Toshiba 65L9400U Service Manual

SERVICE MANUAL

LCD Color Television

65L9400U series

FILE NO. 050-2014124

(System Information)

CONTENTS

1. IMPORTANT NOTICE

2. GREEN PRODUCT PROCUREMENT

3. LEAD-FREE SOLDER

4. SAFETY INSTRUCTION

5. SERVICE MODE

6. LED INDICATIONS FOR SERVICE

7. FIRMWARE UPDATING

8. MAIN BOARD EXCHANGE

9. SETTING SHIPOUT CODE (when Main board is

exchanged)

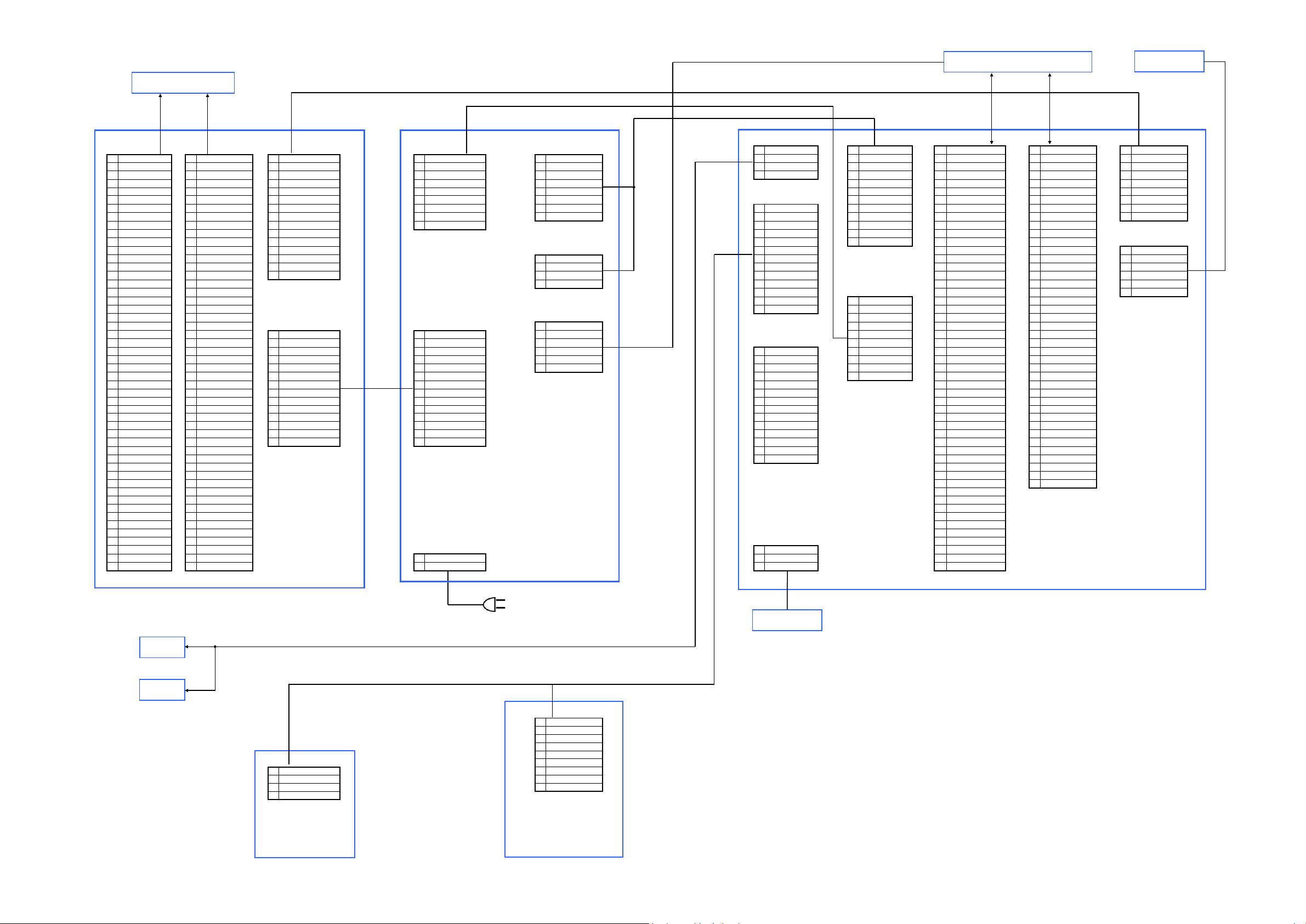

10. INTERCONNECT

11. SCHEMATIC DIAGRAM

1

IMPORTANT NOTICE

WARNING:

You are requested that you shall not modify or alter the information or data provided

herein without prior written consent by Toshiba. Toshiba shall not be liable to

anybody for any damages, losses, expenses or costs, if any, incurred in connection

with or as a result of such modification or alteration.

THE INFORMATION OR DATA HEREIN SHALL BE PROVIDED "AS IS" WITHOUT ANY

WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED WARRANTY OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Toshiba shall not be liable for any damages, losses, expenses or costs, if any,

incurred in connection with or as a result of use of any information or data provided

herein.

GREEN PRODUCT PROCUREMENT

The EC is actively promoting the WEEE & RoHS Directives that define standards for

recycling and reuse of Waste Electrical and Electronic Equipment and for the Restriction of

the use of certain Hazardous Substances. From July 1, 2006, the RoHS Directive will

prohibit any marketing of new products containing the restricted substances.

Increasing attention is given to issues related to the global environmental. Toshiba

Corporation recognizes environmental protection as a key management tasks, and is doing

its utmost to enhance and improve the quality and scope of its environmental activities. In

line with this, Toshiba proactively promotes Green Procurement, and seeks to purchase

and use products, parts and materials that have low environmental impacts.

Green procurement of parts is not only confined to manufacture. The same green parts

used in manufacture must also be used as replacement parts.

LEAD-FREE SOLDER

This product is manufactured using lead-free solder as a part of a movement within the

consumer products industry at large to be environmentally responsible. Lead-free solder

must be used in the servicing and repair of this product.

WARNING: This product is manufactured using lead free solder.

DO NOT USE LEAD BASED SOLDER TO REPAIR THIS PRODUCT!

The melting temperature of lead-free solder is higher than that of leaded solder by 54ºF to

72ºF (30ºC to 40ºC). Use of a soldering iron designed for lead-based solders to repair

product made with lead-free solder may result in damage to the component and or PCB

being soldered. Great care should be made to ensure high-quality soldering when servicing

this product especially when soldering large components, through-hole pins, and on PCBs

as the level of heat required to melt lead-free solder is high.

(1/3)

SAFETY INSTRUCTION

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE "SAFETY

PRECAUTION" AND "PRODUCT SAFETY NOTICE" INSTRUCTIONS BELOW.

Safety Precaution

WARNING: SERVICING SHOULD NOT BE ATTEMPTED BY ANYONE UNFAMILIAR

WITH THE NECESSARY PRECAUTIONS ON THIS RECEIVER. THE FOLLOWING ARE

THE NECESSARY PRECAUTIONS TO BE OBSERVED BEFORE SERVICING THIS

CHASSIS.

1. An isolation transformer should be connected in the power line between the receiver

and the AC line before any service is performed on the receiver.

2. Always disconnect the power plug before any disassembling of the product. It may

result in electrical shock.

3. When replacing a chassis in the cabinet, always be certain that all the protective

devices are put back in place, such as nonmetallic control knobs, insulating covers,

shields, isolation resistor-capacitor network, etc.

4. Always keep tools, components of the product, etc away from the children, These

items may cause injury to children.

5. Depending on the model, use an isolation transformer or wear suitable gloves when

servicing with the power on, and disconnect the power plug to avoid electrical shock

when replacing parts. In some cases, alternating current is also impressed in the

chassis, so electrical shock is possible if the chassis is contacted with the power on.

6. Always use the replacement parts specified for the particular model when making

repairs. The parts used in products require special safety characteristics such as

inflammability, voltage resistance, etc. therefore, use only replacement parts that

have these same characteristics. Use only the specified parts when the

indicated in the circuit diagram or parts list.

7. Parts mounting and routing dressing of wirings should be the same as that used

originally. For safety purposes, insulating materials such as isolation tube or tape are

sometimes used and printed circuit boards are sometimes mounted floating. Also

make sure that wirings is routed and clamped to avoid parts that generate heat and

mark is

(2/3)

which use high voltage. Always follow the manufactured wiring routes / dressings.

8. Always ensure that all internal wirings are in accordance before re-assembling the

external casing after a repairing completed. Do not allow internal wiring to be

pinched by cabinets, panels, etc. Any error in reassembly or wiring can result in

electrical leakage, flame, etc., and may be hazardous.

9. NEVER remodel the product in any way. Remodeling can result in improper

operation, malfunction, or electrical leakage and flame, which may be hazardous.

10. Always perform an AC leakage current checking on the exposed metallic parts of the

cabinet such as antennas, terminals, screw heads, metal overlays, control shafts

and etc. to be sure that the set is safe to operate without any dangerous of electrical

shocks before returning the set to the customer.

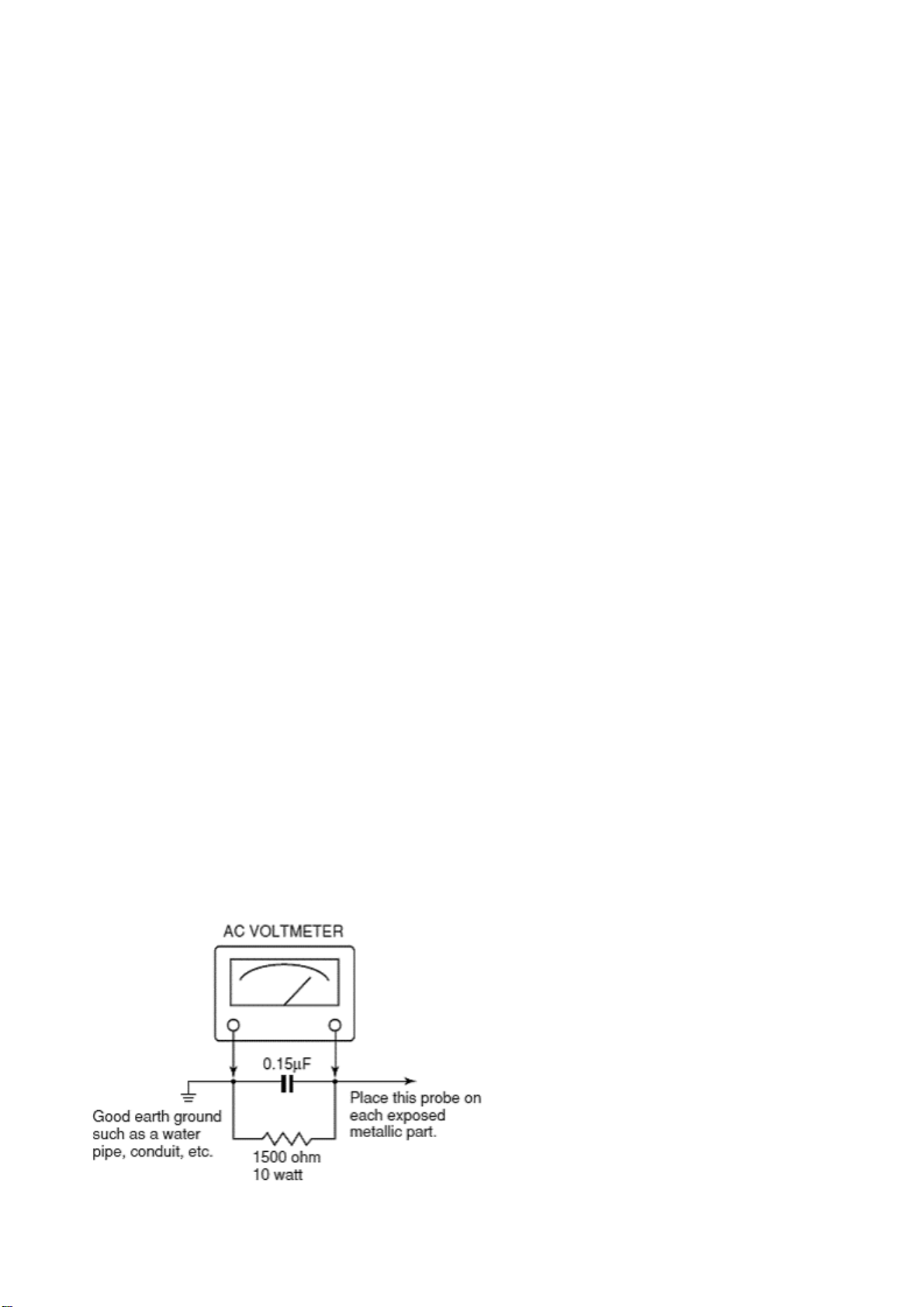

11. The leakage current checking. (After completing the work, measure the leakage

current to prevent an electrical shock.)

Plug the AC line cord directly into a 120V AC outlet. Do not use an isolation

transformer for this check.

Use an AC voltmeter having 5000 ohms per volt or more sensitivity in the following

manner.

Connect a 1500 ohm 10 watt resistor, paralleled by a 0.15 µF, AC type capacitor, between

a known good earth ground (water pipe, conduit, etc.) and the exposed metallic parts, one

at a time. Measure the AC voltage across the combination of 1500 ohm resistor and 0.15

µF capacitor. Reverse the AC plug at the AC outlet and repeat AC voltage measurements

for each exposed metallic part. Voltage measured must not exceed 0.3 volts rms. This

corresponds to 0.2 milliamp. AC. Any value exceeding this limit constitutes a potential

shock hazard and must be corrected immediately.

(3/3)

Product Safety Notice

Many electrical and mechanical parts in this chassis have special safety-related

characteristics. These characteristics are often passed unnoticed by a visual inspection and

the protection afforded by them cannot necessarily be obtained by using replacement

components rated for higher voltage, wattage, etc. Replacement parts which have these

special safety characteristics are identified in this manual and its supplements; electrical

components having such features are identified by the international hazard symbols on the

schematic diagram and the parts list.

Before replacing any of these components, read the parts list in this manual carefully. The

use of substitute replacement parts which do not have the same safety characteristics as

specified in the parts list may create electrical shock, fire, or other hazards.

SERVICE MODE

ENTERING SERVICE MODE

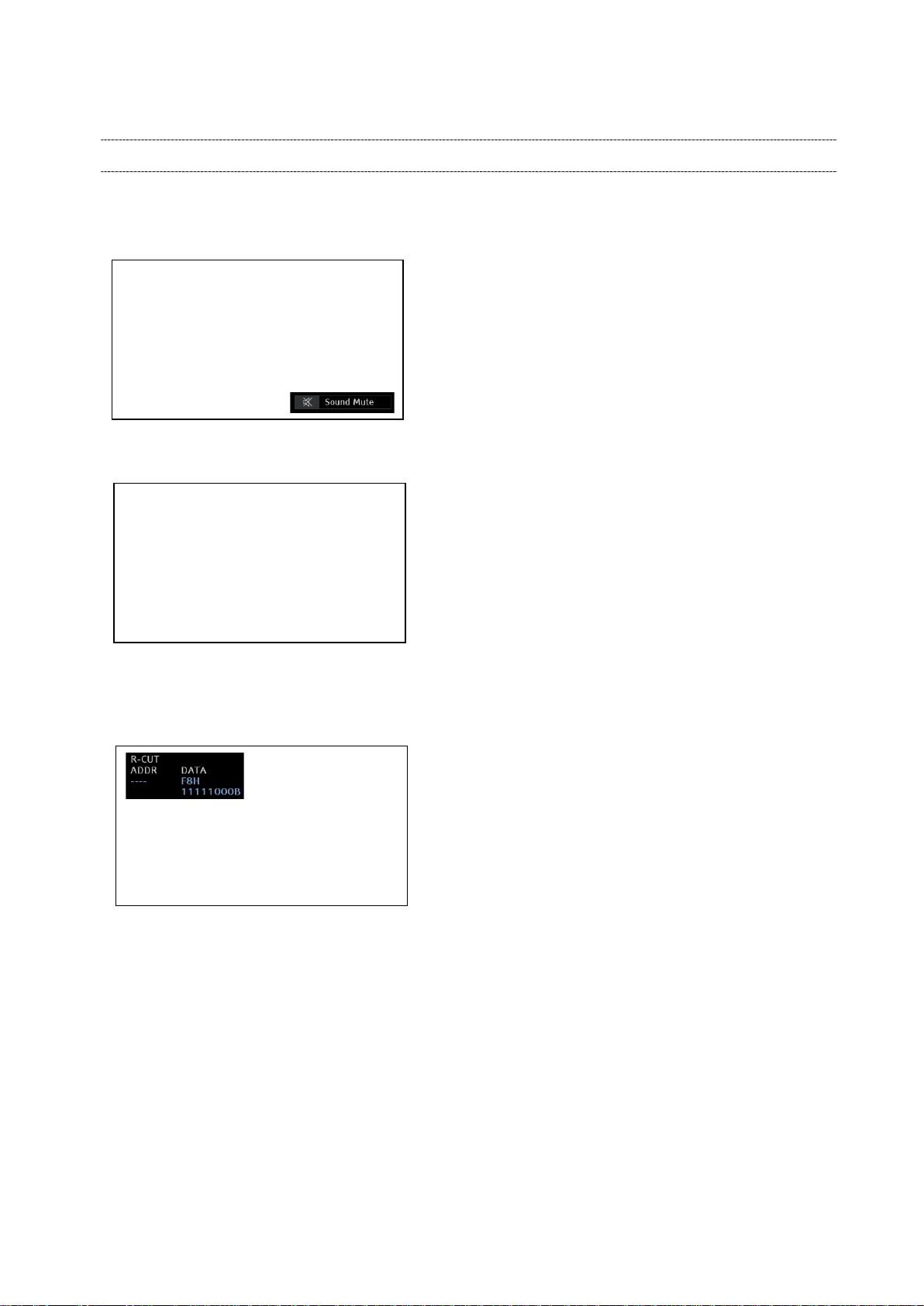

1. Press MUTE button twice on Remote Control.

TV mode changes as follows. Un-Mute => 1/2Mute => Mute

2. Press MUTE button again and keep pressing.

(1/3)

(Sound Mute is canceled)

3. While pressing the MUTE button, press CH/INPUT button on TV control panel.

(Enter Service Mode)

(2/3)

Normal

KEY FUNCTION IN THE SERVICE MODE

The following key entry during display of adjustment menu provides special functions.

