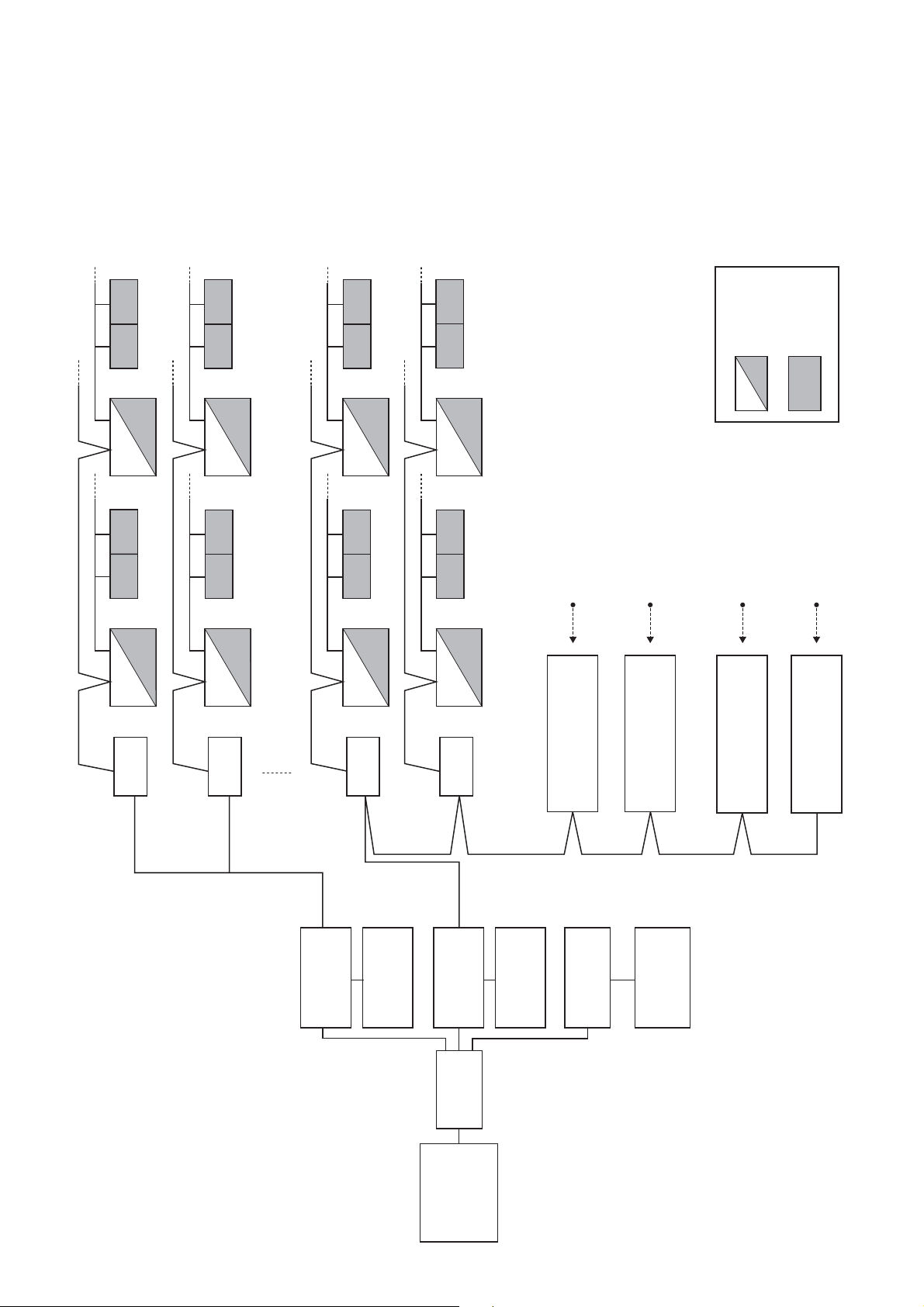

2-1 Touch screen controller system configuration

RS-485

Ethernet

Touch Screen Controller

(BMS-TP0640/5120)

InteIligent Server

(BMS-LSV2E)

Compact

Flash

TCS-NET

Relay I/F

(BMS-IFLSV1E)

Main Bus

Max. 64 air conditioners

per relay I/F

Max. 512 indoor

units (64 units x 8)

per Intelligent

Server

Intelligent Server Software

(BMS-STCC01E)

(*) A Switching HUB is required when using

two or more Intelligent Servers or when

connecting a PC for energy monitoring

and billing.

Switching HUB

PC for Energy

Monitoring and

billing

TCS-NET

Relay I/F

(BMS-IFLSV1E)

MAX 8 per

Intelligent server

Energy

Monitoring

Relay I/F

(BMS-IFWH3E)

Energy

Monitoring

Relay I/F

(BMS-IFWH3E)

MAX 4 per

Intelligent server

Main Bus

Max. 64 air conditioners

per relay I/F

Power meter 1

(with pulse generator)

Power meter 8

(with pulse generator)

Power meter 1

(with pulse generator)

Power meter 8

(with pulse generator)

Max. 8 power

meters per relay I/F

Max. 32 (8 x 4)

power meters per

Intelligent Server

Max. 8 power

meters per relay I/F

Digital I/O

Relay I/F

(BMS-IFDD01E)

Digital I/O

Relay I/F

(BMS-IFDD01E)

MAX 4 per

Intelligent server

Input contact 1

Input contact 8

Device 1

Device 4

Input contact 1

Input contact 8

Device 1

Device 4

Max. 8 input

contacts per

relay I/F

Max. 4 devices

per relay I/F

Max. 8 input

contacts per

relay I/F

Max. 4 devices

per relay I/F

Max. 32 (8 x 4)

digital inputs per

Intelligent Server

Max. 16 (4 x 4)

digital outputs

per Intelligent

Server

18

Page 19

System Configuration Table

...

(×

available –

...

not available)

Touch Screen Controller

Air conditioning monitoring/control

Energy monitoring and billing

Indoor units connected

Function

Intelligent Server

Intelligent Server Software

TCS-NET Relay I/F

Component

Energy Monitoring Relay I/F

Digital I/O Relay I/F

Switching HUB

Ethernet wire

PC

Power meter

*1:The number of ethernet wires and the number of switching HUB ports vary with the number of Intelligent Servers

connected.

*2:100 BASE-T compliant is required when using 5 or more servers, or 2 or more controllers.

*3:The number of power meters vary with power meter specifications.

• Two or more refirgerant systems can be connected to one power meter.

• For heat recovery VRF (SHRM) and “Super digital inverter”, “Digital inverter”, it is necessary to install the power meter

independently.

• All power meters connected to the same controller must be set to the same pulse generator constants.

BMS-LSV2E

BMS-STCC01E

BMS-IFLSV1E

BMS-IFWH3E

BMS-IFDD01E

Procured on site

Procured on site

Procured on site

Procured on site

BMS-TP0640ACE BMS-TP0640PWE BMS-TP5120ACE BMS-TP5120PWE

×

–×

Max. 64 units

1 unit

1 unit

Max. 8 units

– Max. 4 units

Max. 4 units

Comply with 10BASE-T

1

*

Number of ports: As required

Category 5 UTP straight wire

OS: Windows 2000 or newer, Excel 2000 or newer

Pulse output type

Pulse generator constants:

3

1 kWh/pulse or 10 kWh/pulse

*

Pulse duration: 50 - 1000 ms

Output terminal: ON/OFF contactor

2

*

–×

1 unit per Intelligent Server

(max. 4 units in total)

Up to 8 units per Intelligent Server

(max. 32 units in total)

– Max. 4 units

×

Max. 512 units

Max. 4 units

Max. 4 units

19

Page 20

System configuration examples

The following lists detail the required component devices for each category.

1. Without energy monitoring

(A) Up to 64 indoor units

Device

Touch Screen Controller

Intelligent Server

Intelligent Server Software

TCS-NET Relay Interface

Digital I/O Relay Interface

Ethernet wire

(B) Up to 512 indoor units

Model

BMS-TP0640ACE

BMS-LSV2E

BMS-STCC01E

BMS-IFLSV1E

BMS-IFDD01E

Procured on site

Quantity

1

1

1

Max. 8

Max. 4

1

*

Up to 8 units per Intelligent Server

Category5 UTP cross cable

Remarks

Device

Touch Screen Controller

Intelligent Server

Intelligent Server Software

TCS-NET Relay Interface

Digital I/O Relay Interface

Ethernet wire

Switching HUB

2. With energy monitoring

(A) Up to 64 indoor units

Device

Touch Screen Controller

Intelligent Server

Intelligent Server Software

TCS-NET Relay Interface

Energy Monitoring Relay

Interface

Digital I/O Relay Interface

Ethernet wire

Switching HUB

PC

Power meter

Model

BMS-TP5120ACE

BMS-LSV2E

BMS-STCC01E

BMS-IFLSV1E

BMS-IFDD01E

Procured on site

Procured on site

Model

BMS-TP0640PWE

BMS-LSV2E

BMS-STCC01E

BMS-IFLSV1E

BMS-IFWH3E

BMS-IFDD01E

Procured on site

Procured on site

Procured on site

Procured on site

Quantity

1

Max. 4

Max. 4

Max. 32*

Max. 16*

1

*

1

Quantity

1

1

1

Max. 8

Max. 4

Max. 4

1

*

1

1

5

*

Remarks

Same quantity as Intelligent Server

required

2

*2 Up to 8 units per Intelligent Server

3

*3 Up to 4 units per Intelligent Server

Category5 UTP straight cable

10 BASE-T compliant *

4

number of ports: As required

Remarks

Up to 8 units per Intelligent Server

Category5 UTP straight cable

10 BASE-T compliant *

4

number of ports: As required

OS: Windows 2000 or newer

Excel: Excel 2000 or newer

Pulse output type

Pulse generator constants:

