Page 1

TOSVERT VF-FS1 series

E6581371c

L

ONWORKS

®

Communication option LIU007Z

Instruction Manual

NOTICE

1.

Make sure that this instruction manual is delivered to the end user of

LONWORKS communication option.

2.

Read this manual before installing or operating the LONWORKS communication

option. Keep it in a safe place for reference.

3.

All information contained in this manual are subject to change without notice.

Please confirm the latest information on our web site “www.inverter.co.jp”.

Page 2

E6581371c

Safety precautions

On the inverter and in its instruction manual, important information is contained for preventing

injuries to users, damages to assets, and for proper use of the device.

Read the instruction manual attached to the inverter along with this instruction manual to

completely understand the safety precautions, the symbols and indications shown below. Please

adhere to the contents of these manuals at all times.

Explanation of markings

Marking Meaning of marking

Danger

Warning

(*1) Such things as injury, burns or shock that will not require hospitalization or long periods of outpatient

(*2) Physical property damage refers to wide-ranging damage to assets and materials.

Meanings of symbols

Marking Meaning of marking

Indicates that errors in operation may lead to death or serious injury.

Indicates that errors in operation may lead to injury (*1) to people or that these errors may

cause damage to physical property. (*2)

treatment.

Indicates prohibition (Do not do it).

What is prohibited will be described in or near the symbol in either text or picture

form.

Indicates something mandatory (must be done).

What is mandatory will be described in or near the symbol in either text or picture form.

Indicates danger.

What is dangerous will be described in or near the symbol in either text or picture form.

Indicates warning.

What the warning should be applied to will be described in or near the symbol in

either text or picture form.

- 1 -

Page 3

E6581371c

Limitation of use

Safety precaution

Never use this unit with any device other than TOSVERT VF-FS1 series inverters. Doing so may cause

an accident.

Handling in general

Danger

Never disassemble, modify or repair the product.

Never

Disassemble

Prohibited

Mandatory

Disassembling the product may cause electric shocks, fire or injuries.

For repairs, call your sales/repair agency.

Do not open the front cover on the inverter while the inverter power is on.

It may lead to electric shocks.

Do not remove this option from VF-FS1 while the power is on.

It may lead to electric shocks.

Do not put or insert foreign objects such as waste cable, bars or wires into the product.

It may lead to electric shocks or fire.

Do not splash water over the product, and do not wipe the body with a wet cloth.

It may lead to electric shocks or fire.

Turn off the power immediately in case of any abnormalities such as smoke, smell or

abnormal noise.

Neglect of these conditions may lead to fire.

For repairs, call your sales/repair agency.

Do not touch the sharp portions (such as leads of parts on the board, the corner of board,

or etc.) on this option

It may lead to injuries.

This option is an electrostatic discharge sensitive device. Handle it, where the

Mandatory

Transportation and installation

Prohibited

Mandatory

environment is protected against electrostatic electricity.

Otherwise, permanent damage to device will result.

Do not apply a dropping shock or other physical shocks.

Otherwise, damage or malfunction will result.

Do not install or operate the inverter if it is damaged or any part of it is missing.

Operating a defective inverter may lead to electric shocks or fire.

For repairs, call your sales/repair agency.

Do not put any flammable material near the product.

It may catch fire due to the product sparking in the case of a malfunction.

Use this product under the environmental conditions prescribed in the instruction manual.

Usage it under any other conditions may result in malfunction.

An emergency stop device must be installed that fits with system specifications

(e.g. shut off input power then engage mechanical brake).

Operation cannot be stopped immediately by the inverter or this unit alone, thus risking

an accident or injuries.

Install this option into VF-FS1 and secure it by tightening the terminal board fixing screws

to the specified torque. Otherwise, it may cause the product falling, the damage, or

malfunctions.

When installing this option, do not touch its sharp portions such as leads of parts on the

board, the corner of board or etc.

Doing so may result in injury.

Warning

Danger

- 2 -

Page 4

Wiring

Mandatory

Operations

Prohibited

Mandatory

E6581371c

Warning

Electrical construction work must be done by a qualified expert.

Connection of input power by someone who does not have expert knowledge may result

in electric shocks or fire.