Button Function

INPUT button (on Remote) Test signal selection

CH (on Remote) Selection of the adjustment items

VOL +/– (on Remote) Change of the data value

[7] button Automatic A/D Adjustment

(PC, Component, Composite(PAL, NTSC))

[9] button Self Check display ON

[Exit] button Exit from Service mode

Self Check display Off

CAUTION: Never try to perform initialization unless you have changed the memory IC.

TEST SIGNAL SELECTION

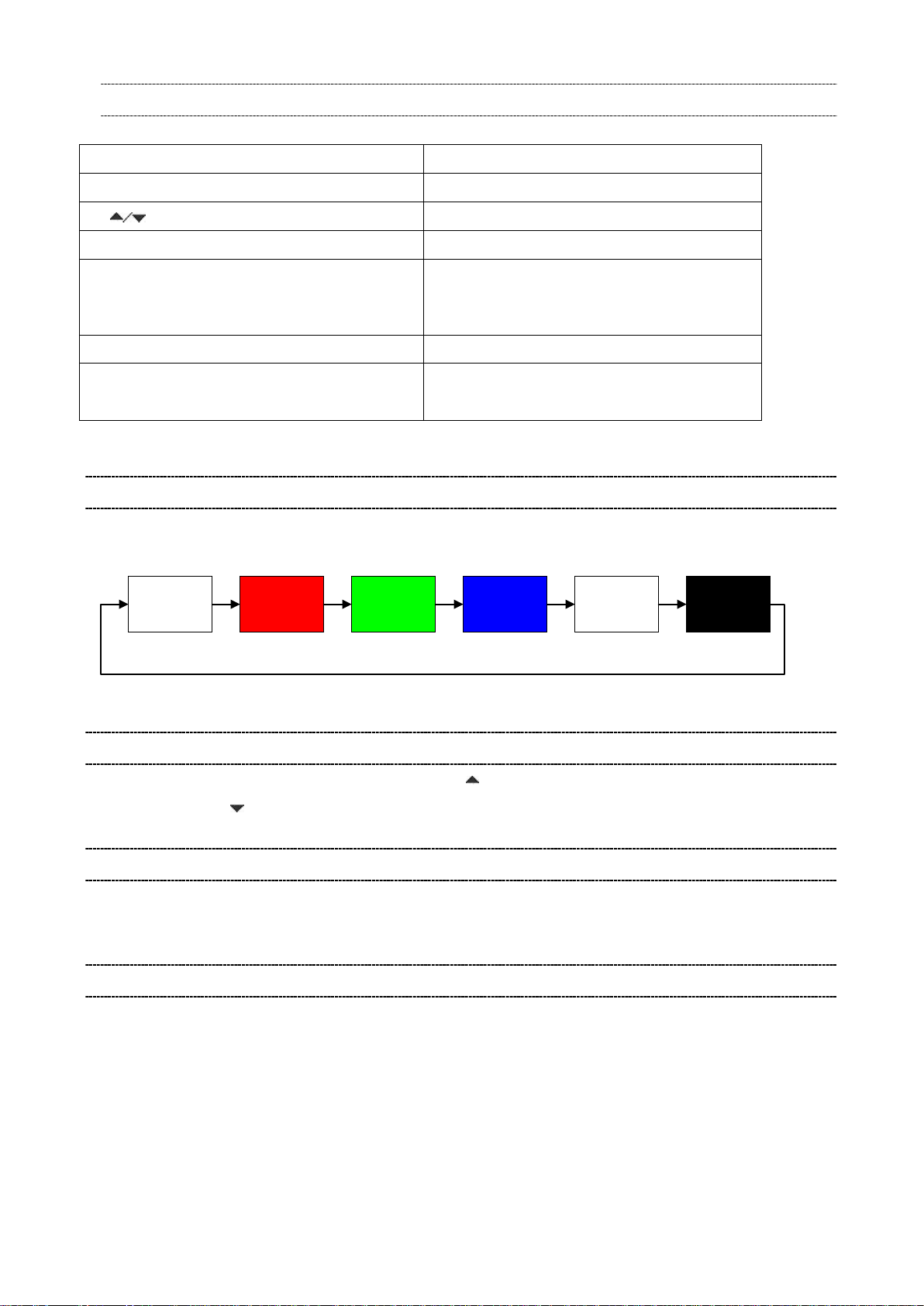

1) While displaying the adjustment menu, every pressing of INPUT button on the Remote Control changes the

built-in test patterns on screen as described below.

When a pattern is changed at the time of an ATV display, it can display only for a moment.

Picture

Red screen Green screen

Blue screen

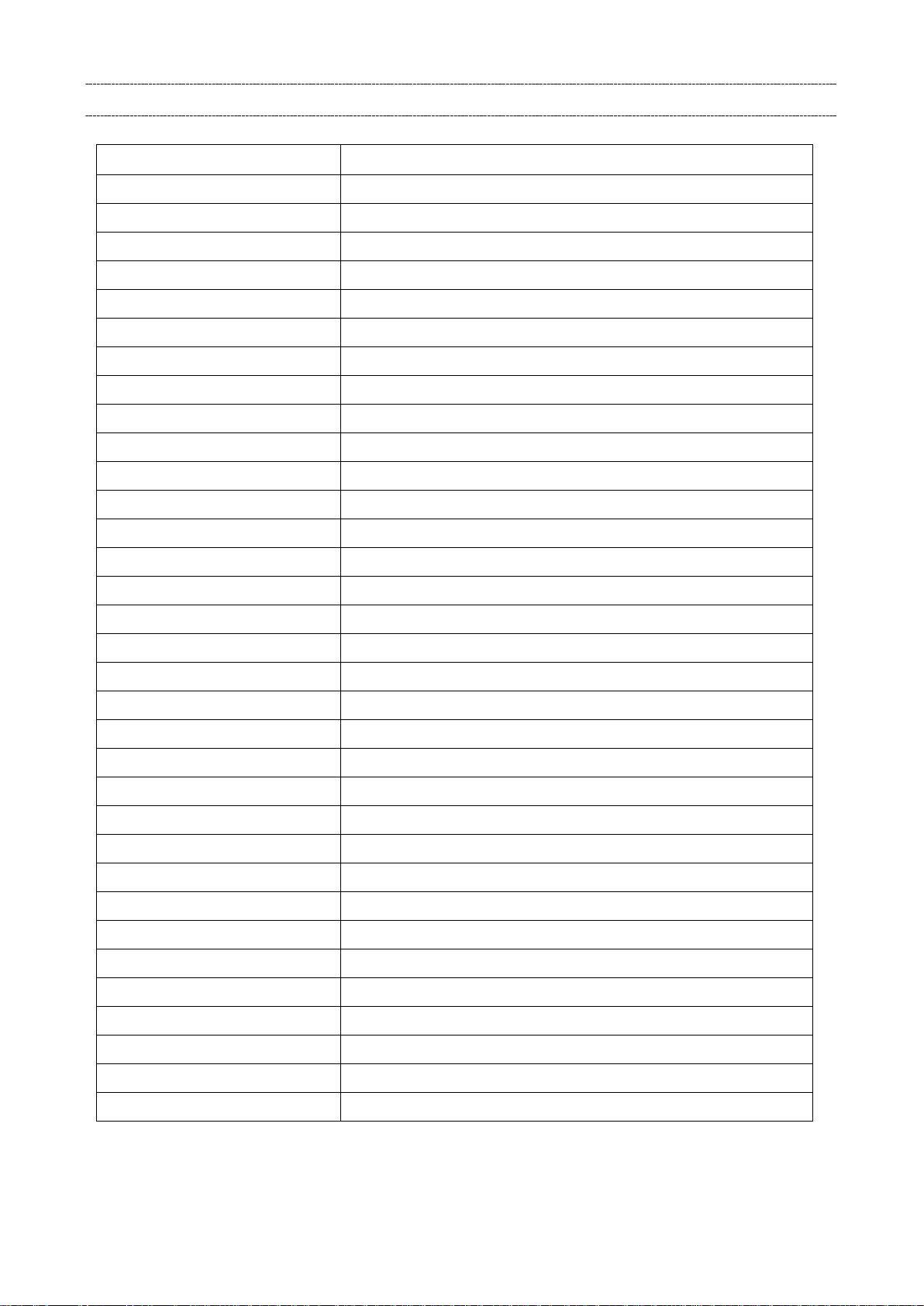

SELECTING THE ADJUSTING ITEMS

1) While displaying the adjustment menu, press the CH button to cycle through the adjustment items in the

order of table. (CH

button for reverse order)

ADJUSTING THE DATA

1) While displaying the adjustment menu, press the VOL +/– button to change the value of data in the range

from 00H to FFH. The variable range depends on the adjusting item.

EXIT FROM SERVICE MODE

1) Press the [Exit] button on Remote.

ADJUSTING ITEMS IN THE SERVICE MODE

Item Description

RCUT RED CUTOFF

GCUT GREEN CUTOFF

BCUT BLUE CUTOFF

RDRV RED DRIVE

GDRV GREEN DRIVE

BDRV BLUE DRIVE

OSRC COOL R-CUTOFF-OFFSET for COOL

OSRC NATURAL R-CUTOFF-OFFSET for NATURAL

OSRC WARM R-CUTOFF-OFFSET for WARM

OSGC COOL G-CUTOFF-OFFSET for COOL

OSGC NATURAL G-CUTOFF-OFFSET for NATURAL

OSGC WARM G-CUTOFF-OFFSET for WARM

(3/3)

OSBC COOL B-CUTOFF-OFFSET for COOL

OSBC NATURAL B-CUTOFF-OFFSET for NATURAL

OSBC WARM B-CUTOFF-OFFSET for WARM

OSRD COOL R-DRIVE-OFFSET for COOL

OSRD NATURAL R-DRIVE-OFFSET for NATURAL

OSRD WARM R-DRIVE-OFFSET for WARM

OSGD COOL G-DRIVE-OFFSET for COOL

OSGD NATURAL G-DRIVE-OFFSET for NATURAL

OSGD WARM G-DRIVE-OFFSET for WARM

OSBD COOL B-DRIVE-OFFSET for COOL

OSBD NATURAL B-DRIVE-OFFSET for NATURAL

OSBD WARM B-DRIVE-OFFSET for WARM

OSRD 3D COOL R-DRIVE-OFFSET for COOL (3D)

OSRD 3D NATURAL R-DRIVE-OFFSET for NATURAL (3D)

OSRD 3D WARM R-DRIVE-OFFSET for WARM (3D)

OSGD 3D COOL G-DRIVE-OFFSET for COOL (3D)

OSGD 3D NATURAL G-DRIVE-OFFSET for NATURAL (3D)

OSGD 3D WARM G-DRIVE-OFFSET for WARM (3D)

OSBD 3D COOL B-DRIVE-OFFSET for COOL (3D)

OSBD 3D NATURAL B-DRIVE-OFFSET for NATURAL (3D)

OSBD 3D WARM B-DRIVE-OFFSET for WARM (3D)

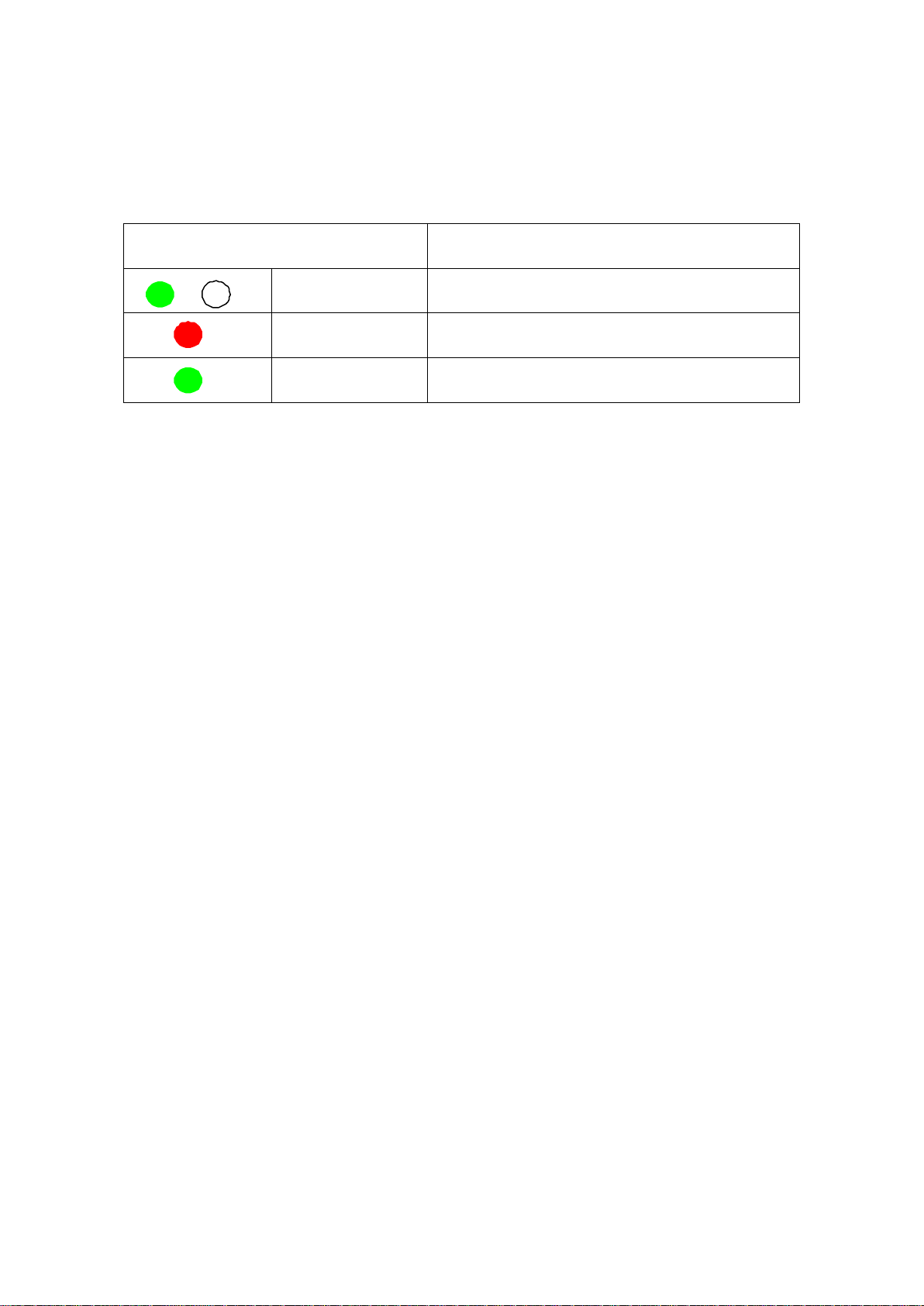

LED INDICATIONS FOR SERVICE

/

SW Upgrade and Error conditions indicated by the Power LED is described below.

Power LED

Green blink SW Upgrade in Progress

Red SW Upgrade Failed

Green SW Upgrade Successful

(1/3)

FIRMWARE UPDATING

To upgrade FW for L8400U/L9400U series via USB mass storage device, please follow the

steps below:

1. Use the USB mass storage device formatted with “FAT32”.

2. Copy the following 3 files to the root directory of the USB mass storage device.

Model: 58L8400U

L8400.meta

L8400_FRC_xxxx.fwu

L9400_9.12.xx.yy.zz.1.fwu

Model: 65L9400U

L9400.meta

L9400_FRC_xxxx.fwu

L9400_9.12.xx.yy.zz.1.fwu

3. Plug and turn on the DTV, waiting until the picture is displayed on the screen.

4. Insert the USB mass storage device to the U SB -1 slot(Bottom side) of the DTV.

("9.12.xx.yy.zz.1" is a FW version number.) (Same as L9400 model)

("9.12.xx.yy.zz.1" is a FW version number.)

