Toshiba B-EX Series, B-EX4T1-G, B-EX4T1-T, B-EX4T2-G, B-EX6T2-G Key Operation Specification

...

TOSHIBA Bar Code Printer

B-EX Series

Key Operation Specification

First edition: April 1, 2011

2nd edition: July 7, 2011

Table of Contents

Page

1 SCOPE ................................................................................................................................................1

2 OUTLINE .............................................................................................................................................1

3 OPERATION PANEL...........................................................................................................................1

4 OUTLINE OF EACH MODE.................................................................................................................2

4.1 ONLINE MODE ......................................................................................................................................2

4.1.1 Threshold setting mode ......................................................................................................................2

4.2 SYSTEM MODE.....................................................................................................................................2

4.3 USER SYSTEM MODE..........................................................................................................................2

4.4 DOWNLOAD MODE ..............................................................................................................................2

4.5 AUTO CONFIGURATION MODE ..........................................................................................................2

5 GENERAL VIEW OF KEY OPERATION.............................................................................................3

6 ONLINE MODE....................................................................................................................................4

6.1 KEY FUNCTION.....................................................................................................................................4

6.1.1 Online Mode Display ..........................................................................................................................4

6.1.2 Help Display........................................................................................................................................5

6.1.3 Manual Threshold Setting Display......................................................................................................5

6.2 LED FUNCTION.....................................................................................................................................6

6.3 LCD FUNCTION.....................................................................................................................................6

6.4 ONLINE MODE LCD DISPLAY..............................................................................................................6

6.4.1 Online Mode LCD Display Example ...................................................................................................6

6.4.2 Icon .....................................................................................................................................................8

6.4.3 Online Mode Display Transition, Operation example.........................................................................9

6.5 HELP DISPLAY....................................................................................................................................10

6.5.1 Explanation of Help Display..............................................................................................................10

6.5.2 Help Display Transition, Operation Example....................................................................................11

6.6 MANUAL THRESHOLD SETTING.......................................................................................................12

6.6.1 Outline of Threshold setting..............................................................................................................12

6.6.2 Threshold Setting Operation Example .............................................................................................13

6.7 JOB CANCELLATION..........................................................................................................................17

6.7.1 Outline of the Job Cancellation.........................................................................................................17

6.7.2 Job Cancellation Operation Example ...............................................................................................17

6.8 LCD MESSAGES AND LED INDICATIONS ........................................................................................18

7 DISPLAY PATTERN AND KEY OPERATION FOR SYSTEM MODE ANDUSER MODE ................ 25

7.1 LIST BOX WITH SCROLLBAR ............................................................................................................25

7.2 VALUE SETTING DISPLAY.................................................................................................................29

7.3 INFORMATION DISPLAY ....................................................................................................................31

7.4 SENSOR ADJUSTMENT DISPLAY.....................................................................................................33

7.5 TEMPERATURE DISPLAY ..................................................................................................................35

7.6 File Selection Display ...........................................................................................................................36

8 SYSTEM MODE.................................................................................................................................37

8.1 OUTLINE OF SYSTEM MODE ............................................................................................................37

8.2 REFLECTING THE SYSTEM MODE SETTINGS IN THE PRINTER..................................................38

8.3 DIAG.....................................................................................................................................................39

8.3.1 MAINTENANCE CONT ....................................................................................................................39

8.3.2 AUTO DIAGNOSTIC ........................................................................................................................52

8.3.3 HEAD CHECK ..................................................................................................................................60

8.4 PARAMETER SET ...............................................................................................................................61

8.4.1 PRINTER SET..................................................................................................................................61

8.4.2 SOFTWARE SET .............................................................................................................................64

8.4.3 PANEL ..............................................................................................................................................71

8.4.4 PASSWORD.....................................................................................................................................72

8.5 ADJUST SET........................................................................................................................................74

8.5.1 FEED ADJ. .......................................................................................................................................75

8.5.2 CUT ADJ...........................................................................................................................................76

8.5.3 BACK ADJ. .......................................................................................................................................81

8.5.4 X ADJUST ........................................................................................................................................82

8.5.5 TONE ADJ. (TRANS.) ......................................................................................................................82

8.5.6 TONE ADJ. (DIRECT) ......................................................................................................................82

8.5.7 RBN ADJ.<FW>................................................................................................................................83

8.5.8 RBN ADJ.<BK> ................................................................................................................................83

8.5.9 THRESHOLD <REFL.> ....................................................................................................................83

8.5.10 THRESHOLD <TRANS.> .............................................................................................................83

8.6 TEST PRINT.........................................................................................................................................85

8.6.1 PRINT CONDITION..........................................................................................................................85

8.6.2 SLANT LINE (1DOT) ........................................................................................................................88

8.6.3 SLANT LINE (3DOT) ........................................................................................................................89

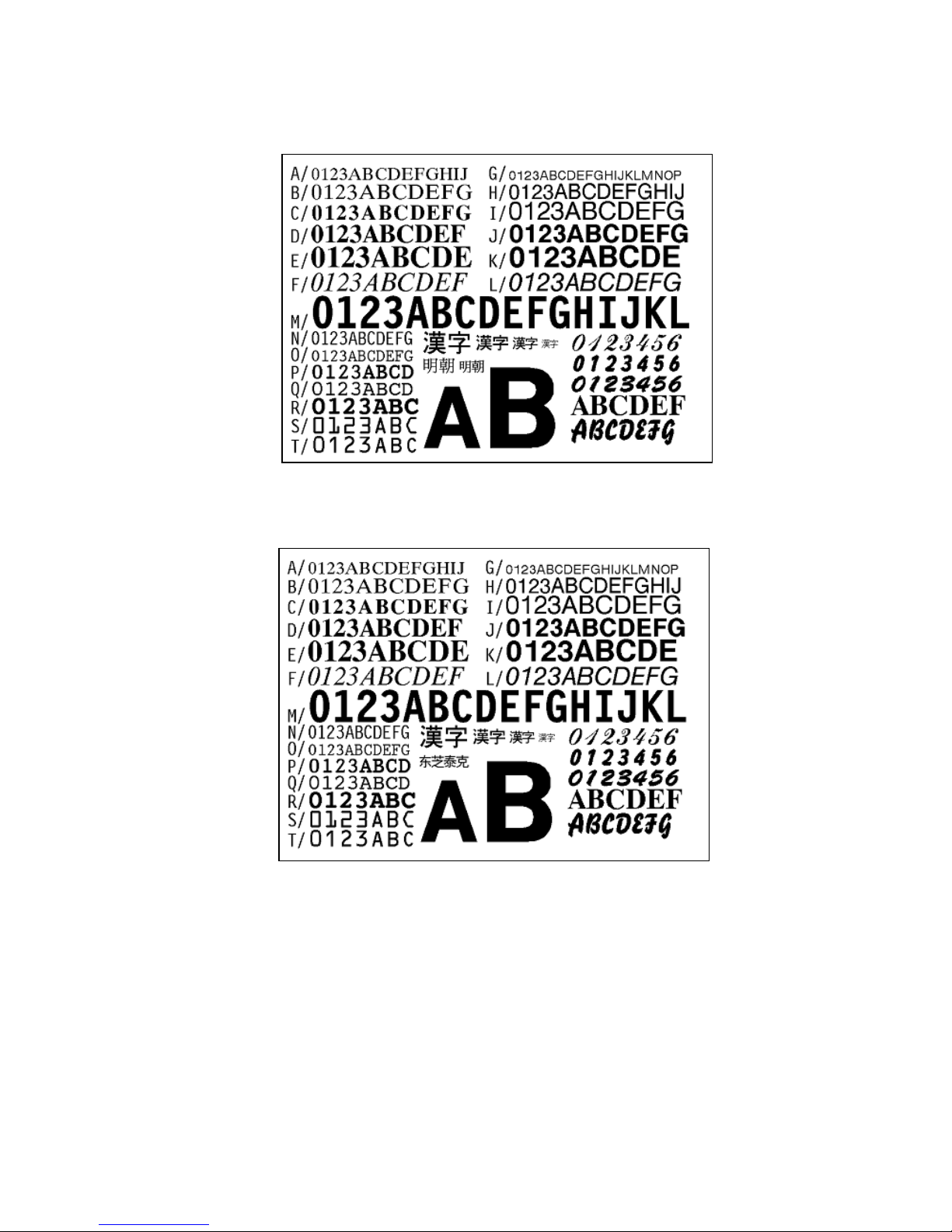

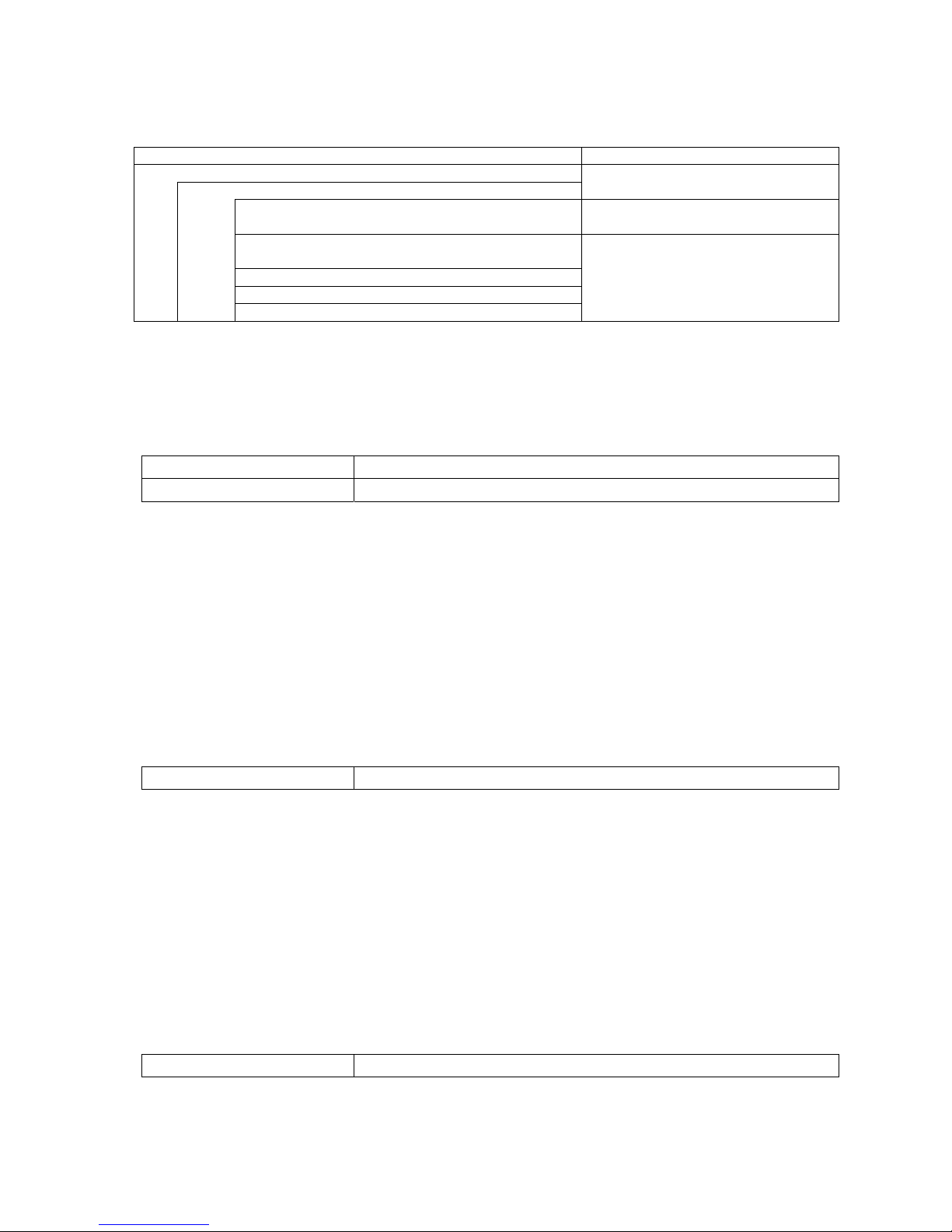

8.6.4 CHARACTERS.................................................................................................................................90

8.6.5 BARCODE ........................................................................................................................................91

8.6.6 NON-PRINTING ...............................................................................................................................91

8.6.7 FACTORY TEST ..............................................................................................................................91

8.6.8 AUTO PRINT (TRANS.) ...................................................................................................................92

8.6.9 AUTO PRINT (REFL.) ......................................................................................................................92

8.7 SENSOR ADJUST ...............................................................................................................................93

8.7.1 TEMPERATURE...............................................................................................................................93

8.7.2 REFLECT .........................................................................................................................................93

8.7.3 TRANS..............................................................................................................................................93

8.7.4 PE REFL./TRANS.............................................................................................................................94

8.7.5 RIBBON ............................................................................................................................................94

8.8 RAM CLEAR.........................................................................................................................................95

8.8.1 NO RAM CLEAR ..............................................................................................................................95

8.8.2 MAINTE.CNT CLEAR.......................................................................................................................95

8.8.3 PARAMETER CLEAR ......................................................................................................................96

8.9 INTERFACE .......................................................................................................................................102

8.9.1 NETWORK .....................................................................................................................................102

8.9.2 USB.................................................................................................................................................107

8.9.3 RS-232C .........................................................................................................................................108

8.9.4 CENTRO.........................................................................................................................................109

8.10

BASIC.................................................................................................................................................110

8.10.1 BASIC .........................................................................................................................................110

8.10.2 FILE MAINTENANCE .................................................................................................................110

8.10.3 TRACE........................................................................................................................................110

8.10.4 EXPAND MODE .........................................................................................................................110

8.11 FOR FACTORY..................................................................................................................................111

8.11.1 HEAD UP ADJUST.....................................................................................................................111

8.11.2 PANEL TEST ..............................................................................................................................111

8.11.3 KEY TEST...................................................................................................................................112

8.12 RFID ...................................................................................................................................................114

8.12.1 TEST...........................................................................................................................................114

8.12.2 MODULE.....................................................................................................................................116

8.12.3 RETRY........................................................................................................................................117

8.12.4 UHF SETTING............................................................................................................................119

8.12.5 OTHER .......................................................................................................................................122

8.13 RTC ....................................................................................................................................................124

8.13.1 DATE TIME.................................................................................................................................124

8.13.2 BATTERY CHECK......................................................................................................................124

8.13.3 RENEWAL ..................................................................................................................................124

8.14 Z-MODE .............................................................................................................................................125

8.15 USB MEMORY...................................................................................................................................126

8.15.1 USB TO PRINTER......................................................................................................................127

8.15.2 PRINTER TO USB......................................................................................................................127

8.16 RESET................................................................................................................................................128

9 USER SYSTEM MODE....................................................................................................................129

9.1 OUTLINE OF USER SYSTEM MODE ...............................................................................................129

9.2 RESET................................................................................................................................................130

9.3 PARAMETER SET .............................................................................................................................130

9.4 ADJUST SET......................................................................................................................................130

9.5 LAN/WLAN .........................................................................................................................................131

9.5.1 LAN/WLAN .....................................................................................................................................131

9.5.2 SNMP..............................................................................................................................................131

9.6 BASIC.................................................................................................................................................132

9.7 Z-MODE .............................................................................................................................................132

9.8 AUTO CALIB ......................................................................................................................................133

9.9 DUMP MODE .....................................................................................................................................135

9.9.1 BUFFER .........................................................................................................................................135

9.9.2 DUMP LIST.....................................................................................................................................135

9.10 LOG ....................................................................................................................................................138

9.10.1 PRINTER TO USB......................................................................................................................138

10 DOWNLOAD ................................................................................................................................139

11 AUTO CONFIGURATION MODE ................................................................................................141

11.1 Outline of the Auto Configuration Mode .............................................................................................141

11.2 Preparation for USB Memory .............................................................................................................141

11.3 Auto Configuration File.......................................................................................................................142

11.3.1 Format.........................................................................................................................................142

11.3.2 Model Information .......................................................................................................................142

11.3.3

Display Message.........................................................................................................................142

11.3.4 Firmware File to be Downloaded................................................................................................142

12 POWER SAVE FUNCTION..........................................................................................................143

Copyright © 2011

by TOSHIBA TEC CORPORATION

A

ll Rights Reserved

570 Ohito,Izunokuni-shi,Shizuoka-ken,JAPAN

1

1 SCOPE

This specification describes key operations using the keys and the LCD display of the B-EX4T1-G and

B-EX4T1-T (hereinafter collectively referred to as “B-EX4T”) high-end industrial general-purpose bar code

printers.

2 OUTLINE

Key operations are different depending on the printer mode: Online mode, in which operations are carried out

through the keys and error messages are displayed while the printer is connected to the host such as a PC, and

the system mode, in which self-test and setting of various parameters are performed.

This specification describes the key operation procedures with the printer keys and the LCD panel.

The names of the keys and LCD messages used in this specification are written in English

3 OPERATION PANEL

Graphic LCD

ERROR LED

PAUSE key

ENTER key

RIGHT key

UP key

RESTART key

ONLINE LED

FEED key

MODE key

CANCEL key

LEFT key

DOWN key

2

4 OUTLINE OF EACH MODE

This chapter describes the outline of each mode supported by the printer. Refer to each chapter for detailed

information.

4.1 ONLINE MODE

This mode is mainly used by users (operators).

The label or tag can be issued in the online mode. When an error occurs, the help function shows the

cause of an error, troubleshooting, and recovery from the error. The threshold setting, described below, is

also a part of the online mode.

4.1.1 Threshold setting mode

Threshold setting mode is provided to correct a print failure with pre-printed media.

When using pre-print label, detection of a print position may be disabled with the usual media sensor

threshold, depending on the ink type. Such error can be prevented by setting the threshold just for the

pre-printed media to be used. Since the threshold setting value is stored in the non-volatile memory, it is

unnecessary to set the threshold again as long as the same pre-print media is used.

4.2 SYSTEM MODE

Turning the power on while holding down the both [FEED] and [PAUSE] keys, or the [MODE] key alone

activates the system mode. This mode is mainly used by service persons or the Production Dept. for

adjustment before shipment. The system mode contains the menus which might be changed not so

frequently.

In addition to the menus common to the User System Mode, such as parameter setting, fine adjustment,

and BASIC setting, there are sensor adjustment, interface, RFID and RTC setting menus.

Furthermore, self-diagnosis, test print, RAM clear to initialize the printer settings, pre-shipment adjustment

for factory use, and the menu which enables saving parameter settings, external characters, TPCL

commands to the external USB memory or copying the data from the USB memory to the printer are

provided. The values set in this mode are stored in the non-volatile memory.

4.3 USER SYSTEM MODE

The user system mode is accessible from the online mode. This mode, mainly used by users

(administrator) or service persons, contains the menus which might be frequently changed.

In addition to the menus common to the System Mode, such as parameter setting, fine adjustment, and

BASIC setting, there are LAN/WLAN setting, auto calibration, dump function which enables the printer to

dump received data.

The values set in this mode are stored in the non-volatile memory.

4.4 DOWNLOAD MODE

This mode is used to download boot and main programs.

4.5 AUTO CONFIGURATION MODE

This mode is used to update printer firmware stored in USB memory.