Turn off input power before wiring.

Wait at least 10 minutes and make sure that the charge lamp (on the inverter unit) is no

longer lit. Otherwise, it may lead to electric shocks.

Tighten the screws on the terminal blocks to the specified torque when connecting cables

to terminal blocks.

Otherwise, it may lead to fire.

Danger

Do not pull on the cable and connector.

It may cause damage or malfunctions.

Use this option under the environment specified in the instruction manual.

Usage under the environment other than them may cause damages or malfunctions or

an accident.

Use an additional safety device with your inverter or system to prevent a serious accident

due to the unit malfunctions.

Usage without an additional safety device may cause an accident.

Mandatory

Disposal

Mandatory

Warning

Set up “Communication error trip function (see below)” to stop the inverter when the

option unit is deactivated by an unusual event such as an operating error, power outage,

failure, etc.

- Communication error trip time

(f803, see the inverter instruction manual for details)

- Receive heart beat timer

(See the VF-FS1

Deactivated option unit may cause an accident, if the “Communication error trip function”

is not properly set up.

Make sure that the operation signals are STOP before clearing the inverter’s fault. The

motor may suddenly start and that may result in injuries.

LONWORKS Communication Function Manual for details)

Warning

If you dispose off this unit, have it done by a specialist in industrial waste disposal*.

Improper disposal may result in explosion of capacitors or produce noxious gases,

resulting in injuries.

(*) Persons who specialize in the processing of waste and known as “Industrial Waste

Product Collectors and Transporters” or “Industrial Waste Disposal Persons.” If the

collection, transport and disposal of industrial waste is done by someone who is not

licensed for that job, it is a punishable violation of the law (Laws in regard to cleaning and

processing of waste materials).

Notes on operation

Avoidinstalling in a place where ambient temperature or/and humidity change sharply.

Keep the transmission cable separate from the power cable of the inverter to prevent the

inverter from malfunctioning due to electromagnetic noise.

Ground of SHLD terminal on this option at the grounding terminal separated from those of

inverters and motors. It may cause malfunction due to noise.

Notes

- 3 -

Page 5

E6581371c

Preface

Thank you for purchasing the “LONWORKS communication option (LIU007Z)” for TOSVERT VF-

FS1 inverter. By Installing this board into the VF-FS1, data communication can be made with a host

computer or other device via L

Before using this unit, carefully read this instruction manual in order to completely and correctly

utilize excellent performance of this unit. Besides this instruction manual, the “VF-FS1 L

Communication Function Manual” which includes the contents to install into LONWORKS network is

prepared. If it is required, please contact with our branch offices, sales offices or web site

“www.inverter.co.jp”.

(“VF-FS1 L

ONWORKS Communication Function Manual”: E6581373)

After reading this instruction manual, please keep it handy for future reference.

ONWORKS network.

ONWORKS

* Echelon

®

, LONWORKS®, LonTalk®, Neuron®, LONMARK®, LONMARK Logo® are the registered

trademarks or the trademarks of Echelon Corporation in the USA and other countries.

ONMARK and LONMARK Logo are managed, granted, and used by LONMARK International

* L

under a license granted by Echelon Corporation.

