Page 1

MULTIFUNCTIONAL DIGITAL SYSTEMS

Troubleshooting Guide

Page 2

©2009 TOSHIBA TEC CORPORATION All rights reserved

Under the copyright laws, this manual cannot be reproduced in any form without prior written permission of TTEC. No patent liability

is assumed, however, with respect to the use of the information contained herein.

Page 3

Preface

Thank you for purchasing TOSHIBA Multifunctional Digital Systems. This manual describes how to troubleshoot the

problems that could occur while you are using the equipment. Keep this manual within easy reach, and use it to configure

an environment that makes the best use of the e-STUDIO’s functions.

This equipment provides the scanning function as an option. However, this optional scanning function is already installed in some

models.

How to read this manual

Symbols in this manual

In this manual, some important items are described with the symbols shown below. Be sure to read these items before

using this equipment.

Indicates a potentially hazardous situation which, if not avoided, could result in death, serious

injury, or serious damage, or fire in the equipment or surrounding objects.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate

injury, partial damage to the equipment or surrounding objects, or loss of data.

Indicates information to which you should pay attention when operating the equipment.

Other than the above, this manual also describes information that may be useful for the operation of this equipment with

the following signage:

Describes handy information that is useful to know when operating the equipment.

Pages describing items related to what you are currently doing. See these pages as required.

Screens

y Screens on this manual may differ from the actual ones depending on how the equipment is used, such as the status

of the installed options.

y The illustration screens used in this manual are for paper in the A/B format. If you use paper in the LT format, the

display or the order of buttons in the illustrations may differ from that of your equipment.

Trademarks

y The official name of Windows 2000 is Microsoft Windows 2000 Operating System.

y The official name of Windows XP is Microsoft Windows XP Operating System.

y The official name of Windows Vista is Microsoft Windows Vista Operating System.

y The official name of Windows Server 2003 is Microsoft Windows Server 2003 Operating System.

y The official name of Windows Server 2008 is Microsoft Windows Server 2008 Operating System.

y Microsoft, Windows, Windows NT, and the brand names and product names of other Microsoft products are

trademarks of Microsoft Corporation in the US and other countries.

y Apple, AppleTalk, Macintosh, Mac, Mac OS, Safari, TrueType, and LaserWriter are trademarks of Apple Inc. in the US

and other countries.

y Adobe, Adobe Acrobat, Adobe Reader, Adobe Acrobat Reader, and PostScript are trademarks of Adobe Systems

Incorporated.

y Mozilla, Firefox and the Firefox logo are trademarks or registered trademarks of Mozilla Foundation in the U.S. and

other countries.

y IBM, AT and AIX are trademarks of International Business Machines Corporation.

y NOVELL, NetWare, and NDS are trademarks of Novell, Inc.

y TopAccess is a trademark of Toshiba Tec Corporation.

y Other company names and product names in this manual are the trademarks of their respective companies.

Preface 1

Page 4

Page 5

CONTENTS

Preface....................................................................................................................................... 1

Chapter 1 TROUBLESHOOTING FOR THE HARDWARE

Messages Displayed on the Touch Panel .............................................................................. 8

Clearing a Paper Jam ............................................................................................................. 11

Locating a paper jam ........................................................................................................... 11

Clearing a paper jam ........................................................................................................... 12

Paper jam in the Reversing Automatic Document Feeder (Lower) ..................................... 13

Paper jam in the Reversing Automatic Document Feeder (Upper) ..................................... 14

Paper jam in the bypass tray ............................................................................................... 15

Paper jam in the External Large Capacity Feeder (optional)............................................... 16

Paper jam in the Finisher, Hole Punch Unit and Inserter (all optional)................................ 17

Paper jam inside of the equipment ...................................................................................... 22

Clearing paper jams caused by a wrong paper size setting ................................................ 26

Clearing a Staple Jam ............................................................................................................ 31

Staple jam in the Finisher MJ-1027 / Saddle Stitch Finisher MJ-1028 ................................ 31

Staple jam in the Saddle Stitch Finisher MJ-1029............................................................... 32

Staple jam in the saddle stitch unit ...................................................................................... 34

Replacing a Toner Cartridge ................................................................................................. 37

Replacing a “Near Empty” toner cartridge ........................................................................... 40

Refilling With Staples............................................................................................................. 42

Refilling Finisher MJ-1027 / Saddle Stitch Finisher MJ-1028 staples.................................. 42

Refilling Saddle Stitch Finisher MJ-1029 staples ................................................................ 43

Refilling saddle stitch unit staples........................................................................................ 45

Cleaning the Hole Punch Dust Bin ....................................................................................... 47

Chapter 2 TROUBLESHOOTING FOR COPYING

Copying Problems.................................................................................................................. 50

Chapter 3 TROUBLESHOOTING FOR PRINTING

Print Job Problems................................................................................................................. 54

Clearing print job errors .......................................................................................................54

Cannot remember the document password for a Private Print job...................................... 56

Printer Driver Problems .........................................................................................................57

Cannot print (port setting problems) .................................................................................... 57

Command line options not processed ................................................................................. 57

Retrieval of printer configuration failed................................................................................ 57

Cannot print a job as expected using PS3 printer driver ..................................................... 58

Cannot change settings on the [Fonts] tab and the [Configuration] tab .............................. 58

Network Connection Problems ............................................................................................. 59

Cannot print with the equipment (network connection problems)........................................ 59

Cannot print with SMB print................................................................................................. 59

Cannot print properly with AppleTalk print........................................................................... 59

Client Problems ..................................................................................................................... 60

Checking the client status.................................................................................................... 60

Hardware Problems................................................................................................................ 61

Startup page not printed ...................................................................................................... 61

CONTENTS 3

Page 6

Print jobs not output ............................................................................................................ 61

Chapter 4 TROUBLESHOOTING FOR SCANNING

Scanning Problems ................................................................................................................ 64

Cannot E-mail my scans...................................................................................................... 64

Cannot find the data saved in the shared folder.................................................................. 64

Chapter 5 TROUBLESHOOTING FOR e-Filing

e-Filing Web Utility Problems ................................................................................................ 66

e-Filing Web Utility terminates the session.......................................................................... 66

Numerous sub windows repeatedly appear ........................................................................ 66

Displaying the items in the Contents Frame takes a long time............................................ 66

Error messages ................................................................................................................... 67

Chapter 6 TROUBLESHOOTING FOR NETWORK CONNECTIONS

Locating the Equipment in the Network............................................................................... 70

Cannot locate the equipment in the network ....................................................................... 70

Cannot locate the equipment with Local Discovery............................................................. 71

Equipment does not respond to ping command .................................................................. 72

LDAP Search and Authentication Problems........................................................................ 73

Network shutdown occurs or touch panel disabled after LDAP search ............................... 73

LDAP authentication takes a long time................................................................................ 73

Printing Problems (Network Related) ................................................................................... 74

SMB print and Point&Print in a Windows operating system environment ........................... 74

Raw TCP or LPR print in a Windows operating system environment ................................. 74

IPP print in a Windows operating system environment ....................................................... 75

Novell print in a NetWare environment................................................................................ 75

Macintosh environment ....................................................................................................... 76

UNIX/Linux environment...................................................................................................... 76

Network Fax (N/W-Fax) Driver Problems.............................................................................. 77

N/W-Fax Driver Installation Error Messages ....................................................................... 77

N/W-Fax Driver General Errors ........................................................................................... 78

Chapter 7 CHECKING THE EQUIPMENT STATUS WITH TopAccess

Hardware Status Icons on TopAccess [Device] Tab........................................................... 80

Error Messages ...................................................................................................................... 82

Error Codes............................................................................................................................. 86

Error codes on print jobs ..................................................................................................... 86

Error codes on transmission and reception ......................................................................... 88

Error codes on scan jobs..................................................................................................... 91

Chapter 8 WHEN SOMETHING IS WRONG WITH THE EQUIPMENT

When You Think Something Is Wrong With the Equipment............................................... 96

General operations ..............................................................................................................96

Originals and paper .............................................................................................................97

4 CONTENTS

Page 7

Regular Maintenance .............................................................................................................98

INDEX ..................................................................................................................................................................... 99

CONTENTS 5

Page 8

6 CONTENTS

Page 9

1.TROUBLESHOOTING FOR THE

HARDWARE

This chapter describes how to troubleshoot problems with paper, toner and other finishing processes.

This chapter also describes how to supply the paper, toner and staples.

Messages Displayed on the Touch Panel .............................................................................. 8

Clearing a Paper Jam............................................................................................................. 11

Locating a paper jam............................................................................................................................................11

Clearing a paper jam ............................................................................................................................................12

Paper jam in the Reversing Automatic Document Feeder (Lower) ......................................................................13

Paper jam in the Reversing Automatic Document Feeder (Upper) ......................................................................14

Paper jam in the bypass tray................................................................................................................................15

Paper jam in the External Large Capacity Feeder (optional)................................................................................16

Paper jam in the Finisher, Hole Punch Unit and Inserter (all optional).................................................................17

Paper jam inside of the equipment .......................................................................................................................22

Clearing paper jams caused by a wrong paper size setting.................................................................................26

Clearing a Staple Jam............................................................................................................31

Staple jam in the Finisher MJ-1027 / Saddle Stitch Finisher MJ-1028 .................................................................31

Staple jam in the Saddle Stitch Finisher MJ-1029 ................................................................................................32

Staple jam in the saddle stitch unit .......................................................................................................................34

Replacing a Toner Cartridge ................................................................................................. 37

Replacing a “Near Empty” toner cartridge ............................................................................................................40

Refilling With Staples............................................................................................................. 42

Refilling Finisher MJ-1027 / Saddle Stitch Finisher MJ-1028 staples...................................................................42

Refilling Saddle Stitch Finisher MJ-1029 staples..................................................................................................43

Refilling saddle stitch unit staples.........................................................................................................................45

Cleaning the Hole Punch Dust Bin ....................................................................................... 47

Page 10

1 TROUBLESHOOTING FOR THE HARDWARE

Messages Displayed on the Touch Panel

When a message appears on the touch panel, see the table below to solve the problem.

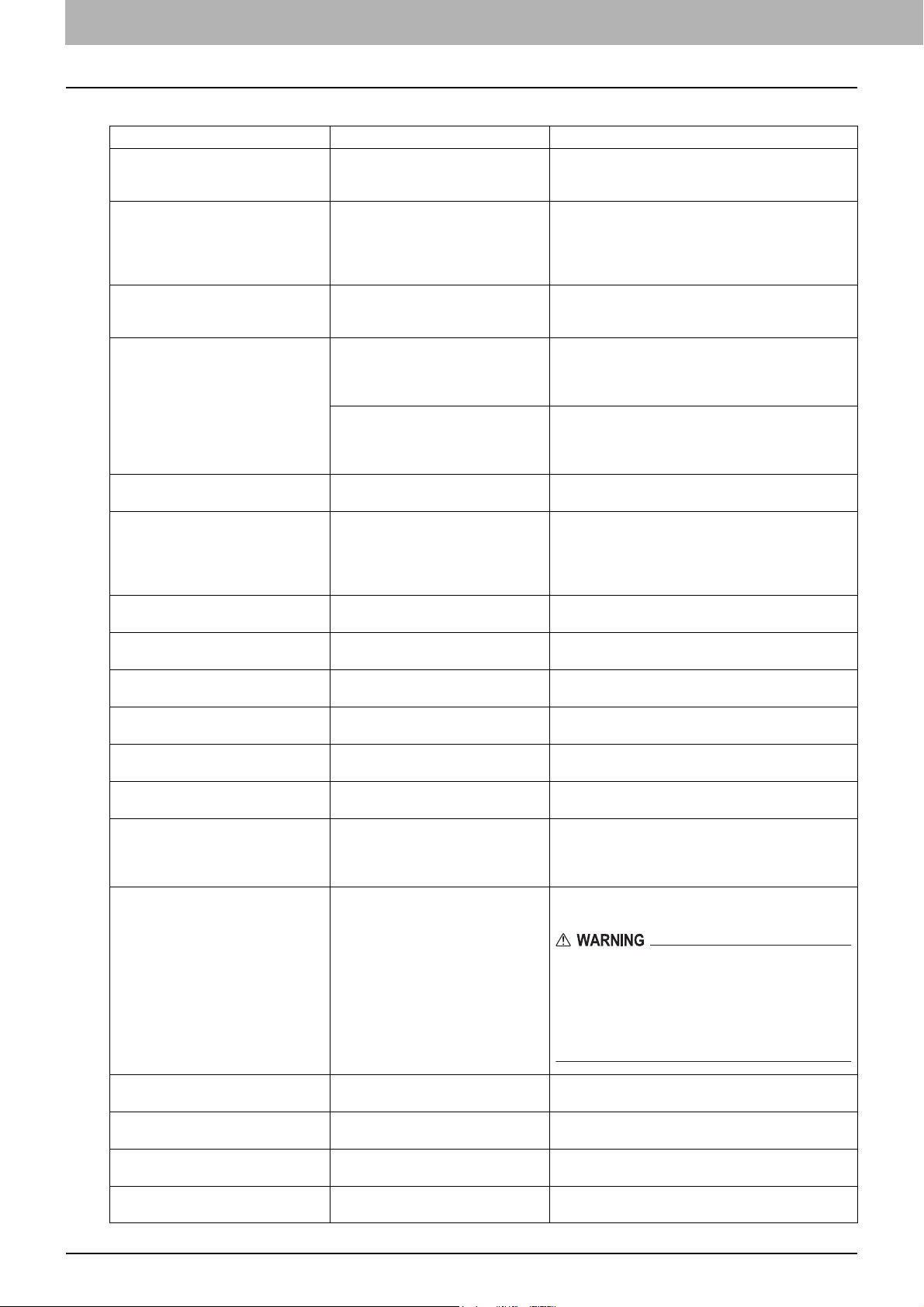

Message Problem Description Corrective Action

Misfeed in *** Paper jam has occurred inside the

equipment.