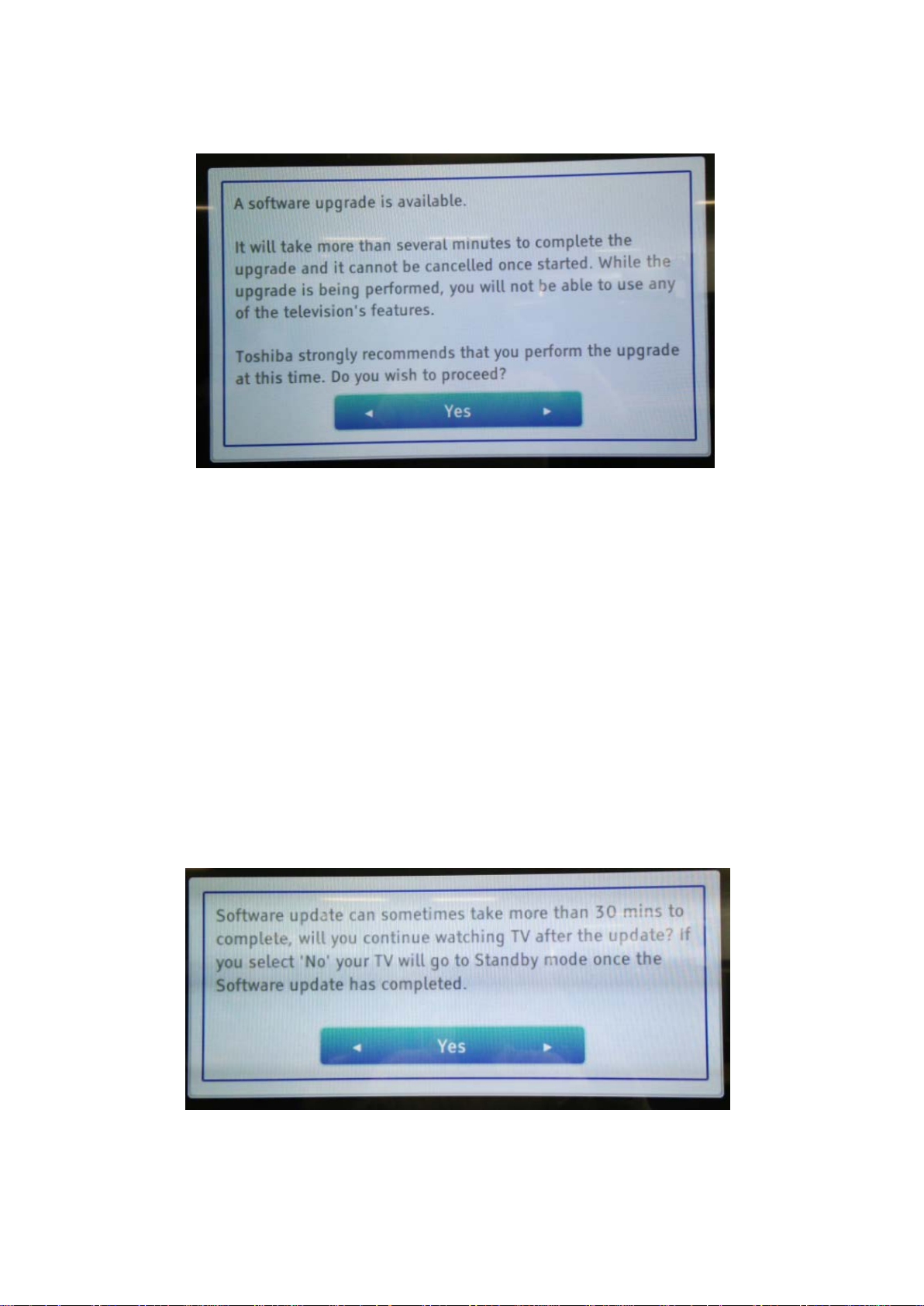

5. After the following message appears, select “Yes” with Left/Right key, and push “OK”

NOTE:

This message may not appear if the TV was using a network

function at the time the USB Flash Drive was connected. In this

case, please select the ANT/CABLE input and then remove and

reconnect the USB Flash Drive

key to start FW upgrade.

(2/3)

6. Then, the following message appears to enable users to select their preferable behaviour

after the SW upgrade completes. If YOU want DTV to reboot automatically after FW

upgrade, select “Yes”. If YOU want DTV to go to standby after that, select “No”.

7. When FW upgrade starts, the following message appears. Please leave the DTV alone

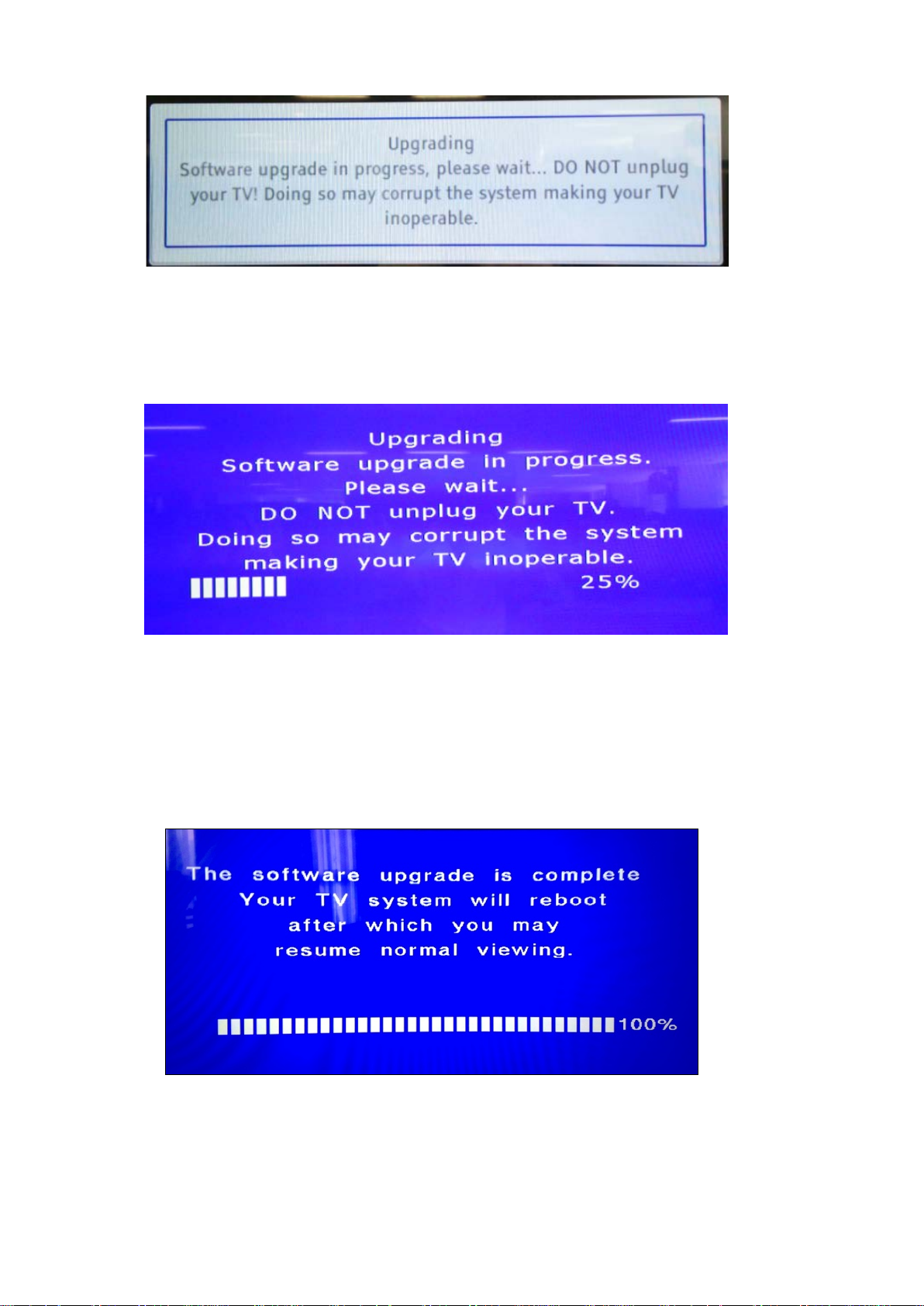

until FW upgrade completes as described in No.9 below.

8. After that, the following gauge screen appears. Wait until the gauge display reaches

100%.

9. If FW upgrade succeeds, the following message appears. After that, the DTV will reboot

or go to standby automatically according to the user setting on No.6 above.

10. Unplug USB mass storage device from the DTV.

02: Mexico

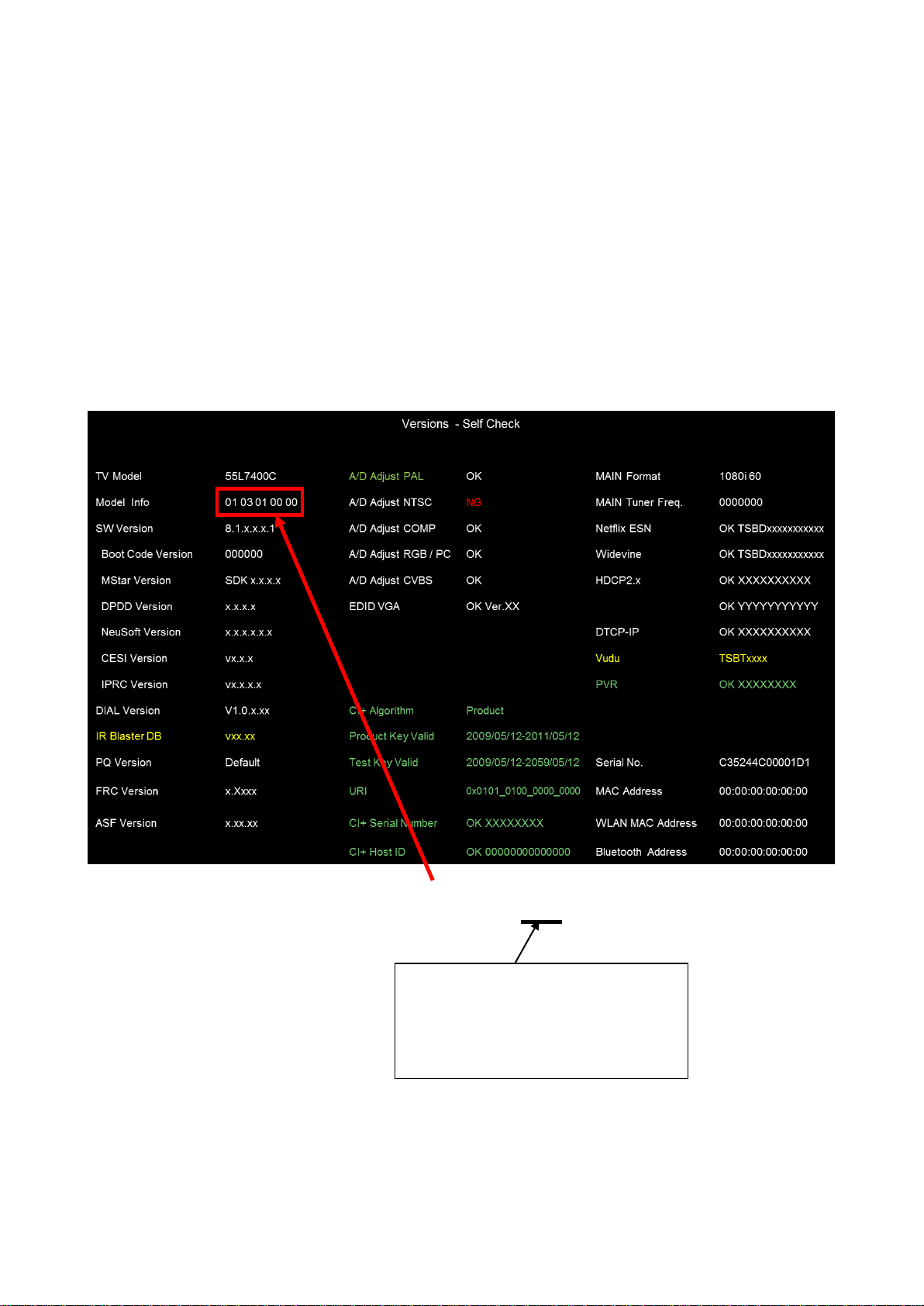

MAIN BOARD EXCHANGE

1. Whenever Main Board is exchanged, you are required to confirm the Destination (Ship

Out Code Setting).

If the Setting is not valid, change the Ship Out Code.

(See “SETTING SHIPOUT CODE_TM14NA4K”)

2. Check the shipout code by using self check screen.

How to enter the self check screen.

1 Press SETUP on remote control unit.

2 Select “Get Help” >> “System Information”

3 Press “3” “5” “7” “4”

00 00 00 00 00

The 4th byte is the Shipout code.

00: USA

01: Canda

(1/3)

SETTING SHIPOUT CODE (when Main board

is exchanged)

When Main board is exchanged, the shipout code needs to be set up according to the each

Destination.

Please install the each Model Setting File in the following procedure.

1. Use the USB mass storage device formatted with “FAT32”.

2. Cop y the following file to the root of the USB mass storage device.

<Use below file to change the shipout code to USA>

58L8400U: USA¥Model_Setting_L8400_58_C.bin

65L9400U: USA¥Model_Setting_L9400_65_C.bin

<Use below file to change the shipout code to Canada>

58L8400UC: Canada¥Model_Setting_L8400_58_C.bin

65L9400UC: Canada¥Model_Setting_L9400_65_C.bin

<Use below file to change the shipout code to Mexico>

58L8400UM: Mexico¥Model_Setting_L8400_58_C.bin

65L9400UM: Mexico¥Model_Setting_L9400_65_C.bin

(2/3)

3. Inser t the USB mass storage device USB-1 slot(Bottom side) of the TV set.

4. While pushing “VOL –“ key on the local key that is installed on the side of DTV, plug and

turn on the DTV, waiting for TOSHIBA logo OSD to appear.

5. Wait for about 2 minutes, and unplug USB mass storage device.

6. Push “MENU” key on the remote, select “Installation”> > “Reset TV”.

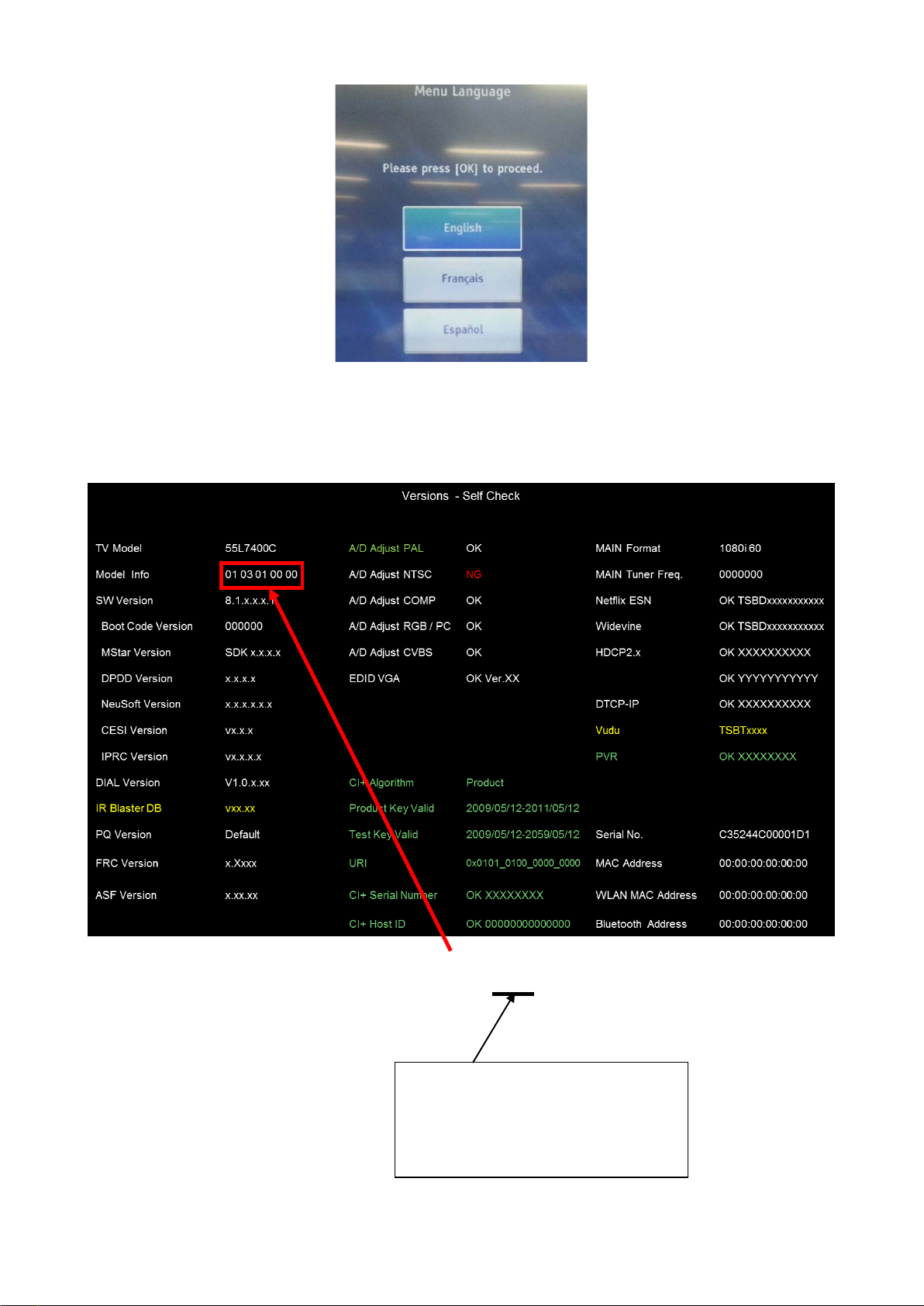

7. After the followi ng message appears, select “Yes” with Left/Right key, and

push“OK”key.

