Page 1

STE 58769–

INSTRUCTION MANUAL

TOSHIBA MACHINE'S FA SCHOOL TEXTBOOK

FOR

ROBOT TRAINING COURSE

INDUSTRIAL ROBOT SR–H SERIES

(ROBOT CONTROLLER: SR7000)

May, 1998

TOSHIBA MACHINE CO., LTD.

TOKYO, JAPAN

Page 2

Preface

The training session you are going to attend this time is the FA school robot course.

This textbook describes the robot language and basic operating procedures for the user

who will operate the SR–H series industrial robot (robot controller SR7000) in his plant

or factory.

For the detailed specifications and usage of the robot, see the appropriate specifications

manual and instruction manual. When the shipment has reached your office, confirm

the following instruction manuals which are attached to the robot. You are also

requested to read through them before the use.

List of instruction manuals

• Industrial robot SR

series

Startup manual ·········· Simple operating procedures

• Industrial robot SR

series

• Industrial robot SR

series

• Industrial robot SR

series

• Industrial robot SR

series

• Industrial robot SR

series

• Industrial robot SR

series

• Industrial robot SR

series

Copyright 1998 by Toshiba Machine.

All rights reserved.

Operating manual ·········· Detailed operating

Robot language

manual

Interface manual ·········· External I/O, electrical

Transportation and

installation manual

Maintenance manual ·········· Regular inspection and

Communication

manual

Safety manual ·········· Safety measures

procedures

·········· Descriptions of SCOL

language

specifications

·········· Mounting hand and wiring &

piping

maintenance

·········· Communication protocol

No part of this document may be reproduced in any form without obtaining prior written

permission from Toshiba Machine.

The information contained in this manual is subject to change without prior notice to

effect improvements of the robot functions and training details.