Check paper size setting on control

panel for drawer N

Wait (Performing Self-check) The equipment is undergoing

Check the original and set it again The original is jammed inside of the

Change direction of original The orientation of the original placed

Change from this mode

Count over, cannot store anymore

READY (CHECK SADDLE STITCH

STAPLER)

READY (CHECK SADDLE STITCH

STAPLER)

READY (CHECK STAPLER) Staple jam has occurred in the stapler

READY (CHECK STAPLER) No staples are left in the stapler of the

READY (HOLE PUNCH DUST BIN IS

FULL)

READY (INNER TRAY FULL) The exit tray of the equipment is full of

Add paper No paper is left in a drawer or on the

Call for service The equipment requires adjusting by

Paper jam has occurred because of

the mismatch between the paper size

placed in drawer N and the size

registered for the drawer N in the

equipment.

maintenance to keep its imaging

quality.

Reversing Automatic Document

Feeder.

The direction or the size of the

original placed on the Reversing

Automatic Document Feeder is

incorrect.

on the original glass is incorrect.

The number of originals to be

scanned has reached the limit of

2000 sheets during scanning. (The

magazine sort or page number

function is used.)

Staple jam has occurred in the stapler

of the saddle stitch unit.

No staples are left in the stapler of the

saddle stitch unit.

of the finisher.

finisher.

Hole punch dust bin is full of paper

punchings.

paper.

bypass tray.

a service technician.

Remove the jammed paper following the guidance

displayed on the touch panel.

P.11 “Clearing a Paper Jam”

Just removing the jammed paper does not prevent

another paper jam. Be sure to correctly register the

paper size in the equipment.

P.26 “Clearing paper jams caused by a wrong

paper size setting”

Wait until the adjustment is completed and the

message disappears.

Remove the jammed original following the guidance

on the touch panel.

P.13 “Paper jam in the Reversing Automatic

Document Feeder (Lower)”

Check the direction and the size of the original and

then replace it on the Reversing Automatic Document

Feeder. Then reattempt the operation.

Change the orientation of the original by 90 degrees

and place it on the original glass.

Reduce the number of originals to be scanned to less

than 2000 sheets, and try again.

Remove the jammed staples.

P.34 “Staple jam in the saddle stitch unit”

Refill the staples.

P.45 “Refilling saddle stitch unit staples”

Remove the jammed staples.

P.31 “Clearing a Staple Jam”

Refill the staples.

P.42 “Refilling With Staples”

Remove the paper punchings.

P.47 “Cleaning the Hole Punch Dust Bin”

Remove the paper from the exit tray of the equipment.

Set paper in the drawer or on the bypass tray. The

touch panel indicates which drawer (or the bypass

tray) has no paper.

To set paper, refer to the Copying Guide.

Contact your service representative with the error

code displayed on the right side of the touch panel.

Examine stapler in the Saddle Stitch

unit

Check staple cartridge in the Saddle

Stitch unit

Check staple cartridge No staples are left in the stapler of the

Examine Stapler Staple jam has occurred in the stapler

Staple jam has occurred in the stapler

of the saddle stitch unit.

No staples are left in the stapler of the

saddle stitch unit.

finisher.

of the finisher.

8 Messages Displayed on the Touch Panel

Never attempt to repair, disassemble or modify

the equipment by yourself.

You could cause a fire or get an electric shock.

Always contact your service representative for

maintenance or repair of the internal parts of the

equipment.

Remove the jammed staples.

P.34 “Staple jam in the saddle stitch unit”

Refill the staples.

P.42 “Refilling With Staples”

Refill the staples.

P.42 “Refilling With Staples”

Remove the jammed staples.

P.31 “Clearing a Staple Jam”

Page 11

1 TROUBLESHOOTING FOR THE HARDWARE

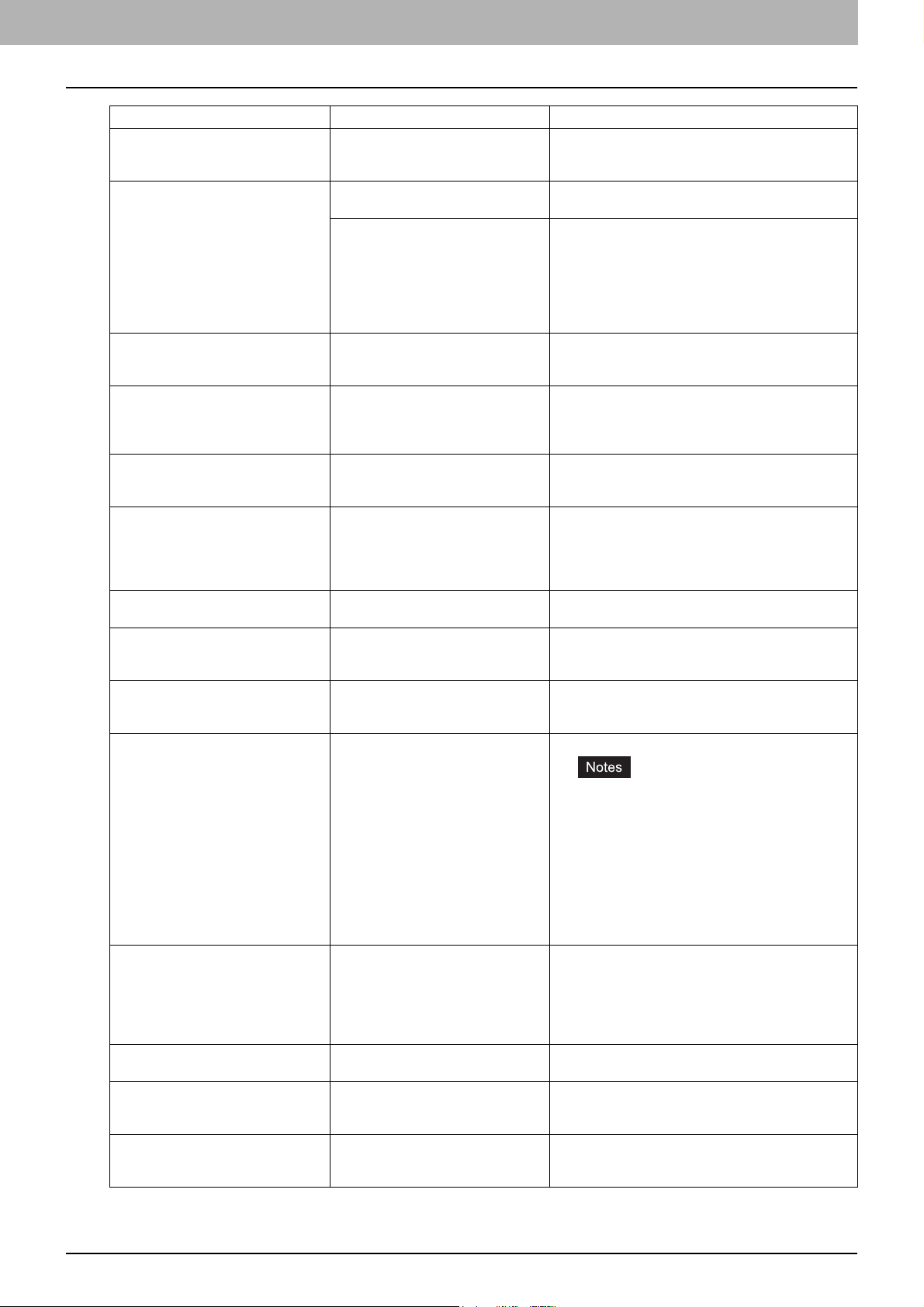

Message Problem Description Corrective Action

Saving energy Press START button The equipment has entered into the

CHANGE DRAWER TO CORRECT

PAPER SIZE

Time for periodic maintenance The equipment requires inspection

POWER FAILURE A job was interrupted by a power

ERASING DATA The Data Overwrite Enabler is

Check paper size setting on control

panel for Bypass

Set the paper on the bypass tray

again.

Check the direction or size of the

paper on the bypass tray and press

START

Reboot the machine An error has occurred in the

Toner near Empty Toner is running out. Prepare a new toner cartridge.

energy saving mode since it has not

been used for a certain time.

No paper suitable for the original is

set.

The size of the original is not detected

correctly because the original is sent

from the Reversing Automatic

Document Feeder at a skew.

and maintenance by a service

technician.

failure or some other reason.

clearing the data.

Paper jam has occurred because of a

mismatch between the paper size

placed in the bypass tray and the size

registered for the bypass tray in the

equipment.

The paper placed on the bypass tray

jammed.

The direction or the size of the paper

placed on the bypass tray is incorrect.

equipment and it stopped normal

operation.

Press any of the [START], [COPY], [e-FILING],

[SCAN], [PRINT], [FAX] and [ENERGY SAVER]

buttons to clear the energy saving mode.

Place the suitable size paper for the original in the

drawer.

Replace the original while aligning the side guides of

the Reversing Automatic Document Feeder to its

width so that it will be placed straight.

If you do not want the equipment strictly to distinguish

A4 and LT, or A3 and LD at the scanning of the

original, contact your service technician or service

representative.

Contact your service representative for maintenance.

The print or fax job may be incomplete. Press [JOB

STATUS] to check whether any jobs are unfinished.

To clear the messages, press the [FUNCTION

CLEAR] button twice.

This message is displayed if the Data Overwrite

Enabler (optional) is installed. You can operate the

equipment while the message is displayed.

Register the paper size correctly. Just releasing the

paper jam does not prevent another paper jam.

P.26 “Clearing paper jams caused by a wrong

paper size setting”

Remove the jammed paper and set the paper again.

Check the direction and the size of the paper and then

replace it on the bypass tray.

Rebooting the equipment may correct the error. To

reboot the equipment, turn the main power switch off

and then on.

y Replace a toner cartridge after the message

“Install new toner cartridge” is displayed.

y If you replace a toner cartridge with a new one

while some toner is still left, make sure to

clear the counter. This is necessary for the

equipment to display the next “Toner near

Empty” message at the proper time. For the

procedure, see below.

P.40 “Replacing a “Near Empty” toner

cartridge”

Open the toner cover

Install new toner cartridge

Please Empty Hole Punch Waste The Hole Punch Unit dust bin is full. Remove the paper punchings.

The number of originals exceeds the

limit

Will you copy stored originals?

Not enough Work Space to store

originals

Will you print out stored originals?

No toner is left. Open the toner cover and replace the toner cartridge

with a new one.

(About another 2000 copies can be made after this

message appears. The number varies depending on

the conditions of copying.)

P.37 “Replacing a Toner Cartridge”

P.47 “Cleaning the Hole Punch Dust Bin”

The number of image scanning

exceeded the maximum (about 2000

in A4 or LT).

Internal memory available ran out

while scanning.

To print out the data for the originals stored (scanned)

until the message appeared, press [YES] on the touch

panel. To delete the stored data, press [NO].

To print out the data for the originals stored (scanned)

until the message appeared, press [YES] on the touch

panel. To delete the stored data, press [NO].

Messages Displayed on the Touch Panel 9

Page 12

1 TROUBLESHOOTING FOR THE HARDWARE

Error Codes

The error codes indicating the status of the equipment may appear on the touch panel. You can find the listings of these

error codes in Chapter 7.

