Page 1

INSTALLATION MANUAL

DIGITAL INPUT/OUTPUT

RELAY INTERFACE

BMS-IFDD02E2

• Thank you very much for purchasing this TOSHIBA Digital Input/Output Relay Interface.

• Please read this manual carefully beforehand for proper installation of the relay interface.

CONTENTS

Precautions for Safety.................................................................................................................... 1

Introduction ..................................................................................................................................... 2

Before Installation .......................................................................................................................... 3

1 Installation.................................................................................................................................... 4

2 Conection of Power cables/Earth wires/Singl wires ............................................................... 5

3 Setting .......................................................................................................................................... 8

4 Trial Operation Check ................................................................................................................. 9

Page 2

Precautions for Safety

• Read these “Precautions for Safety” carefully before installation.

• The precautions described below include important items regarding safety. Observe them without fail.

• After the installation work, perform a trial operation to check for any problem. Follow the Owner's

Manual to explain how to use and maintain the unit to the customer. Ask the customer to keep this

Installation Manual together with the Owner’s Manual.

WARNING

• Ask an authorized dealer or qualified installation professional to install or reinstall the relay

interface.

Improper installation may result in electric shock or fire.

• Turn off the main power supply switch or breaker before attempting any electrical work.

Make sure all power switches are off. Failure to do so may cause electric shock.

• Perform installation work properly according to this Installation Manual.

Improper installation may result in electric shock or fire.

• Do not modify the unit.

Any modification may cause a malfunction, resulting in overheating or fire.

CAUTION

• Perform wiring correctly in accordance with specified the current capacity.

Failure to do so may result in short-circuiting, overheating, or fire.

• Connect the specified cables for the terminals securely to prevent external forces from

affecting them.

Failure to do so may result in disconnection, overheating, or fire.