STE 58769

– 2 –

Page 3

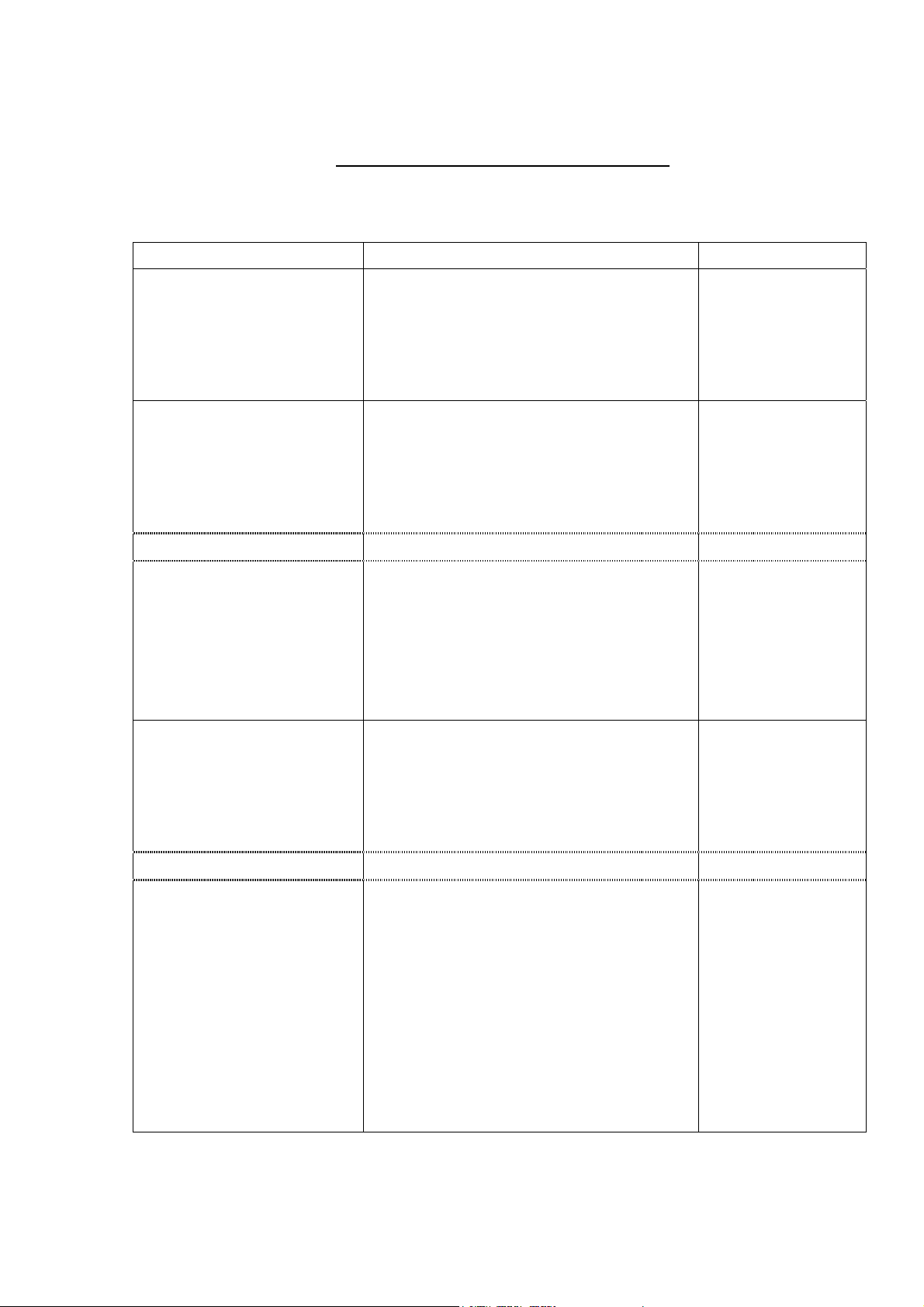

Industrial Robot Training Schedule

C Course (SR–H Robot): 2.5 Days

Time Descriptions Place

1st day 13:30 ~ 13:40 Greetings at starting the course. Classroom

13:40 ~ 15:00 Explaining the outline. Classroom

15:00 ~ 15:15 Break

15:15 ~ 16:25 Explaining the programming. Classroom

16:25 End

2nd day 8:30 ~ 9:30 Explaining the programming. Classroom

9:30 ~ 10:15 Instructing the safety. Classroom

10:15 ~ 10:25 Move to the training room.

10:25 ~ 11:50 Explaining the operation. Training room

11:50 ~ 12:00 Move to the classroom.

12:00 ~ 13:00 Lunch

13:00 ~ 13:10 Move to the training room.

13:10 ~ 14:45 Training the operation. Training room

14:45 ~ 15:00 Break

15:00 ~ 16:15 Training the operation.

16:15 ~ 16:25 Move to the classroom.

16:25 End Classroom

3rd day 8:30 ~ 8:40 Move to the training room. Classroom

8:40 ~ 9:45 Training the programming. Training room

9:45 ~ 10:00 Break

10:00 ~ 11:50 Training the programming Training room

11:50 ~ 12:00 Move to the classroom.

12:00 ~ 13:00 Lunch

13:00 ~ 13:10 Move to the practical training room.

13:10 ~ 14:45 Training the programming Training room

14:45 ~ 15:00 Break

15:00 ~ 15:50 Explaining the maintenance. Training room

15:50 ~ 16:00 Move to the classroom.

16:00 ~ 16:15 Questions and answers Classroom

16:15 ~ 16:25 Awarding a certificate of completing

the course and greetings at finishing

the course.