P.86 “Error Codes”

10 Messages Displayed on the Touch Panel

Page 13

1 TROUBLESHOOTING FOR THE HARDWARE

Clearing a Paper Jam

Locating a paper jam

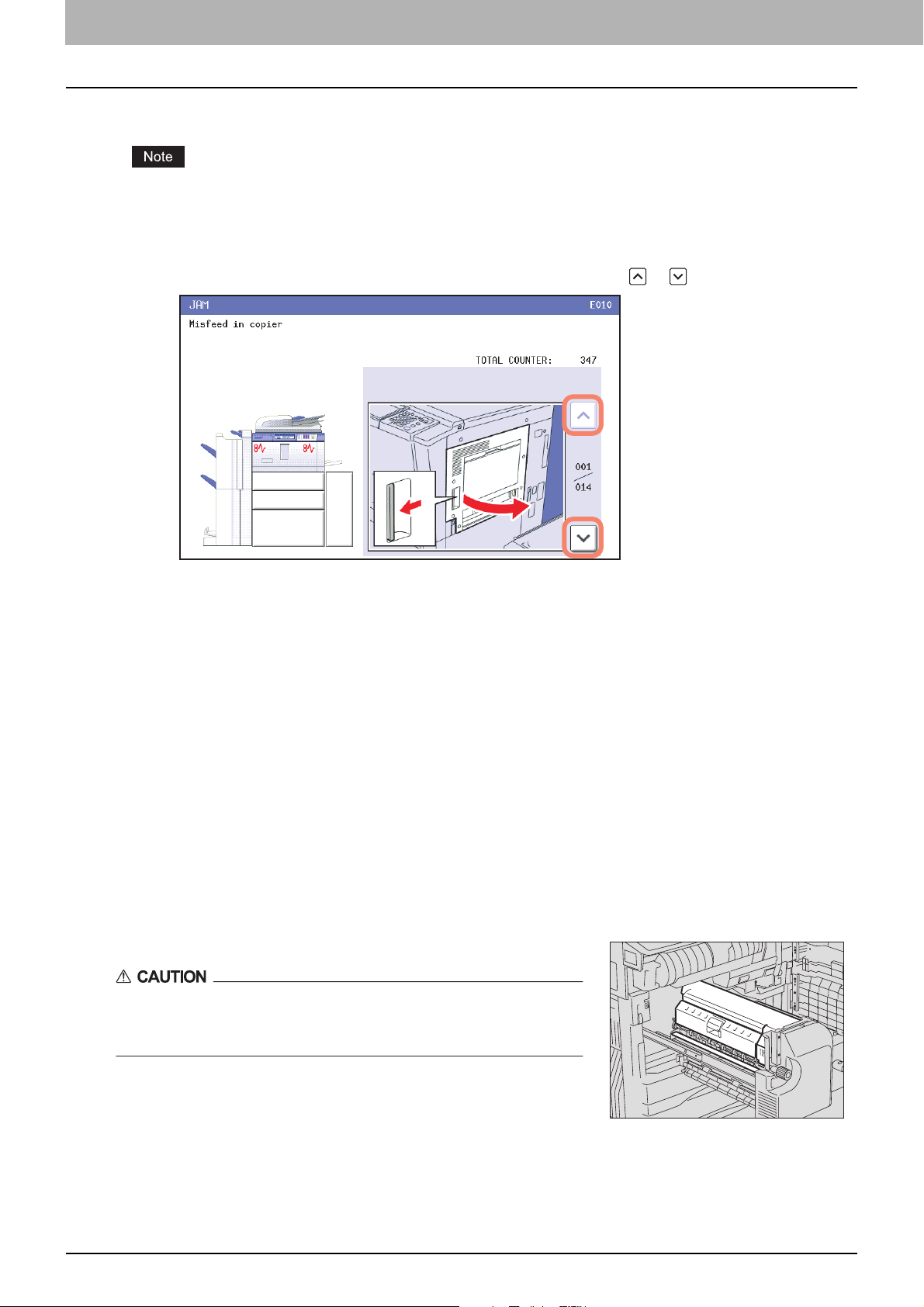

The equipment stops copying when the original or copy paper is jammed. Paper jams are notified on the touch panel as

follows:

Error code

Error message

Guidance for

clearing paper jams

Paper jam symbols

The paper jam symbol helps you locate the paper jam.

7

8

12

4 5321 6

11 9

10

1. Finisher and Hole Punch Unit (both optional) ( P.1 7 )

2. Inserter (optional) ( P.17)

3. Reversing Automatic Document Feeder (lower) ( P.1 3 )

4. Reversing Automatic Document Feeder (upper) ( P.14)

5. Inside of the equipment (paper exit area) ( P.2 2 )

6. Inside of the equipment (paper transport area) ( P.2 2 )

7. Bypass tray ( P. 1 5 )

8. External Large Capacity Feeder (optional) ( P.1 6 )

9. Inside of the equipment (paper feed area) ( P.22)

10. Inside of the equipment (duplexing unit area) ( P. 2 2 )

11. Inside of the equipment (reversing area) ( P.22)

12. Saddle stitch unit (optional) ( P.17)

The picture of the hardware device shown on the touch panel differs depending on the finisher options installed.

Clearing a Paper Jam 11

Page 14

1 TROUBLESHOOTING FOR THE HARDWARE

Clearing a paper jam

Remove paper jammed inside the equipment after you have cleared all other jams. If you fail to clear all other jams

first, the jammed paper may be torn and left inside the equipment.

Clear the paper jam

1

Clear the paper jam following the guidance shown on the touch panel. Press or to scroll the pages.

After clearing the jam, close all the opened covers.

2

The equipment starts the warm-up. Follow the guidance on the touch panel.

Tips on removing the jammed paper

Note the following points in removing the jammed paper.

Remove paper jammed inside the equipment after you have cleared all other jams.

If you fail to clear all other jams first, the jammed paper may be torn and left inside the equipment. Remove paper

jammed inside the equipment after you have cleared all other jams.

Remove the jammed paper carefully so as not to tear it.

To avoid tearing the jammed paper, remove the paper slowly with both hands. Using force may tear the paper, making it

more difficult to remove. See also that no pieces of torn paper are left inside the equipment.

When the paper jam sign remains after removing the jammed paper;

Depending on the timing of the occurrence, no jammed paper may be found where the paper jam sign indicates. If the

sign does not disappear after you have removed the jammed paper, follow the steps as instructed on the touch panel.

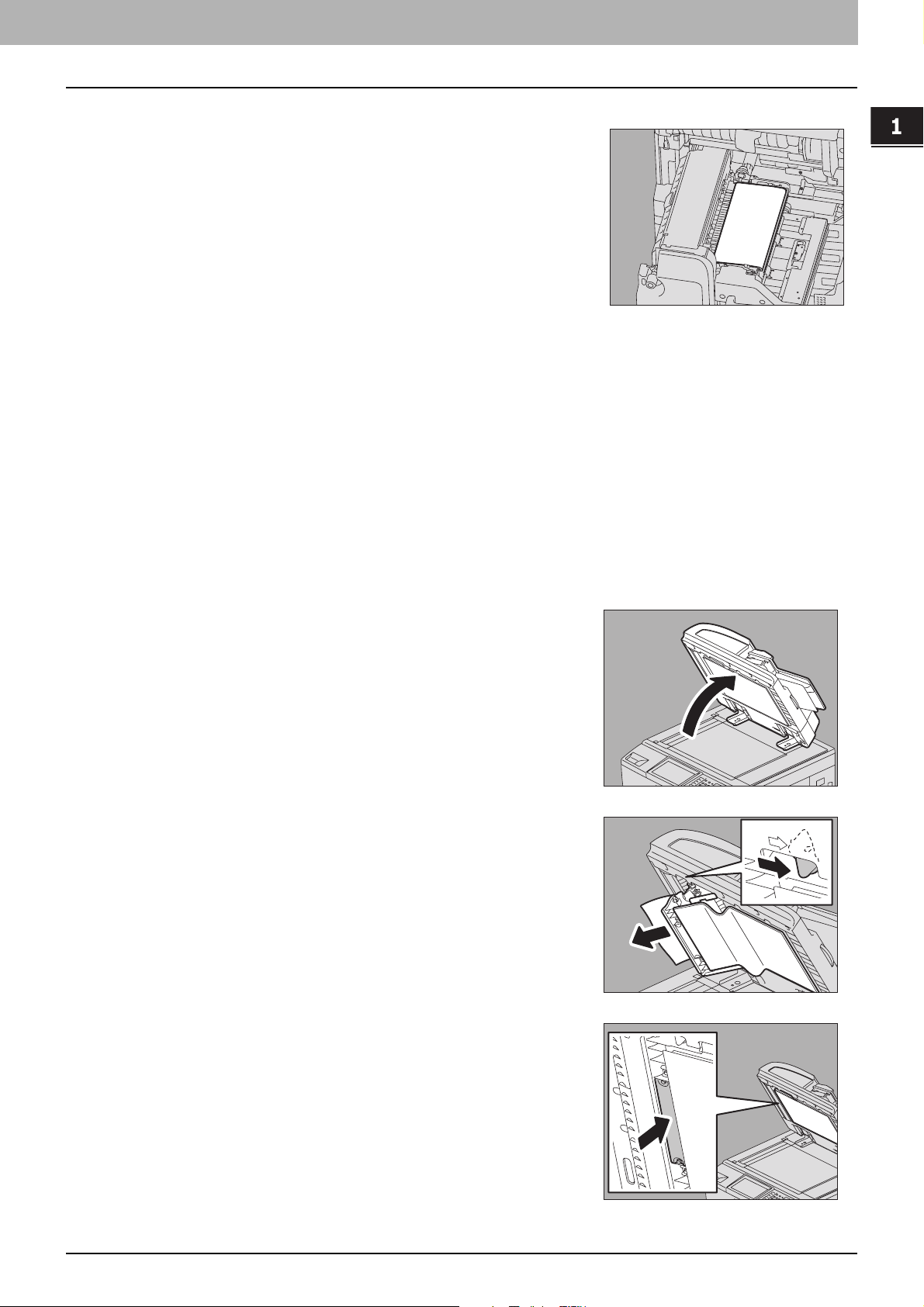

Do not touch the fuser unit or the metal portion around it.

Do not touch the fuser unit or the metal portion around it when removing the

paper jammed inside the equipment. This could burn you or the shock could

cause you to get your hand injured in the machine.

12 Clearing a Paper Jam

Page 15

1 TROUBLESHOOTING FOR THE HARDWARE

1.TROUBLESHOOTING FOR THE HARDWARE

Do not touch the transfer belt.

Do not touch the transfer belt when you removing the paper jammed inside

the equipment. Doing so may cause damage on the equipment or result in a

poor output.

If paper jams occur frequently

The following are the common causes of paper jams. If the problem persists, check for the following situations.

y An unsuitable original is placed on the Reversing Automatic Document Feeder.

y Unavailable paper with the equipment is used.

y Paper sizes are not consistent between the size in a drawer or the bypass tray and the size registered in the

equipment.

y All the jammed paper has not been removed.

y There is too little or too much of a gap between the paper and the side guide in the drawer.

y The amount of paper placed in a drawer exceeds the limit indicated on the side guide of the drawer.