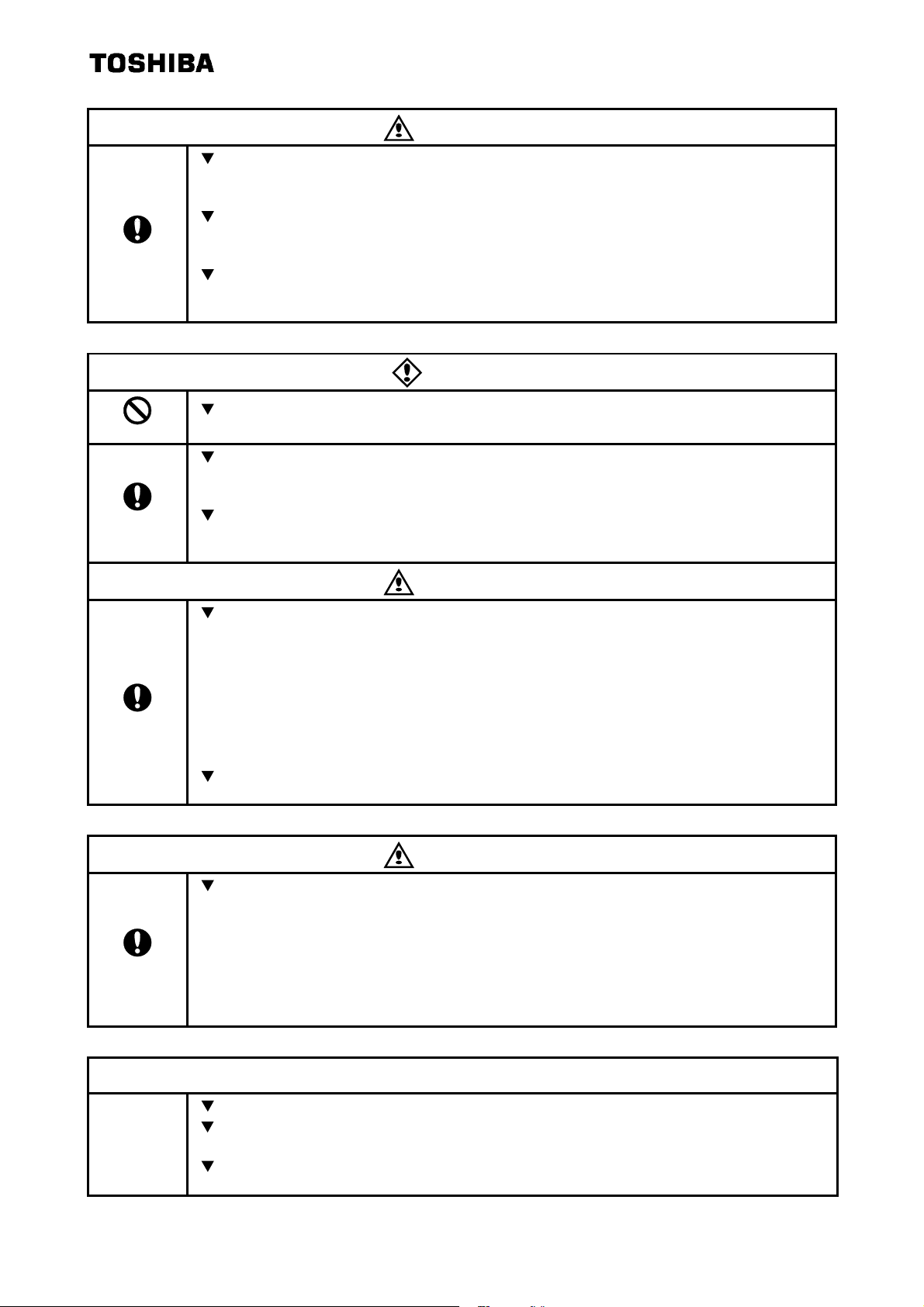

- Part numbering

LIU 007 Z

0

–

Revision number

Cable length ( “Z” means “without cable” )

Model number of LONWORKS option

Symbol of LONWORKS option

- Accessory check list

L

ONWORKS communication option is shipped together with the following accessories. On

opening the packing case, check to see if the following accessories are contained or not.

(1) Instruction manual

English (E6581371) ......................................1 copy (This book)

Instruction

Manual

(2) Cabling label & Name plate ............................1 sheet.

(1 cabling label and 2 name plates)

(3) Insulating sheet...............................................1 sheet.

(4) Neuron ID Label..............................................4 sheets.

(These are stuck on the unit)

- 4 -

||||||||||||||||||||

xxxxxxxxxx

Page 6

E6581371c

Table of Contents

1. Overview ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 6

2. Names and functions・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 6

2.1. Service pin ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 6

2.2. Use of RS485 communication port ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 6

2.3. Description of terminals ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 7

3. Installation and Setup ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 8

3.1. Installation method ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 8

3.2. VF-FS1 communication parameters ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 9

3.3. Network cable connection ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 9

3.4. Network configuration・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 10

3.5. Termination resistor ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 11

3.6. Wiring of a control terminal ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 11

4. Before making a service call ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 12

4.1. Display of service LED ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 12

4.2. Other problems ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 12

5. Specifications ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 13

6. Warranty ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 14

- 5 -

Page 7

E6581371c

1. Overview

LONWORKS technology is a network control system concept developed by Echelon Corporation,

ONWORKS network provides Local Operating Network that is superior in the distributed control.