16:25 End

– 3 –

STE 58769

Page 4

Robot SR–654HSP

Robot controller SR7000 Teach pendant

– 4 –

STE 58769

Page 5

Table of Contents

Page

1. General Descriptions ...................................................................................... 7

1.1 Basic Robot and Controller .................................................................. 7

1.2 Coordinate System of the Robot .......................................................... 13

1.3 External Input/Output Signals............................................................... 15

1.4 Mode System ....................................................................................... 21

1.5 File ....................................................................................................... 22

2. Robot Language ............................................................................................. 24

2.1 Robot Program..................................................................................... 24

2.2 Robot Language................................................................................... 24

2.3 Subprogram ......................................................................................... 40

2.4 Multi-task.............................................................................................. 42

2.5 List of Robot Language SCOL Instruction Words................................. 45

3. Safety Measures............................................................................................. 49

3.1 Cautions on Safety............................................................................... 49

3.2 Safety Functions .................................................................................. 50

3.3 Safety Measures .................................................................................. 52

4. Training Materials ........................................................................................... 55

4.1 Operating Procedures .......................................................................... 55

4.2 Starting up the Robot ........................................................................... 56

4.3 Program Entry and Position Teaching.................................................. 58

4.4 Test Operation ..................................................................................... 65

4.5 Internal Automatic Operation................................................................ 68

4.6 Ending an Operation ............................................................................ 70

4.7 File Operation....................................................................................... 71

4.8 Error Display and Reset ....................................................................... 76

4.9 Utility .................................................................................................... 78

4.10 Operation of Auxiliary Signals .............................................................. 81

4.11 File Selection........................................................................................ 82

– 5 –

STE 58769

Page 6

Page

5. Maintenance and Inspection ........................................................................... 85

5.1 Maintenance Schedule......................................................................... 85

5.2 Maintenance/Inspection Items.............................................................. 87

6. Exercises of Robot Language SCOL .............................................................. 95

Appendixes

Appendix 1 Example Answers to Exercises of Robot Language SCOL ....... 99

Appendix 2 Creating an Error Insertion Monitor Program............................. 108

Appendix 3 Mounting the Hand, Wiring & Piping.......................................... 111

Appendix 4 Mass of Load and Load Offset .................................................. 113

Appendix 5 Restoring Zero Position Data .................................................... 115