8. Following the success of “Reset TV”, shipout change becomes valid.

9. Check the shipout code by using self check screen.

02: Mexico

How to enter the self check screen.

1 Push “MENU” key on the remote.

2 Select “Get Help” >> “System Information”

3 Press “3” “5” “7” “4”

(3/3)

00 00 00 00 00

The 4th byte is the Shipout code.

00: USA

01: Canda

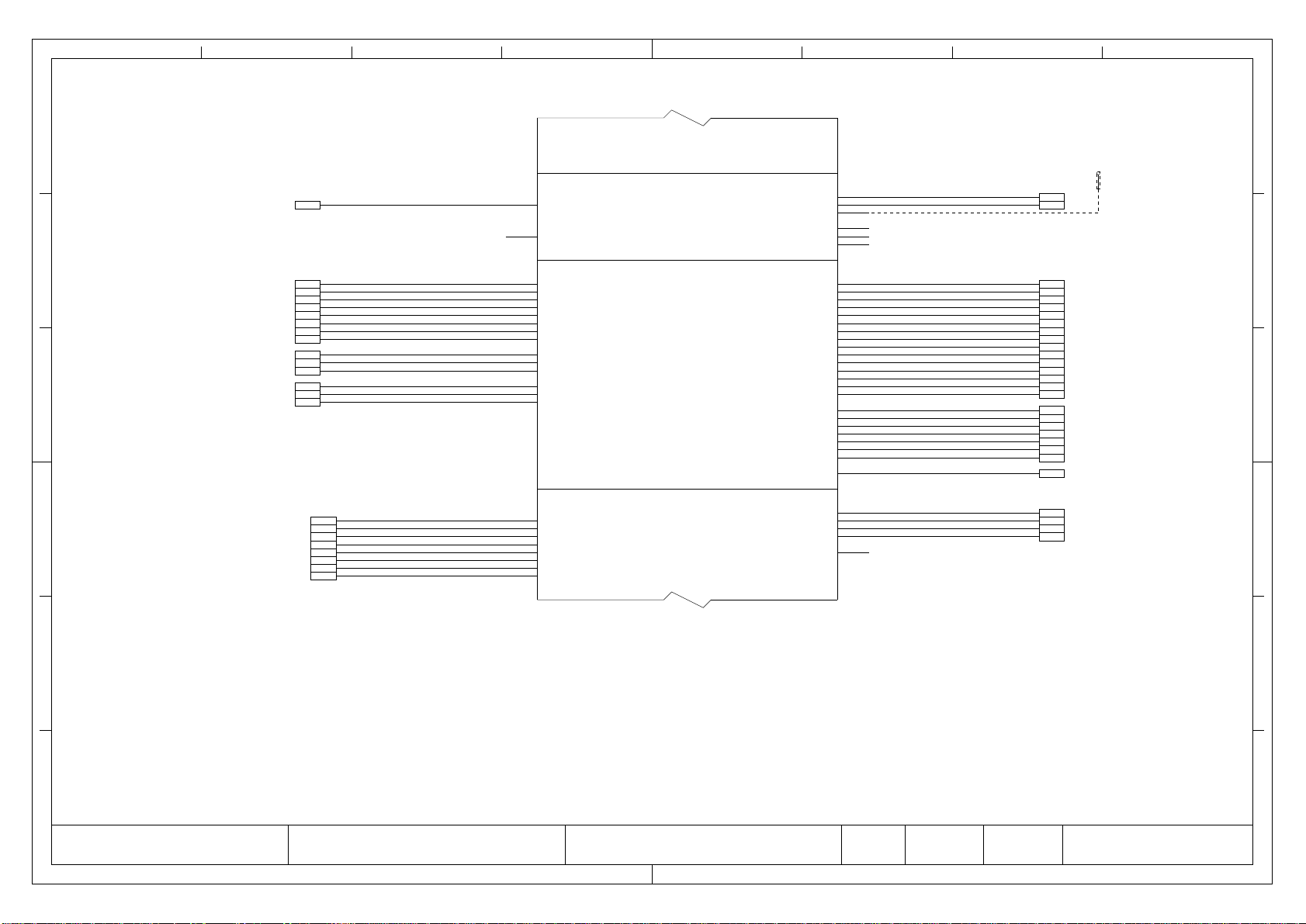

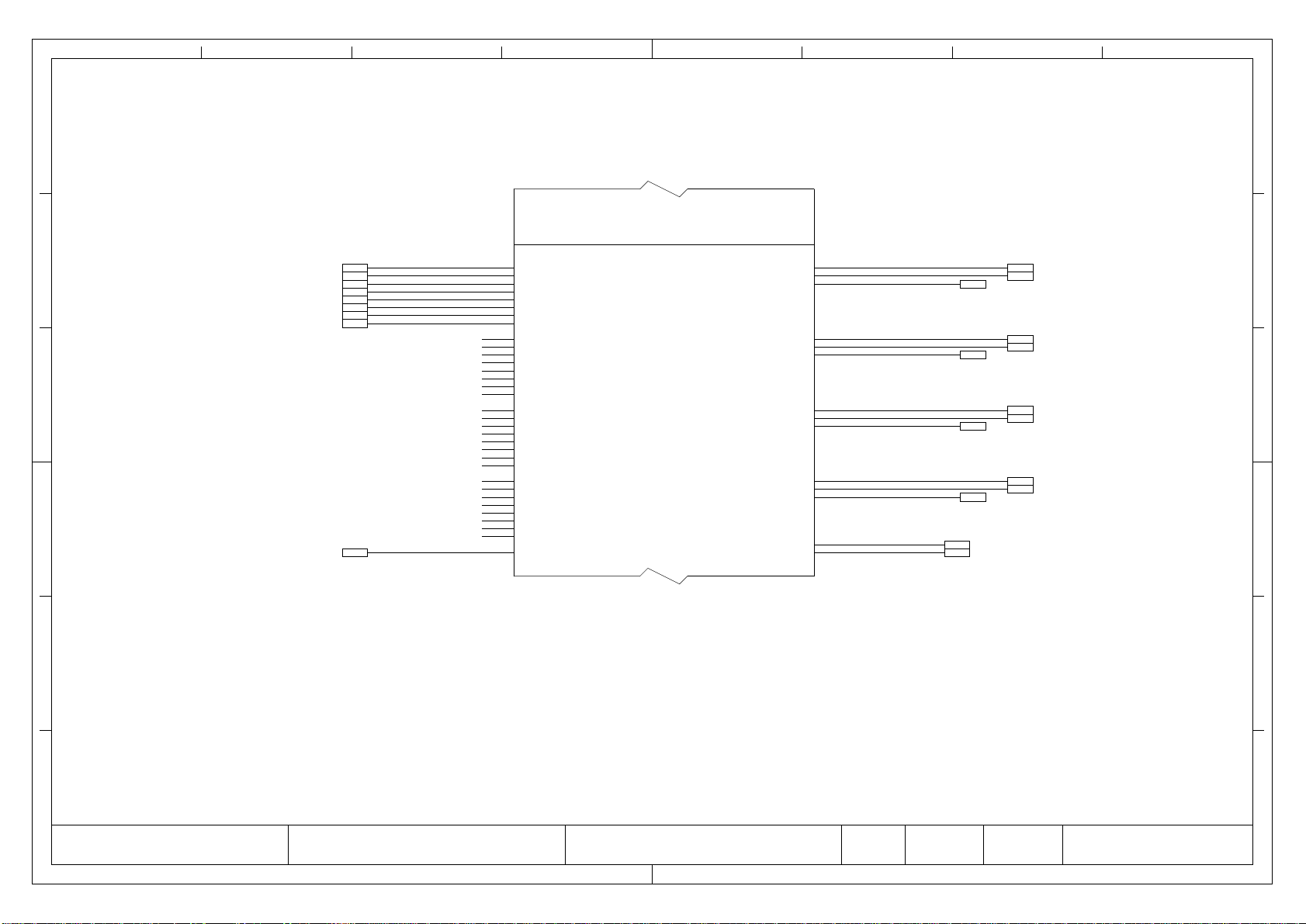

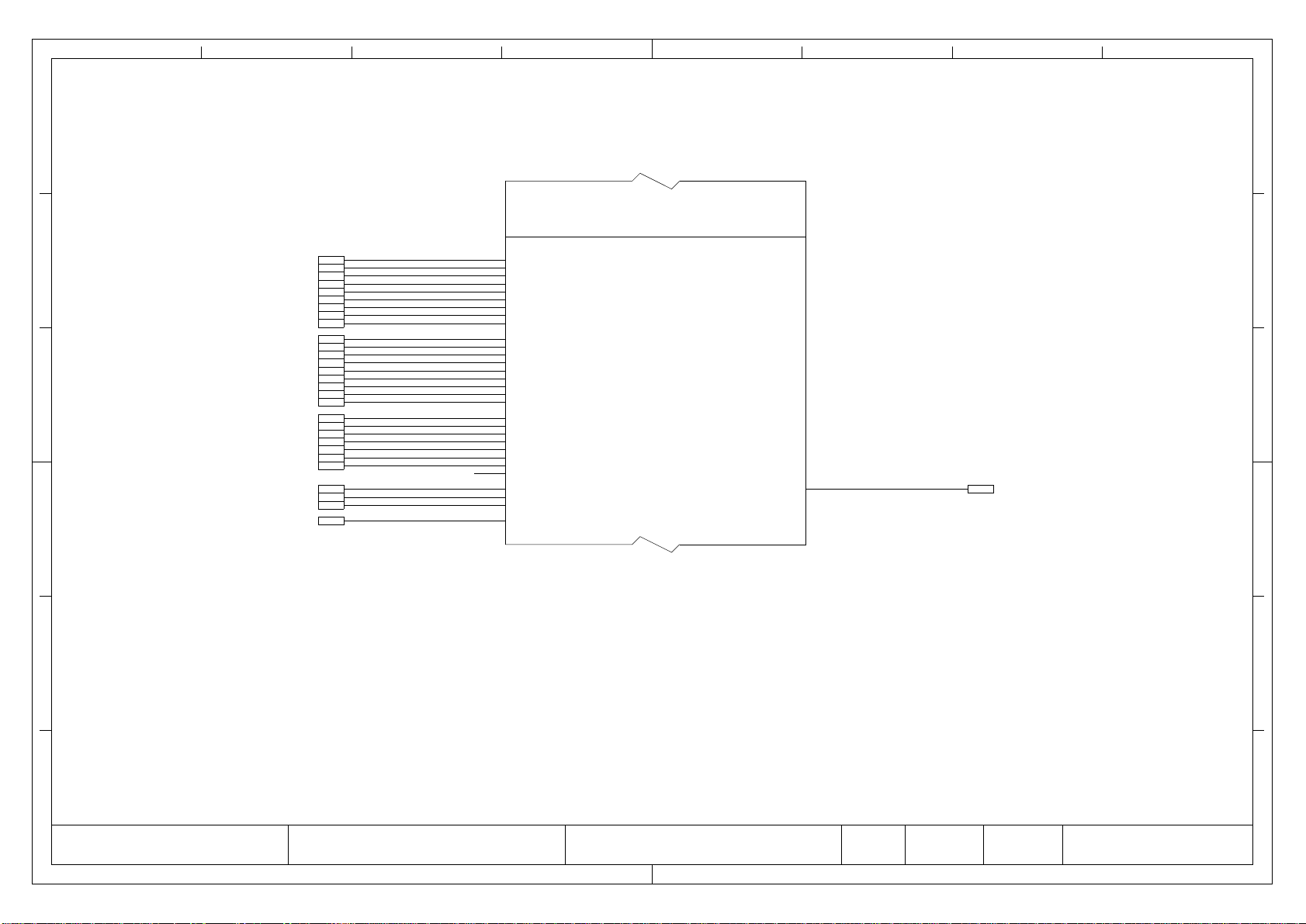

CN740

CN401 6 5V1

3

GND

9 LED_RED

4

C_KEY1(UP)(DOWN)

PE1188

Main

LCON

65":

PANEL BACKLIGHT

PE1183

LED/REMOTE/SENSOR

POWER

65":