1kWh/pulse or 10kWh/pulse

Pulse duration: 50 - 1000 ms

Output terminal: ON/OFF contactor

20

Page 21

(B) Up to 512 indoor units

Device

Touch Screen Controller

Intelligent Server

Intelligent Server Software

TCS-NET Relay Interface

Energy Monitoring Relay

Interface

Digital I/O Relay Interface

Ethernet wire

Switching HUB

PC

Model

BMS-TP5120PWE

BMS-LSV2E

BMS-STCC01E

BMS-IFLSV1E

BMS-IFWH3E

BMS-IFDD01E

Procured on site

Procured on site

Procured on site

Quantity

1

Max. 4

Max. 4

Max. 32*

Max. 16*

Max. 16*

1

*

1

1

Same quantity as Intelligent Server

required

2

*2 Up to 8 units per Intelligent Server

*3 Up to 4 units per Intelligent Server

3

3

*3 Up to 4 units per Intelligent Server

Category5 UTP straight cable

10 BASE-T compliant *

number of ports: As required

OS: Windows 2000 or newer

Excel: Excel 2000 or newer

Remarks

4

Pulse output type

Pulse generator constants:

Power meter

Procured on site

5

*

1kWh/pulse or 10kWh/pulse

Pulse duration: 50 - 1000 ms

Output terminal: ON/OFFcontactor

*1 The number of ethernet wires and the number of switching HUB ports vary with the number of Intelligent servers

connected.

*4 100BASE-T compliant HUB is required when using 5 or more servers, or 2 or more controllers.

*5 The number of power meters vary with power meter specifications.

• Two or more refirgerant systems can be connected to one power meter.

• For heat recovery VRF (SHRM) and “Super digital inverter”, “Digital inverter”, it is necessary to install the power meter

independently.

• All power meters connected to the same controller must be set to the same pulse generator constants.

21

Page 22

22

Page 23

3

INSTALLATION

3-1 Installation work flow

3-2 Setup file data preparation

3-2-1 Control wiring diagram (Connection example)

3-2-2 Power meter wiring diagram (Connection example)

3-2-3

3-2-4 Schedule table

3-3 Setup file creation

3-3-1 Setup file creation software (Excel macro)

3-3-2 Setup file contents

3-4 Control system Installation

3-4-1 External view

3-4-2 Installation method

3-4-3 Device specifications

3-5 Wiring

3-5-1 Wiring specifications

3-5-2 Wiring diagram

3-6 Network connection

3-7 Control system configuration

Air conditioner address table

23

Page 24

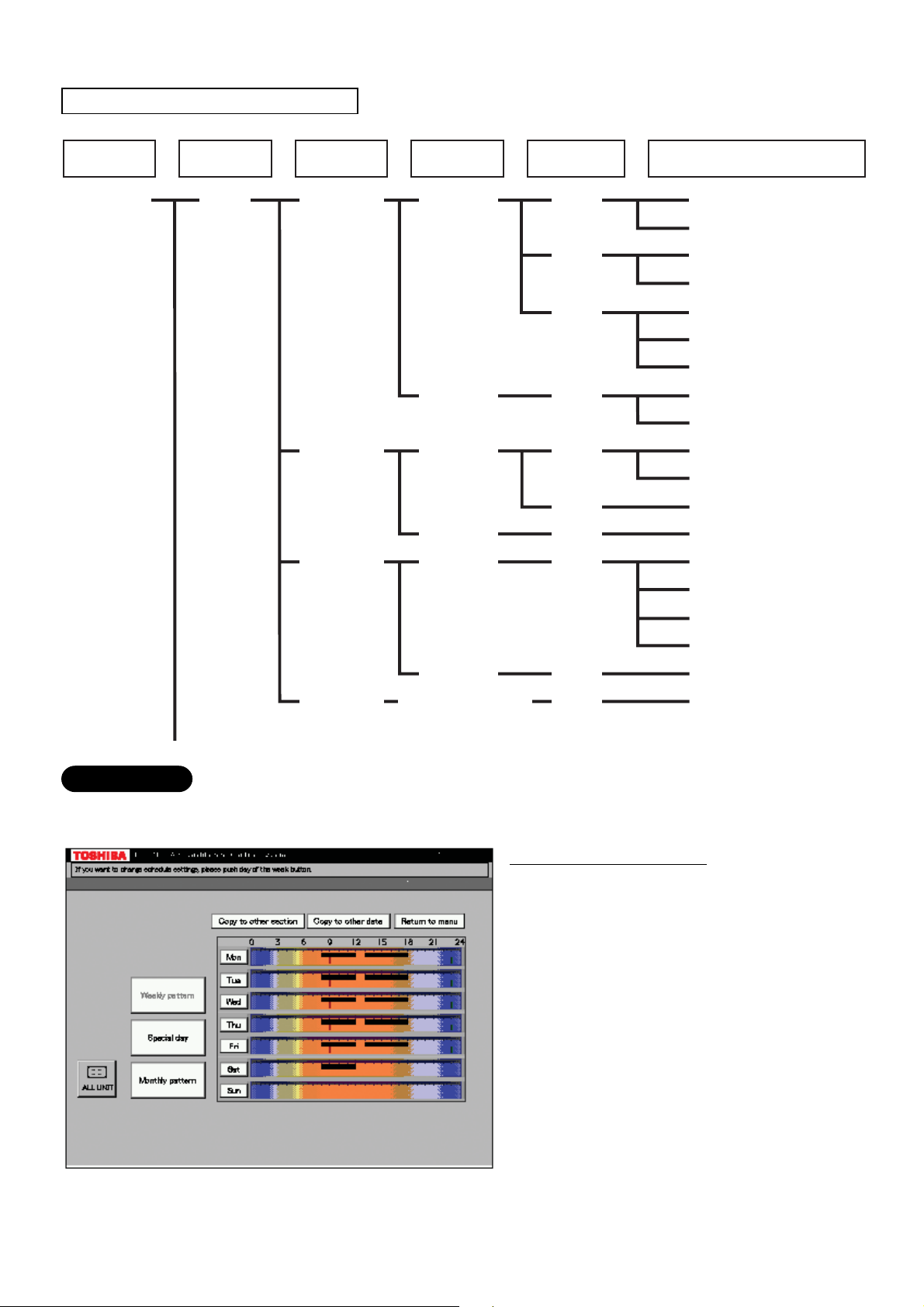

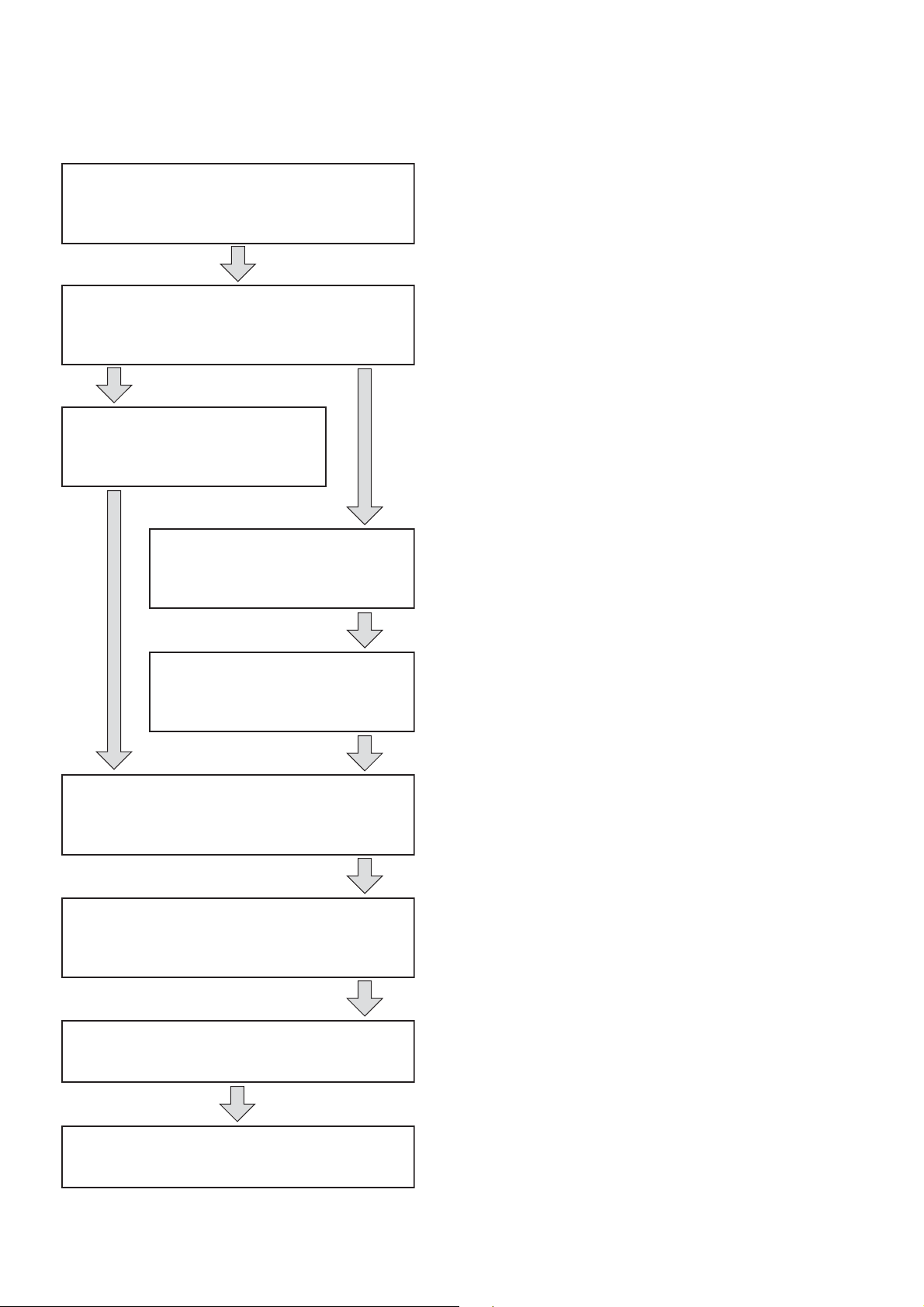

3-1 Installation work flow

Work flow

0. System planning

1. Setup file data preparation

2. Setup file creation

3. On site installation

(Construction work)

Contents Reference No.