– 6 –

STE 58769

Page 7

1. General Descriptions

1.1 Basic Robot and Controller

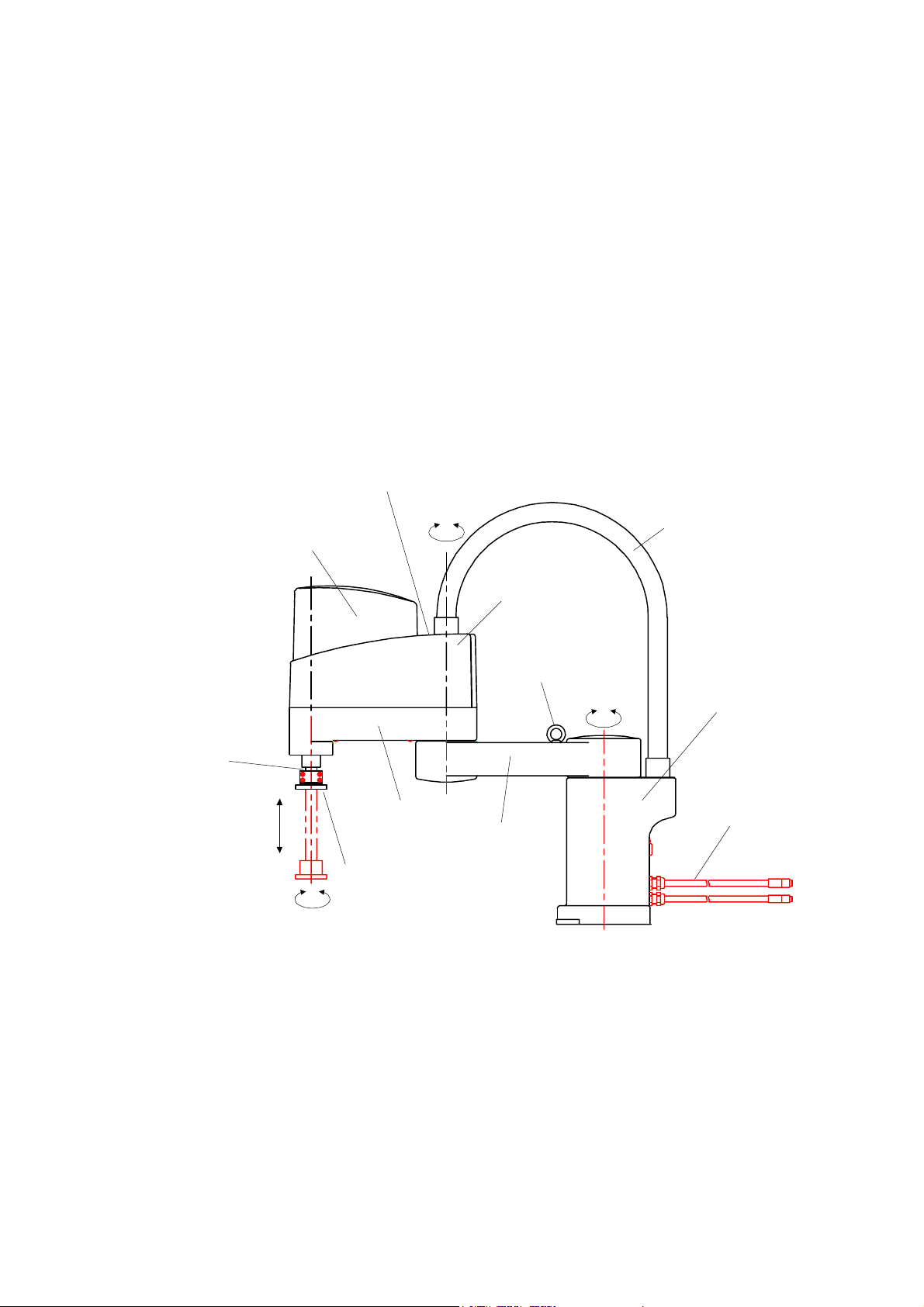

a) Names of the parts of the robot

The SR-H series is a group of robots having four degrees of freedom. Having

two degrees of freedom for positioning in a horizontal plane, one degree of

freedom for positioning in a vertical direction and one for the rotation of the tool

mounting flange, it is good at assembling and handling parts.

• Tool wiring

intake port

• Air fitting for user

Tool shaft

Axis 3

Arm 2 cover

Tool set flange

Axis 4

Arm 2

Axis 2

Connector for user

(built in the cover)

Eye bolt

Axis 1

Arm 1

Cable duct

Fixed base

Controller

connection cable

SR–654HSP

STE 58769

– 7 –

Page 8

b) Names of the parts of the controller

(1) Controller

⑮⑯

⑧⑨⑩⑪

⑦

SERVO POWER EMERGENCY

POWER

10AT

① ②

DC24V

C.P.

POWER

FAULT

EXT

INT

MANU

ONOFF

STARTSTOP

CYCLE STOP

BATTERY

⑫⑭

ALARM

⑰⑱

1) Main power switch

2) Circuit protector

3) J1 connector: connector for communication channel 1

4) J2 connector: connector for communication channel 2

J1

J2

PC

FDD

③

④

⑬

⑥

TP

⑤

5) TP connector: connector for connecting the teaching pendant

6) FDD connector: connector for connecting the floppy disk drive unit

7) Emergency switch

8) Servo power off switch

9) Servo power on switch

10) Stop switch: switch to stop automatic operation

11) Start switch: switch to start automatic operation

12) Cycle stop switch: switch to select the mode of performing 1 cycle of

automatic operation

13) PC connector: connector to connect a PC

STE 58769

– 8 –

Page 9

14) Master mode key switch: switch to select a robot mode

EXT: External automatic mode

INT: Internal automatic mode

MANU: Manual mode

15) Power lamp

16) Fault lamp: controller’s fault lamp

17) Buzzer: it sounds continuously when a fault is detected (since built in, it

is not visible from outside).

18) Battery alarm lamp: turns on or blinks when replacement of batteries is

necessary.

(2) Teaching pendant

17

21 1161514137652424

TOSHIBA

F1 F2 F3 F4 F5 F6

{}

Error

Ins Del

Esc

!;:,%^&,,()

QWERTYUIOP

Ctrl

ASDFGHJKL

Shift

ZXCVBNM

+/ <>?

Alt Exec

Utility

][

=.,*-

AUX

5500

SR-

Move

TEACH PEDANT

Servo ON

World

Work

Tool

Joint

Coordinate

High

X

Med

Low

Free

Inching

Jog

Y

Z

C

T

+-

+-

Teach

098Bs7654321

Speed

Control

Feed

Hold

8 9 10 3 11 12 18 19 20 22 23

1) Emergency stop switch

2) Function keys: Keys to select functions displayed at the

lowermost section of the liquid crystal display

3) Alphanumeric keys

4) Esc (escape) key: Key to cancel an inputted letter and operation

5) Insert key: Key to switch between the insert mode and the

replace mode

Insert mode: Inserts a letter anew between already inserted

letters.