3

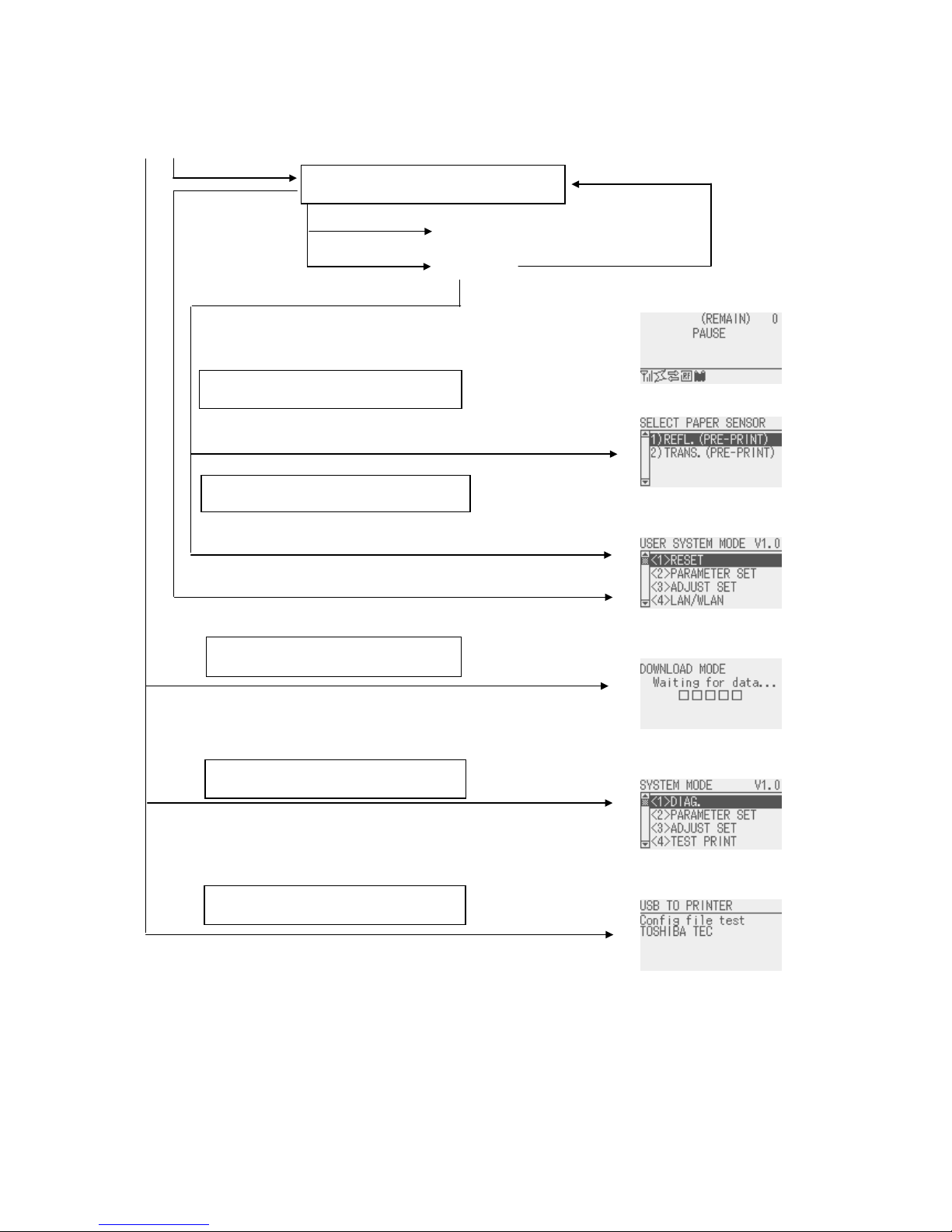

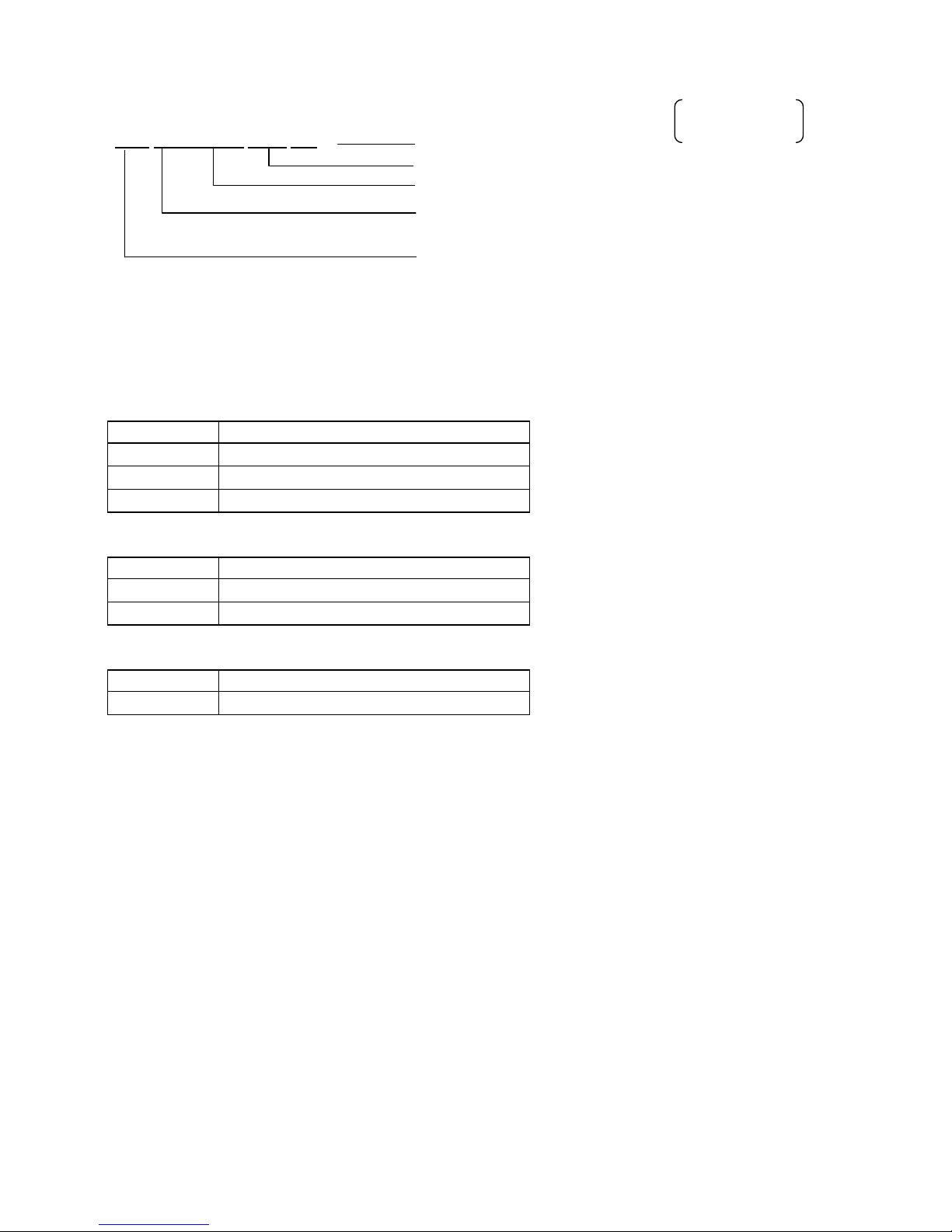

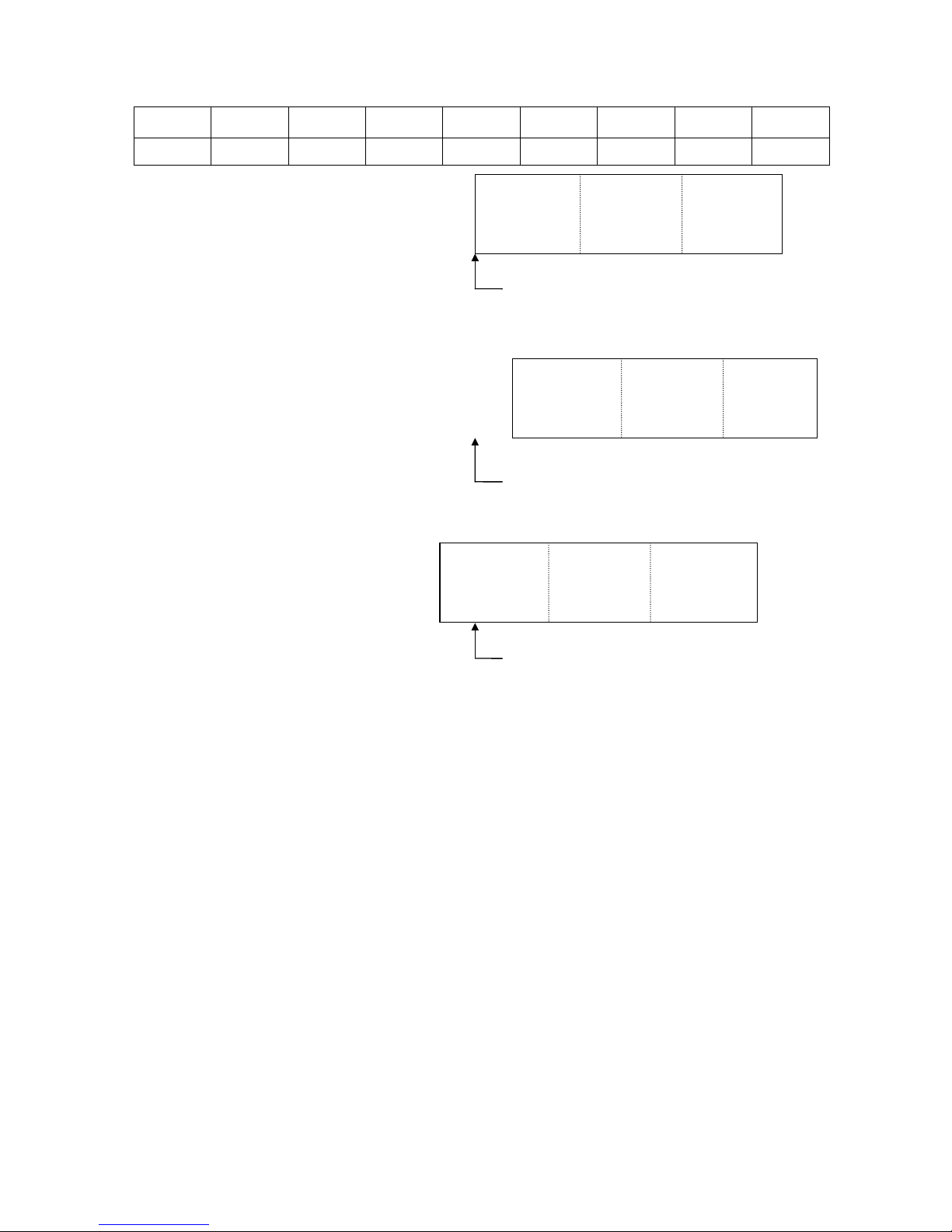

5 GENERAL VIEW OF KEY OPERATION

Display

To enter the download mode, system mode or auto configuration mode, keep holding down the key until each

display is shown.

[Power OFF]

[PAUSE] key

[RESTART] key

[FEED] key

Hold down the [PAUSE] key for a few

seconds.

Hold down the [RESTART] o

r

[MODE] key for a few seconds.

Power on

Turn the power on while holding down the

[FEED] and [PAUSE] keys at the same time o

r

holding down the [MODE] keys.

Threshold setting mode

User mode

Download mode

System mode

Online mode

[Online]

[Feeds one label]

[Pause]

Hold down the [MODE] key for a

few seconds.

Turn the power on while holding down the

[CANCEL] key.

A

uto configuration mode

Turn the power on while holding down the

[FEED], [RESTART] and [PAUSE] keys.

4

6 ONLINE MODE

6.1 KEY FUNCTION

The printer behavior is not guaranteed when undefined key is operated.

6.1.1 Online Mode Display

Key Function

(1) Feeds one piece of media.

Ejects one piece of media.

Used to adjust the media to the proper position. If printing is attempted with the

media improperly positioned, printing is not performed at the proper position. One or

two pieces of media need to be fed to adjust the paper position before printing.

(2) Prints the data in the image buffer on one piece of media according to the system

mode setting.

NOTE: A Clear Command or a command for drawing shall not be sent while printing

caused by a depression of the [FEED] key. If it is sent, the layout will be destroyed,

and the media will not be printed properly. Also, if printing is performed by a

depression of the [FEED] key while the data is being drawn in the image buffer, the

layout may be destroyed.

* For details of the following cases, refer to the parameter setting section.

• How to issue the label stock having the label pitch of 25.4 mm or less in the cut issue

mode when the disc cutter is used.

• How to issue the label stock having the minimum label pitch or less for each print

speed in the cut issue mode when the rotary cutter is used.

* In the strip mode, feeds labels even when the peel-off sensor is detecting a label.

[FEED]

* When Media Load parameter is enabled, a media feed is performed to find the print

start position depending on the condition. For details, refer to Section 8.4.1.1 MEDIA

LOAD.

(1) Resumes printing after a temporary stop of printing or after an error.

(2) Places the printer in the usual initial state, which is obtained when the power is turned

on.

[RESTART]

(3) Places the printer in the user system mode.

(1) Stops label printing temporarily. [PAUSE]

(2) Programs the threshold value.

[MODE] (1) Places the printer in the user system mode.

[CANCEL] (1) Clears the job.

[ENTER] (1) Displays help messages.

[UP] (1) No function.

[DOWN] (1) No function.

[LEFT] (1) No function.

[RIGHT] (1) Displays help messages.

5

6.1.2 Help Display

Key Function

[FEED] (1) Ends help display.

[RESTART] (1) Ends help display.

[PAUSE] (1) Ends help display.

[MODE] (1) Ends help display.

(1) Ends help display.

(2) Returns to the previous help page.

[CANCEL]

(3) Ends help display.

(1) Ends help display.

(2) Goes to the next help page.

[ENTER]

(3) Ends help display.

[UP] (1) Moves the cursor upward.

[DOWN] (1) Moves the cursor downward.

(1) Returns to the previous help page. [LEFT]

(2) Ends help display.

(1) Goes to the next help page. [RIGHT]

(2) Ends help display.

6.1.3 Manual Threshold Setting Display

Key Function

(1) Moves the cursor upward.

[FEED]

(2) Re-sets

[RESTART] (1) Moves the cursor downward.

(1) Sets the threshold. [PAUSE]

(2) Fixes the selection.

[MODE] No function.

[CANCEL] No function.

(1) Fixes the selection. [ENTER]

(2) Ends manual threshold setting.

[UP] (1) Moves the cursor upward.

[DOWN] (1) Moves the cursor downward.

(1) Goes to the judgment result page [LEFT]

(2) Goes to the fine adjustment setting menu

(1) Goes to the detail page. [RIGHT]

(2) Goes to the fine adjustment setting menu

6

6.2 LED FUNCTION

Indicates that the printer is in online state.

Flashes when the printer is communicating with the host.

[ONLINE] LED

Flashes at a 500-msec. interval (ON: 250ms., OFF: 250ms) in synchronization

with the [ERROR] LED when the printer is turned off.

Indicates that the printer is in error state.

Flashes when a ribbon near end condition is detected.

Flashes when a system error occurs (at a 1-second interval (ON: 500 ms., OFF:

500 ms.)

[ERROR] LED

Flashes at a 500-msec. interval (ON: 250ms., OFF: 250ms) in synchronization

with the [ONLINE] LED when the printer is turned off.

NOTE: If the wireless LAN is being linked at power off time, both [ONLINE] and [ERROR] LEDs turn on, not

flash.

6.3 LCD FUNCTION

The LCD displays the messages which indicate the printer status.

Type Graphics LCD

Size 128 dots (W) X 64 dots (H)

LCD

Display structure Maximum of 21 digits x 5 lines

6.4 ONLINE MODE LCD DISPLAY

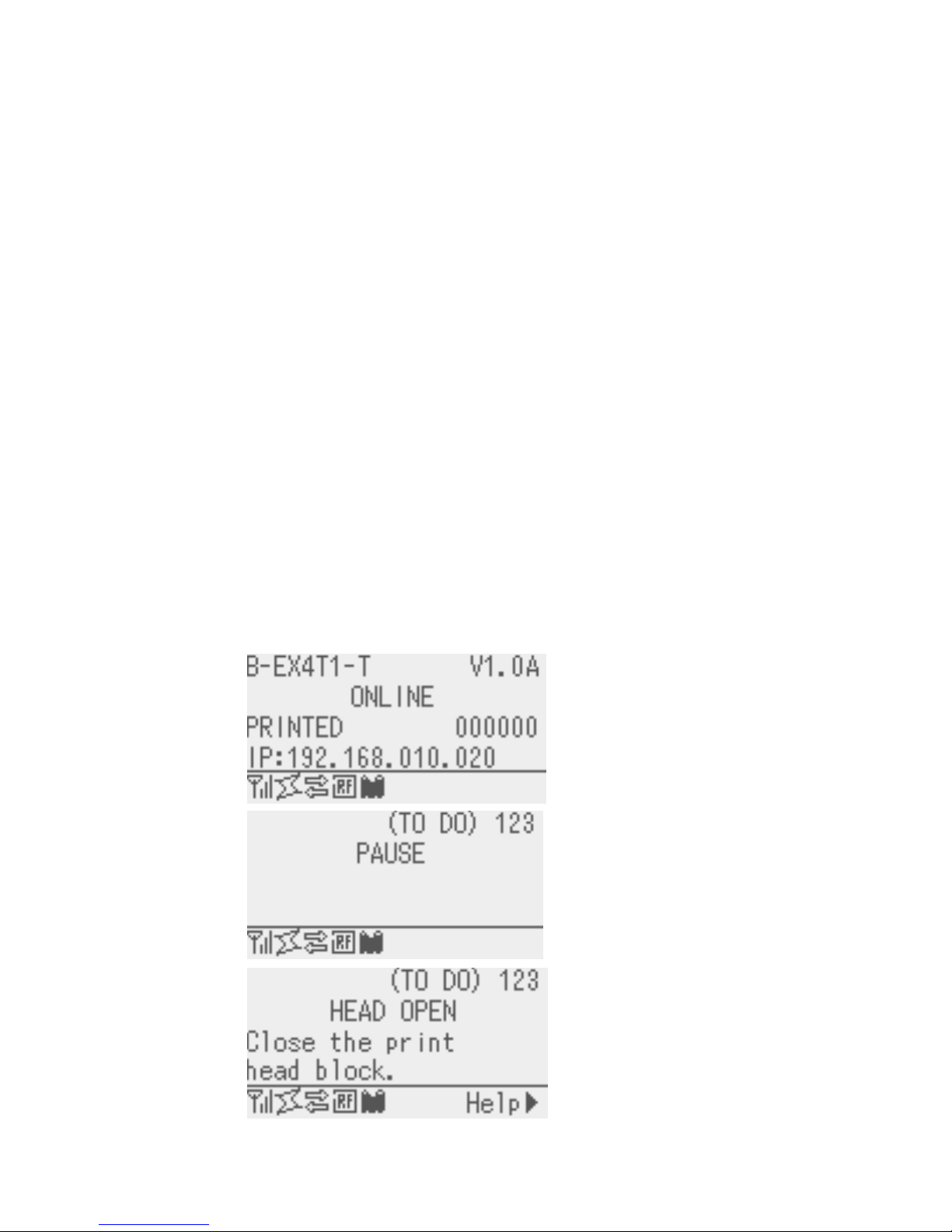

6.4.1 Online Mode LCD Display Example

Printer

condition

LCD Display Display contents

← Model name, Firmware version (*5)

← Message

← The number of labels printed (*1)

← IP address etc. (*4)

Online

← Icon

← The number of remaining labels to print (*2)

← Message

← 1

st

line of the error message

← 2

nd

line of the error message (*6)

Pause

← Icon

← The number of remaining labels to print (*2)

← Message

← 1

st

line of the error message

← 2

nd

line of the error message

Head open

← Icon, Help guide (*3)

7

* Whether to display or hide the 1

st

, 3rd and 4th lines of online mode display can be selected in the system

mode.

* Refer to “Icon display” for Icon in detail.

(*1) The number of labels printed is the cumulative number of labels printed while the printer is activated. It is

reset to zero when the printer is turned on. During an issue with the cut interval specified, the number of

labels is updated when the label is cut normally.

(*2) [The number of remaining labels to print] = [Specified number of labels to print] – [The number of normally

printed labels before occurrence of an error or placing the printer in pause]

When the number of remaining labels to print is zero, it is not displayed. During an issue with the cut

interval specified, the number of remaining labels is updated when the label is cut normally.

(*3) The help guide is displayed only when applicable help message exists.

(*4) The message displayed in this area is IP address or supplemental information like ribbon near end.

• When LAN/WLAN setting is disabled, the IP address is not displayed even if displaying IP address is

enabled in the system mode.

• The ribbon near end message is displayed when a ribbon near end is detected, regardless of whether or

not displaying the ribbon near end message is enabled in system mode.

A ribbon near end is detected depending on diameter of the unused ribbon. The diameter of 38mm is

equivalent to 30-meter ribbon and the diameter of 43 mm is equivalent to 70-meter ribbon, respectively.

(*5) The model name description

B-EX

4 T 1 – T

Head resolution G: 203dpi, T: 305dpi, H: 600dpi

Type 1: Type1, 2: Type2

Print method T: Thermal transfer/Direct thermal

Print width 4: 4” width, 6: 6” width

Series model

(*6) The ribbon near end message may be displayed on this line. The condition for display is the same as *4.

8

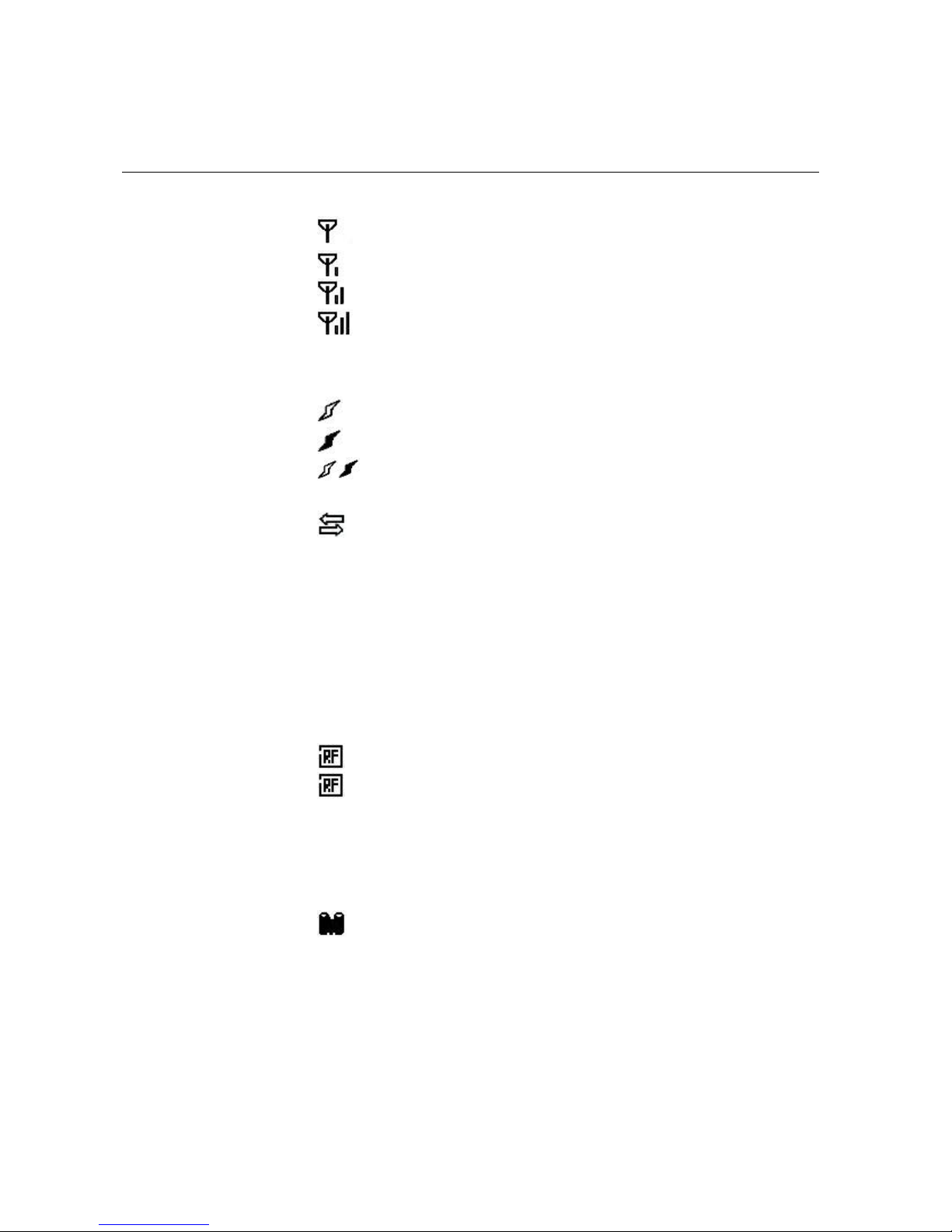

6.4.2 Icon

Five kinds of icon are displayed in the bottom line of the online mode display.