Air conditioner equipment

selection

Control system device selection

System wiring diagram

Power meter wiring diagram

Address list

Schedule list

Create setup files by excel macro

software

Control system installation

Chapter. 2

3-2

3-3

3-4

4. On site installation

(Wiring)

5. On site installation

(Control system configuration)

6. On site installation

(Address setting)

7. Trial operation and adjustment

Wiring power cable/

communication line

Network connection

Energy monitoring PC

configuration

Intellignet server configuration

Setup file installation

Air conditioner address setting

Control system device address

setting

3-5

3-6

3-7

Chapter. 4

Chapter. 5

8. Commissioning

24

Page 25

3-2 Setup file data preparation

Before starting the installation, prepare the materials for creating the setting files.

• Control wiring diagram

• Power meter wiring diagram

• Air conditioner address table

• Schedule table

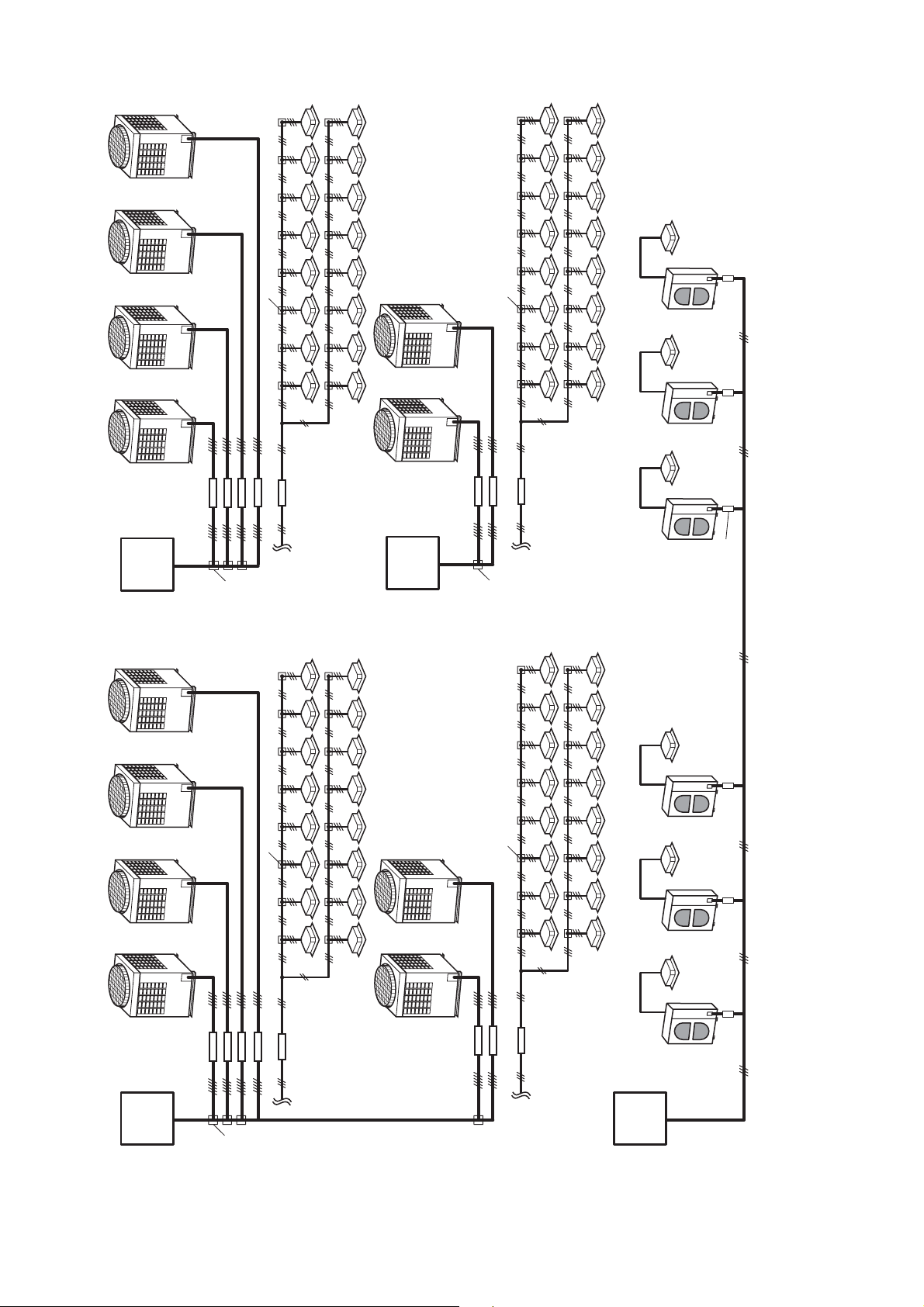

3-2-1 Control wiring diagram (Connection example)

U1,U2

Main BUS

U3,U4

U1,U2 U1,U2 U1,U2 U1,U2

U3,U4

BMS-

IFLSV1E

U1,U2 U1,U2

U3,U4

U1,U2 U1,U2

U3,U4

BMS-

IFLSV1E

U1,U2 U1,U2

U3,U4

U1,U2

U1,U2

U3,U4

BMS-

IFLSV1E

U1,U2

U3,U4

U1,U2

U1,U2

U3,U4

BMS-

IFLSV1E

8 door-lock control signal inputs

BMS-IFDD01E

Relay Interface

Digital Input/Output

8 fire alarm inputs

BMS-IFDD01E

Relay Interface

Digital Input/Output

Outdoor unit

8 power meter inputs

BMS-IFWH3E

Relay Interface

Energy Monitoring

Indoor unit

8 power meter inputs

Relay Interface

Energy Monitoring

BMS-IFWH3E

16th floor

15th floor

TCS-NET Relay Interface

TCS-NET Relay Interface

2nd floor

9th-16th

floor

Server

Intelligent

BMS-LSV2E

1st floor

TCS-NET Relay Interface

software

BMS-STCC01E

Intelligent server

TCS-NET Relay Interface

1st-8th

Server

Intelligent

BMS-LSV2E

HUB

Switching

Touch Screen

Controller

25

floor

software

BMS-STCC01E

Intelligent server

PC for creating

monthly reports

Printer

Page 26

Isolator

Isolator

SMMS

Power meter No.2

Isolator

Isolator

Power meter No.3

SHRM

Isolator

Isolator

Isolator

” it is necessary to install the power meter independently.