Replace mode: A newly-inserted letter replaces one inputted

before.

STE 58769

– 9 –

Page 10

6) Delete key: Key to delete a letter on which the cursor is

placed.

7) Bs (backspace) key: Key to delete a letter just before the cursor.

8) Ctrl (control) key:

9) Shift key

10) Alt key

11) Run key

12) Cursor keys

13) Error display key: Key to display the description of an error on the

liquid crystal display

14) Utility key: Key to use auxiliary functions of the controller

15) Auxiliary signal key: Key to operate the hand and pneumatic- control

shaft of the robot

16) Move key: Key to move the robot to a position which is

taught to the robot

17) Guide coordinate key: Key to select a coordinate system along which

the robot is guided

18) Guide rate key: Key to select a traveling speed of the robot

when it is guided manually.

19) Guide mode key: To select a method for guiding the robot

Free: Mode to move the robot manually

Inching: Mode to move the robot by a certain amount

every time the guide key is pressed.

Jogging: Mode to move the robot while the guide key is

depressed

20) Feed hold key: Key to stop the operation of the robot

temporarily

21) Servo power on switch

22) Guide key: Key to guide the robot manually

23) Deadman switch:

24) Liquid crystal display

– 10 –

STE 58769

Page 11

c) Composition of robot system

Basic composition: Composed of the robot body, controller, teaching pendant,

and the FDD unit

SERVO POWER EMERGENCY

ONOFF

POWER

STARTSTOP

Robot

Basic robot

cable

FAULT

INT

MANU

EXT

CYCLE STOP

BATTERY

ALARM

Portable

(option)

Robot controller

CC24V

C.P.

POWER

10AT

SERVO POWER EMERGENCY

POWER

FAULT

INT

MANU

EXT

CYCLE STOP

FDD cable

ONOFF

STARTSTOP

BATTERY

ALARM

J1

J2

PC

FDD

TP cable

TP

FDD unit (option)

SR7000

FDD UNIT

Teach pendant (option)

TOSHIBA SR-5500

Operation

panel

Operating panel: Panel for starting and stopping automatic operation.

Detachable from the controller (optional), it is convenient

when the controller is stored under a rack. The CP cable

(cable between the operating panel and the controller) is

less than 30 m long.

– 11 –

STE 58769

Page 12

Teach pendant: Detachable from the connector and usable for multiple

robots commonly. Inserting a dummy plug (accessory)

allows automatic operation without the teaching pendant.

Body cable: 3 cables. Standard cable is 5 m long. Optional cables

can be 30 m at the maximum.

TP cable: Standard cable is 7 m long and a 30 m cable is available

as optional.

FDD cable: Standard cable is 2 m long and a 50 m cable is available

as optional.

– 12 –

STE 58769

Page 13

1.2 Coordinate System of the Robot

Coordinate systems include the world, base, tool and workpiece coordinate systems.

In the initial state, the world and workpiece coordinate systems match the base

coordinate system, and the tool coordinate system is a coordinate system whose

origin is a hand mounting flange. The world coordinate system, workpiece

coordinate system and the tool coordinate systems are set in accordance with work

and used. When coordinate systems are set, the robot is guided along the set

coordinate system and can be operated with the same position data to different tools.

There is no need for setting coordinate systems when the robot is guided to positions

where it actually operates and taught the positions. Setting coordinate systems

unnecessarily complicates position teaching operations. If there is no trouble, the

robot should be used at the initial condition without setting coordinate systems.

a) World coordinate system (absolute coordinate system)

Only one coordinate system for the whole of an work area where a robot is installed.

Generally, it is matched to the base coordinate system whose origin is the

cardinal point of installation of the robot.

b) Base coordinate system (machine coordinate system)

The coordinate system based on the center of the robot. Based on the origin posture

where each joint axis is zero. The base coordinate system is the natural

coordinate system determined from the structure of the robot.

c) Workpiece coordinate system (work coordinate system)

The coordinate system to be set for workpieces the robot work on and pallets. Different

workpiece coordinate systems are set for different workpieces.

d) Tool coordinate system

The coordinate system based on the hand mounting frange of the robot.