L

Each device works in a peer-to-peer fashion on LONWORKS network. This LONWORKS option is

equipped with the L

ONWORKS Smart Transceiver (Neuron Chip).

2. Names and functions

The drawing below shows names and functions of main parts.

Selector switch (SW1)

- Logic for F, R terminal

(SINK/SOURCE)

- VIB function

(VIB/PTC)

Optional RS485 communication port

RS485 communication option can be

used. However it makes L

Communication be disabled.

ONWORKS

NETA

SHLD

G/E

FLA

FLB

LONWORKS network detachable terminal

NETB

2.1. Service pin

Service pin is used for commissioning device. Use SW2 on the option board.

Danger

Service pin (SW2)

Service LED

Terminal board fixing

screw hole

(M3 screw)

FLC

Operate Service switch only when a cover for the main circuit terminal is attached.

Otherwise, it may lead to electric shocks.

Mandatory

Operate Service switch using the non-conductive stick. When it is operated with a

conductive stick.

Otherwise, it may lead to electric shocks.

2.2. Use of RS485 communication port

Serial communication (2-wire RS485) option can be used. However, while it is connected, the

internal communication line is switched to RS485 then the communication via L

is disabled. In this case, communication error trip time (f803) is also active. Use RS485 serial

communication option specified by Toshiba.

- 6 -

ONWORKS network

Page 8

2.3. Description of terminals

<Control terminals specification>

E6581371c

Terminal

symbol

NETA

NETB

SHLD

ONWORKS

L

data / reception data

ONWORKS

L

shield terminal.

Function Electrical specifications Internal circuits

transmission

communication

no polarity

This terminal is not

connected to other circuits in

this board.

G/E Grounding terminal Connect to network ground

F

R

VIB

Multifunctional programmable

contact input.

SINK/SOURCE can be

selected with SW1.

Multifunction programmable

analog input.

with internal pull-up resistor

for PTC

No voltage contact input

, 5mA or less

24V

DC

N.B. Use contact parts for low

current.

0 to 10V

DC

input

Using this terminal as PTC

input, set SW1 to PTC side

and set the parameters

(f645 and f646) to

proper value.

CC

Control circuit’s equipotential

terminal

P24 24 VDC power supply output 24VDC-50mA

P24

F, R

CC

NETA

NETB

SHLD

VIB

G/E

P24

PTC

4.7k

PTC

Spark

gap

P24

820

PTC

FT-X1

SOURCESINK

15k

15k

P10

VIB

3.3k

P24

FLA

FLB

FLC

Prohibited

Mandatory

FLA

FLB

FLC

Multifunctional programmable

relay contact outputs

1c contact

-0.5A

30V

DC

250V

250V

-1A (cosφ =1)

AC

-0.5A (cosφ =0.4)

AC

Danger

Do not change switches settings while the power is on.

It may lead to electric shocks or damage.

Turn off the motor operation signals before setting the parameter and the switch

(SW1), when changing the VIB function. Otherwise, the motor may suddenly

start and that may result in injuries.

- 7 -

Ry

Page 9

E6581371c

(

)

3. Installation and Setup

3.1. Installation method

Install the LONWORKS communication option to VF-FS1 as follows.

(1) Turn off the input power of VF-FS1 and wait for at least 10 minutes and then check that the

CHARGE lamp on VF-FS1 is no longer lit.

(2) Open the VF-FS1 front cover, remove the terminal board fixing screw and take off the VF-FS1

standard terminal board.

(Be careful not to lose the terminal board fixing screw when removed since it may be used again.)

(3) Perform wiring an inverter before installing L

(4) Please attach the insulating sheet in VF-FS1.

(Fix to the terminal board fixing screw hole and PWB catch pin.)