1

Page 3

Introduction

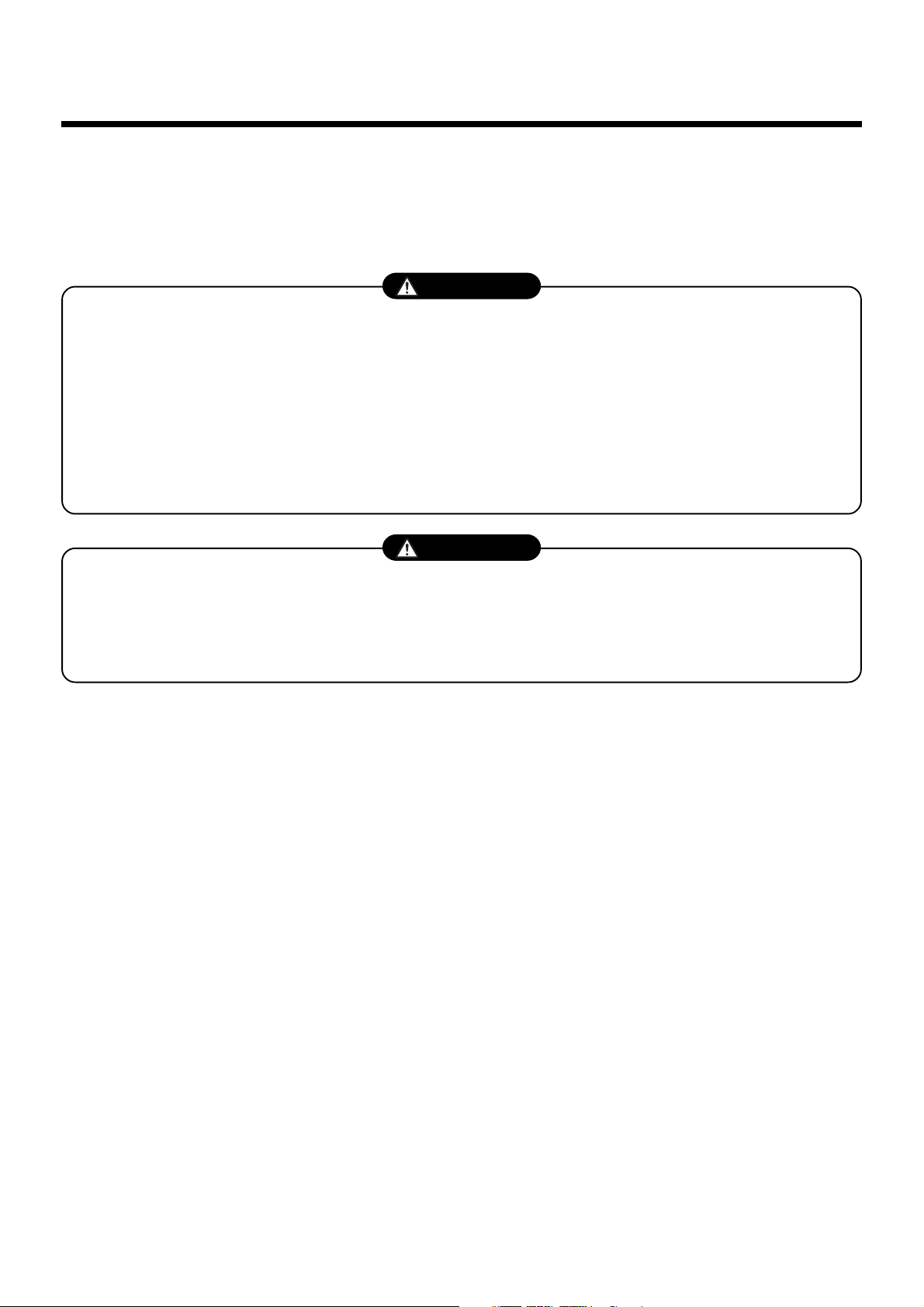

nApplications/Functions/Specifications

Applications/Functions/Specifications

• Applications

The Digital Input/Output Relay Interface is used to control air conditioners by interlocking them with

electric lock signals and fire alarm signals, and to transmit air conditioner failures to other devices.

•

Functions

The Digital Input/Output Relay Interface connects non-voltage contact signals, transmits their input

status to the Touch Screen Controller, and outputs signals from the contacts (open collector) according

to the command from the Touch Screen Controller.

• Specifications

Power supply

Power consumption

Operating temperature/

humidity

Storage temperature

Chassis material

Dimensions

Mass

220 - 240 V, AC 50/60 Hz

6.5 W

0 to 40 °C, 10 to 90% RH

-20 to +60 °C

Galvanized sheet metal 0.8t

(no coating)

66(H) x 193(W) x 246(D) mm

1.65 kg

Digital

input

Digital

output

External power supply for

Input/Output

Input type

Input points

Input registance

Input "ON" current

Output type

Output points

Output current

Output voltage

Photo-coupler insulation

8 points

9 k ohm

1 mA

Open collector

4 points

Max. 35 mA (per point)

Less than DC 24V

DC 12 V, 120 mA

External View

Grommet for

power input

1818 53.5 103.5

234

220

1818

Grommet for

Digital Inputs

92.5

(193)