2

*1: Super digital inverter

” “DI*

1

*2: Digital inverter

Power meter No.1

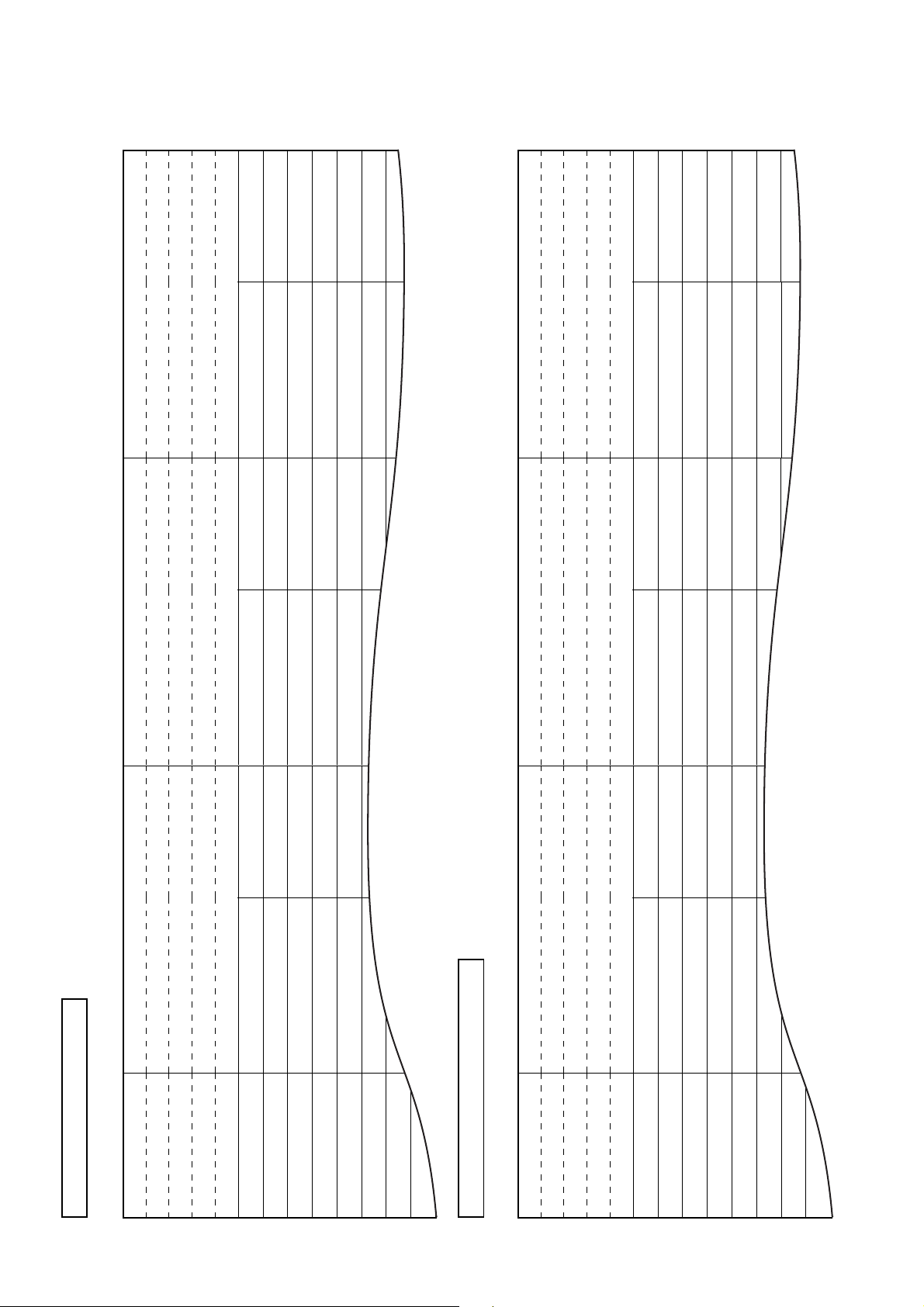

3-2-2 Power meter wiring diagram (Connection example)

SMMS

Isolator

SMMS

26

SDI SDI DI DI DI

SDI

Power meter No.4

• Two or more refirgerant systems can be connected to one power meter.

• For heat recovery VRF (SHRM) and “SDI*

• All power meters connected to the same controller must be set to the same pulse generator constants.

Page 27

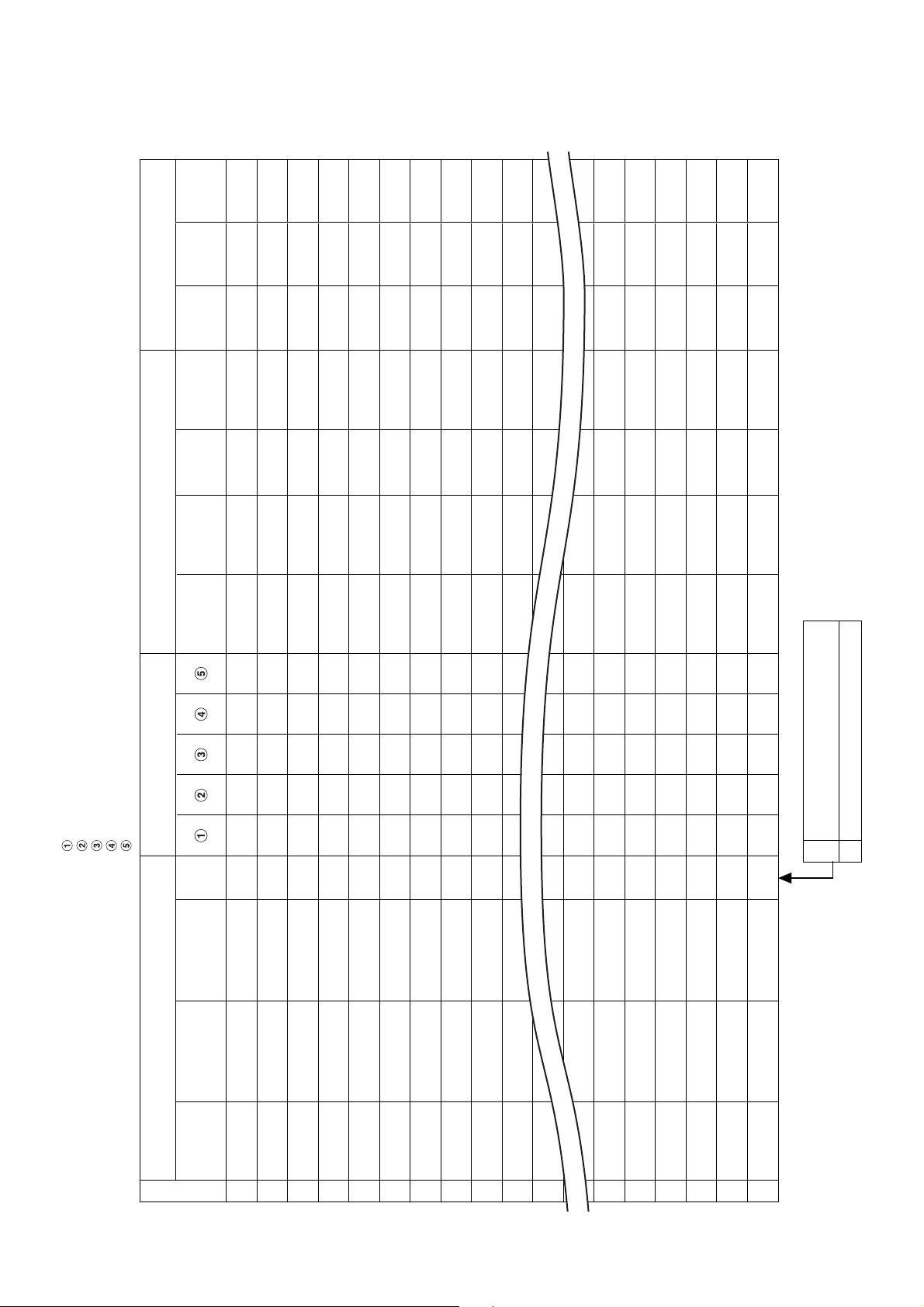

3-2-3 Air conditioner address table

No.

Fire alarm

No.

Key input

Power meter No. and

Input/Output data No.

Power

meter No.

unit

R.C. group/

Area

name

name

Tenant

Block

Address Information Display name

Intelligent Server address

TCS-NET relay I/F address

Line address

Indoor unit address

Group address

Header

Indoor unit

Air Conditioner List

Outdoor unit

name

unit

model name

model name

Header indoor unit of group control.

Indoor unit on individual control.

Follower indoor unit of group control.

1

0

system

Outdoor

refrigerant

• Building name:

1

2

3

4

5

6

7

8

9

10

11

12

15

16

17

18

19

20

27

Page 28

(Example)

No.

Fire alarm

No.

Key input

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

2

Power meter No. and

Input/Output data No.

Power

R.C. group/

Area

Tenant

Block

1

meter No.

unit

PAC-B • 1F-1

name

Shop A

name

Tenant A

1F

name

1

1

1

PAC-B • 1F-1

Shop A

Tenant A

1F

2

2

1

1

PAC-B • 1F-1

PAC-B • 1F-1

Shop A

Shop A

Tenant A

Tenant A

1F

1F

2

2

3

4

1

1

PAC-B • 1F-1

PAC-B • 1F-2

Shop A

Shop B

Tenant A

Tenant B

1F

1F

2

0

5

6

1

1

1

PAC-B • 1F-3

PAC-B • 1F-4

Shop C

Shop D

Tenant B

Tenant B

1F

1F

0

0

7

8

1

2

PAC-B • 1F-5

PAC-M • 1F-1

Shop E

Shop F

Tenant B

Tenant C

1F

1F

0

0

9

1

2

2

PAC-M • 1F-2

PAC-M • 1F-3

Shop F

Shop G

Tenant C

Tenant C

1F

1F

0

0

2

3

2

2

PAC-M • 1F-4

PAC-M • 1F-5

Office

Shop G

Office A

Tenant C

1F

1F

0

0

4

5

2

2

2

PAC-M • 1F-6

PAC-M • 1F-7

Office

Meeting room

Office A

Office A

1F

1F

0

0

6

7

2

3

PAC-S • 2F-1

PAC-M • 1F-8

A

Meeting room

Office A

Shared space

1F

2F

0

1

8

1

3

B

2F

2

2

3

3

PAC-S • 2F-2

Shop H

Tenant D

2F

0

3

Address Information Display name

Intelligent Server address

TCS-NET relay I/F address

Line address

Indoor unit address

Group address

unit

Header

Indoor unit

model name

Air Conditioner List

model name

Outdoor unit

Outdoor

refrigerant

• Building name: XXX Building

1

MMU-AP0091H

system

1

0

0

0

MMU-AP0091H

MMU-AP0091H

MMU-AP0091H

2

3

4

1

1

0

1

1

MMK-AP0091H

MMU-AP0091H

MMY-AP1401HT8

PAC-B

5

MMK-AP0091H

6

7

1

1

1

MMK-AP0091H

MMK-AP0091H

MMK-AP0091H

8

9

10

1

1

1

1

1

MMK-AP0091H

MMK-AP0091H

MMK-AP0091H

MMY-AP1401HT8

PAC-M

11

12

13

1

1

1

MMK-AP0091H

MMK-AP0091H

MMK-AP0091H

14

15

16

1

1

1

1

0

MMK-AP0091H

MMK-AP0091H

MMK-AP0091H

MMY-AP1401HT8

PAC-S

17

18

19

Header indoor unit of group control.