(5) Install the L

ONWORKS communication option over the insulating sheet and secure it with the

board fixing screw (tightening torque of M3 tapping screw: 0.7 to 0.8Nm).

(6) Stick the cabling label for L

ONWORKS communication option on the standard cabling label stuck

on the reverse side of the VF-FS1 front cover. And stick the L

nameplate near the standard nameplate. (Be careful not to cover slits on the VF-FS1 enclosure.

N.B.: To install or remove the terminal board, make it slide in or out in parallel with board.

ONWORKS communication option.

ONWORKS communication option

Cabling label position

Example

VF-FS1 unit

Board catching pin

Terminal board fixing screw

(M3 screw tightening torque: 0.7 to 0.8Nm)

Board fixing screw hole

Stick the LIU007Z nameplate like

bellow figure.

LIU007Z

VF-FS1 name plate

LIU007Z

VF-FS1 Standard terminal board

Insulating seat

(attached)

LONWORKS communication option

LIU007Z

- 8 -

Page 10

E6581371c

A

3.2. VF-FS1 communication parameters

Set up the inverter parameters as follows. To update, reset the power of inverter. If these

parameters are not set to correct value, this unit can not work normally.

Title Function Description

cmod Command mode selection

fmod Setpoint mode selection

f800 Communication speed Set “1: 19200bps” (default).

f801 Parity Set “1: Even” (default).

f803 Communication error trip time Set communication time out period.

f829 Communication protocol Set “1: MODBUS-RTU”

f851 Operation at network error

While L

into VF-FS1, The network command and setpoint are

prior to cmod/fmod. VF-FS1 front panel operation

is prior when LOC lamp on the front panel turns on.

Set the behavior when “Receive heart beat timer”

overflow occurred.

ONWORKS communication option is installed

Warning

Set up “Communication error trip function (f803, see the inverter instruction

manual for details)” to stop the inverter when this option unit is deactivated by an

unusual event such as tripping, an operating error, power outage, failure, etc.

Mandatory

Deactivated option unit may cause an accident, if the “Communication error trip

function” is not properly set up.

3.3. Network cable connection

Connect the LONWORKS network cable to LONWORKS communication option as follows.

(1) Cable selection (a twisted pair cable with shield)

Use Level 4/22 AWG cable for the network cable.

- Recommended cable

Manufacturer: Showa Electric Wire & Cable Co., Ltd.

Model name: LW221S, 22AWG, 1P, With shield, Standard 300m/reel

Use 0.75mm

(2) Terminal blocks

Catches

- Communication terminal NETA, NETB

Connect L

Polarity of the communication terminals NETA and NETB does not have to be considered.

- Communication shield terminal SHLD

Connect the shield of network cable. Refer to next section for grounding.

- G/E terminal

Connect the network ground.

(3) Connection

Cable sheath should be peeled off by about 7mm.

For wiring work, use a flat blade screwdriver with a 0.6mm thick and 3.5mm width blade.

Tightening torque for the terminal block is 0.5Nm.

2

wire for grounding to the earth terminal (G/E) of the board.

Manufacturer: PHOENIX CONTACT

Model name: MSTB 2,5/3-ST-5.08

SHLD

NET

ONWORKS

NETB

transmission/reception data cable.

- 9 -

Page 11

3.4. Network configuration

A

A

A

Make up the network as follows.

- Transmission/reception signals (NETA, NETB)

Make up the communication path by connecting all transmission/reception data cables (No polarity).

- Grounding the shield of cable (SHLD)

Connect the all shield lines of network cable. Ground through a metal film resistor of 470k ohm,

1/4W, 10% or more accurate so that static electricity does not increase (at the point where it

separated from the power ground of inverters or motors).

- Termination resistor (Please refer to “3.5. Termination resistor”)

Only one terminal resistor is needed for the segment of the free topology. It can also be placed

wherever it is on the free topology segments. (2 termination resistors in case of Bus topology)

- Network cable length (for recommended cable usage)

Free-Topology: device-to-device distance is 400m or less, total wire length is 500m or less

Bus-Topology: total wire length is 1400m or less, stub length is 3m or less.