Depending on hands mounted on the robot, a tool coordinate system can be set

in a manner of matching it to the work point of the robot. The coordinate system

also moves with the operation of the robot.

Positions of the robot are expressed by X, Y, Z, C and T.

X, Y, Z: X, Y, Z coordinate values in an orthogonal coordinate system (in mm)

C: Rotation of the head of the tool (in degrees)

T: Rotation or direct advance of the 5th axis (in degrees or mm)

STE 58769

– 13 –

Page 14

A

A

Zt

0t

Xt

Yt

Tool coordinate system

ZB

Xw

Zw

Yw

0w

Wo rld c oordina te

system

Xw

Zw

0w

Wo rk c oordina te syste m

Yw

XB

0B

YB

Base coordinate system

Note) A plural number of work coordinate

system and tool coordinate system

can be set.

STE 58769

– 14 –

Page 15

1.3 External Input/Output Signals

A

a) External interface

Panel is separated (option).

Operation panel

7 m

Teach pendant

(option)

FDD

FDD unit

(option)

Personal

computer

For serial

communication

2 m

PC

J1

J2

C/P

TP

Controller

CN4

CN3

CN2

CN5

CN6

CN12

J3

CN13

CN1

Robot

body

5 m

External I/O and

operation I/O signals

For serial communication

TC200/terminal block I/O

Power supply

For end

effector

ir

Note: Cables for connecting the operating panel, teaching pendant, FDD unit, and

robot to the controller can be extended up to 30 m long at the maximum.

CN1: Power supply

CN2: Power cable for the main body of the robot

CN3: Robot body encoder wire

CN4: Robot body sensor signal, hand control signal

CN5: External operation input signal

CN6: External operation output signal

C/P: Signal wire for the operating panel (used to draw out the operating panel)

TP: Serial port for the teaching pendant

J1 to J3: Serial ports for users

CN12: External input output signals

CN13: RS485 port for connecting TC200/terminal board I/O

STE 58769

– 15 –

Page 16

a) Input output signals

1) External operation input signal (CN5)

External operation input signals are those to control the start and stop of the

robot controller SR7000 from external equipment such as a sequencer.

• "Stop," "Cycle operation mode," and "Low speed command" are b contact

point input. If this signal is not used, connect CN5-16, CN5-35, CN5-36 to

either of CN5-18, CN5-19 or CN5-37.

SR7000 robot

controller

(X8C1 printed

board)

CN5

1

20

2

21

3

22

4

23

5

24

6

25

7

26

8

27

9

28

10

29

11

30

12

31

13

32

14

33

15

34

16

35

17

36

18

37

19

Case

Customer's side

DI1

DI2

DI3

DI4

DI5

DI6

DI7

DI8

DI9

DI10

DI11

DI12

DI13

DI14

DI15

DI16

DI17

DI18

DI19

DI20

DI21

DI22

DI23

DI24

PG

PG

PG

Dsub-37S

Shown in parentheses is

the I/O port number.

(001)

(002)

(003)

(004)

(005)

(006)

(007)

(008)

(009)

(010)

(011)

(012) Digital

(013) Input signal

(014)

(015)

(016)

(017)

(018)

(019)

(020)

(021)

(022)

(023)

(024)

Strobe (245)

Program reset (236)

Step reset (237)

Cycle reset (238)

Output signal reset (239) external operation

Start (208) input signal

Stop (203)

Cycle operation mode (211)

Low speed command (212)

FG

Connection of external input signal wire

– 16 –

STE 58769

Page 17

2) External operation output signal (CN6)

A

3

A

External operation output signals are those which output operating conditions

of the robot controller SR7000.

• When input signals such as "servo off" and "emergency stop" are open, "servo

on" is not feasible.

• User output is open collector output of capacity of DC 24 V, 100 mA.

• Output signals "servo on" and "emergency stop" are 2 output non voltage

output.

• Use the 24 V power supply at a total capacity of 2 A or less including CN12.