PE1121

MN860

MN45

MN6

U04A

T-CON

WLAN

U802

MN91

CN201 CN202 CN102 PJ91 PJ90 1 R+_AMP 1 12V 1 CML_GND 1 NC 1 TEST-MODE

1 L64_Cathode 1 R11_Anode 1 GND 1 AC_DETECT 1 12V 2 R-_AMP 2 12V 2 VX1TX7P 2 Temp_SEL0 2 VSYNC_IN

2 L34_Cathode 2 R41_Anode 2 NC 2 POWER_TV 2 12V 3 L-_AMP 3 12V 3 VX1TX7N 3 Temp_SEL1 3 GND

3 L63_Cathode 3 R12_Anode 3 TEST-MODE 3 5V1 3 12V 4 L+_AMP 4 12V 4 CML_GND 4 NC 4 SCREEN_SIZE

4 L33_Cathode 4 R42_Anode 4 NC 4 GND 4 12V 5 GND 5 VX1TX6P 5 NC 5 BL_ONOFF

5 L62_Cathode 5 R13_Anode 5 VSYNC-IN 5 18V(LNB) 5 GND 6 GND 6 VX1TX6N 6 NC 6 SERIAL_DATA

6 L32_Cathode 6 R43_Anode 6 NC 6 GND 6 GND CN45 7 GND 7 CML_GND 7 NC 7

7 L61_Cathode 7 R14_Anode 7 GND 7 BL_ON/OFF 7 GND 1 3.3V_TVM 8 GND 8 VX1TX5P 8 NC 8 GND

8 L31_Cathode 8 R44_Anode 8 SCREEN SIZE 8 POWER_LCD 8 GND 2 REMOTE_IN 9 18.5V_AUDIO 9 VX1TX5N 9 NC 9 3D_EN

9 L54_Cathode 9 R21_Anode 9 BL_ONOFF 9 NC 3 GND 10 18.5V_AUDIO 10 CML_GND 10 NC

10 L24_Cathode 10 R51_Anode 10 SERIAL_DATA 4 OP_IN 11 GND_AUDIO 11 VX1TX4P 11 NC

11 L53_Cathode 11 R22_Anode 11 GND 5 3.3VD 12 GND_AUDIO 12 VX1TX4N 12 NC

12 L23_Cathode 12 R52_Anode 12 SERIAL_CLK PJ92 6 5V1 13 CML_GND 13 NC 1 5V_WLAN

13 L52_Cathode 13 R23_Anode 13 GND 1 18V(Audio) 7 GND 14 VX1TX3P 14 NC 2 S_USBO2DM

14 L22_Cathode 14 R53_Anode 14 3D_EN 2 18V(Audio) 8 LED_GREEN 15 VX1TX3N 15 NC 3 S_USBO2DP

L51_Cathode 15 R24_Anode 15 GND 3 GND(Audio) 9 LED_RED 16 CML_GND 16 NC 4 GND

15

16 L21_Cathode 16 R54_Anode 4 GND(Audio) 10 KEY_POWER 17 VX1TX2P 17 CML_GND 5

17 L44_Cathode 17 R31_Anode 11 KEY_IN2 CN91 18 VX1TX2N 18 VX1TX15P 6 GND

18 L14_Cathode 18 R61_Anode 12 GND 1 AC_DETECT 19 CML_GND 19 VX1TX15N

19 L43_Cathode 19 R32_Anode 13 KEY_IN1 2 POWER_TV 20 VX1TX1P 20 CML_GND

20 L13_Cathode 20 R62_Anode PJ93 3 5V 21 VX1TX1N 21 VX1TX14P

21 L42_Cathode 21 R33_Anode CN101 PJ860 1 GND 4 GND 22 CML_GND 22 VX1TX14N

22 L12_Cathode 22 R63_Anode 1 GND 1 GND(LED) 2 GND 5 18V_LNB 23 VX1TX0P 23 CML_GND

23 L41_Cathode 23 R34_Anode 2 GND 2 GND(LED) 3 12V CN355 6 GND 24 VX1TX0N 24 VX1TX13P

24 L11_Cathode 24 R64_Anode 3 GND 3 GND(LED) 4 12V

25 NC 25 NC 4 GND 4 GND(LED) 5 12V 2 8 POWER_LCD 26 LOCK N 26 CML_GND

26 NC 26 NC 5 GND 5 GND(LED) 6 NC 3 9 POWER-DB 27 HTPDN 27 VX1TX12P

27 L64_Anode 27 R11_Cathode 6 GND 6 GND(LED) 4 10 PWM 28 GND 28 VX1TX12N

28 L34_Anode 28 R41_Cathode 7 GND 7 GND(LED) 5 29 3D_SYNCI 29 CML_GND

29 L63_Anode 29 R12_Cathode 8 18V(LED)/24V(LED) 8 18V(LED)/24V(LED) 6 30 3D_SYNCO 30 VX1TX11P

30 L33_Anode 30 R42_Cathode 9 18V(LED)/24V(LED) 9 18V(LED)/24V(LED) 7 31 3D_EN 31 VX1 TX11N

31 L62_Anode 31 R13_Cathode 10 18V(LED)/24V(LED) 10 18V(LED)/24V(LED) 8 32 NC 32 CML_GND

32 L32_Anode 32 R43_Cathode 11 18V(LED)/24V(LED) 11 18V(LED)/24V(LED) 9 33 NC 33 VX1TX10P

33 L61_Anode 33 R14_Cathode 12 18V(LED)/24V(LED) 12 18V(LED)/24V(LED) 10 34 NC 34 VX1TX10N

34 L31_Anode 34 R44_Cathode 13 18V(LED)/24V(LED) 13 18V(LED)/24V(LED) 11 35 NC 35 CML_GND

35 L54_Anode 35 R21_Cathode 14 18V(LED)/24V(LED) 14 18V(LED)/24V(LED) 12 36 NC 36 VX1TX9P

36 L24_Anode 36 R51_Cathode 13 3.3V_IO 37 NC 37 VX1TX9N

37 L53_Anode 37 R22_Cathode 14 GND 38 GND 38 CML _GND

38 L23_Anode 38 R52_Cathode 39 GND 39 VX1TX8P

39 L52_Anode 39 R23_Cathode 40 GND 40 VX1TX8N

40 L22_Anode 40 R53_Cathode 41 GND 41 CML_GND

41 L51_Anode 41 R24_Cathode 42 GND

42 L21_Anode 42 R54_Cathode 43 NC

43 L44_Anode 43 R31_Cathode 44 12V

44 L14_Anode 44 R61_Cathode 45 12V

45 L43_Anode 45 R32_Cathode 46 12V

46 L13_Anode 46 R62_Cathode 47 12V

47 L42_Anode 47 R33_Cathode CN46 48 12V

48 L12_Anode 48 R63_Cathode P801A 1 VCC_FAN 49 12V

49 L41_Anode 49 R34_Cathode 1 Line 2 GND 50 12V

50 L11_Anode

50 R64_Cathode 2 Neutral 3 STOP_FAN 51 12V

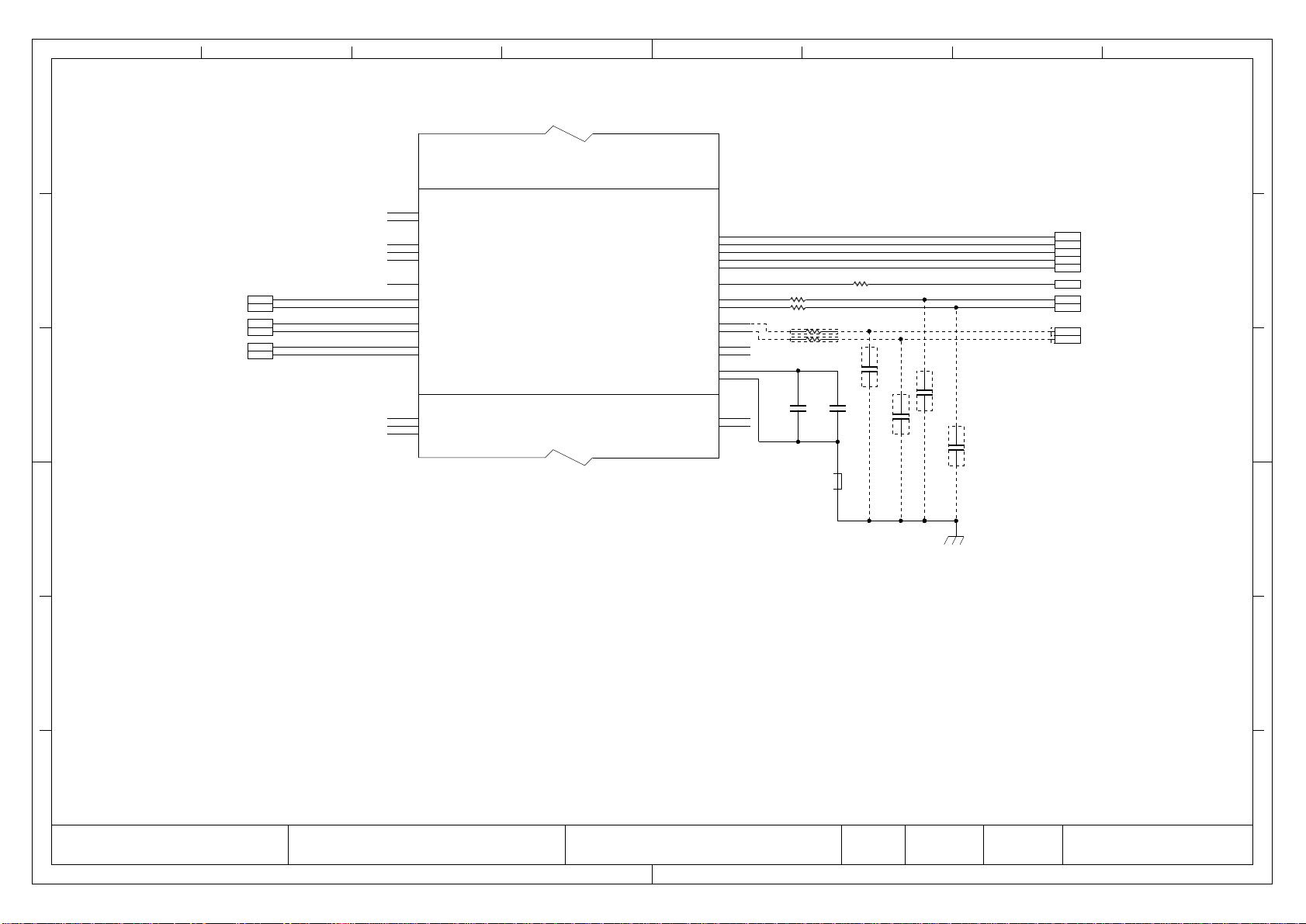

U811

TYL5865TD048A01

U800

N13-535P1A

MN93

MN30

CN30 CN90 CN650 CN651 CN652

1 7 BL-ONOFF 25 CML_GND 25 VX1TX13N

MN90

U01A

MZ01

MZ02

SERIAL_CLK

CN165

C_WWOL_WAKEUP

MN165

Speaker

Speaker

C_POWER_KEY

1

C_KEY2(MODE)