E6581371c

- Connection image

Host computer

/ Router

Terminal 1

Terminal 2

Shield grounding

resistor

Twisted pair cable with shield

LIU007Z

NET

NETB

SHLD

LIU007Z

NET

NETB

SHLD

LIU007Z

NET

NETB

SHLD

Terminal resistor

52.3ohm, 1/8W

Network configuration is shown in the figures below. This LONWORKS communication option has

TP/FT-10 channel type transceiver. The free topology wiring supported by the TP/FT-10 channel

type accommodates bus, star, loop, or several combinations of these topologies shown in below

- Network configuration example

Host computer

Router

LIU007Z

VF-FS1

Number of connected units to the router: 63 nodes at maximum

Free topology: 63 units connected at maximum

Router Router

LIU007Z

VF-FS1

- The free topology wiring example.

Complex topology can be configured

Termination

resistor

means a node

N.B.: Do not connect the SHLD terminal to the power ground of inverters or other units.

Keep the network cables 20cm or more separate from the power cables to prevent from

malfunctioning due to electromagnetic noise.

- 10 -

Page 12

E6581371c

r

3.5. Termination resistor

Terminate the network bus with about 52.3ohm impedance to minimize the reflections. There are

two choices for the termination.

1. Free Topology Network Segment

Only one termination and may be placed anywhere on the free topology segment.

RC network (Following figure), with R1 = 52.3ohm +/-1%, 1/8W

2. Doubly Terminated Bus Topology Segment.

It is necessary to terminate at both ends of a twisted pair bus.

RC network (Following figure), with R1 = 105ohm +/-1%, 1/8W

Terminal circuit

R1

C1

C2

+

+

C1 and C2 are required for connection to link power network.

C1, C2: Aluminum-electrolytic type

100uF, 50V min

3.6. Wiring of a control terminal

Observe the following when wiring.

2

- Use 0.3 to 1.5mm

- Remove the sheath of a cable about 7mm (6mm for FLA, FLB, FLC and G/E) from the end of cable.

- Use a flat-headed screwdriver with its blade 0.6mm in thickness and 3.5mm in width.

- Screw tightening torque for the terminal block screws should be 0.5 to 0.6Nm.

N.B.: Keep the control signal cables 20cm or more separate from the power cables to prevent from

malfunctioning due to electromagnetic noise.

N.B.: Provide an inter-lock system stated in below, when using a programmable controller that has

the open collector output.

When the programmable controller is turned off with the inverter is on, the difference

between each control power potential will cause wrong signals to the inverter as shown in

below figure. Provide an inter-lock so that the programmable controller cannot be turned off

when the inverter power is alive.

solid/stranded wire (AWG 22 to 16) for control cables.

VF-FS1 + LIU007ZProgrammable controller

+24V

Input terminal

External

Fuse blowout

detection

circuit

Fuse

+24V supply

Inverte

internal +24V

COM

- 11 -

Page 13

E6581371c

4. Before making a service call

If a problem arises, please see the following trouble-shooting tables. If the problem can not be

solved, please contact a Toshiba distributor.

4.1. Display of service LED

Service LED indicates the condition of nodes.

1

2

3

4

5

6

Power

ON

No Phenomenon

Although the inverter is turned

1

on, LED remains OFF.

LED continues to be ON after

2

the inverter is turned on.

LED is ON then OFF when

3

the inverter is turned on, and

it continues to be ON.

4 LED blinks every 0.5 second.

5 LED blinks every 1 second.

LED momentarily turns ON

6

then continues to be OFF.

1 3452

Continues to be OFF

Continues to be ON

Momentarily OFF then continues to be ON

Repeats ON and OFF

Repeats ON and OFF

Continues to be OFF

Time (second)

OFFON

Problem & Solutions

Check the connection the inverter and the optional unit. If

abnormality is not found after checking, it needs to be repaired.

Internal application program is abnormal.

It needs to be repaired.

A watch dog is suspected. If the same indication appears after

resetting the power, it needs to be repaired.

This is a normal action of the "Unconfigured" device. If the device

is not "Unconfigured", Internal application program is broken. It

needs to be repaired.

When the program is in the condition of "Configured" status, LED

momentarily turns ON when the inverter is turned on. Then the

LED continues to be OFF for some seconds. The node indicates

"Configured" status that means the normal condition.