These icons are displayed only in the online mode display.

Icon Explanation

Displayed and used when the wireless LAN module is mounted.

The graph shows the strength of radio wave.

Graph 0: Outside the communication range

Graph 1: Strength of radio wave is weak.

Graph 2: Strength of radio wave is middle

Wireless LAN icon

Graph 3: Strength of radio wave is strong

Displayed and used when the wireless LAN module is mounted.

Displayed while the printer is communicating by wireless LAN.

Blinks while roaming.

OFF: No connection

ON: Connecting to an access point

Link icon

Blink: Roaming (*4)

Appears when a print job is present. Data transmission icon

ON: Print job is present.

Displayed and used when the RFID module is mounted.

Appears when a communication between the printer and the RFID

module is enabled.

Blinks during a communication with the RFID module.

- The communication includes the one without radio wave output.

- Blinks after radio wave output is instructed to the module even when no

radio wave is output.

(Blinks while the module stops outputting radio wave or changing the

channel under the influence of other carrier.)

ON: Module type is set and ready to communicate

RFID icon

⇔ Blink: Communicating

Ribbon near end is detected.

Blinks when the ribbon is close to the end.

Ribbon near end is detected depending on the diameter of unused

ribbon. ∅38 mm is equivalent to 30-meter ribbon and ∅43 mm is

equivalent to 70-meter ribbon.

Ribbon near end icon

Blinking: Ribbon near end state (*4)

(*4) Icon blinks at 1-second interval (ON for 500 msec. and OFF for 500 msec.)

9

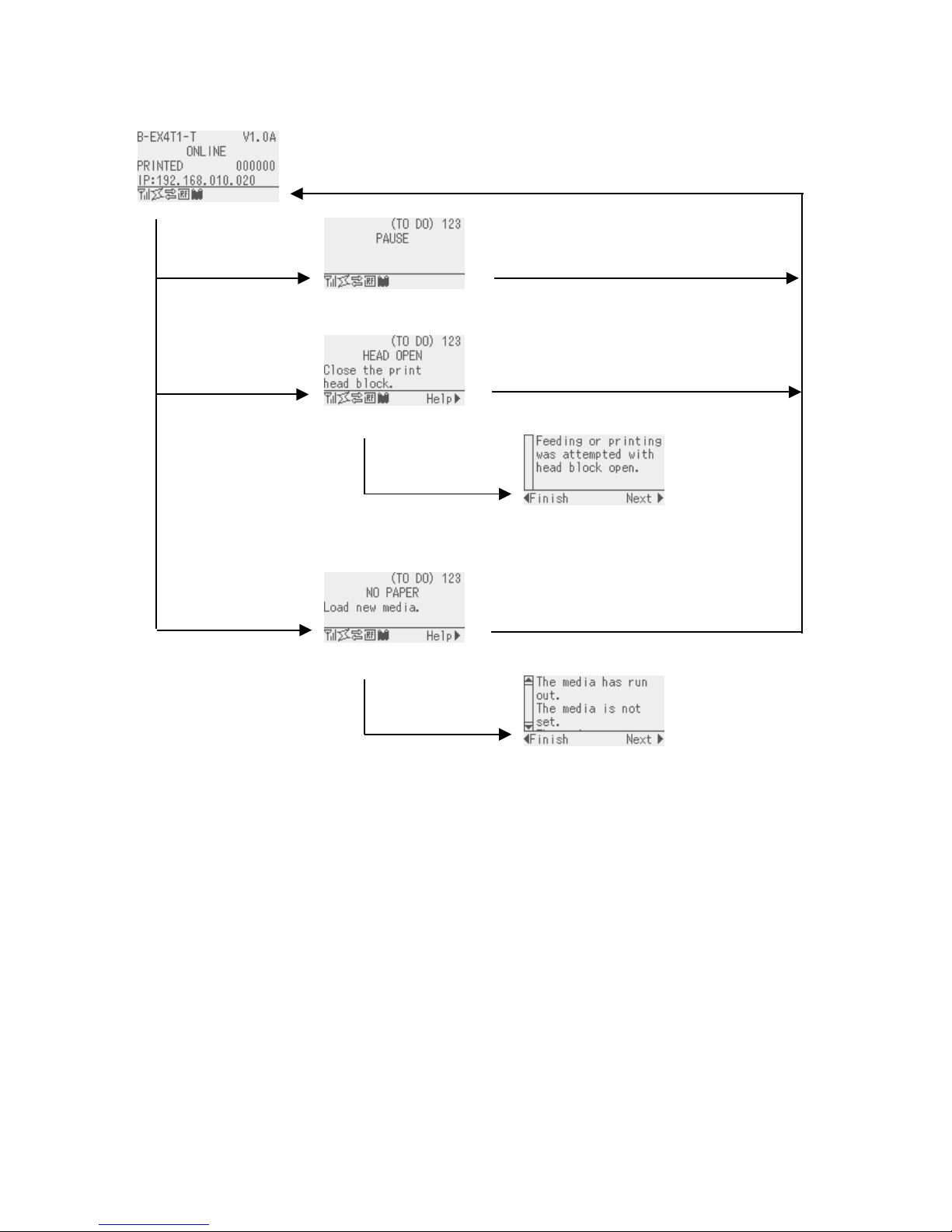

6.4.3 Online Mode Display Transition, Operation example

Idling or normal issuing

Printing is stopped

Help guide is displayed.

Help guide message for head open

(*1)

Printing is stopped and Help

guide is displayed.

Help message for NO PAPER (*1)

(*1) Refer “HELP DISPLAY TRANSITION, OPERATION EXAMPLE” for help display.

If the print head is

opened while idling

If an error occurs

while printing

When [PAUSE] key is

pressed while printing

When [RESTART] key is pressed, the

printer resumes printing if there is

remaining data

Close the print head.

Load media.

When [RESTART] key is pressed, the

printer resumes printing if there is

remaining data.

Press [RIGHT] key.

Press [RIGHT] key.

10

6.5 HELP DISPLAY

6.5.1 Explanation of Help Display

When “Help” is displayed at the lower right of the online mode display, pressing [RIGHT] or [ENTER] key

causes the help message to be shown.

Help message is displayed on the upper four lines. When the message exceeds four lines, the hidden lines

can be displayed by scrolling down. When scrolling is possible, the up and down arrows are provided on the

scrollbar on the left.

Display example:

← 1

st

line of help message

← 2

nd

line of help message

← 3

rd

line of help message

← 4

th

line of help message

← Help guide

Since the help message is within three lines, the scroll bar is not provided with up and down

arrows.

← 1

st

line of help message

← 2

nd

line of help message

← 3

rd

line of help message

← 4

th

line of help message

← Help guide

Since the help message exceeds four lines, the scroll bar is provided with the up and down

arrows.

11

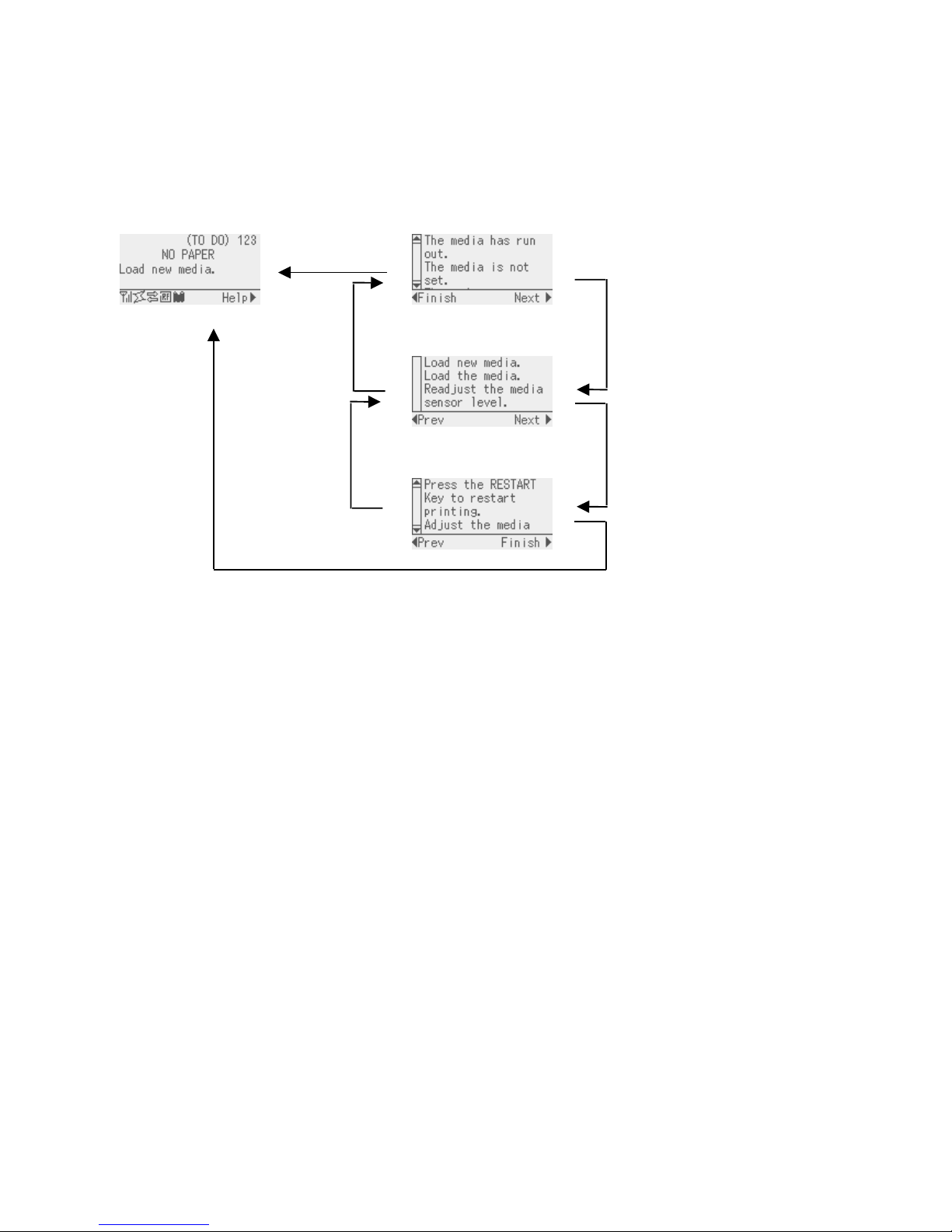

6.5.2 Help Display Transition, Operation Example

The help consists of three pages, which are Help1, Help2 and Help3.

Help1 shows the detail of the error, Help2 shows a troubleshooting, and Help3 shows how to recover from the

error.

Display transition

[LEFT] key

[CANCEL] key

Display transition

[RIGHT] key

[ENTER] key

Online mode Error detail

Scroll the display

with the [UP] or

[DOWN] key.

Troubleshooting

Scroll the display

with the [UP] or

[DOWN] key.

How to recover from error

Scroll the display

with the [UP] or

[DOWN] key.

(*5) When a key other than above is pressed, the help display is ended and returned to the online m

ode display.

12

6.6 MANUAL THRESHOLD SETTING

6.6.1 Outline of Threshold setting

When a label stock is printed, the printer automatically corrects the print position by detecting gaps between

the labels using the transmissive sensor to maintain a constant print position. However, when a preprinted

label is used, some ink may prevent proper gap detection. In this case, it is required to manually program

the transmissive sensor threshold through key operations and store the value in the non-volatile memory.

Selecting “3: Transmissive Sensor (when using the preprinted label)” for the sensor type of the Issue

Command enables printing at a constant print position.

When the media with black marks printed on the back side is used, the printer automatically corrects the

print position by detecting the black marks by using the reflective sensor. However, if there is reflective

rate variation at a portion other than the black mark, the print position cannot be corrected properly. In this

case, it is required to manually program the reflective sensor threshold through key operations and store the

value in the non-volatile memory.

Selecting “4: Reflective Sensor (when using a manual threshold value)” for the sensor type of the Issue

Command enables printing at a constant print position.

13

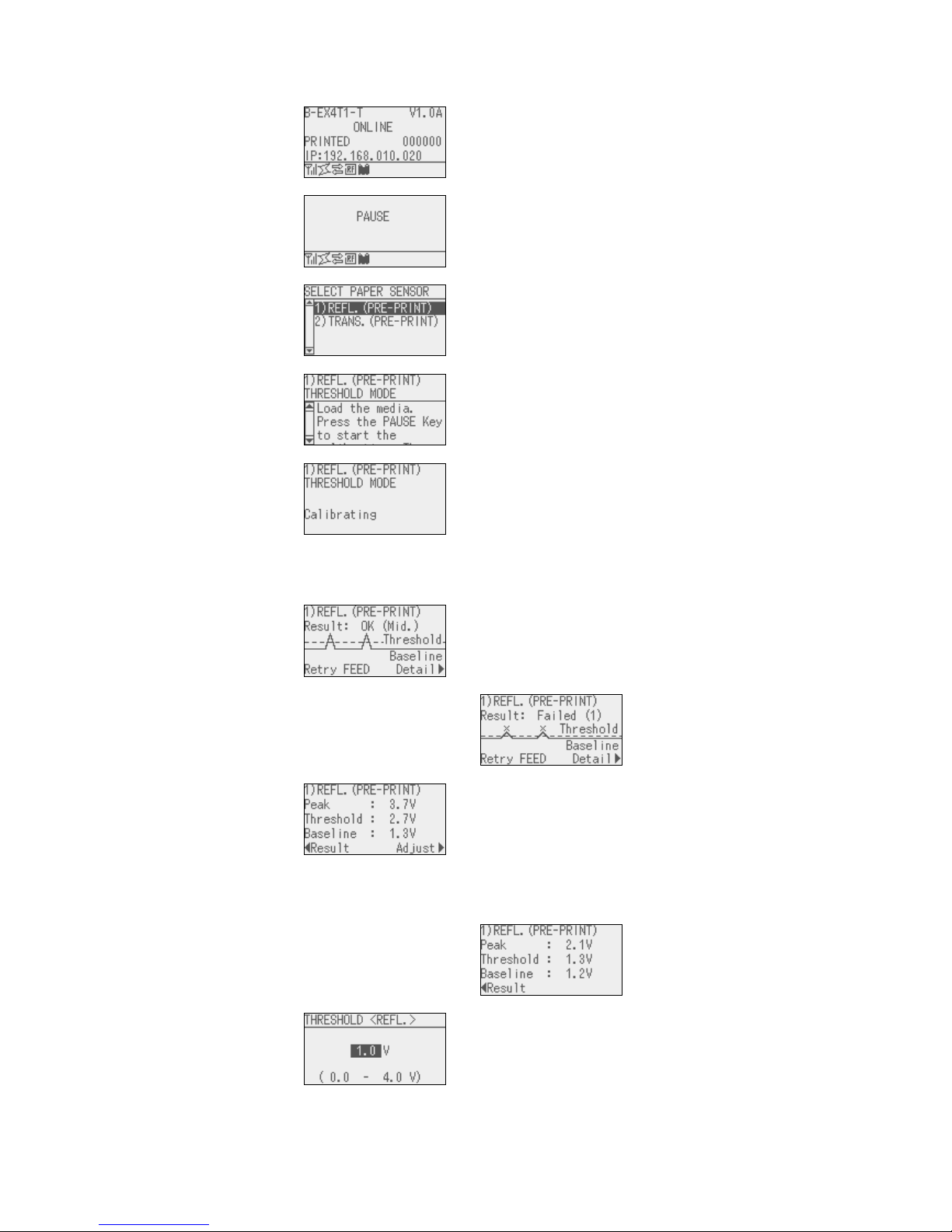

6.6.2 Threshold Setting Operation Example

[Online mode]

1. Normal state

↓ Press [PAUSE] key

[Online mode]

2. Pause state

↓ Hold down [PAUSE] key for 3 seconds

[Threshold setting]

3.

Media sensor

selection

Move the cursor with the

[UP] or [DOWN] key

↓ Press [ENTER] key

[Threshold setting]

4.

Waiting for the

media to be loaded

Scroll the display with the

[UP] or [DOWN] key

↓ Press [PAUSE] key

[Threshold setting]

5. Calibration

Hold down the [PAUSE]

key to keep feeding the

media

↓ Release [PAUSE] key. When the [PAUSE] key is

released, media feed

stops

↓ ↓

[Threshold setting]

6a.

Result: OK (Mid.)

↓

↓

↓

↓

↓ ↓

[Threshold setting]

6b.

Result: NG (1)

↓

↓

↓

Pressing the [FEED] key

returns the display to “3.

Media sensor selection.”

Pressing the [ENTER] key

returns the display to “2.

Pause condition.”

Pressing the [RIGHT] key

causes the display to go

to “7a/7b. Detail.

↓ Press [RIGHT] key ↓

[Threshold setting]

7a.

Detail: OK (Mid.)

↓

↓

↓

↓

↓

↓

Pressing the [RIGHT] key

causes the display to go

to “8a. Sensor Fine

adjustment.”

Pressing the [LEFT] key

returns the display to “6a.

Judgment.”

↓ ↓

[Threshold setting]

7b.

Detail: NG (1)

↓

↓

↓

Pressing the [LEFT] key

returns the display to “6b.

Judgment

↓ Press [RIGHT] key

[Threshold setting]

8a. Sensor fine

adjustment

Operation is same as 8.5.9

reflective sensor fine

adjustment

Pressing the [PAUSE],

[ENTER] or [CANCEL]

key returns the display to

“6a. Judgment

14

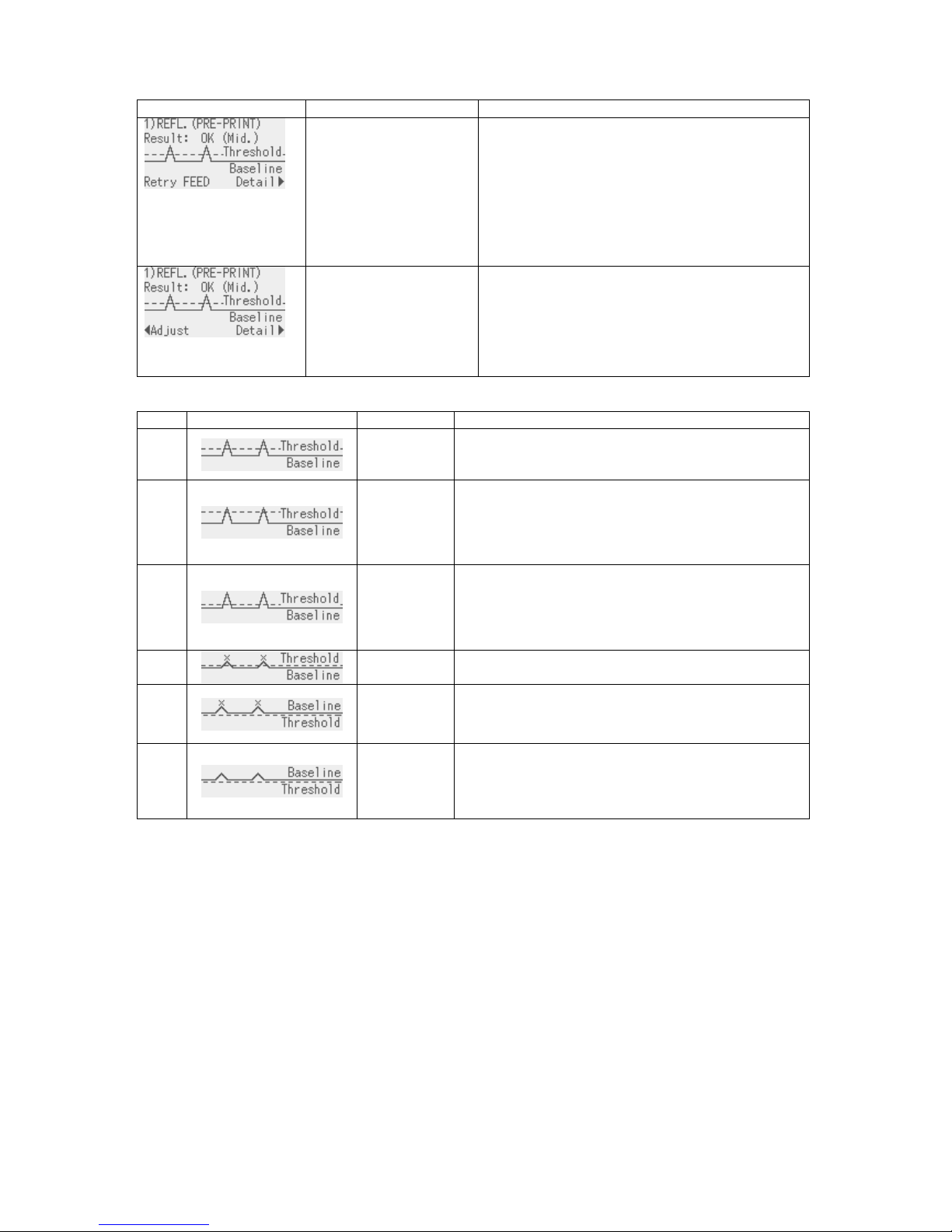

Judgment result

Display example Displayed item Explanation

• Sensor type

• Result (Text)

• Result (Graph)

• Key operation guide

The calibration result is shown.

Pressing the [FEED] key returns the display to

the media sensor selection and enables a

threshold setting.

Pressing the [RIGHT] key shows the measured

voltages.

Pressing the [ENTER] key terminates the

threshold setting.

• Sensor type

• Result (Text)

• Result (Graph)

• Key operation guide

The result of fine adjusted threshold setting is

shown.

Pressing the [LEFT] key returns the display to

the threshold fine adjustment.

The [RIGHT] and [ENTER] keys function in the

same way as above.

The threshold setting result is indicated with one of the following icon types.

No. Display example Icon name Explanation

1

OK (Mid.) Print position is detectable with the media sensor.

Threshold is at the midpoint between the peak and

the baseline.