Indoor unit on individual control.

Follower indoor unit of group control.

1

0

1

MMK-AP0091H

20

28

Page 29

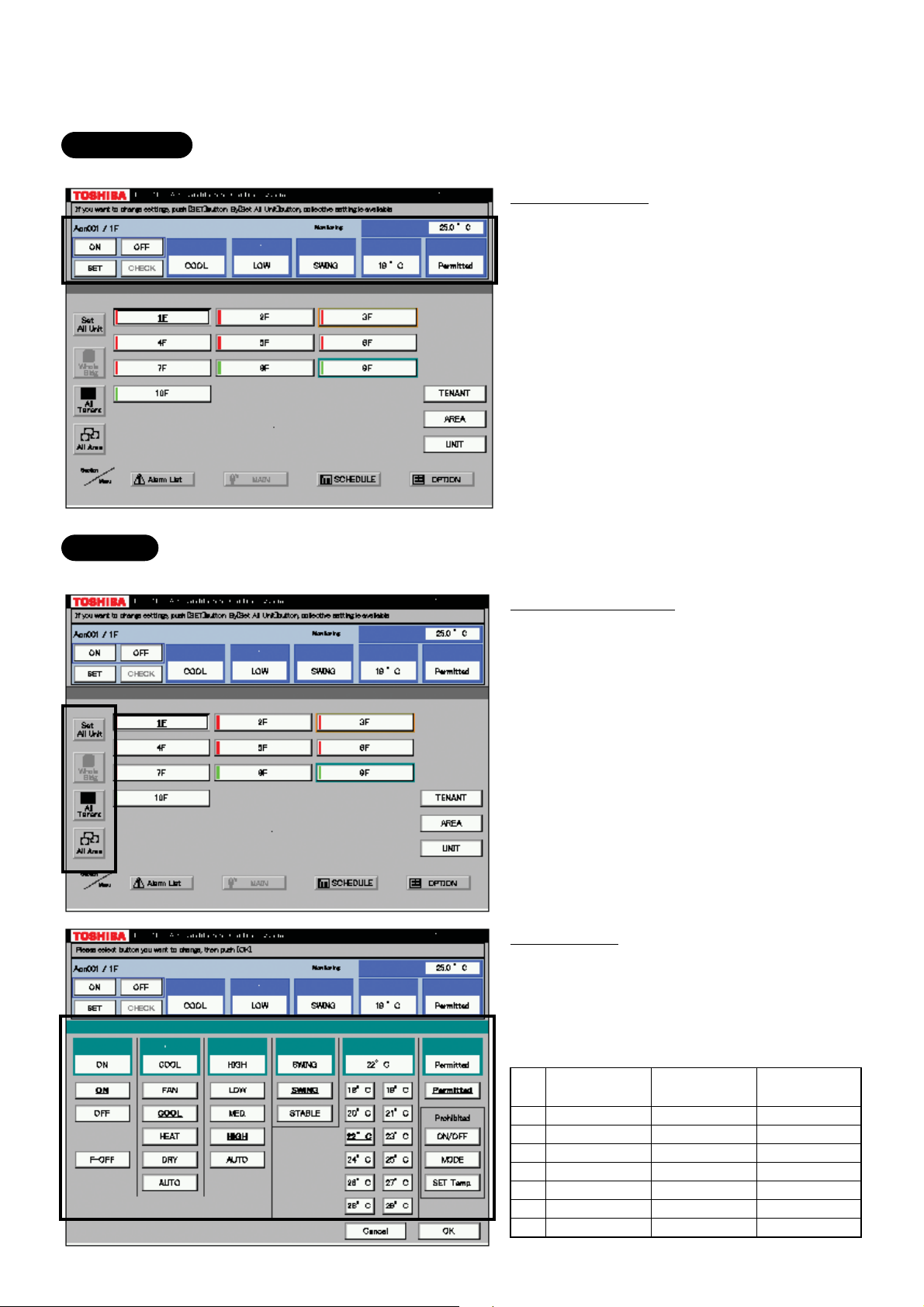

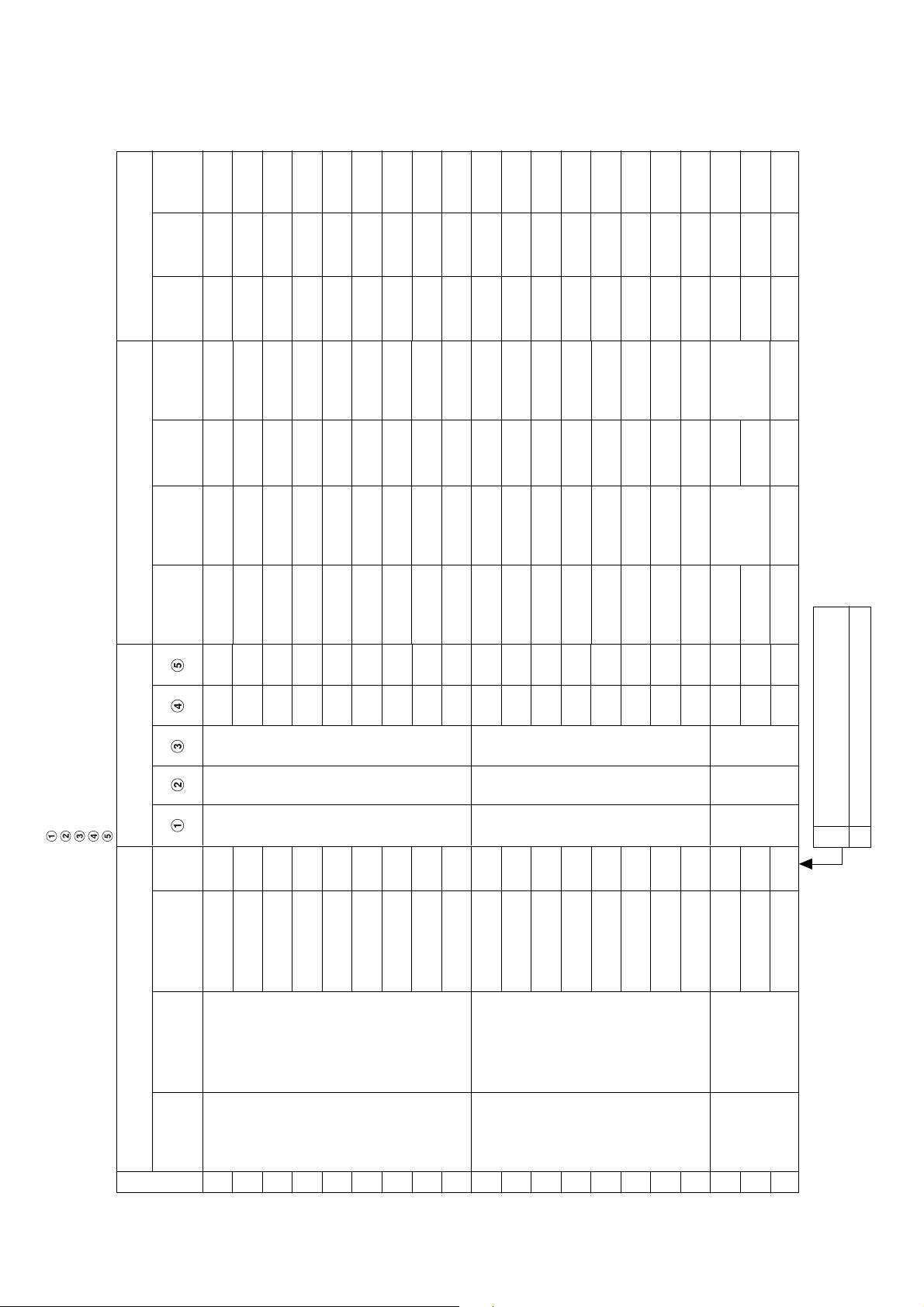

3-2-4 Schedule table

Run

Stop

:

:

:

:

:

:

:

:

PAC-B, 1F-6

Night-duty room

B1

8:00

9:30

Monday to Saturday

Run

Stop

Stop

10:00

Run

Run

16:30

Stop

Stop

22:00

Stop

Stop

23:58

:

:

:

:

:

:

:

:

:

:

PAC-B, 1F-3 to 1F-5

Warehouse

XX Electric Co., Ltd.

B1

:

:

:

:

:

:

:

:

PAC-B, 1F-1

Consultation room

XX Dental Clinic

B1

8:00

12:00

13:00

19:00

Monday to Friday

Run

Stop

Stop

8:00

19:00

Monday to Saturday

:

21:00

21:00

:

:

:

:

:

:

:

Schedule Table ( / )

R.C. group/unit

Area

• Building name:

Tenant

1

Block

Day of the week

2

3

4

5

6

7

8

Schedule Table (Example)

R.C. group/unit

Area

Tenant

• Building name: XXX Building

Block

1

2

3

Day of the week

4

5

6

7

8

29

Page 30

3-3 Setup file creation

Create setup files according to the control wiring system diagram and the address table.

3-3-1 Setup file creation software (Excel macro)

• The setup file creation software is used to create setup files to be installed on the Touch Screen

Controller.