Grommet for

RS485

64.5

Grommet for

Digital Outputs

246

66

63.6

2

Page 4

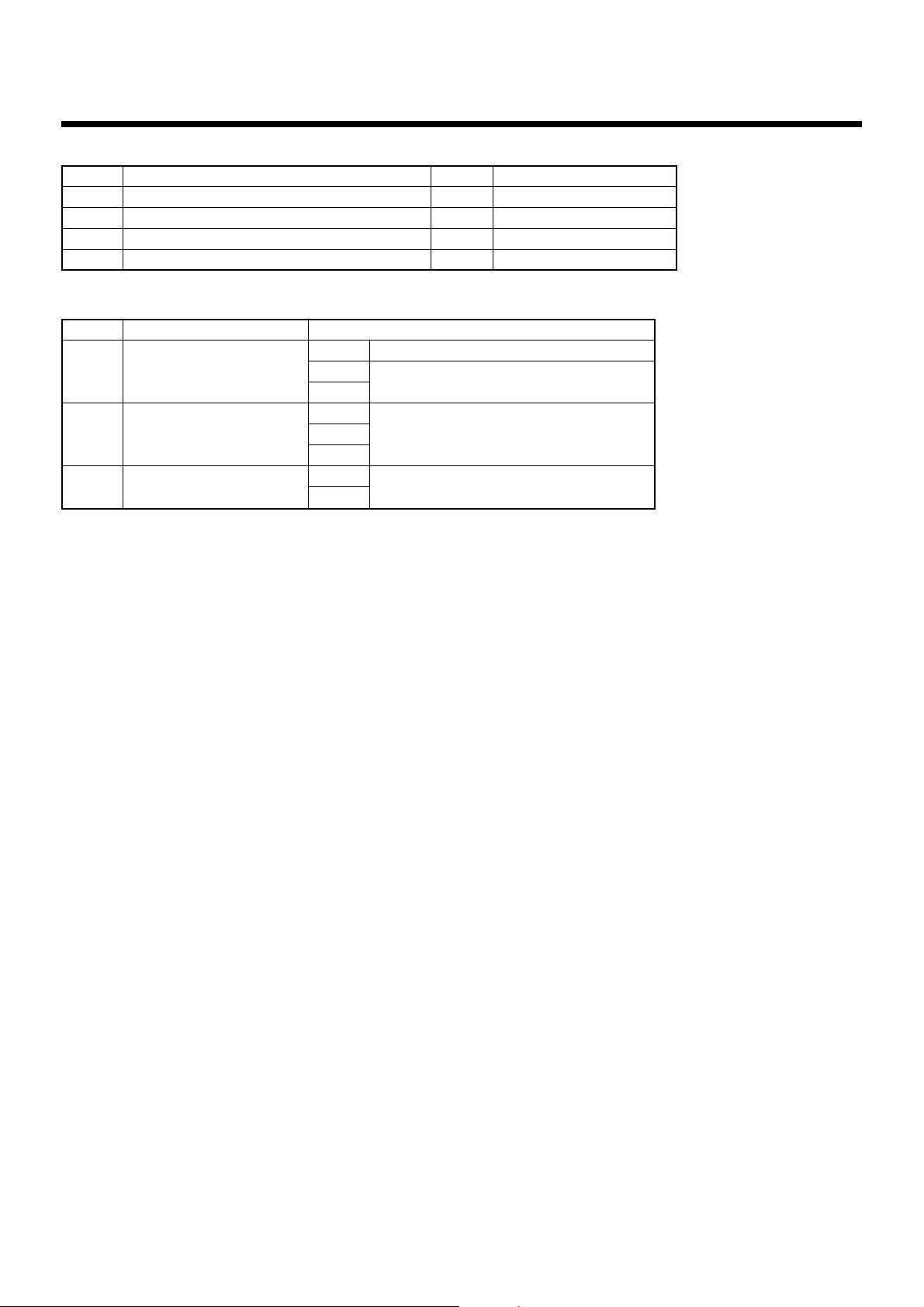

Before Installation

Check the following package contents.

No.

1

DIGITAL INPUT/OUTPUT RELAY INTERFACE

2

Installation Manual

3

Screw

4

Pin terminal

Item

Use the following wiring materials to connect signal lines and power lines. (Procured on site.)

No.

1

2

3

For digital Input/Output

Line

For RS-485

connection

For power

Type

Wire size

Length

Type

Wire size

Length

Type

Wire size

2-core shield wire

1.25mm2, 500m max. (total length)

2-core wire, 0.3mm

H07 RN-F or 245IEC66

0.75mm

Quantity

1

1

4

2

Description

2

, 50 m max.

Remarks

M4 x 12mm tapping screws

2

, 100m max.

3

Page 5

1

Installation

Digital Input/Output Relay Interface Installation Method and Orientation

There are five installation methods for this relay interface as shown below, surface mount or wall mount.

Use the attached screws.

No good

REQUIREMENT

Do not install the unit in any of the following places.

• Humid or wet place

• Dusty place

• Place exposed to direct sunlight

• Place where there is a TV set or radio within one meter

• Place exposed to rain (outdoors, under eaves, etc.)

Installation Space and Maintenance Space

A side space for connecting through cable inlets and an upper space for maintenance must be reserved

before installation.

The other sides can be adjacent to surrounding objects.

100mm

100mm

100mm

4

Page 6

Connection of Power cables/Earth wires/

2

Signal wires

CAUTION

The RS-485 signal wire has polarity. Connect A to A, and B to B. If connected with incorrect polarity,

the unit will not work.

REQUIREMENT

Disconnect the appliance from the main power supply.