2

OK (High) Threshold is near the peak voltage, so detection of

a gap/black mark may fail if the voltage difference is

very small. (Adjusting the threshold to the midpoint

between the peak and the baseline enables more

accurate detection.)

3

OK (Low) Threshold is near the baseline voltage, so detection

of a gap/black mark may fail if the voltage difference

is very small. (Adjusting the threshold to the

midpoint between the peak and the baseline

enables more accurate detection.)

4

NG (1)

Print position is not detectable with the media

sensor. Sensor adjustment is necessary.

5

NG (1)

Print position is not detectable with the media

sensor. Sensor adjustment is necessary.

(Threshold ≤ Baseline)

6

NG (2)

Print position is not detectable with the media

sensor.

(Calibration may enable print position detection,

but it is very difficult.)

15

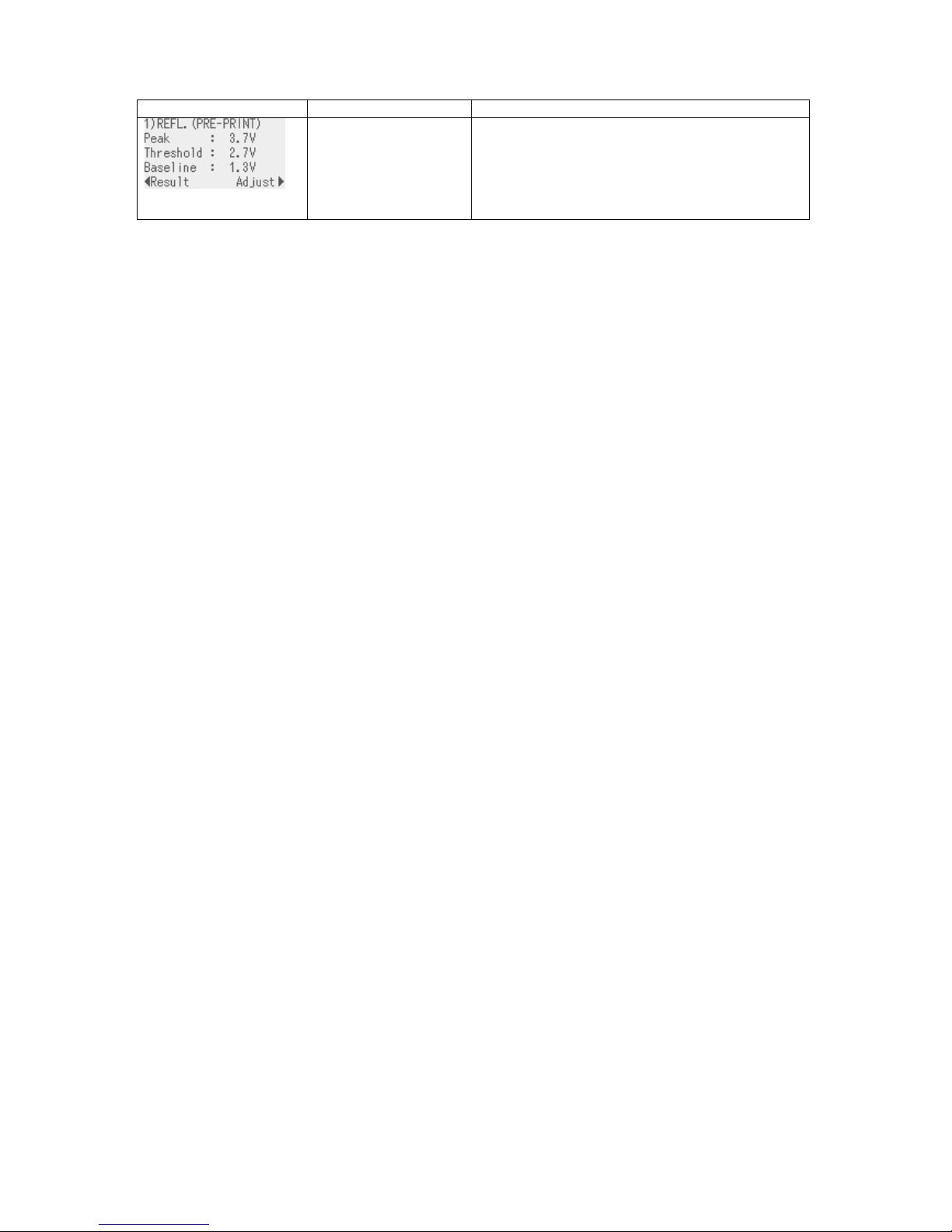

Detailed display

Display example Displayed item Explanation

• Sensor type

• Peak value

• Threshold voltage

• Baseline voltage

• Key operation guid

e

The calibration result and the threshold voltage

are displayed.

Pressing the [RIGHT] key enables setting a

threshold fine adjustment value.

Pressing the [LEFT] key returns the display to the

calibration result display.

(Supplementary Explanation)

(1) When the [PAUSE] key is released within 3 seconds while the printer is paused, the [PAUSE] key is

invalid.

(2) To program the threshold, 1.5 pieces or more label shall be fed. (If the label feed amount is insufficient,

the threshold may not be properly programmed. In this case, the threshold setting is required again.)

(3) While the head is lifted, the [PAUSE] key is invalid even if the [PAUSE] key is held down for 3 seconds or

more.

(4) When the proper print position is not obtained even after threshold setting, the sensor may be improperly

adjusted. In this case, readjust the sensor in system mode, and program the threshold.

When the backing paper of the label is too thick, the transmissive sensor needs to be readjusted.

In addition, make sure that “3: Transmissive sensor (when using the preprinted label)” or “4: Reflective

sensor (when using a manual threshold value)” is selected for sensor type of the Feed Command and

the Issue Command.

(5) Paper end and ribbon end are not detectable during the threshold setting. (The setting continues as long

as the [PAUSE] key is held down even if the printer runs short of media or ribbon.)

(6) The detailed display is shown when the [RIGHT] key is pressed while the result is displayed. The

measured sensor level and the currently programmed threshold fine adjustment value can be checked.

Fine adjustment value = Peak voltage – Threshold voltage

(7) Pressing the [LEFT] key returns the detailed display to the result display. Pressing the [RIGHT] key

causes the display to go to threshold fine adjustment screen. This is the same menu with the threshold

fine adjustment menu in section 8.5.9 (Reflective sensor) or 8.5.10 (Transmissive sensor).

(8) After setting the threshold fine adjustment value, the screen returns to the result display.

(9) While the result of fine adjusted threshold setting is shown, pressing the [LEFT] key returns the display to

the threshold fine adjustment screen and pressing the [RIGHT] key goes to the detailed display.

(10) During threshold setting, the media is fed at the same speed with that for the previous issue.

(11) Whether the threshold setting succeeded or not can be checked with either of the following methods.

Media feed with the [FEED] key

1. While the judgment result is displayed, press the [FEED] key to terminate the threshold setting.

→ The printer is placed in the pause state.

2. Press the [RESTART] key to clear the pause state.

→ The printer is placed in the online state.

3. Hold down the [MODE] key.

→ The printer enters the user system mode.

4. Select “<2>PARAMETER SET”, “Software Set”, then “THRESHOLD SELECT” with the [UP], [DOWN]

and [ENTER] keys.

5. Select the applicable media sensor type (“REFLECT” or “TRANS.”) and press the [ENTER] key.

→ The selected sensor type display is shown.

6. Select “MANUAL SET”, press the [ENTER] key, then [MODE] key.

→ User system mode menu is displayed.

16

7. Select “<1> RESET” and press the [ENTER] key.

→ After the printer is reset, it is placed in the online mode.

8. Press the [FEED] key to feed the media.

→ If a paper jam occurs or the media does not stop at the print start position, retry the threshold setting.

Sending Issue command

1. Press the [FEED] key while the judgment result is displayed to terminate the threshold setting.

→ The printer is placed in the pause state.

2. Press the [RESTART] key to clear the pause state.

→ The printer is placed in the online state.

3. Hold down the [MODE] key.

→ The printer enters the user system mode.

4. Select “<2>PARAMETER SET”, “Software Set”, then “THRESHOLD SELECT” with the [UP], [DOWN]

and [ENTER] keys.

5. Select the media sensor type (“REFLECT” or “TRANS.”) depending on the sensor type specified by the

Issue Command, and press the [ENTER] key.

Sensor type in Issue Command Setting

0: No sensor Whether the threshold setting succeeded or not cannot be

checked.

1: Reflective sensor Select “REFLECT”.

When the selected sensor type display is shown, select

“MANUAL SET” and press the [ENTER] key.

* Select the media sensor type to the one for which the

threshold was set.

2: Transmissive sensor (when using

normal labels)

Select “TRANS.”

When the selected sensor type display is shown, select

“MANUAL SET” and press the [ENTER] key.

* Select the media sensor type to the one for which the

threshold was set.

3: Transmissive sensor (when using

preprinted labels)

No setting is necessary.

4: Reflective sensor (when using a

manual threshold value)

No setting is necessary.

6. Press the [MODE] key.

→ User system mode menu is displayed.

7. Select “<1> RESET” and press the [ENTER] key.

→ After the printer is reset, it is placed in the online mode.

8. Send an Issue Command to make the printer print.

→ If a paper jam occurs or the media does not stop at the print start position, retry the threshold setting.

17

6.7 JOB CANCELLATION

6.7.1 Outline of the Job Cancellation

The [CANCEL] key enables cancellation of subsequent print jobs.

Holding down the [CANCEL] key for 3 seconds while the printer is in an error* or pause state causes the

printer to start a quick reset and shift to the online mode.

As long as the [CANCEL] key is held down, the data in the receive buffer is all discarded.

Job cancellation is finished when the [CANCEL] key is released, and the printer restores to the normal

condition.

*: Errors which can be recovered by a depression of the [RESTART] key.

For details, refer to Section 6.8 LCD MESSAGES AND LED INDICATIONS.

*: A command error may occur if the [CENCEL] key is released before the all received data has been

discarded.

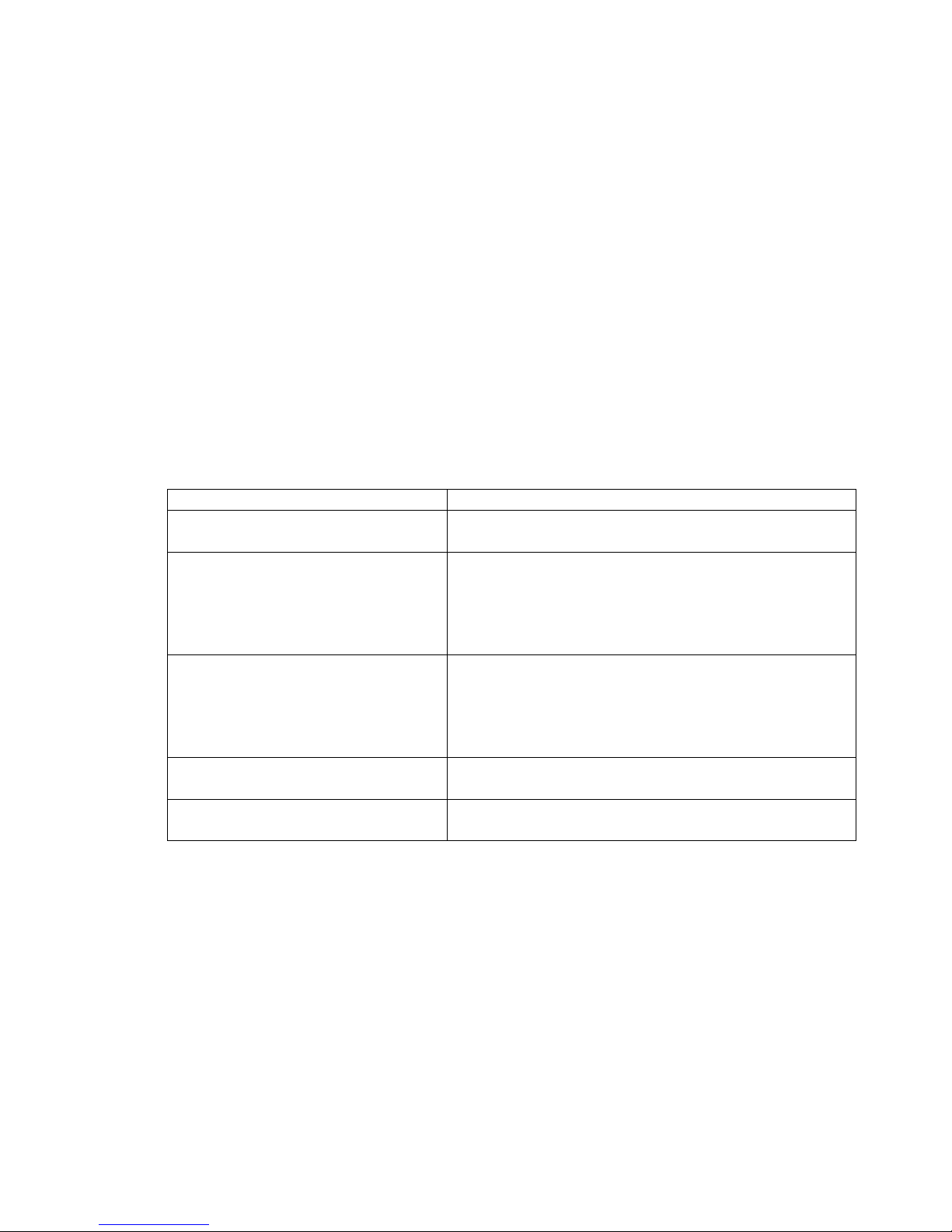

6.7.2 Job Cancellation Operation Example

[Online mode]

1. Normal condition

↓ Occurrence of an error of depression of the

[PAUSE] key.

[Online mode]

2. Pause or error

condition

↓ Hold down [PAUSE] key for 3 seconds.

[Online mode]

3. Job cancellation

after quick reset

As long as the [CANCEL]

key is held down, received

data is discarded.

↓ Release the [CALCEL] key.

[Online mode]

4. Normal condition

The printer restores to the

online mode.

18

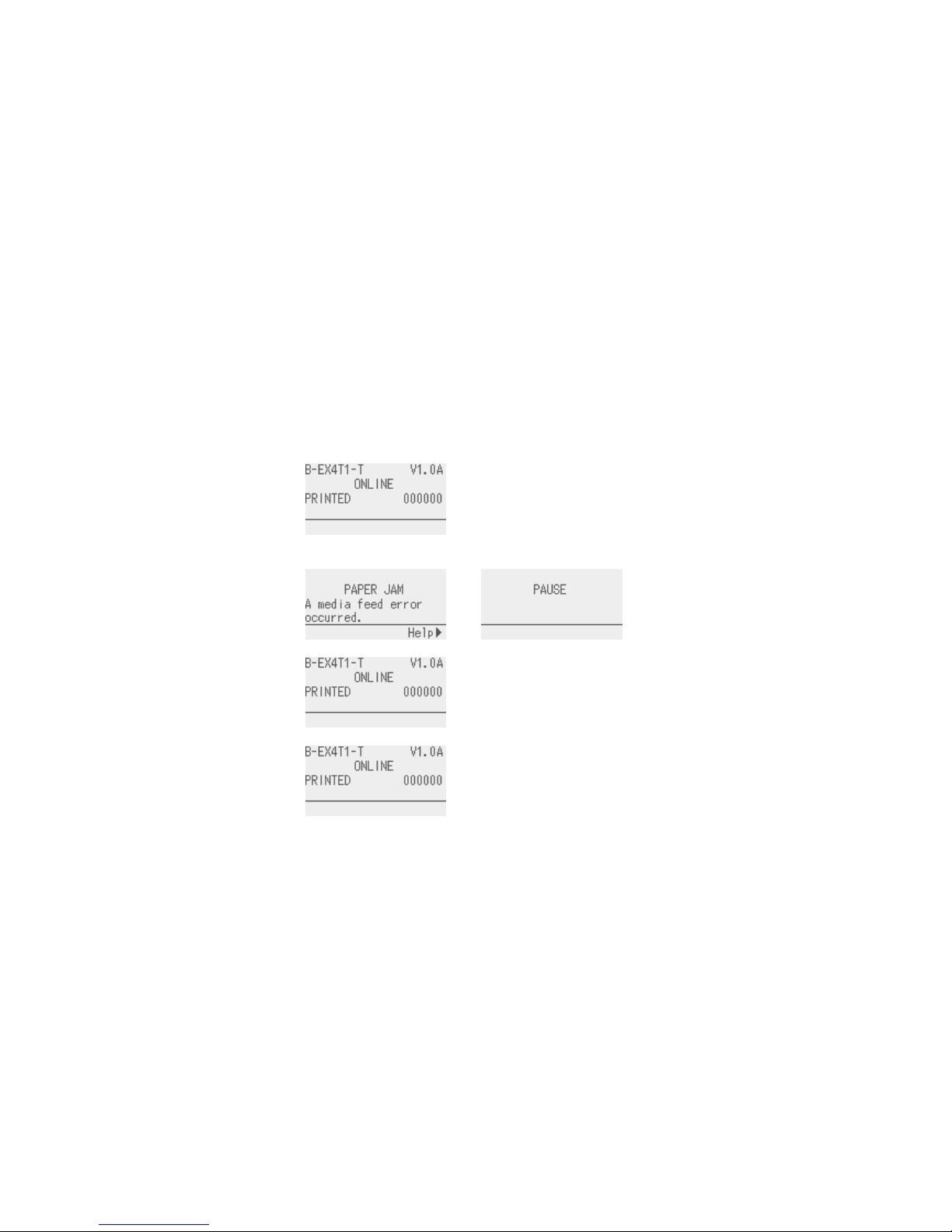

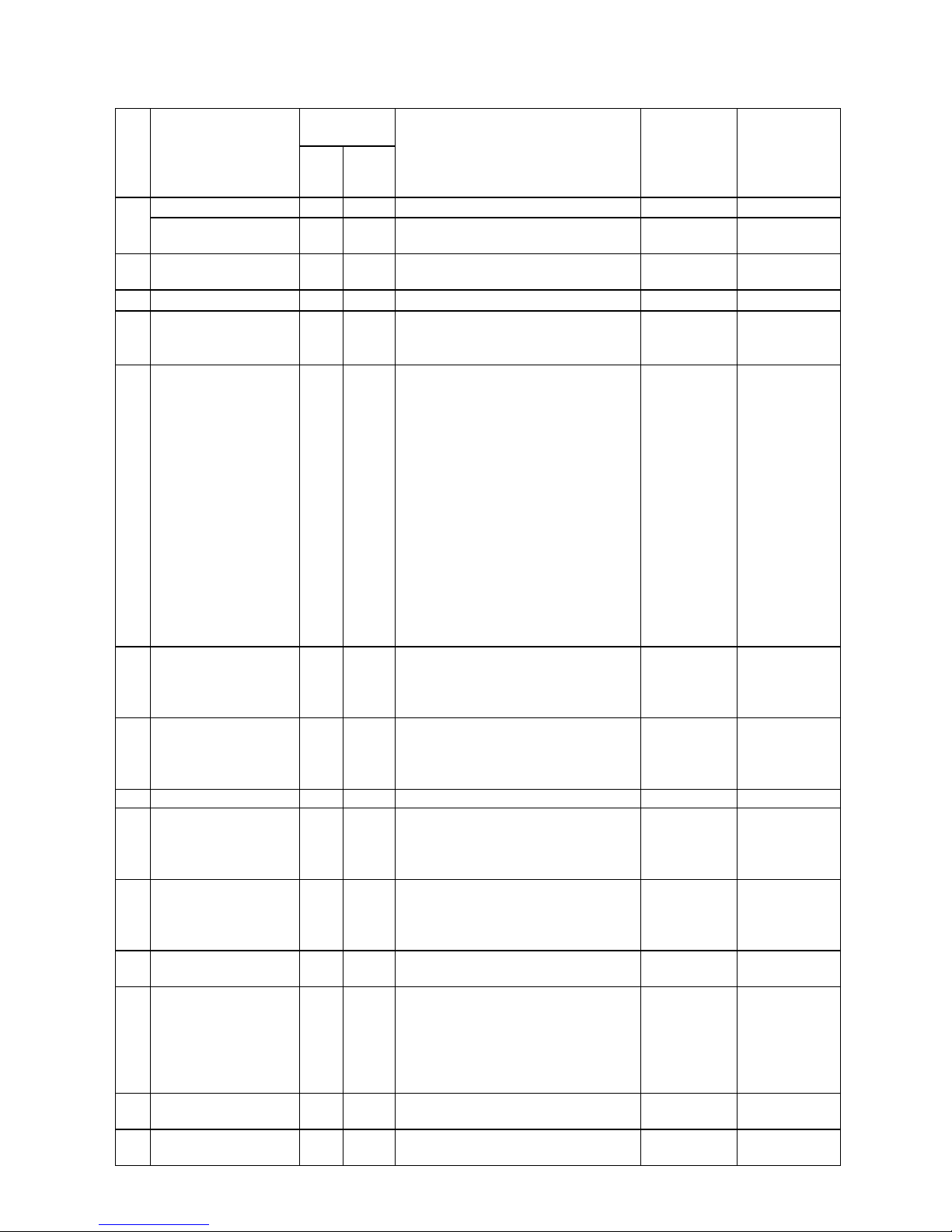

6.8 LCD MESSAGES AND LED INDICATIONS

LED

indications

No

LCD Message

2

nd

line

(English)

ON

LINE

ERROR

Printer status

Restoration by

the [RESTART]

key

Yes/No

Acceptance of

Status Request

and Reset

Command

Yes/No

ONLINE ○ ●

In the online mode

-

Yes

1

ONLINE

●

In the online mode

(Communicating)

-

Yes

2 HEAD OPEN ● ●

A feed or an issue was attempted

with the head opened.

-

Yes

3 PAUSE ● ●

In a pause state

Yes Yes

4 COMMS ERROR ●

A parity error or framing error has

occurred during communication by

RS-232C.

Yes Yes

5 PAPER JAM ●

A paper jam occurred during paper

feed.

Paper was not set properly.

Label actually used and the

selected media sensor type do not

match.