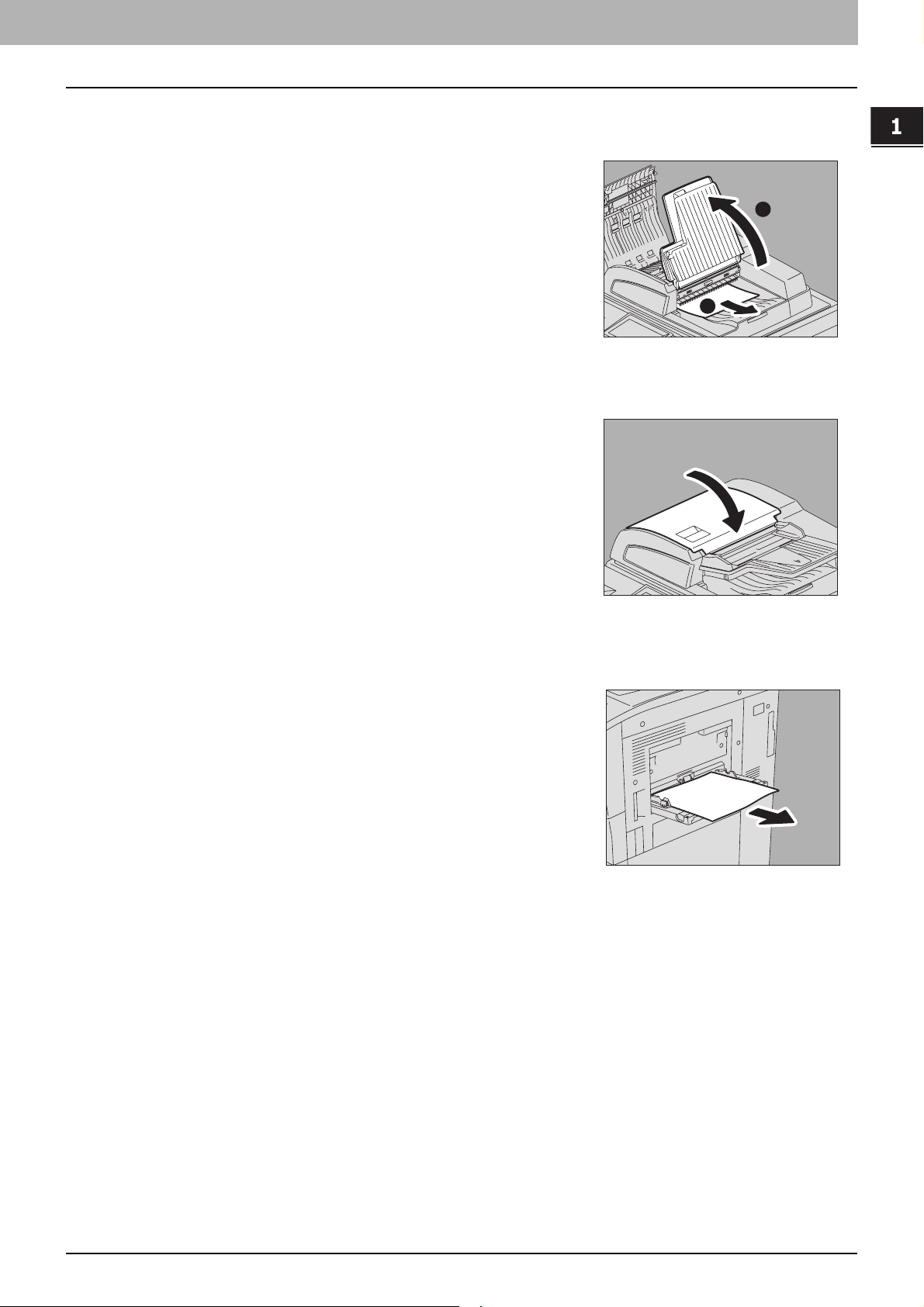

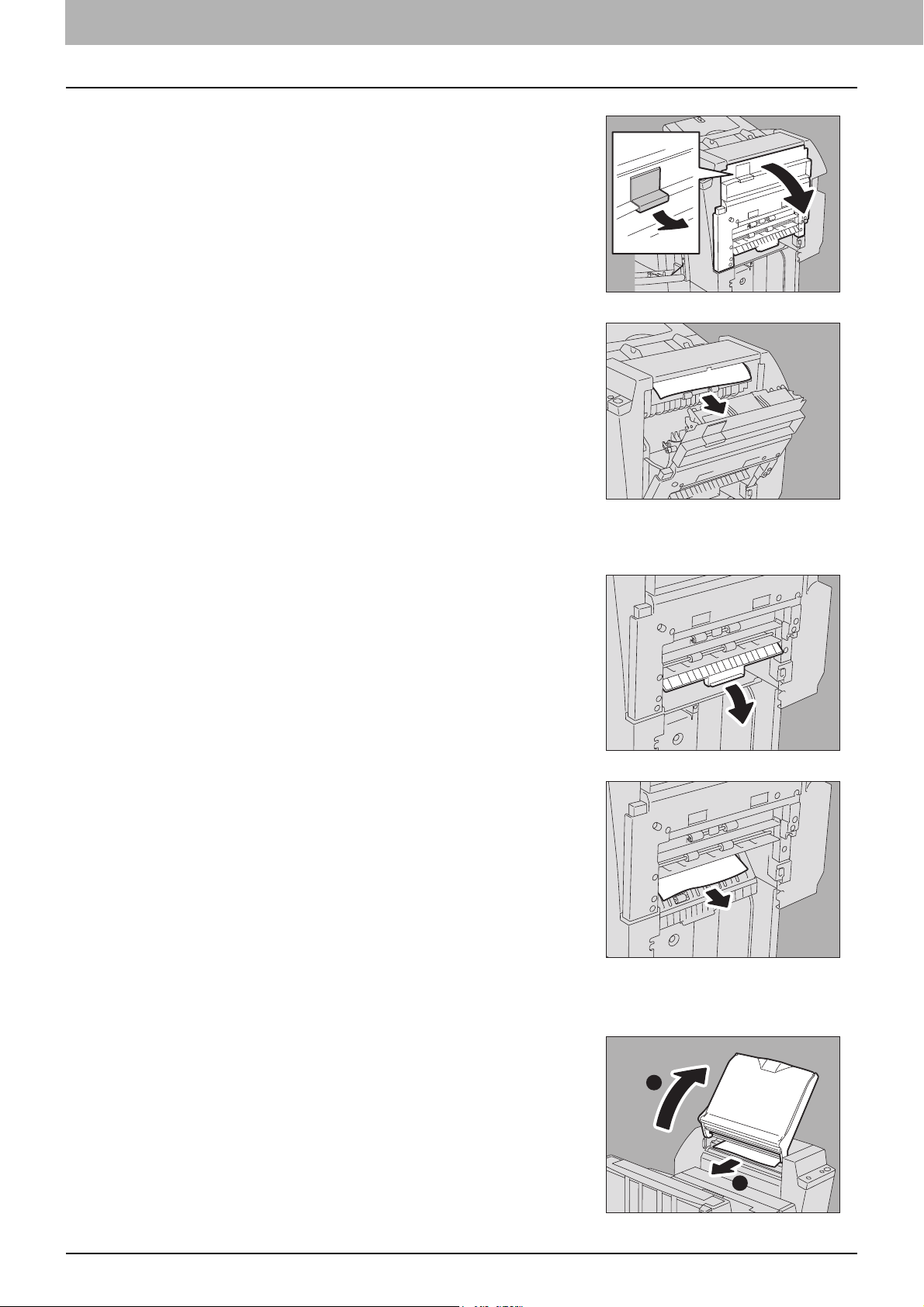

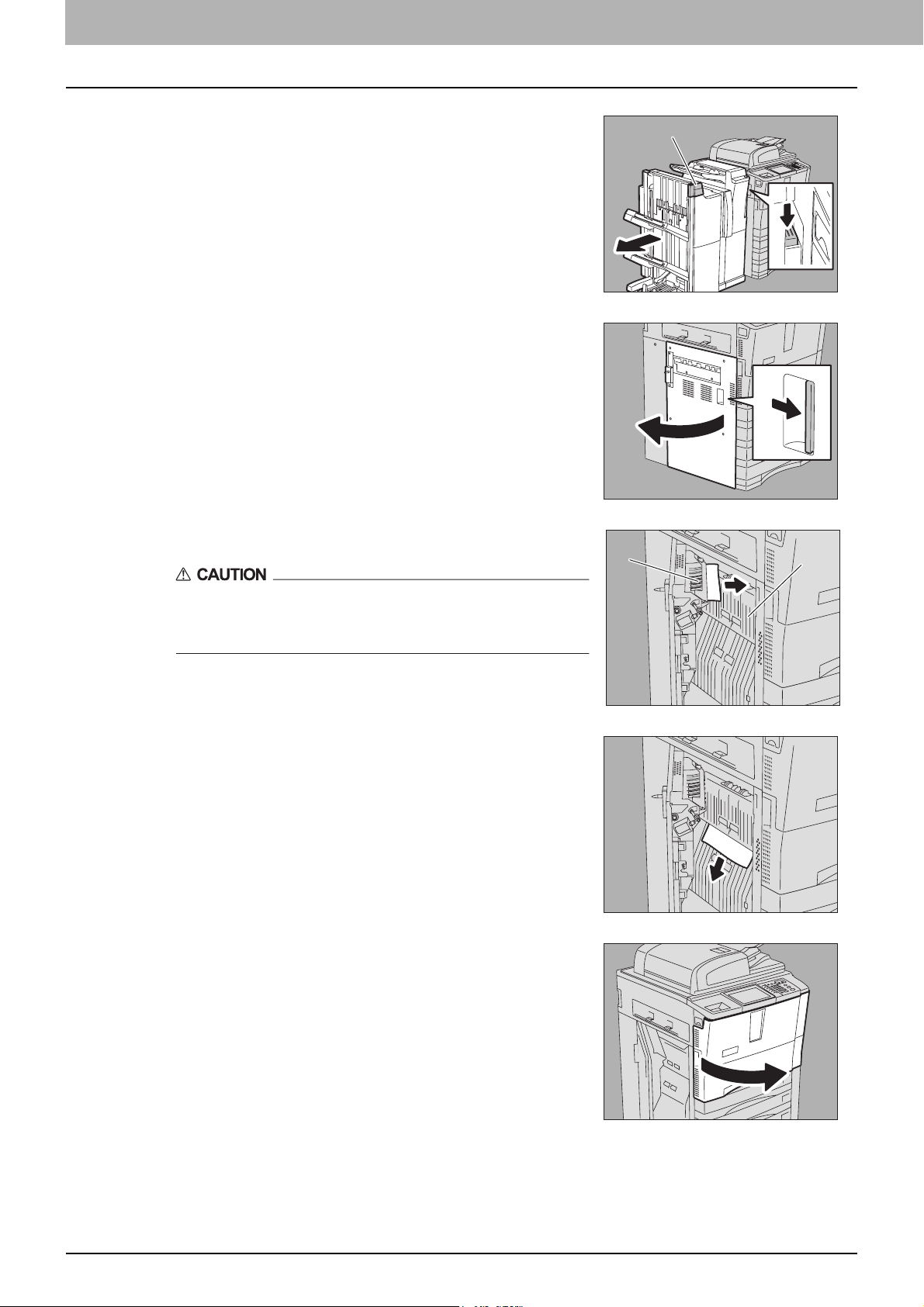

Paper jam in the Reversing Automatic Document Feeder (Lower)

Open the Reversing Automatic Document Feeder.

1

Open the reverse cover and remove the original.

2

Close the reverse cover.

3

Clearing a Paper Jam 13

Page 16

1 TROUBLESHOOTING FOR THE HARDWARE

Close the Reversing Automatic Document Feeder.

4

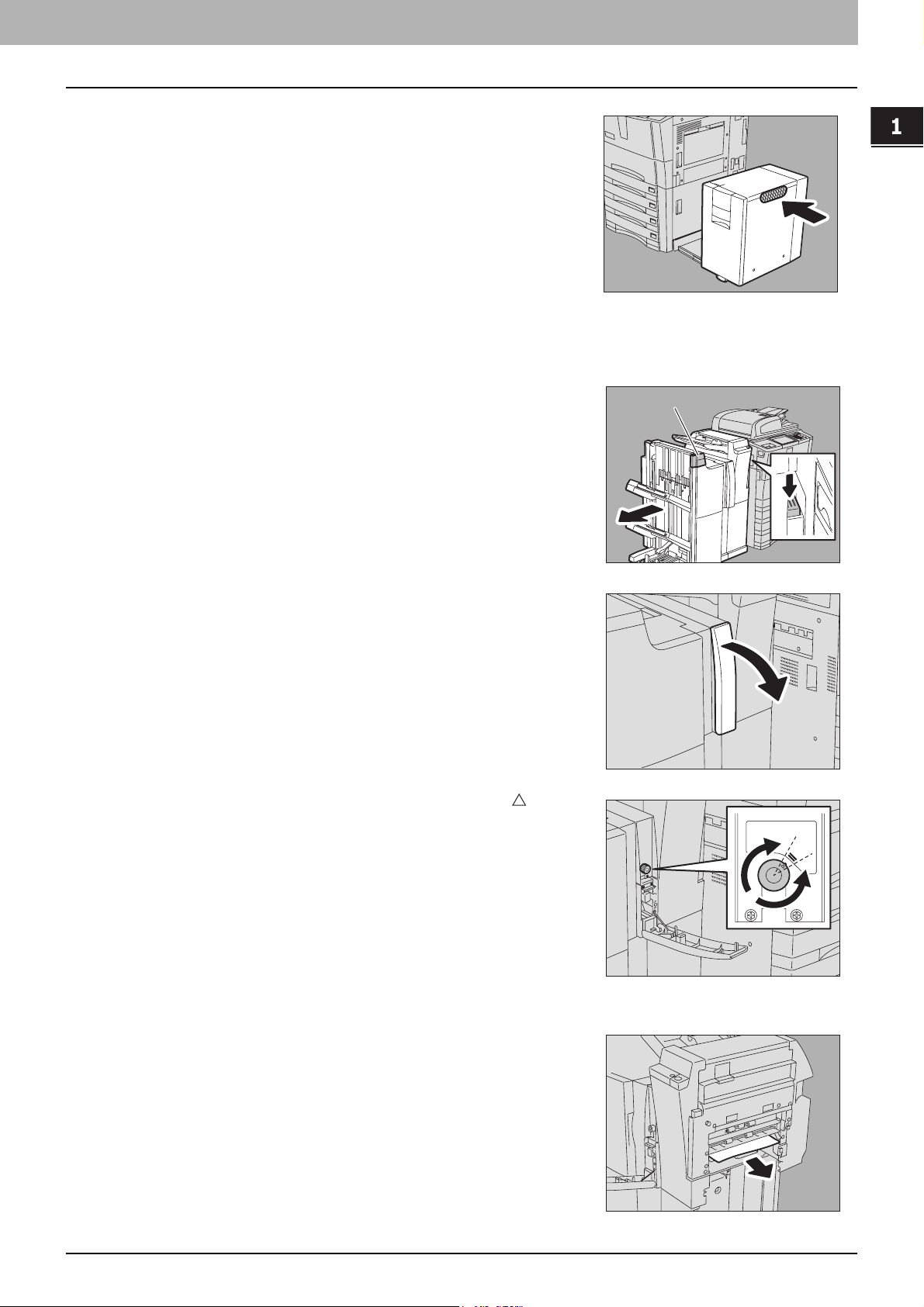

Paper jam in the Reversing Automatic Document Feeder (Upper)

Raise the lever and open the upper cover.

1

2

Remove the original.

2

Turn the dial to remove the original.

3

1

Open the transport guide and remove the original.

4

14 Clearing a Paper Jam

1

2

Page 17

1.TROUBLESHOOTING FOR THE HARDWARE

Close the transport guide.

5

Raise the original feeder tray, and remove the original

6

under the guide plate.

Lower the original feeder tray.

7

Close the upper cover.

8

1 TROUBLESHOOTING FOR THE HARDWARE

1

2

Paper jam in the bypass tray

Pull out the jammed paper in the bypass tray.