2

P801

KEY

AC IN

1 3.3V_TVM

2 RMT_IN

3 GND

4 OP_IN

5 3.3VD

7 GND

8 LED_GREEN

U03A

MN46

Cooling fan

5T03655-2E

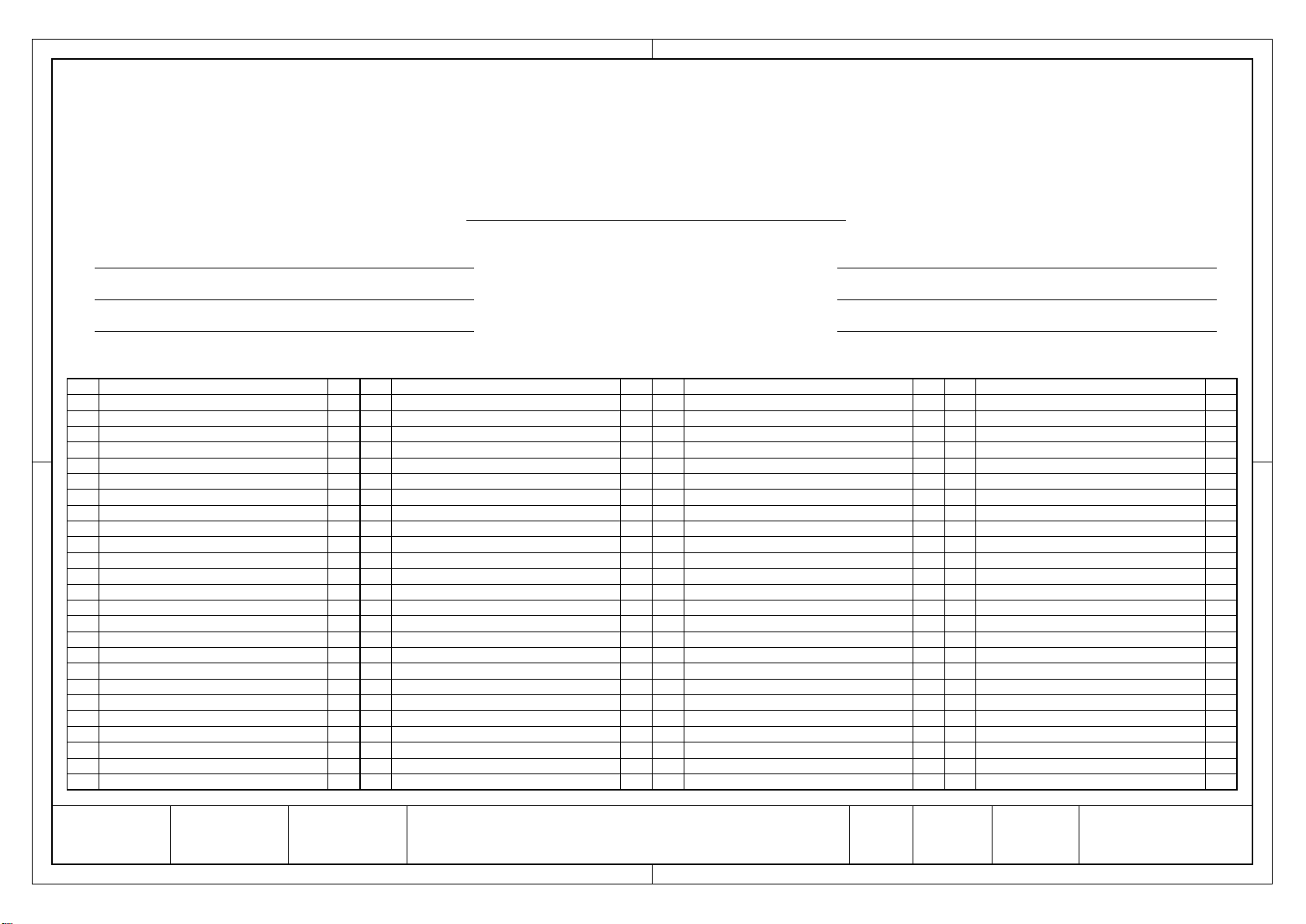

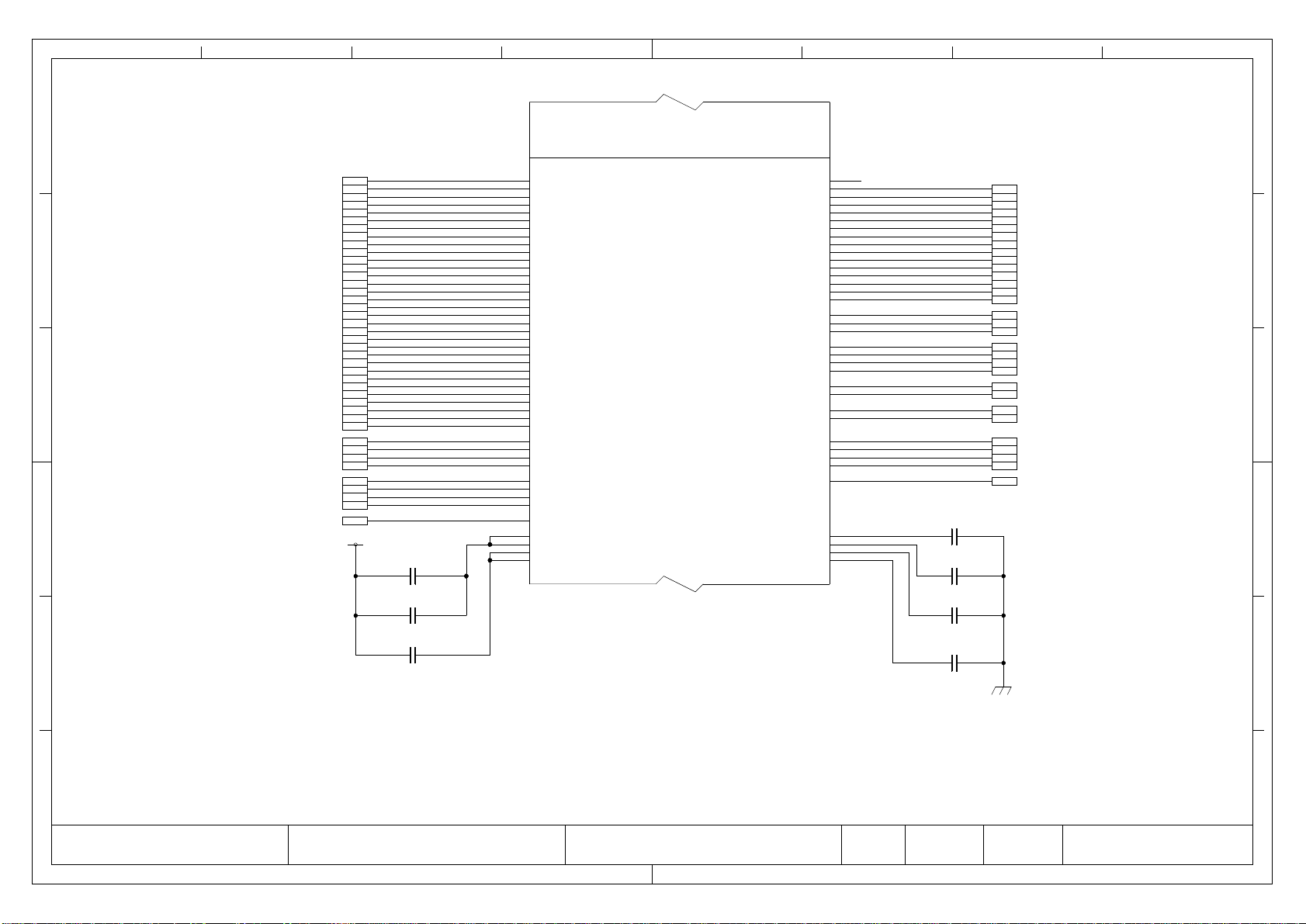

SCHEMATIC DIAGRAMS

UNIT NAME

PWA NAME

PWB NAME

PAGE

101 MSD8832WDK TS/USB/LAN 00

1

102 MSD8832WDK FLASH 00

2

103 MSD8832WDK DDR A 00

3

104 MSD8832WDK DDR B 00

4

105 MSD8832WDK GPIO 00

5

106 MSD8832WDK HDMI 00

6

107 MSD8832WDK LVDS/Vby1 00

7

108 MSD8832WDK AUDIO 00

8

109 MSD8832WDK VIDEO 00

9

110 MSD8832WDK POWER1 00

10

111 MSD8832WDK POWER2 00

11

112 MSD8832WDK POWER3 00

12

113 MSD8832WDK CAPACITOR 00

13

114 MSD8832WDK T2POWER 00

14

115 MSD8832WDK CONFIG 00

15

116 PERI (XTAL, RESET) 00

16

117 PERI (GPIO, I2C, DBG) 00

17

120 DDR3 SDRAM A 00

18

121 DDR3 SDRAM A HIGH 00

19

122 DDR3 SDRAM B LOW 00

20

123 DDR3 SDRAM B HIGH 00

21

124 DDR3 SDRAM POWER 00

22

125 DDR3 SDRAM RESET/CKE 00

23

126 DDR DAMPING REG A 0

24

127 DDR DAMPING REG B 0

25

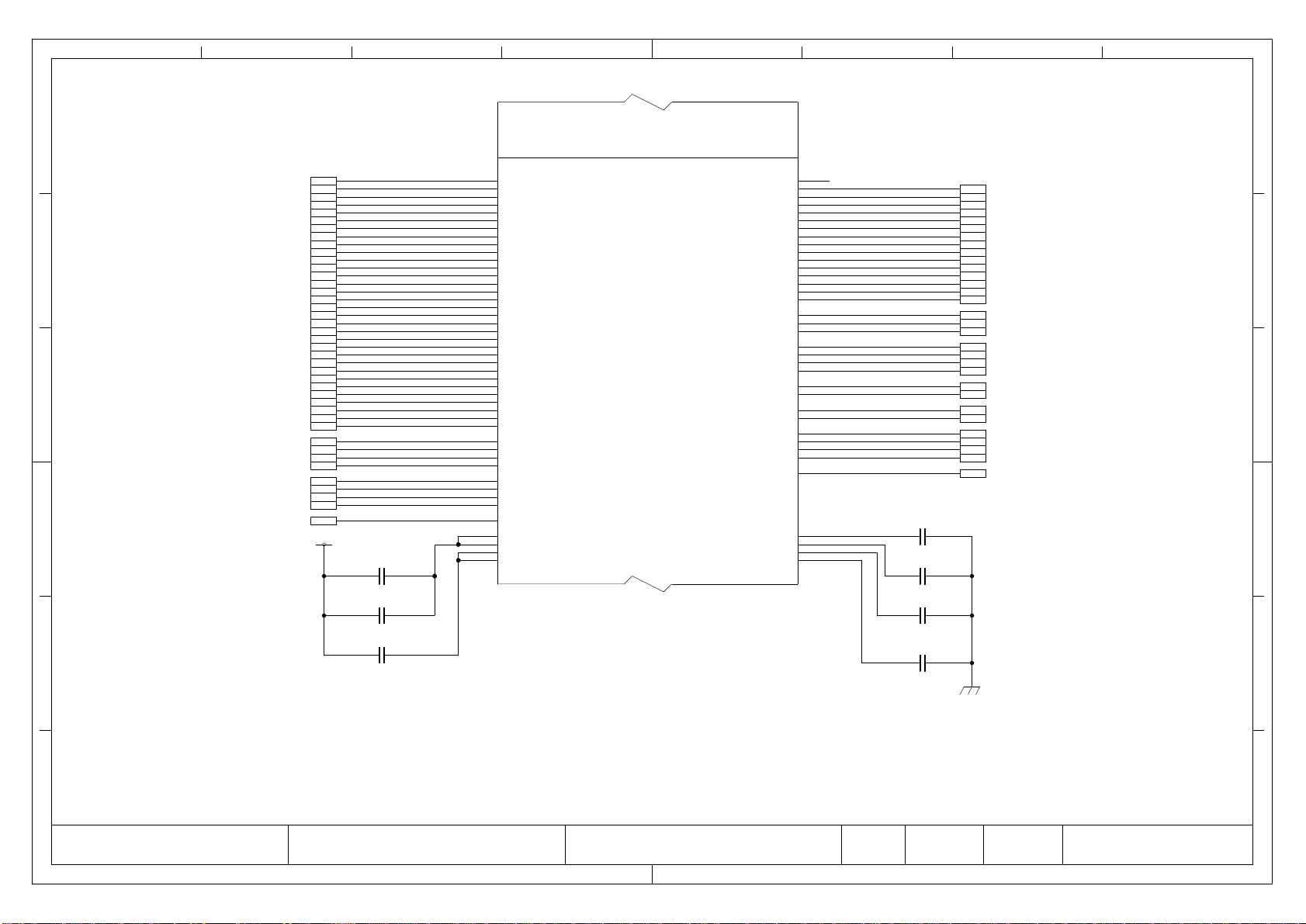

MAIN UNIT

FUNCTION

REV

PRODUCT NAME

PAGE

26

130 SPI FLASH 00

27

131 EMMC 00

28

151 RJ45 CONNECTOR 00

29

160 USB CONNECTOR 00

30

161 Wireless LAN 00

31

310 Audio Line Driver 00

32

320 Headphone AMP 00

33

370 AUDIO D-AMP 00

34

371 AUDIO D-AMP OUT 00

35

372 AUDIO D-AMP Connector 00

36

373 AUDIO MUTE 00

37

501 MST7410DZ Misc./GPIO 00

38

502 MST7410DZ LVDS/VB1 00

39

503 MST7410DZ DDR Ach 00

40

504 MST7410DZ DDR Bch 00

41

505 MST7410DZ HDMI 00

42

506 MST7410DZ POWER1 00

43

507 MST7410DZ POWER2 00

44

508 MST7410DZ POWER3 00

45

509 MST7410DZ POWER4 00

46

510 MST7410DZ POWER5 00

47

515 MST7410DZ CAPACITOR 00

48

516 MST7410DZ CONFIG 00

49

517 DEBUG 00

50

520 DDR3 SDRAM CH0 00

FUNCTION

L84xx/L94xx MP

REV

PAGE FUNCTION FUNCTION

51

521 DDR3 SDRAM CH0 00

52

522 DDR3 SDRAM CH1 00

53

523 DDR3 SDRAM CH1 00

54

524 DDR3 SDRAM POWER 00

55

525 FRC DDR3 SDRAM VTT 00

56

530 SPI FLASH 00

57

600 EURO SCART 00

58

601 PC Audio/Fix Out 00

59

602 DSUB15P PC IN 00

60

603 COMPONENT IN 00

61

604 OPTICAL OUT 00

62

605 EURO SCART OUT 00

63

606 AV INPUT1 00

64

607 AV INPUT2 00

65

608 AV INPUT3 00

66

609 DSUB PC EDID 00

67

650 VB1 CONNECTOR 00

68

651 VB1 CONNECTOR2 00

69

652 BL_Control 00

70

653 T-CON POWER 00

71

655 PANEL_SELECT 00

72

73

74

665 HDMI DDC I2C

75

666 3.3V_HDMI

UNIT NO.

PWA NO.

PWB NO.

PE1188ZA

REV

PAGE

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

00660 HDMI Connector

98

00663 HDMI HPD

99

00

100

00

667 1.0V_HDMI

670 MN864778 1/5

671 MN864778 2/5

672 MN864778 3/5

673 MN864778 4/5

674 MN864778 5/5

690 SII9679 1/2

691 SII9679 2/2

692 SII9679 SPI

696 SII9679 MISC.

700 LED/RMT/KEY IF

704 FAN

705 IR OUT

750 TUNER

755 TUNER IF/AGC

760 DVB-S/S2 Demod

765 DEMOD TSREG

770 LNB

780 TUNER POWER

791 CI CARD SLOT

792 CI BUS1

793 CI BUS2

795 CI CONTROL

CI TS IN/OUT796

REV

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00POWER 3.3V STANDBY901

APPROVED BY CHECKED BY TITLE TOTAL PAGE NO. REV.MARK DRAWING.NO.DESIGNED BY

2014.08.06 16:14

CIRCUIT DIAGRAM 1 0

TITLE

TOSHIBA CORPORATION

5T03655-2E

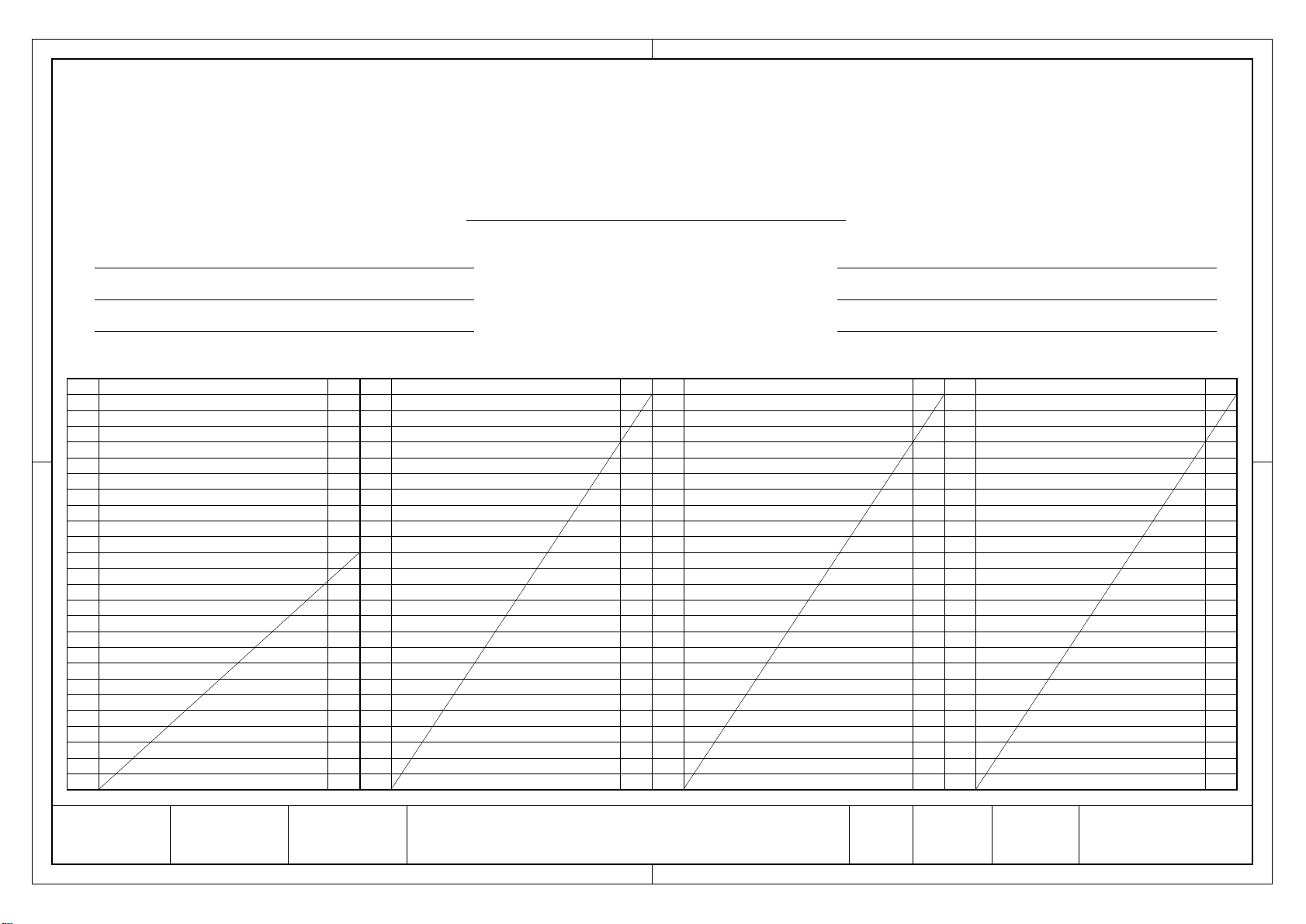

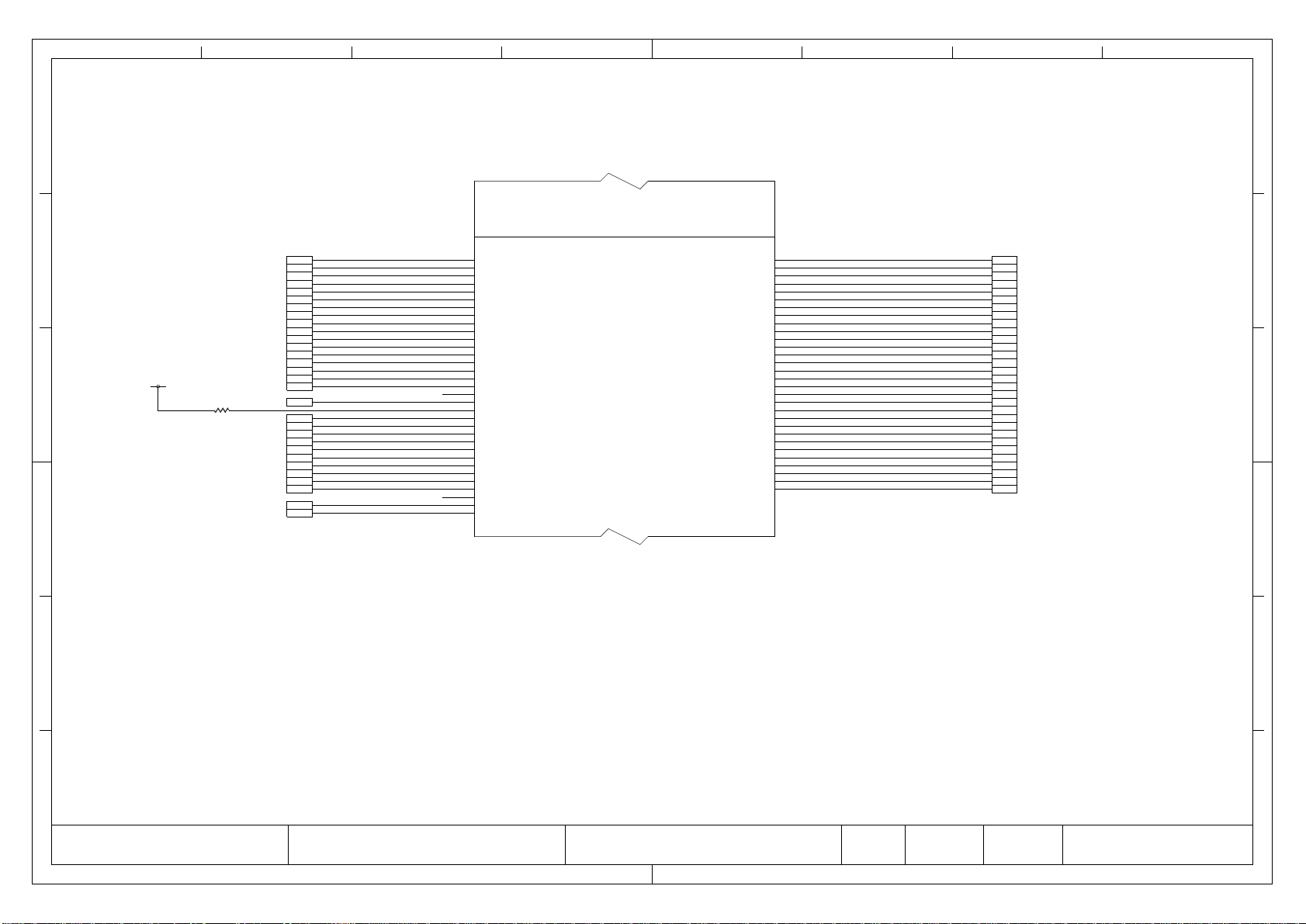

SCHEMATIC DIAGRAMS

UNIT NAME

PWA NAME

PWB NAME

PAGE

902 POWER_VDDC 1.1V

10

1

903 POWER_CPU 1.15/1.1V

10

2

904 POWER_3.3VD

10

3

905 POWER_5VD

10

4

906 POWER_5VD_2

10

5

907 POWER_FRC 1.15V

10

6

908 POWER HDMI 1.2V

10

7

950 POWER CONNECTOR

10

8

960 EMC CONTROL

10

9

990 PRODUCTION SUPPORT

1

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

MAIN UNIT

FUNCTION

REV

00

00

00

00

00

00

00

00

00

00

PAGE

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

PRODUCT NAME

FUNCTION

L84xx/L94xx MP

REV

PAGE FUNCTION FUNCTION

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

UNIT NO.

PWA NO.

PWB NO.

PE1188ZA

REV

PAGE

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

REV

APPROVED BY CHECKED BY TITLE TOTAL PAGE NO. REV.MARK DRAWING.NO.DESIGNED BY

2014.08.06 16:14

CIRCUIT DIAGRAM#2 0

TITLE

TOSHIBA CORPORATION

5T03655D

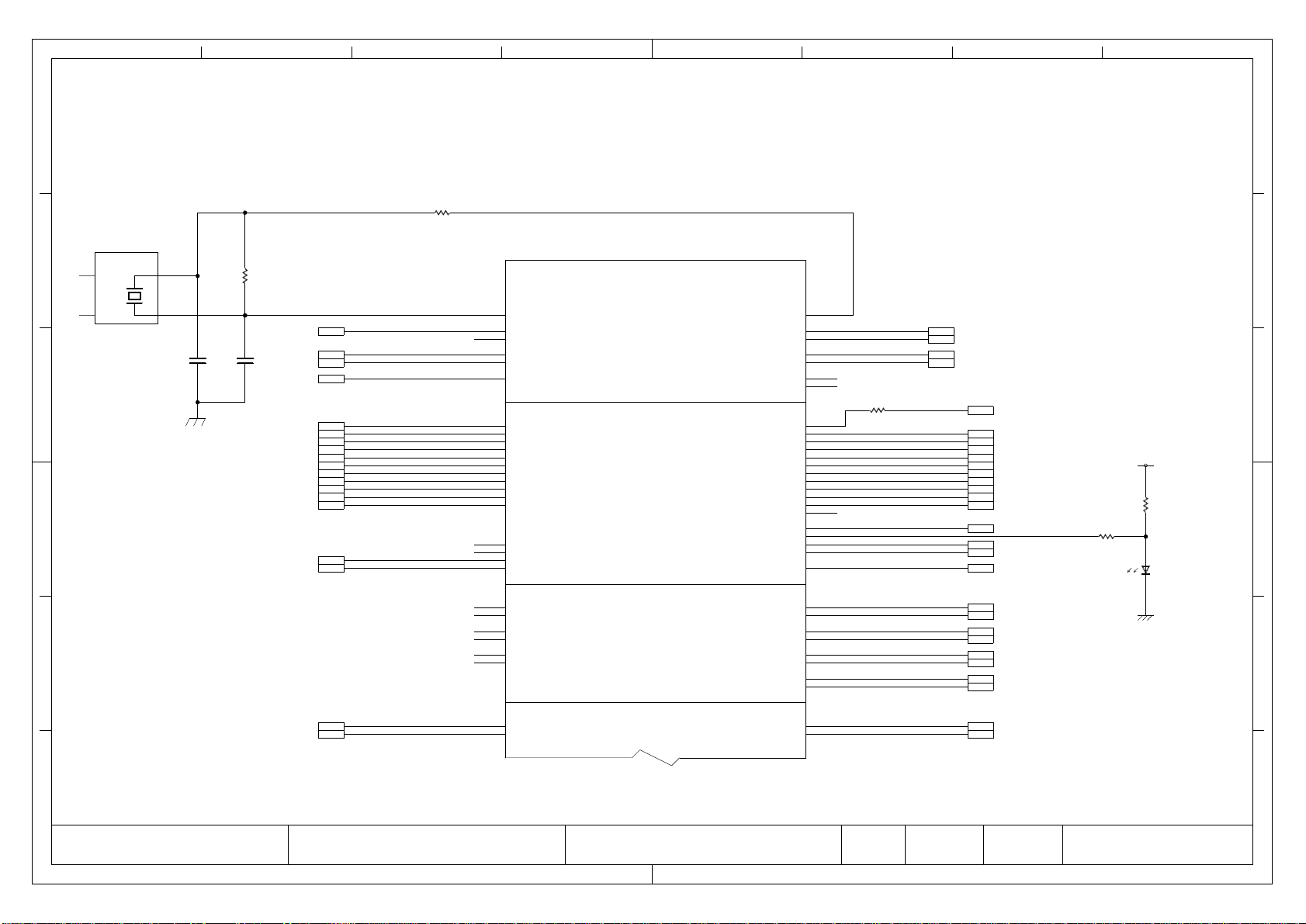

87654321

A

R1001

330(D)