This appliance must be connected to the main power supply by a circuit breaker or switch with a

contact separation of at least 3mm.

Power cables/Earth wires/Signal wires

Connect power cables, earth wires, and signal wires to the specified terminals on the terminal block.

Secure each

cable with a

SW1

SW4 SW7

SW2

SW3

ON

1234

DI1DI2DI3DI4DI5DI6DI7DI8

cable clamp.

Connect the earth

wire to the earth

terminal on the

chassis.

Secure each

cable with a cable

clamp.

Power cable

Length of stripped

power cable

35

10

Digital input

contacts

L

N

FG

Length of stripped

communication wire

35

B

A

RS-485

DO1

DO2

DO3

DO4

GND

+12V

Length of stripped digital

Input/Output connector wire

6

35 6

Touch Screen

Controller

Digital output

load

55 10

Insert the wire by pushing the

lever with a screwdriver. Check

that the wire is inserted securely.

When inserting two RS-485

communication cables into a

single terminal for connection to

another interface, crimp them

using the attached pin terminal.

5

Page 7

Connection of Power cables/Earth wires/

2

Signal wires

(continued)

Wiring Connection

CAUTION

If an inductive load (relay coil) or a bulb is connected, a surge voltage or rush current will be

generated. Take adequate measures against surge voltage or rush current.

The following describes wiring connections of the Digital Input/Output Relay Interface when it is used in

the air conditioner control system.

• Terminator resistor setting

Set the RS-485 terminator resistor by the TCS-NET Relay Interface.

Do not set it by the Digital Input/Output Relay Interface.

• Shield earthing

The shield earth of the RS-485 signal wires should be single-point earth. Earth the wires on the Touch

Screen Controller.

Other shield lines should be closed, and the terminal end should be open and insulated.

• Connection of external digital inputs

Input circuit examples are shown below (electrically isolated using a photo-coupler).

(1) Example of contact input connection

12V

Input terminal

DI-1 to DI-8

Contact

(2) Example of current sink connection

12V

Input terminal

DI-1 to DI-8

Current sink

• Connection of external digital outputs

Output circuit examples are shown below (open collector output electrically isolated using a photocoupler).

(1) Example of load connection

12V

Output terminal

DO1 to DO4

GND

Load

External

power

supply

(2) Example of load connection

12V

+12V

Output terminal

DO1 to DO4

6

Page 8

Connection of Power cables/Earth wires/

2

Signal wires

Connection diagram

Connect the

Yellow

Brown

B

A

Red

Orange

TOUCH SCREEN

CONTROLLER

The shield earth of the RS-485

signal wires should be single-point

earth. Earth the wires on the Touch

Screen Controller.

Set the Digital Input/Output Relay

Interface address with SW1. Assign

1 to 4 to each address to avoid

duplication. You can set the digital

Input/Output Relay Interface address

independently from the TCC-LINK

Relay Interface address or the

Energy Monitoring Relay Interface

address.

CAUTION: The SW1 setting is read

when the power is turned on. Push

the reset switch (SW7) after

changing the address.

shield wire of the

two wires

Crimp 3 wires with

a closed end wire joint.

(continued)

A

B

Power supply

Red/Orange

Brown/Yellow

Power supplyPower supply

FG

U1U2

TCC-LINK

AB

RS-485

LNLNLN

TCS-NET RELAY

INTERFACE

SW1

4

ADDRESS

DIGITAL I/O

INTERFACE

SW1

1

ADDRESS

DI 1

DI 2

DI 3

DI 4

DI 5

DI 6

DI 7

DI 8

DI 1

DI 2

DI 3

DI 4

DI 5

DI 6

DI 7

DI 8

DO1

DO2

DO3

DO4

GND

+12V

Input contact 1

Input contact 2

Input contact 3

Input contact 4

Input contact 5

Input contact 6

Input contact 7

Input contact 8

The RS-485 signal wire has

polarity A and B. Be careful when

connecting the wire.

B

A

RS-485

Load 1

Load 2

Load 3

Load 4

Input contact 1

Input contact 2

Input contact 3

Input contact 4

Input contact 5

Input contact 6

Input contact 7

Input contact 8

CAUTION: Set the RS-485

terminator resistor on the TCS-NET

Relay Interface. No terminator

resistor setting switch is provided

on the Digital Input/Output Relay

Interface.