• In the air conditioning control system, setting values are defined in accordance with the air conditioner

installation conditions within the building. If a wrong value is set, a problem such as an interruption in

communication with the air conditioner will occur.

• Setting items: Air conditioner information, device information, Touch Screen Controller display

information.

• A operator enters details on the Excel spreadsheet and then creates 23 setup files using the information

entered.

Operating environment and others

Operating environment Windows 2000 or newer

OS

Excel

Excel 2000 or newer is required separately.

System Configuration

Setup file creation software for Touch Screen Controller

Excel

Provided from installation

company and building

Default data file

Product information file

Setup file

• Tenant name, etc.

• Air conditioner information, etc.

• Setting values for energy monitoring

and billing

Air conditioner specific characteristic values

Tenant names for reports

management company.

Setup file

Record on CF card

Air conditioner information

Location, indoor unit group setting,

control address (I/F, indoor, outdoor),

device type, product model, number

of devices

Device information

Power meter No., pulse constant,

fire alarm/door-lock input No.,

emergency output No.

Control display information

Block/area/tenant/R.C. Group, unit

names

Building operation information

Meter read date

Schedule (operation, charging)

Energy

monitoring I/F

Power meter

RS-485

Intelligent Server

TCS-NET

Relay I/F

Main BUS

Air conditioner

Touch Screen

Controller

Ethernet Ethernet

HUB

30

Set by scheduler function of

Touch Screen Controller.

Power

distribution

software

Printer

Page 31

3-3-2 Setup file contents

(1) Display setup file

• File name: DISP_FORM.DEF

•

Enter the entire building display mode, number of block display buttons, number of tenant display buttons,

number of area display buttons, number of R.C. group/indoor display buttons, and the schedule setting unit.

• For the entire building display mode, specify display unit when the entire building button is pressed.

[0: block, 1: tenant, 2: area, 3:

• For the number of buttons, enter the number of lateral buttons in each display mode. The number of

vertically arranged buttons is always 6.

• Specify schedule setting unit. [0: area, 1:

• Specify filter sign display mode. [0: no display, 1: display]

(2) Error code definition file

• File name: ERROR_CODE.DEF

• Enter reception code (hexadecimal), error code, error code name, display mode, and external

output.

• Specify display mode [0: no display (normal), 1: display].

• Specify external output [0: no output emergency, 1-64: emergency output No. (output to

corresponding number)].

(3) Touch Screen Controller IP address definition file

• File name: CONT_IP.DEF

• Enter the Touch Screen Controller IP address.

R.C. group/indoor

R.C. group/indoor

]

]

(4) Intelligent Server IP address definition file

• File name: LSV_IP.DEF

• Enter an Intelligent Server number and IP address.

(5) I/O Controller IP address definition file

• File name: IO_IP.DEF

• Enter the I/O Controller IP address.

• Only one address can be entered. Do not enter a IP address when the I/O Controller is not used.

(6) Building name definition file

• File name: BUILD_NAME.DEF

• Enter a building name.

(7) Block name definition file

• File name: BLOCK_NAME.DEF

• Enter a block number/name.

• Specify font size. [0 (small) -3 (large) 2 (standard)]

(8) Tenant name definition file

• File name: TENANT_NAME.DEF

• Enter tenant numbers/names (up to 512).

• Specify font size. [0 (small) -3 (large) 2 (standard)]

(9) Area name definition file

• File name: AREA_NAME.DEF

• Enter area numbers/names (up to 512).

• Specify font size. [0 (small) -3 (large) 2 (standard)].

(10) R.C. group/indoor name definition file

• File name: AC_NAME.DEF

• Enter

• Specify font size. [0 (small) -3 (large) 2 (standard)]

R.C. group/indoor

numbers/names (up to 512).

31

Page 32

(11) Door-lock input definition file

• File name: KEY_CH.DEF

• Enter door-lock input numbers (1-64), input device IDs, input channels, and signal logic (up to 64).

• When no door-lock input is used, do not enter.

• An input device ID means the following:

0 to 7: I/O module device ID

10: general-purpose input to the touch panel

100 or more: digital I/O interface (Second digit: Intelligent Server No., first digit: Relay Interface No.)

• Specify signal logic. [0: negative logic, 1: positive logic]

(12) Fire alarm input definition file

• File name: FIRE_CH.DEF

• Enter fire alarm input numbers (1-64), input device IDs, input channels, and signal logic (up to 64).

• When no fire alarm input is used, do not enter.

• An input device ID means the following:

0 to 7: I/O module device ID

10: general-purpose input to the touch panel

100 or more: digital I/O interface (Second digit: Intelligent Server No., first digit: Relay Interface No.)

• Specify signal logic. [0: negative logic, 1: positive logic]

(13) Emergency external output definition file

• File name: EMGOUT_CH.DEF

• Enter external emergency output numbers (1-64), output device IDs, and output channels (up to 64).

• When no external emergency output is used, do not enter.

• An output device ID means the following:

0 to 7: I/O module device ID

20: general-purpose output to the touch panel

100 or more: digital I/O interface (Second digit: Intelligent Server No., first digit: Relay Interface No.)

(14) R.C. group/indoor setup file

• File name: AC_MAP.DEF

• R.C. group/indoor No., Intelligent Server No., Relay Interface No., outdoor system No., indoor unit

address, device type, block No., tenant No., area No., key No., fire alarm No.

• Device type

0: SMMS, SHRM, 1: SDI, DI, 2: HA interface

•Key No.

0: no door-lock interlocking, 1-64: When a signal is input from the number defined in (11), a stop

command is sent to the system.

• Fire alarm No.

0: no fire alarm interlocking, 1-64: When a signal is input from the number defined in (12), a stop

command is sent to the system.

• Indoor unit set in this file is for the header unit only.

(15) Indoor unit group config file

• File name: AC_GROUP.DEF

•

R.C. group/indoor

address, device type, outdoor unit No., header/follower, tenant No.

• Used for energy monitoring and billing. No data is provided when energy monitoring and billing is not

performed.

(16) Outdoor unit group config file

• File name: OUT_GROUP.DEF

• Outdoor unit No., Intelligent Server No., Relay Interface No., system No., outdoor unit address,

device type

• Used for energy monitoring and billing. No data is provided when energy monitoring and billing is not

performed.

No., Intelligent Server No., Relay Interface No., outdoor system No., indoor unit

32

Page 33

(17) Power meter input definition file

• File name: WHM_CH.DEF

• Power meter No. (1-64), interface address, channel No., pulse generator constants

• Used for energy monitoring and billing. No data is provided when energy monitoring and billing is not

performed.

• An interface address means the following:

1 to 31: energy monitoring interface

100 or more: pulse counter interface (Second digit: Intelligent Server No., first digit: Relay Interface

No.)

• Pulse generator constants (kWh/pulse): Used by the energy monitoring and billing Excel macro

software, but not used by the controller.

(18) Report setup file

• File name: REPORT.DEF

• Daily report limit time (meter-read time), Monthly report limit date

(19) Operation mode setup file

• File name: RUN_MODE.DEF

• Operation mode range, scheduled operation central setting, door-lock interlocking central setting

• Operation mode range 0: all enabled, 16: cooling/dry/fan only, 32: heating/fan only

• Scheduled operation central setting

Setting

0

1

2

3

Stop (10 minutes later)

Stop

Stop + “run/stop” changeover

prohibition reset

Stop + “run/stop” changeover

prohibition reset

Stop + “run/stop” changeover

prohibition reset

Stop (within 10 minutes)

Stop

Stop + “run/stop” changeover

prohibition reset

Stop + “run/stop” changeover

prohibited

Stop + “run/stop” changeover

prohibited

Run

Run

Run + “run/stop” changeover

prohibition reset

“Run/stop” changeover

prohibition reset

Run + “run/stop” changeover

prohibition reset

• Door-lock interlocking central setting

Setting

0

1

2

3

* All these files must be included in the “¥DEF” folder.

Stop

Stop

Stop + “run/stop” changeover prohibited

Stop

Lock (OFF to ON)

Unlock (ON to OFF)

No operation

“Run/stop” changeover prohibition reset

“Run/stop” changeover prohibition reset

No operation

33

Page 34

3-4 Control system installation

3-4-1 External view

Touch Screen Controller

Model: BMS-TP0640ACE

BMS-TP5120ACE

BMS-TP0604PWE

BMS-TP5120PWE

CF (Compact Flash)

card slot (CF card for

data files)

Universal Input/

Output port

USB mouse

Ethernet port

Intelligent

Server

Power cable

54

549

242

99.3

M4 Tap (×4 pcs.)

(depth: 10 mm max.)

16

Power input

terminal block

82.5

48

75

302

PCI expansion unit

connector cover

70 75

55.5

19 30

POWER LED

Function switch (F1, F2, F3)

316

249

95.7591.75

256

unit: mm

34

Page 35

Intelligent Server

Model: BMS-LSV2E

Metal case type

Do not remove.

CAUTION

CF (Compact Flash)

card slot

Touch Screen Controller

(Ethernet)

WARNING

Do not decompose.