- LED Flickers CPU is abnormal. It needs to be repaired.

LED is turned on while

-

pushing service pin.

4.2. Other problems

Phenomenon

No replying from LONWORKS

communication option

Communication error

in network variable

Normal operation while pushing service pin.

Problem and Solutions

Check proper termination resister is installed on the network.

(See section 3.5.)

After checking the service LED status, see the previous section.

Remove RS485 communication option from RJ45.

Check the inverter parameter setting (refer to section 3.2).

Check the network cables are not near the power cables.

- 12 -

Page 14

5. Specifications

A

< Environmental specification >

Item Specification

Service environment Conforms to VF-FS1

Operation temperature Conforms to VF-FS1

Storage temperature

Relative humidity 20 to 93% (free from condensation and vapor)

Vibration 5.9m/s2 (0.6G) or less (10 to 55 Hz) (To be complied with JIS C0040.)

< LONWORKS communication option (LIU007Z) side >

Item Specification Note

Applicable

Commun

ication

between

inverter

model

Communication

method

Baud rate 19200bps

Parity Even number

Control power supply 5 V

Logic input terminal

Logic output terminal Nothing

Relay contact output

terminal

Analog input terminals 1 circuit (VIB): 10VDC (R

Analog output terminals Nothing

Power supply output 24VDC-50mA Current limit function

-25 to +65℃

VF-FS1

MODBUS-RTU

DC

2 circuits (F,R)

Slide switch (SW1) enable to select

logical configurations (Source/Sink).

250V

250V

-0.5A

DC

-1A (cosφ =1)

AC

-0.5A (cosφ =0.4)

C

= 30kohm) Not isolated

IN

1 circuit (FL): 30V

Only one board connection is

available.

Set the inverter parameter

(refer to section 3.2)

Supplied from inverter

Not isolated

Isolated

E6581371c

< Network side >

Item Specification Notes

Transceiver

Channel type

TP/FT-10 type

(Free topology transceiver

78kbps

ANSI/EIA/CEA 709.3

Communication signal 2 wires plus shield NETA, SHLD, NETB

Transmission distance

(Free topology)

Transmission distance

(Bus topology)

Number of connected

nodes

Between devices: 400m at maximum

Total cable length: 500m at maximum

Total cable length: 1400m at maximum

Stub length: 3m at maximum

Free topology 63 nodes at maximum

When recommended cable is used:

Level 4/22AWG

When recommended cable is used:

Level 4/22AWG

Because a host and routers are

counted as one board, the option can

be connected up to 63 nodes.

Protocol LonTalk ANSI/EIA 709.1

Address and related

items

Network variables

Service pin Mechanical switch (SW2)

Number of domains: 2

Number of address entries: 37

Number of alias tables: 8

Number of transmission data: 17

Number of receiving data: 8

Number of configuration property: 12

ONMARK Variable Speed Motor Drive

L

functional profile.

Used for notification of Neuron ID to

the host.

Applicable terminal block

Terminal block Detachable terminal block 3-pole

Manufacturer: PHOENIX CONTACT

Type-Form : MSTB 2,5/3-ST-5.08

- 13 -

Page 15

E6581371c

6. Warranty

Any part of LONWORKS communication option that is proved to be defective will be repaired free of

charge under the following conditions:

1. This product will be repaired free of charge, if problem/fault occurs under normal handling

within one year of delivery and is caused obviously by a design or manufacturing defect.

2. The warranty applies only to the delivered product.

3. For the following kinds of failure or damage, the repair cost shall be borne by the customer

even within the warranty period.

i) Failure or damage caused by improper or incorrect use or handling, or unauthorized repair

or modification of the inverter.

ii) Failure or damage caused by the unit falling or an accident during transportation after the

purchase.

iii) Failure or damage caused by fire, salty water or wind, corrosive gas, earthquake, storm or

flood, lightning, abnormal voltage supply, or other natural disasters.

iv) Damage due to the use of L

4. If an additional warranty is provided then those conditions will also apply.

ONWORKS communication option for non-intended purposes.

- 14E -

Page 16

Loading...

Loading...