The media sensor position does

not align with the black mark

position.

The actual media size and the

specified media length do not

match.

The level of media sensor is not

suitable for the actual media.

The gap of label cannot be

detected due to pre-printing.

Yes Yes

6 CUTTER ERROR ●

A paper jam occurred in the cutter.

The cutter did not move from the

home position.

The cutter cover was open.

Yes Yes

7 NO PAPER ●

The media has run out.

The media has not been set.

Media sensor level is not suitable

for the paper used.

Yes Yes

8 NO RIBBON ●

The ribbon has run out. Yes Yes

9 HEAD OPEN ●

A feed or an issue was attempted

with the head opened.

(Except media feed caused by the

[FEED] key or Expansion I/O)

Yes Yes

10 HEAD ERROR ●

A broken dot error has occurred in

the thermal head.

The error has occurred in the head

driver.

Yes Yes

11

EXCESS HEAD

TEMP

●

The thermal head temperature has

become excessively high.

No Yes

12 RIBBON ERROR ●

An abnormal condition occurred

with the sensor for determining the

torque of the ribbon motor.

A ribbon jam occurred.

The ribbon has been torn.

The ribbon has not been set.

Yes Yes

13 REWIND FULL ●

An overflow error has occurred in

the rewinder unit.

Yes Yes

14

SAVING ####KB/&&&&KB

or

●

Writable characters or PC

command save mode.

-

Yes

19

SAVING %,%%%.%%%KB

15

FORMAT ####KB/&&&&KB

or

FORMAT %,%%%.%%%KB

●

Initializing the storage area.

-

Yes

16 NOW LOADING…

●

Downloading TrueType font or

BASIC program

-

Yes

17

MEMORY WRITE

ERR.

●

An error has occurred while writing

data into the memory for storage.

(USB memory, flash ROM on the

CPU board)

No Yes

18 FORMAT ERROR ●

An erase error has occurred while

formatting the memory for storage

(USB memory, flash Rom on the

CPU board)

No Yes

19 MEMORY FULL ●

Saving failed because of the

insufficient capacity of the memory

for storage (USB memory, flash

ROM on the CPU board)

No Yes

20

SYNTAX ERROR

Command error

(Refer *1, *2)

●

A command error has occurred

while analyzing the command. Yes Yes

21 POWER FAILURE ●

A momentary power interruption

has occurred.

No No

22 EEPROM ERROR ●

A backup EEPROM cannot be

read/write pr.

No No

23 SYSTEM ERROR ●

When any abnormal operations as

below are performed, a system error

occurs.

(a) Command fetch from an odd

address

(b) Access to the word data from a

place other than the boundary of

the word data

(c) Access to the long word data from

a place other than the boundary of

the long word data

(d) Access to the area of 80000000H

to FFFFFFFFH in the logic space

in the user system mode.

(e) Undefined command placed in

other than the delay slot has been

decoded.

(f) Undefined command in the delay

slot has been decoded.

(g)

Command to rewrite the delay

slot has been decoded.

No No

24 DHCP CLIENT INIT… ● ●

Initializing DHCP CLIENT.

* Only when DHCP is enabled

- -

25

RFID WRITE

ERROR

●

The printer did not succeed in

writing data onto the RFID tag after

having retried for the specified

times.

Yes Yes

26

RFID ERROR

●

The printer cannot communicate

with the RFID module.

No Yes

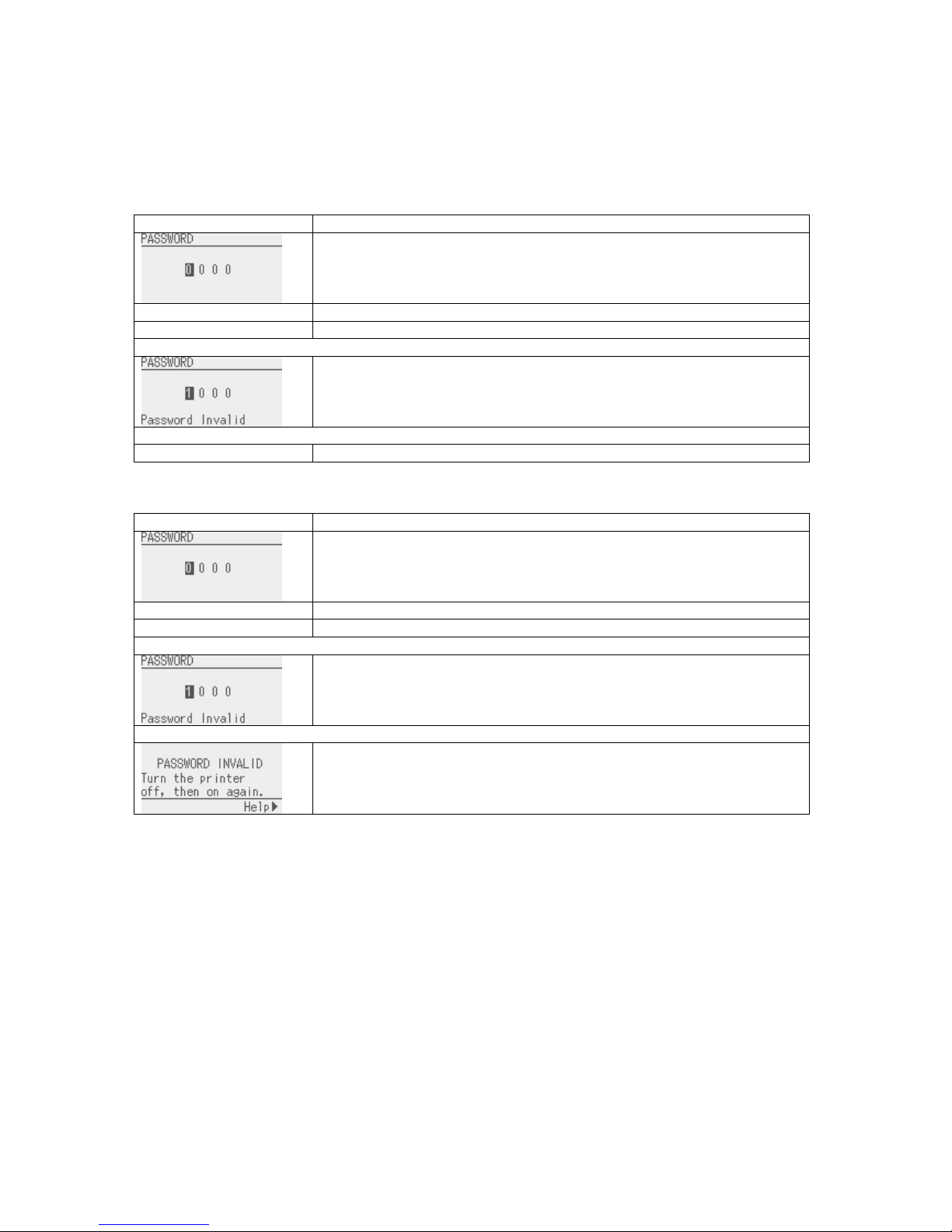

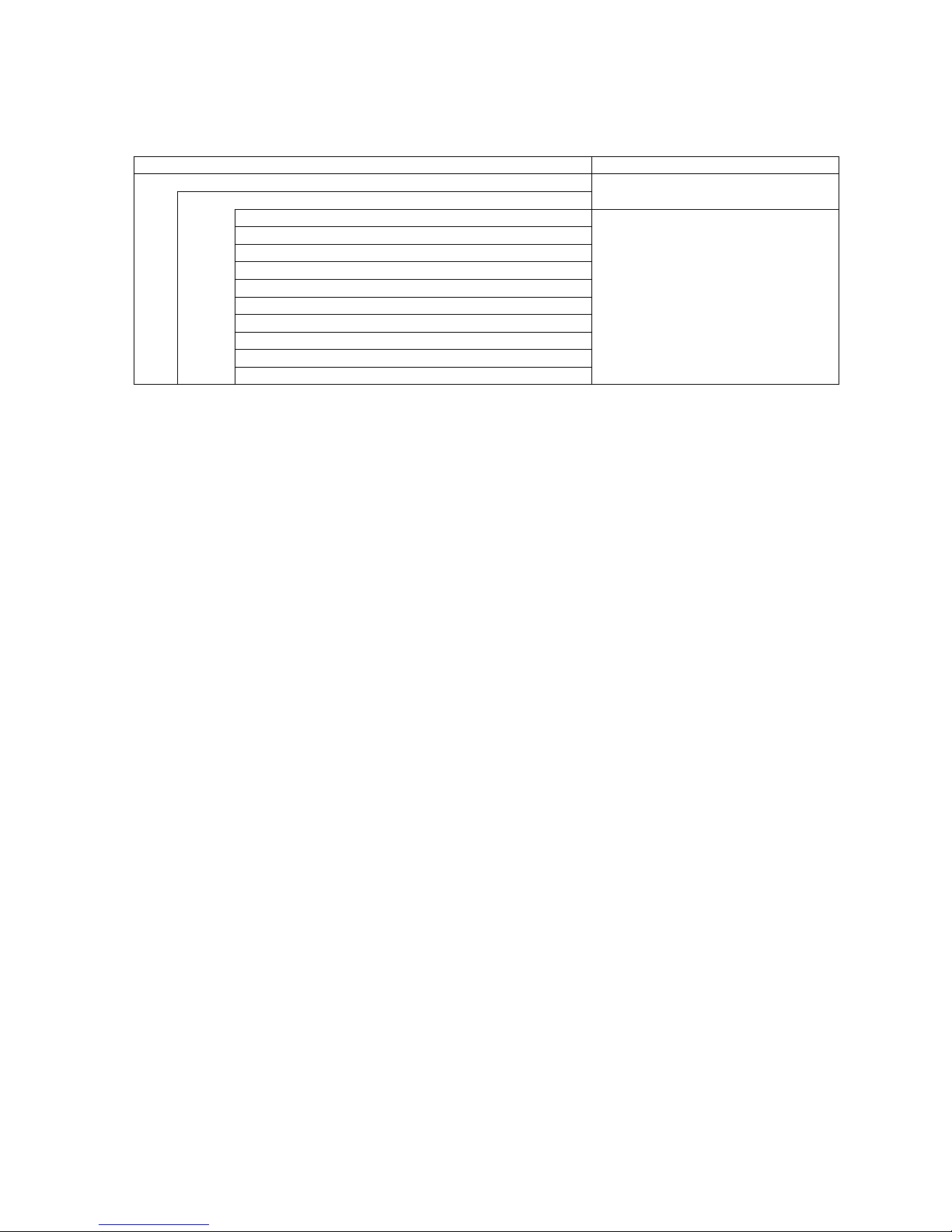

27 INPUT PASSWORD ● ●

The printer is waiting for a

password to be entered.

No No

28

PASSWORD

INVALID

● ●

A wrong password was entered

consecutively for three times.

No No

20

29 RFID CONFIG ERR ●

B-EX700-RFID-U2-EU/US-R only

RFID module’s destination code is

not specified.

No No

30

LOW BATTERY

(Refer to *4,5)

●

RTC battery is low.

No Yes

31

INTERNAL COM

ERR

● ●

A hardware error has occurred in

the internal serial interface.

No No

Explanation of symbols

Symbol Explanation Range

: ON

-

: Blinking

-

: OFF

-

%%,%%%,%%%: Remaining memory size of the external USB

memory

0 to 09,999,999 (Kbyte)

####: Remaining memory size for PC command

storage area in the internal memory

0 to 3072 (Kbyte)

&&&&: Remaining memory size for writable

character storage area

0 to 3147 (Kbyte)

21

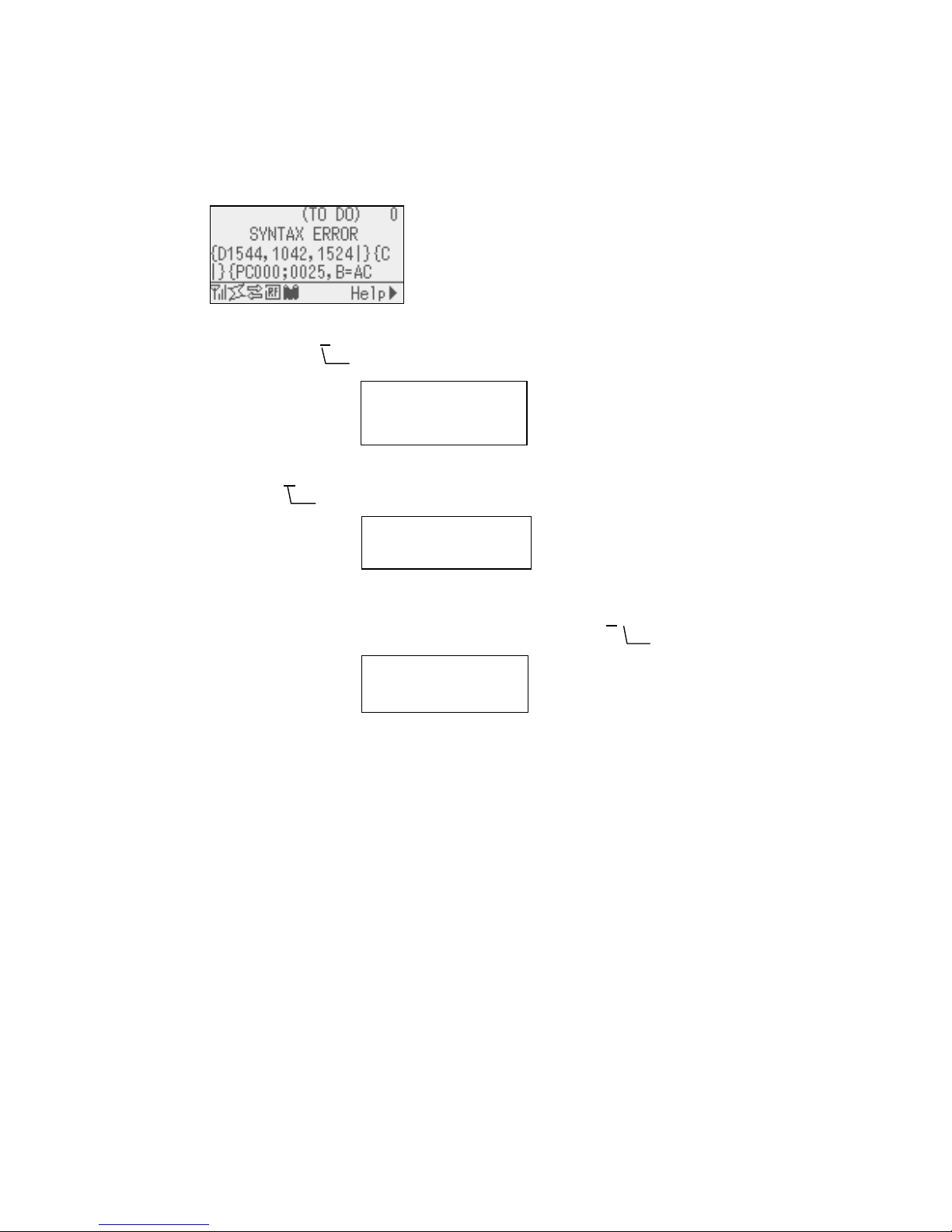

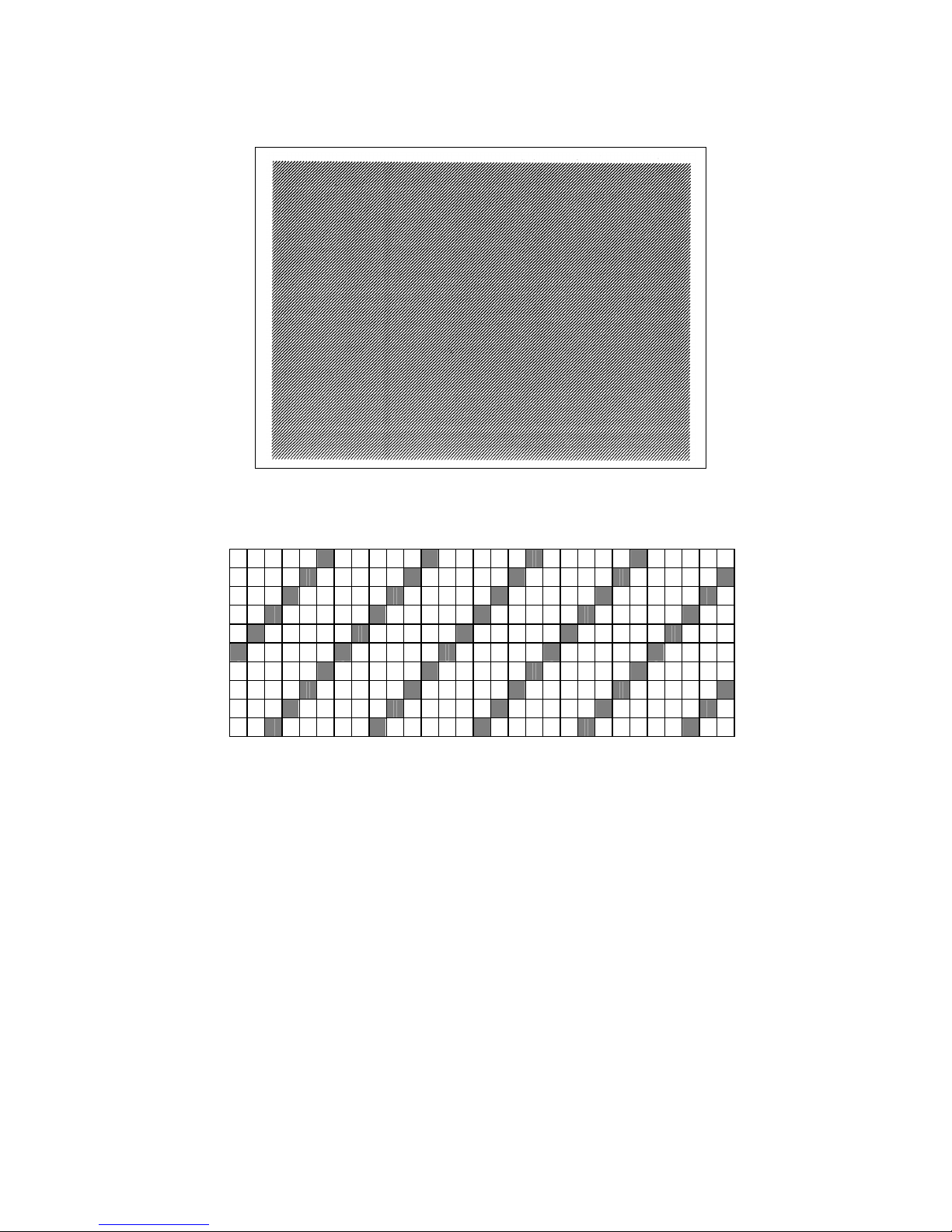

(*1) When there is command error in received command, up to 42 bytes of error command, starting from the

command code, are shown on 3

rd

and 4th lines of the LCD.

(However, [LF] and [NUL] are not displayed. Also, 43rd bytes and later are not displayed.)

Display example

(Example 1)

[ESC] PC001;0A

00,0300,2,2,A,00,B [LF][NUL]

LCD Display

(Example 2)

[ESC]T20G

30[LF][NUL]

LCD Display

(Example 3)

[ESC] PC002;0100,0300,15,15,A,00,00,J0101,+000000000A

,Z10,P1[LF][NUL]

LCD display

(*2) When a command error is displayed, the code other than 20H - 7FH and A0H - DFH is displayed as “?”

(3FH).

(*3) When the ribbon near end detection is enabled, the error LED blinks at 1-second interval (ON for 500

msec. OFF for 500 msec.) while the printer is in a ribbon near end state and displays message number 1,

2 or 3.

(*4) The battery check does not work when the printer is being reset and the RTC is not mounted.

(*5) It is necessary to follow the procedure below to use RTC function under a low battery condition.

Turn off the printer power while the printer is in an error state. Start the printer in the system mode,

set the date and time for the RTC again, then reset the printer to place the printer in online state.

* The printer can print the programmed date and time until it is turned off.