DIGITAL I/O

INTERFACE

7

DO1

DO2

DO3

DO4

GND

+12V

B

A

RS-485

Load 1

Load 2

Load 3

Load 4

Page 9

3

Setting

SW1 SW2

SW4 SW7

NL

SW3

ON

1234

LED2

LED1

LED3

LED17

LED16

LED15

LED14

LED4

LED5

RS-485

DO1

DO2

DO3

DO4

GND

+12V

DI1DI2DI3DI4DI5DI6DI7DI8

SW1

SW2

SW3

SW4

SW7

LED1

LED2

LED3

LED4

LED5

LED14 LED17

B

A

Address set switch

1 - 4 Address

0,5 - F Not used

Operating mode set switch (0 usually)

Test switch (all OFF usually)

Test switch

Reset switch

Power indicator

RS-485 communication status indicator

Not used

Test indicator

Test indicator

Digital output indicator

The following settings are necessary to use Digital Input/Output Relay Interfaces.

• SW1 Address set switch

When two or more Digital Input/Output Relay Interfaces are used, set a different address for each

unit to avoid address duplication.

Assign addresses in ascending order.

CAUTION

• Set relay interface addresses according to the air conditioner address table.

• When the SW1 setting has been changed, push the reset switch SW7. The new address

setting is read.

• SW2 Operation mode set switch

• SW3 Test switch

• SW4 Test switch

• SW7 Reset switch

When performing address setting with SW1, push this reset switch after address setting to read

the set value.

These switches are not used during normal

operation. Set zero (0) or “all OFF”.

8

Page 10

4

Trial Operation Check

Before starting trial operation

Turn on the power of the Digital Input/Output Relay Interface after all cable connections and settings are

completed. Turn on power of the air conditioning control system.

Trial operation

• Confirming external input connection

In the test mode, when the external inputs connected to the input terminals DI-1 to DI-8 are ON, the

respective LEDs will goes on so you can confirm the connection.

Confirming procedure:

Set the operation mode switch SW2 to “3”, and push the reset switch SW7 to enter the test mode.

Unless SW4 is pushed, the respective input status of DI-1 to DI-4 is indicated by LED2 to LED5.

When SW4 is pushed, the respective input status of DI-5 to DI-8 is indicated by LED2 to LED5.

(*) To return to the normal operation, reset SW2 to “zero (0)” and push SW7.

SW4 OFF

SW4 ON

LED2

Displays DI-1 input

status.

Displays DI-5 input

status.

LED3

Displays DI-2 input

status.

Displays DI-6 input

status.

Input ON: LED lights

Input OFF: LED turns off

LED4

Displays DI-3 input

status.

Displays DI-7 input

status.

LED5

Displays DI-4 input

status.

Displays DI-8 input

status.

• Checking external output connection

In the test mode, you can set output terminals DO1 to DO4 to ON or OFF with the test switch. Their

output status is indicated by each LED.

Checking procedure:

Set the operation mode switch SW2 to “3” in the same way as the external input check, and then

push the reset switch SW7 to enter the test mode.

When the bit of the test switch SW3 is set to ON, the external output turns ON; when set to OFF,

the external output turns OFF.

Bits 1 to 4 of SW3 correspond to output terminals DO1 to DO4.

The respective output status of output terminals DO1 to DO4 is indicated by LED14 to LED17.

The LEDs light with the output ON, and goes off with the output OFF.

(*)To return to normal operation, reset SW2 to “zero (0)” and push SW7.

LED14

Displays DO1 output

status.

Output ON: LED lights

Output OFF: LED turns off

LED15

Displays DO2 output

status.

LED16

Displays DO3 output

status.

LED17

Displays DO4 output

status.

• Checking the RS-485 communication status

Use LED2 for checking the RS-485 communication status.

When RS-485 communication with Touch Screen Controller is normal, LED2 will blink.

LED1

LED2

LED3

LED4

LED5

Power indicator

RS-485 communication

status indicator

Not used

Test indicator

Test indicator

Normal

ON

Blinking

OFF

OFF

OFF

Abnormal

OFF

OFF

—

—

—

9

Page 11

Memo

10

Page 12

DH69409102

Loading...

Loading...