1

Clearing a Paper Jam 15

Page 18

1 TROUBLESHOOTING FOR THE HARDWARE

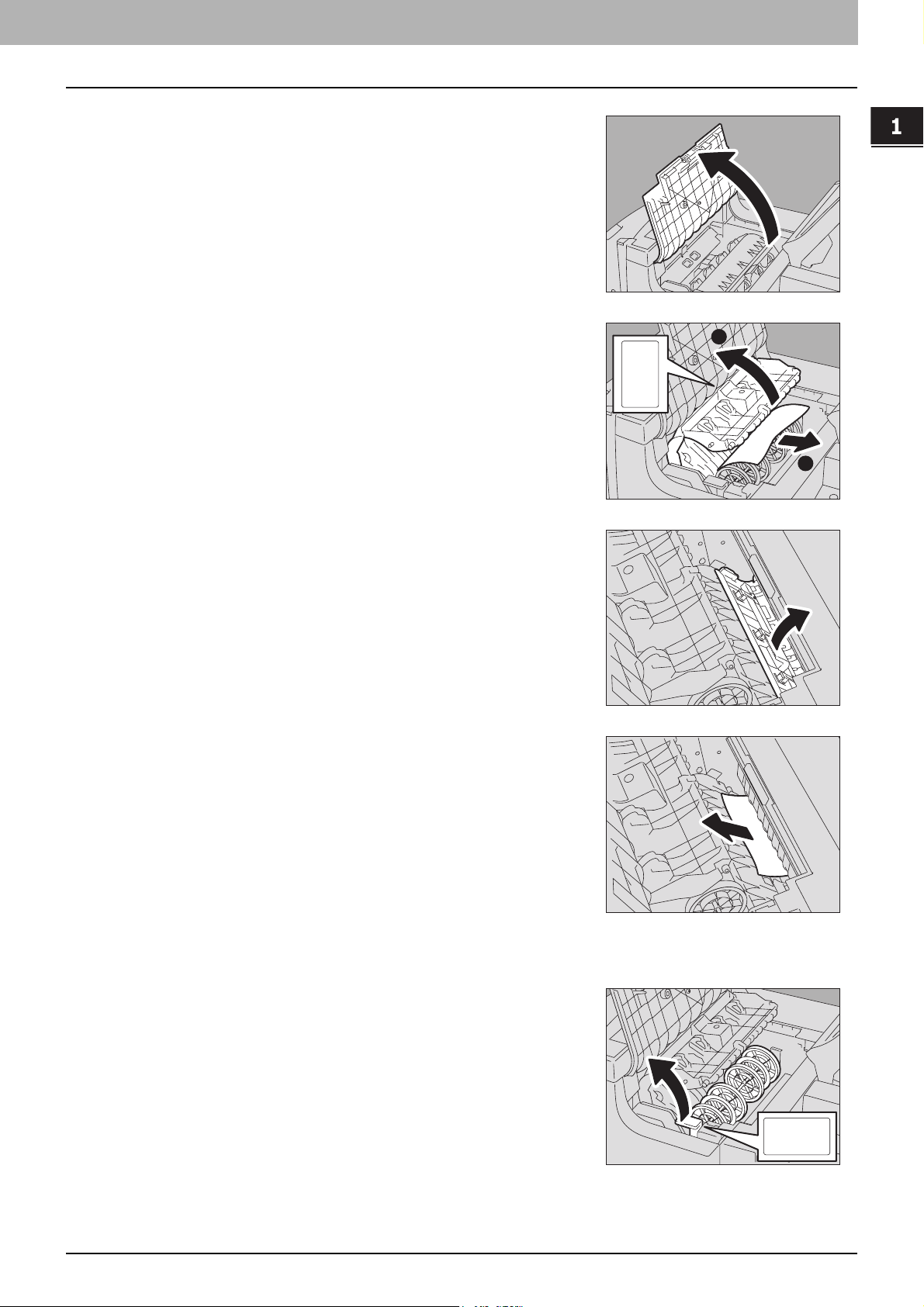

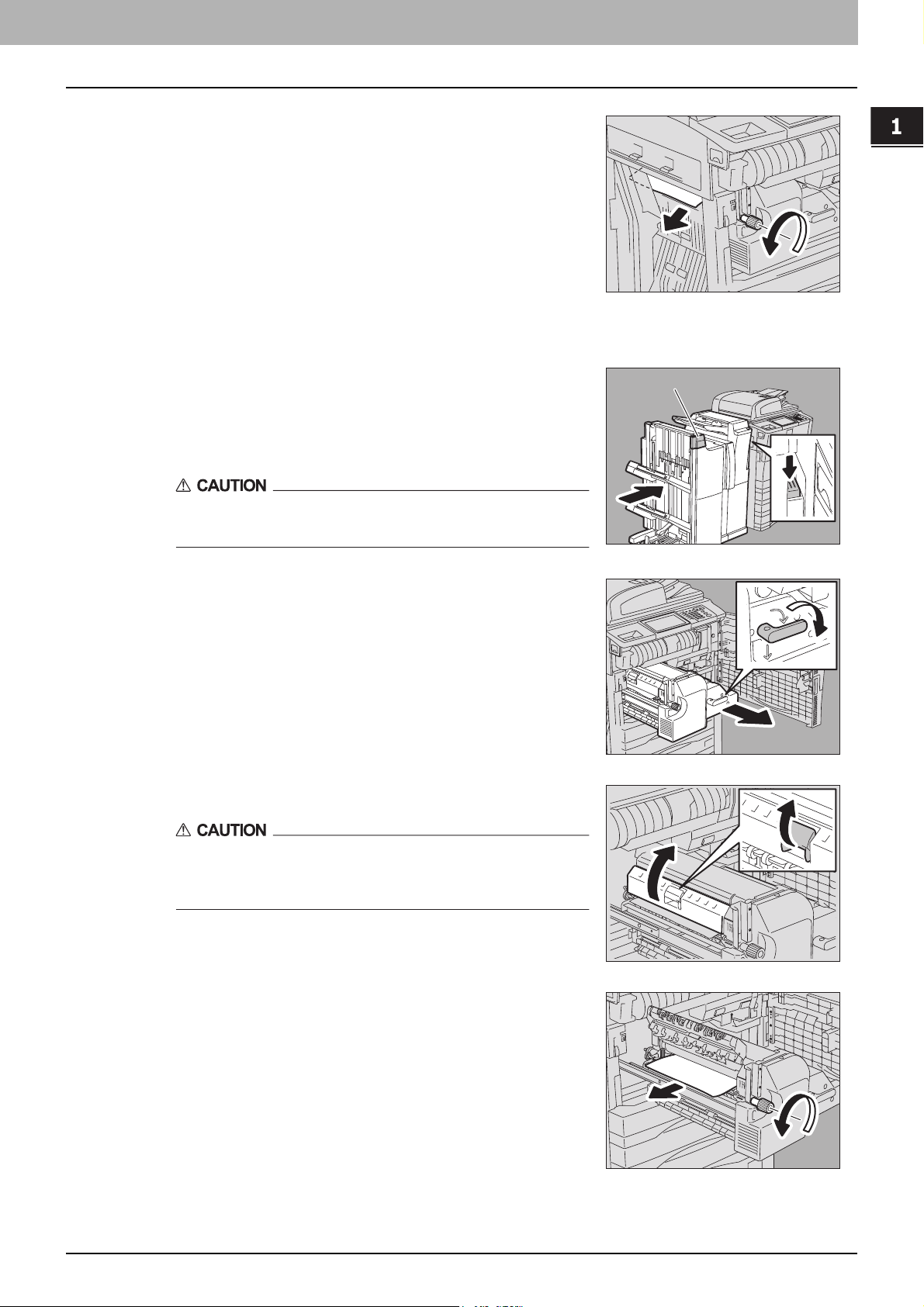

Paper jam in the External Large Capacity Feeder (optional)

Be careful not to let your fingers be caught between the equipment and the External Large Capacity Feeder.

Separate the External Large Capacity Feeder

1

(optional) from the equipment.

Move it slowly while pushing the lock lever.

Remove the jammed paper by turning the green dial.

2

Remove the jammed paper from the equipment.

3

Pull out the feeder tray and remove the jammed

4

paper.

16 Clearing a Paper Jam

Page 19

1 TROUBLESHOOTING FOR THE HARDWARE

1.TROUBLESHOOTING FOR THE HARDWARE

Close the feeder tray and connect the External Large

5

Capacity Feeder to the equipment.

Slowly move the External Large Capacity Feeder placing your hands

on the positions shown in the figure.

Paper jam in the Finisher, Hole Punch Unit and Inserter (all optional)

Separate the finisher from the equipment.

1

Separate the finisher from the equipment while pressing the lock lever.

Place your hand on portion A in the figure and then move the finisher

carefully.

A

When the Hole Punch Unit is installed, open the Hole

2

Punch Unit cover.

Turn the green knob until the triangle mark ( ) falls

3

within the designated area of the label.

Close the Hole Punch Unit cover.

4

Remove paper that sticks out from the paper feeding

5

side.

Clearing a Paper Jam 17

Page 20

1 TROUBLESHOOTING FOR THE HARDWARE

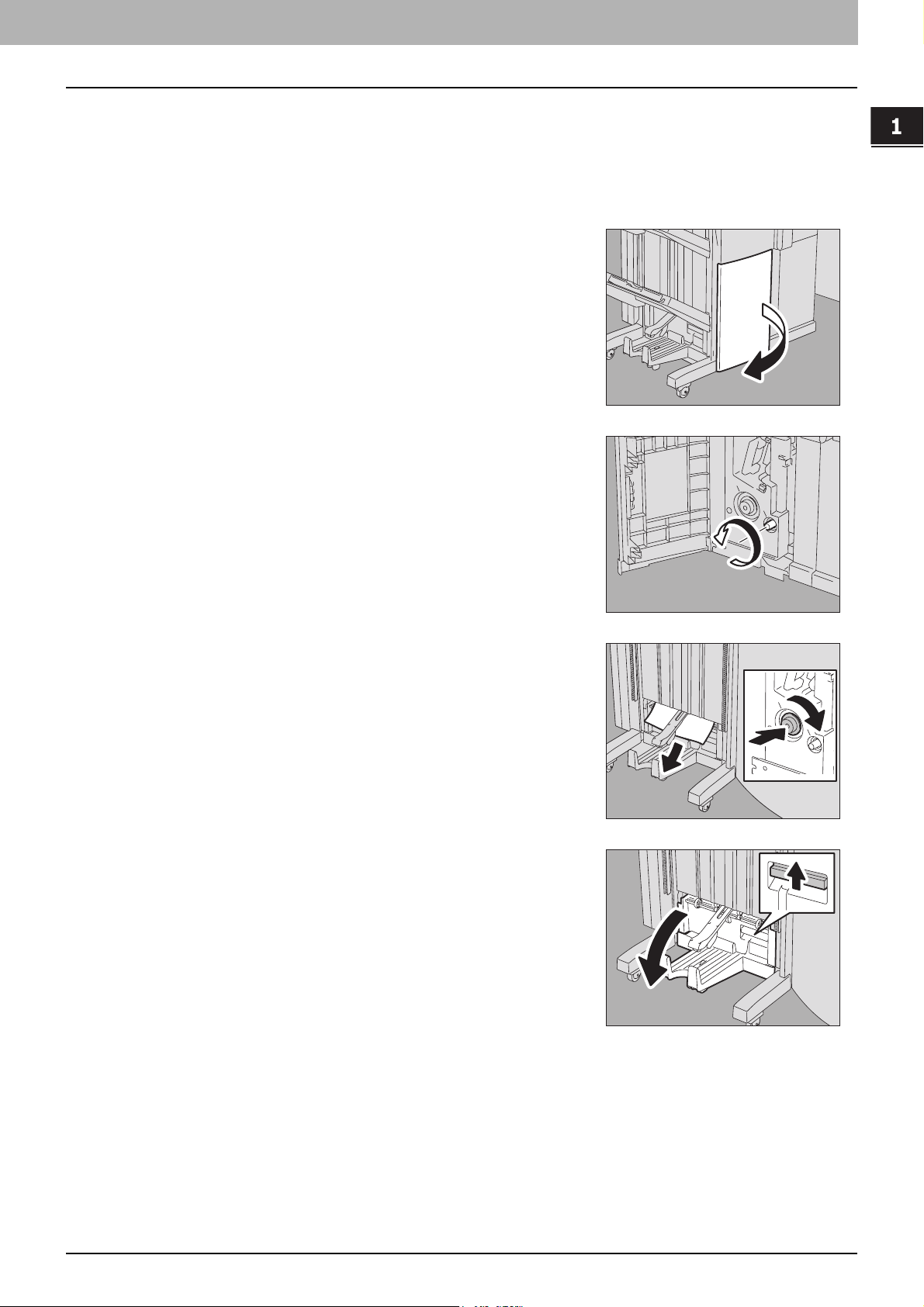

When the Inserter is installed, pull out the lever to

6

open its jam access cover.

Remove the jammed paper.

7

Close the jam access cover of the Inserter.

8

Open the lower cover of the Inserter.

9

Remove the jammed paper.

10

Close the lower cover.

11

Raise the paper feeding tray of the Inserter, and then

12

remove the jammed paper.

18 Clearing a Paper Jam

1

2

Page 21

1.TROUBLESHOOTING FOR THE HARDWARE

Open the upper cover of the finisher.

13

Pull the knob 1 to open the buffer roller cover, and

14

then remove the jammed paper.

1 TROUBLESHOOTING FOR THE HARDWARE

1

1

2

Pull the knob up in the rear side of the finisher to

15

open the guide.

Remove the jammed paper.

16

Close the guide.

17

Pull the knob 2 up to open the buffer roller.

18

2

Clearing a Paper Jam 19

Page 22

1 TROUBLESHOOTING FOR THE HARDWARE

Remove the jammed paper.

19

Remove paper that sticks out from the paper exit side

20

of the finisher.

Close the upper cover of the finisher.

21

Return the paper feed tray of the Inserter to its original position.

22

When the Saddle Stitch Finisher and the Inserter are

23

installed together, open the front cover of the Inserter.

Open the guide plate of the saddle stitch unit.

24

Remove the jammed paper.