Command error

PC001;0A00,0300,2,2,A

,00,B

Command Error

T20G30

Command error

PC002;0100,0300,15,15

,A,00,00,J0101,+00000

Command error

Command error

22

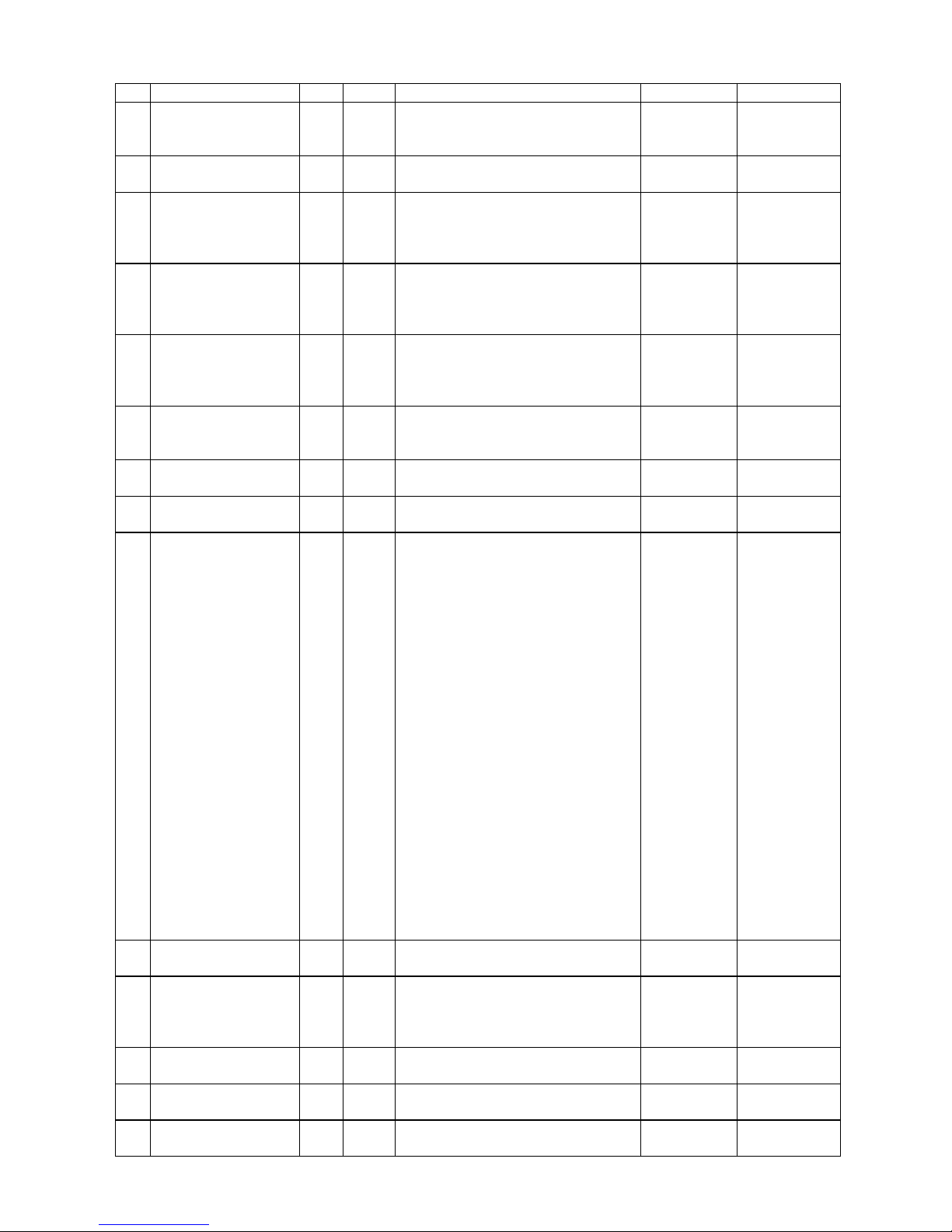

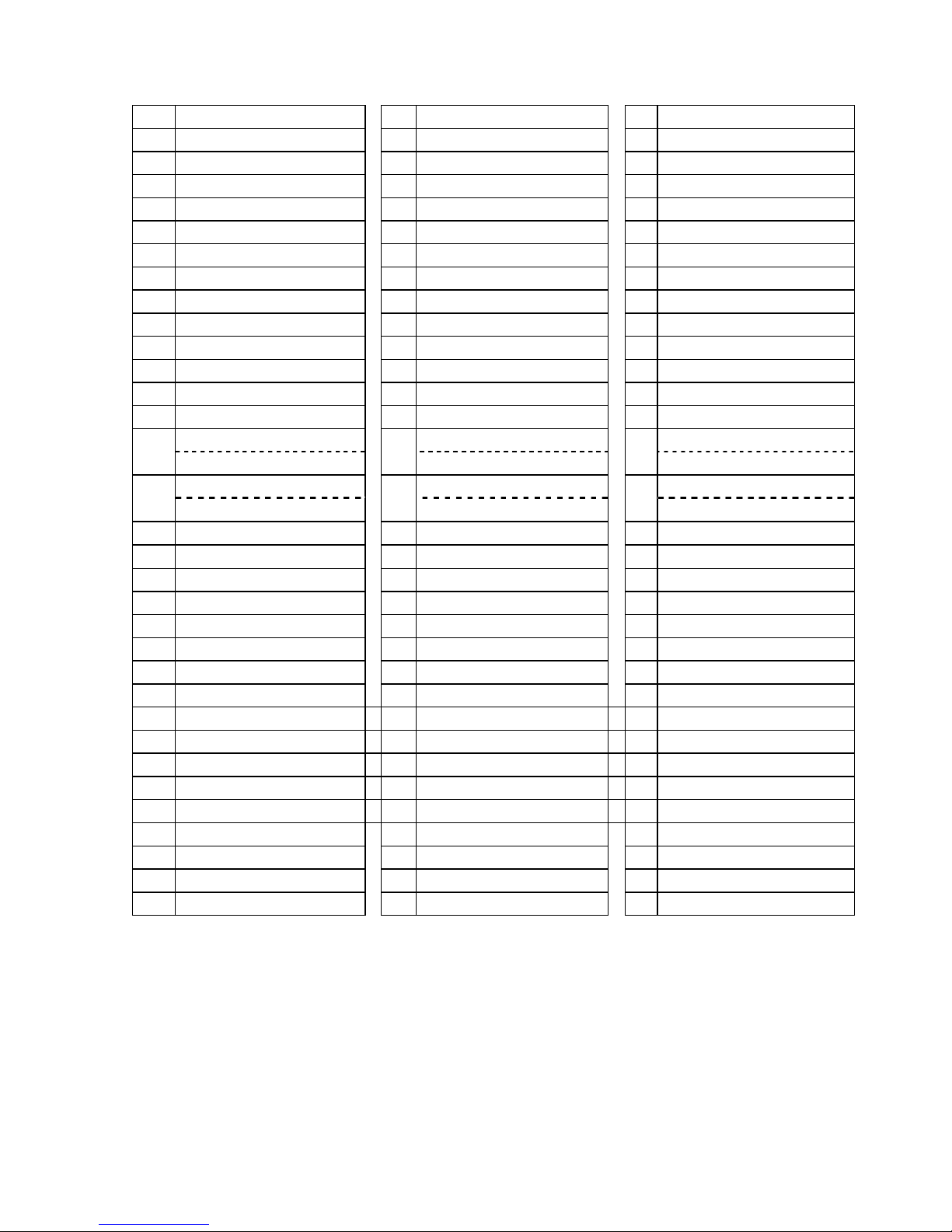

LCD message (2

nd

line)