品種削減のため

21

D]

DTV PROCESSOR 1/13

[V-UMSD8832WDK]

AJ1

XIN

H2

RESET

W6

RESETZ

A10

DDCR_CK

C10

DDCR_DA

H1

IRIN

AJ15

TS0_CLK

AG17

TS0_D[7]

AG15

TS0_D[6]

AG16

TS0_D[5]

AG14

TS0_D[4]

AH13

TS0_D[3]

AH15

TS0_D[2]

AH17

TS0_D[1]

AH14

TS0_D[0]

AJ17

TS0_SYNC

AH16

TS0_VLD

AM7

IP

AM6

IM

AL9

QP

AL10

QM

C1

DM_PSS

D2

DP_PSS

E2

SSUSB_RXN

D1

SSUSB_RXP

C2

SSUSB_TXN

B2

SSUSB_TXP

AL13

RP

AK12 AM13

RN TN

IC100

[TSIF/VIF]

[USB]

[LAN]

VID[1]

VID[0]

DDCA_CK

DDCA_DA

AV_LNK

VSENSE_VDD

TS_CLK

TS_D[7]

TS_D[6]

TS_D[5]

TS_D[4]

TS_D[3]

TS_D[2]

TS_D[1]

TS_D[0]

TS_SYNC

TS_VLD

TS_ERR

TS2_CLK

TS2_D0

TS2_SYNC

TS2_VLD

XOUT

IFAGC

DM_P0

DP_P0

DM_P1

DP_P1

DM_P2

DP_P2

DM_P3

DP_P3

TP

AG20

AJ21

AG21

AH18

AH21

AG19

AJ20

AG18

AJ18

AH19

AH20

AL12

AG26

AJ26

AH26

AG25

AM10

AL14

AK14

AK13

AK1

D12

E12

AB6

Y19

E4

F4

G2

G3

F2

F3

E3

F1

M_VID1

M_VID0

M_DDCA_CK

M_DDCA_DA

R1043

21

33(J)

M_HDMI_RSTN

F_FRC_RESET

R_IFAGC_SoC

902 903

902 903

602 117 990

602 117 990

R_TSCLK

R_DATA7

R_DATA6

R_DATA5

R_DATA4

R_DATA3

R_DATA2

R_DATA1

R_DATA0

R_TSSYC

R_TSVAL

H_PN_INT

M_USB0DM

M_USB0DP

M_USB1DM

M_USB1DP

M_USB2DM

M_USB2DP

M_USB3DM

M_USB3DP

M_LANTDP

M_LANTDN

796 765

796 765

796 765

796 765

796 765

796 765

796 765

796 765

796 765

796 765

796 765

673

117 673 696

501

755

161

161

160

160

160

160

161

161

151

151

R1029

10K(J)

R1028

470(J)

21

[LED]

DS100

3.3VD

2 1

CA

GND

17-21SYGC/S530-E1/TR8

*J [

7V24080018

B

[XF]

X1000

2

NC

4

NC

20ppm

24MHz

1

3

2

C1000

1

10pF(J)

R1000

1M(J)

C1001

6pF(D)

2

1

21

370 117 755

370 117 755

116

700

C_HOSTRST

M_I2CCLK

M_I2CDATA

C_IRIN

C

M_TSI0CLKI

GND

796

796

796

796

796

796

796

796

796

796

796

M_TSI0DATA7

M_TSI0DATA6

M_TSI0DATA5

M_TSI0DATA4

M_TSI0DATA3

M_TSI0DATA2

M_TSI0DATA1

M_TSI0DATA0

M_TSI0SYNC

M_TSI0VALID

D

M_ADCIP

755

M_ADCIN

755

E

M_LANRDP

151

M_LANRDN

151

A

B

C

D

E

F

@Design MAIN BOARD

2014.08.06 16:14

FUNCTIONTITLE

MSD8832WDK TS/USB/LAN

SH.NO.DESIGNED BY

PAGE NO. REV.MARK DRAWING.NO.

101 1 0 PE1188ZA

TOSHIBA CORPORATION

F

5T03655D

87654321

A

130

M_SPI_DO

A4

AF21

PM_SPI_DO

MSPI_DO

B

M_PCM_D7

792

M_PCM_D6

792

M_PCM_D5

792

M_PCM_D4

792

M_PCM_D3

792

M_PCM_D2

792

M_PCM_D1

792

M_PCM_D0

792

M_PCM_IRQA_N

795

M_PCM_WAIT_N

795

M_PCM_CD_N

795

M_CR_SW

607

A_HP_DET

C

D

791 117

601

S_CI_VCC_EN

130

130

130

130

130

130

130

130

M_EMMCD7

M_EMMCD6

M_EMMCD5

M_EMMCD4

M_EMMCD3

M_EMMCD2

M_EMMCD1

M_EMMCD0

AH11

AK15

AG12

AG11

AJ11

AK21

AK22

AL21

AL17

AL19

AJ12

AH22

AG23

AJ24

AH25

AK26

AM26

AM25

AL25

AG24

AL26

AK25

PCM_D[7]

PCM_D[6]

PCM_D[5]

PCM_D[4]

PCM_D[3]

PCM_D[2]

PCM_D[1]

PCM_D[0]

PCM_IRQA_N

PCM_WAIT_N

PCM_CD_N

PCM2_IRQA_N

PCM2_WAIT_N

PCM2_CD_N

NF_CEZ1

NF_CEZ

NF_CLE

NF_REZ

NF_WEZ

NF_WPZ

NF_ALE

NF_RBZ

DTV PROCESSOR 2/13

[V-UMSD8832WDK]

IC100

[SPI]

[CI]

[ENNC/NAND]

PM_SPI_CK

PM_SPI_DI

PM_SPI_CZ

MSPI_CLK

MSPI_DI

MSPI_CSZ

PCM_A[14]

PCM_A[13]

PCM_A[12]

PCM_A[11]

PCM_A[10]

PCM_A[9]

PCM_A[8]

PCM_A[7]

PCM_A[6]

PCM_A[5]

PCM_A[4]

PCM_A[3]

PCM_A[2]

PCM_A[1]

PCM_A[0]

PCM_IORD_N

PCM_IOWR_N

PCM_OE_N

PCM_WE_N

PCM_REG_N

PCM_CE_N

PCM_RESET

PCM2_CE_N

PCM2_RESET

EMMC_CLK

EMMC_CMD

EMMC_RSTN

NF_DQS

AF22

AF25

AM16

AL16

AM22

AH12

AG13

AJ14

AK18

AM17

AL22

AM19

AK19

AL20

AM20

AK17

AM23

AG10

AH10

AK16

AK20

AL15

AL18

AG22

AH23

AL24

AK23

AK24

AH24

AH9

[TP]

DP101

A5

F5

B5

V6

M_SPI_CLK

M_SPI_DI

M_PCM_A14

M_PCM_A13

M_PCM_A12

M_PCM_A11

M_PCM_A10

M_PCM_A9

M_PCM_A8

M_PCM_A7

M_PCM_A6

M_PCM_A5

M_PCM_A4

M_PCM_A3

M_PCM_A2

M_PCM_A1

M_PCM_A0

M_PCM_IORD_N

M_PCM_IOWR_N

M_PCM_OE_N

M_PCM_WE_N

M_PCM_REG_N

M_PCM_CE_N

M_PCM_RST

M_DAMP_MUTE

M_VGA_EEP_WP

M_EMMC_CLK

M_EMMC_CMD

M_EMMC_RST

130

130 115

792

792

792

792

792

792

792

792

792

792

792

792

792

792

792

792

792

792

792

792

792

792

370 117 372

609 117

131

131

131

1

A

B

C

D

E

F

@Design

2014.08.06 16:14

MAIN BOARD

FUNCTIONTITLE

MSD8832WDK FLASH

SH.NO.DESIGNED BY

PAGE NO. REV.MARK DRAWING.NO.

102 2 0 PE1188ZA

TOSHIBA CORPORATION

E

F

5T03655D

87654321

A

M_DDRADQ31

126

M_DDRADQ30

126

M_DDRADQ29

126

M_DDRADQ28

126

M_DDRADQ27

126

M_DDRADQ26

126

M_DDRADQ25

126

M_DDRADQ24

126

M_DDRADQ23

126

M_DDRADQ22

126

M_DDRADQ21

B

C

D

E

126

126

126

126

126

126

126

126

126

126

126

126

126

126

126

126

126

126

126

126

126

126

126

126

126

126

126

126

126

126

126

1.5V_SOC

M_DDRADQ20

M_DDRADQ19

M_DDRADQ18

M_DDRADQ17

M_DDRADQ16

M_DDRADQ15

M_DDRADQ14

M_DDRADQ13

M_DDRADQ12

M_DDRADQ11

M_DDRADQ10

M_DDRADQ9

M_DDRADQ8

M_DDRADQ7

M_DDRADQ6

M_DDRADQ5

M_DDRADQ4

M_DDRADQ3

M_DDRADQ2

M_DDRADQ1

M_DDRADQ0

M_DDRADQS3

M_DDRADQS2

M_DDRADQS1

M_DDRADQS0

M_DDRADQSB3

M_DDRADQSB2

M_DDRADQSB1

M_DDRADQSB0

M_DDRAODT

C1094

220nF(K)

1

C1095

220nF(K)

1

C1096

220nF(K)

1

2

2

2

C30

A_DDR3_DQ[31]

E27

A_DDR3_DQ[30]

D30

A_DDR3_DQ[29]

E28

A_DDR3_DQ[28]

D29

A_DDR3_DQ[27]

E26

A_DDR3_DQ[26]

C29

A_DDR3_DQ[25]

D28

A_DDR3_DQ[24]

B26

A_DDR3_DQ[23]

A28

A_DDR3_DQ[22]

C24

A_DDR3_DQ[21]

C28

A_DDR3_DQ[20]

A25

A_DDR3_DQ[19]

B28

A_DDR3_DQ[18]

C25

A_DDR3_DQ[17]

C27

A_DDR3_DQ[16]

D25

A_DDR3_DQ[15]

D21

A_DDR3_DQ[14]

D26

A_DDR3_DQ[13]

D22

A_DDR3_DQ[12]

E25

A_DDR3_DQ[11]

E21

A_DDR3_DQ[10]

E24

A_DDR3_DQ[9]

F22

A_DDR3_DQ[8]

C21

A_DDR3_DQ[7]

C23

A_DDR3_DQ[6]

C19

A_DDR3_DQ[5]

B24

A_DDR3_DQ[4]

C20

A_DDR3_DQ[3]

B23

A_DDR3_DQ[2]

B21

A_DDR3_DQ[1]

C22

A_DDR3_DQ[0]

A30

A_DDR3_DQS[3]

B27

A_DDR3_DQS[2]

D23

A_DDR3_DQS[1]

A22

A_DDR3_DQS[0]

B29

A_DDR3_DQSB[3]

C26

A_DDR3_DQSB[2]

E22

A_DDR3_DQSB[1]

B22

A_DDR3_DQSB[0]

G21

A_DDR3_ODT

A11

AVDD04_DDR_A

B11

AVDD04_DDR_A

M17

AVDD04_DDR_A

M18 L18

AVDD04_DDR_A AVDD11_DDR_A

DTV PROCESSOR 3/13

[V-UMSD8832WDK]

IC100

[DDR-A]

A_DDR3_A[15]

A_DDR3_A[14]

A_DDR3_A[13]

A_DDR3_A[12]

A_DDR3_A[11]

A_DDR3_A[10]

A_DDR3_A[9]

A_DDR3_A[8]

A_DDR3_A[7]

A_DDR3_A[6]

A_DDR3_A[5]

A_DDR3_A[4]

A_DDR3_A[3]

A_DDR3_A[2]

A_DDR3_A[1]

A_DDR3_A[0]

A_DDR3_BA[2]

A_DDR3_BA[1]

A_DDR3_BA[0]

A_DDR3_CKE

A_DDR3_WEZ

A_DDR3_RASZ

A_DDR3_CASZ

A_DDR3_MCLK

A_DDR3_MCLKZ

A_DDR3_CSB[2]

A_DDR3_CSB[1]

A_DDR3_DQM[3]

A_DDR3_DQM[2]

A_DDR3_DQM[1]

A_DDR3_DQM[0]

A_DDR3_RST

AVDD11_DDR_A

AVDD11_DDR_A

AVDD11_DDR_A

E19

B15

F15

D19

B16

B18

E15

C15

D16

A16

E17

B17

F17

E16

C16

F16

F18

C17

E18

C18

E20

F20

F19

A19

B19

D14

E14

B30

B25

E23

B20

F14

A13

B13

L17

M_DDRAAD14

M_DDRAAD13

M_DDRAAD12

M_DDRAAD11

M_DDRAAD10

M_DDRAAD9

M_DDRAAD8

M_DDRAAD7

M_DDRAAD6

M_DDRAAD5

M_DDRAAD4

M_DDRAAD3

M_DDRAAD2

M_DDRAAD1

M_DDRAAD0

M_DDRABA2

M_DDRABA1

M_DDRABA0

M_DDRACKE

M_DDRAWE

M_DDRARAS

M_DDRACAS

M_DDRACLK

M_DDRABCLK

M_DDRACS2

M_DDRACS1

M_DDRADM3

M_DDRADM2

M_DDRADM1

M_DDRADM0

M_DDRARESET

C1100

220nF(K)

2

C1101

220nF(K)

2

C1102

220nF(K)

2

C1103

220nF(K)

2

126

126

126

126

126

126

126

126

126

126

126

126

126

126

126

126

126

126

125

126

126

126

126

126

126

126

126

126

126

126

125

1

1

1

1

A

B

C

D

E

F

@Design

2014.08.06 16:14

MAIN BOARD

FUNCTIONTITLE

MSD8832WDK DDR A

GND

SH.NO.DESIGNED BY

PAGE NO. REV.MARK DRAWING.NO.

103 3 0 PE1188ZA

TOSHIBA CORPORATION

F

5T03655D

87654321

A

M_DDRBDQ31

127

M_DDRBDQ30

127

M_DDRBDQ29

127

M_DDRBDQ28

127

M_DDRBDQ27

127

M_DDRBDQ26

127

M_DDRBDQ25

127

M_DDRBDQ24

127

M_DDRBDQ23

127

M_DDRBDQ22

127

M_DDRBDQ21

B

C

D

E

127

127

127

127

127

127

127

127

127

127

127

127

127

127

127

127

127

127

127

127

127

127

127

127

127

127

127

127

127

127

127

1.5V_SOC

M_DDRBDQ20

M_DDRBDQ19

M_DDRBDQ18

M_DDRBDQ17

M_DDRBDQ16

M_DDRBDQ15

M_DDRBDQ14

M_DDRBDQ13

M_DDRBDQ12

M_DDRBDQ11

M_DDRBDQ10

M_DDRBDQ9

M_DDRBDQ8

M_DDRBDQ7

M_DDRBDQ6

M_DDRBDQ5

M_DDRBDQ4

M_DDRBDQ3

M_DDRBDQ2

M_DDRBDQ1

M_DDRBDQ0

M_DDRBDQS3

M_DDRBDQS2

M_DDRBDQS1

M_DDRBDQS0

M_DDRBDQSB3

M_DDRBDQSB2

M_DDRBDQSB1

M_DDRBDQSB0

M_DDRBODT

C1097

220nF(K)

1

C1098

220nF(K)

1

C1099

220nF(K)

1

2

2

2

AA27

B_DDR3_DQ[31]

V27

B_DDR3_DQ[30]

AA29

B_DDR3_DQ[29]

W28

B_DDR3_DQ[28]

AA28

B_DDR3_DQ[27]

U27

B_DDR3_DQ[26]

Y27

B_DDR3_DQ[25]

V28

B_DDR3_DQ[24]

V30

B_DDR3_DQ[23]

AA31

B_DDR3_DQ[22]

U31

B_DDR3_DQ[21]

AA30

B_DDR3_DQ[20]

V32

B_DDR3_DQ[19]

Y30

B_DDR3_DQ[18]

V31

B_DDR3_DQ[17]

Y31

B_DDR3_DQ[16]

T29

B_DDR3_DQ[15]

N29

B_DDR3_DQ[14]

T27

B_DDR3_DQ[13]

N27

B_DDR3_DQ[12]

U28

B_DDR3_DQ[11]

N28

B_DDR3_DQ[10]

T28

B_DDR3_DQ[9]

P28

B_DDR3_DQ[8]

P31

B_DDR3_DQ[7]

T31

B_DDR3_DQ[6]

M31

B_DDR3_DQ[5]

T30

B_DDR3_DQ[4]

N31

B_DDR3_DQ[3]

R30

B_DDR3_DQ[2]

N30

B_DDR3_DQ[1]

R31

B_DDR3_DQ[0]