25

20 Clearing a Paper Jam

Page 23

1.TROUBLESHOOTING FOR THE HARDWARE

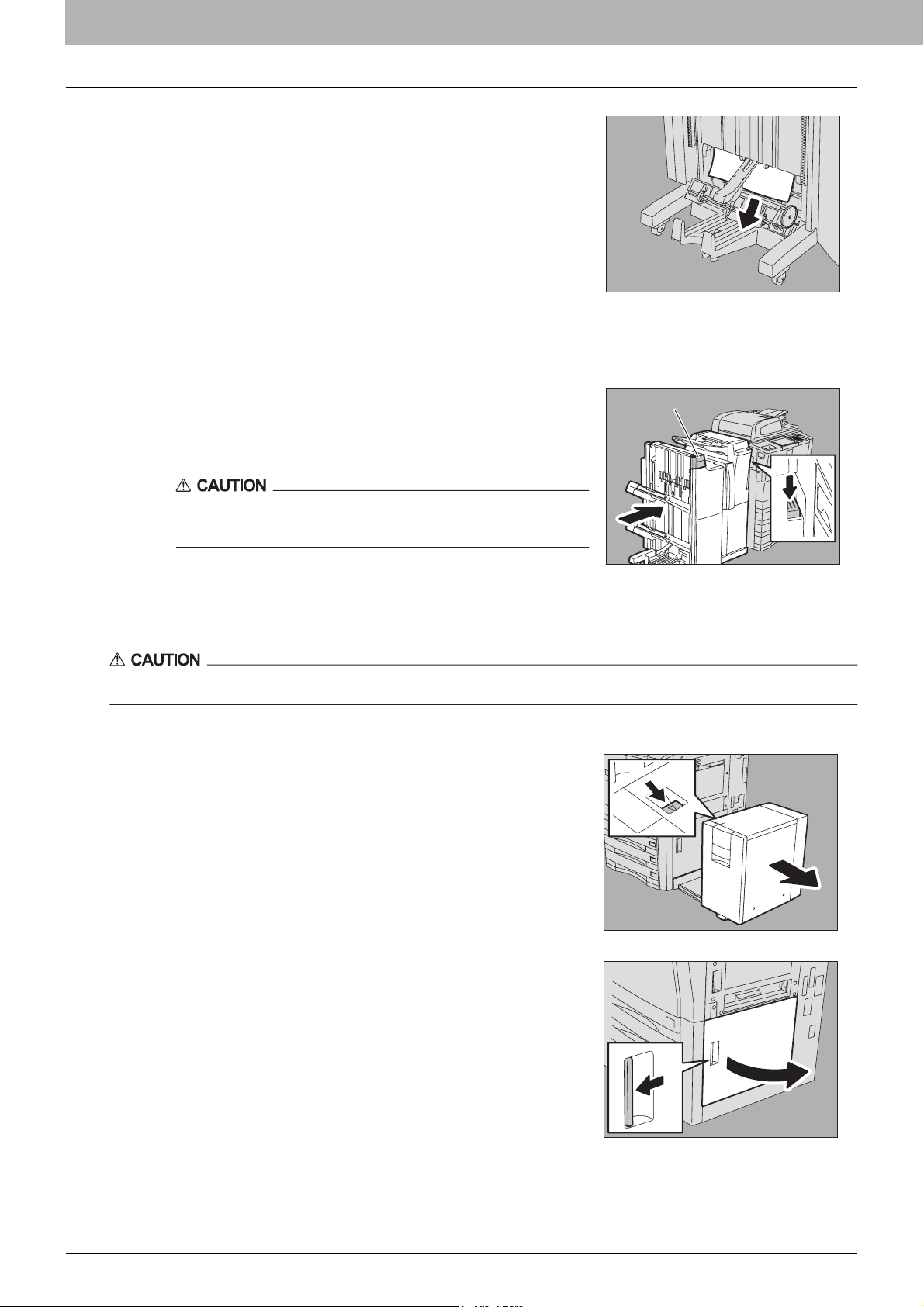

Close the guide plate.

26

When the Saddle Stitch Finisher and the Inserter are installed together, close the lower

27

cover of the Inserter.

When the Saddle Stitch Finisher is installed, open the

28

lower cover of the Saddle Stitch Finisher.

Turn the right-hand knob counterclockwise until it

29

stops.

1 TROUBLESHOOTING FOR THE HARDWARE

While pushing the left-hand knob, turn it clockwise to

30

remove the jammed paper.

Open the paper exit cover of the saddle stitch unit.

31

Clearing a Paper Jam 21

Page 24

1 TROUBLESHOOTING FOR THE HARDWARE

Remove the jammed paper.

32

Close the paper exit cover of the saddle stitch unit and the lower cover of the Saddle

33

Stitch Finisher.

Connect the finisher to the equipment.

34

Connect the finisher with the equipment while pressing the lock lever.

Place your hand on portion A in the figure and then move the finisher

carefully.

A

Be careful not to let your fingers be caught between the

finisher and the equipment.

Paper jam inside of the equipment

Be careful not to let your fingers be caught between the equipment and the External Large Capacity Feeder.

Separate the External Large Capacity Feeder

1

(optional) from the equipment when the External

Large Capacity Feeder is attached.

Move it slowly while pushing the lock lever.

Open the paper feed cover.

2

22 Clearing a Paper Jam

Page 25

1.TROUBLESHOOTING FOR THE HARDWARE

Remove the jammed paper from the drawer.

3

Open the paper source drawer and remove the

4

jammed paper.

1 TROUBLESHOOTING FOR THE HARDWARE

Close the drawer and the paper feed cover.

5

Open the bypass cover.

6

Remove the jammed paper.

7

Close the bypass cover.

8

When the External Large Capacity Feeder is installed,

9

connect it with the equipment.

Move it slowly placing your hands on the point shown in the figure.

Clearing a Paper Jam 23

Page 26

1 TROUBLESHOOTING FOR THE HARDWARE

When the finisher is installed, separate it from the

10

equipment.

Separate the finisher from the equipment while pressing the lock lever.

Place your hand on portion A in the figure and then move the finisher

carefully.

Open the exit cover.

11

A

Remove the jammed paper on the exit cover side.

12

Do not touch the metal portion of the reverse unit (A in the

figure) or the guide plate (B in the figure).

It could burn or injure you.

Remove the jammed paper from the middle of the

13

reverse unit.

Open the front cover of the equipment.

14

B

A

24 Clearing a Paper Jam

Page 27

1.TROUBLESHOOTING FOR THE HARDWARE

Turn the green knob of the fuser unit

15

counterclockwise to remove the jammed paper.

Close the exit cover.

16

When the finisher is installed, connect it with the

17

equipment.

Connect the finisher with the equipment while pressing the lock lever.

Place your hand on portion A in the figure and then move the finisher

carefully.

1 TROUBLESHOOTING FOR THE HARDWARE

A

Be careful not to let your fingers be caught between the

finisher and the equipment.

Turn the lever of the transfer/transport unit clockwise

18

by 90 degrees to unlock it. Then pull out the transfer/

transport unit.

Pull out the transfer/transport unit until it stops.

Open the fuser unit cover.

19

Do not touch the fuser unit and around the metal area around

it.

It could burn or injure you.

Turn the green knob of the fuser unit

20

counterclockwise to remove the jammed paper.

Clearing a Paper Jam 25

Page 28

1 TROUBLESHOOTING FOR THE HARDWARE

Close the fuser unit cover slowly.

21

Open the duplexer guide.

22

Remove the jammed paper.

23

Close the duplexer guide.

24

Push the transfer/transport unit into the equipment

25

carefully while holding its lever. Then turn the lever

counterclockwise by 90 degrees to lock it.

Close the front cover of the equipment.

26

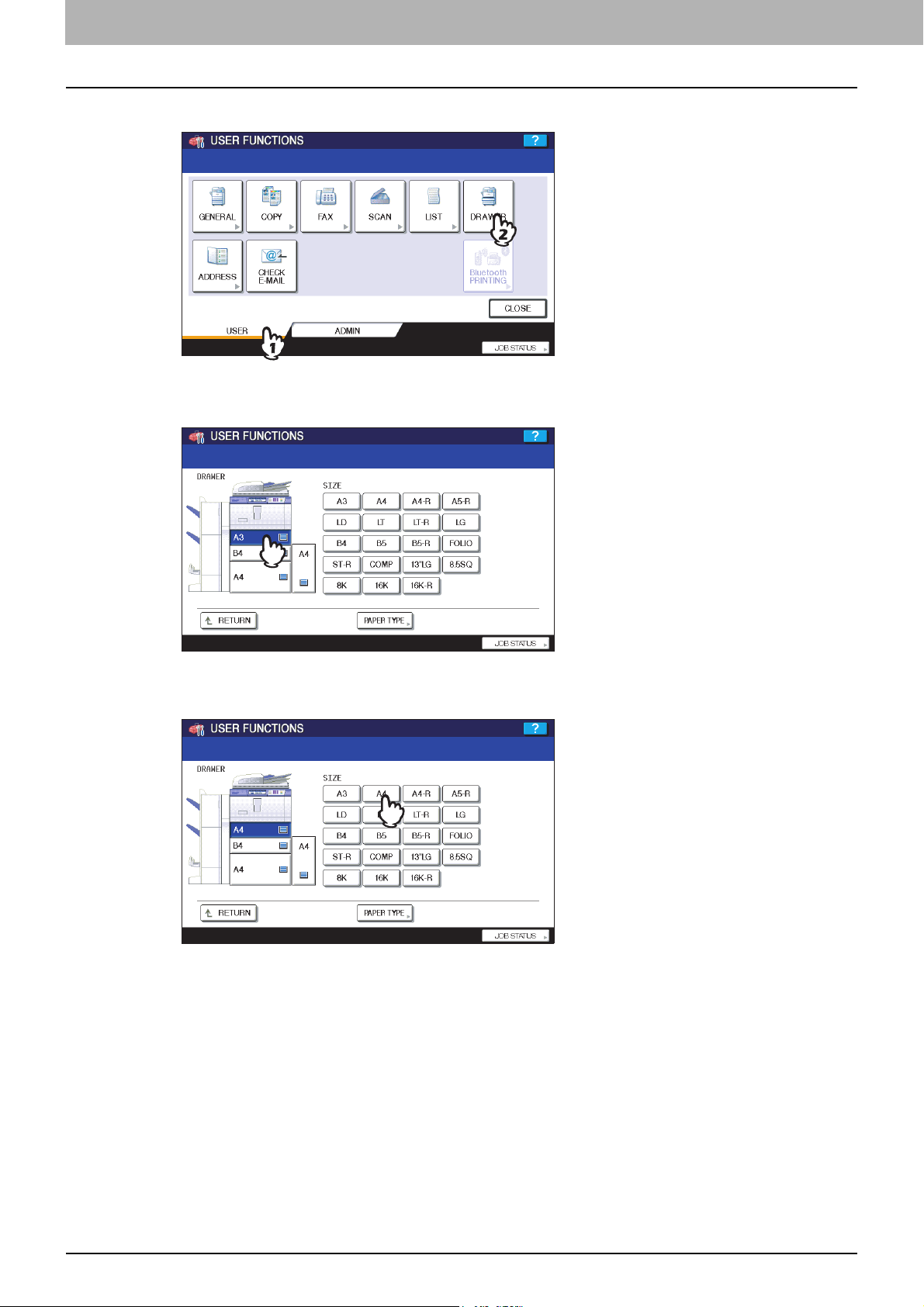

Clearing paper jams caused by a wrong paper size setting

Paper jams occur when there is a mismatch between the size of the paper in a drawer or the bypass tray and the size

registered for the corresponding drawer or the bypass tray in the equipment. The message “Check paper size setting on

control panel for drawer N” or “Check paper size setting on control panel for Bypass” appears on the touch panel.

26 Clearing a Paper Jam

Page 29

1 TROUBLESHOOTING FOR THE HARDWARE

1.TROUBLESHOOTING FOR THE HARDWARE

In this case, just clearing the jammed paper does not prevent another paper jam. Be sure to follow the procedure below.

During the operation, the guidance for clearing the paper jam on the touch panel is not displayed. Take notes of the

following before operation: where the paper jam occurred and for which drawer the paper size setting is incorrectly

registered.

Troubleshooting differs depending on how the paper jam has occurred:

P.27 “Jam when making copies or prints (using a drawer)”

P.29 “Jam when making copies or prints (using the bypass tray)”

P.29 “Jam when printing from the FAX”

Jam when making copies or prints (using a drawer)

Press the [POWER] button on the control panel until a

1

sound is heard.

“Shutdown in progress” appears on the menu. After a while, the power

of the equipment is turned OFF.

Remove the jammed paper.

2

Press the [POWER] button on the control panel.

3

The equipment starts warming-up.

Press the [USER FUNCTIONS] button on the control

4

panel.

Clearing a Paper Jam 27

Page 30

1 TROUBLESHOOTING FOR THE HARDWARE

Press the [USER] tab to enter the [USER] menu and press [DRAWER].

5

Press the drawer button indicated in the message.

6

Press the paper size button for the paper that is set in the drawer.

7

Press the [USER FUNCTIONS] button to return to the basic menu and try copying or

8

printing again.

28 Clearing a Paper Jam

Page 31

1 TROUBLESHOOTING FOR THE HARDWARE

1.TROUBLESHOOTING FOR THE HARDWARE

Jam when making copies or prints (using the bypass tray)

Press the [POWER] button on the control panel until a

1

sound is heard.

“Shutdown in progress” appears on the menu. After a while, the power

of the equipment is turned OFF.

Remove the jammed paper.

2

Press the [POWER] button on the control panel.

3

The equipment starts warming-up.

Place the paper on the bypass tray and set the paper size.

4

Try copying or printing again.

5

Jam when printing from the FAX

Turn off the main power switch.

1

Shutting down via the control panel is not possible in this case.

Remove the jammed paper.

2

Pull out the drawer indicated in the message and

3

remove all the paper from the drawer.