No English No German No French

1 ONLINE 1 ONLINE 1 PRETE

2 HEAD OPEN 2 Kopf offen. 2 TÊTE OUVERTE

3 PAUSE 3 PAUSE 3 PAUSE

4 COMMS ERROR 4 Kommunikations-Fehler 4 ERREURS DE COMMUNICAT

5 PAPER JAM 5 PAPIERSTAU 5 BOURRAGE PAPIER

6 CUTTER ERROR 6 Messer Fehler 6 ERREUR MASSICOT

7 NO PAPER 7 Kein Papier. 7 PAS DE PAPIER

8 NO RIBBON 8 KEIN FARBBAND 8 PAS DE RUBAN

9 HEAD OPEN 9 Kopf offen. 9 TÊTE OUVERTE

10 HEAD ERROR 10 Kopf Fehler 10 ERREUR DE TÊTE

11 EXCESS HEAD TEMP 11 Kopftemp. zu hoch 11 TETE TROP CHAUDE

12 RIBBON ERROR 12 FARBBAND FEHLER 12 ERREUR RUBAN

13 REWIND FULL 13 AUFWICKLER VOLL 13 REENROULEUR PLEIN

SAVING ####KB/&&&&KB SAVING ####KB/&&&&KB SAUVE ####KB/&&&&KB

14

SAVING %%,%%%,%%%KB

14

SAVING %%,%%%,%%%KB

14

SAUVE %%,%%%,%%%KB

FORMAT ####KB/&&&&KB FORMAT ####KB/&&&&KB FORMAT ####KB/&&&&KB

15

FORMAT %%,%%%,%%%KB

15

FORMAT %%,%%%,%%%KB

15

FORMAT %%,%%%,%%%KB

16 NOW LOADING… 16 NOW LOADING... 16 CHARGEMENT ...

17 SETTING MODE 17 SETTING MODE 17 MODE REGLAGES

18 MEMORY WRITE ERR. 18 MEMORY WRITE ERROR 18 ERR. ECRITURE MÉMOIRE

19 FORMAT ERROR 19 FORMAT ERROR 19 ERREUR DE FORMAT

20 MEMORY FULL 20 Speicher voll 20 MÉMOIRE PLEINE

21 SYNTAX ERROR 21 SYNTAX ERROR 21 ERREUR DE SYNTAXE

22 POWER FAILURE 22 POWER FAILURE 22 ERREUR D'ALIMENTATION

23 EEPROM ERROR

23 EEPROM Fehler 23 ERREUR EEPROM

24 SYSTEM ERROR 24 SYSTEM ERROR 24 ERREUR SYSTÈME

25 DHCP CLIENT INIT… 25 DHCP CLIENT INIT... 25 INIT CLIENT DHCP ...

26 RFID WRITE ERROR 26 RFID WRITE ERROR 26 ERREUR ECRITURE RFID

27 RFID ERROR 27 RFID FEHLER 27 ERREUR RFID

28 INPUT PASSWORD 28 INPUT PASSWORD 28 INPUT PASSWORD

29 PASSWORD INVALID 29 PASSWORT ungültig 29 MOT DE PASSE INVALIDE

30 RFID CONFIG ERR 30 RFID CONFIG Error 30 ERREUR CONFIG. RFID

31 LOW BATTERY 31 Batterie schwach 31 BATTERIE FAIBLE

32 INTERNAL COM ERR 32 INTERNAL COMM ERROR 32 ERREUR COMM. INT.

23

No Dutch No Spanish No Japanese

1 IN LIJN 1 PREPARADA 1

2 PRINTKOP OPEN. 2 CABEZAL ABIERTO 2

3 PAUZE 3 PAUSA 3

4 COMMUNICATIE FOUT 4 ERROR DE COMUNICACION 4

5 PAPIER STORING. 5 ATASCO DE PAPEL 5

6 FOUT SNIJMES 6 ERROR DE CORTADOR 6

7 GEEN PAPIER 7 SIN PAPEL 7

8 GEEN LINT 8 SIN CINTA 8

9 PRINTKOP OPEN. 9 CABEZAL ABIERTO 9

10 FOUT PRINTKOP 10 ERROR DE CABEZAL 10

11 PRINTKOP OVERHIT. 11 EXCESO TEMP. CABEZAL 11

12 LINT FOUT 12 ERROR DE CINTA 12

13 OPROLEENHEID VOL 13 REBOBINADOR LLENO 13

OPSLAAN ####KB/&&&&KB SALVAR ####KB/&&&&KB

14

OPSLAAN %%,%%%,%%%KB

14

SALVAR %%,%%%,%%%KB

14

FORMAT ####KB/&&&&KB FORMATO ####KB/&&&&KB

15

FORMAT %%,%%%,%%%KB

15

FORMATO %%,%%%,%%%KB

15

16 LADEN . . . 16 CARGANDO... 16

17 INSTELMODUS 17 MODO CONFIG. 17

18 MEM SCHRIJF FOUT 18 ERROR DE ESCRITURA 18

19 FORMAT FOUT 19 ERROR DE FORMATO 19

20 GEHEUGEN VOL 20 MEMORIA LLENA 20

21 SYNTAX FOUT 21 ERROR DE SINTAXIS 21

22 VOEDING FOUT 22 FALLO DE ALIMENTACION 22

23 FOUT EEPROM

23 ERROR EN LA EEPROM 23

24 SYSTEEM FOUT. 24 ERROR DE SISTEMA 24

25 INIT CLIENT DHCP 25 INIC. CLIENTE DHCP... 25

26 SCHRIJFFOUT RFID 26 ERROR ESCRITURA RFID 26

27 RFID FOUT 27 ERROR EN RFID 27

28 INPUT PASSWORD 28 INPUT PASSWORD 28

29 ONGELDIG PASWOORD 29 CONTRASEÑA NO VALIDA 29

30 RFID CONFIG. FOUT 30 ERROR DE CONFIG. RFID 30

31 LAGE BATTERIJ. 31 BATERIA BAJA 31

32 INTERNE COMM. FOUT 32 ERR INTERNO COMUNIC. 32

24

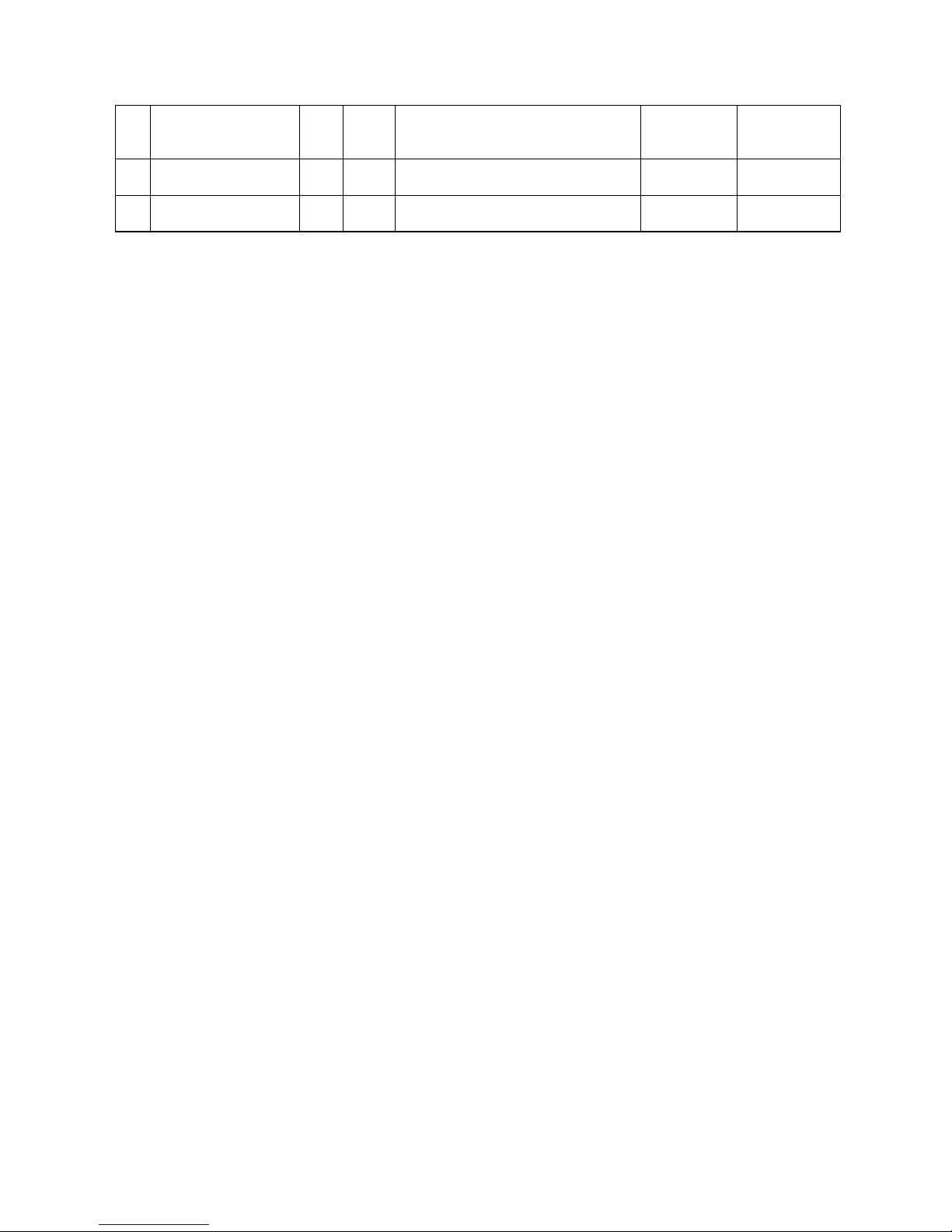

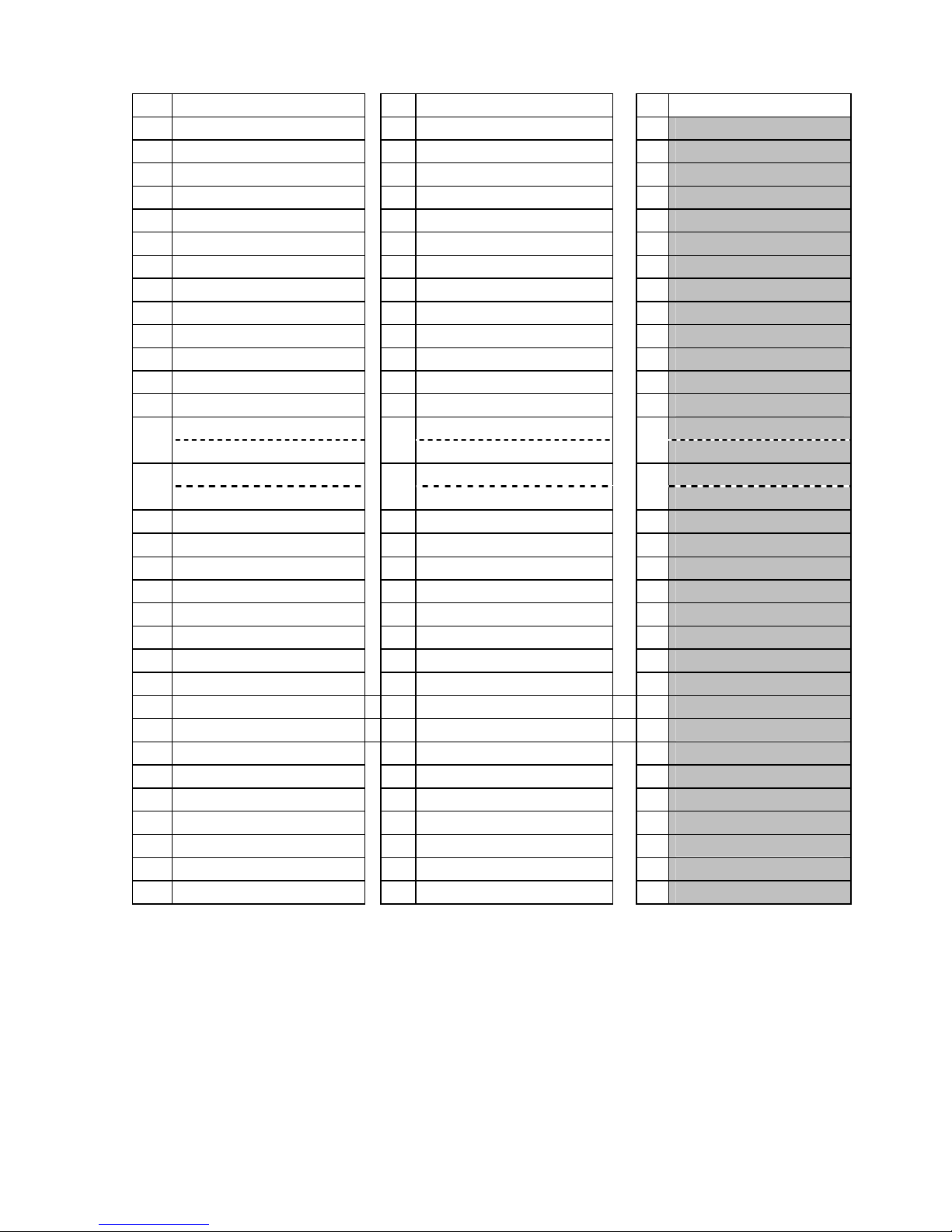

No Italian No Portuguese

1 On Line 1 PREPARADA

2 Testina Aperta 2 CABECA ABERTA

3 PAUSA 3 PAUSA

4 Errore Seriale 4 ERRO DE COMUNICACAO

5 Carta inceppata 5 PAPEL ENCRAVADO

6 Errore Taglierina 6 ERRO DE CORTADOR

7 Manca Carta 7 SEM PAPEL

8 Manca Nastro 8 SEM FITA

9 Testina Aperta 9 CABECA ABERTA

10 ERRORE TESTINA 10 ERRO DE CABECA

11 Temp. testa alta 11 EXCESSO TEMP. CABECA

12 ERRORE NASTRO 12 ERRO DE FITA

13 REWINDER PIENO 13 REBOBINADOR CHEIO

SALVA ####KB/&&&&KB SALVAR ####KB/&&&&KB

14

SALVA %%,%%%,%%%KB

14

SALVAR %%,%%%,%%%KB

FORMAT ####KB/&&&&KB FORMATO ####KB/&&&&KB

15

FORMAT %%,%%%,%%%KB

15

FORMATO %%,%%%,%%%KB

16 CARICAMENT 16 A CARREGAR...

17 Configurazione 17 MODO CONFIG.

18 Err. Scritt. memoria 18 ERRO DE ESCRITA

19 ERRORE FORMATTAZIONE 19 ERRO DE FORMATO

20 Memoria piena 20 MEMORIA CHEIA

21 SYNTAX ERROR 21 ERRO DE SINTAXE

22 ERRORE ALIMENT. 22 FALHA DE ALIMENTACAO

23 Errore EEPROM 23 ERRO NA EEPROM

24 SYSTEM ERROR 24 ERRO DE SISTEMA

25 DHCP CLIENT INIT... 25 INIC. CLIENTE DHCP...

26 RFID WRITE ERROR 26 ERRO ESCRITA RFID

27 RFID ERROR 27 ERRO EM RFID

28 INPUT PASSWORD 28 INPUT PASSWORD

29 PASSWORD ERRATA 29 SENHA INVALIDA

30 RFID CONFIG ERR 30 ERRO DE CONFIG. RFID

31 BATTERIA BASSA 31 POUCA BATERIA

32 Errore Comm Interna

32 ERR INTERNO COMUNIC.

25

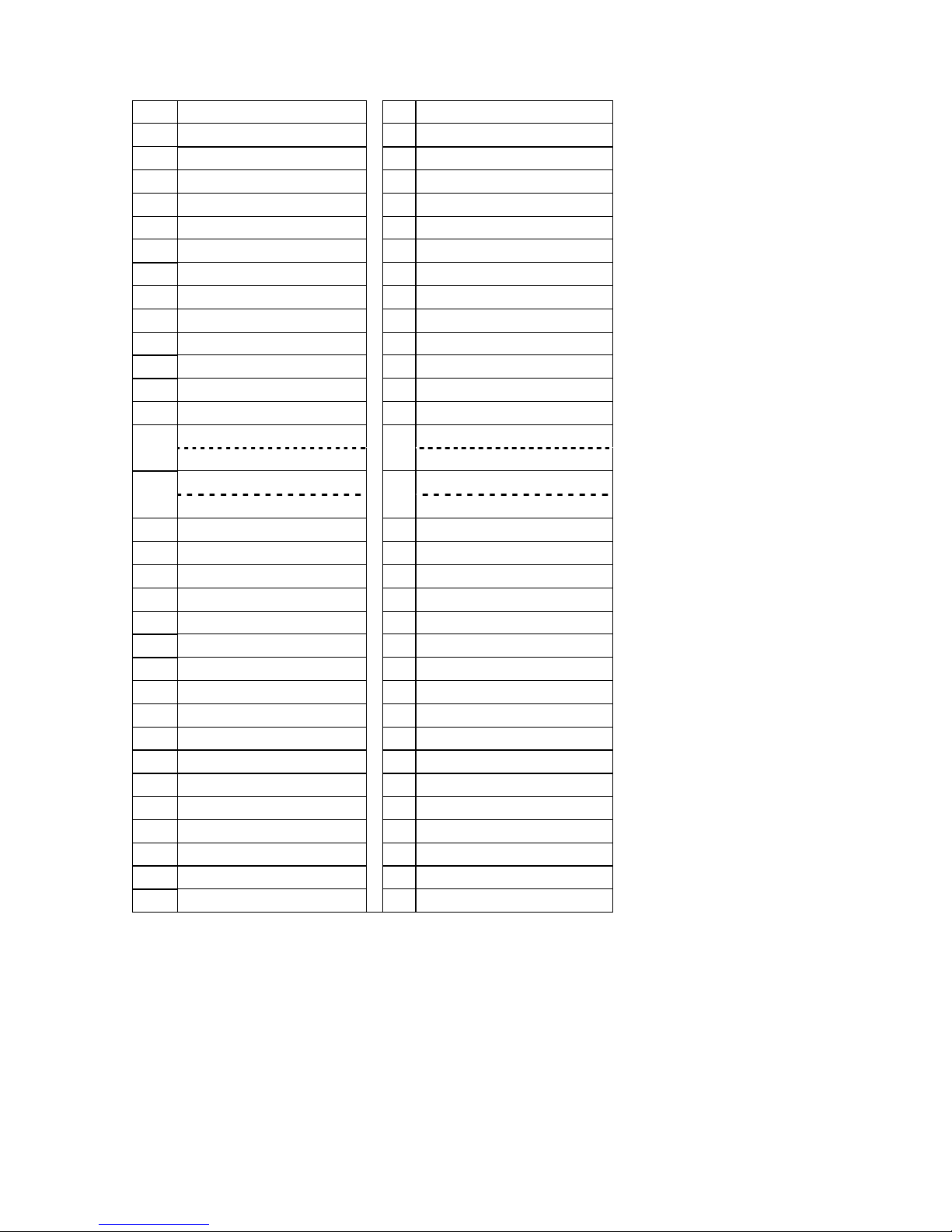

7 DISPLAY PATTERN AND KEY OPERATION FOR SYSTEM MODE AND

USER MODE

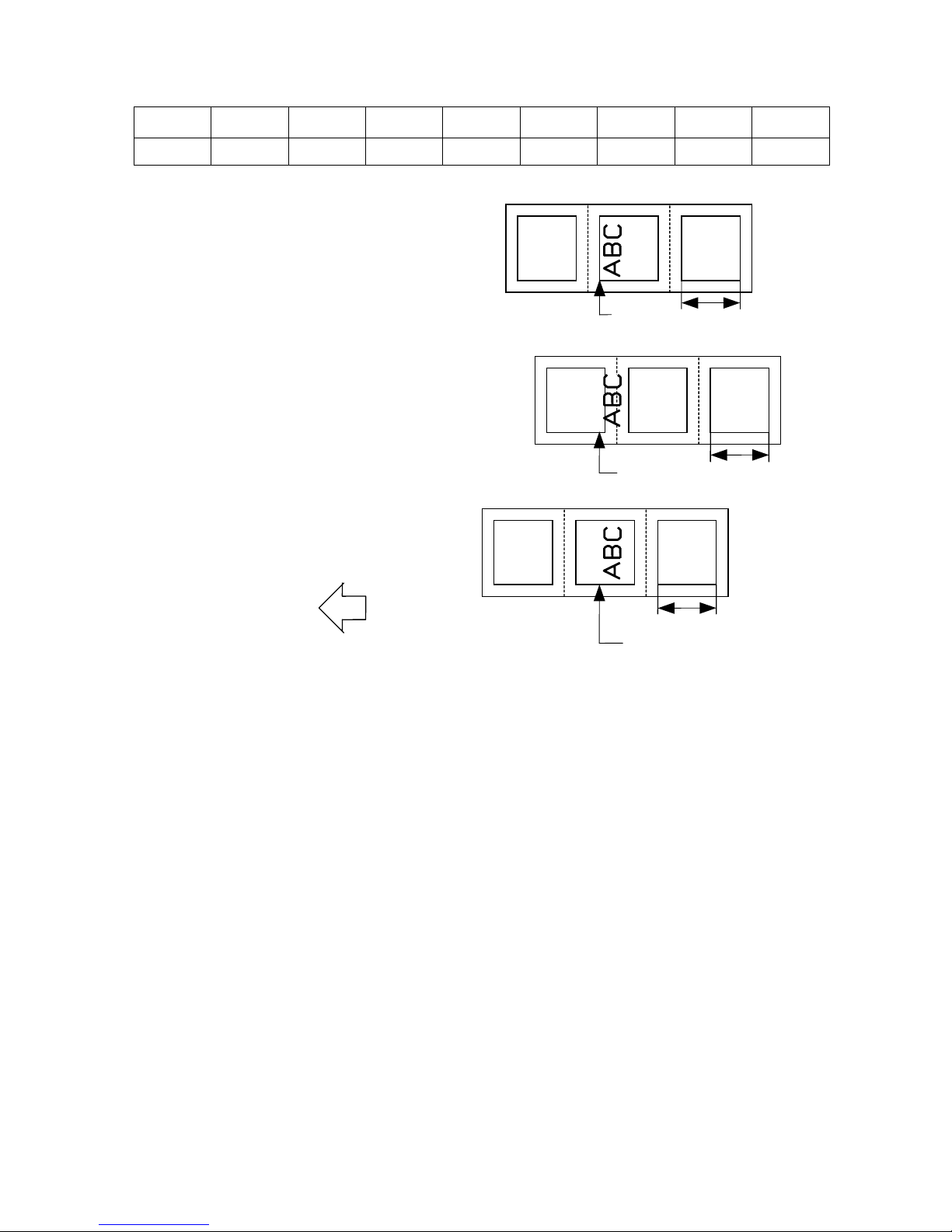

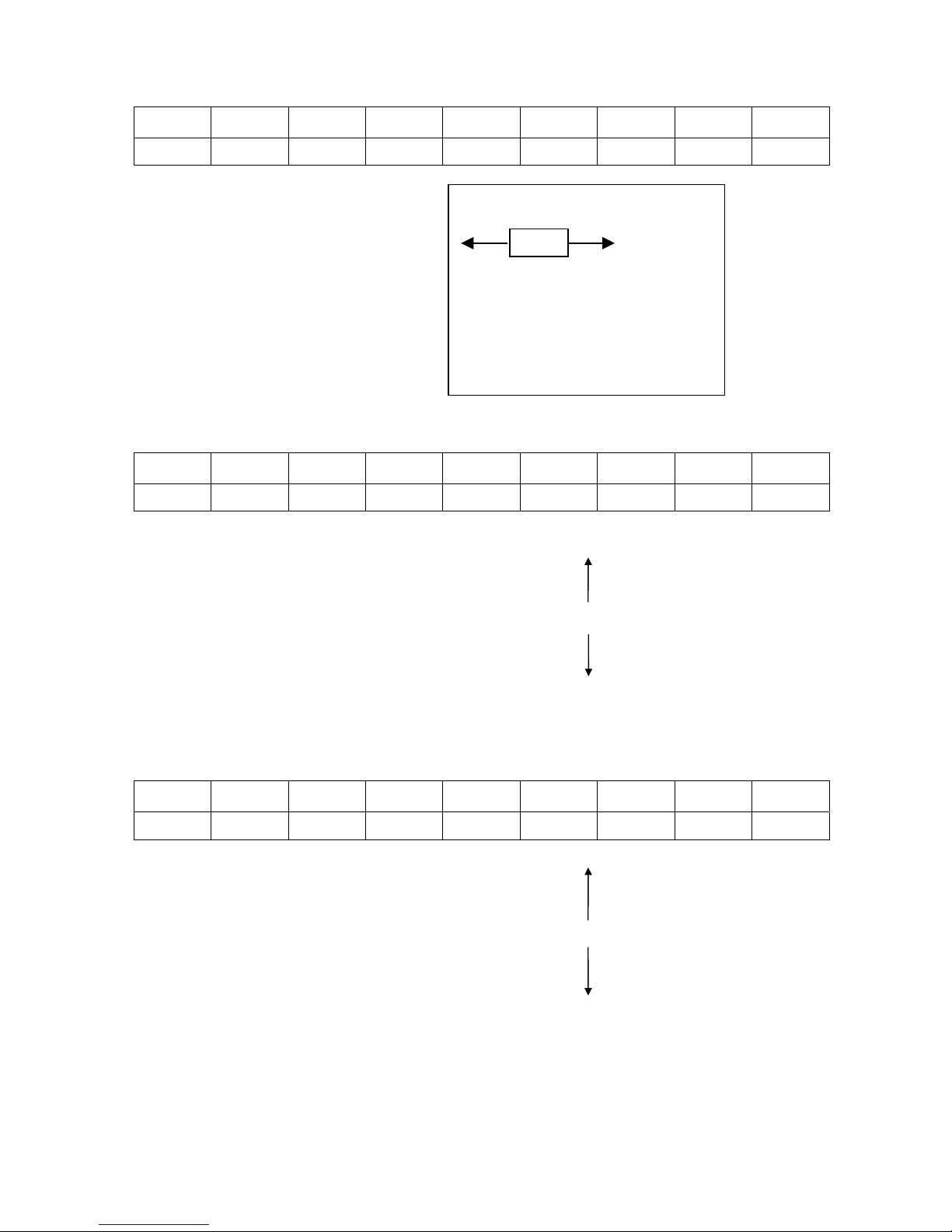

7.1 LIST BOX WITH SCROLLBAR

The list box is used for displaying the menus or items to be selected. It is comprised of the following parts.

The knob appears on the scrollbar when the number of scroll lines is over 4 lines.

There are three types of list box with scrollbar, as follows.

Display

Menu display (without setting value)

Menu display (with setting value)

Setting value selection display

Key function (Menu display)

Key Compatible Key Function

[MODE] None Returns to the top menu without saving changes.

[CANCEL] [FEED] + [RESTART] Returns to the upper hierarchy without saving changes.

[ENTER] [PAUSE] Displays a next screen.

[UP] [RESTART] Moves the cursor upward. The cursor does not move any

further when the selected option is listed at the top.

[DOWN] [FEED] Moves the cursor downward. The cursor does not move any

further when the selected option is listed at the bottom.

[LEFT] None No function

[RIGHT] None No function

Knob

Scrollba

r

Title

Scroll line (up to 4 lines)

26

Key function (value setting display)

Key Compatible Key Function

[MODE] None Returns to the top menu without saving changes.

[CANCEL] [FEED] + [RESTART] Returns to the upper hierarchy without saving changes.

[ENTER] [PAUSE] Saves the changes and returns to the upper hierarchy.

[UP] [RESTART] Moves the cursor upward. The cursor does not move any

further when the selected option is listed at the top.

[DOWN] [FEED] Moves the cursor downward. The cursor does not move any

further when the selected option is listed at the bottom.

[LEFT] None No function

[RIGHT] None No function

When multiple keys other than specified above ([FEED] + [RESTART]) are pressed at the same time, the printer

behavior is not guaranteed.

27

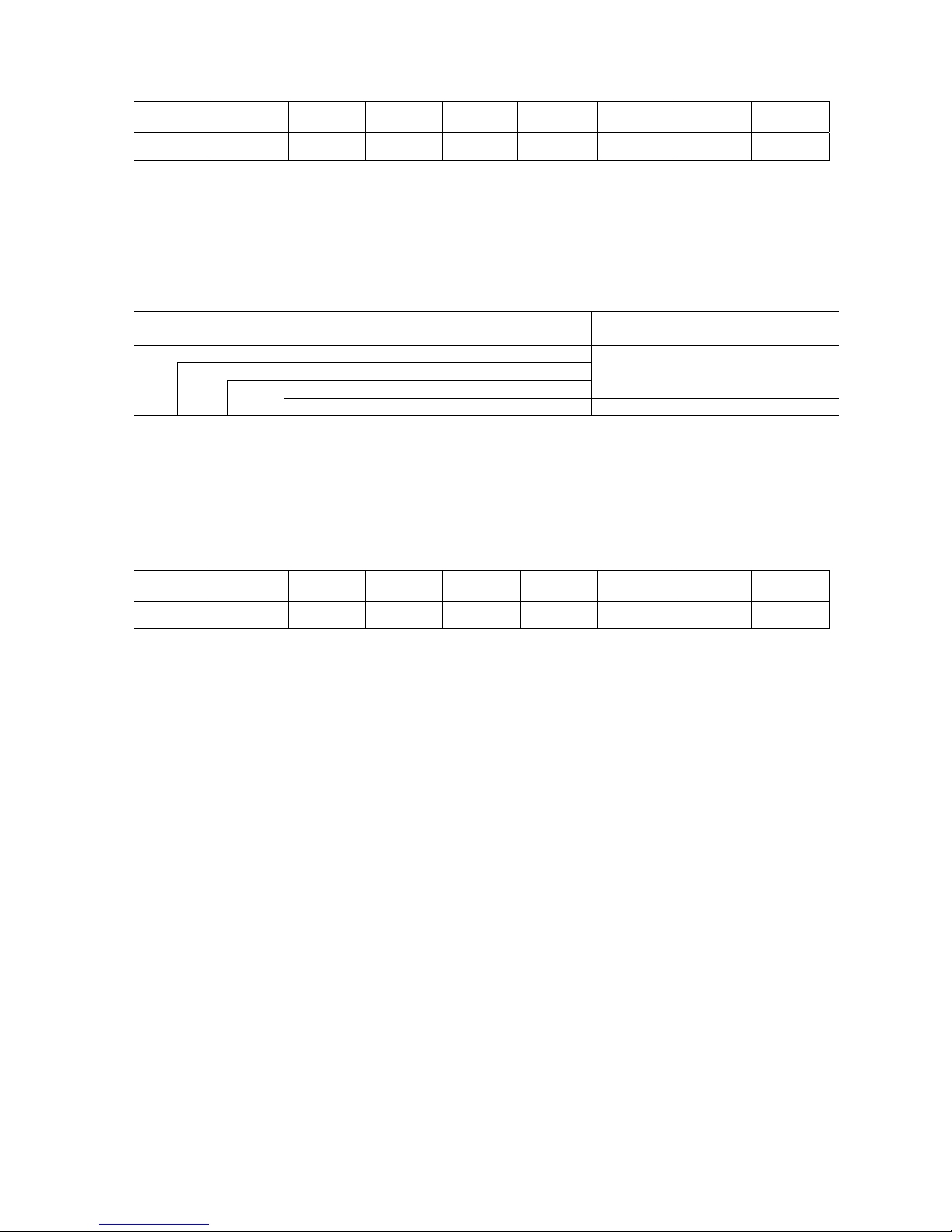

Movement of the cursor when scrolled

The cursor moves in the following way with a depression of the [UP] or [DOWN] key. The following table shows

the example of depression of the [DOWN] key. The [UP] key functions in the same way.

Display Key operation

Press

[DOWN] key

The position of the displayed menus remains

unchanged and only the cursor moves to one line

below.

Press

[DOWN] key

The position of the displayed menus remains

unchanged and only the cursor moves to one line

below.

Press

[DOWN] key

The entire menu moves up by one line and the

cursor moves to the next item.

Press

[DOWN] key

The entire menu moves up by one line and the

cursor moves to the next item.

Press

[DOWN] key

The position of the displayed menus remains

unchanged and only the cursor moves to one line

below.

28

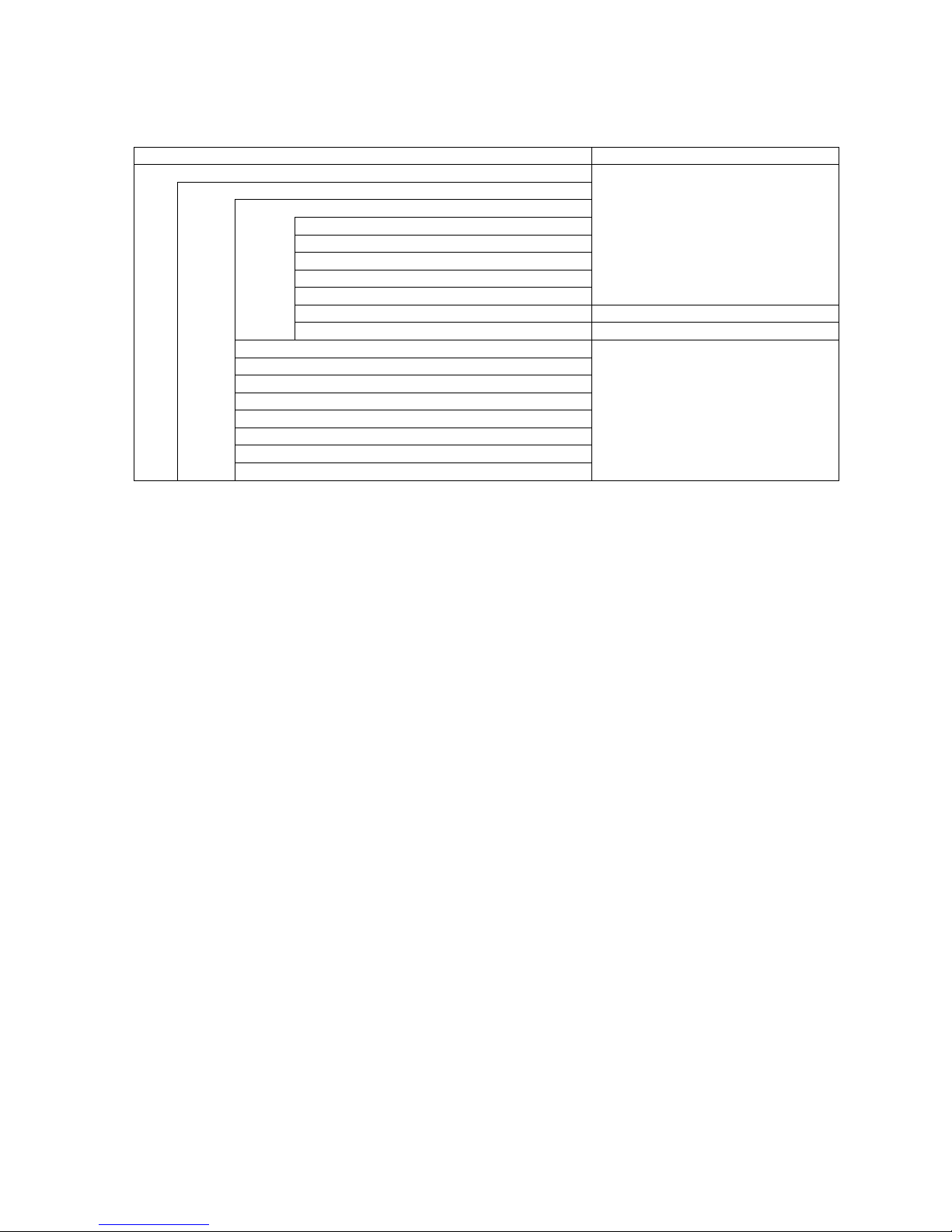

The cursor position when shifting from upper menu to its sub menu

When shifting from upper menu to its sub menu, the cursor is positioned at the topmost item except for RFID

setting menu. (Because the RFID menu items show the setting value.)

The cursor position when shifting from upper menu to its subordinate value setting display

When shifting from upper menu to its subordinate value setting display, the cursor is positioned at the

currently selected item.

The cursor position when shifting from sub menu or value setting display to its upper menu

When shifting from lower menu or value setting display to its upper menu, the cursor is positioned at the

previously selected item.

When the [MODE] key is pressed while the main menu is displayed:

When the [MODE] key is pressed while the main menu of the system mode or user system mode, the cursor

is positioned at the topmost item.

When the [CANCEL] key is pressed while the main menu is displayed:

When the [CANCEL] key is pressed while the main menu of the system mode or user system mode, the

cursor does not move from the current position.

29

7.2 VALUE SETTING DISPLAY

The value setting display is used for setting a value by increasing or decreasing it.

It is comprised of the following parts.

Display example

The currently programmable item is highlighted.

The display of the symbols like “+” and “-“, and the unit of measure like “mm” and “step” differs depending on the

item to be set.

Display

Setting display with one field

Setting display with multiple fields (placed

horizontally)

Setting display with multiple fields (placed

vertically)

Key function (Setting display with one field)

Key Compatible Key Function

[MODE] None

Returns to the top menu without saving changes.

[CANCEL] [FEED] + [RESTART]

Returns to the upper hierarchy without saving changes.

[ENTER] [PAUSE]

Saves the changes and returns to the upper hierarchy.

[UP] [RESTART]

Increases the setting value by specified step. When the setting

value reaches the maximum, it does not increase any further.

[DOWN] [FEED]

Decreases the setting value by specified step. When the

setting value reaches the minimum, it does not decrease any

further.

[LEFT] None No function

[RIGHT] None No function

Setting value

Setting range

Title

30

Key operation (Setting display with multiple fields (horizontal))

Key Compatible Key Function

[MODE] None

Returns to the top menu without saving changes.

[CANCEL] [FEED] + [RESTART]

Returns to the upper hierarchy without saving changes.

[ENTER] [PAUSE]

Saves the changes and returns to the upper hierarchy.

[UP] [RESTART]

Increases the setting value by specified step. When the setting

value reaches the maximum, it does not increase any further.

[DOWN] [FEED]

Decreases the setting value by specified step. When the

setting value reaches the minimum, it does not decrease any

further.

[LEFT] None

Moves the cursor to the left field. The cursor does not move

any further when the left-most field is selected.

[RIGHT] None

Moves the cursor to the right field. The cursor does not move

any further when the right-most field is selected.