CN6

SR7000

Robot controller

(X8C2 printed board)

20

21

22

23

24

25

26

27

28

10

29

11

30

12

31

13

32

14

33

15

34

16

35

17

36

18

37

19

Case

FG

User side

1

2

3

4

5

6

7

8

9

17JE-23370-02(D8A)

(Dsub-37P)

DO1

DO2

DO3

DO4

DO5

DO6

DO7

DO8

DO9

DO10

DO11

DO12

DO13

DO14

DO15

DO16

P24V

P24V

P24V

Signal name in

parenthses.

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

(14)

(15)

(16)

Manual mode ON (222)

External automatic mode ON (22

Operation ready (221)

Fault (216)

Cycle finish (219)

Low speed mode ON (218)

During servo ON.

Emergency stop ON

P24V

Servo ON

Servo OFF

Emergency stop

Digital

output signals

cknowledge (217)

utomatic mode ON (220)

In total, 2 A or less,

including CN12.

Connection of external output signal wire

STE 58769

– 17 –

Page 18

3) External output signals (CN12)

External input output signals are those which input and output the operating

condition of the robot controller SR7000.

• User output is open collector output with a capacity of DC 24 V, 100 mA.

• Use the 24 V power supply at 2A or less including CN6.

CN12

SR7000

Robot controller

(X8C1) printed board

User side

1

14

2

15

3

16

4

17

P24V

5

P24V

18

6

19

7

20

8

21

9

22

10

23

11

24

12

25

13

Case

17JE-23250-02(D8A)

(Dsub-25P)

DI25

DI26

DI27

DI28

DI29

DI30

DI31

DI32

DO17

DO18

DO19

DO20

DO21

DO22

DO23

DO24

PG

PG

Signal name in

parentheses.

(25)

(26)

(27)

(28) Digital

(29) input signals

(30)

(31)

(32)

2 A or less in total (including CN6)

(17)

(18)

(19)

(20) Digital

(21) output signals

(22)

(23)

(24)

FG

Connection of external I/O signal wire

– 18 –

STE 58769

Page 19

4) Auxiliary input and output signals

DC 24 V wires, including five for input signals from sensors and 4 for control

output signals to electromagnetic valves, are routed to the second arm of the

robot, and allow the opening and closing of the hand and the monitoring of

on/off of sensors.

• Output is open collector output and has a capacity of DC24V, 1 A.

• Signal numbers of auxiliary input signals are as given below.

Input: Signal number 220 ··· GRP1 OPN Output: Signal number 214 ··· GRP1

219 ··· GRP1 CLS 213 ··· GRP1

218 ··· GRP2 OPN 212 ··· GRP2

217 ··· GRP2 CLS 211 ··· GRP2

216 ··· WORK

Remove the upper cover of the second

arm and connect your connectors to the

JOES

JOFS

JOFP

JOFS

CN4

JOEP

JOES

two connectors JOES, JOFS inside it.

To control the hand with your sequencer,

remove the connectors and connect a

separate cable from the outside.

– 19 –

STE 58769

Page 20

JOES SM connector 7 poles

Signal

Pin

name

1

GRP1 OPN

2

GRP1 CLS

3

GRP2 OPN

4

GRP2 CLS

5

6

7

WORK

PGND

Shield

Sensor

Color

Yellow

White (yellow)

Green

White (green)

Red

White (red)

Green

JOEP SM connector 7 poles JOES

Signal

Color

Yellow

White (yellow)

Green

White (green)

Red

White (red)

Green

Pin

1

2

3

4

5

6

7

name

GRP1 OPN

GRP1 CLS

GRP2 OPN

GRP2 CLS

WORK

PGND

Shield

Green

Yellow

Brown

Blue

Gray

Green

Color

Red

JOFS SM connector 7 poles

Signal

Pin

name

1

GRP1

2

GRP1

3

P24

GRP2

4

5

GRP2

6

Solenoid valve, etc.

P24

Color

Purple

White

Blue

Brown

Yellow

Brown

JOFP SM connector 7 poles JOFS

Color

Purple

White (purple)

Blue

Brown

Yellow

Brown

Pin

1

2

3

4

5

6

Signal

name

GRP1

GRP1

P24

GRP2

GRP2

P24

Orange

Purple

Pink

Light green

Light blue

Black/white

Color

Connector type

JOES

JOEP

JOFS

JOFP

---- SMP–07V–BC (J.S.T Corporation)

---- SMR–07V–B (J.S.T Corporation)

---- SMR–06V–BC (J.S.T Corporation)

---- SMR–06V–B (J.S.T Corporation)

Provided by the customer.