Y28

B_DDR3_DQS[3]

W30

B_DDR3_DQS[2]

R27

B_DDR3_DQS[1]

R32

B_DDR3_DQS[0]

W29

B_DDR3_DQSB[3]

W31

B_DDR3_DQSB[2]

P27

B_DDR3_DQSB[1]

P30

B_DDR3_DQSB[0]

M28

B_DDR3_ODT

R22

AVDD04_DDR_B

T22

AVDD04_DDR_B

AB31

AVDD04_DDR_B

AB32 AD32

AVDD04_DDR_B AVDD11_DDR_B

DTV PROCESSOR 4/13

[V-UMSD8832WDK]

IC100

[DDR-B]

B_DDR3_A[15]

B_DDR3_A[14]

B_DDR3_A[13]

B_DDR3_A[12]

B_DDR3_A[11]

B_DDR3_A[10]

B_DDR3_A[9]

B_DDR3_A[8]

B_DDR3_A[7]

B_DDR3_A[6]

B_DDR3_A[5]

B_DDR3_A[4]

B_DDR3_A[3]

B_DDR3_A[2]

B_DDR3_A[1]

B_DDR3_A[0]

B_DDR3_BA[2]

B_DDR3_BA[1]

B_DDR3_BA[0]

B_DDR3_CKE

B_DDR3_WEZ

B_DDR3_RASZ

B_DDR3_CASZ

B_DDR3_MCLK

B_DDR3_MCLKZ

B_DDR3_CSB[2]

B_DDR3_CSB[1]

B_DDR3_DQM[3]

B_DDR3_DQM[2]

B_DDR3_DQM[1]

B_DDR3_DQM[0]

B_DDR3_RST

AVDD11_DDR_B

AVDD11_DDR_B

AVDD11_DDR_B

AD31

L28

H31

F31

K29

H30

K30

F30

H32

G31

J32

H28

J30

J27

H29

J31

G28

J28

K31

K28

L31

K27

M27

L27

M32

L30

E32

F29

W27

U30

R28

M30

F32

R21

T21

M_DDRBAD14

M_DDRBAD13

M_DDRBAD12

M_DDRBAD11

M_DDRBAD10

M_DDRBAD9

M_DDRBAD8

M_DDRBAD7

M_DDRBAD6

M_DDRBAD5

M_DDRBAD4

M_DDRBAD3

M_DDRBAD2

M_DDRBAD1

M_DDRBAD0

M_DDRBBA2

M_DDRBBA1

M_DDRBBA0

M_DDRBCKE

M_DDRBWE

M_DDRBRAS

M_DDRBCAS

M_DDRBCLK

M_DDRBBCLK

M_DDRBCS2

M_DDRBCS1

M_DDRBDM3

M_DDRBDM2

M_DDRBDM1

M_DDRBDM0

M_DDRBRESET

C1104

220nF(K)

2

C1105

220nF(K)

2

C1106

220nF(K)

2

C1107

220nF(K)

2

127

127

127

127

127

127

127

127

127

127

127

127

127

127

127

127

127

127

125

127

127

127

127

127

127

127

127

127

127

127

125

1

1

1

1

A

B

C

D

E

F

@Design

2014.08.06 16:14

MAIN BOARD

FUNCTIONTITLE

MSD8832WDK DDR B

GND

SH.NO.DESIGNED BY

PAGE NO. REV.MARK DRAWING.NO.

104 4 0 PE1188ZA

TOSHIBA CORPORATION

F

5T03655D

87654321

A

DTV PROCESSOR 5/13

[V-UMSD8832WDK]

IC100

B

950 904 117 905 906 907

5V1

C

R1002

21

100(J)

700 115

117 124

373 950 990

950 117 990

161 117

117 125

950 117

665 690

665 690

653 115

161 117

C_LED_G

C_LED_R

700

M_PM_UATX1

116

C_POWER_DDR

C_ACDET

C_POWER_DB

M_PM_UARX1

116

M_SPI_CS1N

130

C_POWER_TV

C_GPIO18

115

M_WLAN_POWER

M_CKE_EN

M_I2CDATA_PM

117

M_I2CCLK_PM

117

C_POWER_LCD_PW

H_I2C_SCKM2

H_I2C_SDAM2

M_EXT_AMUTE

373

C_POWER_LCD_MAIN

M_GPIO30

115

M_WWOL_WAKEUP

M_SPI_WP

130

B_PANEL_I2C_SW

650

M_HDMIR0_RSTN

696

C_POWER_KEY

700

C_KEY_1

700

C_OP_IN

700

M_LD_EN

655

F_I2CS_CK

114

F_I2CS_DA

114

E9

C5

P5

B6

M6

P6

N6

P4

L6

D3

H4

C6

G6

G5

H5

L4

L5

K6

H6

J6

E13

F13

F11

B4

A3

C4

E5

D5

D4

B3

F6

AA5

AA6

GPIO[7]/PWM_PM

GPIO[10]

GPIO[11]/PM_UART_TX1

GPIO[12]

GPIO[13]

GPIO[14]

GPIO[15]

GPIO[16]

GPIO[17]

GPIO[18]

GPIO[19]

GPIO[20]

GPIO[21]/PM_UART_TX0

GPIO[22]/PM_UART_RX0

GPIO[23]

GPIO[24]/MHL_CD_SENSE

GPIO[25]/MHL_VBUS_EN

GPIO[26]/MHL_OCD

GPIO[27]

GPIO[28]

GPIO[29]/LED0

GPIO[30]/LED1

GPIO[50]/WOL_INT

GPIO[55]

GPIO[56]

GPIO[57]

GPIO[43]/SAR0

GPIO[44]/SAR1

GPIO[45]/SAR2

GPIO[46]/SAR3

SAR4

I2CS_SCL

I2CS_SDA

[GPIO]

GPIO[60]/UART_TX1

GPIO[61]/UART_RX1

GPIO[62]/UART_TX2

GPIO[63]/UART_RX2

GPIO[64]/UART_TX3

GPIO[65]/UART_RX3

GPIO[69]/UART_TX4

GPIO[70]/UART_RX4

GPIO[171]/I2CM_SCL

GPIO[172]/I2CM_SDA

GPIO[68]

GPIO[81]

GPIO[82]

GPIO[83]

GPIO[84]

GPIO[85]

GPIO[86]

GPIO[150]/PWM0

GPIO[151]/PWM1

GPIO[152]/PWM2

GPIO[153]/PWM3

GPIO[155]

GPIO[156]

GPIO[157]

GPIO[158]

GPIO[159]

GPIO[160]

GPIO[161]

GPIO[162]

GPIO[169]

AG29

AH29

AJ29

AG28

AH28

AJ28

AH27

AJ27

AK11

F10

E11

F12

AJ8

AJ9

E6

D6

F7

E7

D7

E8

B7

D9

F8

R6

U5

Y6

Y5

U6

T6

F9

H_EDID_WPB

M_SCREEN_SIZE

C_FANSTOP_1

C_FANSTOP_2

M_UART3_TX

M_UART3_RX

M_VDBG_EN

M_BL_ONOFF

R_TUNER_BUSSW_EN

M_DSUB_I2CCLK

M_DSUB_I2CDATA

M_I2C_SCKM4

M_I2C_SDAM4

H_I2C_SCKM5

H_I2C_SDAM5

C_FAN_ENABLE1

C_FAN_ENABLE2

F_FRC_CTRL1

M_TEMP_SEL0

M_TEMP_SEL1

M_SDC_HIGH

M_LGD_HIGH

M_3D_ENA

M_BT_POWER

M_USBOVERC

R_TDEMO_RST

B_I2CP_CK

B_I2CP_DA

M_BLPWM

M_USBPW

690

652

117 704

117 704

705

705

602 117

652

117 755

609 665

609 665

117 517

117 517

665 673

665 673

704

704

501

117 501

655

655

655

372 655

652 501 655

161

160

160 117

117 760

650

650

D

A

B

C

D

E

F

@Design

2014.08.06 16:14

MAIN BOARD

FUNCTIONTITLE

MSD8832WDK GPIO

SH.NO.DESIGNED BY

PAGE NO. REV.MARK DRAWING.NO.

105 5 0 PE1188ZA

TOSHIBA CORPORATION

E

F

5T03655D

87654321

A

DTV PROCESSOR 6/13

[V-UMSD8832WDK]

IC100

B

C

D

505

505

505

505

505

505

505

505

663

F_HDMI_TX0N

F_HDMI_TX0P

F_HDMI_TX1N

F_HDMI_TX1P

F_HDMI_TX2N

F_HDMI_TX2P

F_HDMI_TXCN

F_HDMI_TXCP

AVDD5V_MHL

V2

RXA0N

W3

RXA0P

W2

RXA1N

Y3

RXA1P

Y2

RXA2N

Y1

RXA2P

V3

RXACN

V1

RXACP

R2

RXB0N

T3

RXB0P

T2

RXB1N

U3

RXB1P

U2

RXB2N

U1

RXB2P

R3

RXBCN

R1

RXBCP

J2

RXC0N

K3

RXC0P

K2

RXC1N

L3

RXC1P

L2

RXC2N

L1

RXC2P

J3

RXCCN

J1

RXCCP

M2

RXD0N

N3

RXD0P

N2

RXD1N

P3

RXD1P

P2

RXD2N

P1

RXD2P

M3

RXDCN

M1

RXDCP

AC7 U4

AVDD_HDMI_5V_PC CEC

[HDMI]

DDCDA_CK

DDCDA_DA

HOTPLUGA

DDCDB_CK

DDCDB_DA

HOTPLUGB

DDCDC_CK

DDCDC_DA

HOTPLUGC

DDCDD_CK

DDCDD_DA

HOTPLUGD

ARC0

W5

V5

W4

R5

T4

T5

K4

K5

J5

N4

M5

N5

Y4

H_HOTPLUGA

H_HOTPLUGB

H_HOTPLUGC

H_HOTPLUGD

H_ARC0

H_CEC

H_P_RX0SCL

H_P_RX0SDA

663

H_P_RX1SCL

H_P_RX1SDA

663

H_P_RX3SCL

H_P_RX3SDA

663

H_R0_DSCL

H_R0_DSDA

696

660

660

660 665 672

660 665 672

660 665 672

660 665 672

660 665 672

660 665 672

660 665 690

660 665 690

A

B

C

D

E

F

@Design

2014.08.06 16:14

MAIN BOARD

FUNCTIONTITLE

MSD8832WDK HDMI

SH.NO.DESIGNED BY

PAGE NO. REV.MARK DRAWING.NO.

106 6 0 PE1188ZA

TOSHIBA CORPORATION

E

F

5T03655D

87654321

A

DTV PROCESSOR 7/13

[V-UMSD8832WDK]

B

C

D

IC100

[LVDS/VB1]

LVA0N

LVA0P

LVA1N

LVA1P

LVA2N

LVA2P

LVA3N

LVA3P

LVA4N

LVA4P

LVACLKN

LVACLKP

LVB0N

LVB0P

LVB1N

LVB1P

LVB2N

LVB2P

LVB3N

LVB3P

LVB4N

LVB4P

LVBCLKN

LVBCLKP

AK31

AK30

AL31

AL30

AM30

AL29

AM28

AL28

AK27

AL27

AM29

AK28

AE32

AF30

AF32

AF31

AG32

AG31

AJ31

AJ32

AJ30

AK32

AG30

AH31

C1052 100nF(K)

12

C1053 100nF(K)

12

C1054 100nF(K)

12

C1055 100nF(K)

12

C1056 100nF(K)

12

C1057 100nF(K)

12

C1058 100nF(K)

12

C1059 100nF(K)

12

C1060 100nF(K)

12

C1061 100nF(K)

12

C1062 100nF(K)

12

C1063 100nF(K)

12

C1064 100nF(K)

12

C1065 100nF(K)

12

C1066 100nF(K)

12

C1067 100nF(K)

12

M_VX1_4N

M_VX1_4P

M_VX1_5N

M_VX1_5P

M_VX1_6N

M_VX1_6P

M_VX1_HTPDN

M_VX1_LOCKN

M_VX1_OSD_HTPDN

M_VX1_OSD_LOCKN

M_VX1_7N

M_VX1_7P

M_VX1_0N

M_VX1_0P

M_VX1_2N

M_VX1_2P

M_VX1_3N

M_VX1_3P

M_VX1_1N

M_VX1_1P

502

502

502

502

502

502

502

502

502

502

502

502

502

502

502

502

502

502

502

502

A

B

C

D

E

F

@Design

2014.08.06 16:14

MAIN BOARD

FUNCTIONTITLE

MSD8832WDK LVDS/Vby1

SH.NO.DESIGNED BY

PAGE NO. REV.MARK DRAWING.NO.

107 7 0 PE1188ZA

TOSHIBA CORPORATION

E

F

5T03655D

87654321

A

DTV PROCESSOR 8/13

[V-UMSD8832WDK]

IC100

AL11

SIFP

AM11

SIFM

B9

I2S_IN_WS

B10

I2S_IN_BCK

C9

D10

AJ5

AJ4

AK3

AJ3

AH5

AH4

I2S_IN_SD

SPDIF_IN

LINEIN_L0

LINEIN_R0

LINEIN_L1

LINEIN_R1

LINEIN_L2

LINEIN_R2

[GPIO[94] T2 RST]

B

M_AUL0

607

M_AUR0

607

M_AUL1

606

NA E1 IN

E2 IN

606

606

606

M_AUR1

M_AUL2

M_AUR2

C

AC6

NC

AL7

NC

AL8

NC

D

[AUDIO]

[NC]

I2S_OUT_MCK

I2S_OUT_WS

I2S_OUT_BCK

I2S_OUT_SD

I2S_OUT_SD1

SPDIF_OUT

LINEOUT_L0

LINEOUT_R0

LINEOUT_L2

LINEOUT_R2

EAR_OUTL

EAR_OUTR

AUVAG

AUVRM

NOT MOUNT

2

C1152

1

2.2nF(K)

GND

M_I2S_MCLK

M_I2S_LRCK

M_I2S_BCK

M_I2S_DATA

C_A_PWDN

A_SPDIF

M_AOUTL0

M_AOUTR0

M_AOUTL_HP

M_AOUTR_HP

NOT MOUNT

370 372

370 372

370 372

370 372

373 117

604

310

310

320

320

SCART Out/Fix outSCART IN/PC IN

HP Out

C7

A8

A7

B8

C8

E10

R1051 0(X)

AL2

AK4

R1052 0(X)

AJ6

*R1053 0(X)

AH6

AL3

*R1054 0(X)

AM3

AG5

AG6

2

AM8

NC

AM5

NC

6.3V

C1002

1

4.7uF(K)

21

21

6.3V

1uF(K)

21

21

2

C1003

1

100(J)

R1050

2

1

2.2nF(K)

NOT MOUNT

12

FL105

MPZ1608S300AT

21

C1153

2

1

NOT MOUNT

2.2nF(K)

2

1

2.2nF(K)

C1154

C1151

A

B

C

D

E

F

@Design

2014.08.06 16:14

MAIN BOARD

FUNCTIONTITLE

MSD8832WDK AUDIO

SH.NO.DESIGNED BY

PAGE NO. REV.MARK DRAWING.NO.

108 8 0 PE1188ZA

TOSHIBA CORPORATION

E

F

5T03655D

87654321

A

DTV PROCESSOR 9/13

[V-UMSD8832WDK]

IC100

M_RIN0P

B

C

D

608

606

608

606

608

606

608

608

608

608

606

608

606

608

606

606

600

600

606

606

606

606

606

606

606

607

607

606

606

M_RIN0M

M_GIN0P

M_GIN0M

M_BIN0P

M_BIN0M

M_SOGIN0

M_HSYNC0

M_VSYNC0

M_RIN1P

M_RIN1M

M_GIN1P

M_GIN1M

M_BIN1P

M_BIN1M

M_SOGIN1

M_HSYNC1

M_VSYNC1

M_RIN2P

M_RIN2M

M_GIN2P

M_GIN2M

M_BIN2P

M_BIN2M

M_SOGIN2

M_CVBS0

M_CVBS1

M_CVBS2

M_VCOM

AC3

AC2

AB3

AB2

AA3

AA1

AA2

AB4

AB5

AE2

AF3

AD2

AF4

AC1

AD3

AD1

AE3

AC4

AH3

AH2

AG1

AG2

AF2

AF1

AG3

AC5

AE6

AE4

AE5

AD5

RIN0P

RIN0M

GIN0P

GIN0M

BIN0P

BIN0M

SOGIN0

HSYNC0

VSYNC0

RIN1P

RIN1M

GIN1P

GIN1M

BIN1P

BIN1M

SOGIN1

HSYNC1

VSYNC1

RIN2P

RIN2M

GIN2P

GIN2M

BIN2P

BIN2M

SOGIN2

HSYNC2

CVBS0

CVBS1

CVBS2

VCOM

[VIDEO]

CVBS_OUT1

AD6

M_CVBSOUT1

605

A

B

C

D

E

F

@Design

2014.08.06 16:14

MAIN BOARD

FUNCTIONTITLE

MSD8832WDK VIDEO

SH.NO.DESIGNED BY

PAGE NO. REV.MARK DRAWING.NO.

109 9 0 PE1188ZA

TOSHIBA CORPORATION

E

F

Loading...

Loading...