370

Not used

Relay Interface

(RS-485)

19839

42

Power switch

35

unit: mm

Page 36

TCS-NET Relay Interface

Model: BMS-IFLSV1E

Parts name

1

Case

2

Case lid

3

Grommet

4

Grommet

5

Grommet for power supply

Specifications

Galvanized sheet metal

Galvanized sheet metal

C30-SG20A

C30-SG20A

C30-SG20A

200

1

2

6- 5.5 mounting holes

22787822

66

63.6

3

4

170

146.9

5

22787822

156

unit: mm

36

Page 37

Energy monitoring R I/F • Digital I/O R I/F

Model: BMS-IFWH3E

BMS-IFDD01E

234

Grommet for

power input

1818 53.5 103.5

220

1818

Grommet for

power meter

92.5

(193)

Grommet for

RS-485

64.5

Grommet for DO

246

63.6

unit: mm

37

Page 38

3-4-2 Installation method

Touch Screen Controller

Make a space for the installation and service.

Install the Touch Screen Controller in a wall (standard) or on a dedicated stand (when available on site).

In-wall installation

■■

■Conditions for installation

■■

A space of 30 mm or more between the controller

and surrounding objects is required.

Panel

30 mm or more (top)

30 mm or more (bottom)

30 mm or more (rear)

Top view

30 mm or more (side)

Interface side

Panel

■■

■Attaching Fixture

■■

■Panel cut size

+1

303

-0

R1 or less

REQUIREMENT

+1

-0

Use a panel

243

(procured on site)

with a thickness of

1.6-1.7 mm.

Panel thickness: 1.6 -1.7 mm

[mm]

1. Insert the controller from the outside of the panel.

2. Insert the fixtures from the inside of the panel.

Touch Screen

Controller

Panel

Fixture

Bottom view

For reference

Display stand (not supplied with the controller)

Use a CONTEC stand (model: IPC-SND-03).

For details of the stand, visit the CONTEC web site.

Europe: http://www.contec-europe.com

China: http://www.contec.sh.cn

REQUIREMENT

• Check that the installation dimensions on the rear of the

Touch Screen Controller match the installation

dimensions on the CONTEC stand.

• Use the screws supplied with the stand to install the

controller.

38

Tightening screws excessively

may cause the screws to break.

Optimum tightening torque is

0.6N/m.

75 mm

75 mm

Angle adjustment lock screw.

(Loosen the screw and adjust angle.)

Page 39

Intelligent Server Installation Method and Orientation

There are four ways to install the Intelligent Server as shown below: (1) rack mount (2) surface mount (3)

wall mount A, and (4) wall mount B. The rack mount installation requires a support bracket for a 19-inch

rack. Please contact distributor if you need the support bracket.

Use the four bottom screw holes for the wall mount installation.

(1)Rack mount

A support bracket is required to be

fixed to the bottom (rear side) of the

unit.

(3)Wall mount -A

Wall mount with the front side upwards

(2)Surface mount

Standard installation

(4)Wall mount -B

Wall mount with the left side upwards

(Unit: mm)

AC inlet side

308.4 30.830.8

LED side

Screw hole for wall

mount (M4 × 4 pcs.)

30 133 35

REQUIREMENT

Do not install the unit in any of the following places.

• Humid or wet place

• Dusty place

• Place exposed to direct sunlight

• Place where there is a TV set or radio within one meter

• Place exposed to rain (outdoors, under eaves, etc.)

39

Page 40

TCS-NET Relay Interface

■■

■Installation Method and Orientation

■■

There are five installation methods for this relay interface as shown below: surface mount and wall mount.

Use the supplied screws.

No good

REQUIREMENT

Do not install the unit in any of the following places.

• Humid or wet place

• Dusty place

• Place exposed to direct sunlight

• Place where there is a TV set or radio within one meter

• Place exposed to rain (outdoors, under eaves, etc.)

■■

■Installation Space and Maintenance Space

■■

Ensure a minimum space of 100mm is left at the side and top of the device

for connecting cables to enter the cable inlets and maintenance of the

device. As shown in the figure.

The other sides can be directly adjacent to surrounding objects.

100mm

100mm

Energy monitoring Relay I/F • Digital I/O Relay I/F

■■

■Installation Method and Orientation

■■

There are five installation methods for this relay interface as shown below: surface mount and wall mounts.

Use the supplied screws.

No good

REQUIREMENT

Do not install the unit in any of the following places.

• Humid or wet place

• Dusty place

• Place exposed to direct sunlight

• Place where there is a TV set or radio within one meter

• Place exposed to rain (outdoors, under eaves, etc.)

■■

■Installation Space and Maintenance Space

■■

Ensure a minimum space of 100mm is left at the two sides and top of

the device for connecting cables to enter the cable inlets and

maintenance of the device. As shown in the figure.

The other sides can be adjacent to surrounding objects.

40

100mm

100mm

100mm

Page 41

3-4-3 Device specifications

Touch Screen Controller

Device, model

Touch Screen

Controller

BMS-TP0640ACE

BMS-TP5120ACE

BMS-TP0640PWE

BMS-TP5120PWE

Intelligent Server

Device, model

Intelligent Server

BMS-LSV2E

Relay Interface

Device, model

TCS-NET

Relay Interface

BMS-IFLSV1E

Item

Power supply

Power consumption

External dimensions

Weight

Ambient temperature

Ambient humidity

Item

Power supply

Power consumption

External dimensions

Weight

Ambient temperature

Ambient humidity

Item

Power supply

Power consumption

External dimensions

Weight

Ambient temperature

Ambient humidity

Chassis material

Specification

100 - 240 V, AC 50/60 Hz

50 VA

316 (W) x 256 (H) x 54 (D) mm

3.5 kg

0 to 40 °C

20 to 85%RH

Specification

85 - 132 V, 180 - 264 V, AC 50/60 Hz

30 VA

370 (W) x 42 (H) x 198 (D) mm

2.5 kg

0 to 40 °C

10 to 90%RH

Specification

220 - 240 V, AC 50/60 Hz

2.4 W

170 (W) x 66 (H) x 200 (D) mm

1 kg

0 to 40 °C

10 to 90%RH (no condensation)

Galvanized sheet metal 0.8t (no coating)

Energy Monitoring Interface

Device, model

Power supply

Power consumption

Energy monitoring

Relay Interface

BMS-IFWH3E

External dimensions

Weight

Ambient temperature

Ambient humidity

Chassis material

Digital I/O Interface

Device, model

Power supply

Power consumption

Digital I/O Relay

Interface

BMS-IFDD01E

External dimensions

Weight

Ambient temperature

Ambient humidity

Chassis material

Item

Item

Specification

220 - 240 V, AC 50/60 Hz

2.8 W (Energy monitoring)

193 (W) x 66 (H) x 246 (D) mm

1.65 kg

0 to 40 °C

10 to 90%RH

Galvanized sheet metal 0.8t

Specification

220 - 240 V, AC 50/60 Hz

6.5 W

193 (W) x 66 (H) x 246 (D) mm

1.65 kg

0 to 40 °C

10 to 90%RH

Galvanized sheet metal 0.8t (no coating)

41

Page 42

3-5 Wiring

3-5-1 Wiring specifications

Power supply specifications

Device Input voltage

Touch Screen Controller

Intelligent Server

TCS-NET Relay Interface

Energy Monitoring Relay Interface

Digital I/O Relay Interface

100 - 240 V, AC 50/60 Hz

85 - 132 V, AC 50/60 Hz

180 - 264 V, AC 50/60 Hz

220 - 240 V, AC 50/60 Hz

Power

consumption

50 VA

30 VA

2.4 W

2.8 W

6.5 W

Power cable

wire size

0.75 mm

2

Remarks

Procure on site

Communication wiring specifications

Inter-device connection

Intelligent Server ↔ TCS-NET

Relay Interface

Intelligent Server ↔ Energy

Monitoring Relay Interface

Intelligent Server ↔ Digital I/O

Relay Interface

TCS-NET Relay Interface ↔ Air

conditioner

Energy Monitoring Relay Interface

↔ Power Meter

Digital I/O Relay Interface ↔ Digital

Input/Output

*1: Use the D-sub (9 pin) wire supplied with the Intelligent Server software. If the length is to short, use a shielded wire.

*2: Total length per TCS-NET Relay Interface

Control wiring

specifications

D-sub (9-pin) wire *

(If length is short) Use a

shield wire

Shield wire

Shield wire

Shield wire

Shield wire

1

Number of

cores

4

2

2

2

2

2

2

2

Diameter

2

(mm

)

2

1.25 mm

2

1.25 mm

2

1.25 mm

2

1.25 mm

2

2.0 mm

2

0.3 mm

2

0.3 mm

Length

(m)

Max. 500

Max. 500

Max. 500

Max.1000*

Max.2000*

Max. 100

Max. 100

Polarity

With polarity

With polarity

With polarity

2

No polarity

2

No polarity

No polarity

With polarity

Remarks

Supplied with

Intelligent

Server software

Procure on site

Procure on site

Procure on site

Procure on site

Procure on site

Procure on site

Procure on site

Ethernet wire specifications

When Switching HUB is not used

Inter-device connection

Touch Screen Controller ↔

Intelligent Server

Control wiring

specifications

Ethernet (cross)

Category 5 UTP cross wire

When Switching HUB is used

Inter-device connection

Touch Screen Controller ↔

Switching HUB

Switching HUB ↔ Intelligent

Server

Control wiring

specifications

Ethernet (straight)

Category 5 UTP straight wire

Ethernet (straight)

Category 5 UTP straight wire

Number of

cores

Number of

cores

42

8

8

8

Diameter

2

(mm

)

–

Diameter

2

(mm

)

–

–

Length

(m)

Max. 100

Length

(m)

Max. 100

Max. 100

Polarity

–

Polarity

–

–

Remarks

Procure on site

Remarks

Procure on site

Procure on site

Page 43

3-5-2 Wiring diagram

Yellow

Brown

B

A

Red

Orange

Crimp 3 wires with a closed

end wire connector.