Clearing a Paper Jam 29

Page 32

1 TROUBLESHOOTING FOR THE HARDWARE

Close the drawer and turn on the main power switch.

4

The equipment starts warming-up.

Check the paper size registered to the drawer indicated in the message by means of the

5

drawer button on the touch panel.

Place the paper in the drawer indicated in the message. Be sure to place the same-

6

sized paper as the size you checked in step 5.

Printing resumes.

If you change the paper size again after printing has been completed, make sure that the size of the paper placed

in the drawer is the same as the size registered for the corresponding drawer in the equipment.

30 Clearing a Paper Jam

Page 33

1 TROUBLESHOOTING FOR THE HARDWARE

Clearing a Staple Jam

When a staple jam has occurred in the stapler of the finisher or saddle stitch unit, clear the jam following the procedure

below.

P.31 “Staple jam in the Finisher MJ-1027 / Saddle Stitch Finisher MJ-1028”

P.32 “Staple jam in the Saddle Stitch Finisher MJ-1029”

P.34 “Staple jam in the saddle stitch unit”

Staple jam in the Finisher MJ-1027 / Saddle Stitch Finisher MJ-1028

Open the front cover of the finisher.

1

Lower the lever of the stapler to release the lock, and

2

then take out the staple cartridge.

Lower the guide while holding the knob.

3

Do not touch the stapling area (A in the figure).

The actual needle point could cause you personal injury.

Remove any jammed staples with something sharp.

4

1

2

A

Clearing a Staple Jam 31

Page 34

1 TROUBLESHOOTING FOR THE HARDWARE

Holding the knob, raise the guide, and return it to its

5

original position.

Fit the staple cartridge into the stapler.

6

Insert the cartridge until the lever of the stapler goes up to be fixed

securely.

Close the front cover of the finisher.

7

Staple jam in the Saddle Stitch Finisher MJ-1029

Open the front cover of the finisher.

1

Slightly raise and pull out the staple cartridge while

2

holding its lever.

1

2

32 Clearing a Staple Jam

Page 35

1.TROUBLESHOOTING FOR THE HARDWARE

Lower the guide while holding the knob.

3

Do not touch the stapling area (A in the figure).

The actual needle point could cause you personal injury.

Remove any jammed staples with something sharp.

4

1 TROUBLESHOOTING FOR THE HARDWARE

A

Holding the knob, raise the guide, and return it to its

5

original position.

Fit the staple cartridge into the stapler.

6

Insert the staple cartridge until you hear a click sound (the staple

cartridge is latched). Then lower the lever slightly.

Close the front cover of the finisher.

7

1

2

Clearing a Staple Jam 33

Page 36

1 TROUBLESHOOTING FOR THE HARDWARE

Staple jam in the saddle stitch unit

Open the lower cover of the Saddle Stitch Finisher.

1

Slowly pull out the saddle stitch unit.

2

Pull the stapler handle on the saddle stitch unit

3

toward you to unlock it. Then turn the stapler

clockwise by 60 degrees.

The stapler is locked and cannot be turned further when it lies almost

horizontally.

Remove the staple cartridge.

4

While pushing the lever (1 in the figure) downward,

5

pull up the shutter with the knob (2).

2

1

1

34 Clearing a Staple Jam

2

Page 37

1.TROUBLESHOOTING FOR THE HARDWARE

Remove the jammed staples.

6

1 TROUBLESHOOTING FOR THE HARDWARE

Do not touch the stapling area (A in the figure).

The actual needle point could cause you personal injury.

Push the knob (2) to return it to its original position.

7

Make sure that the lever (1) is latched on the shutter.

Fit the staple cartridges.

8

Push down each cartridge until it is fixed with a click.

A

12

Unlock the stapler by pulling its handle toward you.

9

Then return the stapler to its original position.

Carefully insert the saddle stitch unit into the finisher.

10

Make sure of the following two requirements before test stapling:

11

y The Saddle Stitch Finisher is securely attached to the equipment.

y A3, B4, A4-R, LD, or LT-R paper is set in the drawer.

2

1

Clearing a Staple Jam 35

Page 38

1 TROUBLESHOOTING FOR THE HARDWARE

Close the lower cover of the Saddle Stitch Finisher.

12

Test stapling starts automatically.

Test stapling is necessary to prevent void stapling. Note that the test stapling starts automatically when the two

requirements in step 11 are met with the lower cover of the Saddle Stitch Finisher closed. If the test stapling

does not start, make sure to check the two requirements again. Then open and again close the lower cover of

the Saddle Stitch Finisher.

36 Clearing a Staple Jam

Page 39

1 TROUBLESHOOTING FOR THE HARDWARE

Replacing a Toner Cartridge

When the toner cartridge runs out, the message “Open the toner cover Install new toner cartridge” appears. Replace the

toner cartridge following the procedure below when you see this message.

To assure an optimal printing performance, we recommend that you use TOSHIBA toner cartridges.

Never attempt to incinerate toner cartridges.

Dispose of used toner cartridges in accordance with local regulations.

Replacing a Toner Cartridge 37

Page 40

1 TROUBLESHOOTING FOR THE HARDWARE

y You can replace a toner cartridge while the print function is in operation when “Open the toner cover Install new

toner cartridge” is displayed.

y Some toner remains in the toner cartridge while the message “Toner near Empty” is displayed. Although you can

replace the toner cartridge with a new one, make sure you follow the procedure P.40 “Replacing a “Near Empty”

toner cartridge”. This procedure is needed to reset the toner counter to display the next “Toner near Empty”

message at the proper time.

Open the toner cover.

1

Pull out the toner cartridge holder toward you.

2

Take out the empty toner cartridge.

3

Never attempt to incinerate toner cartridges.

Dispose of used toner cartridges in accordance with local

regulations.

Shake the new toner cartridge well to loosen the toner

4

inside.

38 Replacing a Toner Cartridge

Page 41

1.TROUBLESHOOTING FOR THE HARDWARE

Holding the new toner cartridge horizontally, pull out

5

the seal in the direction of the arrow.

Install a new toner cartridge into the toner cartridge

6

holder.

When inserting the toner cartridge, be sure that the shutter of the toner

cartridge and the label on the equipment side (both in orange) are

aligned.

y If it is hard to insert the toner cartridge, rotate it little by little to

insert it in the correct position.

y If the toner scatters, wipe it off completely.

1 TROUBLESHOOTING FOR THE HARDWARE

Return the toner cartridge holder to its original

7

position.

Close the toner cover.

8

Toner supplying operation automatically starts.

Replacing a Toner Cartridge 39

Page 42

1 TROUBLESHOOTING FOR THE HARDWARE

Replacing a “Near Empty” toner cartridge

The message “Toner near Empty” appears on the touch panel when there is not much toner left in a toner cartridge.

Some toner is still left in the toner cartridge while the message “Toner near Empty” is displayed. You can replace the toner

cartridge with a new one, but if you do so, make sure to follow the procedure below. This procedure is necessary for the

equipment to reset the toner counter for displaying the next “Toner near Empty” message at the proper time.

Press the [USER FUNCTIONS] button on the control

1

panel.

Press the [USER] tab on the touch panel to display the user setting menu, and then

2

press [GENERAL].

40 Replacing a Toner Cartridge

Page 43

1.TROUBLESHOOTING FOR THE HARDWARE

Press [REPLACE TONER CARTRIDGE].

3

To replace a toner cartridge, press [YES]. To cancel, press [NO].

4

1 TROUBLESHOOTING FOR THE HARDWARE

Replace the toner cartridge.

5

See P.37 “Replacing a Toner Cartridge” for the correct procedure.

Press [FINISH].

6

Press the [USER FUNCTIONS] or [COPY] button on the control panel.

7

The menu returns to the BASIC menu.

Replacing a Toner Cartridge 41

Page 44

1 TROUBLESHOOTING FOR THE HARDWARE

Refilling With Staples

Refill with staples according to the following procedures when the staples in the stapler of the finisher and saddle stitch

unit run out.

P.42 “Refilling Finisher MJ-1027 / Saddle Stitch Finisher MJ-1028 staples”

P.43 “Refilling Saddle Stitch Finisher MJ-1029 staples”

P.45 “Refilling saddle stitch unit staples”

Refilling Finisher MJ-1027 / Saddle Stitch Finisher MJ-1028 staples

Open the front cover of the finisher.

1

Lower the lever of the stapler to release the lock, and

2

then take out the staple cartridge.

Take the empty staple case out of the staple cartridge.

3

Fit a new staple case on the staple cartridge.

4

Push the staple case into the cartridge until it clicks.

1

2

In this step, do not remove the seal bundling the staples.

42 Refilling With Staples

Page 45

1.TROUBLESHOOTING FOR THE HARDWARE

Pull out the seal bundling the staples straight.

5

Fit the staple cartridge into the stapler.

6

Insert the cartridge until the lever of the stapler goes up to be fixed

securely.

1 TROUBLESHOOTING FOR THE HARDWARE

Close the front cover of the finisher.

7

If the message “Check staple cartridge” remains, repeat the procedure above from steps 1 to 7.

Refilling Saddle Stitch Finisher MJ-1029 staples

The Saddle Stitch Finisher MJ-1029 has two types of staple cartridges; one is for 100-sheet staples and the other is for

50-sheet ones. If you replace the staple cartridge with the other type, turn the power of the equipment OFF and then

back ON after replacing it.

Open the front cover of the finisher.

1

Slightly raise and pull out the staple cartridge while

2

holding its lever.

1

2

Refilling With Staples 43

Page 46

1 TROUBLESHOOTING FOR THE HARDWARE

Press the buttons on both sides of the staple

3

cartridge to open the cover.

Pull out the empty staple case.

4

Fit the new staple case into the staple cartridge.

5

Push the staple case into the cartridge until it clicks.

In this step, do not remove the seal bundling the staples.

Pull out the seal bundling the staples straight. Then

6

close the cover.

Fit the staple cartridge into the stapler.

7

Insert the staple cartridge until you hear a click sound (the staple

cartridge is latched). Then lower the lever slightly.

2

1

44 Refilling With Staples

1

2

Page 47

1 TROUBLESHOOTING FOR THE HARDWARE

1.TROUBLESHOOTING FOR THE HARDWARE

Close the front cover of the finisher.

8

If the message “Check staple cartridge” remains, repeat the procedure above from steps 1 to 8.

Refilling saddle stitch unit staples

When the staples of the saddle stitch unit stapler in the Saddle Stitch Finisher have run out, refill them following the

procedure below.

Open the lower cover of the finisher.

1

Slowly pull out the saddle stitch unit.

2

Unlock the stapler of the saddle stitch unit by pulling

3

its handle toward you. Keep pulling the handle, and

turn the stapler clockwise by about 60 degrees.

The stapler is locked and cannot be turned any further when it lies

almost horizontally.

Remove the empty staple cartridges.

4

Replace both cartridges at a time.

2

1

Refilling With Staples 45

Page 48

1 TROUBLESHOOTING FOR THE HARDWARE

Fit the new cartridges.

5

Insert each cartridge until it is caught by the latch and is fixed with a

click.

Unlock the stapler of the saddle stitch unit by pulling

6

its handle toward you, and lower the stapler to its

original position.

2

1

Slowly insert the saddle stitch unit into the finisher.

7

Make sure that the following two requirements are met before test stapling:

8

y The Saddle Stitch Finisher is securely attached on the equipment.

y A3, B4, A4-R, LD, or LT-R paper is loaded in the drawer.

When the message “Check staple cartridge in the Saddle Stitch unit” is displayed, this step is unnecessary.

Proceed to step 9.

Close the lower cover of the Saddle Stitch Finisher.

9

When the message “READY (CHECK STAPLER)” is displayed, test stapling starts automatically.

Test stapling is necessary to prevent void stapling. Note that the test stapling starts automatically when the two

requirements in step 8 are met with the lower cover of the Saddle Stitch Finisher closed. If the test stapling does

not start, make sure to check the two requirements again. Then open and again close the lower cover of the

Saddle Stitch Finisher.

46 Refilling With Staples

Page 49

1 TROUBLESHOOTING FOR THE HARDWARE

Cleaning the Hole Punch Dust Bin

When the hole punch dust bin becomes full, dispose of the paper punchings following the procedure below.

Open the Hole Punch Unit cover.

1

Pull out the hole punch dust bin.

2

Dispose of the paper punchings.

3

Push back in the hole punch dust bin.

4

Close the Hole Punch Unit cover.

5

Cleaning the Hole Punch Dust Bin 47

Page 50

Page 51

2.TROUBLESHOOTING FOR COPYING

This chapter describes how to troubleshoot the problems on copying and copy output.

Copying Problems.................................................................................................................. 50

Page 52

2 TROUBLESHOOTING FOR COPYING

Copying Problems

See the table below when you have a problem in operating copy function or have an unexpected copy output.

Problem Description Cause Corrective Action

Functions cannot be set. Another function that is unavailable

for the combination has already been

set.

Copying stops while scanning the

originals. (The message “The

number of originals exceeds the

limits Will you print out stored

originals?” appears.)

Copying stops while scanning the

originals. (The message “Not

enough Work Space to store

originals Will you print out stored

originals?” appears.)

Copied image is too light. No toner is left. The message “Open the toner cover Install new toner

Copied image is too dark. Copy density is set too dark. Lighten the density manually or try the automatic density

Copied image has stains. The Reversing Automatic Document

Copy image is skewed. The original is sent from the

Copied image is partially missing. The size or orientation of the copy

Copied image is blurred. There is a gap between the original

The number of scanned pages has

reached the maximum.