Provided by the customer.

5) Serial communication

The SR7000 controller is furnished with hardware and software for

communication with external equipment as standard components.

Controller

• Port: there are four ports including one exclusively used for the teaching

pendant.

J1 and J2 are switchable. Switching is made by operation mode or robot

language instructions.

Equipment to be connected to J1 to J3 is registered in the system

configuration file.

Teach pendant

J1

J3 J1, J3: RS–232C

J2: RS–232C or RS422

J2

Front Controller Back

STE 58769

– 20 –

Page 21

1.4 Mode System

Operation modes include the following.

Master mode: Switching is made by the key switch on the operating panel.

Sub mode: Switching is made by specifying the teaching pendant or system

configuration file.

Master mode Sub mode Description

External automatic Communication mode Operation of the robot by serial

communication.

I/O mode Operation of the robot by external

operation signals.

Internal automatic Operation of the robot from the controller

operating panel.

Manual Test run Running the program at lower speed.

Edit Editing of programs, teaching of

positions, editing of data.

File manipulation Saving, reading and copying of files.

Teaching of joint limits, setting of

coordinates.

Computer

(Internal automatic

operation)

(External automatic

operation)

External operation box

(Manual

operation)

Operation panel

SERVO POWER EMERGENCY

ONOFF

POWER

STARTSTOP

FAULT

INT

EXT

Teach pendant

TOSHIBA SR-5500

BATTERY

ALARM

MANU

CYCLE STOP

– 21 –

STE 58769

Page 22

1.5 File

a) File names

File: Unit of storage for a program, etc.

A maximum of 248 program files used by a user can be stored.

However, memory is limited. 3,000 program steps and 150 points of

position data are a rule of thumb for measuring the size of a file.

File name: “$$$$$$$$.$$$”

Extensions (omission is allowed.)

Up to three alphanumerics

File name

Up to eight alphanumerics (headed by an English letter)

Drive name: Suffixed to a file name and specifies the location of the file.

"A": FDD (floppy disk)

"R": RAM drive (controller memory)

If the drive name is omitted, it is regarded as a file in the RAM

drive.

Floppy disks must be 3.5-inch 2HD. For the SR–5500, 2DD type is used.

b) Types of files

1) Program file “$$$$$$$$.$$$”

File storing robot language programs and position data

2) Batch file “$$$$$$$$.BAT”

File to run multiple commands together

Operations which are performed frequently are registered in the batch file and

run.

To run a batch file, enter the file name of the batch file as a command.

(entering the extension "BAT" is not needed)

Example: "FLOAD.BAT"

LOAD PROG1

LOAD PROG2

LOAD PROG3

LOAD PROG4

→ When FLOAD is run, PROG1 to PROG4 are read out

to the RAM drive.

STE 58769

– 22 –

Page 23

3) System configuration file "CONSTRC.SYS."

File storing an optional configuration of the robot, equipment connected to the

serial port, settings of signals used for selecting files by external signals.

(When necessary, users may change the content. After change, save the

change in a floppy disk).

4) Automatic execution file "AUTOSTR.BAT"

Batch file which is run automatically when the power is turned on (when

necessary, users may change the content. Store it on a floppy disk after

change)

5) System parameter file "SYSTEM.PAR"

File storing control parameters of the robot

6) User parameter file "USER.PAR"

File storing the home position and soft limits of the robot.

When these settings are changed, the content of the file is changed

automatically. (After changed, save the change on a floppy disk)

7) System file "SVPMTX.SYS", "MCPMTX.SYS"

File storing a system to operate the robot.

It is stored only on a system disk. (LOAD, SAVE, COPY commands can not

be used.)

8) Message file "ALARM.MES"

Error messages to be display on the teaching pendant are stored in the file.

They are read out only by the COPY command.

9) External selection file "EXTRNSEL.SYS"

File to be selected by external signals are stored in the file.

10) Library file "SCOL.LIB"

Some instruction words of the robot language are stored in the file.

Sub programs created in the library file can be run in all files.

– 23 –

STE 58769

Loading...

Loading...