A

B

Red/Orange

Brown/Yellow

Power supply

Power supplyPower supplyPower supplyPower supplyPower supply

FG

U1U2

TCC-LINK

ABLNLNLNLNLN LN

FG

U1U2

TCC-LINK

AB

SW6

ON

TCC-LINK

TERMINATOR

12

SW5

RS-485

ON

TERMINATOR

1

2

RS-485

TCS-NET RELAY

INTERFACE

SW6

ON

TCC-LINK

TERMINATOR

12

SW5

ON

RS-485

TERMINATOR

1

2

RS-485

TCS-NET RELAY

INTERFACE

ADDRESS

ADDRESS

U4U3

U2U1

Outdoor

unit

SW1

8

U2U1

U2U1

Indoor unit

Remote

controller

U4U3

U2U1

Outdoor

unit

SW1

1

U2U1

Remote

controller

U2U1

Indoor unit

Outdoor

unit

Indoor unit

Remote

controller

Outdoor

unit

Indoor unit

Remote

controller

U4U3

U2U1

U2U1

U4U3

U2U1

U2U1

U4U3

Indoor unit

U4U3

Indoor unit

Central remote

controller

Central remote

controller

INTELLIGENT SERVER

(BMS-LSV2E)

TOUCH SCREEN CONTROLLER

(BMS-TP0640/5120)

SW1

4

ADDRESS

DIGITAL I/O

INTERFACE

(BMS-IFDD01E)

SW1

1

ADDRESS

DIGITAL I/O

INTERFACE

(BMS-IFDD01E)

SW1

4

ADDRESS

DI 1

DI 2

DI 3

DI 4

DI 5

DI 6

DI 7

DI 8

DI 1

DI 2

DI 3

DI 4

DI 5

DI 6

DI 7

DI 8

DI 1

DI 2

DI 3

DI 4

DI 5

DI 6

DI 7

DI 8

Input contact 1

Input contact 2

Input contact 3

Input contact 4

Input contact 5

Input contact 6

Input contact 7

Input contact 8

B

RS-485

A

DO1

DO2

DO3

DO4

GND

+12V

B

RS-485

A

DO1

DO2

DO3

DO4

GND

+12V

Load 1

Load 2

Load 3

Load 4

Input contact 1

Input contact 2

Input contact 3

Input contact 4

Input contact 5

Input contact 6

Input contact 7

Input contact 8

Load 1

Load 2

Load 3

Load 4

Power meter 1

Power meter 2

Power meter 3

Power meter 4

Power meter 5

Power meter 6

Power meter 7

Power meter 8

TOUCH SCREEN CONTROLLER CONNECTION DIAGRAM

ENERGY

MONITORING

INTERFACE

SW1

1

ADDRESS

ENERGY

MONITORING

INTERFACE

43

DI 1

DI 2

DI 3

DI 4

DI 5

DI 6

DI 7

DI 8

B

RS-485

A

Power meter 1

Power meter 2

Power meter 3

Power meter 4

Power meter 5

Power meter 6

Power meter 7

Power meter 8

B

RS-485

A

Page 44

CAUTION

ON

1 2

ON

1 2

polarity. Connect A to A, and B to

B. If connected with incorrect

polarity, the unit will not work.

• The RS-485 signal lines have

SW1

4

LED4

LED3

SW2 SW3

LED2

SW7 LED1

SW4

N

O

2

1

3

LED5

• The Main BUS signal lines have

35 10

no polarity.

REQUIREMENT

Install a breaker at the primary side

of the power supply.

Connect the shielded wire of the

RS-485 communication wire to the

earth on the Intelligent server side.

Do not connect the shielded wire

to the terminal block. It should be

Connect the shielded wire of the

Main BUS communication wire to

the earth on the air conditioner

side. Do not connect the shielded

wire to the terminal block. It should

Connections (TCS-NET RELAY INTERFACE (BMS-IFLSV1E)

Connect power cables earth wires and signal cables to the specified terminals on the terminal block.

open and insulated.

SW6

ON

FG

be open and insulated.

Air conditioner

Secure each cable

with a cable clamp.

12

SW5

ON

TCC- LINK

U2 U1

Intelligent server

12

RS-485

BA

LN

Power supply

Connect the earth

wire to the earth

terminal on the

chassis.

Length of stripped RS-485

communication wire

L

N

35 10

Length of stripped power

cable

55 10

44

Page 45

U4U3

U4 U3

Outdoor

unit

Central

remote controller

U2 U1

U2 U1

Indoor

unit

U2 U1

Remote

controller

U4U3

U4 U3

Outdoor

unit

Central

remote controller

U2 U1

U2 U1

Indoor

unit

U2 U1

Remote

controller

Main BUS terminator resistor is set on the air conditioner

side. Bit 1 and 2 of SW6 should be OFF.

Set the RS-485 terminator resistor on the No.1 (relay

interface address SW1=1) unit and the Intelligent Server

only. Do not set it here.

SW6

ON

The shield of Main BUS

cable should be open

and insulated. It is not

connected to the

terminal block.

Main BUS U1 and U2

have no polarity.

FG

2

1

U1U2

U4U3

Outdoor

unit

2

1

SW5

ON

RS-485

AB

TCC-LINK

A

B

Brown/Yellow

Red/Orange

U2 U1

Indoor

SW1

8

ADDRESS

U2 U1

unit

Indoor unit

Remote

controller

Power

supply

SW6

Indoor unit

U2 U1

U4U3

Outdoor

unit

2

2

1

1

SW5

ON

ON

RS-485

AB

FG

U1U2

TCC-LINK

Indoor

SW1

1

ADDRESS

U2 U1

unit

LNLN

Power

Remote

controller

supply

Set the TCS-NET Relay Interface address with SW1. Assign 1 to 8 to each

address to avoid duplication.

CAUTION: The SW1 setting is read when the power is turned on. Push the

reset switch SW7 after changing the address.

INTELLIGENT SERVER

(BMS-LSV2E)

TOUCH SCREEN CONTROLLER

(BMS-TP0640/5120)

Connection diagram (TCS-NET RELAY INTERFACE (BMS-IFLSV1E))

Crimp 3 wires with

a closed end wire

connector.

Yellow

Brown

B

A

Orange

Red

Connect the two shield wires

together.

45

The shield of RS-485 cable should be open and

insulated. It is not connected to the terminal block.

CAUTION: RS-485 signals A and B have polarity. Be

careful when connecting the RS-485 wires.

Set the RS-485 terminator resistor on the No.1 (relay interface address SW1=1)

unit. Set bit 1 of SW5 to ON.

Page 46

Insert the wire by pushing the

lever with a screwdriver. Check

that the wire is inserted

securely.

When inserting two RS-485

communication wires into a single

terminal for connection to another

interface, crimp them using the

supplied pin terminal.

CAUTION

The RS-485 signal wire has

polarity. Connect A to A, and B to

B. If connected with incorrect

polarity, the unit will not work.

REQUIREMENT

Install a breaker on the primary

side of the power supply.

Secure each

cable with a

cable clamp.

DI1DI2DI3DI4DI5DI6DI7DI8

SW3

ON

SW2

1234

Power meter

Intelligent Server

BA

FG

RS-485

35 6

Length of stripped

power meter wire

6

35

Length of stripped

communication wire

SW1

Connections (ENERGY MONITORING RELAY INTERFACE (BMS-IFWH3E))

Connect power cables, earth wires, and signal wires to the specified terminals on the terminal block.

SW4 SW7

Connect the earth

wire to the earth

terminal on the

chassis.

Secure each cable

with a cable clamp.

L

46

N

10

35

Length of stripped

power cable

55 10

Power cable

Page 47

Wiring Connection

The following describes the wiring connections of the Energy Monitoring Relay Interface when it is used

in the air conditioner control system.

• Terminator resistor setting

Set the RS-485 terminator resistor on the TCS-NET Relay Interface.

Do not set it by the Energy Monitoring Relay Interface.

• Shield earthing

The shield earth of the RS-485 signal wires should be single-point earth. Earth the wires on the

Intelligent server side.

Other shield lines should be closed and the terminal end should be open and insulated.

• Connection of power meter

Use a power meter with a pulse generator.

Connect the non-voltage contact output of the power meter to the Energy Monitoring Relay Interface.

An external input circuit is shown below.

Input signal is electrically isolated by a photo-coupler.

12V

Power meter

Input

terminal

(with pulse generator)

Energy Monitoring Relay Interface

DI-1 to DI-8

Contact

47

Page 48

Yellow

Brown

B

A

Red

Orange

Crimp 3 wires with a

close end wire connector.

INTELLIGENT SERVER

(BMS-LSV2E)

TOUCH SCREEN CONTROLLER

(BMS-TP0640/5120)

A

B

Power supply

Red/Orange

Brown/Yellow

FG

U1U2

ABLN

SW1

4

ADDRESS

TCC-LINK

RS-485

TCS-NET RELAY

INTERFACE

DI 1

DI 2

DI 3

DI 4

DI 5

DI 6

DI 7

DI 8

CAUTION: No terminator resistor

setting switch is provided on the

Energy Monitoring Relay Interface.

Power meter 1

Power meter 2

Power meter 3

Power meter 4