No available internal memory

remains.

Copy density is set too light. Darken the density manually or try the automatic density

Feeder is not fully lowered.

The original glass, platen sheet,

scanning area and guide are stained.

The copy density is set too dark. Lighten the density manually or try the automatic density

A transparent original such as a

transparency or tracing paper is being

used.

Reversing Automatic Document

Feeder at a skew.

paper and that of the original are not

consistent. The reduction ratio is not

properly set.

The binding margin is too wide. Set the binding margin width to fully cover the original.

The original is larger than the

printable area.

glass and the original.

The copy paper is damp. Replace it with dry copy paper.

Some functions cannot be combined.

For details, refer to Chapter 8 of the Copying Guide.

To copy the scanned images, press [YES]. To cancel,

press [NO].

To copy the scanned images, press [YES]. To cancel,

press [NO].

cartridge” appears when no toner is left. Replace the toner

cartridge.

P.37 “Replacing a Toner Cartridge”

mode.

mode.

Lower them fully to block the outside light.

Clean them.

P.98 “Regular Maintenance”

mode.

To copy a transparent original clearly, put a sheet of blank,

white paper behind the original. Make sure that the paper

is large enough to cover the original.

Replace the original while aligning the side guides of the

Reversing Automatic Document Feeder to its width so that

it will be placed straight.

Fit the copy paper size to the original or set the reduction

ratio for the copy paper.

For details, refer to Chapter 4 of the Copying Guide.

The outside part of the printable area cannot be copied.

Lower the Reversing Automatic Document Feeder fully so

that the original fully contacts the platen glass.

50 Copying Problems

Page 53

2.TROUBLESHOOTING FOR COPYING

Problem Description Cause Corrective Action

Copied image has black streaks

in the horizontal direction.

The scanning area or guides are

stained.

2 TROUBLESHOOTING FOR COPYING

Clean them.

P.98 “Regular Maintenance”

Copying Problems 51

Page 54

Page 55

3.TROUBLESHOOTING FOR PRINTING

This chapter describes how to troubleshoot the problems on printing.

Print Job Problems ................................................................................................................ 54

Clearing print job errors........................................................................................................................................54

Cannot remember the document password for a Private Print job.......................................................................56

Printer Driver Problems.........................................................................................................57

Cannot print (port setting problems).....................................................................................................................57

Command line options not processed ..................................................................................................................57

Retrieval of printer configuration failed .................................................................................................................57

Cannot print a job as expected using PS3 printer driver ......................................................................................58

Cannot change settings on the [Fonts] tab and the [Configuration] tab ...............................................................58

Network Connection Problems............................................................................................. 59

Cannot print with the equipment (network connection problems).........................................................................59

Cannot print with SMB print..................................................................................................................................59

Cannot print properly with AppleTalk print............................................................................................................59

Client Problems......................................................................................................................60

Checking the client status.....................................................................................................................................60

Hardware Problems................................................................................................................ 61

Startup page not printed .......................................................................................................................................61

Print jobs not output .............................................................................................................................................61

Page 56

3 TROUBLESHOOTING FOR PRINTING

Print Job Problems

This section describes how to clear the print jobs errors.

Clearing print job errors

Problem Description

A print job error occurs and [JOB STATUS] blinks when the paper specified by the computer is not set in the drawers of the

equipment.

Corrective Action

Clear the error following the procedure below.

To print by placing paper on the bypass tray

Press the [JOB STATUS] which is blinking.

1

Place paper of the size specified with the computer on the bypass tray, and press the

2

[START] button.

Printing is performed. Press [JOB STATUS] when printing has been completed.

54 Print Job Problems

Page 57

3.TROUBLESHOOTING FOR PRINTING

To print by setting suitable-size paper in the drawer

Press the [JOB STATUS] which is blinking.

1

Press the drawer button whose paper size setting you intend to change.

2

3 TROUBLESHOOTING FOR PRINTING

You can also select the drawer with or .

Place the paper in the drawer.

3

Press the paper size button corresponding to the size of the paper you have placed.

4

Press the [START] button.

5

Printing is performed. Press [JOB STATUS] when printing has been completed.

Printing by selecting a paper size already placed in another drawer

You can perform printing with the paper already placed in the drawers. Some part of the image may not be printed,

however, if the paper size in the drawer is smaller than the one you have specified.

Press the drawer button you intend to use on the touch panel and press the [START] button.

Print Job Problems 55

Page 58

3 TROUBLESHOOTING FOR PRINTING

Cannot remember the document password for a Private Print job

Problem Description

I cannot remember the document password for my Private Print job.

Corrective Action

The document password for a Private Print job is never shown, once the job has been sent to the equipment.

To print the failed Private Print job, submit the document again as a new Private Print job.

The failed Private Print job remains unprinted in the job queue. To delete it, either way below is required. Contact the

administrator of the equipment.

y Enter the administrator’s password in the Private Print job list on the touch panel and delete the job.

For details, refer to the Printing Guide.

y Log on TopAccess with the administrator’s password and delete the job in the Print Job list.

For details, refer to the TopAccess Guide.

56 Print Job Problems

Page 59

3 TROUBLESHOOTING FOR PRINTING

Printer Driver Problems

This section describes the troubleshooting for the printer drivers.

For the error messages that appear during the installation of the printer drivers, refer to the Software Installation

Guide.

Cannot print (port setting problems)

Problem Description

I cannot perform printing with the equipment.

Corrective Action

If the printer driver on the client computer points to a wrong network port, jobs neither appear in the current jobs queue nor

are printed. Fix the problem following the procedure below:

1. Open the Printers folder from the Control Panel.

2. Right-click the printer driver icon.

3. Select Properties from the shortcut menu.

4. Select the [Ports] tab.

5. Make sure that the path to the printer and the device name are correct.

\\<device name>\print

<device name> is the same as the device name set from the touch panel. “print” may be “pcl6” or “ps3” depending on

the printer driver you use.

6. Click the [General] Tab and click [Print Test Page] to confirm that the settings are correct.

Command line options not processed

Problem Description

All the print options are sent to the equipment at the beginning of the print job. If the print file already contains print

commands, they overwrite the command line options you set. For example, if the print file specifies Letter paper, and you

specify A4 paper with the lp command, the document is printed on Letter size paper.

Corrective Action

Change the properties of the document you intend to print to create another print file. Submit the print job using the lp

command without setting additional parameters.

Retrieval of printer configuration failed

Problem Description

When accessing the printer properties, the message “Retrieval of printer configuration failed” is displayed.

Corrective Action

The printer driver cannot communicate with the equipment. Try the steps in the checklist below.

No Check... Yes No Corrective Action

1 Is the equipment turned on? Next Step

2 Can you connect the computer to the equipment

via TopAccess?

3 Does the same message appear again when you

access the property of the printer driver?

Ø

Next Step

Ø

Ö End

Turn on the equipment.

Ö

Restart the equipment.

Ö

Check the printer driver port assignment and

make sure that it is correct.

Printer Driver Problems 57

Page 60

3 TROUBLESHOOTING FOR PRINTING

Cannot print a job as expected using PS3 printer driver

Problem Description

When printing with the PS3 printer driver from the application that creates the PostScript code for printing such as Adobe

Acrobat, the following print options may not work correctly:

y Manual Scale

y Print Paper Size

y Paper Type

y Use Front Cover

y Use Back Cover

y Insert Pages

y Interleave Pages

y Booklet

y Multiple Pages per Sheet

y All options from the [Effect] tab

y All options from the [Image Quality] tab

Corrective Action

Disable [Use PostScript Passthrough] in the [PostScript Settings] dialog box and print the document.

Cannot change settings on the [Fonts] tab and the [Configuration] tab

Problem Description

The [Fonts] tab and [Configuration] tab are grayed out and their settings cannot be changed.

Corrective Action

Users who do not have the privilege to change the printer driver setting cannot change the options in the [Fonts] tab and

[Configuration] tab. Please log on with the Administrator or a Power User.

58 Printer Driver Problems

Page 61

3 TROUBLESHOOTING FOR PRINTING

Network Connection Problems

This section describes the troubleshooting for printing in the network connection environment.

See also the checklists by types of printing and operating systems on P.74 “Printing Problems (Network Related)”

Cannot print with the equipment (network connection problems)

Problem Description

I cannot perform printing with the equipment.

Corrective Action

See the checklist below to determine if the cause of the problem is related to a network.

If it is, see P.74 “Printing Problems (Network Related)”. In that section, several OS- and printing method-based check

lists are provided to help you find an appropriate action to take.

No. Check... Yes No Corrective Action

1 Have you set the protocol settings so they are

compatible with your network and client protocol

settings?

2 Have you set up the appropriate type(s) of print

services that should be supported?

3 If you are using Novell print services, did you set

up the Novell side of network printing, such as

creating print servers and attaching the print

queue?

4 If you set up Novell print services, can you see the

print job using PCONSOLE or NWAdmin?

5 Have you checked the gateway and subnet

settings to make sure that the equipment is part of

the same network gateway as the client from

which you are trying to print?

6 Are other services and communications

performed over the network behaving in the

normal and expected manner?

Next Step

Ø

Next Step

Ø

Next Step

Ø

Next Step

Ø

Next Step

Ø

End Ö

Set up the proper protocol.

Ö

Check the settings required for your printing

Ö

environment.

Set up the NetWare server.

Refer to the Software Installation Guide.

Ö

Refer to your Novell PCONSOLE or NWAdmin

Ö

user documentation for help with using these

utilities.

Set up the TCP/IP correctly.

Ö

Refer to your network documentation or use a

network diagnostic utility to identify the network

problem.

Cannot print with SMB print

Problem Description

When trying to print a document using an SMB connection, the job cannot be printed and such messages continuously

appear as “No more connections can be made to this remote computer” or “Your file could not be printed due to an error”.

Corrective Action

SMB print is supposed to be utilized in a small network. If you can use Windows 2000, Windows XP, Windows Vista,

Windows Server 2003, or Windows Server 2008 as a print server, printing via the Windows Print Server is recommended.

If you cannot use the Windows Print Server in your network, use LPR print instead.

Cannot print properly with AppleTalk print

Problem Description

y Text will be printed as stripe lines when printing an email message.

y Some text is not printed in a document.

y When printing from a web browser, the web page is not printed in spite of the print job being sent to the equipment.

Corrective Action

If the errors above occur with AppleTalk print, use LPR print instead.

Network Connection Problems 59

Page 62

3 TROUBLESHOOTING FOR PRINTING

Client Problems

This section describes how to identify and correct the problems caused by the clients* connected to the equipment.

* One of the common examples of clients is a computer that sends a print job to the equipment and make it perform printing.

Checking the client status

Problem Description

The printing problems are caused by the printer driver settings, network settings, errors in the network connections, and

so forth. First, contact the administrator of the equipment to see if there is one of these kinds of problem, or see the

following sections:

P.57 “Printer Driver Problems”

P.59 “Network Connection Problems”

P.74 “Printing Problems (Network Related)”

Another possible cause is one related to a client. If the print jobs sent from a specific client within a network fails, the

problem may be caused by the client.

The checklist below will help you identify the source of the error and direct you to the information resolving the problem. If

the problem persists after you have followed all of the steps, contact your service representative.

No. Check... Yes No Corrective Action

1 Does the equipment work properly? Are copy jobs

output properly?

2 See the Device page of TopAccess. Are the

options specified for the job supported by the

hardware configuration?

3 Can you print the jobs from other clients?

4 Have you ever printed successfully from this

client?

5 Did you set up the printer driver other than by an

SMB connection?

6 (For Macintosh only)

Can you see the equipment you created in the

Selector?

7 At this point, the problem is most likely to be related to a client-side error. Refer to the Printing Guide to fix the problem.

Next Step

Ø

Next Step

Ø

Next Step

Ø

Next Step

Ø

Next Step

Ø

Next Step

Ø

Check the device status displayed in the Device

Ö

page of TopAccess.

If not, delete the job, install the required

Ö

components, and try again. Contact your service

representative for further information.

See the following section to fix the problem.

Ö

P.59 “Cannot print with the equipment

(network connection problems)”

See the following section to fix the problem.

Ö

P.57 “Cannot print (port setting problems)”

See the following section to fix the problem.

Ö

P.59 “Cannot print with SMB print”

Refer to the Software Installation Guide.

Ö

60 Client Problems

Page 63

3 TROUBLESHOOTING FOR PRINTING

Hardware Problems

This section describes troubles caused by the hardware device (the equipment).

If an icon or a message indicating an error is not displayed, or the problems on printer drivers or the network connection

cannot be specified, a hardware problem is a possible cause of the trouble.

The following are common factors involved in the hardware problems:

y System board, cables, and connectors

y The equipment, and its (optional) components such as the duplexing unit or the Finisher

y System software or firmware of the equipment

Startup page not printed

Problem Description

If the startup page is not printed when you turn on the equipment, even though the Print Startup Page is enabled, there

may be a hardware error. Contact your service representative.

Corrective Action

1. Make sure that Print Startup Page is enabled.

2. Turn on the equipment. (If it is already on, restart it.)

3. Check if the startup page is output.

When the Print Startup Page is enabled, normally the Startup Page is automatically printed. If not, the problem is possibly

caused by the hardware. Contact your service representative.

Print jobs not output

Problem Description

All the clients within a network fail to make the equipment output the print jobs.

Corrective Action

There remains a possibility that an improper settings of the software such as printer drivers caused the problem, however,