Key function (Setting display with multiple fields (vertical))

Key Compatible Key Function

[MODE] None

Returns to the top menu without saving changes.

[CANCEL] [FEED] + [RESTART]

Returns to the upper hierarchy without saving changes.

[ENTER] [PAUSE]

Saves the changes and returns to the upper hierarchy.

[UP] [RESTART]

Increases the setting value by specified step. When the setting

value reaches the maximum, it does not increase any further.

[DOWN] [FEED]

Decreases the setting value by specified step. When the

setting value reaches the minimum, it does not decrease any

further.

[LEFT] None

Moves the cursor to the upper field. The cursor does not

move any further when the topmost field is selected.

[RIGHT] None

Moves the cursor to the lower field. The cursor does not

move any further when the bottom field is selected.

31

7.3 INFORMATION DISPLAY

The information display is used when no input or setting is performed.

It is consists of the following parts.

Display example

Display

Scroll

RFID tag read

Key function

Key Compatible Key Function

[MODE] None Displays the top menu.

[CANCEL] [FEED] + [RESTART] Displays the upper hierarchy.

[ENTER] [PAUSE] Displays the upper hierarchy.

[UP] [RESTART] No function

[DOWN] [FEED] No function

[LEFT] None No function

[RIGHT] None No function

Title

Information

32

Key function (Scroll)

Key Compatible Key Function

[MODE] None Displays the top menu.

[CANCEL] [FEED] + [RESTART] Displays the upper menu.

[ENTER] [PAUSE] Displays the upper menu.

[UP] [RESTART] Moves the cursor upward. The cursor does not move any

further when it is positioned at the top.

[DOWN] [FEED] Moves the cursor downward. The cursor does not move any

further when it is positioned at the bottom.

[LEFT] None No function

[RIGHT] None No function

Key function (RFID tag read)

Key Compatible Key Function

[MODE] None Displays the top menu without saving changes.

[CANCEL] [FEED] + [RESTART] Displays the upper menu without saving changes.

[ENTER] [PAUSE] RFID tag is read again.

[UP] [RESTART] Displays the data of the previous tag. The display does not

change when the first tag data is being shown.

[DOWN] [FEED] Displays the data of the next tag. The display does not

change when the last tag data is being shown.

[LEFT] None No function

[RIGHT] None No function

33

7.4 SENSOR ADJUSTMENT DISPLAY

The sensor adjustment display is used only when the level of the sensors provided on the printer is adjusted.

It is comprised of the following parts.

Display example

Display

Before adjustment

After adjustment

Key function (before adjustment)

Key Compatible Key Function

[MODE] None Displays the top menu.

[CANCEL] None Displays the upper hierarchy.

[ENTER] None When held down for 3 seconds or more, the sensor adjustment

is performed.

When this key is released within 3 seconds, the display returns

to the upper hierarchy display.

[UP] None No function

[DOWN] None No function

[LEFT] None No function

[RIGHT] None No function

Sensor level

Message

Title

34

Key function (after adjustment)

Key Compatible Key Function

[MODE] None Displays the top menu.

[CANCEL] None Displays re-adjustment menu.

[ENTER] None Displays the upper menu.

[UP] None No function

[DOWN] None No function

[LEFT] None No function

[RIGHT] None No function

The asterisk “*” shown on the right side of the adjustment value indicates the completion of adjustment.

The voltage under adjustment is updated approximately every 200 msec.

35

7.5 TEMPERATURE DISPLAY

Temperature display is used only for displaying the print head temperature and ambient temperature.

It is comprised of the following parts.

Display example

Display

Key function

Key Compatible Key Function

[MODE] None Displays the top menu.

[CANCEL] None Displays the upper hierarchy display.

[ENTER] None Displays the upper hierarchy display.

[UP] None No function

[DOWN] None No function

[LEFT] None No function

[RIGHT] None No function

Each temperature is updated approximately every 200 msec.

Title

Ambient temperature

Print head temperature

36

7.6 File Selection Display

File selection display is used for selecting a file when copying data from USB memory to the printer.

It is comprised of the following parts.

Display example

The scrollbar on the file selection display is not provided with the knob regardless of the number of files.

There are two types of file selection displays, as follows.

Copy data selection display

CFG file selection display

Key function

Key Compatible Key Function

[MODE] None Displays the top menu without selecting a file.

[CANCEL] [FEED]+[RESTART] Displays the previous display without selecting a file.

[ENTER] [PAUSE] Displays the next display.

[UP] [RESTART] Moves the cursor upward. The cursor does not move any

further when it is positioned at the top.

[DOWN] [FEED] Moves the cursor downward. The cursor does not move any

further when it is positioned at the bottom.

[LEFT] None No function

[RIGHT] None No function

Printer operation is not guaranteed when multiple keys are pressed except for those mentioned above

([FEED]+[RESTART]).

Title

Scroll lines (4 lines)

Scroll ba

r

37

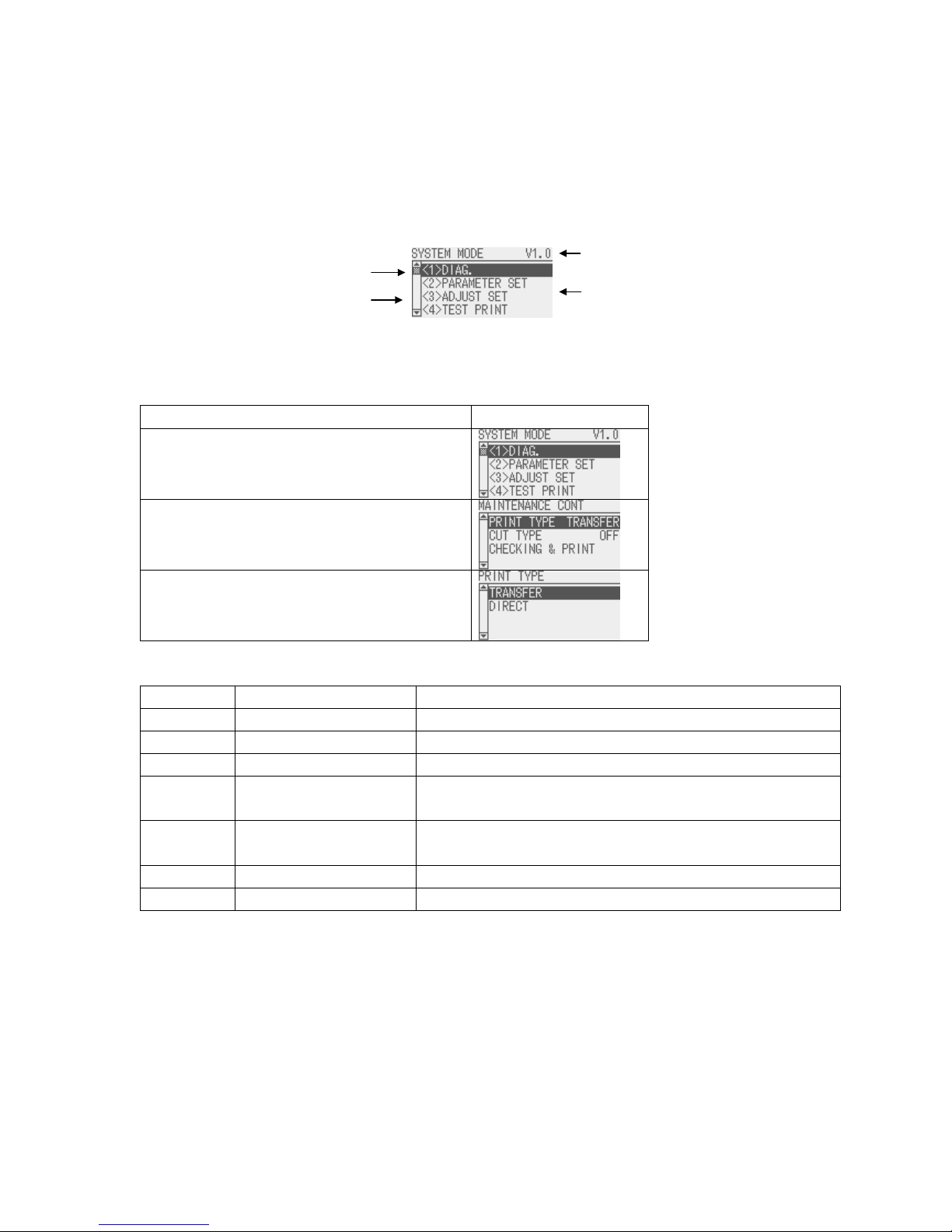

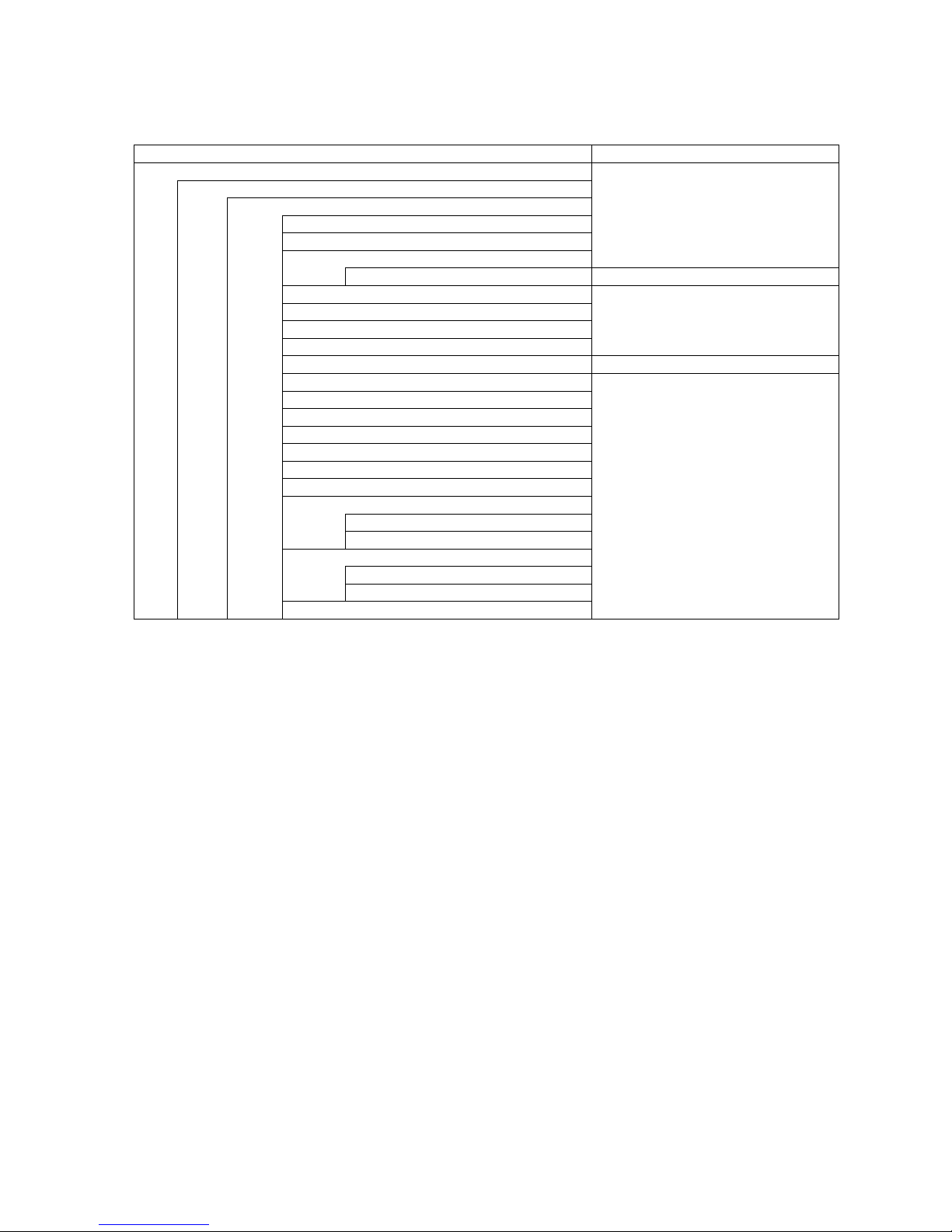

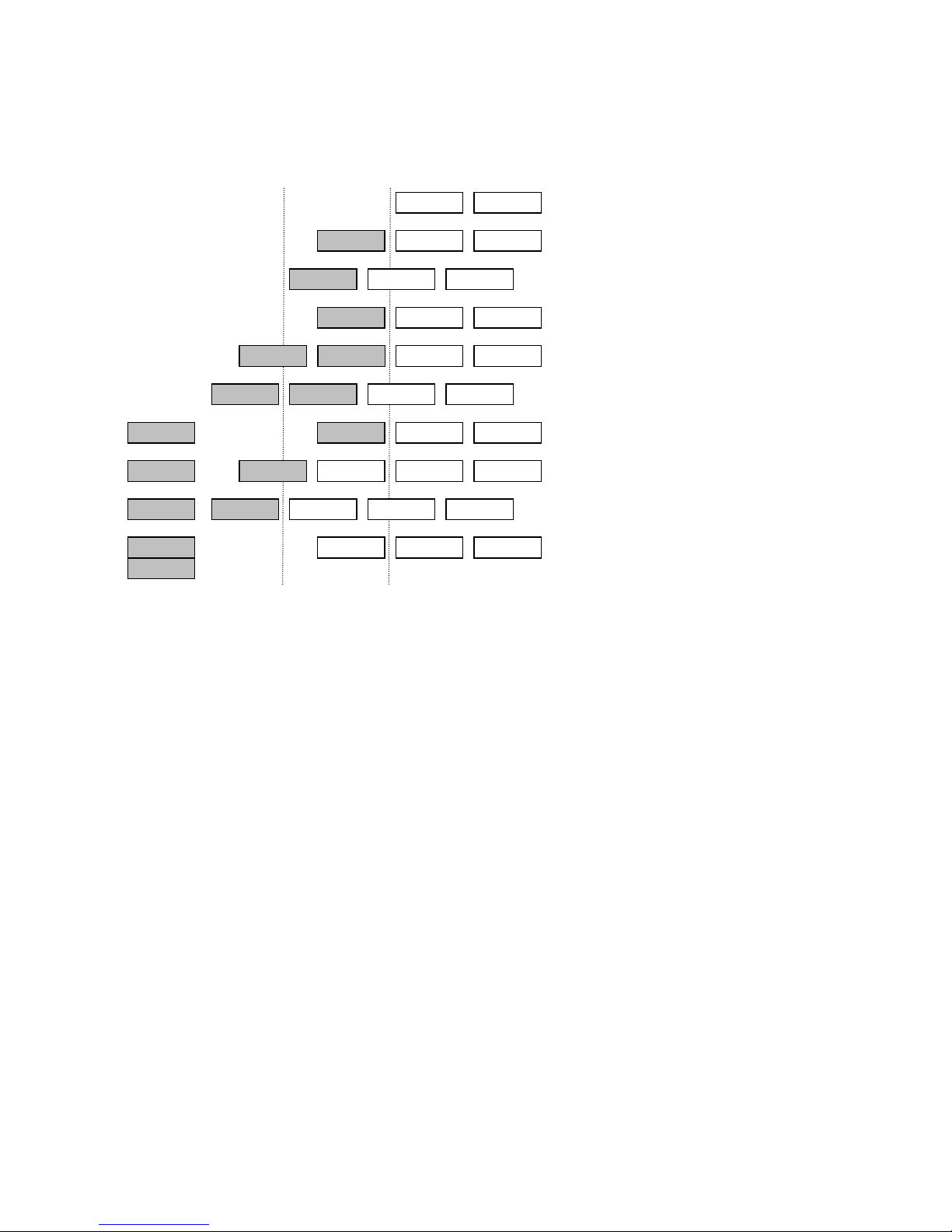

8 SYSTEM MODE

8.1 OUTLINE OF SYSTEM MODE

The printer enters the system mode when the following operation is performed when the printer power is off.

・ Turn on the printer while holding down the [FEED] and [PAUSE] keys at the same time.

・ Turn on the printer while holding down the [MODE] key.

The system mode is intended for performing self-test, parameter setting, and other settings.

When the top menu is displayed, the firmware version is shown on the right side of the title.

The language displayed on the panel is Japanese when Japanese is selected for the LCD language parameter,

and English when English, German, French, Dutch, Spanish, Italian or Portuguese is selected.

The key operations for the system mode are described below.

Key operations follow Section 7.1 LIST BOX WITH SCROLLBAR.

Display

Top menu for QM/CN model

English

<1>DIAG.

<2>PARAMETER SET

<3>ADJUST SET

<4>TEST PRINT

<5>SENSOR ADJUST

<6>RAM CLEAR

<7>INTERFACE

<8>BASIC

<9>FOR FACTORY

<10>RFID

<11>RTC

<12>Z-MODE

<13>USB MEMORY

<14>RESET

38

DIAG. Used to perform self diagnosis, print out the result, check for the print head

broken elements.

PARAMETER SET Used to set the parameters for each printer function.

ADJUST SET Used to fine adjust the printer mechanism position and sensor.

TEST PRINT Used to conduct test print by printing slant lines, characters and barcodes.

SENSOR ADJUST Used to display the ambient temaprature and print head temparature, and adjust

each level of the media sensor.

RAM CLEAR Used to clear the maintenance counter and parameters.

INTERFACE Used to set the parameters of the interface such as network, USB, RS232C and

parallel.

BASIC Used to set the function of the BASIC program when it is loaded printer.

FOR FACTORY Used to adjust the printer before shipment.

RFID Used to set RFID-related parameters.

RTC Used to set the date & time of the real time clock, enable or disable the low

battery check, and choose a real time renewal timing.

Z-MODE Same as BASIC.

USB MEMORY Used to copy data to/from USB memory.

RESET Used to reset the printer.

8.2 REFLECTING THE SYSTEM MODE SETTINGS IN THE PRINTER

The settings configured in the system mode or user system mode are saved in the printer at the following timing,

depending on the items to be saved.

・ Periodic save at 20-msec. interval

・ When Reset menu in the system mode or user system mode is performed

The changes in the settings, with a partial exception, take effect at a power on time or after a reset.

39

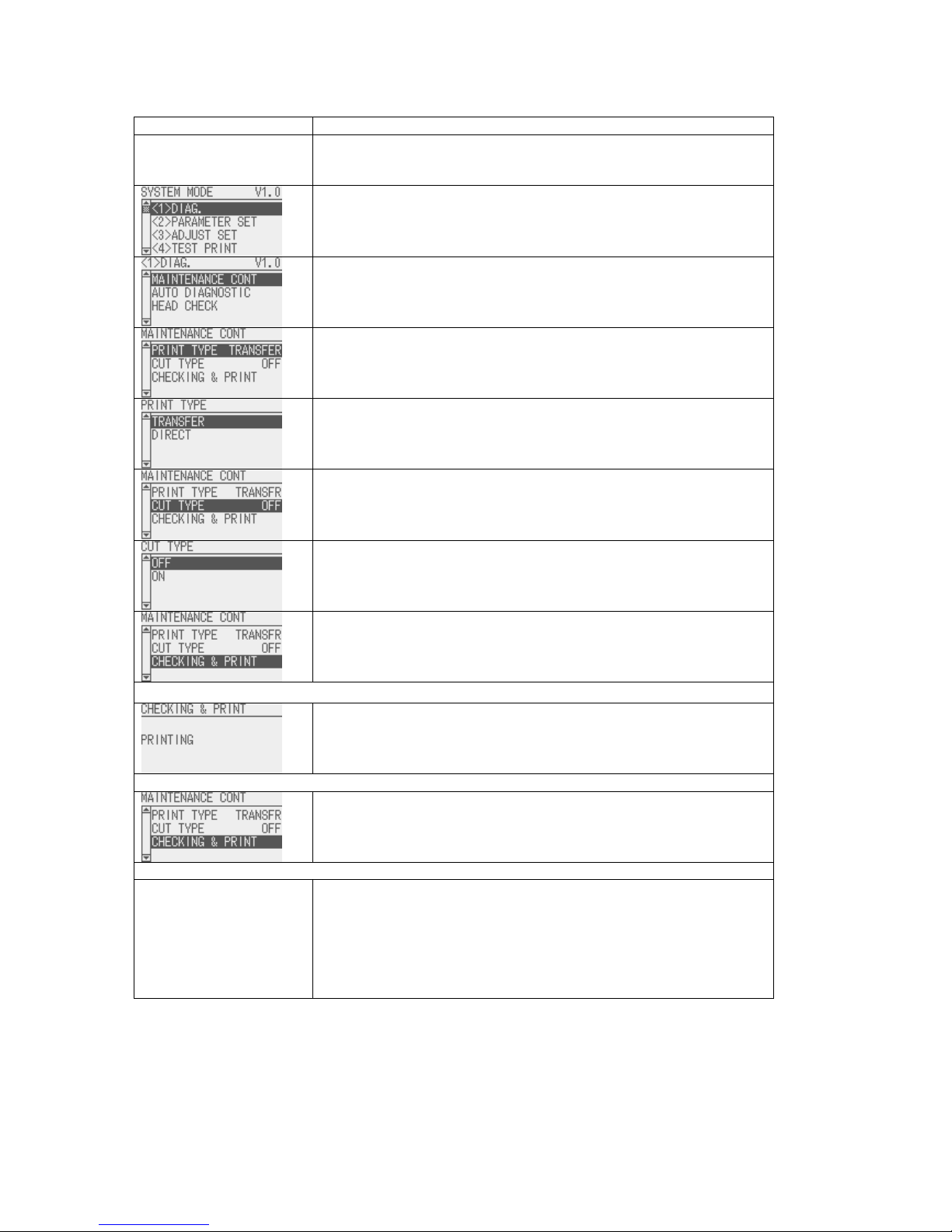

8.3 DIAG

The main firmware version is displayed on the right side of the title.

Contents of DIAG. menu

MENU ITEM Display pattern and key operation

SYSTEM MODE

<1>DIAG.

MAINTENANCE CONT

AUTO DIAGNOSTIC

7.1 LIST BOX WITH SCROLLBAR

HEAD CHECK 7.3 INFORMATION DISPLAY

8.3.1 MAINTENANCE CONT